Patents

Literature

334results about "Planing/slotting tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

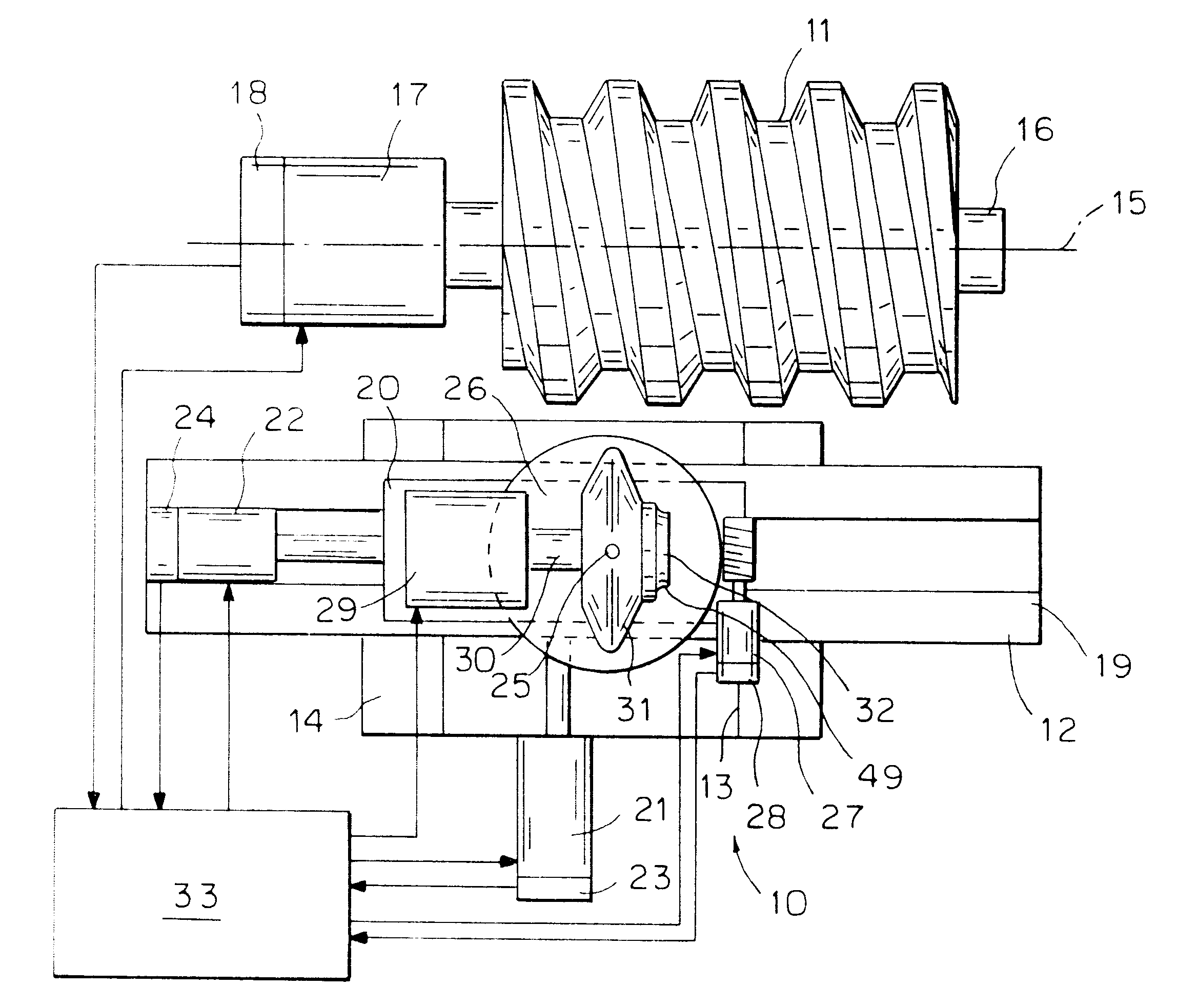

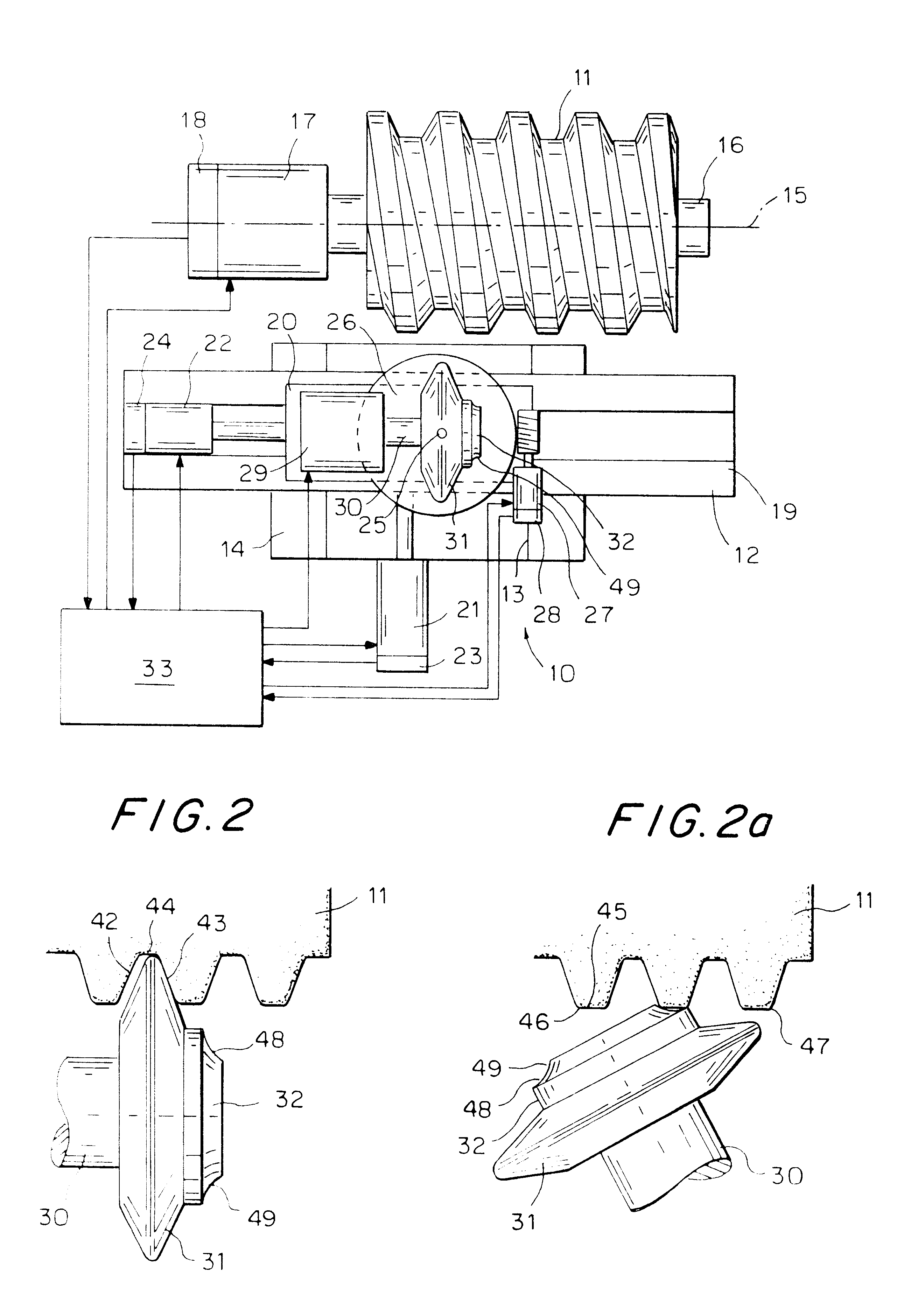

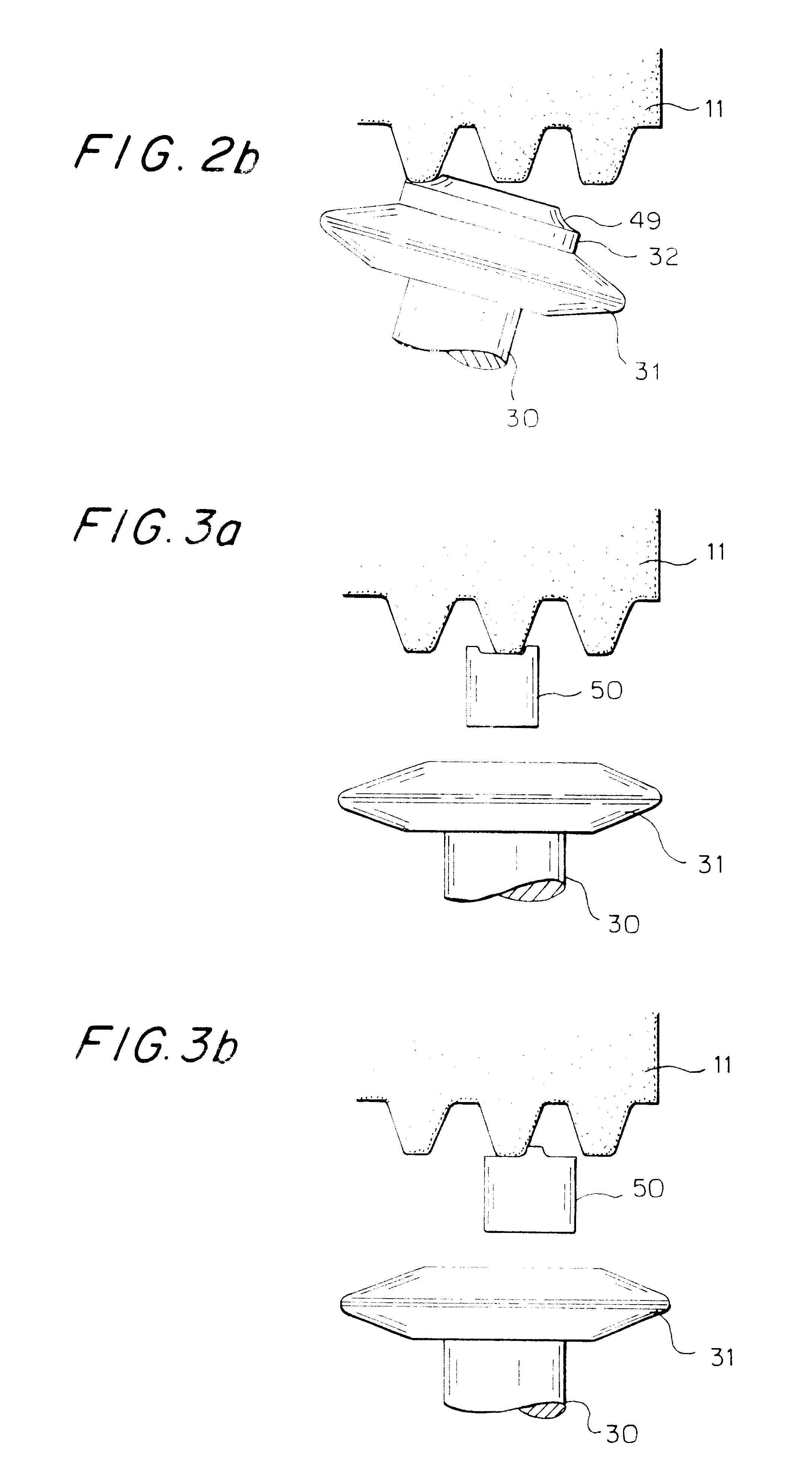

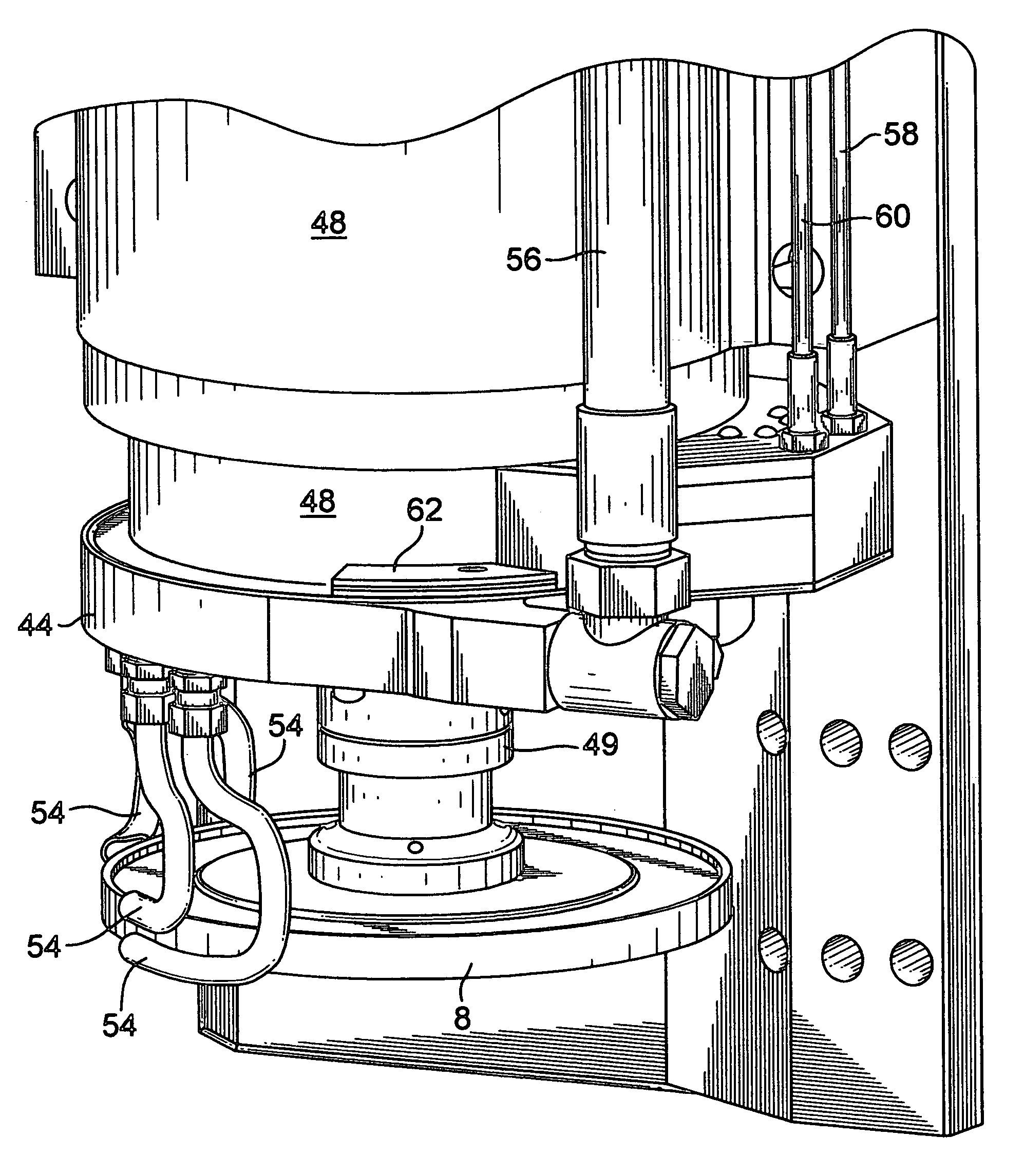

Device and method for profiling grinding worms

InactiveUS6234880B1Short dressing timeLittle effortGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A radius-forming dressing roll (32) having a frustoconical working region (48) and an adjoining concave-toroidal working region (49) is mounted on the dressing spindle (30) coaxially to a dressing disc (31). In a first step, the flanks (42, 43) of the grinding-worm thread are profiled with the disc (31). After the dressing spindle (30) has been pivoted, the two tip radii (46, 47) and the cylindrical outer circumference (45) are profiled with the dressing roll (32). With little resetting effort and high flexibility, the method permits profiling with short dressing times.

Owner:REISHAUER

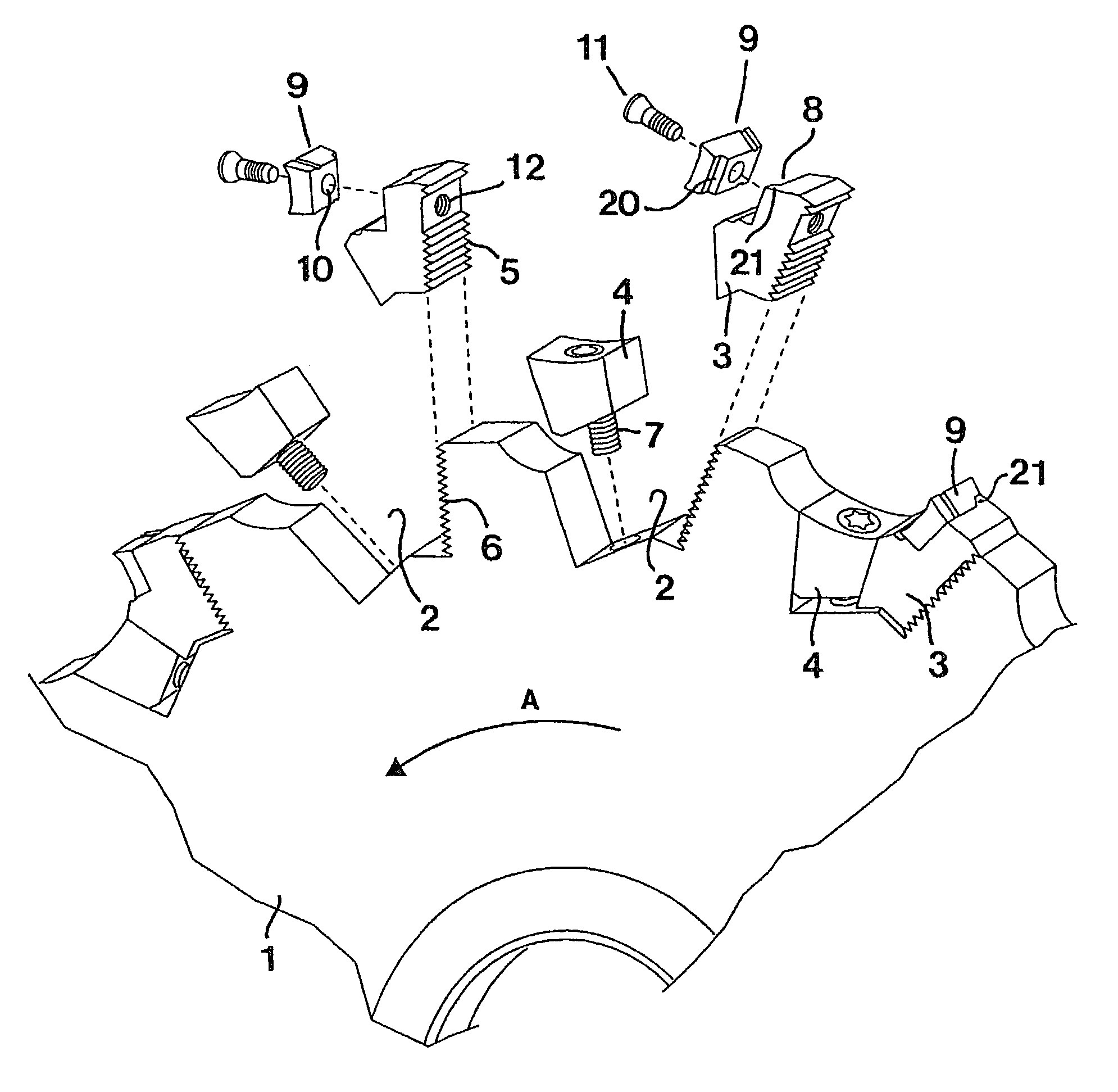

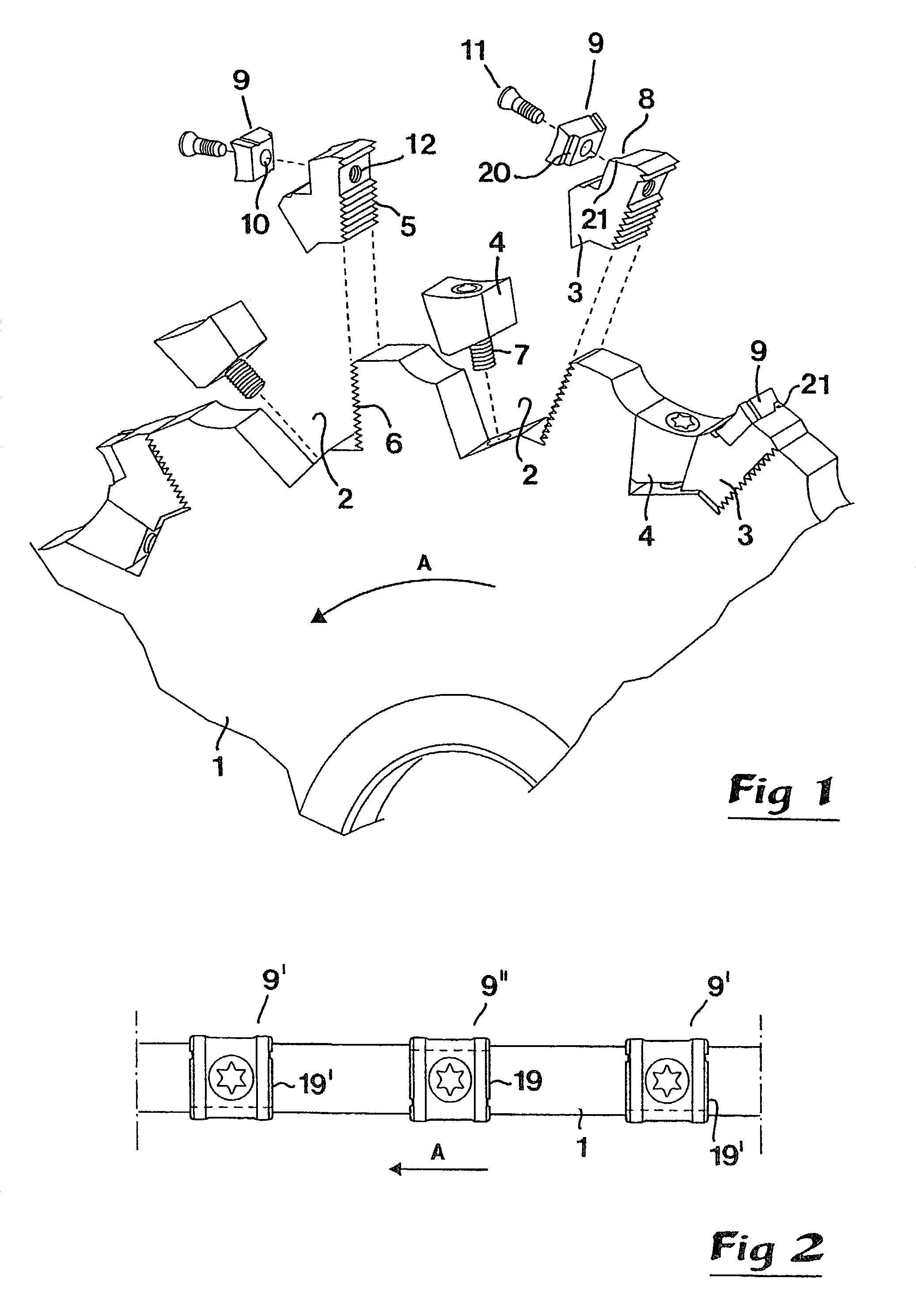

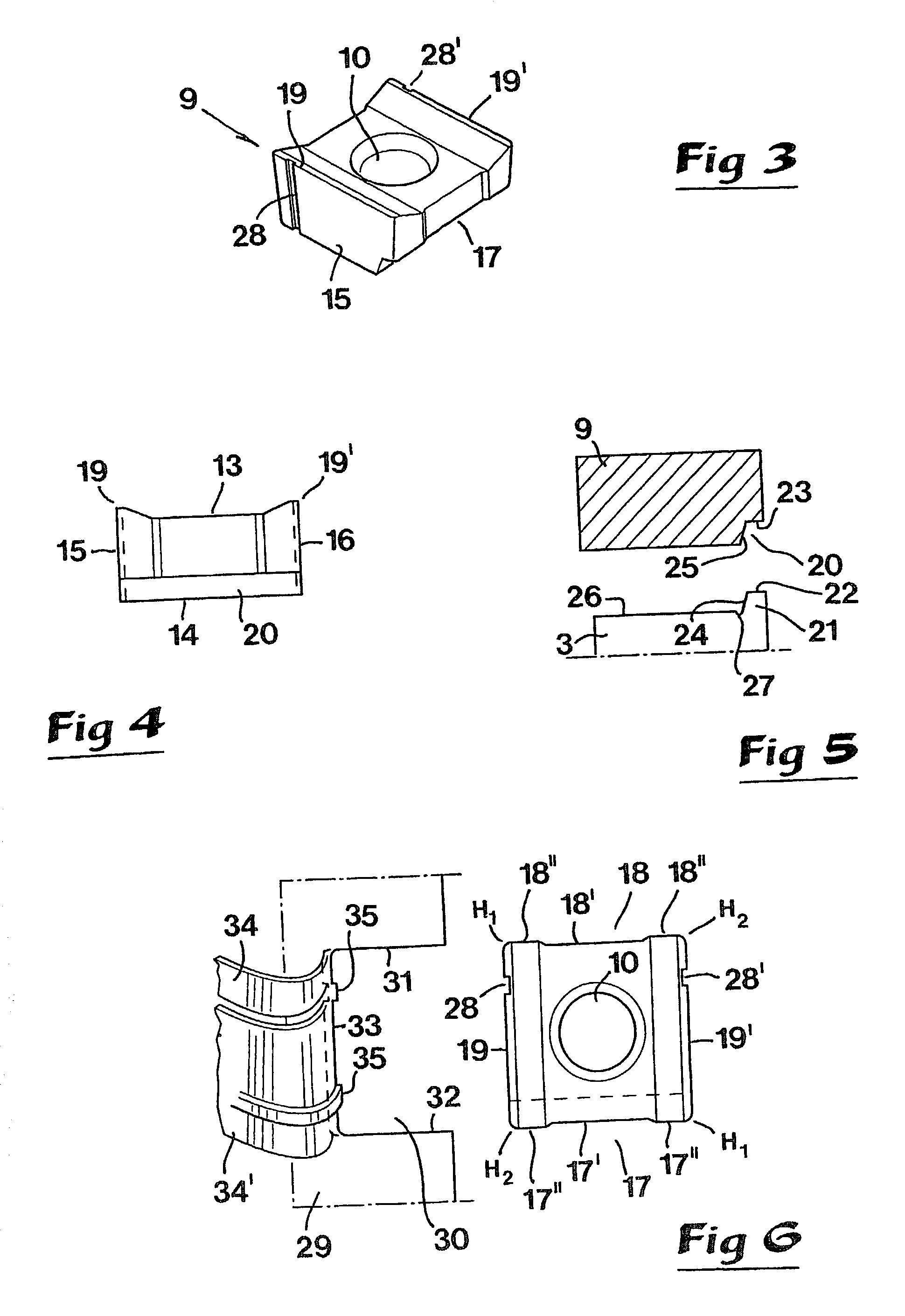

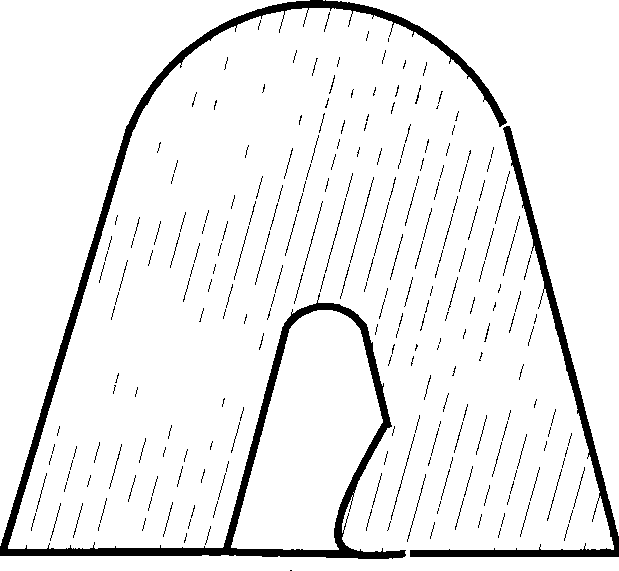

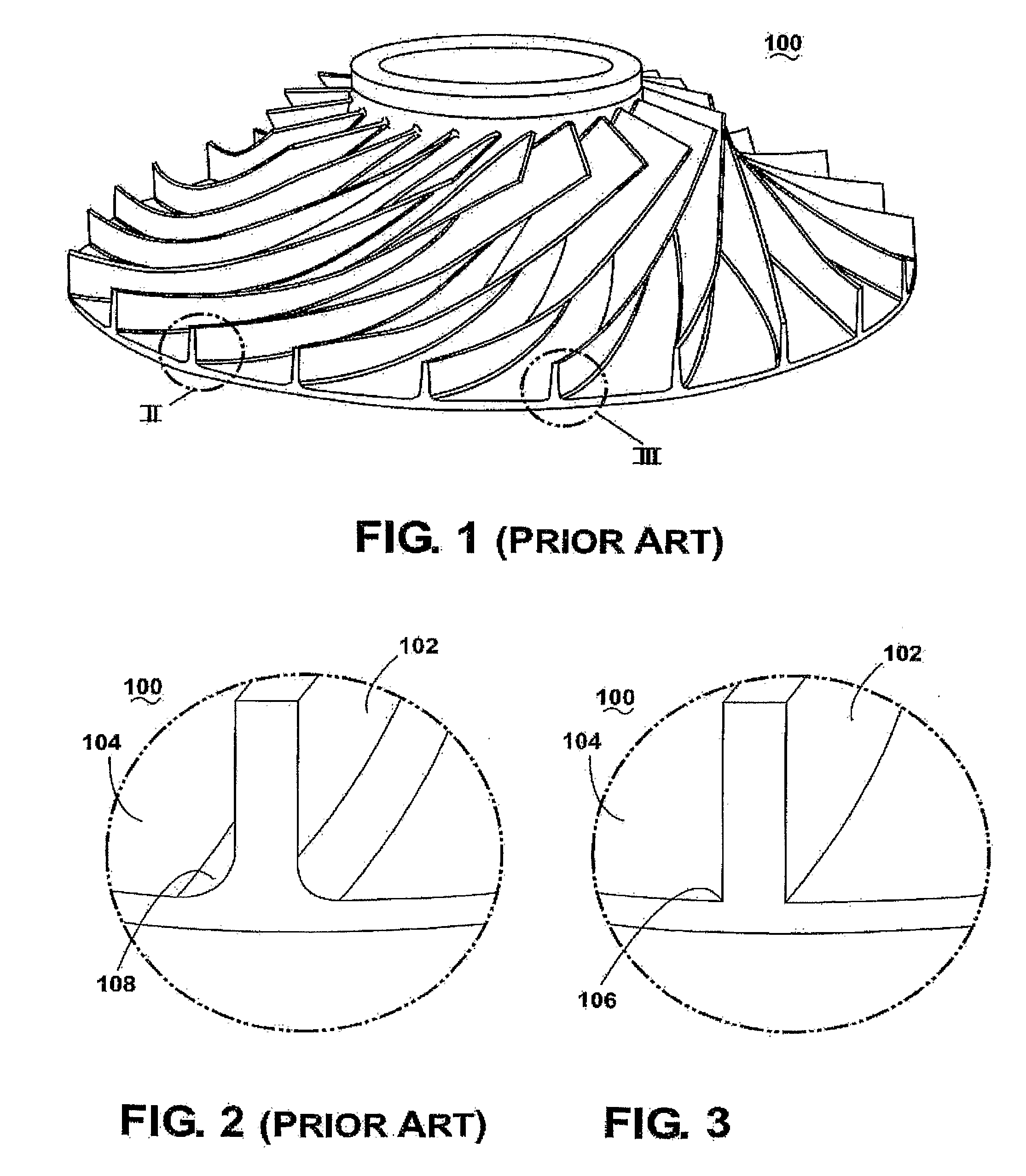

Slotting cutter and cutting insert therefor

A slotting cutter includes a circular disc having an outer periphery along which a plurality of chip channels are formed which define respective seats for receiving respective index able cutting inserts. Each insert includes a planar bottom side. Either the seat or the bottom side has a male locator portion, and the other of the seat and the bottom side has a female locator portion which receives the male locator portion to define therewith and insert-locating structure. The male and female locator portions are offset laterally from a center plane of the insert oriented perpendicular to an axis of rotation of the disc. Alternating ones of the insert-locating structures are disposed on respective opposite sides of the center plane.

Owner:HOGANAS AB +1

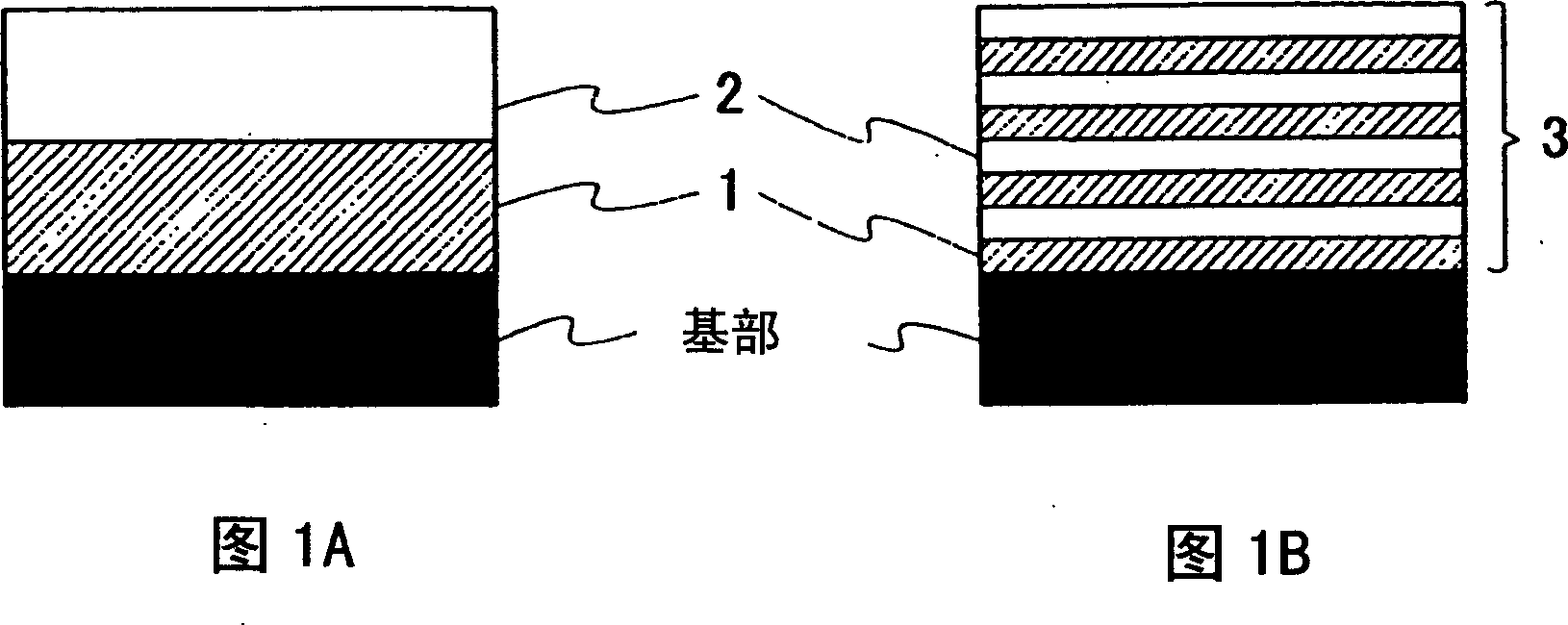

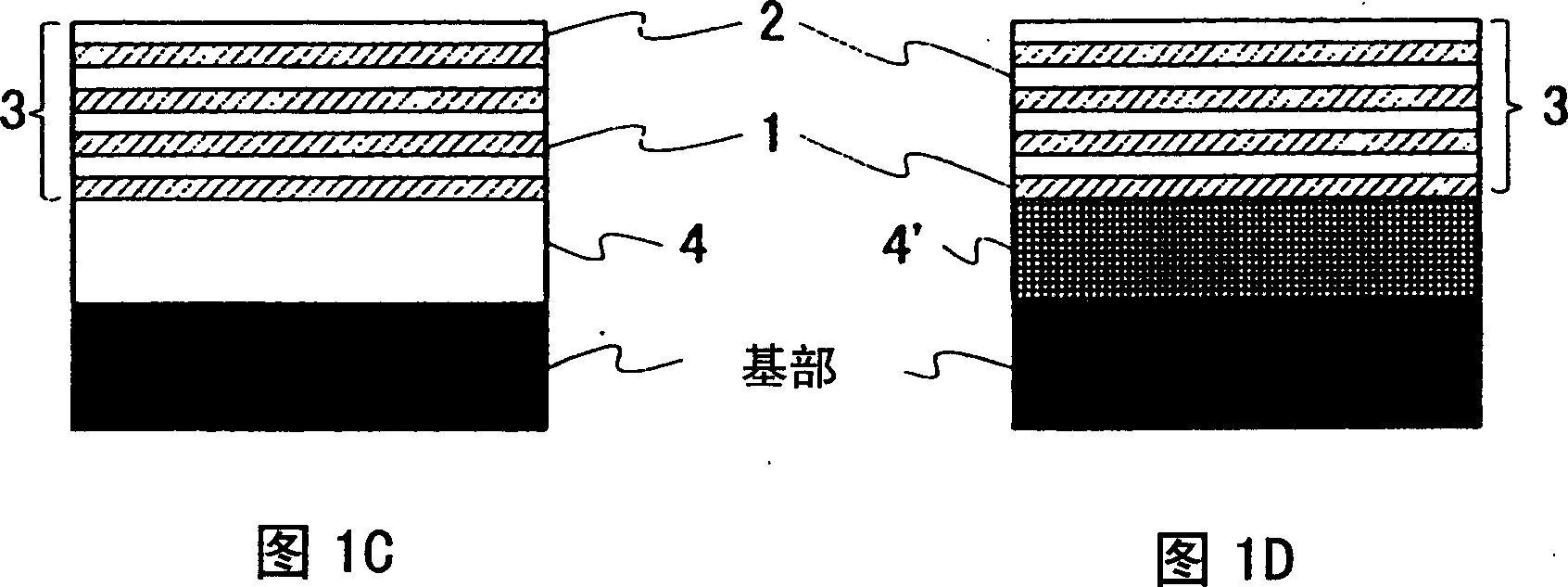

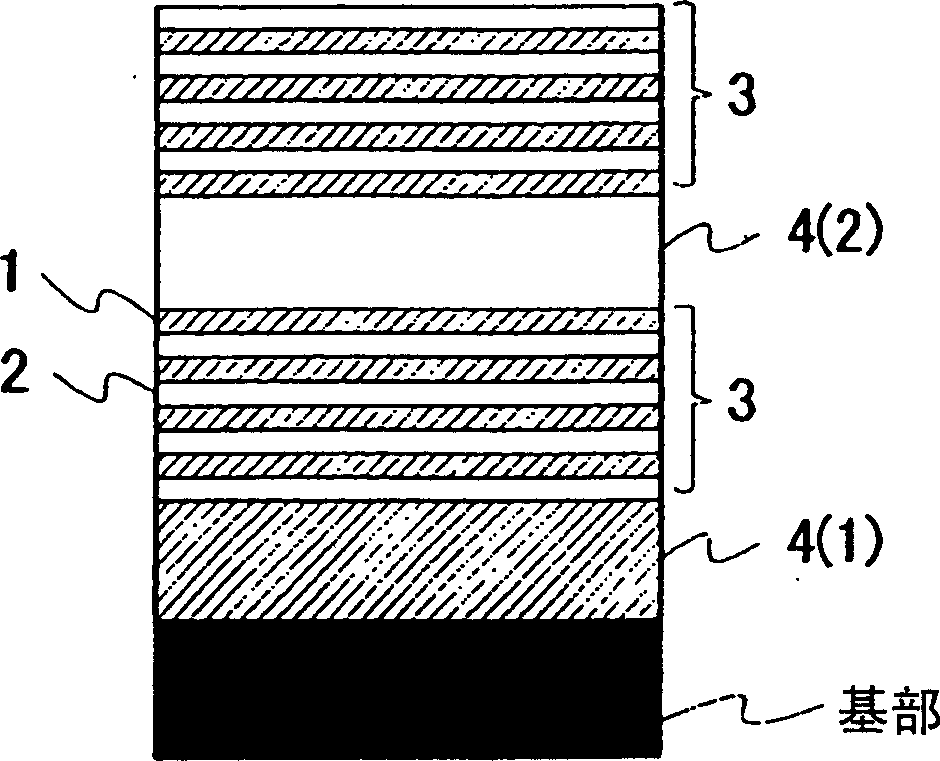

Coating tool

InactiveCN1470350AHigh hardnessImprove wear resistanceMilling cuttersVacuum evaporation coatingCarbideWear resistance

Coating-film furnished coated tools that are lubricative while maintaining resistance to wear are realized by coated tools in which a plurality of coating films is furnished on a base part. Furnished as the coating are one or more layers of, respectively: a first film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of TiSi; and a second film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of one metal M selected from Ti, Cr, and TiCr. The first film and the second film are laminated in alternation.

Owner:SUMITOMO ELECTRIC IND LTD

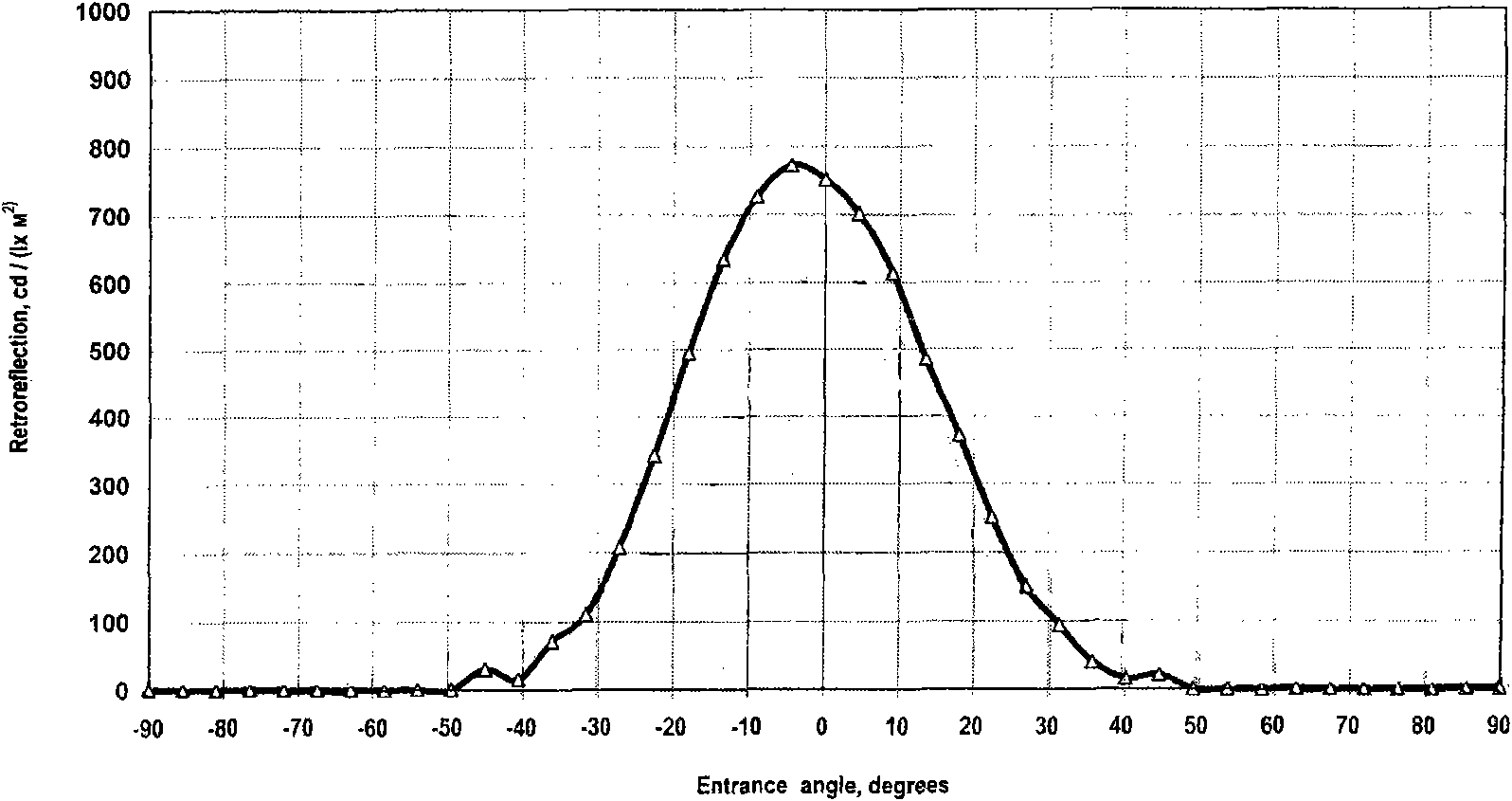

Large-size micro-prism type reflecting material die and preparation method thereof

InactiveCN101571606AReduce manufacturing costReduce the complexity of the production processVacuum evaporation coatingSputtering coatingPolymethyl methacrylateThin membrane

The invention discloses a large-size micro-prism type reflecting material die and a preparation method thereof. The method comprises a die substrate and a metallic film plated on the die substrate; compactly and equably distributed concave prism array structures are compacted on the front face of the die substrate; the metallic film plated on the die substrate is copper metallic film and nickel metallic film in sequence; the die substrate is made of polycarbonate, polymethyl methacrylate or polyimide. The invention further discloses a preparation method of the large-size micro-prism type reflecting material die; the combined technology of precise mechanical process and electro-forming technique are used so that the manufacturing cost is reduced. The large-size micro-prism type reflecting material die provided by the invention can use general cheap PVC material to manufacture large-size micro-prism type reflecting material and product in one step; therefore the difficulty of the production flow and the production cost of the reflecting material and product are reduced.

Owner:ZHEJIANG UNIV OF TECH

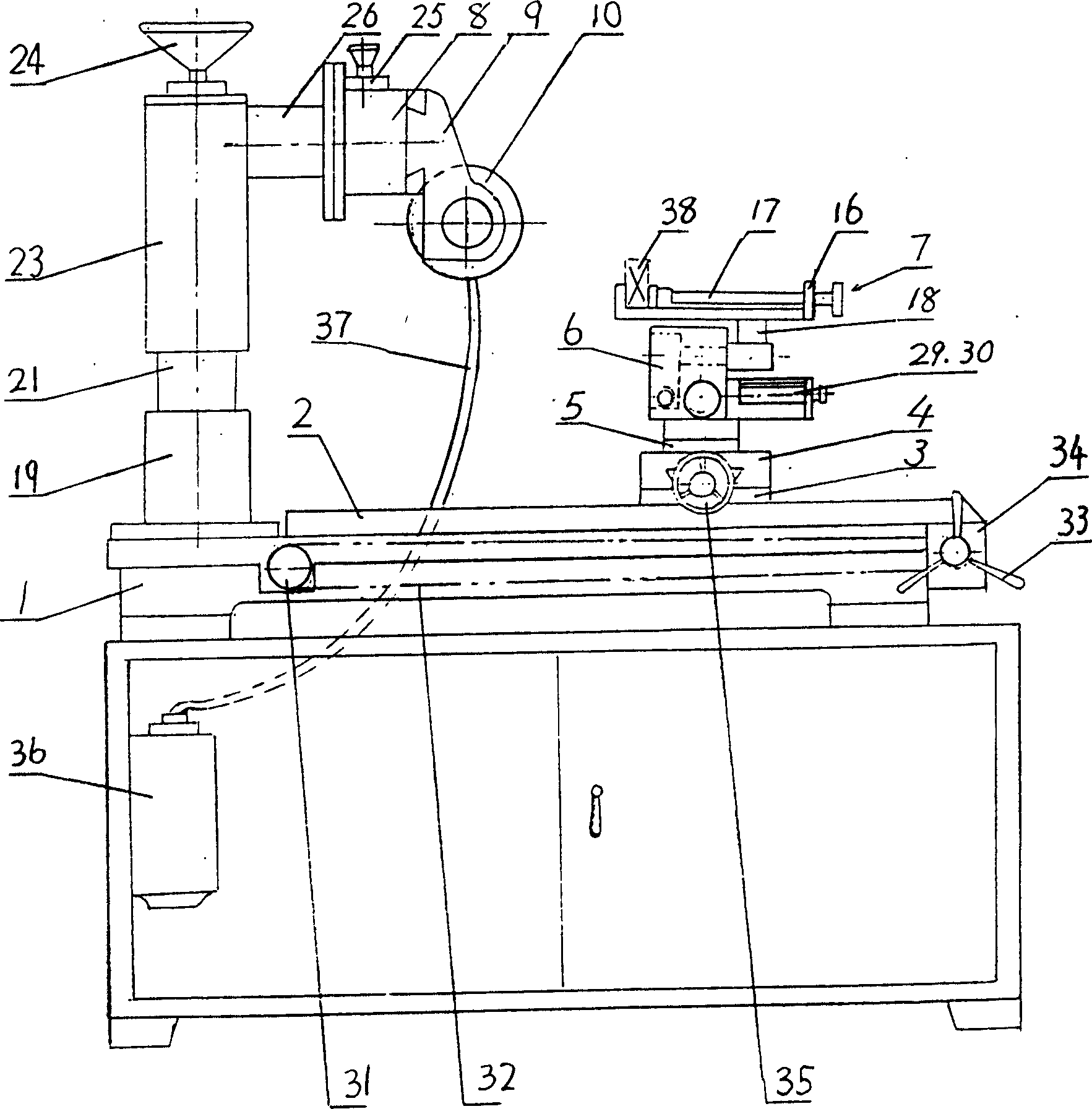

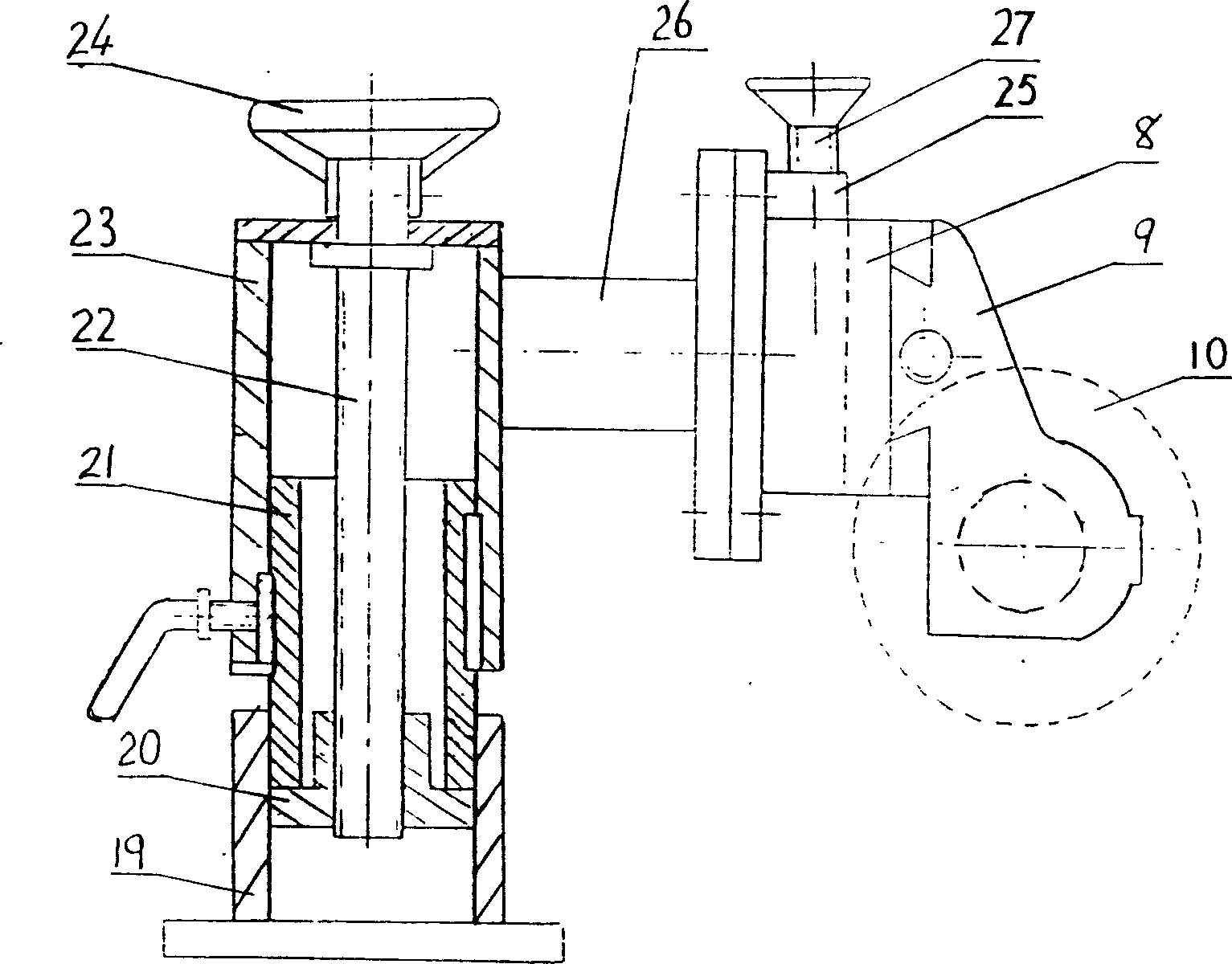

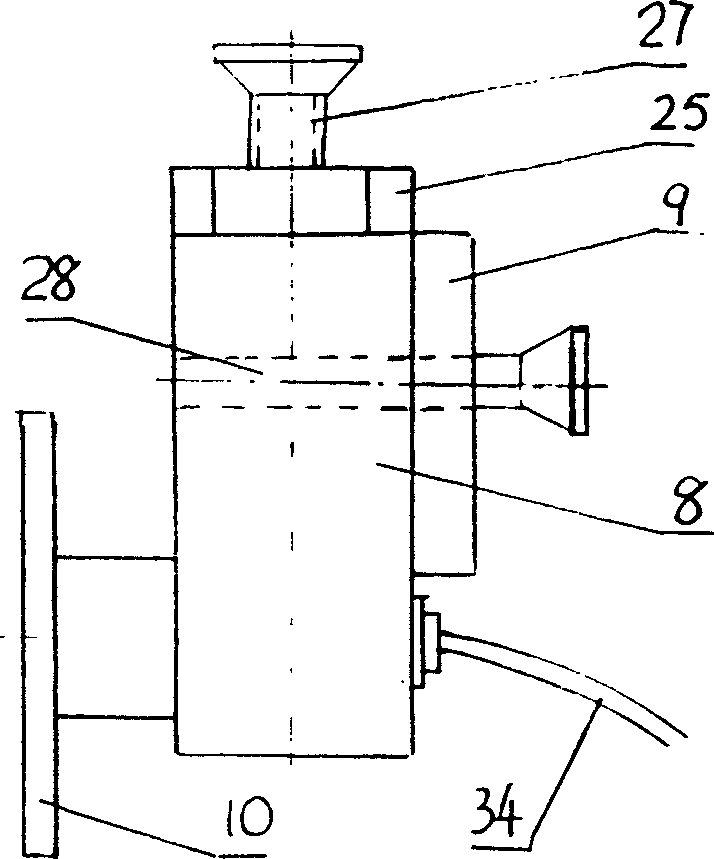

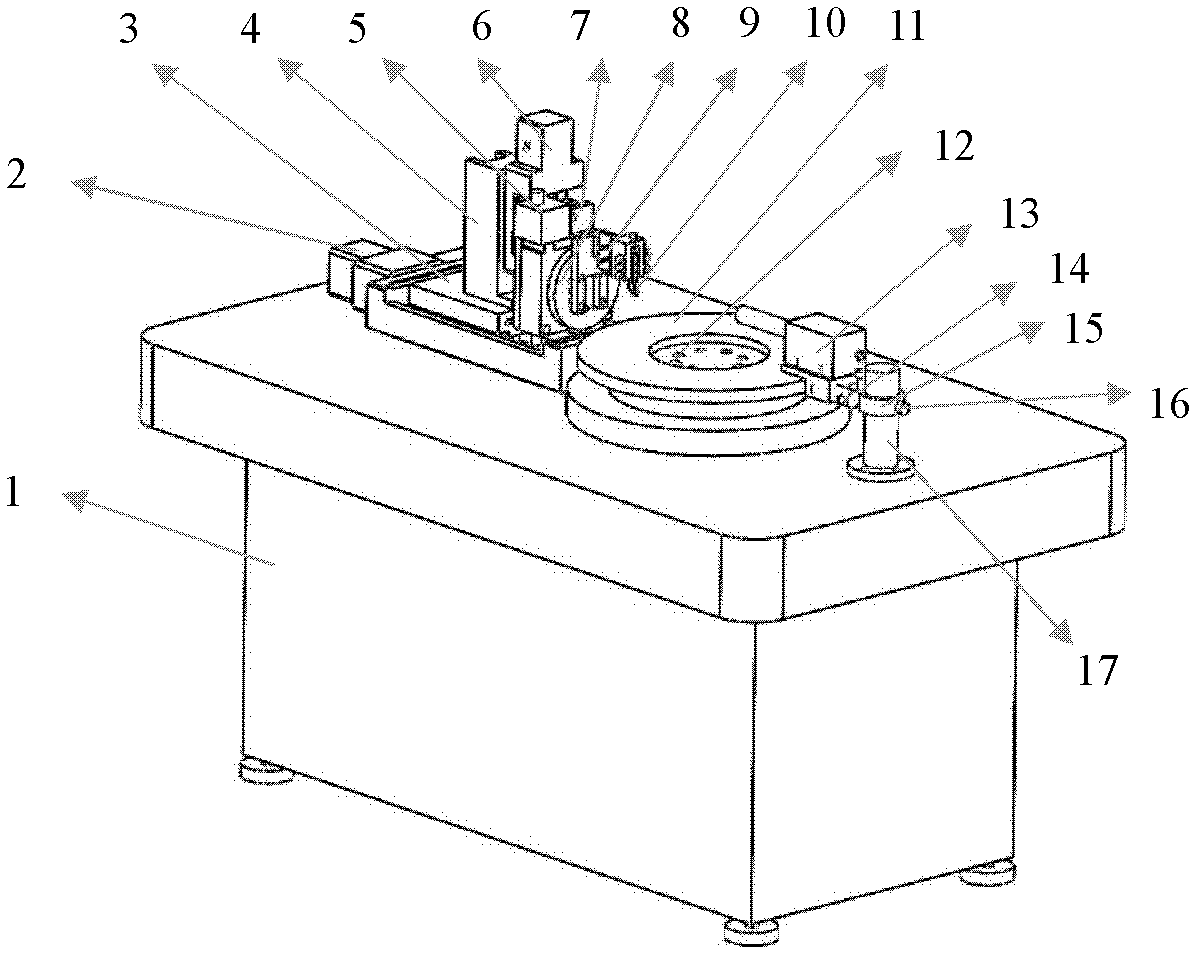

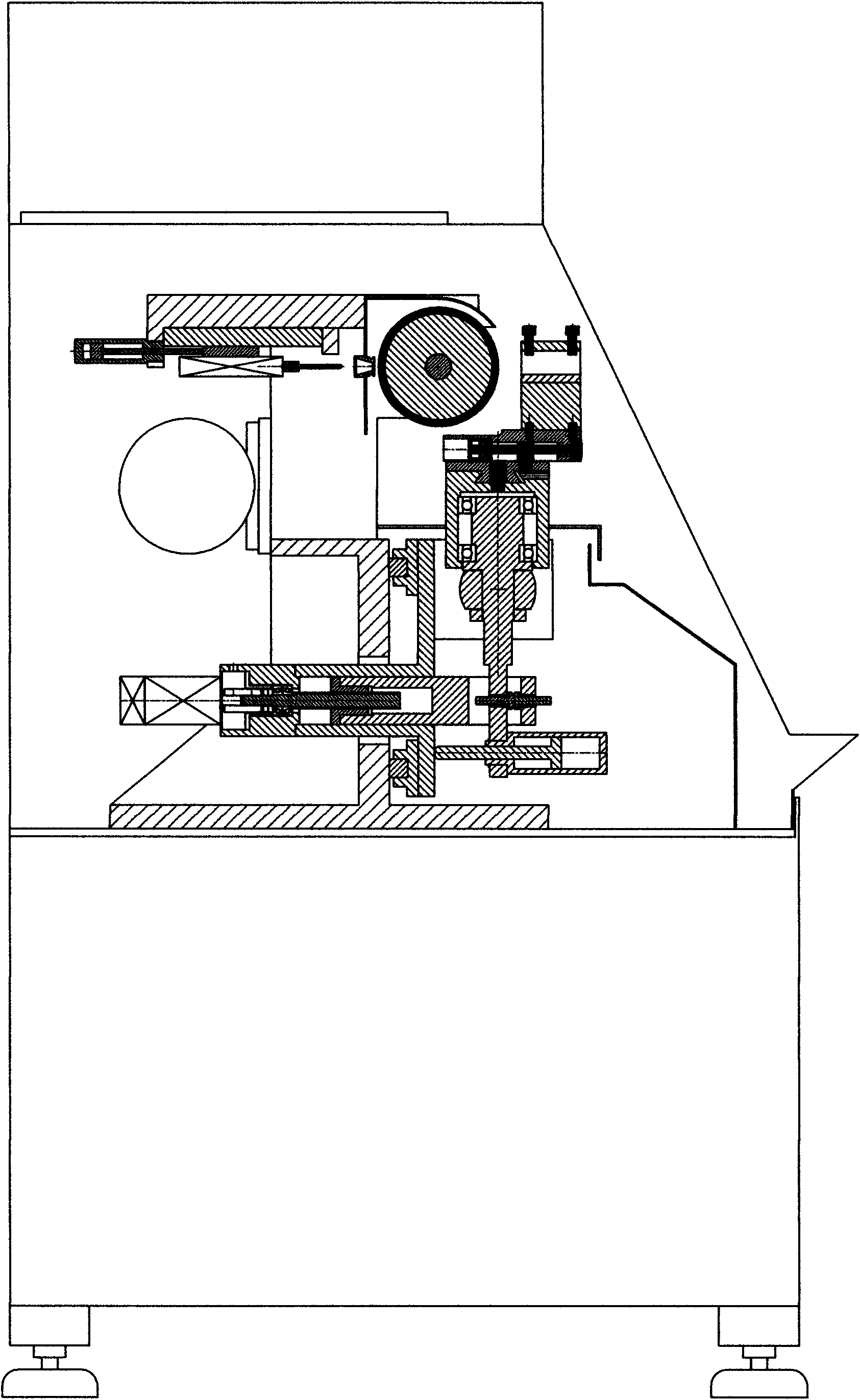

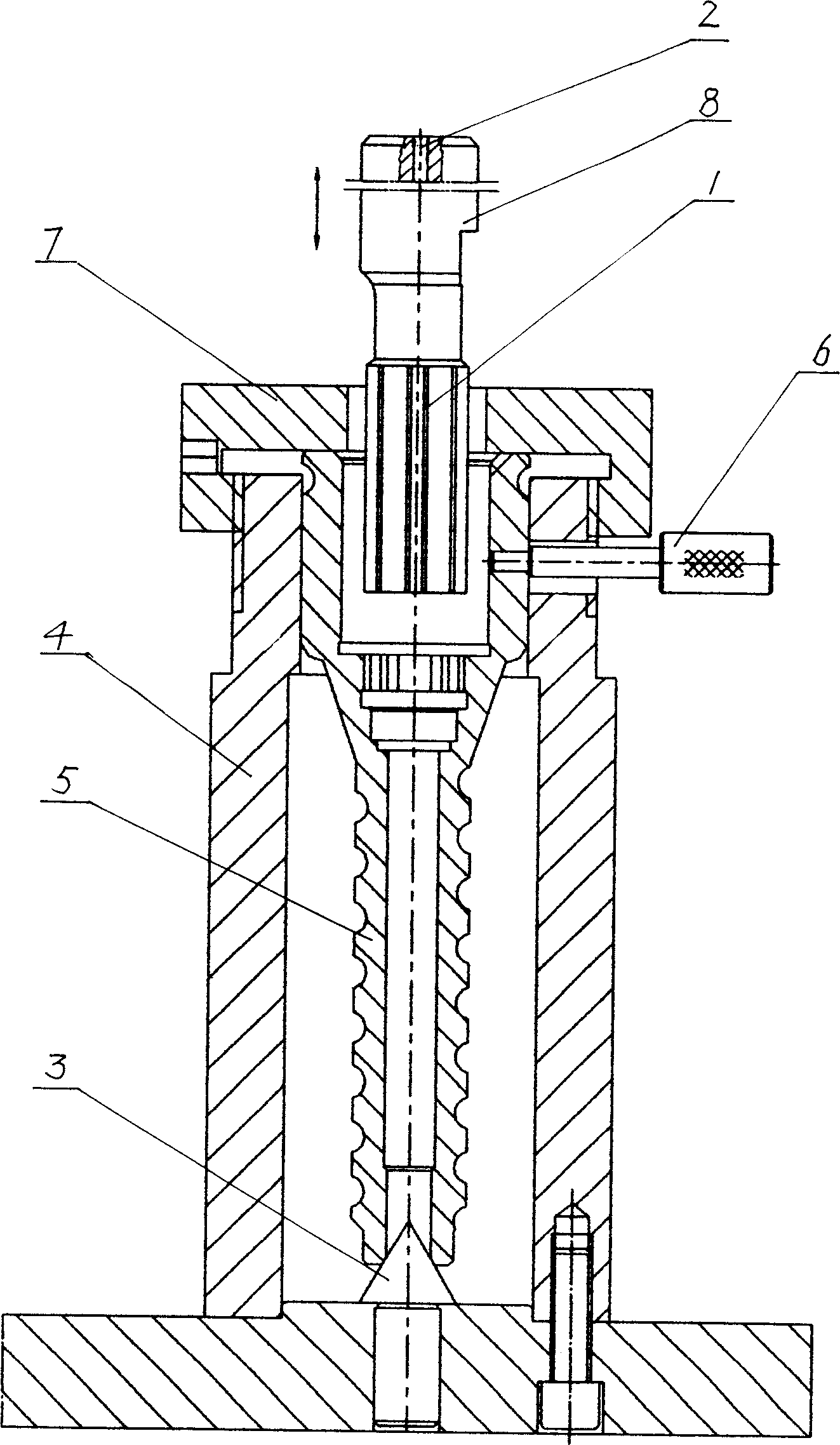

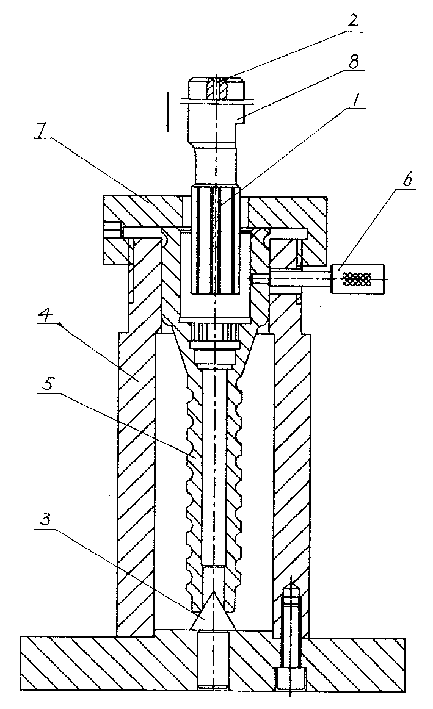

Turning tool and planer tool cutter grinding machine

InactiveCN1528563AMeet sharpening requirementsReasonable structural designPlaning/slotting toolsTurning toolsBench grinderMachine tool

The invention is a turning tool- and planning tool- blade milling machine tool, relating to cutting blade milling device. It provides a turning tool- and planning tool- blade milling machine tool, including: machine base, guide rail, longitudinal drag plate, transverse drag plate, universal clamp assembly composed of longitudinal and transverse dip adjusting mechanisms and circular rotating clamp, and assembly composed of lift mechanism and grinding head including longitudinal and transverse slide blocks and grinding wheel. It has reasonable structure and universal adjusting clamp, not only replacing artificial milling blade and heightening the cutter precision but also meeting the request of special blade form and angle.

Owner:武绩

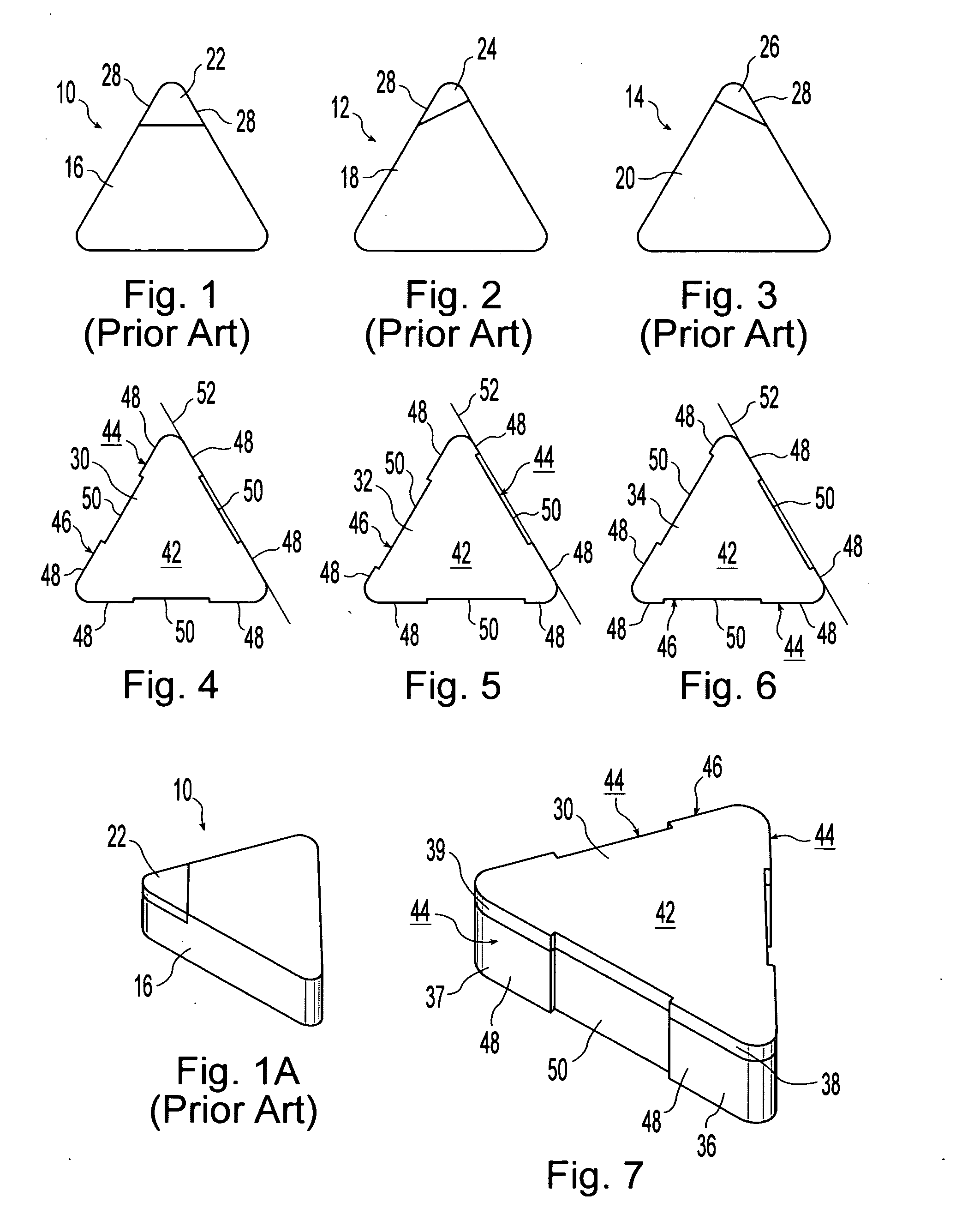

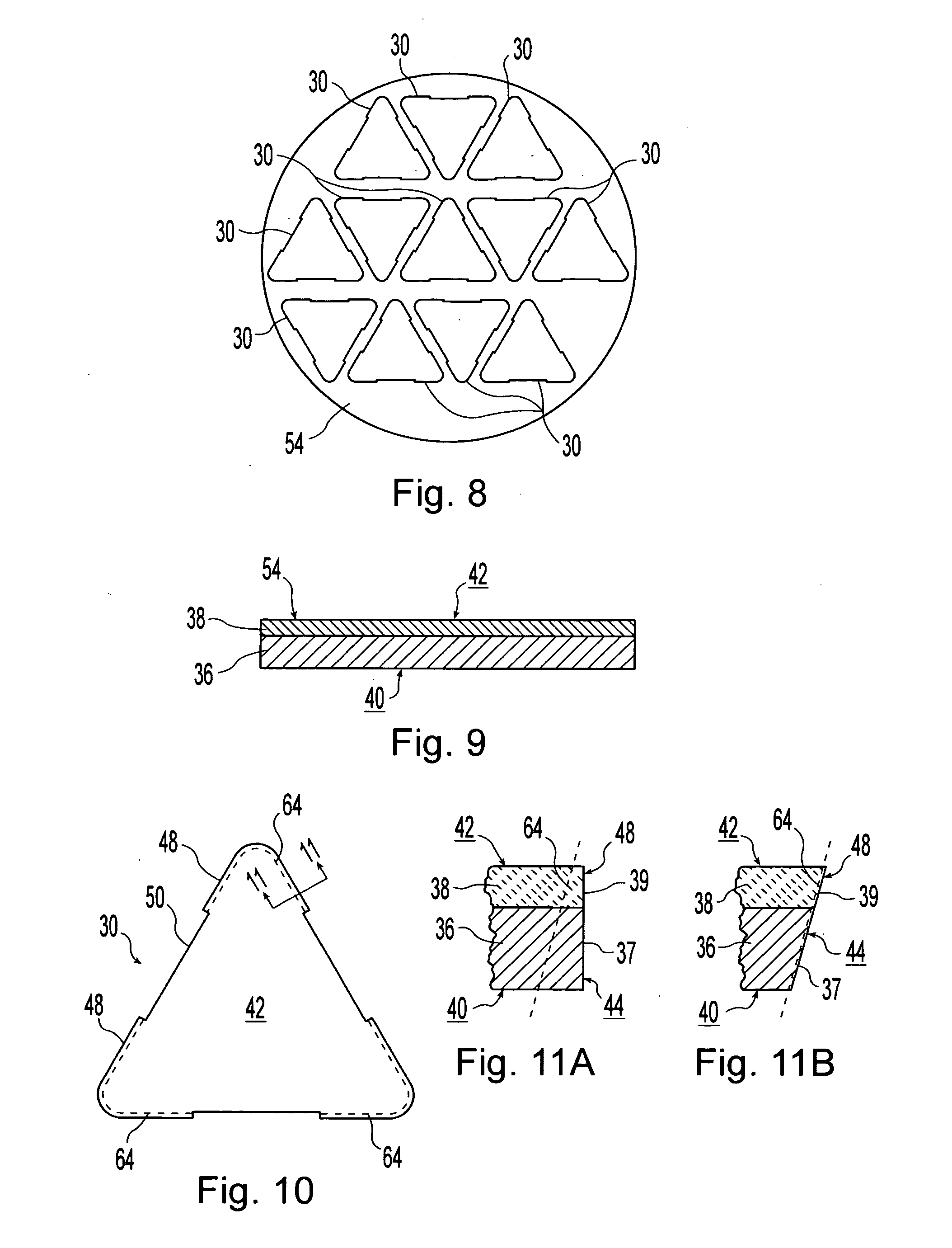

Tool insert blanks and method of manufacture

A tool insert blank including first and second major surfaces and a plurality of edge surfaces defining an outer perimeter of the blank. A first layer defines the first major surface and a first portion of the plurality of edge surfaces proximate the first major surface. A second layer harder than the first layer is disposed substantially co-extensive with the second major surface and a second portion of the plurality of edge surfaces proximate the second major surface. At least one of the edge surfaces includes a projecting portion defining a first engagement plane and a recessed portion spaced inwardly of the engagement plane whereby the grinding wheel is engageable with the projecting portion without engaging the recessed portion. The second layer can be formed out of various materials including polycrystalline diamond and cubic boron nitride materials. A method of forming a tool insert blank is also disclosed.

Owner:CORBIN MFG

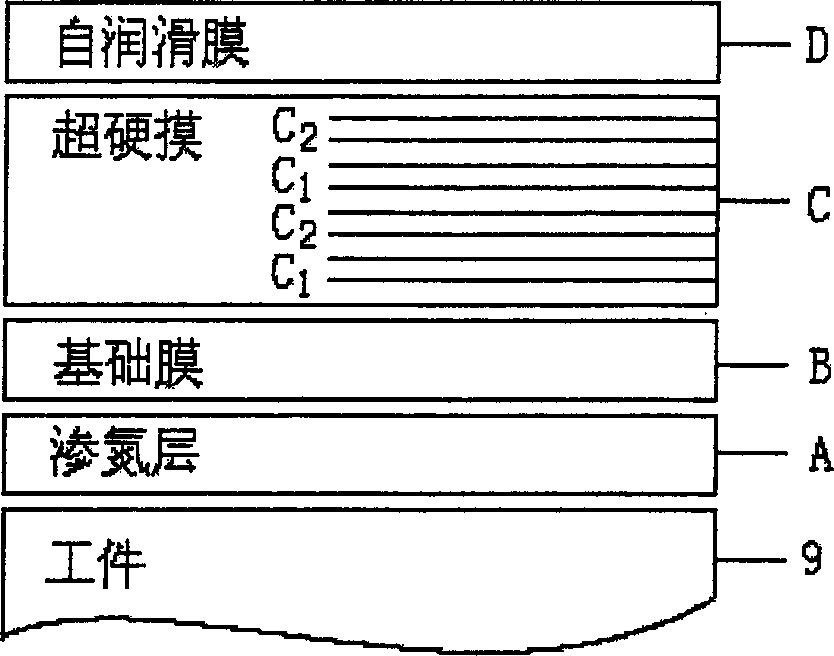

Nano superhard composite film tool with high adhesion and its deposition method

InactiveCN1776015AIncreased oxidation resistance temperatureQuality improvementMilling cuttersVacuum evaporation coatingComposite filmNanometre

The invention relates to a high adhesion nm super-hard compounding film cutting tool and the depositing. It is deposited nitride case, basal film, super-hard film, and self- lubricating film on the cutting tool. The invention has an entire metal cutting tool high quality coating blooming technology. It takes high efficiency plasma nitride-treat to enhance cutting tool basal body, and taking coating super-hard compounding film to make the film has high adhesive force. The invention could be used in kinds of mould and cutting tools.

Owner:吴大维

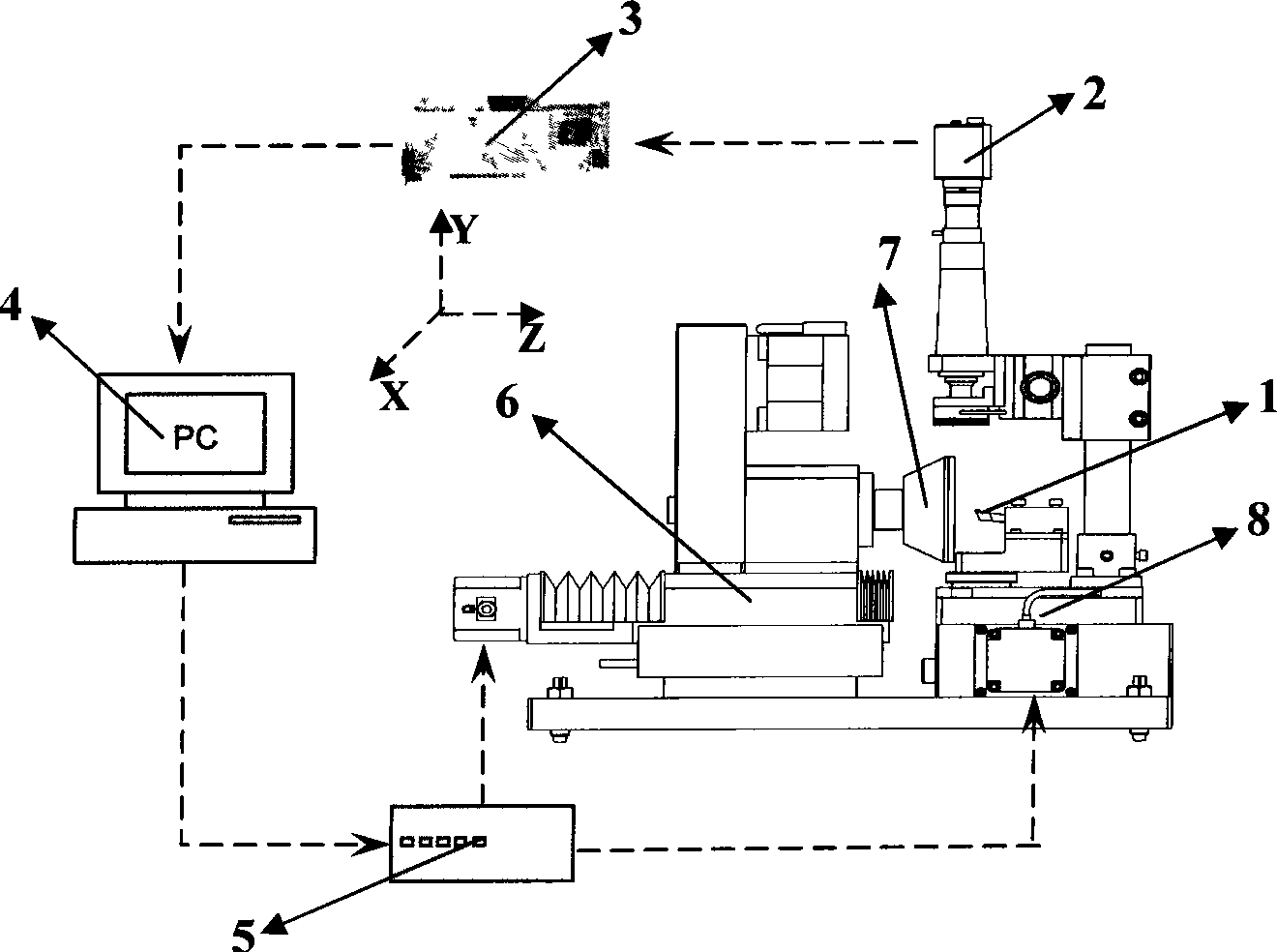

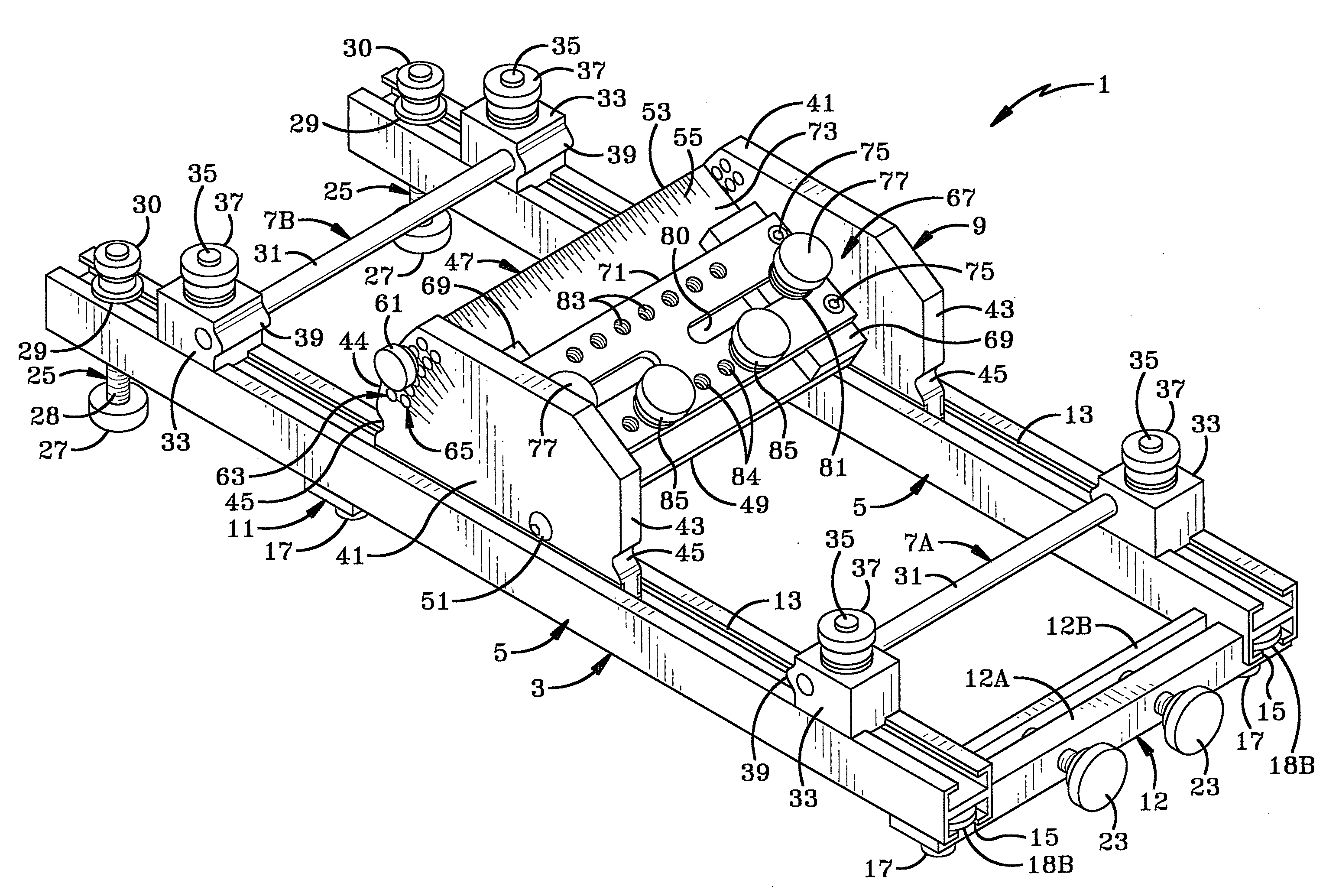

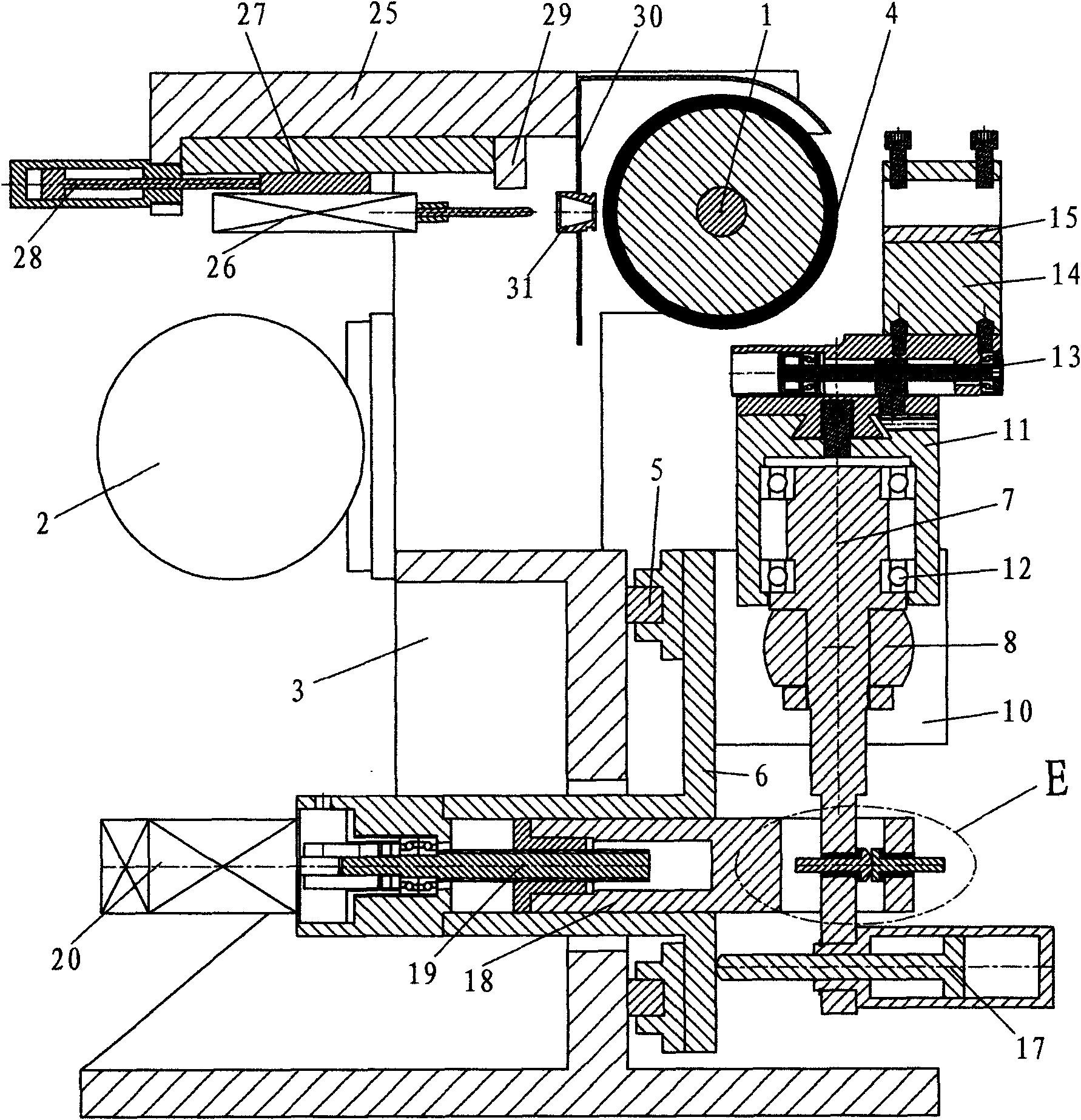

Method for preparing high-precision arc-blade diamond lathe tool

InactiveCN101530975AAvoid the influence of edge shape accuracyQuick removalPlaning/slotting toolsGrinding feed controlCcd cameraContour error

The invention discloses a method for preparing a high-precision arc-blade diamond lathe tool, and the method comprises the steps: firstly fixing the diamond lathe tool on a work bench which can rotate and swing, fixing a CCD camera above the diamond lathe tool; collecting real-time images of the diamond lathe tool to a computer by an image collection card; extracting contour lines of the arc part which needs to be processed and is arranged at the front end of the diamond lathe tool and the edge line parts at two ends for forming a contour line point group; segmenting the point group of the arc part at the front end from the extracted contour line pint group for obtaining an initial arc center of the contour of a cutting blade of the lathe tool, thereby obtaining the contour error of each point on an arc of the contour of the cutting blade of the lathe tool; adjusting the initial arc center of the lathe tool to be coincided with a rotation center of a grinding system and then fixing; driving the lathe tool to rotate and driving a grinding wheel to feed for processing the arc blade of the lathe tool according to the contour error and position information of each point on the arc. The use of the method can realize the stable, high-efficient and high-precision processing of the arc-blade diamond lathe tool.

Owner:TIANJIN UNIV

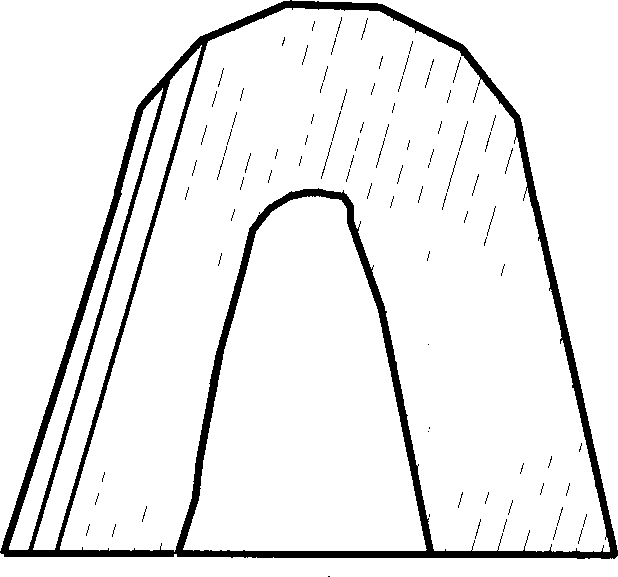

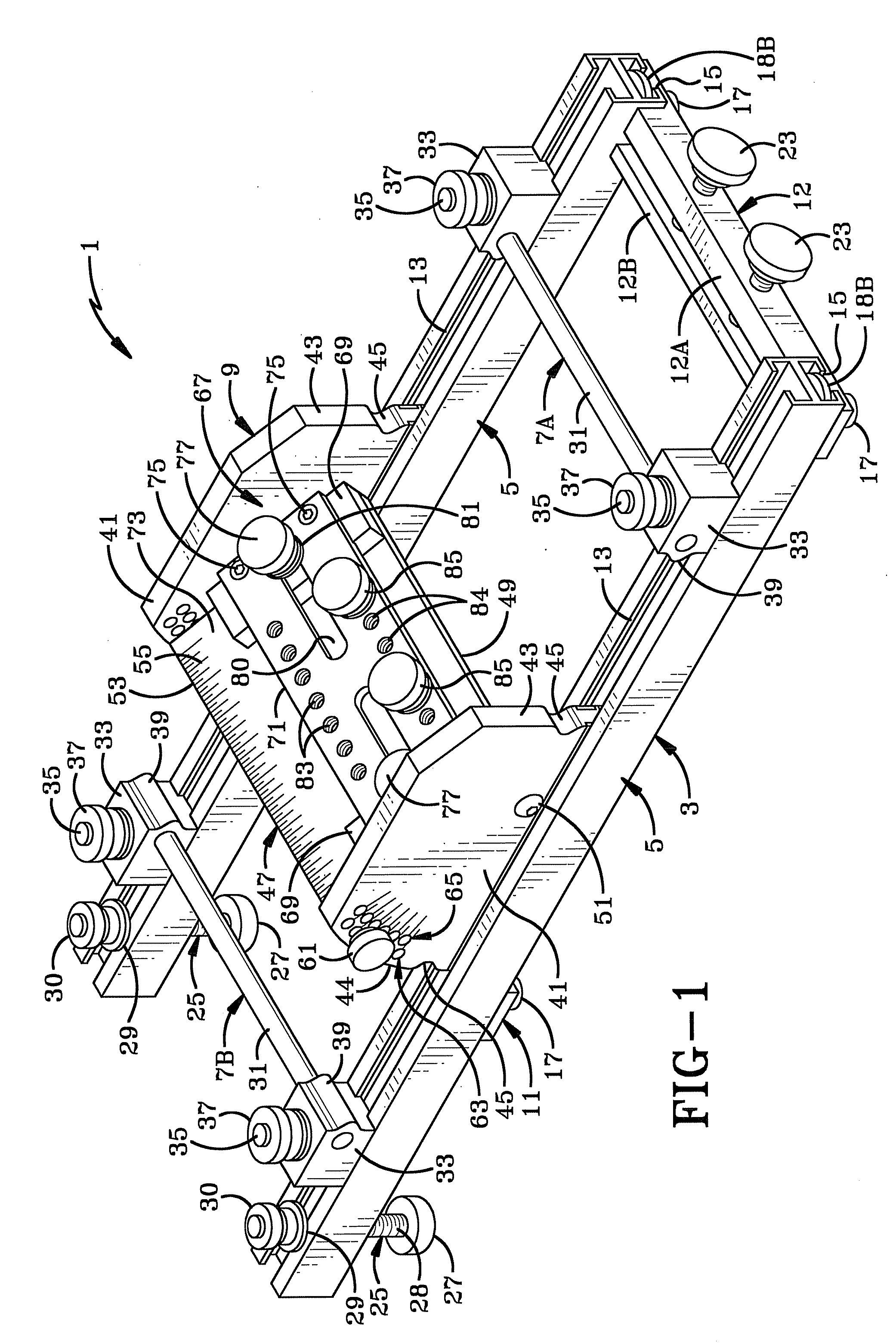

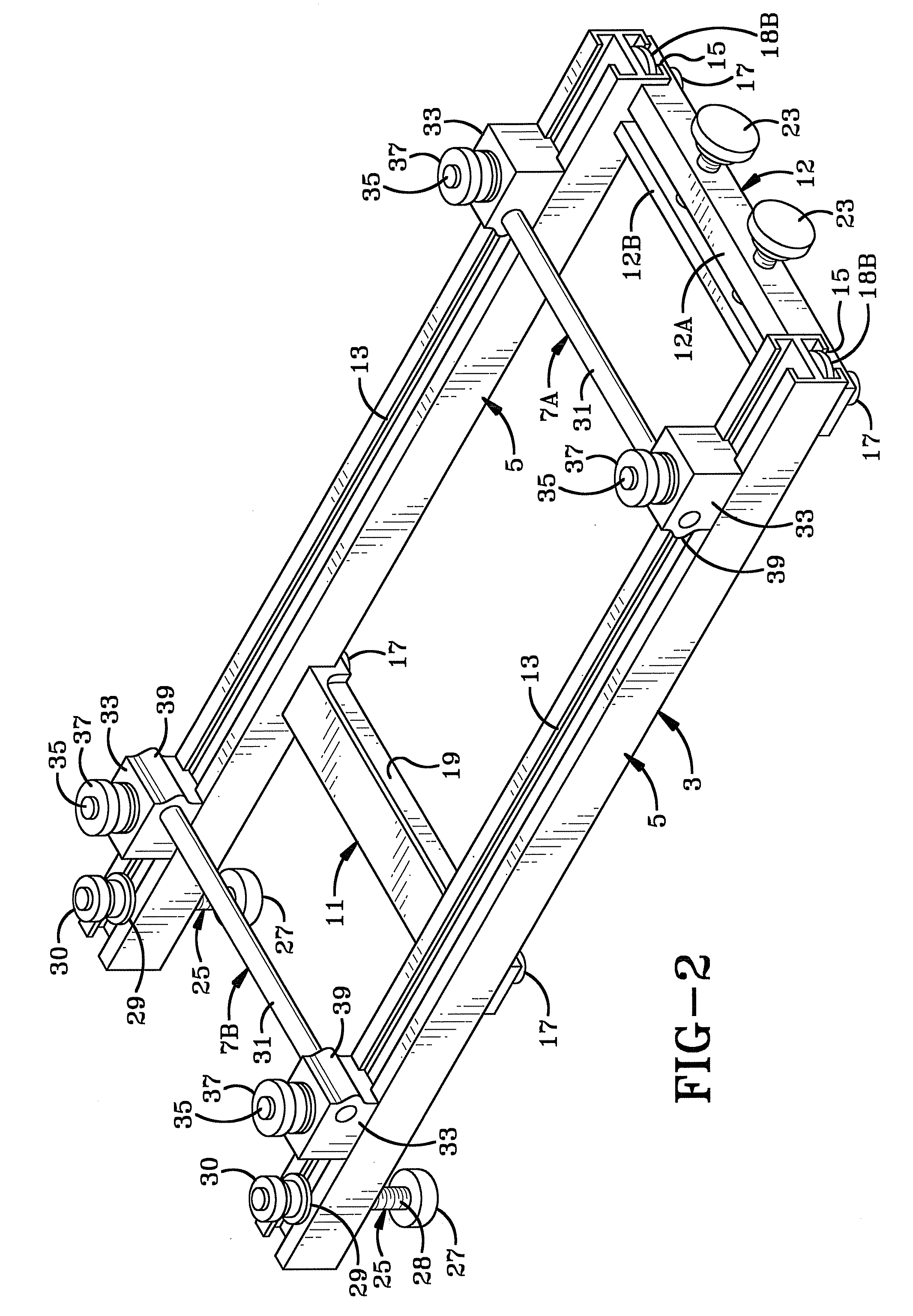

Method and apparatus for sharpening a tool blade

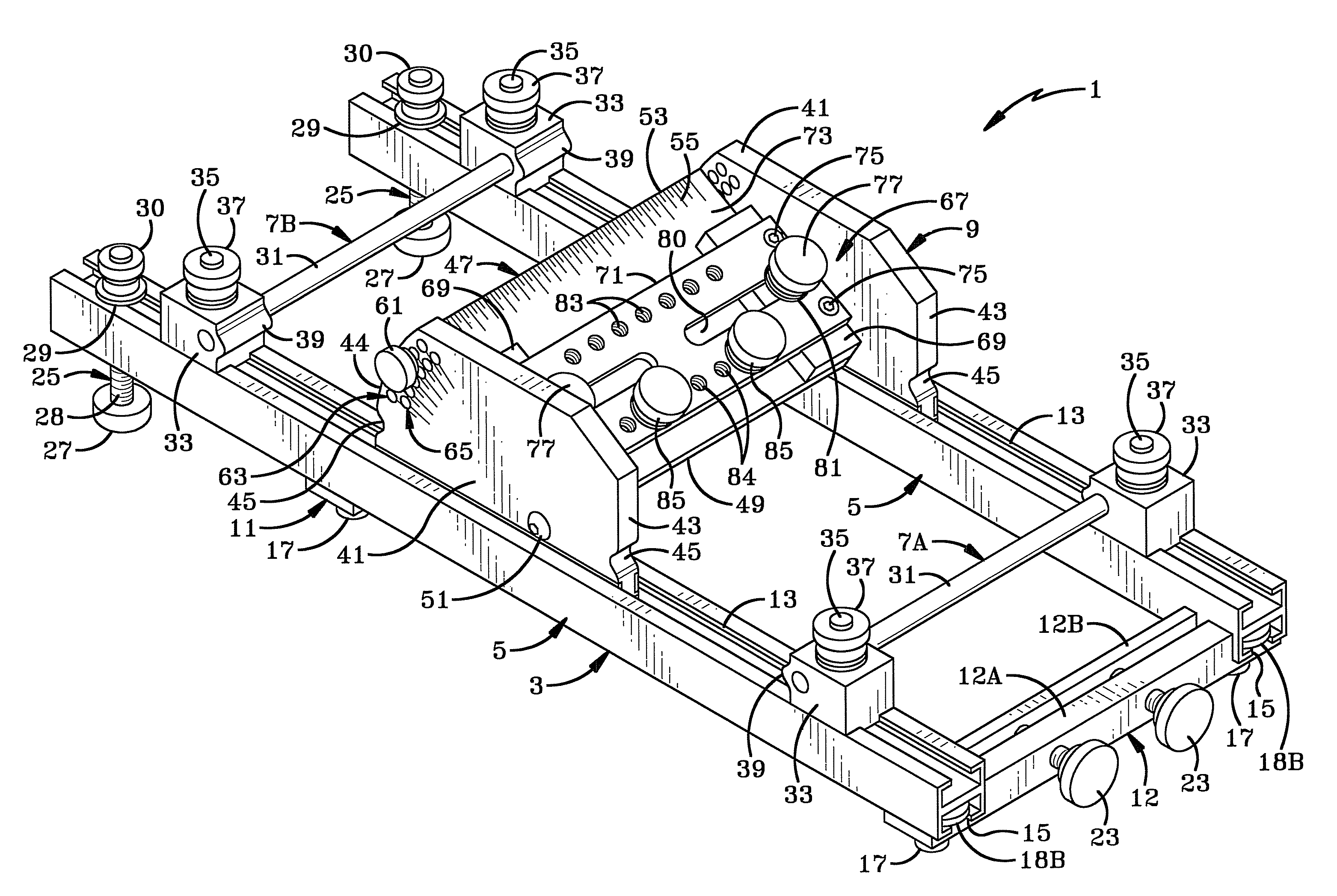

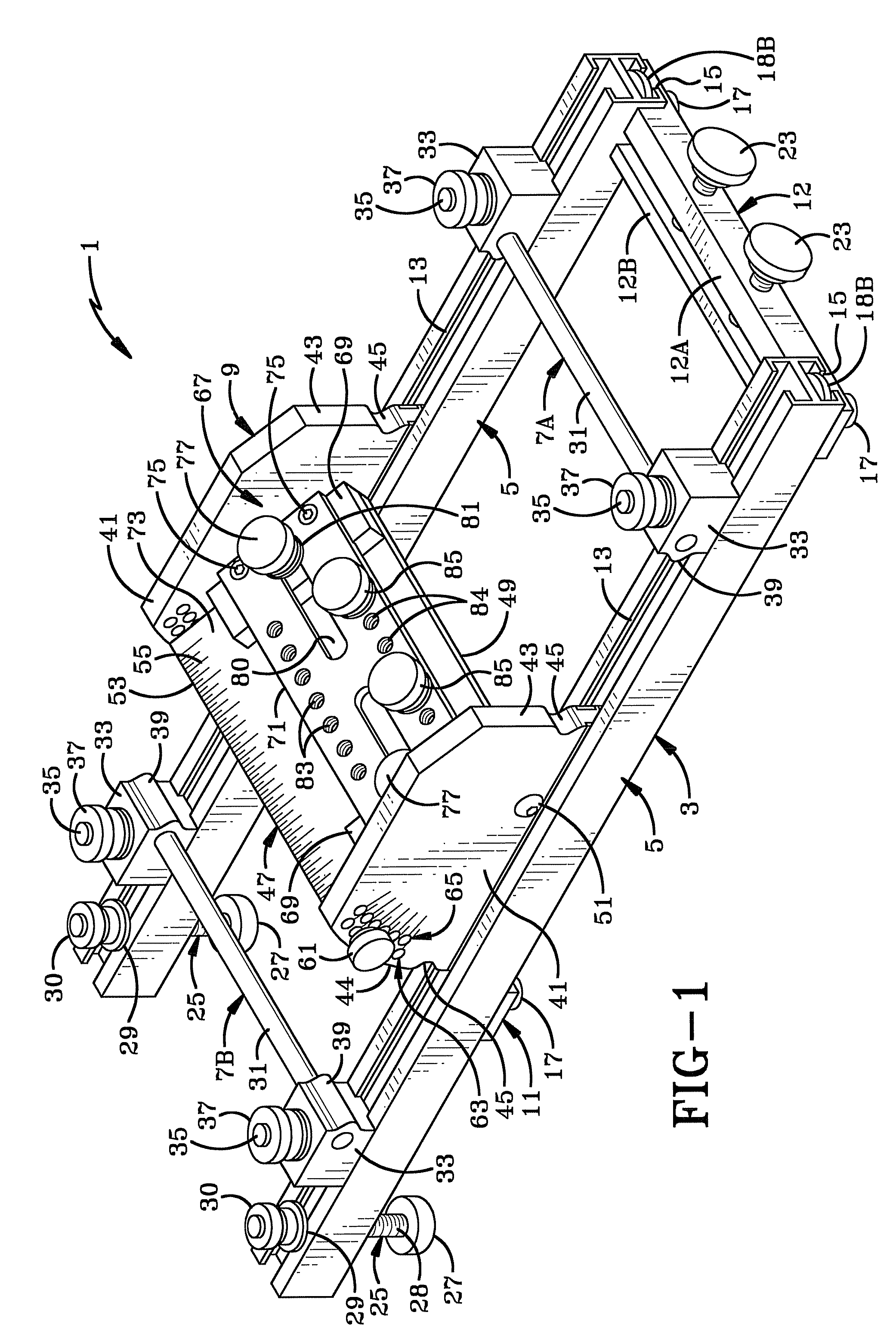

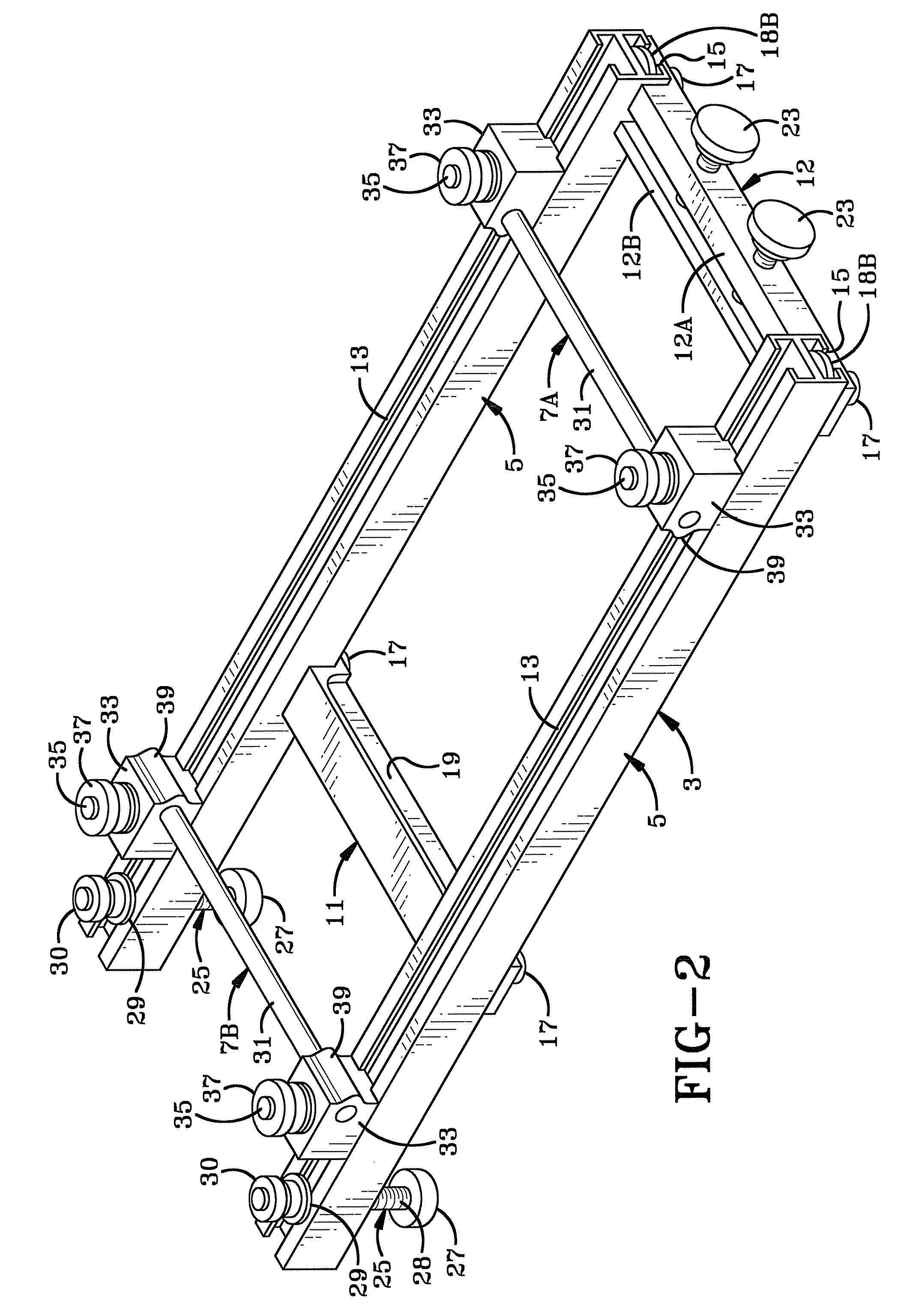

ActiveUS20090088053A1Easy to useHigh precisionPlaning/slotting toolsTurning toolsReciprocating motionSlide plate

A device for sharpening a tool blade has a pair of spaced guide rails and a bracket for mounting a sharpening stone on the guide rails. A carriage is slidably supported on the guide rails and has a pair of spaced slide plates adjustably supporting a blade angle plate thereon. A clamp mechanism secures the tool blade on the angle plate which is secured in an adjusted position for forming a primary angle on the blade cutting edge by reciprocal movement of the carriage along the guide rails. The angle plate and attached tool blade are readjusted on the carriage for subsequently forming a secondary angle on the cutting edge of the tool blade. Printed indicia adjacent a plurality of adjustment holes formed in the slide plates set the primary and secondary angles of the cutting edge. Mating surfaces on the carriage and guide rails set the amount of material to be removed from the blade during reciprocal movement along an abrasive sharpening material.

Owner:WOODPECKERS LLC

Fine grained sintered cemented carbides containing a gradient zone

InactiveCN1891842AImprove toughnessImprove deformation resistanceMilling cuttersPlaning/slotting toolsAlloyCemented carbide

The invention relates to a fine-grained cutting tool insert consisting of a cemented carbide base and a coating. A cemented carbide substrate comprising WC, a binder phase and vanadium containing a cubic carbide phase has a binder phase enriched surface region substantially free of the cubic carbide phase.

Owner:SANDVIK INTPROP AB +1

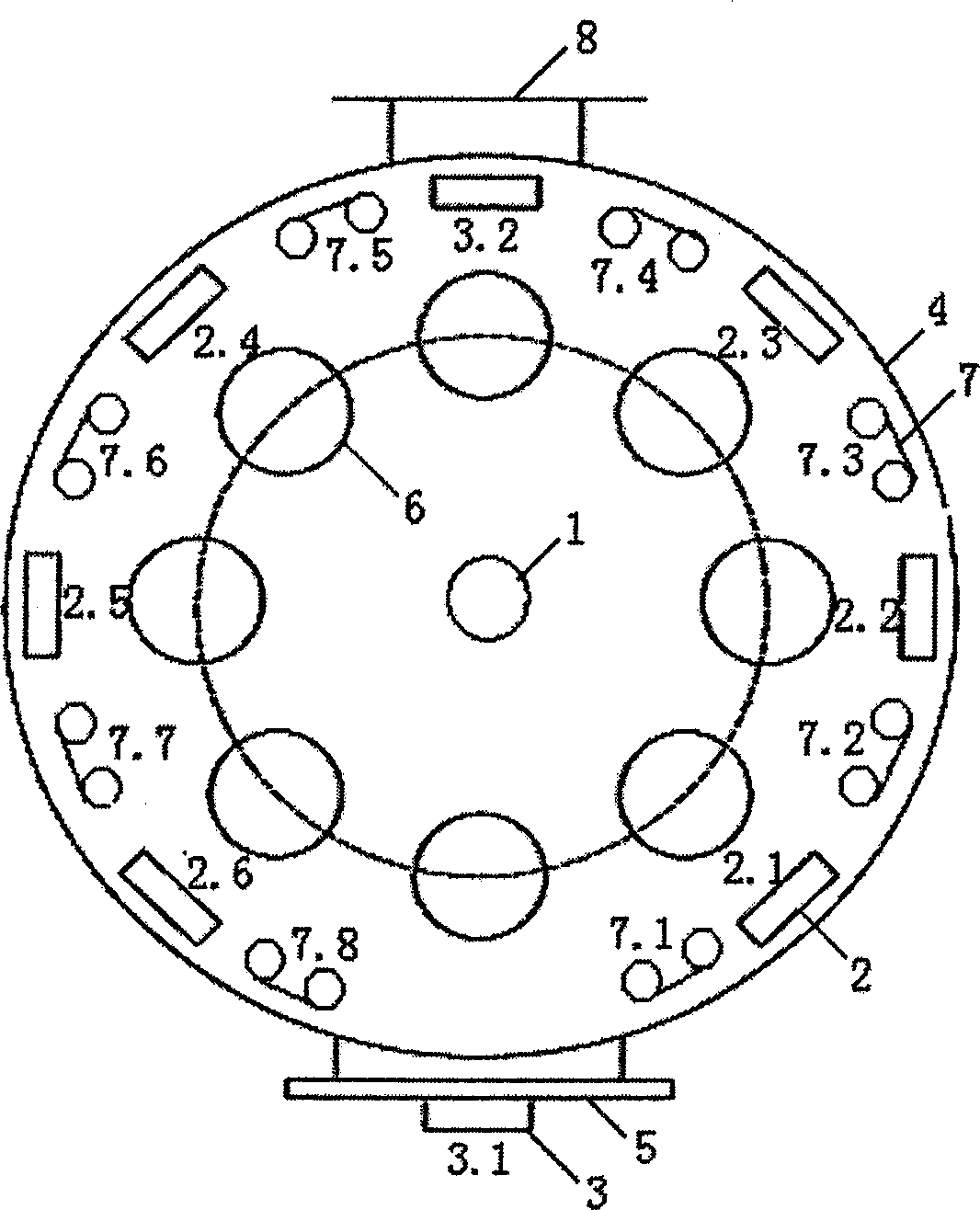

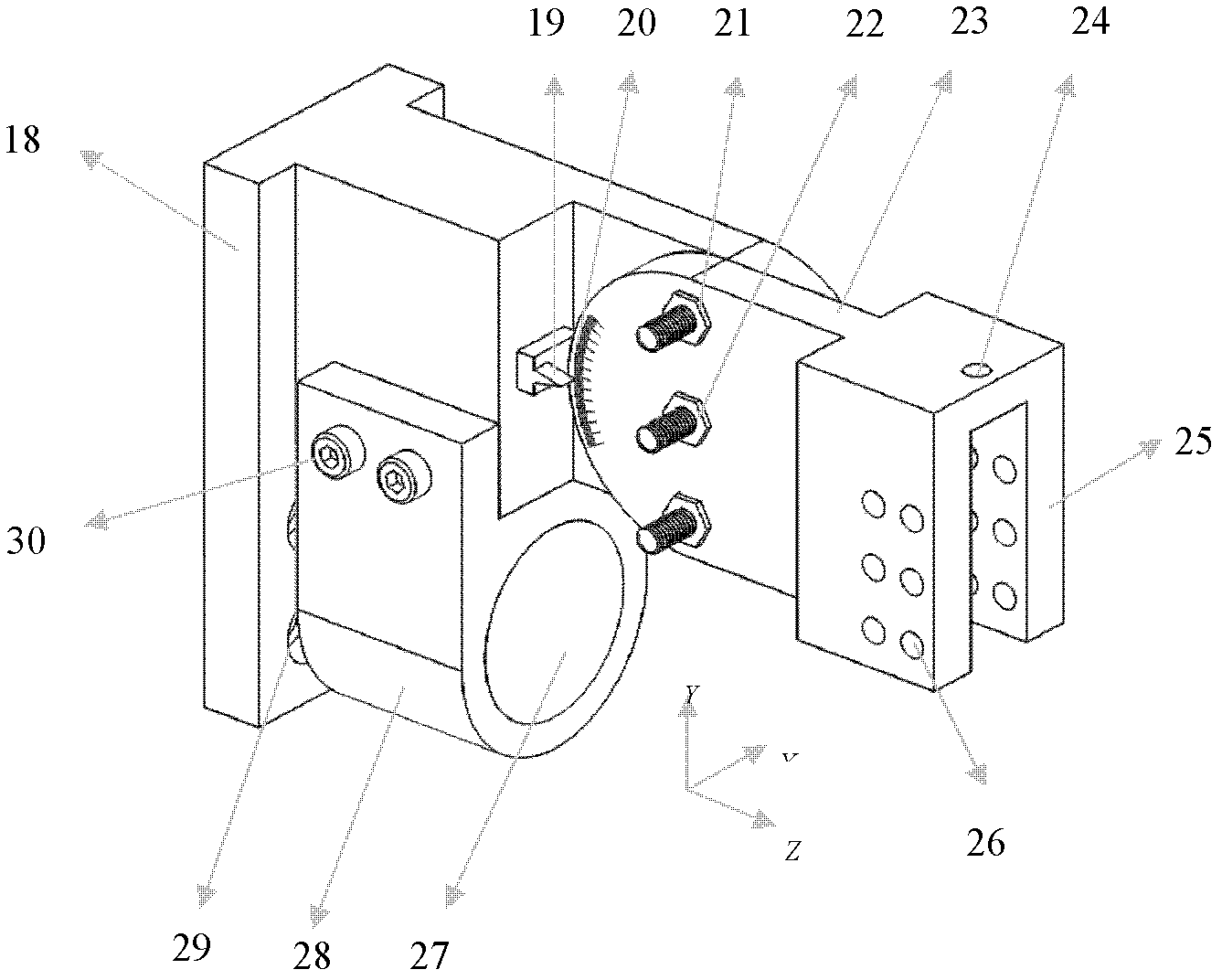

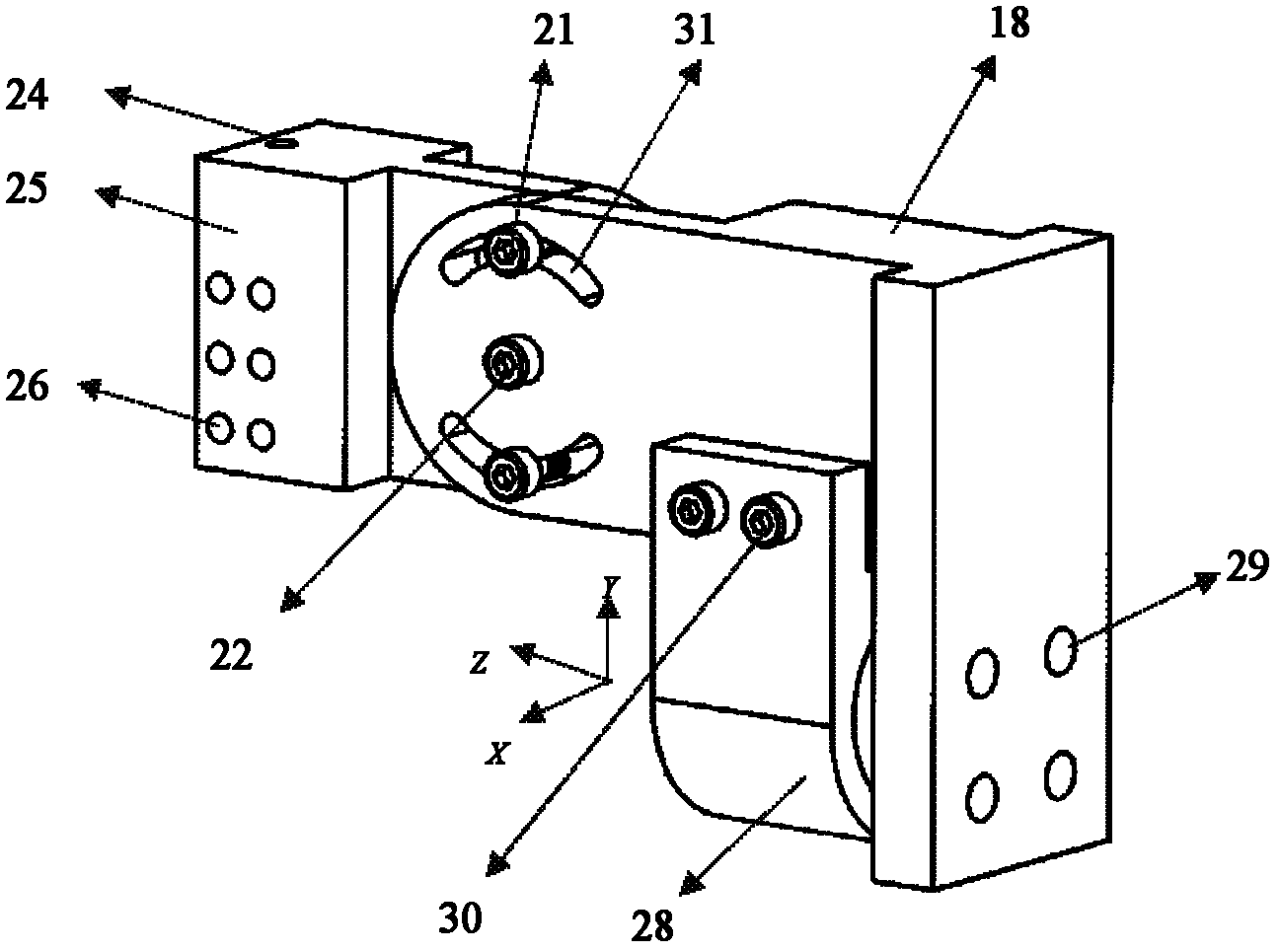

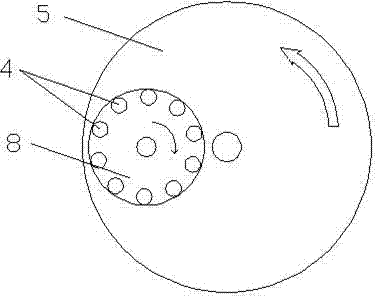

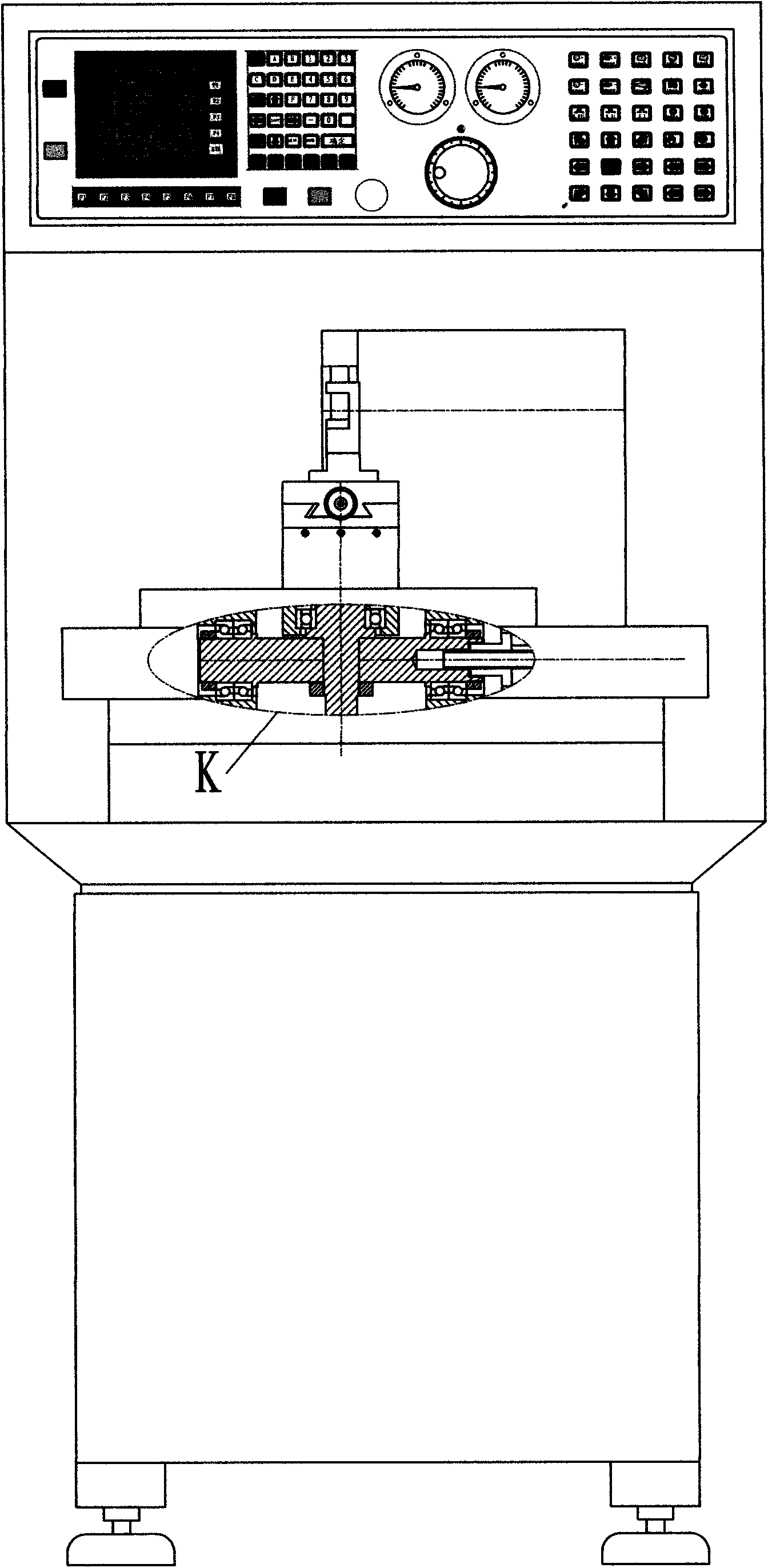

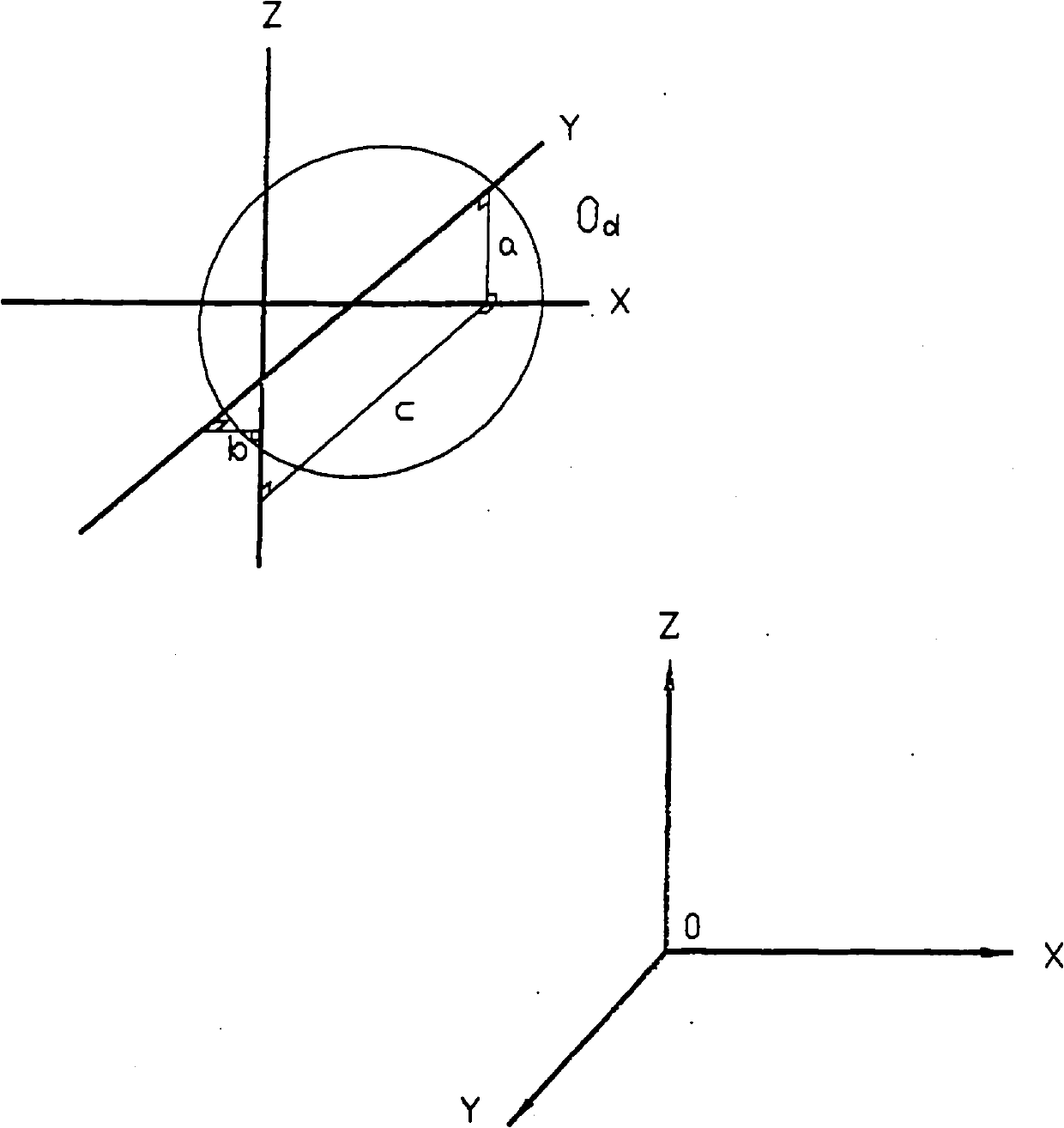

Relief angle adjustable device for automatic grinding of arc-edge diamond lathe tool

InactiveCN102248451AImproving the manufacturing accuracy of blade shapeImprove production efficiencyPlaning/slotting toolsTurning toolsEngineeringDiamond

The invention discloses a relief angle adjustable device for the automatic grinding of an arc-edge diamond lathe tool, comprising a base, wherein a driving device, a grinding disc and a photographing device are sequentially installed on the table board of the base; the driving device comprises a transverse feed device and a longitudinal feed working table connected with the transverse feed device; a longitudinal feed device is arranged on the longitudinal feed worktable; a swing device is connected with the longitudinal feed device; a relief angle adjustable fixture comprises a cantilever part connected with the swing device; the center of one side of an angle adjusting part and the center of the front end of the cantilever part are connected through a shaft and can rotate around the shaft at a certain rotation angle; the rotation angle can be displayed through a reading device; a lathe tool clamping part on which a groove is arranged is connected with one side of the angle adjusting part; and the diamond lathe tool arranged on a tool holder is inserted in and connected with the groove. By utilizing the device provided by the invention, the relief angle of the lathe tool can be accurately adjusted when the arc-edge diamond lathe tool is ground.

Owner:TIANJIN UNIV

Method and apparatus for sharpening a tool blade

ActiveUS8197304B2Easy to useHigh precisionPlaning/slotting toolsTurning toolsReciprocating motionSlide plate

Owner:WOODPECKERS LLC

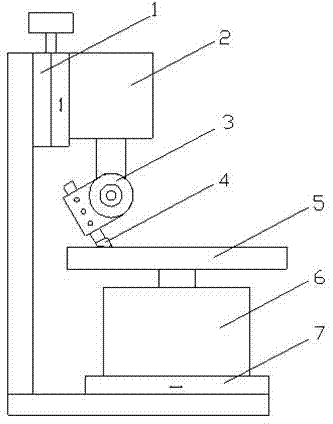

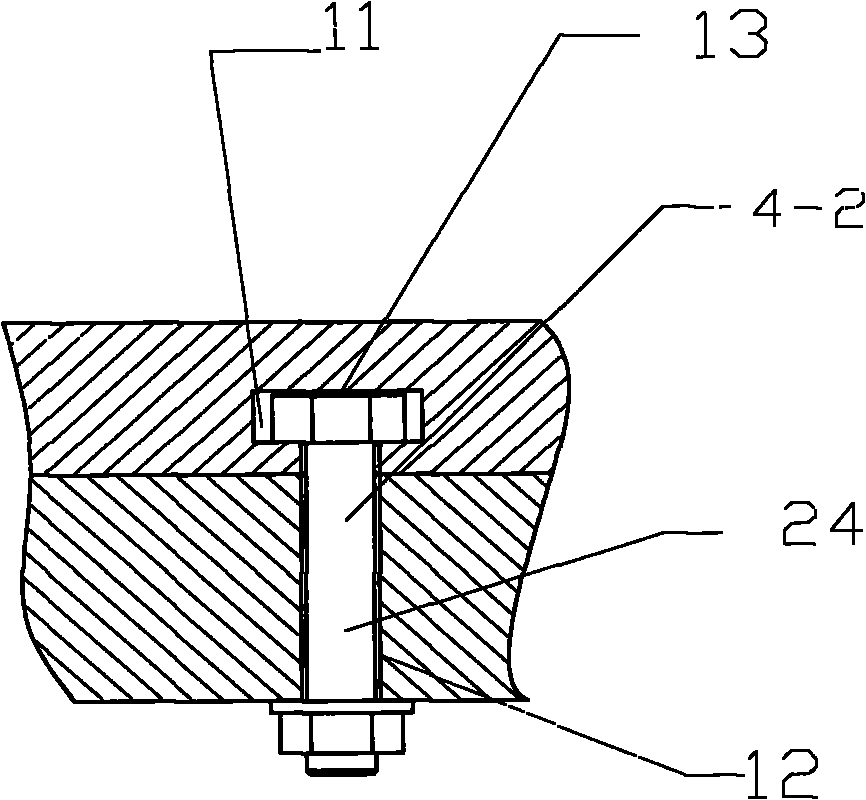

Artificial diamond compact lathe tool grinding device

ActiveCN103042440AGood edge precisionGood precisionPlaning/slotting toolsTurning toolsEngineeringGrinding wheel

The invention discloses an artificial diamond compact lathe tool grinding device. The artificial diamond compact lathe tool grinding device comprises a grinding disc spindle head, a grinding wheel grinding disc, a fixture, a 360-degree rotating fixture spindle and a feeding carriage, wherein the grinding wheel grinding disc is mounted on the grinding disc spindle head, the fixture is connected below the 360-degree rotating fixture spindle in a hinge connection model, and the 360-degree rotating fixture spindle is fixed on the feeding carriage which is capable of moving vertically. The artificial diamond compact lathe tool grinding device has the advantages that high processing efficiency to artificial diamond compact lathe tools is realized, product quality is remarkably improved, grinding consumption is greatly reduced, and the like.

Owner:镇江大有硬质材料有限公司

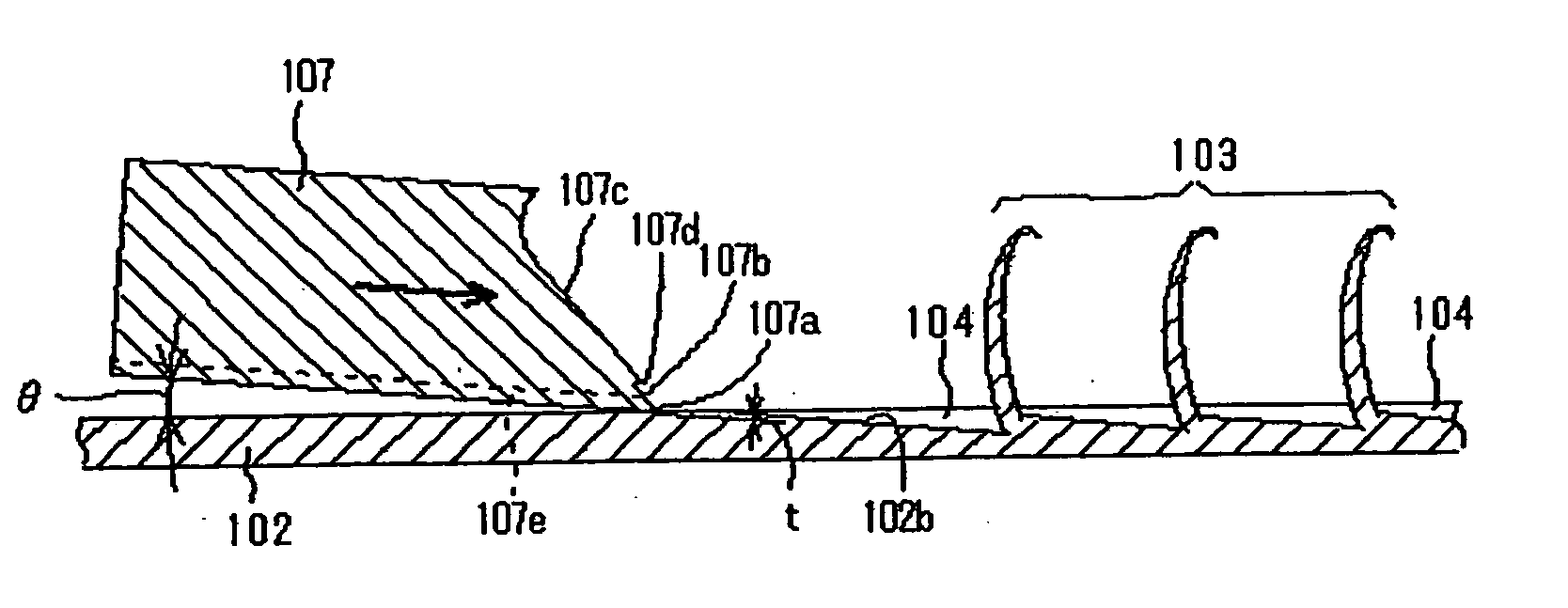

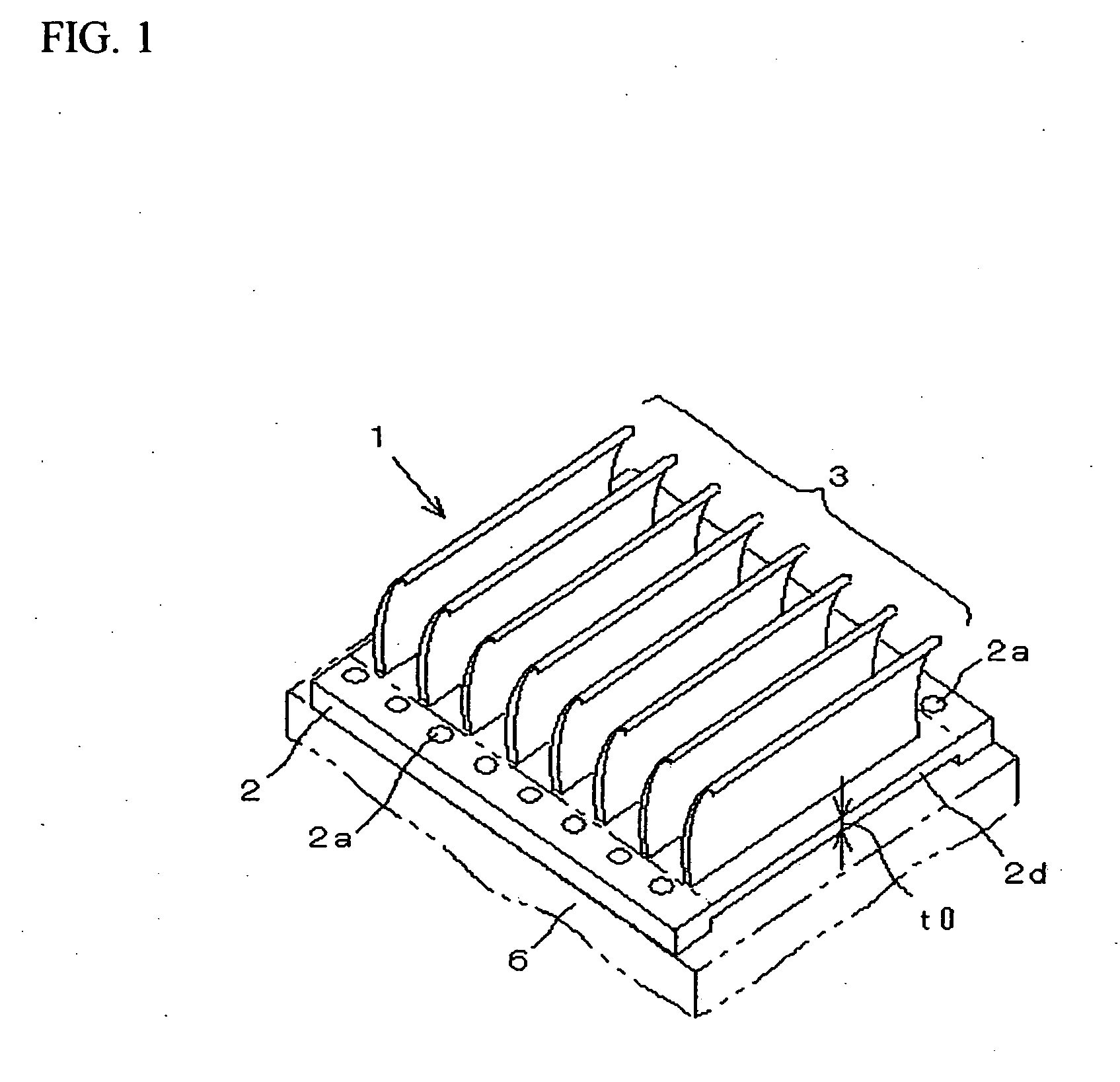

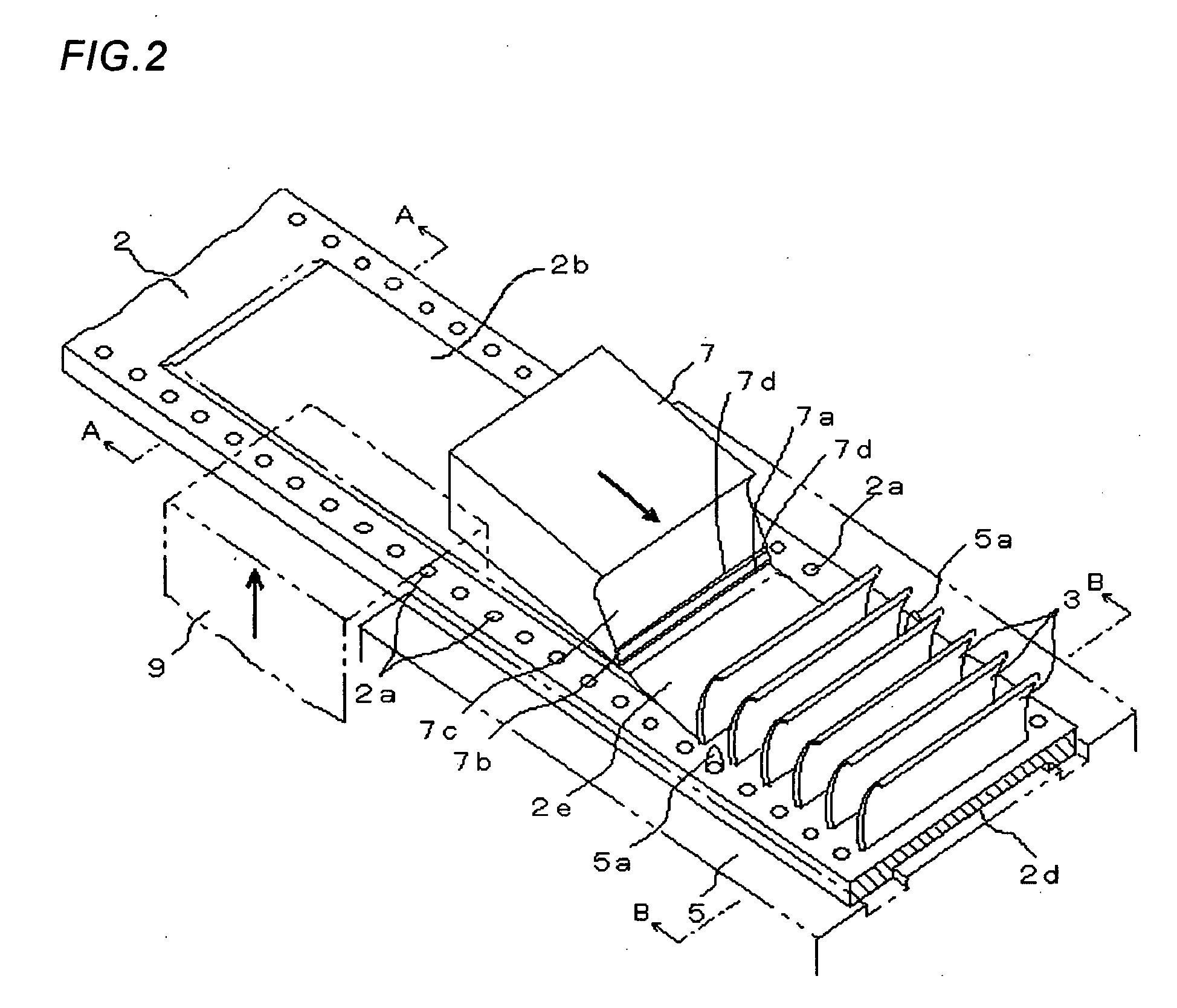

Radiator and method of manufacturing the same

ActiveUS20050193559A1Reduce thicknessIncrease friction forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringCarve out

In a method of manufacturing a radiator, the blade of a carving tool is applied at a specific angle to the surface of a metal plate with a high coefficient of thermal conductivity, the carving tool is advanced while the angle is maintained, and the surface of the metal plate is carved out to form plate-shaped heat-radiating fins vertically upward. A radiator is manufactured in which a plurality of heat-radiating fins are integrally formed vertically upward at a specific pitch from a single metal plate by repeating a step in which the carving tool is retracted at a specific pitch, the metal plate is carved out, and a heat-radiating fin is formed. A radiator that has high radiation efficiency and is highly safe during handling can be manufactured at low cost.

Owner:NAKAMURA IND MFG CO LTD

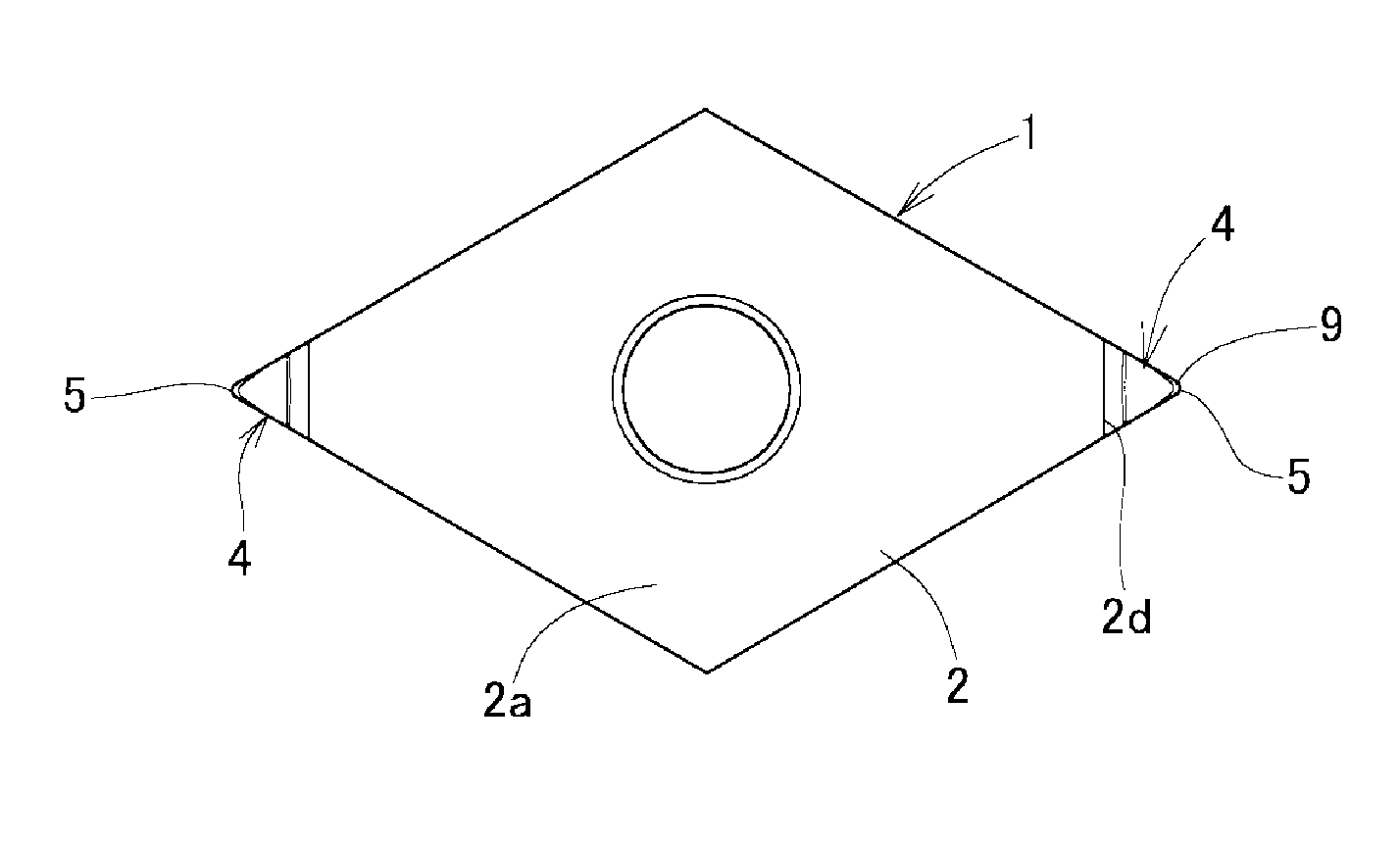

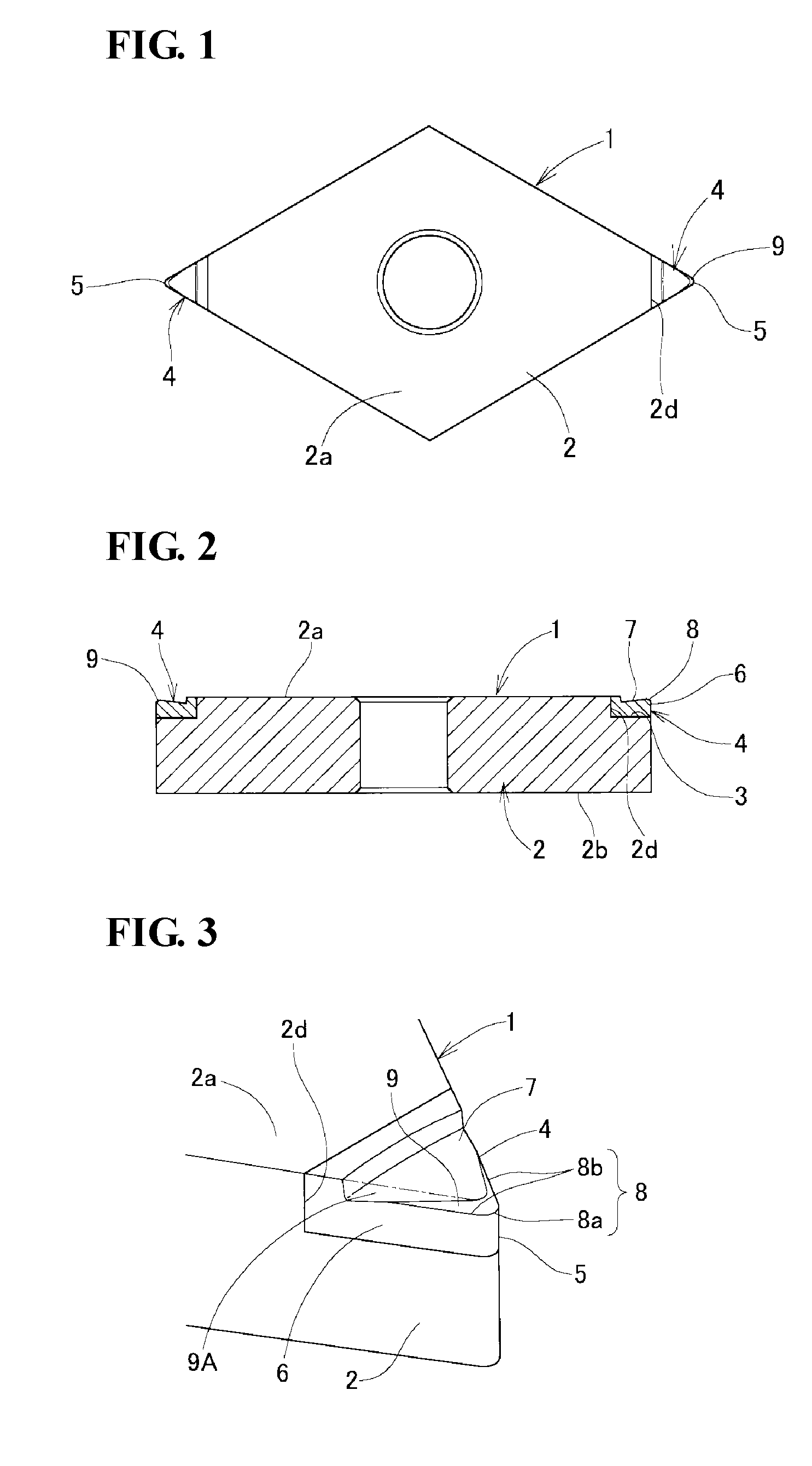

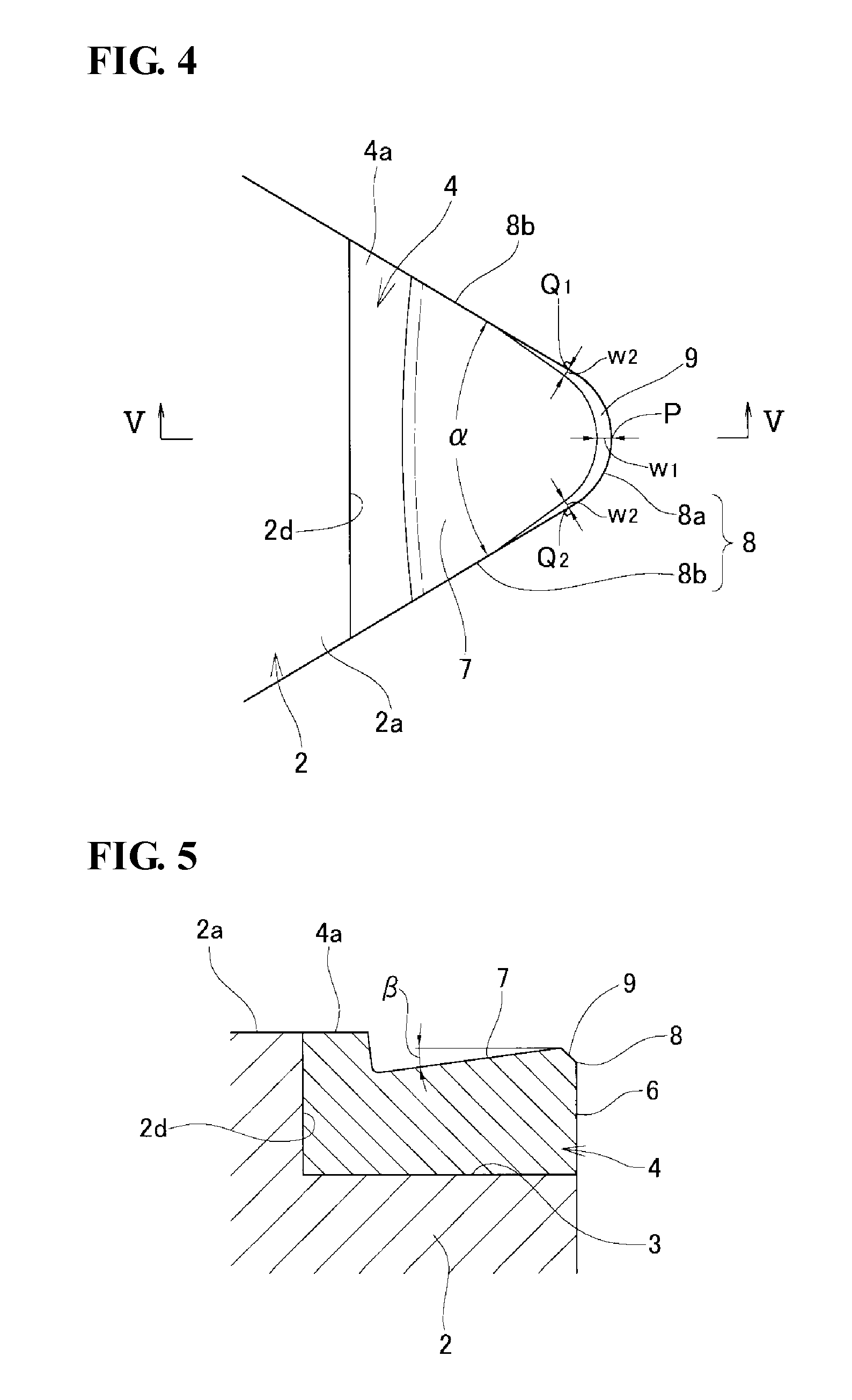

Cutting insert and method of manufacturing the same

ActiveUS20160297010A1Improve fracture resistanceStable lifeCutting insertsPlaning/slotting toolsMetallurgyRake angle

A cutting insert including a surface involved in cutting, for which a cutting tool material of a hard sintered body is used. A radius of a nose R portion is 0.4 mm or greater and 2.4 mm or less, an apex angle α of the nose R portion is 50° or greater and 95° or less, a rake angle β at a position of a bisecting plane of the apex angle of the nose R portion is 1° or greater and 10° or less, a chamfer provided in a cutting edge portion is a negative land with unequal width, and at least on one side of the negative land with respect to a boundary which is an apex of a nose R portion cutting edge, a width of the negative land gradually decreases from the apex of the nose R portion cutting edge to a position at which the nose R portion cutting edge is connected to a linear cutting edge. Let W1 be the width of the negative land at the apex of the nose R portion cutting edge, and W2 be the width of the negative land at both ends of the nose R portion cutting edge, then the W1 is 0.04 mm or greater and 0.2 mm or less, and a ratio of the W1 to the W2 is 1.5 or greater.

Owner:SUMITOMO ELECTRIC IND LTD

Coolant delivery apparatus for machine tool

A coolant delivery apparatus for a machine tool wherein the position of the coolant delivery apparatus is controllable such that coolant may be delivered to the machining contact zone of a tool even though the location of the machining zone of the tool may change such as during machining of a workpiece, or from one workpiece to another.

Owner:GLEASON WORKS

Arc blade milling machine for swing arm tool

InactiveCN102145470AImprove efficiencyHigh precisionPlaning/slotting toolsTurning toolsKnife holderControl system

The invention discloses an arc blade milling machine for a swing arm tool, which mainly comprises a machine body, a control system, a milling head assembly, a small cross-shaped slide seat, a revolving working platform and a tool rest. The arc blade milling machine is characterized in that a feed moving mechanism adopts a swing arm mechanism; the revolving working platform is installed on a swing arm and is provided with the small cross-shaped slide seat, and the small cross-shaped slide seat is provided with the tool rest; the machine body is provided with a reciprocation sliding table parallel to a milling wheel surface direction; and the milling head assembly or the swing arm mechanism is installed on the reciprocation sliding table. The arc blade milling machine for the swing arm tool has the advantages of good feed flexibility, simple and economic structure, strong principal axis rigidity and good blade milling quality, and is widely suitable for milling precise machining tools and super hard tools.

Owner:丁珍华

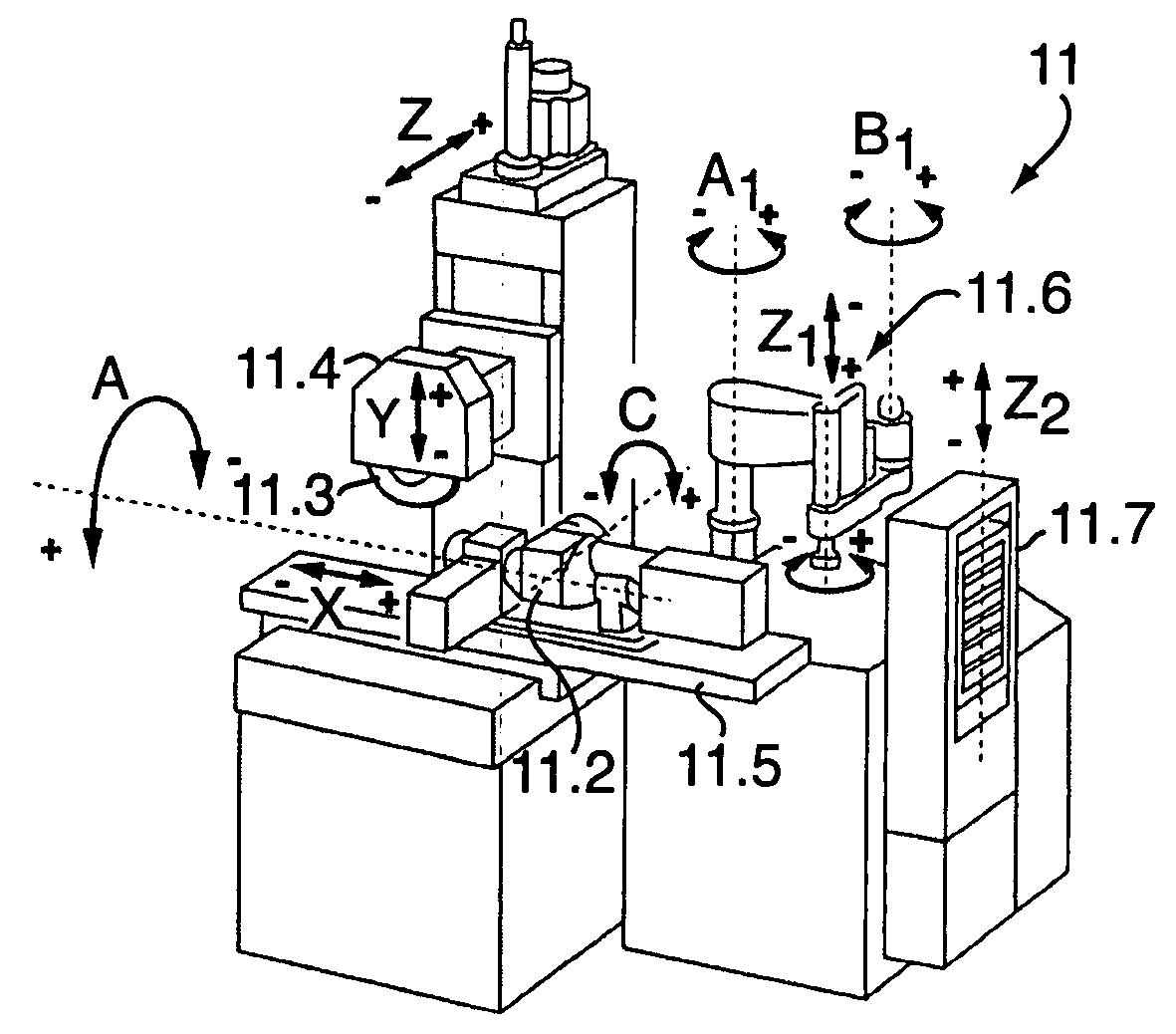

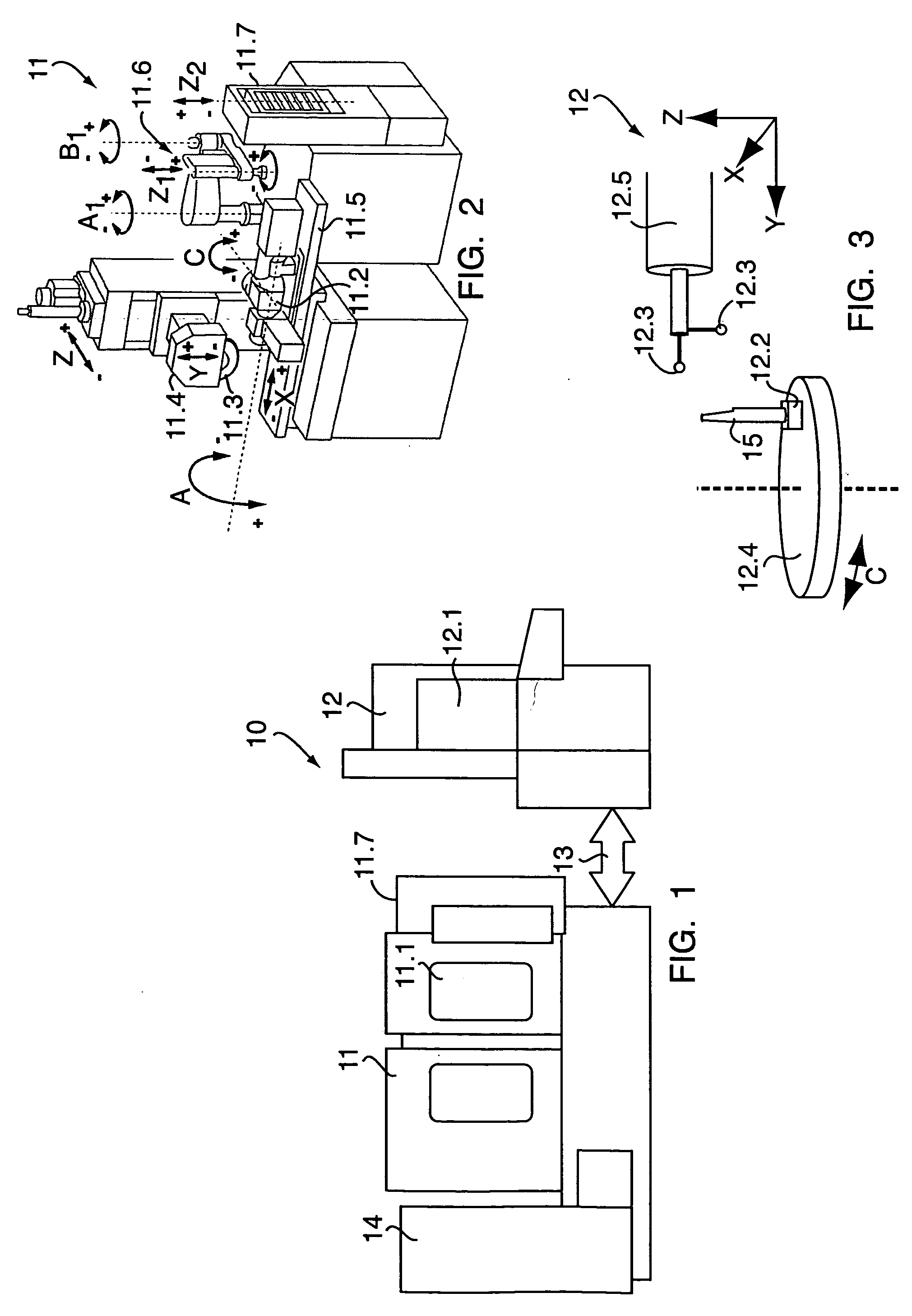

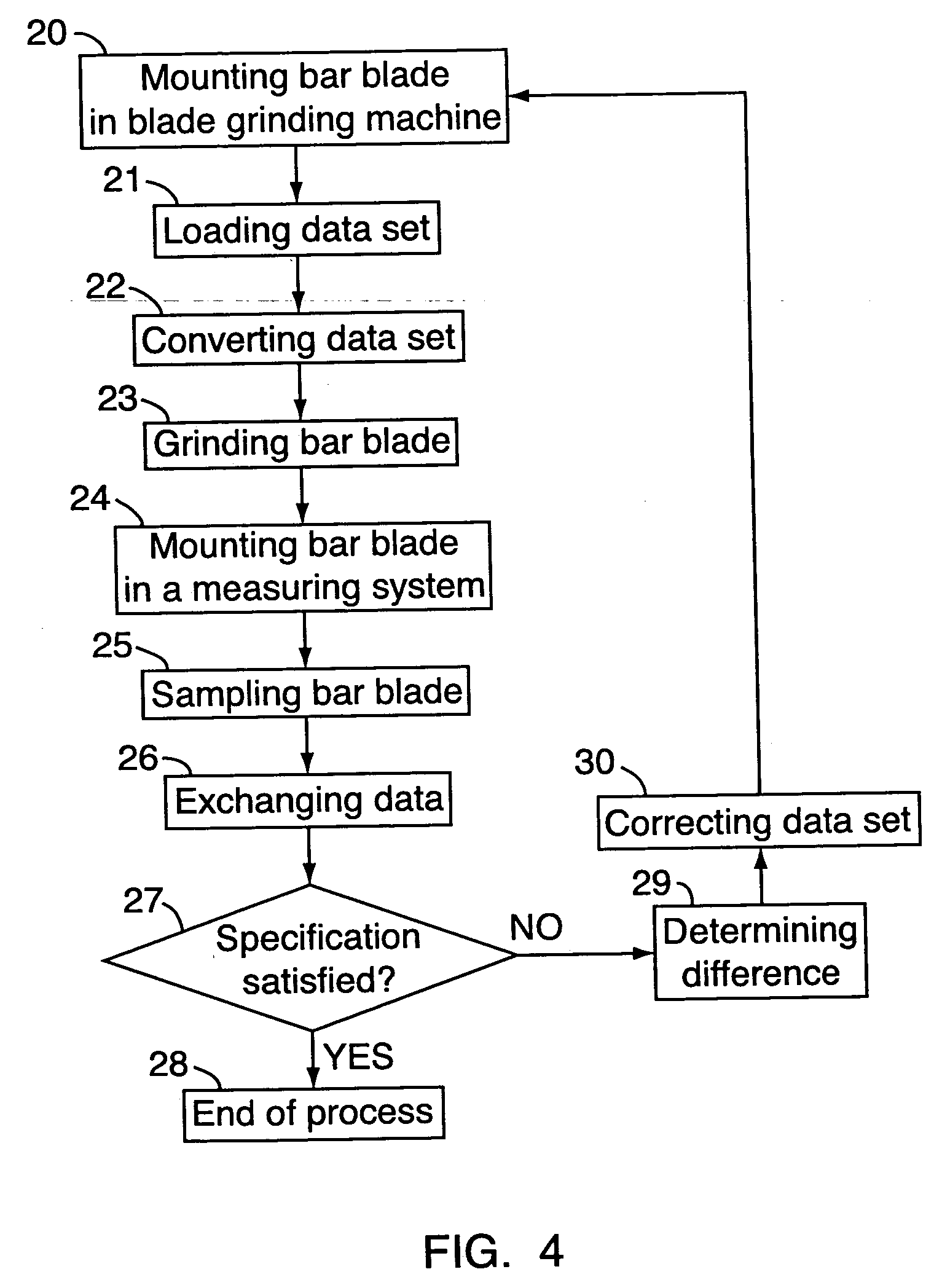

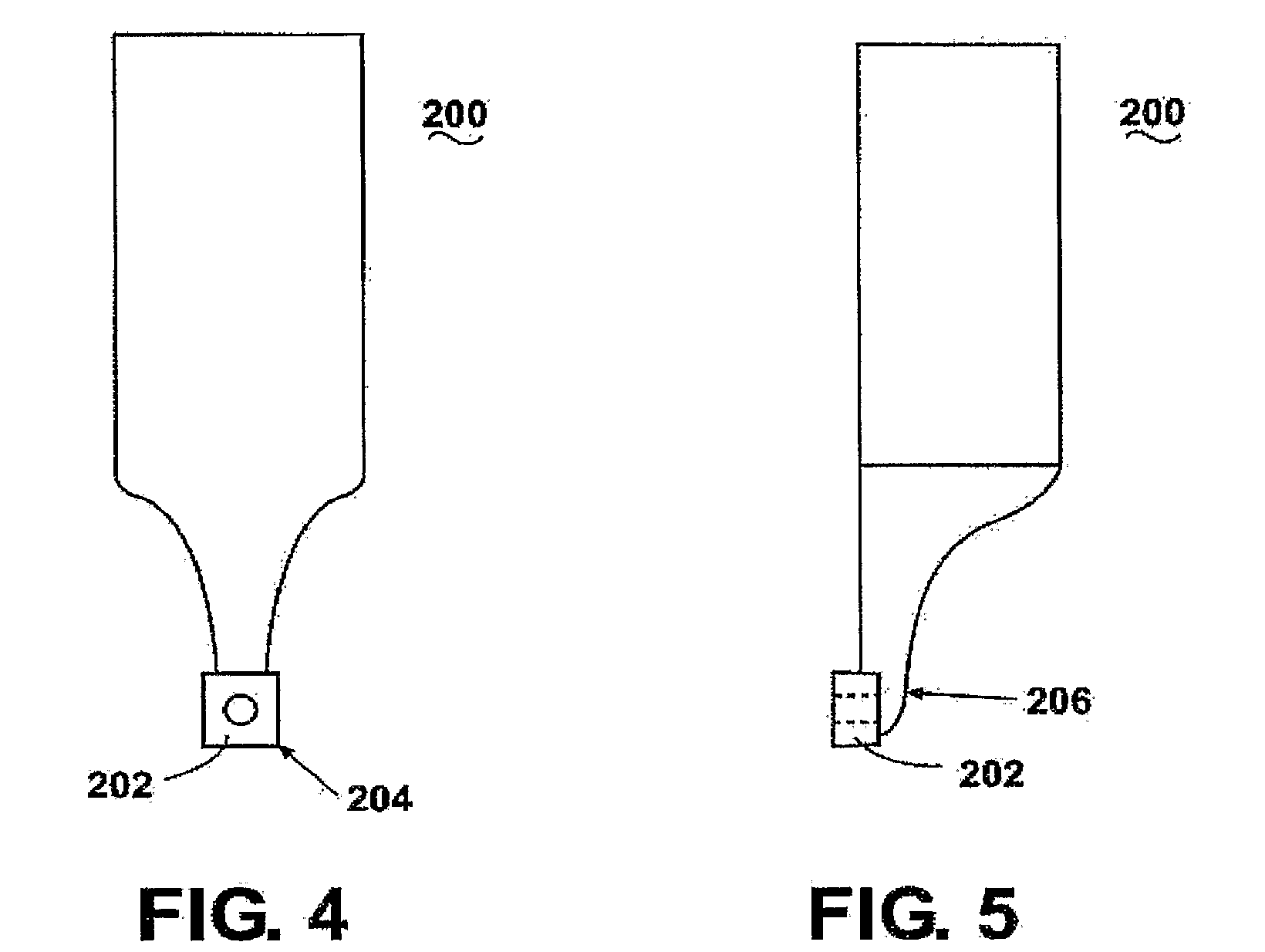

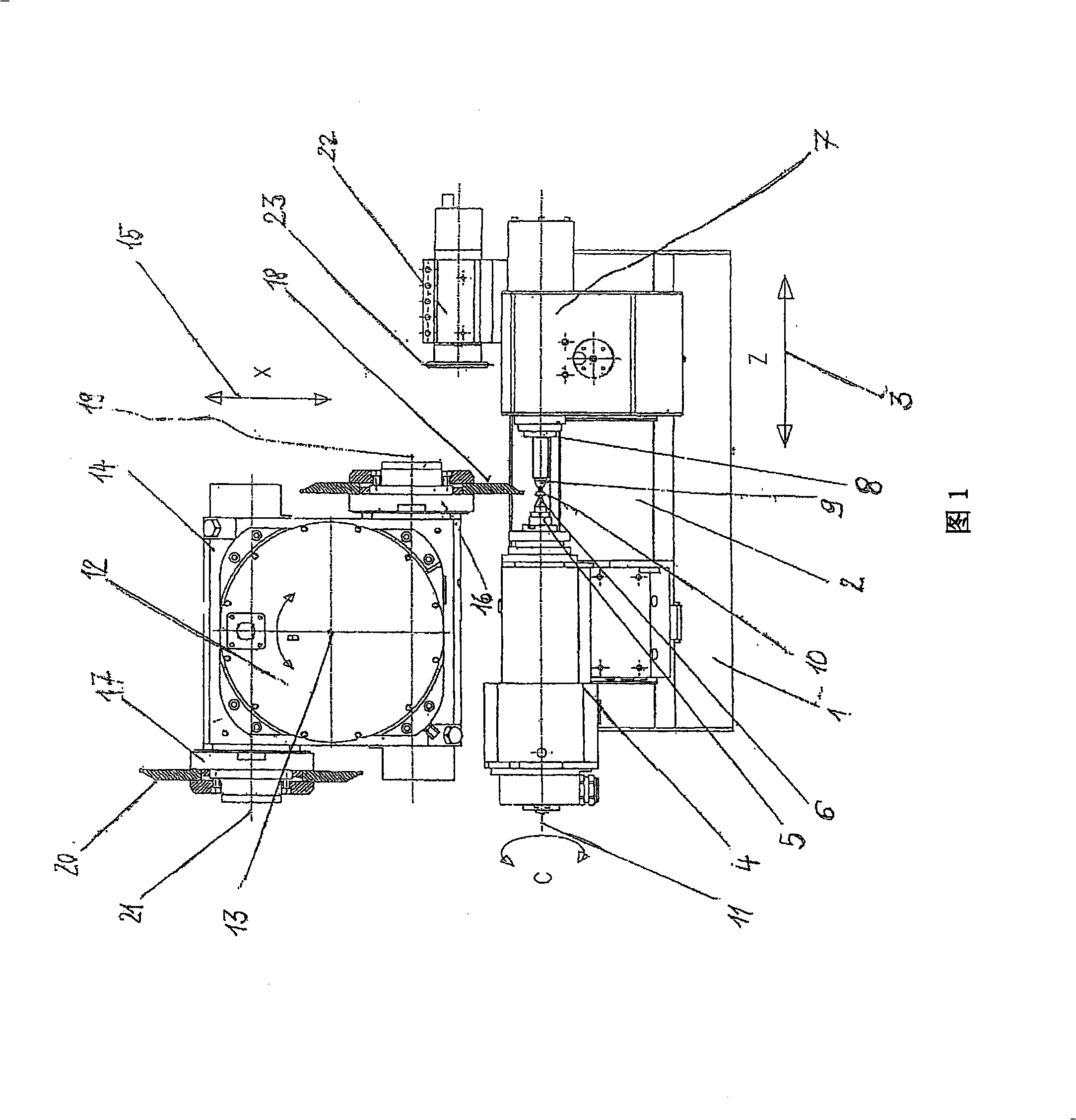

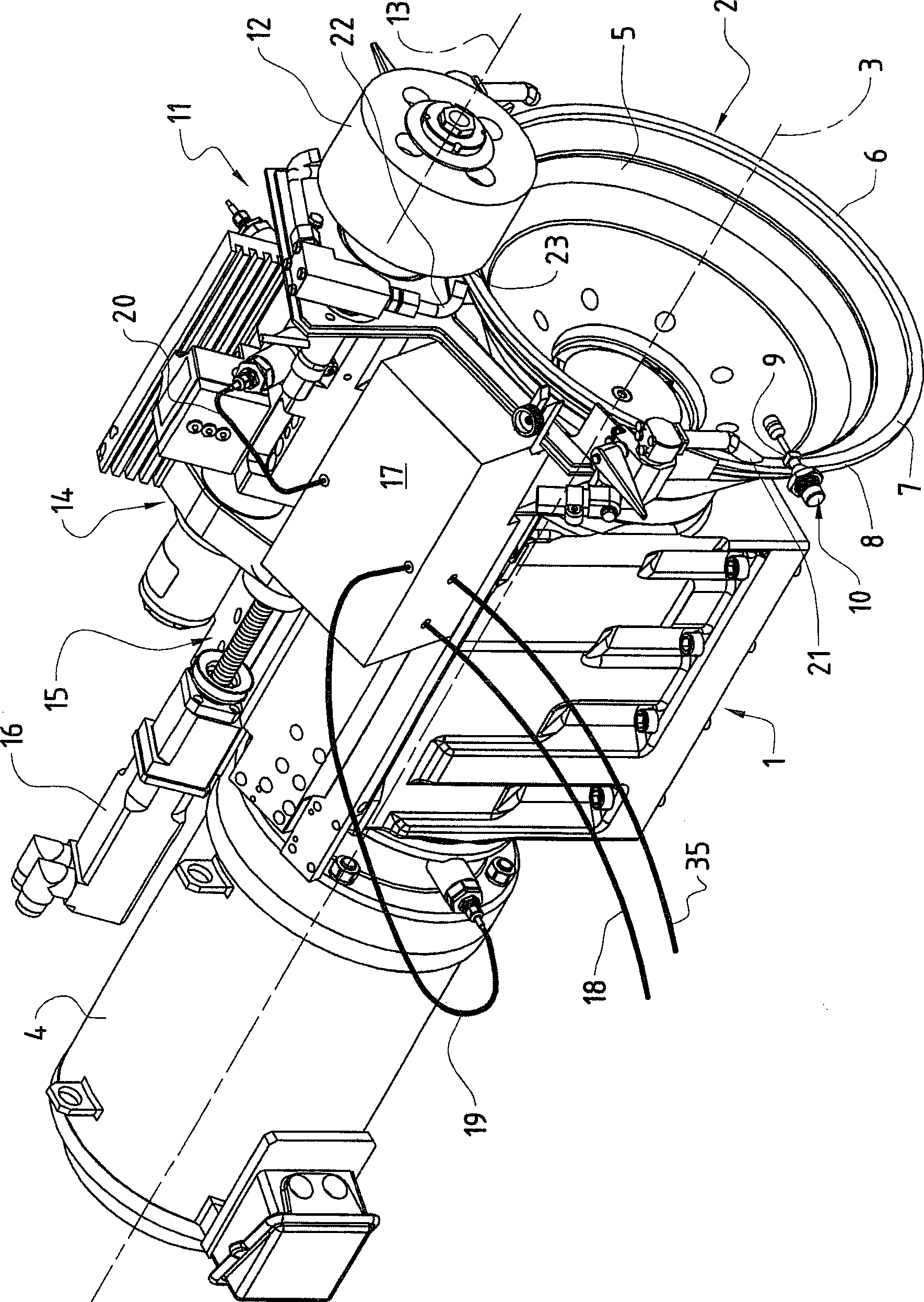

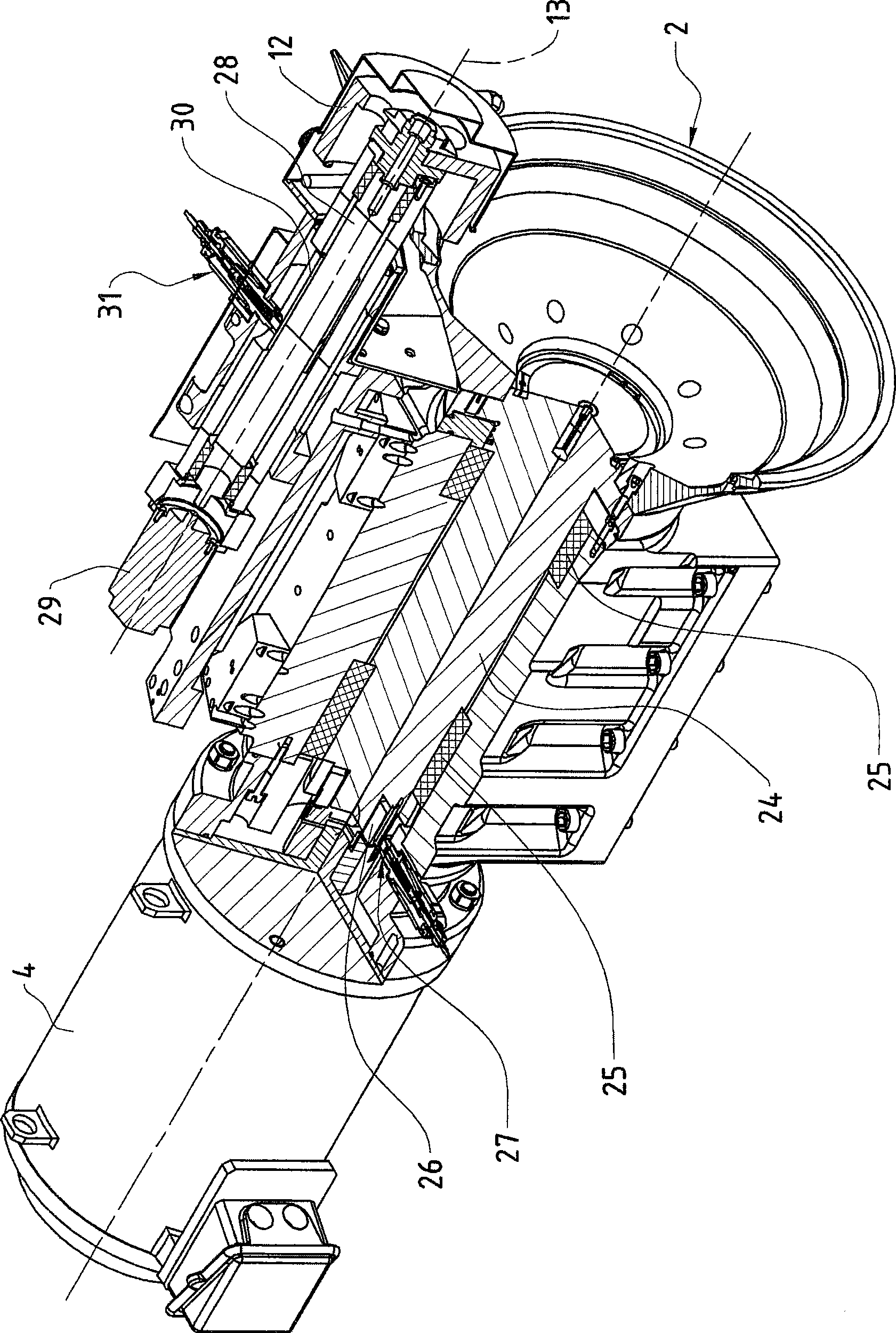

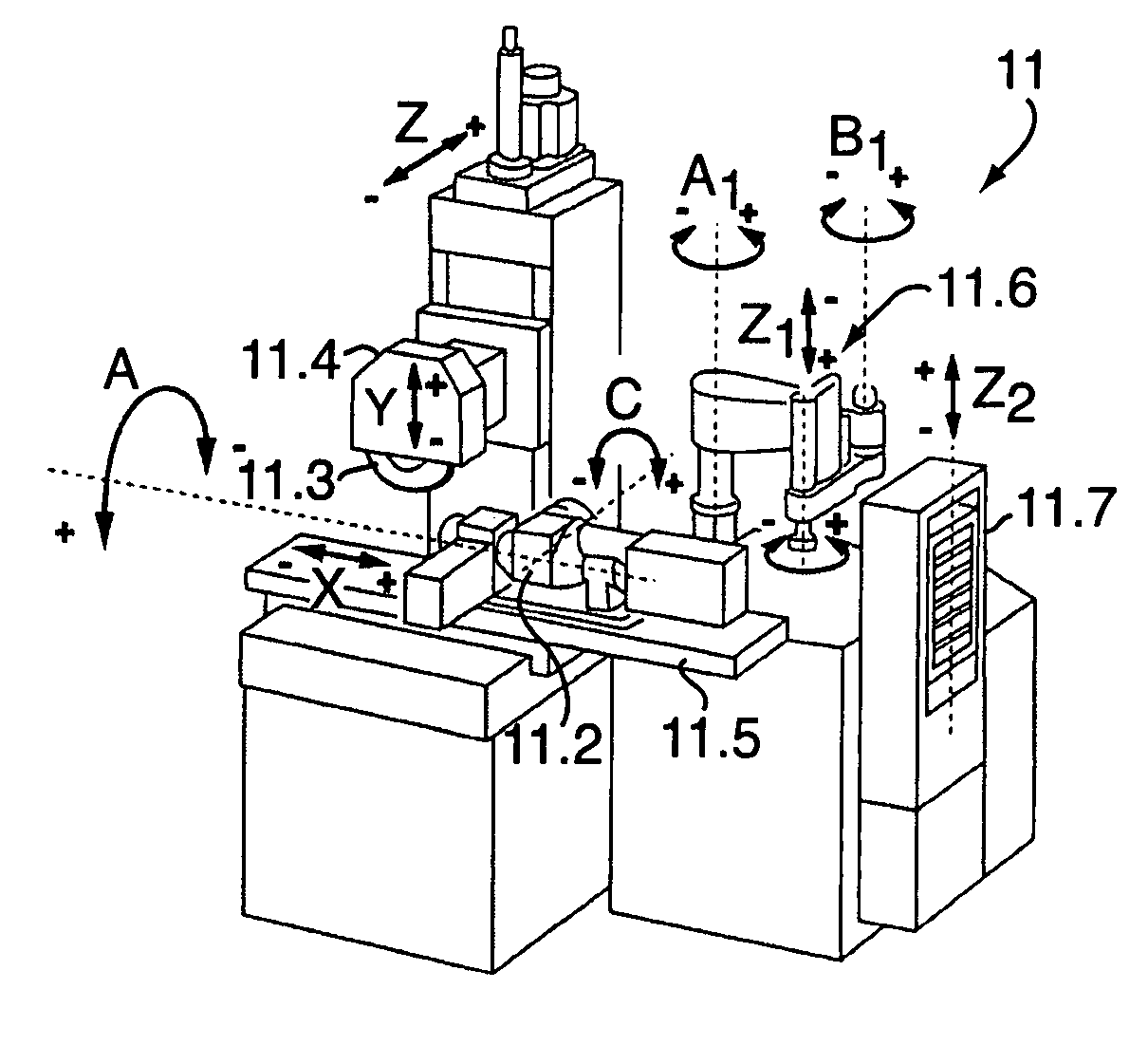

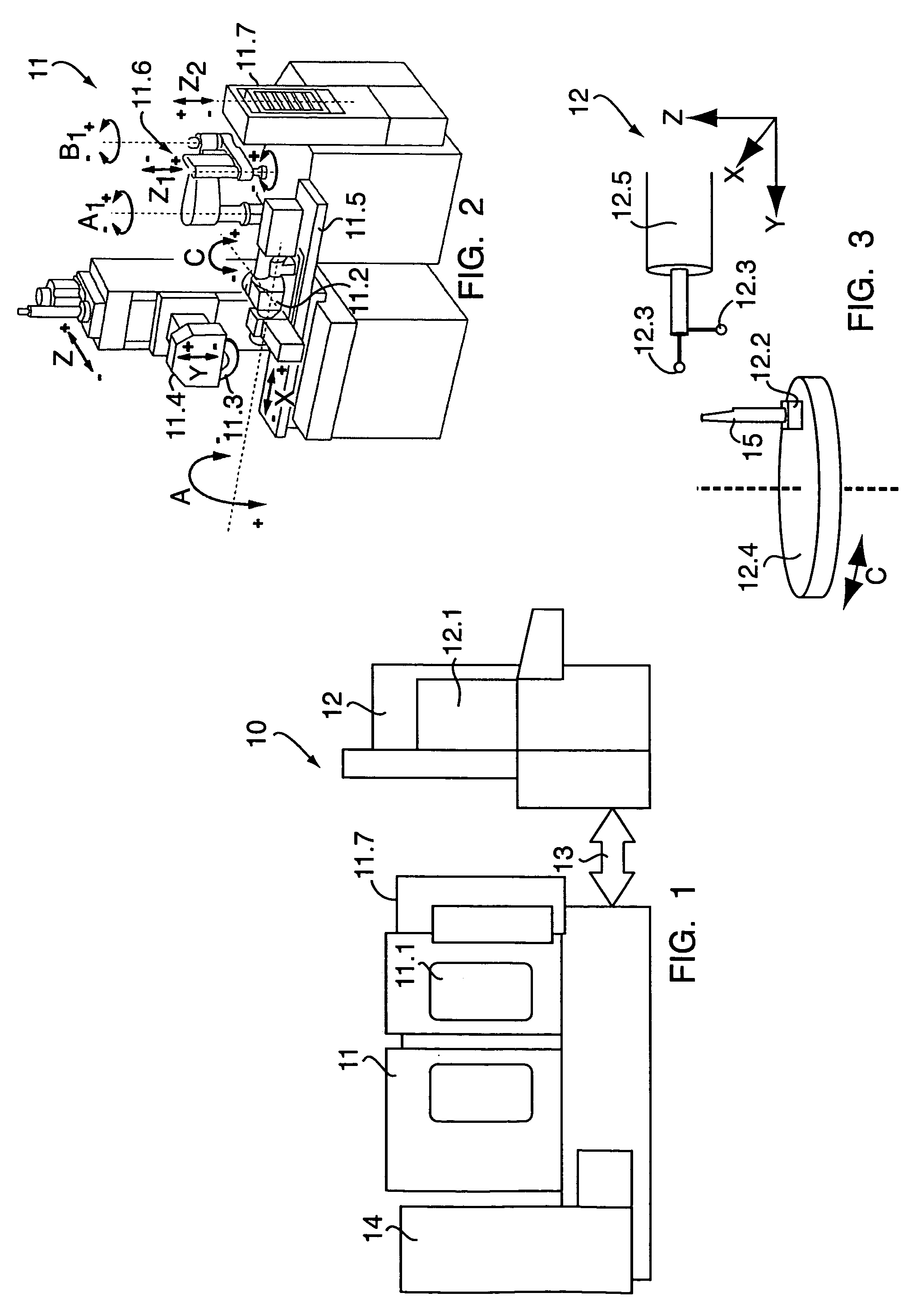

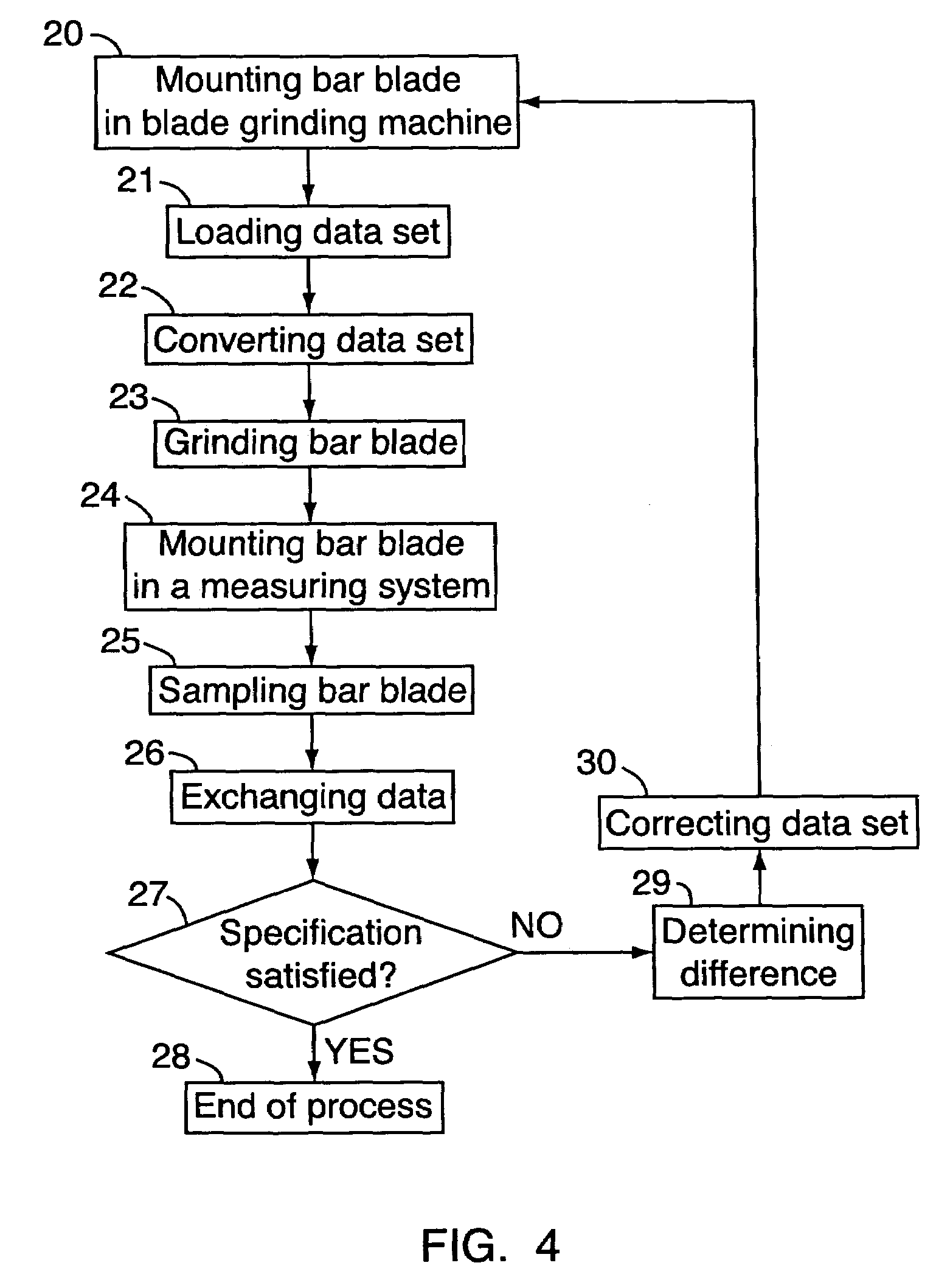

Grinding machine comprising a measuring system and control for providing a master blade and method for providing a bar blade

ActiveUS20050064795A1Avoid mistakesPlaning/slotting toolsGrinding feed controlEngineeringData exchange

An apparatus includes a blade grinding machine, a measuring system and a control for providing a bar blade suitable for cutting work pieces. The blade grinding machine includes a clamping mechanism for mounting the bar blade and a grinding wheel for grinding the mounted bar blade. The measuring system also includes a clamping mechanism for mounting bar blade and at least one probe for three-dimensional sampling of the bar blade mounted on the measuring system. The control enables a data exchange between the blade grinding machine and the measuring system in order to grind and sample the bar blade in an alternating fashion. The apparatus is a closed system in which data exchange is automated.

Owner:KLINGELNBERG AG

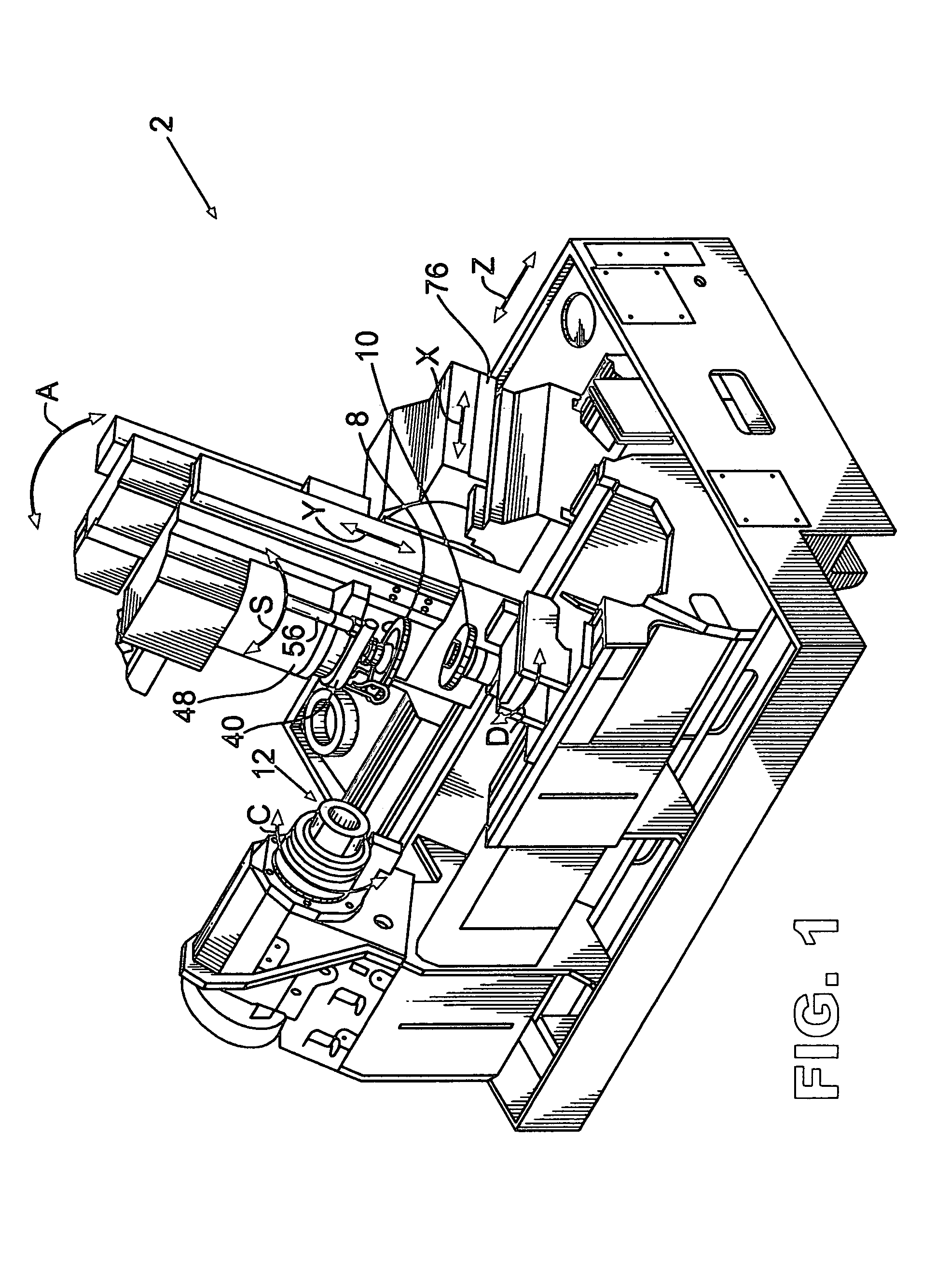

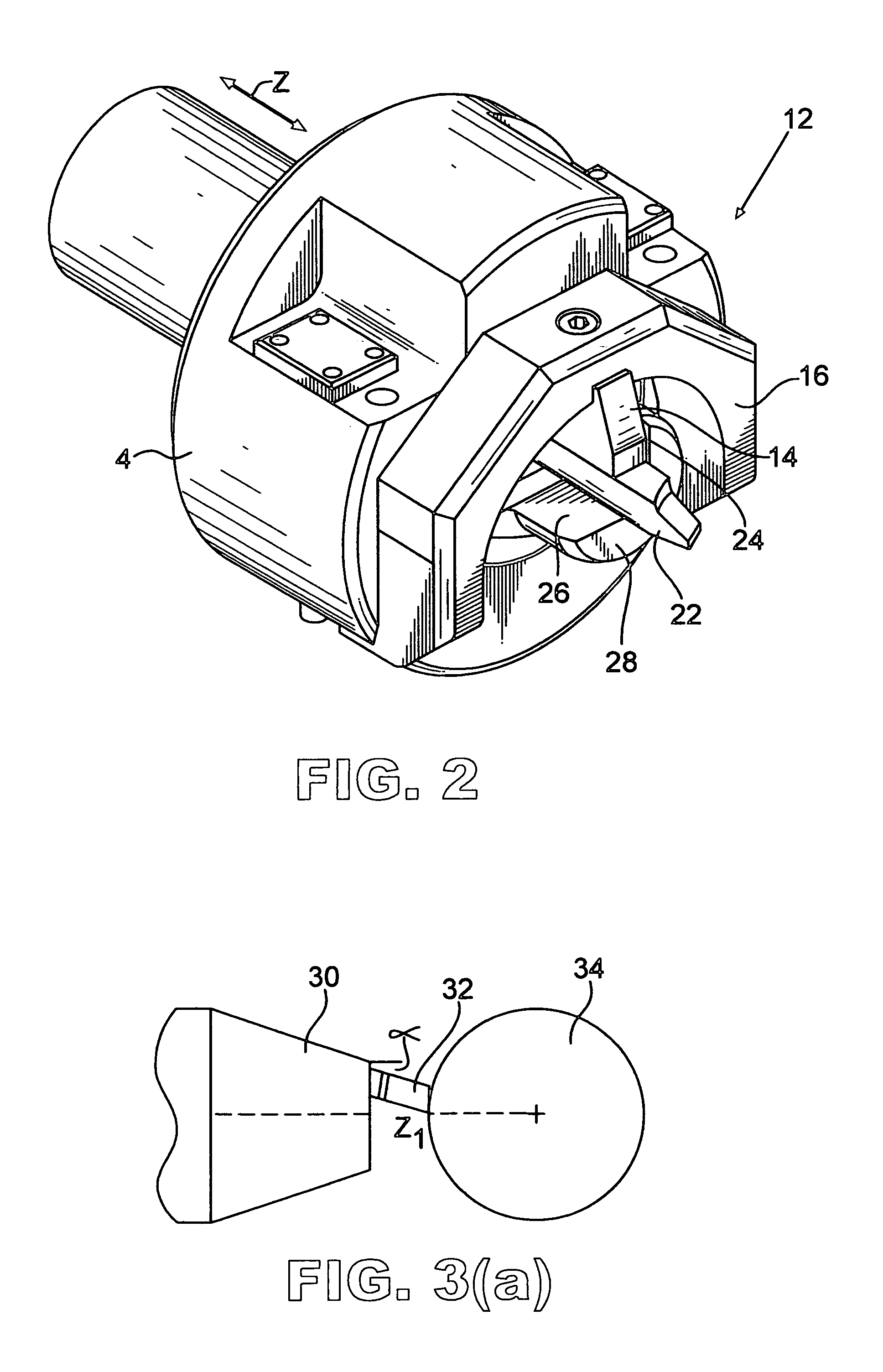

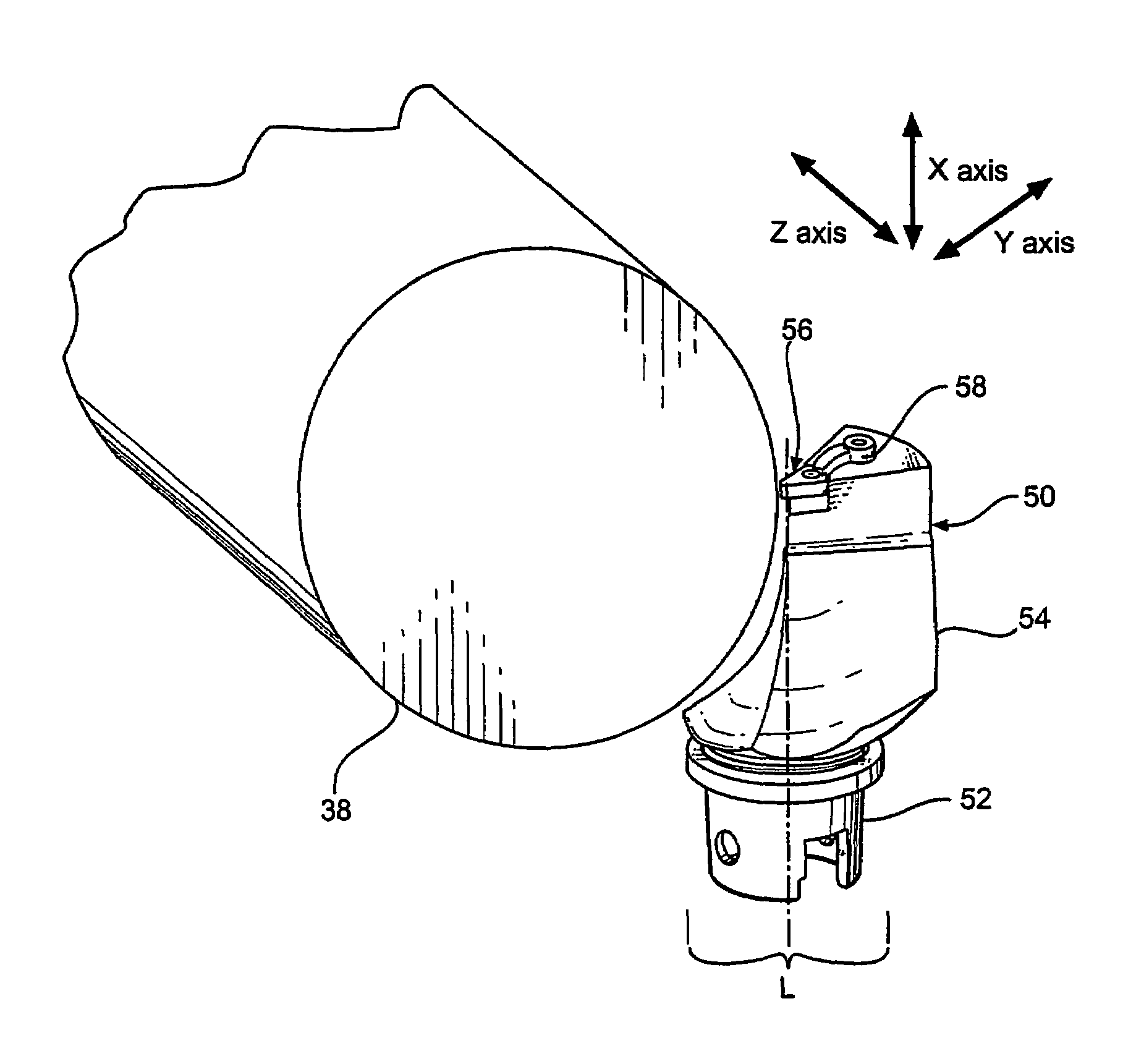

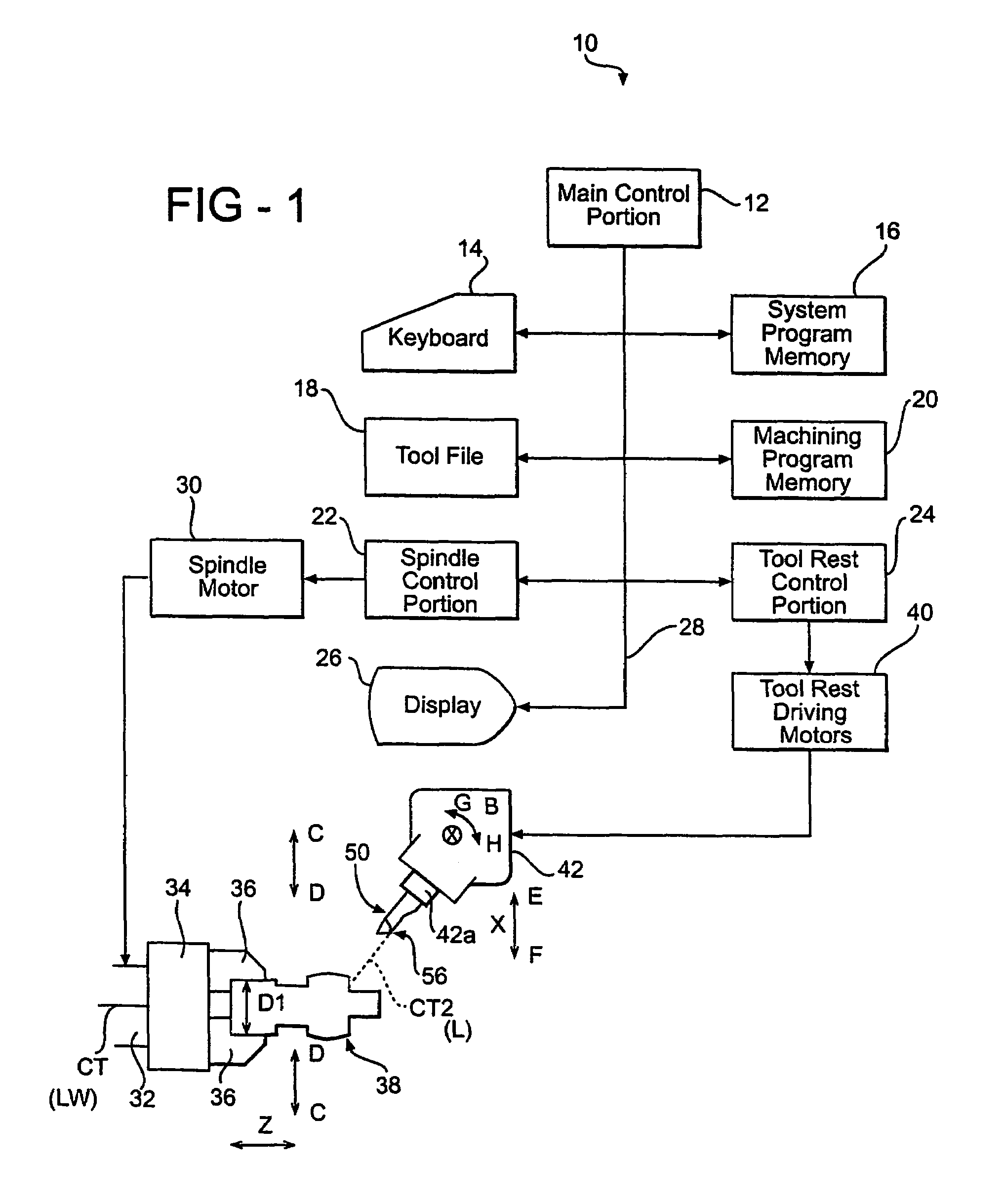

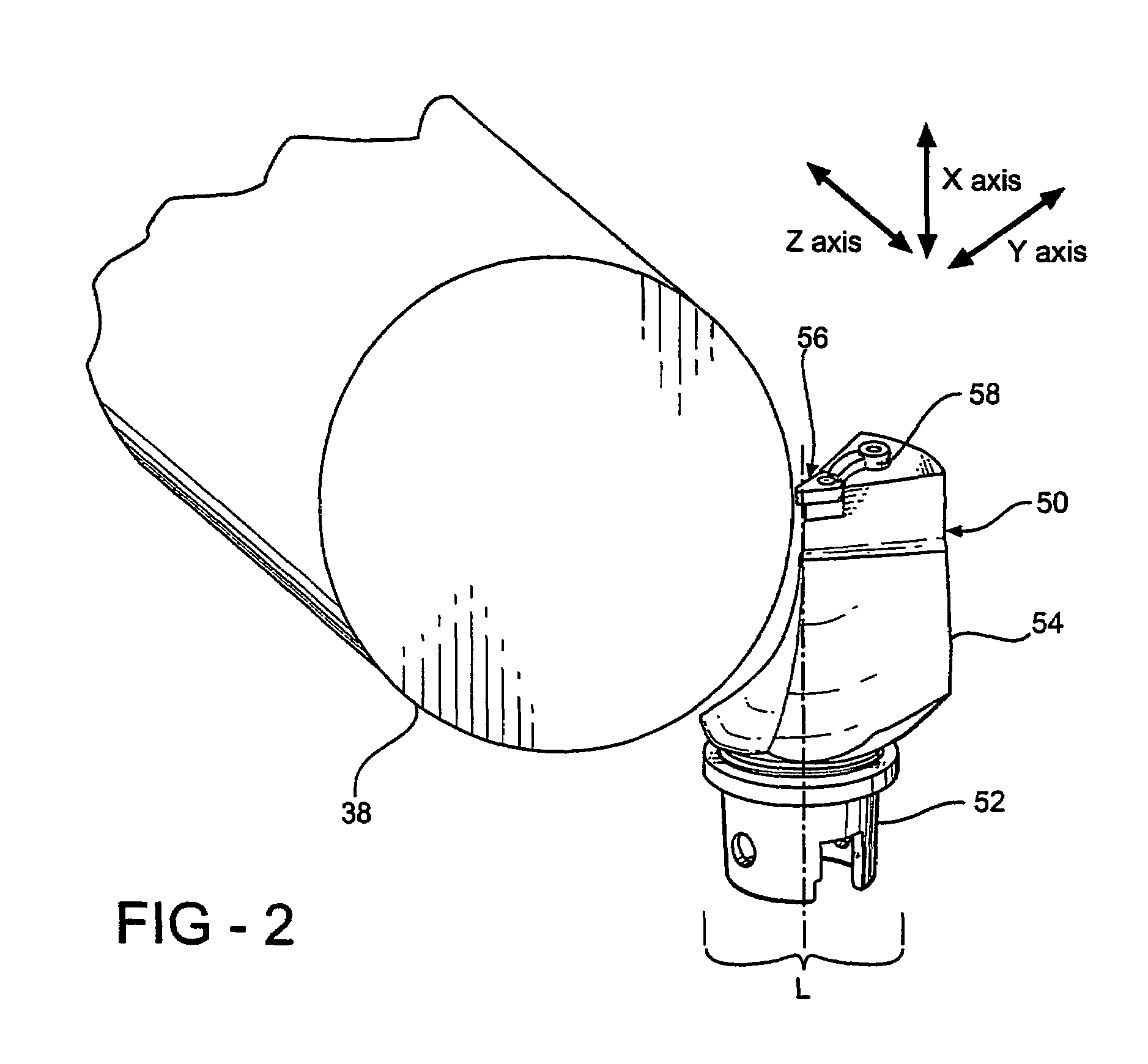

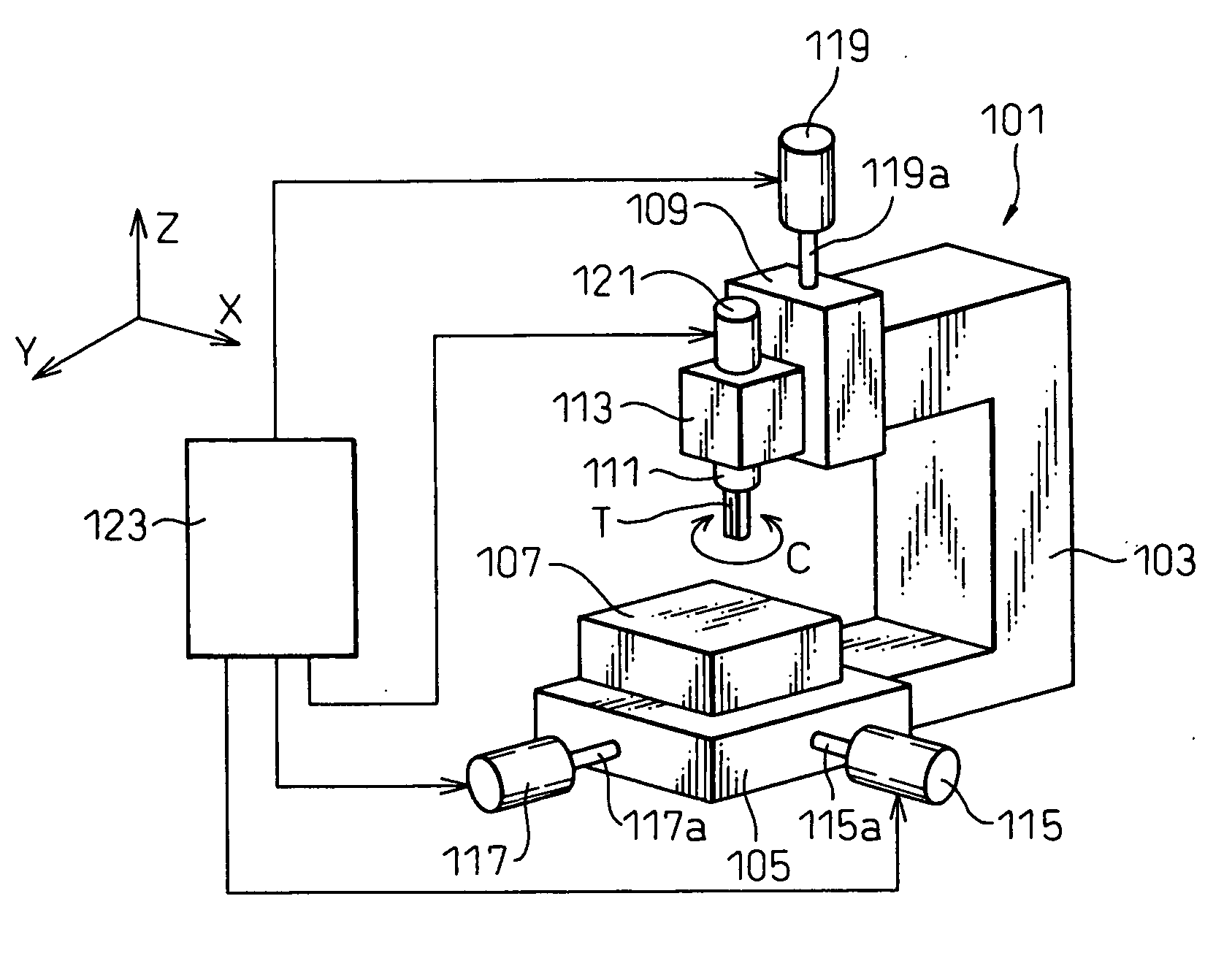

Toolholder

A toolholder (50) with a controllable critical angle, such as a lead, trailing, rake or clearance angles, includes a tool spindle (42a) for retaining the toolholder in a tool rest (42) of a machine tool. The machine tool (10) includes at least one linear axis, for example, three mutually perpendicular axes, a rotary axis and a rotation axis. The rotary axis and / or rotation axis is controllable to move to a specified position in synchronization with a movement of one of the linear axes. An adaptor (54) supports a cutting tool (56) that is retained in the adaptor by a clamp (58). The cutting tool (56) defines a critical angle, such as a lead angle, a trailing angle, a rake angle and a flank clearance angle, wherein the critical angle is corrected as a vector of movement of at least one of the linear axis is changed. In addition, the cutting tool (56) can be positioned on opposite side of a centerline of rotation of the workpiece to effectively double the life of the cutting tool. A method of controlling a toolholder (50) is also disclosed.

Owner:KENNAMETAL INC

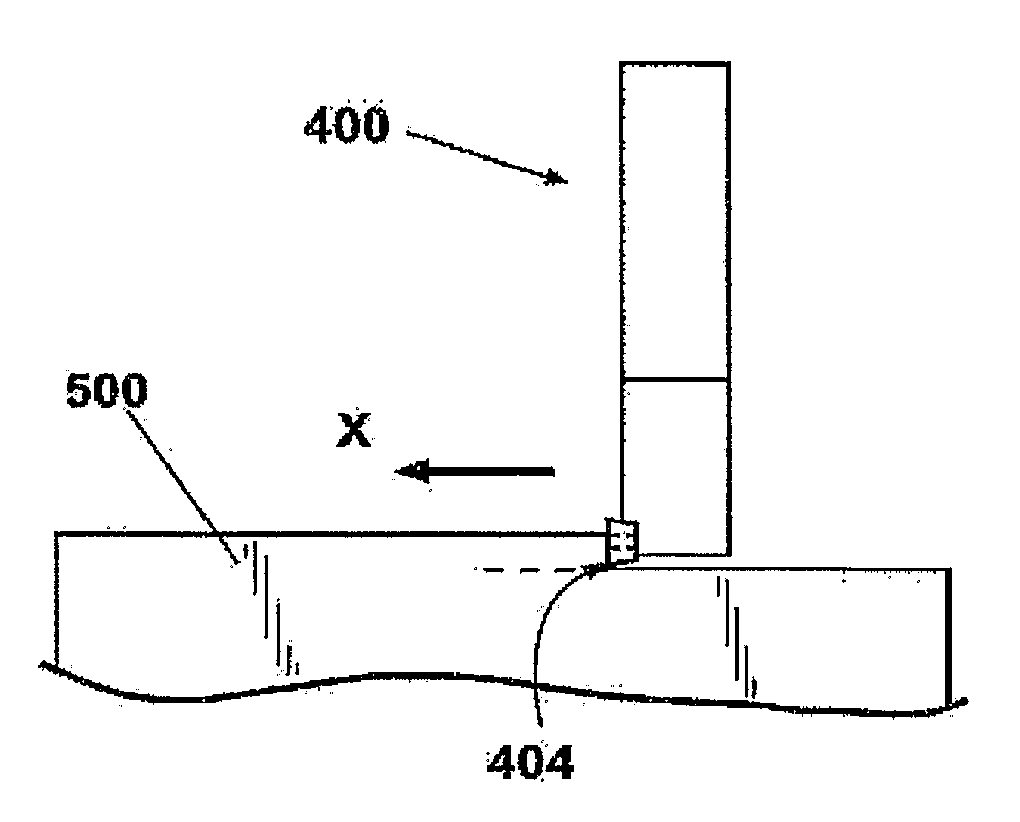

Method and apparatus for non-rotary machining

A non-rotary shaping method (700, 800, 900) and shaping center (600) for forming a part using a non-rotating cutting tool (400) for removing material from a non-rotating workpiece within a three-dimensional work envelope that obsoletes the use of mills for profiling operations. Without the need to rotate to produce sufficient surface footage to remove material, the cutting tool (400) applies constant cutting force to the workpiece along a one-, two-, or three-dimensional cutting path. Also, without the need to rotate, neither the cutting tool nor the part are constrained in shape by axial symmetrical. Therefore, parts without any restriction in shape can be produced with finer surface finishes and higher material removal rates than by milling.

Owner:TENNINE CORP

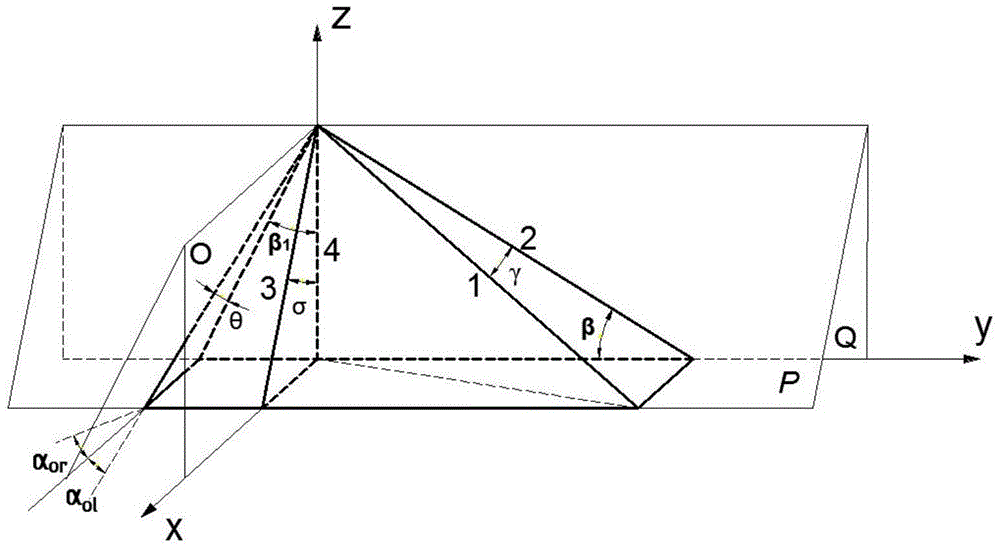

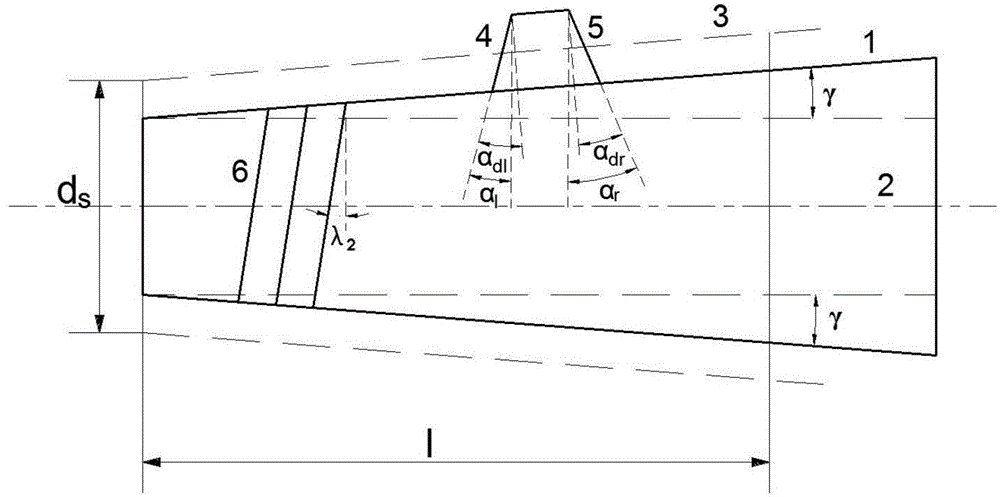

Method for finishing gear shaper cutter by diagonal contour evolution of conical worm grinding wheel

ActiveCN104907897AHigh coincidenceIncrease the lengthPlaning/slotting toolsTurning toolsEngineeringGrinding wheel

The invention belongs to the field of manufacturing of gear cutters, and relates to a method for finishing a gear shaper cutter by the diagonal contour evolution of a conical worm grinding wheel. The worm grinding wheel is trimmed to be conical along the rotating axis of the worm grinding wheel, the gear shaper cutter is machined by adopting a diagonal contour evolution process, and the grinding wheel is also required to move along the radial direction of the gear shaper cutter in a machining process, so that the worm grinding wheel can be ensured to be approximately equivalent to a standard rack at different moments, and a gear shaper cutter capable of meeting an accuracy requirement can be machined.

Owner:CHONGQING UNIV

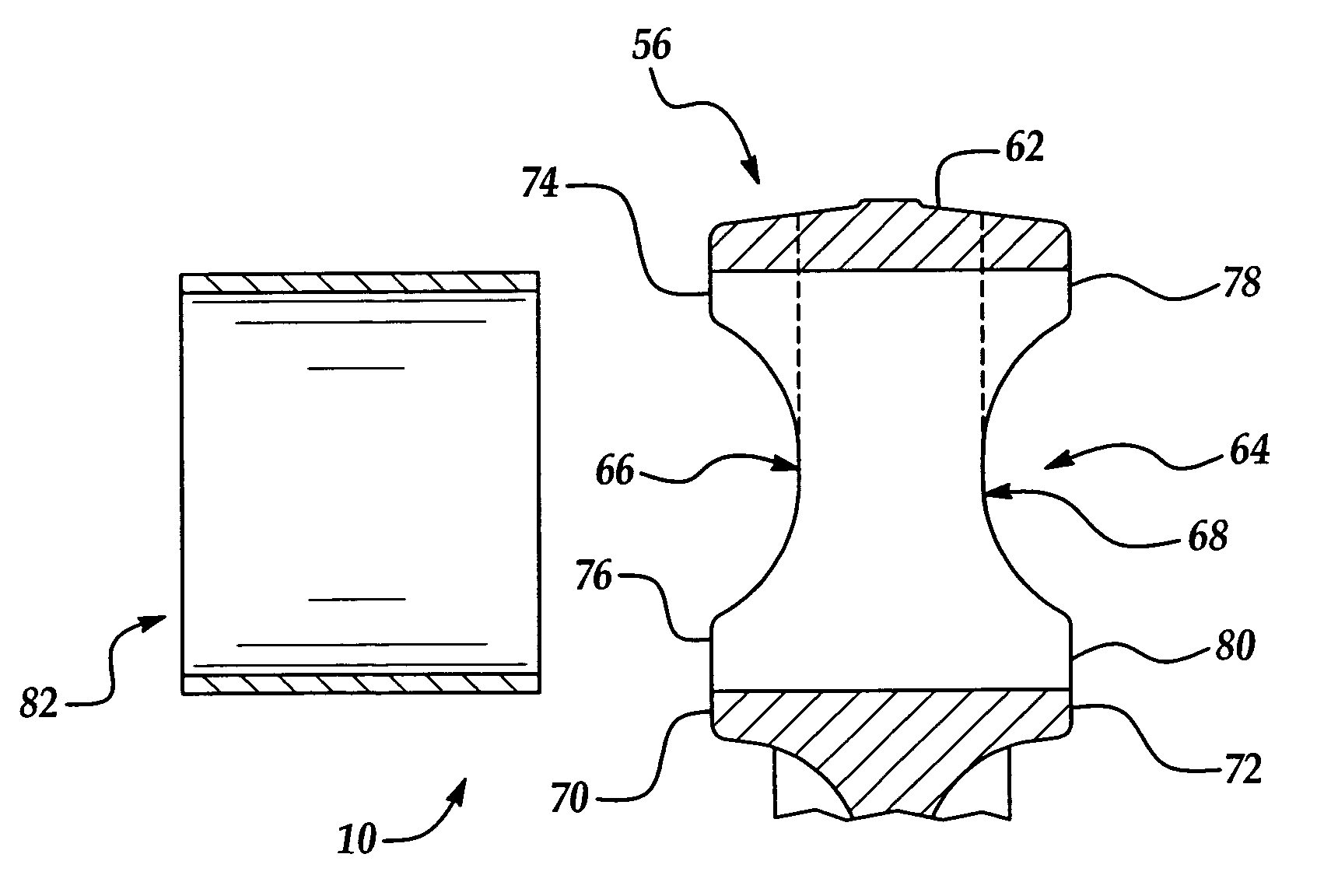

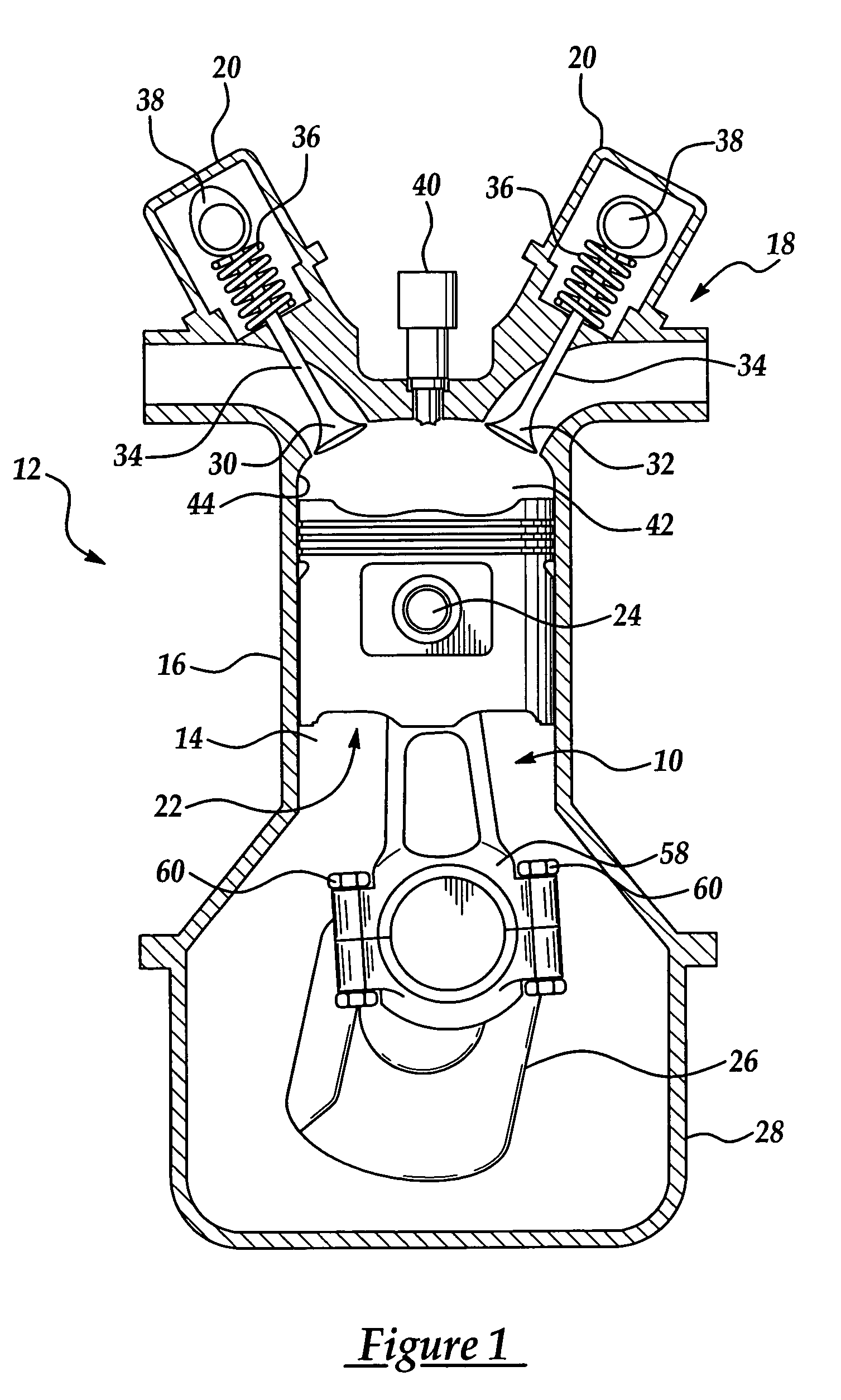

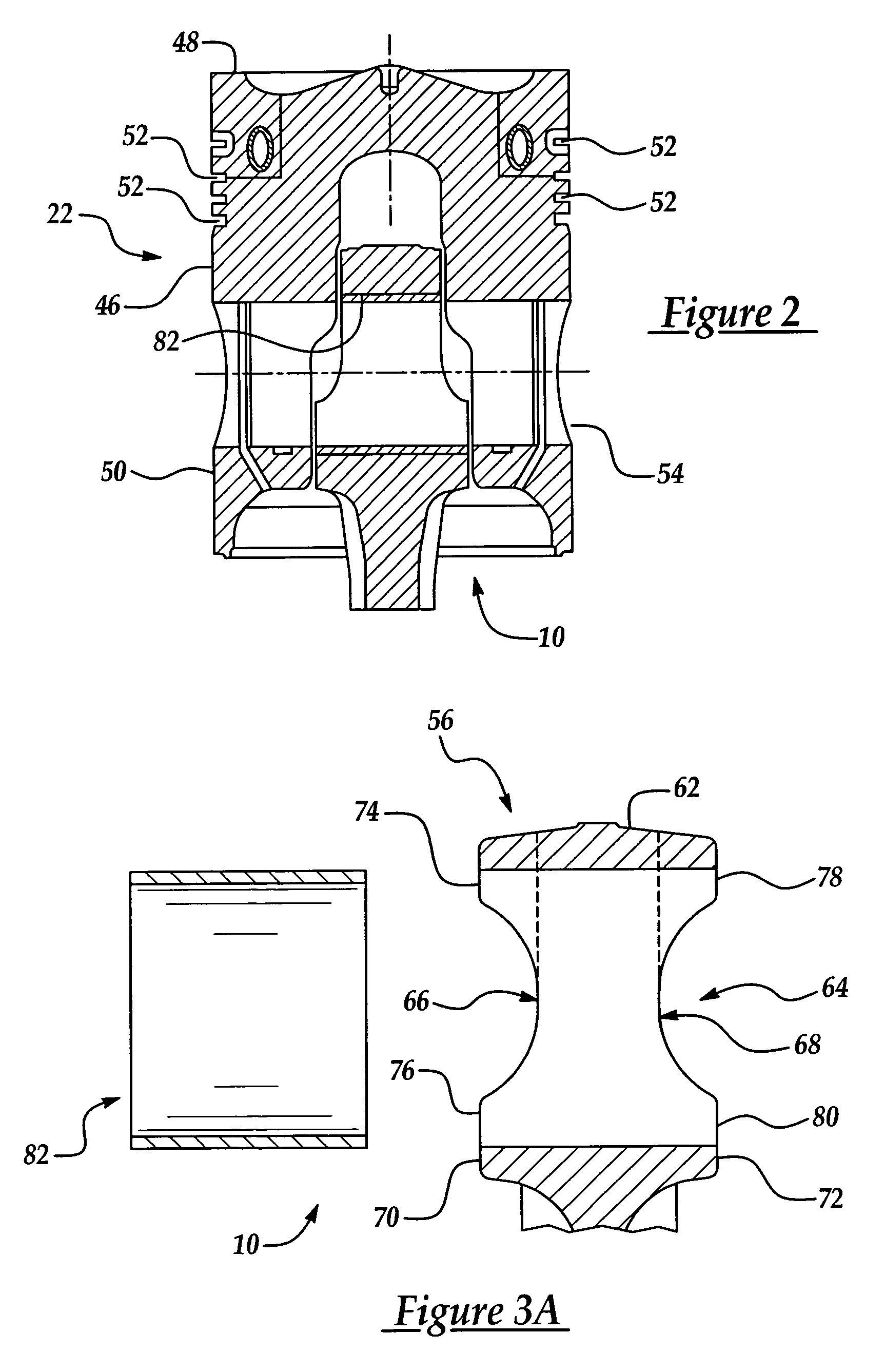

Method of manufacturing a connecting rod assembly for an internal combustion engine

InactiveUS7516546B2Reduce the possibilityEliminate torqueConnecting rod bearingsConnecting rodsInternal combustion engineMachining

Owner:MAHLE TECH

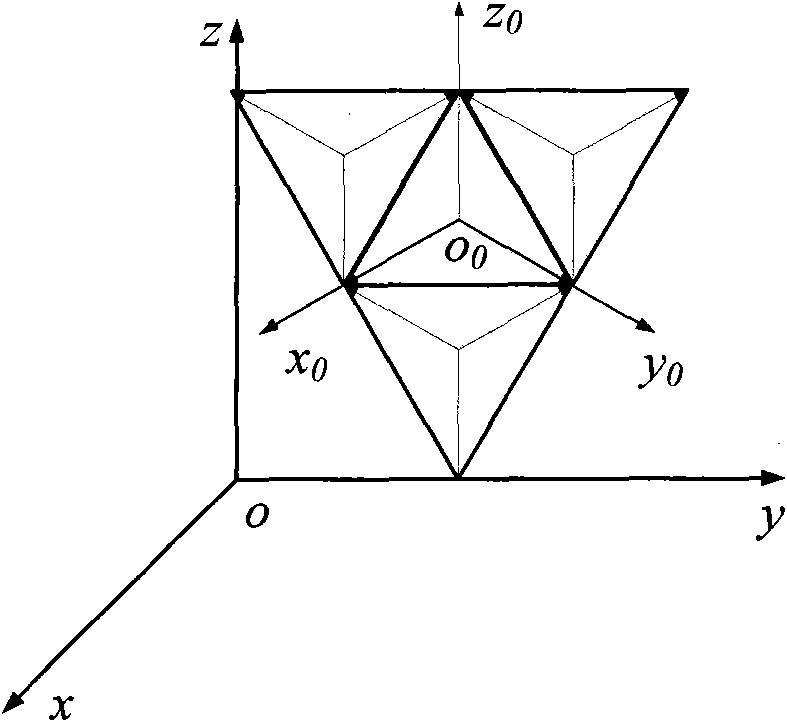

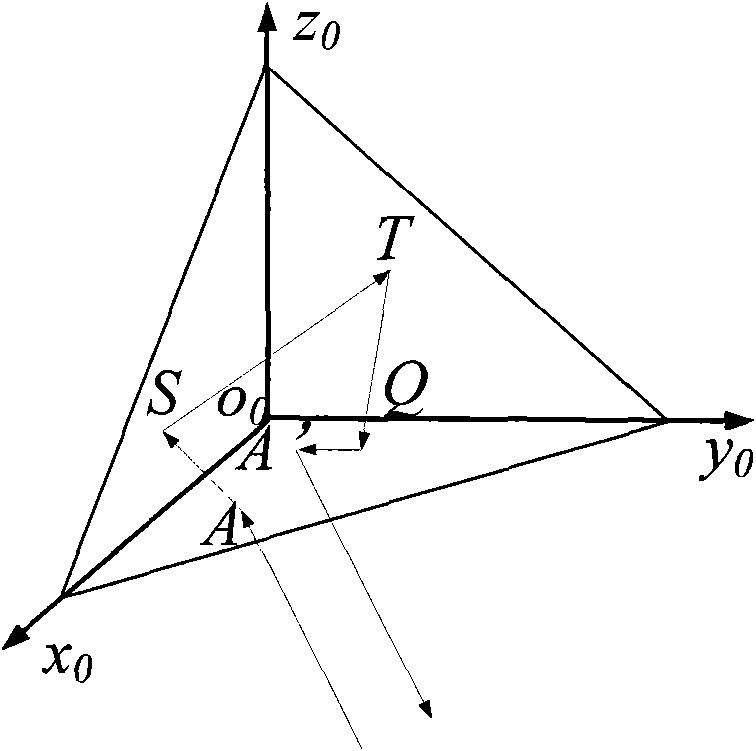

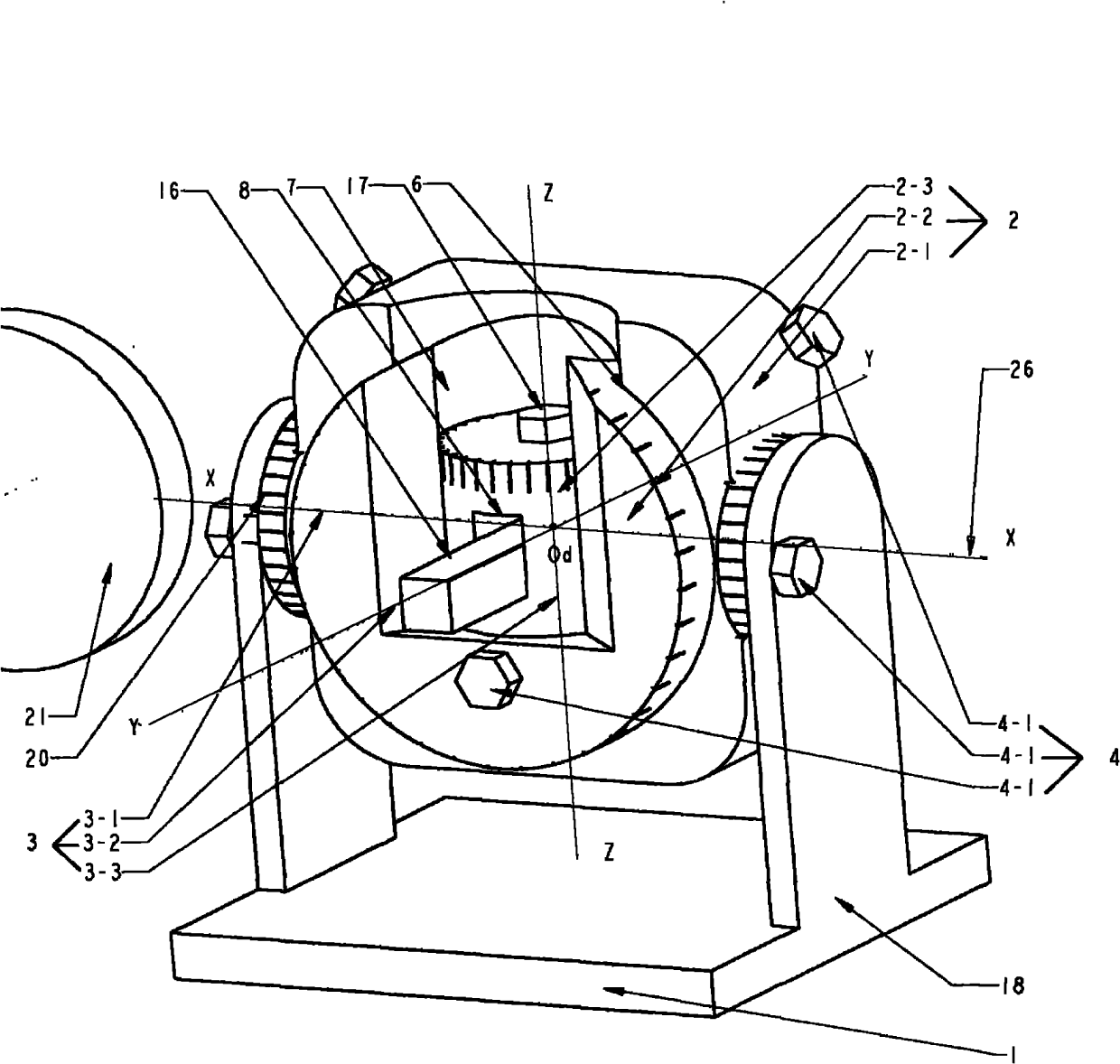

Rotary cutter sharpening seat for cutter

ActiveCN102476328AImprove structural rigidityLarge locking torquePlaning/slotting toolsTurning toolsMiniaturizationEngineering

The invention discloses a rotary cutter sharpening seat for a cutter, comprising a base, rotating pieces, a rotary shaft and a locking piece, wherein the rotary shaft is divided into X, Y and Z rotary shafts; the Z rotating piece is provided with a lathe tool mounting hole, the center line of which is vertical to the Z rotary shaft of the Z rotating piece; the Y rotating piece is provided with a YZ middle-position hole, the center line of which is vertical to the Y rotary shaft of the Y rotating piece; the Z rotating piece is sleeved in the YZ middle-position hole, the center line of which is collinear with the axis of the Z rotary shaft; the X rotating piece is provided with an XY middle-position hole the center line of which is vertical to the X rotary shaft of the X rotating piece; the Y rotating piece is sleeved in the XY middle-position hole the center line of which is collinear with the axis of the Y rotary shaft; the center line of the YZ middle-position hole of the Y rotating piece is crossed on the X rotating piece; the base is also provided with an X rotating support; and the X rotating piece is sleeved on the X rotating support, the rotating shaft of which is collinear with the X rotary shaft of the X rotating piece. When the rotary cutter sharpening seat is used, after a tool grinding machine provided with the cutter sharpening seat is clamped and lathed, continuous multi-face grinding can be performed at any blade surface angles to finish integral lathing and blade sharpening once, the operation of clamping for multiple times is avoided, and angle space conversion is not needed; the big lathing offset when the angle is regulated is eliminated; the rigidity of the cutter sharpening seat is improved; machining errors due to the cutter relieving phenomenon are reduced; and the locking reliability is further improved to increase the convenience in use and realize the miniaturization of a matched tool grinding machine and higher blade grinding precision.

Owner:JIAXING EXPERT MACHINE TECHN

Machining process of spline inside blind hole in shaft end

InactiveCN1486810AImprove rigidityImprove processing efficiencyPlaning/slotting toolsReciprocating motionEngineering

The present invention is machining process of spline inside blind hole in shaft end in high maching speed and high precision. The machining process includes setting the machining shaft vertically inside positioned fixture for positioning and clamping with the end to be machined being in the top; and driving the toothed forming pushing broach for cutting via vertical reciprocation after the working head of the press is positioned. The pushing broached amount is designated to the forming pushing broaches, and, for example, the pushing broached amount for rectangular tooth is designated to 8-11 forming pushing broaches. During the cutting, the toothed forming pushing broaches are used successively in the order from small outer diameter one to large outer diameter one.

Owner:JIANGSU GANGYANG STEERING SYST

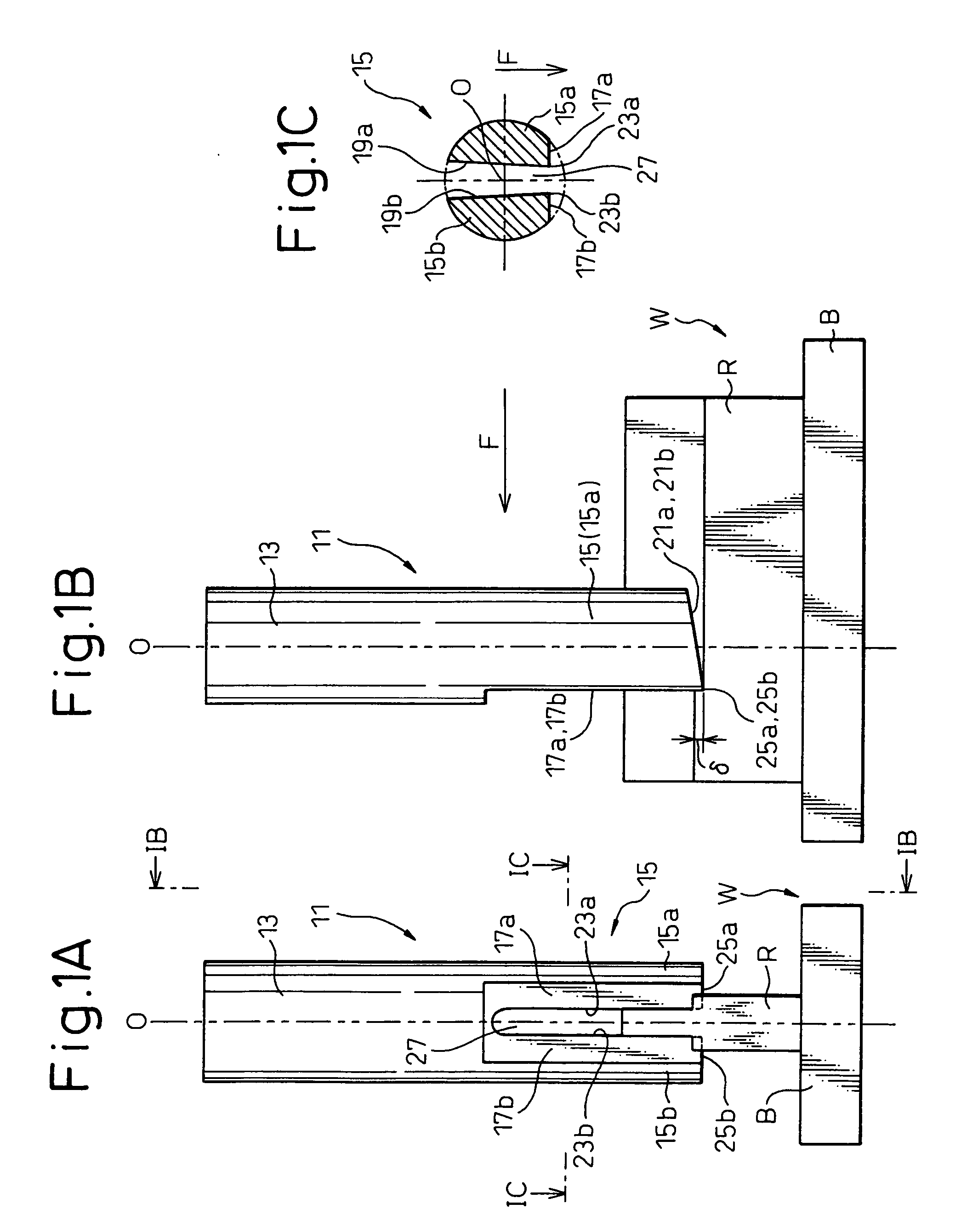

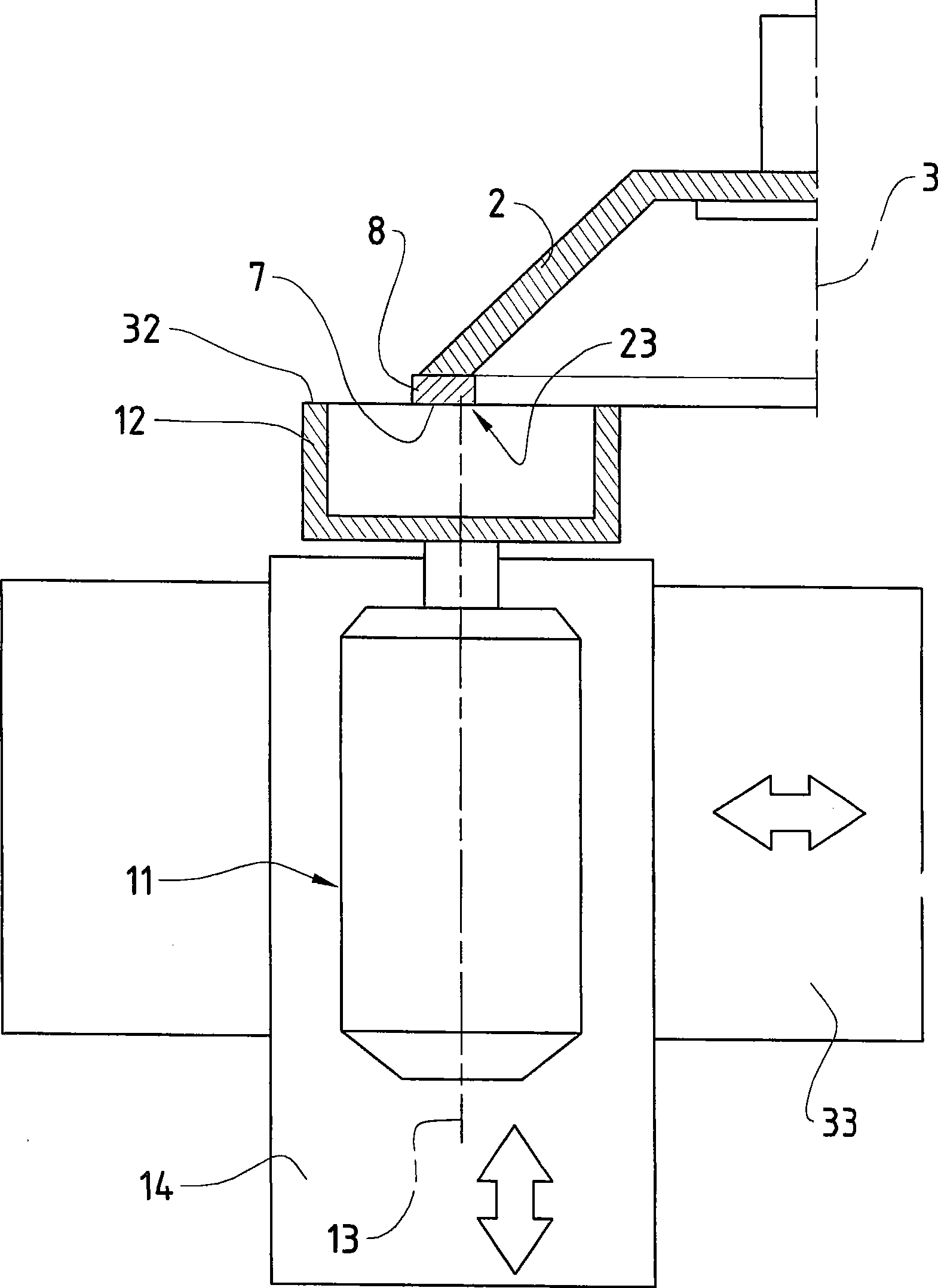

Cutting method and apparatus and rib electrode for electric discharge machining

InactiveUS20070011861A1Improve machining accuracyImprove machine efficiencyPlaning/slotting toolsArc welding apparatusElectric dischargeMachining

An object of the present invention is to provide a cutting method and apparatus and a rib electrode for electric discharge machining which can cut a rib portion of a workpiece efficiently and accurately. For this purpose, a cutting tool 11 having cutting edges 23a, 23b extending in parallel or extending along two straight lines diverging toward the forward end in the same plane is prepared. The cutting tool 11 is arranged with respect to a workpiece W such that the two cutting edges 23a, 23b engage with the two opposed side surfaces of the rib portion R of the workpiece W. The cutting tool 11 is moved relative to the workpiece W along a desired machining path, to thereby cut the two side surfaces of the rib portion R of the workpiece W at one time.

Owner:MAKINO MILLING MASCH CO LTD

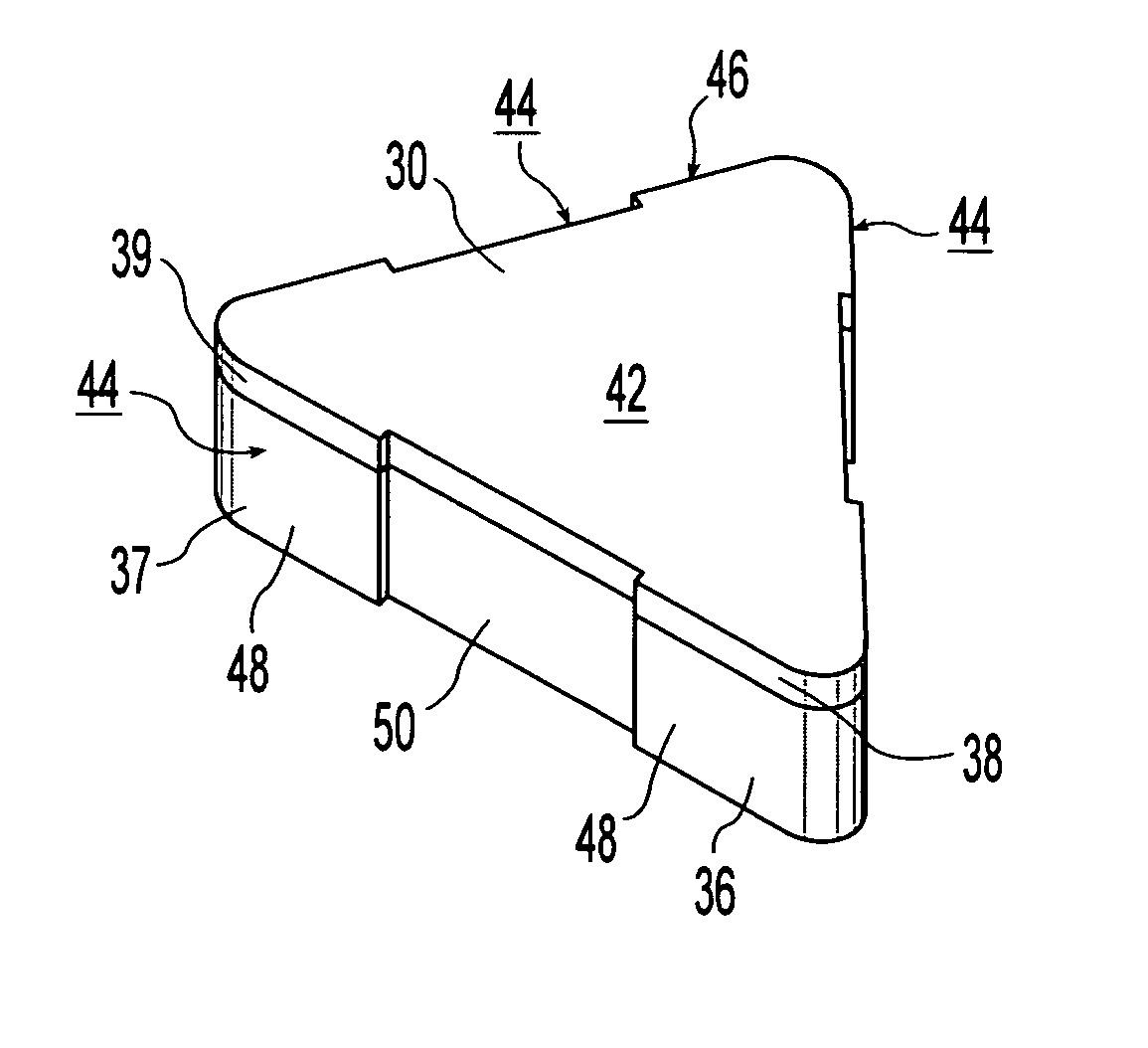

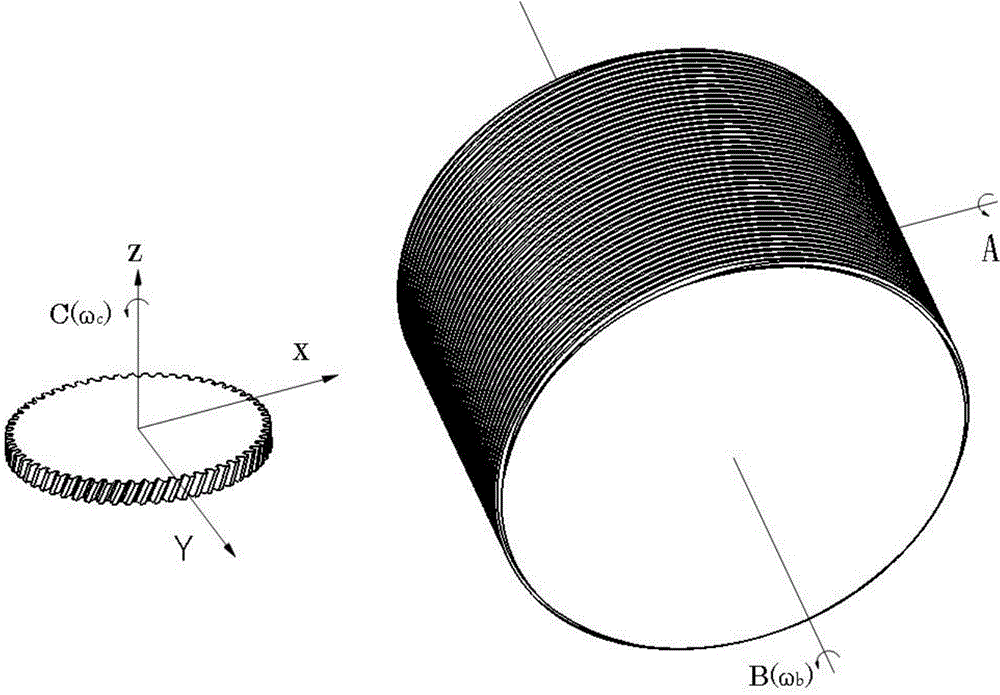

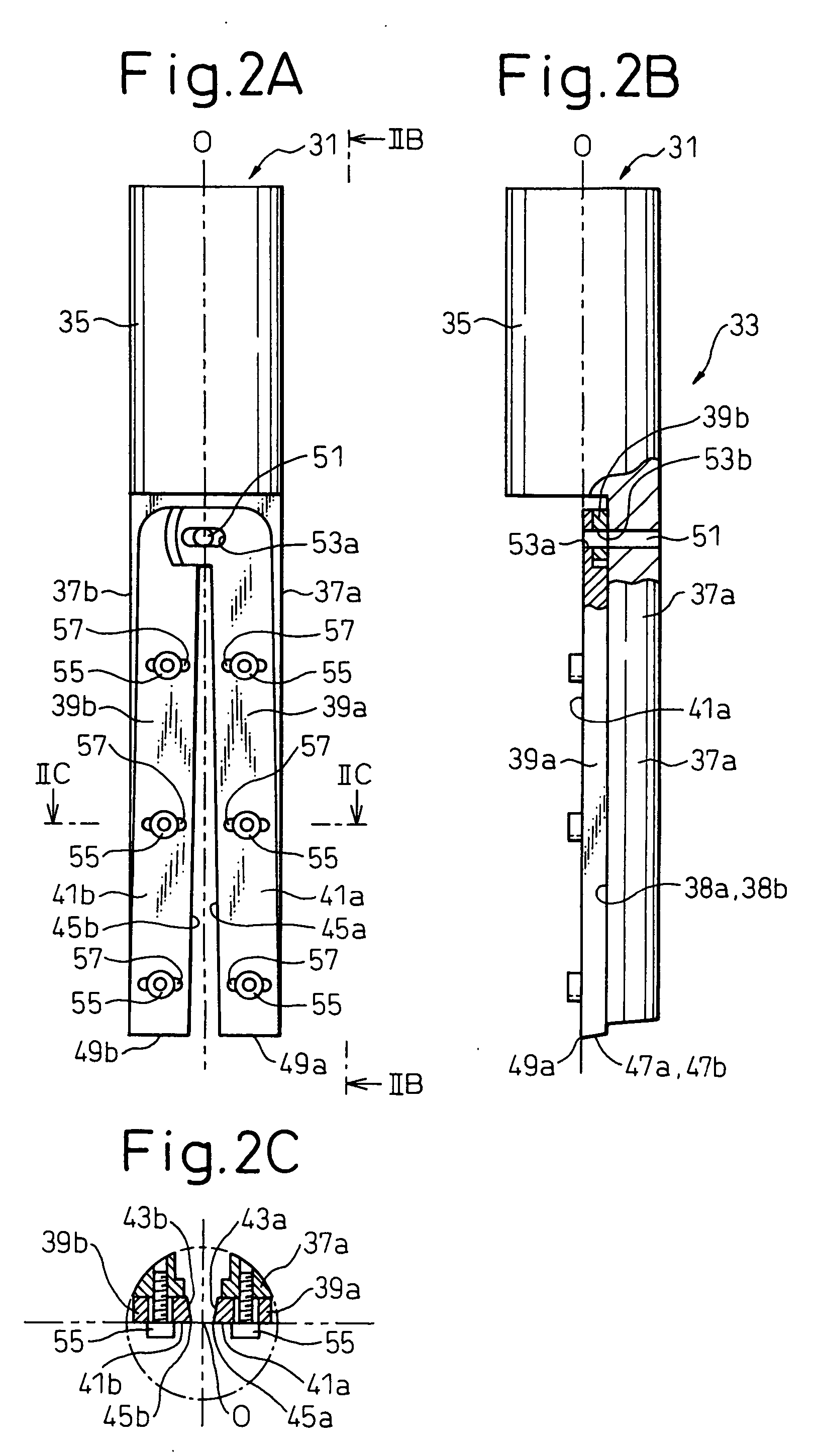

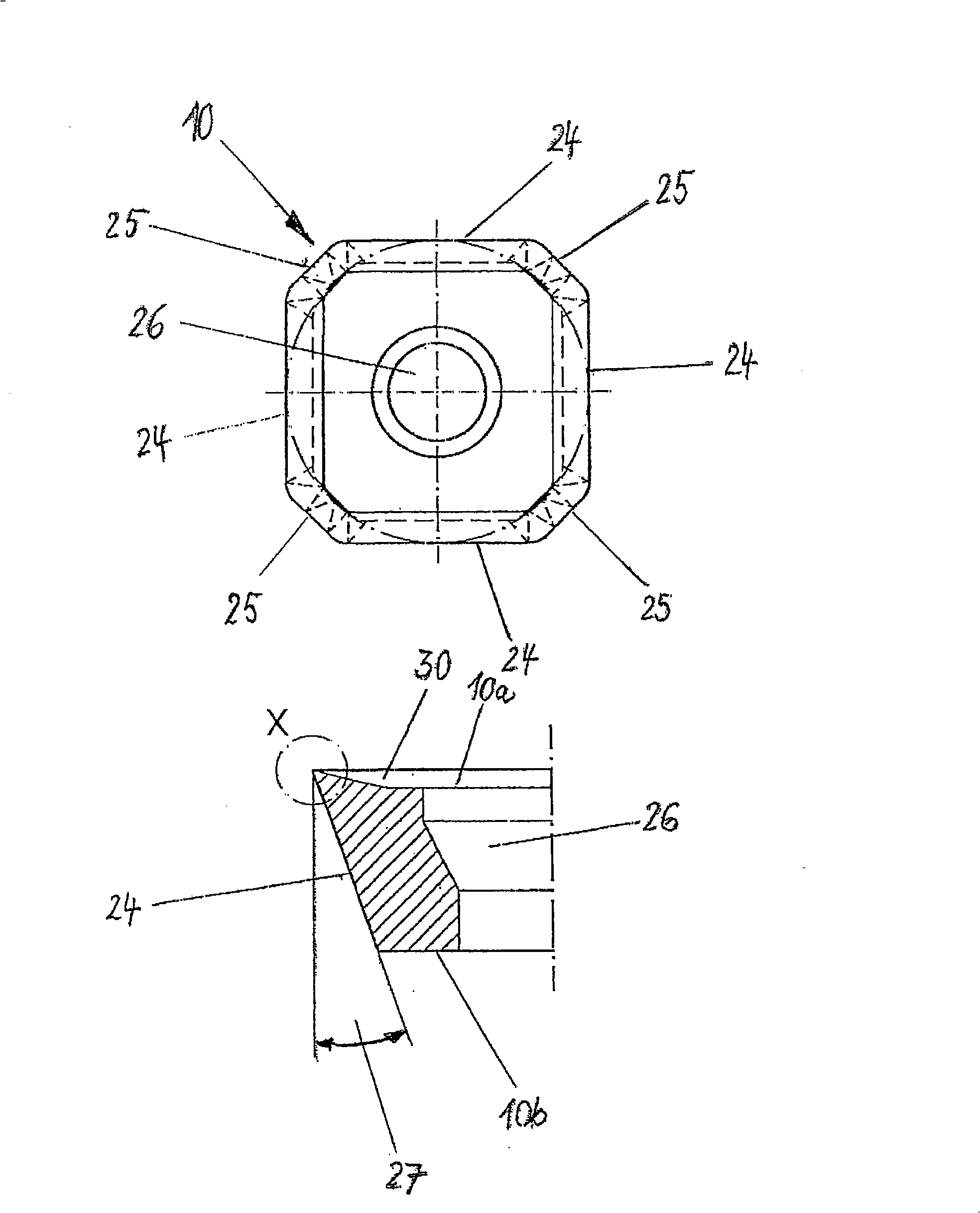

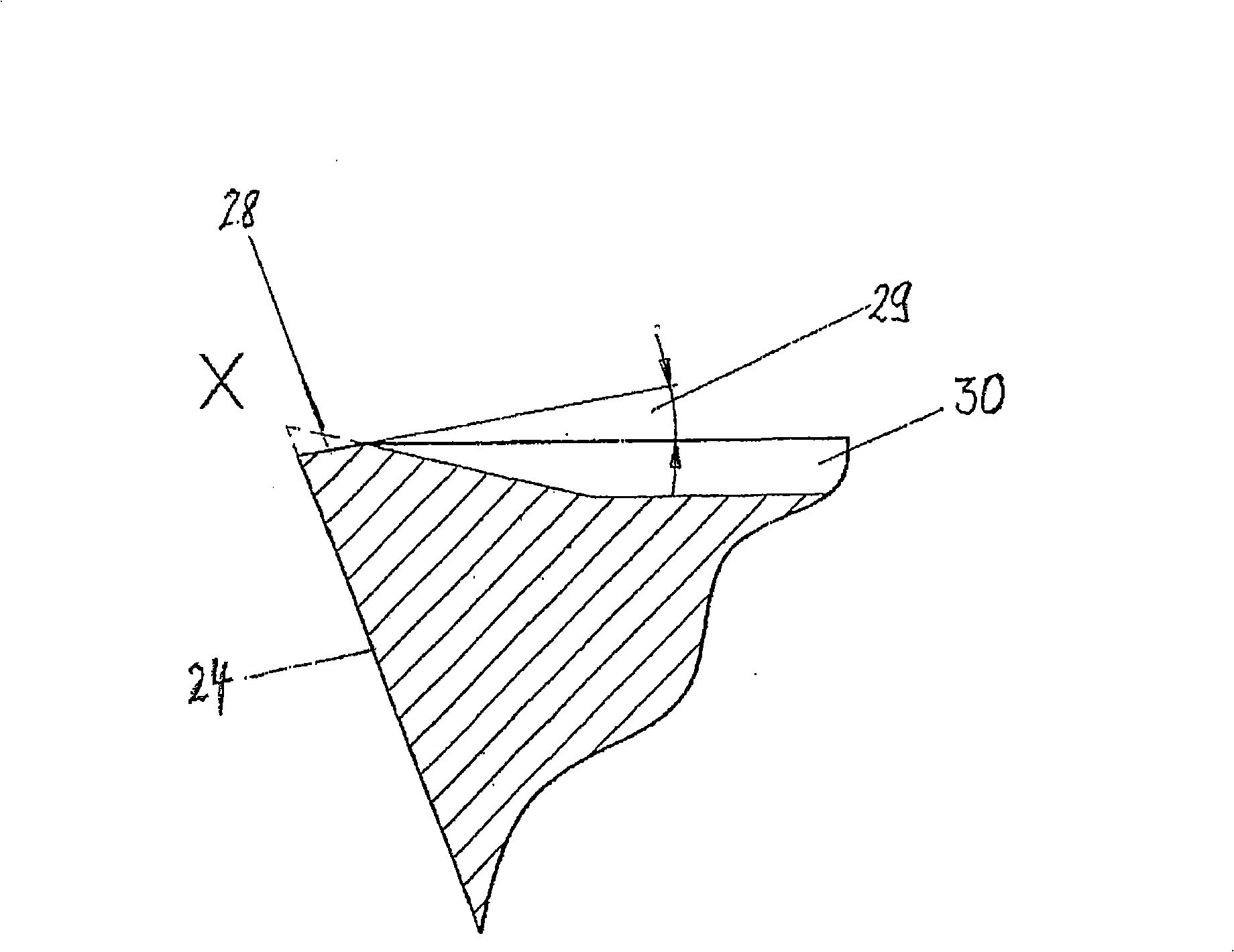

Method of grinding an indexable insert and grinding wheel for carrying out the grinding method

InactiveCN101495269AImprove grinding effectReduce wearAbrasion apparatusPlaning/slotting toolsLeading edgeRelative motion

In an indexable insert having the wide sides 10a, 10b, the inclined narrow sides 24 are to be ground, that is to say the grinding allowance 38 is to be removed. To this end, the indexable insert 10 is set in rotation about the driven axis of rotation 11 (C axis) between a clamping insert 6 and a thrust bolt 9. Serving for the grinding is a grinding wheel 18 which rotates about the rotation axis 19 and which has a circumferential surface 18a contoured in a circular shape and having the largest diameter 43 and is composed of a leading region 41 and a trailing region 42. The grinding wheel 18 is guided relative to the indexable insert 10 along the geometrical defining line 39 which is formed by the generating line of the finished narrow side 24 in the feed direction 44. The leading region 41 tapering forwards effects preliminary grinding of the narrow side 24 by longitudinal grinding, whereas the trailing region 42 effects finish grinding by linear contact with the narrow side 24. The grinding wheel 18 is held with the clamping flanges 40 on a grinding spindle. The grinding operation is effected with controlled movement of the driven axis of rotation 11 (C axis), a first displacement axis 3 (Z axis), a second displacement axis 15 (X axis) and a pivoting movement of the grinding wheel 18 relative to the indexable insert 10 according to double arrow B.

Owner:ERWIN JUNKER MASCHNINENFAB

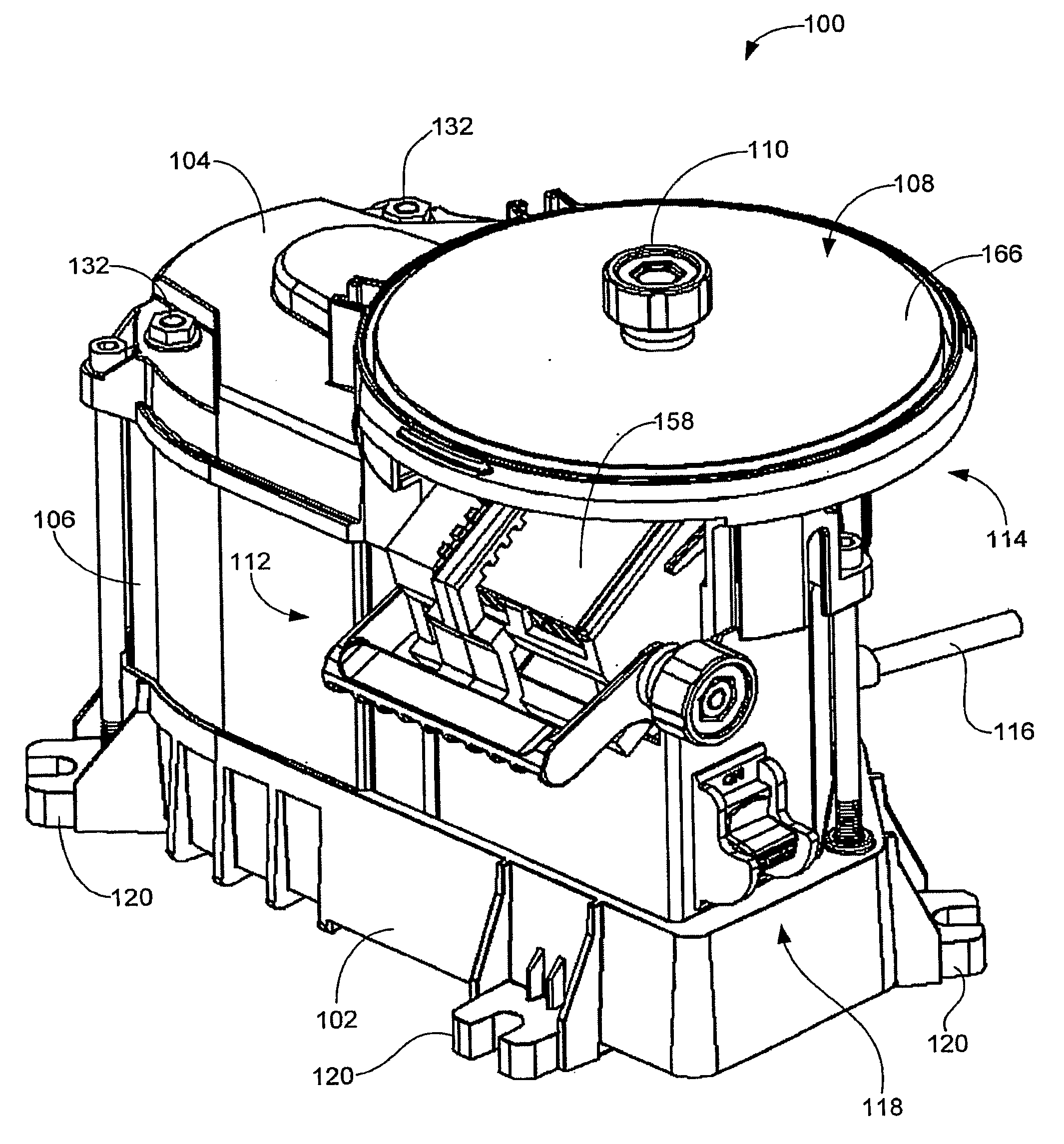

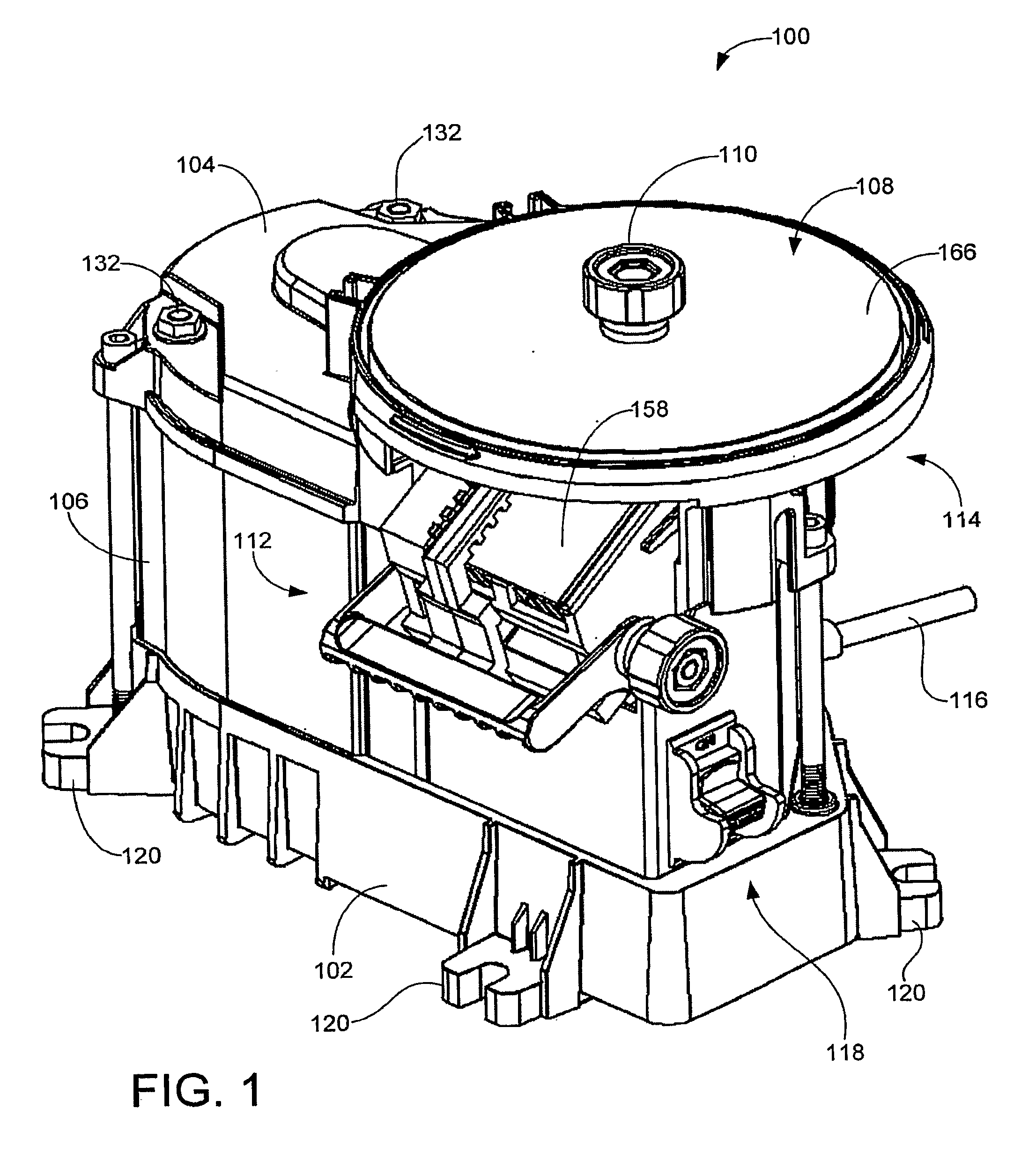

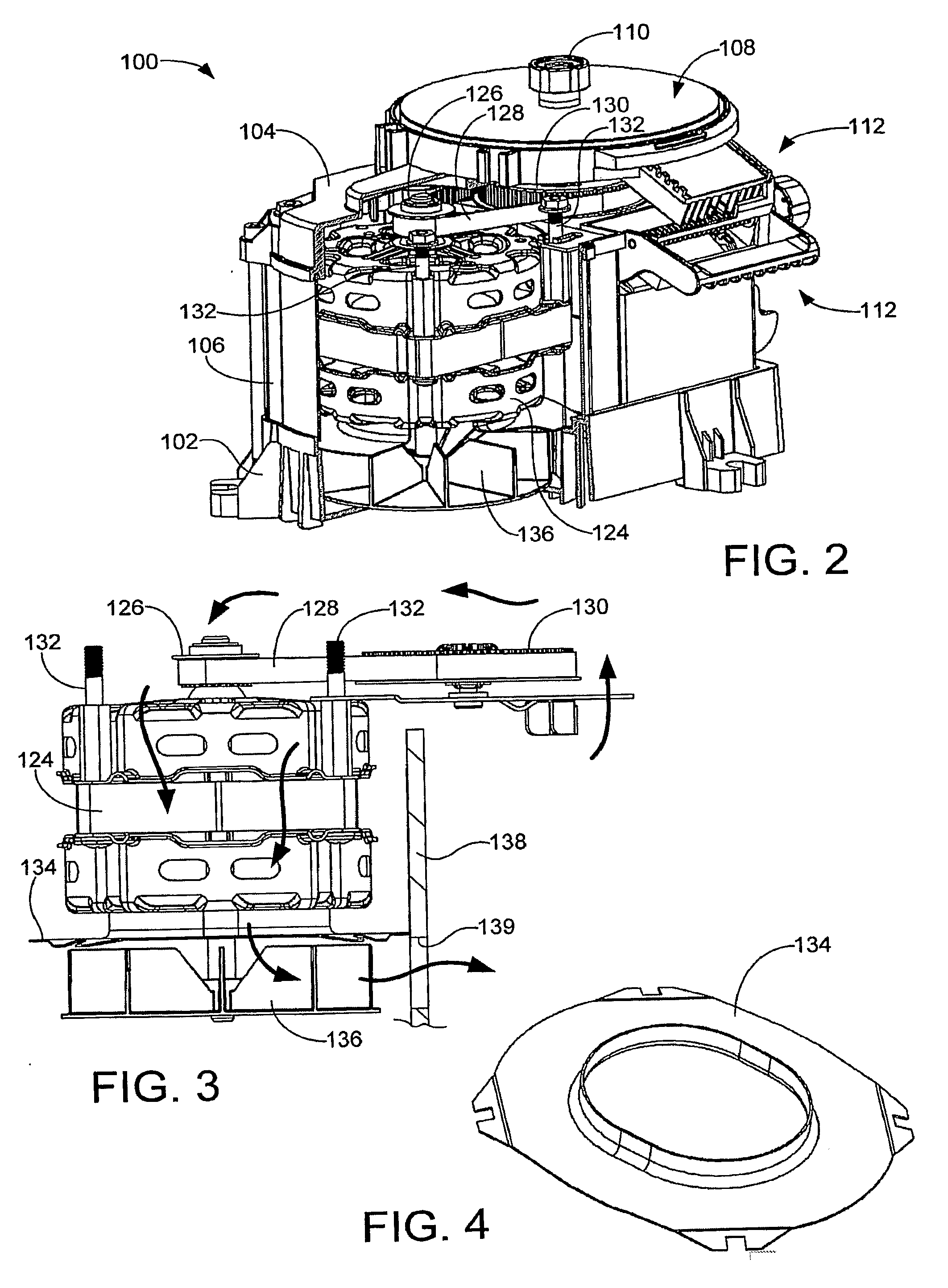

Cutting Tool Sharpener

ActiveUS20080214095A1Reduce the temperatureEdge grinding machinesCutting toolsEngineeringTrailing edge

A tool sharpening assembly (100) suitable for sharpening cutting tools (140,350,366,546,562). In some embodiments, a wedge-shaped port is formed between a rotational first abrasive surface (160,262) and a stationary second abrasive surface (162,264) to sharpen a distal cutting edge (146) of a cutting tool (140,230,546). In other embodiments, a cooling mechanism (136,326,330,334,338) actively draws heat generated during a sharpening operation from a tool (140) and through a tool support structure (170,234,328,332) contactingly supporting the tool, in further embodiments, a rotatable abrasive slotted disc (364) comprises at least one inspection aperture (372) formed from an interior sidewall (390) with upper and lower leading and trailing edges (396,398,400,402) of non-uniform separation distance. In other embodiments, a cylindrical drum abrasive member (572) is provided with an associated stationary support plate (574). In further embodiments, a grinding wheel (580,600) is formed of a substrate (582,602) and a plurality of abrasive layers (584,586,592,612,614) adhered thereto.

Owner:DAREX

Grinding machine with a device for conditioning a grinding wheel and a method of conditioning a grinding wheel

ActiveCN101462243AImprove grinding qualityAvoid cleaningPlaning/slotting toolsTurning toolsEngineeringGrinding wheel

A grinding machine for grinding a workpiece comprises a machine frame, a bearing device provided on the machine frame and movable along guides, in which a cup-shaped grinding wheel is rotatably drivable about a grinding wheel axis and electrically insulated. The grinding wheel is electrically connected to a generator. The device for profile dressing, sharpening and cleaning the grinding wheel consists of a single cup-shaped electrode, which is drivable about its central axis and is placed on a slide, which allows a working gap to exist between the machining surface of the cup-shaped electrode and the annular abrasive surface. A spark erosion discharge occurs in the gap when a voltage is applied. The invention also relates to a method for conditioning the grinding wheel in the grinding machine.

Owner:AGATHON

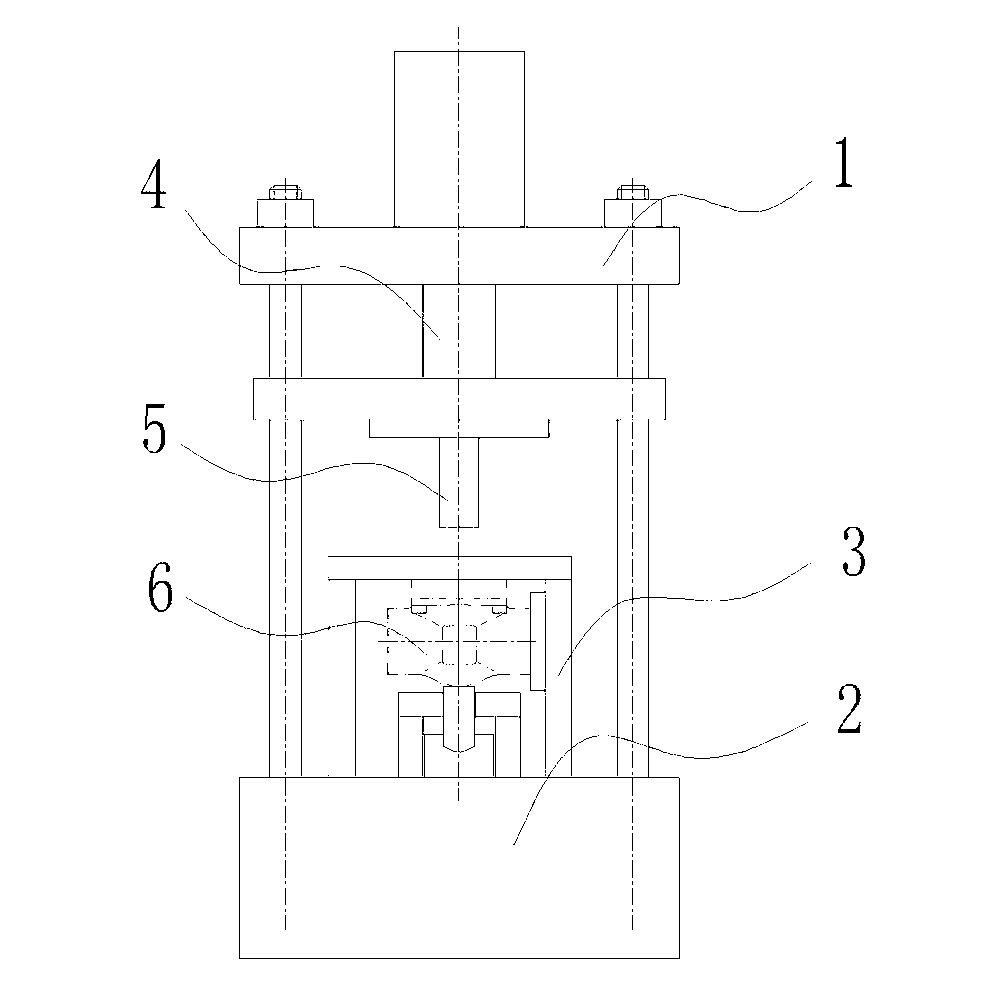

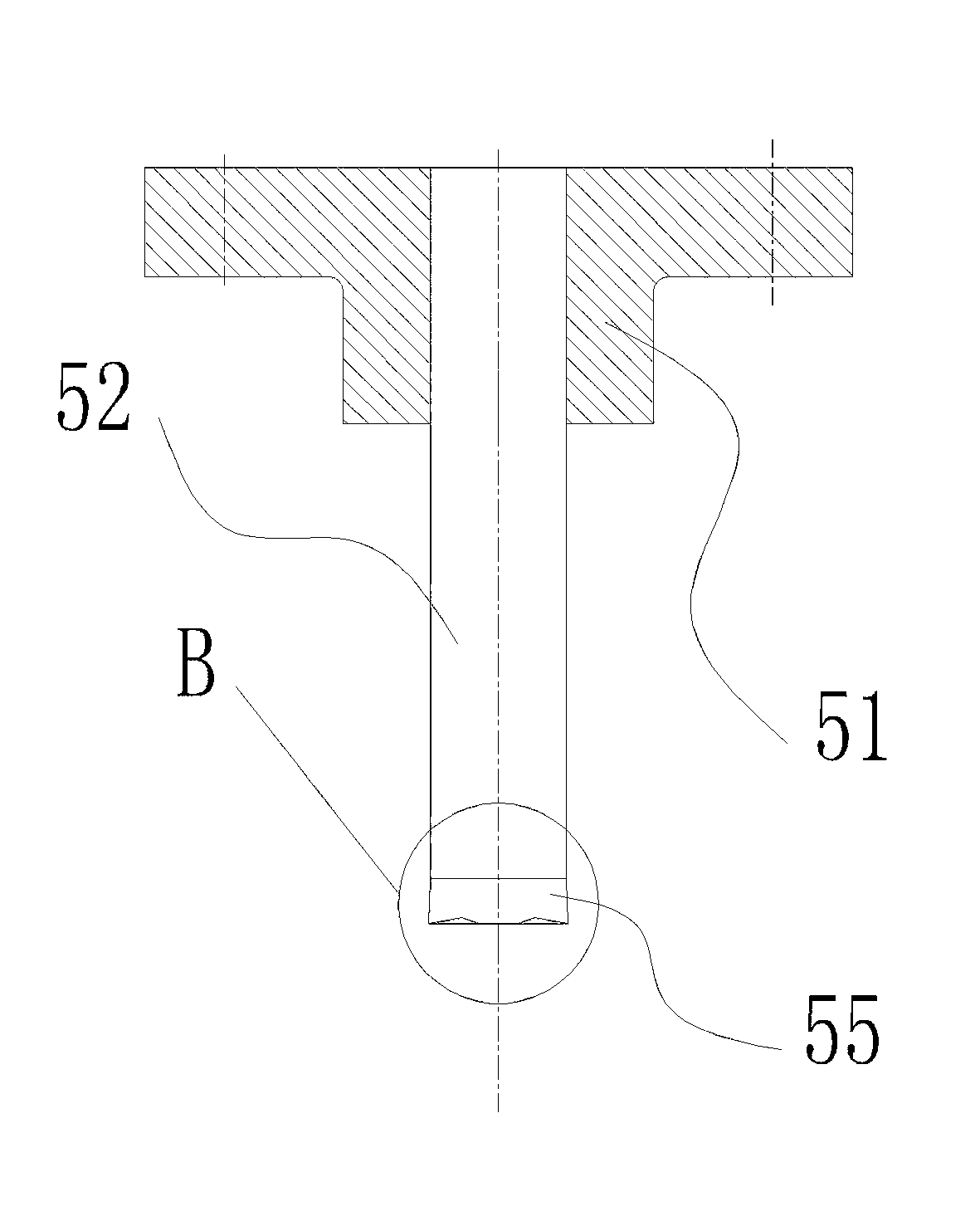

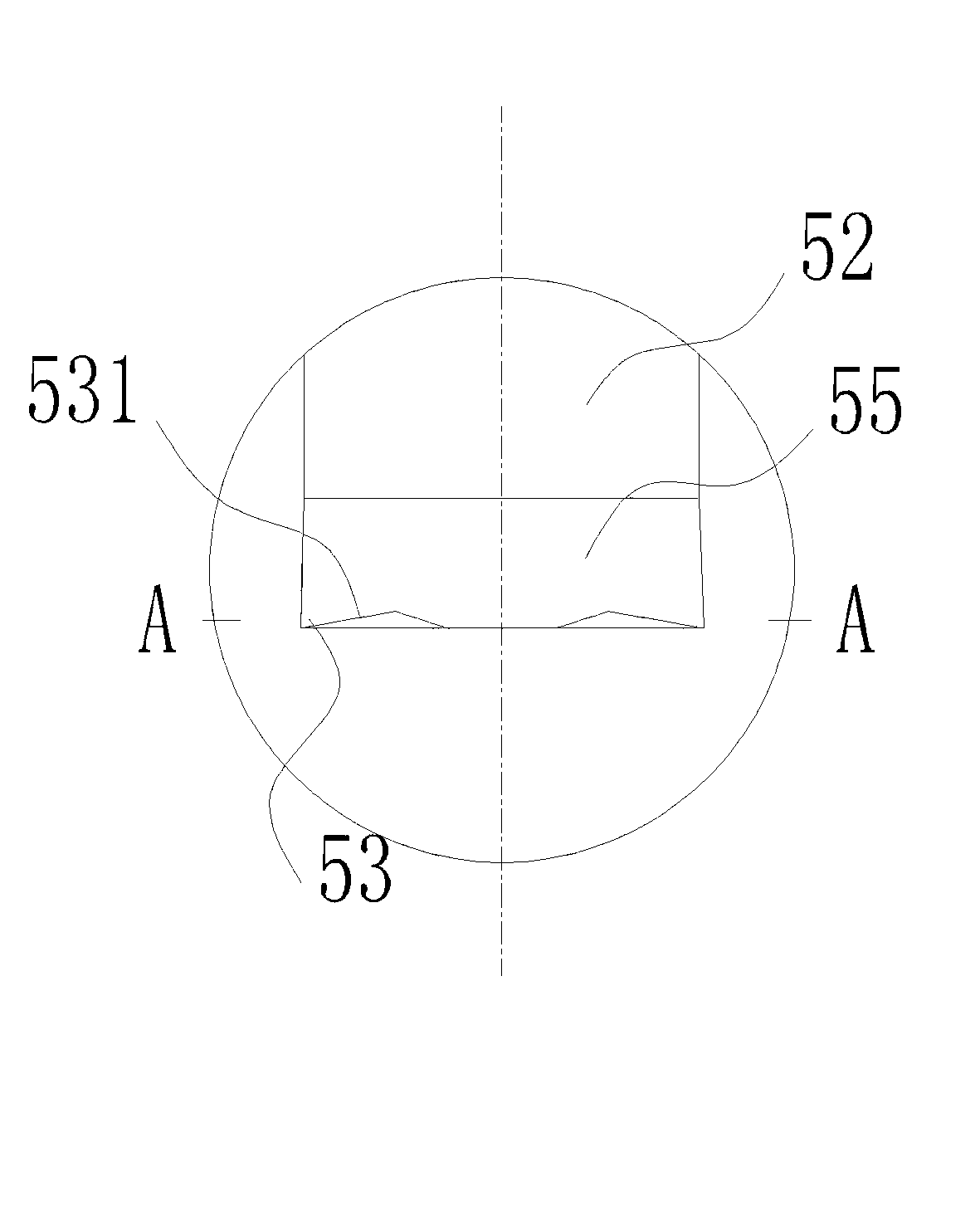

Forged steel gate valve flashboard guide groove processing equipment and forged steel gate valve flashboard guide groove processing method

ActiveCN103286366AReduce manufacturing costImprove labor productivityPlaning/slotting toolsPlaning/slotting machinesProcess equipmentStructural engineering

The invention discloses forged steel gate valve processing equipment and a forged steel gate valve processing method, and provides simply structured forged steel gate valve flashboard guide groove processing equipment and a forged steel gate valve flashboard guide groove processing method, which can greatly improve the processing efficiency under the premise of guaranteeing the gate valve flashboard guide groove processing quality and solve the technical problems that the valve flashboard guide groove processing quality is poor, the efficiency is low and the processing precision is hard to guarantee in the prior art. The equipment comprises a hydraulic press, wherein a main oil cylinder capable of ascending and descending vertically is arranged on the hydraulic press; a working table is arranged under the main oil cylinder; a forming slotting tool is arranged at the lower end of the main oil cylinder; a clamp for clamping a gate valve body is arranged on the working table corresponding to the forming slotting tool; the forming slotting tool comprises a tool shank and a tool body fixed on the tool shank; the tool body adopts a cylindrical structure with a rectangular cross section; the corners of the bottom surface of the tool body are cut to form triangular pyramid-shaped blades; and a chip groove is formed between the inclined surface on the inner side of each blade and the bottom surface of the tool body, and the two ends of the chip groove are communicated with the two side surfaces of the tool body, which correspond to the blade.

Owner:GAODONG VALVE

Grinding machine comprising a measuring system and control for providing a master blade and method for providing a bar blade

An apparatus includes a blade grinding machine, a measuring system and a control for providing a bar blade suitable for cutting work pieces. The blade grinding machine includes a clamping mechanism for mounting the bar blade and a grinding wheel for grinding the mounted bar blade. The measuring system also includes a clamping mechanism for mounting bar blade and at least one probe for three-dimensional sampling of the bar blade mounted on the measuring system. The control enables a data exchange between the blade grinding machine and the measuring system in order to grind and sample the bar blade in an alternating fashion. The apparatus is a closed system in which data exchange is automated.

Owner:KLINGELNBERG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com