Arc blade milling machine for swing arm tool

A technology of circular arc edge and swing arm type, which is applied to the lathe tool, planer/slotting machine tool, planer, etc. It can solve the problems of large friction coefficient, large resilience and high cost of the sliding table. Achieve the effects of improving efficiency and precision, guaranteeing cutting accuracy, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

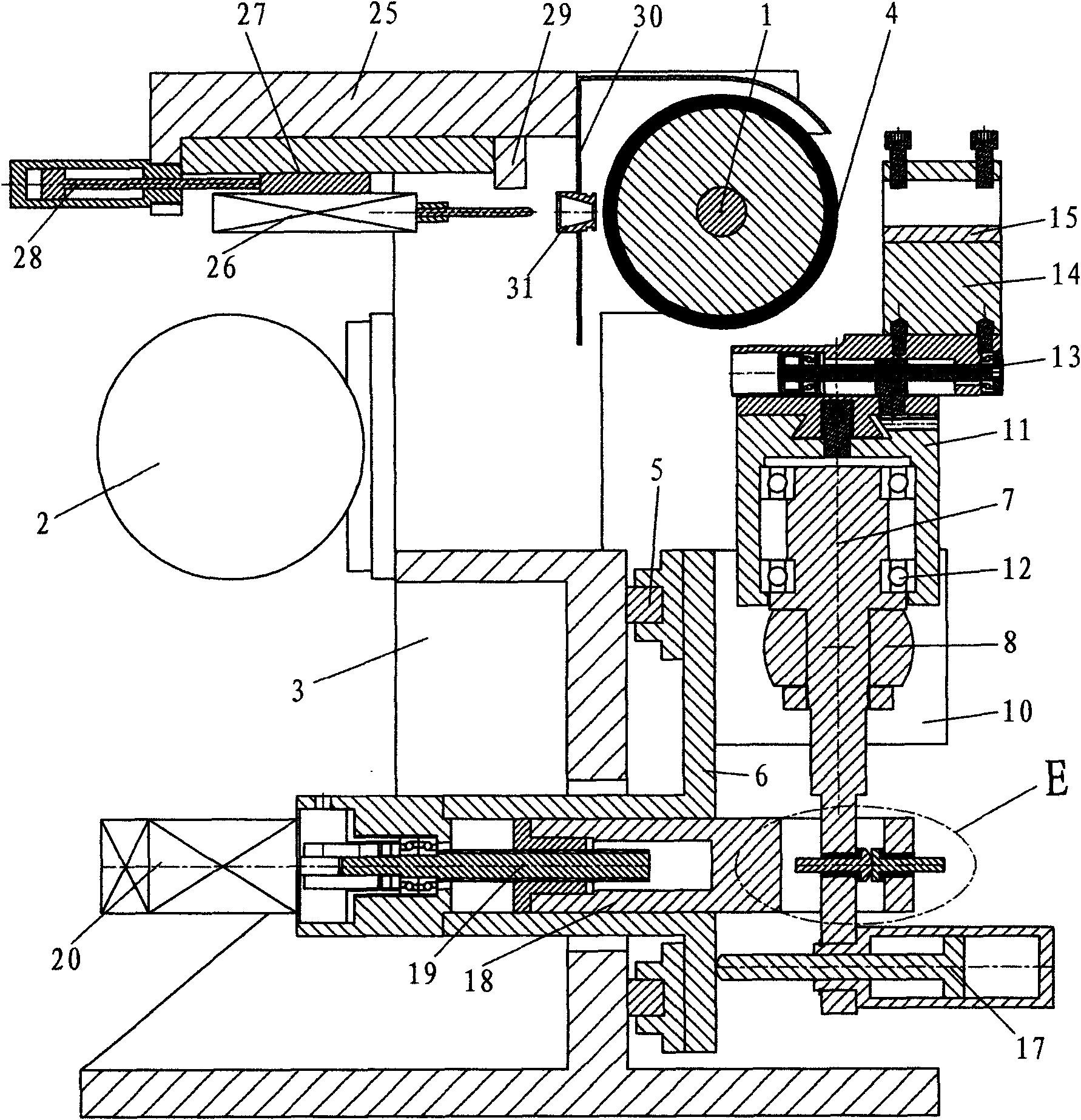

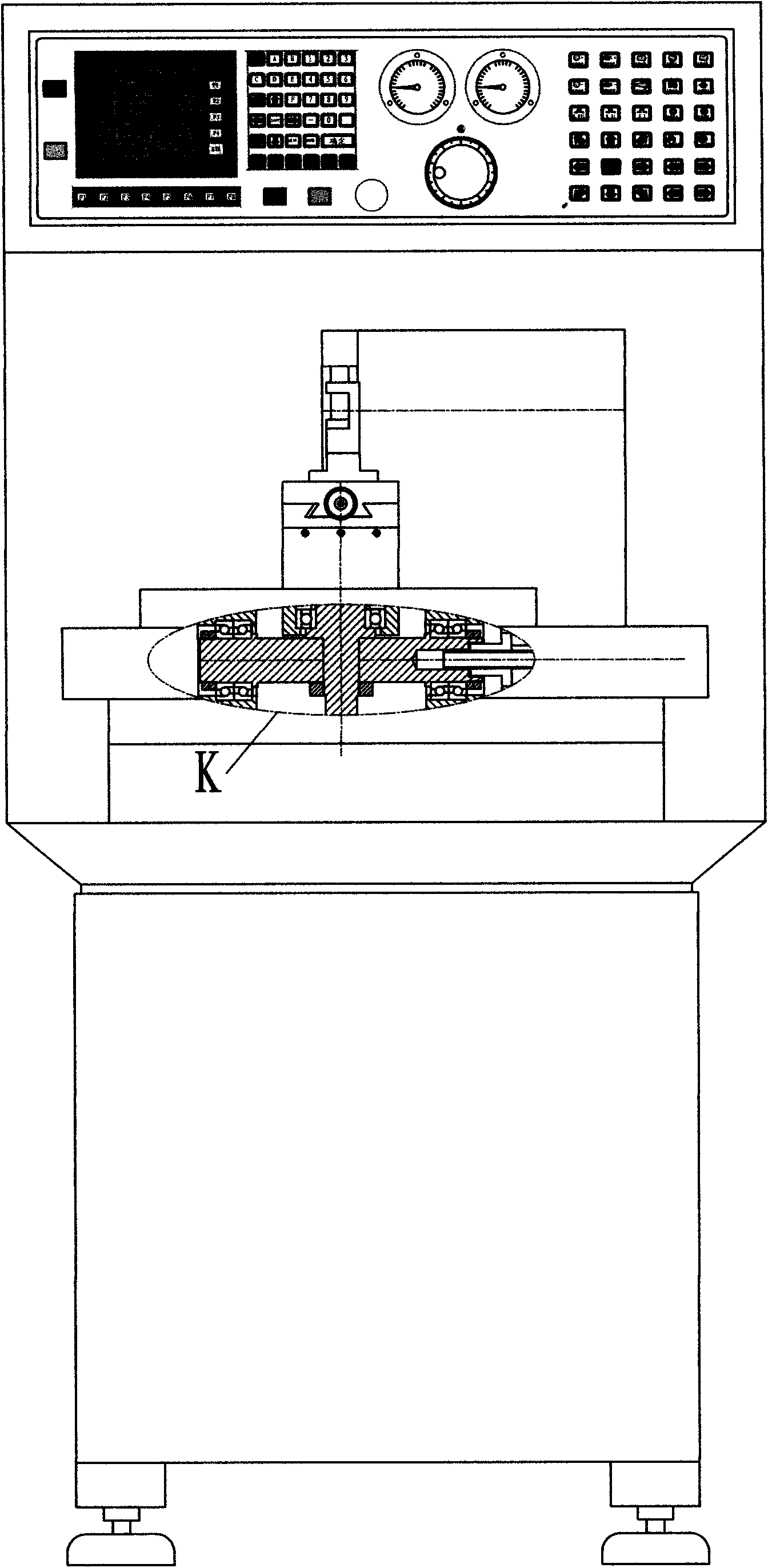

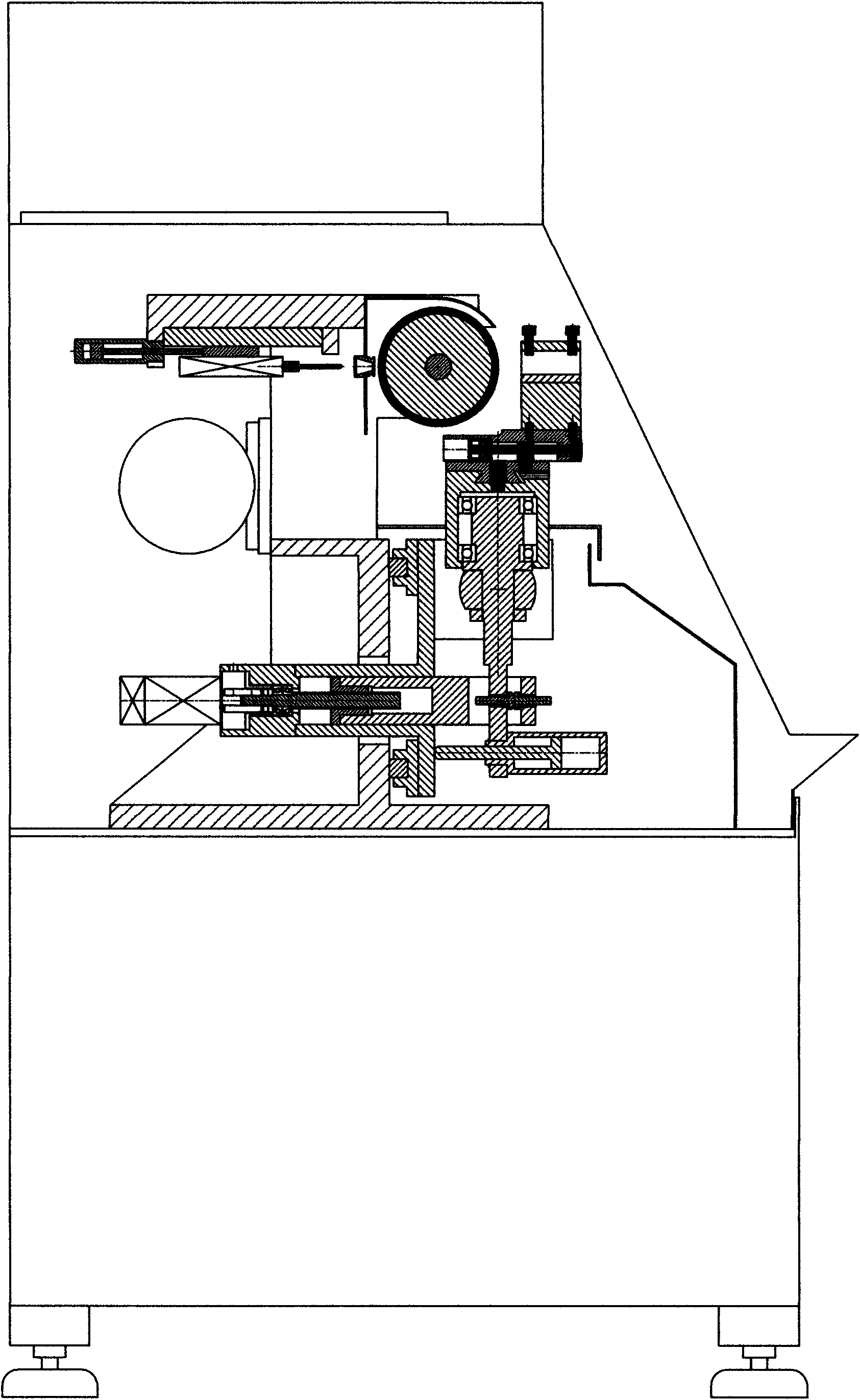

[0021] refer to figure 1 As shown, the grinding head assembly (1) and the motor (2) of this embodiment are fixedly installed on the body (3) together, and the grinding wheel surface (4) is installed in parallel with the grinding head assembly (1). A longitudinal slide table (6) is installed on the body (3) with two rolling guide rails (5) parallel to the grinding head assembly (1). refer to figure 1 , 4As shown, the swing arm in this embodiment is composed of a swing arm (7), a central shaft (8), a bearing (9), and a bearing seat (10). fit into a cross shaft frame; a pair of bearings (9) at both ends of the central shaft (8) are fixedly installed on the longitudinal sliding table (6) through the bearing seat (10), and the central point of the central shaft (8) is at the horizontal 1 mm from the grinding wheel surface in the direction. The upper end of the swing arm (7) is processed into a shaft shape, which is directly used as the mandrel of the rotary table (11), and the ...

Embodiment 2

[0026] refer to Figure 6 , 7 As shown, the present embodiment grinding head assembly 2 (36) and motor 2 (37) are fixedly installed on the body 2 (38), and the emery wheel surface 2 (39) is parallel to the grinding head assembly 2 (36). In this embodiment, the swing arm is directly composed of cross shafts, and the two ends of the swing arm transverse axis (40) are mounted on the body 2 (38) with clearance fit, and the center point of the swing arm transverse axis (40) is horizontal. 2 (39) 1 mm from the grinding wheel face in the direction. The upper end of the vertical shaft of the swing arm (41) is assembled into a flexible rotary table 2 (43) through the bearing 3 (42) and the rotary table; a small cross slide table 2 (44) is installed on the rotary table 2 (43). ), a knife rest 2 (45) is installed on the small cross slide table 2 (44), and a module knife shim 2 (46) is placed in the knife rest 2 (45). In order to improve the precision of the rotary table 2 (43), the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com