A kind of preparation method of anti-stab coated aramid fiber fabric

A fabric and aramid fiber technology, which is applied in the field of preparation of stab-resistant coated aramid fabrics, can solve the problems of enhanced stab-resistant performance of aramid fibers, and achieves improved stab-resistant performance, broad application prospects, good stability and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

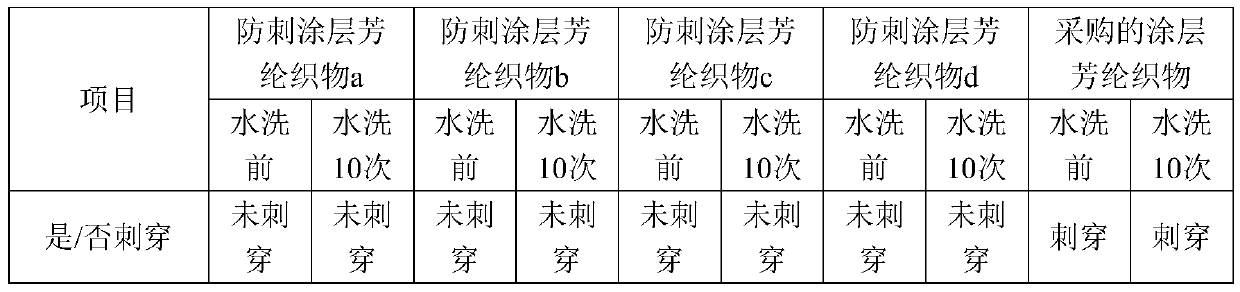

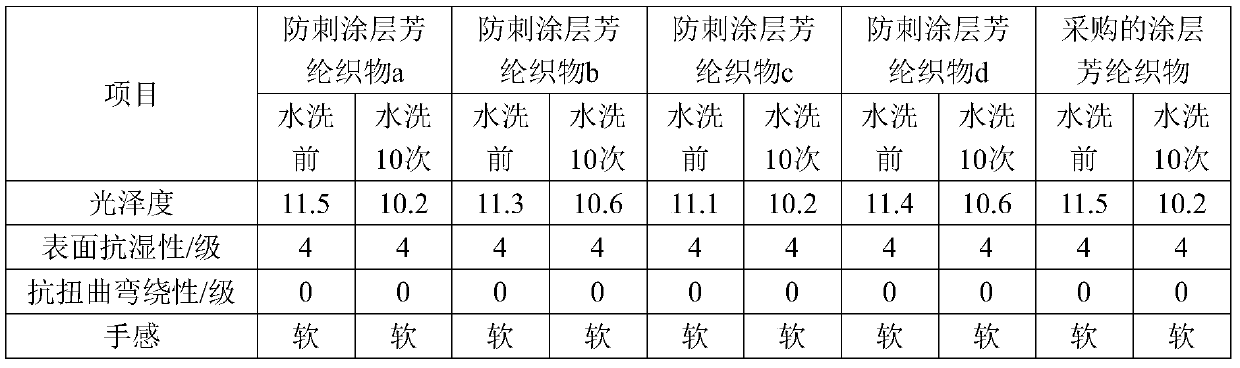

Examples

Embodiment 1

[0017] A preparation method of a stab-resistant coated aramid fiber fabric of the present embodiment, the preparation method comprises the following steps:

[0018] (1) Preparation of dispersant: Dissolve 0.1 mol of methacrylic acid and 0.02 mol of allyl polyoxyethylene ether monomer with a degree of polymerization of 45 in 30 mL of deionized water at the same time to prepare a monomer solution for later use; Under the condition of controlling the temperature at 79-81°C, the configured monomer and ammonium persulfate initiator were respectively added dropwise into a four-necked flask filled with 100mL deionized water, wherein the mass of ammonium persulfate accounted for the total mass of the monomer 0.1% of 0.1%, the dropping time is controlled at 2h, and after the dropwise addition is completed, the insulation is kept for 3h; finally cooling is obtained to obtain the dispersant; the weight average molecular weight of the dispersant measured by gel permeation chromatography is...

Embodiment 2

[0024] A preparation method of a stab-resistant coated aramid fiber fabric of the present embodiment, the preparation method comprises the following steps:

[0025] (1) Preparation of dispersant: Dissolve 0.1 mol of methacrylic acid and 0.03 mol of allyl polyoxyethylene ether monomer with a degree of polymerization of 45 in 30 mL of deionized water at the same time to prepare a monomer solution for later use; Under the condition of controlling the temperature at 79-81°C, the configured monomer and ammonium persulfate initiator were respectively added dropwise into a four-necked flask filled with 100mL deionized water, wherein the mass of ammonium persulfate accounted for the total mass of the monomer 0.1% of 0.1%, the dropping time is controlled at 2h, and after the dropwise addition is completed, the insulation is kept for 3h; the final cooling is to obtain the dispersant; the weight average molecular weight of the dispersant measured by gel permeation chromatography is 15000;...

Embodiment 3

[0031] A preparation method of a stab-resistant coated aramid fiber fabric of the present embodiment, the preparation method comprises the following steps:

[0032] (1) Preparation of dispersant: Dissolve 0.1 mol of methacrylic acid and 0.04 mol of allyl polyoxyethylene ether monomer with a polymerization degree of 45 in 30 mL of deionized water at the same time to prepare a monomer solution for later use. Among them, methyl The molar ratio of acrylic acid to allyl polyoxyethylene ether is 1:0.2; then, under stirring conditions, the temperature is controlled at 79-81°C, and the prepared monomer and ammonium persulfate initiator are respectively added dropwise to a 100mL In a four-necked flask of deionized water, wherein the quality of ammonium persulfate accounts for 0.3% of the total mass of the monomer, the dropping time is controlled at 2 hours, and after the dropping is completed, it is kept for 3 hours; finally cooled to obtain a dispersant; Gel permeation chromatography ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com