Resin laminate, pressure sensitive adhesive sheet, method for working adherend using the pressure sensitive adhesive sheet, and device for separating the pressure sensitive adhesive sheet

A technology of peeling device and resin layer, applied in the direction of lamination device, synthetic resin layered product, lamination, etc., can solve the problems of sticky damage, difficult peeling, no back grinding tape has been found, and achieve the effect of smooth peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1-1

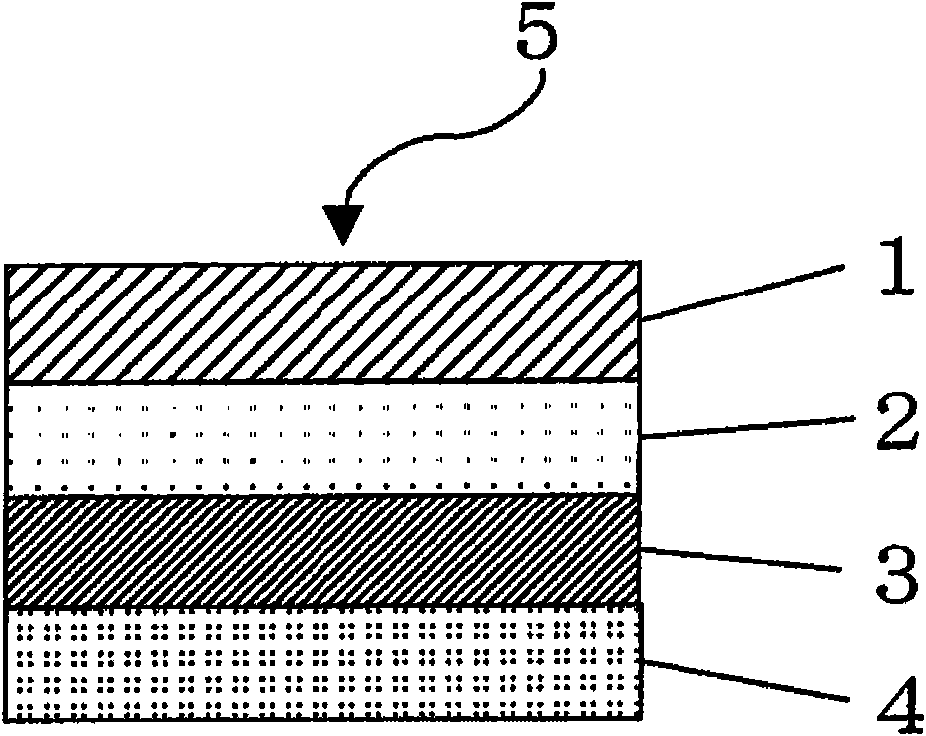

[0113] 100 parts by weight of an acrylic polymer (manufactured by Daiichi Lace, trade name "Leocoat R1020S"), 10 parts by weight of a pentaerythritol-modified acrylate crosslinking agent (manufactured by Nippon Kayaku Co., Ltd., trade name "DPHA40H"), a crosslinking agent ( Mitsubishi Gas Chemical Corporation, trade name "TETRAD C") 0.25 parts by weight, crosslinking agent (NIPPONPOLYURETHANE INDUSTRY CO., LTD., trade name "CORONATE L") 2 parts by weight, active energy ray polymerization initiator (Ciba- 3 parts by weight of Geigy K.K. product, trade name "Irugacure 651") was dissolved in toluene to obtain a polymer solution 1 having a solid content concentration of 15% by weight. The obtained polymer solution 1 was coated on a polyethylene terephthalate film (manufactured by Torayindustries Inc., trade name "LUMIRRORS10", "LUMIRRORS10", etc.) as a low thermal shrinkage substrate layer using a coating machine to a thickness of 30 μm after drying. PET film with surface processi...

manufacture example 1-2

[0115] Polymer solution 1 was obtained in the same manner as in Production Example 1-1 above. The obtained polymer solution 1 was coated on a polyethylene terephthalate film (manufactured by Toray industries inc., trade name "LUMIRRORS10" as a low thermal shrinkage base layer) with a thickness of 30 μm after drying using a coater. , PET film with surface processing for printing, thickness 50μm, rigidity at 80°C 1.86×10 5 N / m) and dried to form an adhesive layer. Then, a biaxially stretched polyester film (manufactured by Toyobo Co., Ltd., trade name "SPACECLEANS 7200", thickness 30 μm, shrinkage rate [A (%) in the main shrinkage direction was laminated on the adhesive layer as a high heat shrinkage base layer. ] and the shrinkage ratio [B (%)] in the direction perpendicular to the main shrinkage direction (A:B) was 40:40), and a resin laminate 2 was obtained.

manufacture example 1-3

[0117] Acrylic polymer: 100 parts by weight of 2-ethylhexyl acrylate / acrylic acid (90 parts by weight / 10 parts by weight) copolymer, 10 parts by weight of dipentaerythritol hexaacrylate, active energy ray polymerization initiator (Ciba-Geigy K.K. (trade name "Irugacure 651"), 3 parts by weight, was dissolved in toluene to obtain a polymer solution 2 with a solid content concentration of 15% by weight. The obtained polymer solution 2 was coated on a polyethylene terephthalate film (manufactured by Toray industries inc., trade name "LUMIRRORS10" as a low thermal shrinkage base layer) with a thickness of 30 μm after drying using a coater. , PET film with surface processing for printing, thickness 38μm, rigidity at 80°C 1.41×10 5 N / m) and dried to form an adhesive layer. Then, a biaxially stretched polyester film (manufactured by Toyobo Co., Ltd., trade name "SPACECLEANS 7200", thickness 30 μm, shrinkage ratio [A (% )] and the shrinkage ratio [B (%)] in the direction perpendicul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com