Nano-composite gel matrix multi-layer fabric stab-resistant composite material and preparation method thereof

A nano-composite, multi-layer fabric technology, used in textiles, papermaking, fiber processing, etc., can solve problems such as non-recycling, and achieve good knife stab resistance, excellent self-healing function, and excellent anti-cone stab effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

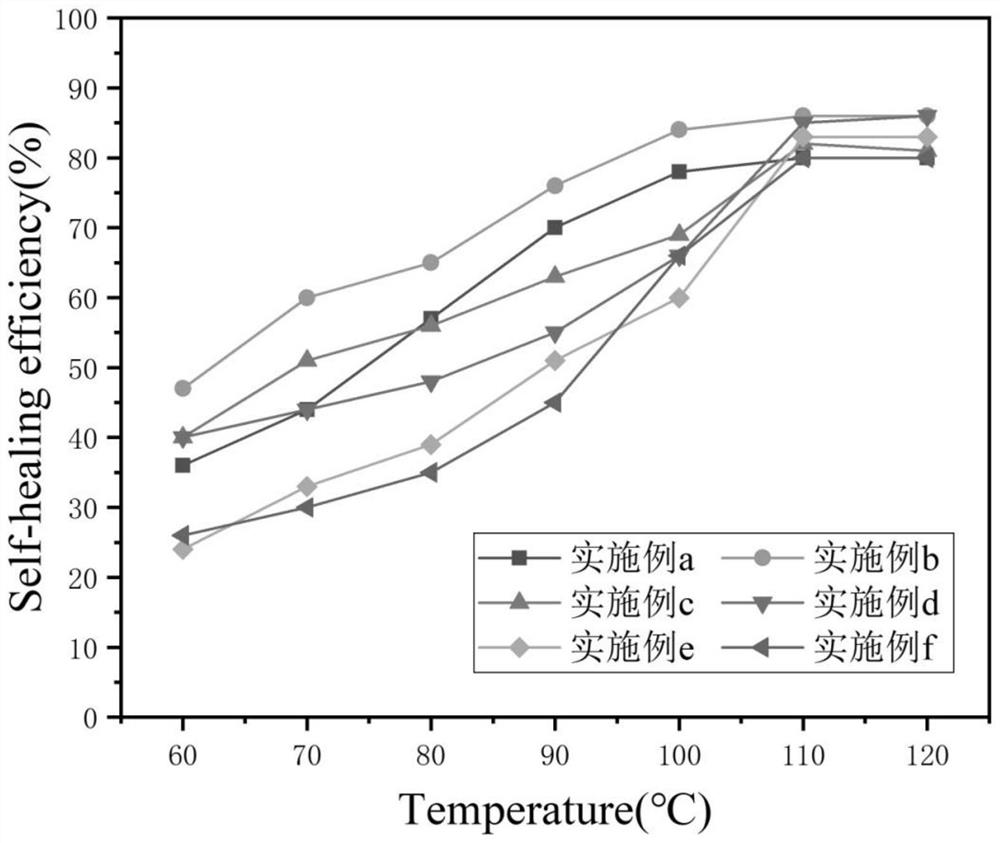

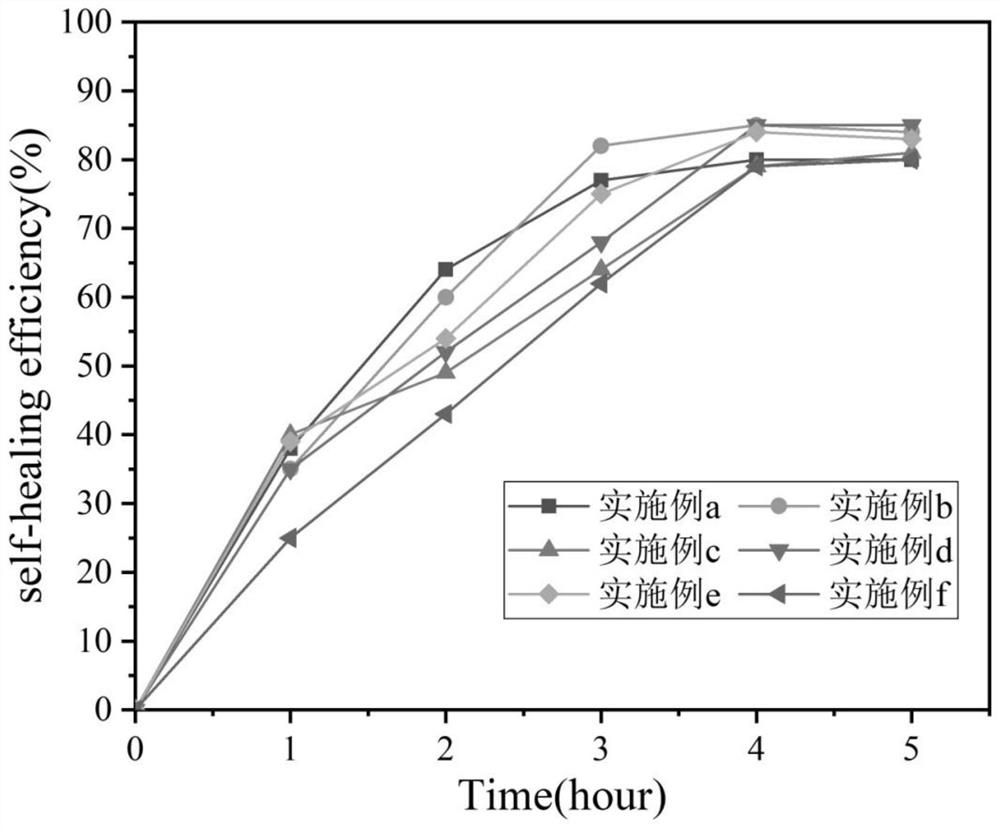

Embodiment a~f

[0056] A method for preparing a nanocomposite hydrogel, comprising the steps of:

[0057] 1) Under a nitrogen atmosphere, in a flask, uniformly disperse polyether F127 in anhydrous dichloromethane, then inject triethylamine and acryloyl chloride into the flask with a syringe, stir at 25°C for 24 hours, filter to remove triethyl Precipitate triethylammonium chloride salt of amine and acryloyl chloride reaction, obtain filtrate, put into excessive methyl tert-butyl ether and precipitate five times (the step of putting into excessive ether every time is: put into excessive Methyl tert-butyl ether, filtered to obtain a precipitate.), to obtain a white precipitate, filtered again (400 mesh) to purify, and vacuum-dried at room temperature 20-25 ° C for 24 hours to obtain polyether F127 diacrylate, wherein, according to In parts by mass, the ratio of polyether F127, anhydrous dichloromethane, triethylamine and acryloyl chloride is 10:136.8:0.35:0.39, and in parts by mass, the ratio o...

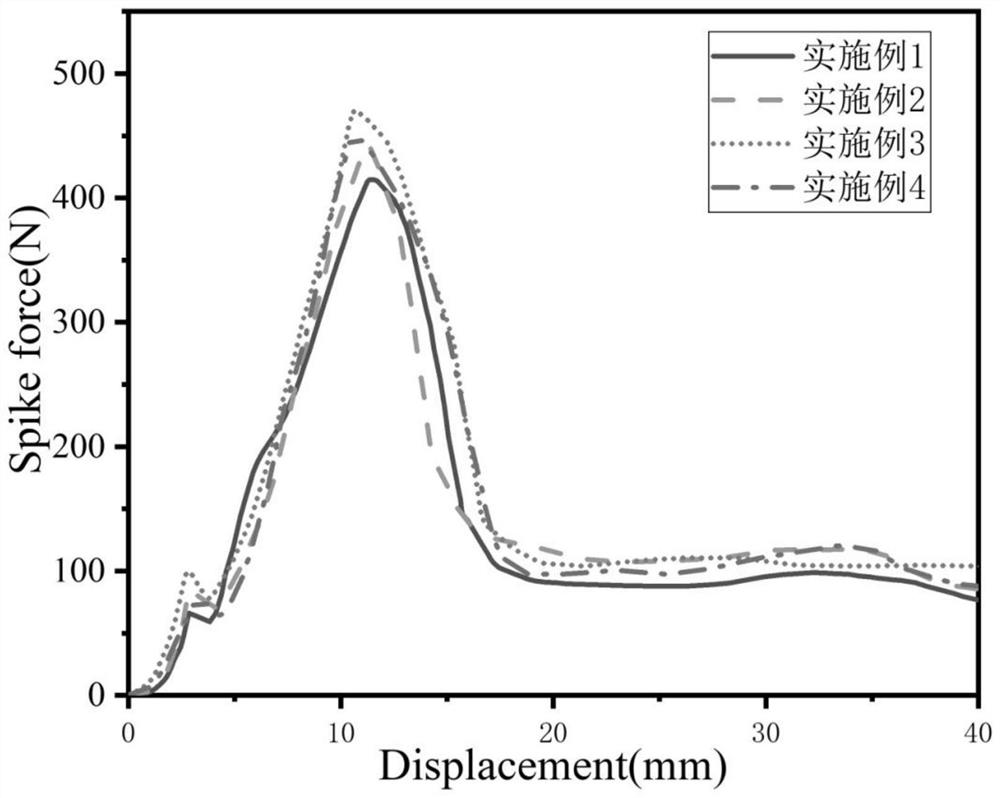

Embodiment 1~7

[0061] A preparation method of a nanocomposite gel matrix multilayer fabric stab-resistant composite material, comprising the following steps:

[0062] 1) Under a nitrogen atmosphere, in a flask, uniformly disperse polyether F127 in anhydrous dichloromethane, then inject triethylamine and acryloyl chloride into the flask with a syringe, stir at 25°C for 24 hours, filter to remove triethyl Precipitate triethylammonium chloride salt of amine and acryloyl chloride reaction, obtain filtrate, put into excessive methyl tert-butyl ether and precipitate five times (the step of putting into excessive ether every time is: put into excessive Methyl tert-butyl ether, filtered to obtain a precipitate.) to obtain a white precipitate, filtered again to purify polyether F127 diacrylate (400 mesh), and vacuum dried at room temperature 20-25°C for 24 hours to obtain polyether F127 diacrylate Acrylate, wherein, by mass parts, the ratio of polyether F127, anhydrous dichloromethane, triethylamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com