Patents

Literature

467 results about "Bench grinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding.

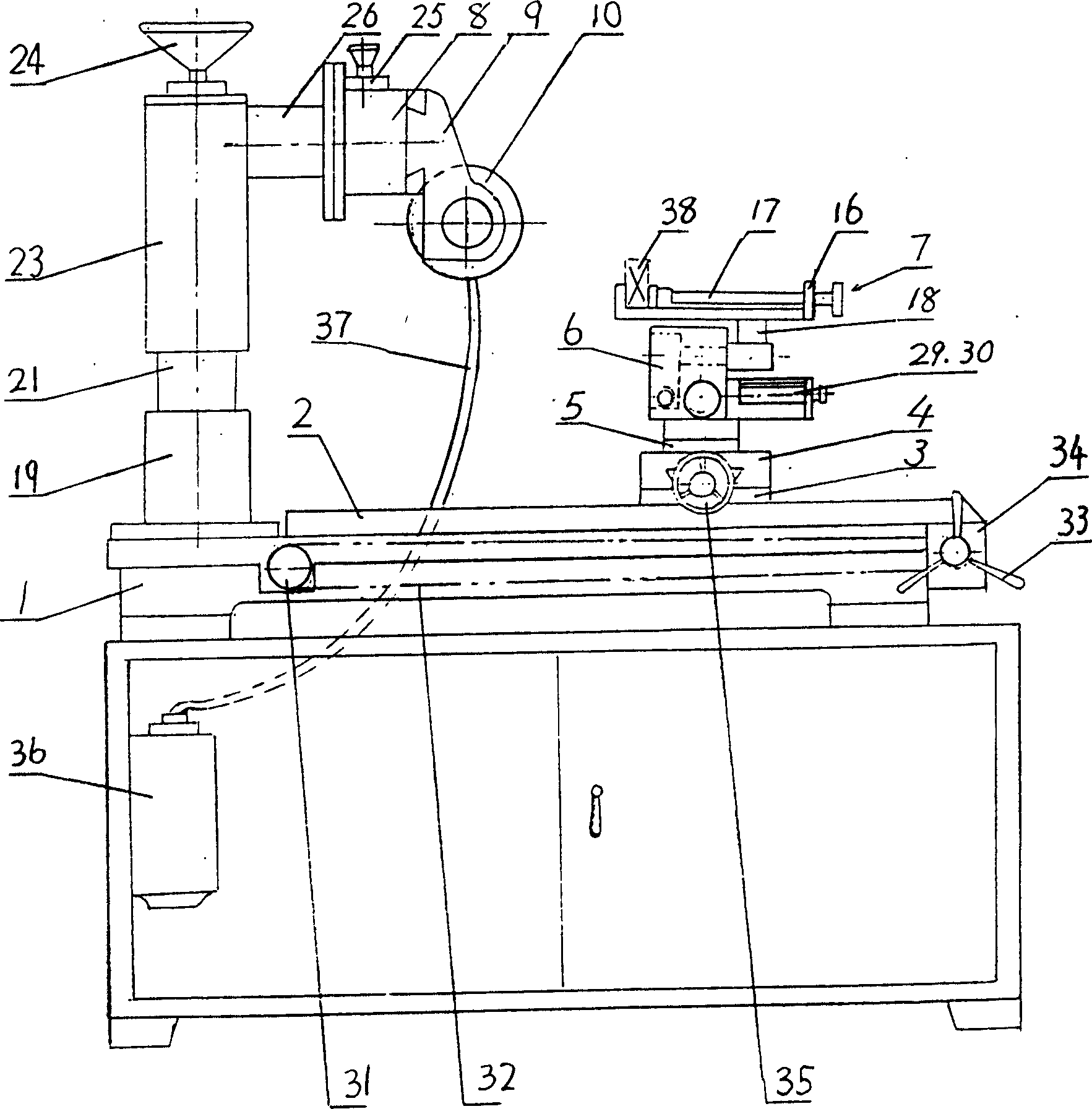

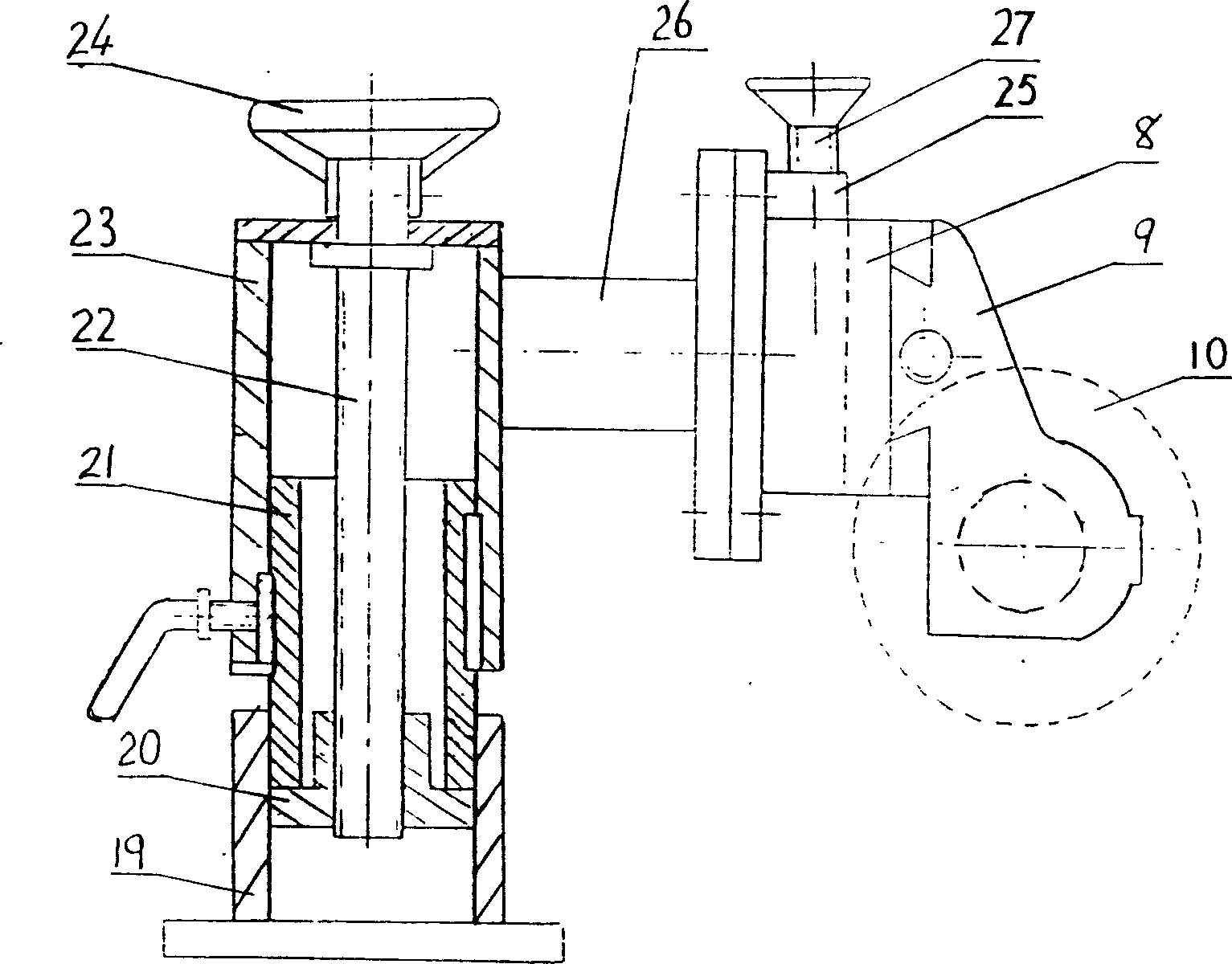

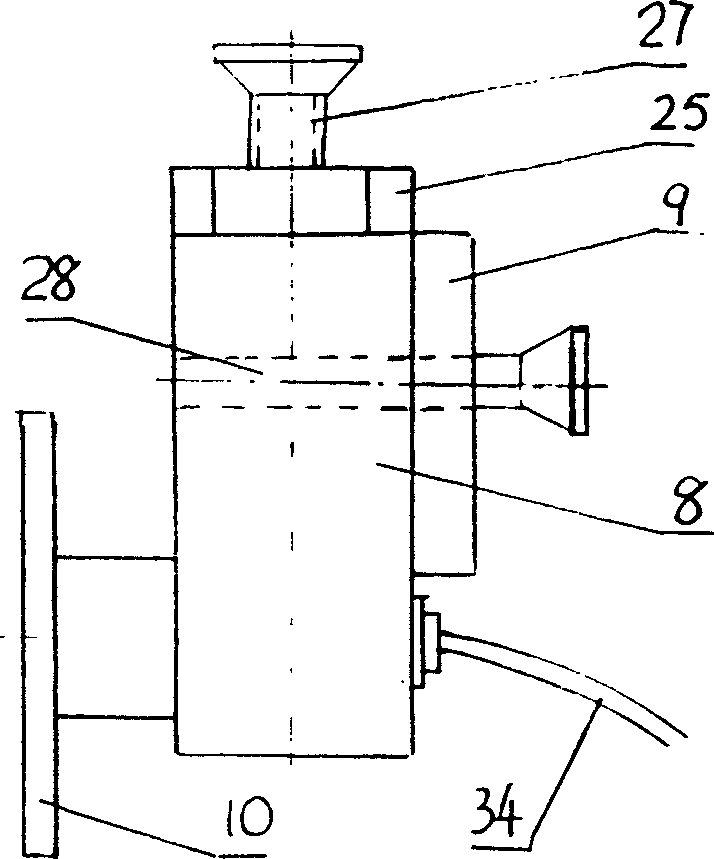

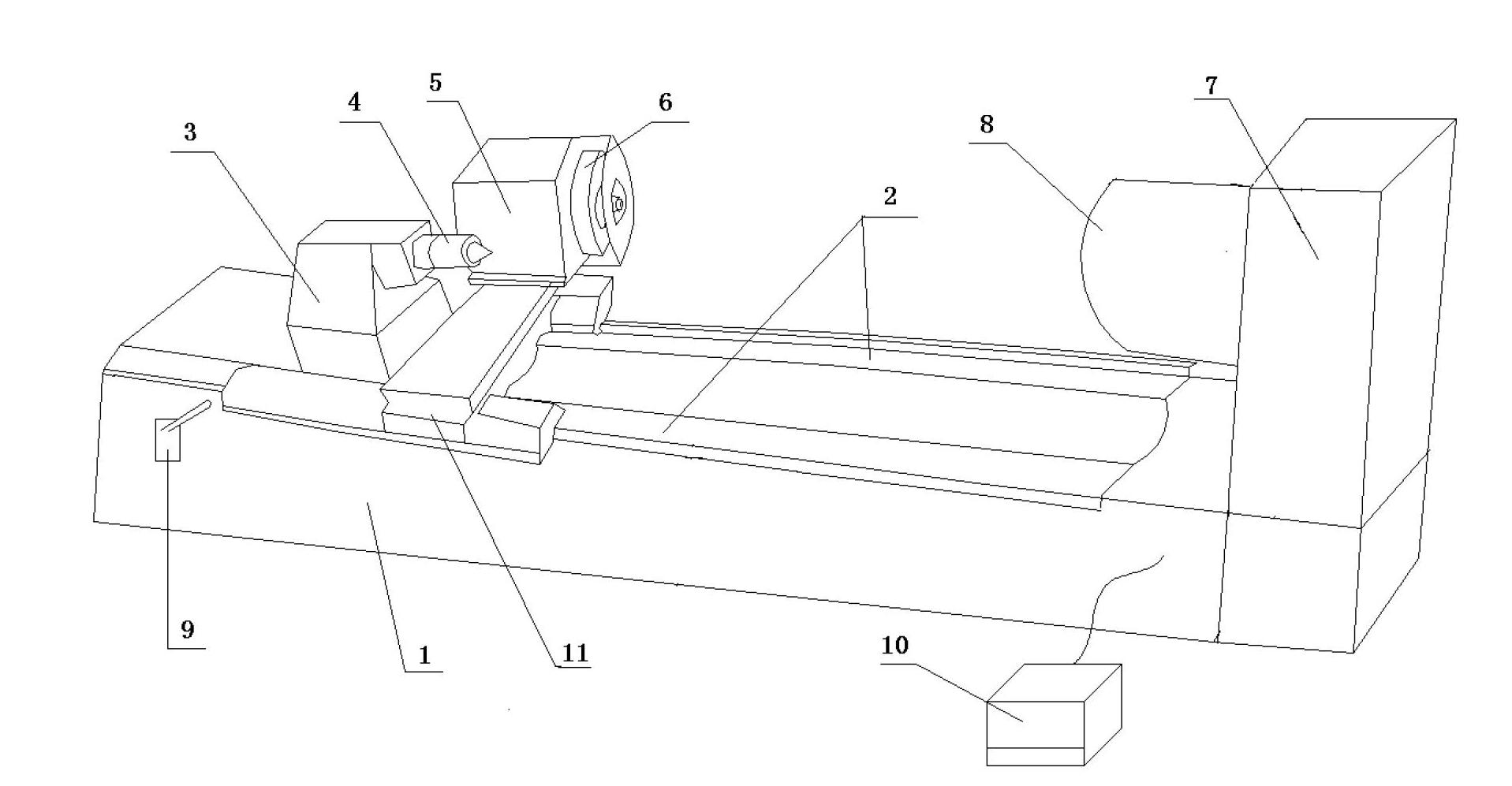

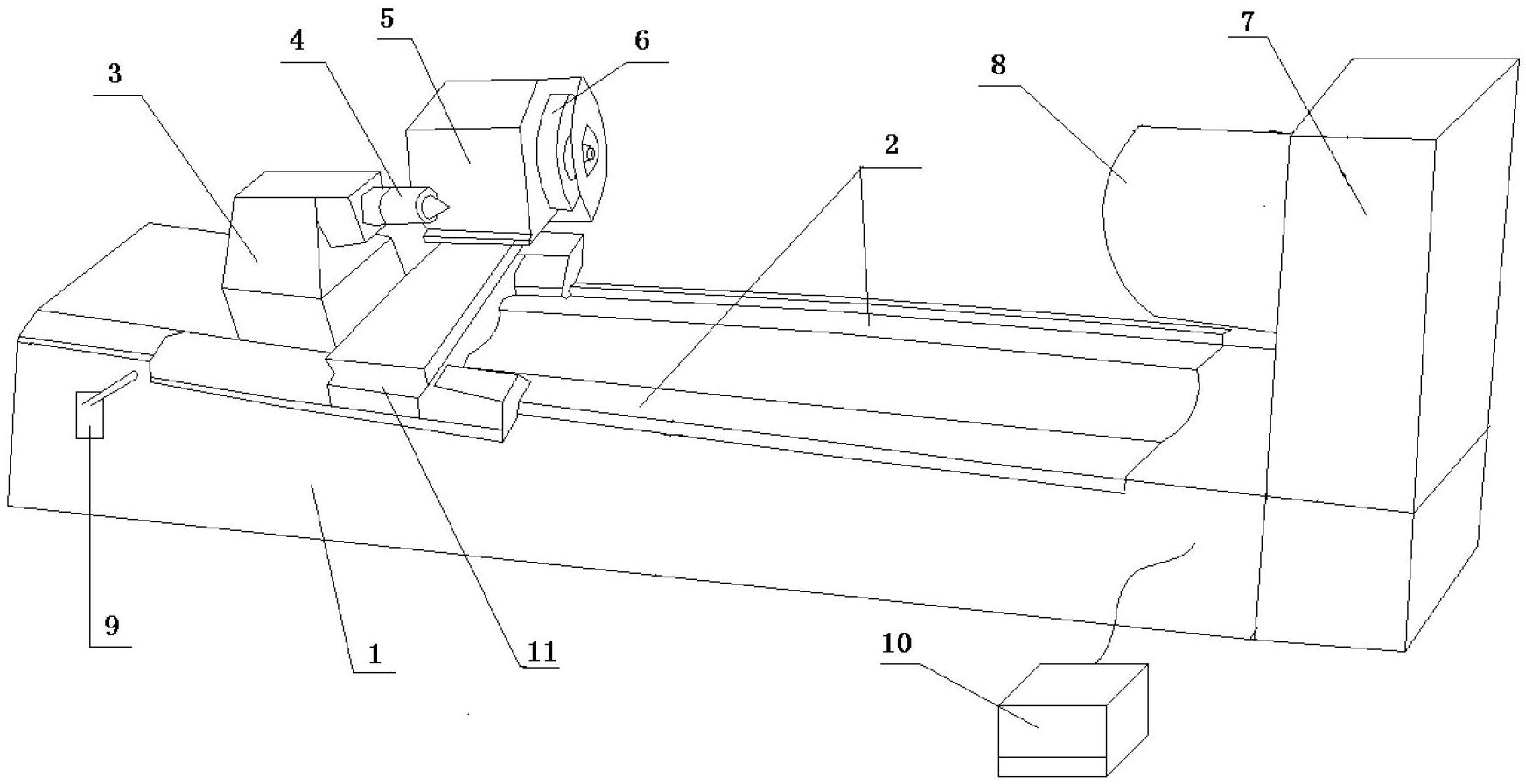

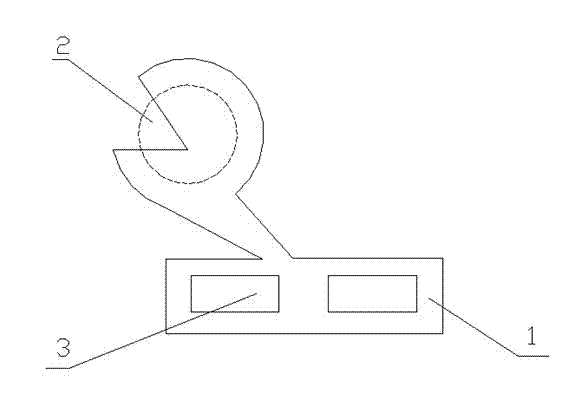

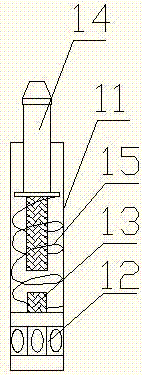

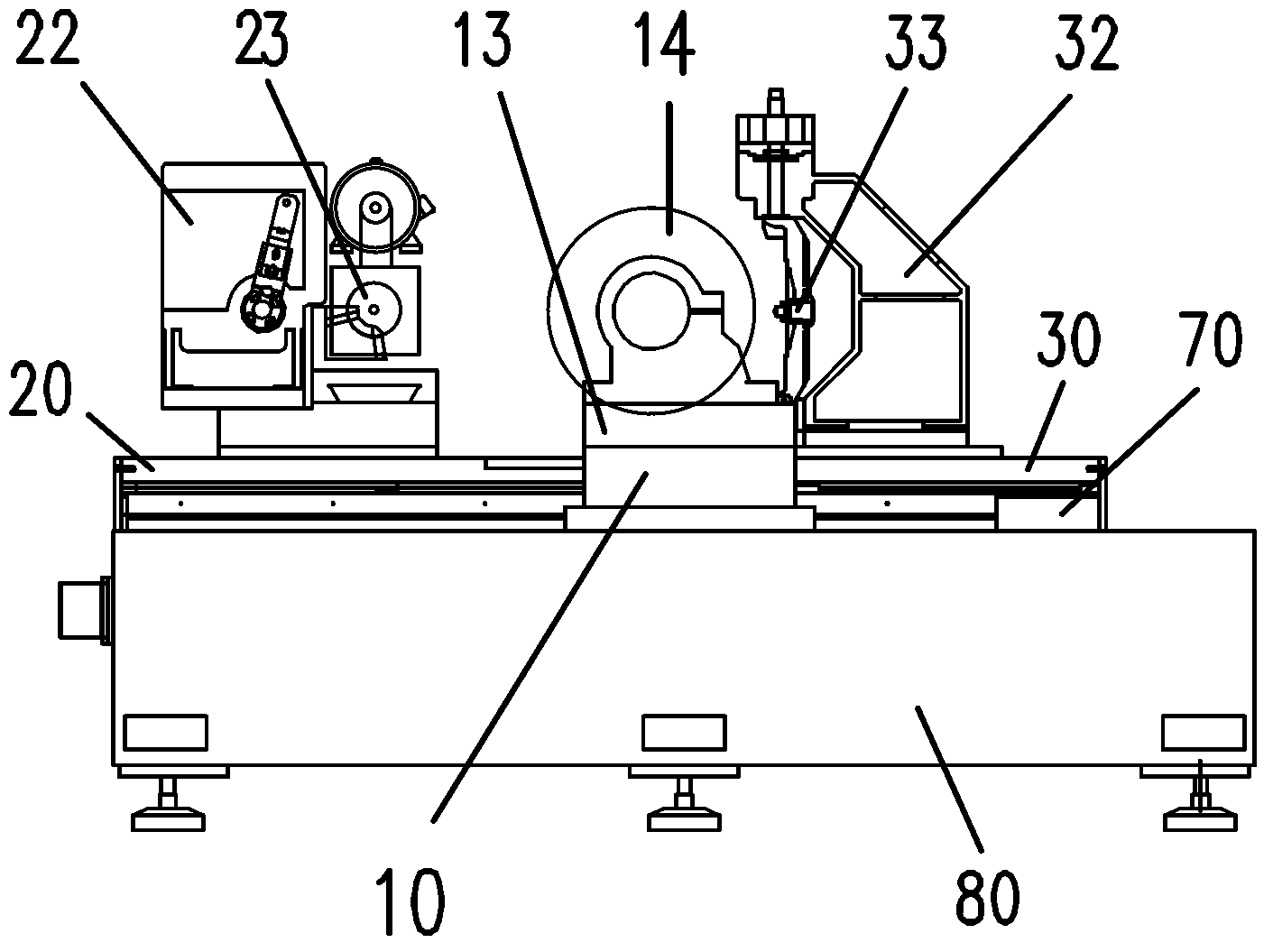

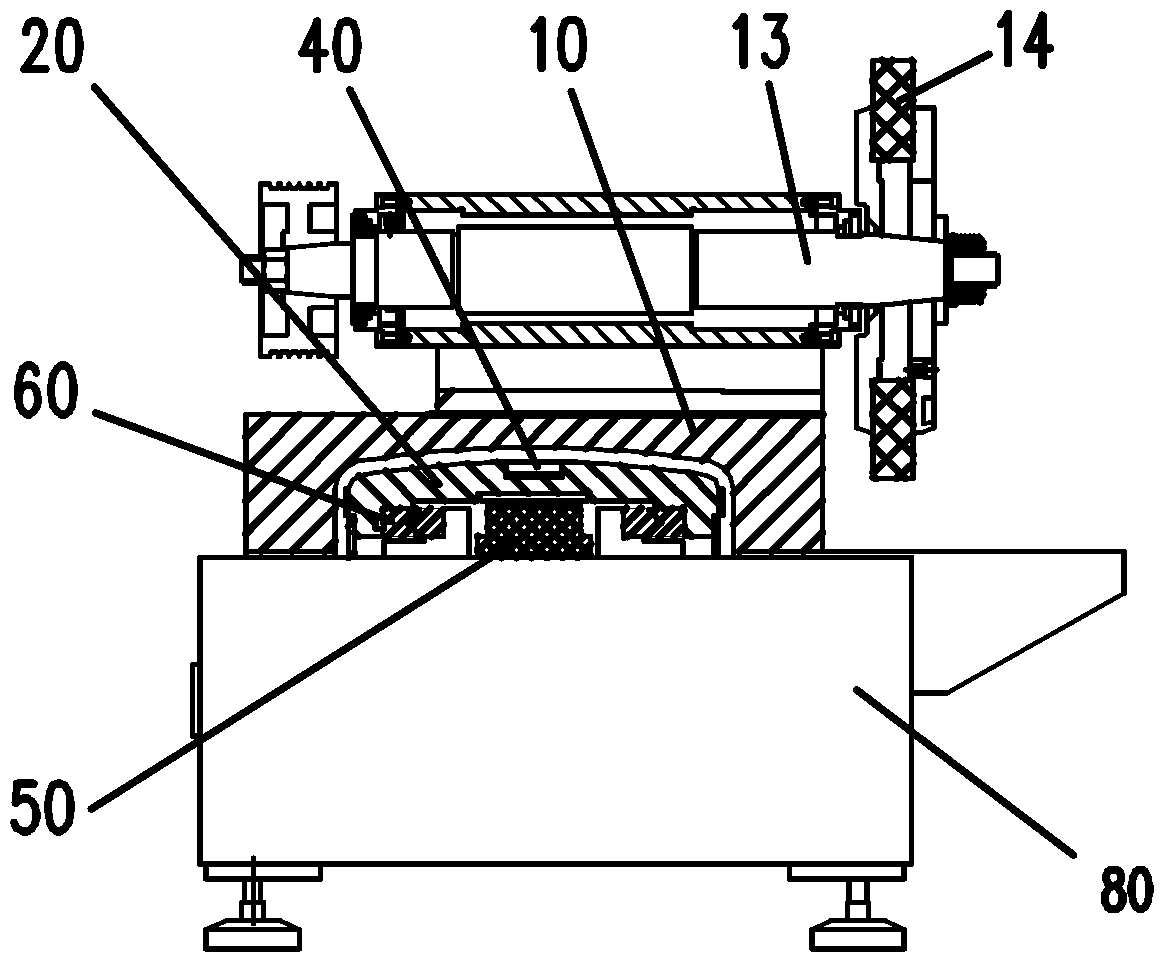

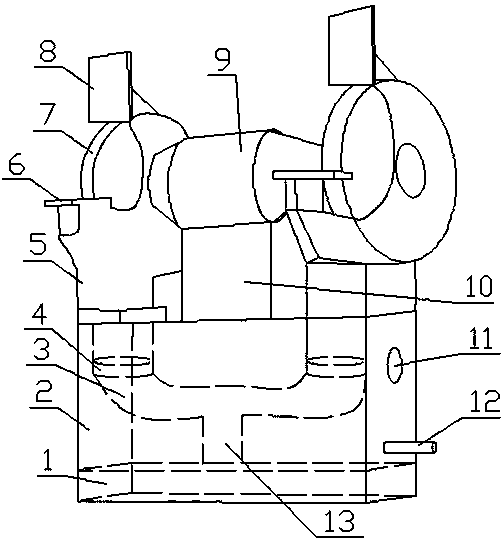

Turning tool and planer tool cutter grinding machine

InactiveCN1528563AMeet sharpening requirementsReasonable structural designPlaning/slotting toolsTurning toolsBench grinderMachine tool

The invention is a turning tool- and planning tool- blade milling machine tool, relating to cutting blade milling device. It provides a turning tool- and planning tool- blade milling machine tool, including: machine base, guide rail, longitudinal drag plate, transverse drag plate, universal clamp assembly composed of longitudinal and transverse dip adjusting mechanisms and circular rotating clamp, and assembly composed of lift mechanism and grinding head including longitudinal and transverse slide blocks and grinding wheel. It has reasonable structure and universal adjusting clamp, not only replacing artificial milling blade and heightening the cutter precision but also meeting the request of special blade form and angle.

Owner:武绩

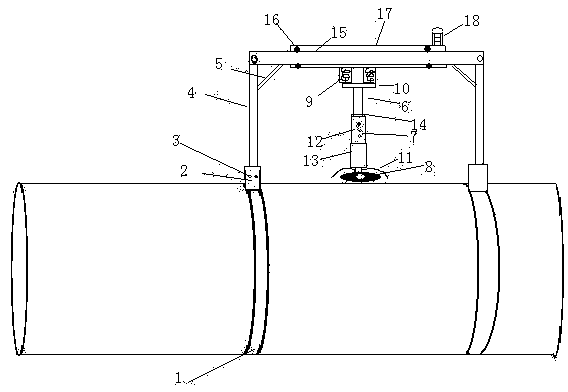

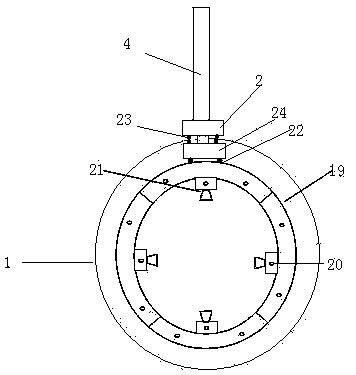

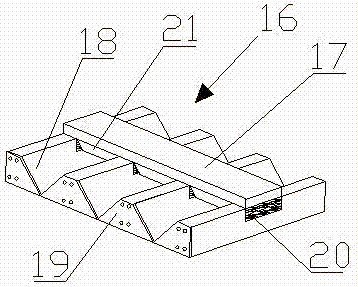

Damage-free detection special pipeline automatic oxide skin polishing device and method thereof

ActiveCN103465143AReduce labor intensityGuaranteed grinding qualityGrinding machinesElectric machineryBench grinder

The invention discloses a damage-free detection special pipeline automatic oxide skin polishing device and a method of the damage-free detection special pipeline automatic oxide skin polishing device. The problems that damage can be caused to a pipeline wall due to manual polishing and the efficiency is low are solved. The automatic oxide skin polishing device comprises at least two sets of annular guiding rails which are arranged outside a pipeline to be detected in a sleeved mode, a door-shaped polishing frame, a horizontal sliding device and a polishing machine. The door-shaped polishing frame is installed on the annular guiding rails and rotates in the circumferential direction along the pipeline to be detected. The horizontal sliding device which can move back and forth relative to a beam is installed on a beam of the door-shaped polishing frame. The polishing machine is installed on the horizontal sliding device through an elastic connecting part and driven by a motor. When the polishing machine works, the elastic connection part can make a polishing wheel of the polishing machine keep in contact with the face, to be polished, of the pipeline to be detected. According to the damage-free detection special pipeline automatic oxide skin polishing device and the method of the damage-free detection special pipeline automatic oxide skin polishing device, the pipeline can be polished automatically, polishing quality is ensured, potential safety risks are eliminated, labor intensity of workers is reduced and working efficiency is improved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

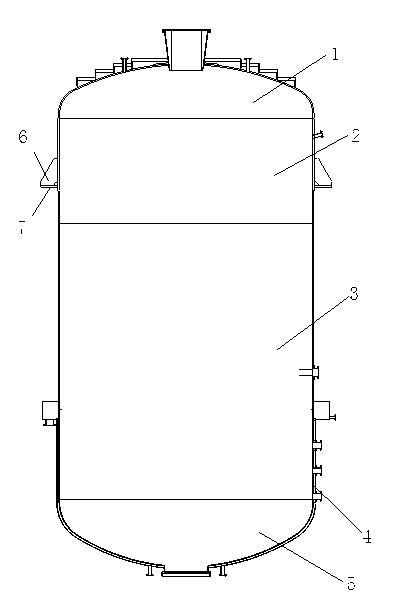

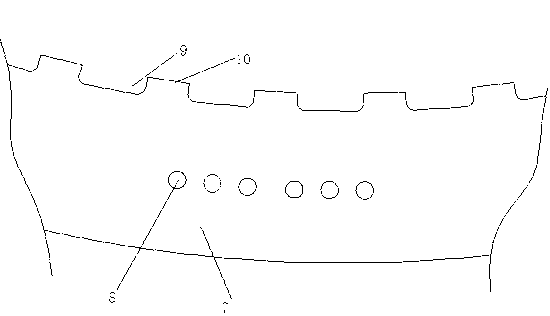

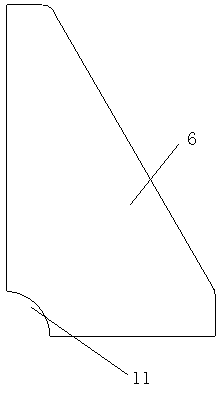

Making and construction method of chlorination furnace

ActiveCN103265066AGuarantee the construction qualityImprove construction progressTitanium halidesBench grinderPlanishing

The invention discloses a making and construction method of a chlorination furnace. The making and construction method comprises the following steps of carrying out processing and blanking in a factory, carrying out installation on a construction site, carrying out integral heat treatment, carrying out a hydraulic pressure test and an air-tight test, and carrying out equipment painting. The chlorination furnace comprises an upper head, an upper cylindrical shell, a lower cylindrical shell and an outer jacket. The upper head is arranged on the upper cylindrical shell. The upper cylindrical shell is arranged on the lower cylindrical shell. The outer jacket surrounds the lower cylindrical shell. Support annular plates are welded on the upper cylindrical shell. Multiple support rib plates and water holes are arranged on the support annular plate at equal intervals. The support rib plate is provided with a water groove. The upper head is provided with four water outlet weir plates. The water outlet weir plates are provided with concave-convex teeth and water holes. A lower part of the lower cylindrical shell is provided with a lower head. The wall plate groove of 50mm is made by butt joint of steel plates having different thickness, and then is processed. In construction, the groove is manufactured by flame machining and is rubbed flat by a grinding machine so that the construction period is reduced and grinding wheel sheet consumption is greatly reduced and manpower is saved.

Owner:CHINA CHEM ENG SECOND CONSTR +1

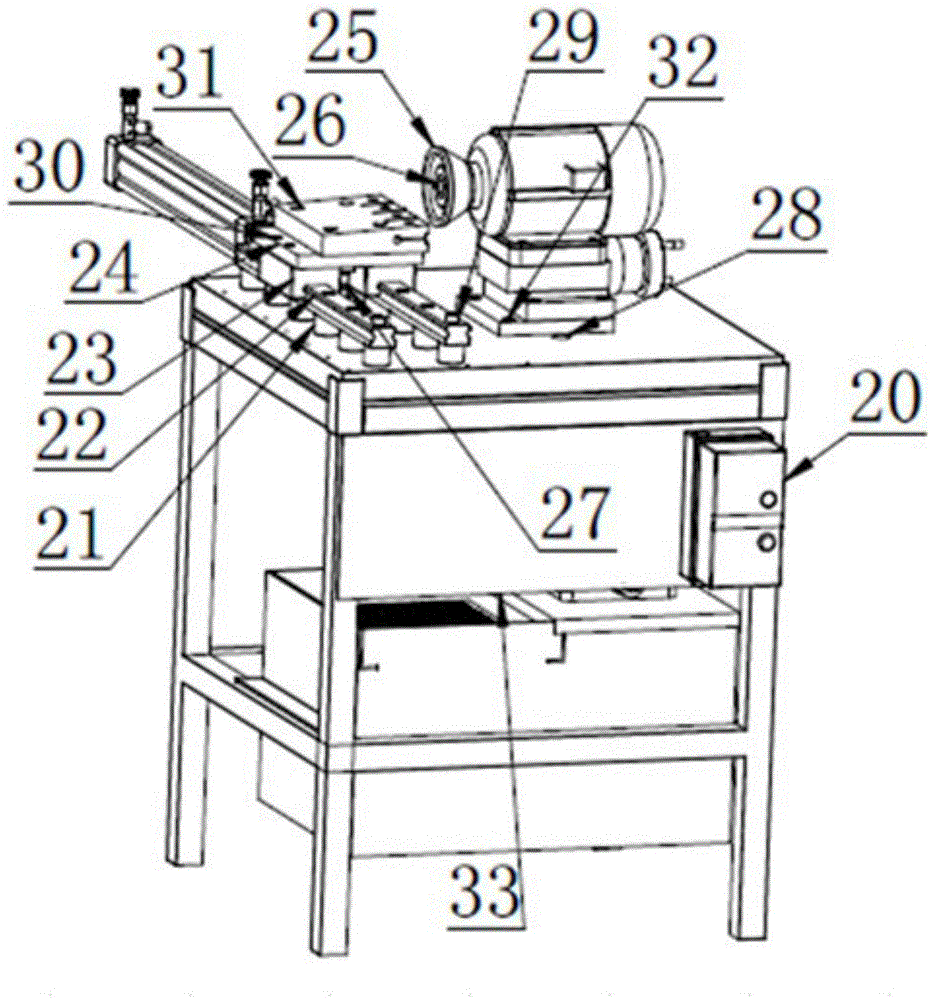

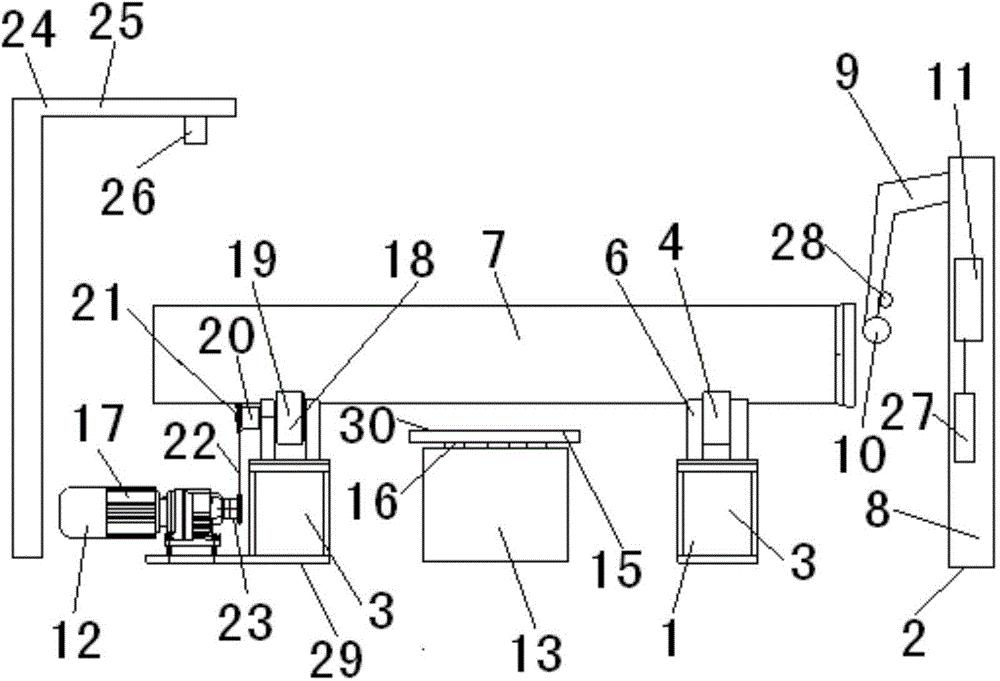

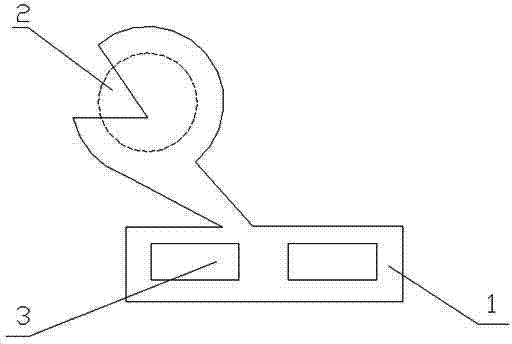

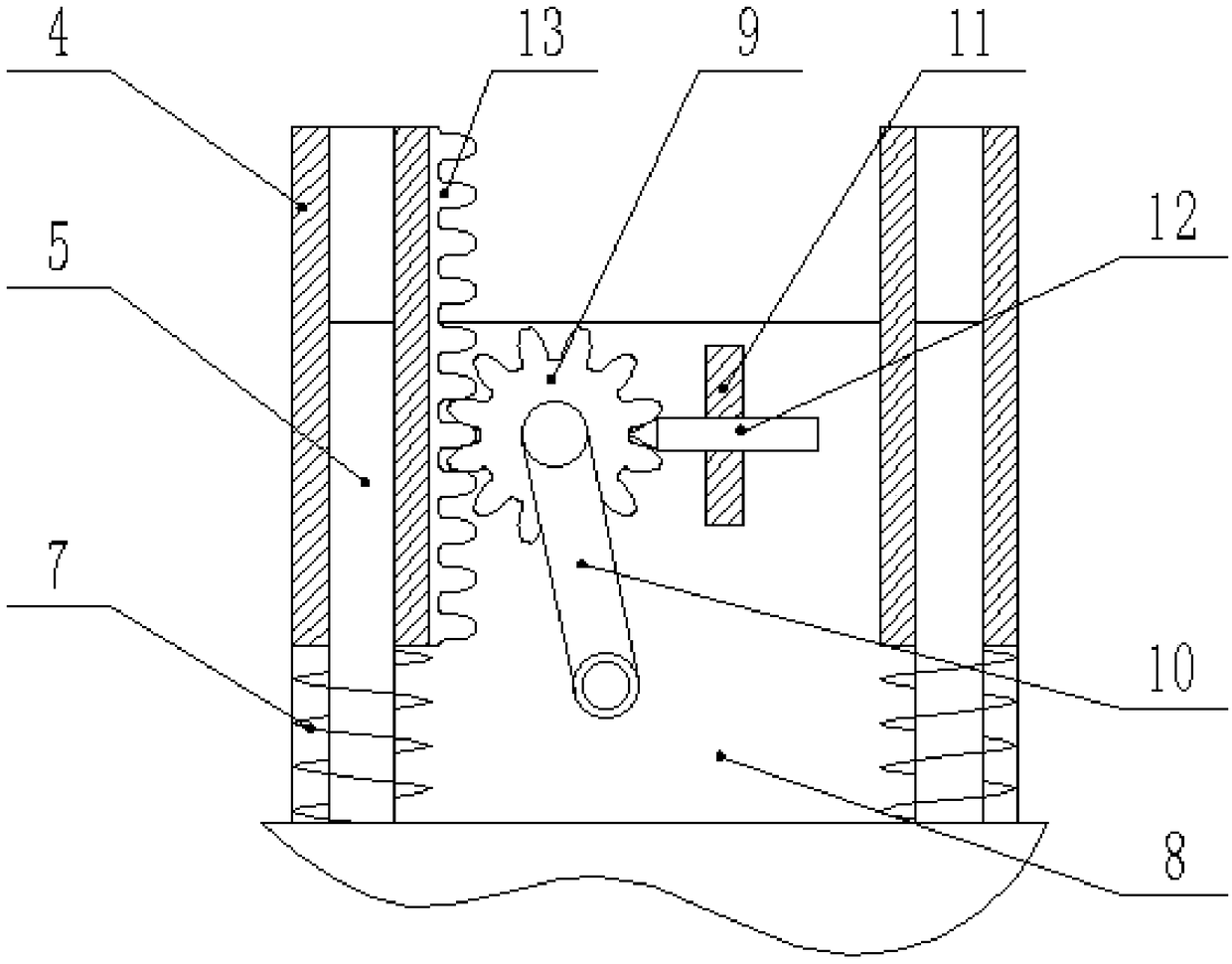

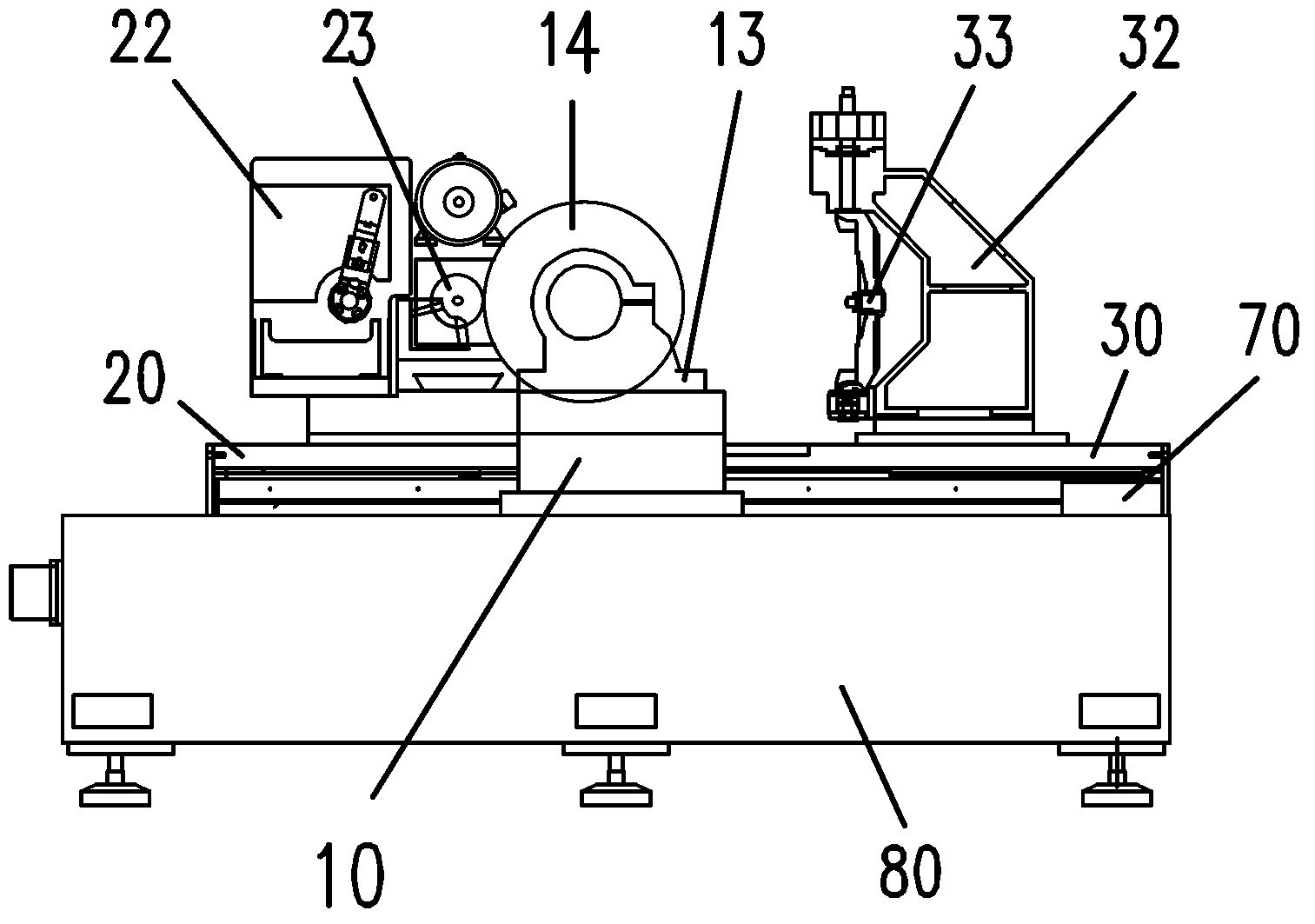

Blade grinding machine

ActiveCN104551876AAvoid wastingFull use of valueGrinding drivesOther manufacturing equipments/toolsEngineeringBench grinder

The invention relates to a blade grinding machine. The blade grinding machine comprises a bracket, wherein a crossbeam for supporting a water tank is arranged at the lower part of the bracket; a water pumping motor is fixed on the water tank; a power switch is arranged on the bracket; the power switch is respectively connected with motors for controlling the water tank and a grinding wheel; a sliding table, two parallel linear rails and an air cylinder connected with an air source control valve are arranged on the bracket; a grinding wheel motor is arranged on the sliding table, and a grinding wheel is arranged on a motor shaft of the grinding wheel motor; a screw rod is arranged on the bottom of the sliding table, and a dial is arranged on the top end of the screw rod; a water pipe is connected to the water pumping motor, and a water outlet of the water pipe is used for casting cooling liquid into the grinding wheel of a grinding wheel machine; a connecting block is arranged on a screw on the top end of a pull rod of the air cylinder, and a clamp bottom plate is arranged on the upper end of the connecting block; the clamp bottom plate is fixed on sliding blocks on the two parallel linear rails; a blade clamp for mounting a blade needing to be ground is also arranged on the clamp bottom plate. According to the blade grinding machine, the blade is machined after being ground into the original precision, and thus resource waste is avoided.

Owner:TIANJIN DA SHIANG PRECISION IND CO LTD

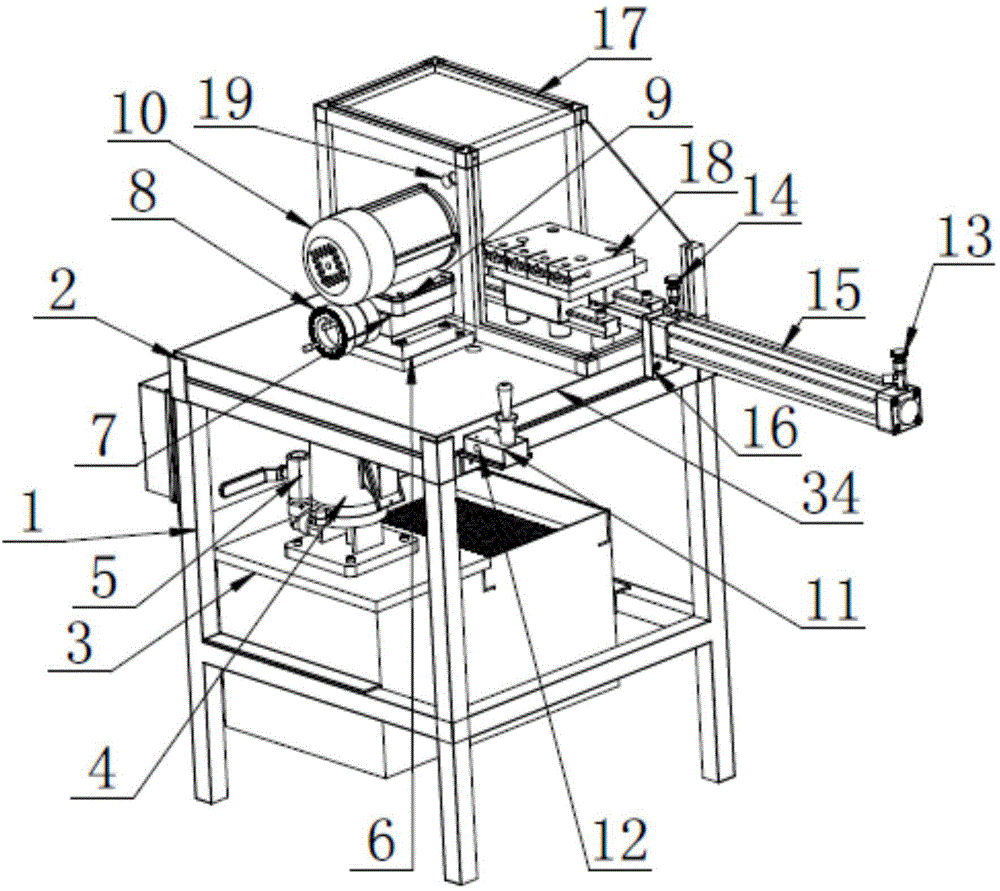

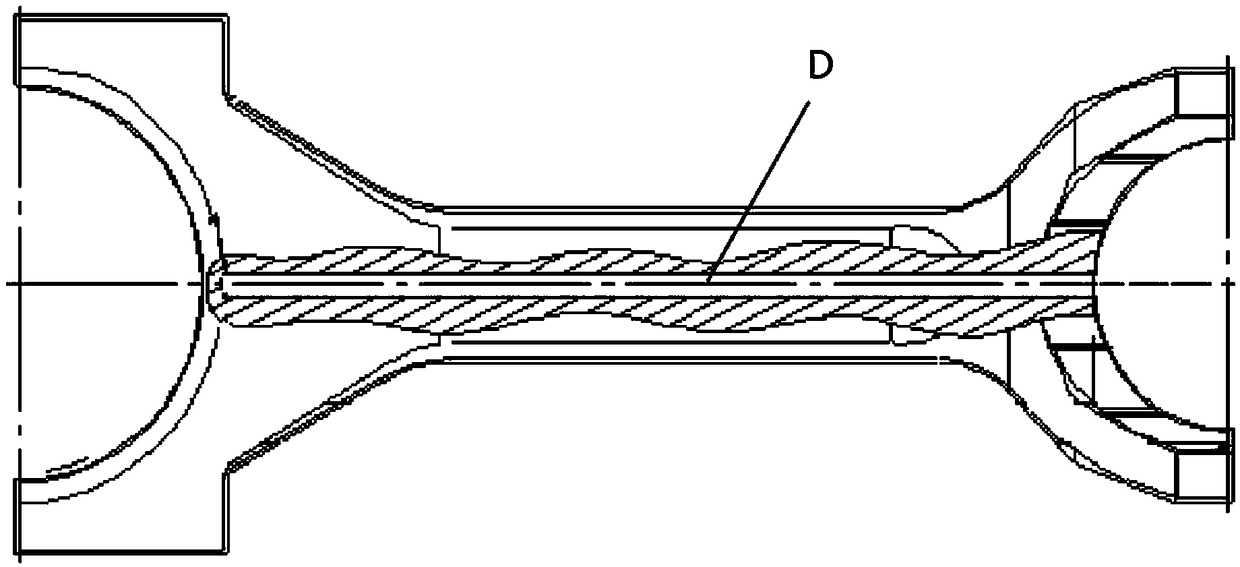

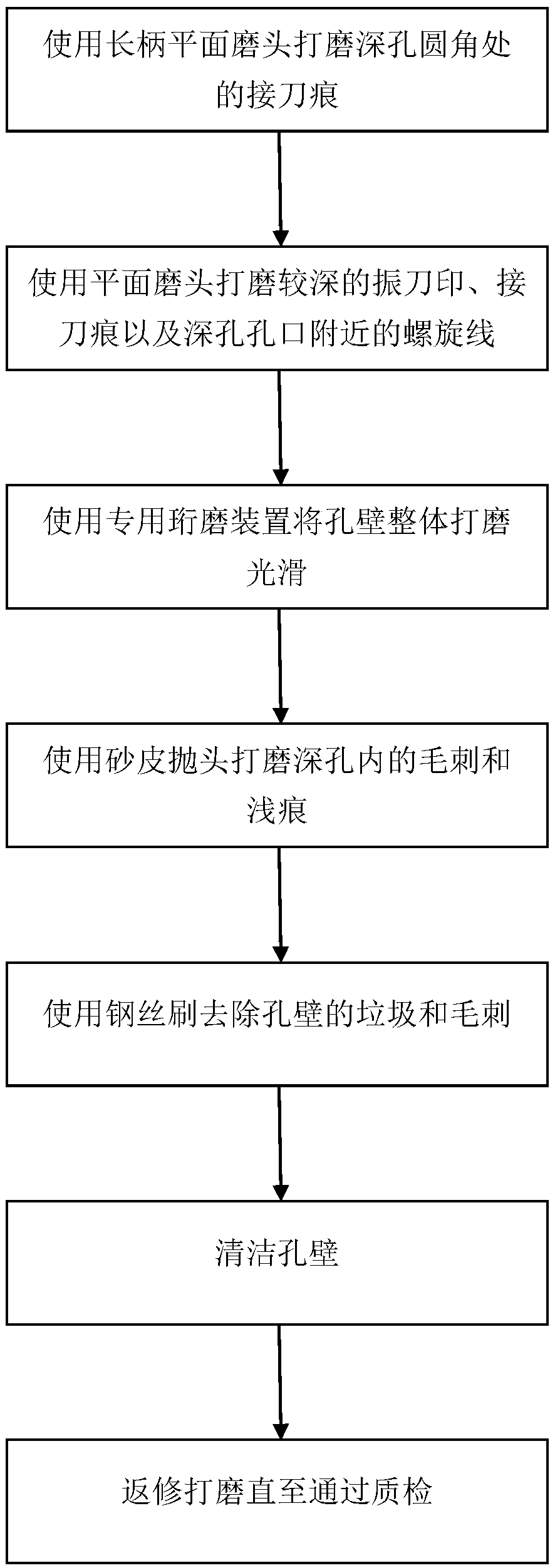

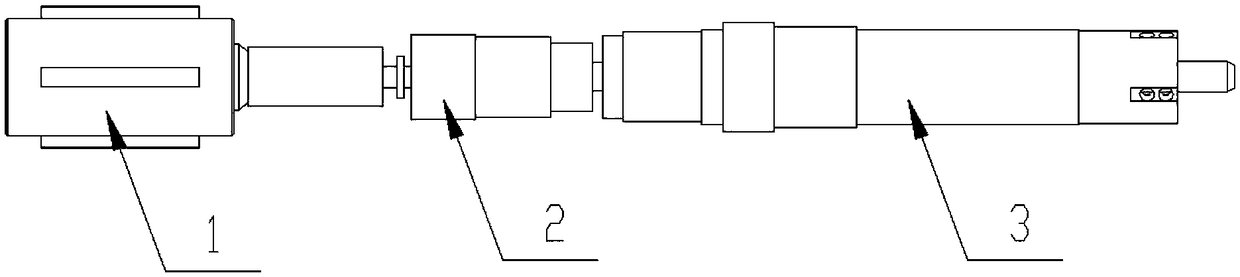

Connecting-rod deep hole grinding method for marine low-speed diesel engine and special honing device

ActiveCN108747608AImprove sanding qualityUniform sanding effectHoning toolsHoning machinesImpellerLow speed

The invention provides a connecting-rod deep hole grinding method for a marine low-speed diesel engine and a special honing device. The connecting-rod deep hole grinding method comprises the followingsteps: 1, grinding machined traces at a rounded corner of a deep hole by using a long-handle plane grinding head; 2, grinding relatively deep vibration knife marks and machined traces as well as spiral lines near an orifice of the deep hole by using a plane grinding head; 3, grinding and smoothening the entire hole wall by using the special honing device, wherein the special honing device comprises a honing head, a universal quick-change adapter and a pneumatic motor and is mounted on an extension rod, the hole wall of the deep hole is tightly supported through an elastic structure, the special honing device is driven by a pneumatic grinder to rotate, the rotating speed of the special honing device is adjusted by using a speed reducer, and then the uniform and efficient deep hole grindingoperation is achieved; 4, grinding burrs and shallow traces in the deep hole by using a sand impeller head; 5, removing waste and burrs on the hole wall by using a steel wire brush; 6, cleaning the hole wall; and 7, carrying out repairing and grinding till quality testing is passed. According to the connecting-rod deep hole grinding method provided by the invention, the grinding effect is uniform, the operation is simple, both the time and the effort are saved, and the entire grinding effect on the deep hole in a connecting rod is improved.

Owner:CSSC MES DIESEL

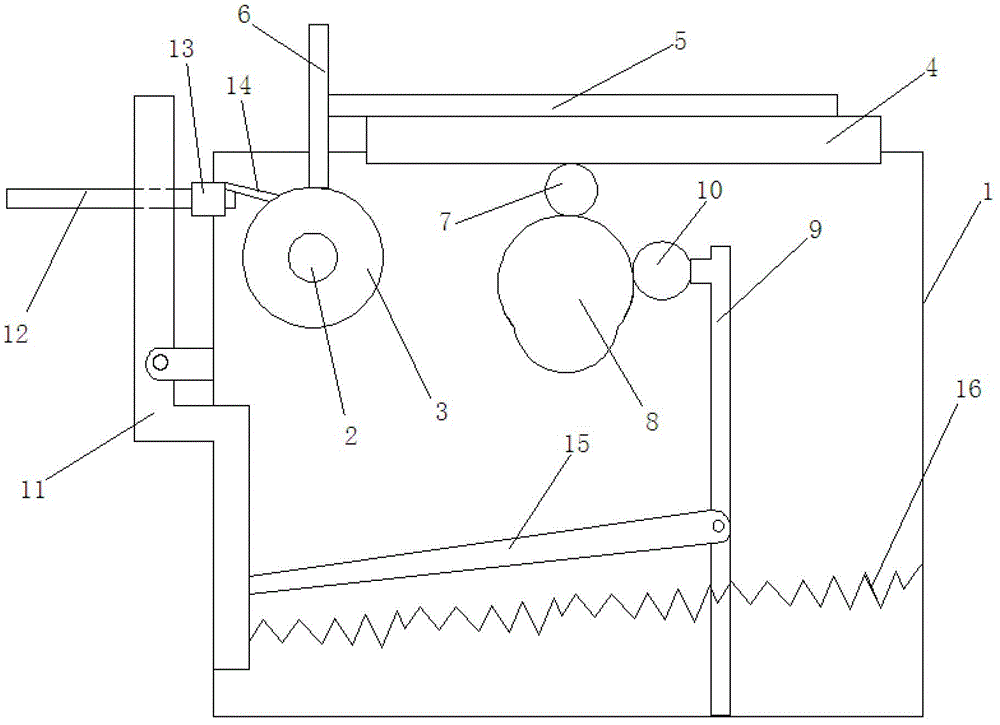

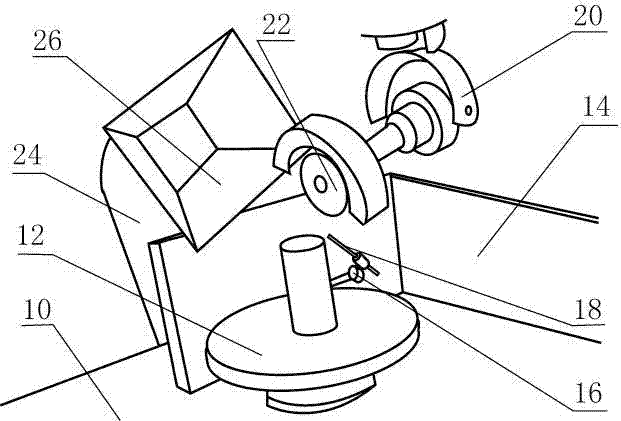

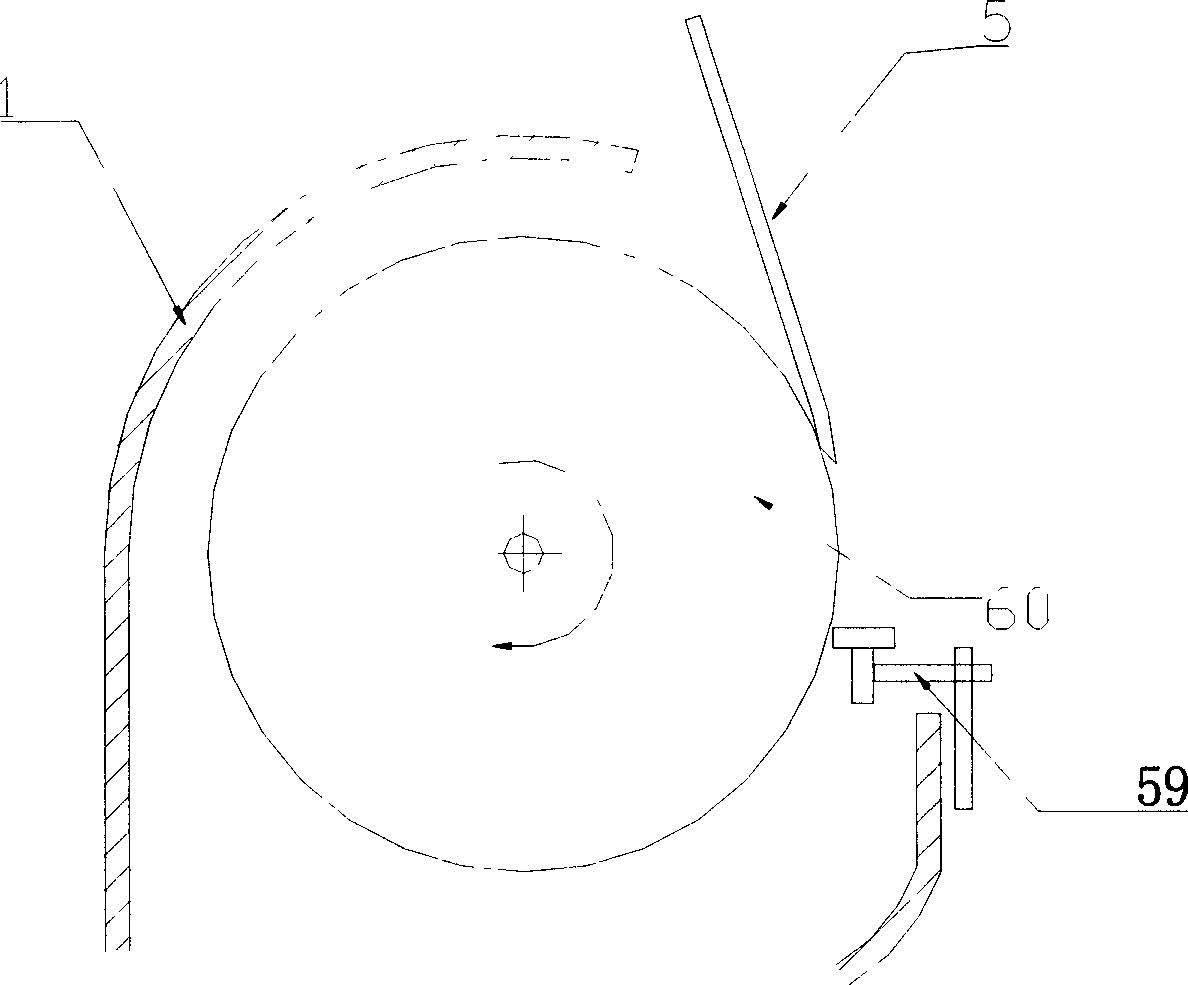

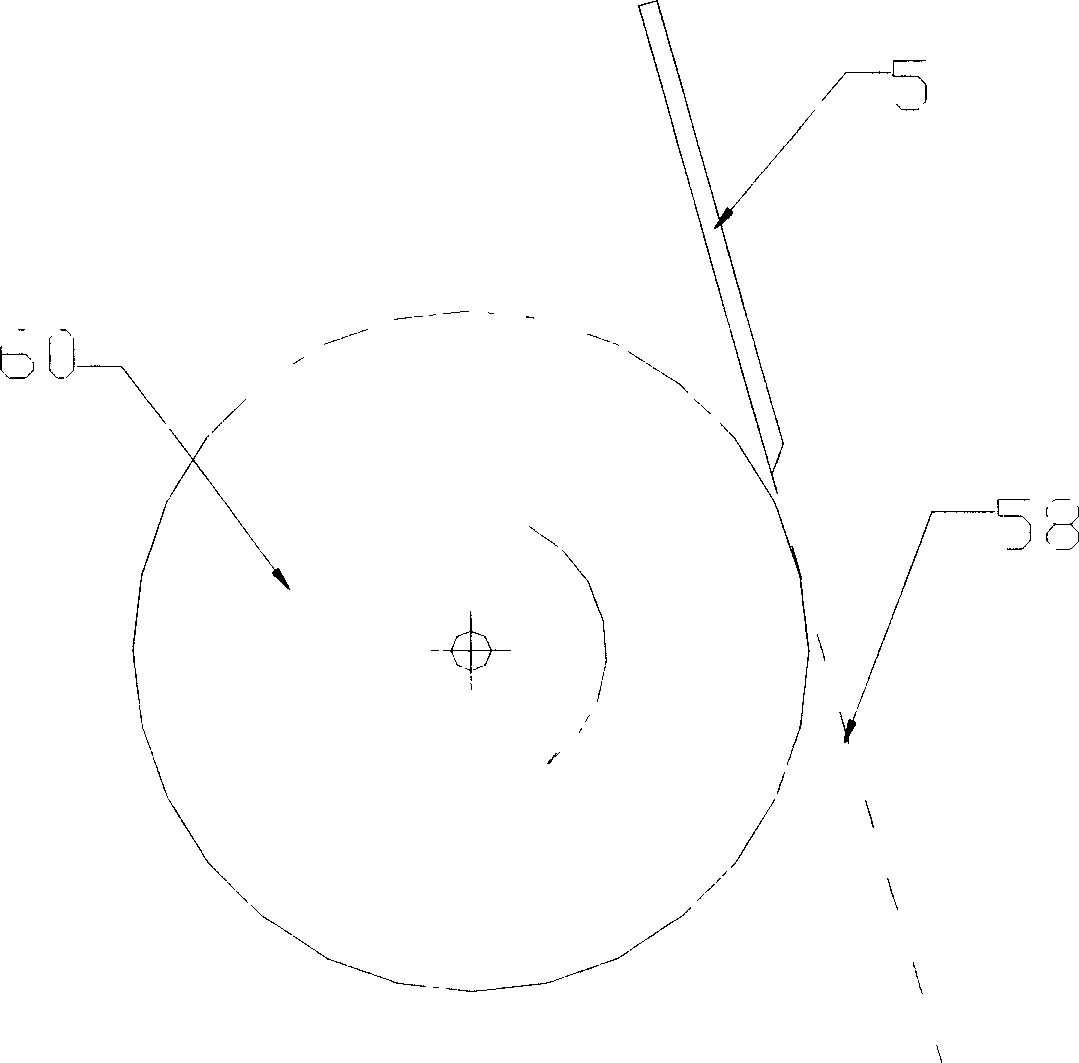

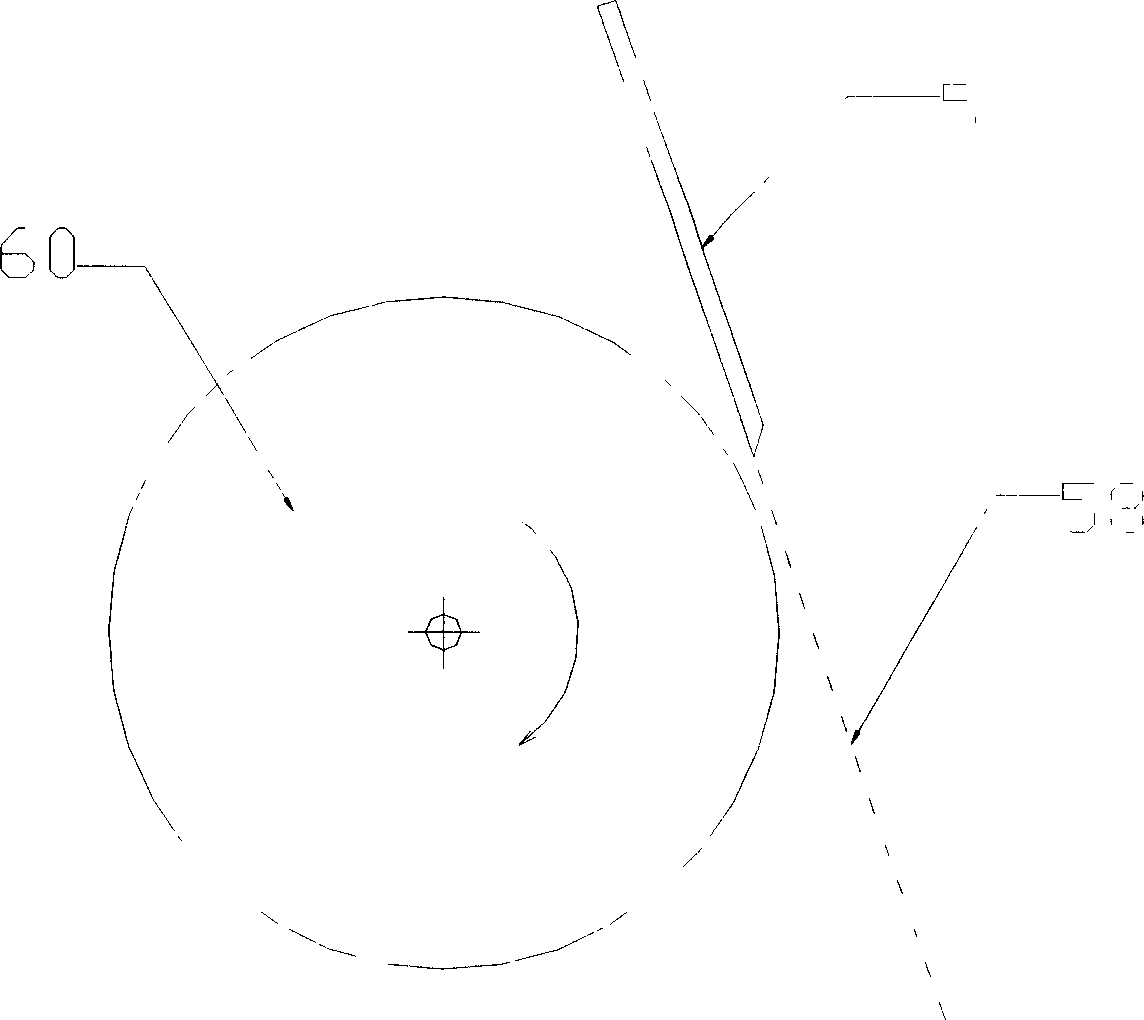

Polishing device for sawtooth on serrated wheel

InactiveCN103331489ASmooth rotationIngenious structural designSawing tools dressing arrangementsPolishingBench grinder

The invention discloses a polishing device for a sawtooth on a serrated wheel. The polishing device for the sawtooth on the serrated wheel comprises a rack, wherein the rack is provided with the serrated wheel; the rack is provided with a horizontal supporting plate capable of vertically swinging; the horizontal supporting plate is rotatably provided with a polishing wheel for polishing the sawtooth on the serrated wheel; the rack is provided with a vertical support frame capable of swinging front and back; the vertical support frame is provided with a lead screw; the sliding sleeve of the lead screw is provided with a push plate; and the end part of the push plate is pressed against the serrated wheel to push the serrated wheel to rotate. The polishing device for the sawtooth on the serrated wheel, which is disclosed by the invention, has an artful design structure, the polishing wheel can vertically swing so as to bring convenience for the rotation the serrated wheel, the serrated wheel is pushed by the push plate to rotate, so that the serrated wheel has a low revolving speed, thereby being convenient to regulate to aim at each sawtooth to polish. The whole process is in automated operation, the practical performance is good, and the working efficiency is improved.

Owner:六安龙啸工艺品有限公司

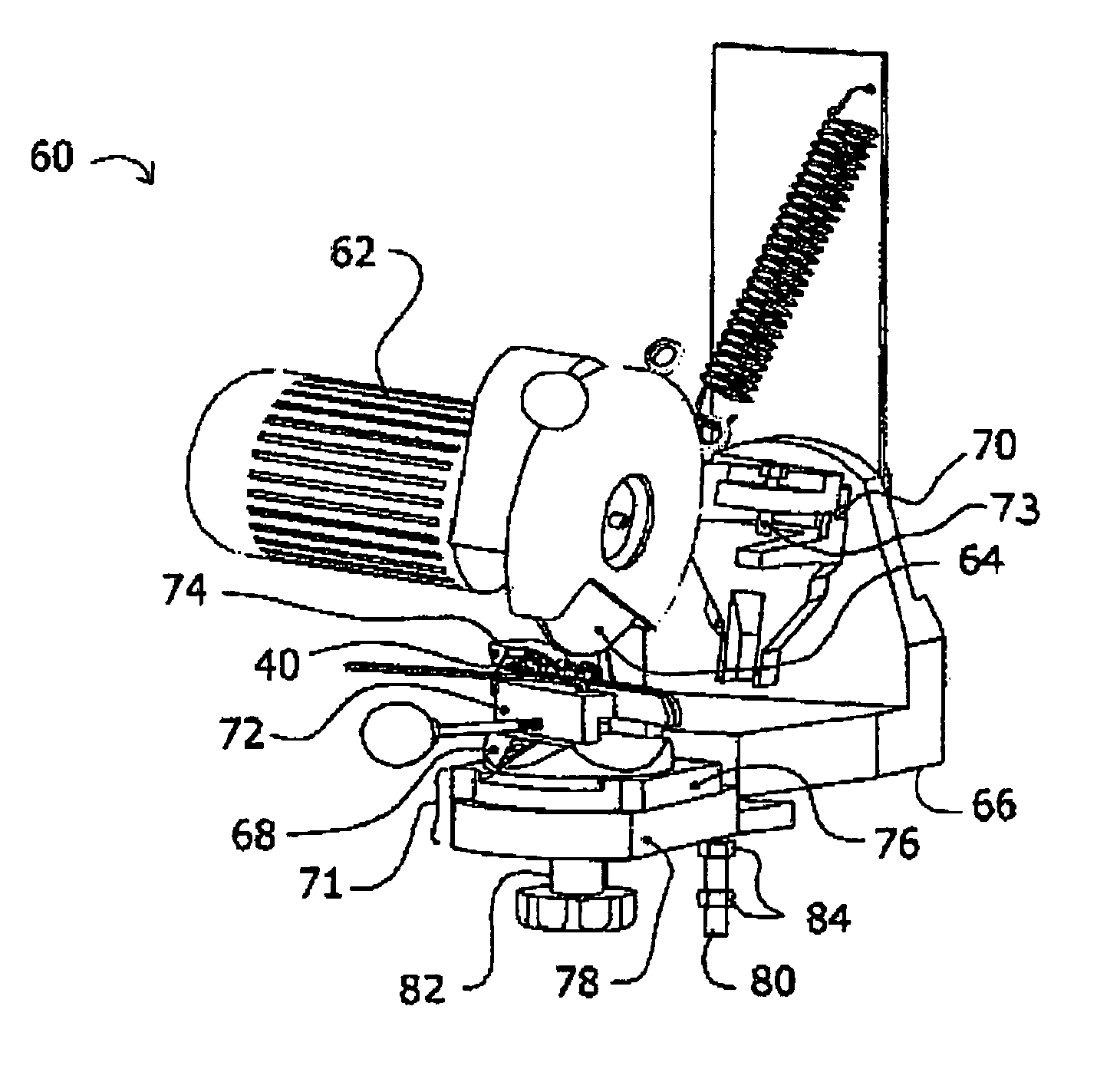

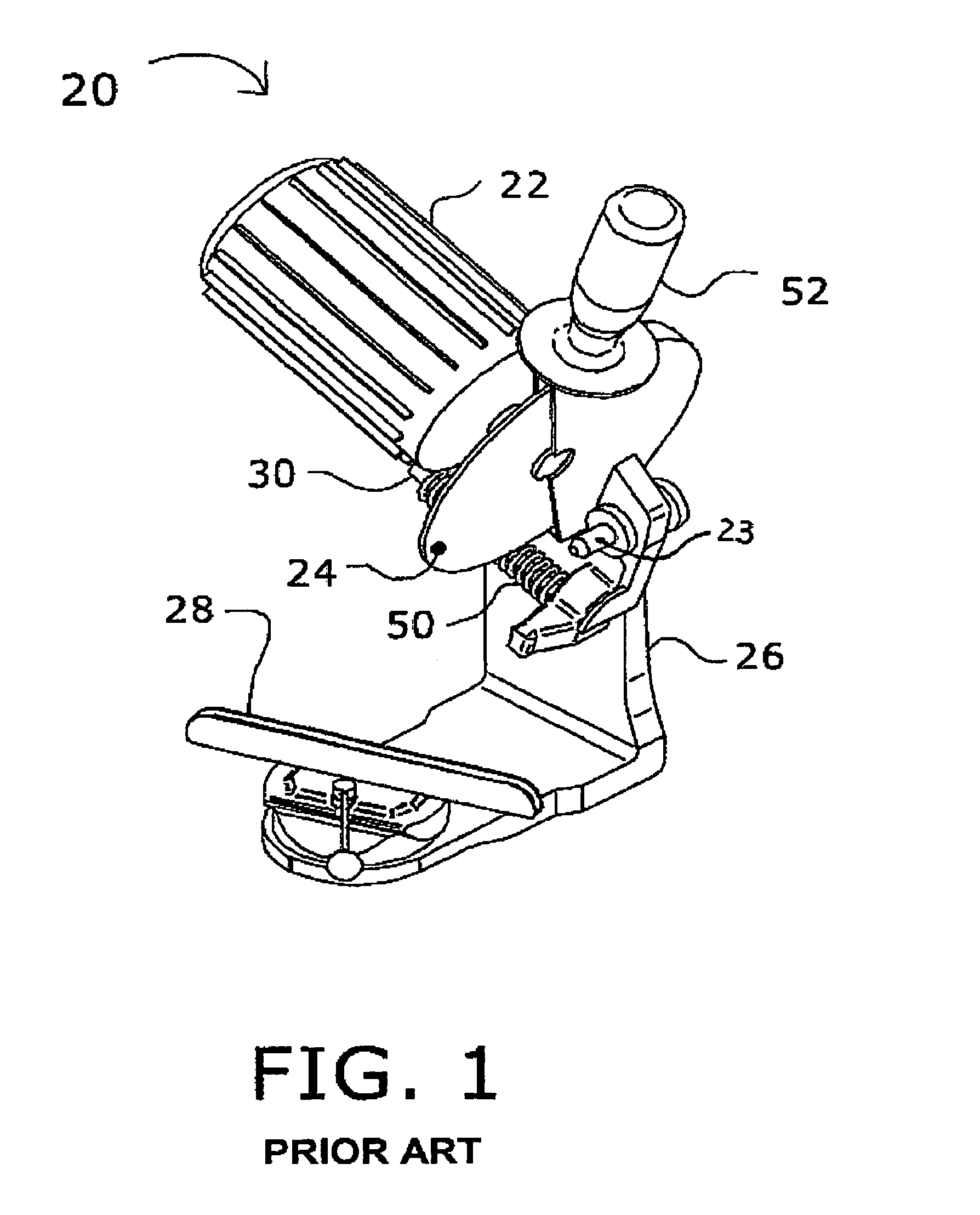

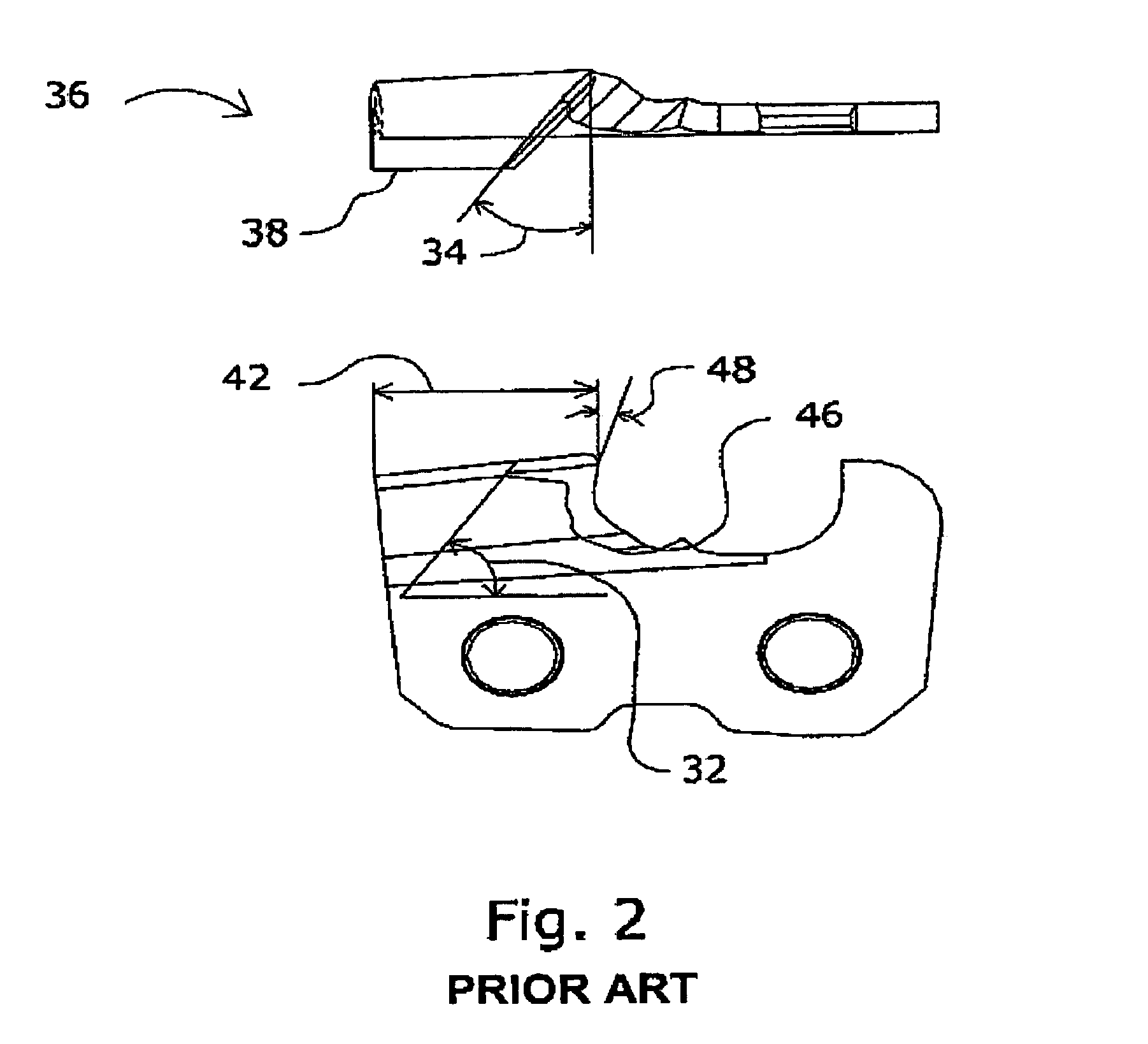

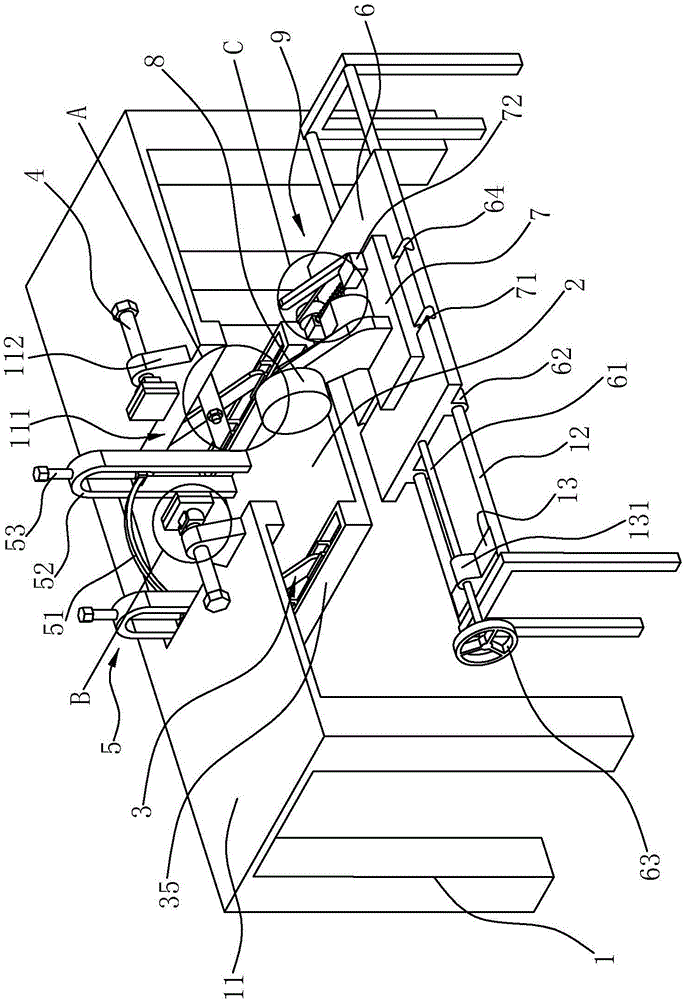

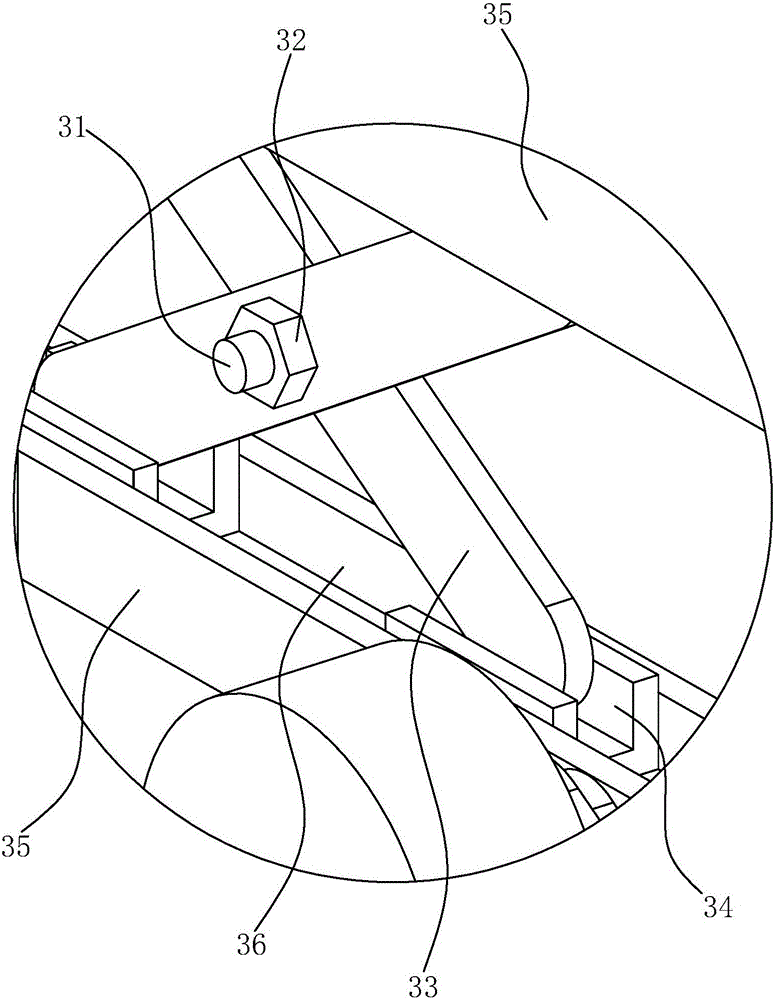

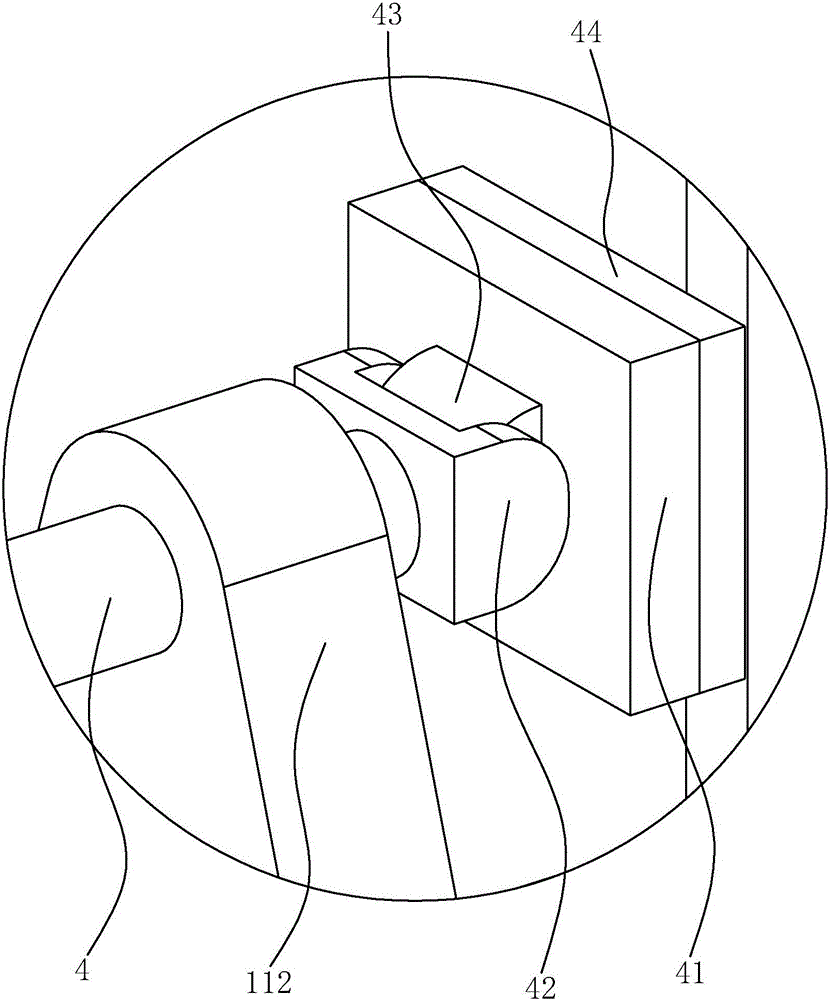

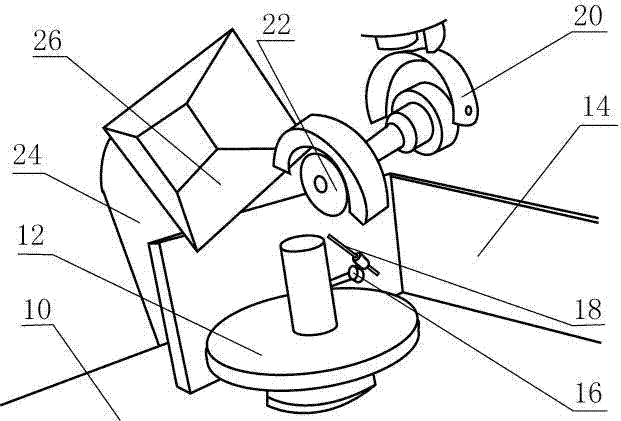

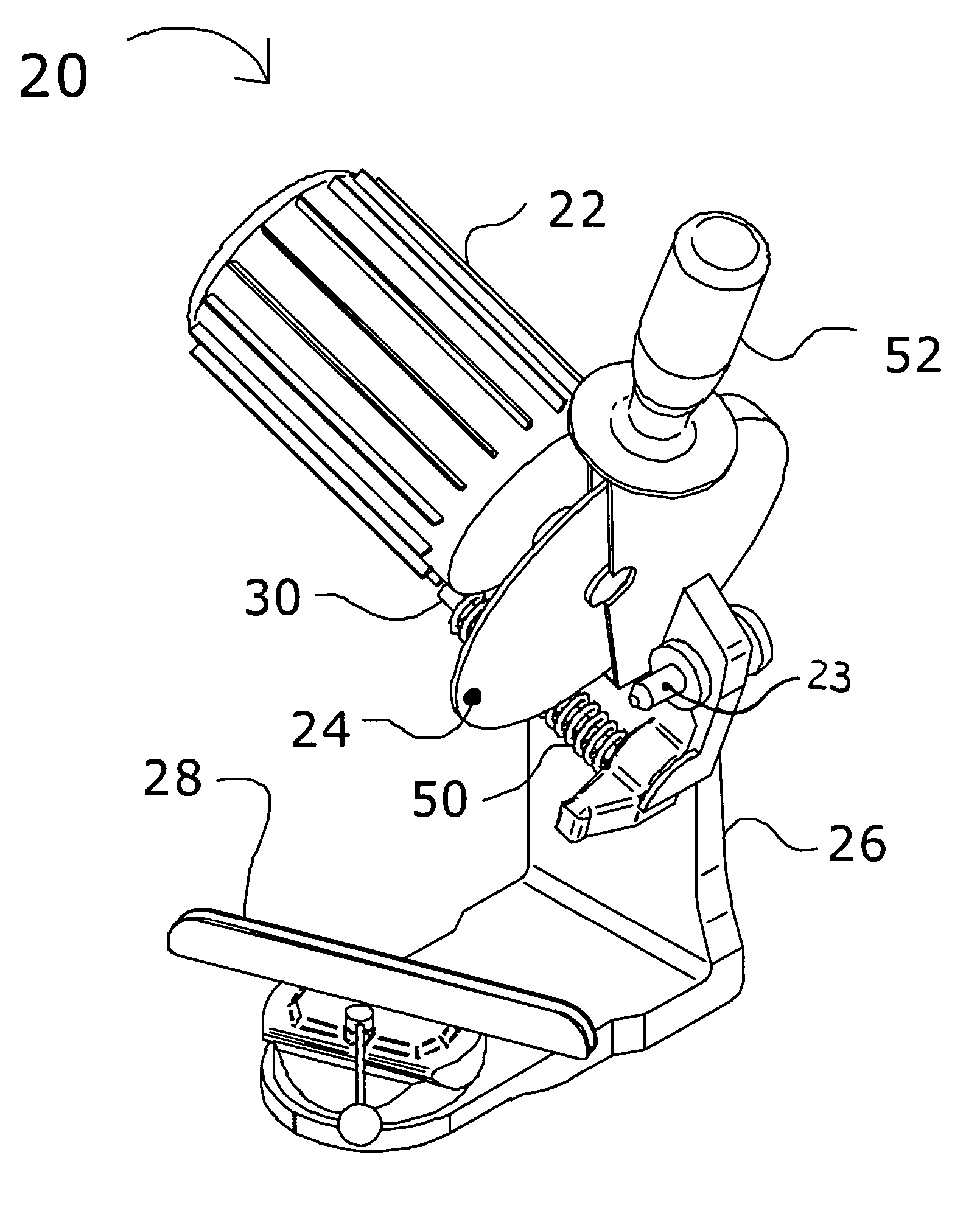

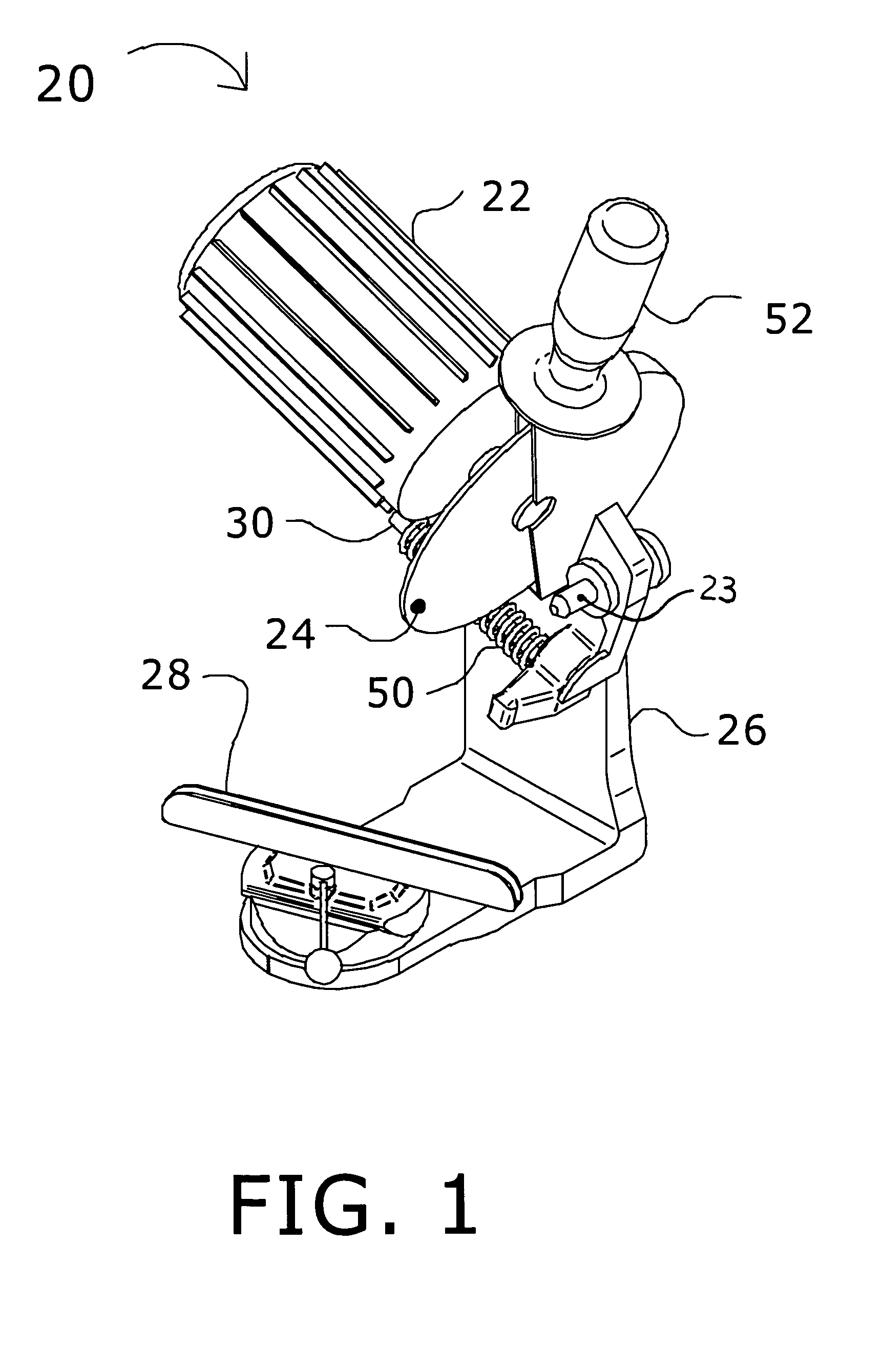

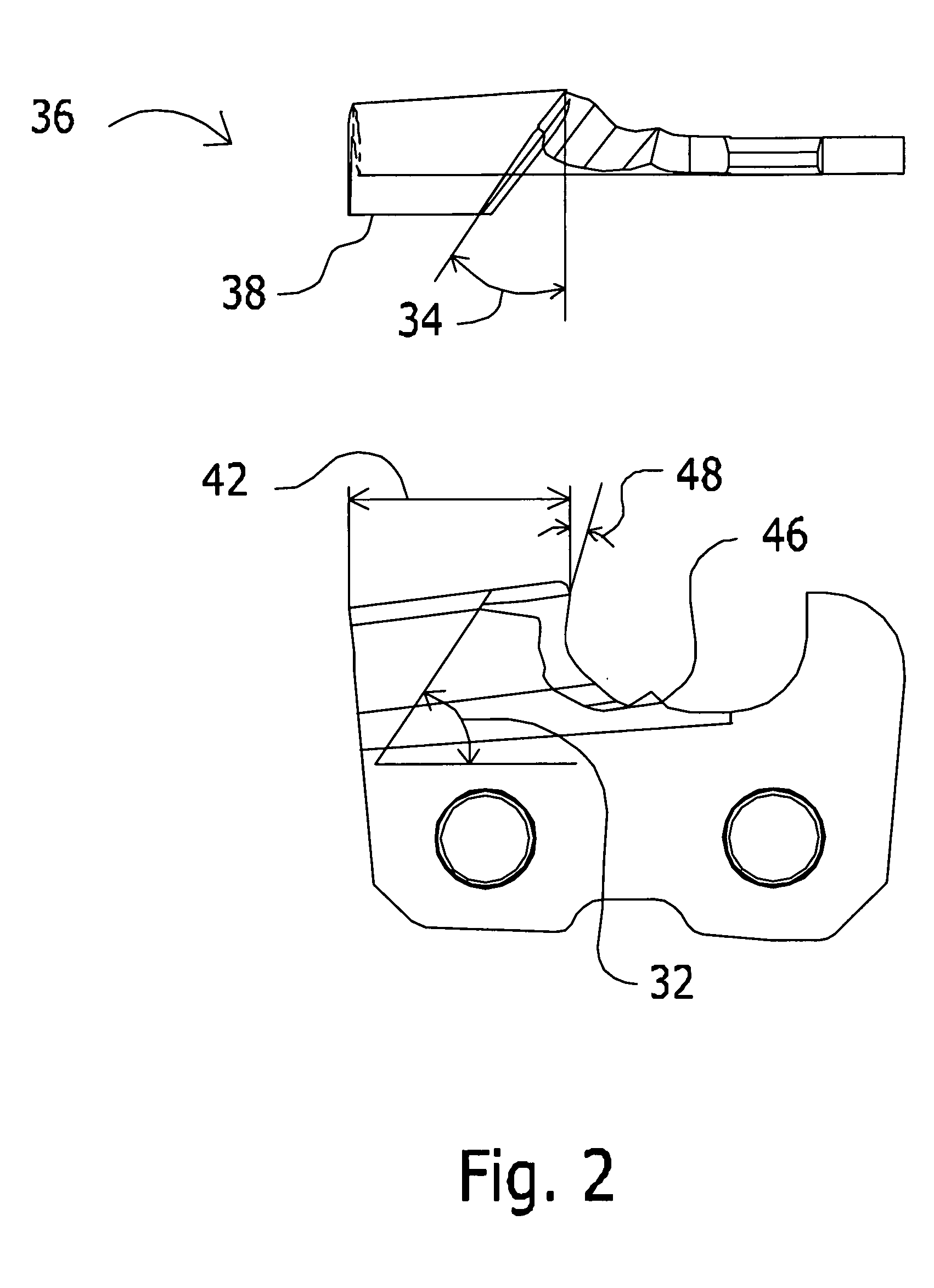

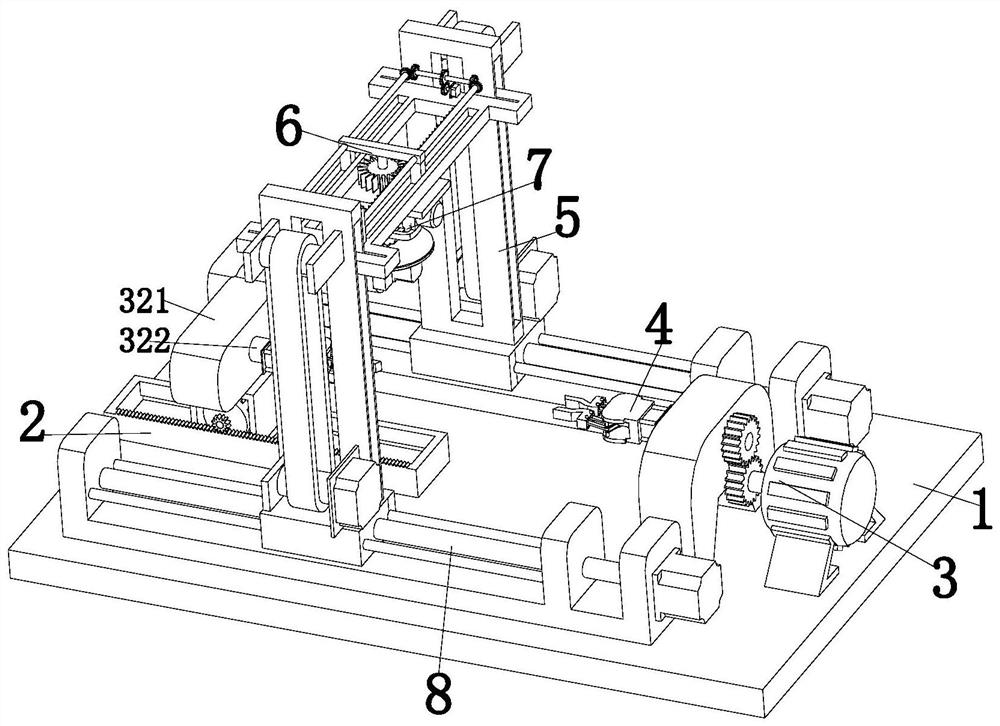

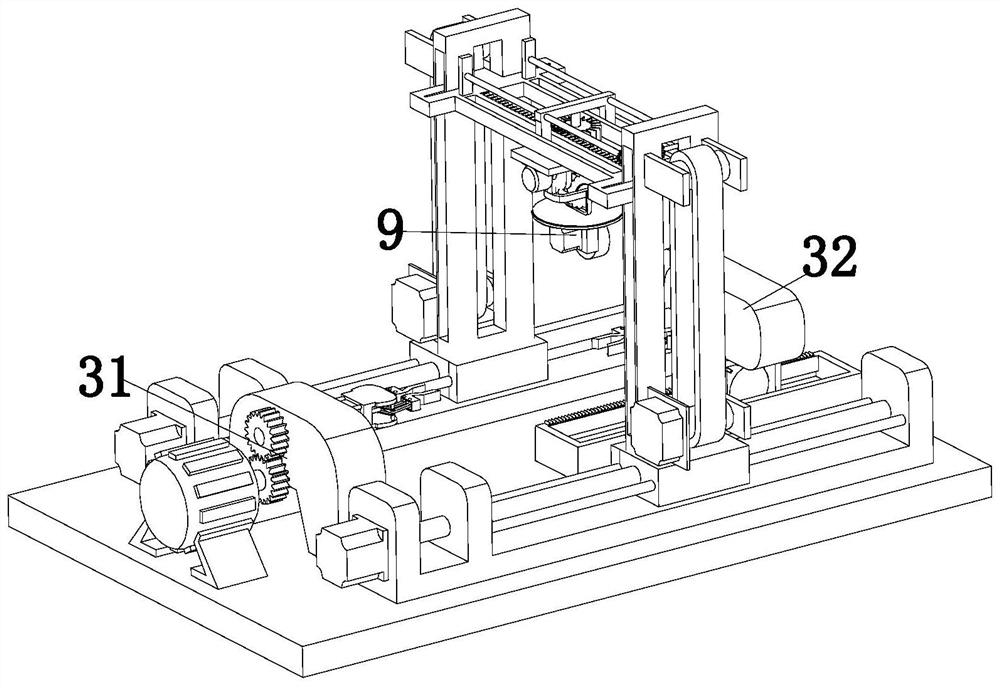

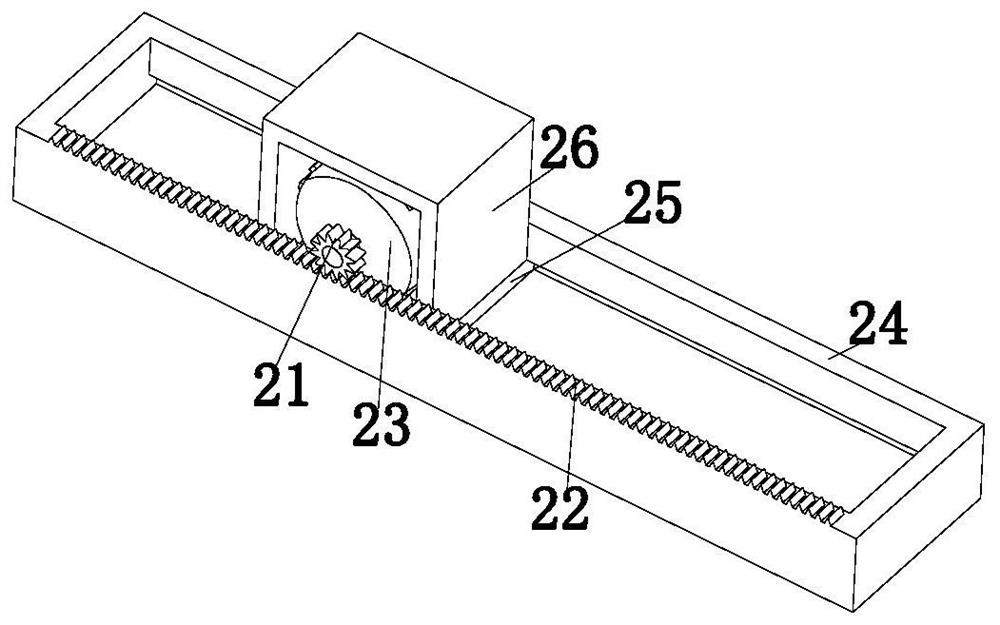

Cutting chain grinder and method of grinding

A cutting chain bench grinder includes a self-centering vise that centers the cutting chain on an axis of rotation of the vise base. By centering the cutting chain to intersect the vise base axis of rotation, consistent top plate lengths and hook angles can be ground into left and right-hand cutters on a cutting chain. The vise base may also be adjusted horizontally in and out from the grinder base to align the vise base axis of rotation with the axis of rotation of the grinding wheel. The vise base may also be adjusted vertically relative to the vise base to vertically compensate for grinding wheel wear and to control grinding depth. A light tension spring may be used to bias the grinding head in both grinding and dressing positions. A down angle positioner may also be provided that rotates the cutting chain in the vise around a longitudinal centerline of the cutting chain.

Owner:OREGON TOOL INC

Grinding machine

InactiveCN105935933APrecise positioningEasy to operateGrinding carriagesGrinding drivesBench grinderScrew joint

The invention provides a grinding machine, and belongs to the technical field of mechanical machining equipment. The problems that an existing grinding machine is unstable in workpiece positioning, and the polishing precision is affected are solved. The grinding machine comprises a rack, a working table board is fixedly connected to the rack, a positioning gap is formed in the working table board, the working table board is in sliding connection with an adjusting plate, positioning screw rods are in screw joint with the working table board, and positioning blocks are hinged to the ends of the two positioning screw rods; a positioning part is further arranged on the adjusting plate, the rack is in sliding connection with a transverse moving seat, a longitudinal moving seat is in sliding connection with the transverse moving seat, and a grinding wheel is rotatably arranged on the longitudinal moving seat; and an operation screw rod is arranged between the transverse moving seat and the rack, and an operation part is arranged between the longitudinal moving seat and the transverse moving seat. The grinding machine is more stable in workpiece positioning, and the polishing precision is further improved.

Owner:ZHEJIANG OCEAN UNIV

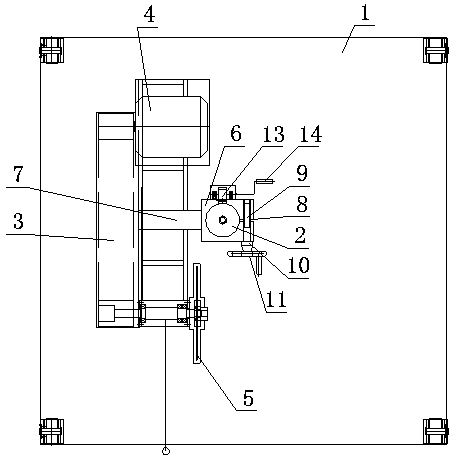

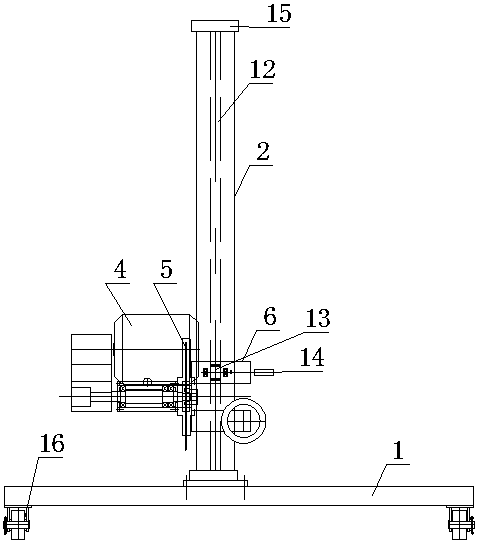

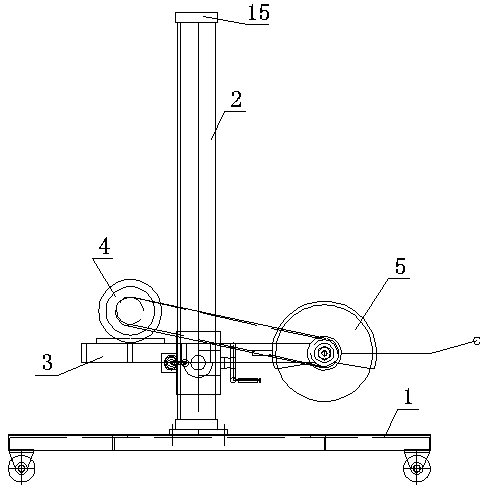

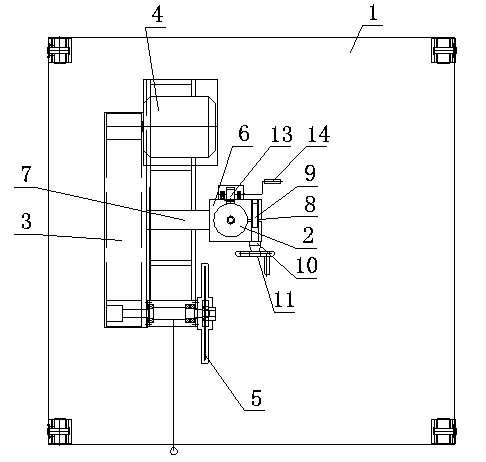

Suspension type grinding machine rotation adjusting device

ActiveCN104029104ARealize horizontal rotation adjustment functionEasy to lockGrinding machine componentsGrinding machinesEngineeringBench grinder

The invention discloses a suspension type grinding machine rotation adjusting device. The suspension type grinding machine rotation adjusting device comprises a rotation base. The middle of the rotation base can be vertically connected to a stand column in a sliding and sleeved mode through a cup joint hole, one side of the rotation base is fixedly connected with a suspension, and the other side of the rotation base is provided with an interval gap used for adjusting locking. The position, on one side of the interval gap, of the rotation base is provided with a horizontal-through through hole, and the position, on the other side of the interval gap, of the rotation base is horizontally provided with a treaded hole right opposite to the through hole. The suspension type grinding machine rotation adjusting device further comprises a locking bolt. The locking bolt penetrates through the through hole through the exterior of the rotation base and is then in threaded connection into the threaded hole in a screwing mode. The part, located on the outer side of the rotation base, of the locking bolt is provided with a limiting boss, and the end of the outer side of the limiting boss is provided with a rotation locking hand wheel. By means of the suspension type grinding machine rotation adjusting device, up-and-down and left-and-right rotation adjusting can be conducted on a sand wheel position, and the multi-angle cutting machining requirement of a grinding machine can be met. Meanwhile, the suspension type grinding machine rotation adjusting device has the advantages of being simple in structure, convenient and fast to adjust, reliable in use and the like.

Owner:宝武特冶航研科技有限公司

Gear chamfering device

InactiveCN102240937AEasy to adjust the angleEasy to adjust the positionEdge grinding machinesGrinding/polishing safety devicesWorking environmentBench grinder

The invention discloses a gear chamfering device which comprises an operating platform, wherein a workpiece bracket is arranged on the operating platform; and a dust exhaust device is arranged on one side of the workpiece bracket. The gear chamfering device is characterized in that driven by a driving device, the workpiece bracket can horizontally rotate; a grinding wheel bracket is arranged above the workpiece bracket; and a grinding machine, the position and direction of which can be adjusted, is arranged on the workpiece bracket. In the gear chamfering device provided by the invention, the adjustable grinding wheel bracket is used for fixing the grinding machine, thereby conveniently adjusting the angle and position of the grinding wheel and stably controlling the grinding machine to operate. Flying chips are absorbed, thereby ensuring the cleanness of the working environment. The gear chamfering device has the advantages of convenience in use, high processing quality, high safety, and the like.

Owner:TATUNG GEAR KUNSHAN

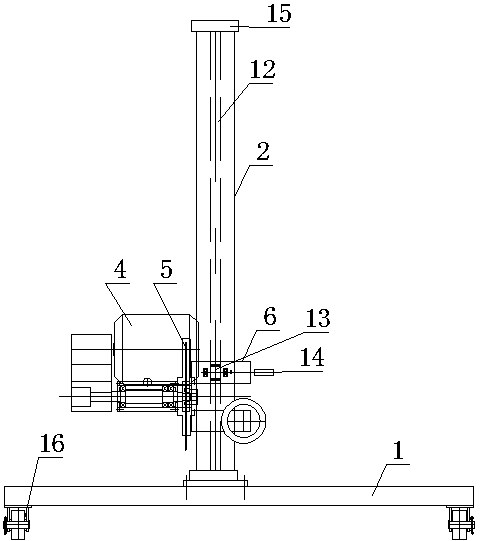

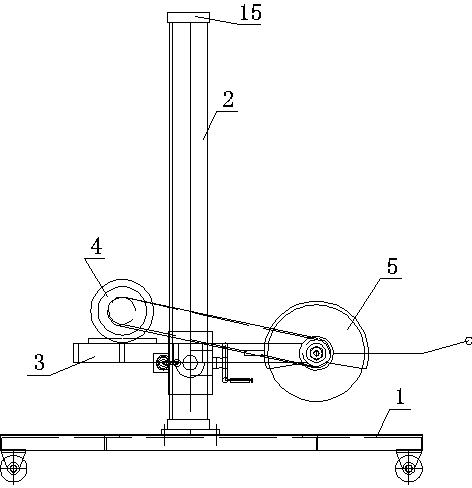

Suspension type grinding machine meeting multi-angle machining requirement

ActiveCN104029105AMeet the requirements of multi-angle cutting processingSimple structureGrinding drivesGrinding machinesBench grinderEngineering

The invention discloses a suspension type grinding machine meeting a multi-angle machining requirement. The grinding machine comprises a base, a stand column, a suspension and a cutting system, wherein the stand column is fixed to the base, the suspension is arranged on the stand column and the cutting system is installed on the suspension. The cutting system comprises a cutting motor, a grinding wheel installation main shaft and a grinding wheel, wherein the grinding wheel is fixedly installed on the grinding wheel installation main shaft, and the output end of the cutting motor is connected with the grinding wheel installation main shaft through a transmission mechanism and drives the grinding wheel to rotate for cutting or trimming. The grinding machine is characterized in that the stand column is a cylinder, the suspension can be horizontally installed on the stand column through a rotary adjusting device in a rotary mode, and a lifting adjusting mechanism is arranged. The position of the grinding wheel can adjusted in the vertical direction and the horizontal direction in a rotary mode, and the multi-angle cutting machining requirement of the grinding machine can be met. Meanwhile, the grinding machine has the advantages of being simple in structure, convenient and rapid to adjust, reliable in using and the like.

Owner:宝武特冶航研科技有限公司

Machining method for milling ship propeller blade through robot

The invention discloses a machining method for milling a ship propeller blade through a robot. Machining materials and tools comprise a propeller hub, the blade, an air chipper and a grinding machinefile. The machining method comprises the following steps that 1, the blade is measured to obtain a result; 2, a machining line is marked out on the blade through a line carver; 3, the blade and the propeller hub are milled through the robot; 4, needless metal on a blank is shoveled through the robot; and 5, the propeller static unbalance is eliminated. According to the machining method for millingthe ship propeller blade through the robot, a program for the robot to machine a propeller is compiled, accordingly, the time for the robot to polish and grind the blade is controlled so that the polishing quality can be improved, and the propeller manufacturing work efficiency is improved; and the blade and the propeller hub of the propeller are connected into a whole, thus, the structure is simple, the part number is small, and the work reliability is improved so that the integral strength of the propeller can be improved.

Owner:ZHENJIANG TONGZHOU PROPELLER

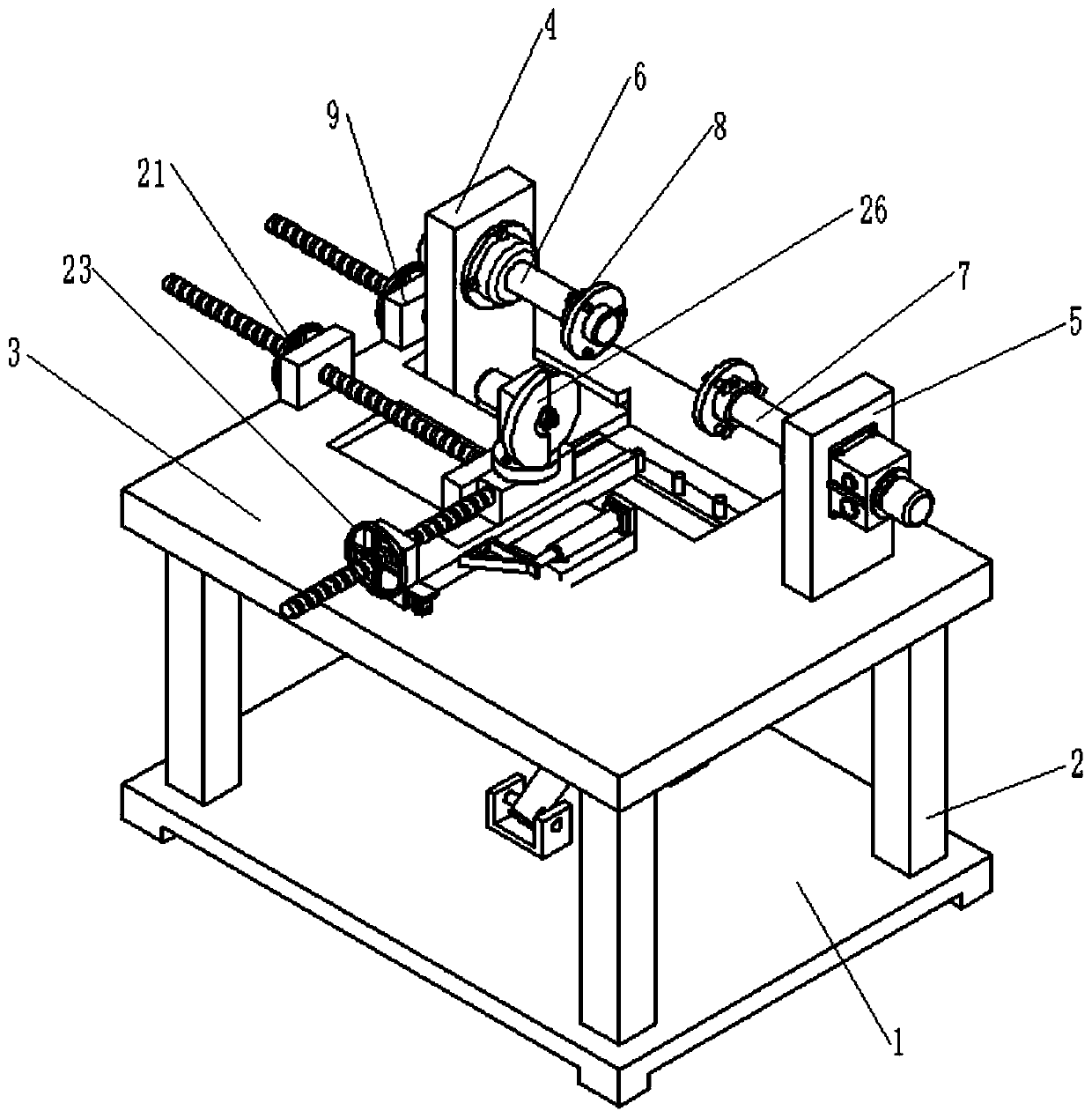

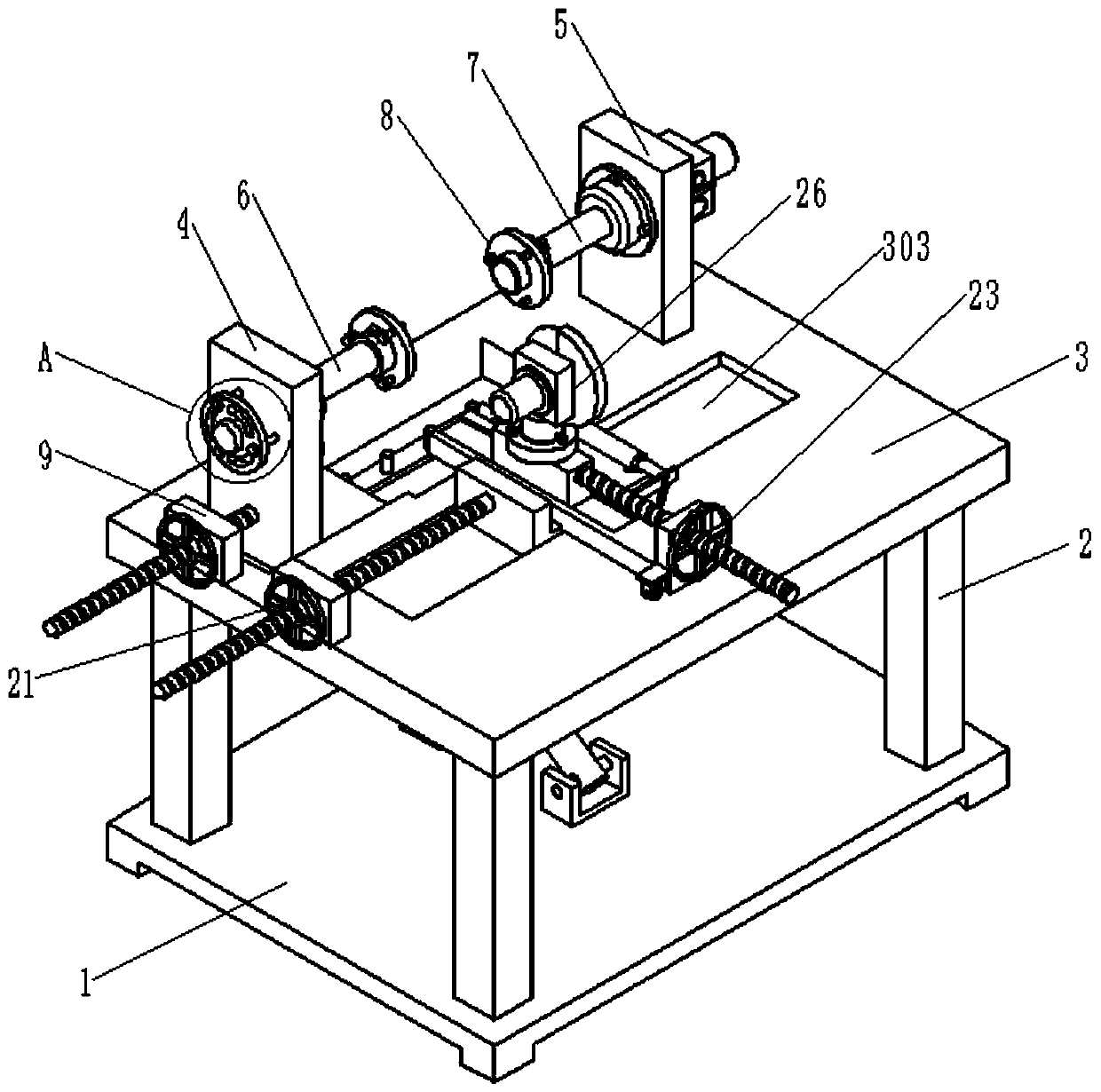

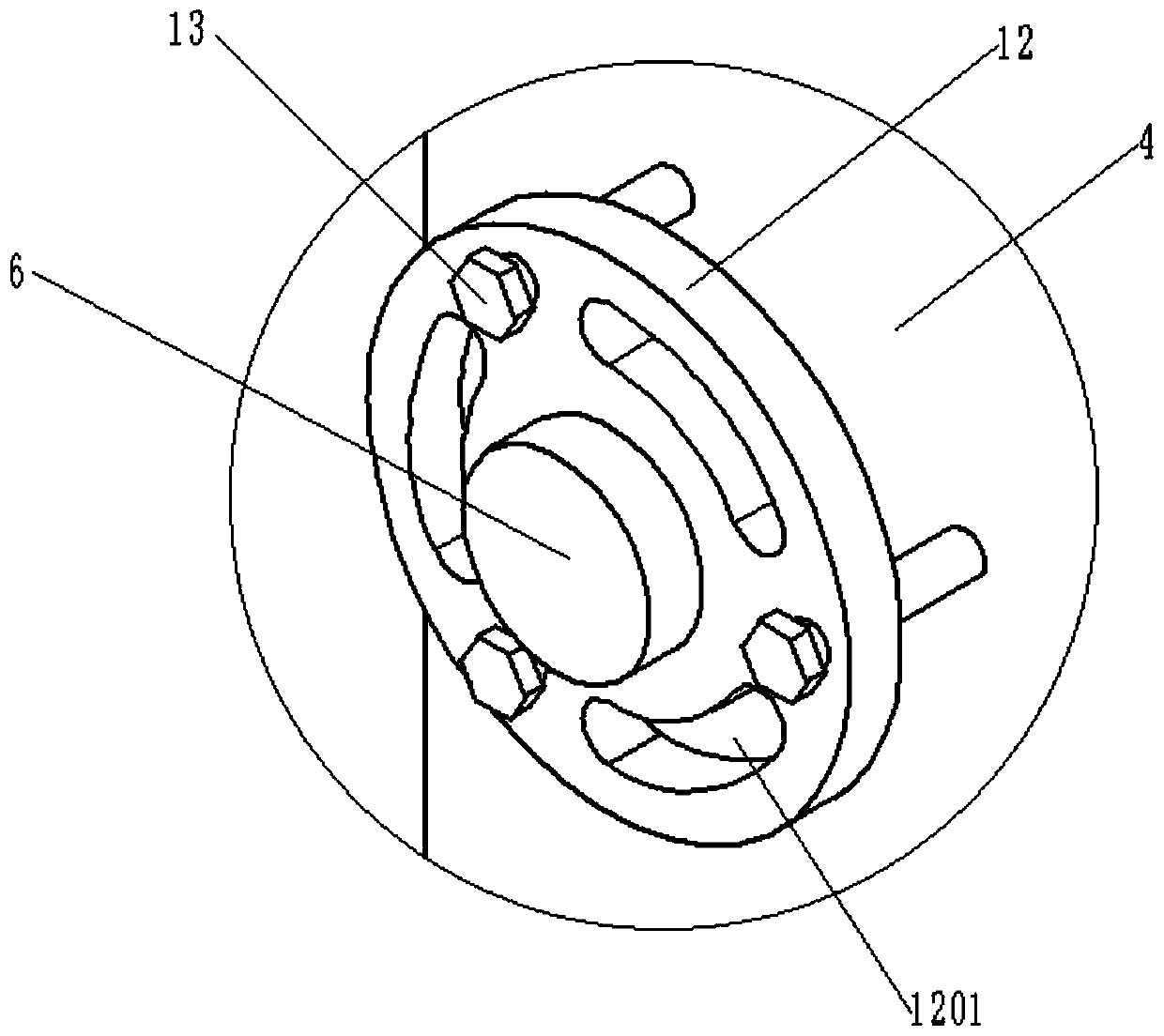

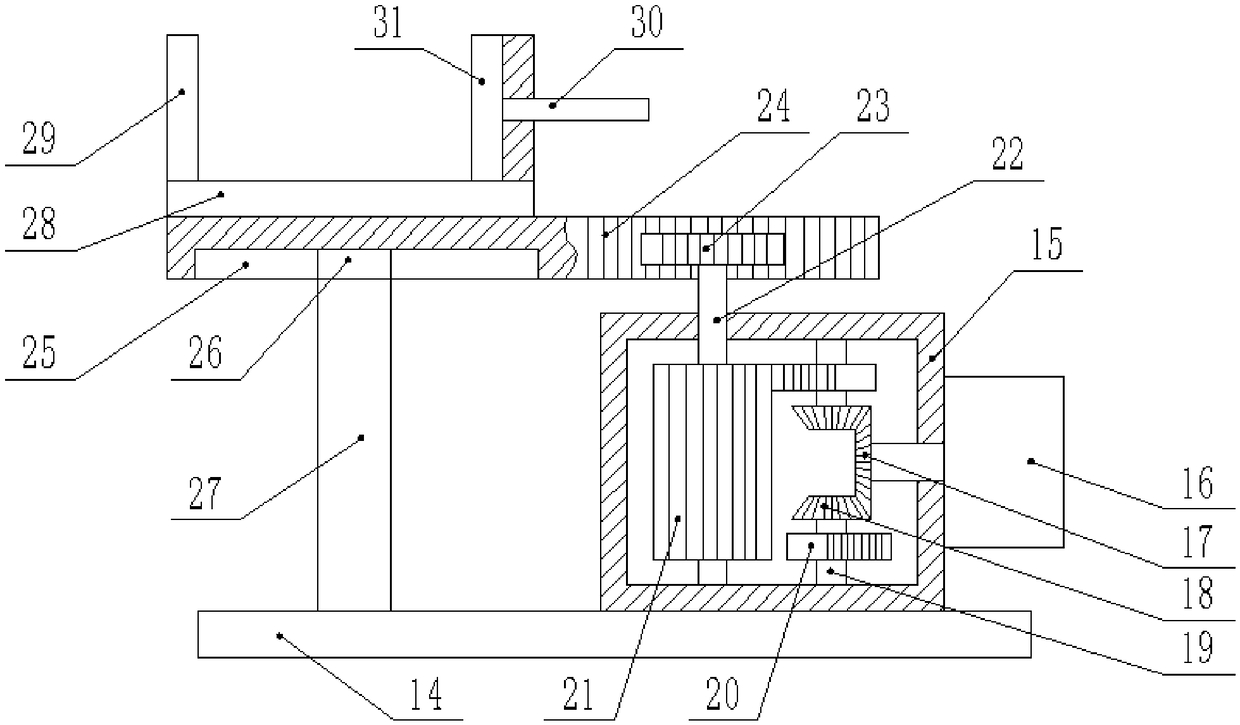

Gear cutter hob sharpening machine with adjustable sharpening angle

InactiveCN110774063AImprove grinding performanceThe solution angle is not adjustableGrinding drivesMilling cuttersHobbingGear wheel

The invention discloses a gear cutter hob sharpening machine with an adjustable sharpening angle. The gear cutter hob sharpening machine with the adjustable sharpening angle includes a base plate, support legs and a working table. The upper end face of the working table is provided with a clamping device and a sharpening device. The sharpening device includes a grinding machine and a moving mechanism for installing the grinding machine. A rotating seat is arranged on the moving mechanism. The upper end face of the rotating seat is provided with a stepped hole with small diameter at the upper end and large diameter at the lower end. The stepped hole is internally provided with a stepped rotating shaft matched with the stepped hole. The upper end face of the rotating seat is provided with athreaded through hole leading to the stepped hole. The threaded through hole is provide with a fourth fixed bolt. The upper end of the stepped rotating shaft extends to the position above the rotatingseat. The grinding machine is arranged at the upper end of the stepped rotating shaft. According to the gear cutter hob sharpening machine with the adjustable sharpening angle, the angle between a center axis of a grinding wheel and a center axis of a hobbing cutter can be adjusted, the problem that the angle between the center axis of the grinding wheel and the center axis of the hobbing cutterof an existing gear cutter hob sharpening device cannot be adjusted is solved, and the grinding effect on the hobbing cutter is enhanced.

Owner:瑞安市浙工大创新创业研究院

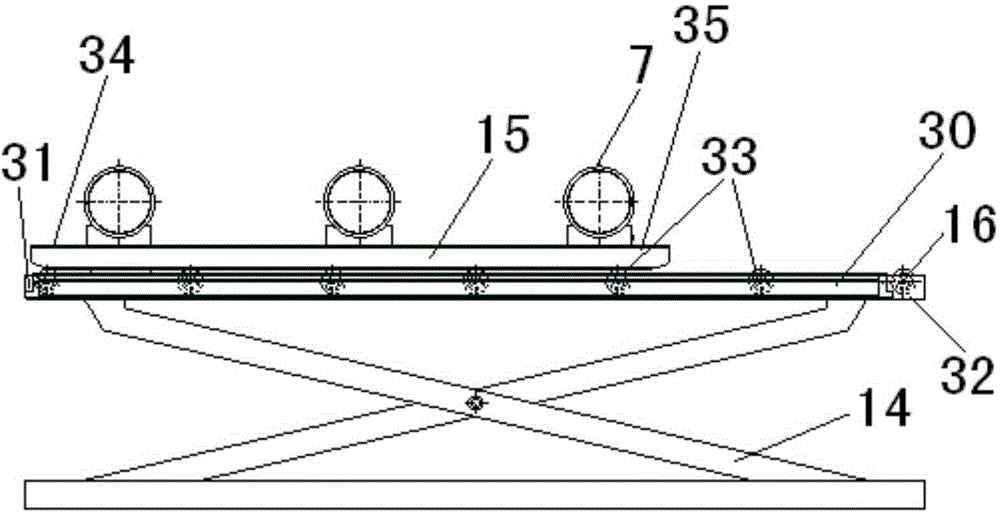

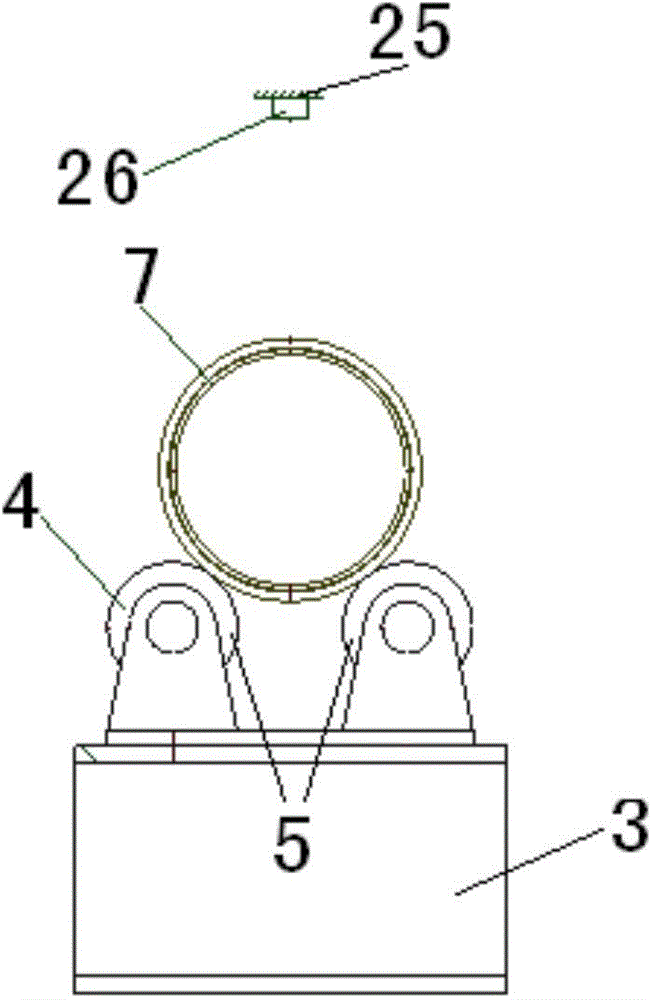

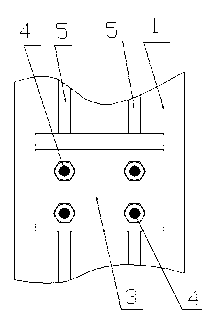

Grinding equipment used for automatically grinding cast tube bell ends

ActiveCN104149006AConvenient and quick automatic grinding operationImprove versatilityEdge grinding machinesAutomatic grinding controlRobotic armEngineering

The invention provides grinding equipment for cast tube bell ends in the technical field of cast tube grinding. A plurality of rollers (4) are arranged on component supports (3) of cast tube positioning components (1) of the grinding equipment, every two rollers (4) form a roller set (5), each roller set (5) is mounted on a bearing block (6) of the corresponding component support (3), a to-be-ground cast tube (7) is of a structure which can be horizontally placed on the roller sets (5), a grinding robot (2) comprises a robot base (8) and a mechanical arm (9), one end of the mechanical arm (9) is movably connected with the robot base (8), the other end of the mechanical arm (9) is mounted with a grinding machine (10), and the mechanical arm (9) is connected with a controller (11). The grinding equipment can grind the cast tube bell ends automatically, conveniently and rapidly, unmanned operation in the whole process from discharging of the cast tube from a tube casting machine to the end of grinding is realized, and production efficiency and product quality are improved obviously.

Owner:EFORT INTELLIGENT EQUIP CO LTD

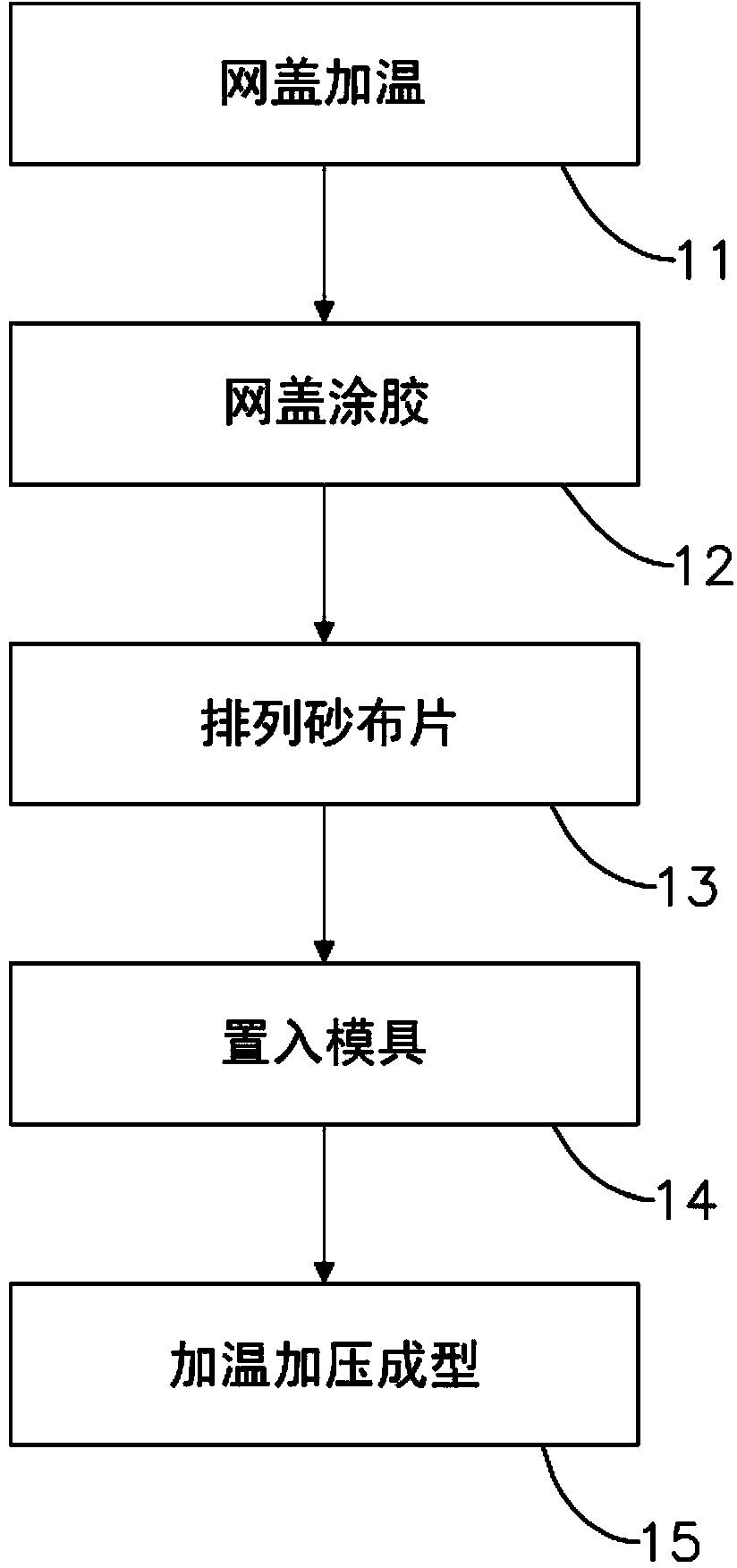

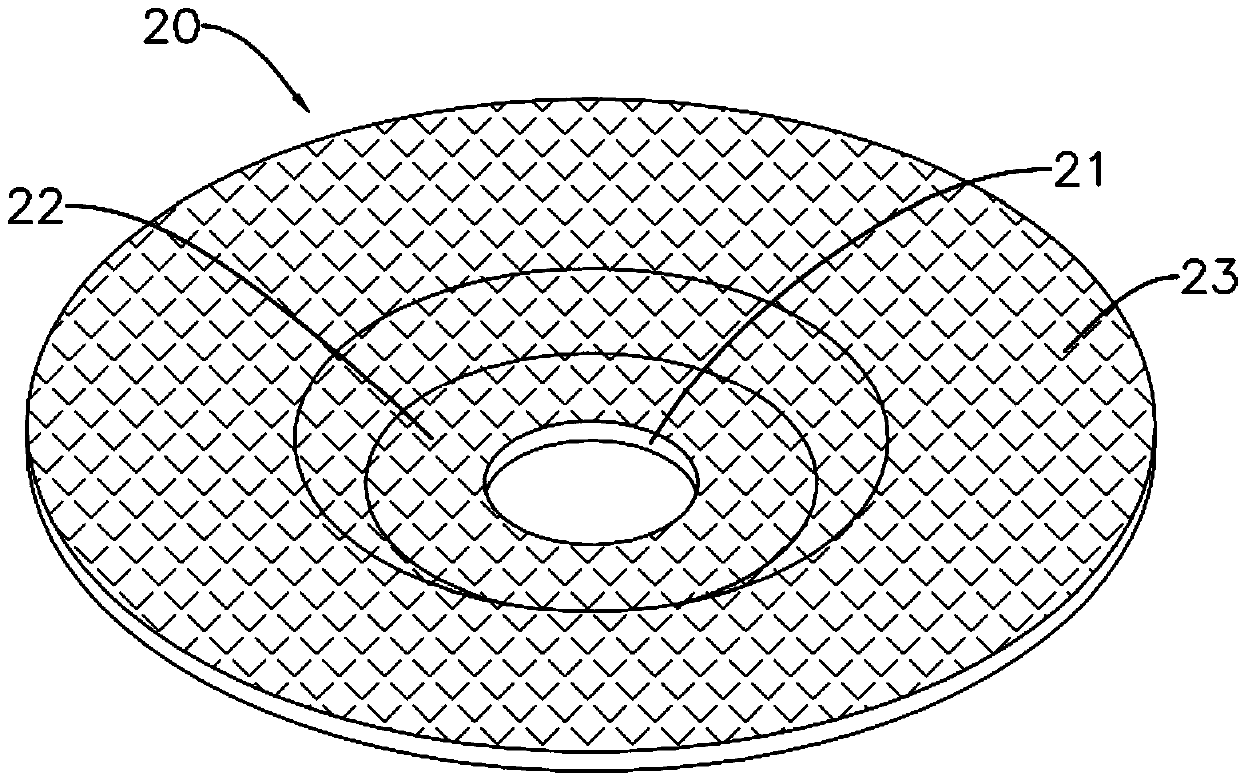

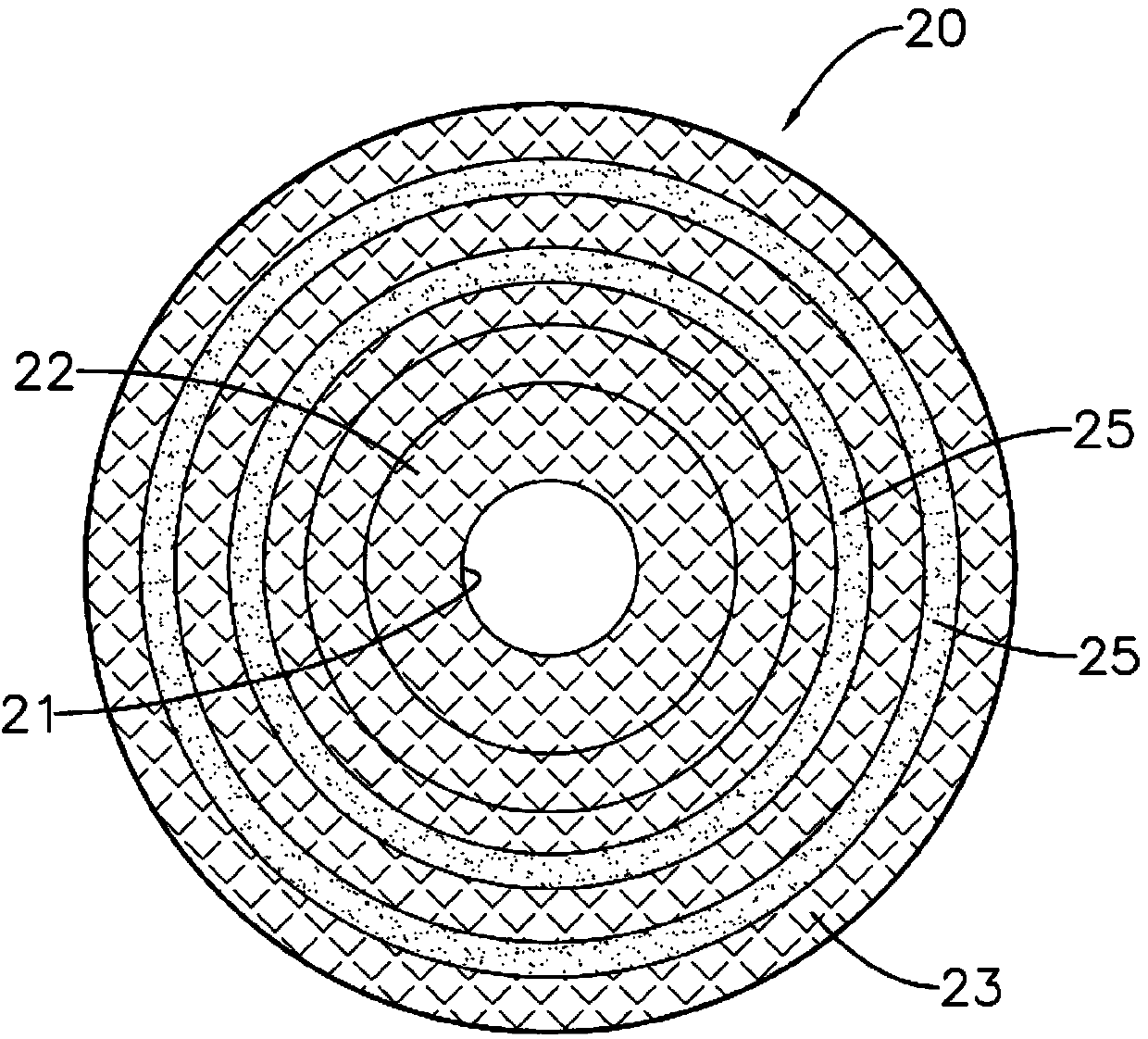

Grinding cloth wheel and manufacturing method of grinding cloth wheel

ActiveCN103465184AGuaranteed flatnessSimple and fast operationFlexible-parts wheelsGrinding devicesBench grinderEngineering

The invention relates to a grinding cloth wheel and a manufacturing method of the grinding cloth wheel. The manufacturing method of the grinding cloth wheel comprises a net cover warming step, a net cover glue coating step, a grinding cloth piece ranging step, a mold placing step and a warming and pressurizing forming step. The grinding cloth wheel manufactured by adopting the manufacturing method has the advantages that the grinding edges of each grinding cloth piece are respectively positioned on the same plane, so when the grinding cloth wheel is arranged on the grinding wheel machine to be used, operators only need to make a rotating shaft of the grinding cloth wheel to be vertical to the surface of a ground object, the grinding edges of all grinding cloth pieces can simultaneously realize the grinding on each position of the surface of the ground object at the uniform force, the smoothness of the surface of the ground object is ensured, the operation is simple and convenient, in addition, the grinding area in the unit time is large, and the grinding efficiency is high.

Owner:宜春长竑砂轮有限公司

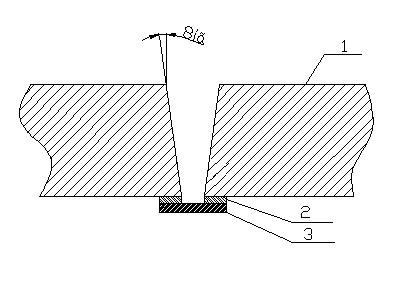

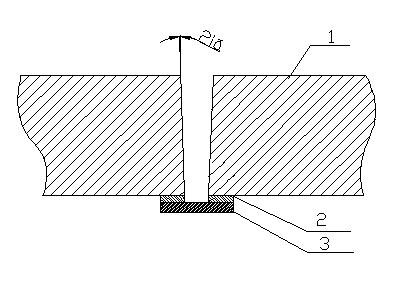

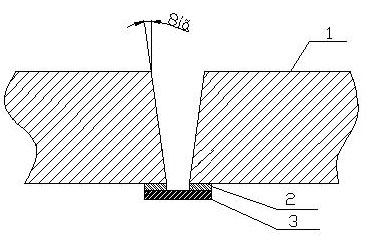

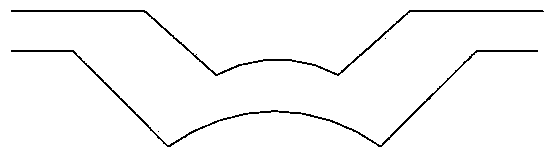

Thick metal plate back gouging-free welding groove technology and machining process

ActiveCN102019513AWon't hurtImprove fusion qualityArc welding apparatusWorkpiece edge portionsBench grinderFlame cutting

The invention relates to thick metal plate back gouging-free welding groove technology. The technology is characterized in that: a welding groove consists of a substrate V-shaped groove and two layers of gaskets connected to the lower surface of the substrate V-shaped groove. A welding process comprises the following steps of: before the two sides of a substrate are rolled, machining a single-sided 2 to 10-degree V-shaped groove on a facing machine, and after the two sides of the substrate are rolled and molded, forming the V-shaped groove with the bottom gap of 16 to 26 mm and the opening of4 to 20 degrees; fixing a first layer of gasket on the two sides of the groove by arc welding; fixing a second layer of gasket on the first layer of gasket by welding; welding an entire welding line according to the requirements of a welding process instruction; chopping a part of the two layers of gaskets by adopting a flame cutting method to keep the weld reinforcement of 3 to 5 mm; and grinding the weld reinforcement off by adopting a grinding wheel machine. In the technology and the welding process, the welding line is molded once, the times of preheating, dehydrogenation and flaw detection are reduced in the welding process, the manufacturing cost is saved and a manufacturing cycle is shortened.

Owner:HANGZHOU BOILER GRP CO LTD

Novel anti-explosion grinder

InactiveCN1586818AEnsure personal safetyGood line of sightGrinding/polishing safety devicesEngineeringGrinding wheel

The novel anti-explosion grinder has guard unit set on the protecting hood. The guard unit includes one adjustable barrier and one barrier position regulating mechanism. The grinder with said guard unit has the features of being safe and reliable except excellent operation performance. In case of damage grinding wheel, the present invention can block the grinding wheel fragment from injuring operator. In addition, the novel anti-explosion grinder coincides somatology and can improve labor environment, reduce dust pollution and lower labor strength.

Owner:朱光明

Rubber roll grinding device

InactiveCN102632439ASimple structureEasy to useRevolution surface grinding machinesSlide plateBench grinder

The invention provides a rubber roll grinding device, which comprises a machine seat, wherein two sides of the machine seat are provided with sliding rails, the front end of the machine seat is provided with a machine head front seat, a rotating shaft is arranged on the machine head front seat, a sliding plate is arranged on the sliding rails, one end of the sliding plate is provided with a grinding wheel machine, a grinding belt is arranged on the grinding wheel machine, the back end of the machine seat is provided with a machine head back seat, a rubber roll fixing device is arranged on the machine head back seat, and a part of the machine seat side surface near the sliding rails is provided with an emergency switch. The rubber roll grinding device has the beneficial effects that a rubber roll is ground in the mode of the autoroatation of the rubber roll and the forward and backward movement of the grinding wheel machine, after the grinding wheel machine completes the movement along the length of the rubber roll, the sliding plate touches the emergency switch, the grinding is stopped, and when accidents occur in the grinding process, workers can pedal a foot pedal switch by feet to stop the machine operation. The rubber roll grinding device has the advantages that the structure is simple, the use is convenient, the maintenance is convenient, the grinding is stable, the precision is high, the grinding efficiency is improved, and the like.

Owner:COMC TIANJIN CO LTD

Dust-suction device for grinder

The invention relates to a dust-suction device for a grinder, which comprises a stand and a grinding wheel arranged on the stand, wherein a scrap collecting groove is arranged under the grinding wheel; and the side of the scrap collecting groove is provided with a separating groove which is internally provided with magnet. The scrap collecting groove which is internally filled with water or cooling liquid is arranged under the grinding wheel, and the side wall of the scrap collecting groove is fixedly provided with the magnet, so that waste scrap and scrap iron which are ground by the grinder can be collected and separated to the utmost extent, and the environment pollution can be prevented.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

Steel bar cutting machine with dust removing and counting functions

PendingCN106985051AEffectively blockSave time and effortUsing liquid separation agentGrinding machinesDust controlElectric machinery

The invention discloses a steel bar cutting machine with dust removing and counting functions. The steel bar cutting machine comprises a base, a supporting arm is arranged on the base, a movable arm is connected to the supporting arm, the right side of the movable arm is provided with a machine cover, a first motor is arranged in the machine cover, the first motor is connected with a grinding wheel, a handle is connected to the outer portion of the machine cover, a counting device and a clamping device are arranged on the base, the counting device comprises a shell, a counter is arranged in the shell, the counter is connected with a counter trigger button, a contact is arranged above the counter trigger button, a first spring is arranged on the outer side of the contact and the counter trigger button, and the base is further connected with a dust removal device. According to the steel bar cutting machine with the dust removing and counting functions, counting can be carried out after the steel bar is cut, the cost is low, and the counting is accurate; and the steel bar can also be clamped, the safety is relatively high, and the dust removing function is achieved, so that the pollution to the environment and the harm to the human body are reduced.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP SAIDE CONSTR CO LTD

Girinding wheel machine bracket adjustable in angle

A grinding wheel machine bracket comprises a fixations eat having a long through hole to receive a screw for fastening the fixation seat with a grinding wheel machine. The fixation seat has a pivoting seat with an axial hole, and a pointer located at the top thereof. A bracket seat is provided with a loading surface, a threaded hole, and an arcuate shoulder plate located over the threaded hole. A threaded rod is engaged with the threaded hole of the fixation seat via the axial hole. The bracket seat is changed in angle in relation to the fixation seat so as to adjust the angle of the loading surface of the bracket seat in relation to the grinding wheel of the grinding wheel machine. The bracket seat is fixed by the threaded rod at an angle so set.

Owner:LIN JUNG HUA

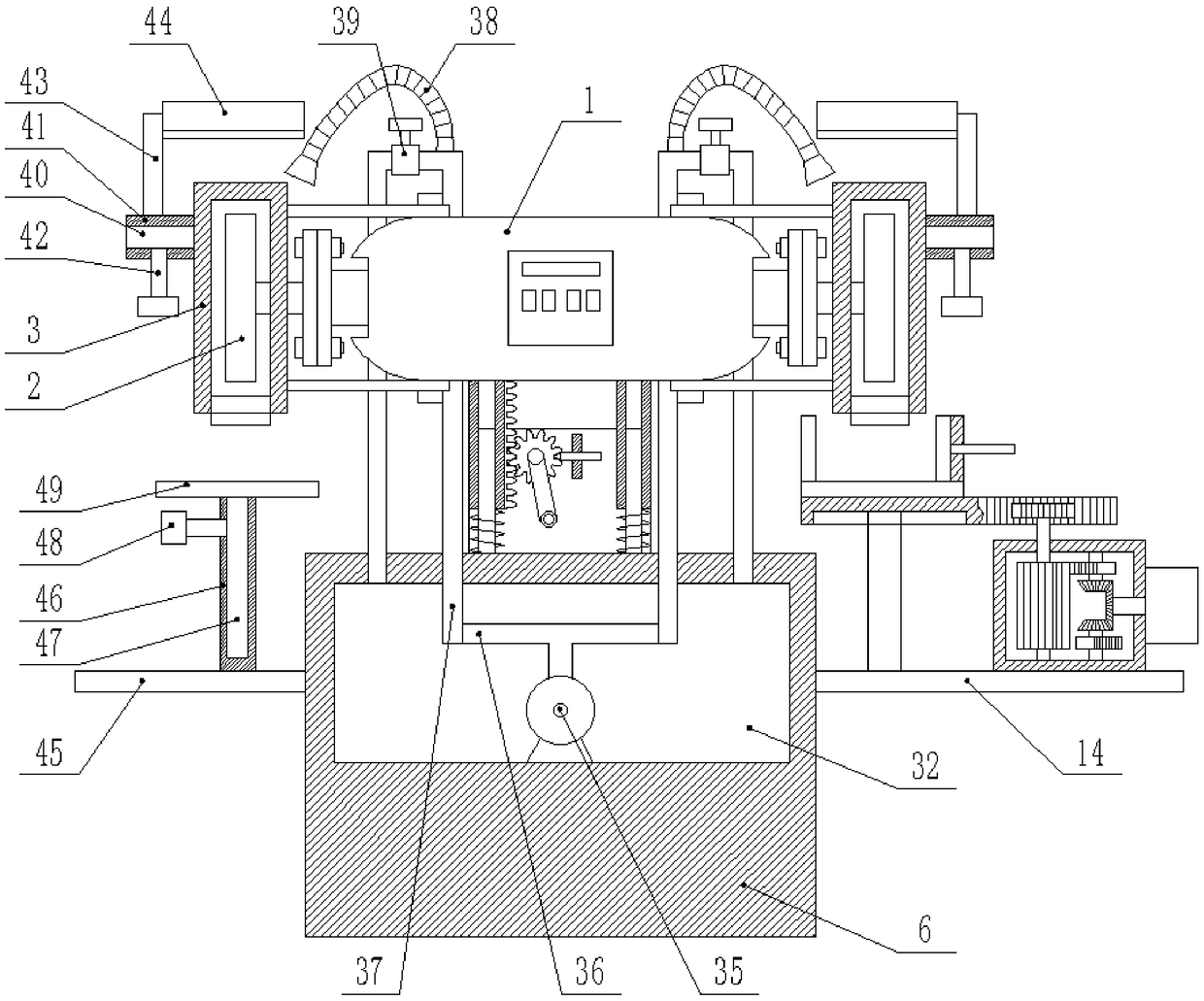

Grinding machine convenient to use

ActiveCN109129114AHeight adjustableEffortless adjustmentOther manufacturing equipments/toolsGrinding machinesBench grinderEngineering

The invention discloses a grinding machine convenient to use. The grinding machine comprises a grinding machine body; grinding wheels are mounted at the two ends of the grinding machine body; a protection cover fixed to the grinding machine body is arranged outside the grinding wheels; first sleeves are fixed to the two sides of the lower end of the grinding machine body; vertical rods are inserted into the lower ends of the first sleeves; a cabinet body is fixed to the lower end of each vertical rod; cushioning springs arranged on the vertical rods in a sleeving mode are arranged between thefirst sleeves and the cabinet bodies; a vertical plate fixed to the cabinet bodies is arranged between the two vertical rods; a first gear is rotationally connected to the front surface of the vertical plate; a hand wheel is fixed to the front surface of the first gear; a connecting plate fixed to the vertical plate is arranged on one side of the first gear; a bolt penetrates through the connecting plate and is in threaded connection with the connecting plate; a rack is fixed to the side end of one of the first sleeves; the first gear meshes with the rack; the end, opposite to the first gear,of the bolt is in a conical shape, and the diameter of the end is smaller than the tooth pitch of the first gear; a transverse shaft is fixed to the side end of the protection cover; and the transverse shaft is sleeved with a second sleeve. The grinding machine is safe, labor-saving and convenient to use.

Owner:JINGDE ANDELI GRINDING TOOL CO LTD

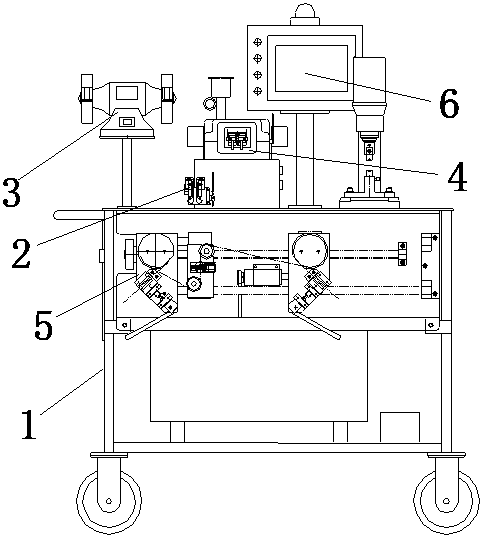

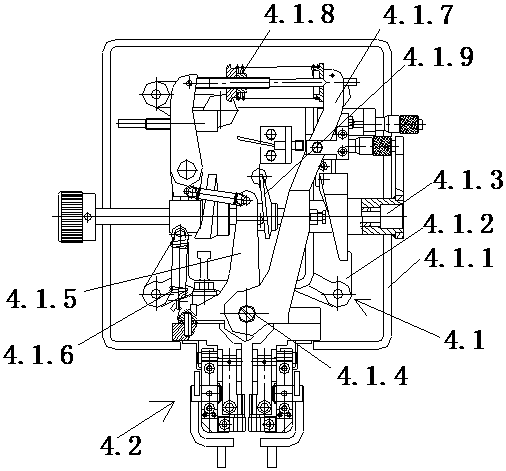

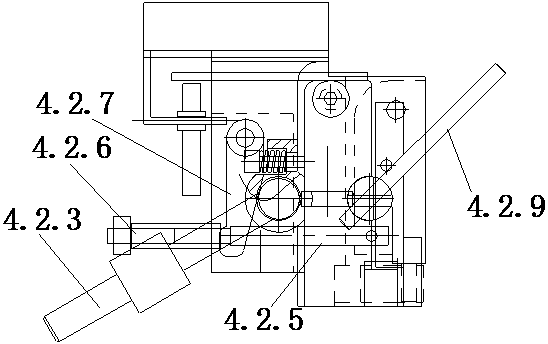

Intelligent steel cord butt welding machine and working method thereof

ActiveCN108326459AReliable contactIncrease success rateFurnace typesOther manufacturing equipments/toolsButt weldingEngineering

The invention relates to an intelligent steel cord butt welding machine. The intelligent steel cord butt welding machine comprises a rack, a steel cord smelting head device, a grinding machine grinding device, a welding mechanism, an inspecting device and a display screen, the steel cord smelting head device, the grinding machine grinding device, the welding mechanism and the display screen are all arranged on the top of the rack, and the inspecting device is arranged in the middle of the rack. According to the intelligent steel cord butt welding machine, detection on steel cord welding pointbending and stretching and the diameter is completed by conducting one-time clamping through a sensor technology and microprocessor control, the detection missing condition is avoided, the welding point qualification rate is increased, and user losses are avoided.

Owner:JIANGYIN KEYU ELECTRIC APPLIANCES

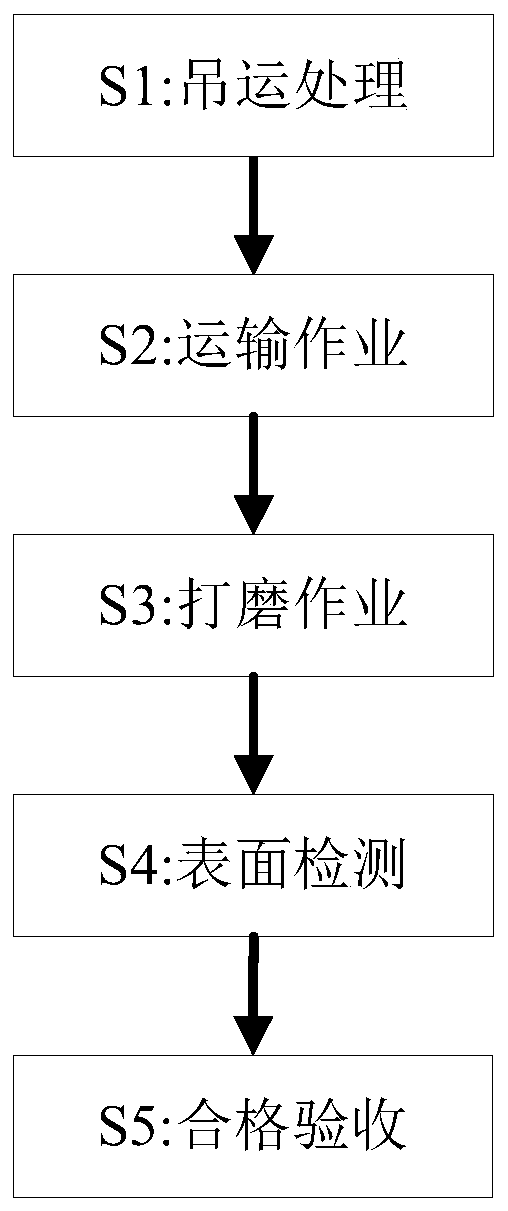

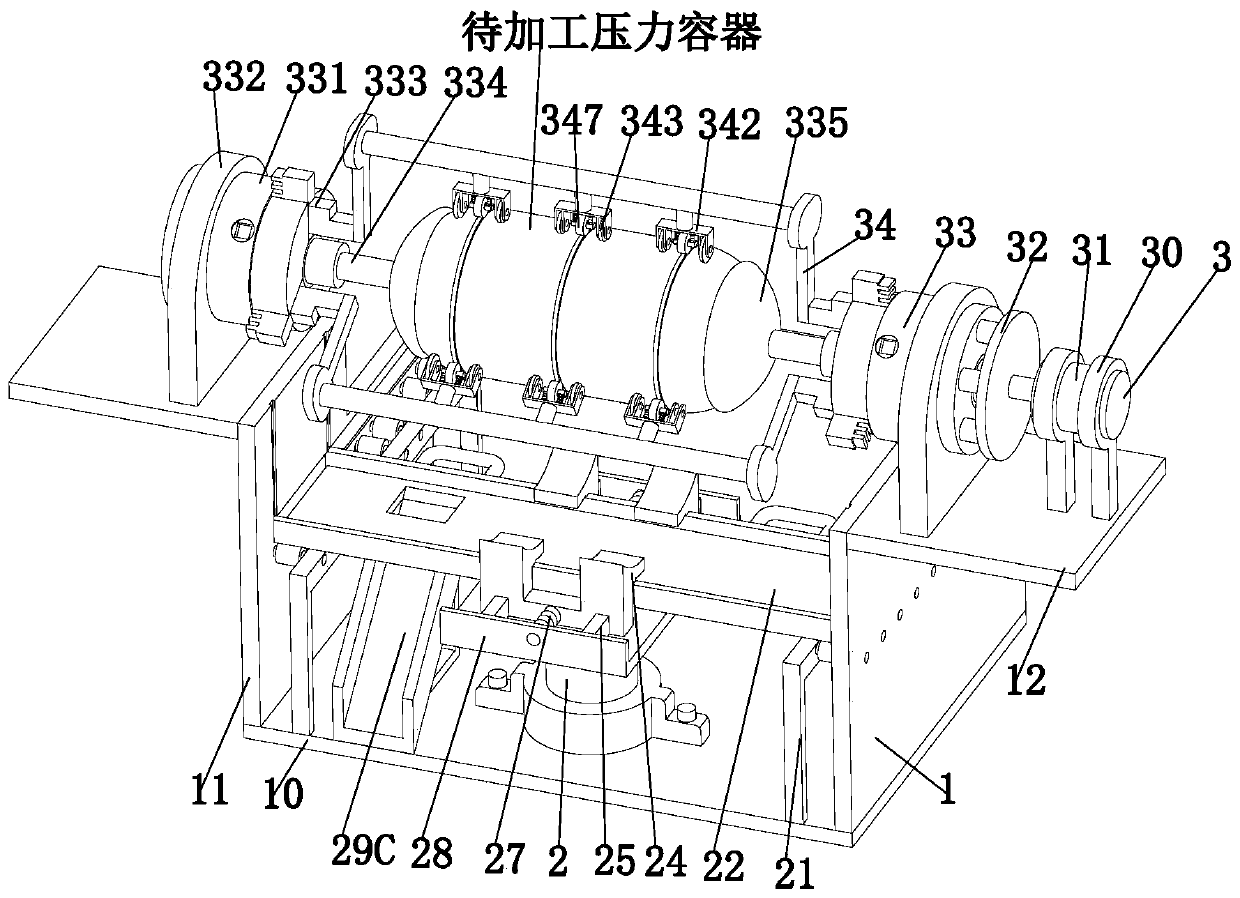

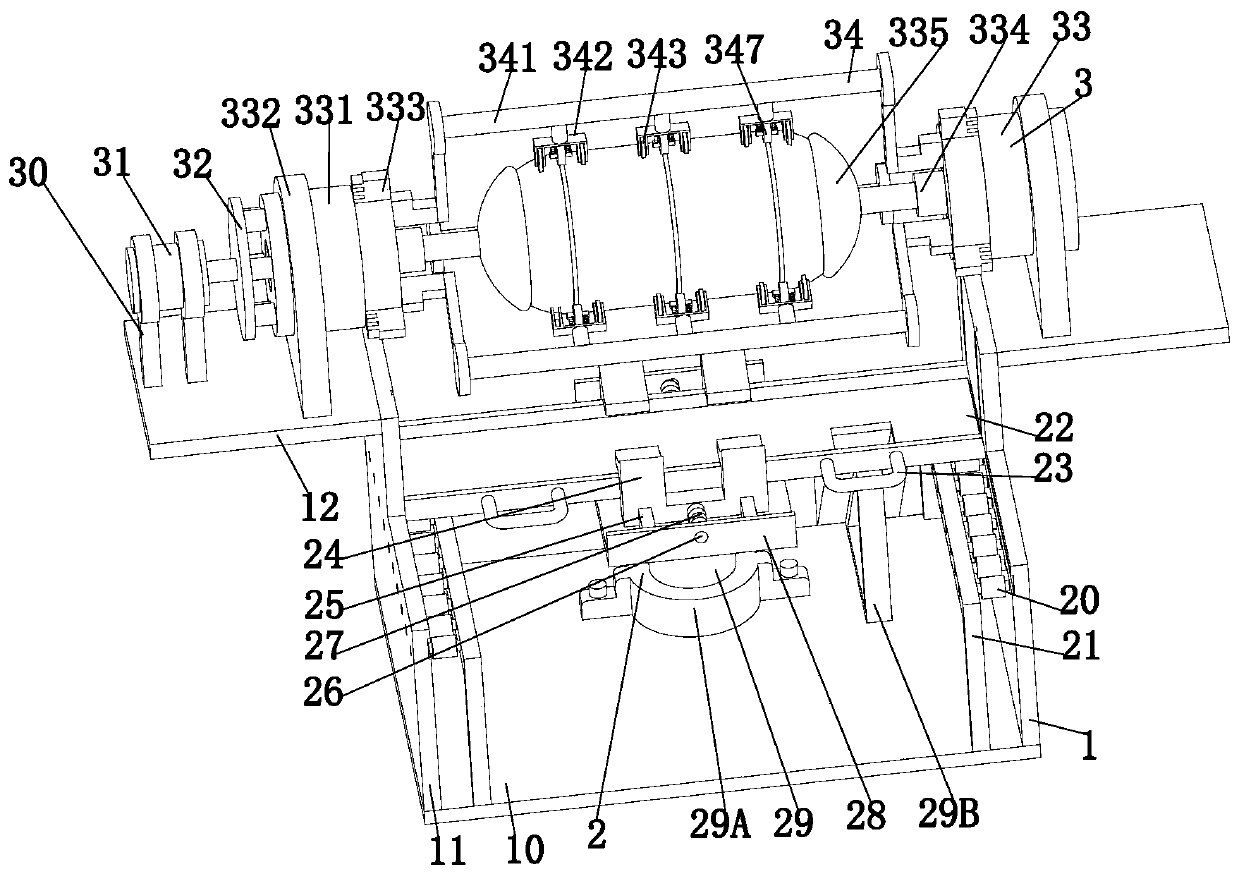

Surface finishing machining process for formed chemical pressure vessel

The invention provides a surface finishing machining process for a formed chemical pressure vessel. A supporting mechanism, a conveying mechanism, an executing mechanism and the like are matched to finish surface finishing machining and grinding of the chemical pressure vessel. According to the invention, the problems in the existing pressure vessel production and manufacturing process are solved;polishing of weld joints on the surface of a container is an important procedure. An automatic polishing machine is usually adopted to polish a linear weld joint on the surface of a smooth workpiece,and time and labor are saved. However, for polishing of the weld joint on the surface of a curved pressure container, production enterprises often adopt manual polishing, an operator holds a grindingmachine by hands to conduct grinding operation so that time and labor are wasted, and the body of the operator is harmed due to the severe working environment.

Owner:浙江临东机械科技有限公司

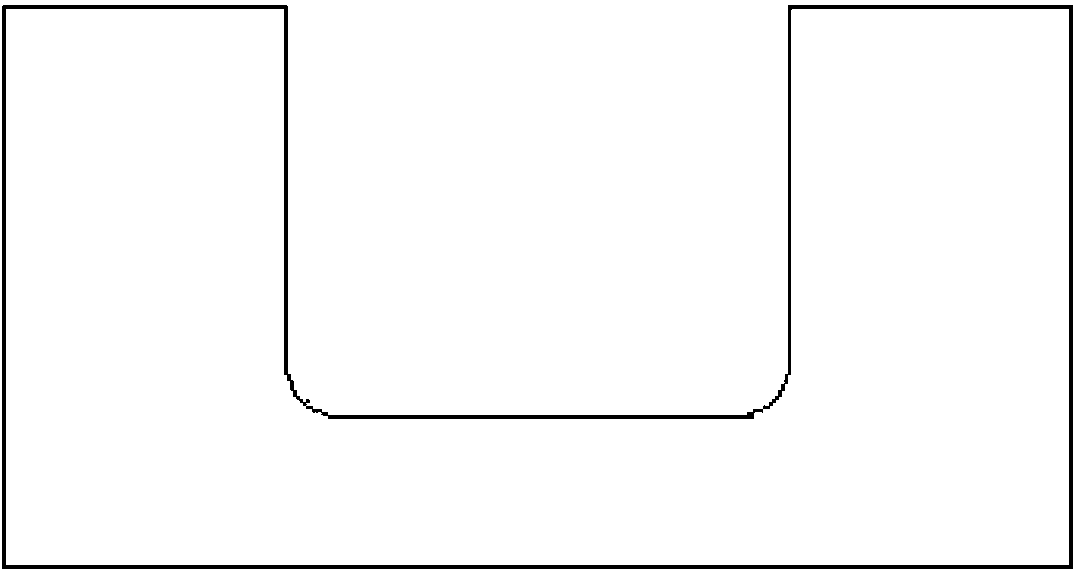

Method for manufacturing titanium alloy U-shaped material

The invention discloses a method for manufacturing a titanium alloy U-shaped material, and belongs to the field of metal processing technologies. The method includes steps of 1, manufacturing titanium alloy round rod from a blank; 2, heating and rolling the round rod by a box-type resistance furnace to obtain a square rod; 3, detecting flaws of the square rod by an ultrasonic flaw detector and polishing the surface of the square rod by a portable grinding machine; 4, rolling the square rod; 5, repairing the surface of the square rod; 6, stretching and straightening the square rod by a tension straightening machine; 7, washing the surface of the square rod by alkaline and acid; 8, detecting flaws of the square rod again by an ultrasonic flaw detector. The method has the advantages that the titanium alloy U-shaped material rolled by the method is high in precision, strength, quality and surface smoothness; requirements on all performance indexes of aviation sectional materials can be met by the rolled U-shaped material; a process for manufacturing the titanium alloy U-shaped material is simple and controllable, the yield can be increased by 35% at least, the material utilization rate can reach about 60%, the product cost can be lowered, and important conditions of batch manufacturing can be met.

Owner:沈阳和世泰通用钛业有限公司

Grinding machine

InactiveCN102935611AGrinding precisionEasy to useGrinding machinesBench grinderPulp and paper industry

A grinding machine is characterized in that on the basis of an existing grinding machine structure, vertical T type grooves are arranged on two sides of a grinding machine base, T type cap bolts are arranged in the T type grooves arranged on two sides of the base, and right angle bended plates are fixed at two sides of the bases through the T type cap bolts. By means of the technical scheme, during workpiece grinding, workpieces can be supported onto the right angle bended plates, simultaneously, in grinding workpieces with specific thicknesses, only the upper planes of the right angle bended plates are required to be adjusted to a specific distance at the downmost end of a grinding wheel, and placing the workpieces between the grinding wheel and the right angle bended plates. Therefore, the grinding machine has the advantages of being safe in use and convenient and in particular has accurate grinding on the workpieces with certain thickness.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

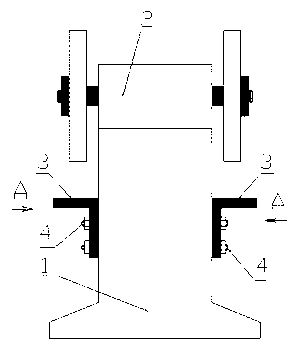

Drag plate structure of numerical control external cylindrical grinding machine

ActiveCN102794707AGuaranteed synchronicityGuaranteed positioning accuracyGrinding drivesNumerical controlGrating

The invention discloses a drag plate structure of a numerical control external cylindrical grinding machine. The drag plate structure comprises a grinding wheel machine seat, a workpiece drag plate and a repairer drag plate, wherein the grinding wheel machine seat adopts the structure of a bridge frame; supporting arms are arranged on the two sides of the bridge frame and connected with a machine body; a grinding wheel machine platform is arranged at the top of the bridge frame; the workpiece drag plate and the repairer drag plate are integrally connected by a connecting plate and mounted under the bridge frame of the grinding wheel machine seat; an arched arc surface is formed in the top of the drag plate; a through cavity is formed in the lower part of the drag plate; a linear motor and a rolling needle guide rail are arranged in the cavity; and a grating ruler is arranged on one side of the repairer drag plate and used for measuring the accurate positions of the workpiece drag plate and the repairer drag plate moving under the grinding wheel machine seat. The drag plate structure has the benefits as follows: the grinding machine seat adopts the structure of the bridge frame, so that the two upper drag plates can be integrally connected and are guaranteed to move synchronously; and the feeding action is driven by the same linear motor driver and positioned by the grating ruler, so that the feeding precision and the workpiece processing quality are improved.

Owner:浙江晟禧精密机械科技有限公司

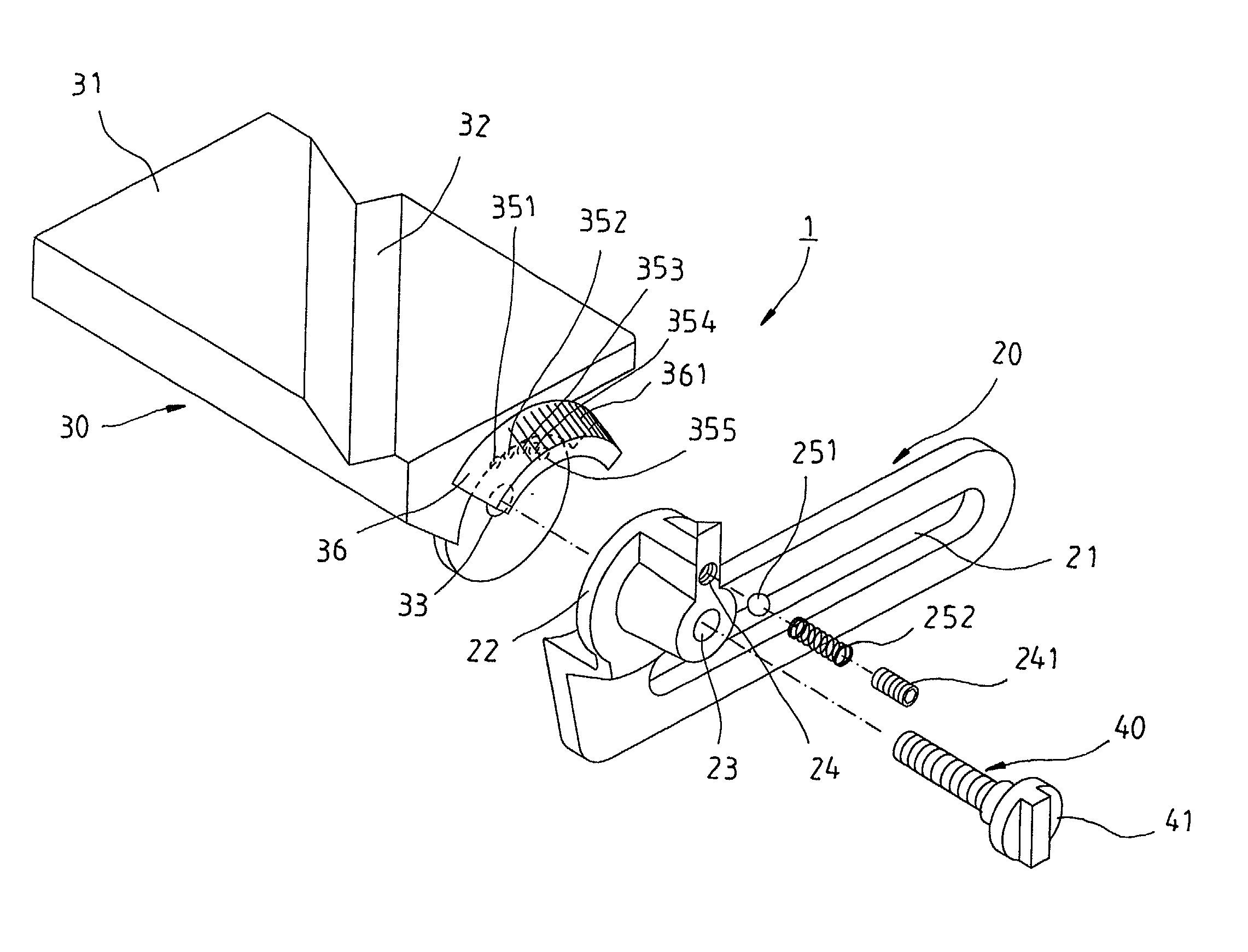

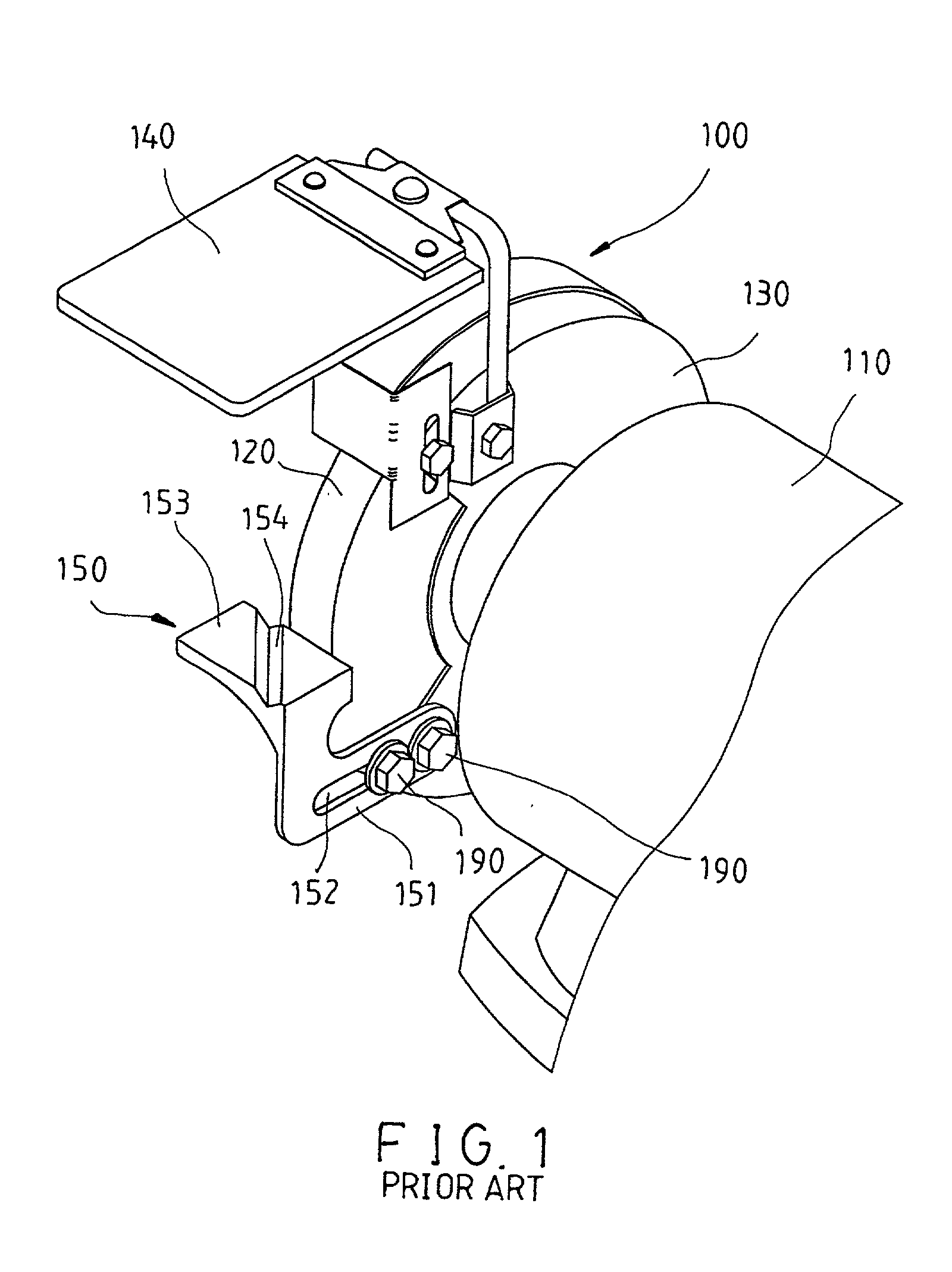

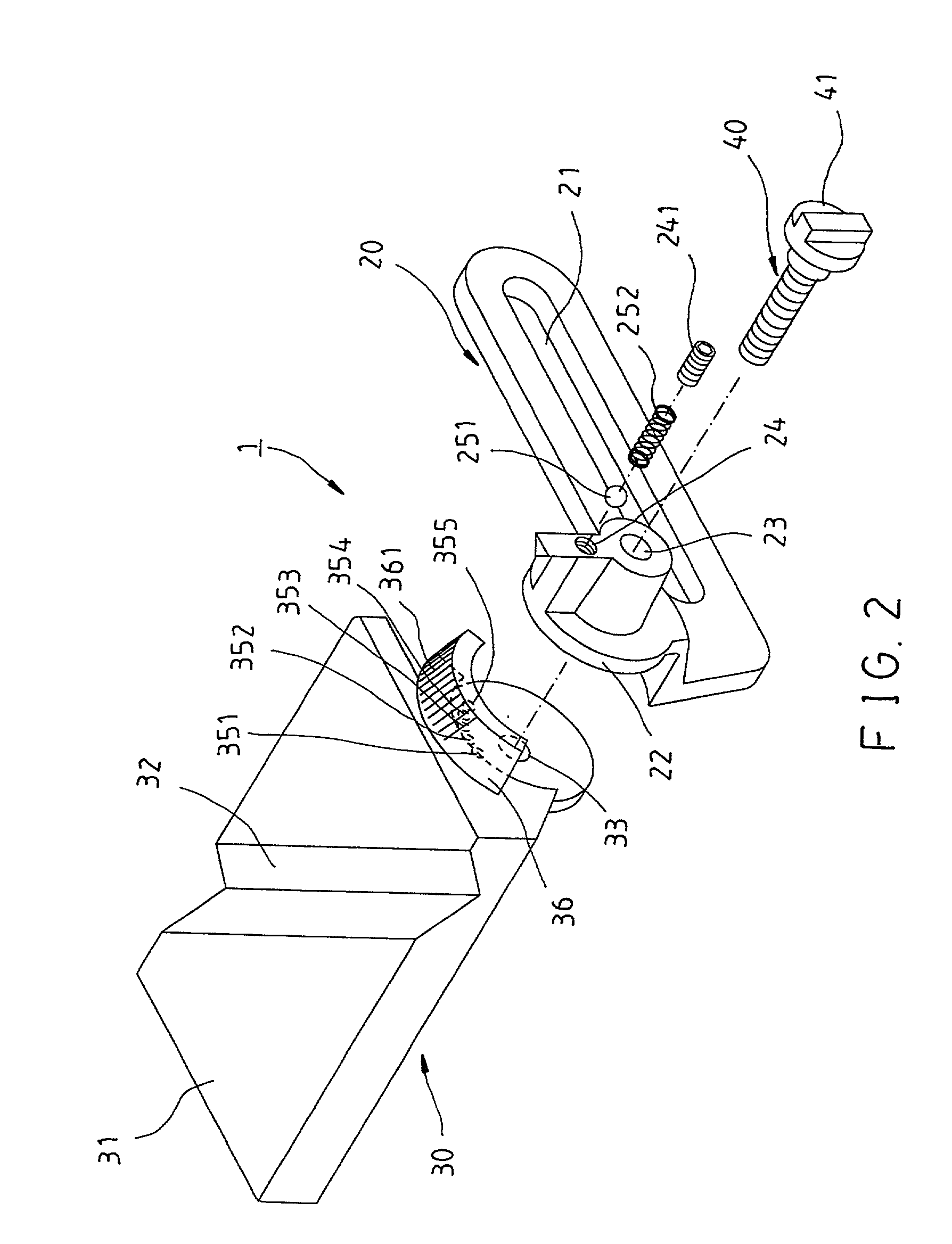

Cutting chain grinder and method of grinding

InactiveUS20050183545A1Edge grinding machinesSawing tools dressing arrangementsRotational axisBench grinder

A cutting chain bench grinder includes a self-centering vise that centers the cutting chain on an axis of rotation of the vise base. By centering the cutting chain to intersect the vise base axis of rotation, consistent top plate lengths and hook angles can be ground into left and right-hand cutters on a cutting chain. The vise base may also be adjusted horizontally in and out from the grinder base to align the vise base axis of rotation with the axis of rotation of the grinding wheel. The vise base may also be adjusted vertically relative to the vise base to vertically compensate for grinding wheel wear and to control grinding depth. A light tension spring may be used to bias the grinding head in both grinding and dressing positions. A down angle positioner may also be provided that rotates the cutting chain in the vise around a longitudinal centerline of the cutting chain.

Owner:OREGON TOOL INC

Flat curved surface grinding machine

InactiveCN112405151AEasy to polishGood sandingGrinding carriagesGrinding drivesEngineeringBench grinder

The invention discloses a flat curved surface grinding machine, and belongs to the technical field of grinding machines. The flat curved surface grinding machine comprises a platform, a moving assembly, a rotating assembly, fixed assemblies, lifting assemblies, a translation assembly, an adjusting assembly, lead screw sliding tables and a grinder, wherein the moving assembly is arranged at one endof the platform; the rotating assembly is divided into a first rotating component and a second rotating component; the first rotating component is arranged at the other end of the platform; the second rotating component is arranged at the working end of the moving assembly; the two sets of fixed assemblies are fixedly arranged at the working end of the first rotating component and the working endof the second rotating component respectively; the two lead screw sliding tables are symmetrically arranged on the two sides of the platform; the two lifting assemblies are arranged at the working ends of the two lead screw sliding tables respectively; the translation assembly is arranged at the working ends of the two lifting assemblies; the adjusting assembly is arranged at the working ends ofthe translation assembly; and the grinder is arranged at the working end of the adjusting assembly. The flat curved surface grinding machine does not need manual overturning, and is better in grindingeffect.

Owner:宣荣康

Grinding machine capable of absorbing dust

InactiveCN103846803AReduce generationProtect healthGrinding/polishing safety devicesPulp and paper industryBench grinder

The invention discloses a grinding machine capable of absorbing dust. The grinding machine comprises a machine base, grinding wheels, grinding wheel bases and a dual-shaft driving motor, wherein two grinding wheel bases and two grinding wheels are provided; the grinding wheel bases are arranged at the two ends of the upper end face of the machine base; the grinding wheels are arranged on the grinding wheel bases; the dual-shaft driving motor is arranged on the machine base between the two grinding wheel bases; the two grinding wheels are connected with output shafts at the two ends of the dual-shaft driving motor respectively; dust-collecting pipes are arranged at the lower ends of the grinding wheel bases; dust collectors are arranged in the dust collecting pipes; leading pipes are connected to the lower ends of the middle parts of the dust-collecting pipes; drawer type water ponds are arranged at the lower ends inside the grinding wheel bases; the lower ends of the leading pipes are soaked into the drawer type water ponds. During use of the grinding machine, by using the drawer type water ponds arranged at the bottom end of the machine base and the dust collectors arranged in the dust collecting pipes, dust generated during machining can be reduced effectively, and the health of operators is ensured.

Owner:杨永明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com