High-density composite board specially used for wood floor and manufacturing method thereof

A technology of composite boards and manufacturing methods, which is applied in the direction of manufacturing tools, wood processing appliances, building structures, etc., and can solve problems that cannot meet the requirements of wood floor hardness, foot feel, dimensional stability, mechanical properties, warping deformation, and impact on physical health. and other issues, to achieve the effect of protecting natural forest resources and maintaining dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

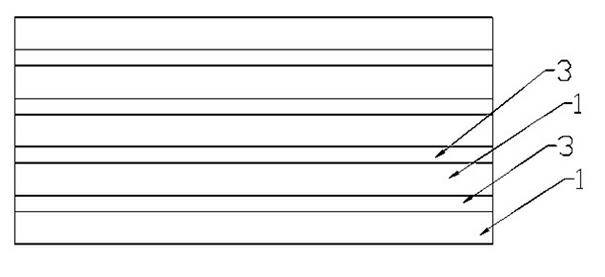

[0021] Embodiment 1: as figure 1 Shown, a kind of manufacturing method of high-density composite board special for wooden floor, concrete implementation steps are as follows:

[0022] The specifications of the implemented high-density composite panels are 1240×620×12㎜, and the density is 1.05 g / cm 3 ;

[0023] (1) Preparation of wood modifier: Add water-soluble phenolic resin with a solid content of 20% into the glue mixing tank, and add sulfonated lignin accounting for 5% of the total volume of the water-soluble phenolic resin with a solid content of 20% , account for the preservative of 3% of the total volume of water-soluble phenolic resin with a solid content of 20%, liquid bentonite that accounts for 10% of the total volume of water-soluble phenolic resin with a solid content of 20%, then open the stirrer and stir for 15 minutes, and The above ingredients are stirred and mixed to form a uniform wood modifier, which is stored in a liquid tank for later use;

[0024] (2)...

Embodiment 2

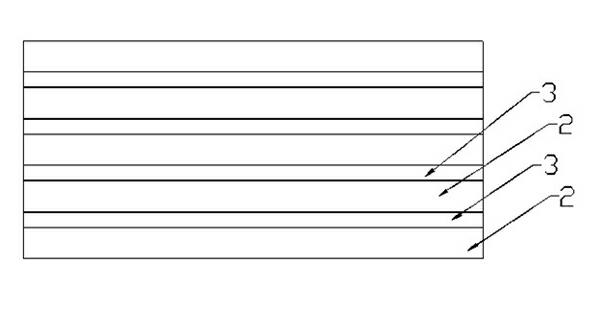

[0028] Embodiment 2: as figure 2 Shown, a kind of manufacturing method of high-density composite board special for wooden floor, concrete implementation steps are as follows:

[0029] The specifications of the implemented high-density composite panels are 1240×620×12㎜, and the density is 1.1 g / cm 3 ;

[0030](1) Deployment of wood modifier: Add water-soluble phenolic resin with a solid content of 25% into the glue mixing tank, and add sulfonated lignin accounting for 6% of the total volume of the water-soluble phenolic resin with a solid content of 25% , account for the preservative of 3% of the total volume of water-soluble phenolic resin with a solid content of 25%, liquid bentonite that accounts for 5% of the total volume of water-soluble phenolic resin with a solid content of 25%, then open the stirrer and stir for 15 minutes, and The above ingredients are stirred and mixed to form a uniform wood modifier, which is stored in a liquid tank for later use;

[0031] (2) So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com