Patents

Literature

3229 results about "Sapphire substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

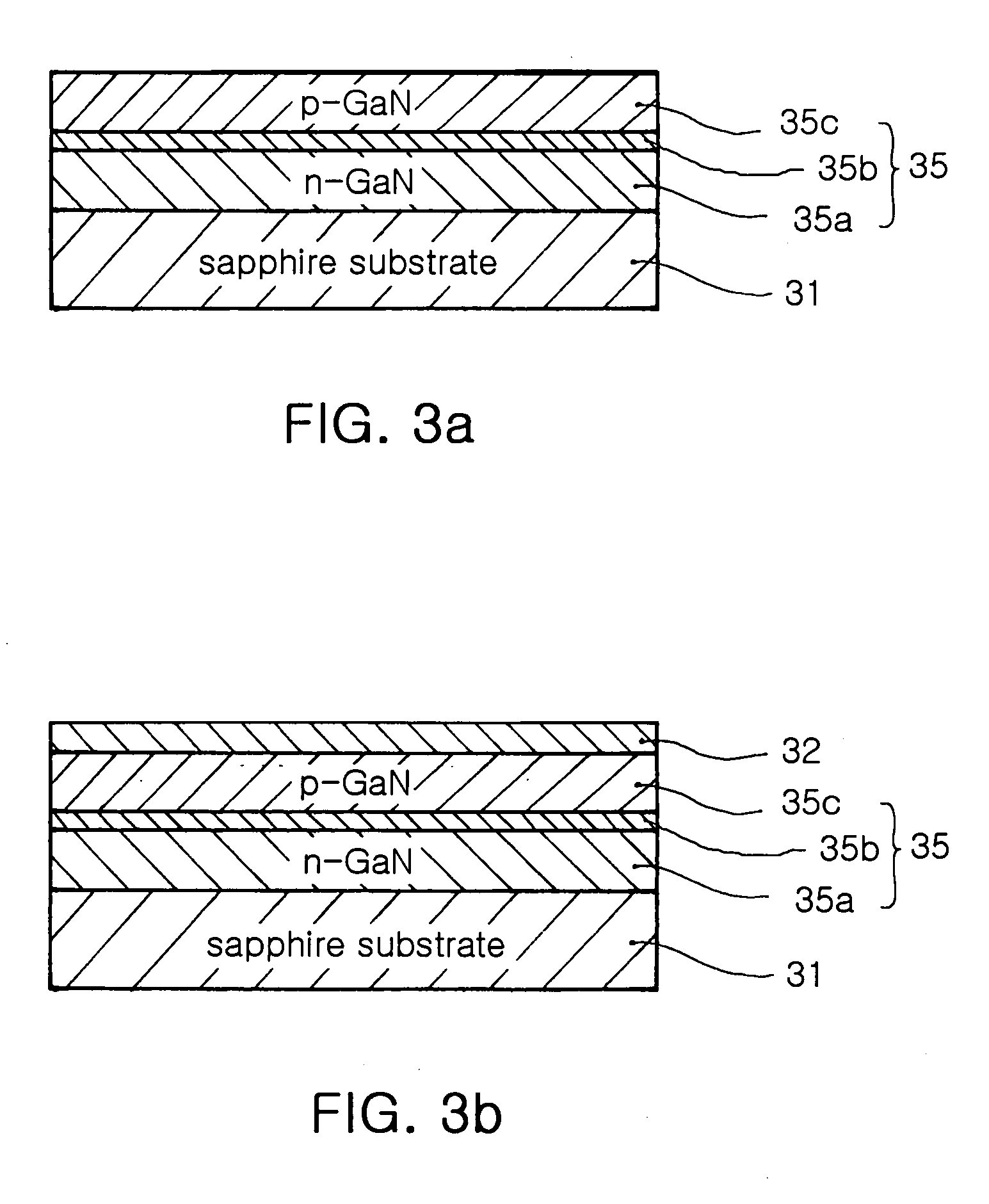

Semiconductor light emitting element, and its manufacturing method

InactiveUS6303405B1Quality improvementImprove electricitySolid-state devicesSemiconductor/solid-state device manufacturingLaser lightHeat stress

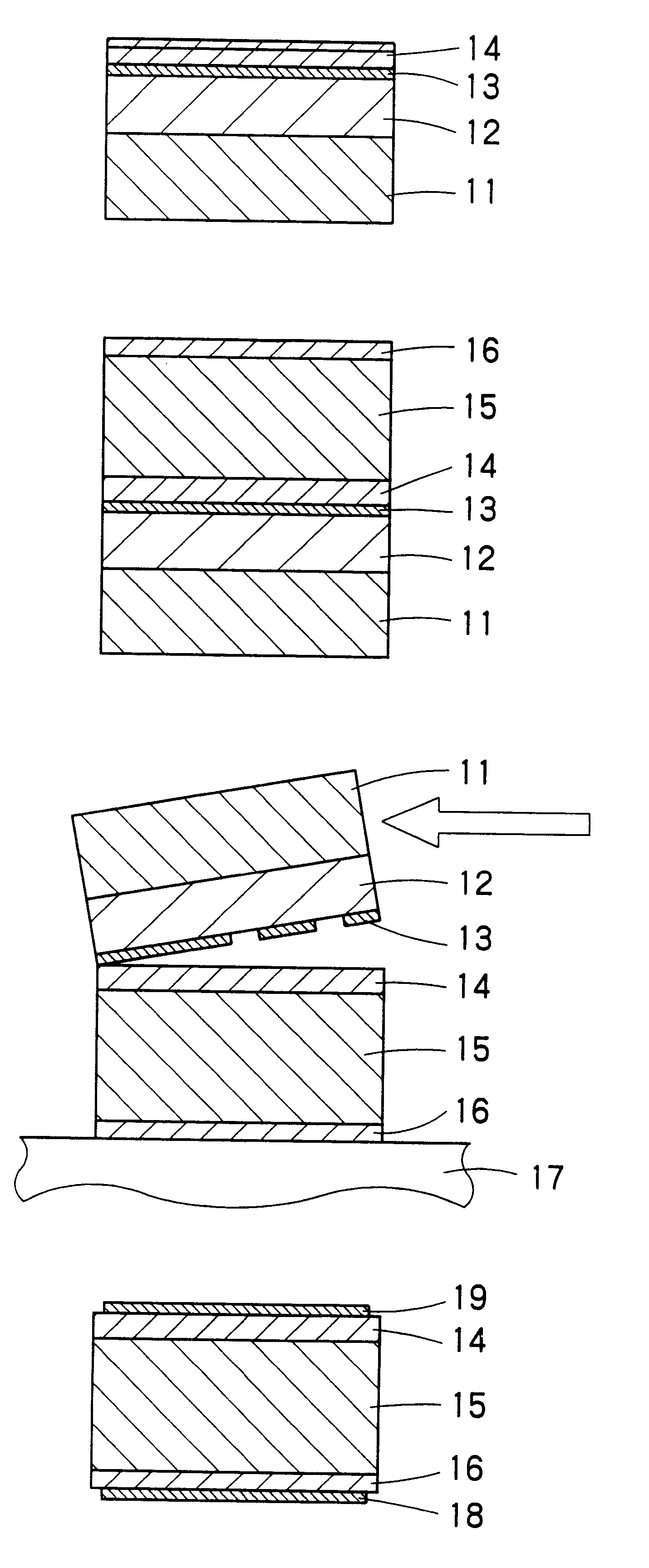

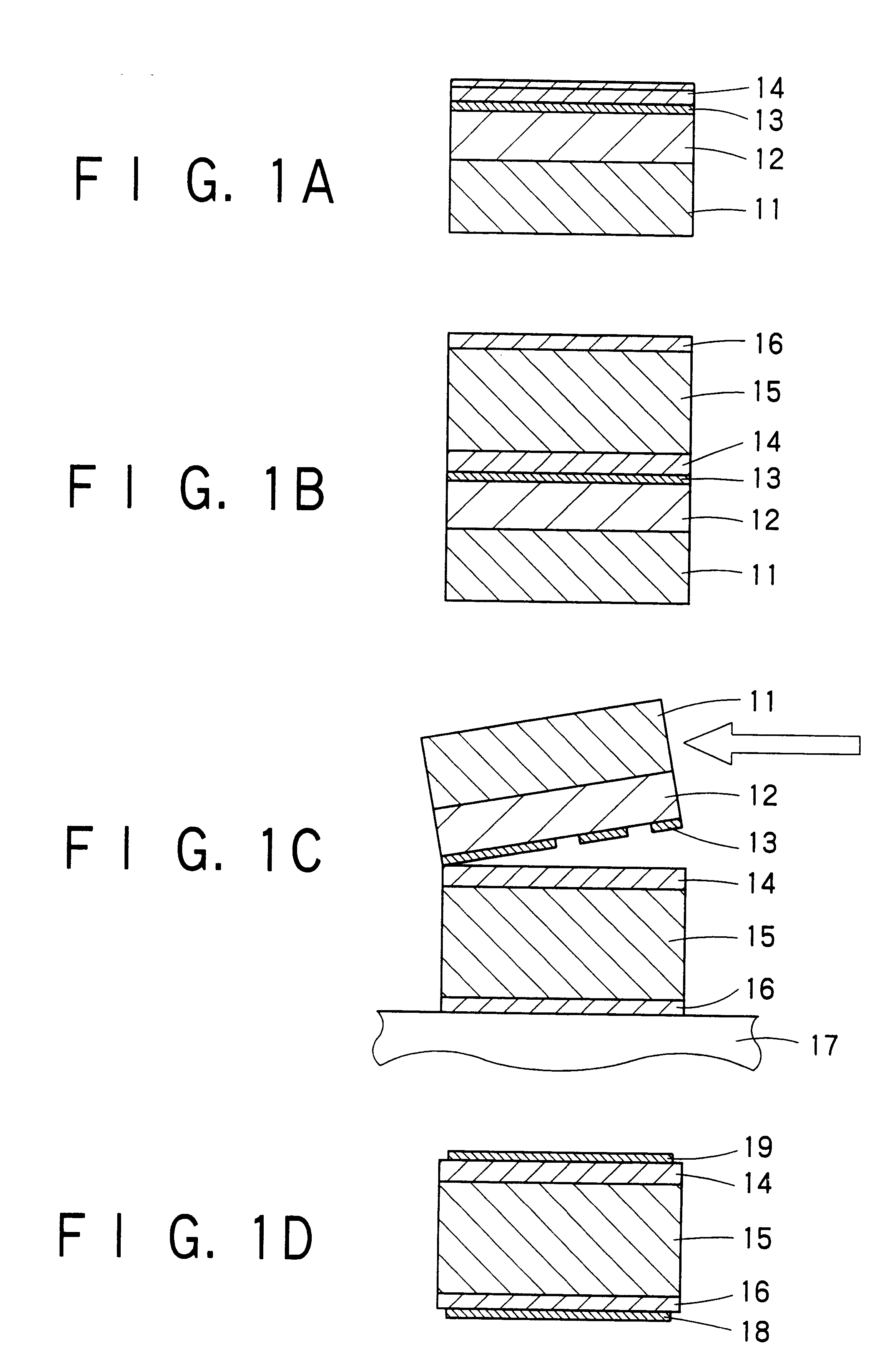

A semiconductor light emitting element of nitride compound semiconductors excellent in cleavability, heat radiation and resistance to leakage is made by epitaxially grow a nitride compound semiconductor layers on a substrate of sapphire, for example, and thereafter separating the substrate. For separating the substrate, there are a technique using a abruption mechanism susceptible to a stress such as a "lift-off layer" and a recesses on a substrate. A technique using laser light to cause a local dense heat stress at the abruption mechanism is effective. A nitride compound semiconductor obtained by separating the substrate may be used as a new substrate to epitaxially grow high-quality nitride compound semiconductors thereon.

Owner:ALPAD CORP

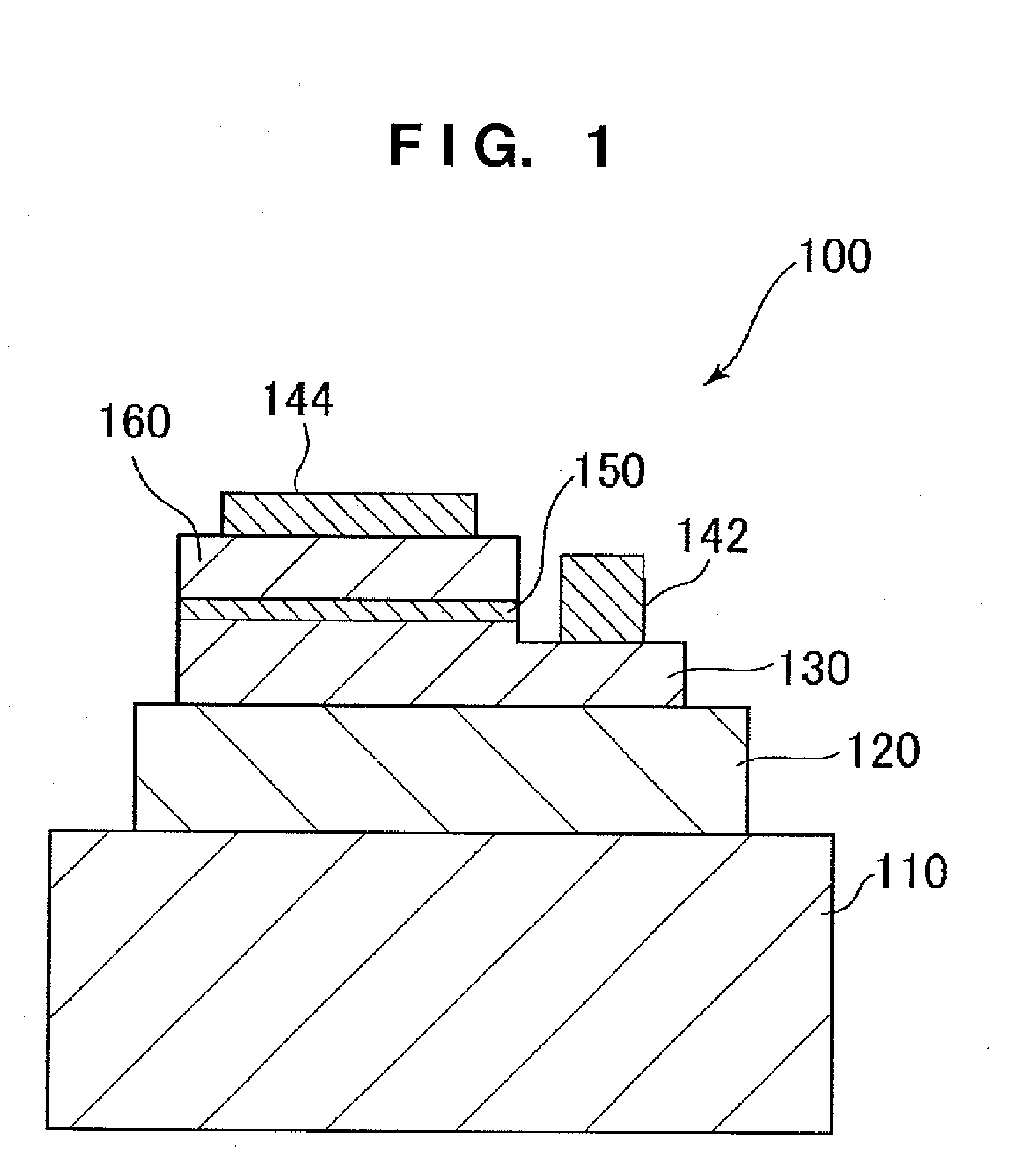

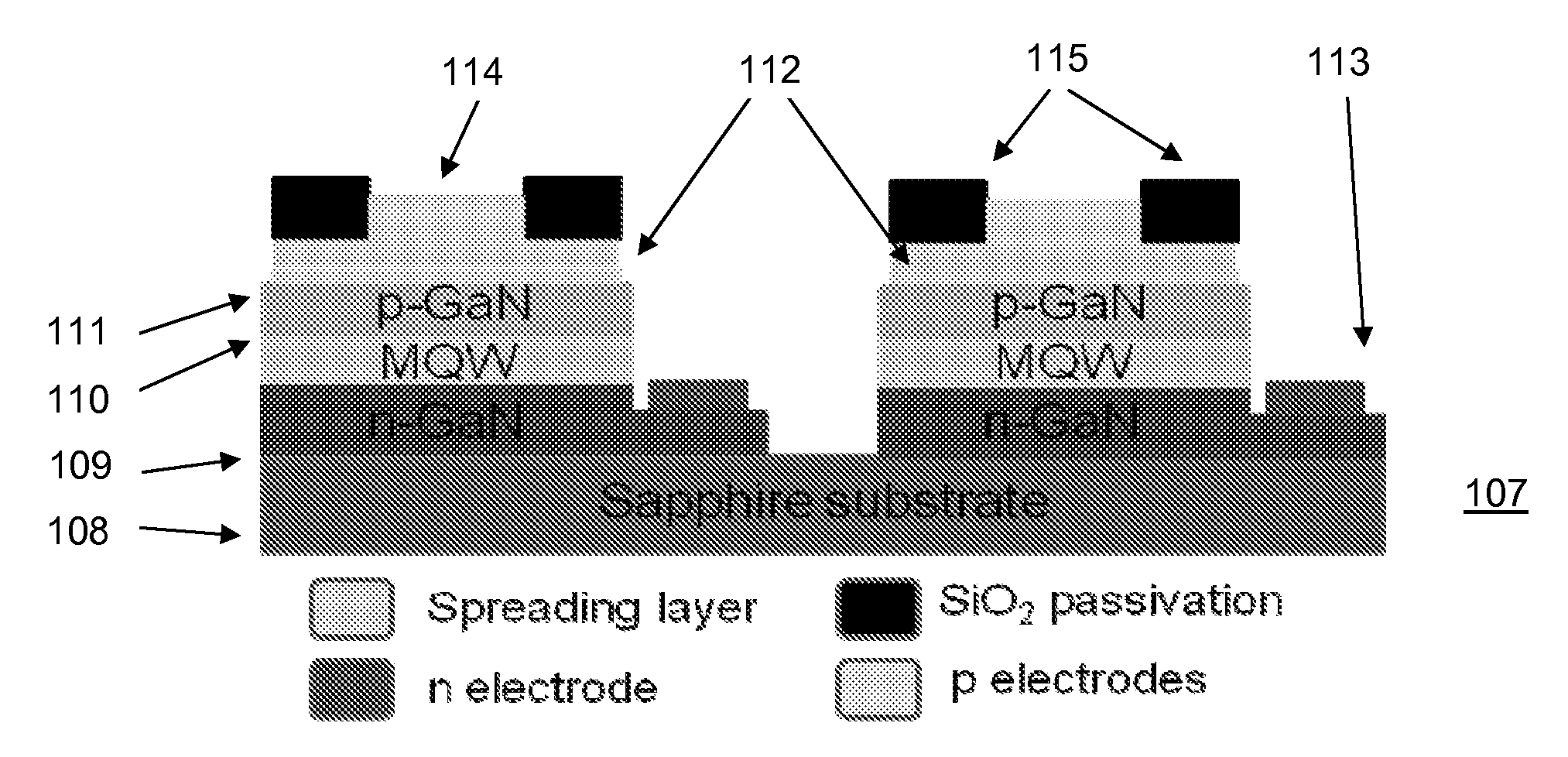

Semiconductor light emitting device integral type semiconductor light emitting unit image display unit and illuminating unit

ActiveUS7002182B2Easily light emittingImprove luminous efficiencySolid-state devicesSemiconductor devicesActive layerLight emitting device

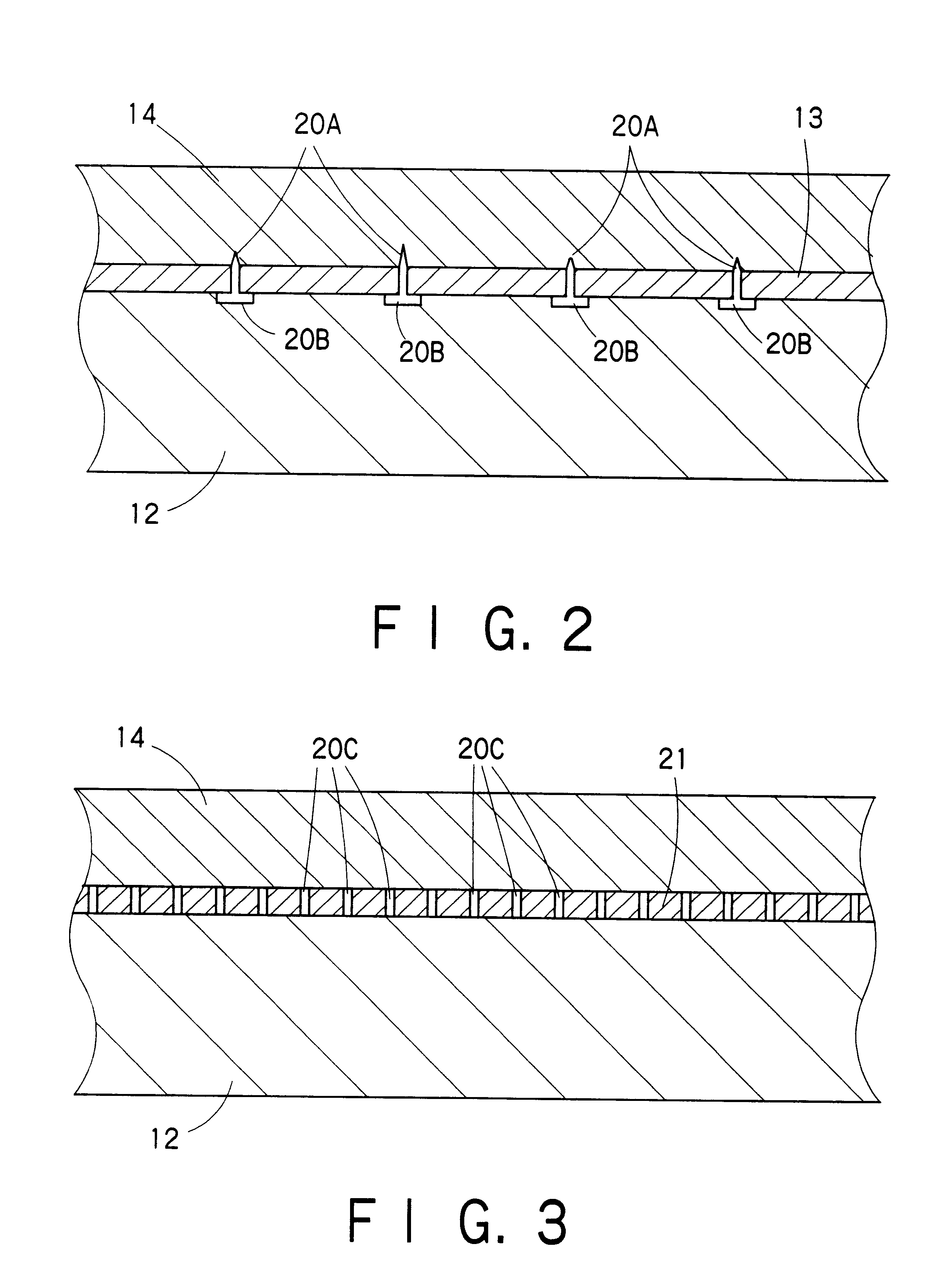

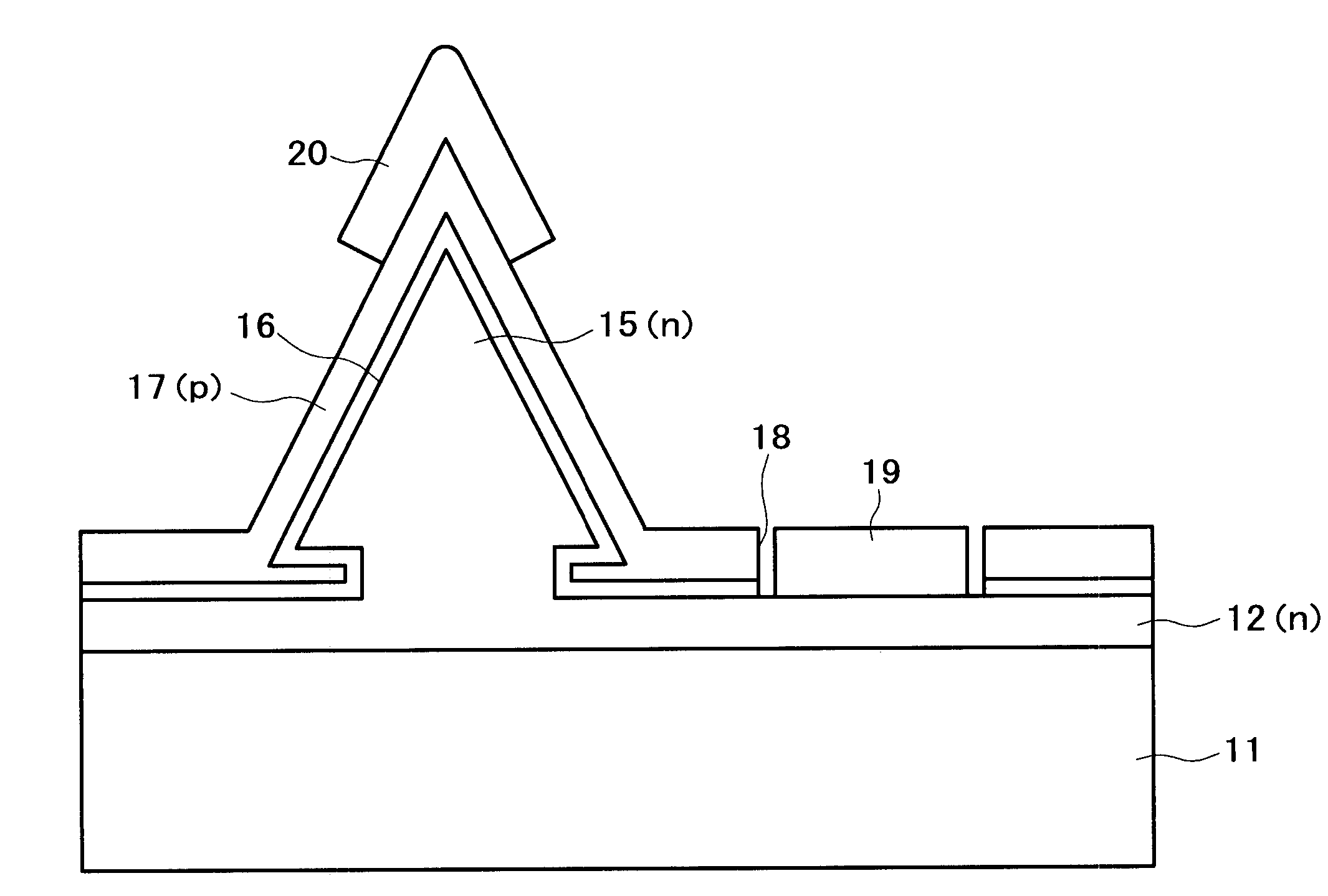

A semiconductor light emitting device with improved luminous efficiency is provided. An underlying n-type GaN layer is grown on a sapphire substrate, and a growth mask made from SiO2 film or the like is formed on the underlying n-type GaN layer. An n-type GaN layer having a hexagonal pyramid shape is selectively grown on a portion, exposed from an opening of the growth mask, of the underlying n-type GaN layer. The growth mask is removed by etching, and then an active layer and a p-type GaN layer are sequentially grown on the entire substrate so as to cover the hexagonal pyramid shaped n-type GaN layer, to form a light emitting device. An n-side electrode and a p-side electrode are then formed.

Owner:SAMSUNG ELECTRONICS CO LTD

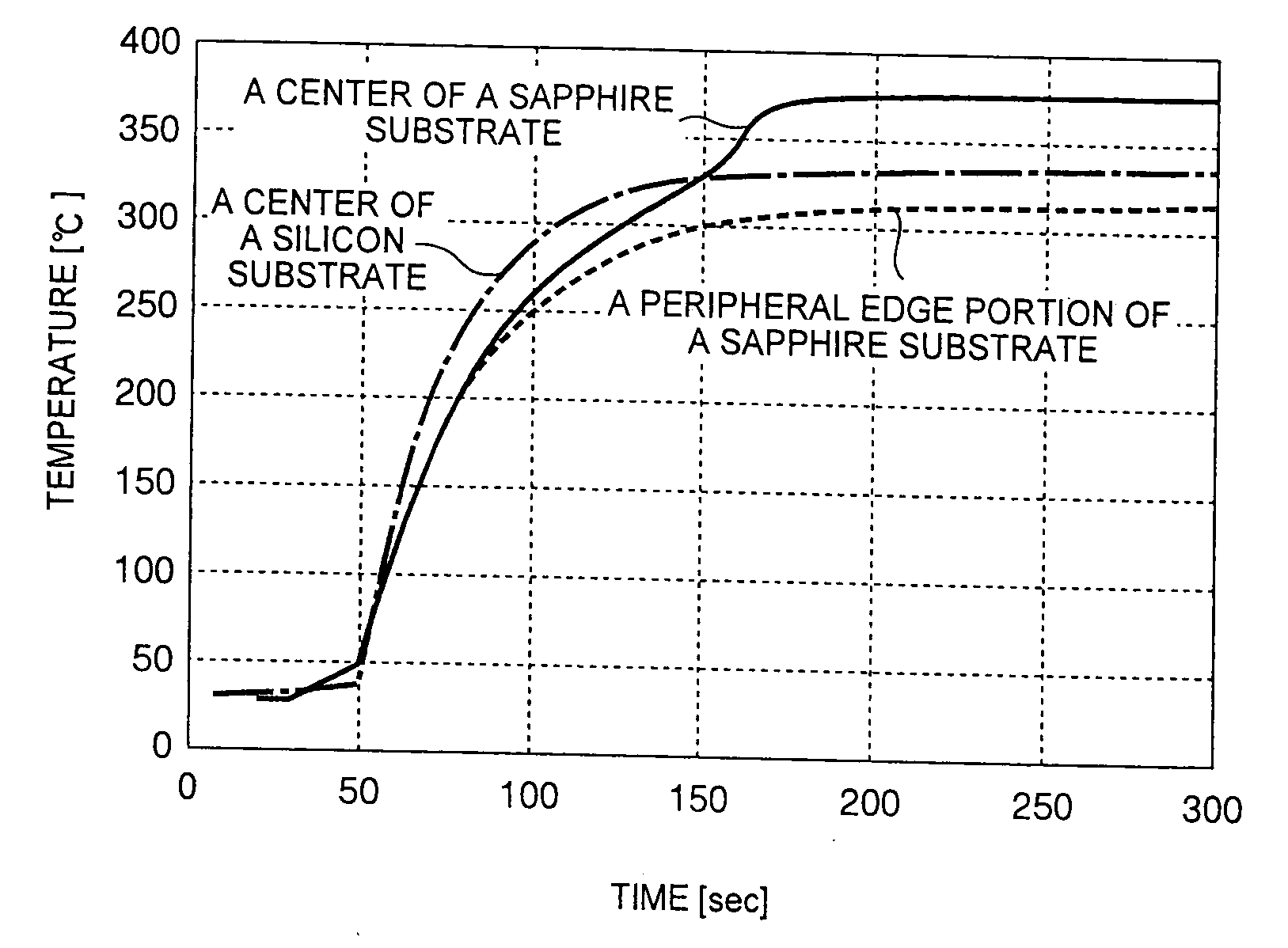

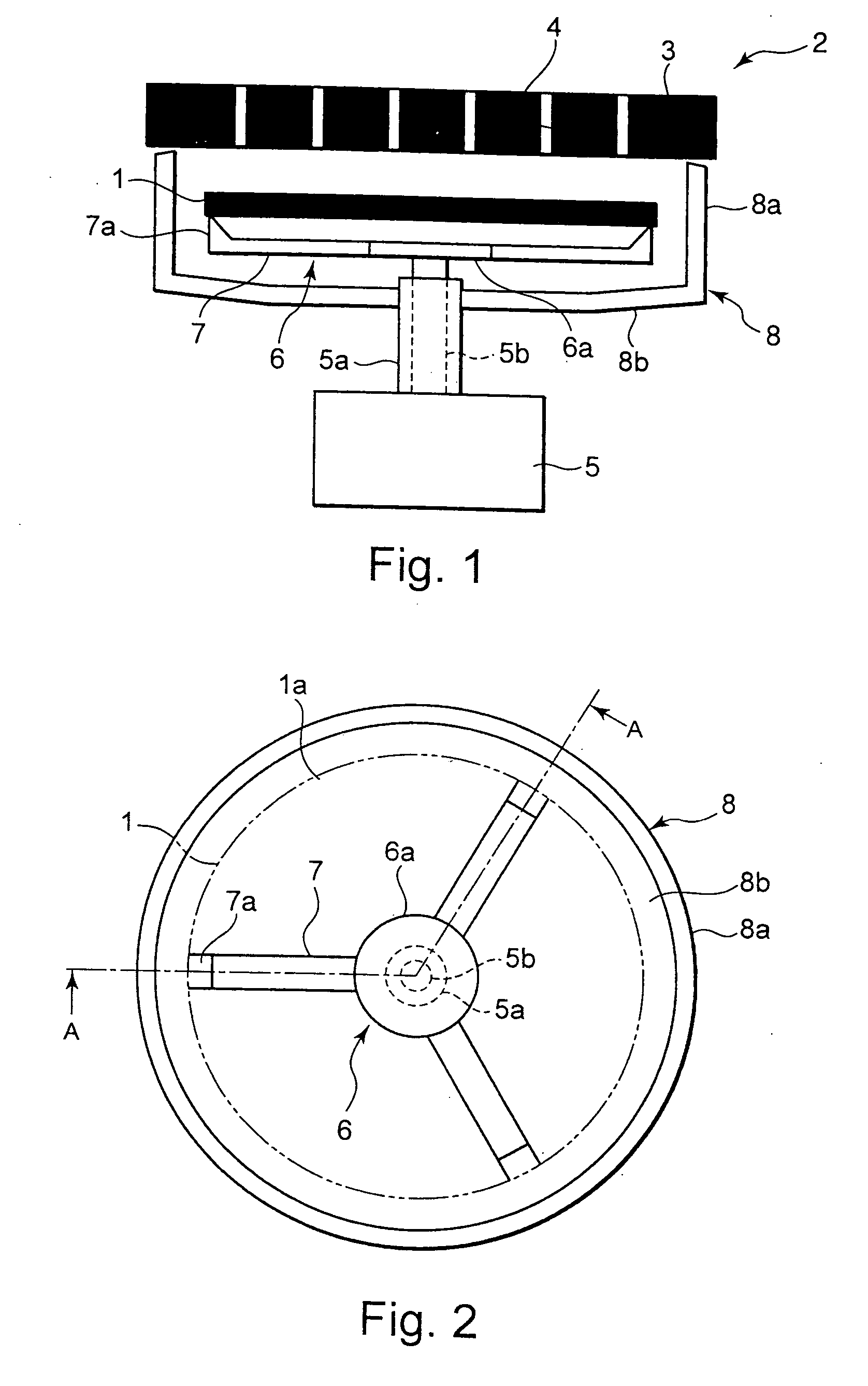

Method for manufacturing semiconductor device

InactiveUS20060240574A1Warpage suppressionPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialManufactured apparatus

A semiconductor manufacturing apparatus A semiconductor manufacturing apparatus comprises a hot plate which heats a sapphire substrate; a support table having a support plate disposed with being spaced away from the hot plate by a predetermined interval, and support portions which respectively support the sapphire substrate with being spaced by a predetermined interval between the hot plate and the support plate and support the sapphire substrate in such a manner that back surfaces of the hot plate and the sapphire substrate are opposite to each other; an elevating device which moves the support table up and down; and a shielding cover which externally blocks off spacing defined between the hot plate and the sapphire substrate and spacing defined between the sapphire substrate and the support plate.

Owner:LAPIS SEMICON CO LTD

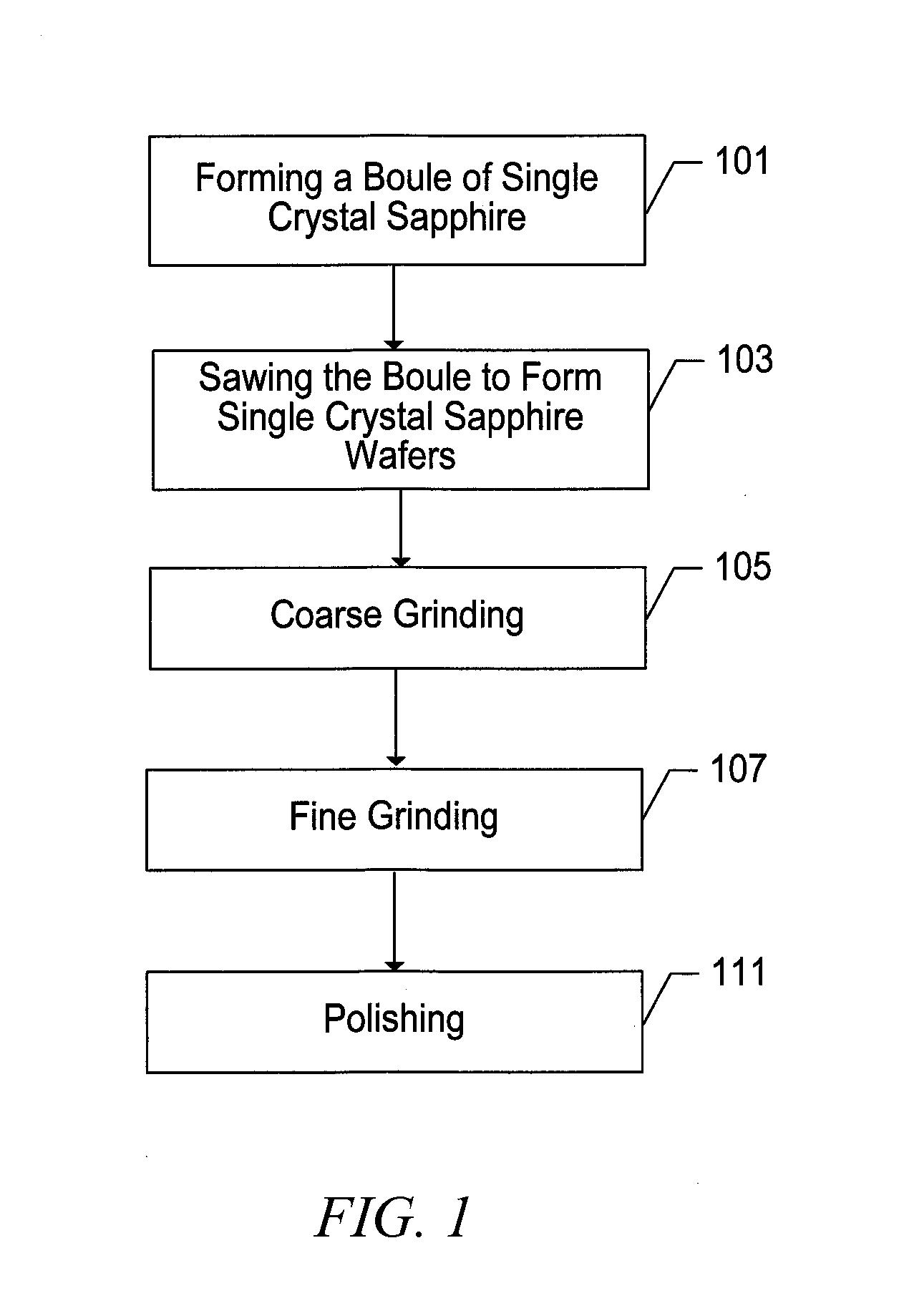

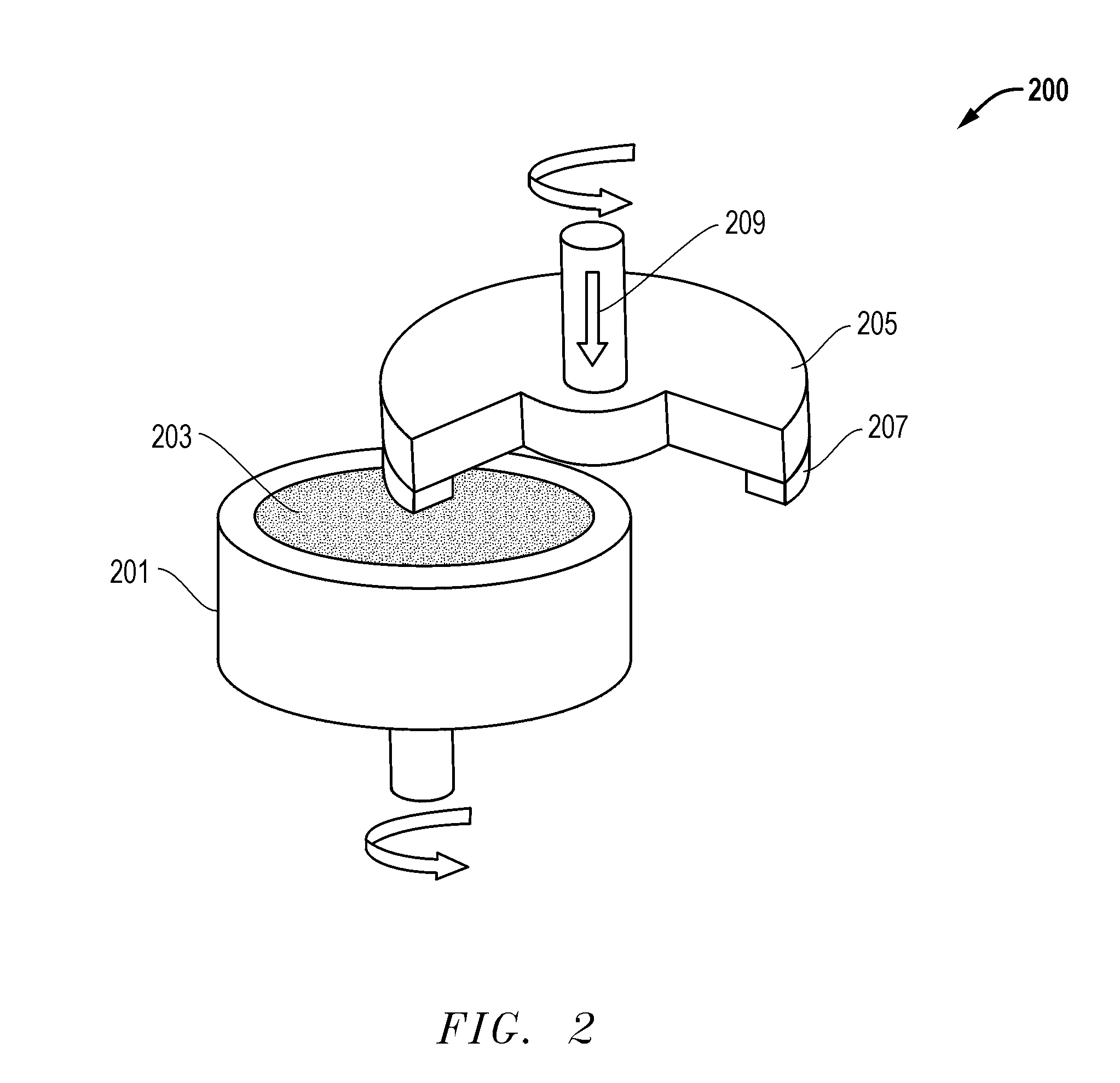

Sapphire substrates and methods of making same

InactiveUS20080164578A1Polycrystalline material growthFine working devicesPlane orientationTotal thickness

A sapphire substrate includes a generally planar surface having a crystallographic orientation selected from the group consisting of a-plane, r-plane, m-plane, and c-plane orientations, and having a nTTV of not greater than about 0.037 μm / cm2, wherein nTTV is total thickness variation normalized for surface area of the generally planar surface, the substrate having a diameter not less than about 9.0 cm.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

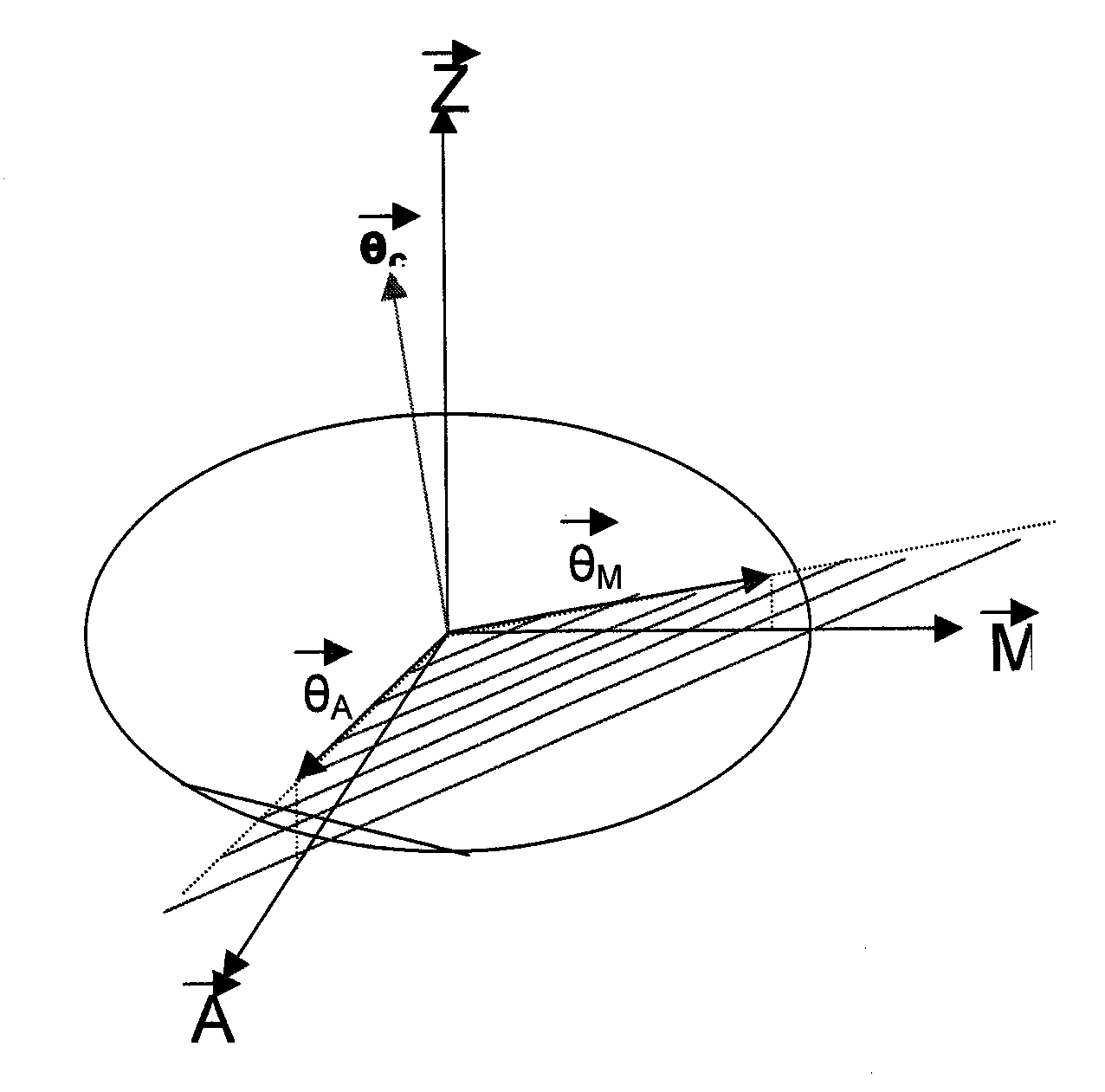

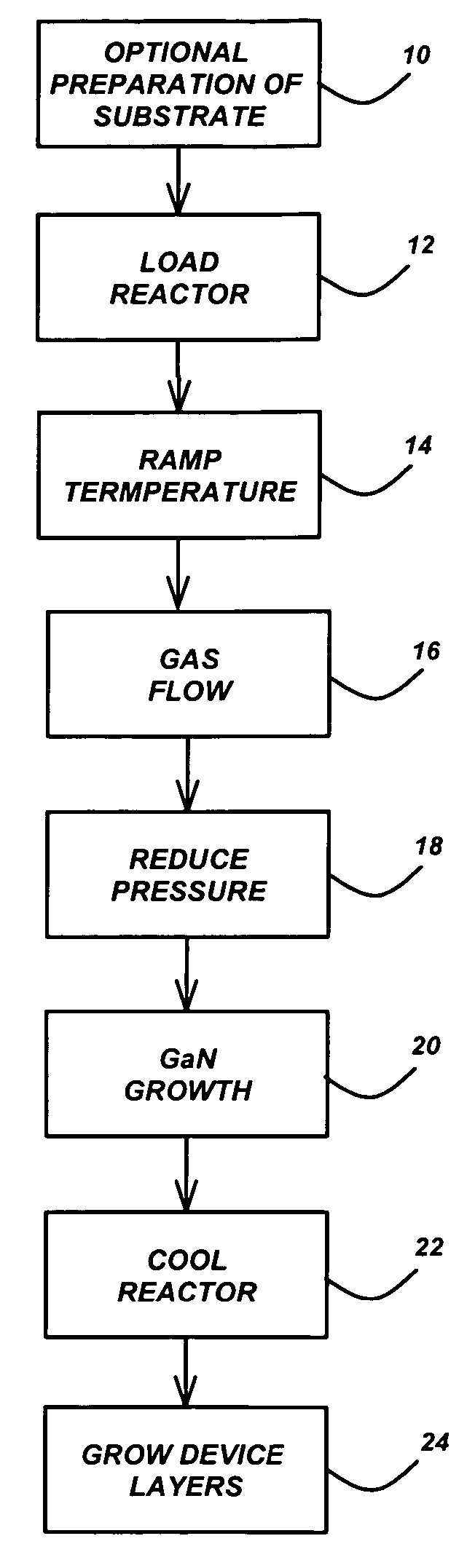

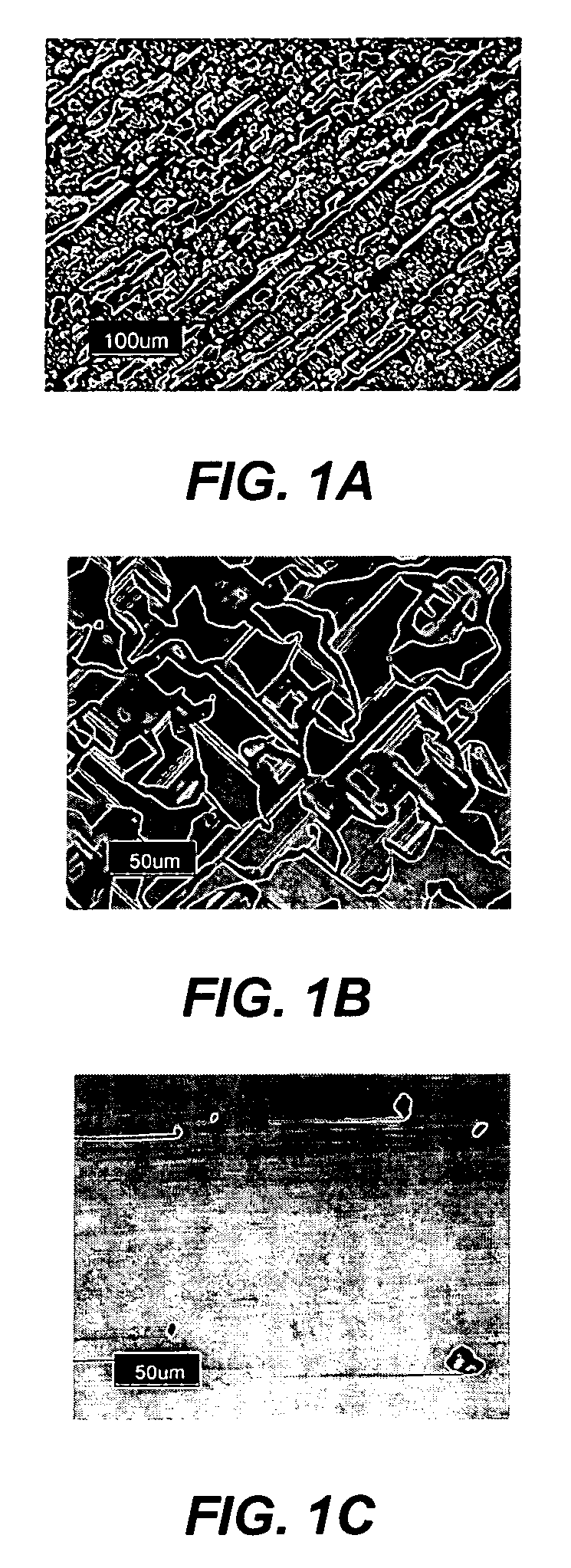

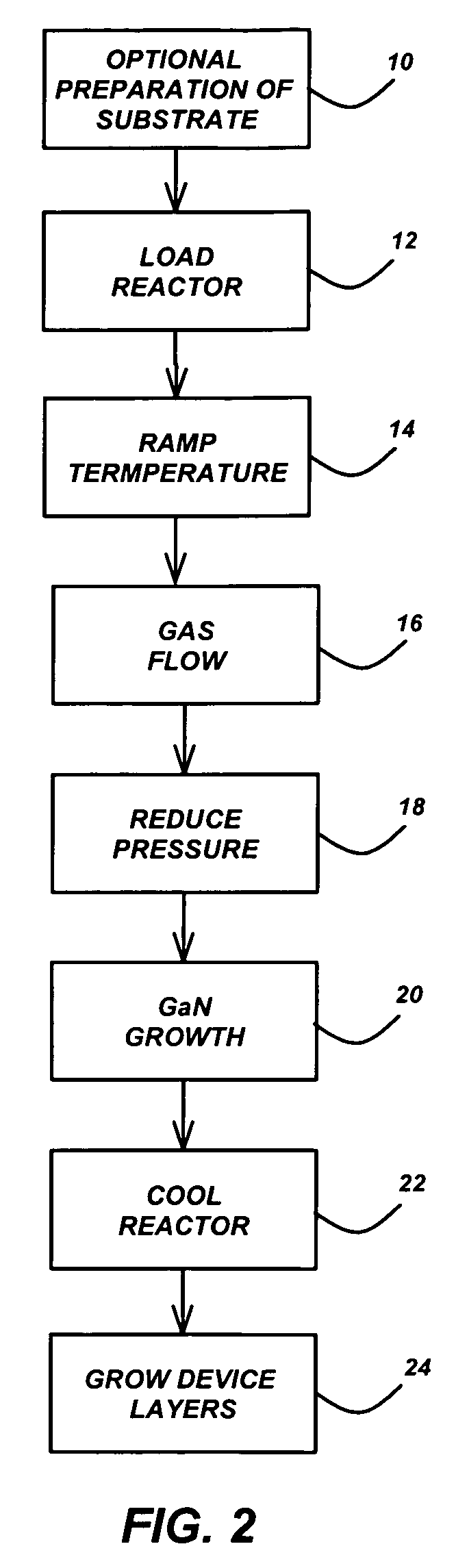

Technique for the growth of planar semi-polar gallium nitride

ActiveUS20060205199A1Reduce the impactReduce impactPolycrystalline material growthSemiconductor/solid-state device manufacturingSpinelGallium nitride

A method for growing planar, semi-polar nitride film on a miscut spinel substrate, in which a large area of the planar, semi-polar nitride film is parallel to the substrate's surface. The planar films and substrates are: (1) {10{overscore (1)}1} gallium nitride (GaN) grown on a {100} spinel substrate miscut in specific directions, (2) {10{overscore (1)}3} gallium nitride (GaN) grown on a {110} spinel substrate, (3) {11{overscore (2)}2} gallium nitride (GaN) grown on a {1{overscore (1)}00} sapphire substrate, and (4) {11{overscore (1)}3} gallium nitride (GaN) grown on a {1{overscore (1)}00} sapphire substrate

Owner:JAPAN SCI & TECH CORP

Method for Growth of Gan Single Crystal, Method for Preparation of Gan Substrate, Process for Producing Gan-Based Element, and Gan-Based Element

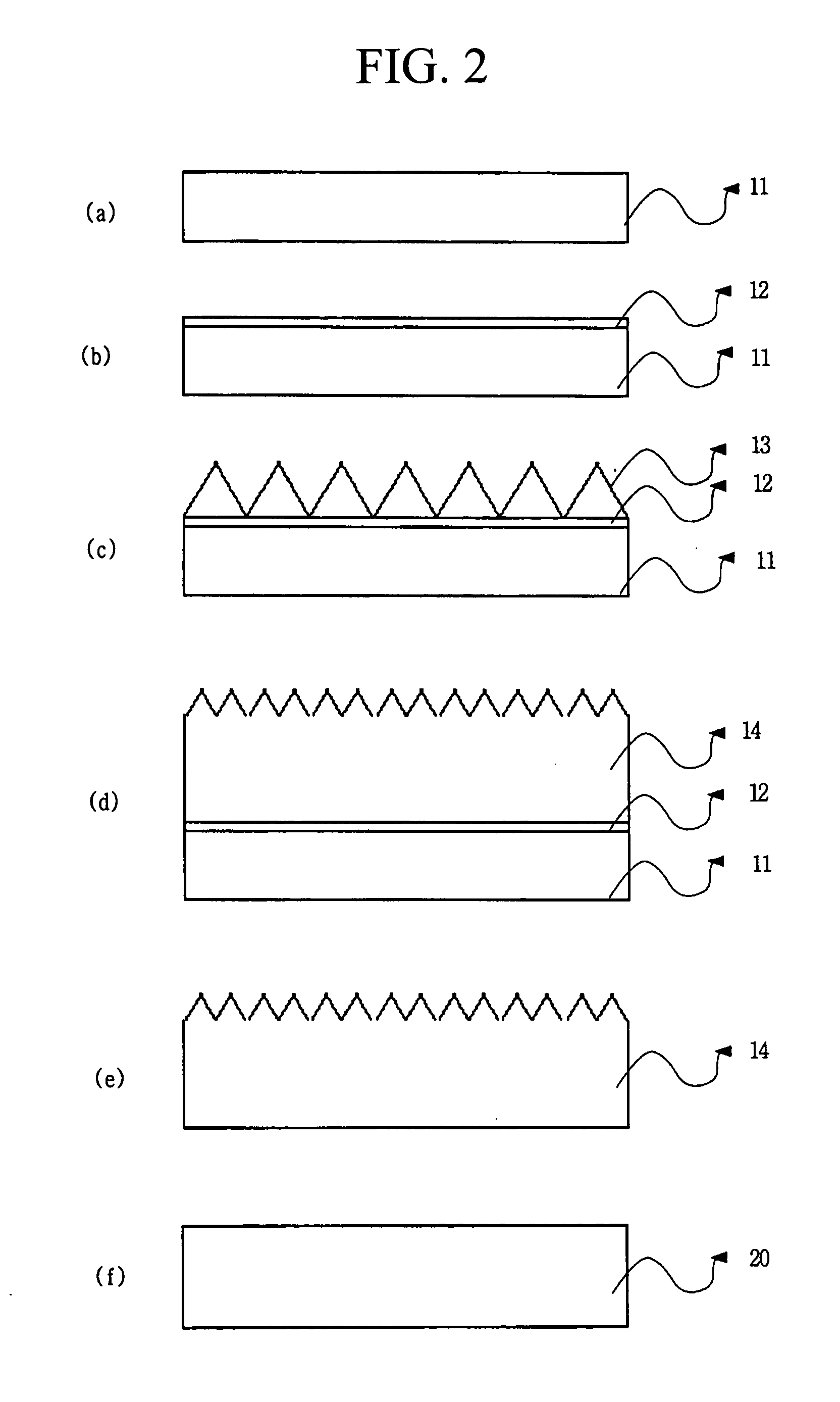

InactiveUS20080261378A1Reduce defectsEasy to operatePolycrystalline material growthSemiconductor/solid-state device manufacturingEtchingGas phase

A GaN-based thin film (thick film) is grown using a metal buffer layer grown on a substrate. (a) A metal buffer layer (210) made of, for example, Cr or Cu is vapor-deposited on a sapphire substrate (120). (b) A substrate obtained by vapor-depositing the metal buffer layer (210) on the sapphire substrate (120) is nitrided in an ammonia gas ambient, thereby forming a metal nitride layer (212). (c) A GaN buffer layer (222) is grown on the nitrided metal buffer layers (210, 212). (d) Finally, a GaN single-crystal layer (220) is grown. This GaN single-crystal layer (220) can be grown to have various thicknesses depending on the objects. A freestanding substrate can be fabricated by selective chemical etching of the substrate fabricated by the above steps. It is also possible to use the substrate fabricated by the above steps as a GaN template substrate for fabricating a GaN-based light emitting diode or laser diode.

Owner:FURUKAWA COMPANY +4

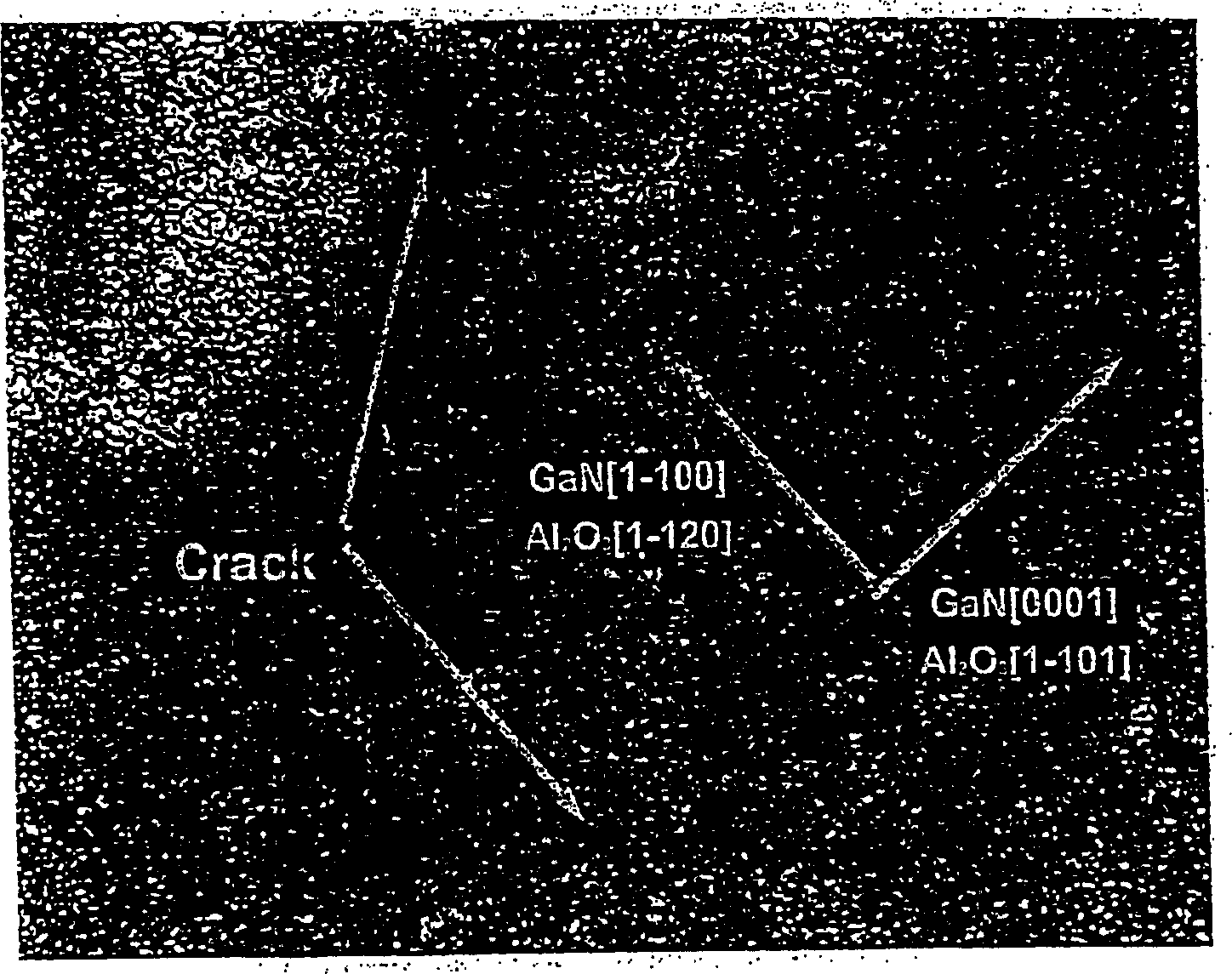

Non-polar single crystalline a-plane nitride semiconductor wafer and preparation thereof

InactiveUS20050247260A1Quality improvementEfficient methodPolycrystalline material growthCoupling device detailsWaferingSingle crystal

A single crystalline a-plane nitride semiconductor wafer having no voids, bending or cracks can be rapidly and effectively prepared by hydride vapor phase epitaxy (HVPE) growth of the a-plane nitride semiconductor film on a single crystalline r-plane sapphire substrate at a temperature ranging from 950 to 1,100° C. and at a rate ranging from 30 to 300 μm / hr.

Owner:SAMSUNG CORNING CO LTD

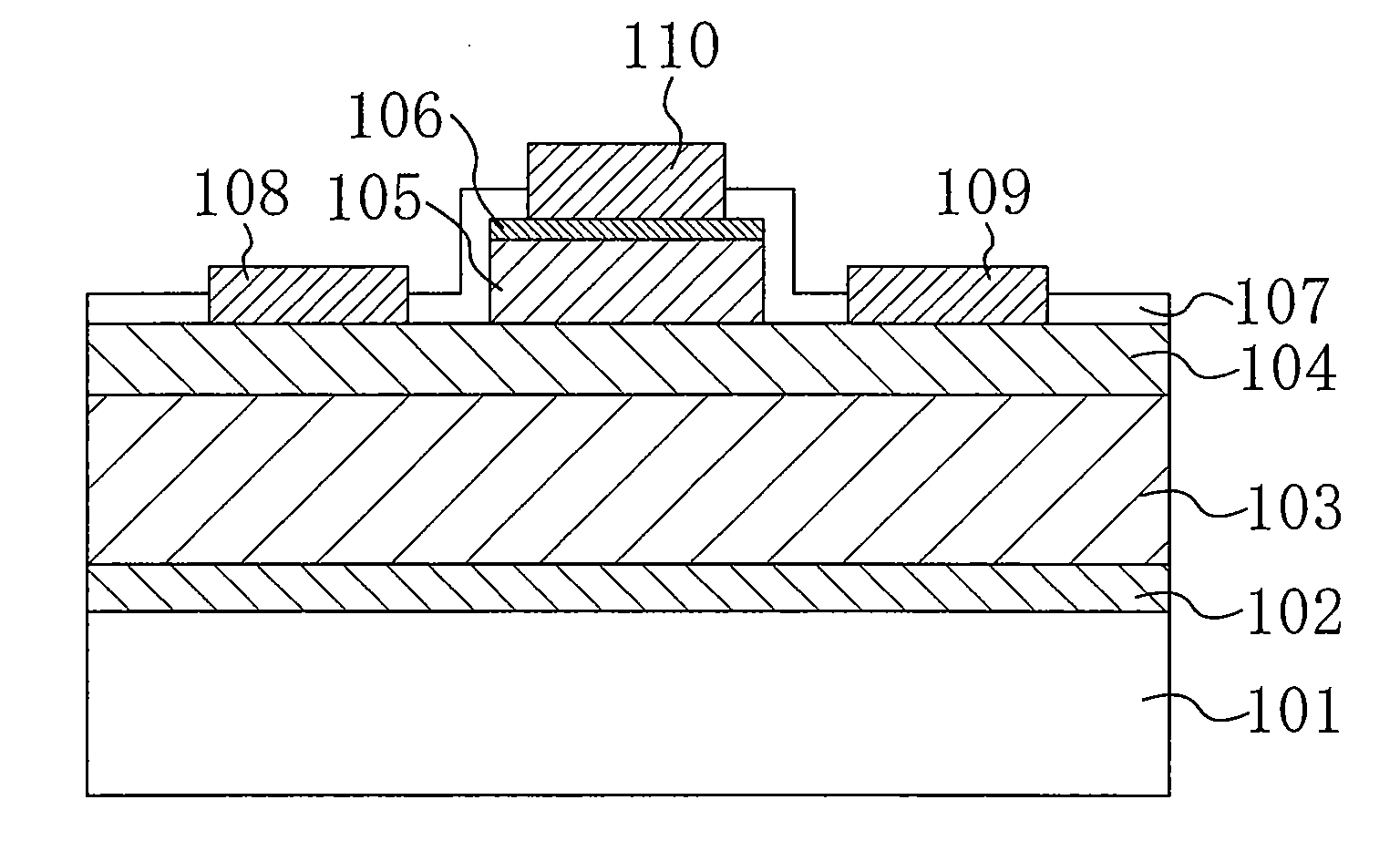

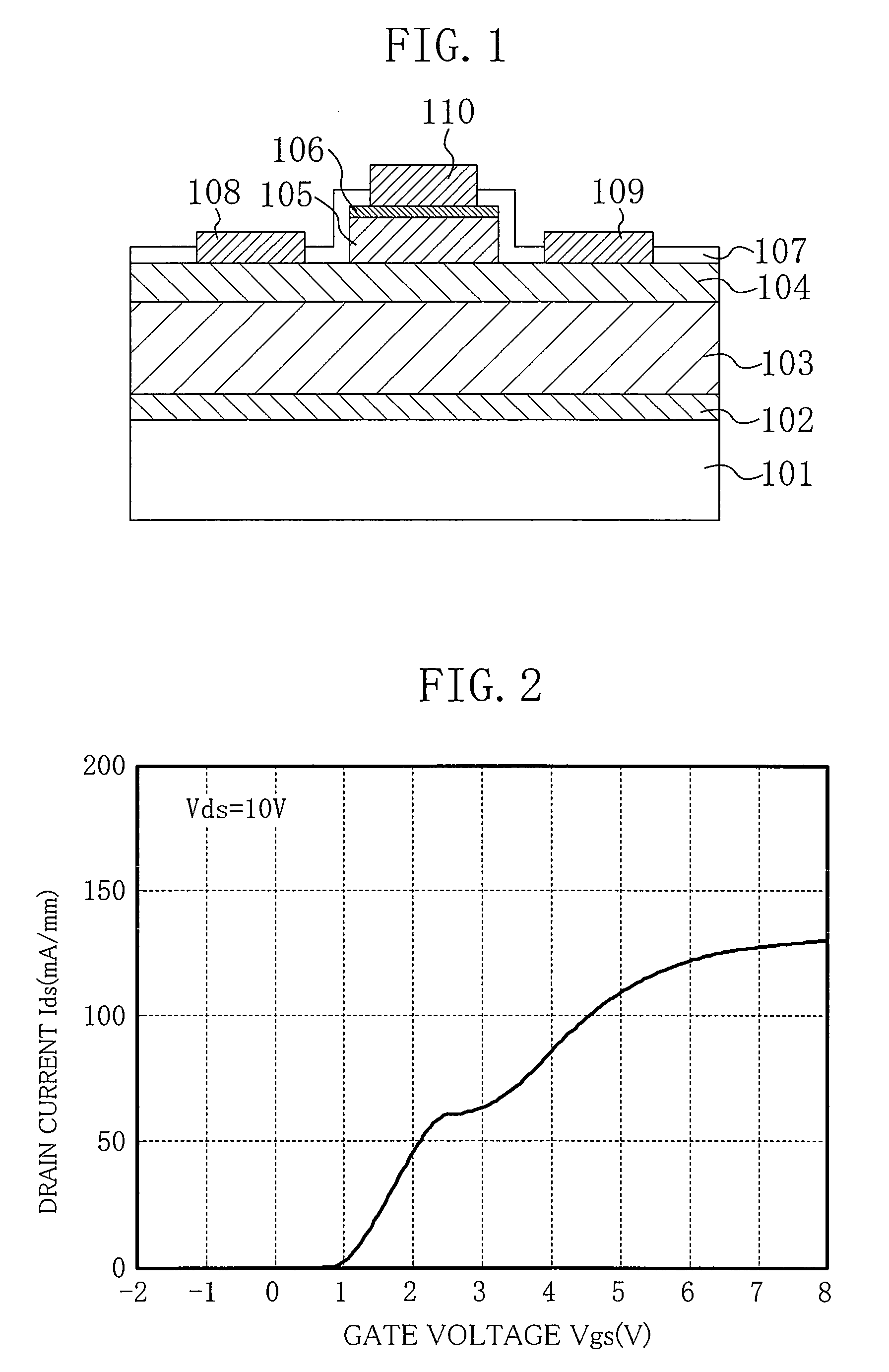

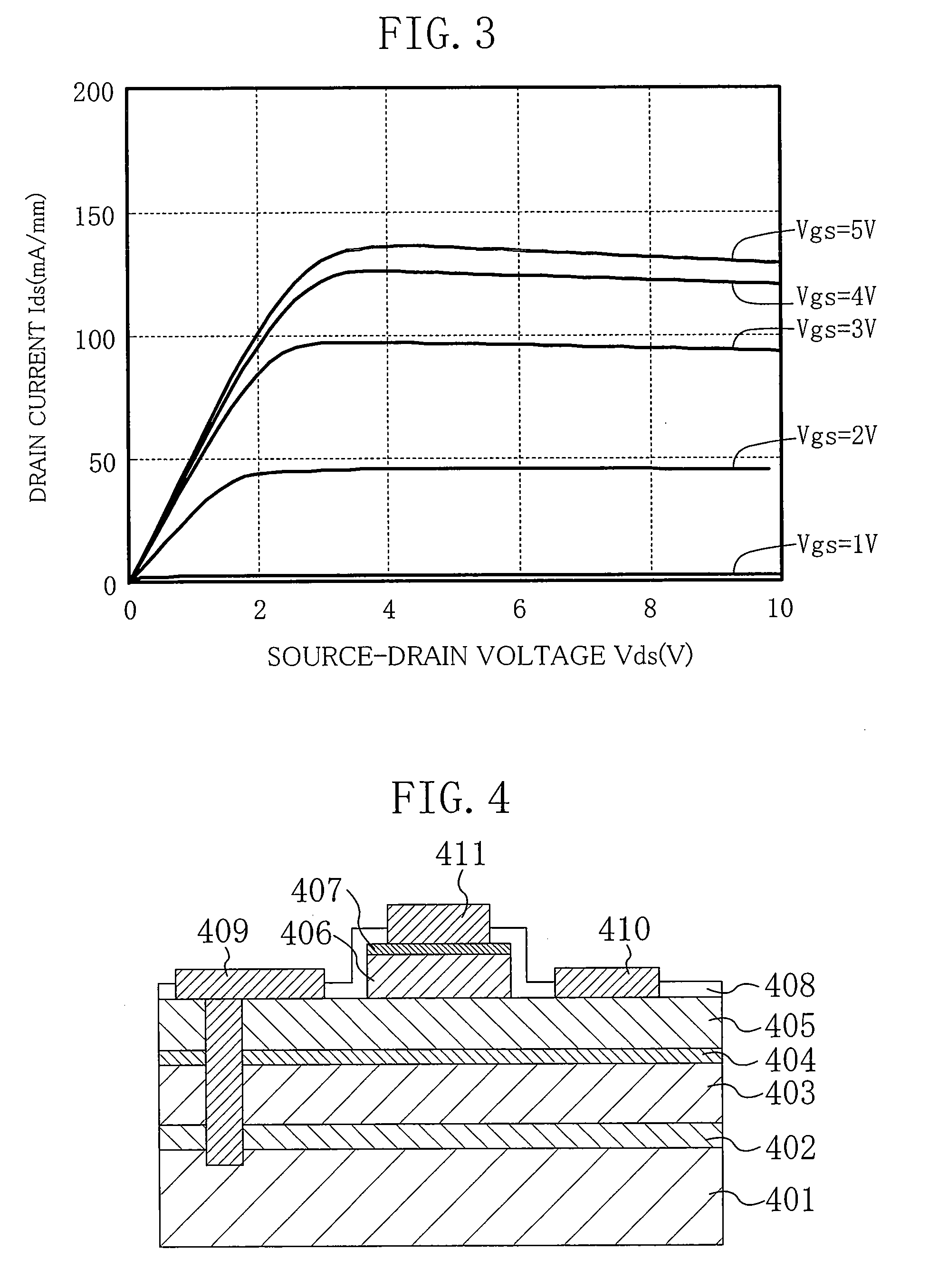

Transistor and method for operating the same

ActiveUS20090121775A1Promote generationIncrease current channelElectronic switchingSemiconductor devicesControl layerOhmic contact

In a transistor, an AlN buffer layer 102, an undoped GaN layer 103, an undoped AlGaN layer 104, a p-type control layer 105, and a p-type contact layer 106 are formed in this order on a sapphire substrate 101. The transistor further includes a gate electrode 110 in ohmic contact with the p-type contact layer 106, and a source electrode 108 and a drain electrode 109 provided on the undoped AlGaN layer 104. By applying a positive voltage to the p-type control layer 105, holes are injected into a channel to increase a current flowing in the channel.

Owner:PANASONIC CORP

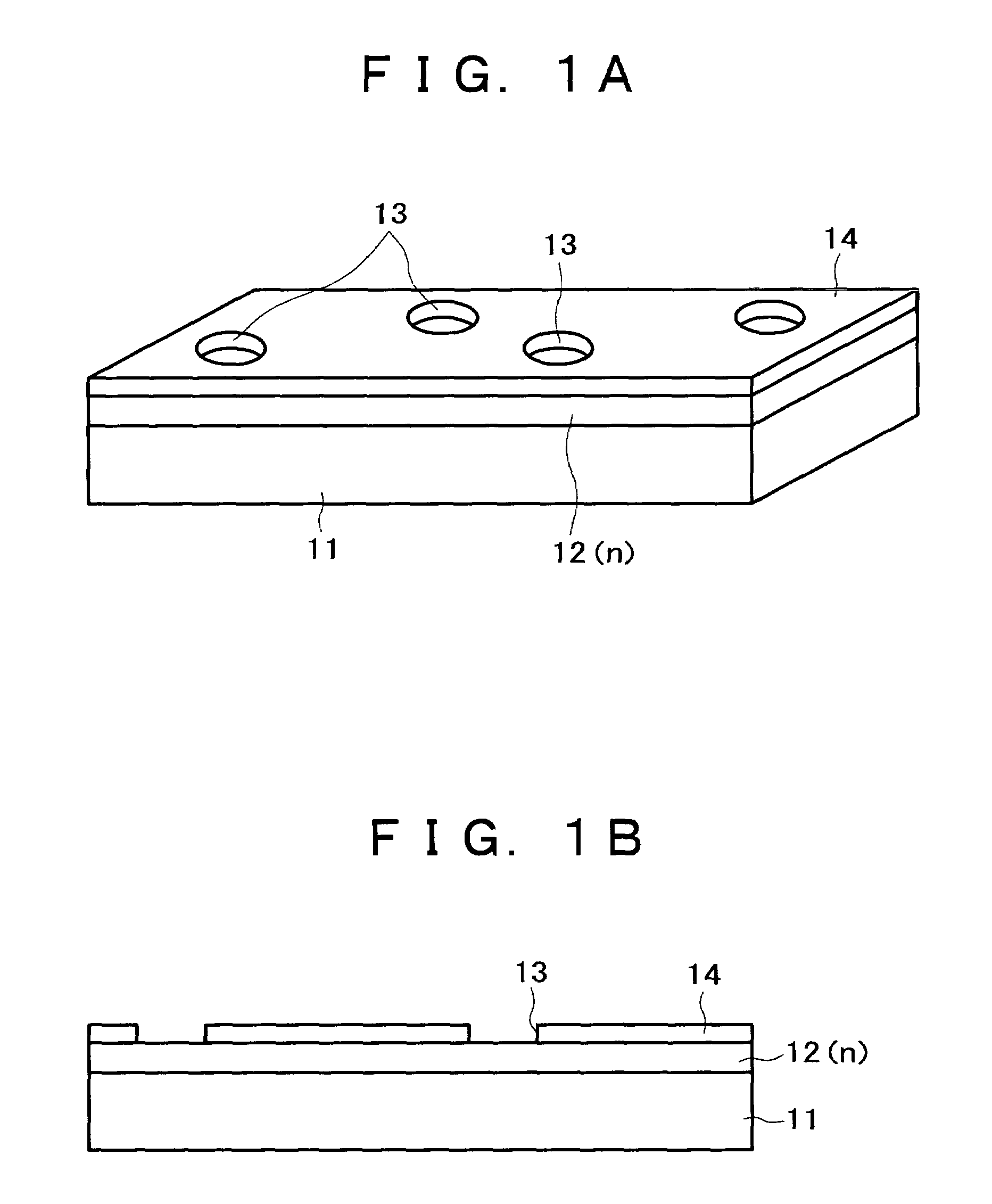

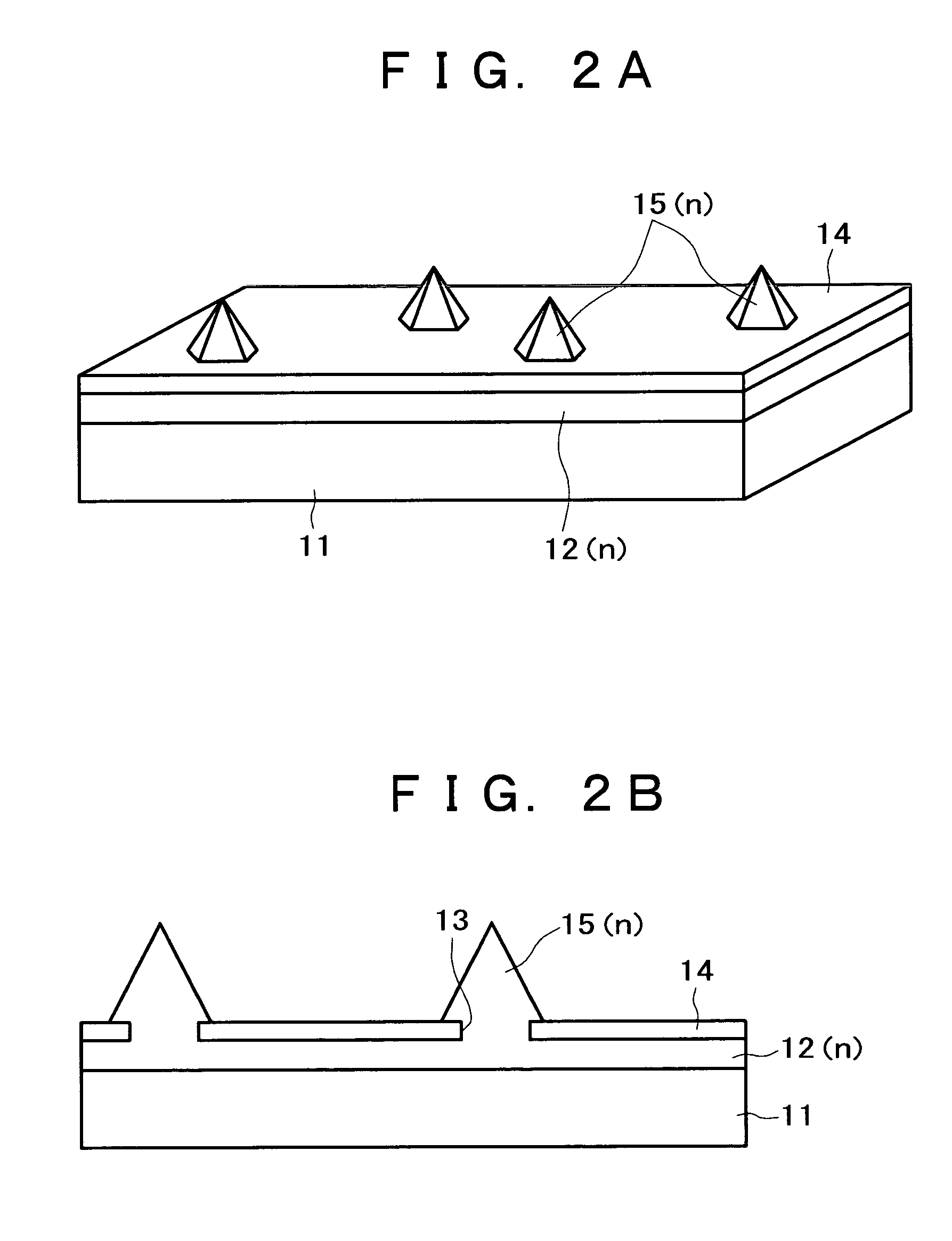

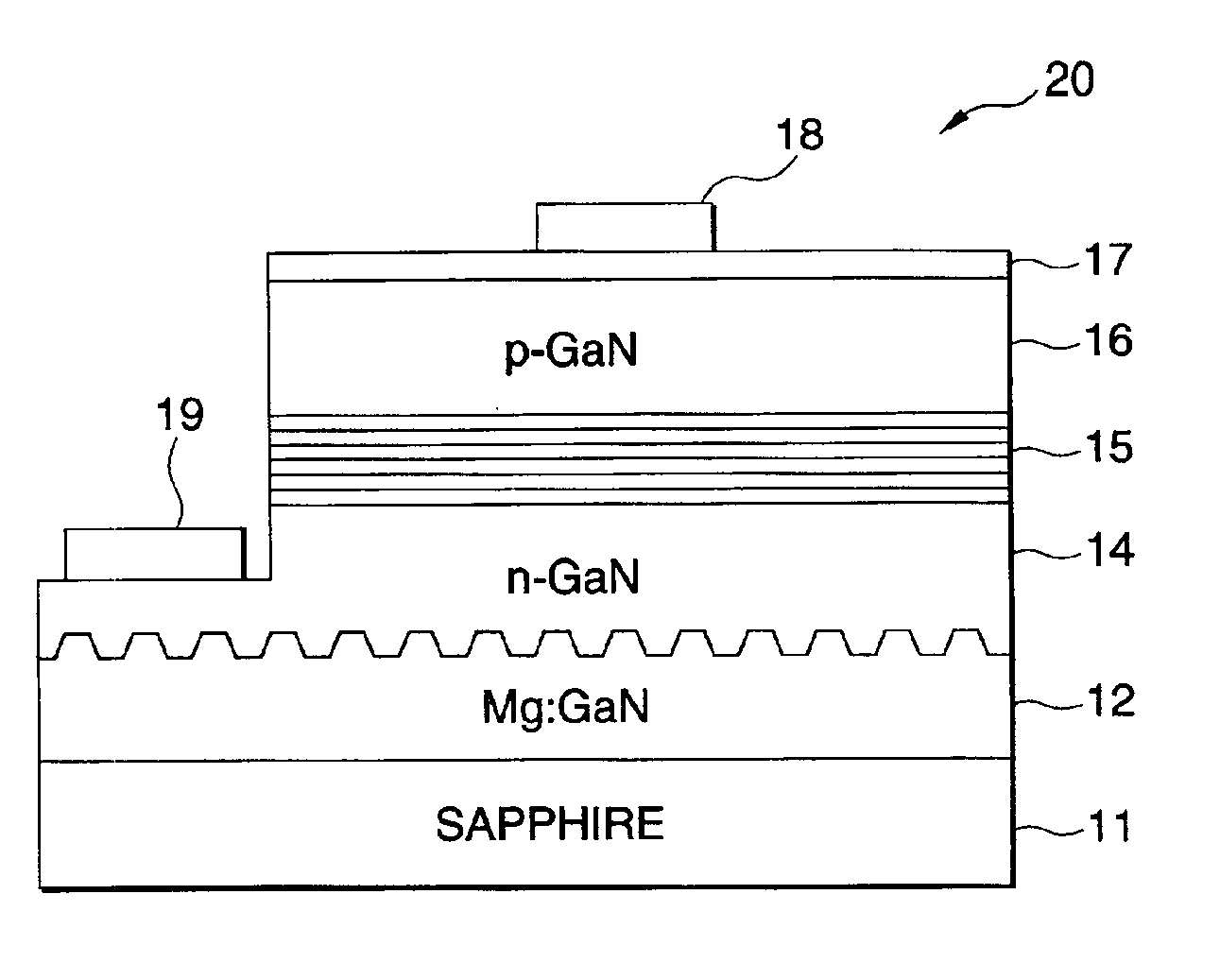

Group III nitride compound semiconductor device and method for producing the same

InactiveUS6841808B2Shorten production timeReduce laborSolid-state devicesSemiconductor/solid-state device manufacturingLateral overgrowthNitride

An AlN layer having a surface of a texture structure is formed on a sapphire substrate. Then, a growth suppressing material layer is formed on the AlN layer so that the AlN layer is partially exposed to the outside. Then, group III nitride compound semiconductor layers are grown on the AlN layer and on the growth suppressing material layer by execution of an epitaxial lateral overgrowth method. Thus, a group III nitride compound semiconductor device is produced. An undercoat layer having convex portions each shaped like a truncated hexagonal pyramid is formed on a substrate. Group III nitride compound semiconductor layers having a device function are laminated successively on the undercoat layer.

Owner:TOYODA GOSEI CO LTD

Non-polar single crystalline A-plane nitride semiconductor wafer and preparation thereof

InactiveCN1702836AQuality improvementPolycrystalline material growthCoupling device detailsSingle crystalVapor phase

A single crystalline a-plane nitride semiconductor wafer having no voids, bending or cracks can be rapidly and effectively prepared by hydride vapor phase epitaxy (HVPE) growth of the a-plane nitride semiconductor film on a single crystalline r-plane sapphire substrate at a temperature ranging from 950 to 1,100 DEG C and at a rate ranging from 30 to 300 mu m / hr.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

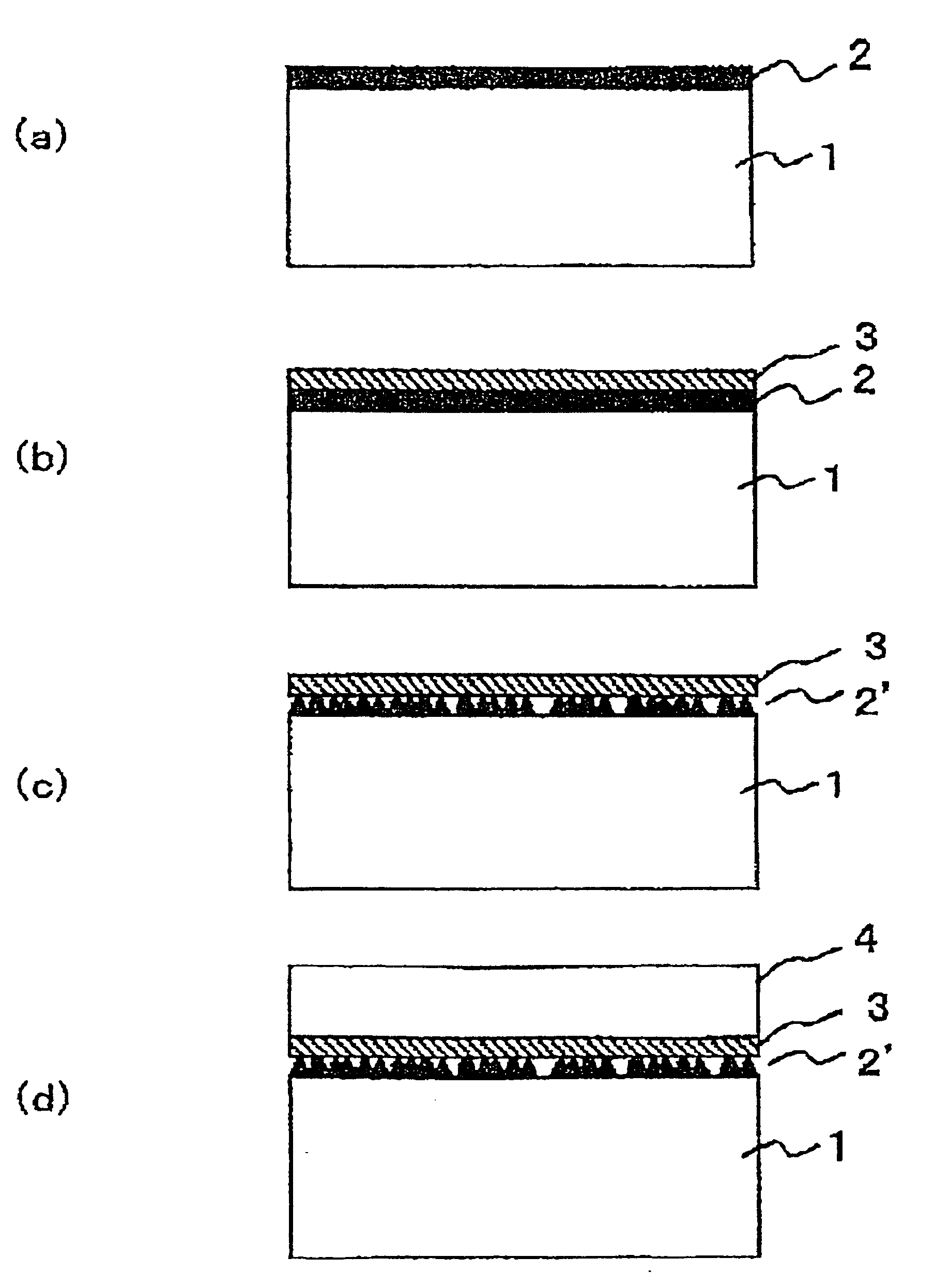

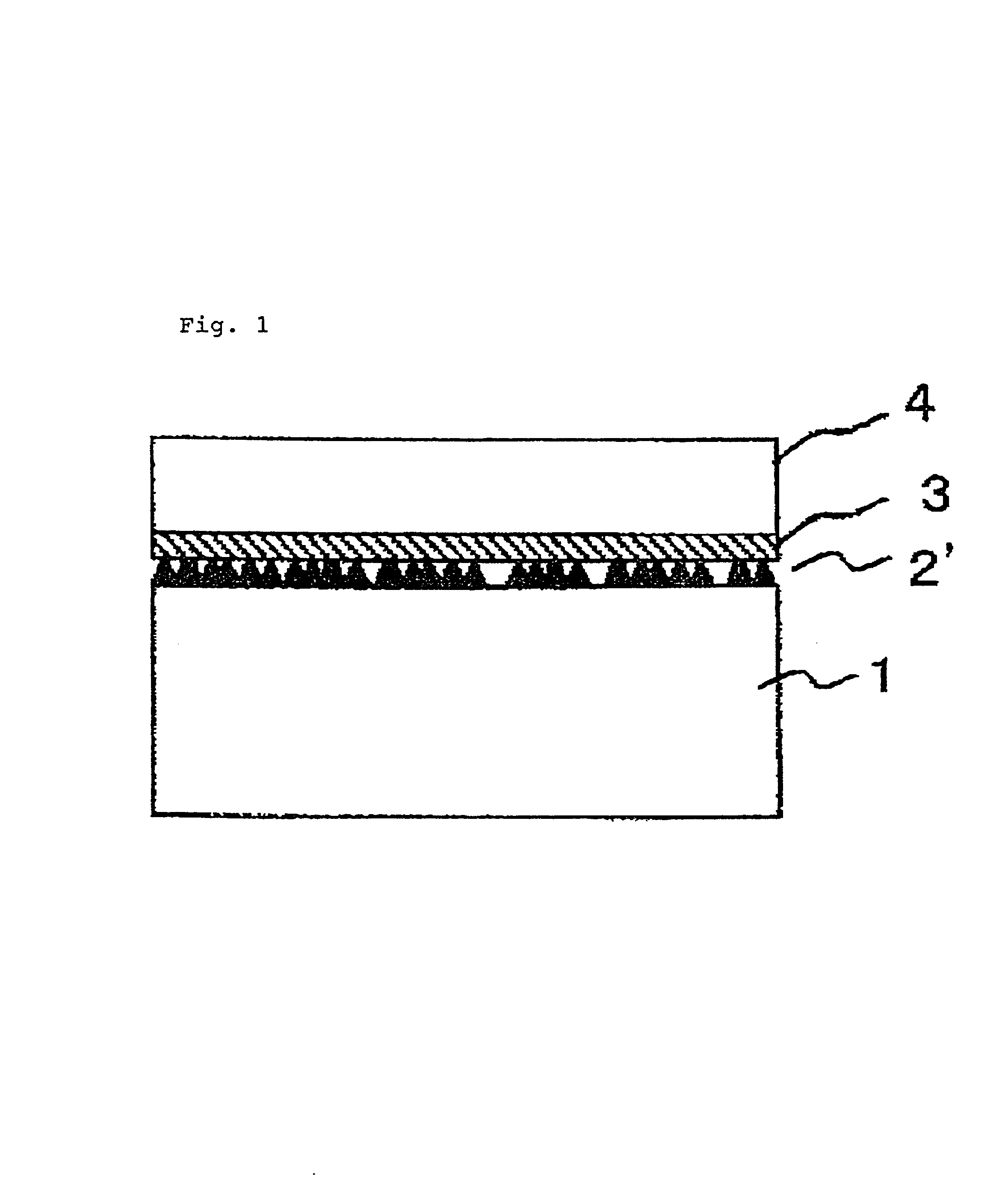

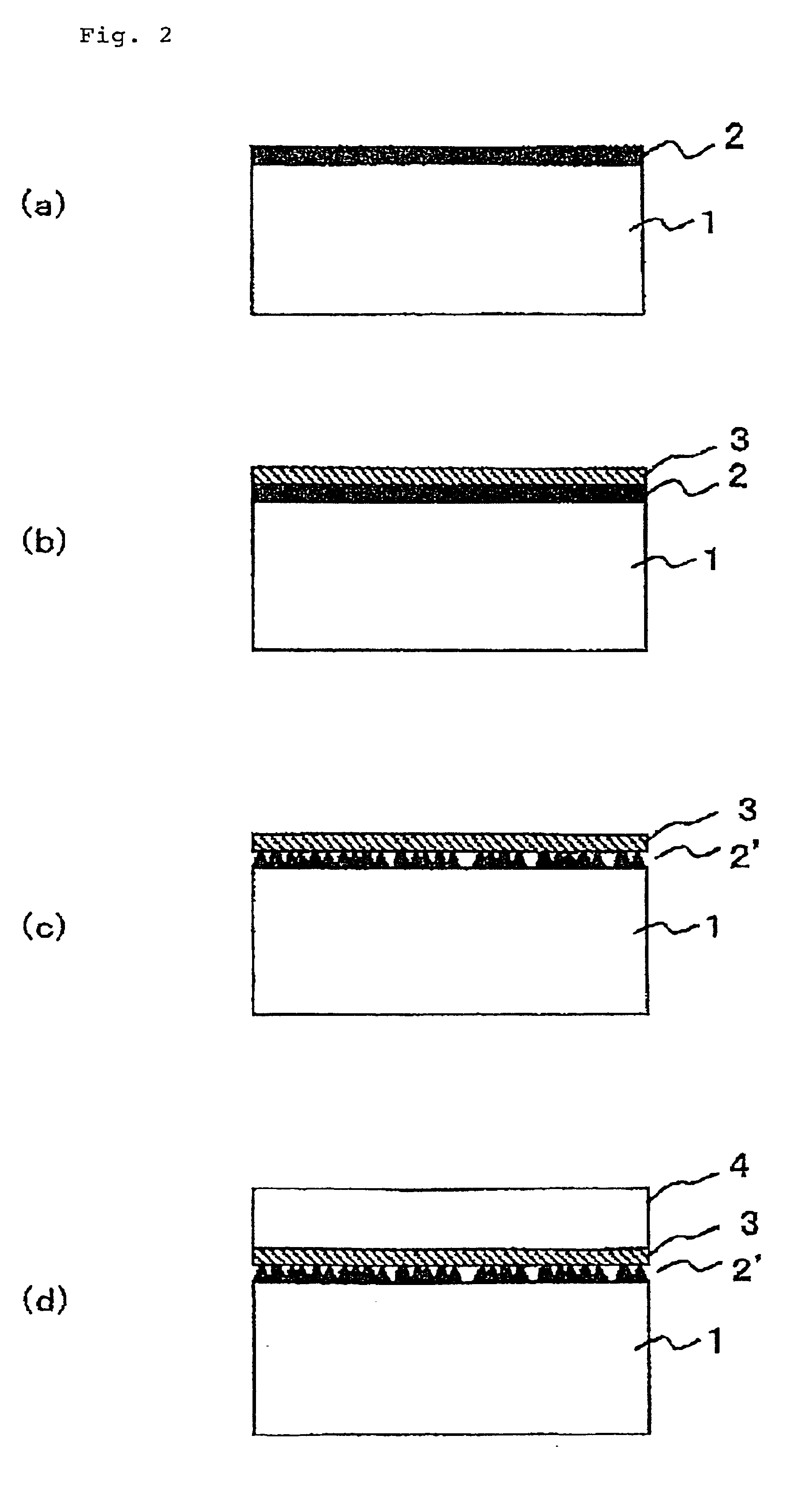

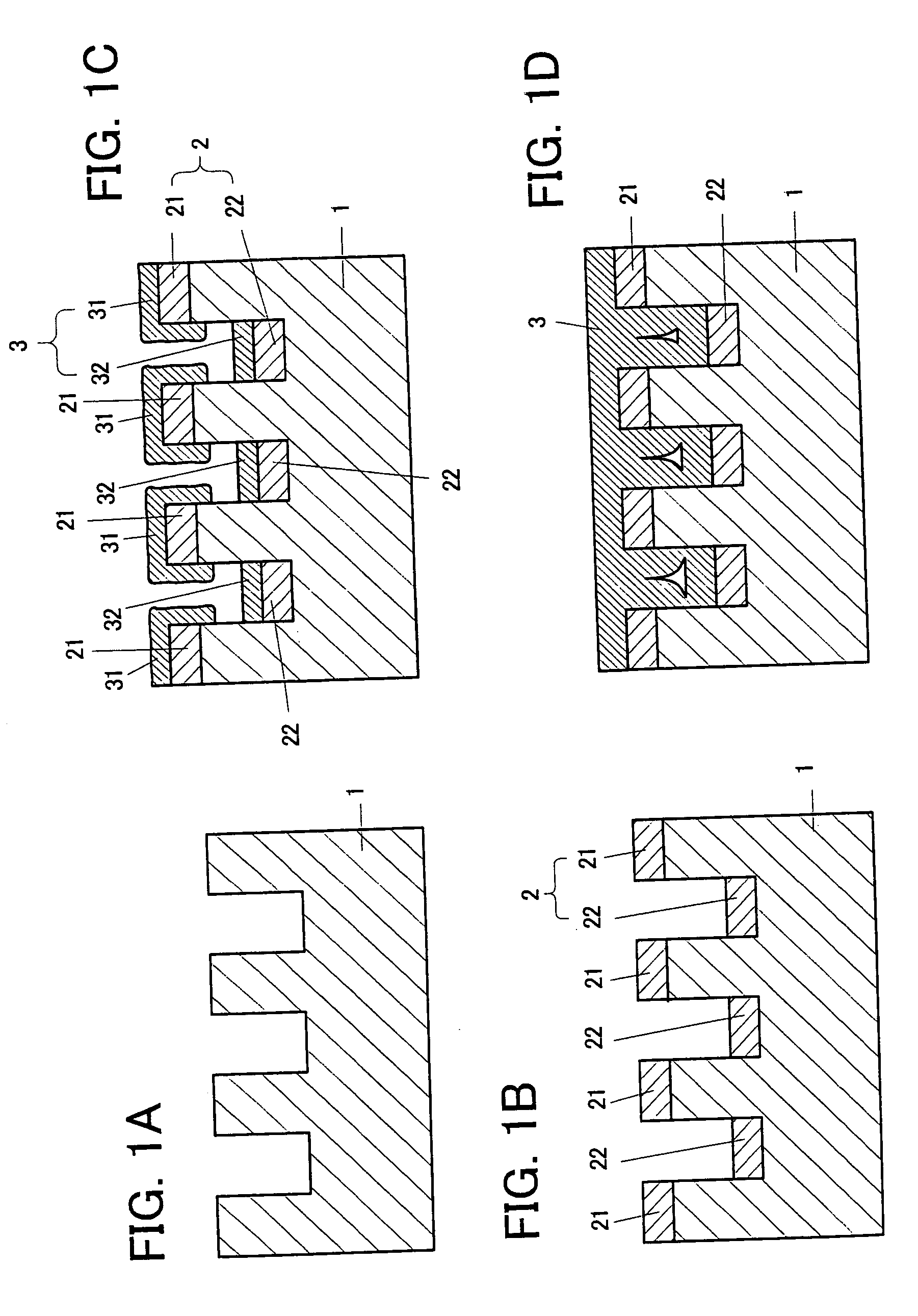

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS6924159B2Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingNitride semiconductorsSapphire substrate

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of:forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2′.

Owner:SUMITOMO CHEM CO LTD

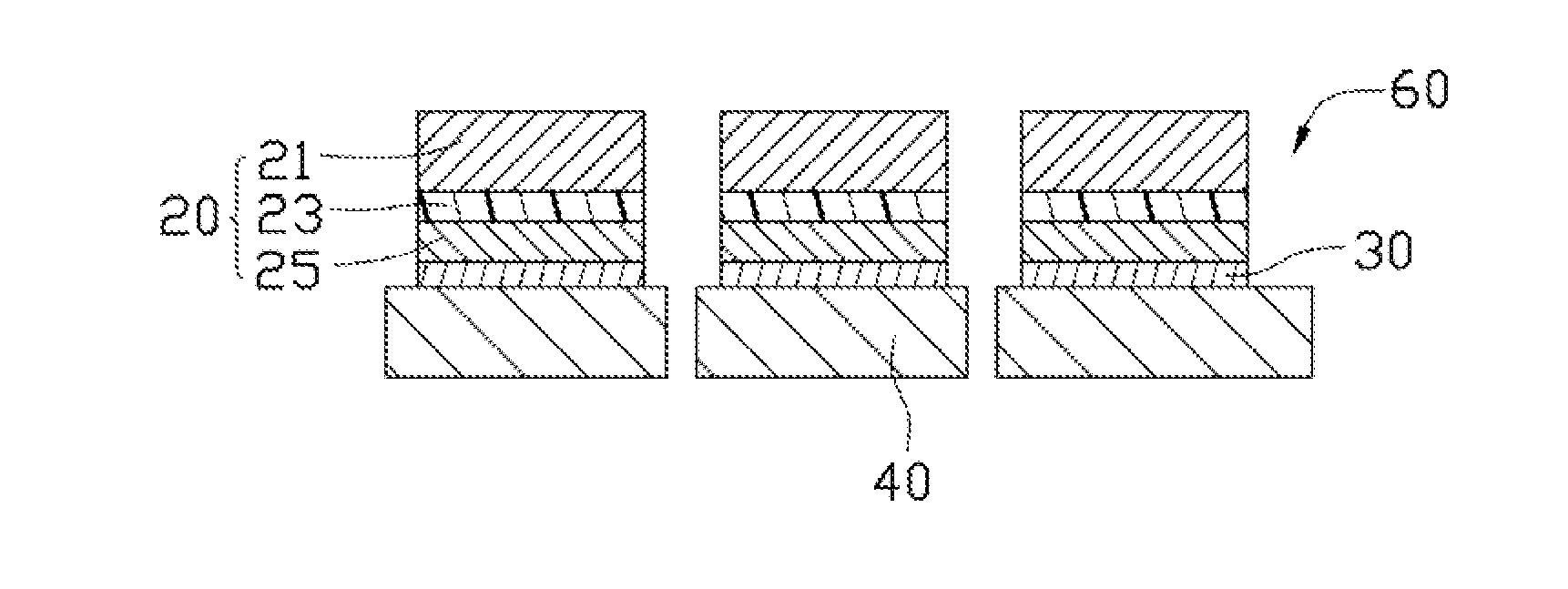

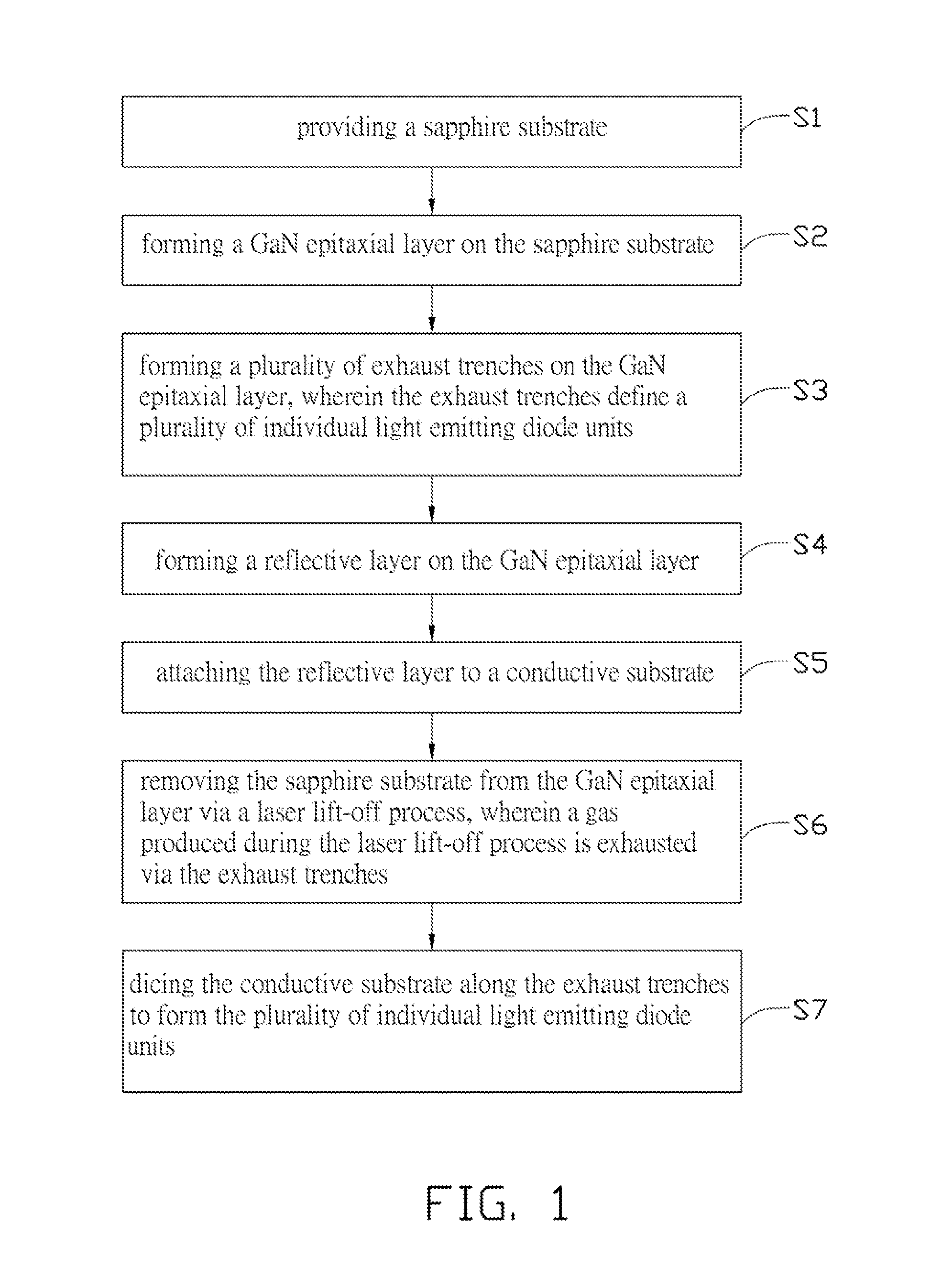

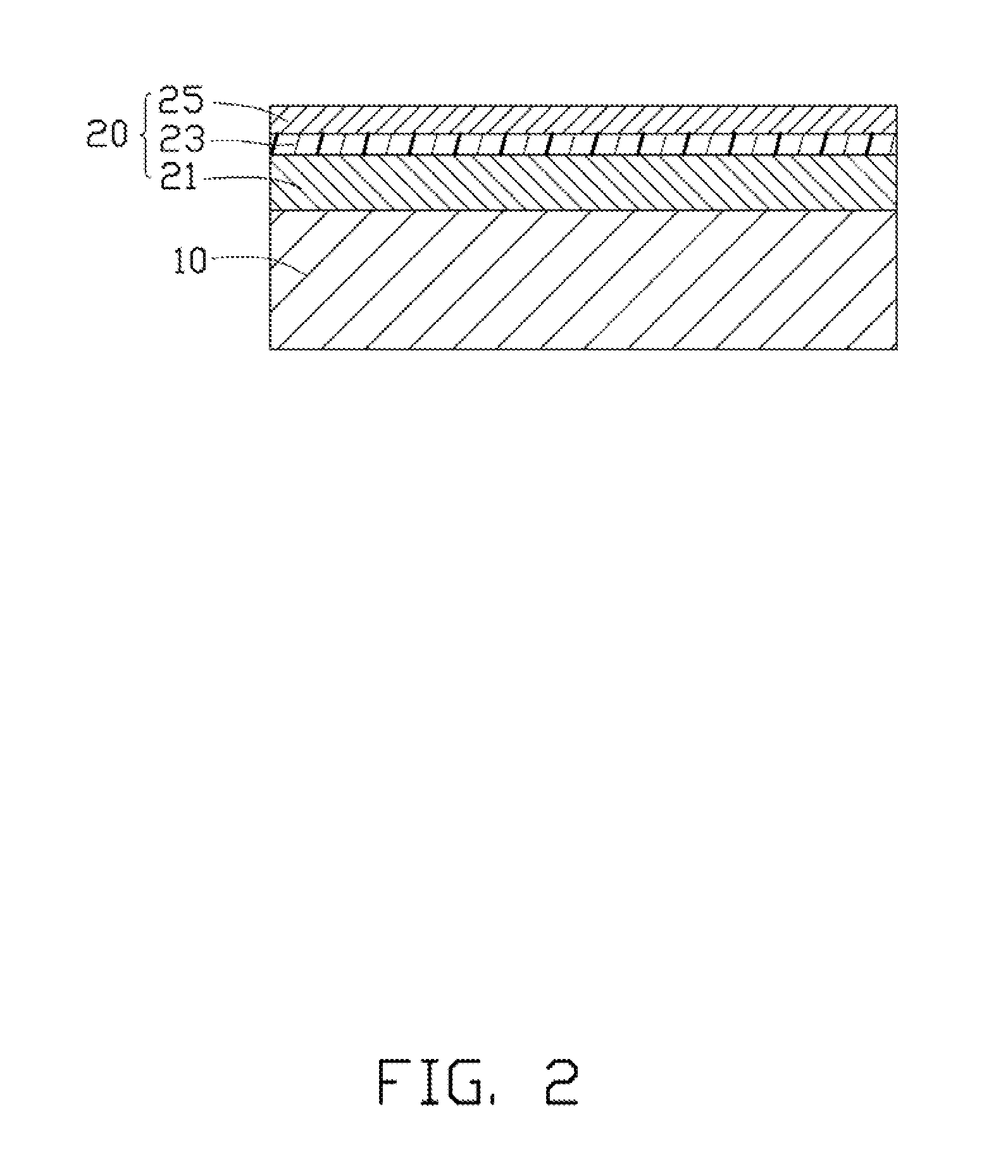

LED units fabrication method

InactiveUS20110159615A1Semiconductor/solid-state device manufacturingSemiconductor devicesReflective layerLight-emitting diode

A method for fabricating a plurality of individual light emitting diode units includes forming a GaN epitaxial layer on a sapphire substrate, forming a plurality of exhaust trenches on the GaN epitaxial layer, wherein the exhaust trenches define a plurality of individual light emitting diode units, forming a reflective layer on the GaN epitaxial layer, attaching the reflective layer to a conductive substrate, removing the sapphire substrate from the GaN epitaxial layer via a laser lift-off process, wherein a gas produced during the laser lift-off process is exhausted via the exhaust trenches, and dicing the conductive substrate along the exhaust trenches to form the plurality of individual light emitting diode units.

Owner:HON HAI PRECISION IND CO LTD

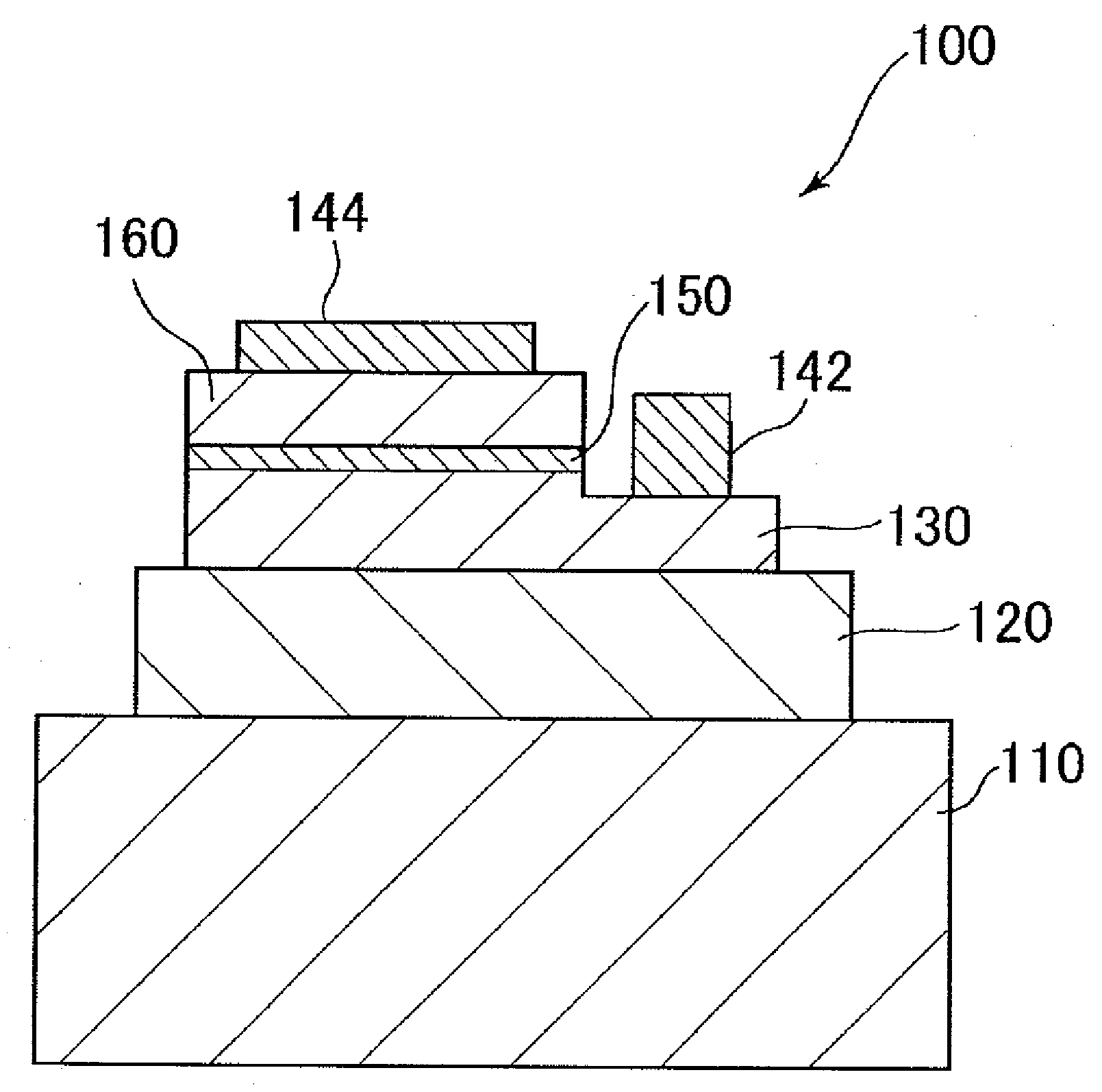

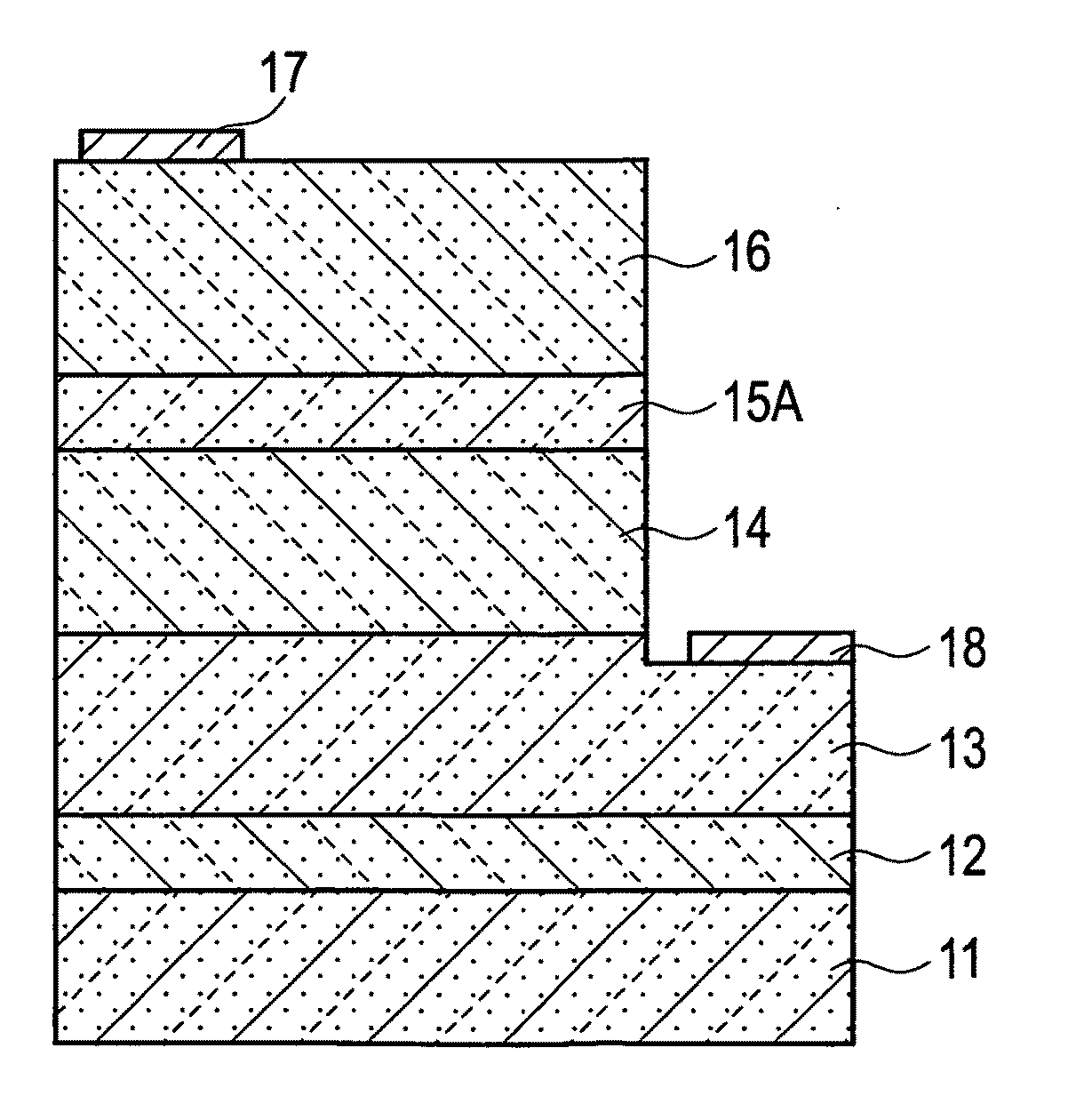

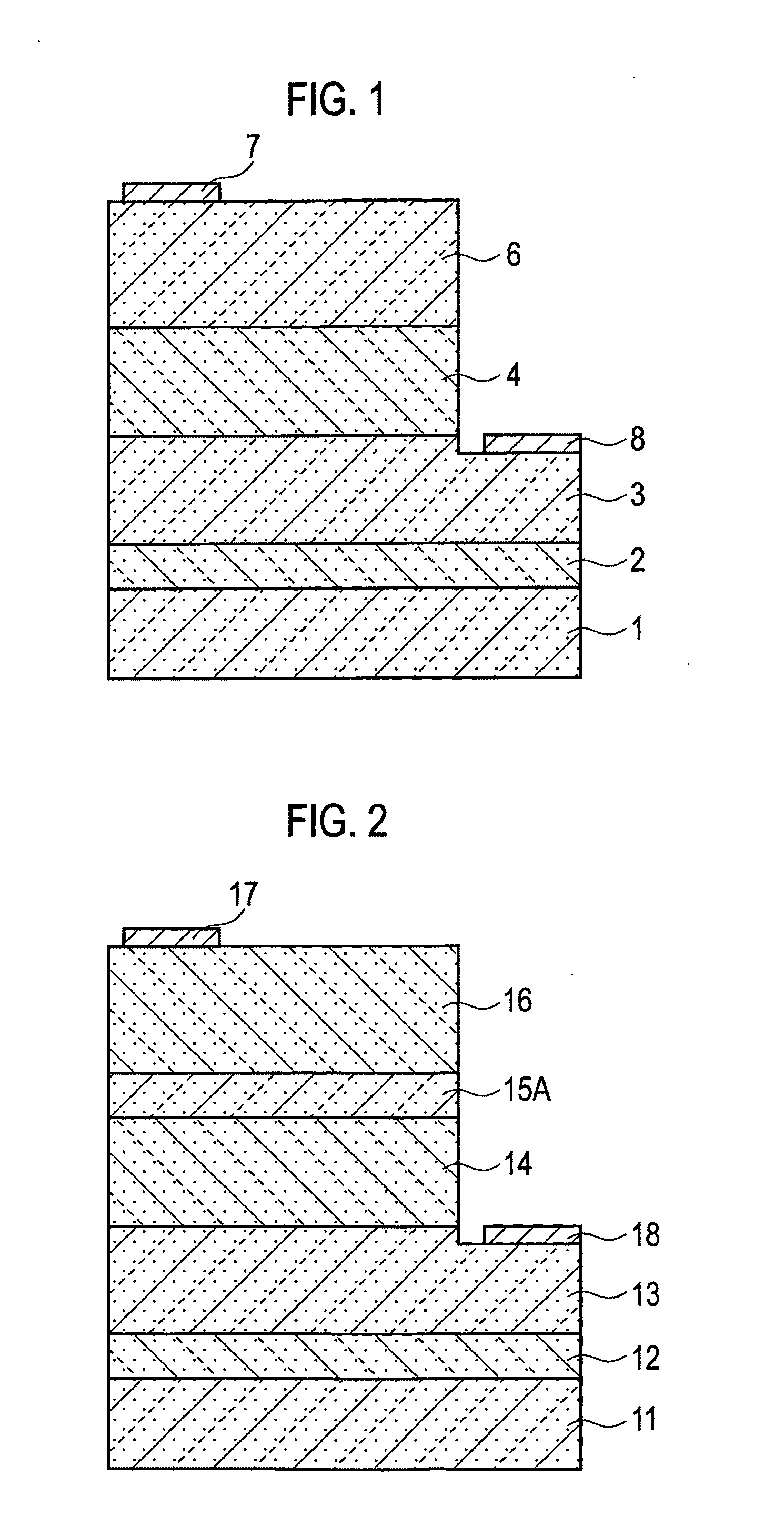

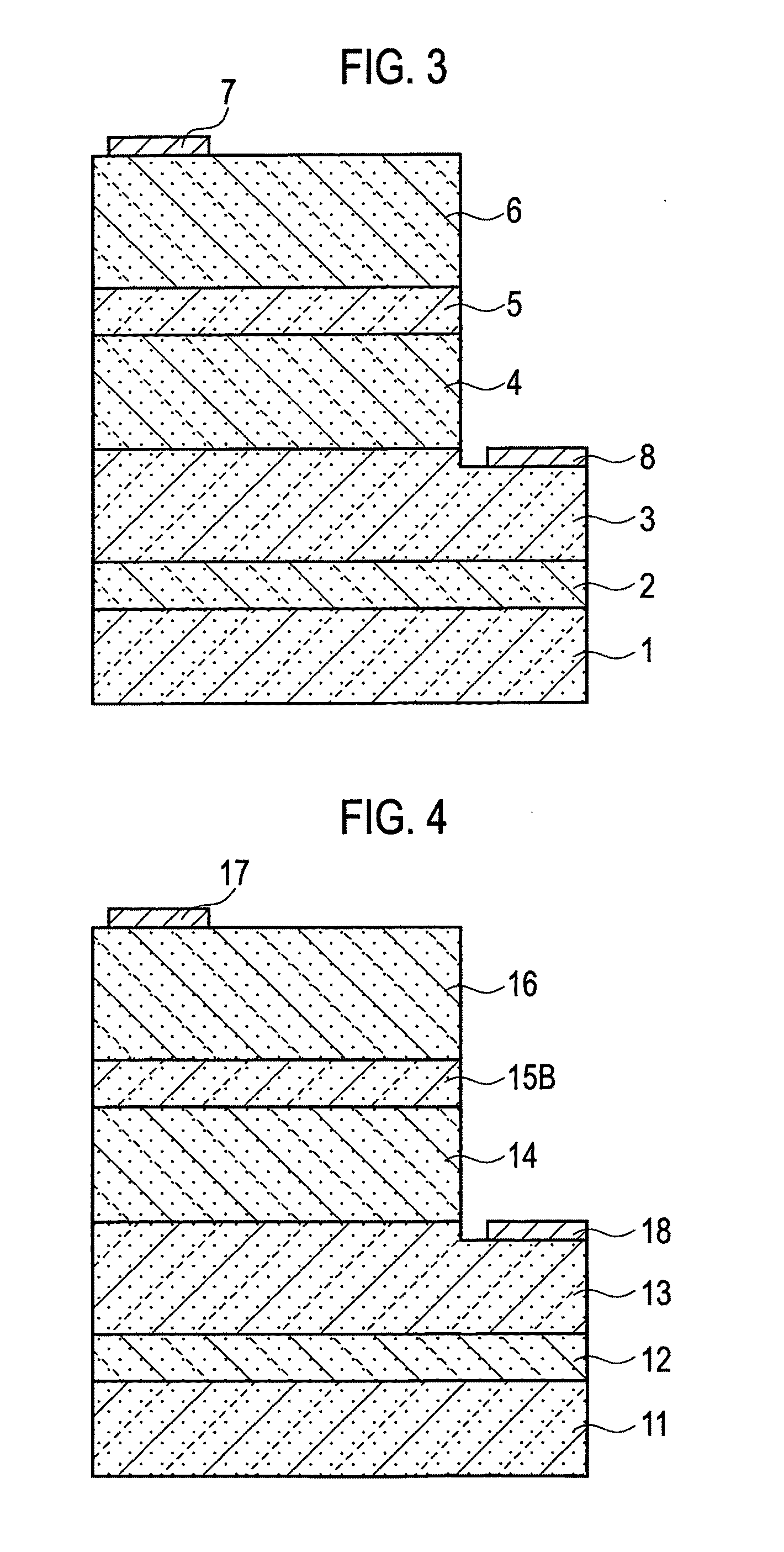

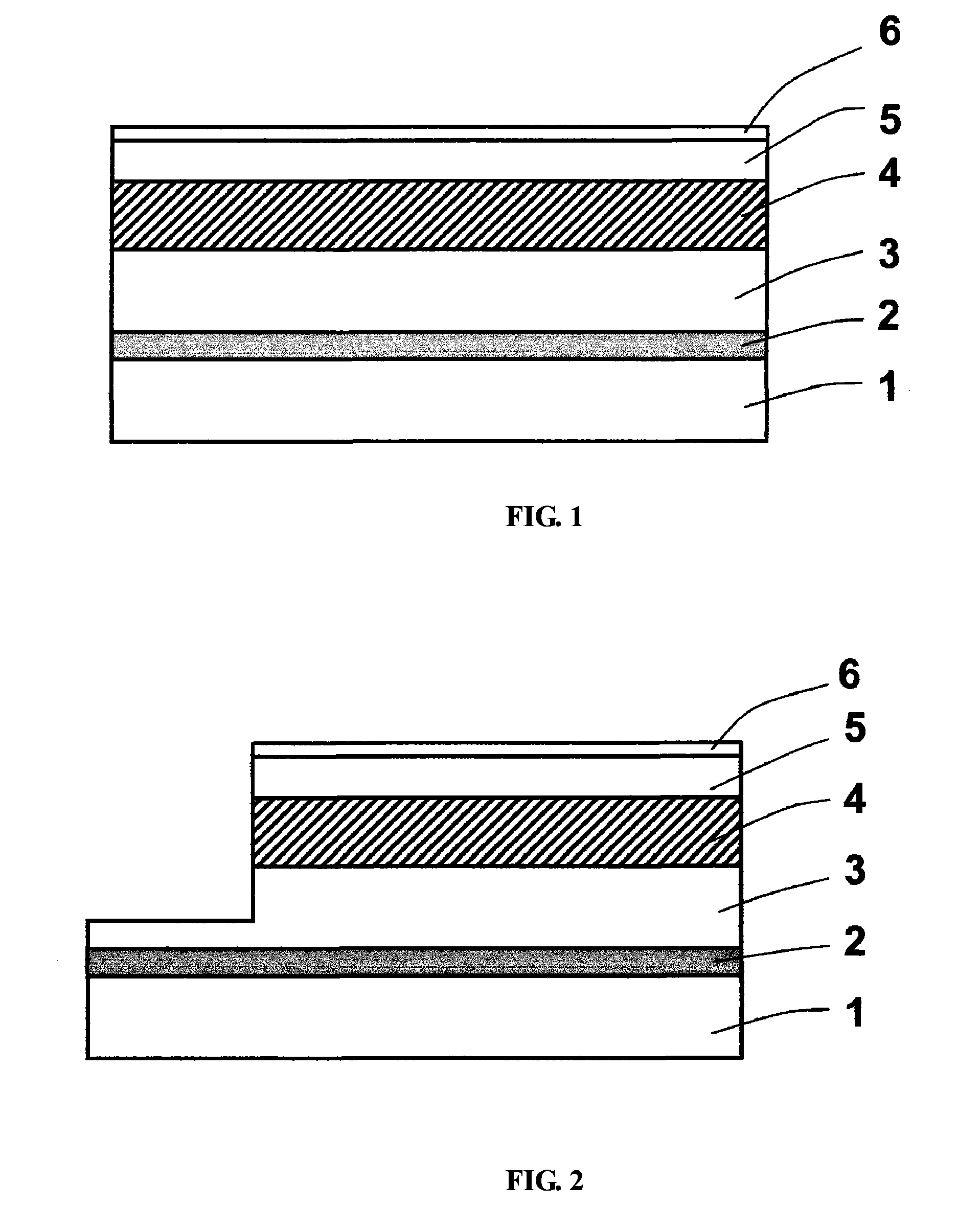

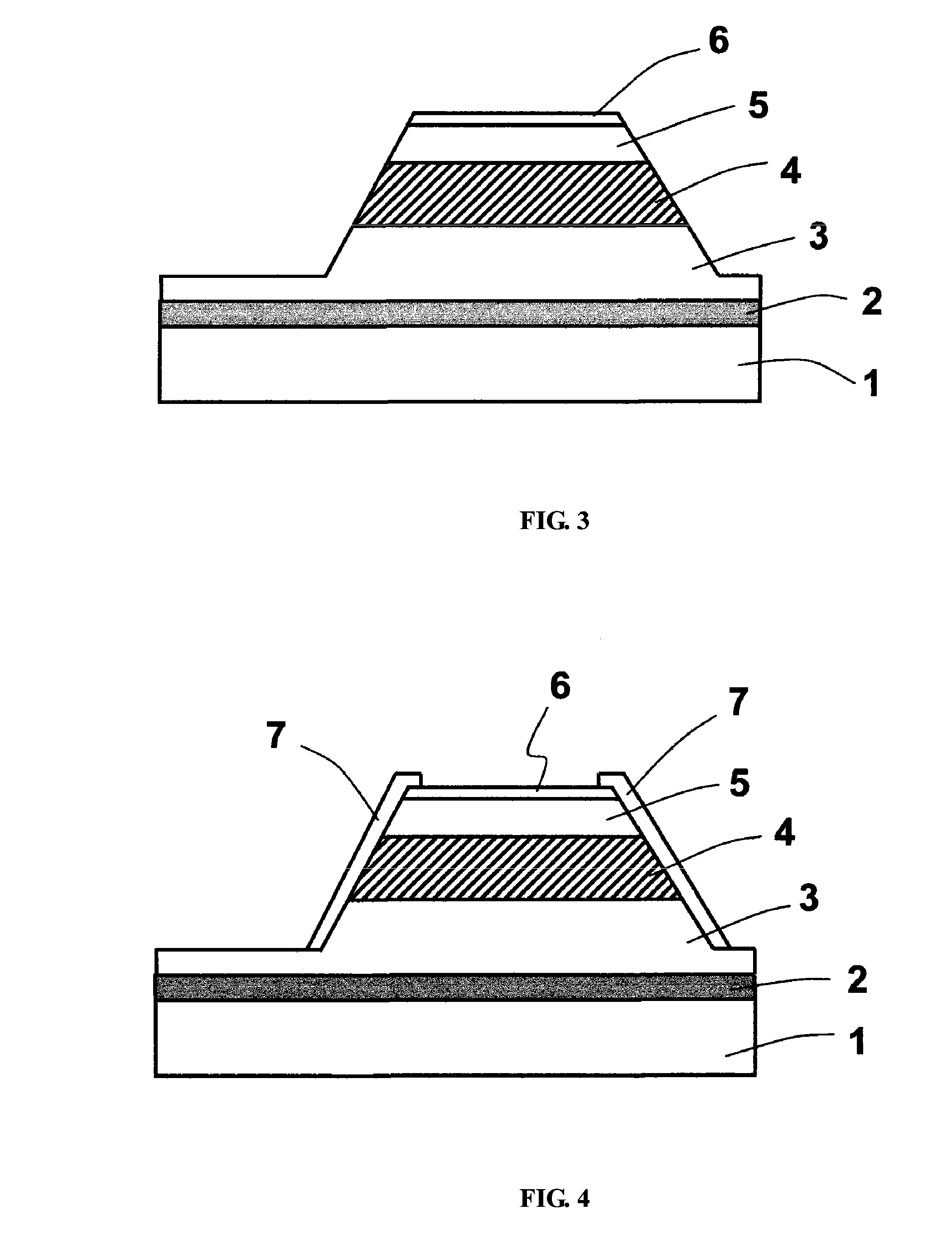

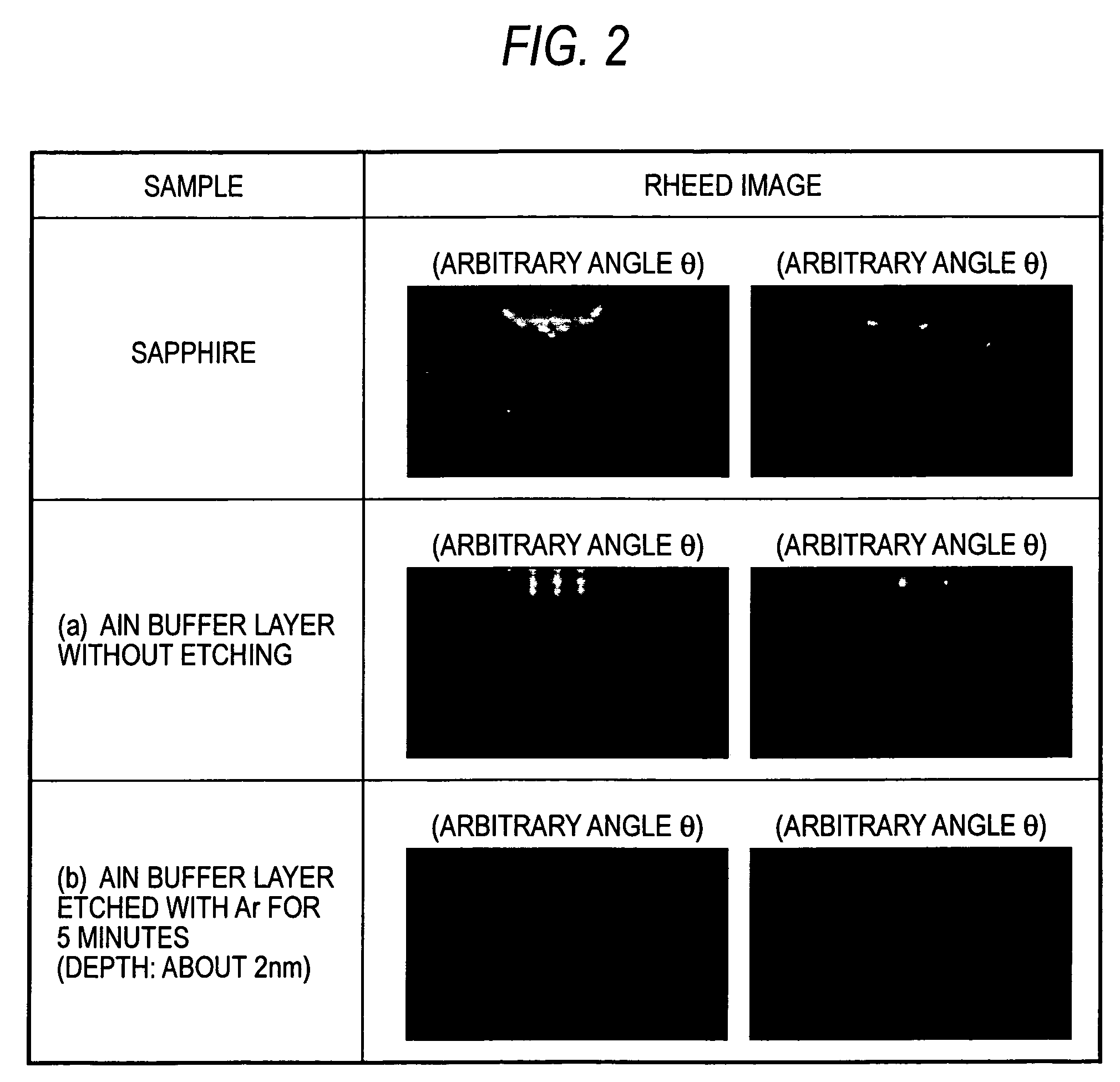

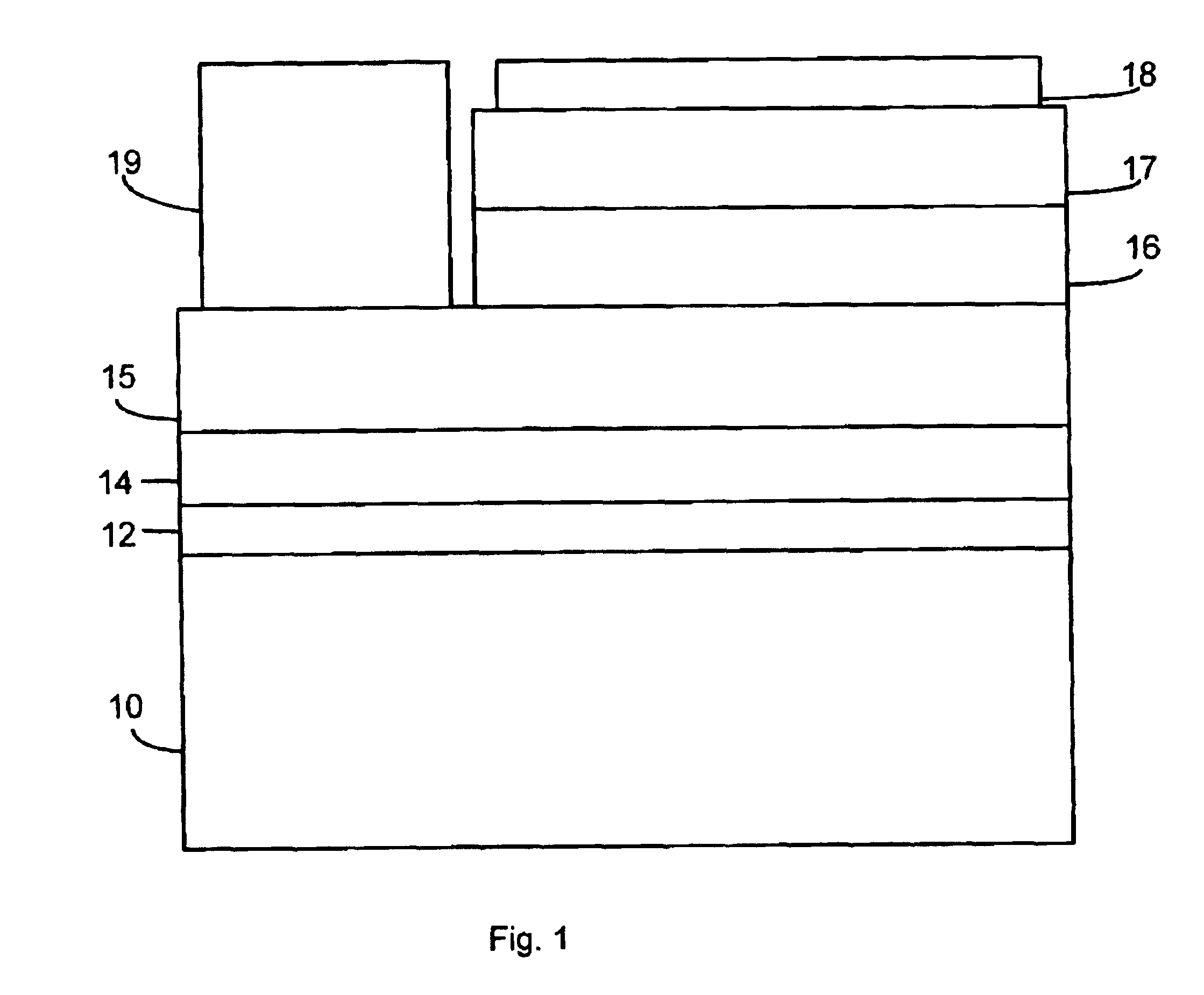

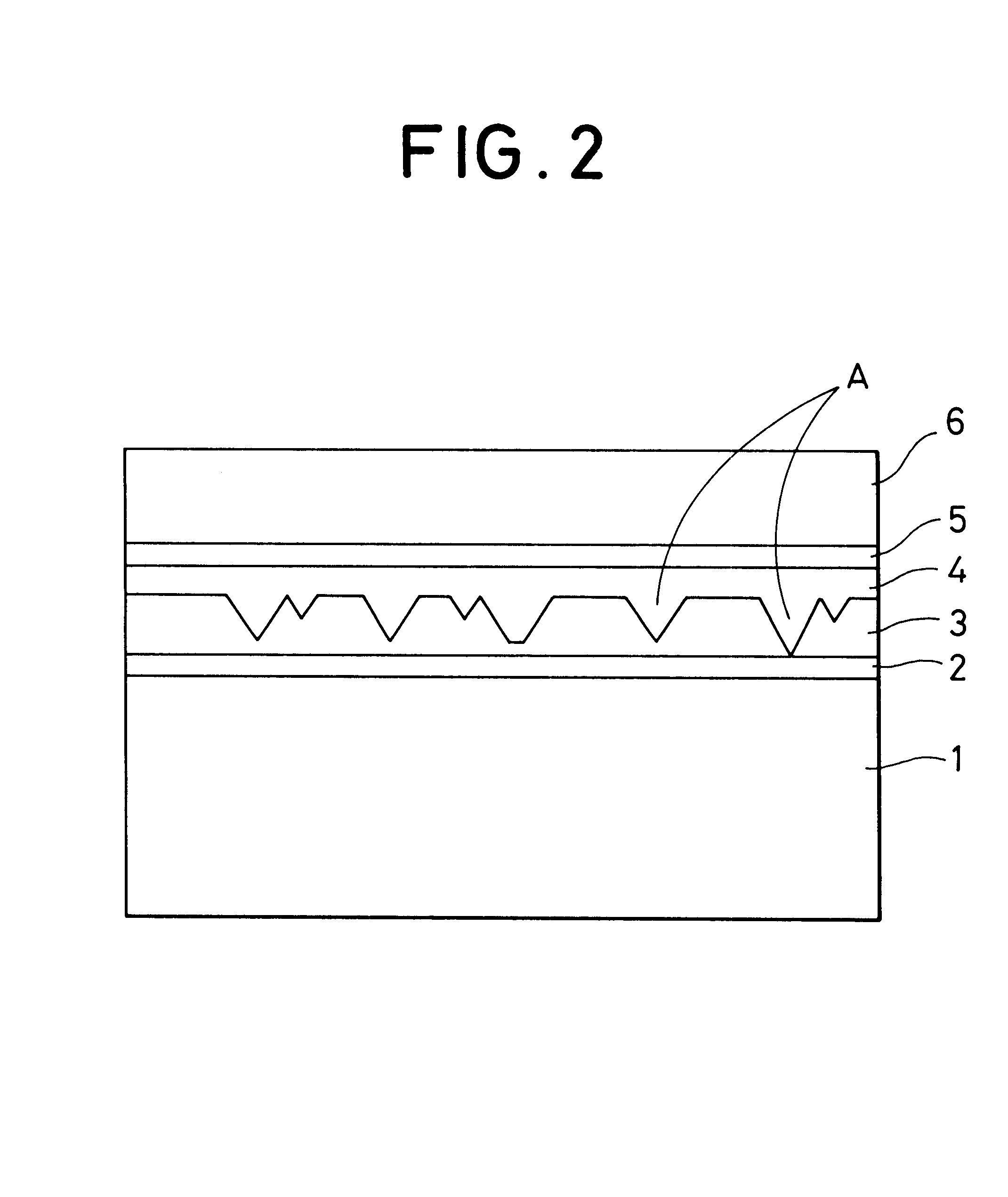

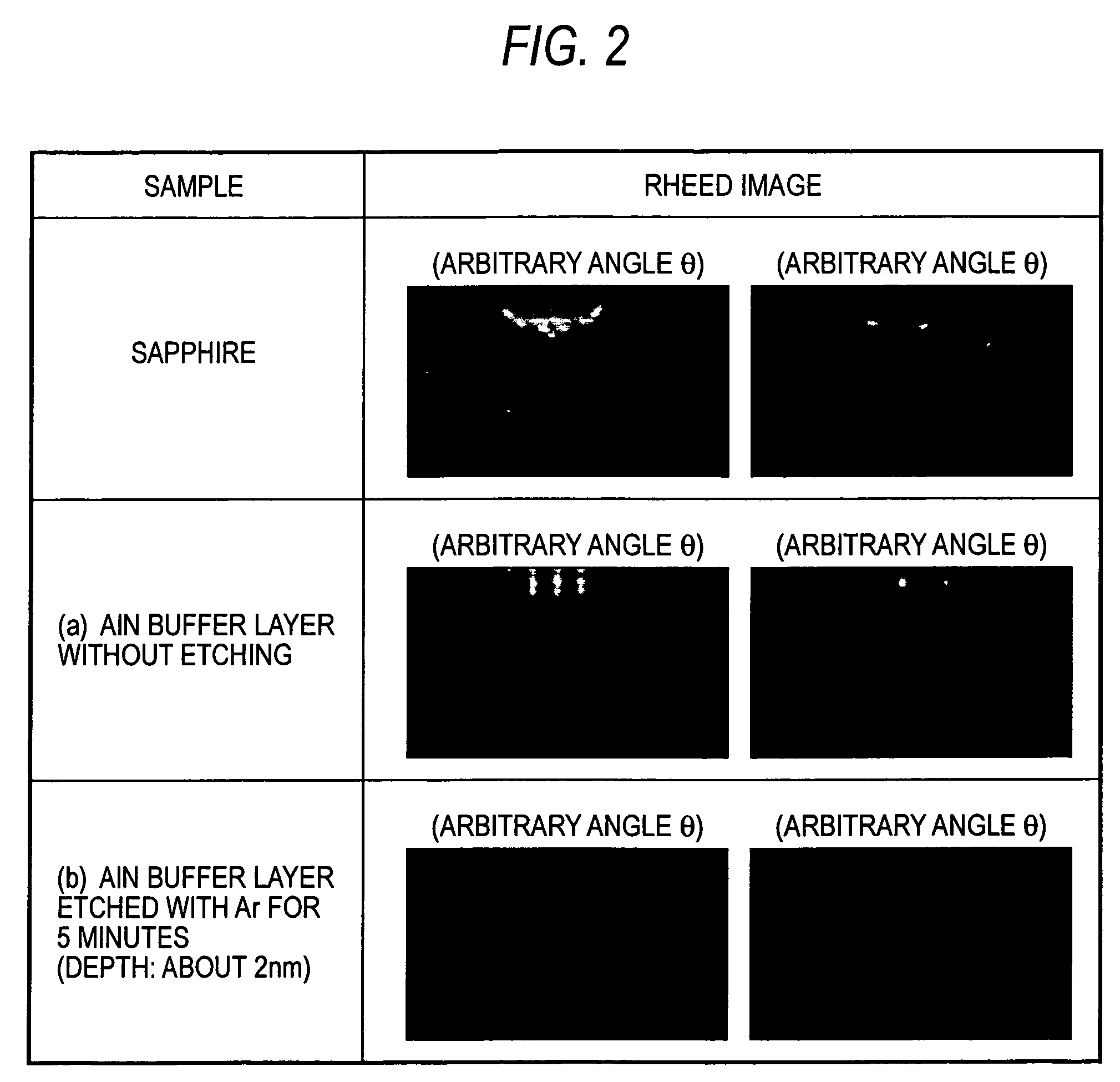

Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

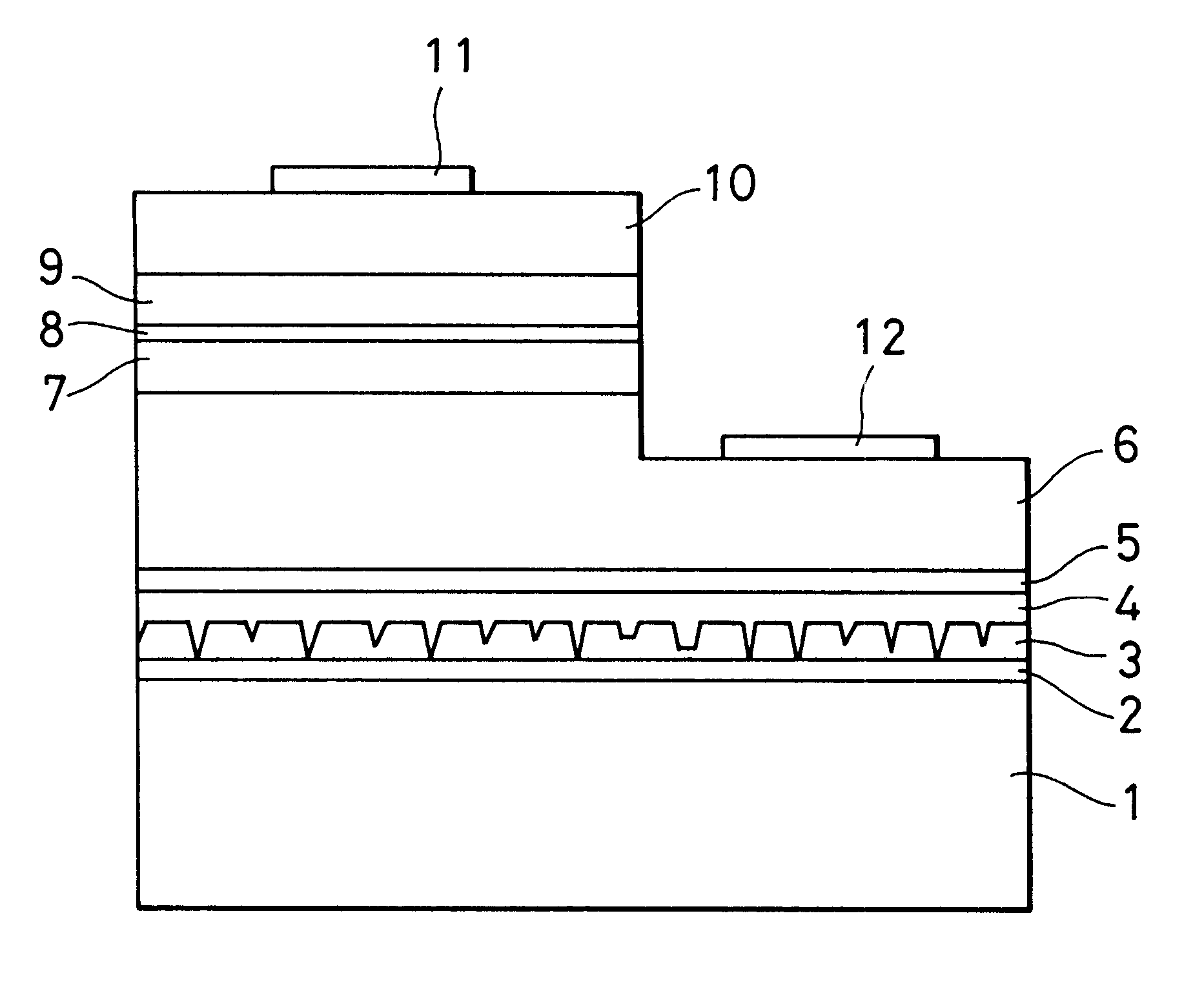

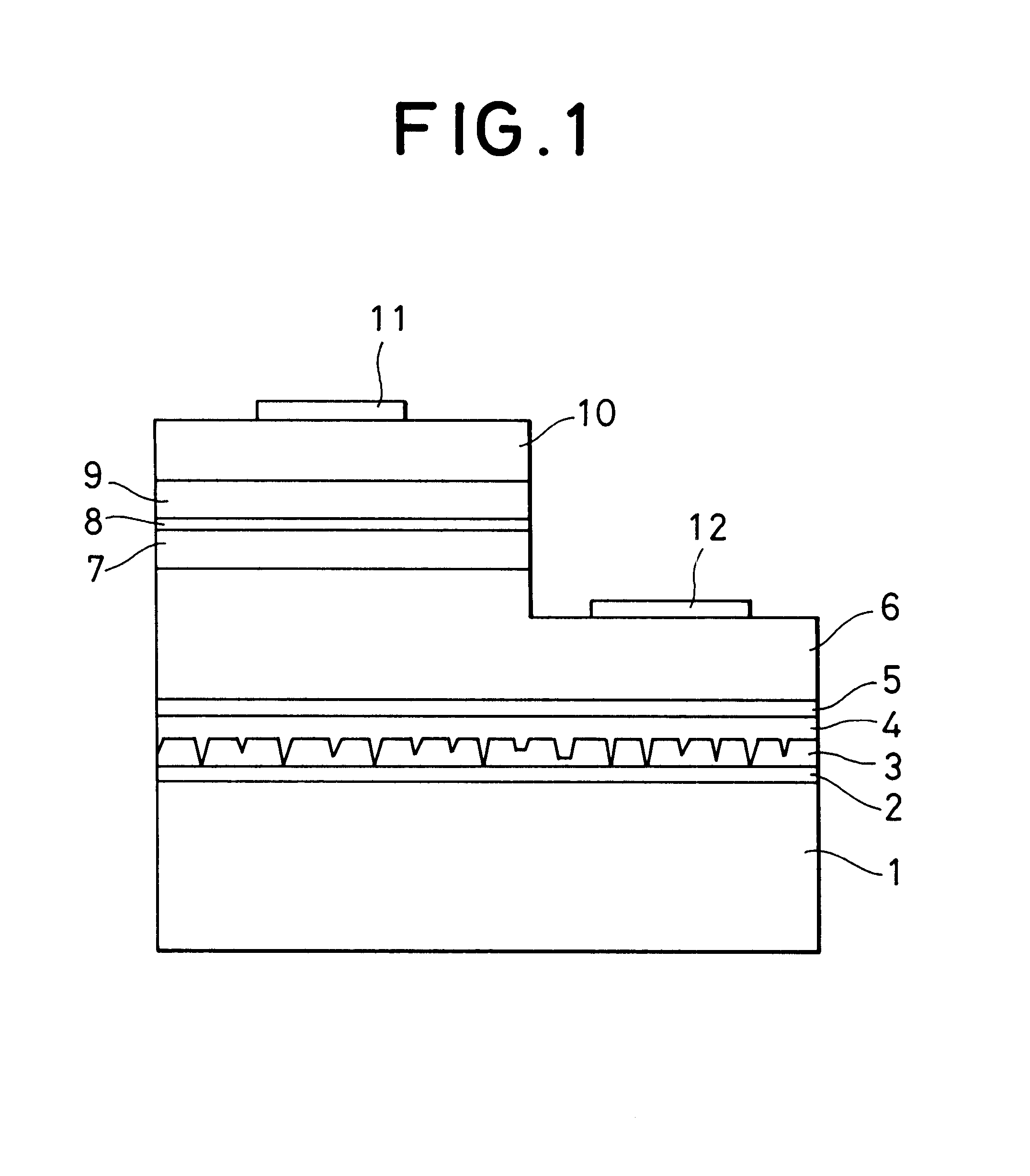

InactiveUS20100133506A1Improve crystal qualityAvoid more failuresSemiconductor/solid-state device manufacturingNanoopticsActive layerLight emission

Provided are a nitride semiconductor light emitting element having a nitride semiconductor layered on an AlN buffer layer with improved qualities such as crystal quality and with improved light emission output, and a method of manufacturing a nitride semiconductor. An AlN buffer layer (2) is formed on a sapphire substrate (1), and nitride semiconductors of an n-type AlGaN layer (3), an InGaN / GaN active layer (4) and a p-type GaN layer (5) are layered in sequence on the buffer layer (2). An n-electrode (7) is formed on a surface of the n-type AlGaN layer (3), and a p-electrode (6) is formed on the p-type GaN layer (5). The n-type AlGaN layer (3) serves as a cladding layer for confining light and carriers. The AlN buffer layer (2) is manufactured by alternately supplying an Al material and an N material at a growing temperature of 900° C. or higher.

Owner:ROHM CO LTD

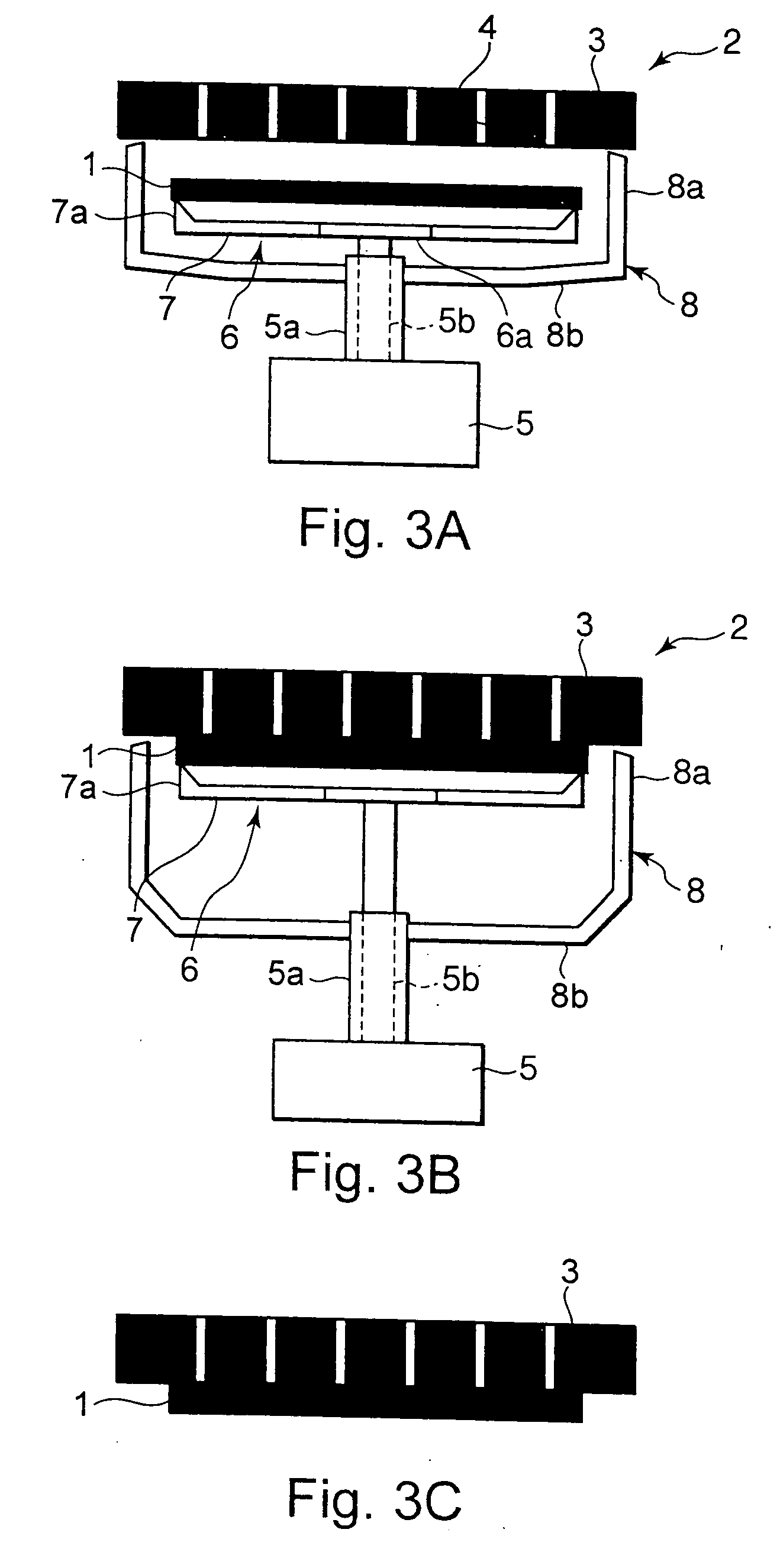

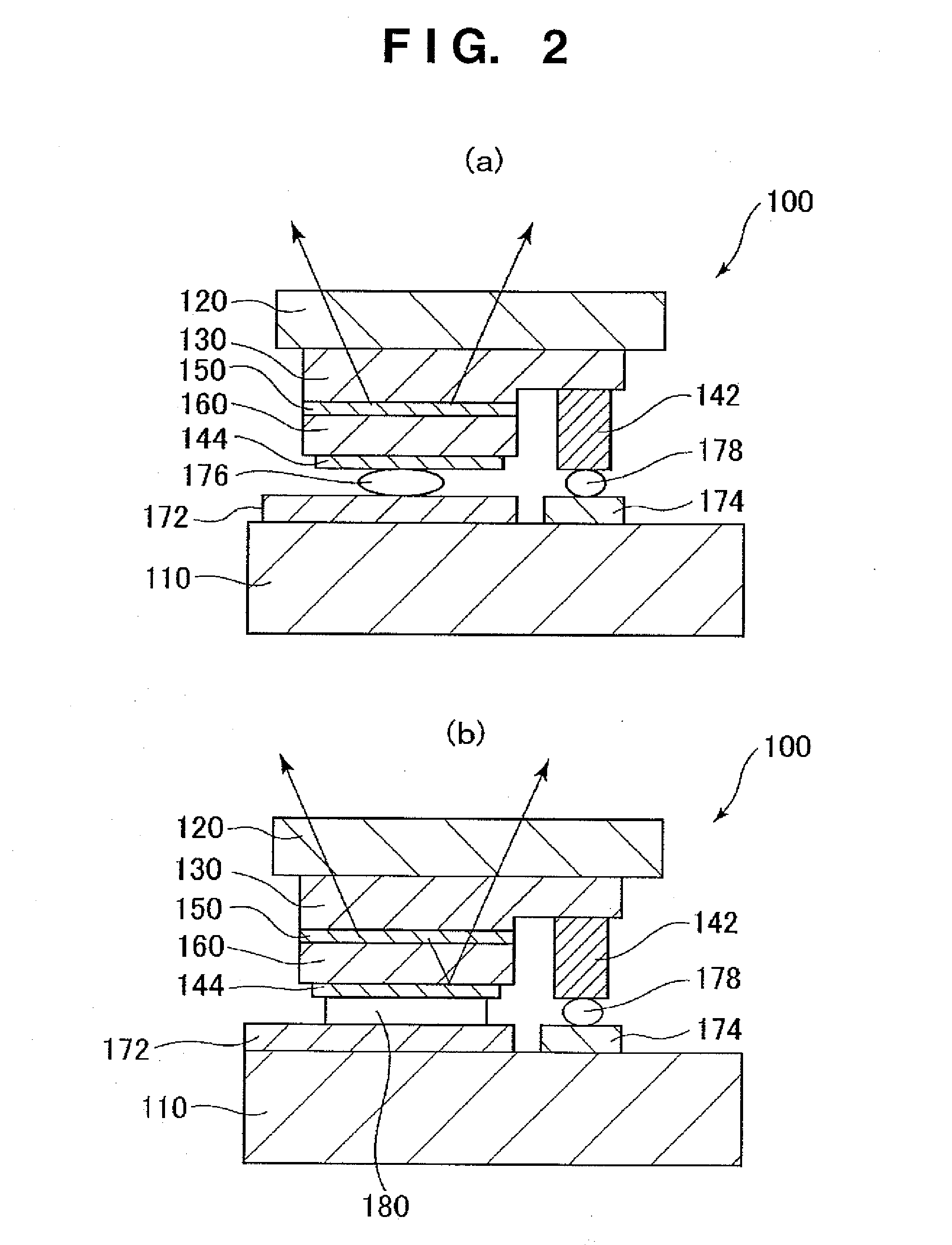

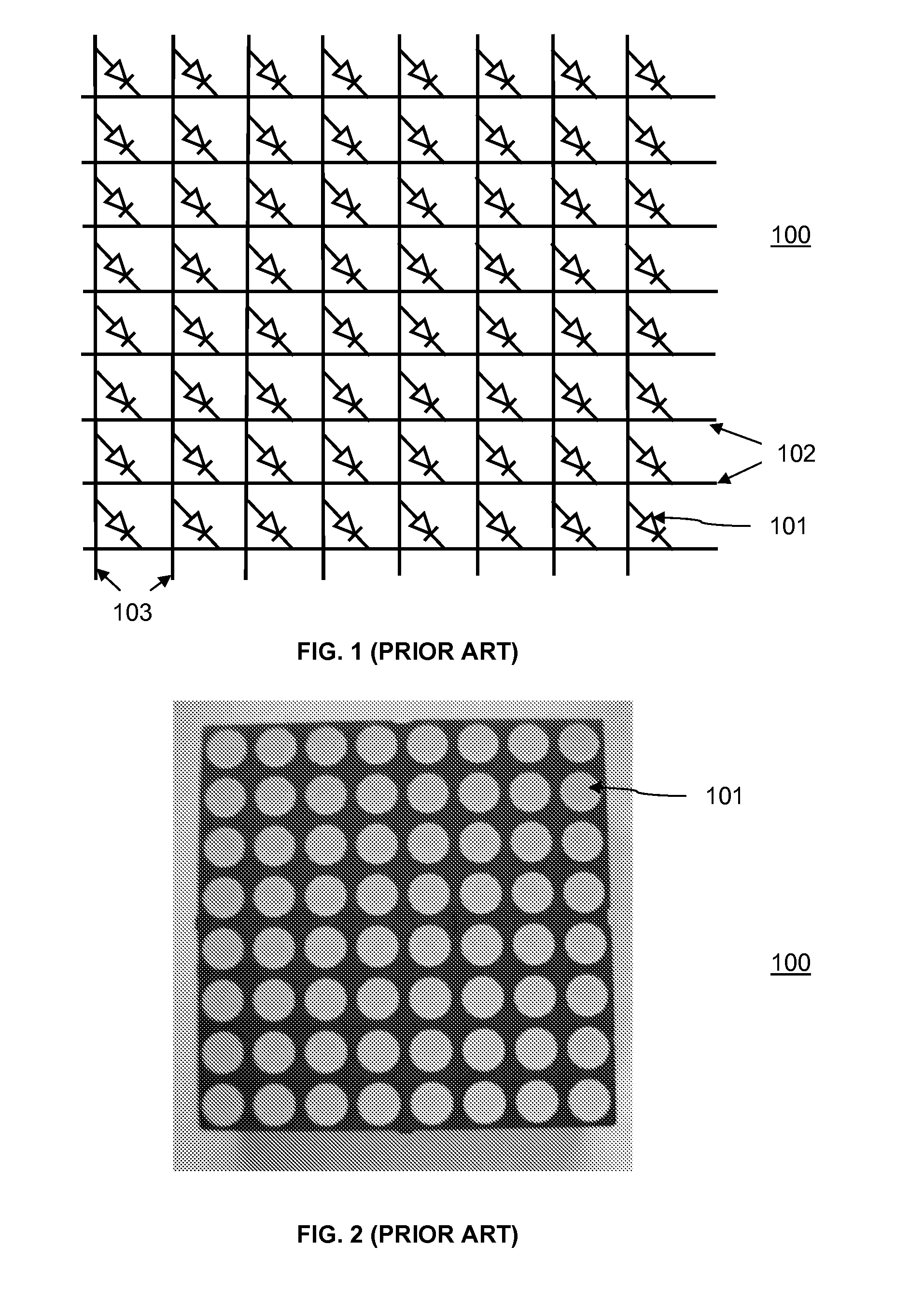

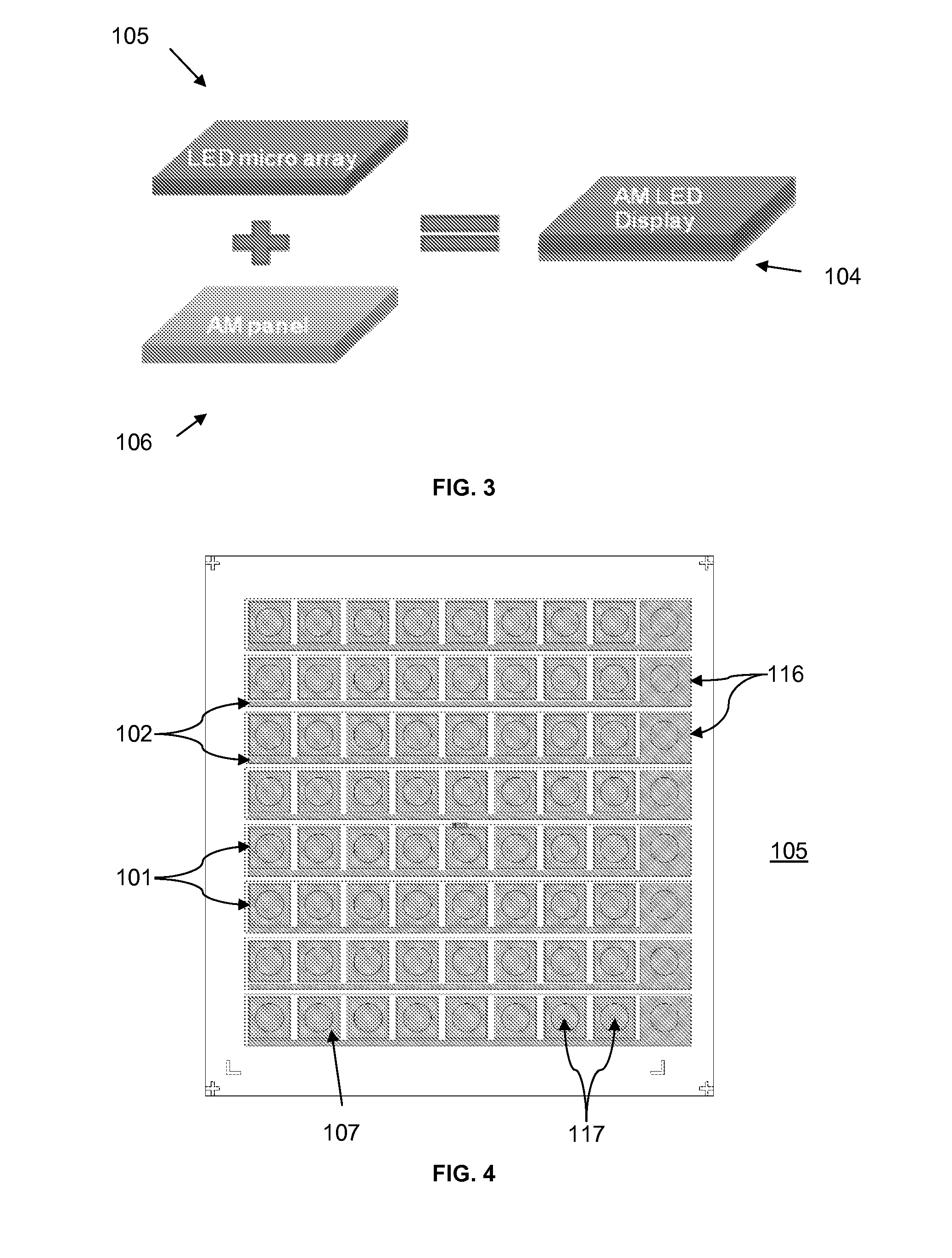

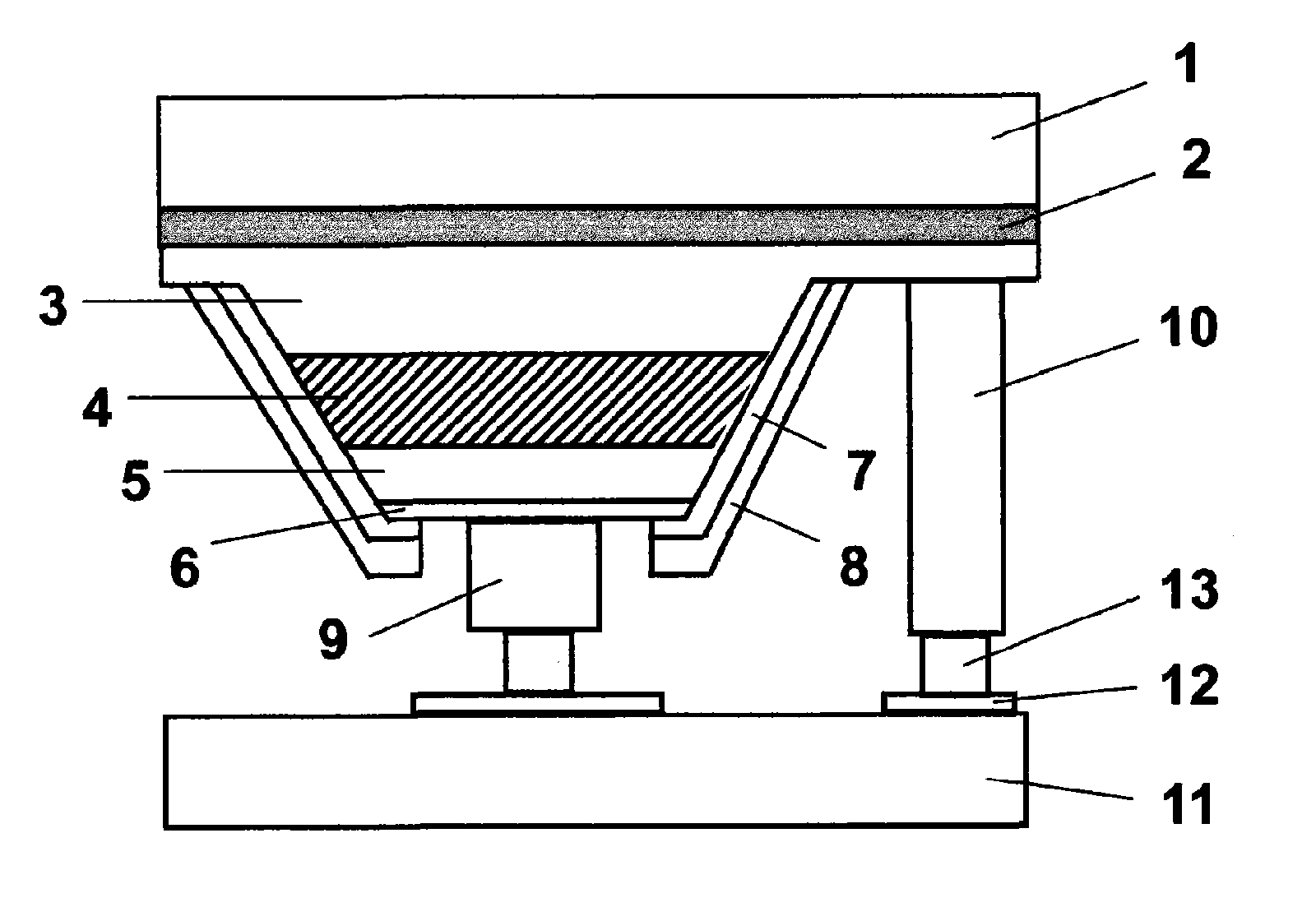

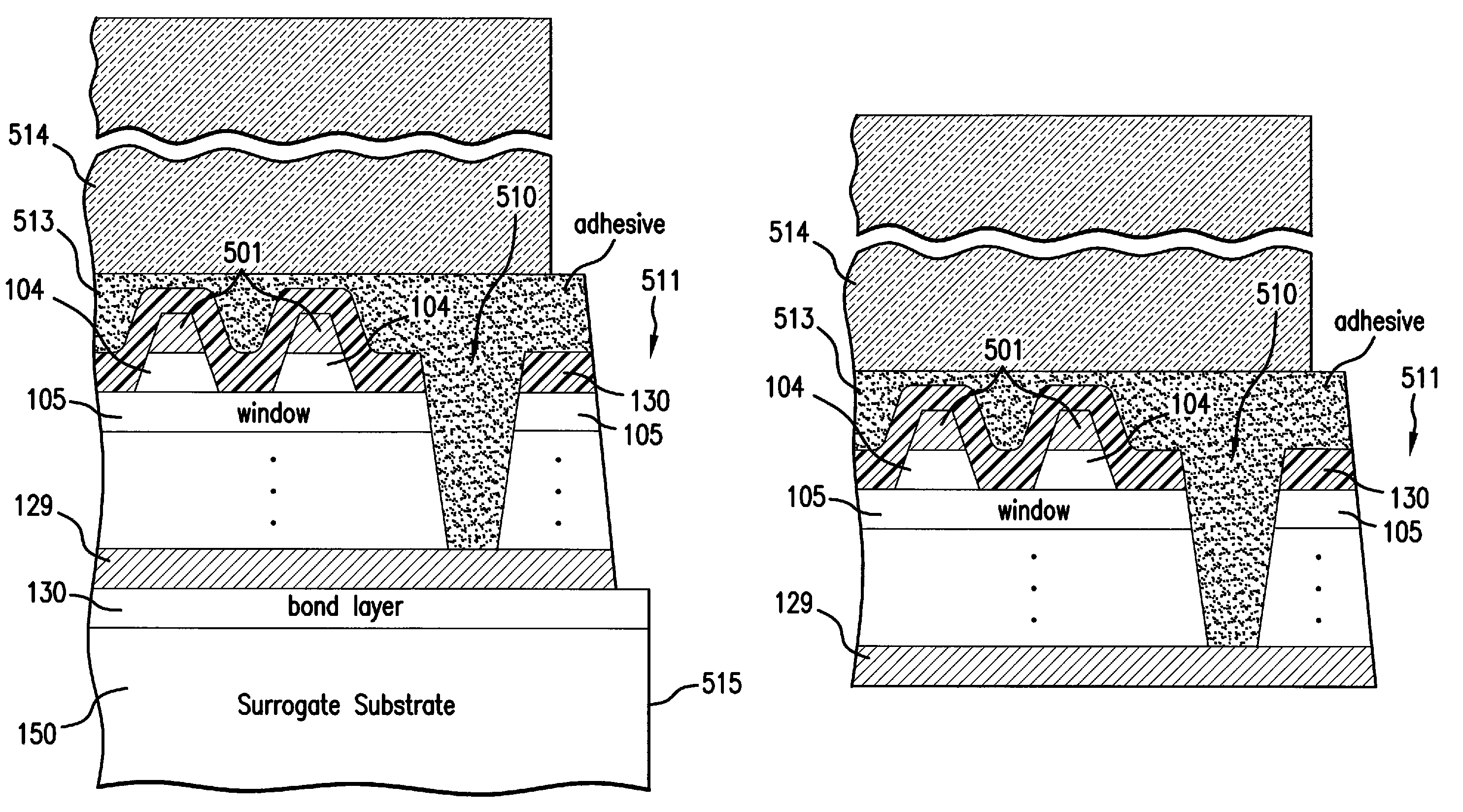

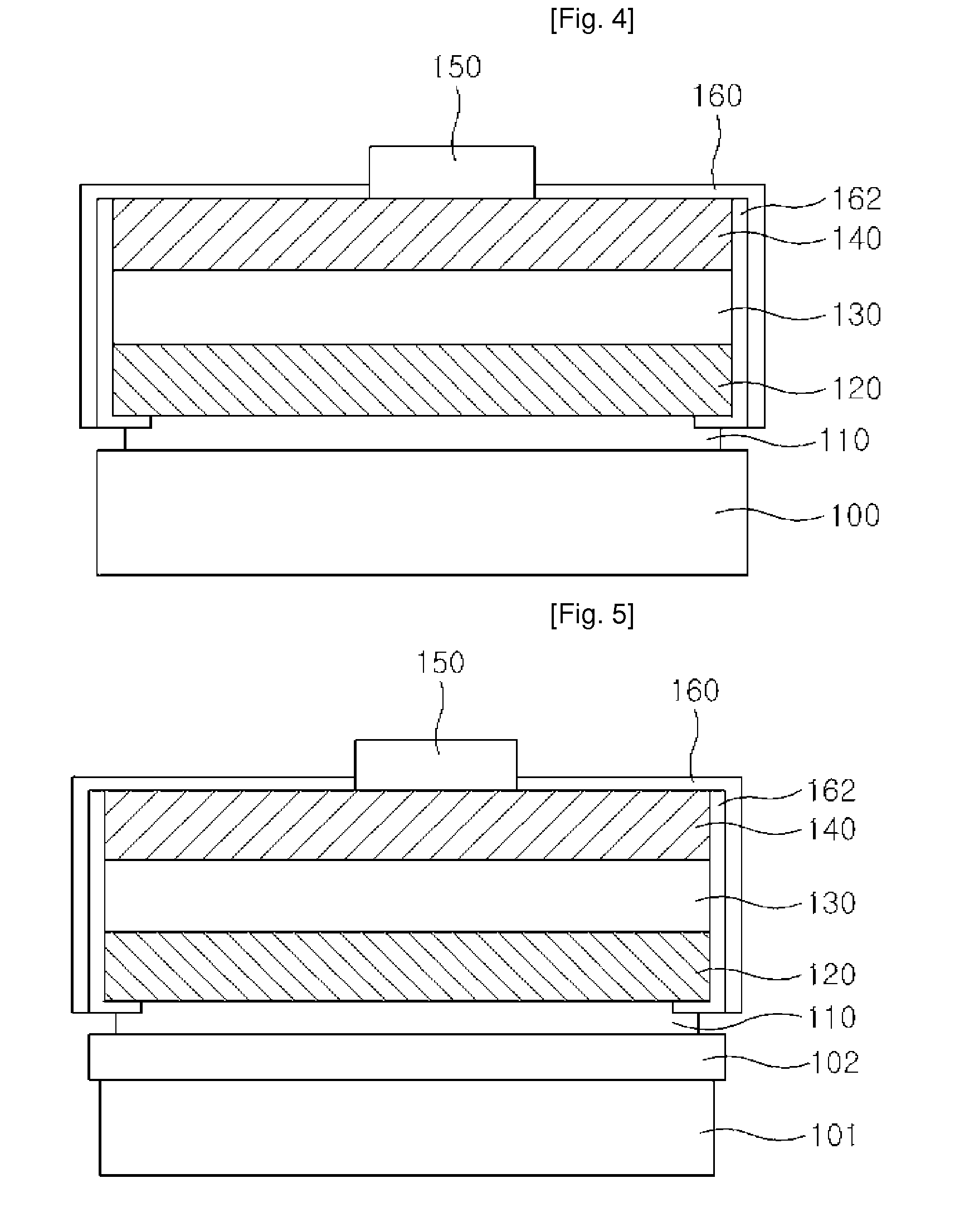

Method for manufacturing a monolithic LED micro-display on an active matrix panel using flip-chip technology and display apparatus having the monolithic LED micro-display

ActiveUS20110309378A1Solid-state devicesSemiconductor/solid-state device manufacturingActive matrixEngineering

A high-resolution, Active Matrix (AM) programmed monolithic Light Emitting Diode (LED) micro-array is fabricated using flip-chip technology. The fabrication process includes fabrications of an LED micro-array and an AM panel, and combining the resulting LED micro-array and AM panel using the flip-chip technology. The LED micro-array is grown and fabricated on a sapphire substrate and the AM panel can be fabricated using CMOS process. LED pixels in a same row share a common N-bus line that is connected to the ground of AM panel while p-electrodes of the LED pixels are electrically separated such that each p-electrode is independently connected to an output of drive circuits mounted on the AM panel. The LED micro-array is flip-chip bonded to the AM panel so that the AM panel controls the LED pixels individually and the LED pixels exhibit excellent emission uniformity. According to this constitution, incompatibility between the LED process and the CMOS process can be eliminated.

Owner:NANO & ADVANCED MATERIALS INST

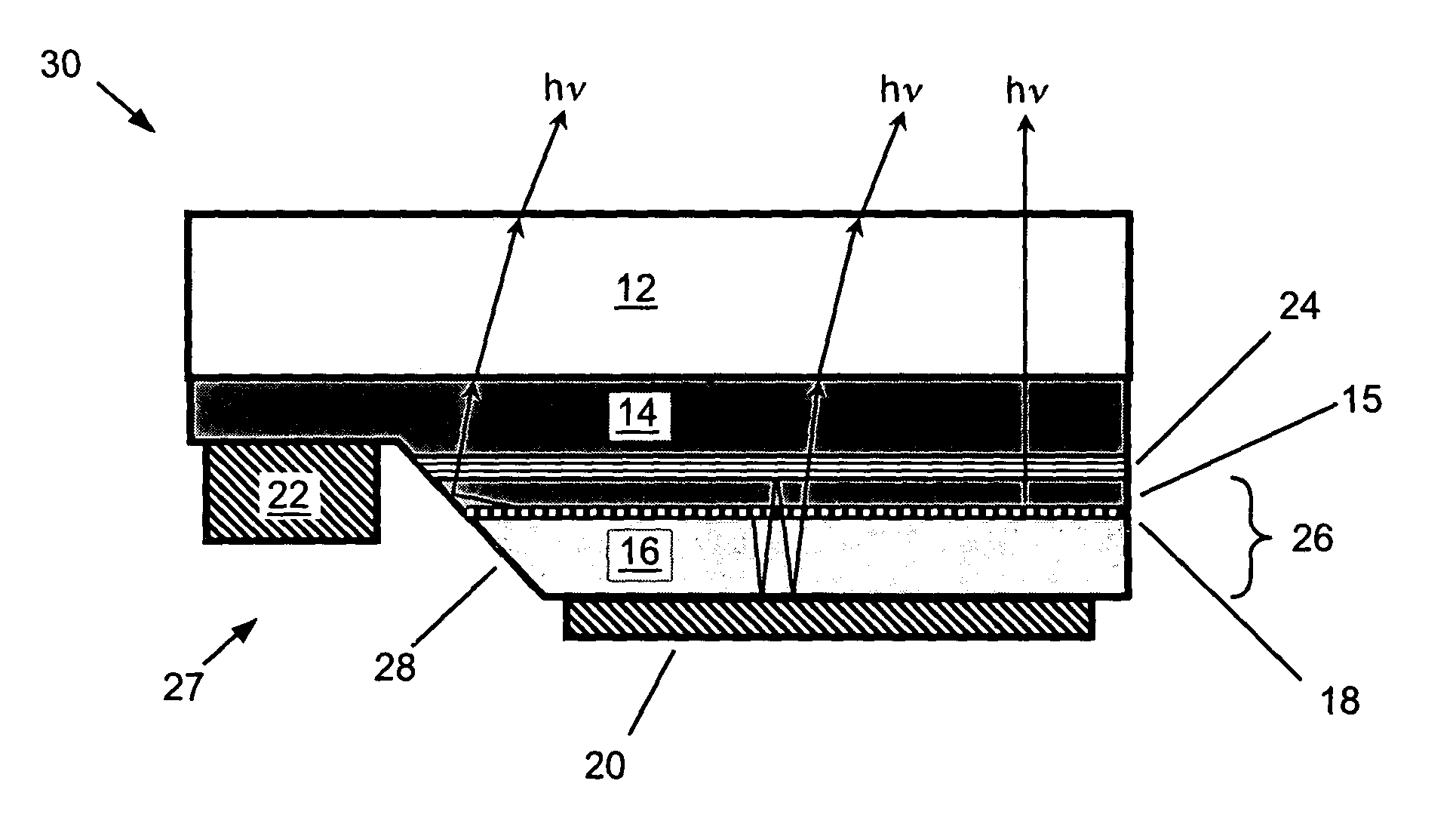

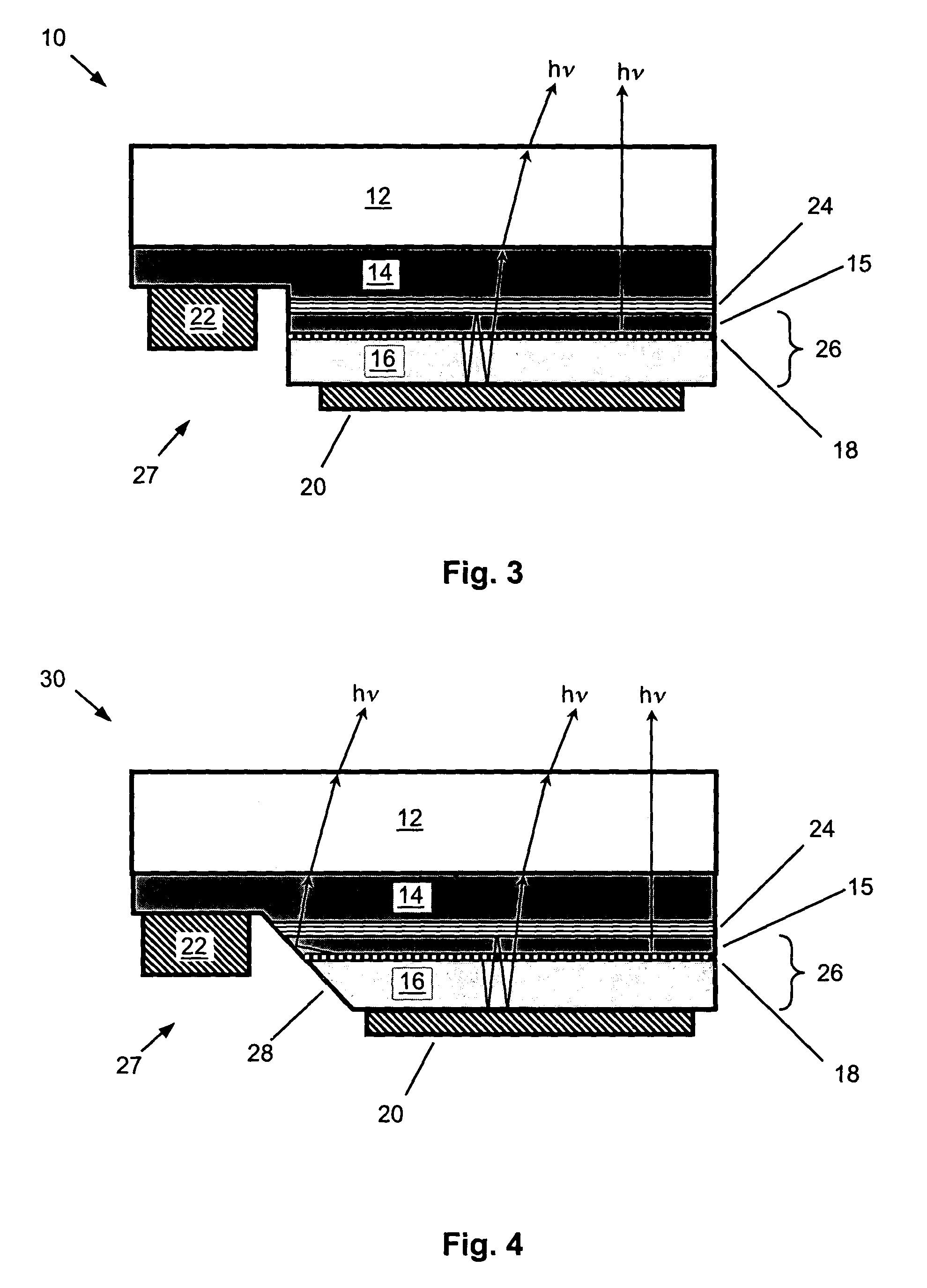

Flip-chip light emitting diode with resonant optical microcavity

InactiveUS6969874B1Improve efficiencyAccelerate emissionsSolid-state devicesSemiconductor devicesDielectric substrateGallium nitride

A flip-chip light emitting diode with enhanced efficiency. The device structure employs a microcavity structure in a flip-chip configuration. The microcavity enhances the light emission in vertical modes, which are readily extracted from the device. Most of the rest of the light is emitted into waveguided lateral modes. Flip-chip configuration is advantageous for light emitting diodes (LEDs) grown on dielectric substrates (e.g., gallium nitride LEDs grown on sapphire substrates) in general due to better thermal dissipation and lower series resistance. Flip-chip configuration is advantageous for microcavity LEDs in particular because (a) one of the reflectors is a high-reflectivity metal ohmic contact that is already part of the flip-chip configuration, and (b) current conduction is only required through a single distributed Bragg reflector. Some of the waveguided lateral modes can also be extracted with angled sidewalls used for the interdigitated contacts in the flip-chip configuration.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

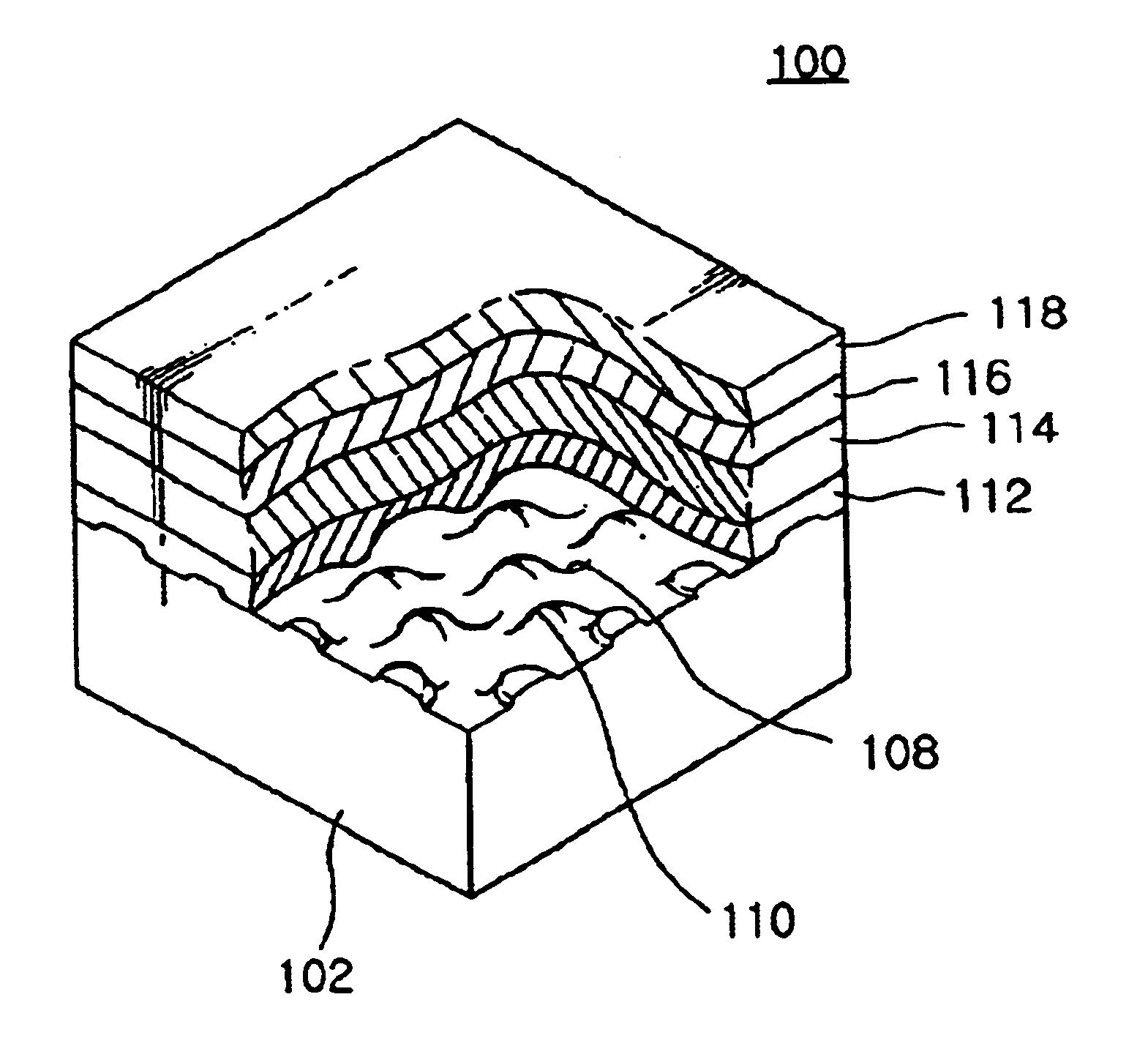

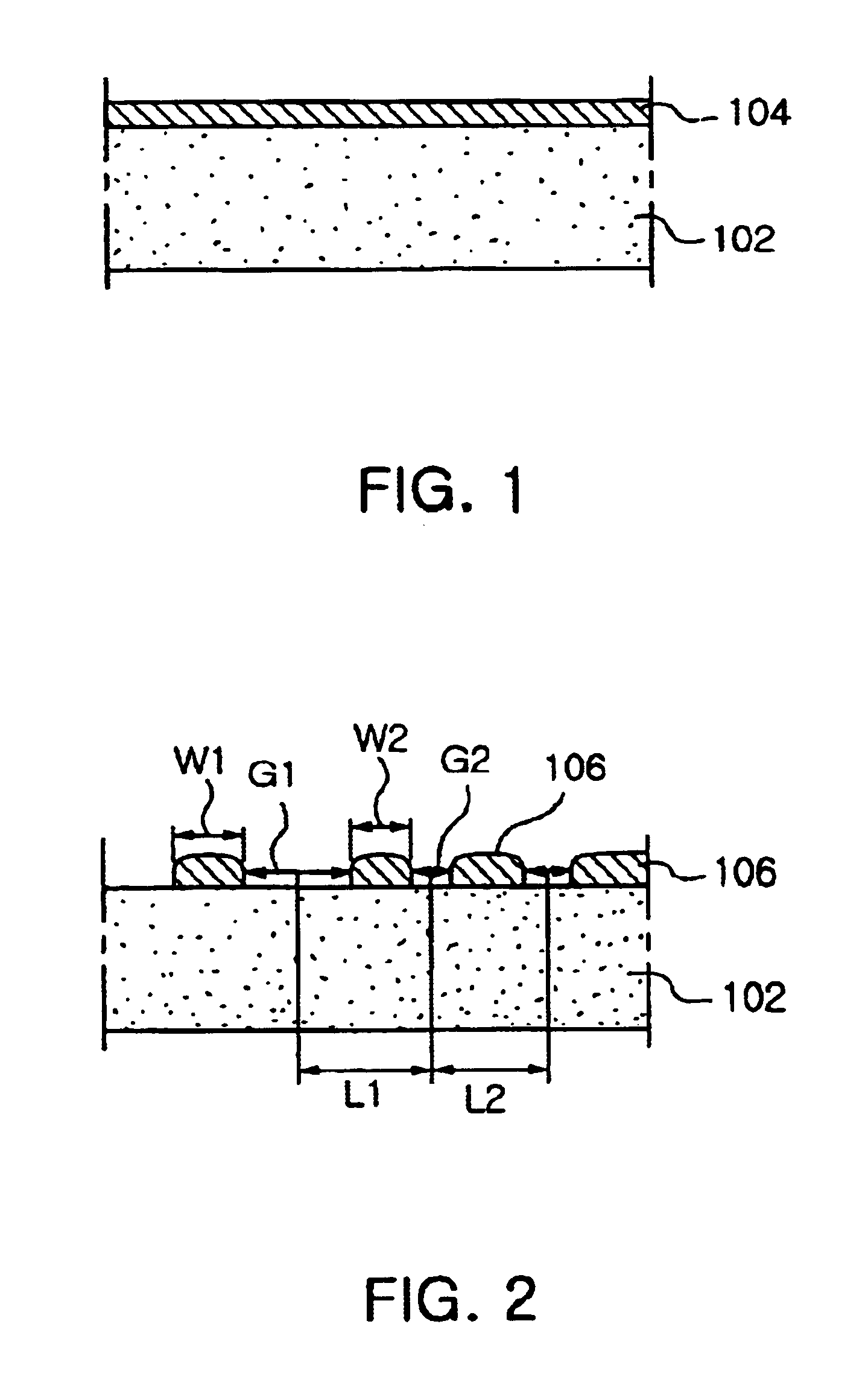

Fabrication method of nitride-based semiconductors and nitride-based semiconductor fabricated thereby

ActiveUS6844569B1Reduce dislocationReduce stressPolycrystalline material growthSolid-state devicesQuantum efficiencyMetal clusters

The present invention relates to a fabrication method of nitride-based semiconductors and a nitride-based semiconductor fabricated thereby. In the fabrication method of the invention, a self-organizing metal layer is formed on a sapphire substrate. The sapphire substrate having the self-organizing metal layer is heated so that self-organizing metal coalesces into nanoscale clusters to irregularly expose an upper surface of the sapphire substrate. Exposed portions of the sapphire substrate is plasma etched using the self-organized metal clusters as a mask to form a nanoscale uneven structure on the sapphire substrate. A resultant structure is wet etched to remove the self-organized metal clusters. The nanoscale uneven structure formed on the sapphire substrate decreases the stress and resultant dislocation between the sapphire substrate and a nitride-based semiconductor layer as well as increases the quantum efficiency between the same.

Owner:SAMSUNG ELECTRONICS CO LTD

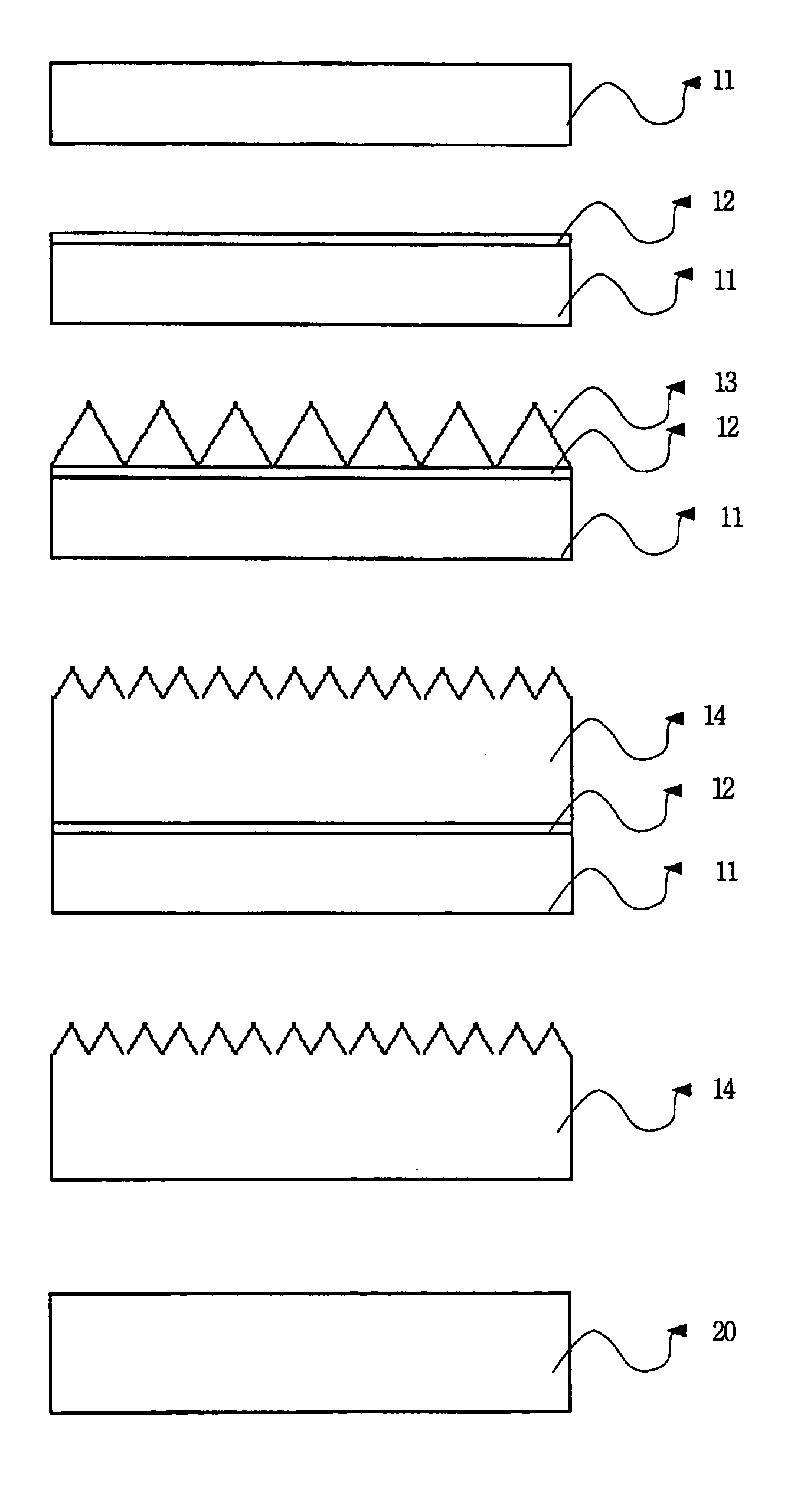

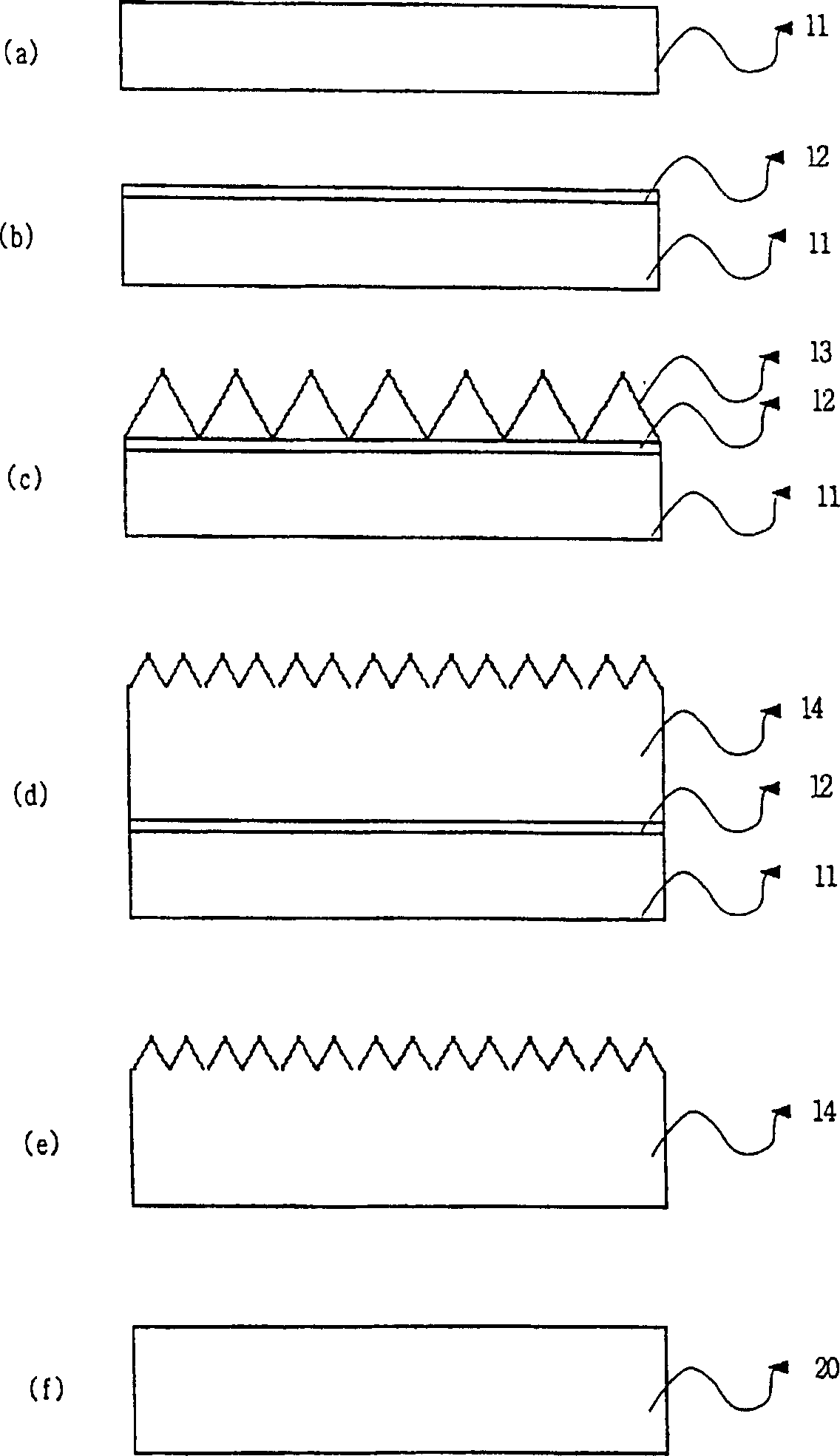

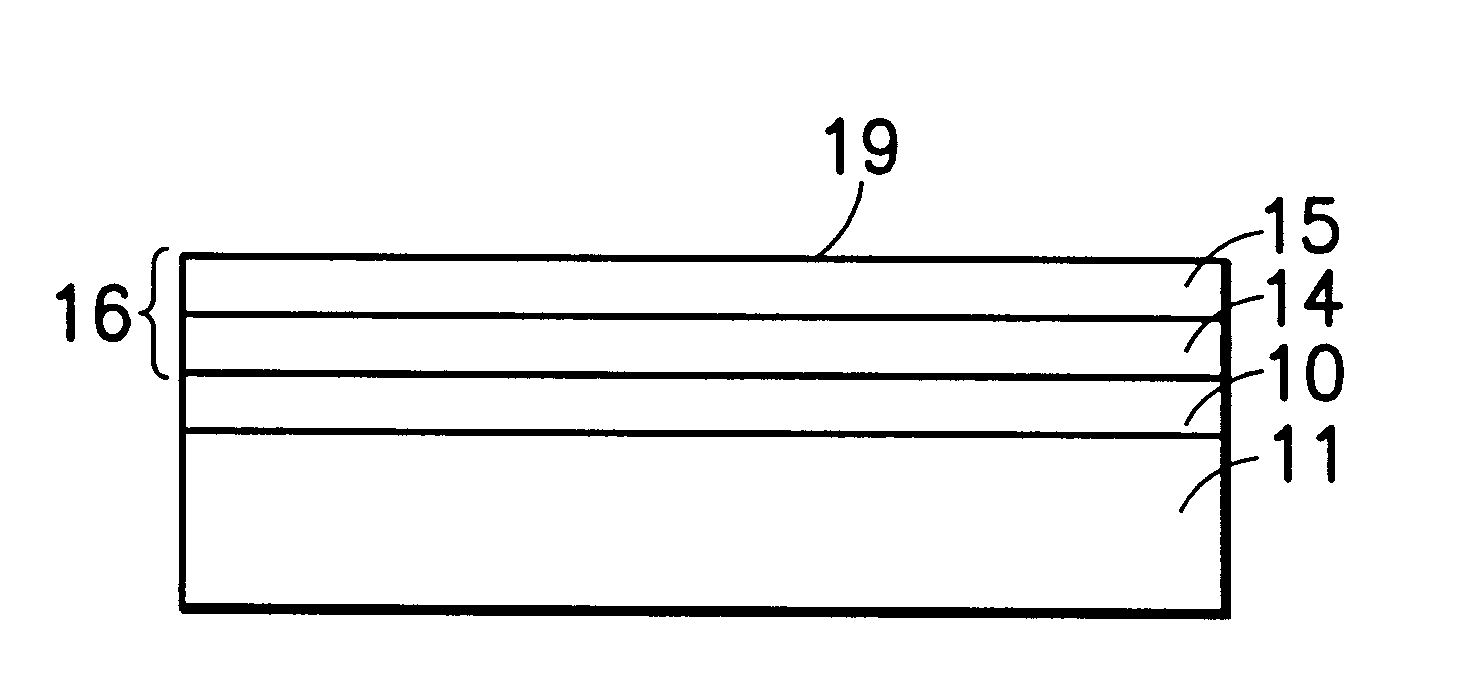

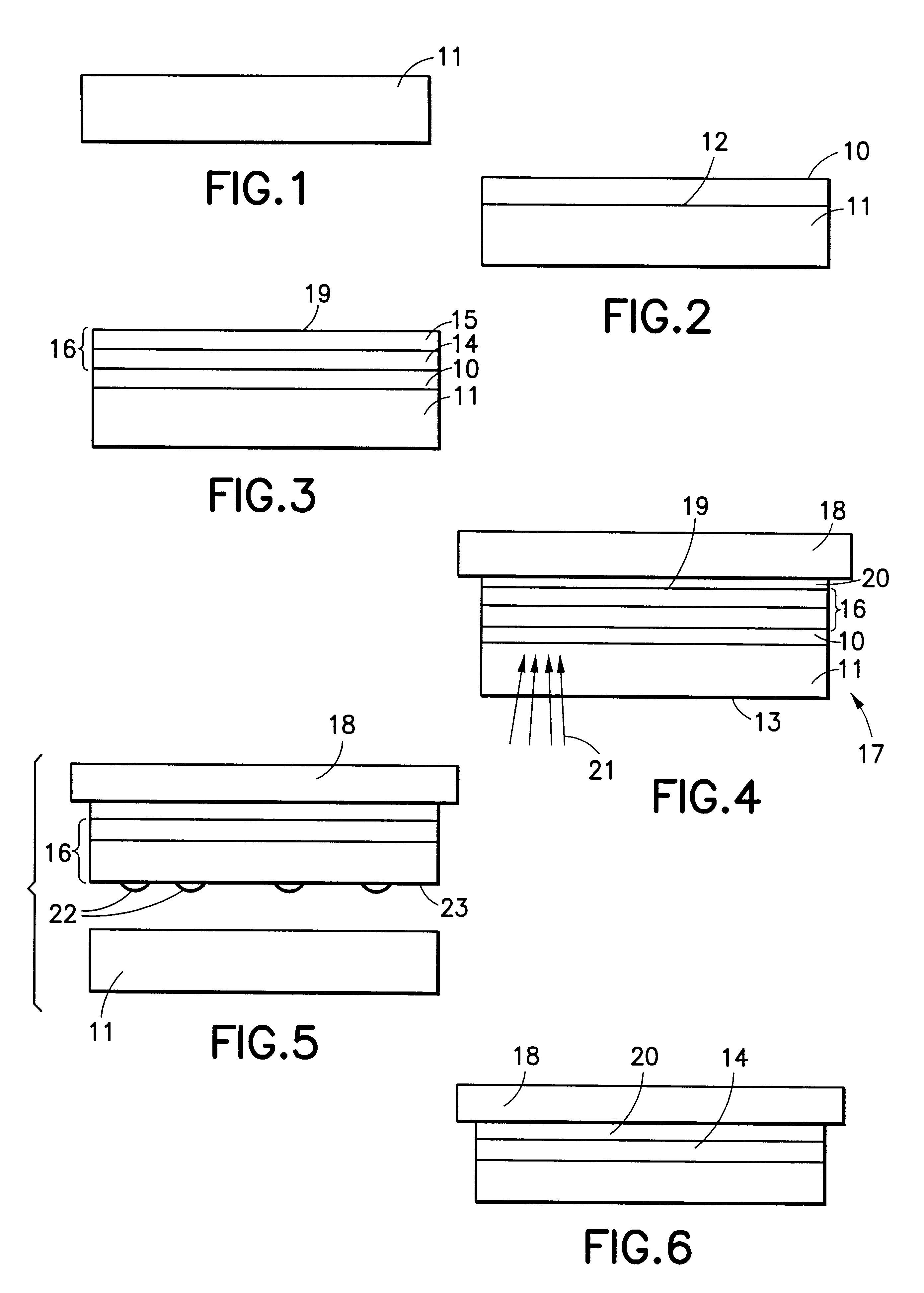

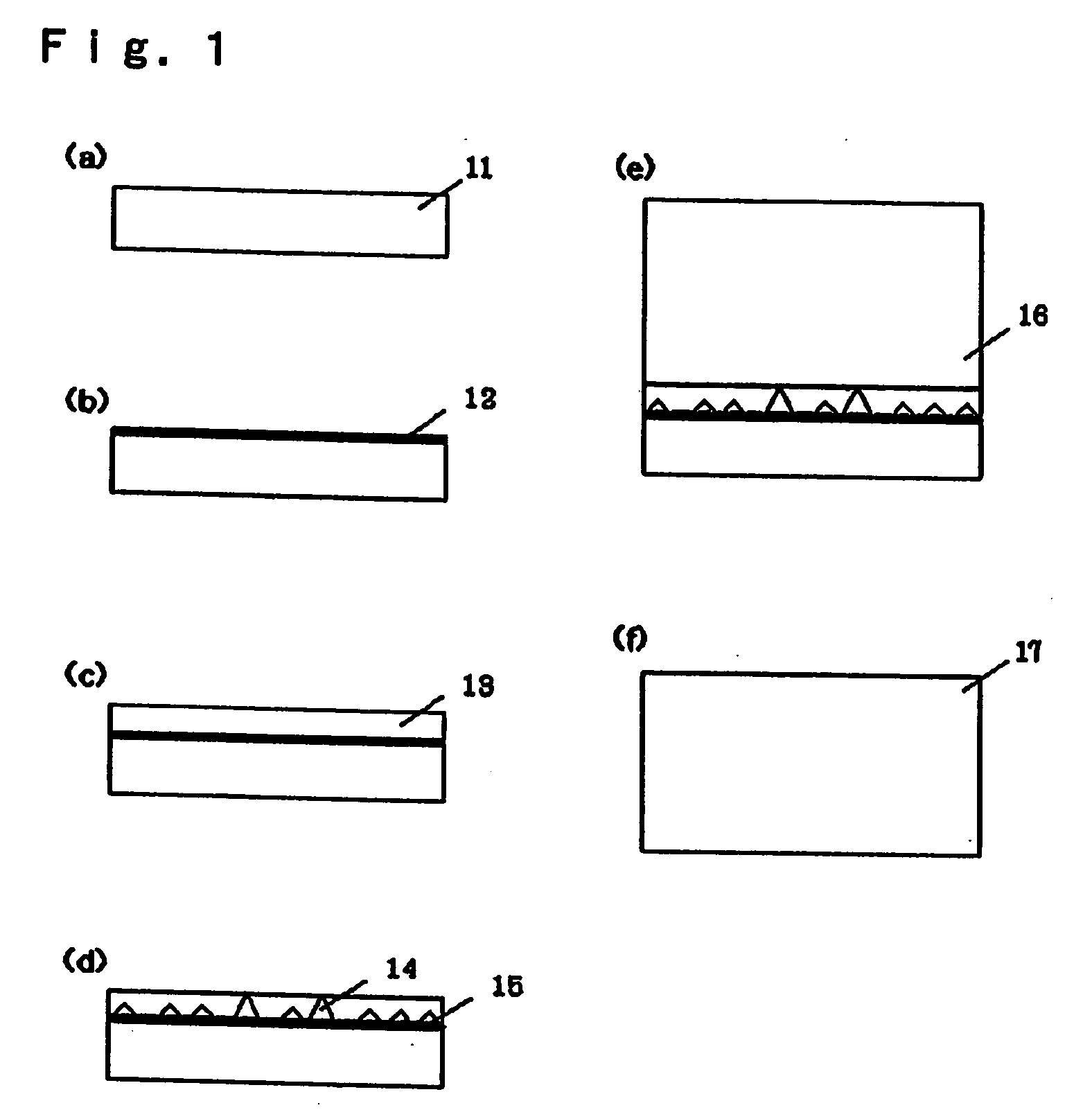

Product and process for forming a semiconductor structure on a host substrate

InactiveUS6210479B1Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor structureNitrogen

A process for cheaply fabricating a substantially single crystal or a polycrystalline semiconductor structure on a host substrate. The process begins by depositing a layer of wide band gap nitride material 10, such as gallium nitride, aluminum nitride and / or indium nitride, on a sapphire substrate 11. The semiconductor structure 14 is then grown on the nitride layer. Next, the host substrate 15 is attached with a bonding agent to an exposed surface area of the semiconductor structure 14. The sapphire substrate is lifted off by irradiation in which nitrogen is dissociated from the nitride layer.

Owner:IBM CORP

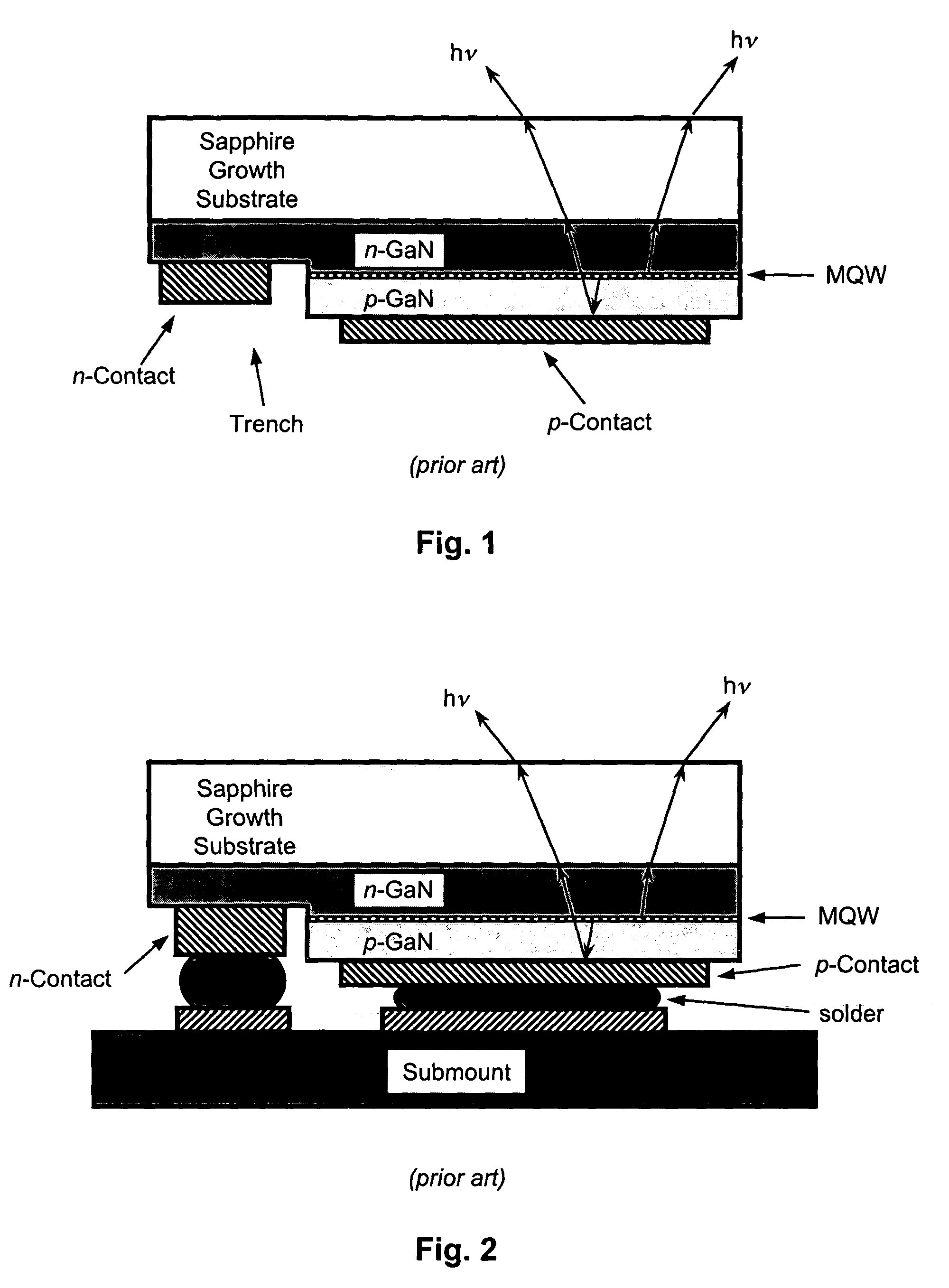

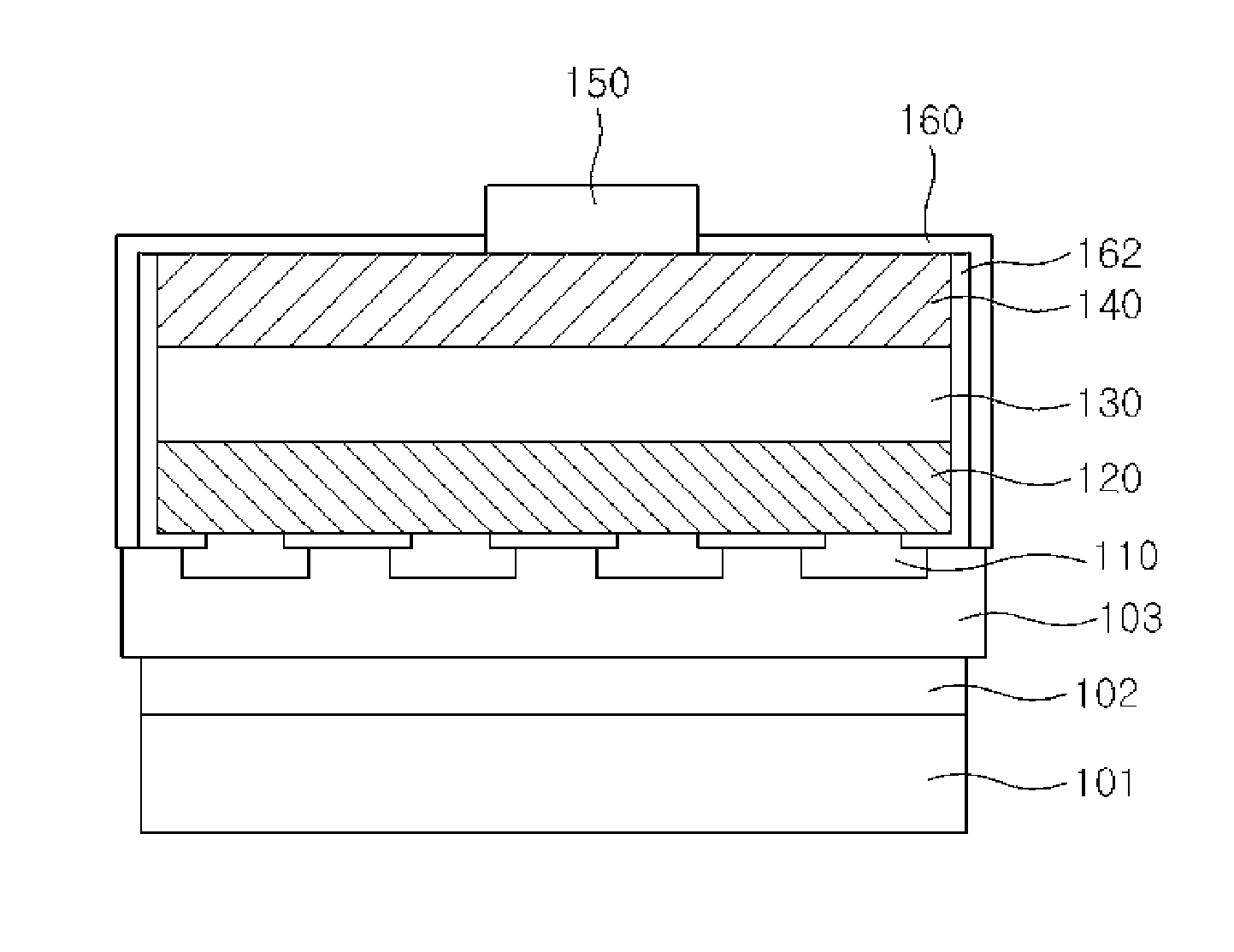

Gallium nitride-based flip-chip light-emitting diode with double reflective layers on its side and fabrication method thereof

InactiveUS20110297914A1Improve luminous efficiencyImprove reflectivitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideLight-emitting diode

The present invention discloses a double-reflective-layer gallium nitride-based flip-chip light-emitting diode with both a distributed Bragg reflector and a metal reflective layer on its side and a fabrication method thereof. The light-emitting diode includes: a sapphire substrate; a buffer layer, an N-GaN layer, a multiple-quantum-well layer and a P-GaN layer stacked on the sapphire substrate in that order; a transparent conductive layer formed on the P-GaN layer; a distributed Bragg reflector formed over a side of the epitaxial layer and the transparent conductive layer; a metal reflective layer formed on the DBR; a P-type ohmic contact electrode formed on the transparent conductive layer; and an N-type ohmic contact electrode formed on the exposed N-GaN layer, wherein the P-type ohmic contact electrode and the N-type ohmic contact electrode are bonded to a heat dissipation substrate through a metal conductive layer and a ball bonder. By arranging a double reflection structure including a DBR and a metal reflective layer on the sloping side of the LED chip, the good reflectivity of the reflective layers can be fully utilized, thereby improving the light-emission efficiency of the LED.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

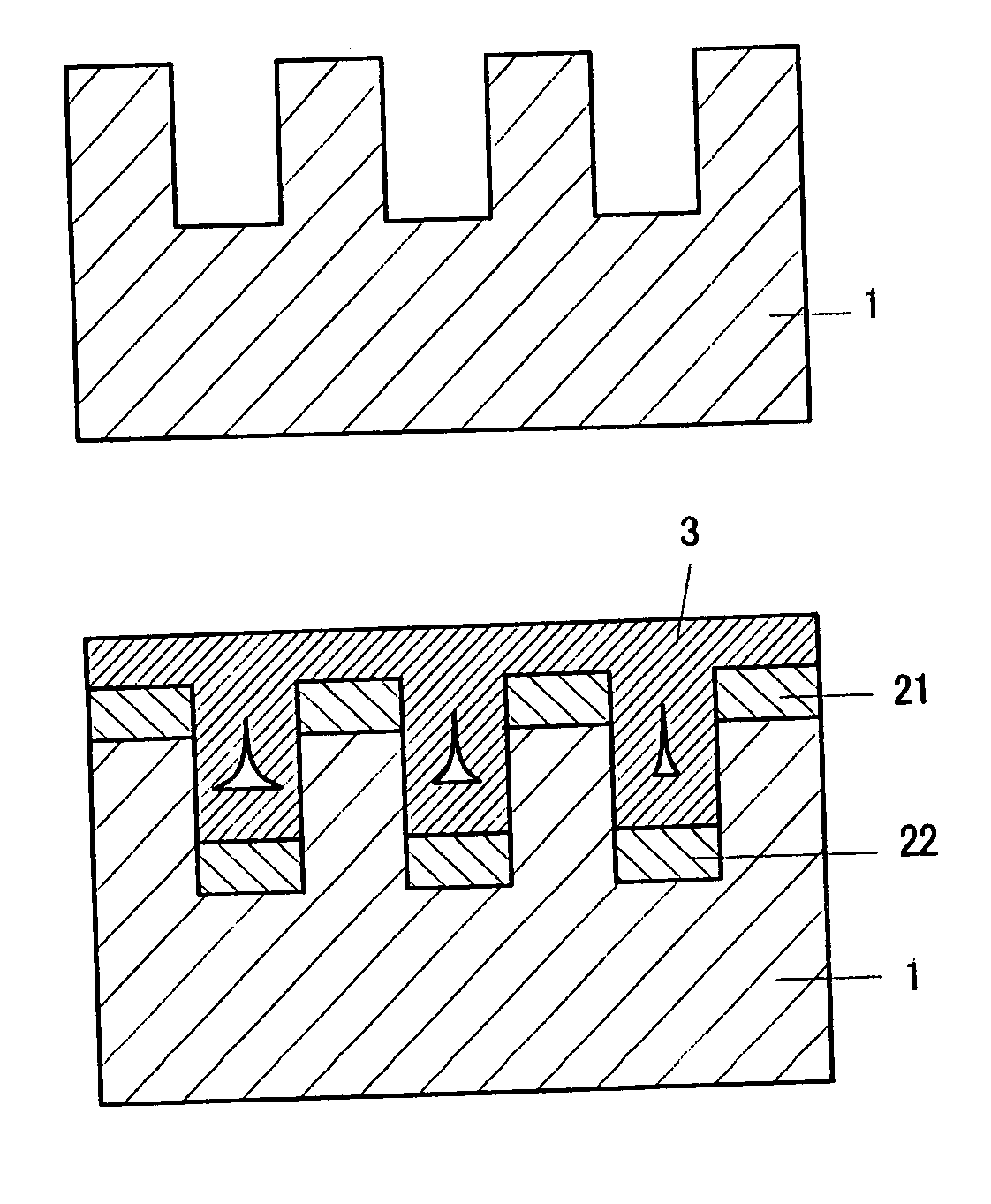

Group III nitride compound semiconductor devices and method for fabricating the same

InactiveUS20060060866A1Avoid problemsQuality improvementLaser detailsSemiconductor laser structural detailsThreading dislocationsDislocation

A sapphire substrate 1 is etched so that each trench has a width of 10 μm and a depth of 10 μm were formed at 10 μm of intervals in a stripe pattern. Next, an AlN buffer layer 2 having a thickness of approximately 40 nm is formed mainly on the upper surface and the bottom surface of the trenches of the substrate 1. Then a GaN layer 3 is formed through vertical and lateral epitaxial growth. At this time, lateral epitaxial growth of the buffer layer 21, which was mainly formed on the upper surface of the trenches, filled the trenches and thus establishing a flat top surface. The portions of the GaN layer 3 formed above the top surfaces of the mesas having a depth of 10 μm exhibited significant suppression of threading dislocation in contrast to the portions formed above the bottoms of the trenches.

Owner:TOYODA GOSEI CO LTD

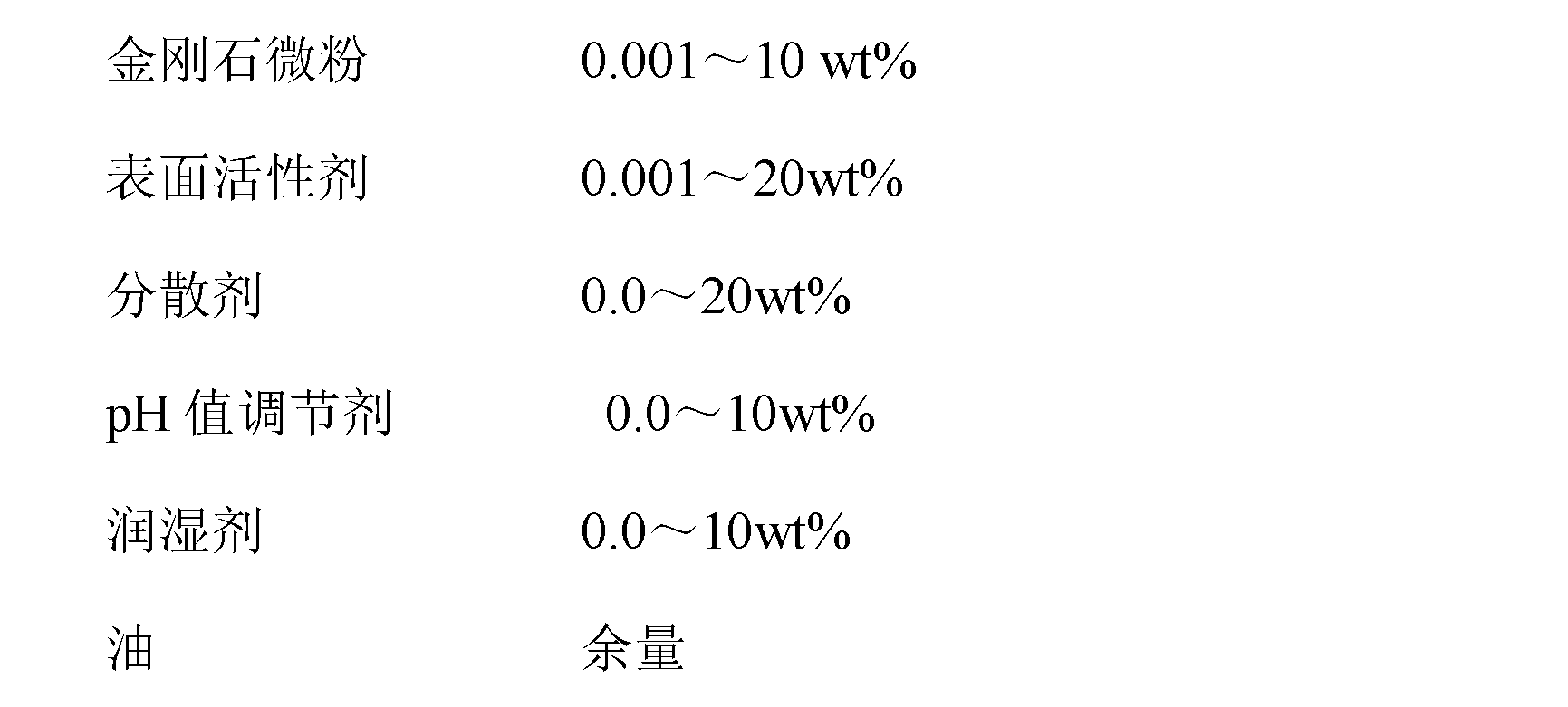

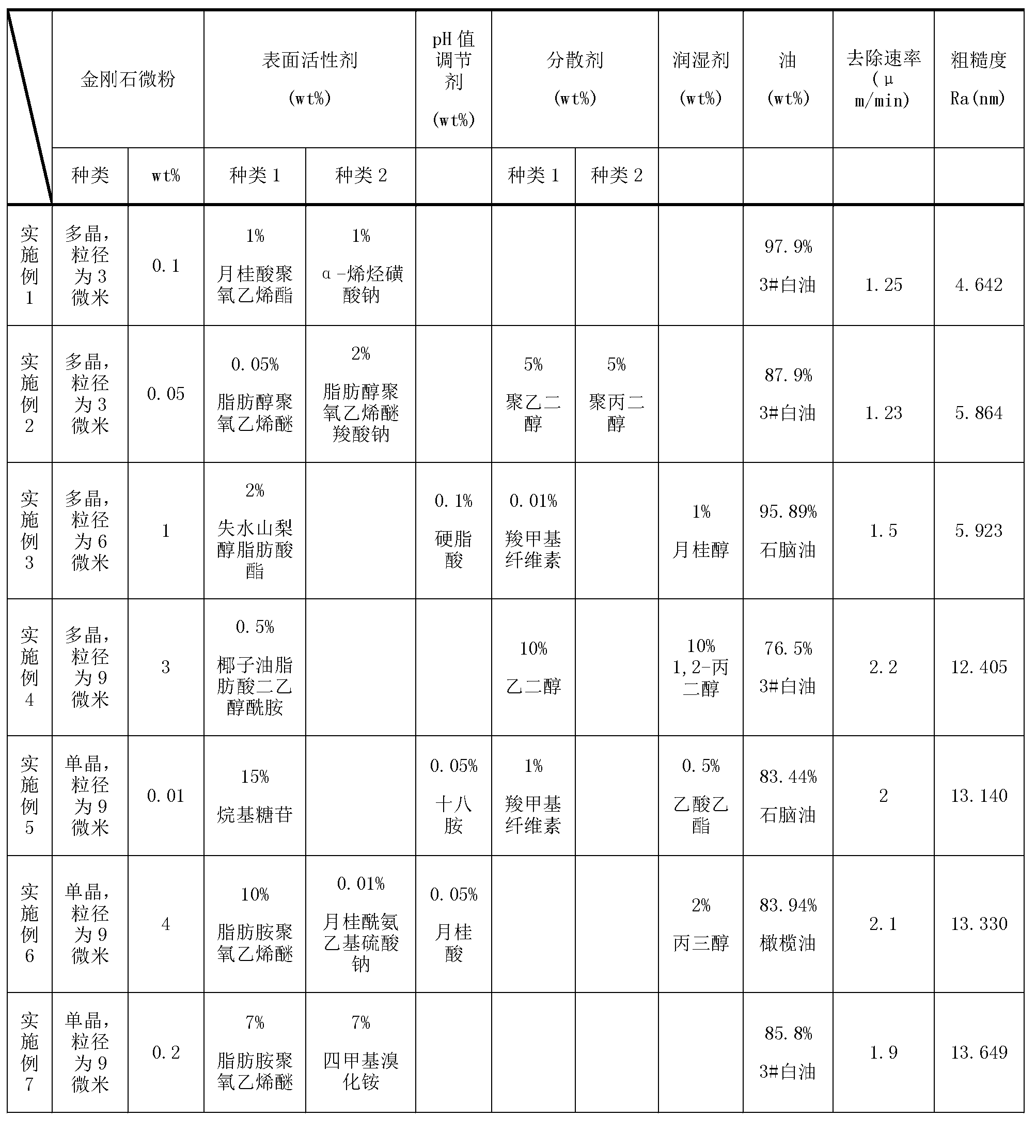

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

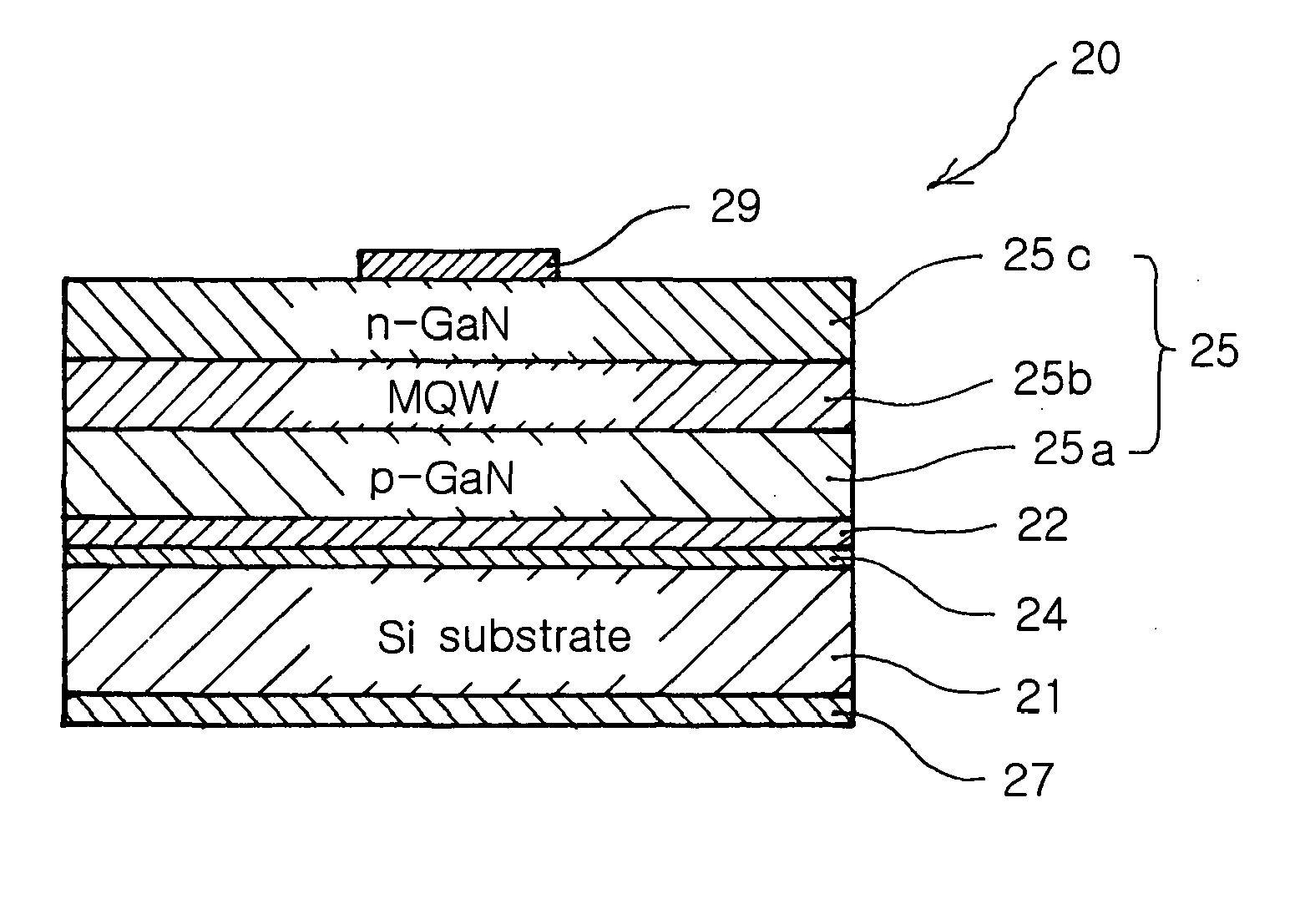

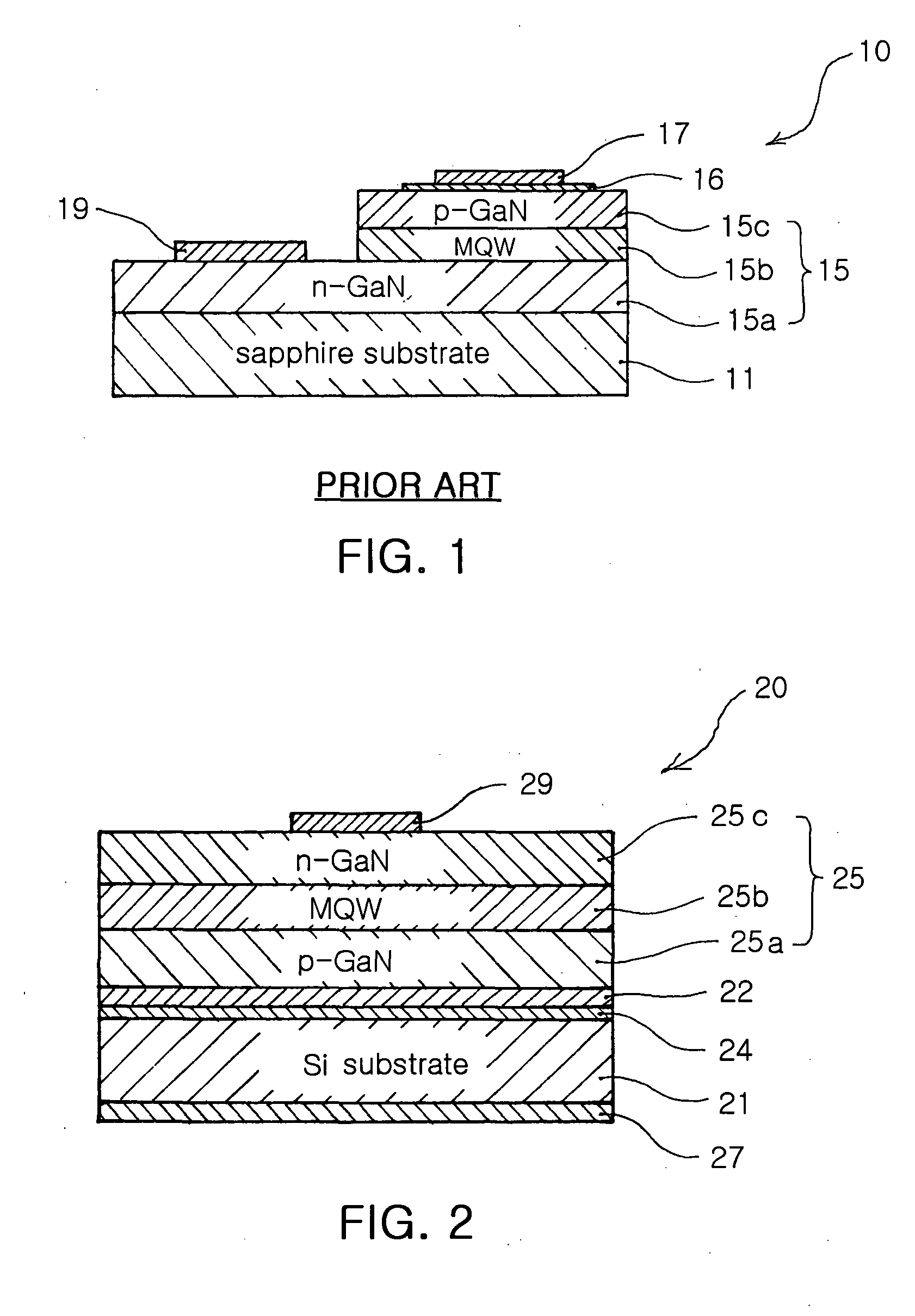

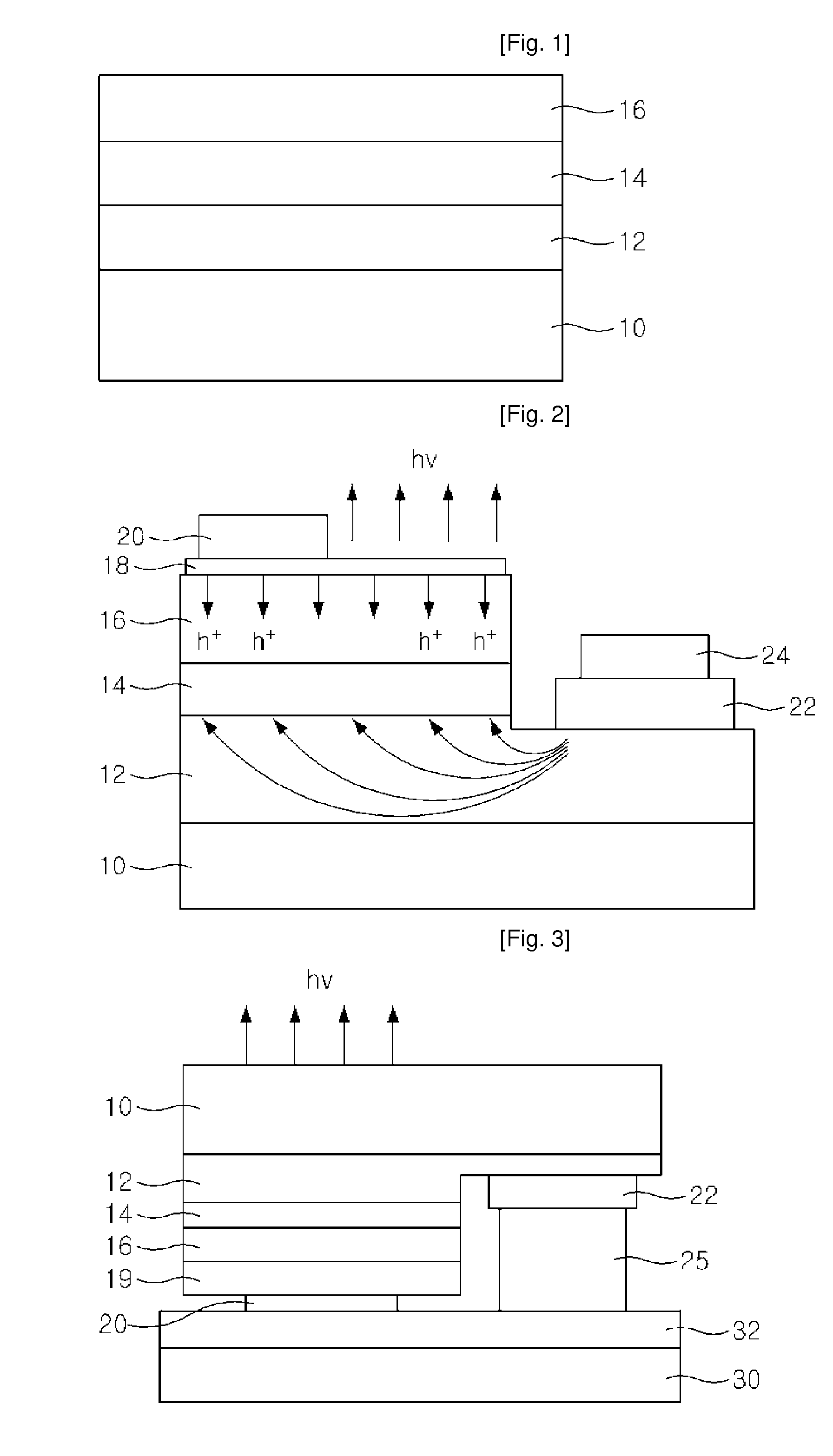

Vertical GaN light emitting diode and method for manufacturing the same

InactiveUS20050173692A1Improved current density distributionIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalActive layer

Disclosed are a vertical GaN light emitting diode and a method for manufacturing the same. The vertical GaN light emitting diode comprises a first conductive GaN clad layer with an upper surface provided with a first contact formed thereon, an active layer formed on a lower surface of the first conductive GaN clad layer, a second conductive GaN clad layer formed on a lower surface of the active layer, a conductive adhesive layer formed on the second conductive GaN clad layer, and a conductive substrate, with a lower surface provided with a second contact formed thereon, formed on a lower surface of the conductive adhesive layer. The method for manufacturing the vertical GaN light emitting diodes comprises the step of removing the sapphire substrate from the light emitting structure so as to prevent the damages on a GaN single crystal plane of the structure.

Owner:SAMSUNG ELECTRONICS CO LTD

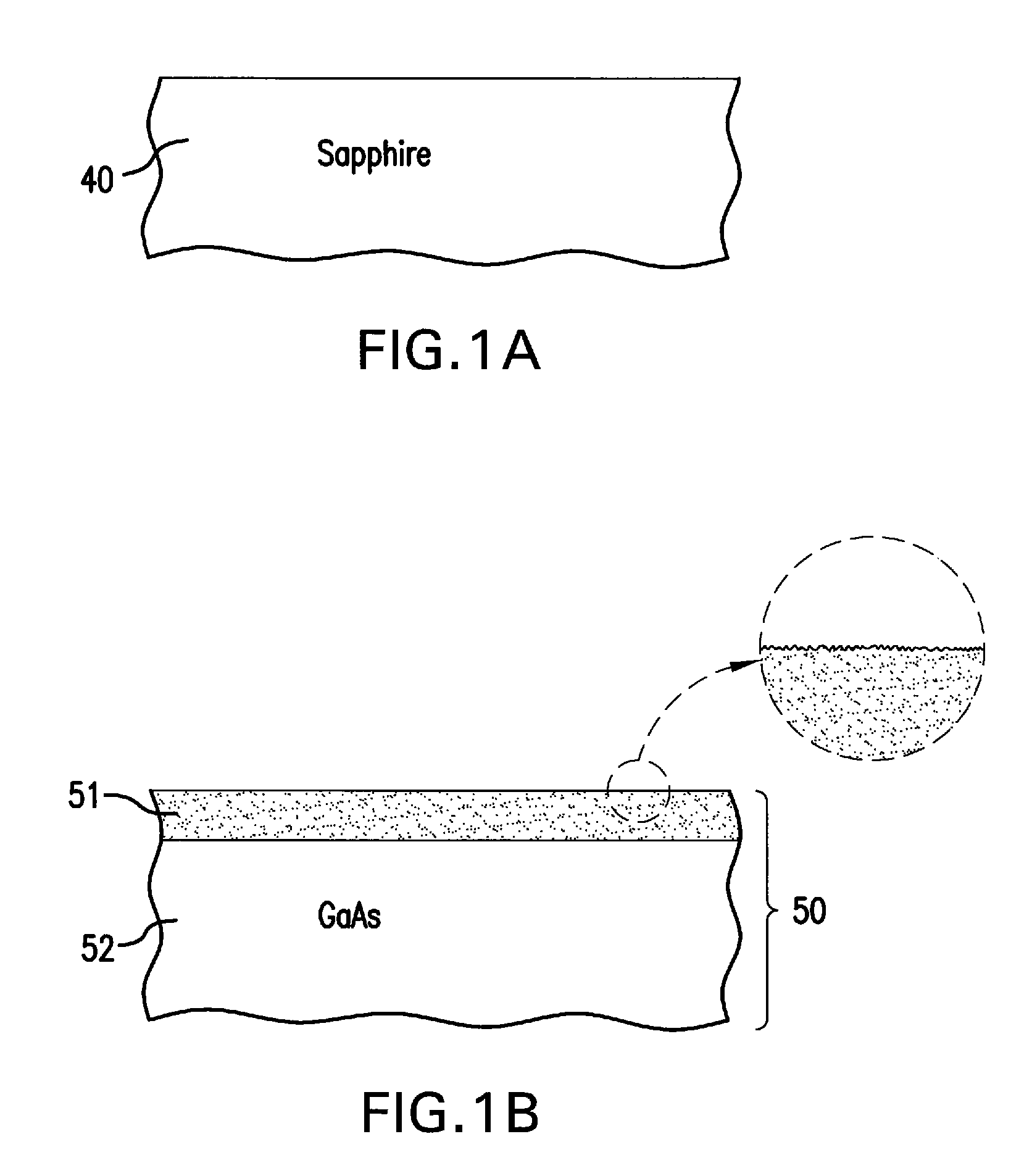

Growth substrates for inverted metamorphic multijunction solar cells

ActiveUS7785989B2Final product manufactureSemiconductor/solid-state device manufacturingSemiconductor materialsSolar cell

A method of manufacturing a solar cell by providing a gallium arsenide carrier with a prepared bonding surface; providing a sapphire substrate; bonding the gallium arsenide carrier and the sapphire substrate to produce a composite structure; detaching the bulk of the gallium arsenide carrier from the composite structure, leaving a gallium arsenide growth substrate on the sapphire substrate; and depositing a sequence of layers of semiconductor material forming a solar cell on the growth substrate. For some solar cells, the method further includes mounting a surrogate second substrate on top of the sequence of layers of semiconductor material forming a solar cell; and removing the growth substrate.

Owner:SOLAERO TECH CORP

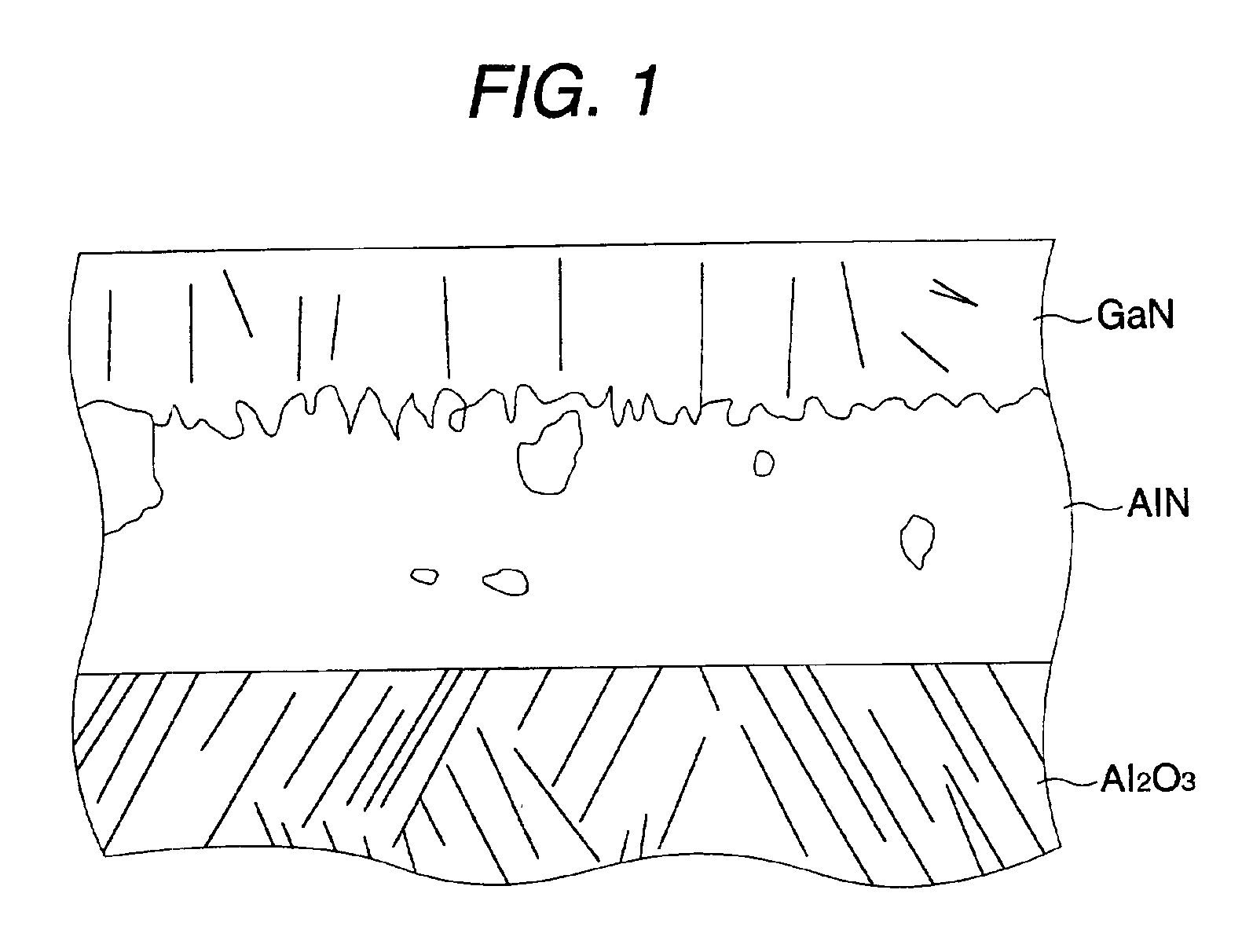

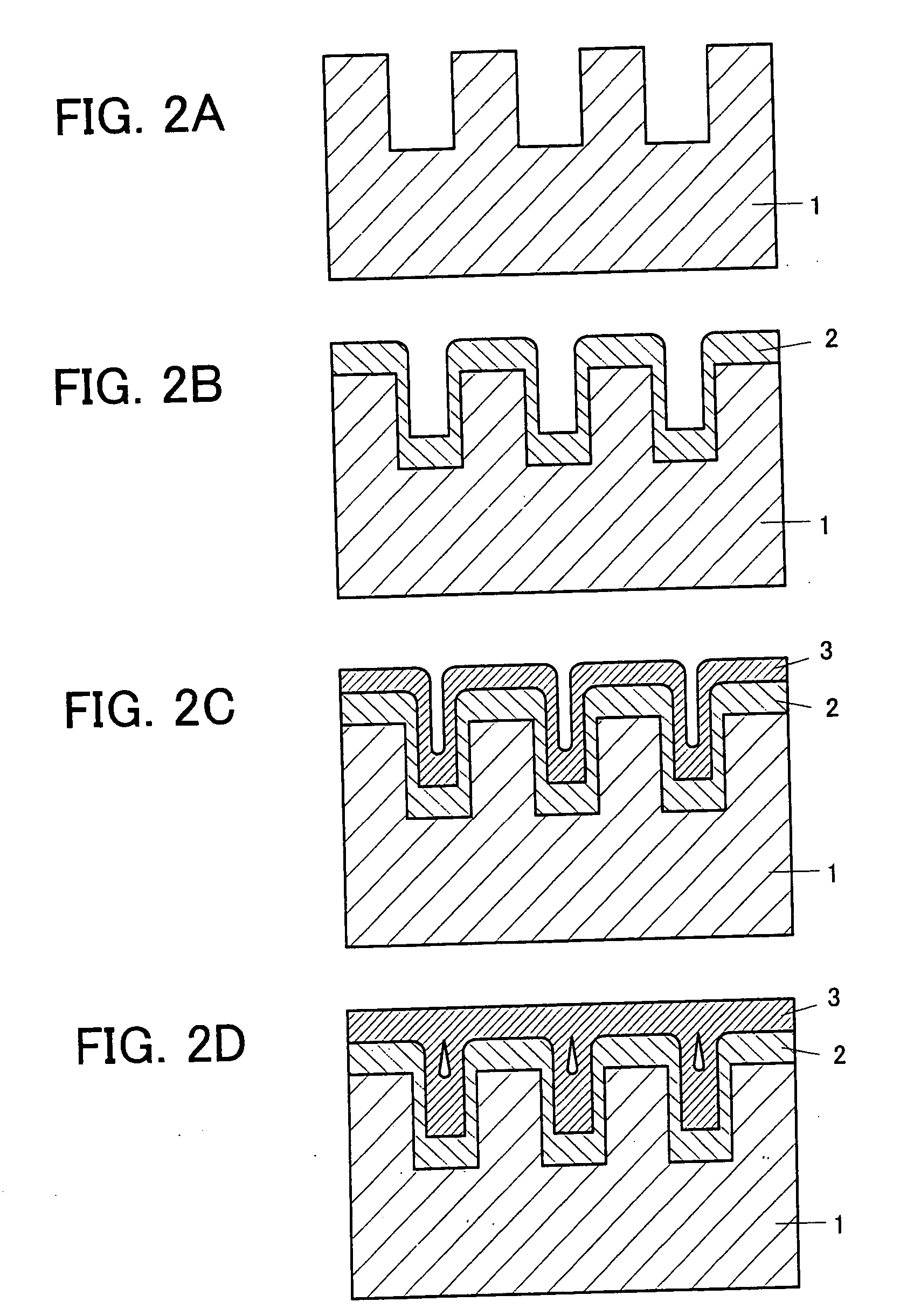

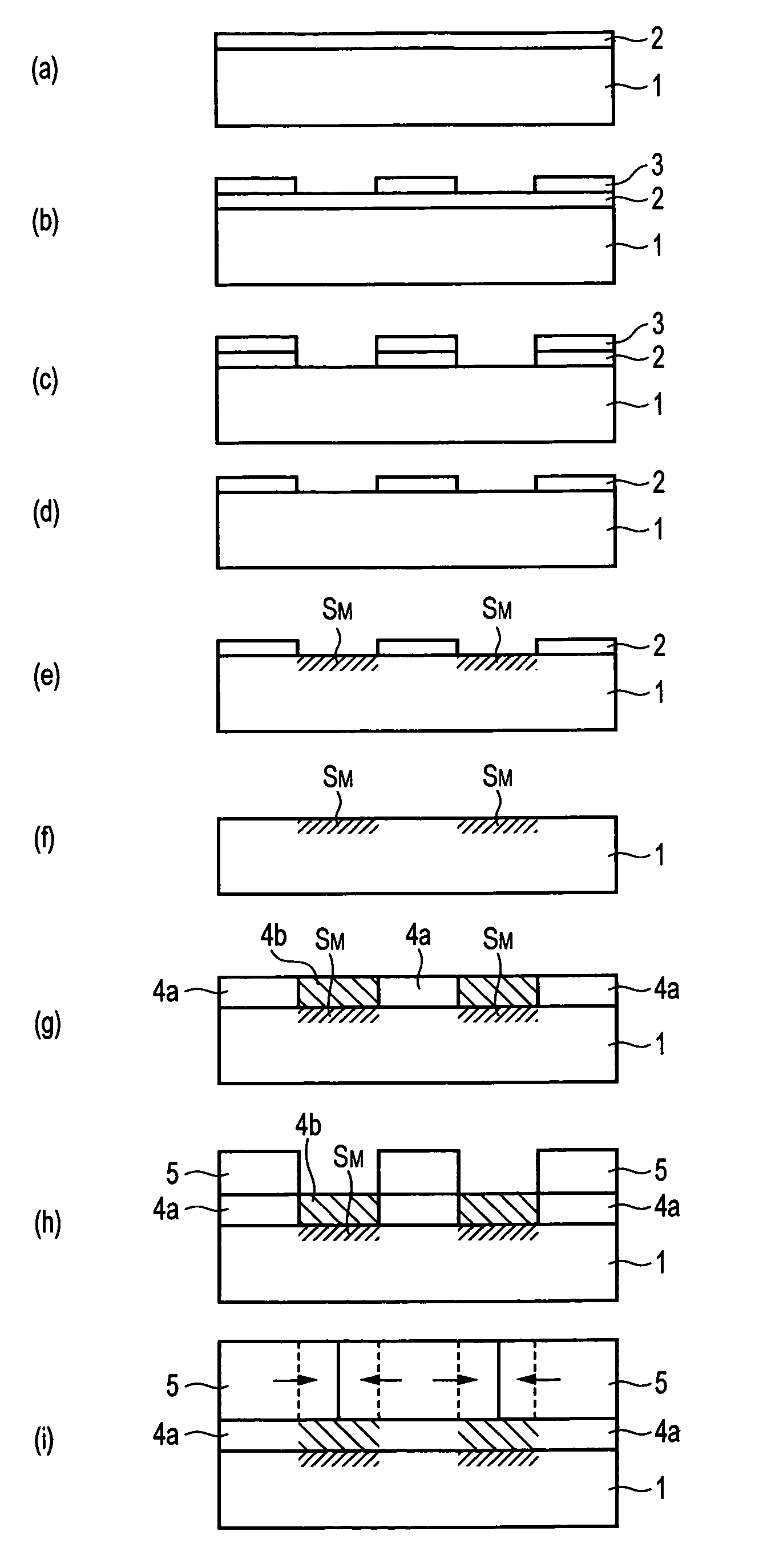

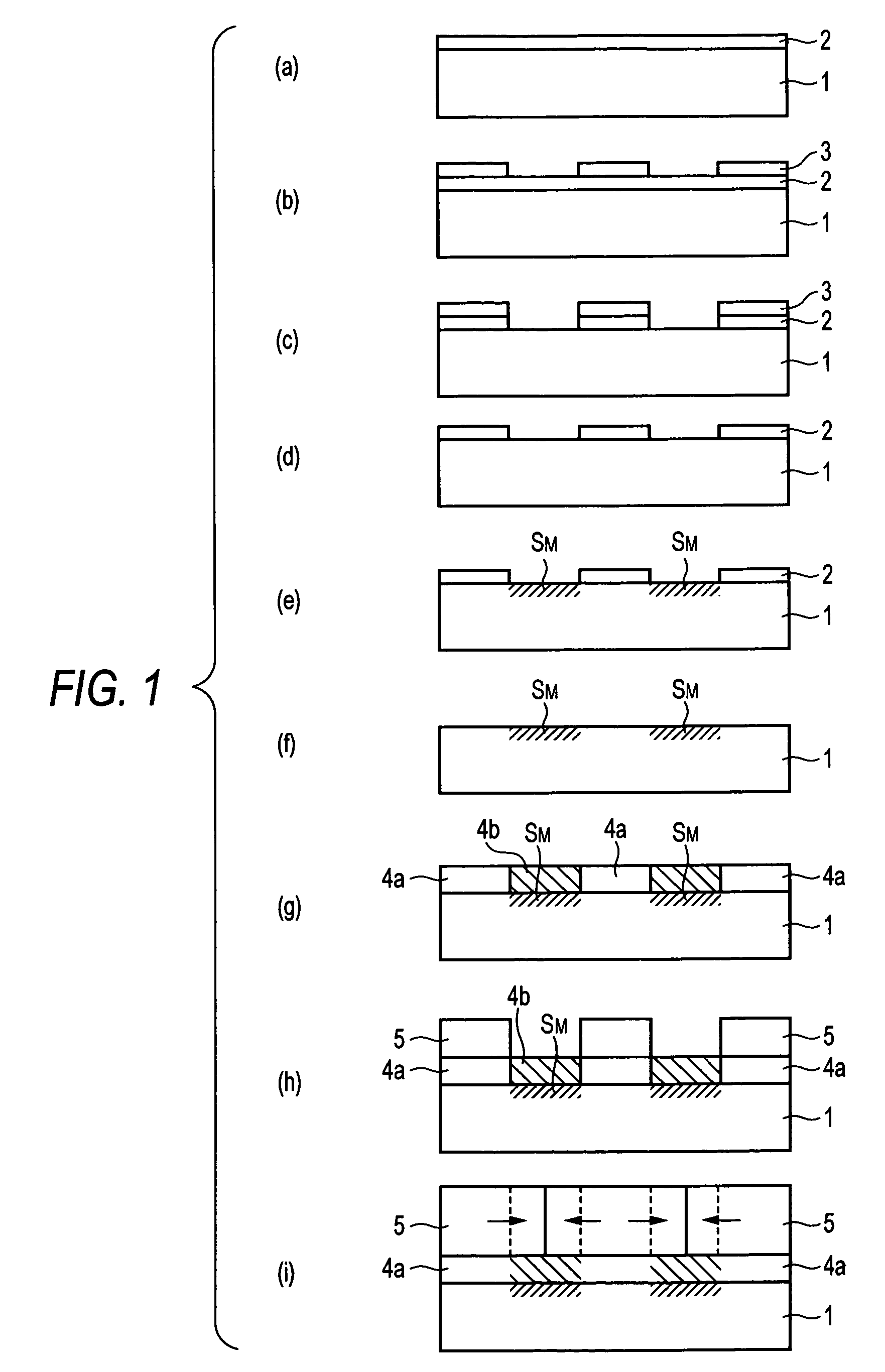

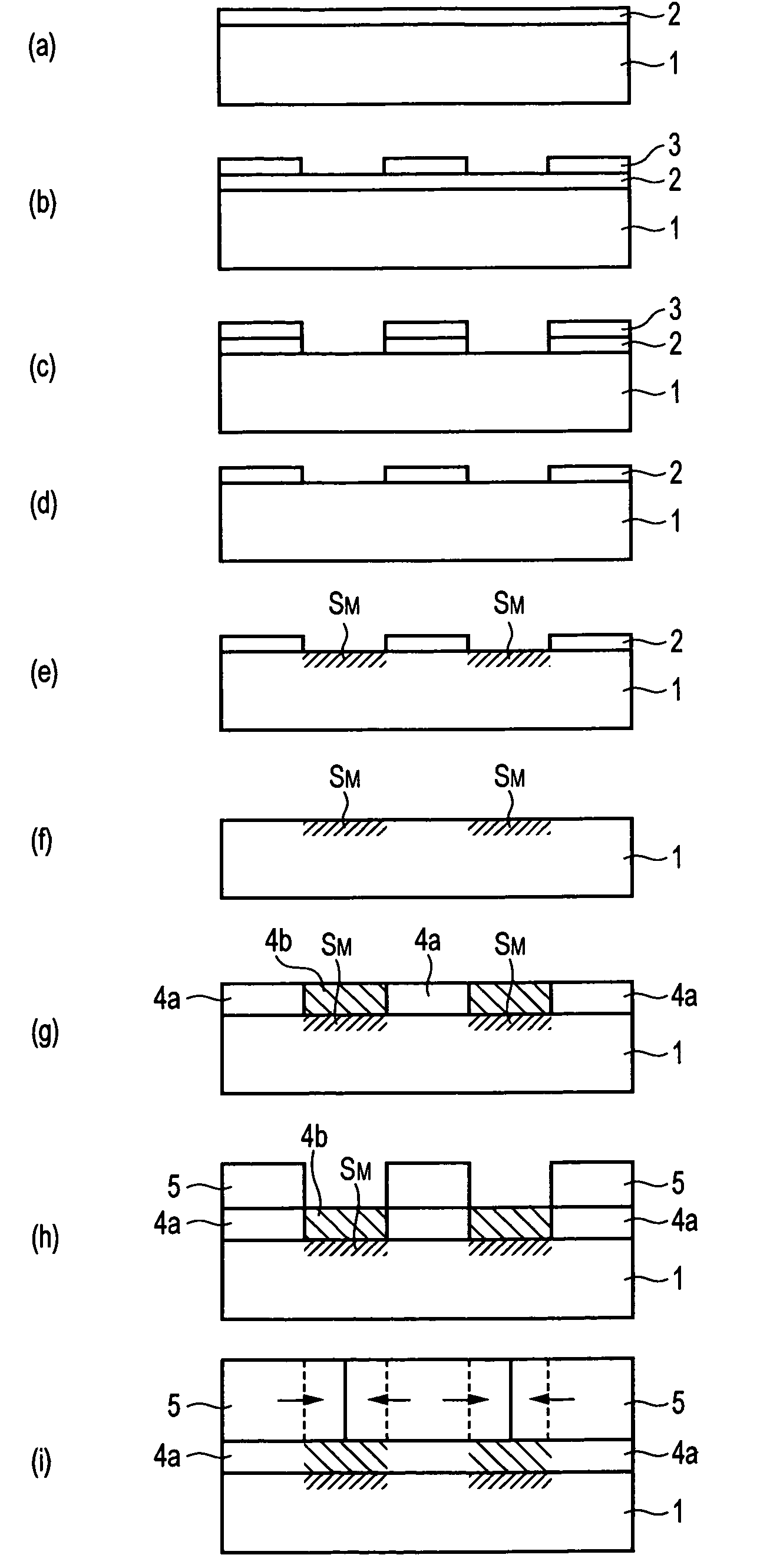

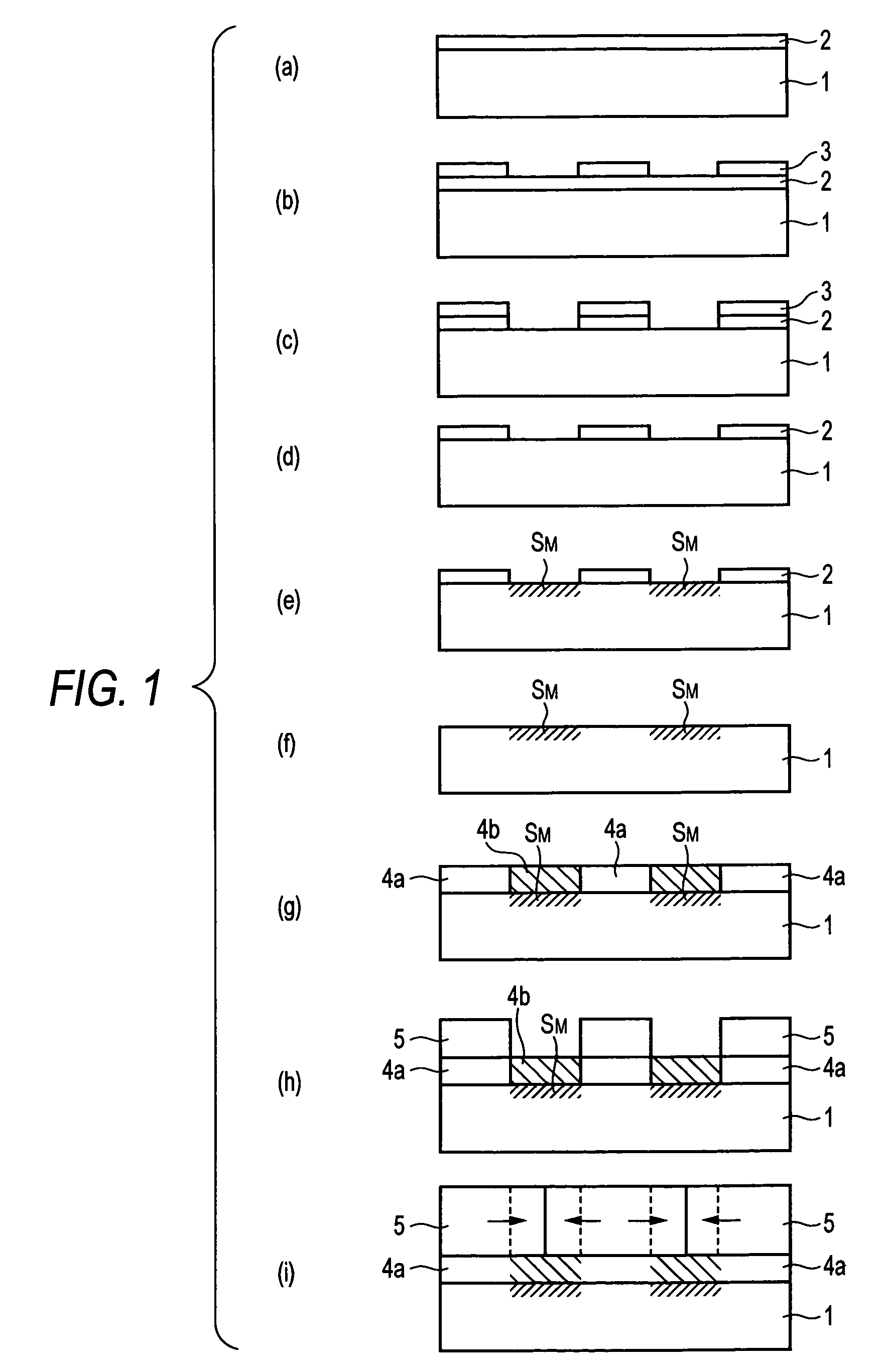

Process for producing group III nitride compound semiconductor

InactiveUS7128846B2Polycrystalline material growthDecorative surface effectsDry etchingMaterials science

A method including the steps of: modifying at least one part of a sapphire substrate by dry etching to thereby form any one of a dot shape, a stripe shape, a lattice shape, etc. as an island shape on the sapphire substrate; forming an AlN buffer layer on the sapphire substrate; and epitaxially growing a desired Group III nitride compound semiconductor vertically and laterally so that the AlN layer formed on a modified portion of the surface of the sapphire substrate is covered with the desirably Group III nitride compound semiconductor without any gap while the AlN layer formed on a non-modified portion of the surface of the sapphire substrate is used as a seed, wherein the AlN buffer layer is formed by means of reactive sputtering with Al as a target in an nitrogen atmosphere.

Owner:TOYODA GOSEI CO LTD

GaN Compound Semiconductor Light Emitting Element and Method of Manufacturing the Same

ActiveUS20080006836A1Easy to separateEasy to operateSemiconductor/solid-state device manufacturingSemiconductor devicesCompound (substance)Gallium nitride

The present invention relates to a gallium nitride (GaN) compound semiconductor light emitting element (LED) and a method of manufacturing the same. The present invention provides a vertical GaN LED capable of improving the characteristics of a horizontal LED by means of a metallic protective film layer and a metallic support layer. According to the present invention, a thick metallic protective film layer with a thickness of at least 10 microns is formed on the lateral and / or bottom sides of the vertical GaN LED to protect the element against external impact and to easily separate the chip. Further, a metallic substrate is used instead of a sapphire substrate to efficiently release the generated heat to the outside when the element is operated, so that the LED can be suitable for a high-power application and an element having improved optical output characteristics can also be manufactured. A metallic support layer is formed to protect the element from being distorted or damaged due to impact. Furthermore, a P-type electrode is partially formed on a P—GaN layer in a mesh form to thereby maximize the emission of photons generated in the active layer toward the N—GaN layer.

Owner:SEOUL VIOSYS CO LTD +1

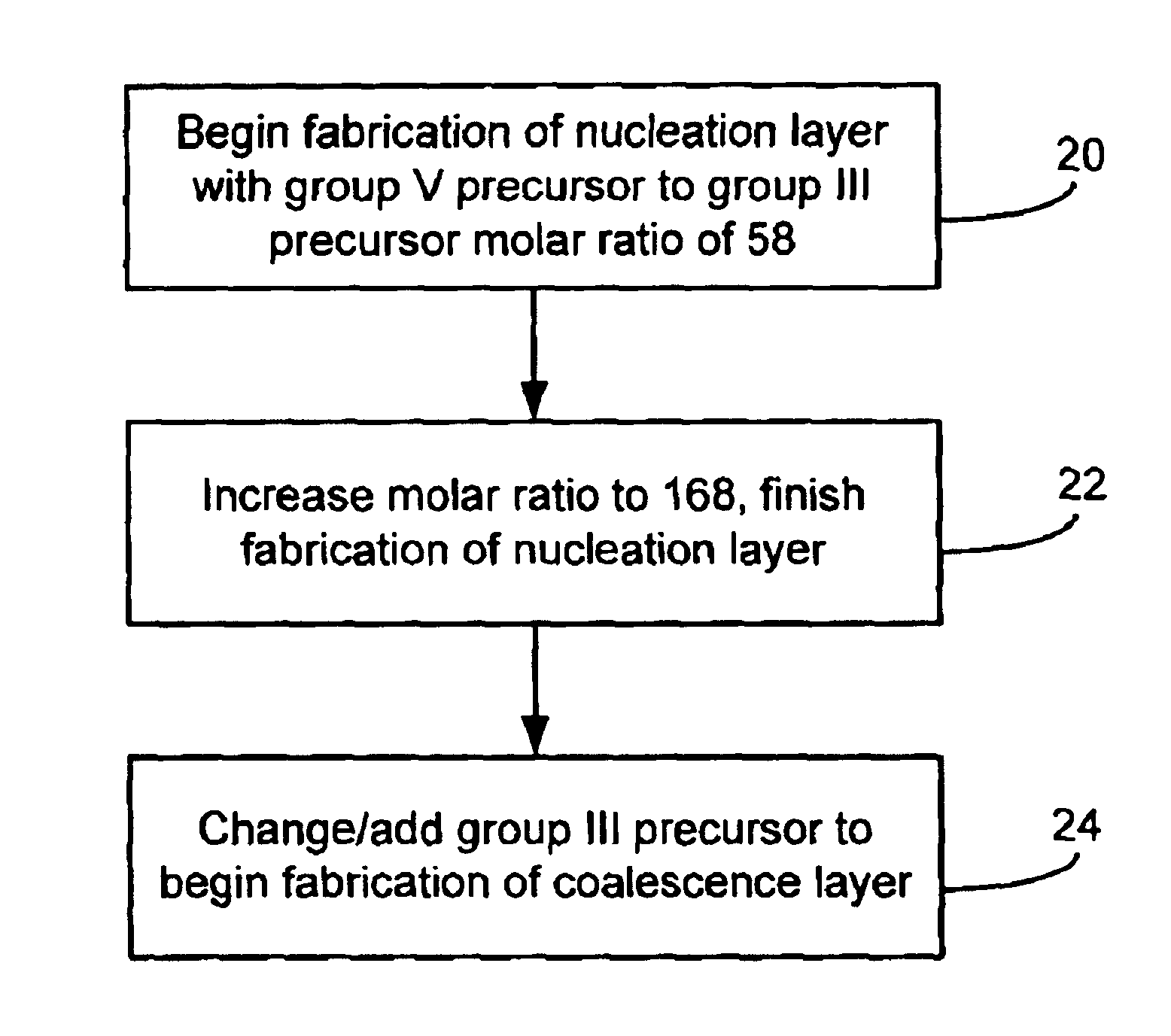

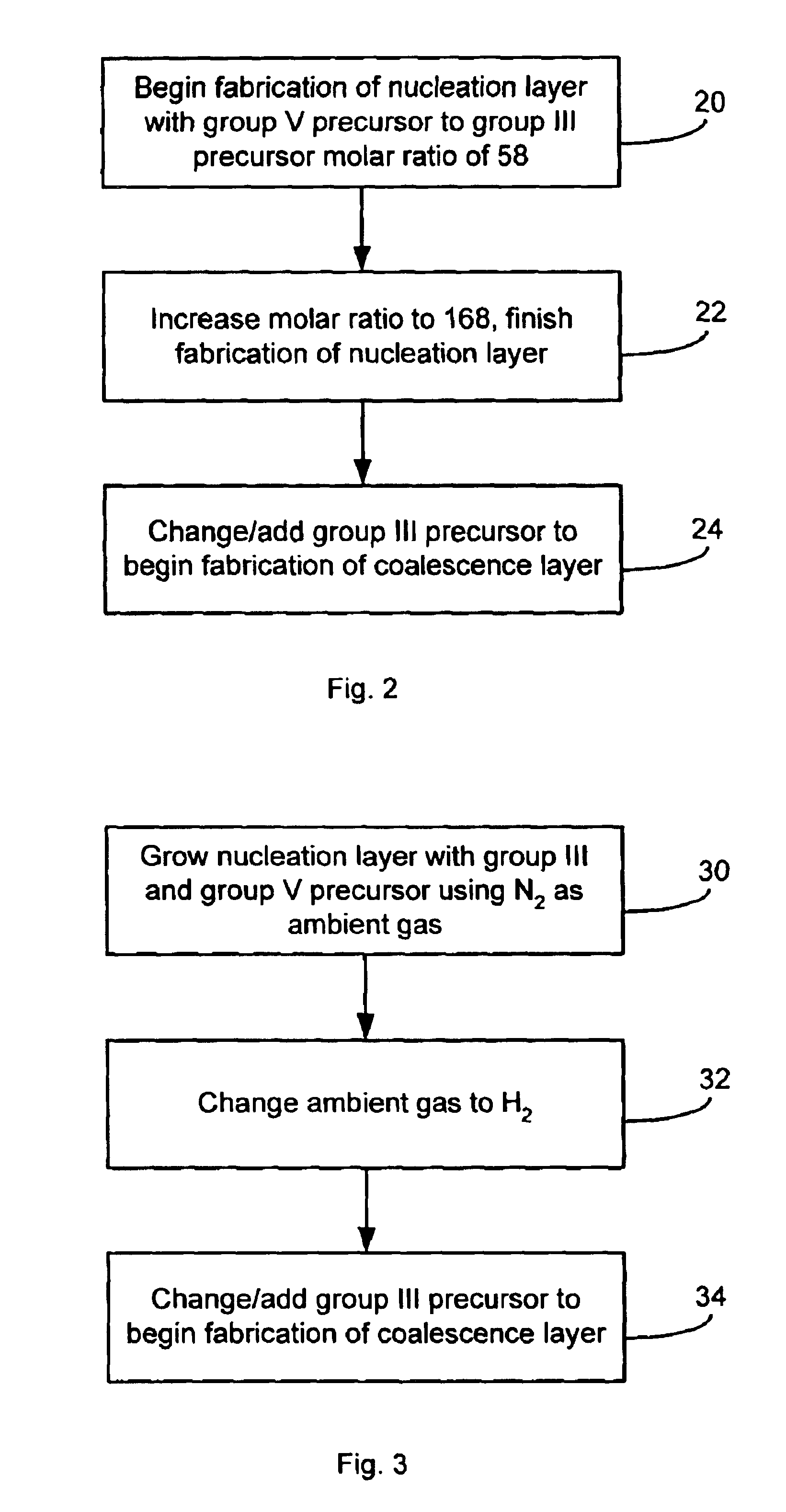

Growth of III-nitride films on mismatched substrates without conventional low temperature nucleation layers

ActiveUS6900067B2ReactionRaise the ratioPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseNitrogen

A method of forming a light emitting device includes providing a sapphire substrate, growing an Al1−xGaxN first layer by vapor deposition on the substrate at a temperature between about 1000° C. and about 1180° C., and growing a III-nitride second layer overlying the first layer. The first layer may have a thickness between about 500 angstroms and about 5000 angstroms. In some embodiments, reaction between the group V precursor and the substrate is reduced by starting with a low molar ratio of group V precursor to group III precursor, then increasing the ratio during growth of the first layer, or by using nitrogen as an ambient gas.

Owner:LUMILEDS

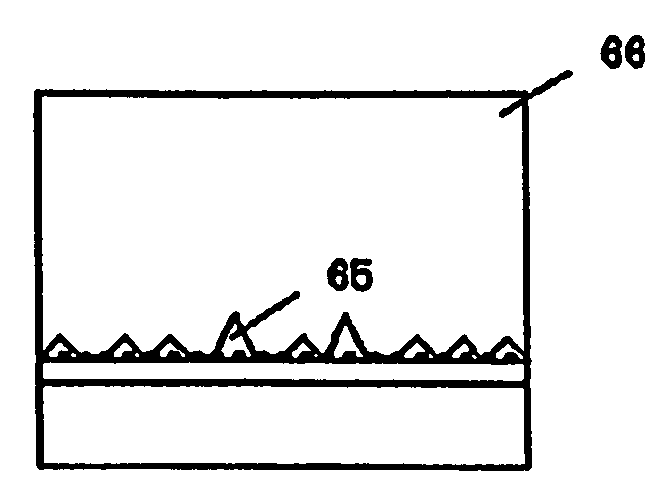

Group III nitride semiconductor substrate and its manufacturing method

InactiveUS20060046325A1Reduce defect densityLittle warpingPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrationTitanium

The present invention provides a group III nitride semiconductor substrate with low defect density as well as small warp and a process for producing the same; for instance, the process according to the present invention comprises the following series of steps of: forming a metallic Ti film 63 on a sapphire substrate 61, followed by treatment of nitration to convert it into a TiN film 64 having fine pores; thereafter growing a HVPE-GaN layer 66 thereon; forming voids 65 in the HVPE-GaN layer 66 by means of effects of the metallic Ti film 63 and the TiN film 64; and peeling the sapphire substrate 61 from the region of the voids 65 to remove it therefrom.

Owner:SUMITOMO CHEM CO LTD

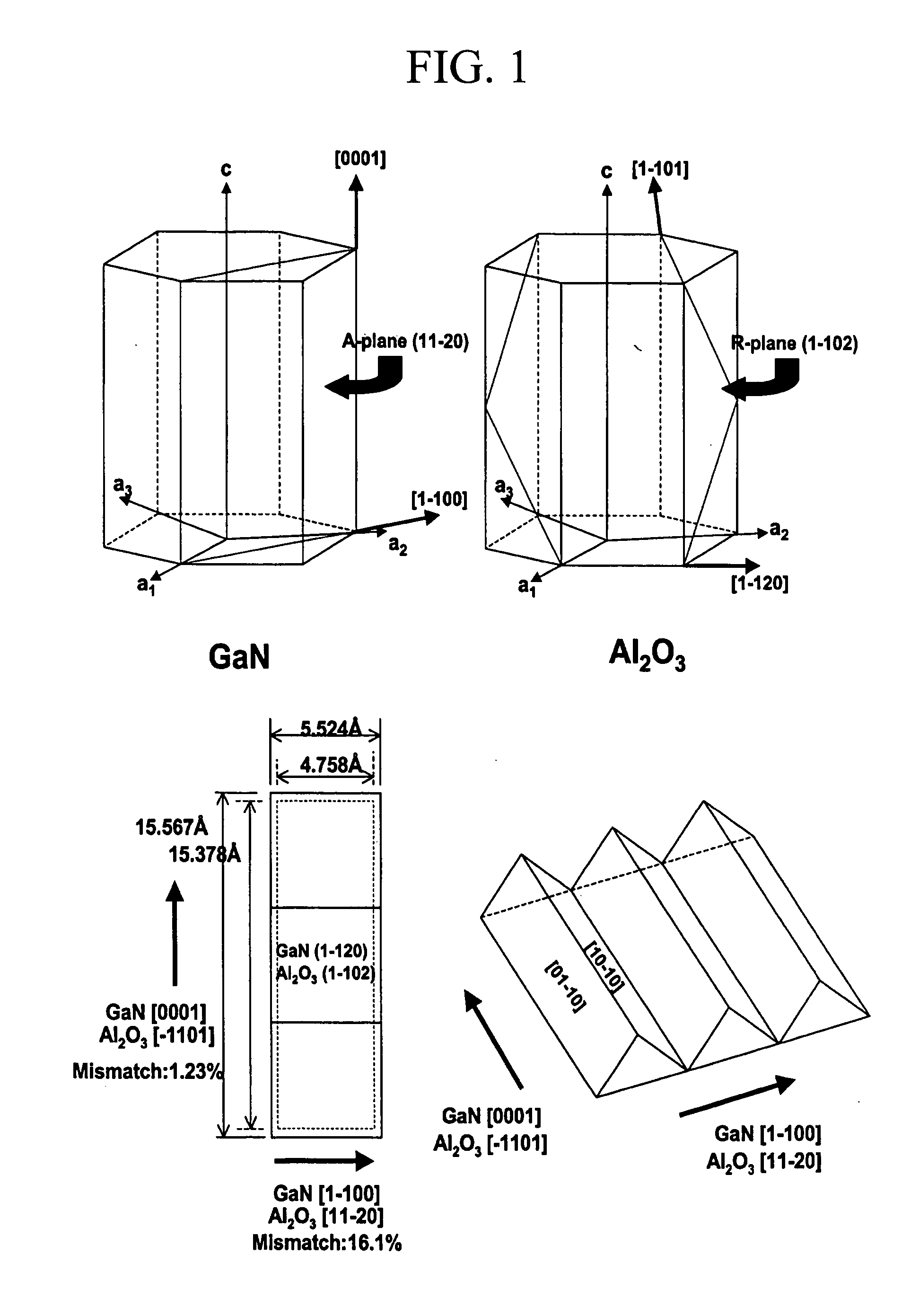

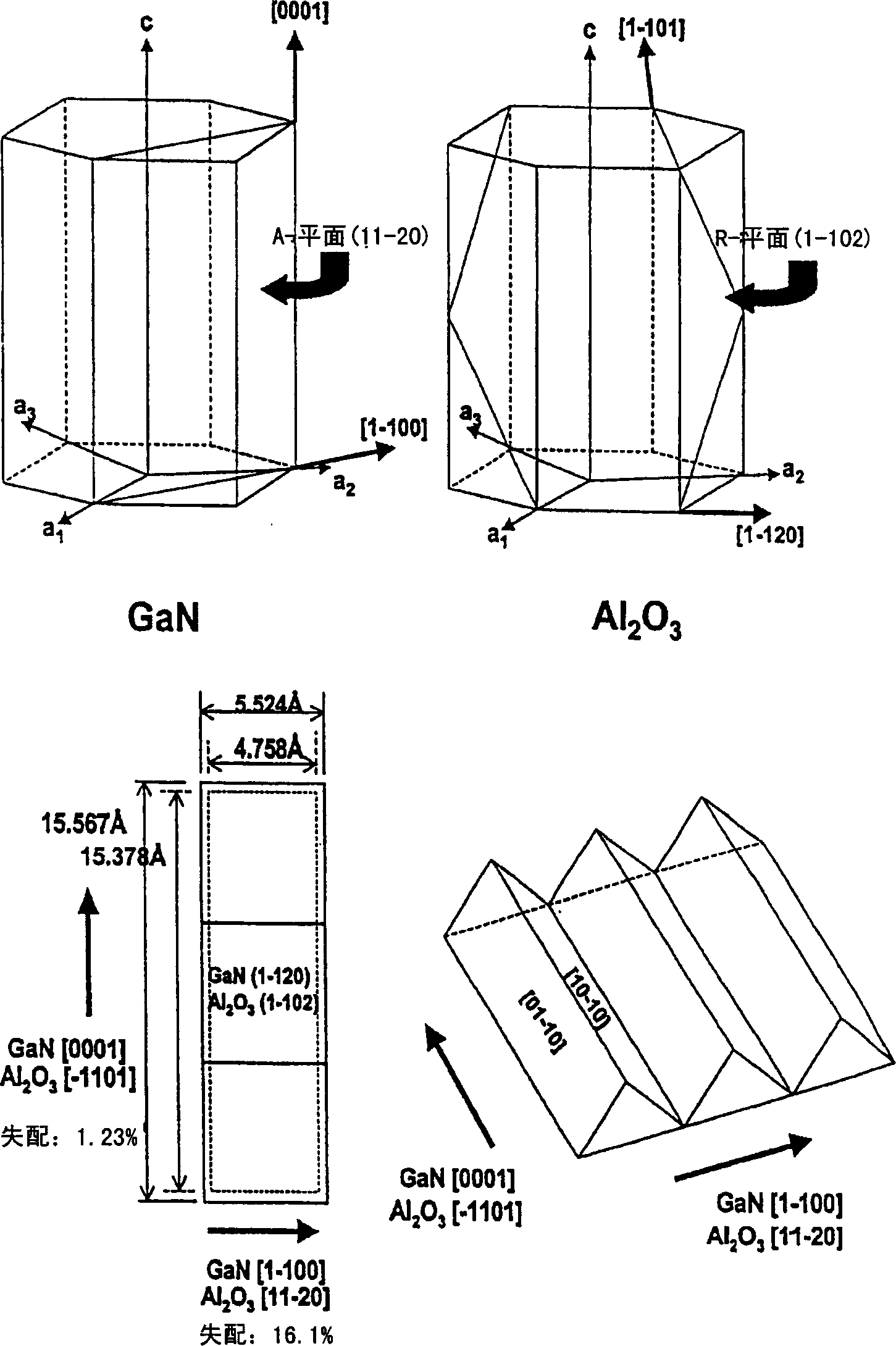

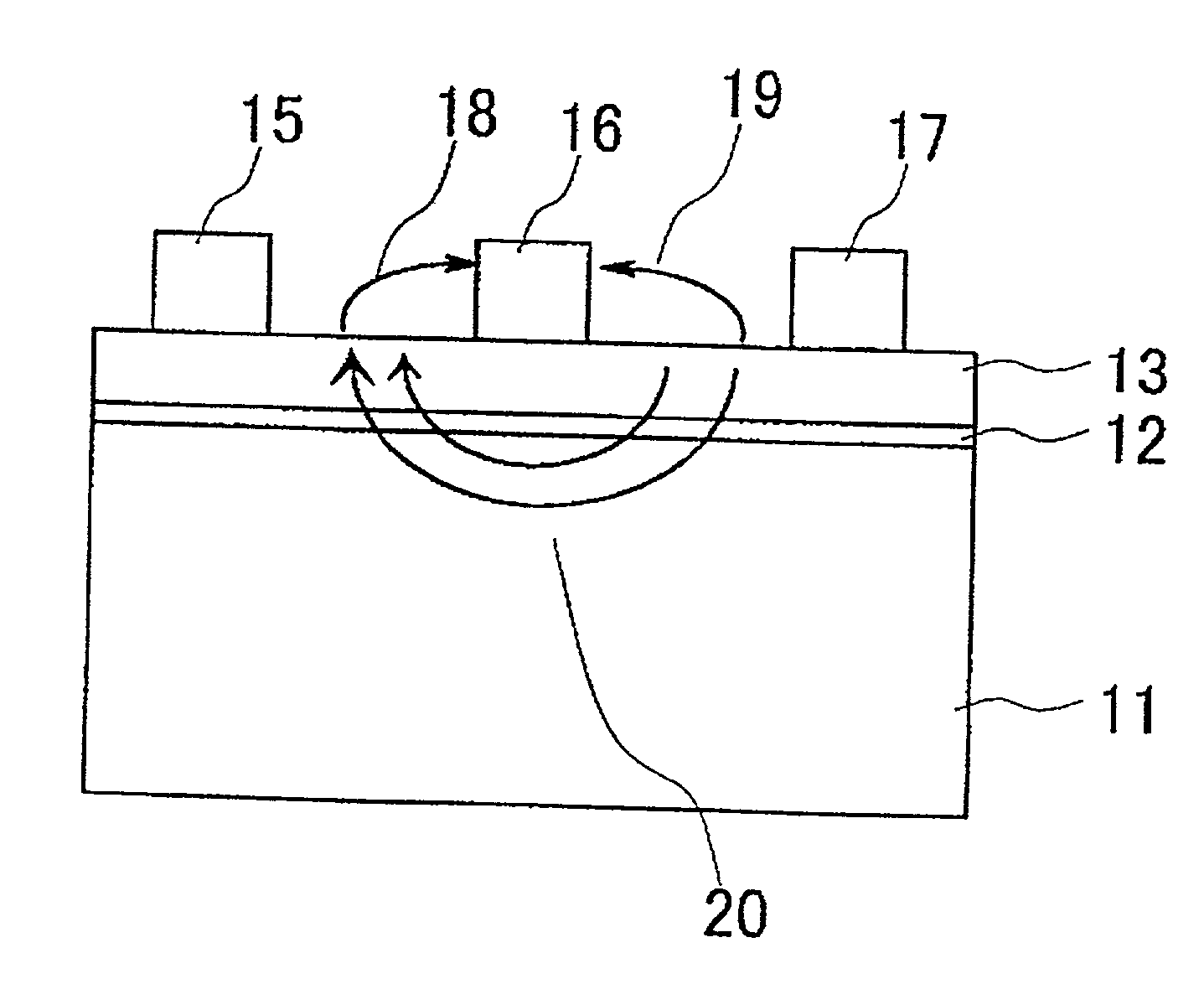

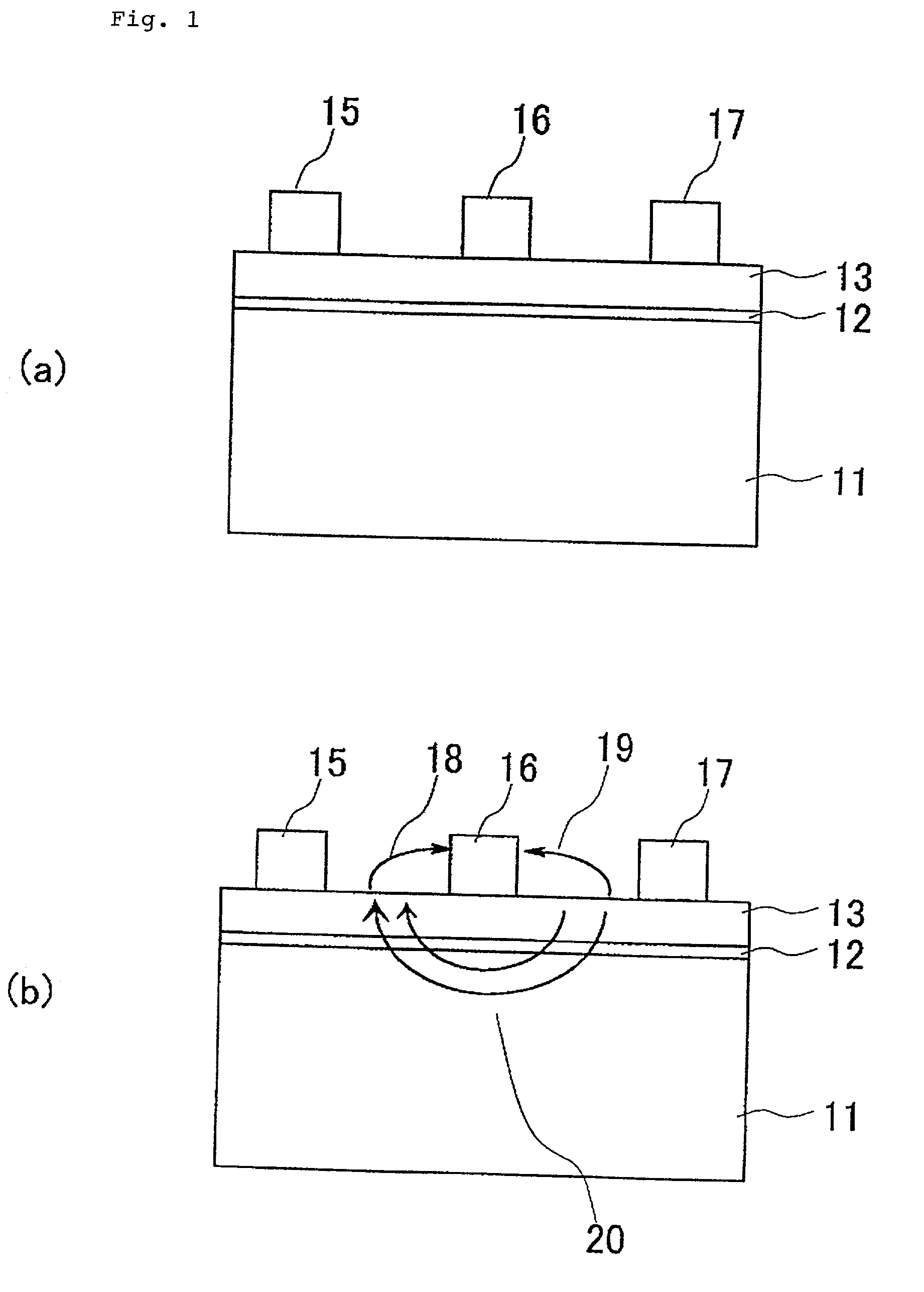

Semiconductor device

InactiveUS20020047113A1Solid-state devicesSemiconductor/solid-state device manufacturingProduction rateNitride semiconductors

An object of the present invention is to improve, in a group III nitride semiconductor device, the productivity, heat radiation characteristic and performance in the element high speed operation; upon a sapphire substrate in which an A plane (an (11-20) plane) is set to be the basal plane, an epitaxial growth layer of a group III nitride semiconductor is formed and, thereon, a gate electrode 16, a source electrode 15 and a drain electrode 17 are formed; these electrodes are disposed in such a way that a direction along which they are laid makes an angle within 20° with respect to a C axis of sapphire.

Owner:NEC CORP

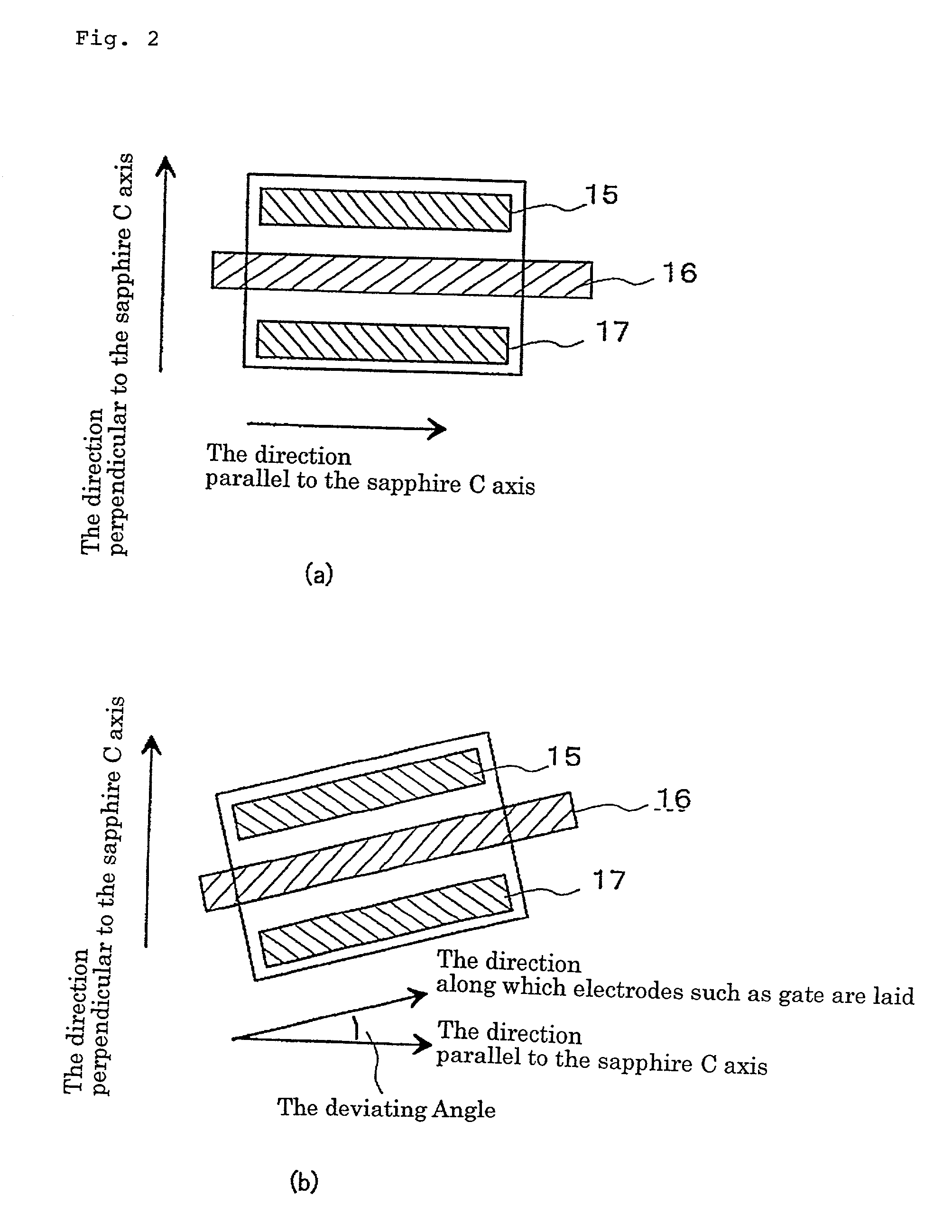

Nitride semiconductor device and method of manufacturing the same

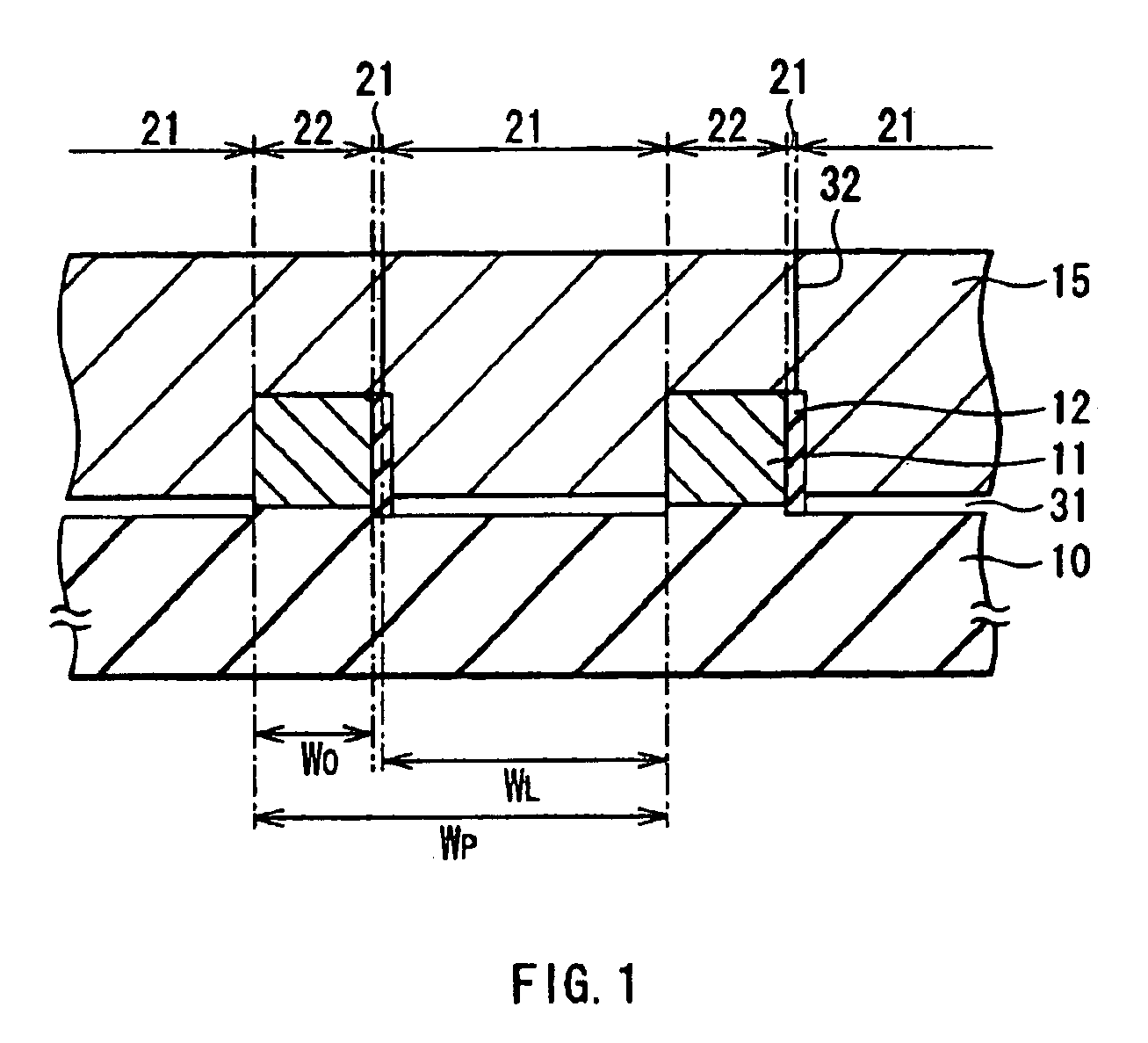

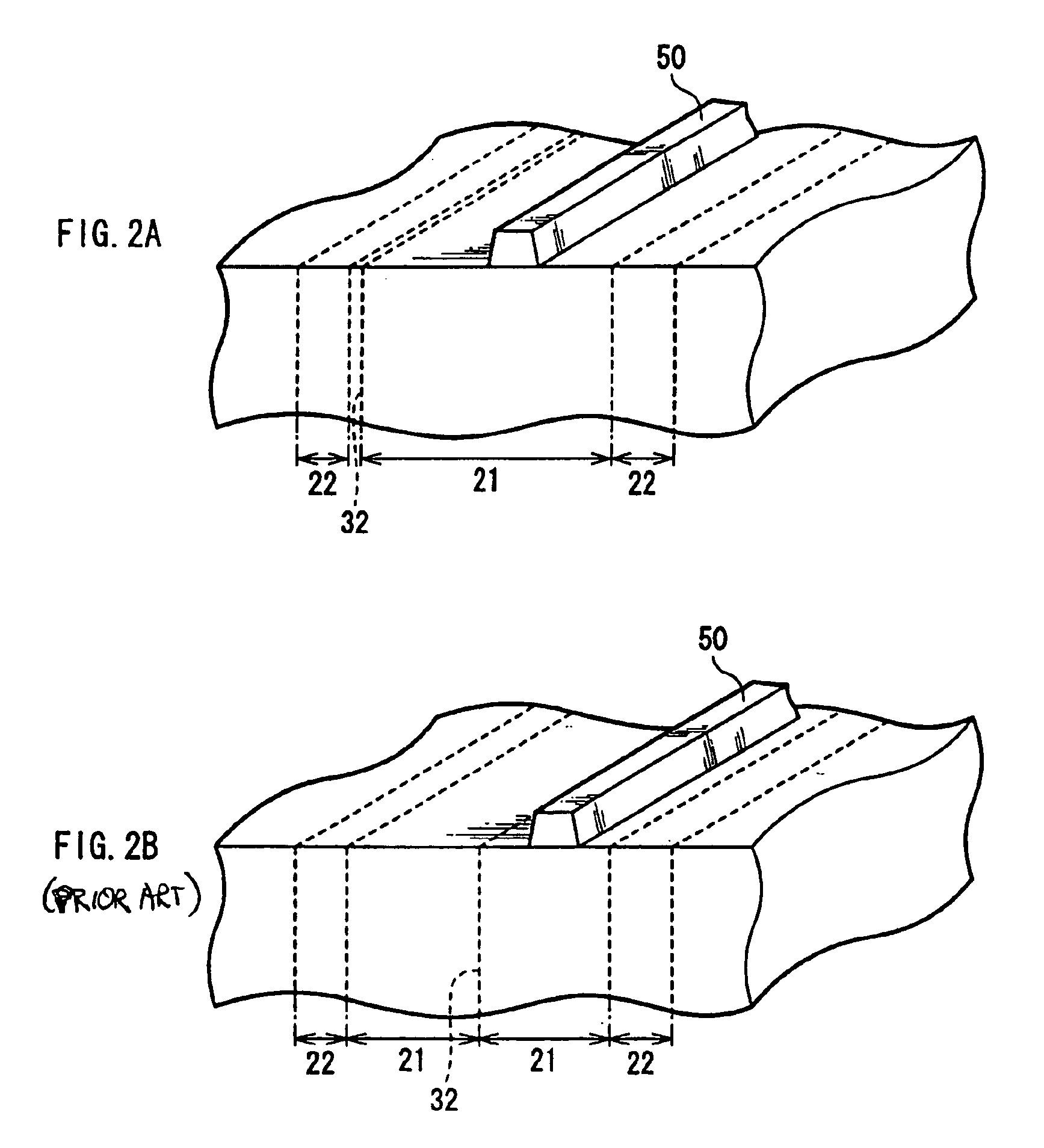

InactiveUS6921673B2Increase horizontal widthIncrease widthOptical wave guidancePolycrystalline material growthLateral overgrowthEngineering

Provided is a nitride semiconductor device with high reliability and high flexibility in design and manufacture of the device. The nitride semiconductor device comprises a seed crystal portion (11) formed on a sapphire substrate (10) and having a mask (12) on one side surface thereof, and a GaN layer (15) grown on the sapphire substrate (10) and the seed crystal portion (11) through epitaxial lateral overgrowth. The GaN layer (15) is grown only from an exposed side surface of the seed crystal portion (11) which is not covered with the mask (12), so the lateral growth of the GaN layer (15) is asymmetrically carried out. Thereby, a meeting portion (32) is formed in the vicinity of a boundary between the seed crystal portion (11) and the mask (12) in a thickness direction of the GaN layer (15). Therefore, as the meeting portion (32) is formed in a position away from the center between the adjacent seed crystal portions (11) in a direction parallel to a surface of the substrate, a width WL of a lateral growth region is larger with respect to a pitch WP of the seed crystal potion (11), compared with conventional configurations.

Owner:SONY CORP

Method for manufacturing a nitride semiconductor device and device manufactured by the method

InactiveUS6555846B1Laser detailsSemiconductor/solid-state device manufacturingThreading dislocationsDopant

A group III nitride semiconductor device is disclosed which has a reduced number of threading dislocations adversely affecting characteristics of the group III nitride semiconductor device. A method for manufacturing the group III nitride semiconductor device controls pit formation in a GaN layer formed on a sapphire substrate.First, a low temperature buffer layer is formed on a sapphire substrate by MOCVD. An undoped GaN layer having a predetermined thickness is then grown on the low temperature buffer layer. Next, a GaN layer containing magnesium as a dopant is formed on the layer at a lower pressure than that of depositing the GaN layer, which results in filling pits generated on the GaN layer to flatten the surface of another GaN layer.

Owner:SHOWA DENKO KK

Process for producing group III nitride compound semiconductor

InactiveUS20050118825A1Efficient productionPolycrystalline material growthDecorative surface effectsNitrogen atmosphereAdemetionine

A method including the steps of: modifying at least one part of a sapphire substrate by dry etching to thereby form any one of a dot shape, a stripe shape, a lattice shape, etc. as an island shape on the sapphire substrate; forming an AlN buffer layer on the sapphire substrate; and epitaxially growing a desired Group III nitride compound semiconductor vertically and laterally so that the AlN layer formed on a modified portion of the surface of the sapphire substrate is covered with the desirably Group III nitride compound semiconductor without any gap while the AlN layer formed on a non-modified portion of the surface of the sapphire substrate is used as a seed, wherein the AlN buffer layer is formed by means of reactive sputtering with Al as a target in an nitrogen atmosphere.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com