Patents

Literature

4451 results about "Nitrogen atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen in the atmosphere is predominantly in the form of molecular nitrogen (N 2), made of two atoms of nitrogen-14. There also exists a small quantity of the heavier nitrogen-15 isotope (an atom of nitrogen with an extra neutron) and, on rare occasions, two nitrogen-15 atoms can bond together to form a nitrogen molecule known as 15N 15N.

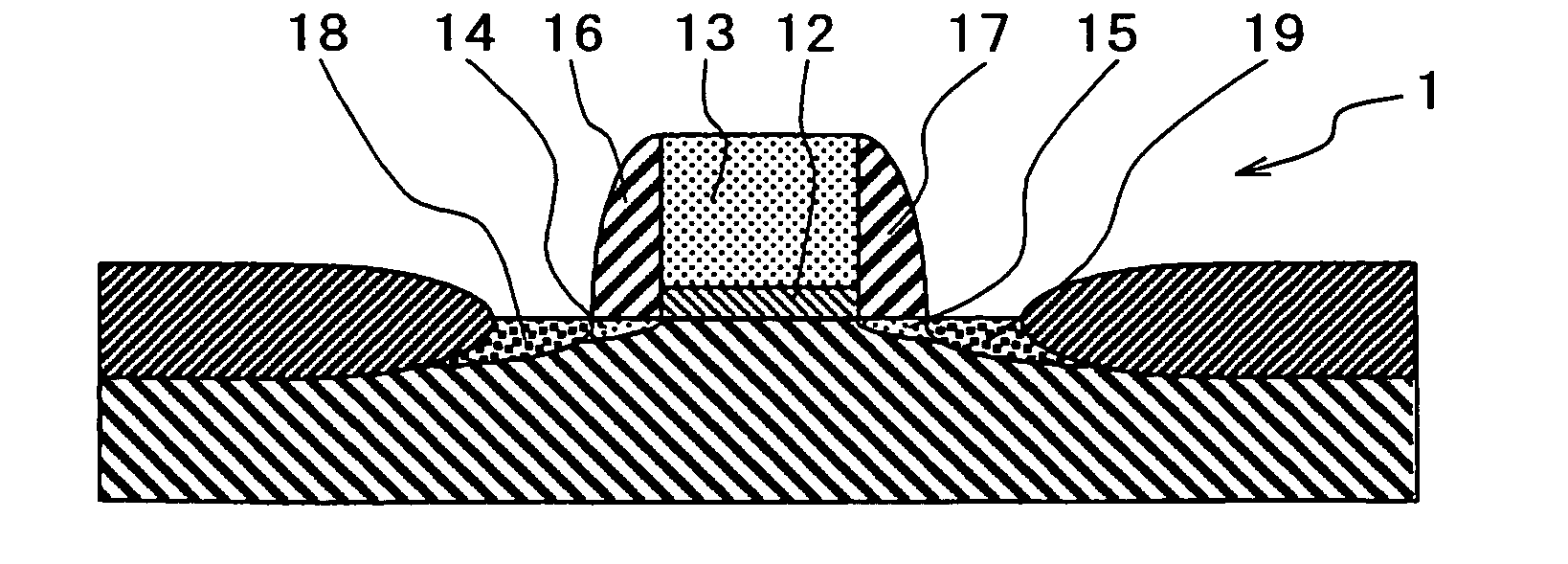

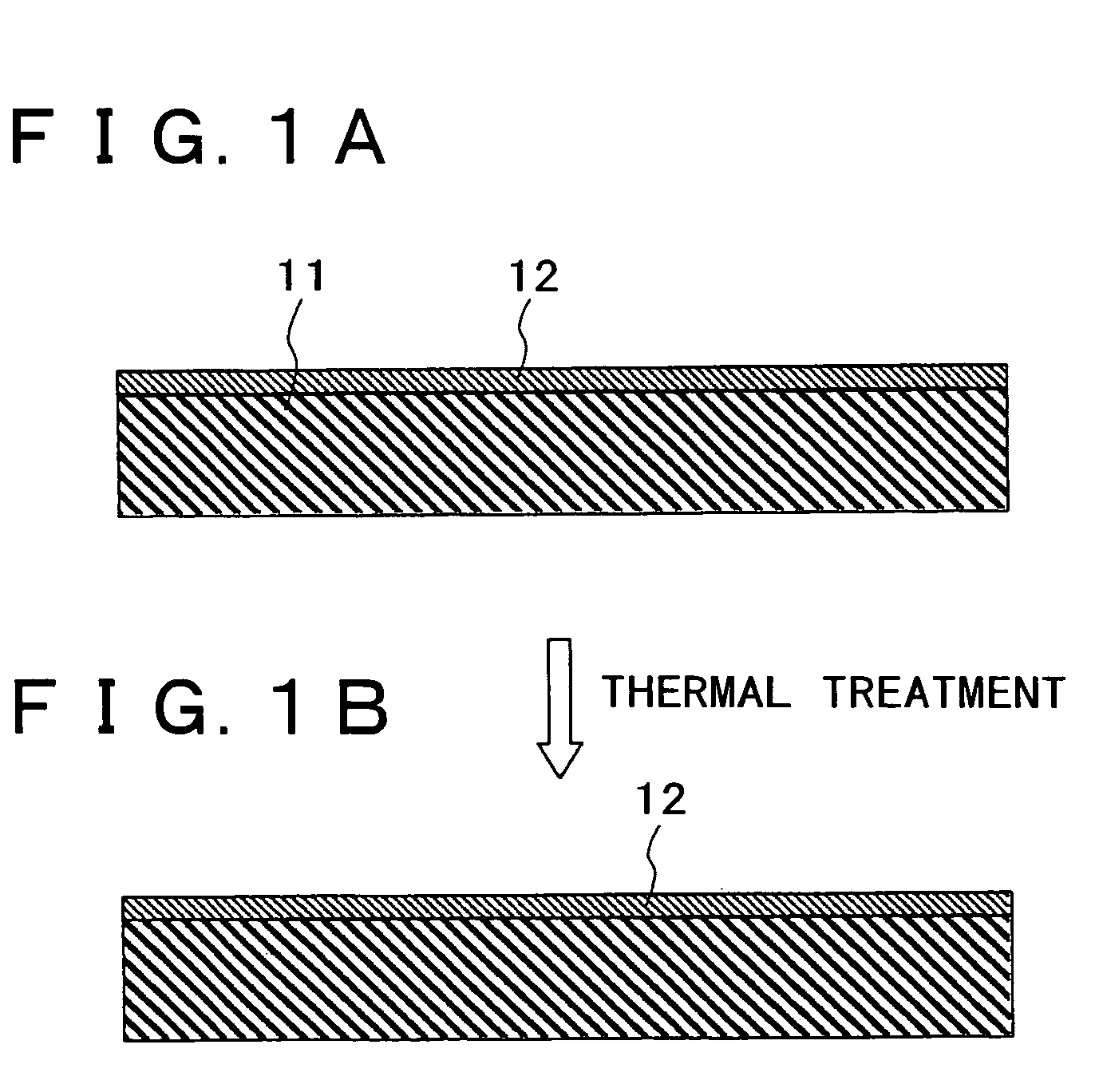

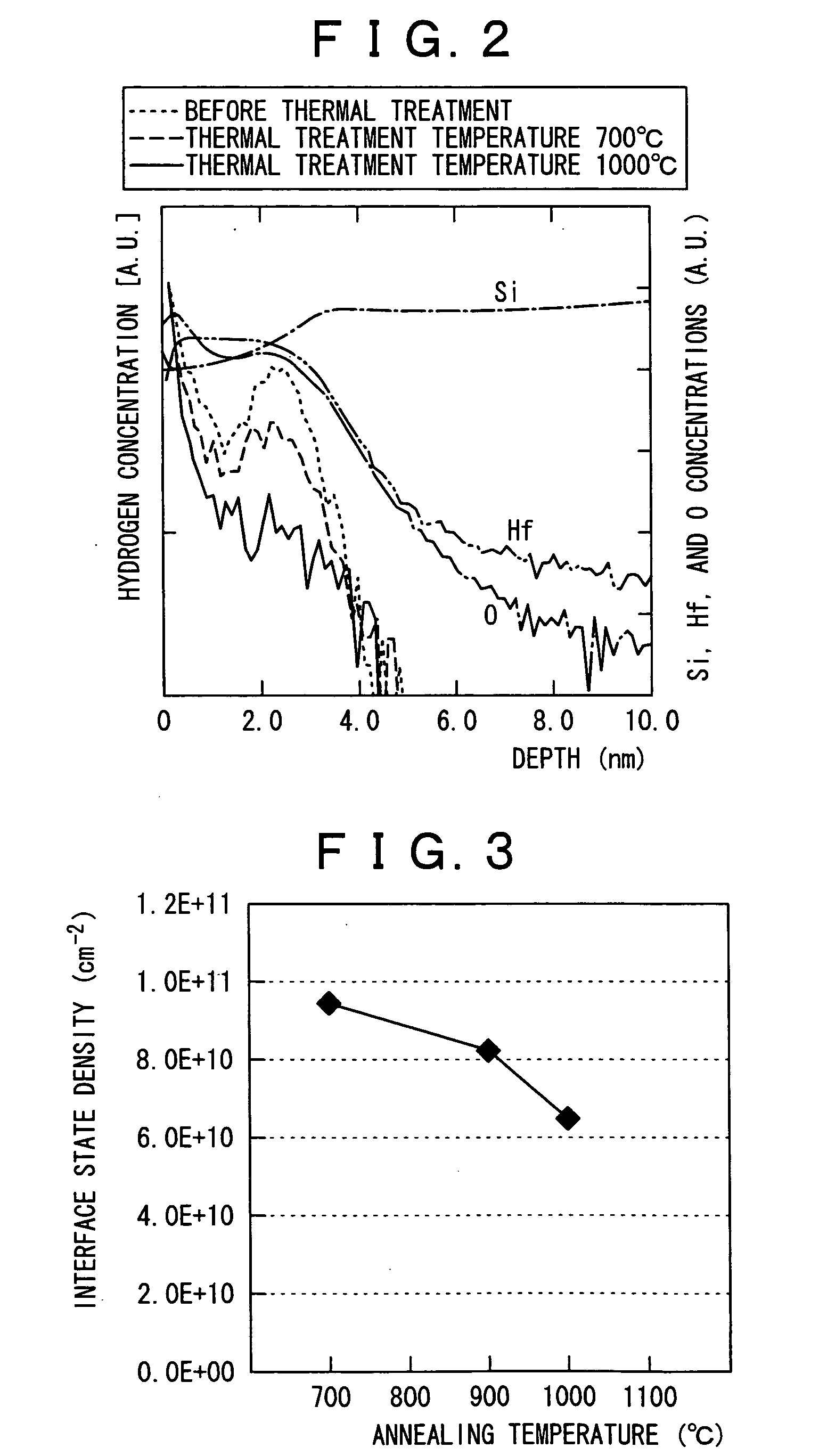

Method for forming a thin film and method for fabricating a semiconductor device

InactiveUS20050070123A1Improve mobility and reliabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricHafnium

By conducting a high temperature annealing in a nitrogen atmosphere at a temperature at which a hafnium silicate film undergoes no phase separation, hydrogen contained in the film is removed and prevention of boron penetration is made possible. The present invention provides a method for forming a thin film including a step of forming a hafnium silicate film on a substrate by an atomic layer deposition method and a step of carrying out thermal treatment on the hafnium silicate film at a thermal treatment temperature equal to or higher than a temperature at which hydrogen contained in the hafnium silicate film is removed and lower than a temperature at which the hafnium silicate film undergoes no phase separation, and a method for fabricating a semiconductor device for forming a gate dielectric film using the method for forming a thin film.

Owner:SONY CORP

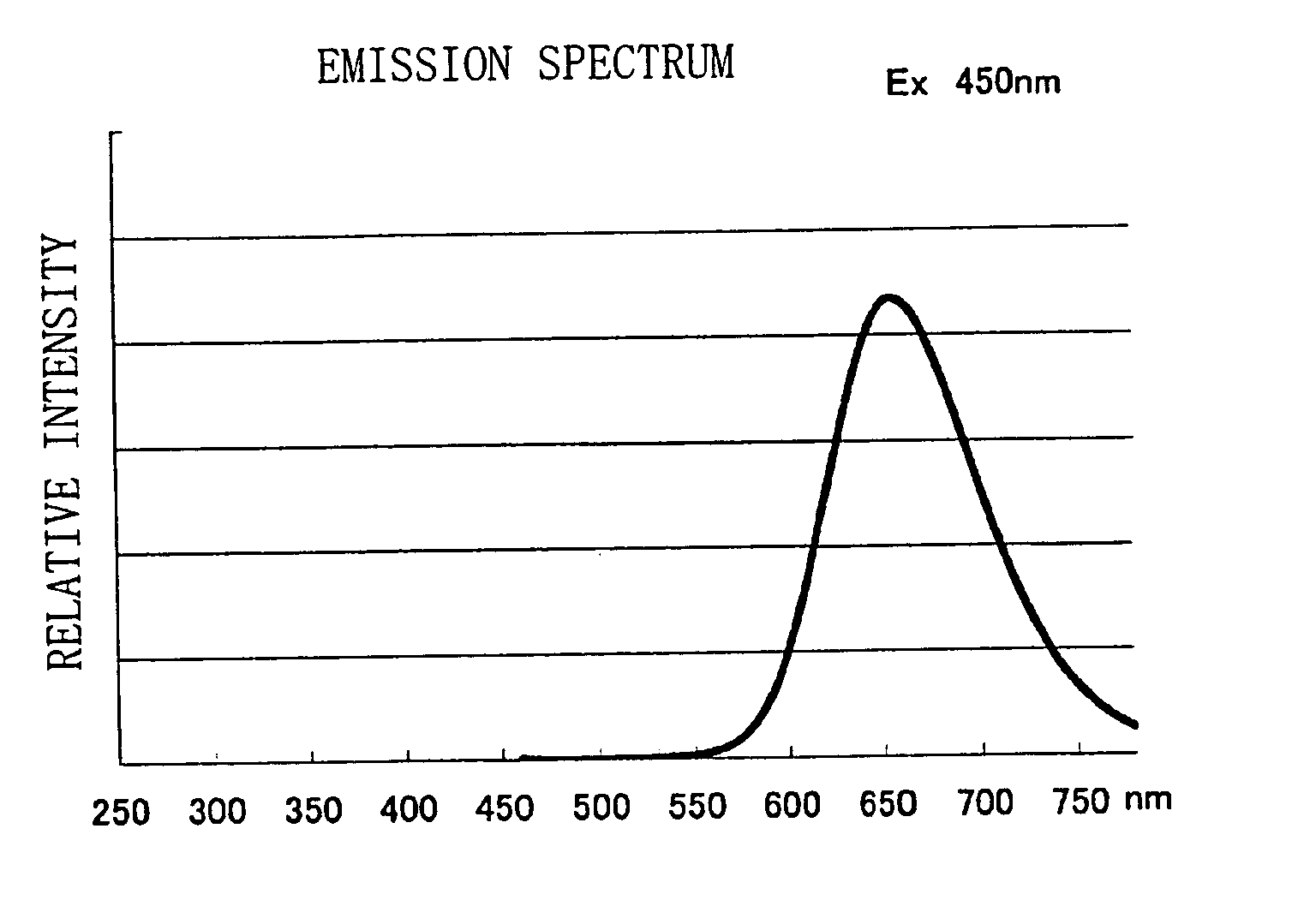

Phosphor, light source and LED

InactiveUS20050189863A1Improve luminance of light lightImprove of visible light lightDischarge tube luminescnet screensLamp detailsPhosphorUltraviolet lights

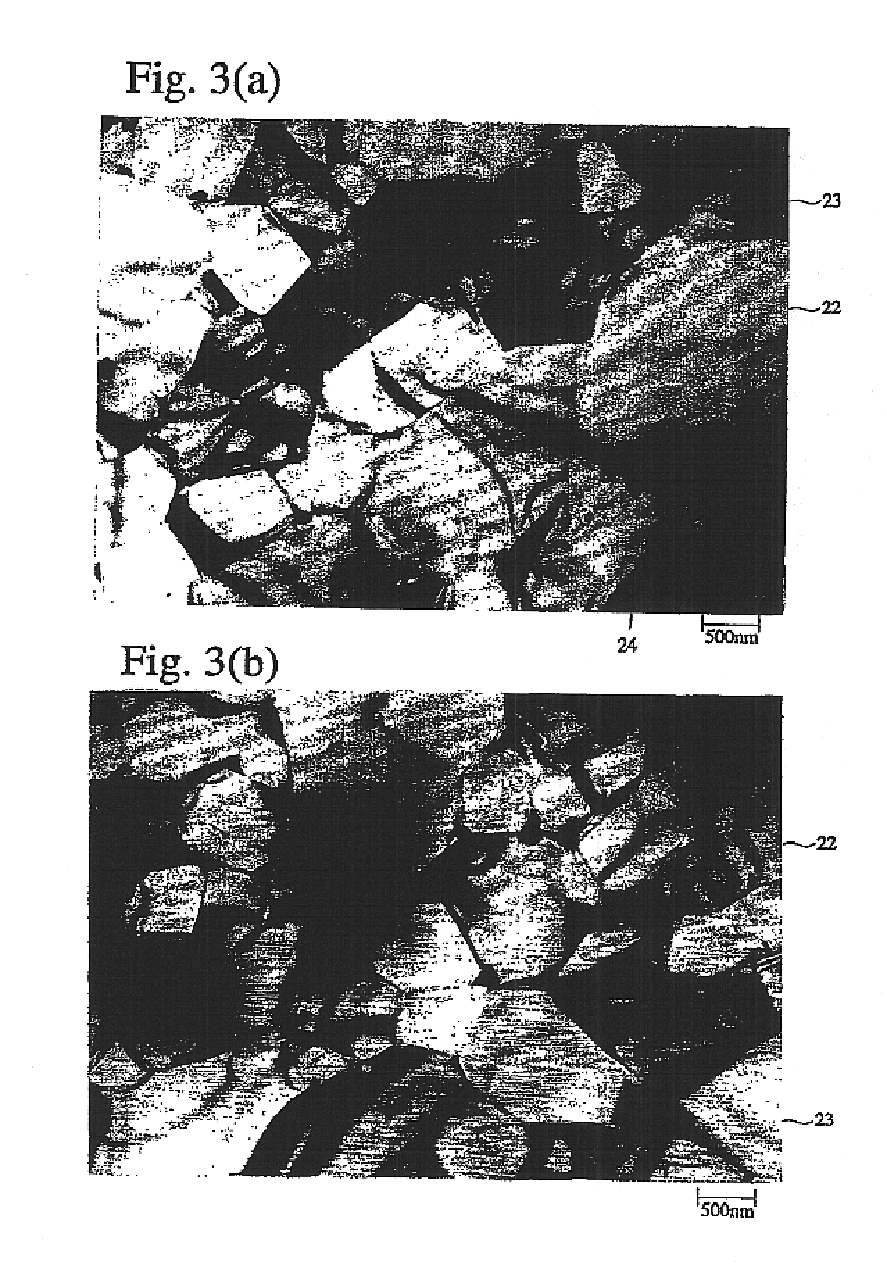

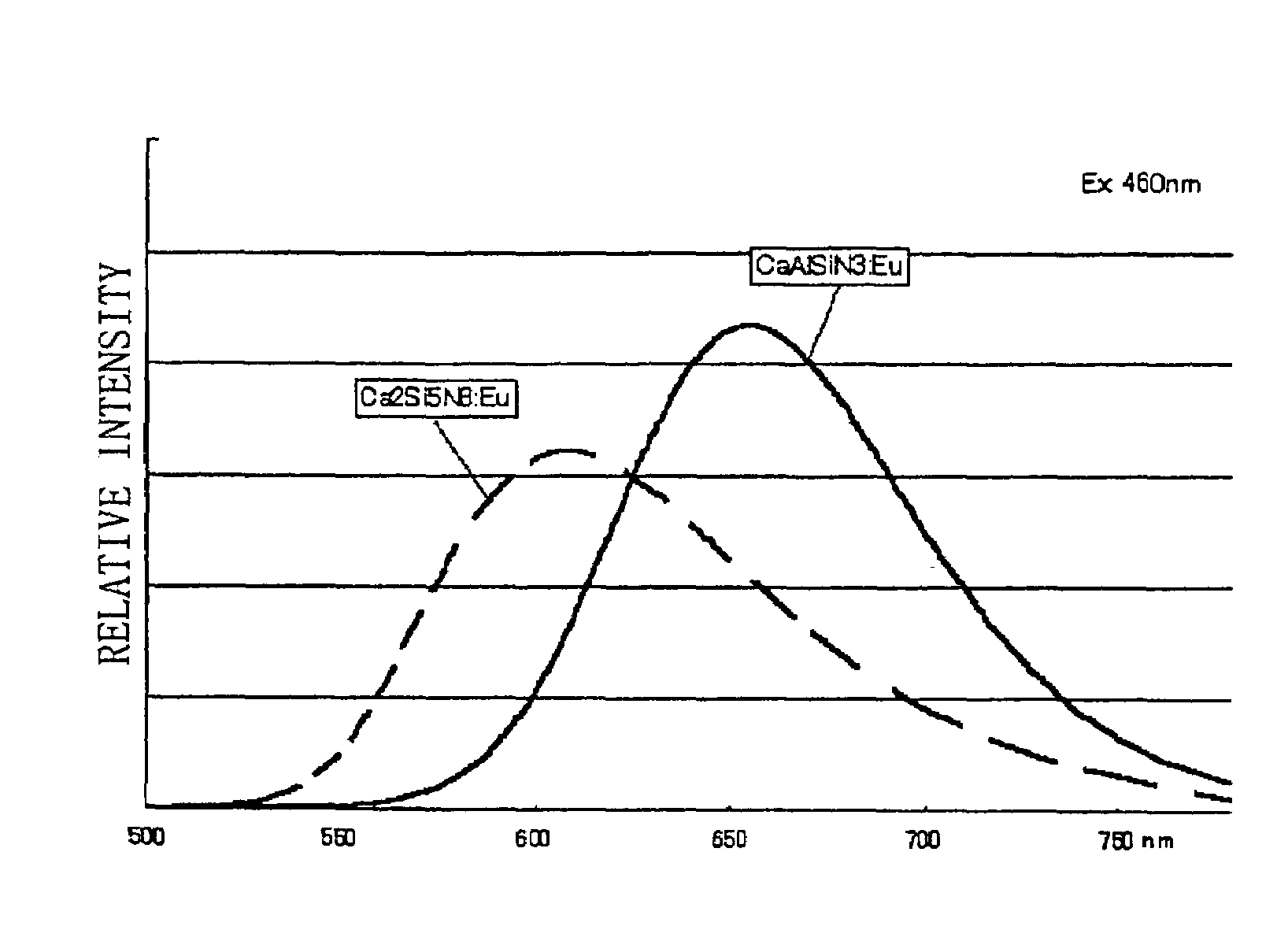

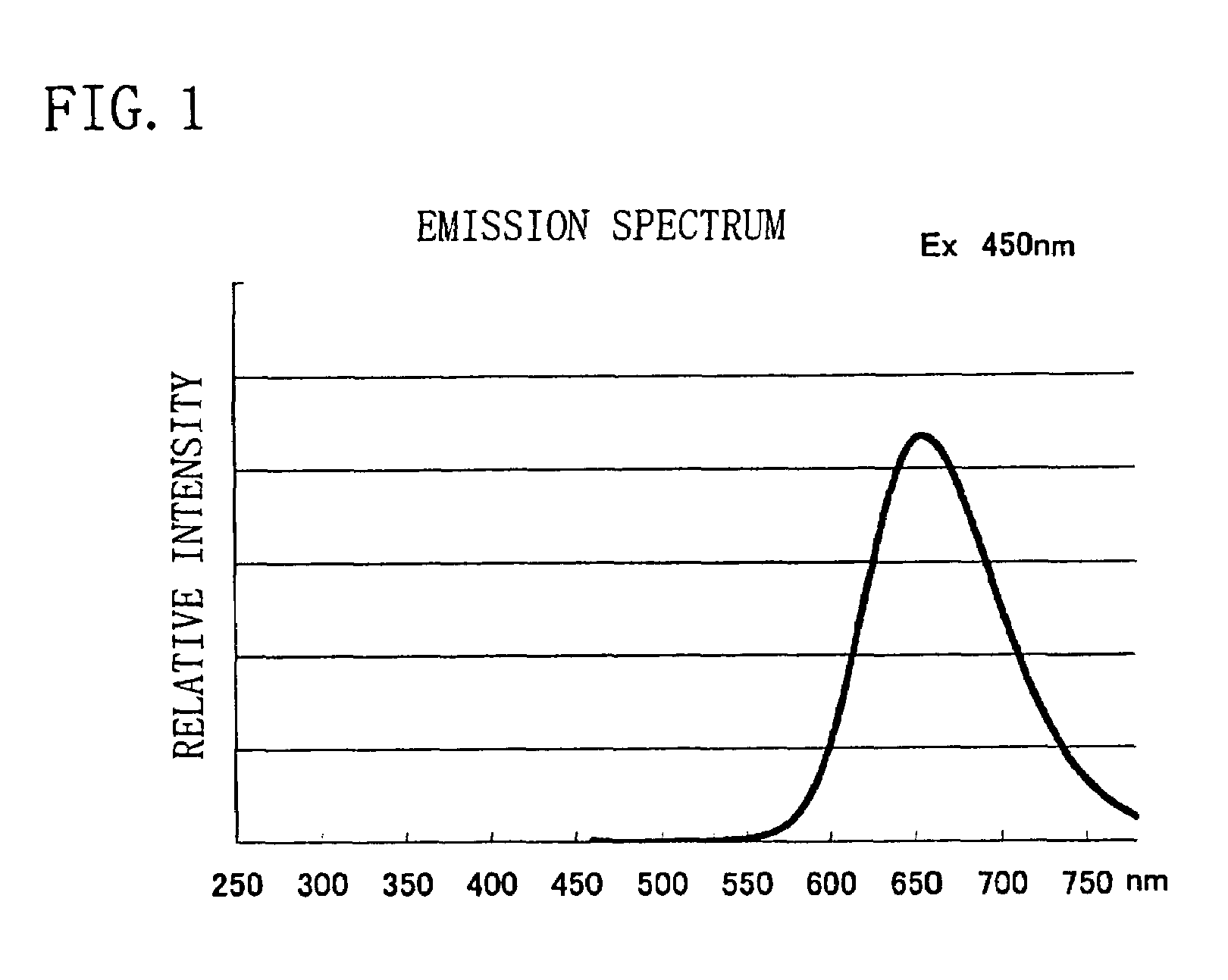

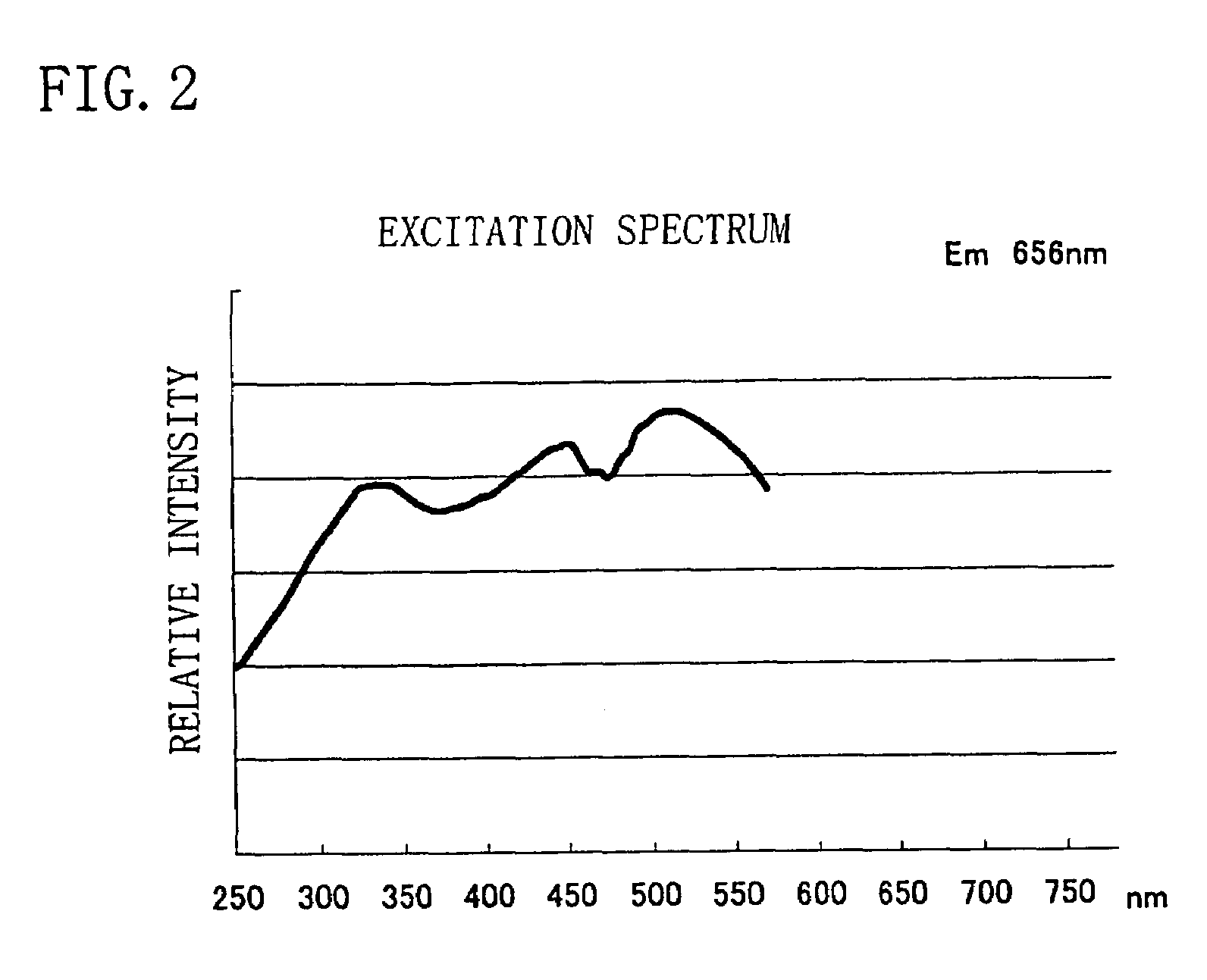

A phosphor with high efficiency having an excitation band corresponding to light of the ultraviolet-visible (300 to 550 nm) wavelength region emitted from a light emitting portion which emits blue or ultraviolet light is provided. A nitride of Ca, a nitride of Al, a nitride QfSi, and an oxide of Eu are prepared, and respective raw materials are weighed so that a mol ratio of respective elements becomes Ca:Al:Si:Eu=0.985:3:1:0.015, mixed under a nitrogen atmosphere, and thereafter fired at 1500° C. in a nitrogen atmosphere to thereby produce a phosphor having a composition formula Ca0.985SiAlN3:Eu0.015.

Owner:NICHIA CORP

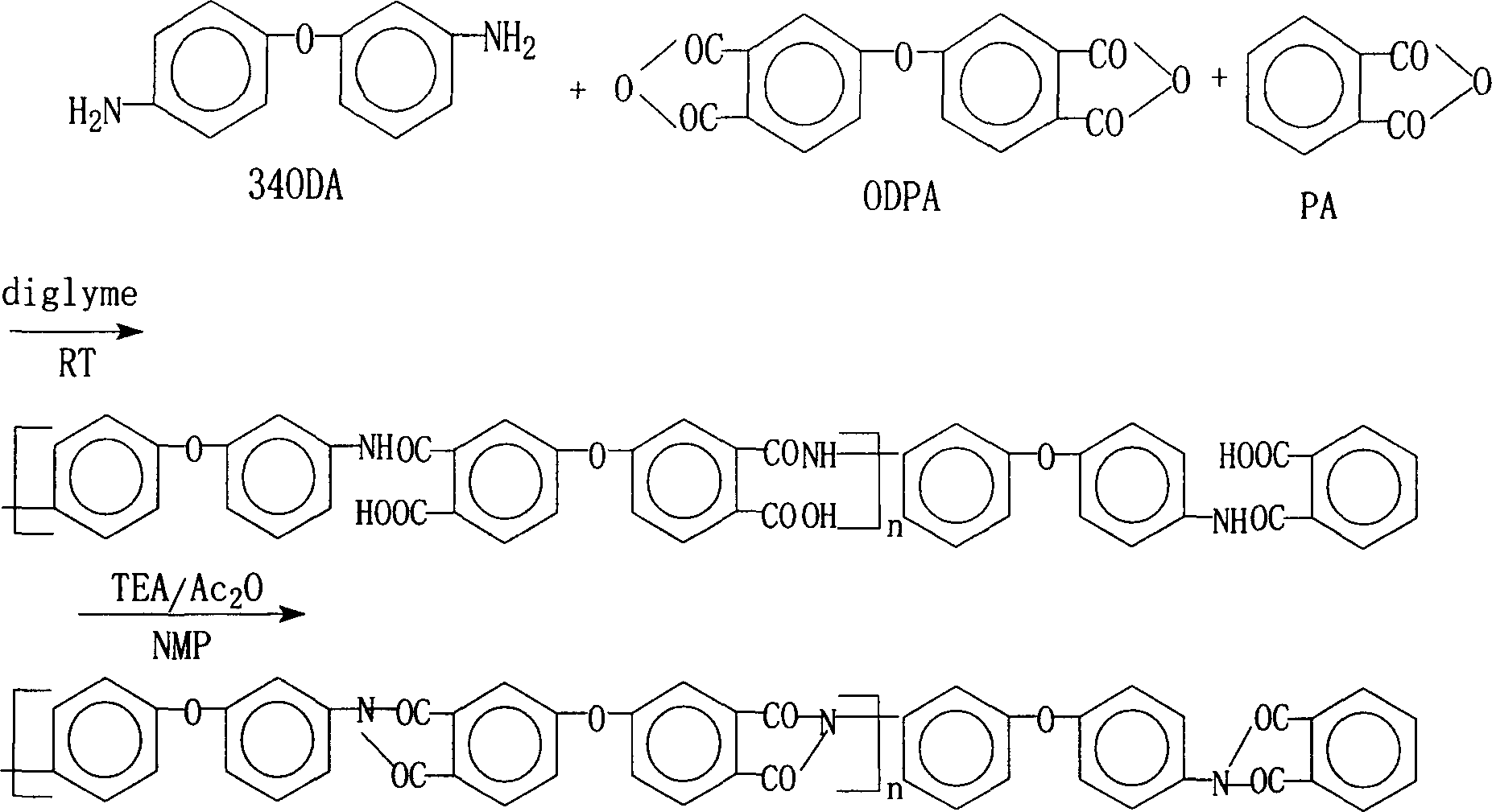

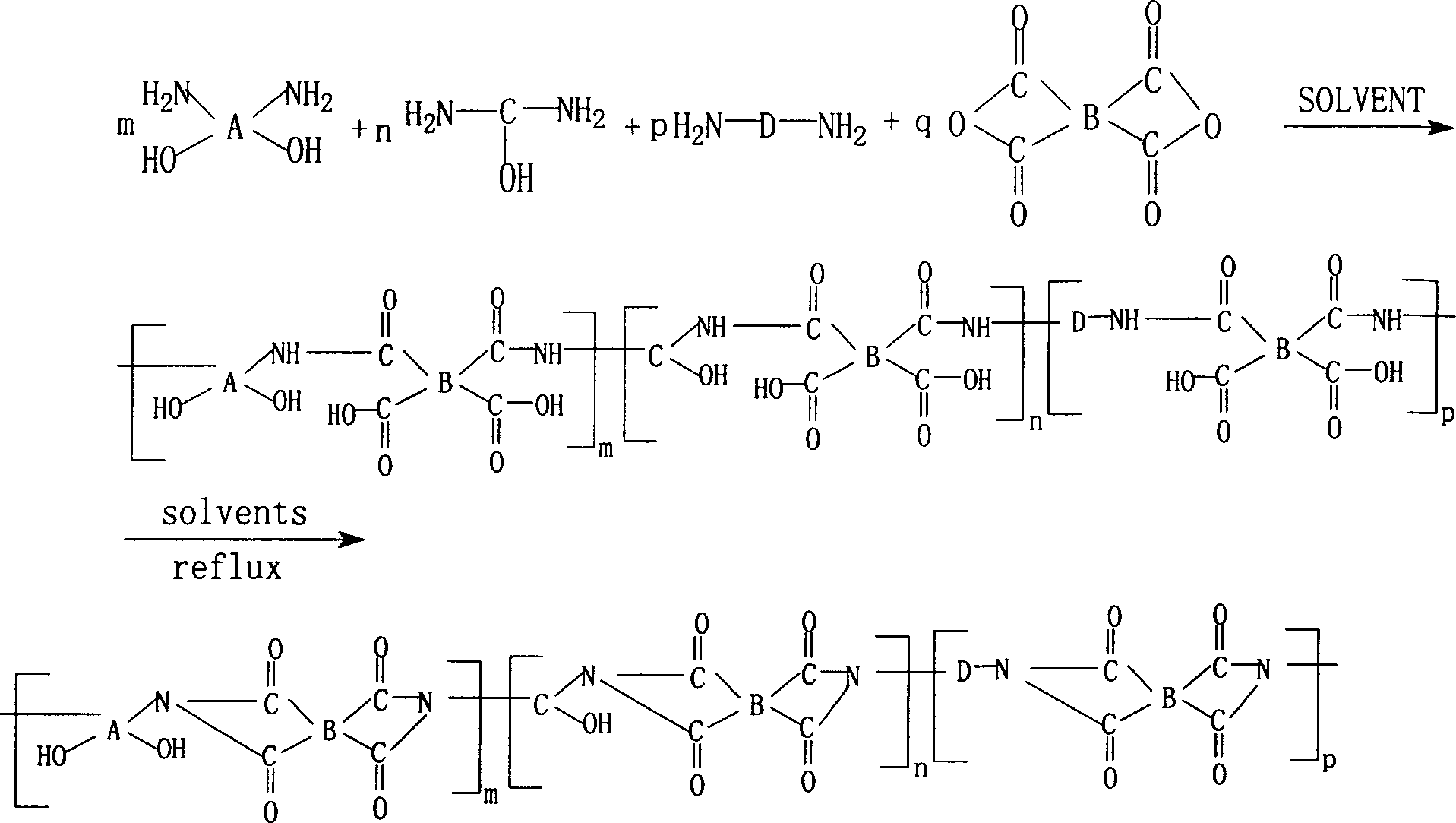

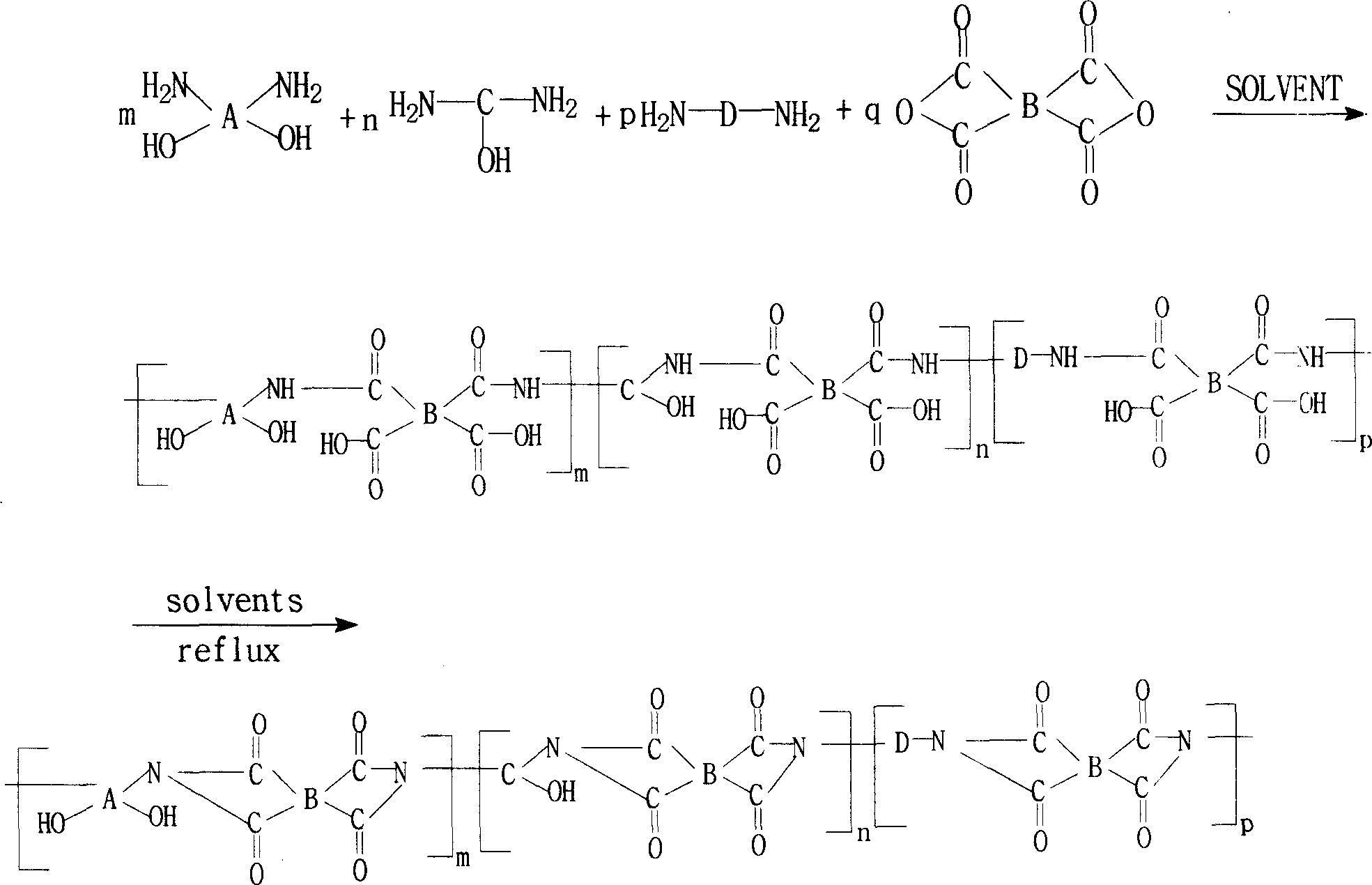

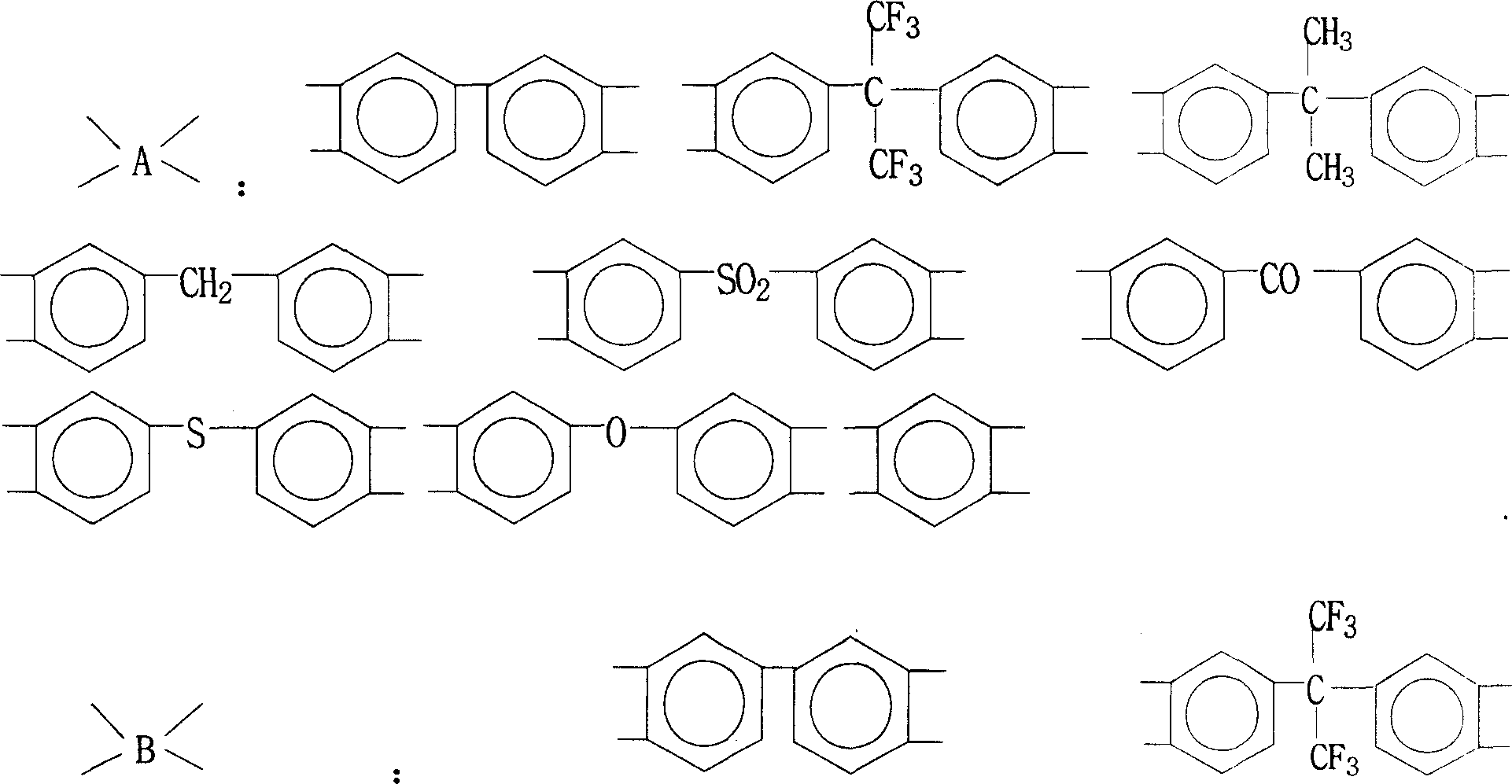

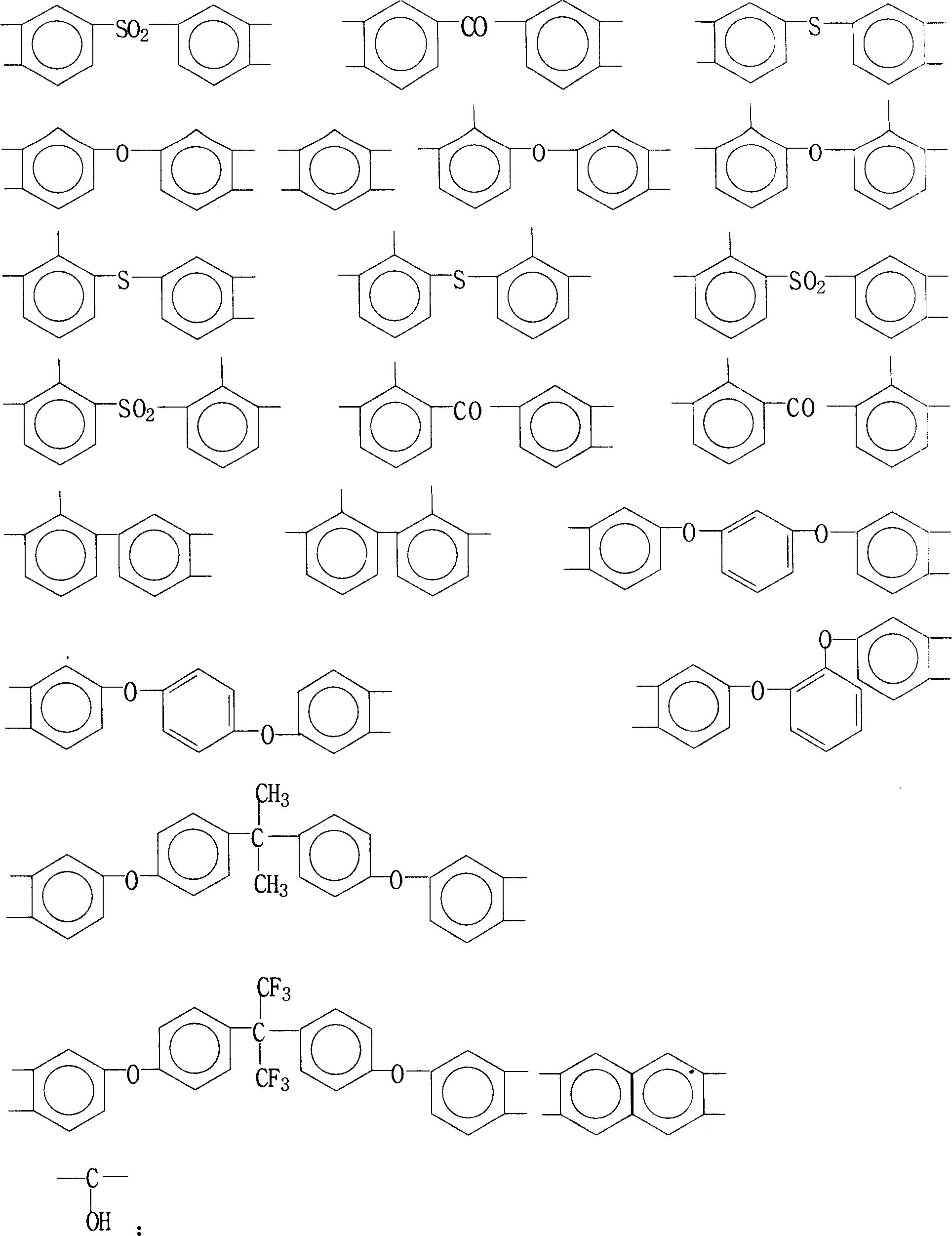

Preparation method of phenolic hydroxyl group containing polyimide powder

The preparation process of phenolic hydroxyl group-containing polyimide powder includes the following steps: 1. reaction of phenolic hydroxyl group-containing aromatic diamine compound or its mixture with other diamine compound and aromatic binary anhydride in the molar ratio of 1 to 1 in strong polar non-protonic organic solvent under protection of nitrogen at 0-30 deg.c for 3-12 hr to obtain transparent ropy polyhydroxy amido acid solution; and 2. adding azeotropic dewatering agent in nitrogen atmosphere and heating to 120-160 deg.c to reflux, azeotropically dewater and imidize for 5-18 hr, cooling to room temperature, washing and vacuum drying to obtain phenolic hydroxyl group-containing polyimide powder. The industrial production process has environment friendship, simple operation, low cost and easy solvent recovery.

Owner:DONGHUA UNIV

Cable semiconducting shields

A semiconducting composition comprising (i) an olefinic polymer and (ii) about 25 to about 45 percent by weight, based on the weight of the composition, of a carbon black having the following properties: (a) a particle size of at least about 29 nanometers; (b) a tint strength of less than about 100 percent; (c) a loss of volatiles at 950 degrees C in a nitrogen atmosphere of less than about 1 weight percent based on the weight of the carbon black; (d) a DBP oil absorption of about 80 to about 300 cubic centimeters per 100 grams; (e) a nitrogen surface adsorption area of about 30 to about 300 square meters per gram or an iodine adsorption number of about 30 to about 300 grams per kilogram; (f) a CTAB surface area of about 30 to about 150 square meters per gram; and (g) a ratio of property (e) to property (f) of greater than about 1.1.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

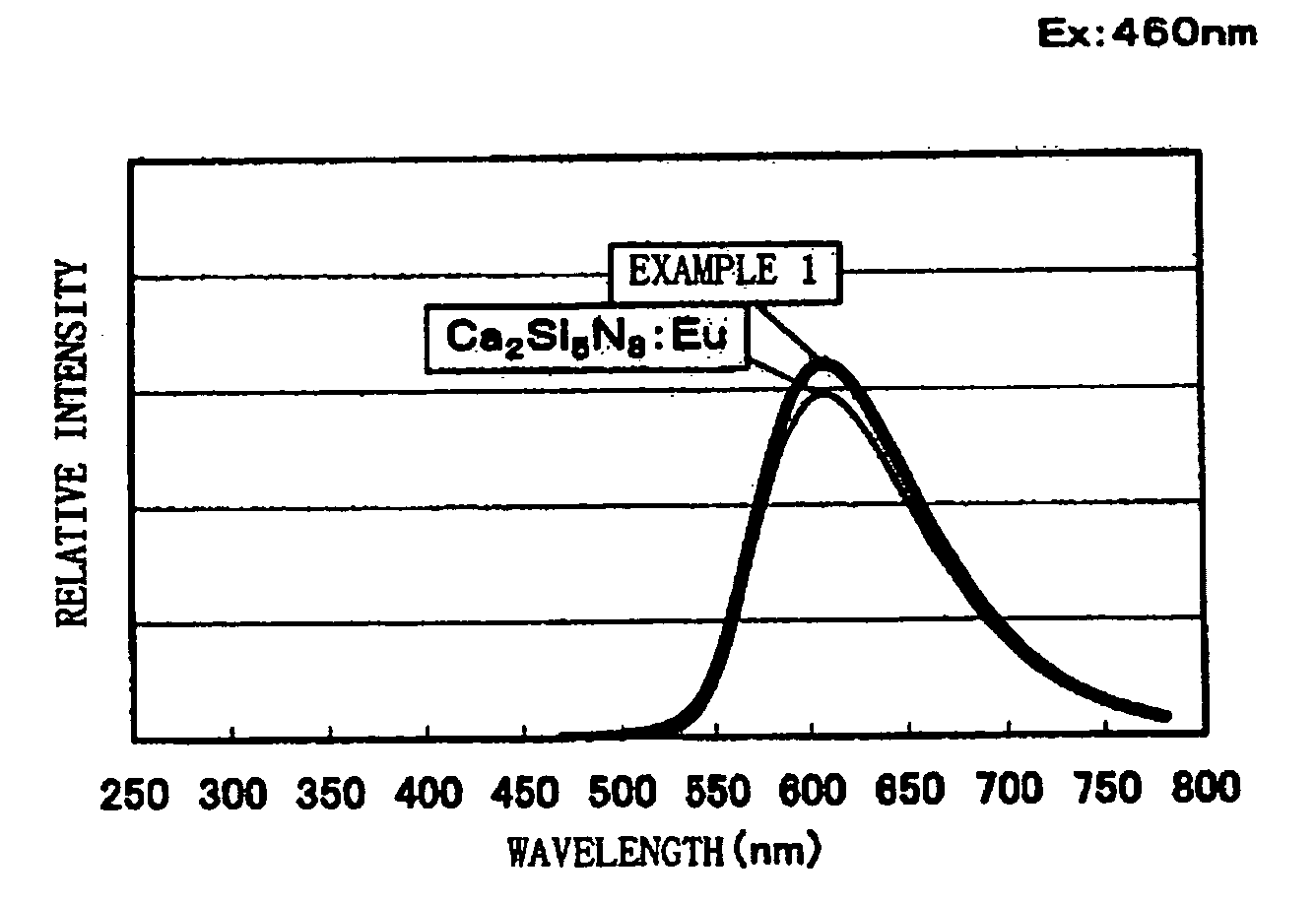

Phosphor and production method of the same, method of shifting emission wavelength of phosphor, and light source and LED

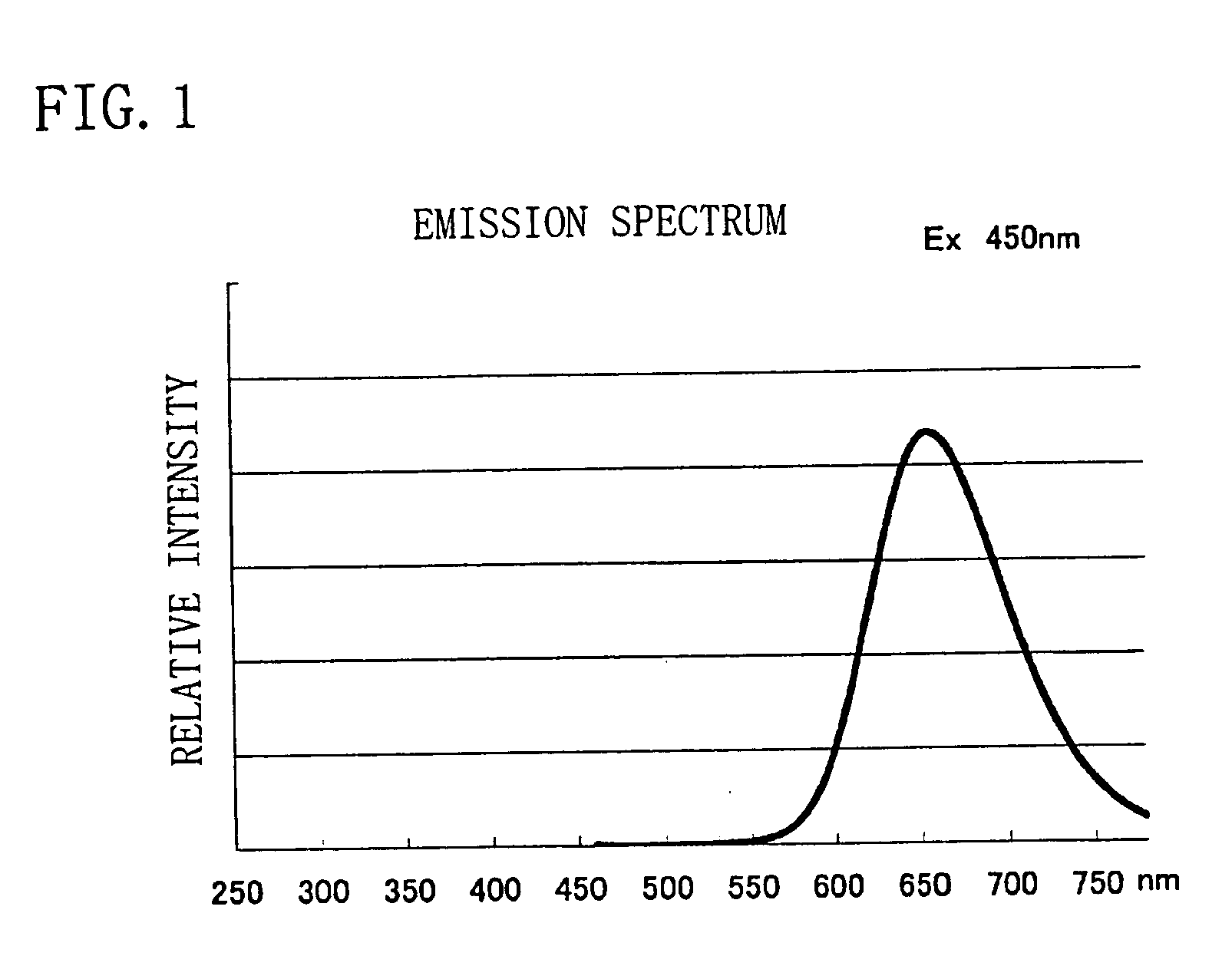

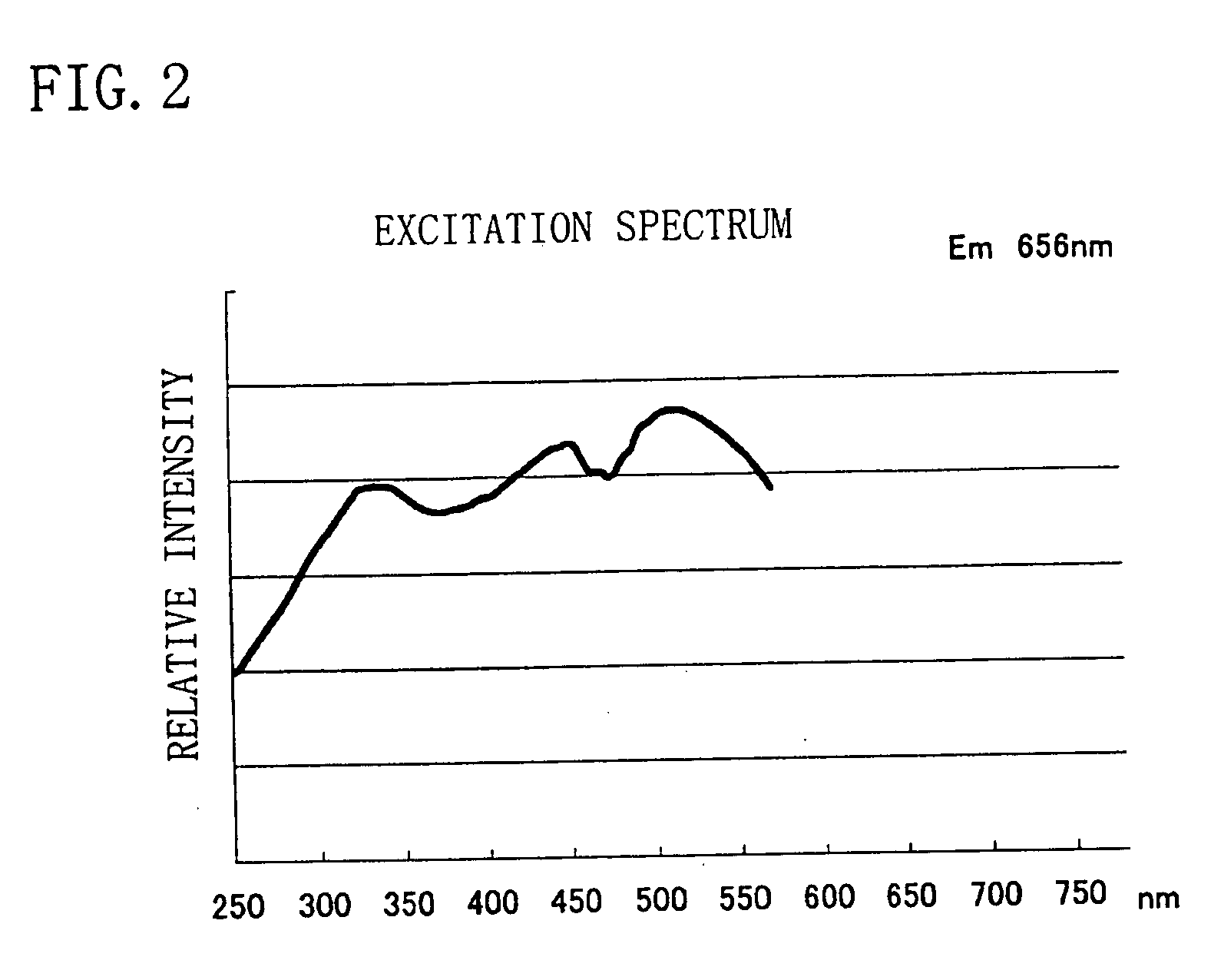

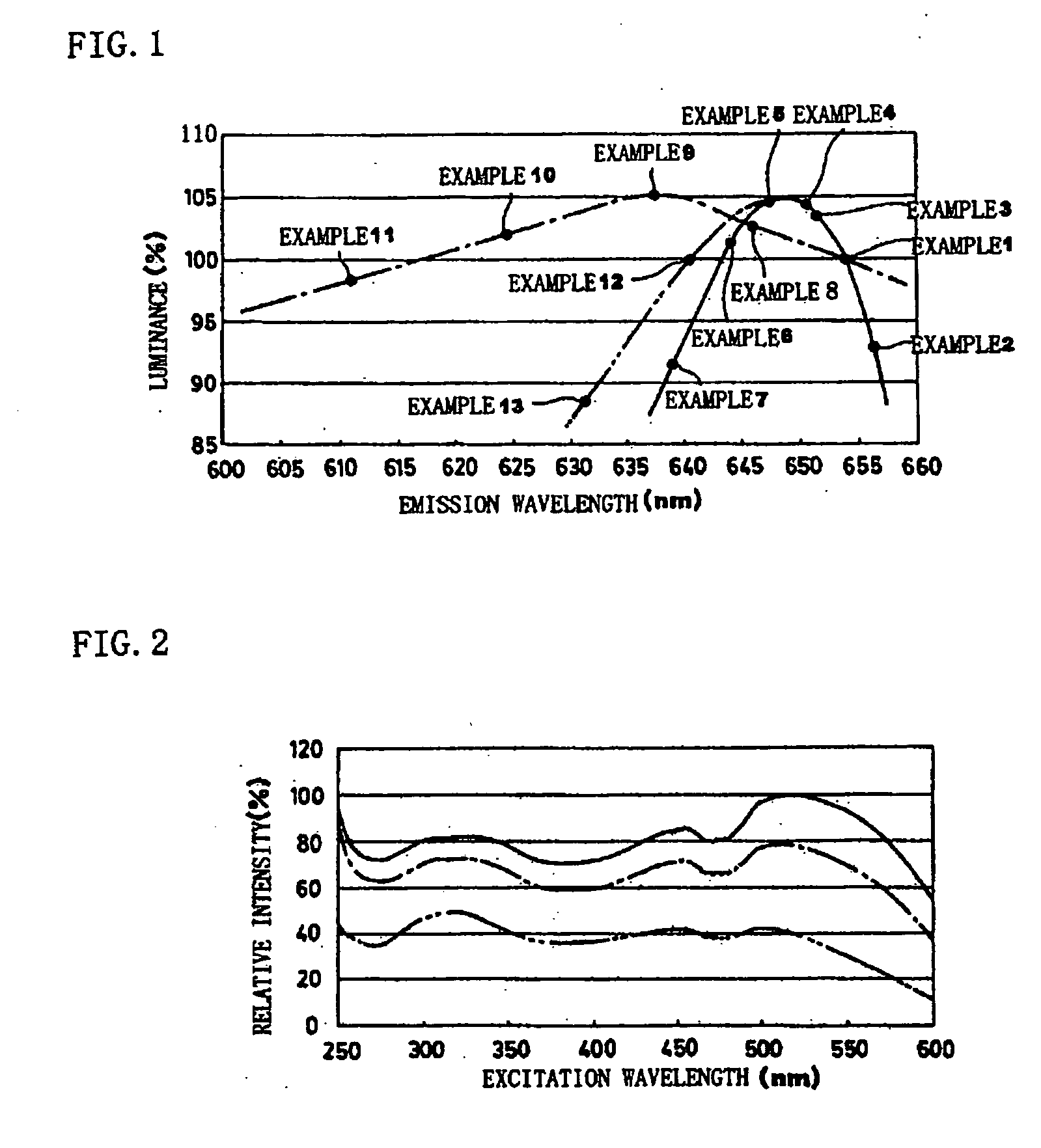

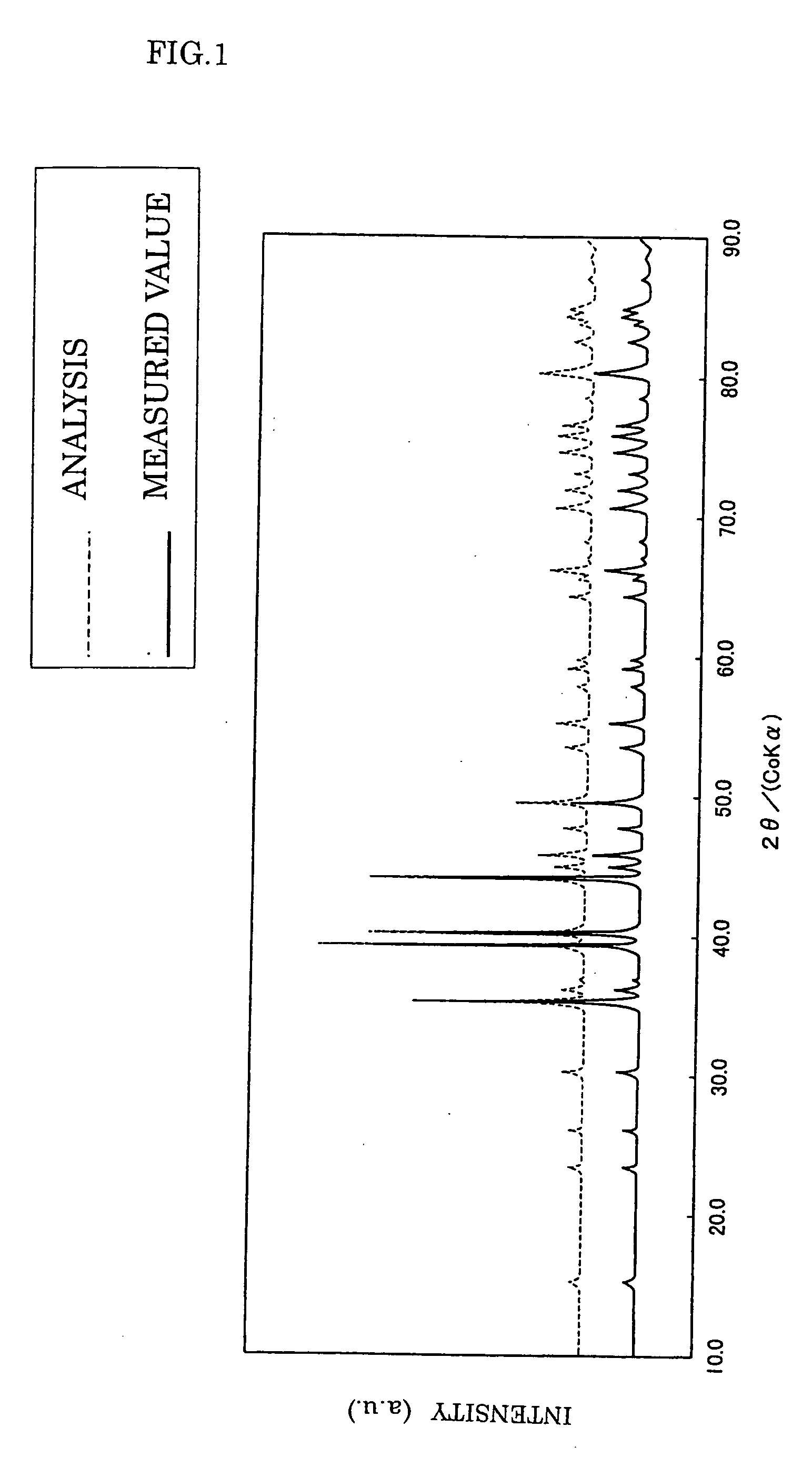

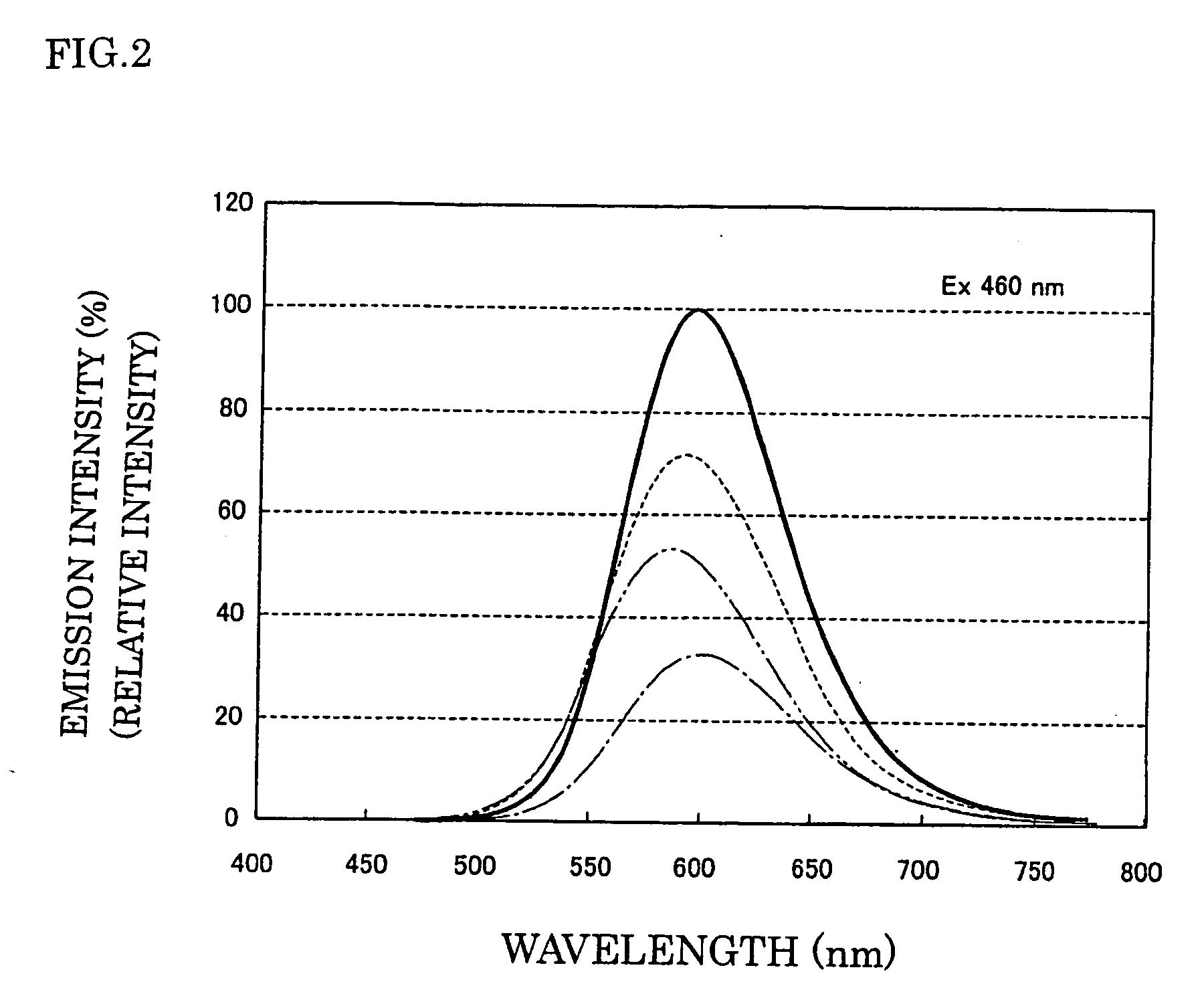

ActiveUS20060017365A1High sensitivityImprove luminous performanceDischarge tube luminescnet screensLamp detailsPhosphorNitrogen atmosphere

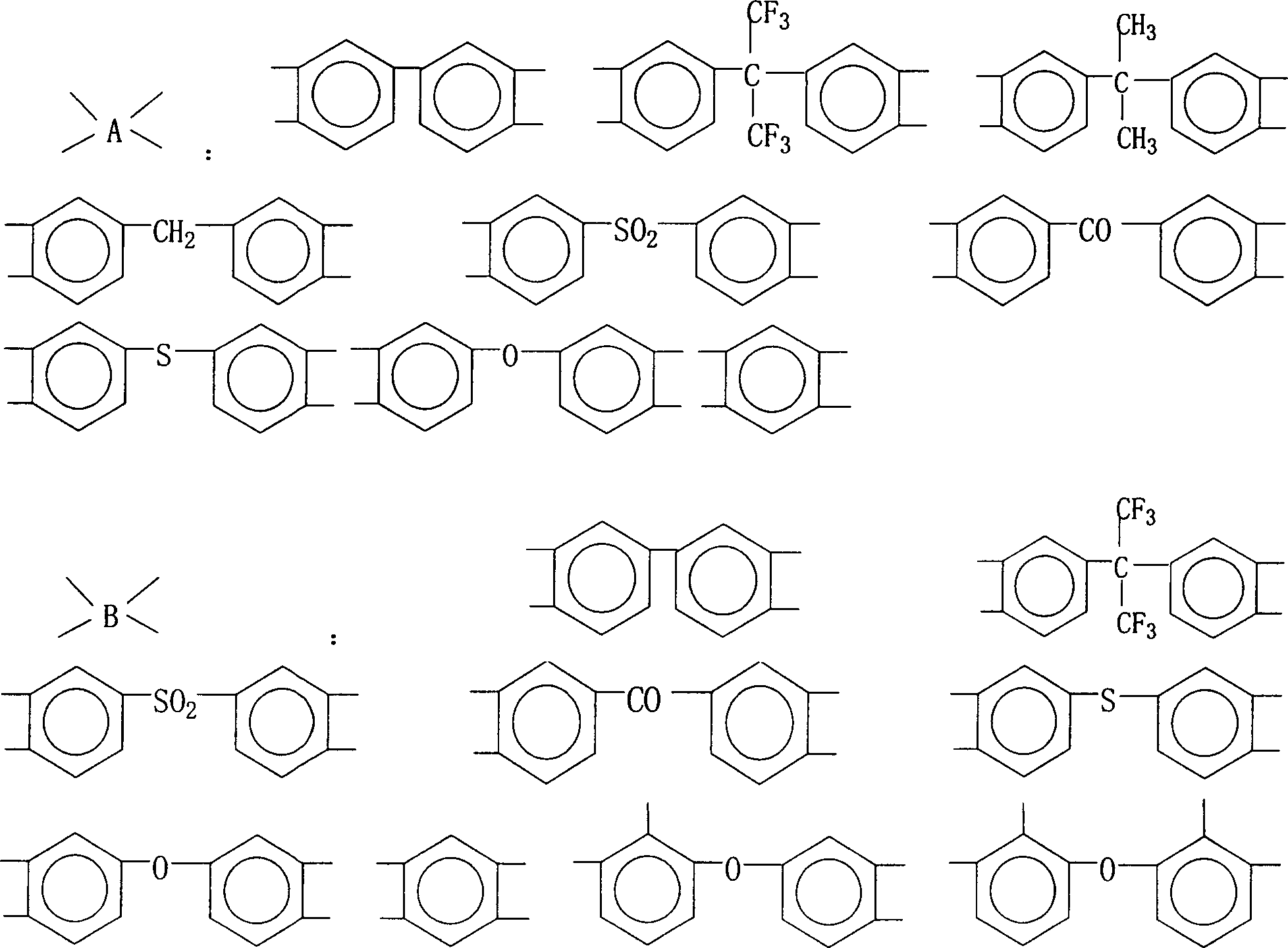

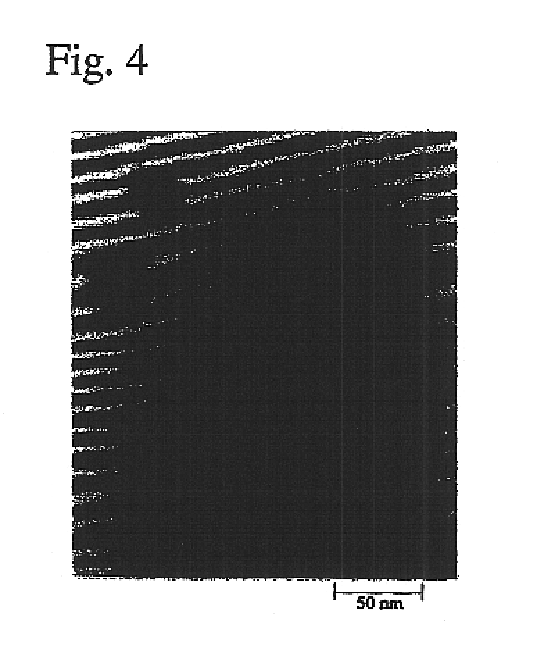

A phosphor of which emission wavelength can be optionally set in a region with high human visual sensitivity to make it possible to enhance lumlinance in the region, and which has an excitation band for light in a wavelength region emitted from the aforesaid light emitting portion, a production method of the same, illumination and an LED using the aforesaid phosphor are provided. As raw materials, for example, Ca3N2, CaO, Al2O3, AlN, Si3N4, and SiO2 an Eu2O3 are prepared, and each of the raw material is weighed so that a mole ratio of each element is, for example, (Ca, Eu): Al: Si=1:1:1, mixed and prepared under a nitrogen atmosphere, fired at 1500° C. under the nitrogen atmosphere to obtain a main production phase of a phosphor expressed by CaAlSiN3:Eu, and by controlling a compounding amount of each raw material at the time of raw material preparation, the oxygen concentration in the constitution of the production phase and mol concentration of Eu doping are controlled to optionally set the emission wavelength of the production phase.

Owner:NICHIA CORP

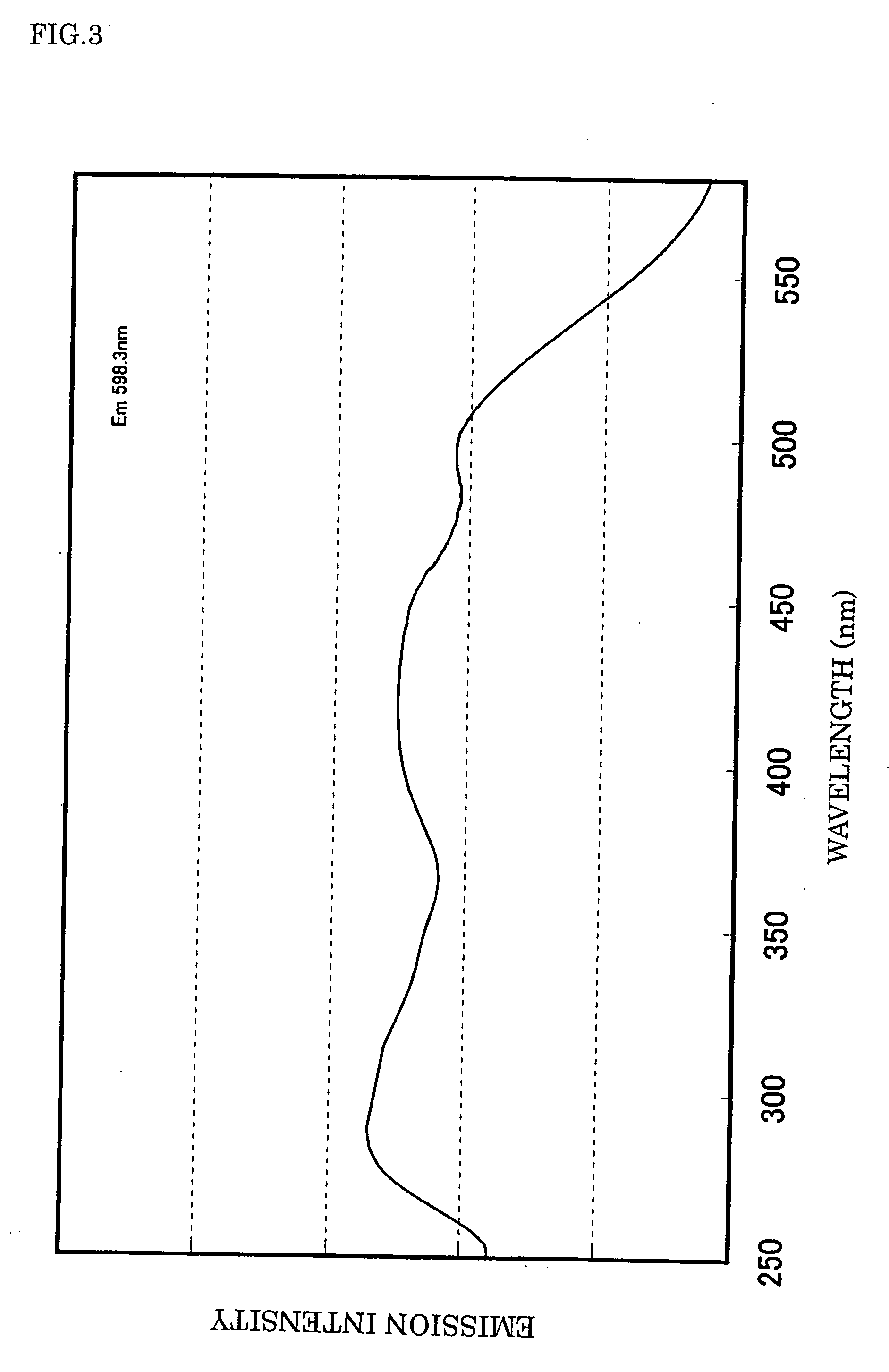

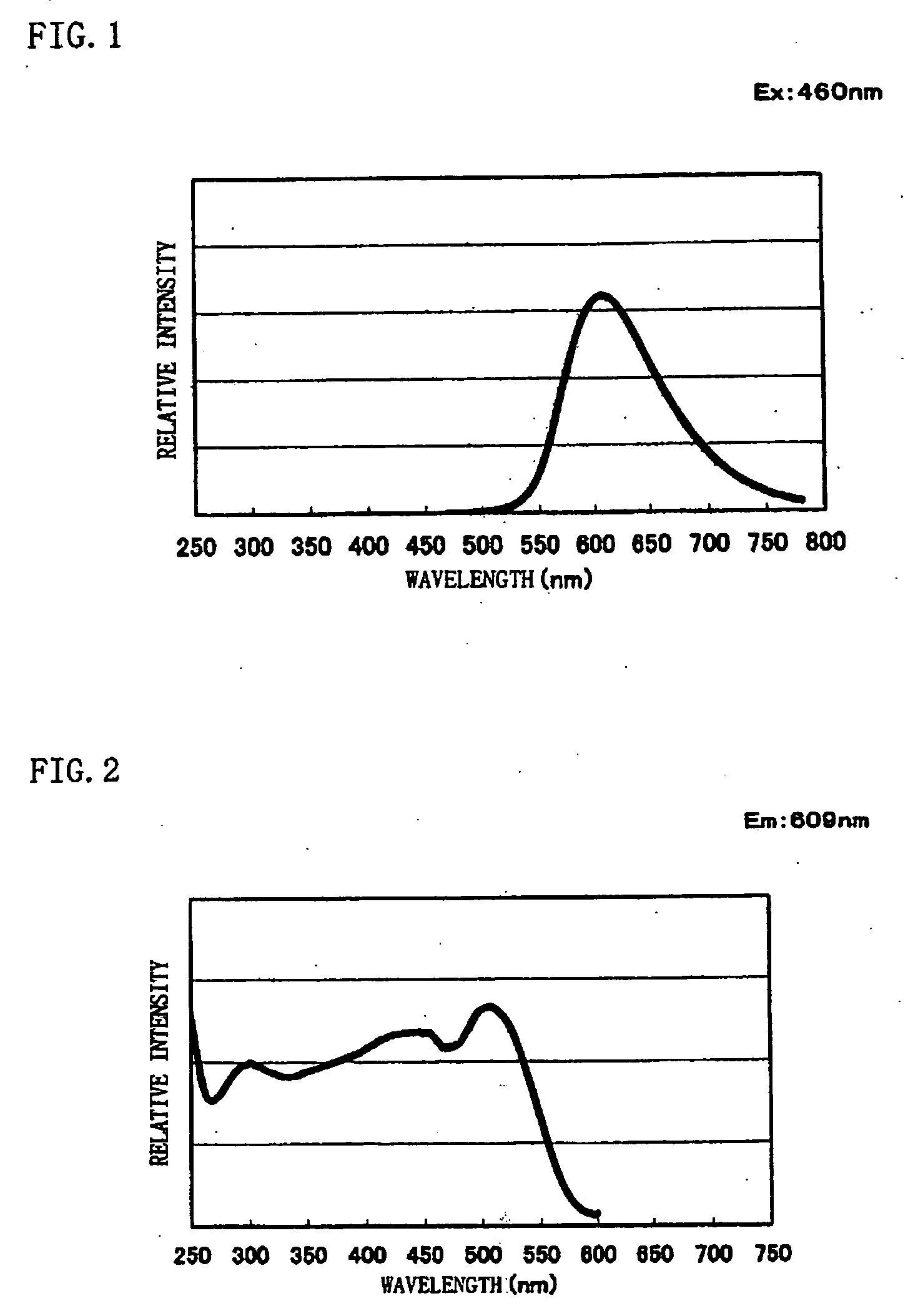

Phosphor and manufacturing method therefore, and light source using the phosphor

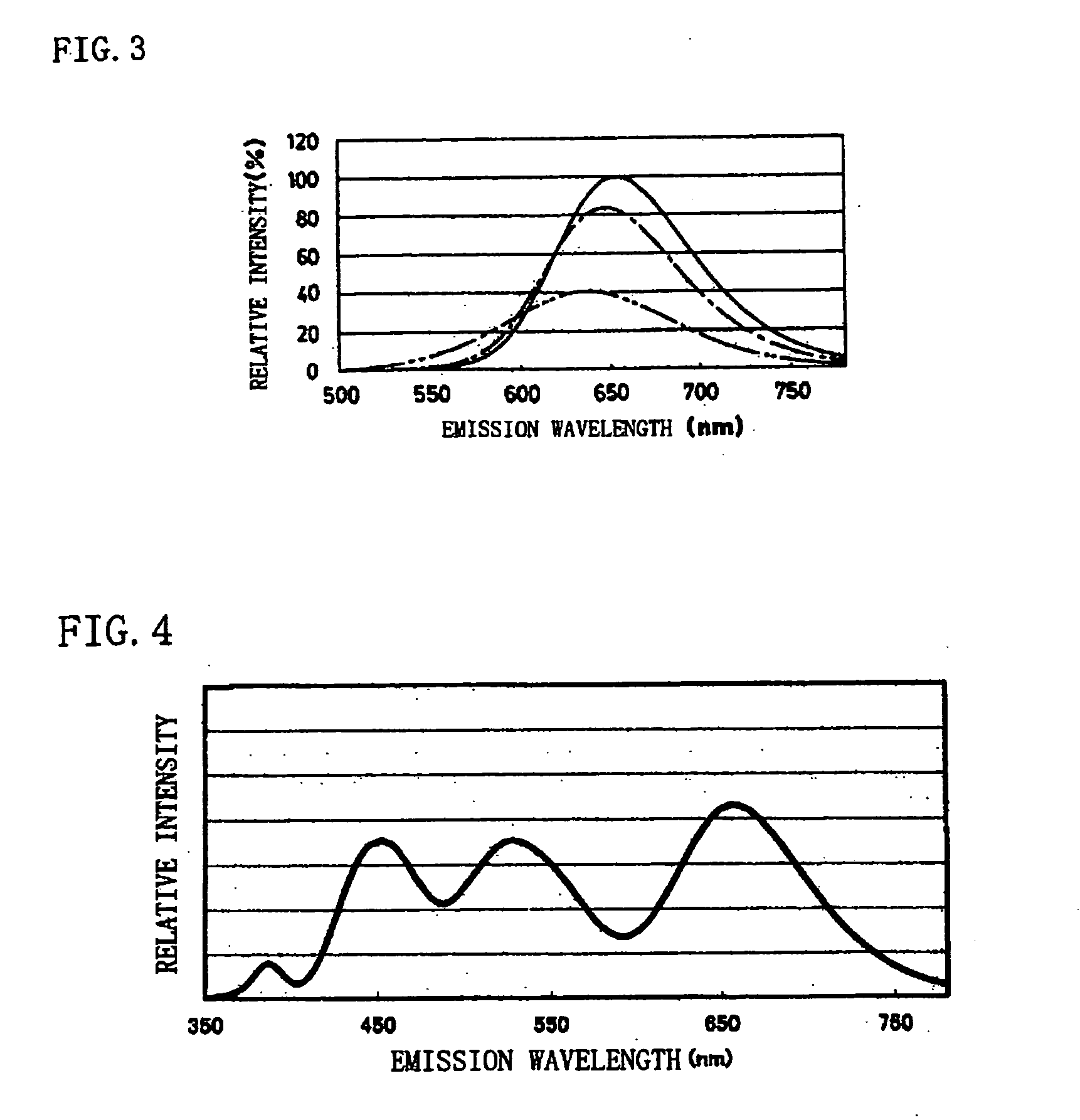

ActiveUS20060043337A1Increase intensityHigh luminanceDischarge tube luminescnet screensLamp detailsLuminous intensityUltraviolet

To provide a phosphor having a broad emission spectrum with a peak in the range from yellow color to red color (wavelength from 570 nm to 620 nm), having a flat excitation band with large area on the long wavelength side from near ultraviolet / ultraviolet to green color (wavelength from 250 nm to 550 nm), and excellent in emission intensity and luminance, and a method of manufacturing the same, and also a light source such as white LED using the phosphor. As raw materials, Ca3N2(2N), AlN(3N), Si3N4(3N), and Eu2O3(3N) are prepared, and out of each raw material, 0.950 / 3 mol of Ca3N2. 2 mol of AlN, 4 / 3 mol of Si3N4, and 0.050 / 2 mol of Eu2O3 are weighed, and the raw materials thus weighed are mixed by using a mortar. The raw materials thus mixed are put in a BN crucible, and retained / fired for 3 hours at 1700° C. in a nitrogen atmosphere, and thereafter cooled from 1700° C. to 200° C., to thereby obtain the phosphor expressed by a composition formula Ca0.950Al2Si4O0.075N7.917:Eu0.050.

Owner:NICHIA CORP +1

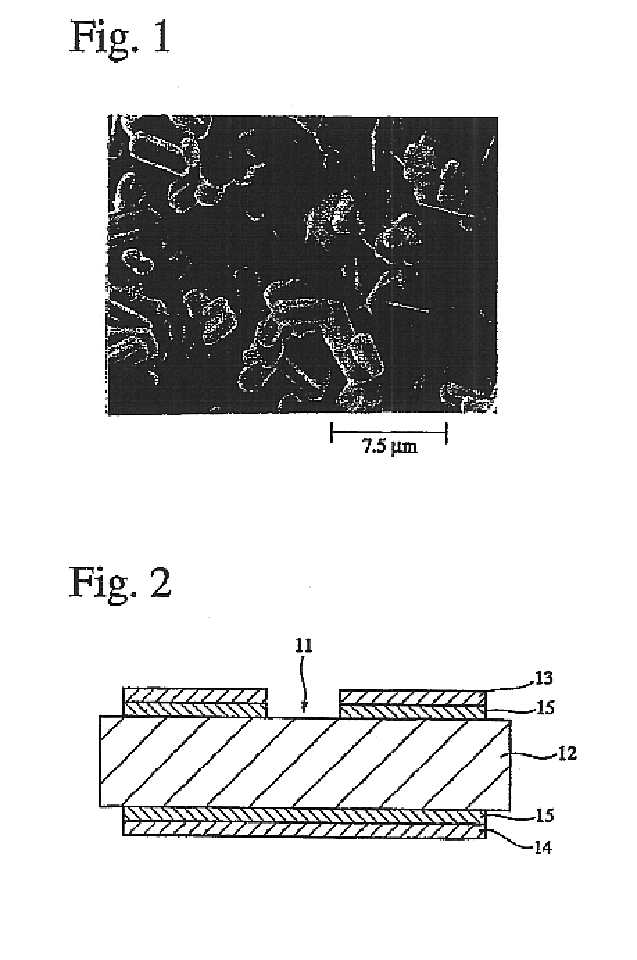

Silicon nitride powder, silicon nitride sintered body, sintered silicon nitride substrate, and circuit board and thermoelectric module comprising such sintered silicon nitride substrate

InactiveUS6846765B2High mechanical strengthImprove thermal conductivityNitrogen compoundsSemiconductor/solid-state device detailsRare-earth elementNitrogen atmosphere

A silicon nitride sintered body comprising Mg and at least one rare earth element selected from the group consisting of La, Y, Gd and Yb, the total oxide-converted content of the above elements being 0.6-7 weight %, with Mg converted to MgO and rare earth elements converted to rare earth oxides RExOy. The silicon nitride sintered body is produced by mixing 1-50 parts by weight of a first silicon nitride powder having a particle ratio of 30-100%, an oxygen content of 0.5 weight % or less, an average particle size of 0.2-10 μm, and an aspect ratio of 10 or less, with 99−50 parts by weight of α-silicon nitride powder having an average particle size of 0.2-4 μm; and sintering the resultant mixture at a temperature of 1,800° C. or higher and pressure of 5 atm or more in a nitrogen atmosphere.

Owner:HITACHI METALS LTD

Phosphor, light source and LED

InactiveUS7252788B2Reduce lightIncrease brightnessDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorUltraviolet lights

A phosphor with high efficiency having an excitation band corresponding to light of the ultraviolet-visible (300 to 550 nm) wavelength region emitted from a light emitting portion which emits blue or ultraviolet light is provided. A nitride of Ca, a nitride of Al, a nitride Si, and an oxide of Eu are prepared, and respective raw materials are weighed so that a mol ratio of respective elements becomes Ca:Al:Si:Eu=0.985:3:1:0.015, mixed under a nitrogen atmosphere, and thereafter fired at 1500° C. in a nitrogen atmosphere to thereby produce a phosphor having a composition formula Ca0.985SiAlN3:Eu0.015.

Owner:NICHIA CORP

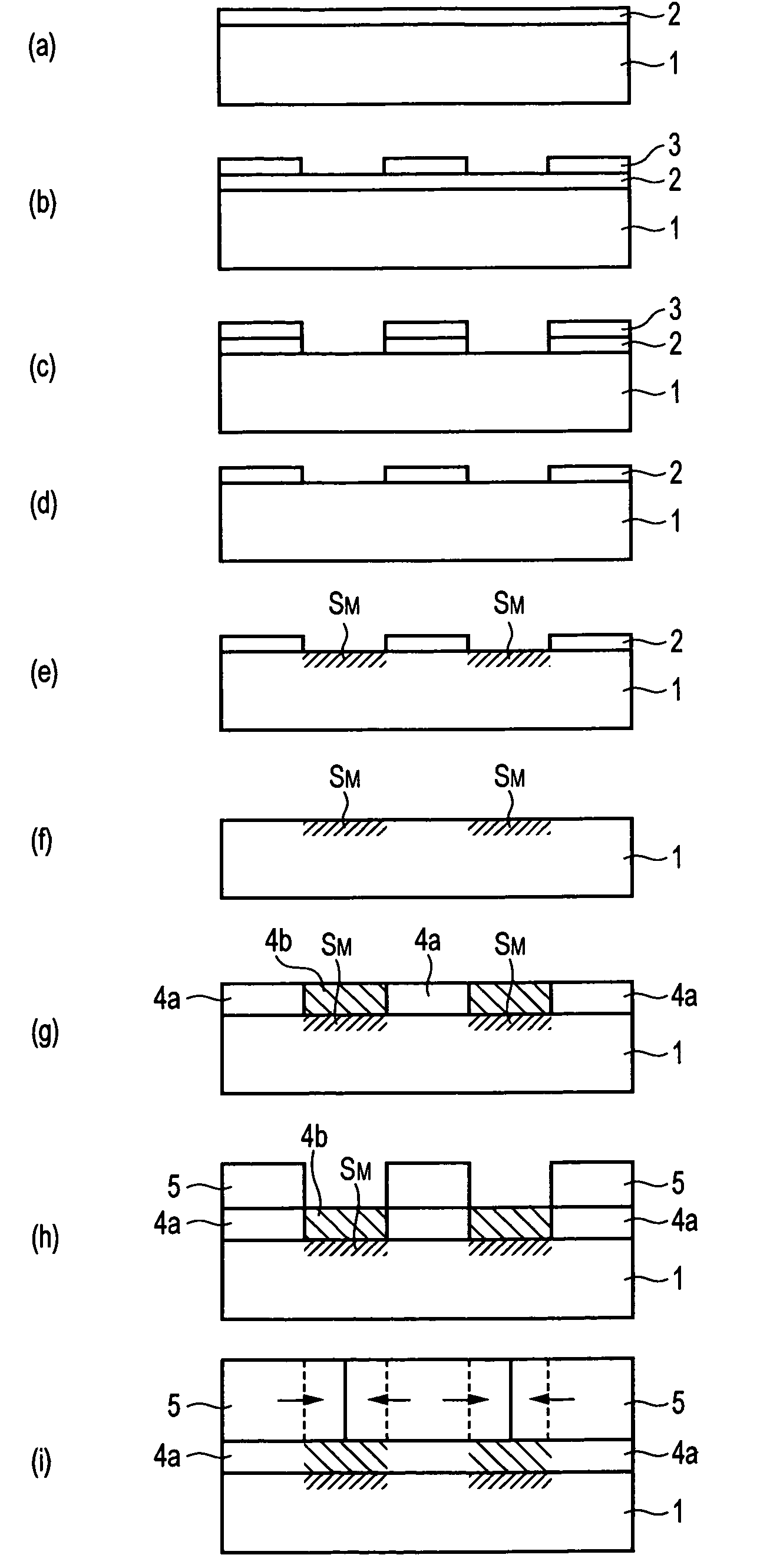

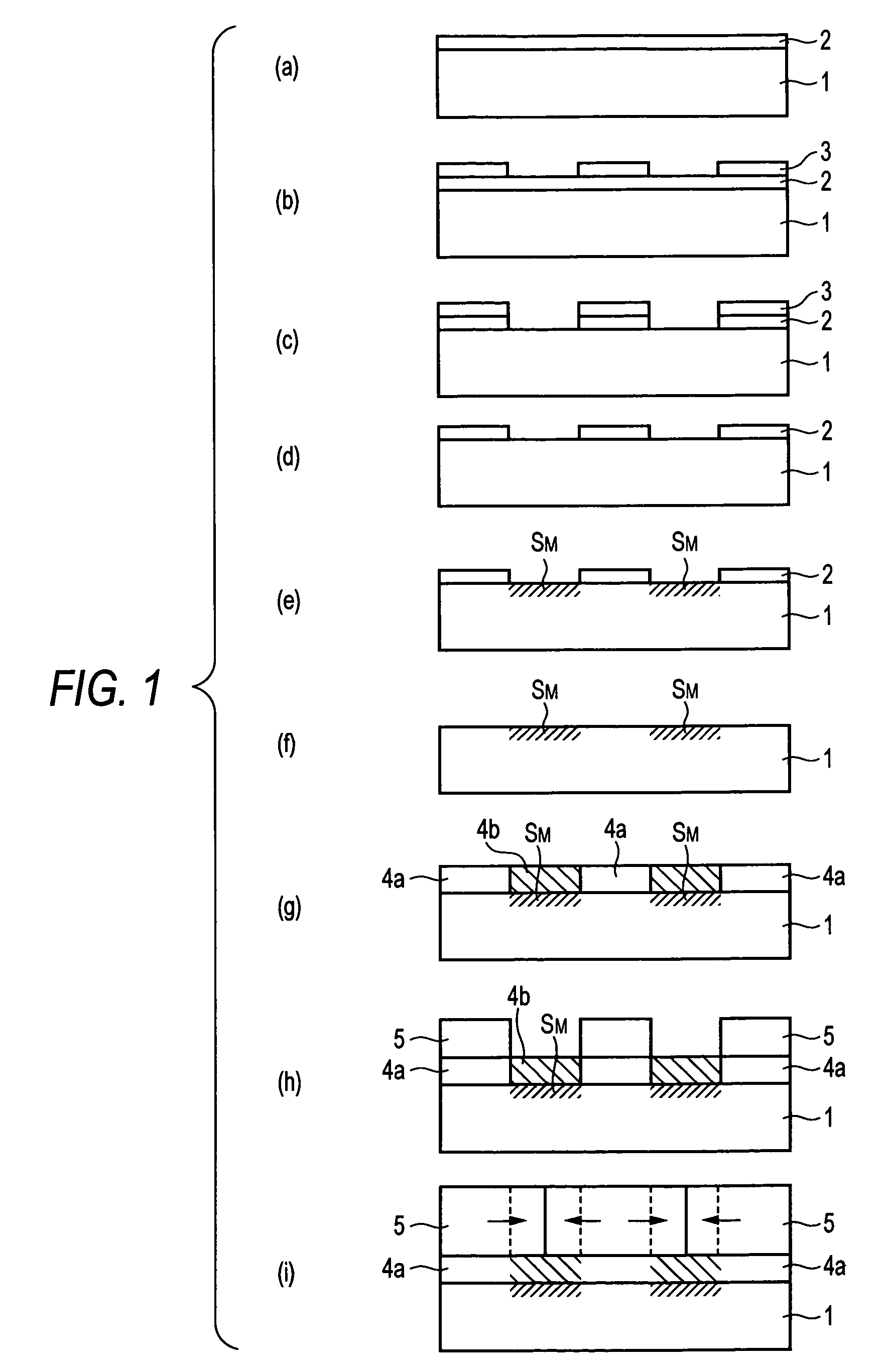

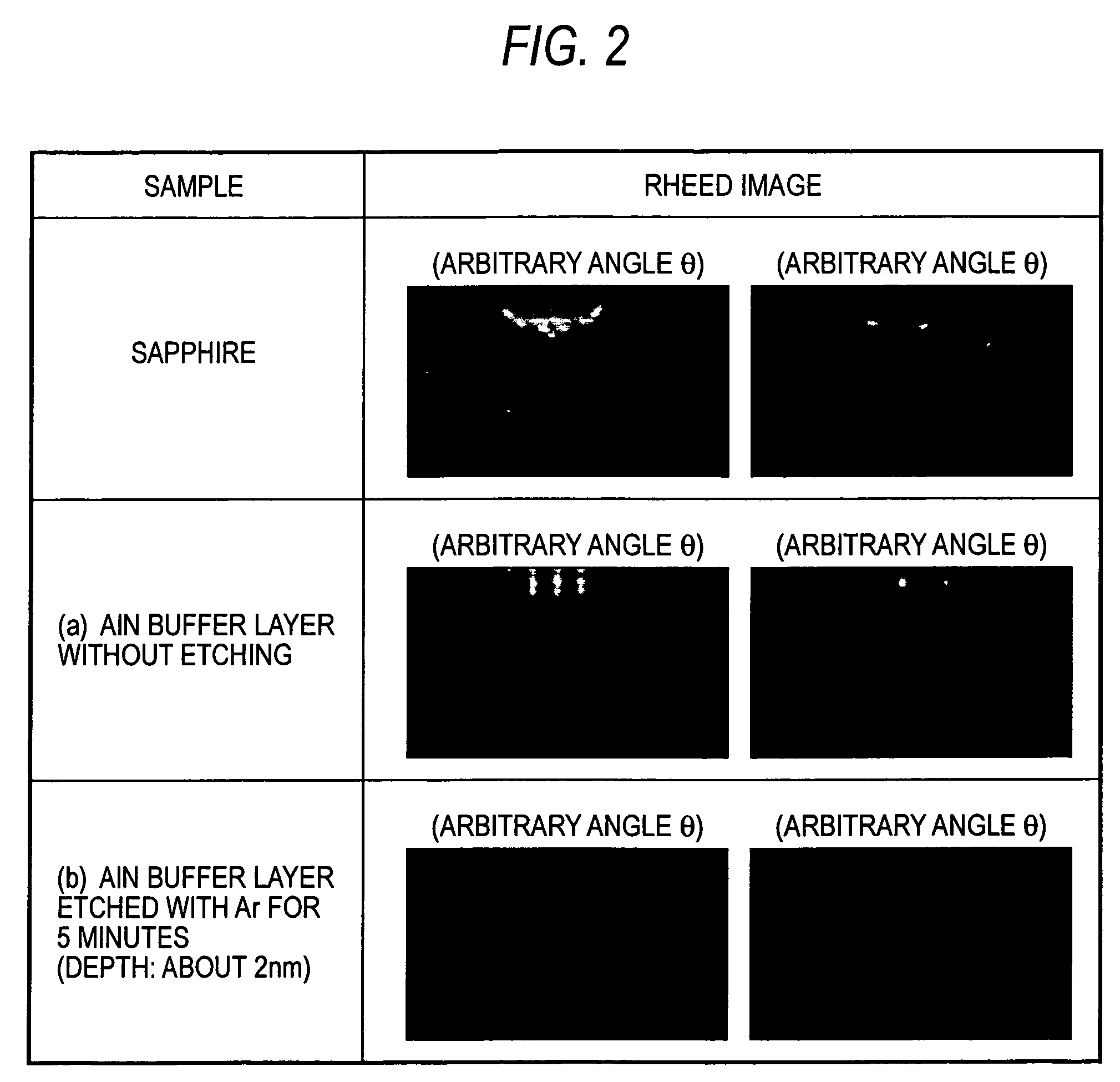

Process for producing group III nitride compound semiconductor

InactiveUS20050118825A1Efficient productionPolycrystalline material growthDecorative surface effectsNitrogen atmosphereAdemetionine

A method including the steps of: modifying at least one part of a sapphire substrate by dry etching to thereby form any one of a dot shape, a stripe shape, a lattice shape, etc. as an island shape on the sapphire substrate; forming an AlN buffer layer on the sapphire substrate; and epitaxially growing a desired Group III nitride compound semiconductor vertically and laterally so that the AlN layer formed on a modified portion of the surface of the sapphire substrate is covered with the desirably Group III nitride compound semiconductor without any gap while the AlN layer formed on a non-modified portion of the surface of the sapphire substrate is used as a seed, wherein the AlN buffer layer is formed by means of reactive sputtering with Al as a target in an nitrogen atmosphere.

Owner:TOYODA GOSEI CO LTD

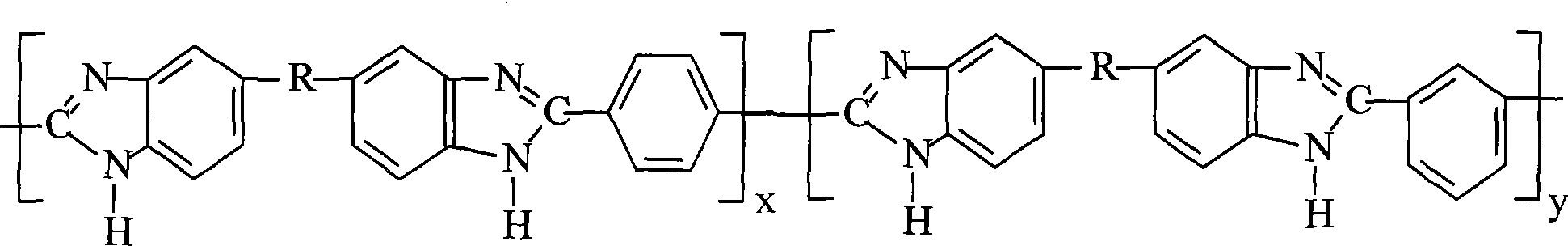

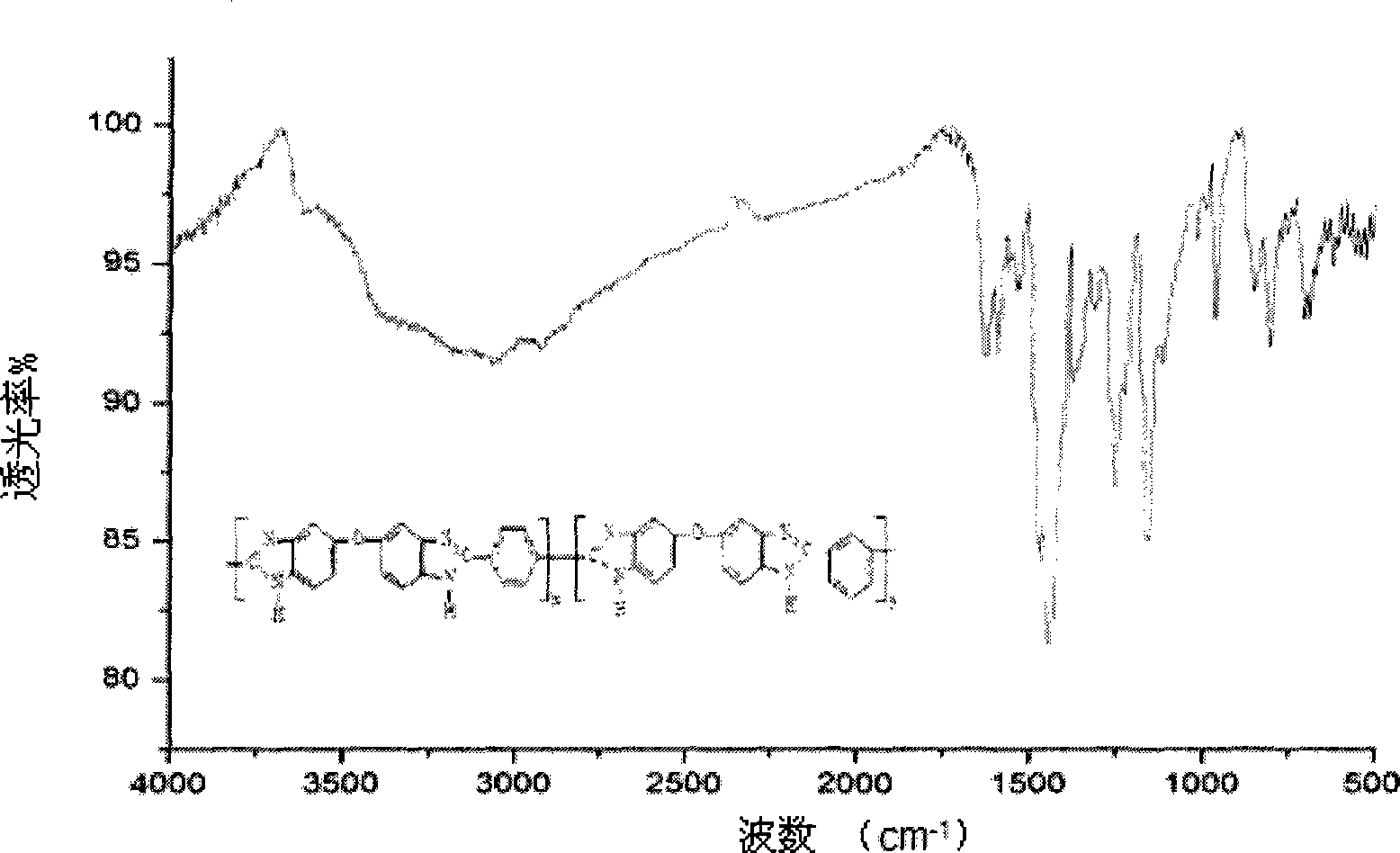

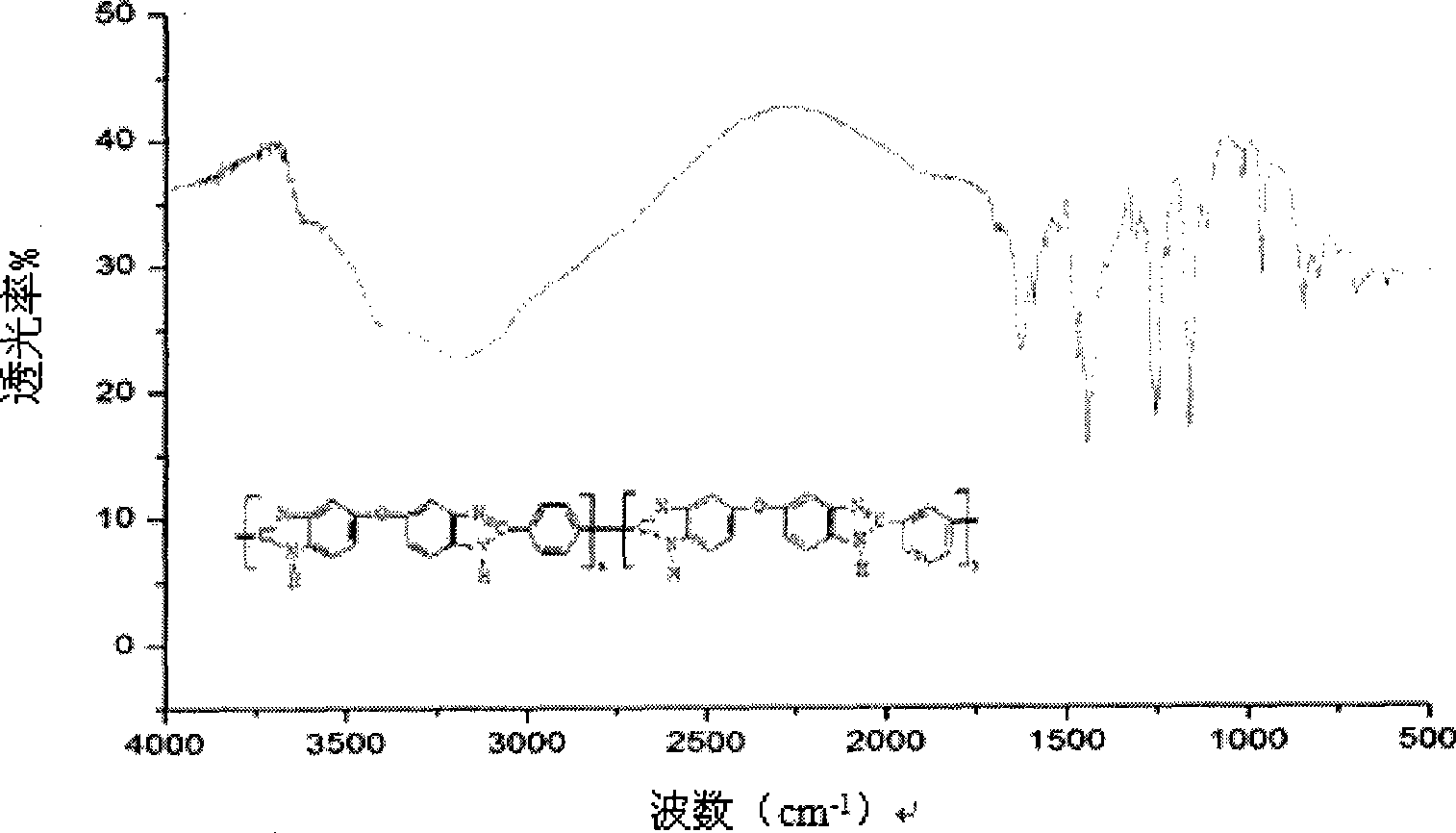

Method for preparing aromatic polybenzimidazole resin film

InactiveCN101456964AHigh molecular weightImprove thermal stabilitySemi-permeable membranesCell component detailsSolubilityNitrogen gas

The invention relates to a preparation method for aromatic series polybenzimidazole resin film, comprising: (1) under function of polyphosphoric acid / phosphorus pentoxide system, condensation polymerization reaction is carried out to aromatic series amine and aromatic series dicarboxylic acids mixed according to mol ratio of 1:1 in nitrogen atmosphere; (2) after cooling, polymer is poured into water and broken down into powder in a resin pulper and washed over and over again by distilled water and soaked for 48 hours in NaHCO3 solution and washed till pH value shows neutral and drawn and filtered for drying in vacuum; (3) the polymer dried is dissolved in even solution prepared by organic solvent with mass percent of 5 percent, and then is dried at temperature of 130 DEG C for 12 hours, and is soaked in hot water for boiling and striping, and is dried in vacuum at temperature of 100 DEG C for 5 hours and then is obtained. The polybenzimidazole prepared by the invention has the advantages of big molecule weight, stable thermal stability, fine solubility and film forming performance, etc. The preparation has simple technology, low cost, convenient operation and can be finished in common equipments through preparation procedure.

Owner:DONGHUA UNIV

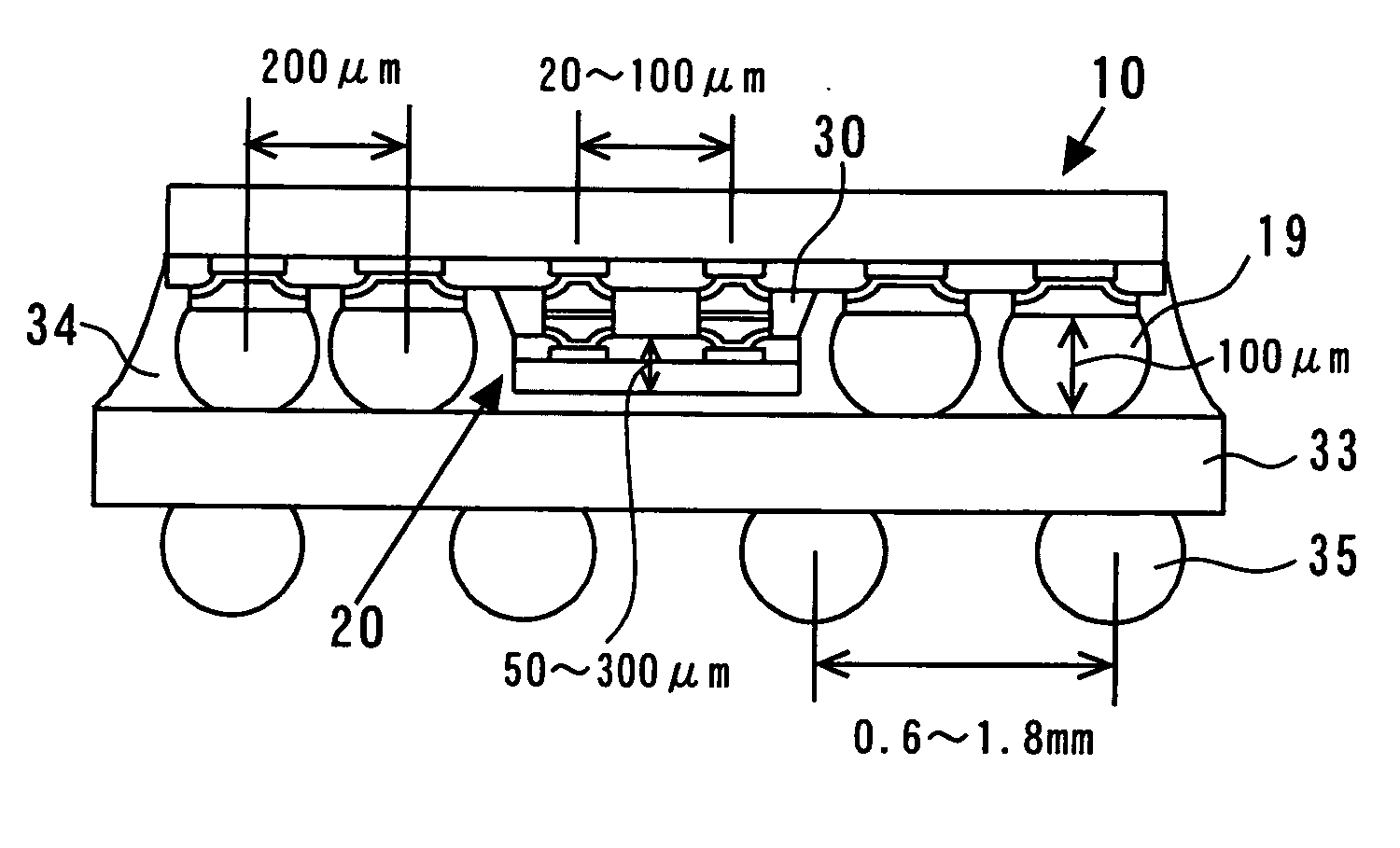

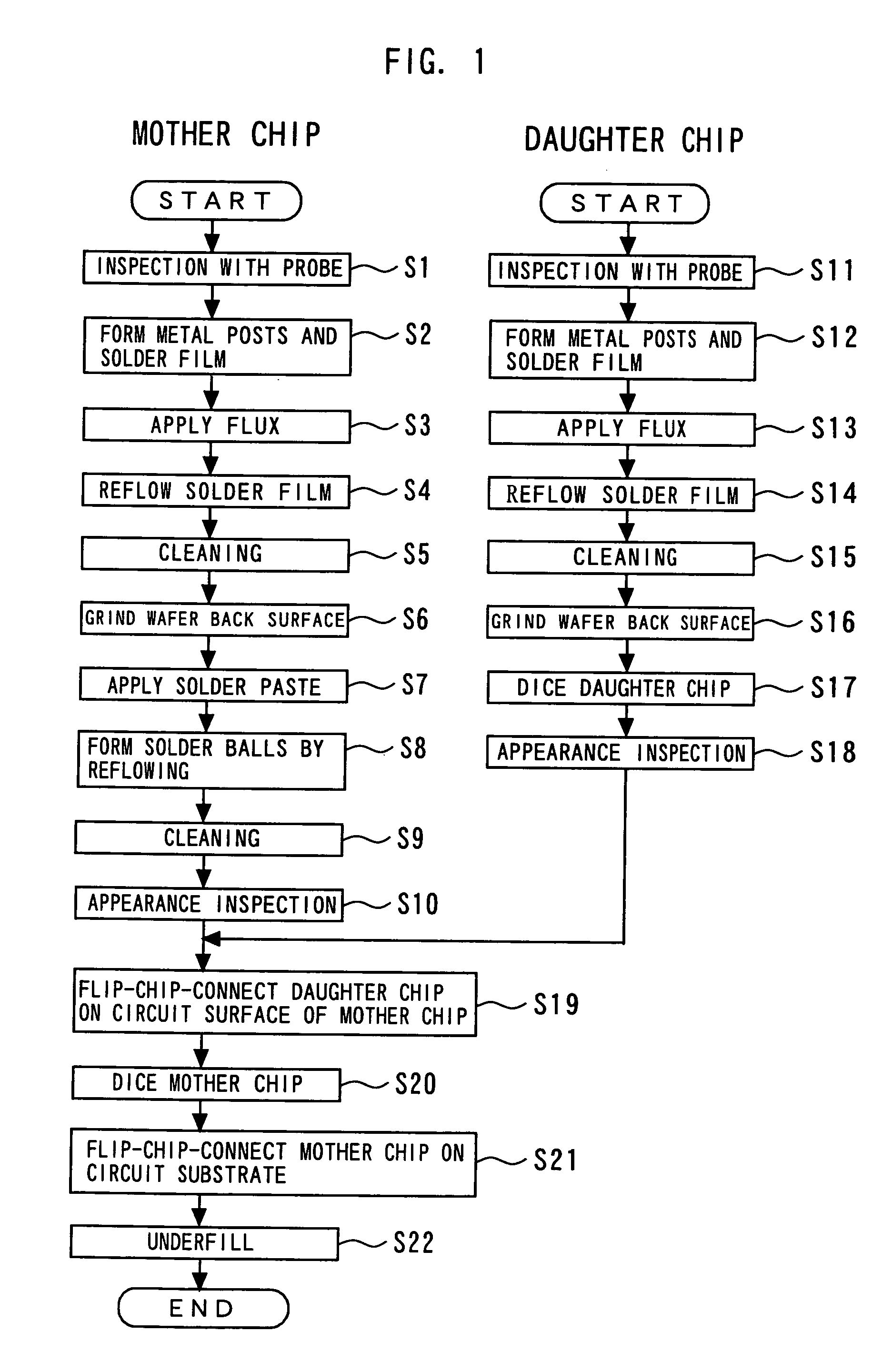

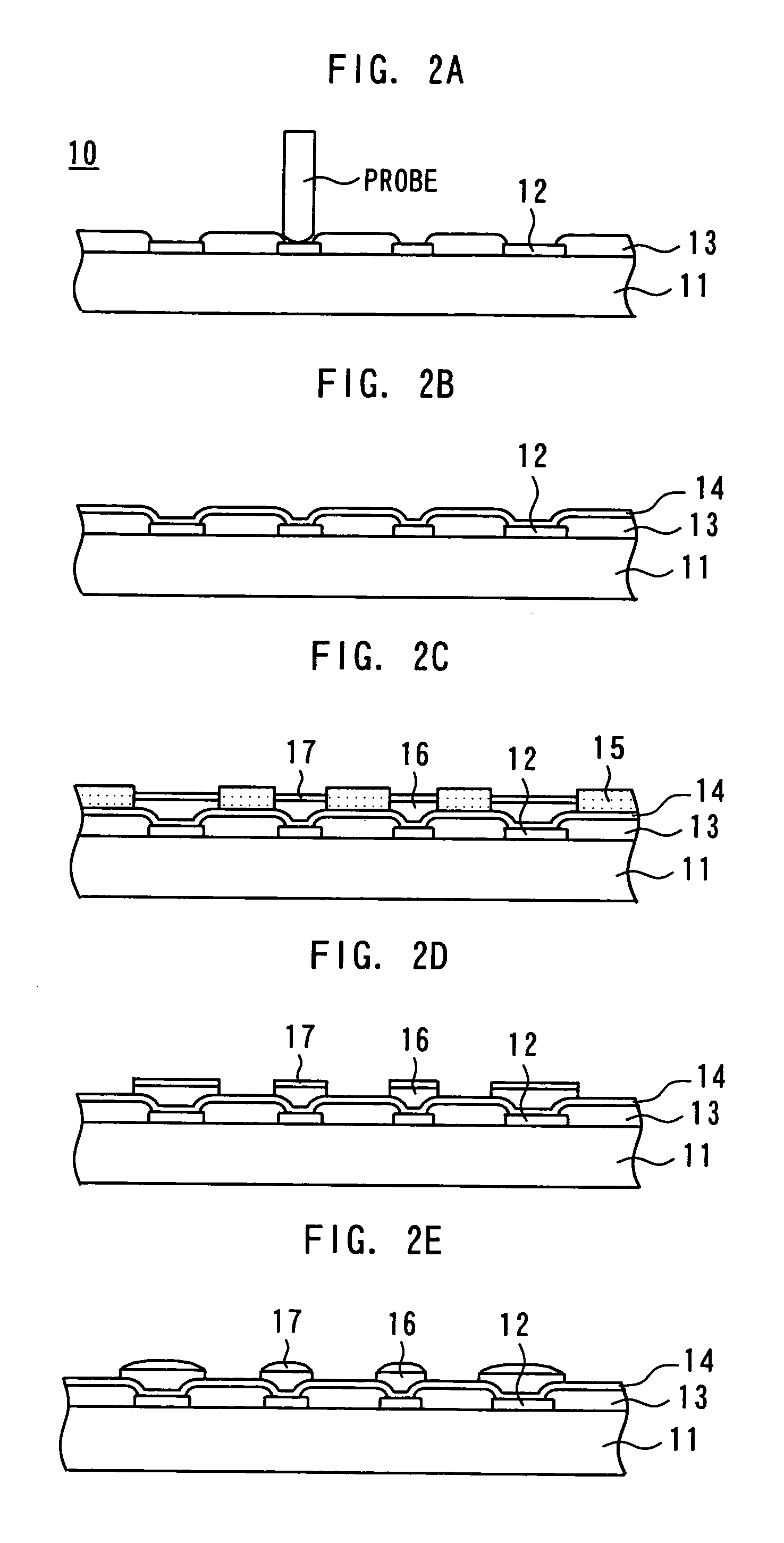

Method of manufacturing semiconductor device

InactiveUS20070141750A1Avoid connection failureSolid-state devicesSemiconductor/solid-state device manufacturingNitrogen atmosphereSolder ball

A method of manufacturing a semiconductor device includes a first step of forming solder film on metal posts of a mother chip, a second step of forming solder balls after the first step by printing a solder paste on the mother chip and heating the mother chip so that the solder paste is ref lowed, a third step of bonding the metal posts of the mother chip and metal posts of a daughter chip to each other in a thermocompression bonding manner by means of the solder film after the second step, and a fourth step of flip-chip-connecting the mother chip on a circuit substrate by using the solder balls. In the second step, the mother chip is heated in a nitrogen atmosphere in which the oxygen concentration is 500 ppm or less.

Owner:RENESAS ELECTRONICS CORP

Phosphor and production method of the same and light source and LED using the phosphor

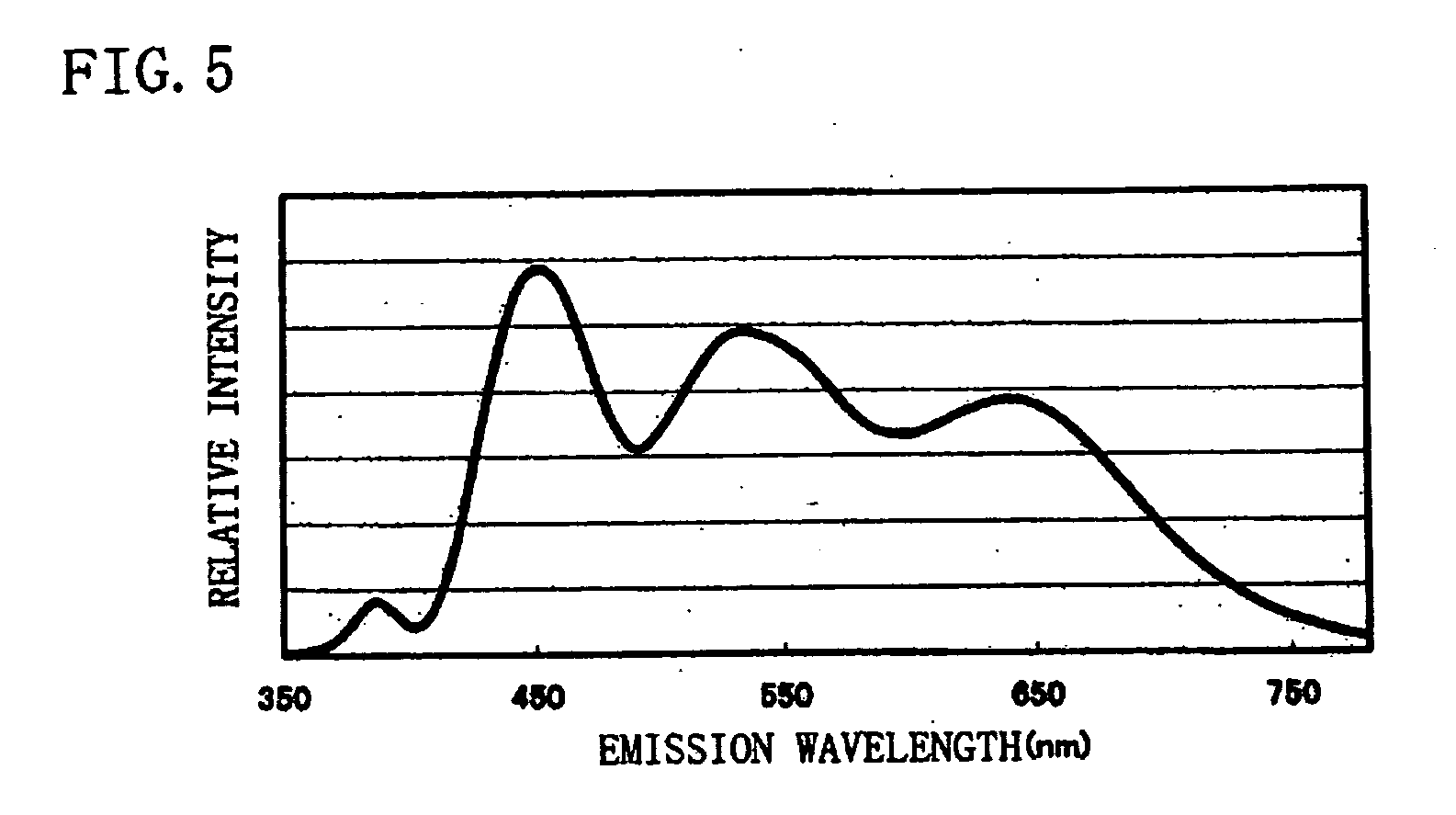

InactiveUS20050253500A1Long life-timeEasy to produceDischarge tube luminescnet screensElectroluminescent light sourcesFluorescencePhosphor

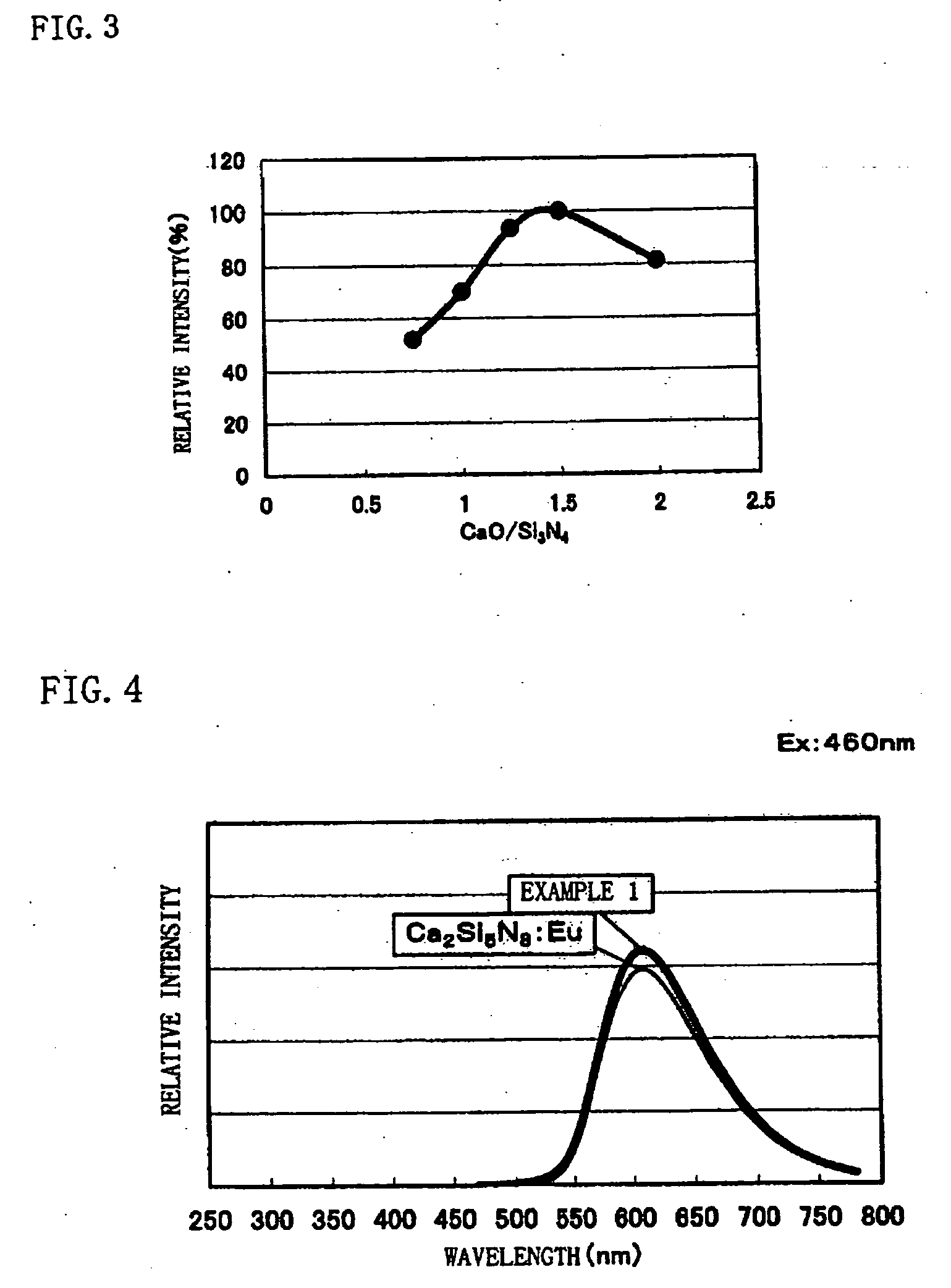

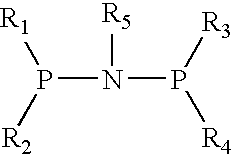

A phosphor with high efficiency having an excitation band corresponding to light of the ultraviolet-visible (300 to 550 nm) wavelength region emitted from a light emitting element which emits blue or ultraviolet light is provided. Commercially available CaO [3N], Si3N4 [3N], and Eu2O3 [3N] are prepared, respective materials are weighed and mixed to have a mol ratio of CaO:Si3N4:Eu2O3=1.4775:1:0.01125, and then the mixture is heated to 1600° C. by a heating rate of 15° C. / min under a nitrogen atmosphere and retained and fired at 1600° C. for three hours. Thereafter, the raw materials are cooled down from 1600° C. to 200° C. for an hour to thereby produce a phosphor having a composition formula Ca1.58Si3O1.63N4.35:Eu0.024.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Catalyst composition for ethylene oligomerization and the use thereof

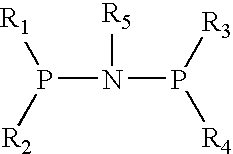

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

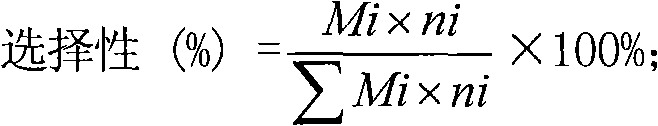

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

Silicon nitride powder, silicon nitride sintered body, sintered silicon nitride substrate, and circuit board and thermoelectric module comprising such sintered silicon nitride substrate

InactiveUS20020164475A1Improve thermal conductivityHigh mechanical strengthNitrogen compoundsSemiconductor/solid-state device detailsRare-earth elementNitrogen atmosphere

A silicon nitride sintered body comprising Mg and at least one rare earth element selected from the group consisting of La, Y, Gd and Yb, the total oxide-converted content of the above elements being 0.6-7 weight %, with Mg converted to MgO and rare earth elements converted to rare earth oxides RExOy. The silicon nitride sintered body is produced by mixing 1-50 parts by weight of a first silicon nitride powder having a beta-particle ratio of 30-100%, an oxygen content of 0.5 weight % or less, an average particle size of 0.2-10 mum, and an aspect ratio of 10 or less, with 99-50 parts by weight of alpha-silicon nitride powder having an average particle size of 0.2-4 mum; and sintering the resultant mixture at a temperature of 1,800° C. or higher and pressure of 5 atm or more in a nitrogen atmosphere.

Owner:HITACHI METALS LTD

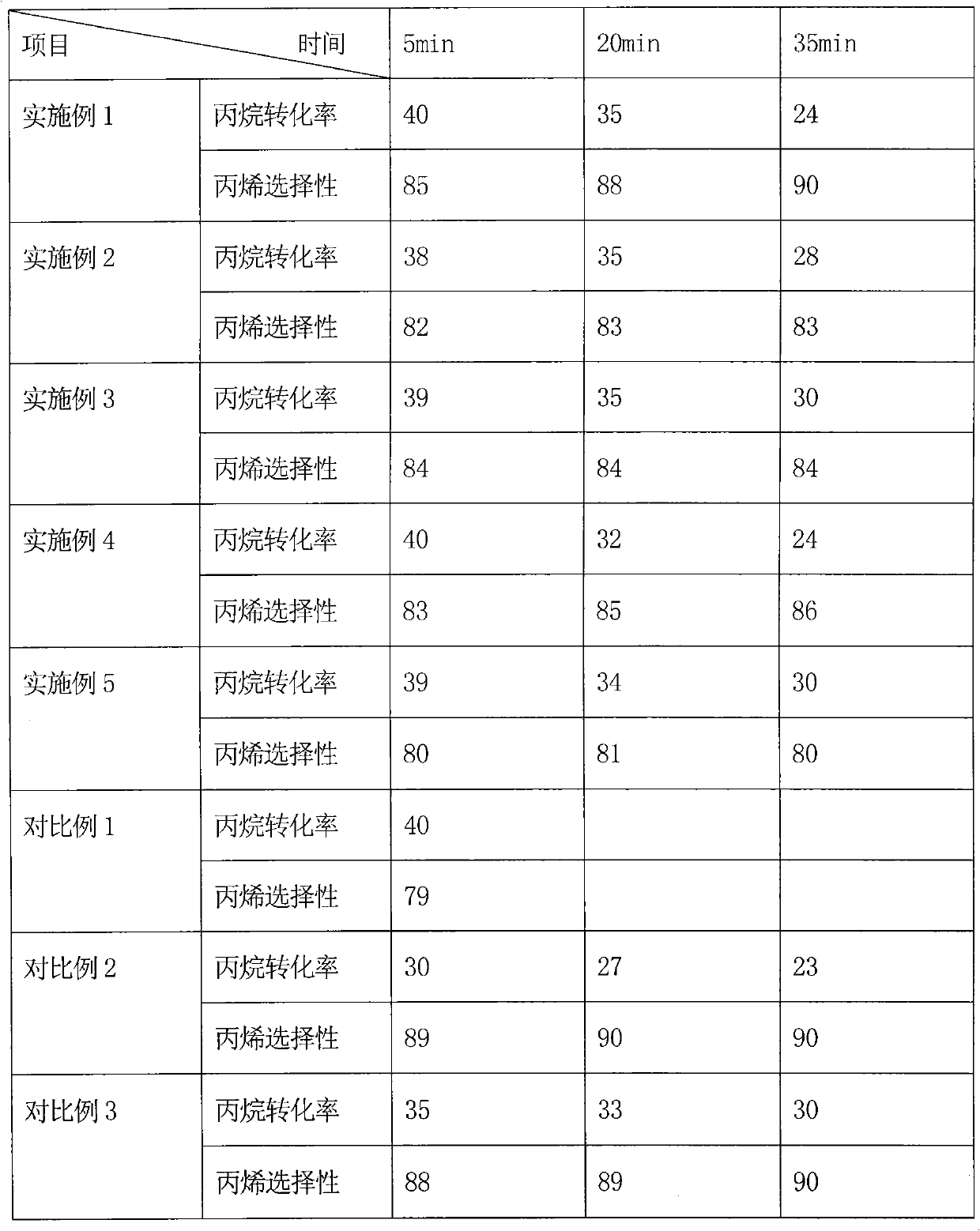

Propane dehydrogenation to propylene catalyst and preparation and applications thereof

InactiveCN102019178ALow costSimple methodCatalyst activation/preparationHydrocarbonsAir atmosphereAlkaline earth metal

The invention relates to a propane dehydrogenation to propylene catalyst and preparation and applications thereof. The propane dehydrogenation to propylene catalyst is characterized by being a composition prepared from Gamma-Al2O3, a kind or many kinds of chromium oxides, a kind or many kinds of rare earth oxides and a kind or many kinds of alkali metal oxides, wherein the Gamma-Al2O3 accounts for 30-95%, the chromium oxides account for 1-50%, the rare earth oxides account for 0-30%, and the alkali metal oxides account for 0-10%. The preparation process comprises the following steps of: adding active components, such as chromium, rare earth, alkali metal and the like into aluminum oxide grout, regulating the pH value of 1-5 to form gelatum with concentrated nitric acid, and spraying and drying to form microballoons; then roasting for 0-5 hours at 250-750 DEG C in a nitrogen atmosphere; and roasting for 0.1-20 hours at 250-1000 DEG C in an air atmosphere. The obtained catalyst is in a fluid bed reactor, and reaction conditions comprise 400-700 DEG C of temperature, 0.01-3MPa of absolute pressure and 10-10000 h-1 of volume hourly space velocity.

Owner:卓润生

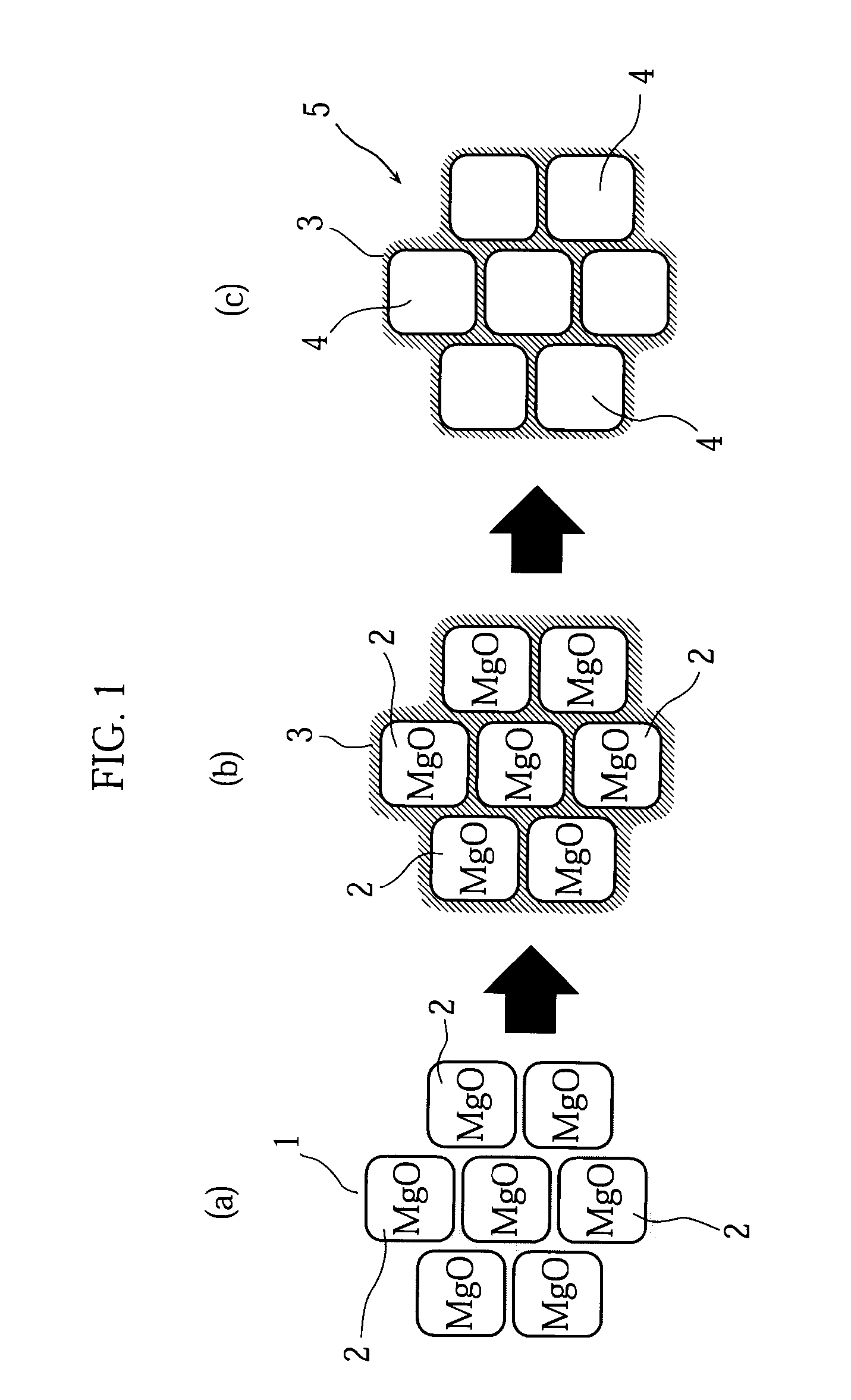

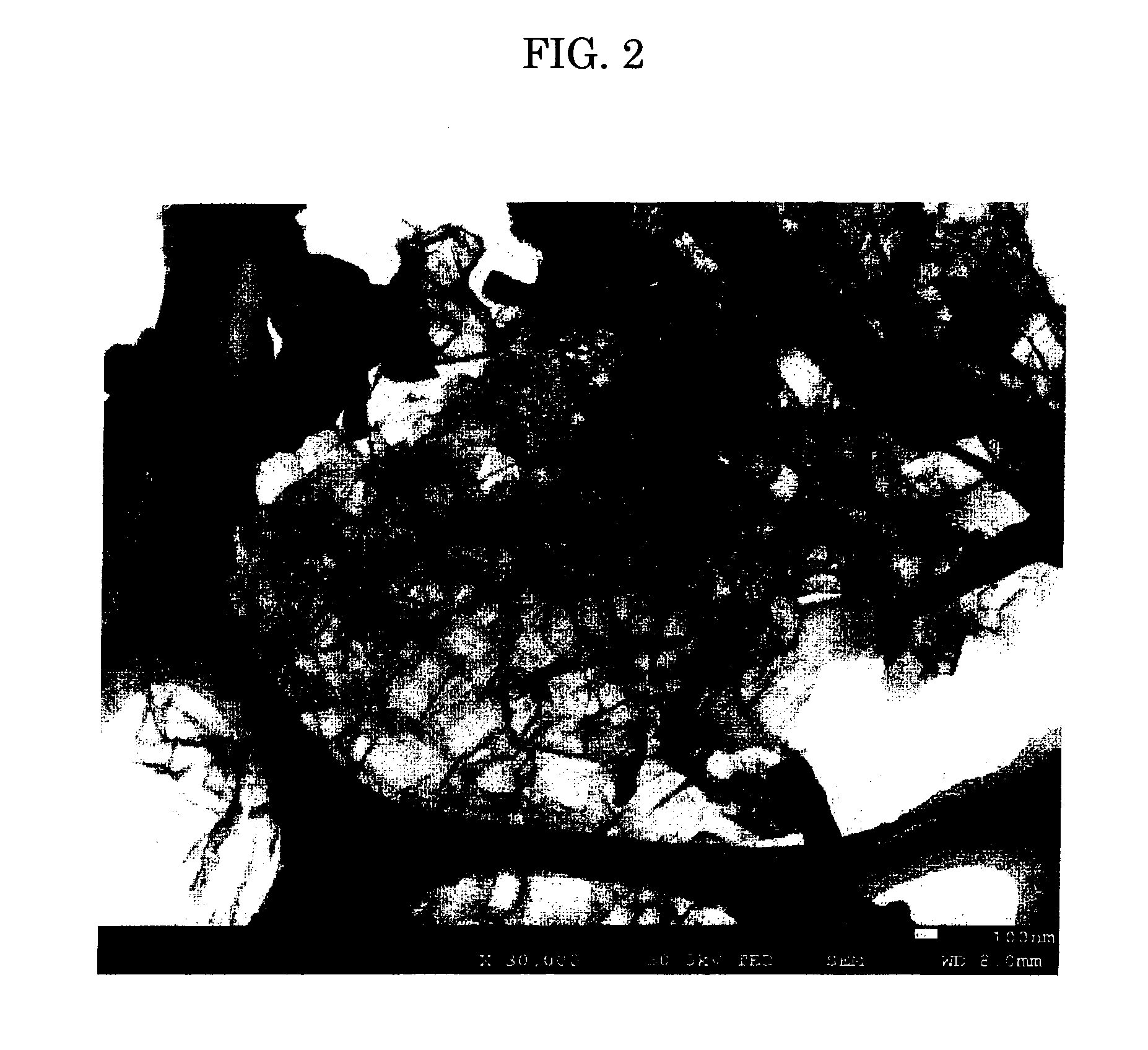

Porous carbon and method of manufacturing same

InactiveUS20110318254A1Pore diameter can be easilyEasy to controlMaterial nanotechnologyCarbon compoundsDecompositionPorous carbon

A porous carbon that retains a three-dimensional network structure and enables the pore diameters of mesopores and micropores to be controlled easily is provided. A method of manufacturing the porous carbon is also provided. The porous carbon is fabricated by mixing a polyamic acid resin 1 as a carbon precursor with magnesium oxide 2 as template particles, heat-treating the mixture in a nitrogen atmosphere at 1000° C. for 1 hour to cause the polyamic acid resin to undergo heat decomposition, and washing the resultant sample with a sulfuric acid solution at a concentration of 1 mol / L to dissolve MgO away.

Owner:TOYO TANSO KK

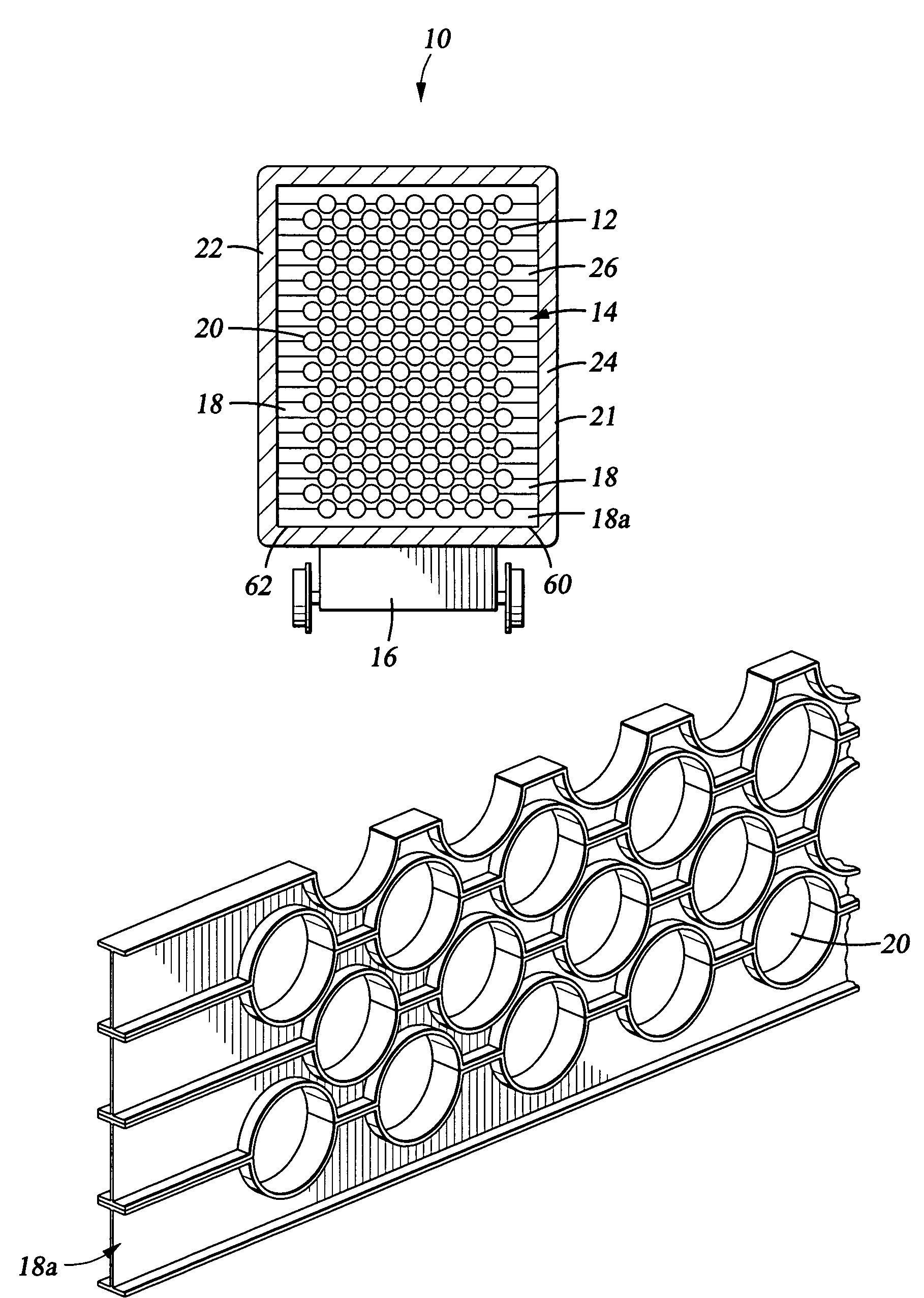

Modular system for storing gas cylinders

InactiveUS6994104B2High procedureIncrease profitabilitySolidificationLiquefactionSystems designGas cylinder

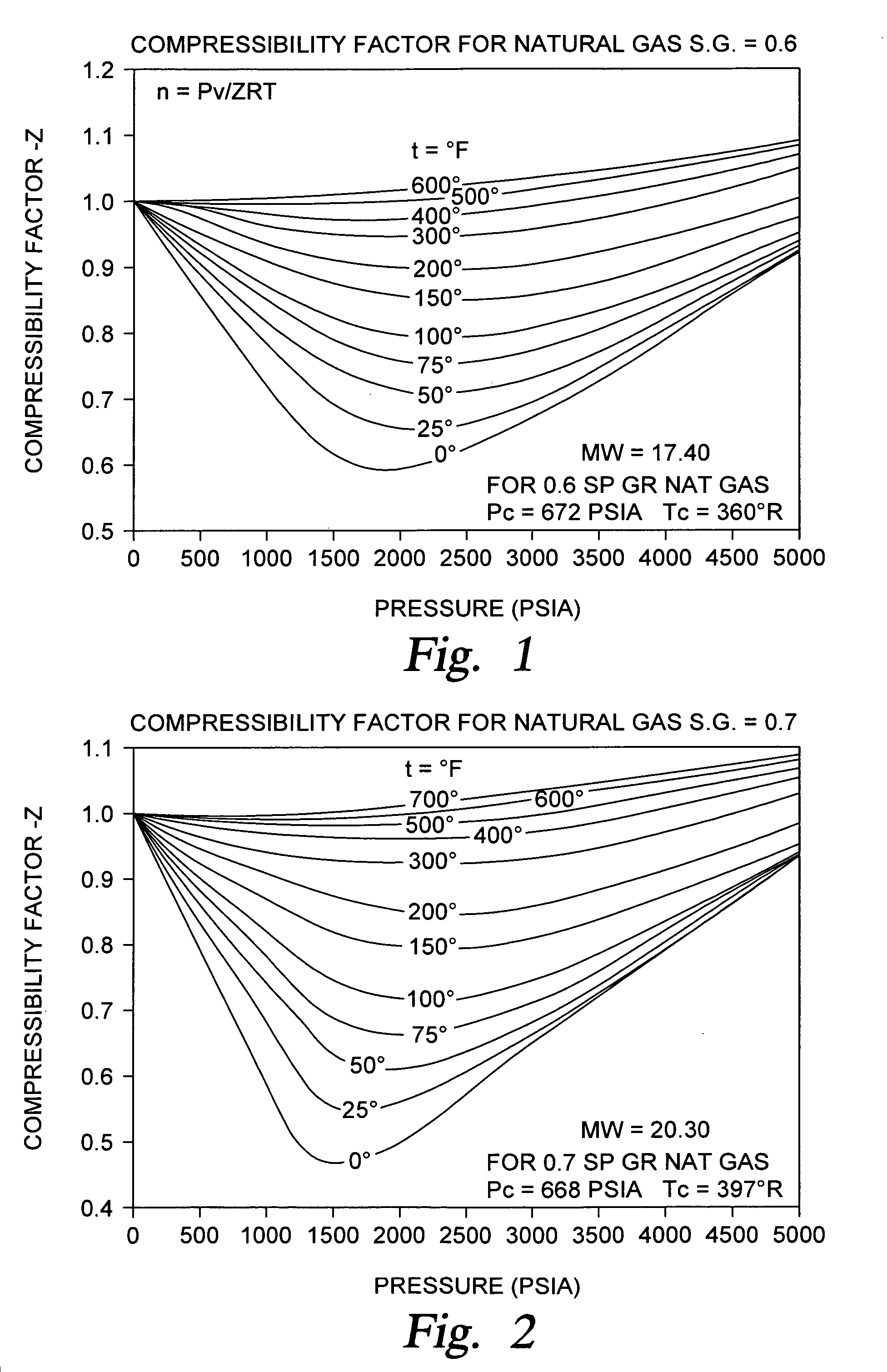

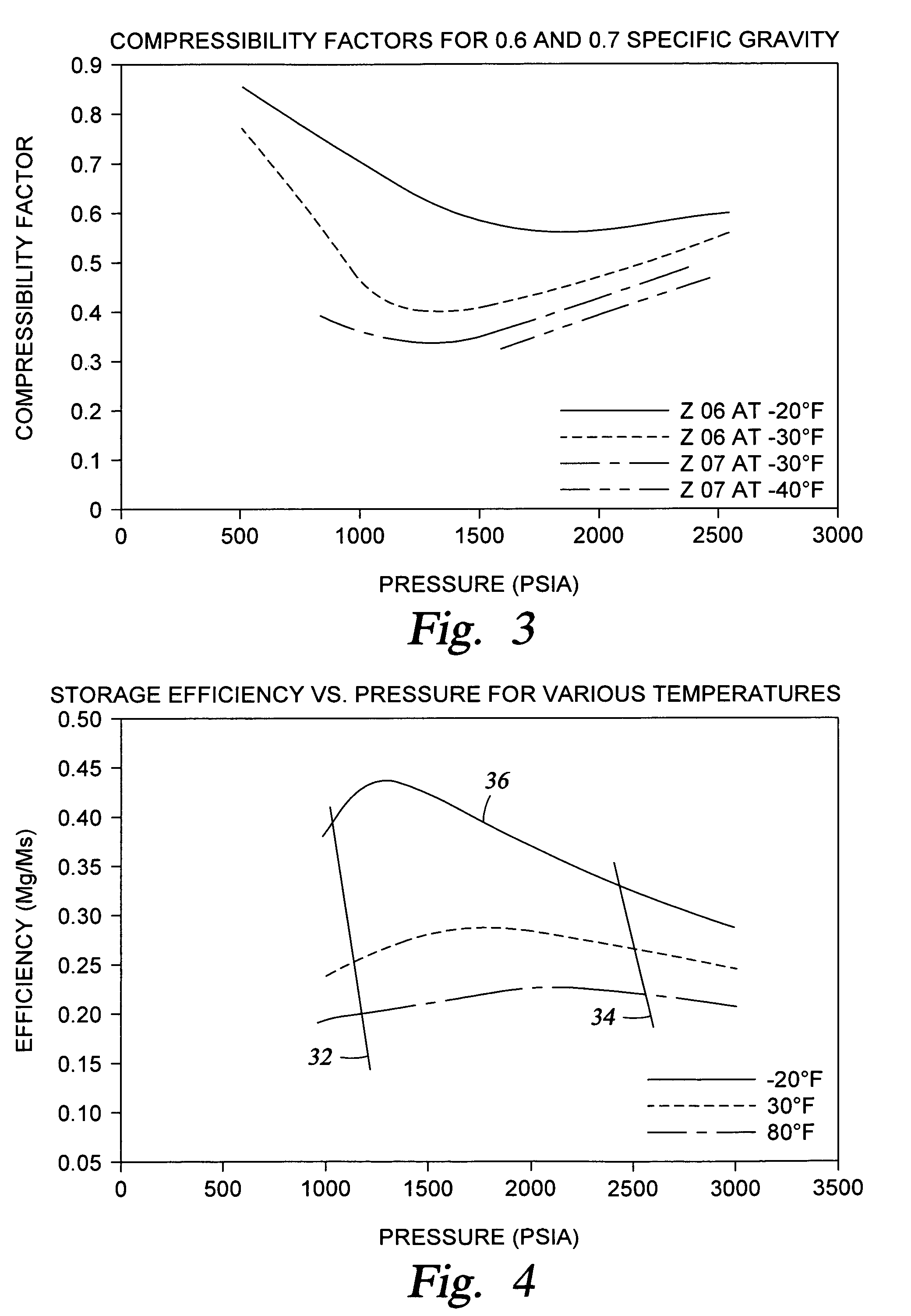

The methods and apparatus for transporting compressed gas includes a gas storage system having a plurality of pipes connected by a manifold whereby the gas storage system is designed to operate in the range of the optimum compressibility factor for a given composition of gas. The pipe for the gas storage system is preferably large diameter pipe made of a high strength material whereby a low temperature is selected which can be withstood by the material of the pipe. Knowing the compressibility factor of the gas, the temperature, and the diameter of the pipe, the wall thickness of the pipe is calculated for the pressure range of the gas at the selected temperature. The gas storage system may either be modular or be part of the structure of a vehicle for transporting the gas. The gas storage system further includes enclosing the pipes in an enclosure having a nitrogen atmosphere. A displacement fluid may be used to offload the gas from the gas storage system. A vehicle with the gas storage system designed for a particular composition gas produced at a given location is used to transport gas from that producing location to a receiving station miles from the producing location.

Owner:ENERSEA TRANSPORT

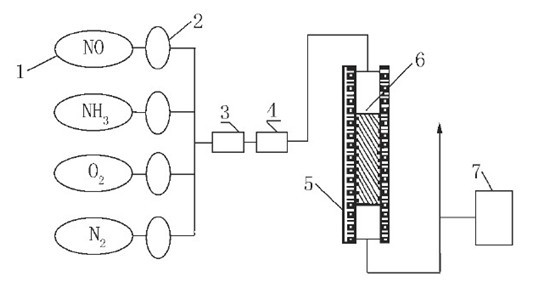

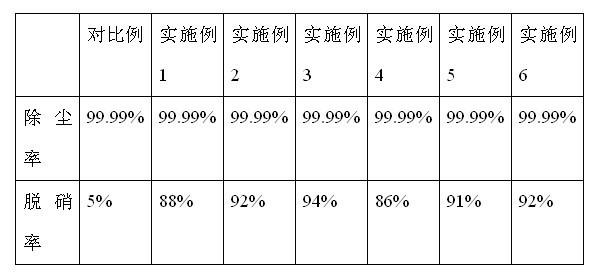

Preparation method of denitration-catalyst-supported polyphenylene sulfide (PPS) filter material

InactiveCN102145241AImprove denitrification rateImprove water resistanceDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsFiberPtru catalyst

The invention provides a supported polyphenylene sulfide (PPS) filter material which belongs to the field of filter materials. The supported PPS filter material is prepared by the following method: making a PPS fiber into a PPS filter material; performing water bath acidification in nitric acid, and washing with deionized water to neutrality; drying to obtain acidified polyphenylene sulfide nitride (PPSN); preparing a catalyst into a solution and stirring; soaking PPSN in the solution; performing water bath baking, and drying in air; and calcining in a nitrogen atmosphere to obtain the supported PPS filter material with denitration function. The denitration-catalyst-supported PPS filter material provided by the invention can be used as a dedusting agent and a denitration agent at the sametime, is prepared by simple steps, realizes dedusting and denitration functions as well, and has the advantages of high denitration rate, high temperature resistance, acid-base resistance, good waterresistance, long service life and the like; and a new application field of the filter-bag catalytic denitration is created.

Owner:FUZHOU UNIV

Method for preparing binder of polyimide of containing phenolic hydroxyl group

This invention discloses a method for preparing phenolic hydroxyl-containing polyimide adhesive. The method comprises: (1) reacting phenolic hydroxyl-containing aromatic diamine, or its mixture with other aromatic diamines, with aromatic dianhydride at a mol ratio of 1:1 in strongly polar non-proton organic solvent at 0-10 deg.C for 4-8 h to obtain uniform, transparent and viscose polyhydroxyamic acid solution; (2) adding azeotropic dehydrator in nitrogen atmosphere, heating, performing imidization reaction under refluxing and dehydration at 120-160 deg.C for 1-6 h, and cooling to room temperature to obtain phenolic hydroxyl-containing polyimide adhesive. The volume ratio of azeotropic dehydrator to strongly polar non-proton organic solvent is 1 :( 1-5). The method has such advantages as easy operation, no special requirement for equipment, and high product quality. The phenolic hydroxyl-containing polyimide adhesive has such advantages as short adhesion and curing time, low energy consumption, and high adhesiveness to copper foil and polyimide thin film, and can be used to produce bi-layer flexible printed circuit boards.

Owner:DONGHUA UNIV

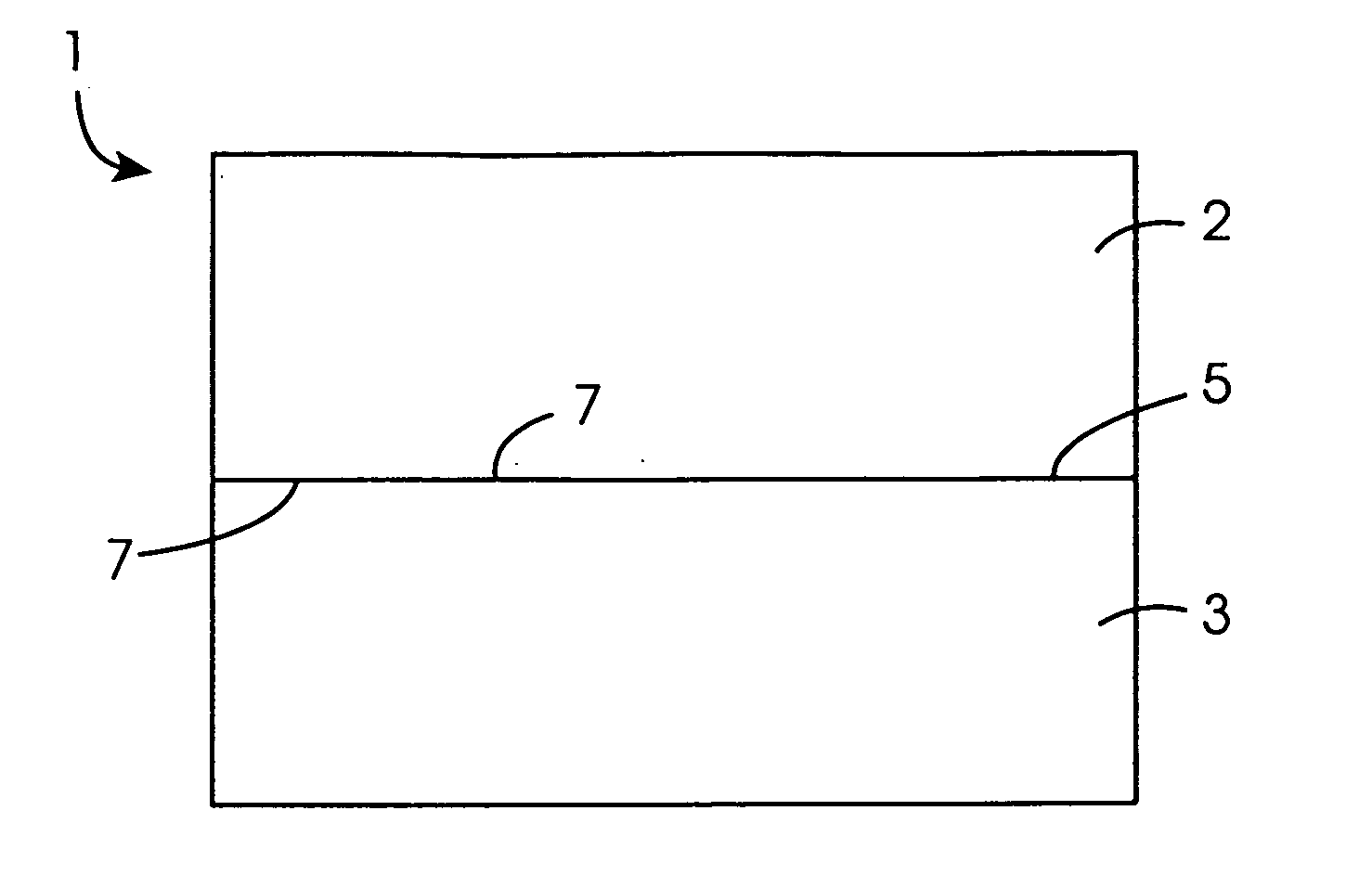

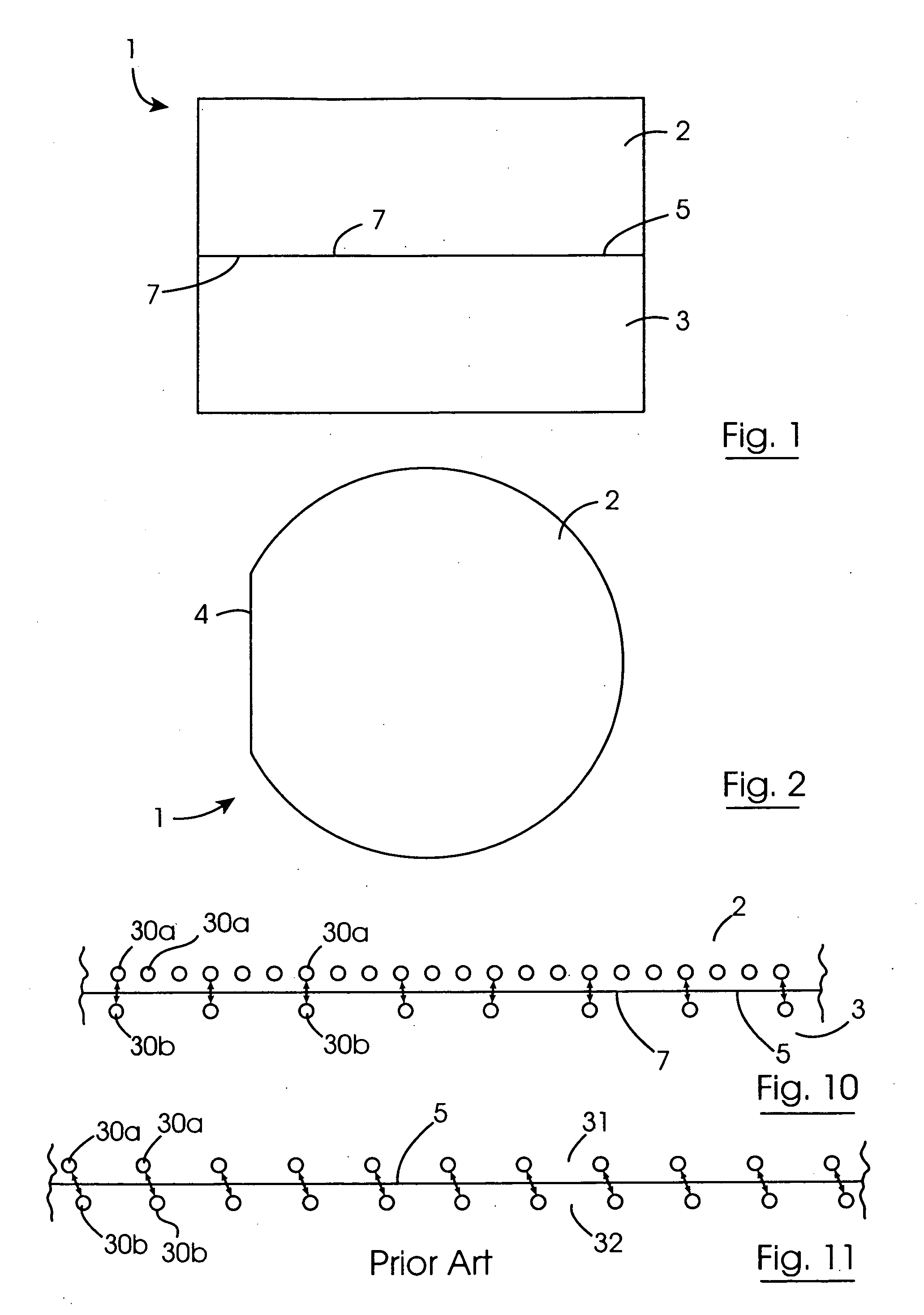

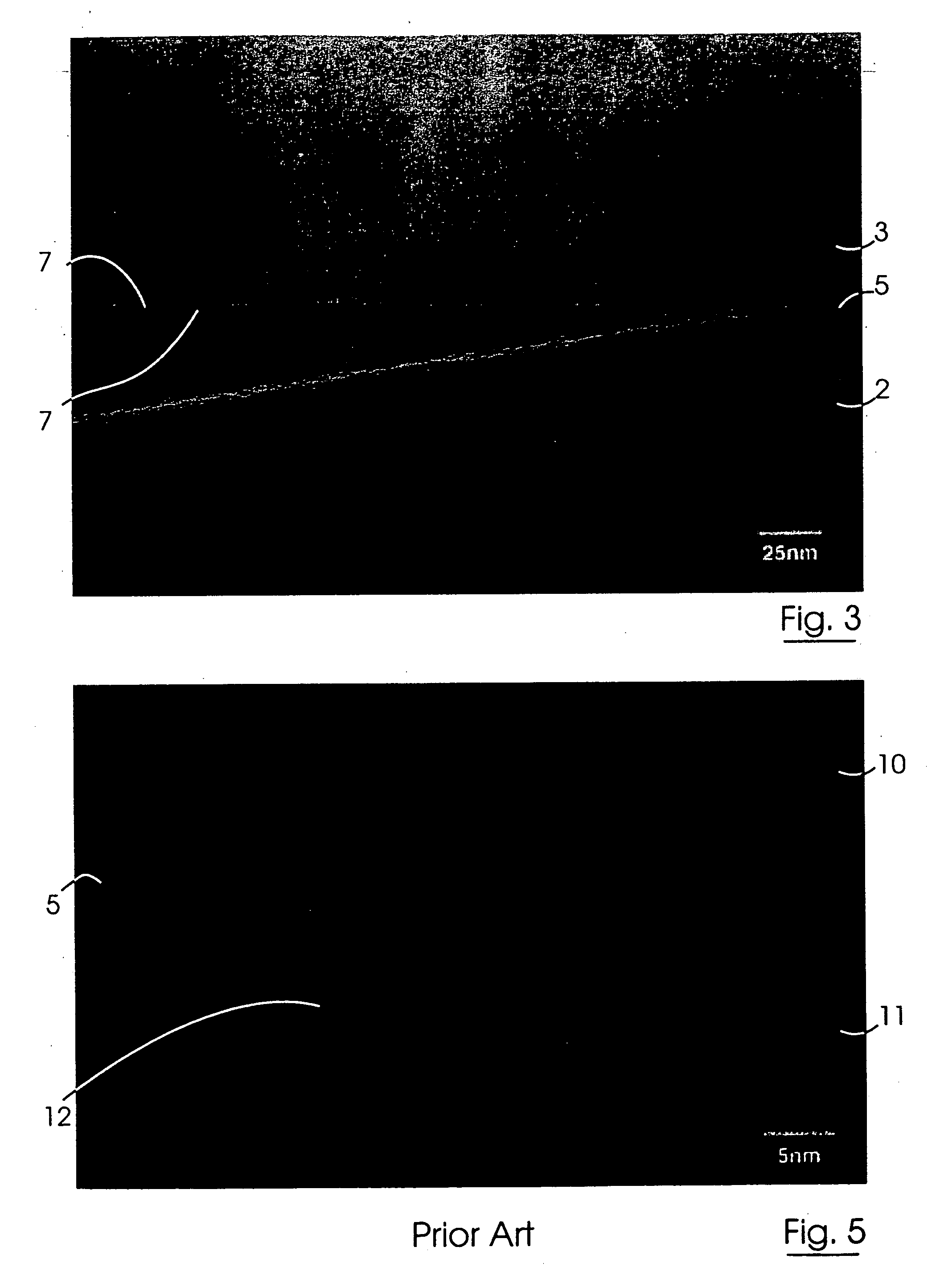

Method for direct bonding two silicon wafers for minimising interfacial oxide and stresses at the bond interface, and an SOI structure

InactiveUS20040087109A1Semiconductor/solid-state device manufacturingInterfacial oxideBond interface

A semiconductor substrate (1) comprises first and second silicon wafers (2,3) directly bonded together with interfacial oxide and interfacial stresses minimised along a bond interface (5), which is defined by bond faces (7) of the first and second wafers (2,3). Interfacial oxide is minimised by selecting the first and second wafers (2,3) to be of relatively low oxygen content, well below the limit of solid solubility of oxygen in the wafers. In order to minimise interfacial stresses, the first and second wafers are selected to have respective different crystal plane orientations. The bond faces (7) of the first and second wafers (2,3) are polished and cleaned, and are subsequently dried in a nitrogen atmosphere. Immediately upon being dried, the bond faces (7) of the first and second wafers (2,3) are abutted together and the wafers (2,3) are subjected to a preliminary anneal at a temperature of at least 400° C. for a time period of a few hours. As soon as possible after the preliminary anneal, and preferably, within forty-eight hours of the preliminary anneal, the first and second wafers (2,3) are fusion bonded at a bond anneal temperature of approximately 1,150° C. for a time period of approximately three hours. The preliminary anneal may be omitted if fusion bonding at the bond anneal temperature is carried out within approximately six hours of the wafers (2,3) being abutted together. An SOI structure (50) may subsequently be prepared from the semiconductor structure (1) which forms a substrate layer (52) supported on a handle layer (55) with a buried insulating layer (57) between the substrate layer (52) and the handle layer (55).

Owner:ANALOG DEVICES INC

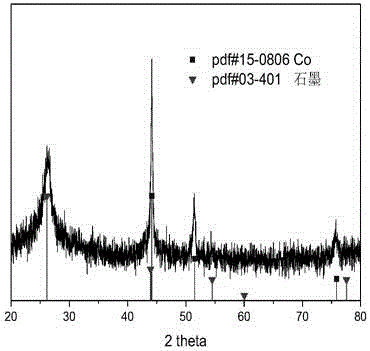

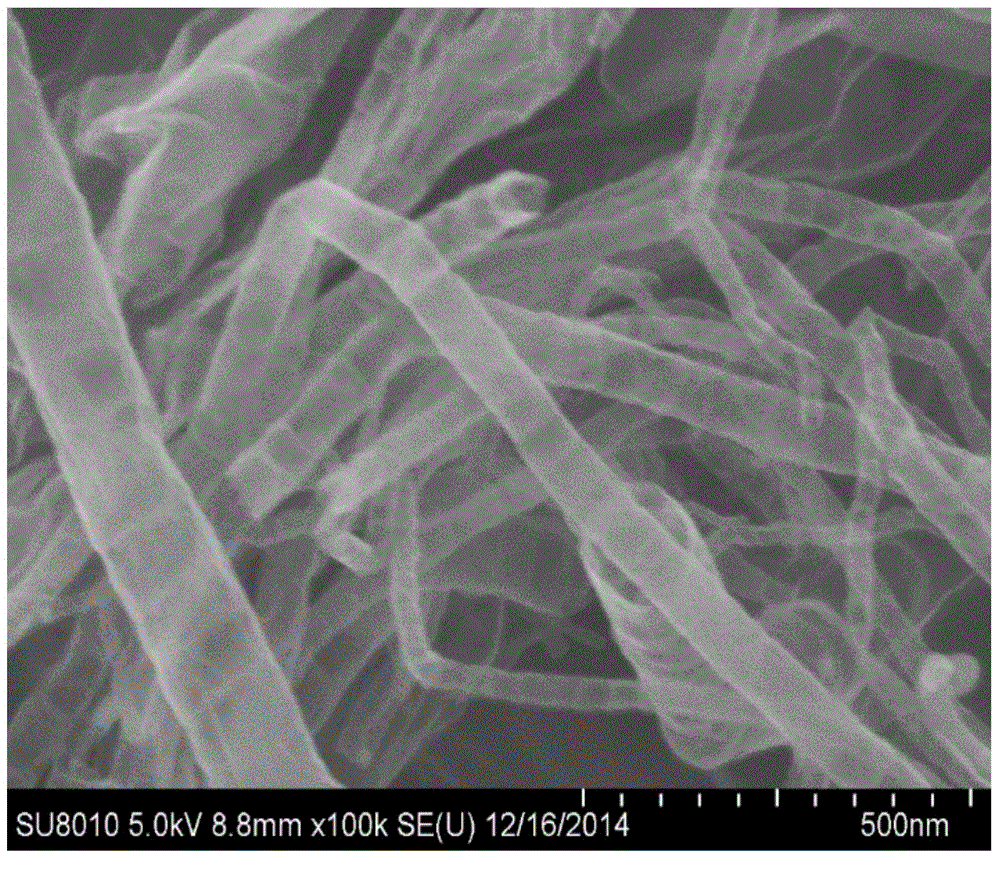

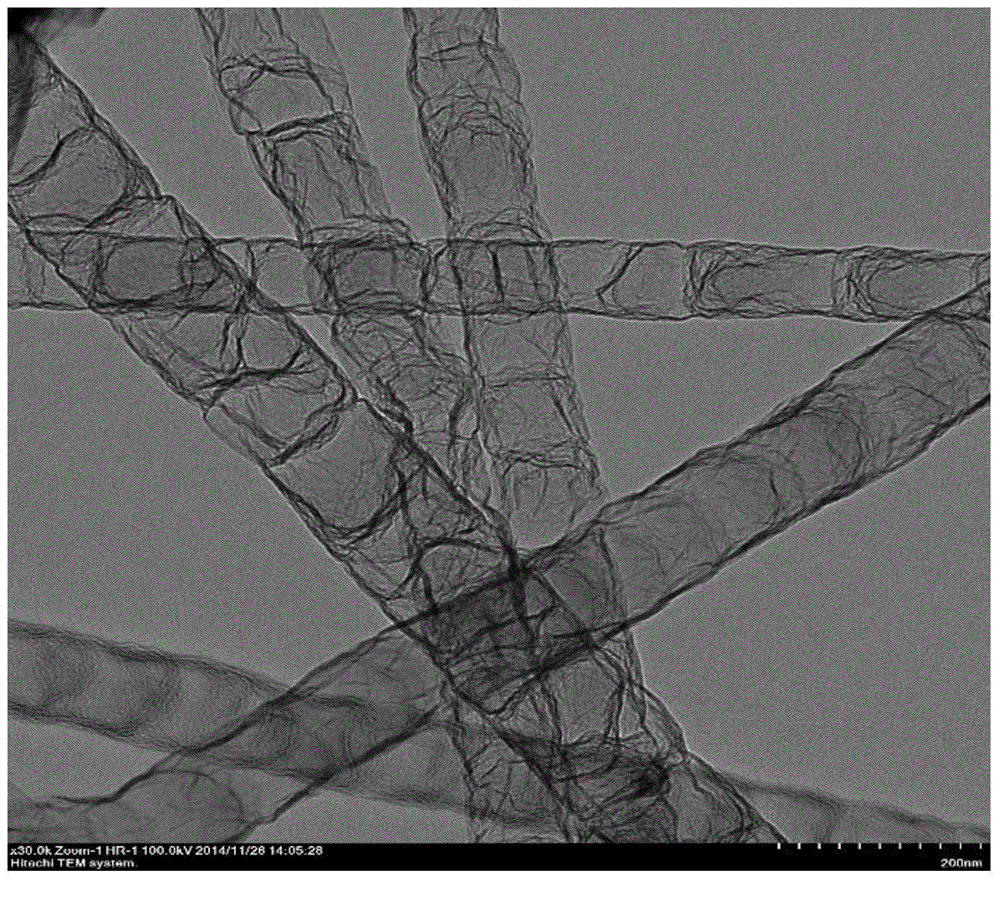

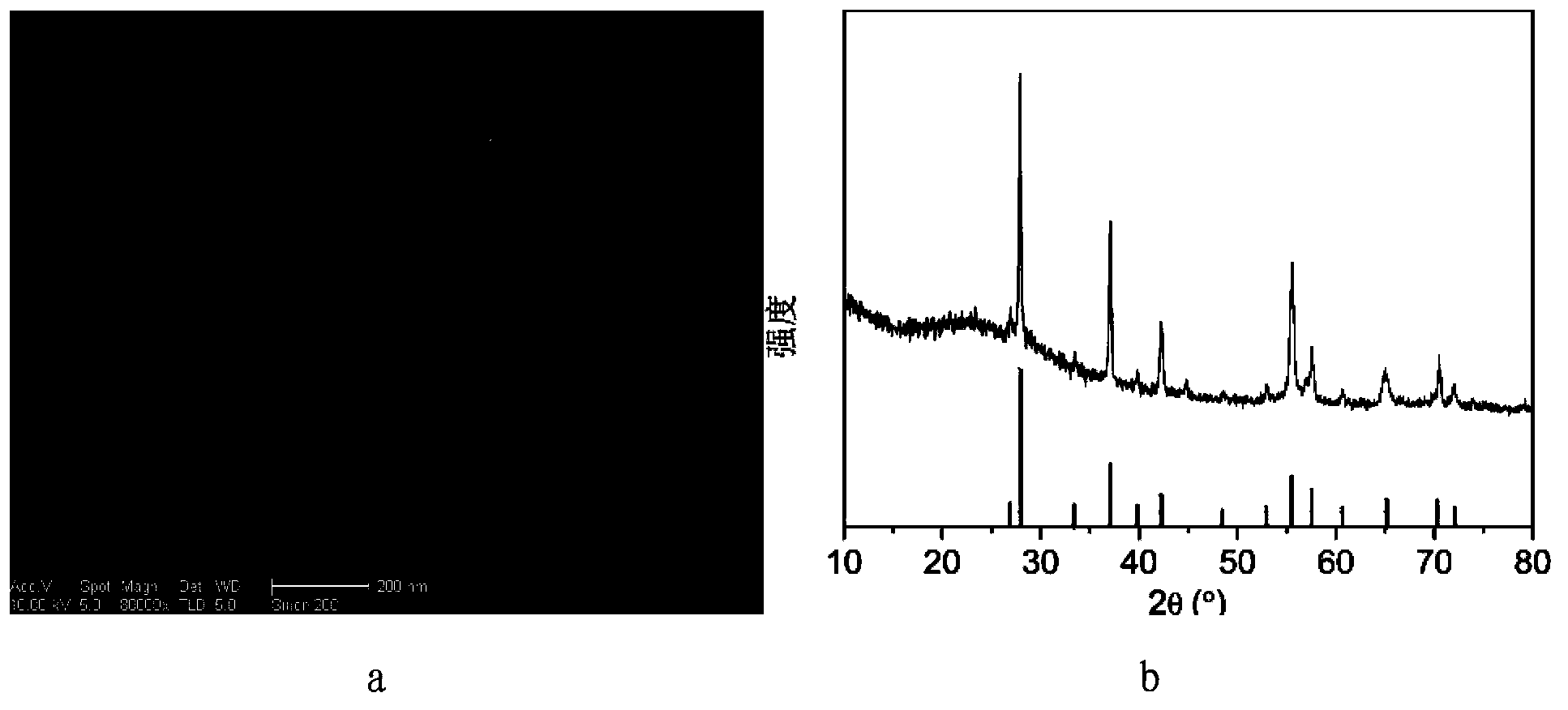

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

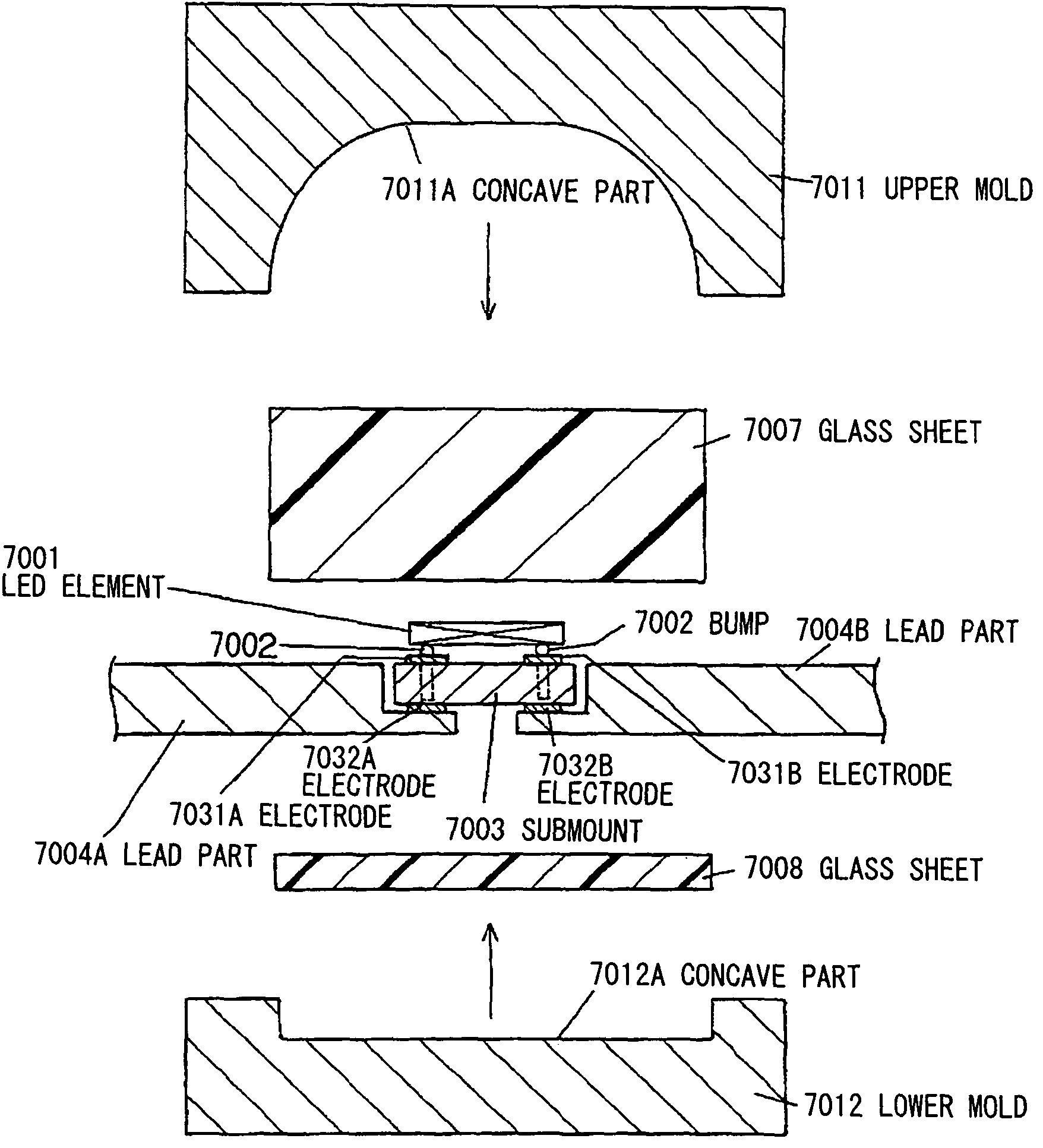

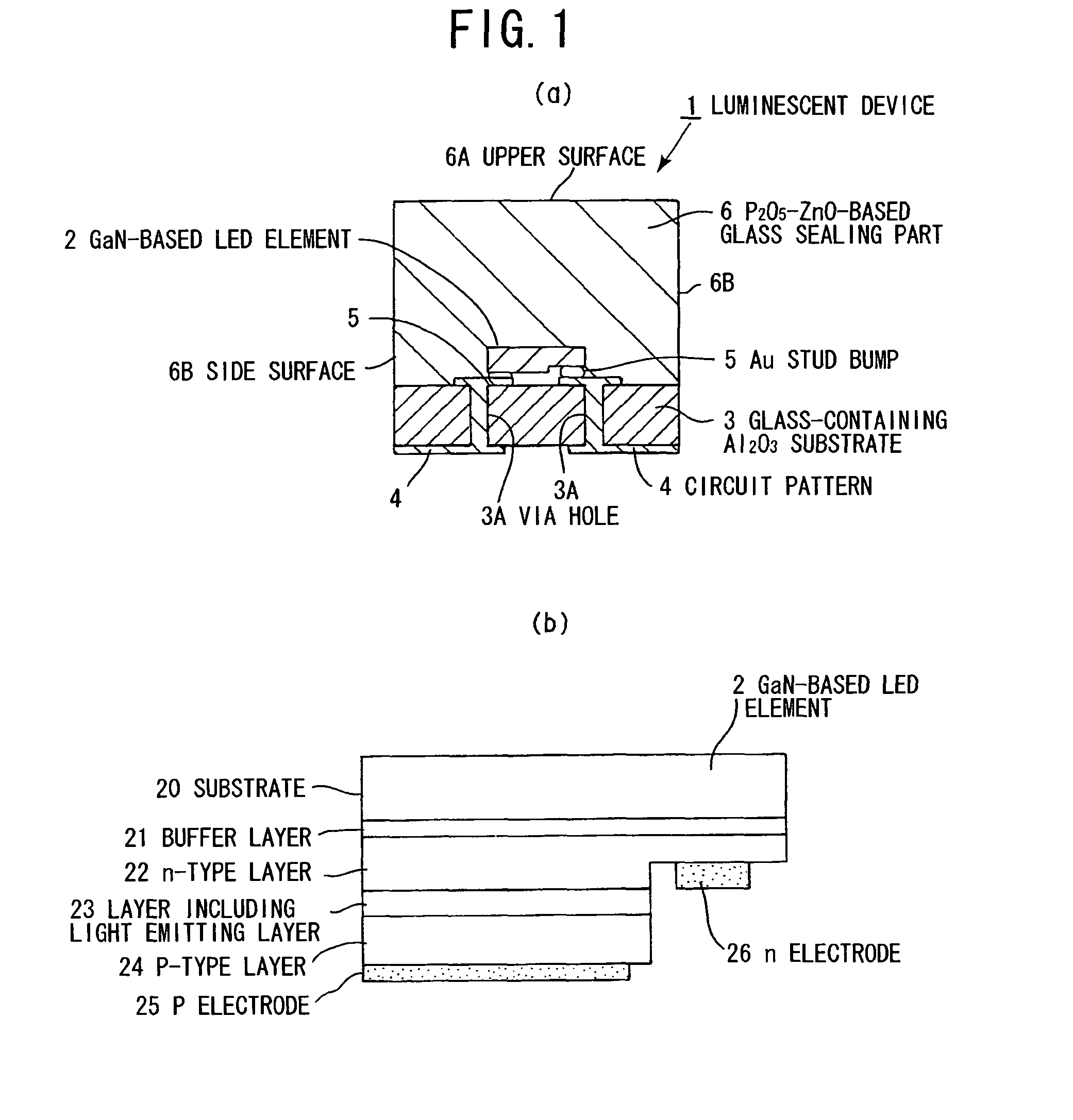

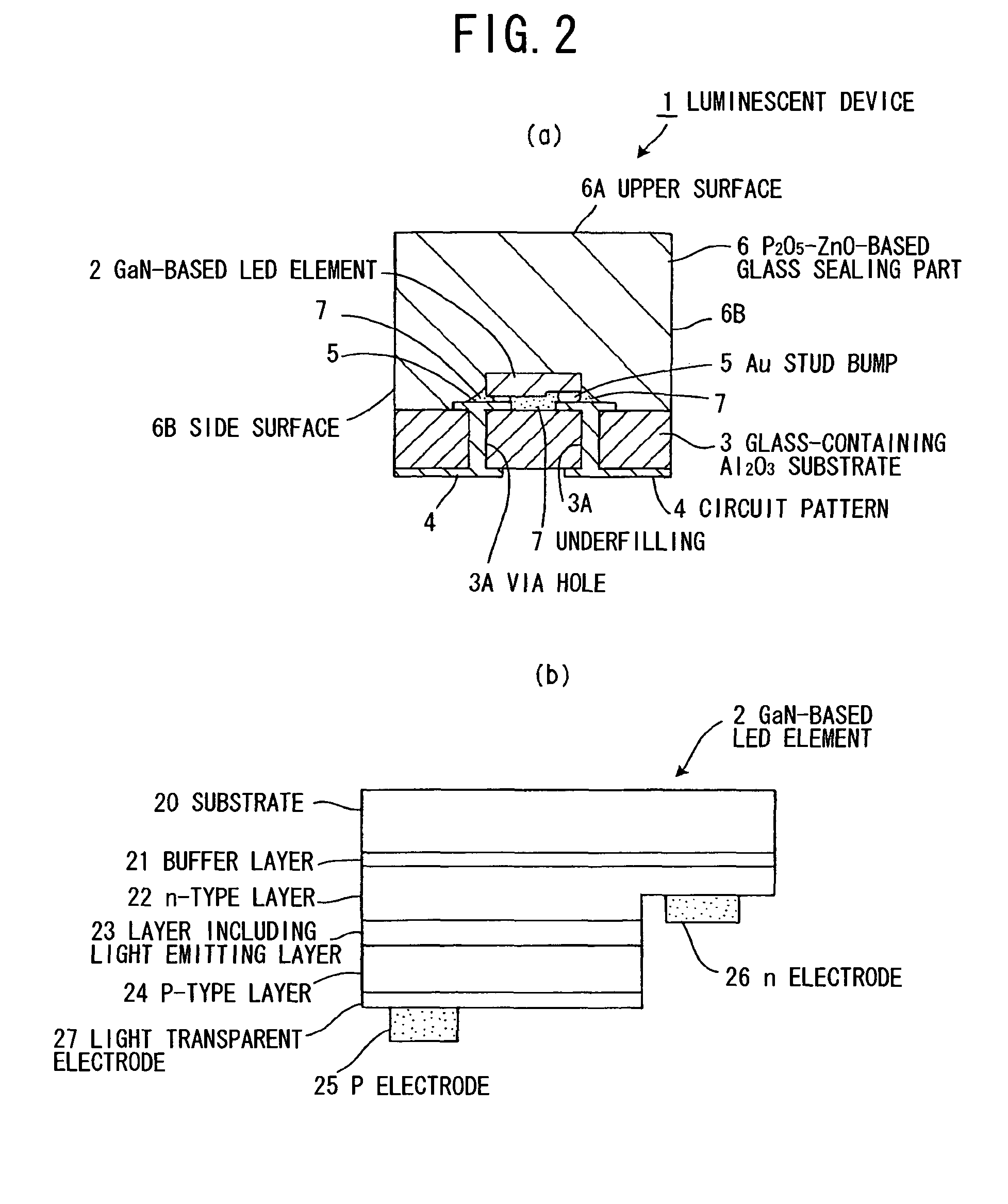

Solid element device and method for manufacturing the same

InactiveUS7824937B2Solid-state devicesSemiconductor/solid-state device manufacturingNitrogen atmosphereOptoelectronics

A method for manufacturing a solid element device, which comprises providing a glass-containing Al2O3 substrate (3) having a GaN based LED element (2) placed thereon, setting a P2O5—ZnO based low melting point glass in parallel with the substrate, and carrying out a press working at a temperature of 415° C. or higher under a pressure of 60 kgf in a nitrogen atmosphere. Under these conditions, the low melting point glass has a viscosity of 109 poise, and is adhered via an oxide formed on the surface of the glass-containing Al2O3 substrate (3). A solid element device manufactured by the above method can be manufactured through a glass sealing working at a low temperature and also has a highly reliable sealing structure.

Owner:TOYODA GOSEI CO LTD +1

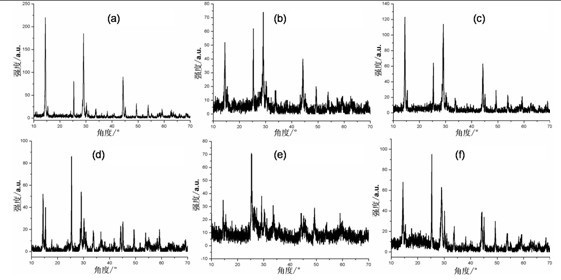

Nitrogen-containing alloy and method for producing phosphor using the same

InactiveUS20090140205A1Suppress rapid progressHigh performanceLuminescent compositionsFluorescenceNitrogen gas

There is provided a method for industrially producing a phosphor with high performance, in particular, high brightness. There is also provided a nitrogen-containing alloy and an alloy powder that can be used for the production method. A method for producing a phosphor includes a step of heating a raw material for the phosphor under a nitrogen-containing atmosphere, in which an alloy containing two or more different metal elements constituting the phosphor is used as the whole or part of the raw material for the phosphor, and in the heating step, the heating is performed under conditions such that the temperature change per minute is 50° C. or lower.It is possible to suppress the rapid progress of a nitridation reaction in heat treatment in producing the phosphor using an alloy for a phosphor precursor as the whole or part of the raw material, thereby industrially producing the phosphor with high performance, in particular, high brightness.

Owner:MITSUBISHI CHEM CORP

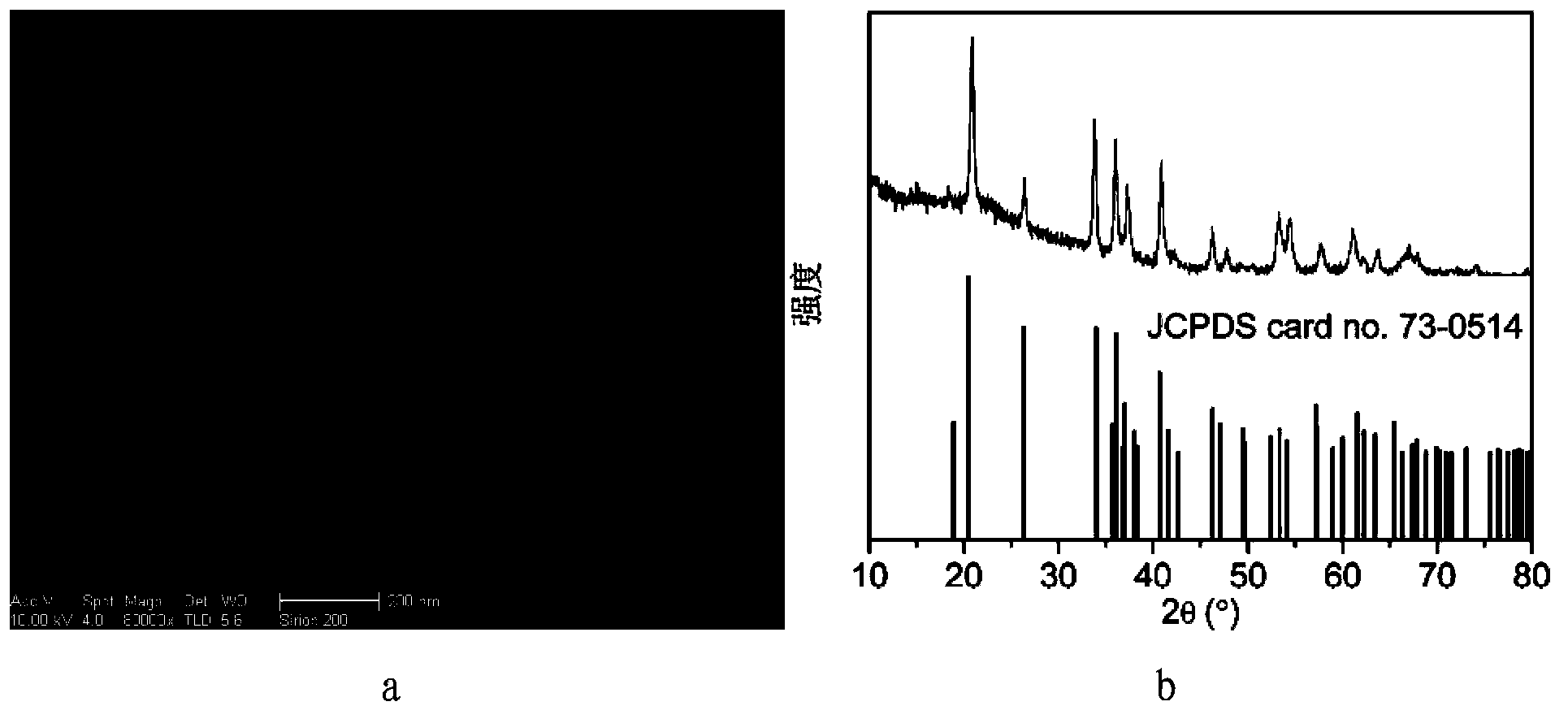

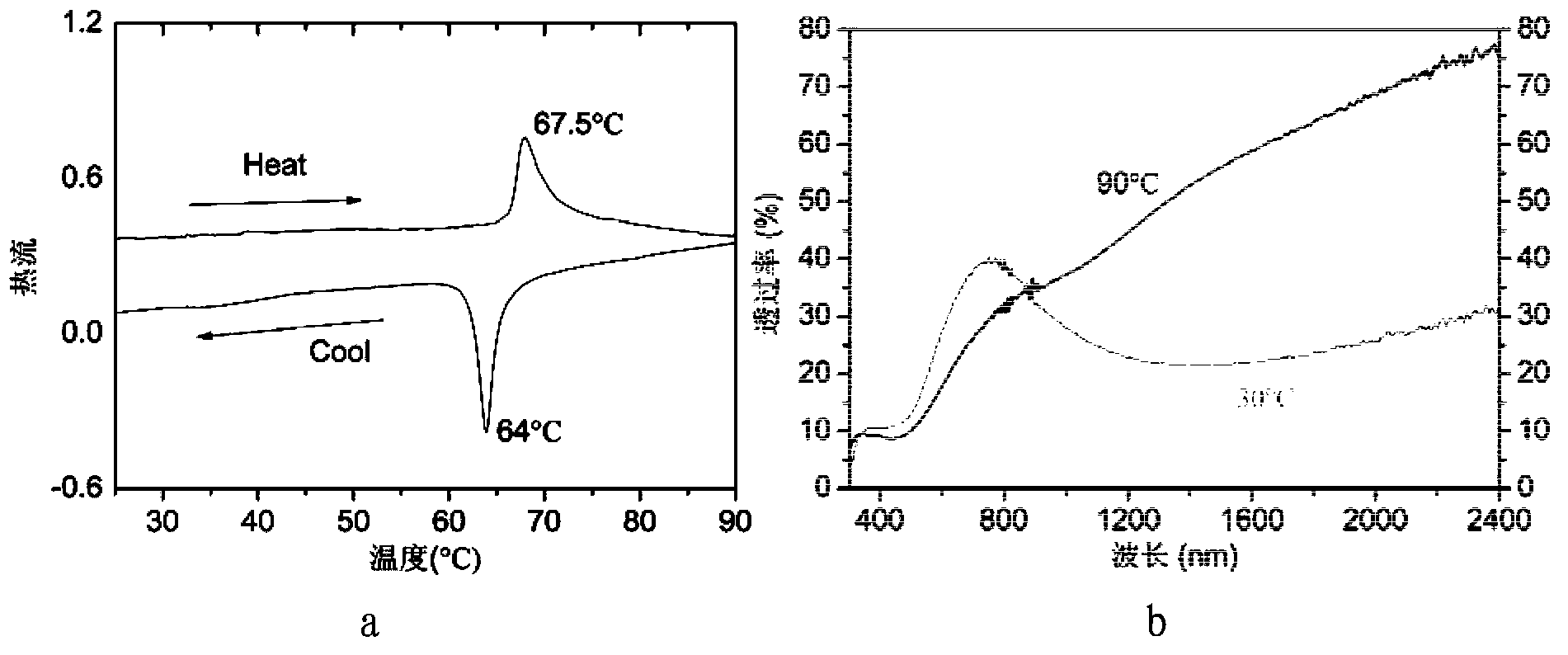

Preparation method for vanadium dioxide and doped powder thereof

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

Preparation method of water-expandable single-component polyurethane sealant

ActiveCN102408866AGood adhesionEasy constructionOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a preparation method of a water-expandable single-component polyurethane sealant, which comprises the following steps: mixing and dispersing water-expandable polyurethane prepolymer, vacuum-dried plasticizer, filler, thixotropic agent and water-absorbing resin according to the formula amount at 30-50 DEG C under the vacuum degree of not less than 0.092 MPa in a double planetary mixer or tri-roller grinder for 1-4.5 hours; in high-purity nitrogen atmosphere under atmospheric pressure, adding catalyst B, bonding accelerator and moisture remover, uniformly mixing and dispersing; removing micromolecules under the vacuum degree of not less than 0.092 MPa; and mixing for 0.3-1 hour to obtain the water-expandable single-component polyurethane sealant. Compared with the prior art, the water-expandable single-component polyurethane sealant is easy for construction, and has the characteristics of favorable bonding performance for seal interface, high water-expansion speed after moisture curing, adjustable expansion rate and the like.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

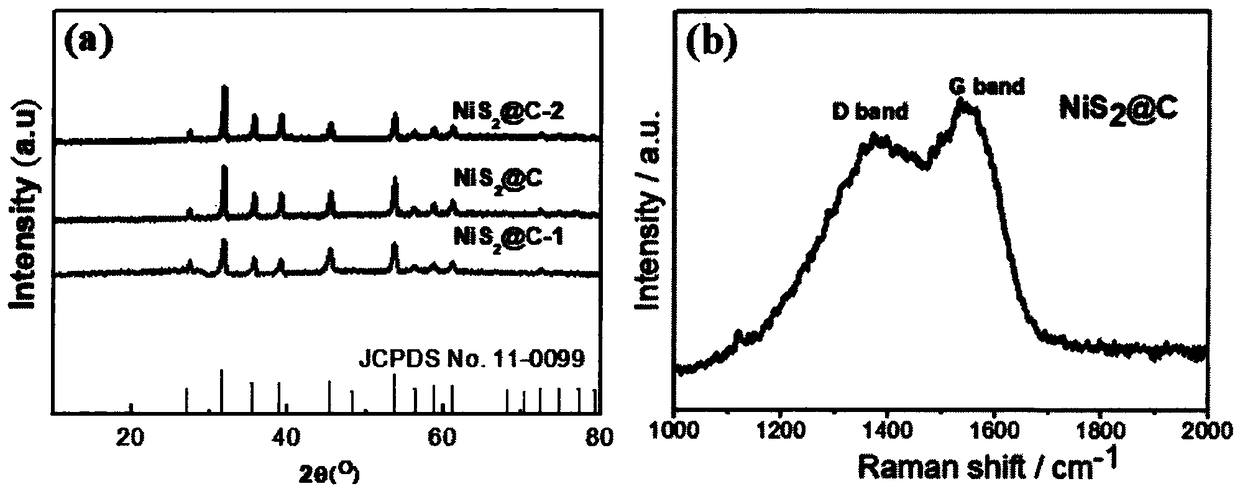

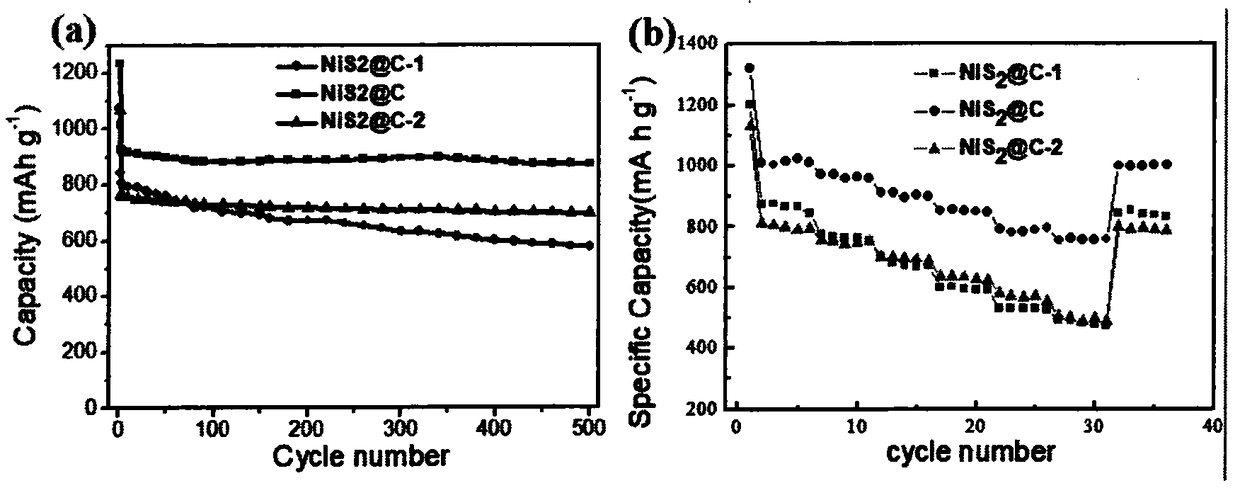

Nickel disulfide carbon nano composite material and preparation method and application thereof

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

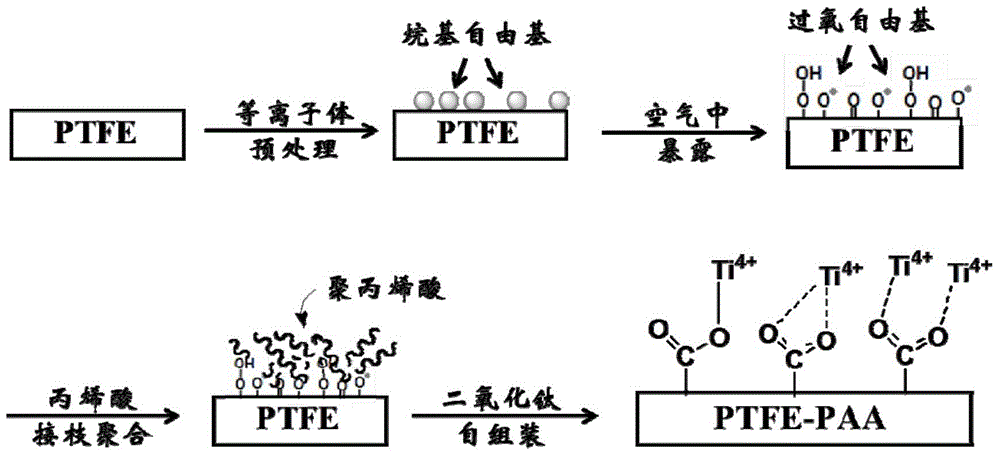

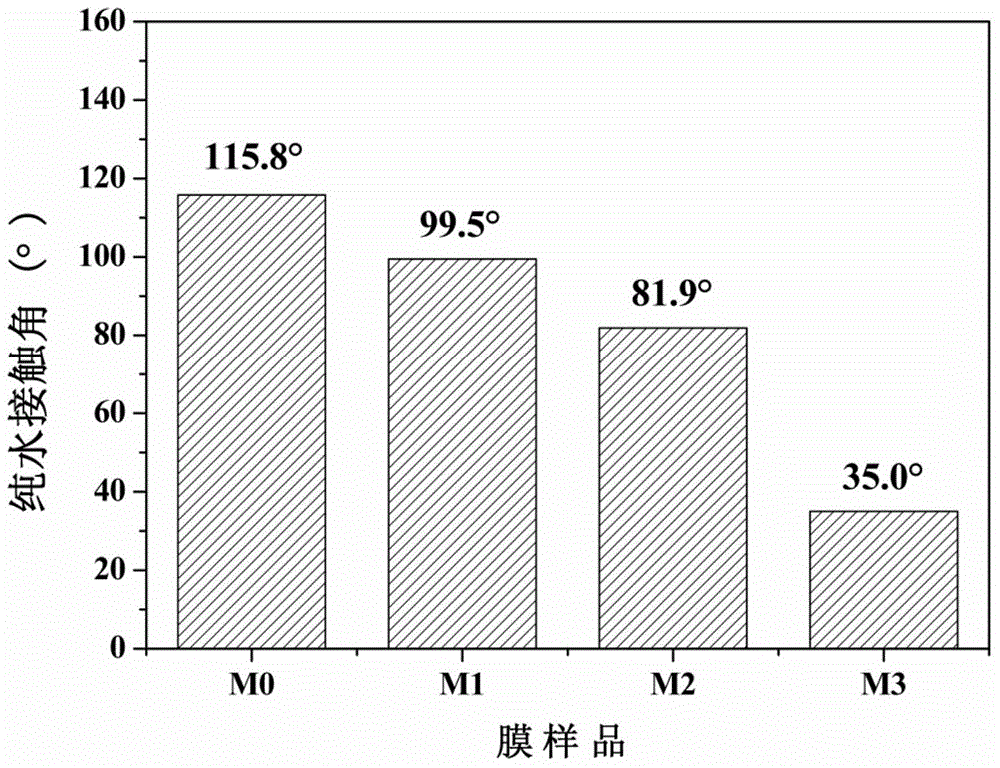

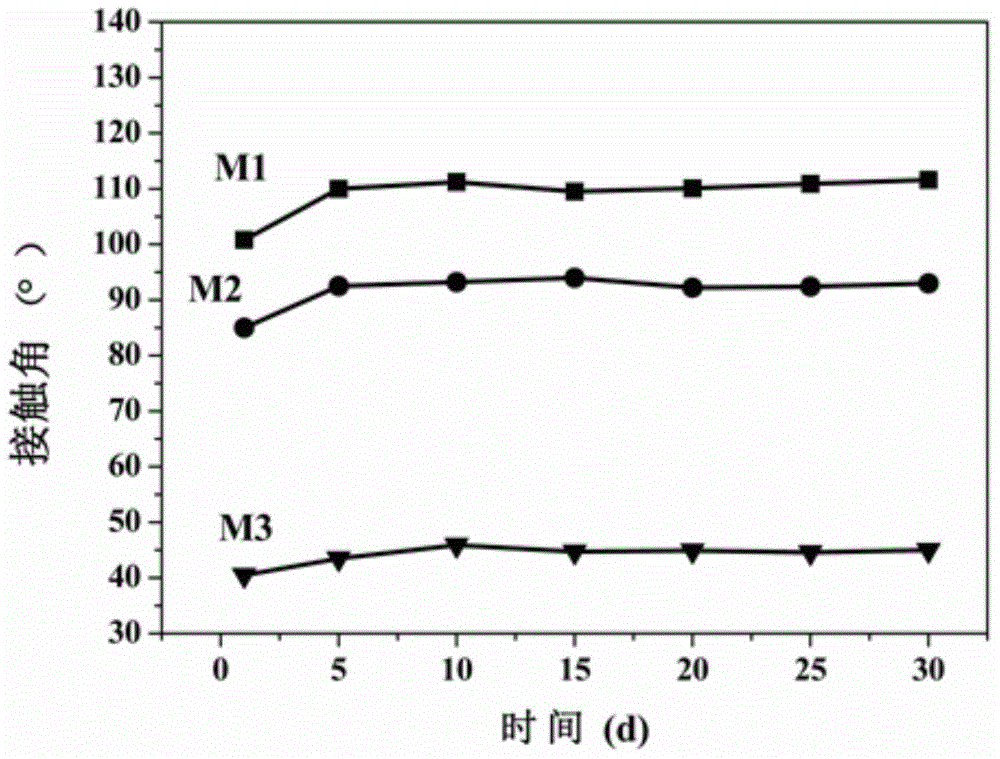

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

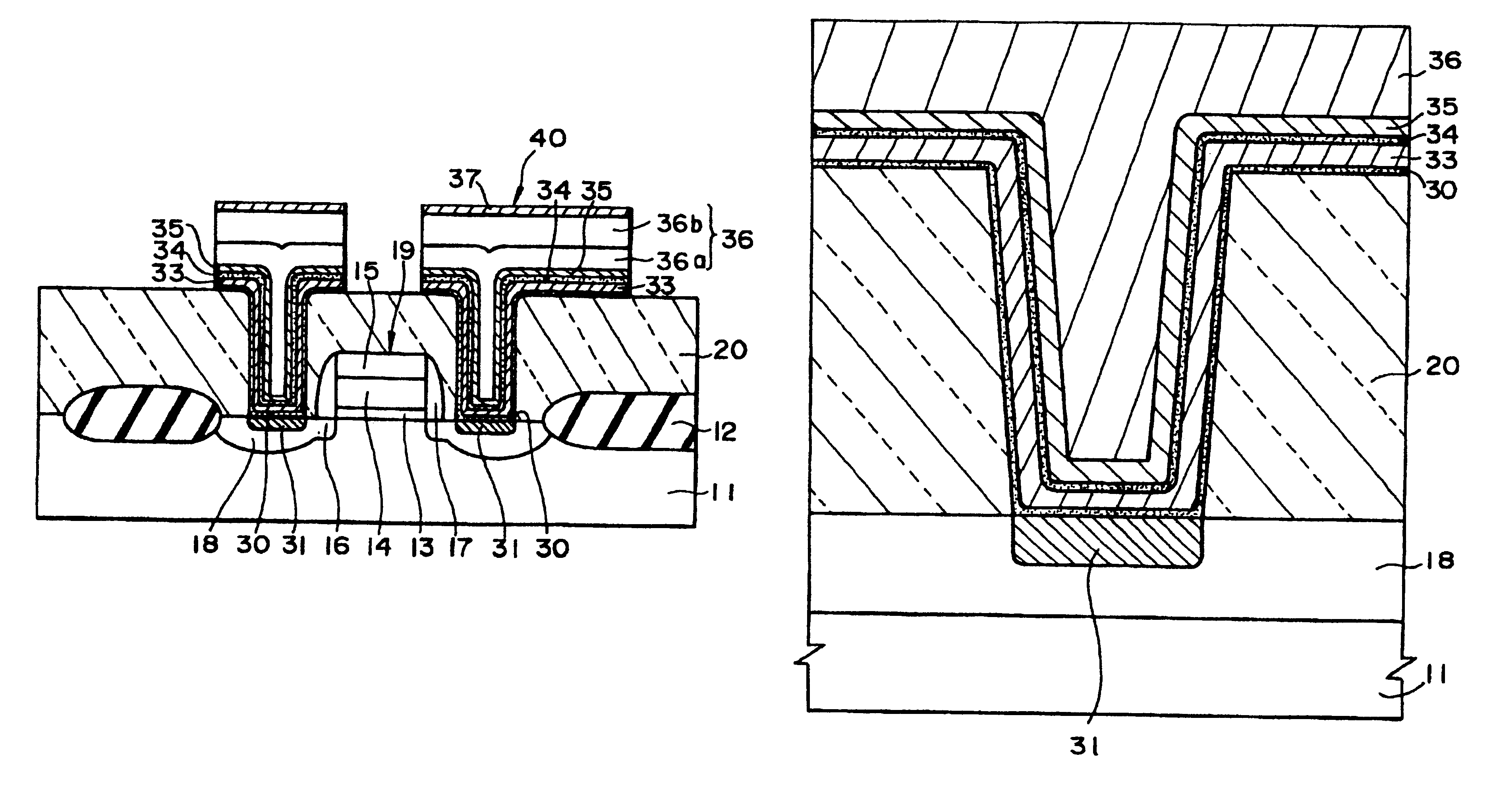

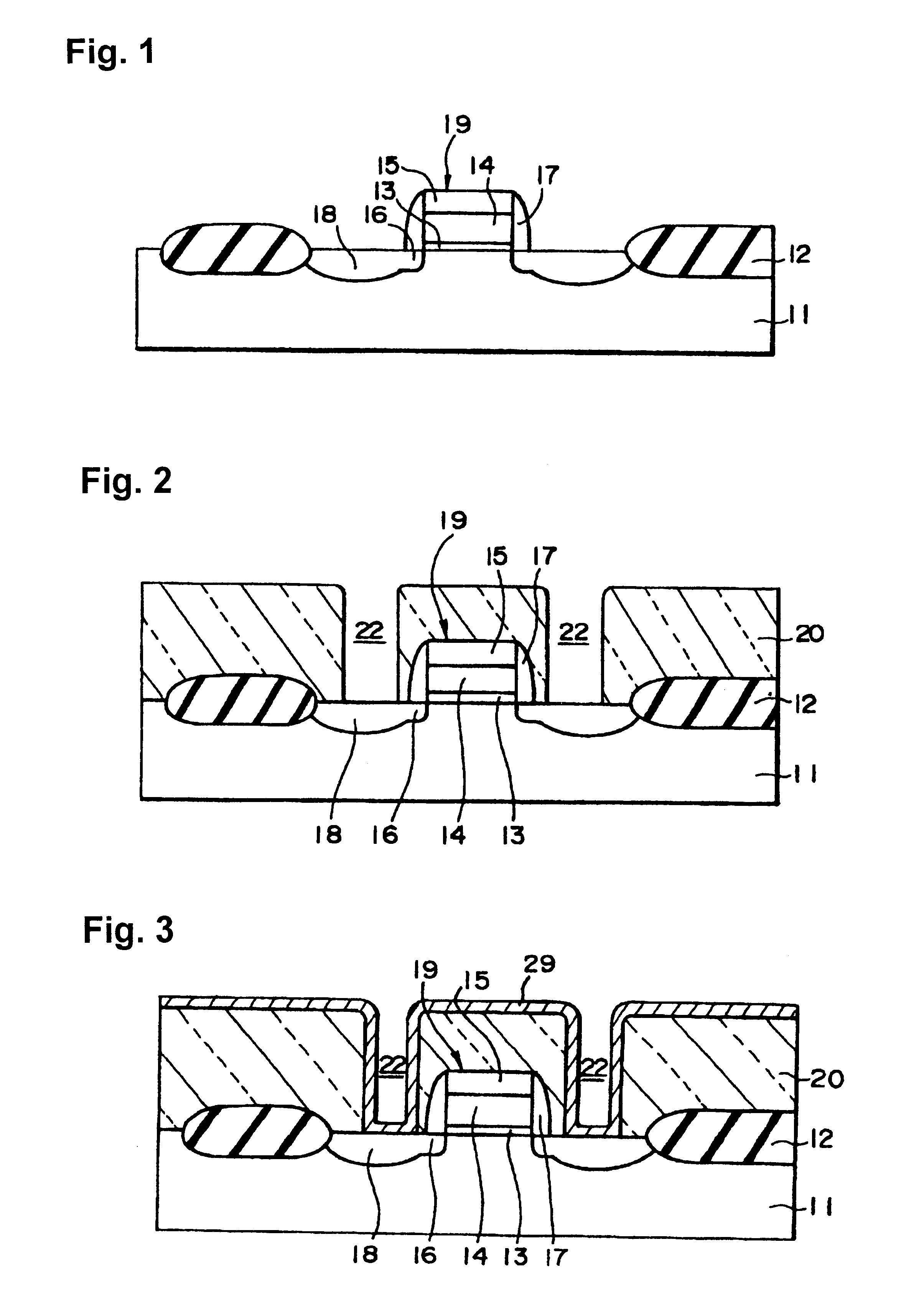

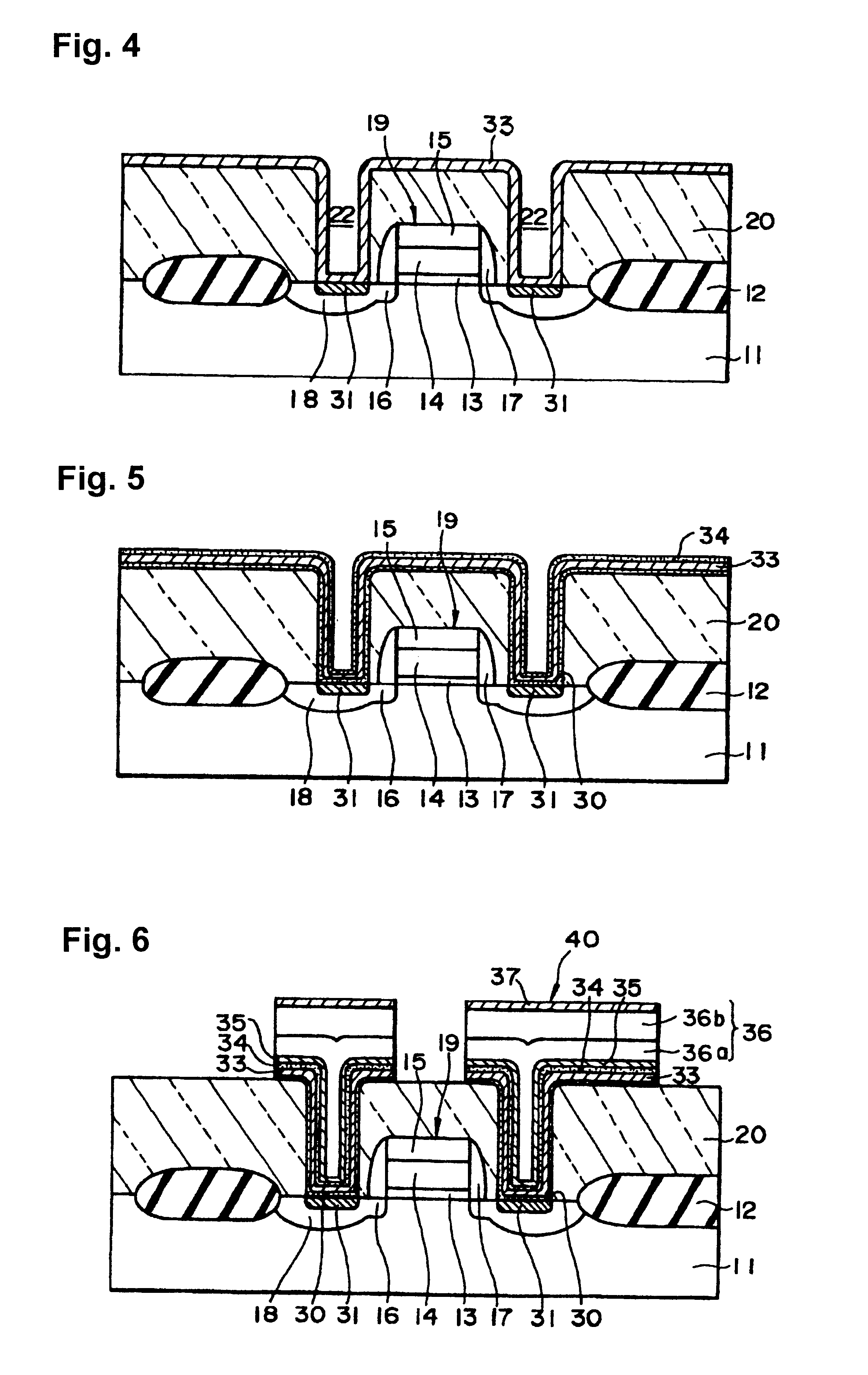

Method for manufacturing semiconductor devices

InactiveUS6350685B1Improve cohesionIncrease coverageSemiconductor/solid-state device detailsSolid-state devicesTitanium nitrideNitrogen atmosphere

A semiconductor device is manufactured by a method including the steps of forming a through hole in an interlayer dielectric layer (silicon oxide layer, BPSG layer, etc.) formed on a semiconductor substrate having a device element. A barrier layer is formed on surfaces of the interlayer dielectric layer and the through hole. A wiring layer is formed on the barrier layer. The barrier layer is formed by a method including the following steps. A titanium layer that forms at least a part of the barrier layer is formed. A heat treatment is conducted in a nitrogen atmosphere to form a titanium nitride layer at least on a surface of the titanium layer. The titanium nitride layer is contacted with oxygen in an atmosphere including oxygen. A heat treatment is conducted in a nitrogen atmosphere to form titanium oxide layers and to densify the titanium nitride layer.

Owner:SEIKO EPSON CORP

Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

InactiveCN104071843AGood phase change propertiesExcellent infrared control performanceMaterial nanotechnologyVanadium oxidesVanadium dioxideDispersity

The invention discloses a preparation method of monodispersed M-phase vanadium dioxide nanoparticles. The preparation method comprises the following steps: mixing vanadium pentoxide, oxalate dihydrate and water according to a molar ratio of (1-2.5) : 1 : (500-800) to obtain mixed liquid, adding 4%-6% of a surfactant based on the volume of the mixed liquid into the mixed liquid, and stirring for at least 2 hours to obtain a precursor solution; reacting the precursor solution in a sealed state at 200-260 DEG C for at least 1 day to obtain reaction liquid; performing solid-liquid separation and washing on the reaction liquid in sequence to obtain orthogonal vanadium dioxide powder; annealing the orthogonal vanadium dioxide powder in a nitrogen atmosphere at 300-600 DEG C for 0.5 hour to obtain the monodispersed M-phase vanadium dioxide nanoparticles with particle sizes of 60nm-80nm. The preparation method has the advantages of environmental protection and no temperature gradient control during annealing, and can be widely used for preparing the M-phase vanadium dioxide nanoparticles with very good dispersity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for modifying TS-1 titanium-silicon molecular sieve catalyst

InactiveCN101602013AImprove catalytic performanceImprove hydrophobicityOrganic chemistryMolecular sieve catalystsMolecular sieveSilazane

The invention relates to a method for modifying a TS-1 titanium-silicon molecular sieve catalyst, which mainly solves the problems that a silanization reagent is easy to hydrolyze to cover the active center of the catalyst and has large consumption, difficult recovery and environmental pollution when being used for processing the TS-1 molecular sieve catalyst in a dipping mode in the prior art. The method better solves the problem by adopting the technical scheme that a TS-1 titanium-silicon molecular sieve catalyst matrix reacts for 0.5-10 hours by leading into the silanization reagent at 50-300 DEG C in a nitrogen atmosphere, and then a modified TS-1 titanium-silicon molecular sieve catalyst is obtained, wherein the silanization reagent is selected from organosilane, organic silylamine, organic silicyl amide or organic silazane, and the dosage of the silanization reagent is 2-20 percent of the weight of the catalyst matrix. The method can be applied to the industrial production of epoxy chloropropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com