Capturing settling agent and method for removing catalyst solid powder in oil slurry

A technology of solid powder and sedimentation agent, applied in chemical instruments and methods, separation methods, petroleum industry, etc., can solve the problems of low sedimentation efficiency, slow sedimentation speed, and large space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment one: according to percentage by weight, octadecyl trimethyl ammonium chloride 8%, cetyl trimethyl ammonium chloride 10%, dodecyl trimethyl ammonium chloride 17% and ethylene diethyl ammonium Alcohol 65% is uniformly mixed to obtain a trapping sedimentation agent.

Embodiment 2

[0054] Embodiment 2: According to weight percentage, 10% of octadecyltrimethylammonium chloride, 15% of cetyltrimethylammonium chloride, 60% of ethylene glycol and 15% of propylene glycol are uniformly mixed to obtain a trapping and settling agent .

Embodiment 3

[0055] Example 3: According to the percentage by weight, 12% of octadecyltrimethylammonium chloride, 10% of polyacrylamide 1% aqueous solution, 48% of ethylene glycol and 30% of glycerol were uniformly mixed to obtain a trapping and settling agent.

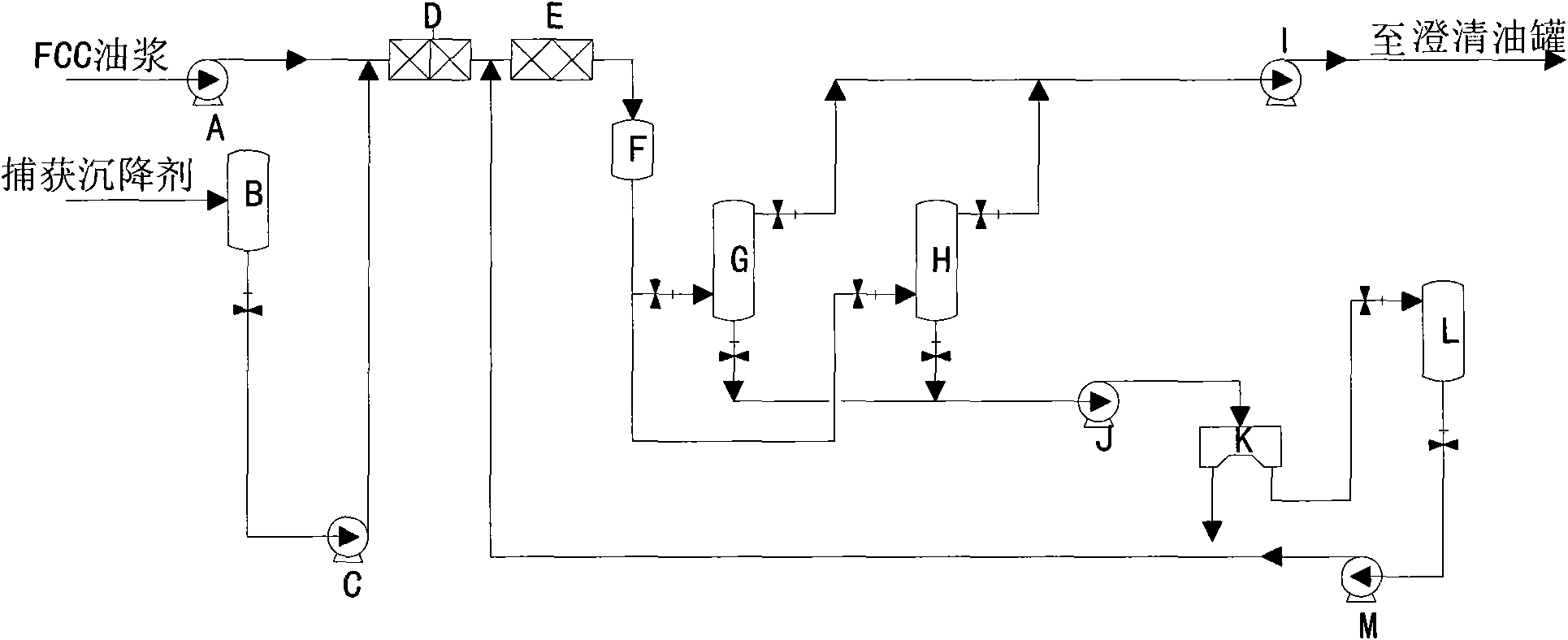

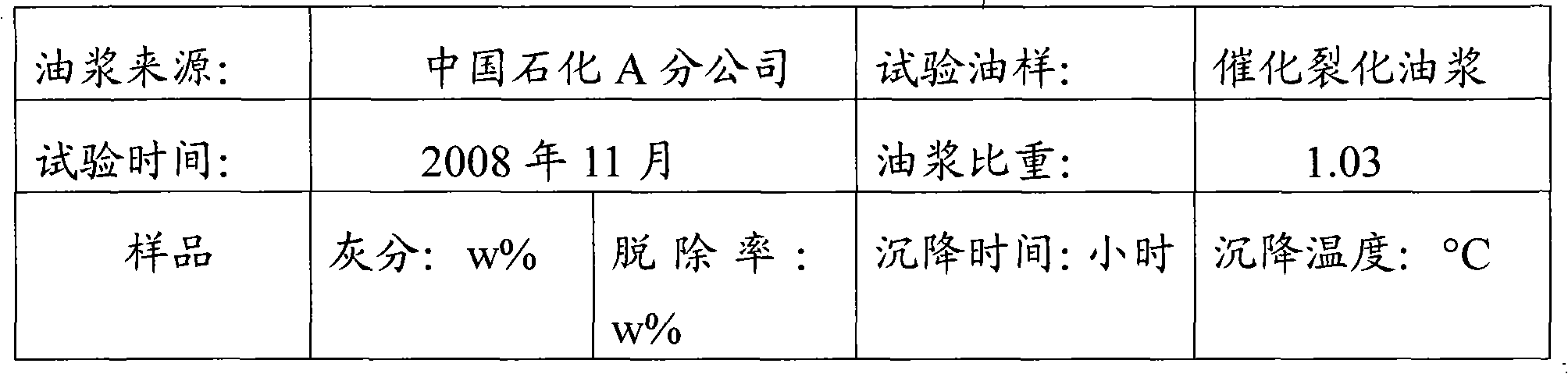

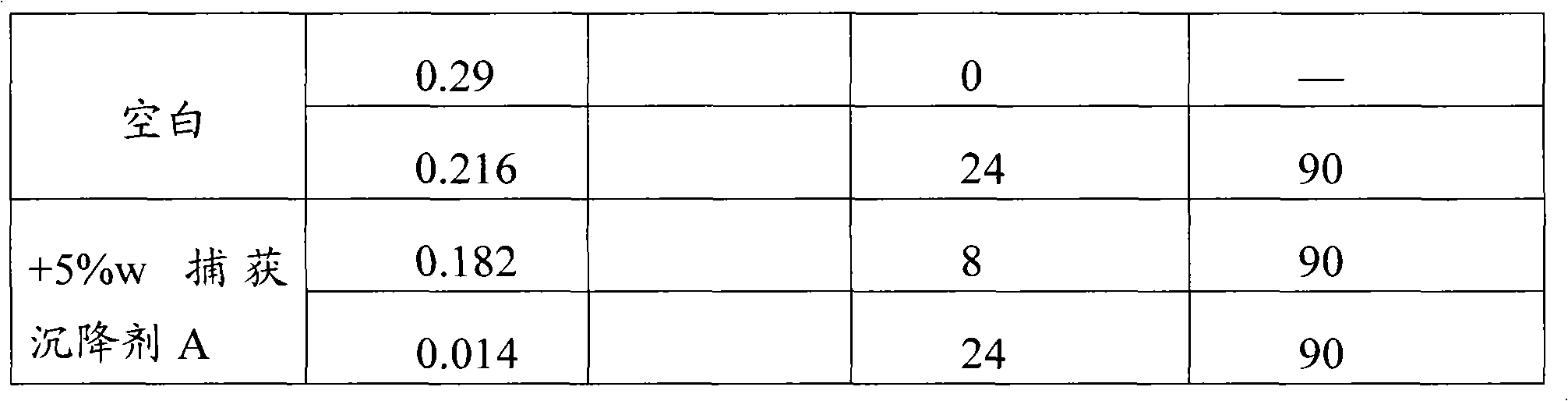

[0056] The embodiment of the present invention also provides a method for removing the catalyst solid powder in the oil slurry. The catalyst solid powder in the catalytic cracking oil slurry is removed by using the trapping and settling agent described in the above embodiment, which can speed up the process of removing the catalyst solid powder in the catalytic cracking oil slurry. The speed of sedimentation and separation from the oil slurry can effectively reduce the ash content or filterable particles of the oil slurry. Such as figure 1 As shown, it includes the steps:

[0057] 1. Take out the captured sedimentation agent from tank B with pump C, and make a homogeneous mixture with the FCC oil slurry sent by pump A with high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com