A kind of automatic piston ring trimming machine

A technology of trimming machine and piston ring, which is applied in the direction of grinding machine parts, grinding heads, grinding machines, etc., can solve the problems of piston ring wear, poor accuracy, unstable operation, etc., so as to reduce the time for changing tooling and reduce the use of Cost and structure are stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

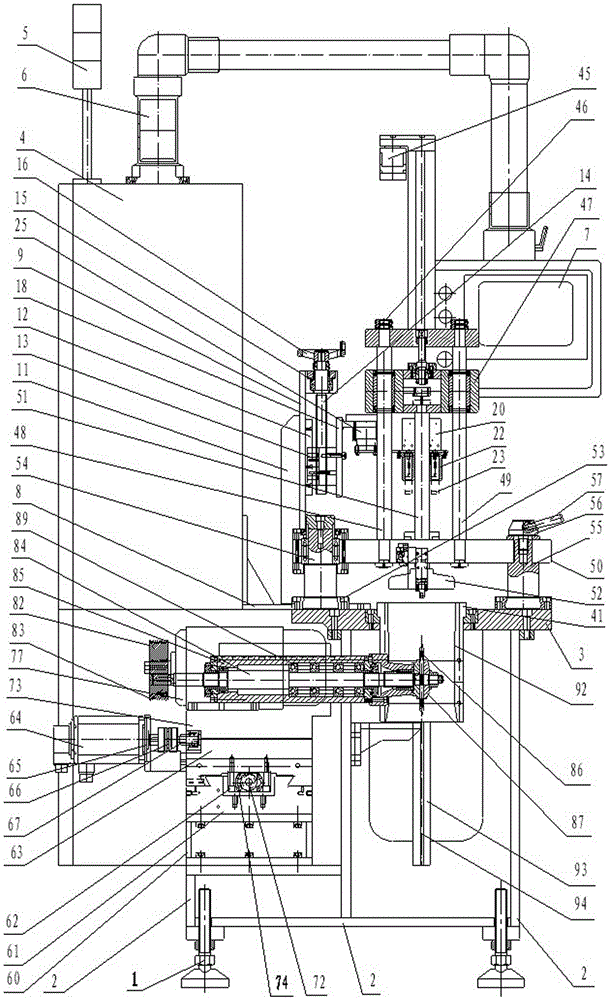

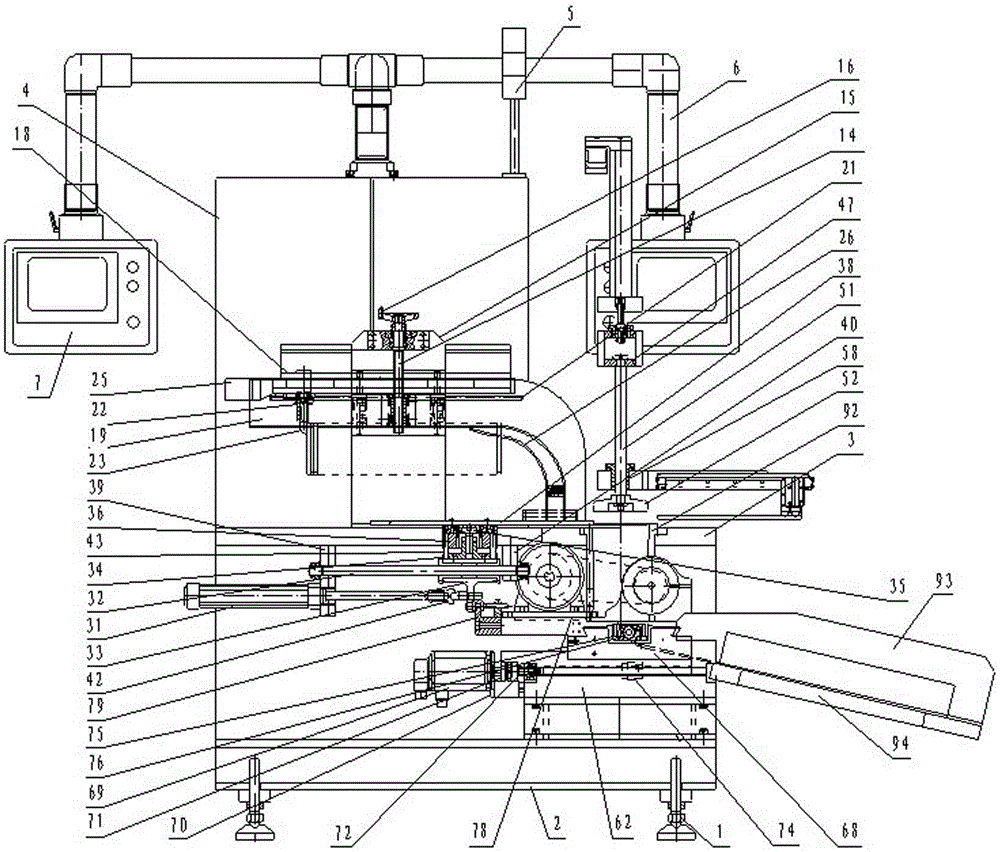

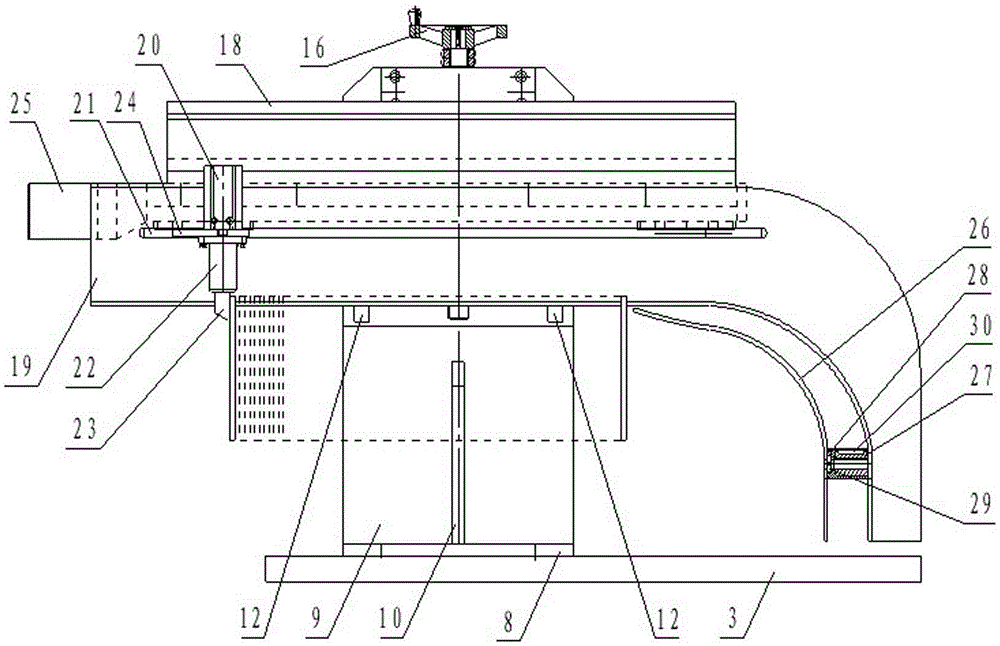

[0023] A kind of automatic piston ring trimming machine of the present invention will be described in further detail below in conjunction with accompanying drawing.

[0024] Depend on figure 1 , figure 2 It can be seen that a kind of automatic piston ring trimming machine of the present embodiment comprises trimming machine adjusting bed foot 1, body 2, machine tool platen 3 fixed on the body 2 and machine tool electrical control device, the machine tool electrical control device is composed of electronically controlled Cabinet 4, the machine tool three-color alarm light 5 installed on the electric control cabinet 4, the machine tool electrical operation cabinet turret 6 and the machine tool electrical control operation cabinet 7, the machine tool electrical operation cabinet turret 6 is installed on the body 2, the electric control cabinet 4 and the machine tool electrical control operation cabinet 7 are respectively installed on the machine tool electrical operation cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com