Preparation method of efficient polyethyleneimine modified cellulose-based heavy metal adsorbent

A technology based on polyethyleneimine and cellulose, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problem of restricting the fixed amount of functional groups, affecting the adsorption effect of adsorbents, and difficult to ensure Epoxy group content and other issues, to achieve the effects of easy control of production operation and temperature, high grafting rate and monomer conversion rate, easy mixing and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

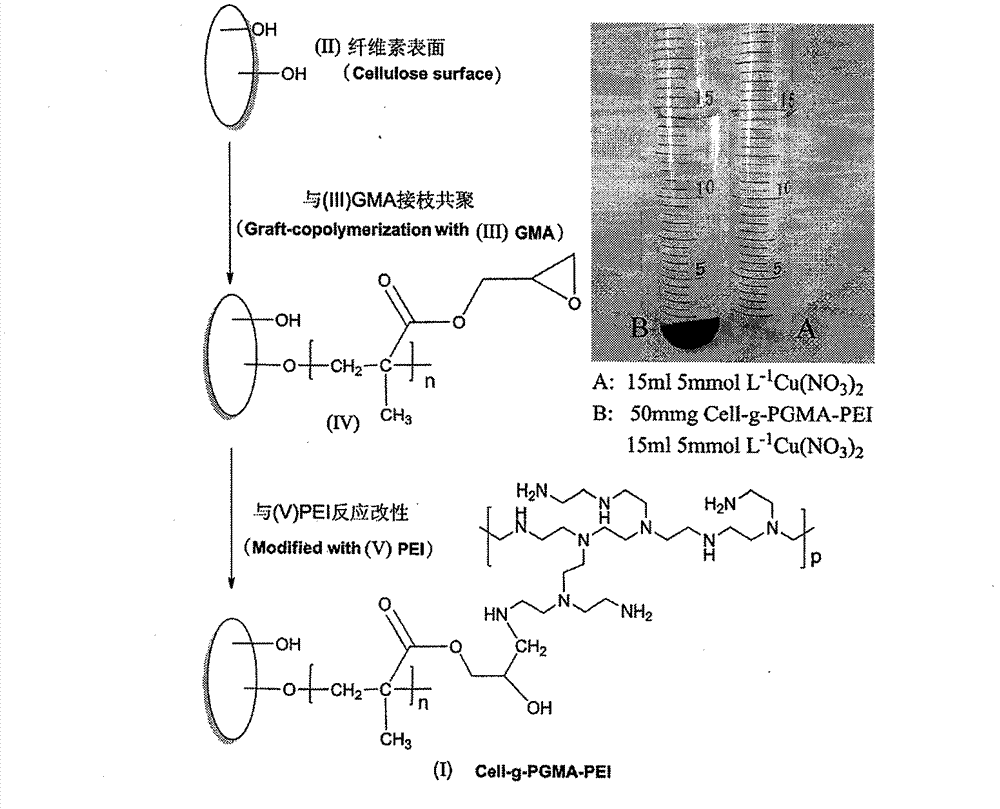

[0035] The preparation of the glycidyl methacrylate graft modified cellulose Cell-g-PGMA shown in embodiment 1. formula (IV)

[0036] (1) 1.0 g of microcrystalline cellulose represented by formula (II) was vacuum-dried at 50°C to constant weight, dispersed in a mixed system of 5mL acetone and 10mL deionized water, the temperature of the water bath was 70°C, stirred with a magnet and passed through nitrogen Deoxygenation for 15 minutes.

[0037] (2) Add the initiator BPO concentration 0.028mol.L to the above system -1 , monomer GMA concentration shown in formula (III) 19.2mmol.L -1 , blow nitrogen and keep at 70°C, stir at constant temperature for 2.5h, then stop heating.

[0038] (3) After the system was cooled to room temperature, the crude product was obtained by suction filtration, and washed with deionized water and acetone.

[0039] (4) Acetone was used as a solvent to remove the homopolymer produced during the reaction to obtain Cell-g-PGMA represented by formula (IV)...

Embodiment 2

[0040] Embodiment 2. As described in Example 1, the difference is that the GMA monomer concentration shown in the change formula (III) is 15.1mmol.L -1 , the calculated grafting rate G P 150%, grafting efficiency G E was 69.9%.

Embodiment 3

[0041] Embodiment 3. as described in embodiment 1, difference is that the GMA monomer concentration shown in changing formula (III) is 11.3mmol.L -1, the calculated grafting rate G P 99.9%, grafting efficiency G E was 62.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com