Patents

Literature

1286results about How to "Settling fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient water treatment flocculant

InactiveCN101327976AEfficient purificationPromote generationWater/sewage treatment by flocculation/precipitationWater qualityHigh intensity

The invention relates to a high efficiency water treatment flocculant for drinking water and water treatment comprising a metal cation flocculant which is characterized in that the high efficiency water treatment flocculant also comprises a high efficiency adsorption component and an assistant medicament to be remixed, inwhich the weight ratio is: the high efficiency adsorption component 5-15%, the metal cation flocculant 50-85%, the assistant medicament 5-15%. The obvious characteristics of the invention are that each component can play the advantages of high intensity of the flocs of the inorganic flocculant and large flocs of the polymeric flocculant, overcomes the drawback of small flocs of the inorganic flocculant and low intensity of the flocs of the organic flocculant. The existence of the high adsorption component plays the action of adsorption of the organic compounds and heavy metal ion which are difficult to flocculat and precipitate, also plays the role of aid-coagulation, decoloration and deflavour. Thus the flocculant of the invention has advantages of good coagulation effect, large alum blossom, rapid settling velocity, good effluent quality and few dosage or the like.

Owner:郭振岳 +1

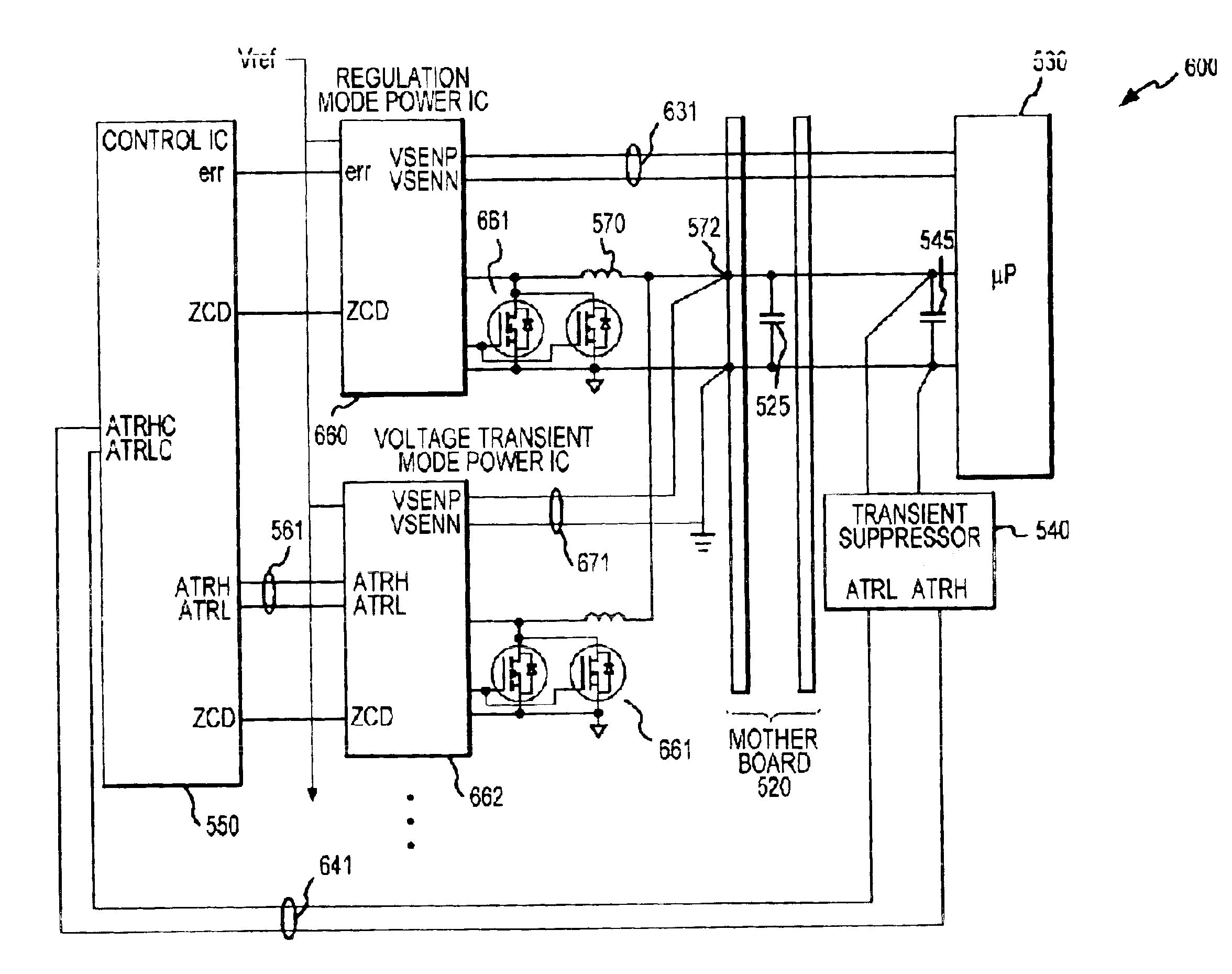

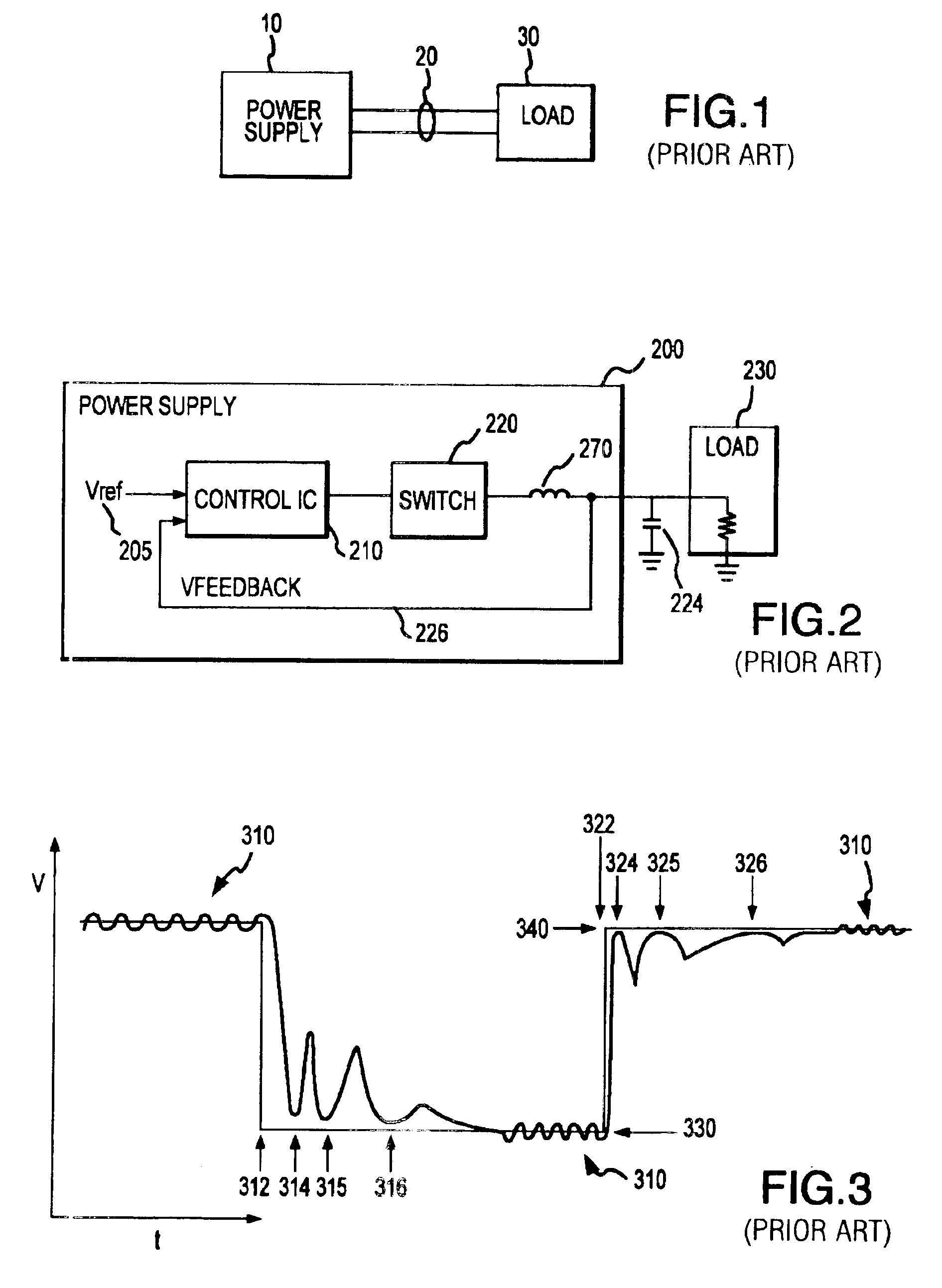

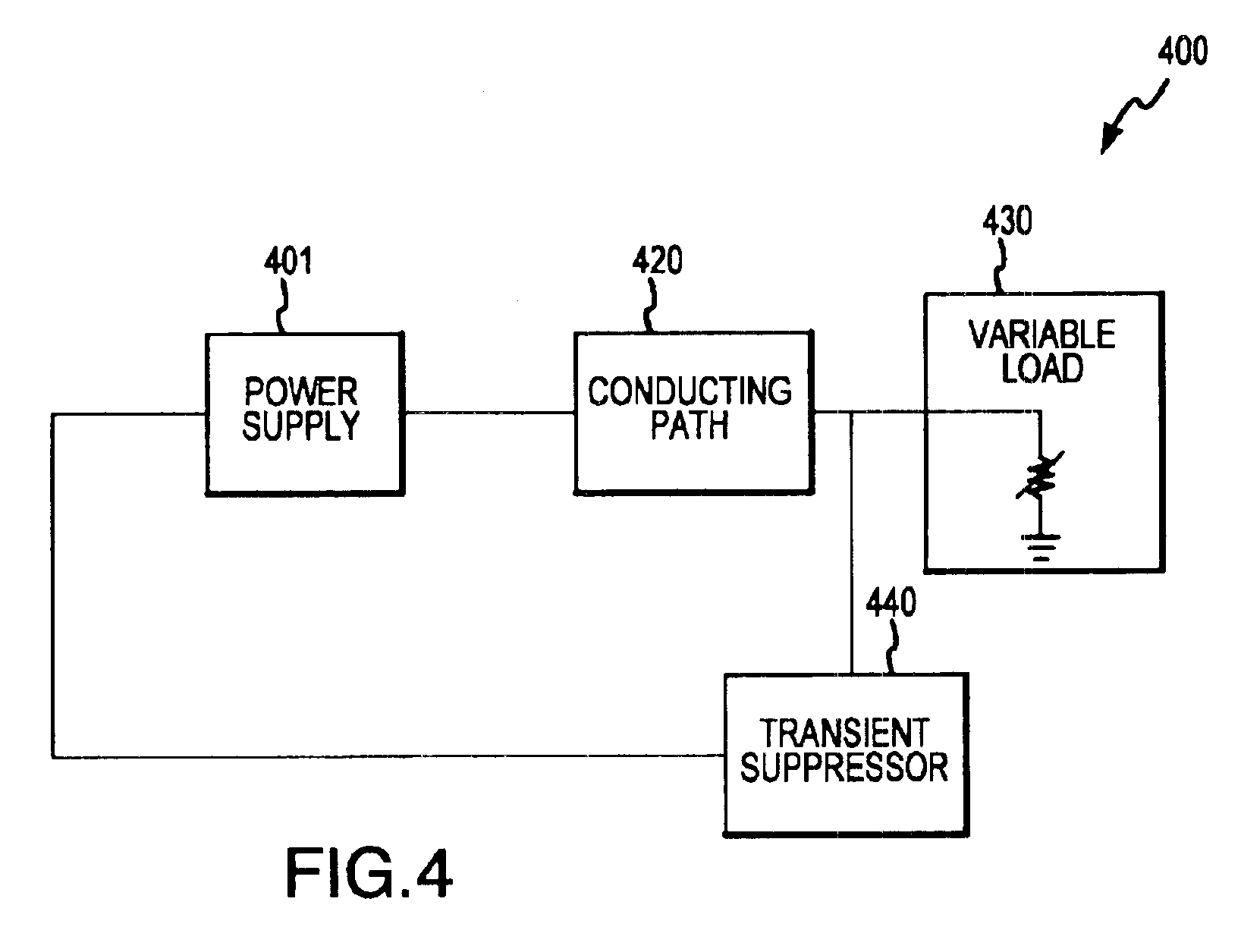

System, device and method for providing voltage regulation to a microelectronic device

InactiveUS6965502B2High speed signal settlingAct quicklyPower supply for data processingArrangements responsive to excess currentEngineeringSteady state

The present invention provides a power regulation system and method with high speed signal settling capabilities for providing rapid active transient response to a microelectronic device. An active transient response system includes a power supply configured to receive external and / or internal signals indicating the occurrence of transient load conditions and to respond to the transient load conditions based on one or more of these signals. The system may further include a transient suppressor configured for early detection of transients, assisting in transient suppression, and early signaling of transient activity to the power supply.The system provides rapid recovery to steady state operation from the active transient response mode by using a digital compensator to quickly modifying the duty cycle and provide a voltage offset proportional to the transient microprocessor load step. Recovery is further improved by current rephasing techniques.

Owner:INFINEON TECH AUSTRIA AG

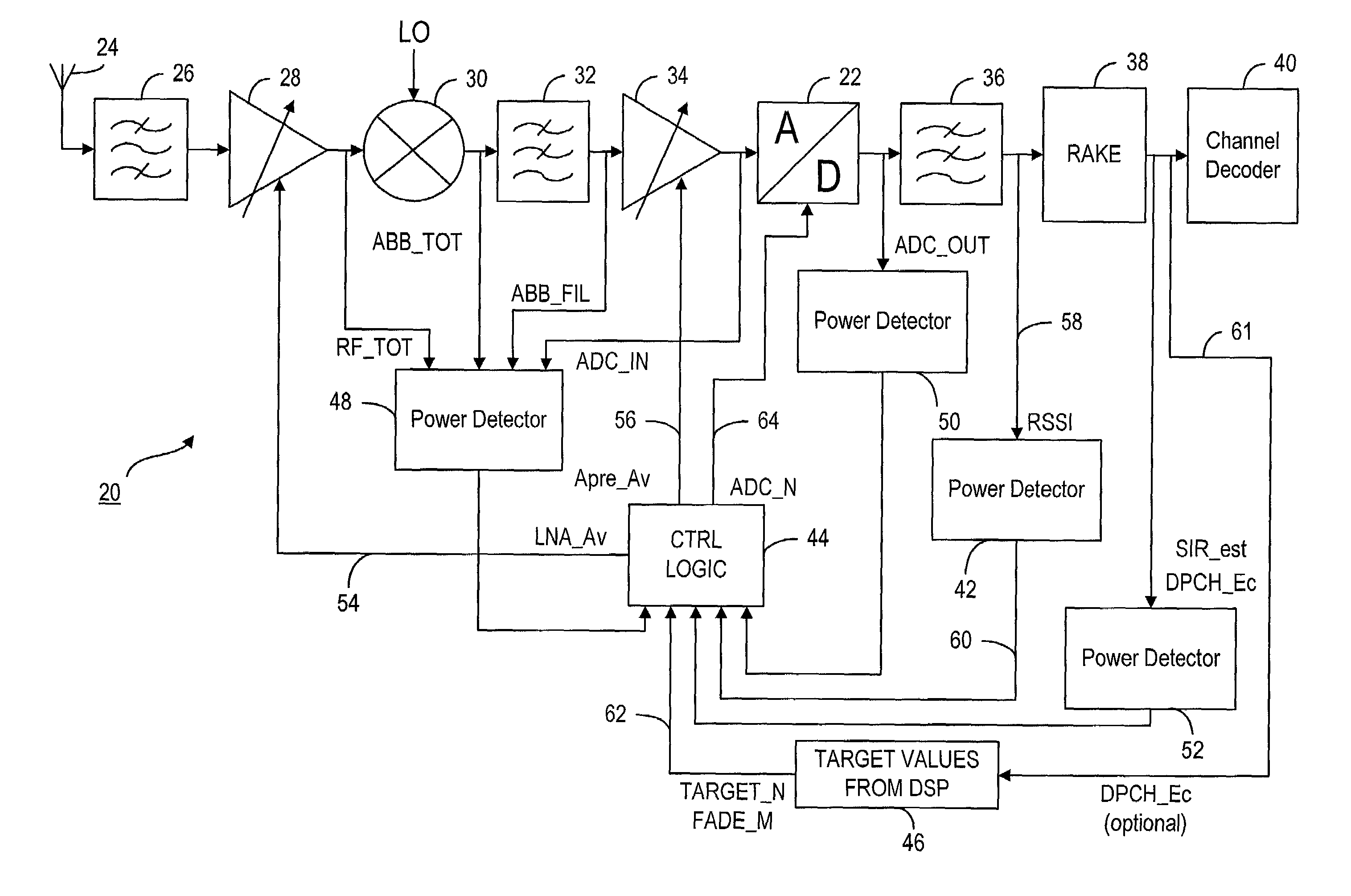

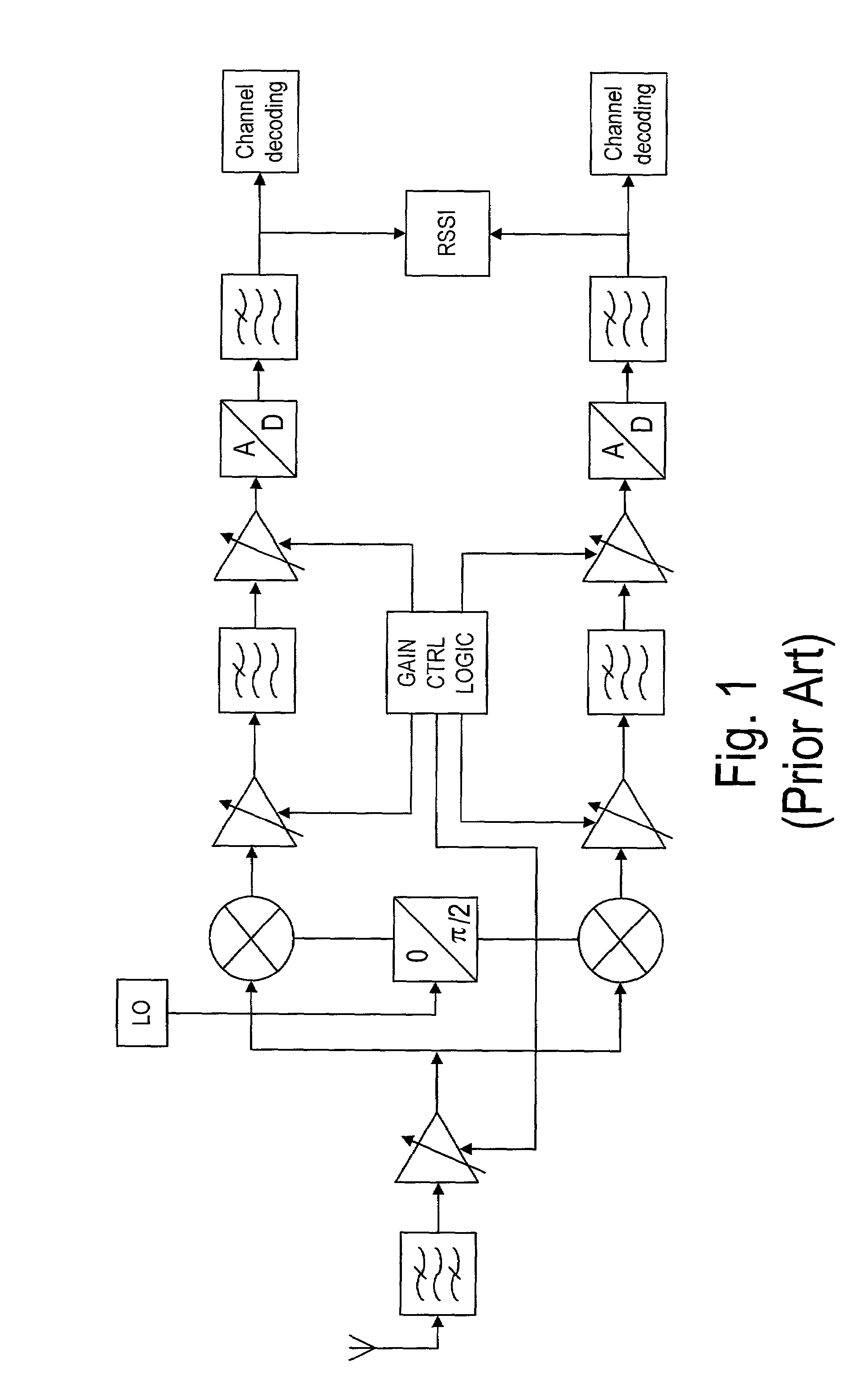

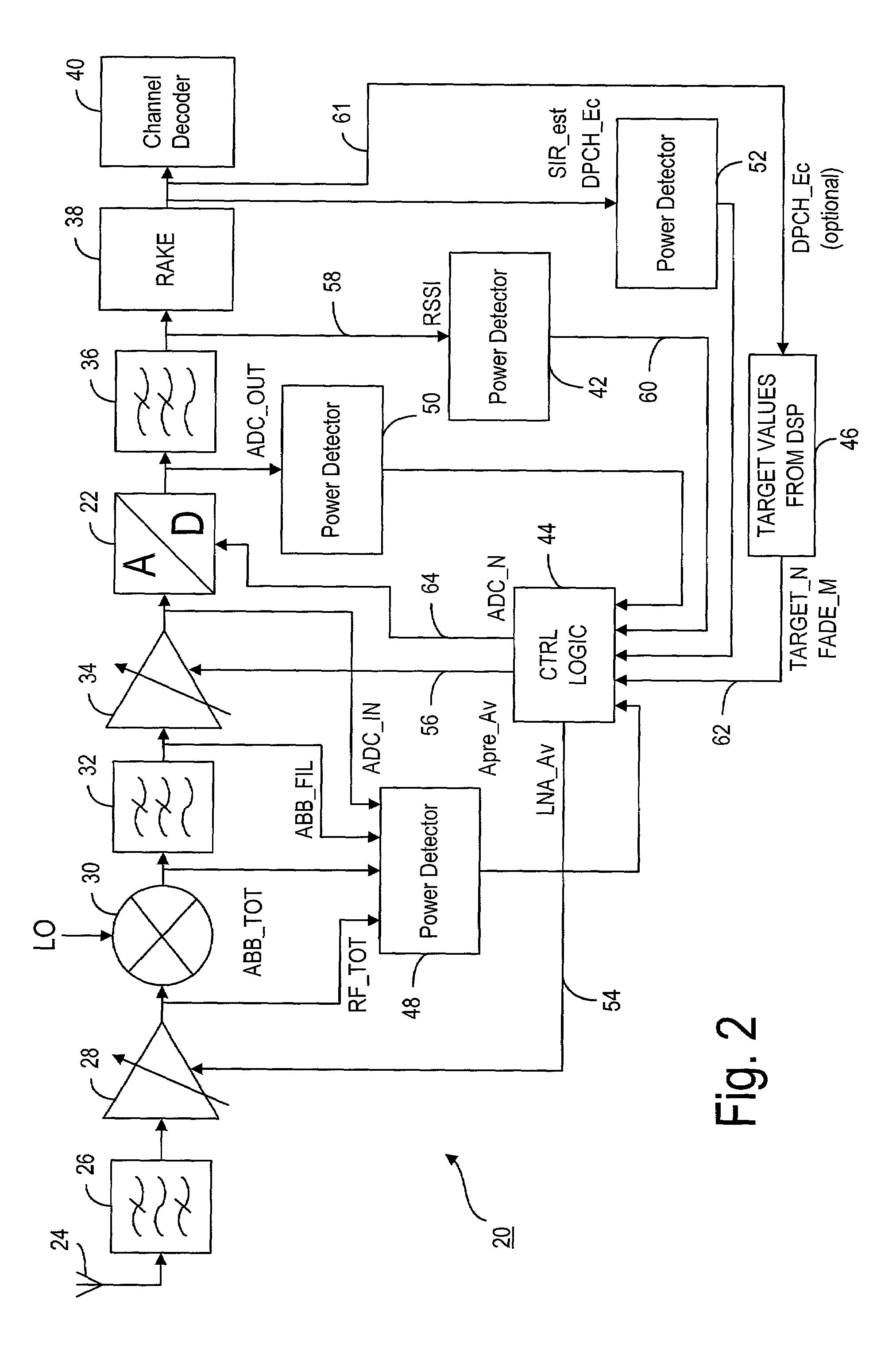

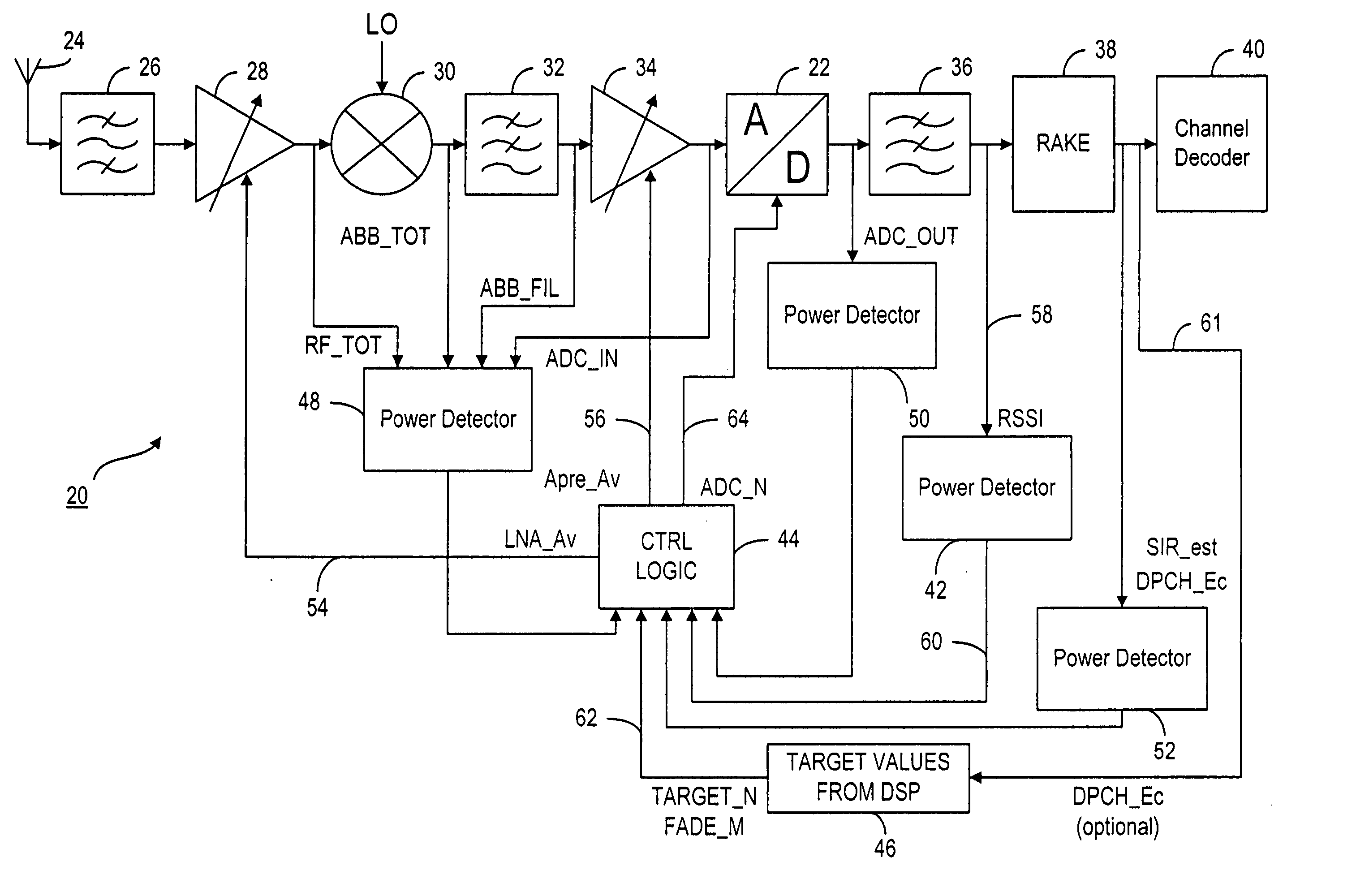

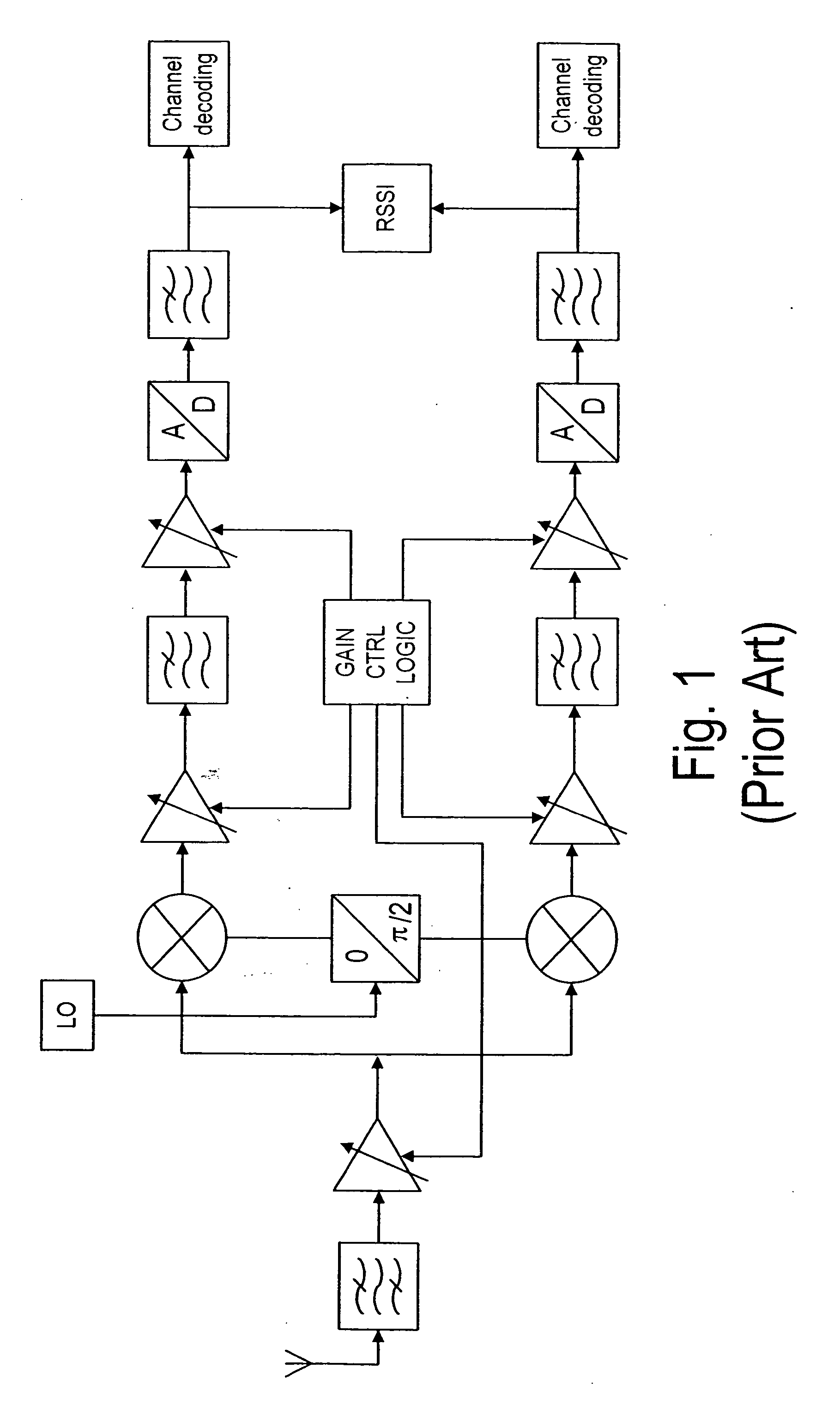

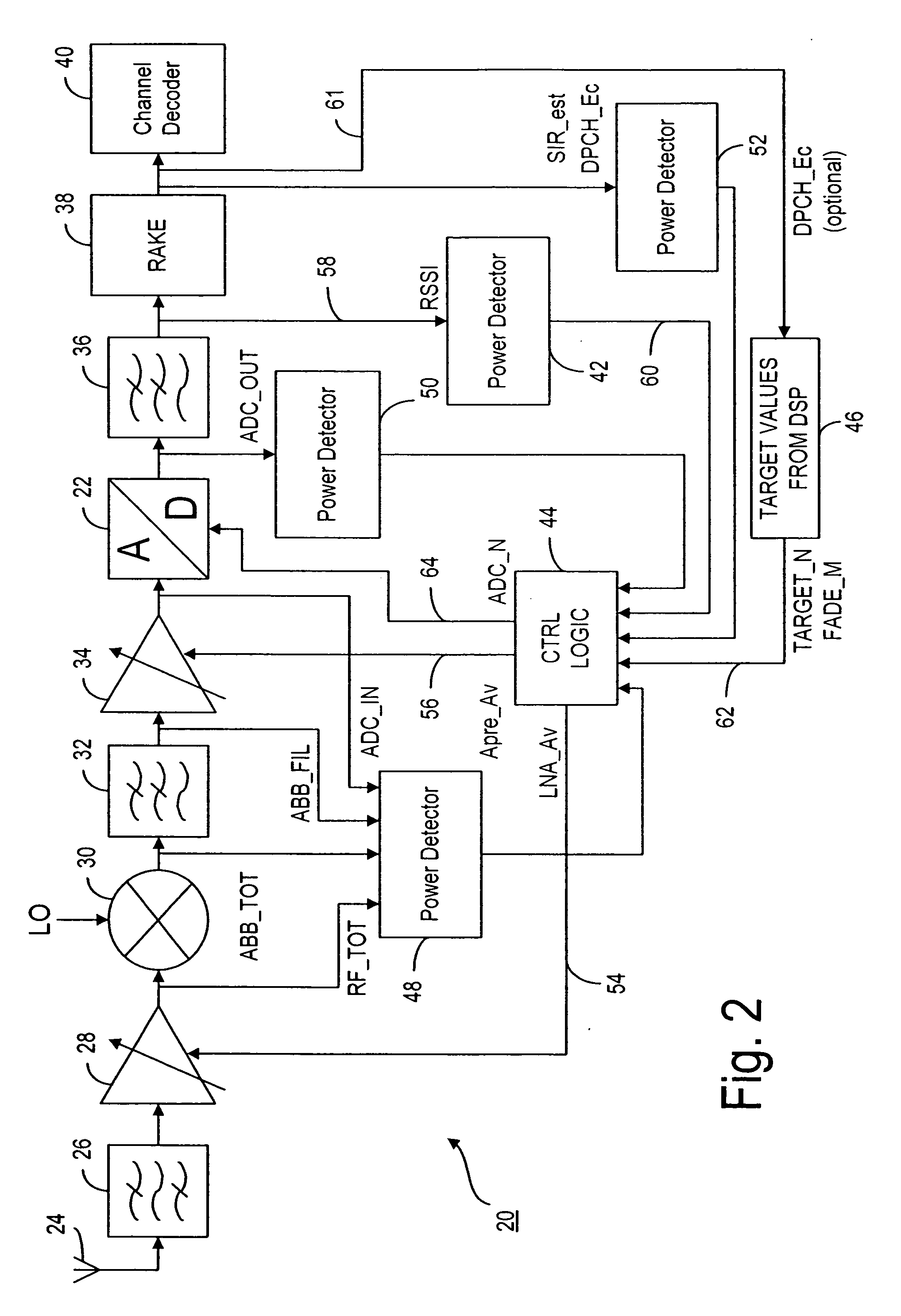

Method and apparatus for continuously controlling the dynamic range from an analog-to-digital converter

ActiveUS6993291B2Optimize power consumptionReduce power consumptionElectric signal transmission systemsGain controlAnalog to digital conversionImage resolution

A method for continuously determining the required dynamic range for an analog-to-digital converter by determining the received signal strength and using this received signal strength value in combination with the overall dynamic range for the ADC and the target resolution of the ADC to decode a radio channel in the absence of interference, wherein the target resolution is also related to the type of decoding to be performed subsequent to analog-to-digital conversion. The method allows for a reduction in power consumption associated with the ADC, especially when the incoming signal is received with few interfering radio channels and with a relatively high signal strength. The present method can be combined with gain control and analog alert detection.

Owner:WSOU INVESTMENTS LLC

Method and apparatus for continuously controlling the dynamic range from an analog-to-digital converter

InactiveUS20060079191A1Minimize power consumptionSettling fastGain controlTransmission monitoringPresent methodImage resolution

A method for continuously determining the required dynamic range for an analog-to-digital converter by determining the received signal strength and using this received signal strength value in combination with the overall dynamic range for the ADC and the target resolution of the ADC to decode a radio channel in the absence of interference, wherein the target resolution is also related to the type of decoding to be performed subsequent to analog-to-digital conversion. The method allows for a reduction in power consumption associated with the ADC, especially when the incoming signal is received with few interfering radio channels and with a relatively high signal strength. The present method can be combined with gain control and analog alert detection.

Owner:WSOU INVESTMENTS LLC

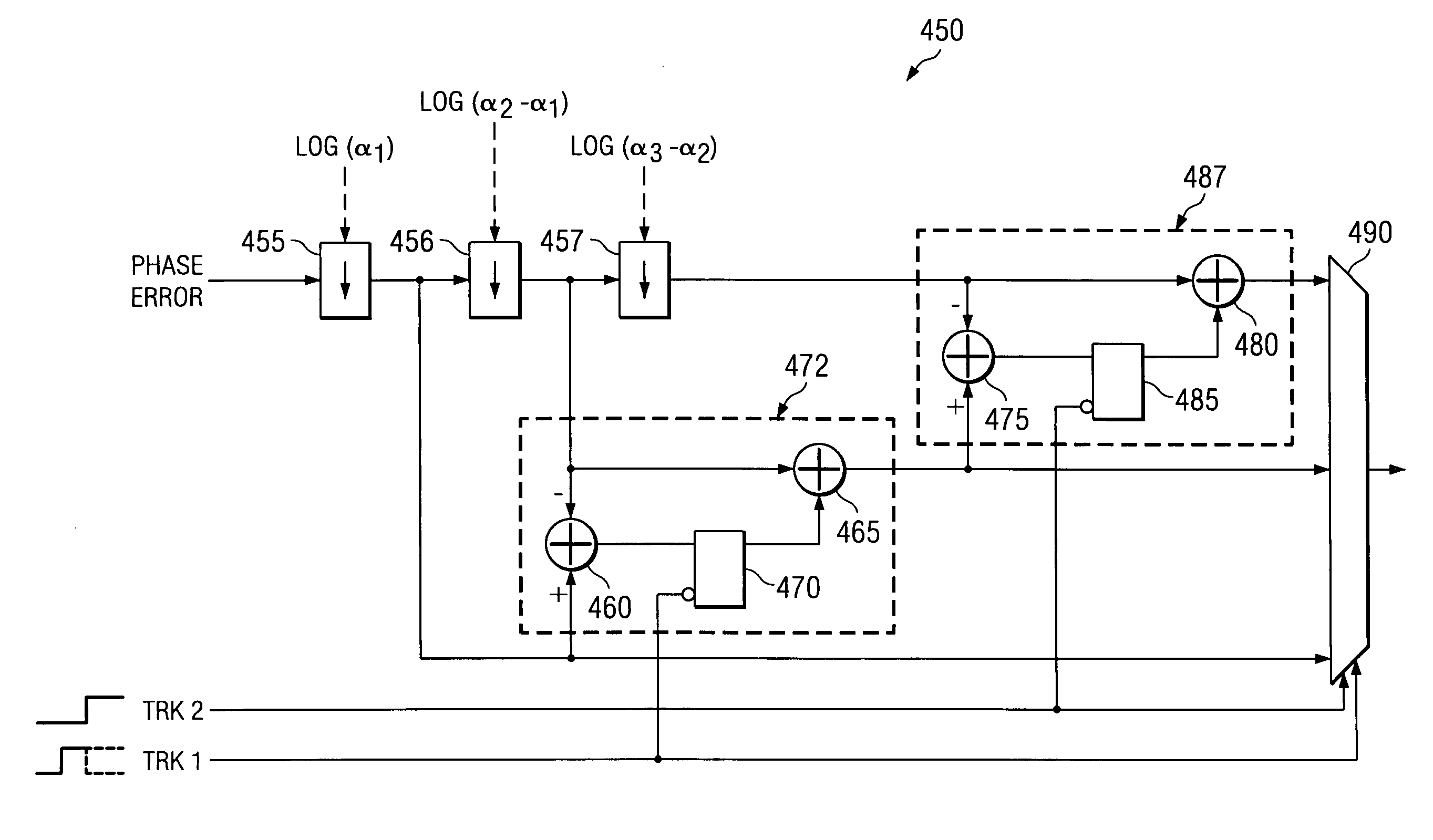

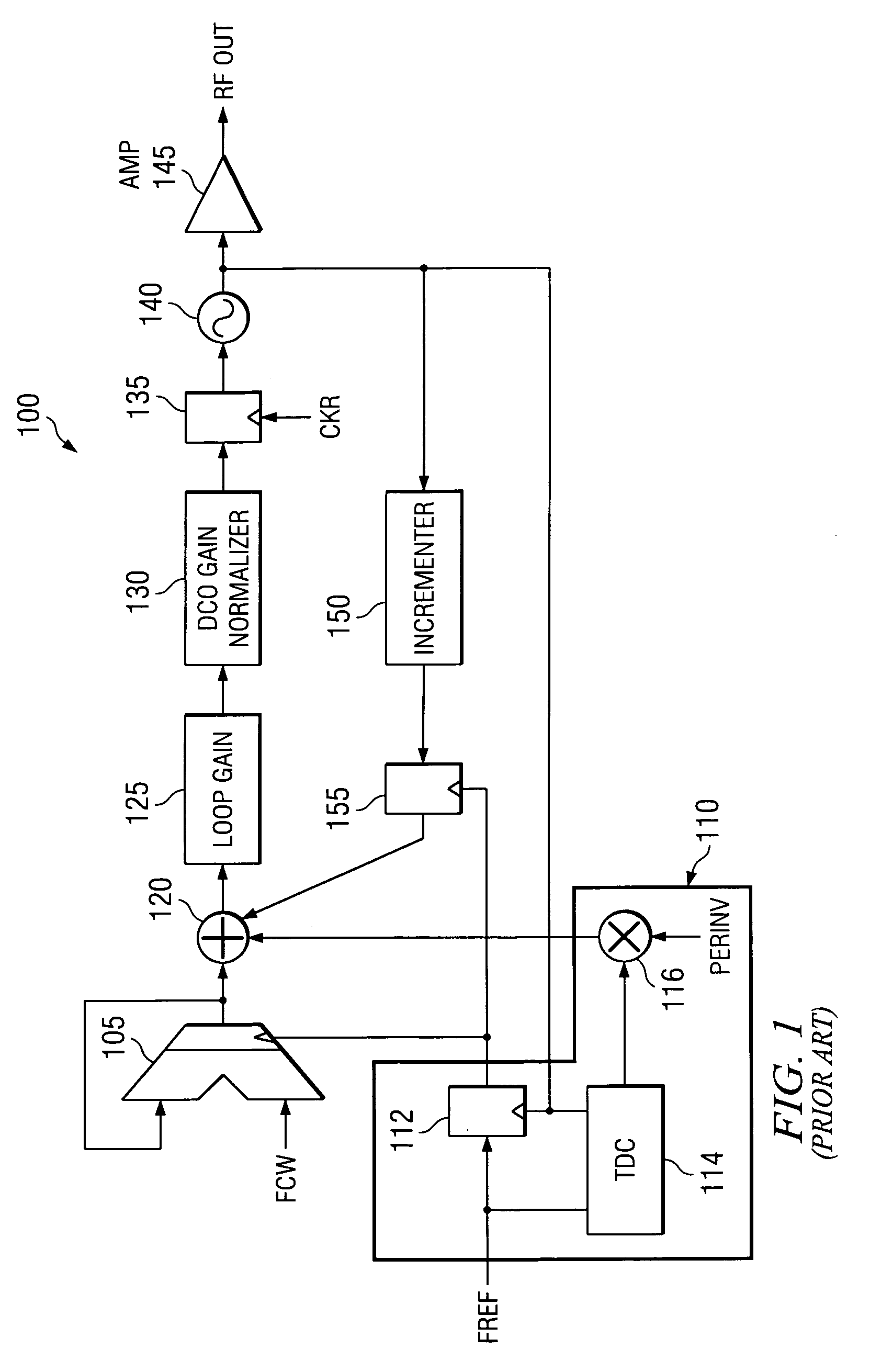

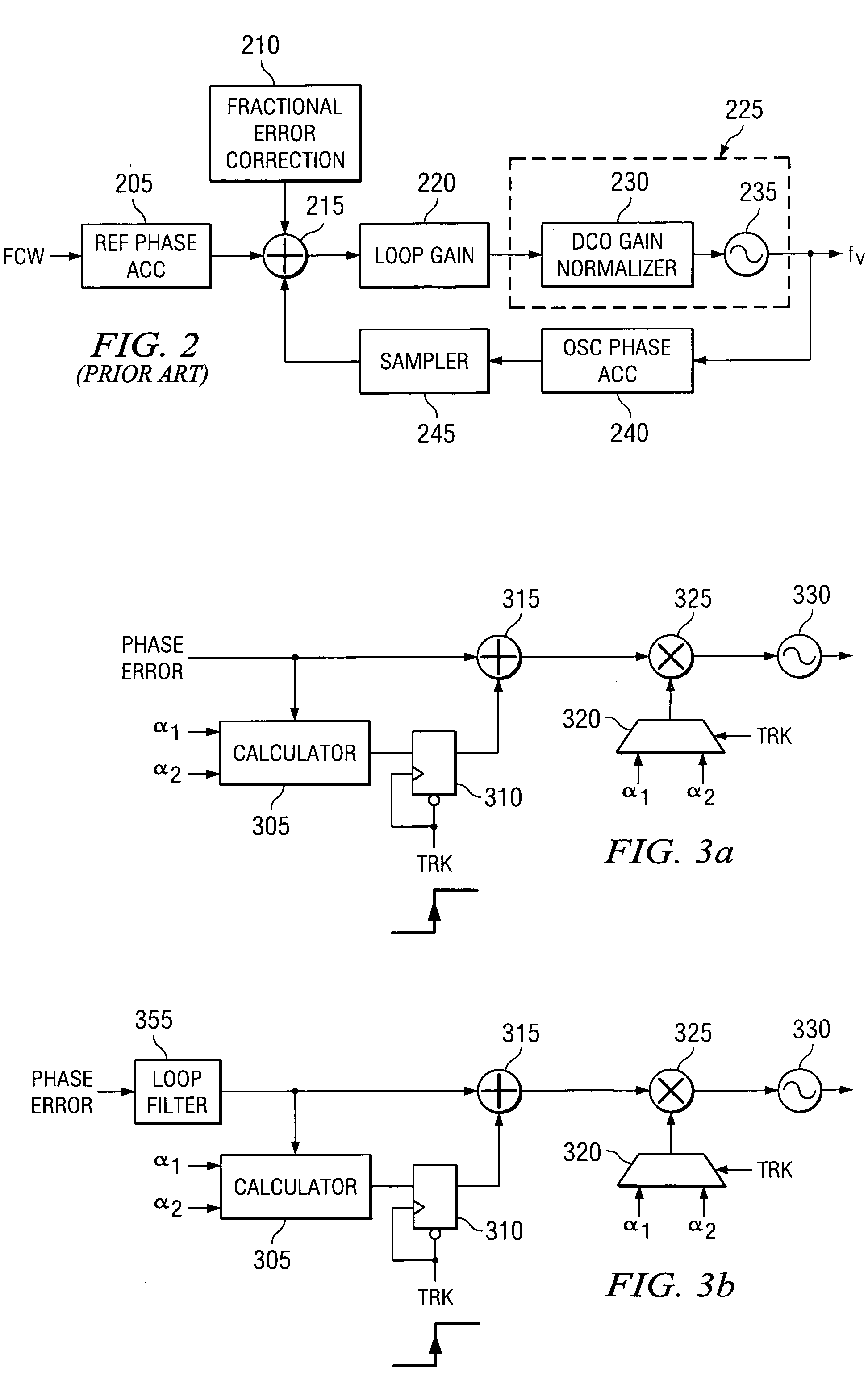

Type-II all-digital phase-locked loop (PLL)

InactiveUS7145399B2Improving signal acquisition performanceFast signal acquisitionAmplifier modifications to reduce non-linear distortionPulse automatic controlLoop filterLoop bandwidth

System and method for providing type-II (and higher order) phase-locked loops (PLLs) with a fast signal acquisition mode. A preferred embodiment comprises a loop filter with a proportional loop gain path (proportional loop gain circuit 1115) and an integral loop gain block (integral loop gain block 1120). The proportional loop gain path is used during signal acquisition to provide large loop bandwidth, hence fast signal acquisition of a desired signal. Then, during the PLL's signal tracking phase, the integral loop gain block is enabled and its output is combined with output from the proportional loop gain path to provide higher order filtering of the desired signal. An offset that may be present due to the use of the proportional loop gain path can be measured and subtracted to help improve signal tracking settling times.

Owner:TEXAS INSTR INC

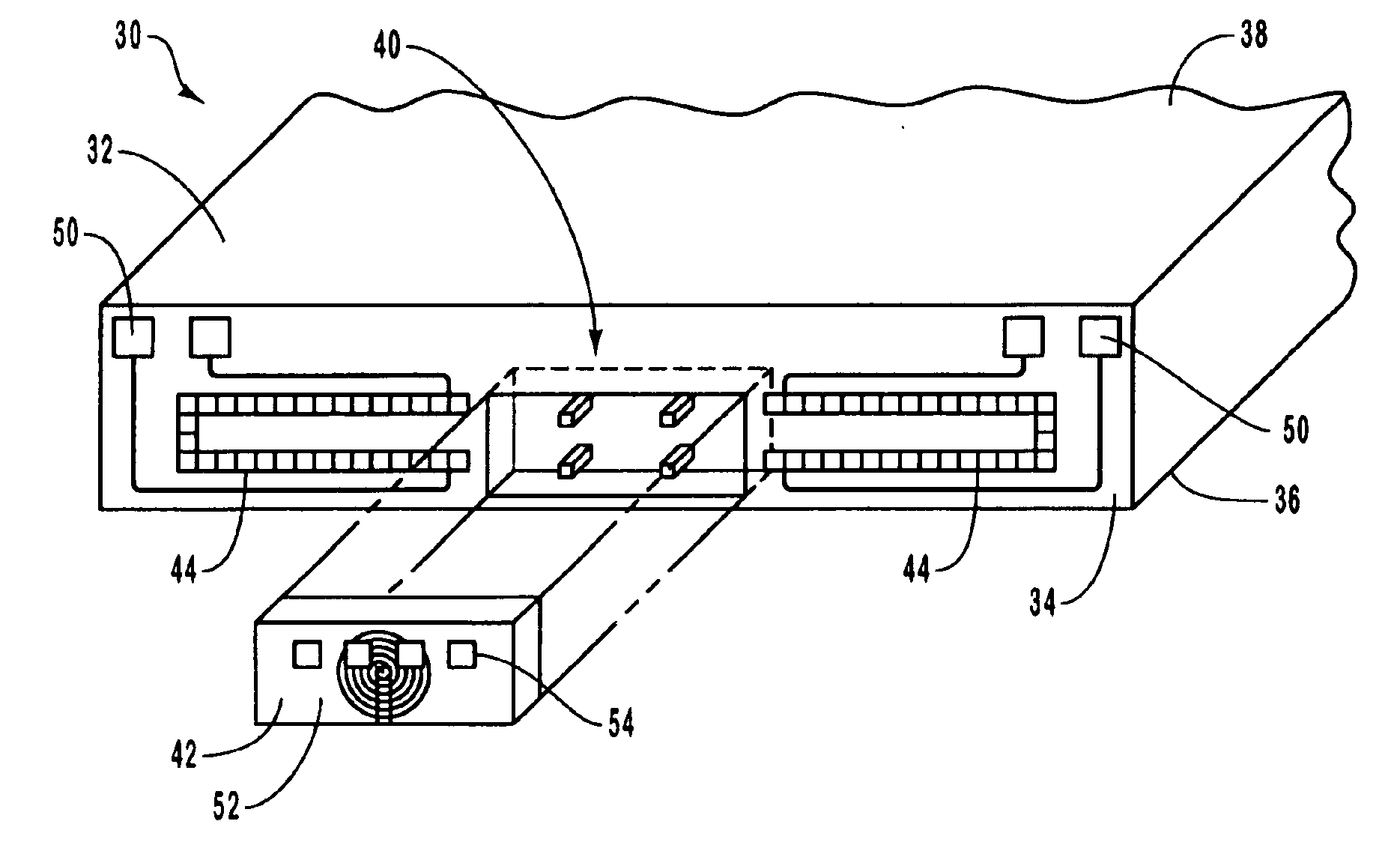

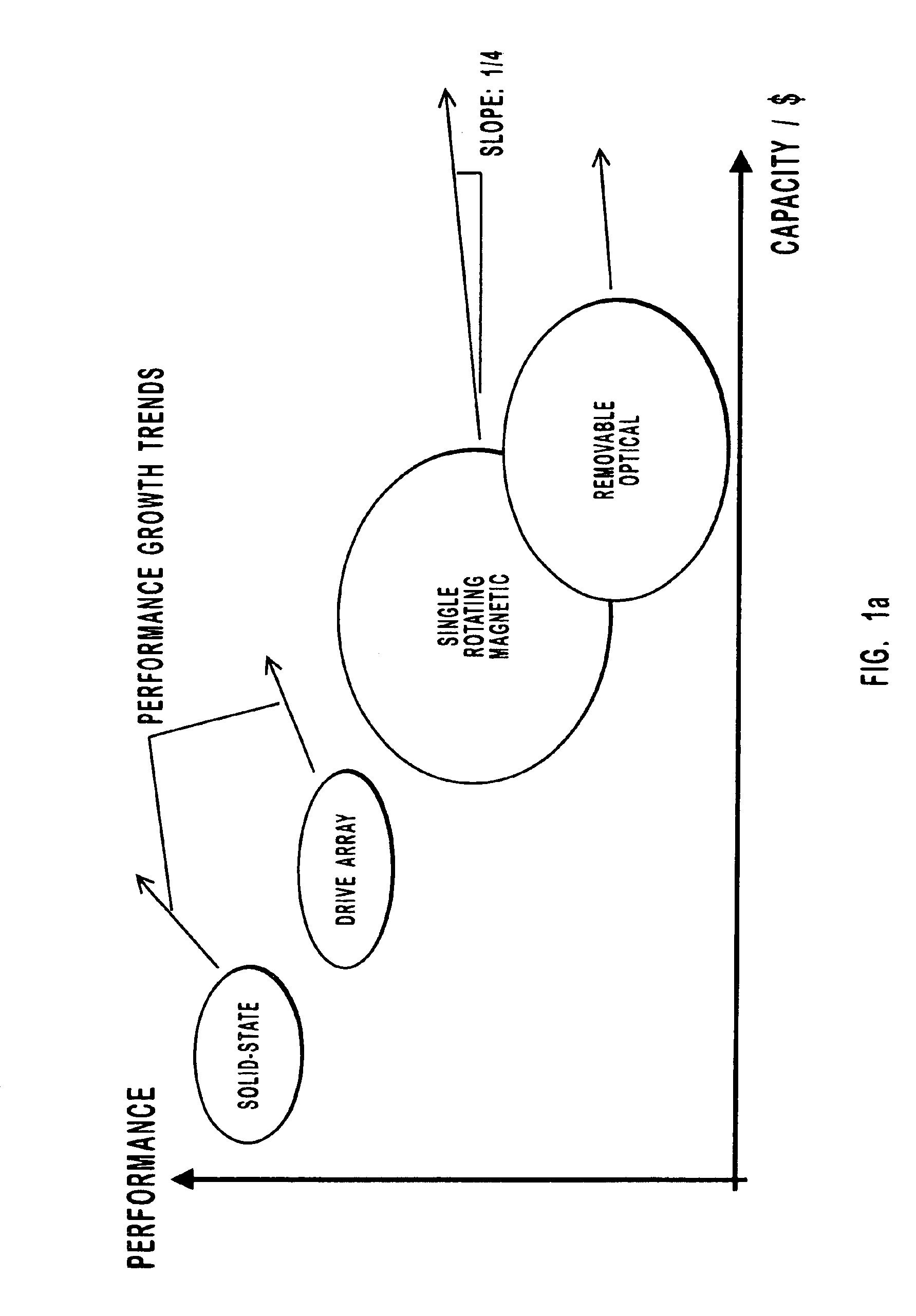

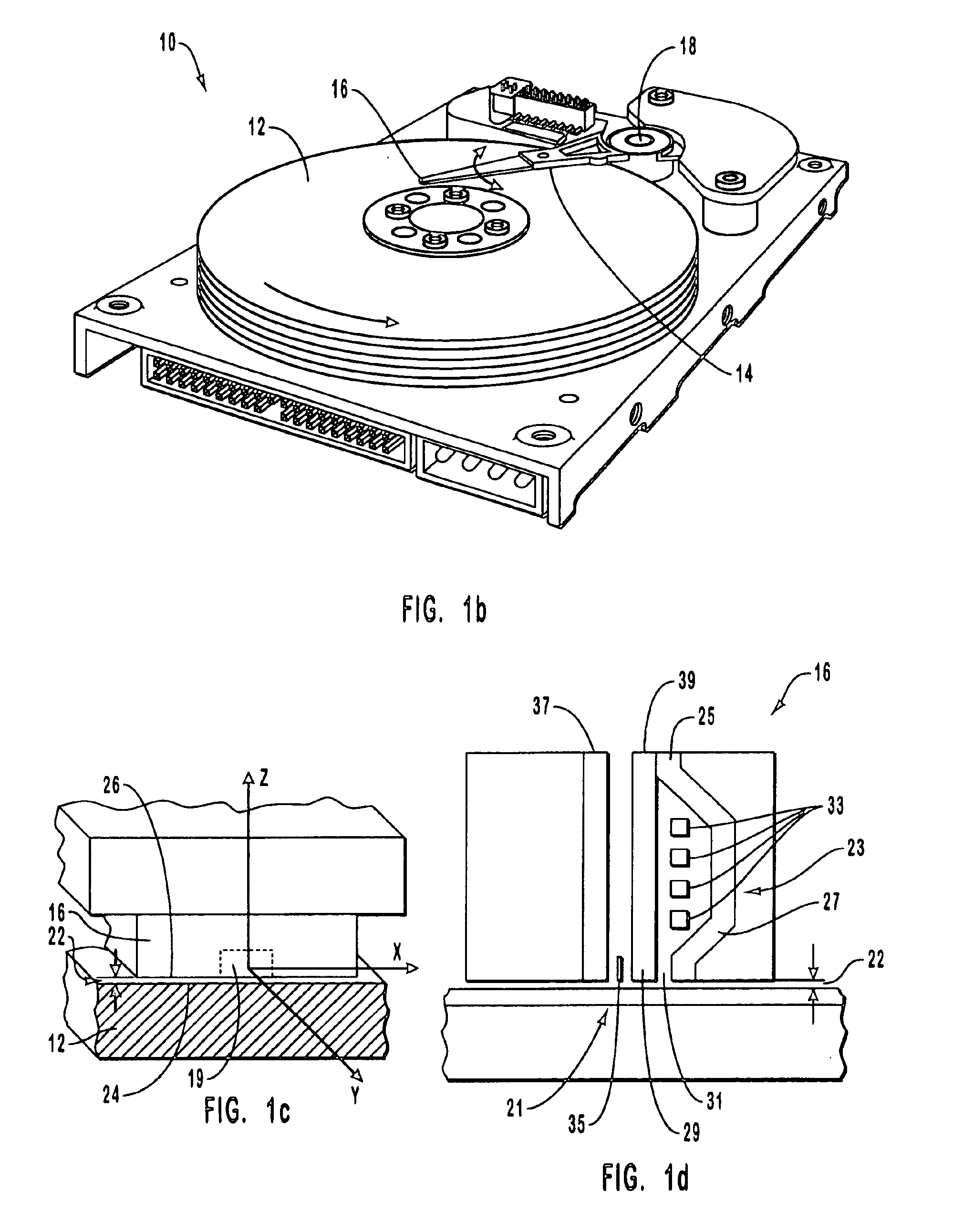

Integrated bidirectional Recording head micropositioner for magnetic storage devices

InactiveUS6859346B1Fast trackReliable trackingConstruction of head windingsFluid-dynamic spacing of headsMagnetic storageAmbient pressure

Transducer elements of recording heads for magnetic storage media are moved independently in either of two directions with respect to the slider of the recording head. The motion is controlled using a micropositioner having magnetic coils integrated into the recording head. The transducer moves in the x direction between data tracks and in the z direction perpendicular to the surface of the magnetic storage medium. The micropositioners are used for small-scale positioning of the transducers over data tracks and to adjust fly heights. Because of the high minimum resonant frequencies and the low mass of the transducers, the micropositioners also improve settling times associated with track following. The micropositioners can be used during fabrication for dimensional control of recording head components. The motion of the transducers in the z direction enables the recording heads to be used reliably in the presence of asperities and changing ambient pressures and temperatures.

Owner:MEYER DALLAS W

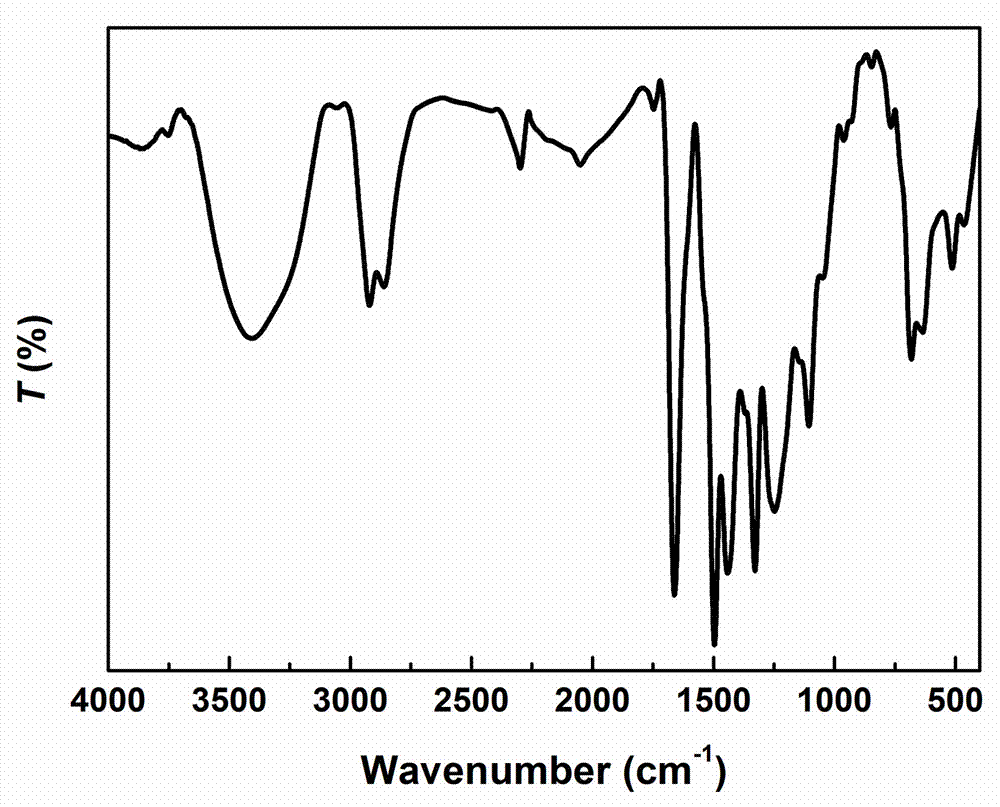

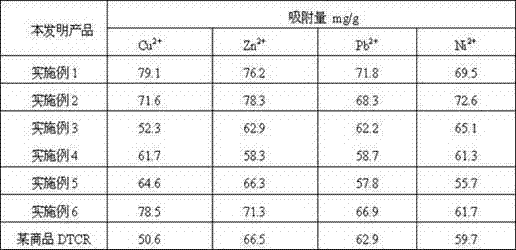

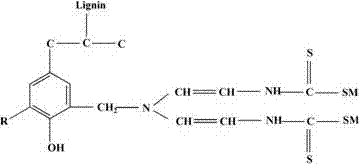

Lignin-based dithiocarbamate heavy metal ion capture agent and preparation method

InactiveCN102784622AReduce manufacturing costThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionAminationDithiocarbamate

The invention discloses a preparation method of a lignin-based dithiocarbamate heavy metal ion capture agent. The method comprises the steps of: (1) adding water into lignin and stirring them, adding an alkaline conditioning agent to adjust the pH to 9-11, then adding an oxidizing agent, conducting heating to raise the temperature to 80-90DEG C for reacting for 1-2 hours; (2) adding an amination reagent, maintaining the reaction temperature at 80-90DEG C, then adding formaldehyde to react for 5-6 hours; (3) cooling the solution to room temperature, adjusting the pH value to 10-11, then adding carbon disulfide to perform an esterification reaction for 4-5 hours at 40-45DEG C; and (4) adding a modifier for reacting for 1-2 hours, then carrying out pumping filtration, and then conducting washing 2-3 times with water and absolute ethyl alcohol, thus obtaining a solid product, i.e. the lignin-based dithiocarbamate. The lignin-based dithiocarbamate heavy metal ion capture agent provided in the invention has the advantages of simple preparation process, low production cost, excellent performance, adaptability to treatment of various heavy metal ion polluted wastewater, good stability, and wide applicable range.

Owner:GUANGXI UNIV

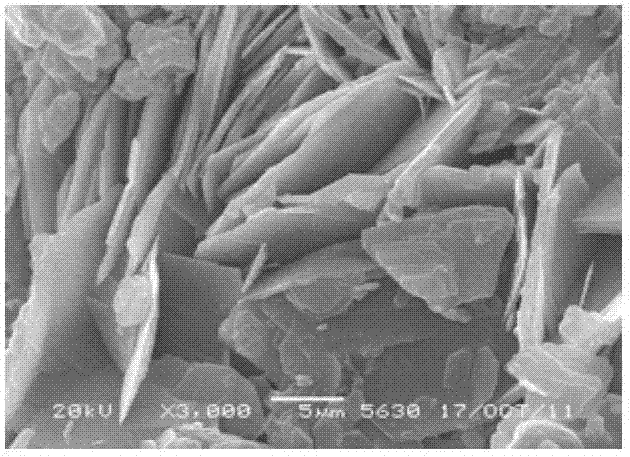

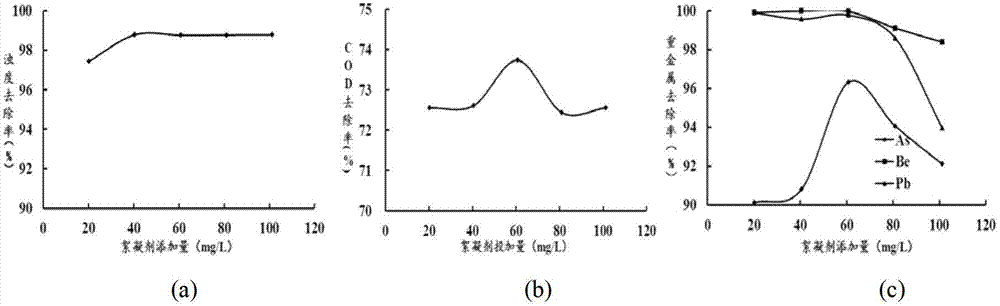

Efficient flocculent precipitate purification method for polymetallic ore benefication wastewater

ActiveCN102730885ASolve the poor effect of flocculation and sedimentationResolve separabilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationParticulatesPurification methods

The invention discloses an efficient flocculent precipitate purification method for polymetallic ore benefication wastewater. Specifically, the purification method comprises the steps of: neutralizing and regulating the pH value of benefication wastewater by adopting a little amount of alkaline materials; then sequentially feeding a proper amount of proper suitable flocculant for efficient flocculation and a little amount of efficient coagulant aids for fast precipitation; separating sludge from water through action of a partition wall, wherein the treated wastewater achieves primary standardof national Integrated wastewater discharge standard (GB8978-1996); through SV30 evaluation; settling for 5minutes to achieve 45-55mL of supernatant by volume; and settling for 15 minutes to achieve 70-80mL of supernatant by volume. The purification method can fully utilize the traditional benefication wastewater lime and sedimentation process, is simple in procedure, and can simultaneously remove suspended particulate matters, organic matters and heavy metal ions in wastewater, is high in flocculation efficiency and fast in sedimentation speed, and can better solve the purification problem of the low-concentration and high-tubidity polymetallic ore benefication wastewater of multiple heavy metals.

Owner:CENT SOUTH UNIV

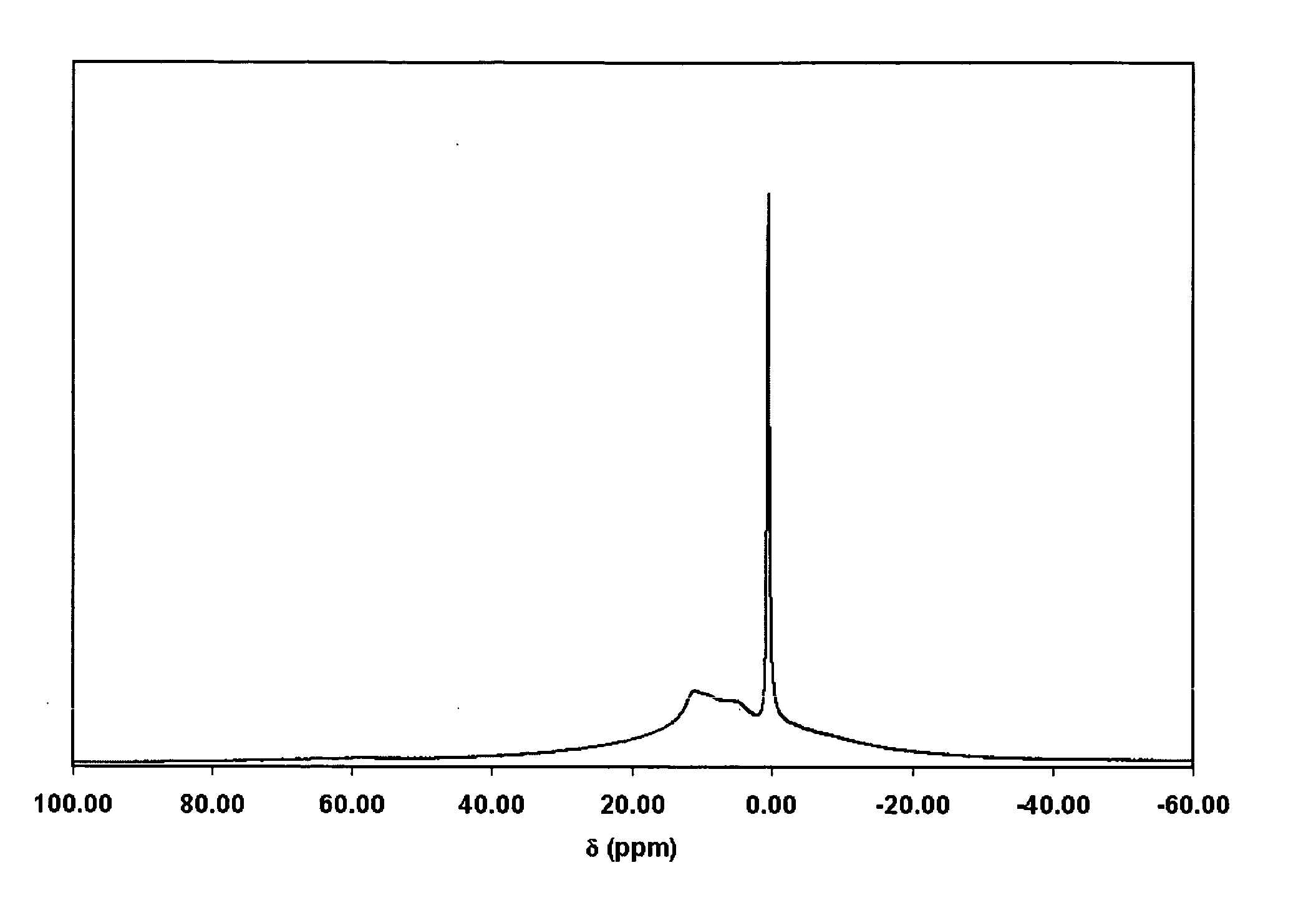

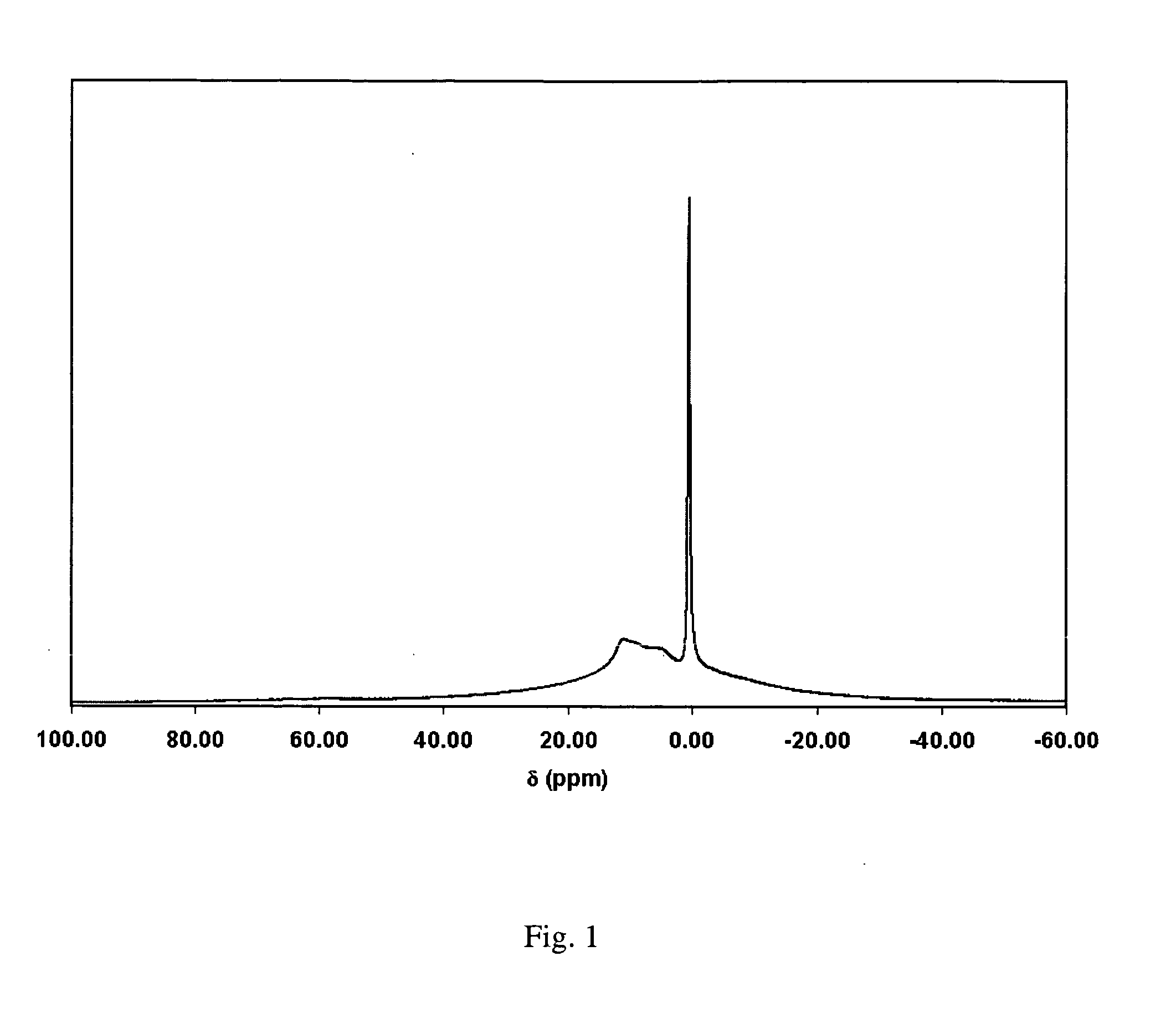

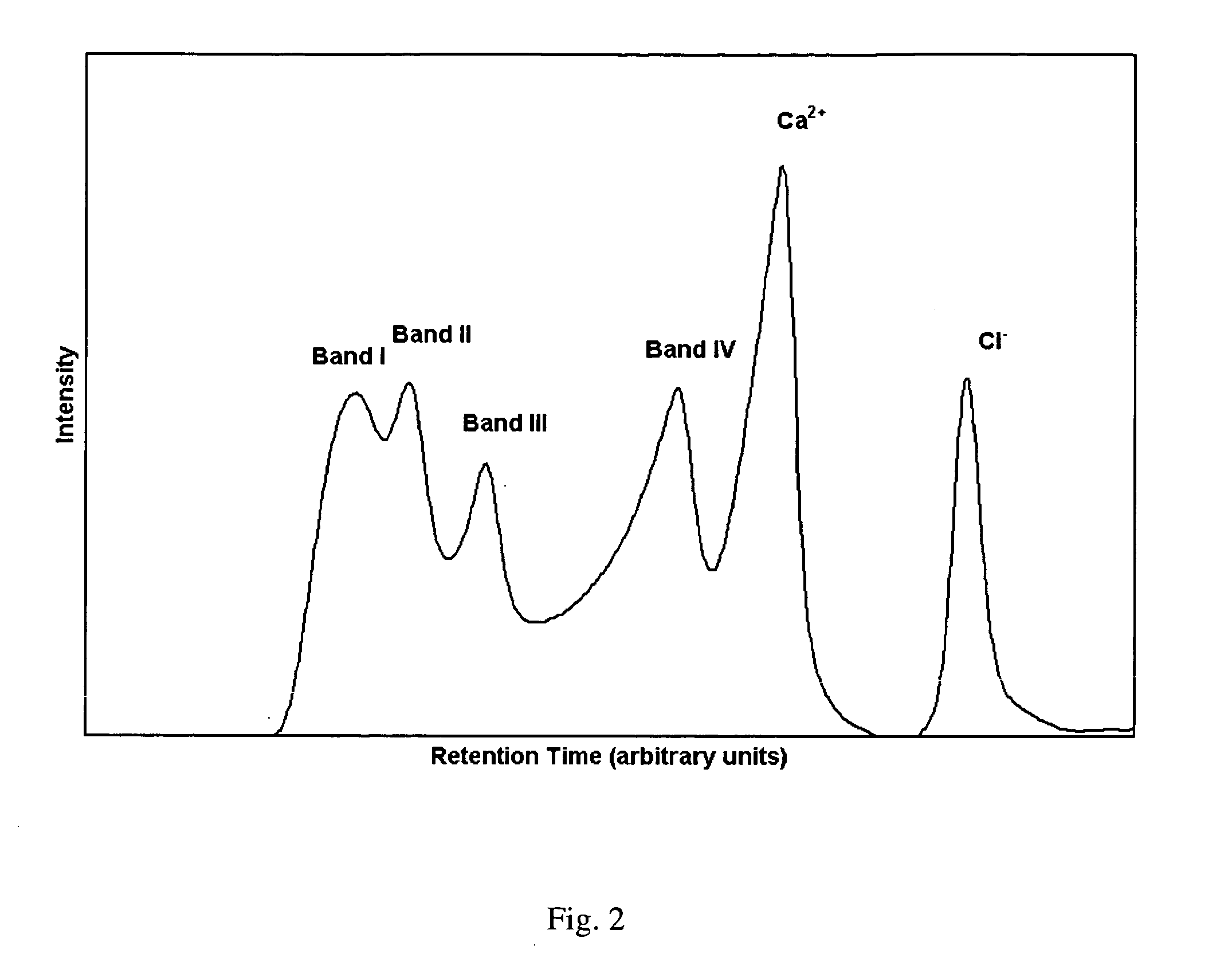

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

Comprehensive electroplating wastewater treating agent

InactiveCN103991916AEasy to useSimple processWater contaminantsWaste water treatment from metallurgical processChemical oxygen demandPollution

The invention relates to a comprehensive electroplating wastewater treating agent. The comprehensive electroplating wastewater treating agent is composed of the following components in percentage by mass: 10-35% of reducing agent, 20-50% of sulfide, 10-30% of aluminum salt, 10-30% of adsorbing material and 5-15% of alkaline substances. The raw materials of the treating agent provided by the invention are low in cost and easy to obtain, and the treating agent is easy to prepare; through compounding the raw materials, a synergistic effect is exerted, and the treating agent is favorable in broad spectrum, capable of effectively removing heavy metals such as nickel, chromium, copper, zinc and the like, high in removal rate up to more than 96% and relatively good in COD (Chemical Oxygen Demand) removal effect; the comprehensive electroplating wastewater treating agent also has the characteristics of strong electroplating wastewater treating capacity, high heavy metal ion sedimentation speed and efficiency, no secondary pollution after treatment and the like; in addition, the treating agent provided by the invention is convenient to use, simple and feasible in treating process, capable of realizing operation by only using a vessel or pool with an aerating agitation device, reducing the floor area and reducing the investment, and easy to realize operation management.

Owner:浙江一清环保工程有限公司

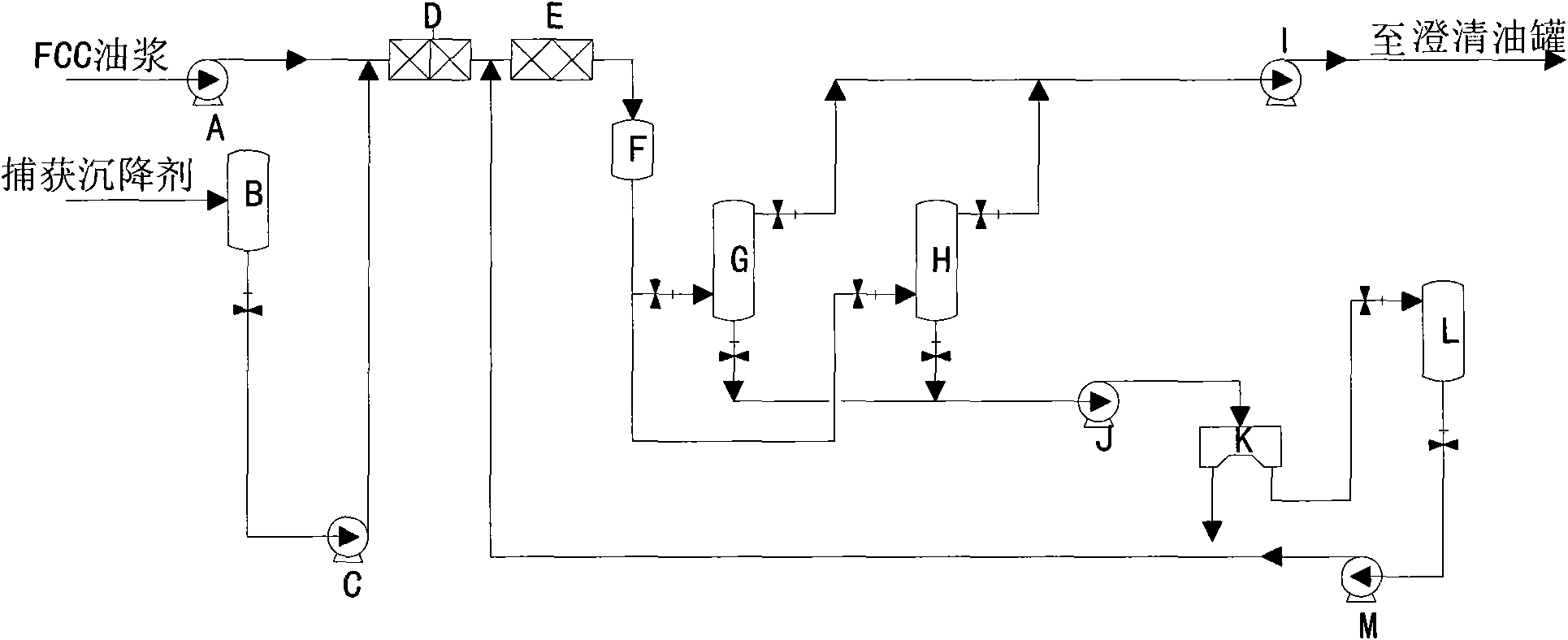

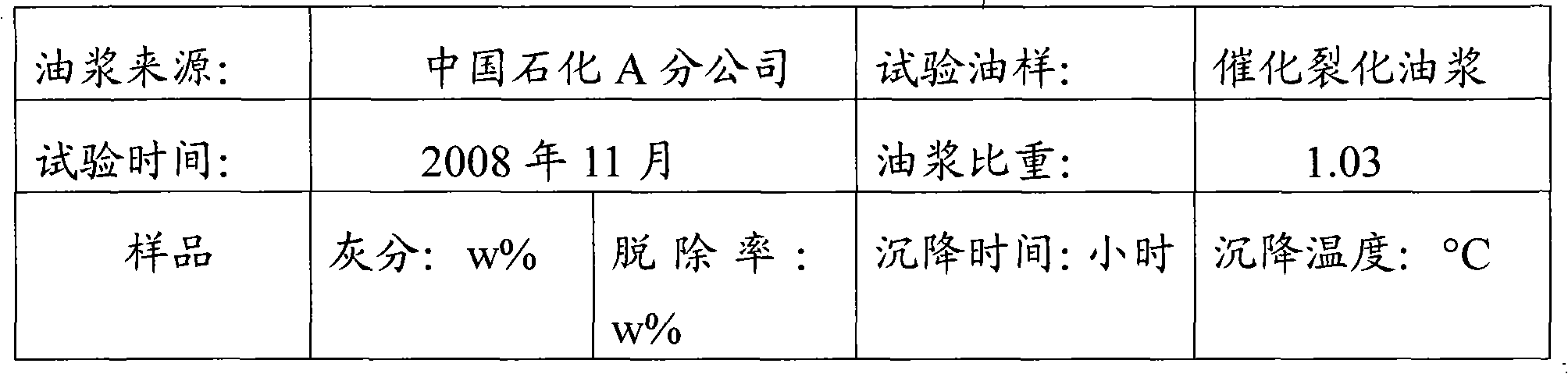

Capturing settling agent and method for removing catalyst solid powder in oil slurry

ActiveCN101670199ASettling fastSedimentation separationHydrocarbon oils refiningPolyolQuality assurance

The invention provides a capturing settling agent and a method for removing catalyst solid powder in oil slurry, the capturing settling agent comprises the following components by weight percent: 0-50% of alkyl R quaternary ammonium salt, 0-40% of flocculant solution and 0-100% of polyol. The method accelerates the settling speed of the catalyst solid powder in the FCC oil slurry by adding the capturing settling agent, overcomes the insufficiencies of the prior FCC oil slurry solid removal technology through a set of complete combined technology of using the capturing settling agent, reduces the ash content of the FCC oil slurry below 0.05%w and provides the quality assurance for the follow-up utilization of the oil slurry.

Owner:SHENZHEN KELADA FINE CHEM CO LTD

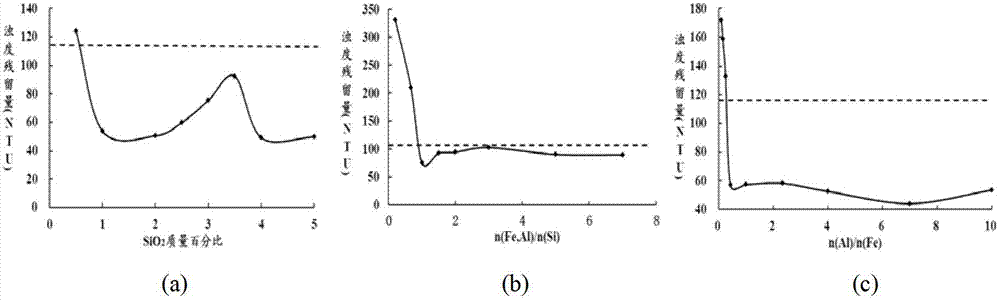

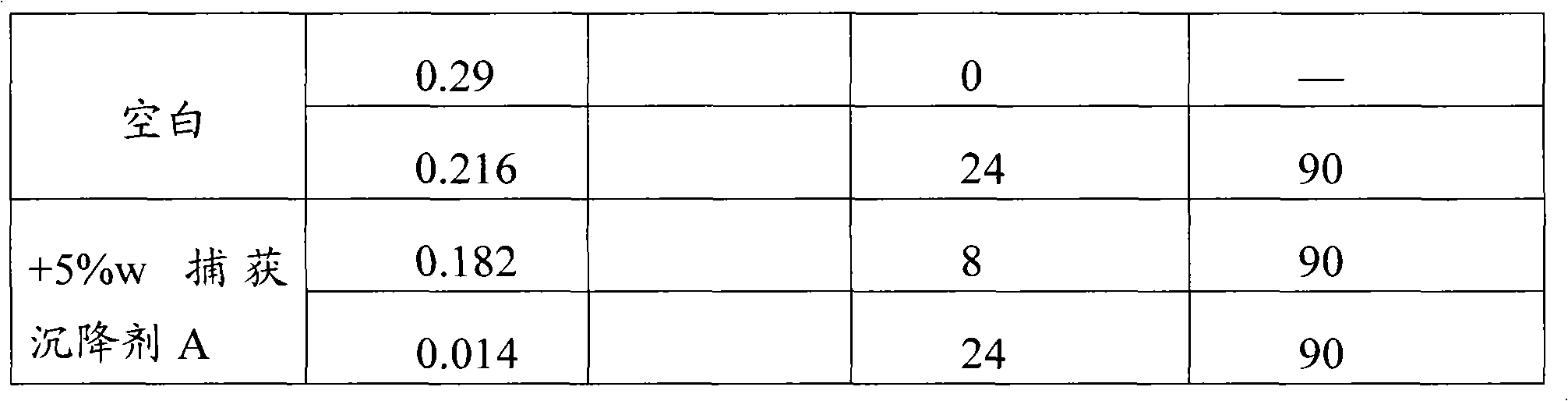

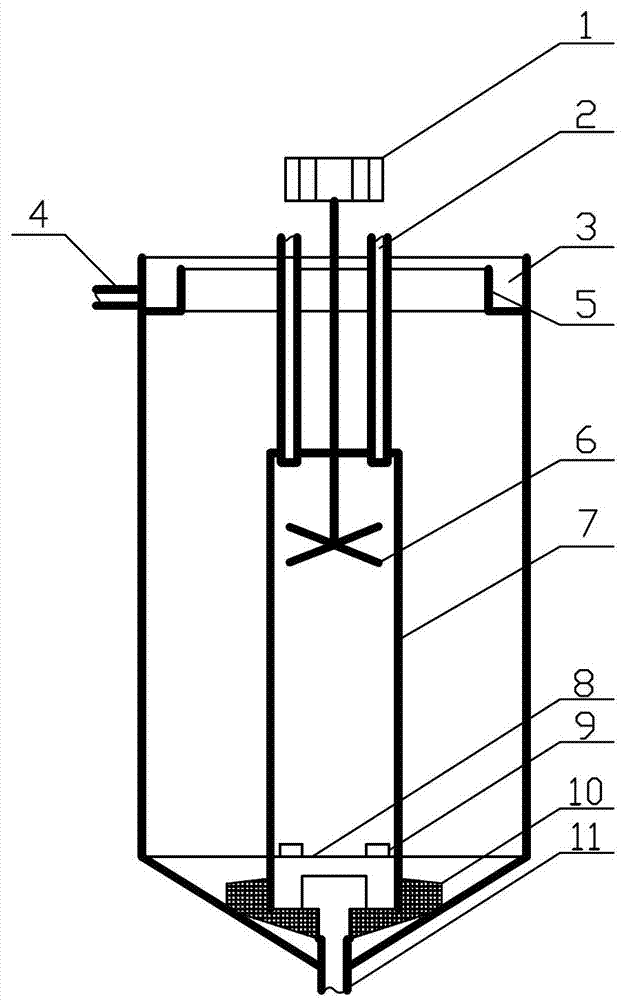

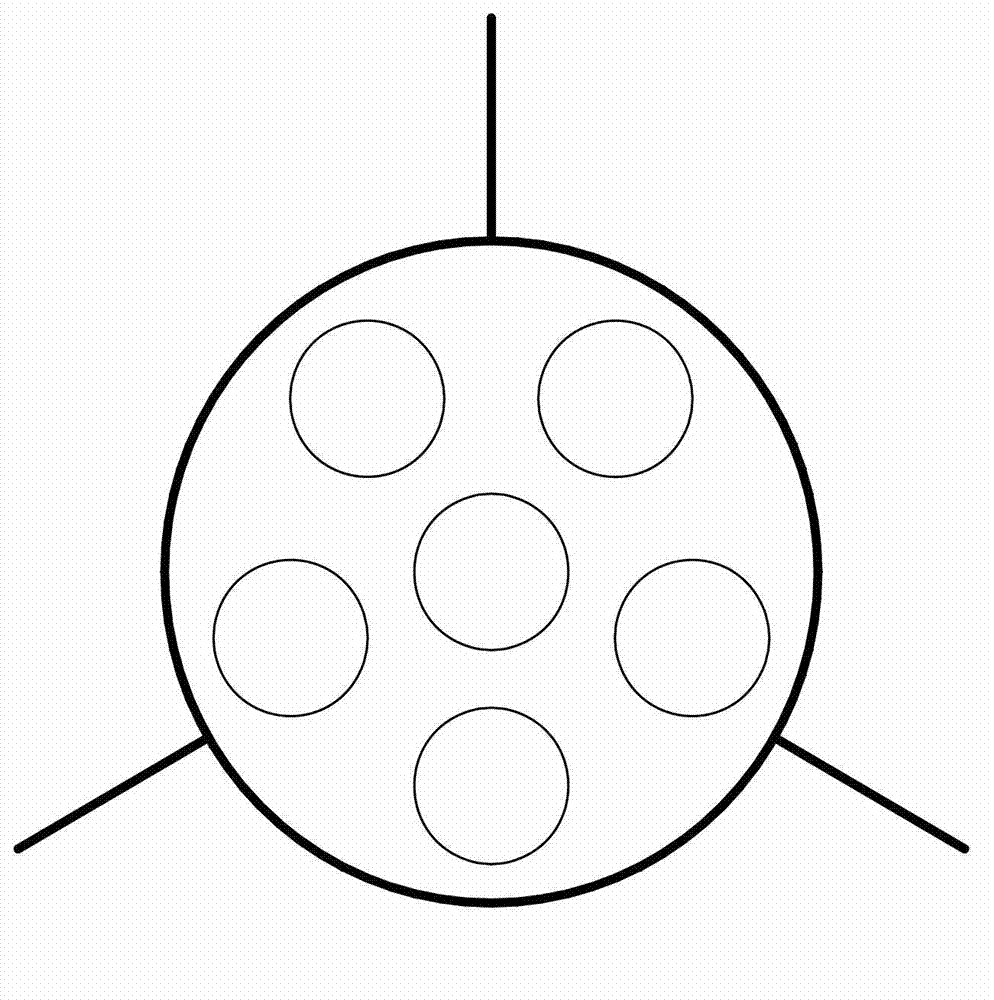

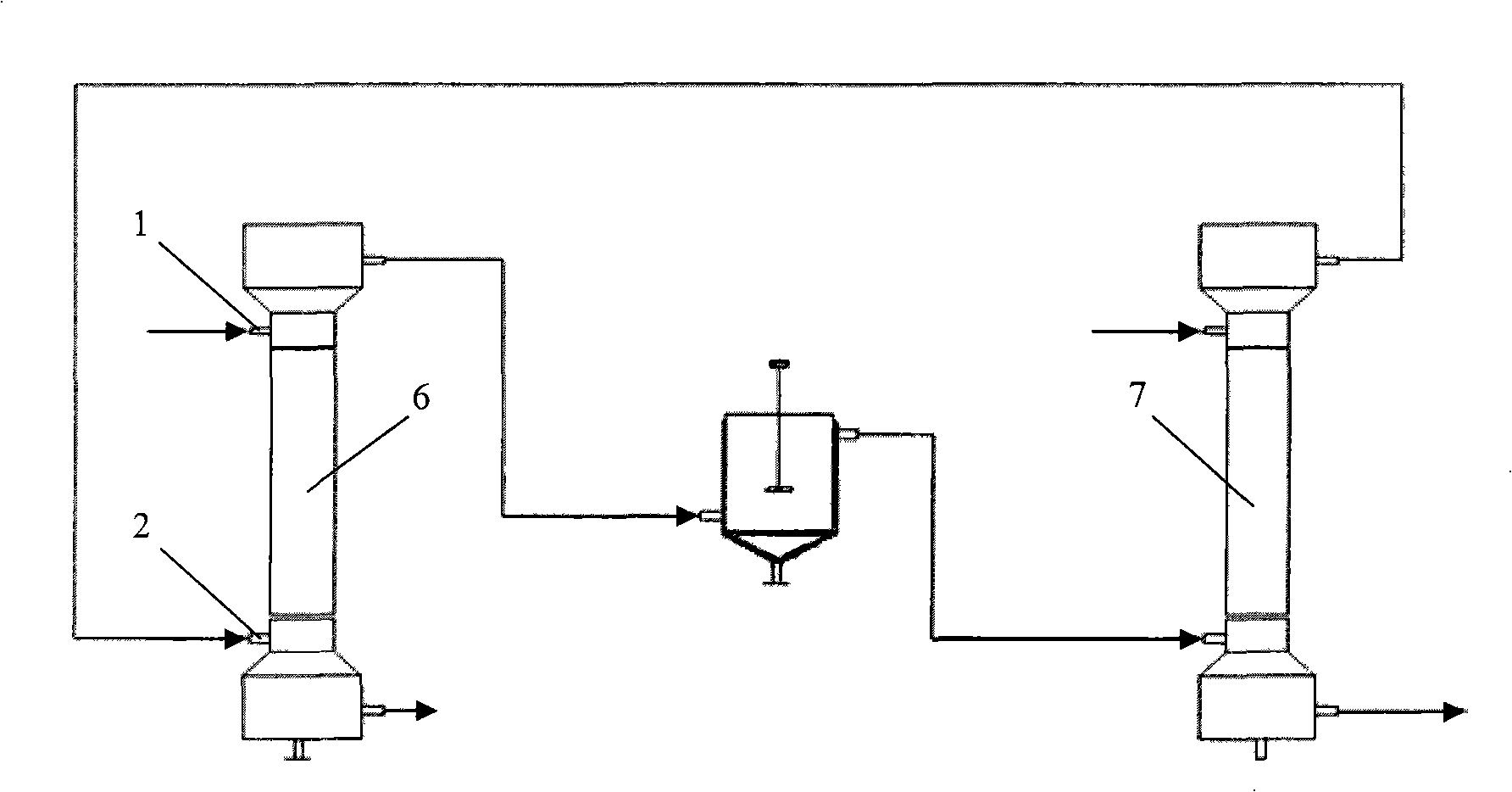

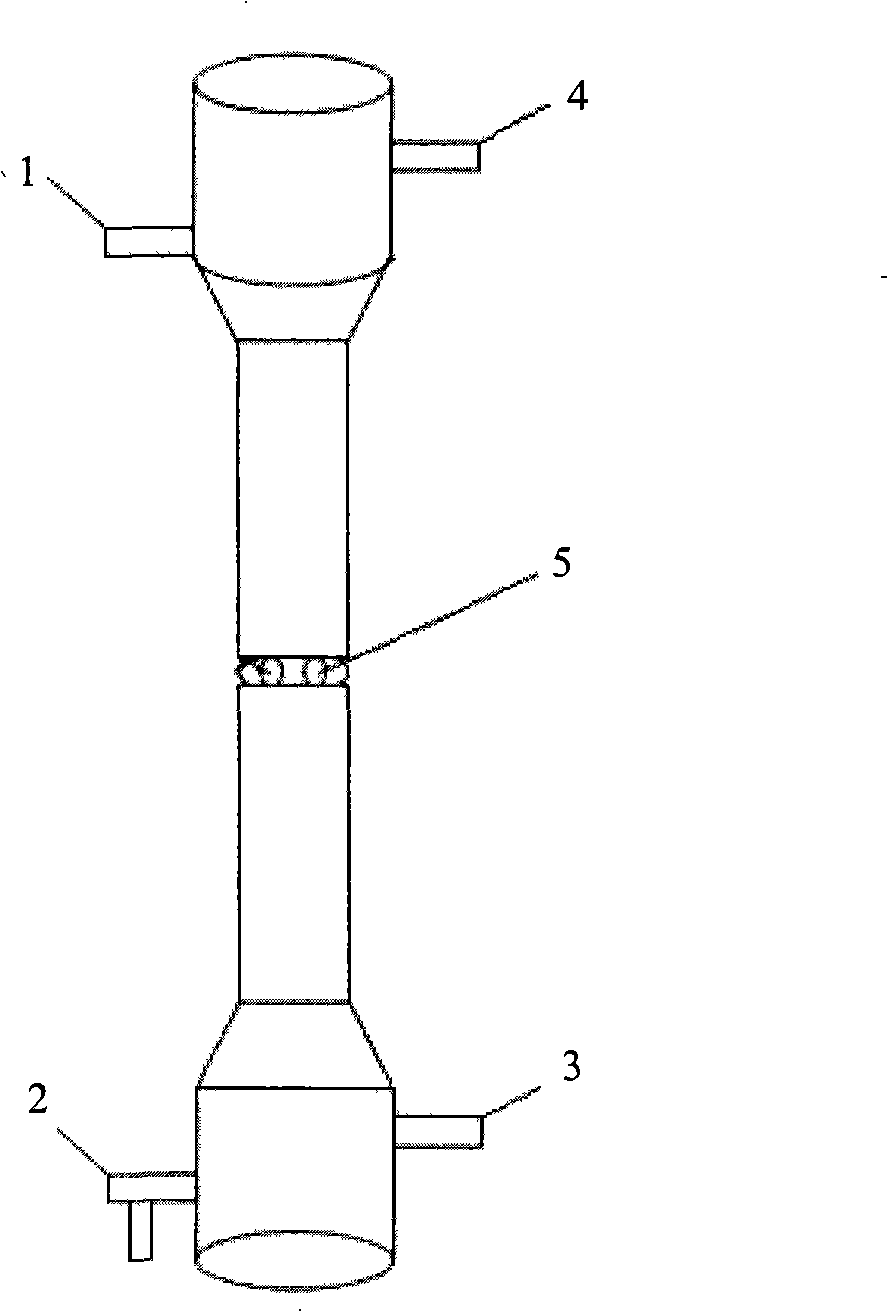

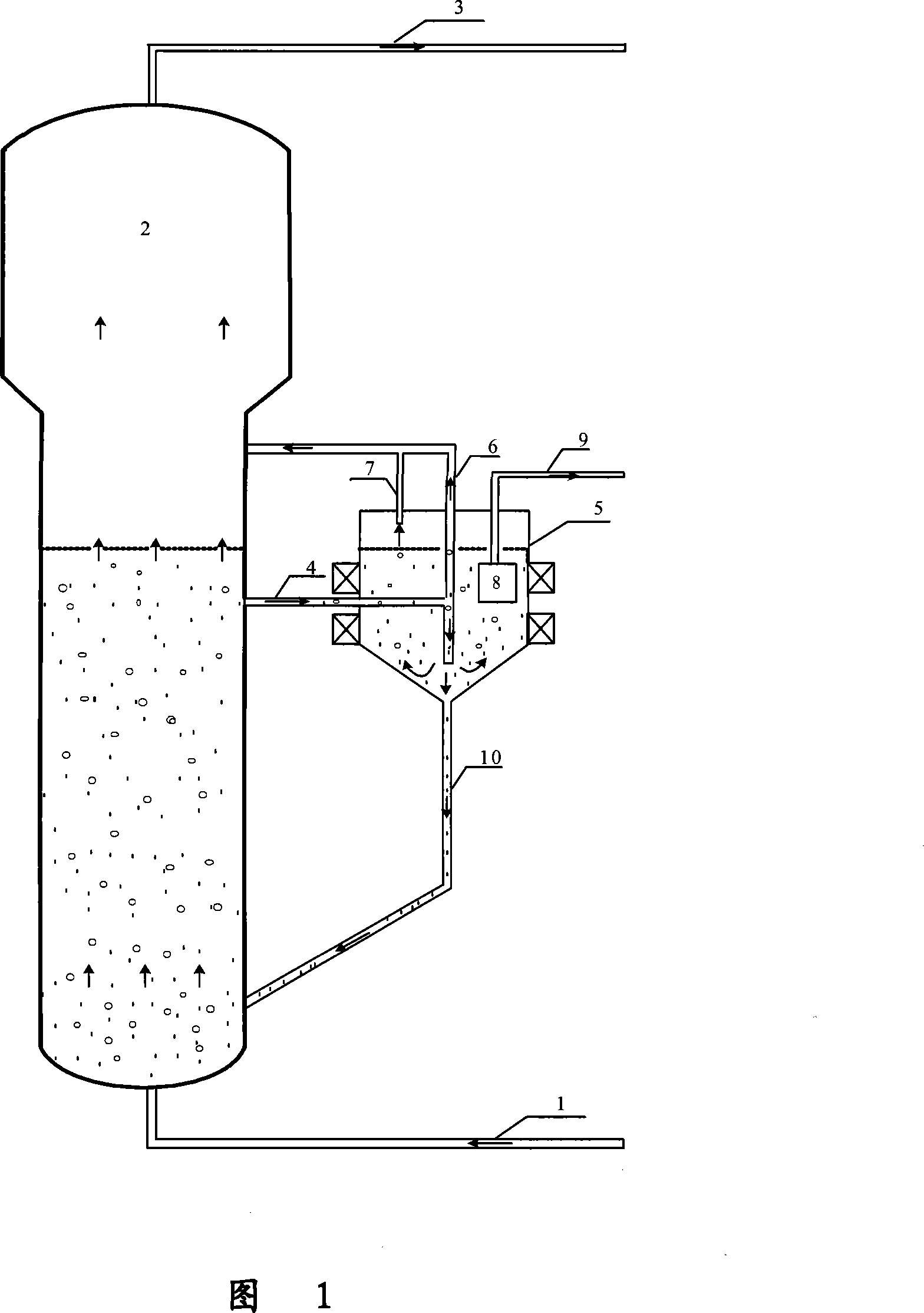

Polymetallic-ore-dressing wastewater coagulating sedimentation device and method

ActiveCN103193339ARealize the coarse granulation of flocsAccelerated settlementWaste water treatment from quariesMultistage water/sewage treatmentFlocculationWater quality

The invention discloses a polymetallic-ore-dressing wastewater coagulating sedimentation device and a polymetallic-ore-dressing wastewater coagulating sedimentation method. The process comprises the following main devices: a coagulation reaction tank, a flocculation, sedimentation and separation integrated device and a separation wall. The process flows are as follows: the polymetallic-ore-dressing wastewater fully reacts with a coagulant in the coagulation reaction tank to enable the wastewater to be destabilized quickly and flocculated efficiently; the coagulated wastewater enters the flocculation, sedimentation and separation integrated device to fully react with coagulant aid to further perform flocculation coarsening and fast sedimentation, so that high-efficiency mud-water separation is realized; and the processed wastewater is discharged directly or deeply purified by the separation wall to be recycled. The device and the method can effectively solve the problems that in the polymetallic-ore-dressing wastewater treatment, the flocculent precipitation is instable, the flocculation time and sedimentation time are long and the like, and can quickly perform destabilization and realize high-efficiency flocculation, high-efficiency sedimentation and high-efficiency separation. The device and the process flow are simple and practical, the wastewater purifying efficiency can be remarkably improved and the effluent water quality is stable and reaches the standard.

Owner:CENT SOUTH UNIV

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Dust fall agent for water mist dust fall

ActiveCN101735771AReduce surface tensionImprove contact effectOther chemical processesDust removalPermeationSURFACTANT BLEND

The invention relates to a dust fall agent for water mist dust fall. 0.06-0.2wt% of wetting agent permeation assistant is added to water, wherein the wetting permeation assistant comprises anionic surfactant, or cationic surfactant, or zwitterionic surfactant, or non-ionic surfactant. Because in the dust fall agent of the invention, 0.06-0.2wt% of wetting agent permeation assistant is added to water, thus the surface tension of the water can be reduced, the contact capacity of the water with dust particles is promoted, and solid materials can be soaked by water more easily through the wetting agent permeation assistant, thereby accelerating the wetting permeation velocity of water to the dust particles, accelerating the fall velocity of the dust particles, and reducing the fall time of the dust particles. Thus, the invention reduces the operation time and the operation cost, protects the health and safety of operation personnel, and can be widely applied to water spray, water sprinkling, dust fall and dust suppression of mines, tunnels or roads.

Owner:北京首创大气环境科技股份有限公司

Technique for purifying and producing industrial phosphoric acid by wet-process phosphoric acid

The invention relates to the technique for purifying and producing industrial phosphoric acid by wet-process phosphoric acid, which comprises the following steps of: (1) desulfurization and defluorination sedimentation-filtration process; (2) the extraction of wet-process phosphoric acid after desulfurization and defluorination process; (3) the washing of organic phase after extraction; (4) the back extraction of the organic phase after washing; (5) the refining of aqueous phase after the back extraction; (6) concentrating till containing 85wt% H3PO4 and recycling organic solvent. The technique has the beneficial effects that (1) the wet-process phosphoric acid produced by adopting the existing sulfuric acid process does need to be preconcentrated; (2) compound extracting agent of the technique has good suitability for the extraction of the wet-process phosphoric acid; (3) the compound extracting agent has better separating effect on iron ions and other heavy metal ions; (4) emulsion generated by the organic phase in the washing process can be eliminated by a warming / stewing mode; (5) the technique adopts amidine fiber adsorption column to refine wet-process phosphoric acid and can effectively absorb trace metal ions, and the clearance of the metal ions can reach 99 wt%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Denitrifying agent for directly removing basic nitrogen compound from shale oil

InactiveCN101967389ASettling fastGood removal effectHydrocarbon oils refiningPhosphoric acidChemistry

The invention relates to a denitrifying agent for directly removing a basic nitrogen compound from shale oil. The denitrifying agent comprises the following components in percentage by weight: 40 to 80 percent of B, 0.5 to 10 percent of L, 0.1 to 0.5 percent of S and the balance of water, wherein B is phosphoric acid; L is Lewis acid; and S is a water-soluble demulsifier. The B in the formula can provide H+ which is complexed into salt with a lone electron pair of the basic nitrogen compound so as to remove the basic nitrogen compound from oil; L can accept the lone electron pair of the basic nitrogen compound to be complexed into salt, and the synergistic effect of B and L has high capacity of removing basic nitrogen; and S has good demulsifying effect and can improve the uniformly mixing degree of the water-soluble B and L agents with oil in the oil stirring process. Therefore, the nitrogen removal efficiency of a primary agent is improved.

Owner:DAQING OILFIELD CO LTD +1

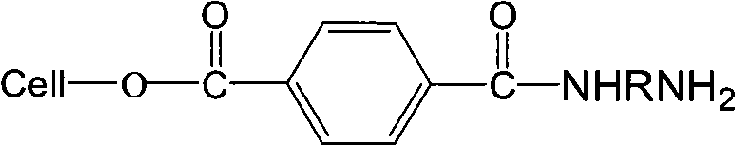

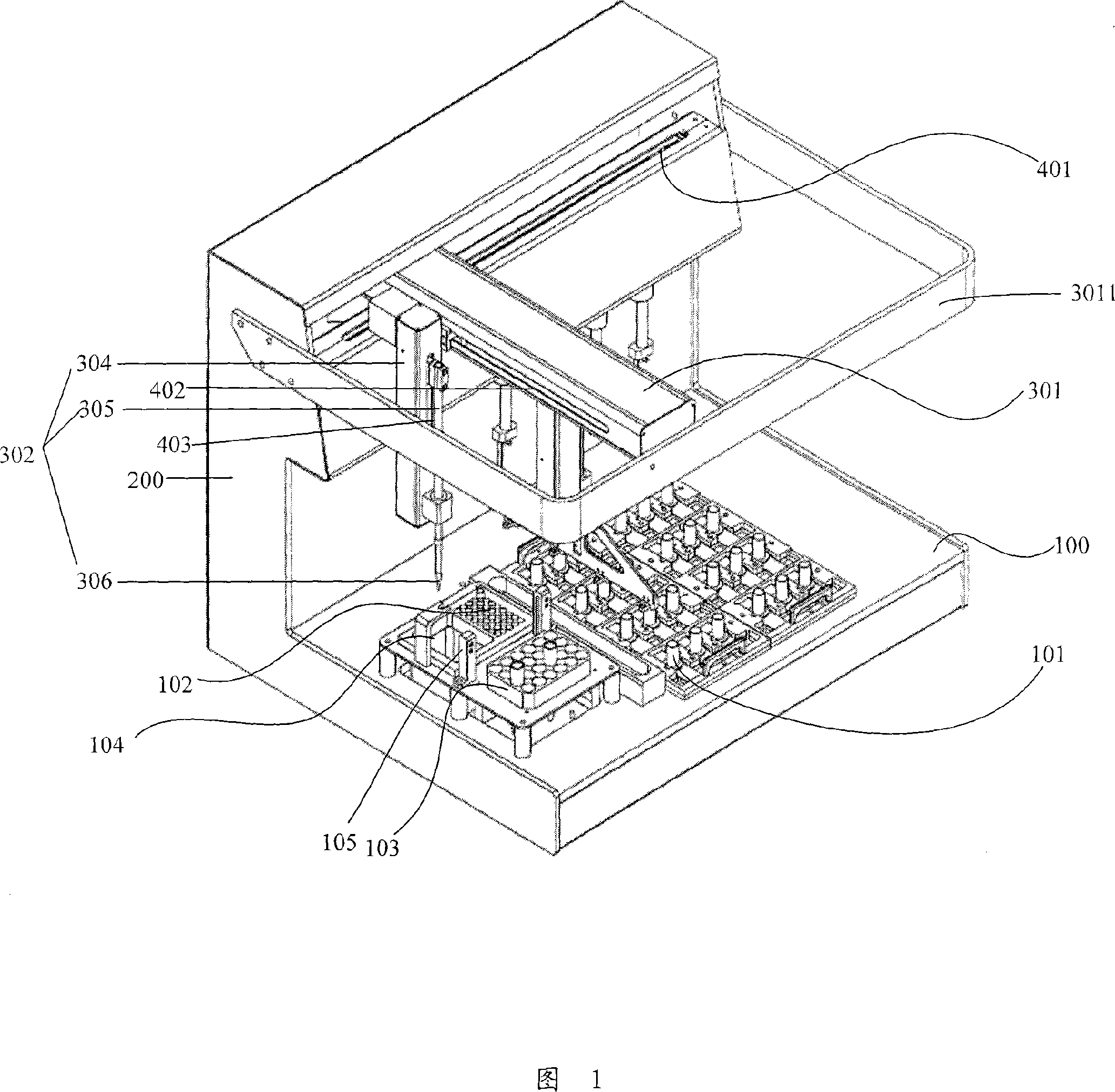

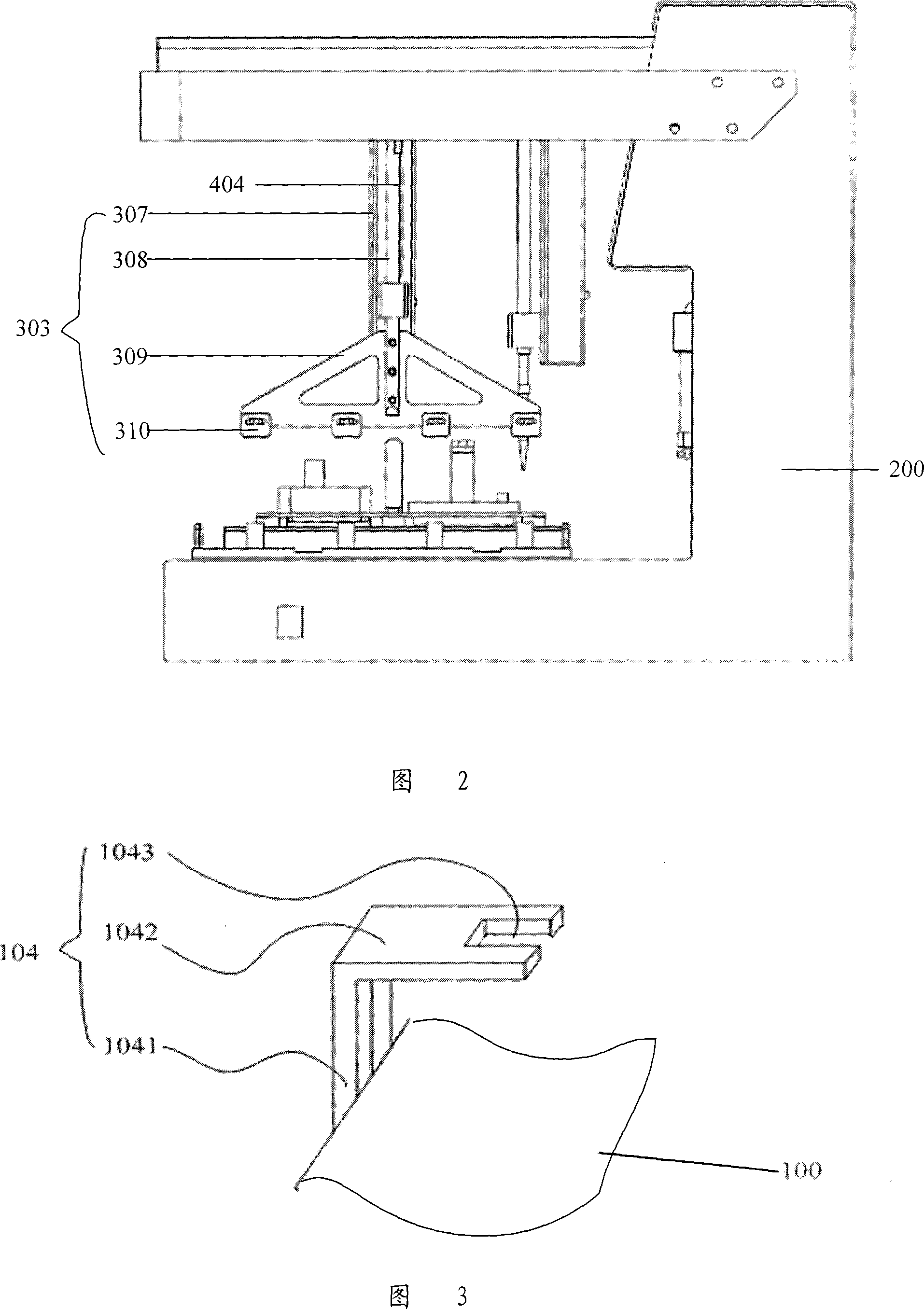

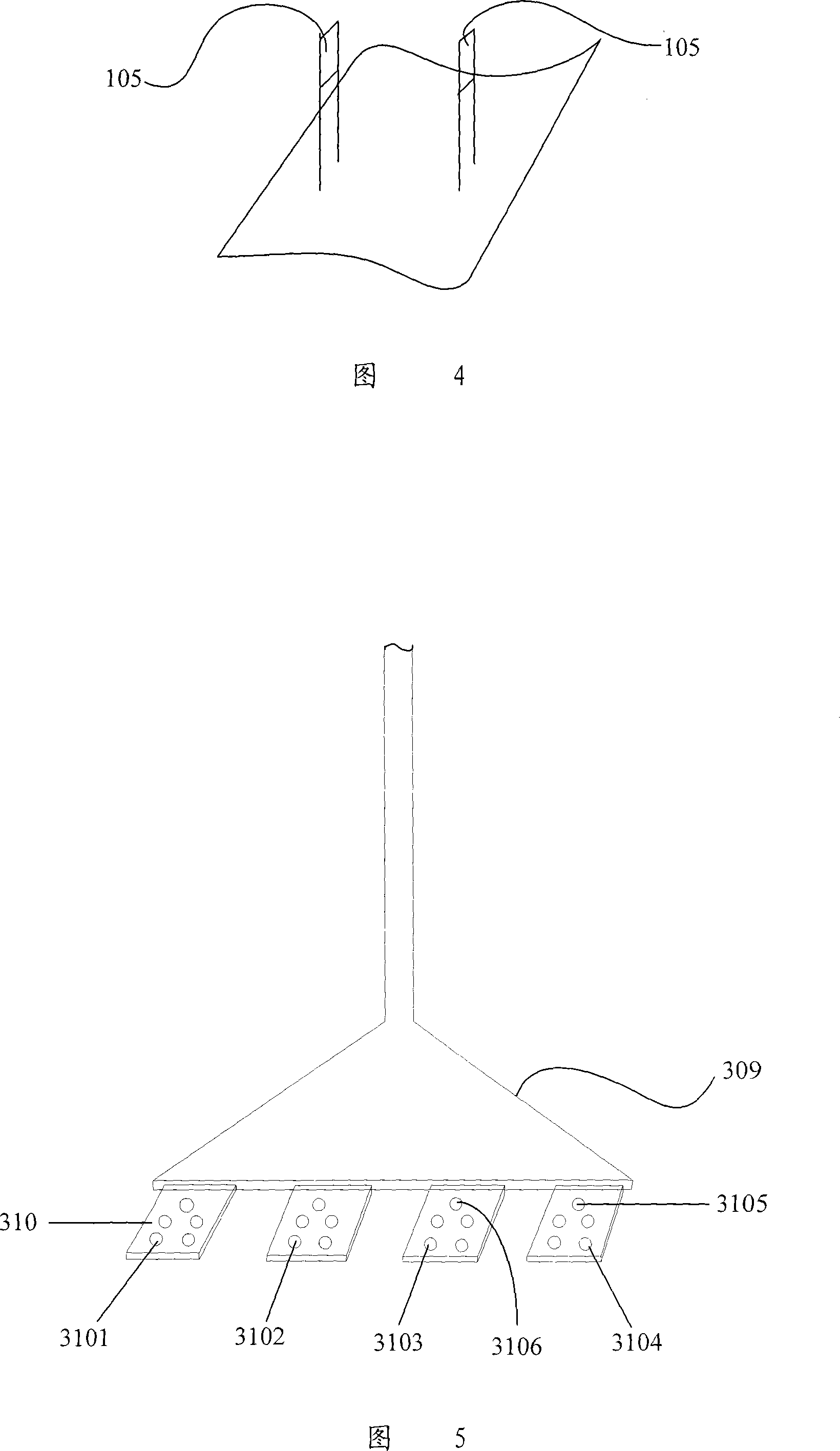

Slide-making staining machine and method for slide-making staining method

ActiveCN101021455AEasy to operateSuitable for usePreparing sample for investigationColor/spectral properties measurementsStainingPipette

The invention relates to testing field of cell pathology. It aims at providing a flaking dyer and a method to flak and dye by this dyer. The dyer contains dye platform (on which set dye chamber with slide in it, pipette and test-tube rack containing test-tubes), loading rack connects with dye platform vertically, mobile device connects with loading rack which has transfer head and a set of conduct pipes. The device integrates dying and flaking to realize automatization of the whole process. It operates conveniently and can flak many pieces at one time, which is suitable for large hospitals and testing centers specially. Pipette retreat device and reclaiming device of the dyer have retinal institution, simple structure and convenient operation.

Owner:GUANGZHOU LBP MEDICINE SCI & TECH

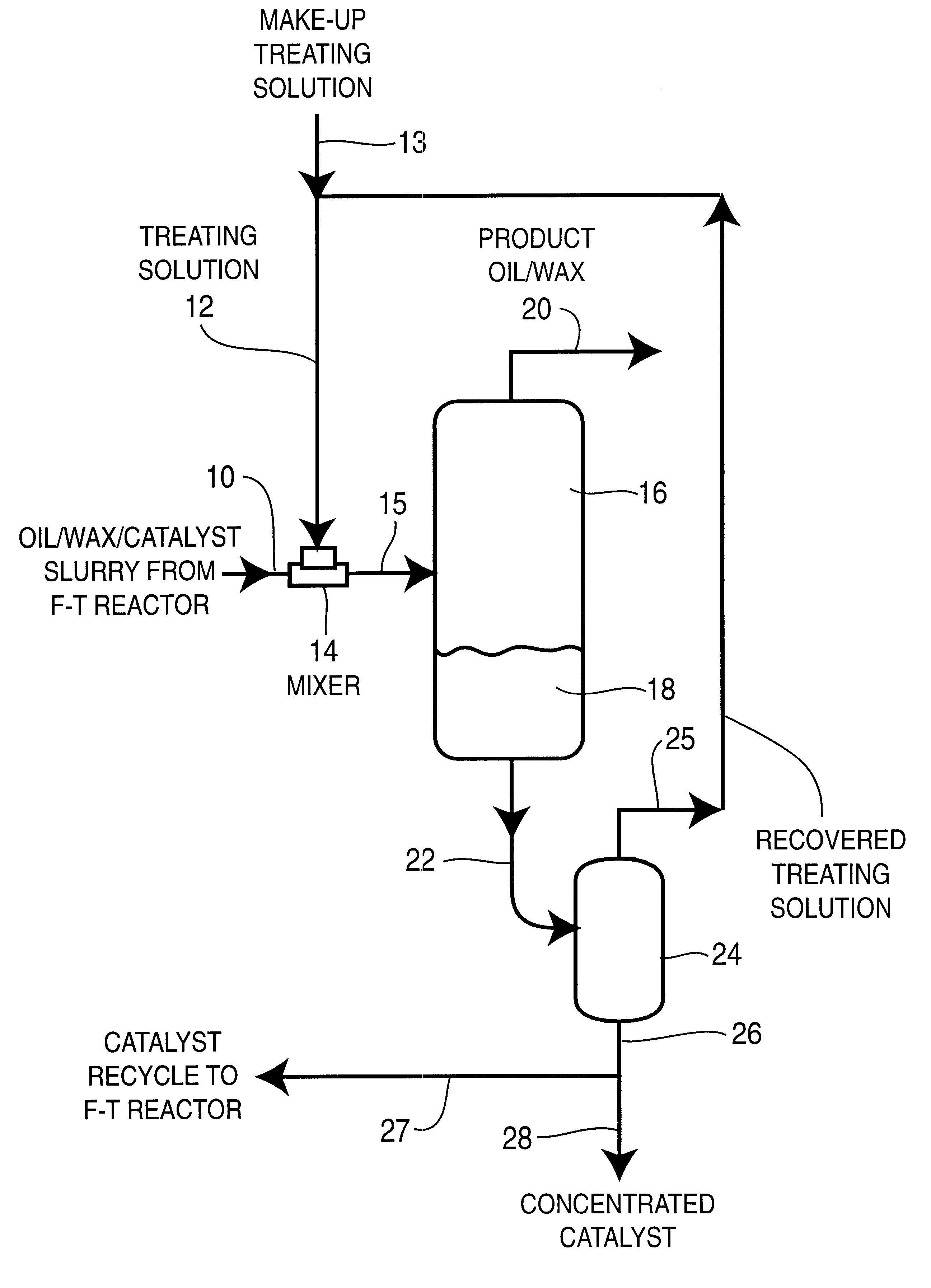

Coalescence enhanced gravity separation of iron catalyst from Fischer-Tropsch catalyst/wax slurry

InactiveUS6476086B1Effectively separateEfficient separationOrganic compound preparationOxygen compounds preparation by reductionWaxGravity separation

Fine iron-based catalyst particles from. Fischer-Tropsch (F-T) synthesis processes are effectively separated from catalyst / liquid / wax slurry by contacting and / or mixing the slurry with a coalescence enhancing treating solution to facilitate gravity separation and settling of such catalyst, and thereby yield a substantially clean hydrocarbon liquid / wax product. The treating solution includes a surface tension reducing agent, an agglutinating agent, and a coalescing agent each in selected proportions in aqueous solution. Useful mixing and settling conditions are 10-250° C. temperature, 0-500 psig pressure and treating solution to slurry volume ratio of 0.5-5:1, with the settling time for at least about 90% and preferably substantially all of the catalyst fines after the mixing step being less than about 15 minutes. The treating solution can be desirably recovered and reused in the F-T synthesis process, and the recovered catalyst either recycled or disposed as desired.

Owner:HYDROCARBON TECH

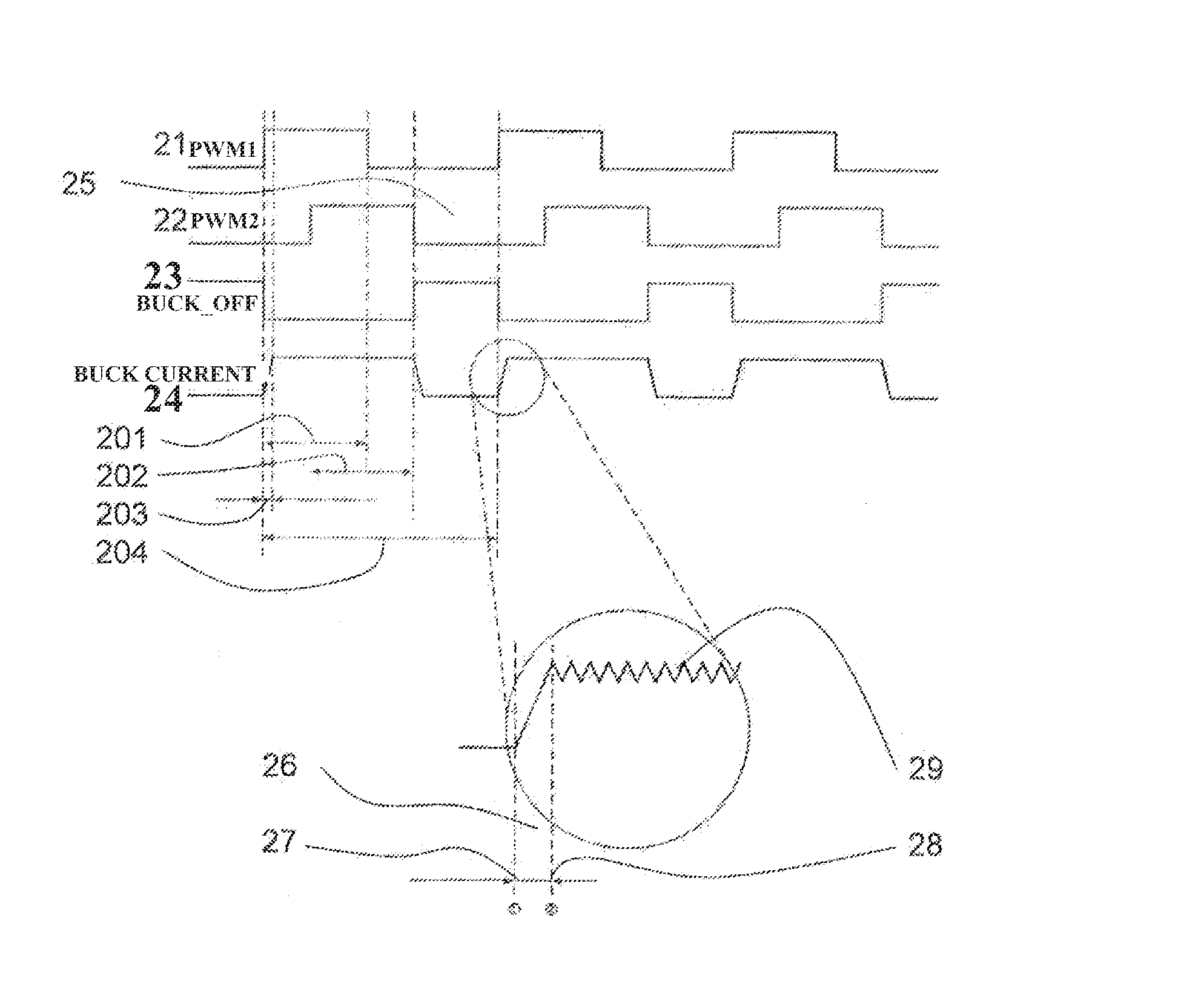

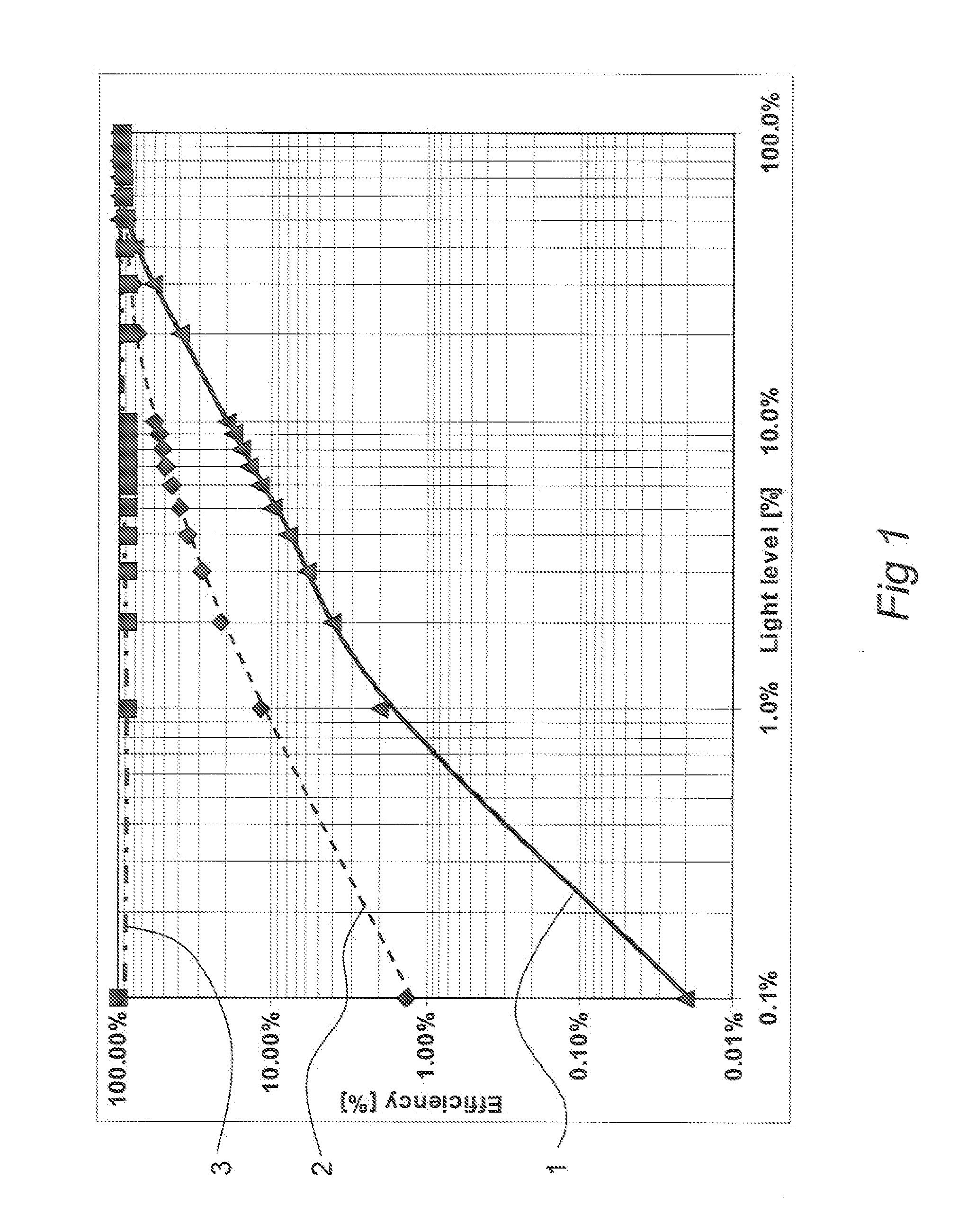

Controller and method of operating a controller

ActiveUS8508204B2Settling fastSure easyElectroluminescent light sourcesElectric light circuit arrangementControl theoryLED circuit

A controller for controlling a power generator circuit, and a method for operation such a controller, is disclosed. The invention is particularly suited to LED current generators. The current generator may be switched off to conserve power when not required for any LED circuits. The method relates to determining the time at which the controller is required to provide power, current or voltage, and to adjust the timing of switching-on of the controller, in order to ensure that power, current or voltage is available for the load when required.

Owner:NXP BV

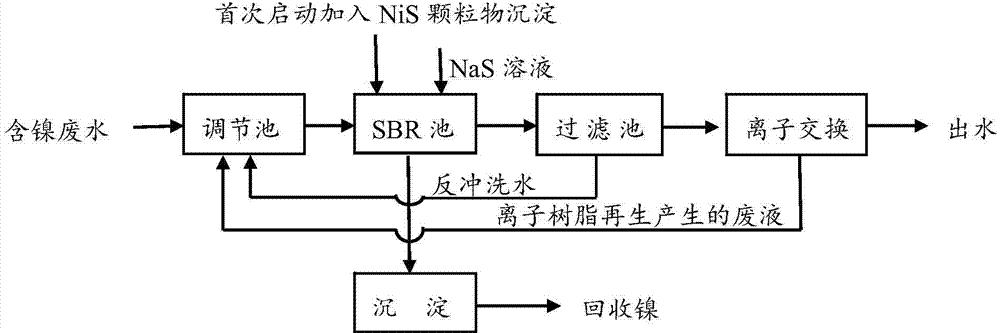

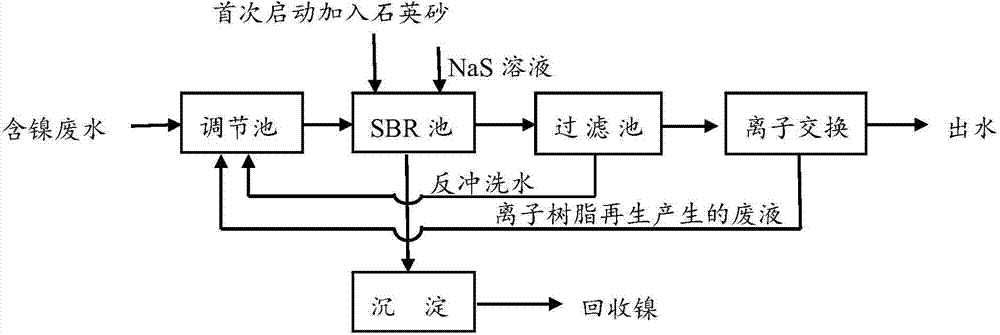

Treatment method of heavy metal wastewater

InactiveCN104261526ATo achieve the purpose of purifying wastewaterLarge particle sizeWater treatment compoundsWater contaminantsParticulatesFiltration

The invention provides a treatment method of heavy metal wastewater, and particularly relates to a method for treating heavy metal wastewater by virtue of a precipitation method. The method comprises the following steps: adding sodium sulfide in a heavy metal wastewater treatment process, reacting sulfur ions with heavy metal ions in the wastewater to generate particulate matters, further adding sulfide precipitates of heavy metal, stirring, standing, and accelerating the sedimentation of micro particulate matters and other substances by using generated particulate matter precipitates; further preferably adding quartz sand, and accelerating the rapid sedimentation of the particulate matters and other substances under the wrapping action of quartz sand; further performing subsequent process treatment including sand filtration and ion exchange on a supernatant liquor obtained after sedimentation to reach the emission standard; and periodically discharging and collecting part of the precipitates, and recycling heavy metals in the precipitates. Because the method provided by the invention is simple in working procedure, low in cost and high in efficiency, the method can be widely applied to the treatment of industrial wastewater particularly the heavy metal wastewater.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

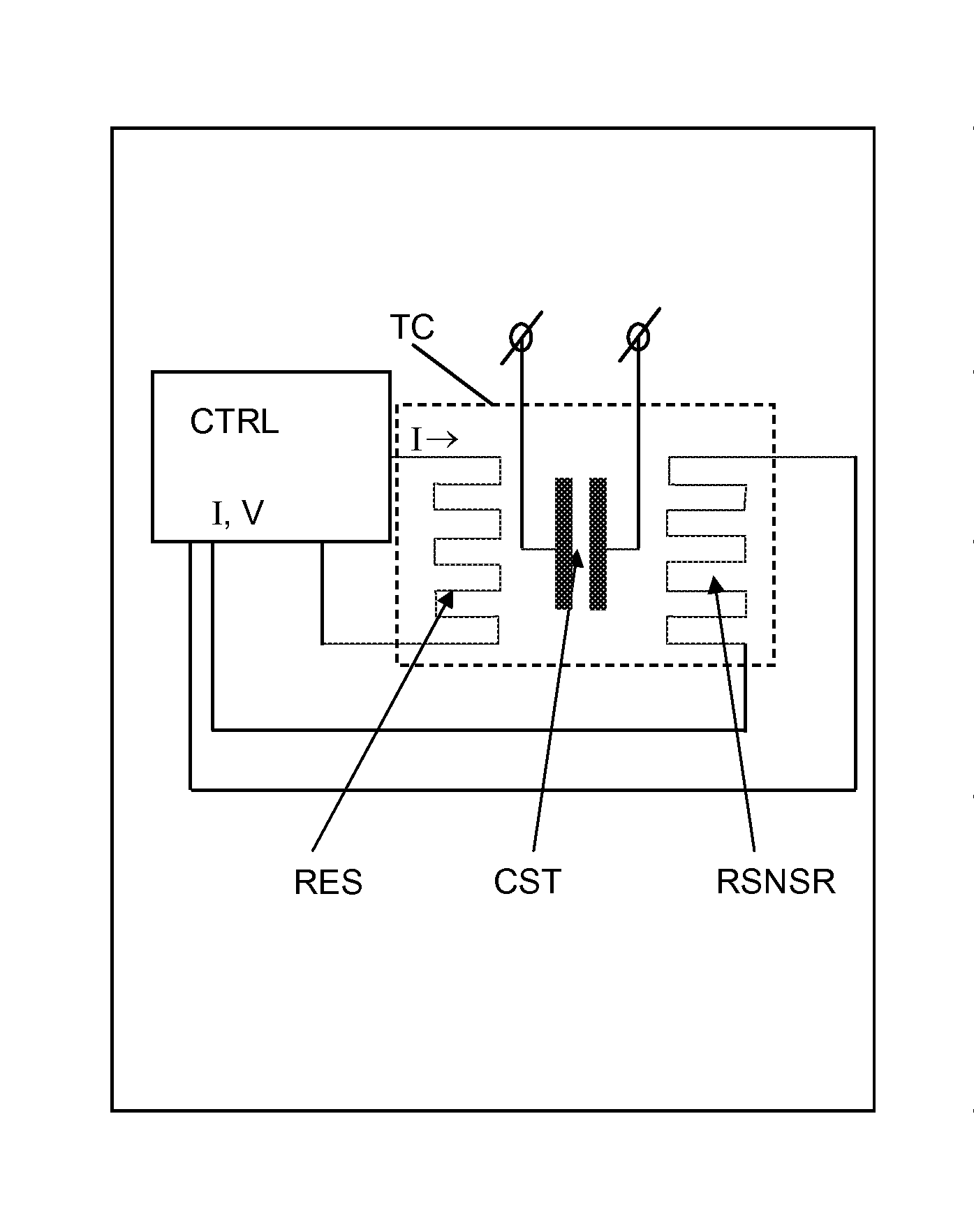

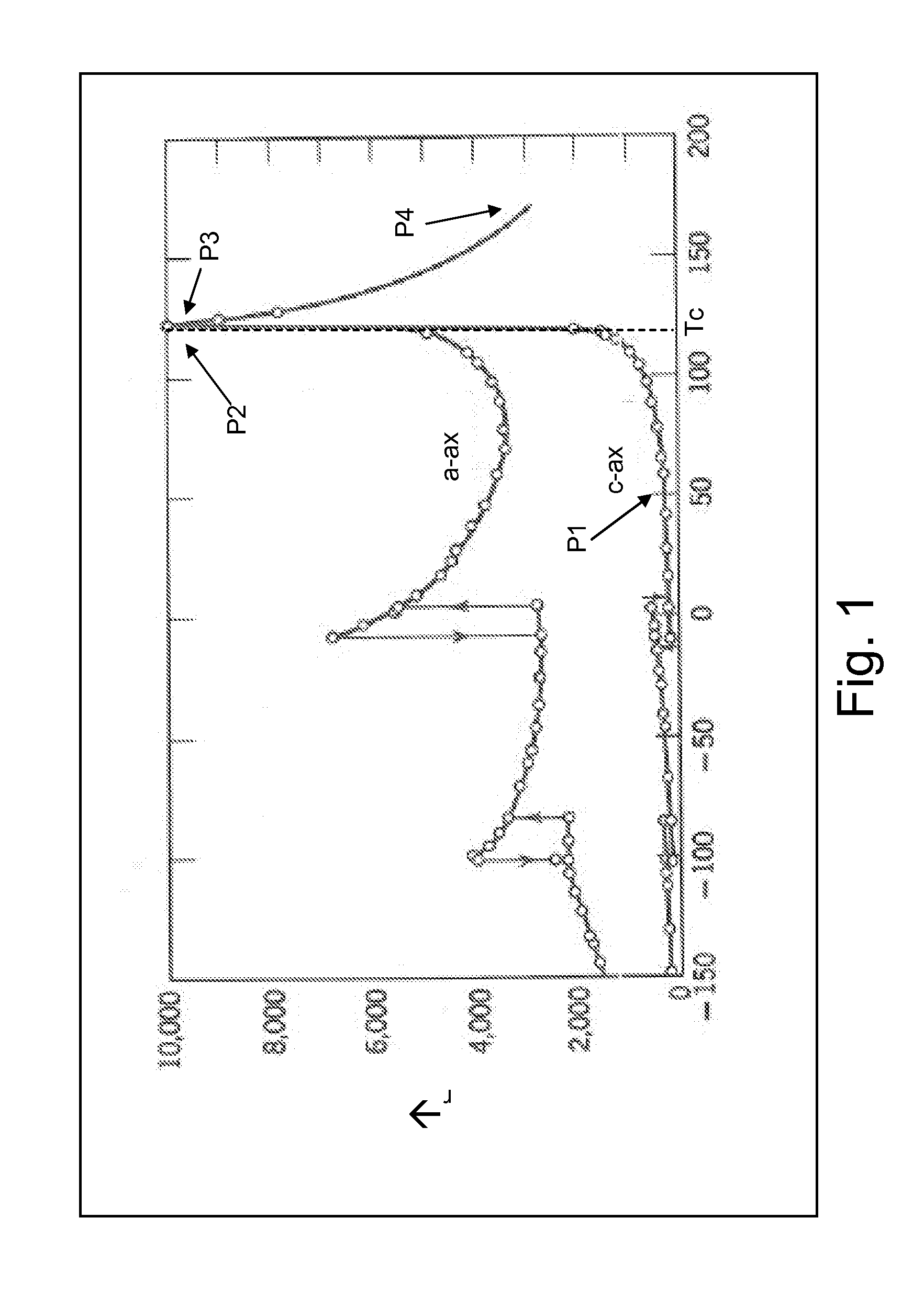

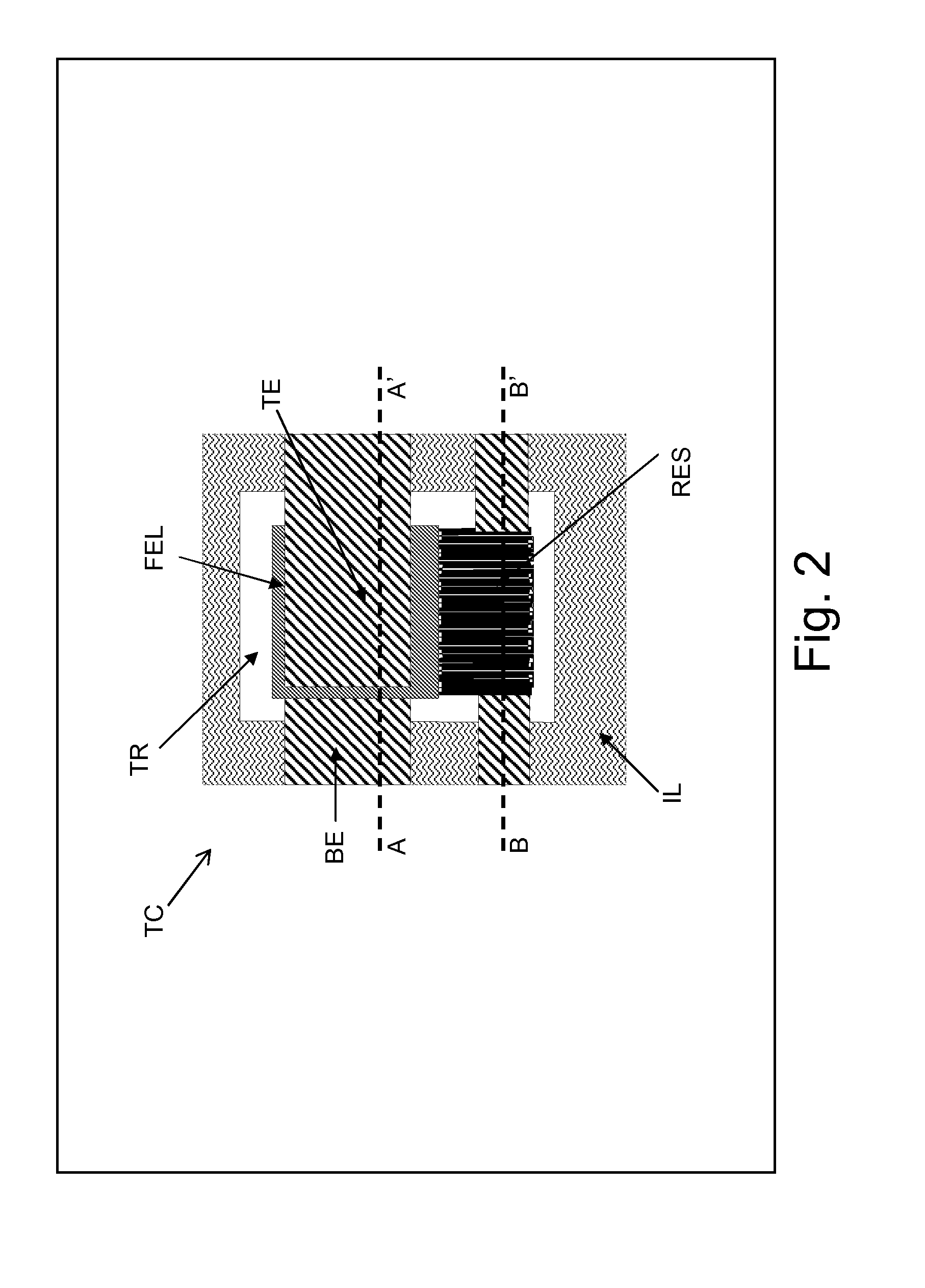

Tunable capacitor

ActiveUS20110051309A1Reduce heat lossSettling fastCapacitor with temperature varied dielectricMechanically variable capacitorsCapacitanceDielectric

The invention relates to electronic device having an operation temperature range, wherein the electronic device comprises a tunable capacitor (CST) comprising a first electrode (BE), a second electrode (TE), and a dielectric (FEL) arranged between the first electrode (BE) and the second electrode (TE). The dielectric (FEL) comprises dielectric material (FEL) having a value of a relative dielectric constant (εr) varying at least within the operation temperature range. The electronic device further comprises a temperature varying means (RES) being thermally coupled to the tunable capacitor for providing a temperature of the dielectric (FEL) causing a predetermined capacitance of the tunable capacitor (CST). The invention, which relies on the idea of varying temperature to vary a capacitance of a capacitor stack, provides an alternative tunable capacitor type for the known types. Advantageous embodiments feature high-tuning ratio, small device area, and stable capacitance value in case the temperature is well controlled. The invention further relates to a semiconductor device comprising the electronic device in accordance with the invention, to an electronic circuit comprising such electronic device, and to a method of manufacturing such electronic device.

Owner:NXP BV

Composite flocculating agent for printing and dyeing waste water treatment

InactiveCN1654348AImprove decolorization efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSludge

The composite flocculant for treating printing and dyeing effluent consists of natural high molecular water soluble chitosan and polyaluminium chloride. The usage of the composite flocculant in treating printing and dyeing effluent includes regulating effluent to pH 6-8, and throwing composite flocculant in the amount of chitosan in 1-2 ppm and polyaluminium chloride in 100-250 ppm to result in printing and dyeing effluent decolorizing rate up to 91 %. The composite flocculant of the present invention has simple compounding process, easy use, low cost, small thrown amount, excellent decolorizing performance, fast deposition, small sludge amount, easy biodegradation, less secondary pollution of water and thus wide application foreground.

Owner:SHANGHAI NORMAL UNIVERSITY

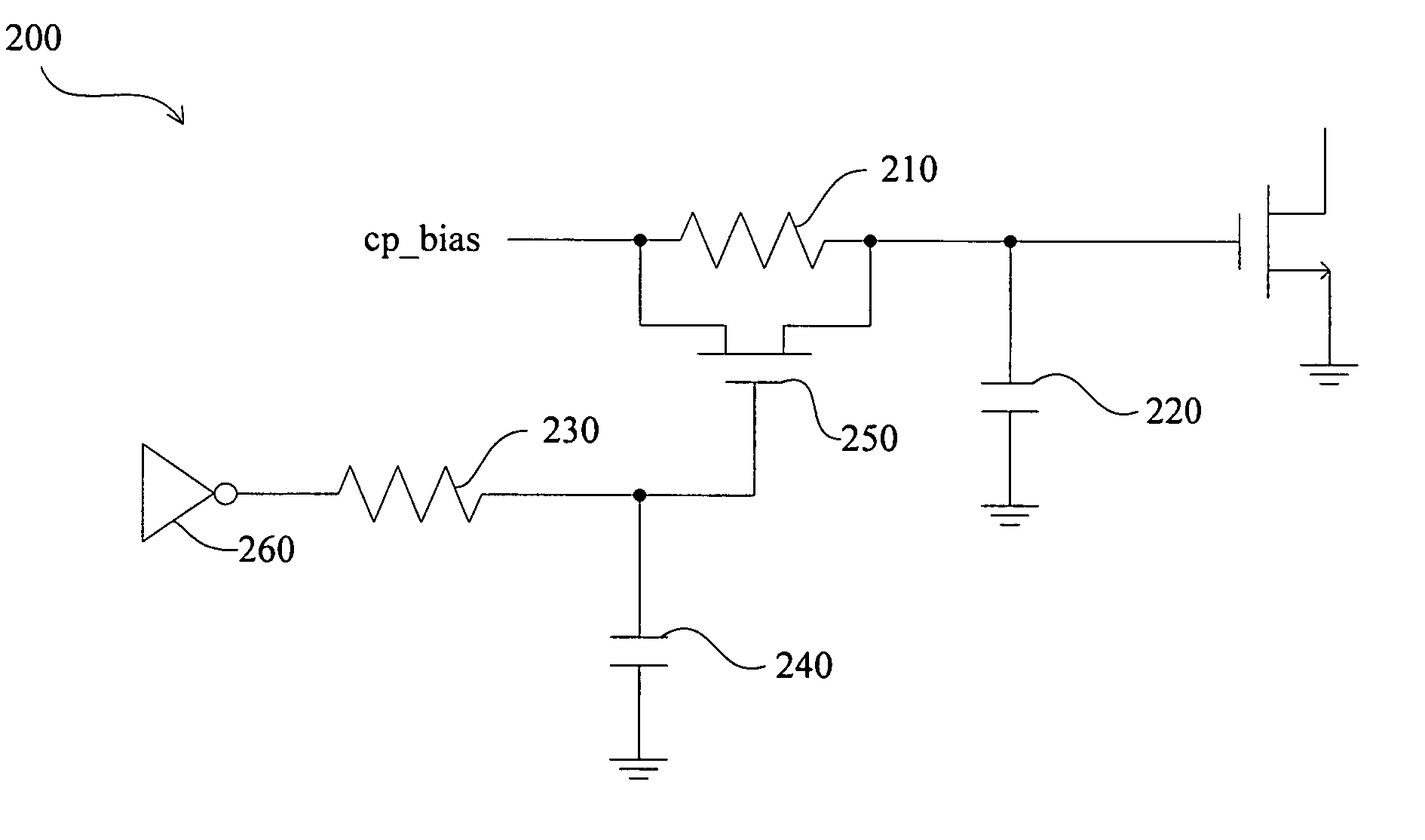

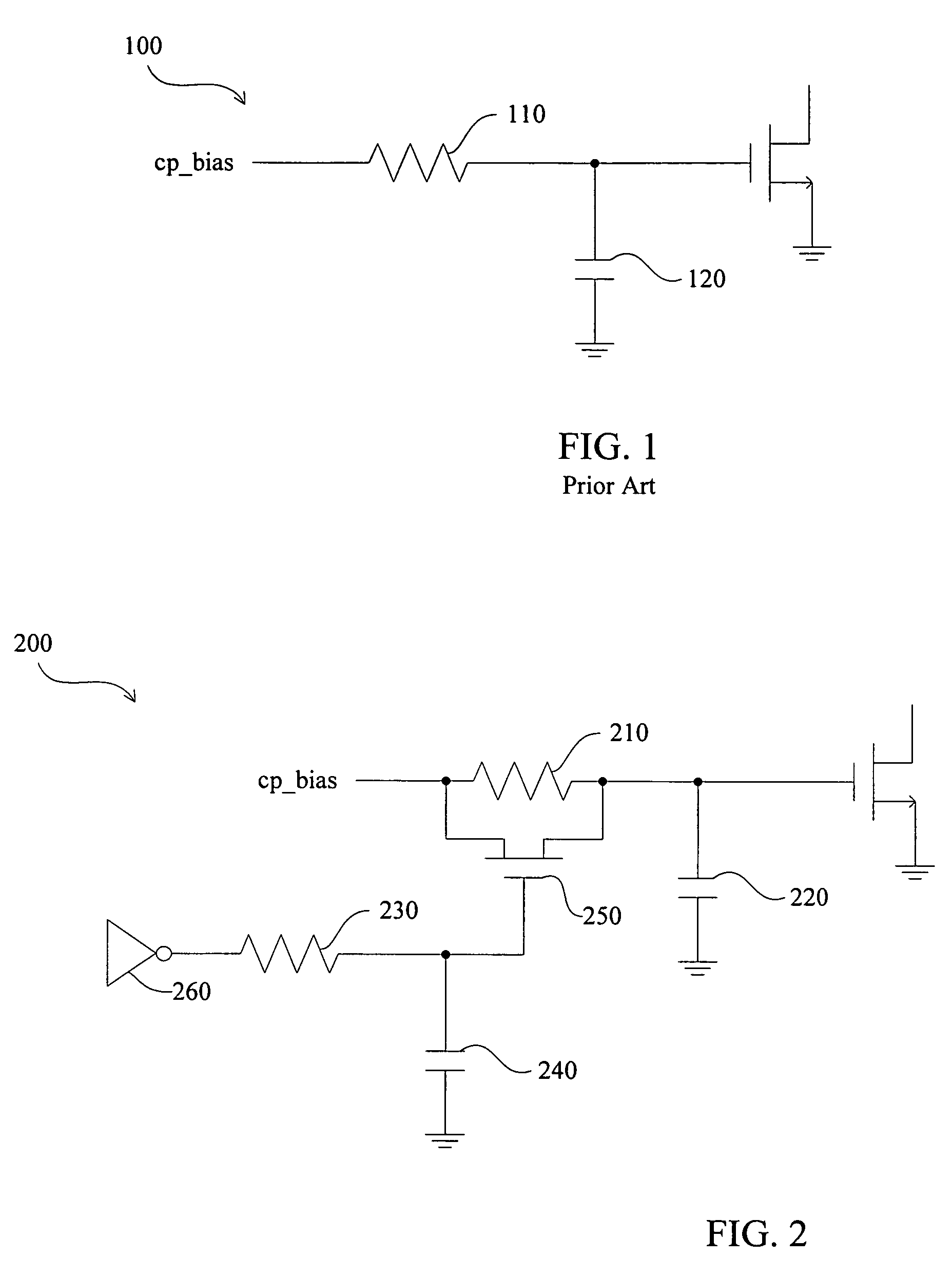

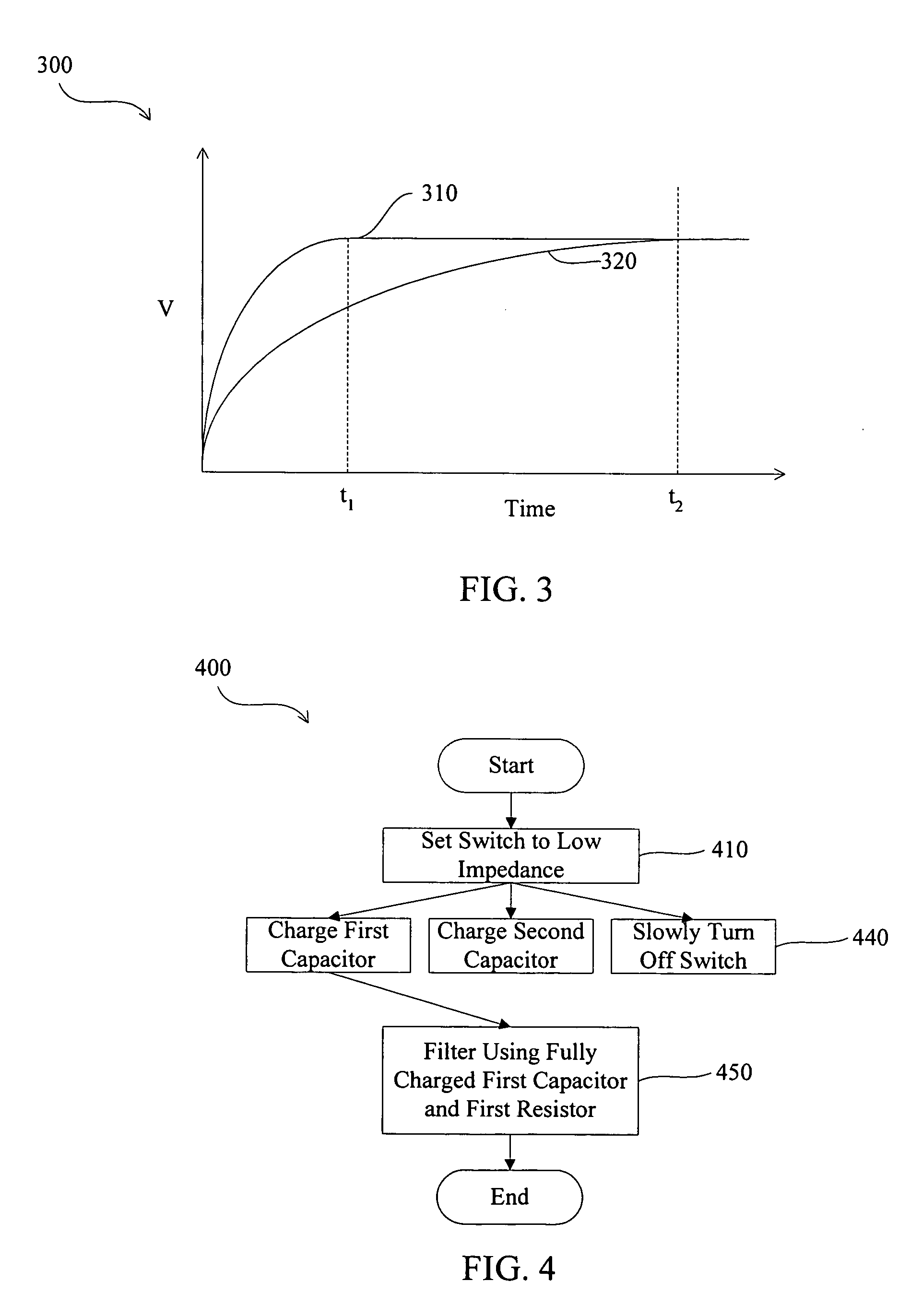

Low-noise, fast-settling bias circuit and method

ActiveUS20050231274A1Settling fastAmplifier modifications to reduce noise influenceAmplifier modifications to reduce temperature/voltage variationCapacitanceLow noise

A low-noise, fast-settling bias circuit includes a first and a second low pass filter, such as RC filters. The second filter initially shorts out a resistor of the first filter with a switch (set to low impedance) in parallel. Accordingly, a capacitor of the first filter quickly charges up to the same voltage as the input bias voltage. As the second filter charges up, the switch slowly shuts off (high impedance). By this time, since the capacitor of the first filter has charged to the same voltage as the bias voltage, a large RC formed by the resistor of the first filter and the capacitor of the first filter is available to provide filtering for the desired bias current.

Owner:AVAGO TECH INT SALES PTE LTD

Method of separating fischer-tropsch synthesis heavy distillate from ferrous iron-base catalyst

InactiveCN101229499ASettling fastReduce loadSedimentation separationMagnetic separationChemistryFischer–Tropsch process

The invention relates to a preparation method for a heavy fraction and iron-based catalyst from fischer tropsch slurry phase, including the following steps: mixing slurry of fischer-tropsch synthesis products heavy fraction and iron-based catalyst from slurry reactor is sent into a deposition tank outside the slurry reactor, so as to facilitate the mixing slurry in deposition tank to realize fast separation for fischer-tropsch synthesis heavy distillates and iron-based catalyst under the function of magnetic field along the direction of magnetic force lines downwards. The separated fischer-tropsch synthesis heavy distillates can be discharged as product through a filter arranged on the top of the deposition tank. The method of the invention can realize fast separation of heavy distillates and iron-based catalyst of fischer-tropsch synthesis products; meanwhile, move than 99.95 percent of catalyst particles can be left in the reaction system to continuously function as catalyst.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

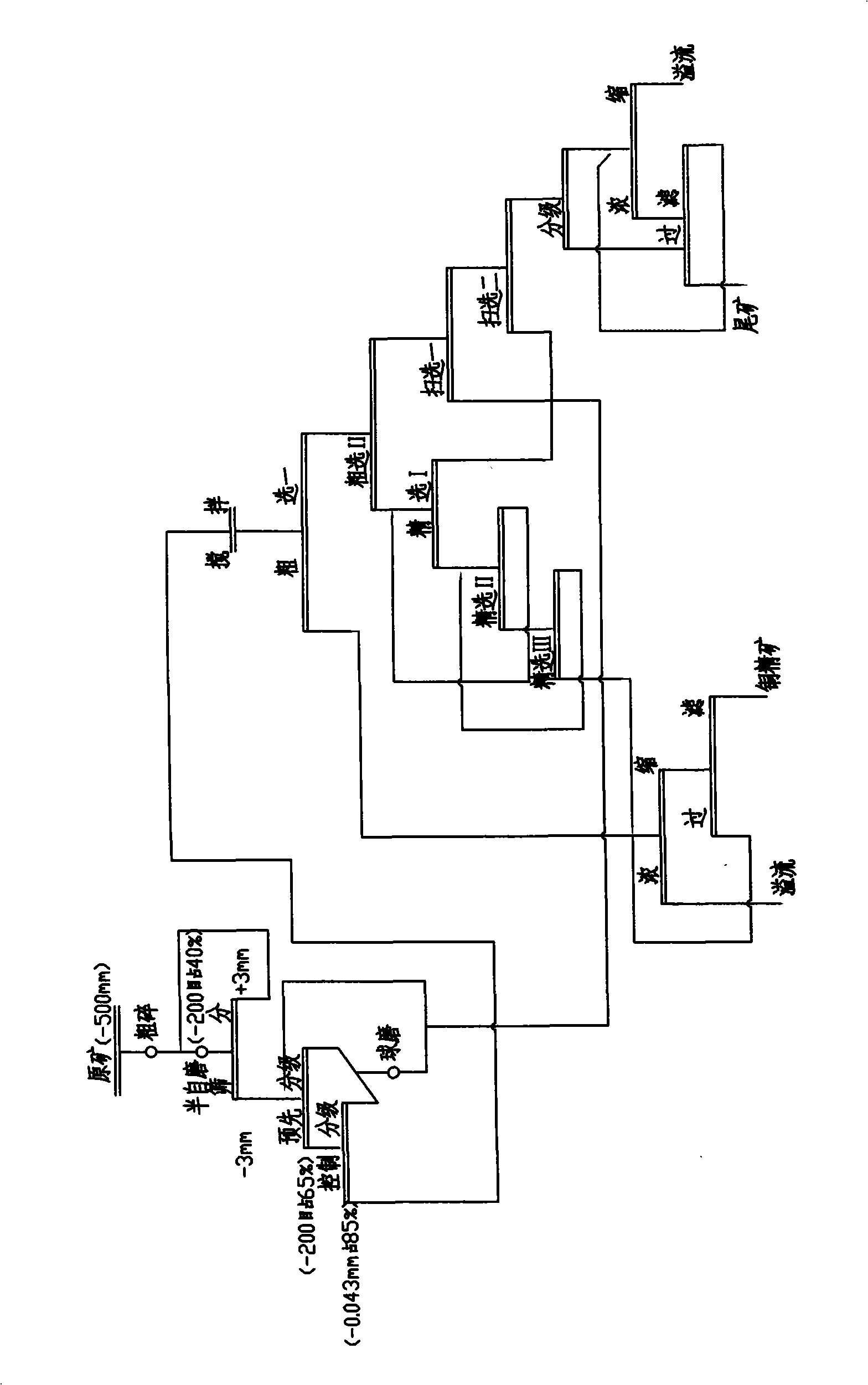

Beneficiation process of mixed dregs using three copper smelting methods of flash smelting furnace, revolving furnace and depletion electric furnace

ActiveCN101491789ASimple processSmooth flowGrain treatmentsWet separationTechnical supportCircular economy

The invention discloses a dressing process for a plurality of sorts of slag mixed materials currently applied to domestic industrial production. The dressing process has better adaptability, and is suitable for the treatment of both mixed slag materials and slag materials generated by various smelting processes, thereby providing an effective way for reclaiming domestic copper slag resource. The dressing process not only has short process flow, less investment, low energy consumption, no pollution and lower production cost, but also breaks through index which cannot be realized by the prior common slag dressing process, thereby obtaining remarkable economical and social benefits. Therefore, the dressing process provides powerful technical support for realizing recycling economy strategy of copper resource from one aspect, and has wide application prospect in the field of copper slag dressing.

Owner:CHINA NERIN ENG

Oxidization coagulant for treating coking wastewater

InactiveCN101734780AWide pH rangeGood removal effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationChemical oxygen demandAqueous solution

The invention discloses an oxidization coagulant for treating coking wastewater, which consists of two parts of an oxidization flocculant and a coagulant aid. The oxidization flocculant comprises the following components according to proportion by weight: 8-20% of flocculant polyferric sulfate, 0.1-2.0% of oxidant ferrate and the balance of water; and the coagulant aid is polyacrylamide aqueous solution. In the invention, the double functions of oxidization and flocculation are available, the removal rate of the coking wastewater CODcr (Chemical Oxygen Demand) can reach more than 70%, the draining water is clear, the colority is less than 80 times, the adding amount is little, and the cost is low, wherein the medicament cost of advanced treatment is only 0.5 RMB / ton; the condition is easy to control and the operation is convenient. The invention provides an economical and efficient method and powerful assurances for the draining standard of advanced treatment of the coking wastewater.

Owner:娄底市裕德科技有限公司

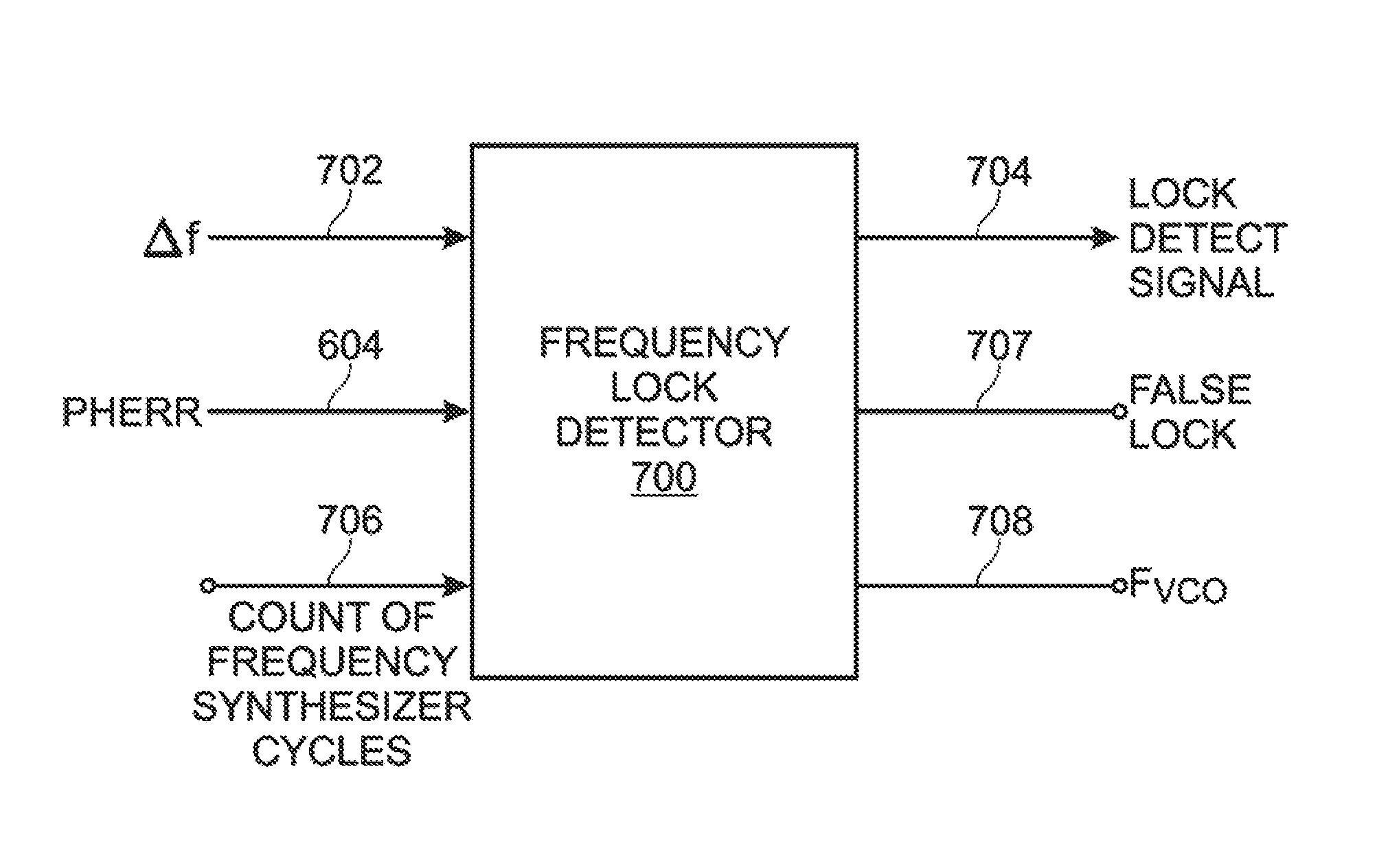

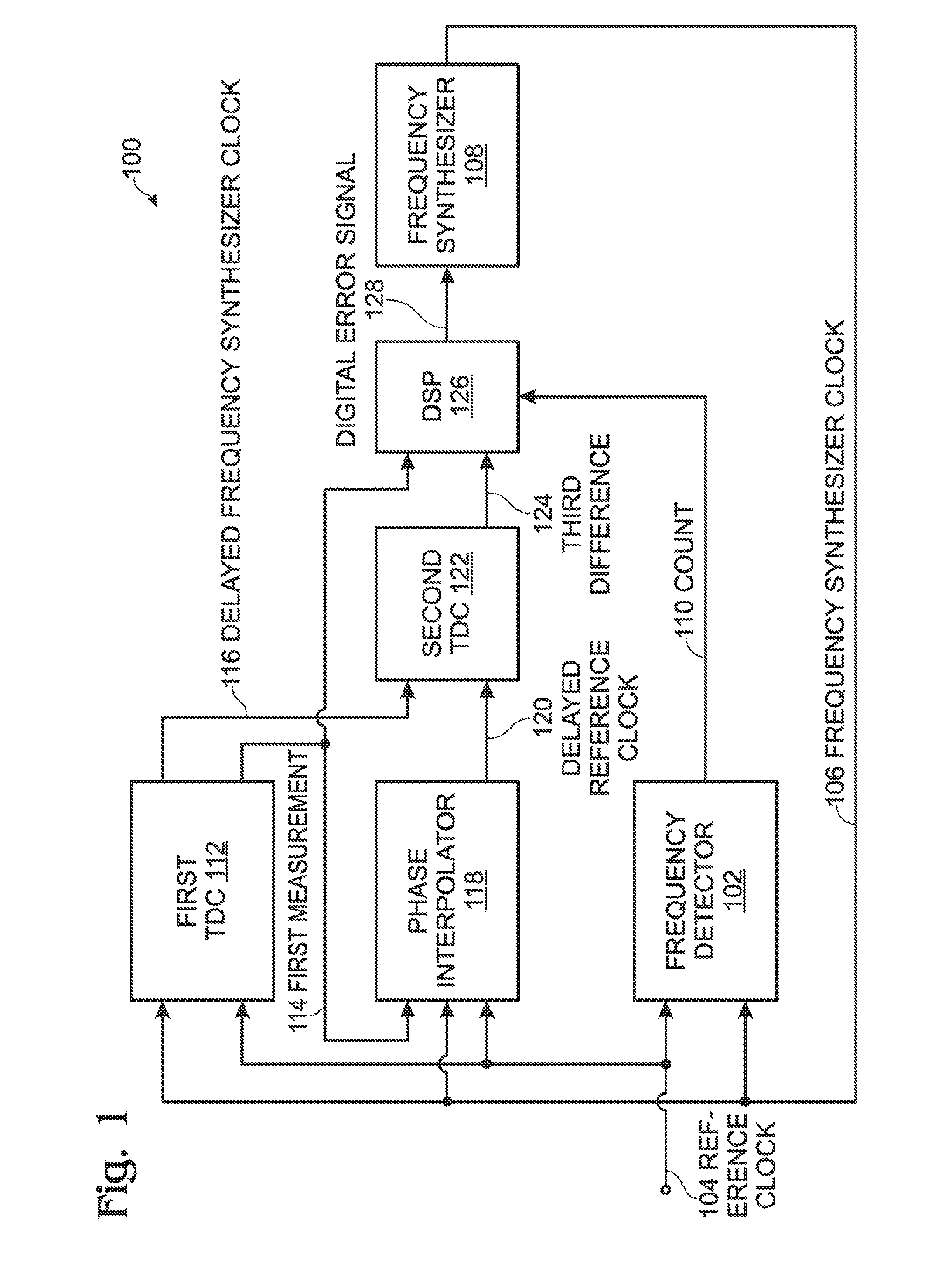

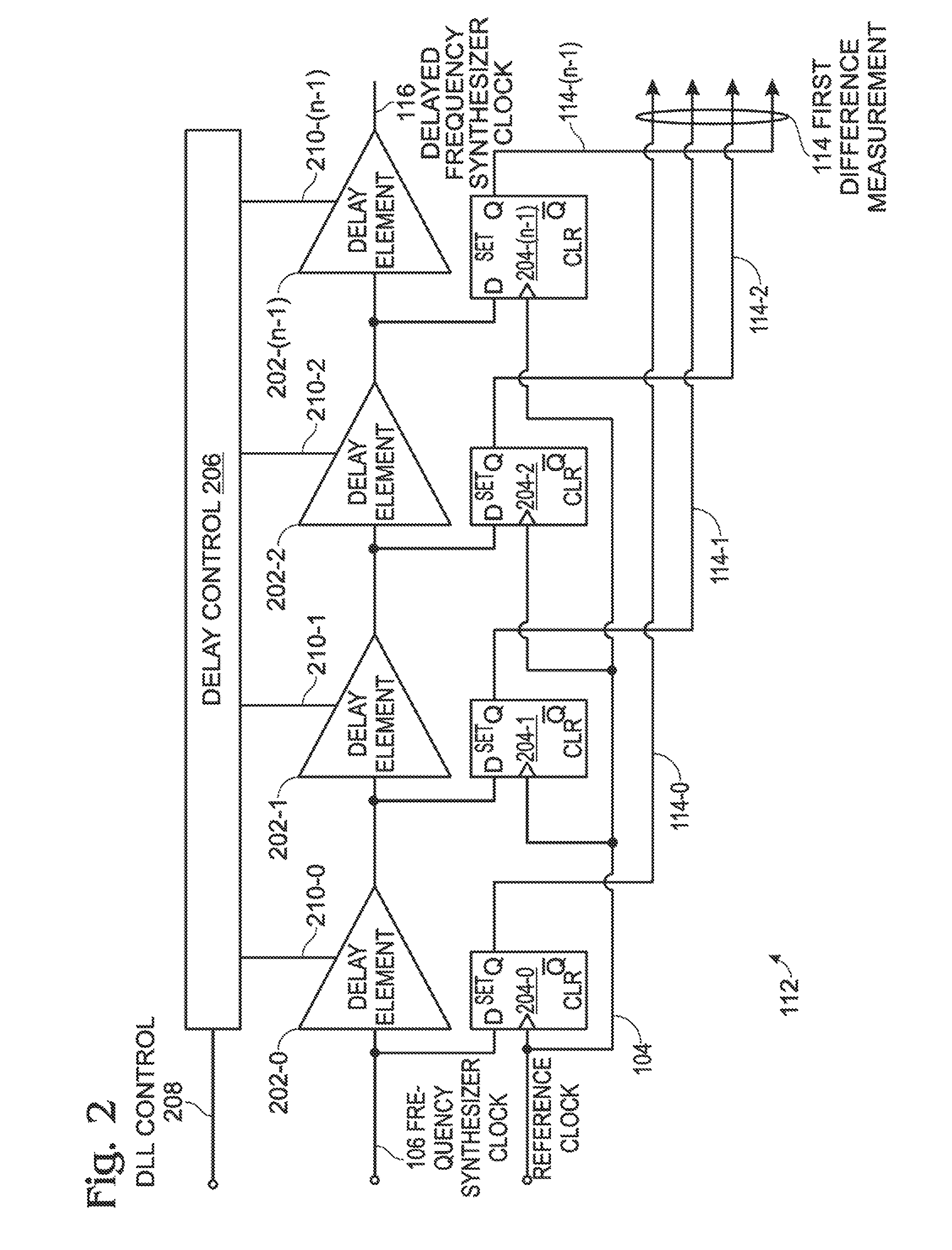

Lock detection using a digital phase error message

ActiveUS8248106B1Improve performanceReduce power consumptionPulse automatic controlFrequency/rate-modulated pulse demodulationClock rateEngineering

A system and method are provided for frequency lock detection using a digital phase error. A lock detection module accepts a digital phase error (pherr) message proportional to an error in phase between a reference clock and a (synthesizer clock*Nf). Also accepted is a unitless frequency error tolerance value (Δf). The lock detection module periodically supplies a lock detect signal, indicating whether the synthesizer clock frequency is within the frequency error tolerance value of the reference clock frequency.

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

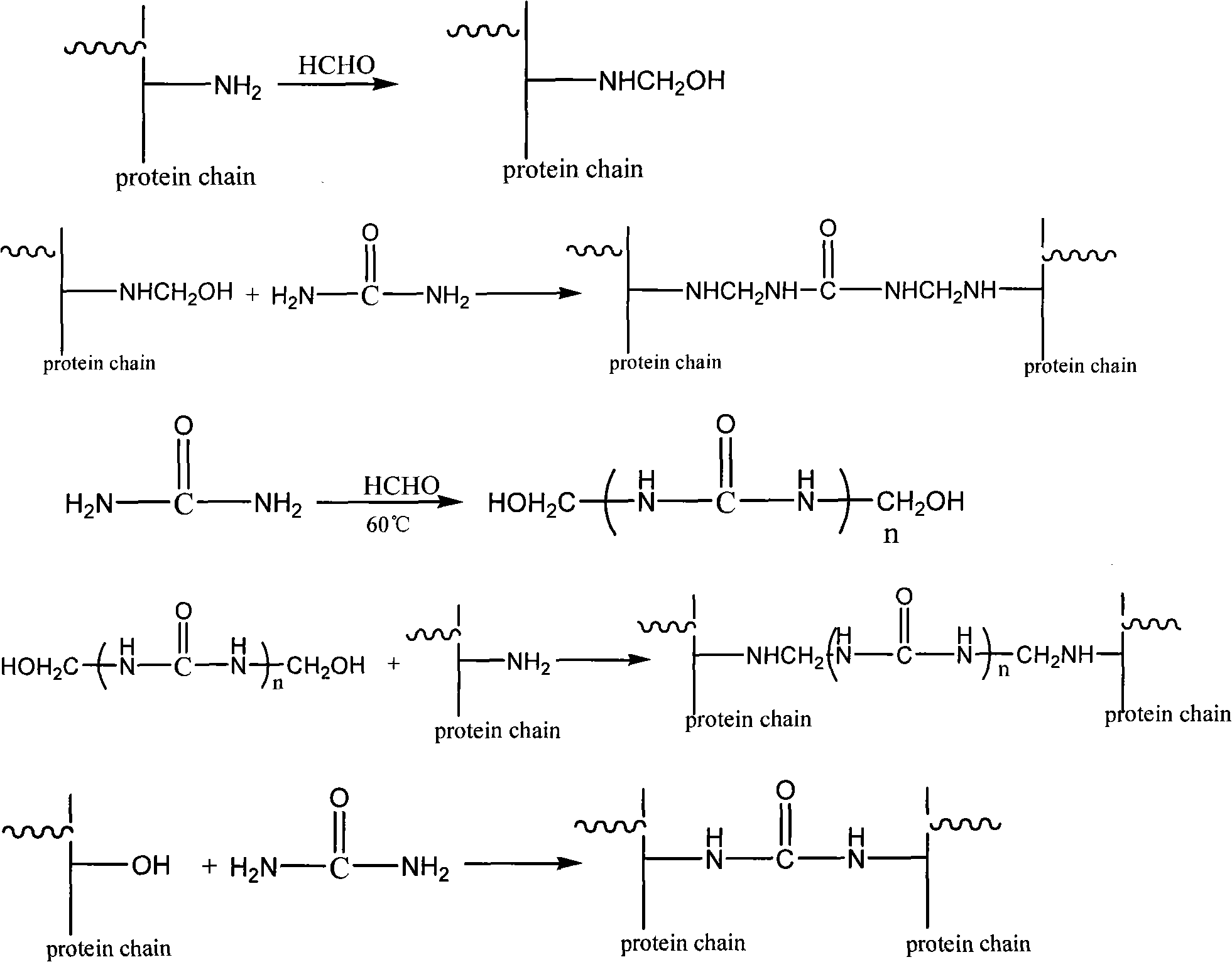

Method for preparing heavy metal ion catching agent

ActiveCN103466775AEasy to synthesizeEasy to operateWater/sewage treatment by flocculation/precipitationFiltrationReaction temperature

The invention discloses a method for preparing a heavy metal ion catching agent. The heavy metal ion catching agent is mainly formed by being prepared by urea, amine compounds, carbon disulfide, an additive, alkaline matter and distilled water. The heavy metal ion catching agent comprises, by weight, 9-30% of the urea, 1-6% of the amine compounds, 0-4.5% of the additive, 21-45% of the carbon disulfide, 8-17% of the alkaline matter and 20-35% of the distilled water. The method comprises the preparation steps of mixing the urea with the water, adding the alkaline matter to adjust the pH value, adjusting the reaction temperature, adding the micromolecular amine compounds, adding the additive, dropwise adding the carbon disulfide, controlling the temperature to conduct the reaction for a certain time, conducting suction filtration, using ethyl alcohol for conducting washing and drying, and obtaining the polyurea dithiocar-bamate heavy metal ion catching agent. According to the method for preparing the heavy metal ion catching agent, the production cost of the dithiocar-bamate heavy metal ion catching agent is remarkably reduced, and the actual treatment effect, on heavy metal ion waste water, of the heavy metal ion catching agent is good.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Purifying treatment agent for coal-washing wastewater and preparation method thereof

InactiveCN103739049AGood flocculation effectGood purification effectWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationSodium polyacrylateChemistry

The invention discloses a purifying treatment agent for coal-washing wastewater and a preparation method thereof. The purifying treatment agent is prepared from the following materials in parts by weight: 30-40 parts of sepiolite, 15-20 parts of montmorillonite, 10-15 parts of medical stone, 15-20 parts of polyacrylamide, 5-10 parts of sodium polyacrylate, 3-6 parts of aluminium polychlorid, 2-4 parts of sodium lignin sulfonate, 3-5 parts of alum powder, 6-9 parts of ferrous sulfate, 8-12 parts of guar gum powder, 5-10 parts of nano carbon, 4-8 parts of porous calcium phosphate, 10-15 parts of carboxymethyl chitosan, 5-10 parts of sodium alginate, 2-3 parts of span-80, 1-2 parts of sodium lauryl sulfate, 1-2 parts of stearic acid and 0.5-1 parts of gamma-aminopropyltriethoxysilane. The purifying treatment agent disclosed by the invention has the advantages that the flocculation effect is good, impurity particles in coal-washing water can be rapidly agglutinate and settled, simultaneously heavy-metal elements in the coal-washing water can be absorbed, the purifying effect is very obvious, the water purifying effect is 4-6 times of that of the common flocculating agent; and the used amount is less, the efficiency is high, the cost is low, the benefit is high, the complete environmental-friendly effect is achieved and the application prospect is wide.

Owner:青岛中科菲力工程技术研发有限公司

Protein flocculant for treating printing and dyeing wastewater

InactiveCN102115239AHigh decolorization rateReduce dosageWater/sewage treatment by flocculation/precipitationWater dischargeProtein molecules

The invention discloses a protein flocculant for treating printing and dyeing wastewater. The protein flocculant for treating the printing and dyeing wastewater is prepared from various animal protein powders originating from cheap waste animal pelts, hoofs, animal fur powders and bean pulps aiming at different groups in a protein molecule and a chemical modifier for reaction. The invention simultaneously provides a protein flocculant compound. The invention provides a simple and practicable method; and by utilizing the method, various dye waste waters discharged in printing and dyeing plants and dye production plants can be effectively treated, and the product cost is cheap.

Owner:中国中化股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com