Flax and viscose elastic fabric

A viscose and fabric technology, applied in fabric surface trimming, textile material treatment, textile material continuous treatment, etc., can solve the problems of monotonous style, easy to wrinkle, hard hand feeling of linen viscose elastic fabric, etc., to reduce energy consumption , Improve stability, improve grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

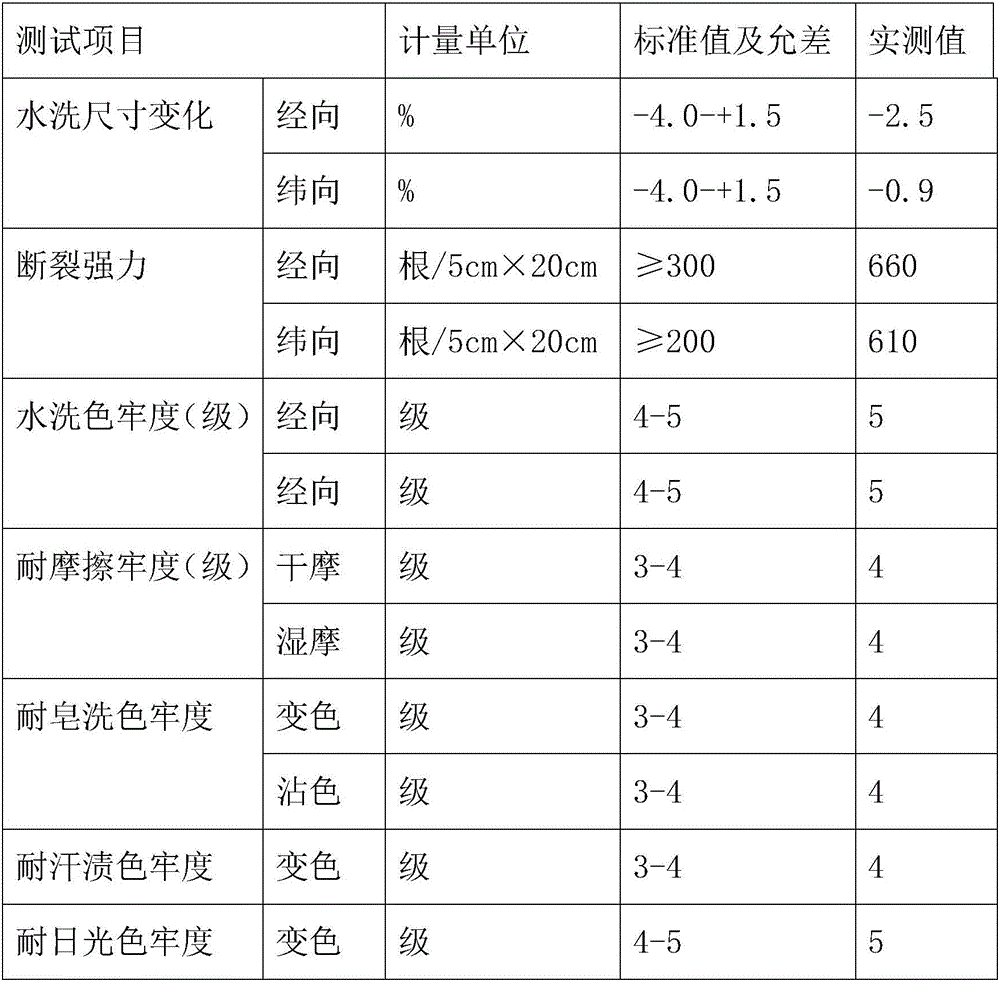

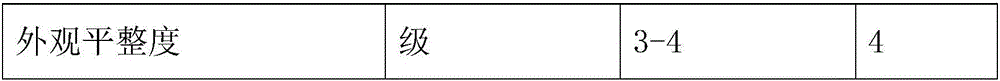

Examples

Embodiment 1

[0021] A linen viscose elastic fabric, the fabric is made by blending linen viscose blended yarn and spandex elastic yarn, and the content of spandex elastic yarn is 3wt%, and then pre-treatment, dyeing, soft finishing, drying and setting get;

[0022] Wherein, in the pretreatment, biological enzymes are used to carry out the cold stacking and oxygen bleaching process, and the cold stacking process includes: padding the enzyme decooking solution at 50°C, two dipping and two rolling, the residual rate is 90%, and the enzyme decooking The solution includes: desizing enzyme 4g / L, flax degumming enzyme 10g / L, cellulase 0.5g / L, enzyme activator 0.3g / L, penetrant 3g / L, piled at room temperature at a speed of 6r / min after rolling Set aside for 20 hours; the oxygen bleaching process includes: padding enzyme refining solution, the enzyme refining solution includes: compound scouring enzyme 8g / L, penetrant 1g / L, rolled and placed at 60°C at a speed of 6r / min 1h, wash with water at 80°C...

Embodiment 2

[0027] A linen viscose elastic fabric, the fabric is made by blending linen viscose blended yarn and spandex elastic yarn, and the content of spandex elastic yarn is 10wt%, and then pre-treatment, dyeing, soft finishing, drying and setting get;

[0028] Wherein, in the pretreatment, biological enzymes are used to carry out the cold stacking and oxygen bleaching process, and the cold stacking process includes: padding and rolling the enzyme decooking solution at 60°C, two dipping and two rolling, the excess rate is 80%, and the enzyme decooking The solution includes: desizing enzyme 6g / L, flax degumming enzyme 8g / L, cellulase 1g / L, enzyme activator 0.1g / L, penetrant 5g / L, and stacked at room temperature at a speed of 5r / min after rolling 25 hours; the oxygen bleaching process includes: padding enzyme refining solution, the enzyme refining solution includes: compound scouring enzyme 5g / L, penetrant 2g / L, after rolling, place it at a speed of 7r / min at 50°C for 0.5 h, washed wit...

Embodiment 3

[0033] A linen viscose elastic fabric, the fabric is made by blending linen viscose blended yarn and spandex elastic yarn, and the content of spandex elastic yarn is 6wt%, and then pre-treatment, dyeing, soft finishing, drying and setting get;

[0034] Among them, biological enzymes are used in the pretreatment to carry out cold stacking and oxygen bleaching processes, and the cold stacking process includes: padding enzyme decooking solution at 55°C, two dipping and two rolling, the residual rate is 85%, and the enzyme decooking The solution includes: desizing enzyme 5g / L, flax degumming enzyme 9g / L, cellulase 0.7g / L, enzyme activator 0.2g / L, penetrant 4g / L, after rolling at room temperature at a speed of 5.5r / min Stacked for 22 hours; the oxygen bleaching process includes: padding enzyme refining solution, the enzyme refining solution includes: compound scouring enzyme 7g / L, penetrant 1.5g / L, after rolling, at 55°C at 6.5r / min Rotate and place for 0.7h, wash with water at 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com