Metal cleaning agent and preparation method thereof

A technology of metal cleaning agent and builder, applied in the field of cleaning agents, can solve the problems of affecting production efficiency and long preparation time, and achieve the effects of improving service life, simple preparation method and prolonging rust prevention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

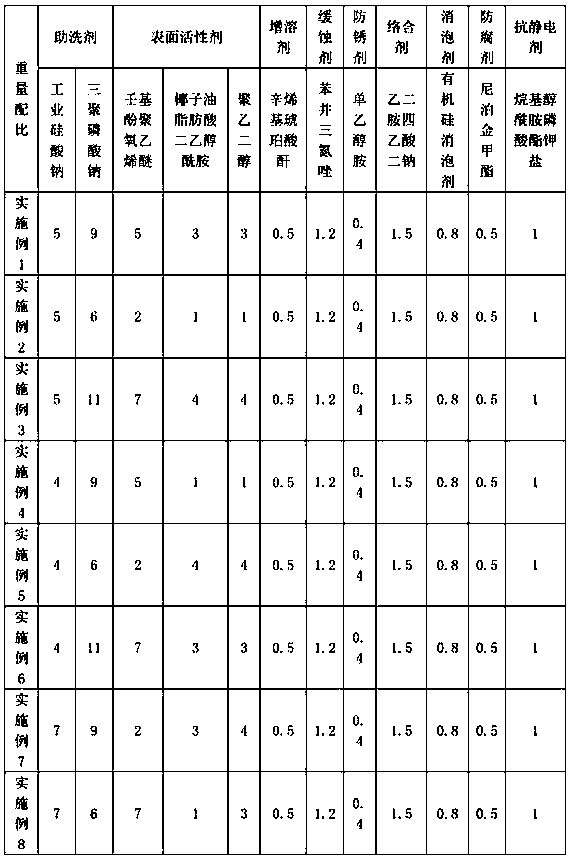

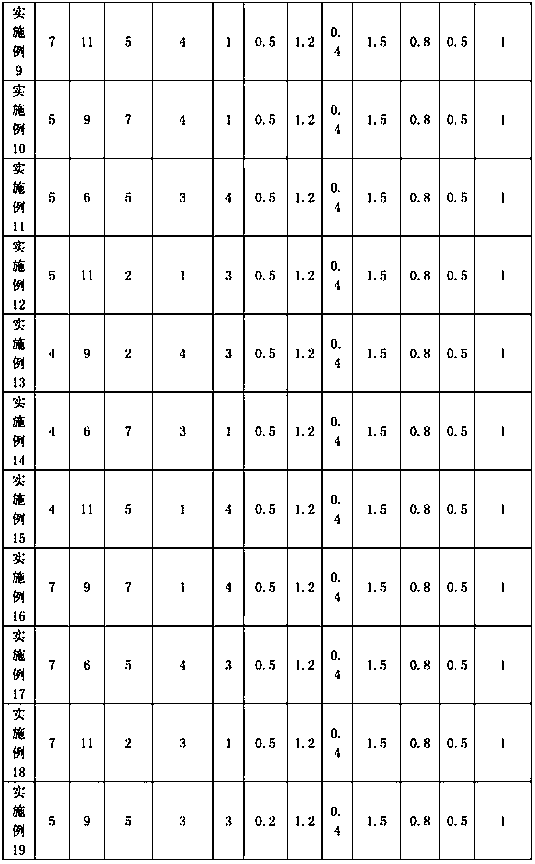

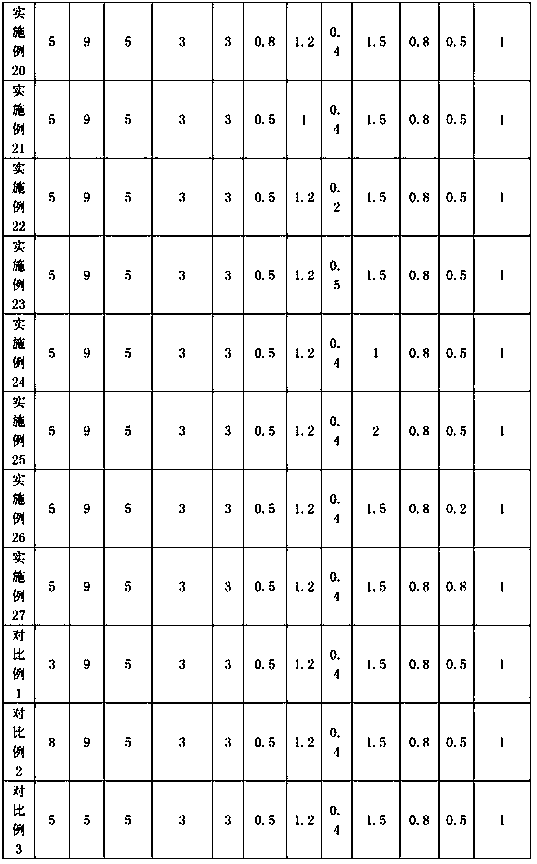

Examples

Embodiment 28

[0054] A metal cleaning agent, the difference between embodiment 28 and embodiment 1 is that the preservative is changed to propylparaben.

Embodiment 29

[0060] A method for preparing the metal cleaning agent of embodiment 1, comprises the following steps:

[0061] (1) Prepare a clean plastic container or measuring cup with a capacity of 1000ml and a small stirrer with a manual speed adjustment of 0-1440rpm;

[0062] (2) Put water in a plastic container with a water temperature of 25°C;

[0063] (3) Put the preservative in a plastic container and stir for 1 minute with a stirrer;

[0064] (4) Put the potassium alkyl alcohol amide phosphate antistatic agent in a plastic container and stir it with a stirrer for 1 minute;

[0065] (5) Put the sodium tripolyphosphate builder in a plastic container and stir it with a stirrer for 1 minute. The liquid in the container is light-colored and translucent, with a small amount of foam floating on the surface of the liquid;

[0066] (6) Put the industrial sodium silicate builder in a plastic container and stir it with a stirrer for 1 minute. The liquid in the container is light-colored and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com