Poured-type azido high-polymer bonded explosive and preparation method of same

A bonded explosive and azide-based technology, which is applied in explosives and other fields, can solve the problems of limiting the comprehensive performance level of PBX explosives, and achieve the effects of overcoming high performance and high sensitivity, increasing energy levels, and shortening curing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

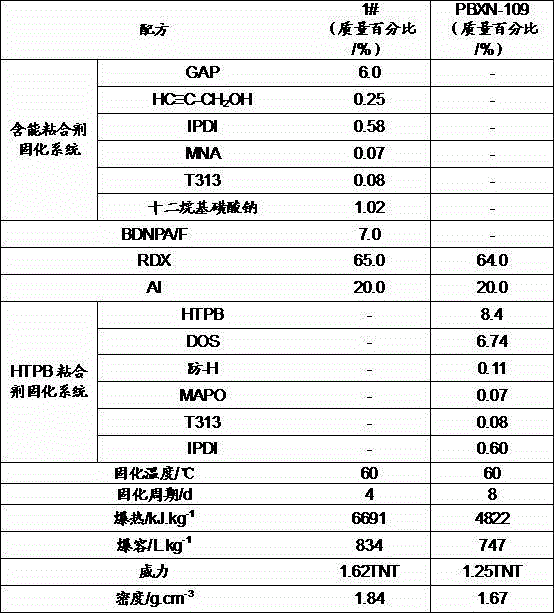

[0052] Table 1 shows the composition and properties of the 1# formula of the present invention and the HTPB-based PBX explosive formula (code PBXN-109) that has been used in the United States.

[0053] Table 11# and PBXN-109 formula composition and performance

[0054]

[0055] It can be seen from Table 1 that the explosive heat, explosive volume, and density of 1# formula are 6691kJ / kg, 834L / kg, and 1.84g / cm respectively. 3 , significantly higher than the PBXN-109 formulation.

Embodiment 2

[0057] The following table 2 has provided PBX explosive 2# formula composition and performance of the present invention:

[0058] Table 22# formula composition and performance

[0059]

[0060] It can be seen from Table 2 that when the curing temperature is 60°C, the curing time of 2# formula is 4 days, the detonation heat is 7167kJ / kg, the detonation volume is 849L / kg, and the power is 1.71TNT. The sensitivities are 49.1J and 20% respectively.

Embodiment 3

[0062] The following table 3 provides PBX explosive 3# formula composition and performance of the present invention:

[0063] Table 33# formula composition and performance

[0064]

[0065] Among them, GAP / PET (3 / 1) is the mass ratio, and NG / TEGDN (2 / 1) is the mass ratio.

[0066] It can be seen from Table 3 that the detonation heat of 3# formula is 6957kJ / kg, the detonation volume is 865L / kg, the power is 1.70TNT, when the curing temperature is 50 ℃, the 3# formula 3.5d curing reaction is complete, and the 3# formula The drop weight impact sensitivity and friction sensitivity are 50.3J and 16% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hot | aaaaa | aaaaa |

| Hot | aaaaa | aaaaa |

| Hot | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com