Patents

Literature

179results about How to "Strong interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

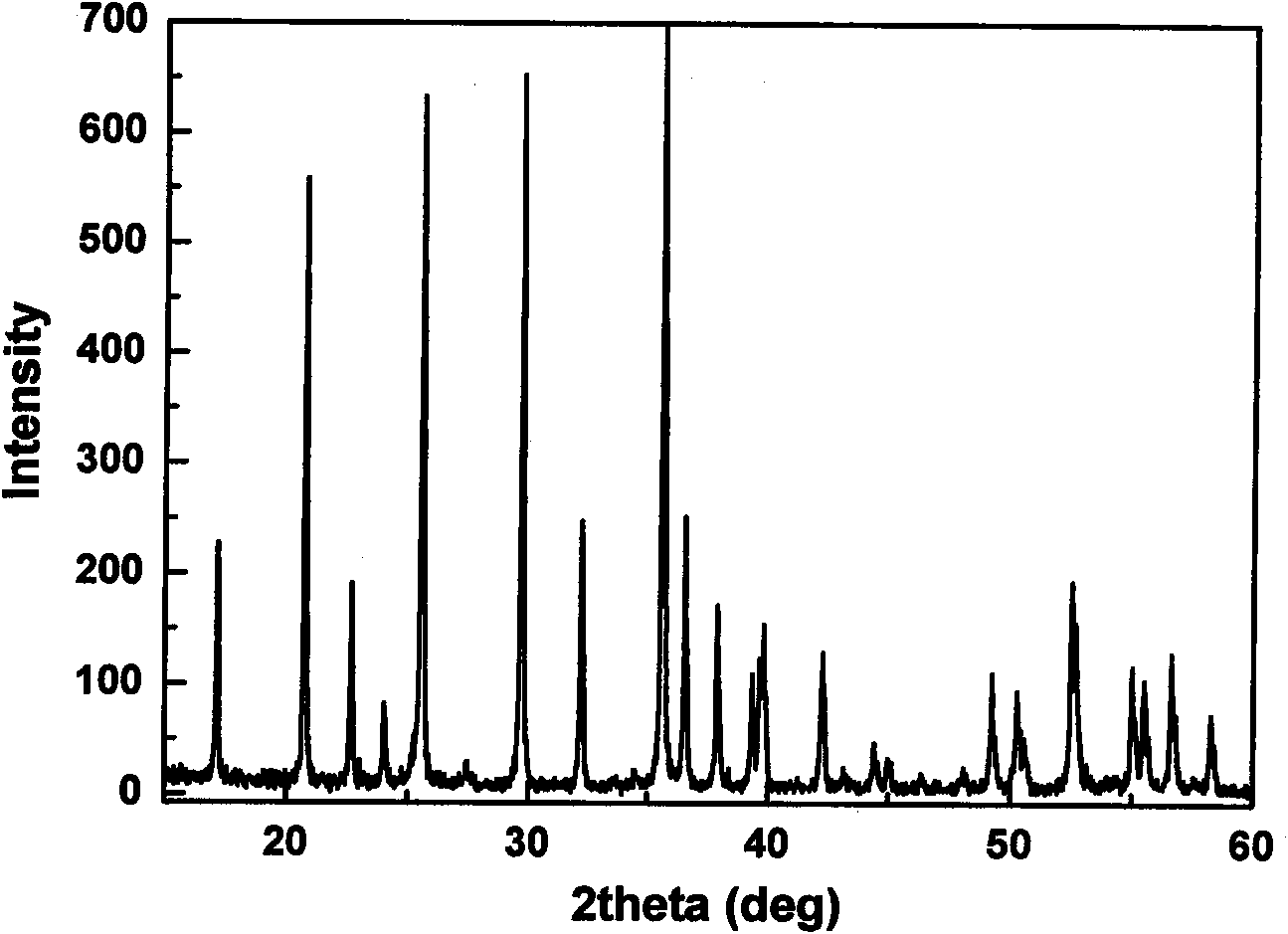

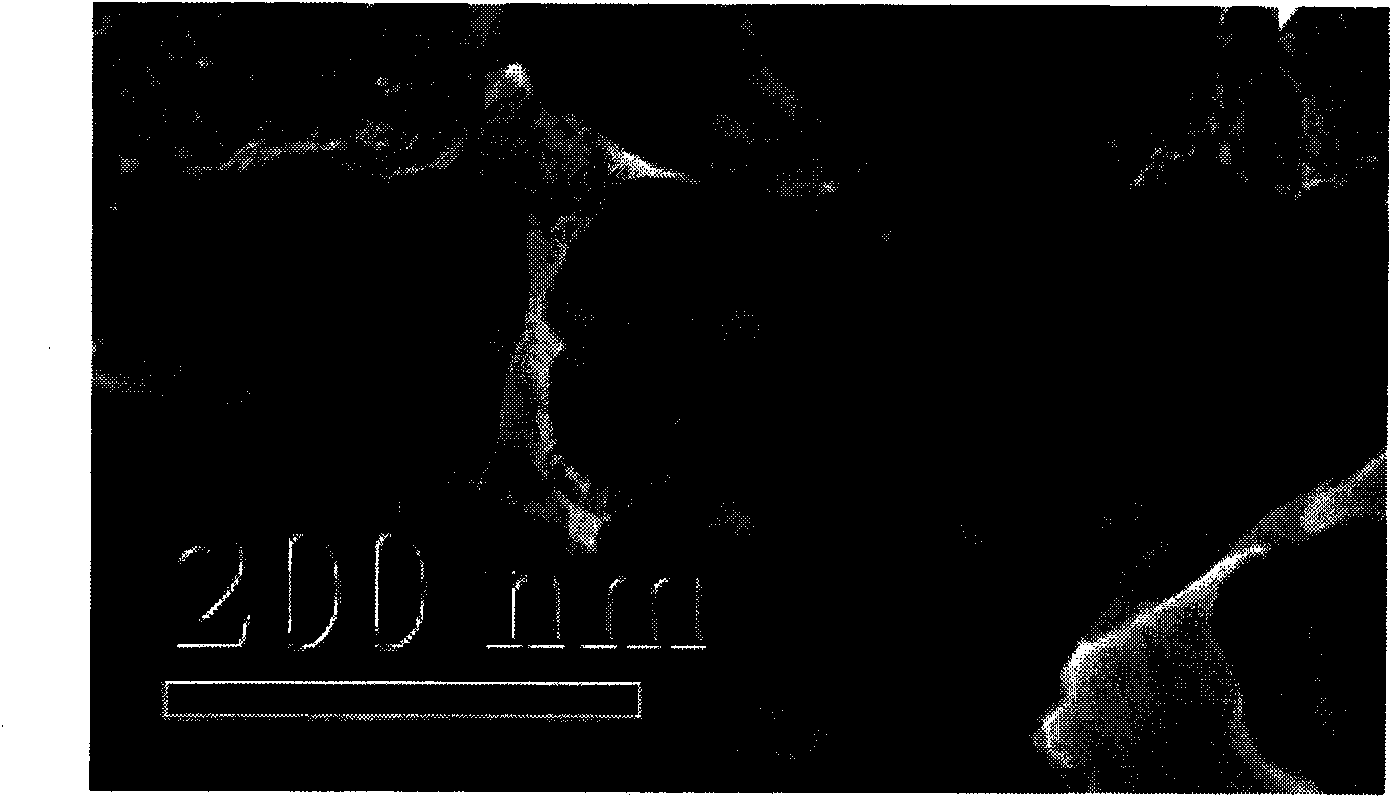

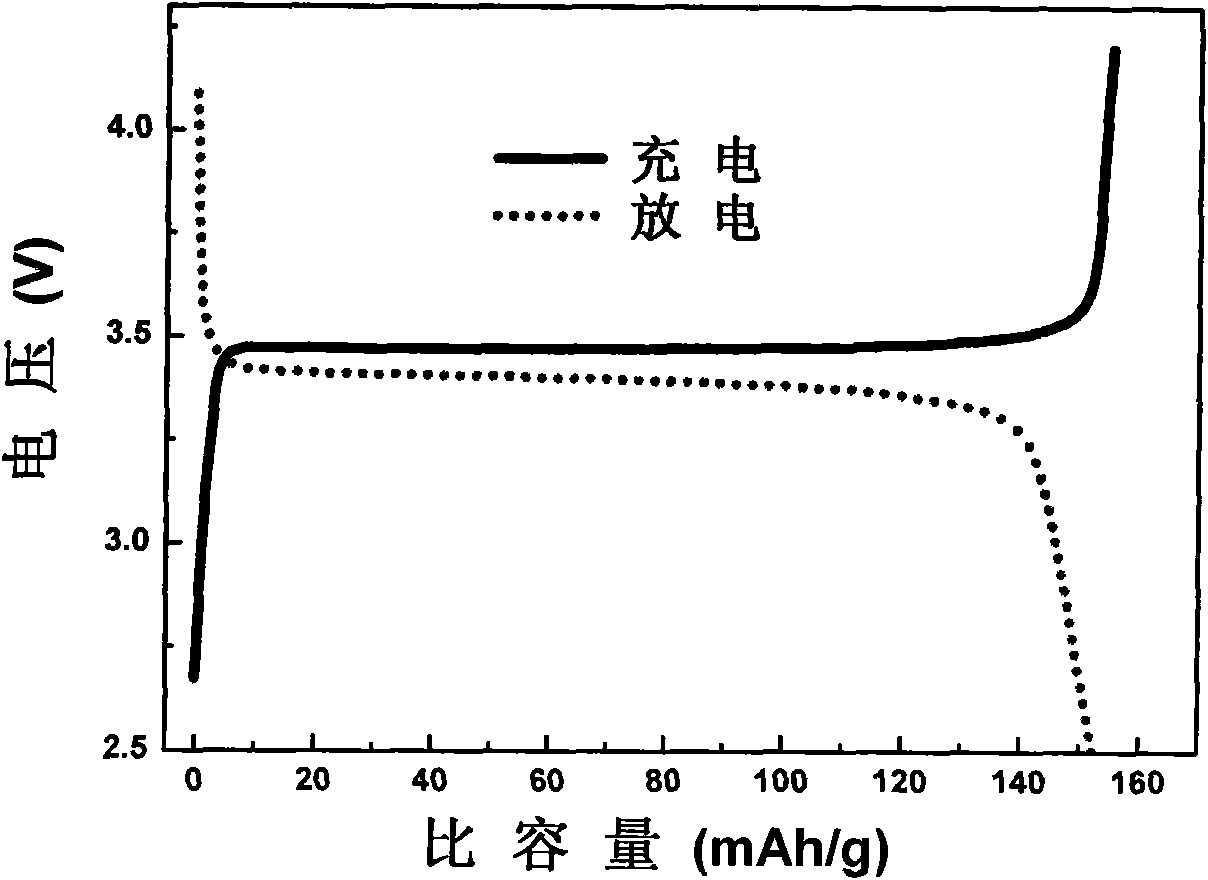

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

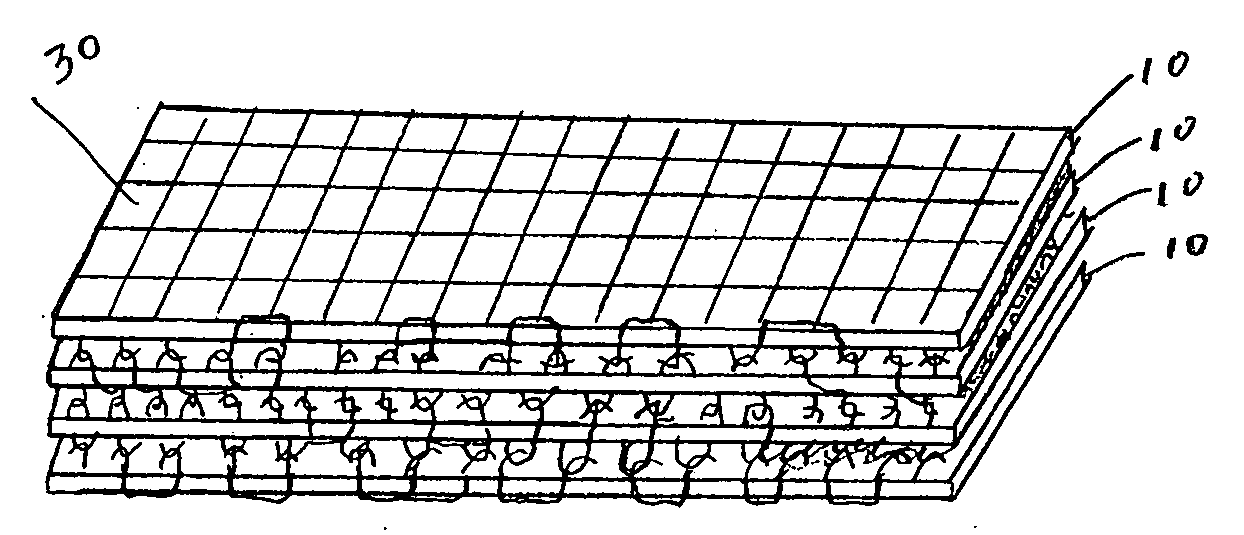

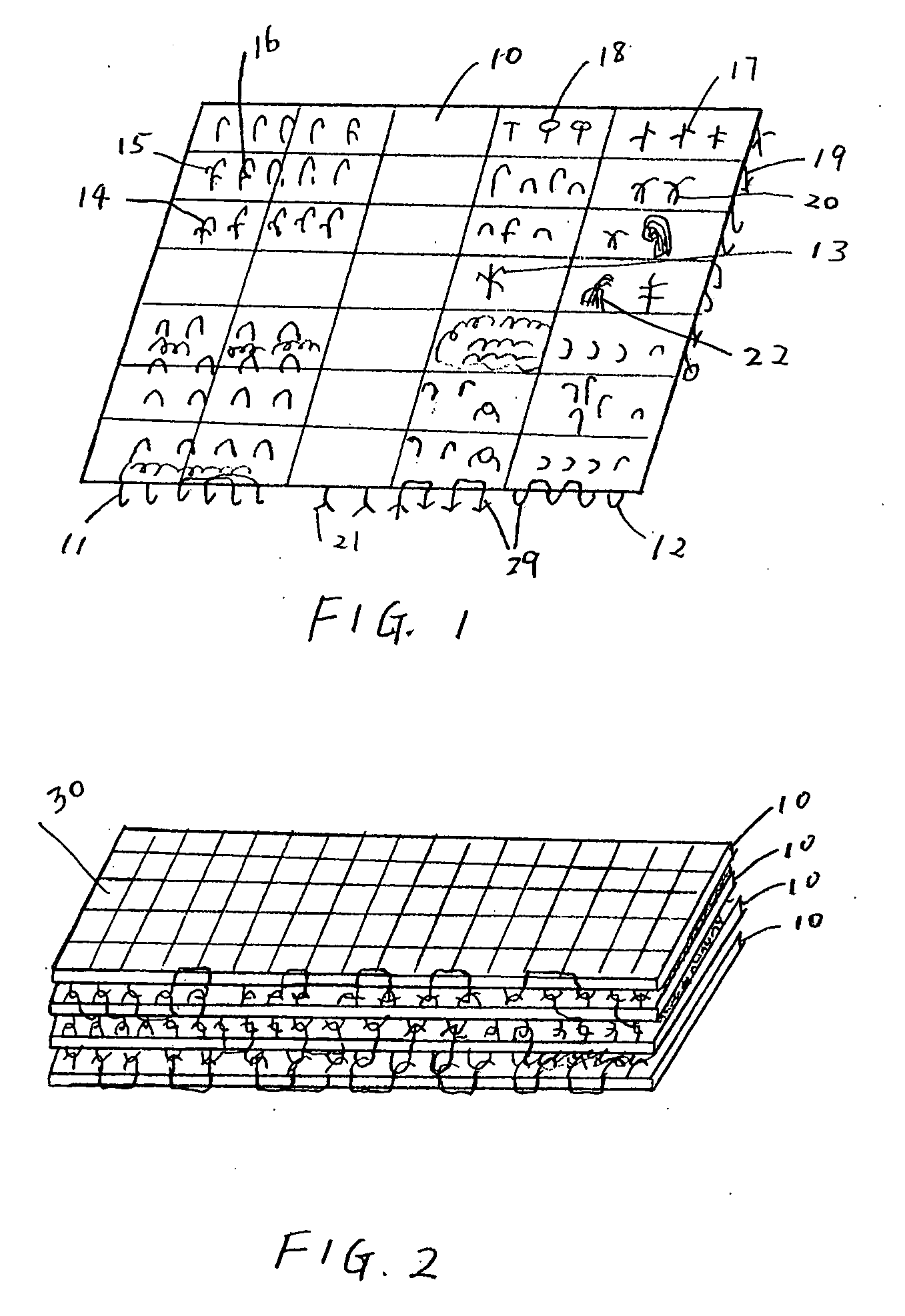

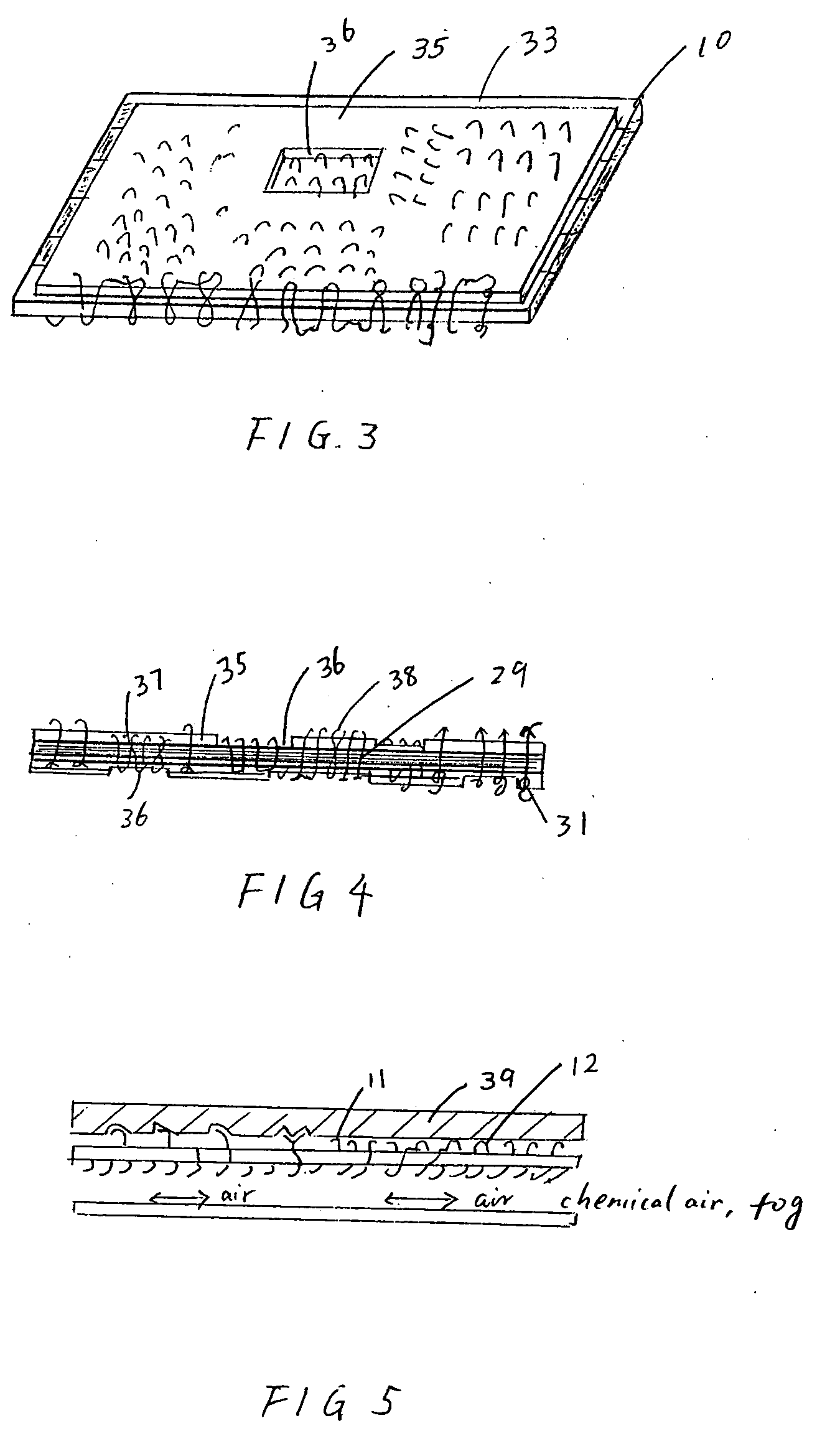

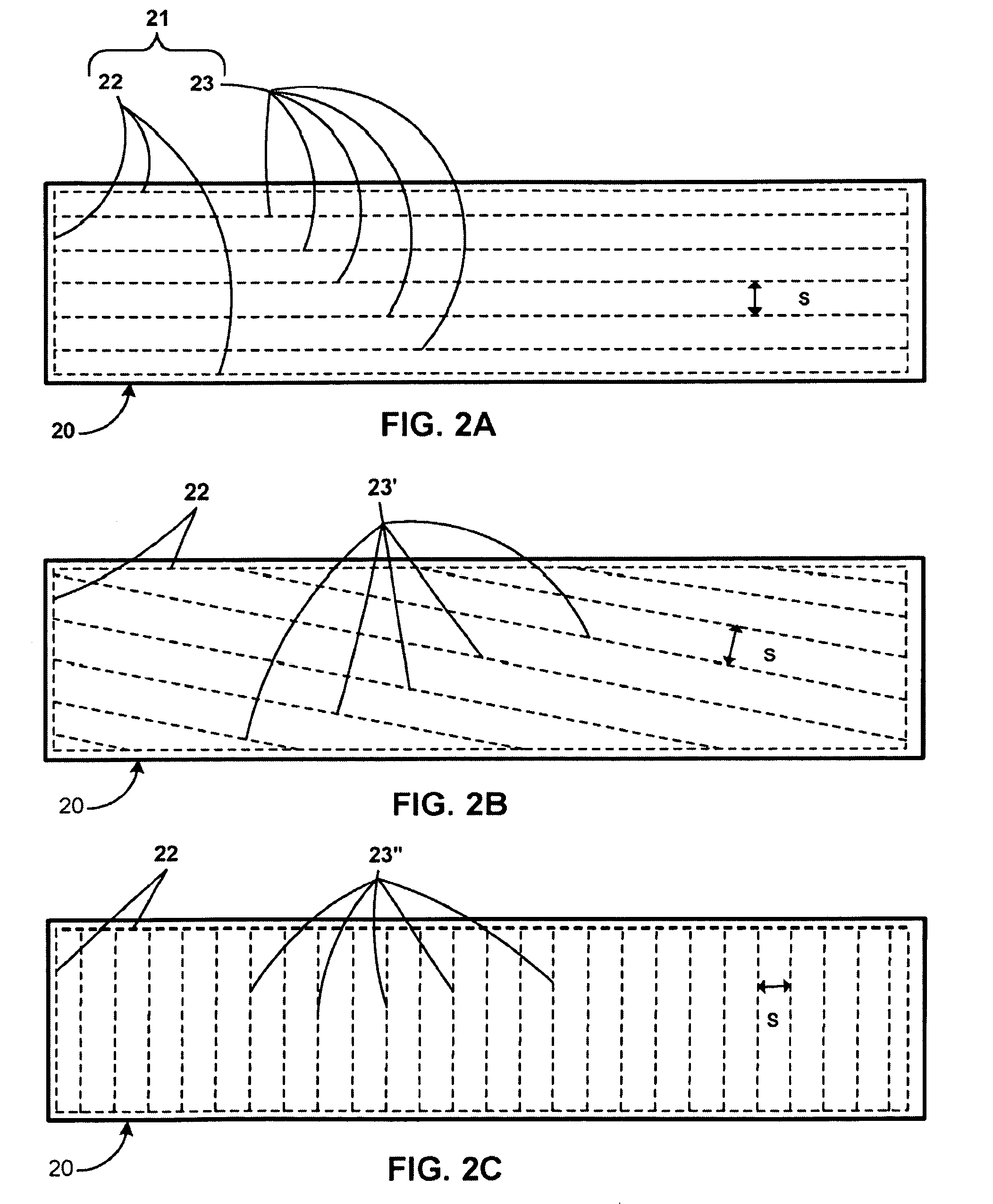

Fiber Products, Prepregs, Composites and Method of Producing Same

InactiveUS20080193709A1Increase strength and interface strengthIncreased strengthSlide fastenersLayered productsFastenerYarn

The present invention is to provide methods to increase composite interlaminate strength and interface strength, and make 3D fibers products, prepregs and composites, by using trans-interface and / or trans-fiber products such as trans-plies, strands and / or yarns fastening components selected from the group comprising of hooks and loops (velcro), hooks and hooks, zipper heads, fish hook shape hooks, staples, arrow heads, forks and mushroom heads. One ply of fibers has one or multiple of the above fasteners on at least one side. Lay-up the plies with said fastening components on its one or two sides to obtain a 3D fiber products with those fastening components locked together. The plies can be separated if need re-lay-up. A thread or a yarn have the fastening components around 0-360 degree on its surface. Lay the threads together or intercross each other to get a 3D fiber products. In those 3D fiber products, two parts of the fastening components lock each other if they meet and engage. A 3D composite can be made using the 3D fiber products.One fiber ply with the fasteners on its at least one side, is impregnated or protruded with matrix materials, a piece of the prepreg with the fasteners prepreg with the fasteners are made. Lay and press the prepreg together fastening components will lock each other if they meet and engage. In most of production processes, the matrix materials might soften and meld, and the fastening components will further interlock each other. So a 3D composite structure is made by the said 3D prepregs. Those fastening components may stay just partially or fully in matrix at matrix surface. The fastening components increase the interface strength when two matrix materials meet just by crossing interface even if they are not locked and without fiber products in matrix.

Owner:HAN NANLIN

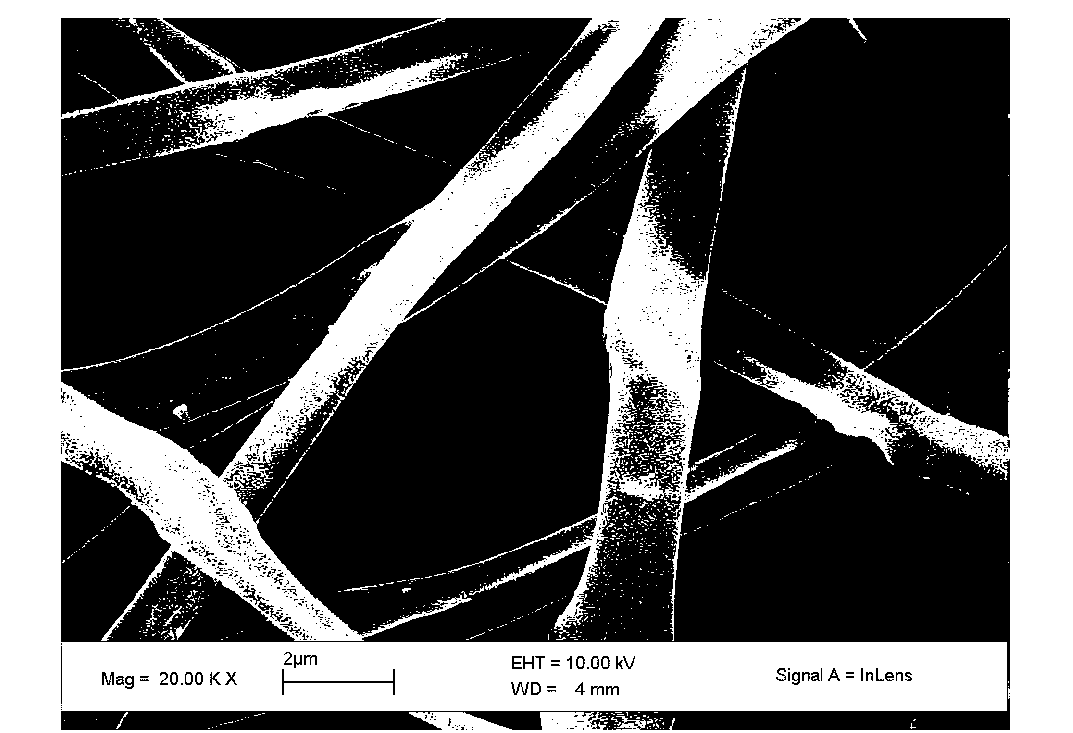

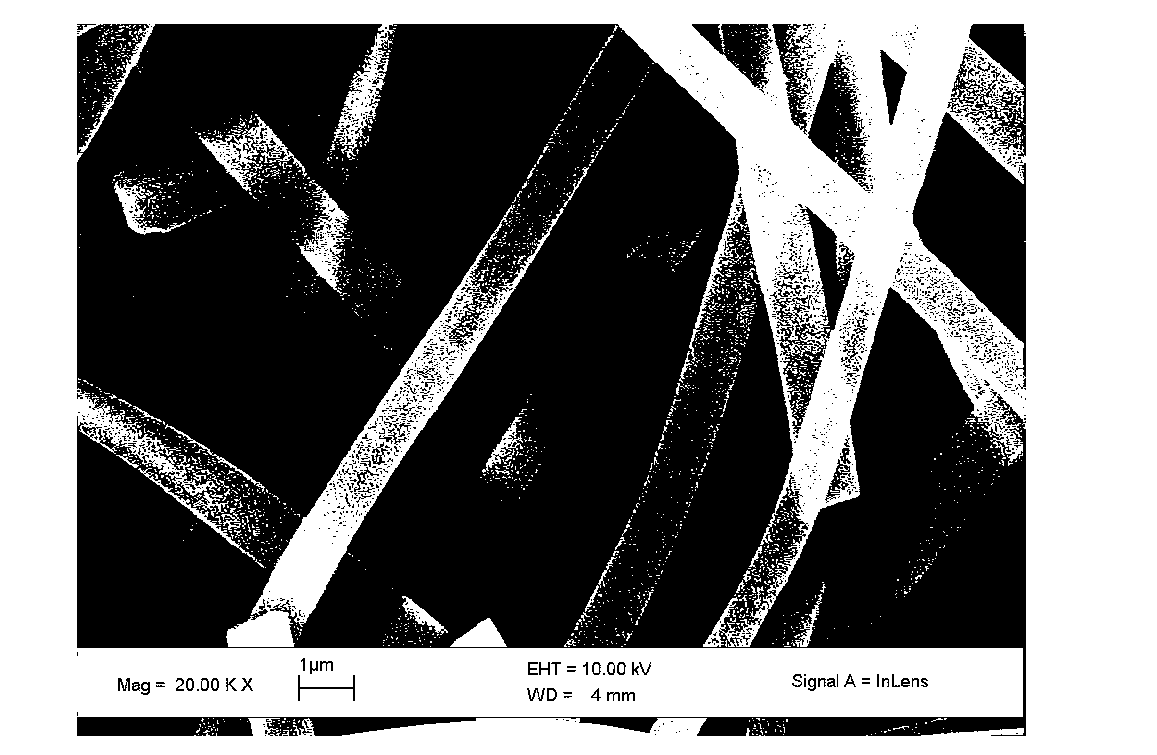

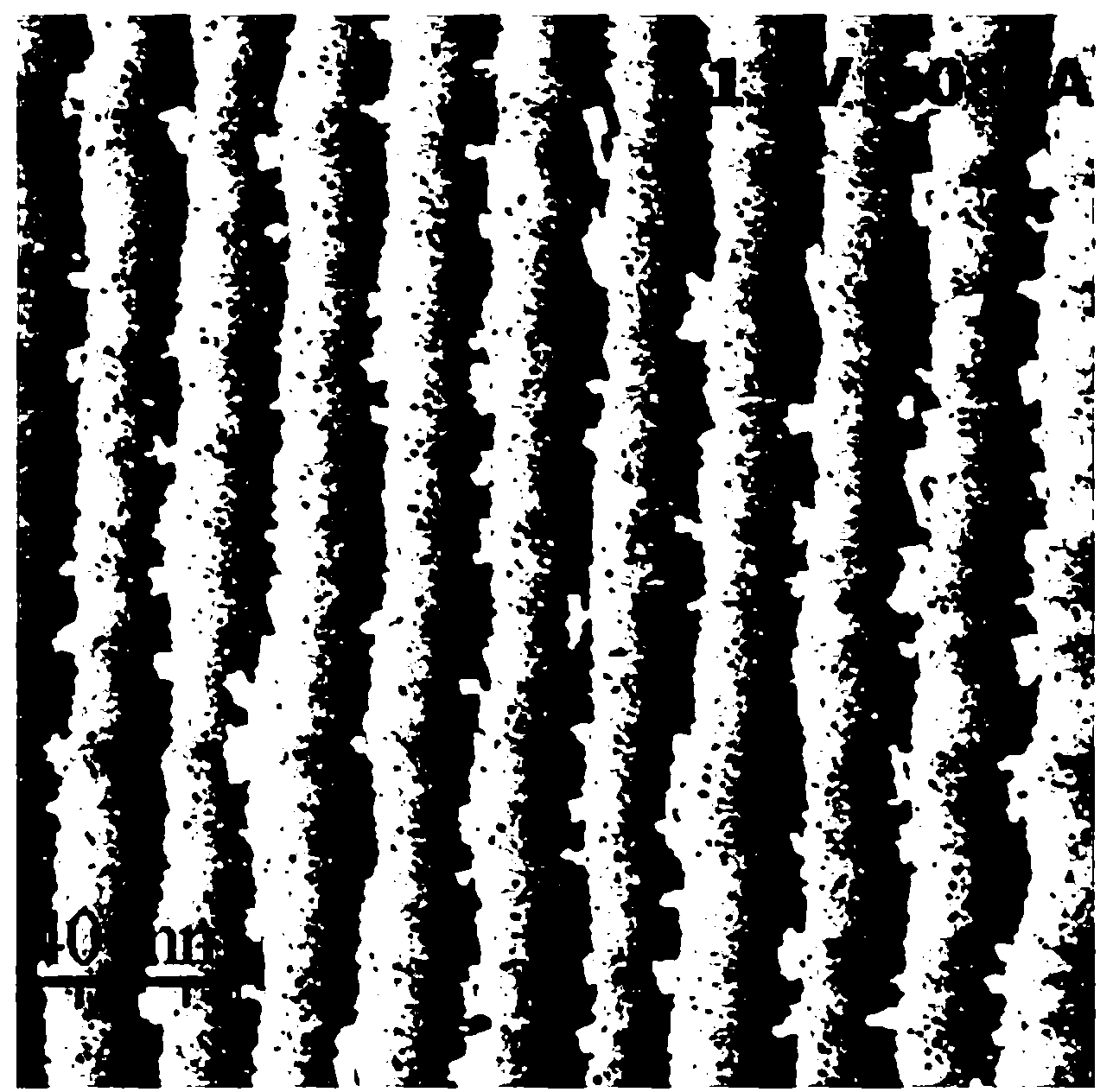

Graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and preparation method thereof

ActiveCN103215693AEvenly dispersedGood flexibilityFibre chemical featuresOrganic solventPorous carbon

The invention relates to graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and a preparation method thereof. The diameter of the fiber is in a range of 0.3-1.7mum, and the specific surface area of the fiber is 500-900m<2> / g. The fiber has a porous structure which is formed by microporous mainly. Micro-pore volume is 0.20-0.50cm<3> / g, and surface oxygen atomic ratio is lower than 10%. The preparation method comprises the steps that: graphene oxide is added into an organic solvent and is subjected to ultrasonic dispersion, such that a graphene oxide solution is formed; termosetting phenolic resin and a high-molecular-weight linear polymer are added into the graphene oxide organic solution, and are completely dissolved by stirring; the mixed solution is spun into composite fiber, and solidification and carbonization are carried out, such that porous phenolic-resin-based carbon / graphite oxide composite ultrafine fiber is obtained. The sources of adopted raw materials are rich. The prepared composite fiber has the advantages of high structural stability, good flexibility, developed pore structure, controllable surface oxygen content, and suitability for practical application.

Owner:TSINGHUA UNIV

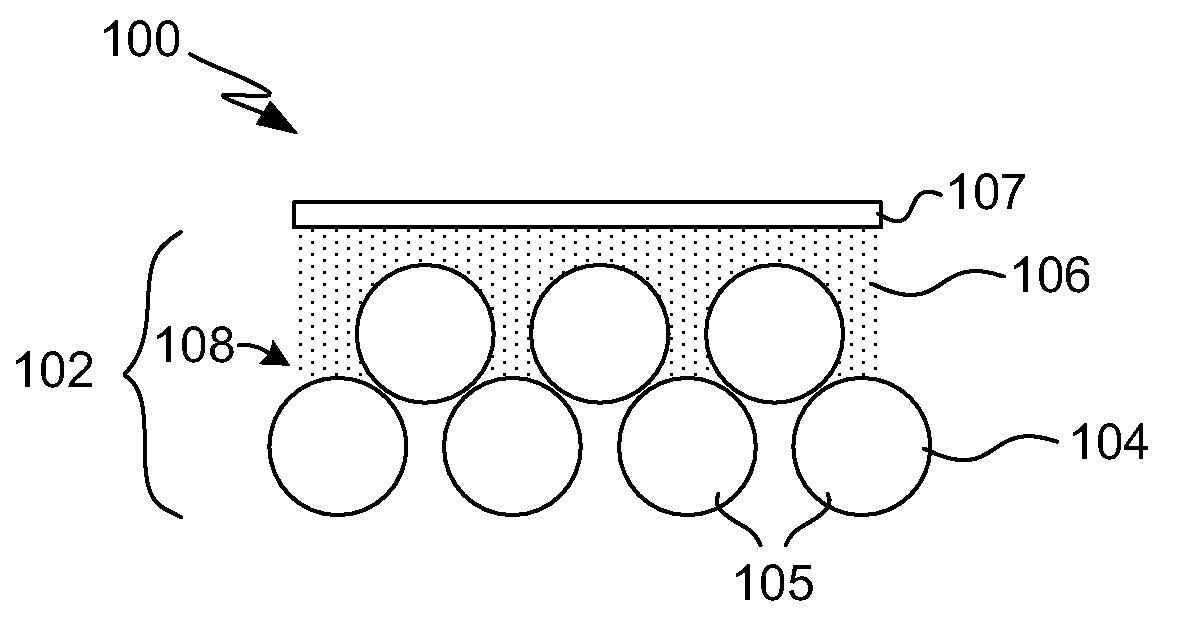

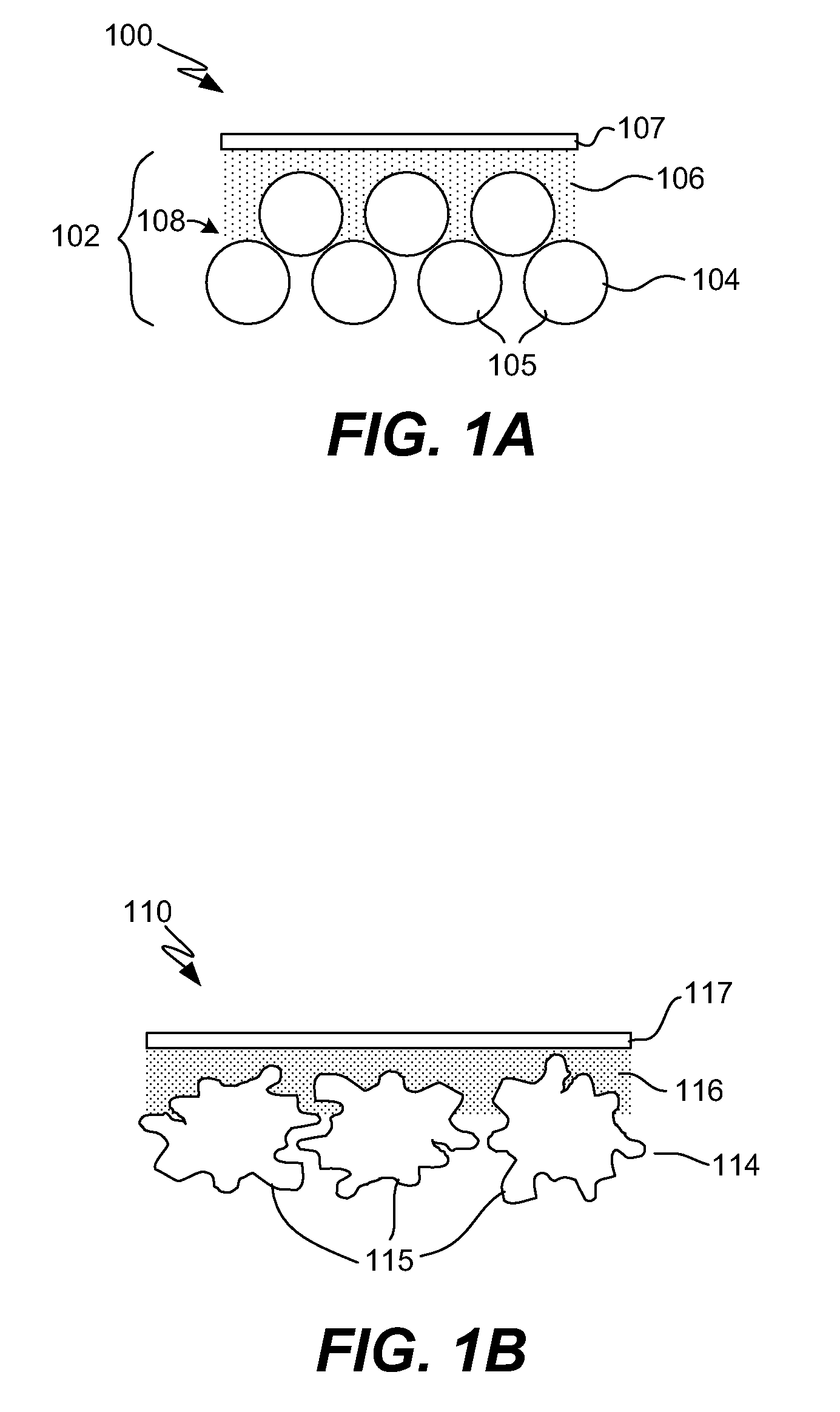

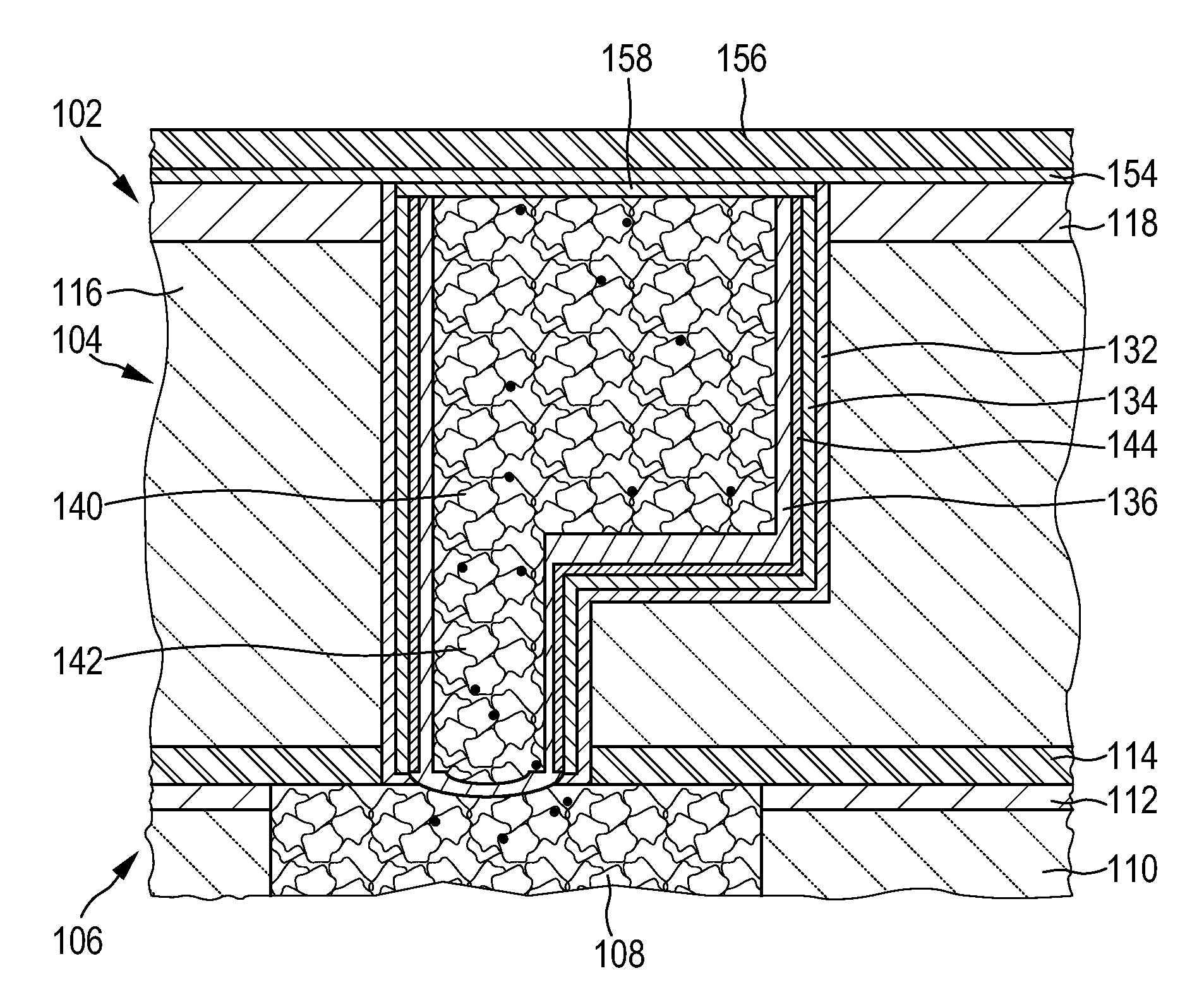

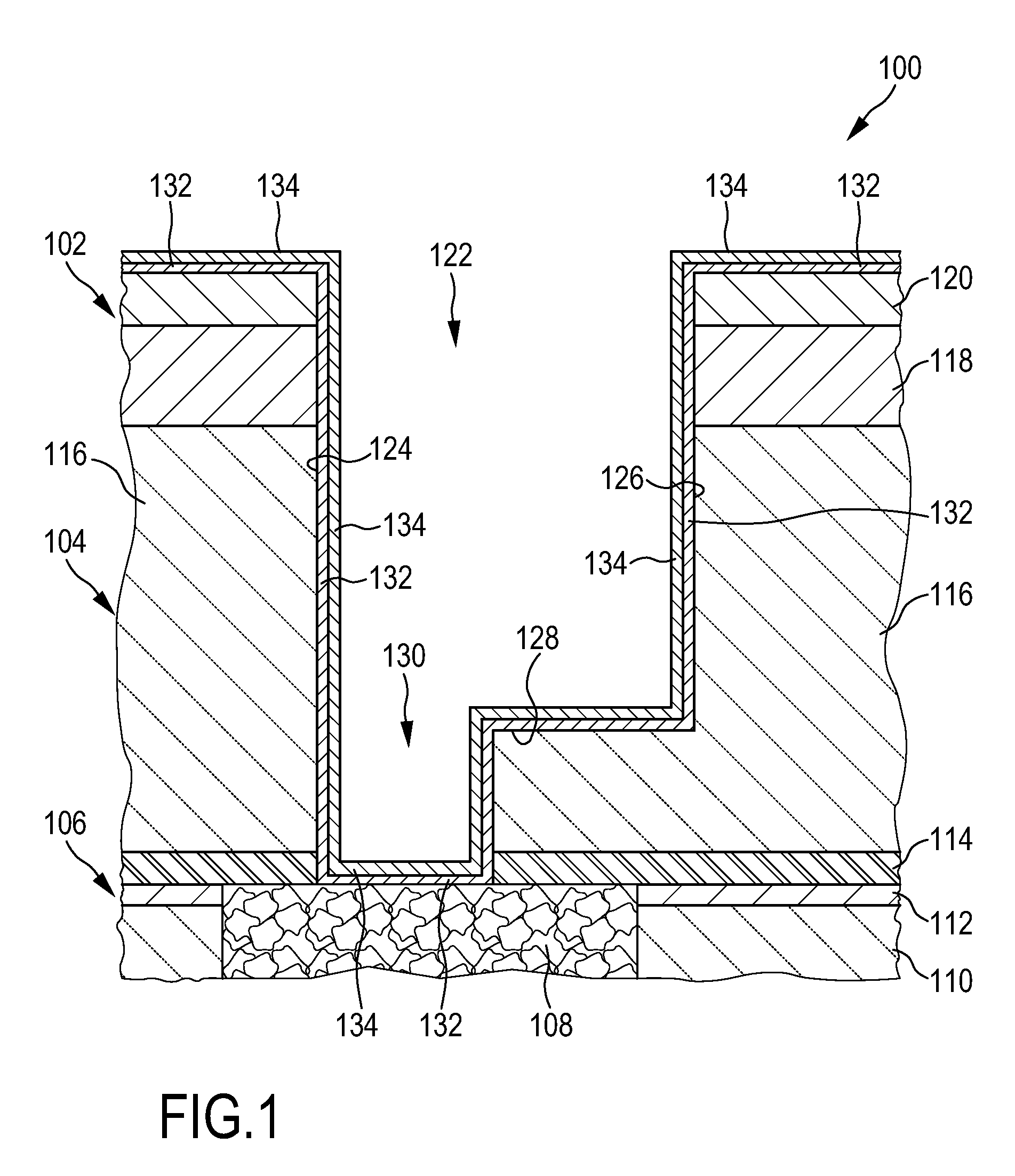

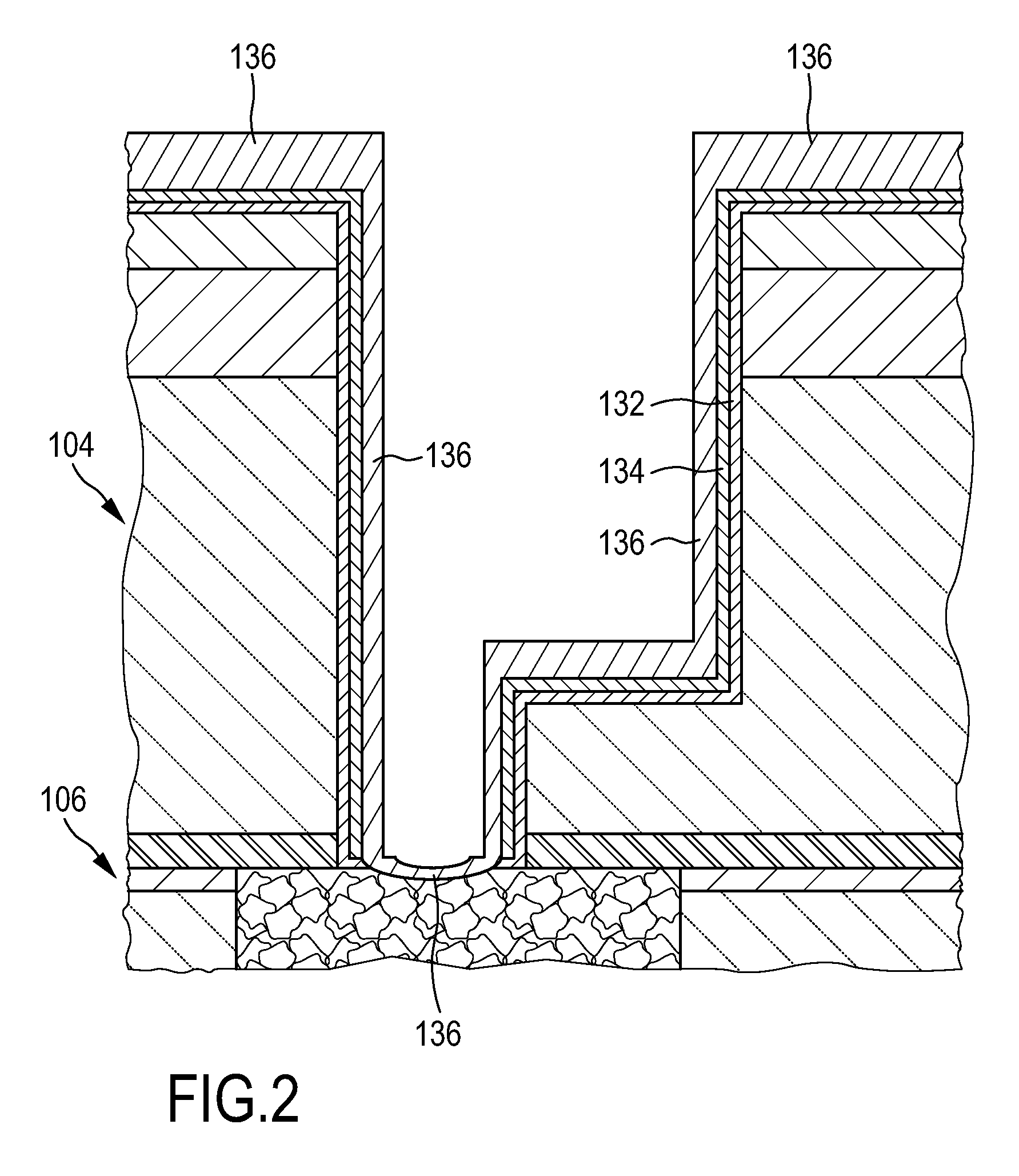

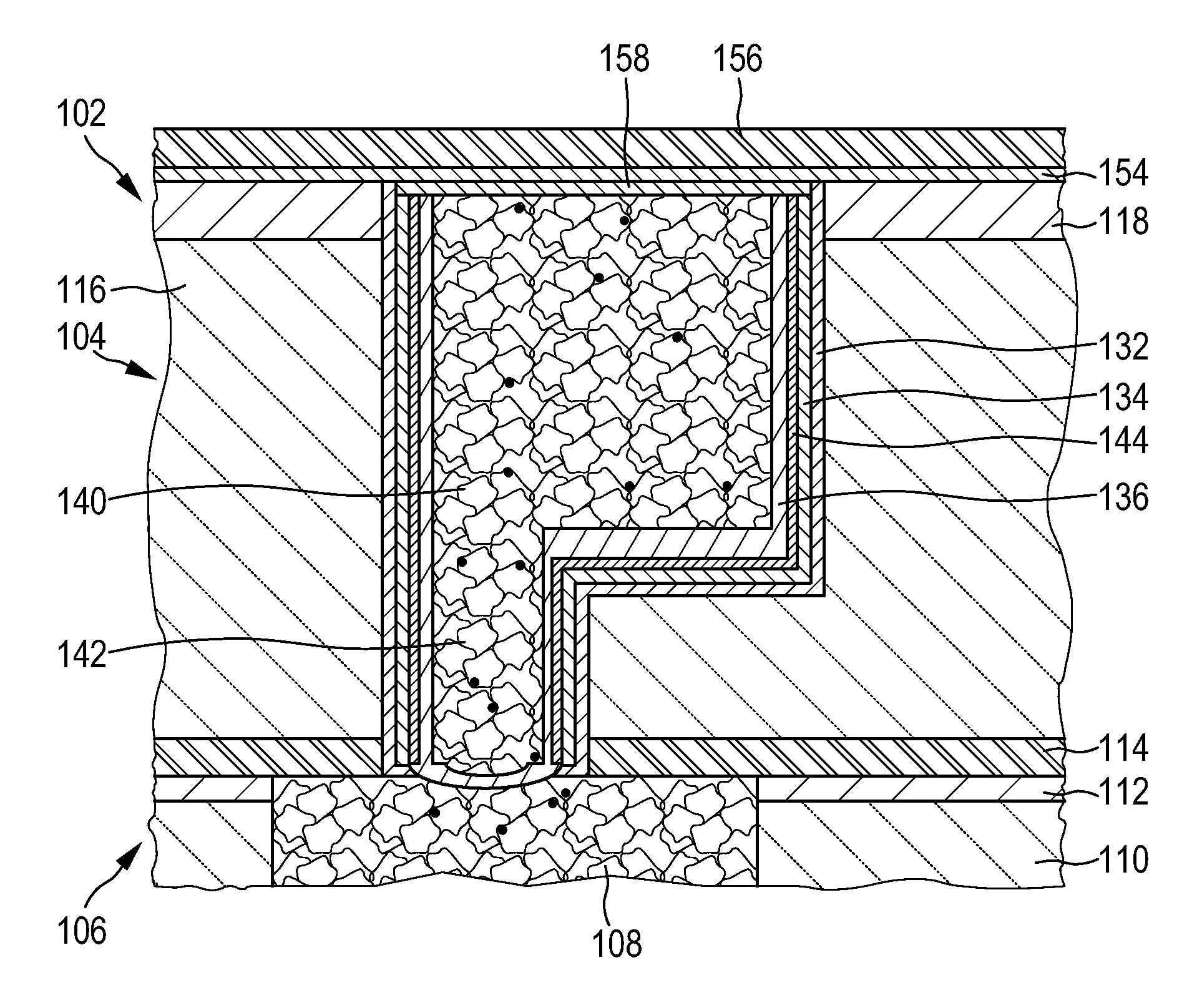

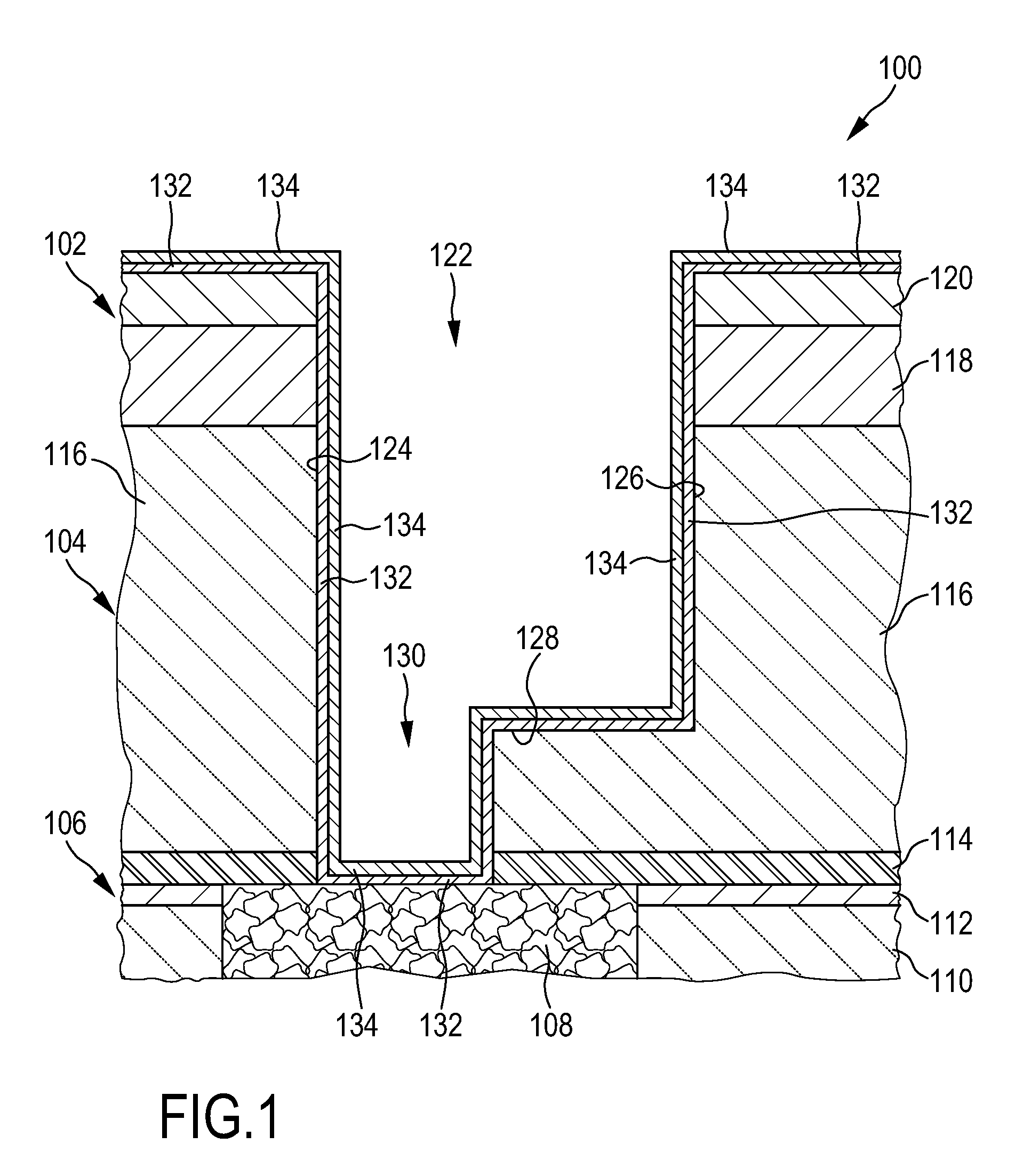

Interlocking structure for high temperature electrochemical device and method for making the same

InactiveUS20100143824A1Low costImprove robustnessCell electrodesFinal product manufacturePorous layerOperating temperature

Layered structures and associated fabrication methods that serve as the foundation for preparing high-operating-temperature electrochemical cells have a porous ceramic layer and a porous metal support or current collector layer bonded by mechanical interlocking which is provided by interpenetration of the layers and / or roughness of the metal surface. The porous layers can be infiltrated with catalytic material to produce a functioning electrochemical electrode.

Owner:RGT UNIV OF CALIFORNIA

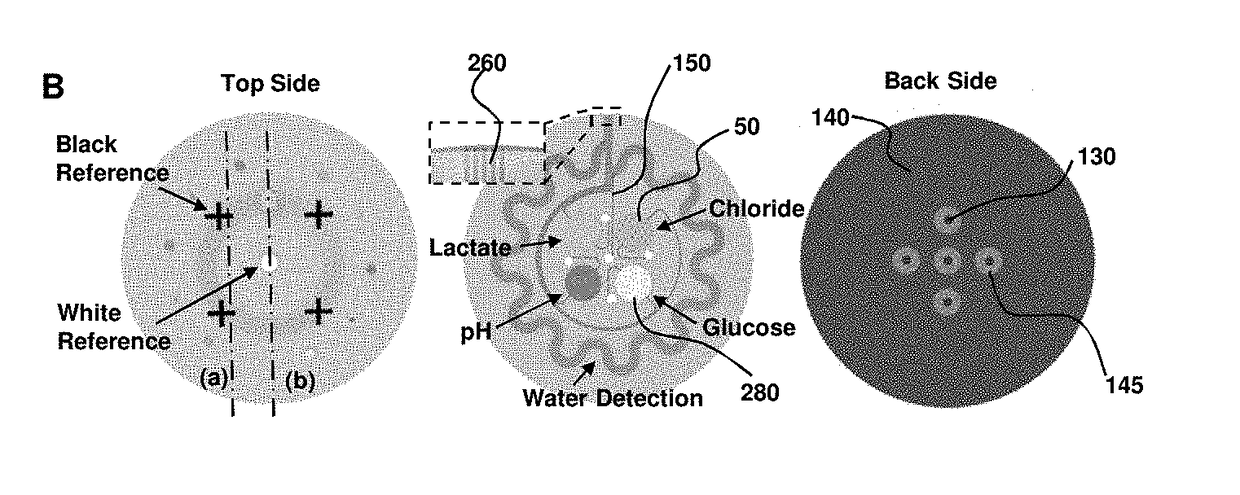

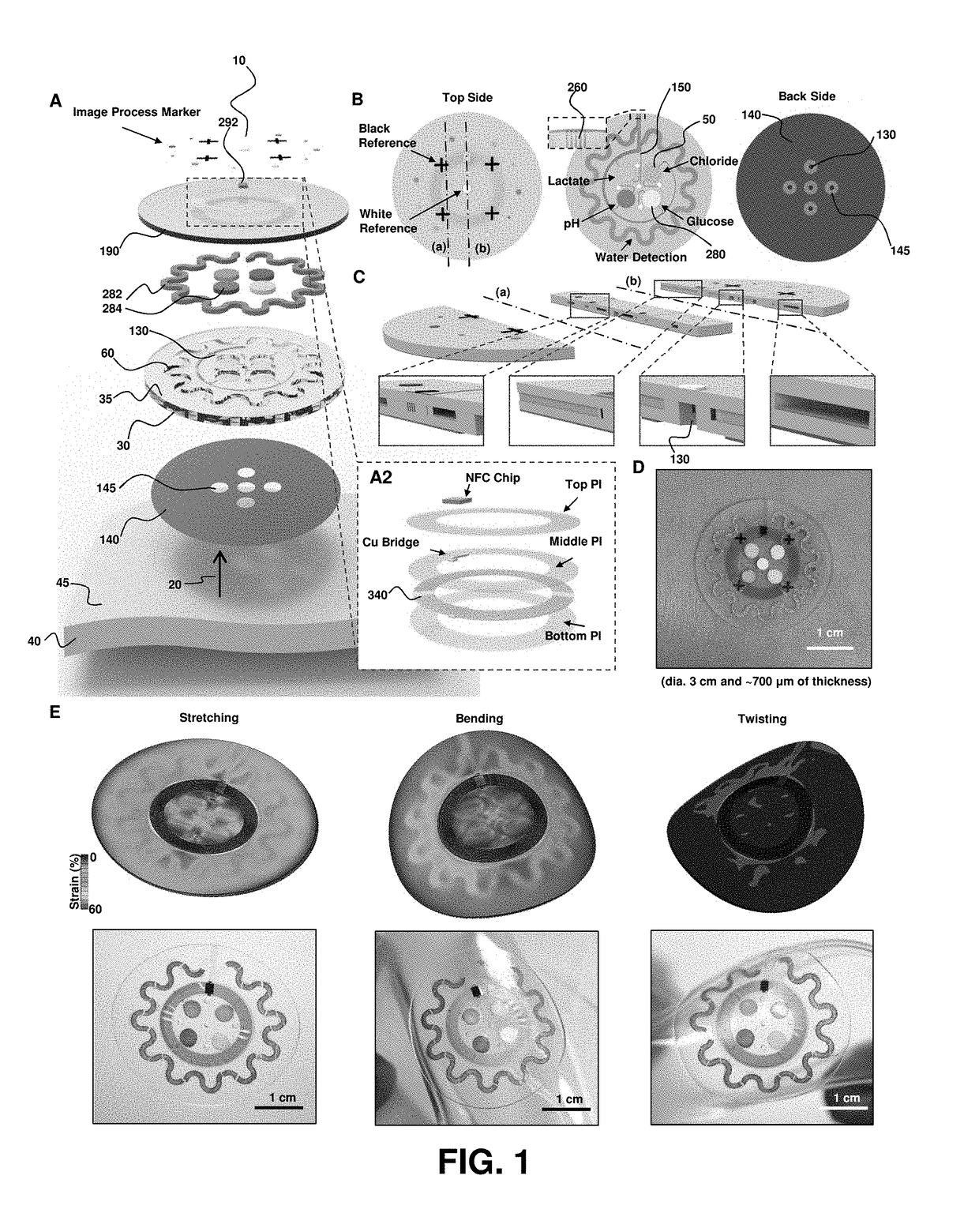

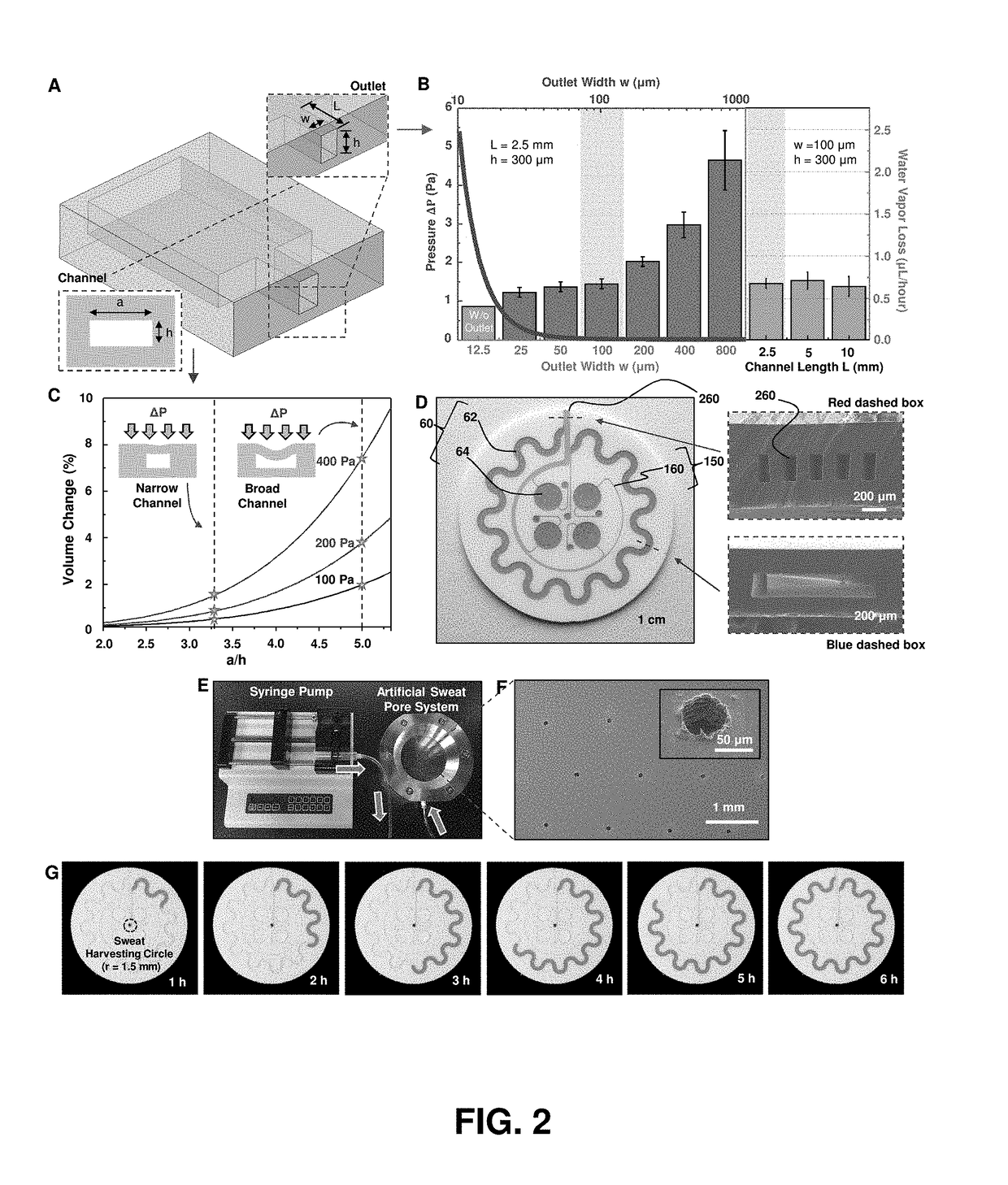

Soft, wearable microfluidic systems capable of capture, storage, and sensing of biofluids

ActiveUS20180064377A1Minimize changeMinimizing artificial changeDiagnostics using lightLaboratory glasswaresComputer science

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

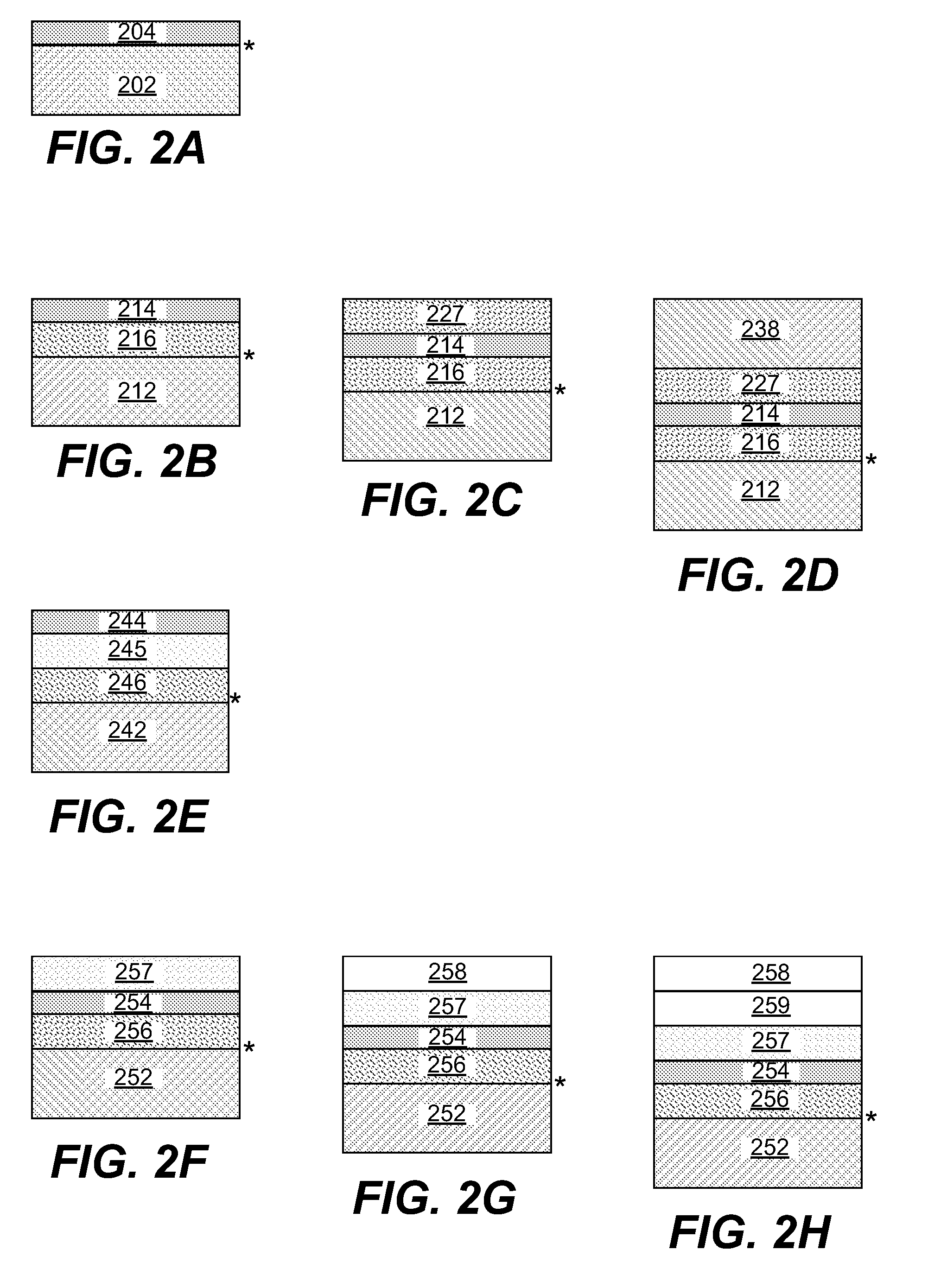

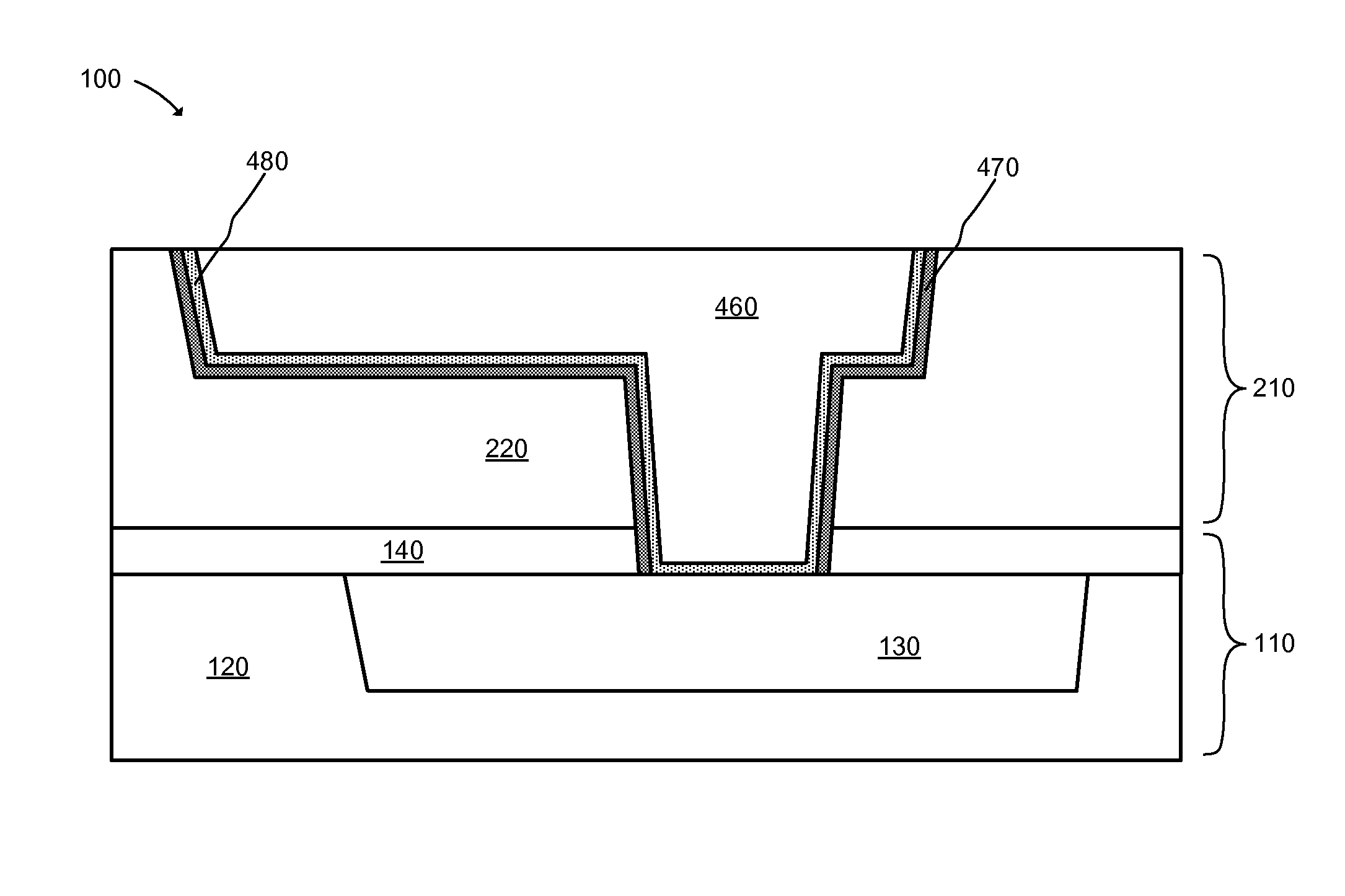

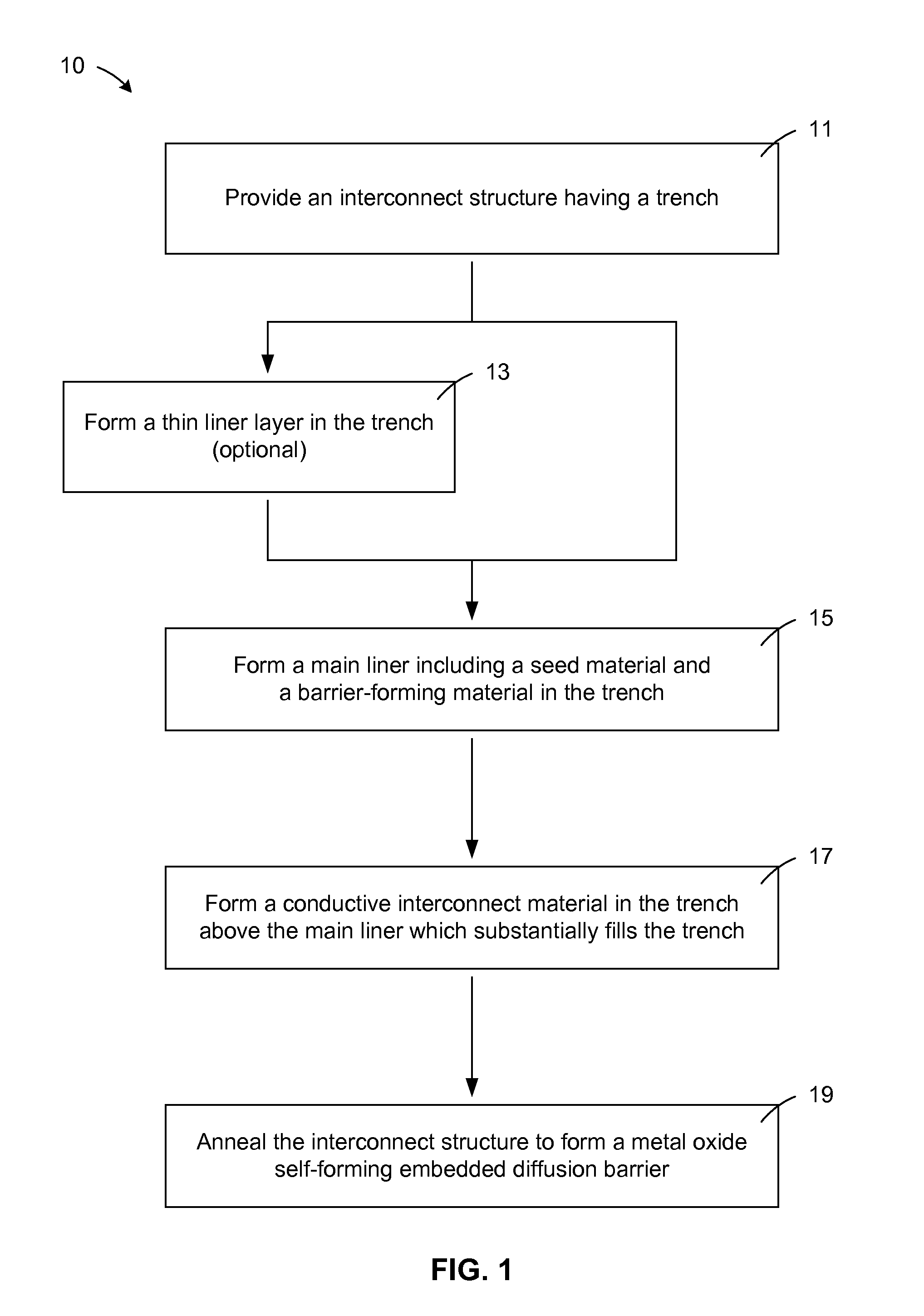

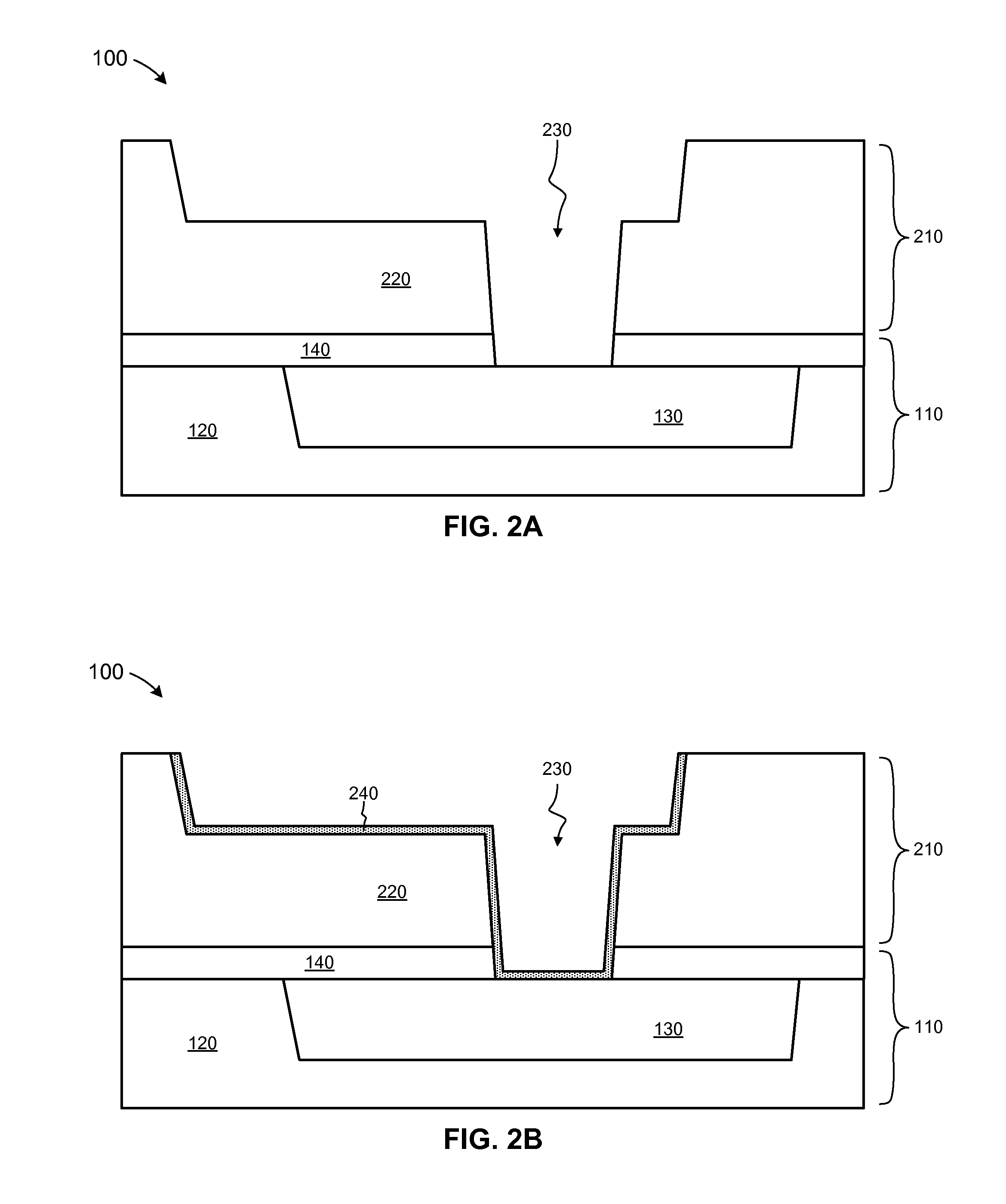

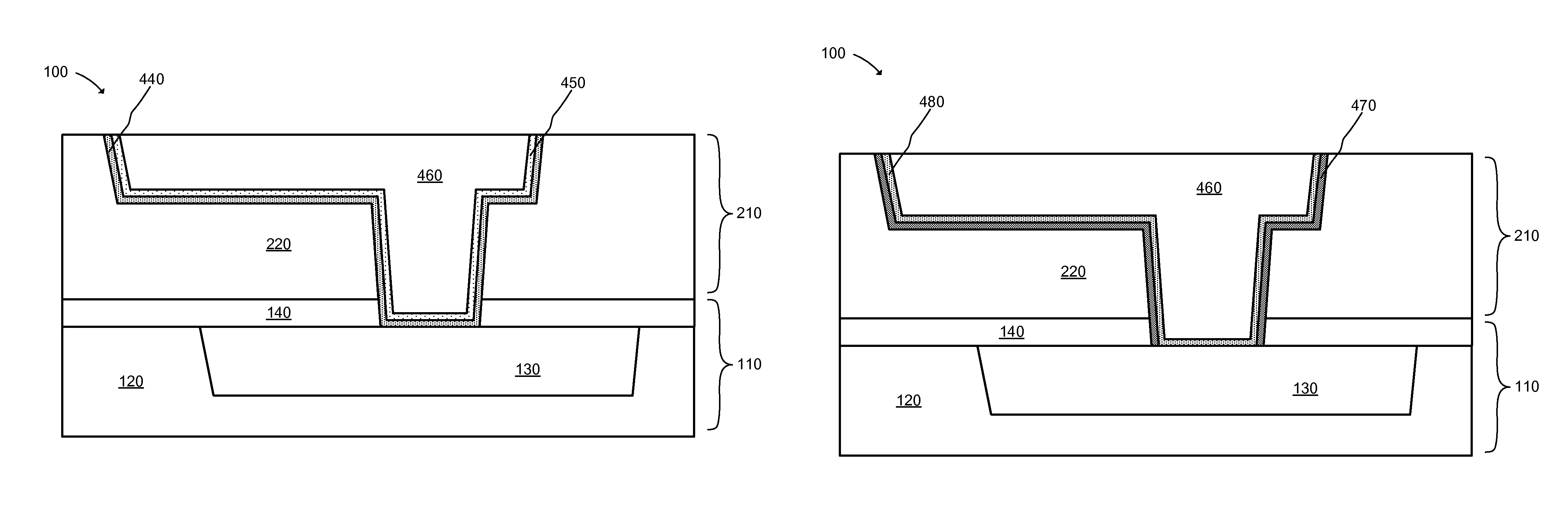

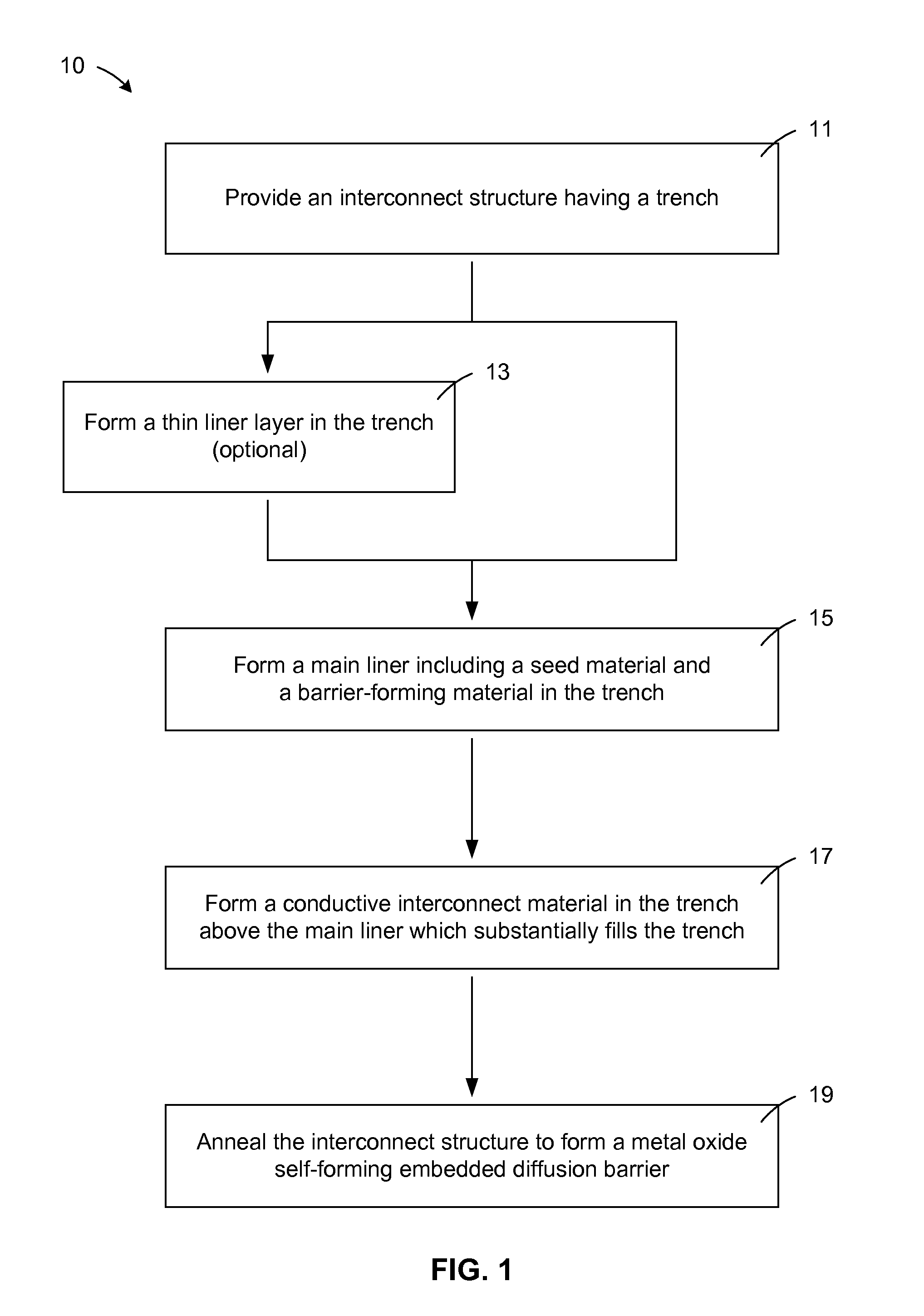

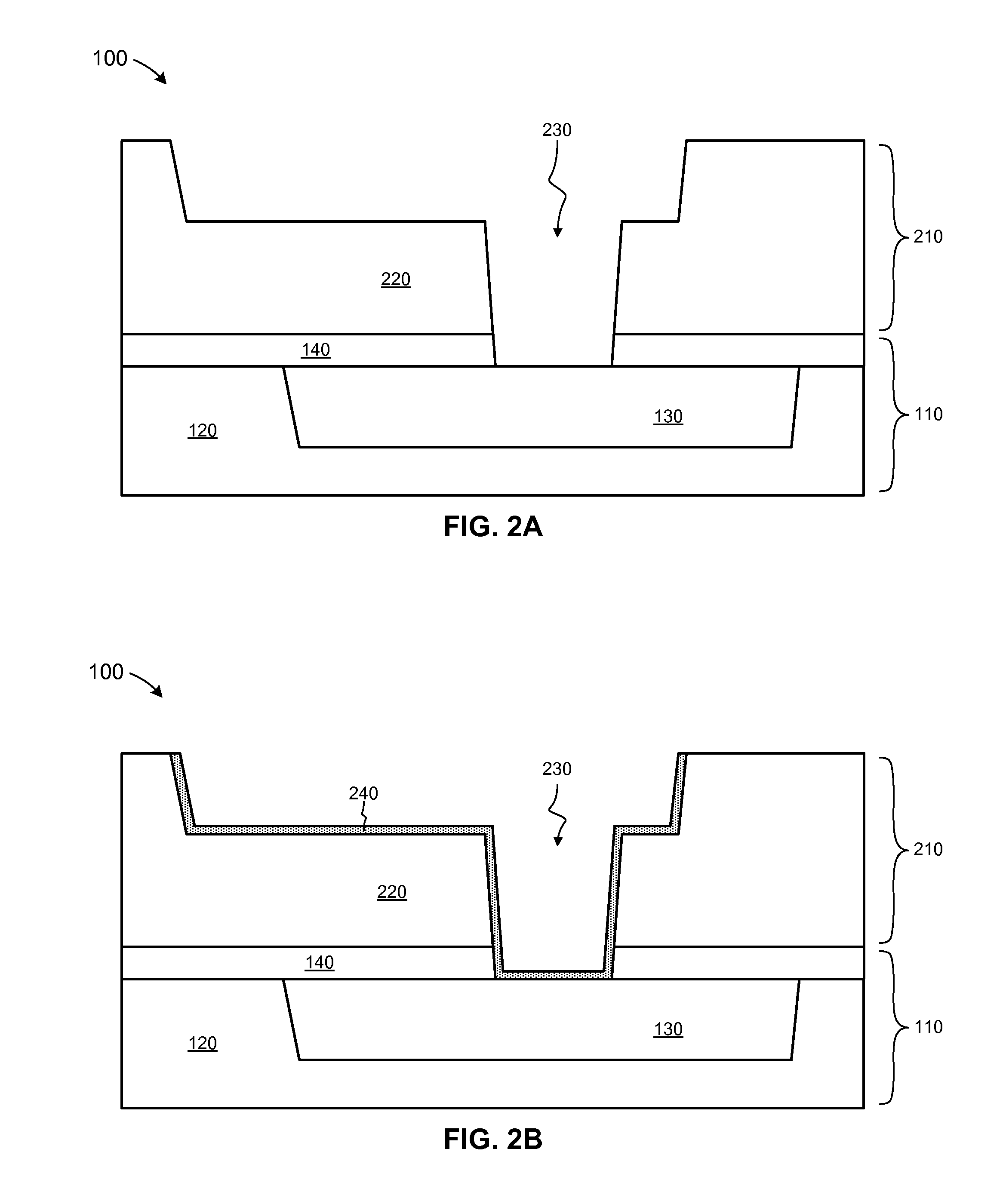

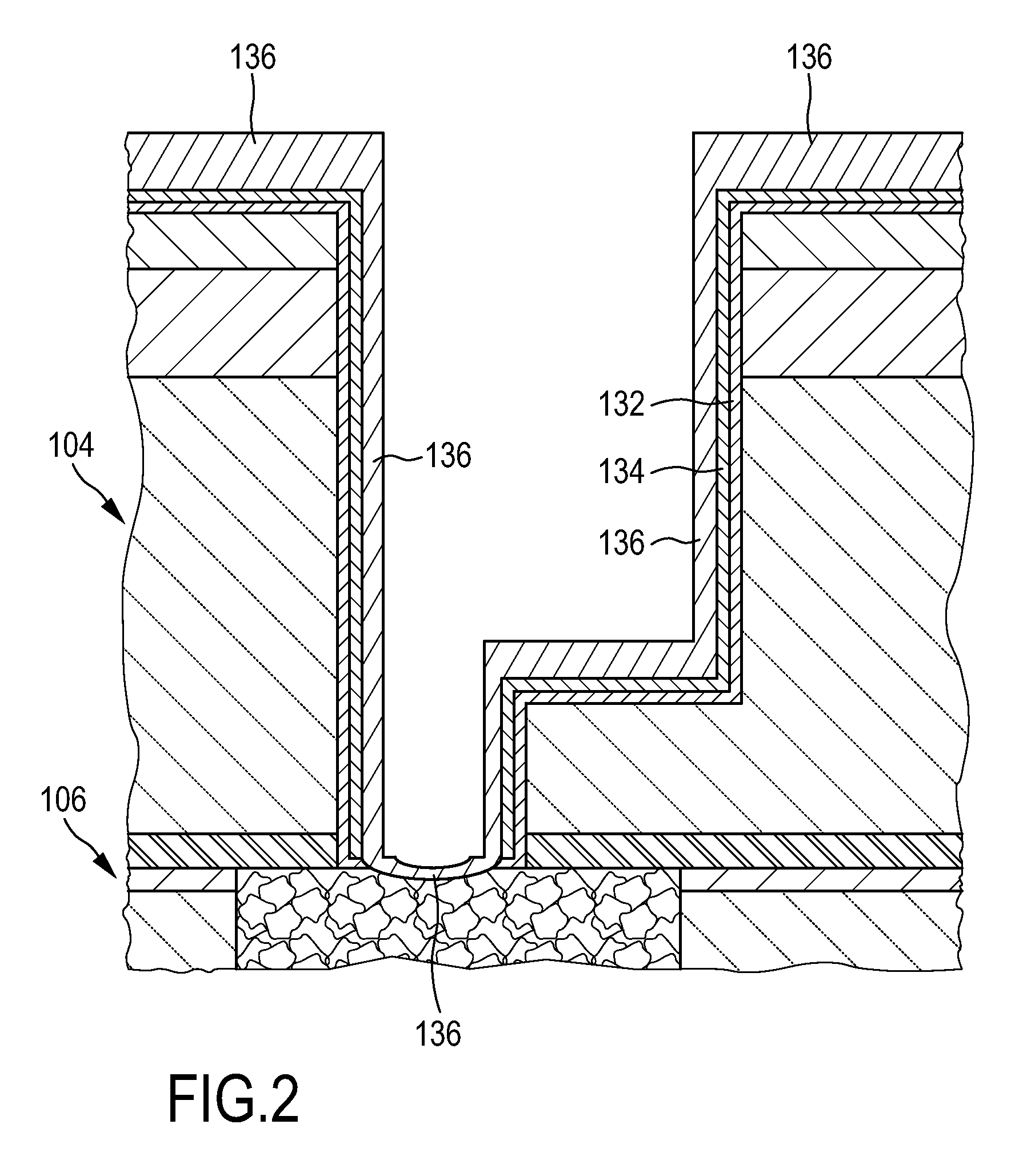

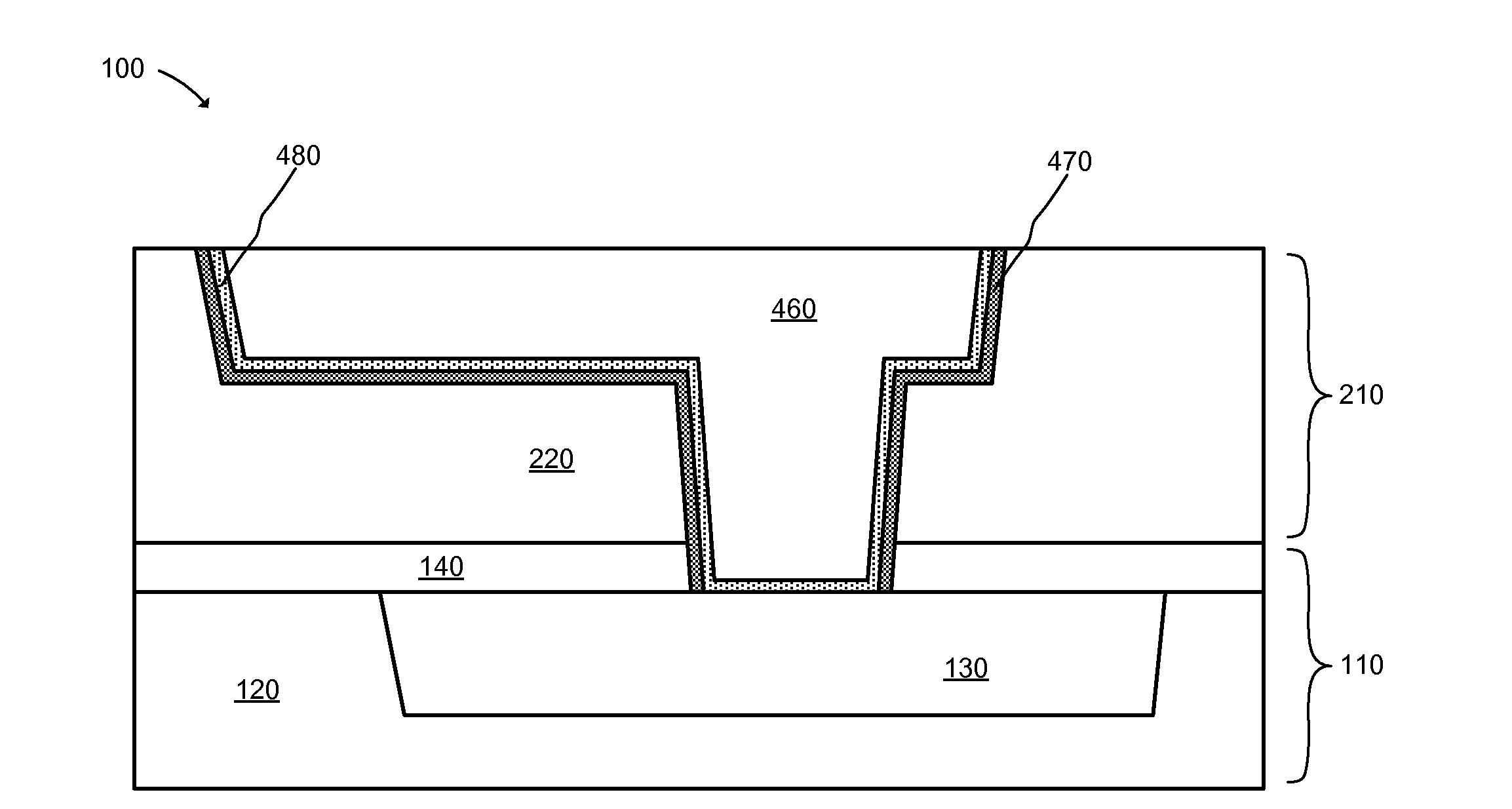

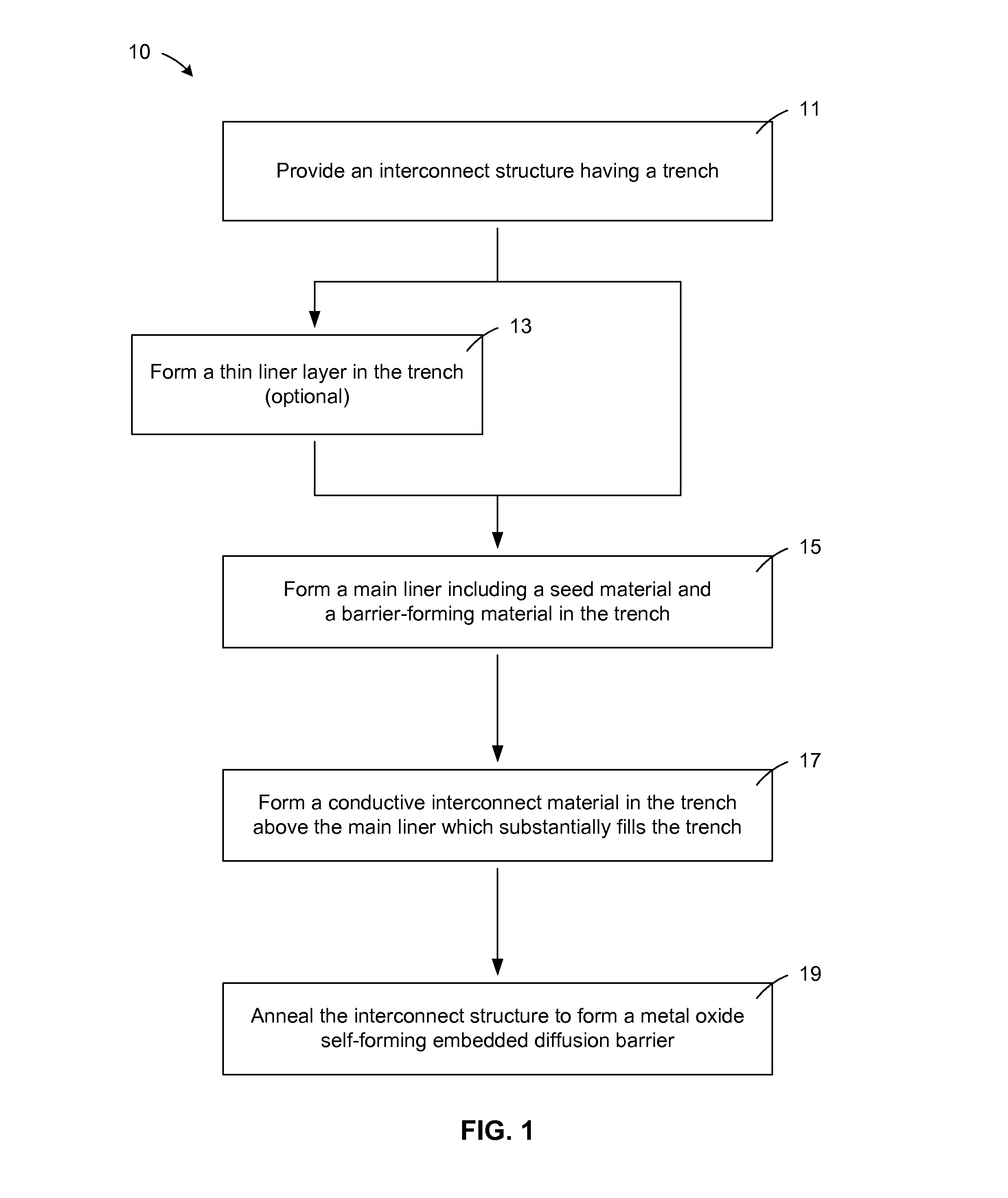

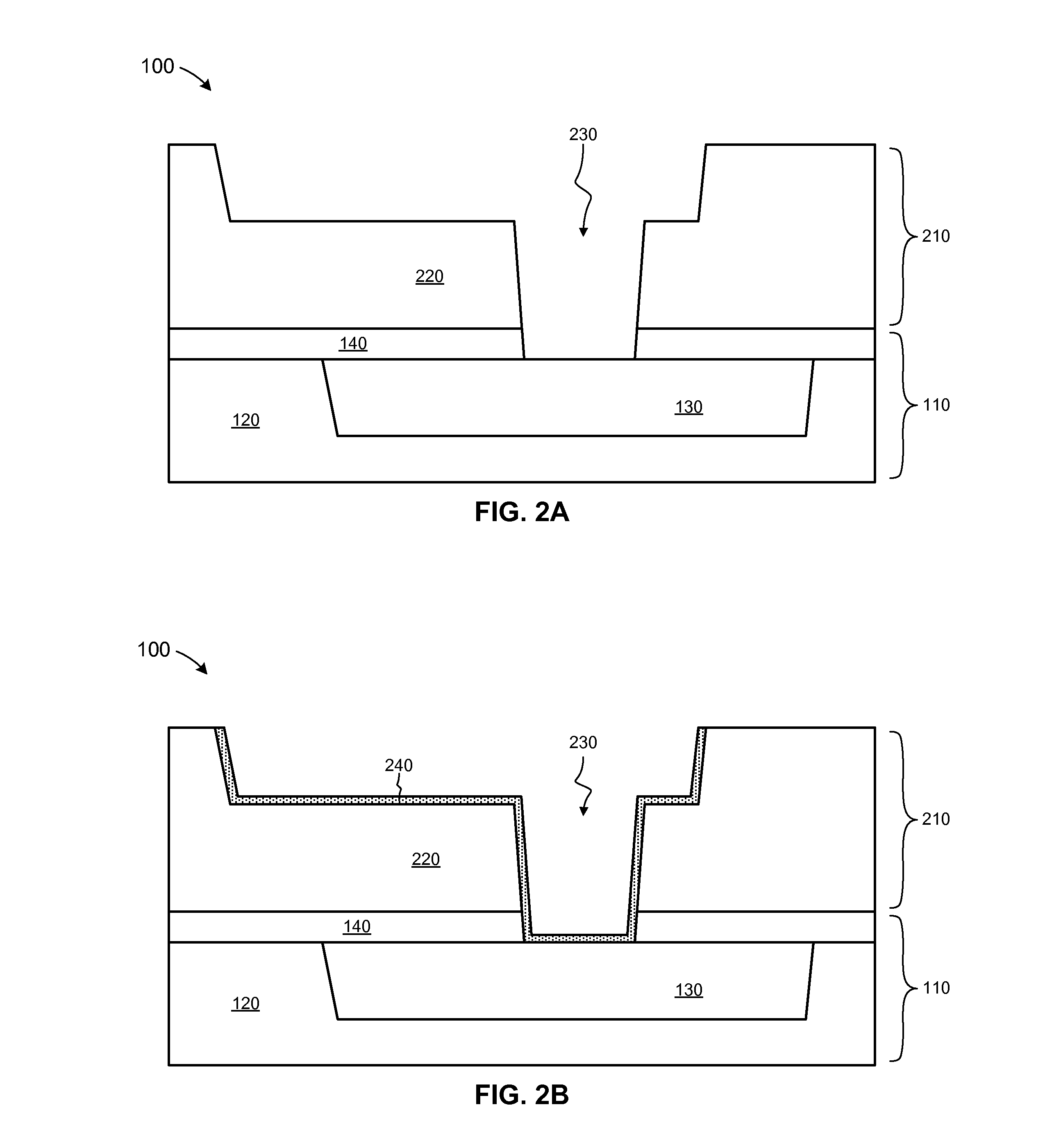

Self-forming embedded diffusion barriers

ActiveUS20140299988A1Controlled diffusionImproved electromigration resistanceSemiconductor/solid-state device detailsSolid-state devicesSelf formingTitanium

Interconnect structures containing metal oxide embedded diffusion barriers and methods of forming the same. Interconnect structures may include an Mx level including an Mx metal in an Mx dielectric, an Mx+1 level above the Mx level including an Mx+1 metal in an Mx+1 dielectric, an embedded diffusion barrier adjacent to the Mx+1 dielectric; and a seed alloy region adjacent to the Mx+1 metal separating the Mx metal from the Mx+1 metal. The embedded diffusion barrier may include a barrier-forming material such as manganese, aluminum, titanium, or some combination thereof. The seed alloy region may include a seed material such as cobalt, ruthenium, or some combination thereof.

Owner:TESSERA LLC

Self-forming embedded diffusion barriers

ActiveUS9190321B2Controlled diffusionStrong interfaceSemiconductor/solid-state device detailsSolid-state devicesDielectricSelf forming

Interconnect structures containing metal oxide embedded diffusion barriers and methods of forming the same. Interconnect structures may include an Mx level including an Mx metal in an Mx dielectric, an Mx+1 level above the Mx level including an Mx+1 metal in an Mx+1 dielectric, an embedded diffusion barrier adjacent to the Mx+1 dielectric; and a seed alloy region adjacent to the Mx+1 metal separating the Mx metal from the Mx+1 metal. The embedded diffusion barrier may include a barrier-forming material such as manganese, aluminum, titanium, or some combination thereof. The seed alloy region may include a seed material such as cobalt, ruthenium, or some combination thereof.

Owner:TESSERA LLC

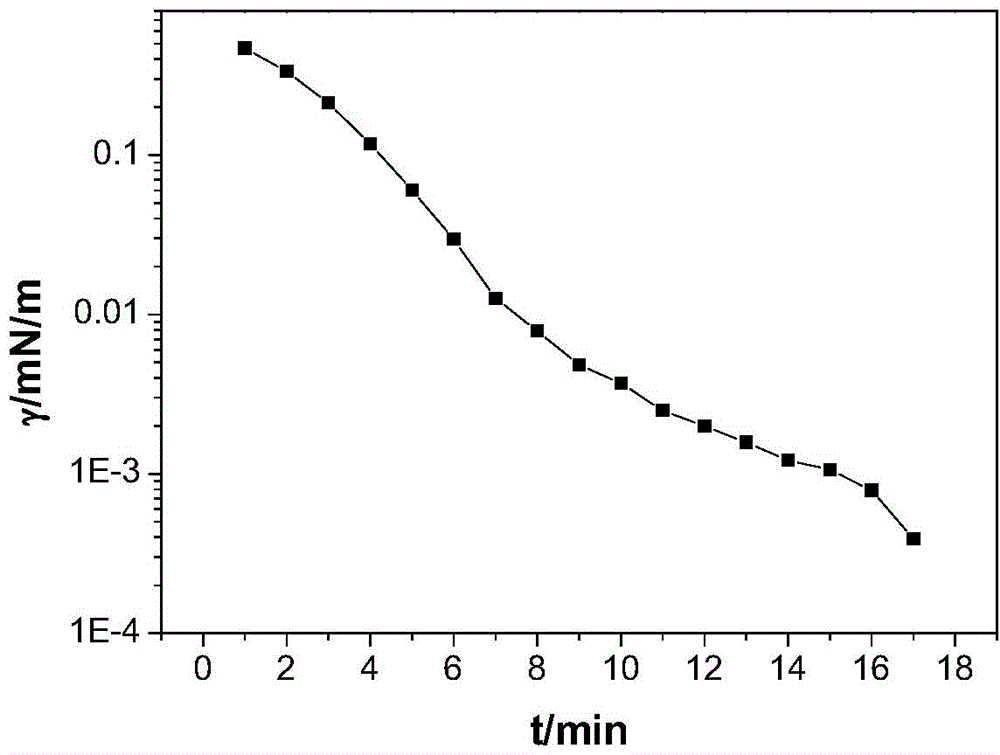

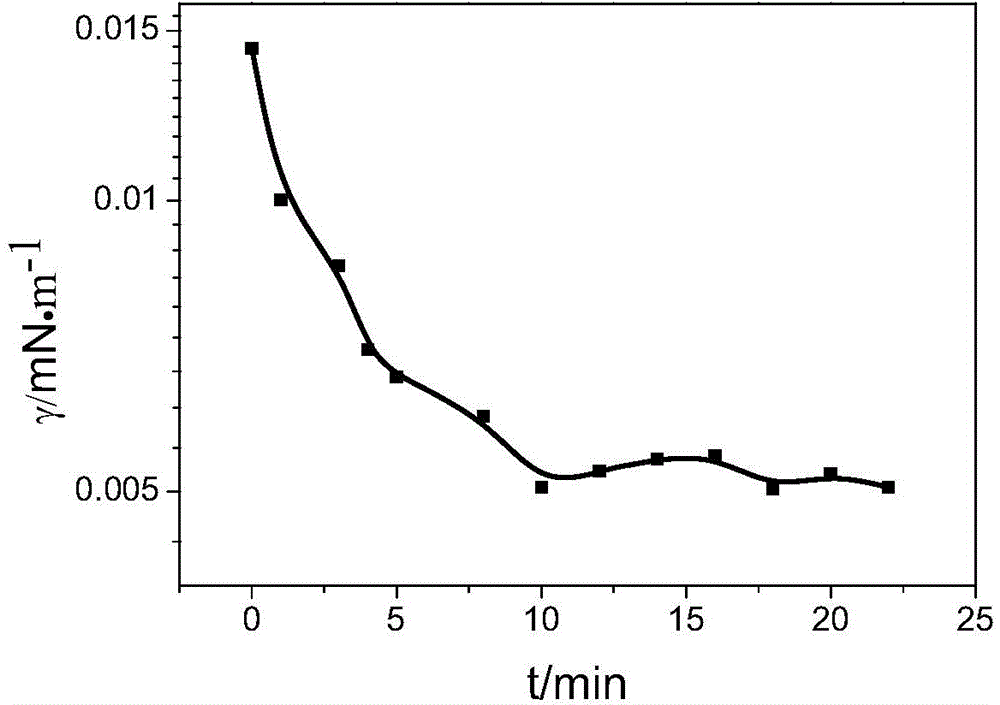

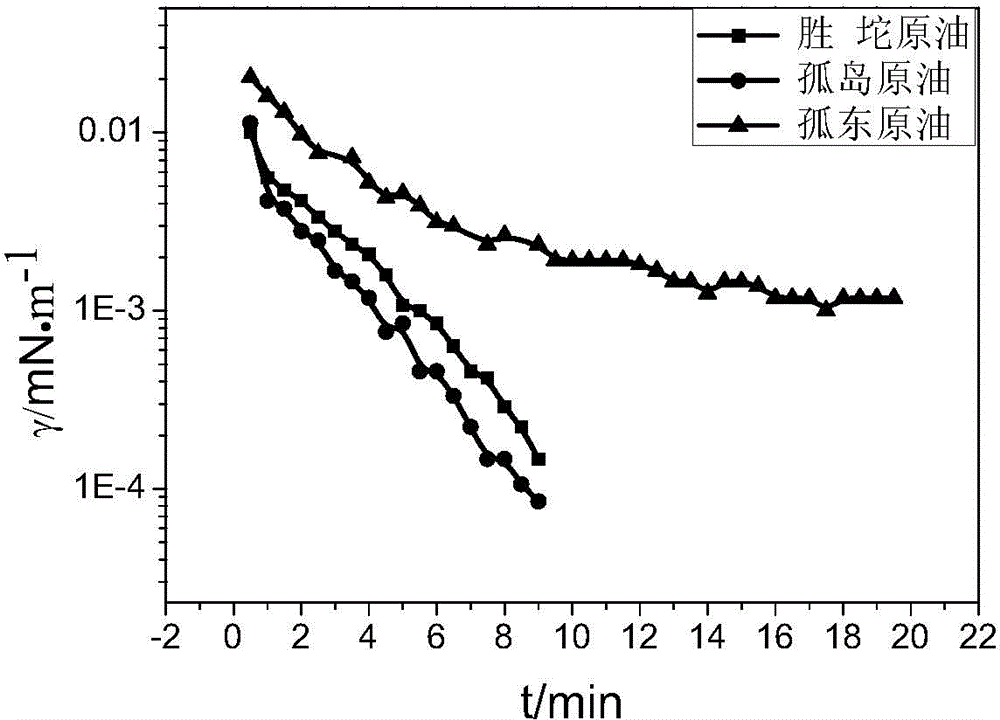

Surfactant compounded system with oil reservoir adaptability

InactiveCN104694103AEnhanced overall recoveryImprove hydrophilicityDrilling compositionSalt resistanceOil phase

The invention relates to a surfactant compounded system with oil reservoir adaptability. The surfactant compounded system consists of nonionic surfactants A, anionic surfactants B and cationic surfactants C. An oil displacement agent related by the invention has the advantages that the Shengli oil field crude oil / water interface tension can be reduced to an ultra-low state in a short time, in addition, certain oil phase adaptability is realized, an important effect is achieved in the aspect of improving the crude oil yield, secondly, the use concentration of the surfactant of the system is low, the salt resistance is good, and the applicability to stratum mineralized water is good.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Reinforced, laminated, impregnated and composite-like materials as crosslinked polyvinyl alcohol hydrogel structures

Owner:CARRIER CORP

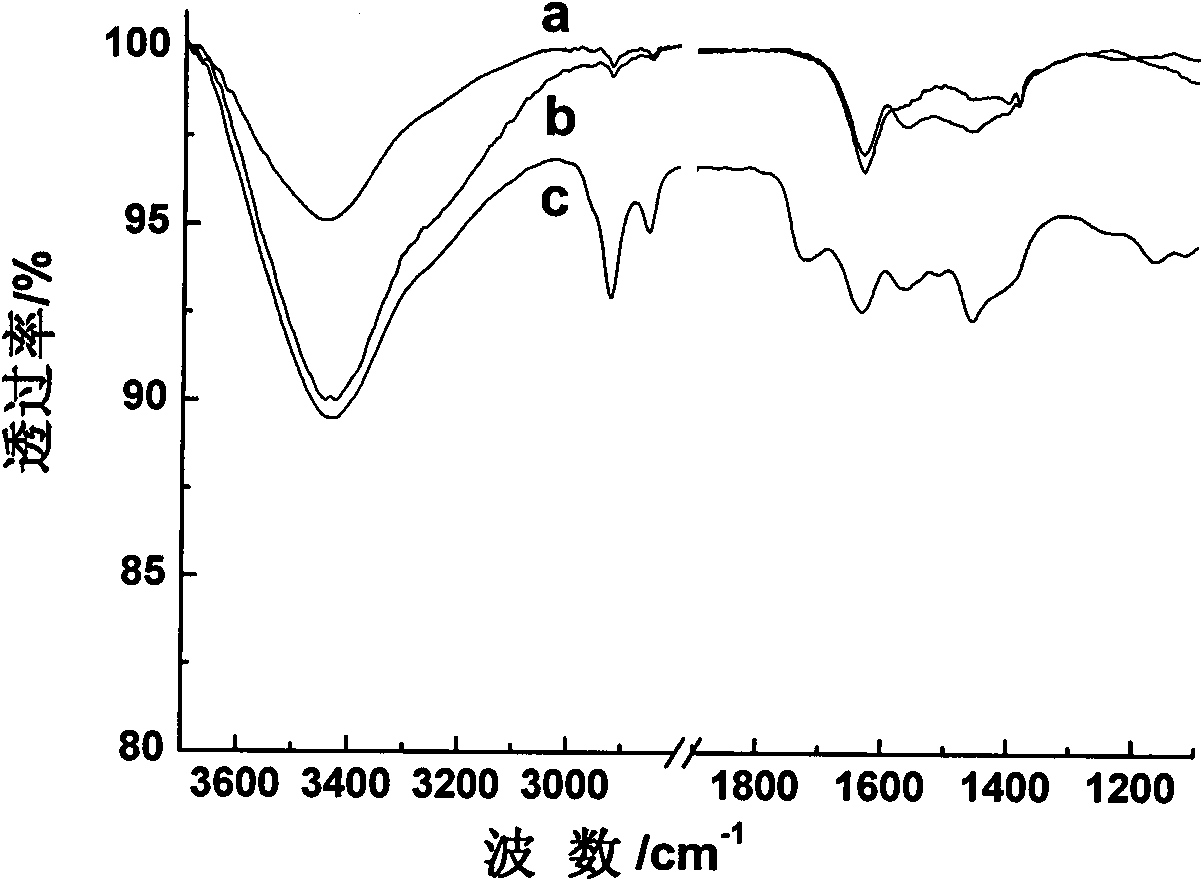

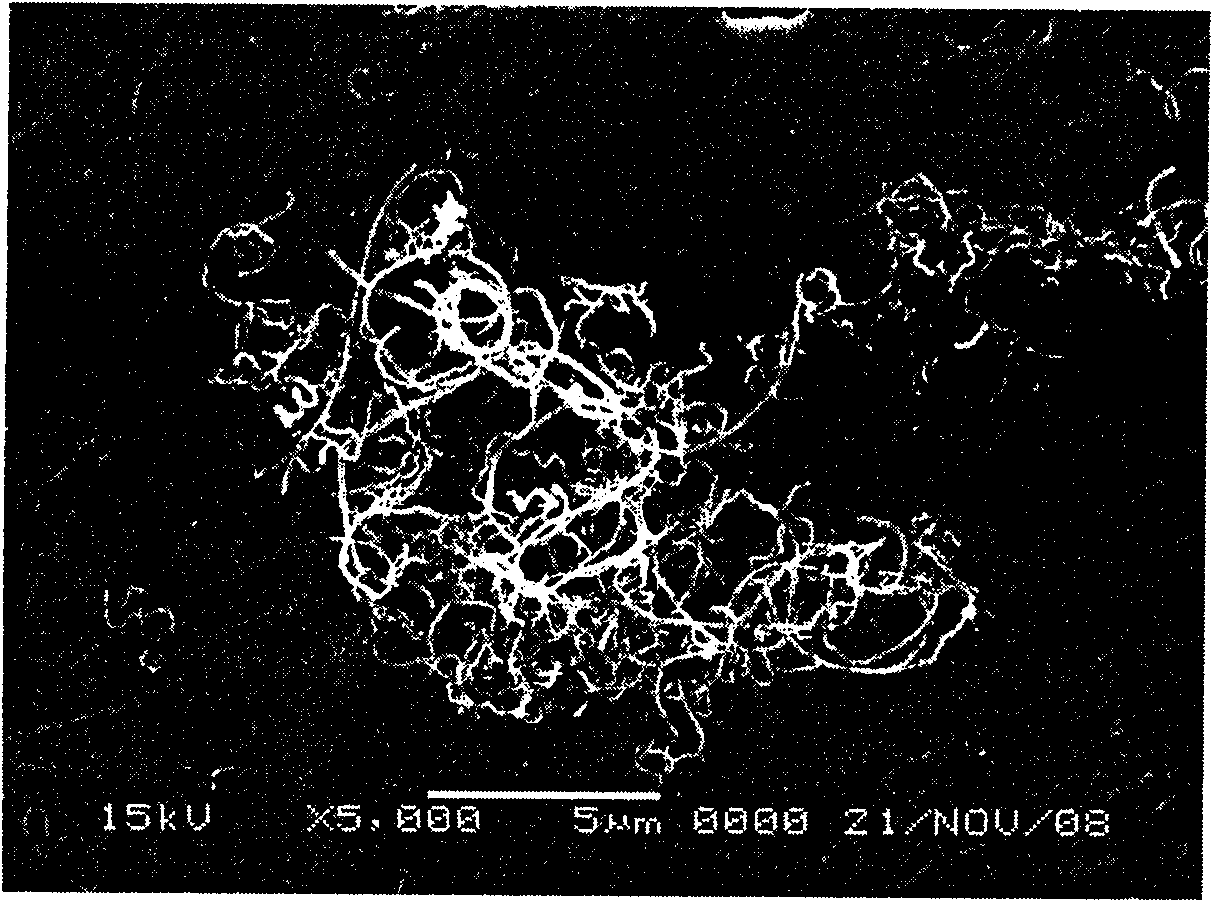

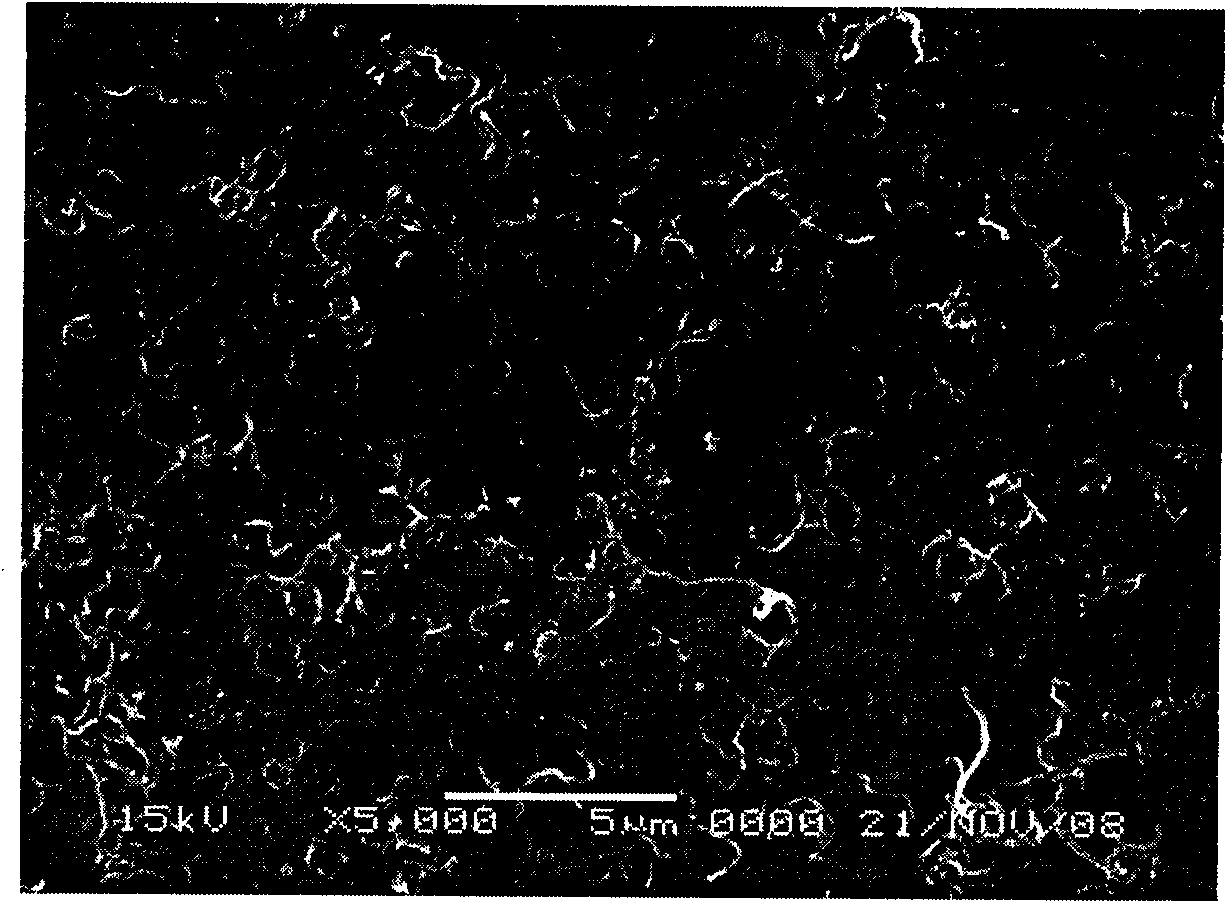

Preparation method of polyaniline modified multi-wall carbon canotube/epoxy resin composite material

InactiveCN101955631AStrong interfaceImprove mechanical propertiesPigment treatment with macromolecular organic compoundsEpoxyIn situ polymerization

The invention discloses a preparation method of a polyaniline modified multi-wall carbon canotubes / epoxy resin composite material. The preparation method comprises the following steps of: firstly, modifying the surfaces of multi-wall carbon canotubes with conducting macromolecular polyaniline through the doping of a functional protonic acid and the in situ polymerization of aniline; then, dispersing the multi-wall carbon canotubes with surfaces modified by polyaniline to an epoxy resin macromolecular solution, and adding a curing agent after removing the solvent; and finally, carrying out vacuum degassing, pouring into molds, heating and curing to prepare the composite material. The preparation method has simple process, low production cost and obvious reinforcing and toughening effects, and can effectively prevent the aggregation of the multi-wall carbon canotubes in epoxy resin and increase the dispersibility and the interfacial bonding of the multi-wall carbon canotubes in the epoxy resin. In addition, the conducting polyaniline is coated on the surfaces of the multi-wall carbon canotubes, and thus, the polyaniline modified multi-wall carbon canotubes / epoxy resin composite material acquires good mechanical properties and good antistatic function.

Owner:CIVIL AVIATION UNIV OF CHINA

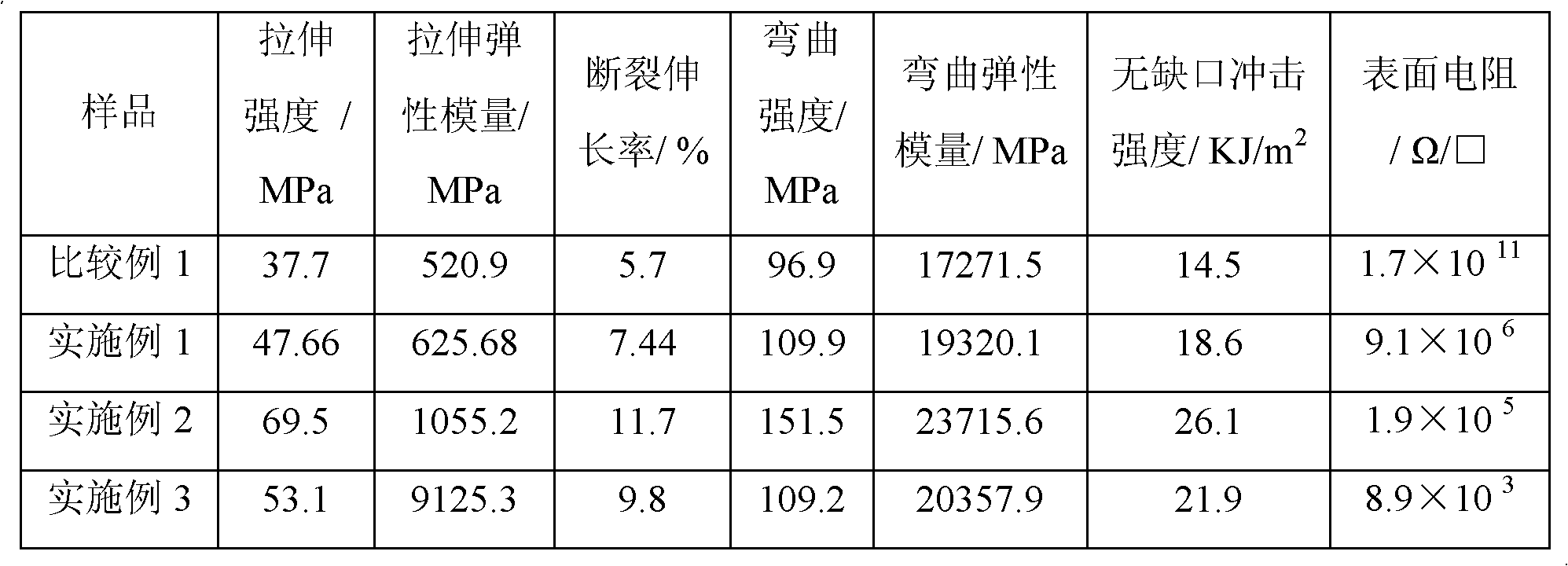

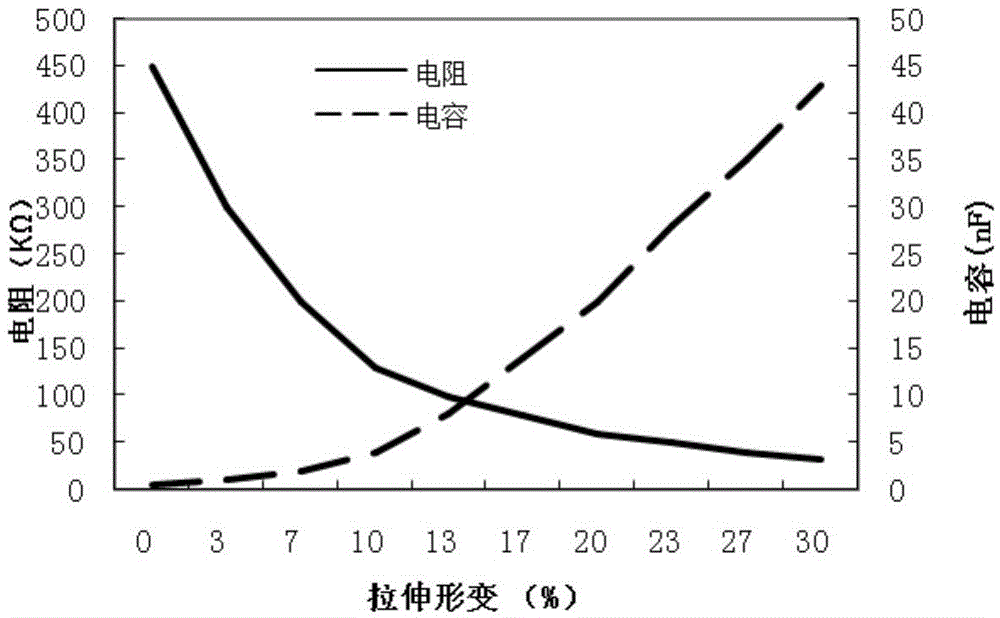

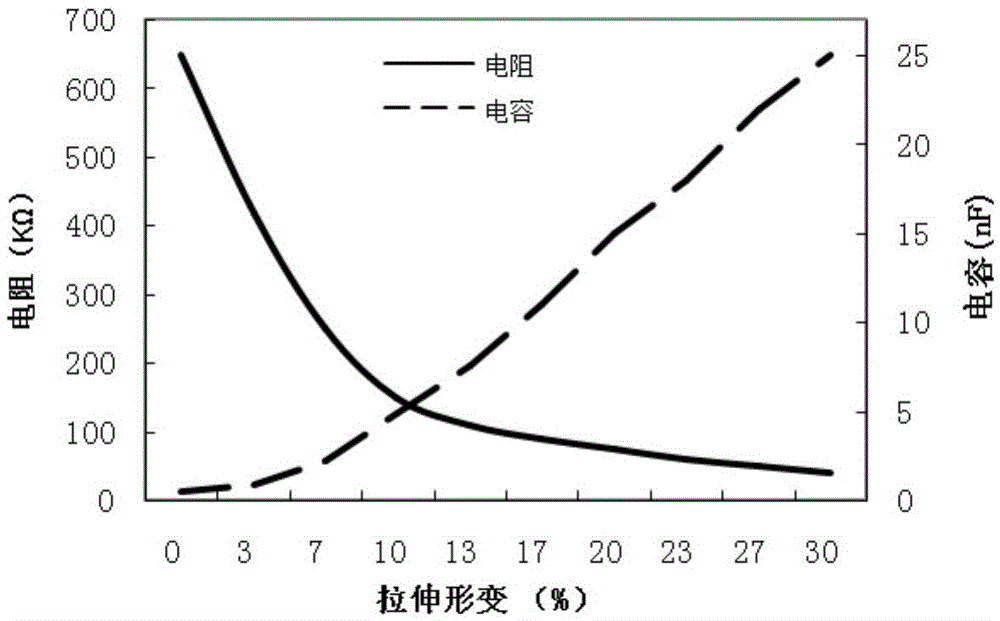

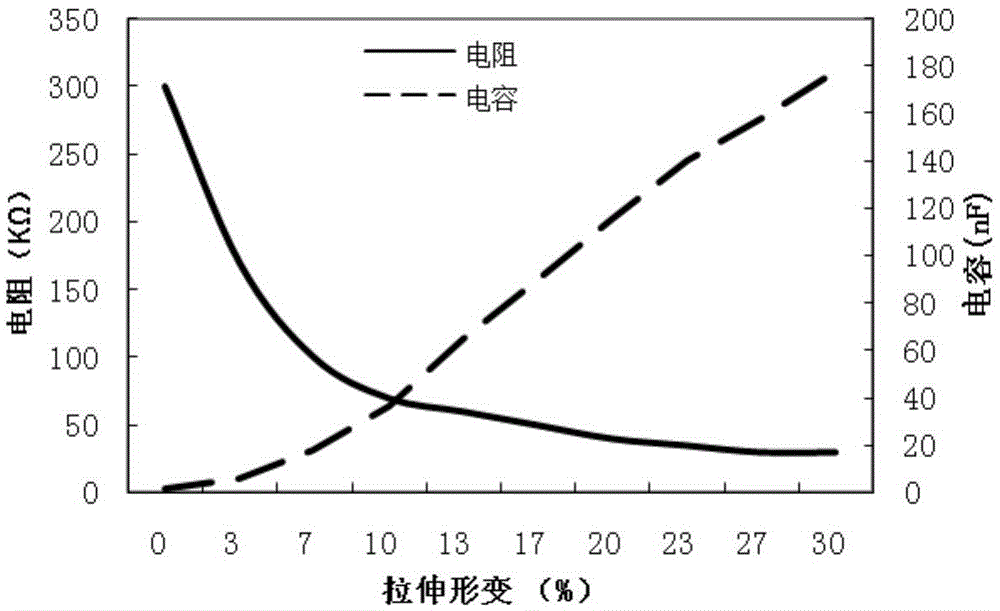

Conductive rubber material for flexible sensor and preparation method and application of conductive rubber material

InactiveCN105482176ANarrow resistance distributionReduce pollutionForce measurementRubber materialEngineering

The invention is applicable to the field of flexible sensors and provides a conductive rubber material for a flexible sensor and a preparation method and application of the conductive rubber material. The conductive rubber material comprises, by weight, 100 parts of rubber base bodies and conductive filler, wherein the conductive filler comprises, by weight, 5-50 parts of conductive black and / or 20-100 parts of silver-containing conductive filler bodies; the conductive rubber material is made in the mode that the conductive filler is dispersed in the rubber material, and radiation crosslinking is conducted through electron beams or gamma rays.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

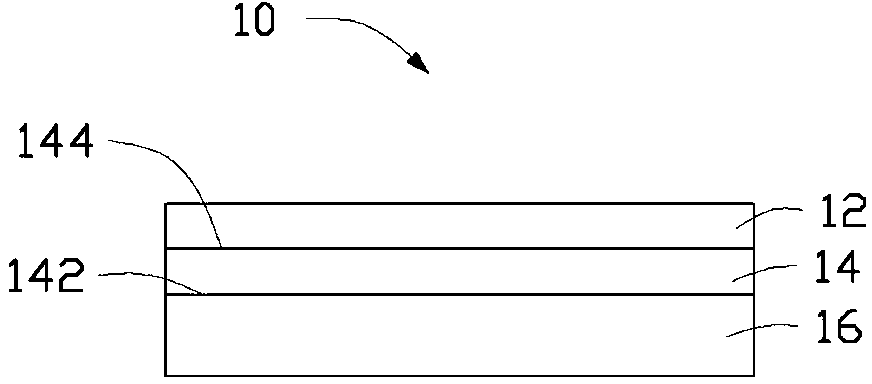

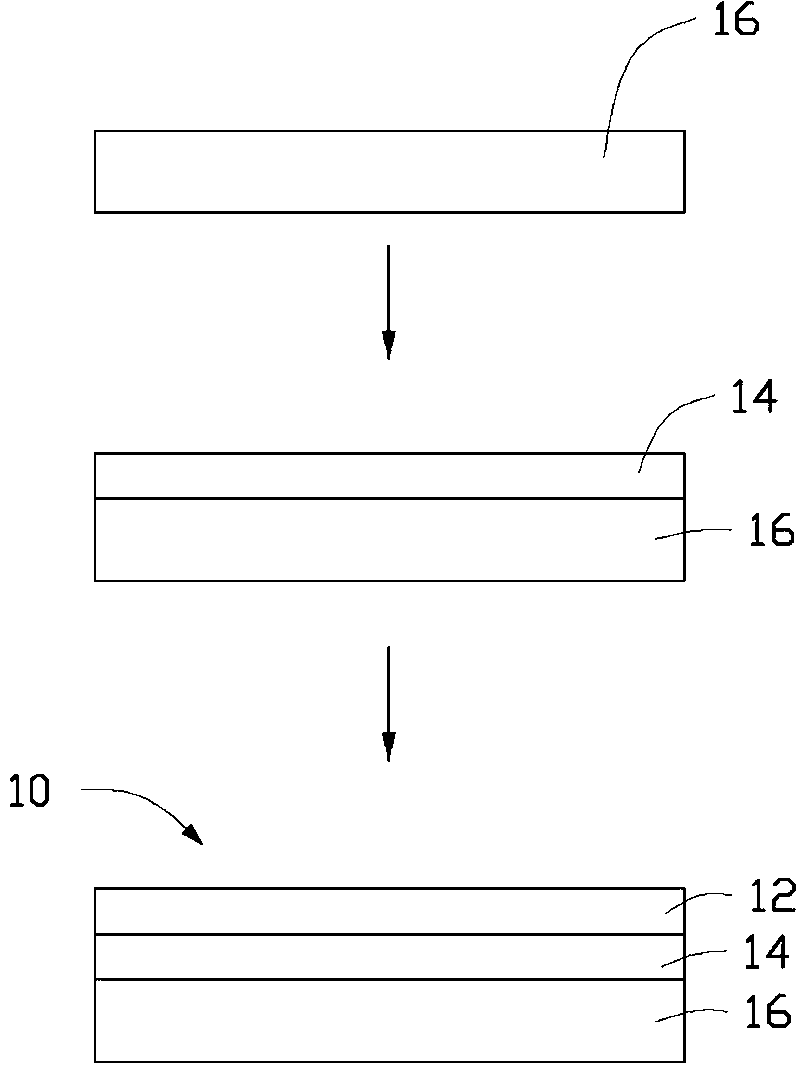

CuSiN/SiN DIFFUSION BARRIER FOR COPPER IN INTEGRATED-CIRCUIT DEVICES

ActiveUS20090273085A1High CMP-selectivityReduce surface roughnessSemiconductor/solid-state device detailsSolid-state devicesState of artCopper

The present invention relates to an integrated-circuit device that has at least one Copper-containing feature in a dielectric layer, and a diffusion-barrier layer stack arranged between the feature and the dielectric layer. The integrated-circuit device of the invention has a diffusion-barrier layer stack, which comprises, in a direction from the Copper-containing feature to the dielectric layer, a CuSiN layer and a SiN layer. This layer combination provides an efficient barrier for suppressing Copper diffusion from the feature into the dielectric layer. Furthermore, a CuSiN / SiN layer sequence provides an improved adhesion between the layers of the diffusion-barrier layer stack and the dielectric layer, and thus improves the electromigration performance of the integrated-circuit device during operation. Therefore, the reliability of device operation and the lifetime of the integrate-circuit device are improved in comparison with prior-art devices. The invention further relates to a method for fabricating such an integrated-circuit device.

Owner:NXP BV

CuSiN/SiN diffusion barrier for copper in integrated-circuit devices

ActiveUS8072075B2Strong interfaceImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesDiffusion barrierMaterials science

The present invention relates to an integrated-circuit device that has at least one Copper-containing feature in a dielectric layer, and a diffusion-barrier layer stack arranged between the feature and the dielectric layer. The integrated-circuit device of the invention has a diffusion-barrier layer stack, which comprises, in a direction from the Copper-containing feature to the dielectric layer, a CuSiN layer and a SiN layer. This layer combination provides an efficient barrier for suppressing Copper diffusion from the feature into the dielectric layer. Furthermore, a CuSiN / SiN layer sequence provides an improved adhesion between the layers of the diffusion-barrier layer stack and the dielectric layer, and thus improves the electromigration performance of the integrated-circuit device during operation. Therefore, the reliability of device operation and the lifetime of the integrate-circuit device are improved in comparison with prior-art devices. The invention further relates to a method for fabricating such an integrated-circuit device.

Owner:NXP BV

Nano composite water absorbing material, and preparation method

A nano-class composite hydroscopic material is prepared through proportionally adding acrylamide and acrylic acid to deionized water, dissolving, adding sodium carbonate to neutralize the acrylic acid in solution, sequentially adding cross-linking agent and starch, heating while stirring for gelatinizing starch, adding modified montmorillonite, stirring, cooling to 60 deg.C, adding trigger, gelatinizing and laying aside for 1 hr to obtain gel block. Its advantages are high hydroscopicity and strength after water is absorbed and high resistance to high temp and salt.

Owner:SOUTHWEST PETROLEUM UNIV

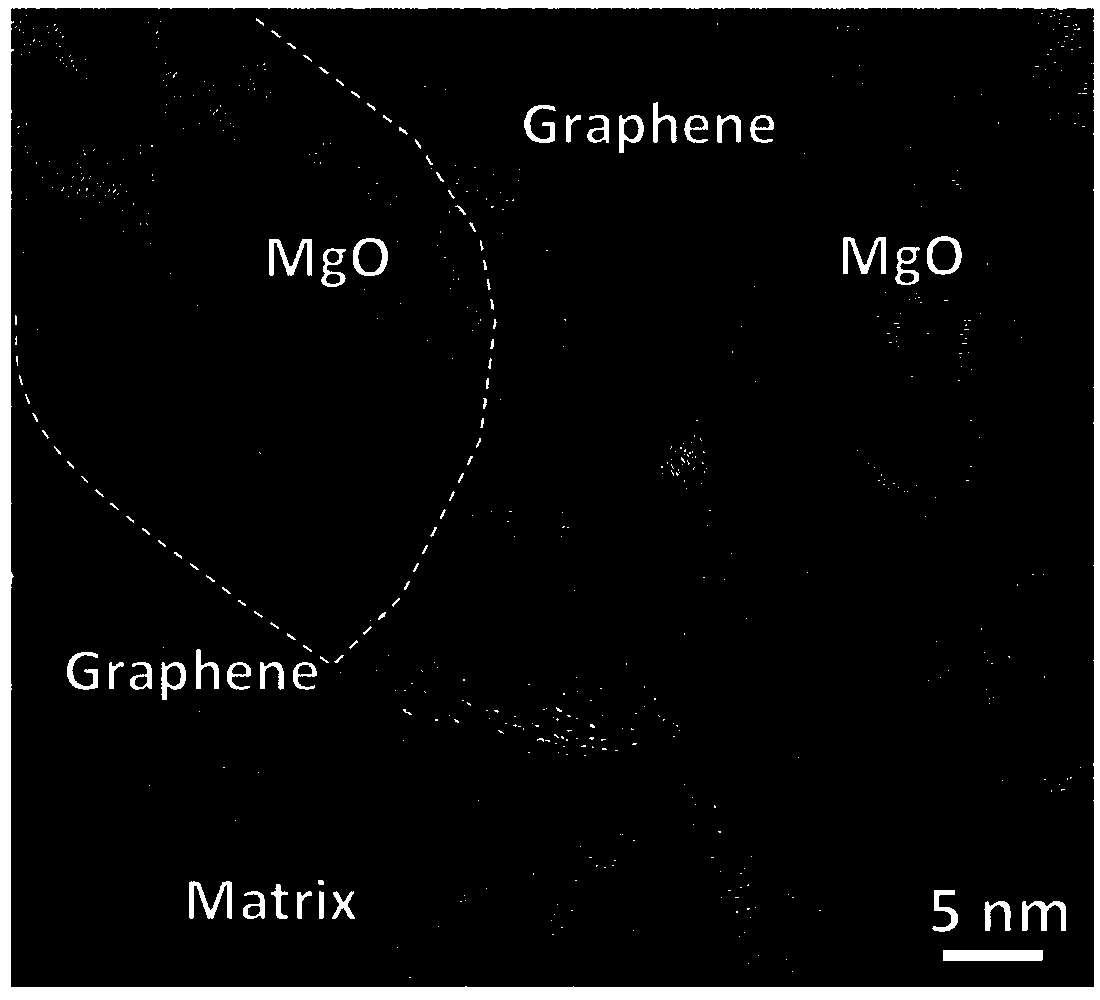

Graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and preparing method thereof

ActiveCN108754264AHigh densityImprove the bonding strength of the interfaceMagnesium matrix compositeCvd graphene

The invention discloses a graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and a preparing method thereof, relates to a graphene enhanced magnesium-based composite material and a preparing method thereof, and aims at solving the problems that in existing composite materials, graphene and magnesium matrix wettability is poor, graphenedispersibility is poor, and the interface bonding strength is low. The composite material is prepared through three raw materials including oxide, graphene and a magnesium matrix. The method comprises the steps that firstly, stirring casting or powder metallurgy is conducted; and secondly, heat deformation is conducted, and a cast-state composite material or a sintered-state composite material issubjected to hot extrusion or rolling deformation. The interface position of the composite material prepared through the method is free of holes and impure phases, graphene and matrix wettability isgood, and the interface interaction between graphene and a matrix is high. The graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and thepreparing method thereof are used in the magnesium-based composite material field.

Owner:HARBIN INST OF TECH

Preparation method of high-temperature superconducting thin film

ActiveCN103184513AGuaranteed 2D epitaxial growthAtomic level flatteningPolycrystalline material growthFrom chemically reactive gasesCrystal structureCondensed matter physics

The invention relates to a preparation method of a high-temperature superconducting thin film. The method specifically comprises steps as follows: providing an SrTiO3 substrate and placing the SrTiO3 substrate in a super-high vacuum system, growing an FeSe monocrystal layer on the surface of the SrTiO3 substrate by adopting a molecular beam epitaxy growing technology, and growing a protective layer with a layered crystal structure by adopting the molecular beam epitaxy growing technology and covering the surface of the FeSe monocrystal layer with the protective layer. By means of the method, the high-quality and ultrathin high-temperature superconducting thin film can be prepared, the starting temperature of superconducting transition of the thin film is above 54K, and the critical current density is higher than 106A / cm<2> when the starting temperature of superconducting transition of the thin film is 12K.

Owner:TSINGHUA UNIV +1

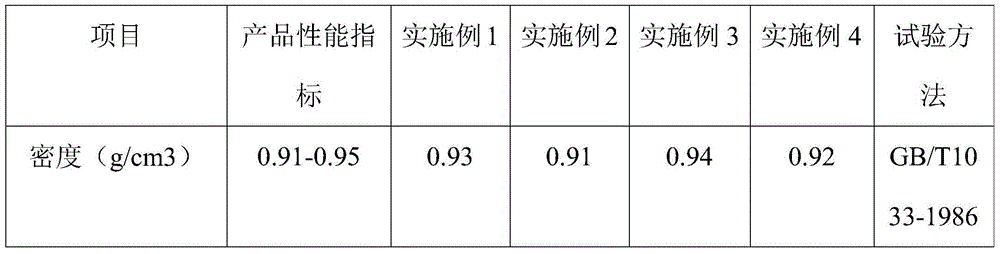

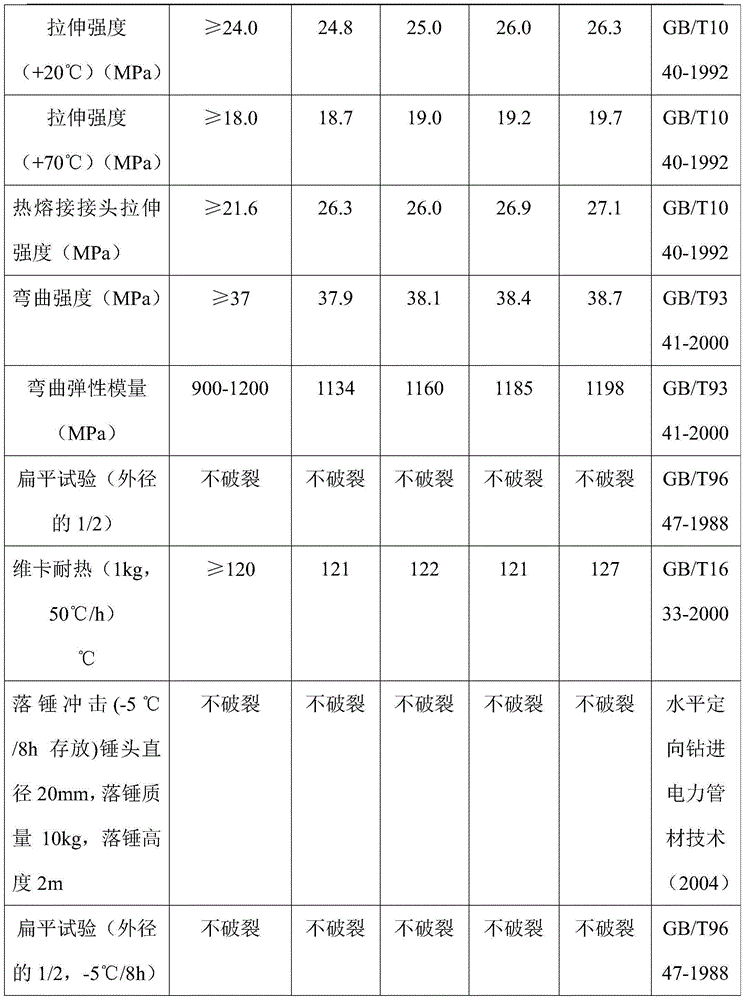

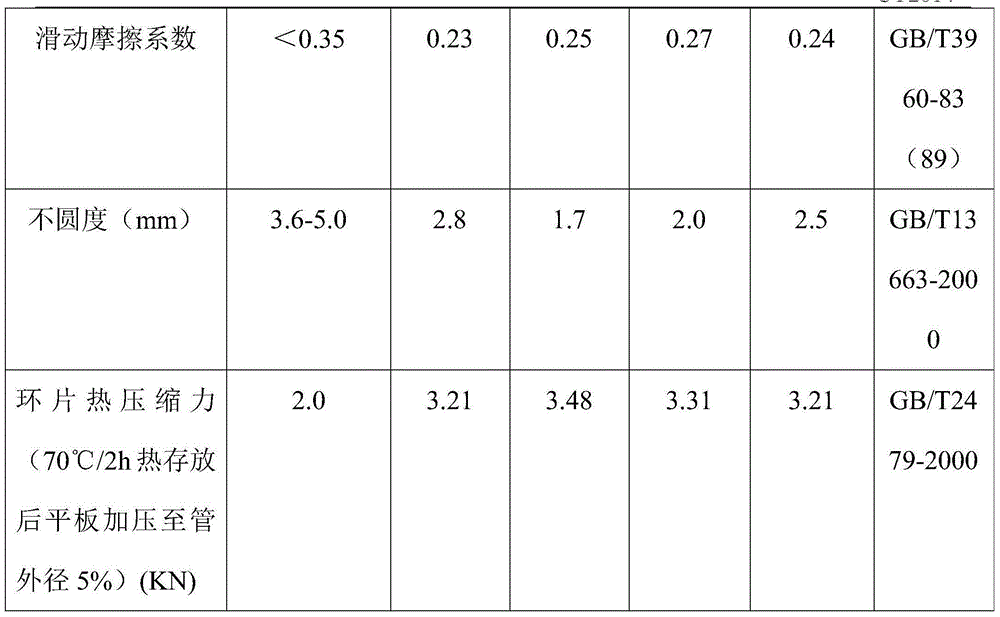

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

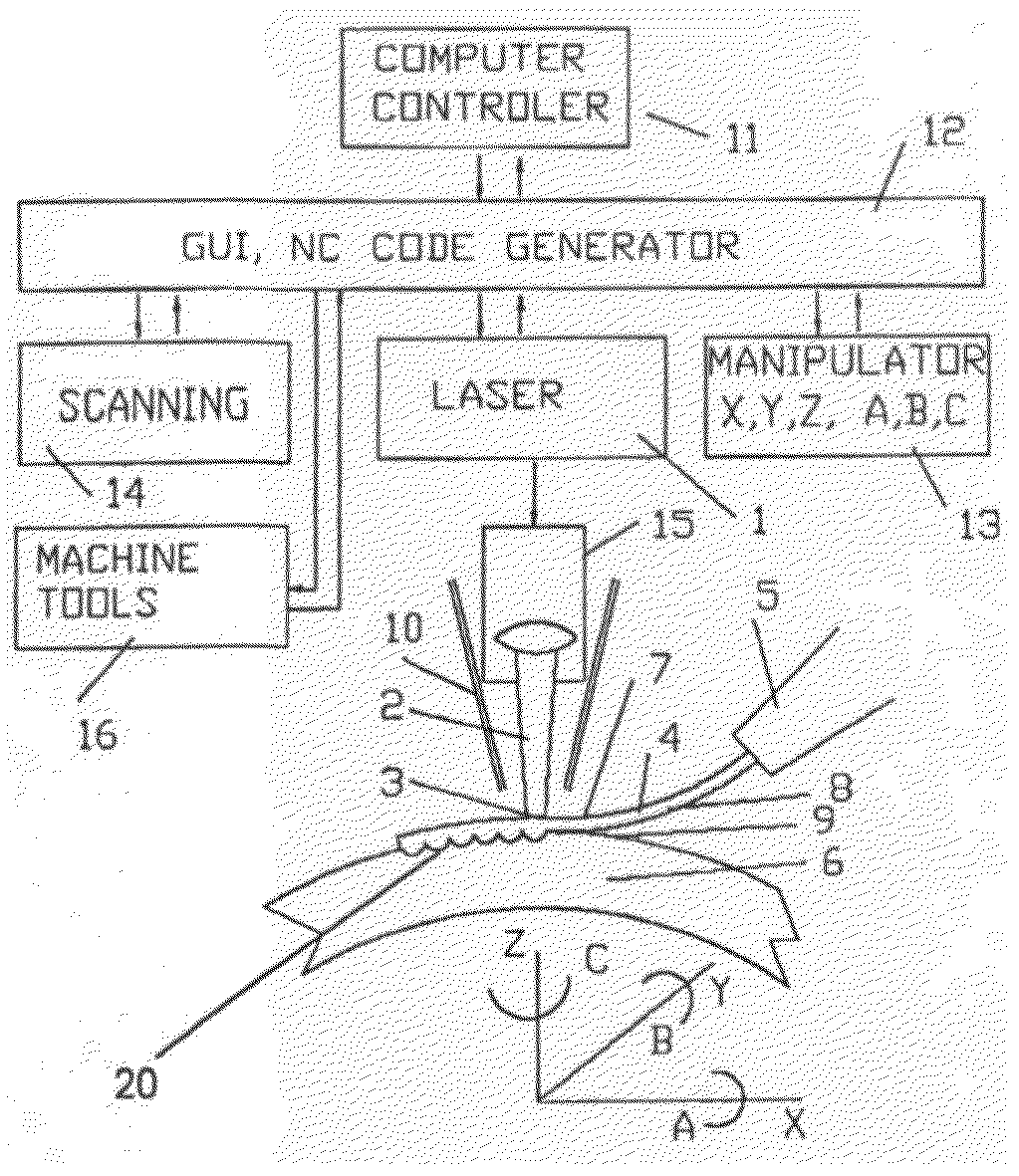

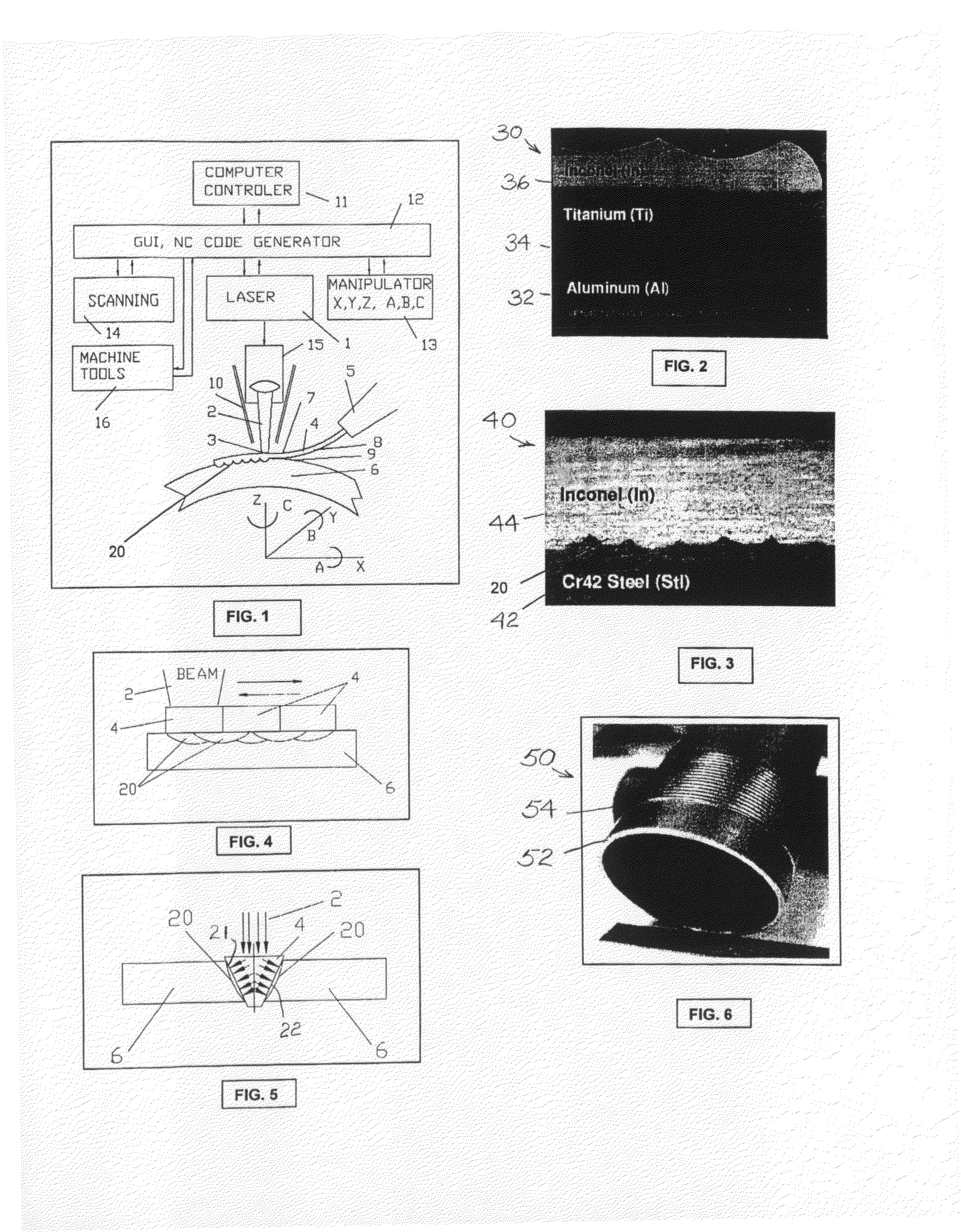

Process for energy beam solid-state metallurgical bonding of wires having two or more flat surfaces

InactiveUS20100155374A1Strong wave-shape interface morphologyLow costAdditive manufacturing apparatusElectron beam welding apparatusWire rodBeam energy

An energy beam assisted solid-state welding welds a wire material to a substrate. A wire of coating or repairing material is placed in contact with a surface or surfaces of a substrate. A beam is directed into an outer flat surface of the wire, which heats the wire through flat outer surface of the wire with beam energy. Beam energy produces compression stress-waves that drive molecules of the material flat wire into a surface of the substrate, joining the material and the substrate with strong wave shaped interfaces.

Owner:RABINOVICH JOSHUA E

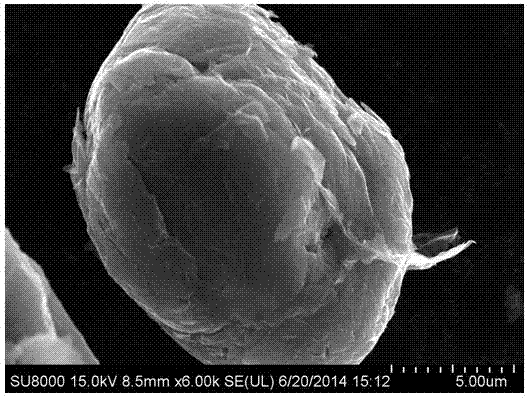

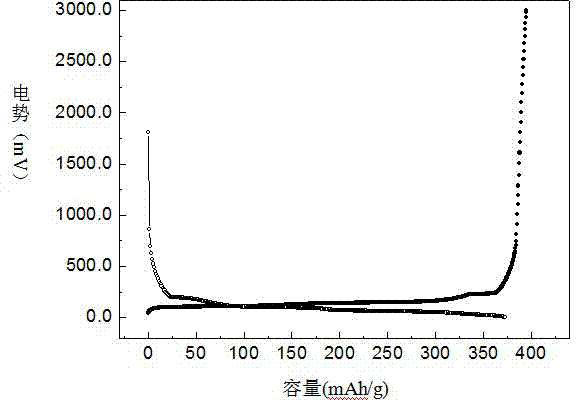

Graphite negative electrode material for lithium ion battery and preparation method of graphite negative electrode material

InactiveCN104124431AStrong interfaceReduce polarizationCell electrodesSecondary cellsElectrical batteryPyrolytic carbon

The invention provides a graphite negative electrode material for a lithium ion battery. The graphite negative electrode material uses a graphite material as an inner core, a conductive network membrane consisting of lignin pyrolytic carbon and graphene coats the surface of the graphite material, and the weight of the conductive network membrane is 0.03-8 percent of the weight of the graphite negative electrode material. The negative electrode material is prepared by adopting the following steps: (1), uniformly mixing graphite powder, lignin and oxidized graphene in a dispersing medium; and (2), drying a prepared mixture, then placing the dried mixture in a sintering furnace, roasting in an inert atmosphere or reducing mixture atmosphere at the constant temperature of 350-600 DEG C for 3-10 h, then roasting at constant temperature of 650-1200 DEG C for 5-20 h, and then cooling to room temperature. According to the graphite negative electrode material, the electric conductivity of the graphite negative electrode material is remarkably increased, and thus the high magnification performance and the cycle performance of the graphite negative electrode material for the lithium ion battery are improved, and the irreversible capacity of the graphite negative electrode material for the lithium ion battery is reduced.

Owner:CHANGSHA SAIWEI ENERGY TECH

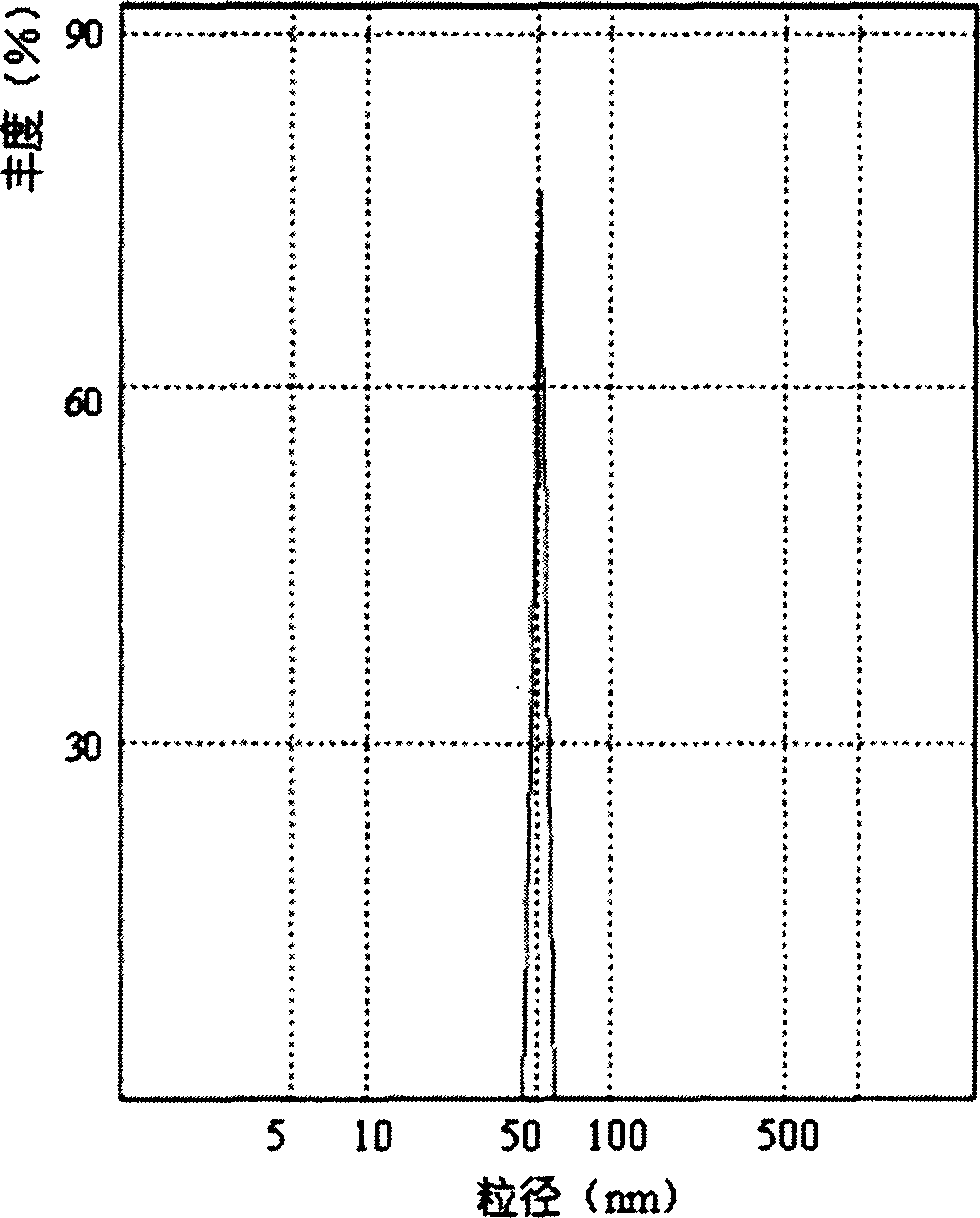

Nano macromolecule microball of carboxy function type cross-linked nucleocapsid structure and preparation process thereof

The invention is a carboxyl functional cross-linked core-shell nano high molecular microsphere and its preparing method, using multiple alkene monomers and alkene monomers with carboxyl functional groups as raw materials, on the condition of emulsifier, initiator and buffering agent, and preparing it by emulsion or suspension polymerization using water as medium; the product has a cross-linked structure inside both the core and shell, the core and shell are linked through chemical bonds, the carboxyl functional groups are grafted on the microsphere surface, and the particle size is less than 100 nm. By changing the composition of the core and shell, it obtains a nano high molecular microsphere with multiple different physico-chemical properties, and has very high freedom in selecting structure design. It solves the problem that the precious core-shell high molecular microshperes have no nano size and that the precious cores and shells are mostly linear polymers, and simultaneously by introducing ionizable and reactable carboxyl functional groups on the surface, and makes this microsphere have a completely wide application prospect in nano technical filed.

Owner:TSINGHUA UNIV

Self-forming embedded diffusion barriers

ActiveUS20150340323A1Controlled diffusionStrong interfaceSemiconductor/solid-state device detailsSolid-state devicesDielectricSelf forming

Interconnect structures containing metal oxide embedded diffusion barriers and methods of forming the same. Interconnect structures may include an Mx level including an Mx metal in an Mx dielectric, an Mx+1 level above the Mx level including an Mx+1 metal in an Mx+1 dielectric, an embedded diffusion barrier adjacent to the Mx+1 dielectric; and a seed alloy region adjacent to the Mx+1 metal separating the Mx metal from the Mx+1 metal. The embedded diffusion barrier may include a barrier-forming material such as manganese, aluminum, titanium, or some combination thereof. The seed alloy region may include a seed material such as cobalt, ruthenium, or some combination thereof.

Owner:TESSERA LLC

Method for preparing carbon nanotube grafted with vinyl macromolecular chain on the surface

The invention provides a method for preparing carbon nanotube grafted with vinyl macromolecular chain on the surface. The method is characterized in that carbon nanotube is processed by Fenton reagent formed by soluble ferrous salt and oxyful, so as to realize surface hydroxylation; a coupling agent containing unsaturated double bond functional groups is used for surface treatment; and the carbon nanotube of which the surface is provided with double bonds, and vinyl monomer are processed by graft polymerization reaction to obtain the carbon nanotube grafted with vinyl macromolecular chain on the surface. The method has the advantages of environmental protection, high efficiency, low cost and simple process, and is suitable for industrial production. The obtained functionalized carbon nanotube has excellent oil solubility or water solubility, vinyl monomer used for graft is adjusted to realize that the carbon nanotube can be endued with favorable dispersibility in a majority of polymer materials and higher interfacial function which mainly depends on chemical bonds can be formed by the carbon nanotube and the polymer materials, and therefore, the excellent performances of the carbon nanotube can be fully utilized to prepare high performance or functionalized polymer composite materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

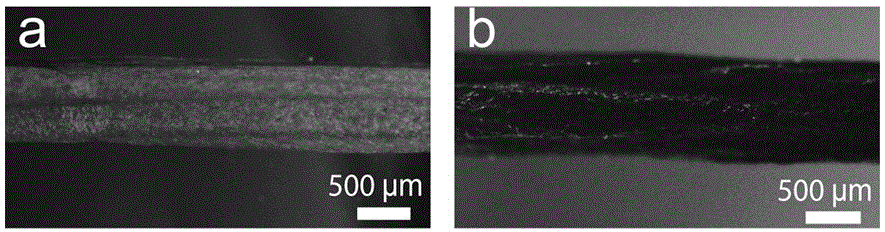

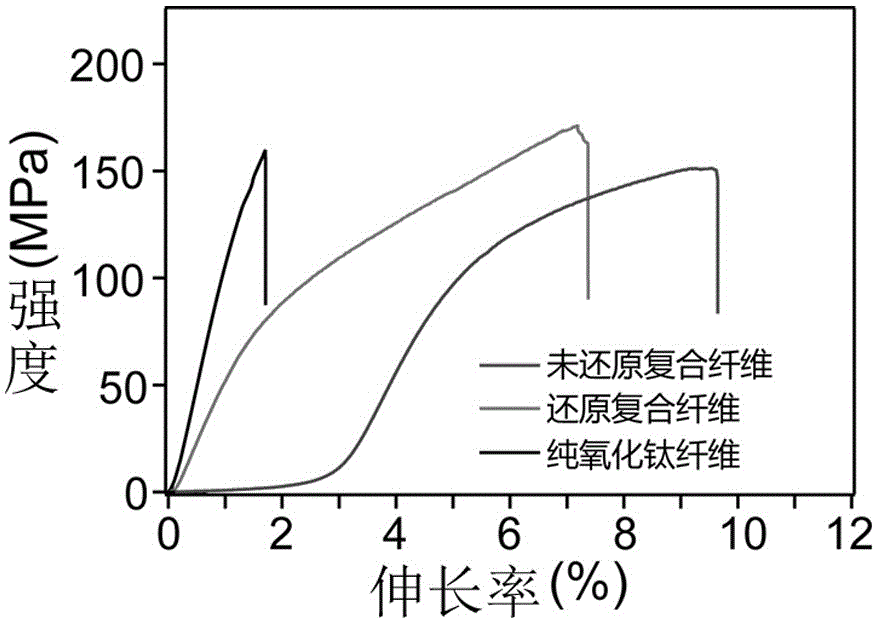

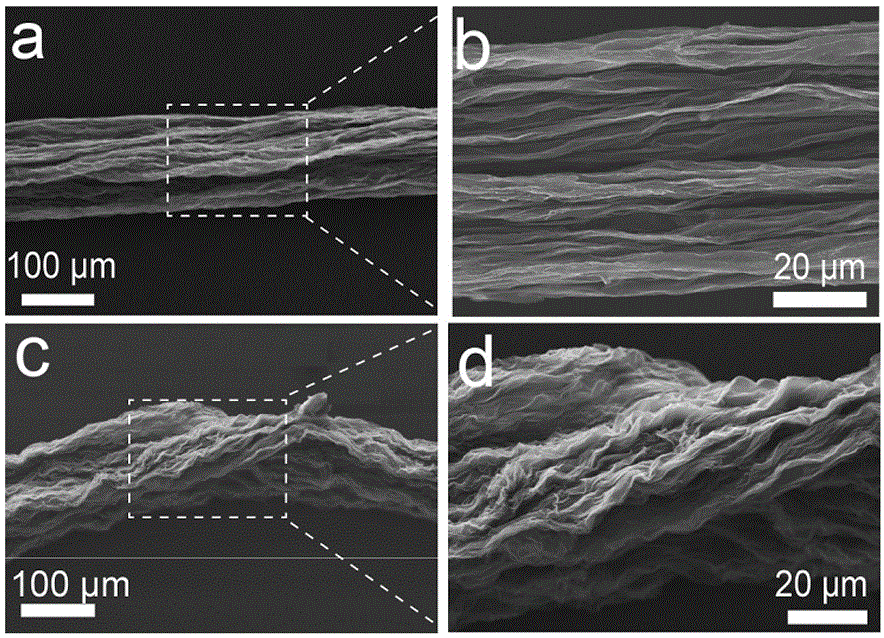

ActiveCN107180947AGood mechanical propertiesExcellent electrochemical performanceFinal product manufactureCell electrodesCvd grapheneHydroiodic acid

The invention relates to a flexible cell based on metallic oxide / graphene composite macroscopic fibers and a preparation method. The preparation method comprises the following steps: after mixing an anionic metal oxide aqueous solution with graphene oxide to obtain a spinning solution, adding the spinning solution in wet spinning equipment to obtain nascent fibers; repeatedly washing the obtained nascent fibers with deionized water, and drying the nascent fibers to obtain metallic oxide and graphene oxide composite fibers; reducing the metallic oxide and graphene oxide composite fibers with hydroiodic acid, and then washing and drying the metallic oxide and graphene oxide composite fibers to obtain the metallic oxide and graphene composite fibers; placing the composite fibers, lithium lines and lithium manganate loaded carbon cloth fibers in a shrinkable tube in parallel; and adding diaphragms and electrolyte so that half cells and total cells can be assembled respectively. The preparation process is simple and controllable, and large-scale production is facilitated. The metallic oxide and graphene composite fibers which are prepared by the preparation method for the first time have unlimited prospects in the field of energy storage of flexible cells.

Owner:SUZHOU UNIV

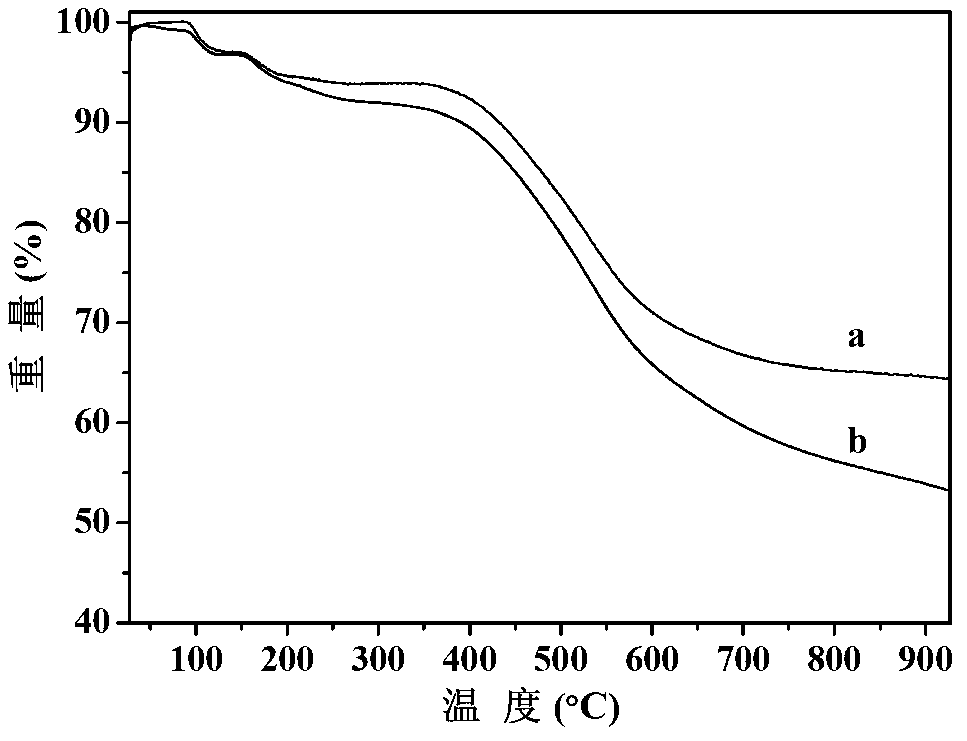

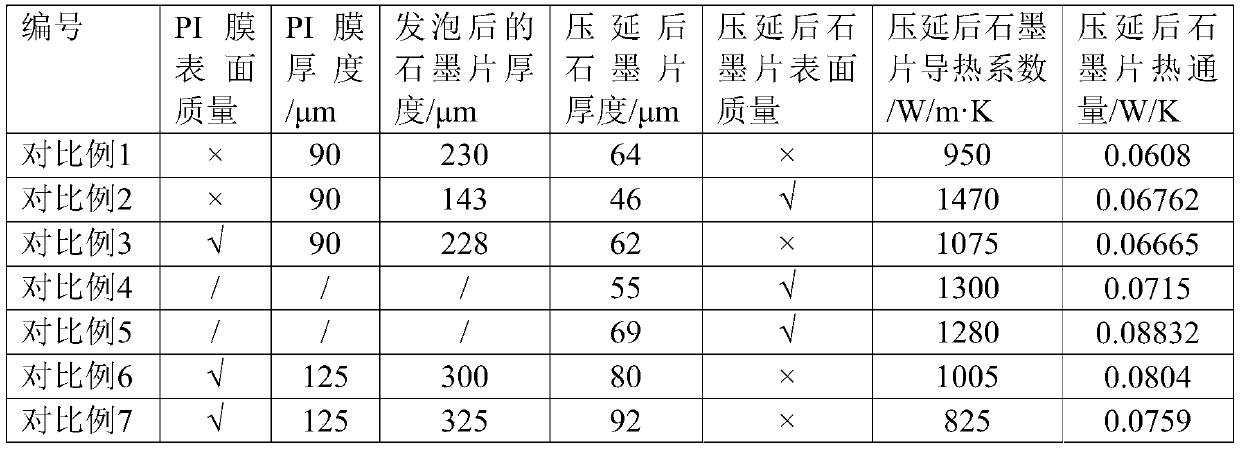

Ultra-thick type polyimide film and preparation method thereof, and graphite sheet

ActiveCN110423467AThe end point of the reaction is controllableResin viscosity is stableCarbon compoundsDiaminePolyimide membrane

The invention discloses an ultra-thick type polyimide film and a preparation method thereof. The preparation method comprises the following steps: dissolving surface-modified carbon nanotubes and inorganic filling materials in an organic solvent, and stirring uniformly; then adding a diamine monomer, adding a dianhydride monomer in batches after the diamine monomer is dissolved, and finally addinga cross-linking type end capping agent, and performing defoaming to obtain polyamide acid resin; and then adding a dehydrating agent and a catalyst for uniformly mixing to obtain precursor resin, andforming by salivation, high-temperature imidization, cross-linking, and annealing and heat setting. The ultra-thick type polyimide film is subjected to carbonization, graphitization and calendering treatment to obtain a graphite sheet with the single-layer thickness of 45-130 [mu]m, and the technical problem that an ultra-thick PI film in a current industry generates excessive expansion during ahigh-temperature graphitization process, and a single-layer thickness type graphite sheet cannot be obtained is solved.

Owner:株洲时代华鑫新材料技术有限公司

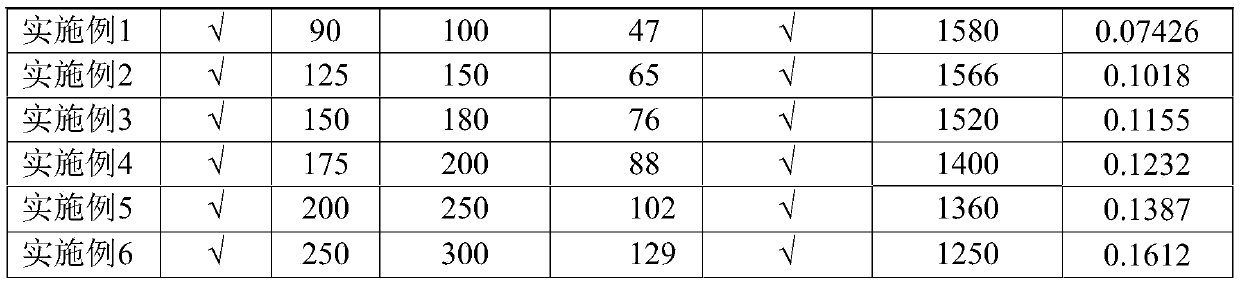

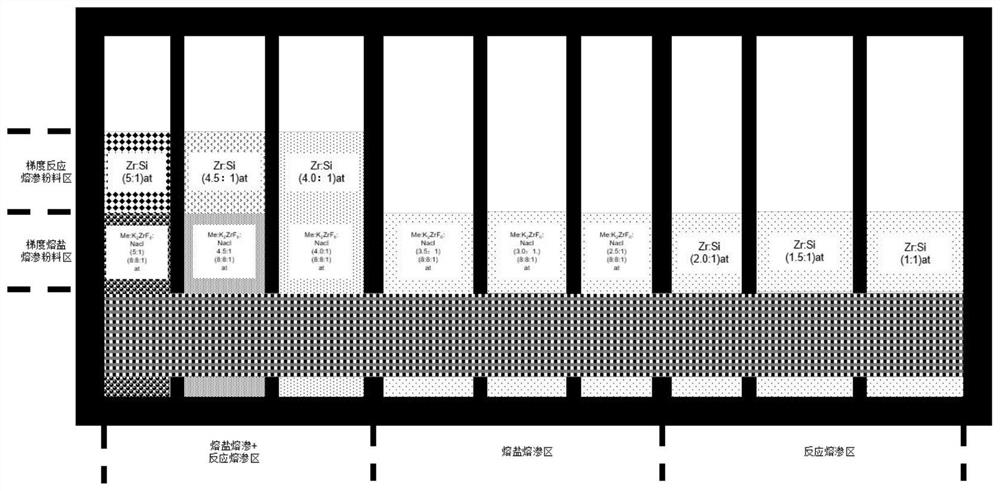

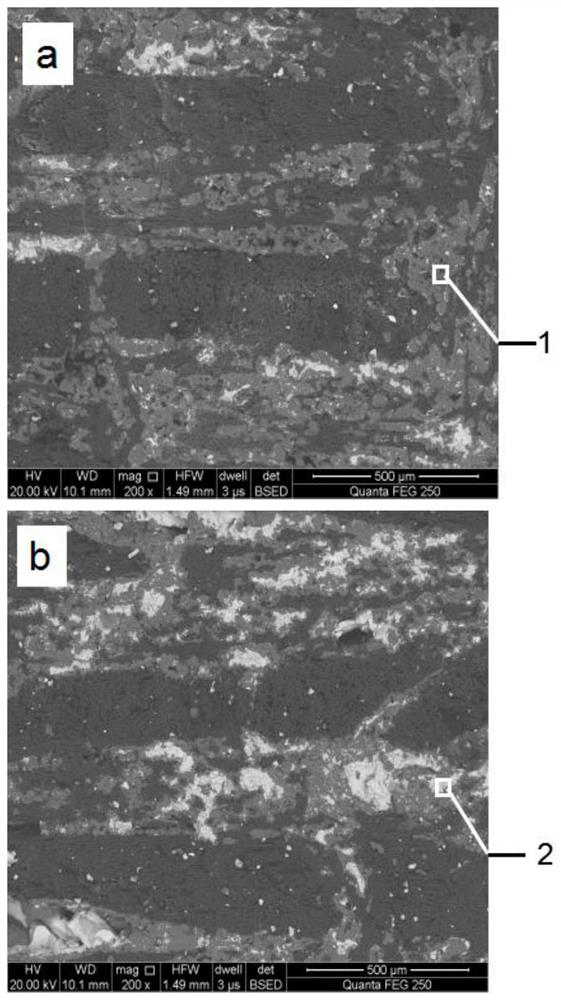

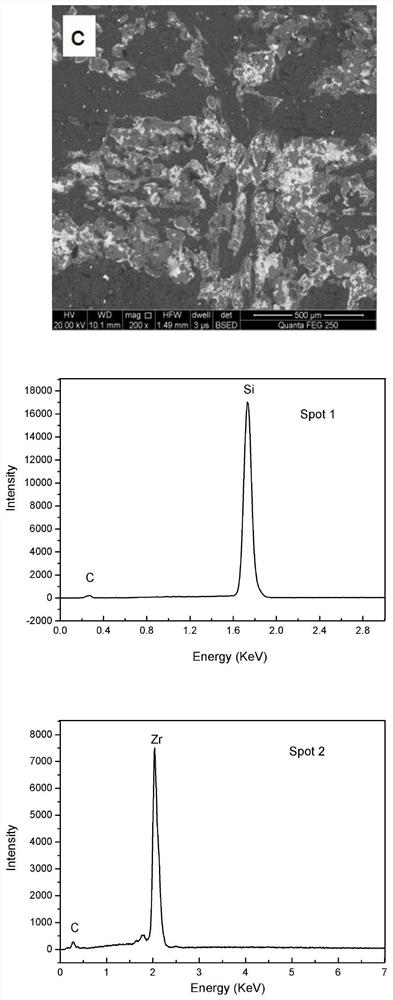

Preparation method of component- gradient -controllable multi-element ultrahigh-temperature ceramic modified C/C composite material

ActiveCN112457056AAvoid stress concentrationImprove anti-ablation performanceCeramicwareMolten saltUltrahigh temperature ceramics

The invention discloses a preparation method of a component-gradient-controllable multi-element ultrahigh-temperature ceramic modified C / C composite material. Through multi-section design of various ultrahigh-temperature ceramics (ZrC, HfC, HfB2 and the like) and high-temperature ceramic (SiC) composite modified C / C composite materials, a ceramic phase forms a continuous component gradient distribution form in a C / C matrix, ablation resistance and oxidation resistance requirements of different temperature range fields are met regionally, and meanwhile the defect that the mechanical property isreduced due to component mutation is overcome. According to the invention, a preparation process of combining molten salt infiltration and common reaction infiltration and gradient infiltration powder configuration are adopted in sections, so that near-ablation-end strong ceramic phase interface design is realized, and ceramic phase distribution realizing that the content of an ultrahigh-temperature ceramic phase is sequentially decreased from the near ablation end to a far ablation end and the high-temperature ceramic phase is sequentially increased is regulated and controlled; finally, thegradient ceramic-based composite material with different ceramic phase components and contents in gradient change and meeting the performance requirements of the material is formed.

Owner:CENT SOUTH UNIV

Natural antibacterial skin-care polypropylene fiber and preparation method thereof

InactiveCN105821507AWell mixedSolve for uniformityMonocomponent polyolefin artificial filamentArtifical filament manufacturePhenolMechanical property

The invention provides a natural antibacterial and skin-care polypropylene fiber and a preparation method thereof. The raw material formula of the polypropylene fiber includes 65-90% of polypropylene slices, 5-16% of sea mud powder, and 2.5-90% of echinacea extract. 6%, 1.5-5% of herb extract, 0.1-1.3% of nonylphenol polyoxyethylene ether, 0.5-3% of Xinggu oilseed oil, 0.1-0.7% of ellagic acid, 0.1 of isopropyl myristate ~1.3, coupling agent 0.2~1.7. The above-mentioned raw materials are compounded reasonably and synergistically. Its fragrance is elegant and clear, and it has good compatibility and skin affinity. It not only has a wide antibacterial spectrum, good antibacterial effect and long-lasting effect, but also provides the necessary nutrients for skin cell renewal. Skin cleansing, to achieve comprehensive care for human skin, and better improve the spinnability, moisture absorption, air permeability, dyeing uniformity and mechanical properties of the fiber, can be widely used in the production of textiles and medicines that are in close contact with the human body Industrial work clothes greatly broaden the application field of sea mud.

Owner:陆建益

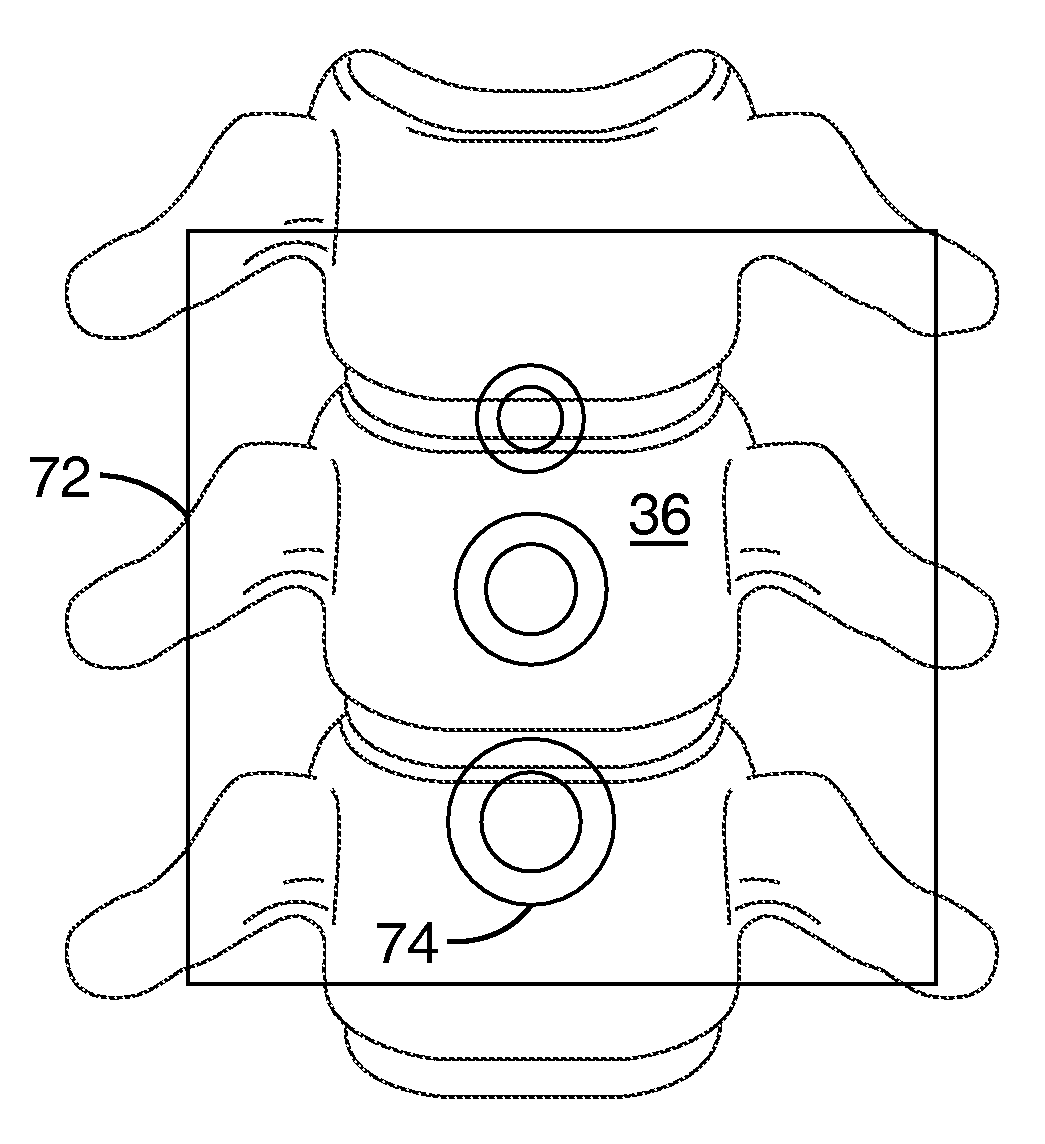

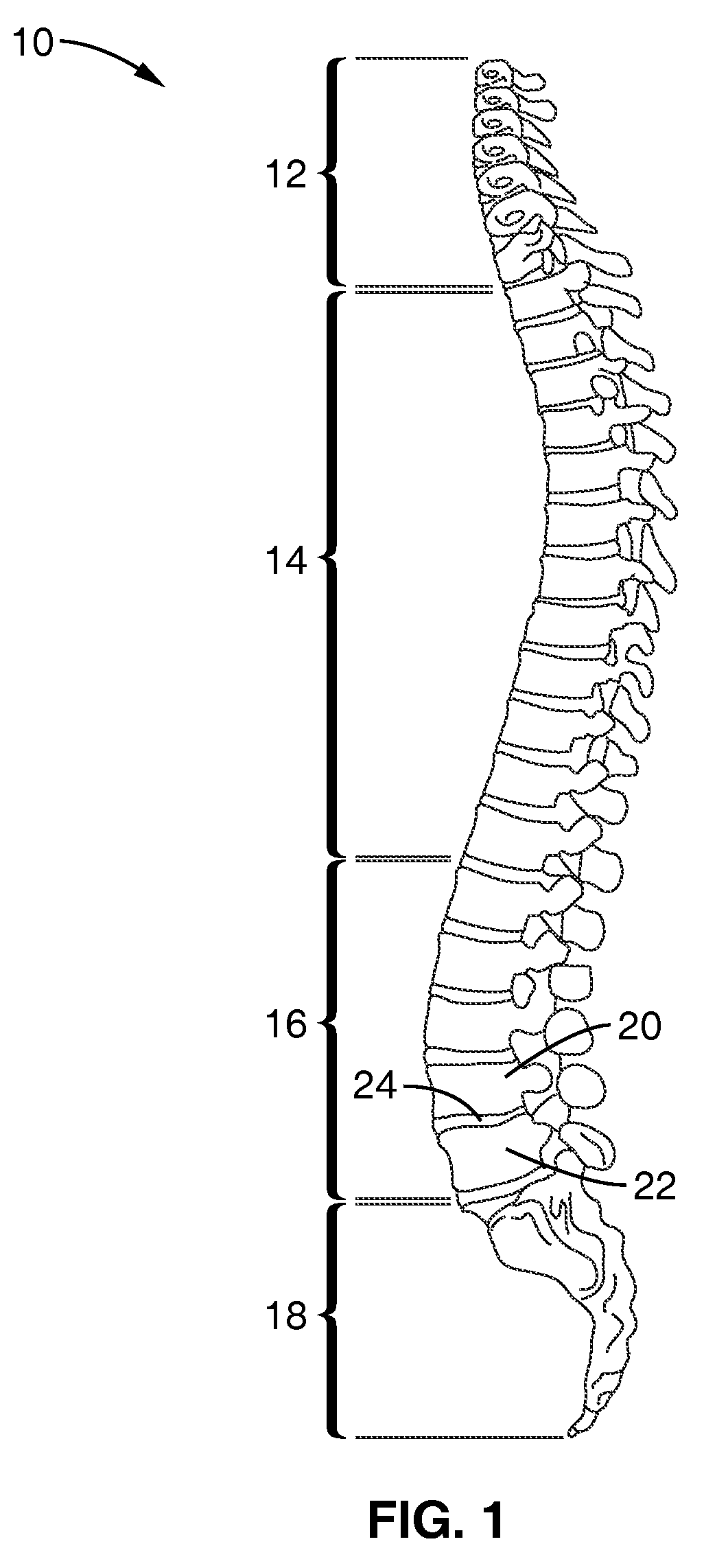

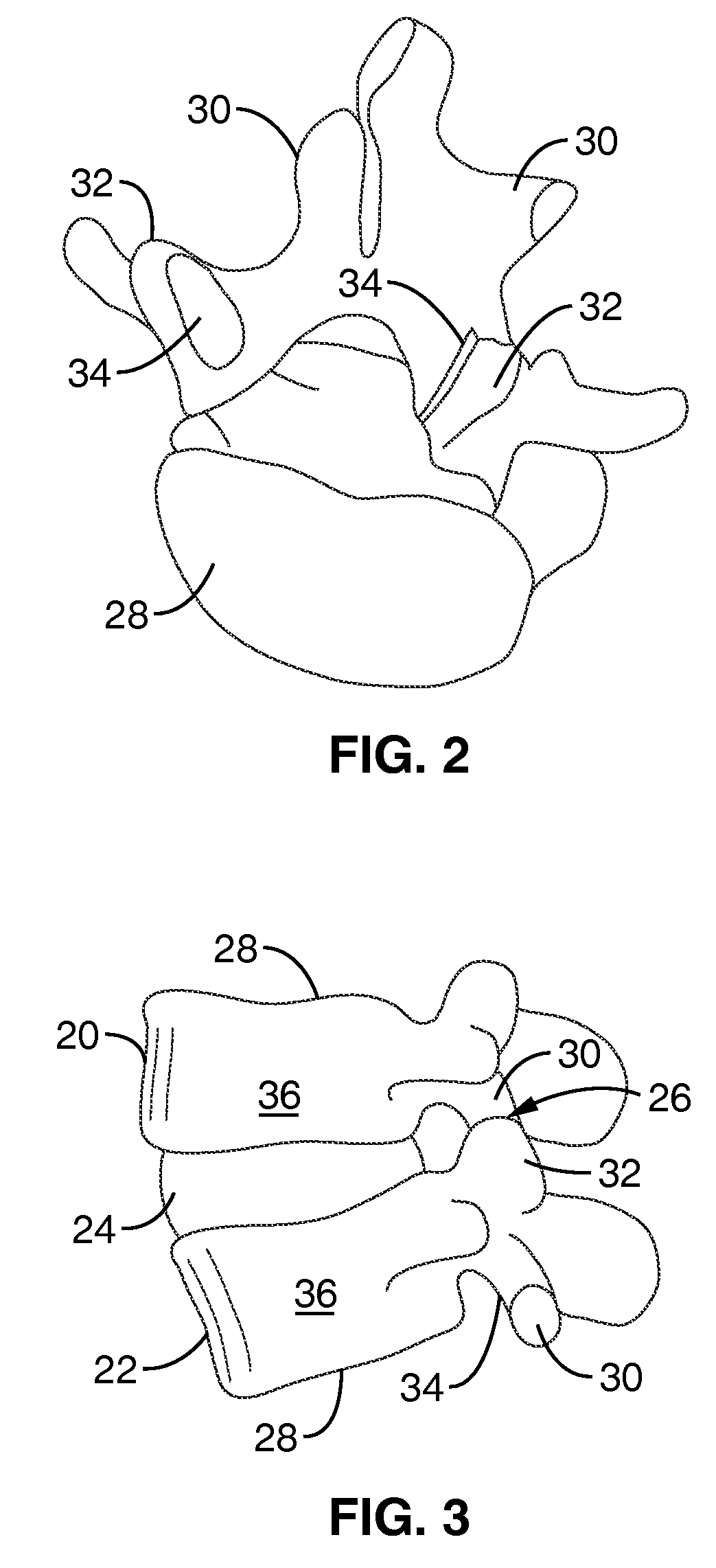

Minimally invasive spine internal fixation system

InactiveUS20090112261A1Strong interfaceIncrease percentageSuture equipmentsInternal osteosythesisInternal fixationLumbar vertebral column

A minimally invasive modular system is disclosed for stabilizing the anterior column of the spine through an anterior or lateral approach. Bone anchors are implanted into the vertebral bodies of adjacent vertebrae and serve as a foundation for a fixation system. The anchors comprise an interface surface that allows an interconnecting link to be secured to the anchors in a low-profile manner with minimum protrusion beyond the vertebral members. The link may be secured to the bone anchors to affect a compressive interlocking force between the bone anchors and vertebrae.

Owner:BARRY RICHARD J

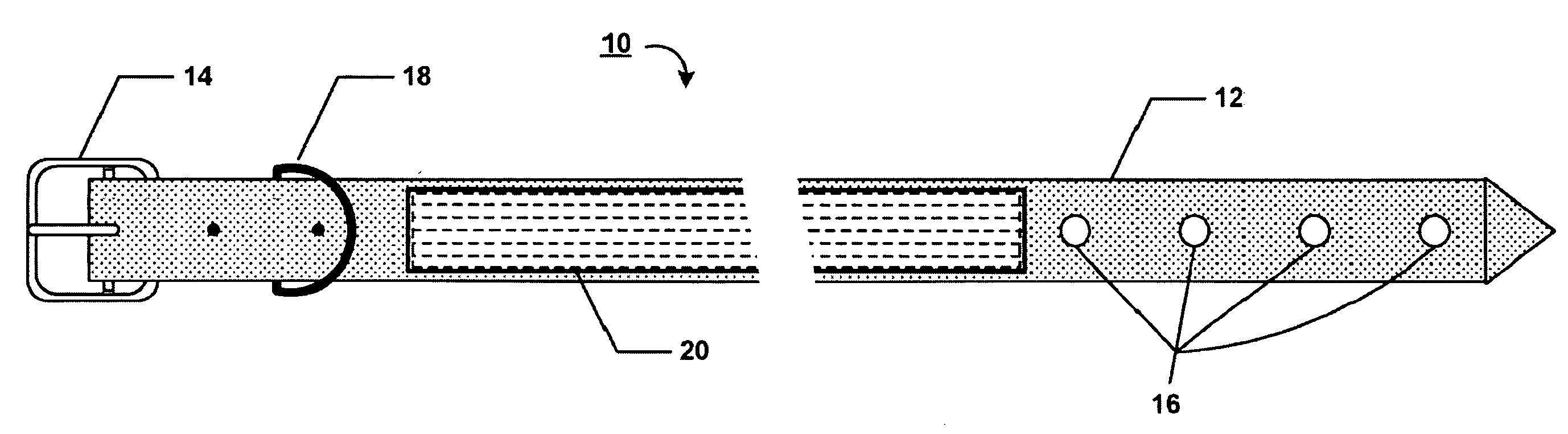

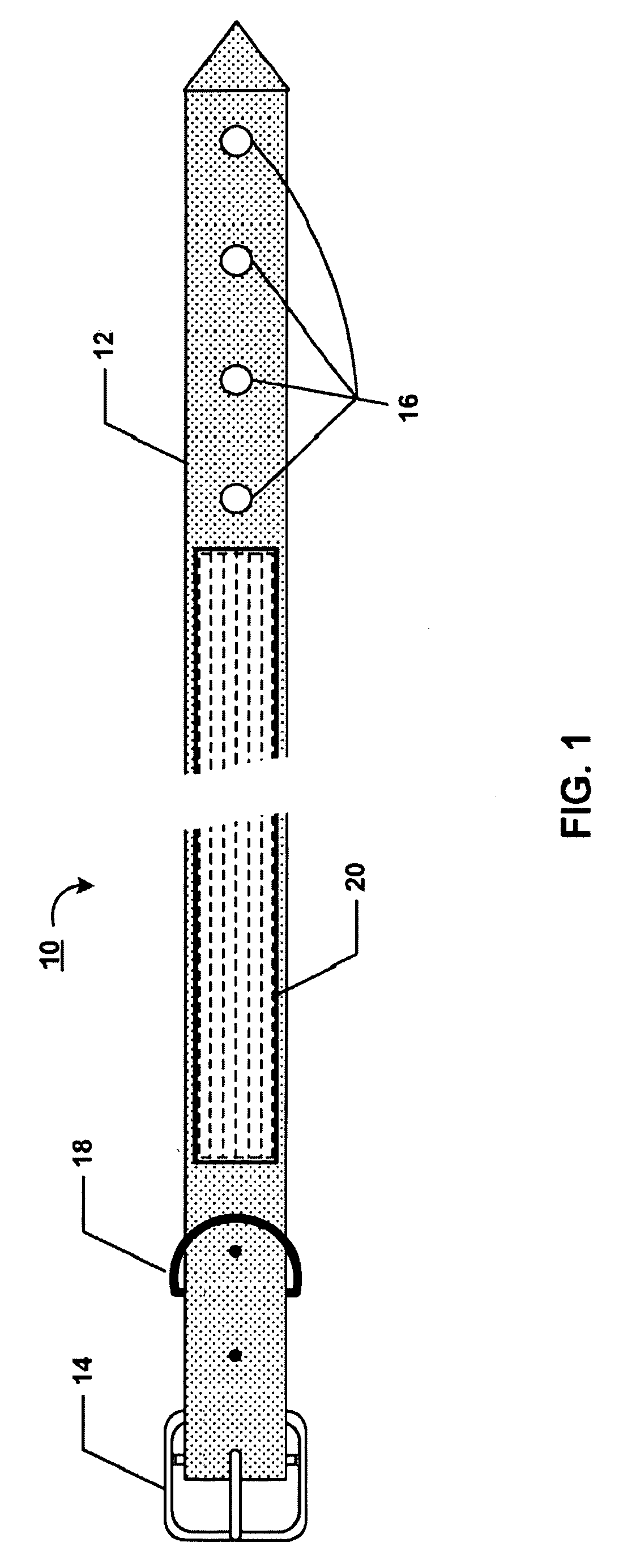

Glow-in-the-dark animal collars

InactiveUS20090283056A1Unwanted foldingUnwanted creasingSafety beltsTaming and training devicesEpoxyAdhesive

Glow-in-the dark animal collars are provided, in which photoluminescence elements formed from thin flexible sheets or films with luminescent properties are secured to strap members of conventional animal collars with stitching patterns that prevent creasing, folding or delamination of the photoluminescent elements without having to use glue, adhesives, or epoxy materials.

Owner:MATTERA JOHN

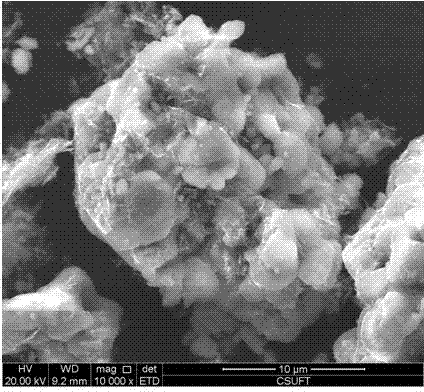

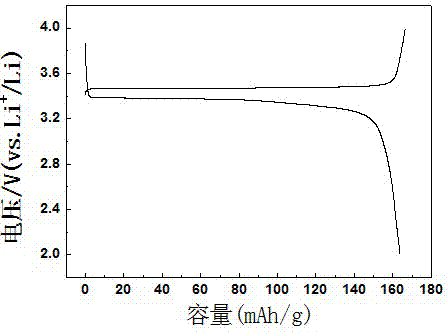

Lithium iron phosphate composite positive electrode material with surface coated with titanium nitride and graphene as well as preparation method and application of material

InactiveCN104124437ALower internal resistanceStrong interfaceCell electrodesSecondary cellsElectrically conductiveLithium electrode

The invention provides a lithium iron phosphate composite positive electrode material with a surface coated with titanium nitride and graphene, a preparation method of the material and an application of the material in preparation of a lithium ion battery. According to the lithium iron phosphate composite positive electrode material, a lithium iron phosphate material is used as an inner core; the surface of the lithium iron phosphate material is coated with a conductive network film which consists of titanium nitride and graphene; and the mass of the conductive network film is 0.2%-10% of the mass of the lithium iron phosphate material. The preparation method of the material comprises the following steps: uniformly mixing the lithium iron phosphate material with graphene, a nitride source and a titanium-containing compound in a dispersion medium to prepare a mixed material, drying the mixed material, subsequently sintering the mixed material at 400 DEG C to 900 DEG C for 6-24 hours in the presence of inert protective atmosphere so as to prepare the lithium iron phosphate composite positive electrode material with the surface coated with titanium nitride and graphene. The lithium iron phosphate composite positive electrode material is relatively high in conductivity and tap density and relatively good in rate capability and cycle performance; and the preparation method is simple in steps, low in cost and simple to operate.

Owner:CHANGSHA SAIWEI ENERGY TECH

Two-component interface agent and use method thereof

The invention provides a two-component interface agent. The two-component interface agent comprises a slurry A and a powder B, and the slurry A comprises 80-150 parts of styrene acrylic emulsion, 100-200 parts of water, 0.3-0.8 parts of an antifoaming agent, 0.5-1.5 parts of a bactericide and 1-5 parts of a water reducer; the powder B comprises 400-600 parts of cement, 400-600 parts of quartz powder and 0.2-0.5 parts of HPMC; and the interface agent is formed by mixing the slurry A with the powder B according to a ratio of 1:2.5-4. The two-component interface agent can provide good interface effects for original face bricks and walls, effectively improves the construction quality and the construction progress in the secondary finishing process, has a wide application range, and has good adaptability to various tiles, glass mosaics, polished tiles, vitrified tiles, marbles, terrazzos, granitic plasters, concretes, cements and mortars. The two-component interface agent also has a good waterproof effect.

Owner:湖北鲁邦建材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com