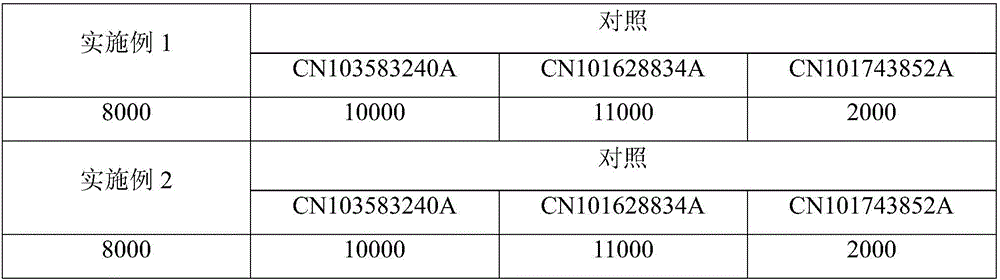

Patents

Literature

5613results about How to "Create pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process method for preparing ultra-hydrophobic surface by electrochemical method

ActiveCN101665968AEndows the superior performance of "self-cleaning"Apparent nanostructureAnodisationSpecial surfacesPhysical chemistryElectrochemistry

The invention discloses a process method for preparing an ultra-hydrophobic surface by the electrochemical method. The process adopts two processing steps: forming the micro nanometer double-structurerough surface by first electrochemical etching and then oxalic acid anodic oxidation; and preparing the ultra-hydrophobic surface by modifying the surface with fluorosilane. The method is simple andpractical, uses mature electrochemical etching and anodic oxidation technology, allows for easy mass production and avoids environmental pollution.

Owner:甘肃中安瑞科科技有限公司

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

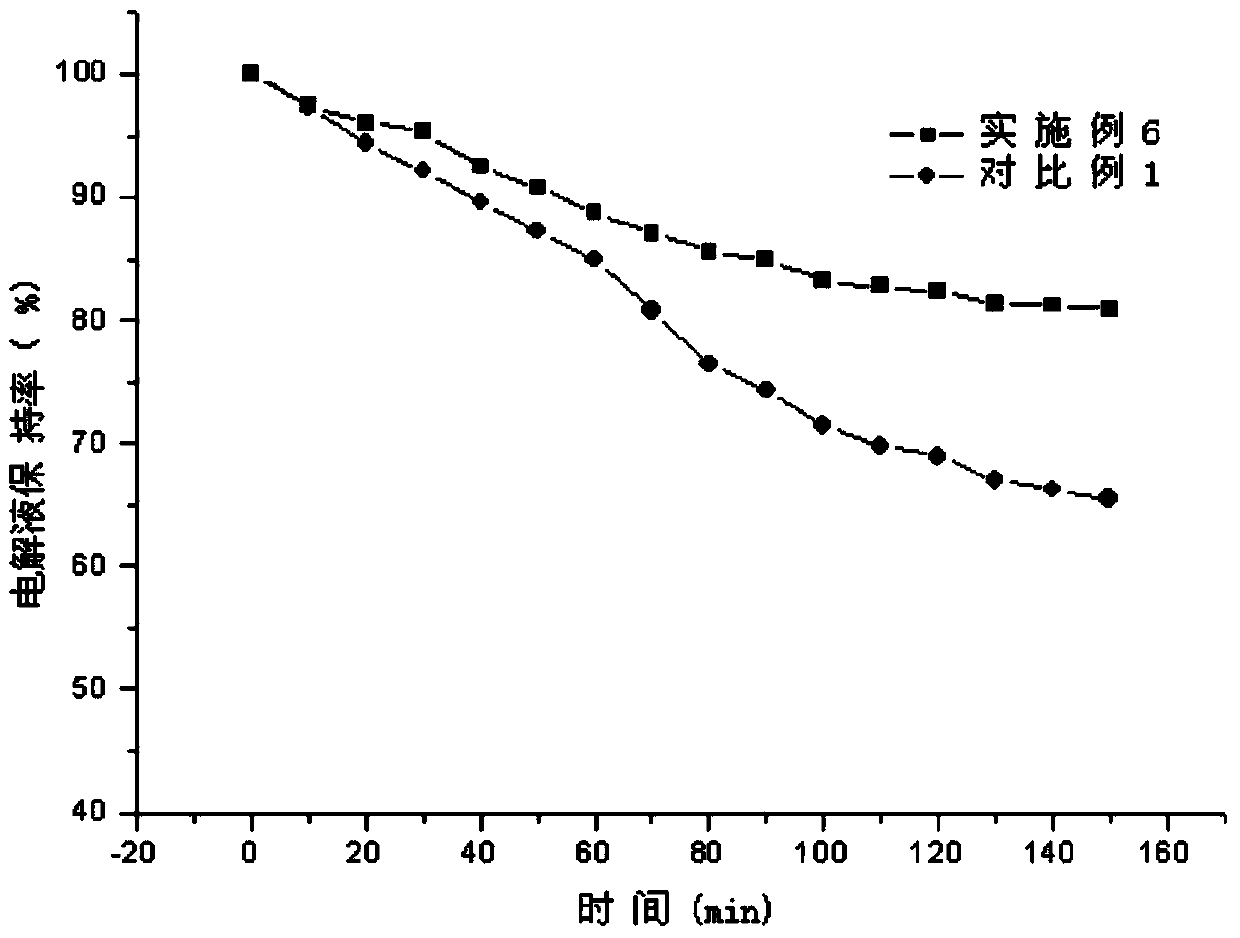

Coating composite separation membrane and preparation method thereof

ActiveCN103746085ACreate pollutionNot harmful to healthSynthetic resin layered productsCell component detailsAbsorption capacityAdhesive

The present invention relates to the field of lithium battery processing, and discloses a coating composite separation membrane and a preparation method thereof. The coating composite separation membrane comprises a base film and a polymer covering layer coated on the surface of the base film, wherein the polymer covering layer comprises a water-soluble adhesive, a surfactant, a dispersing agent, a thickening agent, deionized water and polymer powder particles. The invention further discloses the preparation method for the coating composite separation membrane. The preparation method comprises: 1) preparing an aqueous slurry; 2) coating the polymer covering layer on the base film; 3) drying; and 4) winding. According to the present invention, absorption capacity and retention capacity of the separation membrane on the electrolyte are well improved, safety of the liquid state lithium battery during the use process is increased, and advantages of environmental protection and low cost are provided.

Owner:SHENZHEN SENIOR TECH MATERIAL

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

Safe efficient environment protection type feedstuff

InactiveCN101380056AImprove digestibilityReflect environmental protectionFood processingAnimal feeding stuffAnimal scienceSide effect

A safe and high-efficient environment-friendly feed comprises the following raw materials in terms of weight percentage: 6 to 20 percent of corn gluten feed, 3 to 25 percent of soybean meals, 1 to 20 percent of powder, 0 to 15 percent of rice bran, 0 to 40 percent of corn, 3.5 to 10 percent of rapeseed dregs, 1 to 5 percent of cotton seed meals, 1 to 5 percent of bone meals, 2 to 6 percent of fish meals, 1 to 6 percent of meat meals, 3 to 15 percent of wheat and right amount of additives. According to the required amounts of all nutritional components of the livestock in different growing stages, the invention combines energy feed, protein feed and various additives in equilibrium according to certain percentages by adopting a scientific method, thus leading various livestock to obtain the largest feed digesting rate and leading the livestock to absorb the feed to the largest degree; the excrement after the digestion of the livestock have no obvious smell and cause no pollution to the surrounded environmental sanitation and the environment protection after the feed being eaten is shown; moreover, no banned substances are added in the process of the feed processing and the feed is processed from natural products, which have no residue side effects on the livestock.

Owner:罗喜华

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

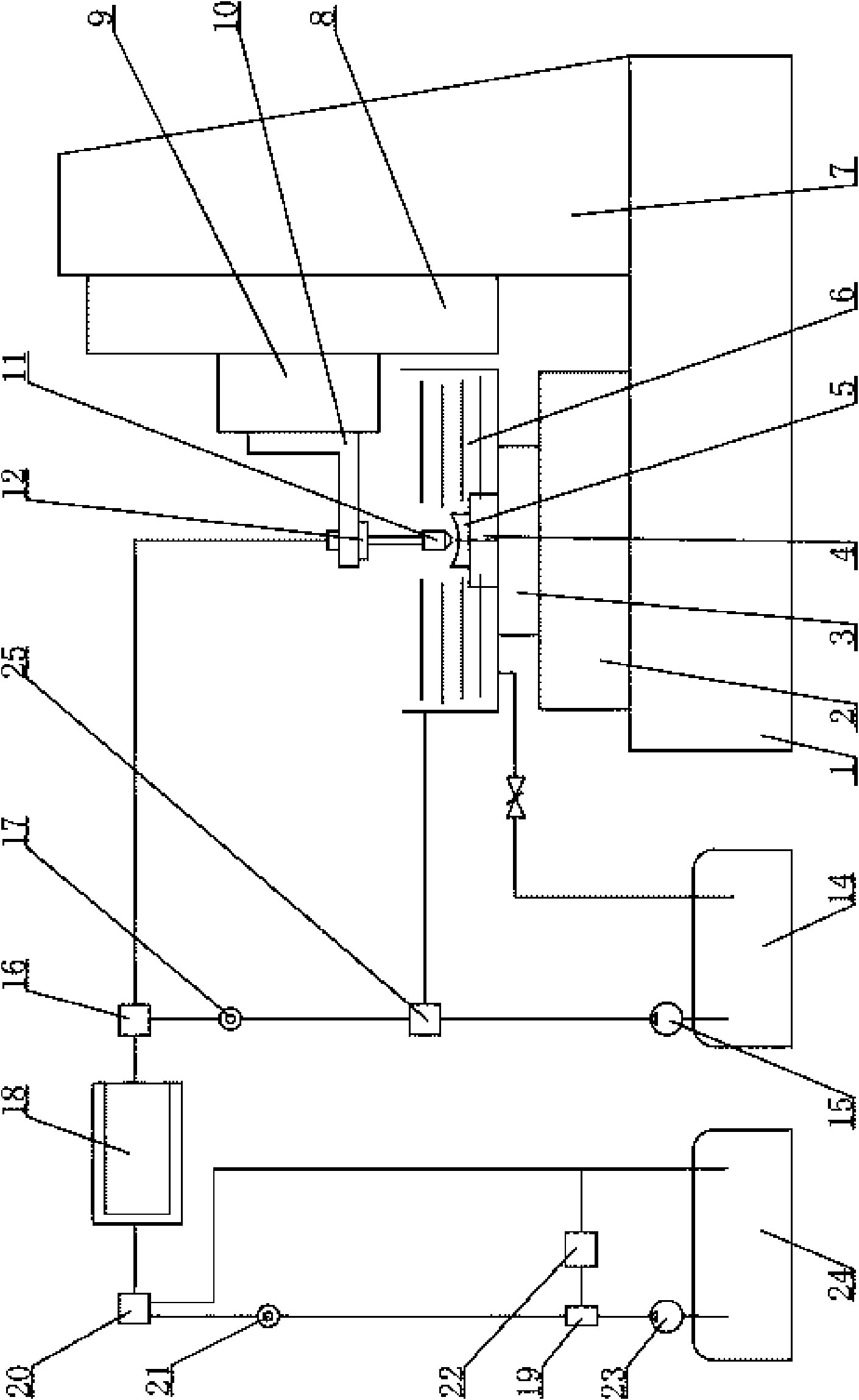

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

Method for improving oil well yields by means of oil pool indigenous microorganisms

ActiveCN103291267ASave on-site testing costsStrong targetingFluid removalDrilling compositionRecovery methodInjection rate

The invention relates to a microorganism enhanced oil recovery method, in particular to a method for improving oil well yields by means of oil pool indigenous microorganisms. The method includes the following steps of (1) screening of a test oil well, (2) screening of activating agents, (3) confirming of the injection rate of the activating agents, (4) confirming of well closing time and (5) on-site testing. By means of the indigenous microorganisms existing in the activated oil well, on-site test cost is thereby saved, different formulas of the activating agents are chosen according to the different indigenous microorganisms, activating effects and on-site test effects are effectively improved, the stratum cannot be damaged and the environment cannot be polluted when nutrient substances are injected, and therefore the method can be widely used for microorganism enhanced oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

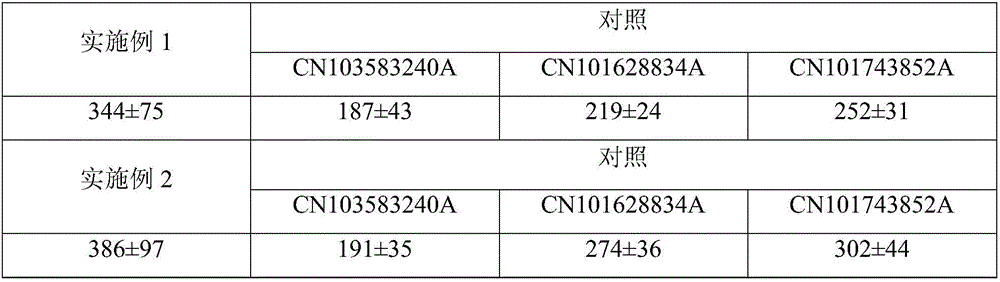

Method for preparing reactive fluid rubber-epoxide resin polymer

The invention provides a method for preparing reactive fluid rubber-epoxide resin polymer, and belongs to the technical field of modified epoxide resin. The method comprises the following steps: 5 to 50 portions of reactive fluid rubber containing carboxyl or hydroxyl as a modifier, and 0.1 to 2.0 portions of catalyst are added into 100 to 200 portions of epoxide resin by weight; when the reactive fluid rubber containing the hydroxyl is used as the modifier, isocyanate or estolide with the same weight portion as the epoxide resin is required to be added; and an active group in the reactive fluid rubber reacts with an epoxide group in the epoxide resin for 2 to 6 hours at a temperature of between 100 and 180 DEG C to prepare the reactive fluid rubber-epoxide resin polymer with excellent toughness. The modified epoxide resin has improved toughness, non organic solvent is used in the whole synthesizing process, non environmental pollution is caused, the synthesizing process is simple and easily controlled, and the problem is not found in amplification experiments carried out for small amount, medium amount and large amount respectively, so that the method is applicable to industrial production.

Owner:JIANGNAN UNIV

Preparation method for vanadium dioxide and doped powder thereof

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

Graphene-containing silicone rubber composite material with high thermal conductivity and preparation method thereof

InactiveCN103627179AImprove thermal conductivityUnique two-dimensional sheet structureHeat-exchange elementsRubber materialVulcanization

The invention belongs to the field of a heat conducting polymer-based composite, and particularly relates to a graphene-containing silicone rubber composite material with the high thermal conductivity and a preparation method thereof. The composite material comprises a matrix, a heat conducting filler and a vulcanizing agent. The preparation method comprises the following steps: mixing at a room temperature so as to obtain a mixed rubber material; and carrying out hot press molding and one-stage vulcanization on the mixed rubber material by using a flat vulcanizing machine, and putting in a drying oven, carrying out two-stage vulcanization, thus obtaining the silicone rubber composite material with the high thermal conductivity. As graphene is high in thermal conductivity and has a unique two-dimensional lamellar structure, an interconnected heat conducting network is easy to form in the composite material, and the thermal conductivity of the silicon rubber composite material is obviously increased; and the thermal conductivity of the graphene-containing silicone rubber composite material is 0.3W / m.K-1.5W / m.K, and the hardness of the silicone rubber composite material can be reduced. The graphene-containing silicone rubber composite material with the high thermal conductivity is simple in preparation technology, high in production efficiency and easy for the realization of industrialization mass production, and meanwhile, a direction is pointed out for the batch application of graphene.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

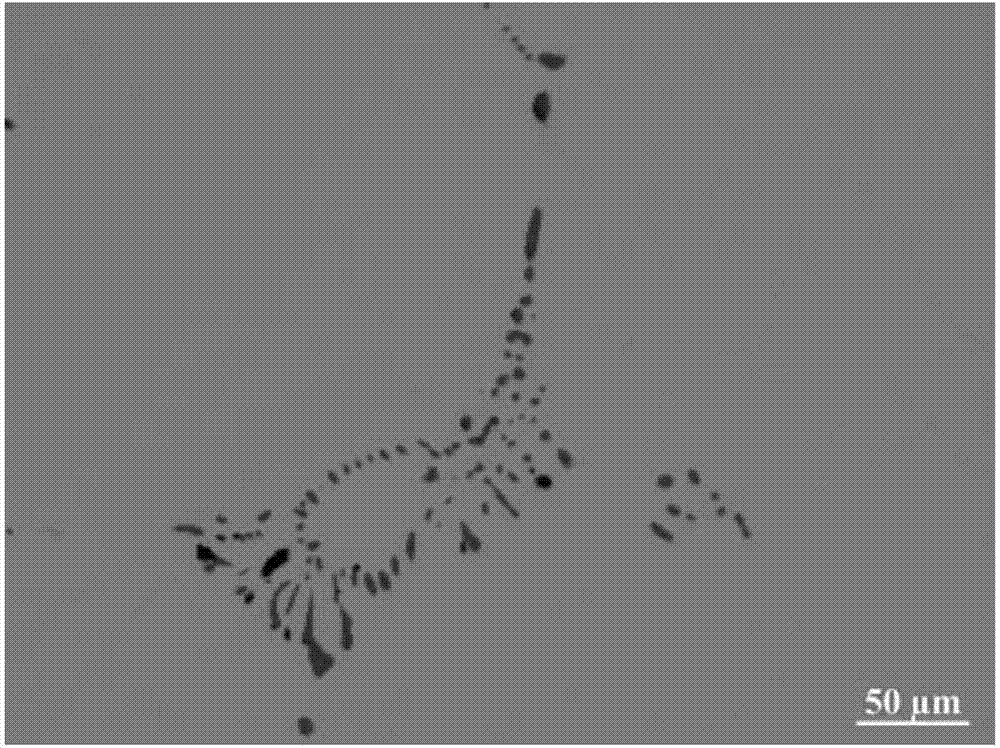

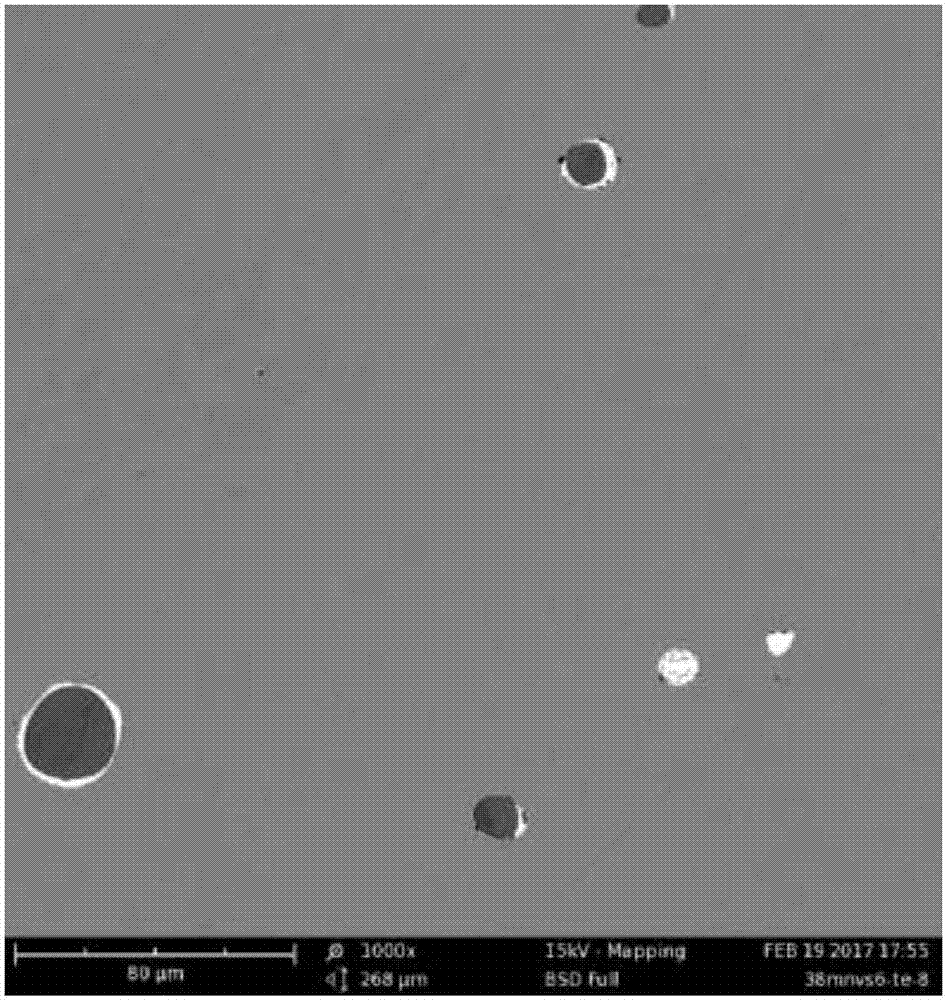

Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

ActiveCN107287504AExcellent machinabilityReduce precipitationProcess efficiency improvementSulfurImpurity

The invention discloses medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and a production technological method thereof. The non-quenched-and-tempered steel mainly comprises 0.35%-0.50% of C, 0.10%-0.80% of Si, 0.75%-1.60% of Mn, 0-0.03% of P, 0.02%-0.08% of S, 0-0.08% of Mo, 0-0.025% of Nb, 0.02%-0.12% of V, 0.012%-0.016% of N, 0.02%-0.08% of Te, 0.001%-0.003% of Ca, and the balance Fe and inevitable impurities. The ratio of the tellurium to the sulfur is 0.25-2.5. According to the free-cutting non-quenched-and-tempered steel disclosed by the invention, occluded foreign substances in the steel can be subjected to modifying treatment by adding the tellurium, the cutting properties, fatigue resistance and the like of the non-quenched-and-tempered steel can be improved obviously, and pollution to the environment can be avoided.

Owner:SHANGHAI UNIV

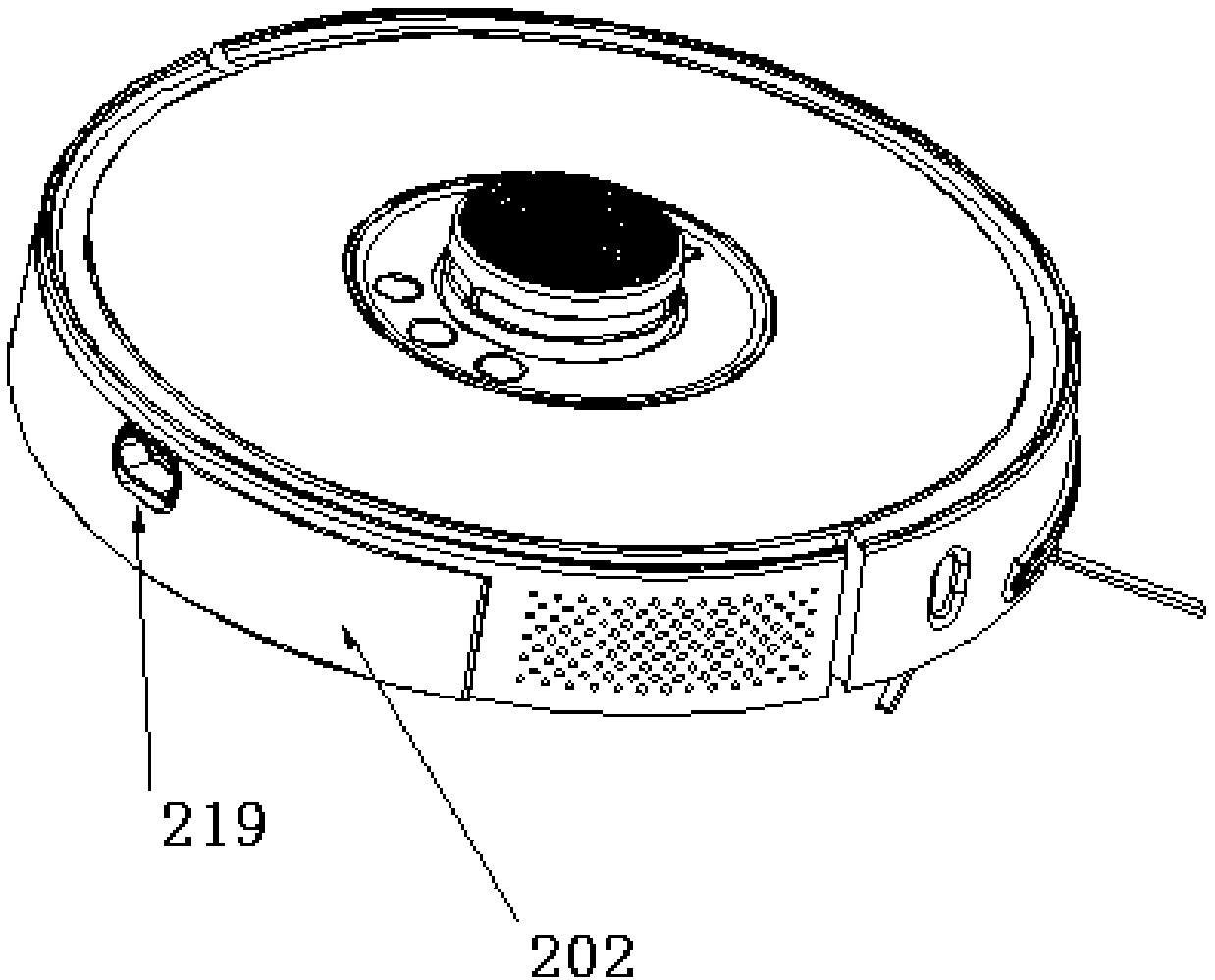

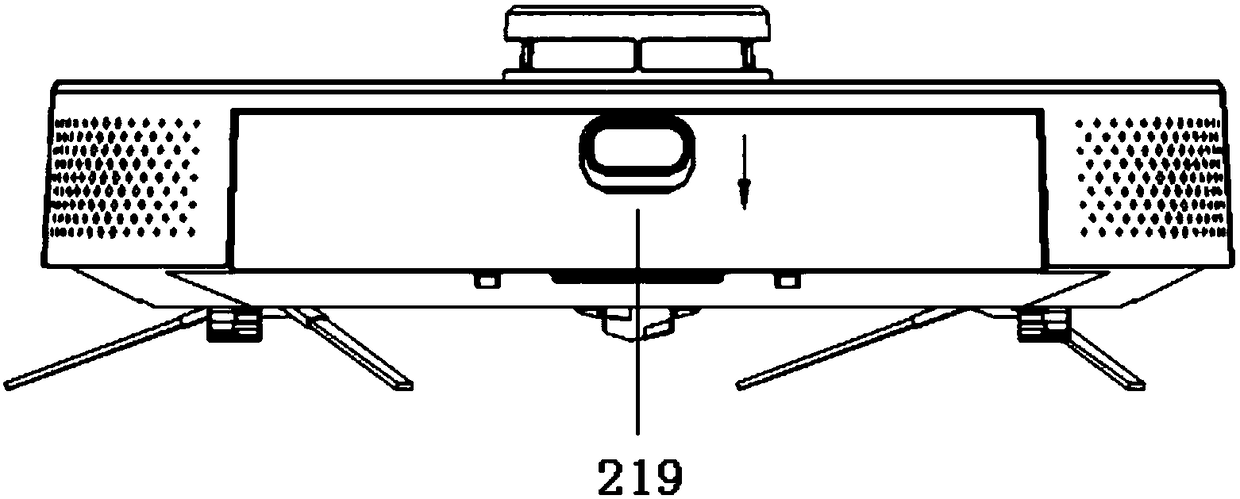

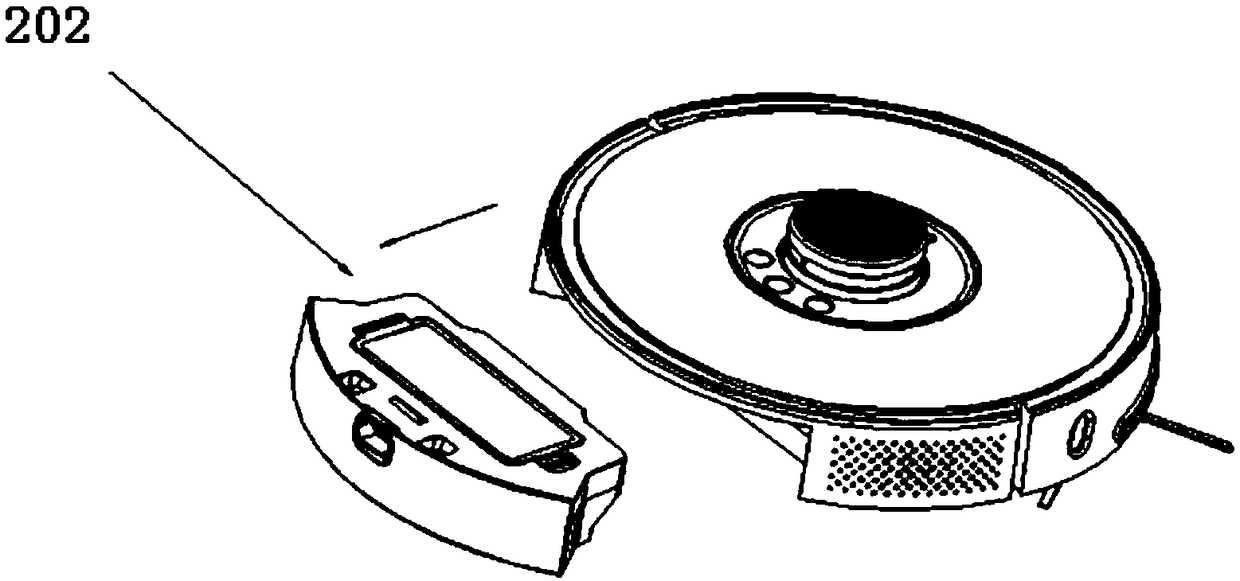

Dust-collecting charge device and dust-collecting charge method of floor-sweeping robot

ActiveCN109480714ARealize chargingAchieve normal workCarpet cleanersFloor cleanersEngineeringPollution

The invention provides a dust-collecting charge device and a dust-collecting charge method of a floor-sweeping robot. The floor-sweeping robot is provided with a floor-sweeping robot body, wherein oneside of the floor-sweeping robot body is provided with a dust box, the bottom of the dust box is provided with a dust box discharging port, the dust box discharging port corresponds to a maintenancestation dust-collecting port and can be pressed on the outside of the maintenance station dust-collecting port, and further communication between the maintenance station dust-collecting port and the dust box discharging port is achieved. The dust-collecting charge device and the dust-collecting charge method haves the advantages that charging and dust removal maintenance work of the floor-sweepingrobot are achieved simultaneously, and the floor-sweeping robot is diversified in function; when the maintenance work of dust removal is conducted on the floor-sweeping robot at a maintenance station, and a vacuum mode is adopted to suck dust and other waste in the dust box of the floor-sweeping robot into a dust bag of the maintenance station. Therefore, the dust box does not need to be taken out of the floor-sweeping robot for cleaning, and the dust-collecting charge device has the advantages of being convenient to clean and having no pollution to the outside environment.

Owner:BEIJING XIANGJIE SCI & TECH LTD

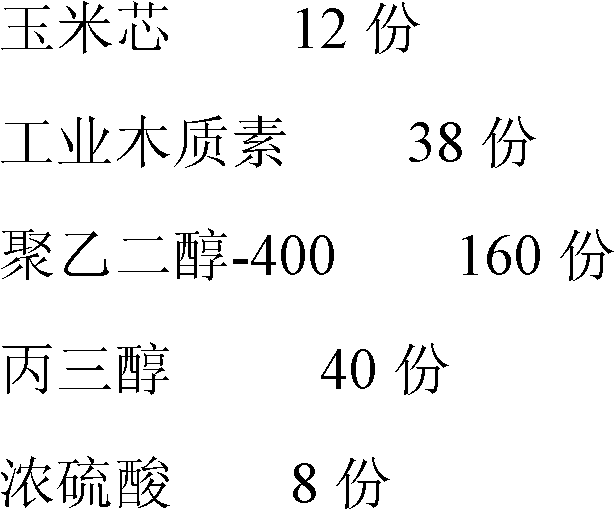

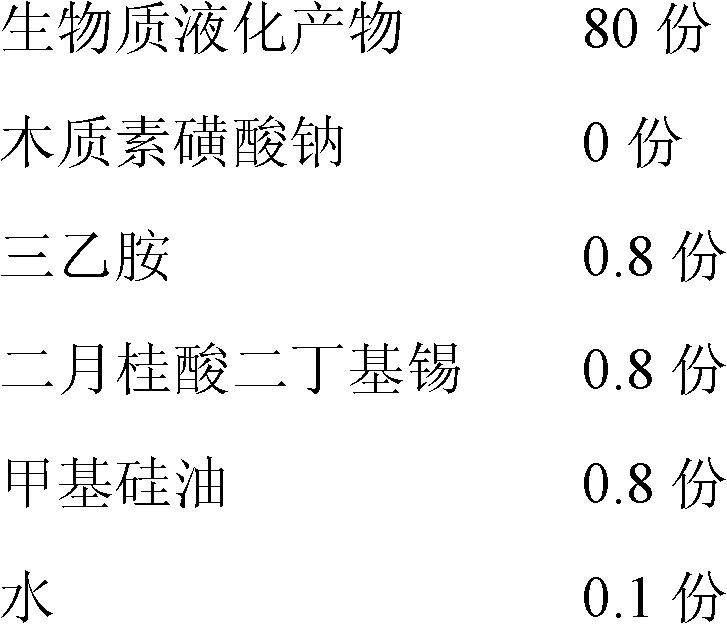

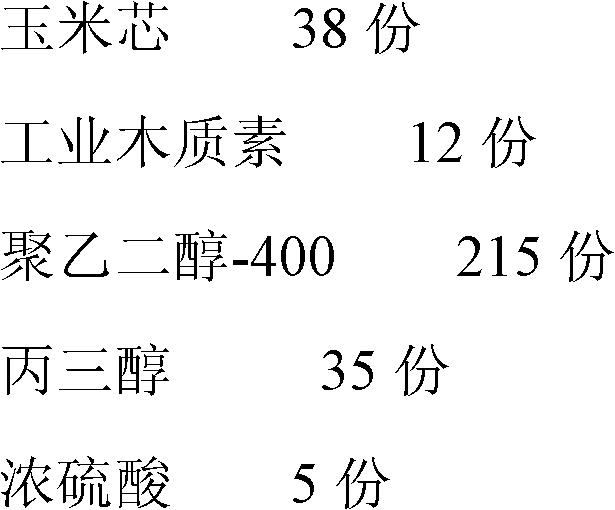

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

Multilayered gradient diamond like nano composite coating for aluminum alloy piston and preparation method thereof

InactiveCN102092166AOvercome stressOvercome adhesionLayered productsVacuum evaporation coatingDiamond-like carbonSurface layer

The invention discloses a multilayered gradient diamond like nano composite coating for an aluminum alloy piston and a preparation method thereof. The coating consists of a piston matrix, a bottom adhesive layer, a middle transition layer and a surface layer in turn, wherein the bottom is provided with a metal Ti or Cr adhesive layer; the middle transition layer is metal nitride and a Si layer; and the surface layer is a metal-doped diamond like carbon film. The wear life of the coating is improved by more than 40 times compared with that of a single-layer diamond like coating with the same thickness directly formed on the surface of aluminum alloy, and the friction coefficient under the oil lubricating condition is stabilized to be 0.05. The piston with the diamond like coating has better comprehensive performance than a piston of which the skirt is treated by MoS2, and can meet the requirements on high speed, high efficiency and low emission of a modern engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

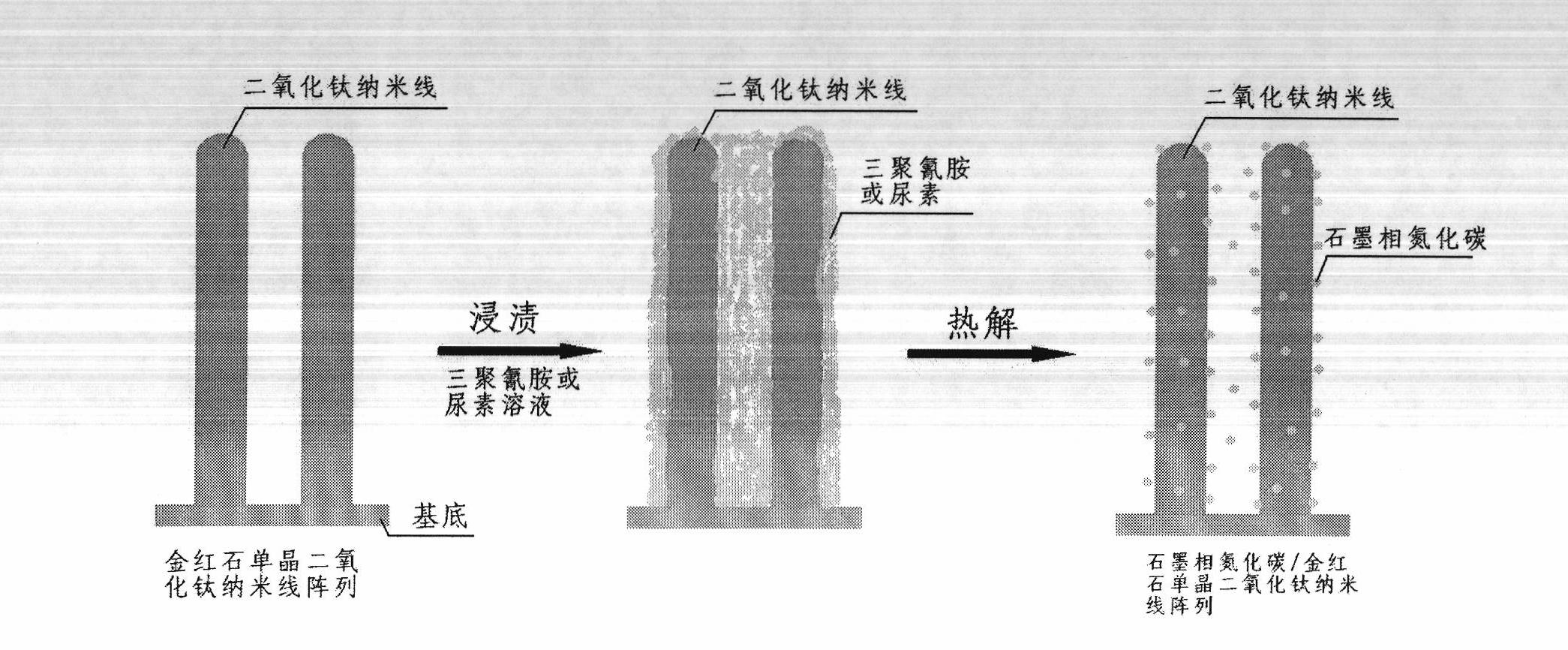

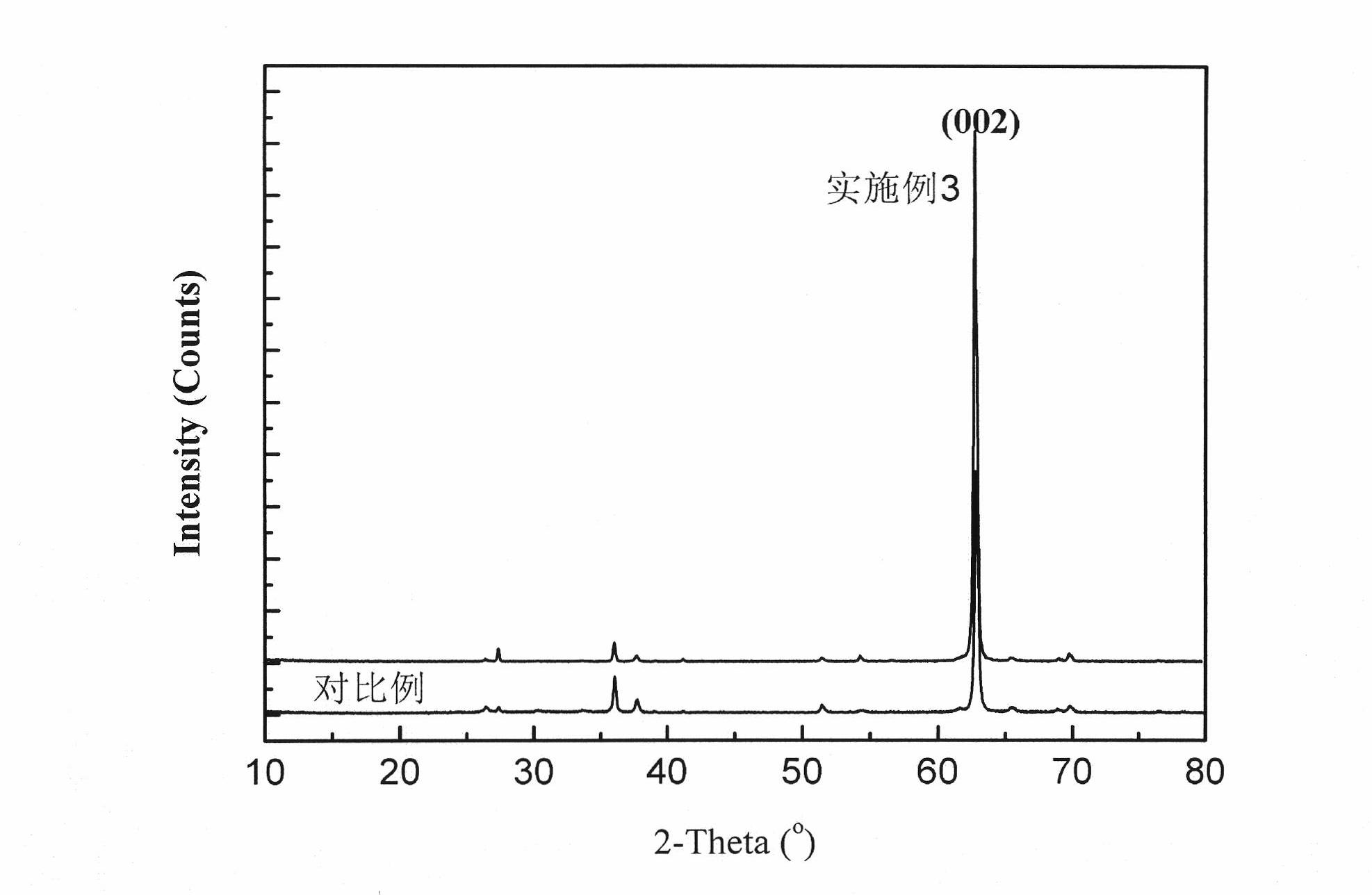

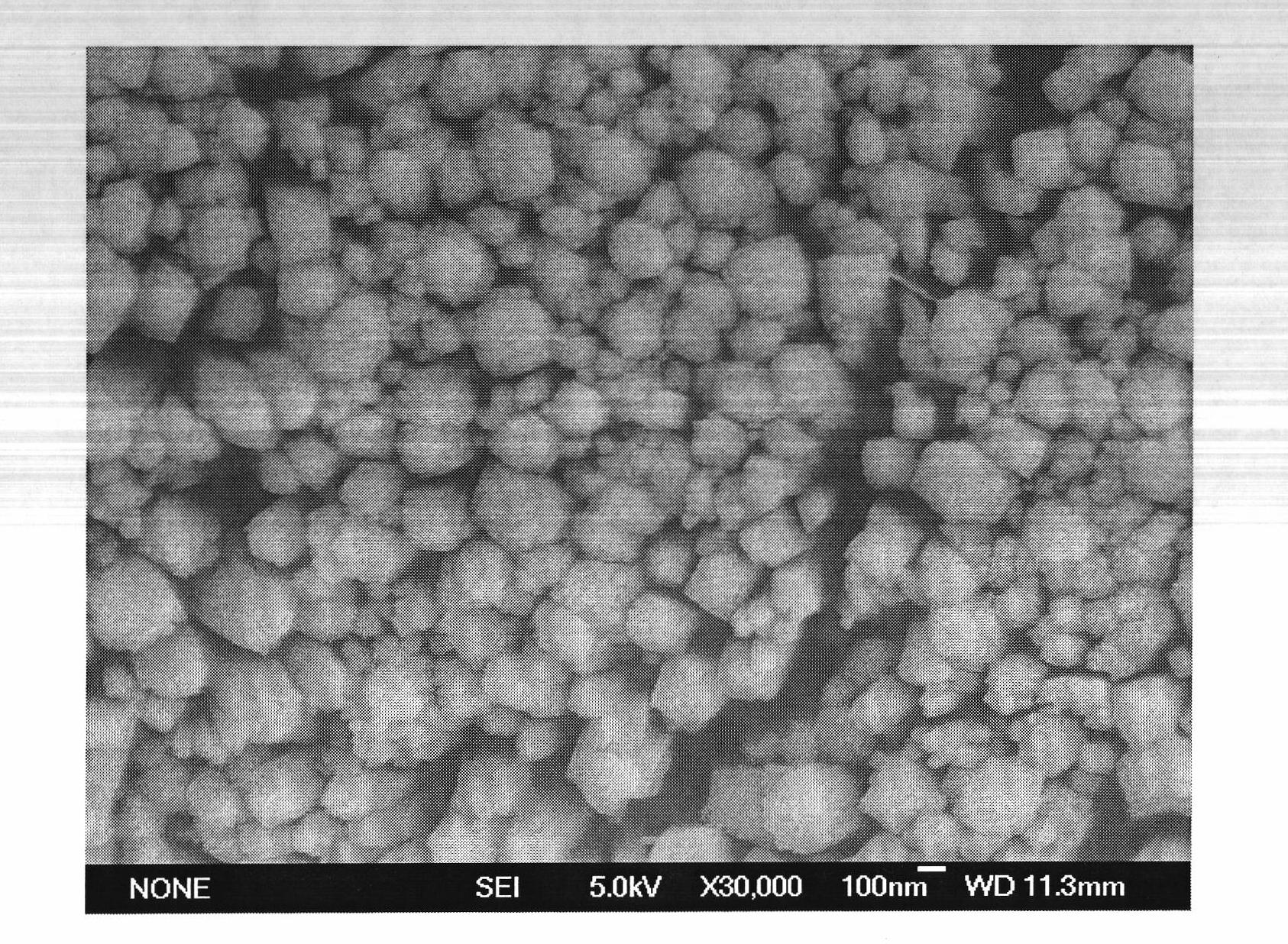

Preparation method of graphite phase carbon nitride/rutile monocrystal titanium dioxide (TiO2) nanowire array

InactiveCN102125863ALow costEasy to useCatalyst activation/preparationSingle crystalCyanamide compound

The invention discloses a preparation method of a graphite phase carbon nitride / rutile monocrystal titanium dioxide (TiO2) nanowire array. The preparation method is characterized by comprising the following steps: (a) dissolving a cyanamide compound or urea in a solution, immersing the prepared rutile monocrystal TiO2 nanowire array into the obtained cyanamide compound or urea solution, and then taking out and drying the nanowire array; and (b) performing heat treatment on the dried nanowire array to finally obtain the graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array. The preparation method has the advantages of simple process and low cost, thus being applicable to large-scale industrial production; and the prepared graphite phase carbon nitride / rutile monocrystal TiO2 nanowire array has good visible light response activity, and can be widely applied to the fields such as photocatalysis, hydrogen production by photocatalytic decomposition of water, photoelectric conversion and the like.

Owner:XIANGTAN UNIV

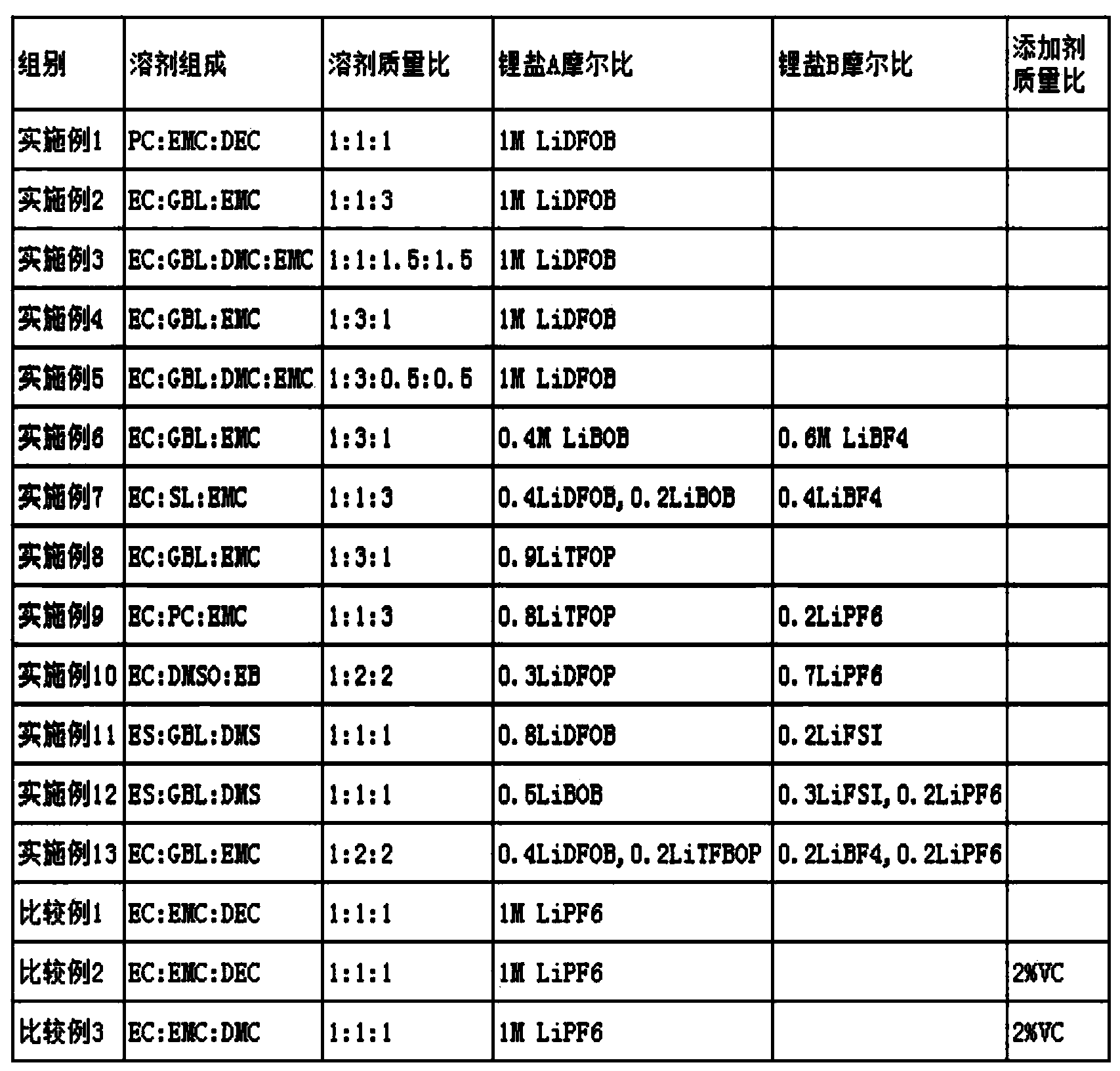

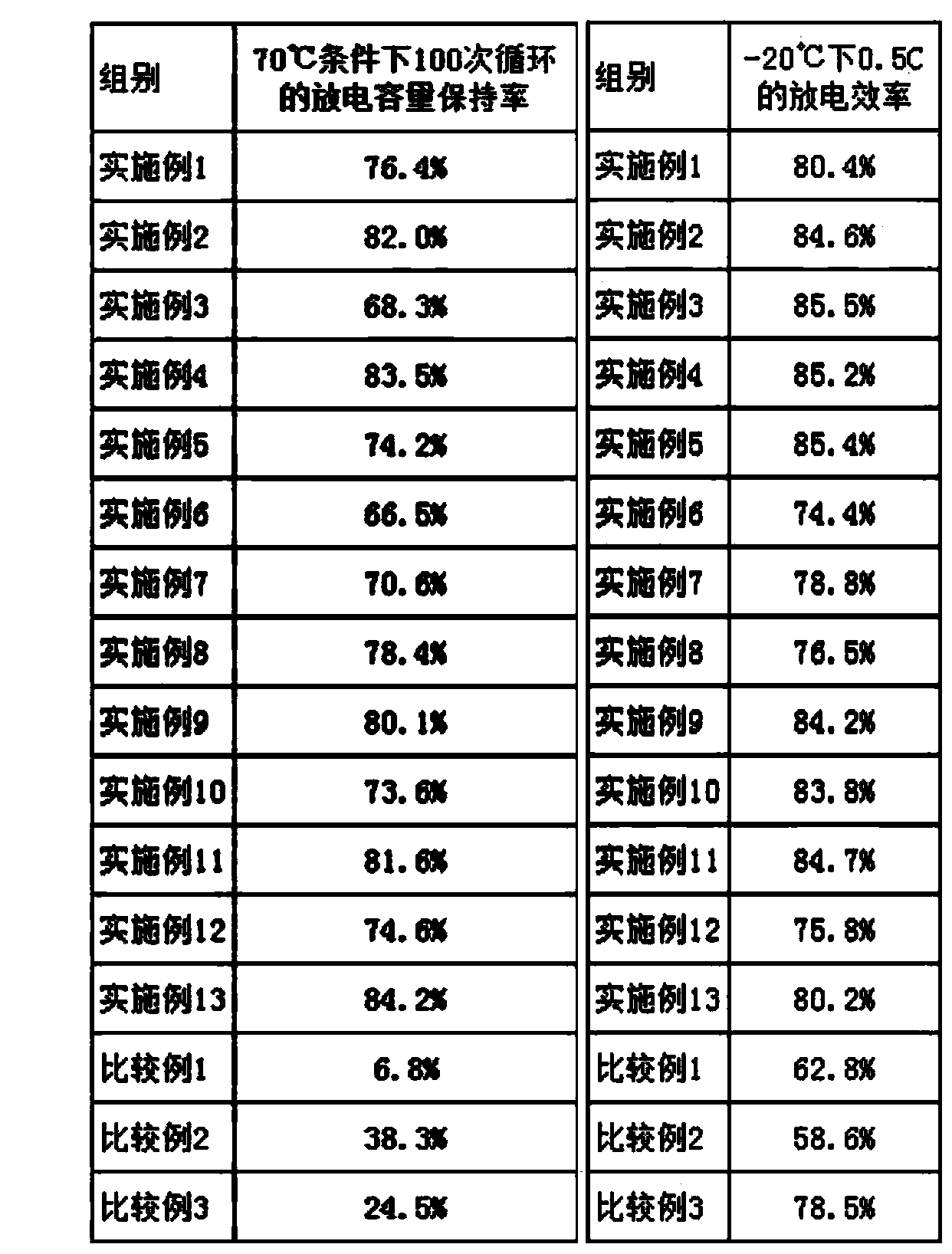

Lithium ion battery electrolyte solution

InactiveCN103943884AImprove conductivityGood thermal stabilitySecondary cellsOrganic electrolytesSulfoneEther

The invention discloses a lithium ion battery electrolyte solution which comprises a lithium salt and a non-aqueous organic solvent, wherein the lithium salt is a lithium salt A or a mixture of the lithium salt A and a lithium salt B; the lithium salt A contains oxalate groups, and the lithium salt B does not contain oxalate groups; the lithium salt A comprises one or mixture of several of lithium bis(oxalate)borate (LiBOB), lithium difluoroborate (LiDFOB), lithium difluorophosphate (LiDFOP) and lithium tetrafluorophosphate (LiTFOP); the non-aqueous organic solvent is one or mixture of several of common carbonate, carboxylate, ethers, sulfone compounds and the like. Due to the lithium ion battery electrolyte solution, the safety and the high-low-temperature performance of a lithium ion battery can be greatly improved, and the use temperature range of the lithium ion battery can be expanded.

Owner:陈琛

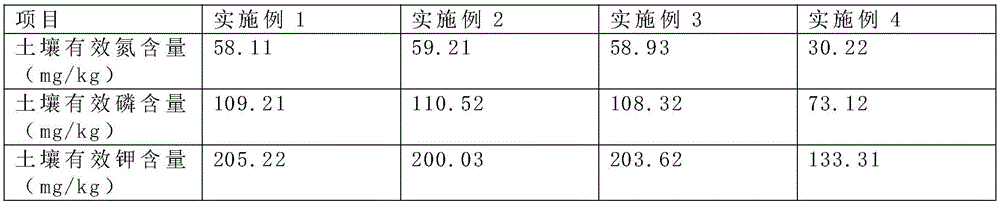

Functional nutrition fertilizer and preparation method thereof

InactiveCN106116925APromote seedling growthGood insecticidal effectBiocideCalcareous fertilisersHorticultureUrea

The invention discloses a functional nutrition fertilizer, which comprises the following raw materials in parts by weight: 200-500 parts of organic wastes, 20-60 parts of grass carbon, 60-120 parts of livestock manure, 200-600 parts of rice washing water, 50-100 parts of seaweed mud, 10-50 parts of EM bacteria agent, 1-3 parts of ferrous sulfate, 1-3 parts of copper sulfate, 1-3 parts of zinc sulfate, 0.5-2 parts of manganese sulfate, 0.5-3 parts of ammonium molybdate, 0.3-2 parts of sodium tetraborate, 0.3-3 parts of strontium nitrate, 0.5-1 parts of selenium dioxide, 2-6 parts of magnesium sulfate, 3-8 parts of potassium chloride, 2-8 parts of calcium carbonate, 3-10 parts of bentonite, 5-10 parts of urea, 10-50 parts of traditional Chinese medicine extract, and 10-30 parts of traditional Chinese medicine residue fermented product. According to the functional nutrition fertilizer, the nutrition components are complete and balanced, the disease and insect resistance capacity of soil can be enhanced, the fertilizer efficiency of soil can be increased, and the functional nutrition fertilizer has no environment pollution. The invention further discloses a preparation method of the functional nutrition fertilizer.

Owner:李怀峰

Biomimetic preparation method of high-strength regenerated silk protein fiber

ActiveCN103498210AHigh crystallinityHigh strengthConjugated cellulose/protein artificial filamentsWet spinning methodsMechanical propertyProtein fiber

The invention discloses a biomimetic preparation method of a high-strength regenerated silk protein fiber. The method takes high crystallization degree, high strength, high modulus nano cellulose whiskers with a large length-diameter ratio to simulate the beta-fold microcrystal in the natural silk fiber, then mixes the nano cellulose whiskers with a regenerated silk fibroin solution, and finally prepares the high-strength regenerated silk protein fiber through a wet spinning method. The characteristic that a large amount of hydroxyl groups in the molecular chains of the rigid nano cellulose whiskers can form intermolecular hydrogen bonds with polar groups such as carboxyl groups, amino groups, and the like, in the molecular chains of silk protein is utilized to achieve the structural bionics of the regenerated silk protein fiber, and thus improves the mechanical properties of the regenerated silk protein fiber. The preparation method is simple, and does not pollute the environment. The mechanical properties of the obtained regenerated silk fiber are equal to or even better than those of natural silk, and the regenerated silk fiber has the similar micro-structure and configuration as the natural silk.

Owner:浙江枫翎新材料科技有限公司

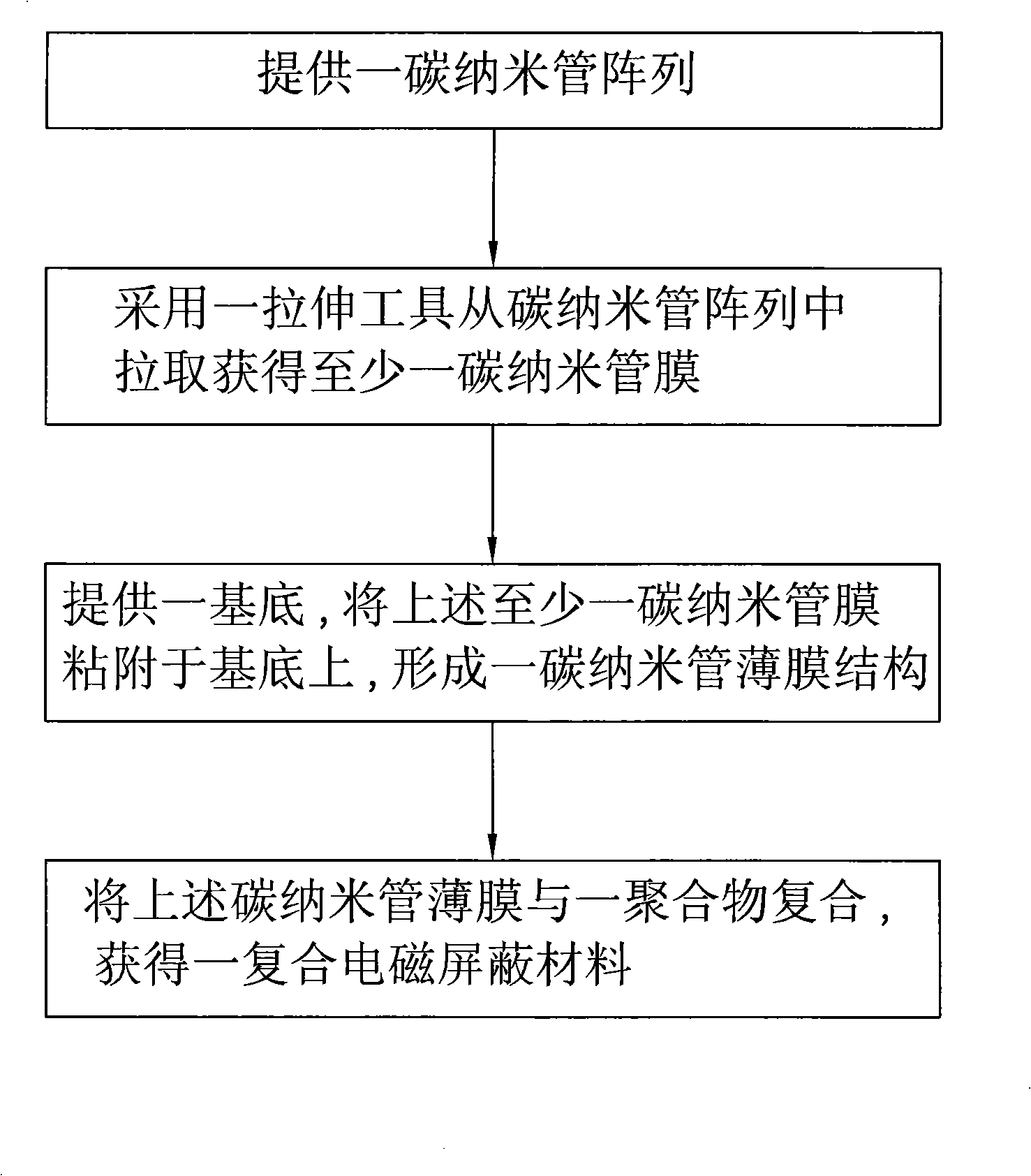

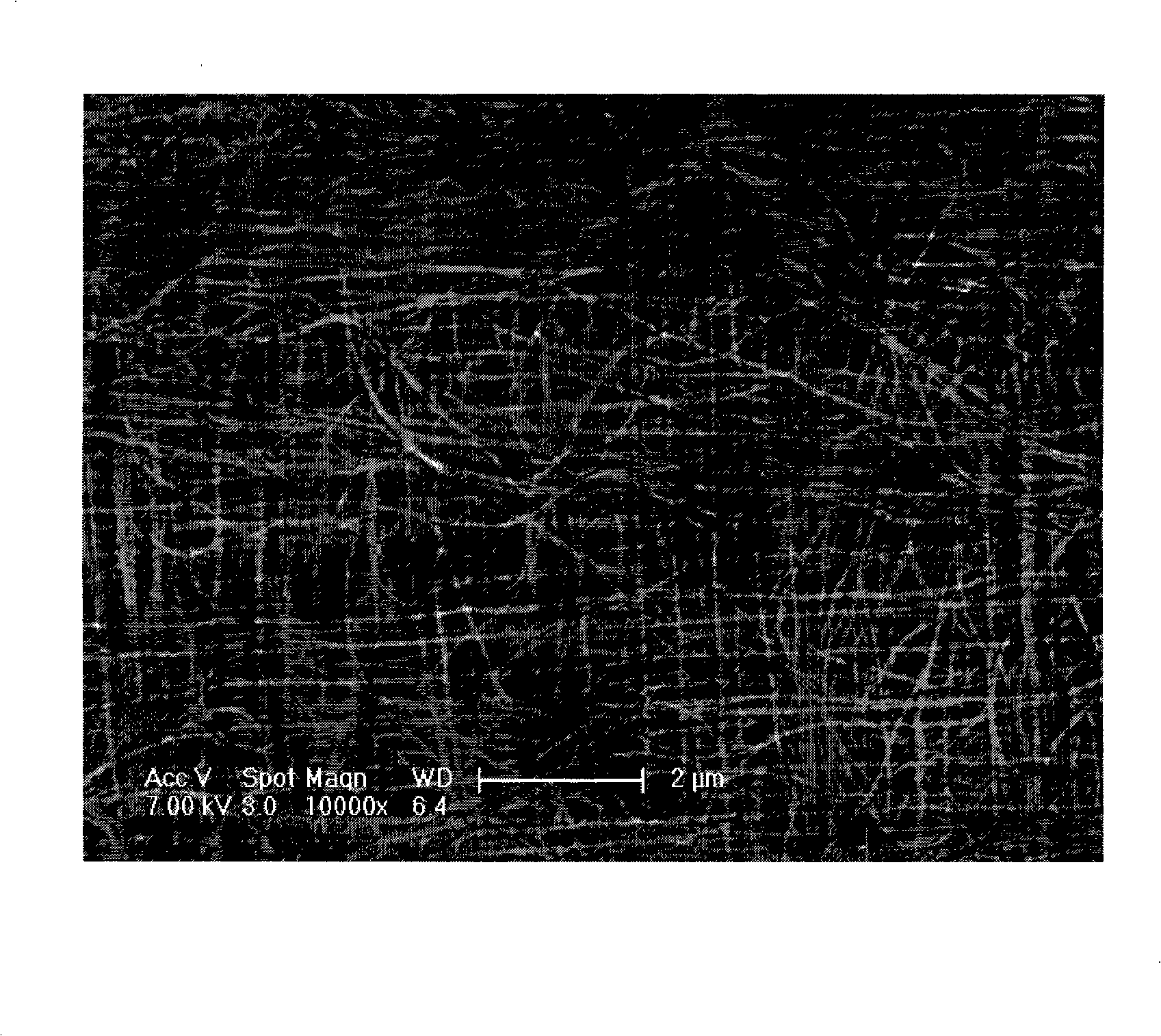

Composite electromagnetic shielding material and preparation method thereof

ActiveCN101409999AUnrestricted contentWide range of choicesLamination ancillary operationsMagnetic/electric field screeningResidual carbonCarbon nanotube

The invention provides a composite electromagnetic shielding material, comprising a polymer and a plurality of carbon nano-tubes; wherein, a plurality of carbon nano-tubes are arranged in the polymer in the form of carbon nano-tube film. A preparation method used for preparing the composite electromagnetic shielding material comprises the steps as follows: a carbon nano-tube array is provided; atleast a carbon nano-tube film is gained by the pulling in the carbon nano-tube array by a tensile tool; a substrate is provided; at least a carbon nano-tube film is attached to the substrate, thus forming the carbon carbon-tube film structure and removing the residual carbon nano-tube film structure out of the substrate; the carbon nano-tube film structure is composed with the polymer, thus gaining the composite electromagnetic shielding material.

Owner:TSINGHUA UNIV +1

Method for treating sludge heavy metal

InactiveCN101045599AImprove passivation effectControl Oxidation/Reduction PotentialSludge treatmentWater contaminantsSludgeSorbent

Owner:重庆市天境生态环境有限公司

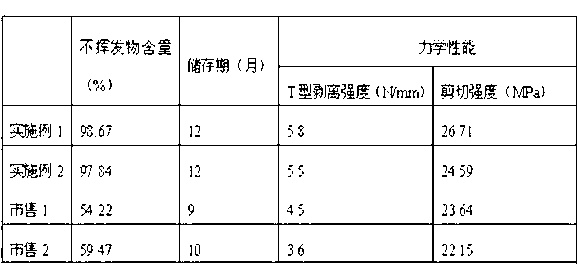

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

Method for preparing environment-friendly type anti-corrosive and anti-fingerprint metal surface coating

InactiveCN101392142AImprove anti-corrosion performanceGood fingerprint resistancePretreated surfacesAnti-corrosive paintsEpoxyMicrocrystalline wax

The invention relates to a composition for protecting metal surfaces, in particular to a preparation method of an environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. The composition contains an A component and a B component, the A component takes waterborne epoxy resin as a matrix resin and nano-silica, a silane coupling agent, microcrystalline wax disperse liquid, zirconium complex, deionized water, defoamer and a levelling agent are added, thus obtaining the A component; the B component contains a waterborne epoxy modified amine curing agent and a certain quantity of epoxy curing promoter. The two components are mixed and stirred evenly at a ratio of 4:1 to 3:1 to form the environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. After coating, metal can be heated by going through a baking channel at a certain temperature, the film forming time can be controlled by adjusting the heating period and finally a transparent coating layer which has quite good anticorrosive protection function over metal and fingerprint resistant function is formed.

Owner:TONGJI UNIV

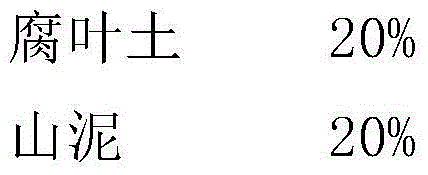

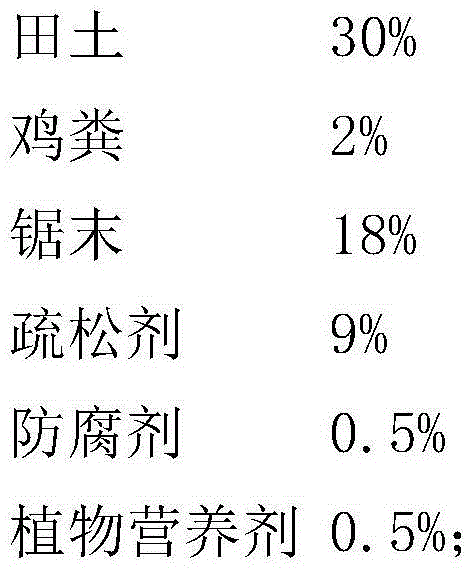

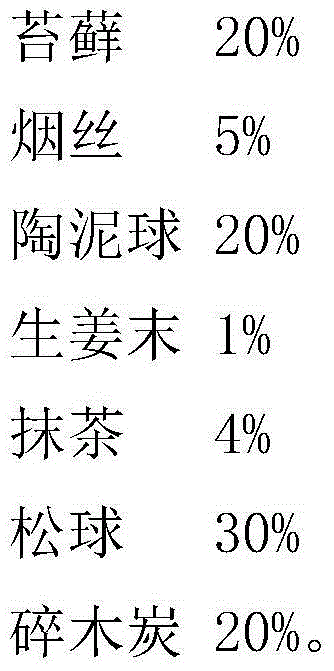

Nutrient soil for flowers

InactiveCN104016787AGood water and gas control performanceEasy to cultivate and manageFertilizer mixturesWoody plantPlant nutrition

The invention discloses nutrient soil for flowers, relating to the technical field of biofertilizers. The nutrient soil is composed of the following components in percentage by mass: 20% of leaf mould, 20% of mountain clay, 30% of soil, 2% of chicken manure, 18% of saw dust, 9% of bulking agent, 0.5% of preservative and 0.5% of plant nutrients. The nutrient soil is rich in nutrient, low in preparation cost, favorable in sterilization and insecticide functions and suitable for households; in addition, the nutrient soil can provide relatively-large proportional long-acting solid-phase organic matters, a stable pH value and favorable water and air control performance for plants, so that the plants are more convenient in cultivation management, the plants are promoted to be rapidly rejuvenated after the roots of the plants grow, the nutrient requirements of the flowers can be met, and the environment can not be polluted; the soil can be used for most of gramineous plants and a part of woody plants with short branches and compact crowns.

Owner:范青明

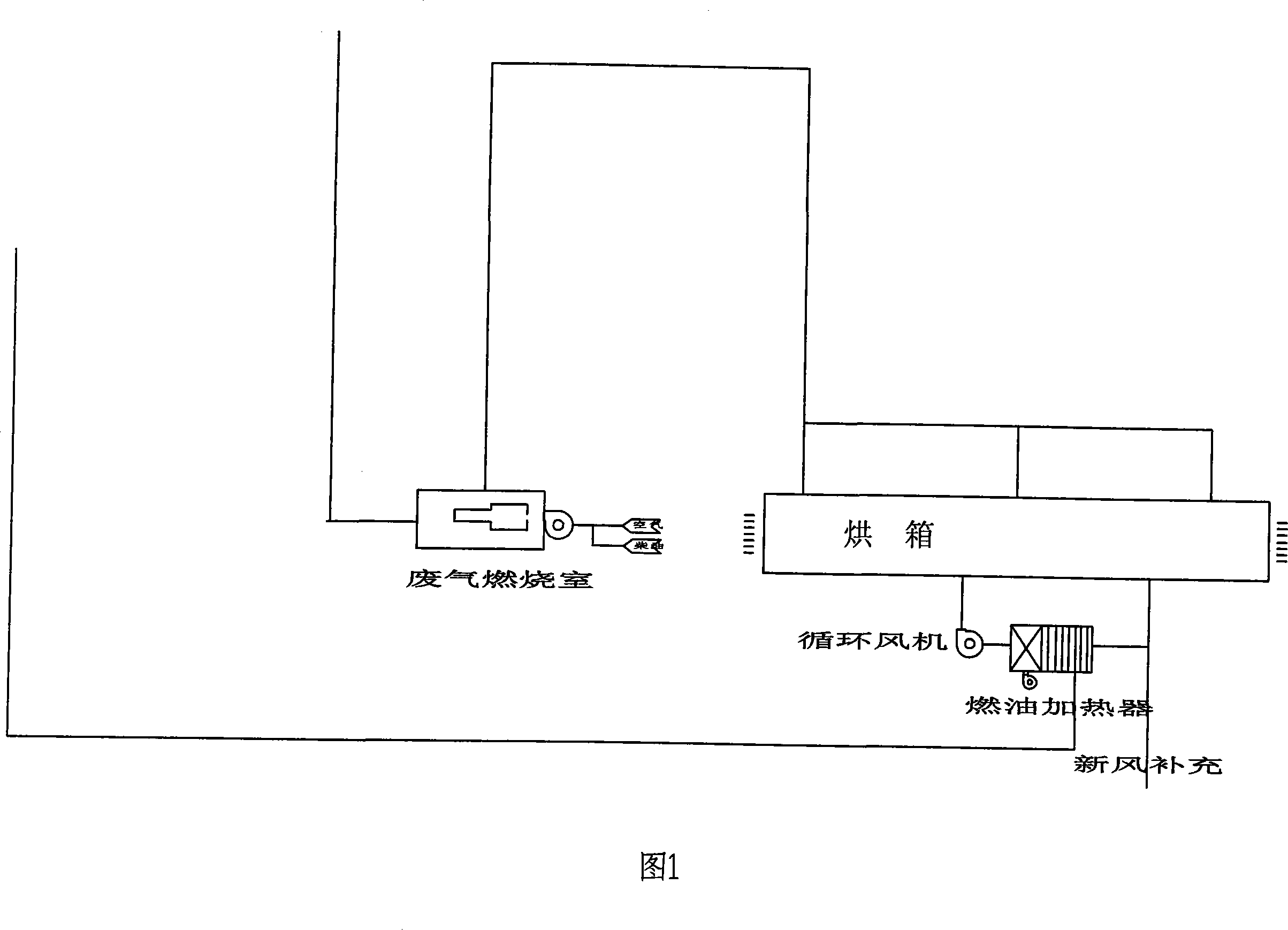

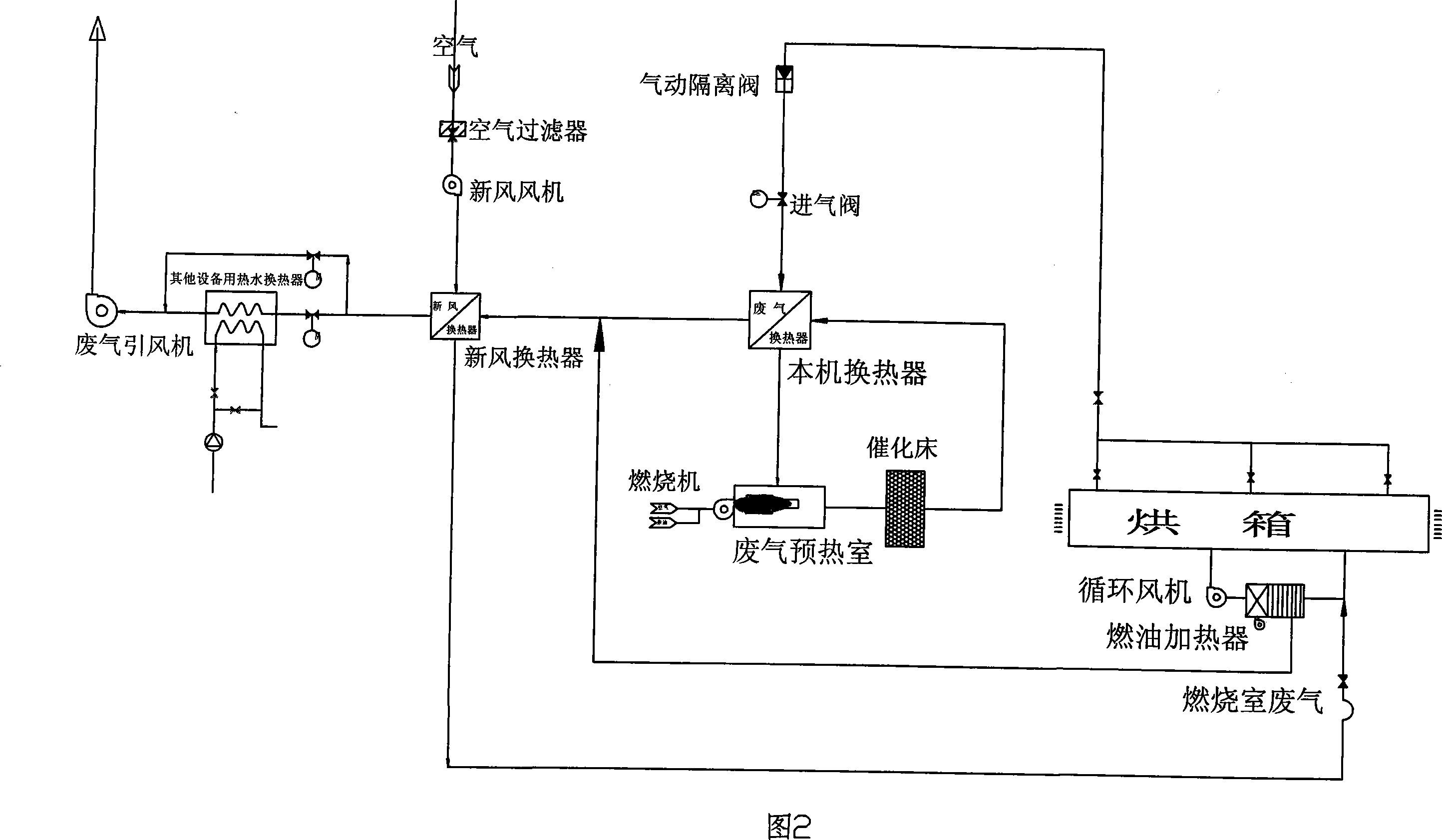

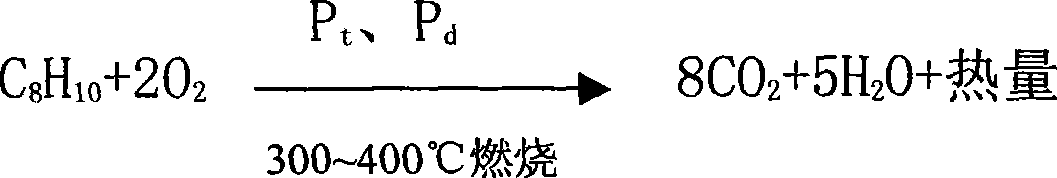

Color-coating waste gas heat recovery method

InactiveCN101162123ACreate pollutionAchieve the purpose of recyclingDrying gas arrangementsIncreasing energy efficiencyRecovery methodOrganic solvent

The invention relates to a method for heat reclaiming colorized painting exhaust gas and mainly solves the problem of air pollution caused by the prior art incapable of treating harmful gas with organic solvent when the colorized painting exhaust gas is heat reclaimed. The invention further solves the technical problems of higher temperature needed by an oven, the need of the additionally heating new wind up to the temperature needed by the oven and great waste of energy. The steps of the invention are as follows: the exhaust gas coming from the oven goes through a local heat interchanger and then is inlet into the local heat interchanger through an exhaust gas preheating chamber and a catalytic bed; the exhaust gas does heat exchange with high temperature catalyzed gas and is heated up to the catalyzing and initiation temperature; the exhaust gas heated up to the catalyzing and initiation temperature enters into the catalytic bed to do catalytic reaction; the high temperature gas after being catalyzed is inlet into a hot water heat interchanger for other devices through a new wind heat interchanger, doing heat exchange with the new wind from an air filter and a new wind blower; the new wind from the air filter and new wind blower is heated by the new wind heat interchanger and then conveyed to a circulated air system of oven.

Owner:HANGZHOU TAIXIN IND

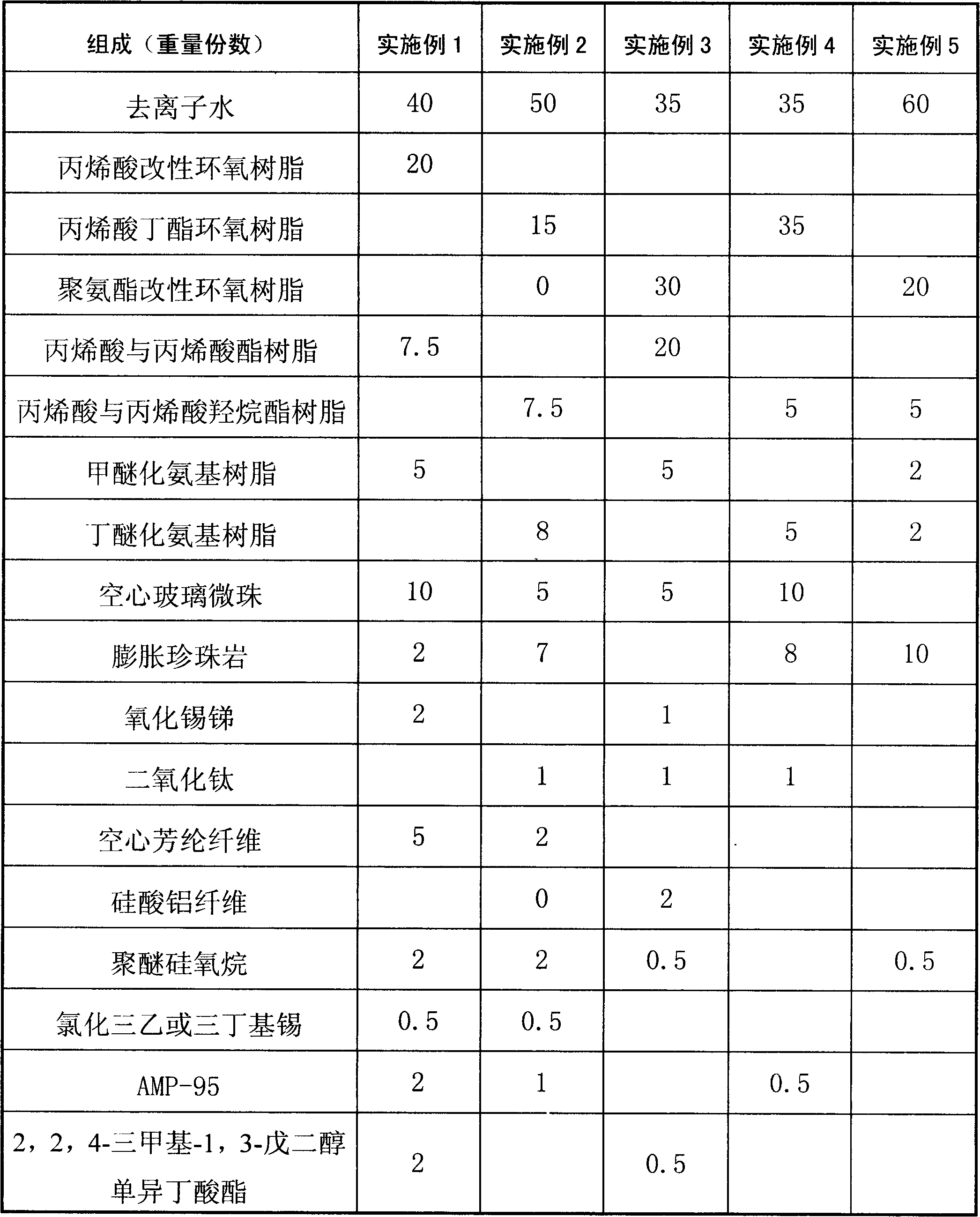

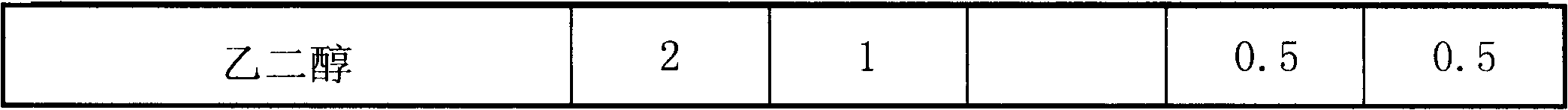

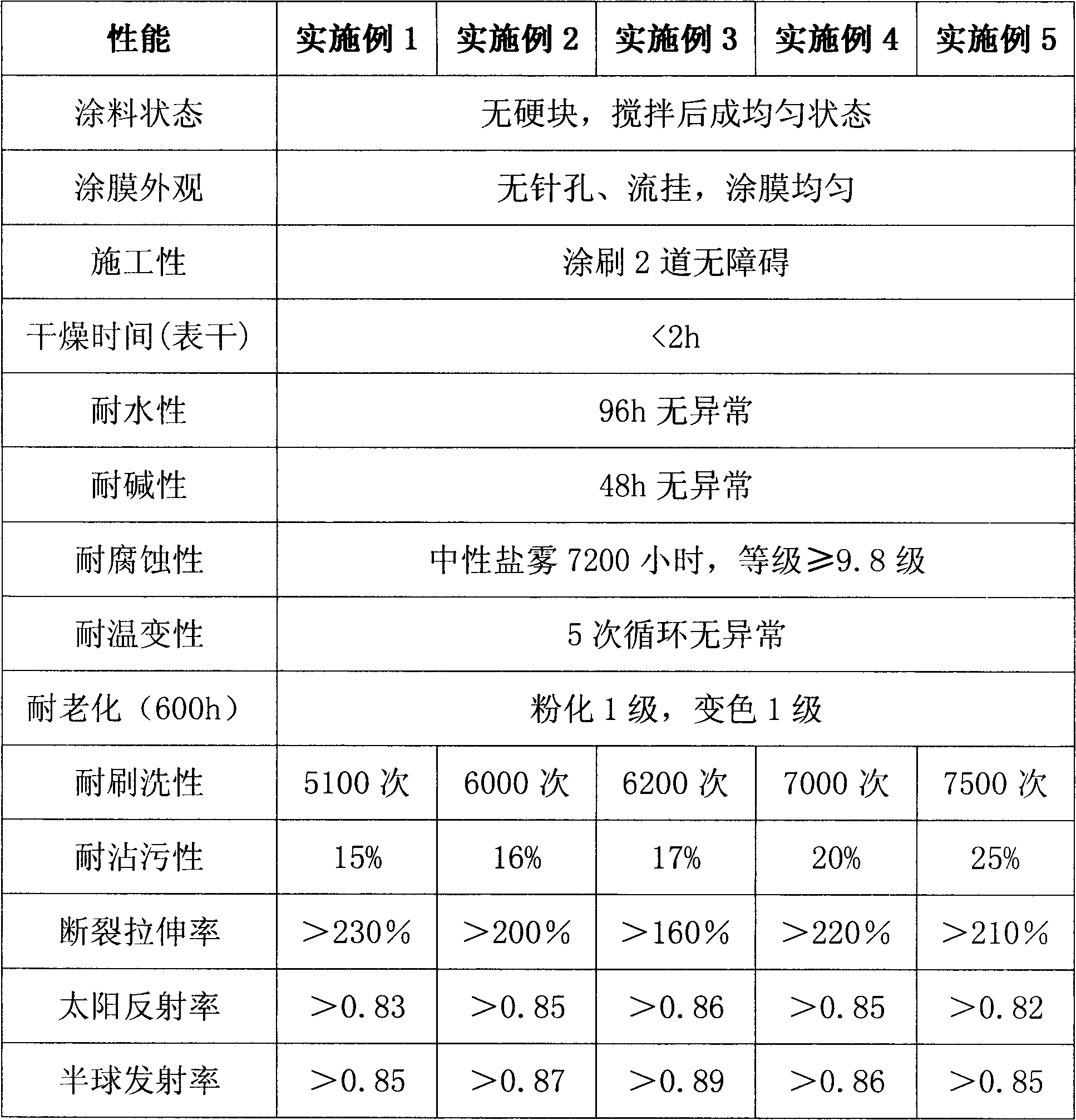

Epoxy acrylate modified high anticorrosion heat insulation paint containing porous ceramic addictive and production method thereof

InactiveCN103450773AStrong adhesionHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to a kind of heat insulation paint with a high anticorrosion performance and a preparation method thereof. The anticorrosion heat insulation paint is composed of following components in percentage by weight: 35 to 60% of deionized water, 20 to 40% of modified epoxy resin, 5 to 30% of modified acrylic resin, 1 to 8% of amino resin, 10 to 25% of heat insulation materials, 0 to 8% of strengthening materials, and 1 to 10% of auxiliary agent. The preparation method comprises following steps: orderly adding deionized water, modified epoxy resin, modified acrylic resin, and amino resin into a reactor, starting the stirrer, evenly mixing the materials, adjusting the pH value of the system to a range of 7 to 9, then orderly adding the auxiliary agent, the heat insulation materials, and the strengthening materials, stirring for 1 to 3 hours in a high speed, and evenly mixing so as to obtain the anticorrosion heat insulation paint. The preparation method has the advantages of simple technology, high production efficiency, and low energy consumption. The prepared paint does not contain any organic solvent, so no solvent will volatilize during the coating solidification process, so no pollution is generated to the environment. The paint has the advantages of excellent mechanical properties of bonding strength, hardness, scratch resistance, wear resistance, and water resistance, and good properties of anticorrosion, salt smog resistance, forming ability, heat resistance, and deflection resistance.

Owner:BOYIFEI EQUIP INST FOR NEW MATERIALS

Method for cultivating morchella

InactiveCN106358751AAvoid or reduce useAvoid or reduce the use of food ingredientsCalcareous fertilisersMagnesium fertilisersNutrientEdible mushroom

The invention belongs to the technical field of edible mushroom cultivation, in particular relates to a method for cultivating morchella, and aims to solve the technical problem of providing a novel method for cultivating morchella. The main improvement is that the method is achieved by adopting a cultivation mode and a novel cultivation medium in match. The method provided by the invention comprises the following steps: A, pretreating a cultivation land; B, opening ridges, and putting morchella bags on the ground; C, covering the morchella bags with soil, and constructing the ridges; D, growing the morchella; E, placing nutrient bags; and F, inducing the morchella till the morchella is harvested. By adopting the method provided by the invention, the cost of each mu of the land can be reduced, moreover, the yield of the morchella can be remarkably increased, and the method is worthy of popularization and application.

Owner:INST OF SOIL FERTILIZER SICHUAN ACAD OF AGRI SCI

Novel environmental-friendly double-component acrylate adhesive and preparation method thereof

InactiveCN103074000ASmall smellCreate pollutionPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveAdhesivePollution

The invention relates to a novel environmental-friendly double-component acrylate adhesive, which is composed of a component A and a component B in mass part ratio of 1 to 1, wherein the component A is composed of the following raw materials in mass part: 45-75 parts of acrylic monomer, 15-45 parts of toughened resin, 0.5-10 parts of initiating agent, 0.01-1 part of stabilizing agent, 0.1-5 parts of coupling agent and 0.5-10 parts of thixotropic agent; and moreover, the component B is composed of the following raw materials in mass part: 45-75 parts of acrylic monomer, 15-45 parts of toughened resin, 0.5-10 parts of accelerating agent, 0.01-1 part of stabilizing agent, 0.1-5 parts of coupling agent and 0.5-10 parts of thixotropic agent. The novel environmental-friendly double-component acrylate adhesive provided by the invention has very little smell, does not produce substances harmful to the body, and cannot cause pollution to the environment; and meanwhile, the adhesive with the structure has favorable adhesive property and storage stability.

Owner:BEIJING HYSTIC NEW MATERIALS

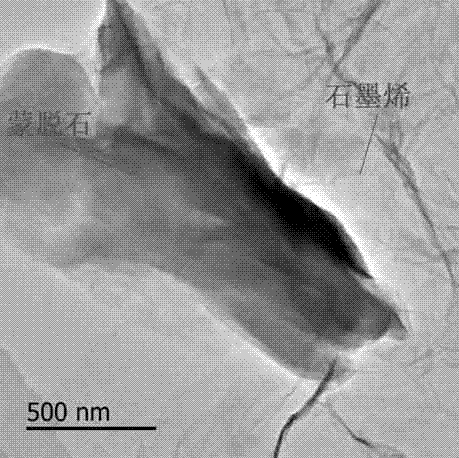

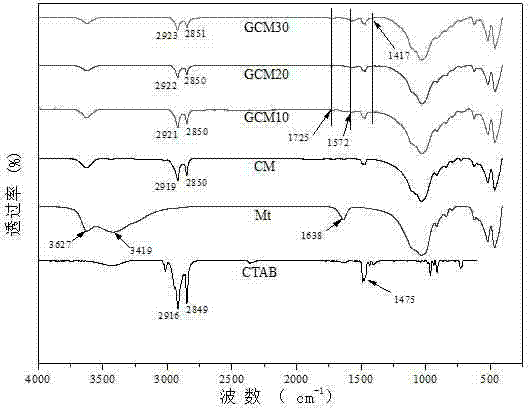

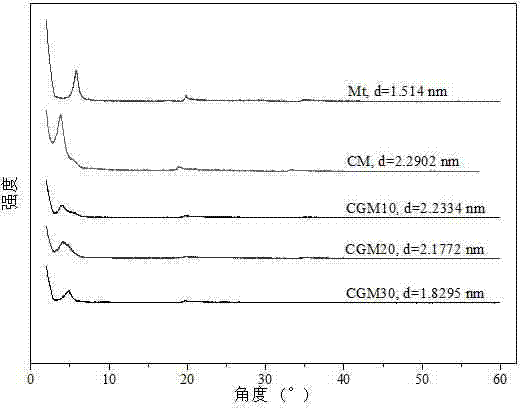

Graphene / montmorillonite nano composite material, and preparation method and application thereof

ActiveCN104772113AEasy to manufactureLow equipment requirementsOther chemical processesWater/sewage treatment by sorptionFiltrationWastewater

The invention discloses a graphene / montmorillonite nano composite material, and a preparation method and application thereof. The preparation method of the graphene / montmorillonite nano composite material is as below: uniformly mixing cetyl trimethyl ammonium bromide modified montmorillonite suspension and graphene oxide suspension subjected to ultrasonic treatment, fully stirring, adding a reducing agent for reduction, so as to obtain a black flocculent precipitate after the reaction, and conducting washing, suction filtration, drying, grinding and screening to obtain the graphene / montmorillonite nano composite material. The graphene / montmorillonite nano composite material prepared by the method can be used as an adsorbent in the field of water pollution control, especially adsorption and removal of the heavy metal pollutants in wastewater, and has the advantages of simple preparation method, high adsorption speed, easy regeneration, and reuse. The raw materials have wide sources, low cost and high actual application value.

Owner:SOUTH CHINA UNIV OF TECH

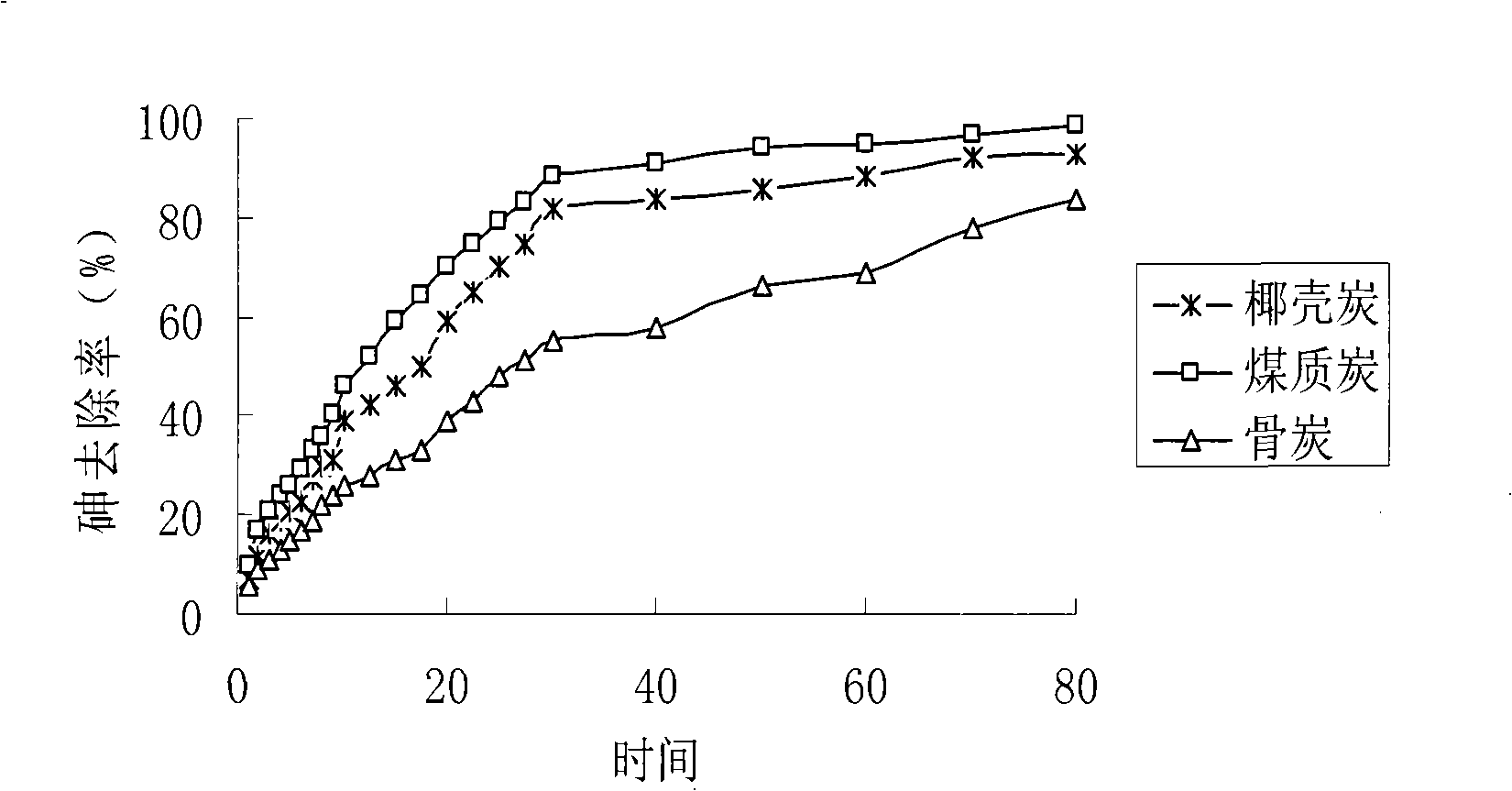

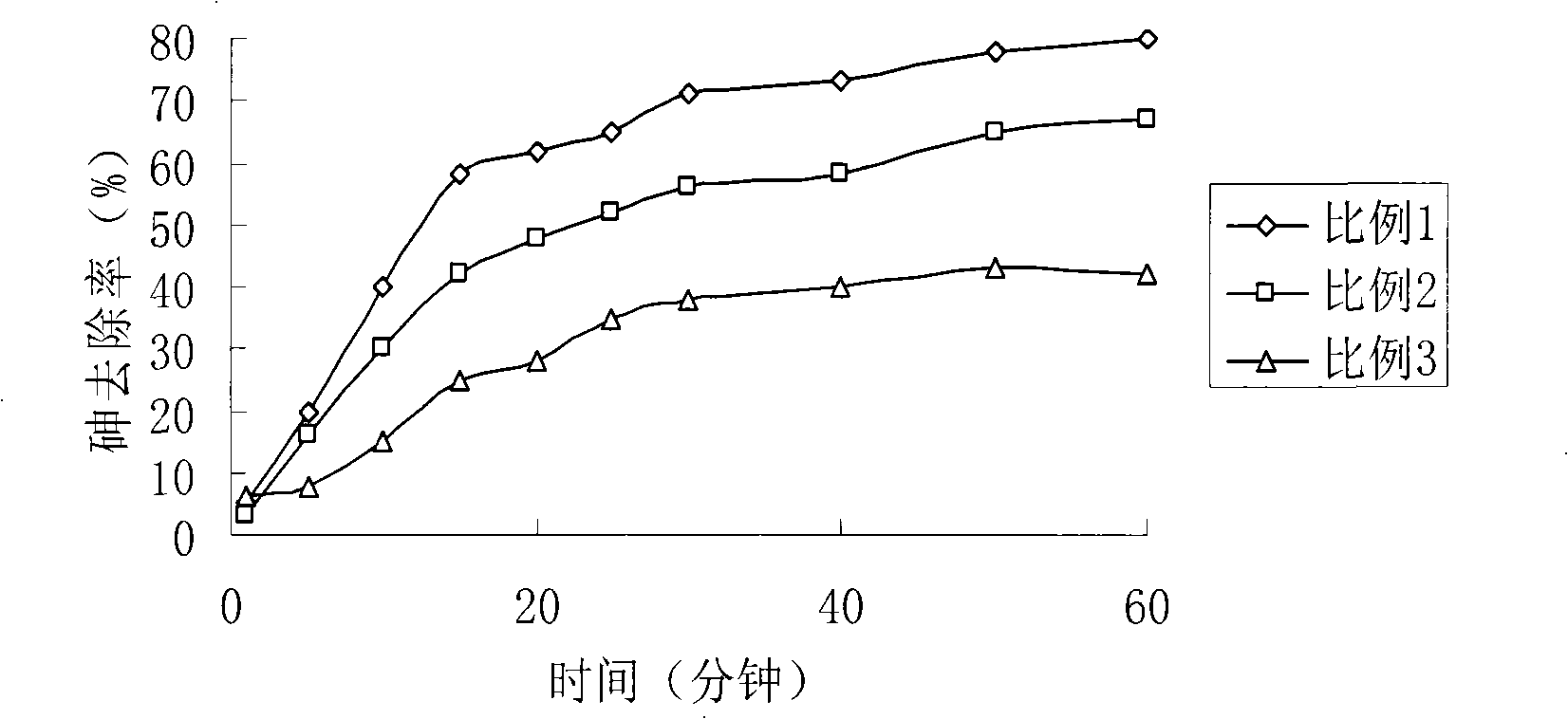

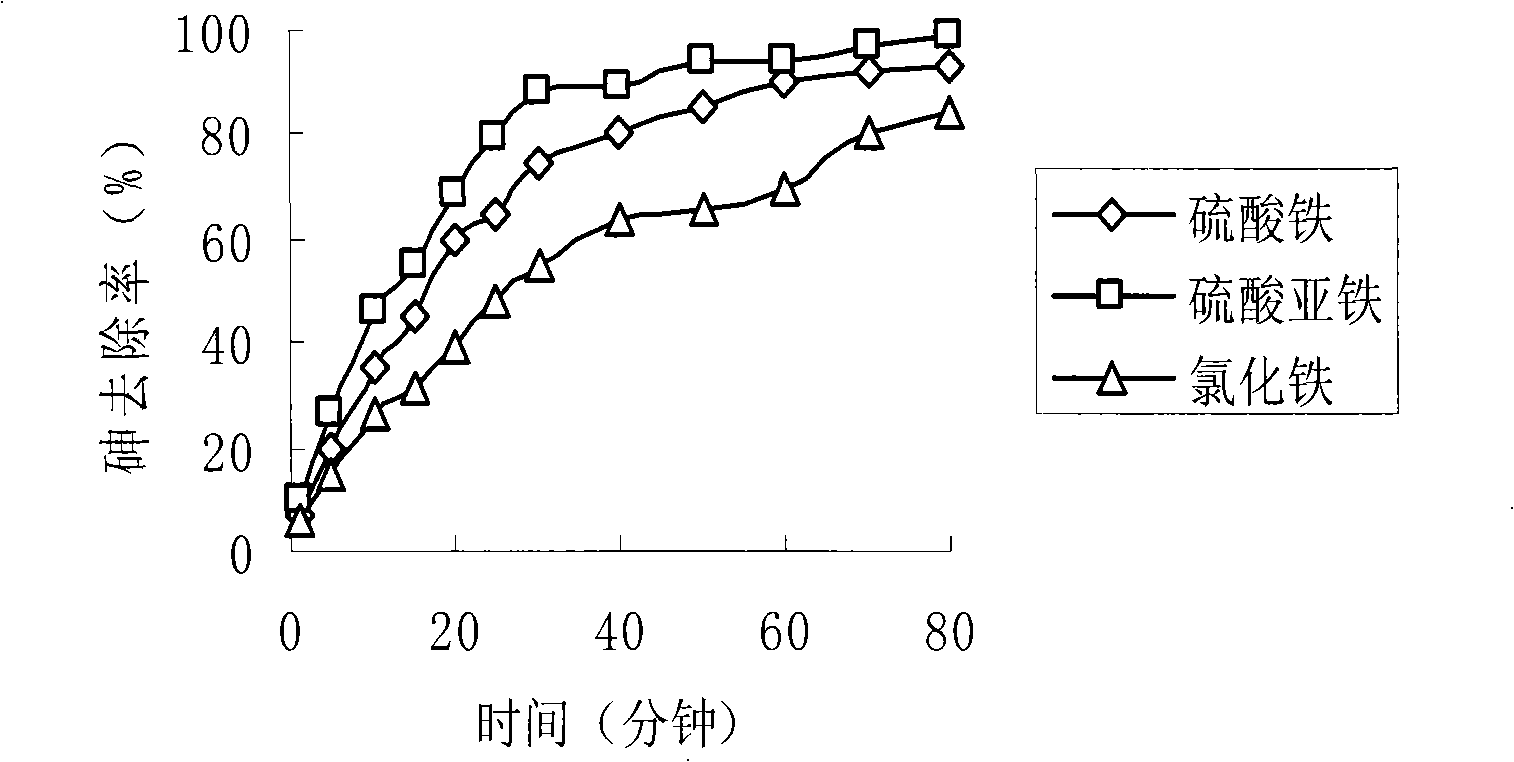

Method for preparing load type nano arsenic-removing sorbent for drinking water

InactiveCN101347717ALarge adsorption capacityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPotassium borohydrideSorbent

The invention relates to the elimination of the arsenic in drinking water, in particular to a preparation method of a supported type nano-adsorbent for removing arsenic from drinking water; the method includes the following steps: (1) activated carbon material with pore volume of 0.100-0.500cm<3> / g is selected for pretreatment; (2) soluble ferric salt solution is firstly used for soaking the activated carbon for 10-120 min; (3) alcoholic solution is taken as a dispersant to be added into the ferric salt solution; (4) under the protection of inert gases at room temperature, a strong reductant, potassium borohydride or sodium borohydride, is used for titrating the ferric salt, and agitation is carried out under the protection of inert gases; after the titration of potassium borohydride or sodium borohydride solution, agitation lasts for 10-120 min; (5) after agitation, centrifugation is carried out; oxygen-free water is firstly used for washing for 1-3 times, then organic solvent is adopted for washing for 1-3 times, and vacuum drying is done at 40-100 DEG C for 12-48h to obtain the product. The adsorbent of the invention has large adsorption capacity and small volume and is safe, stable and easy to store and transport.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com