Grinding machine convenient to use

A grinding machine and grinding wheel technology, which is applied in the field of grinding machines, can solve problems such as time-consuming and labor-intensive, sparks splashing from grinding debris, and flying out of tools when the tool is not gripped tightly, so as to save labor in the adjustment process, improve grinding accuracy, and reduce personnel injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

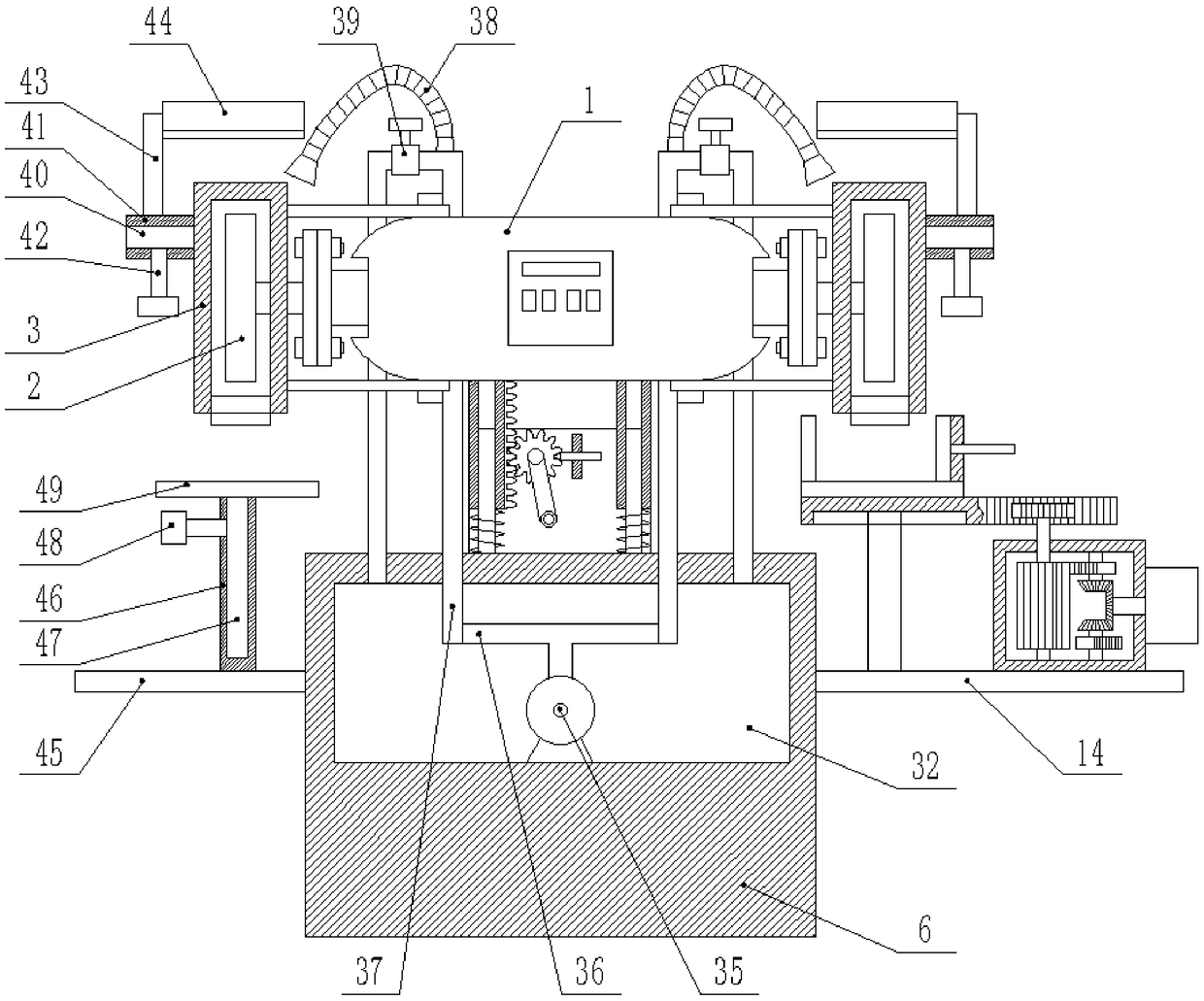

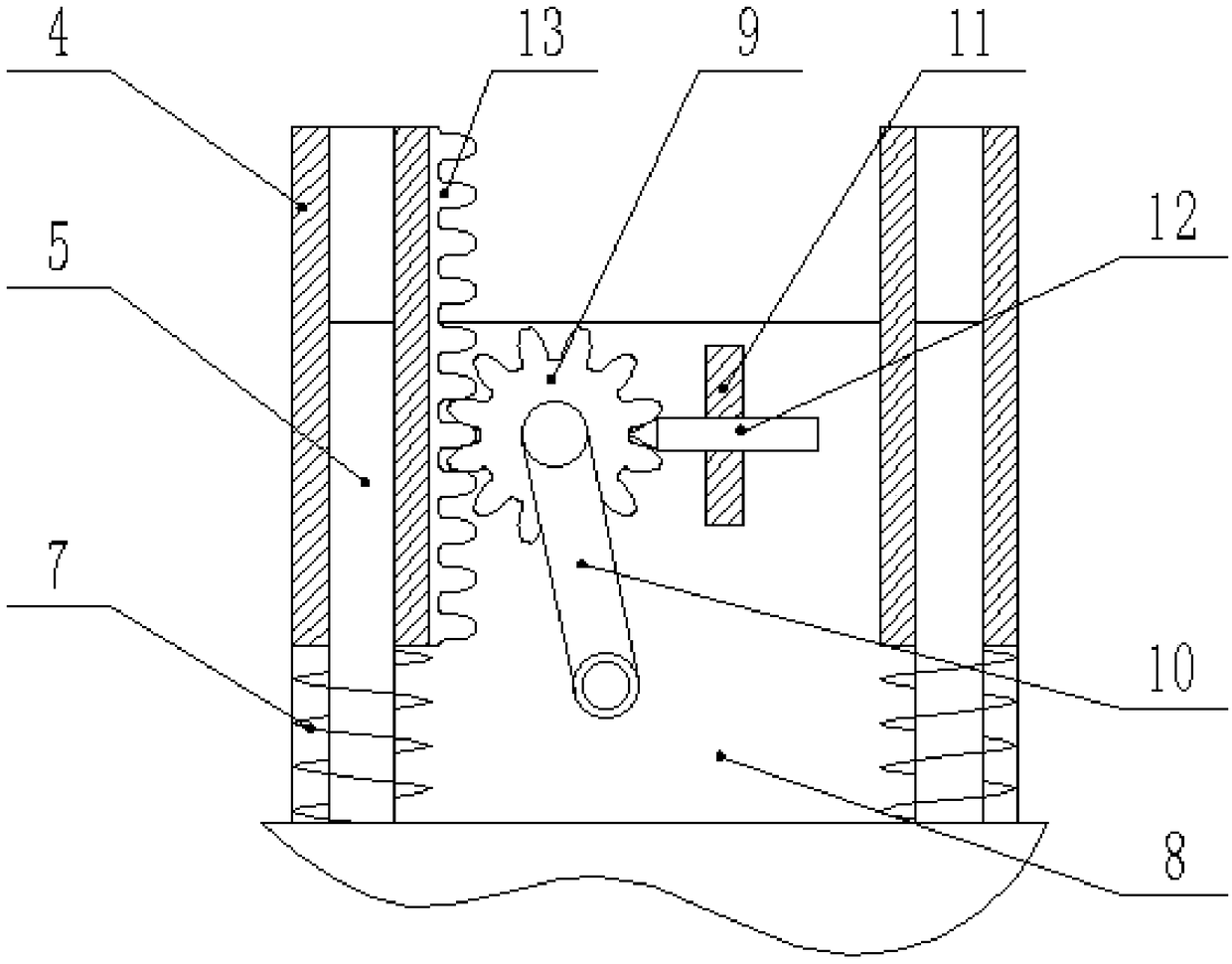

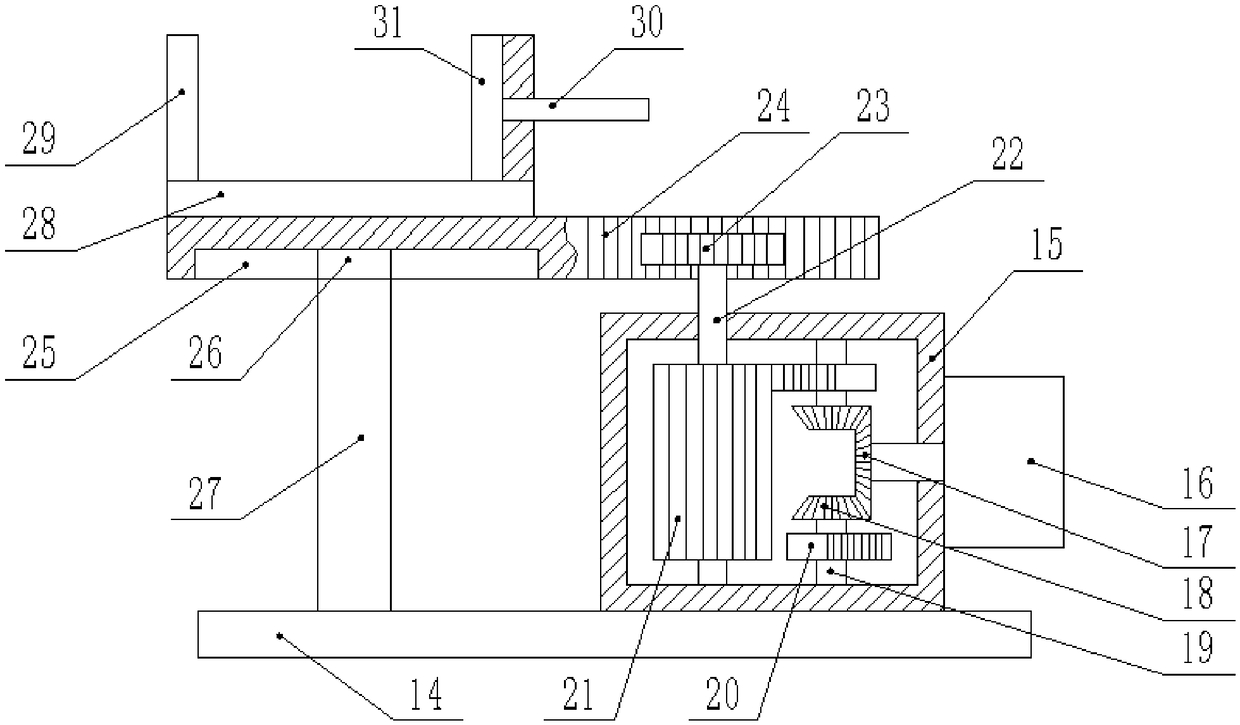

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an easy-to-use grinder includes a grinder body 1, a grinding wheel 2 is installed at both ends of the grinder body 1, and a guard 3 fixed to the grinder body 1 is provided on the outside of the grinder 2. The first sleeve 4 is fixed on both sides of the lower end of the grinder body 1, and a vertical rod 5 is inserted into the lower end of the first sleeve 4, and a cabinet body 6 is fixed at the lower end of the vertical rod 5, and the first sleeve 4 and the cabinet Between the body 6 there is a damping spring 7 set on the vertical rod 5, between the two vertical rods 5 there is a vertical plate 8 fixed to the cabinet body 6, the front of the vertical plate 8 is rotatably connected to the first gear 9. The front of the first gear 9 is fixed with a hand wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com