Patents

Literature

3224 results about "Dibenzoyl Peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzoyl peroxide is in the peroxide family of chemicals. When used for acne it works by killing bacteria. Benzoyl peroxide was first made in 1905 and came into medical use in the 1930s. It is on the World Health Organization's List of Essential Medicines, the most effective and safe medicines needed in a health system.

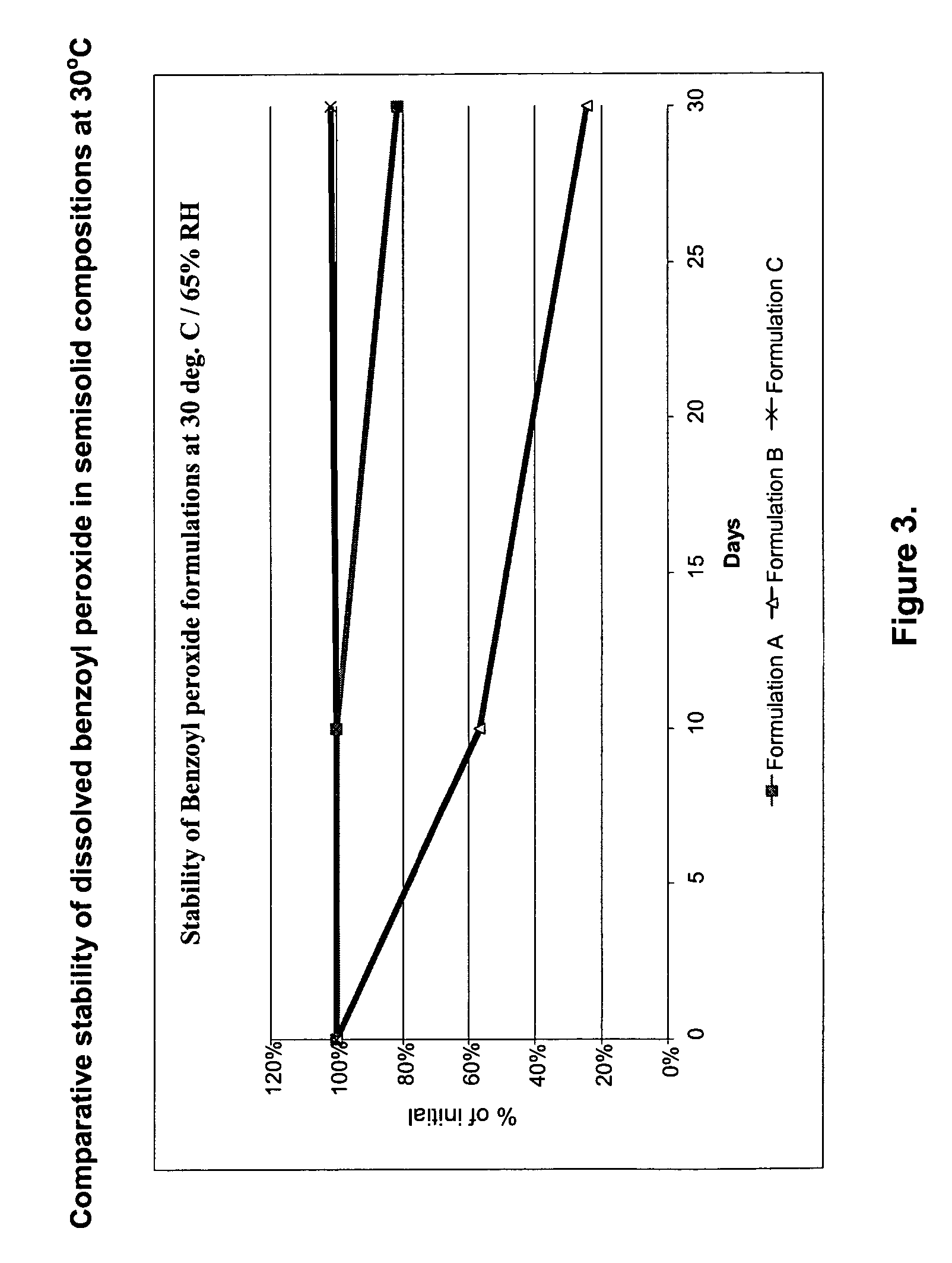

Composition exhibiting enhanced formulation stability and delivery of topical active ingredients

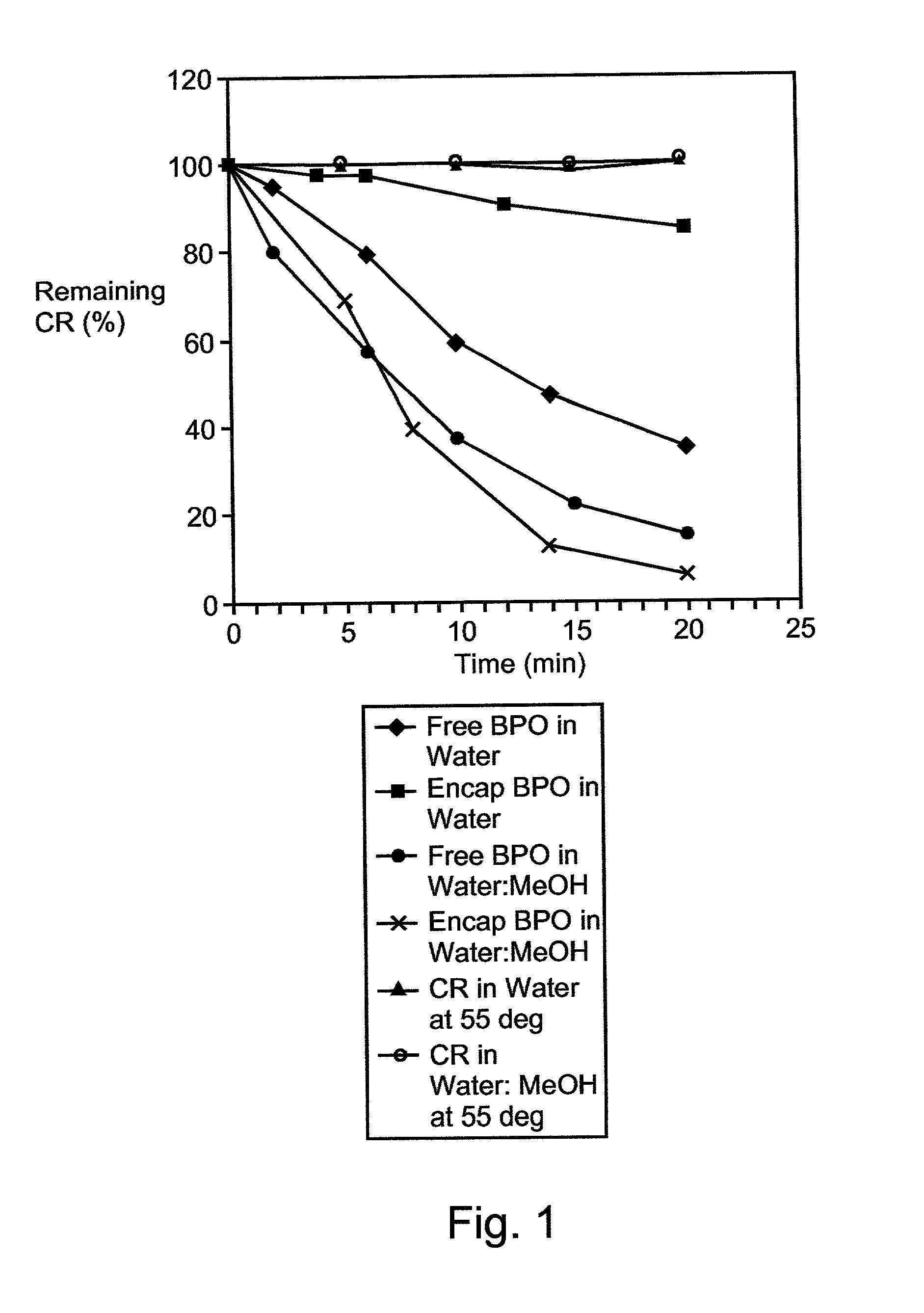

InactiveUS7758888B2Improve stabilityExtended shelf lifeAntibacterial agentsCosmetic preparationsBenzoyl peroxideMedicine

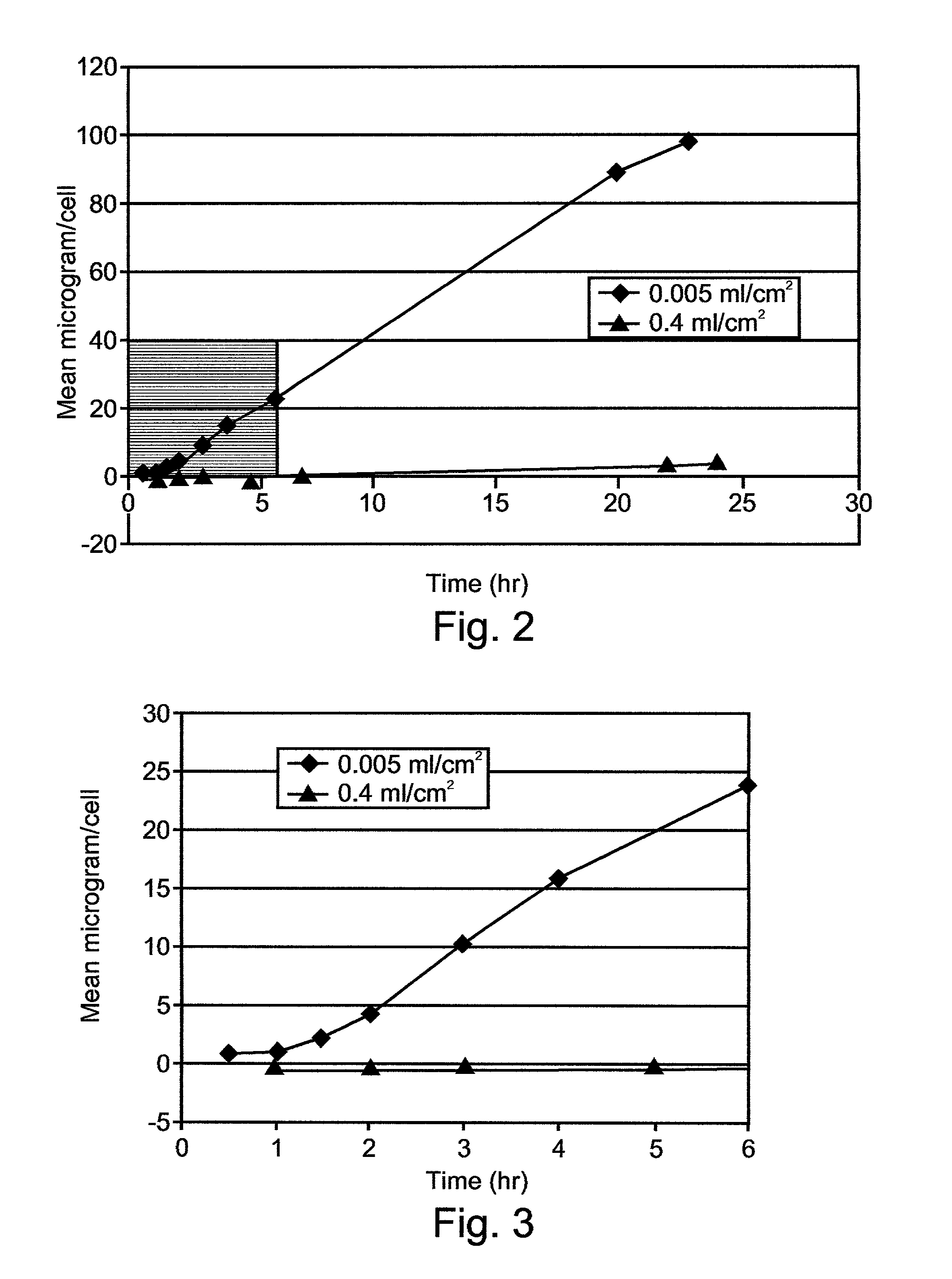

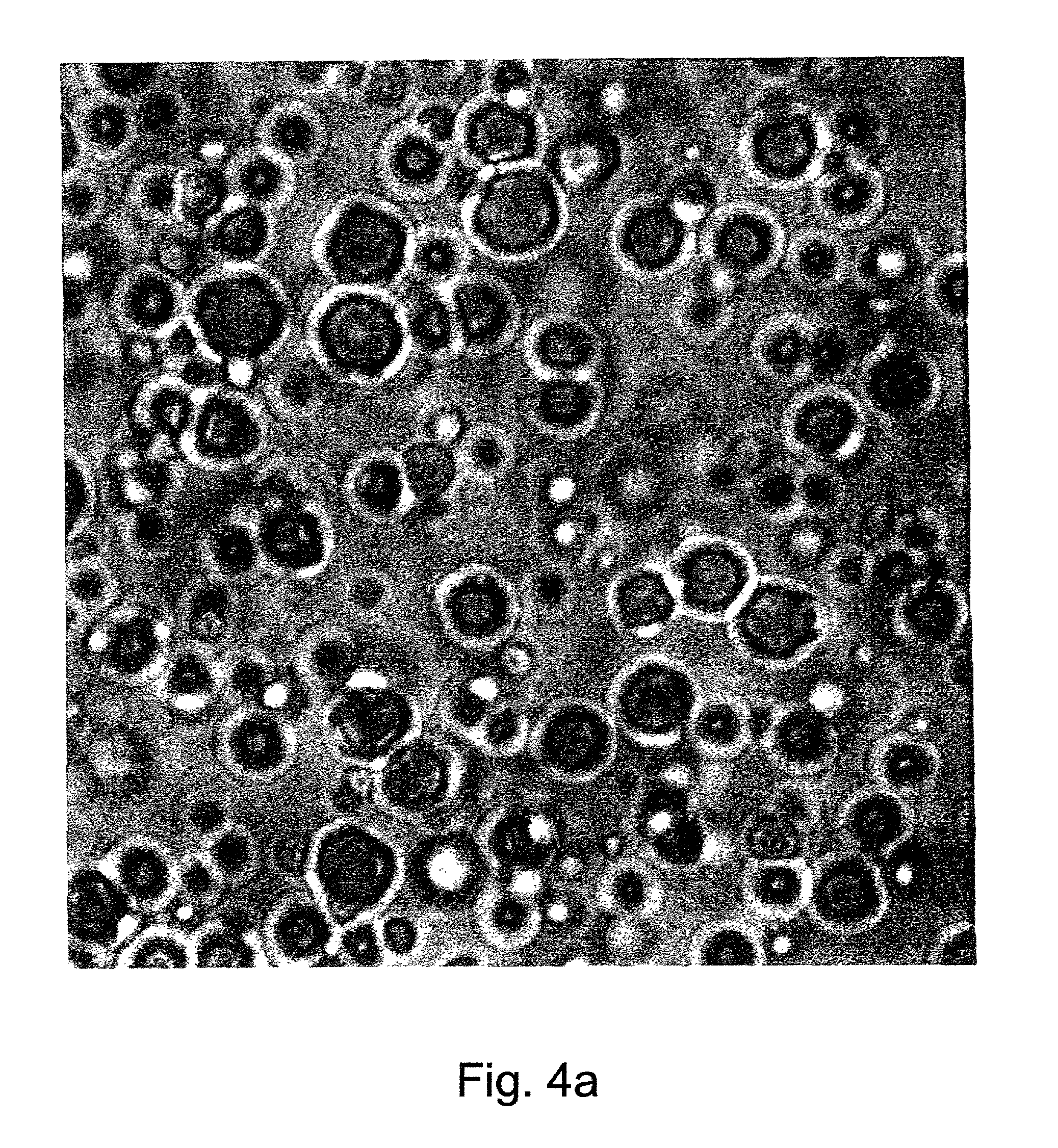

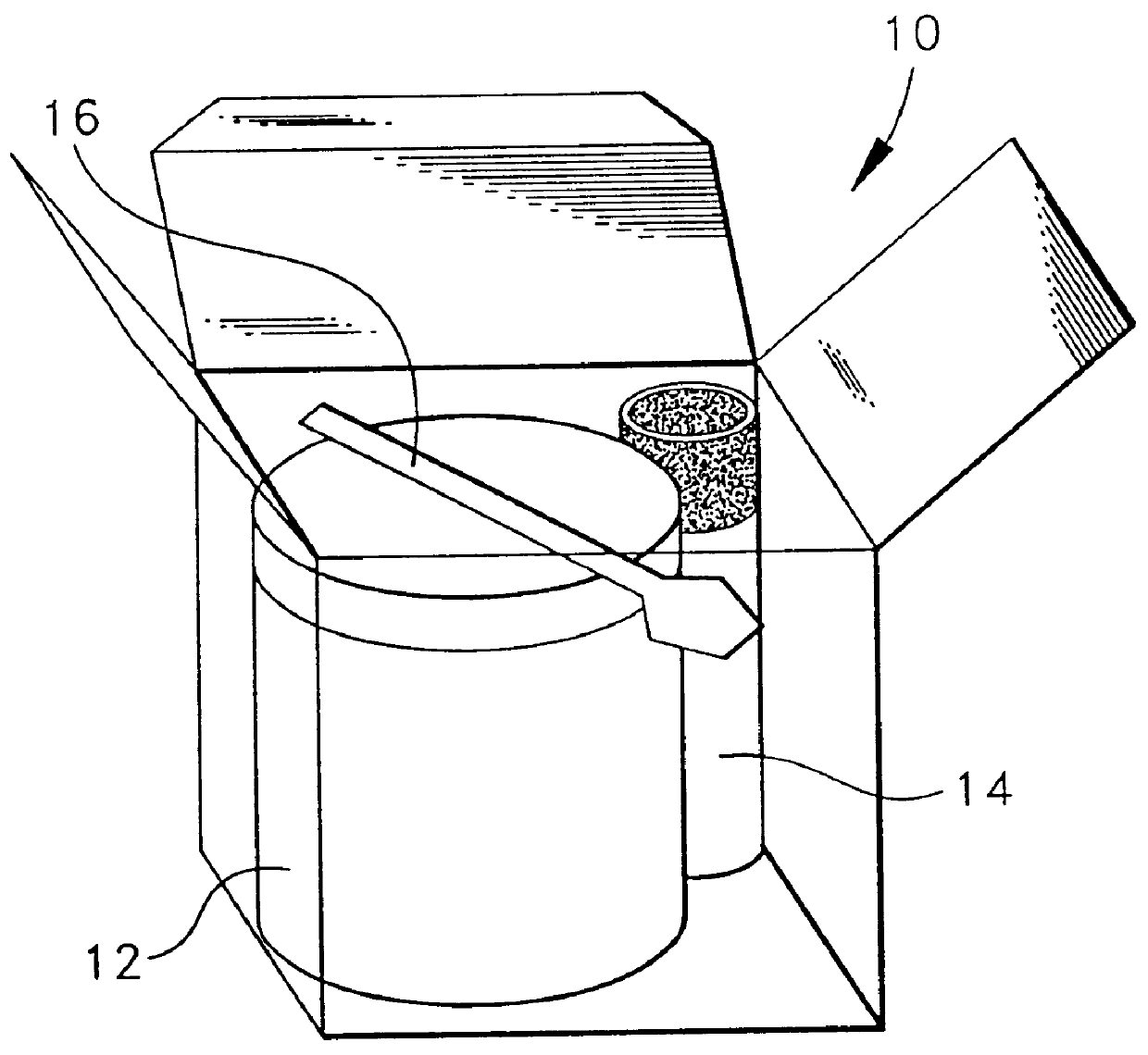

A therapeutic, cosmetic or cosmeceutic composition for topical application, capable of stabilizing an active ingredient and delivering the active ingredient, comprising a plurality of microcapsules having a core-shell structure. The microcapsules have a diameter of approximately 0.1 to 100 micron. The core of each microcapsule includes at least one active ingredient and is encapsulated within a microcapsular shell. The shell is comprised of at least one inorganic polymer obtained by a sol-gel process, and the shell protects the active ingredient before topical application and is designed to release the active ingredient from the microcapsules following application. The composition is useful in encapsulating active ingredients, such as benzoyl peroxide, that are unstable in other formulation, or are irritating to the skin.

Owner:SOL GEL TECH

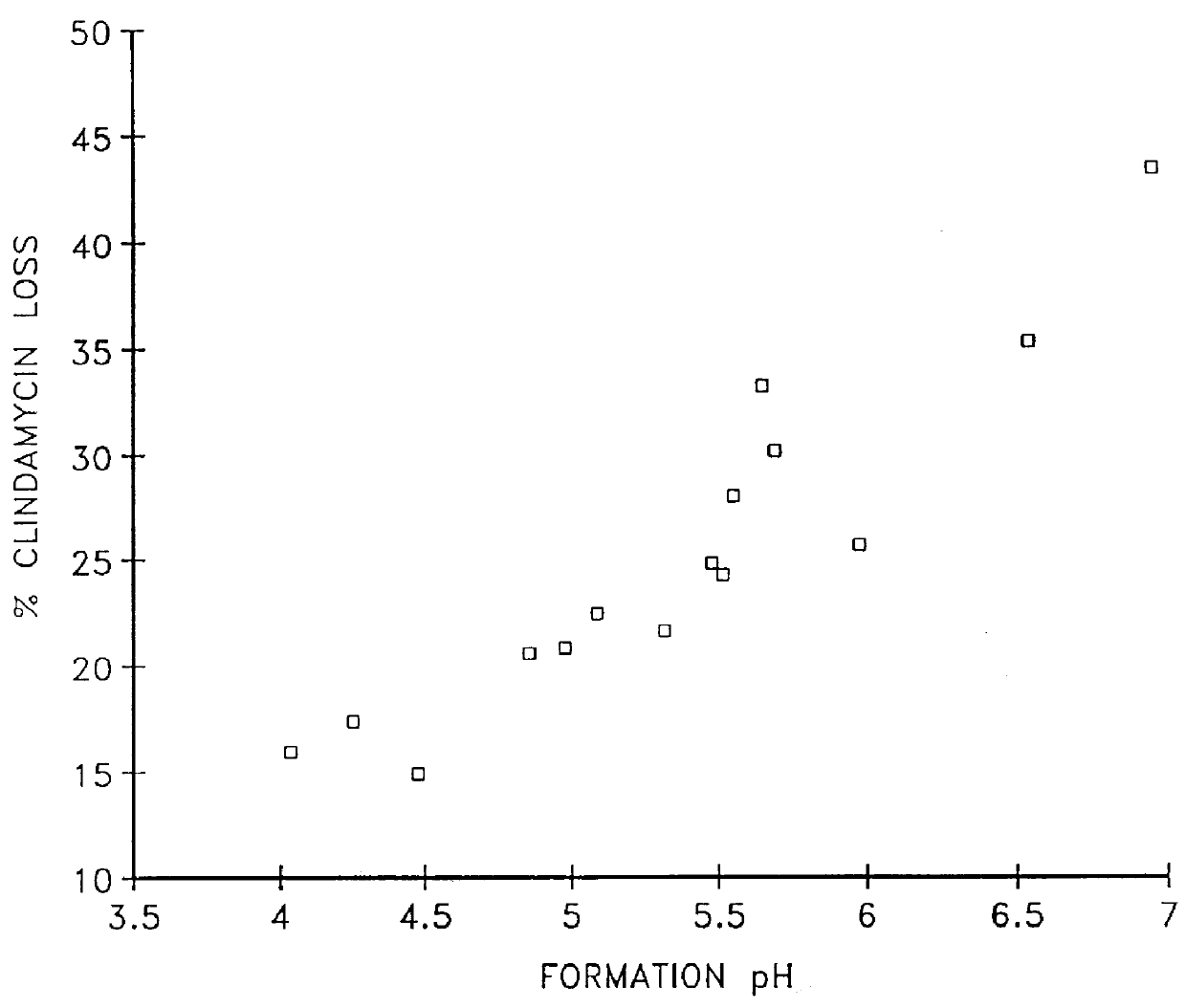

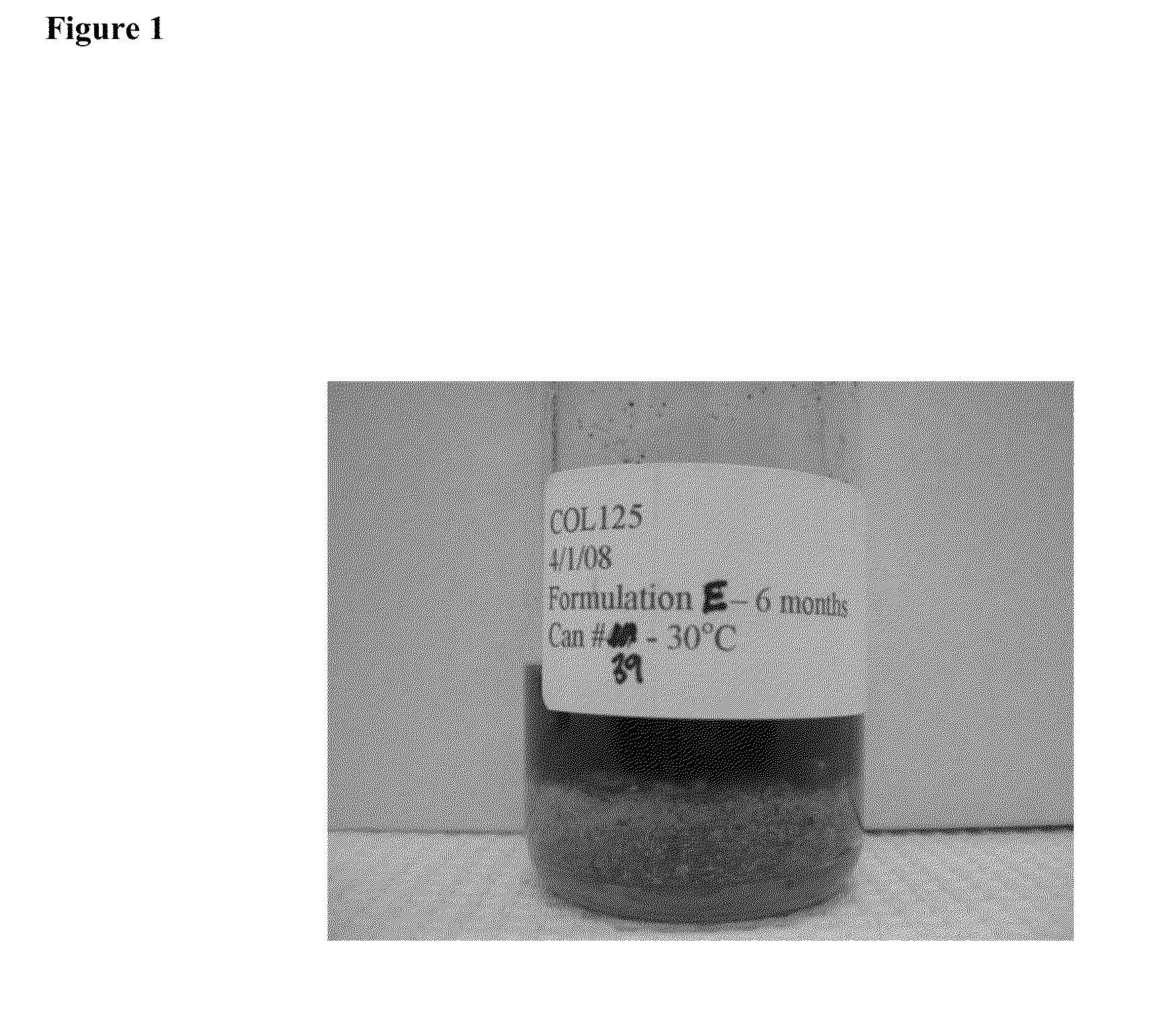

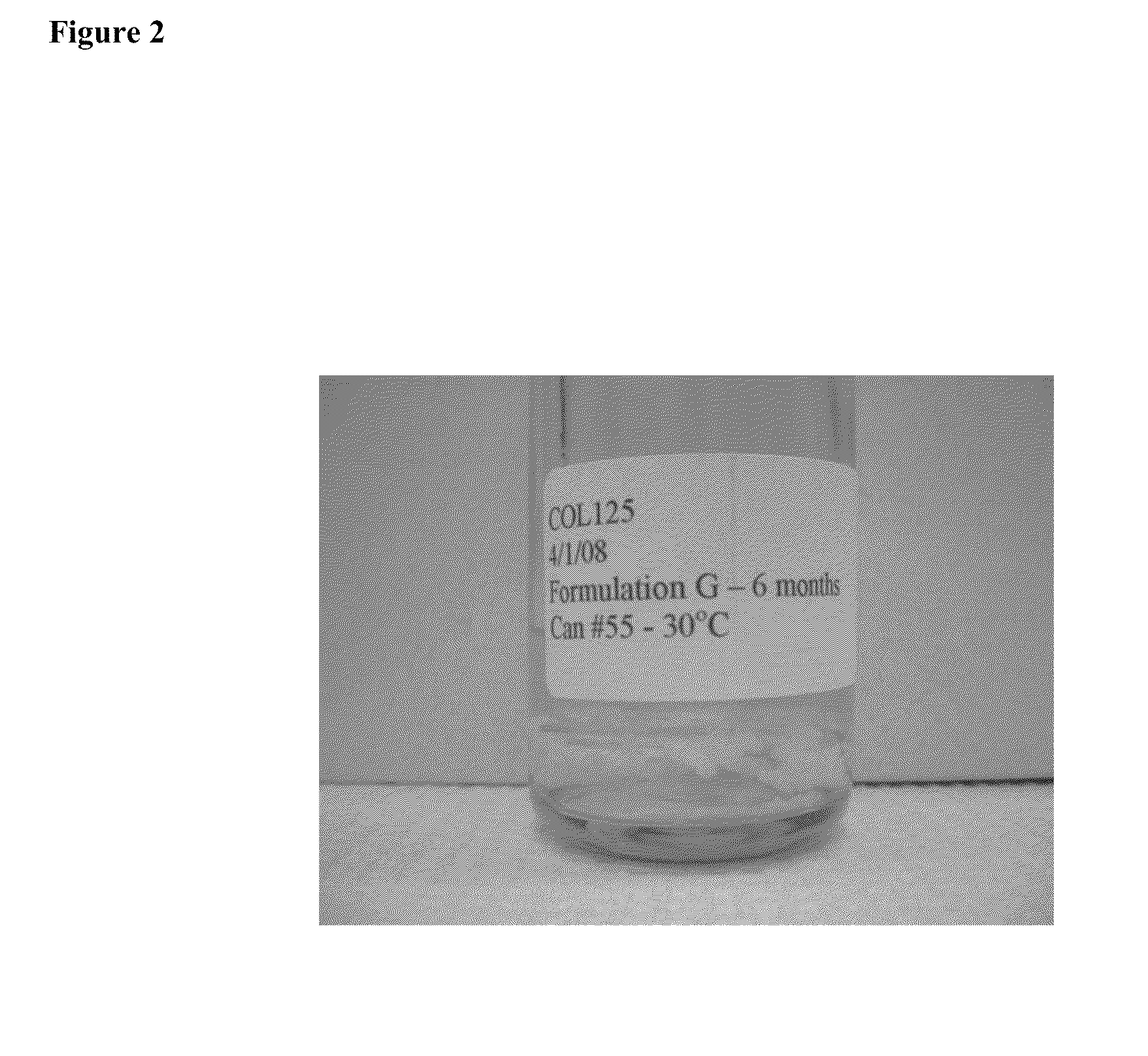

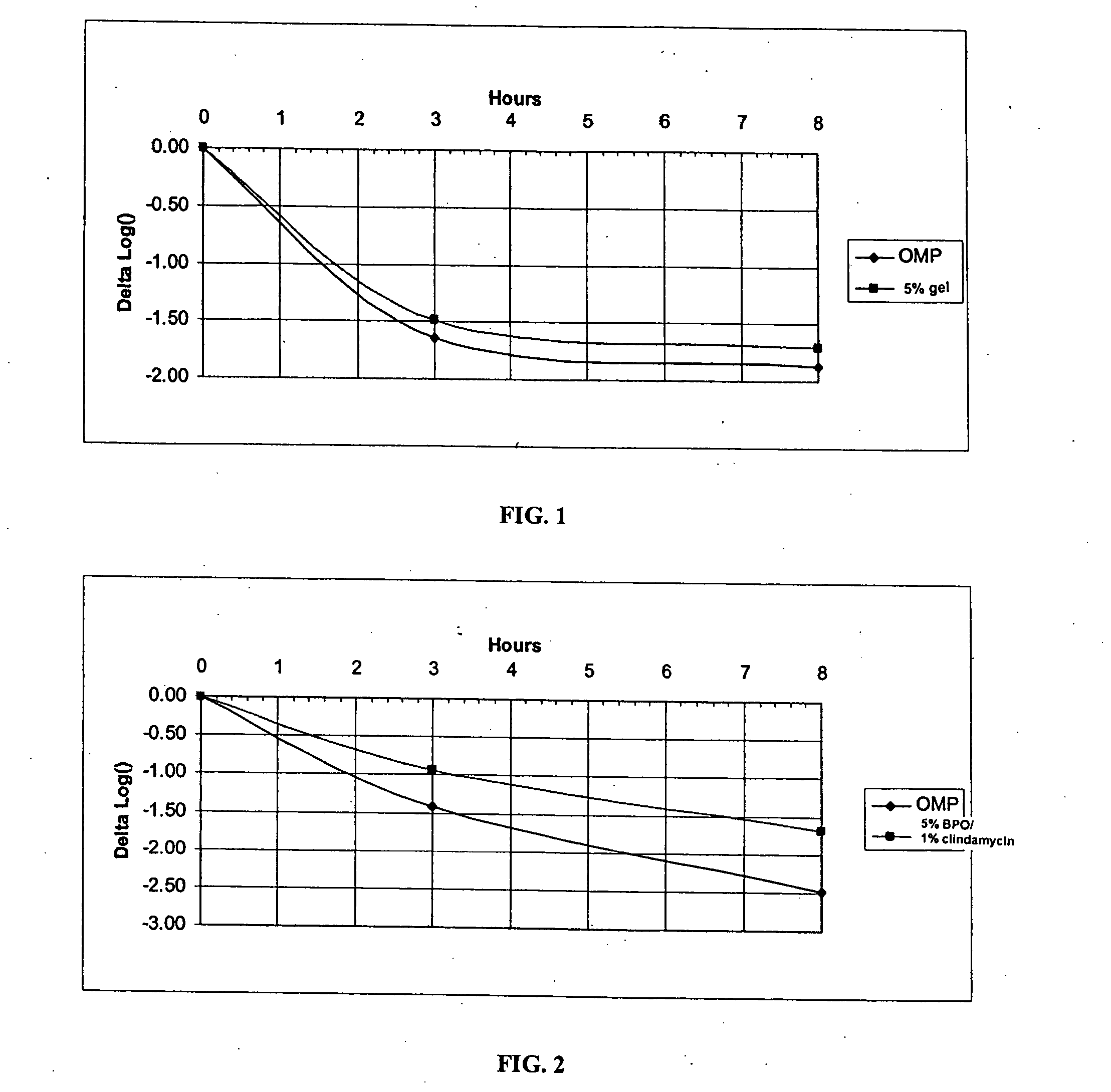

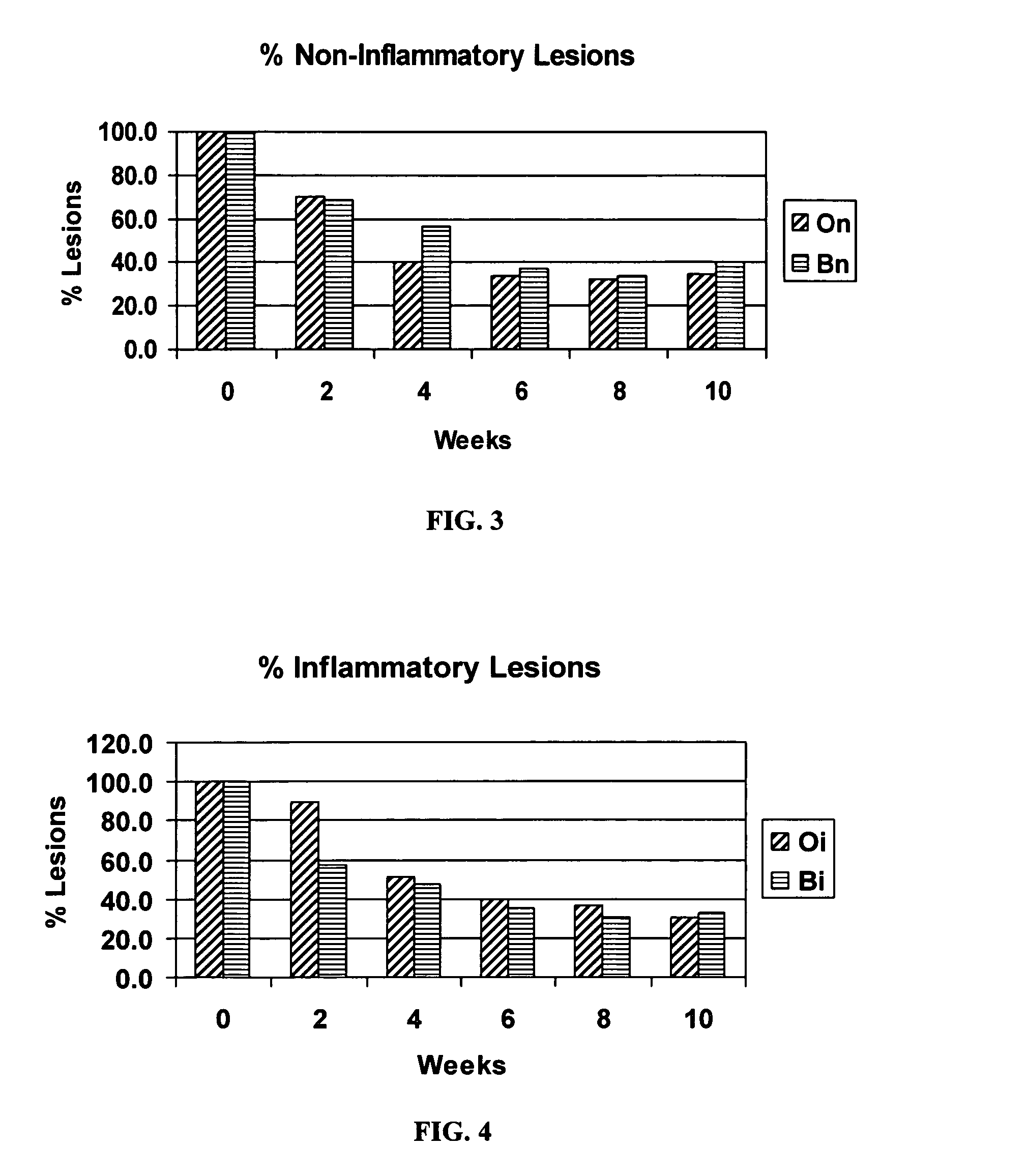

Compositions for the treatment of acne containing clindamycin and benzoyl peroxide

A pharmaceutical composition containing clindamycin and benzoyl peroxide is disclosed for the treatment of acne. The composition is stable for several months when stored at room temperature. Methods of preparing and of using the composition are disclosed.

Owner:BAROODY LLOYD J +1

Topical skin care composition

The present invention is directed to a topical skin care composition. The composition has the unique ability to treat acne without drying out the user's skin. In particular, the composition includes a base, an antibacterial agent, at least one anti-inflammatory agent, and at least one antioxidant. The antibacterial agent may be benzoyl peroxide.

Owner:DERMADOCTOR LLC

Topical skin treating compositions

Topical compositions and methods of using same for treating various skin disorders or conditions. In a particular aspect, these compositions comprise a storage-stable mixture of a benzoyl peroxide-containing composition, an antibiotic or a pharmaceutically acceptable salt or ester thereof, and a retinoid or a pharmaceutically acceptable salt thereof. In an alternative embodiment, these compositions comprise a storage-stable mixture of a retinoid or a pharmaceutically acceptable salt thereof and either a benzoyl peroxide-containing composition or an antibiotic or a pharmaceutically acceptable salt or ester thereof.

Owner:STIEFEL LABORATORIES

Treatment methods with peroxides and tertiary amines

InactiveUS20070244195A1Good curative effectBiocidePeroxide active ingredientsBenzoyl peroxideSide chain

This invention relates to methods of increasing the efficacy of peroxides such as benzoyl peroxide in the treatment of skin conditions such as acne. In a preferred embodiment, the invention relates to methods of increasing radicals formed by peroxides on / in the skin, more specifically near / in the comedone, for topical use in dermatology. In a specific embodiment, the invention relates to the use of transitional metals such as Cu(l) and ferrous ions to increase the efficacy of peroxides such as benzoyl peroxide. In another embodiment, the invention relates to a method by which a peroxide such as benzoyl peroxide and its activator are added to the skin surface at the same time. In another embodiment, the invention relates to the use of a more soluble form of peroxide such as benzoyl peroxide to increase its efficacy. In another embodiment, the invention relates to the addition of a side chain to a peroxide such as benzoyl peroxide so that it is activated by light. In a further embodiment, the invention relates to the addition of a tertiary amine to a peroxide such as benzoyl peroxide at the time of skin application, to improve the efficacy of the peroxide. In another embodiment, the invention relates to the addition of dapsone or other material to a peroxide such as benzoyl peroxide to improve its efficacy.

Owner:BURKHART CRAIG N +1

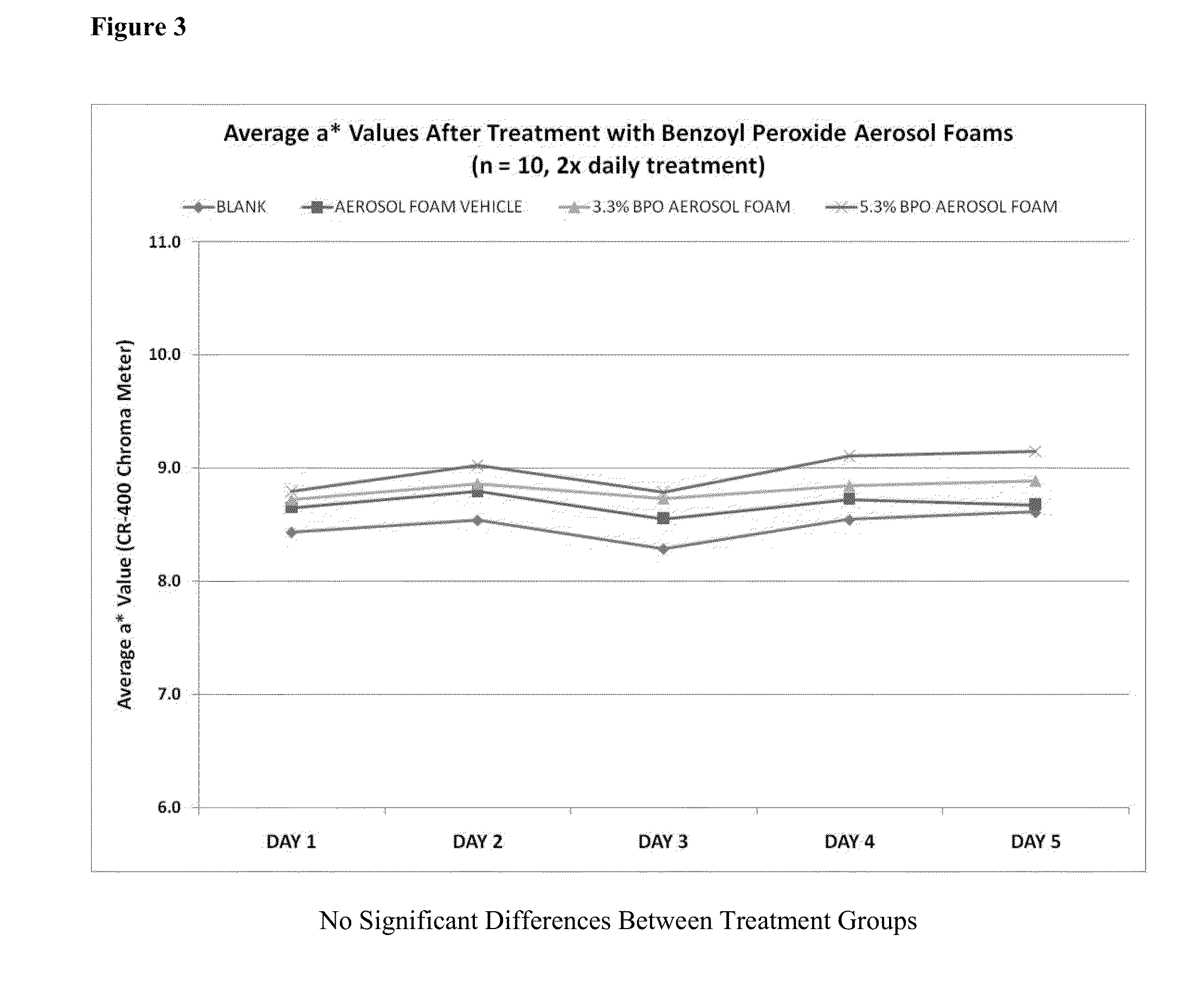

Foamable Benzoyl Peroxide Compositions for Topical Administration

Described herein are benzoyl peroxide compositions useful in the treatment of acne and other skin conditions, which exhibit enhanced stability, even under accelerated conditions. The compositions also exhibit reduced color formation, reduced irritation, and enhanced moisturizing properties. They can be formulated into a topical aerosol foam with inert, non-flammable propellants, such as hydrofluoroalkanes, and may be used in cosmetics or pharmaceuticals. Additionally, methods of formulating these compositions are described.

Owner:ENCORE DERMATOLOGY

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

Benzoyl peroxide compositions and methods of use

Solutions of benzoyl peroxide, in one or more solvents are provided that are suitable for direct topical application to the skin of a user or can be formulated into a product that is suitable for topical application to the skin of a user. In embodiments, the solutions include benzoyl peroxide and optionally additional active or inactive ingredients, and a solvent or mixture of solvents in which the benzoyl peroxide is prepared as a clear solution at 25° C. Methods of using the solutions are also described. Product formulations such as emulsion are also described. The solutions and product formulations can increase the efficacy and percutaneous absorption of benzoyl peroxide.

Owner:JR CHEM LLC

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

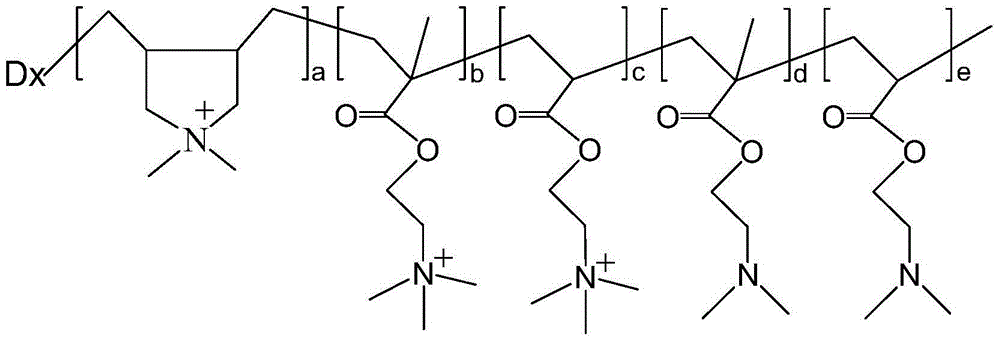

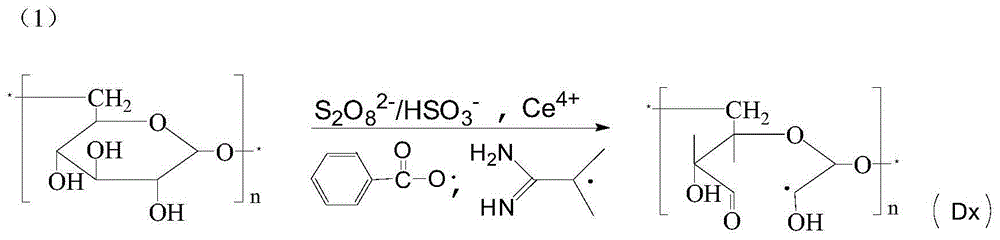

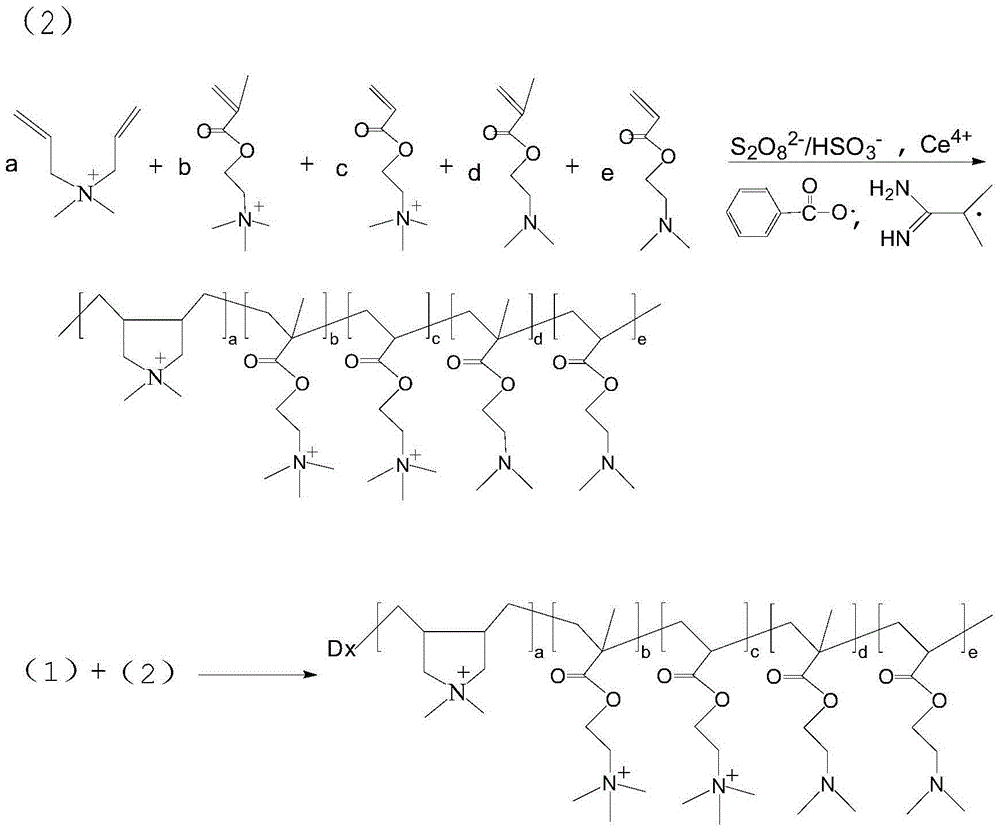

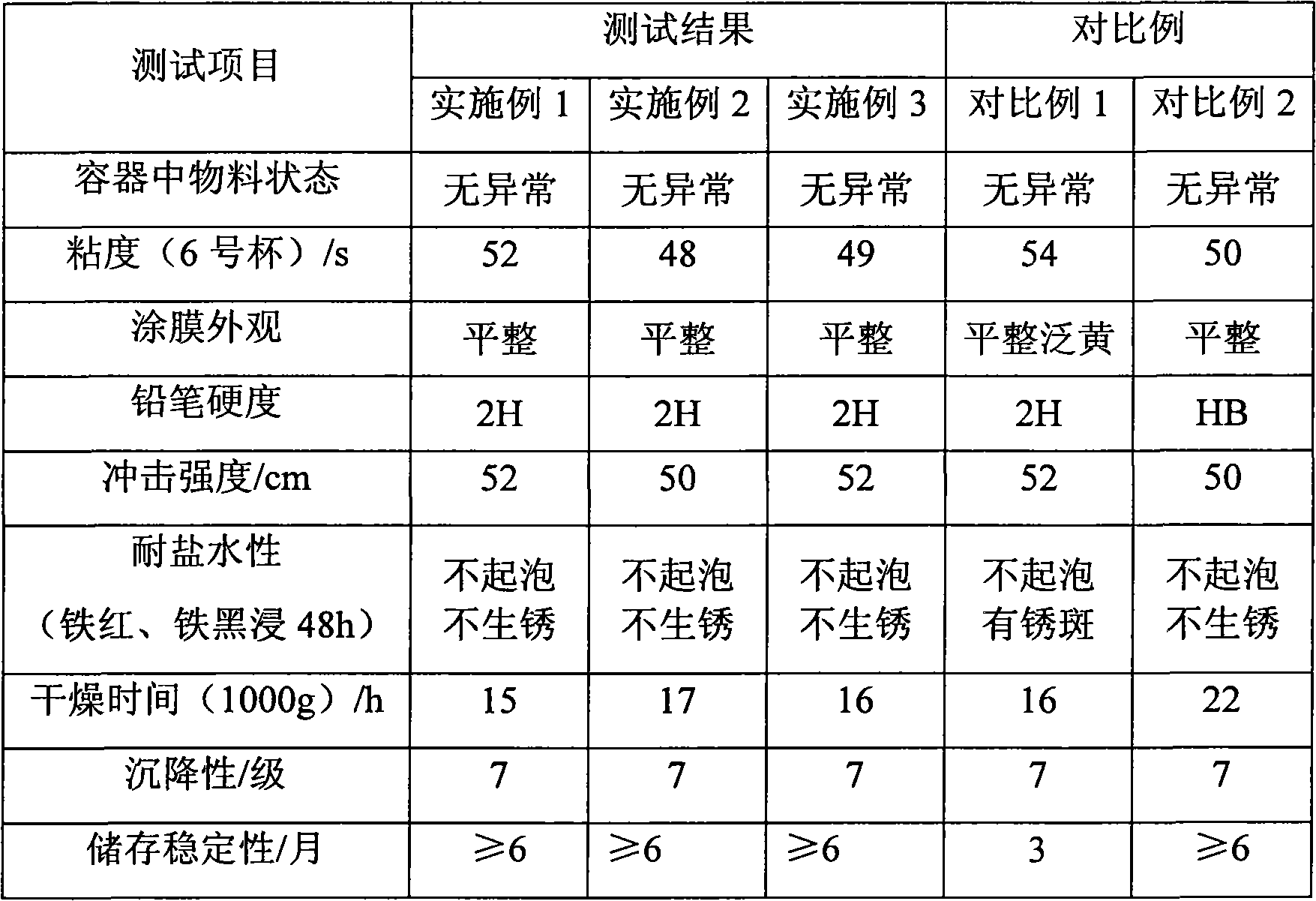

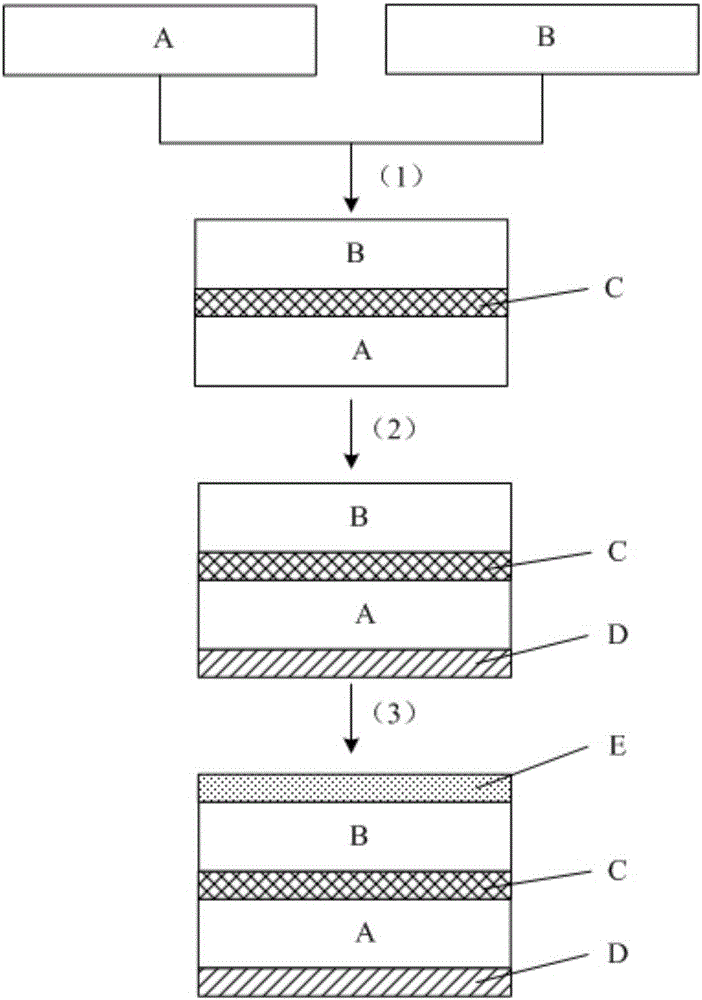

Grafted copolymerized cationic polysaccharide bioflocculant and preparation method thereof

ActiveCN104130351AImprove adsorption capacityHigh positive charge densityWater/sewage treatment by flocculation/precipitationMethacrylateSodium bisulfate

The invention relates to a grafted copolymerized cationic polysaccharide bioflocculant and a preparing method thereof. A product with the cationic degree (DC) of 3-63% is finally prepared through an aqueous solution polymerization technology with a present nonionic polysaccharide bioflocculant (Dx) as a raw material, one or more of dimethyl diallyl ammonium chloride (DMDAAC), methacryloxyethyltrimethyl ammonium chloride (DMC), acryloyloxyethyltrimethyl ammonium chloride (DAC), dimethylaminoethyl methacrylate (DMAEMA), dimethylaminoethyl acrylate (DMAEA) as a monomer, and one or two of ammonium persulfate / sodium bisulfate and dibenzoyl peroxide (BPO) (AIBA) as an initiator. The preparation method is simple, and is easy to control, and the product obtained in the invention has good flocculation effect and high treatment efficiency, and can be widely used in the field of treatment various sewages, the sludge dewatering field and the like.

Owner:威海汉邦生物环保科技股份有限公司

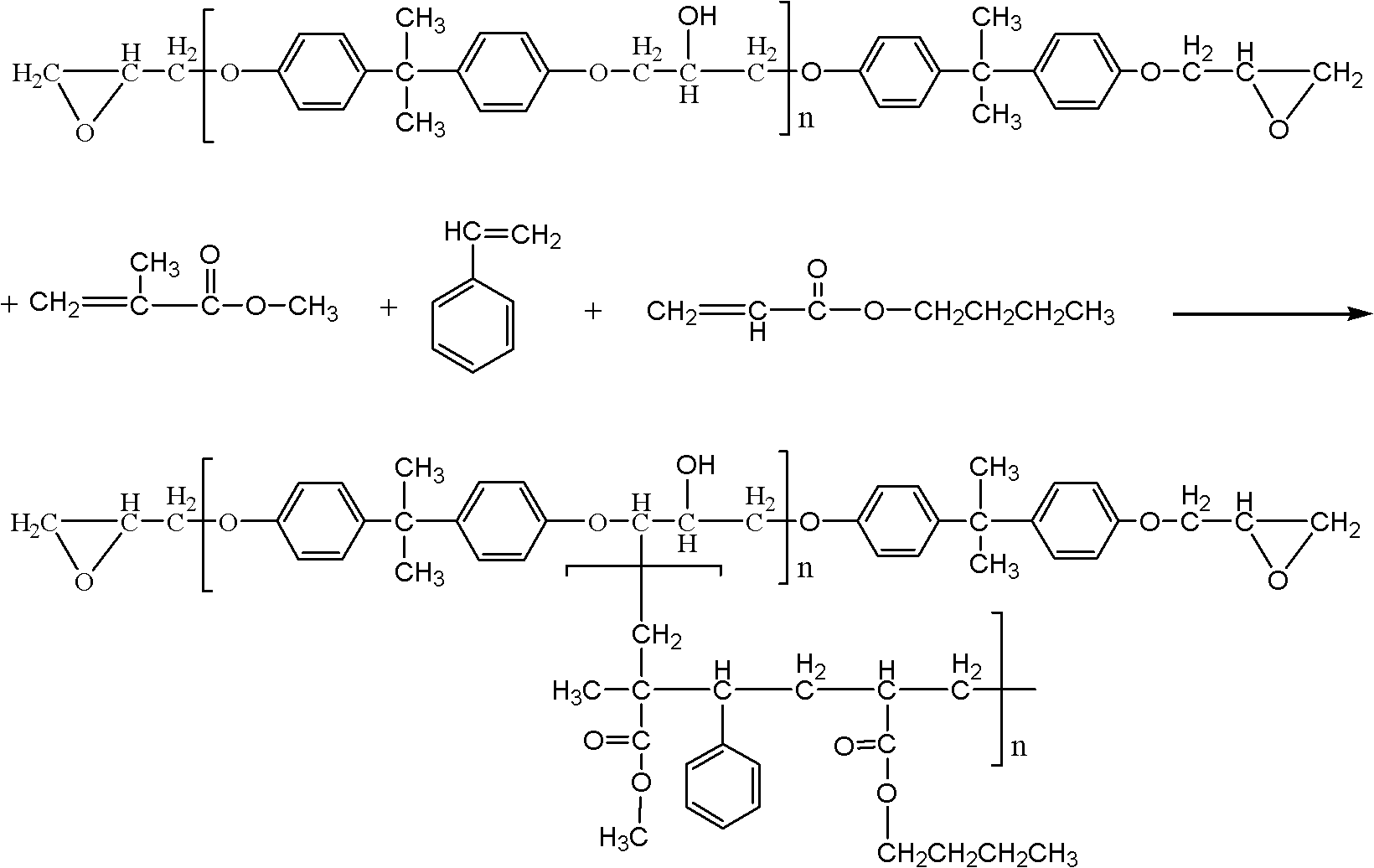

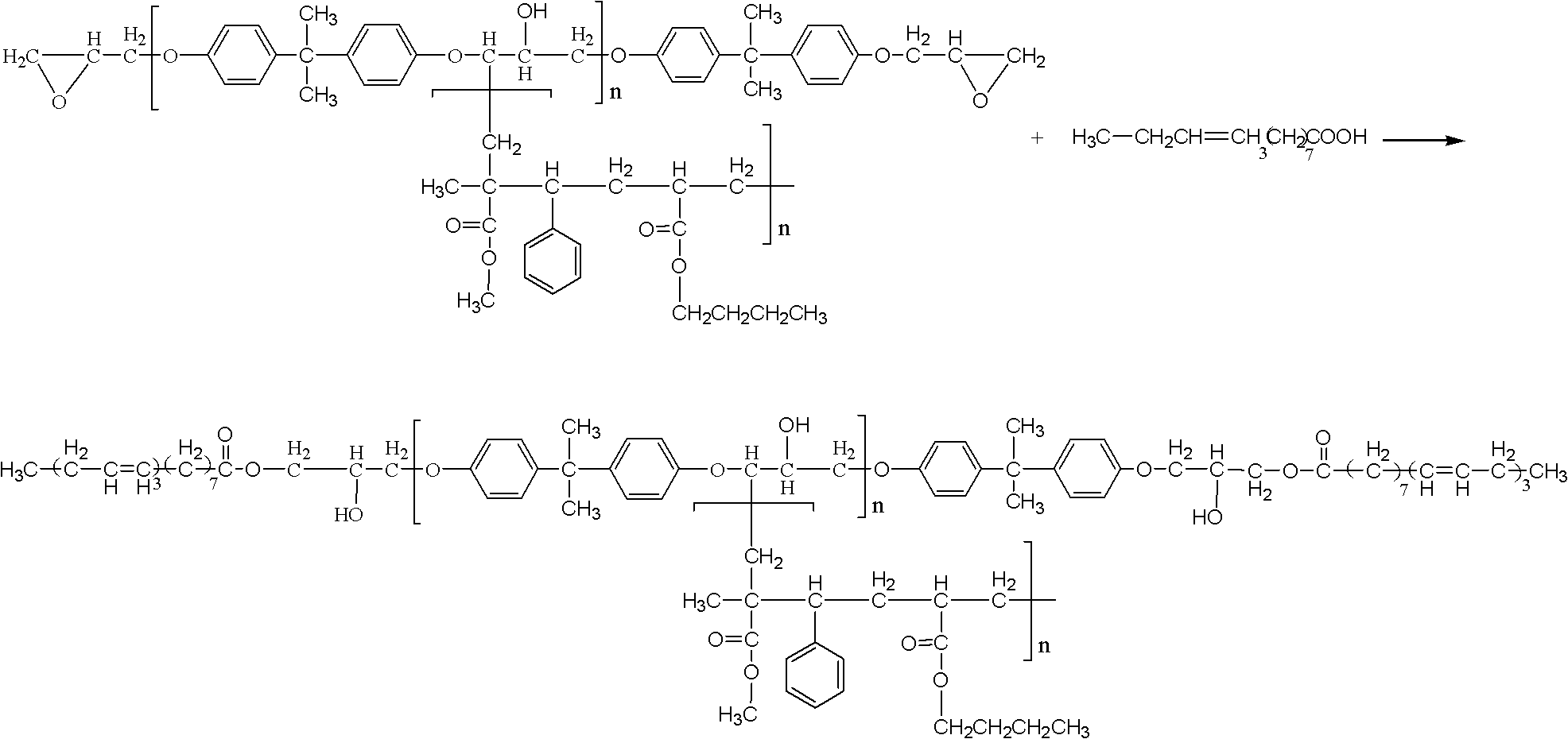

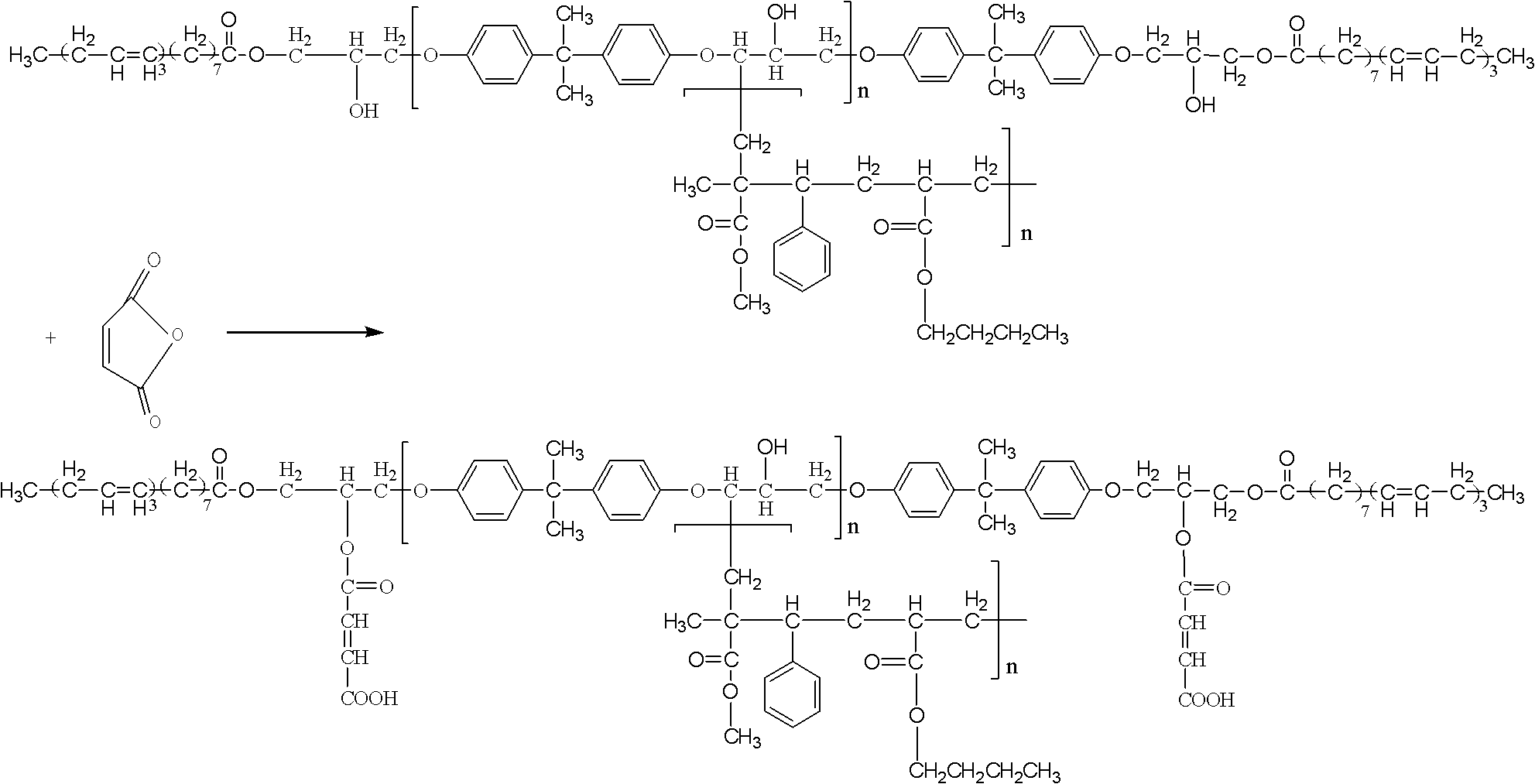

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

Topical Skin Treating Compositions

Owner:STIEFEL LABORATORIES

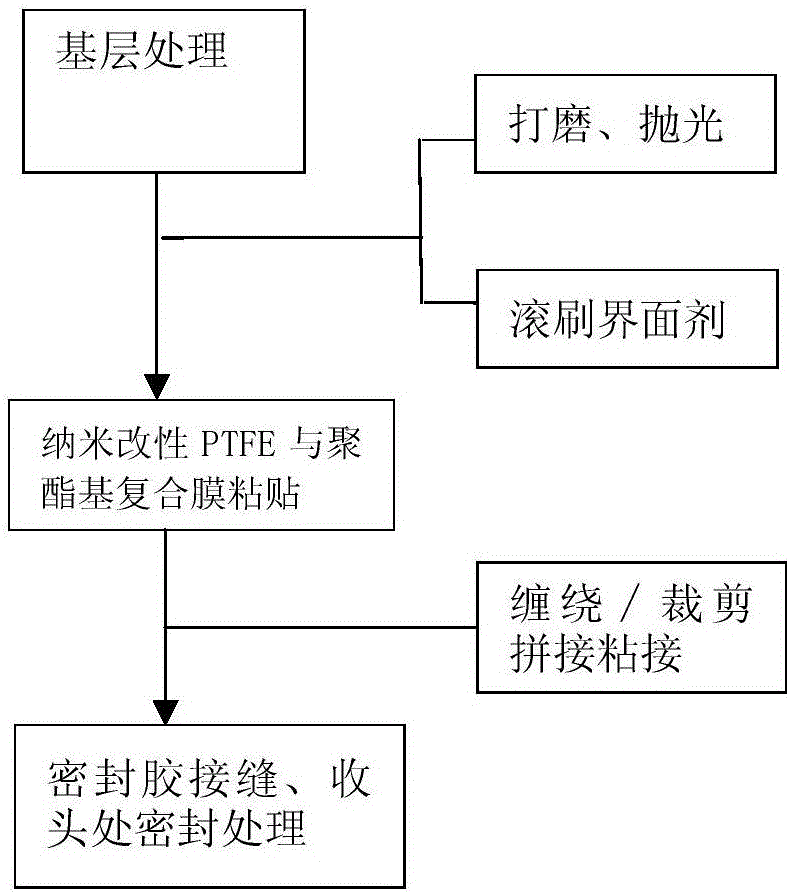

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

Method for manufacturing homogeneous ion exchange membrane

The invention discloses a method for manufacturing a homogeneous ion exchange membrane, which comprises the following steps: impregnating a polyethylene and ethylene-octylene copolymer elastomer blended alloy membrane or a polyethylene, ethylene-octylene copolymer elastomer, and polyisobutylene rubber blended alloy membrane, which serves as a substrate membrane, with solution of styrene, divinyl benzene and benzoyl peroxide, pressurizing and heating the impregnated membrane for polymerization to obtain a base membrane; and chloromethylating the base membrane in chloromethyl ether solution containing anhydrous stannic chloride to obtain a chloromethyl membrane, and quaternizing the chloromethyl membrane in aqueous solution of trimethylamine to obtain the ion exchange membrane. The method has the advantages of greatly reducing an impregnation temperature, and reusing solution of styrene and divinyl benzene. The capacity of the manufactured ion exchange membrane is up to 2.2 milligram equivalent per gram of dry membrane, and the sheet resistance of the manufactured ion exchange membrane is about 6 omega m<2>.

Owner:福建省延润膜环保科技有限公司

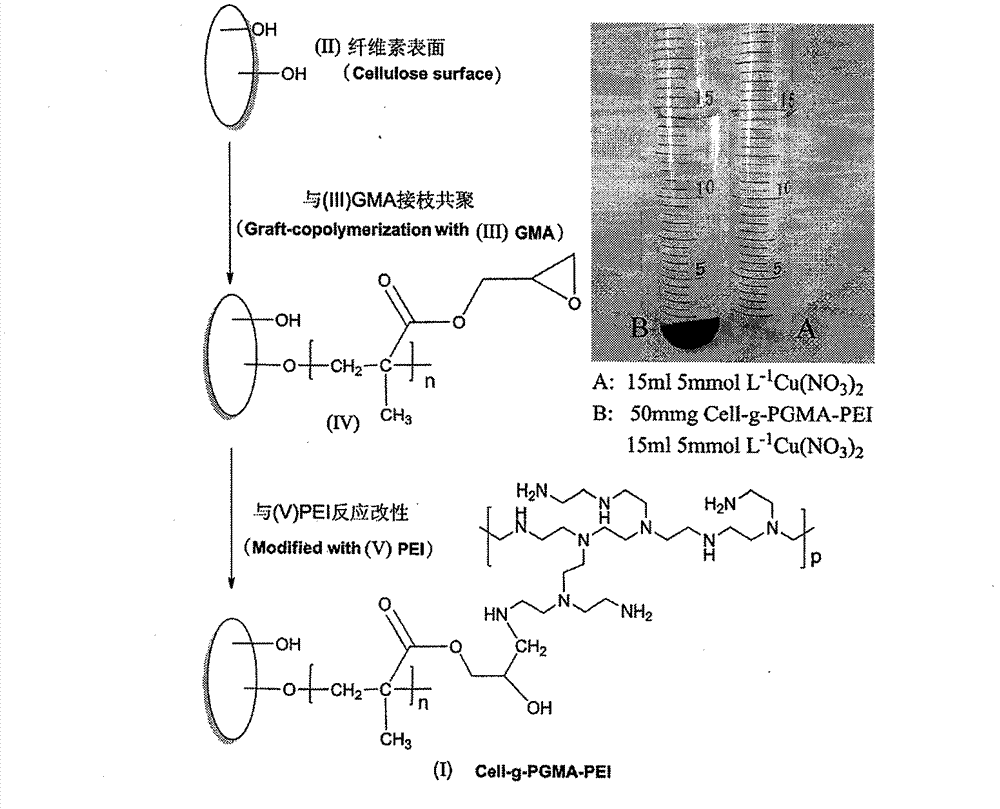

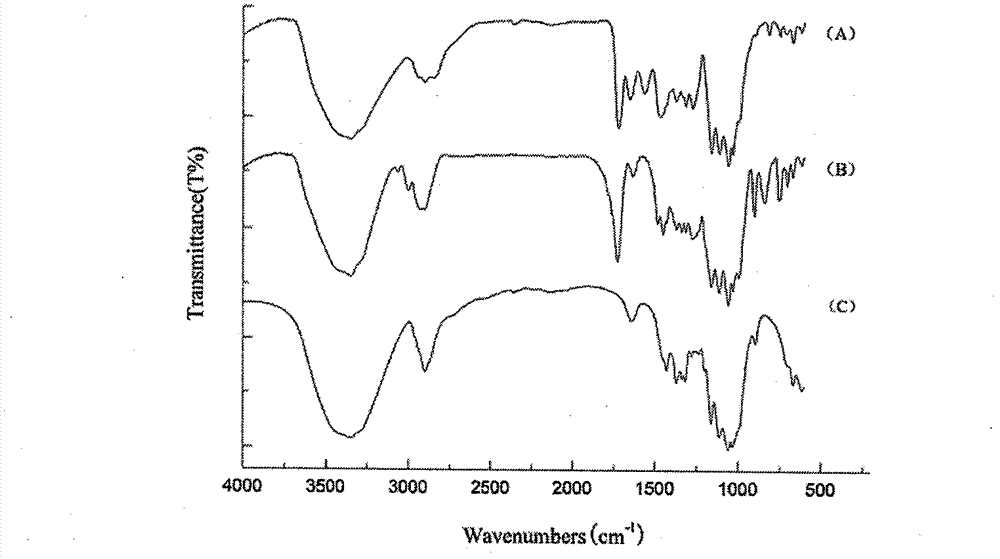

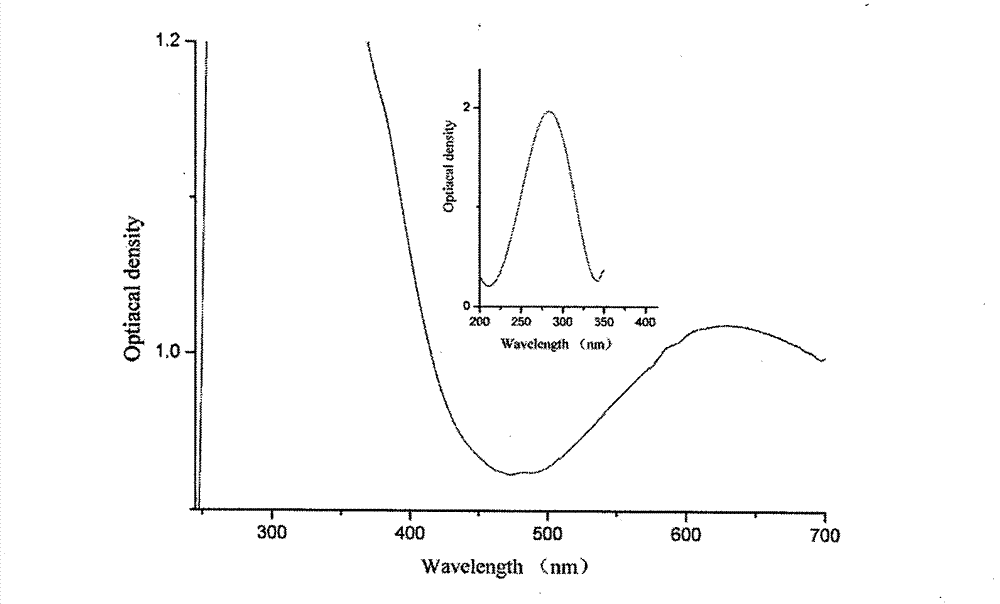

Preparation method of efficient polyethyleneimine modified cellulose-based heavy metal adsorbent

InactiveCN103304820AEasy to useLow toxicityOther chemical processesWater/sewage treatment by sorptionGlycidyl methacrylateBenzoyl peroxide

The invention discloses a preparation method of an efficient polyethyleneimine modified cellulose-based heavy metal adsorbent shown by a formula (I), belonging to the technical field of high-molecular function modification and synthesis of a natural material. By adopting cellulose as a framework, benzoyl peroxide (BPO) as an initiator, a mixture of water and acetone as a solvent and glycidyl methacrylate (GMA) shown by a formula (III) as a monomer, the method comprises the following steps of: performing a free radical-initiated graft copolymerization reaction on the surface of microcrystalline cellulose shown by a formula (II); performing amination on a graft product shown by a formula (IV) by use of graft polyethyleneimine (PEI) shown by a formula (V); and washing and drying the product to obtain a powdery solid product, wherein the reaction is easy to operate, and the conditions are mild. The heavy metal adsorbent prepared by the preparation method has the advantages of excellent adsorption property, large adsorption capacity and fast adsorption, can be regenerated and recycled, and has broad application prospects in the water treatment fields such as control of heavy metal industrial pollutants and the like.

Owner:SHANDONG UNIV

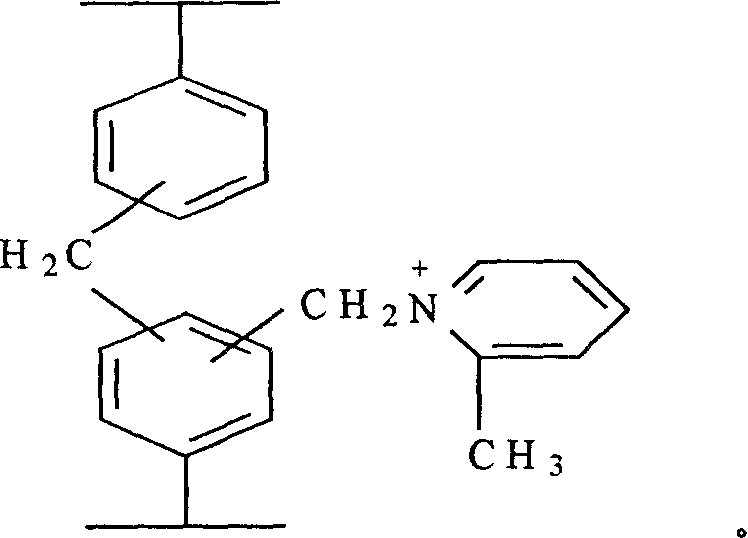

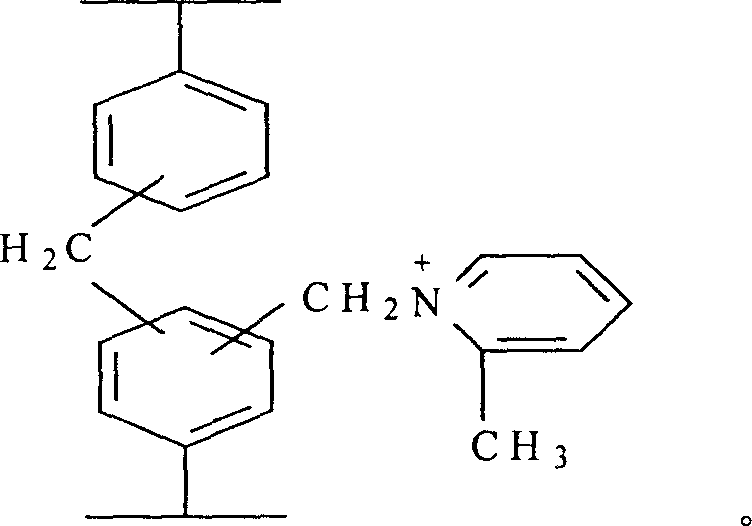

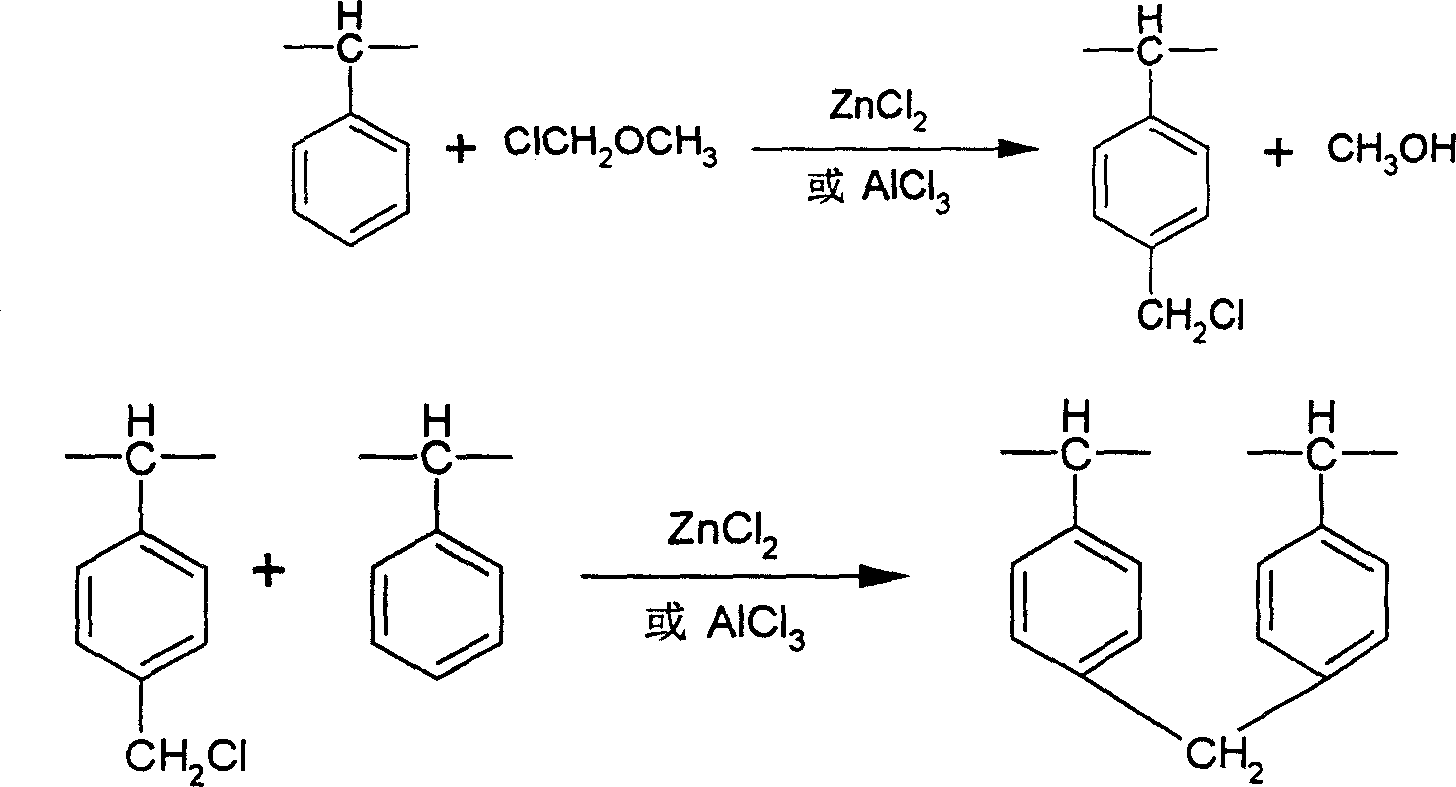

Pyridyl modified composite function super high crosslinked adsorptive resin and its preparing method

InactiveCN1858088AImprove temperature resistanceImprove thermal stabilityOther chemical processesCross-linkBenzoyl peroxide

The produce discloses a kind of pyridyl modified composite functional adsorption resin with very high crosslinking degree and pyridyl radical as functional radical and its preparation process. The preparation process includes polymerization with styrene as monomer, divinyl benzene as cross-linking agent, liquid wax as pore-creating agent, magnesium carbonate as dispersant and benzoyl peroxide as initiator to produce low crosslinking degree macroporous polystyrene; the subsequent cross-liking reaction with swellant of nitrobenzene, etc. and catalyst Lewis acid, etc. to obtain composite functional resin precursor with different crosslinking degree; and final adding alpha-methyl pyridine for reaction to prepare the pyridyl modified composite functional adsorption resin. The resin has both adsorbing and ion exchanging functions, and may find its wide application in medicine separation, food decoloring, water treatment, etc.

Owner:NANJING UNIV +1

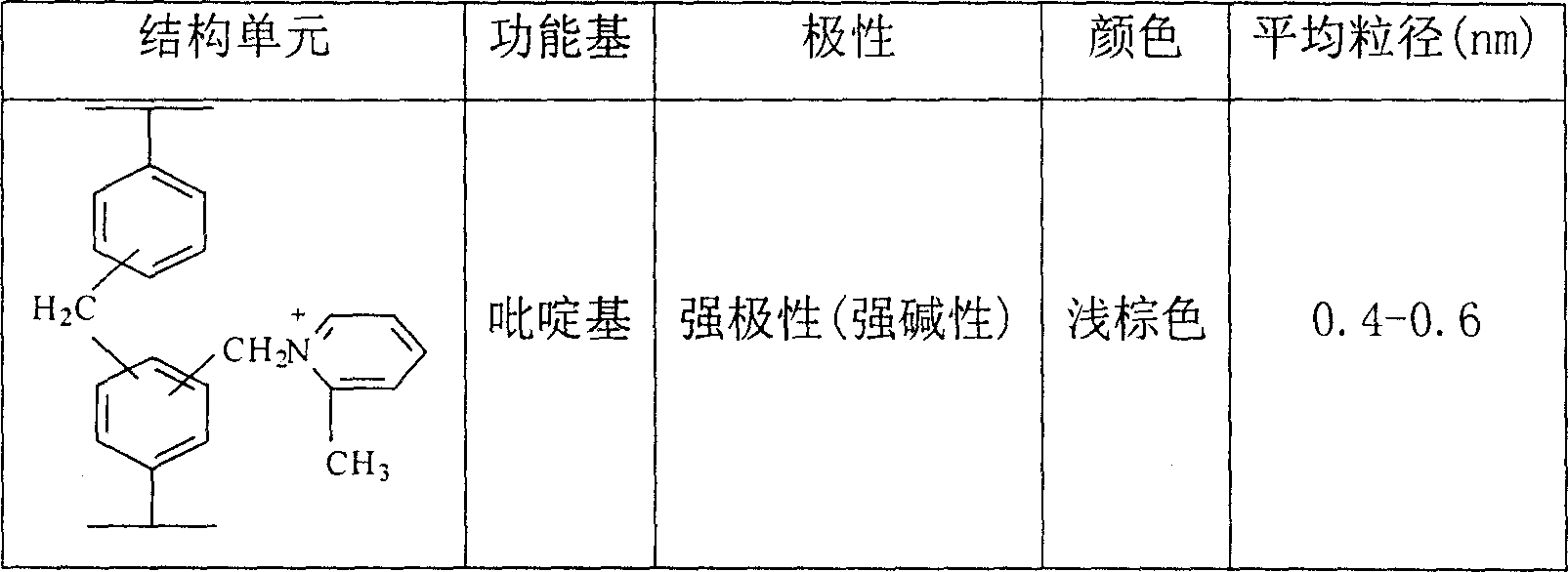

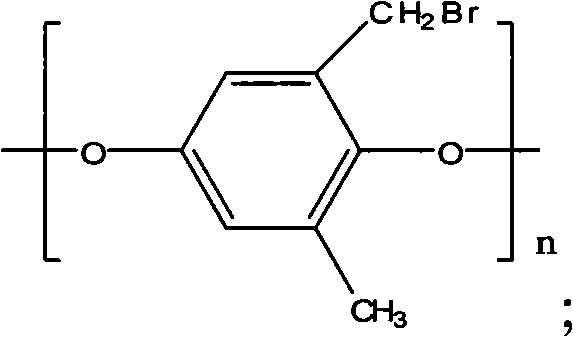

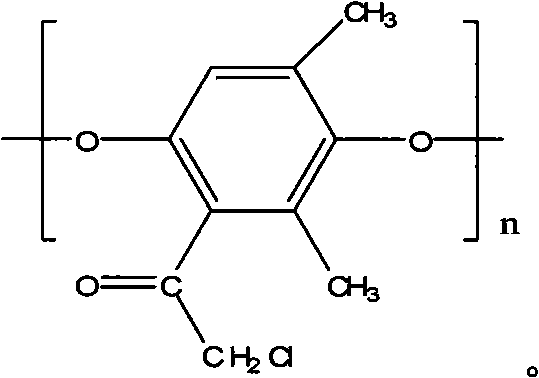

Homogeneous phase anion-exchange membrane and preparation method thereof

ActiveCN101306331AHigh strengthHas a cross-linked structureSemi-permeable membranesAnion exchangersCross-linkBenzoyl peroxide

The invention discloses a homogeneous anion exchange membrane as well as the preparation method thereof. The invention is characterized in that the homogeneous anion exchange membrane takes chloromethylated styrene, styrene or / and alkyl styrene as monomers, takes divinyl benzene as a cross-linking agent, takes benzoyl peroxide or azobisisobutyronitrile as an initiator, and takes bromomethylation poly (1,4- dimethyl2, 6- phenylene oxide) or chloroacetylized poly (1,4-dimethyl2, 6-phenylene oxide) as a polymer reinforcing agent, so as to prepare a uniform solution which is used for pasting a membrane on reinforced fabrics, and the homogeneous anion exchange membrane can be obtained by pretreating a basal membrane obtained by polymerization and then carrying out quaternary ammoniation. The invention obtains a functional group through adopting aromatic polymer, thereby the obtained anion exchange membrane has high exchange capacity, good electrochemical properties, uniform structure and good heat resistance; the slurry is homogeneous, thereby being easy for pasting; the monomers serving as the solvent can be polymerized, thereby being a green and solvent free process; the polymer content and the cross-linking degree can be adjusted, and the types of the sustainer can be changed, thereby obtaining products with different structural morphologies and functions.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

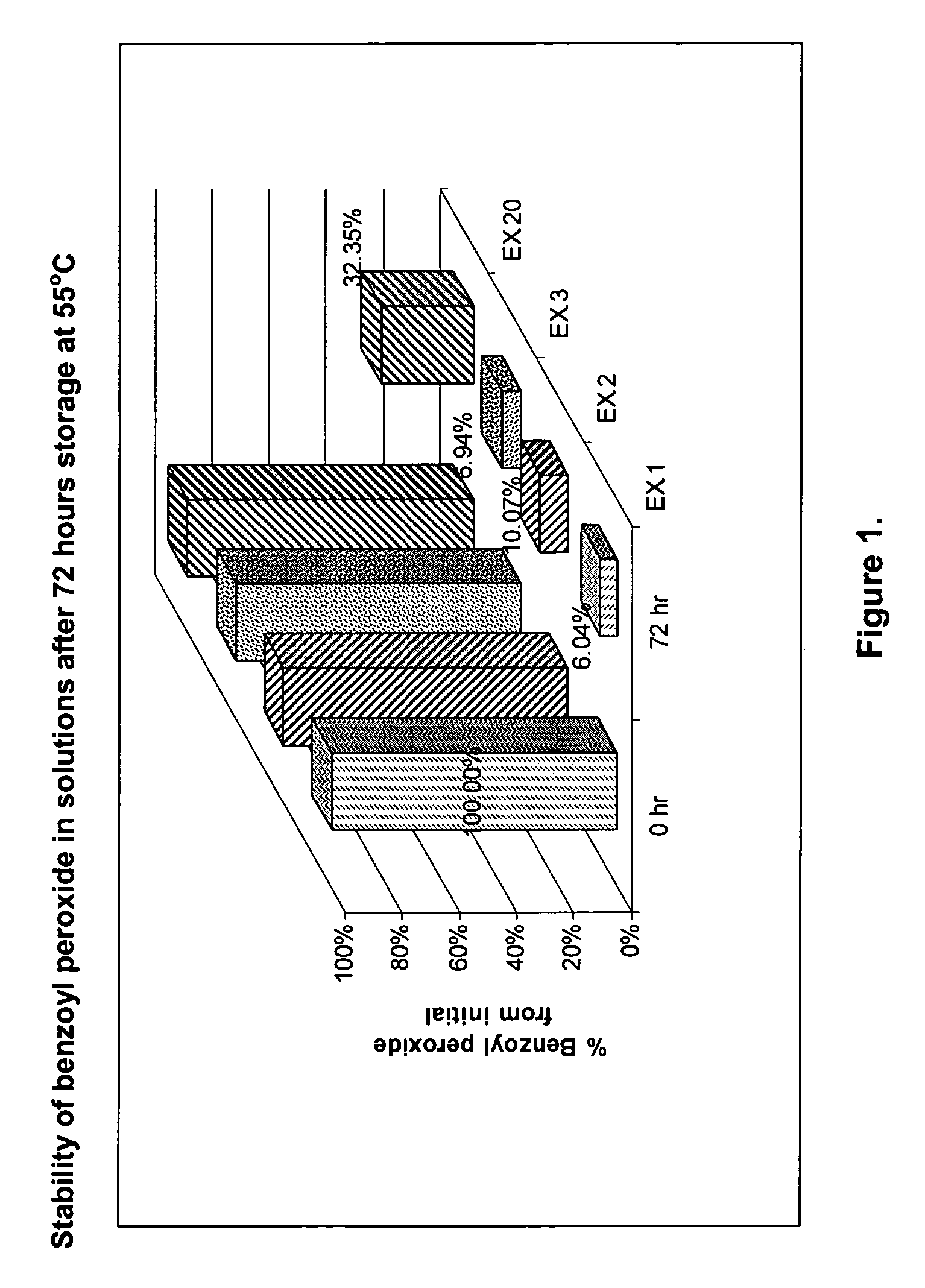

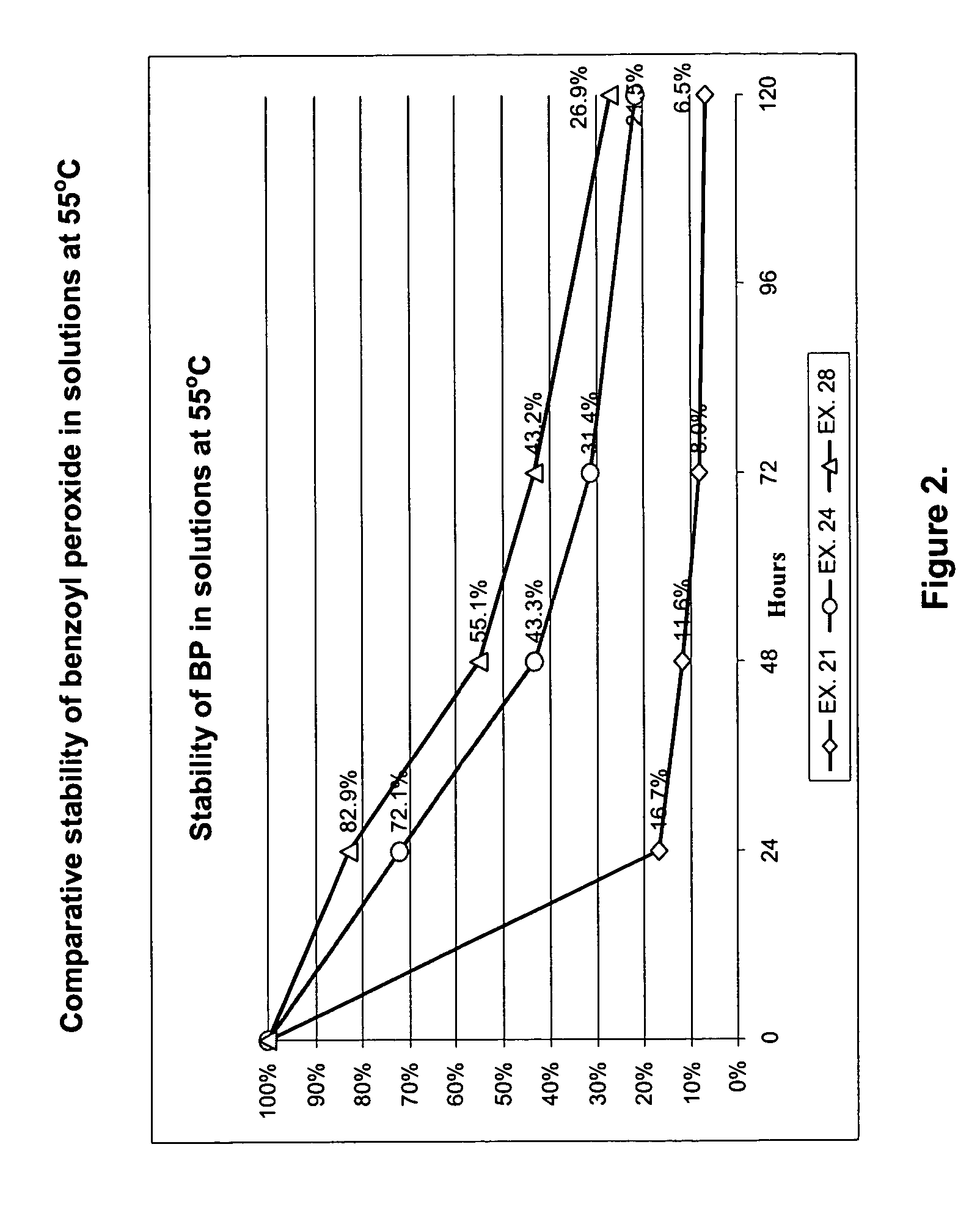

Stabilization of benzoyl peroxide in solution

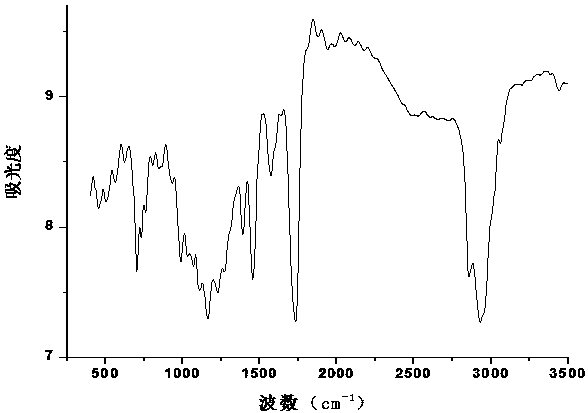

InactiveUS7153888B2Minimal skin irritating propertiesPrevent degradationBiocideOrganic compound preparationBenzoyl peroxideDibenzoyl Peroxide

The stabilization of benzoyl peroxide for extended periods of time is disclosed. The stabilized solution contains from between 0.5% and 20% organic peroxide and a stabilizer for preventing degradation of said peroxide in the solution.

Owner:ALPHARX

Single component room temperature stable heat-curable acrylate resin adhesive

A single component liquid heat-curable adhesive formulation that is stable at room temperature. The formulation includes from about 5 to about 70 wt % of at least one acrylate monomer, from about 5 to about 94 wt % of an acrylate oligomer, and from about 0.1 to about 10 wt % of a thermal initiator selected from the group consisting of diacyl peroxides, benzoyl peroxides and peroxy esters. A photo initiator may be included thereby rendering the stable liquid formulation to be both heat-curable and UV-curable.

Owner:ADDISON CLEAR WAVE

Synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical

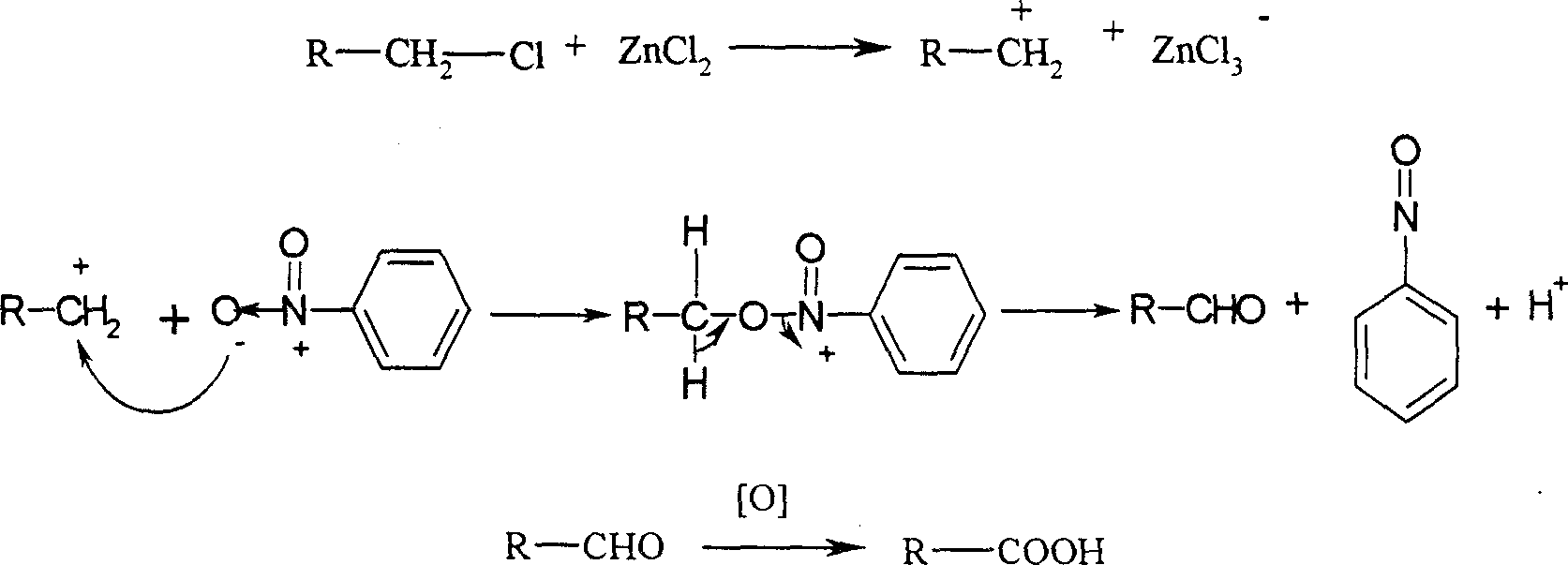

The present invention discloses the synthesis of composite functional super high cross-linked adsorbing resin containing sulfo radical. The synthesis process of the present invention adopts styrene as monomer, divinyl benzene as cross-liking agent, liquid paraffin and other material as pore creating agent, magnesium sulfate and other material as dispersant, benzoyl peroxide as initiator, nitrobenzene and dichloro ethane or chloroben as sweller, and zinc chloride, ferric trichloride or tin tetrachloride and Lewis acid as catalyst, and prepares composite functional resin through preparing chloromethylated low cross-linked polystyrene resin, post-crosslinking reaction to obtain composite functional resin precursor of different crosslinking degree and final sulfonating with high concentration sulfuric acid to obtain composite functional resin with different specific surface area and different exchange capacity. The resin product has both adsorption and ion exchange function and thus wide application range.

Owner:NANJING UNIV +1

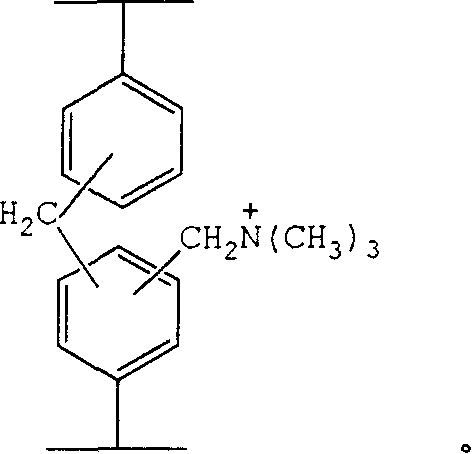

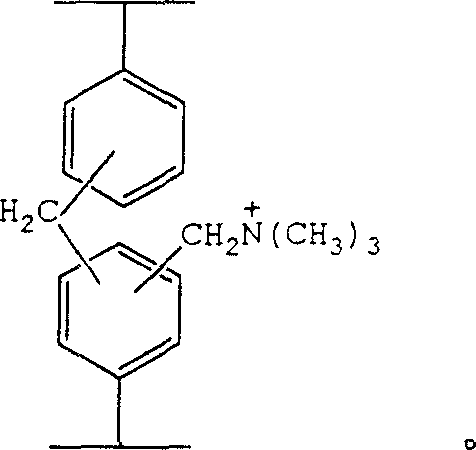

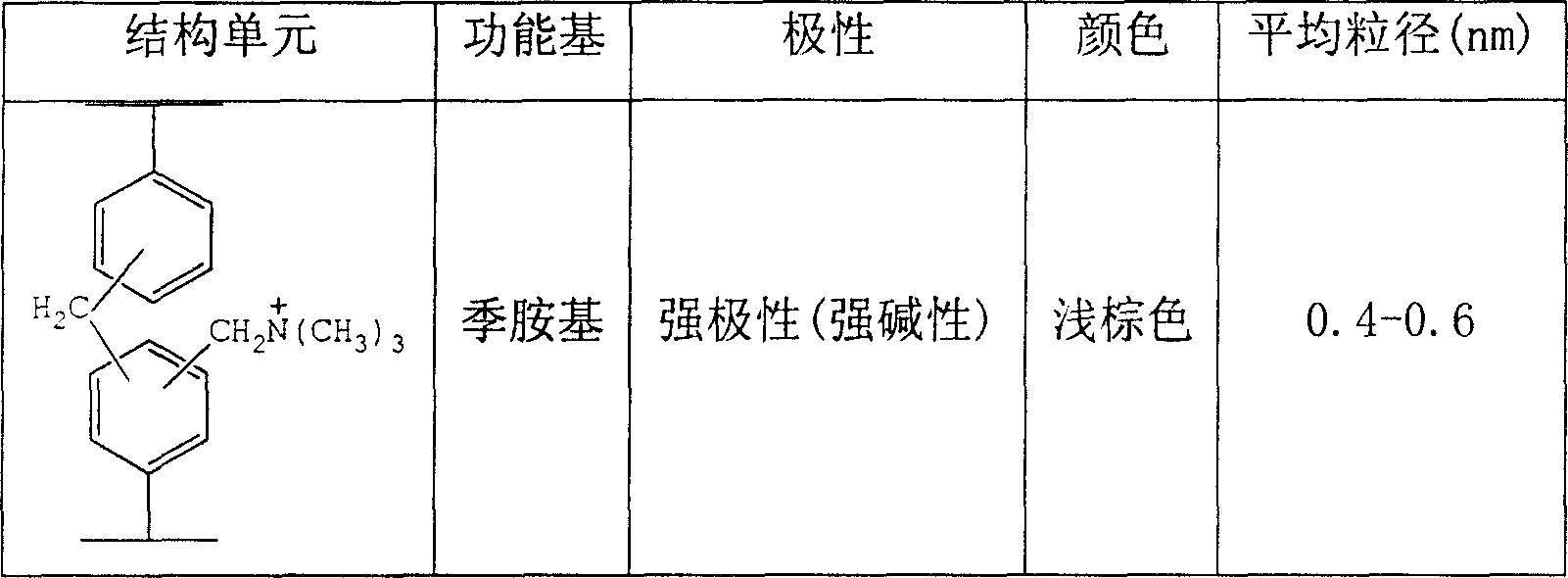

Composite functional super high cross-linked adsorption resin containing quaternary amine group, and its preparation method

ActiveCN1865302AHighlight hydrogen bondsProminent electrostatic effectOther chemical processesDibenzoyl PeroxideDisperser

The invention discloses a super high cross-linking adsorption resin with quaternary amines base composite function and making method, which comprises the following steps: utilizing phenylethene as monomer, diphenyl ethylene as cross linking agent, liquid wax as hole-sealing agent, magnesium carbonate as disperser, benzoyl peroxide as initiator; adopting nitrobenzene, substituted nitrobenzene, dichloroethanes or orthodichlorobenzene as swelling agent in the cross-linking reaction course of chloromethylation low cross-linking large-hole polyphenylacetylene; using zinc chloride, ferric chloride or tin tetrachloride as catalyst to produce different cross linking composite functional resin priority in the preset time and temperature condition; adding trimethylamine to aminate to produce the product. The resin possesses double functions of adsorption and ion exchanging, which can be applied in drug separation, little polluted water source and organic chemical waste water harnessing.

Owner:NANJING UNIV +1

Single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and preparation method thereof

The invention discloses single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and a preparation method thereof. The method comprises the following steps of: adding epoxy resin, n-butyl alcohol, and ethylene glycol monobutyl ether into a reactor, heating to form a homogeneous phase, controlling temperature to be 110 to 120 DEG C, and dripping acrylic ester monomers in which initiator benzoyl peroxide (BPO) is dissolved to obtain an acrylic ester monomer modified epoxy resin; and heating the acrylic ester monomer modified epoxy resin to 120 to 150 DEG C, adding unitary unsaturated fatty acid and catalyst triphenylphosphorus, adding maleic anhydride, reacting for 1.0 to 2.0 hours, reducing temperature to 50 to 55 DEG C, adding triethylamine, neutralizing for 0.5 to 1.0 hour, adding water and dispersing for 0.5 to 1.0 hour to obtain the single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature. The aqueous epoxy resin emulsion which is obtained by the method can be cured at normal temperature to form a film under the condition of not adding a curing agent, is convenient to use, and high in water resistance and corrosion resistance, and can be used for metal corrosion-resistant paint and the like.

Owner:广州玖盈化工材料有限公司

Method for controlloing oxygen containing functional group in surface in synthesizeing adsorptive resin of crosslinked polystyrene

InactiveCN1872889AEfficient extractionSimple control methodWater/sewage treatment by sorptionBenzoyl peroxideNitrobenzene

This invention discloses a method for controlling the oxygen-containing functional groups on the surface of crosslinked polystyrene adsorption resins. The method uses styrene as the monomer, divinylbenzene as the crosslinking agent, liquid wax as the pore-forming agent, magnesium carbonate as the dispersant, and benzoyl peroxide as the initiator. The method comprises: (1) preparing macroporous styrene-divinylbenzene copolymer resins with a low crosslinking degree; (2) chloromethylating to obtain chloromethylated macroporous styrene-divinylbenzene copolymer resin balls; (3) swollening in nitrobenzene, adding the catalyst, introducing nitrogen, oxygen or air, and reacting to obtain crosslinked styrene-divinylbenzene copolymer resins having carbonyl, hydroxyl, ester or carboxyl on the surface. The resins can be used to treat industrial wastewater or extract drugs. The method has such advantages as simple process and simple equipment.

Owner:NANJING UNIV +1

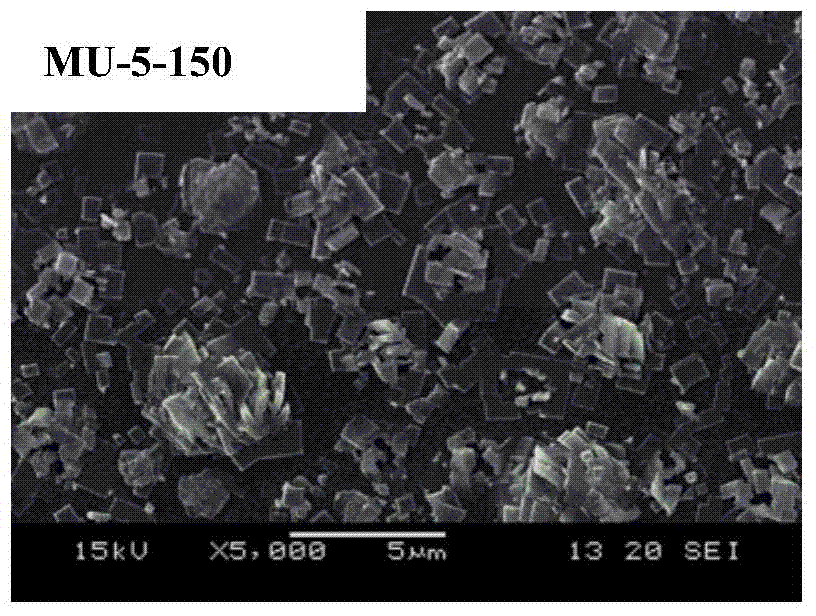

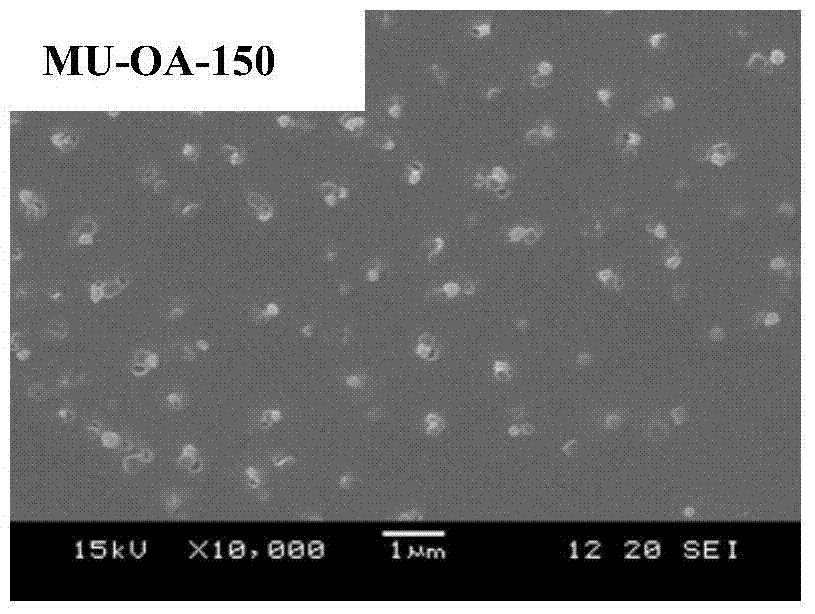

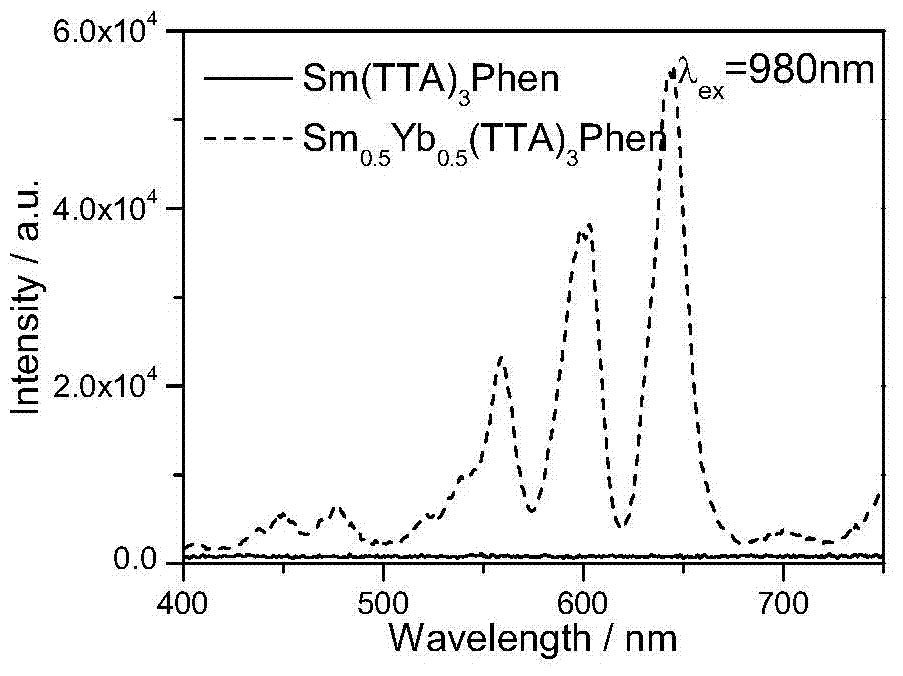

Solar cell EVA packaging adhesive film material having light conversion function, and preparation method thereof

InactiveCN103709946AImprove efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkBenzoyl peroxide

The invention discloses a solar cell EVA packaging adhesive film material having a light conversion function. The material is obtained by compounding a rare earth organic complex with an EVA packaging adhesive; the rare earth organic complex is a nano-micro-scale rare earth organic complex having ultraviolet down-conversion and near infrared up-conversion functions; and the EVA packaging adhesive is an ethylene-vinyl acetate copolymer, wherein the content of vinyl acetate (VA) in the EVA packaging adhesive is 25-42%, and the melt index of the EVA packaging adhesive is 10-45g / 10min. The invention also discloses a preparation method of the material. The method comprises the following steps: dissolving the EVA in THF according to a certain ratio at room temperature to form a THF solution of the EVA, setting an ultrasonic dispersion power, and dispersing the rare earth organic complex in a solvent to form a complete clear solution; adding the formed THF solution into the formed clear solution, adding a cross-linking agent benzoyl peroxide, reacting for 1-6h, drying to form a film, and squeezing the film by using a flat vulcanizing machine to obtain the transparent light-conversion adhesive film material having a transmissivity of 90% or more, wherein the thickness of an EVA packaging adhesive film is 0.1-5.0mm.

Owner:NANJING UNIV OF TECH

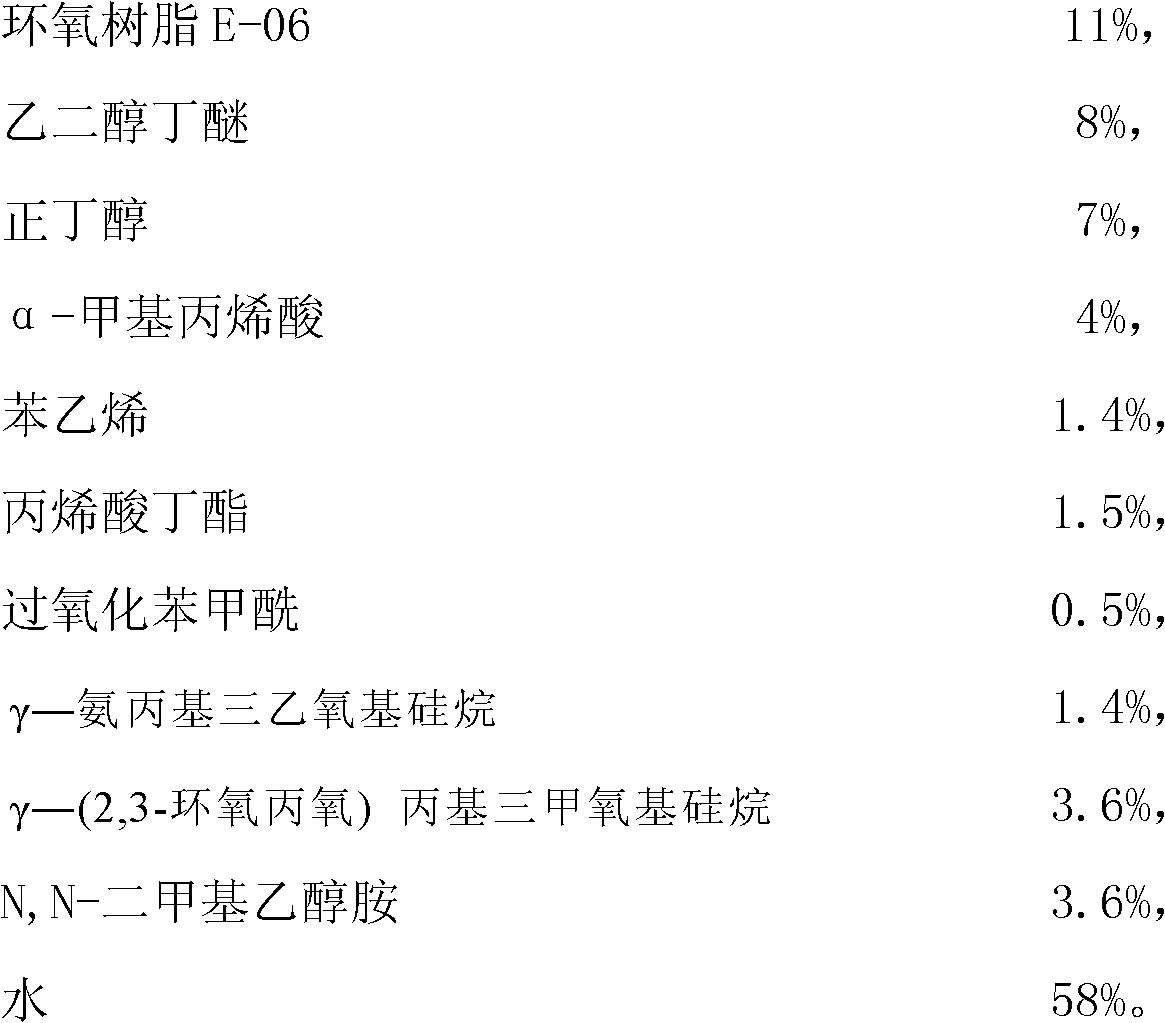

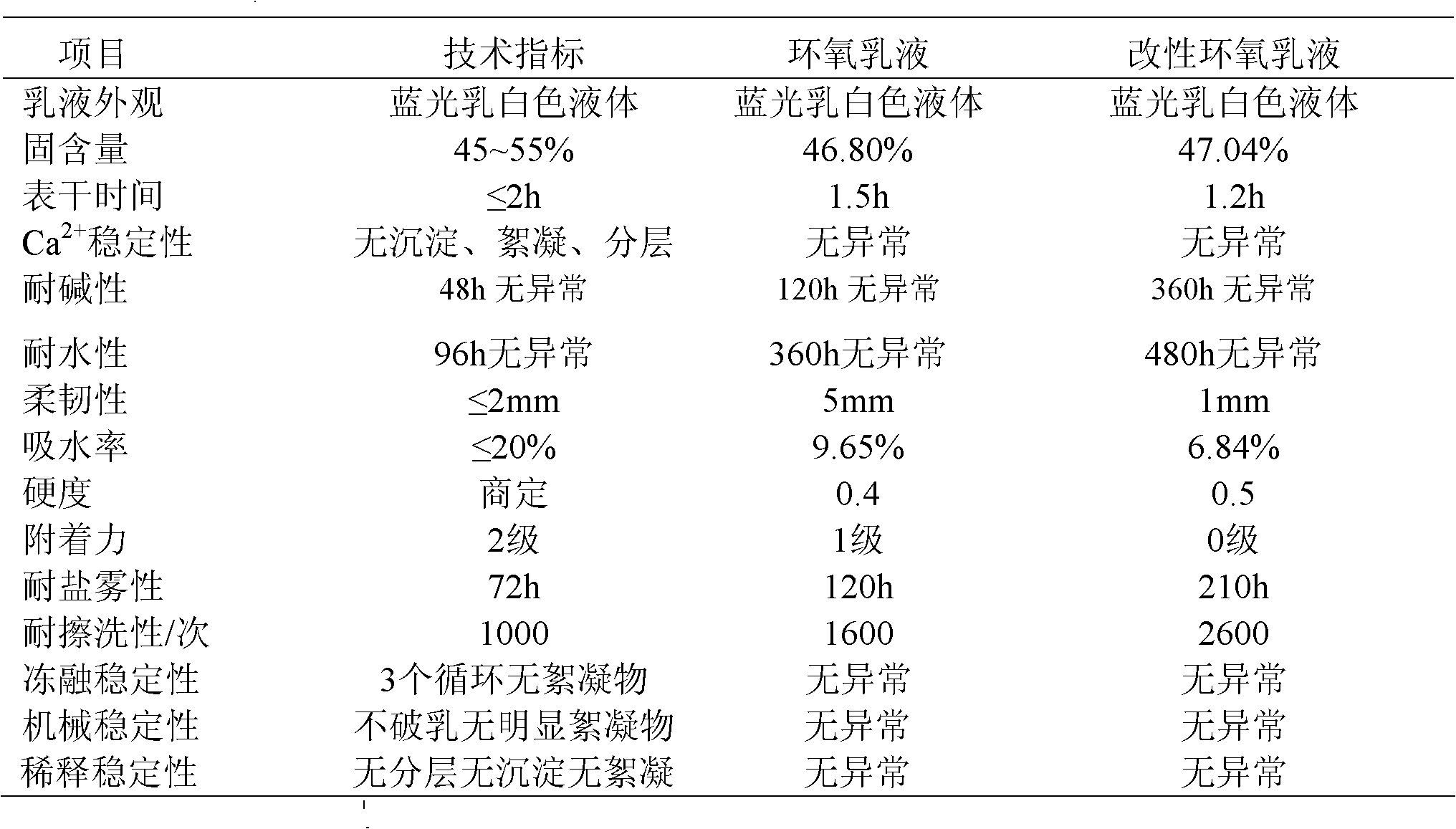

Modified epoxy emulsion and preparation method thereof

InactiveCN102585111AGood film formingGood physical and mechanical propertiesCoatingsHydrophilic monomerEpoxy

The invention discloses a modified epoxy emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 10-15 percent of epoxy resin E-06, 8-10 percent of ethylene glycol monobutyl ether, 7-8 percent of n-butyl alcohol, 4-4.5 percent of alpha-methacrylic acid, 1-1.5 percent of styrene, 1-1.5 percent of butyl acrylate, 0.4-0.8 percent of benzoyl peroxide, 1-1.5 percent of gamma-aminopropyl triethoxy silane, 3.2-4 percent of gamma-trimethoxypropylsilane, 3.2-4.2 percent of N,N-dimethylethanolamine and 50-60 percent of water. The preparation method comprises the following steps of: preparing for graft copolymerization; then, introducing hydrophilic monomers by utilizing the graft copolymerization method; and adding a mixture for further modification to obtain the modified epoxy emulsion. The modified epoxy emulsion has the characteristics of strong adhesion, good flexibility, hardness, corrosion resistance, water resistance, alkali resistance, scrub resistance and simple preparation process.

Owner:JIANGSU UNIV OF SCI & TECH

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

Benzoyl peroxide compositions having increased potency

InactiveUS20050256200A1Good curative effectHeavy metal active ingredientsCosmetic preparationsBenzoyl peroxideDibenzoyl Peroxide

A benzoyl peroxide composition having increased potency includes benzoyl peroxide, a tertiary amine and / or a transition metal, and a base that increases radicals formed by the peroxide.

Owner:BURKHART CRAIG G +1

Heavy metal sewage treatment agent

InactiveCN104118921ARemove reachEasy to remove by filtrationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationCelluloseCarbamate

The invention relates to a heavy metal sewage treatment agent which is prepared from dodecyl diethylene triamine, dimethyl diallyl ammonium chloride, acrylamide, dibenzoyl peroxide, powdered activated carbon, ethylene diamine tetraacetic acid, tert-butylamine, carbamate, dithiocar-bamate, thiocarbamic acid ester, starch, cellulose, water soluble starch xanthate ester, sodium silicate, potassium peroxodisulfate, sodium hydrosulfite, strong base and water. The heavy metal sewage treatment agent disclosed by the invention is formed by being modified with a high-molecular compound; the mixture contains a plurality of active groups which can be complexed, chelated, absorbed and exchanged with heavy metal, so that heavy metal ions in the aqueous solution can be removed; the heavy metal sewage treatment agent has good removal effect on heavy metal ions, the removal rate is above 97%, and furthermore, the heavy metal sewage treatment agent has stronger Ca2+ and Mg2+ resistant capability; the removal rate of cadmium-containing sewage is 99.8%, which meets the national emission standard; and the removal rate of chromium-containing sewage is above 99.6%.

Owner:江西省恩皓环保有限公司

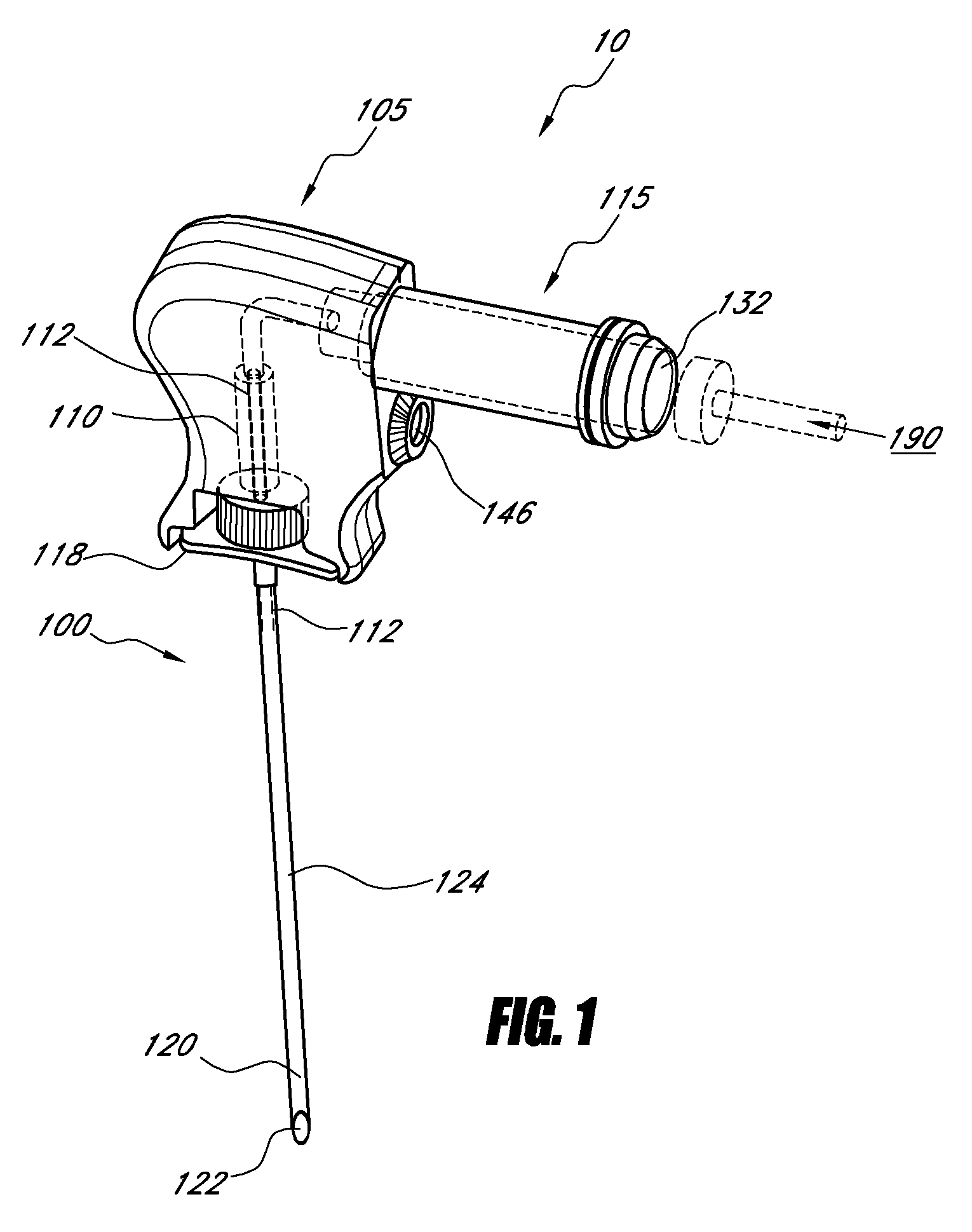

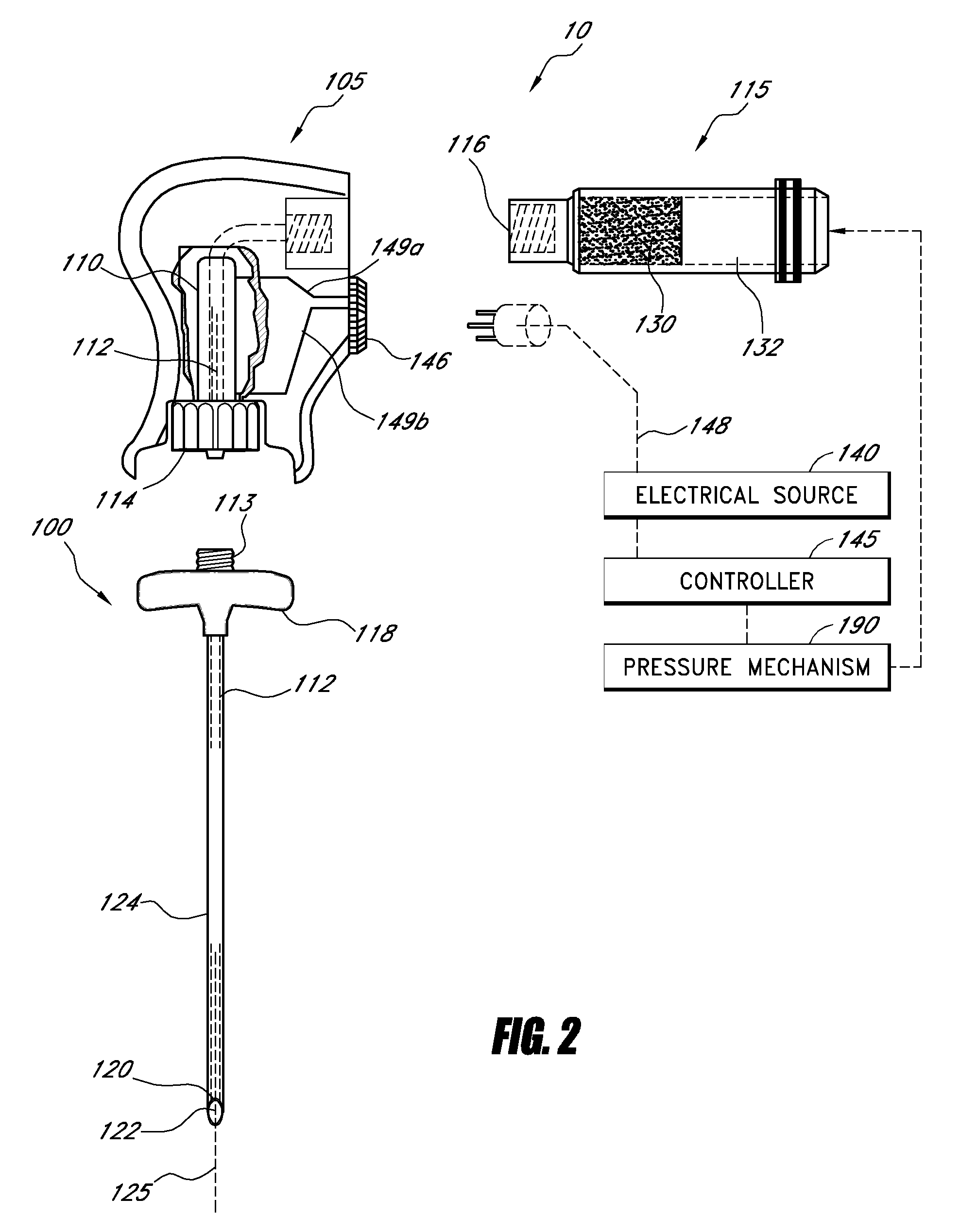

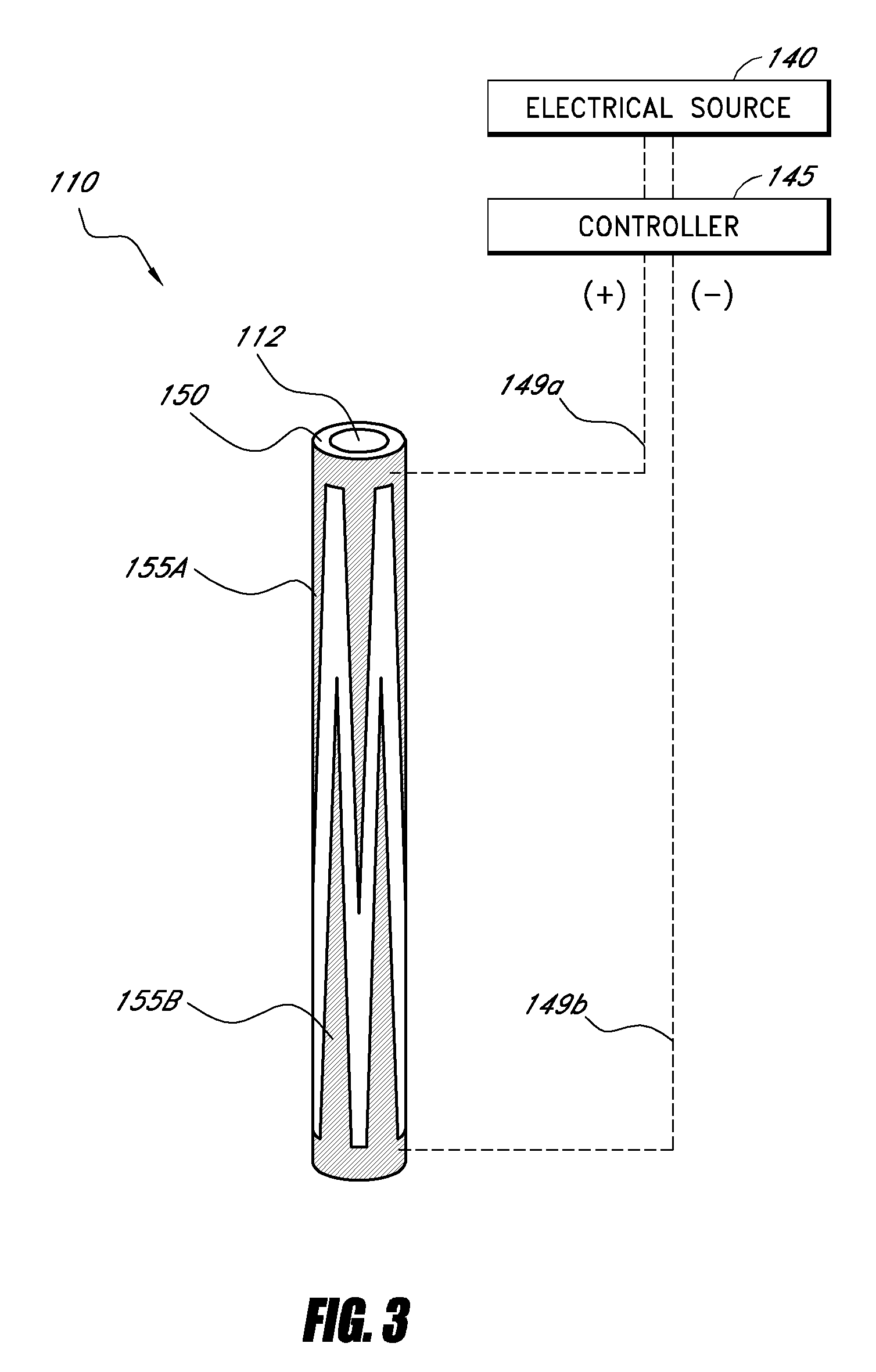

Bone treatment systems and methods

The present disclosure relates to bone cement formulations that have an extended working time for use in vertebroplasty procedures and other osteoplasty procedures together with cement injectors that include energy delivery systems for on-demand control of cement viscosity and flow parameters. The bone cement formulations may include a liquid component having at least one monomer and a non-liquid component including polymer particles and benzoyl peroxide (BPO). The non-liquid component may be further configured to allow controlled exposure of the BPO to the liquid monomer so as to enable control of the viscosity of the bone cement composition.

Owner:DFINE INC

Methods and compositions for treating acne

InactiveUS20100226948A1Cleanse and medicate skinImprove stabilityBiocideOintment deliveryBenzoyl peroxideTreatment acne

A method for treating acne on the skin. The method has the steps of (a) providing an drapeable or flexible porous article impregnated with an aqueous cleansing composition having a carrier, benzoyl peroxide, and one or more cleansing agents; (b) contacting an area of the skin affected by acne with the porous article such that the skin is contacted by the composition; and (c) removing the composition from the skin wherein residual benzoyl peroxide remains on the skin in an anti-acne effective amount. There are also anti-acne compositions.

Owner:MEDICIS PHARMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com