Patents

Literature

302 results about "Octadecyl trimethyl ammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam washing fluid and preparation method thereof

The invention relates to foam washing fluid, which is applied to an oilfield development and washing work process. The foam washing fluid is characterized by comprising the following components by weight: 3.5 to 6 percent of hexadecyl-octadecyl trimethyl ammonium chloride, 18 to 30 percent of thioalcohol polyoxyethylene ether SSA-80, 8 to 12 percent of polyoxyethylene (10) octyl phenol ether, 1 to 2 percent of potassium chloride, 0.05 to 0.1 percent of fluorocarbon surfactant FC-3B, 0.5 to 1 percent of vitamin A, 0.05 to 0.1 percent of fluorocarbon surfactant FN-3, and the balance of water. The foam washing fluid has the effects that: when an oil well is thermally washed, the foam washing fluid is added into well washing fluid, and the oil well does not generate well killing phenomenon; and when a water injection well is washed, the foam washing fluid is evenly added into injection fluid, then dead oil in a shaft can be thoroughly washed out, and simultaneously, the aim of eliminating the pollution of a near wellbore zone is achieved.

Owner:PETROCHINA CO LTD

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

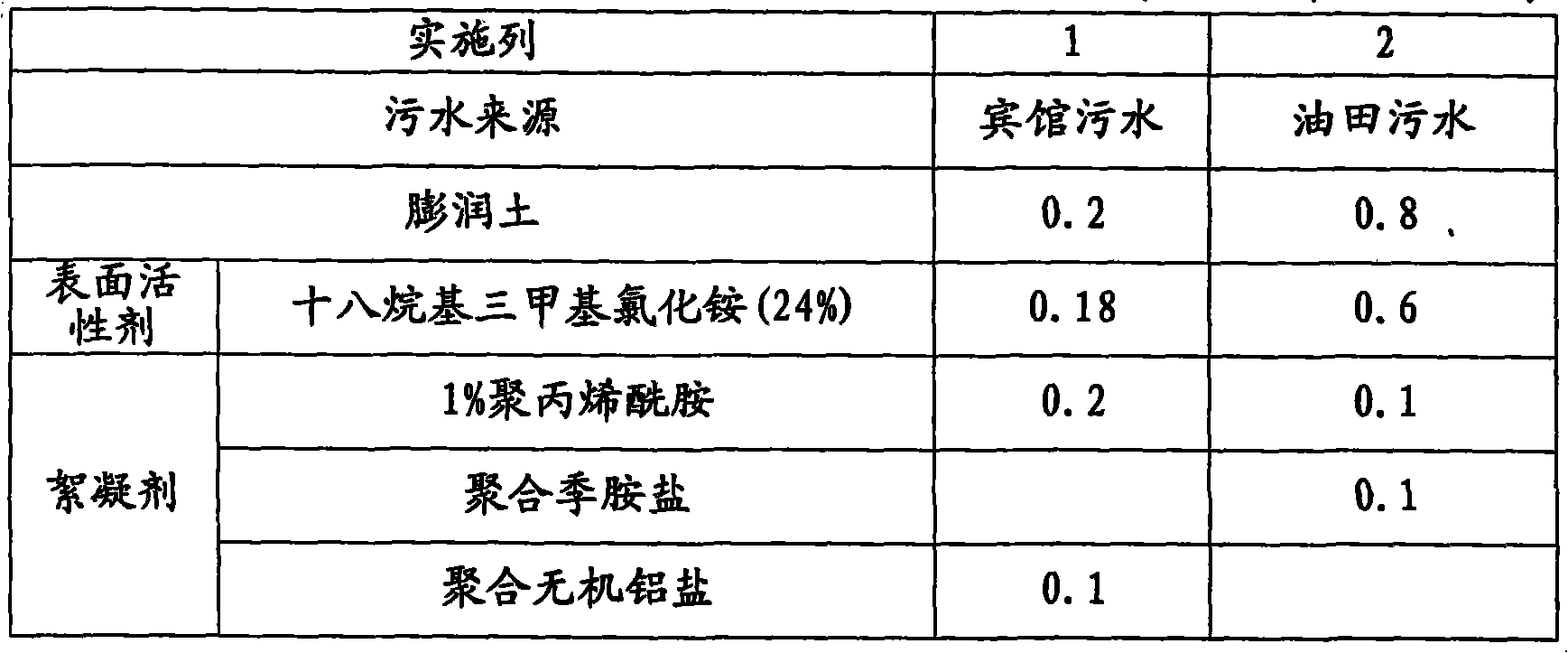

Bentonite sewage water treating method

ActiveCN101254959ALow costImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSodium BentoniteSludge

A bentonite sewage handling method is to grind the calcium base or the sodium base or the acid bentonite into 101 to 600 meshes and then pour the calcium base or the sodium base or the acid bentonite into the awaiting sewage to stir. Then, 24 percent of octadecyl trimethyl ammonium chloride is poured into the sewage and stirred; then a flocculent is poured into the sewage and stirred and settled, and the water-soil separation, microorganism treatment and standard discharge are carried out. The weight ratio of the sewage and any kind of bentonite is 1000:0.1 to 1000:1.0; the dosage ratio of the bentonite and the octadecyl trimethyl ammonium chloride is 1:1 to 1.5:1; the dosage ratio of the bentonite and the flocculent is 1:1.5 to 4:1. The method can be used for treating hotel sewage and oilfield sewage and has the advantages of low treatment cost, wide application range, and less sludge deposit. Furthermore, the method does not affect the successive microorganism treatment.

Owner:浙江华特新材料有限公司

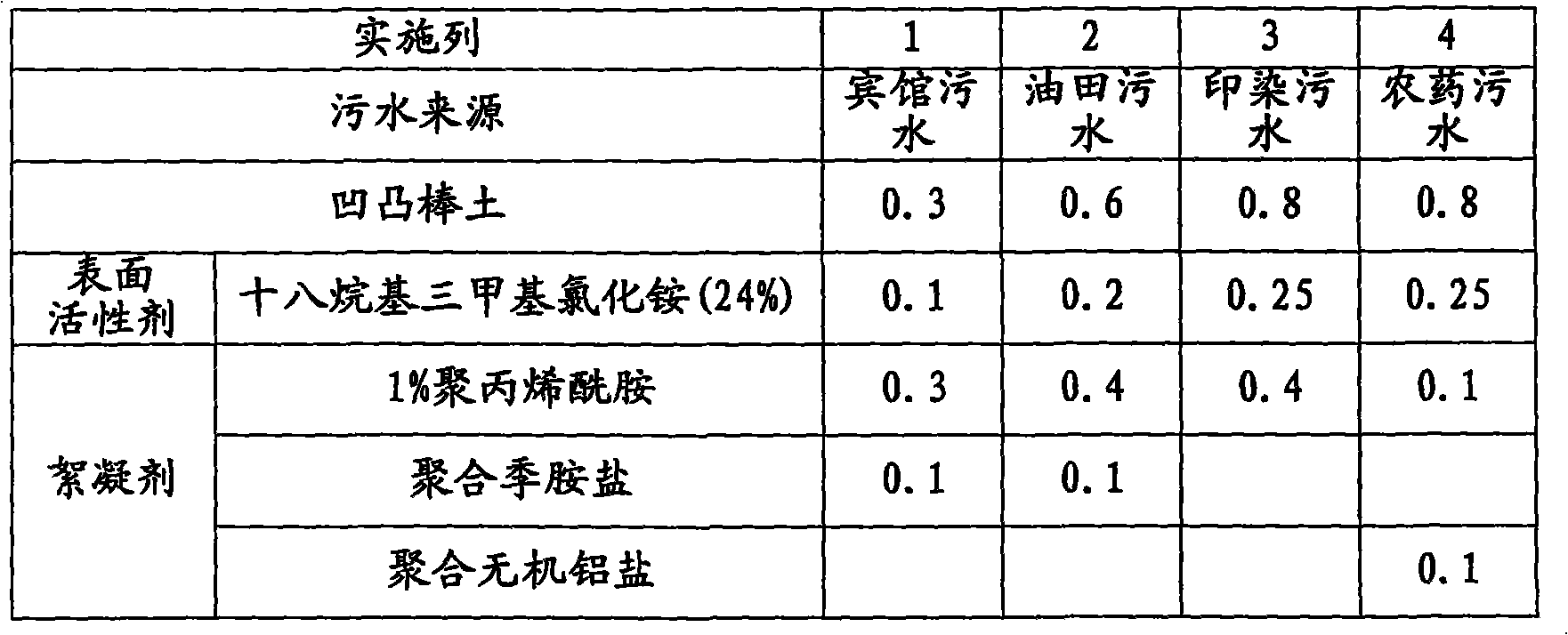

Attapulgite sewage water treating method

InactiveCN101254958AReduce typesEasy to purchaseWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFlocculationSewage

An attapulgite sewage handling method is to grind the attapulgite powder into attapulgite of 101 to 600 meshes and then pour the attapulgite into the awaiting sewage to stir. Then, 24 percent of octadecyl trimethyl ammonium chloride is poured into the sewage and stirred; then a flocculent is poured into the sewage and stirred and settled, and the water-soil separation, microorganism treatment and standard discharge are carried out. The weight ratio of the sewage and the attapulgite is 1000:0.1 to 1000:1.5; the dosage ratio of the attapulgite and the octadecyl trimethyl ammonium chloride is 4:1 to 4:3; the dosage ratio of the attapulgite and the flocculent is 1:1 to 4:1. The method can be used for treating hotel sewage, dyeing sewage, pesticide sewage and oilfield sewage and has the advantages of low treatment cost, saved time and labor, strong flocculation and easy raw material attainment.

Owner:浙江华特新材料有限公司

Micro-suspension self-selection water shutoff and profile control agent and application method thereof

ActiveCN102516960AEliminate cloggingThe space occupied by the blockage is formed to eliminate the mechanical blockage of the water flowDrilling compositionSealing/packingHigh water contentSodium hydroxide

A micro-suspension self-selection water shutoff and profile control agent. A layer self-selection water shutoff and profile control agent applied to oil deposit with middle and high water content can carry out self-selection water shutoff and profile control in a layer of complex oil deposit with middle and high water content, a lateral well and a secondary big pore channel. The water shutoff and profile control agent comprises 5-50% of asphalt, 1-5% of olefin, 0.5-1.0% of octadearyl dimethyl ammonium chloride, 0.1-0.15% of carboxymethyl cellulose sodium, 5-15% of stable control agent sodium hydroxide aqueous solution and the balance of water. The preparation method comprises step of processing the raw materials into stable micro fluid suspension with a particle size of 1 mum-1mm through machinery crushing and grinding by a colloid mill. The invention has the following beneficial effects: the water shutoff and profile control agent can be applied to layer self-selection water shutoff and profile control of oil deposit with high water content; a main agent asphalt can be dissolved in light oil completely but not in water; plastic colloid can be precipitated; and blocking of different strength can be realized through reasonable selection and assembly of softening points of the main agent.

Owner:PETROCHINA CO LTD

High-wear-resistant antibacterial acrylate paint

InactiveCN106366899AImprove wear resistanceGood solvent resistanceFireproof paintsAntifouling/underwater paintsWear resistantUnsaturated polyester

The invention discloses high-wear-resistant antibacterial acrylate paint. The high-wear-resistant antibacterial acrylate paint is prepared from the raw materials: an aqueous acrylate emulsion, alkyd resin, organosilicon modified unsaturated polyester resin, silica sol, cellulose acetate butyrate, polyvinyl pyrrolidone, modified nano-titania, calcium carbonate whiskers, octadecyl trimethyl ammonium chloride modified montmorillonite, hollow glass beads, zinc oxide, ethylene glycol mono-n-propyl ether, di-propanediol butyl ether, triethylene glycol monoethyl ether, an anti-settling agent, a humectant, an antifoamer, per-methoxylation melamine resin, 3,5-dimethyl-2-aminobenzoic acid, trimethylaniline, a leveling agent, vinyl triethoxysilane and deionized water. The high-wear-resistant antibacterial acrylate paint provided by the invention is high in hardness, good in wear resistance, excellent in antibacterial performance and long in service life.

Owner:ANHUI JINDUN PAINT

Binding waterproofing material of high-performance chemical structural netting modified and emulsified asphalt bridging

InactiveCN1854238AImprove adhesionMeet special requirementsOther chemical processesWorking-up pitch/asphalt/bitumenChemical structureEpoxy

A high-performance chemical-structured modified emulsified binding water-proofing material for bituminized bridging floor takes AH-90# petroleum asphalt and water as main raw material in proportion of 1.2-1.8, and it takes cation surface activator 1631 and 1831 and cocoanut oil propylene bisamine and OPin proportion of 4:5:4:3, it selects SBS and SBR latex in proportion of 3.5:1.5 as chemical modified mother, and it uses epoxy-resin emulsion as additive. It has better binding ability, excellent low and high-temperature resistances and no environmental pollution.

Owner:栗培龙

Intumescent flame retardant for mine

The invention provides an intumescent flame retardant for a mine. The intumescent flame retardant is characterized in that the intumescent flame retardant comprises following components by weight part: 100 parts of polyvinyl chloride, 50 parts of nickel hypophosphite Ni(H2PO4)2.6H2O, 20 parts of aluminum phosphate, 20 parts of organic montmorillonite processed by using dodecyl-to-octadecyl trimethyl ammonium chloride or ammonium bromide, 30 parts of zinc borate, 10 parts of heat stabilizers, 10 parts of one of or a mixture of melamine, melamine polyphosphate, ammonium polyphosphate (APP), phosphinate, melamine pyrophosphate (MPP) and melamine cyanurate (MCA), 5 parts of modifiers, 3 parts of processing additives, 3 parts of wear resisting agents and 5 parts of oxidants.

Owner:SHANDONG HEXING SCI & TECH DEV

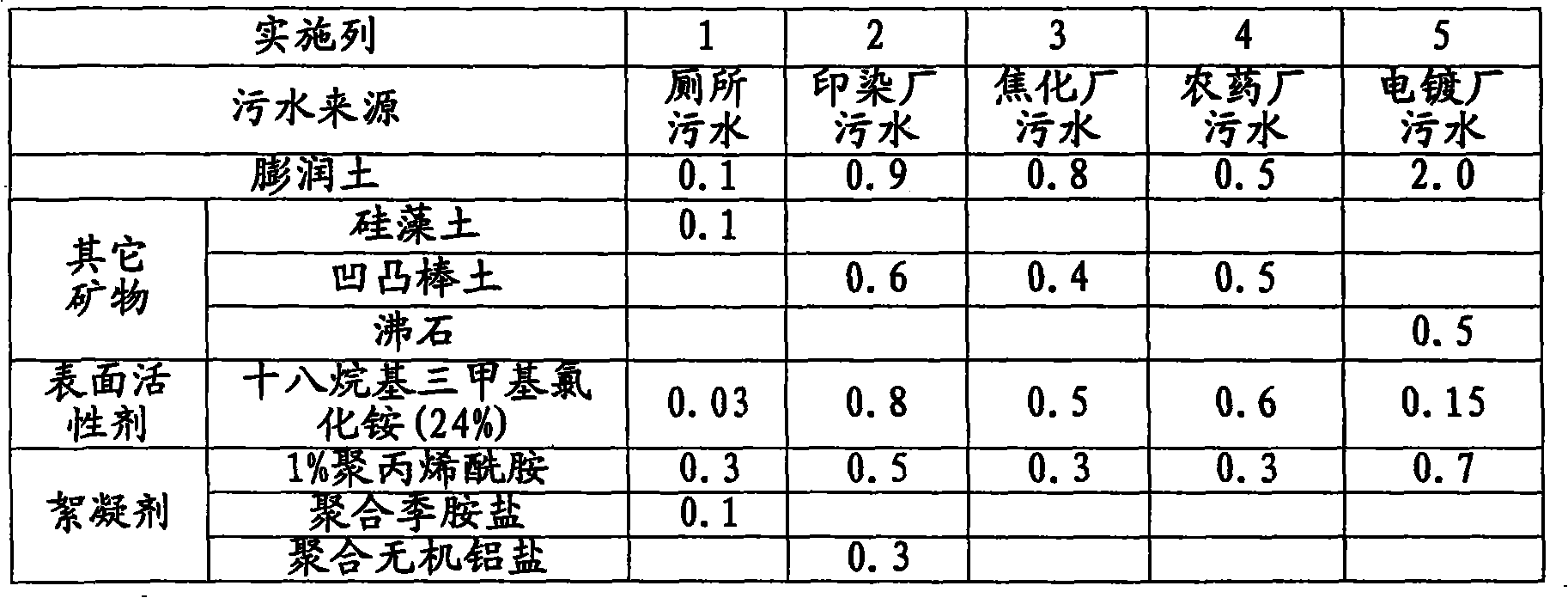

Mineral complex sewage treating method

ActiveCN101254994ALow costImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSodium BentoniteSludge

The invention relates to a mineral composite sewage treatment method. calcium based, sodium based or acidic bentonite is crushed into 101 to 600 mesh, other minerals are crushed into 60 to 600 mesh, the bentonite and other kinds of minerals form a mineral composite, the mineral composite is poured into sewage to be treated, and is blended, then 24% octadecyl trimethyl ammonium chloride is poured into the sewage and stirred, then a flocculating agent is poured into the sewage and stirred for subsiding, and then soil and water separation and micro-organism treatment are performed , and satisfying drainage standard can be reached; the weight ratio of the sewage and the added mineral composite is (1000:0.2)-(1000:2.5), the ratio of the dosage of the bentonite and the dosage of any another mineral is (1:1)-( 4:1), the dosage ratio of the mineral composite and the octadecyl trimethyl ammonium chloride is (2:1)-(17:1), and the dosage ratio of the mineral composite and the flocculating agent is (0.5:1)-(4:1). The method can be used for the treatment of toilets, printing and dyeing, coking, agricultural chemicals and galvanization sewage, and has the advantages of low treatment cost, wide application range and smaller sludge deposit, and has no influence on the subsequent microorganism treatment.

Owner:浙江华特新材料有限公司

Soluble chemical paraffin removal ball and preparation method and use method of soluble chemical paraffin removal ball

ActiveCN108559675APrevent redepositionPlay the role of physical wax removalCationic surface-active compoundsDetergent mixture composition preparationSodium stearateOctadecyltrimethylammonium bromide

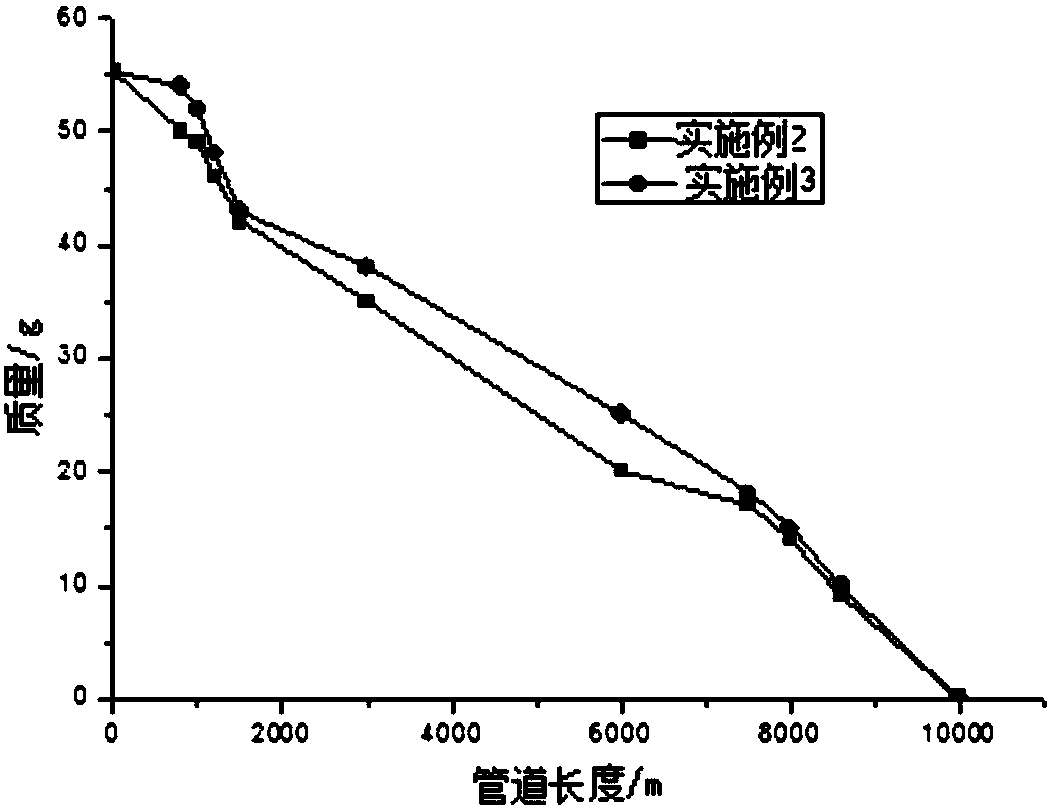

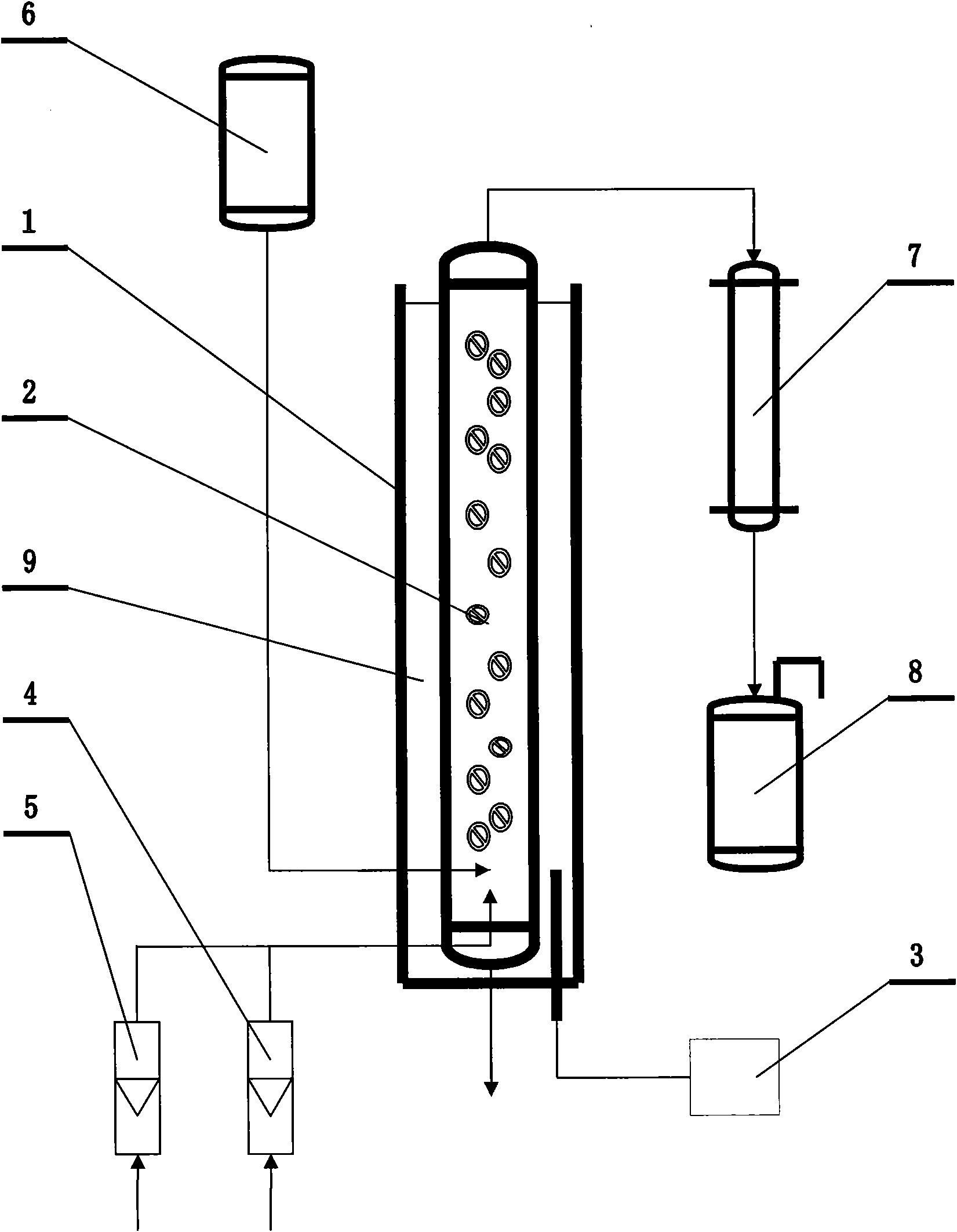

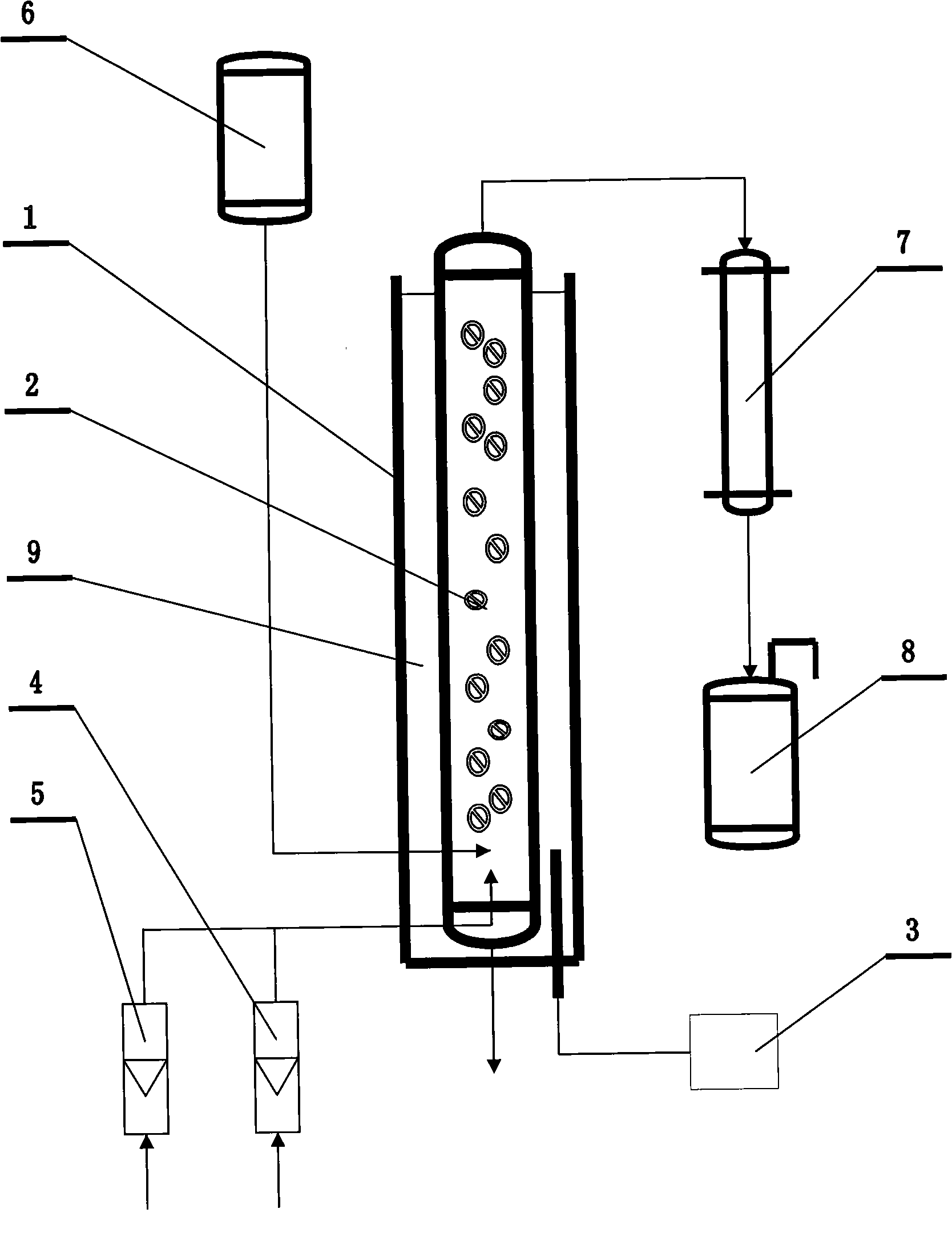

The invention provides a soluble chemical paraffin removal ball and a preparation method and a use method of the soluble chemical paraffin removal ball. The soluble chemical paraffin removal ball comprises the following raw materials: 60-104 parts of a surfactant and 7-27 parts of a thickener; the surfactant is one or more of sodium stearate, hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, sodium laurate, octadecyl trimethyl ammonium chloride, and octadecy trimethyl ammonium bromide; the thickener comprises 2-10 parts of sodium carboxymethylcellulose, 2-10 parts ofpolyacrylamide and 2-7 parts of sodium polyphosphate. The raw materials are proportionally added into absolute ethyl alcohol, stirred evenly, formed through a mould, and dried to obtain the soluble chemical paraffin removal ball. The paraffin removal ball is added according to the conditions of the pipeline length and the paraffin precipitation. The chemical paraffin removal ball has double effects of physically removing paraffin and chemically preventing paraffin, and the problem of paraffin precipitation in a transportation pipeline of the crude oil is solved.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for preparing compound 4-hydroxy butyl vinyl ether

InactiveCN101898939AHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionSurface-active agentsButanediol

The invention belongs to a method for preparing a vinyl ether compound, in particular to the method for preparing 4-hydroxy butyl vinyl ether. In the reaction of 1,4-butanediol and acetylene, dimethyl sulfoxide is added so that beneficial effects are achieved for the reaction, wherein the content of a 4-hydroxy butyl vinyl ether crude product is improved to 81 percent from 72 percent before adding; and a cyclic acetal byproduct is reduced to about 4 percent from 6 percent before adding. The content of the crude product can be further improved by 1 to 2 percent by adding a cationic surface active agent, namely octadecyl trimethyl ammonium chloride.

Owner:焦作新景科技有限公司

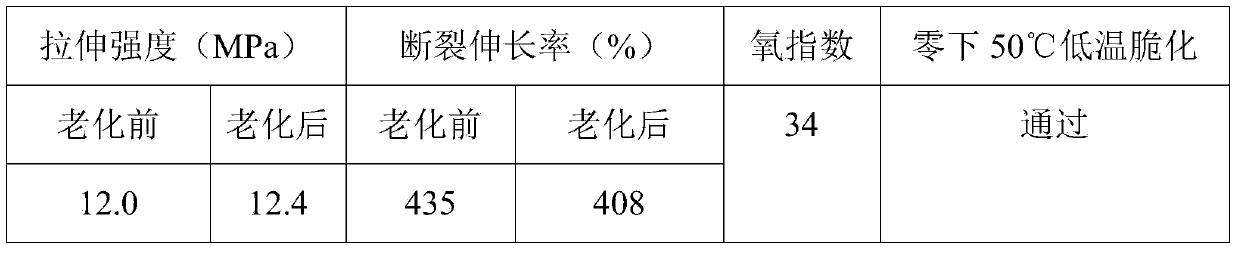

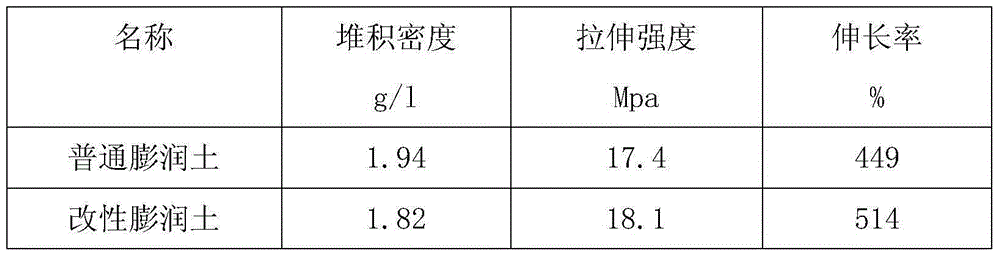

Method for preparing nano montmorillonite modified natural emulsion medical product

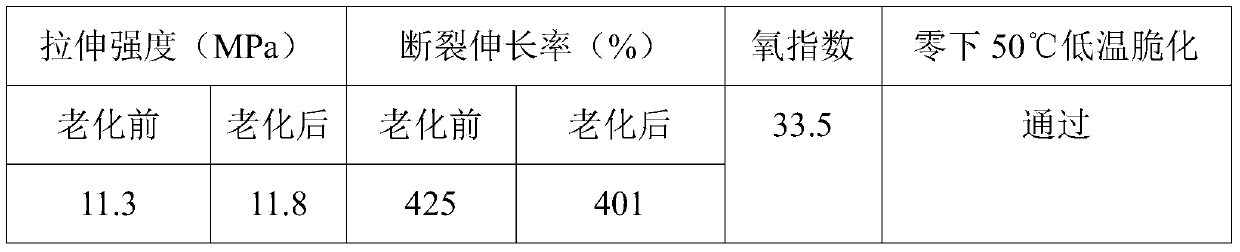

InactiveCN1821289AImprove aging resistanceImprove tensile propertiesMale contraceptivesDiagnosticsPolymer scienceMedical product

The present invention discloses the preparation process of nanometer montmorillonite modified natural latex for medical product. Montmorillonite, which may be natural montmorillonite mineral, nanometer montmorillonite, organic montmorillonite treated with C12-C18 alkyl trimethyl ammonium chloride or ammonium bromide or nanometer montmorillonite through mechanical and chemical grinding, is added into natural rubber latex in the sulfurizing or cooperating stage, and through the subsequent dispersion, pressurizing or dipping, washing, filtering and sulfurizing drying, the modified product is obtained. The present invention has simple technological process, and the prepared medical product has excellent ageing resistance, high tensile and breaking strength, and good microbe permeation resistance.

Owner:JINAN UNIVERSITY

Rubber material for wind power generation cable sheath

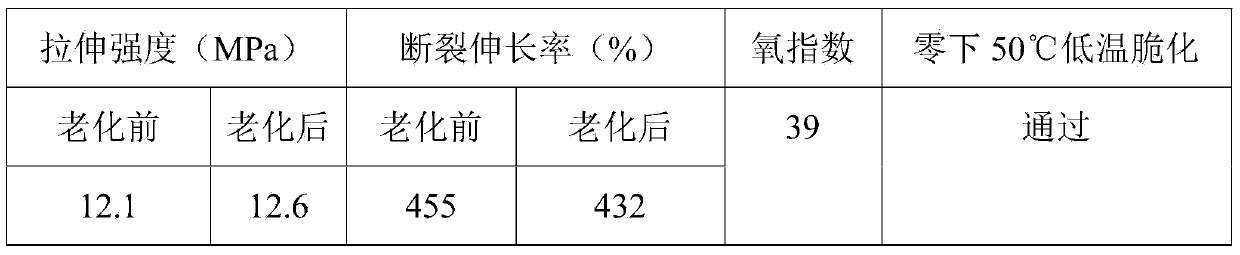

InactiveCN104194106AIncrease the degree of cross-linkingImprove mechanical propertiesRubber insulatorsInsulated cablesRubber materialPolyisocyanurate

The invention discloses a rubber material for a wind power generation cable sheath. The rubber material is prepared from the following raw materials in parts by weight: 50-70 parts of chloroprene rubber, 10-18 parts of butadiene rubber, 20-32 parts of natural rubber, 15-20 parts of organic modified montmorillonite, 1-1.5 parts of magnesium oxide, 0.8-1.3 parts of zinc oxide, 1.5-2.8 parts of dicumyl peroxide, 0.3-0.8 part of triallyl polyisocyanurate, 1-3 parts of diisobutyl adipate, 0.8-2.2 parts of ethyl oleate, 5-8 parts of hazelnut oil, 1.2-1.6 parts of stearic acid, 20-35 parts of carbon black, 10-15 parts of carbon black purple, 1.0-1.5 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 0.5-1.6 parts of tetramethyl thiuram disulfide, 1.8-2.2 parts of N-isopropyl-N'-phenyl p-phenylenediamine and 0.4-0.8 part of N-phenyl-2-naphthylamine. The organic modified montmorillonite is prepared by the following steps: adding sodium-based montmorillonite into water, stirring and standing and taking supernate; and after heating the supernate, adding octadecyl trimethyl ammonium chloride, carrying out ultrasonic treatment for 60-80 minutes, and after stirring, filtering and washing. The rubber material for the wind power generation cable sheath, which is disclosed by the invention, has low-temperature resistance and high elasticity and the flame retardance is further improved.

Owner:ANHUI LAND GRP

Preparation method of acrylic resin / nano SIQ2 composite paint

InactiveCN1657581AGood physical and mechanical propertiesImprove water resistanceCoatingsWater bathsAcrylic resin

A decorative composite acrylic resin / nano-SiO2 paint for leather is prepared from ethyl silicate and the mixture of absolute alcohol and ammonium octadecyltrimethyl chloride through mixing, stirring, heating to 35-45 deg.C, dropping the mixture of secondary distilled water and absolute alcohol, regulating pH=8-9, stirring to obtain nano-SiO2 sol, mixing with acrylic acid under water bath and ultrasonic treating.

Owner:SHAANXI UNIV OF SCI & TECH

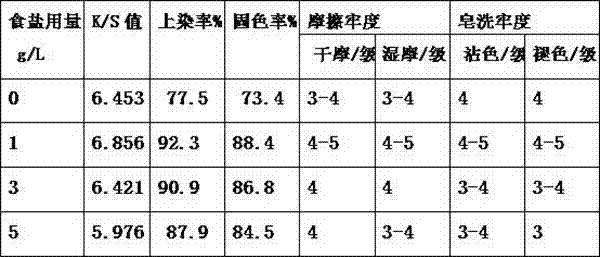

Tussah silk fiber or fabric cation modified finishing agent thereof and modified technique thereof

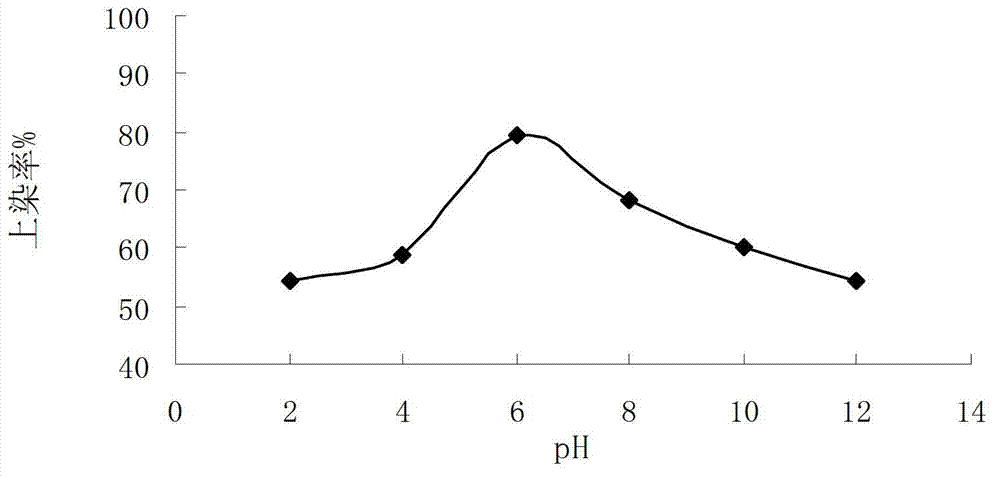

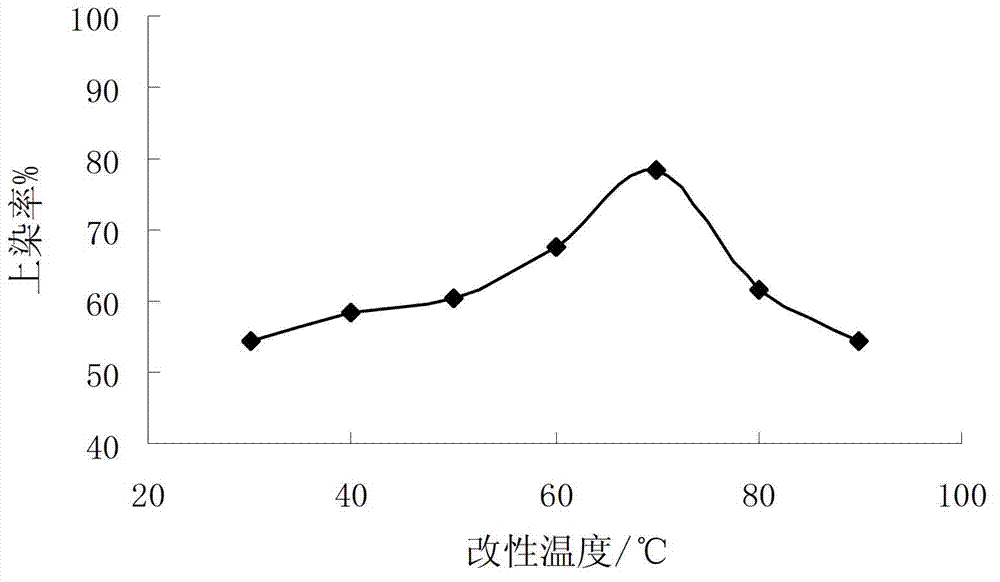

ActiveCN102965927AImprove adsorption capacityImprove dye uptakeAnimal fibresCooking & bakingFatty alcohol

The invention provides tussah silk fiber or a fabric cation modified finishing agent thereof and a modified technique thereof, wherein tussah silk fiber or the fabric cation modified finishing agent thereof is formed by mixing quaternary ammonium salt and a penetrant; the quaternary ammonium salt is at least one of solutions of dodecyl trimethyl ammonium chloride, myristyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride or octadearyl dimethyl ammonium chloride; the penetrant is a fatty alcohol-polyoxyethylene ether solution JFC in a nonionic surfactant; and the modified technique comprises the steps of: steeping degummed tussah silk or a fabric of the degummed tussah silk in the modified finishing agent for 20-30 minutes at the modified temperature of 65-75 DEG C, and then carrying out pre-drying and baking for 3 minutes, so as to obtain the modified tussah silk fiber or the fabric of the degummed tussah silk. The technical scheme provides an effective implementation scheme for high-performance and pollution-free dyeing of reactive dyes of the tussah silk fiber or the fabric of the degummed tussah silk.

Owner:EASTERN LIAONING UNIV

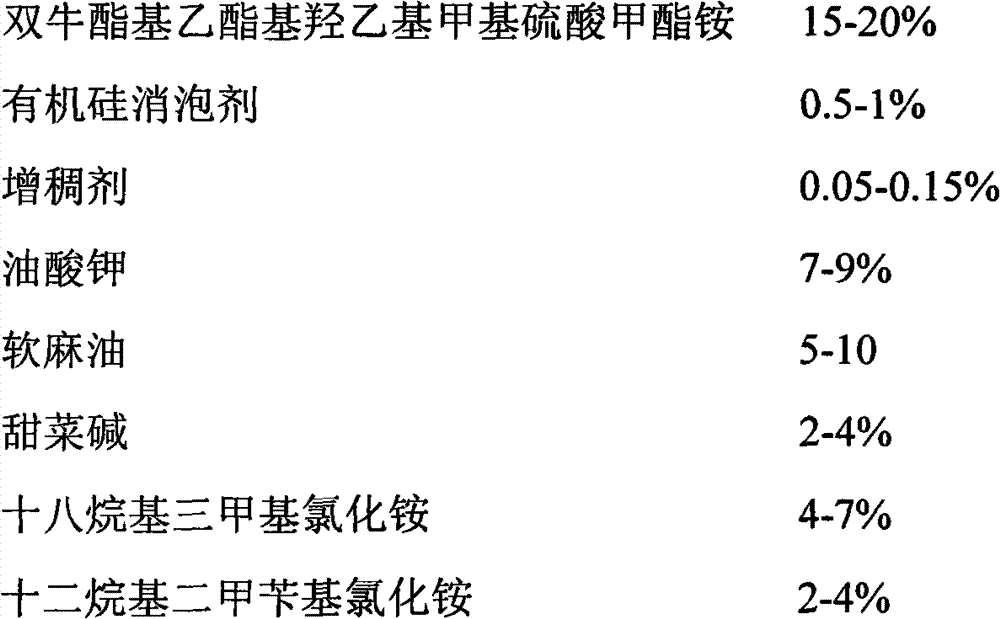

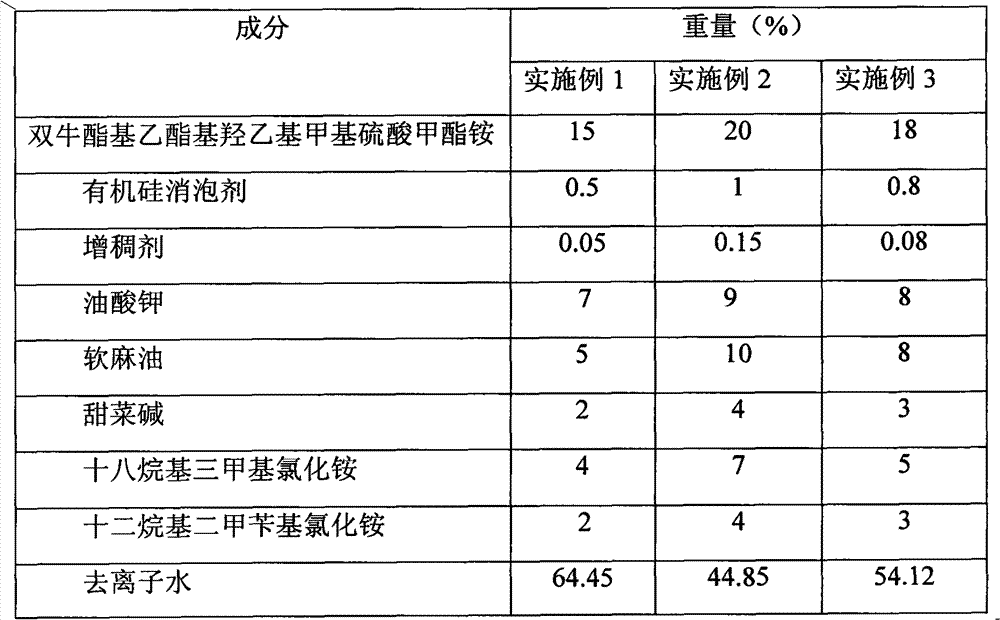

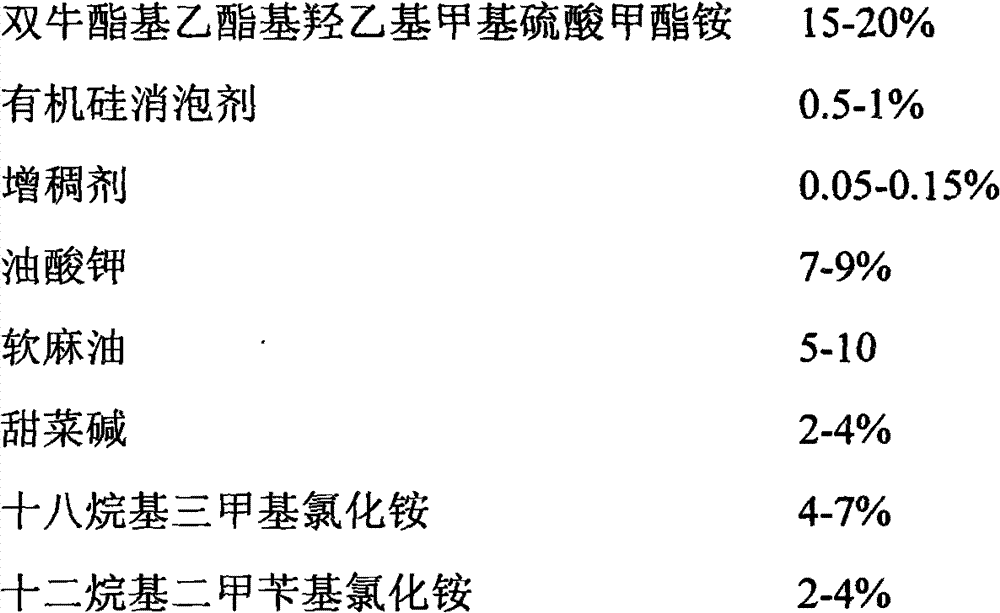

Bacteriostatic linen fiber softener

InactiveCN102877294APromote degradationBiodegradability is superior to dialkyl quaternary ammonium saltsBiochemical fibre treatmentVegetal fibresFiberAlkalinity

The invention relates to a bacteriostatic linen fiber softener, which comprises the following ingredients in percentage by weight: 15 to 20 percent of bitallow ethoxycarbonyl ethoxyl methyl sulfate, 0.5 to 1 percent of organosilicone defoamer, 0.05 to 0.15 percent of thickening agent, 7 to 9 percent of potassium oleate, 5 to 10 percent of linen softening oil, 2 to 4 percent of glycine betaine, 4 to 7 percent of octadecyl trimethyl ammonium chloride, 2 to 4 percent of dodecyl dimethyl benzyl ammonium chloride and the balance of deionized water, wherein 1 to 2 weight percent of marine biological rhzomorph and 0.3 to 0.5 weight percent of bacitracin can also be added into the softener. The clothes softener has high softness and antistatic property. By the clothes softener, clothes are soft and comfortable; and the clothes softener is faintly acidic, so that alkalinity in a detergent can be neutralized, and the clothes are close to the PH values of human bodies. The bacteriostatic linen fiber softener has high killing effect on common microbes and particularly pathogenic bacteria.

Owner:QINGDAO SANDING SANITARY PROD

Filtrate reducer for oil-based drilling fluids and production method thereof

InactiveCN105586017AImprove lipophilicityDoes not affect high temperature resistanceDrilling compositionFiltrationCarbon chain

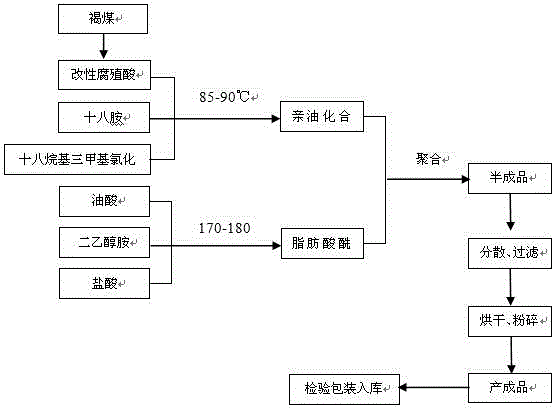

The invention provides a filtrate reducer for oil-based drilling fluids and a production method thereof. The production method is characterized in that humic acid undergoes surface modification and the humic acid is grafted with an alkyl group of long carbon chain, and a product which has oleophylic emulsifying property and ammonium salt undergo polymerization so as to obtain the required product. The production method comprises the following concrete operations: stirring a certain amount of brown coal, caustic soda and water and reacting for a period of time, and extracting a humic acid solution; preparing grafted humic acid from the obtained humic acid solution and octadecylamine and octadecyl trimethyl ammonium chloride; preparing fatty acid amide from oleic acid, diethanolamine and concentrated hydrochloric acid; and preparing humic acid acetamide, dispersing, filtering and drying to obtain a finished product. According to the method, humic acid is modified to be grafted with the alkyl group of long carbon chain, and then the humic acid filtrate reducer has remarkable lipophilicity, can be dissolved or dispersed in oil and can be directly used in water-in-oil drilling fluids. Humic acid and amine are combined firmly, and high temperature resistance is strong. The product has a certain emulsification capability and good filtration reduction effects. The production method is simple, and the environment is not polluted.

Owner:TIANJIN TIANCHENG TUOYUAN TECH DEV

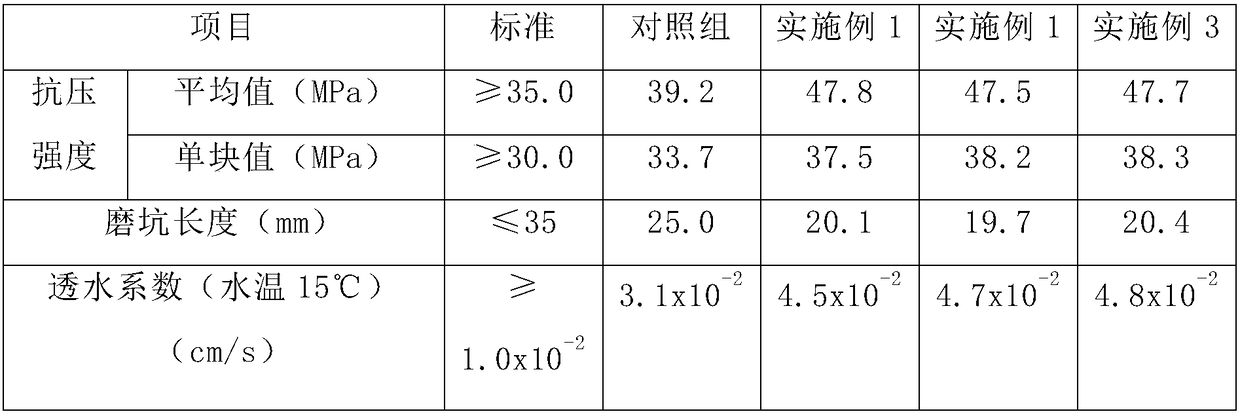

Novel pressure-resistant anti-cracking water permeable brick

The invention relates to the technical field of building materials and in particular relates to a novel pressure-resistant anti-cracking water permeable brick which comprises the following raw materials: basalt aggregate, quartz sand, cement, coal ash, an inorganic pigment, octadecyl trimethyl ammonium chloride, a foaming agent, a hydrophobic modification ore fiber, a water reduction agent and water, wherein the hydrophobic modification ore fiber is an inorganic fiber with surface hydrophobic modification treatment; the inorganic fiber is a mixture of a brucite fiber and a wollastonite fiber;the basalt aggregate is crude aggregate which is crushed by using a jaw crusher and has a particle size of 1.5-3mm after screening; the foaming agent is hydrogen peroxide. The novel pressure-resistantanti-cracking water permeable brick has good water permeability and wearing resistance, and in addition, the brick is high in strength, very excellent in pressure resistance and not liable to crack when being used.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Preparation method of high-dispersion organic bentonite

InactiveCN106179232AGood dispersionImprove surface activityOther chemical processesWater/sewage treatment by sorptionSodium BentoniteBentonite suspension

The invention relates to a preparation method of high-dispersion organic bentonite, and belongs to the field of chemical industry. The method comprises the steps that octadecyl trimethyl ammonium chloride and tetramethyl ammonium bromide serve as organic modifiers to conduct organic modification on sodium-based bentonite powder, treatment is conducted, and organic bentonite suspension is obtained; tea seed cake is subjected to fermentation, by means of tea saponin, inoculation of bacillus subtilis and inoculation of pseudomonas aeruginosa are conducted, culture is conducted, and biosurfactant is obtained; the biosurfactant and the organic bentonite suspension are mixed, and the dispersing performance of sodium-based bentonite is improved. According to the preparation method of the high-dispersion organic bentonite, the biosurfactant and the organic bentonite suspension are mixed, the surface activity of organic bentonite particles is improved, the dispersing performance of the organic bentonite can be improved, the specific surface area can reach 50 m<2> / g to 100 m<2> / g, the preparation steps are simple, and the required cost is low.

Owner:仇颖莹

Antibacterial softener

Owner:QINGDAO SANDING SANITARY PROD

Natural vegetable hair-dyeing agent and preparation method thereof

InactiveCN108158940ASafe hair coloringLong-lasting safe dyeingCosmetic preparationsHair cosmeticsSide effectMonoglyceride

The invention discloses a natural vegetable hair-dyeing agent and a preparation method thereof. The natural vegetable hair-dyeing agent is prepared from a hair-dyeing cream agent I and a hair-dyeing cream agent II, wherein the hair-dyeing cream agent I is prepared from the following components in parts by weight: 65-75 parts of deionized water, 7-10 parts of cetyl alcohol, 5-8 parts of cysteine hydrochloride, 3-5 parts of octadecyl trimethyl ammonium chloride, 3-5 parts of propylene glycol, 3-5 parts of natural vegetable melanin, 3-5 parts of isopropyl palmitate, 2-3 parts of jojoba oil, 2-3 parts of monoglyceride stearate, 1-2 parts of lanolin and 0.5-1 part of essence. The natural vegetable hair-dyeing agent does not relate to oxidizing agents and reducing agents, does not stimulate thescalp and is not allergic, and the safety is superior to that of a permanent hair-dyeing agent. The hair-dyeing effect can be kept for one month or more in a lasting manner, and the washing-resistantdegree is superior that of a semipermanent hair-dyeing agent. The natural vegetable hair-dyeing agent is safe and healthy, has no side effect and does not stimulate the scalp.

Owner:广州市骄子日化有限公司

Composite surfactant with excellent surface activity and spumescence

InactiveCN106669538AImprove surface activityGood foaming performanceTransportation and packagingMixingBetainePhenyl Ethers

The invention discloses a composite surfactant with excellent surface activity and spumescence, and the composite surfactant is prepared from the following materials of modified polymer surfactant, modified fluorosilicone surfactant, triethanolamine, EDTA (ethylene diamine tetraacetic acid) disodium, polyethyleneglycol monooleate, sodium alkyl phenyl ether disulfonate, sodium oxalate, lauryl sodium sulfate, sodium alpha-olefin sulfonate, CTAB (cetyl trimethyl ammonium bromide), lauramidopropylamine oxide, octadecyl trimethyl ammonium chloride, sodium di(2-ethyl-hexyl)sulfosuccinate, Tween 40, polysorbate 40, sodium alpha-olefin sulfonate, dodecyloxy hydroxypropyl betaine, triethanolamine dodecylbenzenesulfonate, tetralkyl ammonium chloride and ethyl alcohol. The composite surfactant disclosed by the invention has excellent surface activity and spumescence.

Owner:安徽艾蒂贝生物股份有限公司

Latex and plush combined toy and production process thereof

InactiveCN103059356AImprove tear resistanceAccelerated corrosionDollsSilanesDiethyldithiocarbamic Acid

The invention discloses a latex and plush combined toy. Latex comprises the following components in parts by weight: 90-100 parts of natural latex, 30-40 parts of modified calcium carbonate, 1-2 parts of octadecyl trimethyl ammonium chloride, 1-2 parts of ethidene diamine tetramethylene phosphonic acid sodium, 1-2 parts of zinc oxide, 1-2 parts of sulfur, 1-1.5 parts of sodium carboxymethylcellulose, 1-1.6 parts of tetramethyl thiuram monosulfide, 0.8-1 part of 3-(isobutene acyloxy) propyl trimethoxy silane, 0.8-1 part of antioxidant DM, 0.8-1 part of sodium tripolyphosphate, 0.6-0.8 part of 2,2,4-trimethyl-1,3-pentanediol isobutyrate and 0.3-0.5 part of zinc diethyl dithiocarbamate. According to the latex and plush combined toy, modified calcium carbonate is added instead of conventional argil, bentonite and the like, so that the filling effect and the very strong reinforcement effect are achieved and the tear resistance of the toy is improved.

Owner:ANHUI JIABAO TOYS

Antibacterial softener

InactiveCN103556460AChange ionicityEasy to dissolve and disperseBiochemical fibre treatmentFoaming agentChemistry

The invention relates to an antibacterial softener which comprises the following components in parts by weight: 3 parts of dihydrogenated tallowoylethyl hydroxyethylmonium methosulfate, 4 parts of an organic silicon de-foaming agent, 1 part of a thickening agent, 4 parts of potassium oleate, 5 parts of linen softening oil, 1 part of glycine betaine, 2 parts of octadecyl trimethyl ammonium chloride, 5 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of de-ionized water, 7 parts of isopropanol, 4 parts of rhzomorph of marine organisms and 1 part of bacitracin. Compared with the prior art, the antibacterial softener has the beneficial effects that after the softener is applied to clothes washing, clothes are relatively soft and comfortable, the iconicity of the surface of the clothes can be changed, the clothes are relatively easy to level, and water is saved by 10% in comparison with that in clothes which are not washed using the softener; the softener is relatively easy to air, biodegradable, relatively easy to dissolve and disperse in water and convenient to use, and is a green raw material.

Owner:QINGDAO SANDING SANITARY PROD

Porous modified bentonite with foaming effect and preparation method thereof

InactiveCN105126779APorousReasonable formulaOther chemical processesAlkali metal oxides/hydroxidesPorositySodium Bentonite

Owner:安徽雪城超细碳酸钙有限公司

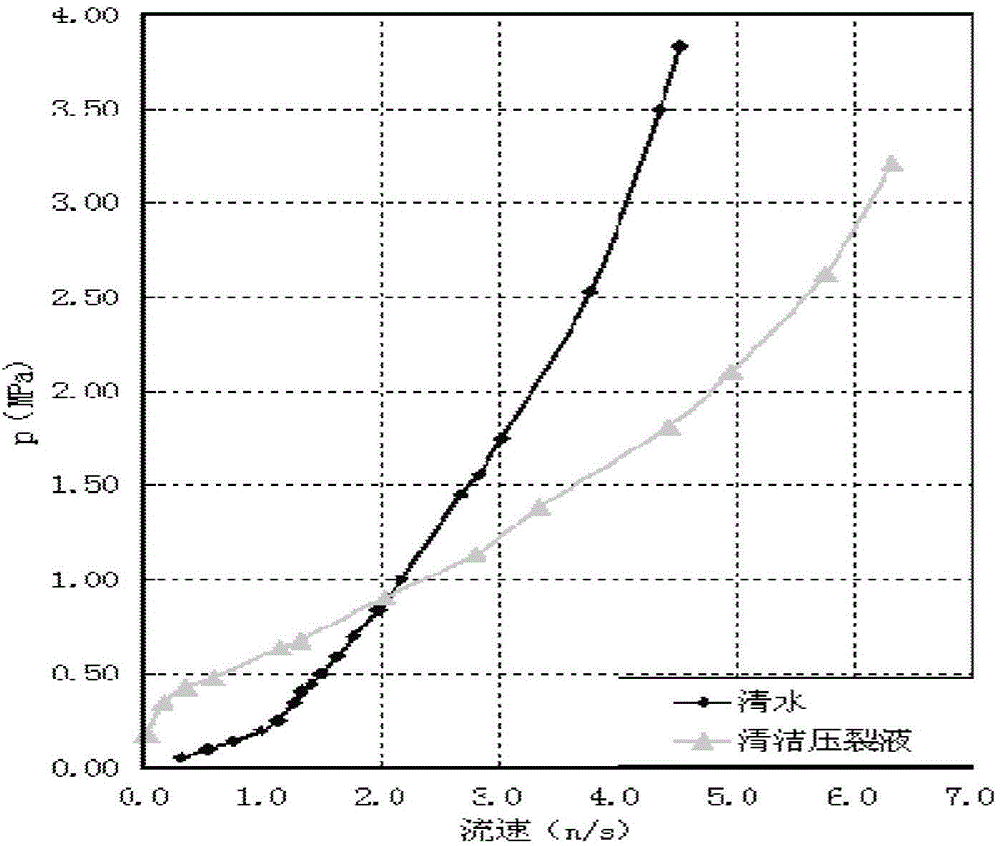

Clean fracturing fluid for low-temperature coal-bed gas reservoirs and application thereof

InactiveCN104629709AEasy to make and useImprove swelling effectFluid removalDrilling compositionFracturing fluidPotassium

The invention relates to a clean fracturing fluid for low-temperature coal-bed gas reservoirs and application thereof. The clean fracturing fluid for low-temperature coal-bed gas reservoirs is composed of 0.2-0.4% of cationic surfactant, 0.10-0.15% of salicylate, 1.0-1.5% of potassium chloride, 0.06% of pH regulator, 0.06-0.08% of residue preventer and the balance of water. The cationic surfactant is selected from cetyl trimethyl ammonium chloride, octadecyl trimethyl ammonium chloride or cetrimide. The preparation method comprises the following steps: adding the water into a large fluid preparation tank, sequentially adding the salicylate, potassium chloride, pH regulator and residue preventer under stirring conditions, adding the cationic surfactant after the previous components are completely dissolved, and stirring until the concentration or viscosity of the fluid in the big tank is uniform, thereby obtaining the clean fracturing fluid, wherein the application temperature for the fractured coal-bed gas reservoir is 15-30 DEG C.

Owner:PETROCHINA CO LTD

Compound organosilicone surfactant

InactiveCN106622018AGood activity and stabilityGood chemical stabilityTransportation and packagingMixingPhosphoric acidFatty alcohol

The invention discloses a compound organosilicone surfactant. The compound organosilicone surfactant is prepared from the following raw materials: a phosphate type organosilicone surfactant, a carboxyl polyether organosilicone surfactant, a polyether modified polysiloxane nonionic surfactant, sodium lauryl sulfate, nonylphenol polyoxyethylene ether, octaphenyl polyoxyethyiene ether, isomeric tridecanol fatty alcohol polyoxyethylene ether, octadecyl trimethyl ammonium chloride, cetyl trimethyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride, petroleum sodium sulfonate, sorbitan oleate and nonylphenol polyoxyethylene ether. The compound organosilicone surfactant disclosed by the invention has excellent surface activity and chemical stability, good emulsifying property and low surface tension.

Owner:定远县新海岸生态农业发展有限公司

High-strength water-proof plaster block containing nonmetal nano material and preparation method thereof

The invention discloses a high-strength waterproof plaster brick with non-metal nanometer material and making method, which comprises the following steps: 1. adding 0.3-0.5% hydrogenous silicon oil into 35-40% water; 2. adding 0.005-0.01% ammonium chloride trimethyl octadecyl; 3. blending 45-50% hemi-hydrate plaster powder, 3-10% sepiolite powder and 3-5% metolline powder into liquid; 4. pouring the liquid into moulding box; stripping; culturing; obtaining the product. The invention makes the water adsorbing rate not more than 5% within 2 h and the conversion factor over 0.75, which improves the strength by 2-8 times and increases the toughness for frame-typed non-bearing wall.

Owner:李雨加 +1

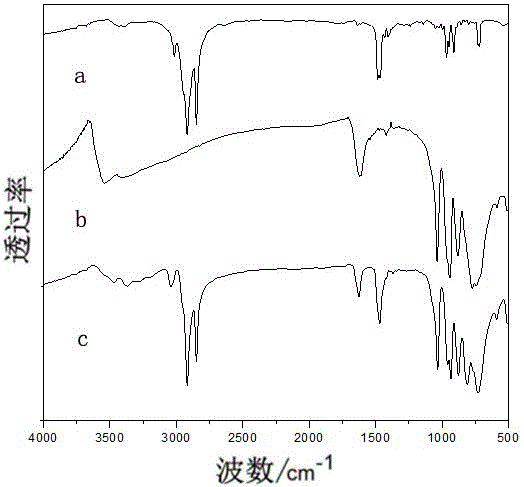

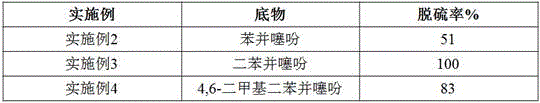

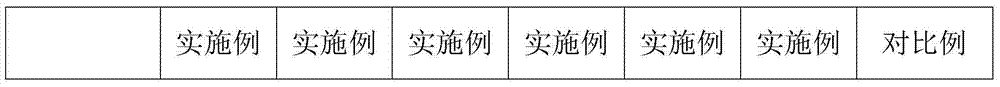

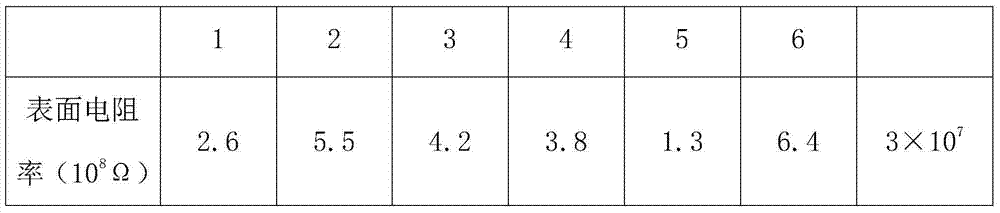

Amphiphilic cobalt-containing sandwich type heteropolyacid and application thereof

ActiveCN105879912AEfficient desulfurizationNo significant reduction in desulfurization efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystActive agent

The invention belongs to the fields of preparation of functional catalytic materials and fuel purification and relates to amphiphilic cobalt-containing sandwich type heteropolyacid and an application of heteropolyacid in catalytic desulfurization. The molecular formula of the catalyst is [C18H37N(CH3)3]10[Co4(H2O)2(PW9O34)2], and amphiphilic cobalt-containing sandwich type heteropolyacid is obtained through self-assembly of cobalt-containing sandwich type heteropolyacid K10[Co4(H2O)2(PW9O34)2] and a cationic surfactant, namely, octadecyl trimethyl ammonium chloride through ion exchange under electrostatic force. The catalyst is mixed with hydrogen peroxide and an ionic liquid [Bmim]PF6 to form an extraction, catalytic oxidation and desulfurizing system, and the purpose of super-deep desulfurization can be achieved at normal temperature. The preparation method of the catalyst is simple, the desulfurization reaction condition is mild, the catalytic system can be at least used 6 times without remarkable reduction of catalytic efficiency, and the preparation method is an efficient, economical and environment-friendly production process.

Owner:NORTHEAST NORMAL UNIVERSITY

Preparation method of novel ABS resin based material

The invention provides a preparation method of a novel ABS resin based material. The preparation method comprises the following steps: (1) adding montmorillonite into deionized water to obtain a suspended montmorillonite aqueous solution, adding a phosphoric acid solution of octadecyl trimethyl ammonium chloride, heating and stirring to obtain organic montmorillonite; (2) magnetically stirring the organic montmorillonite, polyaniline and hydrochloric acid solution together, dropwise adding an ammonium persulfate solution to obtain a green mixed solution, taking out, washing, drying and grinding to obtain a polyaniline-montmorillonite composite material; (3) hydrolyzing a coupling agent into an aqueous solution of acetone, adding tetrapod-like zinc oxide whiskers, ultrasonically stirring to obtain modified zinc oxide whiskers; (4) mixing ABS resin, a compatilizer, the polyaniline-montmorillonite composite material to obtain a premix; and (5) extruding and granulating the premix to obtain a granular material and drying to obtain the ABS resin based material.

Owner:HUZHOU GUOXIN MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com