Automobile outer plate processing technic method

A processing technology, automobile technology, applied in the field of automobile outer panel processing technology, can solve the problems of springback, stamping cracking, and surface inequality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

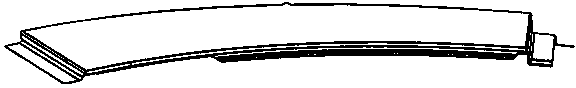

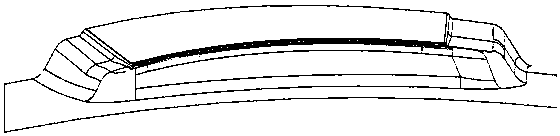

[0028] Aiming at the contradictory situation of eliminating the drawing cracking and insufficient thinning of the outer panel for the automobile roof, such as Figure 4 As shown, the present invention processes the process supplementary surface of the top cover, and it can be seen that the angle between the slope of the process surface and the binder surface is much smaller, and the binder surface is also different.

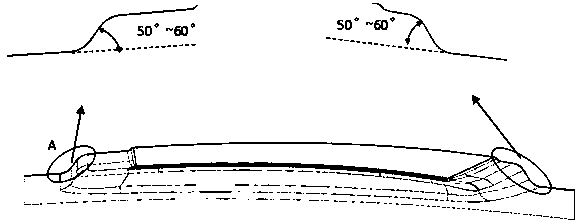

[0029] According to the situation in the drawing process in the past, the method of reducing the angle of the inclined plane is adopted. This method greatly improves the cracking phenomenon of the inclined plane and meets the qualified requirements. and for image 3 In the middle A area, the thinning rate of this area is less than 4%. For this case, the prior art adopts to increase the local drawbead coefficient in this area. However, due to the characteristics of the material itself, if only increasing the drawbead coefficient here can not meet the thinning ra...

Embodiment 2

[0033] Aiming at the defects of springback in the molding process of the outer panel of the automobile hood, such as Figure 7 As shown, the circled part of the windshield protrudes upwards and rebounds, and the rebound exceeds 4mm. In the face of such a shape of rebound, use a wave-shaped flanging knife block to improve it.

[0034] Such as Figure 8 As shown in the figure, the wavy cutter block is used for flanging the outer panel of the machine cover, and the middle of the cutter block contacts the sheet material 20mm earlier than the two ends, so that the material in the middle is deformed first, and the deformation of the middle material is more sufficient due to the large contact of the cutter block , using such a shape of the flanging knife block for the flanging process can effectively reduce the springback at the windshield.

[0035] Further, when the wave flanging knife is still not enough to make the rebound at this place meet the requirements, the following techn...

Embodiment 3

[0039] Aiming at the defect that the outer surface of the outer panel of the automobile hood is easily corrugated after flanging, by comparing the state of the defect in the whole process, it can be known that the corrugation is generated in the flanging process, and the direct cause of the defect is that when the flanging The internal stress of the material is unstable and the change is uneven.

[0040] For corrugation due to material instability, the pressure and gap of the pressing core during the flanging process are changed. Partially reduce the gap of the pressing core near the flanging by 0.1-0.2 times the material thickness, so that the corrugated area may be in a local strong pressure state, increase the material thickness pressure and reduce its fluctuation.

[0041] For the instability of the outer surface to produce ripples, uneven changes are formed on the outer surface due to the stress and strain generated by the change of the flanging material. Reduce the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com