Patents

Literature

43results about How to "Improve stab resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

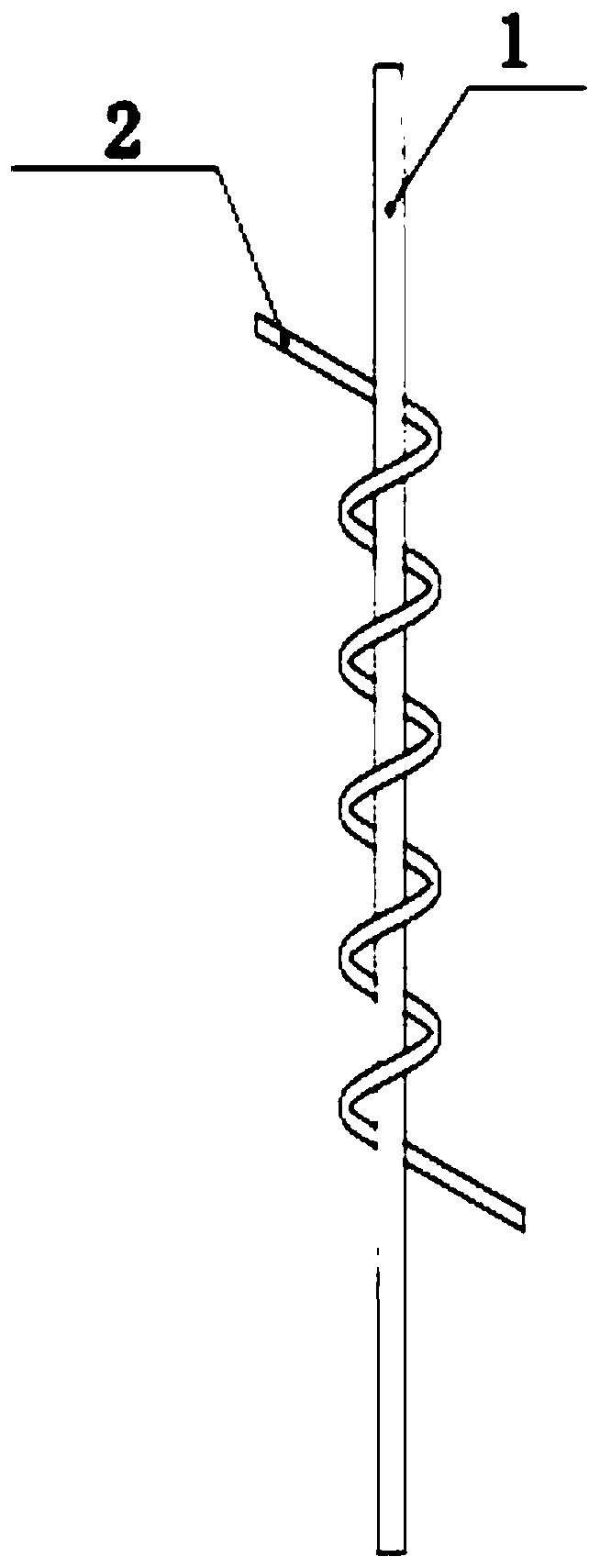

High-performance non-metal puncture-proof sheet

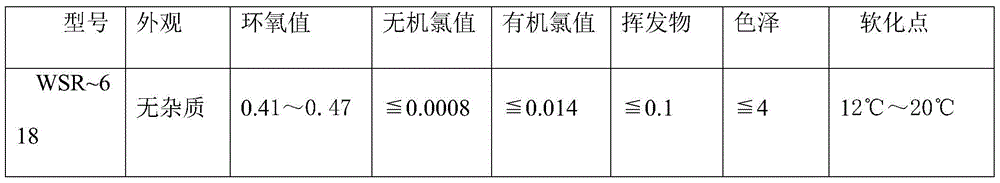

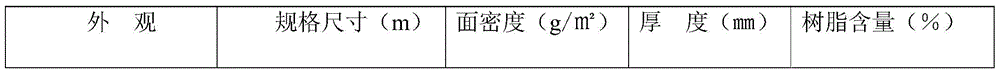

InactiveCN105696357AHigh hardnessImprove stab resistanceLamination ancillary operationsSynthetic resin layered productsEpoxyMass ratio

This patent application discloses a stab-proof sheet, especially relates to a high-performance non-metallic stab-proof sheet and its manufacturing process. The high-performance non-metal stab-proof sheet is made by painting a certain proportion of mixed resin on both sides of the aramid woven fabric, and then performing molding and drying and curing. By adding a resin matrix to the aramid woven fabric to increase the hardness of the material and enhance its mechanical properties such as impact resistance and shear strength. The mixed resin is formed by stirring epoxy resin and acetone into a mixture at a mass ratio of 3.7-4.3:1, and then mixing the mixture with polyamide resin at a mass ratio of 2:1-1.2. This patent overcomes the defects of low anti-stab performance, poor stability and high production cost in the existing non-metallic anti-stab material technology, and provides a anti-stab material with low cost, strong anti-stab performance and high stability , the cost is lower than that of imported anti-stab film.

Owner:CHONGQING SHIELD KING IND

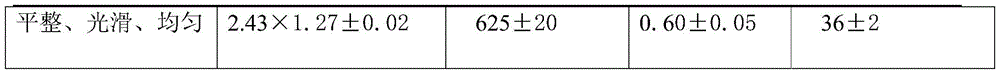

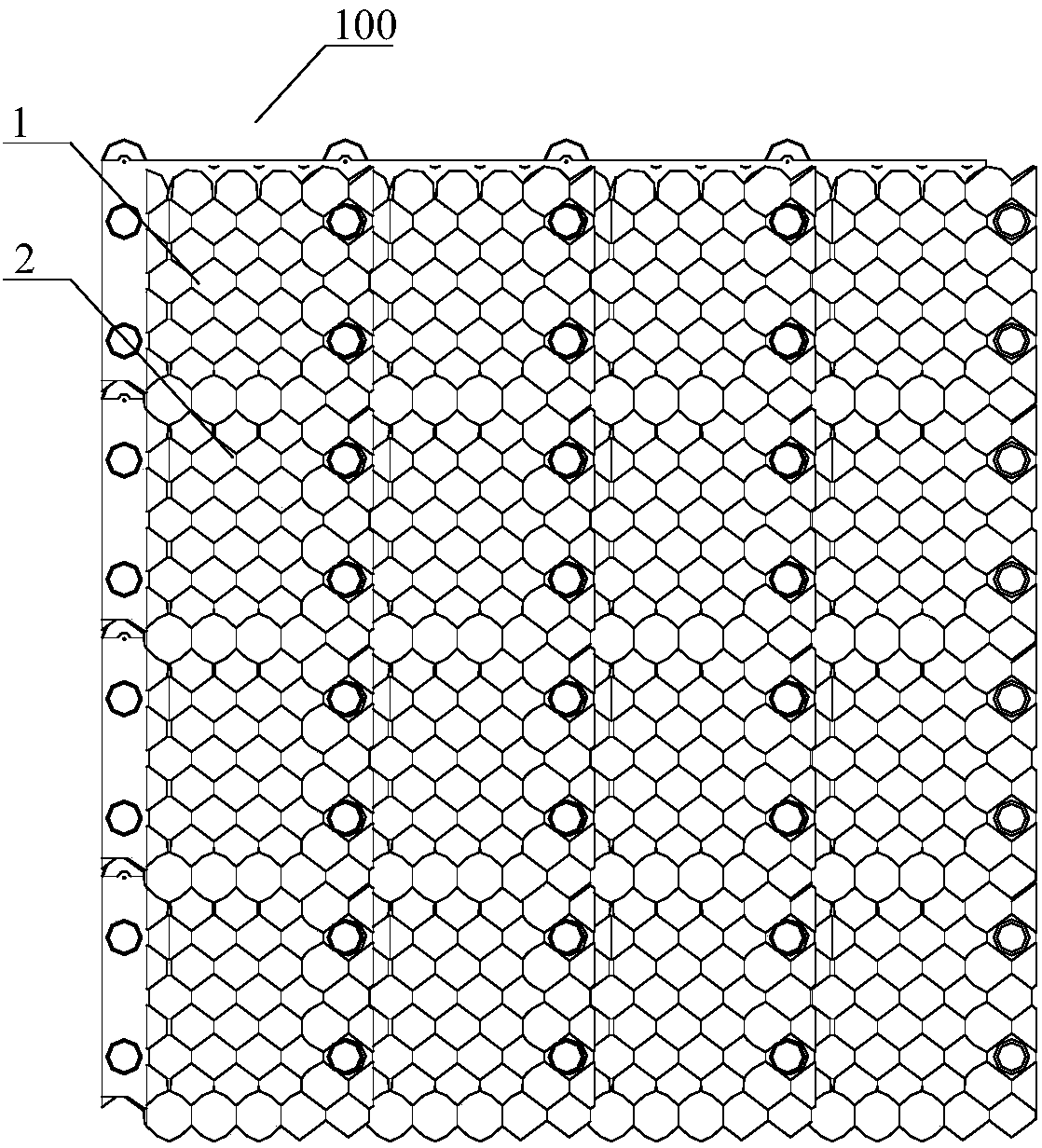

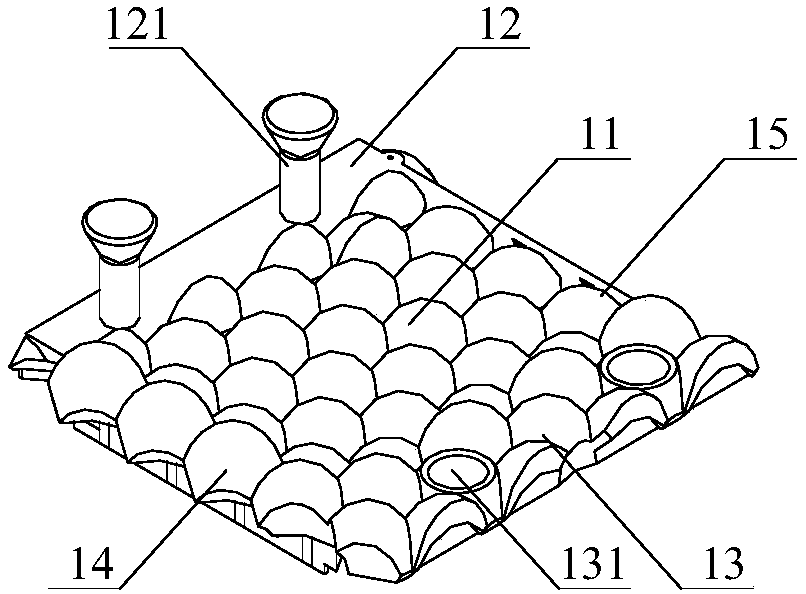

Armour splicing-type stab-proof vest based on hollow micro-egg shell structure

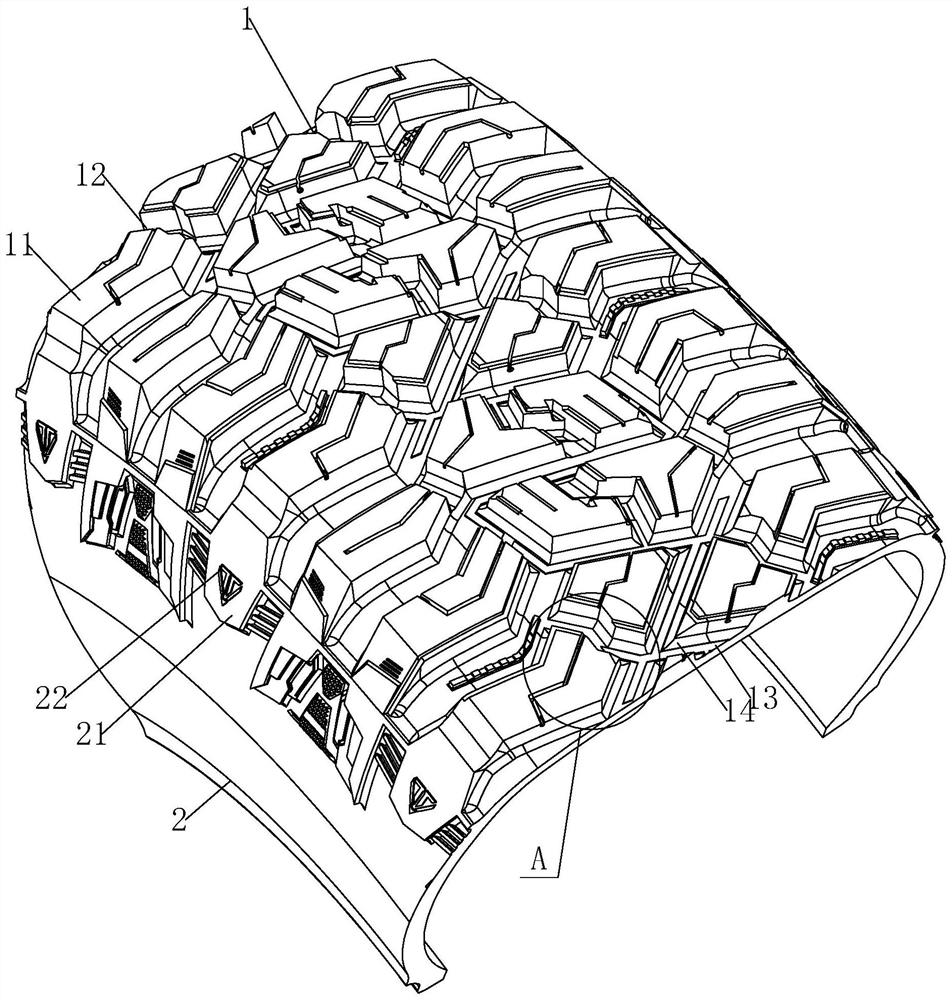

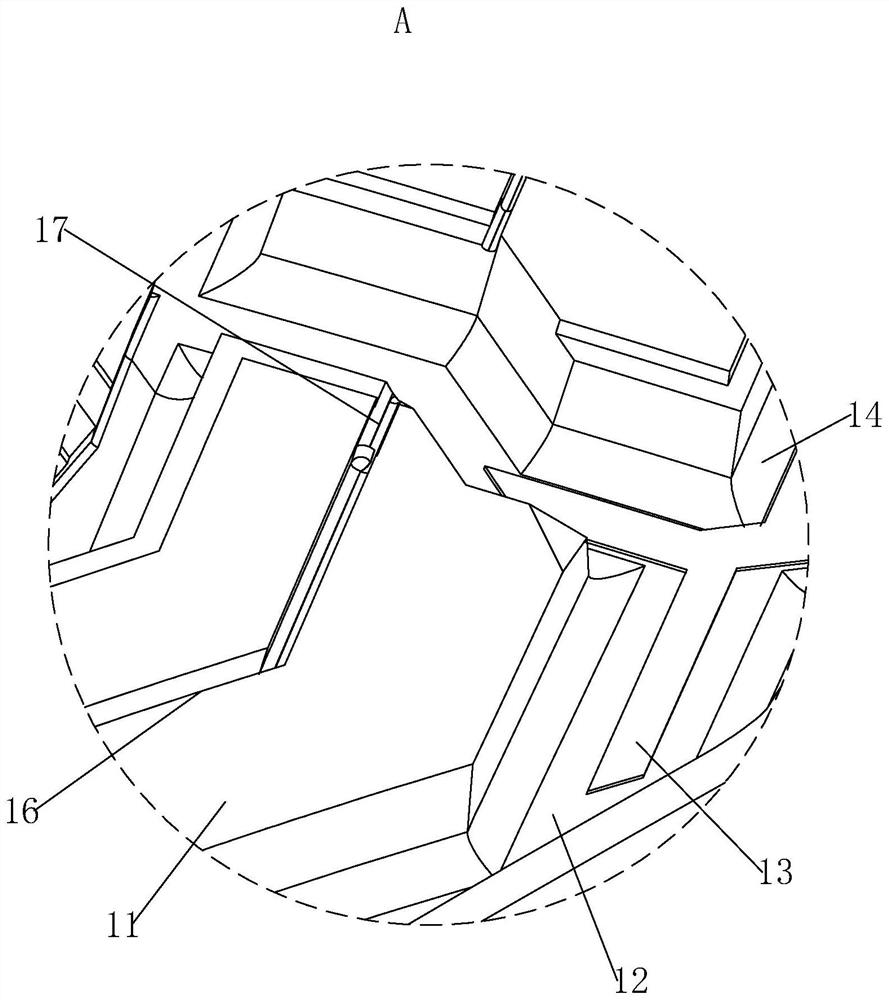

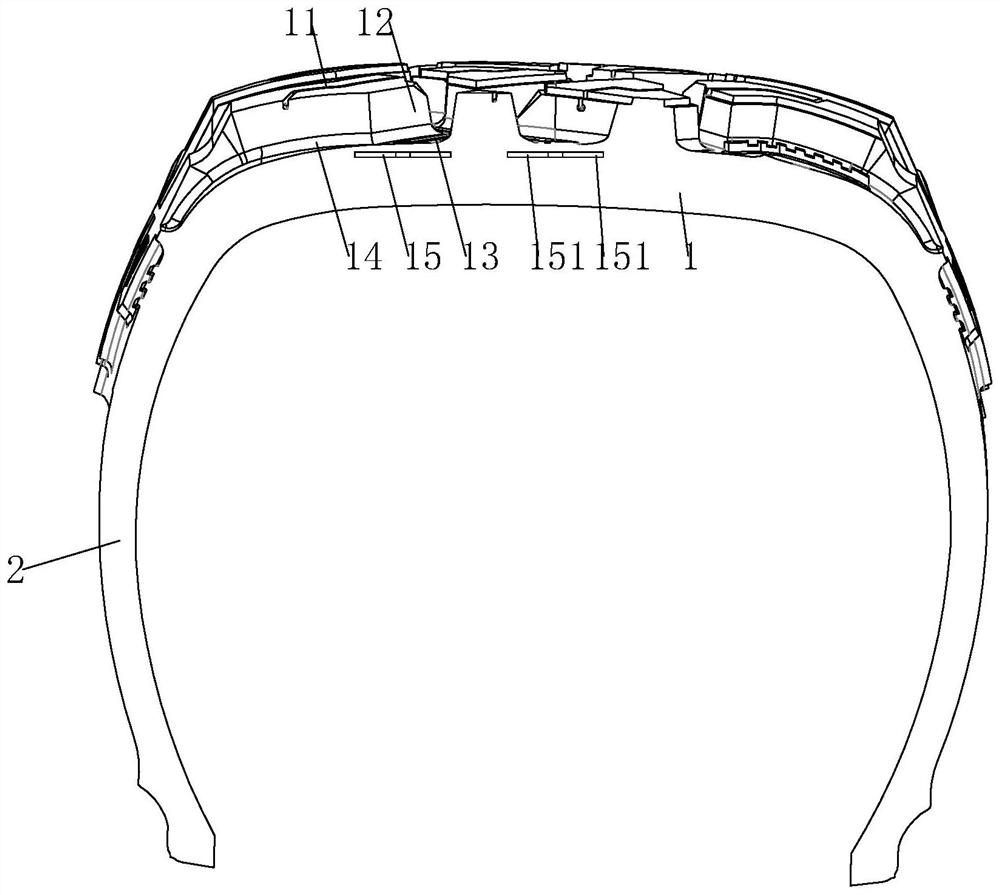

PendingCN108095222AIncrease flexibilityReduce heat and moisture resistanceProtective garmentPlastic materialsMoisture permeability

The invention discloses an armour splicing-type stab-proof vest based on a hollow micro-egg shell structure. The stab-proof vest comprises a plurality of stab-proof sheet sets, each stab-proof sheet set comprises a first stab-proof base plate and a second stab-proof base plate connected with the first stab-proof base plate, the first stab-proof base plate and the second stab-proof base plate are made of a plastic material by means of a 3D printing-laser sintering technology, and the first stab-proof base plate in each stab-proof sheet set is connected with the first stab-proof base plate and the second stab-proof base plate in adjacent stab-proof sheet set. Compared with an existing stab-proof vest, the armour splicing-type stab-proof vest uses an arrangement mode of hierarchical overlapping of animal scales and shells for reference, all the stab-proof base plates are horizontally arranged according to the arrangement of upper-lower layering, overall surface density is reduced, overallcomfort and flexibility are improved, and diathermanous effects and moisture permeability effects are improved; a plurality of hollow semi-ellipsoidal shells are sequentially arranged in a staggeredmanner to effectively disperse the impact force of sword stabbing, and the stab-proof performance of the stab-proof base plates can be enhanced; the stab-proof vest has the advantages of simple production process, high efficiency, light weight, raw materials savings, low cost and good market competitiveness.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

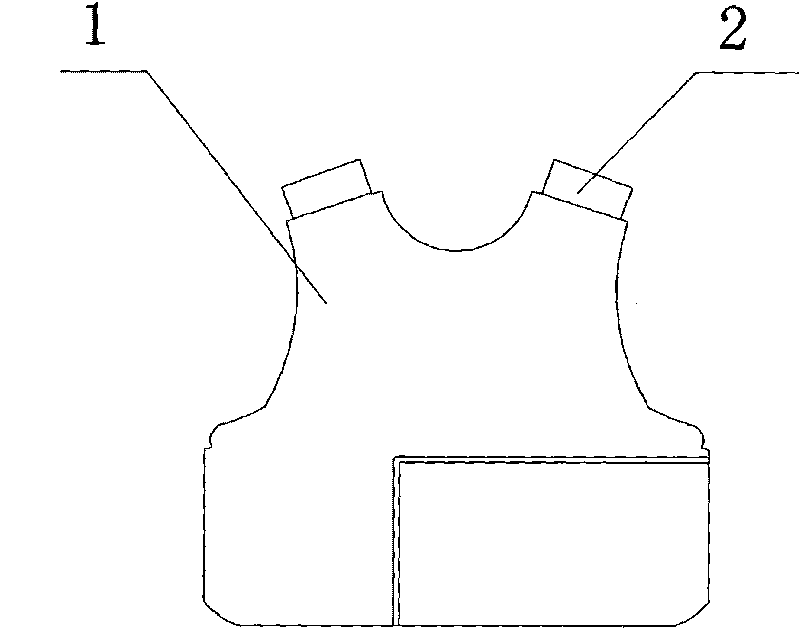

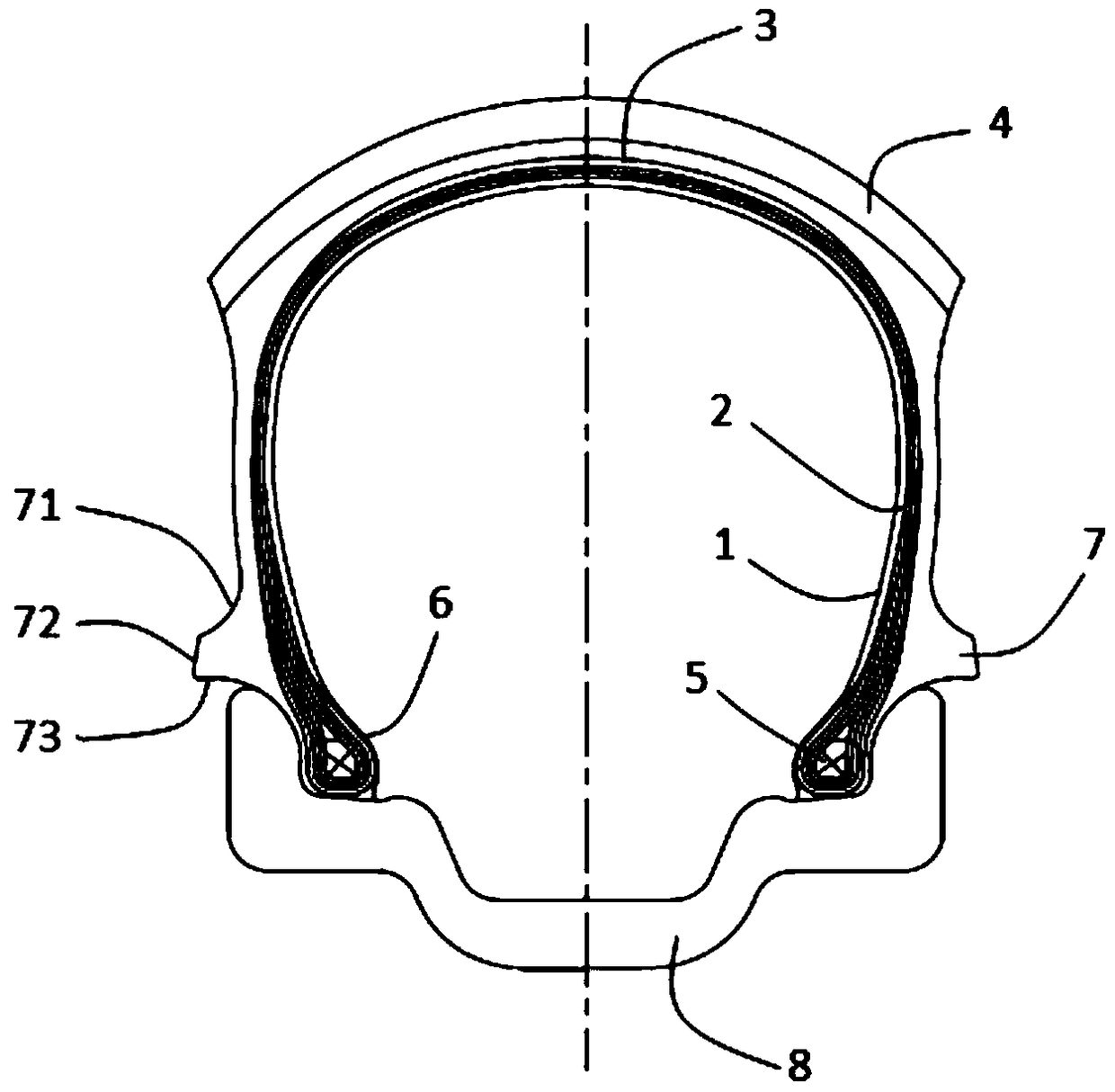

Nonmetal bulletproof stabproof jacket

ActiveCN101709932AMaintain and Play BallisticBulletproof stabilityPersonal protection gearArmour platesEpoxyPolyamide

The invention discloses a nonmetal bulletproof stabproof jacket which comprises an overcoat and a liner, wherein the liner comprises a waterproof lucifugal protective sleeve and a bulletproof stabproof layer, and the bulletproof stabproof layer is sealed by the waterproof lucifugal protective sleeve. The invention is characterized in that the bulletproof stabproof layer comprises aramid fiber non-woven cloth, soft coated aramid fiber fabrics and an aramid fiber stabproof felt from outside to inside; the coating technology is realized in a way that: gelatinizing epoxy resin and polyamide in the proportion of 2:1-2:1.2, and solidifying at 80-100 DEG C under the pressurization condition; and the aramid fiber fabrics are made of aramid fiber K129.

Owner:CHONGQING SHIELD KING IND

Aramid fiber non-woven fabric with bulletproof and anti-prick functions and dual-protection garment comprising same

InactiveCN107653573APlay the role of bulletproofImprove stab resistanceNon-woven fabricsWoven fabricWater soluble

The invention provides an aramid fiber non-woven fabric. The aramid fiber non-woven fabric has the dual functions of bullet and prick resistance. The aramid fiber non-woven fabric is obtained by performing spreading, coating and hot-air drying on aramid fiber and then performing a special pressing technology. An adhesive is one or more of waterborne polyurethane, waterborne phenolic aldehyde, waterborne epoxy and water soluble amino resin, the solid content is larger than or equal to 35%, and a secondary reaction can be performed under high temperature. The special pressing technology comprises a hot-pressing technology and a cold-pressing technology; the pressure of the hot-pressing technology is 2.5-15 MPa; the temperature is 125-170 DEG C, and the pressing time is 5-30 min; the pressureof the cold-pressing technology is 2.5-15 MPa; the temperature is room temperature, and the pressing time is 2-7 min. The aramid fiber non-woven fabric has the dual functions of bullet and prick resistance, certain layers are stacked so as to be directly applied to a dual-protection garment, the dual-protection garment has the advantages that the garment is made of uniform materials, and no bulletproof layer or anti-prick layer is arranged distinguishingly; the garment is made of the aramid fiber non-woven fabric, can be bent at any angle, and is comfortable to wear, low in mass and portable.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD +1

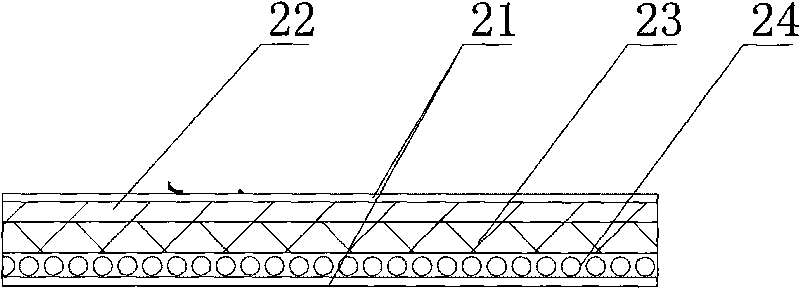

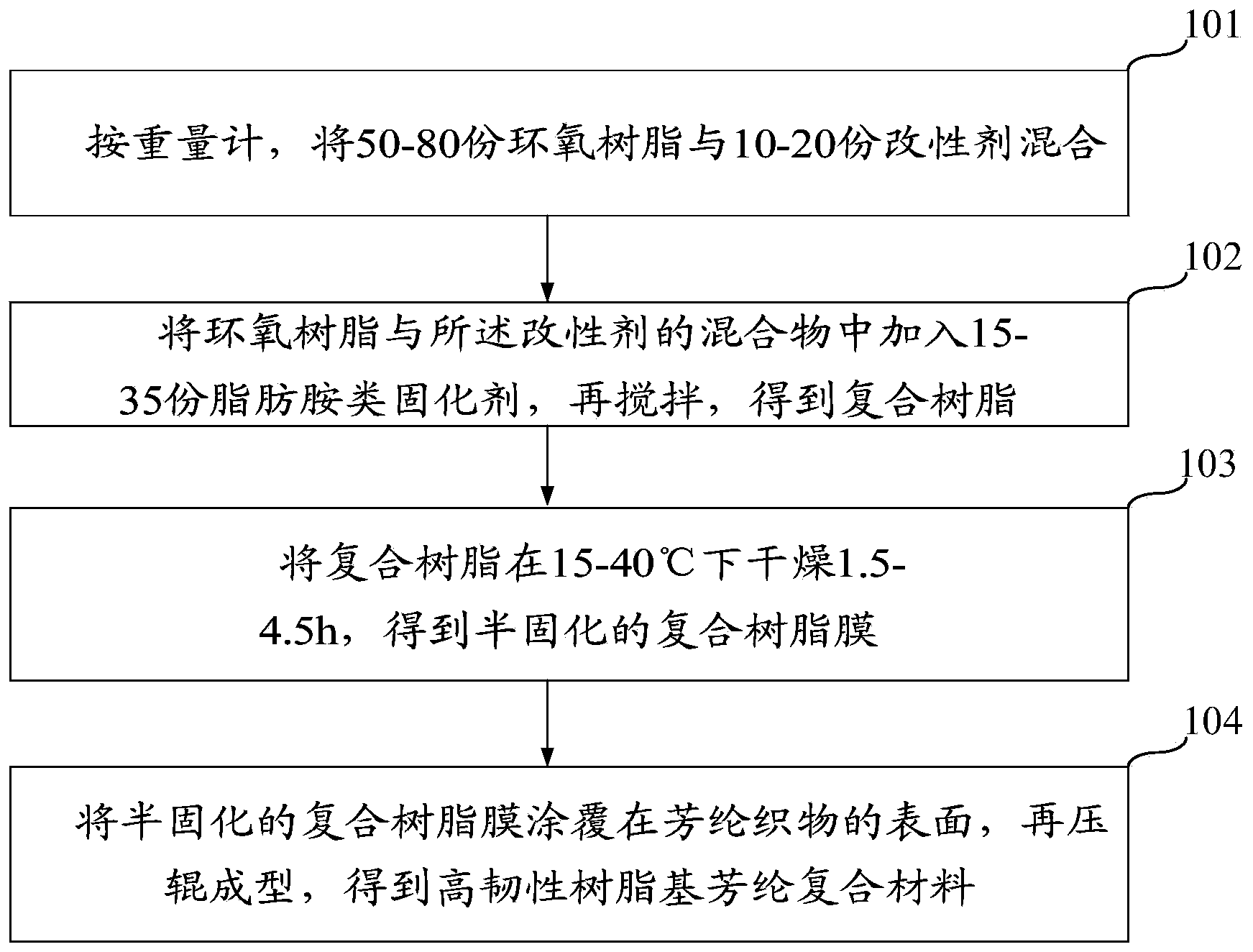

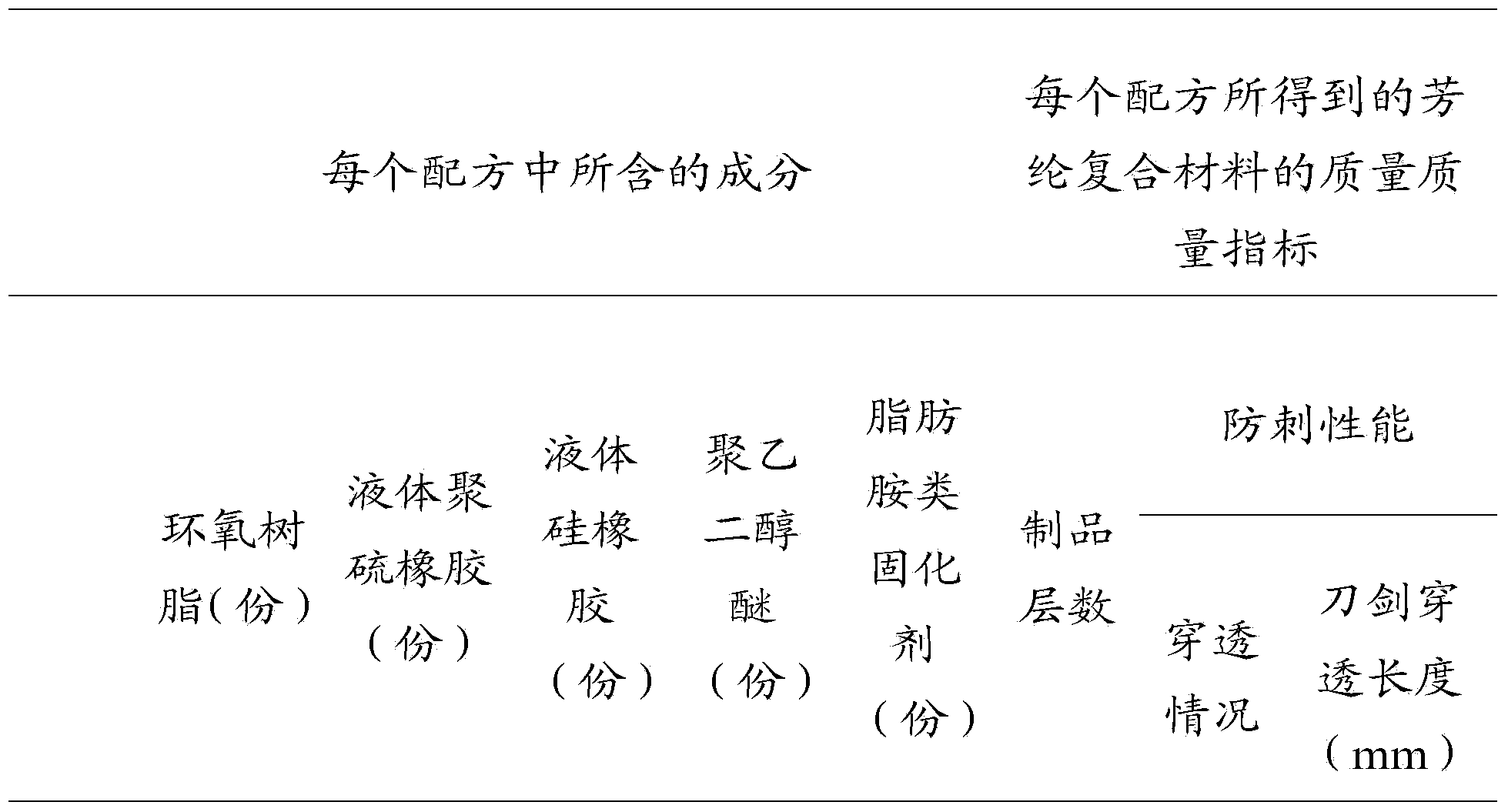

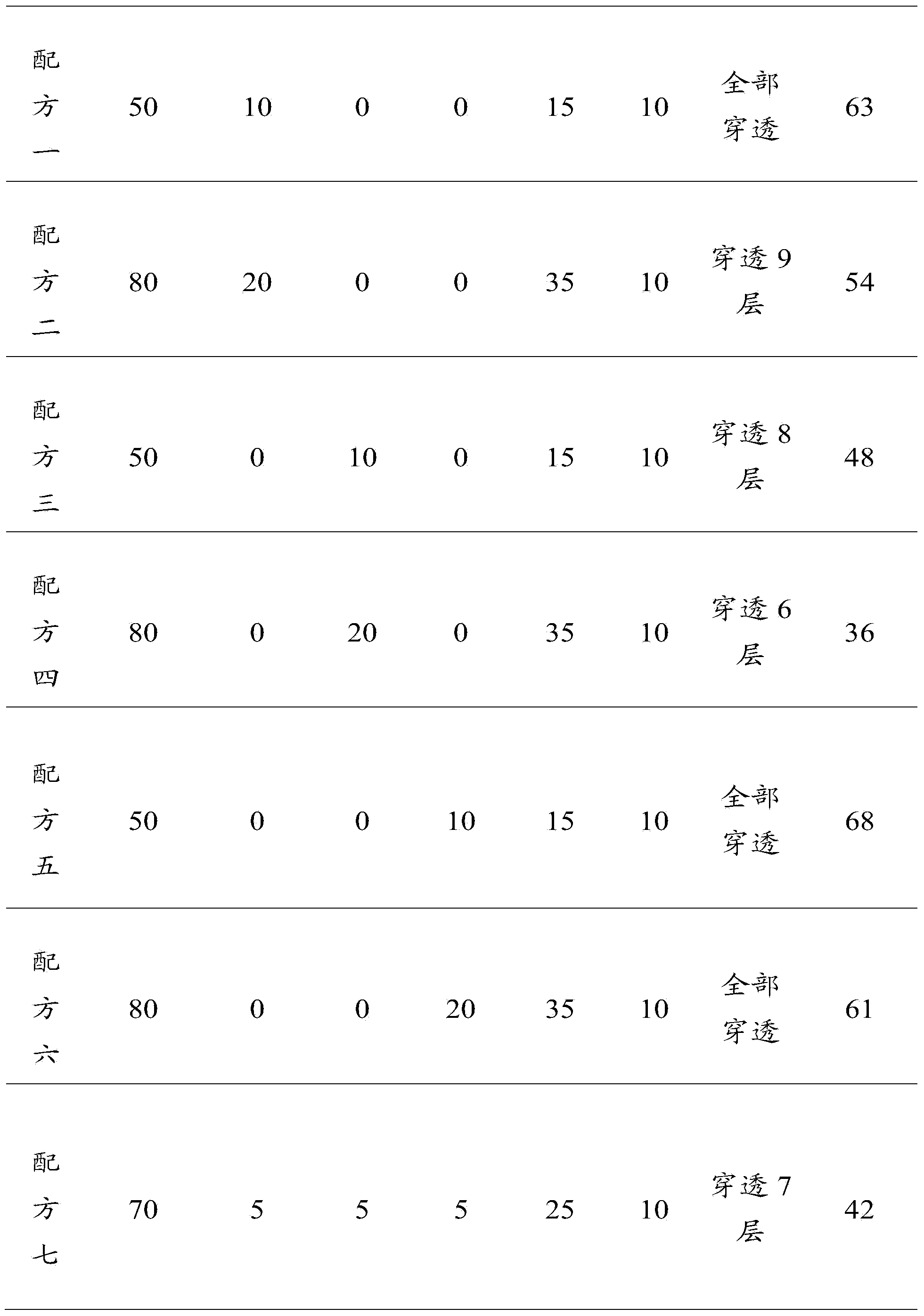

High-toughness resin-based aramid fiber composite material and production method thereof

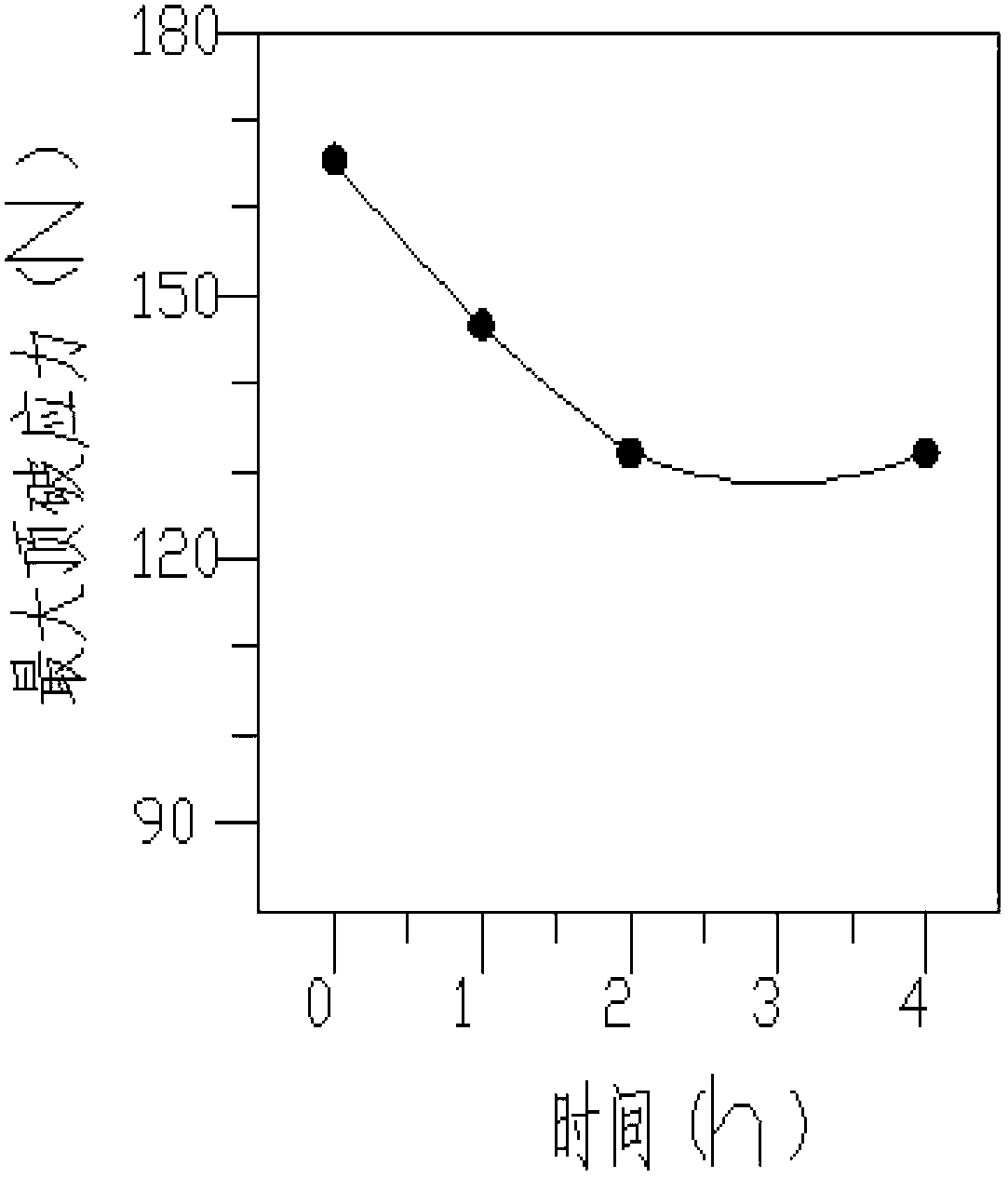

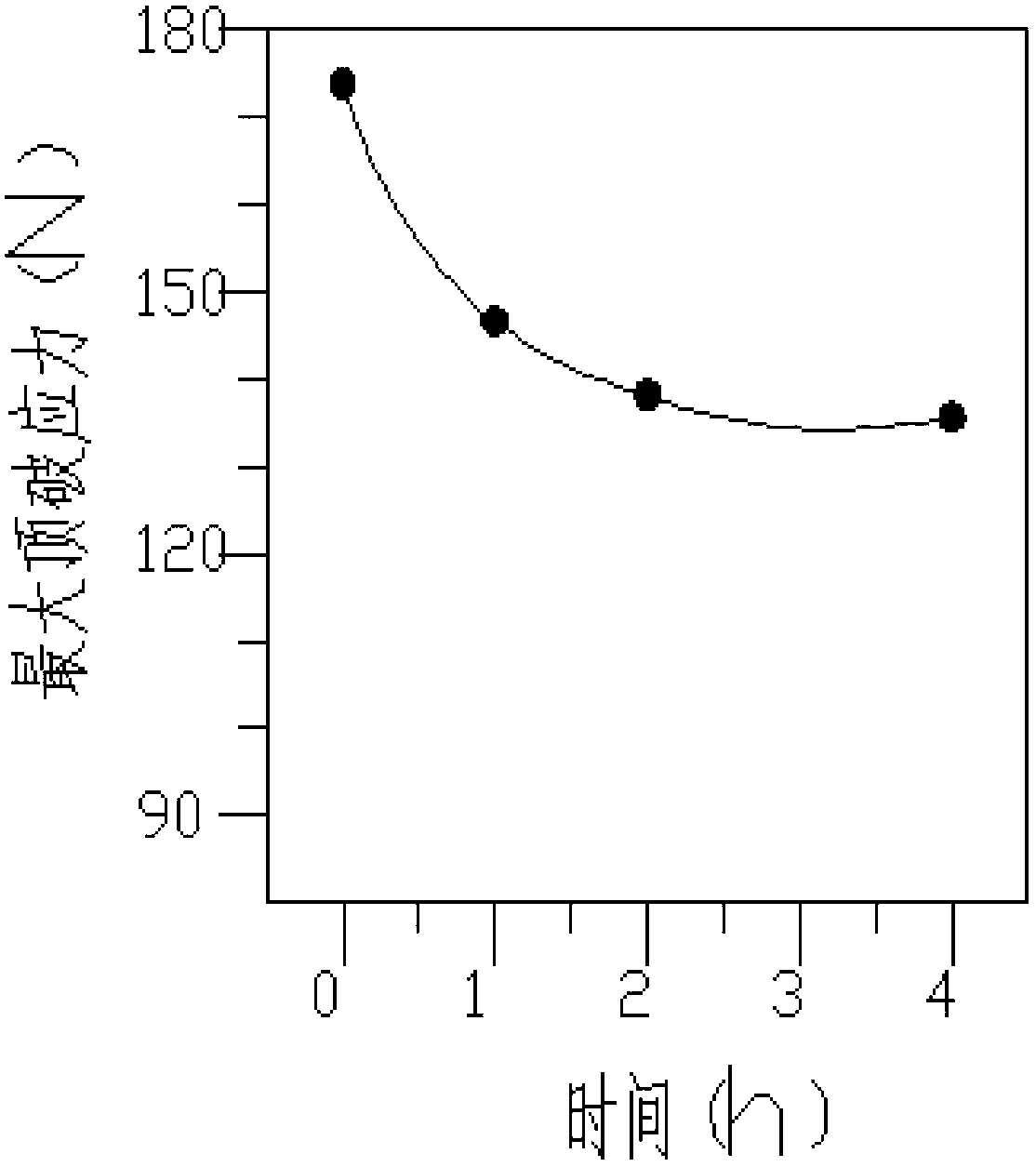

ActiveCN103753904AUniform stab resistanceImprove stab resistanceSynthetic resin layered productsPolysulfide rubberFatty amine

The invention relates to the technical field of textiles and in particular relates to a high-toughness resin-based aramid fiber composite material and a production method thereof. The production method of the high-toughness resin-based aramid fiber composite material comprises the following steps: mixing 50-80 parts by weight of epoxy resin and 10-20 parts by weight of a modifier, wherein the modifier is one or more of liquid polysulfide rubber, liquid silicone rubber and polyglycol ether; adding 15-35 parts by weight of a fatty amine curing agent into the epoxy and modifier mixture, and stirring again to obtain composite resin; drying the composite resin at 15-40 DEG C for 1.5-4.5 hours to obtain a half-cured composite resin film; coating the surface of an aramid fiber fabric with the half-cured composite resin film, and molding through a pressing roller to obtain the high-toughness resin-based aramid fiber composite material. Compared with a conventional presoaking technology in the prior art, the production method disclosed by the invention has the advantages that the obtained high-toughness resin-based aramid fiber composite material is high in puncture prevention performance, and the puncture prevention performance is uniformly distributed.

Owner:SHANGHAI LIANBO SECURITY EQUIP

Anti-cutting socks and manufacturing method thereof

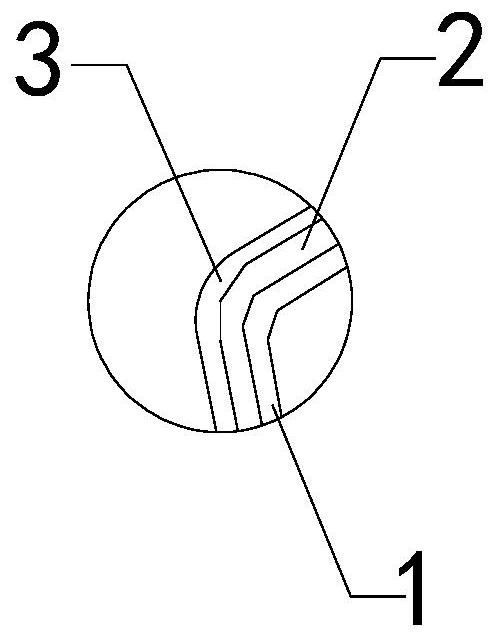

The invention discloses anti-cutting socks and a manufacturing method thereof. The anti-cutting socks are formed by knitting yarns; the yarns comprise anti-cutting yarns; the anti-cutting yarns mainlycomprise core materials (also called as core yarns) and wrap yarns (also called as covered yarns) covering the core materials; the core materials are inorganic fibers or metal wires; and the warp yarns are inorganic fibers. The anti-cutting socks are high in elasticity, have high flexibility and comfort level, have high anti-cutting performance and high impact resistance, have an effective protection on feet, ankles and shank parts of human bodies, and protect a user from being cut by sharp edge objects such as a cutting edge.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY

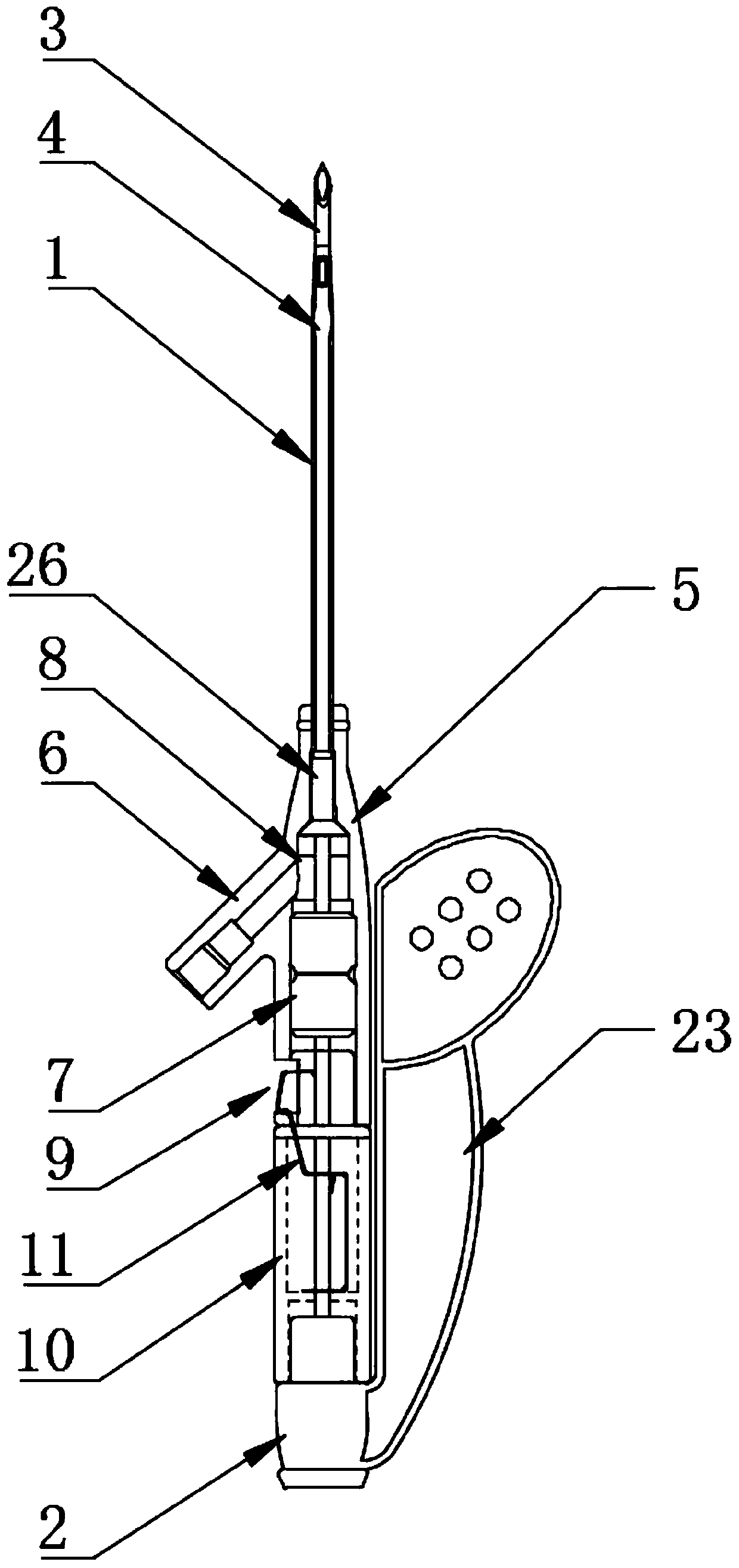

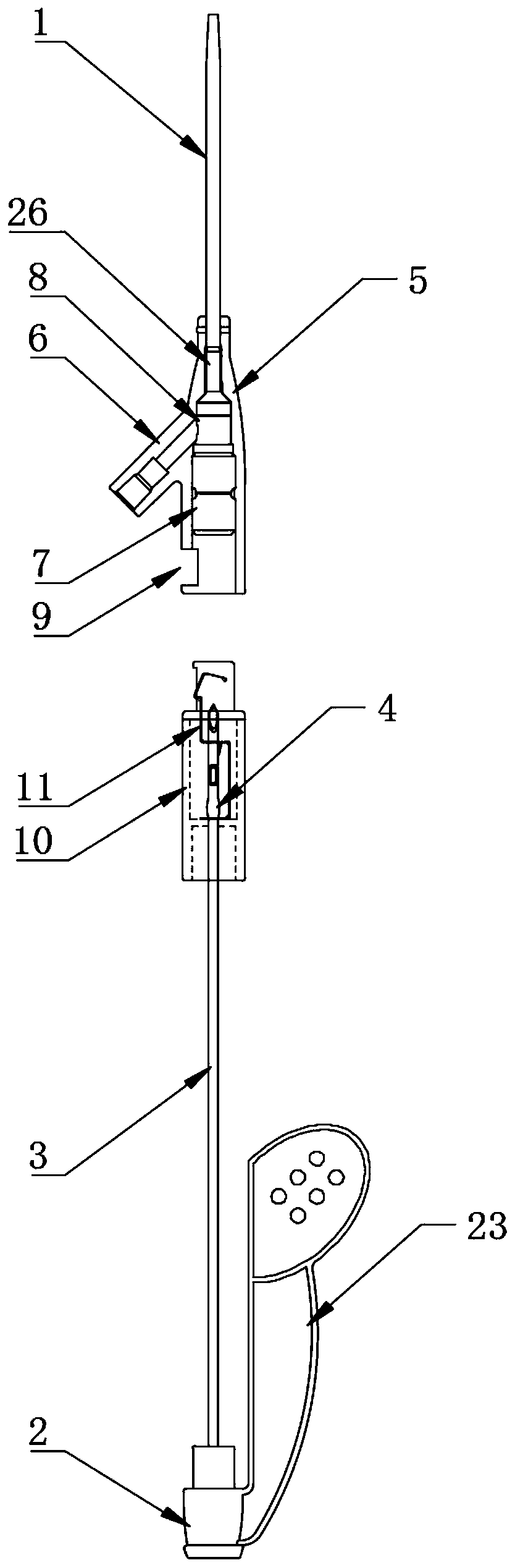

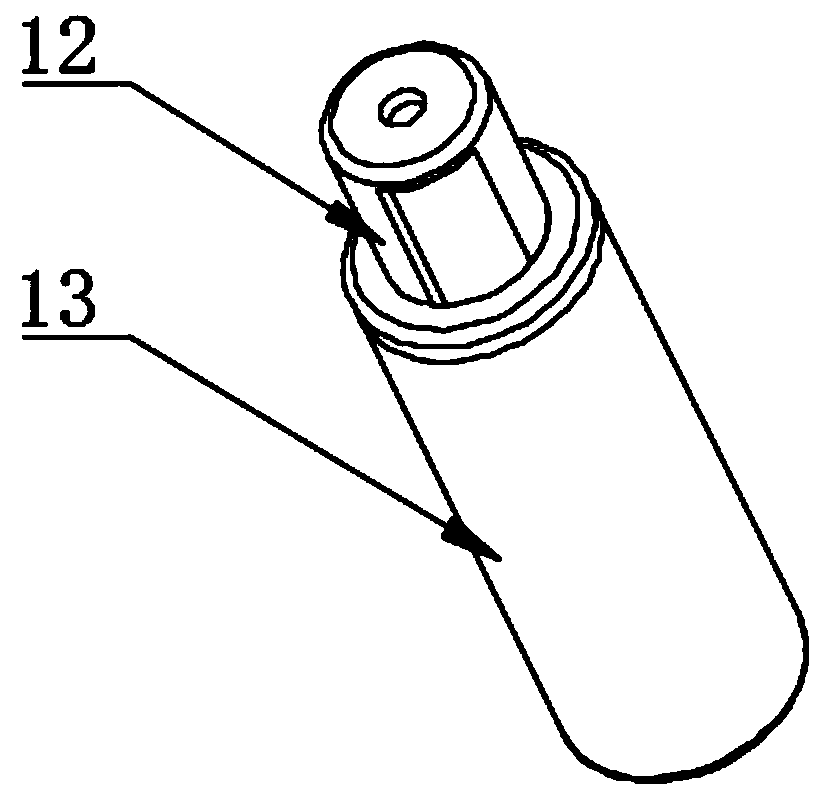

Anti-puncture remaining needle assembly

The invention provides an anti-puncture remaining needle assembly and belongs to the field of medical apparatus and instruments. The assembly comprises a puncture assembly, a hose holder, a hose and an anti-puncture assembly; a bulge with outer diameter larger than that of a steel needle is formed on the steel needle, and a notch is formed in the side edge of the hose holder; an elastic piece baseis a tubular base provided with an opening in the bottom, an elastic piece groove in the side part and an elastic piece baffle at the top, a partition is fixedly mounted in a sleeve, and steel needlepassing holes with outer diameter larger than outer diameter of the bulge are formed in the elastic piece baffle and the partition; a propping piece propped against the outer wall of the steel needleis fixed on an anti-puncture elastic piece, and the steel needle is enabled to lean against the inner side of the anti-puncture elastic piece; the elastic piece base is sleeved with the sleeve, and the anti-puncture elastic piece is mounted in the elastic piece groove and the sleeve; the elastic piece base is inserted into the hose holder, and the anti-puncture elastic piece bulges out of the elastic piece groove and is clamped at the notch in a hanging manner. The anti-puncture remaining needle assembly which can be used for storing and protecting the steel needle during needle withdrawal issimple in structure, convenient to mount and good in anti-puncture effect.

Owner:JIANGSU SUYUN MEDICAL MATERIALS

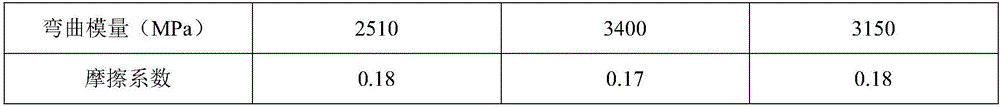

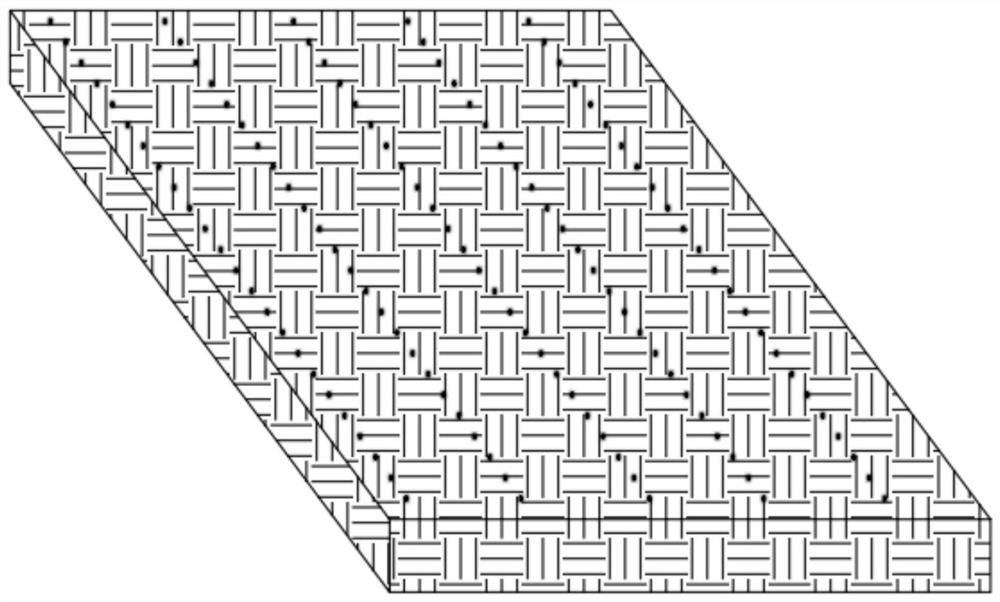

Multi-layer multi-raw material flexible stab-resistant fabric and a weaving method therefor

InactiveCN106120081AImprove stab resistanceGood anti-stab performanceMulti-ply fabricsPolyesterEngineering

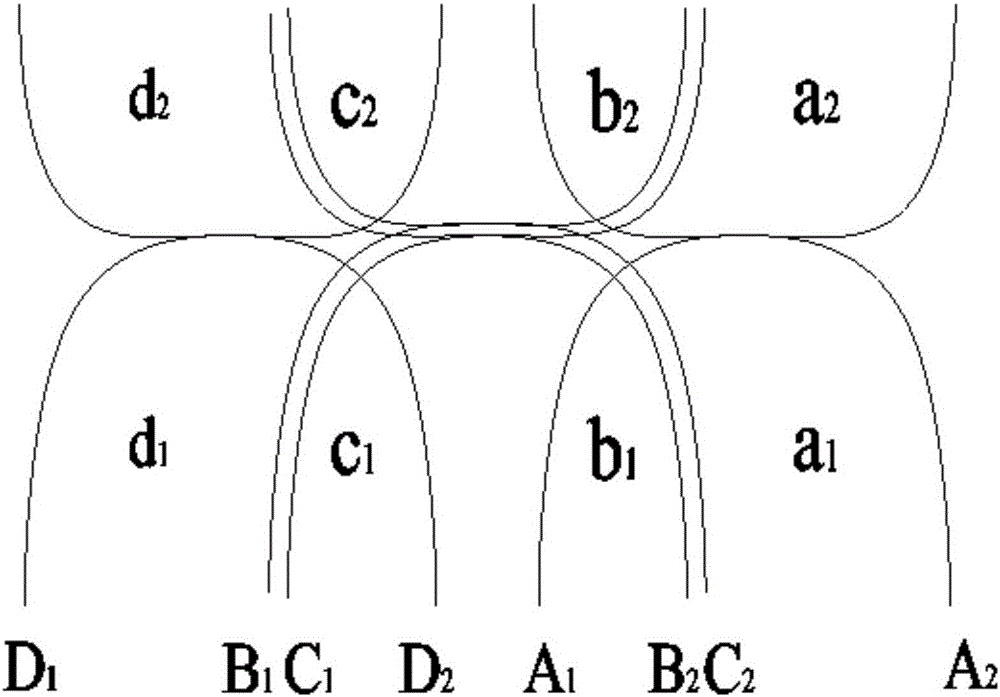

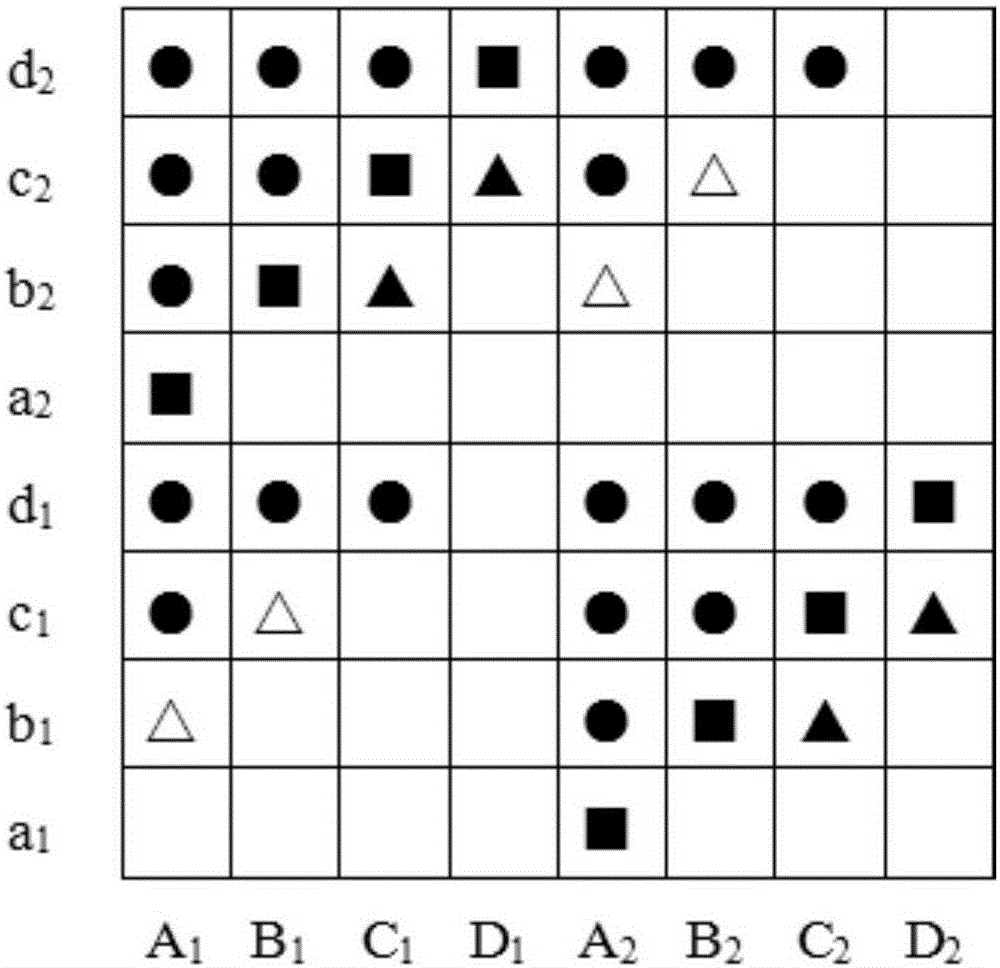

The invention provides multi-layer multi-raw material flexible stab-resistant fabric comprising four layers. Each layer of the fabric is a plain weave and the layers are connected mutually, so that the stab-resistant requirement is met; the fabric is light, soft and efficient and the problem of insufficient comfort of conventional stab-resistant fabric is solved. The invention also provides a weaving method for the multi-layer multi-raw material flexible stab-resistant fabric, and the method employs a multi-warp beam rapier loom for weaving. The method comprises a first step of warping: ultra-high molecular weight polyethylene filaments, which are the raw materials for weaving the first layer, are wound around a weave beam, high-tenacity polyester filaments, which are the raw materials for weaving the second layer and the third layer, are wound around a second weave beam, and aramid fibers, which are the raw materials for weaving the fourth layer, are wound around a third weave beam; a second step of performing drafting by using a straight draft method; a third step of weaving; a rapier sample loom is used for weaving, and during weaving, the humidity control of warp yarn requires an environmental relative humidity of 70%-75%, and a protective twist of 80-100 twists / m is added to warp yarn.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation method of white carbon black enhanced UHMWPE (ultrahigh molecular weight polyethylene) fiber composite non-weft fabric

ActiveCN103015041AImproved impact and heat resistanceImproved stab and ballistic resistanceNon-macromolecular adhesive additivesNon-woven fabricsPolymer chemistryAdhesive

The invention belongs to the field of bulletproof protective products and relates to a preparation method of white carbon black enhanced UHMWPE (ultrahigh molecular weight polyethylene) fiber composite non-weft fabric. The preparation method includes: pretreating white carbon black; further functionally modifying the pretreated white carbon black to allow the white carbon black to be dispersed evenly in matrix adhesives; well mixing the functionally modified white carbon black with the adhesives; sizing the UHMWPE fiber; and drying. By adding gas phase white carbon black, energy caused bullet impact on fibers can be absorbed more, bulletproof performance is improved, and overall heat resistance is improved. Live ammunition tests applied to a certain layers of the composite non-weft fabric according to the GA141-2001 standard shows the composite non-weft fabric completely accords to the requirements of the standard, use temperature is increased by 5 DEG C, and impact resistance is increased by about 20%.

Owner:JIANGSU LINRY NEW MSTAR TECH

Adhesive used for preparing stab-resistant fabrics

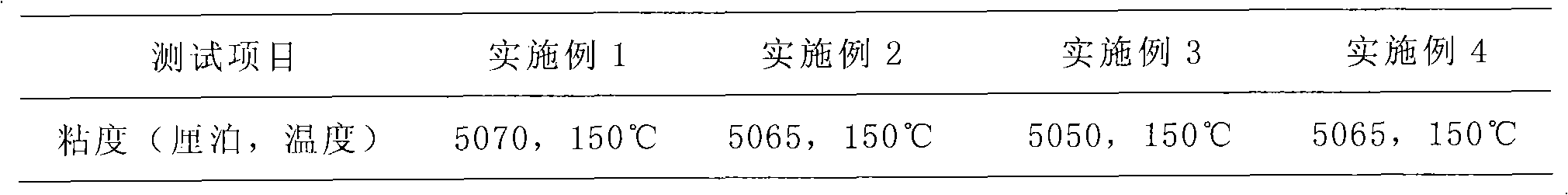

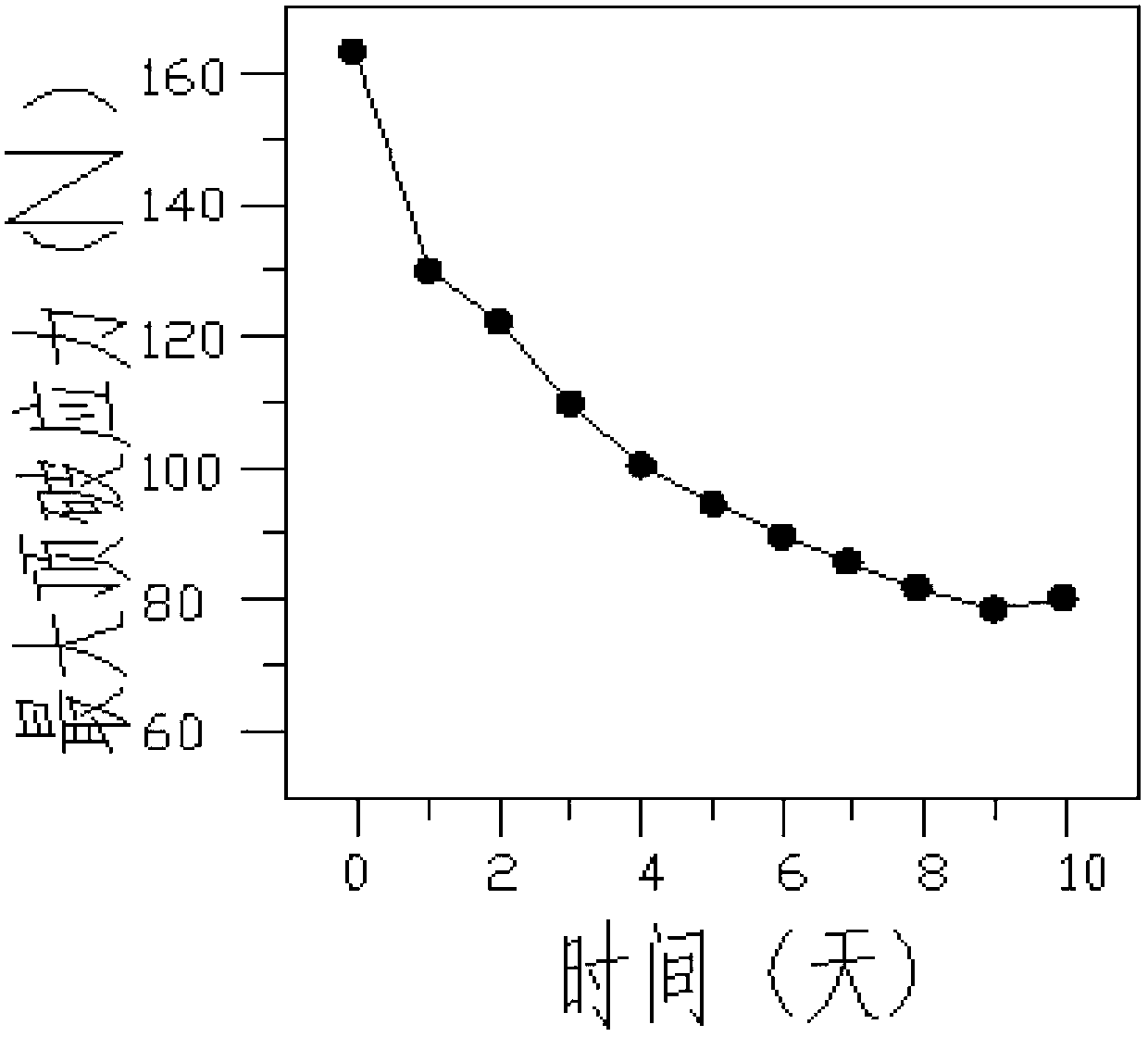

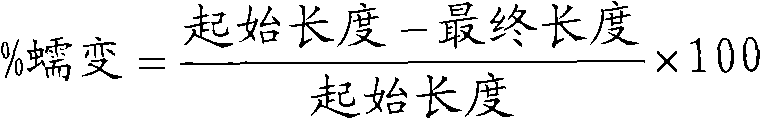

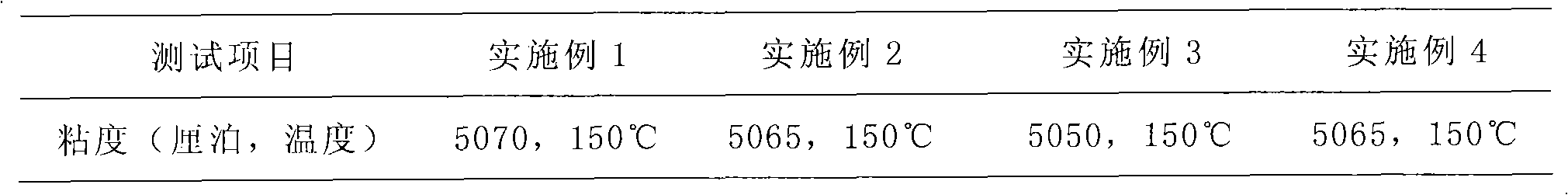

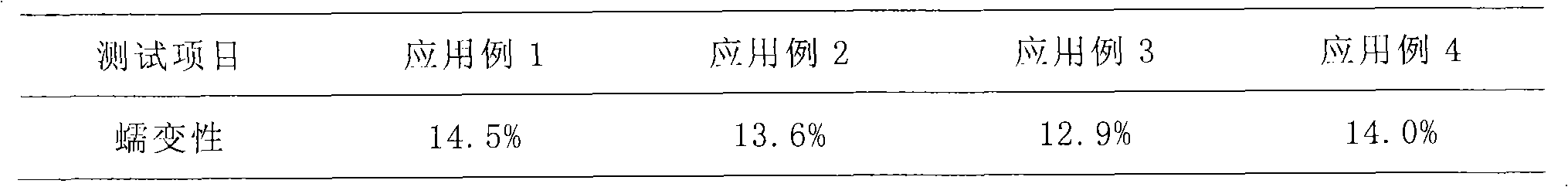

InactiveCN102115651AGood anti-stab performanceImprove stab resistanceFibre treatmentHydrocarbon polymer adhesivesFiberElastomer

The invention provides an adhesive for preparing stab-resistant fabrics, which comprises 5 to 12 weight percent of polystyrene elastomer, 1 to 3 weight percent of tackifying resin, 0.5 to 1.2 weight percent of plasticizer, 1 to 3 weight percent of fire retardant and the balance of solvent. The adhesive contains the polystyrene elastomer and the tackifying resin which have good compatibility with superhigh molecular weight polyethylene fibers, and the bonding strength of the adhesive is improved; moreover, the adhesive also contains the plasticizer and the fire retardant, and the creep properties and the fire retardancy of the adhesive are improved; therefore, the prepared stab-resistant fabrics have better stab resistance, the fire retardancy of the stab-resistant fabrics is improved, and the application range of the stab-resistant fabrics is widened.

Owner:杨珍芬

Method for preparing shearing-preventing thickening liquid for enhancing protection of fencing clothes

ActiveCN107334199AImprove stab resistanceInstantaneous shear strength enhancementOther chemical processesProtective garmentPolyethylene glycolAqueous solution

The invention discloses a method for preparing a shearing-preventing thickening liquid for enhancing protection of fencing clothes, and relates to the weaving material technology field. The preparation method comprises the steps of selecting titanium dioxide powder, polyethylene glycol and polyvinylpyrrolidone as raw material; preparing a polyvinylpyrrolidone aqueous solution in which the quality fraction of the polyvinylpyrrolidone is 40%; mixing the polyethylene glycol with the polyvinylpyrrolidone aqueous solution prepared in step 2 in a volume ratio of 5:1 to obtain a mixing solution; adding the titanium dioxide powder in the mixing solution prepared in step 3, and then stirring to make sure the disperse is uniform. In his way, the shearing-preventing thickening liquid can be obtained. The shearing-preventing thickening liquid is used as a protection material to make fencing gym suit, so that the gym suit has a good stab-resistant capability as well as good flexibility and comfortableness.

Owner:丹阳市斯鲍特体育用品有限公司

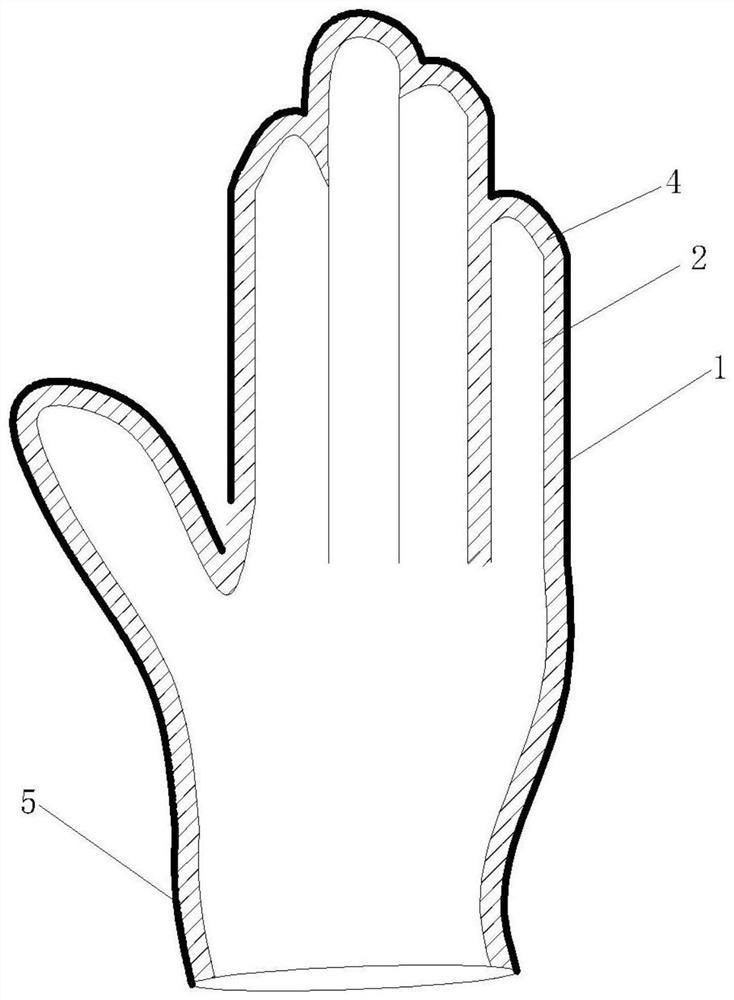

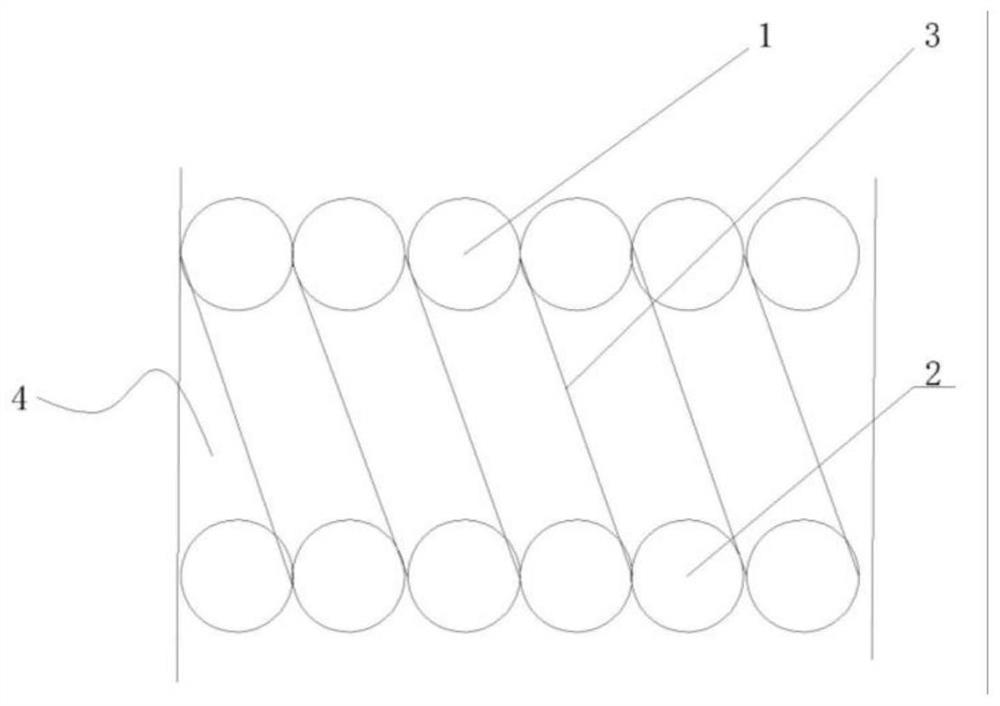

Medical puncture-proof glove with warp knitting three-dimensional structure

The invention relates to a medical puncture-proof glove with a warp-knitted three-dimensional structure. The glove is characterized by being manufactured by the following steps: (1) sewing a glove body by adopting a warp-knitted three-dimensional structure fabric; (2) carrying out plasma treatment on the glove body to form etching on the fiber surface; and (3) spraying a puncture-proof coating onthe glove body after the plasma etching on the fiber surface. The puncture-proof coating is prepared by the following method: putting silicon dioxide particles and an aminated silane coupling agent into an acetone solvent, and then carrying out dispersion treatment on a mixed solution by adopting ultrasonic waves, so that the silicon dioxide particles can be uniformly dispersed in the solution; and uniformly mixing the dispersed solution with acrylic resin, and reacting under the condition of ultrasonic stirring; According to the puncture-proof glove, the puncture-proof capacity of the fiber layer is enhanced through the inorganic particles, the problem that an existing puncture-proof glove becomes poor in flexibility after being worn is solved while the puncture-proof capacity is guaranteed, and the flexibility of finger operation is kept.

Owner:WUXI NO 5 PEOPLES HOSPITAL

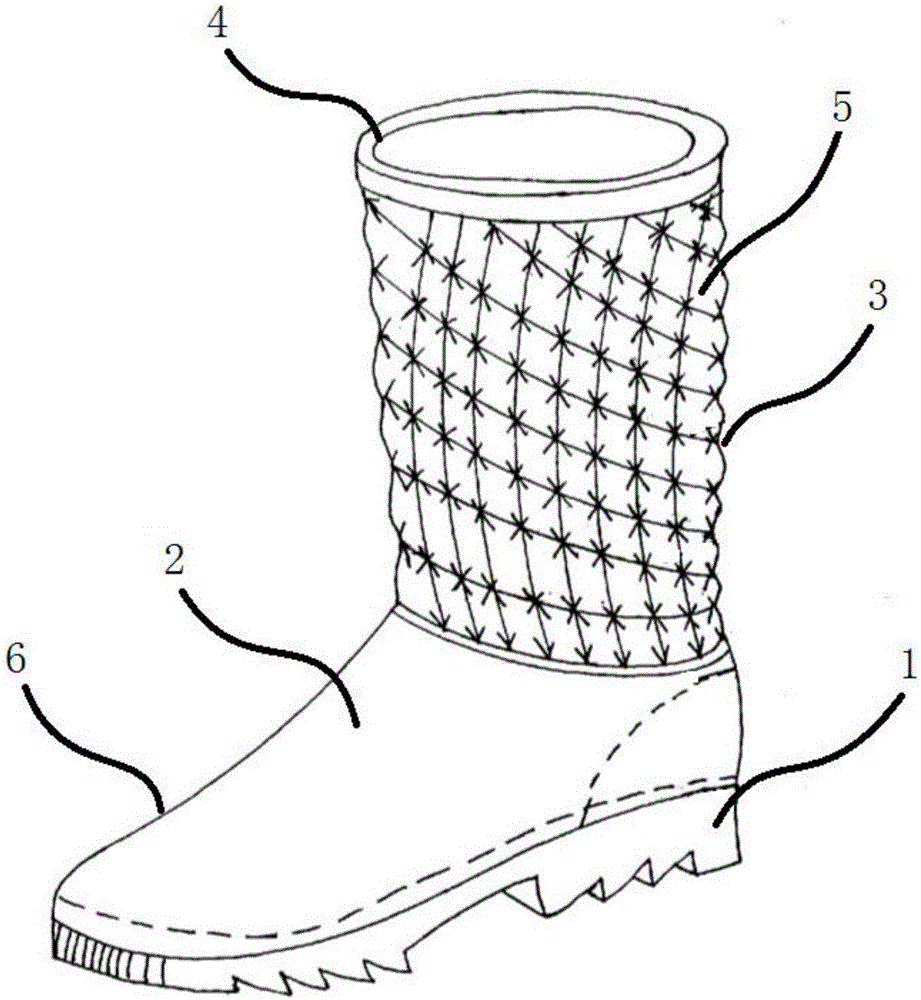

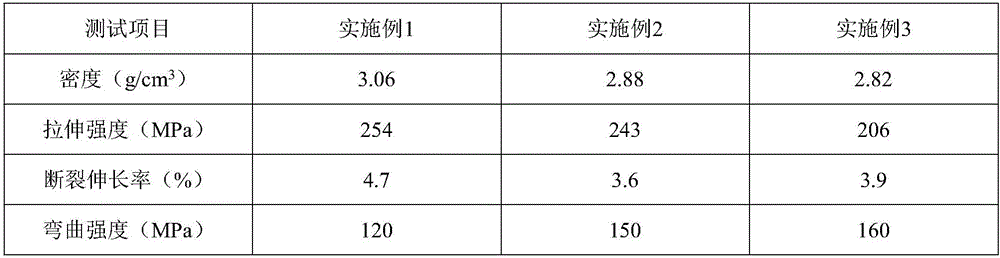

Puncture-proof rain boot

InactiveCN106564248AChange a single waterproof functionImprove stab resistanceInsolesSynthetic resin layered productsPolyesterAntioxidant

A puncture-proof rain boot comprises a sole, a vamp and a shoe tube, the vamp and the shoe tube are integrally molded, the vamp and the shoe tube respectively have a three-layer structure and respectively concretely comprise a waterproof layer, a buffering and puncture proofing layer and a lining foot protection layer from outside to inside, above three layers are sequentially bonded together, the waterproof layer is made of rubber or a PVC material, and the buffering and puncture proofing layer is made of a puncture-proof high toughness material and prevents pointed hard objects from puncturing the vamp; the buffering and puncture proofing layer is made from, by weight, 30-60 parts of nylon6, 20-40 parts of short glass fibers, 1-1.2 parts of dimethicone, 0.5-1 part of an antioxidant, 5-10 parts of linear polyethylene, 3-5 parts of polylactic acid, 1-5 parts of a synergistic agent, 0.5-1 part of a nucleating agent, 0.5-1 part of an ultraviolet ray absorber, 0.5-1 part of a surfactant, 1-3 parts of a chain extender, 0.5-1 part of dry oxhide gelatin powder and 0.5-1 part of ceramsite nanopowder; and the lining foot protection layer is formed by blending polyester fibers, bamboo fibers and man-made spider fibers, and the lining foot protection layer has good elasticity and toughness, allows skins in contact with the lining foot protection layer to be comfortable, and has an antibacterial effect.

Owner:界首市鑫一龙机械设备购销有限公司

Multi-layer multi-material flexible stab-resistant fabric and its weaving method

InactiveCN106120081BImprove stab resistanceGood anti-stab performanceMulti-ply fabricsPolyesterAramid

Owner:XI'AN POLYTECHNIC UNIVERSITY

A preparation method of shear thickening liquid for fencing protection clothing reinforcement

ActiveCN107334199BImprove stab resistanceInstantaneous shear strength enhancementOther chemical processesProtective garmentPolyethylene glycolAqueous solution

The invention discloses a method for preparing a shearing-preventing thickening liquid for enhancing protection of fencing clothes, and relates to the weaving material technology field. The preparation method comprises the steps of selecting titanium dioxide powder, polyethylene glycol and polyvinylpyrrolidone as raw material; preparing a polyvinylpyrrolidone aqueous solution in which the quality fraction of the polyvinylpyrrolidone is 40%; mixing the polyethylene glycol with the polyvinylpyrrolidone aqueous solution prepared in step 2 in a volume ratio of 5:1 to obtain a mixing solution; adding the titanium dioxide powder in the mixing solution prepared in step 3, and then stirring to make sure the disperse is uniform. In his way, the shearing-preventing thickening liquid can be obtained. The shearing-preventing thickening liquid is used as a protection material to make fencing gym suit, so that the gym suit has a good stab-resistant capability as well as good flexibility and comfortableness.

Owner:丹阳市斯鲍特体育用品有限公司

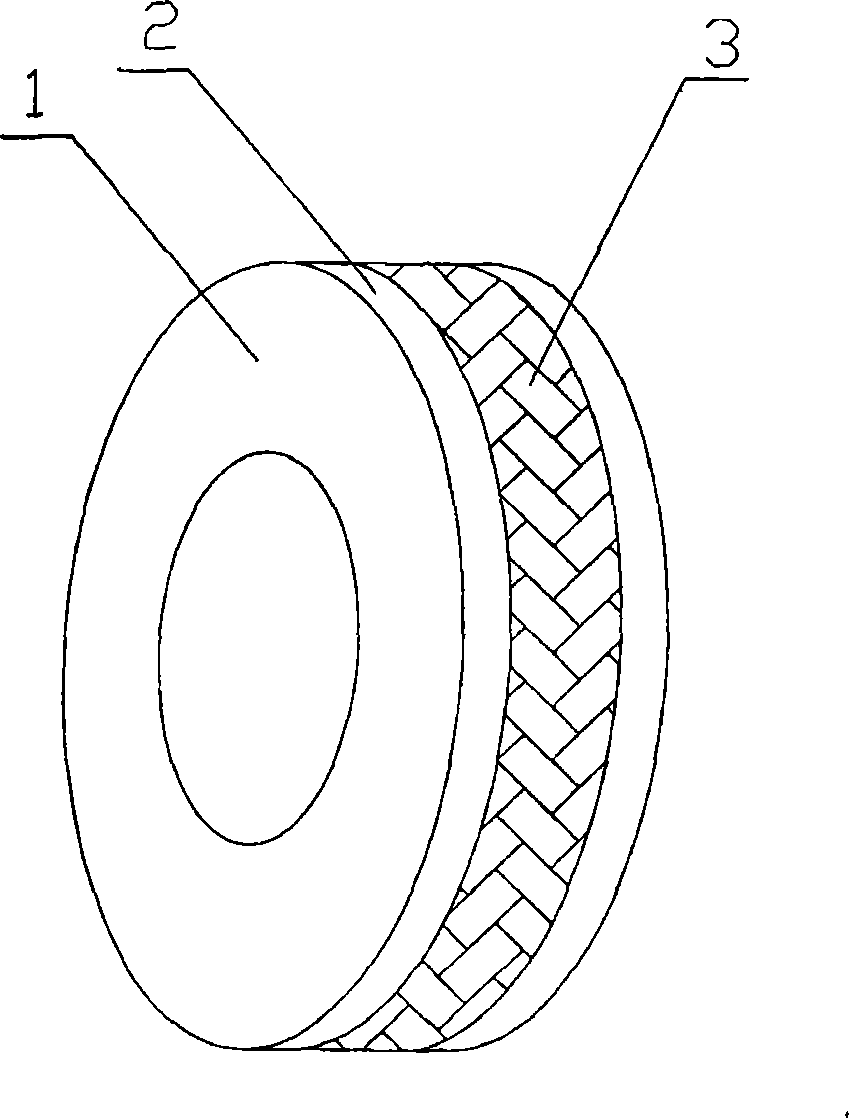

Tire retreading method

InactiveCN103831987AWithout breaking the balanceImprove handling comfortTyresRough surfacePuncture resistance

The invention relates to a method for retreading and recycling a radial all-steel wire waste tire. The method comprises the following steps: grinding the surface of a tire body, namely grinding the steel wire tire to remove the polluted and damaged tire surface and enable the surface to be a threaded rough surface; gluing, namely brushing a mixture of glue paste and glass steel resin onto the tire surface; winding a brand-new glue steel wire tire fabric onto a tire crown and fitting cushion rubber; after gluing the tire surface, fitting matched tread rubber onto the tire crown wound with the steel wire fabric; vulcanizing in a tank, namely feeding the tire with an enhanced belt layer into a vulcanizing tank for vulcanizing. According to the method, the balance of the tire cannot be destroyed and the operating comfortableness can be improved; the puncture resistance and the burst resistance of the tire crown are improved, a framework of the tire body of the tire is kept non-deformed, and the re-retreading probability of the tire is increased; due to the glue steel wire fabric and the thickness of the cushion rubber, the effect of bonding between the tire body and the tire surface is enhanced, the tear resistance of a pattern block is improved, the chunking situation is reduced, and the bearing and buffering capabilities of the tire are improved.

Owner:山东忠诚橡胶有限公司

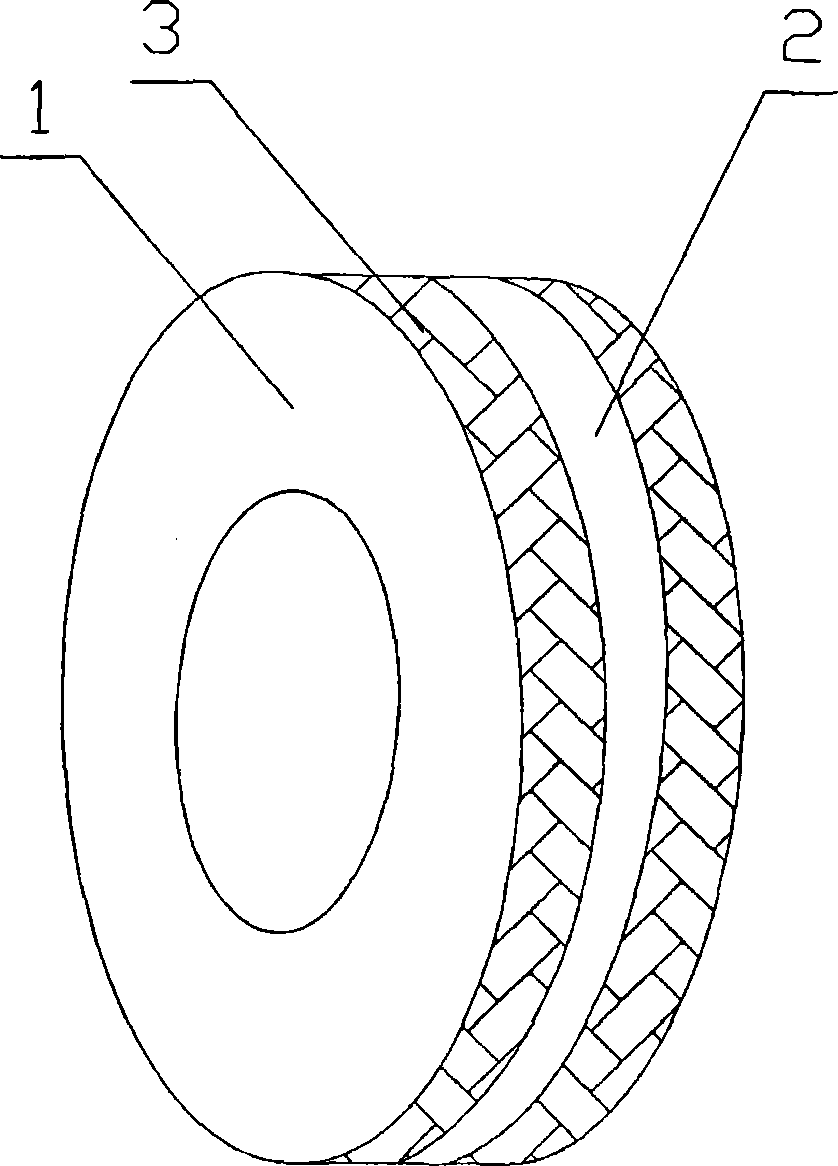

Steel wire structured anti-burst tyre

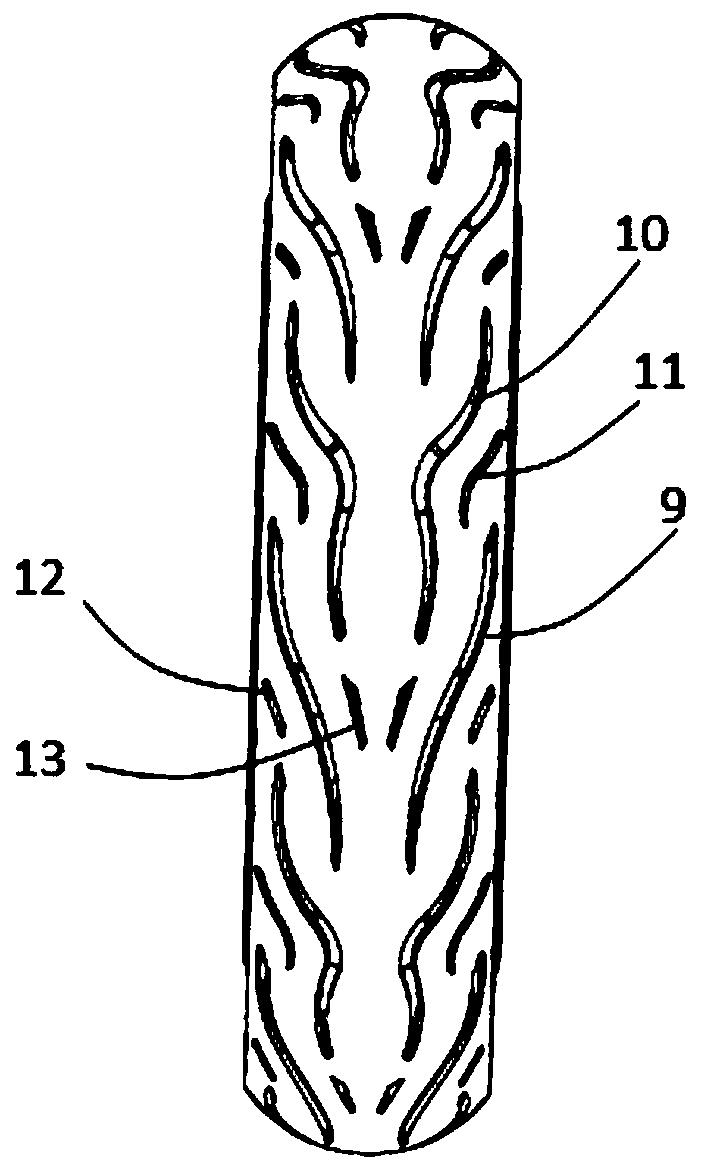

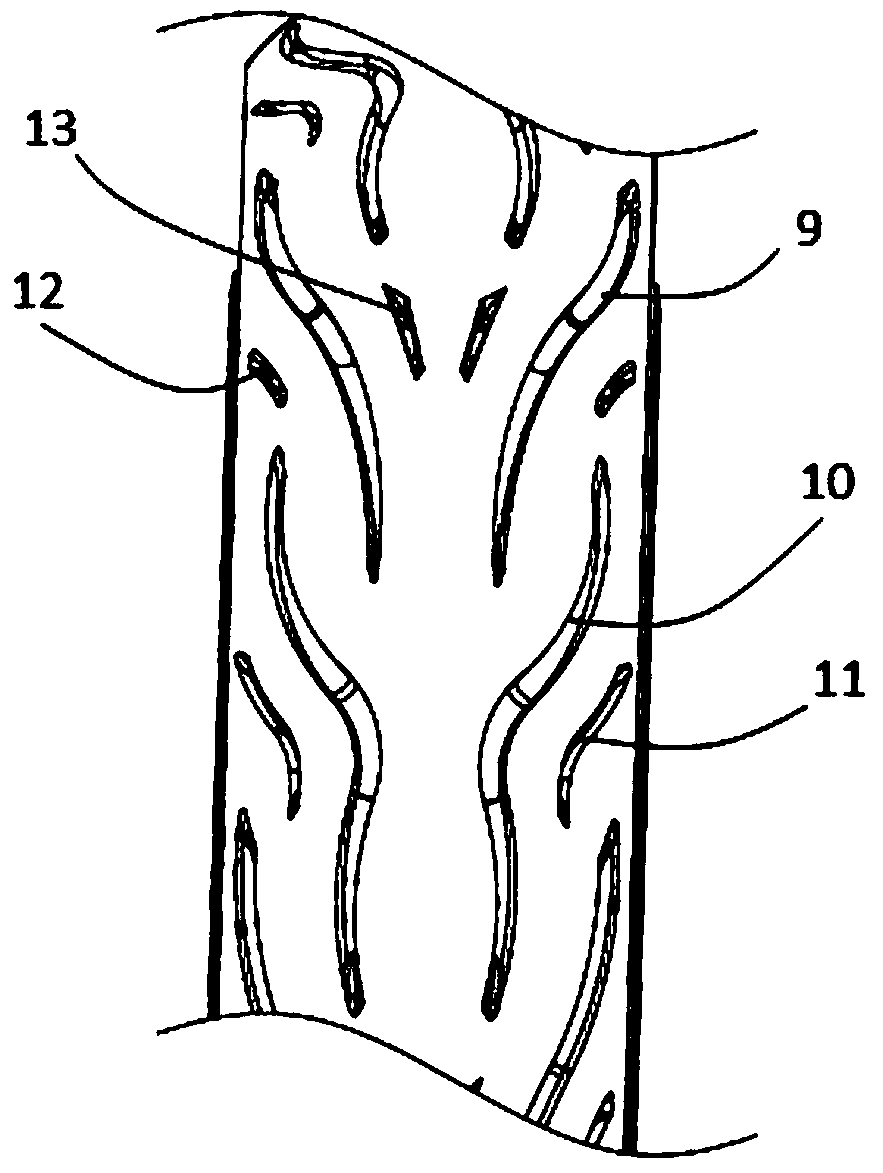

PendingCN108891204ASmall amount of deformationImprove stab resistanceMotorcycle tyresPneumatic tyre reinforcementsSurface layerMotorcycle tyre

The invention discloses a steel wire structured anti-burst tyre. The steel wire structured anti-burst tyre is composed of an inner surface layer, a reinforcing layer, a steel wire circle buffer layerand a tyre surface layer, wherein the reinforcing layer wraps a steel wire ring and extends onto a tyre roll rim; the bottom of the steel wire structured anti-burst tyre is provided with a bead whichis provided with an eagle beak-like protrusion, the eagle beaklike is provided with an upper protrusion surface, a side protrusion surface and a lower protrusion surface, the upper protrusion surfaceis an inward recessed arc surface, the side protrusion surface is an inclined surface, and the lower protrusion surface is a level surface; the surface of the tyre surface layer is provided with a plurality of continuous pattern groove units which are composed of first pattern grooves, second pattern grooves, third pattern grooves, fourth pattern grooves and five pattern grooves. Therefore, the steel wire structured anti-burst tyre can improve puncture-proof performance by higher than 35% and the wear-resisting performance by at least 10% compared with common nylon buffer layers, thereby meeting the marketing requirements on low-air-pressure ridability, high puncture-proofness and impact-proofness and easy operability.

Owner:KENDA RUBBER CHINA

Curing agent reinforcement aramid fiber composite no-woven cloth and preparation method and applications of the same

ActiveCN103122556AImprove low temperature performanceBursting Force GuaranteePersonal protection gearNon-woven fabricsPolymer scienceAcrylate ester

The invention belongs to the field of bulletproof protective articles, and discloses curing agent reinforcement aramid fiber composite no-woven cloth and a preparation method and applications of the curing agent reinforcement aramid fiber composite no-woven cloth. The curing agent reinforcement aramid fiber composite no-woven cloth is made after silk is spread, aramid fiber is evenly, parallelly and straightly arranged, glued and dried, wherein curing agent is contained in an adhesion agent used in the process of gluing. The curing agent is trimethylolpropane triacrylate. The quantity of the added curing agent accounts 0.8-1.6% of the weight of the adhesion agent. The curing agent reinforcement aramid fiber composite no-woven cloth can overcome defects existing in the prior art to a large extent, not only changes heat stability of materials, improves anti-impact, bulletproof and anti-pricking performance of the aramid fiber composite no-woven cloth, but also can improve high-low-temperature performance of the aramid fiber composite no-woven cloth, and production efficiency.

Owner:JIANGSU LINRY NEW MSTAR TECH

Adhesive used for preparing stab-resistant fabrics

InactiveCN102115651BGood anti-stab performanceImprove stab resistanceFibre treatmentRosin adhesivesFiberElastomer

The invention provides an adhesive for preparing stab-resistant fabrics, which comprises 5 to 12 weight percent of polystyrene elastomer, 1 to 3 weight percent of tackifying resin, 0.5 to 1.2 weight percent of plasticizer, 1 to 3 weight percent of fire retardant and the balance of solvent. The adhesive contains the polystyrene elastomer and the tackifying resin which have good compatibility with superhigh molecular weight polyethylene fibers, and the bonding strength of the adhesive is improved; moreover, the adhesive also contains the plasticizer and the fire retardant, and the creep properties and the fire retardancy of the adhesive are improved; therefore, the prepared stab-resistant fabrics have better stab resistance, the fire retardancy of the stab-resistant fabrics is improved, andthe application range of the stab-resistant fabrics is widened.

Owner:杨珍芬

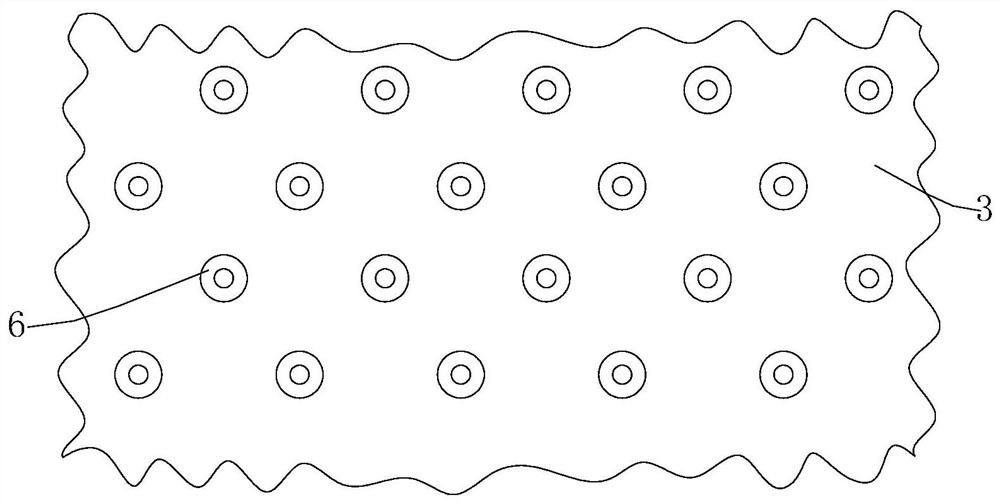

Puncture-proof fabric with porous buffer structure and preparation method of puncture-proof fabric

PendingCN114858002AImprove stab resistanceImprove puncture displacementPersonal protection gearDomestic articlesEpoxyHeat press

The invention discloses a stab-resistant fabric with a porous buffer structure and a preparation method of the stab-resistant fabric, and relates to the field of protective textile materials. The porous buffer structure and the garment fabric are uniformly adhered to the surface of the garment fabric through epoxy resin. A porous buffer structure is obtained through a 3D printing technology; a main body stab-resistant structure is obtained through a 3D printing technology, an injection molding technology or a manual lay-up molding technology; uniformly coating the garment fabric with a layer of epoxy resin, and neatly arranging the porous buffer structures on the garment fabric; coating a layer of epoxy resin on the uniformly arranged porous buffer structures, and integrally arranging the main body puncture-proof structure on the porous buffer structures; the arranged whole stab-resistant fabric is pressurized, cured and shaped on a flat plate hot press, and the stab-resistant fabric with the porous buffer structure is obtained. The weight of the prepared stab-resistant clothes can be reduced, the safety performance of the stab-resistant clothes can be guaranteed, and the requirements of civil and even military fields are met.

Owner:DONGHUA UNIV

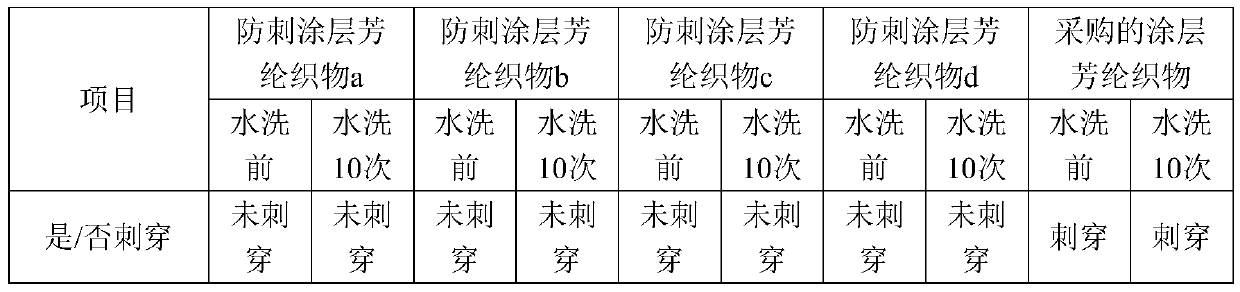

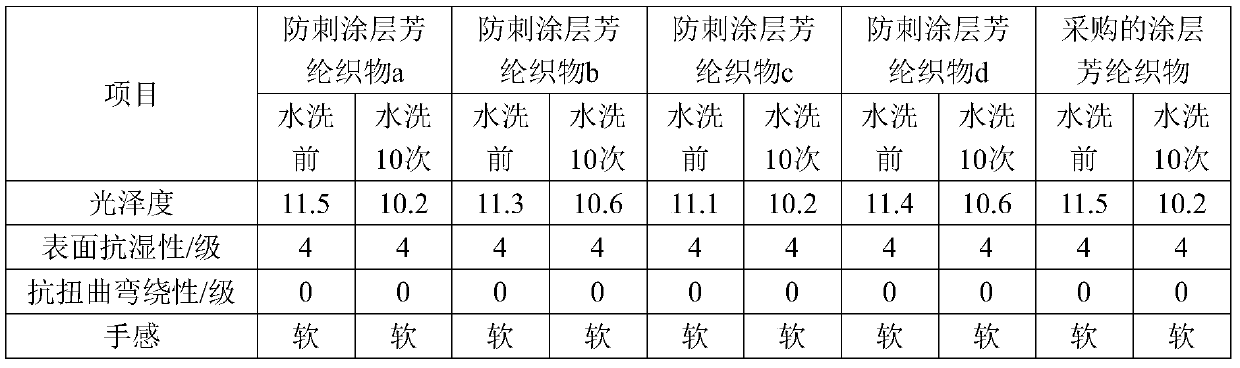

A kind of preparation method of anti-stab coated aramid fiber fabric

ActiveCN109610190BAnti-stab effectStrong anti-stab performanceLayered productsTextiles and paperEmulsionCopper

The invention relates to a preparation method of puncture-proof coating aramid fabric. The preparation method of the puncture-proof coating aramid fabric is characterized by comprising the steps of preparing a dispersing agent first, grinding copper powder into nanometer particles and then dissolving nanometer copper particles into the dispersing agent to prepare a nanometer copper particle dispersion; polymerizing and emulsifying monomers such as acrylic acid, butyl acrylate and styrene to prepare a polyacrylate emulsion; compounding the nanometer copper particle dispersion and the polyacrylate emulsion to prepare a nanometer copper particle / polyacrylate composite emulsion; and carrying out coating finishing on aramid fabric by using the emulsion to prepare the puncture-proof coating aramid fabric. The puncture-proof coating aramid fabric prepared by the preparation method of the puncture-proof coating aramid fabric, provided by the invention, has the advantages that obvious puncture-proof performance is realized; other various indexes of the puncture-proof coating aramid fabric are almost approximate to various indexes of market-purchased coating aramid fabric; each index of thepuncture-proof coating aramid fabric is not obviously reduced after being washed by water for 10 times; and therefore, it is shown that the stability and durability of the puncture-proof coating aramid fabric are both very good.

Owner:YANCHENG LANBANG TECHN FIBER

Anti-puncturing safe tyre

The invention relates to an anti-puncturing safe tyre, which comprises a tyre body, and is manufactured according to the following process steps: (1) heating and smelting hot-melt adhesive; (2) mounting the tyre body in a rigid cylindrical mold of which inner diameter is less than the external diameter of the tyre body; (3) utilizing a sprayer to spray the smelted hot-melt adhesieve onto the inner surface of the cleaned tyre body; (4) cooling and shaping; (5) circulating the steps (3) and (4), for several times till a tyre inner coating layer which is 0.5-10 mm in thickness is formed. The anti-puncturing safe tyre not only improves traveling safety, but also has the characteristics of avoidance of tyre replacement and repair, improvement on traveling efficiency and trye airtightness, reduction of dynamic balance deviation, decrease of tyre traveling resistance, consumption reduction, oil economization, ultra-strong temperature adaptability, no anxiety for high-speed traveling, reduction of noise generated by the tyre during traveling, reduction of abrasion, prolongation of the service life and the like.

Owner:杭州绿奇科技有限公司

Method for processing anti-stab coating of machine woven fabric

InactiveCN111021081AThe overall thickness is thinReduce weightTextiles and paperEngineeringMechanical engineering

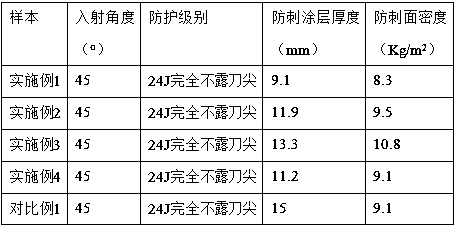

The invention provides a method for processing an anti-stab coating of a machine woven fabric. The method includes the following steps of (1) first coating preparation, (2) second coating preparationand (3) coating treatment. The anti-stab coating of the machine woven fabric is thin in thickness and can meet the protection standard with a minimum of only 9.1mm, the weight is light, the density ofthe anti-stab surface is at least 8.3 Kg / m<2>, and the GA68-2008 anti-stab clothes test standers of Ministry of Public Security can be fully met. According to the method for processing the anti-stabcoating of the machine woven fabric, the anti-stab performance of protective clothes is improved, the protective clothe are light to wear, the flexibility of actions of wearer is increased to a certain extent, and the load is reduced.

Owner:JIANGSU LINRY NEW MSTAR TECH

Semi-steel UTV tire

PendingCN114872497AImprove stab resistanceImprove overall securityTyre tread bands/patternsTyre sidewallsPuncture resistanceAll terrain vehicle

The invention relates to a semi-steel UTV tire, and relates to the technical field of tires, the semi-steel UTV tire comprises a tread and a sidewall, pattern blocks are arranged on the tread at intervals, grooves are formed between the pattern blocks, anti-puncture strips are arranged at the bottoms of the grooves in the groove trend, the width of the anti-puncture strips is smaller than that of the grooves, the thickness of the anti-puncture strips is set to be 1-3 mm, and the width of the anti-puncture strips is set to be 1-3 mm. The tread structure layer is provided with a stab-resistant strip, transition slopes are connected between the bottoms of the grooves on two sides of the stab-resistant strip and the pattern blocks, a metal reinforcing frame is arranged in the tread structure layer below the stab-resistant strip, the metal reinforcing frame is arranged along the trend of the grooves, and the width of the metal reinforcing frame is greater than that of the stab-resistant strip. The semi-steel UTV tire disclosed by the invention has better puncture resistance, and the running safety of an all-terrain vehicle can be improved.

Owner:TIANJIN WANDA TYRE CO LTD

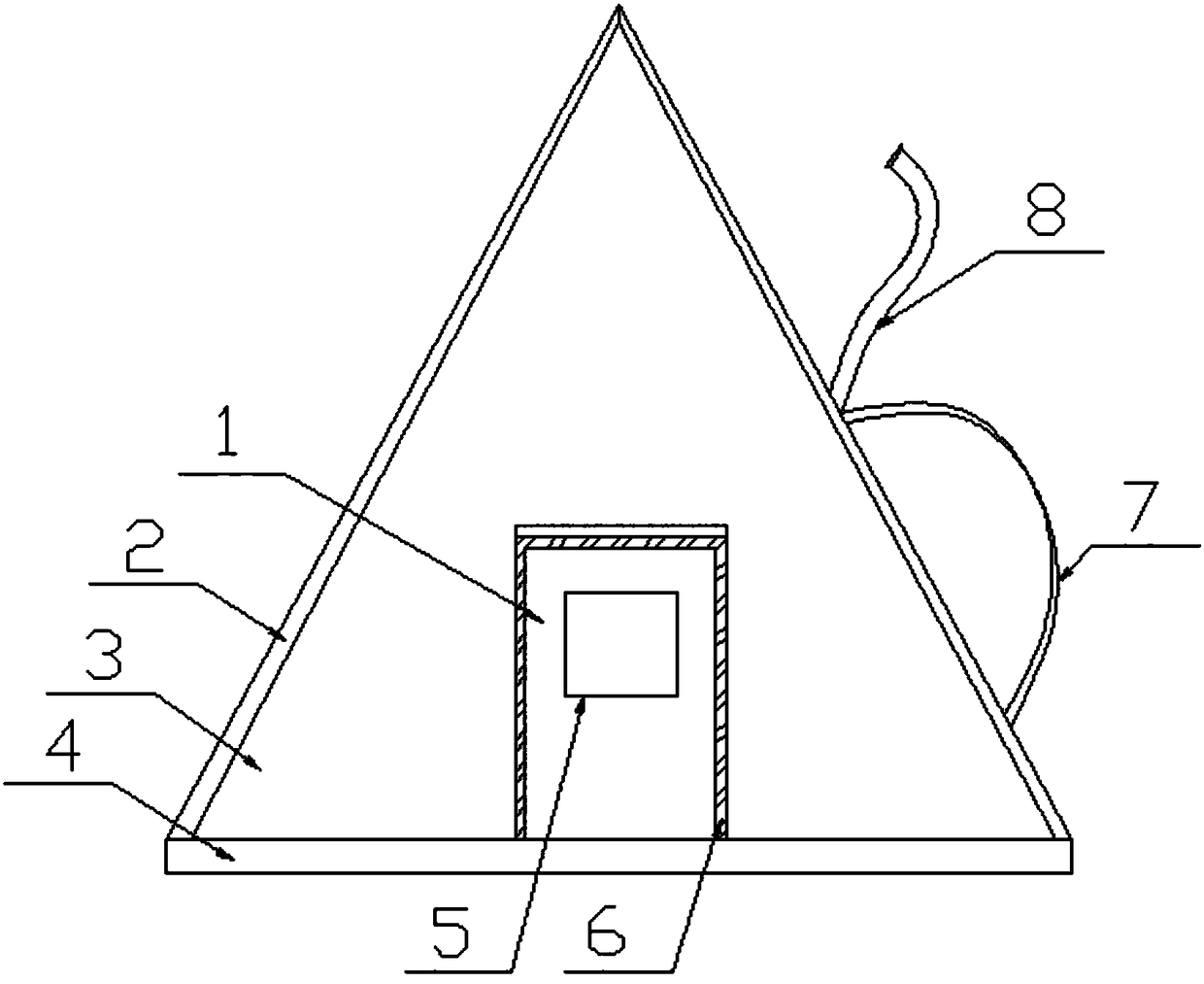

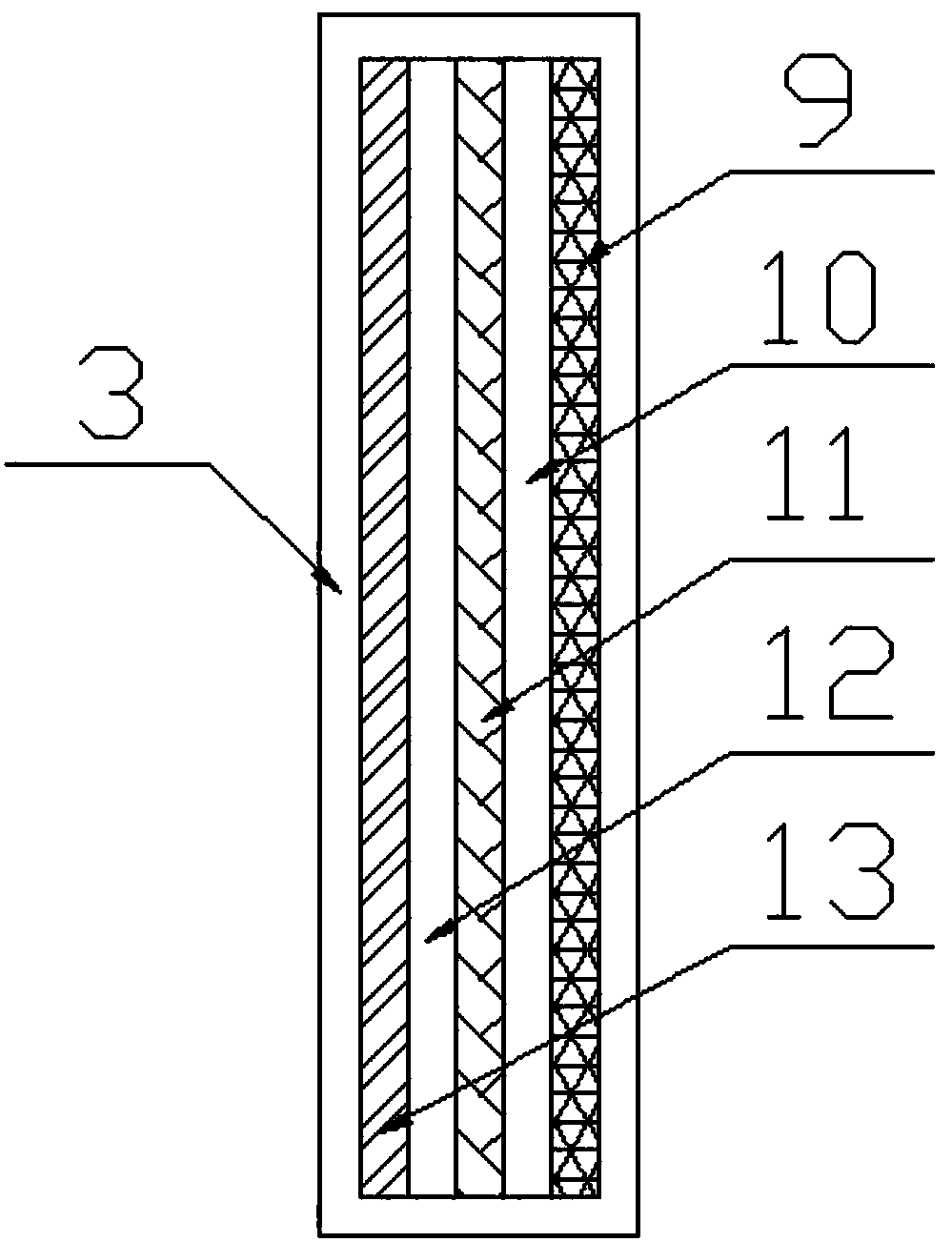

Portable safe outdoor tent

PendingCN108468464AHas the ability to stretchImprove tensile propertiesLayered productsTents/canopiesFiberCarbon fibers

The invention provides a portable safe outdoor tent. The tent comprises a tent door, tent rods, tent cloth, ground cloth, an observing window, a zipper, a strap, a bundling belt, a carbon fiber fabriclayer, a sound absorbing layer, a high-temperature resistance fabric layer, a water-proof fabric layer and a puncture-proof fabric layer, the tent rods are arranged at the edge of the tent cloth, andthe lower ends of the tent rods are connected with the ground cloth; the tent door is arranged on the surface of the tent cloth, the observing window is arranged on the surface of the tent door, andthe tent cloth is connected with the tent door through a zipper; the strap is arranged on one side of the tent cloth, the bundling belt is arranged on the upper end of the strap, and through the arrangement of the strap on one side of the tent cloth, the tent can be conveniently carried on the back; through the arrangement of the bundling belt on the upper end of the strap, the bundling belt is used for bundling the tent, the arranged carbon fiber fabric layer makes the tent have a stretch-proof property, and the arranged sound absorbing layer is used for weakening interference of noises on sleep in outdoor environments.

Owner:连江县维佳工业设计有限公司

Impact-resistant composite structure

The invention relates to an impact-resistant composite structure, which comprises a first fabric, a second fabric layer, a non-woven fabric, a fiber resin layer and a polymer adhesive, wherein the first fabric comprises a surface weave surface and an inner weave surface, the surface weave surface and the inner weave surface are opposite to each other, the thickness between the surface weave surface and the inner weave surface is not smaller than 2.0 mm, the second fabric layer has a front weave surface and a rear weave surface, the fiber tensile strength of the front weave surface and the rearweave surface is not less than 10 g / d, the non-woven fabric is clamped between the inner weave surface of the first fabric and the front weave surface of the second fabric layer, the fiber resin layer is provided with a roughened surface, the roughened surface is attached to the rear tissue surface of the second fabric layer, and the first fabric, the non-woven fabric, the second fabric layer andthe fiber resin layer are adhered by the polymer adhesive.

Owner:刘军忠

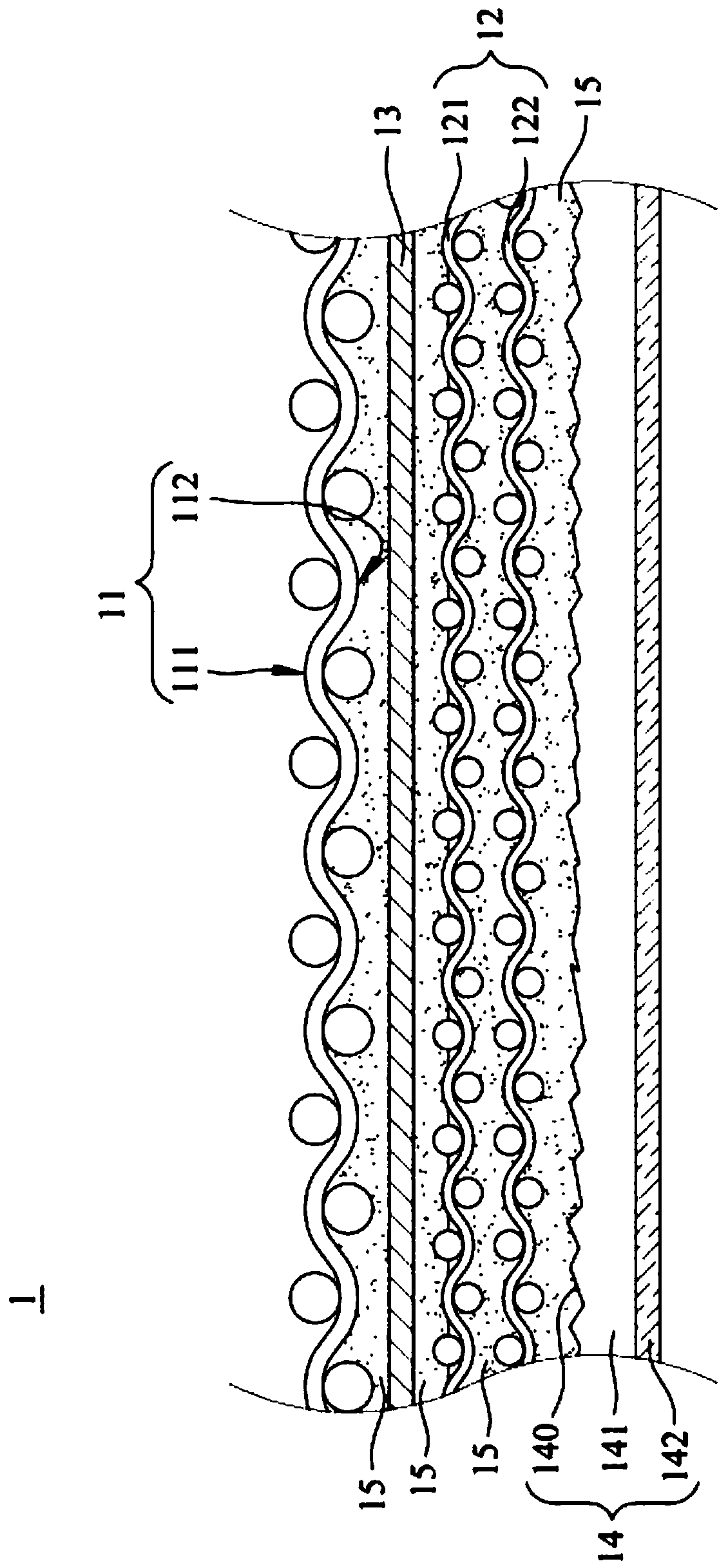

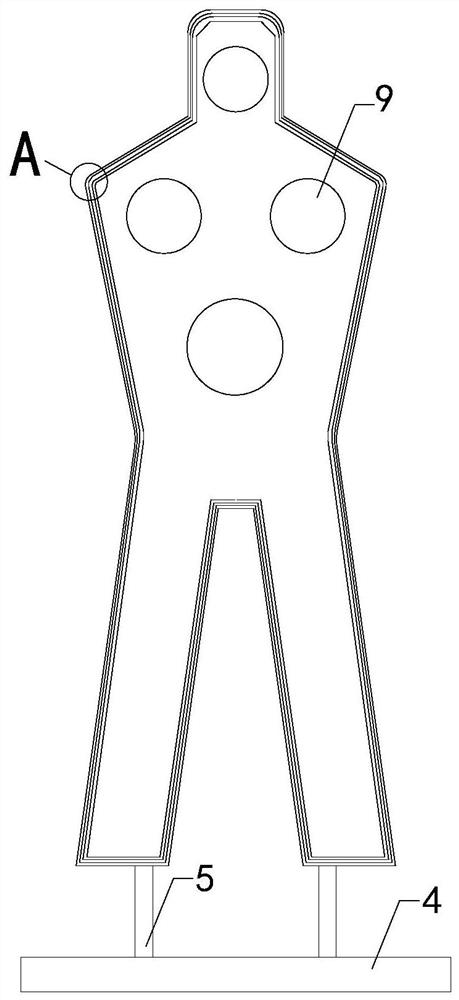

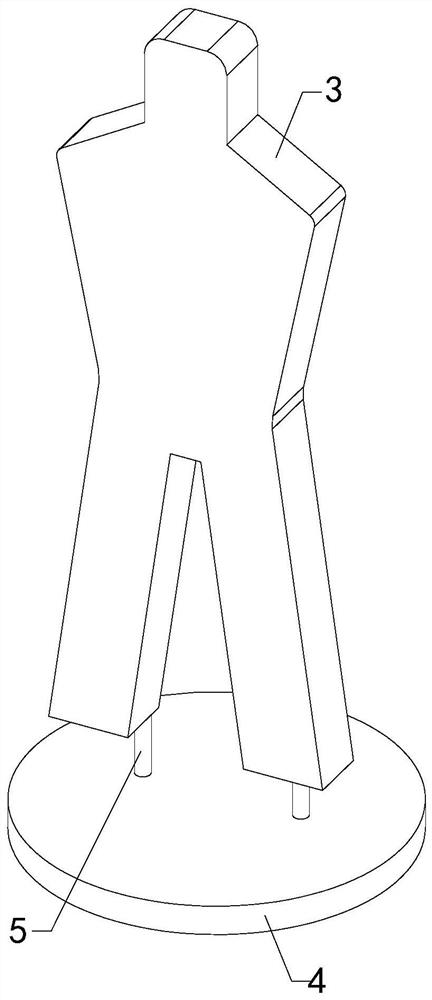

Killing human-shaped target for training and production process of killing human-shaped target

InactiveCN113797513AImprove stab resistanceRealize repeated useSport apparatusBiotechnologyColloidal silica

The invention relates to the technical field of killing human-shaped targets, in particular to a killing human-shaped target for training. The target comprises a non-woven fabric human-shaped mold, the non-woven fabric human-shaped mold comprises a non-woven fabric layer structure, the surface of the non-woven fabric layer structure is coated with an adhesive layer, the adhesive layer is infiltrated into the non-woven fabric layer structure, and a composite silica gel plate is arranged on the surface of the adhesive layer. The production process comprises the following steps: a human-shaped mold is processed, non-woven fabric is pasted on the surface of the human-shaped mold, the surface of the non-woven fabric is glued, a glue layer is cured and formed, a composite silica gel plate is pasted, a base is installed and lifted, and the non-woven fabric layer structure is glued, cured and formed to serve as a base layer of the human-shaped mold, so the puncture-proof effect is improved, glue can be brushed for repairing after use, repeated utilization can be achieved, the service life is prolonged, and practicability is improved.

Owner:河北天科瑞格新材料科技有限公司

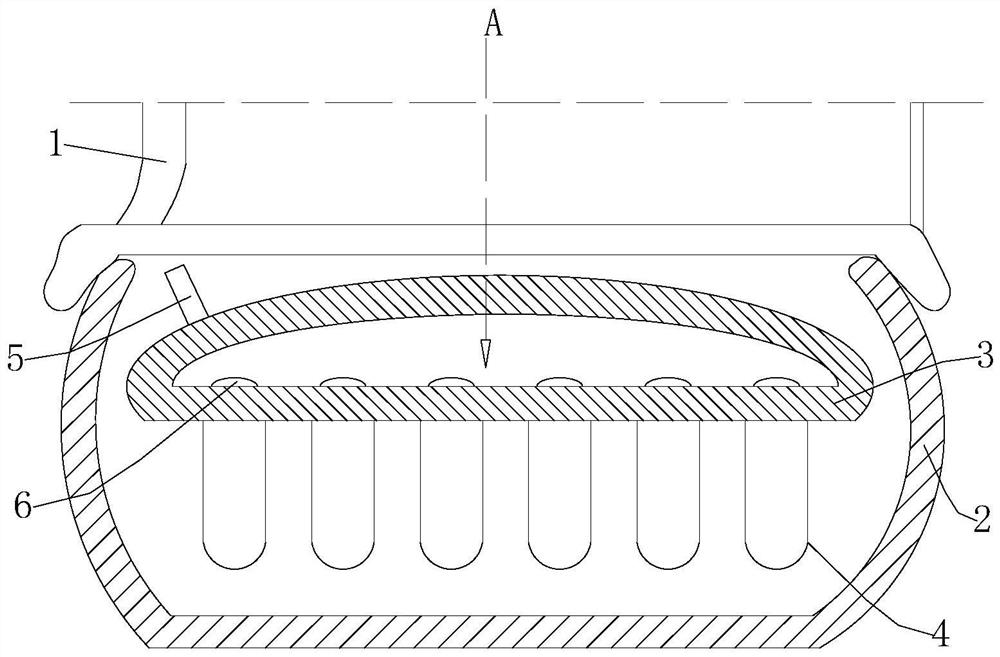

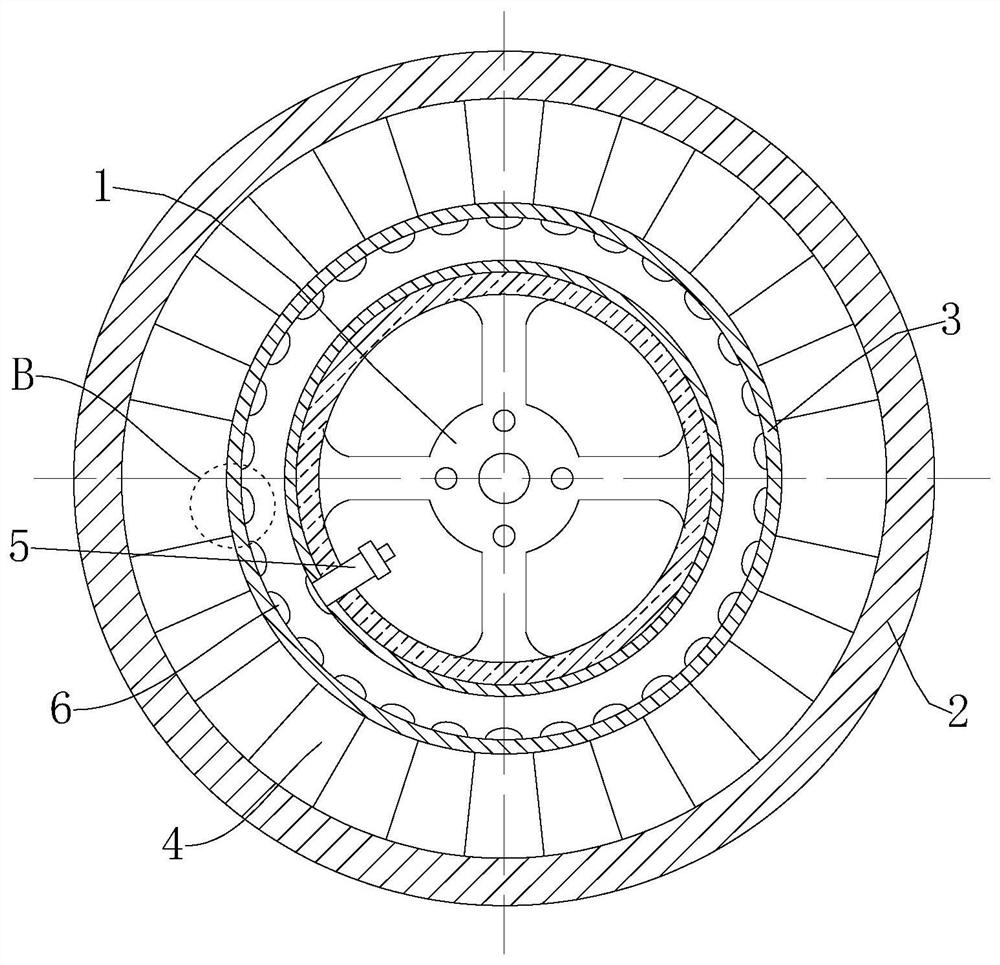

Puncture-proof tire and inflation method thereof

InactiveCN112092544AWith anti-stab functionReduce manufacturing costWith separate inflatable insertsWith multiple inflatable chambersEngineeringHeavy load

The invention discloses a puncture-proof tire and an inflation method thereof. The puncture-proof tire comprises a rim, an outer tire and a multi-air chamber inner tire, wherein the multi-air chamberinner tire is arranged in the outer tire; the multi-air chamber inner tire comprises a central air chamber and a plurality of micro air chambers which are arranged outside the central air chamber andare in one-way communication with the central air chamber; the communication direction is from the central air chamber to the micro air chambers; and both the central air chamber and the micro air chambers are elastic inflation bodies which can be independently removed. According to the puncture-proof tire, the central air chamber and the plurality of micro air chambers form the multi-air chamberinner tire so as to replace an inner tire of a conventional tire, when the tire is pierced by sharp objects such as nails, only one micro air chamber is damaged, continuous driving can be achieved inthe condition that the heavy load of a vehicle is not influenced, and a puncture-proof function is achieved; the processing technique of the multi-air chamber inner tire is equal to that of the conventional inner tire, and the manufacturing cost is relatively lower; and the tire structure which is generally used at present is used, and the puncture-proof tire can be suitable for all kinds of vehicles and is more suitable for the mass market.

Owner:杭州杉林科技有限公司

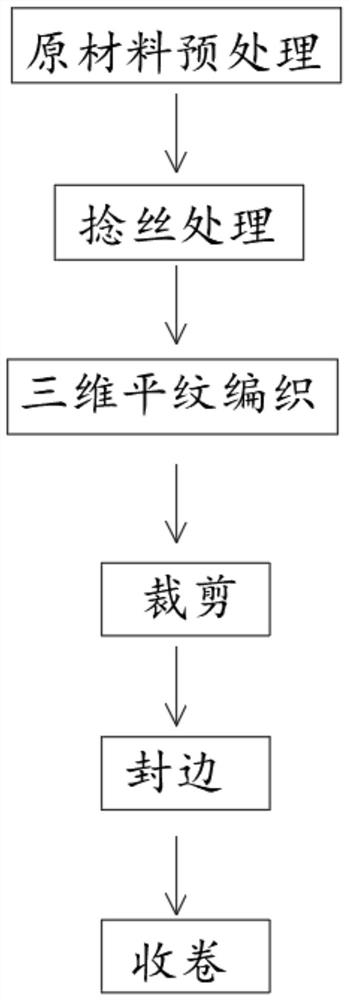

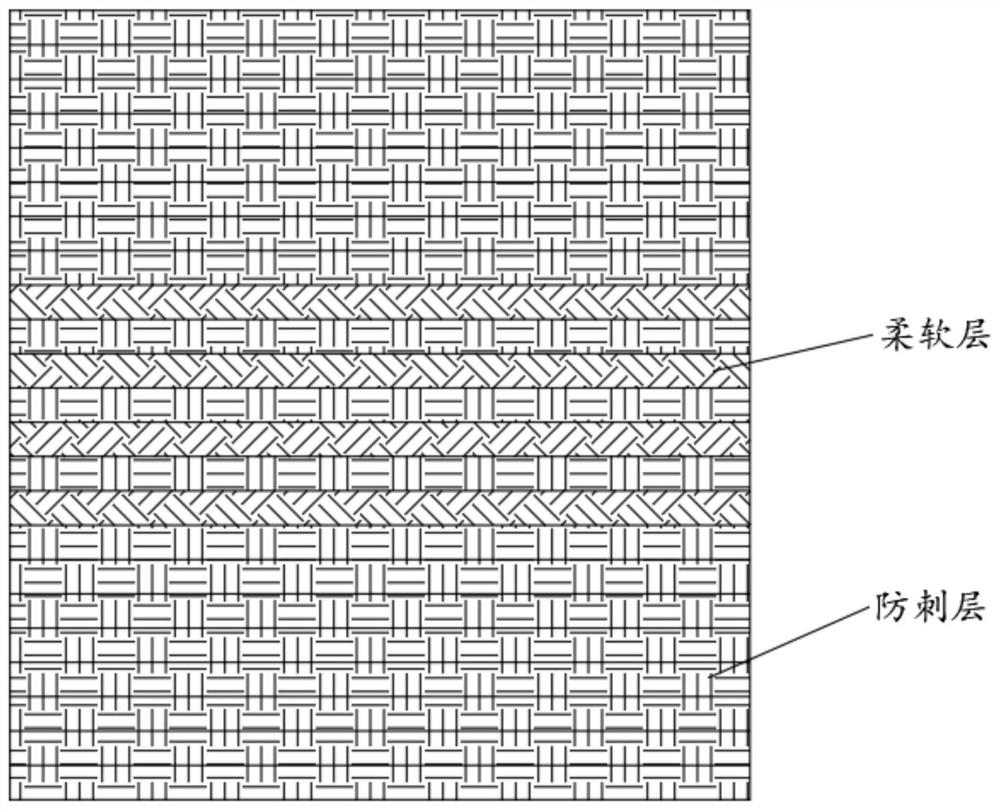

Penetration inhibition type stab-resistant cloth capable of preventing scratching and stabbing and process thereof

PendingCN113388949AImprove compactnessHigh strengthPersonal protection gearWoven fabricsPolymer scienceEngineering

The invention provides penetration inhibition type stab-resistant cloth capable of preventing scratching and stabbing and a process thereof, and relates to the technical field of garment production. Ultra-high molecular weight polyethylene fiber filaments and high-strength viscose fibers are adopted for three-dimensional plain weaving, so that plain weaving between layers in the Z direction is carried out according to the number of layers while warp and weft plain weaving is carried out, the stab-resistant cloth is integrally woven and formed, the compactness between the layers is higher, and the strength between the layers is enhanced; twill weaving is performed by the high-strength viscose fibers, and the hydrophilicity of the stab-resistant cloth is improved while the stab-resistant performance of the stab-resistant cloth is improved through the ultra-high molecular weight polyethylene fiber filament layers and the high-strength viscose fiber layers which are distributed in a staggered mode, so that the softness of the stab-resistant cloth is improved; and the three-dimensional weaving process is simple and convenient, the working time is saved, the working efficiency is improved, and batch production and use are facilitated.

Owner:深圳市汉唐世家服饰有限公司

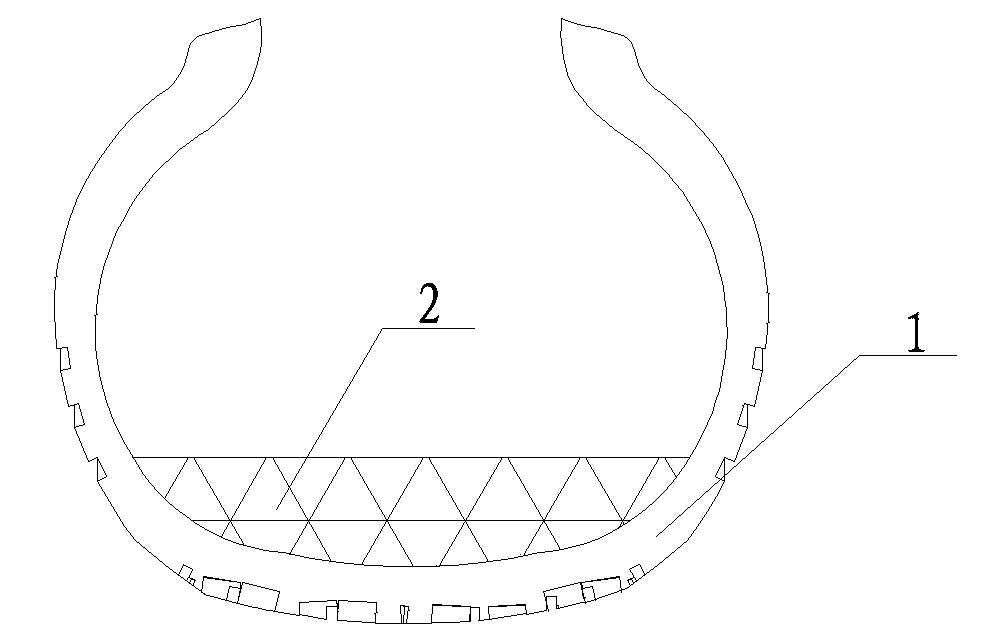

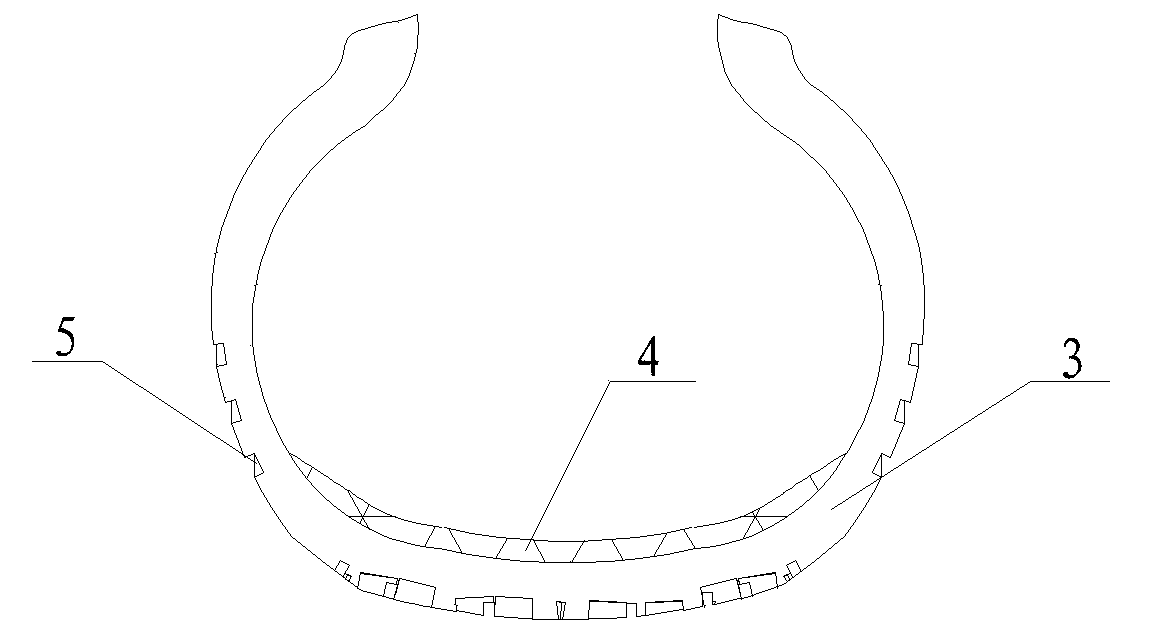

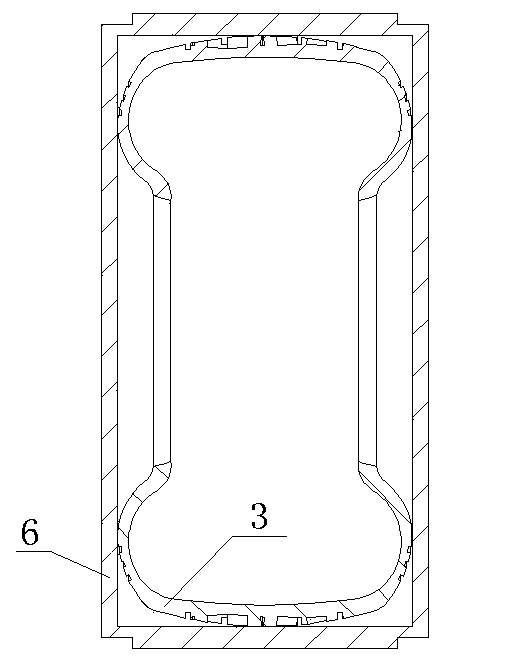

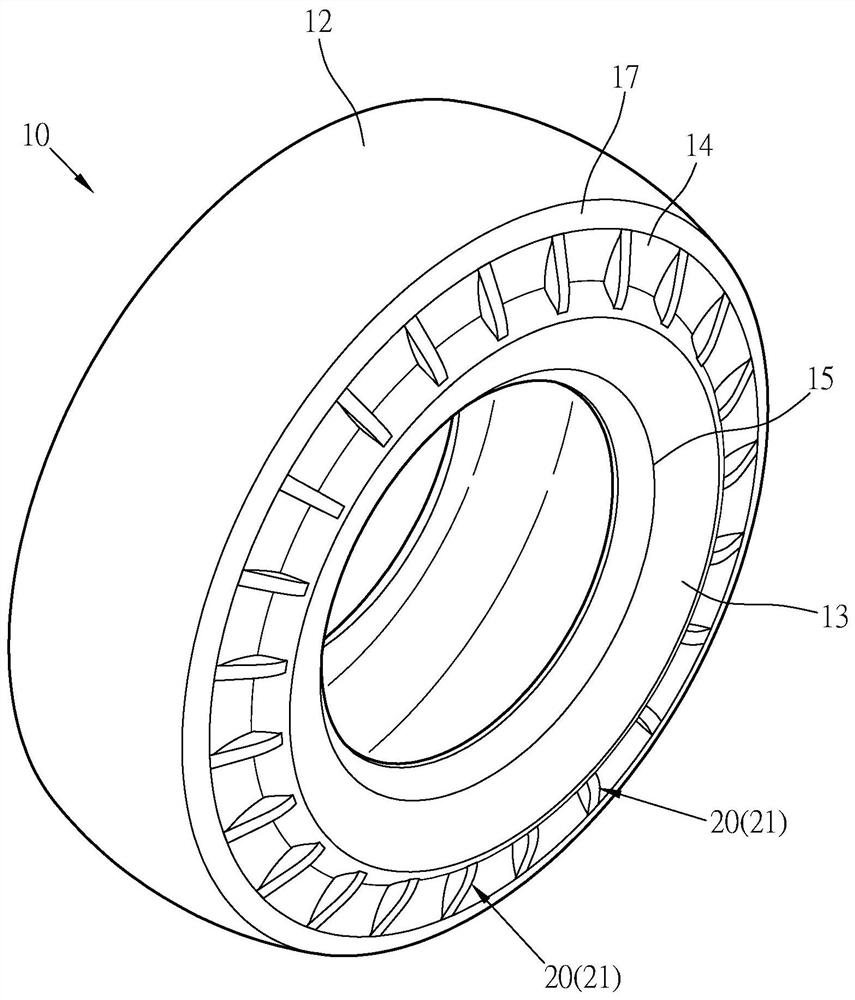

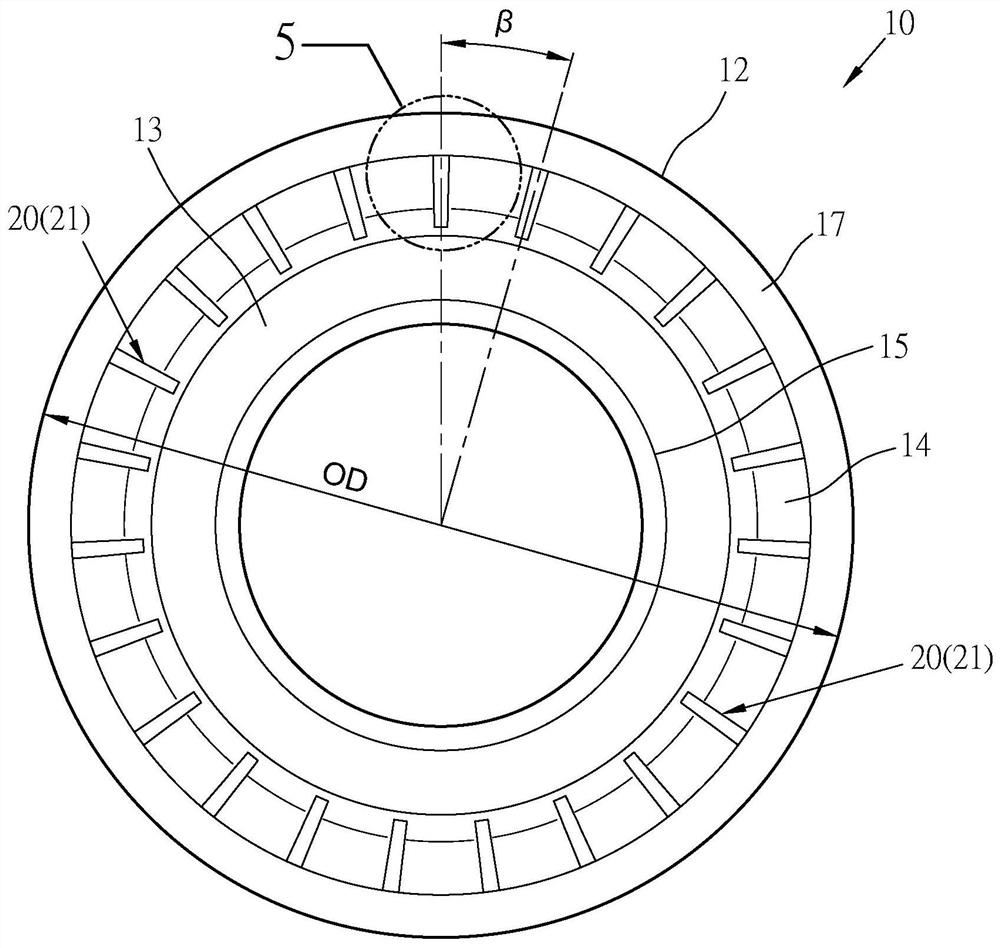

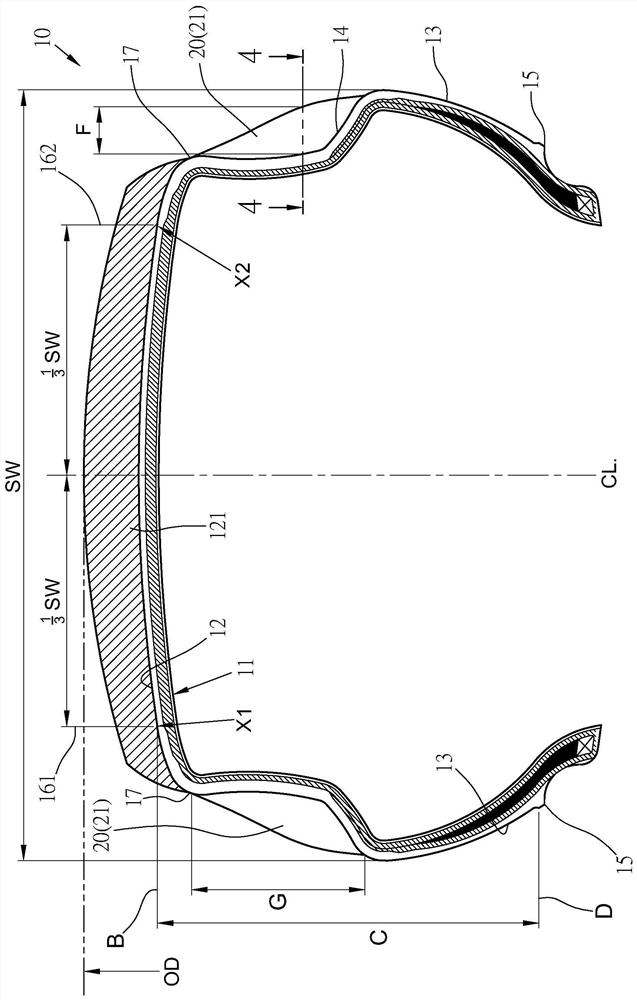

Tire with tire bead structure

The invention mainly provides a tire with a tire bead structure, which comprises an annular tire body, a tire tread and two tire beads respectively extending from two sides of the tire tread, and the preset part of each tire bead is provided with an annular concave groove part; convex pieces which are arranged in the groove parts at preset intervals in an annular arrangement mode, and the convex pieces protrude by a certain height from the bottom edges of the groove parts; by means of the components, by means of the structural design of the rib-shaped protruding pieces formed on the tire bead, blade rotation can be generated to bounce off and break off long foreign matter, in cooperation with the design of the quite-hollowed-out groove part, foreign matter puncture can be effectively avoided, the probability that the tire bead is punctured is reduced, the puncture-proof effect is improved, and under the condition that wind pressure is insufficient or the tire bead is impacted, the supporting performance of the tire can be maintained. The structural design of the groove parts and the rib-shaped convex pieces of the tire bead does not increase the overall weight of the tire.

Owner:CHENG SHIN RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com