Film and adhesive/bonding sheet

A technology of adhesive sheets and films, which is applied in the direction of adhesives, thin material processing, synthetic resin layered products, etc., and can solve problems such as difficulty in recycling, deformation, and reattachment of adhesive sheets to adherends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

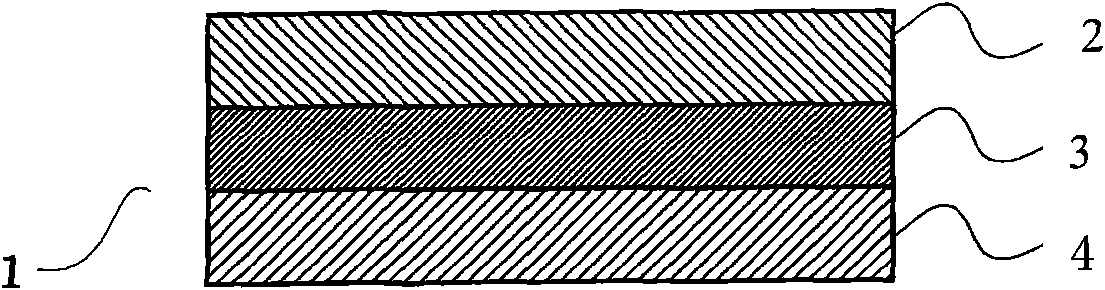

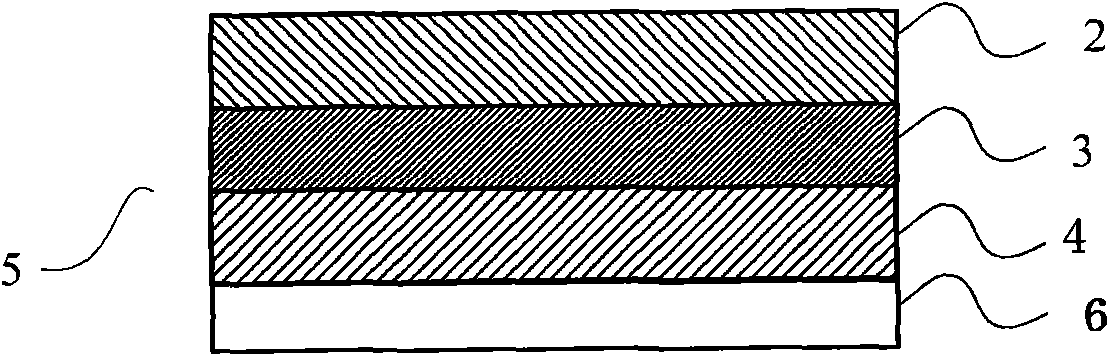

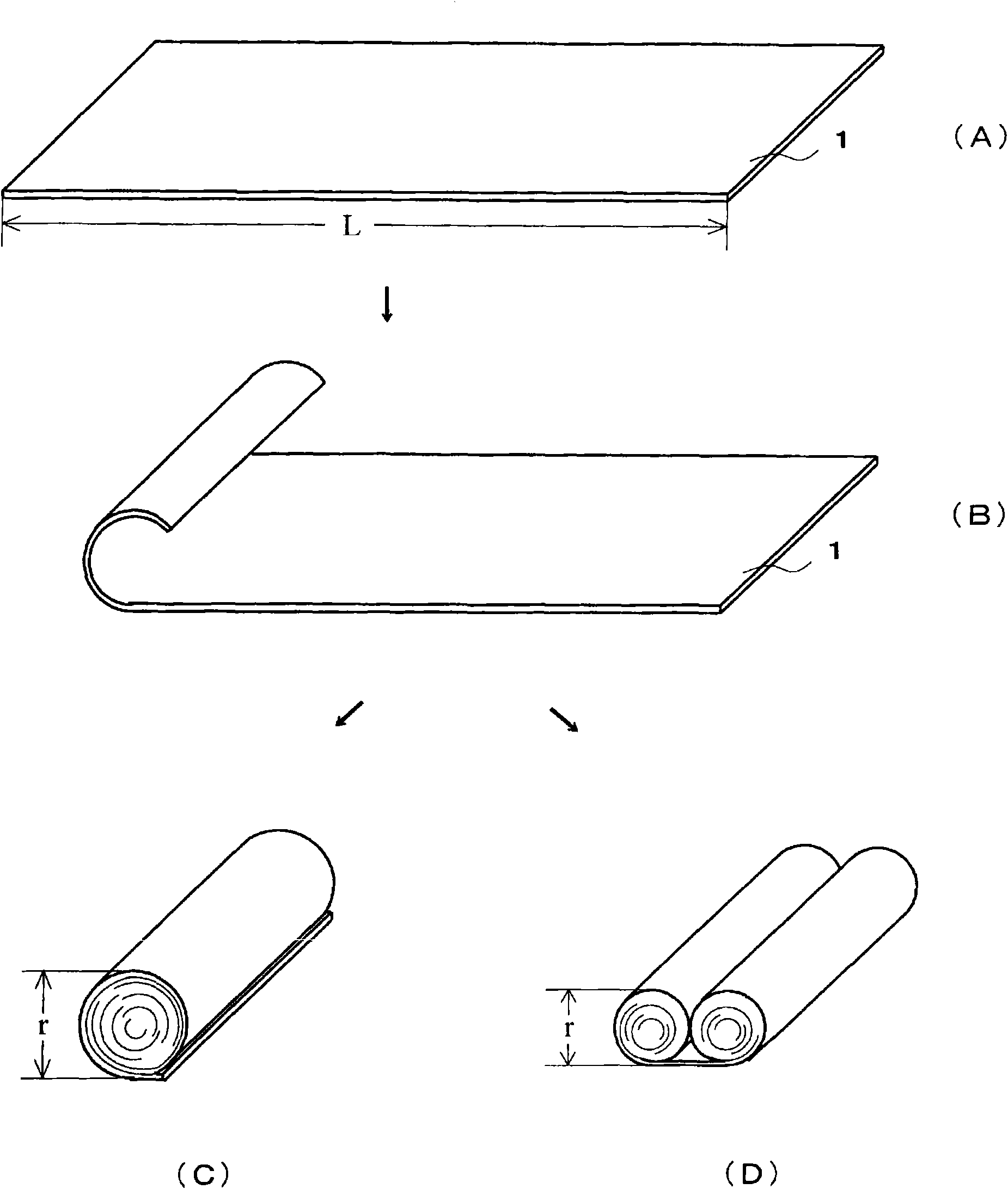

Method used

Image

Examples

Embodiment 1

[0104] As shown in Table 1, Spaceclean S7200 (thickness: 30 μm) manufactured by Toyobo Co., Ltd. (the product of Young’s modulus and thickness is 102000 N / m) was used as the heat-shrinkable base material. As the alcohol-based adhesive, Lumirror S105 (38 μm in thickness) manufactured by TORAY INDUSTRIES, INC., which is a non-heat-shrinkable base material, was laminated on the heat-shrinkable base material to obtain a film.

Embodiment 2

[0106] A film was obtained in the same manner as in Example 1, except that the non-heat-shrinkable substrate was Lumirror E10 (thickness: 12 μm) manufactured by TORAY INDUSTRIES, INC.

Embodiment 3

[0108] A film was obtained in the same manner as in Example 1 except that the adhesive resin layer was formed of an acrylic adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com