Preparation method of high-temperature superconducting thin film

A high-temperature superconducting thin film, single crystal thin film technology, applied in chemical instruments and methods, from chemical reactive gases, single crystal growth, etc. Impurities and other problems, to achieve the effect of reducing electron scattering, maintaining superconducting properties, and small lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The high-temperature superconducting thin film provided by the present invention and its preparation method will be further described in detail below with reference to the accompanying drawings and specific examples.

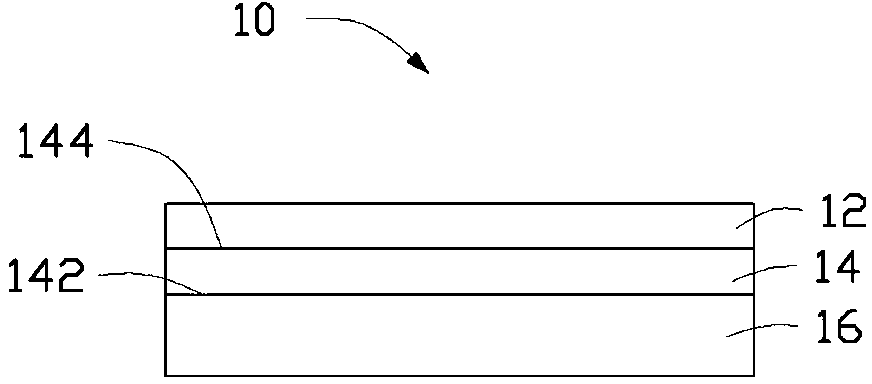

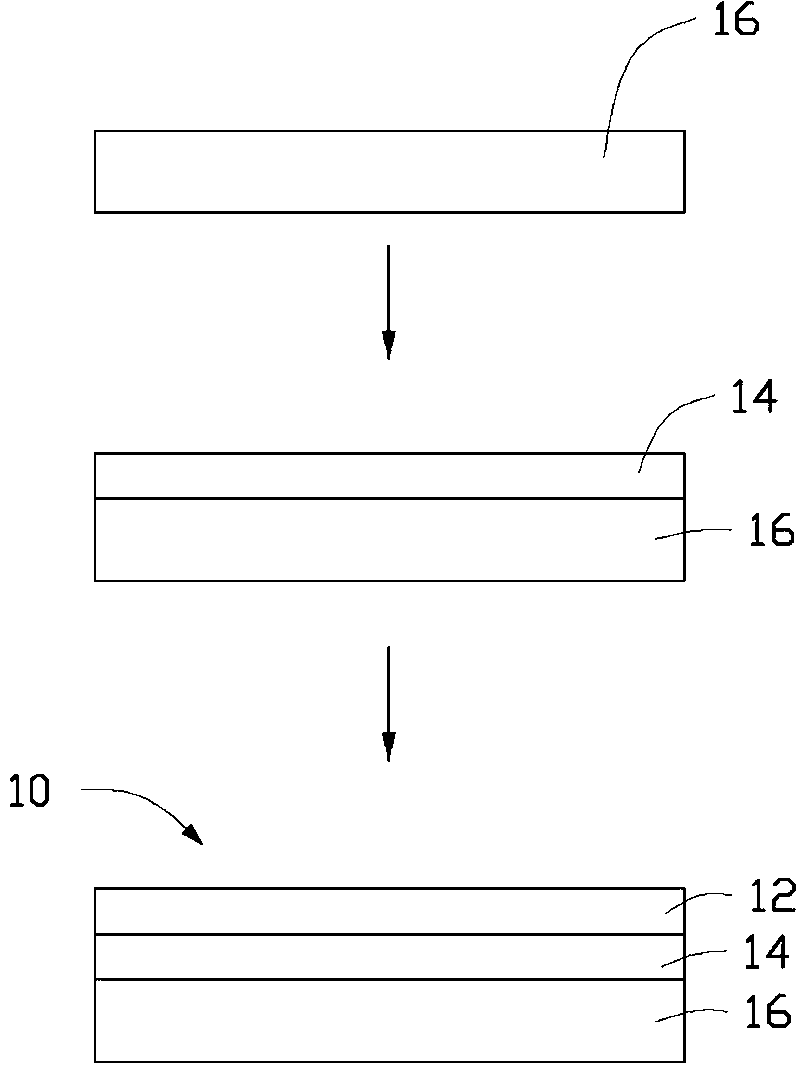

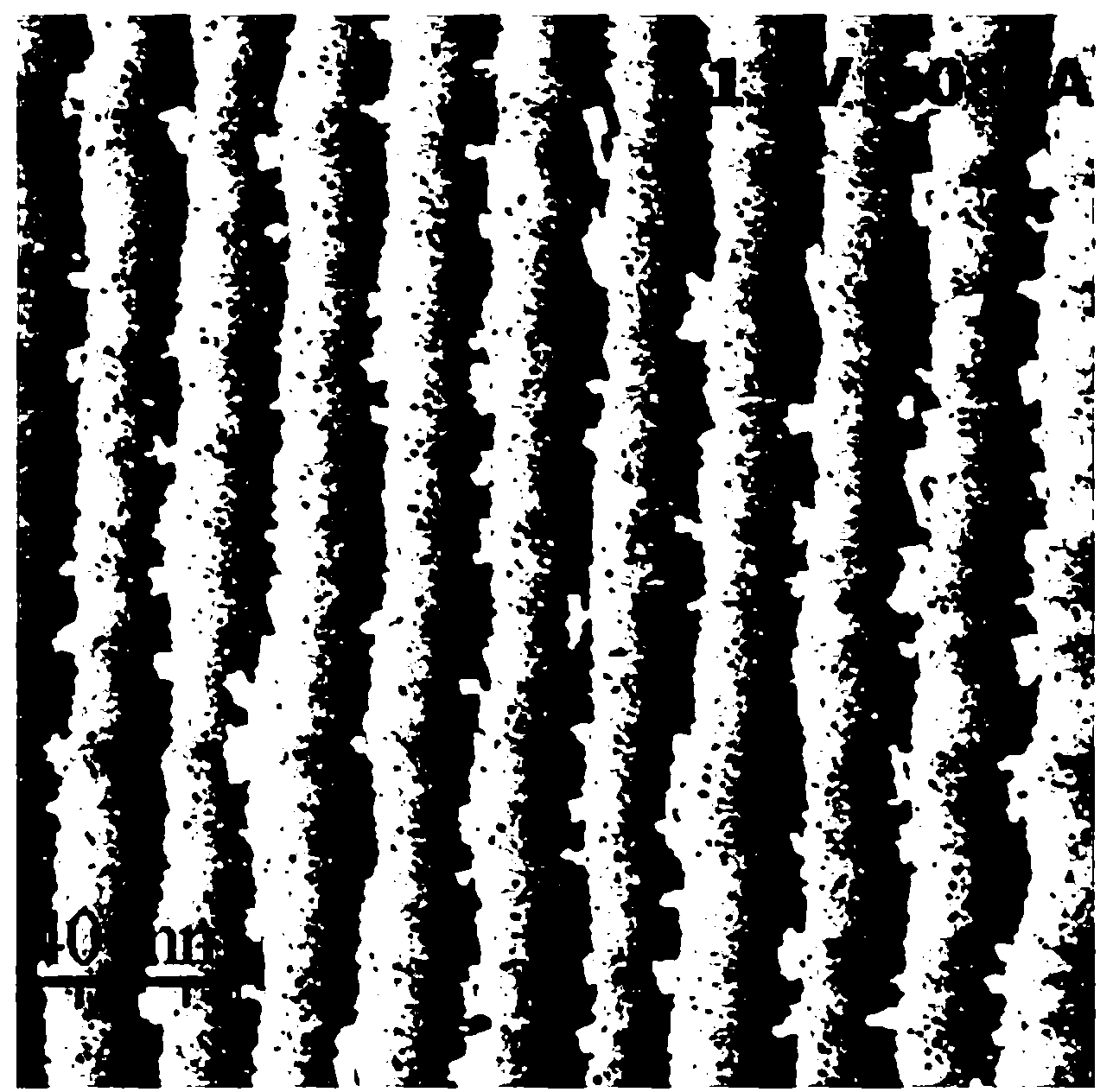

[0025] See figure 1 , the embodiment of the present invention provides an iron-based high-temperature superconducting film 10, the iron-based high-temperature superconducting film 10 includes a strontium titanate (SrTiO 3 ) substrate 16 , an iron selenium (FeSe) single crystal layer 14 , and a protective layer 12 . The SrTiO 3 The substrate 16, the FeSe single crystal layer 14 and the protective layer 12 are sequentially stacked, wherein the FeSe single crystal layer 14 is located on the SrTiO 3 between the substrate 16 and the protective layer 12 . The SrTiO 3 The substrate 16 , the FeSe single crystal layer 14 and the protective layer 12 are all stacked by epitaxial growth. The FeSe single crystal layer 14 and the SrTiO 3 There is an atomic level ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com