High-performance non-metal puncture-proof sheet

A non-metallic, high-performance technology, applied in lamination, coating, layered products, etc., can solve the problems of poor penetration resistance, weak function of external impact resistance, poor wearing comfort and close-fitting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of embodiment one anti-stab sheet

[0018] 1 Preparation of raw materials:

[0019] 1.1 Aramid woven fabric

[0020] The main technical indicators of aramid woven fabrics are shown in Table 5.

[0021] Table 1 Main technical indicators of aramid fabric

[0022] Fineness (dtex) Monofilament type organize Warp and weft density (root / ㎝) Square meter weight (g / ㎡) 1500 H258 plain weave 6.4×6.4 405

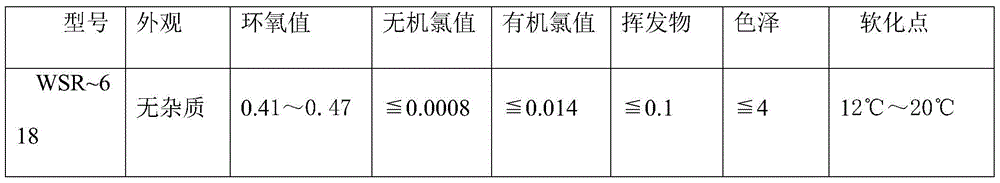

[0023] 1.2 Epoxy resin

[0024] The main technical indicators of epoxy resin are shown in Table 2.

[0025] Table 2 The main technical indicators of epoxy resin

[0026]

[0027] 1.3 Polyamide resin

[0028] The main technical indicators of polyamide resin are shown in Table 3.

[0029] Table 3 Main technical indicators of polyamide resin

[0030] model Amine value viscosity curing time 651 390~410KOHmg equivalent / g 2000~10000cp / 40℃ 60°C, 3 hours

[0031] 1.4 Acetone

[0032] The main technic...

Embodiment 2

[0046] Embodiment 2 detection method

[0047] 1 appearance inspection

[0048] The appearance of the aramid-coated composite was visually inspected.

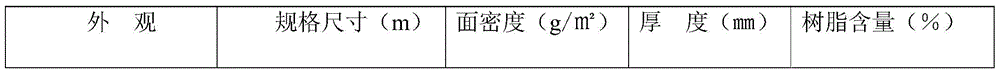

[0049] 2 size inspection

[0050] Use a measuring tool with an accuracy of 1 mm to measure the size of the aramid-coated composite material.

[0051] 3 surface density test

[0052] Use an electronic scale with an accuracy of 1g to weigh the mass per unit area and calculate the surface density.

[0053] 4 thickness inspection

[0054] Use a thickness gauge with an accuracy of 0.01 mm to measure the thickness of a single piece of aramid-coated composite material.

[0055] 5 resin content inspection

[0056] From the measured areal density, calculate the resin content.

[0057] 6 Anti-stab performance test

[0058] 15 layers of anti-stab sheets are superimposed with a 6mm thick sponge to form a sample of the anti-stab layer, and the anti-stab layer is heat-sealed with a heat-sealing cloth to make a anti-stab test piece. T...

Embodiment 3

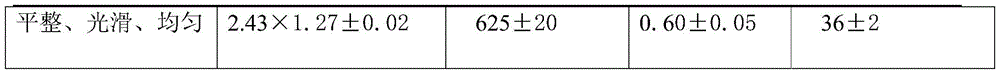

[0065] Example three test results

[0066] According to the detection method of embodiment two, obtain detection result, as shown in table 5 and table 6:

[0067] table 5

[0068]

[0069]

[0070] table 5

[0071]

[0072] Table 6

[0073] Test results: After the above-mentioned adaptability test and stab-proof performance test under normal temperature and high and low temperature conditions, it can be seen that none of the test knives penetrated the stab-proof layer. The high-performance non-metal stab-proof sheet of the invention has good stab-proof performance, is less affected by temperature changes, and has stable and reliable performance.

[0074] Aramid fabric has high strength, tight knitting and soft hand feeling. The non-toxic, environmentally friendly and stable performance resin coating material system is selected, and the special coating process makes it have good flexibility, chemical stability, and durability. Mechanical properties such as high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com