Solvent-free bicomponent road marking paint

A road marking, two-component technology, applied in the field of coatings, can solve the problems of poor adhesion, spraying polyurea elastomer road marking paint, etc., to achieve outstanding weather resistance, overcome unsatisfactory aging resistance, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

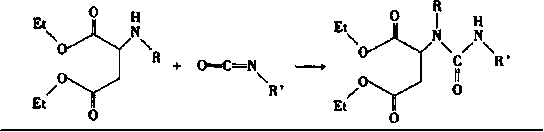

Method used

Image

Examples

Embodiment 1

[0042] Add 30kg of polyaspartate polyurea resin, 0.8kg of organic bentonite, 1.5kg of polyamide wax, 0.2kg of polycarboxylate ammonium salt, 0.3kg of silicone defoamer, and 0.2kg of silicone wetting agent into the reactor in sequence , use a disperser to stir at a low speed, and the speed of the disperser is 200 rpm, until the mixture is uniform.

[0043] Add 20kg of rutile titanium dioxide, 10kg of 800-mesh heavy calcium, and 22kg of 400-mesh spherical quartz into the above reaction kettle in sequence, adjust the speed of the disperser to 1000 rpm, and stir until the mixture is uniform; then adjust the stirring speed of the disperser to To medium speed, the rotating speed is 500 rpm, slowly add hollow glass microspheres S38HS 5kg, stir for 20 minutes, and obtain the main paint;

[0044] Stir the above-mentioned main paint at a low speed, and the speed of the disperser is 200 rpm, until all the large bubbles and micro-bubbles in it disappear, and the volume of the main paint d...

Embodiment 2

[0050] Add 33kg of polyaspartate polyurea resin, 0.5kg of organic bentonite, 1kg of polyamide wax, 0.2kg of polycarboxylate ammonium salt, 0.2kg of silicone defoamer, and 0.1kg of silicone wetting agent into the reaction kettle in sequence , use a disperser to stir at a low speed, and the speed of the disperser is 250 rpm, until the mixture is uniform.

[0051] Add 15kg of rutile titanium dioxide, 15kg of 800-mesh heavy calcium, and 20kg of 400-mesh spherical quartz into the above reaction kettle in sequence, adjust the speed of the disperser to a high speed, and the speed of the disperser is 900 rpm, and stir until it is evenly mixed; then The stirring speed of the disperser is adjusted to medium speed, the rotating speed of the disperser is 400 rpm, slowly add 5 kg of hollow glass microspheres S38HS, and stir for 30 minutes to obtain the main paint;

[0052] Pump the above-mentioned reaction kettle to negative 0.5 atmospheric pressure, and use a disperser to stir the main pa...

Embodiment 3

[0058] Add 30kg of polyaspartate polyurea resin, 0.5kg of organic bentonite, 1kg of polyamide wax, 0.2kg of polycarboxylate ammonium salt, 0.2kg of silicone defoamer, and 0.1kg of silicone wetting agent into the reaction kettle in sequence , use a disperser to stir at a low speed, the speed of the disperser is 300 rpm, until the mixture is uniform.

[0059] Add 15kg of rutile titanium dioxide, 10kg of 800-mesh heavy calcium, and 25kg of 400-mesh spherical quartz into the above reaction kettle in sequence, adjust the speed of the disperser to a high speed, and the speed of the disperser is 1100 rpm, and stir until it is evenly mixed; then The stirring speed of the disperser is adjusted to medium speed, the rotating speed of the disperser is 600 rpm, slowly add 8 kg of hollow glass microspheres S38HS, and stir for 20 minutes to obtain the main paint;

[0060] Stir the above-mentioned main paint at a low speed, and the speed of the disperser is 200 rpm, until all the large bubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com