Preparation method of aluminum nitride film

A technology of aluminum nitride film and metal-organic chemistry, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increased difficulty of film formation, high production cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

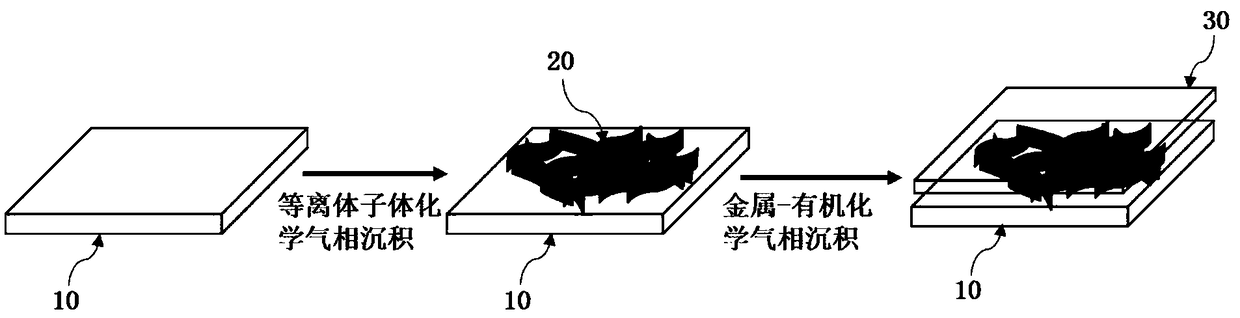

[0030] In the preparation method of one embodiment of the present invention, the vertical graphene nanosheet is used as the buffer layer for the growth of aluminum nitride, and an AlN film is formed on the vertical graphene buffer layer, so that an atomically smooth and stress-free aluminum nitride film can be obtained .

[0031] In one embodiment, the graphene perpendicular to the substrate is grown on the substrate to obtain a vertical graphene-substrate structure, which provides a new growth substrate for the growth of aluminum nitride films. The preparation method of vertical graphene-substrate is simple, which can realize industrialization and large-area growth.

[0032] In one embodiment, the substrate for growing vertical graphene may be high temperature resistant glass.

[0033] In one embodiment, the high-temperature-resistant glass substrate used for growing vertical graphene can be quartz glass, sapphire glass, high-temperature-resistant borosilicate glass, etc., p...

Embodiment 1

[0056] 1) Cleaning of sapphire wafer substrate:

[0057] Put the sapphire wafer substrate into ethanol, acetone, and isopropanol solutions successively for ultrasonic cleaning, and finally ultrasonically clean it with deionized water, and dry it with nitrogen gas to obtain a clean sapphire wafer substrate.

[0058] 2) Carry out the growth of vertical graphene nanosheets on the surface of the sapphire disc substrate to obtain a low-density graphene nanosheet sapphire substrate partially covered with graphene:

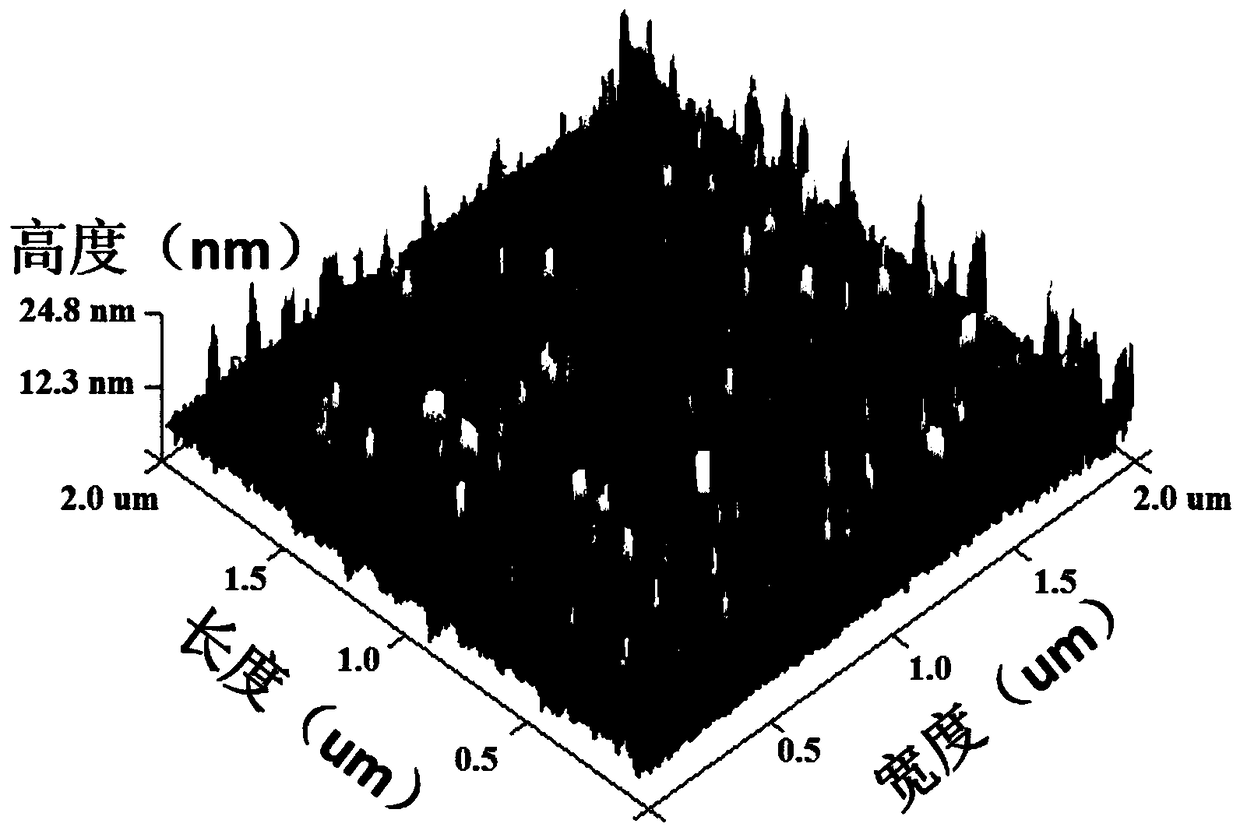

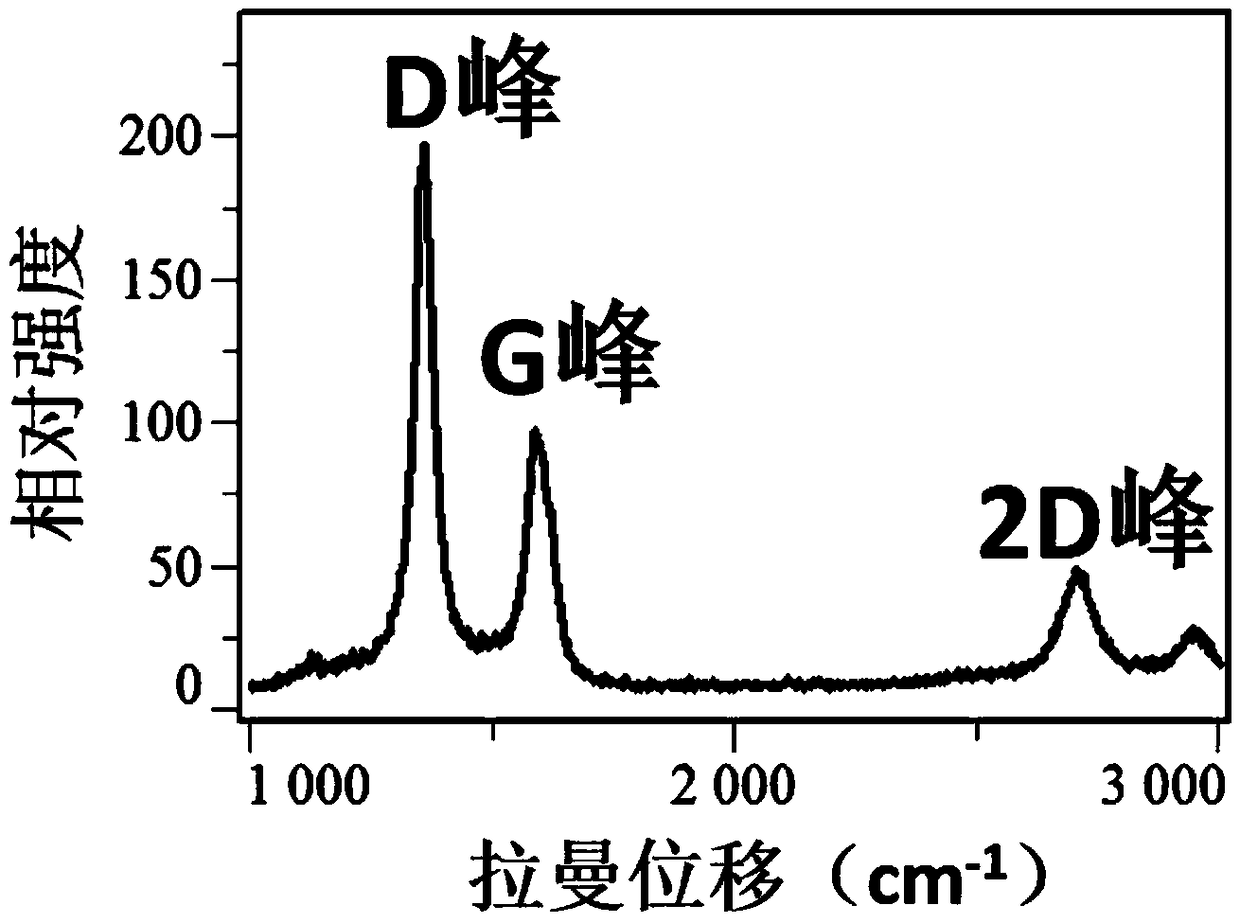

[0059] Based on the AIXTRON BLACK MAGIC system, the low-temperature growth of vertically structured graphene nanosheets was performed using DC plasma-enhanced chemical vapor deposition technology. The specific implementation conditions are: the growth temperature is controlled at about 580°C, the chamber temperature is heated to 580°C in an argon gas atmosphere with a flow rate of 200sccm, and the applied power is 100W, and then 40sccm methane carbon source and 20sccm hy...

Embodiment 2

[0064] The density of graphene nanosheets can be achieved by changing the growth parameters. A specific growth example is as follows: the steps and conditions of this embodiment are basically the same as those of embodiment 1. The growth conditions of the vertical graphene nanosheets are a growth temperature of 580 °C, an applied power of 100 W, and 40 sccm CH 4 and 20sccmH 2 carbon source concentration, the difference is to change the growth time, increase the growth time to 10 minutes, and obtain high-density graphene nanosheets (about 180 / micron 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com