Patents

Literature

1994 results about "Explosive Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic explosives initiating device

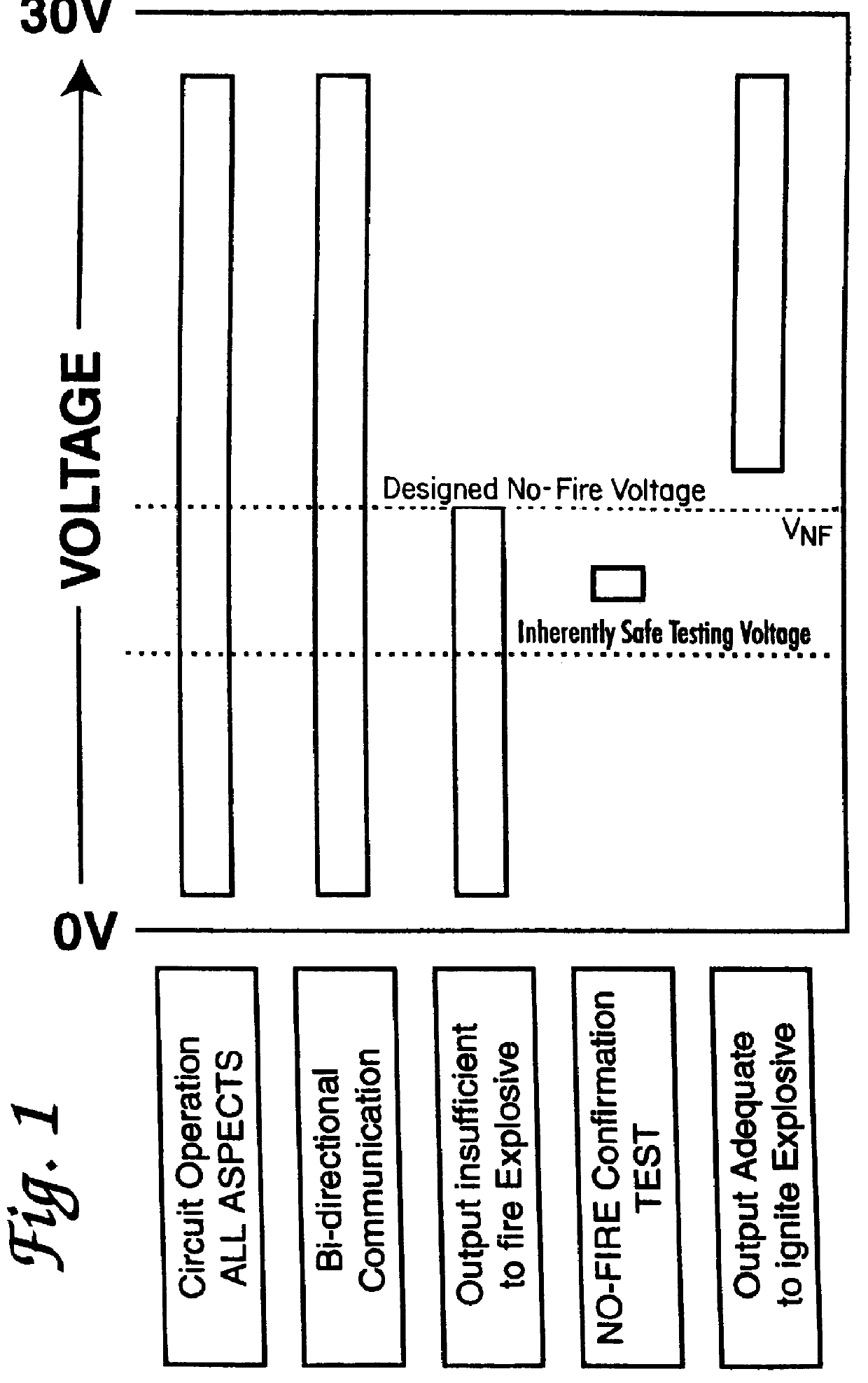

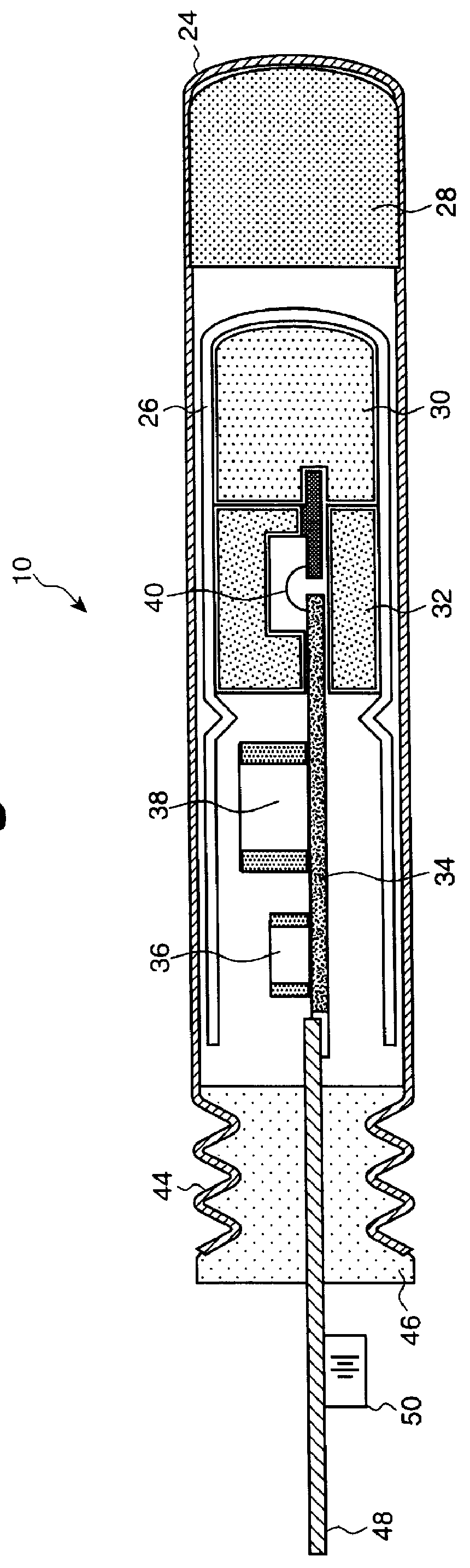

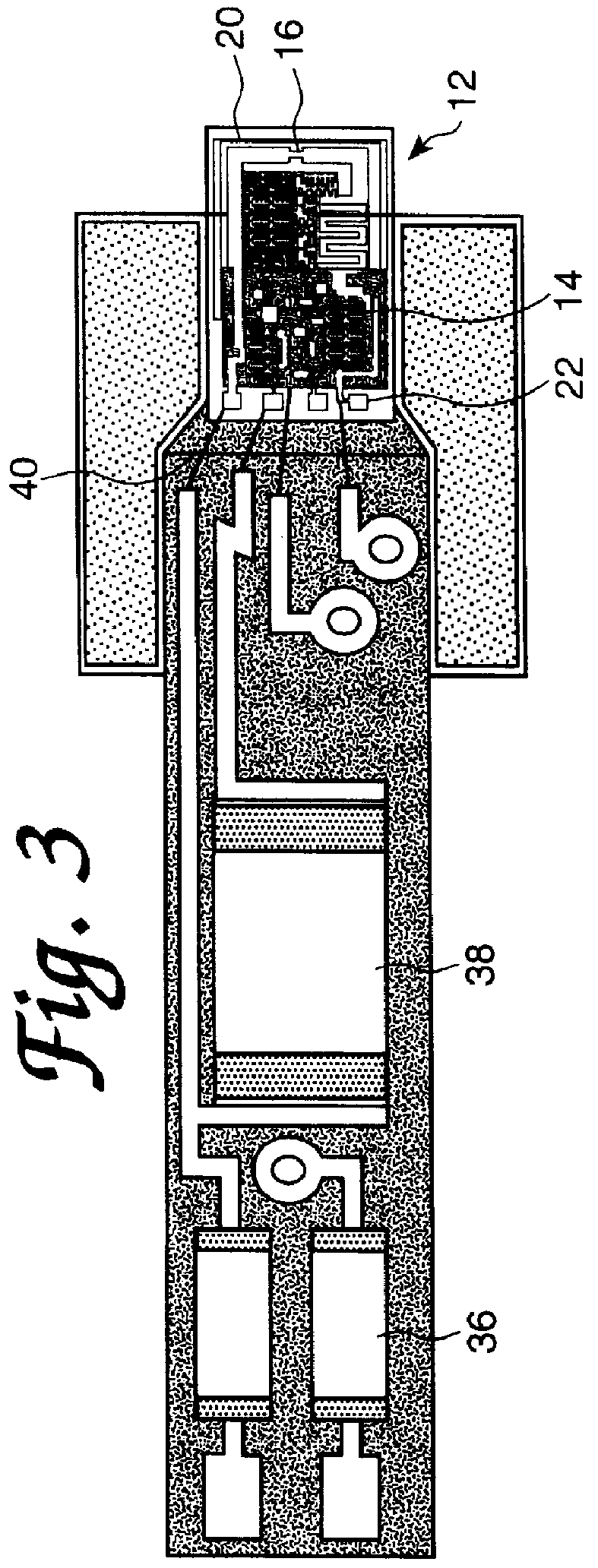

InactiveUS6085659AInherent flexibilityPosition information can be generated with easeIncandescent ignitionBlasting cartridgesVoltageExplosive Agents

PCT No. PCT / GB96 / 02987 Sec. 371 Date Dec. 10, 1998 Sec. 102(e) Date Dec. 10, 1998 PCT Filed Dec. 4, 1996 PCT Pub. No. WO97 / 21067 PCT Pub. Date Jun. 12, 1997An electronic explosives initiating device which includes a firing element which has a designed no-fire voltage and an operating circuit which operates at any voltage in a range of voltages which straddles the designed no-fire voltage.

Owner:ORICA EXPLOSIVES TECH PTY LTD

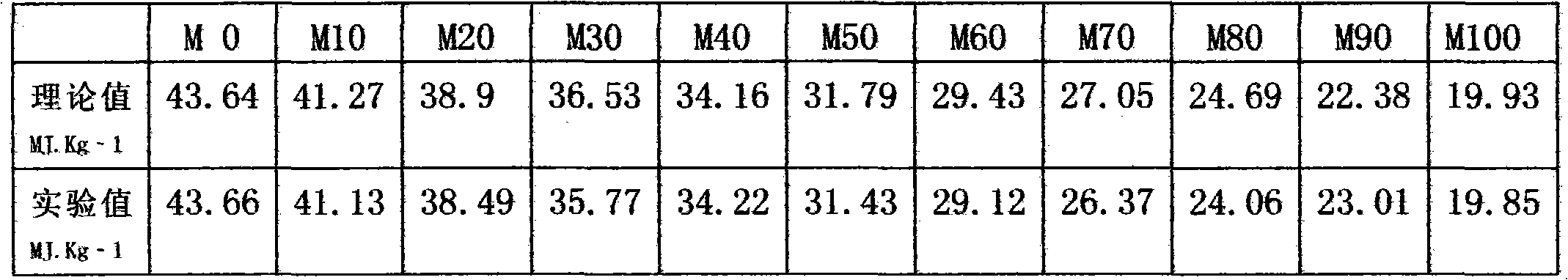

Methanol diesel oil manufacturing mode

The invention relates to a manufacturing mode of environment-friendly and energy-saving M15_M85 methanol diesel oil. The methanol diesel oil is composed of diesel oil, methanol, and additives. The methanol diesel oil is prepared with operations under normal temperatures and normal pressures. The invention discloses a plurality of common additives used for preparing methanol diesel oil in modern times. If explosives and aviation fuels are appropriately utilized, methanol defalcated heat value can be well compensated. The theory is tentatively considered as a gaseous detonation theory. The additives can be selected from nitric acid esters, nitrates, nitro compounds, non-aromatic compounds, peroxides, and the like.

Owner:陈若歆

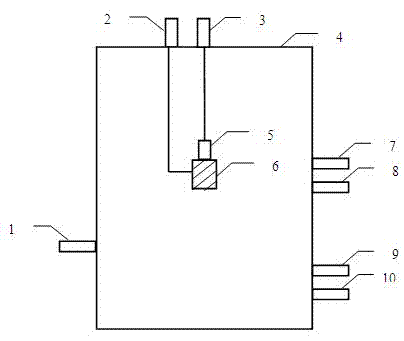

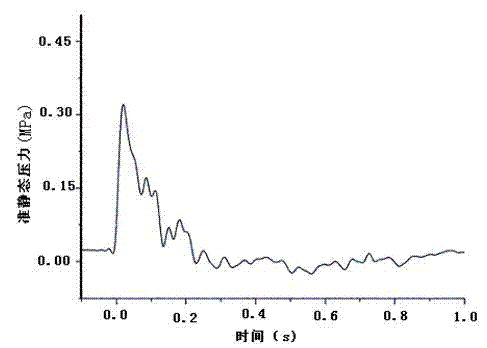

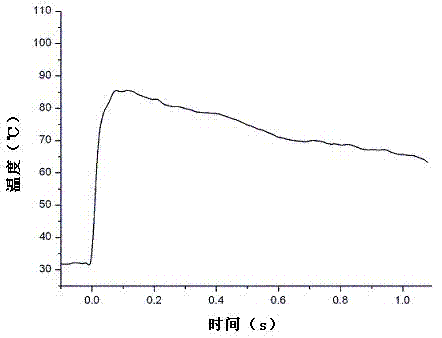

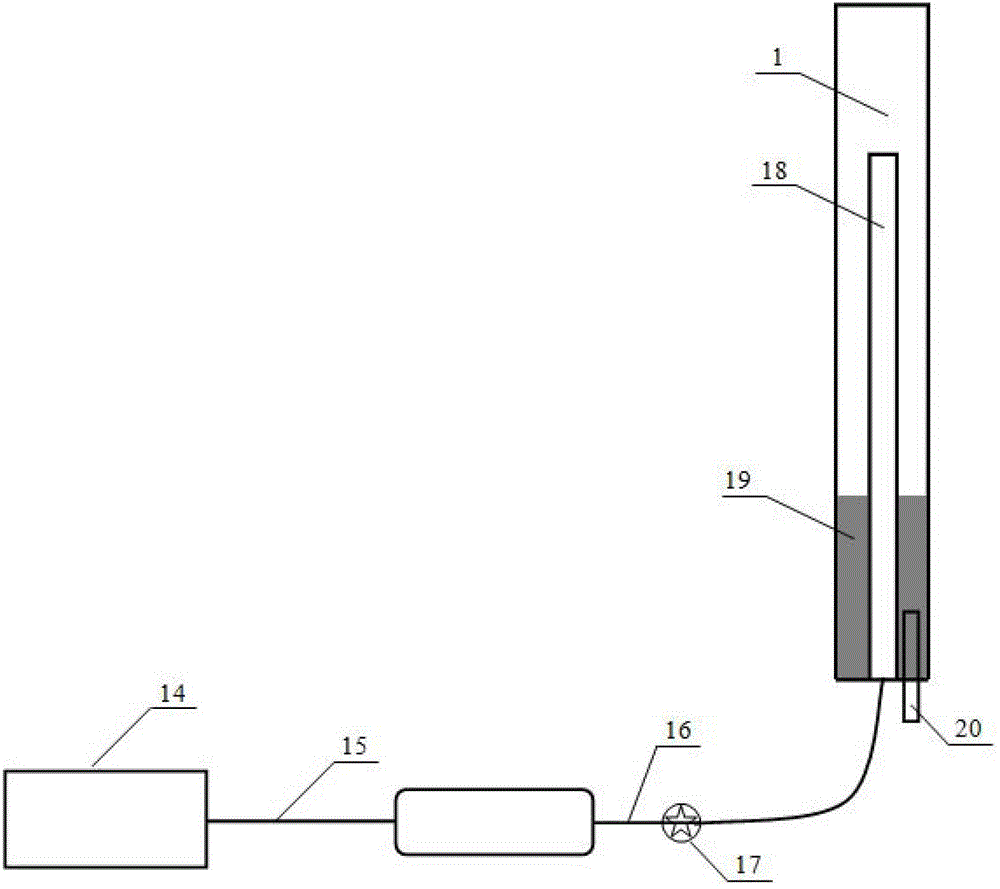

Detonation performance test method for high-energy imploding explosive

InactiveCN102253083AFlexible simulationRealize synchronized measurementsMaterial exposibilityDetonatorExplosive Agents

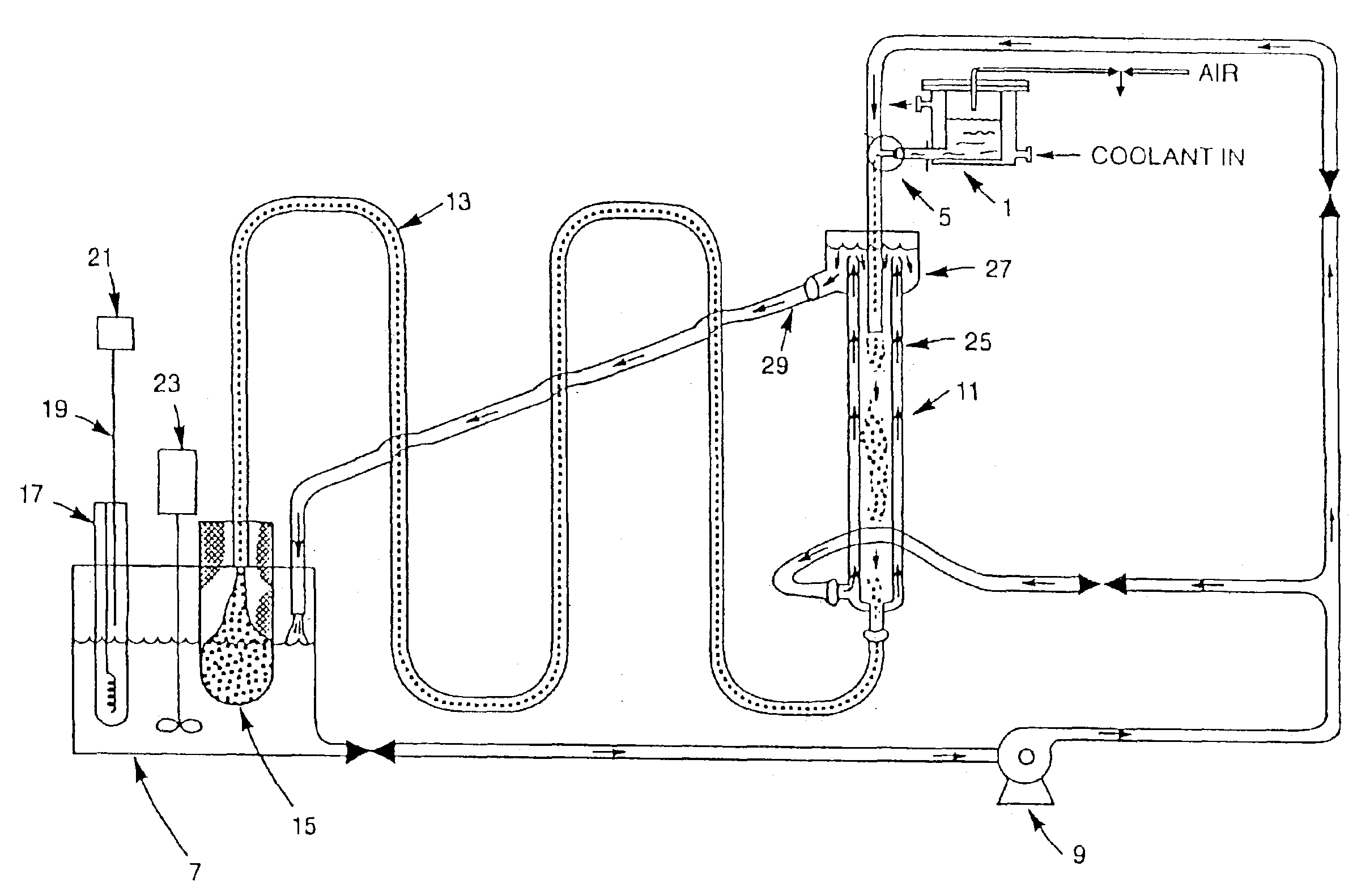

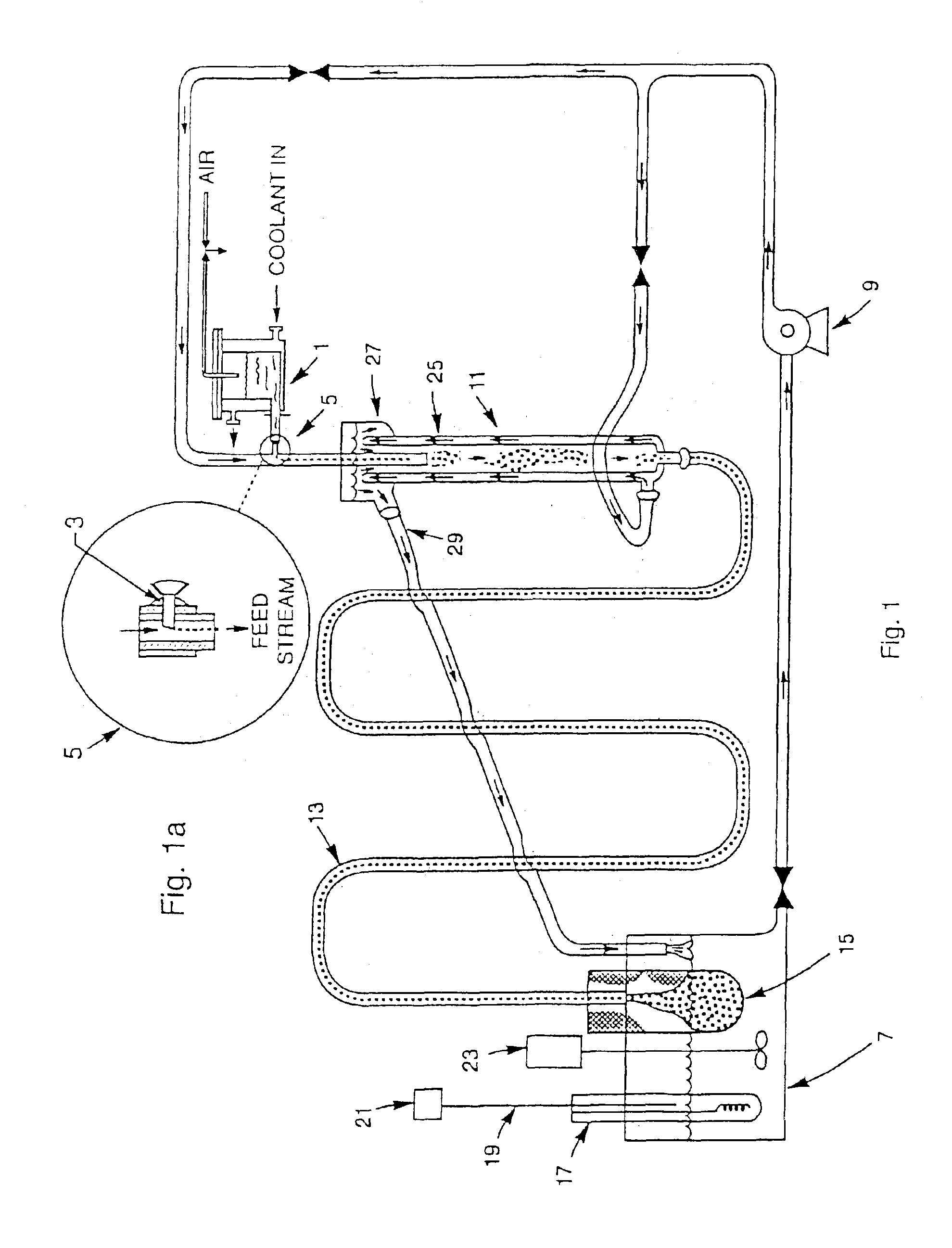

The invention discloses a detonation performance test method for high-energy imploding explosive. The method is characterized in that: a explosive grain with a detonator is placed in a sealed explosion vessel; quasi-static pressure of the explosive, transient temperature of the explosive, detonation velocity of the explosive and gas components of the explosive are detected; a temperature sensor is arranged on the sealed explosion vessel, and is provided for monitoring the temperature changing in the sealed explosion vessel during the test process, a pressure sensor is arranged on the sealed explosion vessel, and is provided for monitoring the pressure changing in the sealed explosion vessel during the test process; the sealed explosion vessel is further connected with a gas collection andtest system, a firing device, a detonation velocity test device, a mechanical vacuum pump and a gas cylinder. The method is applicable for the performance tests of various imploding explosives, and can be provided for performing laboratory quantitative evaluation to the gas expansion working.

Owner:XIAN MODERN CHEM RES INST

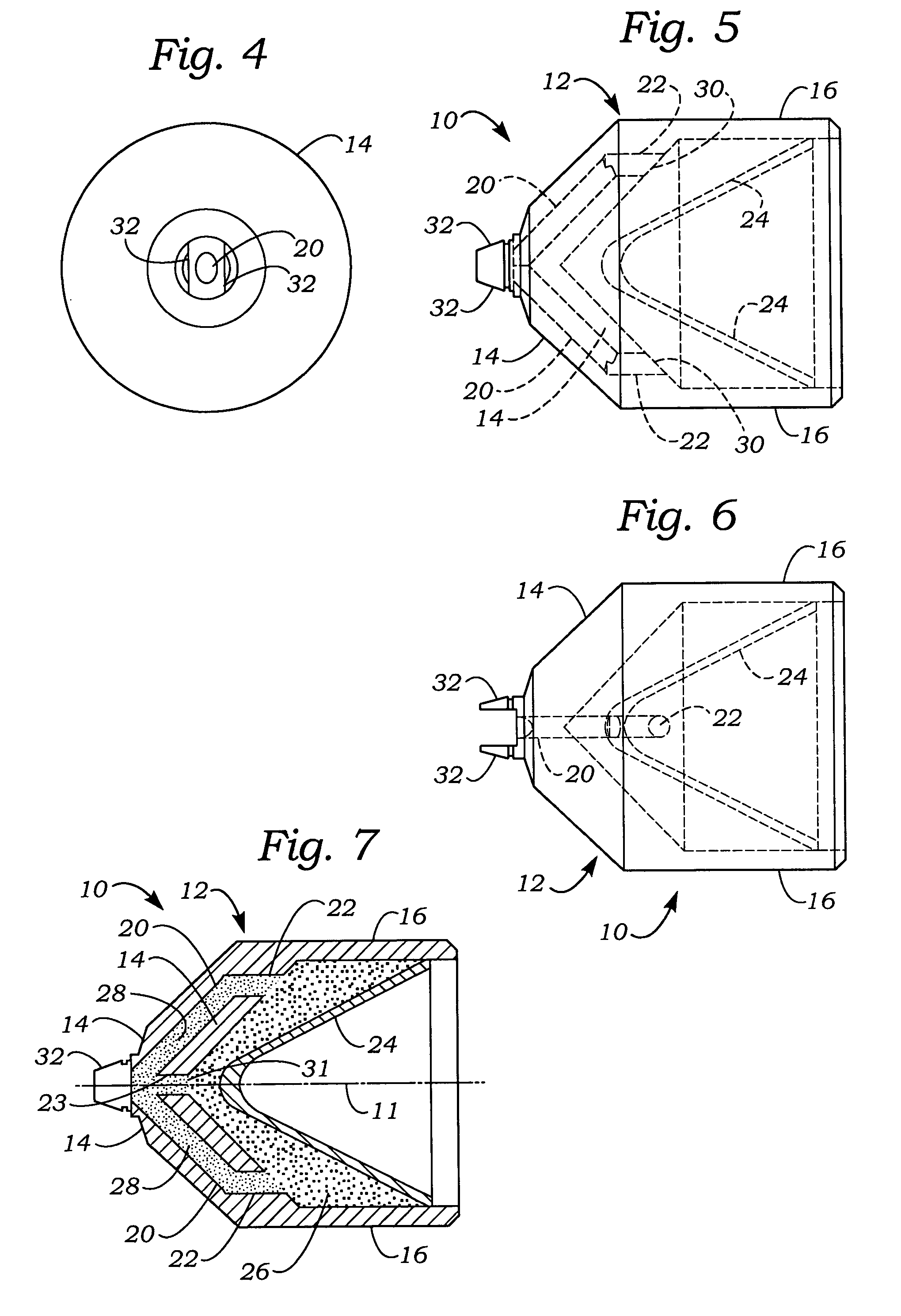

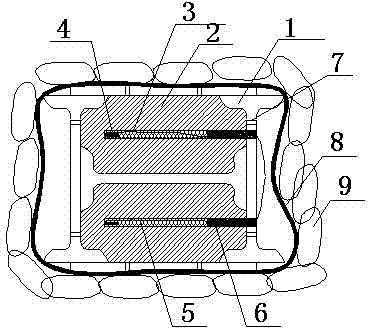

Multi-Shot Charge for Perforating Gun

ActiveUS20180274342A1Increase the number ofSmall sizeExplosive chargesBlasting cartridgesDetonationEngineering

A multi-shot explosive charge includes a plurality of chambers divided by shared walls between adjacent chambers. Explosive material within at least one of the chambers creates an explosive force in an outward direction upon detonation and a perforating jet through the open end of the chamber. A perforating charge includes at least one explosive material producing explosive forces, upon detonation that collide within the chamber to create a perforating jet. Such perforating charge may be a chamber(s) within a multi-shot explosive charge, or an individual charge. First and second explosive materials can have the same or different compositions and detonation rates that together with the arrangement of materials within the chamber create the collision of forces. A plurality of multi-shot explosive charge or stand-alone perforating charges with colliding forces can be interconnected in an array, and can be included in a perforating gun(s).

Owner:IDEASCO LLC

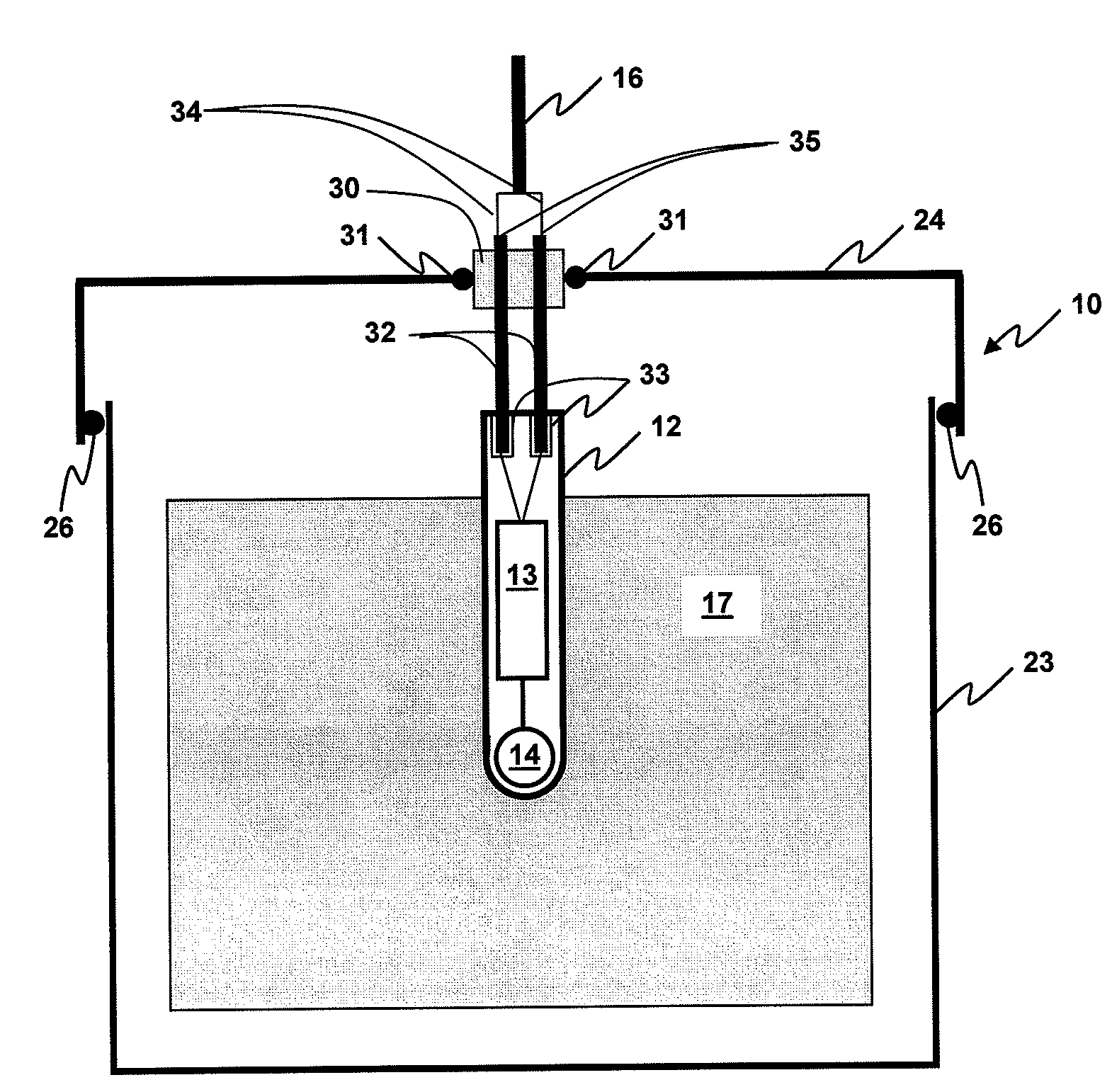

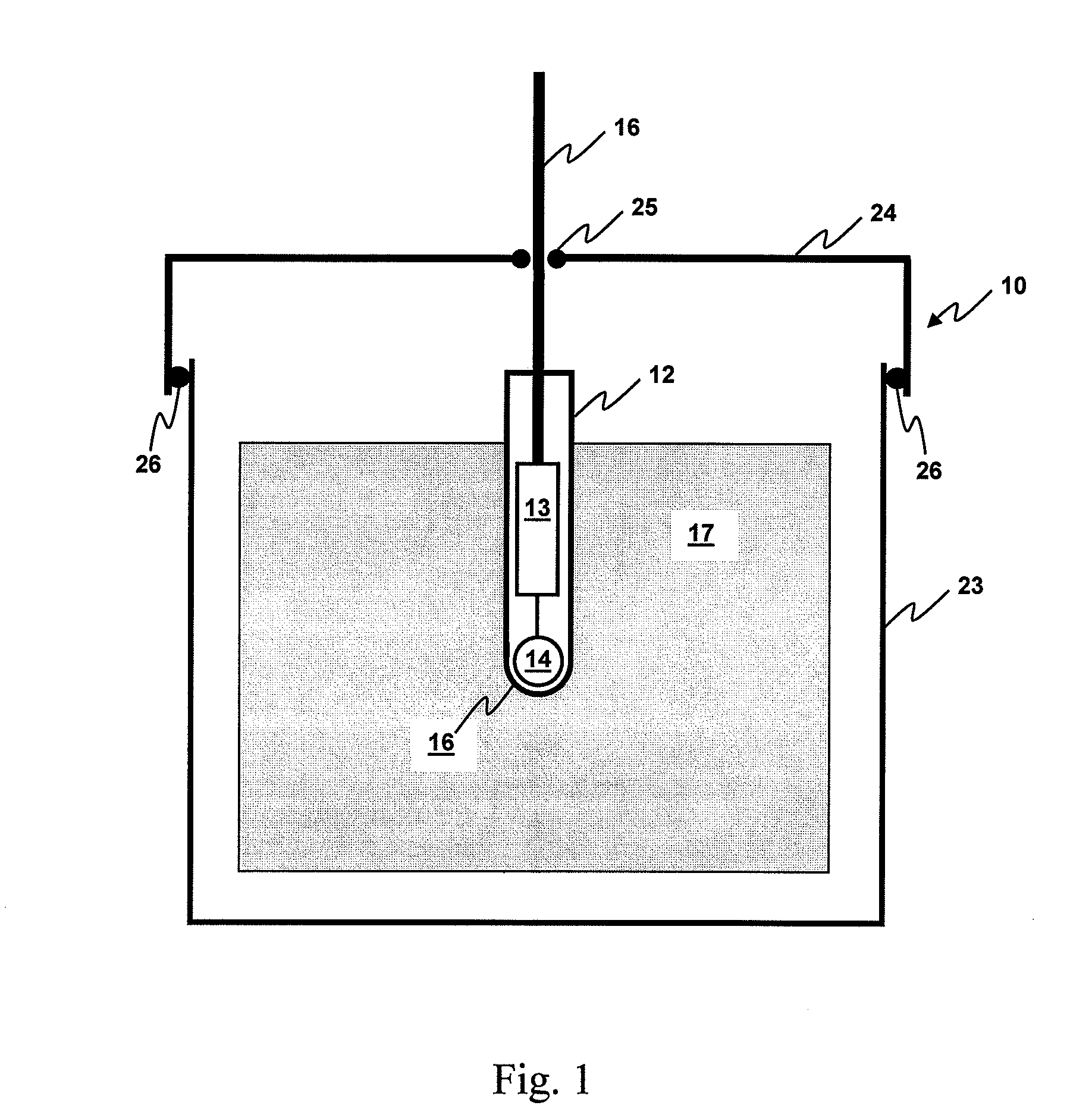

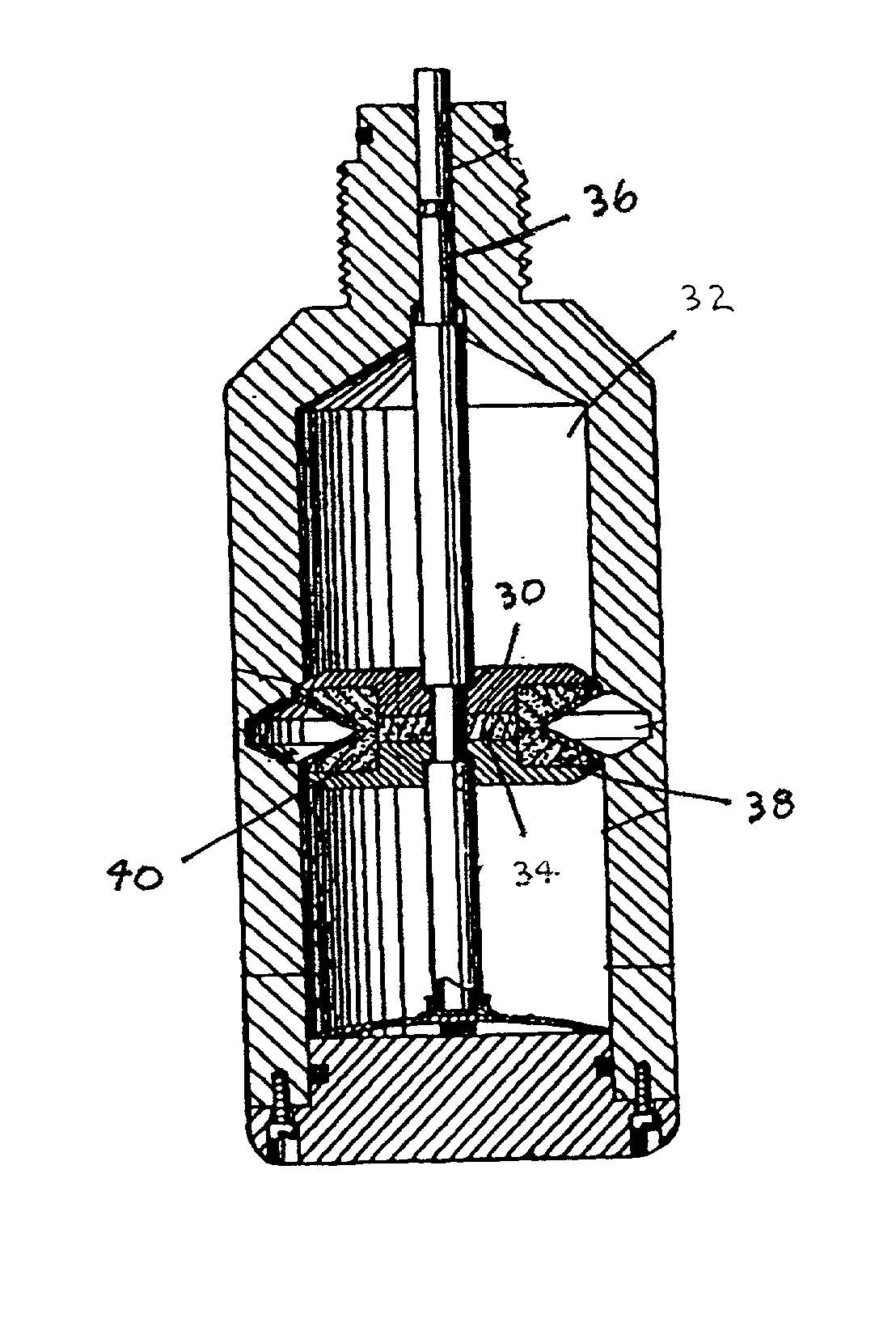

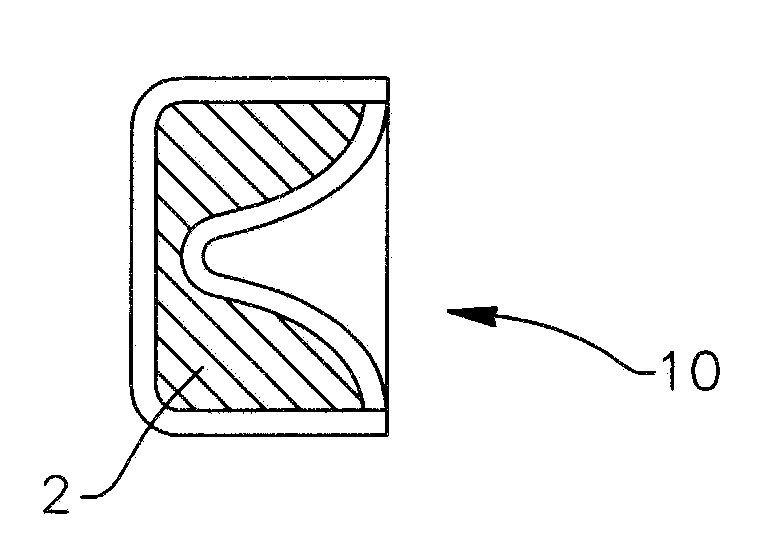

Connector for detonator, corresponding booster assembly, and method of use

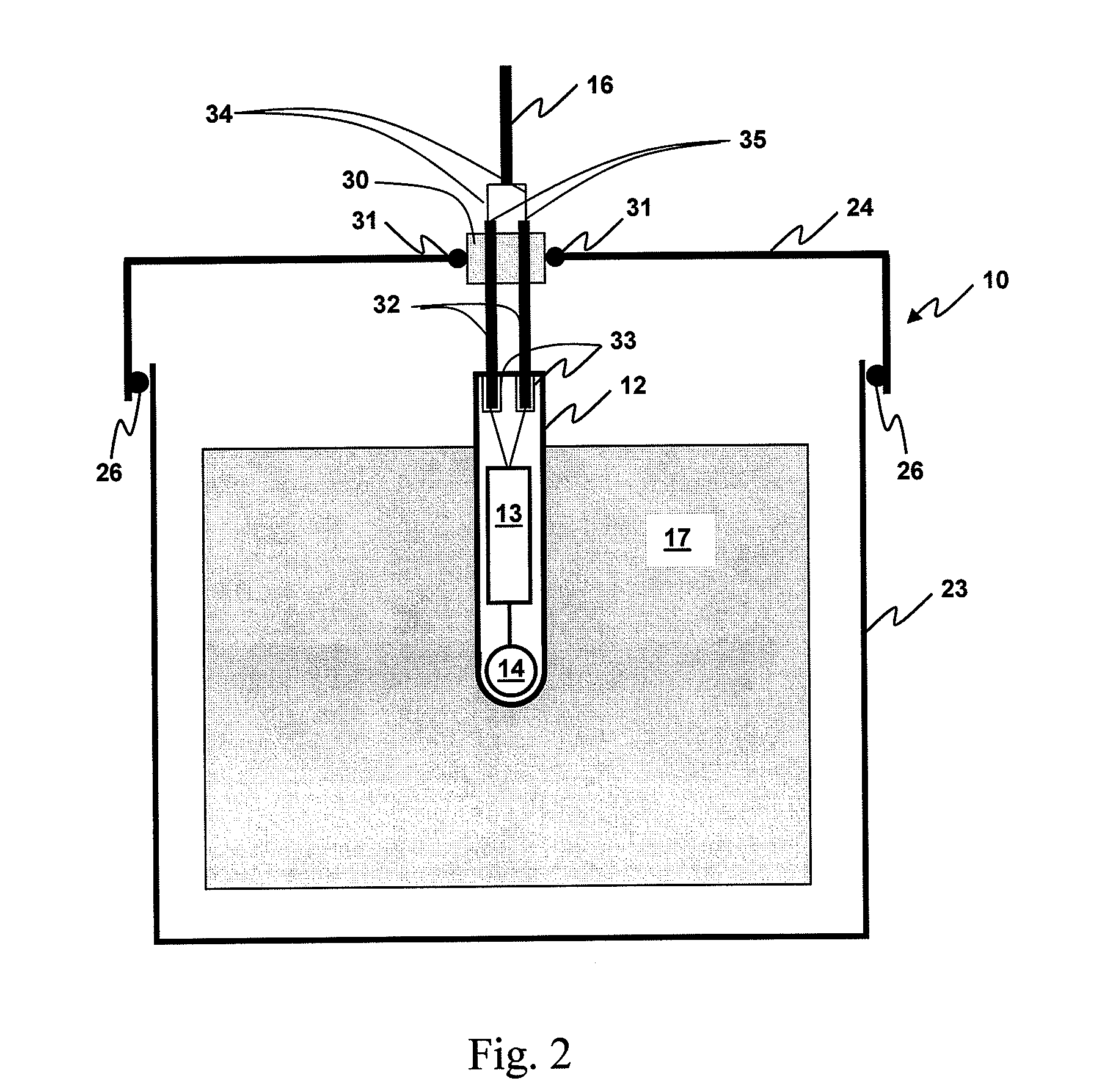

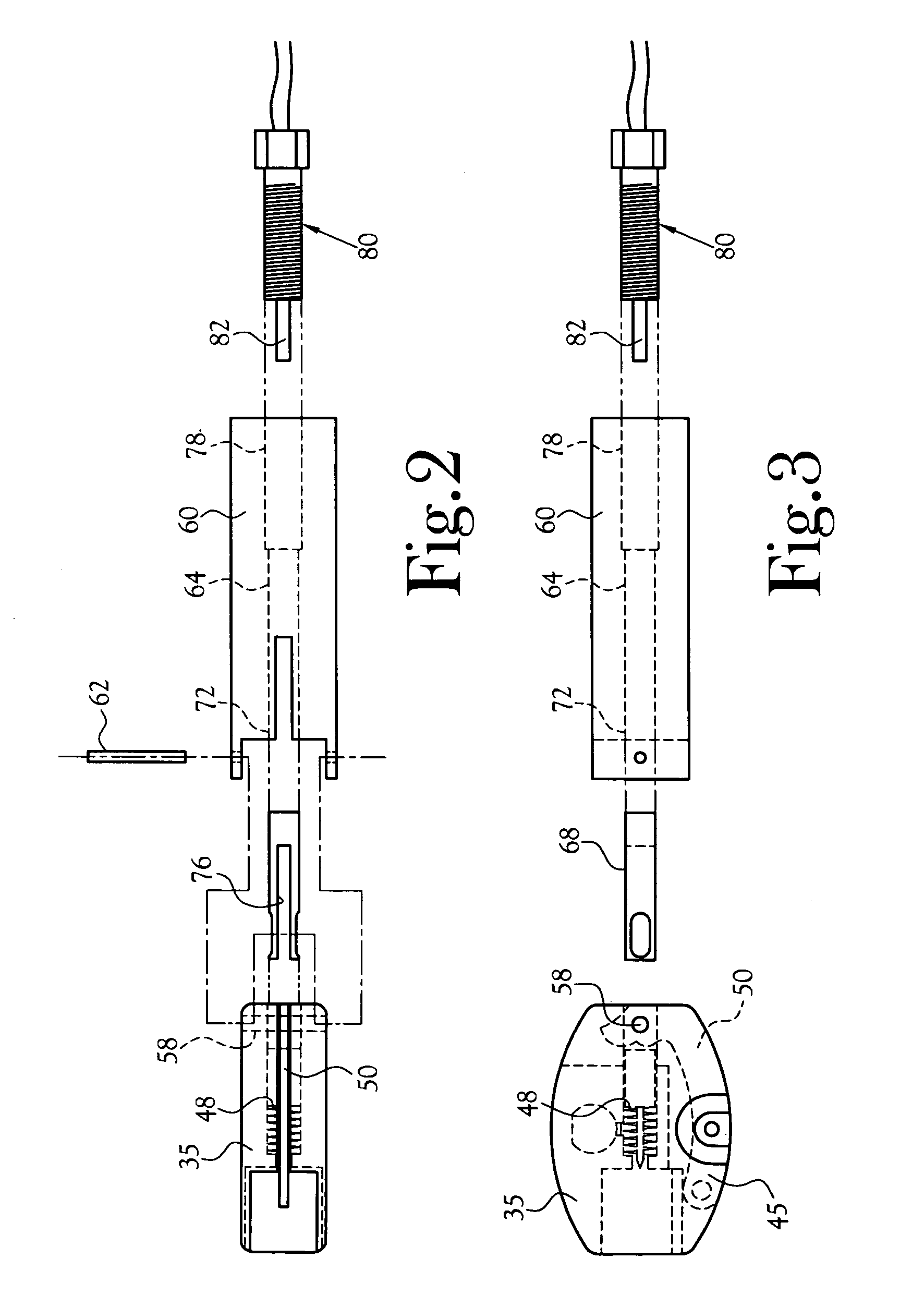

InactiveUS20080173204A1Increase contactAvoid problemsIncandescent ignitionBlasting cartridgesTransmission lineElectricity

Mining operations frequently involve the use of electric or electronic delay detonators in operative association with an explosive charge contained in a booster. Disclosed herein are connectors for connecting a signal transmission line to a detonator associated with a booster. In this way, the connectors, at least in preferred embodiments, allow the production of a substantially sealed booster assembly having a secure electrical connection to a signal transmission line. Also disclosed are methods of producing substantially sealed booster assemblies, and methods for their use in mining operations.

Owner:ORICA EXPLOSIVES TECH PTY LTD

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

Method and device for tunnel advance geology forecast with tunnel face blasting as focus

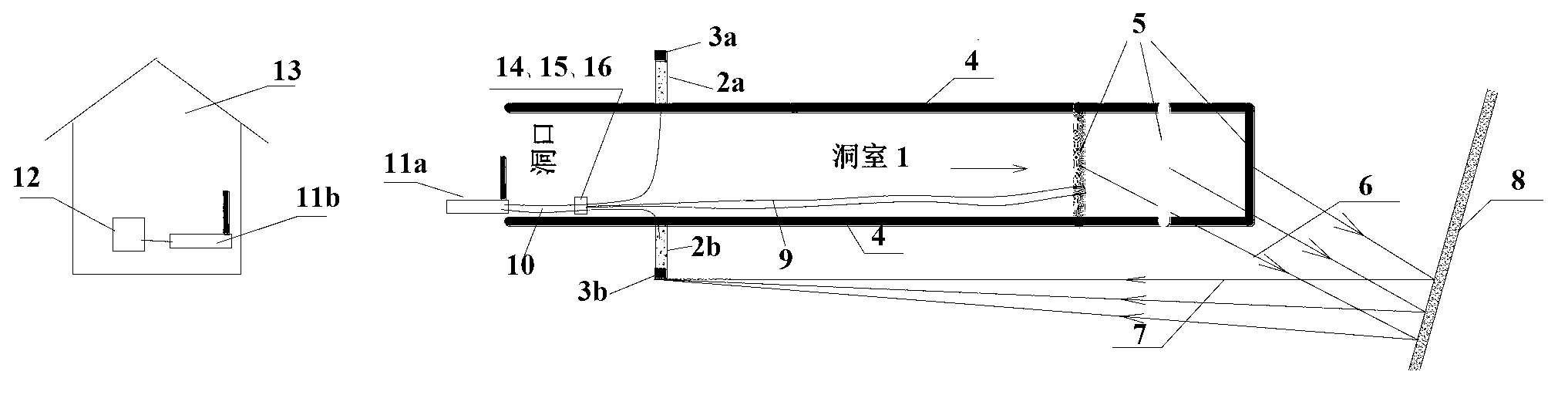

InactiveCN103217703AImprove signal-to-noise ratioUnfavorable Geological Body ForecastSeismic signal receiversCopper wireEngineering

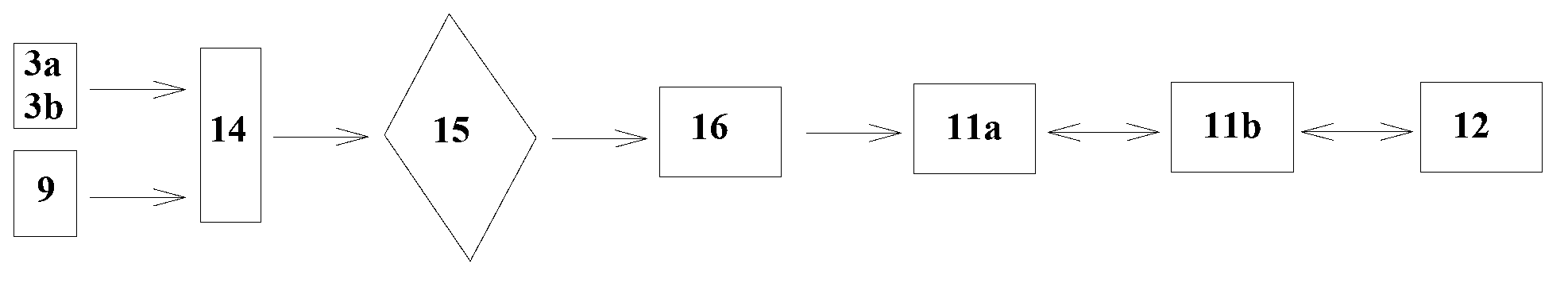

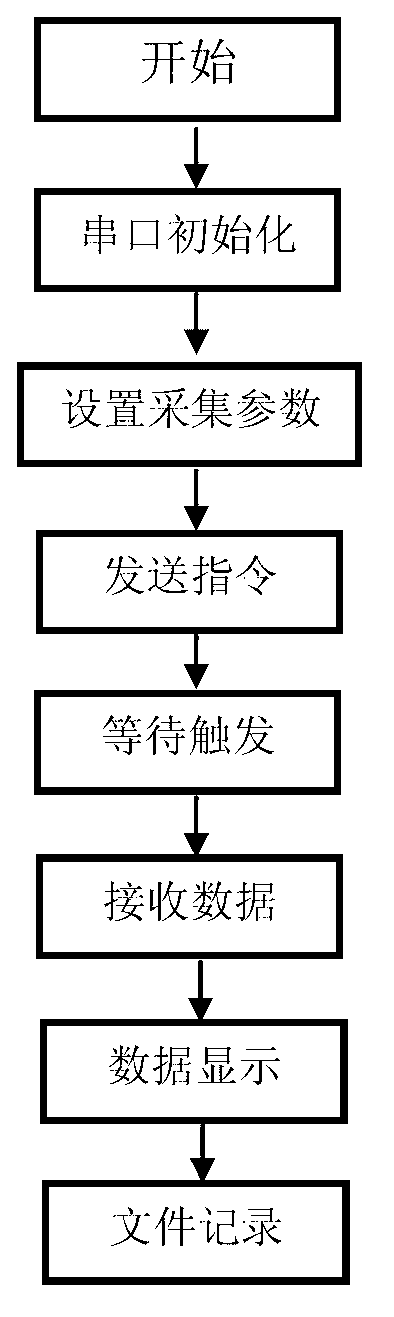

Provided are a method and a device for tunnel advance geology forecast with tunnel face blasting as a focus. The method comprises the steps of (1) drilling holes on two lateral walls at the inlet position in a tunnel; (2) filling a coupling agent into the drilled holes, and attaching weave detectors to the walls of the drilled holes; (3) winding a trigger circuit copper wire on cartridged explosive, and placing the cartridged explosive into a blasted hole of the tunnel face; (4), enabling two three-component weave detectors buried in a tunnel hole to receive reflective earthquake wave signals; (5) sending the signals to an amplifier after the signals are selected by a multi-way switch; (6) enabling the amplifier to amplify the signals and then transmit the signals to an analog / digital (A / D) converter through wireless transmission; (7) enabling a wireless communication module of a control chamber to receive a wireless signal and then transmit the wireless signal to a host, and recording the signal; and (8) achieving geology forecast through an processing program installed in the host. The device comprises signal acquisition, wireless communication and control and a data analyzing system. The method is simple, easy and low in cost, can be used for advance geology forecast of tunnels, holes and roadway underground spaces, and achieves automation and normalization of geology forecast.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

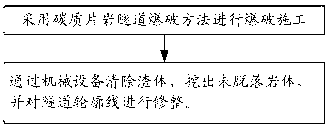

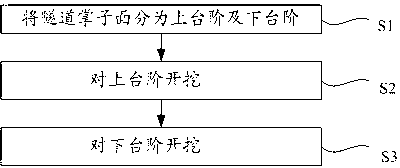

Carbonaceous schist tunnel blasting method and construction method

The invention discloses a carbonaceous schist tunnel blasting method and construction method. The carbonaceous schist tunnel construction method includes the steps of carrying out blasting in the carbonaceous schist tunnel blasting method, clearing away residues and digging out rock mass which does not fall off by using mechanical equipment, and revising a tunnel contour line. The carbonaceous schist tunnel blasting method includes the steps of dividing a tunnel face into a carbonaceous schist area and a none-carbonaceous schist area; arranging a plurality of blast holes in the tunnel face to form a hole pattern, wherein the density of the blast holes in the carbonaceous schist area is smaller than that of the blast holes in the none-carbonaceous schist area; filling explosives and detonators into the blast holes; connecting the detonators into a network; detonating the explosives according to a preset detonating sequence. The tunneling method of combining blasting and machinery is adopted, blasting is carried out first, rock does not need to be thrown out completely, and therefore disturbance and damage to surrounding rock are reduced; then the residues are cleared away and the rock mass which does not fall off is dug out by using the mechanical equipment, thus, tunneling efficiency can be improved, disturbance to the surrounding rock is little, and damage on the surrounding rock is reduced; in addition, the back break control effect is good, the tunneling effect is improved, and tunneling quality is high.

Owner:WUHAN UNIV OF SCI & TECH

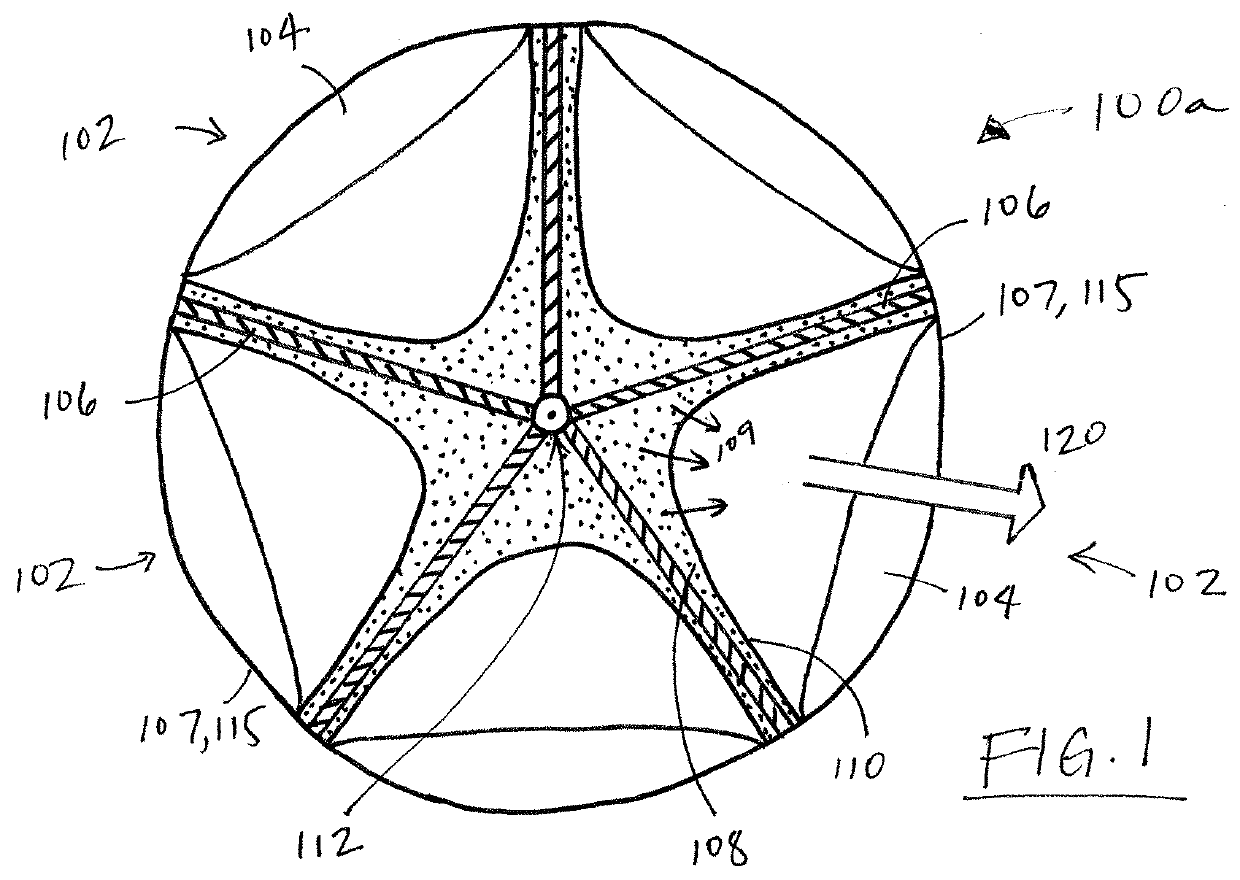

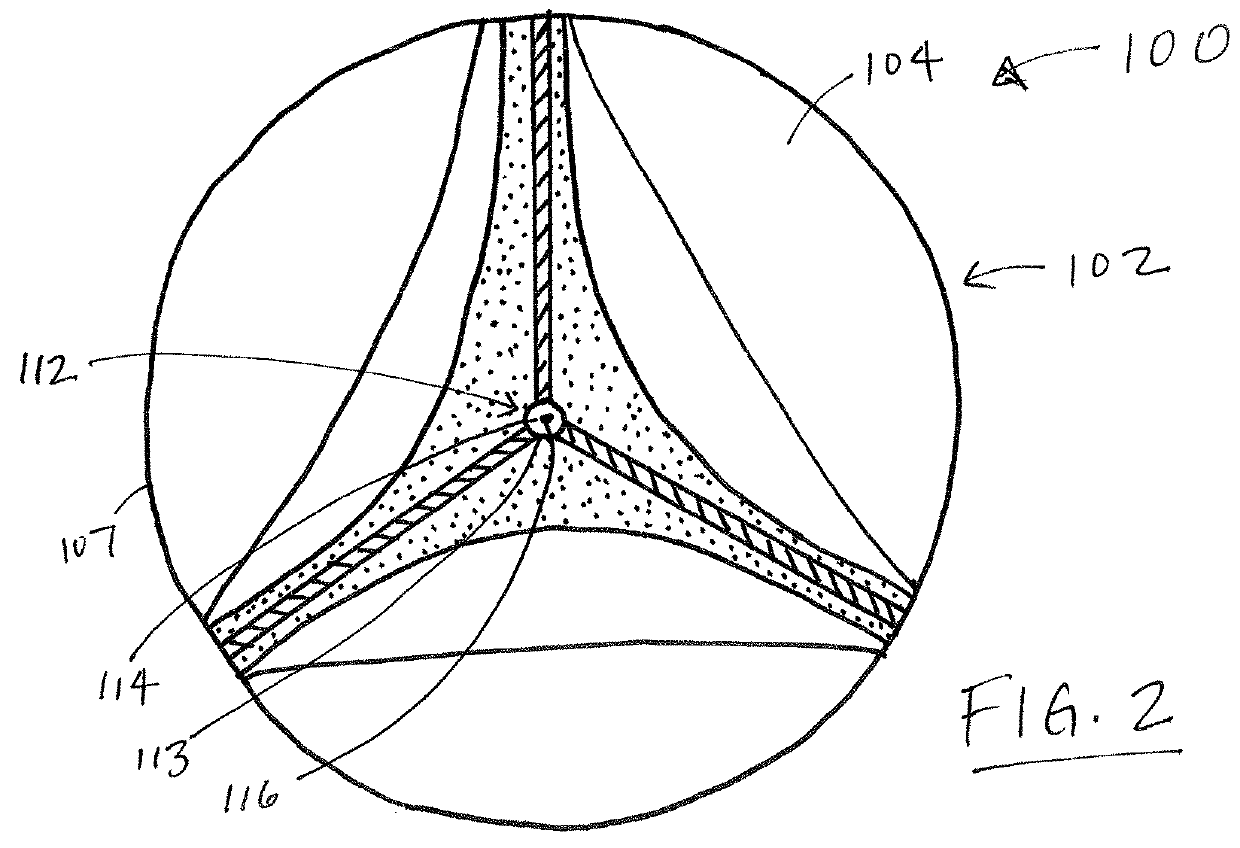

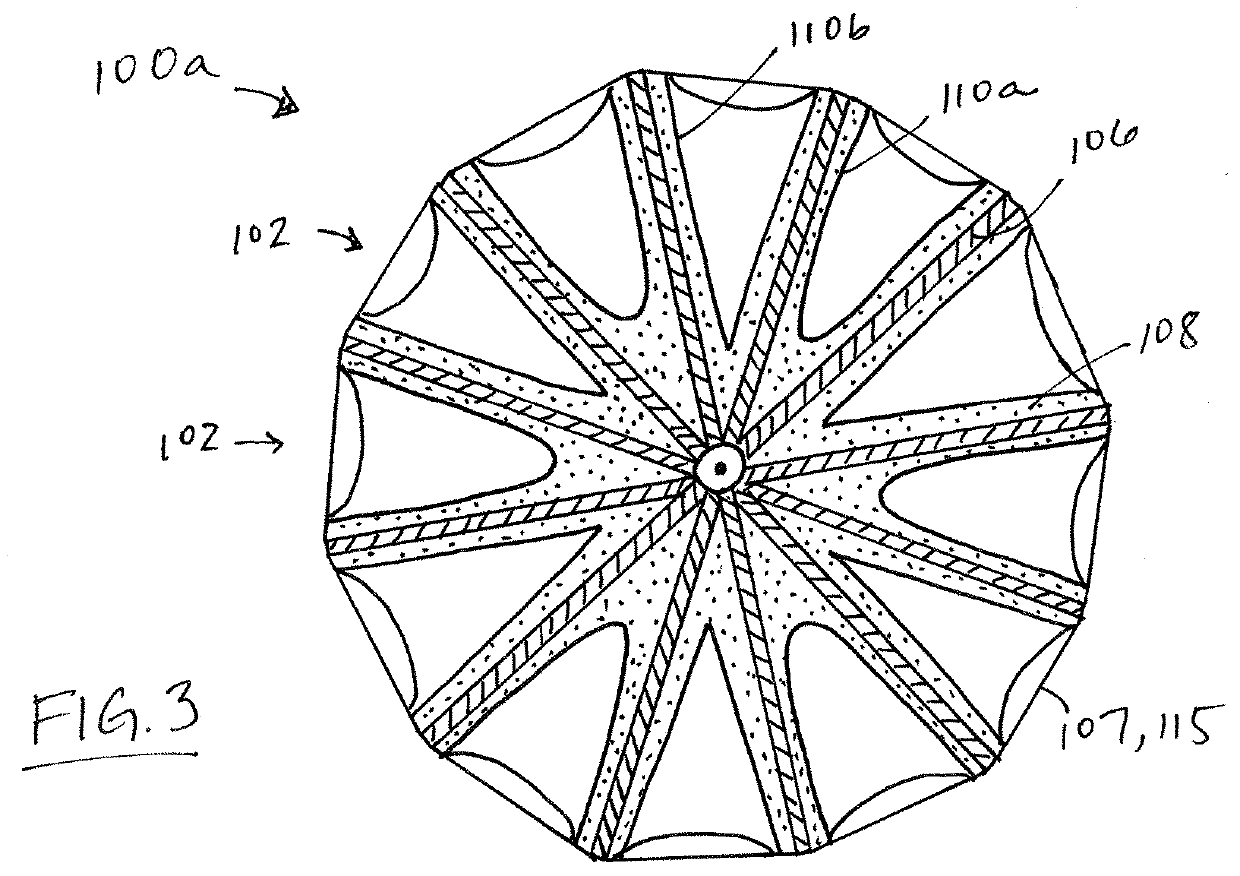

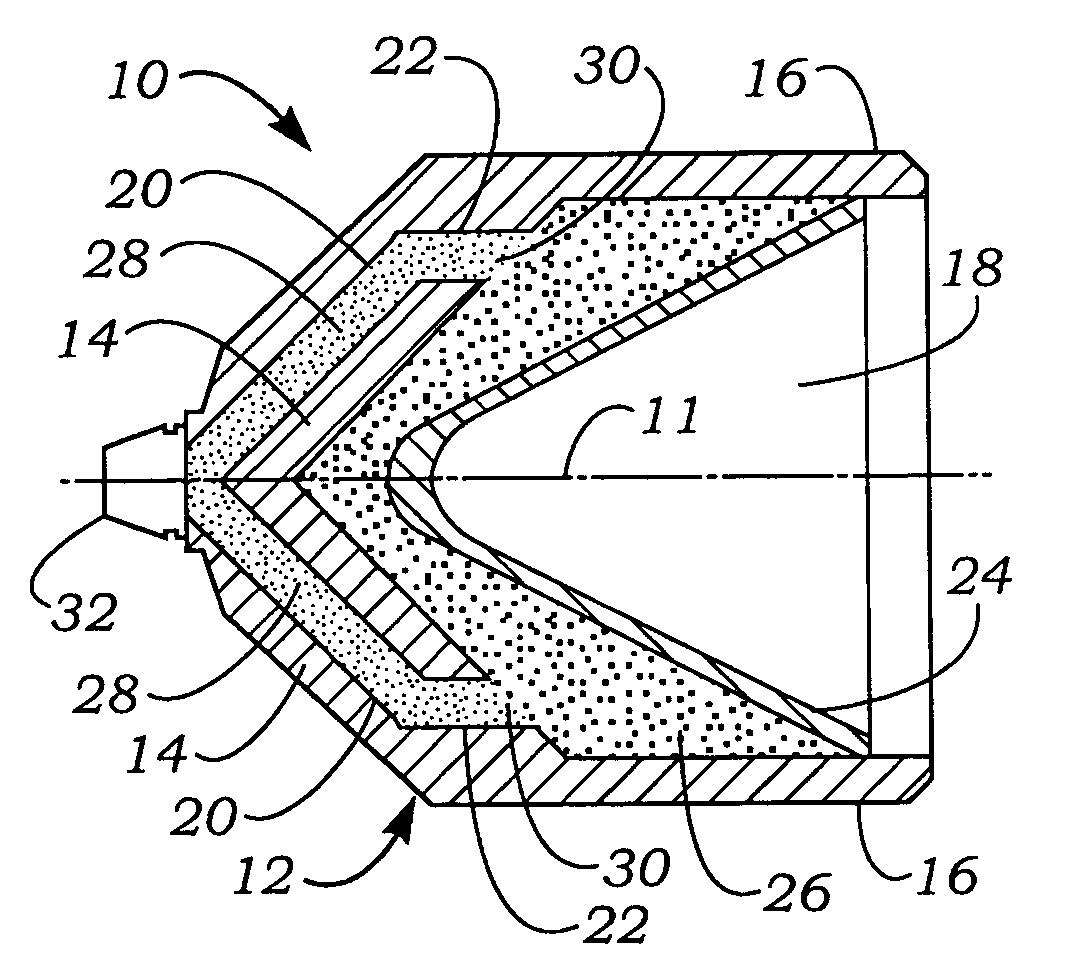

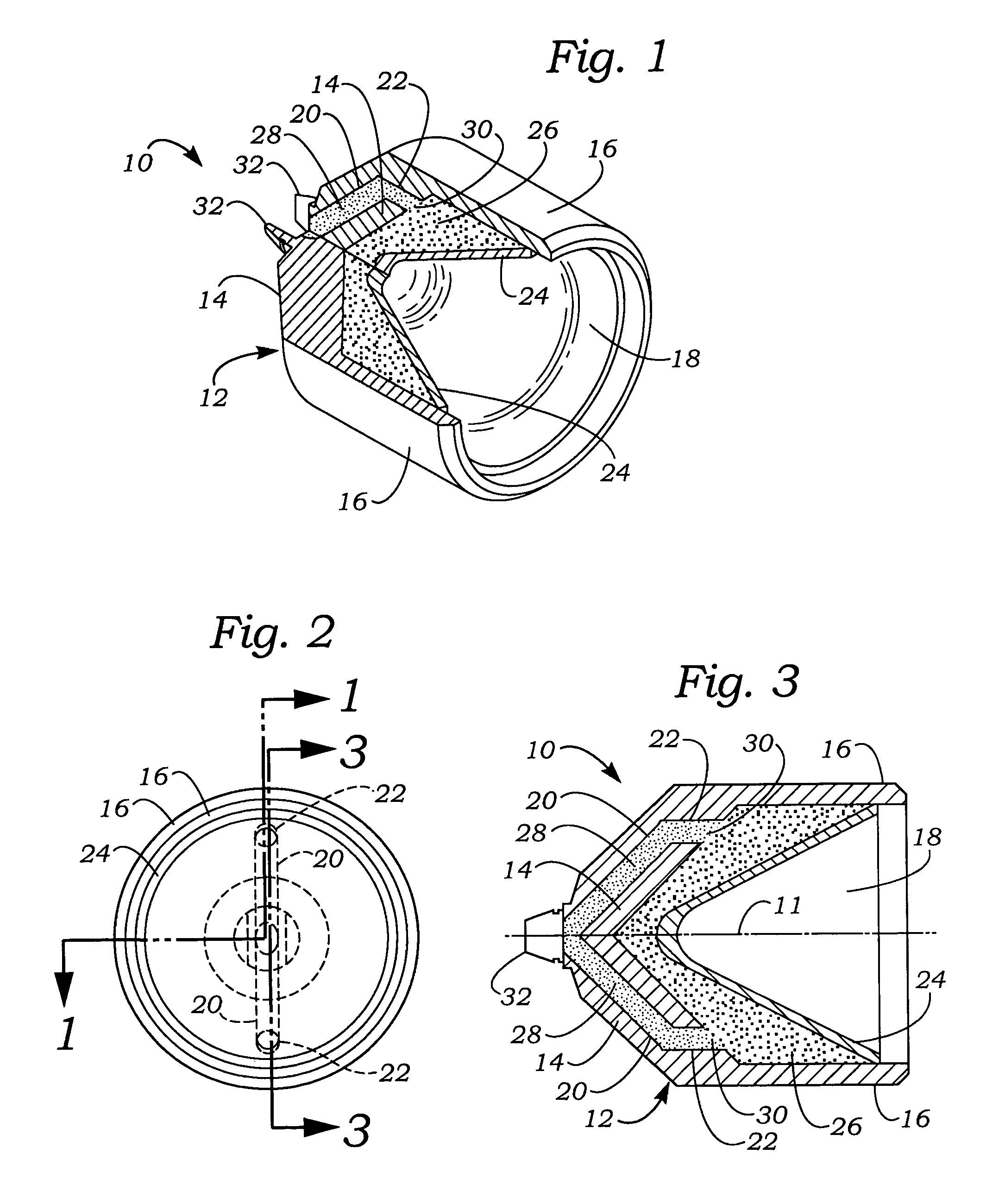

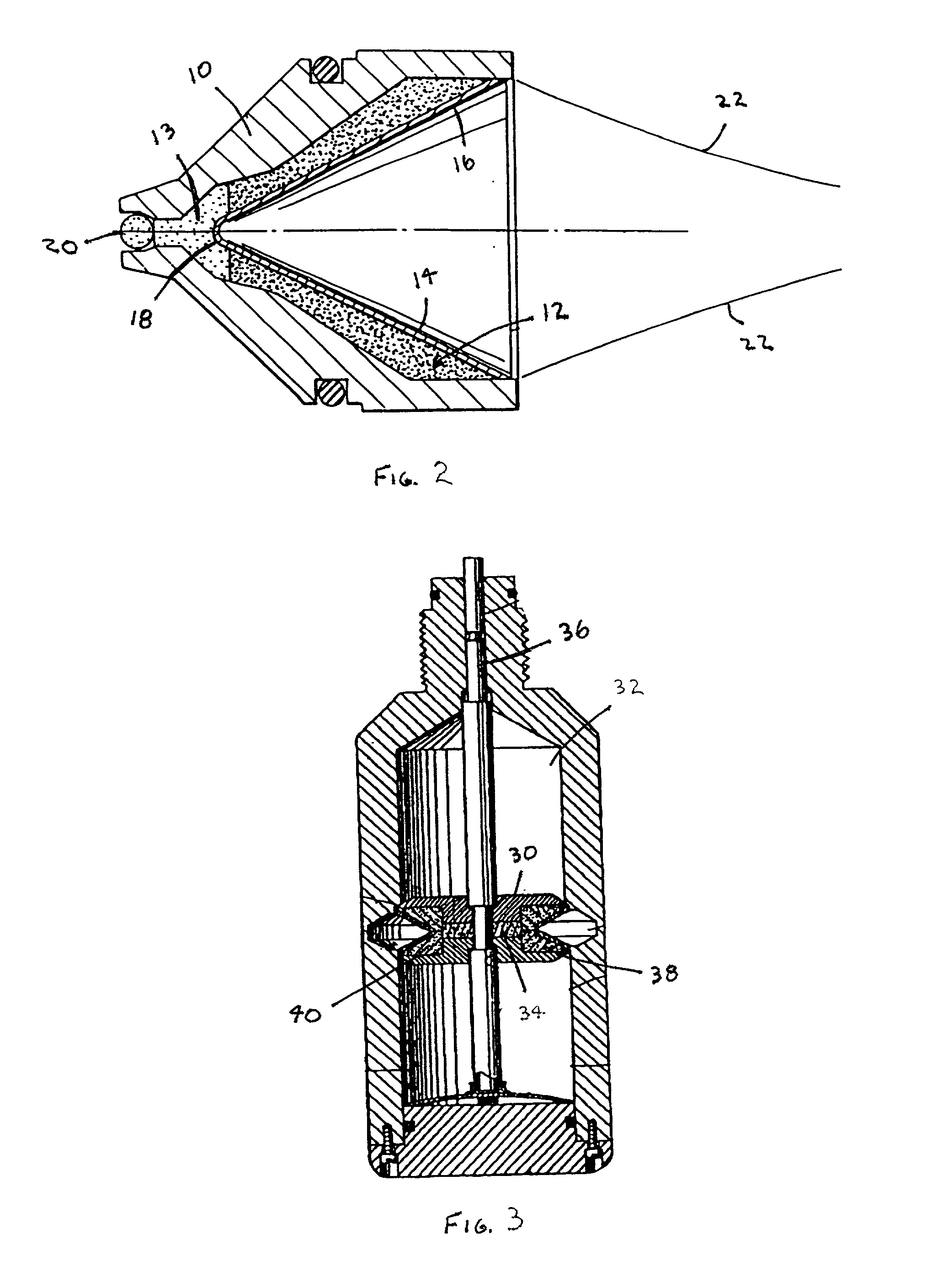

Method and apparatus to improve perforating effectiveness using a unique multiple point initiated shaped charge perforator

InactiveUS6925924B2Minimize potentialImprove effectivenessExplosive chargesDomestic stoves or rangesInitiation pointExplosive Agents

A non-linear shaped charge perforator for use in perforating an oil and gas formation into which a wellbore has been drilled comprises a monolithic, axisymmetric metal case in which is disposed a main explosive charge between the front of the case, which is closed with a concave metal liner, and the closed back end of the case. The main explosive charge contains multiple initiation points, preferably two initiation points located about 180° apart on the outside surface of the charge, so that when the perforator is detonated the main charge is initiated such that the metal liner is collapsed into a non-circular jet, preferably a fan-shaped jet, that pierces the casing of the wellbore and forms non-circular perforations, preferably slot-shaped perforations, in the surrounding formation.

Owner:ARMY US GOVT AS REP BY THE SEC OF +1

Linear shaped charge system

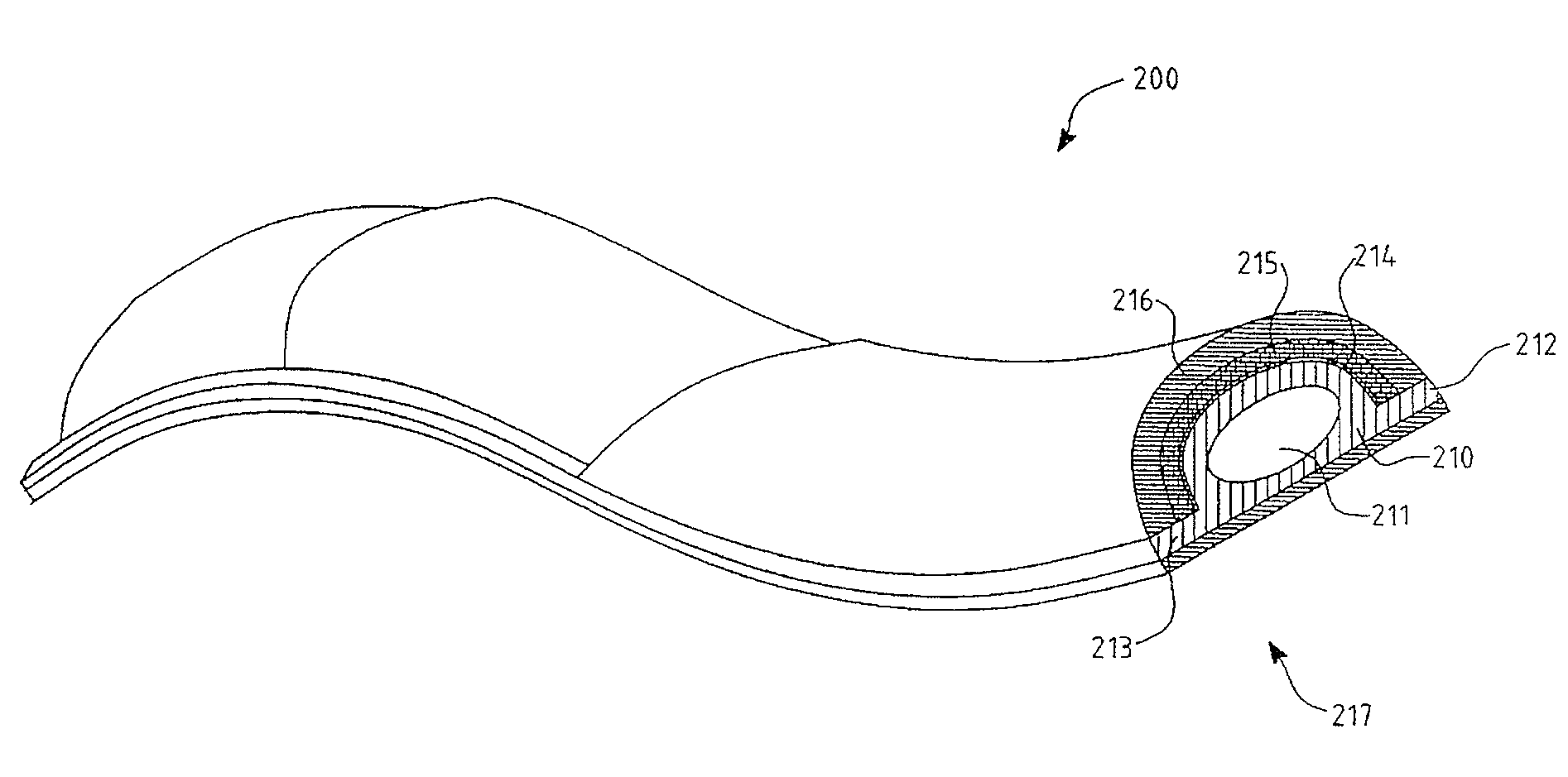

An elongate explosive charge element (25), said explosive charge element (25) including a flexible frangible cutting sheet (26) and an explosive agent (27) said charge element (25) adapted to the penetration of a barrier structure.

Owner:APPLIED EXPLOSIVES TECH

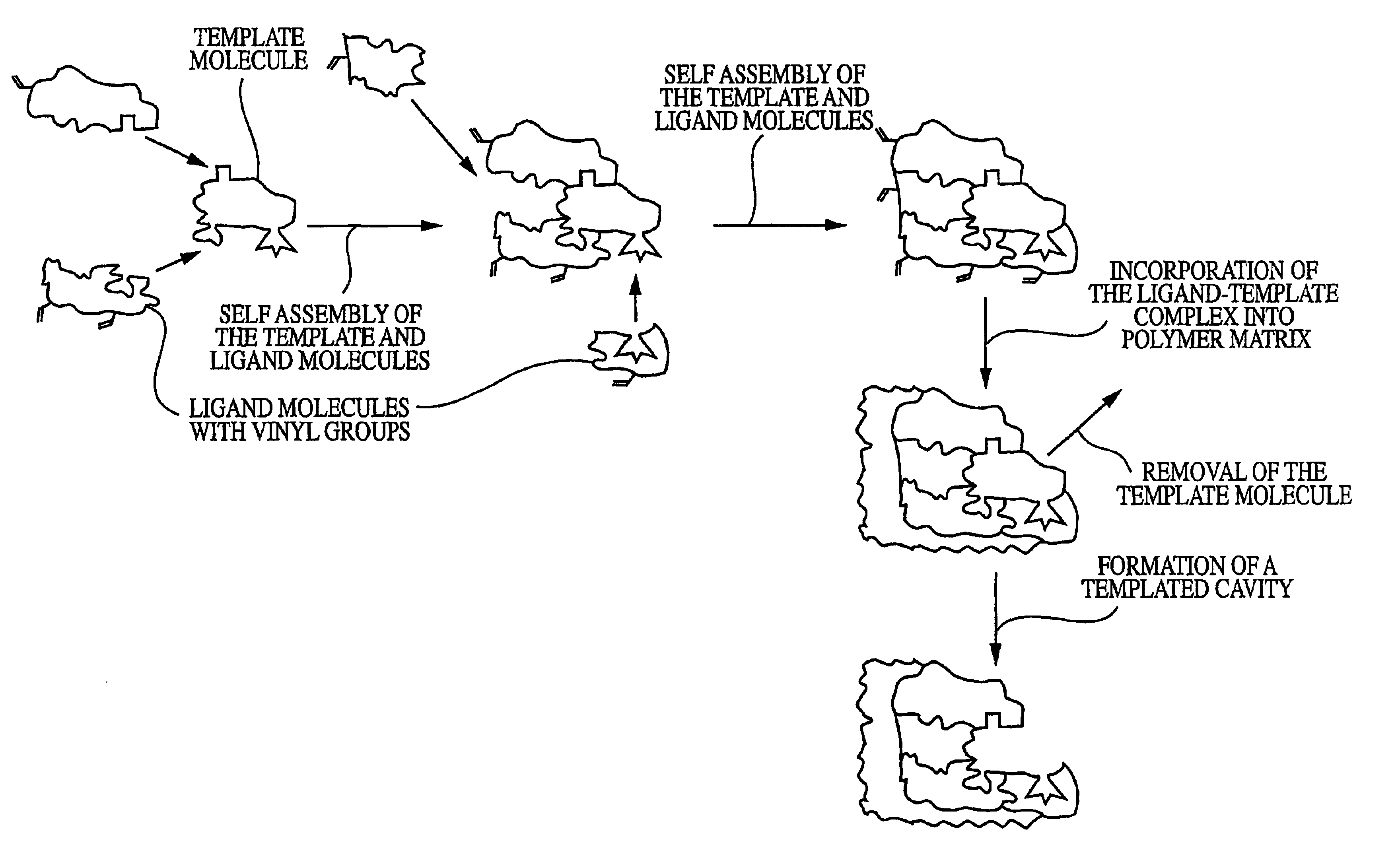

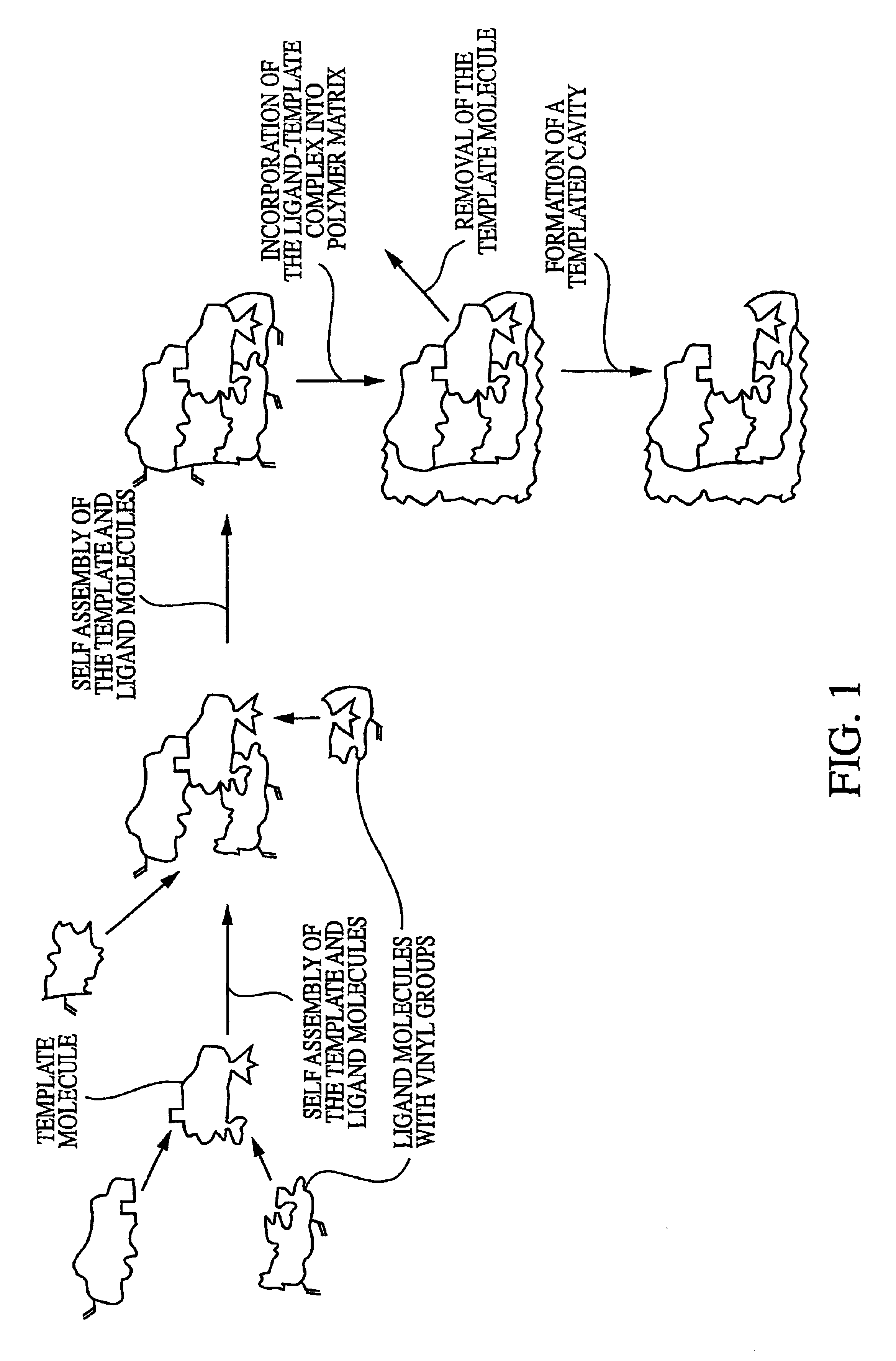

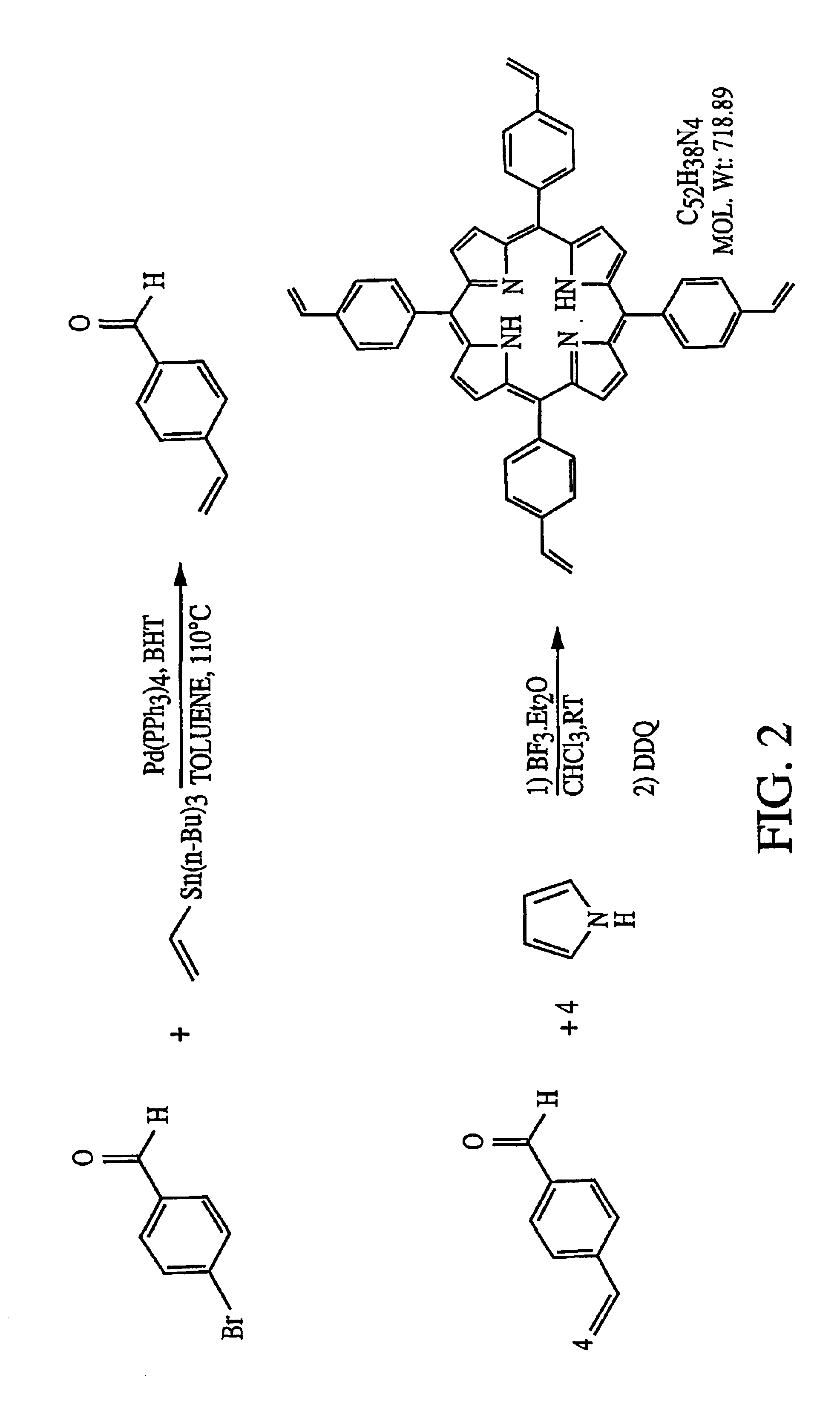

Molecularly imprinted polymeric sensor for the detection of explosives

InactiveUS6872786B2Analysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by observing effect on chemical indicatorPhysicsMolecularly imprinted polymer

A molecularly imprinted polymeric explosives sensor is provided which possesses selective binding affinity for explosives, such as 2,4,6-trinitrotoluene (TNT) and 1,3,5-trinitrobenzene (TNB). The polymeric sensor incorporates a porphyrin which undergoes a detectable change in absorption and / or emission of electromagnetic radiation when the polymer is exposed to explosives.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY +1

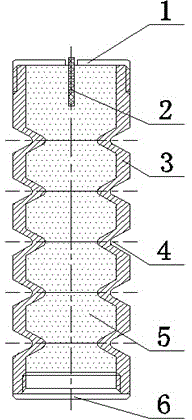

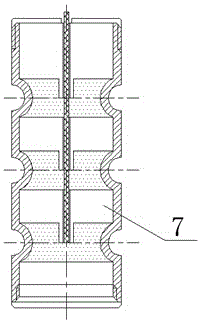

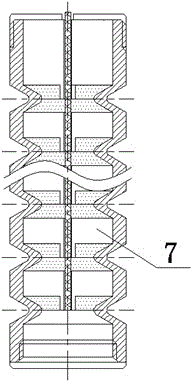

Case circular discontinuous energy concentrating jet flow cracker

InactiveCN103983153AHas energy-gathering effectSpeed up meltingFluid removalBlastingExplosive AgentsEngineering

The invention belongs to the technical field of engineering blasting and ammunition engineering. A circular discontinuous energy concentrating jet flow cracker comprises a round tube-shaped case, an end cover and a detonating unit; explosives are mounted inside the cavity the round tube-shaped case; the detonating unit is leaded out of the case through a hole formed in the end cover; the outer round surface of the round tube-shaped case is provided with circular grooves which are parallel to one another, and the circular grooves are in a conical or semicircular shape and form circular protrusions in the corresponding shape on the inner wall surface of the cavity of the round tube-shaped case; the width of the circular grooves is 1 / 2-1 / 5 as much as the outer diameter of the case, the length of the generatrix of the conical cross sections or the diameter of the semicircular cross sections of the circular grooves is 1-7 times larger than the thickness of the wall of the case, the apex angle of the conical cross sections is 40-120 degrees, and the distance between the central axises of every two neighboring circular grooves is 1.5-40 times as large as the width of the circular grooves. The circular discontinuous energy concentrating jet flow cracker impacts a target at a high speed through the high-temperature, high-pressure and energy-concentrated discontinuous jet flows which are generated by the case, is simple in structure, convenient to machine and use, small in amounts of explosives used in a single blasting, low in vibration, low in production cost and capable of ensuring the safety and meeting various usage requirements.

Owner:UNIV OF SCI & TECH OF CHINA

High temperature explosives for downhole well applications

InactiveUS20020129940A1Suitable characteristicFluid removalNitrated aromatic explosive compositionsBiologyExplosive Agents

Owner:SCHLUMBERGER TECH CORP

High energy insensitive press-fitting high polymer bonded explosive

ActiveCN107879867AHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Stimulating unconsolidated producing zones in wells

InactiveUS6155348AQuickly and efficiently removeReduce necessityFluid removalDrilling compositionExplosive materialWellbore

Owner:HALLIBURTON ENERGY SERVICES INC

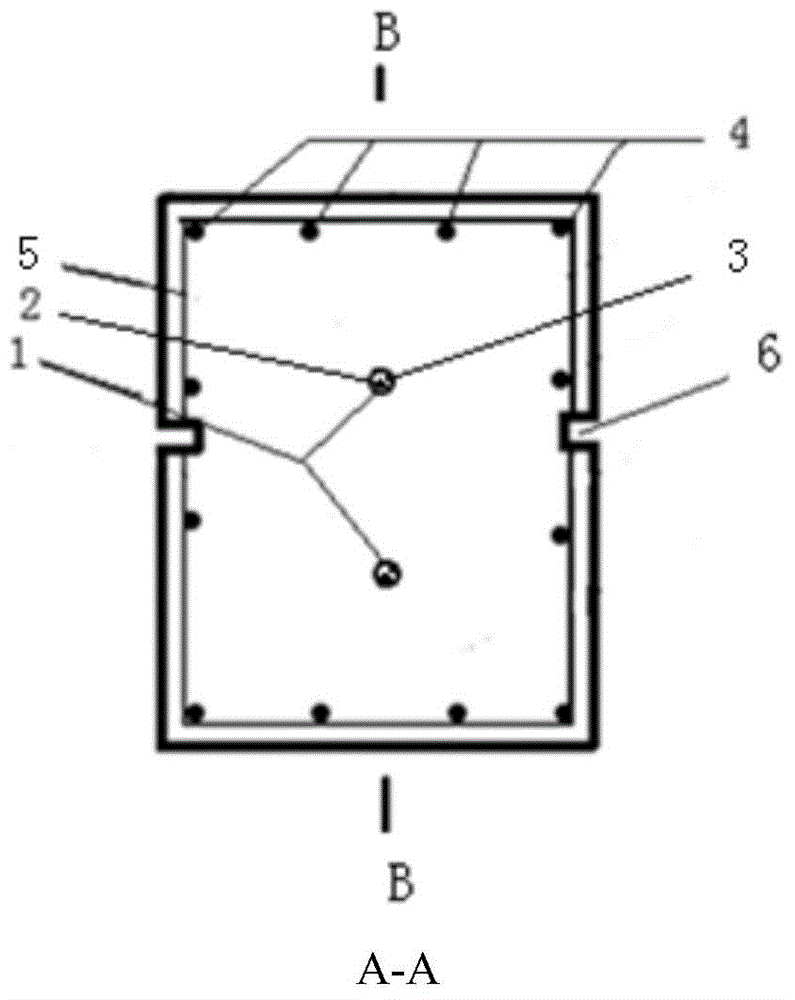

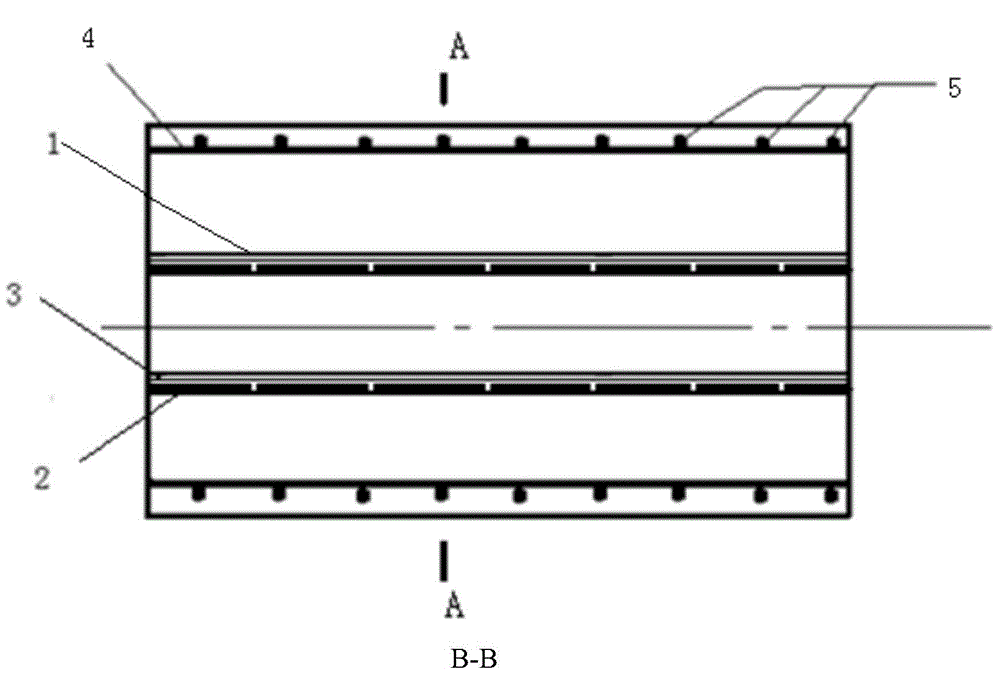

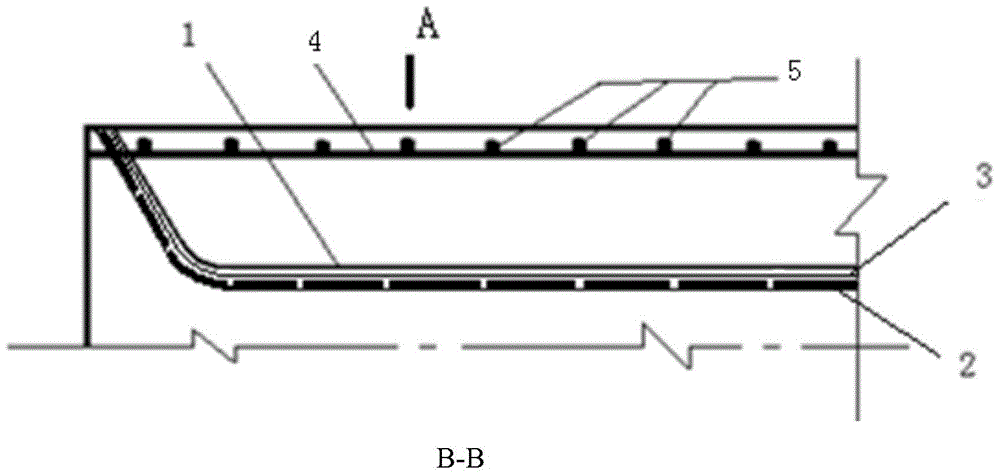

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

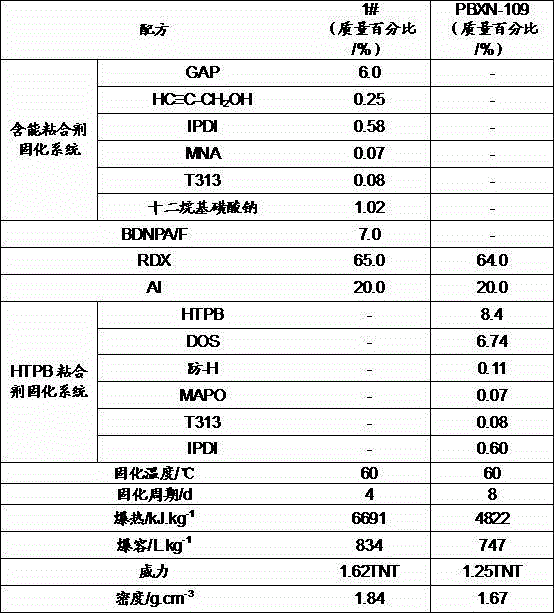

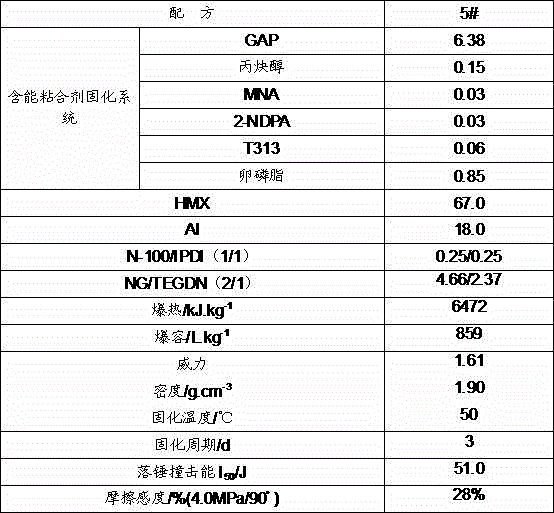

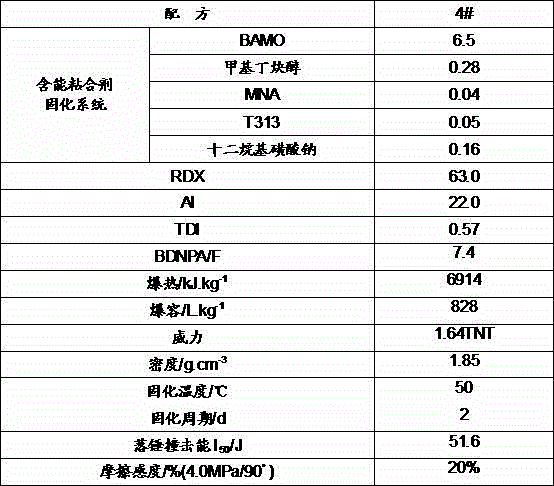

Poured-type azido high-polymer bonded explosive and preparation method of same

A poured-type azido high-polymer bonded explosive and a preparation method of same. For solving a problem of low energy of an HTPB-based PBX explosive, an azido polyether energetic binder is added to a formula system of the PBX explosive, and by means of addition of an alkynol compound as a curing additive agent, a curing reaction time of the azido polyether binder system is greatly reduced. By means of addition of a high-energy-density main explosive and a metal fuel component, the obtained poured-type azido PBX explosive has high explosion heat and explosion volume, is higher than 1.80 g / cm<3> in density and is more than 1.60 TNT in power. Meanwhile, the poured-type azido PBX explosive has a low sensitivity level, is higher than 49 J in drop hammer impact energy I50 and is not more than 40% in friction sensitivity.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

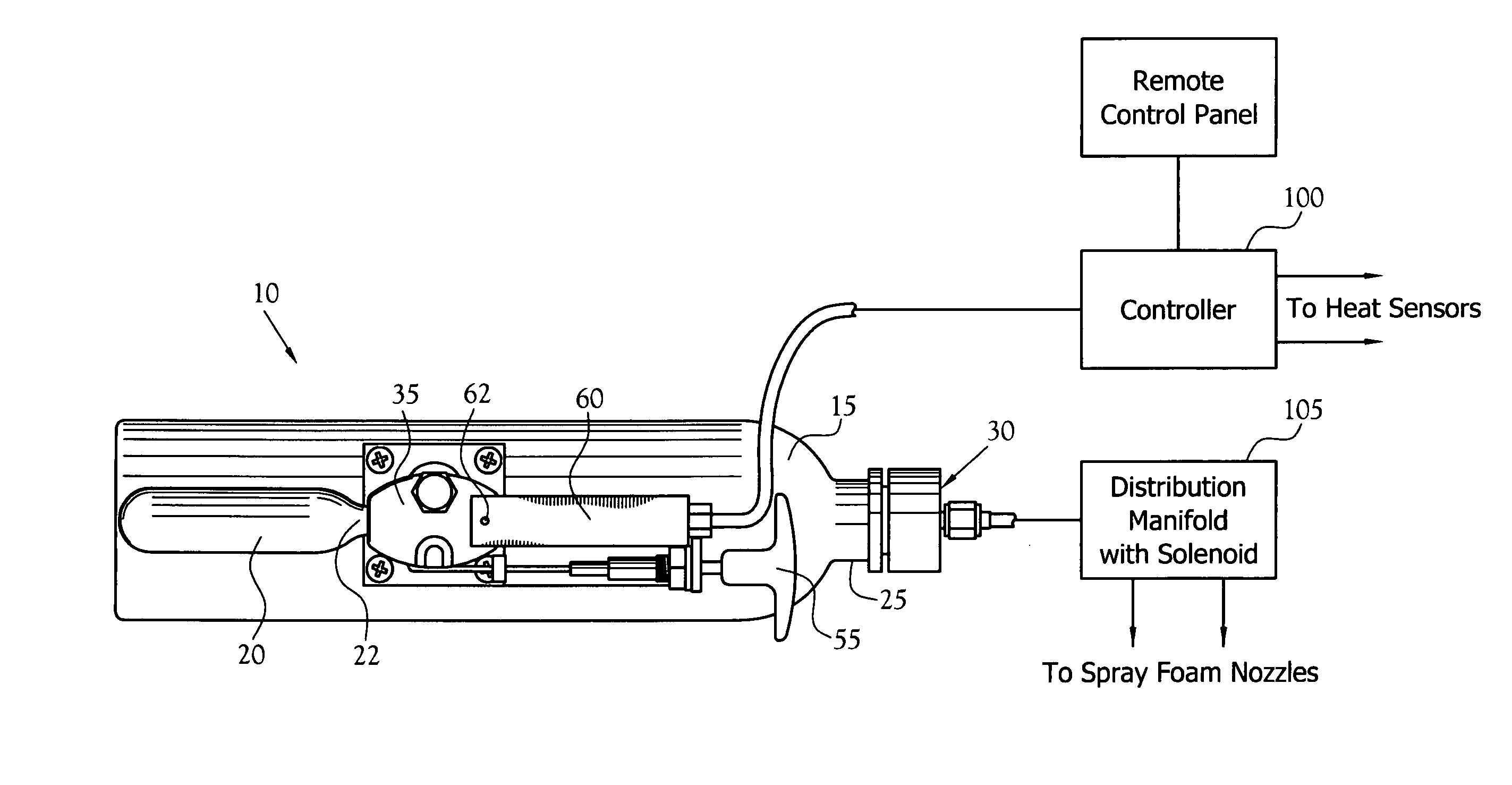

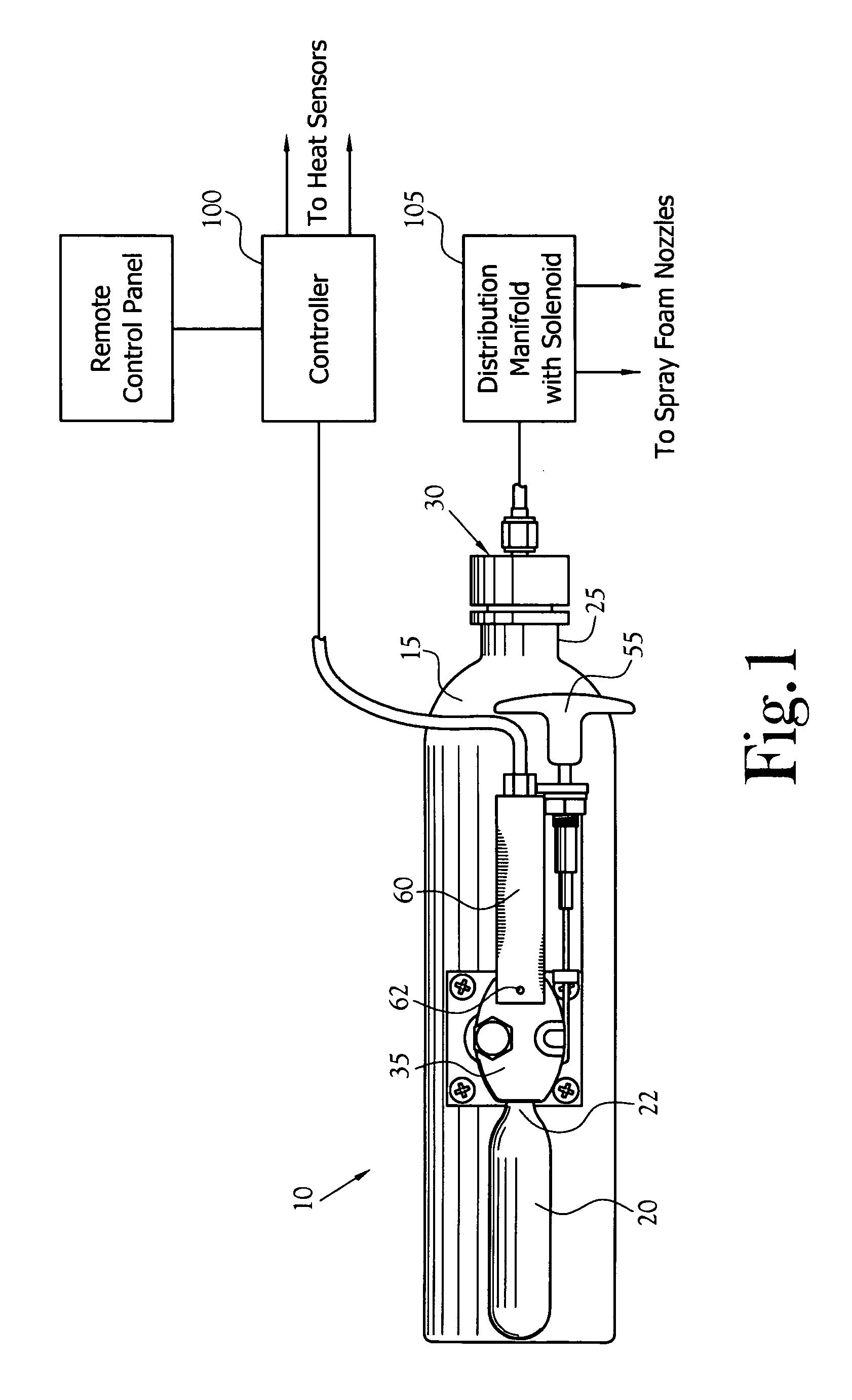

Fire suppression system

A vehicular and marine fire suppression system for detecting and suppressing and quenching fires. The vehicular and marine fire suppression system including a first canister, a second canister and an actuation mechanism. The first canister houses a fire suppressing agent and is in fluid communication with a manifold assembly for providing delivery of the fire suppression agent from the first canister to the area to be protected by the fire suppression system. The second canister contains a pressurizing / agitation agent and is in fluid communication with the first canister via a valved actuator assembly. The second canister includes a threaded neck defining an outlet and a pierceable seal disposed about the outlet. The actuator assembly includes a piercing member for rupturing the pierceable seal of the second canister. The piercing member is in active engagement with a piston carried by a squib. Ignition of an explosive agent within the squib is used to drive the piston to an extended position thus causing the piercing member to rupture the pierceable seal of the first canister. State-of-the-art heat / smoke detection circuitry and a programmable logic circuit are provided for detecting a fire and delivering an electrical signal to the squib. A handle member and a linkage in operative engagement with the piercing member is provided for manual actuation of the fire suppression system. Alternatively, an electrically actuated solenoid could be used to actuate the piercing member.

Owner:MCLANE JR SAMUEL D

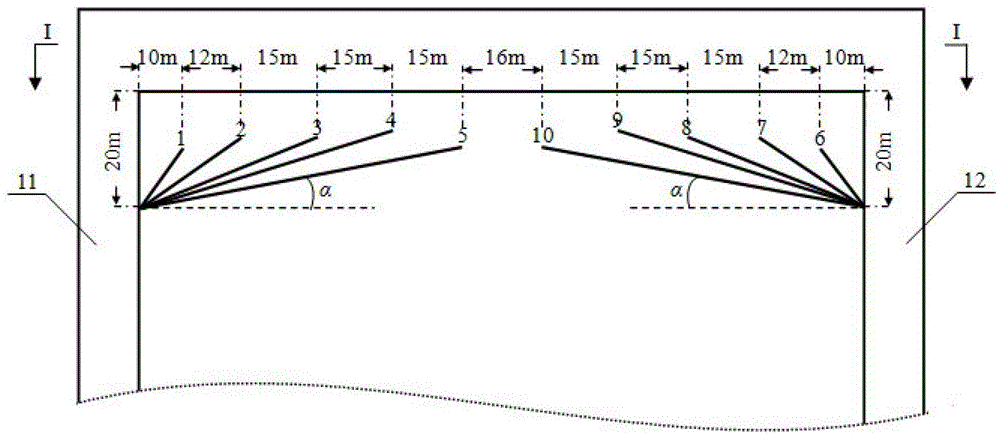

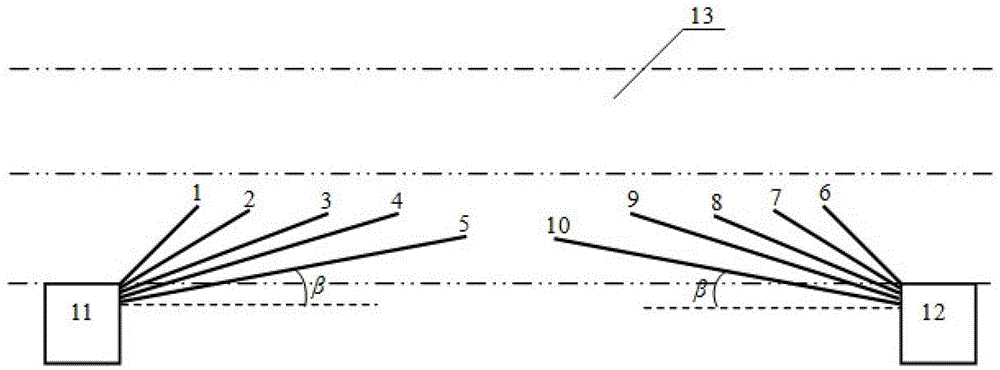

High-pressure gas blasting-based coal seam roof advance presplitting method

ActiveCN103334790ASmall power disturbanceGood pre-cracking effectMining devicesChemical explosiveExplosive Agents

The invention discloses a high-pressure gas blasting-based coal seam roof advance presplitting method, which belongs to the technical field of mine safety. The method is performed according to the following steps: (1) forming a group of drilled holes in a coal seam roof every a certain distance on a conveying roadway and a track roadway of a working face, wherein each group of drilled holes is arranged in a fan shape and faces towards a goaf; (2) placing a gas detonation gun which is connected with a high-pressure gas compression system in the drilled hole and sealing the hole by using high-strength fast setting concrete or resin; (3) starting the high-pressure gas compression system and instantaneously releasing high-pressure gas in a high-pressure gas storage tank in the drilled hole through the gas detonation gun to blast so as to communicate the crack around the drilled holes with adjacent drilled holes; and (4) repeating the steps (2) and (3) on each group of drilled holes in sequence to finish advance presplitting of the coal seam roof. According to the method, the potential spark hazard of chemical explosive blasting is eliminated; and since the pressure of the high-pressure gas is controllable and impact blasting can be repeatedly performed on the rock body, the dynamic disturbance of a coal seam is small, the roof presplitting effect is good, and the method is environment-friendly, safe and reliable.

Owner:LIAONING TECHNICAL UNIVERSITY

Methods and compositions for degradation of nitroaromatic and nitramine pollutants

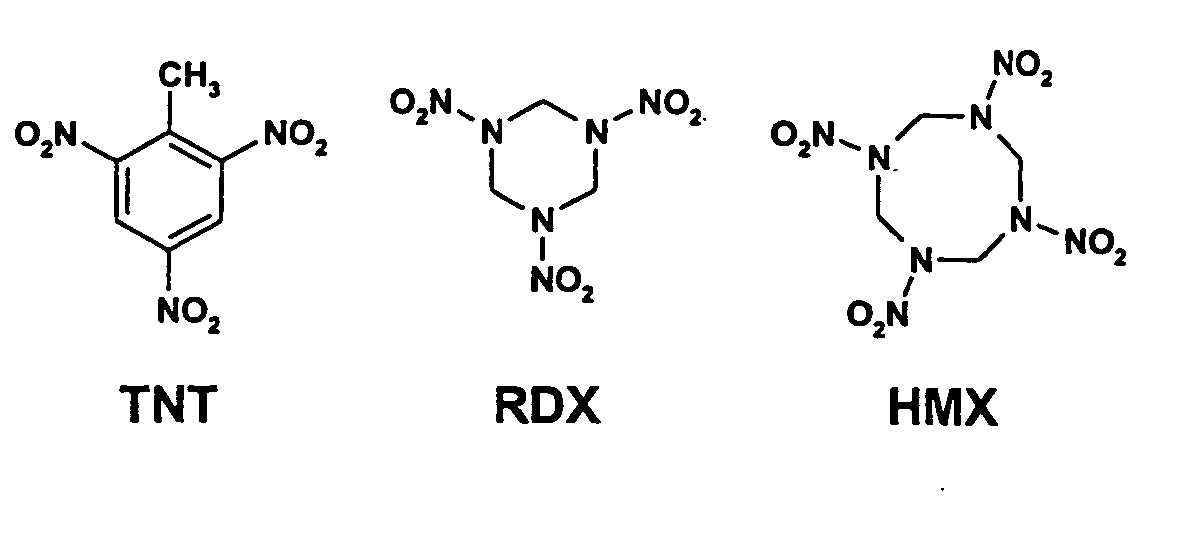

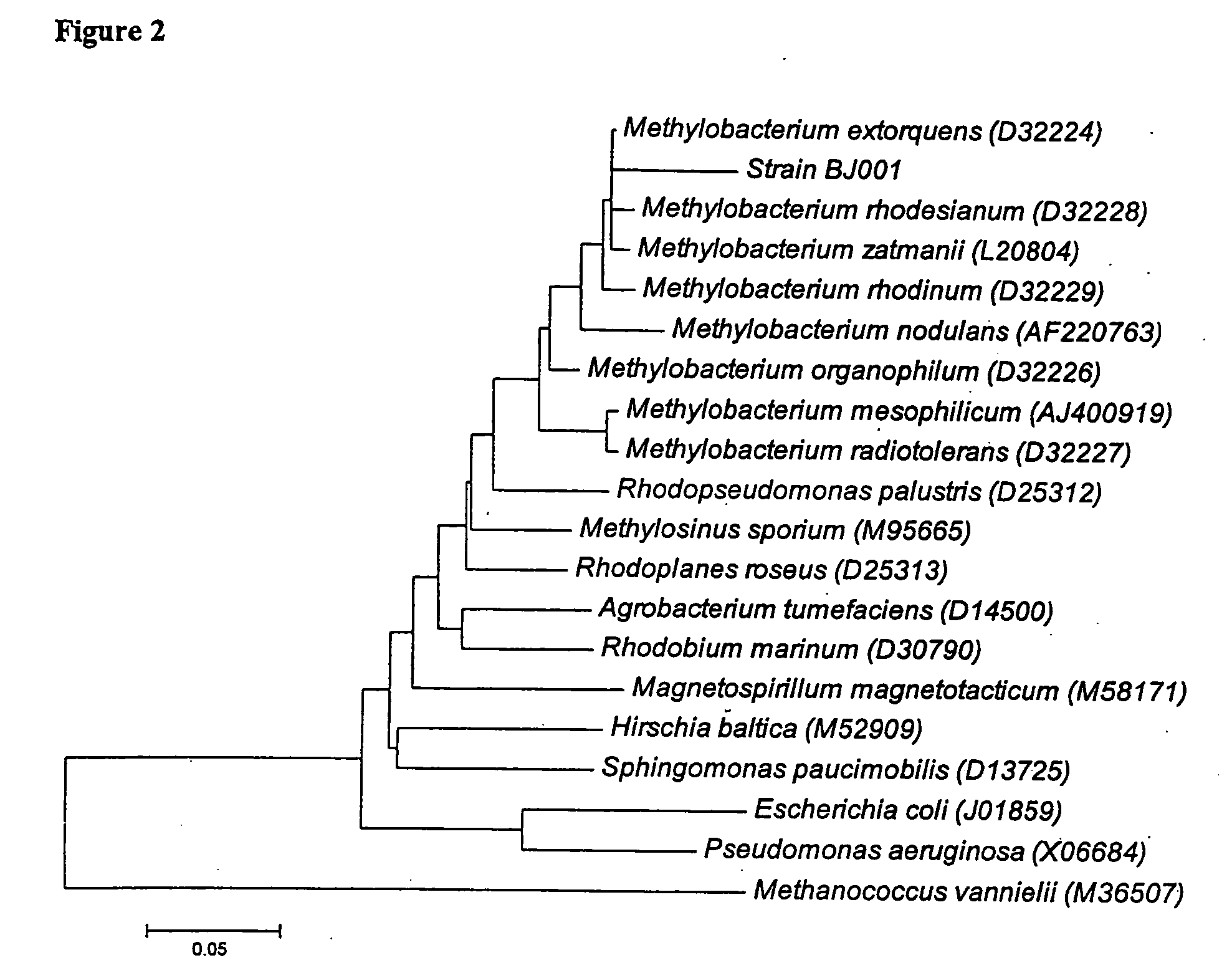

InactiveUS20050054030A1Improve abilitiesReduced activityBacteriaMicrobiological testing/measurementBioremediationMethylobacterium

The invention relates to novel Methylobacterium species that are capable of degrading nitroaromatic and nitramine compounds. Compositions, kits and methods of using the Methylobacterium species for the degradation of nitroaromatic and nitramine pollutants are provided. More specifically, compositions and methods for the degradation or bioremediation of nitroaromatic and nitramine explosives and explosive residues are provided.

Owner:UNIV OF IOWA RES FOUND

Ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and preparation method thereof

InactiveCN101570459AReduce material consumption and energy consumptionObvious superiorityInorganic oxygen-halogen salt explosive compositionsDiamineEthylenediamine

The invention discloses an ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and a preparation method thereof. The initiating explosive is a eutectic compound of ethylenediamine perchlorate and triethylene diamine perchlorate, can be initiated under the action of outside excitation energy and has better explosion output power. The preparation method is as follows: the eutectic compound of the ethylenediamine perchlorate and the triethylene diamine perchlorate is prepared by the neutralization reaction through using ethylene, triethylene diamine and perchloric acid as raw materials under the solution state, wherein the molecular ratio of the ethylenediamine perchlorate and the triethylene diamine perchlorate in the prepared eutectic compound is 1:1. The invention has the advantages of small moisture absorption, large explosion power, simple manufacture process, energy saving, consumption reduction, and no harm to environment.

Owner:NANJING UNIV OF SCI & TECH

Propellant with high energy and low temperature sensitive coefficient of burning

ActiveCN105130720ABoost energy levelsLow burning rate temperature sensitivity coefficientExplosivesAl powderExplosive Agents

A propellant with high energy and low temperature sensitive coefficient of burning comprises 12-15% of an adhesive, 10-13% of a plasticizer, 15-18% of an oxidant, 38-50% of an energetic explosive, 10-18% of a metal fuel and 1.5-2.0% of a small group, wherein the adhesive is glycidyl azide polymer; the plasticizer is triethylene glycol dinitrate or 2,4-dinitro-2,4-diazaalkane; the oxidant is ammonium perchlorate; the energetic explosive is octogen; and the metal fuel is aluminum powder. The propellant has the characteristics of high energy (standard measured specific impulse is greater than 2450N.s / kg) and low temperature sensitive coefficient of burning (not greater than 0.15%K<-1>), and is suitable for tactical missile engines with far required range, strong penetration ability, high reliability and accurate guidance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

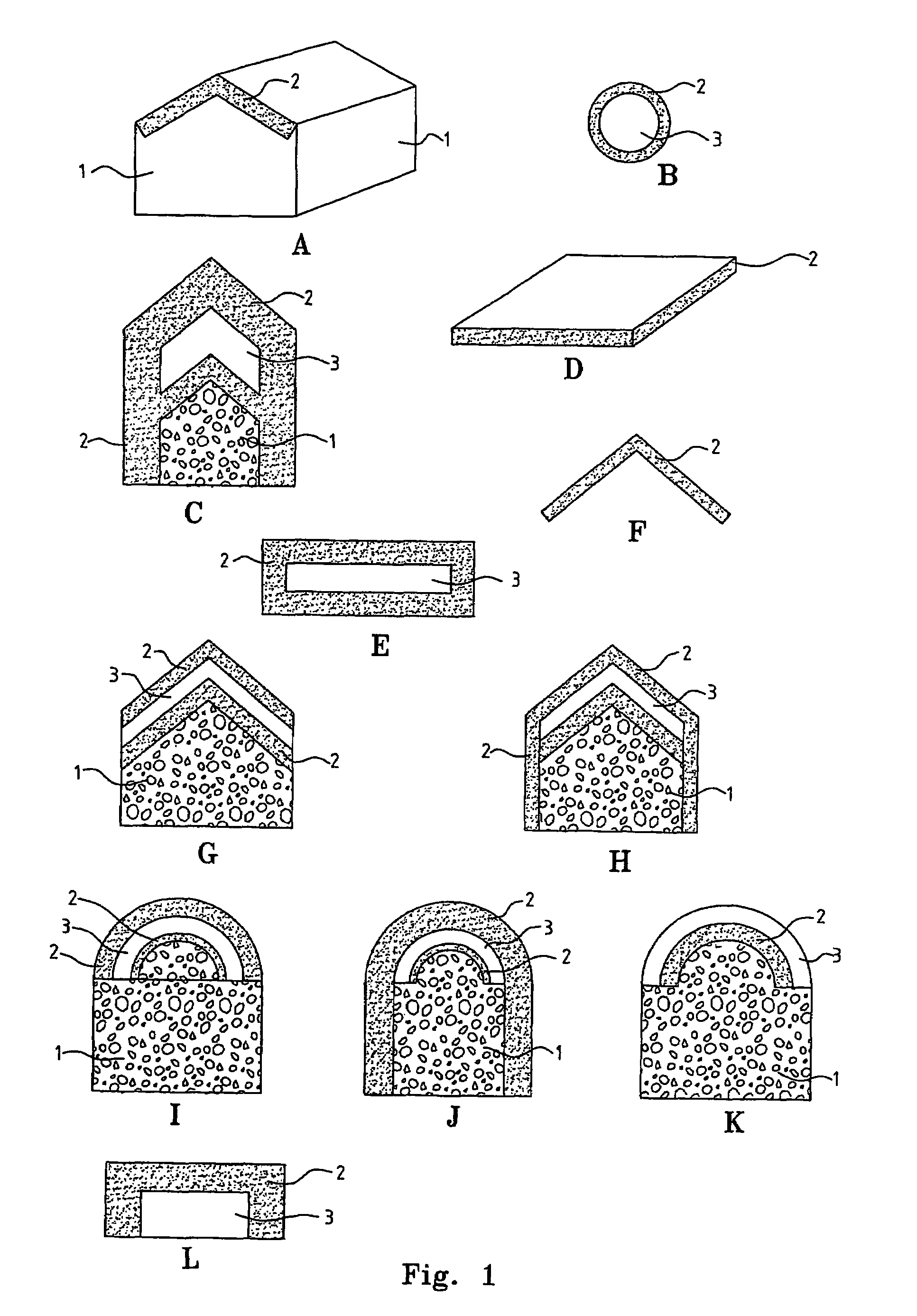

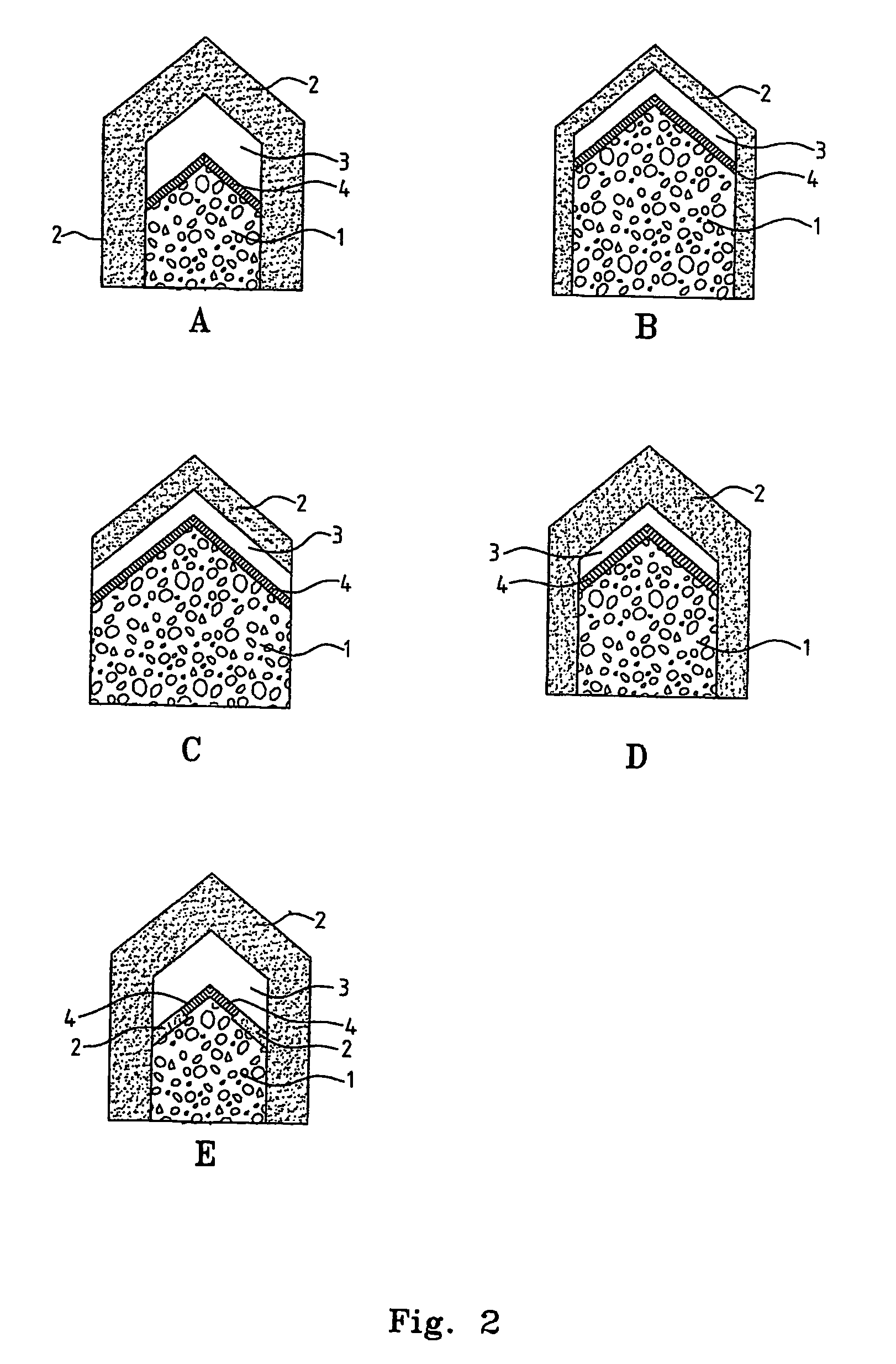

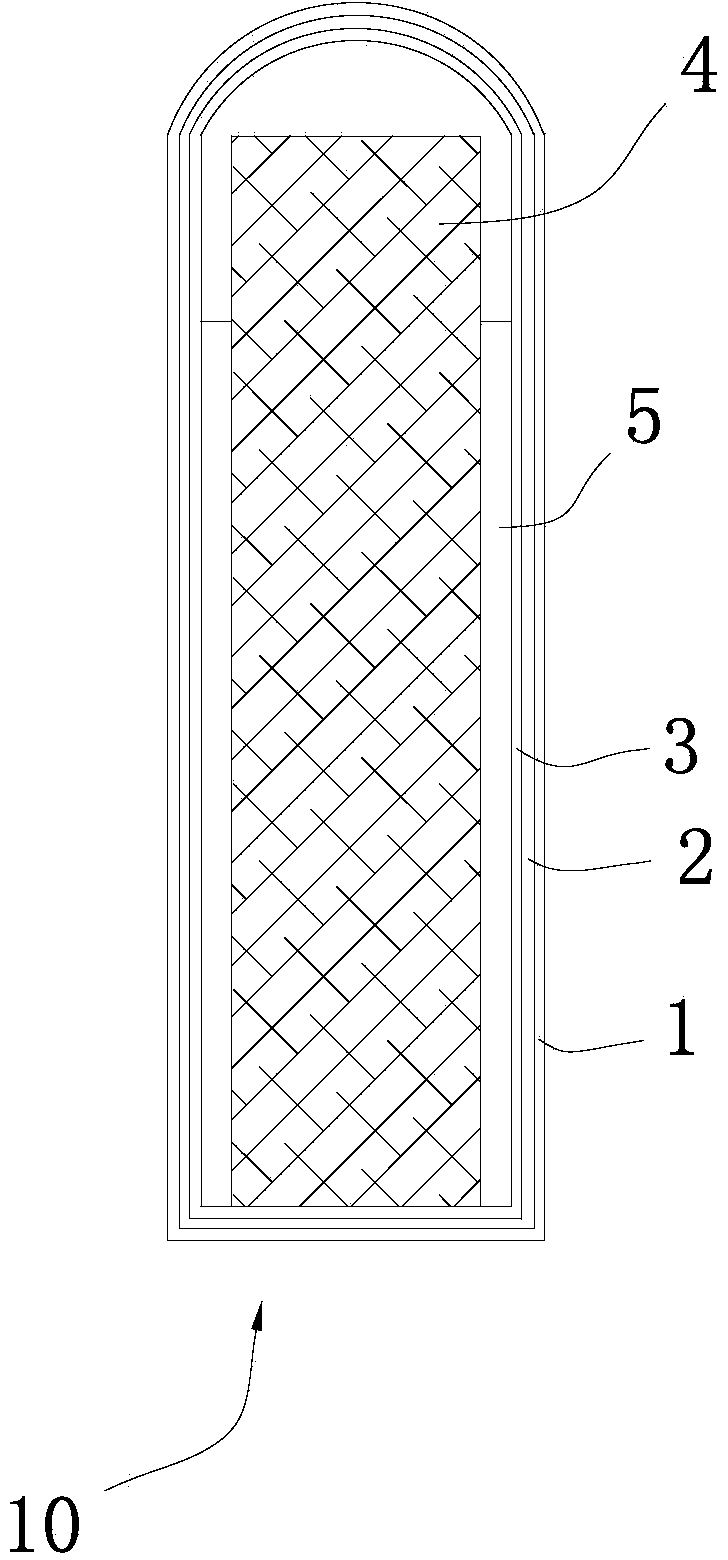

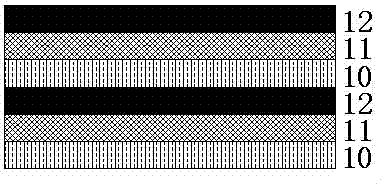

Temperature-resistance thermal insulation protecting bush

ActiveCN104006709ALow thermal conductivitySafe blasting operationsThermal insulationBlastingInsulation layerDynamite

The invention discloses a temperature-resistance thermal insulation protecting bush which is used for charge blasting in a high-temperature blast hole and comprises a cylinder body with a cavity. The cylinder body is formed by stacking a fireproof layer, an insulation layer and a waterproof layer from exterior to interior in a composite mode, the cavity of the cylinder body is filled with a stick dynamite in a non-coupling mode, the gap between the inner wall of the cylinder and the stick dynamite is filled with high heat capacity liquid, the cylinder body is formed by stacking the fireproof layer, the insulation layer and the waterproof layer in the composite mode, each layer is made of heat insulation flame retardant materials, the heat conductivity coefficient is small, in the process that external heat energy is transmitted to the interior of the cylinder body, and the heat is gradually and greatly attenuated. Meanwhile, the high heat capacity liquid serving as energy consumed liquid is contained, the high specific heat capacity characteristics of the liquid are utilized for achieving energy conversion, a large amount of heat is absorbed, it is ensured that the temperature of the stick dynamite in the cylinder body is within the suitable range, under the heat insulation action of the cylinder and the heat absorption action of the high thermal capacity liquid, even though the temperature of the blast hole is high, blasting work can be safely performed, the bush is not limited by construction conditions, and operation is convenient and rapid.

Owner:HONGDA MINING IND

Optical and laser differential absorption remote detection of TATP peroxide based explosives

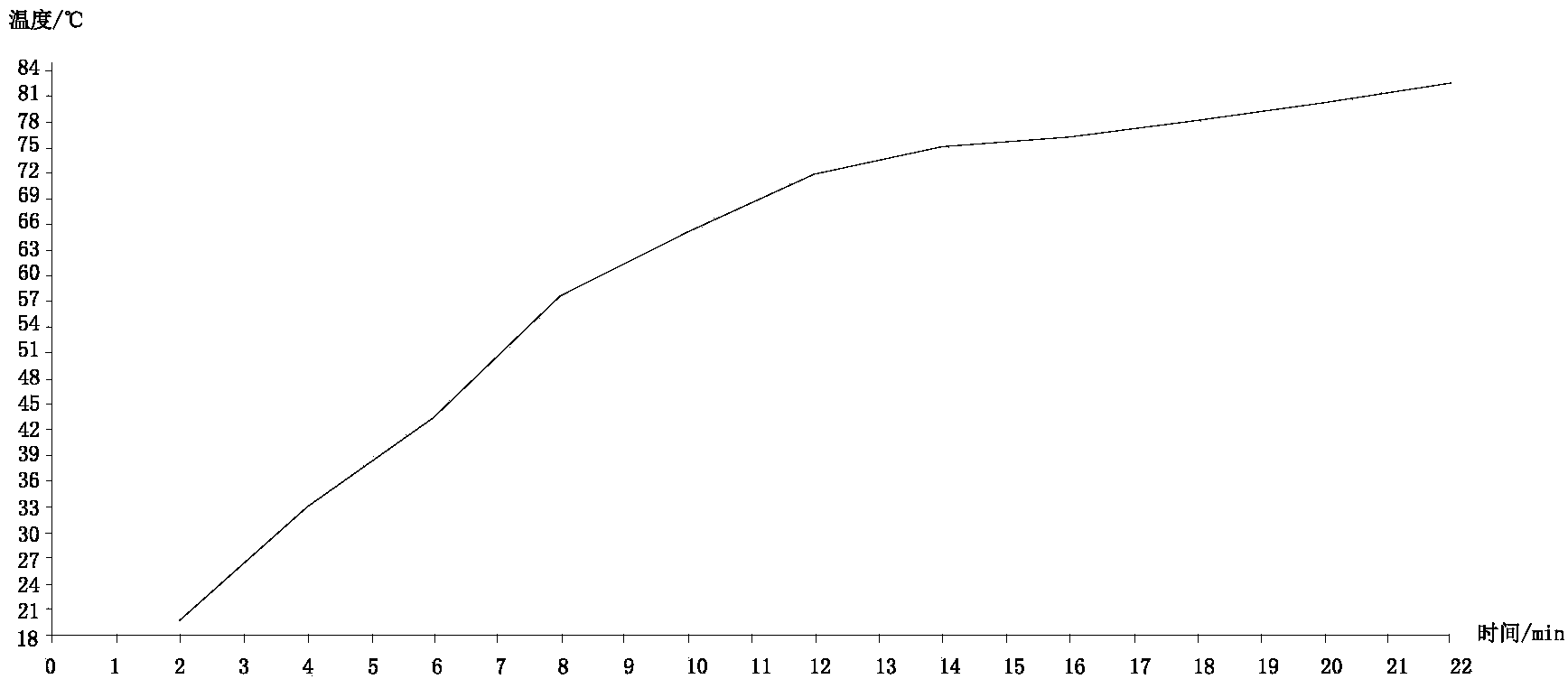

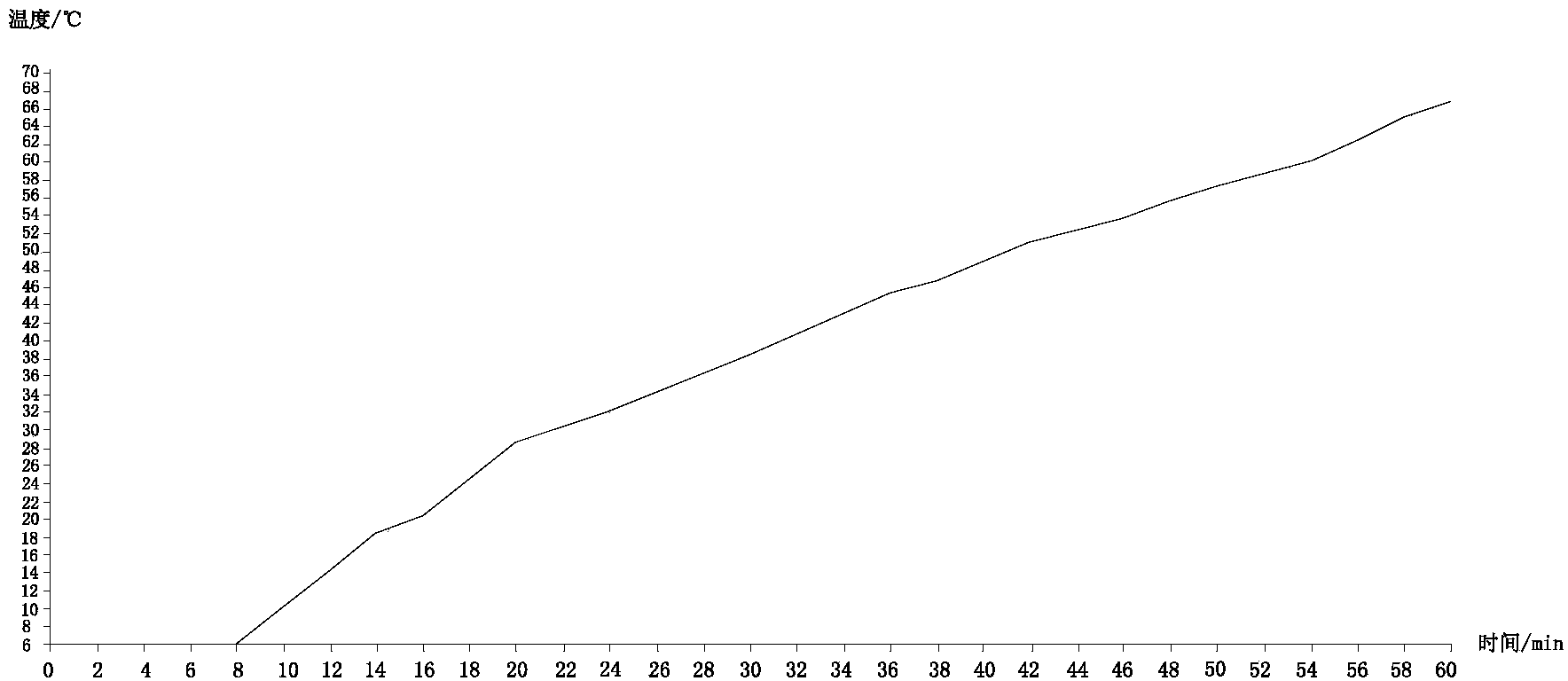

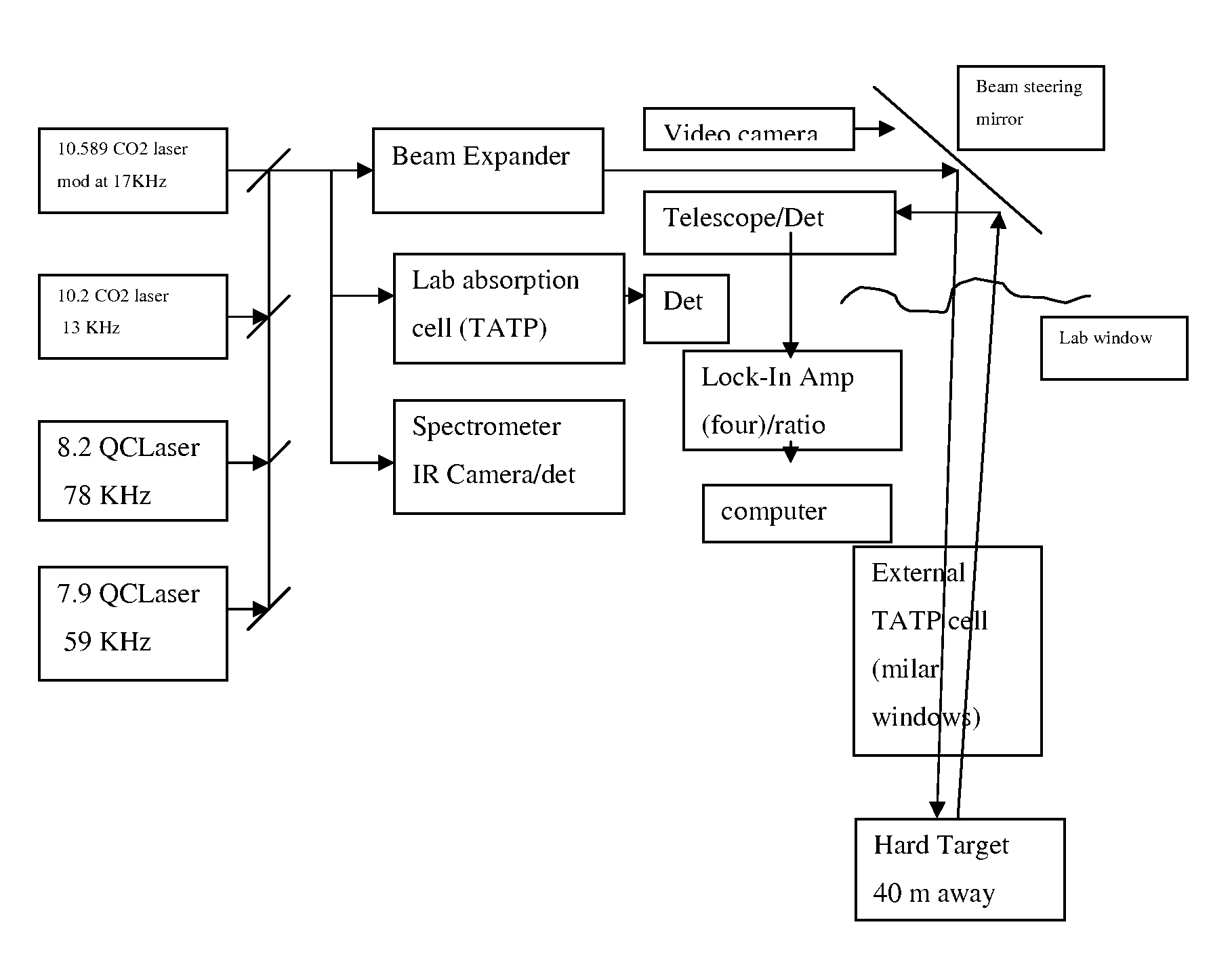

A triacetone triperoxide cloud associated with a triacetone triperoxide explosive attached to a hard target is remotely detected by operating differential-absorption lidar lasers to transmit a laser beam toward the hard target at differing wavelengths. A backscattered laser beam reflected from the lidar target (hard target, person, aerosols, clouds, buildings) is detected because a cloud of triacetone triperoxide in front of the lidar target and between the lidar target and the differential-absorption lidar system produces a differential-absorption signal having characteristics that identify the triacetone triperoxide. In a second embodiment, a triacetone triperoxide cloud that is absorbing optical radiation from its ambient environment and which is attached to a hard target is detected from a location remote from the triacetone triperoxide explosive by detecting an optical radiation absorption signature characterized by triacetone triperoxide absorption lines.

Owner:NEWTEC SERVICES GROUP +2

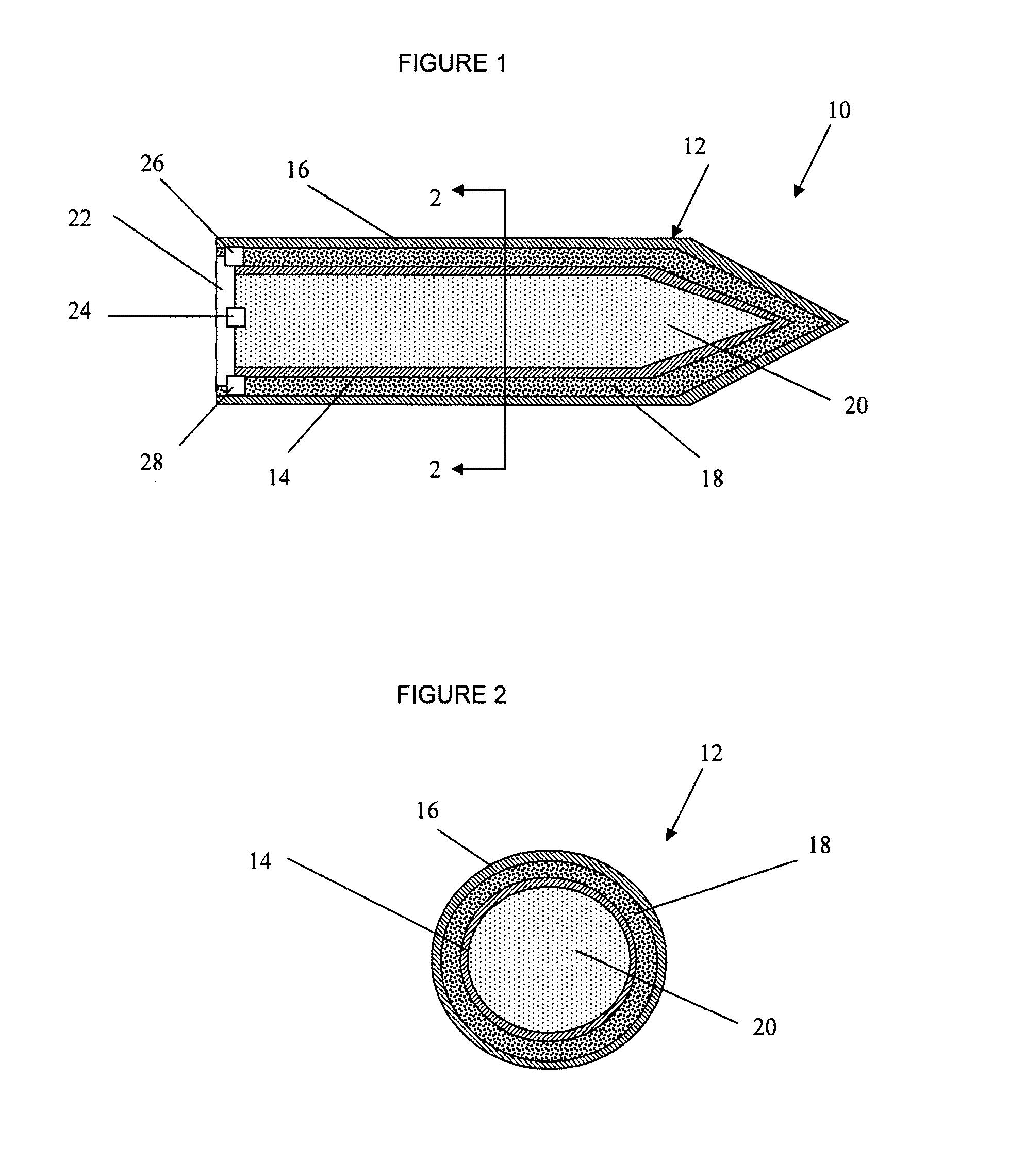

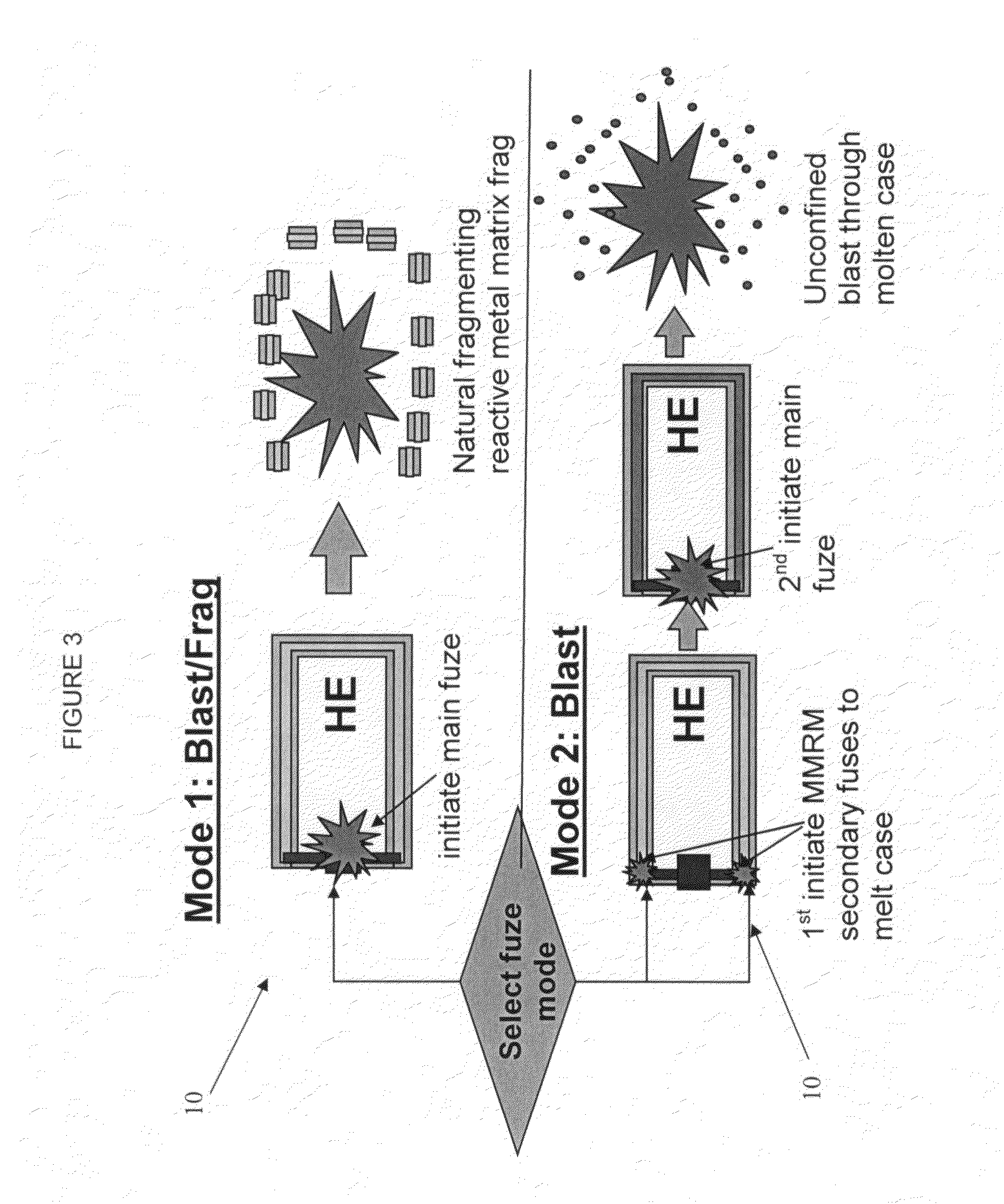

Selectable effect warhead

ActiveUS20100282115A1Reduce impactSelectively eliminatedAmmunition projectilesProjectilesExplosive AgentsBlast effects

A munition includes a casing, the casing formed at least in part from a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; an explosive payload contained within the casing; and a fuze arrangement, the fuze arrangement comprising a main fuze configured and arranged to ignite the high explosive, and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change. A method of selectively altering the mode of operation of a munition includes: forming a casing, the casing comprising a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; introducing an explosive payload into the casing; providing a fuze arrangement comprising a main fuse and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change; and selectively activating the main fuze and the at least one secondary fuze in a manner that provided at least a first and a second mode of operation, the first mode of operation comprising blast coupled with fragmentation effects, and the second mode of operation comprising mainly blast effects.

Owner:LOCKHEED MARTIN CORP

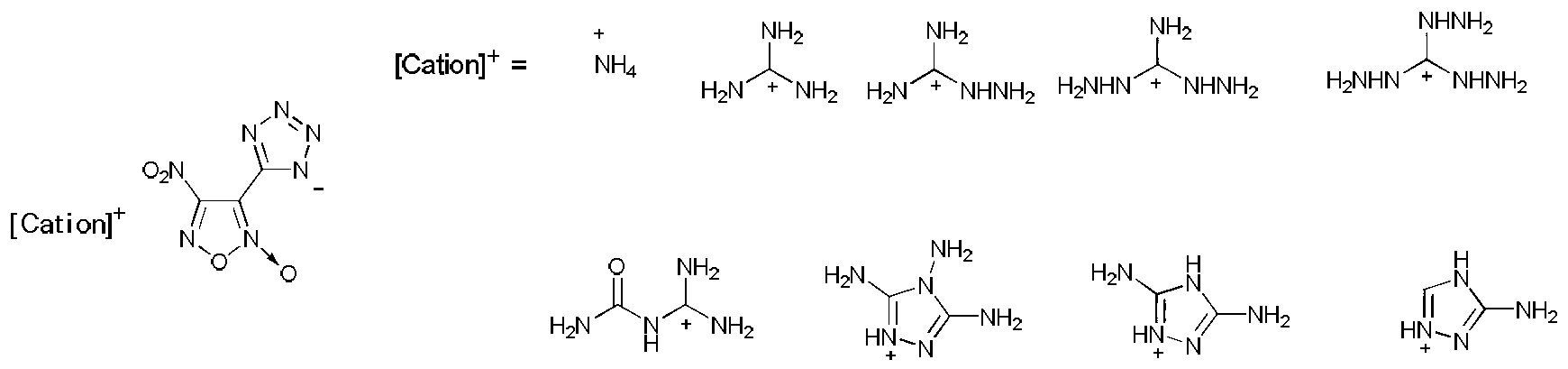

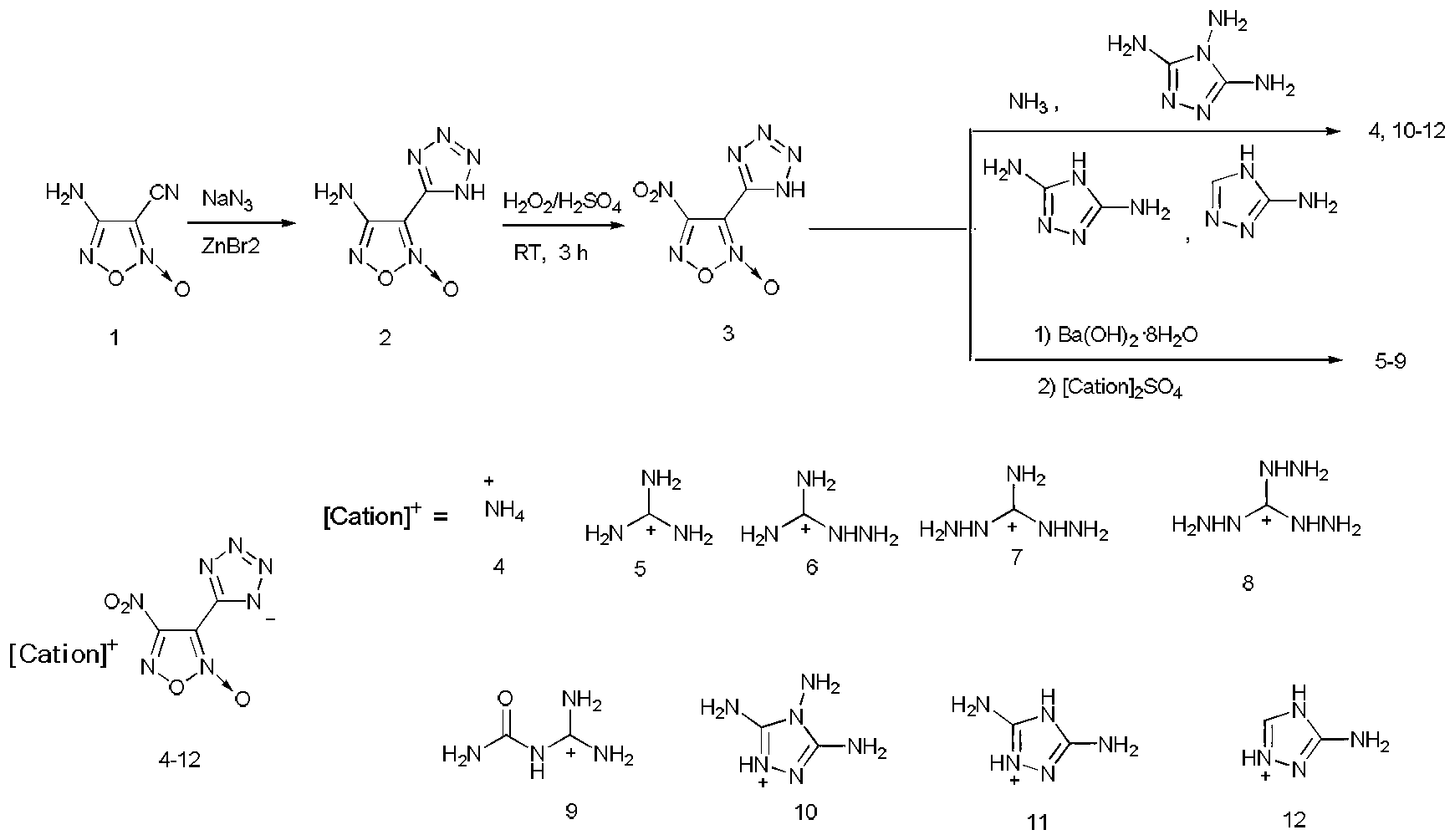

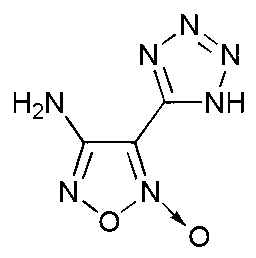

4-nitro-3-(5-tetrazole) furoxan energetic ionic salt and preparation method thereof

InactiveCN103059009AThe synthesis method is simpleMild conditionsOrganic chemistryOrganic compound preparationDetonationHigh density

The invention discloses a 4-nitro-3-(5-tetrazole) furoxan energetic ionic salt and a preparation method thereof, belongs to the technical field of energetic materials. A synthesis method of the 4-nitro-3-(5-tetrazole) furoxan energetic ionic salt is as follows: directly reacting the 4-nitro-3-(5-tetrazole) furoxan with a corresponding cation, and steaming for eliminating a solvent so as to obtain a target product; reacting the 4-nitro-3-(5-tetrazole) furoxan with the sulfate of the equimolar corresponding cation after mixing the 4-nitro-3-(5-tetrazole) furoxan with equimolar Ba(OH)2.8H2O, filtering and precipitating, steaming and eliminating the solvent in the filtrate to obtain the target product. The synthesis method provided by the invention is simple and easy to industrialize. The referred 9 energetic ionic salt has high density (rho: 1.55-1.84g / cm3), wherein the degree of percussion sensitivity of two compounds is more than 40J, and the energetic ionic salt belongs to insensitive explosive. The energetic ionic salt has excellent calculation detonation property and is a potential energetic material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

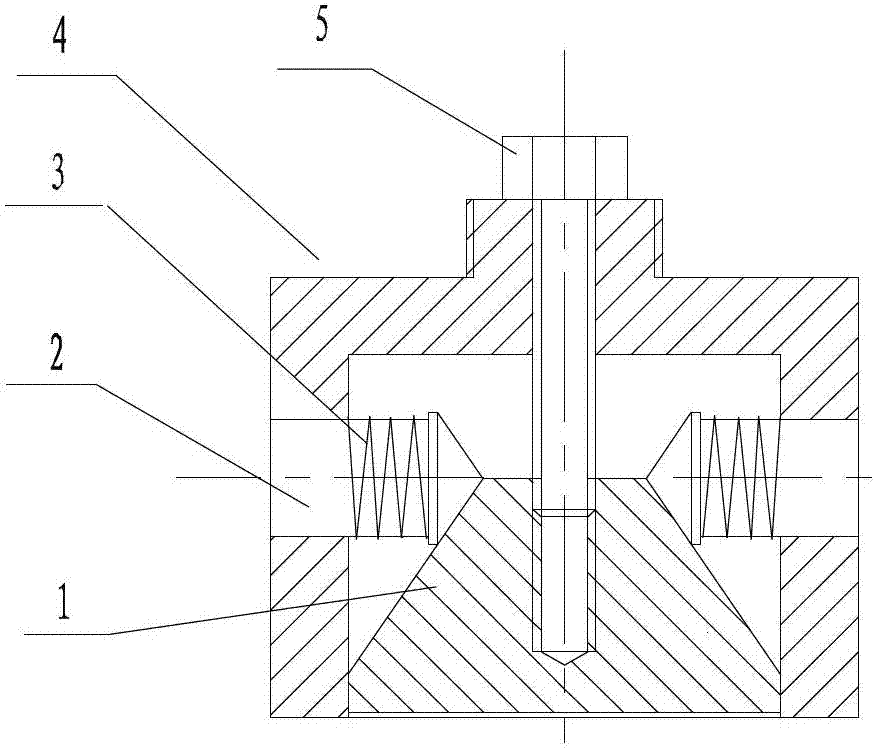

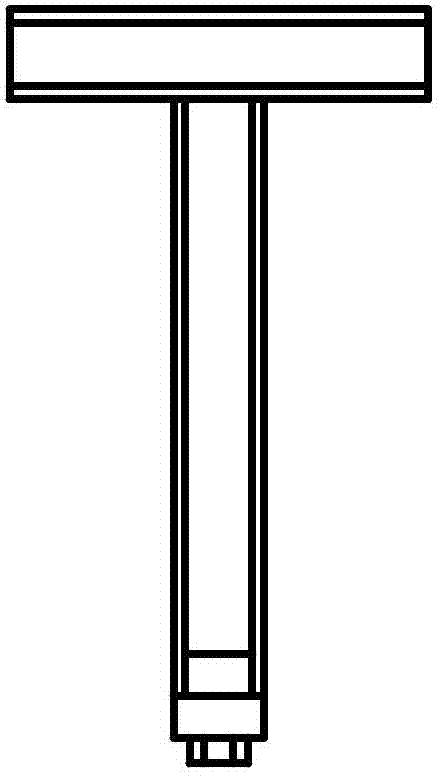

Large-aperture static blasting method and hole plugging device thereof

InactiveCN103591858ASolve punching problemsImprove energy utilizationBlastingExplosive AgentsPunching

The invention discloses a large-aperture static blasting method and a hole plugging device thereof. According to the hole plugging device, a taper body is arranged inside a housing, four taper pins are arranged inside four holes formed in the housing, springs are sleeved outside the taper pins and snapped inside the housing, and a bolt is connected with the taper body through the threads inside the taper body. The method includes, firstly, determining the hole pattern parameters of a large-aperture static blasting design scheme according to the mechanical parameters of a body to be blasted, drilling blast holes 0.5-1 m deep through a phi 76 mm drill; then utilizing a hydraulic expanding drill to expand the lower diameter of the blast holes to phi 101 mm; then uniformly mixing explosive agent and water at a ratio of 4:1-3:1, and filling the blast holes of phi 101 mm; plugging the blast holes through the hole plugging device and sealing the blast holes with gravel and soil. The large-aperture static blasting method and the hole plugging device thereof effectively solve the punching problem during static blasting, enable the static blasting technique to be applicable to large-aperture blast holes of more than 50 mm, effectively reduce blasting waiting time and accordingly improve the efficiency of static blasting.

Owner:南京君缘科爆工程技术有限公司

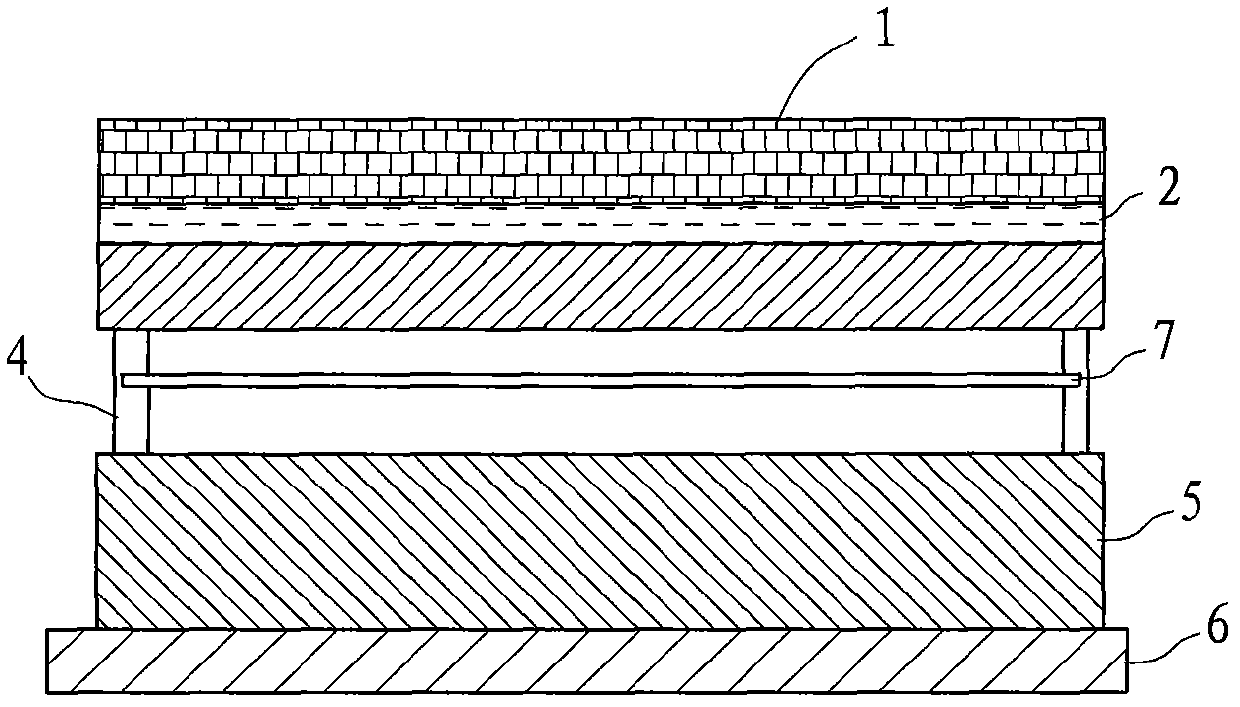

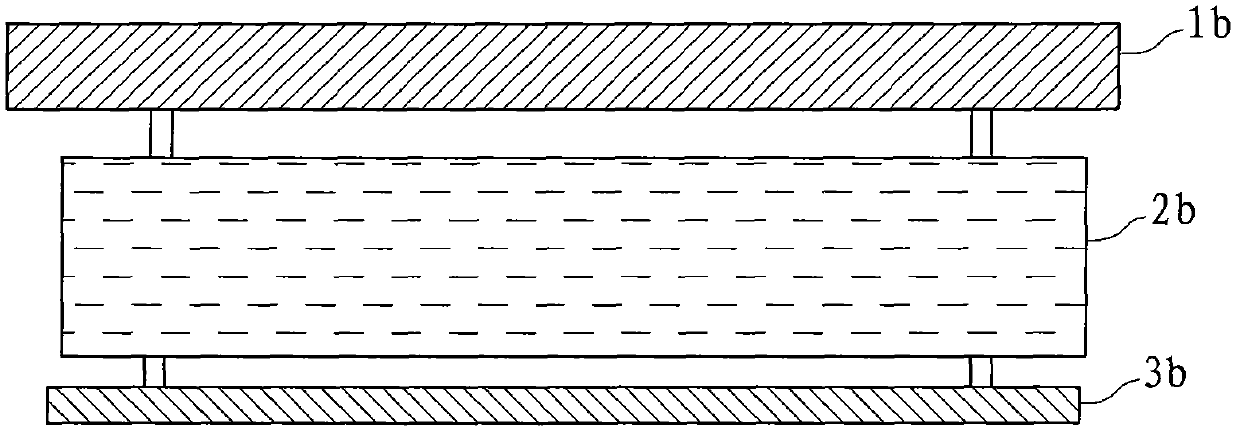

Compound preparation method of aluminum alloy and magnesium alloy laminated plate

ActiveCN101992345ASolve the problem of poor corrosion protection performanceAvoid surface crackingNon-electric welding apparatusFiberExplosive Agents

The invention relates to a compound preparation method of an aluminum alloy and magnesium alloy laminated plate, which is characterized by comprising the following steps: (1) preparation of a base plate and a compound plate: leaving an interval of 20-100mm at the circumference of the compound plate based on the overall size of the compound plate, machining grooves of 1-5mm in the compound plate corresponding to the edge of the base plate based on the thickness of the compound plate, and carrying out smoothing and surface polishing and cleaning on the base plate and the compound plate, wherein the size of the compound plate is greater than that of the base plate, and the base plate and the compound plate are respectively aluminum alloy and magnesium alloy or magnesium alloy and aluminum alloy; (2) pre-heating treatment of the base plate and the compound plate: prior to explosion cladding, heating the base plate and the compound plate to 120-200 DEG C, and preserving the temperature; (3) foundation of explosion cladding: compacting with clay or fine sand, laying a fiber compound plate of 3-8mm on the surface to act as an explosion cladding base; and (4) preparation of explosives. Thus, the overall explosion cladding process is simple and easy to operate, and the metal of the compound plate can obliquely collide the metal of the base plate at a high speed under the explosive load effect of the explosives, thereby firmly connecting the metal of the compound plate with the metal of the base plate.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Non-toxic percussion primers and methods of preparing the same

Owner:FEDERAL CARTRIDGE

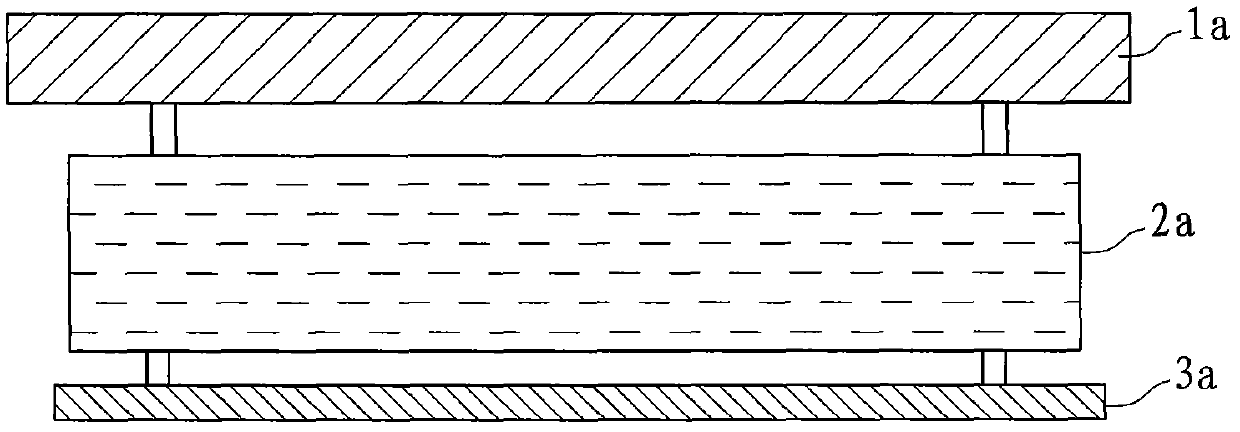

Blasting demolition method for cylindrical steel column structure buildings

The invention belongs to the technical field of engineering blasting and particularly relates to a blasting demolition method for various cylindrical steel column structure components and buildings, wherein the cross sections of the cylindrical steel column structure components and buildings are shaped like Chinese character 'tian' or 'ri' or are of a square shape. The blasting demolition method is characterized by comprising the steps of (a) pouring concrete 2 in a columnar steel structure 1 to be blasted, (b) maintaining the concrete 2, (c) conducting oxyacetylene metal-cutting and drilling a blast hole 3 in the obverse side of the columnar steel structure 1, (d) precutting a seam 7 in the columnar steel structure 1, (e) determining blasting parameters, charging powder and connecting lines, (f) conducting protection and (g) conducting blasting. By means of effective implementation of the blasting demolition method for the cylindrical steel column structure buildings, the purpose of blasting demolition of the cylindrical steel column structure components or buildings through industrial explosive materials (emulsion explosives) can be achieved, and the blasting demolition method has the technical advantages of being safe, efficient and low in cost compared with a traditional manual demolition means.

Owner:中铁二十三局集团(湖北)爆破有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com