Method for preparing load type nano arsenic-removing sorbent for drinking water

A nano-adsorption and drinking water technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of increasing costs, achieve low cost, good application prospects, and overcome high loss rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

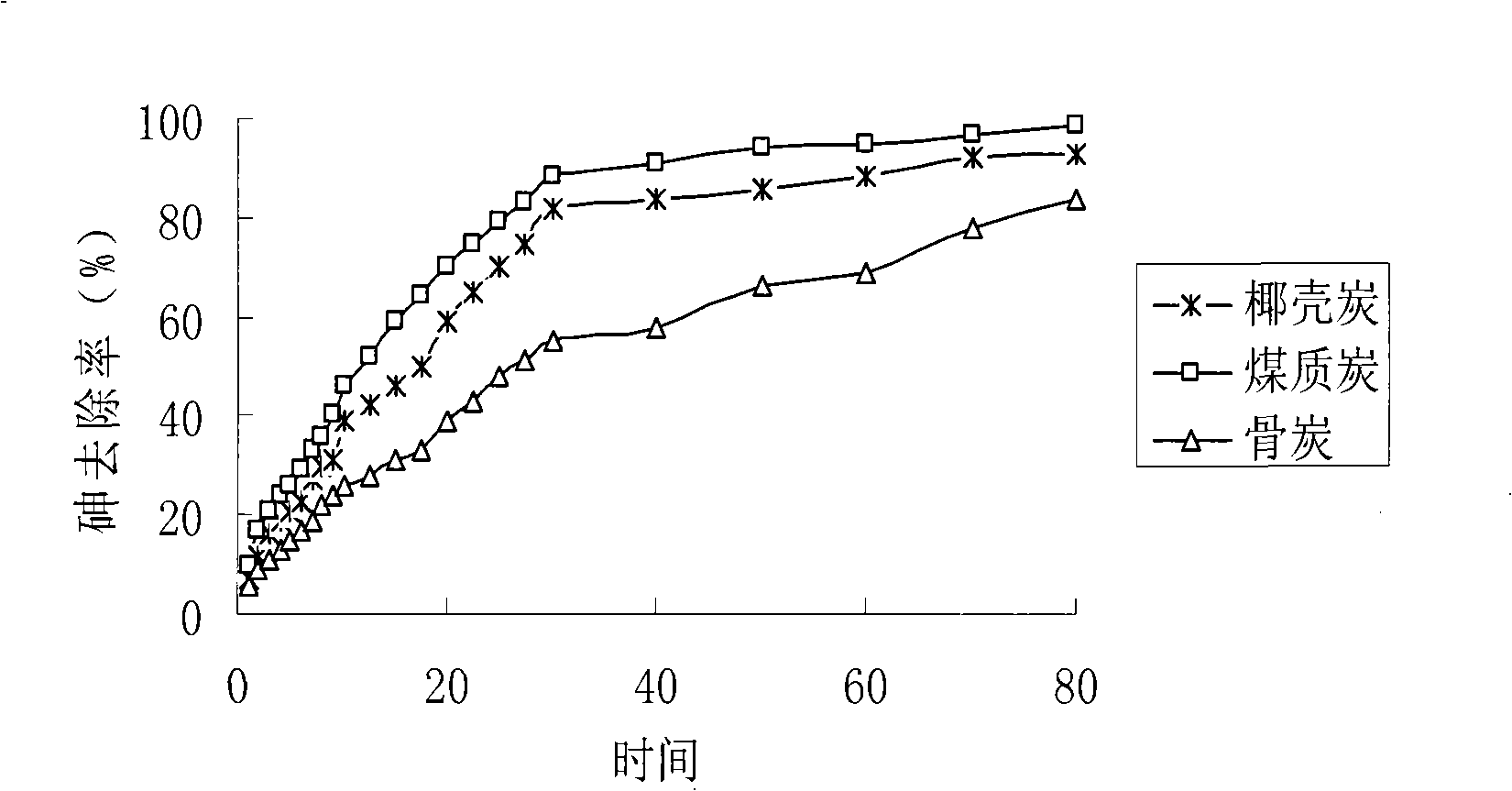

[0032] The selected materials are: choose different matrix activated carbon: coconut shell carbon (pore volume is 0.326cm 3 / g), coal-based carbon (pore volume is 0.145cm 3 / g), bone charcoal (pore volume is 0.250cm 3 / g); ferric chloride, potassium borohydride, organic solvents (common), monoalcohols (C 1 -C 10 ), low-carbon polyol series (C 1 -C 10 ), polyethylene glycol series (200-40000), anaerobic water, inert gas (common), etc.

[0033] The specific steps are:

[0034] (1) select commercially available coconut shell charcoal (the pore volume is 0.326cm 3 / g), coal-based carbon (pore volume is 0.145cm 3 / g), bone charcoal (pore volume is 0.250cm 3 / g) and other activated carbon materials, washed 3 times with deionized water, and then ultrasonically treated for 30min;

[0035] (2) At room temperature, in a 250ml three-neck flask equipped with a magnetic stirrer, activated carbon, and a dropping funnel, add 30 ml of 0.15M ferric chloride solution (coconut shell cha...

Embodiment 2

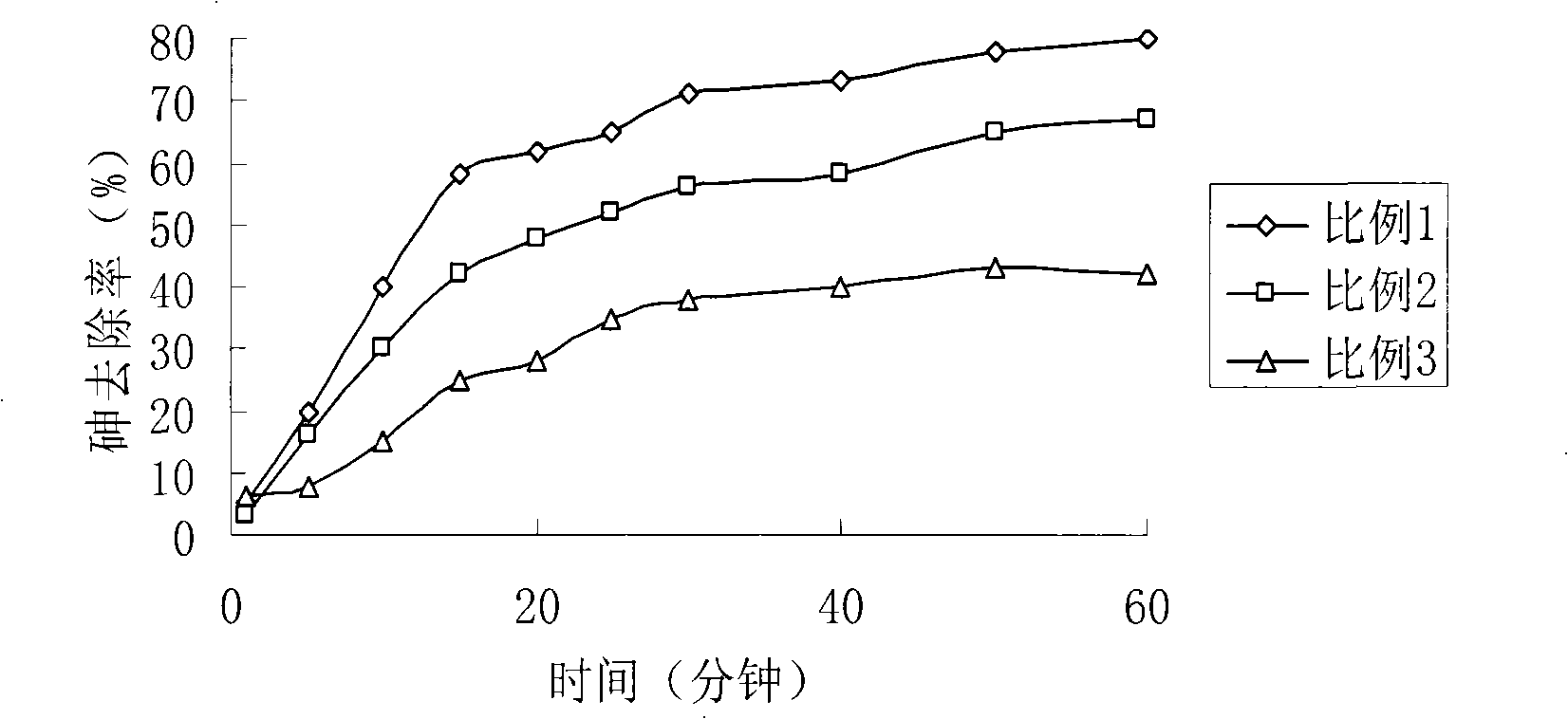

[0041] The selected material is: activated carbon (obtained from coal-based carbon treatment, the pore volume is 0.168cm 3 / g), ferrous sulfate, potassium borohydride, organic solvent (common), ethanol, glycerin, polyethylene glycol 200, polyethylene glycol 4000, anaerobic water, inert gas (common), etc.

[0042] The specific steps are:

[0043] (1) Select the pore volume as 0.168cm 3 / g of commercially available coal-based activated carbon, washed 3 times with deionized water, and then sonicated for 30 min;

[0044](2) At room temperature, in a 250ml there-necked flask equipped with a magnetic stirrer, gac, and dropping funnel, add 30 milliliters of 0.2M ferrous sulfate solution (soak the coal-based charcoal in advance for 60 minutes with ferrous sulfate), Then 45 ml of dispersant (ratio 1 of ethanol, glycerol, polyethylene glycol 200 and 4000 is 1:1:1, ratio 2 is 2:2:0.5, ratio 3 is 2:1:0.1) is added.

[0045] (3) Under the protection of inert gas (flow rate 60 ml / min), p...

Embodiment 3

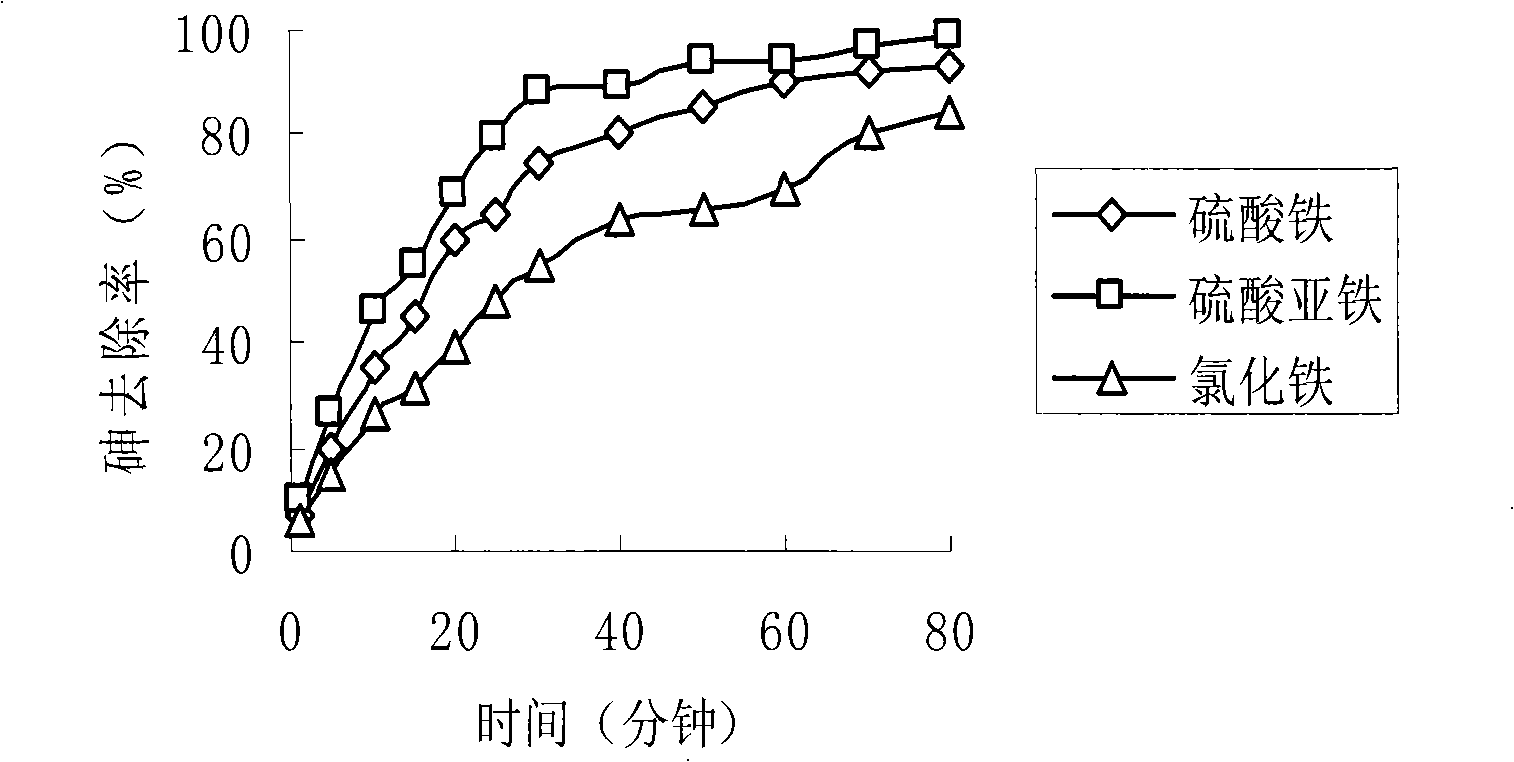

[0050] The selected material is: activated carbon (obtained from coal-based carbon treatment, the pore volume is 0.214cm 3 / g), iron salt (ferric chloride, ferrous sulfate, ferric sulfate), potassium borohydride, organic solvent (common), ethanol, glycerin, polyethylene glycol series 200, anaerobic water, inert gas (common )Wait.

[0051] The specific steps are:

[0052] (1) Select the pore volume as 0.214cm 3 / g of commercially available coal-based activated carbon, washed 3 times with deionized water, and then sonicated for 30 min;

[0053] (2) At room temperature, in a 250ml three-neck flask equipped with a magnetic stirrer, activated carbon, and dropping funnel, add 0.1M ferric chloride, ferric sulfate, and ferrous sulfate solution 30ml iron salt for 60 minutes), and then add 60 milliliters of dispersant (ethanol, glycerin, polyethylene glycol 4000 ratio 2:1:0.1).

[0054] (3) Under the protection of nitrogen gas (flow rate 60 ml / min), potassium borohydride solution wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com