Patents

Literature

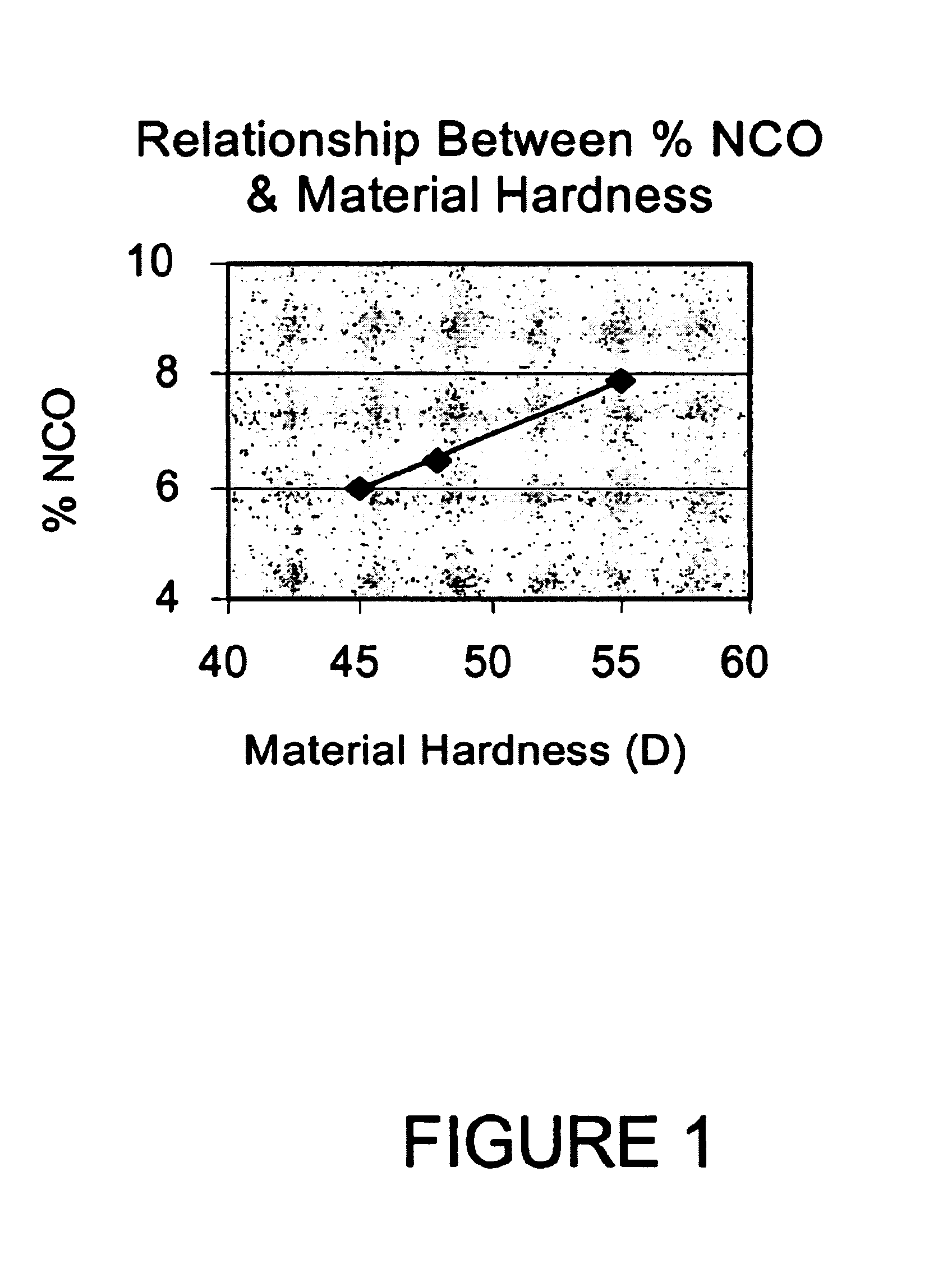

485 results about "Material hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardness: A material’s ability to withstand friction, essentially abrasion resistance, is known as hardness. Diamonds are among the hardest substances known to man, it is incredibly difficult to scratch a diamond.

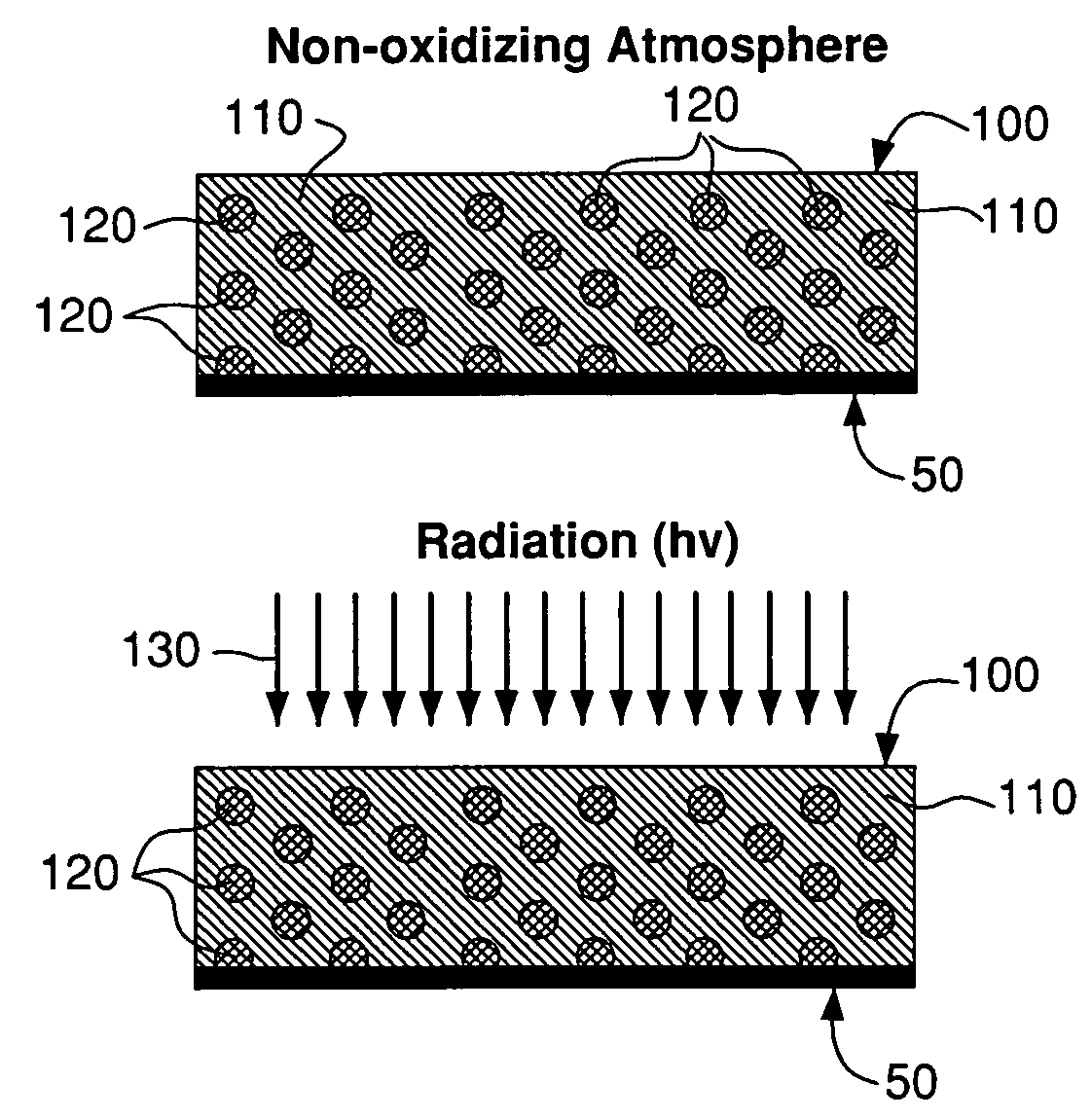

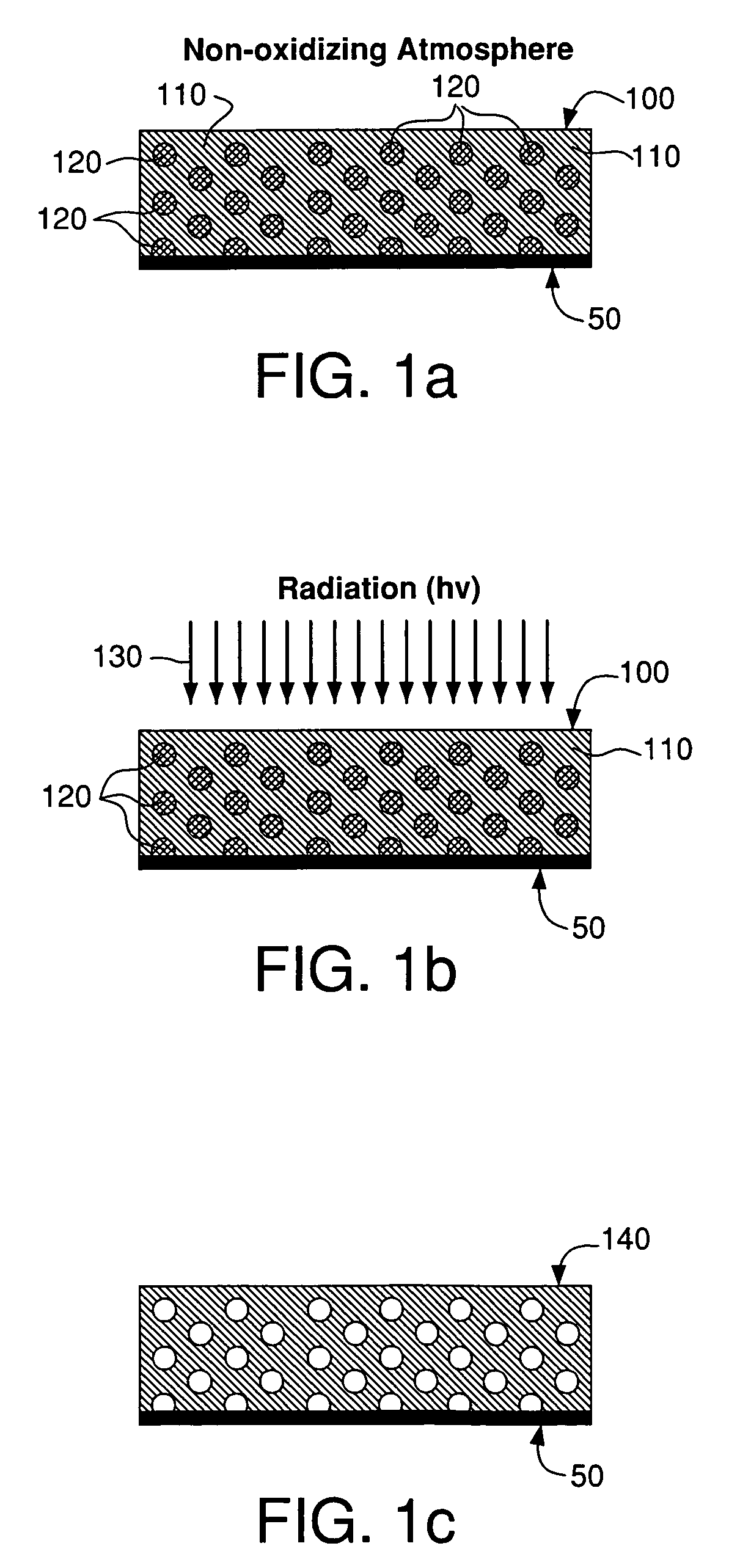

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7098149B2Low dielectric constantIncrease modulusSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricUltraviolet lights

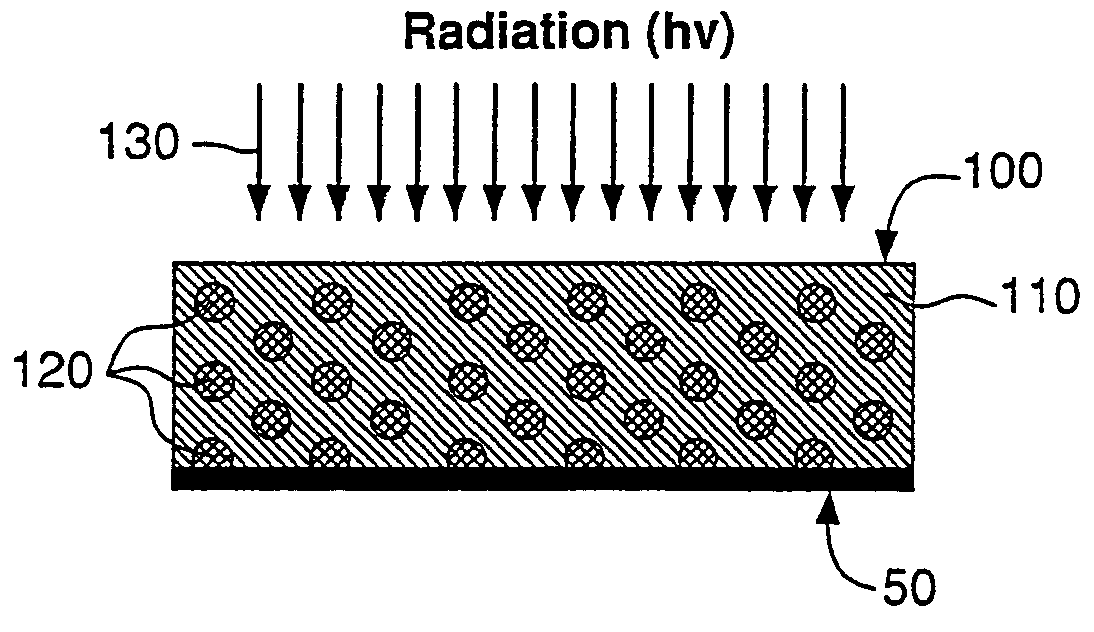

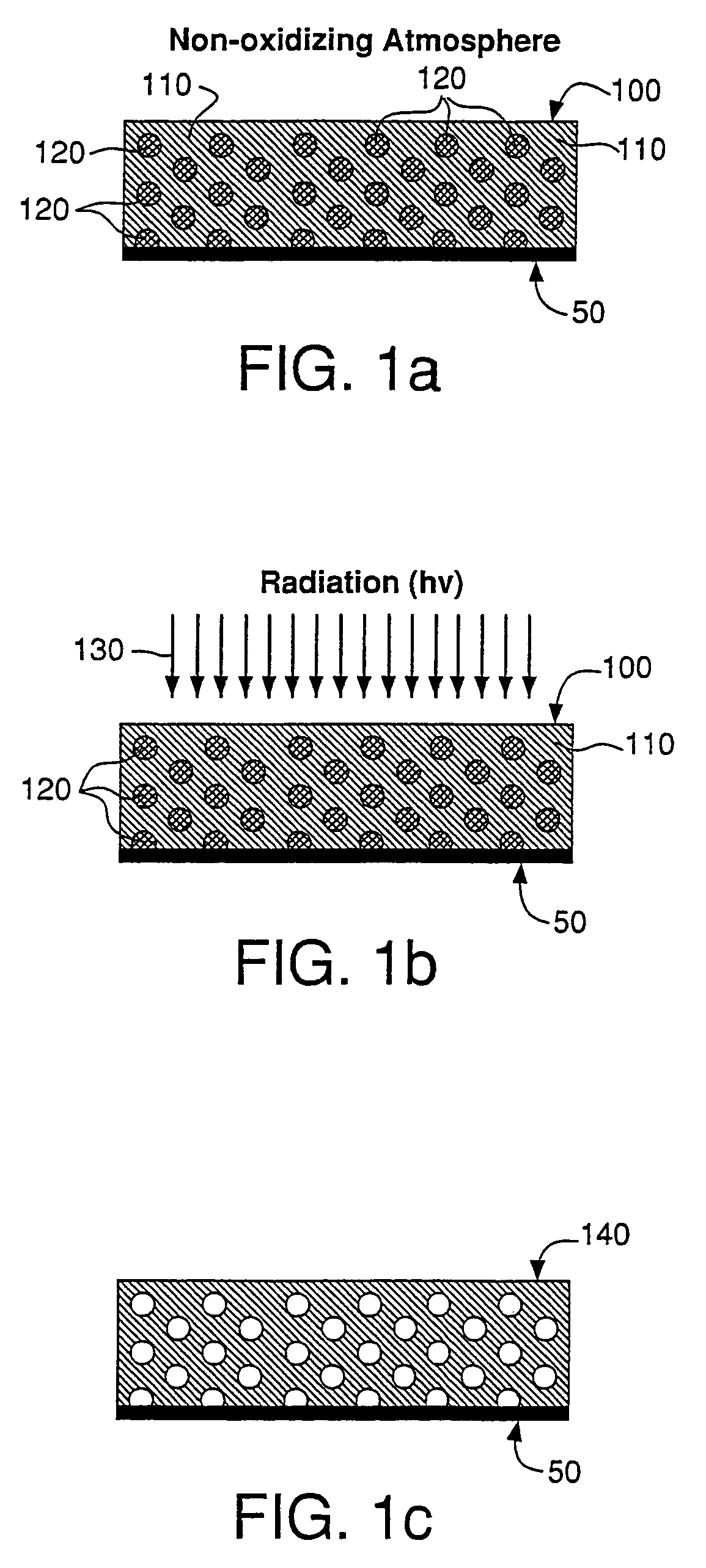

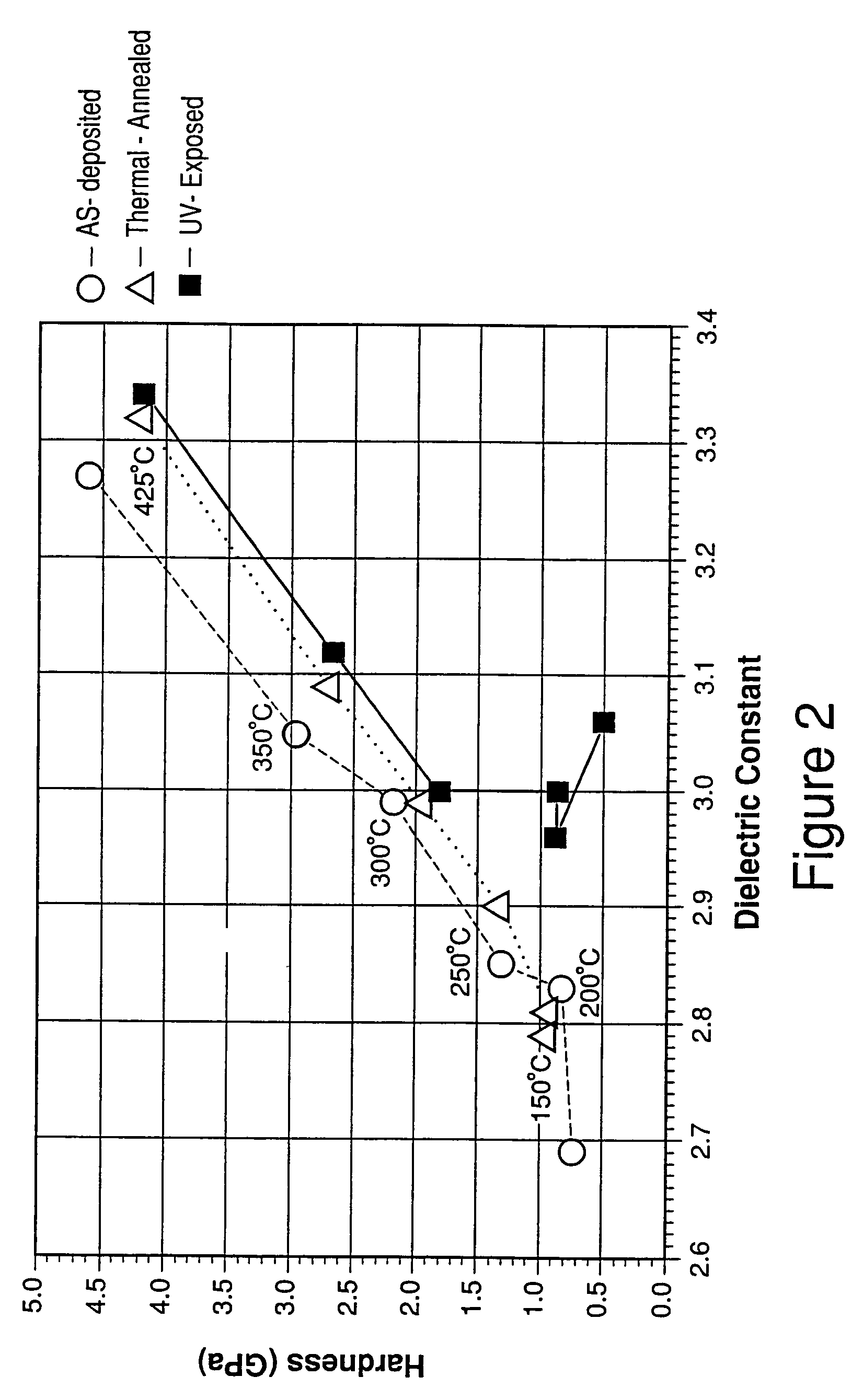

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

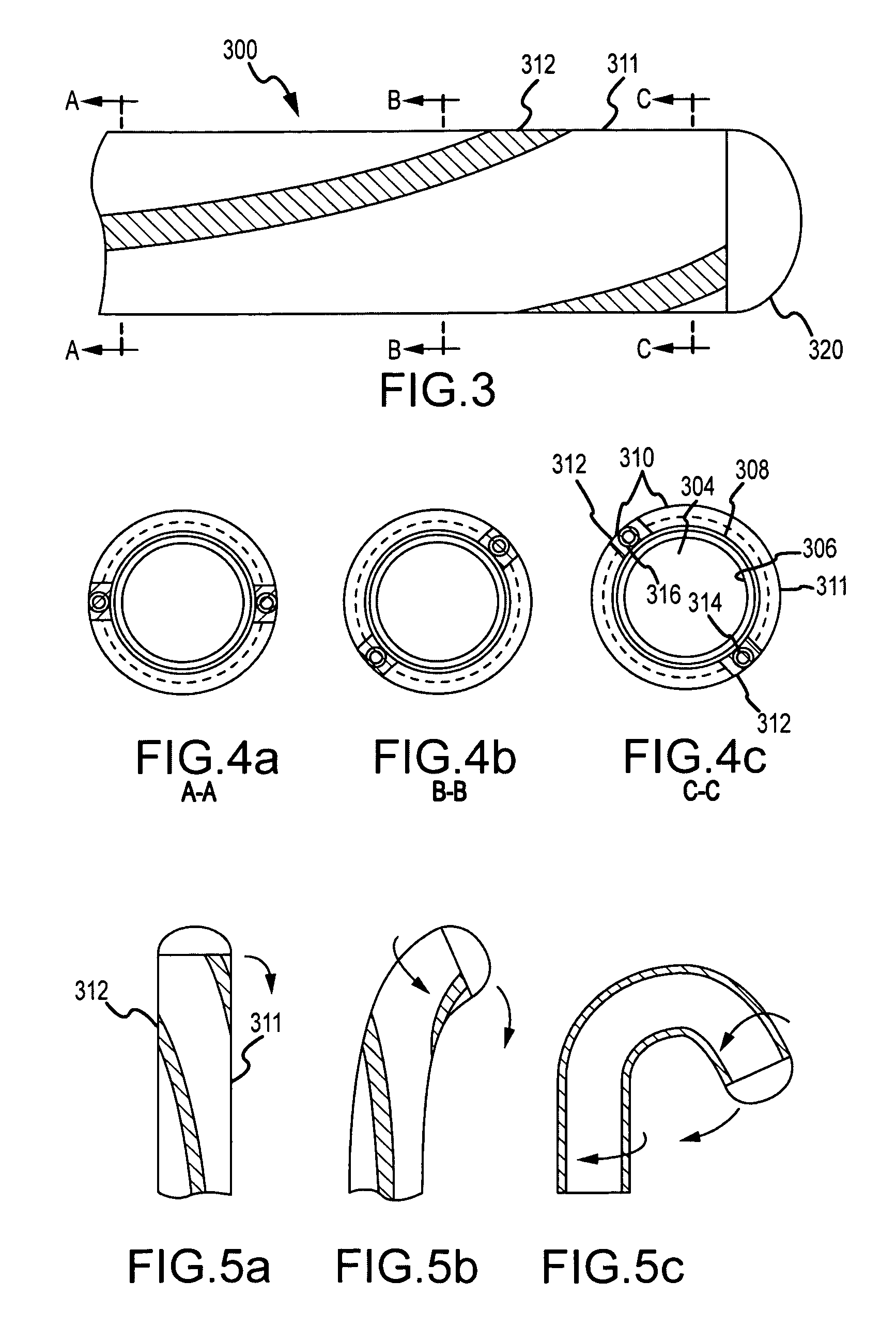

True angular catheter shaft deflection apparatus

InactiveUS7731706B2Significant changePrevent crashTransvascular endocardial electrodesSurgeryGuide tubeCatheter device

The invention relates to a steerable catheter having a distal section with reduced variation in deflection path during deflection. The distal section of the catheter includes stripes of different material hardness along the length of the distal section affecting the directionality of catheter deflection upon the application of a deflection force like that applied by pull wires. The stripes result in preferential bending in a desired path with greater reproducibility.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

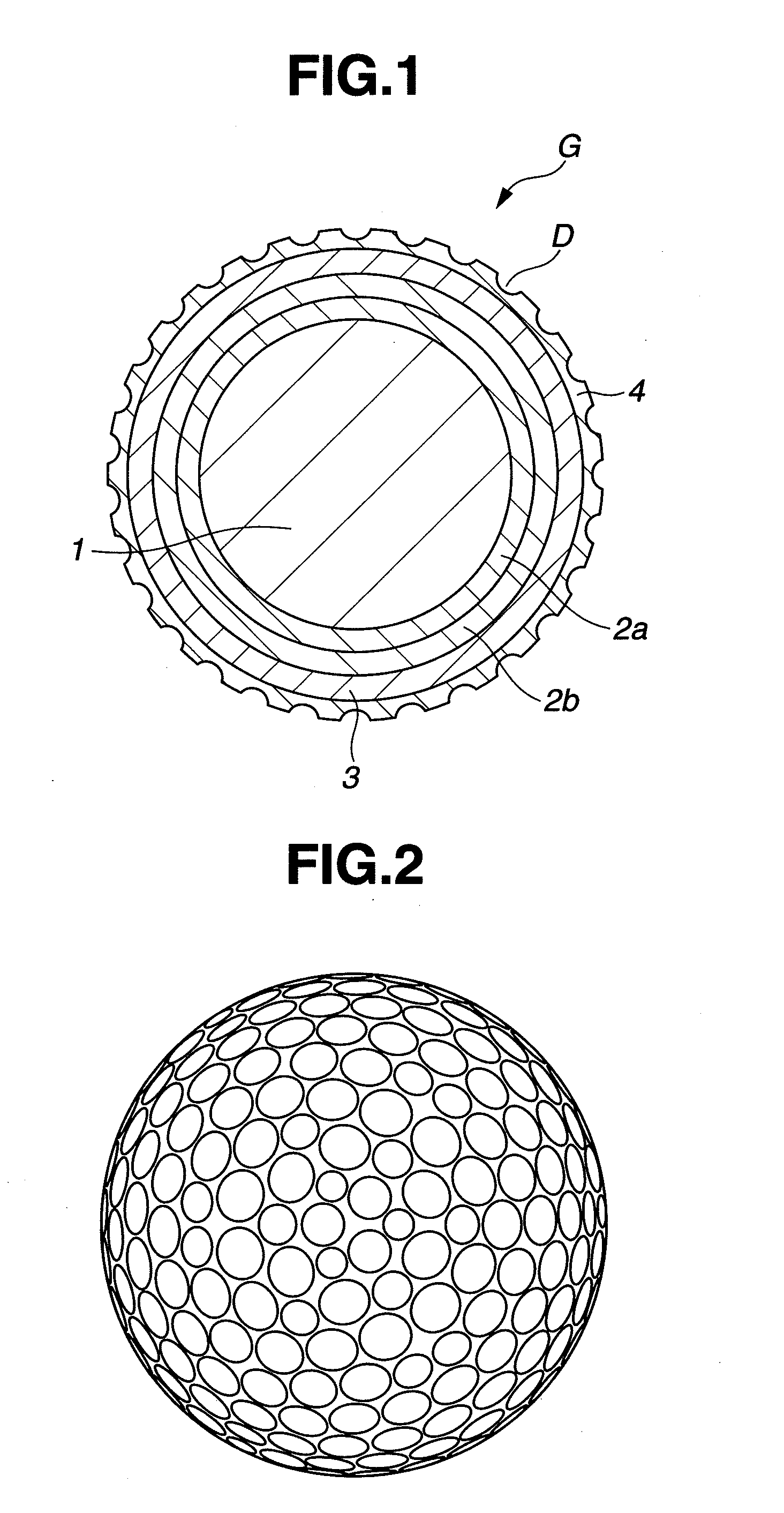

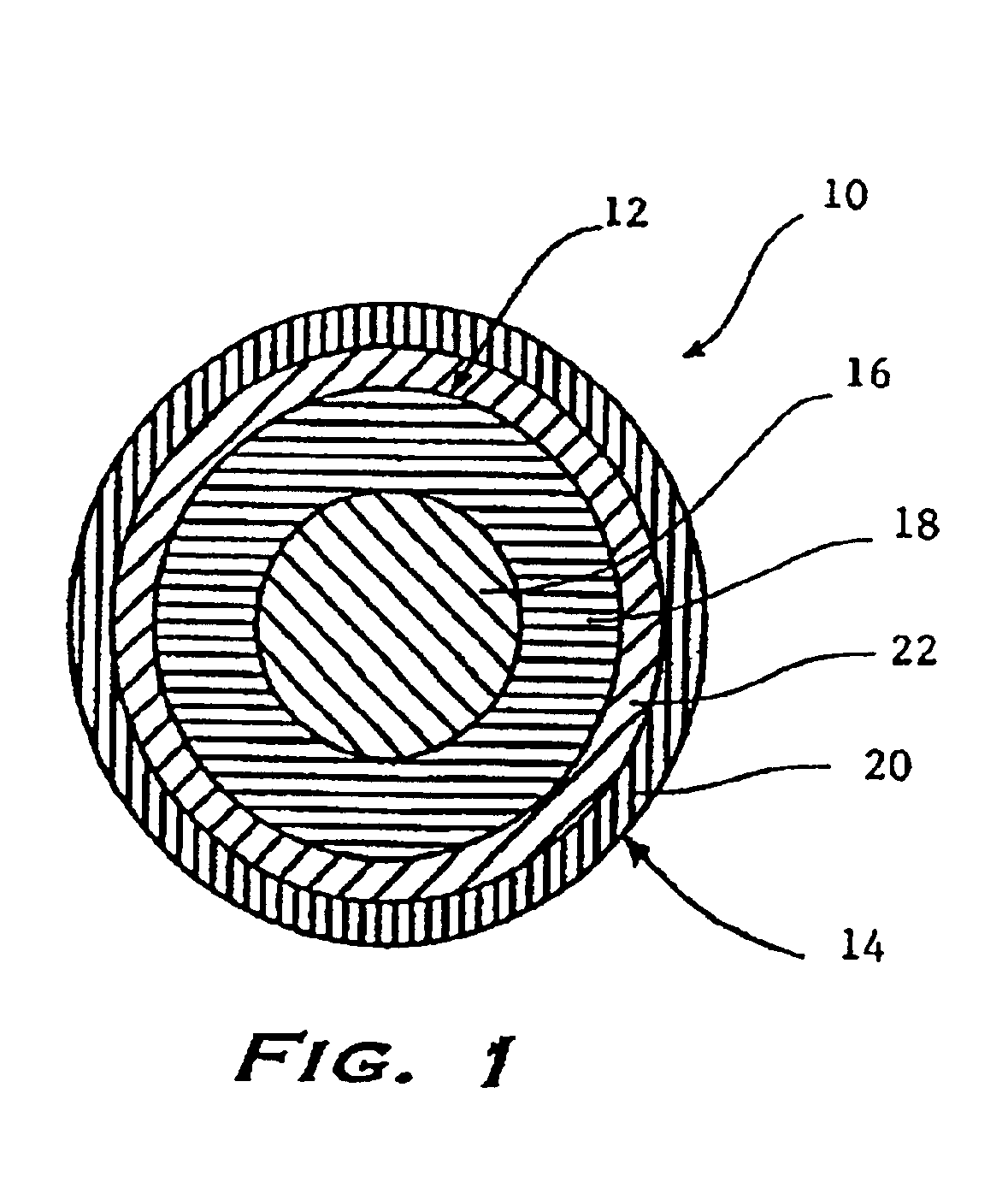

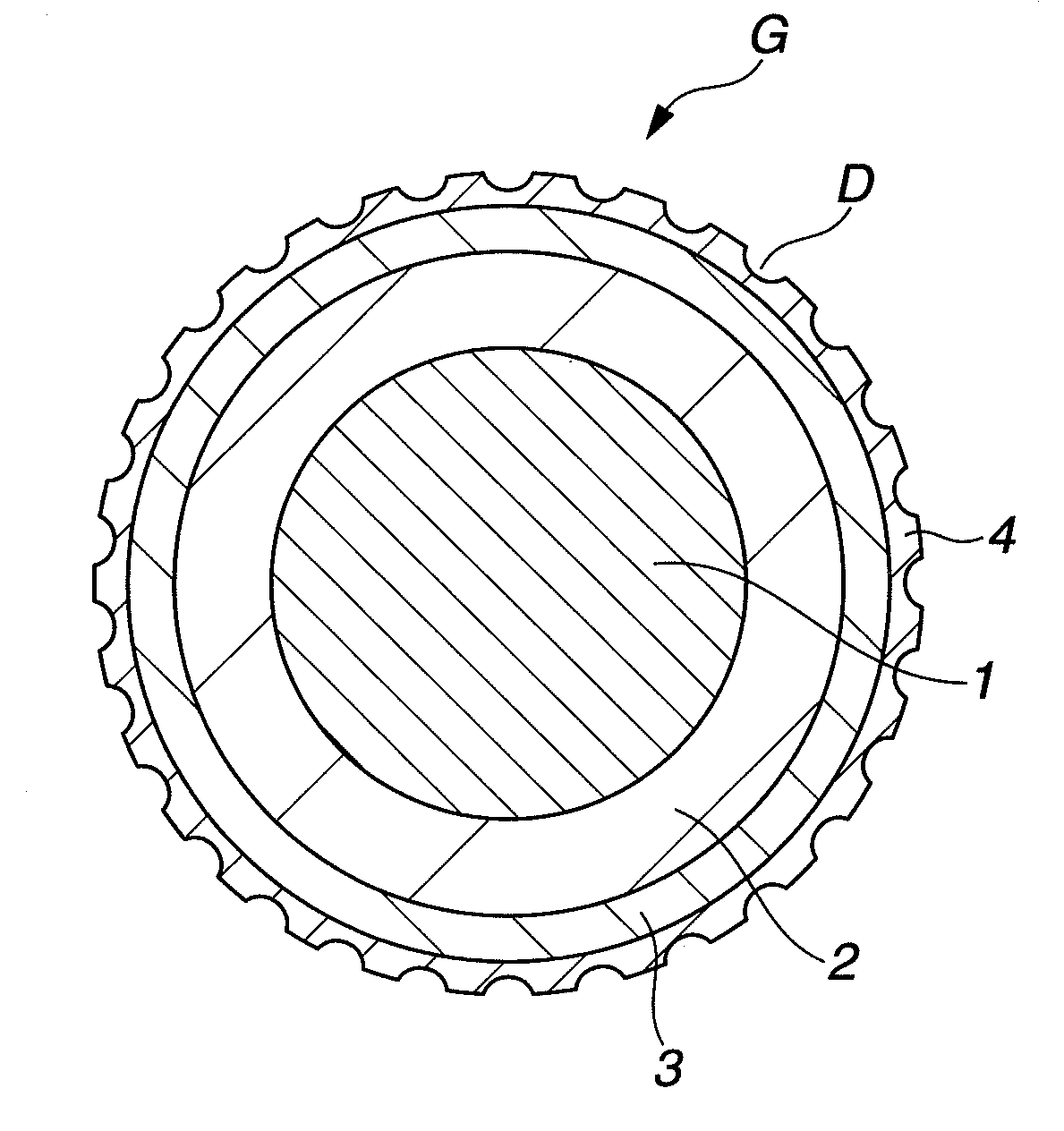

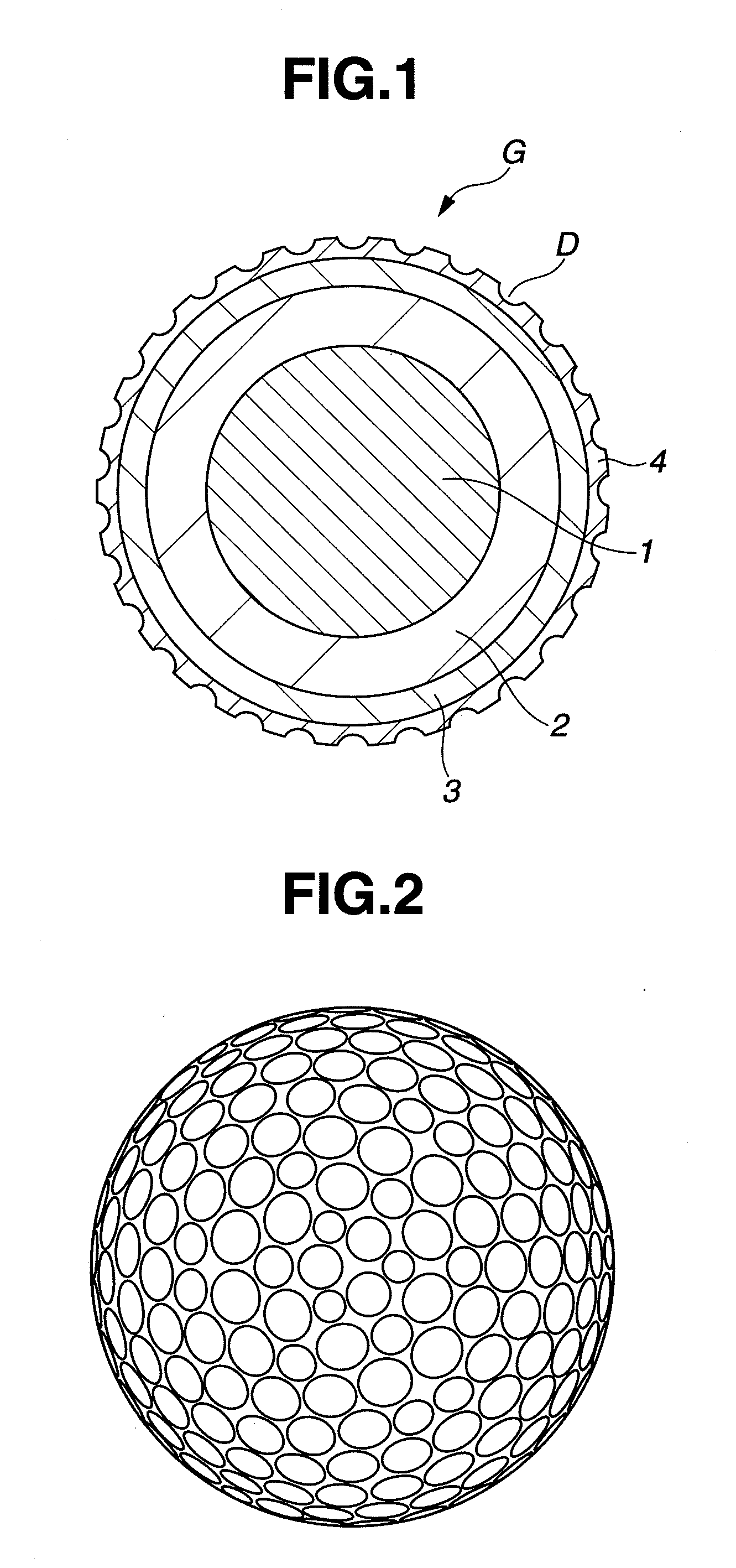

Three-layer-cover golf ball

A golf ball comprising a core; and a cover comprising an inner cover layer; an outer cover layer having a material hardness of 60 Shore D or less; and an intermediate cover layer disposed between the inner and outer cover layers; wherein at least two of the inner, intermediate, and outer cover layers comprise a non-ionomeric material.

Owner:ACUSHNET CO

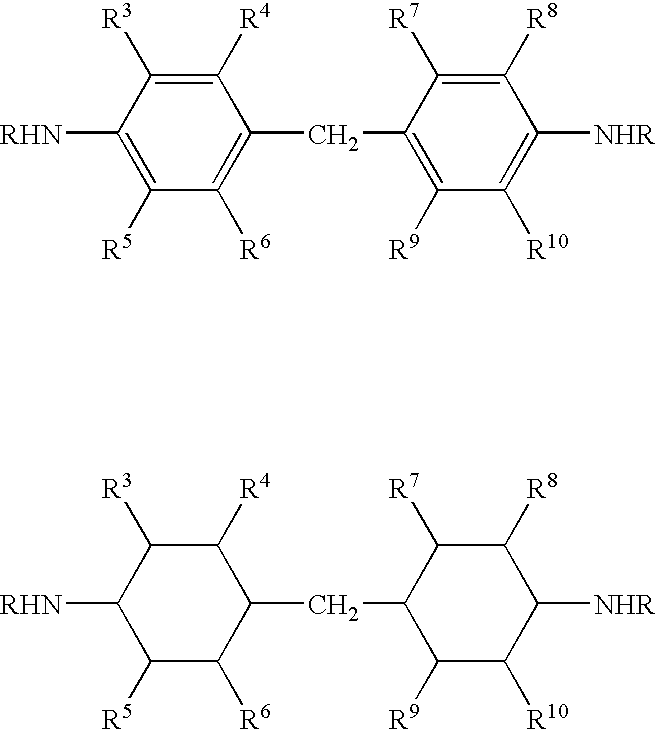

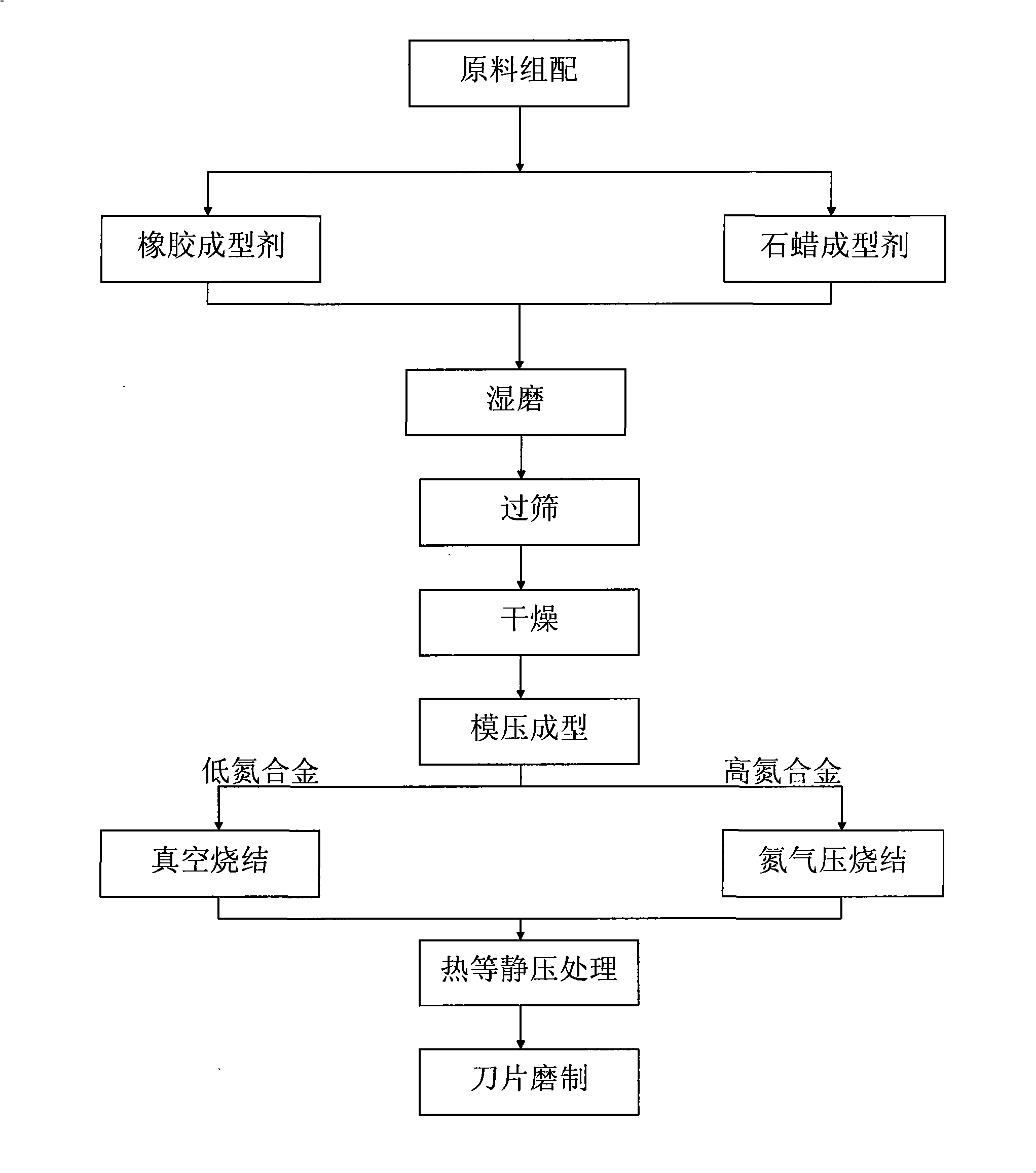

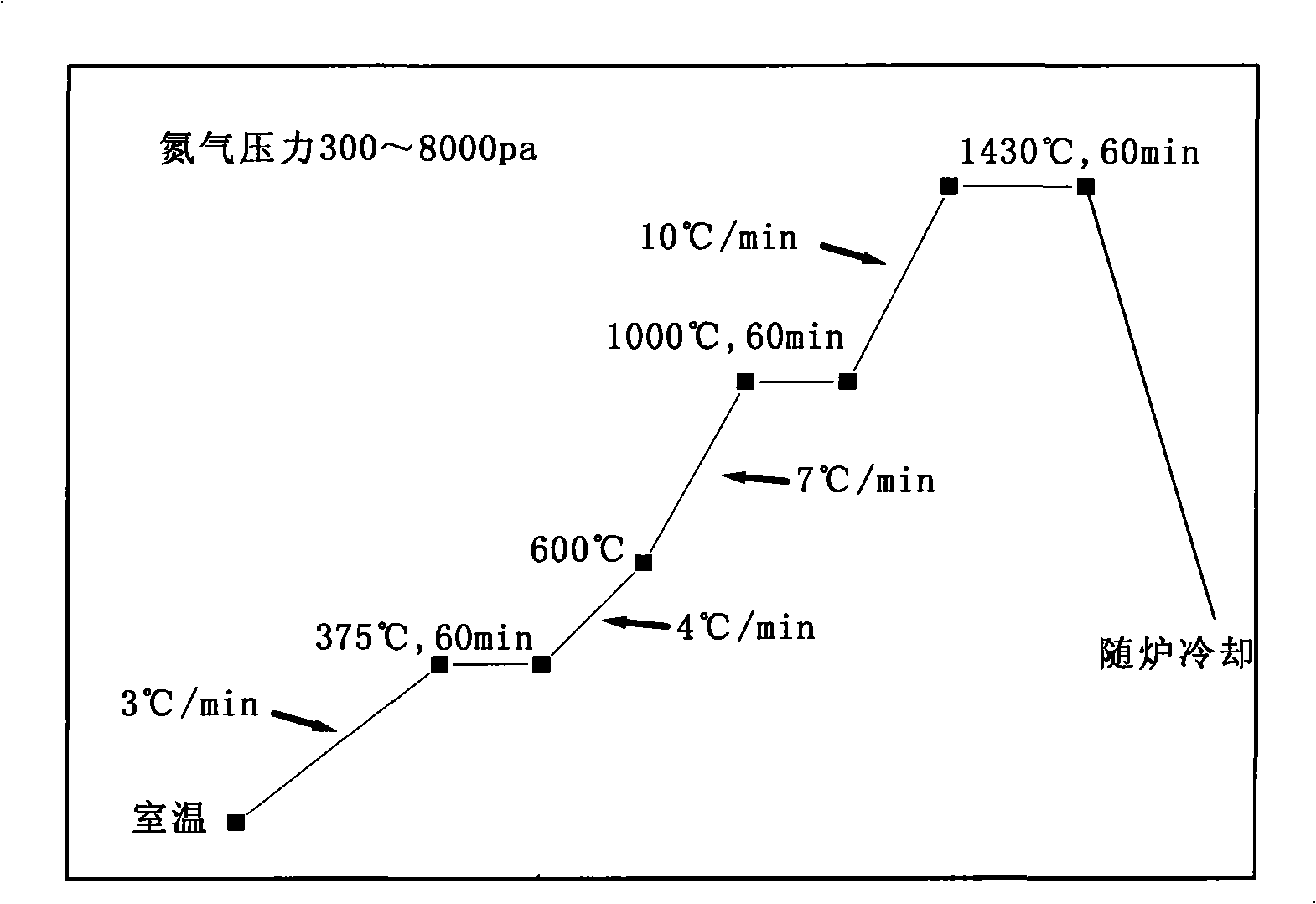

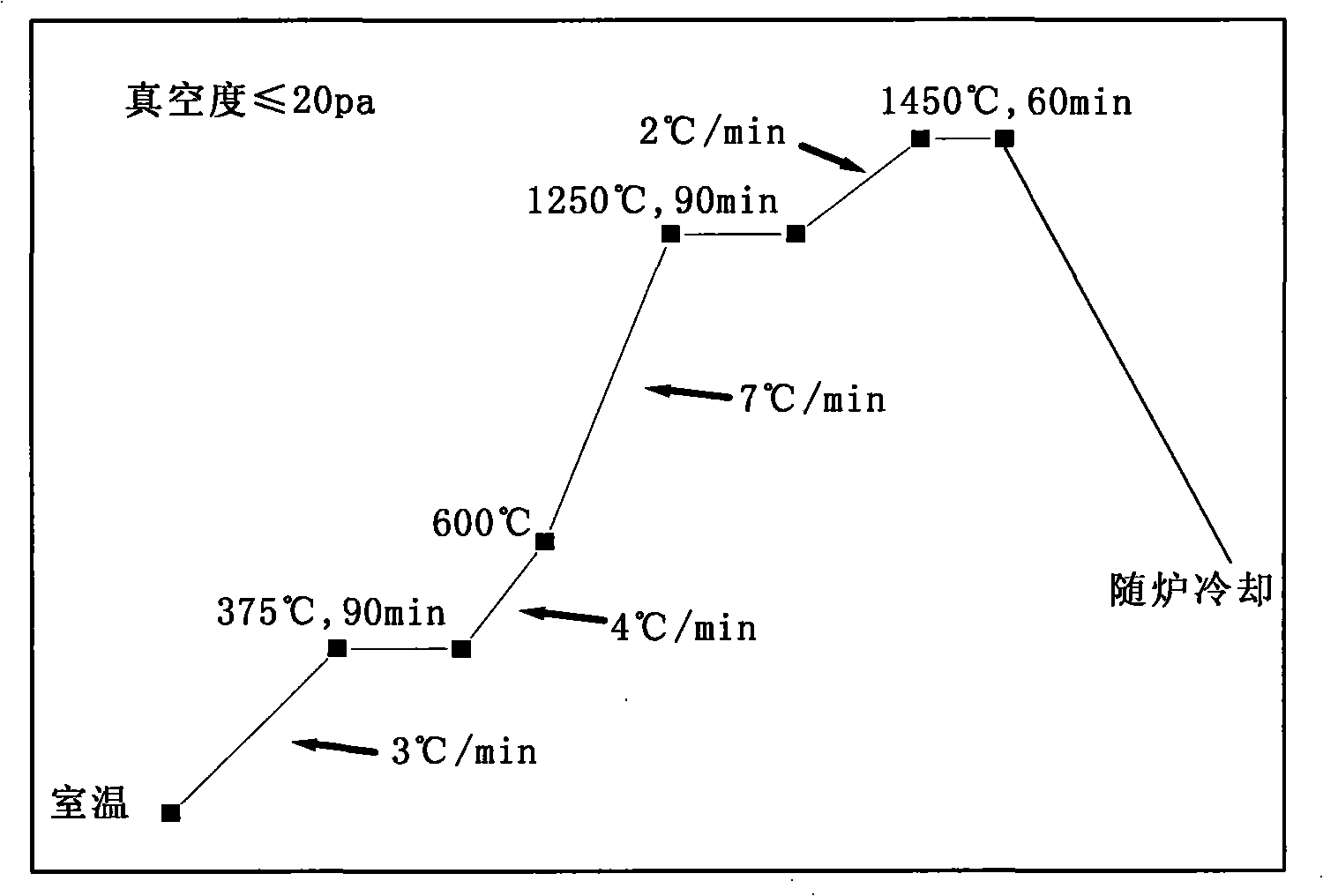

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

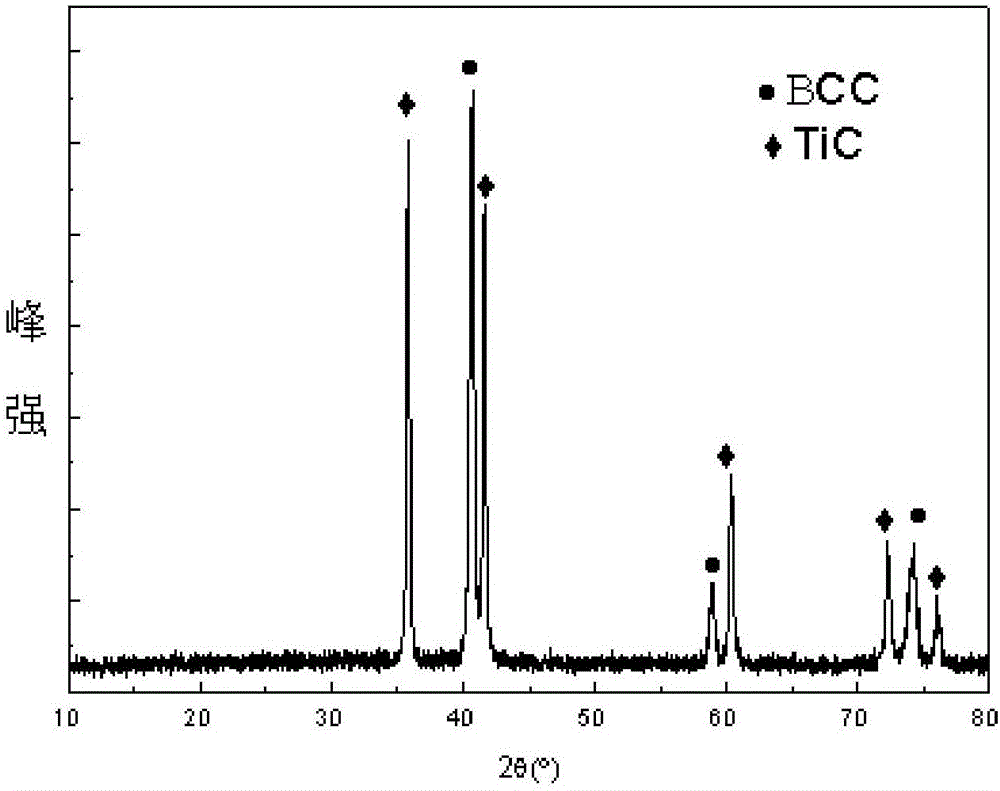

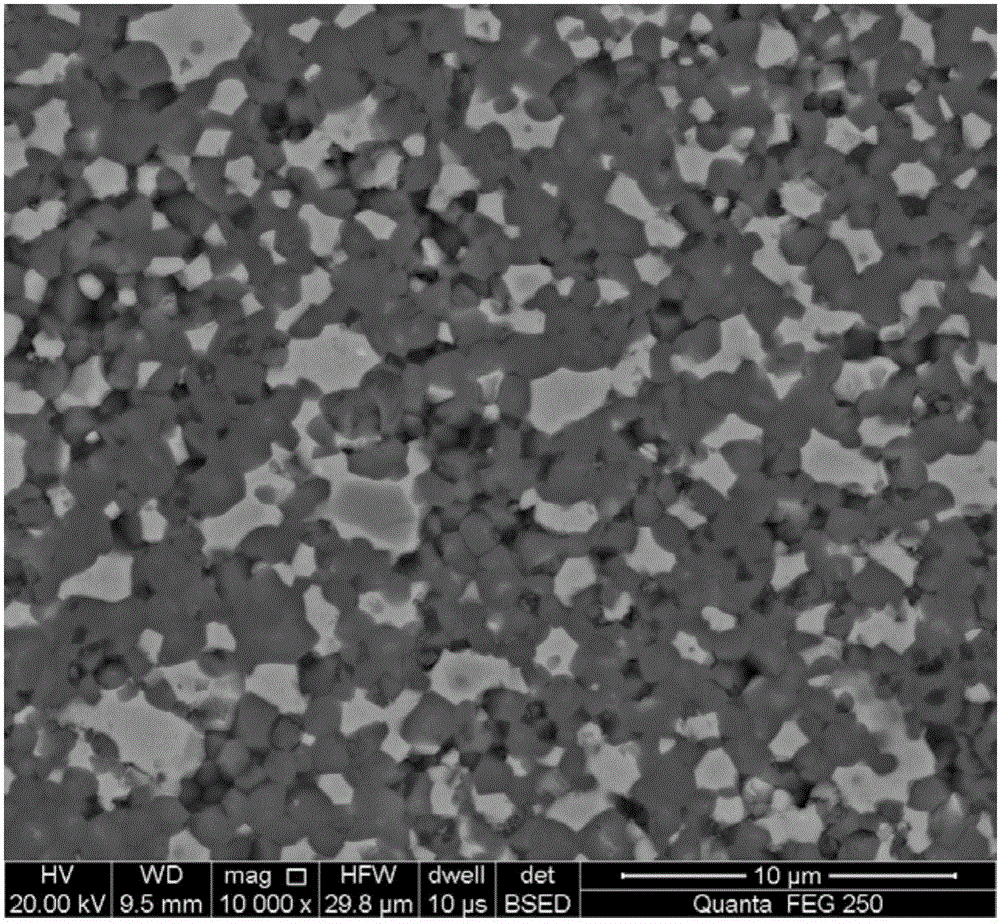

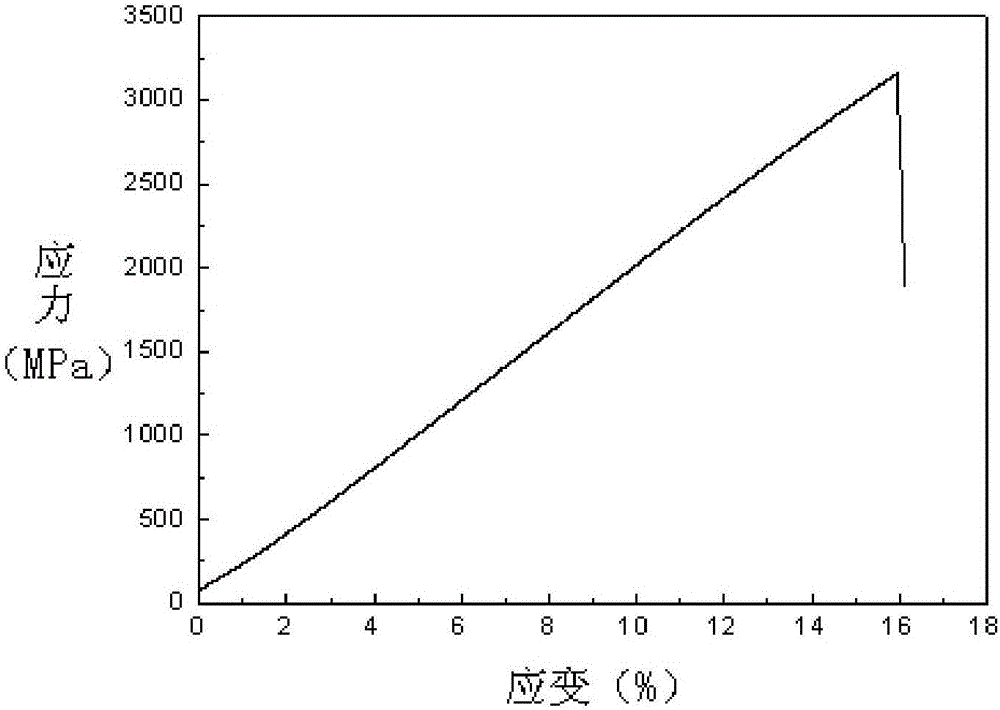

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

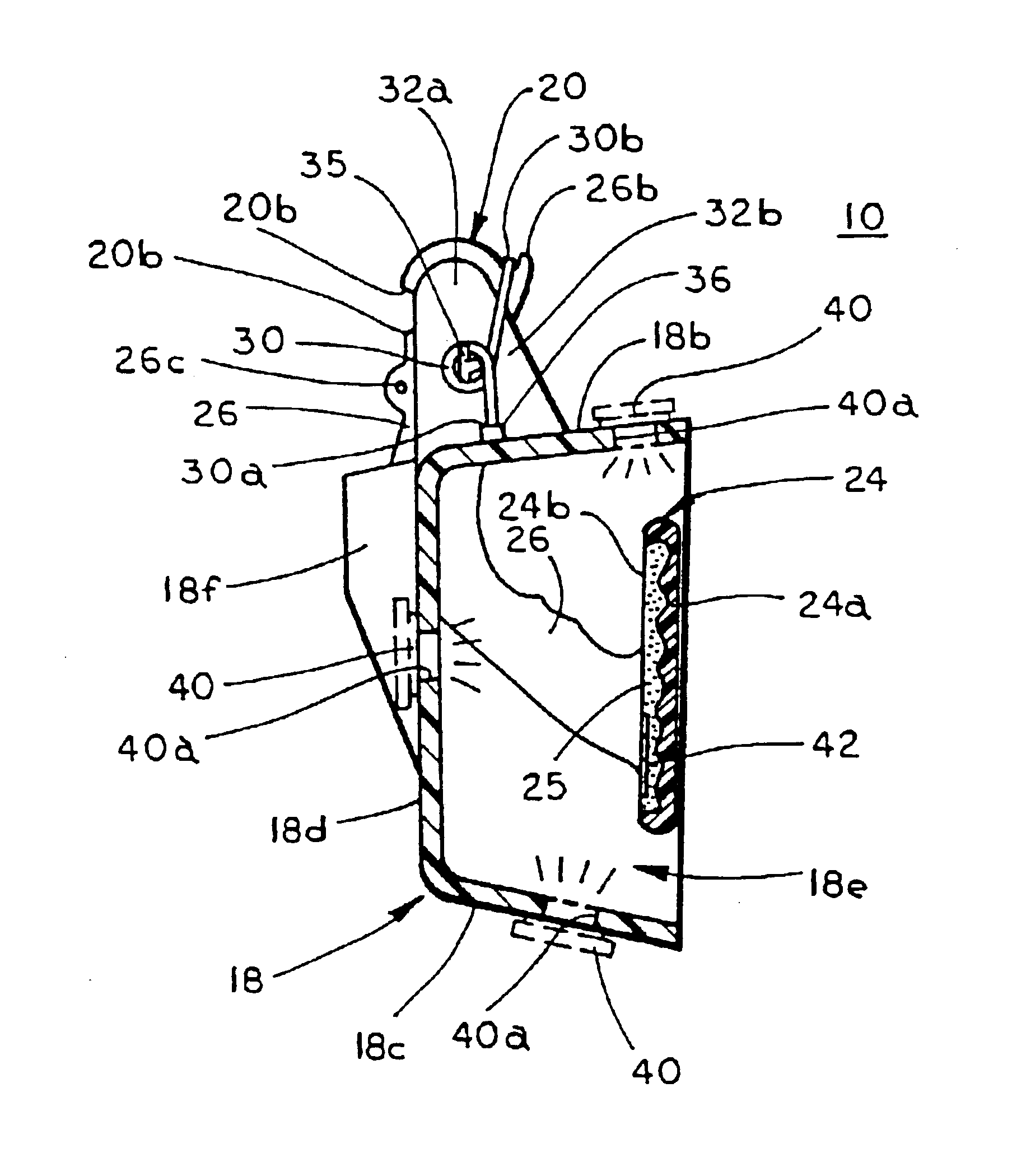

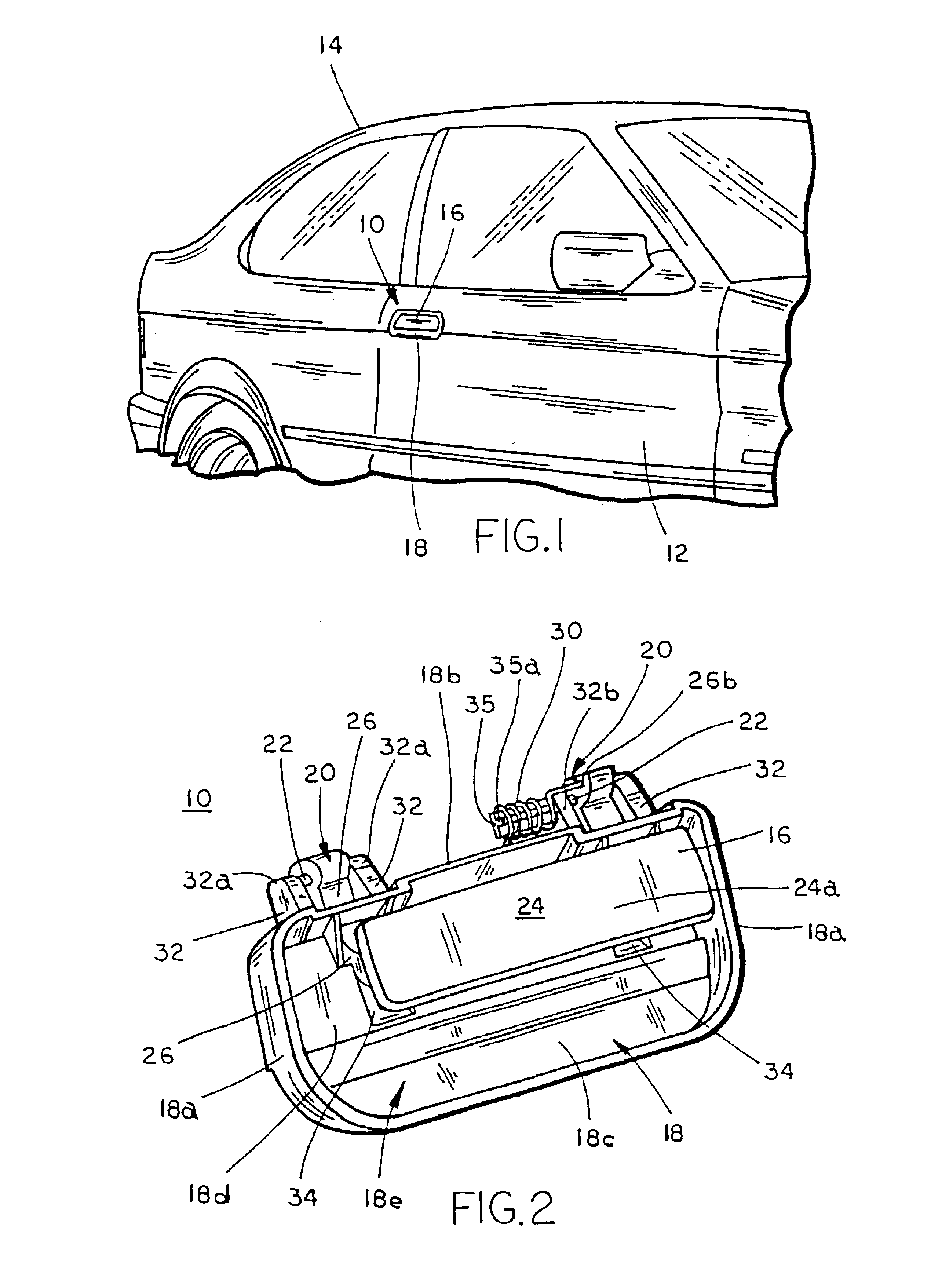

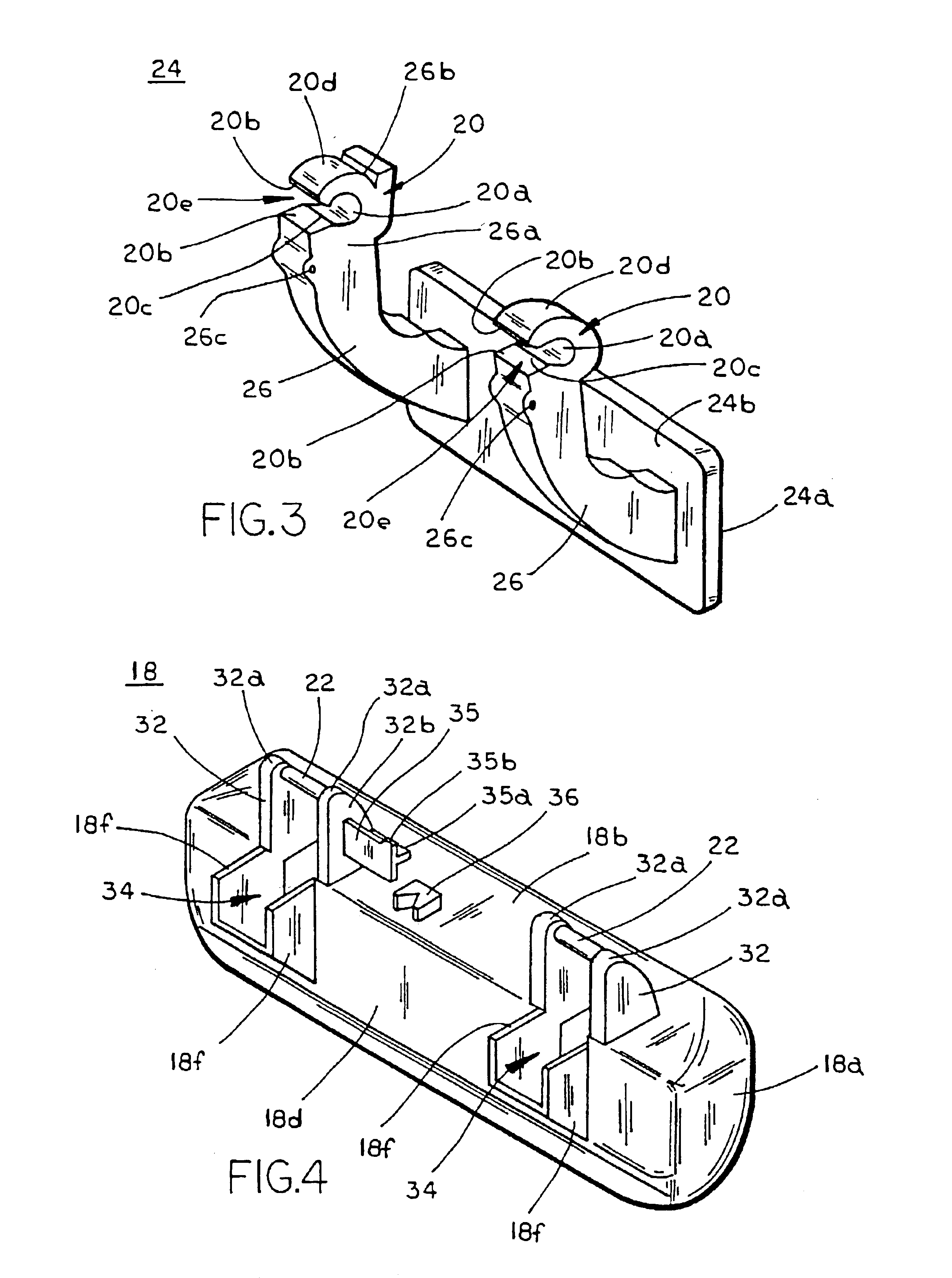

Vehicle door handle

A vehicle door handle assembly for opening a door of a vehicle includes a base which is mountable at the door of the vehicle and a handle portion which is operable to open the door via movement of the handle portion relative to the base. The handle portion includes a first portion having a first material hardness and a second portion having a second material hardness. The first material hardness is greater than the second material hardness, such that the second portion provides a softer feel to a user of the door handle assembly when opening the door of the vehicle. The door handle assembly may further include an illumination source for illuminating the handle portion and / or a heating element for heating the handle portion.

Owner:DONNELLY CORP

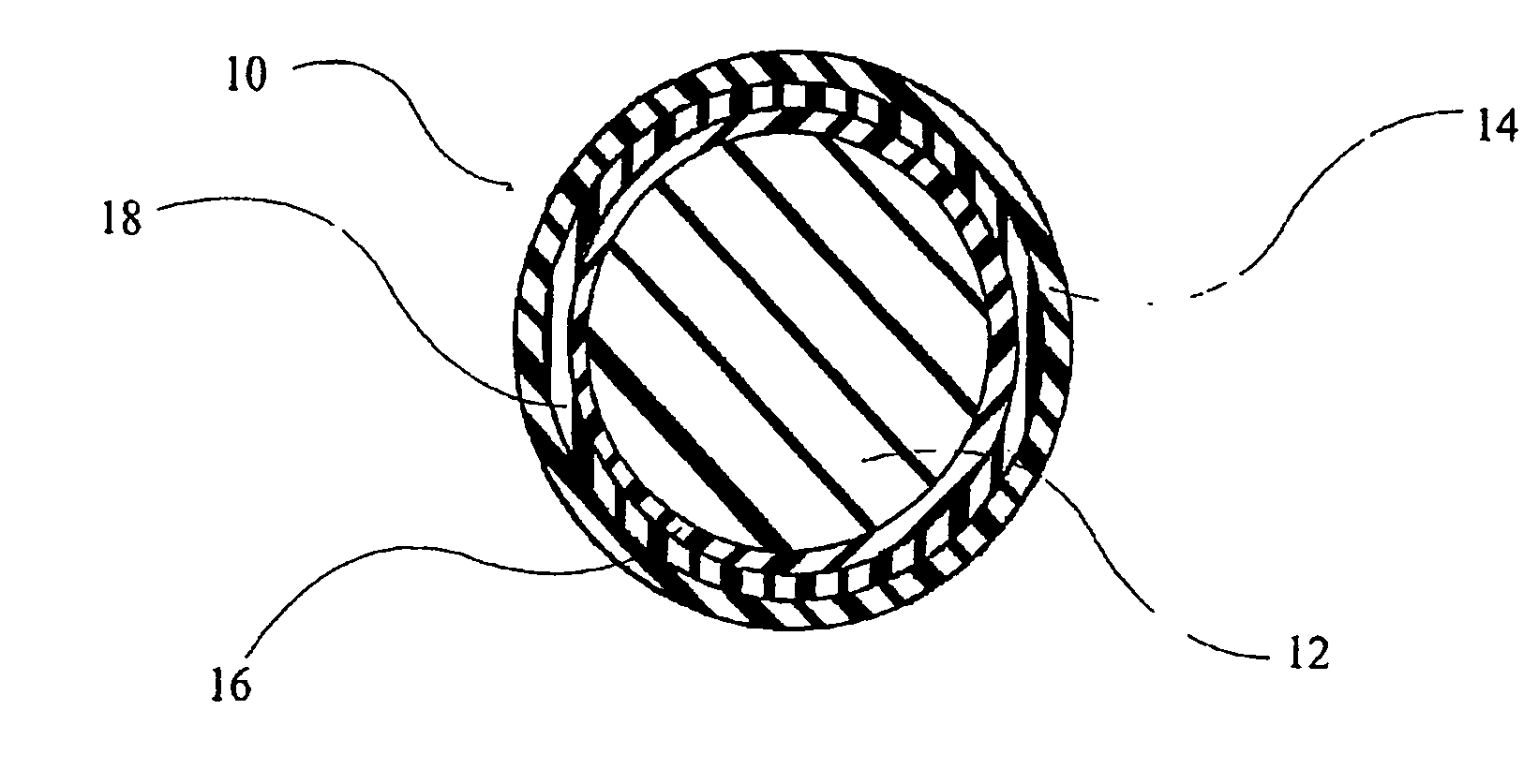

Multi-piece golf ball comprising low hardness gradient core

A golf ball includes a single core formed from a substantially homogenous rubber composition, an inner cover disposed about the core, and an outer cover. The inner cover includes an ionomeric material and has a hardness of about 60 Shore D or greater. The outer cover layer is disposed about the inner cover layer, is formed from a castable polyurea or polyurethane, and has a material hardness of about 60 Shore D or less. The outer surface of the core has a trans content of about 12% or less and a hardness of about 71 to 88 Shore C, the geometric center of the core has a trans content of about 10% or less and a hardness of about 70 to 80 Shore C, and the core surface hardness is greater than the geometric center hardness by about 1 to 10 Shore C to define a shallow positive hardness gradient.

Owner:ACUSHNET CO

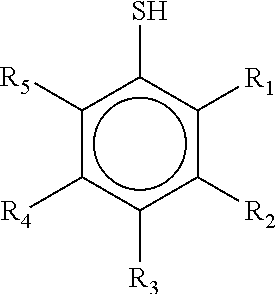

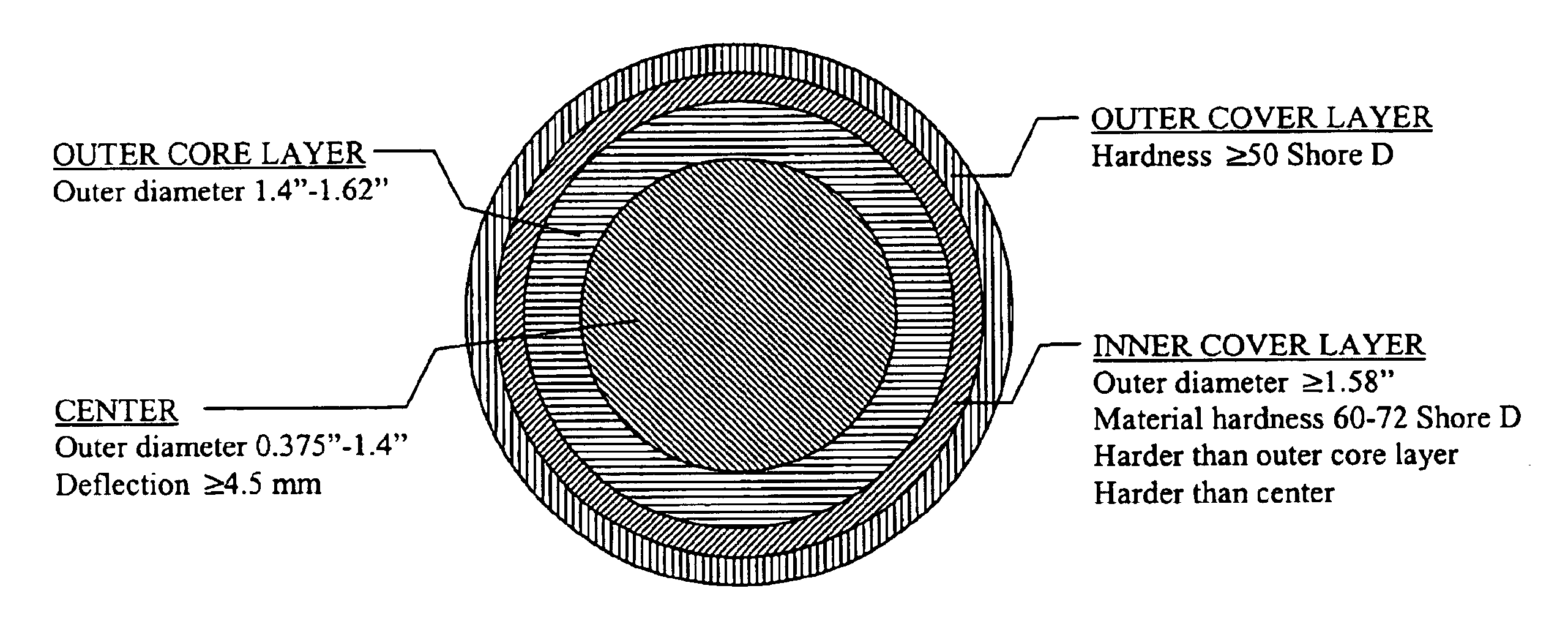

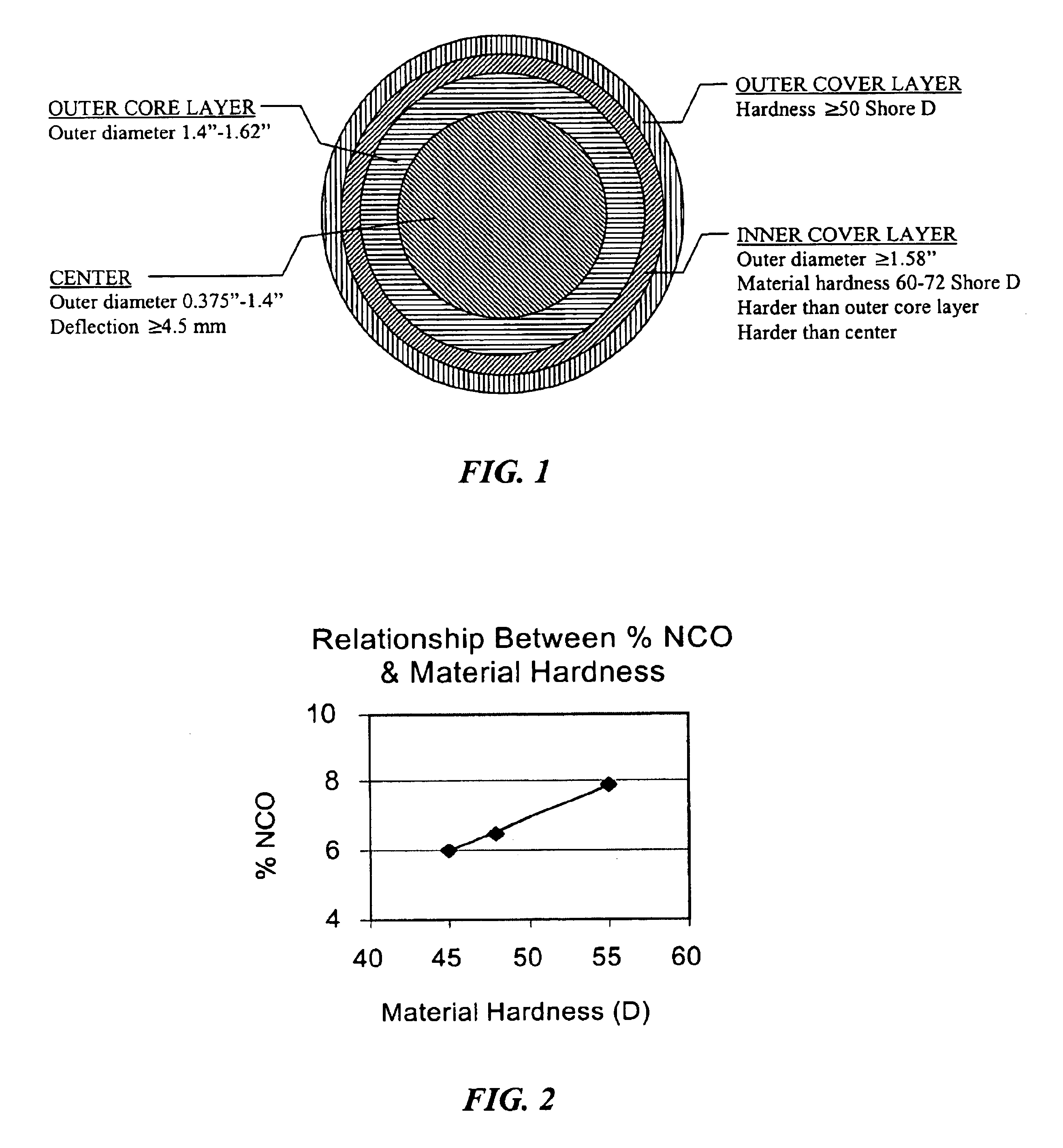

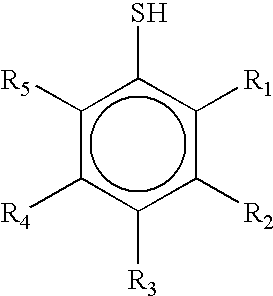

Thin, thermoset, polyurethane-covered golf ball with a dual core

A golf ball comprising a core and a cover disposed about the core, wherein the core comprises a center and an outer core layer, and the cover comprises an inner cover layer and an outer cover layer; and wherein the center has an outer diameter from about 0.375 inches to about 1.4 inches and deflection of greater than about 4.5 mm under a load of 100 Kg; the outer core layer has an outer diameter of from about 1.4 in to about 1.62 in; the inner cover layer has an outer diameter of greater than about 1.58 in and a material hardness of less than about 72 Shore D; and the outer cover layer has a hardness of greater than about 50 Shore D and a material hardness of less than about 50 Shore D.

Owner:ACUSHNET CO

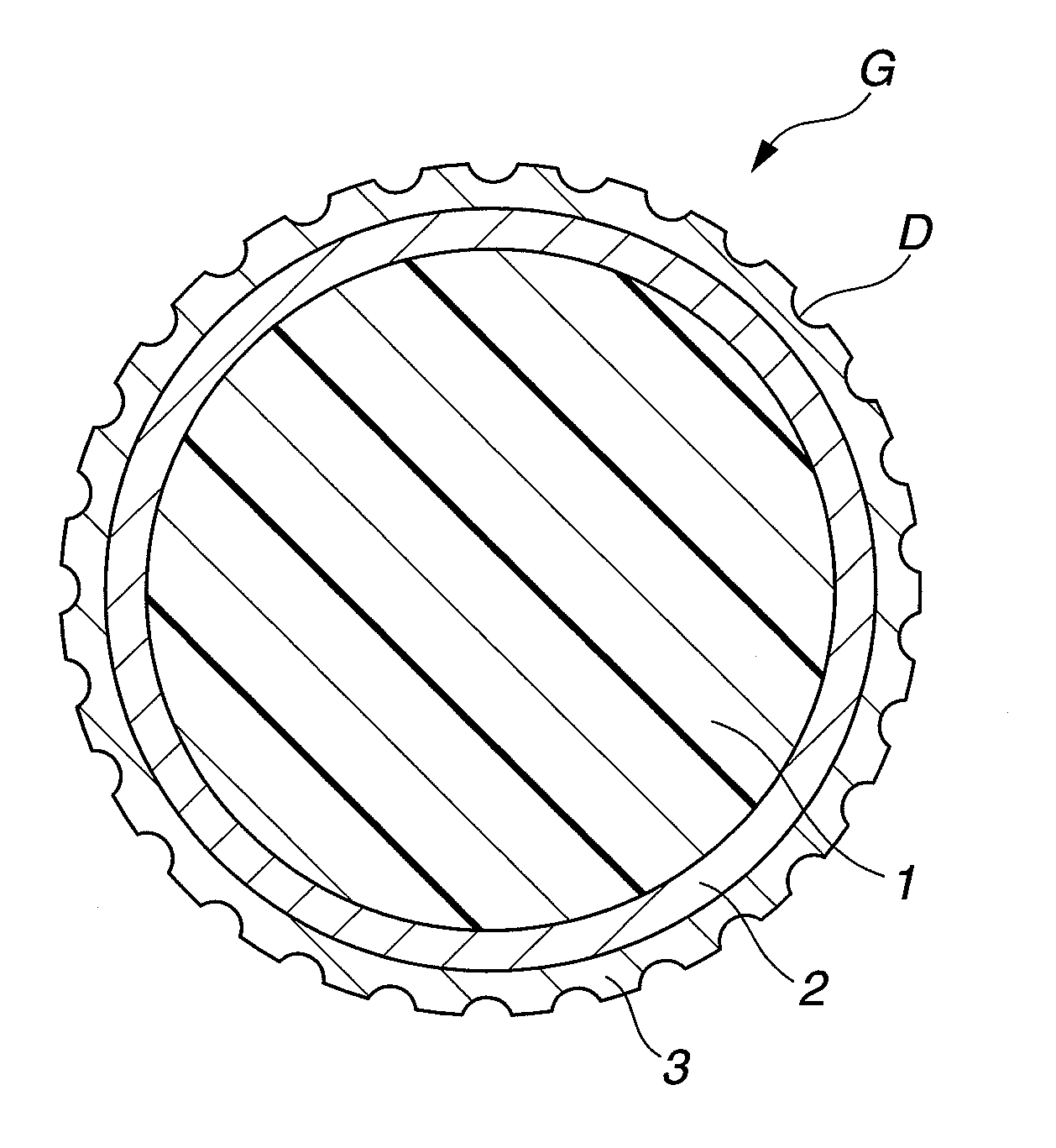

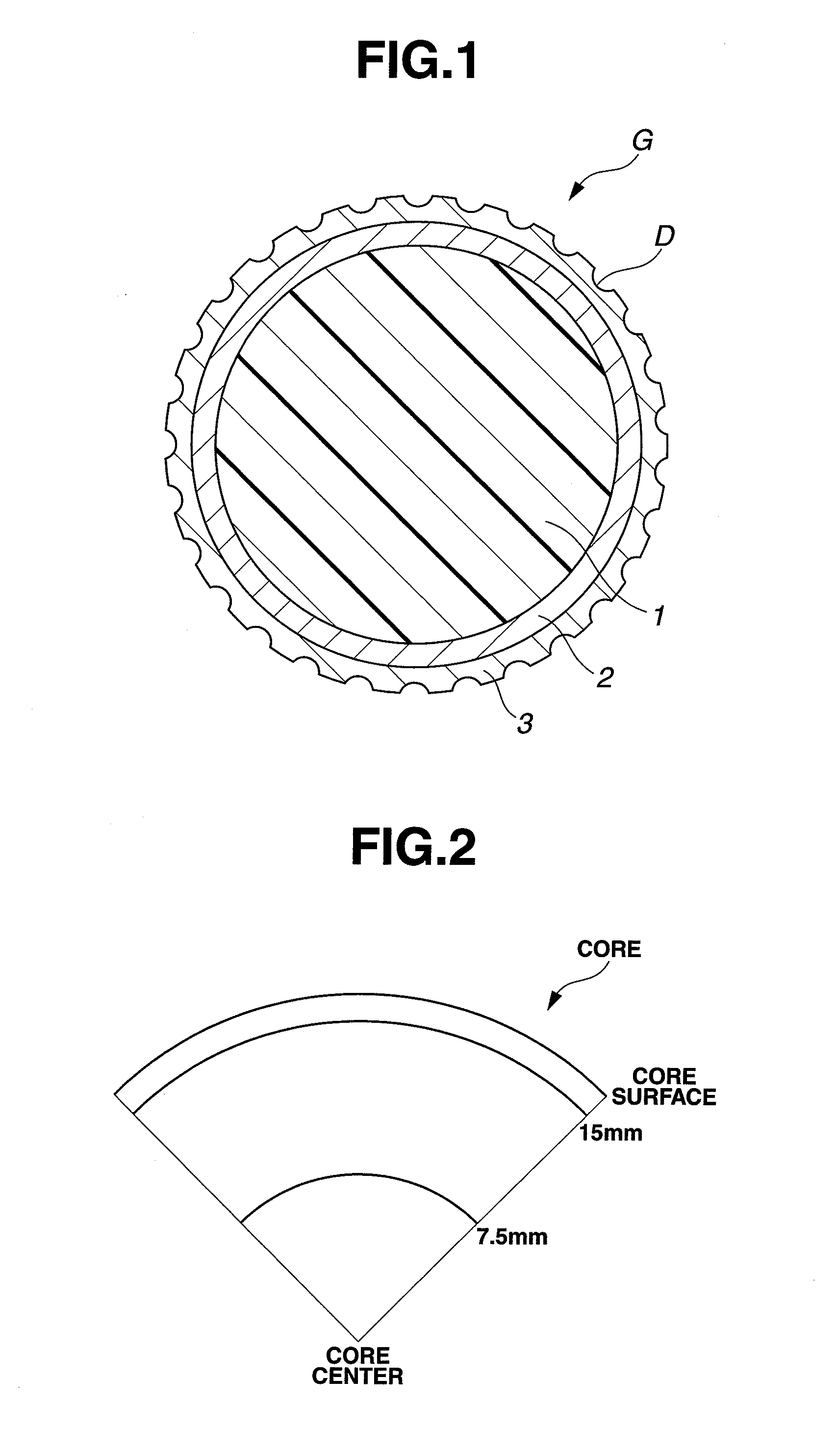

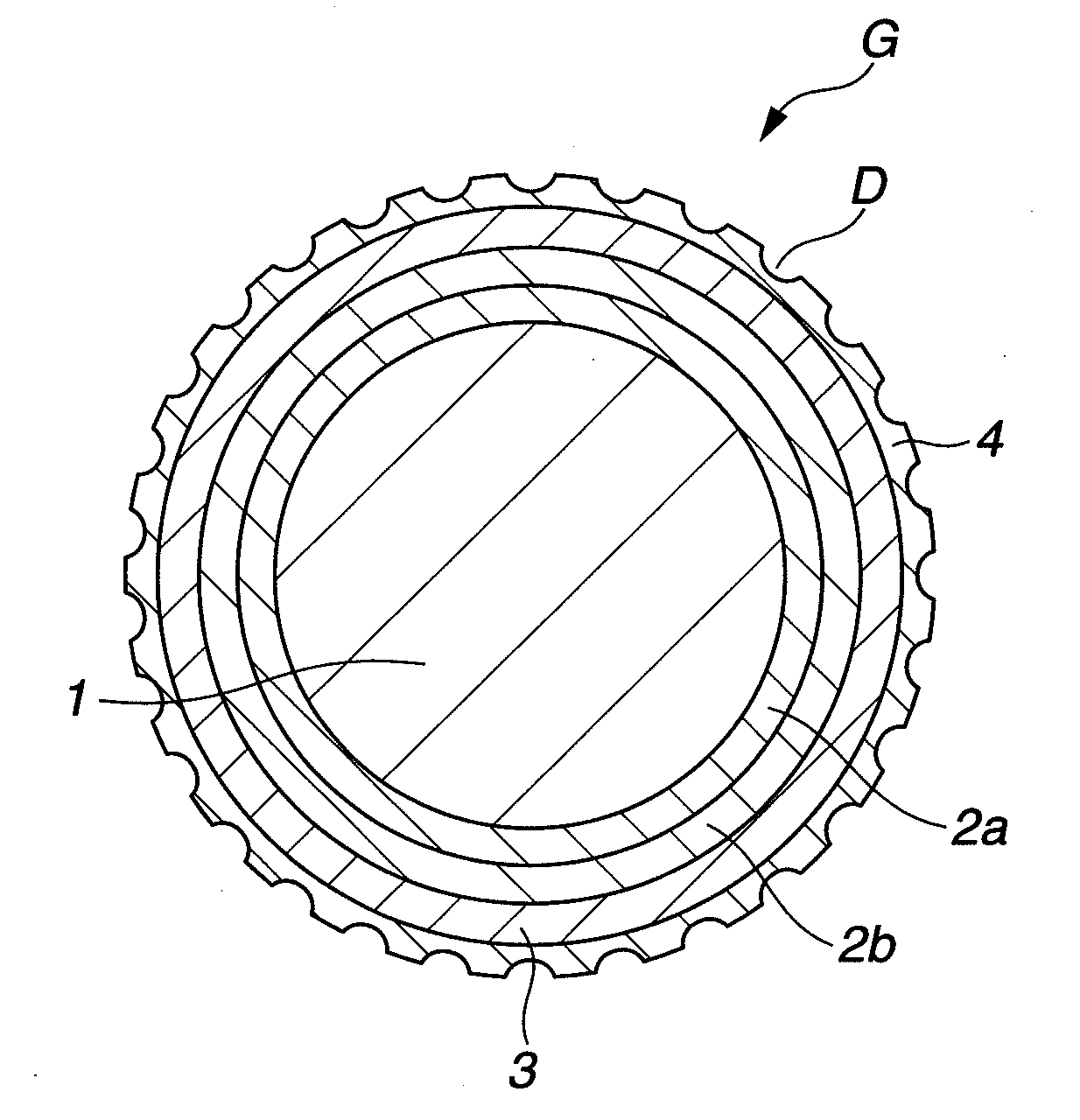

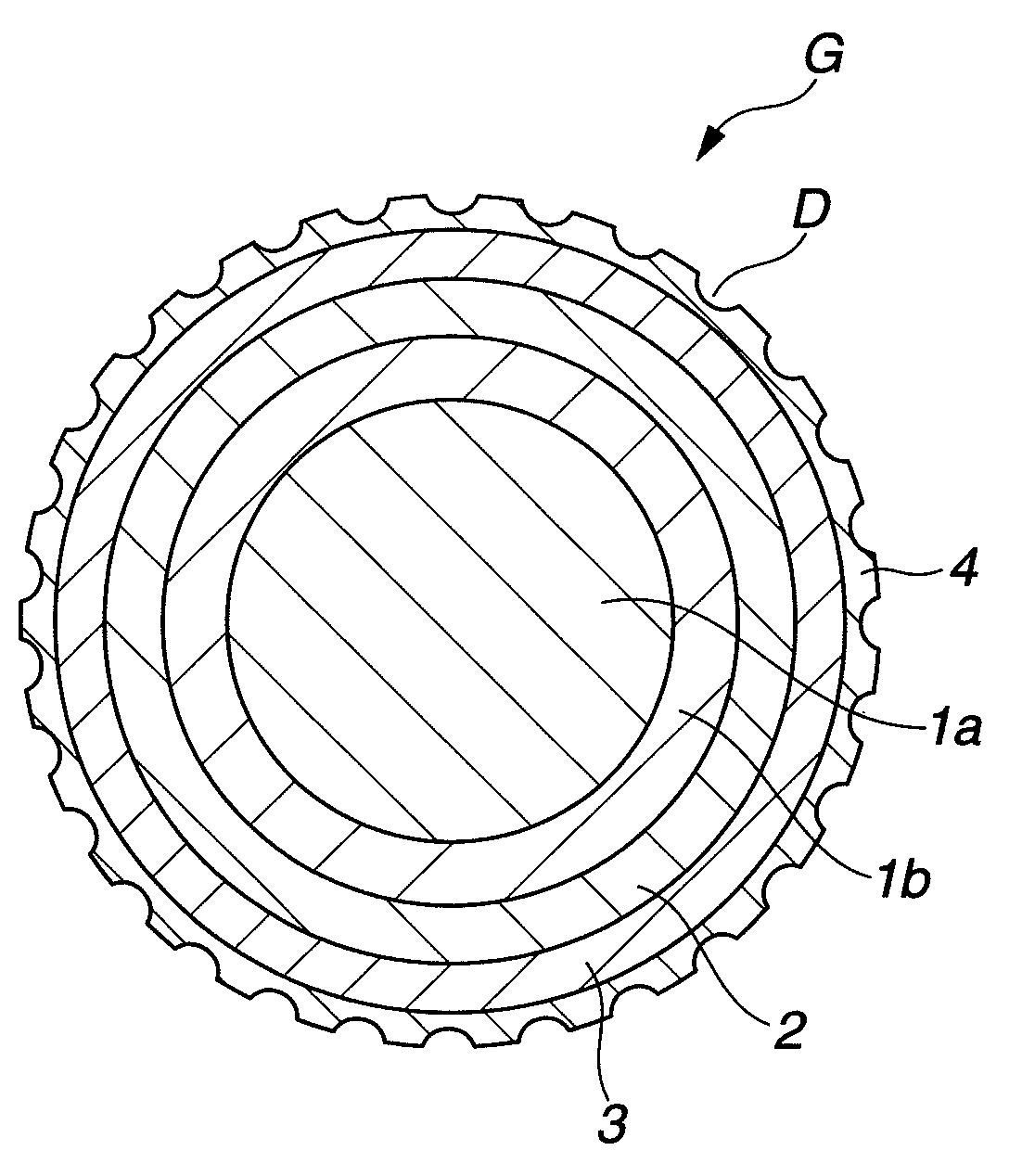

Multi-piece solid golf ball

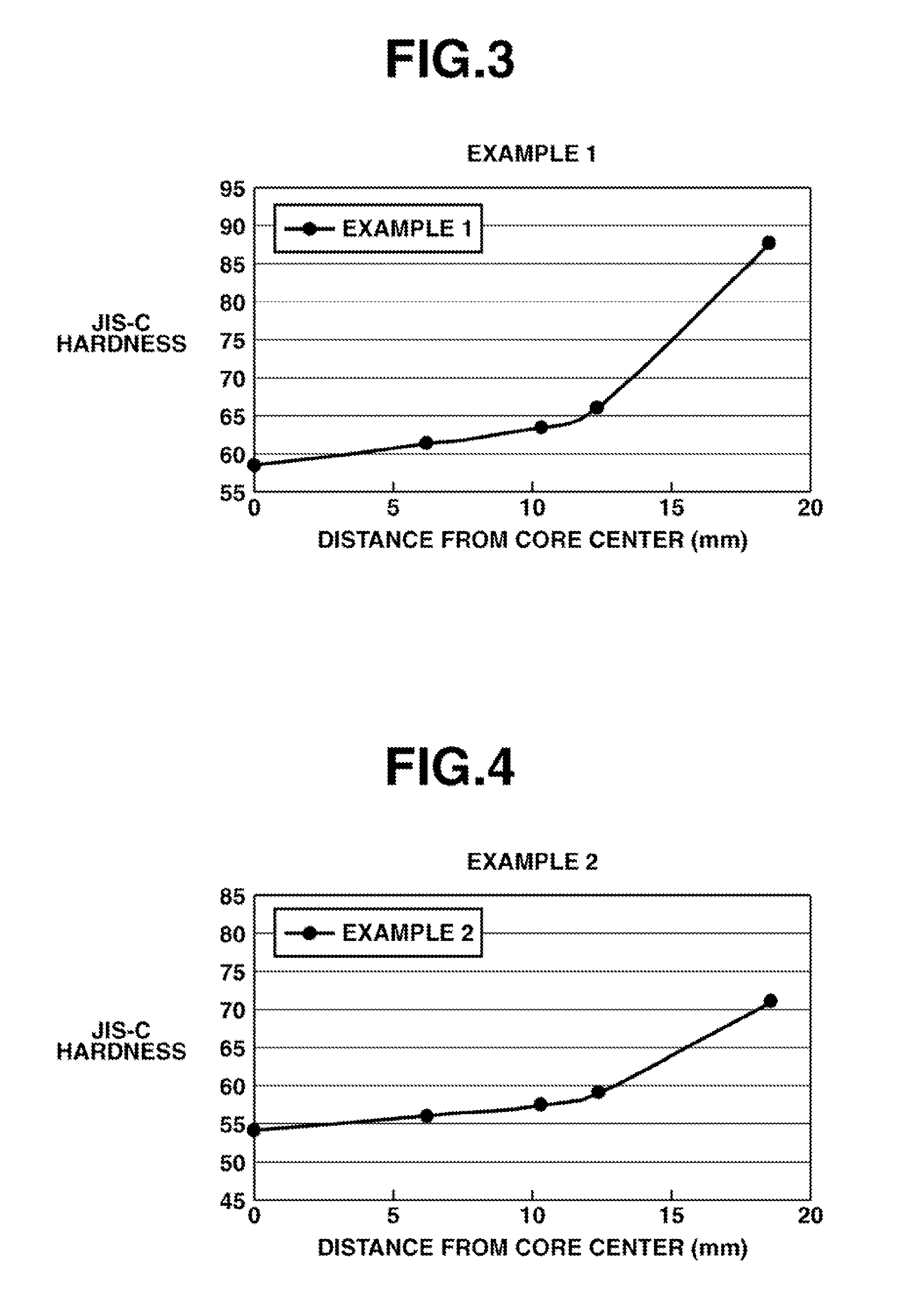

The invention provides a multi-piece solid golf ball having a solid core, at least one intermediate layer and a cover. The core has a hardness which gradually increases from a core center to a core surface, with the hardness difference in JIS-C hardness units between the core center and the core surface being at least 15 and, letting (I) be the average value for the cross-sectional hardness at a position 15 mm from the core center and the cross-sectional hardness at the core center and letting (II) be the cross-sectional hardness at a position 7.5 mm from the core center, the hardness difference (I)-(II) in JIS-C hardness units being not more than ±2. The intermediate layer has a material hardness and the core has a surface hardness which together satisfy the condition (JIS-C hardness of intermediate layer material)−(JIS-C hardness of core surface)>0. A sphere composed of the core encased by the intermediate layer has an initial velocity and the core has an initial velocity which together satisfy the condition (initial velocity of sphere composed of core encased by intermediate layer)−(initial velocity of core)≧0. The sphere composed of the core encased by the intermediate layer has a deflection and the core has a deflection which together satisfy the condition 0.80≦(deflection of sphere composed of core encased by intermediate layer) / (deflection of core). The cover is formed primarily of polyurethane, and the cover material has a Shore D hardness and the intermediate layer material has a Shore D hardness which together satisfy the condition (Shore D hardness of cover material)−(Shore D hardness of intermediate layer material)≦0. The golf ball of the invention has an excellent flight performance and feel, a good durability to repeated impact, and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

Multi-Layer Golf Ball

Golf balls consisting of a dual core and a single layer cover are disclosed. The dual core consists of an inner core layer formed from a rubber composition and an outer core layer formed from a highly neutralized polymer composition. The Shore C hardness of the outer core layer's outer surface is preferably greater than the material hardness of the inner cover layer, and more preferably is 56 Shore D or greater.

Owner:ACUSHNET CO

Multi-piece solid golf ball

ActiveUS20120100933A1Improve controllabilityFeel goodGolf ballsSolid ballsRubber materialEngineering

A multi-piece solid golf ball has a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The envelope layer is formed of an inner envelope layer, an intermediate envelope layer and an outer envelope layer. The inner, intermediate and outer envelope layers, the intermediate layer and the cover are each formed primarily of a resin material which may be of the same or different types, and the core is formed primarily of a rubber material. The cover has a material hardness which is the same as or lower than the core center hardness. One of the inner layers has a material hardness which is higher than either or both of the cover material hardness and the average core hardness (defined as the arithmetic mean of the core surface hardness and the core center hardness). The golf ball, even when used by those golfers among professionals and skilled amateurs who, on striking a ball with a driver, tend to generate shots having a rather low spin rate and a low launch angle, has an excellent flight performance and also excellent controllability in the short game that are acceptable to such users. In addition, it has a good feel on impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

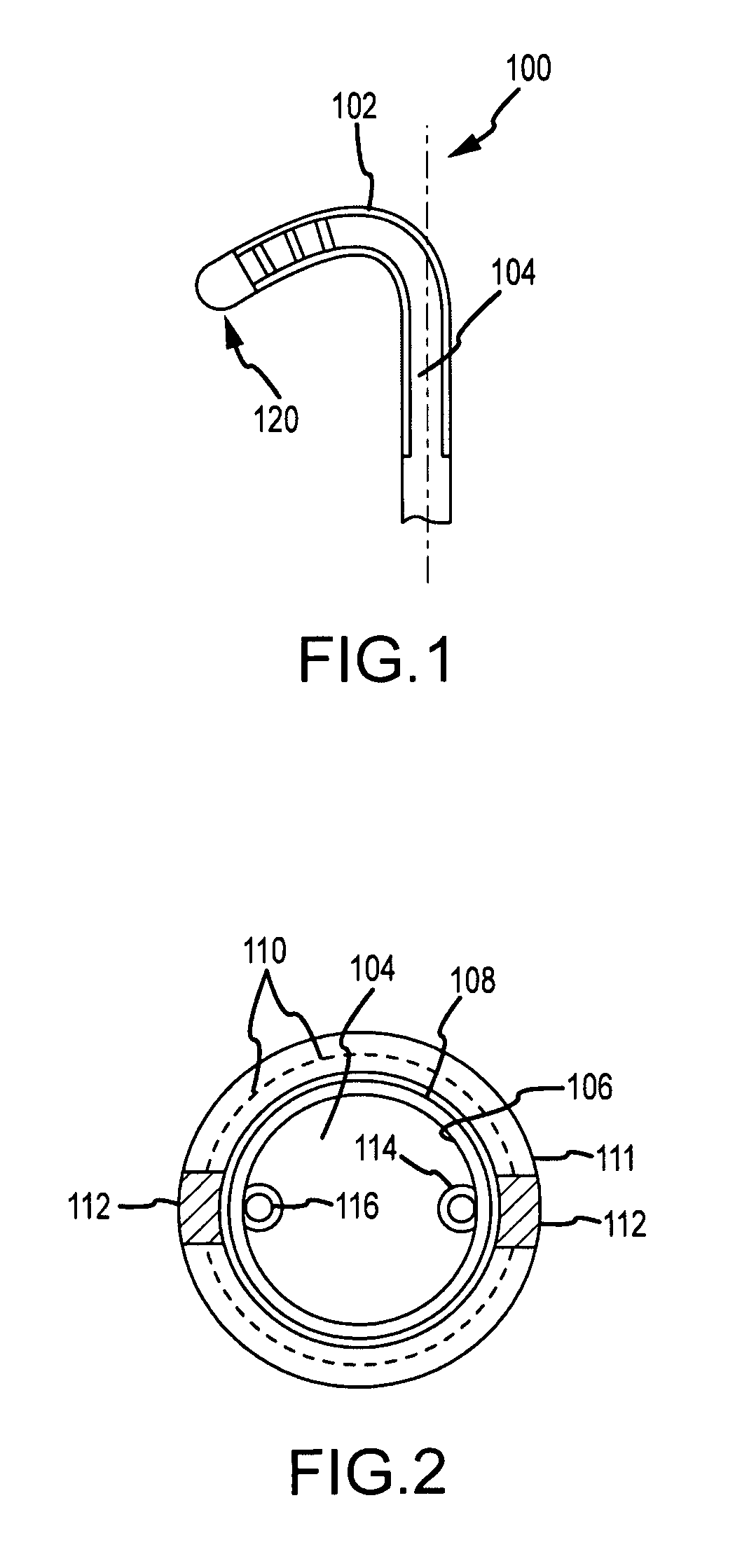

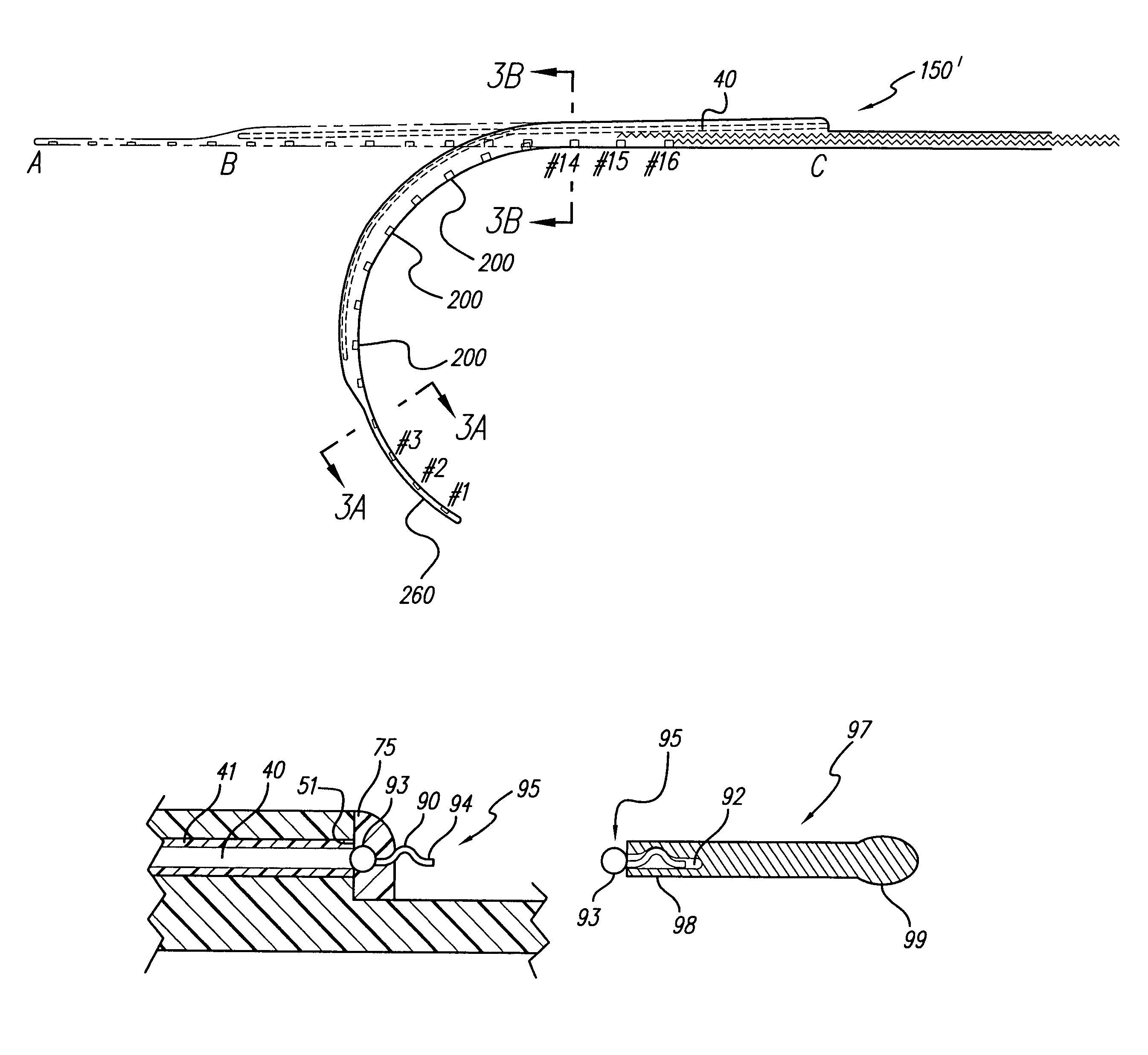

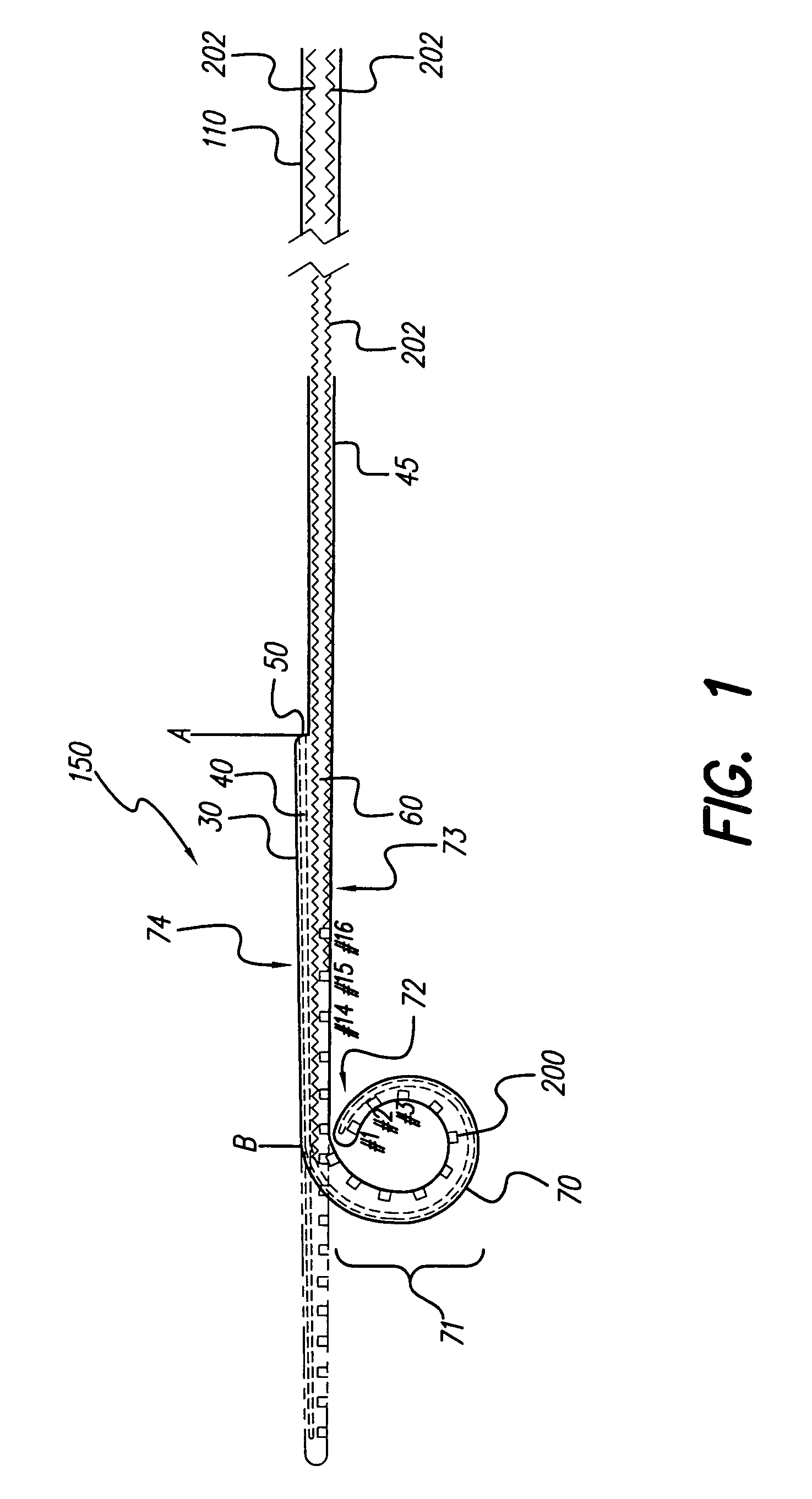

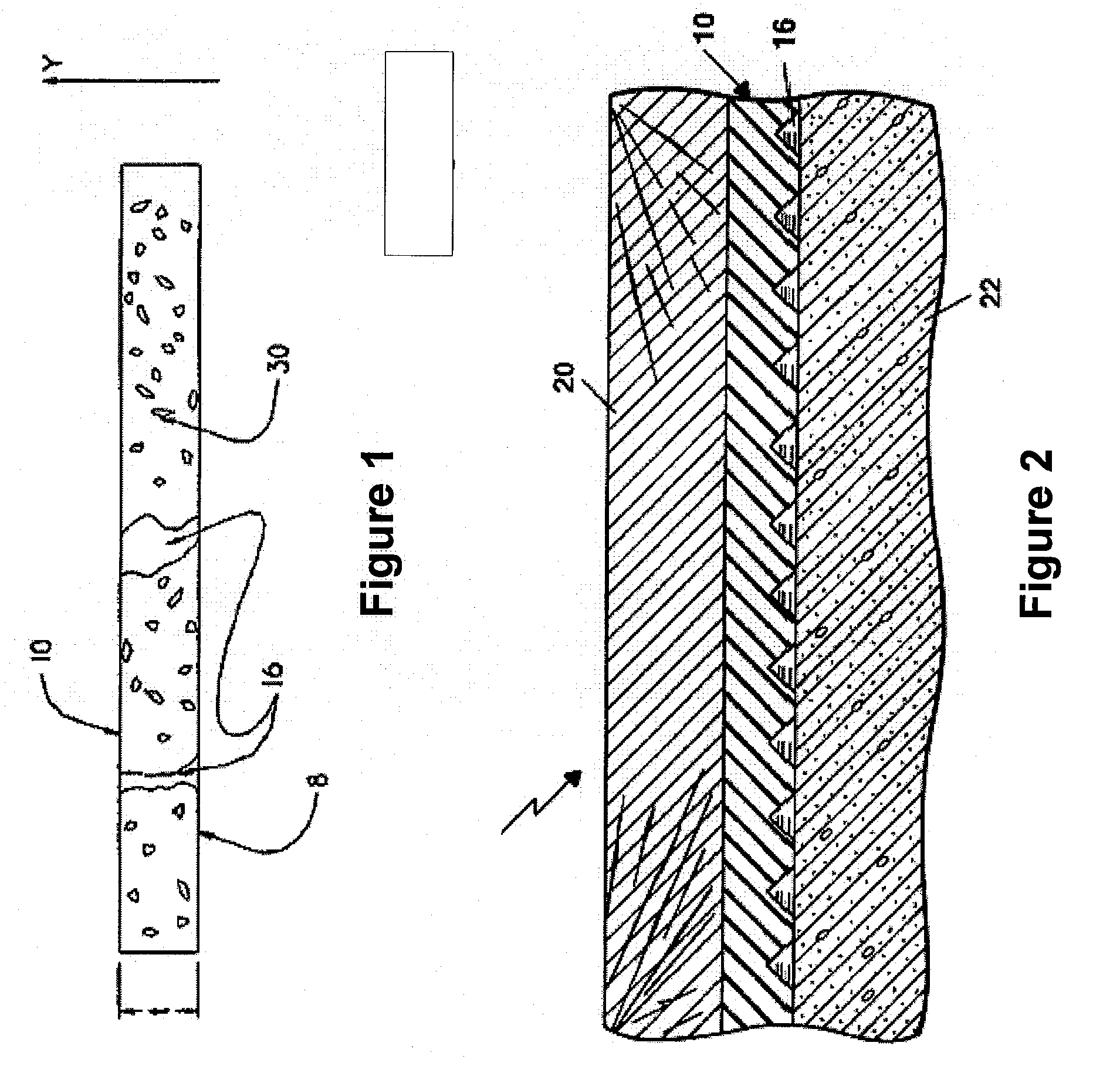

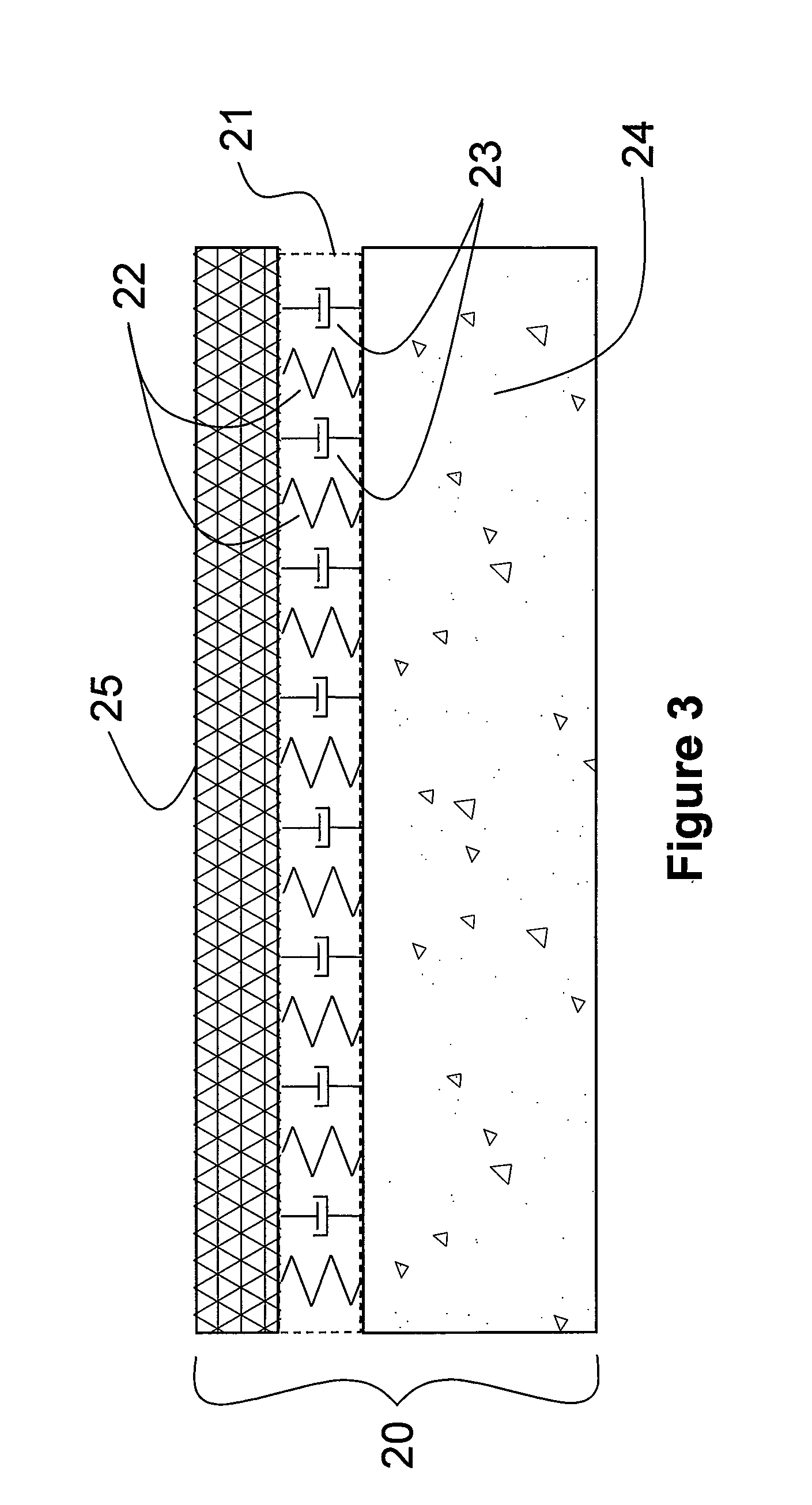

Cochlear implant electrode and method of making same

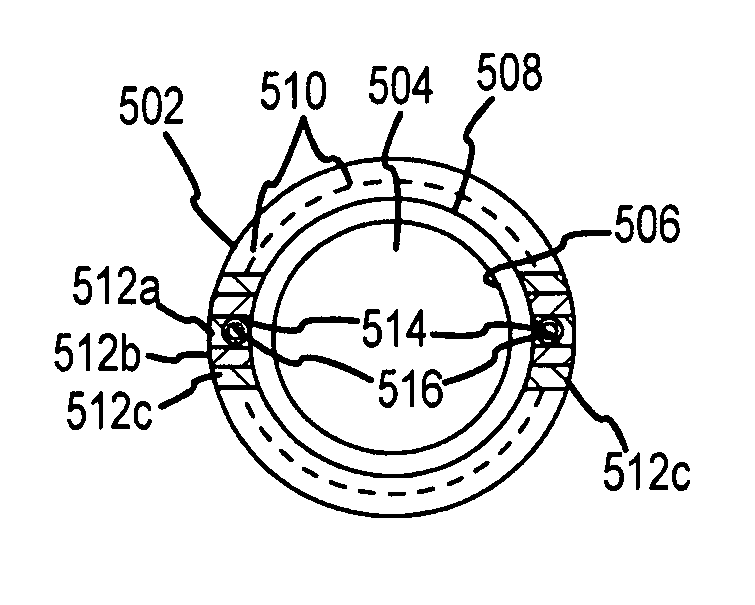

InactiveUS7315763B2Increase stiffnessEasy to insertHead electrodesExternal electrodesCochlear implantationElectrode array

A cochlear stimulation lead having a pre-curved electrode array is provided. The molding process provides memory to the curved part of the lead. The lead may be made having a stylet insertion channel that extends from a slightly curved or substantially straight section and into the highly curved section of the lead. Because high compliance is desired for the lead in cochlear stimulation applications, the compliance is controlled not only by the taper at the distal end of the lead and overall lead thickness, but also by choosing the material hardness of the lead carrier / covering and employing compliant zigzagged conductor wire. In addition, differential lead compliance / stiffness can be achieved by using a stiff tubing that forms part of the stylet insertion channel.

Owner:ADVANCED BIONICS AG

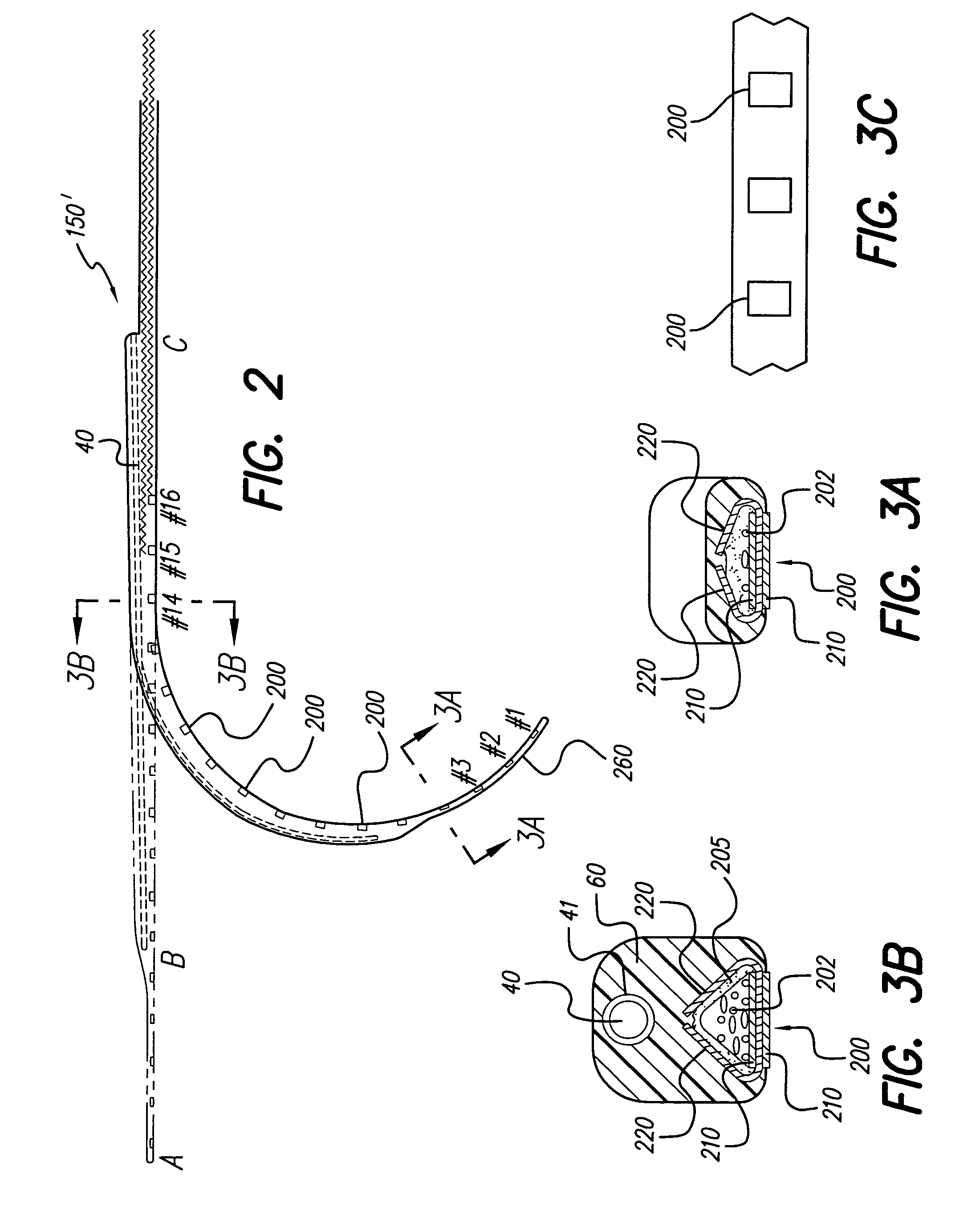

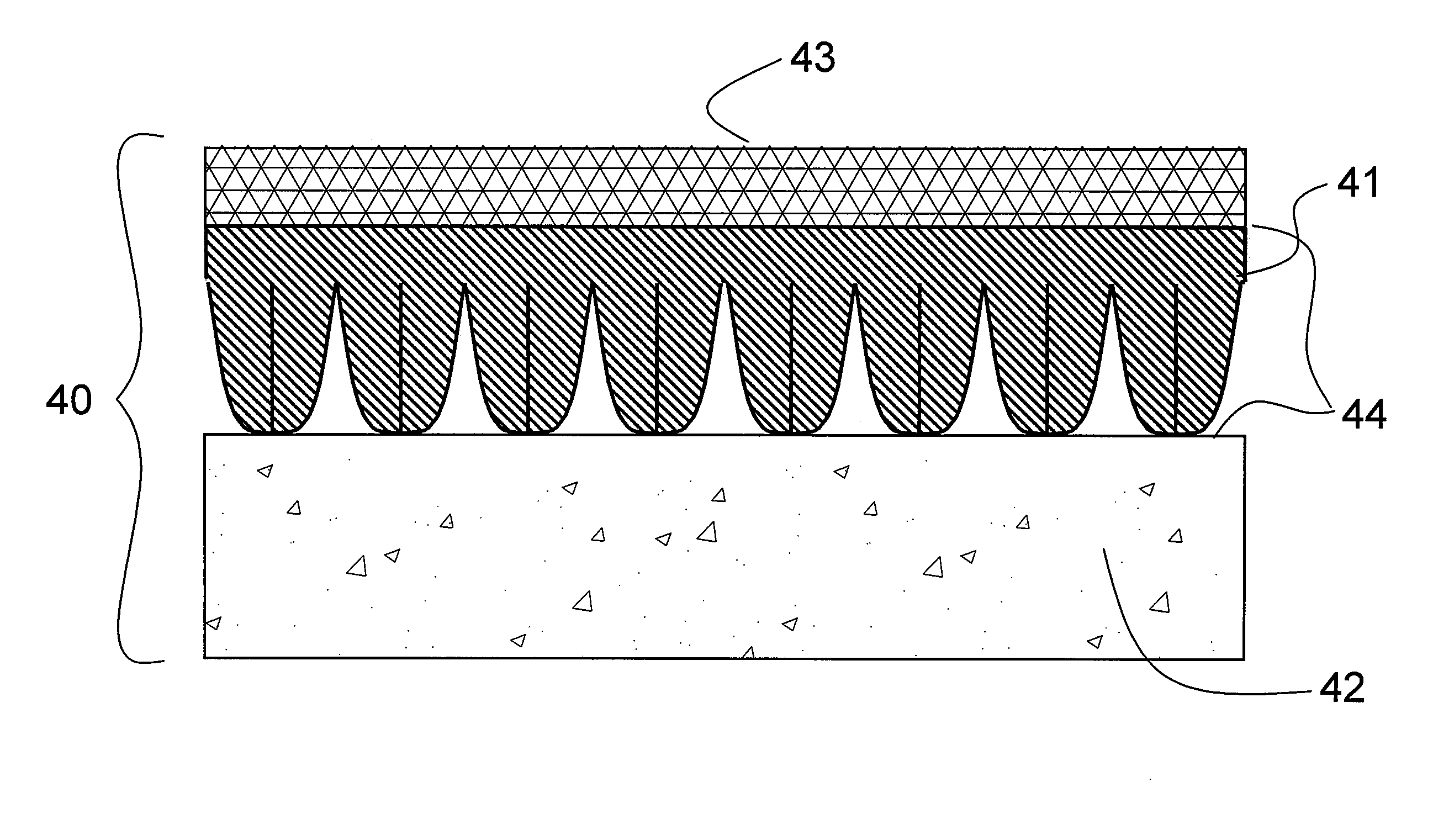

Noise isolating underlayment

ActiveUS20080236097A1Improve performanceImproved impact noise isolating propertyConstruction materialCovering/liningsEngineeringUltimate tensile strength

A noise-reducing substrate for use in a flooring system, the flooring system having a subfloor and a decorative upper layer. The substrate comprises a series of edge butted panels, each of which has a bottom surface, a top surface and side surfaces. Each panel's top surface and oppositely facing bottom surface are parallel to each other and are spaced apart by the thickness of the substrate. A profile in the bottom surface of the substrate changes the substrate's effective stiffness and improves the noise isolation of the substrate compared to the stiffness and noise isolation of the panel without the profile. Additionally, the profile reduces the weight of the panel, thereby reducing manufacturing and installation costs. When the substrate is positioned between the subfloor and the decorative top layer, the material hardness and the flat profile of the upper surface provide a platform with the strength and texture required to allow for installation of the decorative floor layer without the need for an additional rigid backing material. Such a system greatly improves the impact noise reduction on a variety of floor / ceiling systems while keeping the installation cost low and the adding very little to the total system thickness.

Owner:PACIFIC COAST BUILDING PRODS

Thin, thermoset, polyurethane-covered golf ball with a dual core

A golf ball comprising a core including a center having an outer diameter from about 0.375 inches to about 1.4 inches and deflection of greater than about 4.5 mm under a load of 100 Kg and an outer core layer having an outer diameter of from about 1.4 in to about 1.62 in, wherein at least one of the center or core layer includes polybutadiene rubber composition including a halogenated organosulfur compound or a metal salt thereof, and a cover including an inner cover layer having an outer diameter of greater than about 1.58 in and a material hardness of less than about 72 Shore D and an outer cover layer having a hardness of greater than about 50 Shore D and a material hardness of less than about 50 Shore D.

Owner:ACUSHNET CO

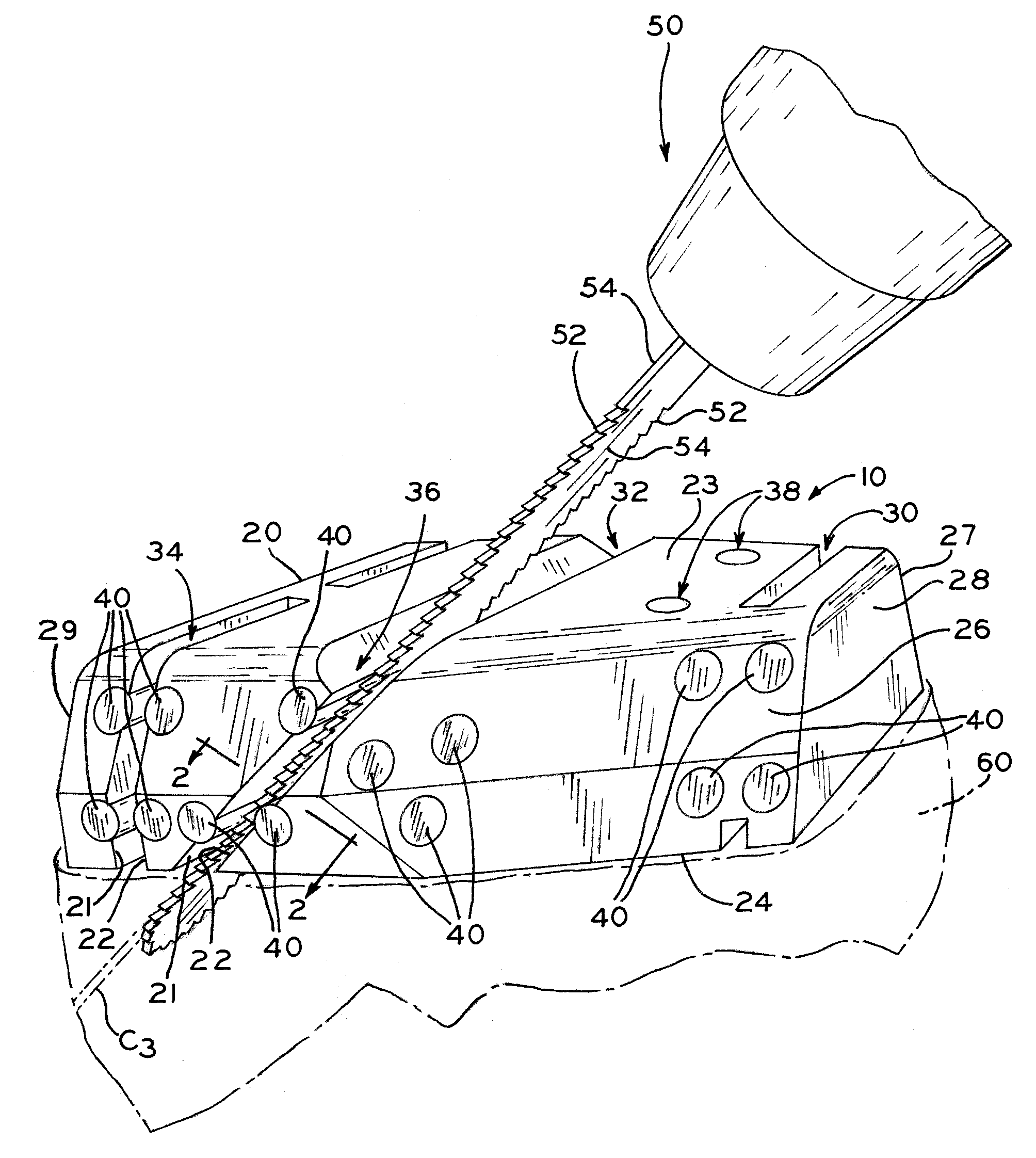

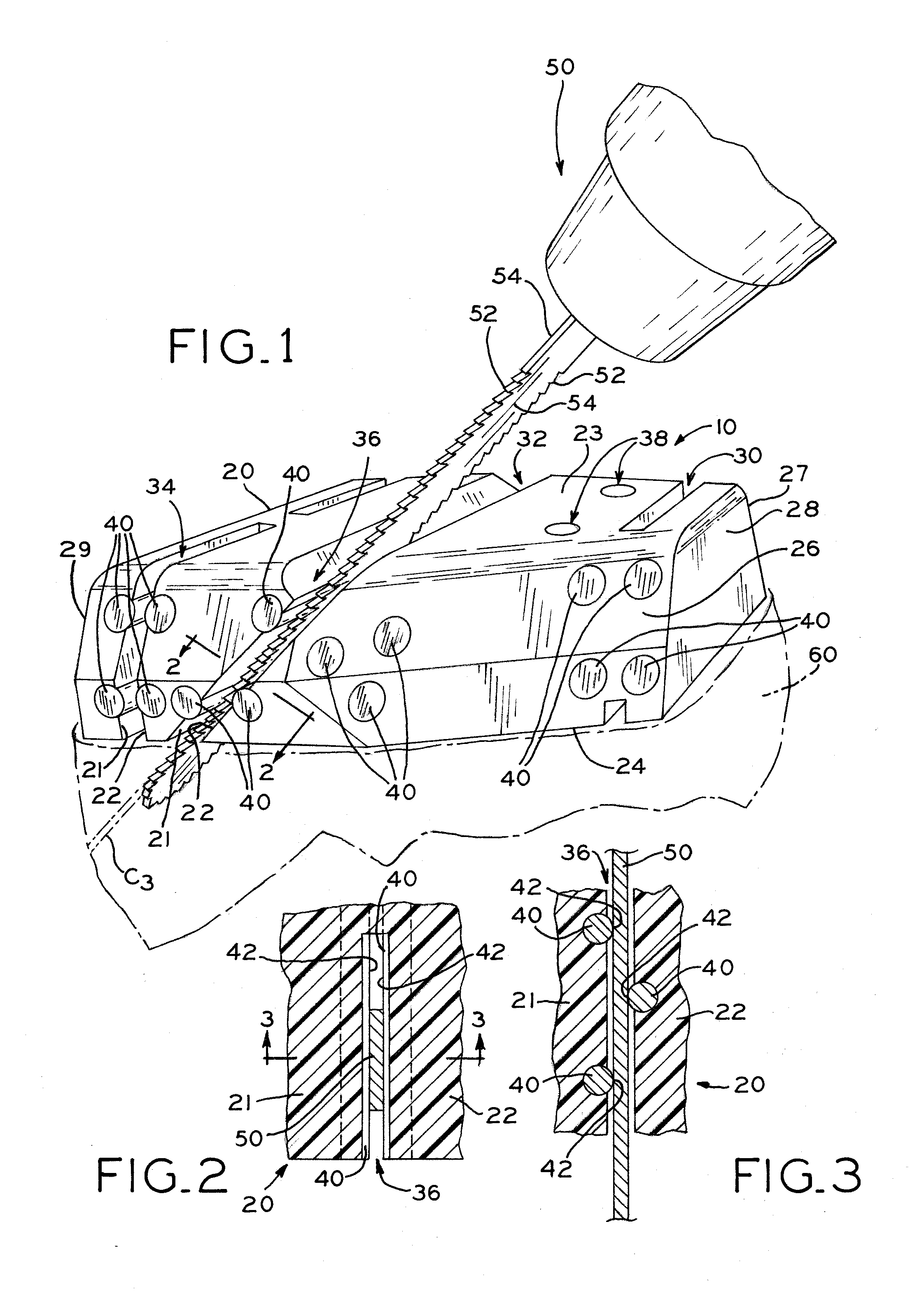

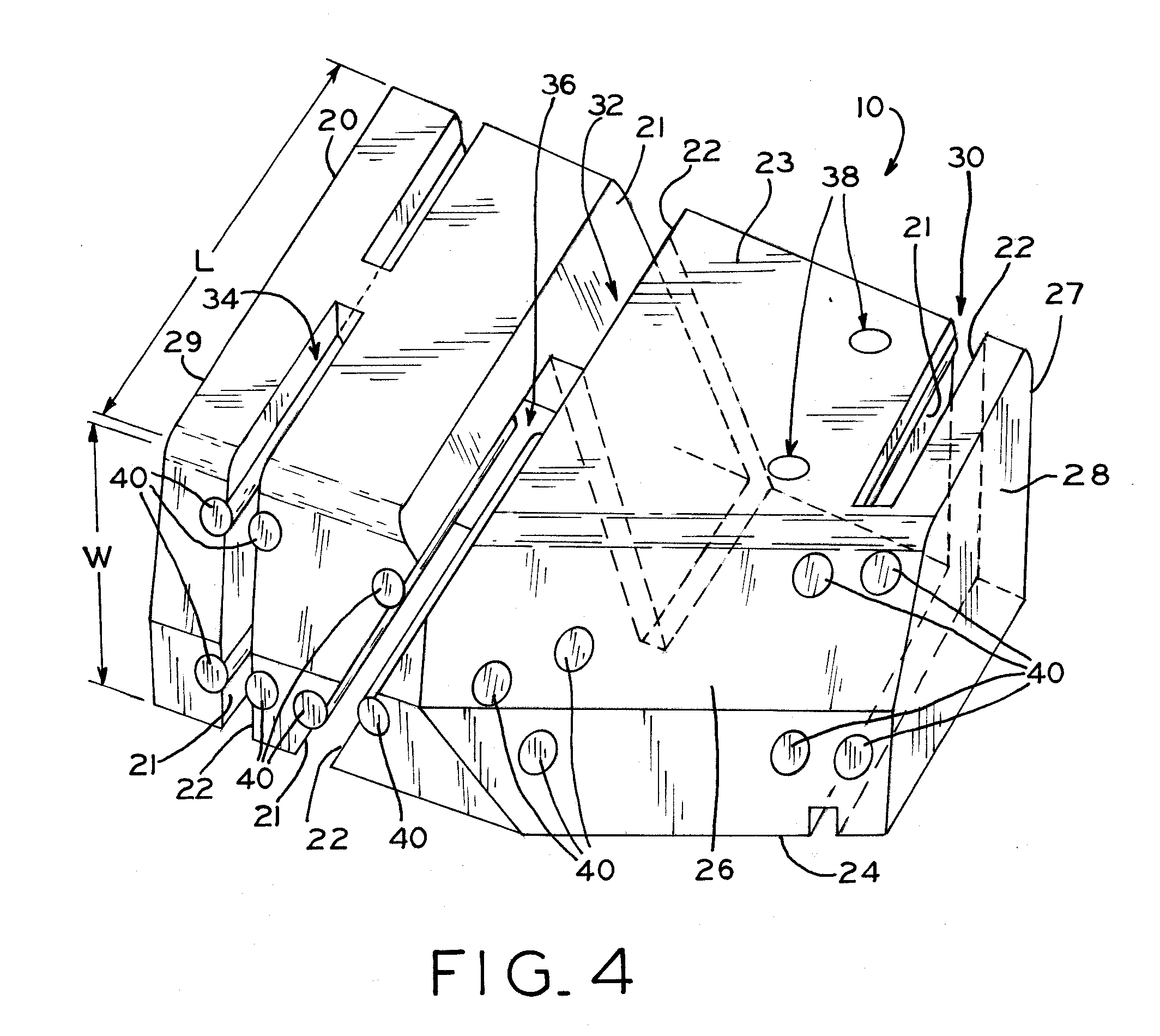

Composite surgical instrument

ActiveUS20120109135A1Low costReduce the amount requiredNon-surgical orthopedic devicesSurgical sawsAnatomical structuresEngineering

A surgical instrument and method are provided for guiding a cutting tool to resect an anatomical structure. The surgical instrument includes a guide body formed of a guide body material having a guide body material hardness, and a first bearing and a second bearing formed of a bearing material having a bearing material hardness. The bearing material hardness is greater than the guide body material hardness. The first bearing and the second bearing are secured to the guide body with at least a portion of the first bearing and at least a portion of the second bearing exposed from the guide body. Also, the second bearing is spaced a distance from the first bearing. By arranging the first bearing and the second bearing in this manner, the first bearing and the second bearing provide a discontinuous bearing surface for a cutting tool to contact when moving within the guide body. Additionally, the first bearing and the second bearing are each sized and arranged so that with the cutting tool positioned for guiding by the surgical instrument, the first bearing and the second bearing prevent contact between the cutting tool and the guide body.

Owner:ZIMMER INC

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7468290B2Solid-state devicesSemiconductor/solid-state device manufacturingDielectricUltraviolet lights

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

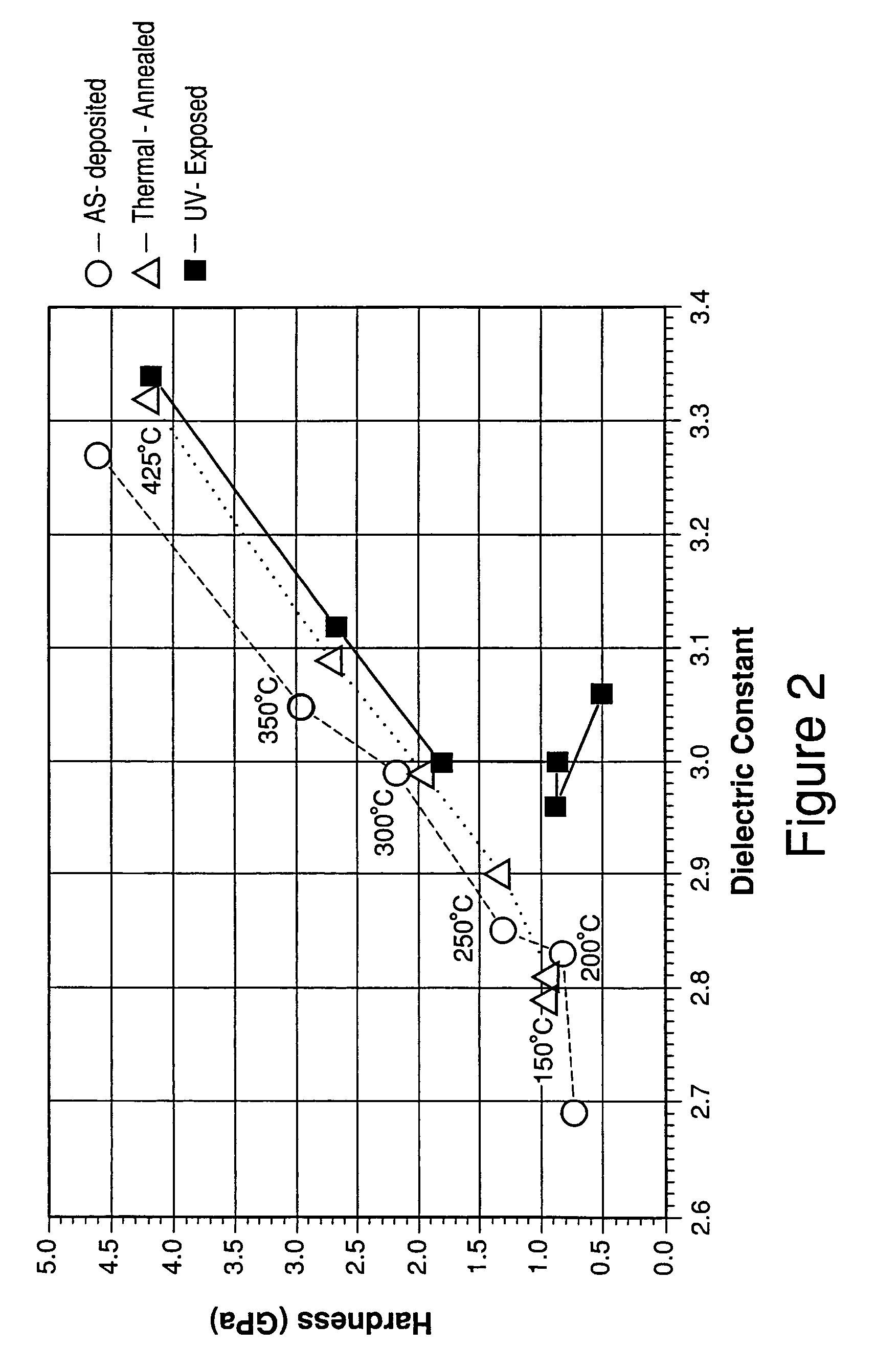

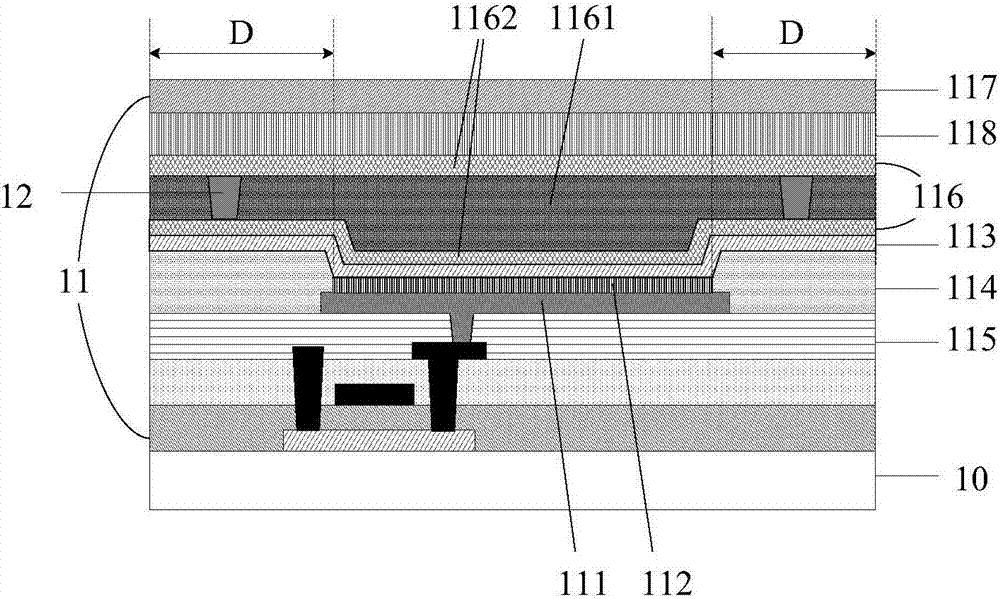

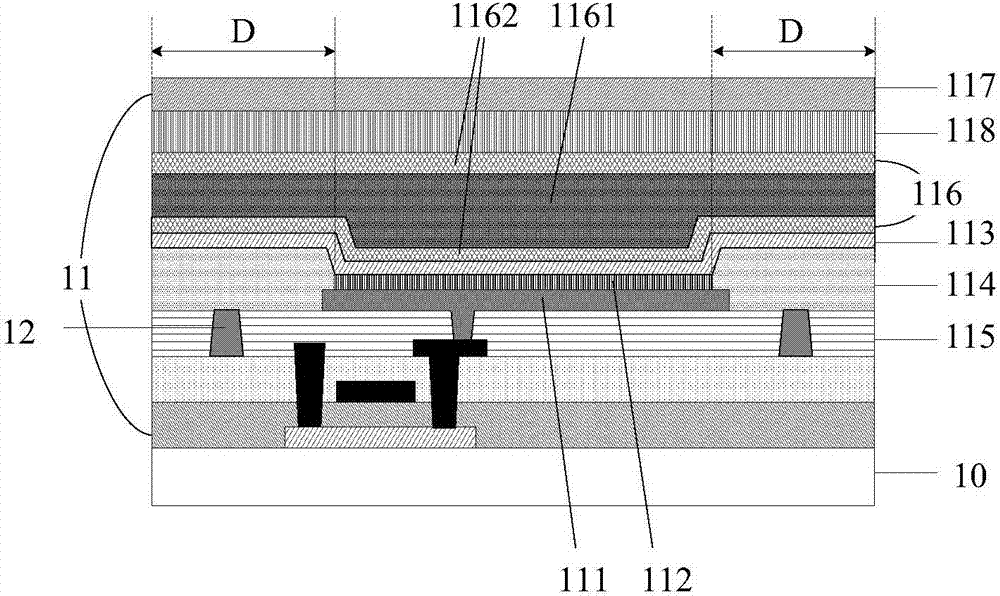

Flexible display panel and manufacturing method thereof and display device

ActiveCN106920826AGood anti-collision performanceAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic layer

The invention relates to a flexible display panel and a manufacturing method thereof and a display device and aims at solving the problem of abnormal display due to the fact that an internal film layer easily generates a crack after colliding with a hard object, of an existing flexible display panel. The flexible display panel comprises a flexible substrate, various functional film layers arranged on the flexible substrate and at least one support post, wherein the various functional film layers comprise multiple organic layers; the support post is arranged in at least one organic layer; the support posts are arranged in non-pixel light-emitting areas of the flexible display panel; and the material hardness of various support posts is greater than that of the corresponding organic layers on which the support posts are located, and the heights are not greater than the thicknesses of the corresponding organic layers on which the support posts are located. The support posts of which the heights are not greater than the thicknesses of the corresponding organic layers on which the support posts are located are arranged in the non-pixel light-emitting areas of the organic layers, so that normal display of the display panel and the thicknesses of the organic layers are affected, and meanwhile, the internal film layer can be prevented from generating the crack due to collision with the hard object, thereby improving the anti-collision ability of the display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

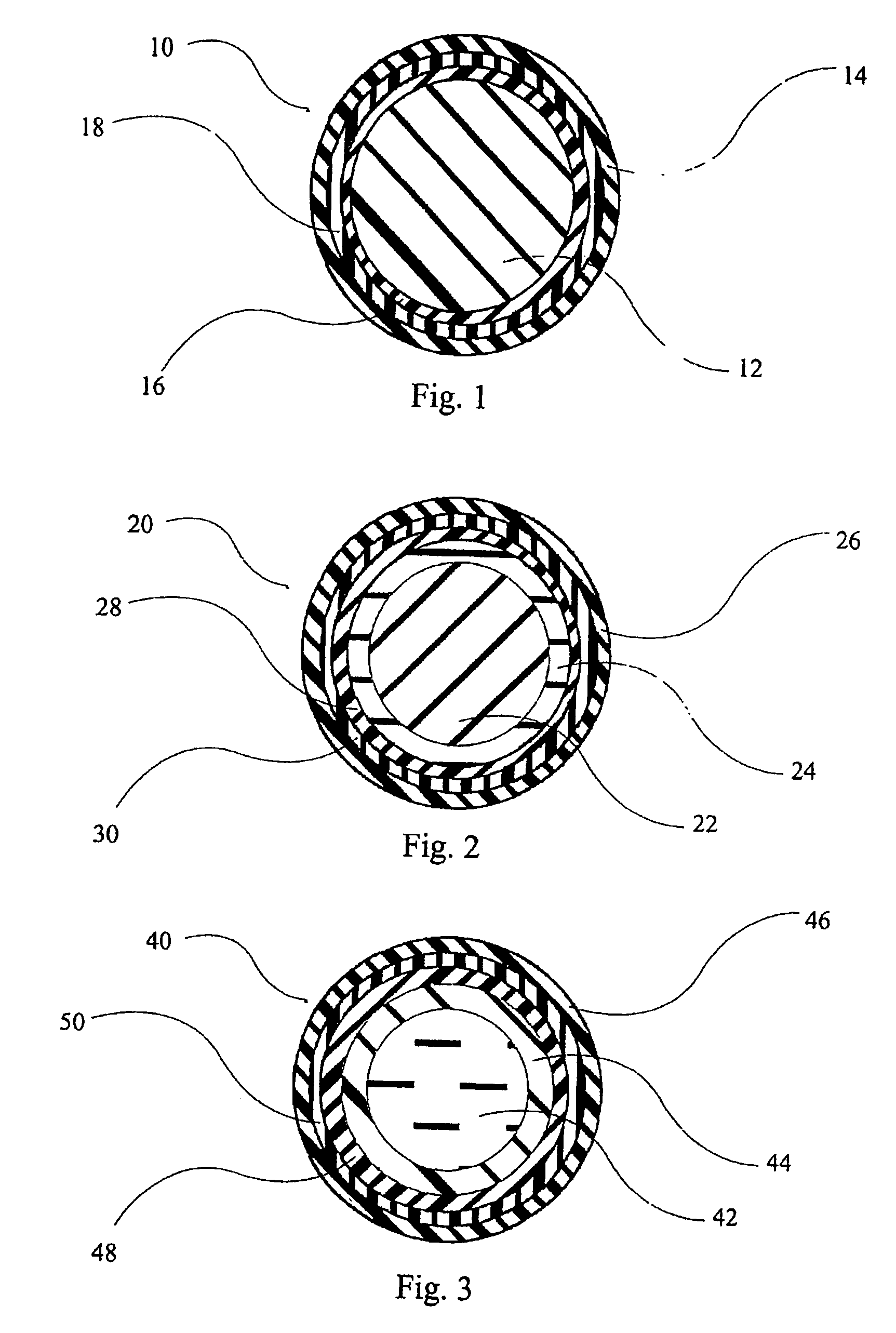

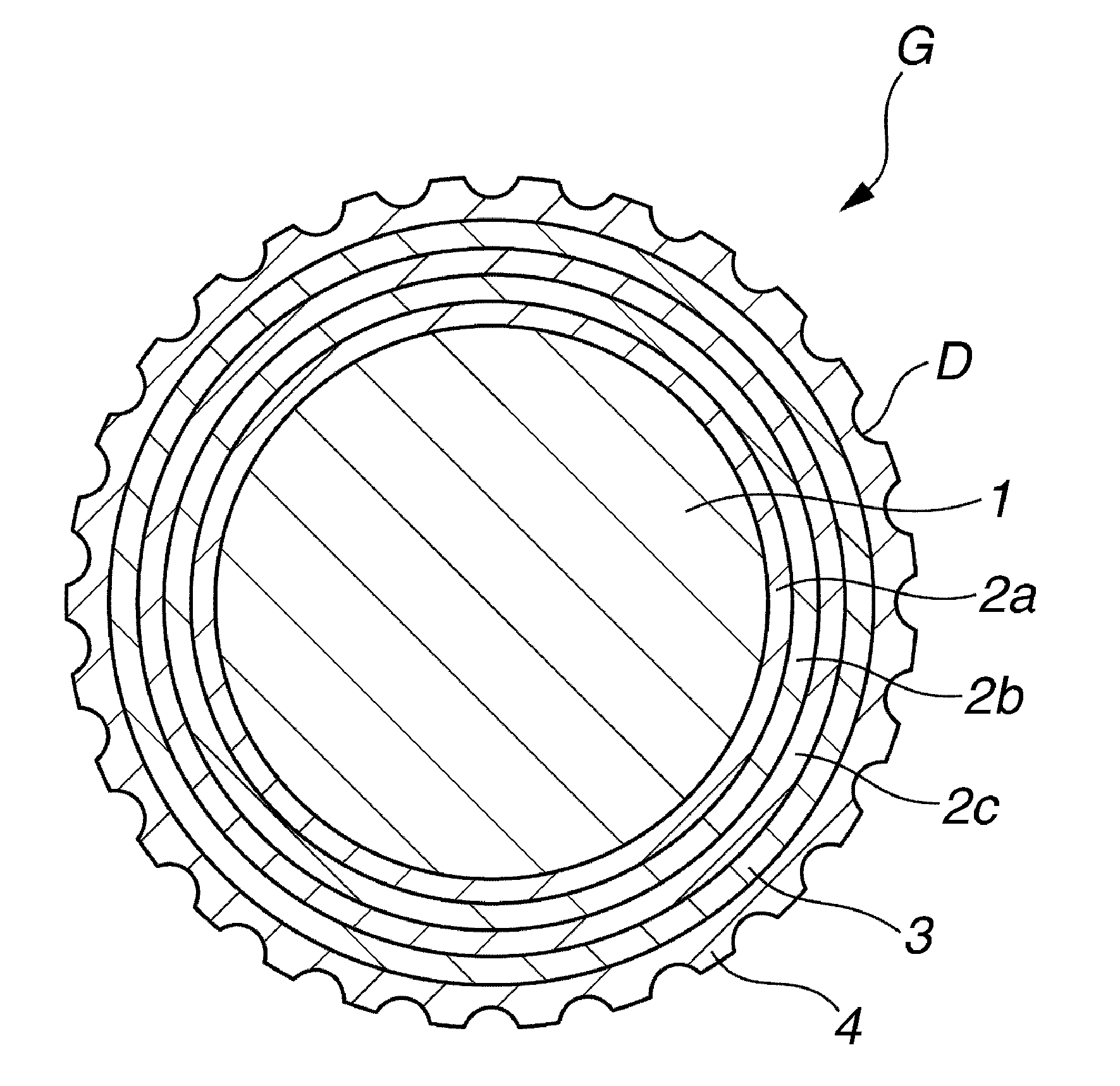

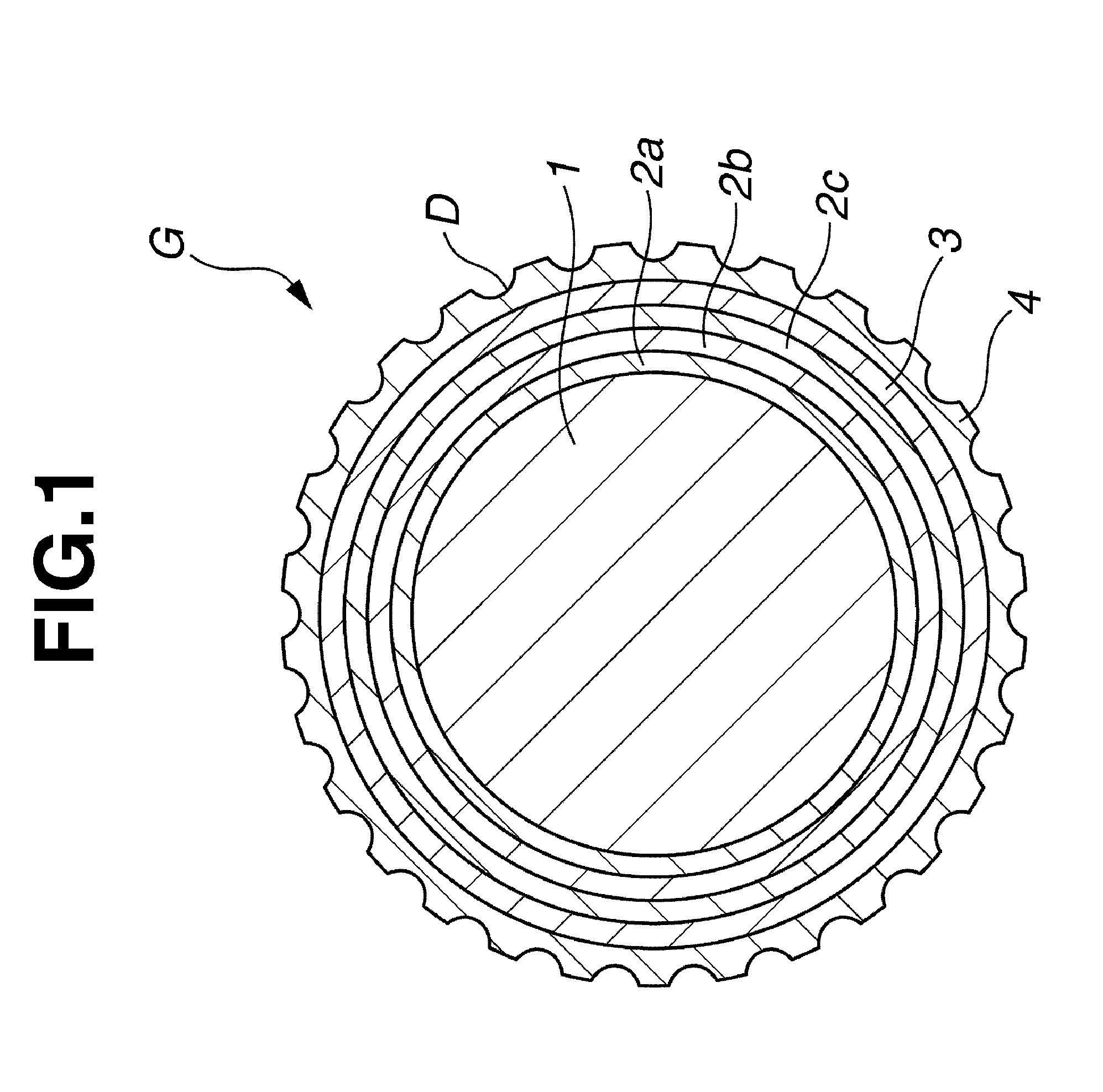

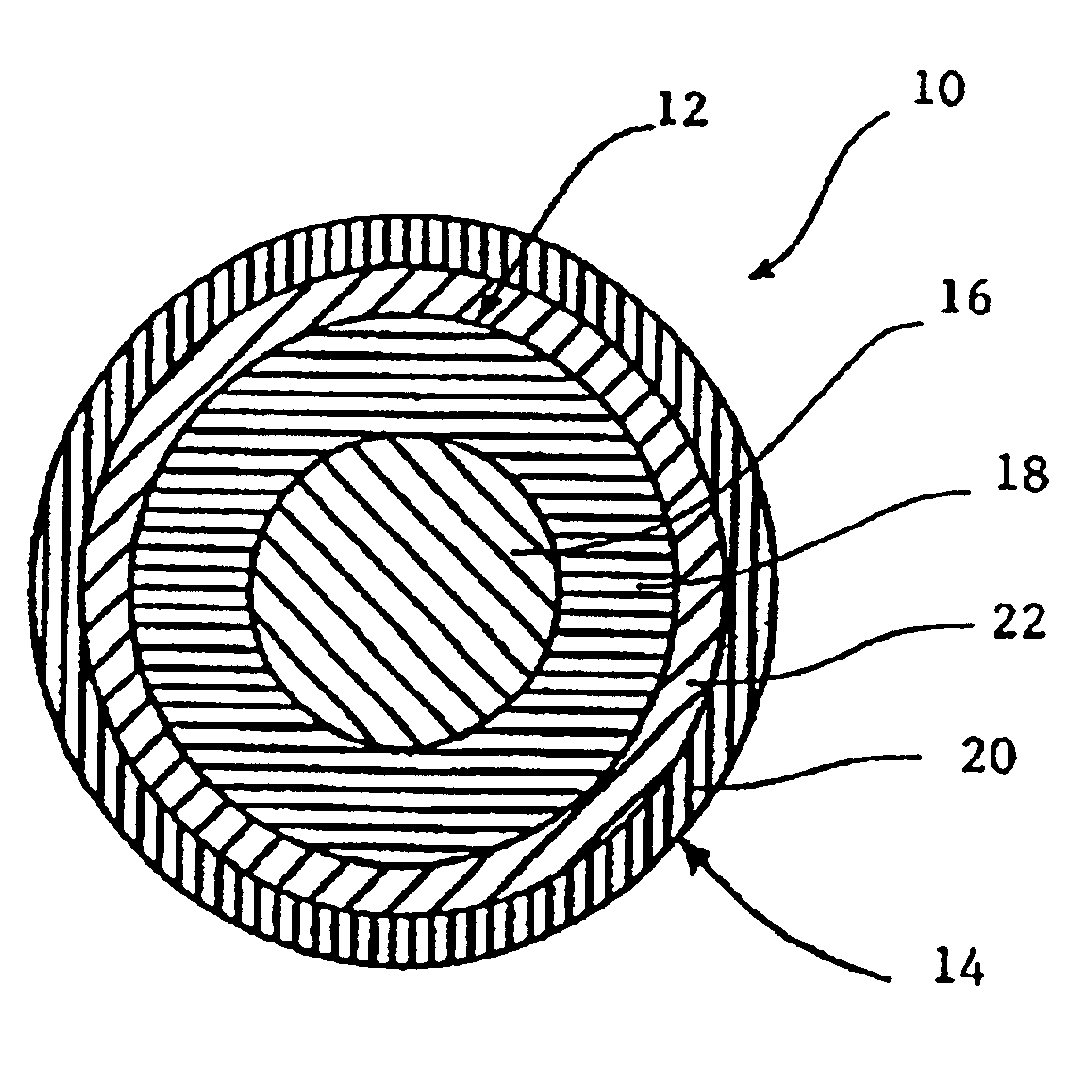

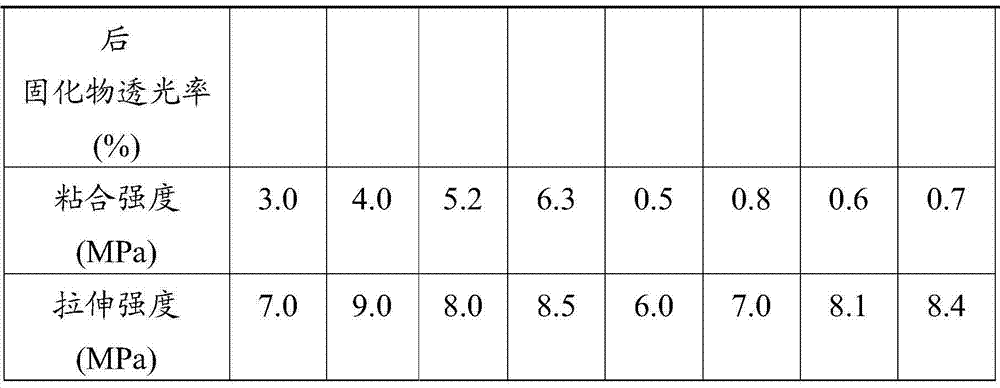

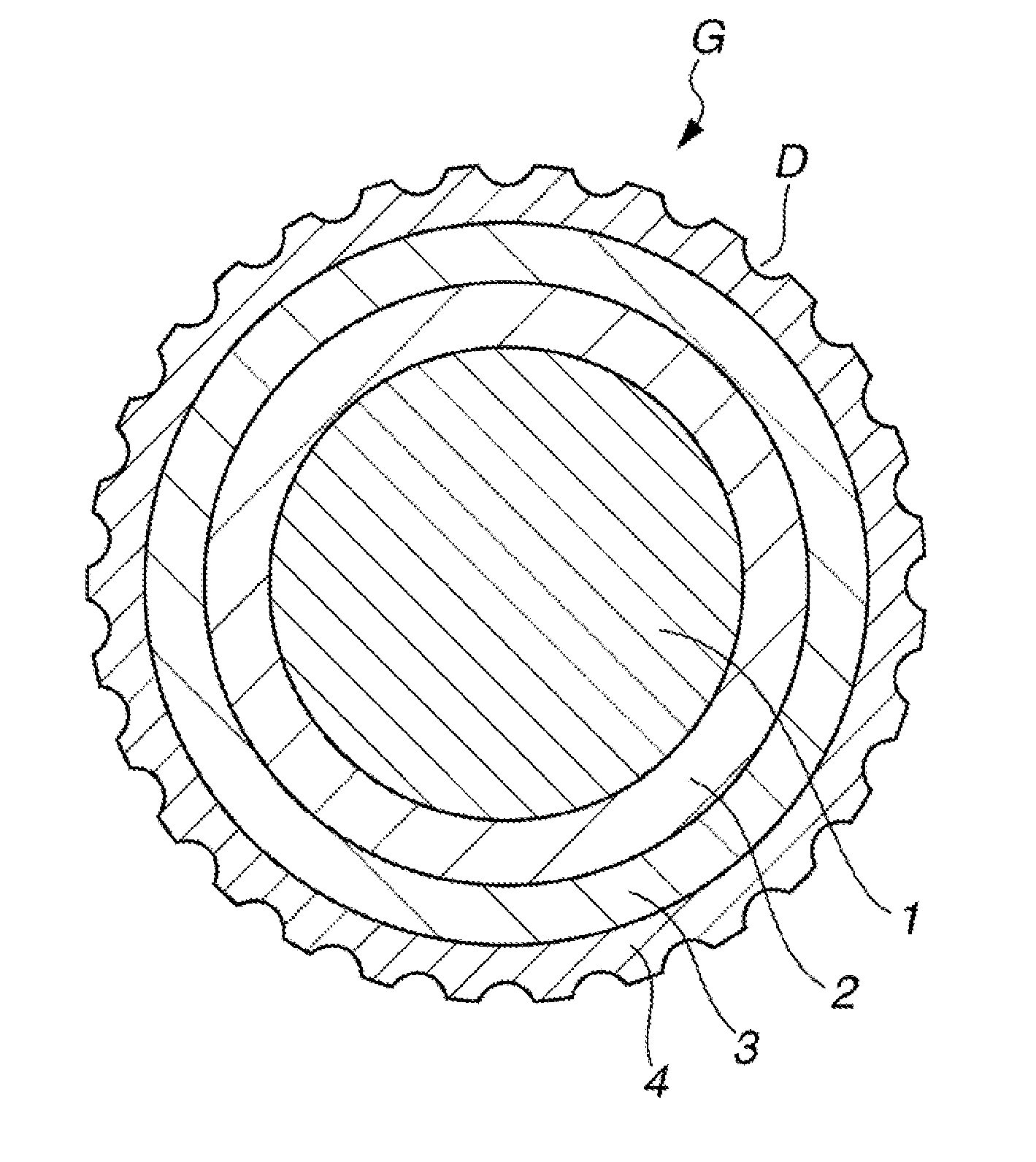

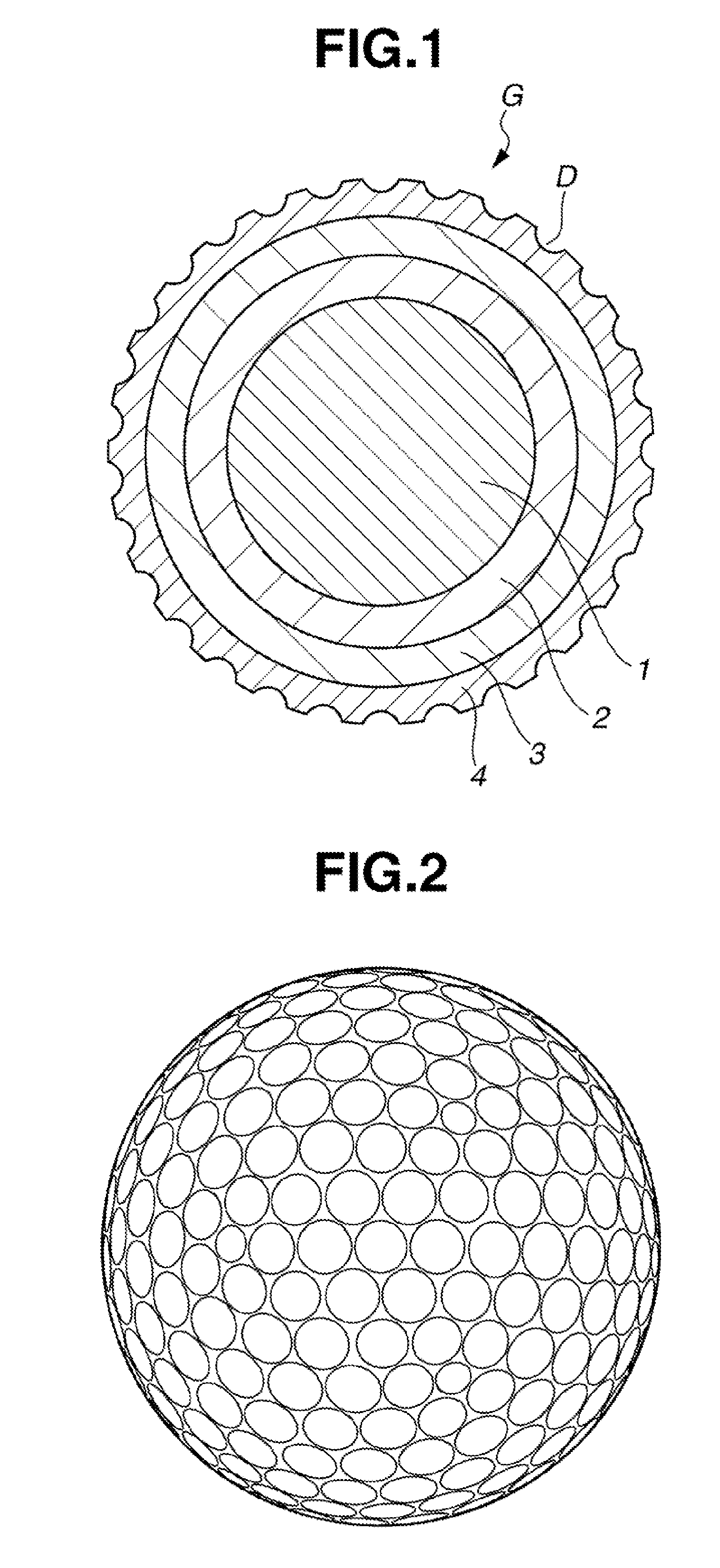

Multi-piece solid golf ball

InactiveUS20090111608A1Satisfactory controllabilitySatisfactory flight performanceGolf ballsSolid ballsRubber materialDriver/operator

The present invention provides a multi-piece solid golf ball having a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is composed overall of an inner layer and an outer layer which are each formed primarily of a rubber material, with the outer core layer being harder than the inner core layer. The envelope layer, intermediate layer and cover have respective thicknesses which satisfy the condition: cover thickness<intermediate layer thickness<envelope layer thickness, and have respective material hardnesses (Shore D hardness) which satisfy the condition: envelope layer material hardness<intermediate layer material hardness>cover material hardness. The golf ball has a lower spin rate on full shots with a driver, further increasing the distance traveled by the ball. Moreover, it has a good controllability, maintaining in particular a straight trajectory on full shots, and also has an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

Multi-piece solid golf ball

ActiveUS7625302B2Improve controllabilityImprove wear resistanceGolf ballsSolid ballsRubber materialDriver/operator

The present invention provides a multi-piece solid golf ball having a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is composed overall of an inner layer and an outer layer which are each formed primarily of a rubber material, with the outer core layer being harder than the inner core layer. The envelope layer, intermediate layer and cover have respective thicknesses which satisfy the condition: cover thickness<intermediate layer thickness<envelope layer thickness, and have respective material hardnesses (Shore D hardness) which satisfy the condition: envelope layer material hardness<intermediate layer material hardness>cover material hardness. The golf ball has a lower spin rate on full shots with a driver, further increasing the distance traveled by the ball. Moreover, it has a good controllability, maintaining in particular a straight trajectory on full shots, and also has an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

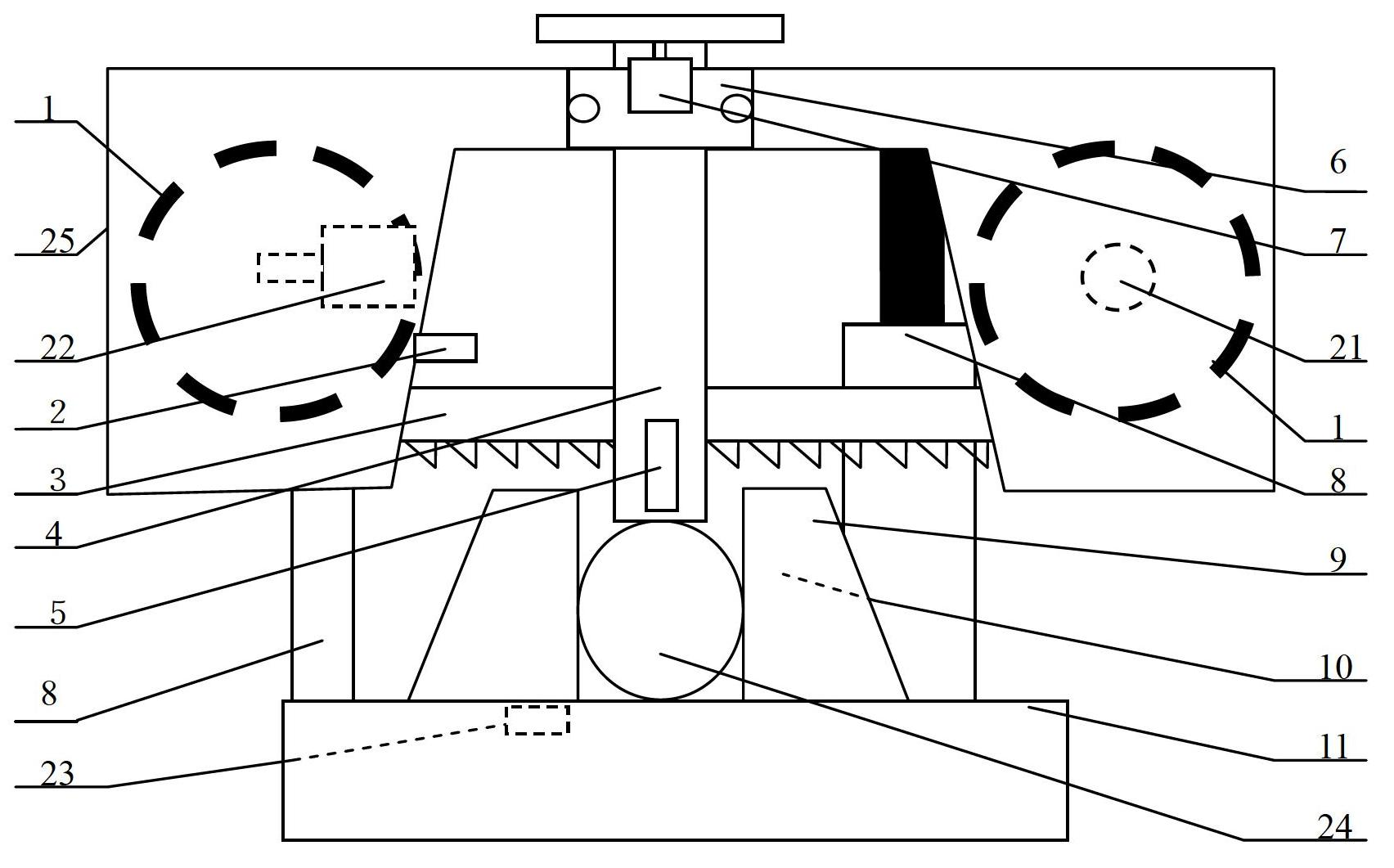

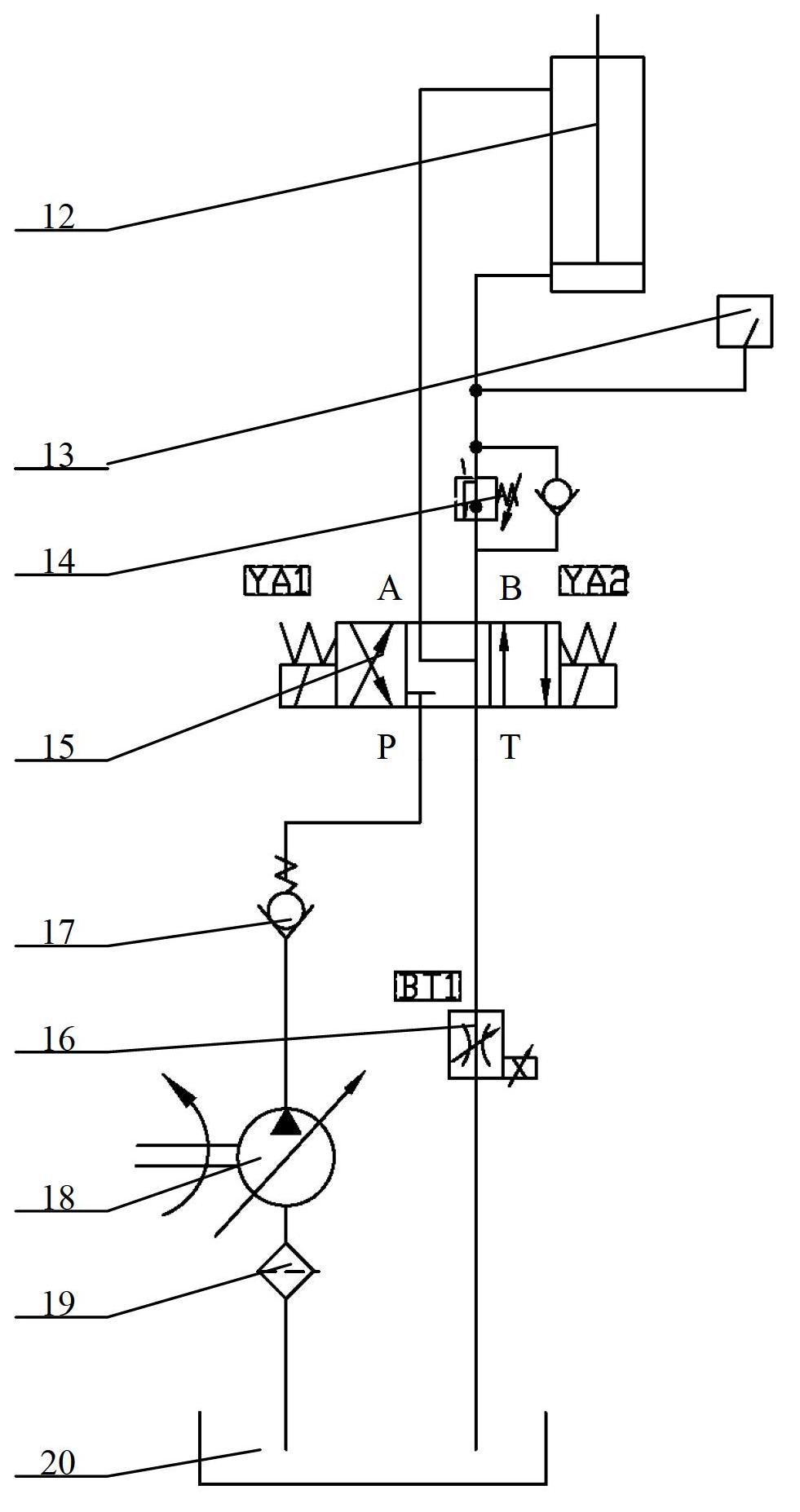

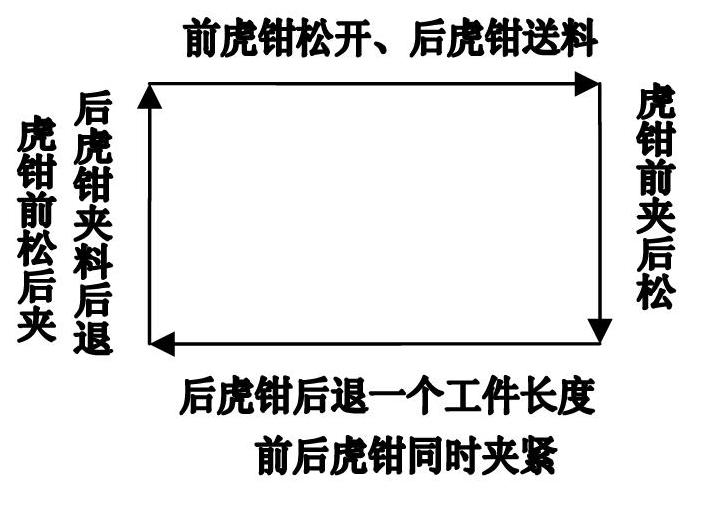

Saw frame feeding system with constant saw cutting force and variable feeding speed and saw frame feeding method

ActiveCN102672271AImprove qualityImprove the efficiency of the sawing machineMetal sawing devicesAutomatic control devicesNon real timeMulti machine

The invention discloses a saw frame feeding system with the constant saw cutting force and the variable feeding speed and a saw frame feeding method. The system consists of a saw frame, a hydraulic system and a control system, wherein the saw frame is arranged on a sawing machine through double upright posts and is driven by an oil cylinder to vertically move along the upright posts. The control system is in a multilayer multi-machine cooperative hardware system structure, real-time / non-real-time tasks are allocated to each processing unit according to the types, and the reliability of the system is improved through a hard logic gate circuit. According to workpiece cross section types and parameters selected by operators, the system implements the variable feeding speed feed forward control on the basis of the workpiece saw cutting width variable by combining the measured saw frame displacement and the workpiece material hardness. The constant saw cutting force closed loop feedback feeding control is carried out according to oil cylinder oil pressure value collected by a pressure sensor, the quality of saw cutting workpieces and the work efficiency of the sawing machine are improved, and the saw blade consumption is reduced. Through the adoption of control strategies of customized cutting-in and cutting-out feeding and fast ascending reset of the saw frame, the solution of thesaw frame feeding control system is more prefect.

Owner:浙江锯力煌工业科技股份有限公司

Thin-layer-covered multilayer golf ball

A golf ball comprising a core and a cover disposed about the core, wherein the core comprises a center and at least one outer core layer adjacent the center, and the cover comprises at least one inner cover layer and an outer cover layer, wherein the center has an outer diameter from about 0.375 in to about 1.4 in and deflection of greater than about 4.5 mm under a load of 100 Kg, the outer core layer has an outer diameter of from about 1.4 in to about 1.62 in, the inner cover layer has an outer diameter of greater than about 1.58 in and a material hardness of less than about 72 Shore D, and the outer cover layer has a hardness of greater than about 50 Shore D.

Owner:ACUSHNET CO

High-thermal-conductivity reaction-sintered silicon carbide ceramic material and preparation method thereof

The invention relates to a high-thermal-conductivity reaction-sintered silicon carbide ceramic material and a preparation method thereof. The high-thermal-conductivity reaction-sintered silicon carbide ceramic material comprises 50-90wt.% of silicon carbide, 0.5-12.5wt.% of graphene, 1-3wt.% of surfactants, 0.5-2.5wt.% of dispersing agents and 0.3-1.5wt.% of binders. The high-thermal-conductivity reaction-sintered silicon carbide ceramic material is prepared by means of raw material mixing, shaping and reactive sintering for 8-12 hours at the temperature of 1650-1800 DEG C under a vacuum condition. The prepared SiC (silicon carbide) ceramic material has the advantages of high hardness, low thermal expansion coefficient, high thermal conductivity, more uniformity in material performance and higher service reliability.

Owner:SHANDONG UNIV

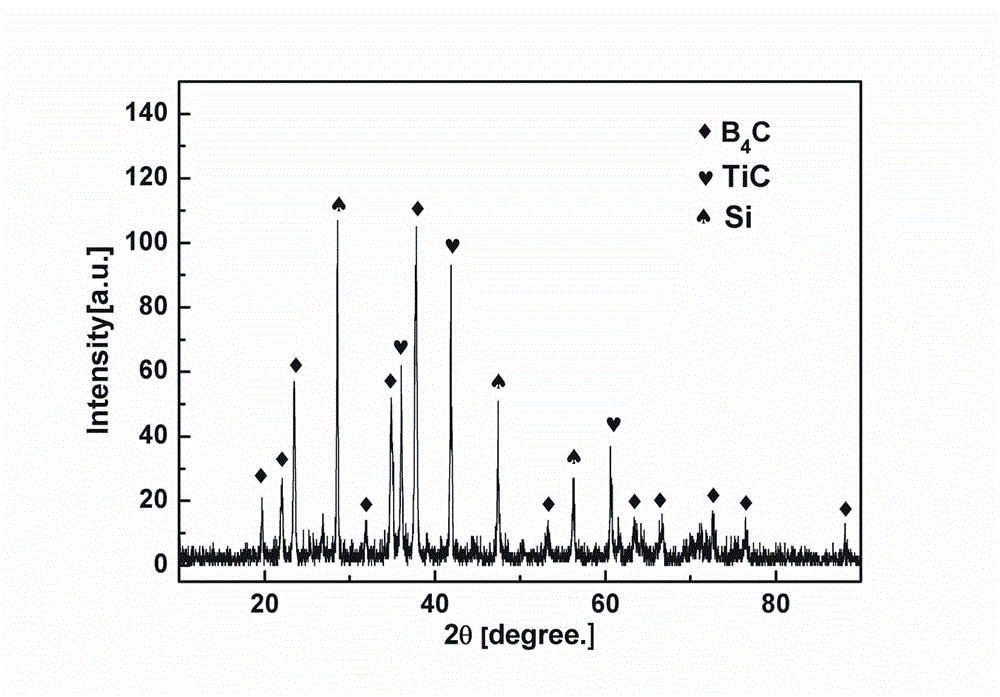

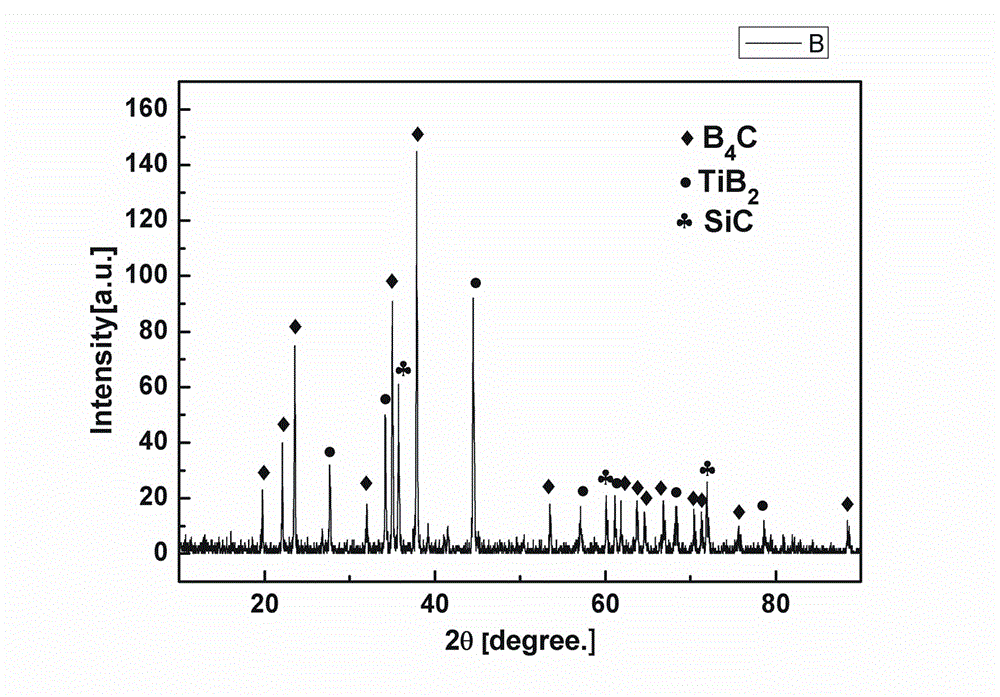

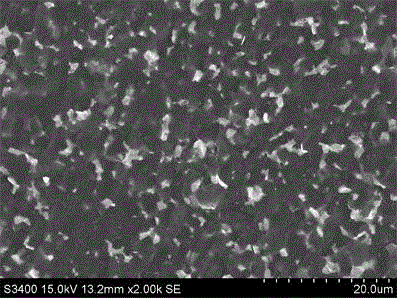

High-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and preparation method thereof

The invention relates to a high-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and a preparation method thereof, and belongs to the technical field of a ceramic material. The composite ceramic is prepared from boron carbide, silicon carbide and silicon powder in a hot-pressing sintering manner via reaction. The composite ceramic contains 50-90wt% of boron carbide, 27-5.4wt% of titanium boride and 23-4.6wt% of silicon carbide. The defects of overhigh sintering temperature, and difficulty of improvement of the toughness and the hardness at the same time of the existing boron carbide ceramic are solved; carbon generated by reaction of the boron carbide and the titanium boride is removed by monatomic silicon; and the carbon for reducing the hardness of the base material is converted into hard material silicon carbide which is evenly dispersed, so as to play roles in enhancing the toughness and improving the material hardness. The high-toughness boron carbide composite ceramic can be prepared at low temperature on the premise of not reducing the hardness of a base body.

Owner:WUHAN UNIV OF TECH

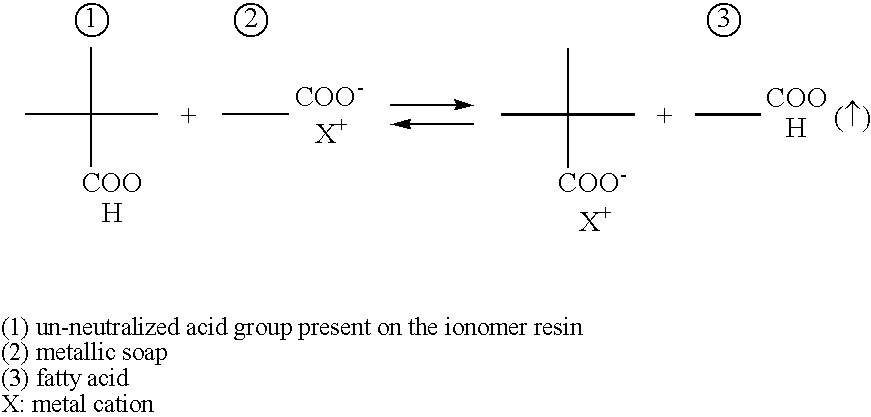

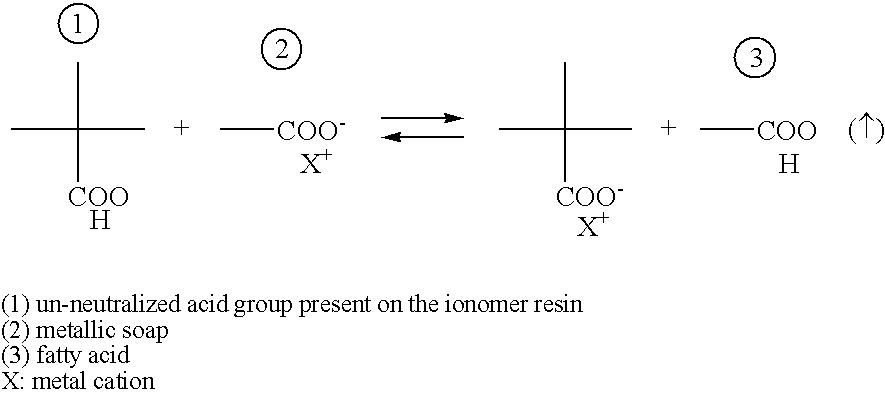

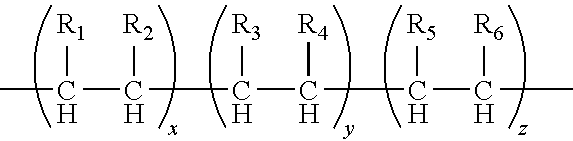

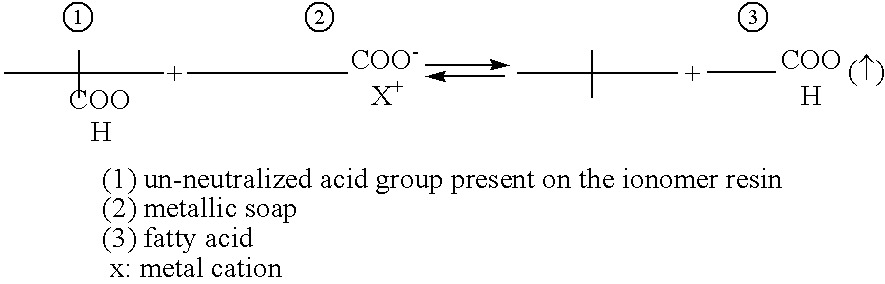

Golf balls containing highly-neutralized acid polymer blends

InactiveUS20090247323A1Fibre treatmentSynthetic resin layered productsInter layerFatty acid formation

A golf ball having a core, a cover layer, and an optional intermediate layer disposed between the core and the cover layer is disclosed and described. One or more of the core, the cover layer, or the intermediate layer is formed of a highly neutralized polymer blend of an acid copolymer and a metallocene-catalyzed copolymer, an olefinic block copolymer, a sufficient amount of a suitable cation source and a fatty acid or salt of a fatty acid. The highly neutralized polymer blend is neutralized from 80% to 100% while still retaining processability. Further, the core can have a diameter of 0.5 inches to about 1.62 inches and an Atti compression less than or equal to 105. The cover layer can have a material hardness between about 30 and 70 Shore D.

Owner:ACUSHNET CO

Multi-piece solid golf ball

ActiveUS20090111610A1Satisfactory controllabilitySatisfactory flight performanceGolf ballsSolid ballsElastomerRubber material

The present invention provides a multi-piece solid golf ball having a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is formed primarily of a rubber material, the envelope layer and the intermediate layer are each formed primarily of the same or different resin materials, and the cover is formed primarily of a thermoplastic resin or a thermoplastic elastomer. The envelope layer, intermediate layer and cover have thicknesses which satisfy the condition: cover thickness<intermediate layer thickness<envelope layer thickness, and the condition: (cover thickness+intermediate layer thickness)<envelope layer thickness. The core surface, envelope layer, intermediate layer and cover have Shore D hardnesses which satisfy the condition: core surface hardness≦envelope layer material hardness<intermediate layer material hardness>cover material hardness. The golf ball has an outstanding flight performance and controllability which are acceptable to professionals and other skilled players, in addition to which it has an excellent durability to cracking under repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

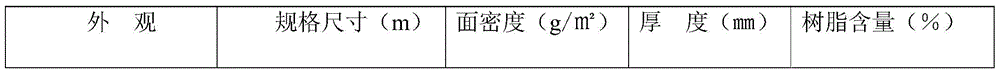

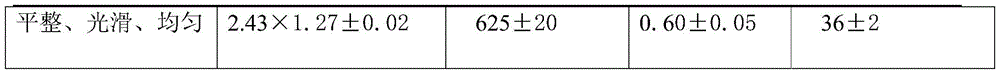

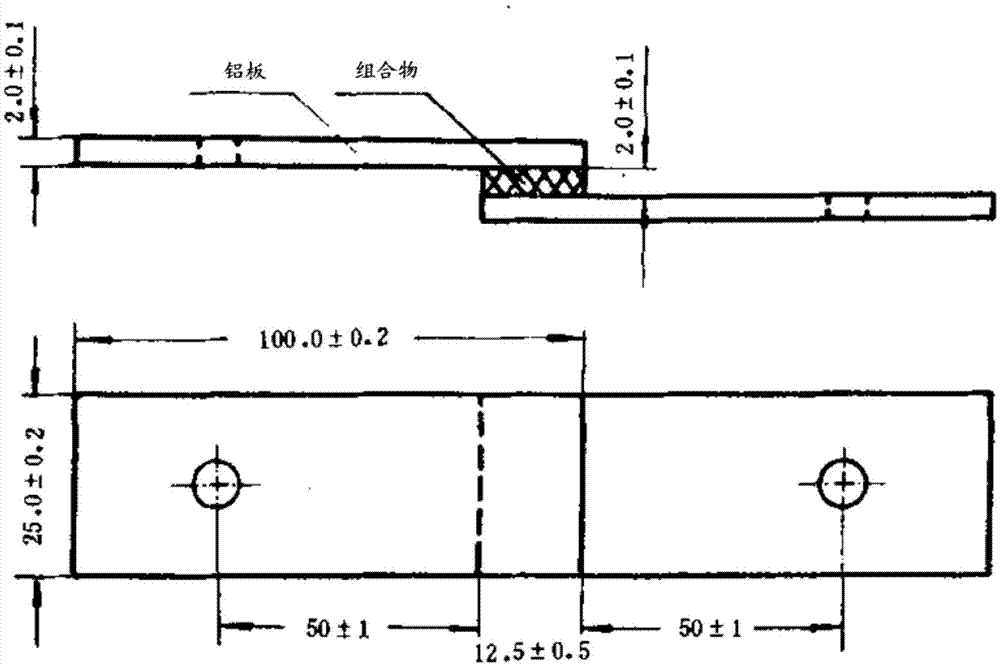

High-performance non-metal puncture-proof sheet

InactiveCN105696357AHigh hardnessImprove stab resistanceLamination ancillary operationsSynthetic resin layered productsEpoxyMass ratio

This patent application discloses a stab-proof sheet, especially relates to a high-performance non-metallic stab-proof sheet and its manufacturing process. The high-performance non-metal stab-proof sheet is made by painting a certain proportion of mixed resin on both sides of the aramid woven fabric, and then performing molding and drying and curing. By adding a resin matrix to the aramid woven fabric to increase the hardness of the material and enhance its mechanical properties such as impact resistance and shear strength. The mixed resin is formed by stirring epoxy resin and acetone into a mixture at a mass ratio of 3.7-4.3:1, and then mixing the mixture with polyamide resin at a mass ratio of 2:1-1.2. This patent overcomes the defects of low anti-stab performance, poor stability and high production cost in the existing non-metallic anti-stab material technology, and provides a anti-stab material with low cost, strong anti-stab performance and high stability , the cost is lower than that of imported anti-stab film.

Owner:CHONGQING SHIELD KING IND

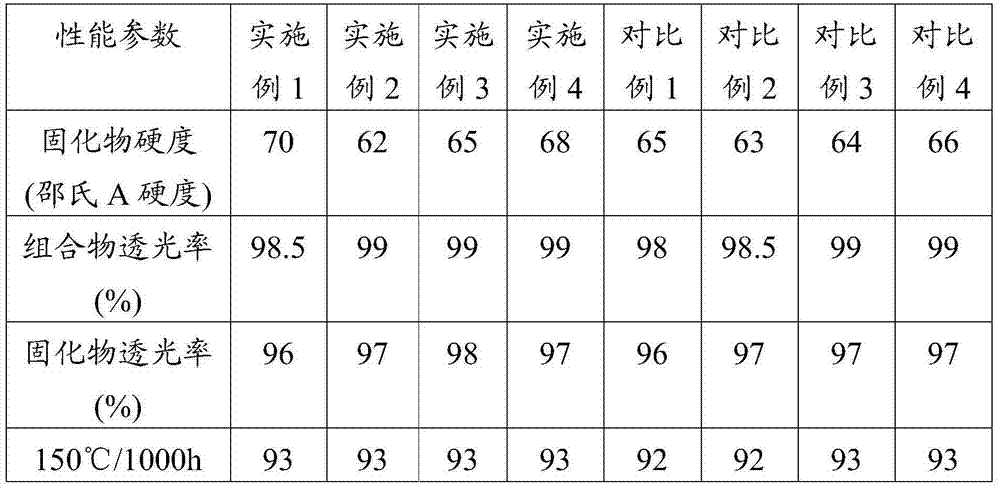

Tackifying and reinforcing modified polysiloxane and preparation method and application thereof

The invention discloses a tackifying and reinforcing modified polysiloxane and a preparation method and application thereof. The modified polysiloxane is prepared from an intermediate polysiloxane product and an organic compound containing a tackifying group and a vinyl group through hydrosilylation reaction in the presence of a hydrosilylation reaction catalyst, wherein the intermediate polysiloxane product is prepared by terminating methyl vinyl polysiloxane by using a terminator and the tackifying group refers to an organic group capable of increasing adhesion to a substrate. The adhesive strength of a packaging adhesive prepared from the tackifying and reinforcing modified polysiloxane is improved greatly; in addition, other properties such as cured material hardness, light transmittance and tensile strength, are excellent.

Owner:SHENZHEN CAPCHEM TECH

Golf ball

InactiveUS20130296075A1Improve crack resistanceSatisfactory distanceGolf ballsSolid ballsHardnessGolf Ball

The invention provides a golf ball having a core and a cover of at least one layer. The cover includes an outermost layer and at least one intermediate layer interposed between the outermost layer and the core. The core has a cross-sectional hardness which, letting R (mm) be the radius of the core, A be the JIS-C hardness at the center of the core, B be the JIS-C hardness at a position R / 3 mm from the core center, C be the JIS-C hardness at a position R / 1.8 mm from the core center, D be the JIS-C hardness at a position R / 1.5 mm from the core center, and E be the JIS-C hardness at the surface of the core, satisfies formulas (1) B-A<D-B, (2) C-A@8, and (3) E-B>=15. The intermediate layer and the outermost layer have a hardness relationship therebetween which satisfies the formula "material hardness of intermediate layer>=material hardness of outermost layer."

Owner:BRIDGESTONE SPORTS

Application of high-entropy alloy powder to laser cladding

InactiveCN105401042AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysHardness

Owner:TIANJIN UNIV

Preparation method of laser cladding high-entropy alloy powder and cladding layer and application

InactiveCN104141084AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysManganese

The invention discloses a preparation method of laser cladding high-entropy alloy powder and a cladding layer and application. The laser cladding high-entropy alloy powder is composed of iron, nickel, chromium, aluminum, silicon and manganese element powder, the Fe, Ni, Cr, Al and Si are in equal mole ratio, and the mole ratio x of Mn is 0-1. The preparation method includes: conducting proportion calculation according to the mole ratio of each element, accurately weighing the mass of each component, then mixing the components fully and evenly, mixing the components with ethanol, coating the surface of a matrix material with the mixture evenly, performing drying, and then carrying out laser cladding so as to obtain the cladding layer. Specifically, the matrix material is 42CrMo steel. According to the preparation method of the laser cladding high-entropy alloy powder and cladding layer provided by the invention, the good cladding layer can be formed, and the material hardness and wear resistance can be improved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com