Soluble chemical paraffin removal ball and preparation method and use method of soluble chemical paraffin removal ball

A wax removal ball and soluble technology, which is applied in the field of soluble chemical wax removal ball and its preparation, can solve the problems of wax deposition and other problems, and achieve the effects of avoiding pollution, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw materials include: 80 parts of sodium stearate, 2 parts of polyacrylamide, 3 parts of sodium polyphosphate, 1 part of ethylenediaminetetraacetic acid, 4 parts of cetyltrimethylammonium chloride, sodium carboxymethylcellulose 2 servings.

[0049] Mix the drug according to the above proportions and add it into absolute ethanol, stir it evenly, mold it, and dry it at 80°C for 48 hours to obtain a soluble chemical wax removal ball.

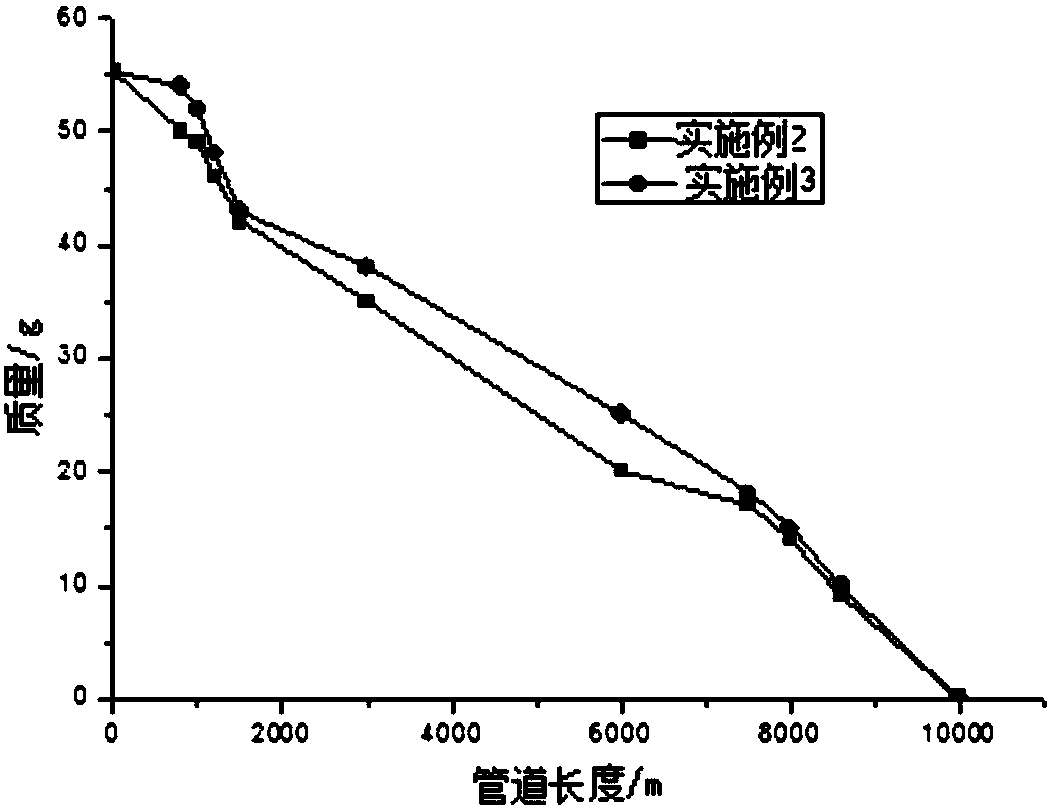

Embodiment 2

[0051]Raw materials include: 45 parts of sodium stearate, 10 parts of polyacrylamide, 7 parts of sodium polyphosphate, 3 parts of ethylenediaminetetraacetic acid, 8 parts of cetyltrimethylammonium chloride, cetyltrimethylammonium 7 parts of ammonium bromide, 10 parts of sodium carboxymethylcellulose, and 10 parts of n-docosane.

[0052] The preparation method is as follows:

[0053] Heat and dissolve n-docosane at 45°C, mix other medicines in proportion and add absolute ethanol, use absolute ethanol as a solvent to dissolve sodium stearate, stir it evenly, and add it to the hot-melt n-docosane Alkanes, fully stirred, molded with a spherical rubber mold with an inner diameter of 45mm, put it into an oven for drying at 80°C for 48 hours, and obtained soluble chemical wax removal balls.

Embodiment 3

[0055] Raw materials include: 60 parts of sodium stearate, 3 parts of polyacrylamide, 2 parts of sodium polyphosphate, 8 parts of ethylenediaminetetraacetic acid, 12 parts of cetyltrimethylammonium chloride, cetyltrimethylammonium 12 parts of ammonium bromide, 2 parts of sodium carboxymethylcellulose, and 1 part of n-docosane.

[0056] The preparation method is as follows:

[0057] Heat and dissolve n-docosane at 70°C, mix other medicines in proportion and add absolute ethanol, use absolute ethanol as a solvent to dissolve sodium stearate, stir it evenly, and add it to the hot-melt n-docosane In alkane, fully stirred, molded with a spherical rubber mold with an inner diameter of 45mm, and put it into an oven for drying at 100°C for 36h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com