Preparation method for vanadium dioxide and doped powder thereof

A technology of vanadium dioxide and vanadium pentoxide, applied in the direction of vanadium oxide, etc., can solve the problems of uneven dispersion of dopants, unfavorable large-scale growth, long reaction time, etc., and achieve simple process, excellent phase change performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

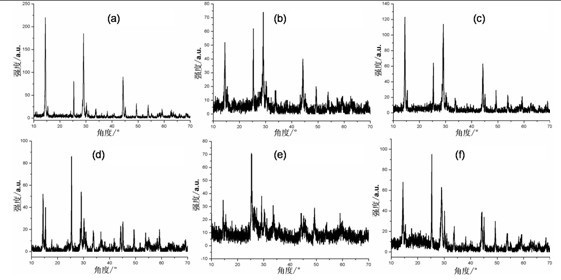

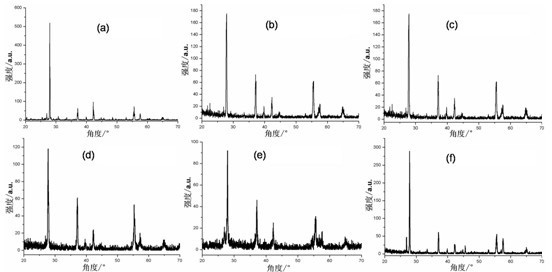

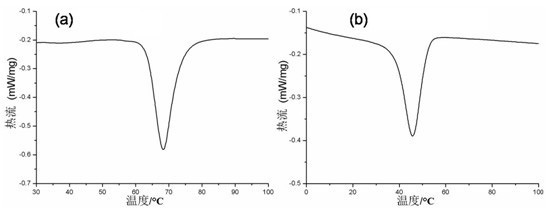

[0042] Add 0.45 g of vanadium pentoxide to 23.00 g of distilled water, and add 2.22 g of hydrogen peroxide to prepare V 5+ 4.08 g reductant ethanol was added to the complex solution, and a magnetic stirrer was used to stir for 0.5 h to obtain a clear solution; the obtained clear solution was transferred to a hydrothermal reaction kettle and heated at 180 After reacting at ℃ for 24 h, the material was naturally cooled to room temperature and discharged, centrifuged, washed with deionized water, and dried in vacuum to obtain undoped VO 2 , figure 1 a is the obtained VO 2 The XRD spectrum of the figure, it can be seen from the figure that VO 2 VO 2 (B). Finally, the resulting VO 2 (B) Calcined in a high-purity argon atmosphere at 700 °C for 2 h to obtain the final product VO with phase transition properties 2 , figure 2 a shows the XRD pattern of the final product, as can be seen from the figure, the final product is monoclinic VO 2 (M); Adopting differential scanning ca...

Embodiment 2

[0044] Add 0.15 g of vanadium pentoxide to 27.00 g of distilled water, and add 2.85 g of hydrogen peroxide to prepare V 5+ 12.00 g reducing agent ethanol was added to the complex solution, and a magnetic stirrer was used to stir for 0.5 h to obtain a clear solution; the obtained clear solution was transferred to a hydrothermal reaction kettle and heated at 140 After reacting at ℃ for 168 h, the material was naturally cooled to room temperature and discharged, centrifuged, washed with deionized water, and dried in vacuum to obtain undoped VO 2 (B); Finally, the obtained VO 2 (B) Calcined at 700 °C for 10 min in a high-purity argon atmosphere to obtain the final product VO with phase transition properties 2 (M).

Embodiment 3

[0046] Add 3.64 g of vanadium pentoxide to 25.48 g of distilled water, and add 7.28 g of hydrogen peroxide to prepare V 5+ 1.82 g reducing agent ethanol and 1.82 g surfactant sodium dodecyl sulfate (SDS) were added to the complex solution, and stirred with a magnetic stirrer for 2 h to obtain a clear solution; The obtained clear solution was transferred to a hydrothermal reaction kettle, reacted at 220 °C for 72 h, cooled down to room temperature naturally, and discharged, centrifuged, washed with deionized water, and dried in vacuum to obtain undoped VO 2 (B); Finally, the obtained VO 2 (B) Calcined at 400 °C for 720 min in a high-purity argon atmosphere to obtain the final product VO with phase transition properties 2 (M).

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com