Patents

Literature

357results about How to "Not easy to bend and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

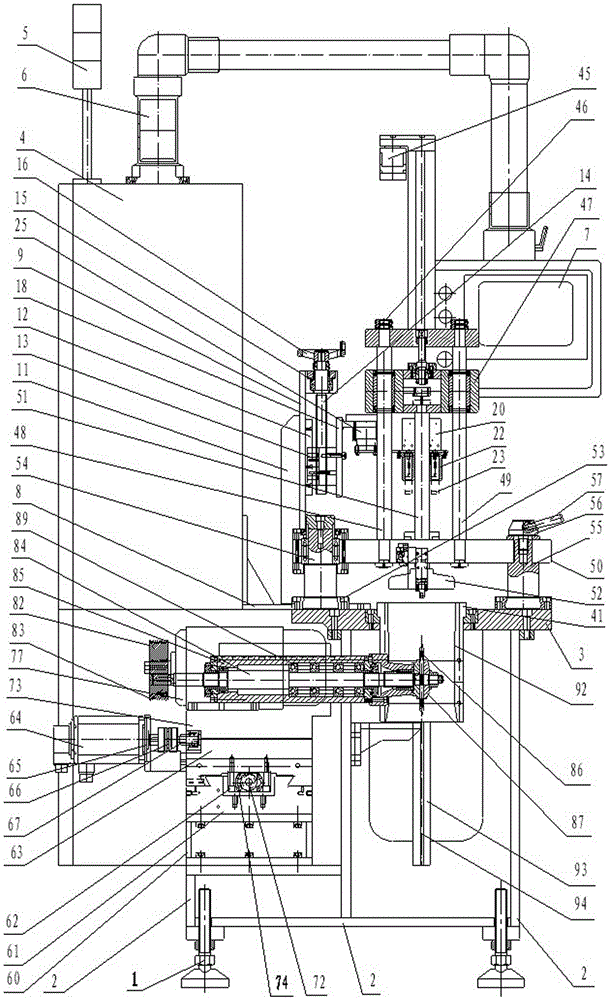

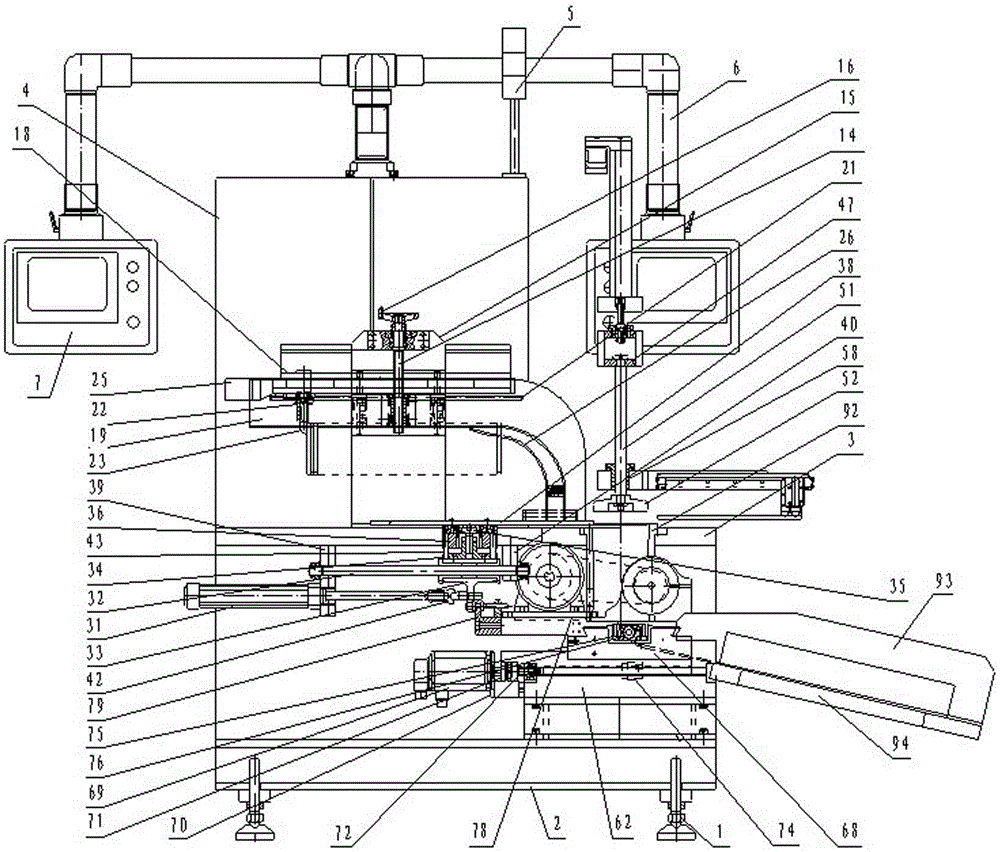

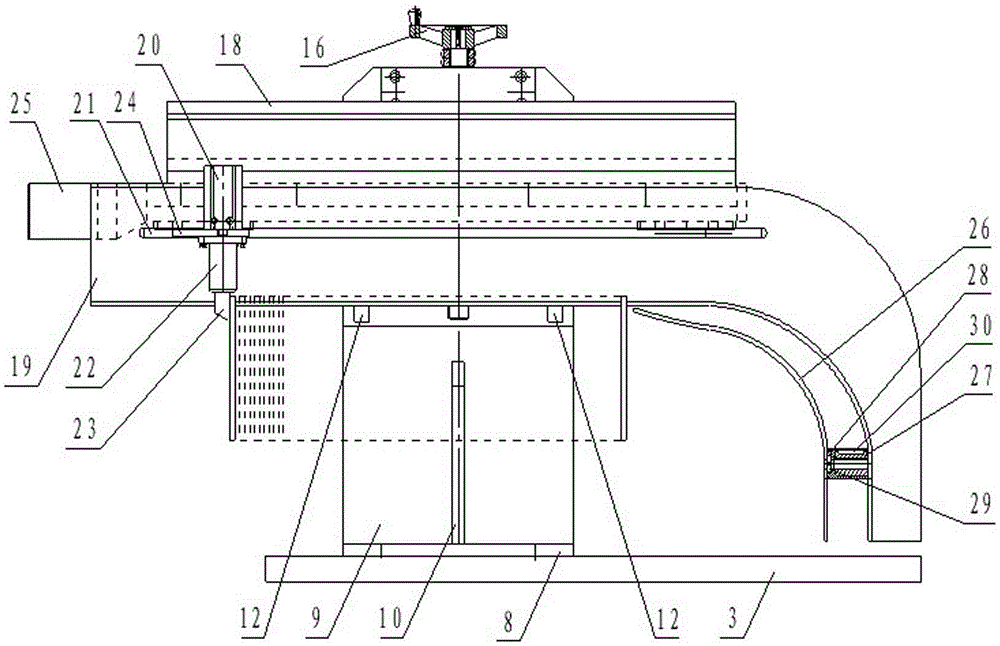

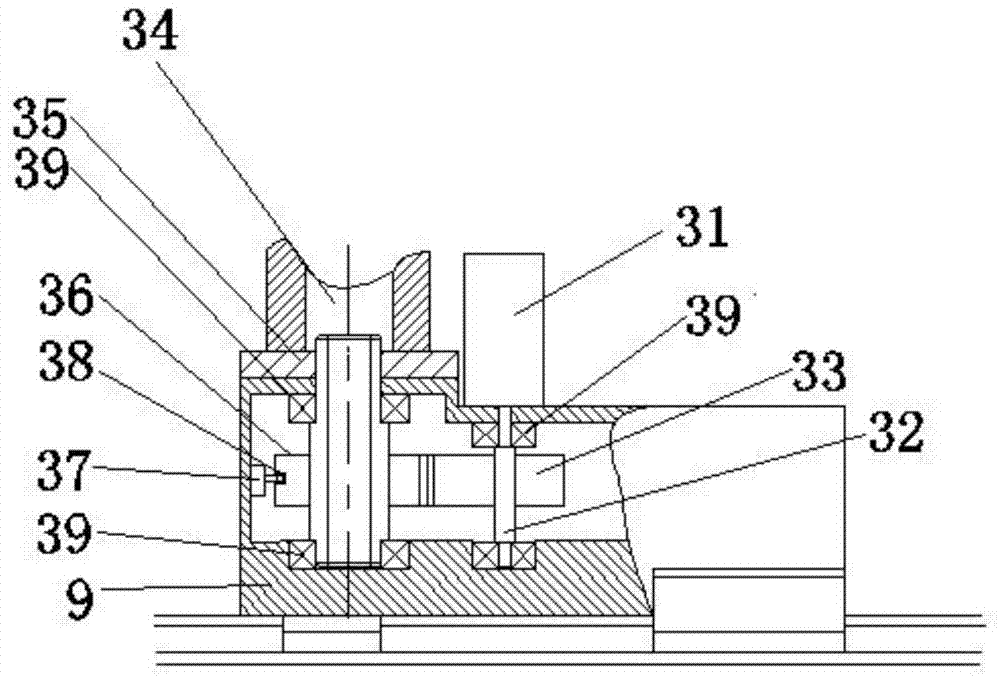

A kind of automatic piston ring trimming machine

ActiveCN103753374BImprove machining accuracyMeet the process requirementsGrinding machinesGrinding headsNumerical controlPiston ring

Owner:NANTONG JUNQI MACHINERY

Method for quickly preparing large-size single-crystal graphene

ActiveCN104389016ASpread flatEasy to manufacturePolycrystalline material growthFrom chemically reactive gasesLiquid copperWater vapor

The invention relates to a method for quickly preparing large-size single-crystal graphene on a liquid copper substrate by a chemical vapor deposition process. The method comprises the following steps: in a hydrogen and inert gas atmosphere, introducing vapor and a carbon source, growing large-size single-crystal graphene by using catalytic cracking of the carbon source on the liquid copper substrate surface, and cooling to room temperature in an inert gas atmosphere to obtain the large-size single-crystal graphene. Compared with the traditional solid metal substrate, the liquid copper substrate used in the method has the advantages of high growth speed, uniform nucleation and the like and can be recycled in the aspect of graphene preparation. The carbon source and water content are regulated to implement the controllable graphene size, thereby obtaining the centimeter-sized single-crystal graphene. The prepared graphene is applicable to preparing field-effect transistor devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI

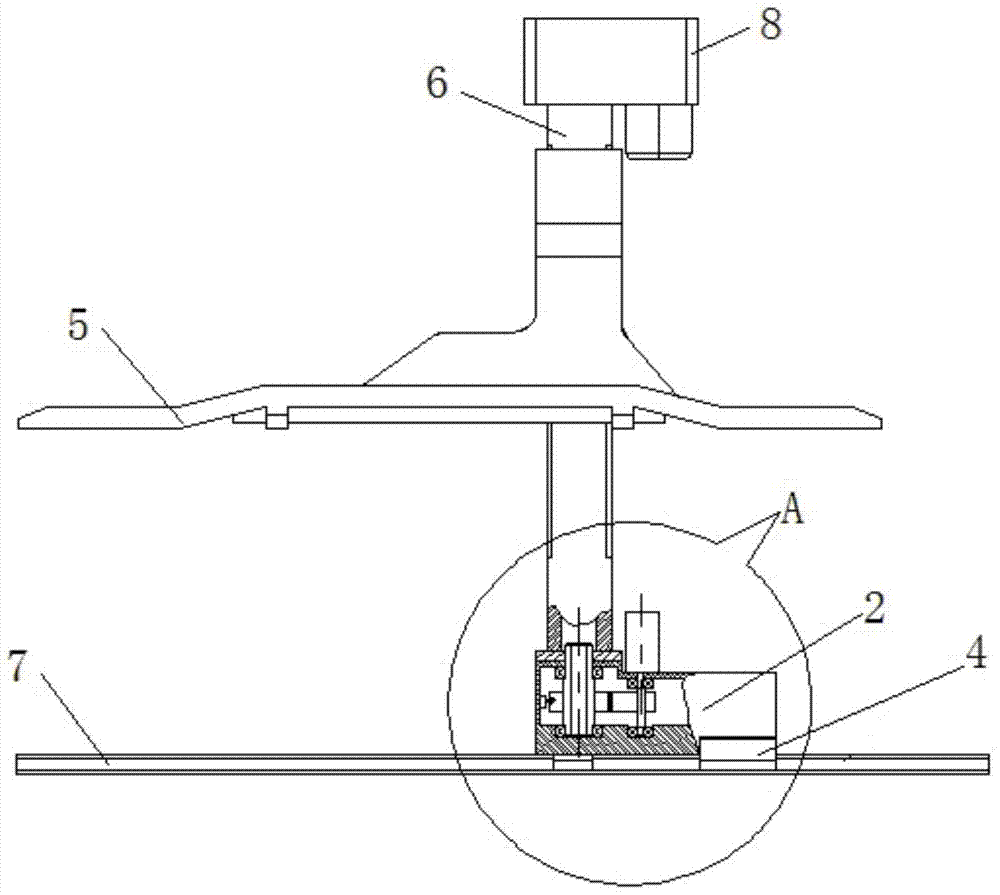

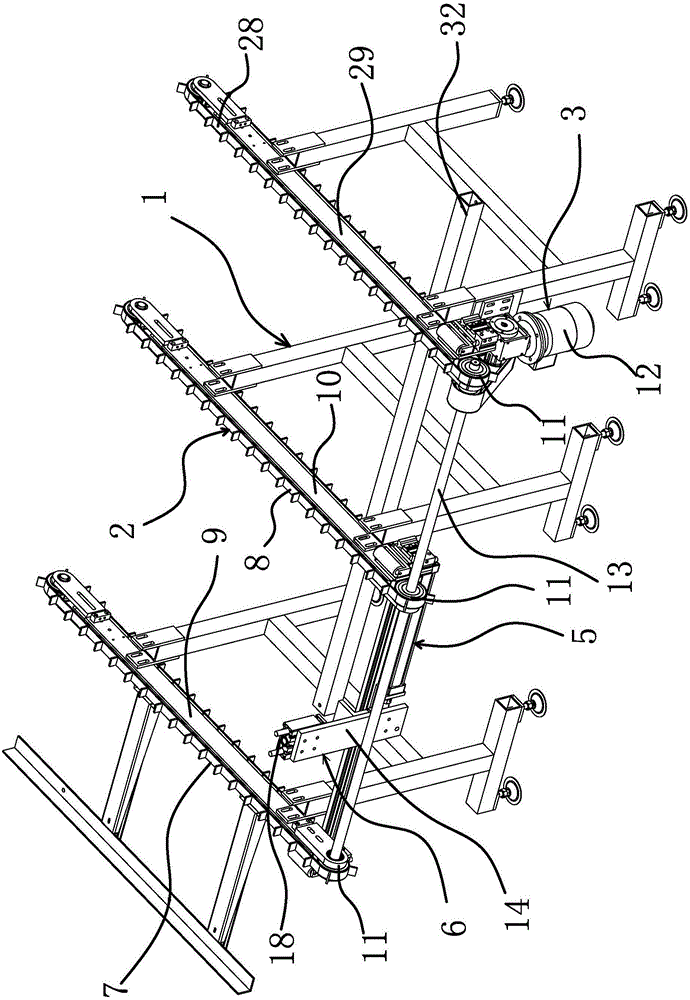

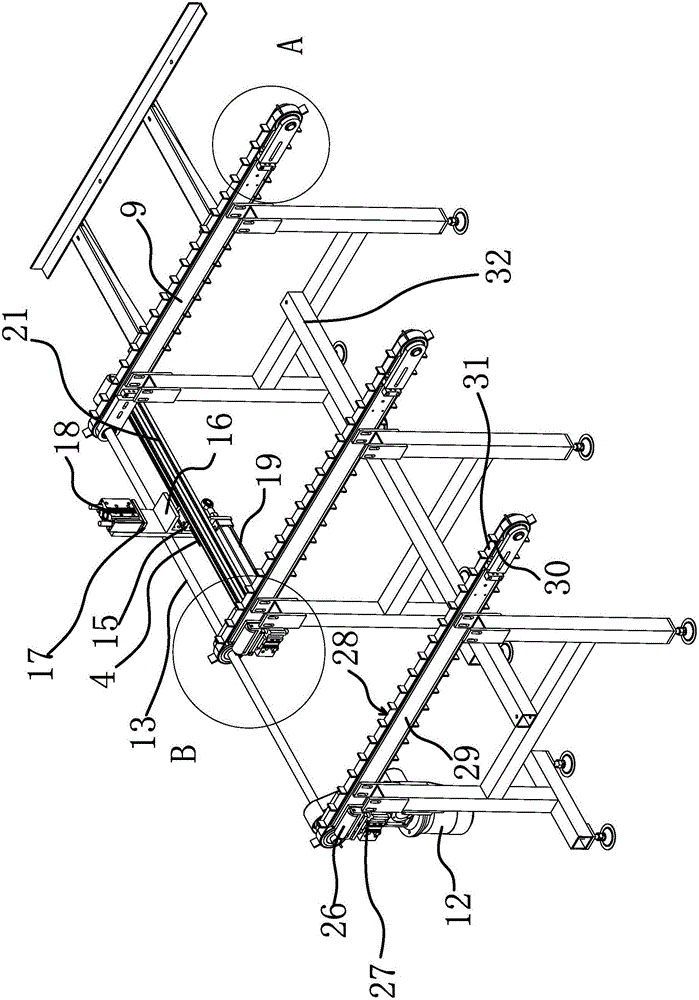

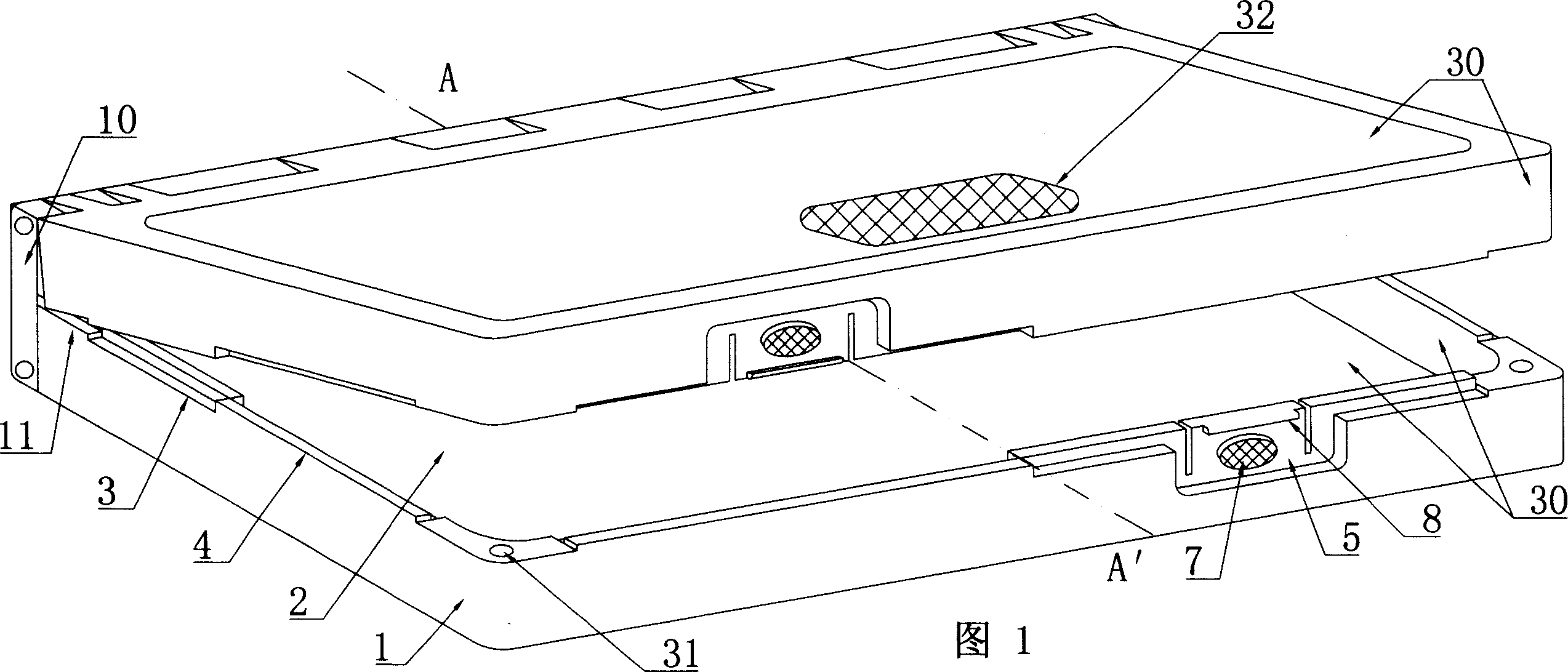

Avoidance needless type stereoscopic garage

InactiveCN103572996ASimple controlSimple transmission structureParkingsElectric machineryControl mode

The invention discloses an avoidance needless type stereoscopic garage. The avoidance needless type stereoscopic garage comprises an upright post, a vehicle carrying board, a track, a lifting device, a rotating device, a moving device and an anti-falling device, wherein the vehicle carrying board is mounted on the upright post and can be controlled by the lifting device to move up and down along the upright post; the upright post is mounted on the rotating device which can drive the upright post to rotate, and the rotating device is mounted on the moving device, a driving wheel and a guide wheel of the moving device are mounted on the track and drive the rotating device to move along the track horizontally; the anti-falling device is further arranged on the upright post; the lifting device adopts chain transmission for transmission, so that the transmission is stable; the rotating device adopts an incomplete gear mechanism for transmission, so that the installation space of the avoidance needless type stereoscopic garage is saved; and the anti-falling device adopts an anti-falling baffle which is arranged in a transverse sliding chute of the upright post, and the anti-falling safety performance is good. The avoidance needless type stereoscopic garage adopts three motors for independent control, the control mode is simple, further, the structure is simple, and maintenance and repairing are facilitated.

Owner:GUANGXI UNIV

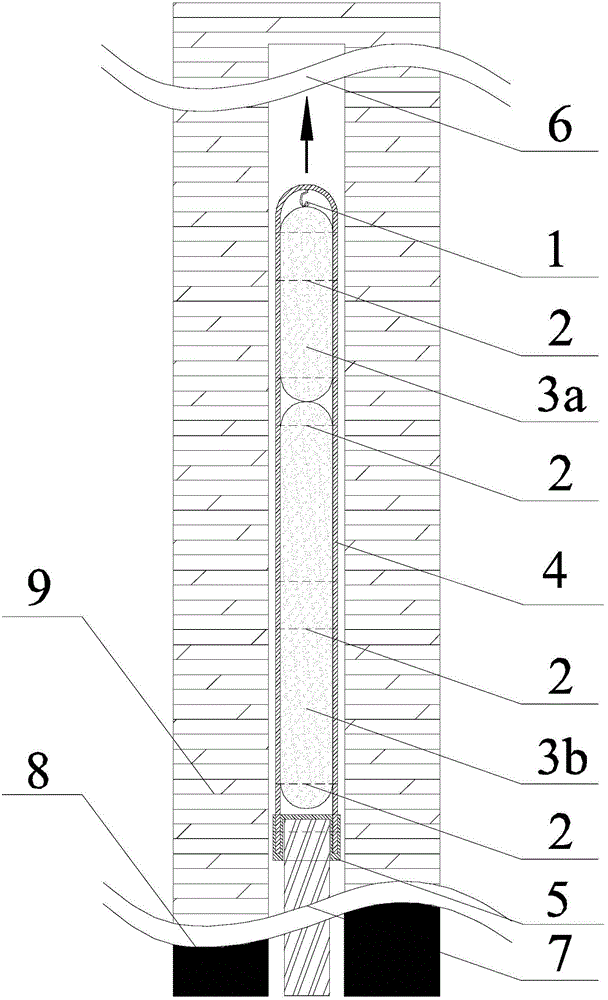

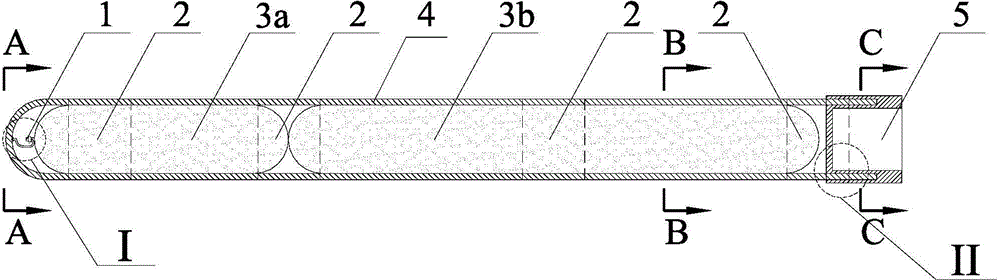

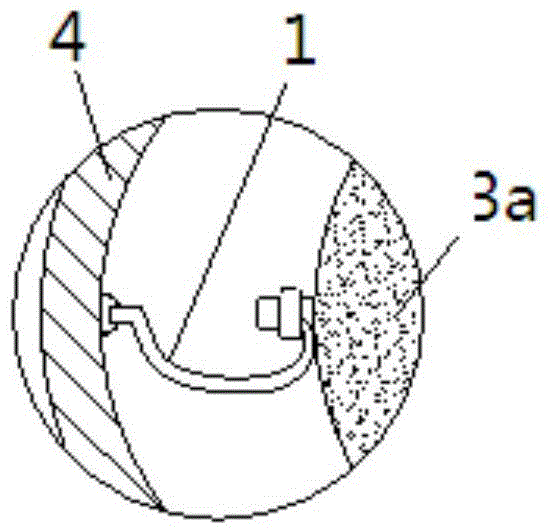

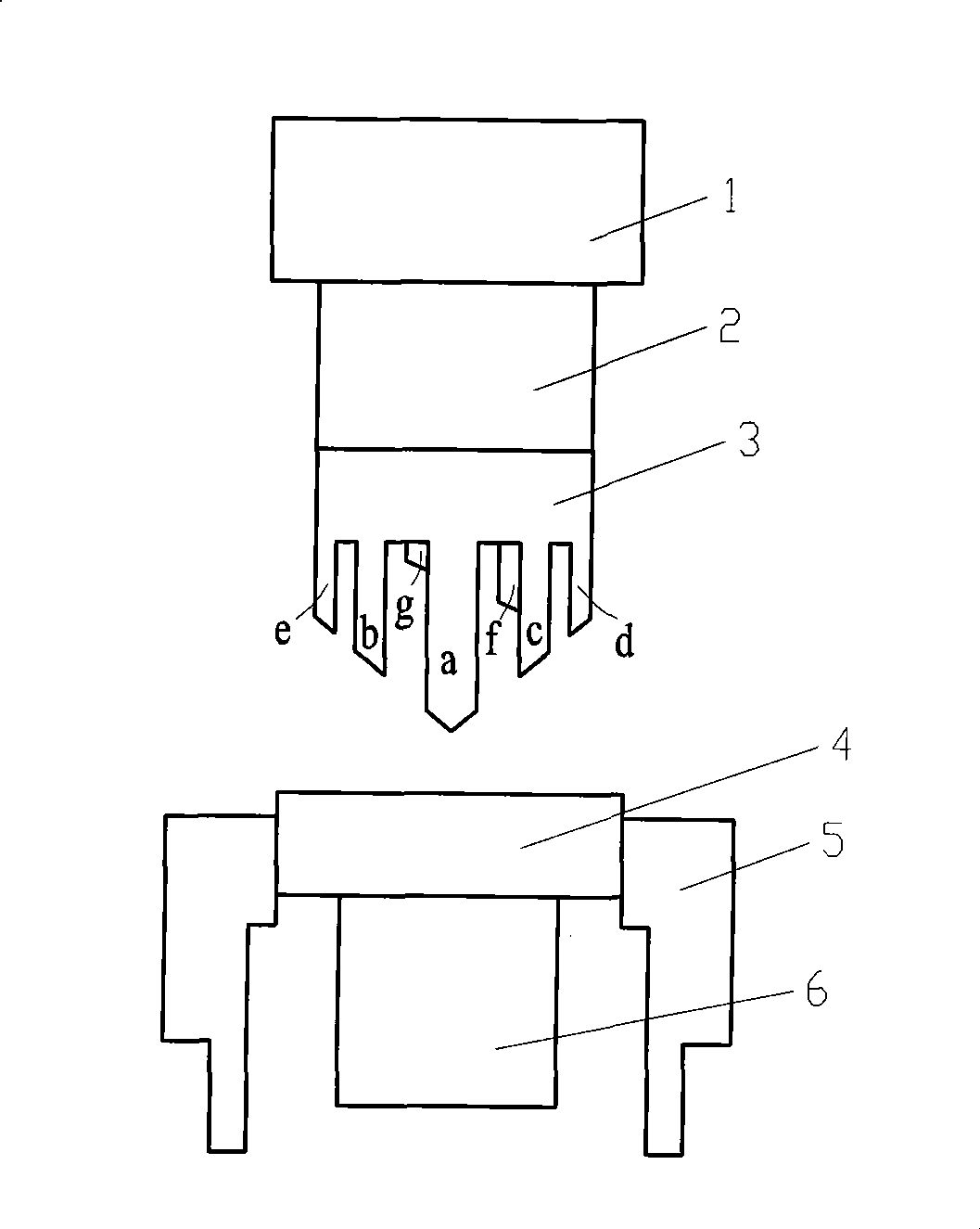

Integral push-lead type device and method for installation of tunnel anchor cable anchoring agent

ActiveCN104695990AAvoid multiple pushesReduce labor intensityAnchoring boltsHigh probabilityUltimate tensile strength

The invention discloses an integral push-lead type method for the installation of a tunnel anchor cable anchoring agent. The method comprises the following steps: connecting multiple anchoring agent cartridges filled with the anchoring agent integrally; installing the integrally connected anchoring agent cartridges in a push-lead mechanism; propping an anchor cable against a base plate at the rear end of the push-lead mechanism, and then inserting the push-lead mechanism equipped with the anchoring agent cartridges into a drilled hole formed in rock or coal; pushing the anchor cable toward a drilling direction, so that the push-lead mechanism reaches the top of the drilled hole, using a roof bolter for continuing to push and stir the anchor cable correspondingly, so that the multiple anchoring agent cartridges in the push-lead mechanism are broken, and the anchor cable is anchored in the stable rock or coal by using the anchoring agent. In addition, the invention further provides a device for the method; the device has the advantages of simple structure and good stability, and can effectively solve the problems of multiple-time installation of the anchoring agent cartridges, high probability of blockage of drilled holes, complicated installation process, long support time, high labor intensity of workers and other difficulties restricting the development of the tunnel support technology in the installation process of the existing anchoring agent cartridges.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

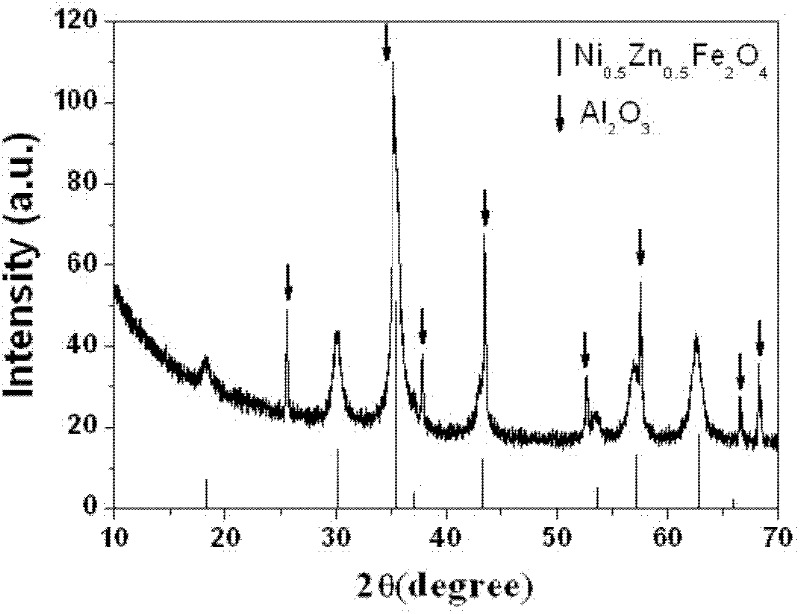

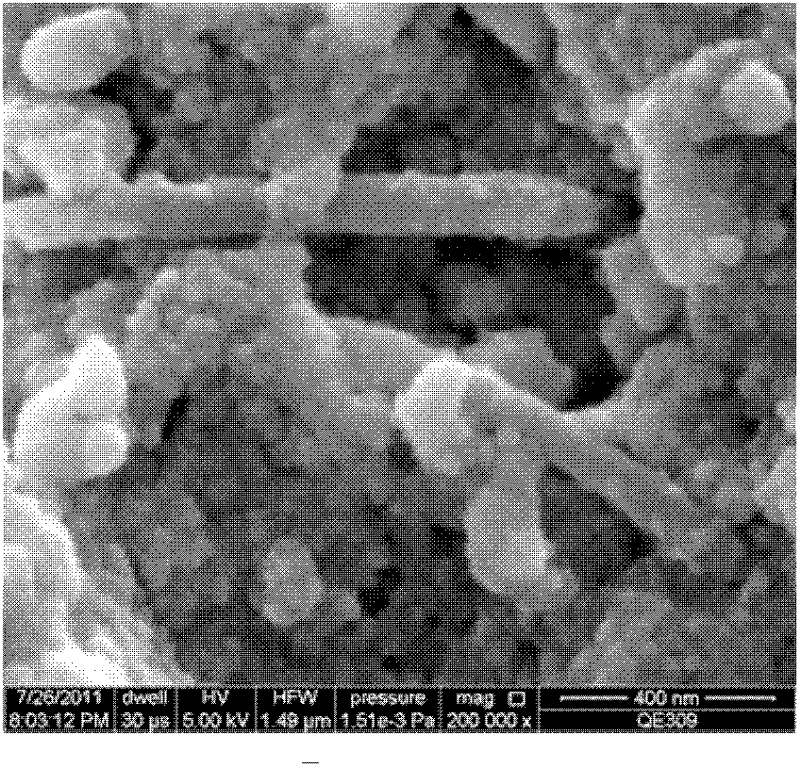

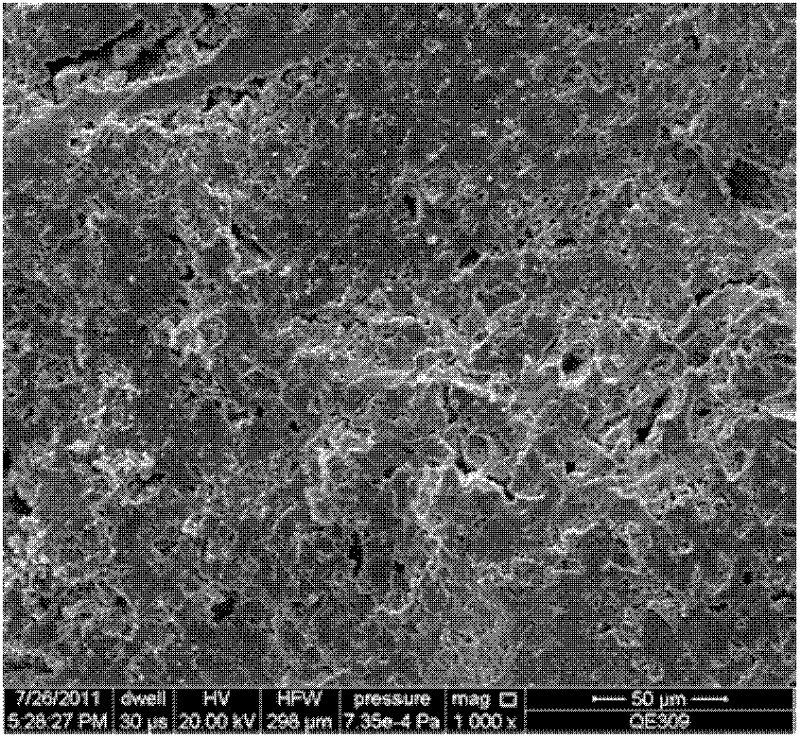

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

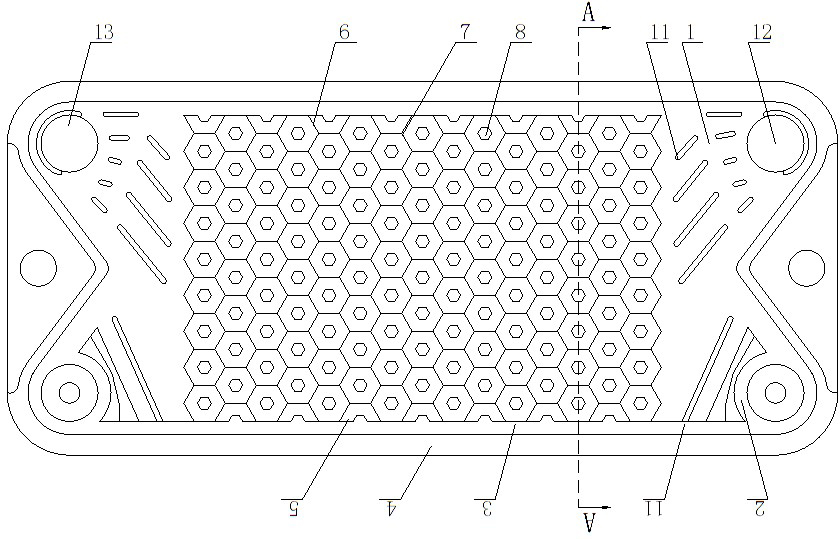

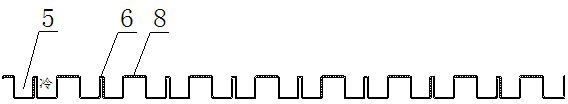

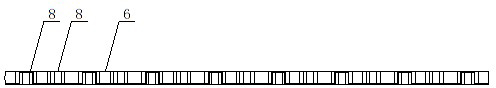

Bionic honeycomb-type plate sheet for plate-type heat exchanger

InactiveCN102435086AEfficient heat exchangeImprove heat exchange efficiencyLaminated elementsConvex structureHoneycomb

The invention discloses a bionic honeycomb-type plate sheet for a plate-type heat exchanger, comprising a flow guiding region, a sealing region, a honeycomb region and a frame, wherein the honeycomb region is composed of a plurality of peripheral regular hexagons which are sequentially connected with each other in longitudinal and transverse directions, so as to form a honeycomb shape; a plurality of peripheral regular hexagons are uniformly and densely distributed on the bionic honeycomb-type plate sheet; a central regular hexagon is arranged at the center of each peripheral regular hexagon and the central regular hexagon is in a protruding structure; a connecting part between two peripheral regular hexagons is in a protruding structure and a ripple-like structure is formed by connection of connecting parts among the plurality of the peripheral regular hexagons; and a flow channel is formed by the peripheral regular hexagons between each protruding central regular hexagon and the ripple-like structure. According to the invention, the fluid is interfered by the flow channel and concave-convex structures of the central regular hexagons and the ripple-like structure in the process of flowing in a hollow cavity, and the heat-exchanging efficiency is improved; and the dense honeycombs such a plurality of I beams, which are mutually limited, can dispersedly bear pressure from a panel, so as to increase the use condition and range of the plate sheet.

Owner:广州汇迪新能源科技有限公司

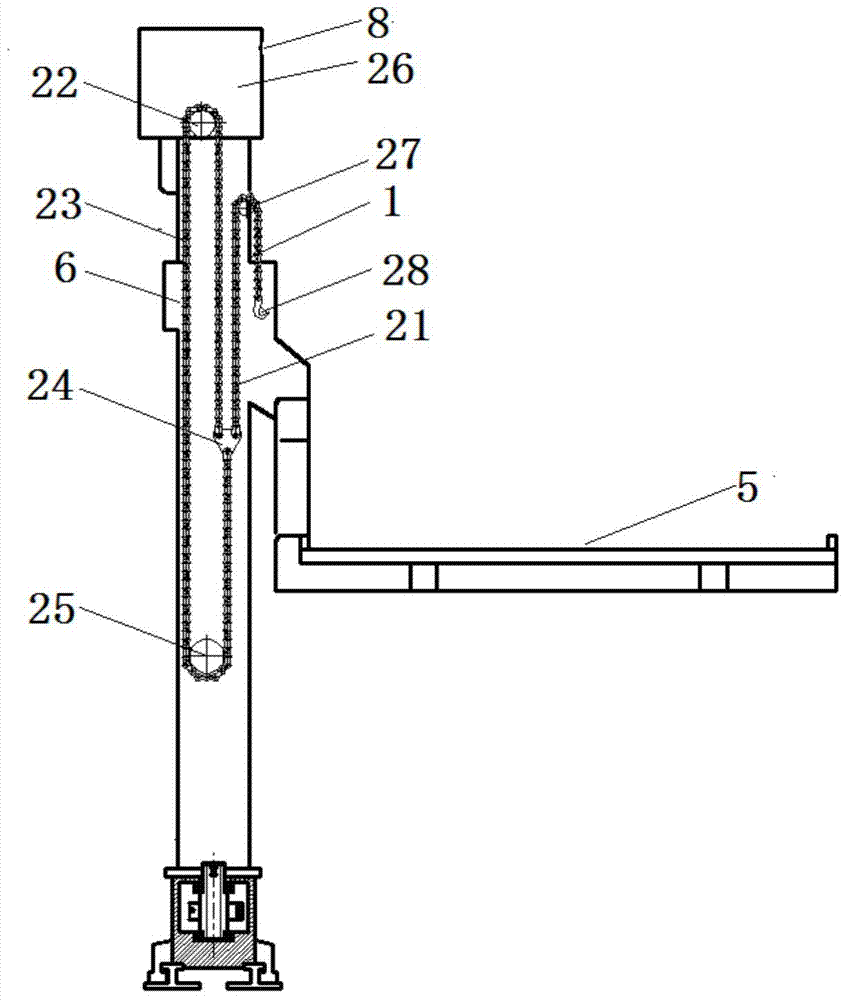

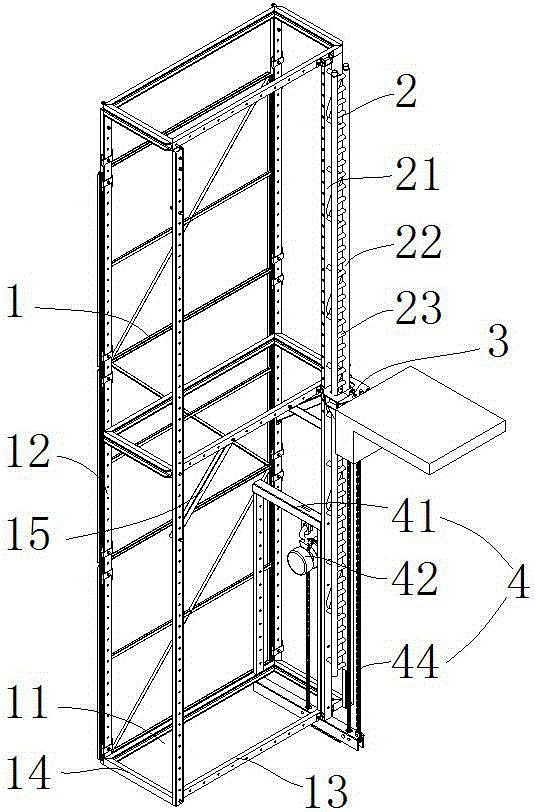

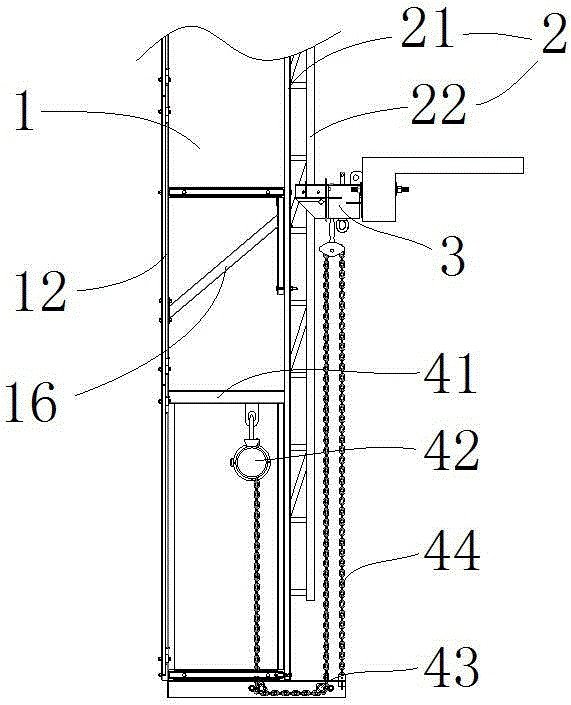

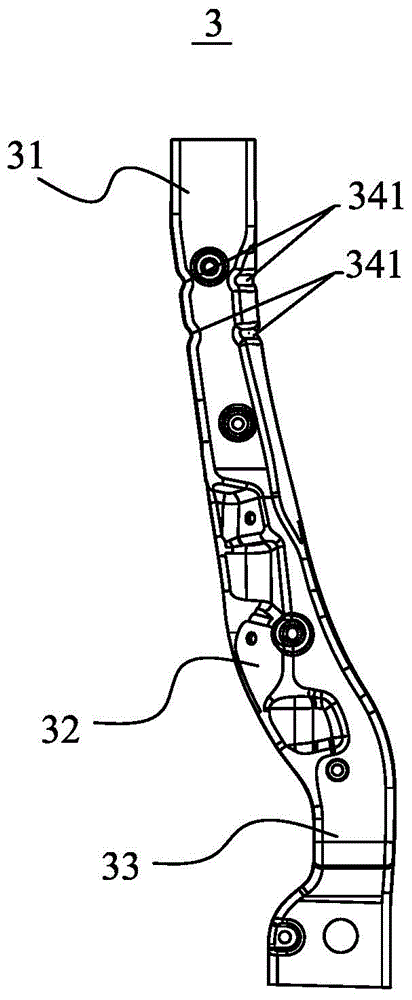

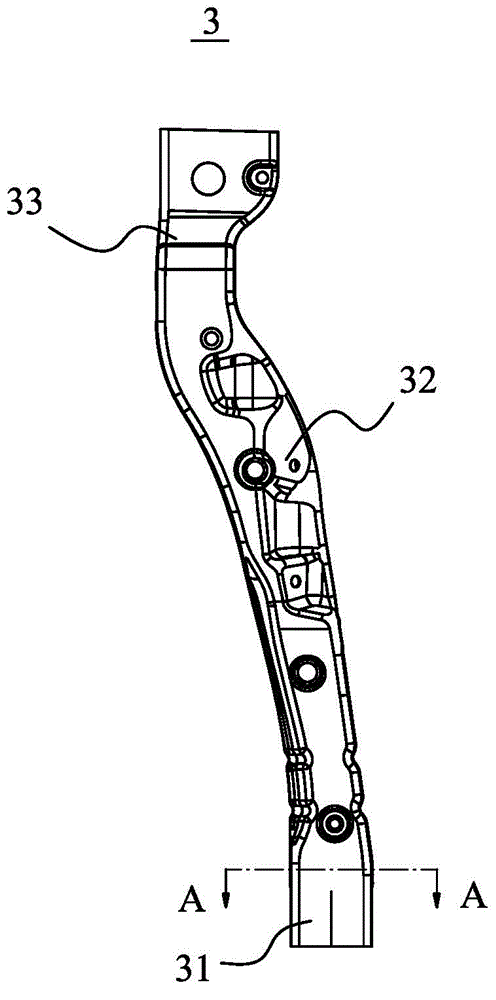

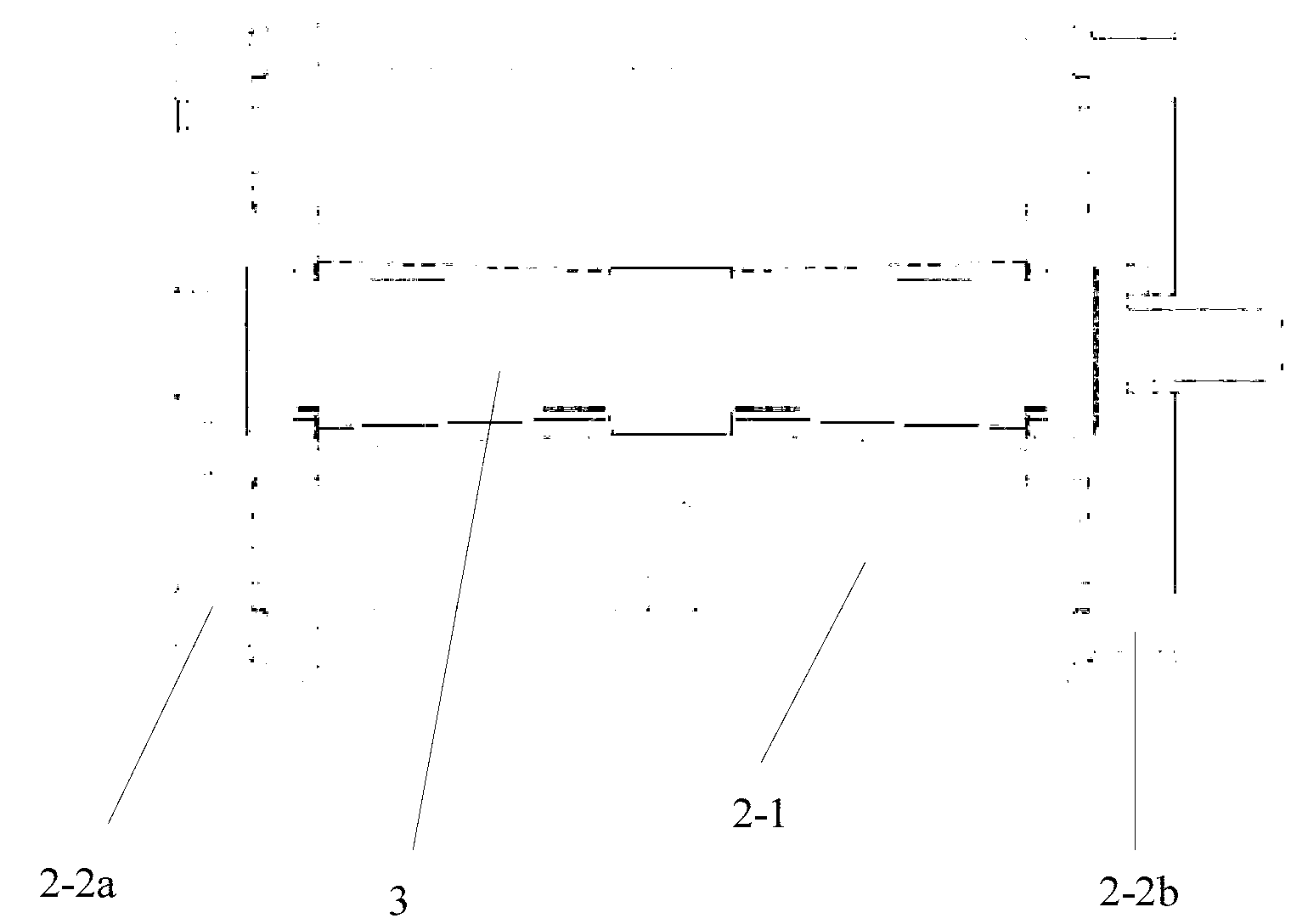

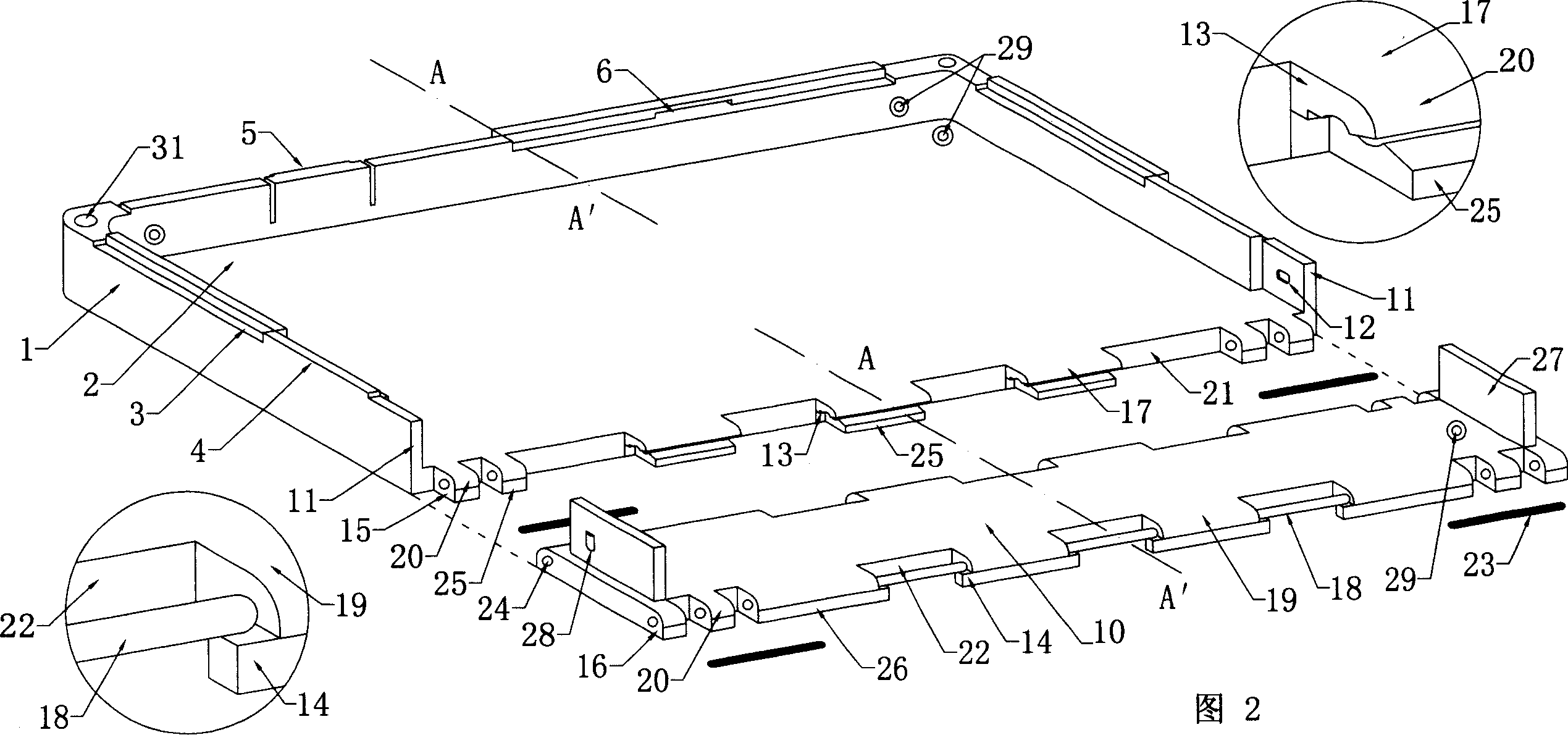

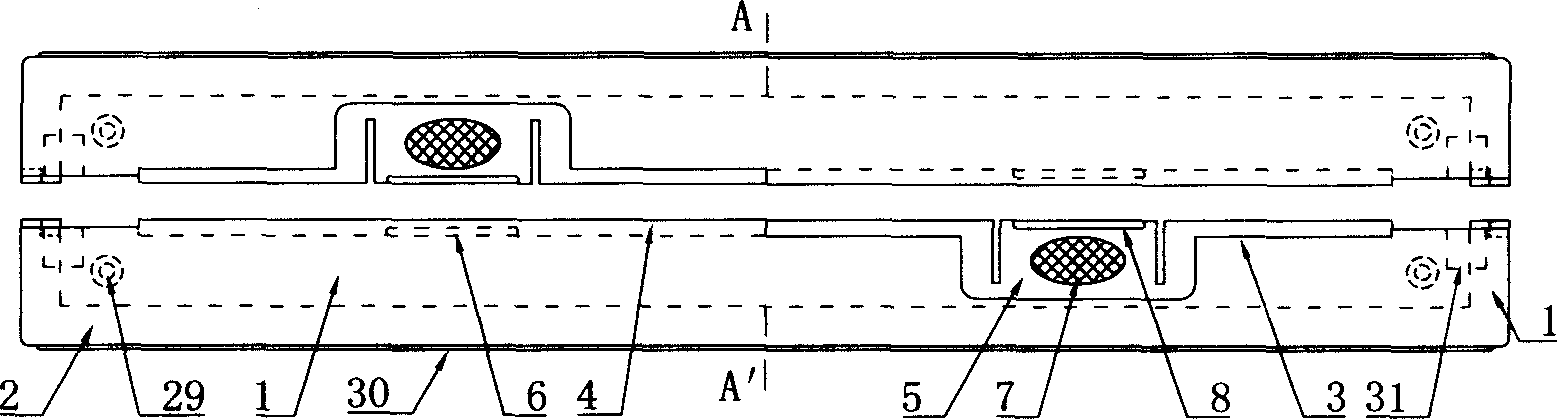

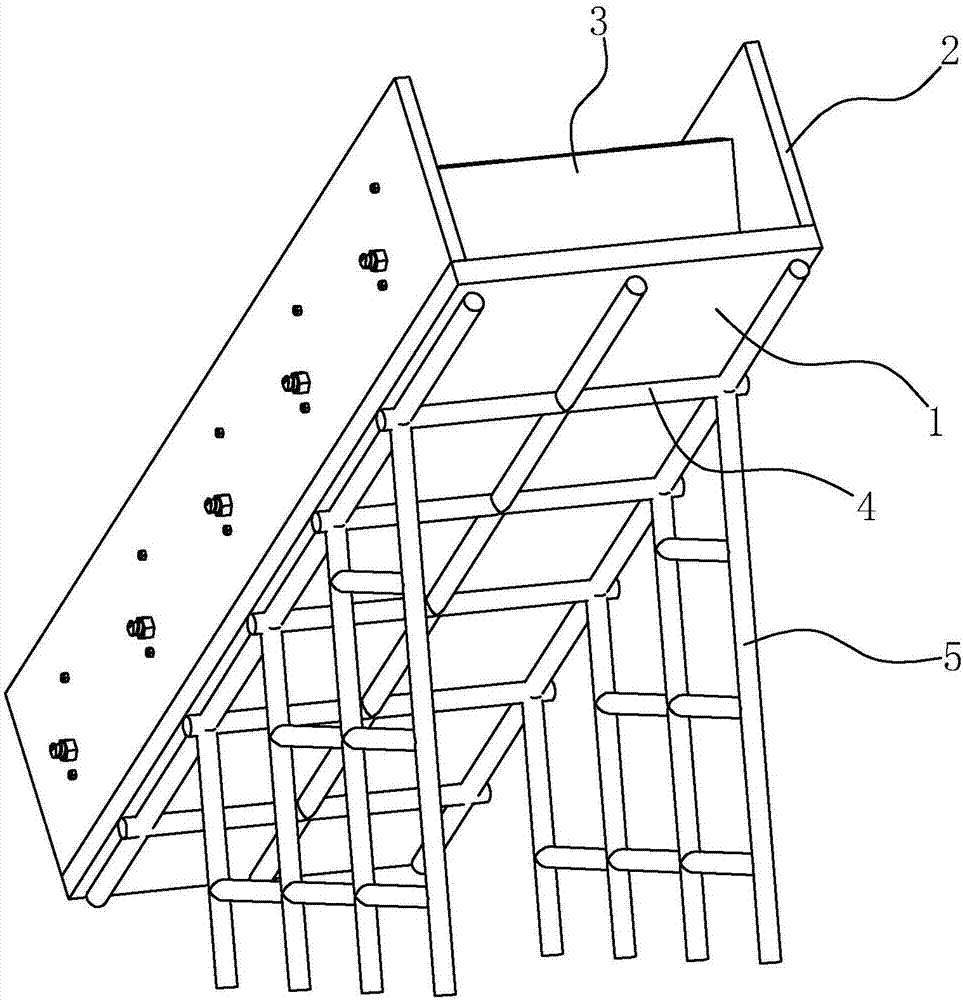

Attachment type lifting scaffold and lifting method

InactiveCN105401714AReduce weightNot easy to bend and deformBuilding support scaffoldsIndustrial engineeringBuilding construction

The invention discloses an attachment type lifting scaffold. The attachment type lifting scaffold comprises a scaffold body, a guide rail vertically arranged on the scaffold body and a wall attaching guiding device matched with the guide rail. The wall attaching guiding device and the guide rail can slide in the length direction of the guide rail. The attachment type lifting scaffold further comprises a lifting mechanism. The lifting mechanism comprises a rectangular lifting frame vertically arranged in the longitudinal direction of the scaffold body. The lifting frame and the scaffold body are fixedly connected. An electric chain hoist is fixedly installed on a beam at the upper end of the lifting frame, and two guiding wheels are fixedly installed on a beam at the lower end of the lifting frame. The attachment type lifting scaffold is characterized in that a hoisting chain of the electric chain hoist sequentially winds around the bottoms of the two guiding wheels and is connected to the wall attaching guiding device located above the guiding wheels, and the guiding wheels are hoisting chain wheels. The attachment type lifting scaffold has the beneficial effects that safety is good, the weight is low, operation is convenient, the construction efficiency can be improved, and the construction cost is reduced.

Owner:CHONGQING DONGCHEN BUILDING MACHINERY INSTALLATION ENG CO LTD

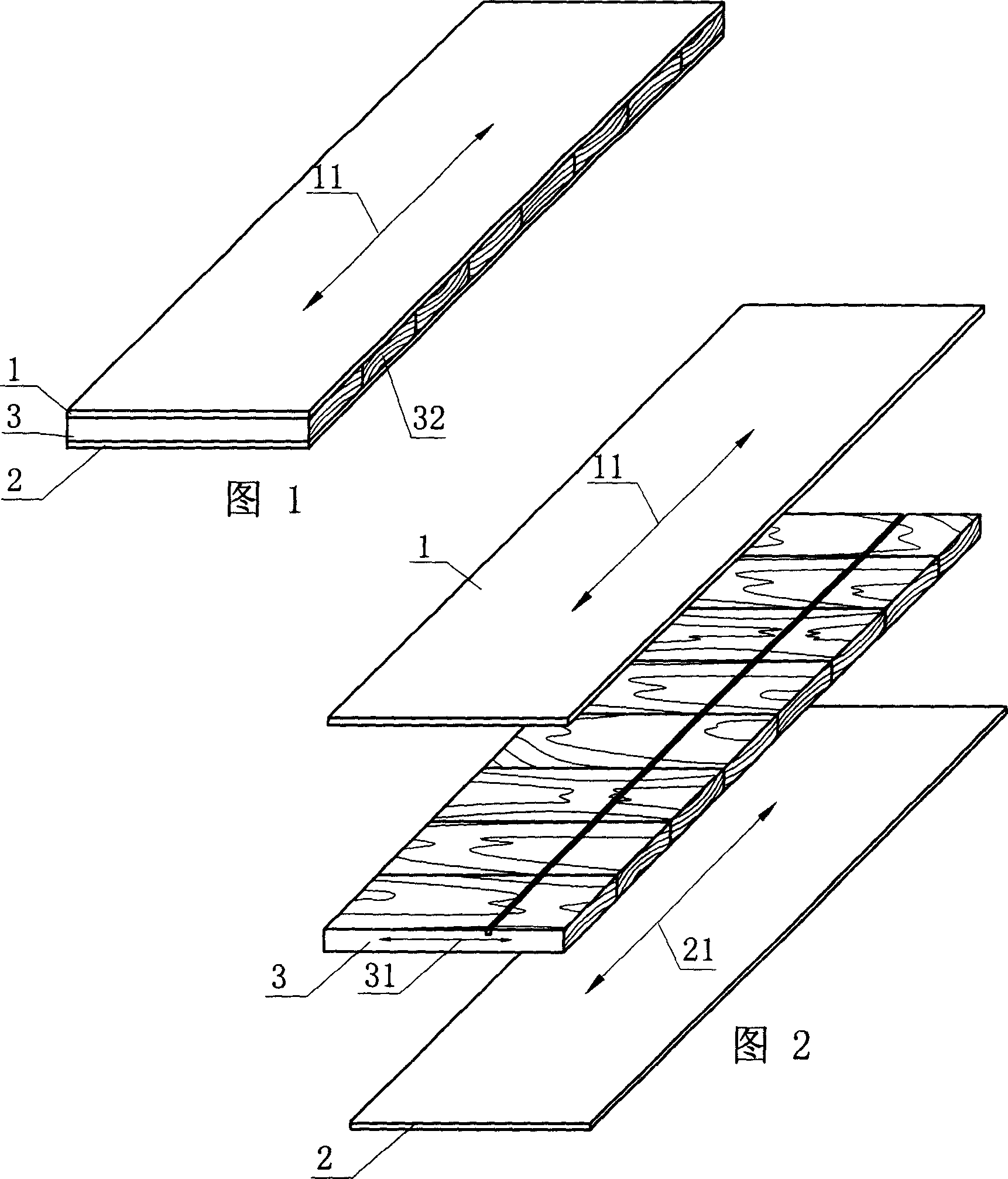

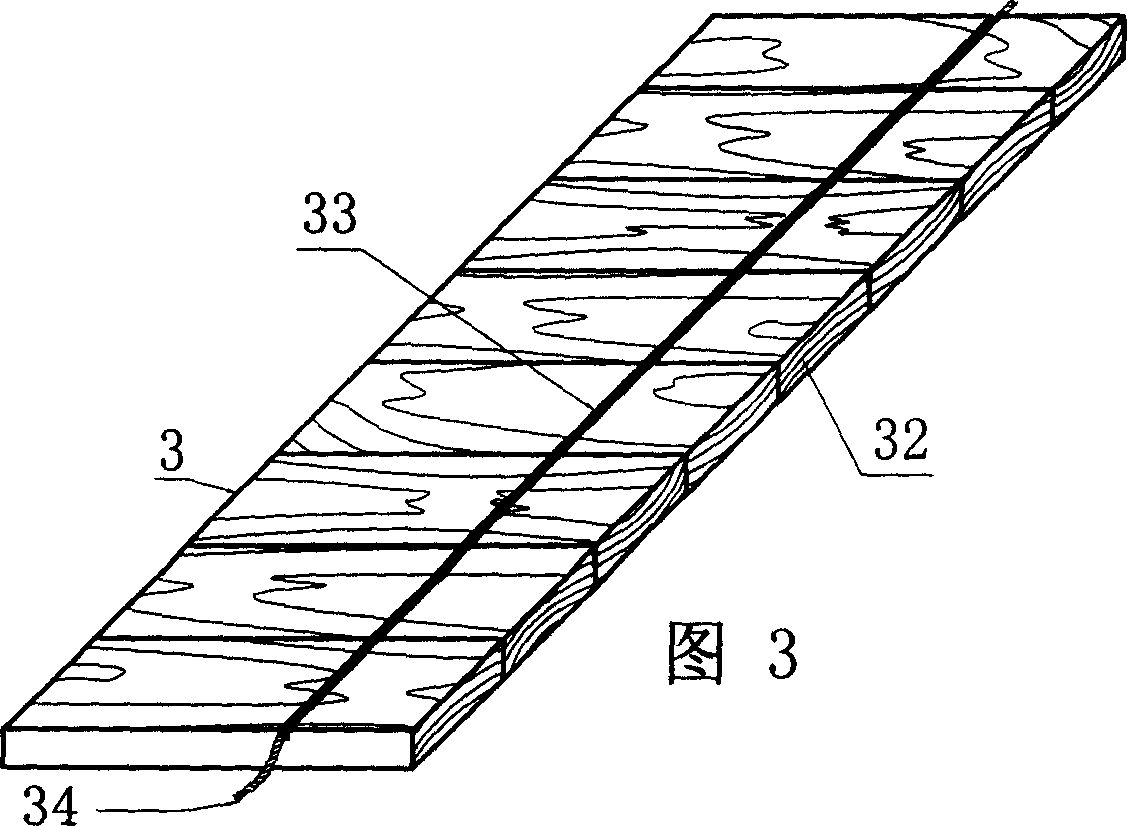

Bamboo wood compound floor board

InactiveCN1912311AHas surface hardnessImprove qualityWood layered productsFlooringSolid woodSurface layer

A bamboo-wood composite floor is prepared as using heavy bamboo material to prepare surface layer board and bottom layer board and using wood as intermediate layer board, crossing fiber orientation of adjacent layer and setting fiber orientations of surface layer board and bottom layer board to be identical, forming said bamboo material by mixing and high-pressure pressing bamboo filigree or bamboo splints.

Owner:浙江坚林林业股份有限公司

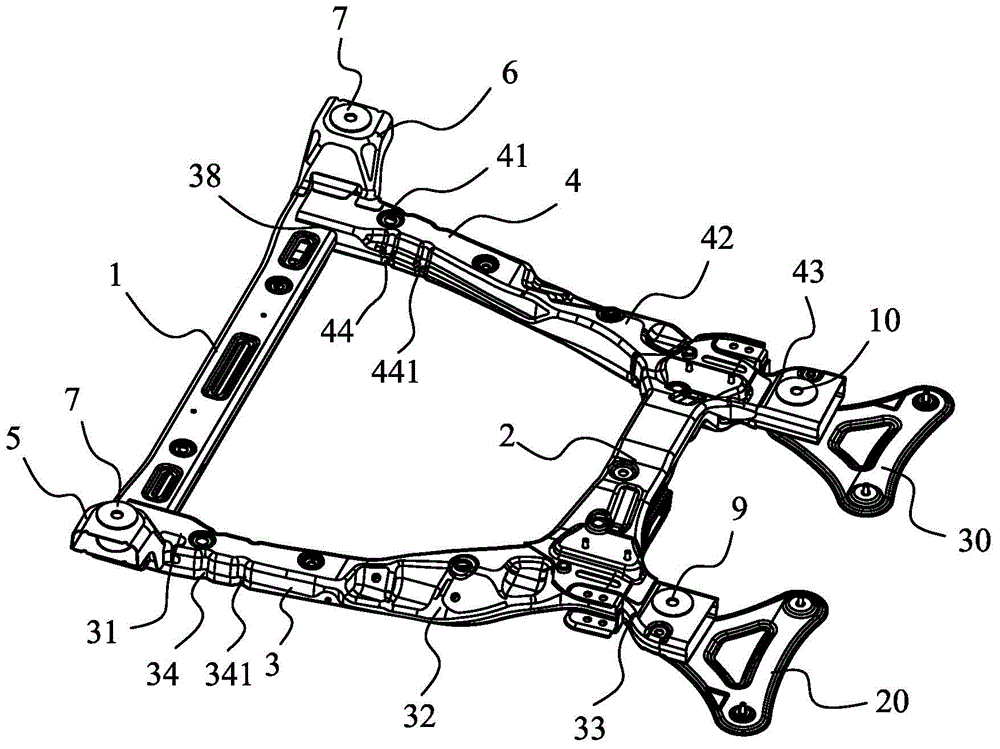

Front automotive auxiliary frame

ActiveCN105292262ASmall amount of deformationProtection securityUnderstructuresVehicle frameEnergy absorption

The invention provides a front automotive auxiliary frame which comprises a front cross beam, a rear cross beam, a left longitudinal beam and a right longitudinal beam, wherein the left longitudinal beam orderly comprises a first front crumpling segment, a first transition segment and a first rear crumpling segment from front to back, and a first crumpling energy absorption rib is arranged on the first front crumpling segment; the right longitudinal beam orderly comprises a second front crumpling segment, a second transition segment and a second rear crumpling segment from front to back, and a second crumpling energy absorption rib is arranged on the second front crumpling segment; the first front crumpling segment, the second front crumpling segment and the front cross beam are on the same plane, and the first front crumpling segment and the second front crumpling segment are respectively parallel to the front end of a left front longitudinal beam of an automobile body and the front end of a right front longitudinal beam of the automobile body. According to the front automotive auxiliary frame, the left longitudinal beam and the right longitudinal beam of the automotive auxiliary frame is not easy to generate bending deformation to a passenger compartment, so that the amount of deformation of the passenger compartment can be reduced during collision, and the safety of passengers in the automobile is protected.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD +1

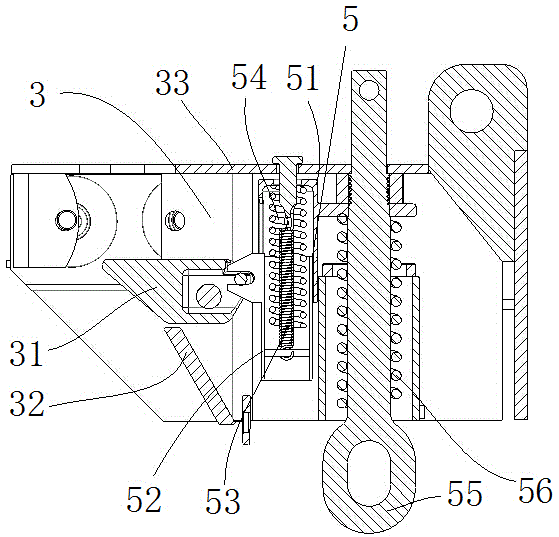

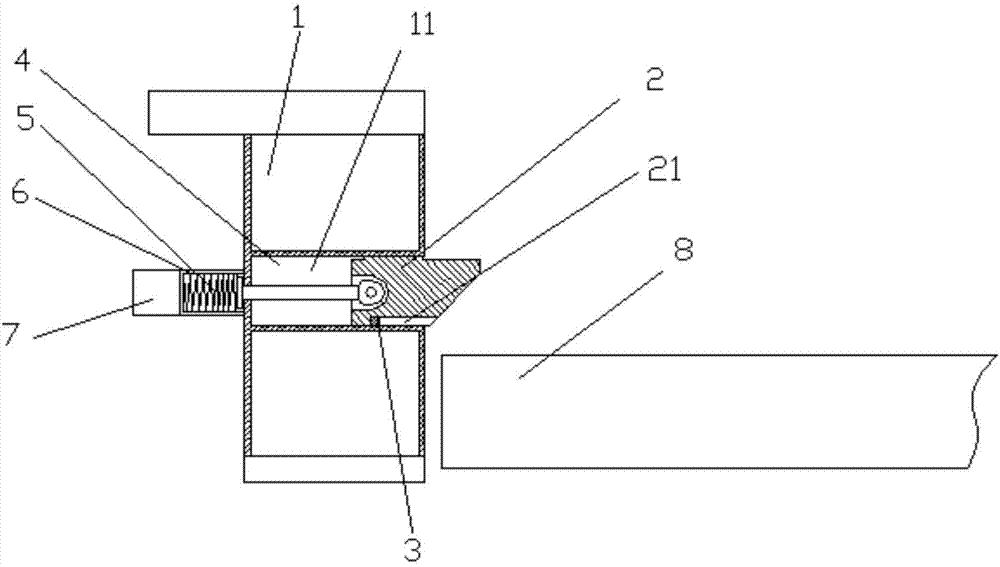

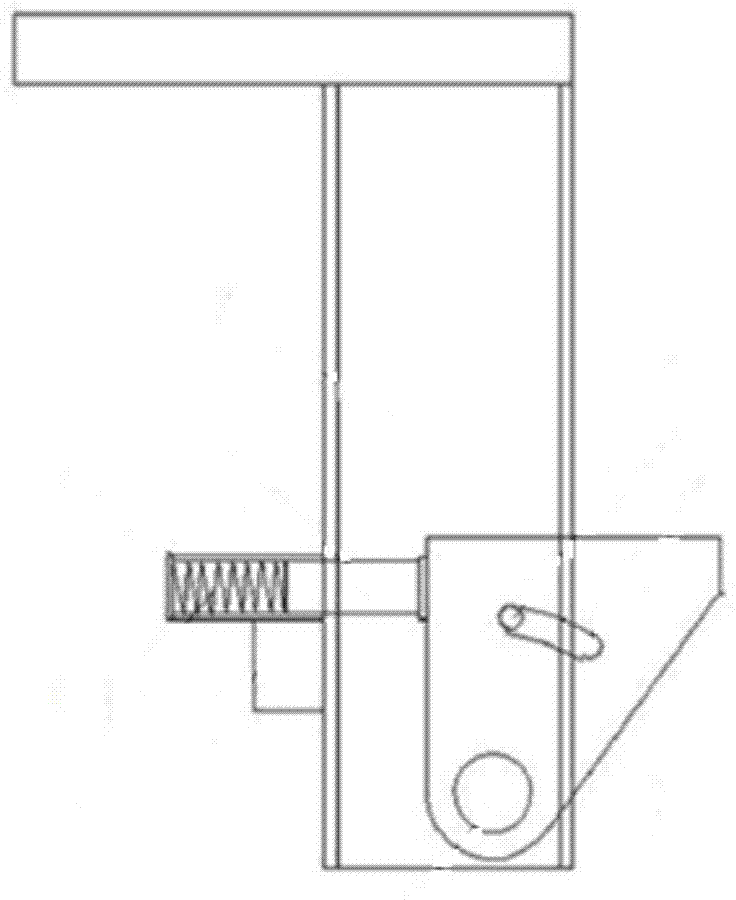

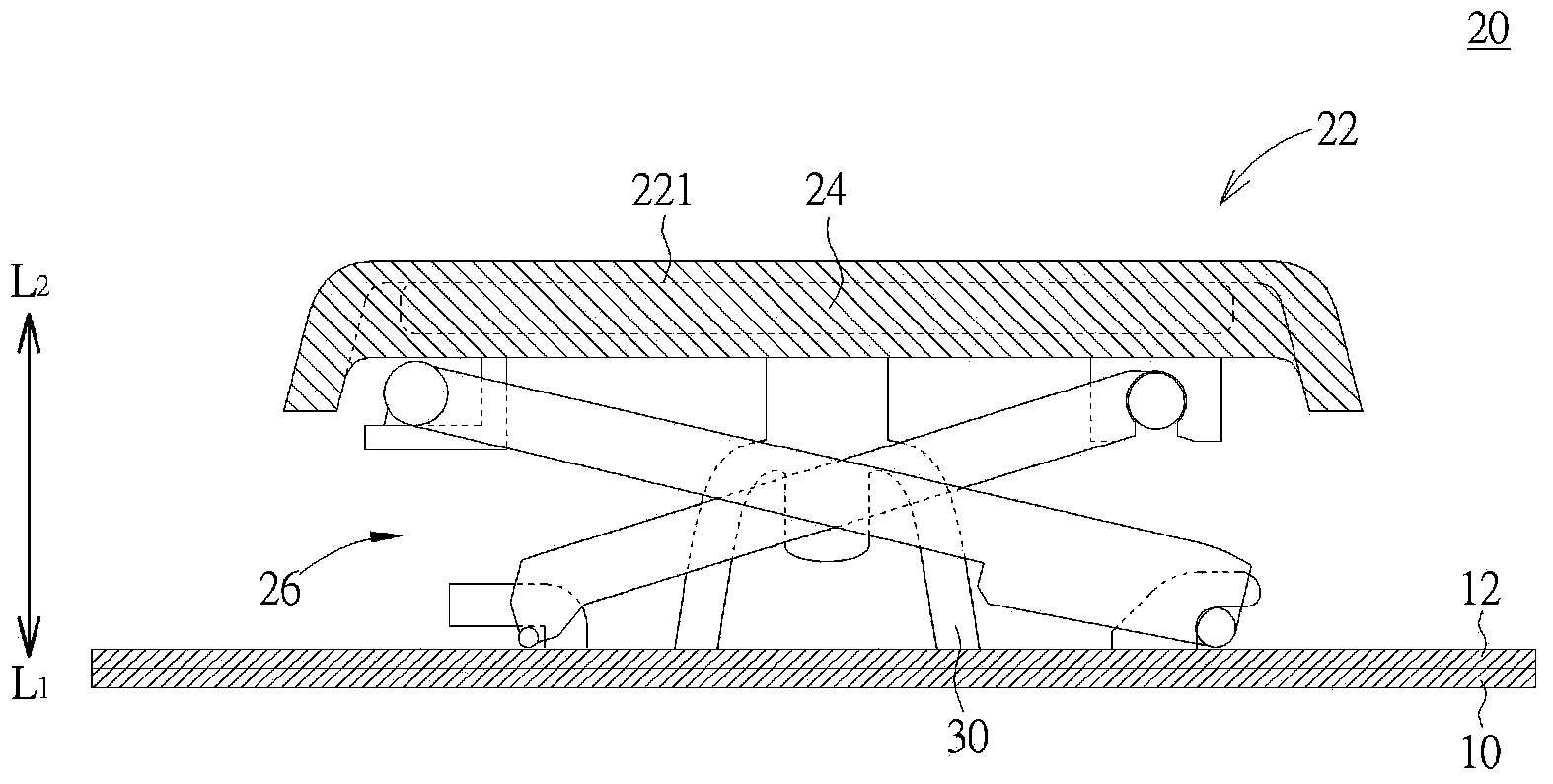

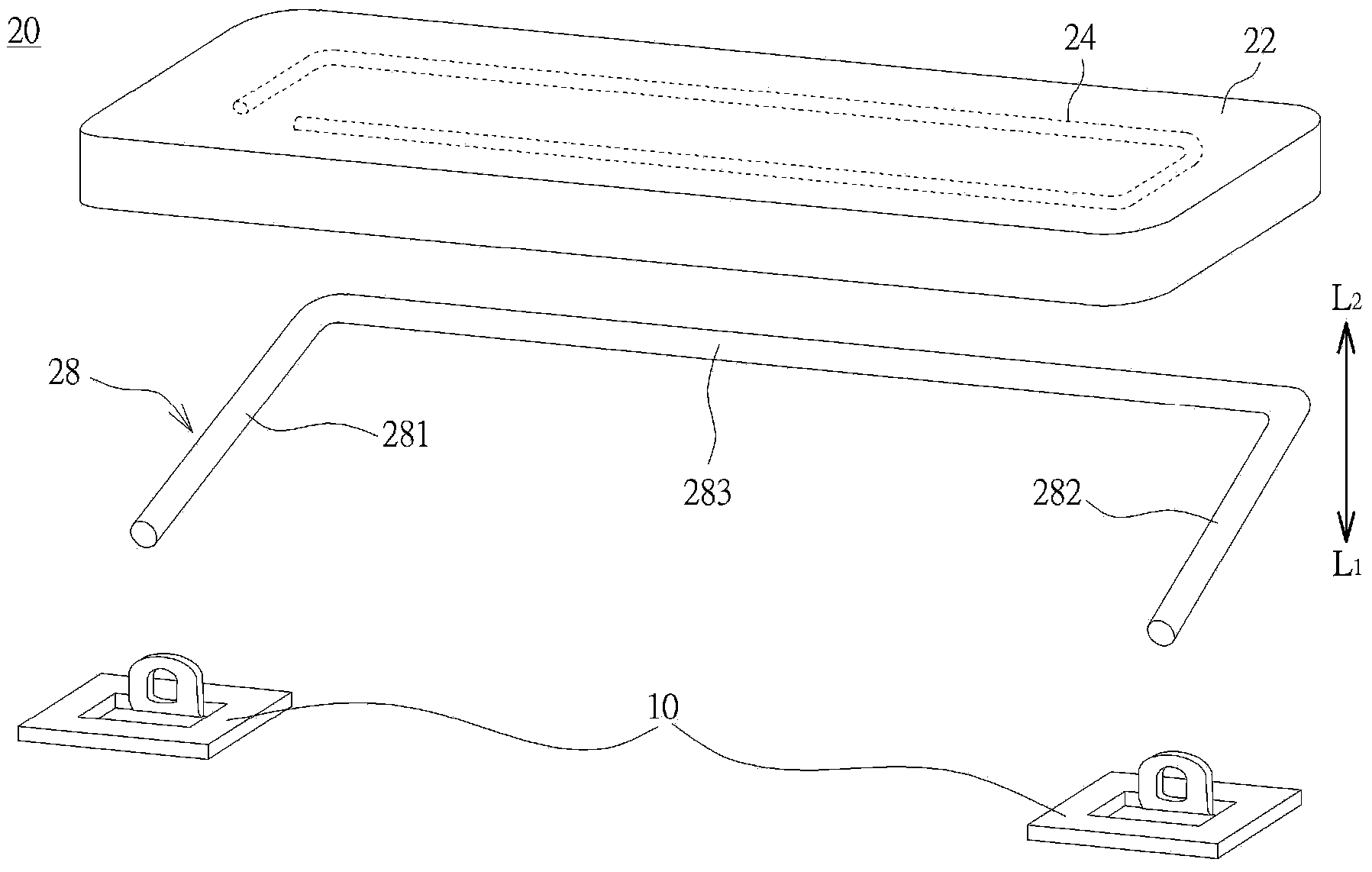

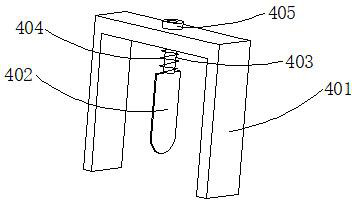

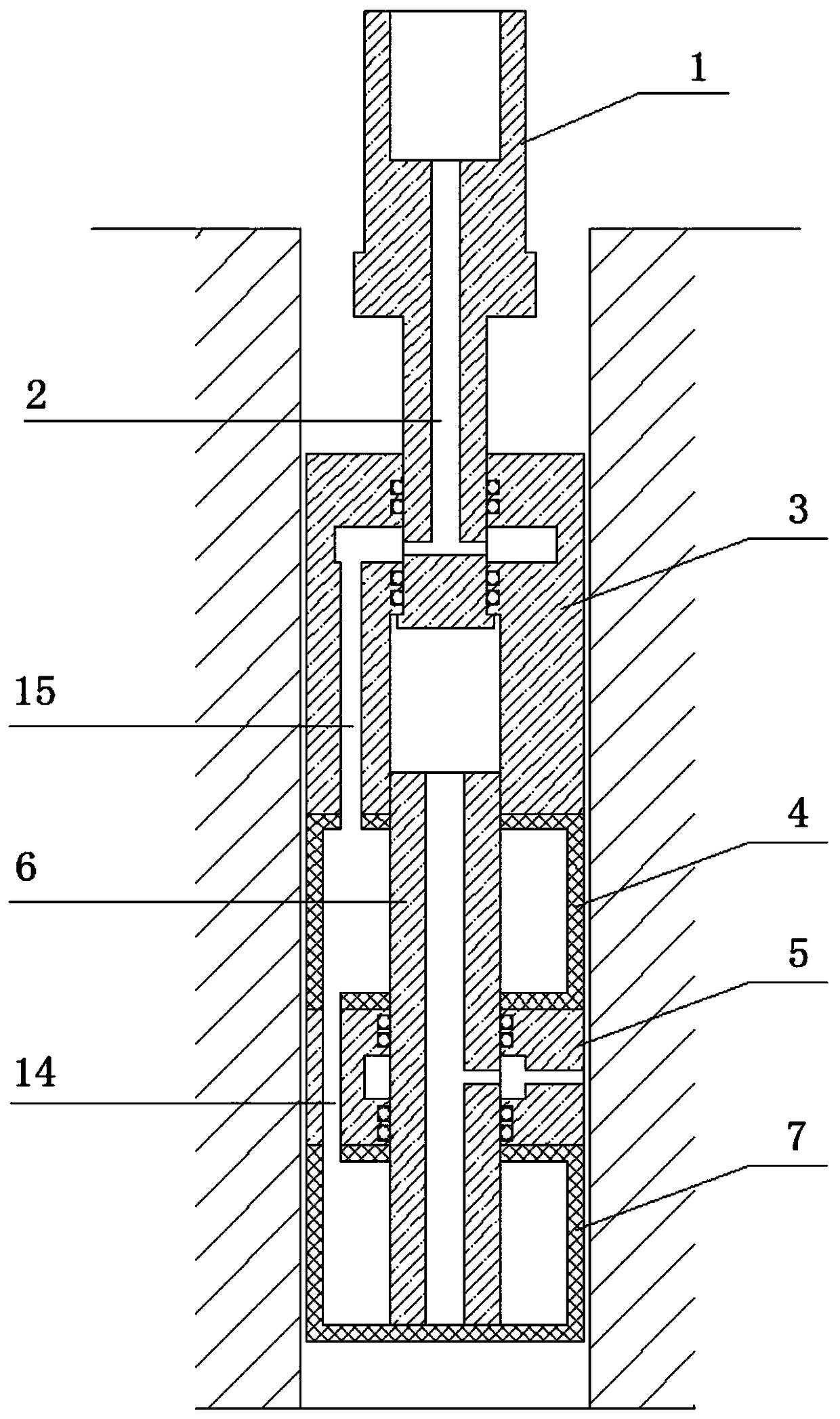

Anti-falling device of stereo garage

InactiveCN103573000APrevent damage to partsImprove securityParkingsEngineeringMechanical engineering

The invention discloses an anti-falling device of a stereo garage. The anti-falling device comprises a transverse chute in an upright post as well as an anti-falling baffle capable of sliding in the chute, wherein a limit groove is formed in the anti-falling baffle; a limit pin matched with the limit groove is arranged in the chute; a free end of the anti-falling baffle extends out of the upright post, a connecting end is hinged to one end of an ejector rod, and the other end of the ejector rod penetrates into a sleeve and is connected with a compression spring mounted in the sleeve; and the tail end of the sleeve is fixedly connected with an electromagnet. According to the anti-falling device, the anti-falling baffle is arranged in the chute of the upright post, so that when a car loading board falls accidentally, stressed pressure or impact of parts which are directly connected or contacted with the anti-falling baffle is reduced, the parts which are directly connected or contacted with the anti-falling baffle are effectively prevented from damage, and the security during accidental falling of the car loading board is improved; and when the car loading board is lifted or dropped, the ejector rod only receives small radial force action and is not prone to bending deformation, and a deadlocking phenomenon due to bending deformation of the ejector rod is avoided.

Owner:GUANGXI UNIV

High-strength anchor bolt and production method thereof

InactiveCN102876965AFast heatingOnline production is stableFurnace typesIncreasing energy efficiencyUltimate tensile strengthMechanical property

The invention provides a high-strength anchor bolt and a production method thereof. The high-strength anchor bolt comprises the following components in percentage by weight: 0.25 to 0.50 percent of C, 0.2 to 1.5 percent of Si, 0.5 to 2.0 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S and the balance of iron and inevitable impurities. The high-strength anchor bolt is subjected to continuous sensing heat treatment, wherein the mechanical properties of the high-strength anchor bolt are that the tensile strength sigma b is 830 to 1,220MPa, the shear strength is more than or equal to 0.7 sigma b, the percentage elongation after fracture is more than or equal to 14 percent, and ballistic work at the temperature of 20 DEG C is more than or equal to 60J. The high-strength anchor bolt has the advantages of high strength, high ductility and impact resistance, and can effectively solve the problem of brittle rupture.

Owner:CHINA IRON & STEEL RES INST GRP +1

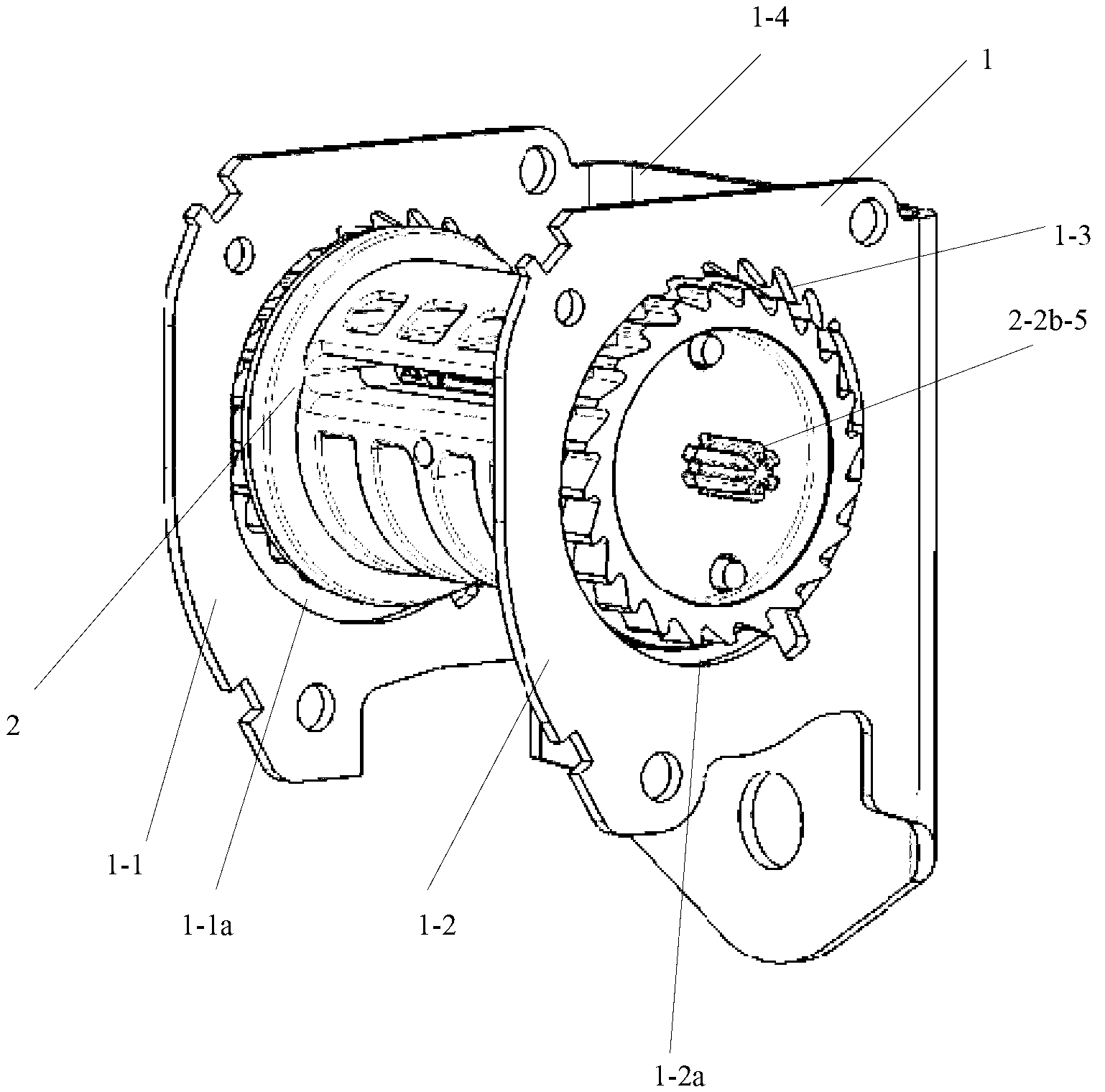

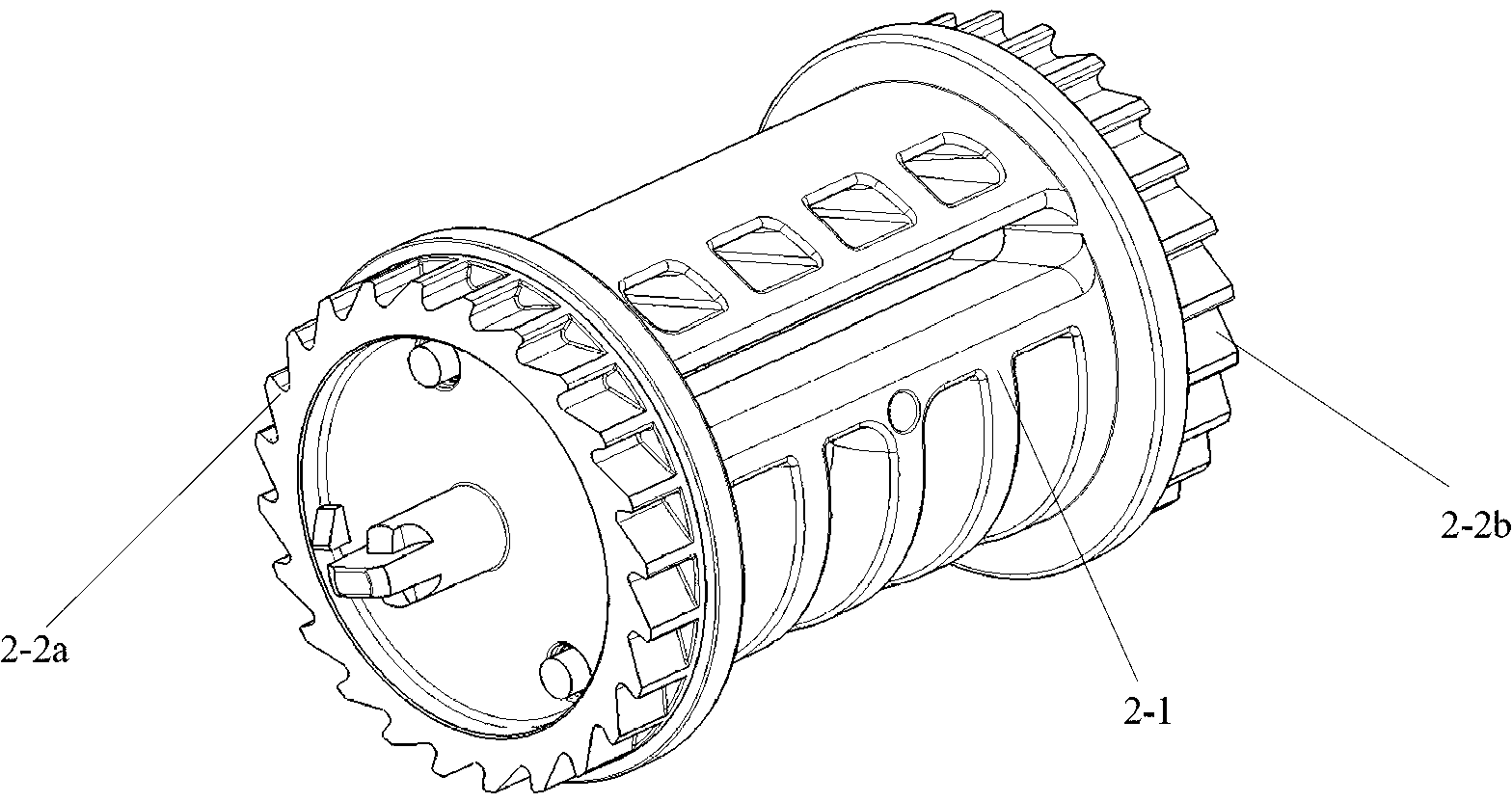

Retractor for safety belt and safety belt assembly

ActiveCN102837664AOvercoming the problem of unfixed locking positionImprove accuracyBelt retractorsEngineeringBelt safety

The invention provides a retractor for a safety belt. A retractor frame comprises two opposite side walls, and corresponding positions of the two opposite side walls are provided with round holes with inner tooth sections. The tooth sections are arranged at a position corresponding to the outward traction direction of a braided belt. A retraction shaft comprises a core shaft which is provided with a though hole along the central axis and is used for winding the braided belt, and two separating end covers which are respectively installed at two ends of the core shaft. The periphery of each end cover is provided with outer teeth matched with inner teeth on the frame. A torsion bar is bar-shaped, the axial middle of the torsion bar is provided with a middle section of outer teeth, and the inner teeth matched with the outer teeth are installed in the though hole of the core shaft. Connection between the torsion bar and the two separating end covers at two ends is achieved at a crossing position between the torsion bar and the two separating end covers through a gear installed at the crossing position and gears correspondingly installed at the end covers. The retractor for the safety belt overcomes the shortcoming that the position of the locking of a retractor is unfixed, and improvement of control accuracy of the retractor is benefited. The invention further provides a safety belt assembly.

Owner:和励科技有限公司

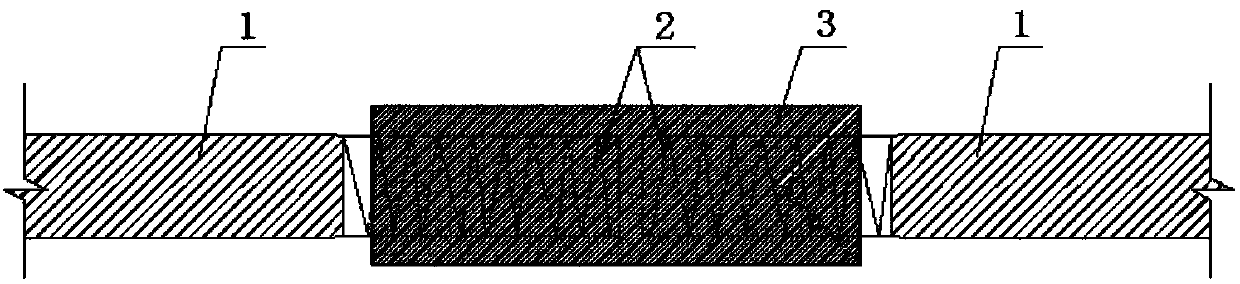

Method for preparing thin-wall composite steel pipe with ceramic lining

Owner:南京金陶耐磨管道有限公司

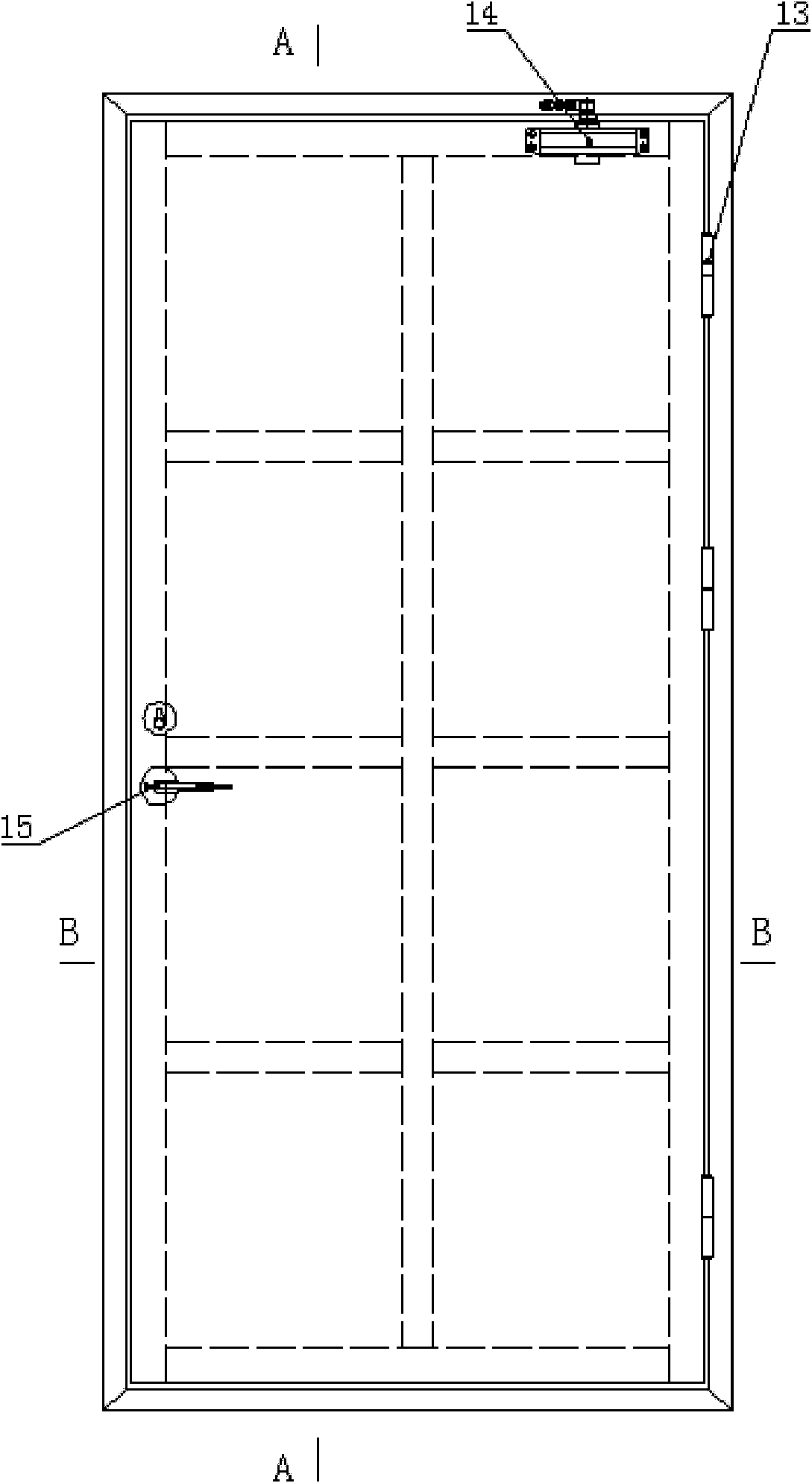

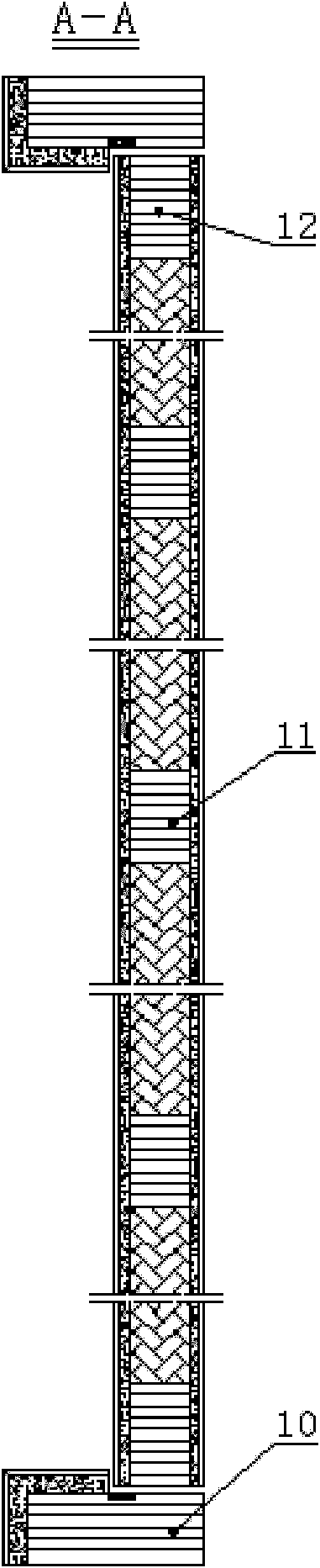

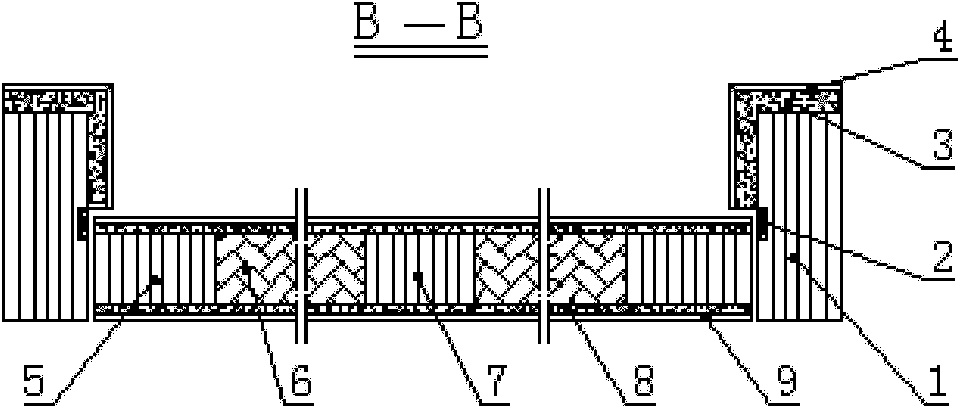

Flame-retardant laminated veneer lumber wooden fireproof door and manufacturing method thereof

The invention discloses a flame-retardant laminated veneer lumber wooden fireproof door and a manufacturing method thereof. The manufacturing method comprises the following steps of: manufacturing flame-retardant laminated veneer lumber by using low-grade fast growing wood; and manufacturing a door frame and a door leaf framework by using the flame-retardant laminated veneer lumber, wherein the door frame consists of a vertical frame and a horizontal frame through tenon combination; the door leaf framework consists of two edge horizontal keels, two edge vertical keels, a plurality of middle vertical keels and a plurality of middle horizontal keels through tenon combination; the longitudinal textures of the wood grain of the laminated veneer lumber are parallel to the length directions of the frames of the door frame and the keels of the door leaf framework, and an adhesive layer surface is vertical to the surface of the door leaf; the width of the frames of the door frame is 90 to 110mm, and the thickness is 40 to 50mm; and the width of the edge keels of the door leaf framework is 50 to 60mm, the width of the middle keels is 40 to 50mm, and the thickness of the door leaf framework is 35 to 40mm. The flame-retardant laminated veneer lumber wooden fireproof door is made of the low-grade fast growing wood, the use value of the low-grade wood is improved and natural forest resources are protected.

Owner:宿迁新缘林木业有限公司

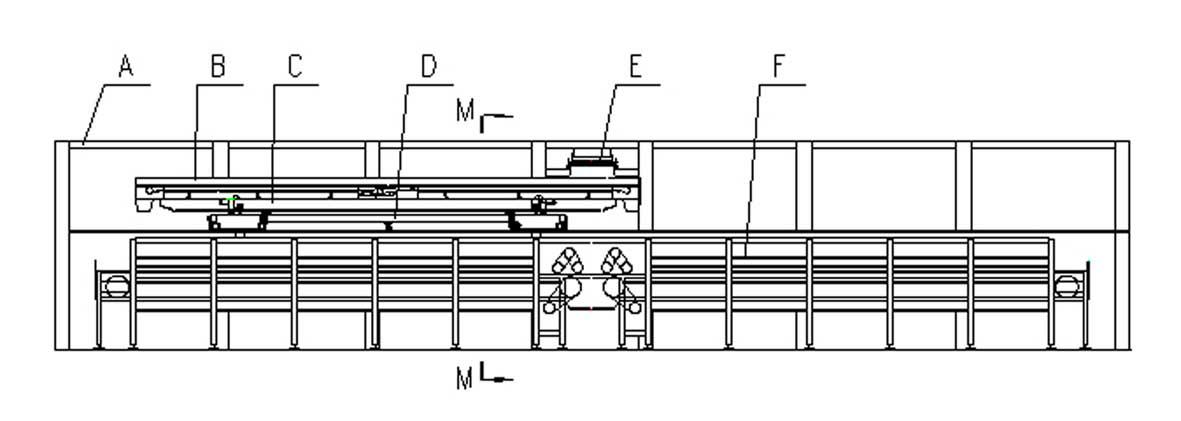

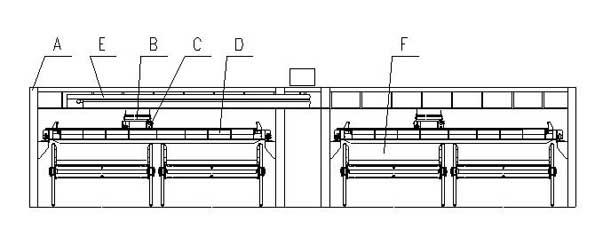

Automatic circulating feeding device for battens

The invention provides an automatic circulating feeding device for battens, and belongs to the technical field of machinery. The automatic circulating feeding device solves the technical problem that in the feeding process of an existing feeding mechanism, it is difficult to separate the adjacent two battens when the battens are tightly arrayed. The automatic circulating feeding device for the battens comprises a machine frame. Conveyor belt assemblies capable of circularly conveying the battens in the horizontal direction are arranged on the machine frame. A first drive source for driving the conveyor belt assemblies to operate is arranged on the machine frame. A horizontal guide rail is further fixed to the machine frame. The sliding direction of the horizontal guide rail is perpendicular to the transportation direction of the conveyor belt assemblies. The horizontal guide rail is in slide connection with a mechanical arm used for clamping the battens on the conveyor belt assemblies. A second drive source used for driving the mechanical arm to move along the horizontal guide rail is further arranged on the machine frame. By means of the automatic circulating feeding device, the battens can be effectively transferred, and the production efficiency can be improved.

Owner:TAIZHOU EVOK MASCH CO LTD

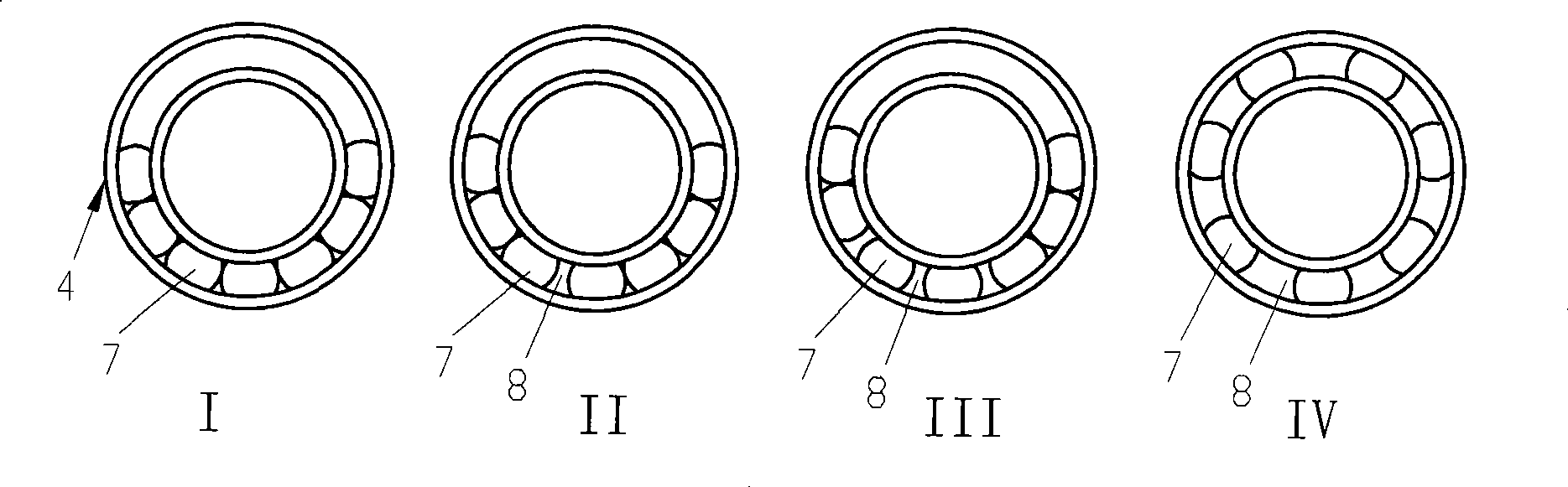

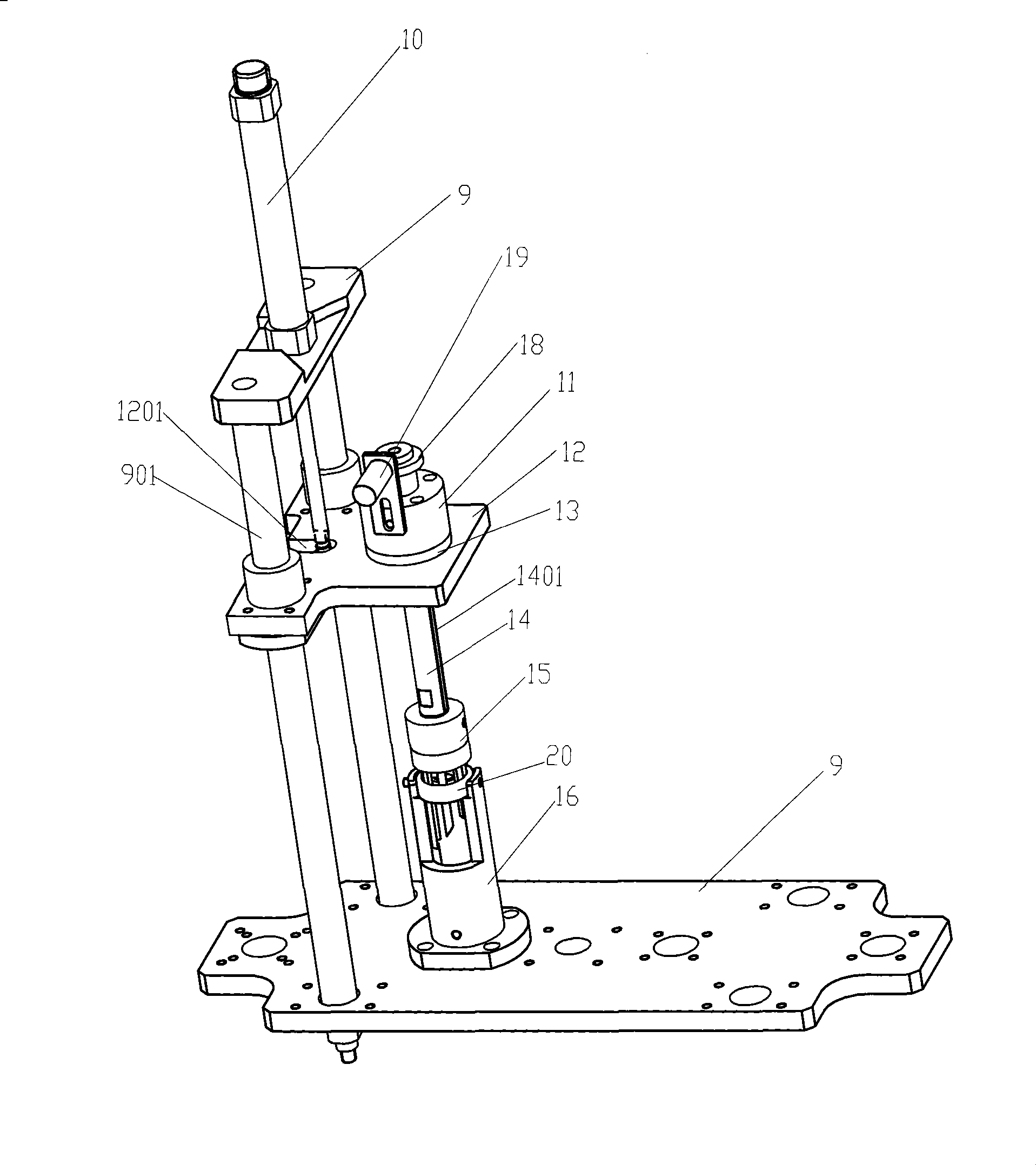

Ball separating device of bearing ball separating holder assembly machine

InactiveCN101363478AImprove work efficiencyNot easy to break or bend out of shapeBearing componentsEngineeringPiston rod

The invention relates to a ball separating device of a bearing ball separating retainer assembly machine, and is characterized in that the ball separating device comprises a frame and an electric control system; a cylinder is arranged above the frame, a piston rod of the cylinder passes through a hole of a support plate, the front end of the piston rod is provided with a lifting and pulling head, the lower end of a mandrel is provided with a ball separating head, the upper end thereof is provided with an axle cap, a lower die of a locating bearing is arranged on the frame below the mandrel; the ball separating head includes a base which is arranged at the lower end of the mandrel, and a plurality of ball separating pins are sequentially arranged on the base by a sleeve chuck; the outer layer of the ball separating pin is made of metaformaldehyde or nylon, and the center thereof is embedded with a metal strip. By adopting the deadweight of the mandrel and a guide block to realize ball separating, the ball separating device does not cause damage to steel balls and the grooves on inner and outer rings and has high work efficiency. In addition, with the structure, the ball separating pin is not likely to snap, bend or deform during use, thus prolonging the service life of the ball separating pin and causing no scratch to the surfaces of the steel balls.

Owner:无锡市江益轴承自动化设备有限公司

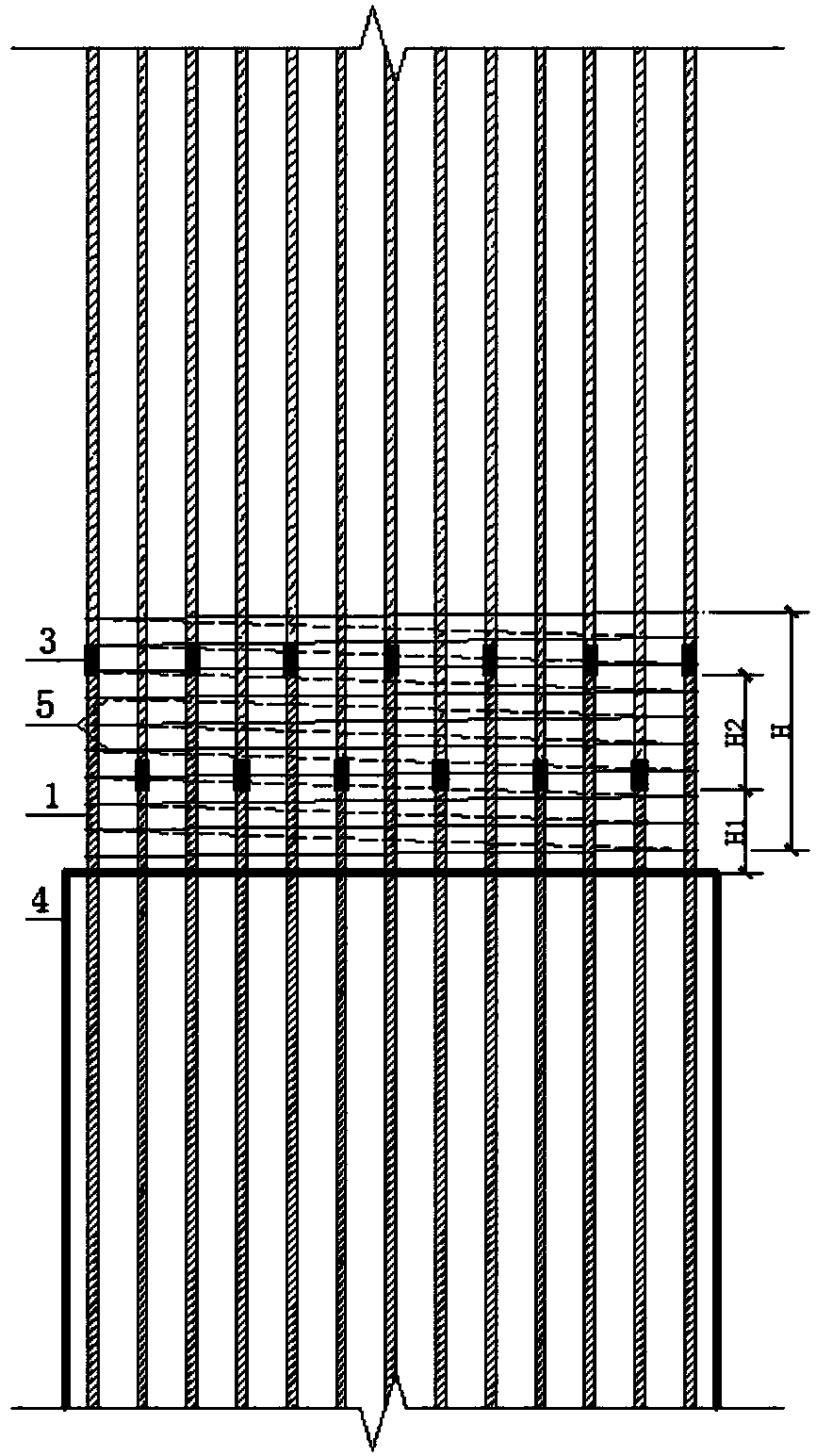

Large-diameter and super-long reinforcement cage and construction method thereof

InactiveCN107816170AEasy to operateMeet the time limit and quality requirementsBuilding reinforcementsBulkheads/pilesRebarBuilding construction

The invention discloses a large-diameter and super-long reinforcement cage and a construction method thereof. The reinforcement cage comprises a plurality of reinforcement cage units; each reinforcement cage unit comprises a plurality of spaced and parallel reinforcing ribs; a plurality of main ribs are equidistantly arranged in the circumferential direction of the reinforcing ribs; the main ribsand the reinforcing ribs are welded together; a screw is arranged at each of two ends of each main rib respectively; adjacent two reinforcement cage units are connected as a whole through the main ribs and sleeves in threaded connection with the main ribs; stirrups are also arranged in the circumferential direction of the joint between adjacent two reinforcement cage units. The construction methodcomprises the following steps: building of a rebar processing table, processing of the main ribs, making and mounting of the reinforcement cage units, hoisting of the reinforcement cage, lengtheningof the orifice and the like. According to the large-diameter and super-long reinforcement cage disclosed by the invention, the sleeve connection operation is convenient, hoisting and sinking can be performed after the reinforcement cage is tested qualified, the technical requirement of lengthening the orifice of the reinforcement cage as well as the requirements in construction period and qualitycan be met, and the value in promotion and application is relatively high.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

Concave appliance and its application method

InactiveCN1903666ASave resourcesLow costBoard gamesContainer/bottle contructionLocking mechanismEngineering

Owner:赵琛琛

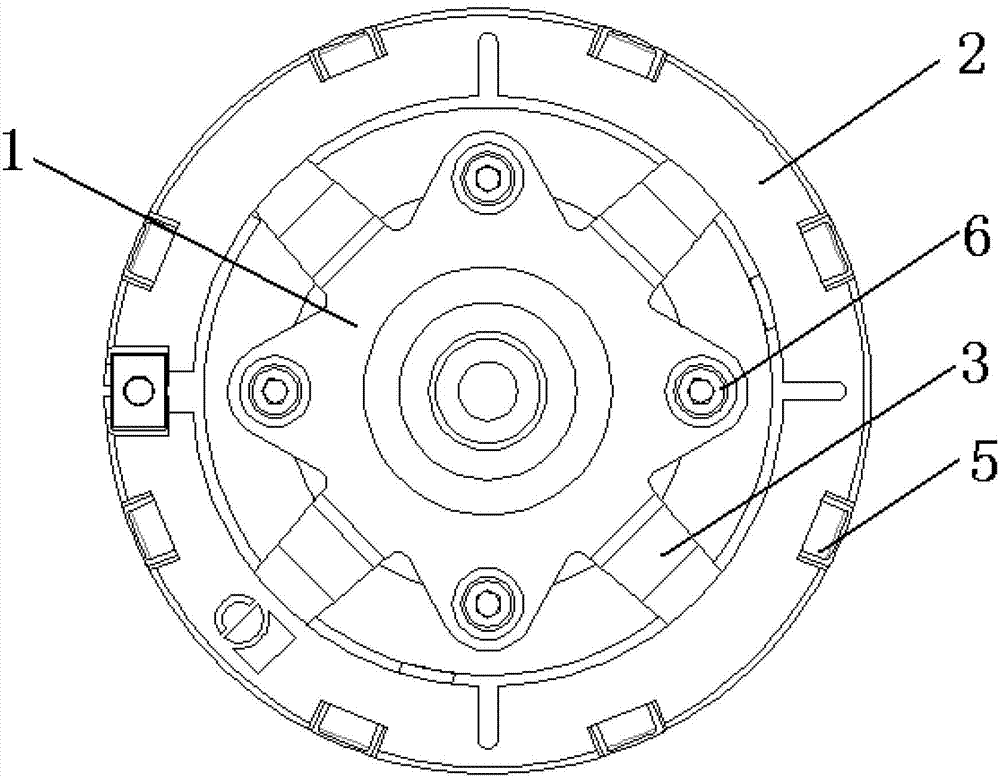

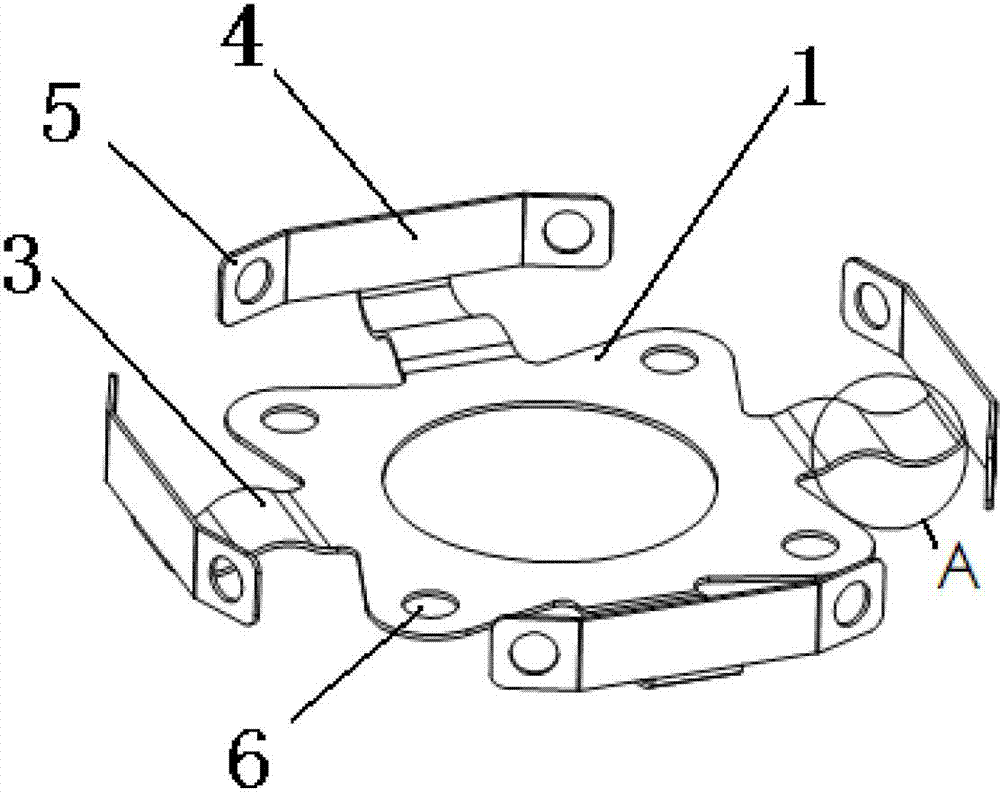

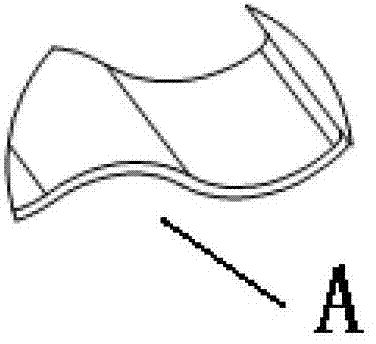

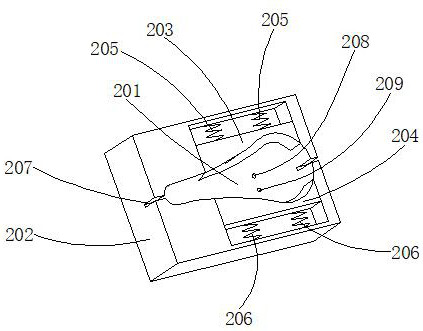

Encoder cushioning structure

ActiveCN102788609AImprove shock absorptionEvenly dispersedMeasurement apparatus for damping movement partsCushioningEngineering

An encoder cushioning structure is installed between an encoder and a motor support and is characterized in that the encoder cushioning structure comprises a cushioning ring elastic sheet and a cushioning ring outer casing, the cushioning ring elastic sheet is a four-claw elastic sheet with four extension ends which are evenly distributed at the periphery and extend from the center, and tail ends of the four extension ends are fixedly installed on an inner edge of the cushioning ring outer casing through screws. Encoder fixing holes fixed with the encoder are further arranged on the cushioning ring elastic sheet. The encoder cushioning structure improves an elastic sheet structure in the cushioning structure, the four extension ends can averagely disperse vibration ranges, the four extension ends are divided into eight screw fixing positions to further promote cushioning and damping effects, simultaneously the extension ends of the four-claw elastic sheets have hyperbolic-curve wavy fluctuation and have better fluctuation cushioning effects for facing strong vibration than those of straight rib sheets, and the encoder cushioning structure is good in whole cushioning effect and even in vibration dispersion, guarantees good mechanical behavior, and is not easy to bend and deform.

Owner:FUJISAN IND TECH CO LTD OF SHENZHEN CITY

Melamine decorative veneer hot-pressing concavo-convex forming process

InactiveCN102139496ADifficult to fall offAvoid crackingLayered productsWood veneer joiningWater vaporEngineering

The invention provides a melamine decorative veneer hot-pressing concavo-convex forming process. By the process, the problems that compaction degree of the product produced by the process is low, the melamine decorative veneer is easy to drop off, the product is fragile and is susceptible to bending deformation, a base plate generates displacement, and the melamine decorative veneer is bubbled easily caused by water vapor are solved. The process comprises the following steps of: softening the base plate; paving the melamine decorative veneer with double surfaces coated with melamine resin glue on the base plate; placing the base plate on a mould-pressing mould to perform mould pressing, wherein the mould-pressing mould comprises an upper template and a lower template, a convex plate is arranged on the upper template, and a groove is formed on the lower template; placing the base plate, where the melamine decorative veneer is paved, on the lower template of the mould-pressing mould; and settling the upper template to press until the convex plate on the upper template and the groove on the lower template are closed and pressed, so that the base plate with the melamine decorative veneer forms a concavo-convex shape under the action of the convex plate and the groove.

Owner:陈亮

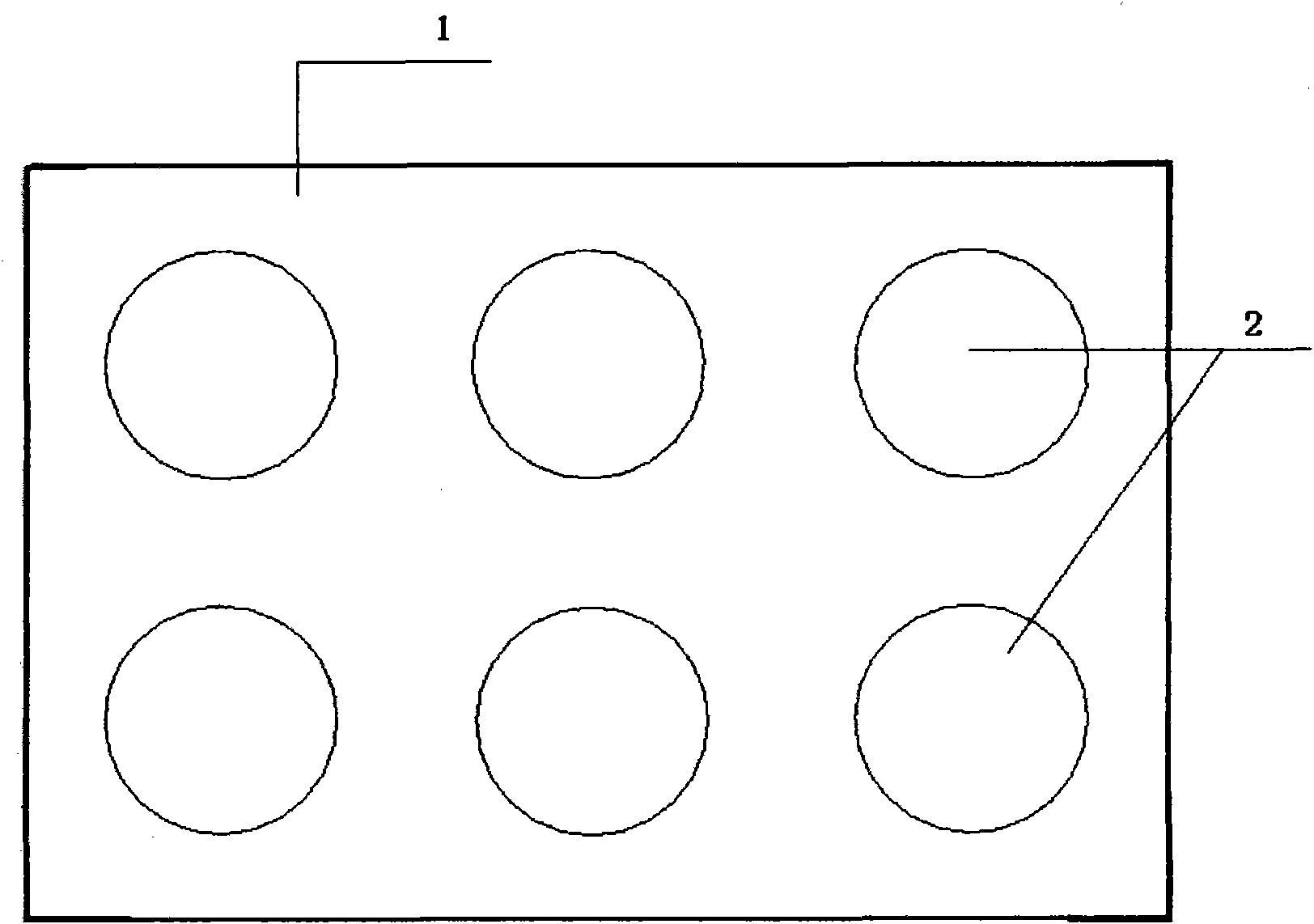

Formula and preparation method of vulcanized fiber paper

ActiveCN103321101ANot easy to bend and deformLoss of flatnessSpecial paperPaper/cardboardFiberChloride

The invention discloses a formula and a preparation method of vulcanized fiber paper, and is characterized in that the formula of the vulcanized fiber paper is as follows: the vulcanized fiber paper comprises the components of, by weight, 5-15% of wood pulp, 30-60% of cut pile, and 30-50% cotton linter; the preparation method of the vulcanized fiber paper comprises the steps: the above materials are subjected to stewing, beating and forming paper treatments, then are soaked in a dense zinc chloride solution, and are molded on a gelling machine when being heated to a temperature in a range from 38 DEG C to 50 DEG C; through heating and pressurization by a press roll, fibers are intersected with each other and glued together to synthesize semi-finished product raw vulcanized fiber paper; the raw vulcanized fiber paper is subjected to an ageing treatment in an aging room, then is subjected to a desalination process in a desalination tank which contains zinc chloride, then is washed by clear water to leach out zinc chloride in the inner of the raw vulcanized fiber paper; and finally the raw vulcanized fiber paper is dried in a drying room and shaped by a press machine, and the vulcanized fiber paper is obtained. The vulcanized fiber paper is advantaged in that the vulcanized fiber paper is not liable to generate bending deformation and lose original smoothness; the surface of the vulcanized fiber paper is fine and smooth; and the vulcanized fiber paper does not fade, and has a long service life and a high whole performance.

Owner:启东市洁慧新材料有限公司

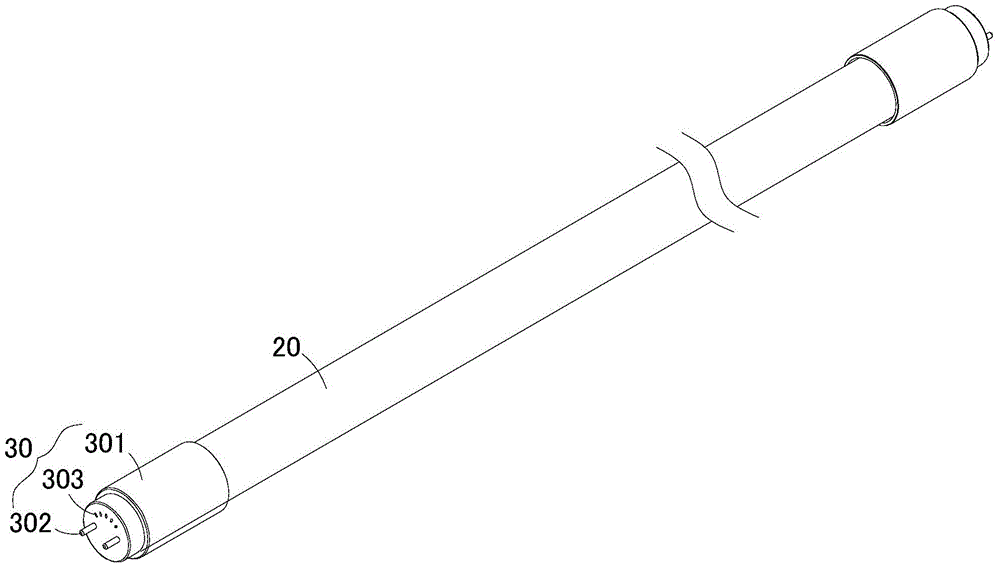

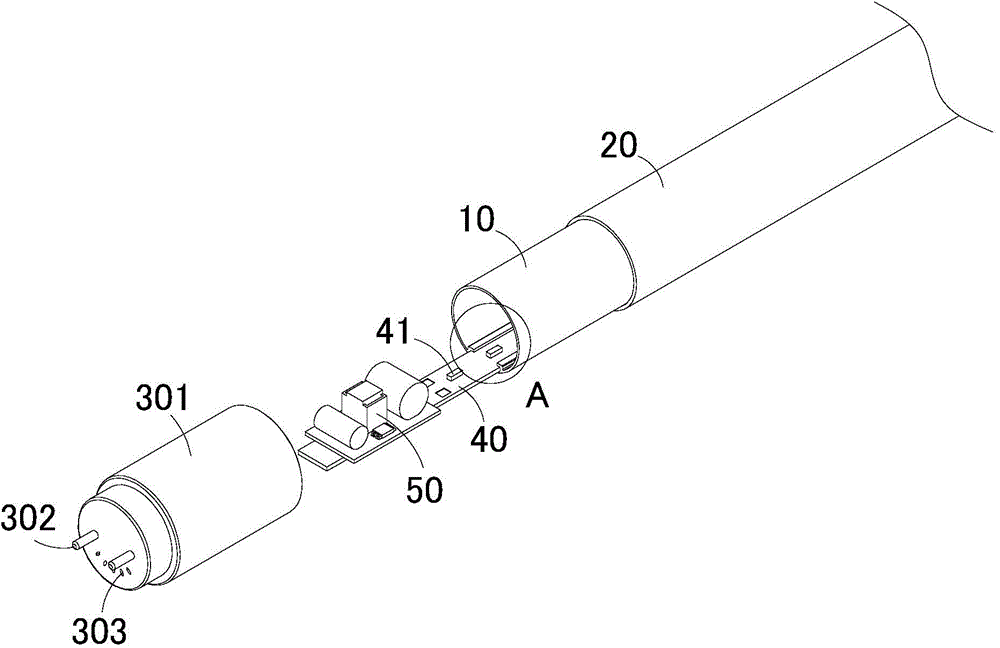

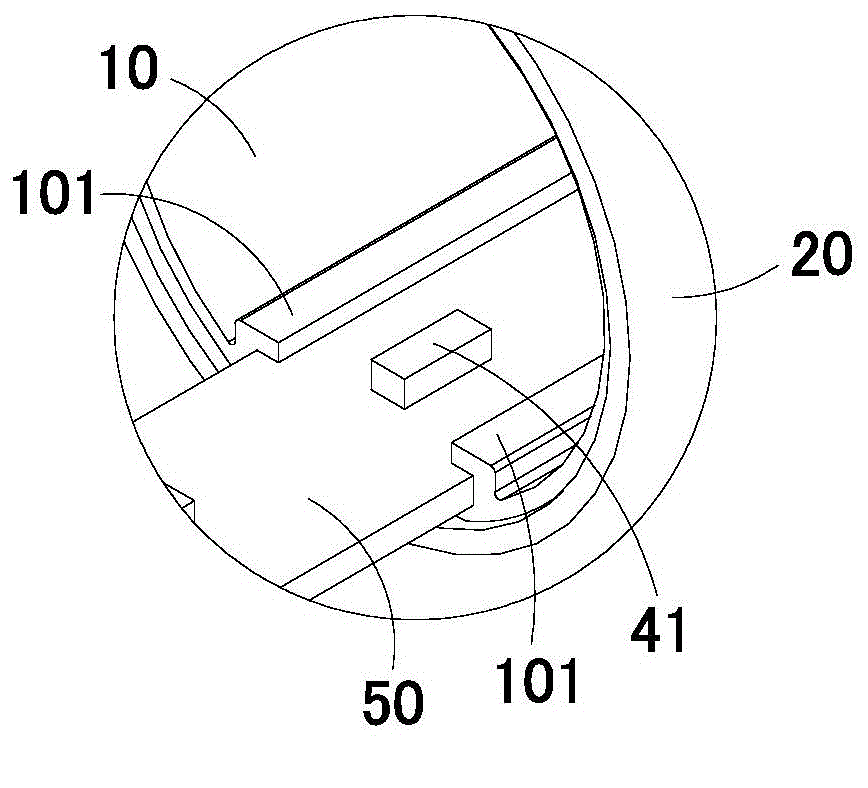

LED lamp tube

InactiveCN104089209AEasy to fixPlay a supporting rolePoint-like light sourceElectric lightingLED lampLight source

The invention discloses an LED lamp tube which comprises a plastic tube cover, a glass tube and two lamp caps, wherein the plastic tube cover is provided with a containing cavity which can be stretched out and drawn back in the axial direction, an LED substrate is arranged in the containing cavity, and multiple LED light sources are arranged on the LED substrate; the plastic tube cover is sleeved with the glass tube, and the two lamp caps are arranged at the two ends of the glass tube respectively in a sleeved mode so as to seal the containing cavity. According to the LED lamp tube, the plastic tube cover is sleeved with the glass tube, so that on one hand the glass tube plays a role in supporting the plastic tube cover, the plastic tube cover cannot be bent to deform, and the use effect is better; on the other hand, under the support of the internal plastic tube cover, the glass tube is not prone to breakage, and even if the glass tube is broken, the whole LED lamp tube can be normally used as well; in addition, the glass tube can accelerate heat dissipation, and the heat dissipation effect of the whole LED lamp tube is improved.

Owner:SHENZHEN RUIFENG DISPLAY TECH

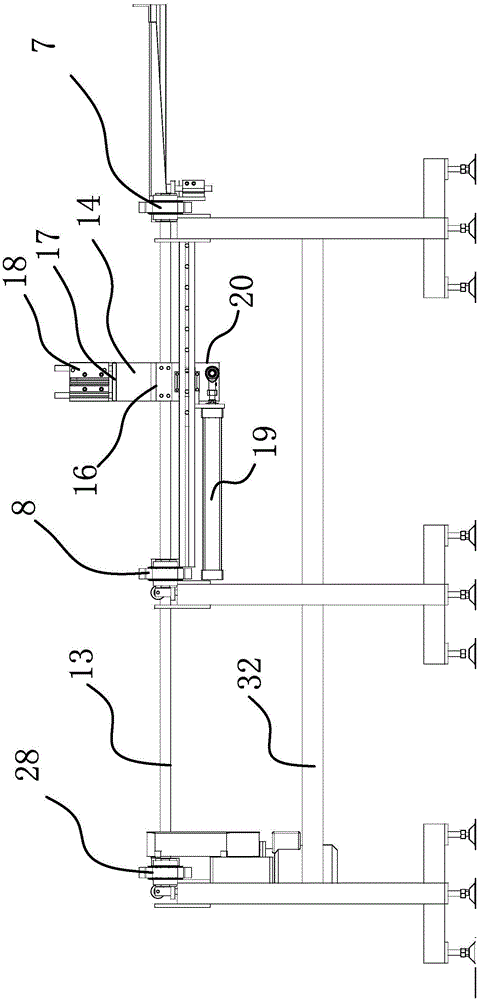

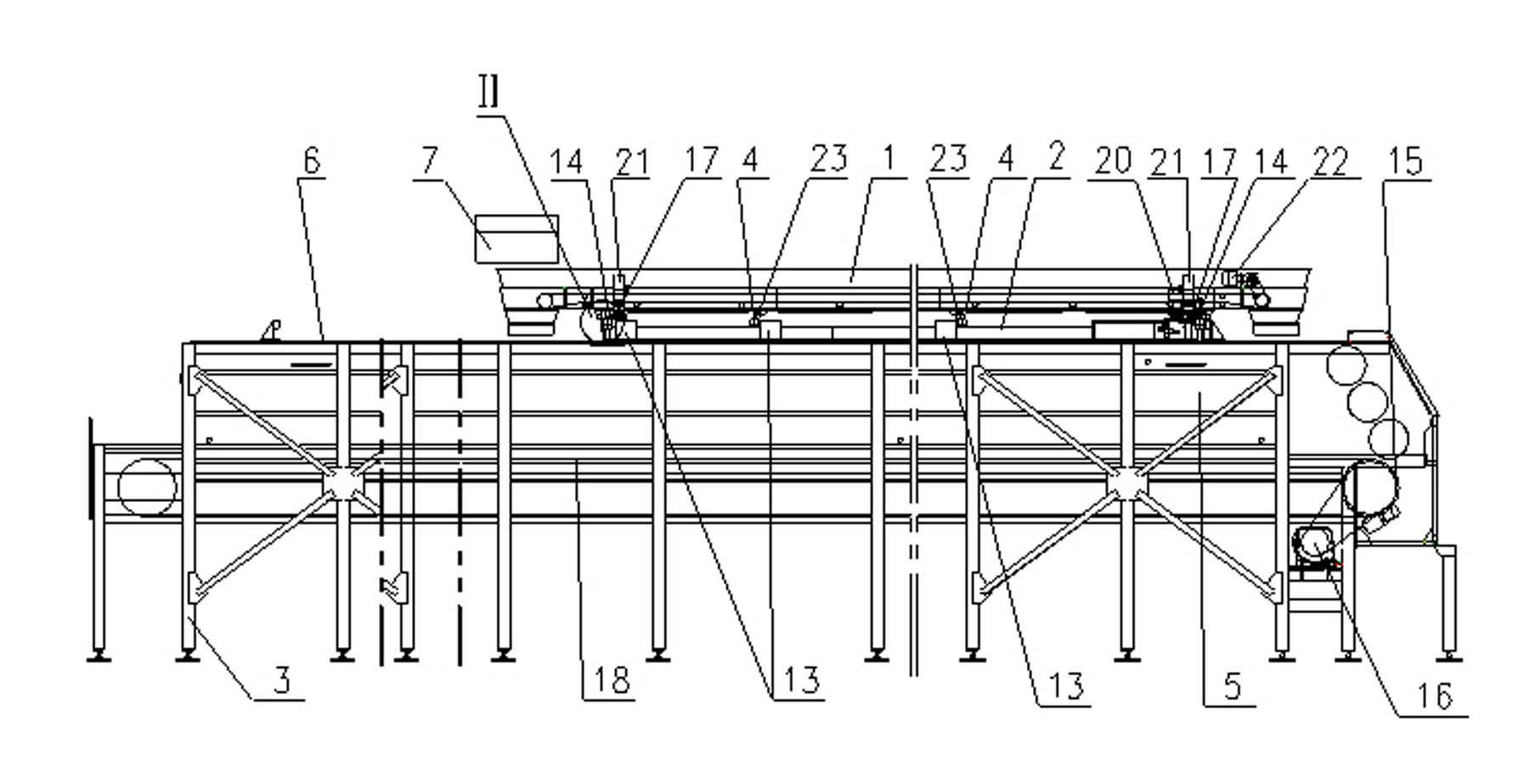

Integrated storage cabinet with flexible material distribution effect

InactiveCN102530578AMeet proportional mixing needsNot easy to bend and deformTobacco preparationLoading/unloadingReciprocating motionEngineering

The invention discloses an integrated storage cabinet with the flexible material distribution effect, which comprises a storage cabinet (5), a longitudinal reciprocating trolley (2), a transversal reciprocating trolley (1) and a conveyer belt, wherein L-shaped chain tracks (18) are symmetrically arranged on the inner side of a storage cabinet frame (3) and extend in the longitudinal direction of the storage cabinet, a conveyor chain belt (19) is arranged on the chain tracks, the two sides of a supporting bar (8) which is positioned at the bottom of the storage cabinet are arranged on a conveyer chain (11) of the conveyor chain belt, and a chain driving device (16) drives the conveyer chain to move the conveyor chain belt on the chain tracks; the width of the storage cabinet is 1400 mm to 5500 mm, and the storage capacity is 2 tons to 60 tons; a longitudinal guide track (6) is arranged at the top of the storage cabinet, and the longitudinal reciprocating trolley is positioned on the longitudinal guide track and makes a reciprocating motion; a transversal guide track (4) is arranged on the frame of the longitudinal reciprocating trolley, and the transversal reciprocating trolley is positioned on the transversal guide track and driven by a multipoint driving device (21) to make a reciprocating motion and selectively distribute materials in any region in the width direction of the storage cabinet; and a support roller guide track (10) is arranged at the bottom of the storage cabinet frame, a support roller component (9) is arranged at the bottom of the supporting bar and in the position corresponding to the support roller guide track, and the support roller component is assembled on the support roller guide track. The storage cabinet can distribute materials in any position in the width direction of the storage cabinet and ensure uniform distribution of materials, meets the requirements for large-formula proportional mixing of materials, has simple structure and low cost, and runs reliably.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

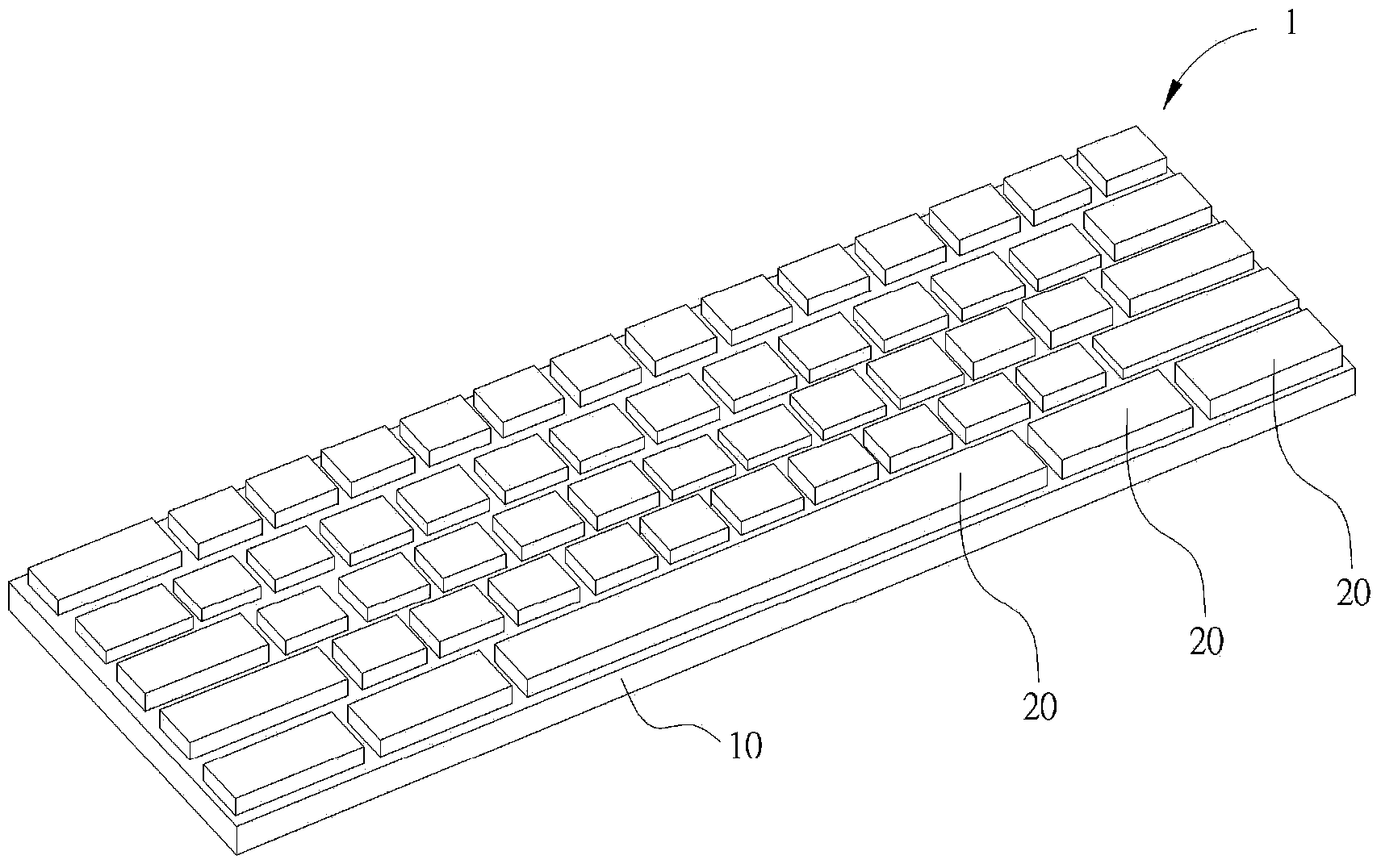

Key and keyboard

The invention provides a thin key and a keyboard design. A reinforcing rod with asymmetric section or oblong section is disposed on the lower surface of a keycap. The rigidity and strength of the keycap is improved, the keycap less easily deforms or bends during high-frequency push, and the see-saw effect when the keycap is pushed is reduced. As the machining processes such as stamping are performed, the sectional size of the reinforcing rod, in the moving direction of the keycap, is smaller than that in other directions, the shank strength of the reinforcing rod is maintained and the motion of the keycap is unaffected.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Novel material spectacle frame processing and forming method

The invention provides novel material epoxy resin spectacle arm wires, a novel material epoxy resin spectacle frame and a processing and forming method thereof. The material of the spectacle arm wires and the spectacle frame is prepared from an epoxy resin raw material, a diluents, a curing agent and a softener; the processing and forming technique of the spectacle arm wires and the spectacle frame comprises: preparing raw materials, preheating a mold, preparing glue, defoaming, filling mold, curing, cooling, demolding, polishing and assembling. The spectacle arm wires and the spectacle frame processed and formed by the method have the advantages that: the wear is comfort; the appearance is beautiful; the spectacle frame is firm and durable; and the like. The production cost is low and is acceptable for common consumers.

Owner:方国彪

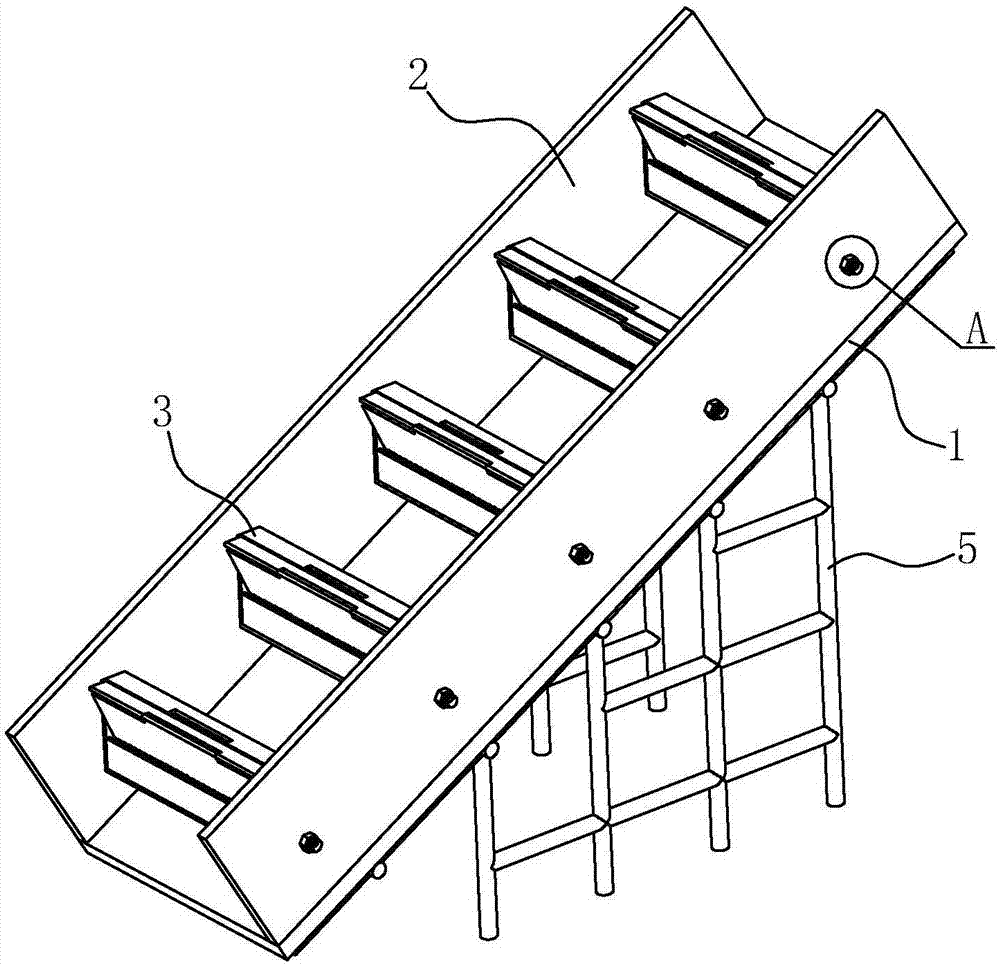

Stair formwork structure and stair construction method adopting same

ActiveCN106988529ANot easy to damageExtended service lifeTreadsForms/shuttering/falseworksSteel platesStairs

The invention discloses a stair formwork structure and a stair construction method adopting the same. The formwork structure comprises stair side formworks, a stair bottom formwork and a supporting structure for the stair bottom formwork; a plurality of stair spacing formworks are further included, each stair spacing formwork is of a rectangular structure, and the stair spacing formworks are formed by cutting, bending and welding steel plates; one side of each stair spacing formwork is a plane and used for blocking concrete; the other side of each stair spacing formwork forms a groove-shaped structure with side walls, wherein the side walls comprise the upper and lower long side walls and the left and right short side walls; mounting holes are formed in each short side wall, and the stair spacing formworks are fixedly connected to the stair side formworks through screws penetrating through the mounting holes; each stair side formwork is a batten; and a prying opening is formed in the upper long side wall of each stair spacing formwork. The formwork has the advantages of being convenient to construct and remove, not prone to being damaged and long in service life.

Owner:闫相明

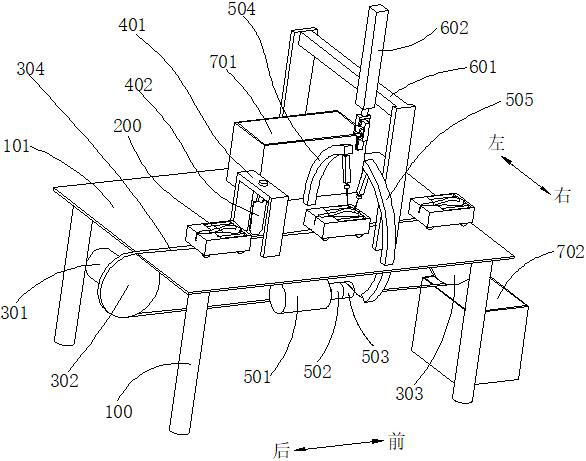

Chicken leg boning equipment

InactiveCN111887285ASimple structureEasy to operatePoultry deboningPoultry transferring/conveying devicesAnatomyEngineering

The invention discloses chicken leg boning equipment. The chicken leg boning equipment comprises a rack, a circulating conveying module, a dissection module, a breaking-off module, a gripping module and a plurality of traveling blocks, wherein the circulating conveying module, the dissection module, the breaking-off module and the gripping module are all mounted on the rack, the traveling blocks are sequentially mounted on the circulating conveying module and are driven by the circulating conveying module to do reciprocating circulating motion, and a cavity for placing a chicken leg is formedin each traveling block; and the breaking-off module comprises a guiding driving unit, a left telescoping unit and a right telescoping unit, the left telescoping unit and the right telescoping unit are separately inserted into the corresponding chicken leg from the two sides of an incision during outstretching, the guiding driving unit is used for drawing the two telescoping units after the left telescoping unit and the right telescoping unit outstretch, and thus, the two telescoping units can swing towards mutual-outlying directions so as to break off the corresponding chicken leg from the incision and expose chicken leg bones. The chicken leg boning equipment is simple in structure and good in boning effect.

Owner:从海彬

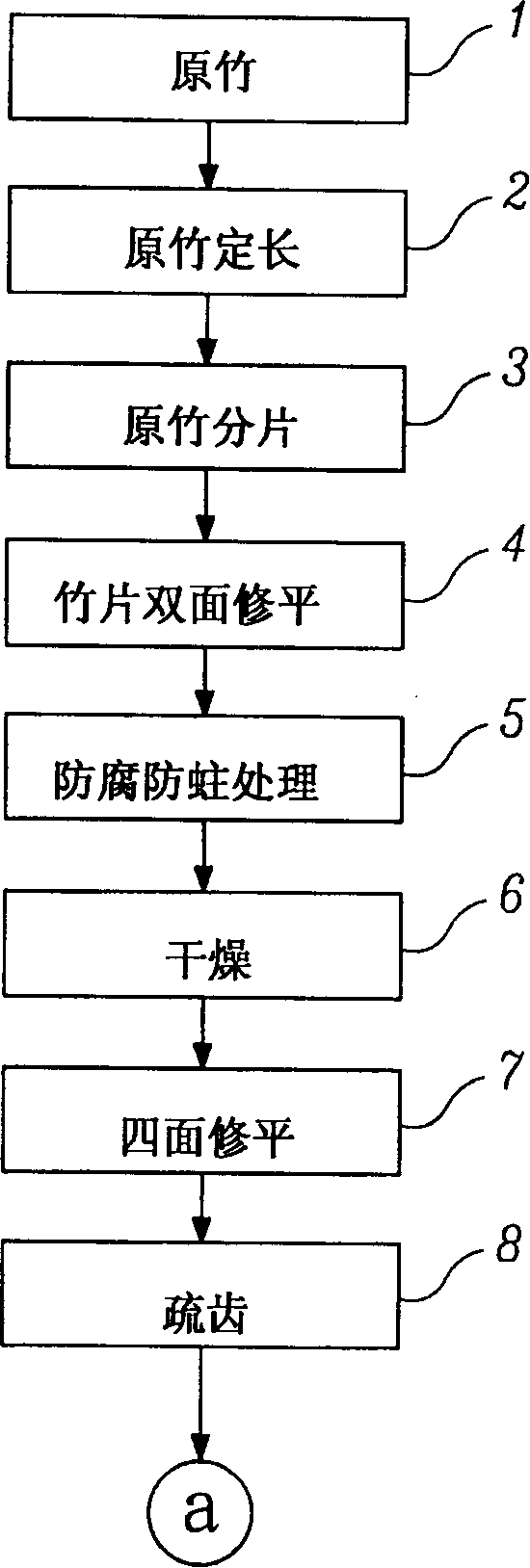

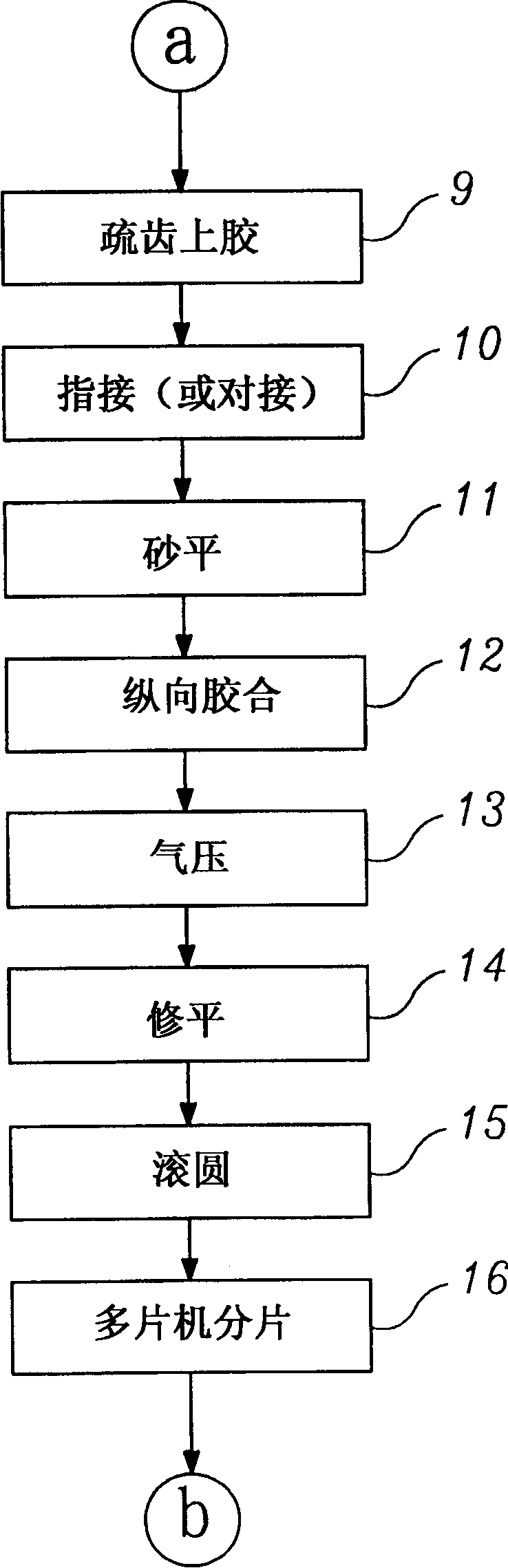

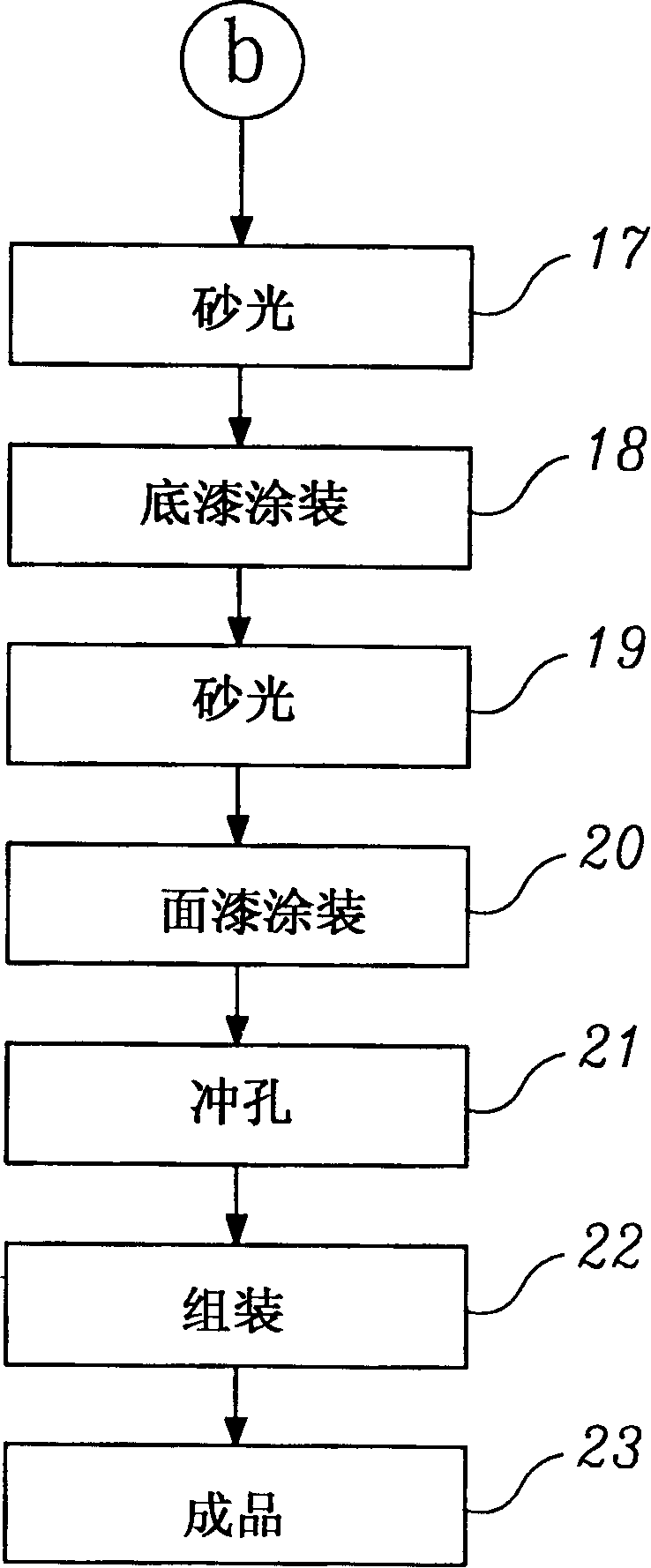

Bamboo louvre blade and its production method

InactiveCN1395021AOvercome the problem of length extensibility requirementsImprove stabilityCane mechanical workingLight protection screensEngineeringRot-proof

The present invention relates to a bamboo window curtain blade and its production method. Said method includes the following steps: selecting bamboo material, defining length of raw bamboo, spliting raw bamboo to obtain bamboo sheet, rot-proofing and moth-proofing treatment, drying, flattening four sides of bamboo sheet, joining, moulding and broaching, glueing, joint, sand-flattening, veneering, matching, sand-polishing, coating prime paint, sand-polishing and coating face paint so as to obtain the invented product.

Owner:程丰原

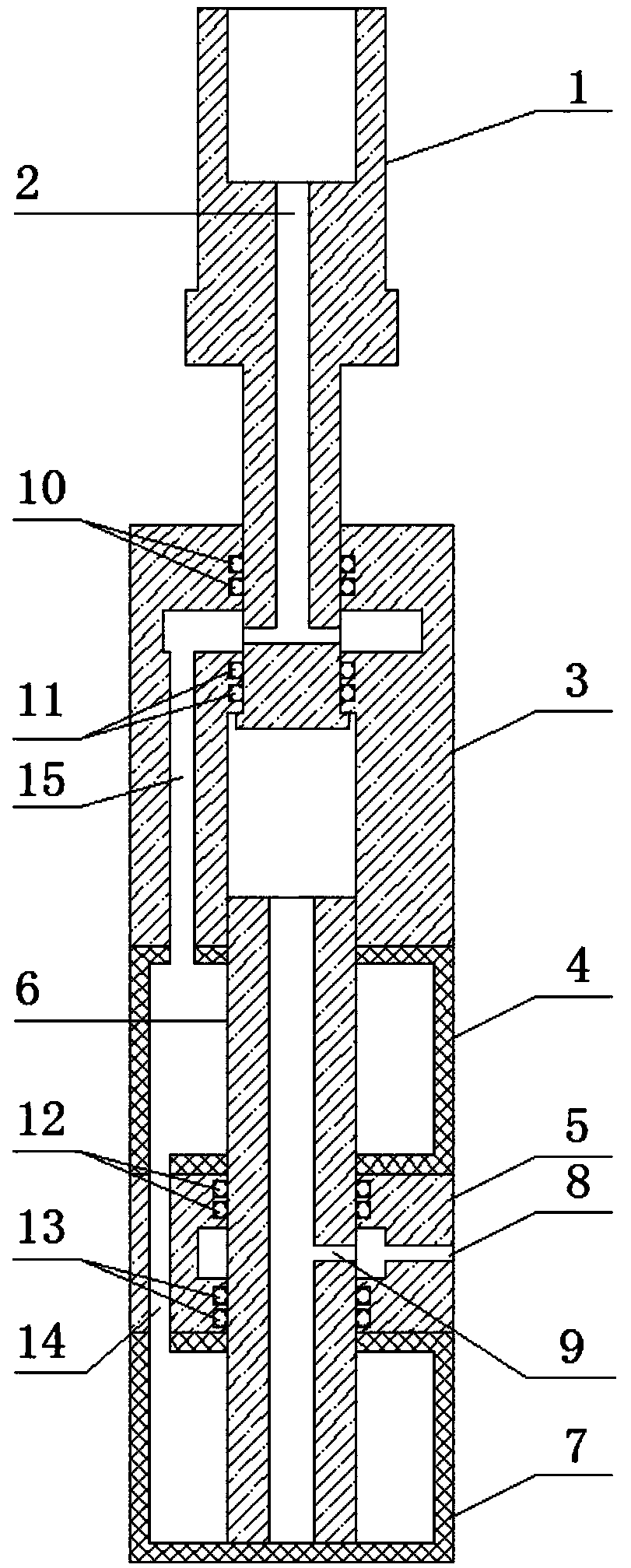

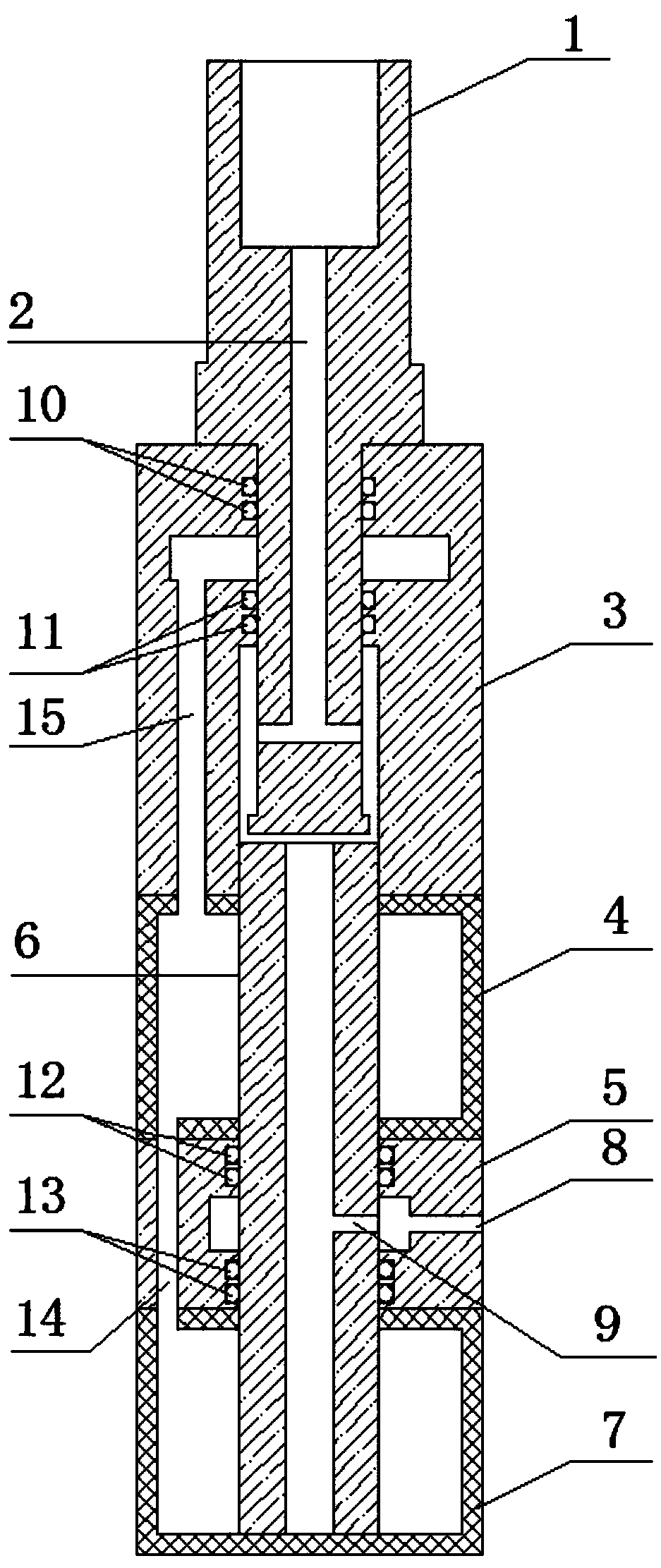

Hydraulic fracturing ground stress testing device with equal diameter design

PendingCN108756872AReduce gapEliminate stuck problemsFluid removalGeothermal energy generationHydraulic fracturingEngineering

The invention discloses a hydraulic fracturing ground stress testing device with equal diameter design. The hydraulic fracturing ground stress testing device comprises a sliding valve rod, a valve seat, an upper packer, a lower packer, a fracturing shock tube and a central rod. The sliding valve rod is disposed in the valve seat in a penetrating mode and extends out of the upper end to be connected to the lower end of a drill pipe. The sliding valve rod is internally provided with a valve rod water hole communicating with an inner hole of the drill pipe. The central rod is connected to the lower end of the valve seat and is sleeved with the upper and lower packers and the fracturing shock tube. The valve seat, the upper and lower packers and the fracturing shock tube have the same outer diameter. An L-shaped through hole communicating an inner cavity of the valve seat with an inner cavity of the upper packer is formed in the valve seat. A packer communicating hole communicating an inner cavity of the upper packer with an inner cavity of the lower packer is formed in one side of the fracturing shock tube, a fracturing water hole communicating with an inner hole of the central rod isformed in the other side of the fracturing shock tube. The sliding valve rod is provided with two stations including an upper station and a lower station in the inner cavity of the valve seat, and asingle loop is achieved. The hydraulic fracturing ground stress testing device with the equal diameter design has the advantages that the appearance is attractive, bending and deformation are not prone to occurring, and the phenomenon of getting stuck in a drill hole is not prone to occurring.

Owner:地泰科学仪器(武汉)有限公司

A kind of formula of steel paper and preparation method thereof

ActiveCN103321101BNot easy to bend and deformLoss of flatnessSpecial paperPaper/cardboardFiberChloride

Owner:启东市洁慧新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com