Patents

Literature

152 results about "Natural forest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

NATURAL FORESTS. Definition of a natural forest. A natural forest is a generally multilayered vegetation unit dominated by trees (largely evergreen or semi-deciduous), whose combined strata have overlapping crowns (i.e. the crown cover is 75% or more), and where grasses in the herbaceous stratum (if present) are generally rare.

Pholiota nameko culture method

InactiveCN102613006ATake full advantage of the mushrooming effectRaw materials are easy to getHorticultureFertilizer mixturesPholiotaMycelium

The invention relates to a pholiota nameko culture method, which comprises the steps of: culture material proportioning and preparation, sterilization, inoculation and bagging, mycelium culture, summer-crossing management and primordium inducement fruiting. The pholiota nameko culture materials comprise the following recipe and mixture ratios: 30 to 50 parts of corncobs, 30 to 50 parts of soft mixed hardwood sawdust, 10 to 20 parts of bran, 2 to 4 parts of corn starch, 0.5 to 1.5 parts of gypsum and 0.5 to 1.5 parts of lime. The culture raw materials adopt the corncobs and the soft mixed hardwood sawdust as major materials, a good basis is laid for the smooth implementation of the Natural Forest Protection Projects and the pholiota nameko planting in flat areas, planting trays are omitted, the culture cost can be saved by 15 percent, the culture process is simple and is easy to implement, the work efficiency is improved, the edge fruiting effect of the pholiota nameko bag type culture is improved by 30 percent through being compared with that of the disc type culture, the edge fruiting effect of the edible fungi is sufficiently utilized, the yield can be improved by more than 10 percent, and the high-quality fruiting rate is improved by more than 40 percent.

Owner:沈阳蕈丰食用菌科技有限公司

Production and cultivation of glossy ganoderma with tea branch, tea, stem material

The invention relates to a production process method for mythic fungus cultivation by tea branches, tea and peduncle-replaced materials. The production process method is characterized in that the proportions are as follows: 33-53% of tea branches, 17-27% of peduncles, 18-48% of wheat bran, 1-2% of brown sugar, 0.5-1% of gypsum and 0.1-0.5% of calcium superphosphate. A plurality of wasted tea branches generated during the cutting process in tea garden, tea and peduncles in the tea making process are sufficiently utilized; furthermore, special inducible factors such as tea polysaccharides, vitamin, trace elements, etc. that are rich in the tea branches and tea peduncles can be utilized to produce the mythic fungus with the 1.5-2.5% of the content of the tea polysaccharides which is higher than that of the current mythic fungus cultivated by the replacing material such as tree sawdust, cotton seed shell, etc. by 24.5-35.8%; meanwhile, the tea can prompt the synthesis of extracellular polysaccharide of mythic fungus, improves the quality and medicinal efficacy of the mythic fungus, cultivates the mythic fungus by the tea branches, tea and peduncle-replaced material, increases new replacing material for the mythic fungus cultivation, prompts the development of Chinese mythic fungus production, and is beneficial to the execution of the Chinese natural forest protection engineering.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Method for building near-natural forest for subtropical city

The invention discloses a method for building a near-natural forest for a subtropical city. The method is characterized in that deciduous broad-leaf trees with seedling age as 4-5 years and evergreen broad-leaf trees with the seedling age as 2-3 years are adopted for building a different-age multiple-layer deciduous-evergreen broad leaf mixed near-natural forest. The lower layer of the mixed near-natural forest is evergreen broad-leaf trees with seedling height as 0.2-1.0 meter accounting for 70% of mixed biocoenosis, the upper layer of the mixed near-natural forest is deciduous broad-leaf trees with seedling height as 1.5-2.5 meters accounting for 30% of the mixed biocoenosis, a different-age biocoenosis structure is formed, and view of the near-natural forest for the subtropical city is fast built. Compared with the prior art, the method is simple, the near-natural forest is easy to build, low in cost, complete in biocoenosis structure, rich in diversity of species, high in biomass and less in manual management. The method is especially suitable for building the subtropical near-natural forest view for cities in a Yangtze river delta area.

Owner:EAST CHINA NORMAL UNIV

Dendrobiumpaxt natural forest implantation high-yield culture technique

ActiveCN104429472AImprove yield and qualityProtect environmentGrowth substratesFertilising methodsEconomic benefitsPest control

Disclosed is a dendrobiumpaxt natural forest implantation high-yield culture technique. Seedlings cultured artificially are transplanted to main attachment trees in the natural forest, artificial protection and production are carried out, broad-leaved evergreen trees in the natural forest in the proper environment are selected as the main attachment trees to transplant artificially-cultured fine breed cutting seedlings, water and fertilizer application, pest control and artificial management are carried out to obtain the organic high-yield dendrobium, forest resources are protected, planting cost is lowered, and social benefits and economic benefits are good, and the technique is suitable for being popularized.

Owner:LONGLING COUNTY RES INST OF DENDROBIUM

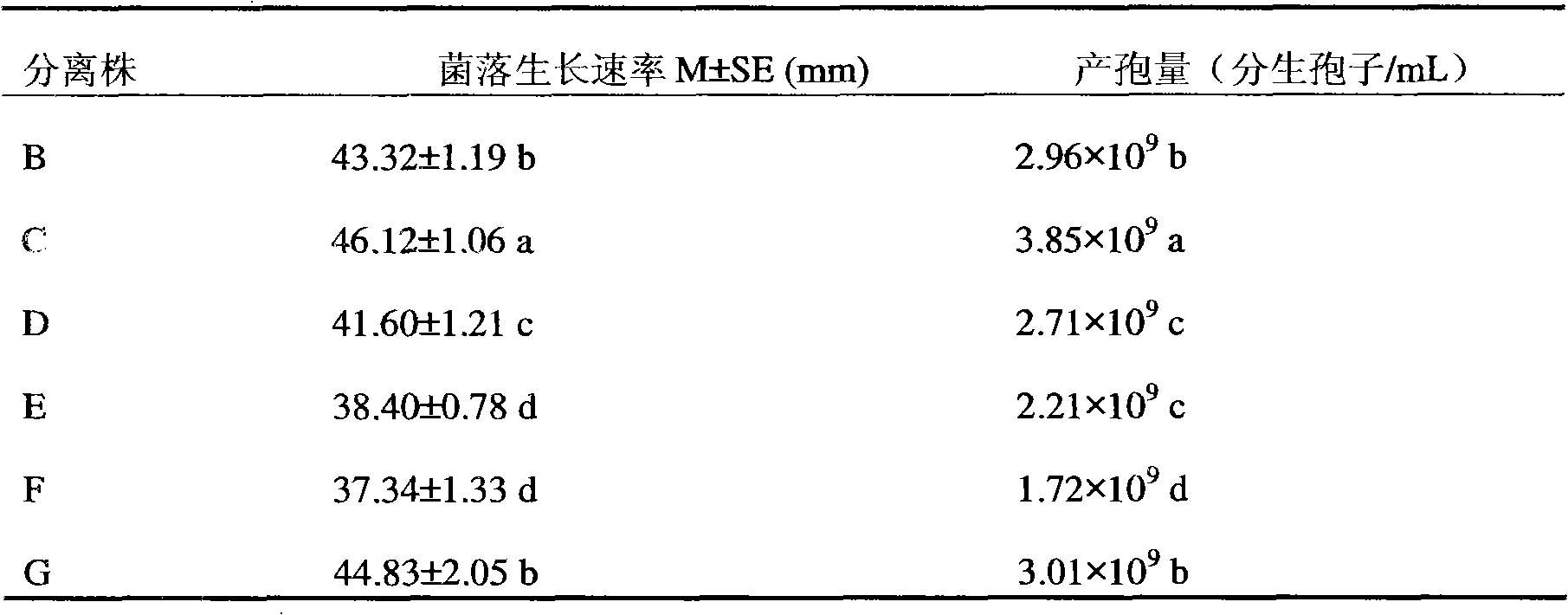

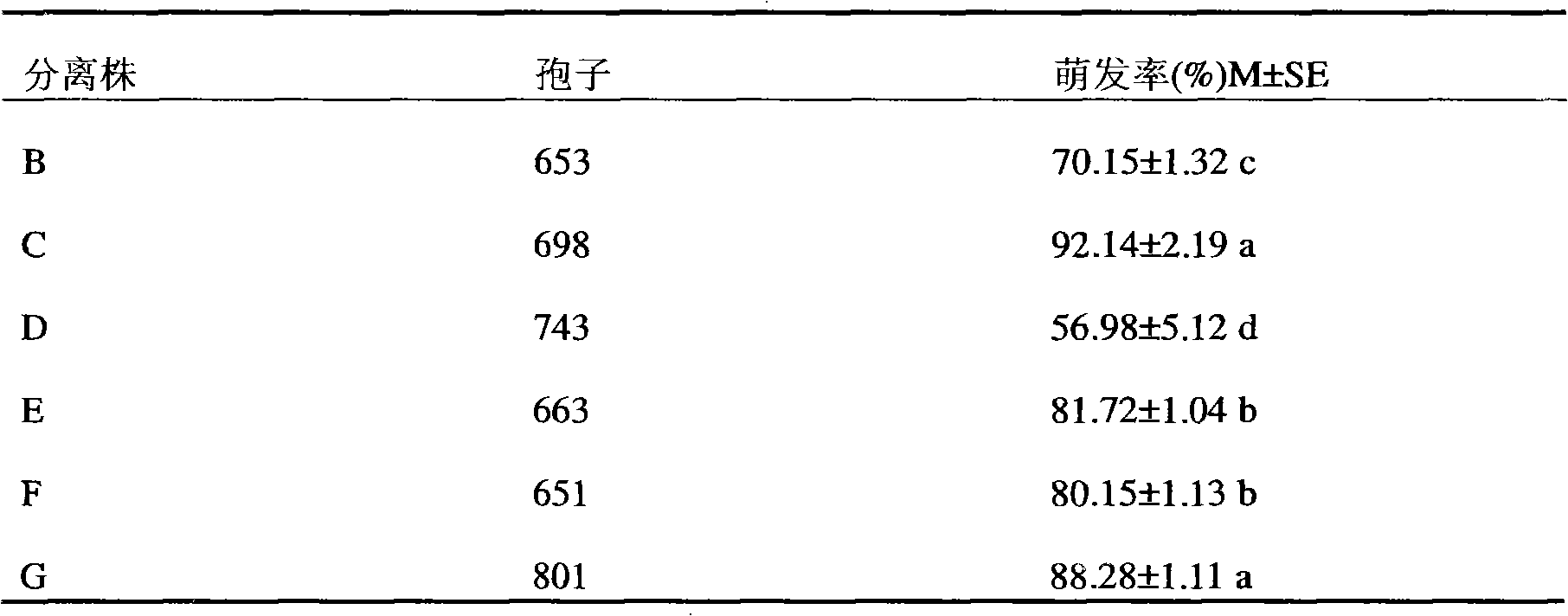

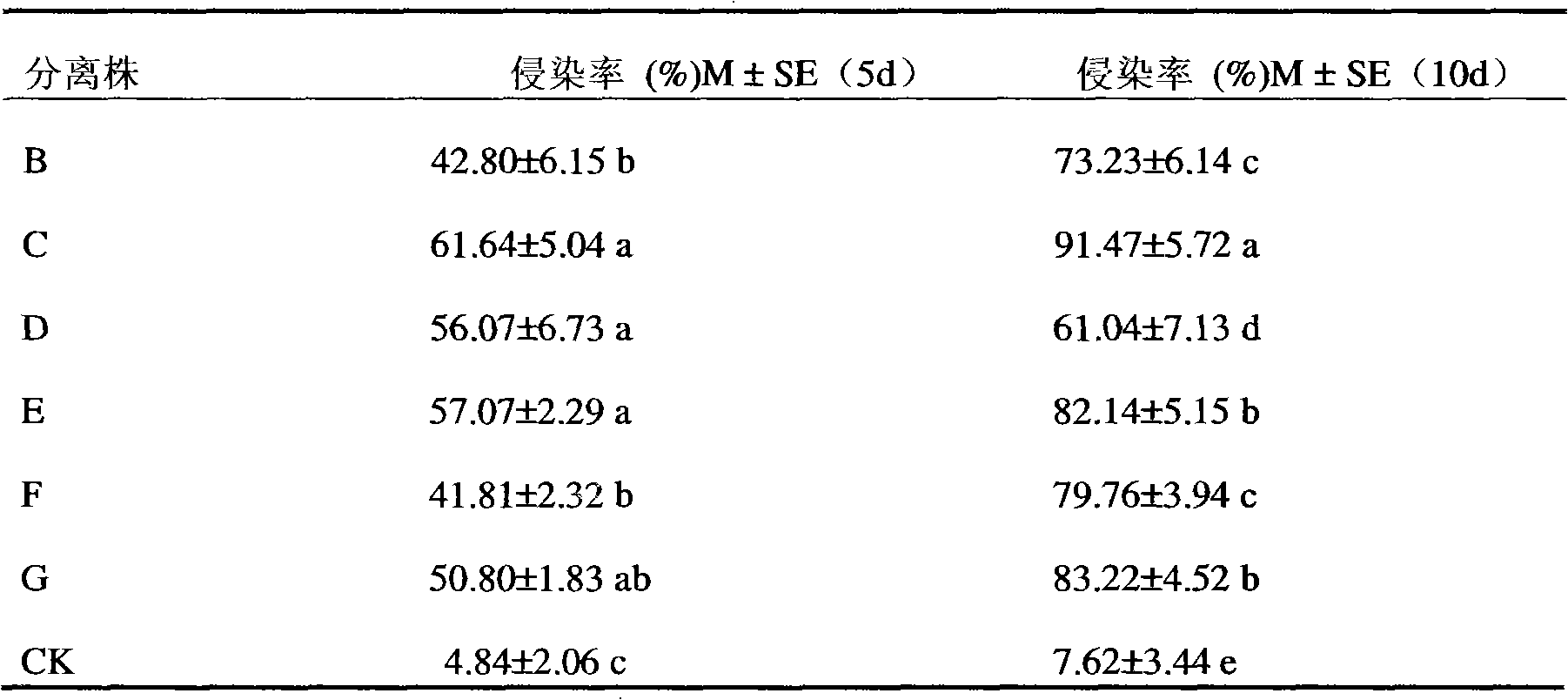

Fungi Imperficti strain and uses thereof

InactiveCN101343614AAdapt to production requirementsNo pollution in the processBiocideFungiBiotechnologyPlutella

The invention discloses paecilomyces javanicus strain and the application thereof. The strain adopts paecilomyces javanicus IJ-N2, the strain is preserved in the China Center for Type Culture Collection on tenth of June in 2008 with a CCTCC No of M208085. The strain is wild strain obtained through separating a plutella xylostella body naturally infested by entomogenous fungous from Nonggang Natural Forest Reserve Areas in Guangxi, the paecilomyces javanicus strain is obtained through the wild strain being back inoculated to the plutella xylostella body for rejuvenation, and depurative strain is obtained through the monospore separating operation being performed to the strain. The paecilomyces javanicus strain has strong infestation and insecticidal effect to aleyrodids, solenopsis invicta buren, spodoptera litura, aphid and plutella xylostella according to long-term infection biology study and indoor bioassay.

Owner:GUANGDONG XINJINGXIANG BIOLOGICAL ENG CO LTD

Method for planting dendrobium officinale on living tree

InactiveCN106982724AHigh outputReduce land costCultivating equipmentsSoilless cultivationDiseaseCollection period

The invention relates to a method for planting dendrobium officinale on a living tree. The method is characterized by comprising the following steps of 1, selecting a planting site, 2, selecting and processing the living tree used for planting the dendrobium officinale, 3, selecting and processing nursery stocks, 4, planting is conducted and 5, after-planting management. The method takes full use of natural forest resources, saves the land cost and improves the yield of a standing forest, by controlling water in the planting site, pests, diseases and other aspects, the dendrobium officinale growing on the living tree is obtained, the problem that the collection period is short is solved, and the reliability and safety of the products are ensured; naturalized dendrobium officinale tissue culture seedlings vigorous in growth and developed in root system are selected as the nursery stocks, then the nursery stocks are planted on the living tree, and the survival rate is high; materials are easy to obtain, the production cost is low, the operation is simple and convenient, and the method has good economic and social and ecological benefits.

Owner:恩施土家族苗族自治州林科所

Culturing method capable of improving egg hatching rate and chick immunity

The invention relates to a culturing method capable of improving egg hatching rate and chick immunity. The culturing method comprises steps of (A) selecting seeds and preparing seeds, (B) collecting and sieving hatching eggs and make preparation before hatching, (C) hatching eggs under light condition, (D) breeding chicks in a greenhouse under light condition, (E) managing young chick without heat supply under the light condition, and (F) breeding children with a method of combining stocking and supplementary feeding in a natural forest land. Compared with the prior art, the culturing method is simple and convenient to operate, requires less investment and has obvious economic effects; fertility rate, oviposition quality and quality of to-be-hatched eggs can be improved during chick culturing, so hatching rate and young chick survival rate can be improved; young chick growth and development can be promoted, immunity of chicks can be improved and chick culturing survival rate can be guaranteed; free range chicks with tender meat quality, fresh taste and high nutrient value as well as meeting green food standards can be achieved; and the chicken and eggs produced by the culturing method are advantaged by high protein, high vitamin, low cholesterol and low fat.

Owner:SICHUAN AGRI UNIV

Method for reforming closed pure pinus massoniana forest into mixed forest

InactiveCN106358974AGrowth is not suppressedReduce construction costsClimate change adaptationAfforestationBiological propertyEconomic benefits

The invention discloses a method for reforming a closed pure pinus massoniana forest into a mixed forest. The method comprises the following steps: selecting proper mixing tree species from the closed pure pinus massoniana forest according to retention density after intermediate cutting and biological characteristics of the mixing tree species, and planting 1-5 mixing tree species randomly according to a certain ratio. The method aims to form a long-term pinus massoniana artificial mixed near-natural forest with both ecological and economic functions, and on the basis of the time that a young pinus massoniana forest, a middle-aged pinus massoniana forest and a near-mature pinus massoniana forest are subjected to intermediate cutting for multiple times, and the sufficient consideration of the biological characteristics of the mixing tree species, proper mixing tree species with economic values can be reasonably selected. Practical applications show that the method is suitable for reforming the pure pinus massoniana forest into the mixed forest after closing under conditions of different tree ages and environments, the efficiency in artificially constructing the mixed forest can be remarkably improved, the mixed forest construction time can be shortened, the planting cost of mixed forest construction can be reduced, and due to multiple tree species and long and short-term planting, the economic benefits and the ecological benefits of the mixed forest can be sufficiently brought into play.

Owner:GUANGXI FORESTRY RES INST

High-density composite board specially used for wood floor and manufacturing method thereof

ActiveCN102409835AChange material propertiesMeet the decoration needsWood working apparatusFlooringHigh energyHigh pressure

The invention relates to a high-density composite board specially used for a wood floor and a manufacturing method thereof. The manufacturing method comprises the following steps of: taking wood from a reproducible quickly growing tree as a main raw material; forming a wood modifier by water-soluble phenolic resins, preservatives, sulphonating lignin and liquid bentonite; modifying a veneer or wood strip and then forming a blank together with non-woven fabrics; and gluing the blank under high temperature and high pressure, thereby manufacturing the high-density composite board with a density of 0.8-1.2g / cm<3>. The wood property of wetting swelling and drying shrinkage of the wood is changed, thereby being capable of meeting the demands of the wood floor on various indexes, such as hardness, dimensional stability, appearance, foot feeling, mechanical property, environmental protection, and the like. Instead of natural hard wood, the high-density composite board specially used for the wood floor is used for manufacturing the wood floor, thereby meeting a floor decorative requirement of people while protecting a natural forest, reducing the usage of high energy-consumption floor decorative materials such as cement and ceramic tiles, and indirectly achieving an effect of energy conservation and emission reduction.

Owner:内蒙古清研沙柳产业工程技术中心有限公司

Large-scale high-density wood-based material and method for manufacturing same through microwave heating, pressing and gluing

InactiveCN103991111AHigh hardnessGood mechanical propertiesWood treatment detailsWood veneer joiningWood veneerCotton gauze

The invention relates to a large-scale high-density wood-based material. The blank of the large-scale high-density wood-based material is jointly formed by wood veneer from quick growing species of trees or salix psammophila wicker from shrubs, net-shaped cotton gauze and phenolic resin. By means ofThrough a method for manufacturing the large-scale high-density wood-based material through microwave heating, pressing and gluing, the blank undergoes the five procedures including pre-pressing, heating softening, pressing densifying, heating solidifying and pressure keeping cooling in a vertical and horizontal integrated microwave heating press and then can be manufactured into the large-scale high-density wood-based material of 2500mm-30000mm*400mm*300, the density of the material is larger than or equal to 0.7 g / cm<3>, and the mechanical indexes of the material can meet various index requirements of building materials. Thus, an environment-friendly and energy-saving wood engineering structure material is provided for the building industry, favorable support is provided for developing multi-storey wood structure houses, and the large-scale high-density wood-based material is favorable for protecting natural forest resources and controlling desert.

Owner:ERDOS CITY HUALIN SALIX TECH CO LTD

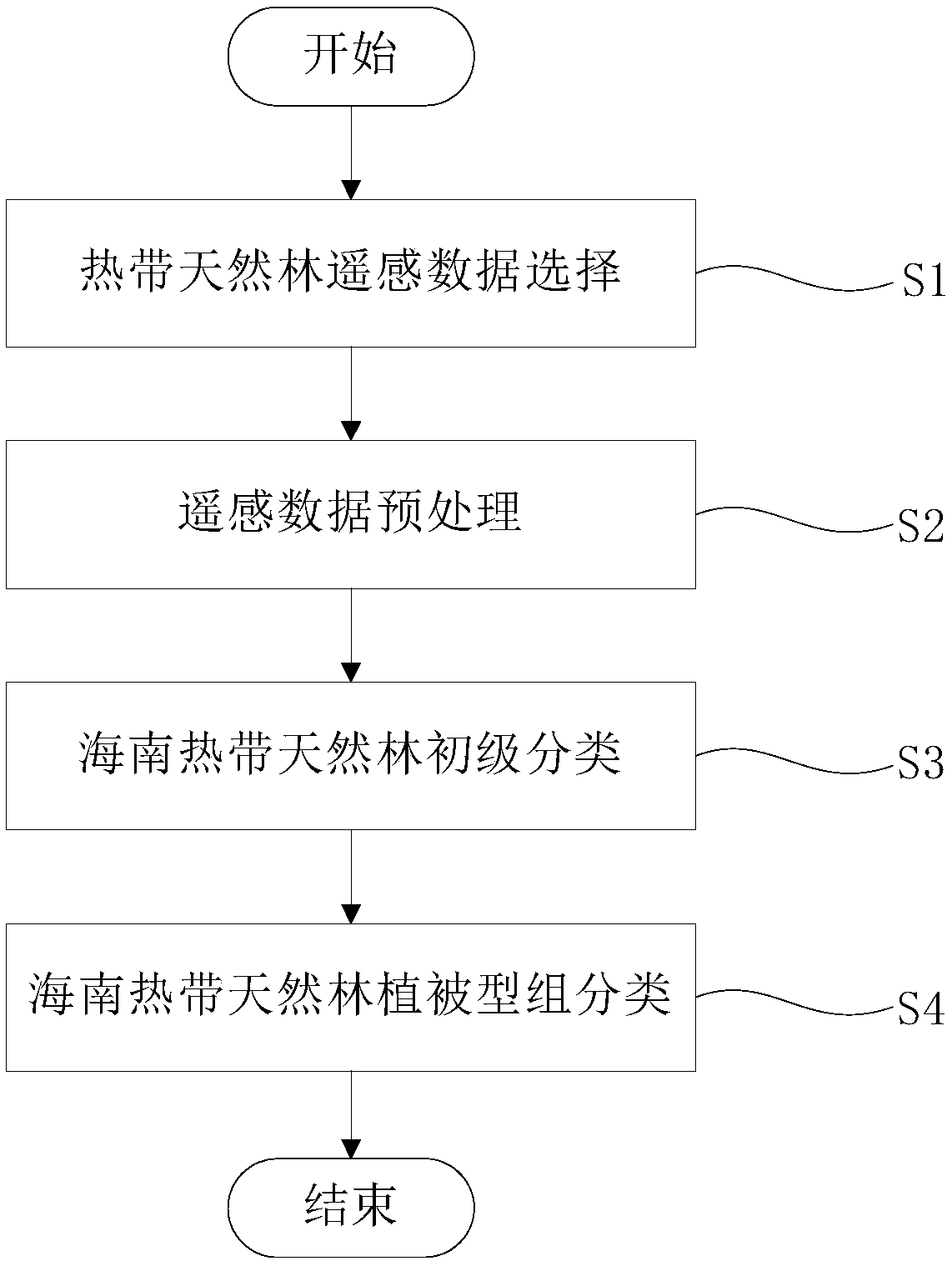

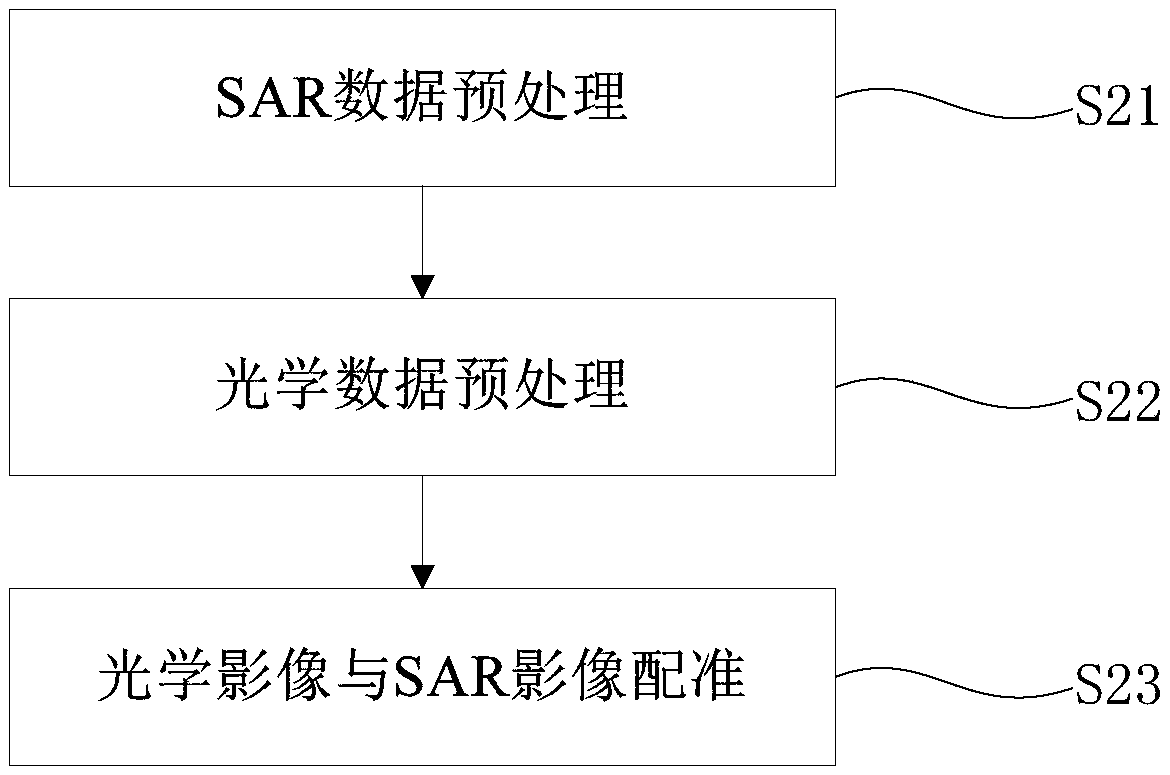

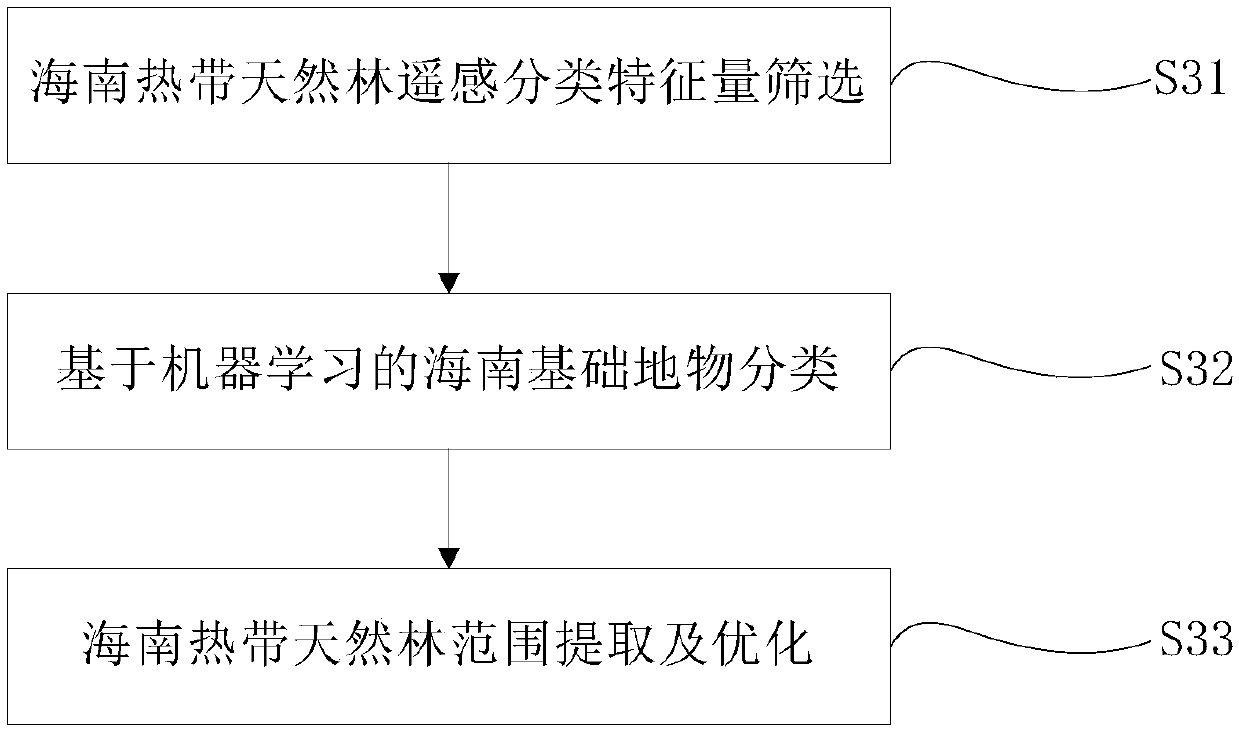

Classification method of tropical natural forest vegetation type groups in Hainan

InactiveCN108681715AImprove classification effectGood effectComputing modelsScene recognitionThree levelSensing data

The invention discloses the classification method of tropical natural forest vegetation type groups in Hainan. In the invention, multi-temporal SAR data and mono-temporal less-cloud-covered optical remote sensing data are used to analyze a typical tropical forest land spectrum and scattering characteristic difference and dry and rainy season change information. A Hainan tropical natural forest vegetation type group type and a Hainan tropical natural forest growth distribution rule are combined and a remote sensing vegetation type group classification system suitable for a Hainan tropical natural forest is provided. Based on that, a Hainan tropical natural forest classification method based on machine learning is established. The method provides a solution for the remote sensing classification problem of a natural forest vegetation type group (three-level class) in the Hainan Island, and classification precision is higher than 80%.

Owner:三亚中科遥感研究所 +1

Bamboo-wood composite board with high-strength bamboo plywood coated on the surface and manufacturing method thereof

ActiveCN102717409AEfficient use ofGrow fastSynthetic resin layered productsLaminationWood veneerAgricultural engineering

The invention relates to the technical field of composite boards, and in particular to a secondary-shaped bamboo-wood composite board, comprising a veneer layer, a bamboo plywood layer, and a bamboo curtain layer. The bamboo-wood composite board is characterized in that: the veneer layer includes a vertical-texture eucalyptus wood veneer, a horizontal-texture eucalyptus wood veneer or a vertical fir wood sheet; the bamboo plywood layer includes a second bamboo plywood layer or a third bamboo plywood layer; and the bamboo curtain layer includes a vertical bamboo curtain, a horizontal bamboo curtain or a bamboo mat. Wood in our country and from around the world, such as various coniferous wood and broad-leaved wood in natural forests and planted forests as well as bamboo, a resource with the advantages of fast growth, short cycle, being selectively cut every year and long time of sustainable utilization, can be effectively used. By using the materials compositely based on scientific design and reasonable combination, the problem of hardwood shortage around the world can be solved, and qualified passenger car floors, container floors, truck fences and the like can be mass produced.

Owner:ZHUJI GUANGYU BAMBOO IND

Plant composition for air purification agent

The invention discloses a plant composition for an air purifying agent. The plant composition is characterized by consisting of aloe, bracket-plant, sansevieria, orchis cyclochila, monstera deliciosa, hedera helix, cycas, chrysanthemum, kumquat, pomegranate, sun plant, China rose, camellia, aglaia odorata, daisy, calyx canthus, marigold, orchid, sweet osmanthus, caladium bicolor, excoecaria cochinchinensis, lichen, seaweed, rose, violet, jasmine, lemon, rosebush, crape myrtle, carnation, lily of the valley, cactus, sansevieria trifasciata, agave, opuntia basilaris, laciniate kalanchoe herb, stonecrop, bryophyllum and cultivated pineapple. The product can imitate the principle of natural forest plant purification, quickly decompose various toxic and harmful gases indoors through strong chelate reaction and high-order complexing action, can kill colon bacillus, pseudomonas aeruginosa, staphylococcus aureus and the like with sterilizing rate reaching 99.7 percent, can effectively decompose various toxic and harmful gases, and remove off flavor.

Owner:施忠菊

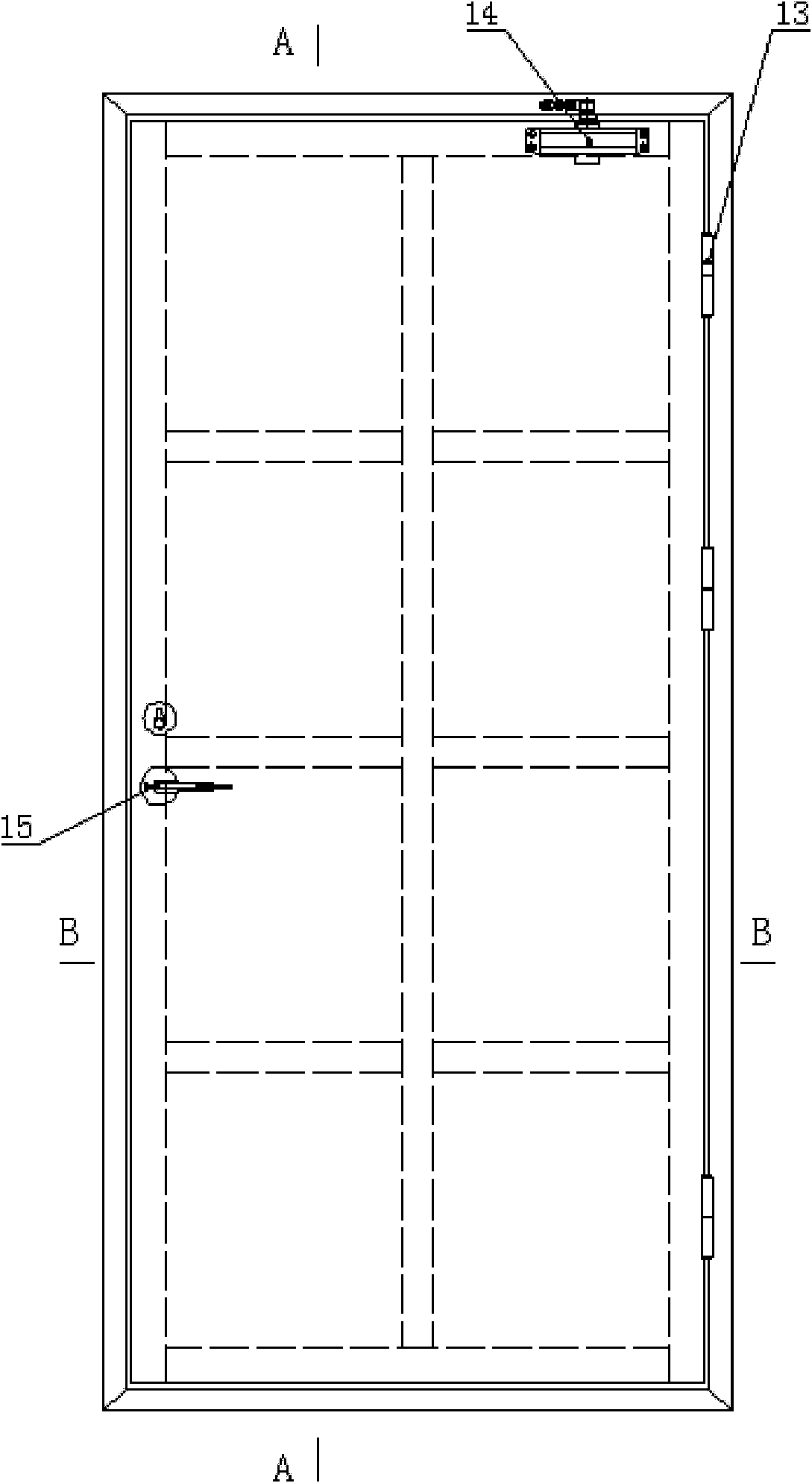

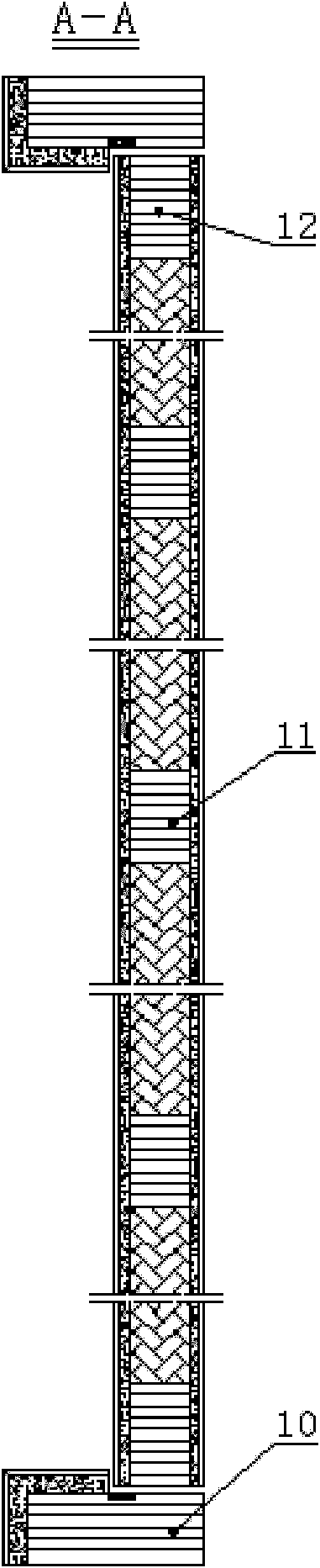

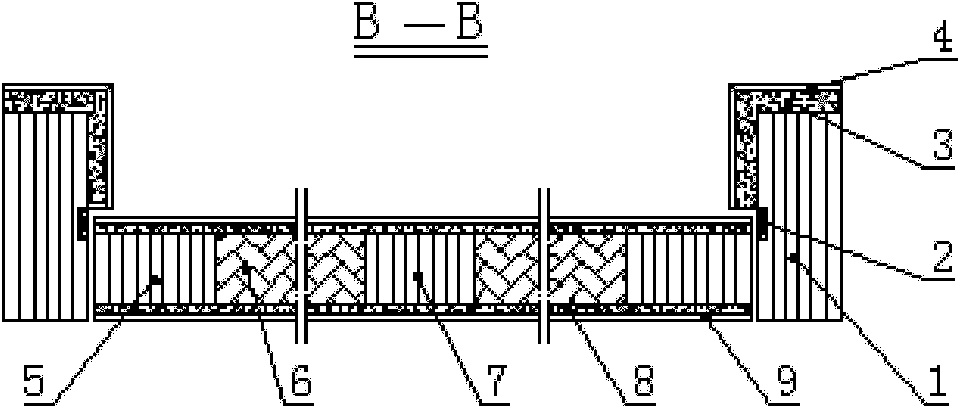

Flame-retardant laminated veneer lumber wooden fireproof door and manufacturing method thereof

The invention discloses a flame-retardant laminated veneer lumber wooden fireproof door and a manufacturing method thereof. The manufacturing method comprises the following steps of: manufacturing flame-retardant laminated veneer lumber by using low-grade fast growing wood; and manufacturing a door frame and a door leaf framework by using the flame-retardant laminated veneer lumber, wherein the door frame consists of a vertical frame and a horizontal frame through tenon combination; the door leaf framework consists of two edge horizontal keels, two edge vertical keels, a plurality of middle vertical keels and a plurality of middle horizontal keels through tenon combination; the longitudinal textures of the wood grain of the laminated veneer lumber are parallel to the length directions of the frames of the door frame and the keels of the door leaf framework, and an adhesive layer surface is vertical to the surface of the door leaf; the width of the frames of the door frame is 90 to 110mm, and the thickness is 40 to 50mm; and the width of the edge keels of the door leaf framework is 50 to 60mm, the width of the middle keels is 40 to 50mm, and the thickness of the door leaf framework is 35 to 40mm. The flame-retardant laminated veneer lumber wooden fireproof door is made of the low-grade fast growing wood, the use value of the low-grade wood is improved and natural forest resources are protected.

Owner:宿迁新缘林木业有限公司

Method of cultivating landscaping trees by wild-to-artificial cultivation of Choerospondias axillaris

ActiveCN104620828AGuaranteed genetic endowmentPlant cultivationCultivating equipmentsGermplasmSterile water

The invention relates to the technical field of natural forest protection and recovery, in particular to a method of cultivating landscaping trees by wild-to-artificial cultivation of Choerospondias axillaris. The method includes the steps of a, preparing a nursery and a cutting bed; b, selecting cuttings; c, pruning and treating the cuttings, to be specific, pruning cuttings, and treating the cuttings; d, performing cuttage; e, performing post-cuttage management, to be specific, managing temperature and humidity, applying fertilizers, removing weeds, and controlling disease and pest damage; f, transplanting saplings. The method is characterized in that the cuttings are selected from the male trees of Choerospondias axillaris, which are tall, straight from top to bottom, in leafy profusion and attractive in appearance and which grow for 8 to 10 years; the cuttings are selected from late May to early middle of June, after successive five sunny days, at 8 to 10 AM; the cuttings are treated with 70% ethyl alcohol for 20s and soaked in 0.1% mercury bichloride for 8min, shaking is performed nonstop, and the cuttings are washed five times with sterile water. The method has the advantages that the cuttings are all from male plants of Choerospondias axillaris and Genetic endowment of germplasm resources of wild Choerospondias axillaris can be better guaranteed.

Owner:深圳市高山水生态园林股份有限公司

Production method of charred compound wood

InactiveCN103317567AReduce defective rateRefreshing log colorWood treatment detailsWood charring/burningSolid woodMasson pine

The invention discloses a production method of charred compound wood, belonging to the technical field of processing of forest products. The charred compound wood is produced by three working stages of common solid wood processing, homogeneous charred wood processing and charred compound solid wood processing. The production method has the beneficial effects that common solid wood and homogeneous charred wood have basically same characteristics by adopting common solid wood and homogeneous charred wood which are processed in the same batch as raw materials, and thus the rejection ratio of the charred compound solid wood product is greatly reduced. The charred compound wood is particularly suitable for an outer wall of a wooden house so that the clear color of log on the indoor wall space can be kept, the chemical preservation is replaced and the anti-corrosion property of the outdoor wall space is greatly improved. The charred compound wood can be produced by adopting masson pine wood as a raw material, and thus the application field of the masson pine wood is greatly enlarged, the economical value is increased, valuable timbers and tree species can be replaced, and the contribution is made for maintaining natural forest resources and protecting the nature environment.

Owner:重庆家和琴森木业有限公司

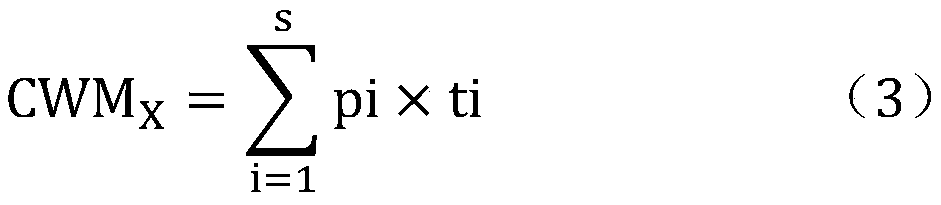

Method for determining wood ages by adopting model method

InactiveCN105808963ANo fellingImprove forecasting efficiencyInformaticsSpecial data processing applicationsModel methodDiameter at breast height

The invention discloses a method for determining wood ages by adopting a model method. The method adopts the mathematic model method to predict the wood ages for a natural different-age-wood forest class consisting of the same tree species and comprises the steps that firstly, woods in the small class are sequentially marked from young trees according to diameter class from small to large; secondly, a mathematic model of the natural forest class consisting of the same tree species is established according to wood diameters at breast heights of all diameter classes marked before observation in successive years; finally, the ages of the woods are calculated through substitution by combining a parameter expression. The method does not need wood felling, does not damage the woods and is small in working amount and easy to operate.

Owner:BEIJING FORESTRY UNIVERSITY

Ecological chicken raising method

The invention relates to a chicken raising method, in particular to an ecological chicken raising method. The method includes the following steps that chicken breeds are selected, specifically, the local native chicken breed suitable for being raised in a free-range mode is selected; a raising site is selected, specifically, a prairie meadowland, a natural forest land, a farm field and the like are selected as the raising site for ecological chicken raising, and transportation is convenient; chicks are raised; the chicks are trained, specifically, the chicks are raised in small fences in a free-range mode after being raised in a house for 4 weeks, and the chicks can be completely raised in a free-range mode after being trained for 4-6 weeks; as for feed stuff, the chicken flocks need reinforced supplement of nutrition apart from self-help feeding with weeds, insects and other natural feed stuff in the forest; the diseases are prevented and treated, specifically, epidemic prevention and treatment need to be well done on the first day after hatching, and vaccination is performed; and raising management is performed, specifically, rope nets or fences can be adopted to form barriers so as to prevent chickens from escaping. By means of the ecological chicken raising method provided by the invention, through nurturing of the natural environment and feeding with organic food, the chicken meat recovers required natural and high quality and is fresh, tasty, high in nutrition value and free of antibiotic residues.

Owner:柳江县素情家禽专业合作社

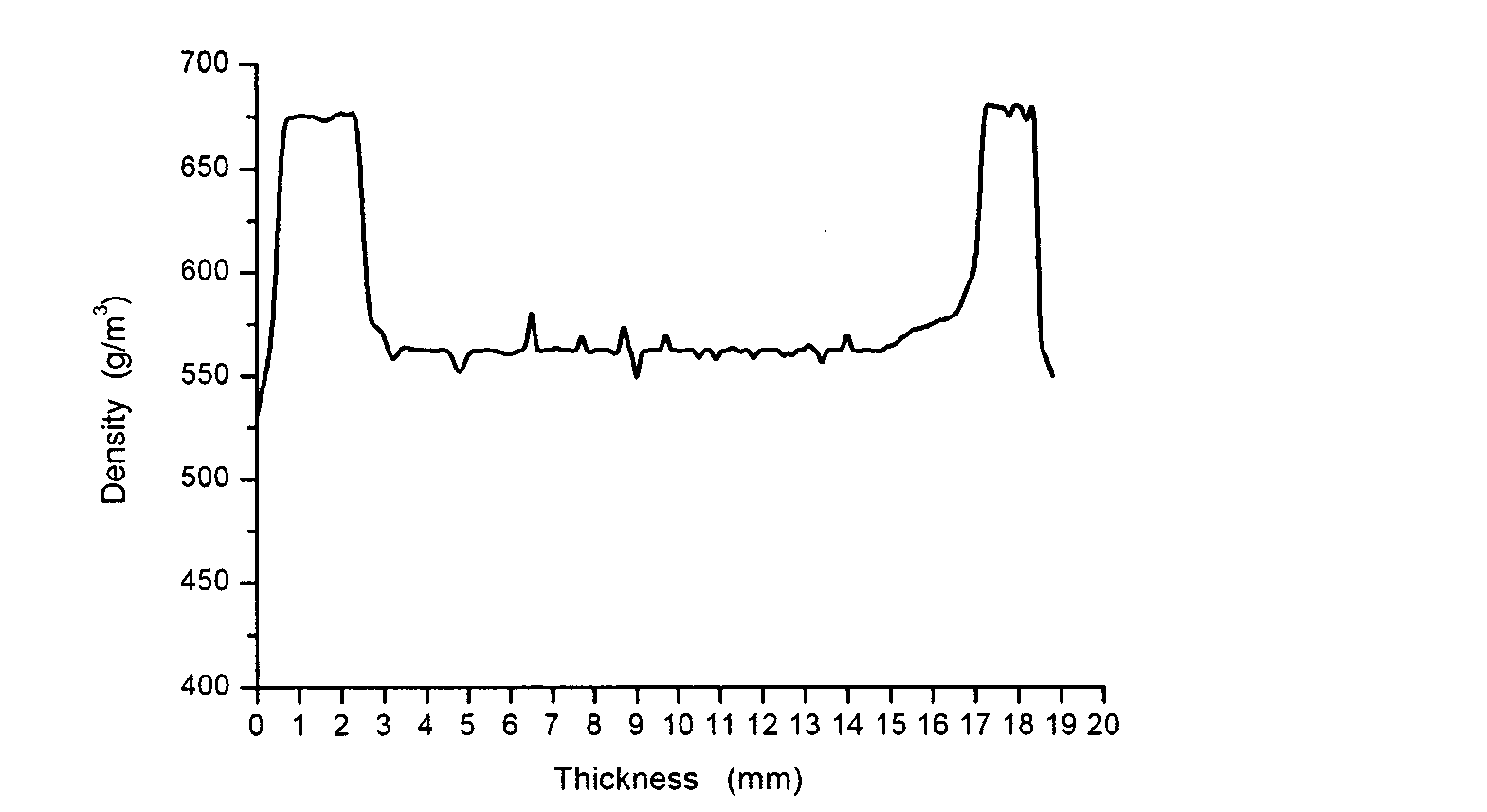

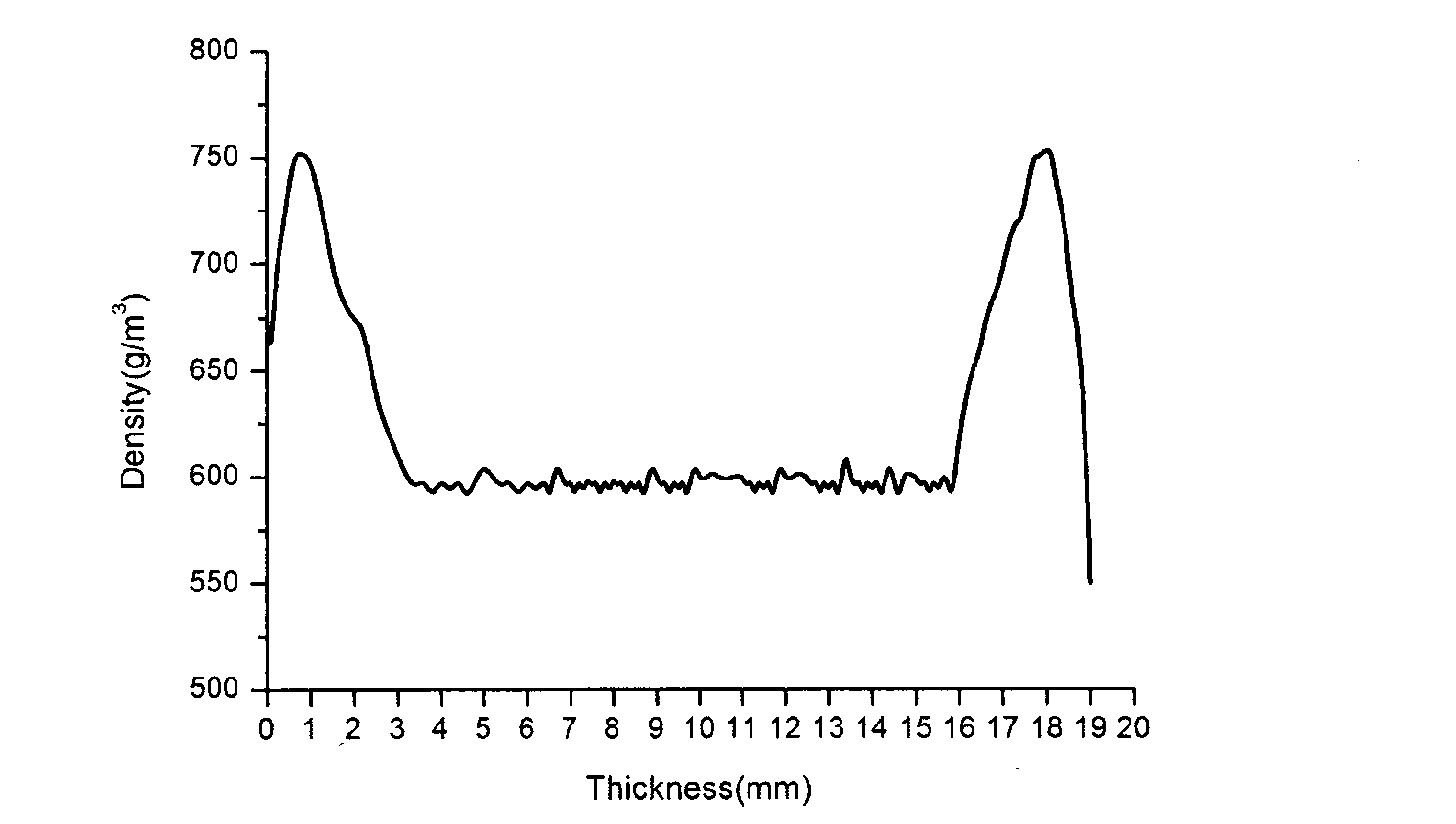

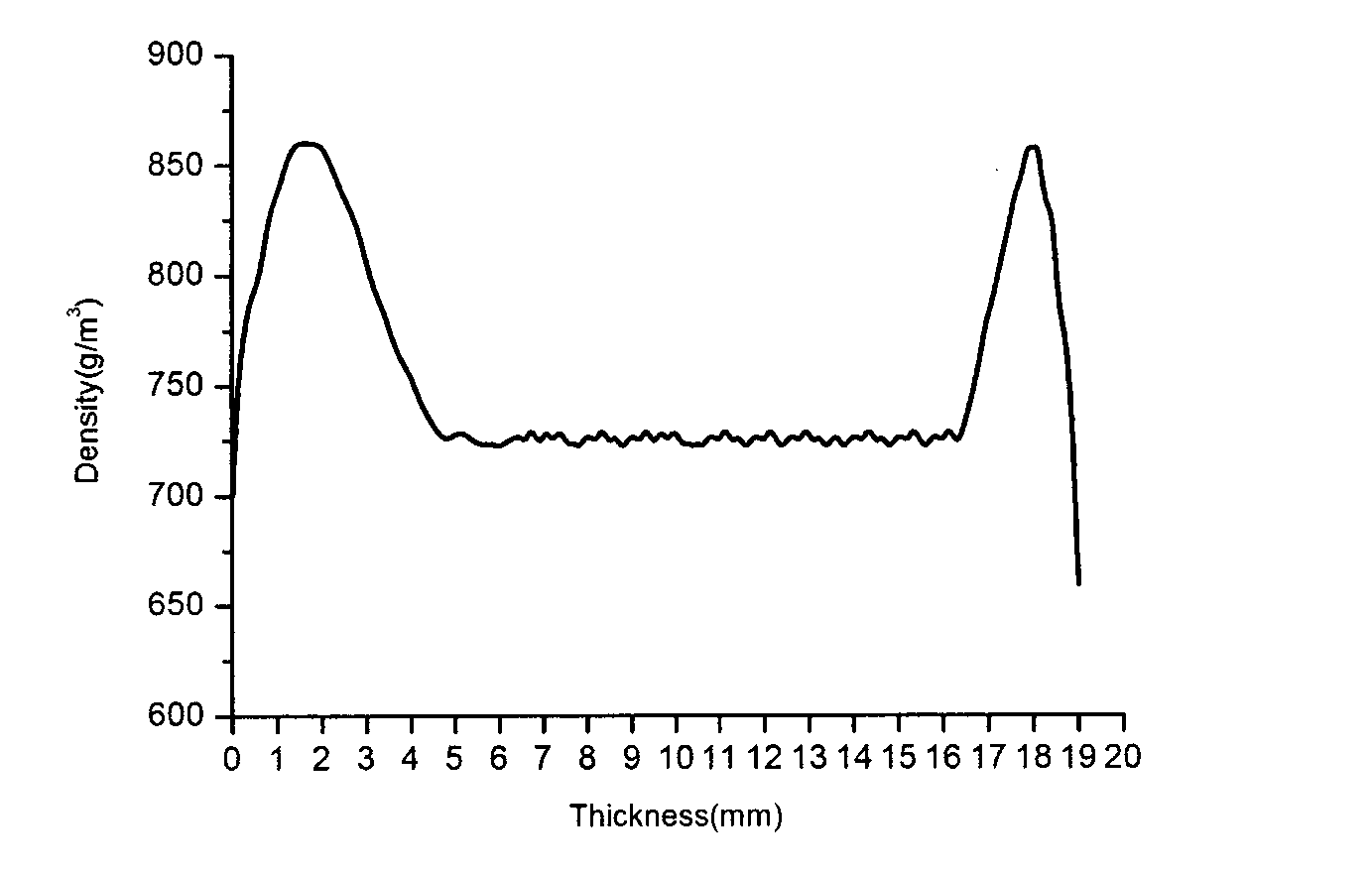

Method for manufacturing solid wood floorings by utilizing densified fast growing woods

InactiveCN102407548AImprove poor materialImprove defects that cannot be directly used to manufacture solid wood floorsWood compressionSolid woodVolumetric Mass Density

The invention relates to a method for manufacturing solid wood floorings by utilizing fast growing woods as raw materials, belonging to the technical field of solid wood flooring preparation. The invention aims to ensure the densified plates to have certain density gradient in the thickness direction by the methods of compressive densification and high temperature heat treatment, improve the surface density, overall density and mechanical properties of the fast growing woods as well as the dimensional stability and corrosion resistance of the densified woods, change the situation that the fast growing woods can not be directly used as the solid wood floorings, expand the application range of the fast growing woods in the industry of solid wood floorings and improve the use value of the fast growing woods. Besides, by adopting the fast growing woods to manufacture the solid wood floorings, on the one hand, the fast growing woods can replace the precious woods, thus protecting the natural forest resources in China and meeting the increasing demands of people, and on the other hand, the bottleneck of solid wood flooring development, caused by shortage of precious raw materials, is mitigated to a certain extent and solid wood flooring development in China is promoted.

Owner:NANJING FORESTRY UNIV

Organic culture method of edible wood-rotting fungi

InactiveCN101536649ASimple recipeScientific nutritional ratioHorticultureBiotechnologyAdditive ingredient

The invention relates to a culture method of edible fungi, in particular to an organic culture method of edible wood-rotting fungi, which comprises the steps of: choosing natural timber waste, branches, fruit tree wood shavings or sawdust which are aged for more than one year as stroma of culturemedium; choosing large or middle-sized wheat bran without nonpersistent pesticide as minor ingredient; adopting bar-typed cultivated strain or bag-typed strain organic culture method, and sterilizing the culturemedium with alcohol and inoculating the culturemedium with steam; choosing ingredients of the culturemedium including 81 percent of sawdust, 18 percent of wheat bran and 1 percent of plaster; mechanically bagging the culturemedium with high-density and low-pressure polyethylene venting bags; sterilizing the culturemedium with an atmospheric pressure kiln, and then cooling the culturemedium in an awning after stewing the culturemedium. The awning is internally provided with plastic tents which are available for ten thousand fungi everyday. Inoculating and spawn running are conducted by using a rapid inoculation method after the tents are sterilized by spraying lysol water or alcohol. Bacteria are cultivated by cutting off the water supply once a first fungi appears; and a second fungi is stimulated after the first fungi is fully rejuvenated; the fungi is sterilized with lime at regular intervals to keep the culturemedium in alkaline environment; and insect pests are trapped and killed by adopting a targeted elimination method. The invention has the advantage of guaranteeing the safety of the edible fungi.

Owner:赵建荣

Process for manufacturing high-strength laminated wood board

InactiveCN102371603AEliminate defects that are prone to warping and deformationReduce the amount of planingWood veneer joiningFiberHigh intensity

The invention discloses a process for manufacturing a high-strength laminated wood board. The process comprises the following steps of: cutting a log in a rotary mode to form veneers with a certain thickness by using a rotary cutting machine, and drying; arranging the dried veneers in the direction that wood grain fibers are consistent at high temperature under high pressure, and bonding to form a board block with a certain thickness; splitting the board block to form laths with a certain thickness along the length direction of wood growth (the direction of the wood grain fibers) according to requirements; cutting the laths into short laths with different lengths; and arranging the short laths of which the narrow surfaces are coated with glue in a staggered mode, and splicing to form a high-strength laminated wood core board with a certain length and width. In the laminated wood board manufactured by the process, a transverse arrangement structure of battens of the conventional board core material is changed into a longitudinal arrangement structure to overcome the defect that the conventional board is easy to warp and deform; therefore the planing quantity of machining the battens is reduced, leftovers formed in the process of machining wood also can be utilized, namely the leftovers serving as scraps are changed into valuables, and the utilization rate of the wood thus is improved greatly; and economic forests with short growth period can be used as raw materials for core board layers, so the materials are saved, the cost is reduced, natural forests are protected, and environment friendliness is facilitated.

Owner:郭侃

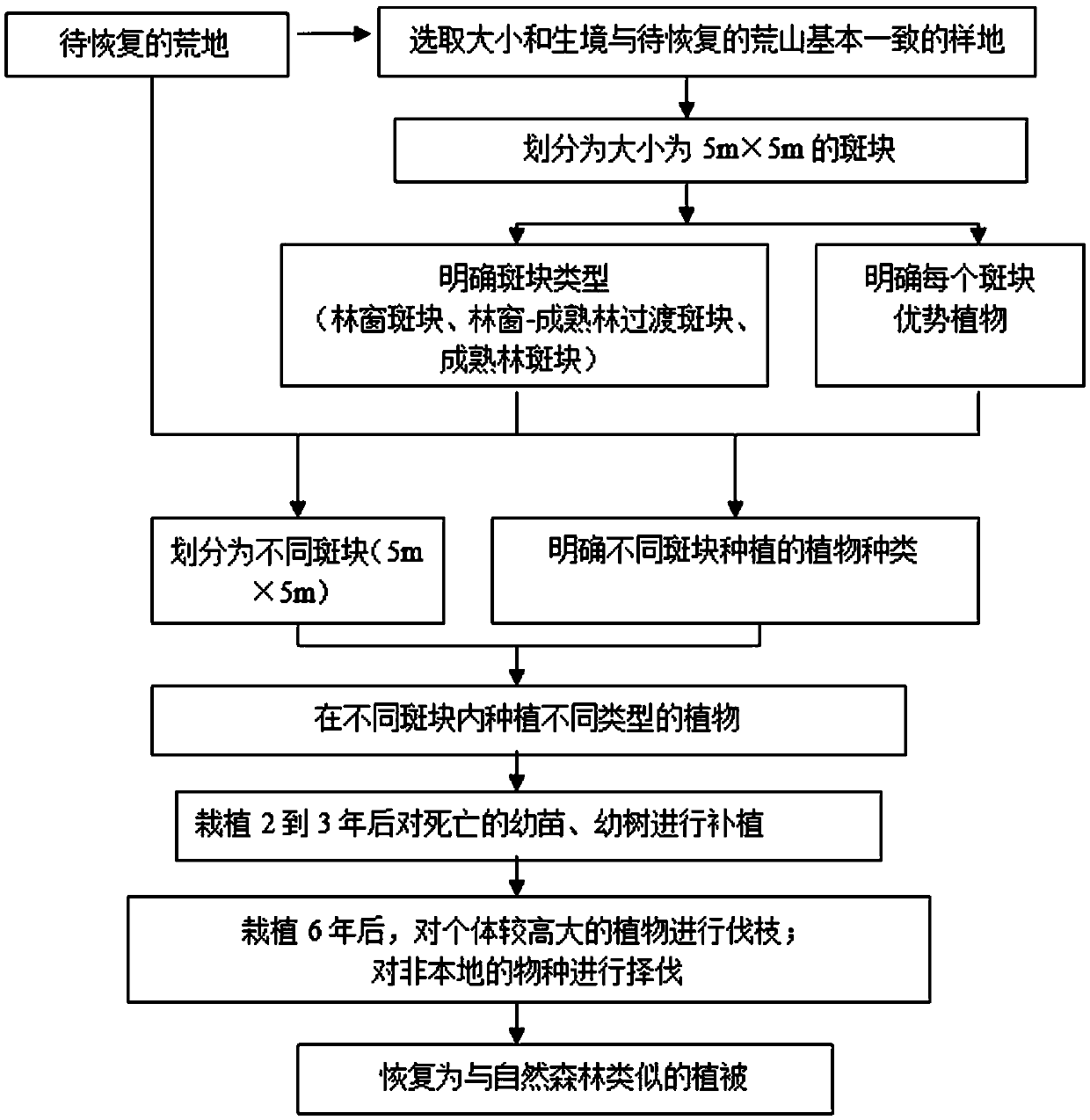

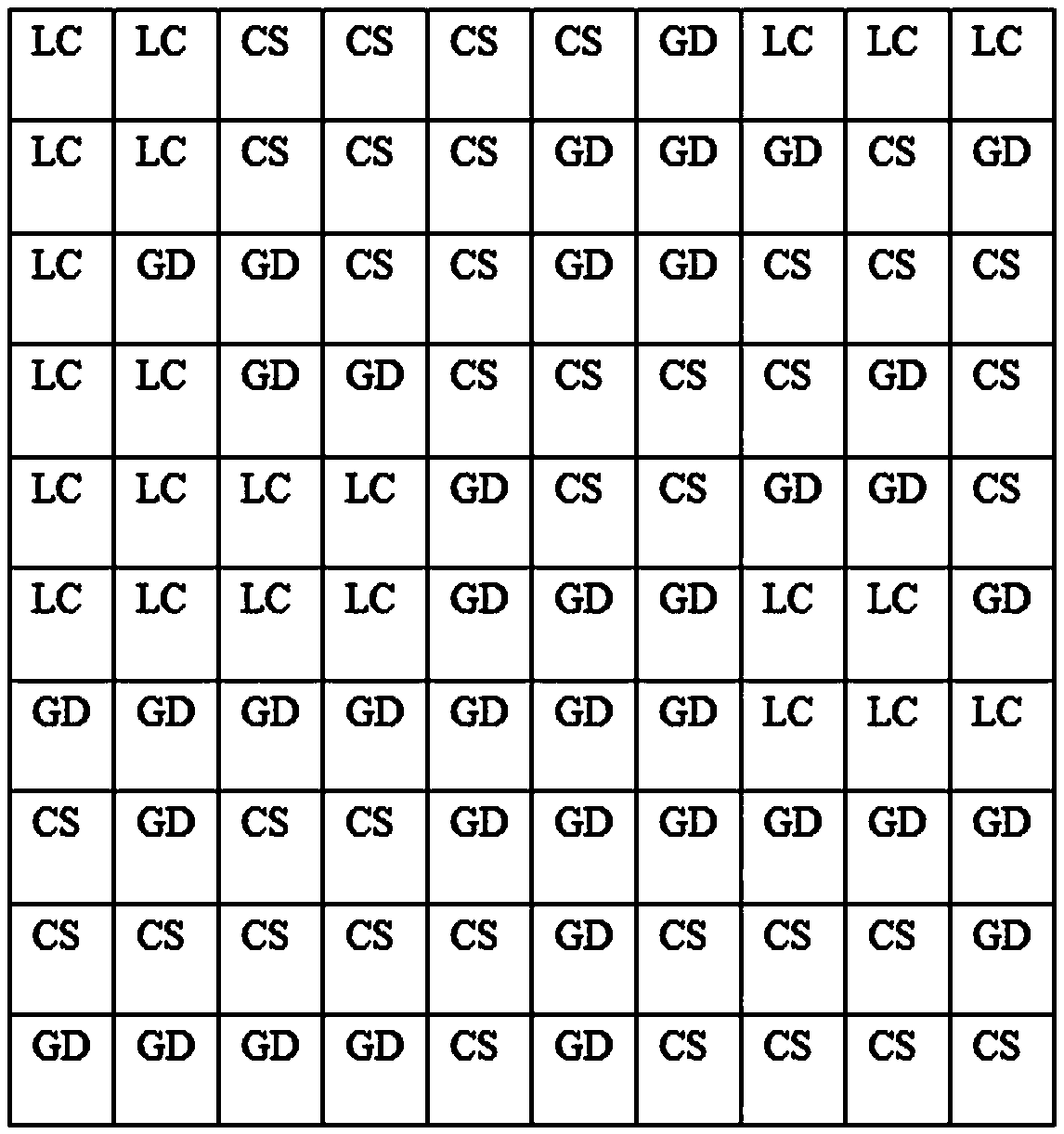

Method for rapid recovery of plants in barren mountain

The invention discloses a method for rapid recovery of plants in a barren mountain. The method comprises steps as follows: A, a local natural forest is searched; B, sample land is selected and divided into blocks with the size being 5m*5m; the variety and the size of plants in each block and common arbors in each block are researched; C, the to-be-recovered barren mountain is divided into grids with the size being 5m*5m, and the variety of plants in each block on the barren mountain is clarified by comparison with that in the blocks of the natural forest; D, different types of plants are planted in different blocks; the variety of the plants planted in each block is determined according to the advantageous community of the researched outdoor natural forest; E, 2-6 years later after planting, complementary planting is performed for dead seedlings and saplings; 6 years later after planting, branches of the larger plants are pruned to provide space for growth of other species, non-local species are selectively cut, and damage by alien species is avoided. The method is economical and convenient, the defect of single man-made forest or planting type is overcome, and natural updating and biodiversity protection of the forest are realized.

Owner:ANQING NORMAL UNIV

Method for artificial mingled forest afforesting design and intermediate cutting management through simulation of natural forest

ActiveCN105165529AMode validMiao JidaClimate change adaptationAfforestationSustainable managementEngineering

The invention relates to a method for artificial mingled forest afforesting design and intermediate cutting management through simulation of a natural forest. For the problem of artificial afforesting on non-forest land, an observation result of a local natural forest is simulated, and the technology of age-class intermediate cutting year by year is utilized, so that the problem of a single age class of artificial afforesting is solved, the land utilization is maximized in the afforesting process, an optical afforesting mode of an artificial forest is achieved, the purposes that the afforesting cycle is short and the annual harvest yield is high are achieved, and sustainable management is achieved.

Owner:BEIJING FORESTRY UNIVERSITY

Production technology for improving quality of cyclocarya paliurus tea

The invention discloses a production technology for improving quality of cyclocarya paliurus tea. The production technology has the advantages that the three technologies are improved, such as selection of stand, picking of tender leaves by stages, and single tea preparation by picked tender leaves by stages; 1, the raw material for production is the high-quality and health matured artificial stand which grows in the natural environment, the nutritional ingredients are richer than the nutritional ingredients of artificial young forest, the original ecology attribute of the cyclocarya paliurus tea is guaranteed, and the original natural forest resource of cyclocarya paliurus is protected; 2, according to the phenological period of tender leaf growth of cyclocarya paliurus, the tender leaves are picked by stages; the parameters of the production technology are adjusted according to the shape, size and water content of leaf, and the fine processing is performed; under the synergistic function of steps, the color, shape, fragrance and mouth feel of the cyclocarya paliurus tea are effectively improved, and the inherent quality of the cyclocarya paliurus tea is furthest improved.

Owner:CHUNAN COUNTY XINANJIANG DEVELOPMENT GENERAL COMPANY

Method for promoting regeneration of natural forest of phoebe bournei

InactiveCN109362457ASimple structureOptimizationCultivating equipmentsLand preparationNatural forest

The invention provides a method for promoting regeneration of a natural forest of phoebe bournei. The method comprises the following steps of (1) selective intermediate cutting, (2) land preparation and hole digging, and (3) seedling planting. In the natural forest of phoebe bournei, artificial auxiliary measures are adopted to promote the regeneration of the natural forest of phoebe bournei, notonly are a stand structure and understory illumination conditions improved, the restriction of natural conditions on natural regeneration is overcome, but also a seedling bank of the regeneration of the natural forest is supplemented, the problem that regeneration individuals are lacking in the regeneration process of the natural forest of phoebe bournei is solved, and the conversion from phoebe bournei seedlings into phoebe bournei saplings is effectively promoted. The method for promoting the regeneration of the natural forest of phoebe bournei has the advantages that the method is simple, convenient and feasible, the cost is low, the natural regeneration of phoebe bournei can be promoted, and the social and ecological benefits are better.

Owner:GUANGXI FORESTRY RES INST

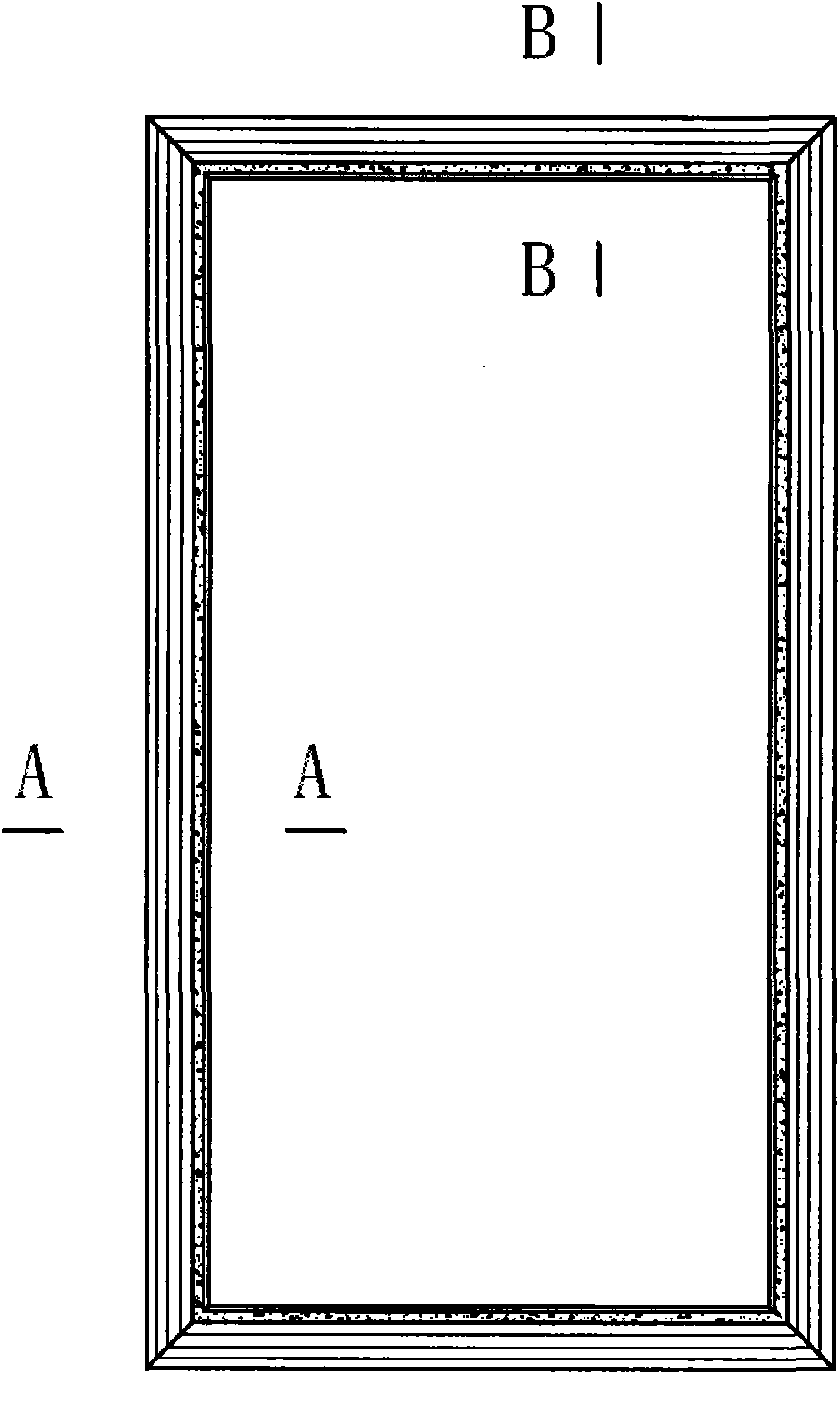

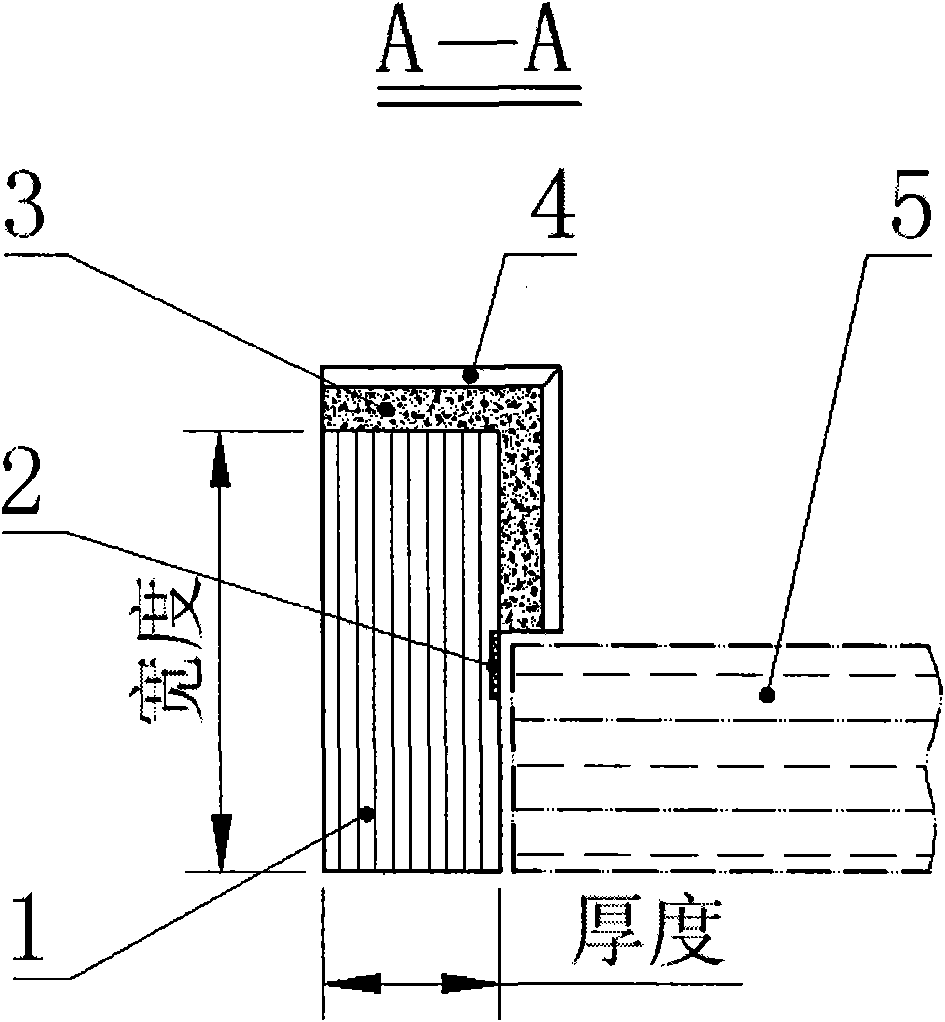

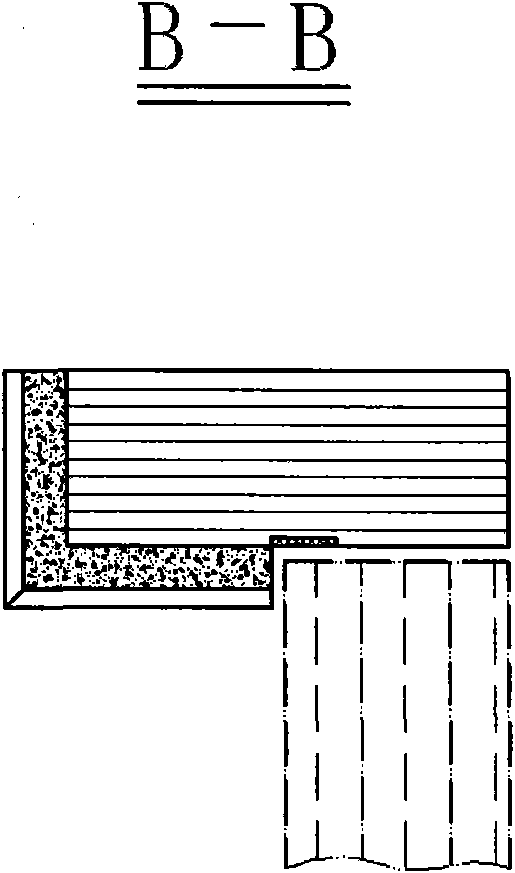

Flame-retardant veneer laminated fireproof door frame and manufacturing method

InactiveCN101915049AReduce absorptionImprove use valueFireproof doorsWindow/door framesSingle plateEngineering

The invention relates to a flame-retardant veneer laminated fireproof door frame and a manufacturing method. The door frame comprises a framework 1, a fireproof expanded sealing strip 2, a fireproof plate 3 and a decorative splint 4, wherein the framework 1 is made of flame-retardant veneer laminated material, the longitudinal texture of wood grains is parallel to the length directions of the vertical rim and the upper and lower horizontal rims of the door frame, and meanwhile the adhesive layer surface is vertical to the surface of a door leaf 5; and the rim width of the framework 1 is 90 to 110 millimeters, and the thickness is 40 to 50 millimeters. The method comprises the main manufacturing processes of: manufacturing the flame-retardant veneer laminated material by using inferior wood, manufacturing the framework of the door frame by using the flame-retardant veneer laminated material, then pressing the fireproof plate and the decorative splint on a fire receiving surface of the framework, and finally arranging the fireproof expanded sealing strip in a groove on the inner side of the framework. Because the inferior wood is used for manufacturing the fireproof door frame of the flame-retardant veneer laminated material, the use value of the inferior wood is improved, the natural forest resource is protected, and the door frame has high physical and mechanical properties, good flame-retardant performance, low manufacturing cost and deformation resistance.

Owner:NANJING FORESTRY UNIV

Modified processing method for fast-growing cotton woods

ActiveCN102152354AWith high temperature resistanceWaterproofWood treatment detailsDrying gas arrangementsFlexural strengthEngineering

The invention relates to a modified processing method for fast-growing cotton woods, which comprises the technologies as follows: a medicine used for modified processing on the fast-growing cotton woods is prepared; the cotton woods are pre-treated; the woods in a vacuum tank are vacuumized and pressurized; the medicine is added and the woods are secondarily vacuumized; then the woods are fed into a drying room to dry; the temperature of the drying room is maintained; dry temperature balance is implemented on the woods; secondary dry temperature balance under natural conditions is implemented on the woods; and finished woods are put in storage, etc. The modified processing method for the fast-growing cotton woods has the advantages that the fast-growing cotton woods after modified processing are tested to completely reach the requirements on density, rigidity, wear resistance, stretching resistance and bending strength resistance of same woodiness growing naturally, such as briar woods, maples, basswoods, etc. Meanwhile, the modified fast-growing cotton woods also have special functions and special using effects, such as inflaming retarding, high temperature resistance, anti-deformation, no cracking, water prevention, and corrosion resistance, which are not provided by the woods growing in natural forests. The modified processing method solves the single usage and the primary processing mode that the fast-growing cotton woods can only be used for producing plywood cores, cement templates and multi-layer plates through rotatably cutting veneers; therefore, the application scope of the cotton woods is enlarged.

Owner:朱黄达

Construction method for carbon sink forests in eastern subtropical area in China based on functional trait proportion of plant communities

InactiveCN110050660AEnhance community stabilityAddressing Early RecessionArtificial lifeForestryAbove groundPlant community

The invention discloses a construction method for carbon sink forests in an eastern subtropical area in China based on functional trait proportions of plant communities. The construction method comprises the following steps: investigating species composition of natural forest communities, carbon fixation functional traits of plants and above-ground carbon reserve volumes under different site conditions; establishing a structural equation model based on the composition of the functional traits of the plant communities and the above-ground carbon reserve volumes; screening plant community typeswith a remarkable carbon sink function, selecting good carbon fixation species according to weight formed by the functional traits of the plant communities; furthermore, screening optimal carbon fixation species adapting to the different site conditions according to topographic dependence of a relation between the composition of the functional traits of the plant communities and the above-ground carbon reserve volumes; quantifying a species quantitative proportion of target carbon sink plant communities according to the weight ratio of the composition of the functional traits of the plant communities; finally, forming a complete efficient carbon sink forest construction method by integrating the composition of functions of the plant communities, quantity configuration, plant configurationdensity, a planting method, young forest tending and the like. The construction method has the advantages of high carbon sink efficiency, strong adaptability, good growth, low cost and the like.

Owner:EAST CHINA NORMAL UNIV

Production increasing method for bolete in forests

The invention relates to a production increasing method for mycorrhizal edible fungi in forests, which comprises the steps of: eliminating non-target host plants and mycorrhiza of non-target mycorrhizal fungi in a forest on the premise of identifying and positioning bolete host plants and mycorrhiza distribution area in a traditional artificial forest or a natural forest, and supplementing mycorrhiza seedlings inoculated with the bolete. The updated treatment technology is beneficial to faster enlarging fungal distribution ranges and fungal dominance degree in the traditional forest land producing the bolete so as to connect bolete ponds in the forest into a whole, thereby further greatly improving the yield of the bolete.

Owner:HUNAN ACAD OF FORESTRY

Method for propagating boletus edulis

The invention relates to a method for propagating boletus edulis, belonging to the technical field of edible fungus. The technical scheme of the method comprises the following steps: selecting a propagating land, preparing a liquid strain, seeding the strain, maintaining and managing the forest land and collecting the boletus edulis. The method fills the gap that sporocarp is not cultivated successfully artificially; artificial strains of boletus are spread in a natural forest with corresponding technical measures under a proper habitat condition, and promoted to propagate in natural condition, so that the natural yield and quality of the boletus edulis can be improved, the natural yield of the boletus edulis can be remarkably improved, and preferable economical benefit can be provided while breakthrough is generated in technology.

Owner:SCI INST YUNNAN SUPPLY & SALE COOP +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com