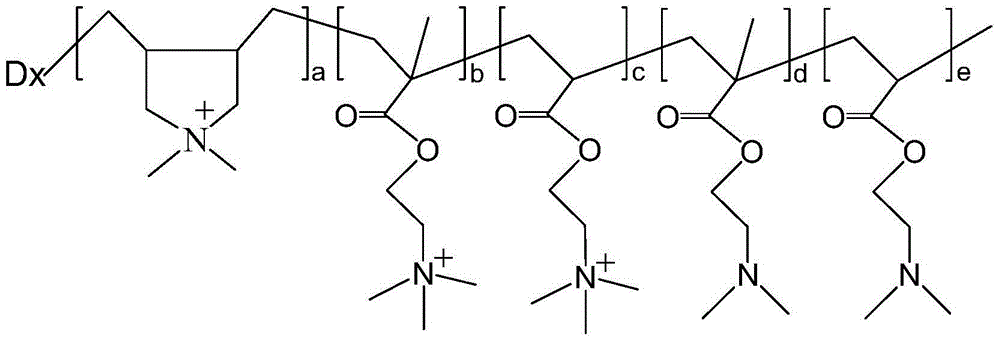

Grafted copolymerized cationic polysaccharide bioflocculant and preparation method thereof

A technology of biological flocculant and cationic polysaccharide, applied in the field of graft copolymerization type cationic polysaccharide biological flocculant and its preparation, can solve the problems of inseparability and difficult to compare with adsorption bridging, and achieve high positive charge density and good social Economic benefits, the effect of accelerating the settling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

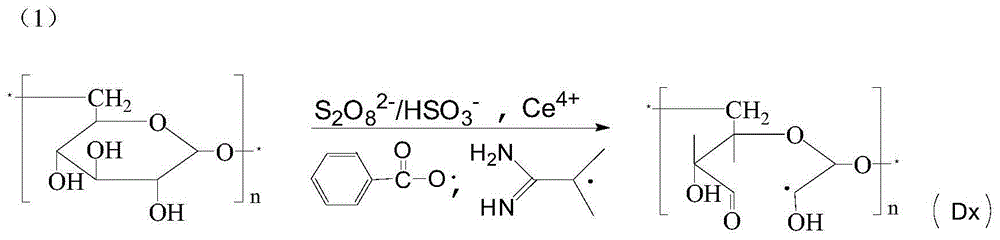

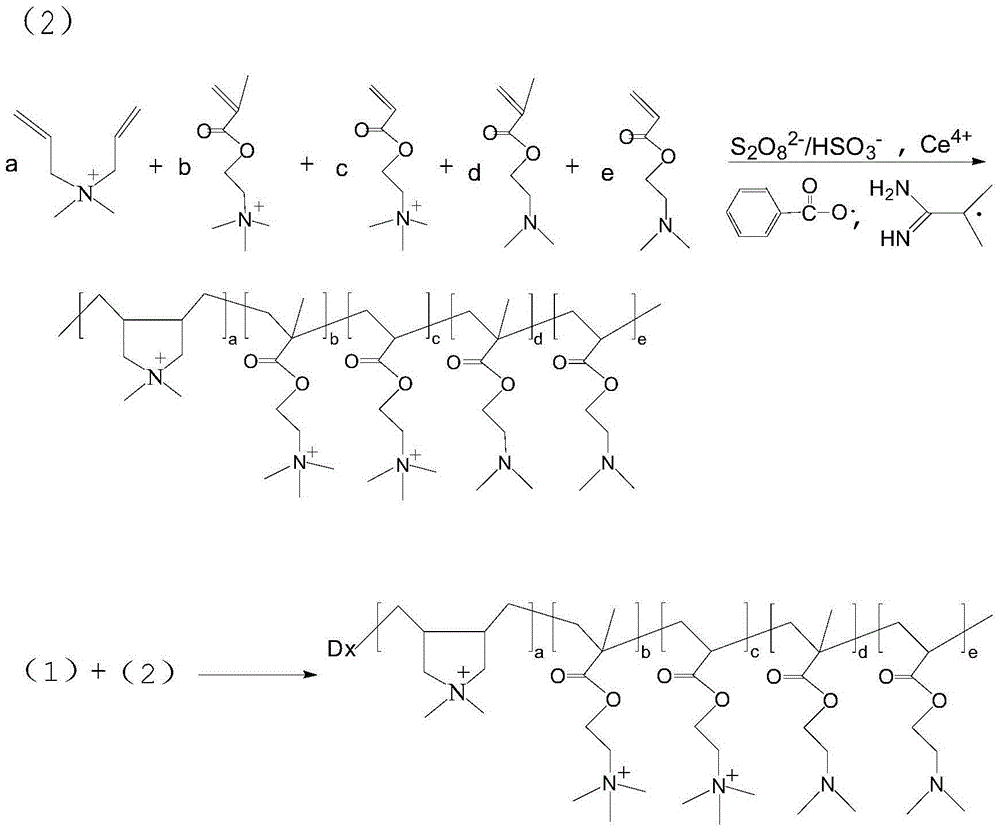

Method used

Image

Examples

Embodiment 1

[0032] Nonionic polysaccharide bioflocculants grafted with methacryloyloxyethyltrimethylammonium chloride and acryloyloxyethyltrimethylammonium chloride.

[0033] In a 500ml three-necked flask, add 200g of a nonionic polysaccharide bioflocculant (Dx) solution with a mass concentration of 15%, start stirring, and sequentially add methacryloyloxyethyltrimethylammonium chloride with a mass concentration of 78% ( DMC) solution 50g and acryloyloxyethyl trimethylammonium chloride (DAC) solution 25g with a mass concentration of 80%, after deoxidizing with nitrogen, the temperature was raised to 30°C, and 0.36g of ammonium persulfate was added, and bisulfite was added. Sodium 0.09g, after the reaction for 1h, the temperature was raised to 60°C and 0.09g of dibenzoyl peroxide (BPO) was added. After continuing to stir for 3h, the nitrogen flow was stopped, and air was introduced to terminate the reaction, and the product was precipitated with ethanol. After water extraction and washing,...

Embodiment 2

[0036] Nonionic polysaccharide bioflocculants grafted with dimethylaminoethyl methacrylate and dimethylaminoethyl acrylate.

[0037] In a 500ml three-necked flask, add 200g of nonionic polysaccharide bioflocculant (Dx) solution with a mass concentration of 15%, start stirring, and sequentially add 30g of dimethylaminoethyl methacrylate (DMAEMA) and dimethylaminoethyl acrylate ( DMAEA) 30g, after passing nitrogen to remove oxygen, the temperature was raised to 50 °C, and 0.45g of ceric ammonium nitrate was added. After 8 hours of reaction, nitrogen flow was stopped, air was passed to terminate the reaction, and the product was precipitated with ethanol and extracted with ethanol and water. , After washing, bake in a vacuum drying oven at 50°C to constant weight and grind.

[0038] The results showed that the conversion rate of monomer was 69.5%, the cationic degree was 34.6%, and the flocculation effect was good.

Embodiment 3

[0040] Nonionic polysaccharide bioflocculant grafted with methacryloyloxyethyltrimethylammonium chloride.

[0041]In a 500ml three-necked flask, add 200g of a nonionic polysaccharide bioflocculant (Dx) solution with a mass concentration of 15%, start stirring, and add an aqueous solution containing 60g of methacryloyloxyethyltrimethylammonium chloride (DMC), After deoxidizing with nitrogen, the temperature was raised to 40°C, and 0.45 g of ceric ammonium nitrate was added. After 4 hours of reaction, the nitrogen flow was stopped, air was introduced to terminate the reaction, and the reaction was taken out. The product was precipitated with ethanol, extracted with ethanol and water, and washed at 50 ℃ dried in a vacuum drying oven to constant weight and ground.

[0042] The results showed that the conversion rate of monomer was 62.7%, the cationic degree was 43.53%, and the flocculation effect was obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com