Patents

Literature

149results about How to "Hard material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

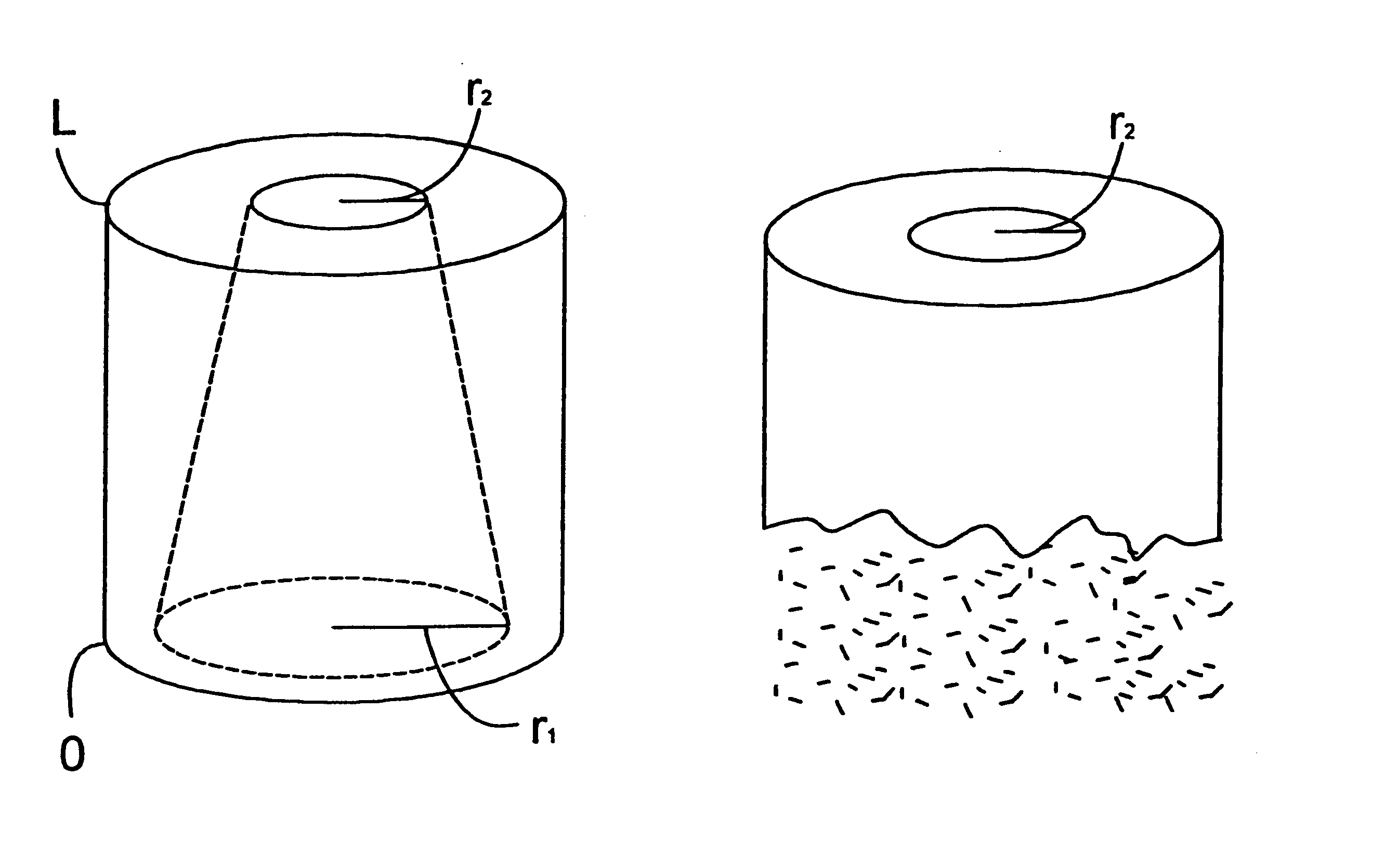

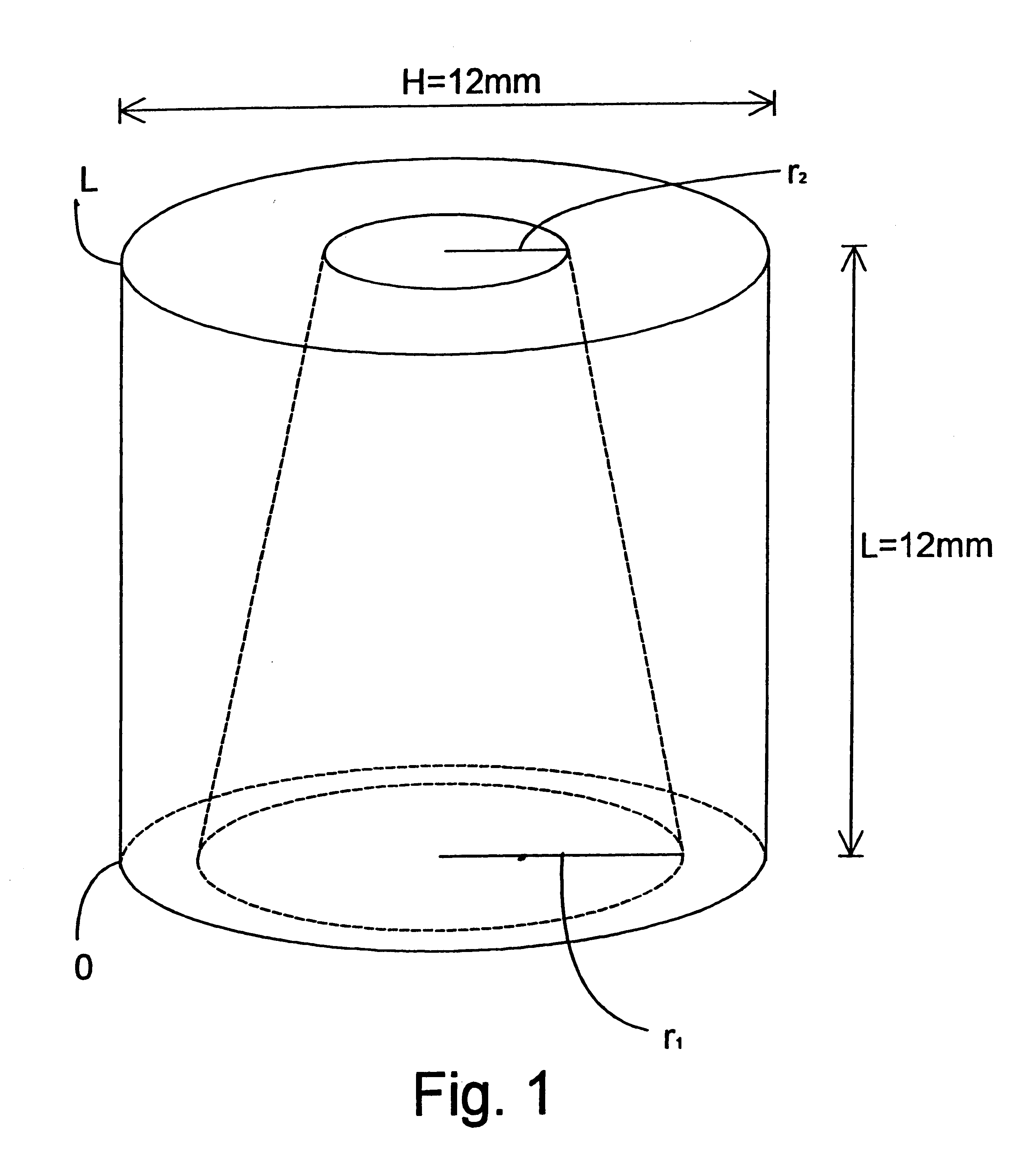

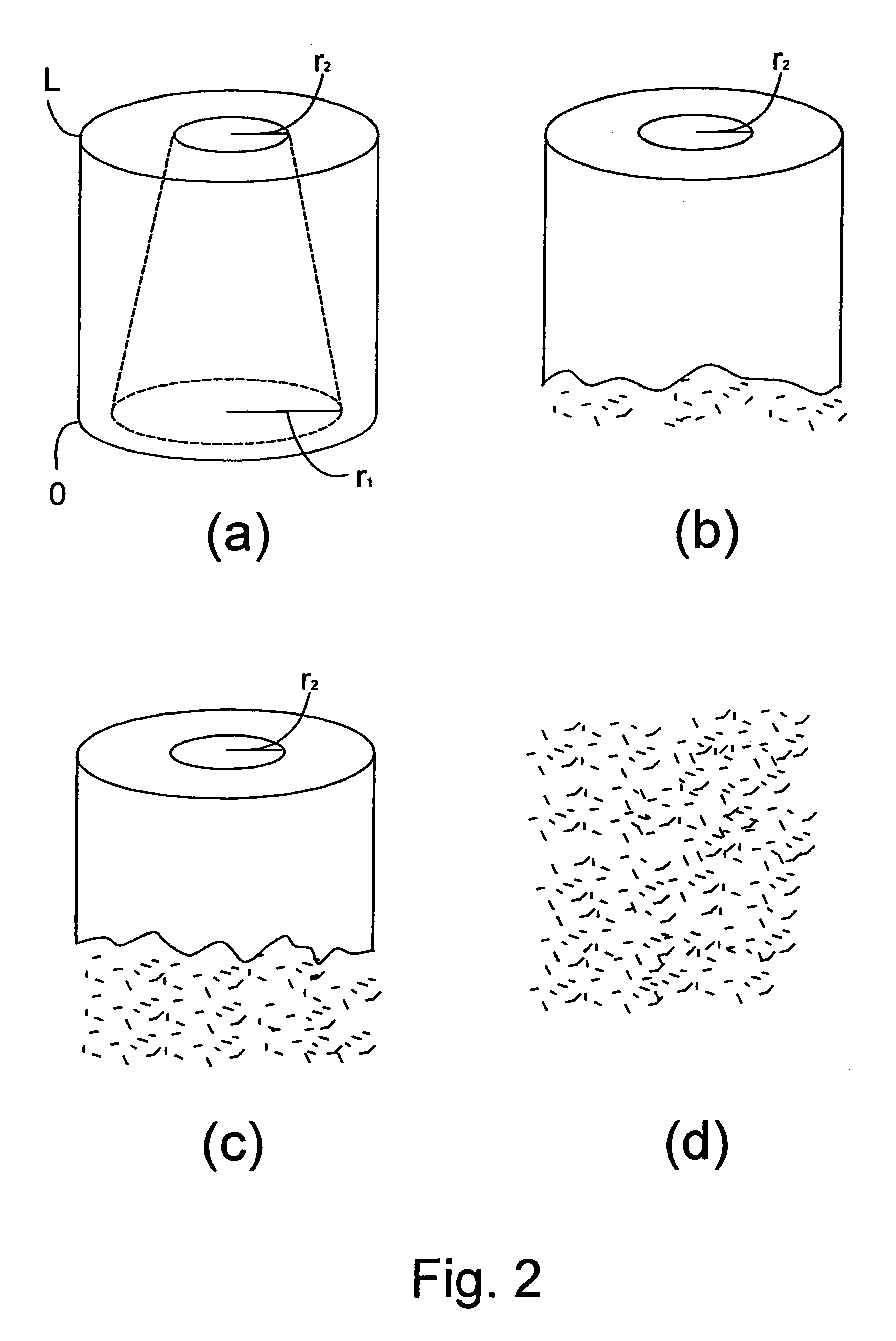

Biodegradable implant manufactured of polymer-based material and a method for manufacturing the same

The invention relates to a biodegradable implant or the like manufactured of polymer-based material and intended to be installed in tissue conditions. In the macroscopic structure of the implant two or several zones are created in a manner that the biodegradable polymer-based material has in different zones a different detaching time from the macroscopic structure under tissue conditions.

Owner:BIONX IMPLANTS

Soft ceramic mud and preparation method thereof

The invention discloses a soft ceramic mud and method for preparation, which is prepared by polyvinylchloride pasty resin 15-40 parts by weight, dioctyl phthalate 20-55 parts by weight, calcium carbonate 15-35 parts by weight, plasticizer 0.1-0.4 parts by weight, toner 0.5-0.15 parts by weight, and trace moisture and impurity. The invention also discloses a method for preparation, which comprises steps as follows, each component is weighed proportionally and is placed into stirrer to stir until all components doesn't display nodular powder to be kneaded together evenly and the color is uniform, the evenly stirred mud is placed in the molder to squeeze and mould. The invention provides the soft ceramic mud which is hard and fine in texture under normal temperature, low in softening temperature to soften by hand temperature, low in toasting temperature and short in time, and the toasted material is as hard as ceramic without any odor, further protecting environment.

Owner:东莞市汇欣工贸有限公司

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

Inorganic optical taggant and method of making

InactiveUS20050092408A1Overcomes shortcomingDesired performanceCell electrodesMachines/enginesCamouflageYttrium

Sintered, translucent ceramic microbeads, preferably alumina, titania, zirconia, yttria, zirconium phosphate, or yttrium aluminum garnet (YAG) are doped with one or more optically active species. The beads may be added to substances such as explosives in order to create a distinctive optical signature that identifies a manufacturer, lot number, etc. in the event of the need for forensic analysis. Because the beads have a generally spherical surface, the radius of curvature provides an additional distinguishing characteristic by which a particular sample may be identified. The beads could also be formulated into paints if needed to create distinctive optical signatures for camouflage, decoys, or other countermeasures and could also be applied as a dust to track the movement of personnel, vehicles, etc.

Owner:UT BATTELLE LLC

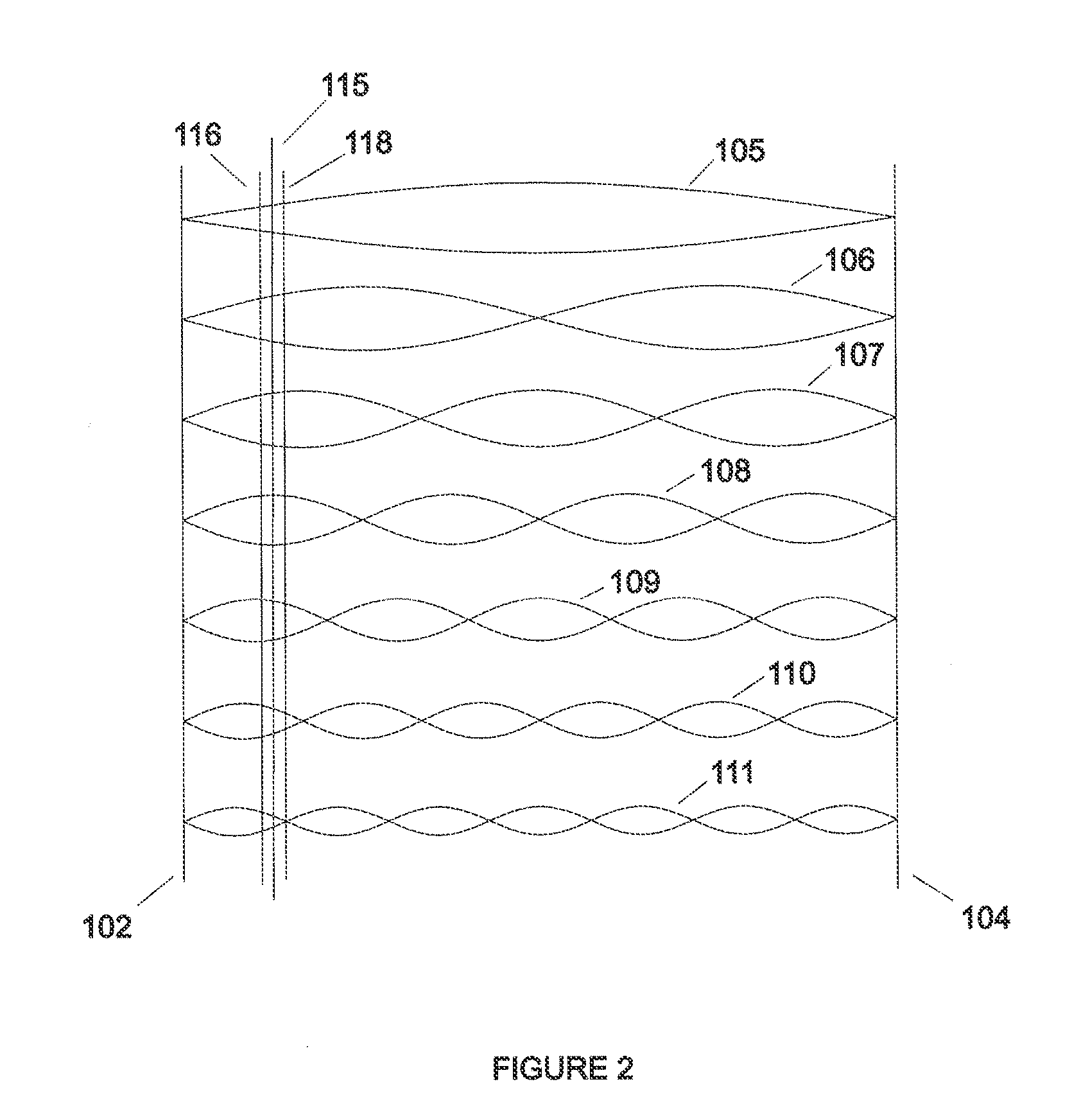

Sawing Yarn

InactiveUS20070261690A1Improve cutting performanceTrue cylindrical shapeAbrasion apparatusMetal sawing toolsFiberYarn

A sawing yarn comprises an abrasive mixture which contains a bonding resin and an abrasive material, as well as a multifilament core made of fibers which are resistant to breaking. The fibers are arranged substantially parallel to one another and are enveloped by the abrasive mixture. The bonding resin contains no polytetrafluoroethylene, and the quantity of abrasive material in the mixture gradually decreases from the surface of the abrasive yarn inward. The yarn is suitable for cutting hard and brittle materials such as single-crystal silicon.

Owner:SIA ABRASIVES IND

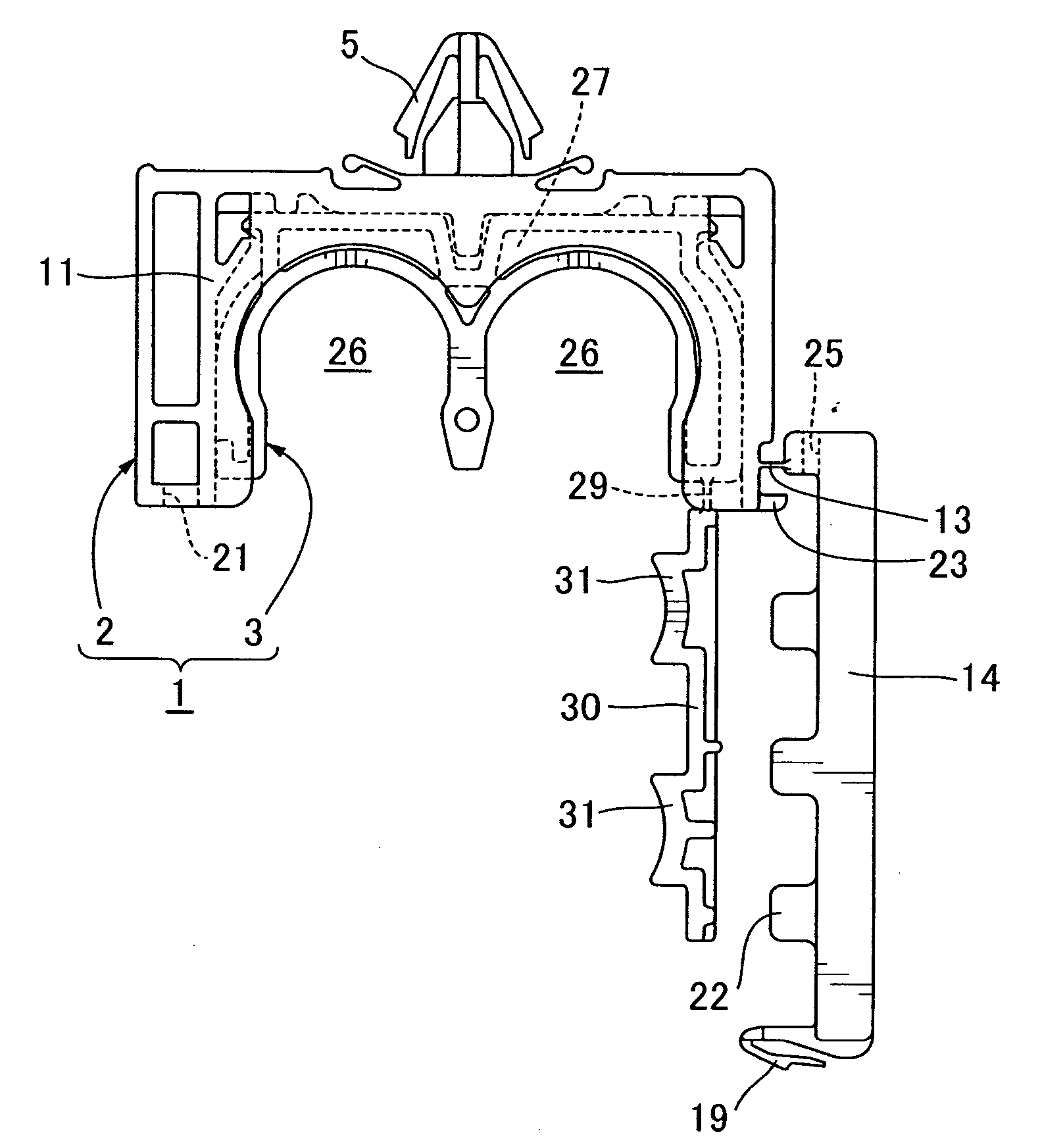

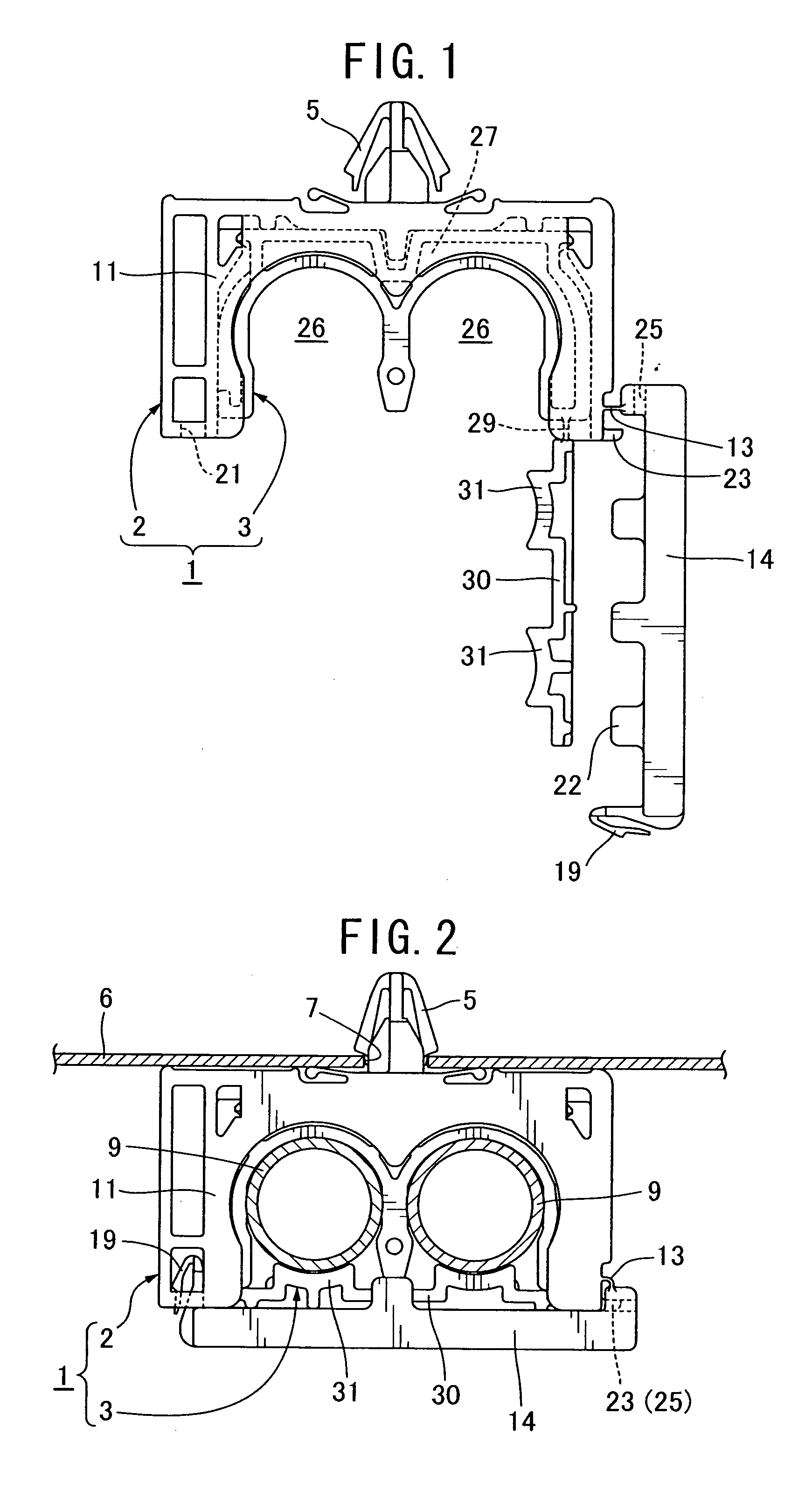

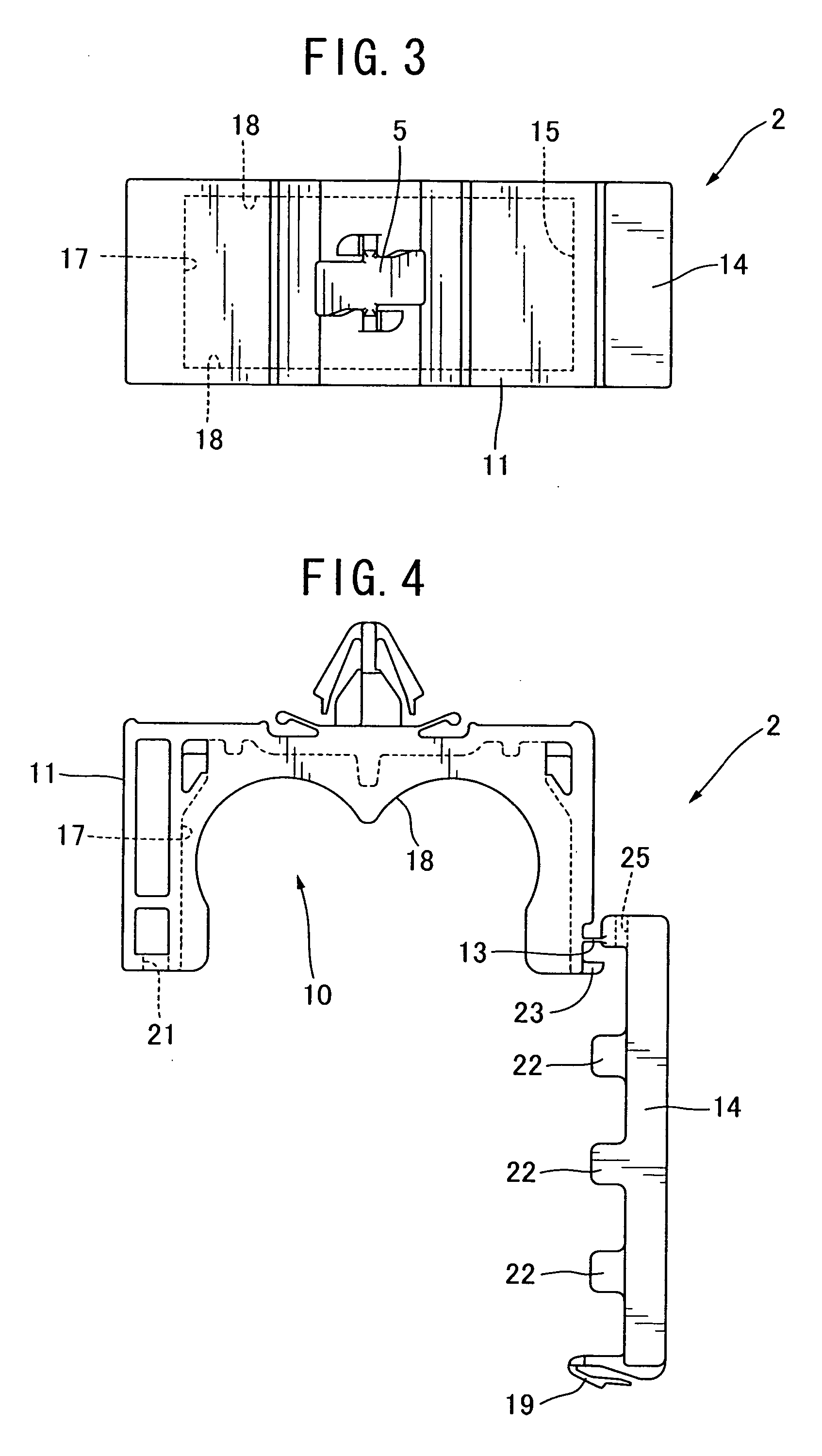

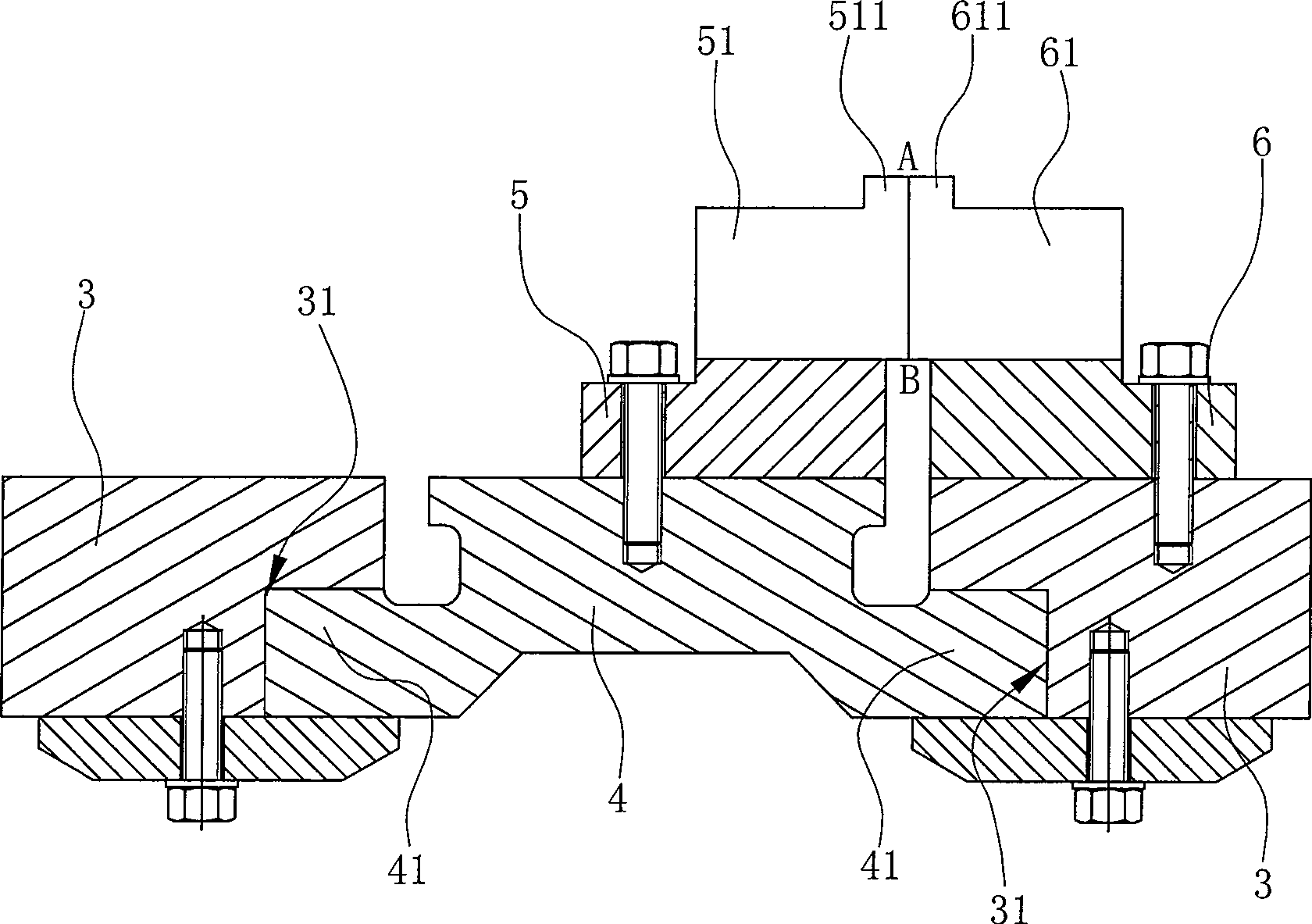

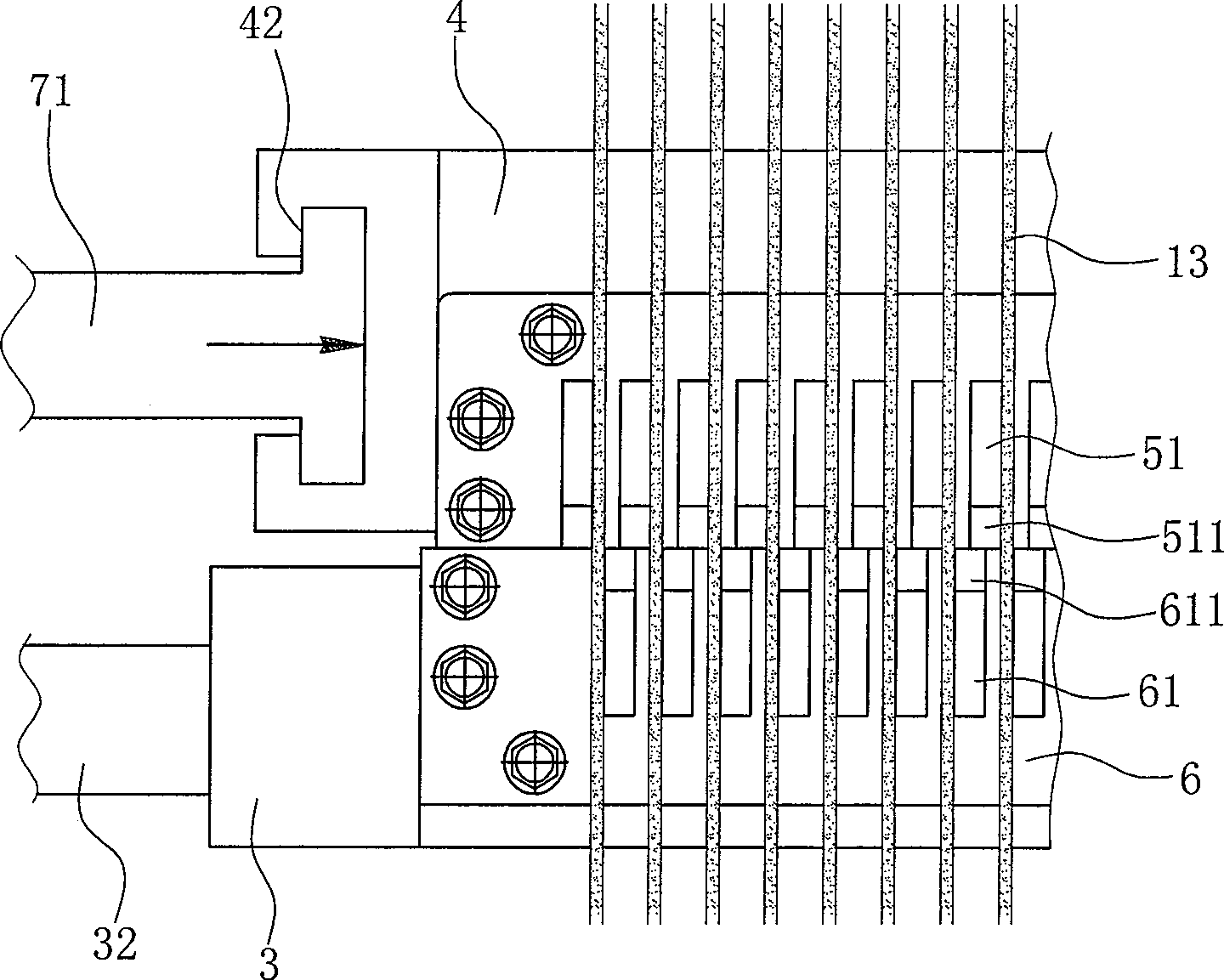

Heat-resistant clamp device for pipes or similar objects

A clamp device for connecting a high-temperature elongated component to a support comprises a first clamp mountable to the support and a second clamp for holding the elongated component. The first clamp includes a clamp holder for holding the second clamp and is made of a non-heat-resistant hard plastic material. The second clamp includes a holder for holding the elongated component and is made of a heat-resistant hard plastic material. Preferably, the outer peripheral surface of the second clamp is covered by a layer of vibration-resistant elastic plastic material that prevents transmission of vibrations between an elongated component, such as a heater pipe, and a support, such as an under floor of an automobile.

Owner:NEWFREY

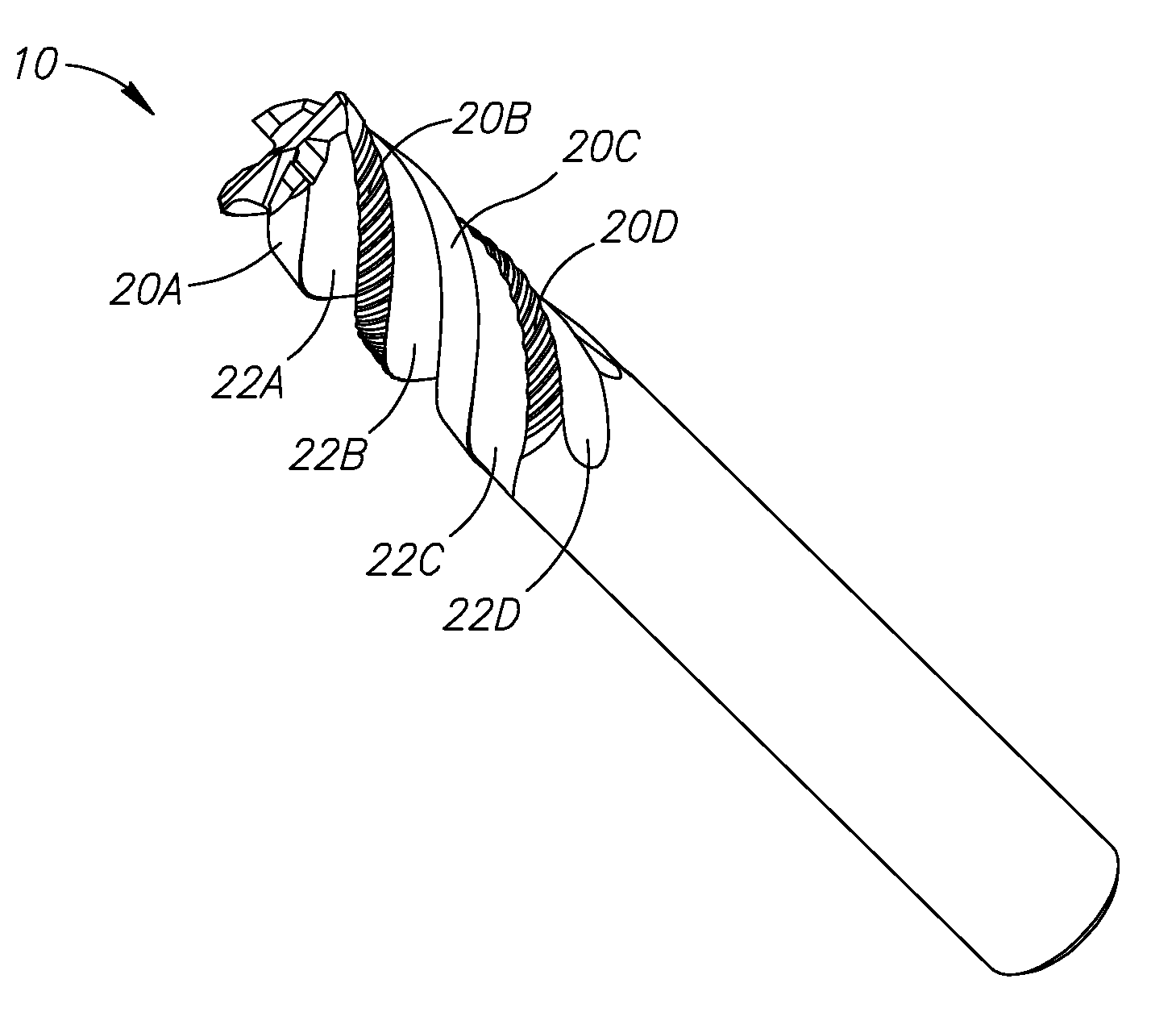

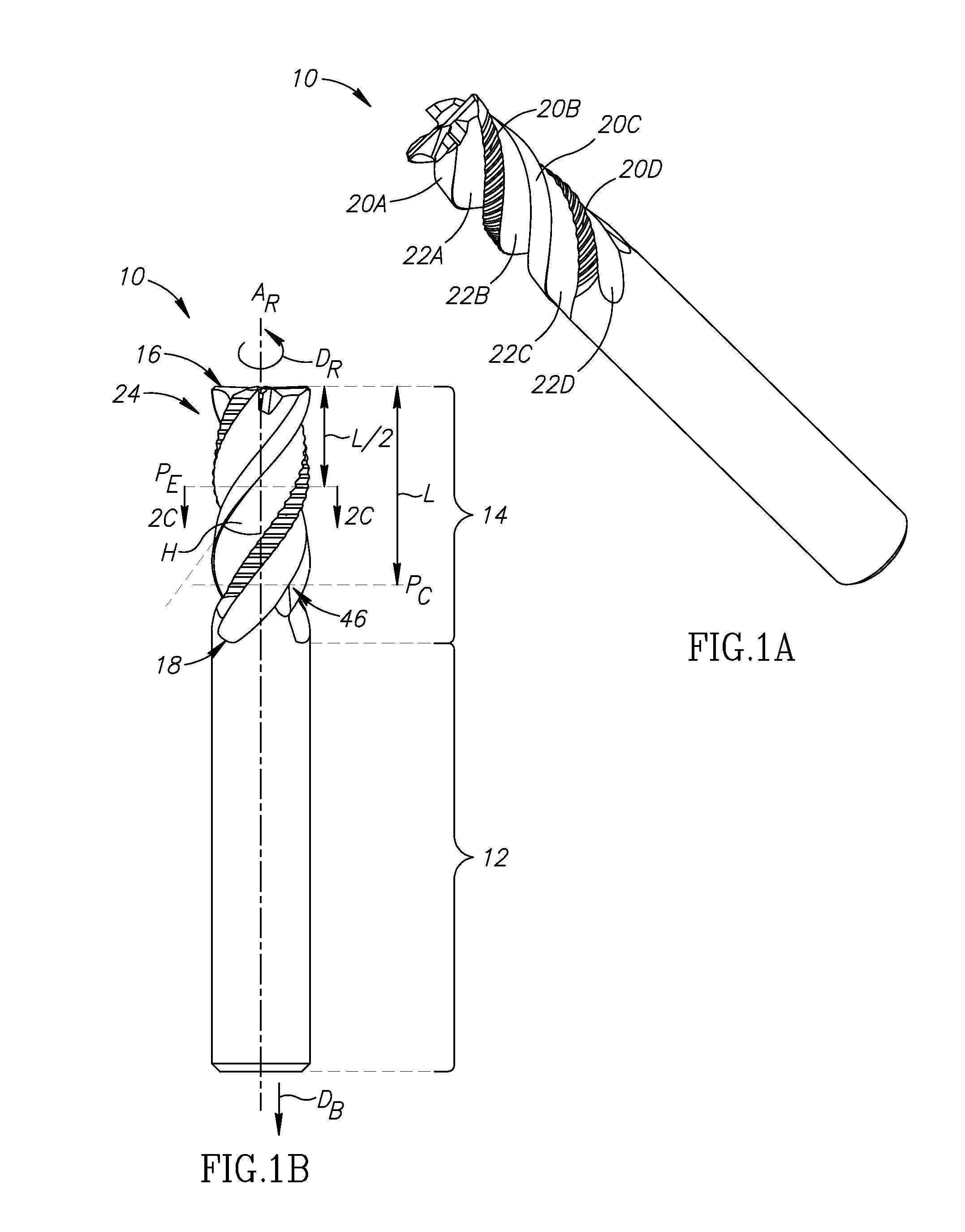

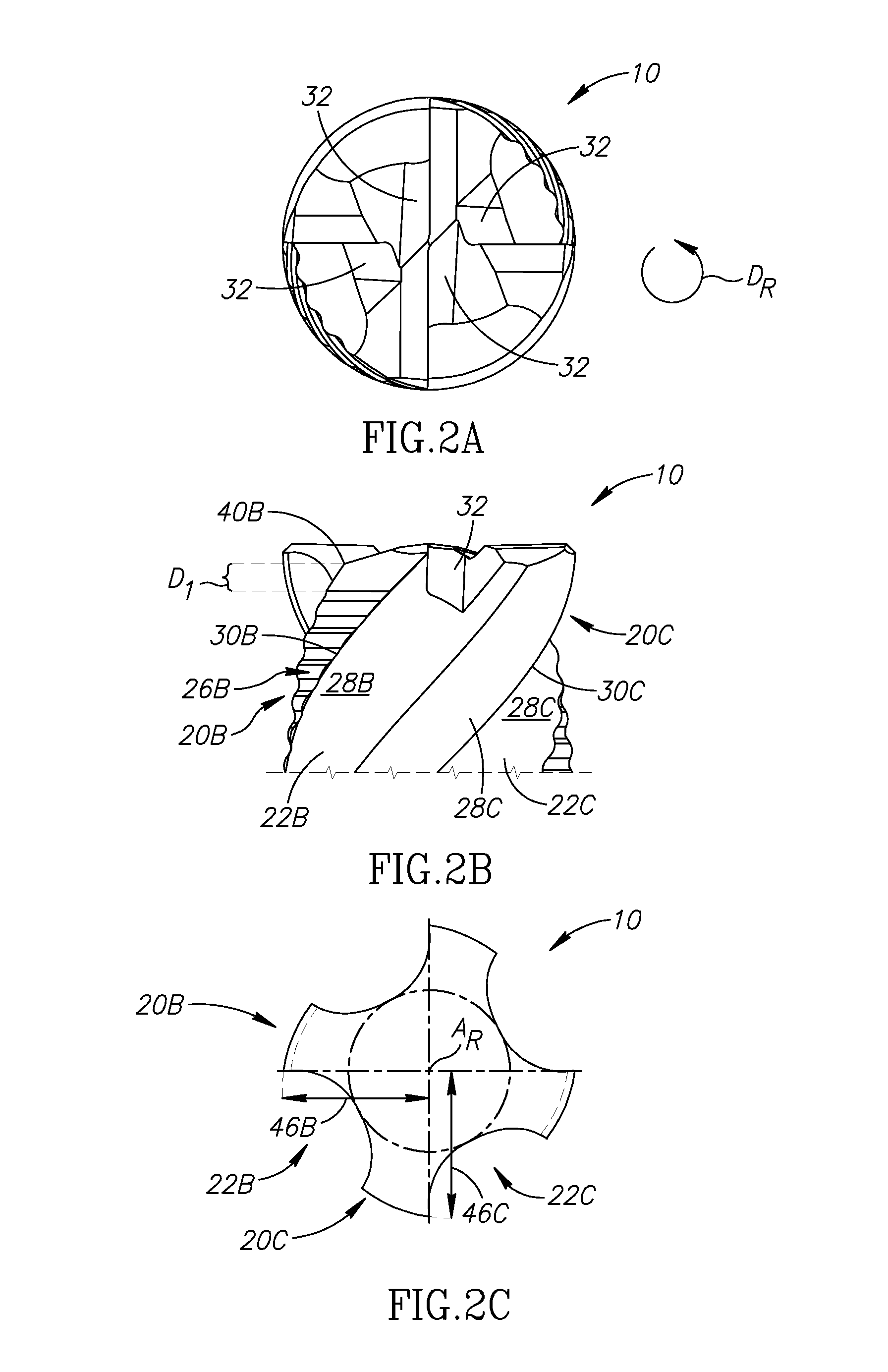

Roughing and Semi-Finishing End Mill Having Serrated and Non-Serrated Cutting Teeth

An end mill having a plurality of teeth configured for both roughing and semi-finishing applications, the teeth being alternated with a plurality of flutes. At least one tooth of the plurality of cutting teeth is a serrated tooth formed with serrations along a relief surface thereof and at least one other tooth is free of serrations. Each tooth of the plurality of cutting teeth includes an actual internal cutting angle formed at an intersection of a rake cutting sub-surface and a relief surface. The actual internal cutting angle of each tooth has a greater value than an imaginary internal cutting angle formed at an intersection of imaginary extension lines of a rake recessed sub-surface and a relief surface of the same tooth.

Owner:ISCAR LTD

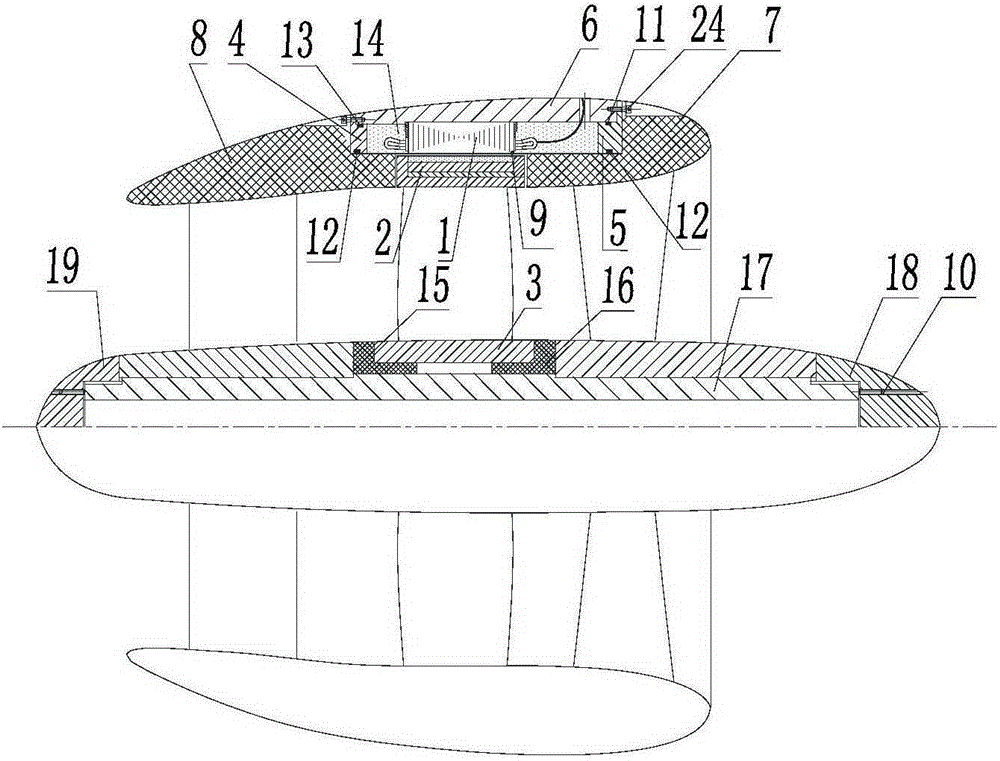

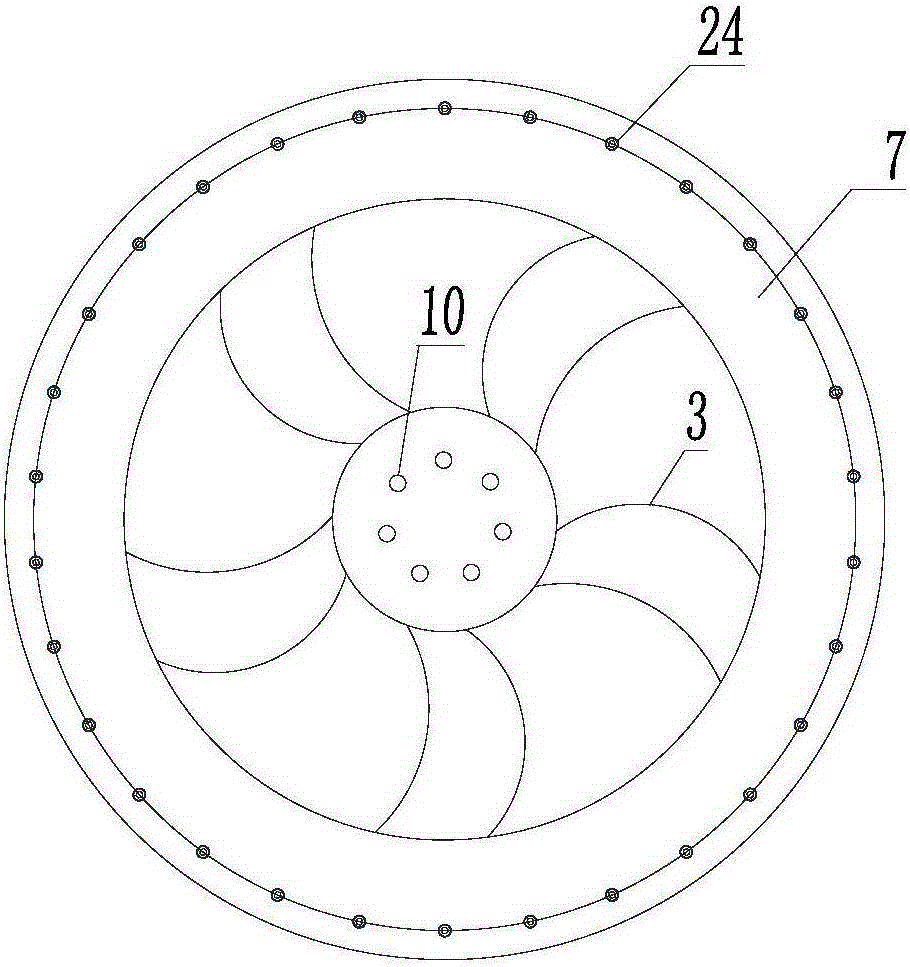

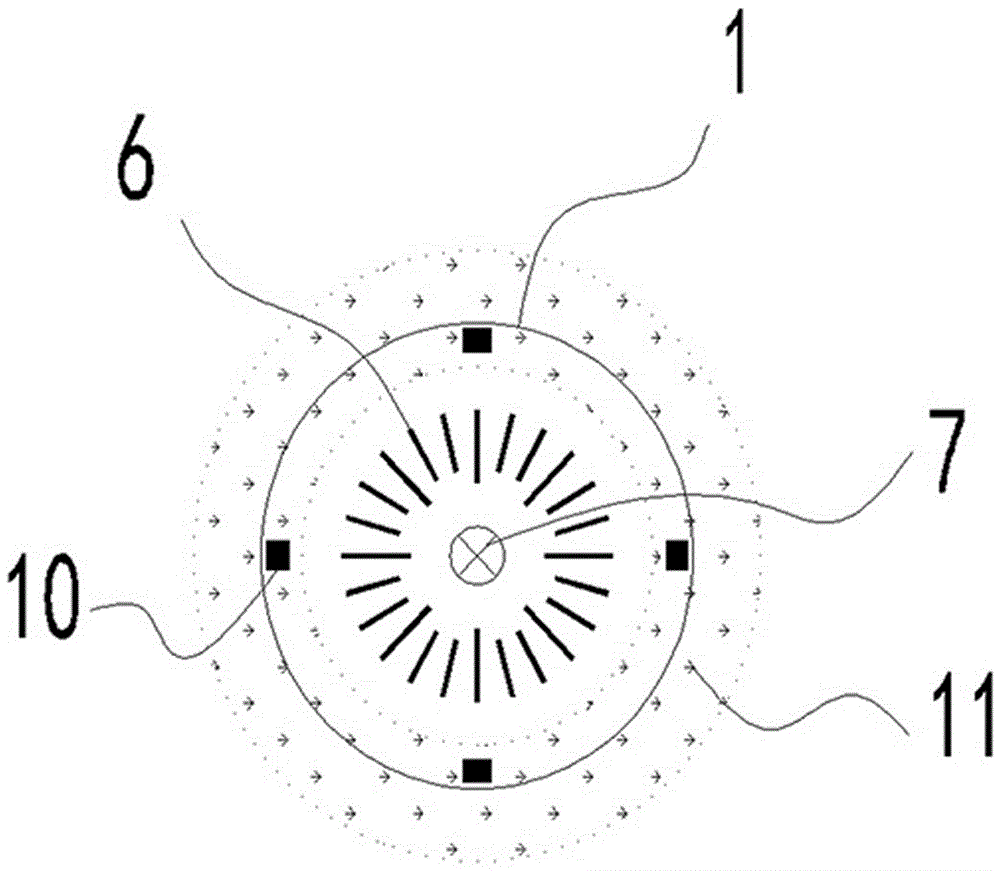

Ship flange integration propulsion device

ActiveCN105292424ASolve technical problems with access to the interior of the statorImprove sealingPropulsion power plantsPropulsive elementsFiberEngineering

The invention discloses a ship flange integration propulsion device. The ship flange integration propulsion device comprises a motor stator assembly, a motor rotor assembly, a propeller assembly, a guide tube, a rear guide cover, a front guide cover, a first water lubricated bearing, a second water lubricated bearing, an axle, a rear propeller hub cap, a front propeller hub cap, front guide cover connecting plates, rear guide cover connecting plates, a front end cover, a rear end cover and a fiber reinforced polymer sleeve, wherein the front end cover, the rear end cover and the fiber reinforced polymer sleeve are used for sealing the stator assembly, a closed space is formed among the stator assembly, the guide tube, the front end cover, the rear end cover and the fiber reinforced polymer sleeve, and the closed space is filled with epoxy resin. A static sealing structure is formed between the motor stator assembly and the guide tube, the sealing effect is good, and the technical problem that in the prior art, seawater may enter a stator can be effectively solved. In addition, due to the fact that a flange structure mode is adopted, paddles transmit hydrodynamic load at paddle tip conveniently; meanwhile, tip vortex is avoided, and the propulsive efficiency is further improved.

Owner:青岛海西电气有限公司

Planarization composition for removing metal films

InactiveUS6267909B1Accelerate removabilityMaterial be quite hardNanotechData processing applicationsThinningPolymer chemistry

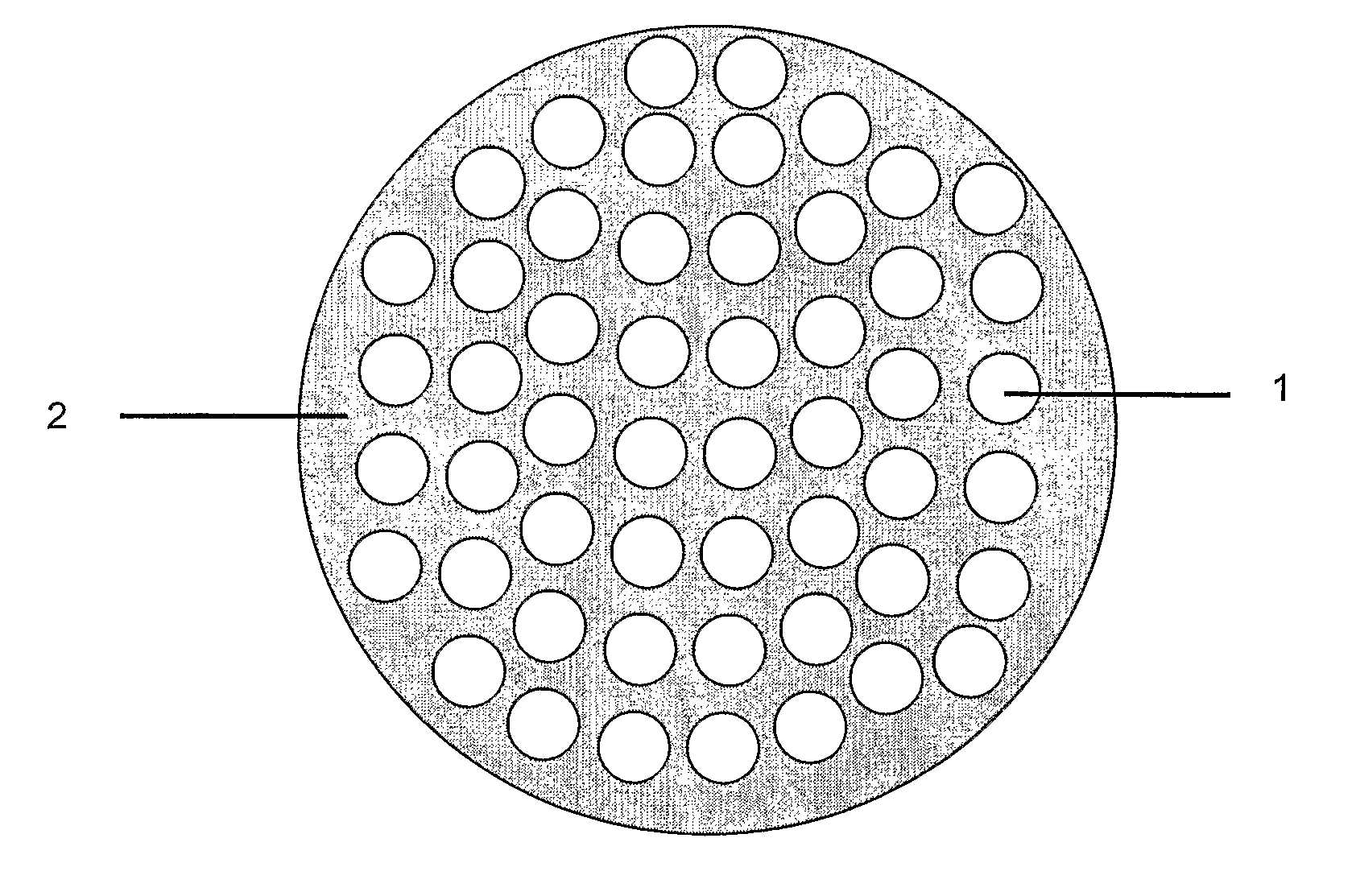

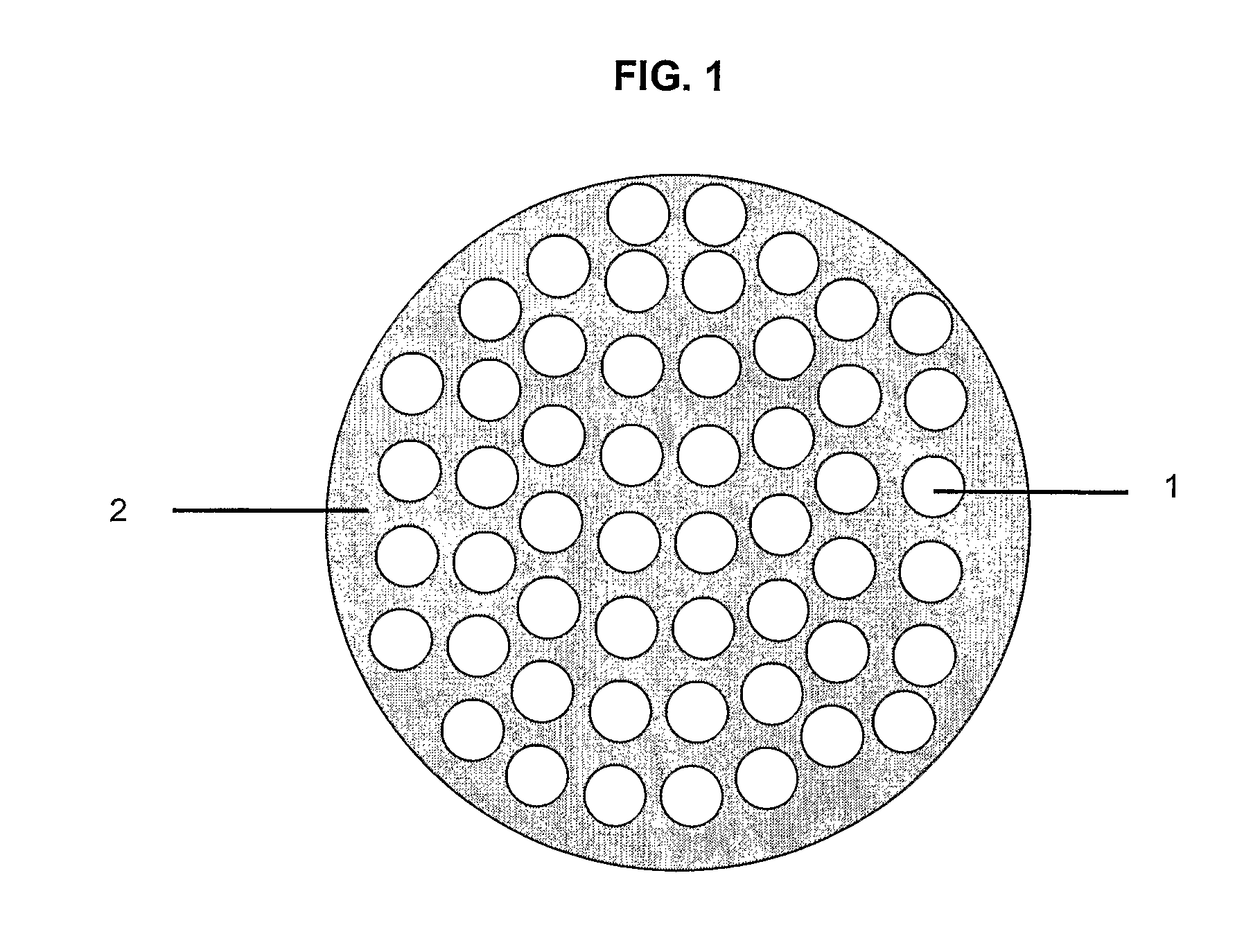

A planarization composition is set forth in accordance with an embodiment of the invention. The composition comprises spherical silica particles having a weight average particle diameter which falls within the range from about 0.03mu to about 2mu and is monodisperse in that at least about 90 weight percent of the particles have a variation in particle diameter from the average particle diameter of no more than about ±20%. A liquid carrier comprising up to 20 weight percent ROH, and an amine hydroxide which is NR4OH or NR2NR3OH, where each R is HCH3, CH2CH3, C3H7 or C4H9, in the amount of 0.1 to 10 weight percent; an oxidizer which is in the amount from about 0.5% to 15% weight percent; an acid stabilizer for adjusting the pH to fall within a range from about 7.0 to about 0.5; and the remainder is water. The invention also relates to a thinning, polishing and planarizing apparatus and to a method for carrying out the thinning, polishing and planarizing operation.

Owner:ENTEGRIS INC

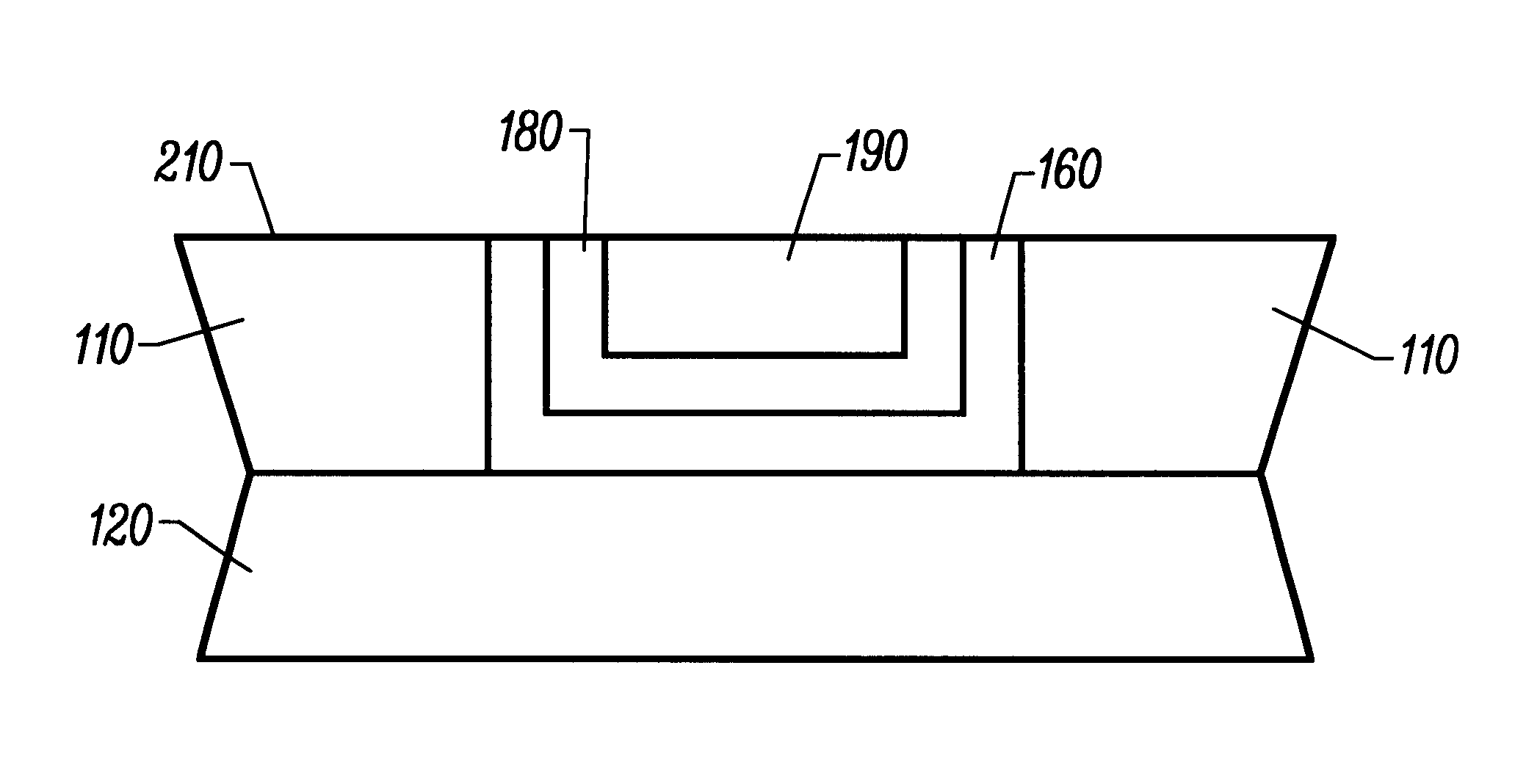

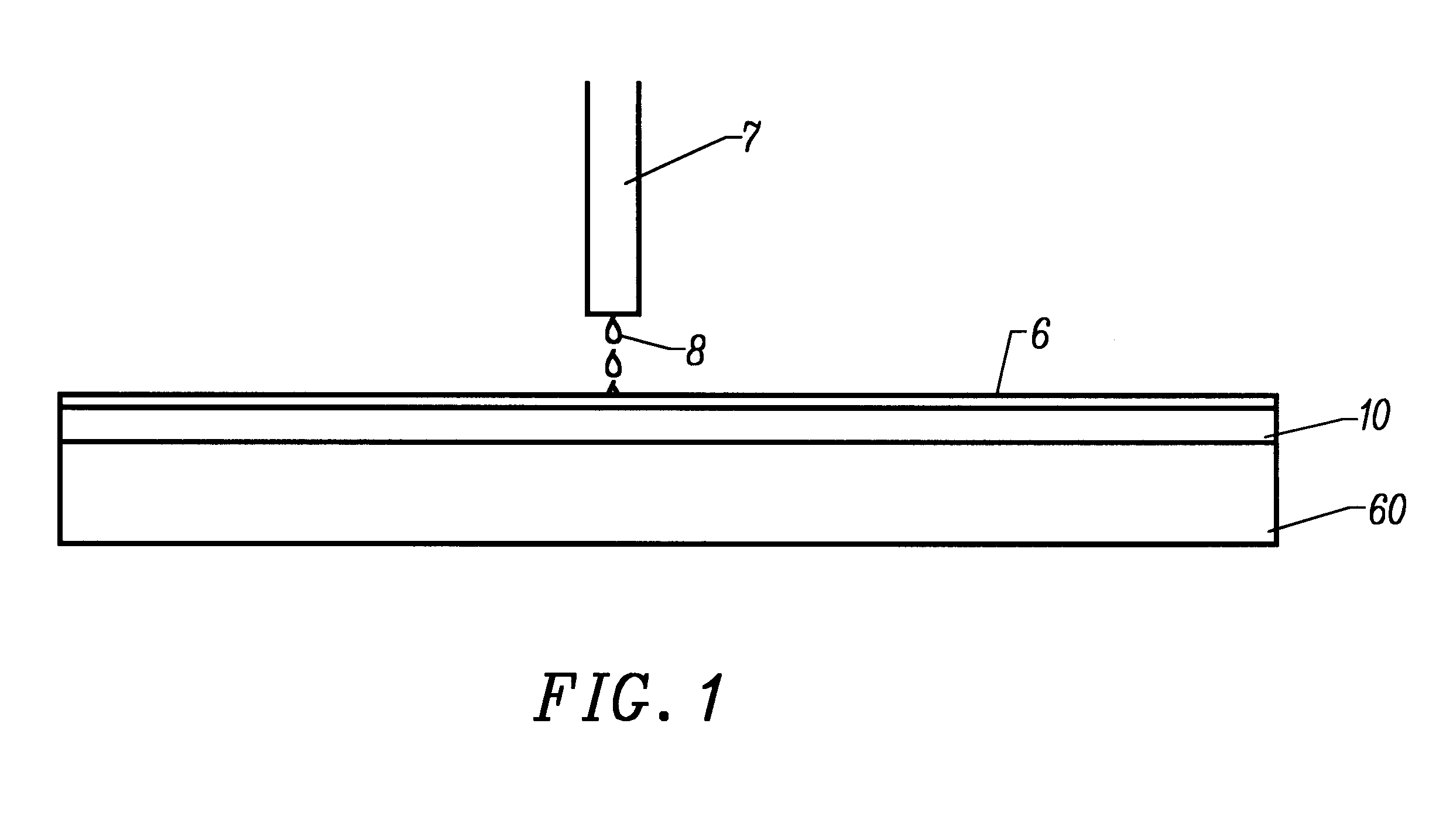

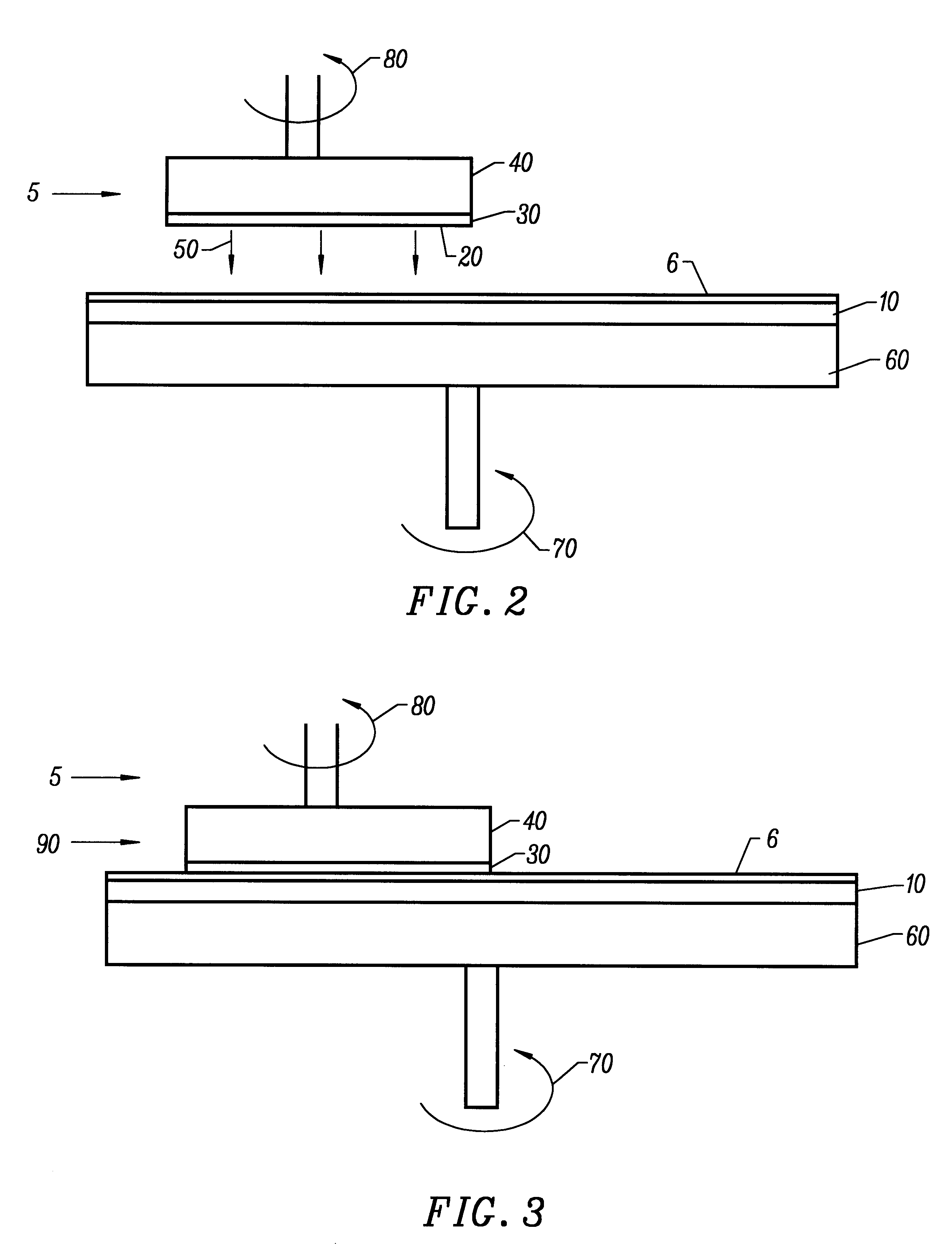

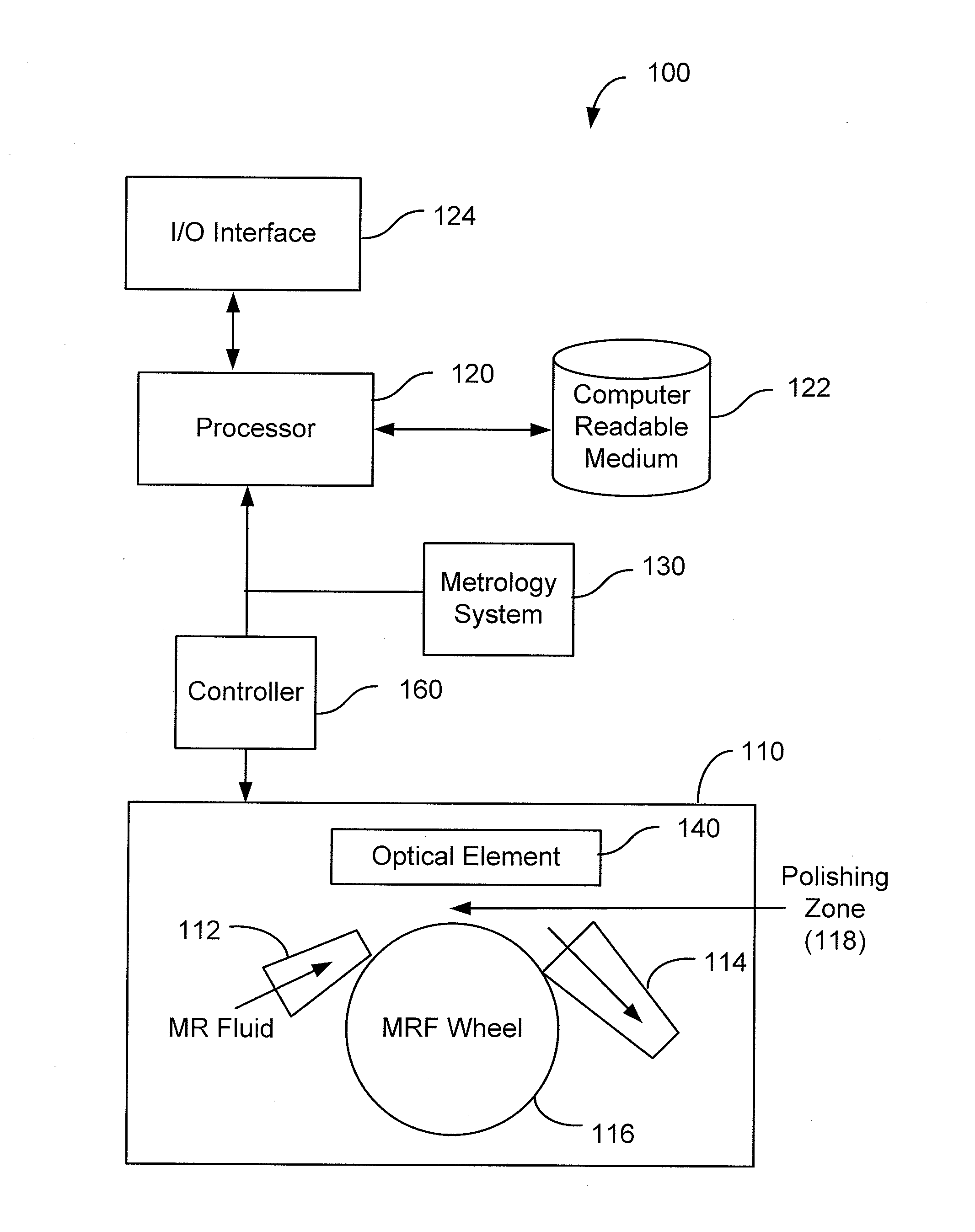

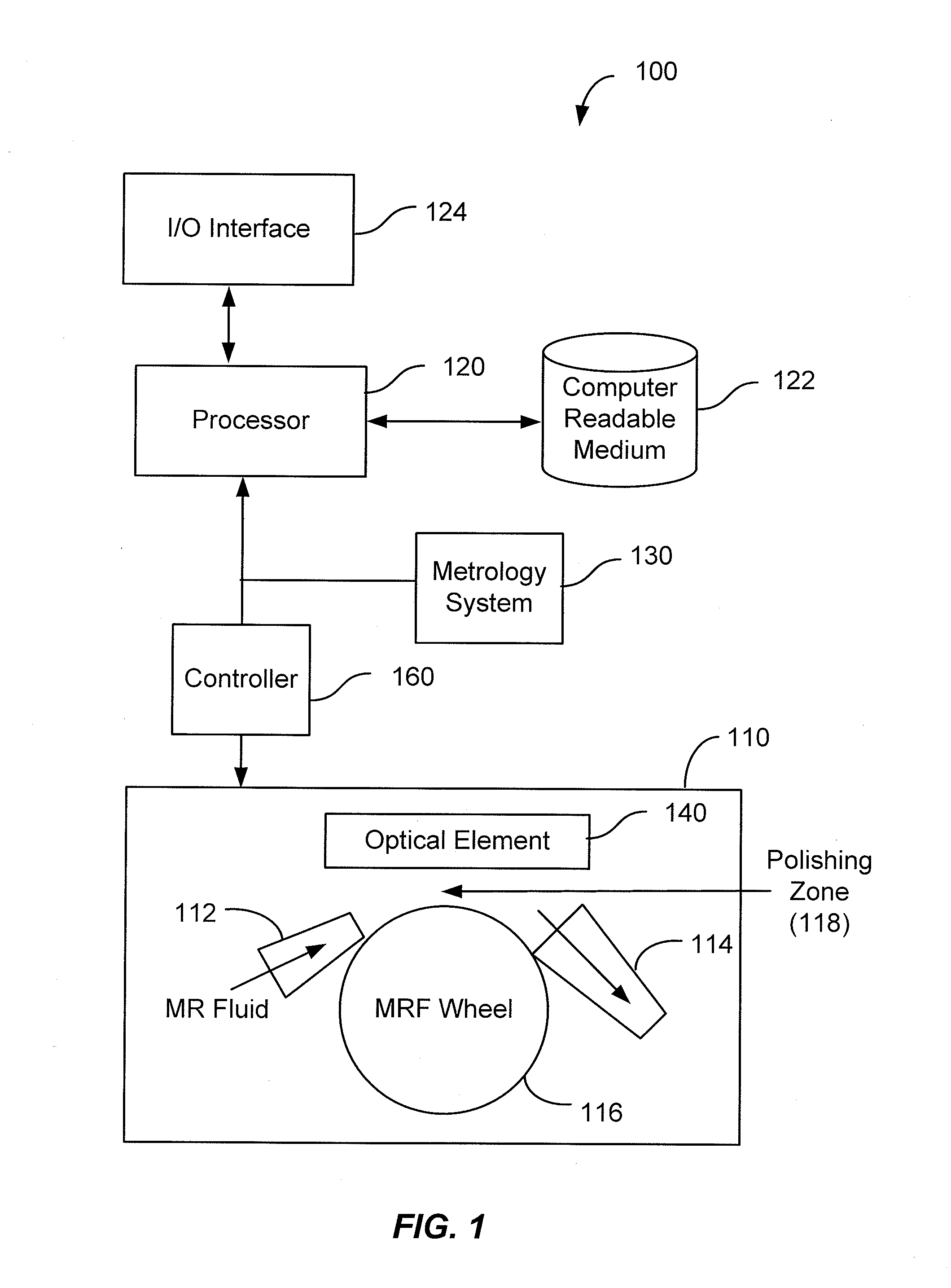

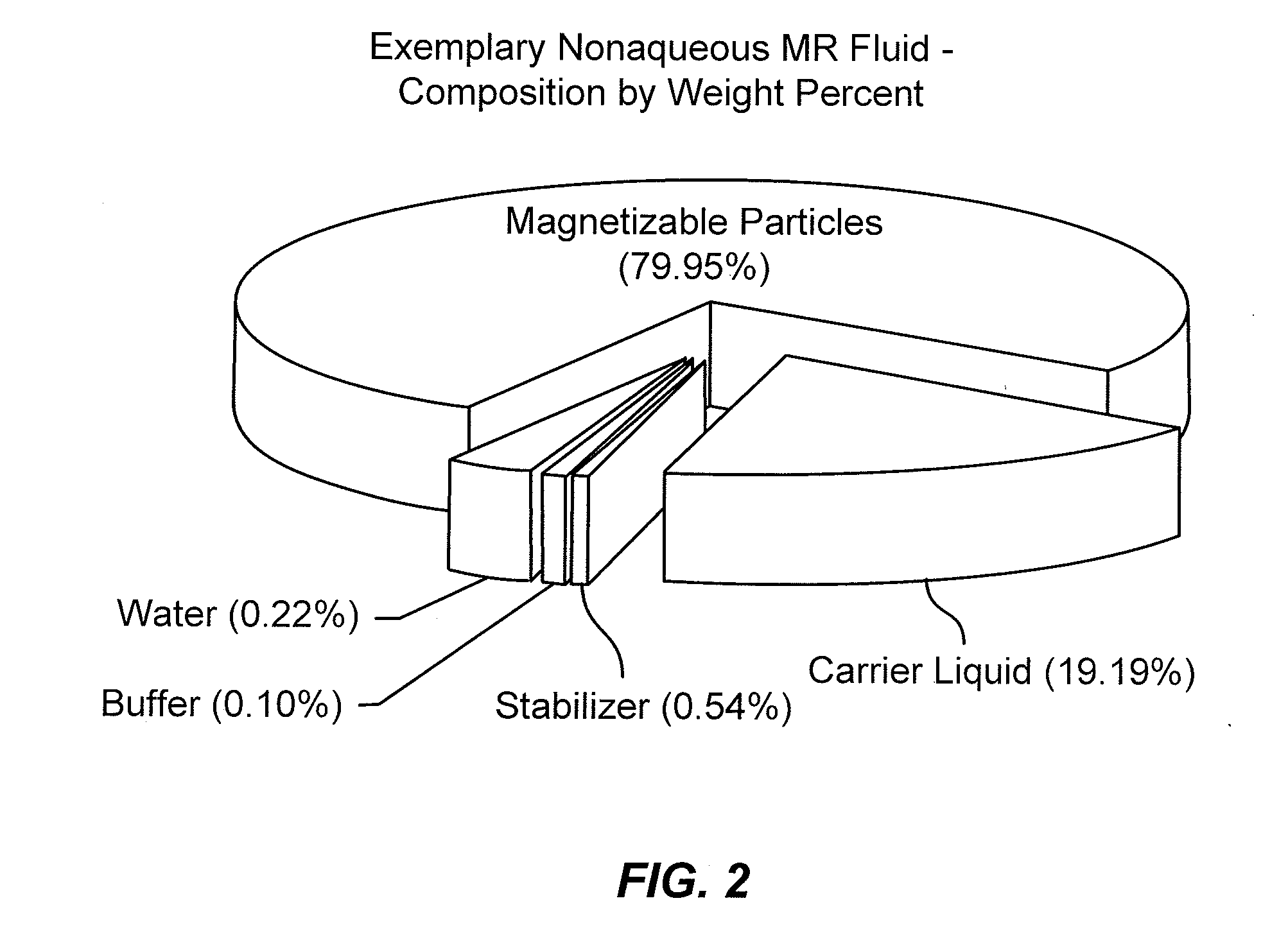

Method and System for Polishing Materials Using a Nonaqueous Magnetorheological Fluid

ActiveUS20110275286A1Improved laser damage performanceHard materialMagnetic paintsFerroso-ferric oxidesMagnetorheological fluidEnvironmental geology

A nonaqueous magnetorheological fluid includes a primarily organic carrier liquid and magnetizable particles. The magnetorheological fluid also includes a buffer, a stabilizer, and water. A pH of the magnetorheological fluid is between 6.5 and 9.0.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

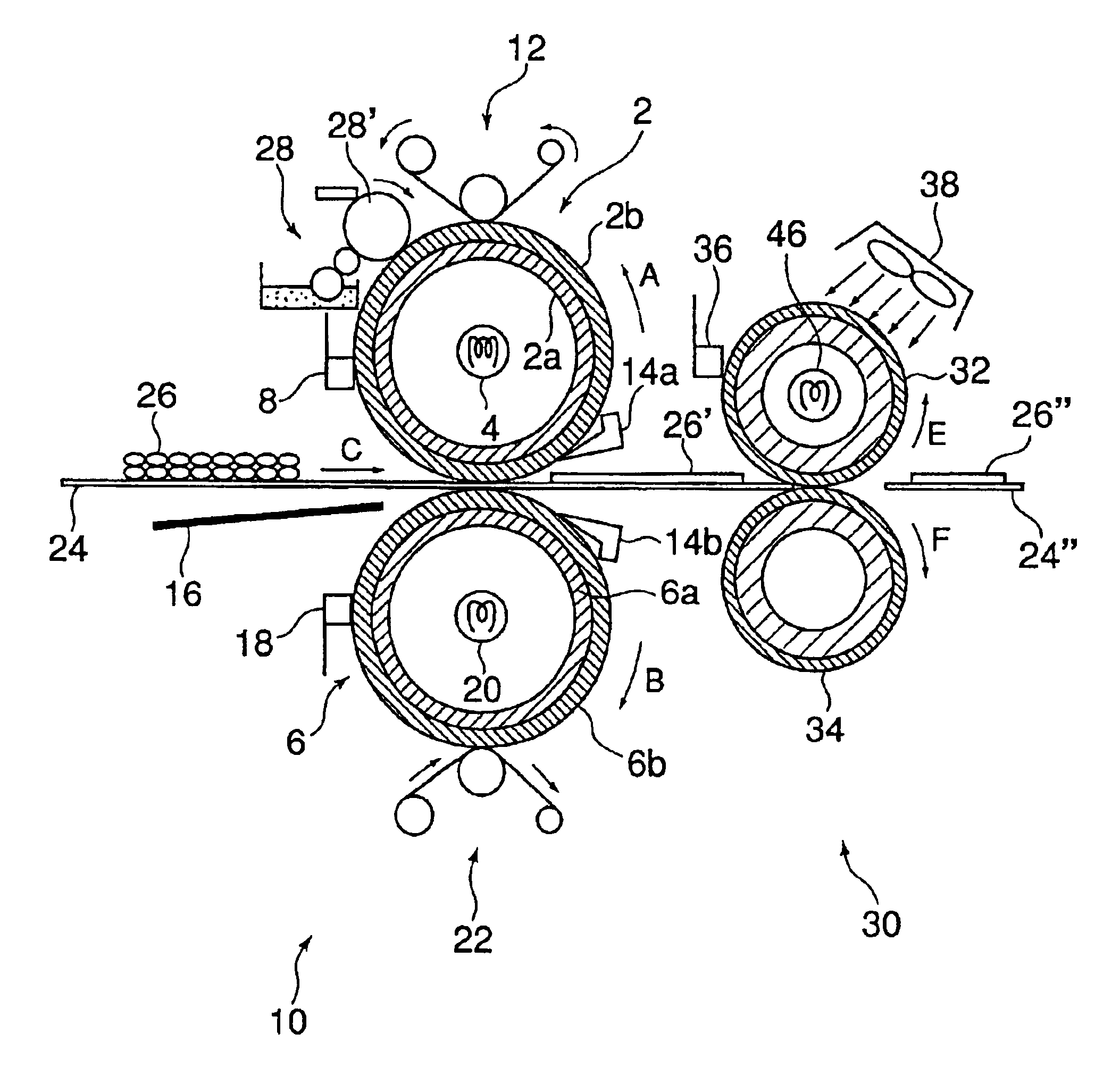

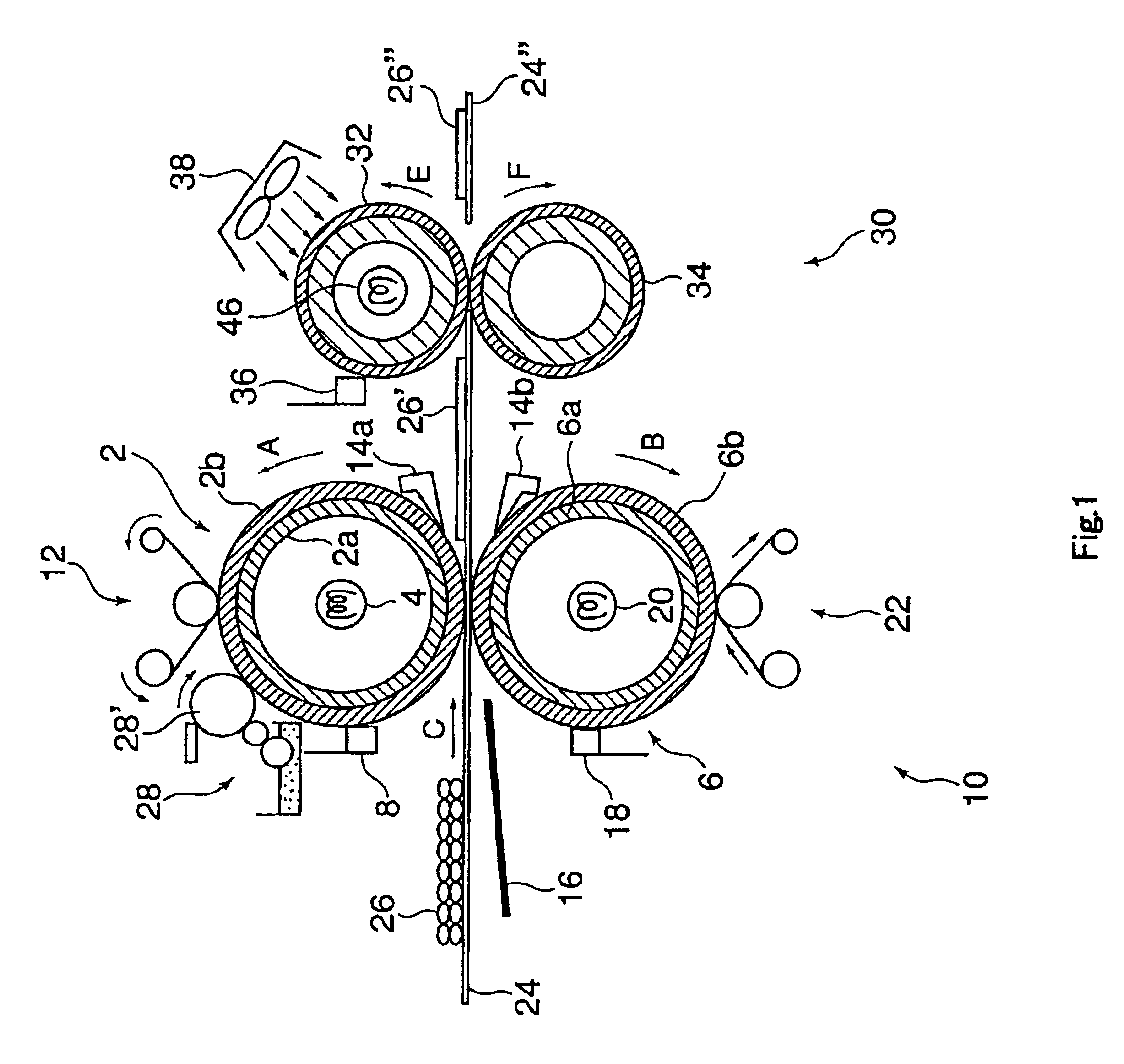

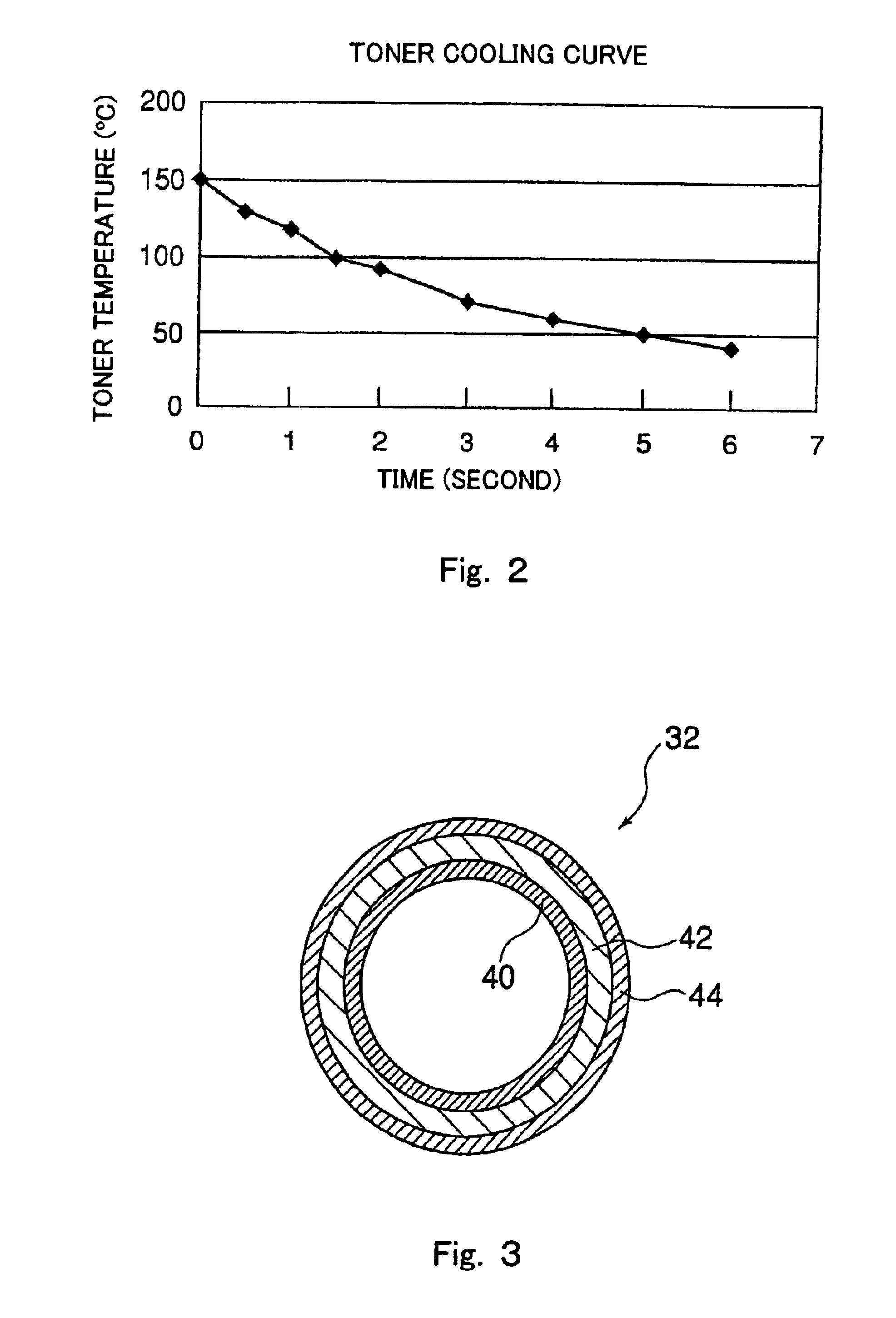

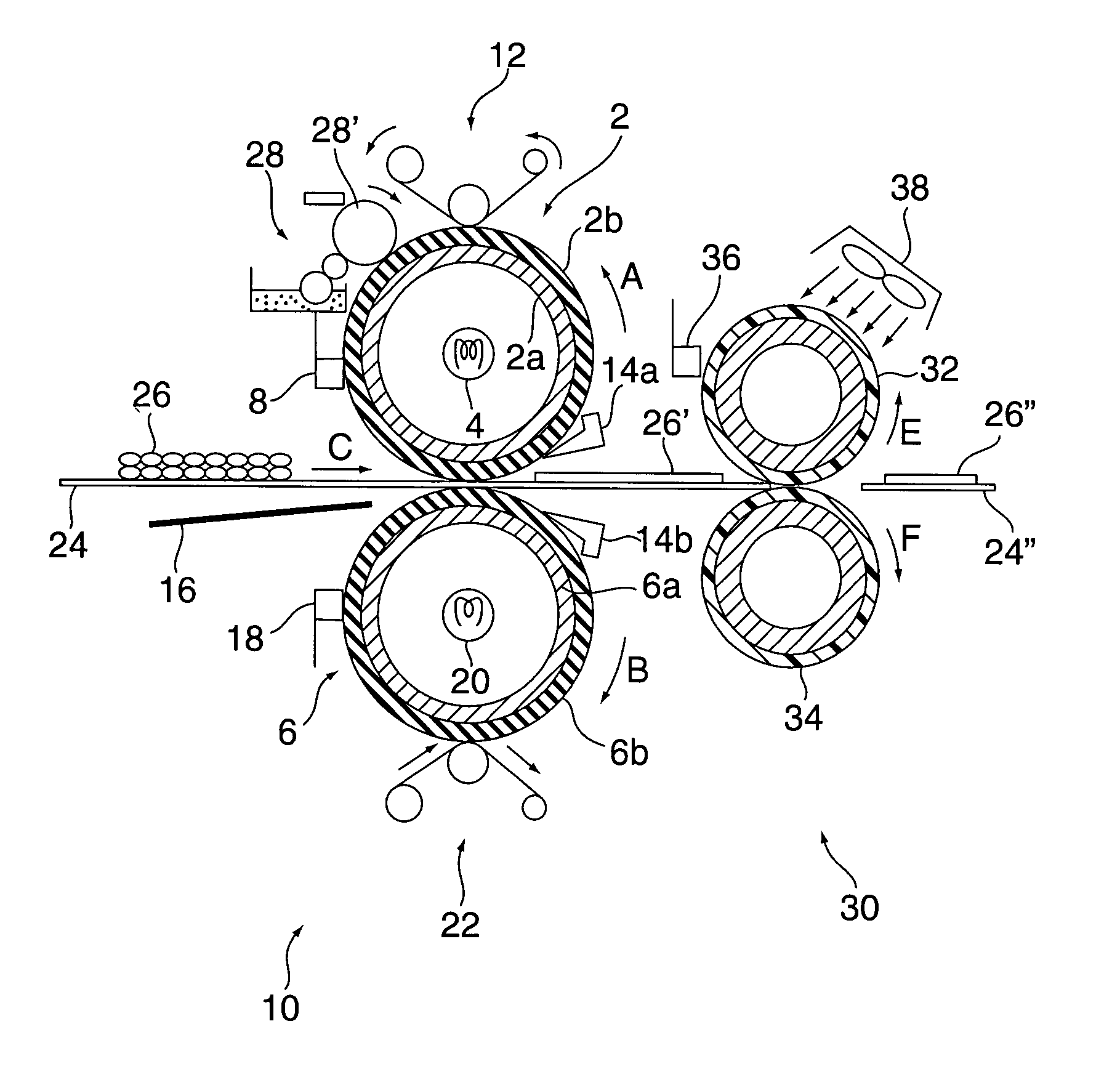

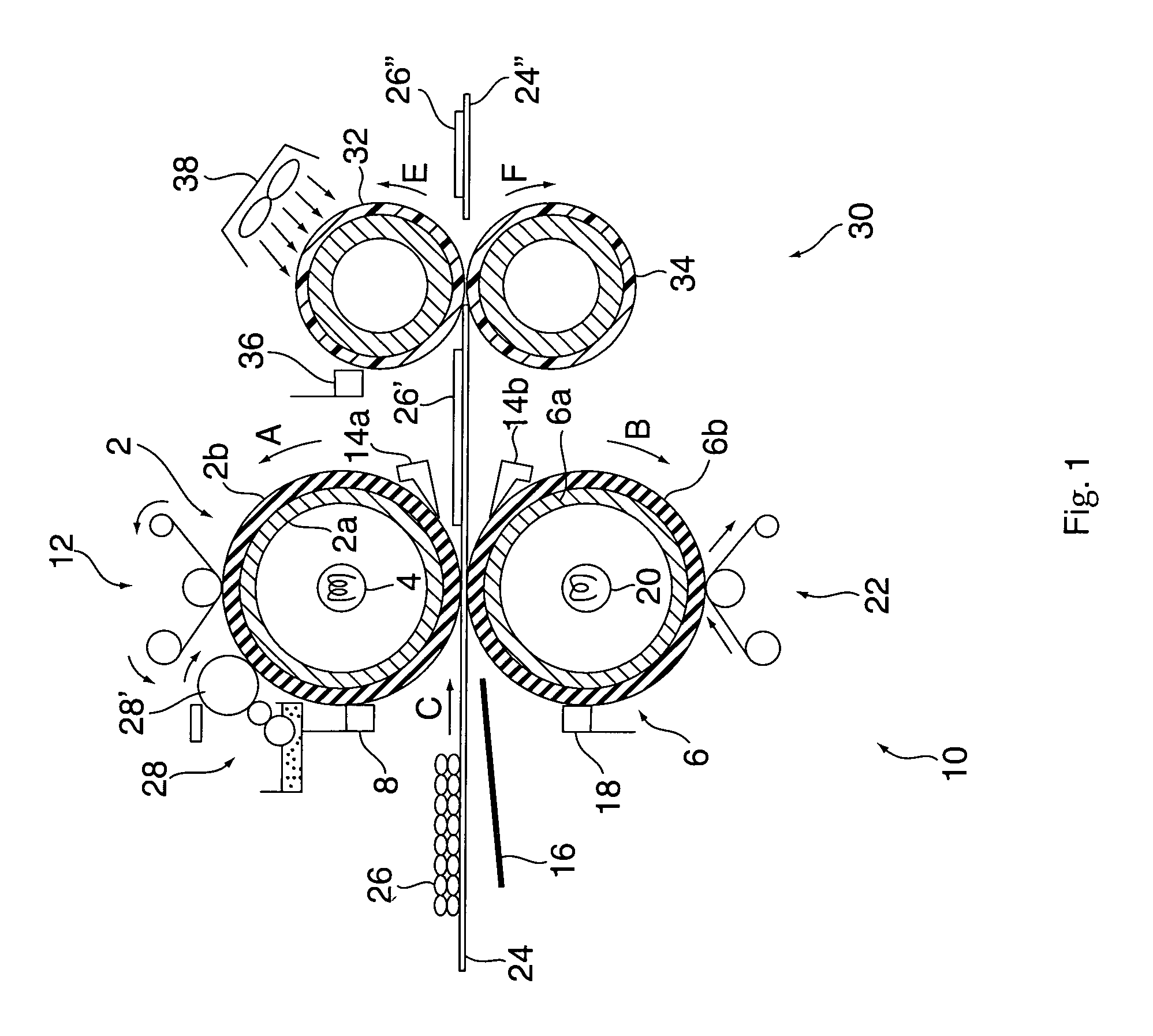

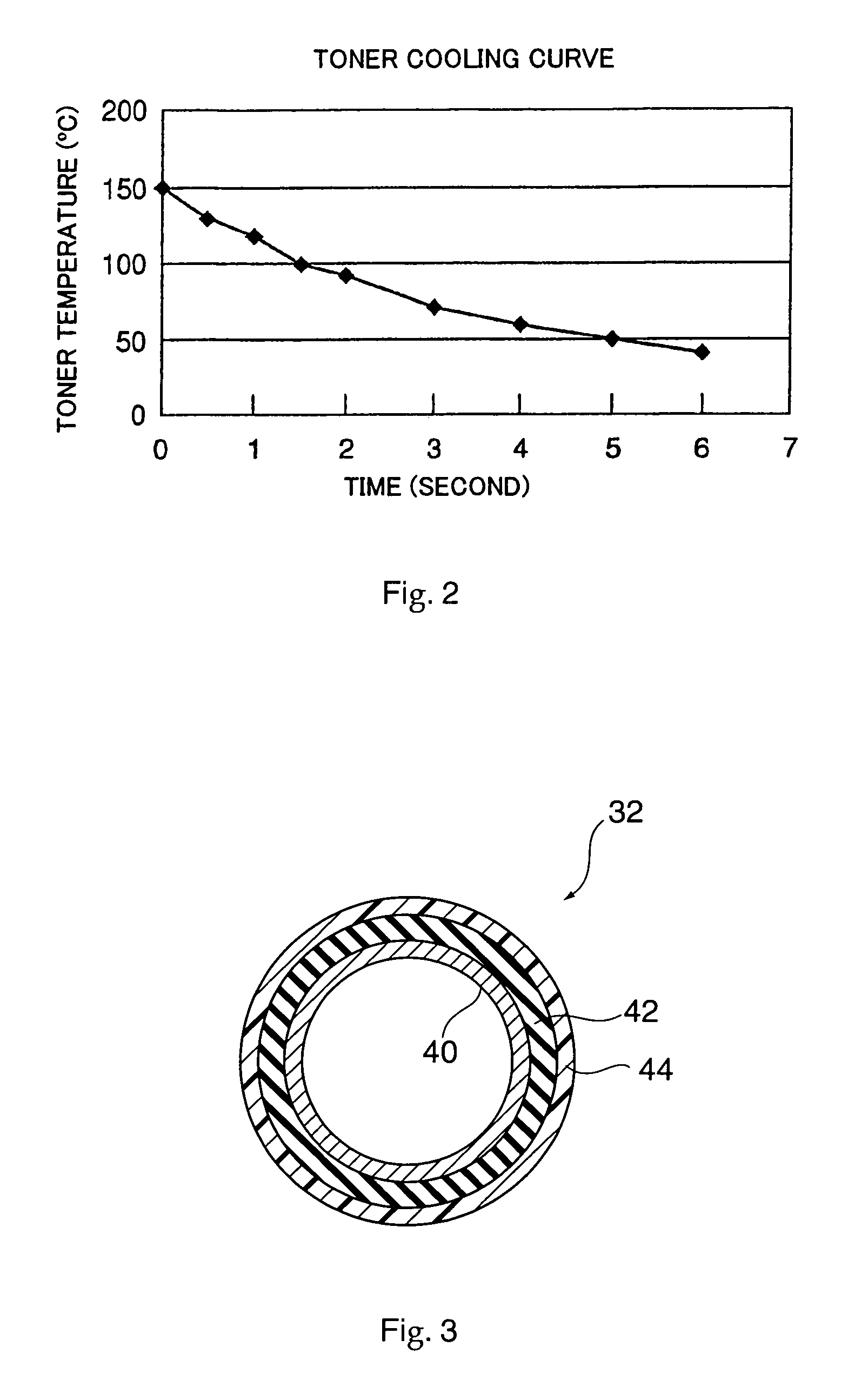

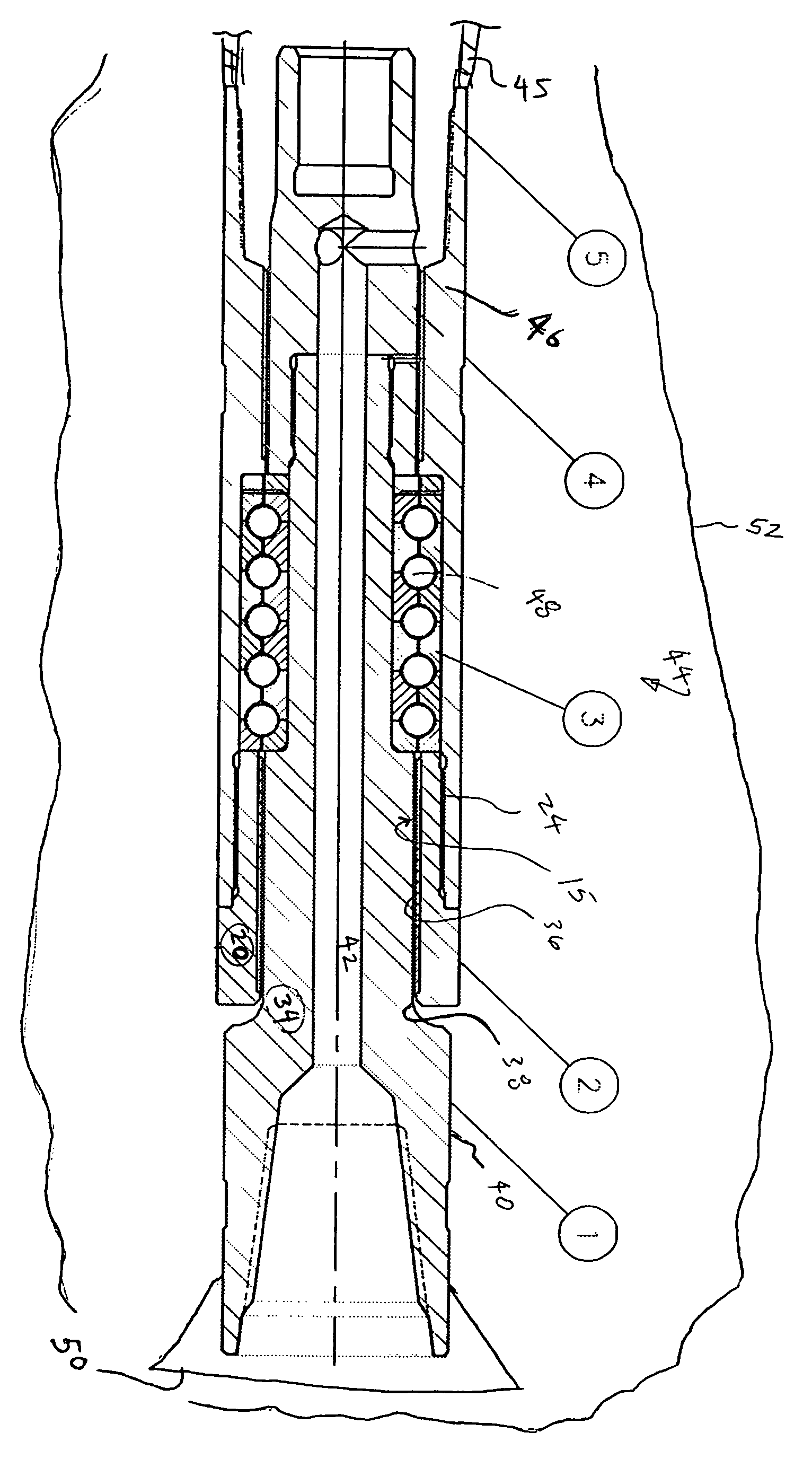

Fixing device, fixing method and image forming apparatus

InactiveUS6898388B2Image quality excellent in transparency of toner imageHigh glossElectrographic process apparatusImaging qualityImage formation

The present invention provides a fixing device and a fixing method, and an image forming apparatus using the fixing device, wherein at least heat is applied to an unfixed toner image formed on a recording material to soften or melt toner of the unfixed toner image into a state of being able to be deformed by an external force, and, while the toner is maintained in the state of being able to be deformed by an external force, the toner is pressed to be flowed with a pressing surface having a temperature adjusted to be lower than a temperature at which the toner can be deformed by an external force to be flowed, whereby it is possible to obtain an image which is free from wasteful energy consumption, and has image quality excellent in transparency of a toner image and in OHP permeability, and has a high glossiness and free from gloss nonuniformity, and with which curl is hardly caused in a recording material.

Owner:FUJIFILM BUSINESS INNOVATION CORP

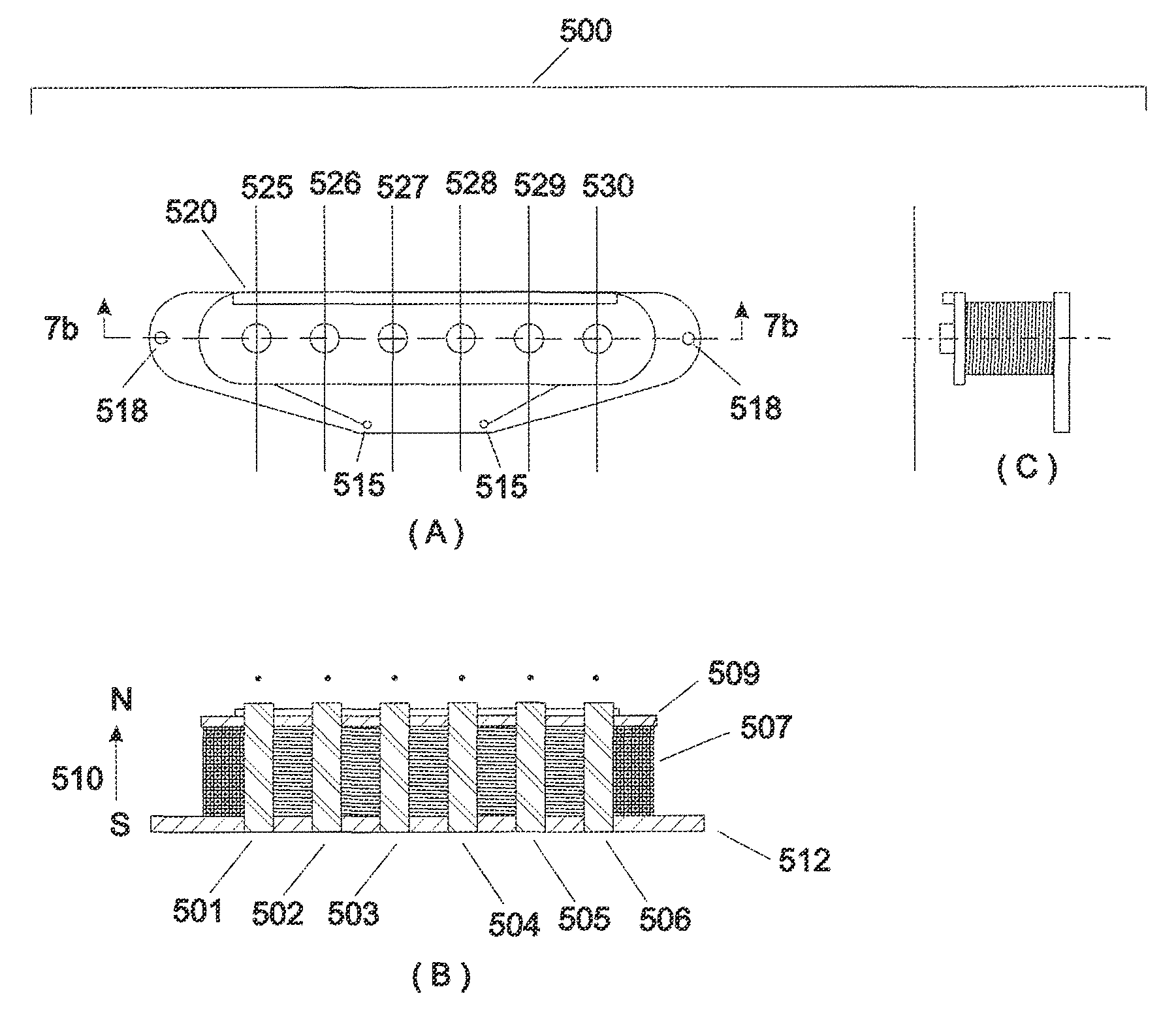

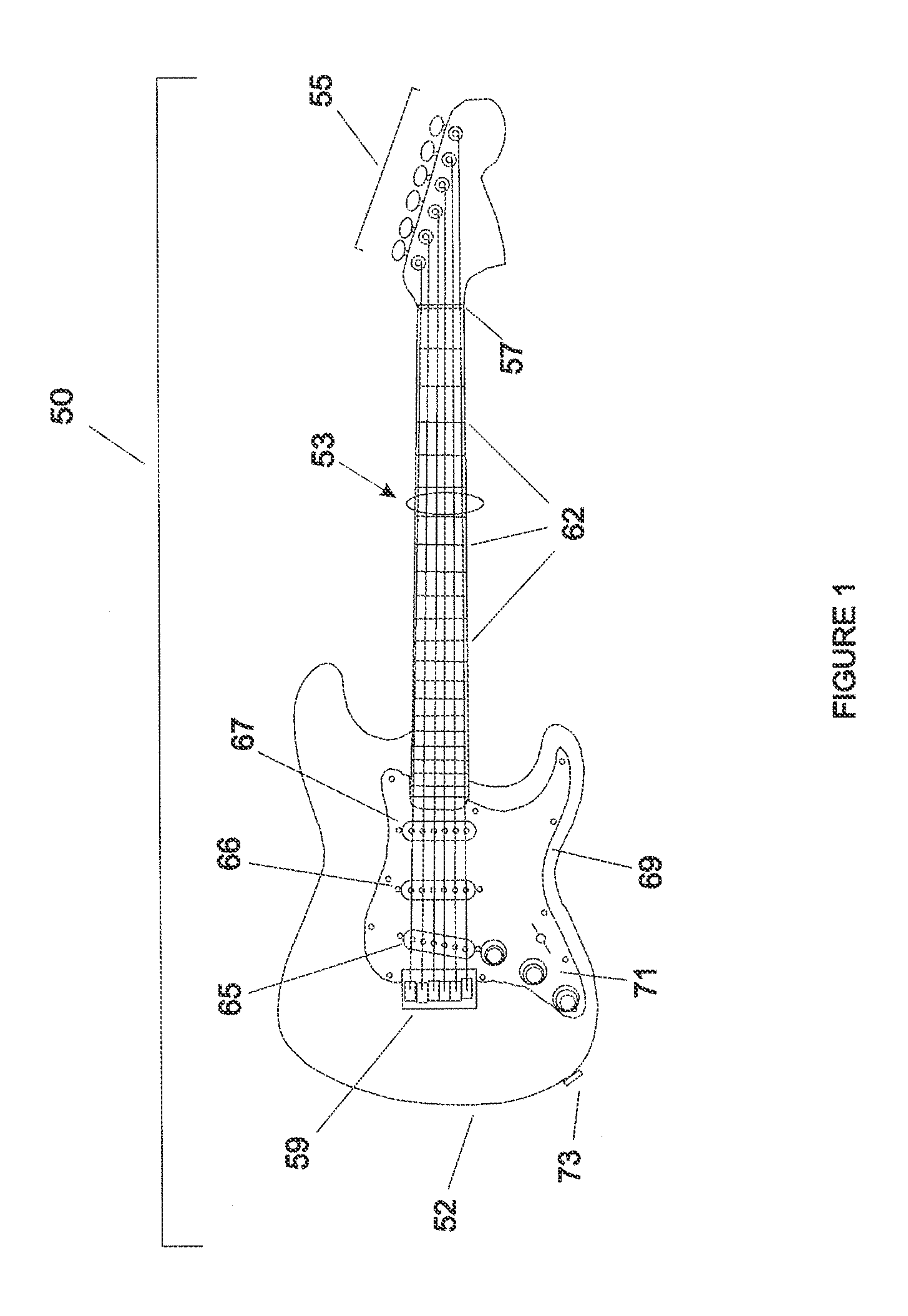

Musical instrument pickup with field modifier

InactiveUS8969701B1Simple and inexpensiveIncrease rangeElectrophonic musical instrumentsMagnetic sourceAcoustics

A magnetic pickup for a stringed musical instrument with a secondary magnetic source that modifies the primary magnetic field distribution of the pickup. The secondary source comprises at least one permanent magnet and may further comprise a ferromagnetic loss component. A method for retrofitting and changing the tone of a pickup by attaching one or more secondary magnetic sources to the pickup.

Owner:DIXON GEORGE J

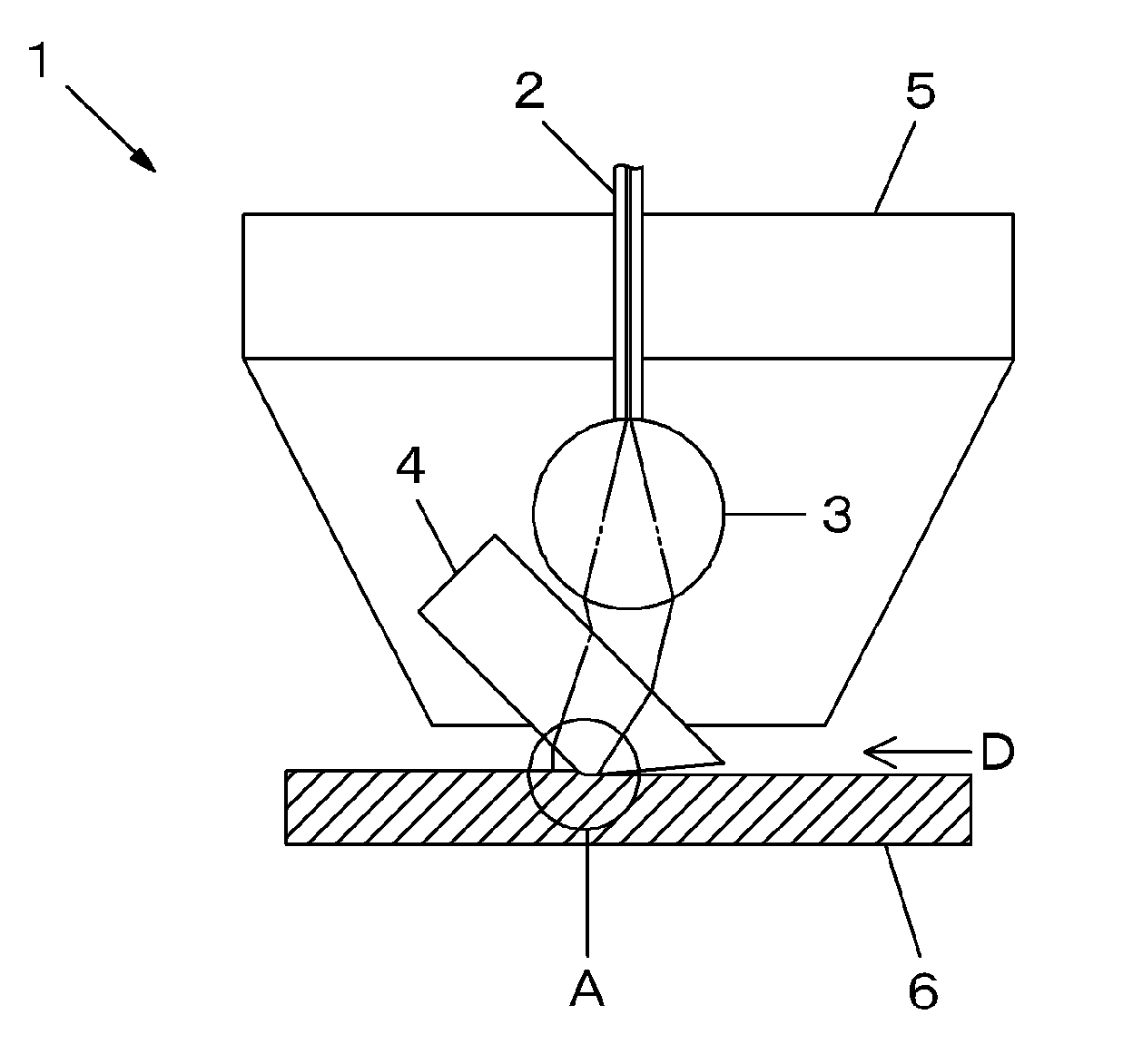

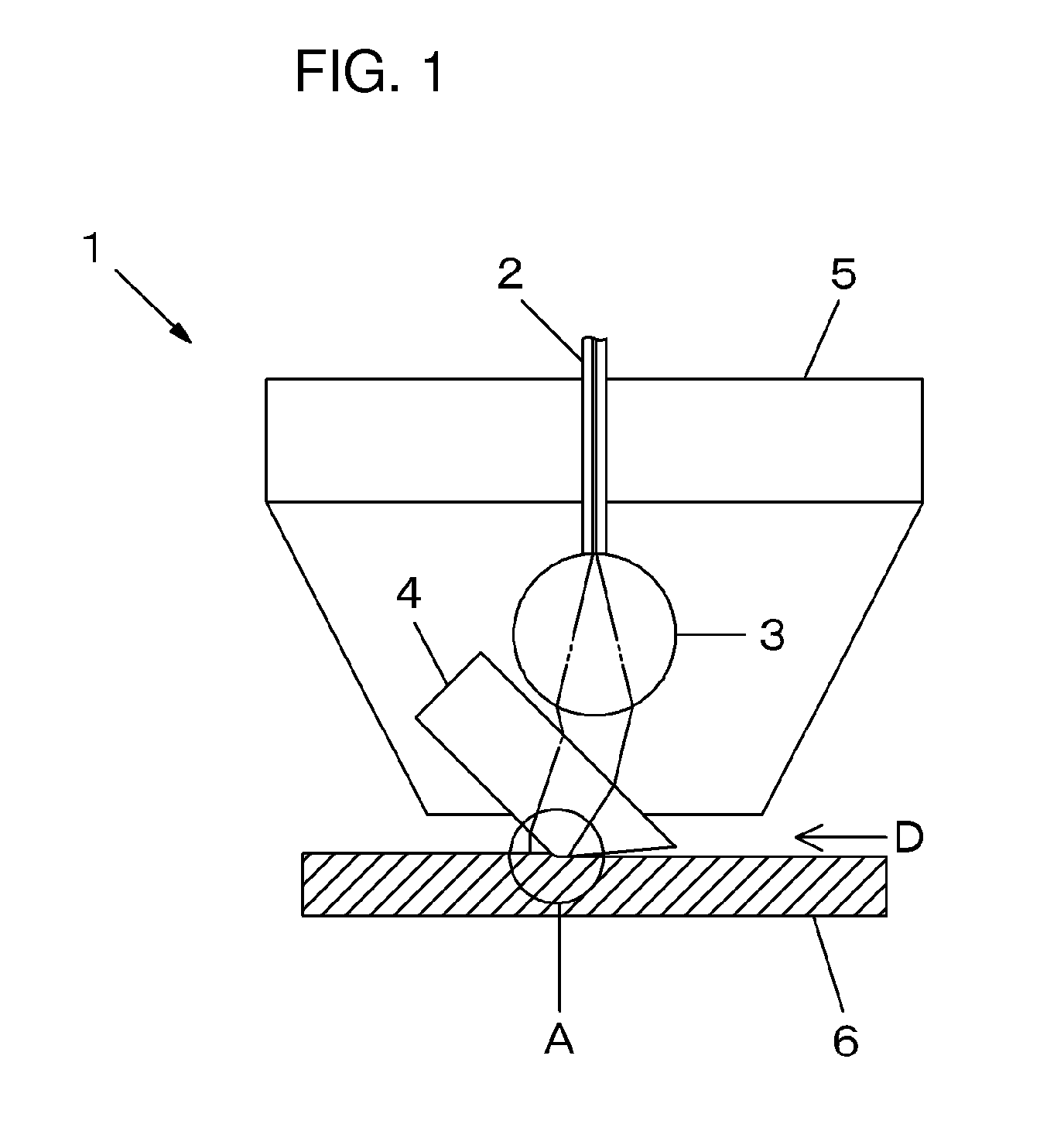

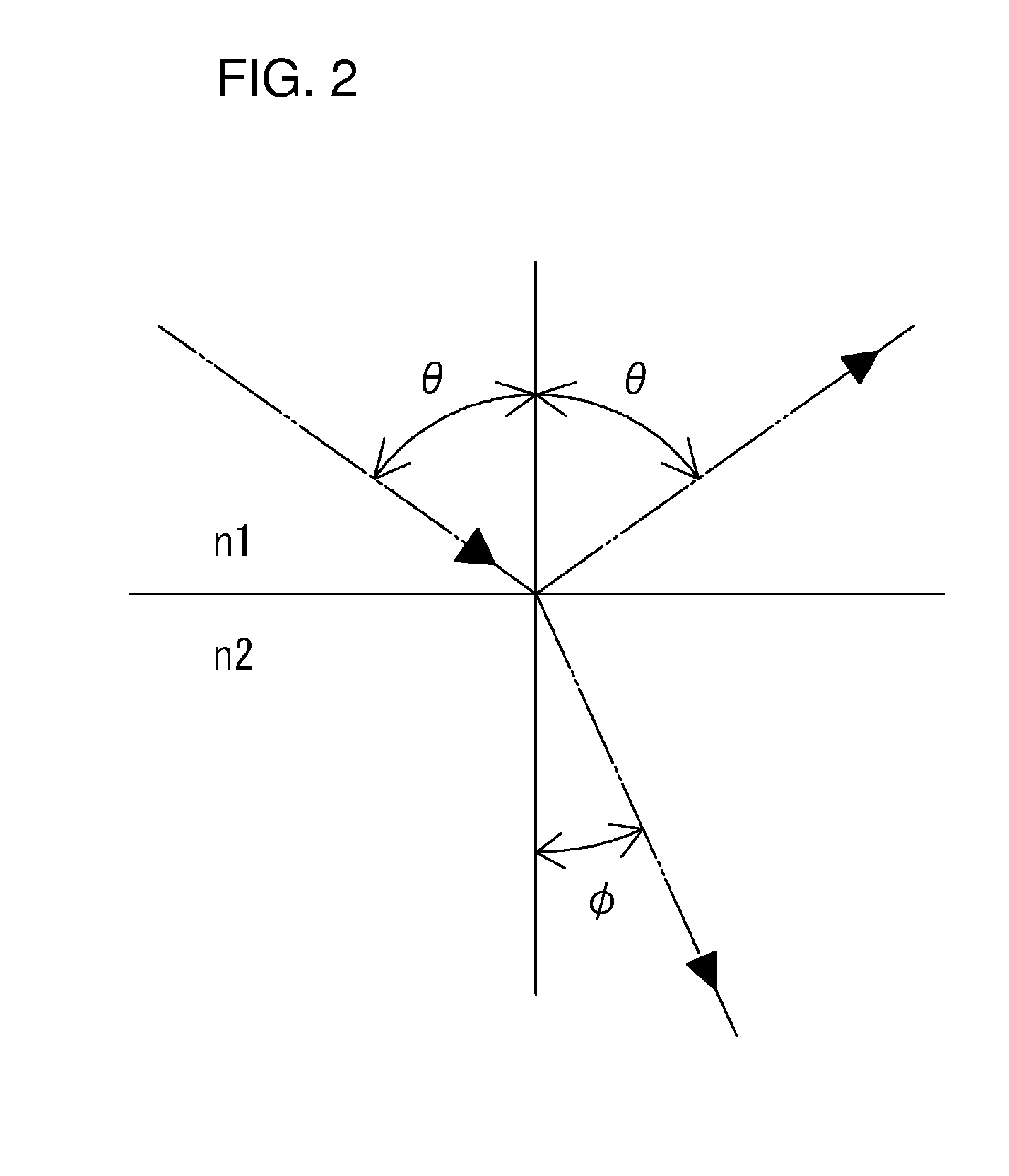

Cutting tool and cutting method

InactiveUS20150217418A1Improve efficiencyAvoid reflectionsTurning toolsShaping cuttersLaser lightMaterials science

A cutting tool for cutting a hard brittle material is formed from a light-transmittable material through which laser light can pass and is provided with a rake angle, the laser light is propagated through the cutting tool, the cutting tool and the hard brittle material are brought into contact with each other, the laser light is incident to at least a contact part where the cutting tool and the hard brittle material are in contact with each other and a part with the rake angle, the laser light except for Fresnel reflection light on an end surface of the cutting tool is incident to the hard brittle material through the contact part and the rake angle part to soften the hard brittle material, and the softened hard brittle material is cut.

Owner:ADAMANT IND +1

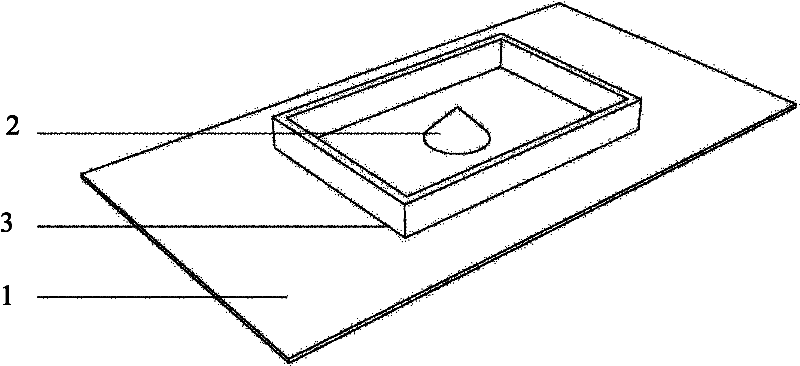

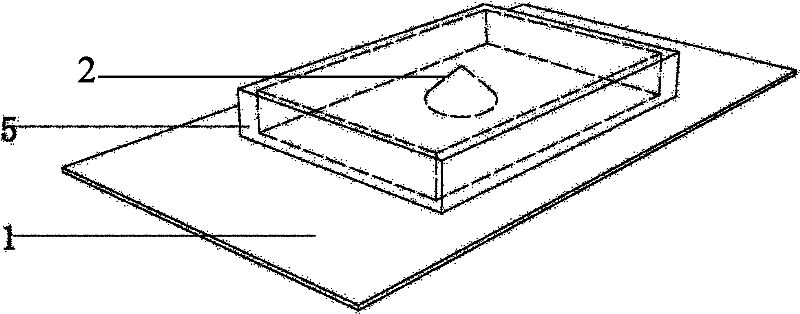

Rapid product remodeling method, mold and rapid product molding method

The invention relates to a rapid product remodeling method, a mold and a rapid product molding method. The rapid product remodeling method comprises the following steps of: fixing a product, namely fixing a prototype of the product on a bottom plate, and coating a demolding agent; manufacturing a surrounding mold, namely surrounding a rubber plate at the periphery of the prototype of the product; pouring glue and curing, namely pouring the glue in the surrounding mold to cover the prototype of the product and curing; manufacturing a sleeve mold, namely removing the rubber plate after the glue is cured, and manufacturing the sleeve mold outside a rubber mold through gypsum; and cutting the product, namely removing the sleeve mold, taking the rubber mold down from the bottom plate, cutting the rubber mold along a preset water gap position to take the prototype of the product out, and thus obtaining the rubber mold and the sleeve mold of the product. The process is simple and easy to learn and has extremely low cost, precise products can be manufactured, are made of hard materials and are difficult to deform, the method is suitable for manufacturing hand plate models and artware, and the problems of incapability of unifying cost, time and products of medium / small-scale production are solved.

Owner:华强方特(深圳)智能技术有限公司

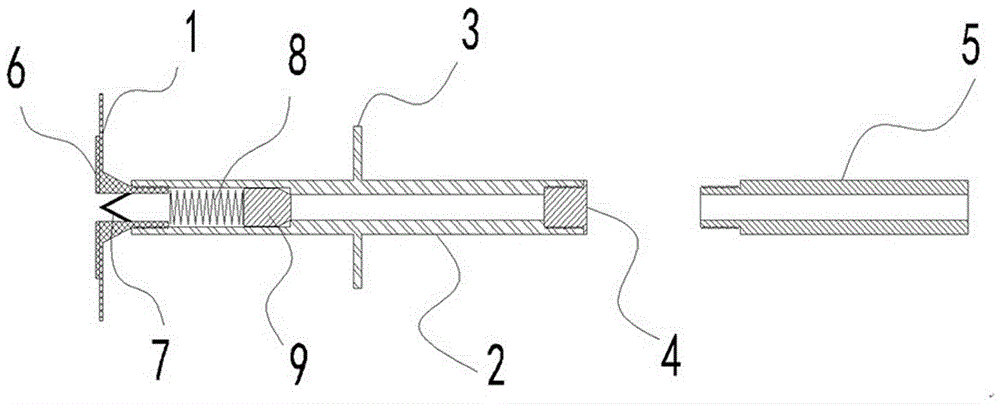

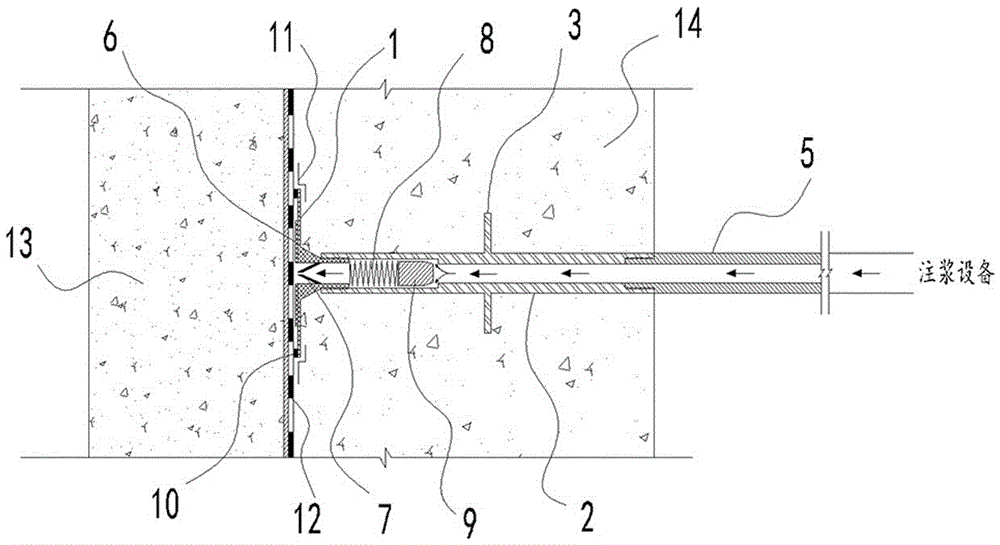

Grouting system and grouting method used for composite lining structure backfill and grouting

ActiveCN105697034ASolve the problem that grouting cannot be repeatedRealize repeated groutingUnderground chambersTunnel liningScrew threadGrout

The invention discloses a grouting system and a grouting method used for composite lining structure backfill and grouting.The grouting system comprises a one-way non-return suction cup, a one-way non-return grouting pipe, a water-stopping ring, a sealing plug and a connection pipe, wherein the one-way non-return suction cup is composed of a grouting disc and a non-return hole; the one-way non-return grouting pipe comprises a grouting pipe first end and a grouting pipe second end, a one-way valve is arranged at the grouting pipe first end, and the grouting pipe first end is communicated with a grout inlet of the grouting disc through a screw thread; the water-stopping ring is located on the outer wall of the middle of the one-way non-return grouting pipe; the sealing plug is connected with the grouting pipe second end through a screw thread; the connection pipe comprises a first end and a second end; the first end of the connection pipe is connected with the grouting pipe second end are connected through a screw thread, and the second end of the connection pipe is used for being connected with grouting equipment.The water-stopping ring is additionally arranged on the middle of the grouting pipe, and the water-stopping effect of a contact face between the outer wall of the pipe and a secondary lining structure can be effectively improved.The one-way non-return suction cup is arranged at the tail end of the one-way non-return grouting pipe, repeated grouting can be achieved, and the defect that a traditional grouting system cannot achieve repeated grouting is overcome.

Owner:BCEG CIVIL ENG

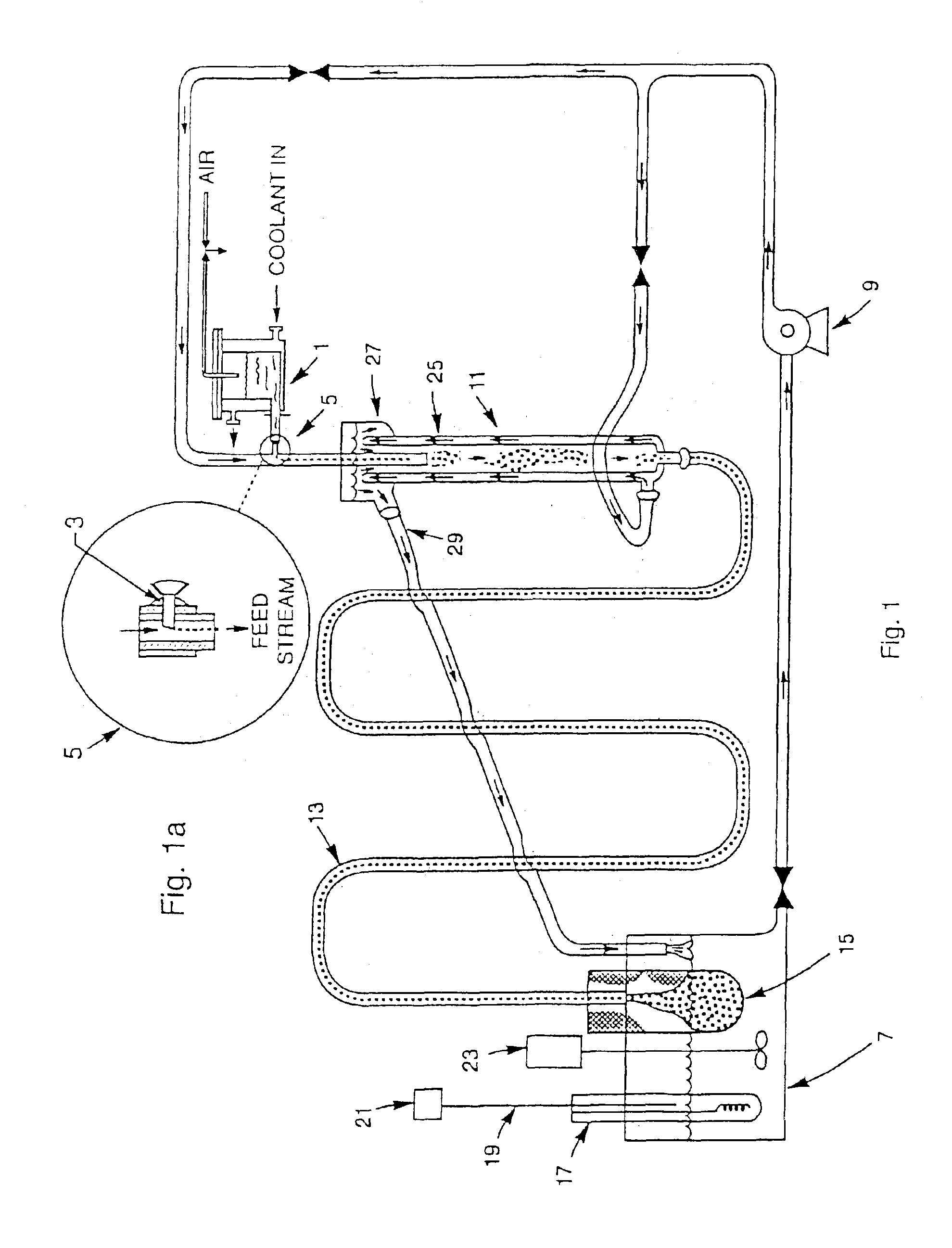

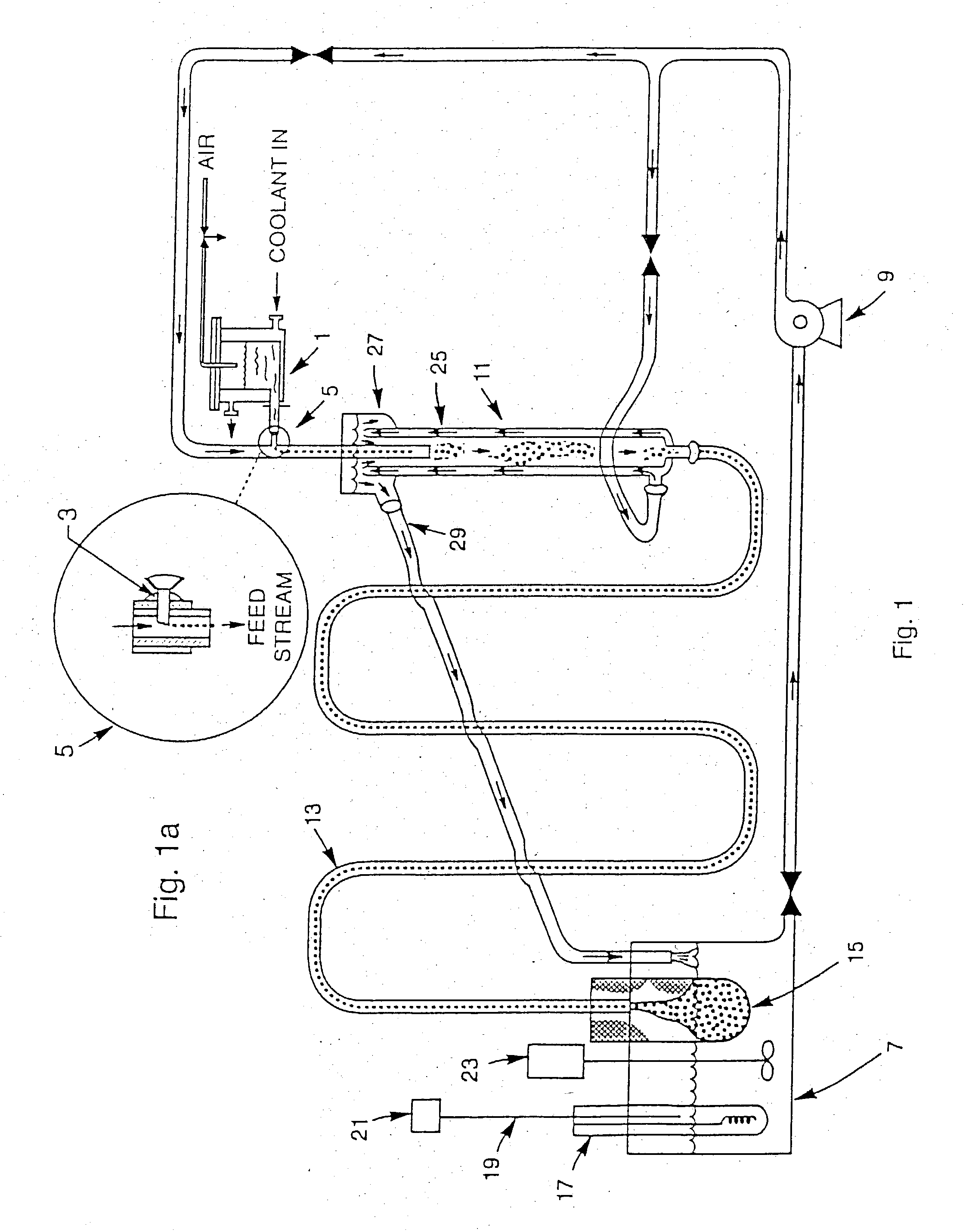

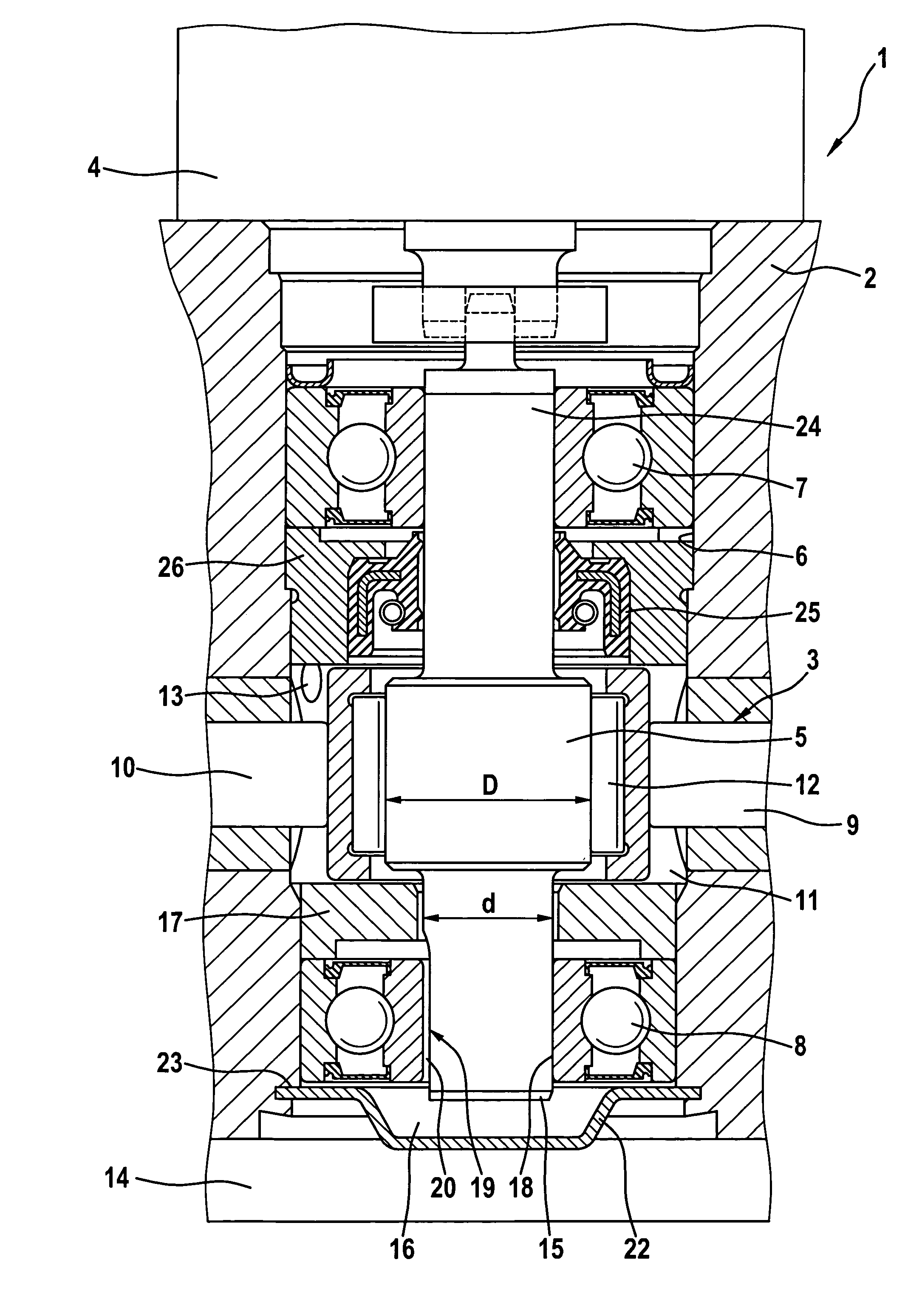

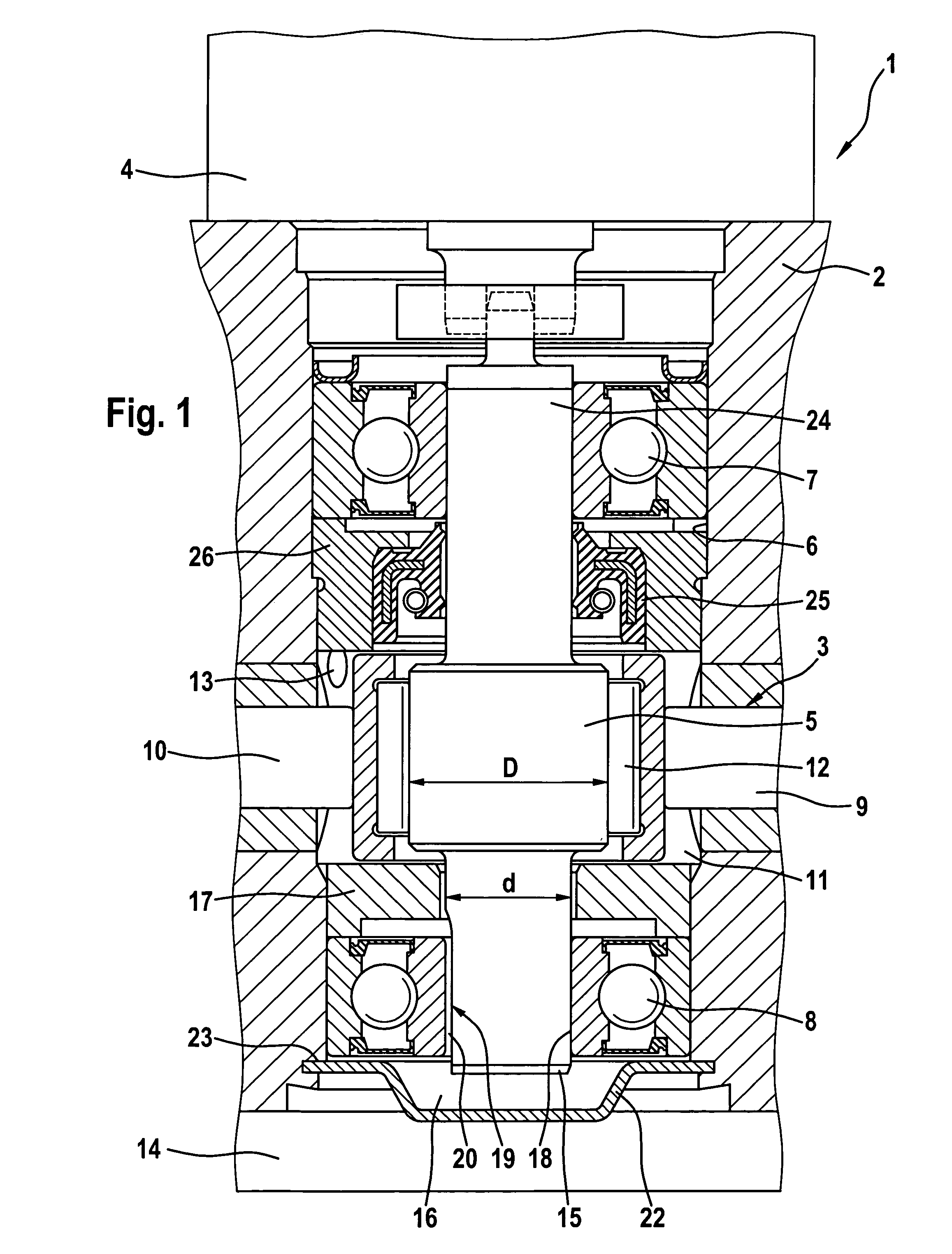

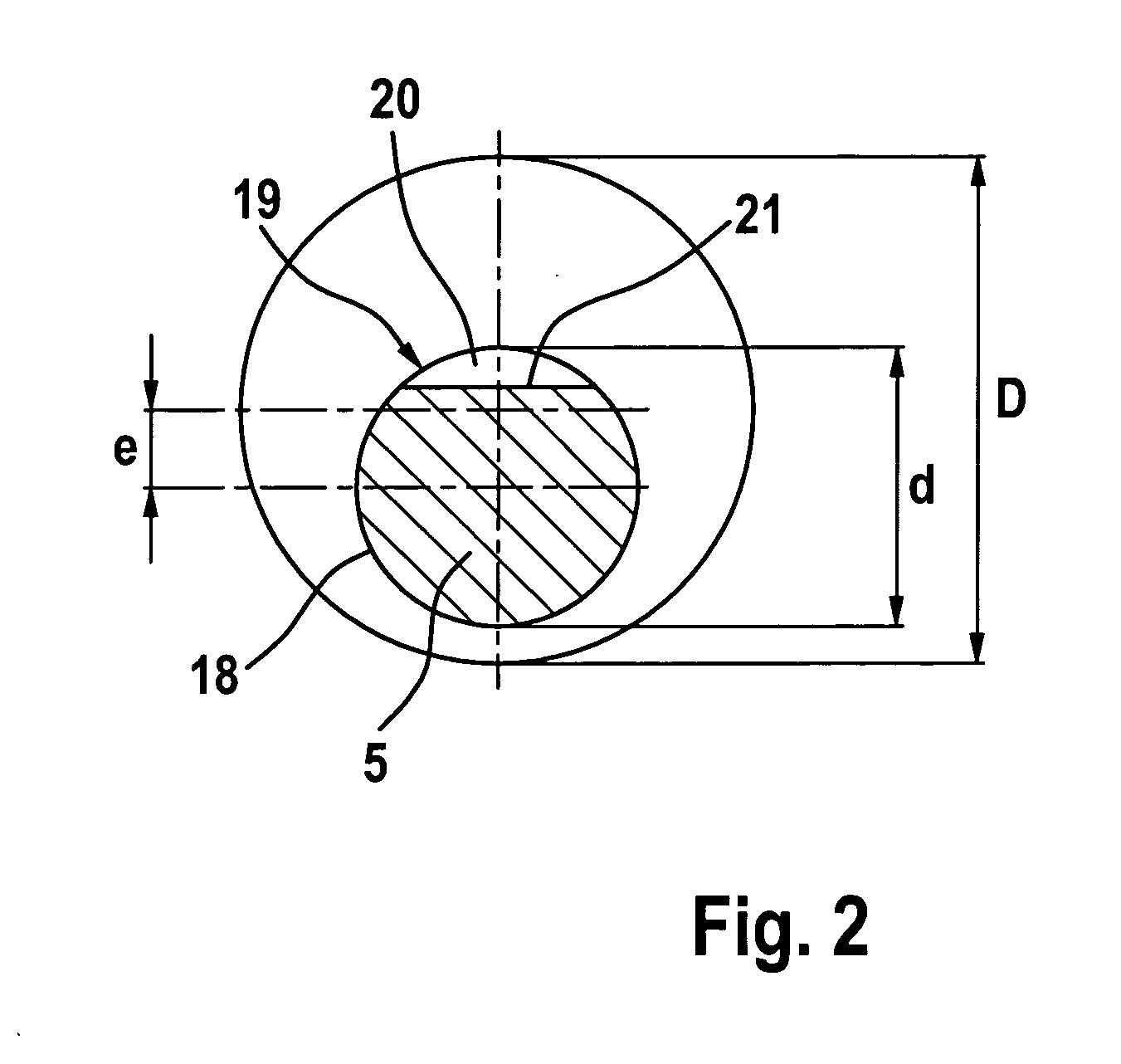

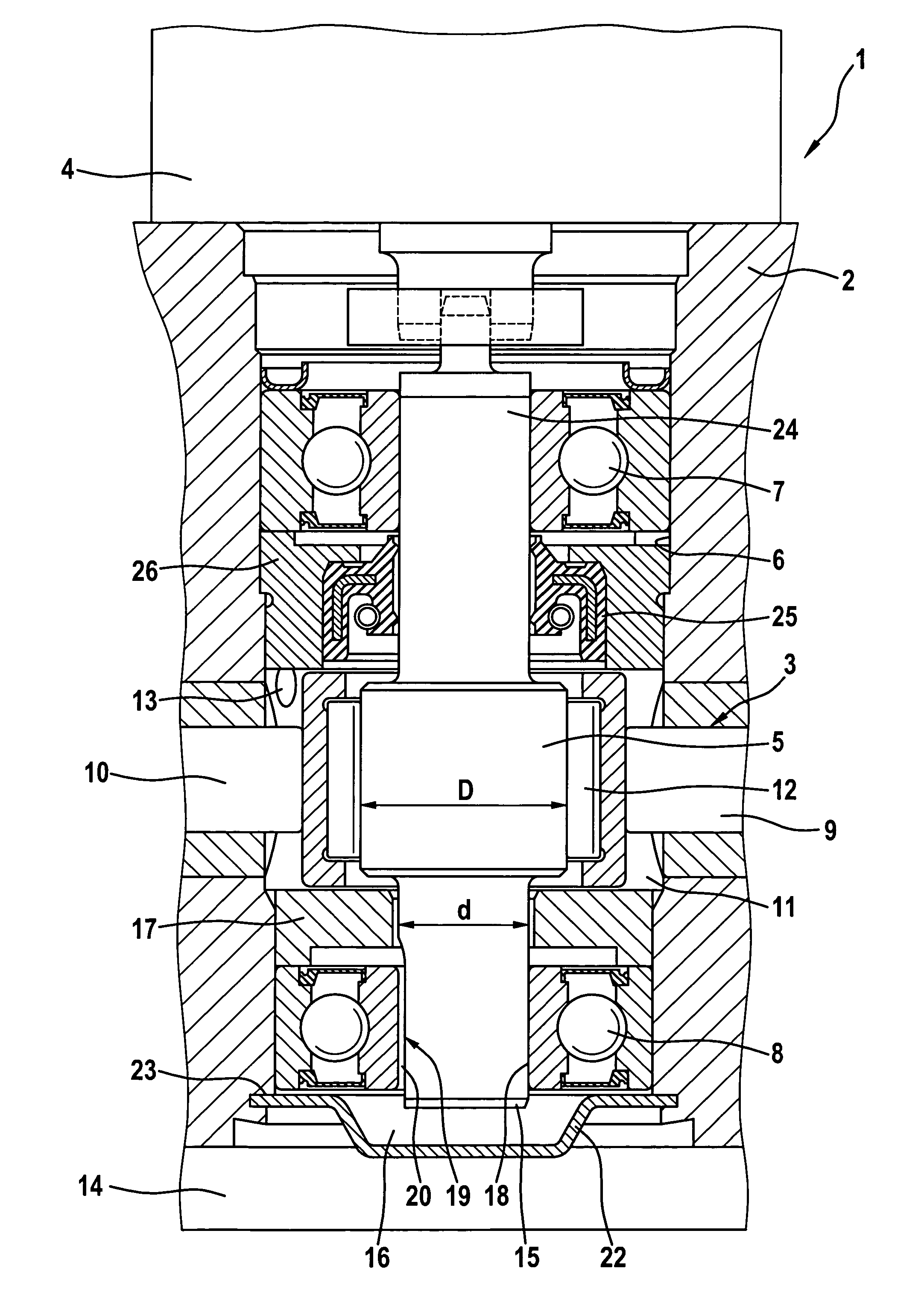

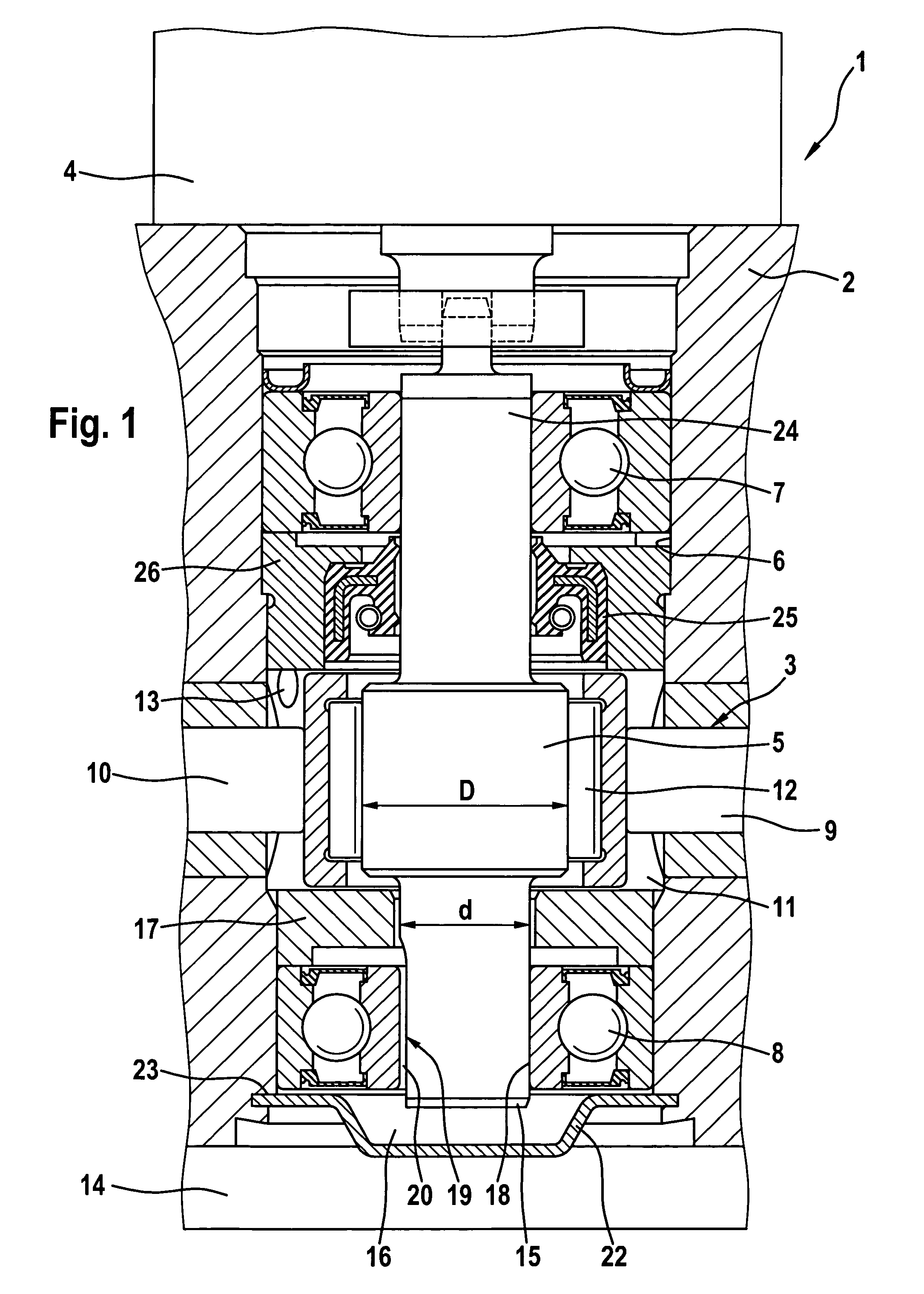

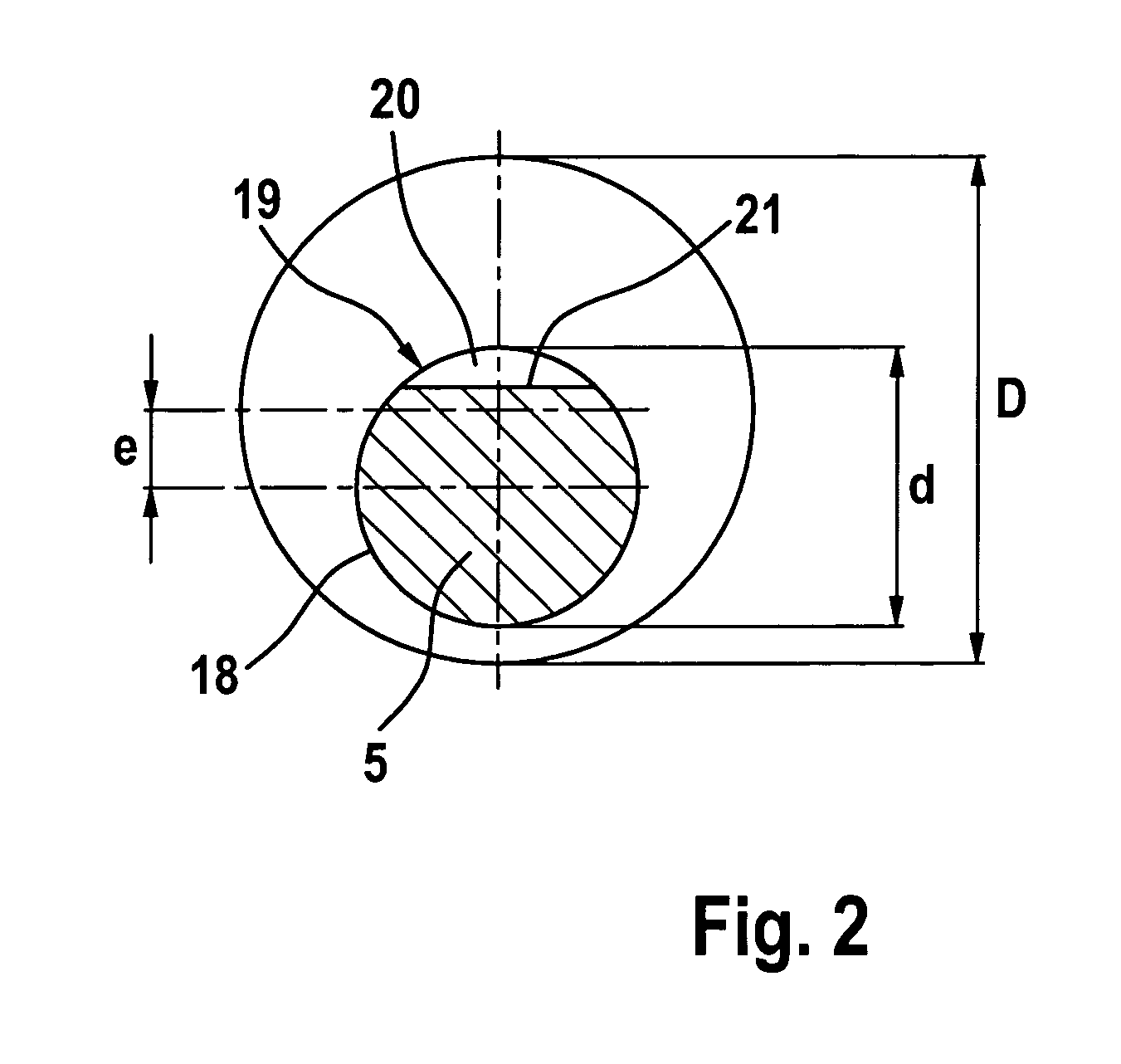

Motor-pump unit

InactiveUS20060056995A1Risk of harmProtection washoutPositive displacement pump componentsPiston pumpsEngineeringBraking system

The invention relates to a motor-pump unit for a motor vehicle brake system, comprising a motor and a pump which is provided with a shaft that is driven by said motor, with the shaft end being rotatably mounted by means of at least one bearing in an accommodating member having valves and connecting channels, said shaft driving displacement means which are disposed in a chamber that can be filled with pressure fluid. In order to improve vacuum filling of the brake system with pressure fluid, the invention discloses that the shaft end terminates into a free space, and that at least one connection is provided between the free space and the chamber.

Owner:CONTINENTAL TEVES AG & CO OHG

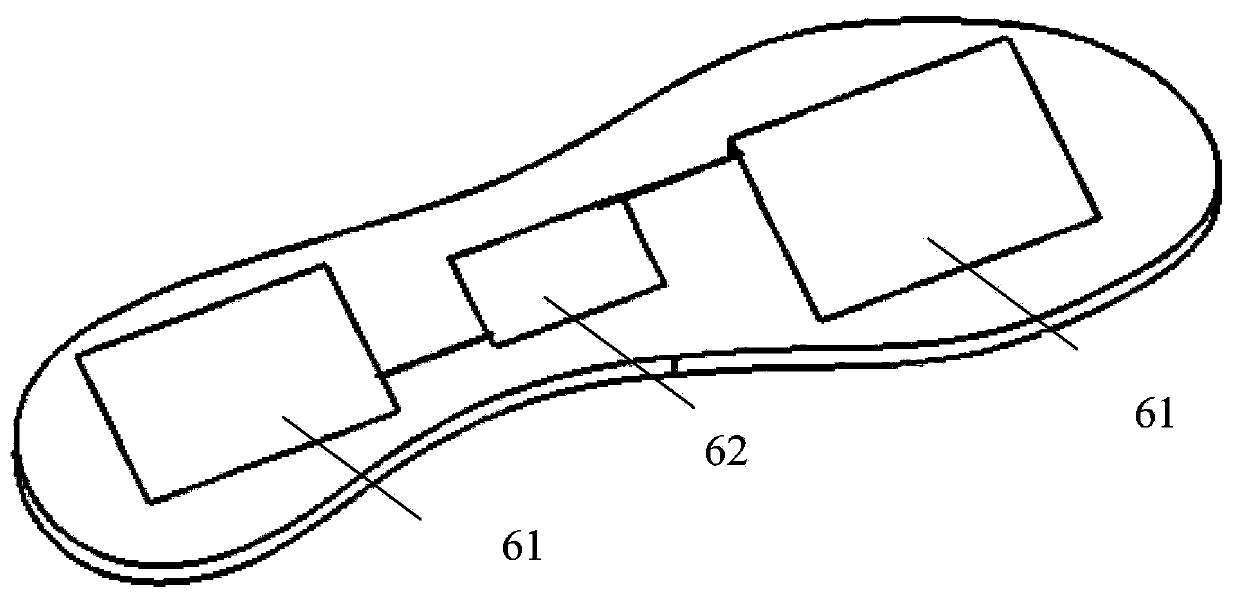

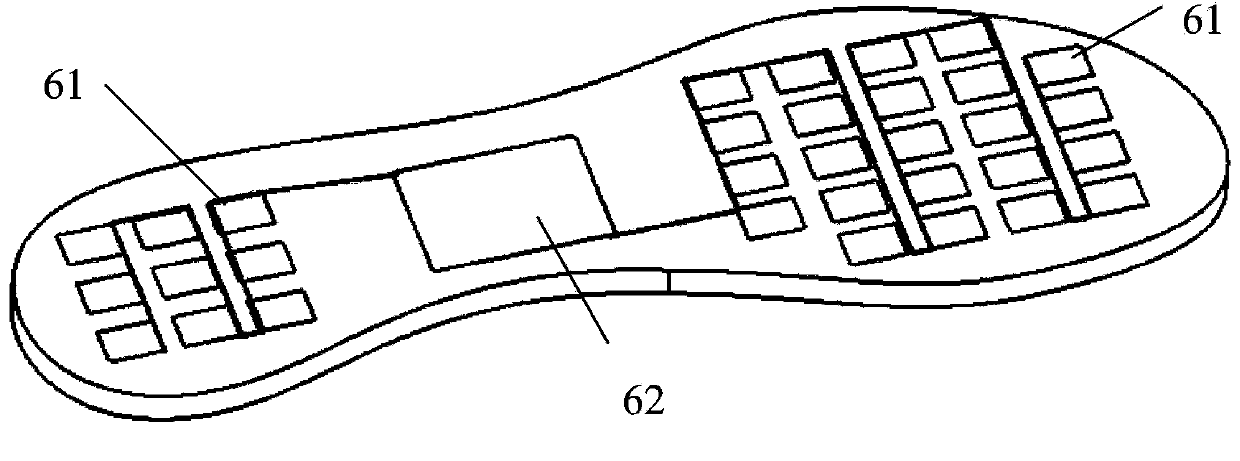

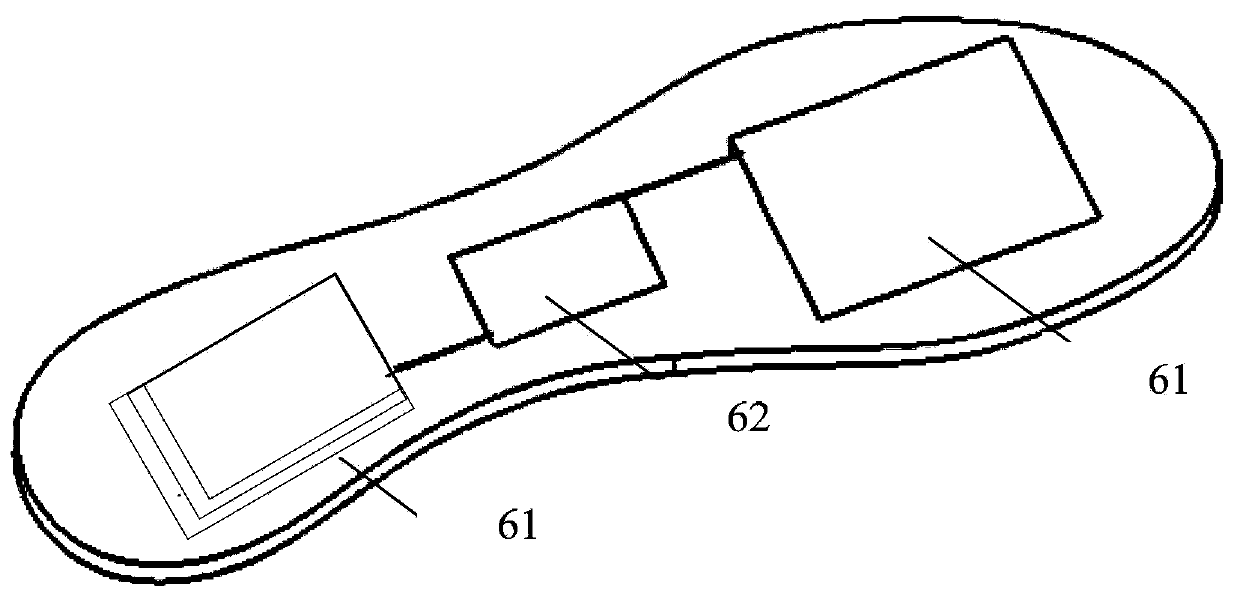

Power generation shoe

The invention discloses a power generation shoe. The power generation shoe is used for solving the problems of complex structure, low power generation efficiency and discomfort in wearing of an existing power generation shoe. The power generation shoe comprises a nanometer friction generator used for converting mechanical energy into electric energy and an electrical storage device connected with the nanometer friction generator and used for storing the electric energy generated by the nanometer friction generator.

Owner:NEWNAGY TANGSHAN

Ice-crack-shaped polished crystal tile and manufacturing method thereof

The invention discloses an ice-crack-shaped polished crystal tile comprising a ceramic tile blank, a coloured glaze layer, an ice crack layer and a transparent frit layer, wherein the coloured glaze layer comprises the following components in percentage by mass: printing glaze, glaze pigment, kaolin, methylcellulose and sodium tripolyphosphate; the ice crack layer is made of ice flower crystals with crystal glaze as the main material. The ice-crack-shaped polished crystal tile is manufactured sequentially through the steps: manufacturing a flower net; blending coloured glaze; pushing-printing the coloured glaze and ice flower crystal powder; pushing-printing frit particles; firing; and polishing. According to the invention, a crystal effect liked by people is integrated into the transparent frit layer of the polished crystal tile to form a snowflake-like natural, clean and varied embedded crystal effect, so that the tile with the novel technology has stronger decorative performance; the manufacturing method of the ice-crack-shaped polished crystal tile is simple and rapid, capable of realizing large-batch mechanical production under the condition of no great change of the original equipment, extremely simple in operation and capable of realizing flexible production for tiles with different deigned styles.

Owner:FOSHAN MAY ROSE CERAMIC

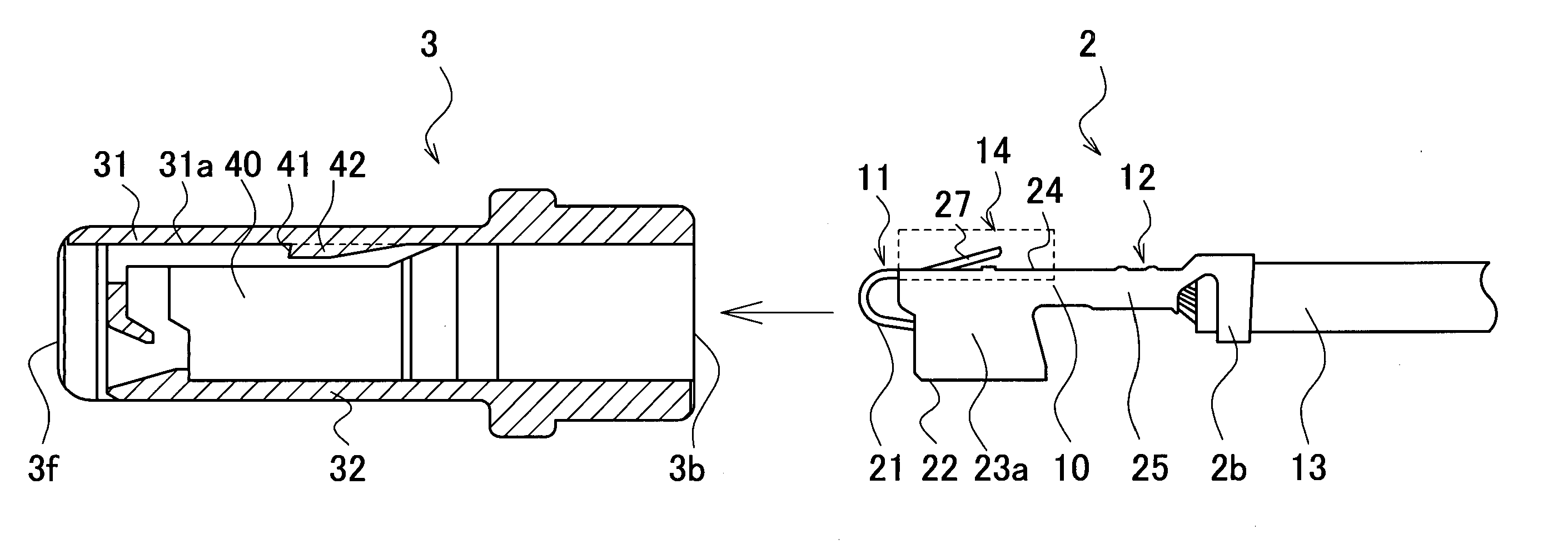

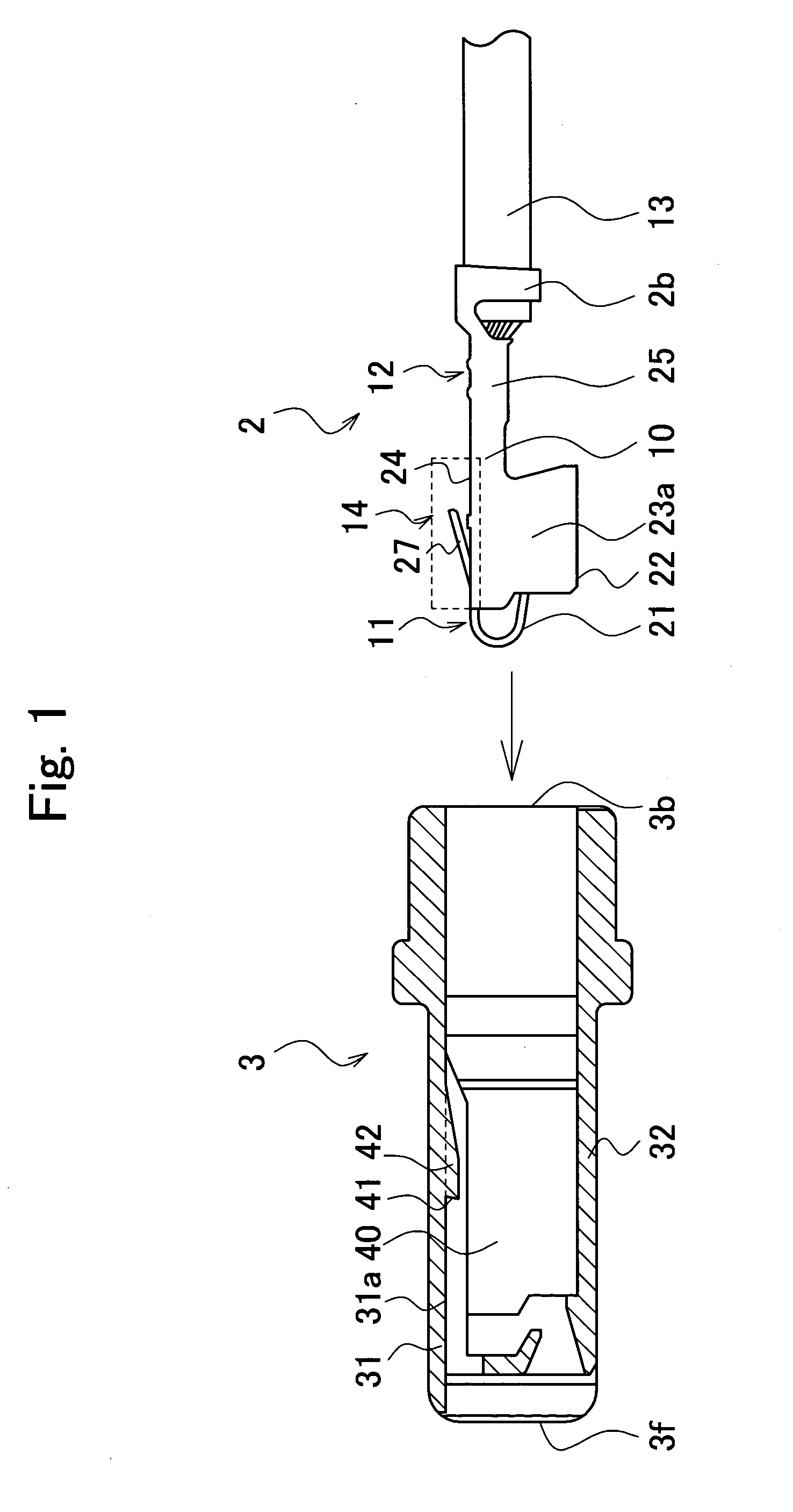

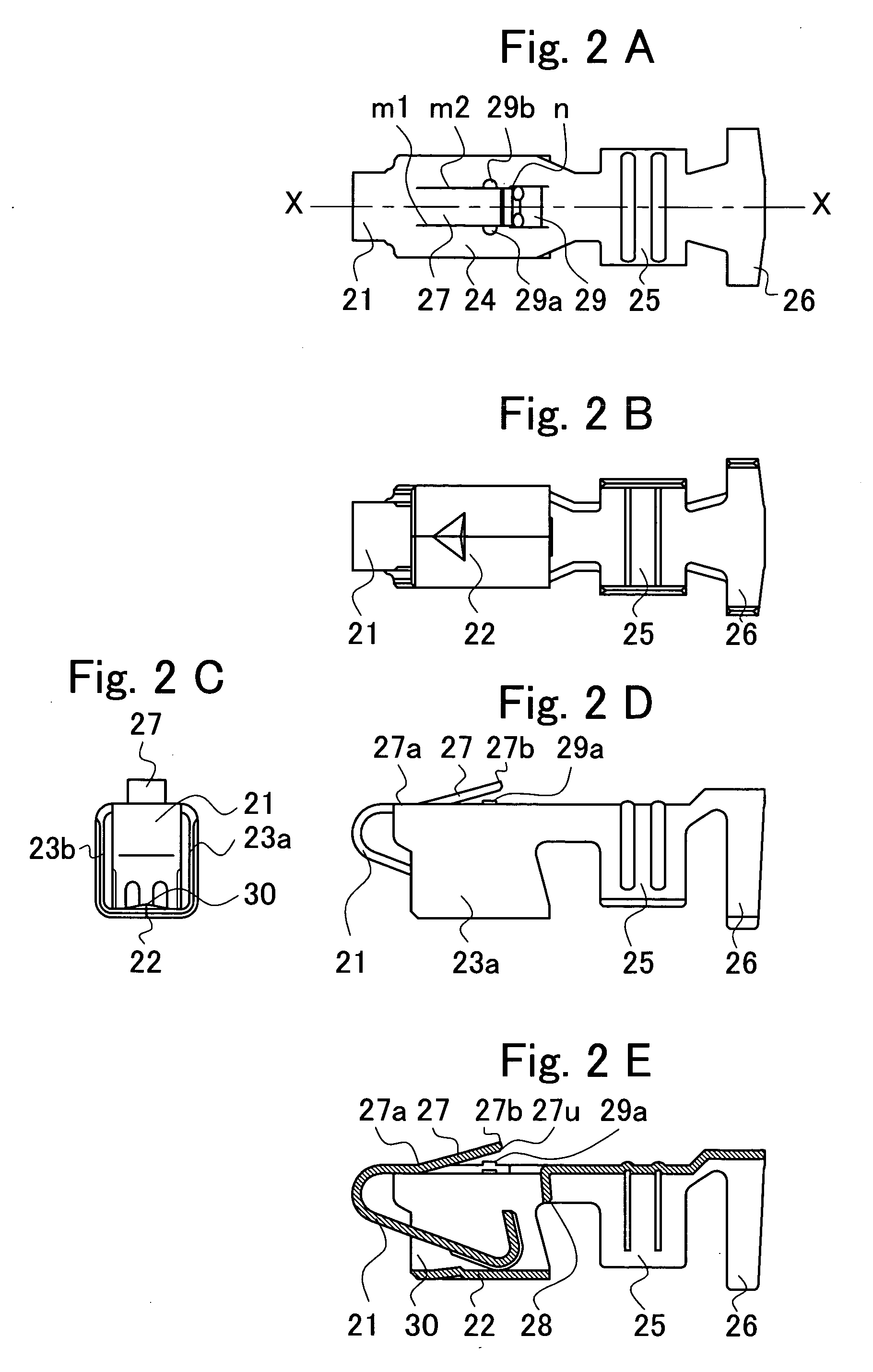

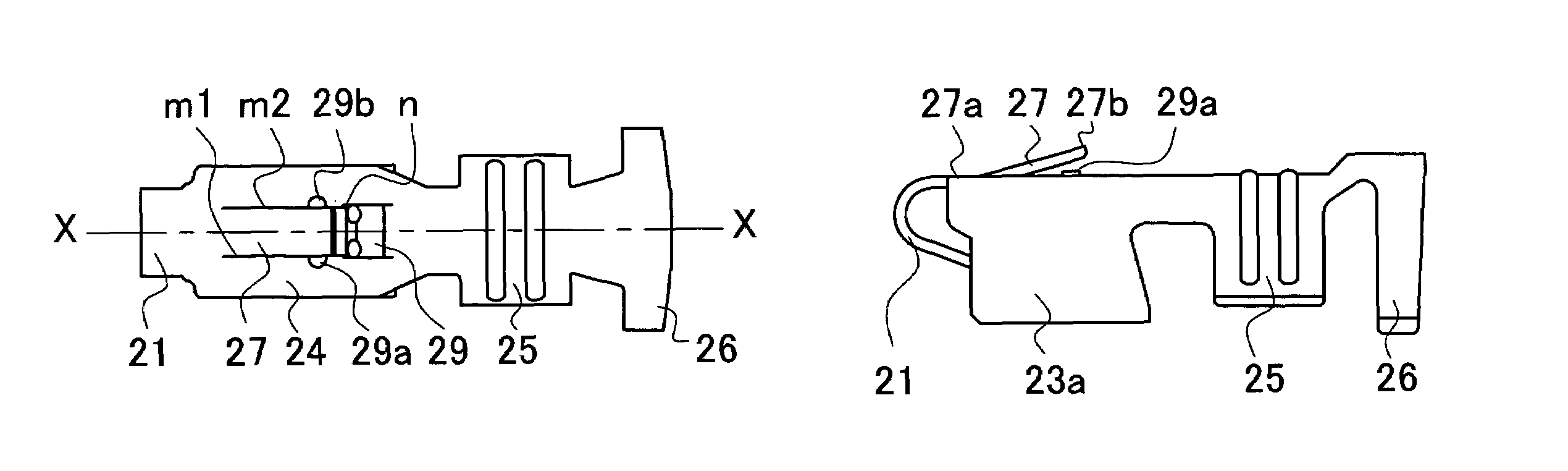

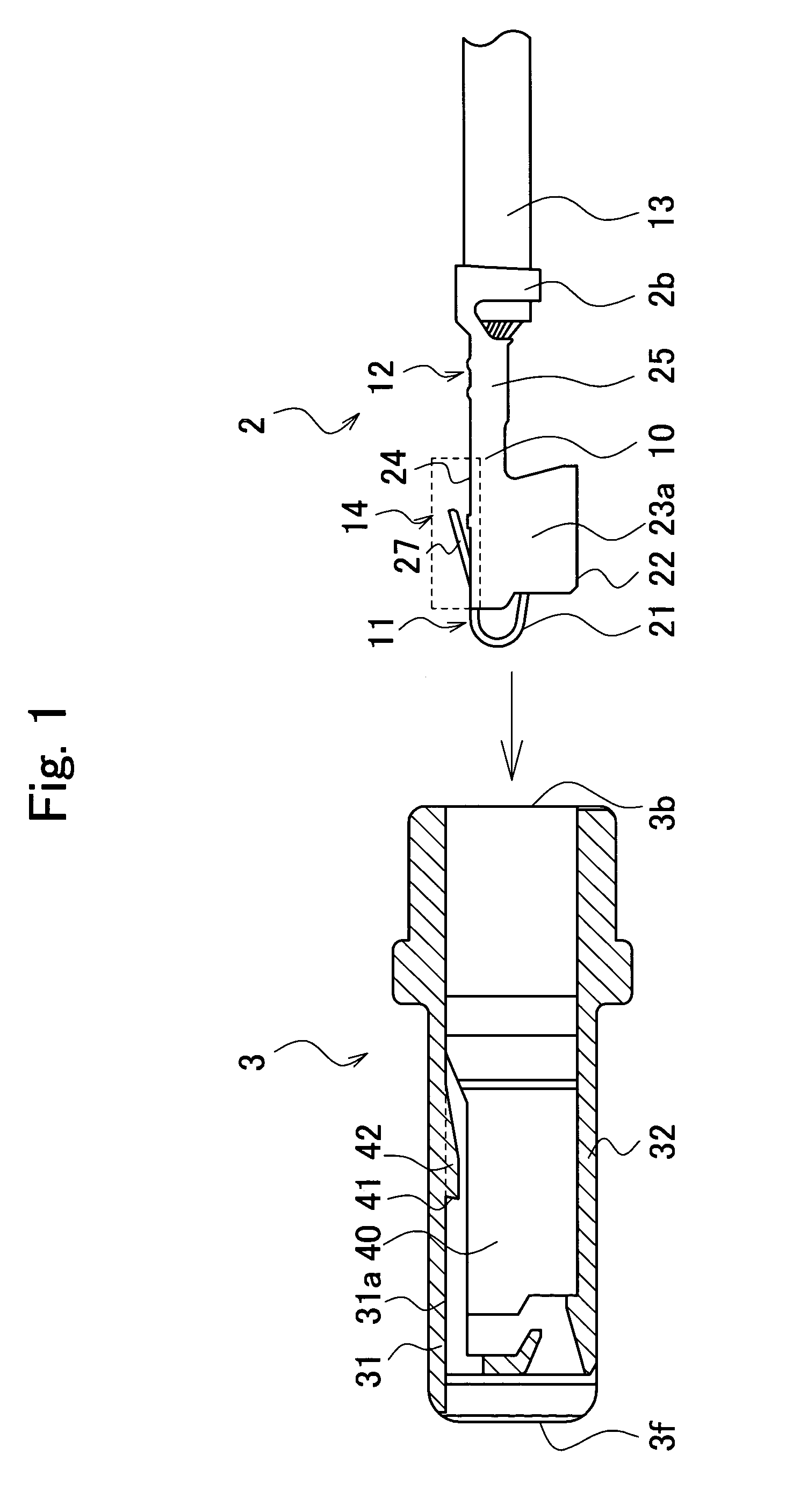

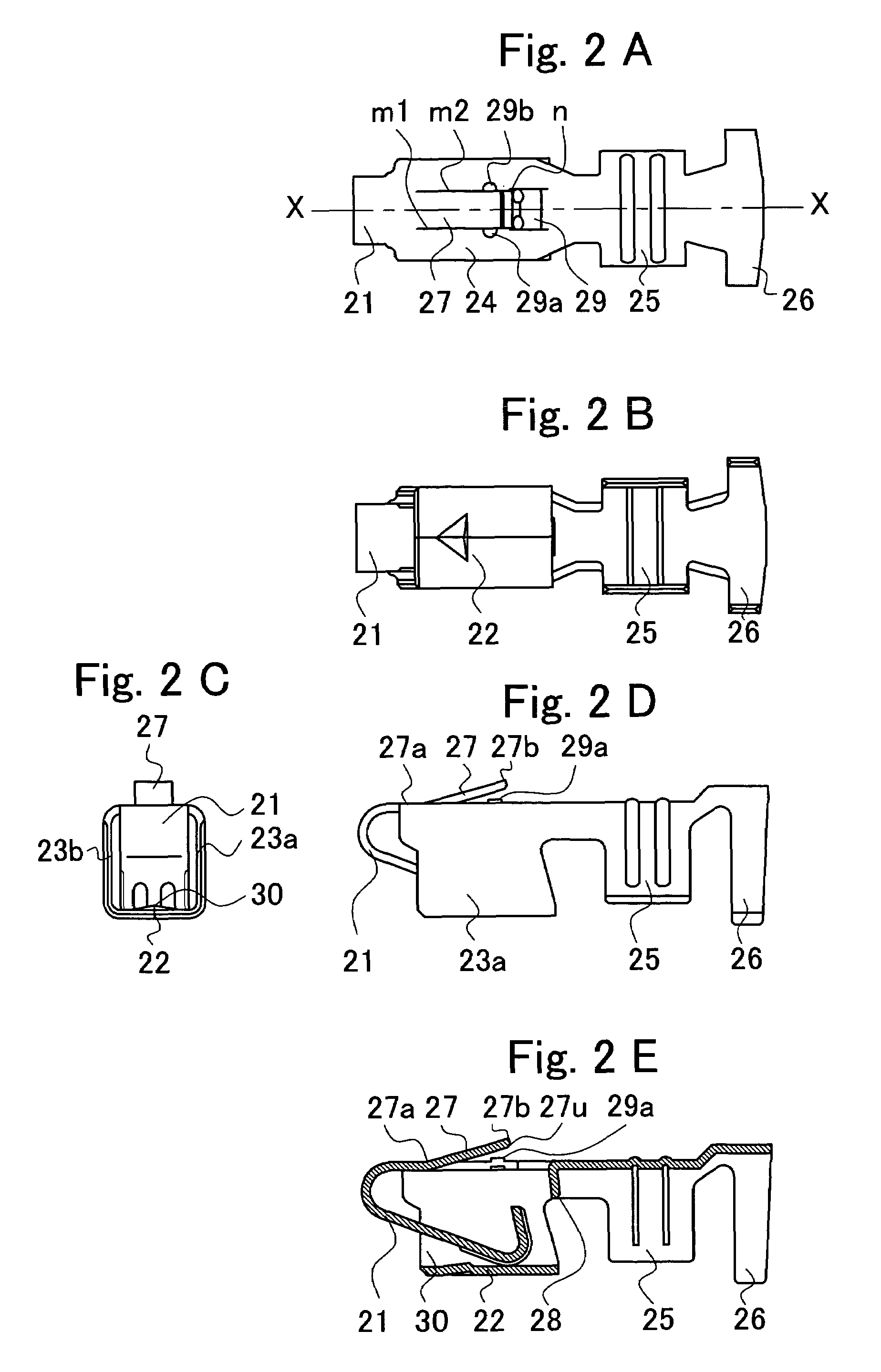

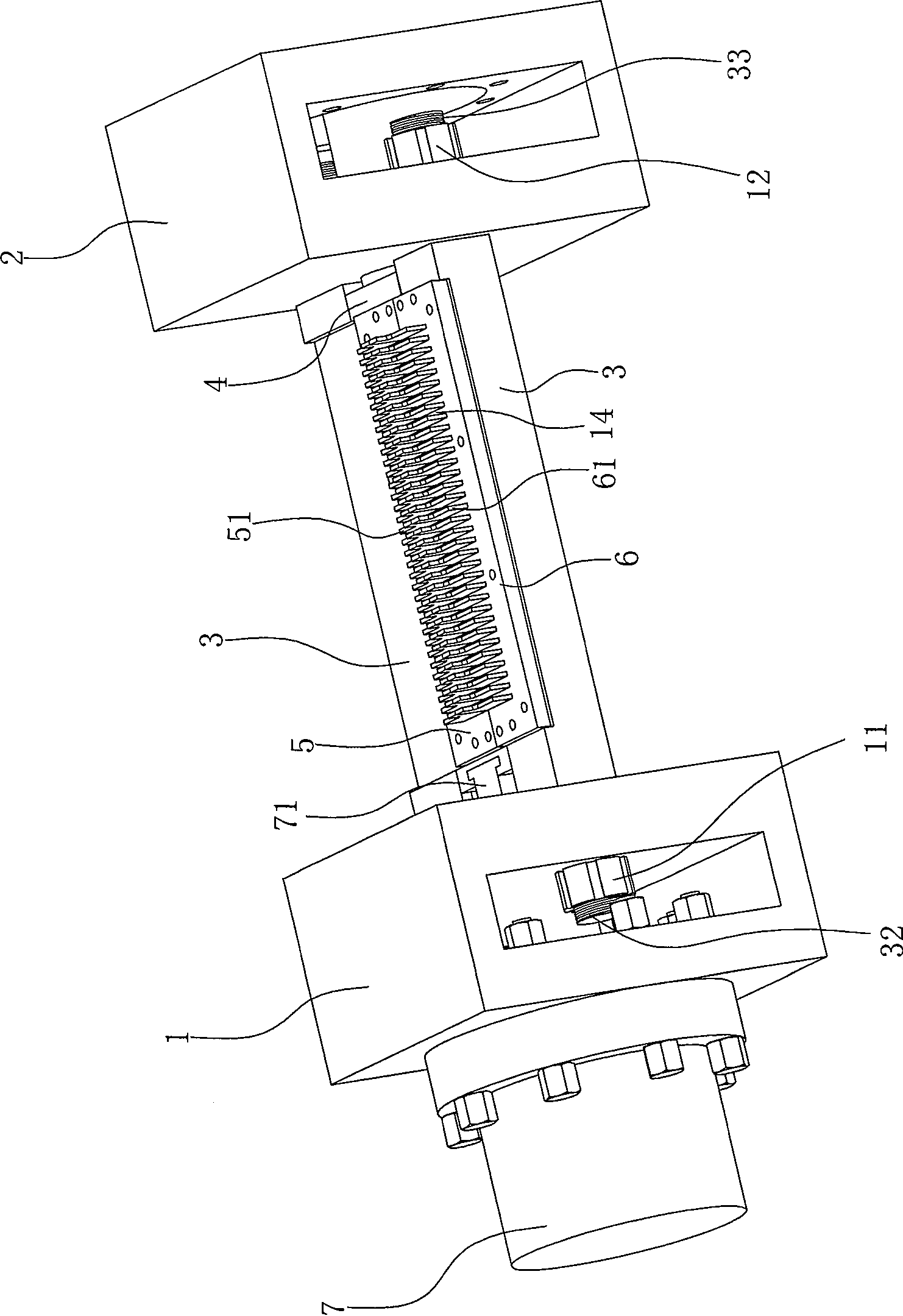

Connector

InactiveUS20050202730A1Improve retentionSmooth engagementContact member manufacturingSecuring/insulating coupling contact membersProximal pointBiomedical engineering

Owner:JST MFG CO LTD

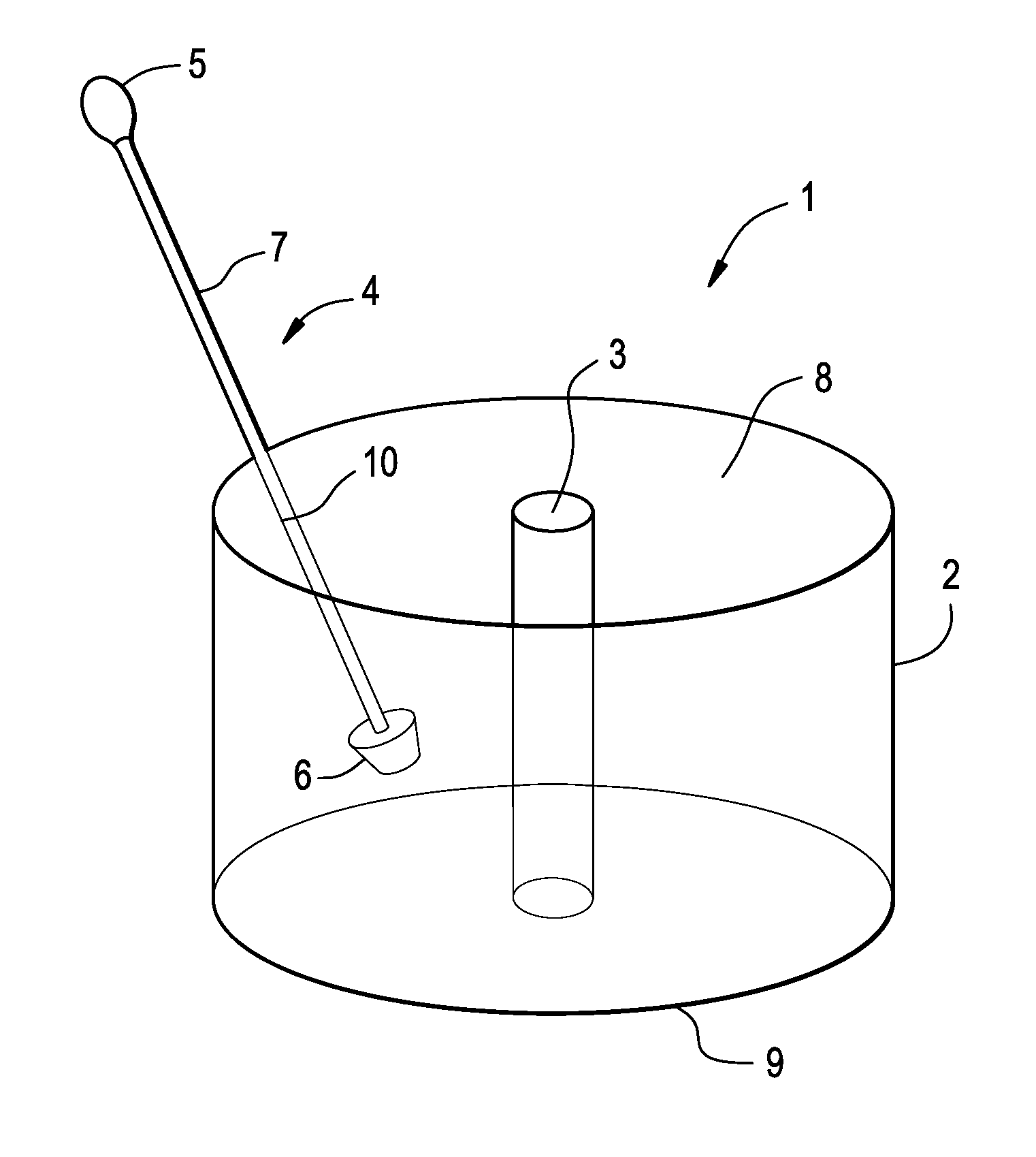

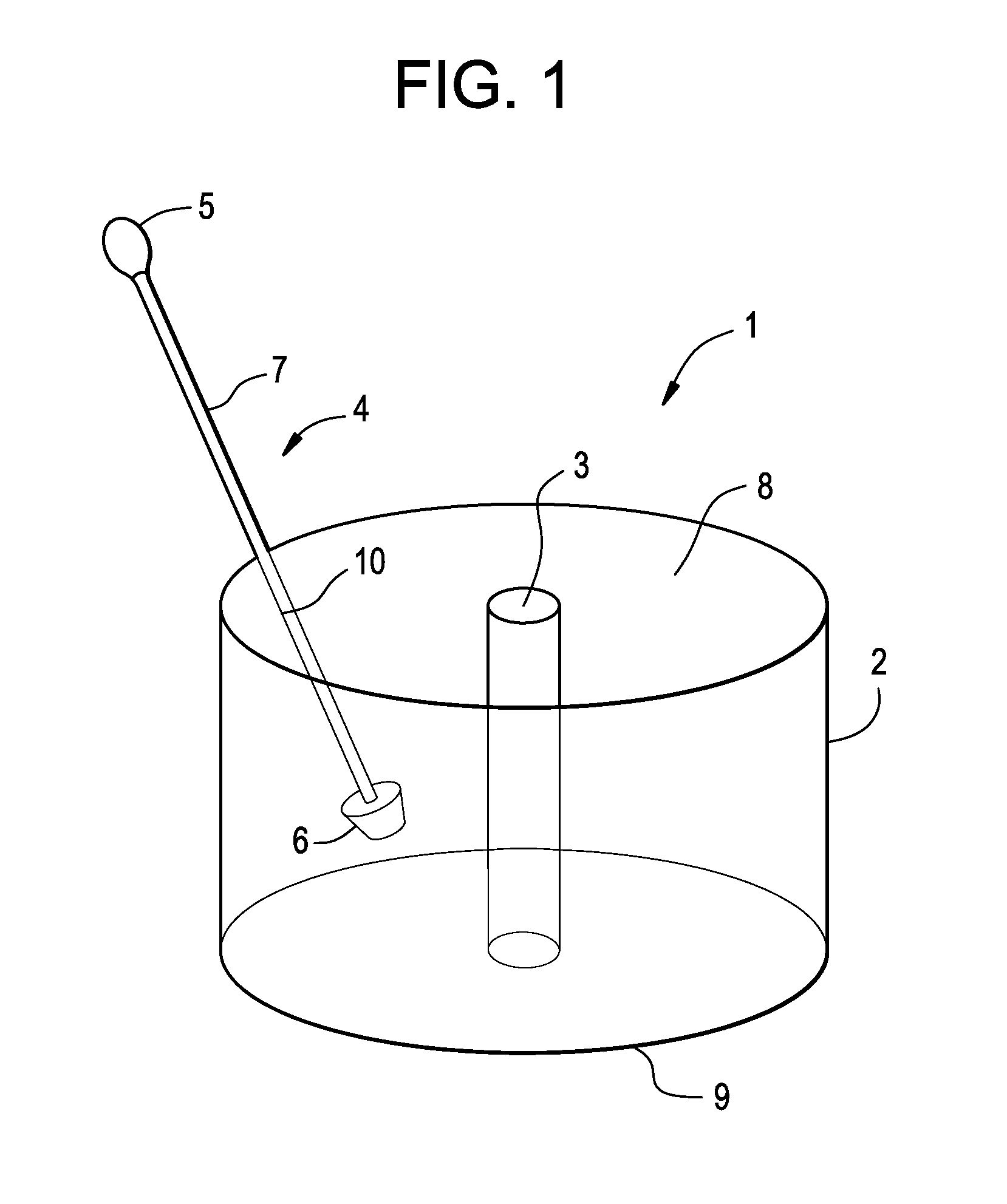

Hearing aid ear plug with an extraction cord

ActiveUS20130014768A1Hard materialSimple and durable wayElectrical transducersRecord carriersHearing aidEngineering

An ear plug (1) for a hearing aid is made of a resilient material and provided with an extraction cord (4) for providing a grip by which a user can pull the ear plug (1) out of an ear canal. The extraction cord (4) is arranged partly in the resilient material and partly outside the ear plug. A securing bulge (6) is arranged on the part of the extraction cord arranged in the resilient material, in order to secure the position of the extraction cord in the resilient material. The extraction cord is bonded to the resilient material. The invention further concerns a method for manufacturing the ear plug.

Owner:WIDEX AS

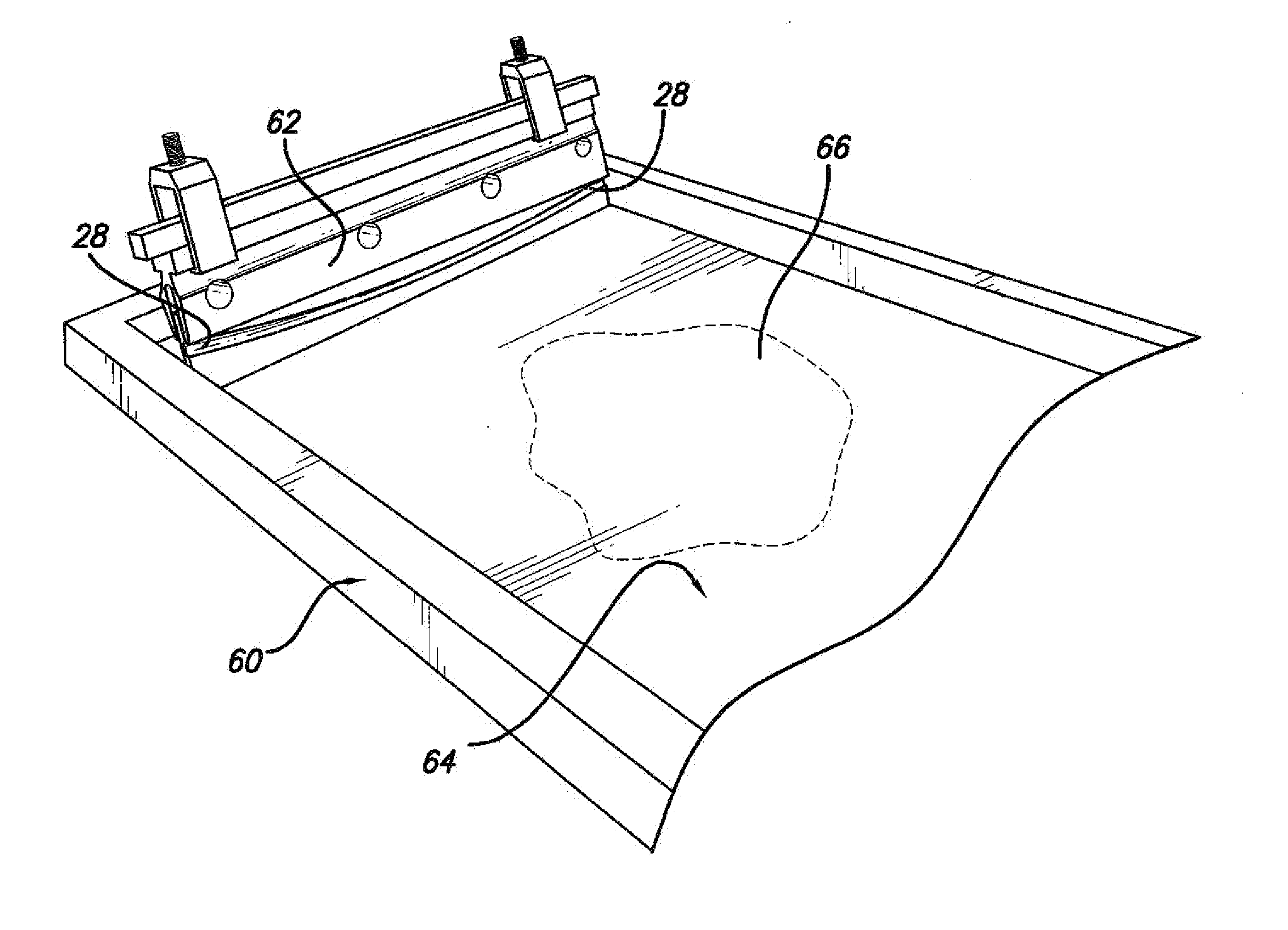

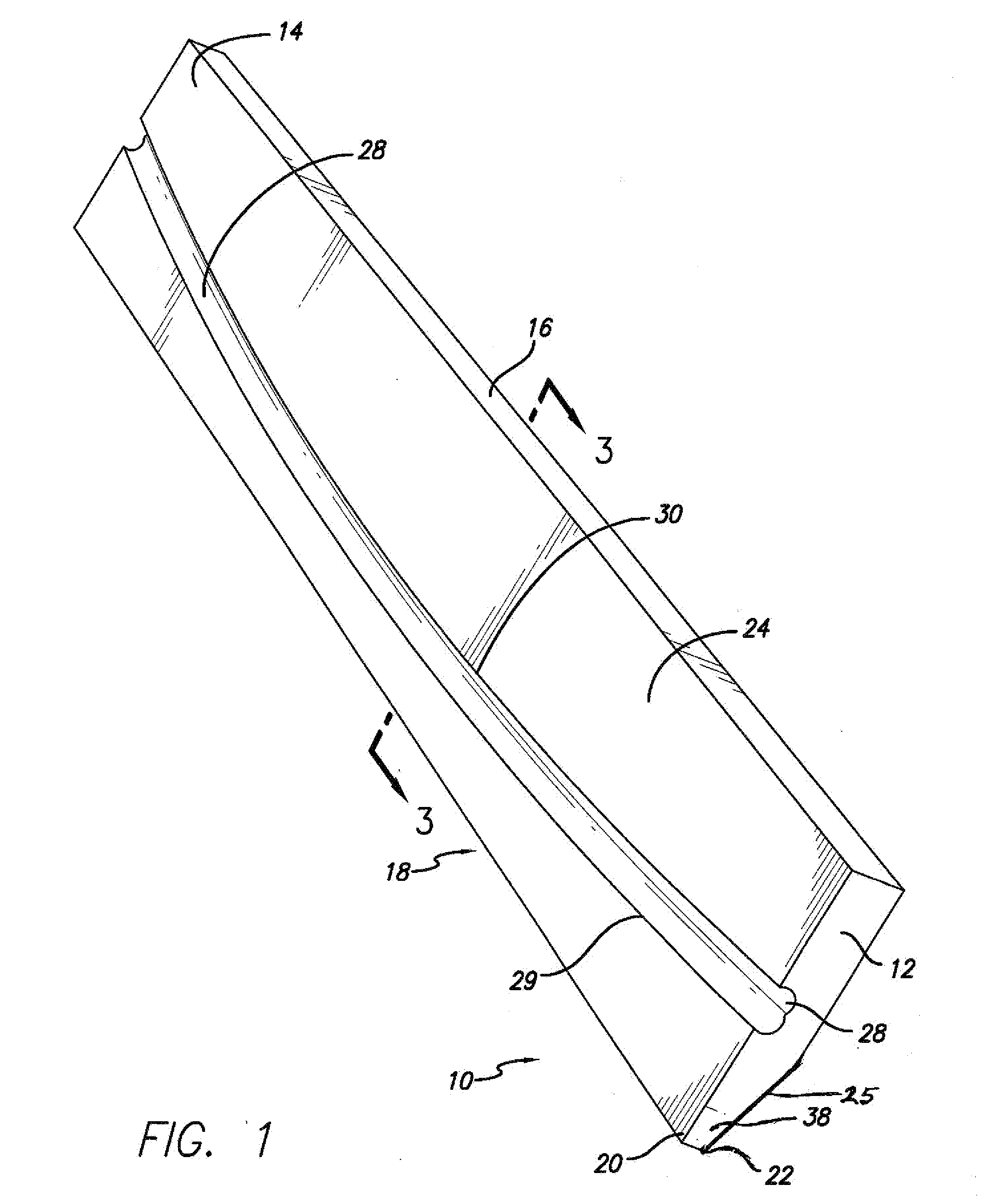

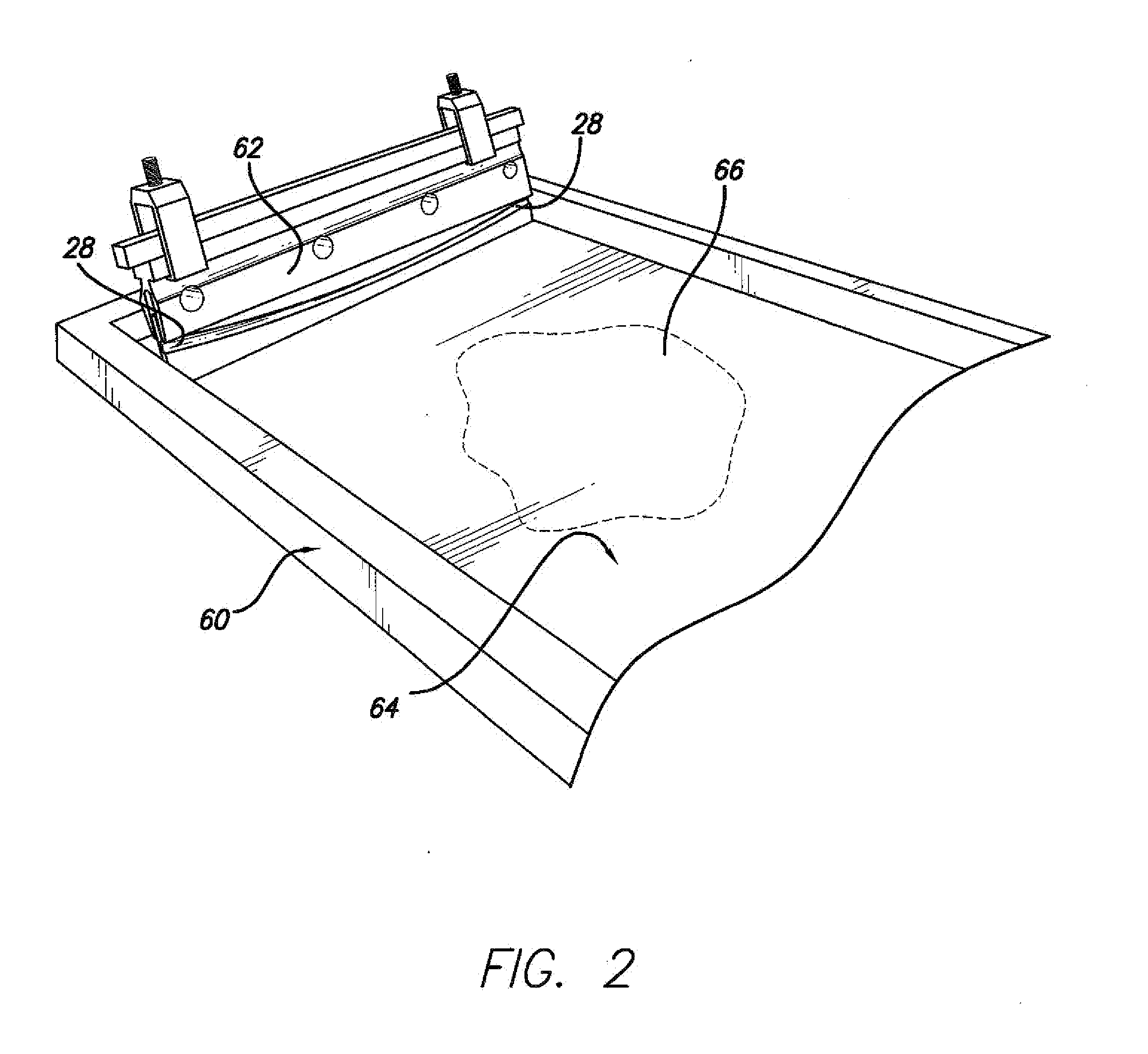

Squeegee Blade For Screen Printing And Methods Of Manufacture And Use Of Same

InactiveUS20130139711A1Quality improvementHard materialLiquid surface applicatorsInking apparatusEngineeringPrinting press

The present invention is directed to improved screen printing squeegee blades, which include a first end, a second end, a top portion for receipt by a blade holder, a bottom portion adapted for contacting the screen of a screen printing press along at least one printing edge, a front face, a back surface, and a buckle control channel formed in either the front face or the back surface.

Owner:CLARKE JOE

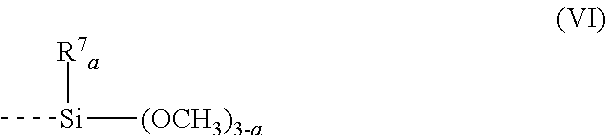

Polyurethane composition that contains organomethoxysilane and has anisotropic material properties

InactiveUS20110198031A1Soft materialHard materialPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolymer sciencePtru catalyst

A single-component, moisture-curing composition, including at least one polyisocyanate, a polyaldimine, an organomethoxysilane, an acid as well as a tin catalyst in special proportions that can be matched to one another. An exemplary composition cures by moisture as much as possible without forming bubbles. In the curing of the composition by atmospheric humidity, an anisotropic material is produced with a predominantly elastic sheath that is virtually tack-free on the surface and a predominantly plastic core. An exemplary composition can be especially well suited as a flexible sealant.

Owner:SIKA TECH AG

Fixing device, fixing method and image forming apparatus

InactiveUS7024148B2Without consuming useless energyImprove image qualityElectrographic process apparatusImaging qualityImage formation

Provided is a fixing device and a fixing method, and an image forming apparatus using the fixing device, in which at least heat is applied to an unfixed toner image formed on a recording material to soften or melt toner of the unfixed toner image into a state of being able to be deformed by an external force, and while maintained in the state of being able to be deformed by the external force, the toner is pressed in a nonheating manner to be flowed. Accordingly, device structure can be simplified to be free of wasteful energy consumption, an image of image quality excellent in transparency of a toner image and in OHP permeability as well as of high glossiness which is free from gloss nonuniformity can be obtained while preventing curling of a recording material.

Owner:FUJIFILM BUSINESS INNOVATION CORP

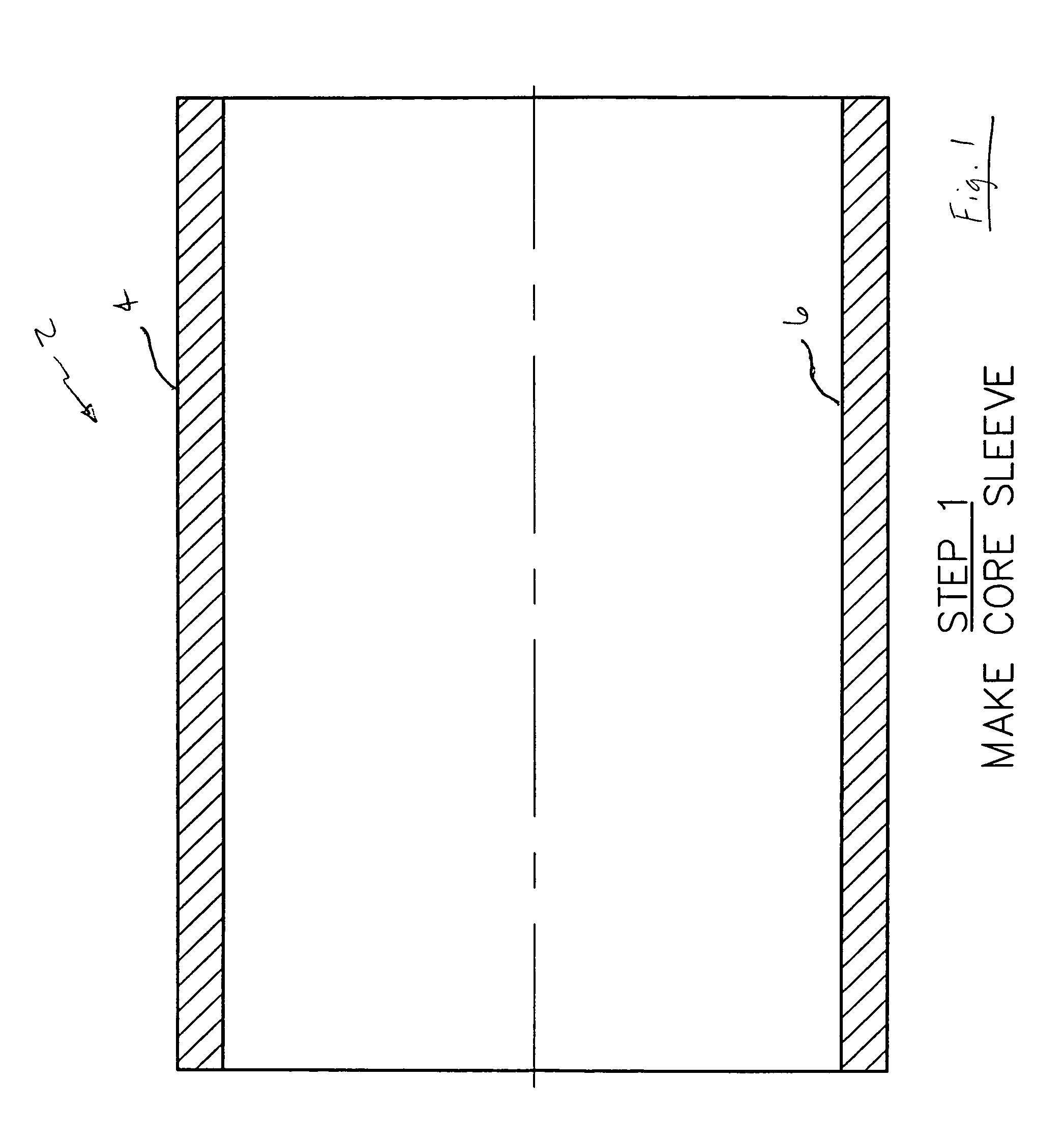

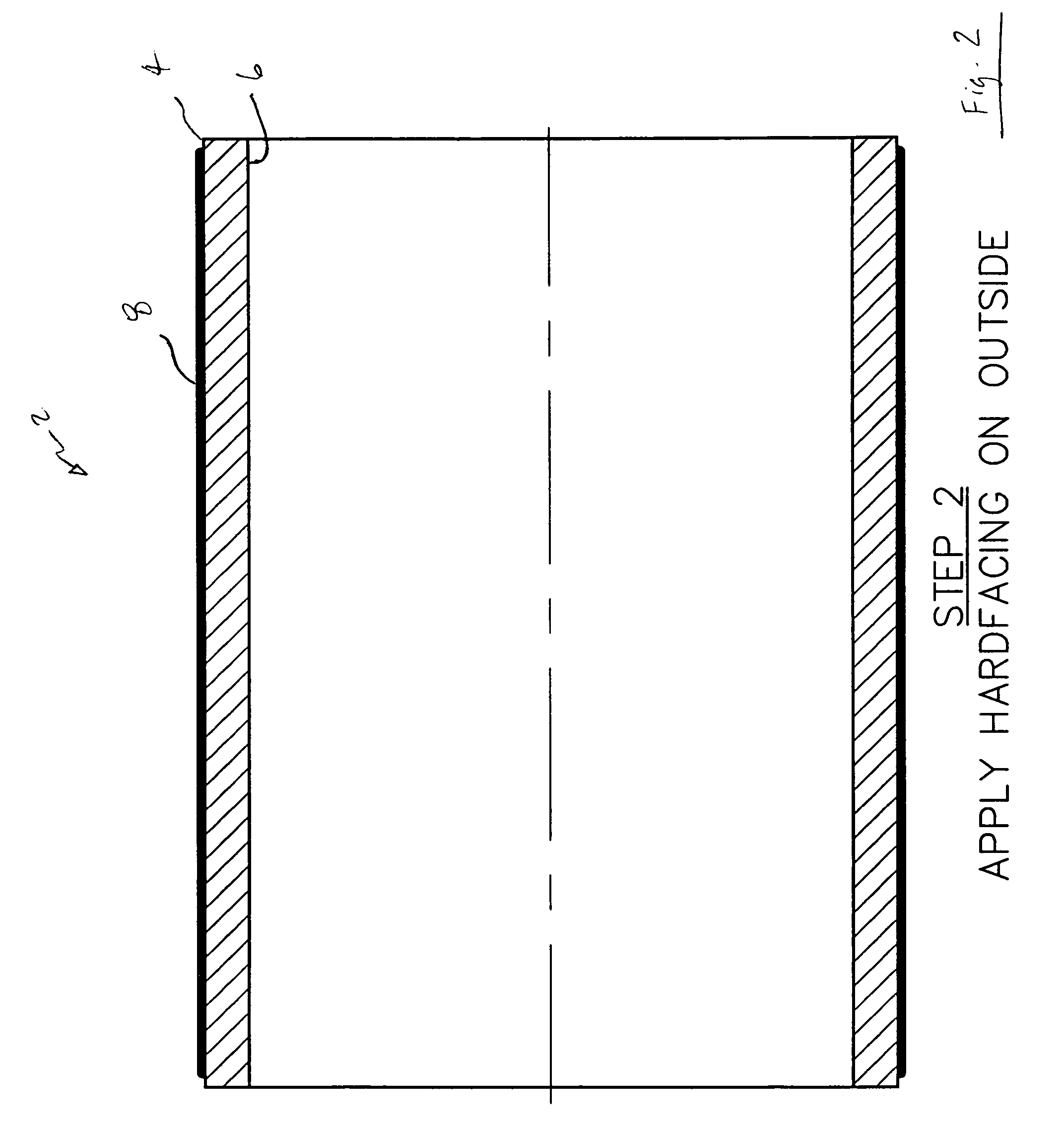

Process for manufacturing a bearing

InactiveUS7882638B2Strong and more ruggedEliminate needDrilling rodsShaftsEngineeringMechanical engineering

A process for manufacturing a bearing. The bearing may be used in a tool disposed within a bore hole. The process comprises providing a tubular sleeve and applying a hard facing material on the outer diameter of the tubular sleeve so that the hard facing material is fused onto the outer diameter, and thereafter applying a material layer on the outer diameter so that the material layer is fused onto the outer diameter. The method further includes machining the outer diameter so that a portion of the material layer is removed, and then machining the inner diameter so that only the hard facing material is left as an inner diameter. The method further includes machining the outer diameter and the inner diameter in order to form the bearing. In the most preferred embodiment, the method further includes placing the bearing into a housing, and inserting a mandrel into the bearing, and wherein a hard coating of the mandrel abuts the bearing. A mud motor for rotating a bit in a well bore is also disclosed.

Owner:RIVAL DOWNHOLE TOOLS LC

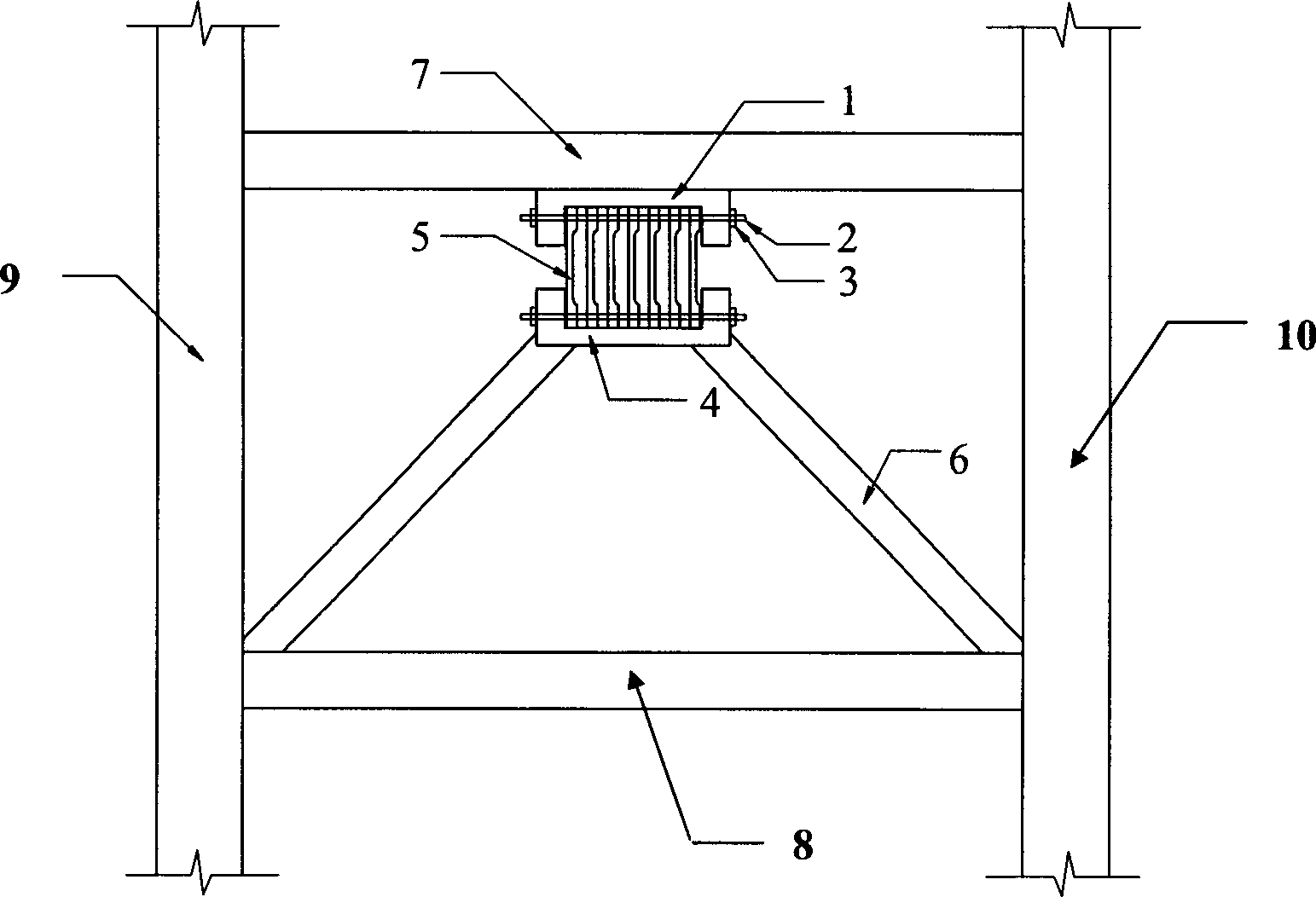

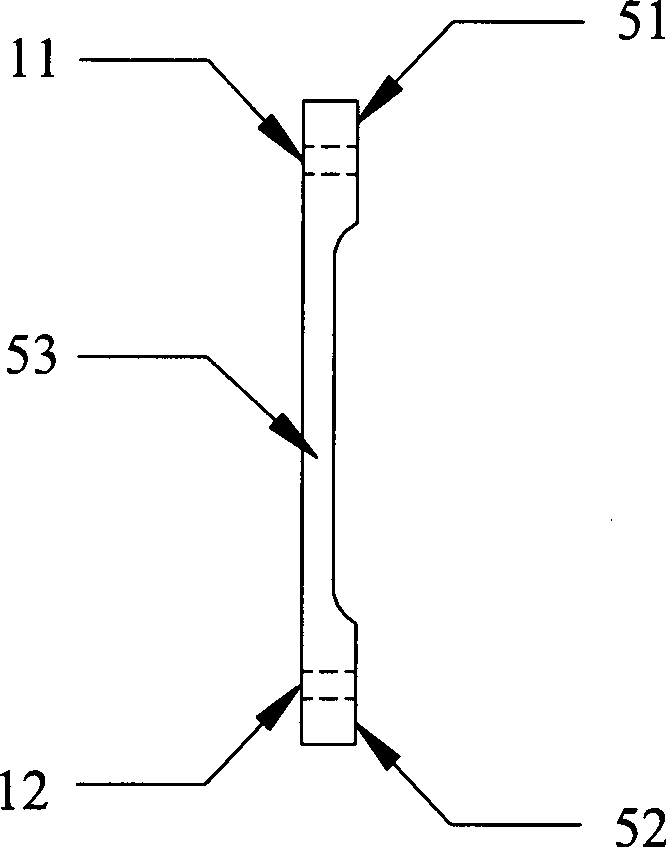

Wood-bamboo combined energy-dissipating shock-absorbing support structure

The invention relates to a compound wood-bamboo energy-absorbing and damping support structure, belonging to construction field. The support structure, applicable on wooden buildings, is made of wood and bamboo and comprises an energy-absorbing bamboo plate, wooden connecting pieces, and a wooden slanting support pole. The upper end and the lower end of the energy-absorbing bamboo plate are respectively connected with the wooden connecting pieces, and the wooden connecting piece at the lower end is also connected with the wooden slanting support pole. The support structure is respectively connected with upper and lower girders of a wooden frame of the building through the wooden connecting piece at the upper end and the wooden slanting support pole, and is fixed and installed in the wooden frame. The support structure is installed in the wooden frame which demands shock resistance and is simple in connection with the main body of the wooden frame, convenient to construct and reliable in force transmission and is simple to replace and maintain if being damaged in an earthquake. The support structure can be used to reduce earthquake impact on small wooden buildings to help small wooden buildings to avoid and minimize damages in earthquakes.

Owner:TONGJI UNIV

Connector

InactiveUS7255611B2Improve retentionSmooth liftContact member manufacturingSecuring/insulating coupling contact membersProximal pointBiomedical engineering

Owner:JST MFG CO LTD

Multi-edge shear

InactiveCN101480735ASmall sectionLight materialShearing machinesShearing toolsHydraulic cylinderEngineering

The invention relates to multi-cutting-edge shears, comprising a front wall board and a rear wall board which are mutually separated. The multi-cutting-edge shears are characterized in that two guide ways are parallelly and compartmentally arranged between the front wall board and the rear wall board, a slip block which can reciprocate along a two-guide ways-restrained horizontal direction is restrained between the two guide ways, a moving-blade row with clipboards is arranged on the slip block, a static-blade row with a plurality of clipboards is arranged on one of the guide ways, a hydraulic cylinder is fixed outside the front wall board, the cylinder lever of the hydraulic cylinder is directly connected with the slip block by passing through the front wall board so as to push the slip block and the moving-blade row to move, and the clipboards on the moving-blade row slip with regard to the clipboards on the static-blade row in a misaligned way so as to form a shearing force. The shearing can be carried out as follows: a plurality of strip shaped metal plates are arranged after the strip shaped plow grooves of the two blade rows, and the moving-blade row is driven by the slip block to reciprocate with regard to the static-blade row so as to form the shearing force and shear the strip shaped metal plates. The shearing has no waste material and no pollution to the environment.

Owner:NINGBO JIULONG MACHINERY MFG

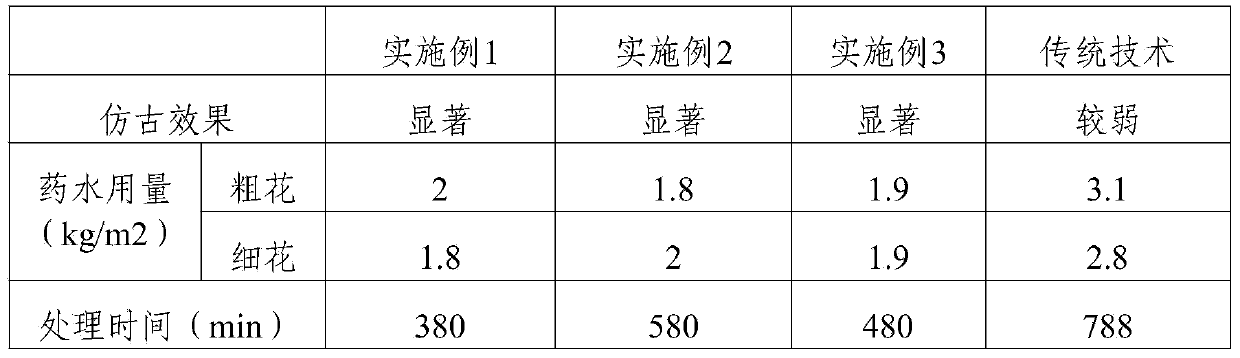

Treatment method for antique-imitating face of marble of sedimentary rock attribute

The invention relates to the technical field of building materials and particularly relates to a treatment method for an antique-imitating face of marble of sedimentary rock attribute. The method comprises the following steps: corroding the surface of a marble block of sedimentary rock attribute twice; and alternately using coarse flower antique-imitating water and fine flower antique-imitating water on the surface of the block according to primary and secondary corrosion so as to enhance the antique-imitating effect of surface treatment of the marble block. Therefore, the block is of more natural color and closer to antique-imitating odor.

Owner:韩勤

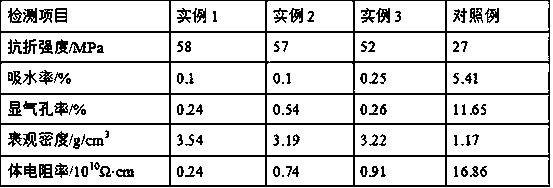

Anti-static ceramic tile and preparation method thereof

InactiveCN108640651AImprove conductivitySimple processCeramic materials productionClaywaresRare-earth elementBrick

The invention relates to an anti-static ceramic tile and a preparation method thereof, and belongs to the technical field of ceramic materials. Rare earth elements are loaded on a graphene structure;through an excellent synergistic performance of a rare earth compound, the rare earth compound is compounded with graphene so as to produce a synergistic interaction function, so that an electrical conductivity of the graphene is strengthened; the graphene is uniformly dispersed into a ceramic tile blank to form a conductive network, meanwhile, vanadium pentoxide and zinc oxide are utilized to replace part of stannic oxide to prepare an electric conduction glaze, so that an anti-static enamel layer is formed on the tile blank, the anti-static enamel layer on the surface is connected with an electric conduction blank on the bottom layer, and anti-static ceramic tile process technologies including a glaze conductivity type and a whole body conductivity type are perfectly combined, so that whole body conductivity is realized, the process is simple, the product material is hard, the anti-static performance is stable, and the anti-static ceramic tile is durable. The preparation method is simple and convenient to operate, the used chemical material types are less, the adding amount of the conductive material is less, the process stability of the anti-static ceramic tile is improved, theefficiency is improved, and meanwhile, the manufacturing cost is saved.

Owner:常州五荣化工有限公司

Motor-pump unit

InactiveUS7293495B2Risk of harmProtection washoutPositive displacement pump componentsPiston pumpsBraking systemVehicle brake

The invention relates to a motor-pump unit for a motor vehicle brake system, comprising a motor and a pump which is provided with a shaft that is driven by said motor, with the shaft end being rotatably mounted by means of at least one bearing in an accommodating member having valves and connecting channels, said shaft driving displacement means which are disposed in a chamber that can be filled with pressure fluid. In order to improve vacuum filling of the brake system with pressure fluid, the invention discloses that the shaft end terminates into a free space, and that at least one connection is provided between the free space and the chamber.

Owner:CONTINENTAL TEVES AG & CO OHG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com