Patents

Literature

110 results about "Friction sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction sensitivity is an approximation of the amount of friction or rubbing a compound can withstand before prematurely exploding. For instance, nitroglycerin has an extremely high sensitivity to friction, meaning that very little rubbing against it could set off a violent explosion. There is no exact determining the amount of friction required to set off a compound, but is rather approximated by the amount of force applied and the amount of time before the compound explodes.

High energy insensitive press-fitting high polymer bonded explosive

ActiveCN107879867AHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

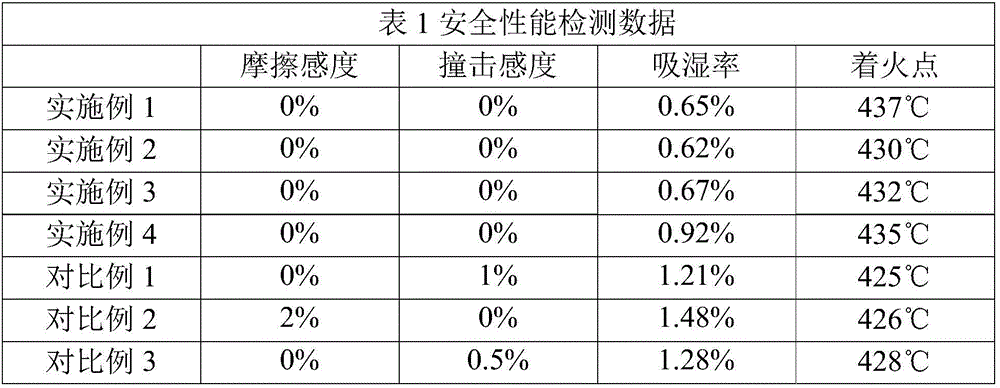

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

Metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and preparation method thereof

ActiveCN103588595AHigh strengthImprove toughnessNitroglycerine explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMetal fiberFriction sensitivity

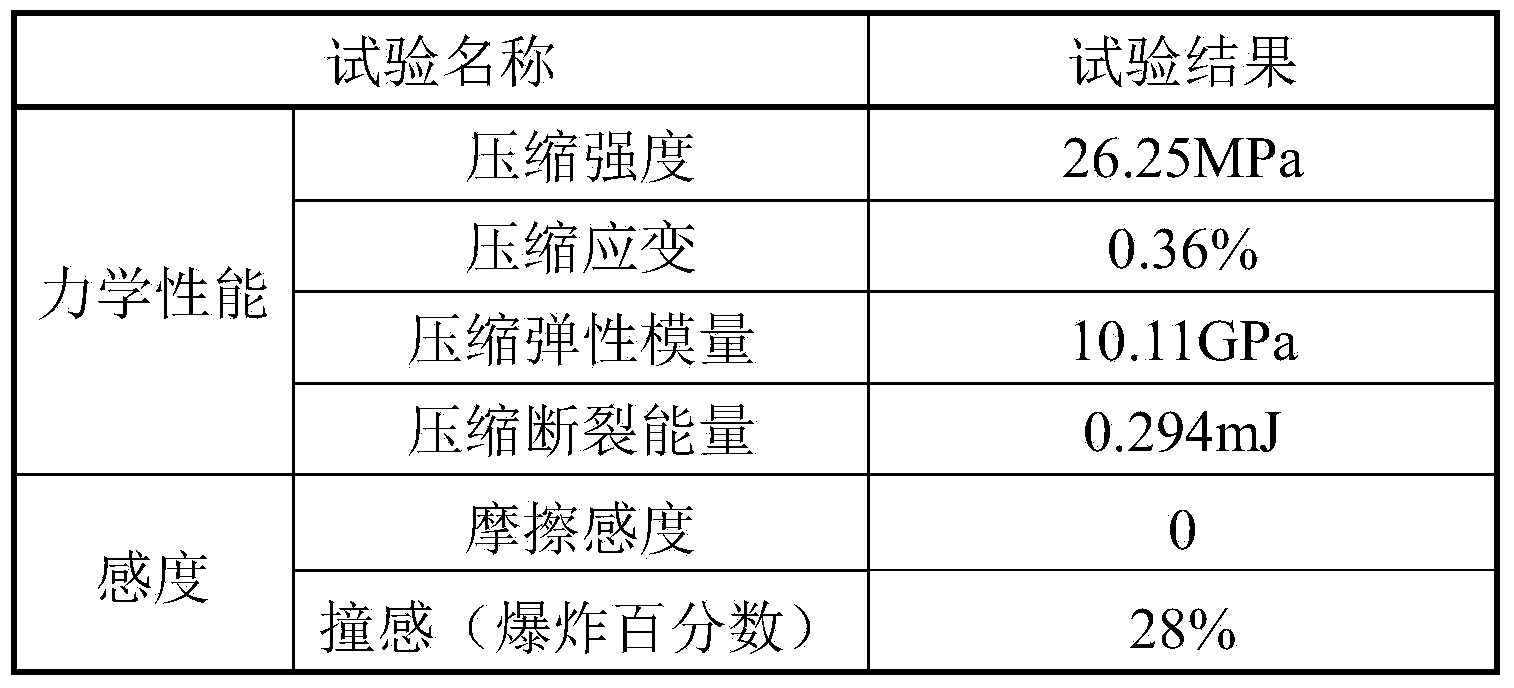

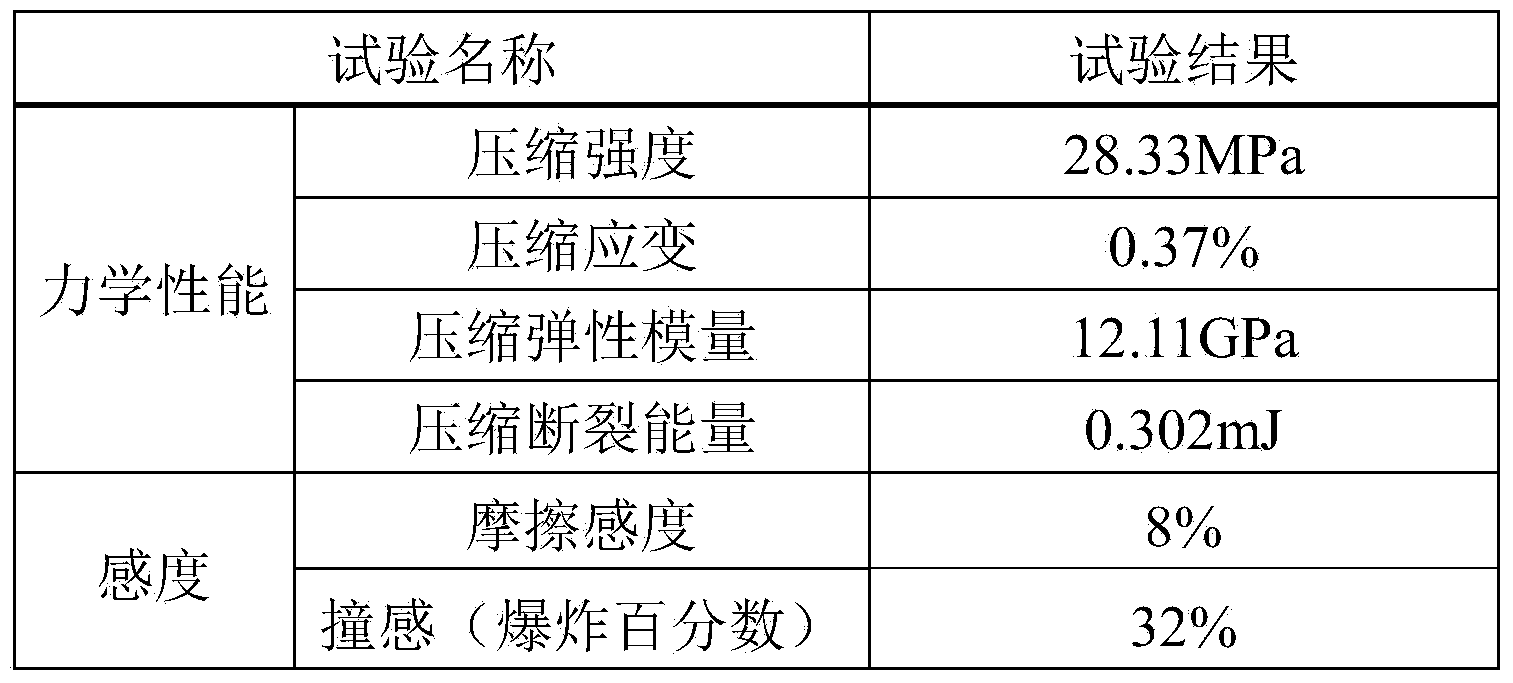

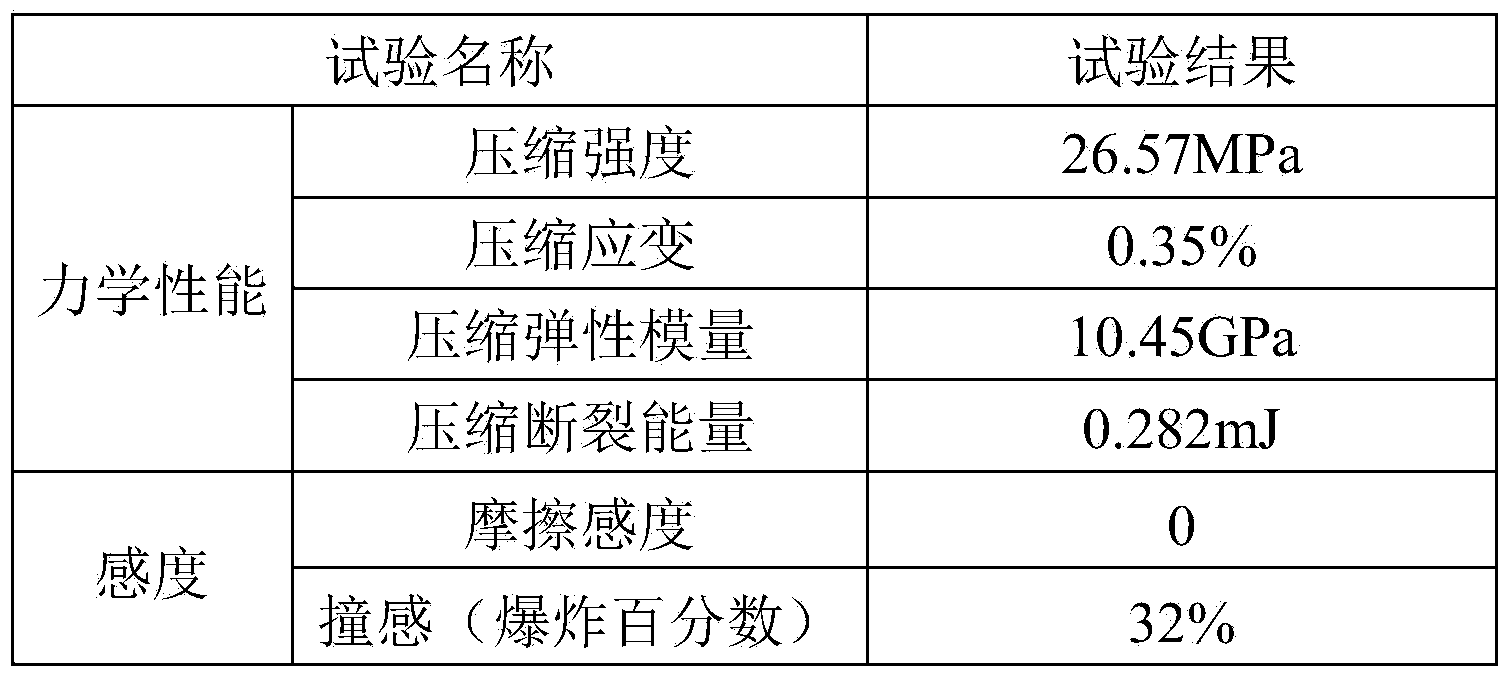

The invention discloses metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and a preparation method thereof. The melt-cast explosive comprises components in parts by weight as follows: 30-40 parts of TNT, 60-70 parts of hexogen or octogen, 0-3 parts of metal fiber and 0-2 parts of paraffin. The preparation method comprises the steps as follows: a surfactant solution is used for treating the metal fiber; materials are compounded; the materials are placed in an explosive melting machine for mixing; and casting is performed under atmospheric pressure. The TNT-based melt-cast explosive has the mechanical properties as follows: the compressive strength is larger than or equal to 24 MPa, the compressive strain is larger than or equal to 0.33%, the compressive modulus of elasticity is larger than or equal to 9 GPa, lower mechanical sensitivity is provided, the friction sensitivity is 0%-10%, and the impact sensitivity is 20%-40%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

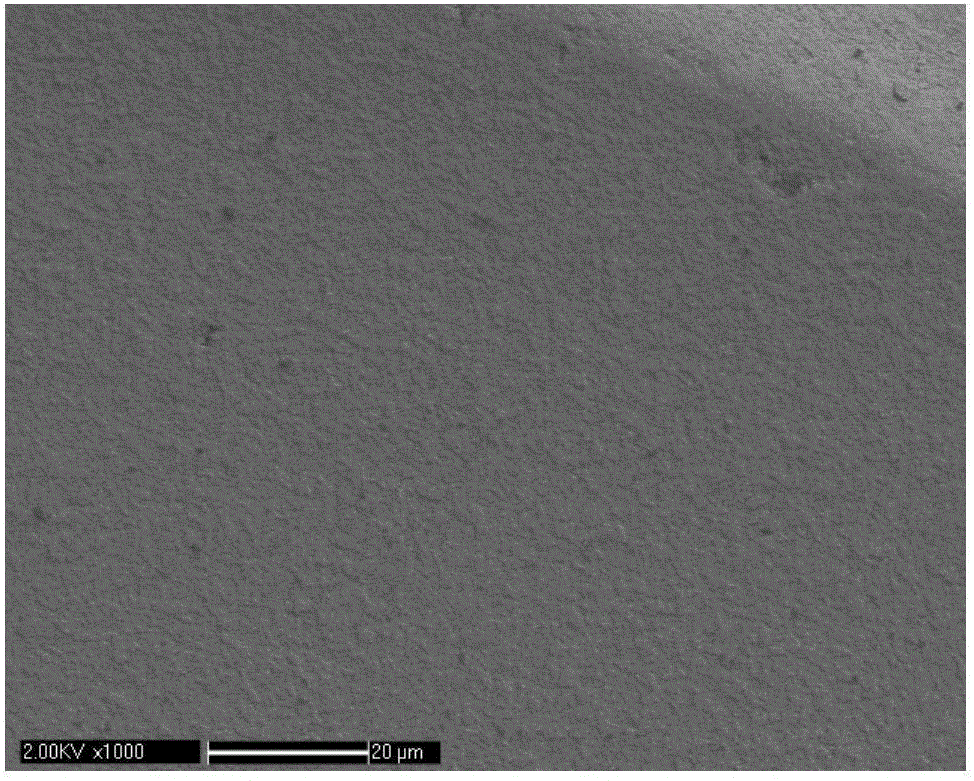

Fine-particle high-energy low-sensitivity explosive compound and preparation method thereof

ActiveCN104193564ALow mechanical sensitivitySuitable for mass productionNitroparaffin explosive compositionsFriction sensitivityOrganic solvent

The invention relates to a fine-particle high-energy low-sensitivity explosive compound and a preparation method thereof. The method comprises the following steps: mixing an explosive with a macromolecular bonder according to a weight part ratio of 100 to (2-5), and stirring at 40-60 DEG C for dissolving in an organic solvent to obtain an explosive compound solution with 5%-30% by weight of explosives; putting the explosive compound solution into an ejection tank, pumping air into the ejection tank to increase the pressure in the ejection tank to be 0.3-0.7MPa, ejecting the explosive compound solution into an explosive antisolvent with the temperature of -10 DEG C to 10 DEG C, performing centrifugal separation on a solid product, washing, and drying to obtain the explosive compound. According to the explosive compound, explosive particles are micron-sized, the CL-20 surface is densely wrapped with the macromolecular bonder in the form of an interwoven mesh shape, the impact sensitivity of the wrapped CL-20 is reduced to be 24%-40% from 100%, and the friction sensitivity is reduced to be 66%-92% from 100%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

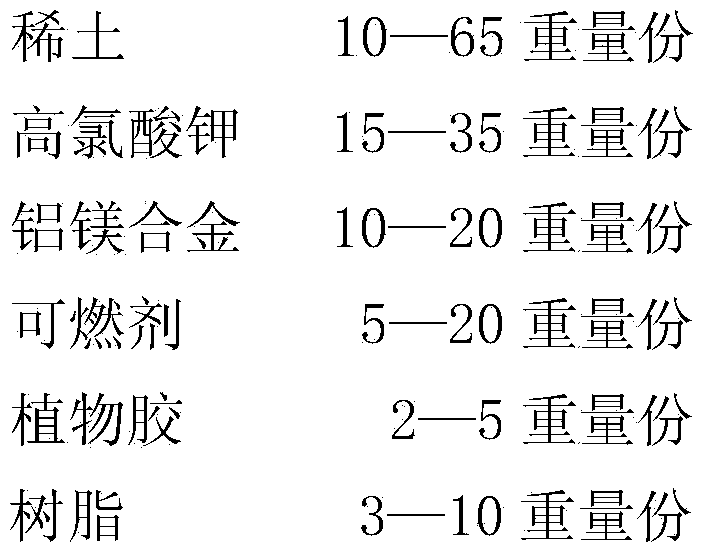

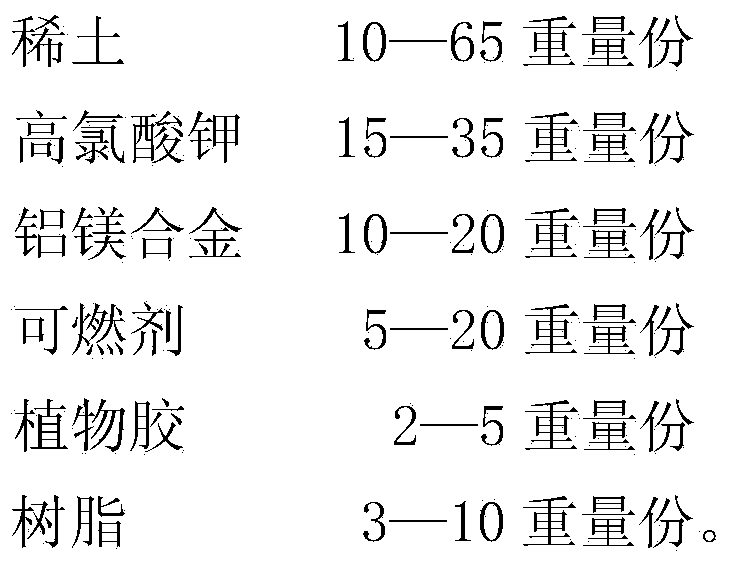

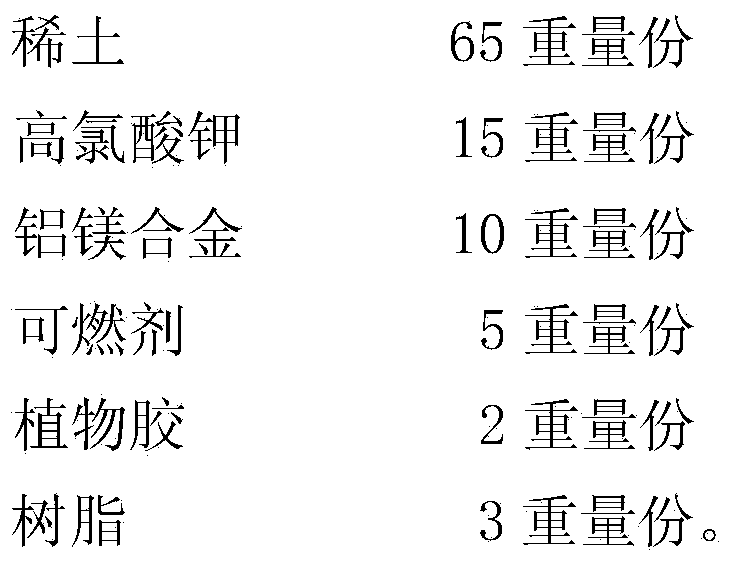

Environment-friendly firework propellant

The invention discloses an environment-friendly firework propellant which is characterized by being composed of the following components in parts by weight: 10-65 parts of rare earth, 15-35 parts of potassium perchlorate, 10-20 parts of aluminum magnesium alloy, 5-20 parts of combustible agent, 2-5 parts of plant gum and 3-10 parts of resin, wherein the combustible agent is selected from any one or combined by any two from hemp xyloid stem carbon powder and Chinese fir carbon powder at any proportion, and the plant gum is a rice flour adhesive. The environment-friendly firework propellant is free of chlorate, small in horizontal launching force, low in moisture absorption property, low in impact and friction sensitivity, small in dosage of charges for preparing fireworks, slight in smoke, long in shelf life and displaying time, free of residues after displaying, good in physical and chemical stability, simple in processing technology and suitable for various firework propellants.

Owner:喻自达

Preparation method for reducing mechanical sensitivity of HMX

ActiveCN105801324ADoes not change crystal shapeDoes not change densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityFiltration

The invention provides a preparation method for reducing mechanical sensitivity of HMX. The preparation method comprises the following steps of: preparing an alkali solution with a pH value being 8-11; dissolving catechol substances into the alkali solution to obtain a catechol alkali solution with concentration being 0.1g / L-20g / L, wherein the pH value of the completely dissolved solution is greater than 7; putting HMX into the catechol alkali solution and stirring for 0.1-24 hours to obtain a mixed dispersion liquid; carrying out suction filtration cleaning on the mixed dispersion liquid treated in the step III, and cleaning the mixed dispersion liquid by distilled water; drying the mixed dispersion liquid for 1-24 hours at a temperature of 50-80 DEG C to obtain an modified HMX material. The preparation method is simple in process, and physical characteristics such as crystal shape, density and the like of the HMX are not changed; and the modified HMX material has relatively low mechanical sensitivity, so that the friction sensitivity can be reduced by 30%, characteristic height is improved by more than one time, and therefore, the HMX has relatively high safety performance.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

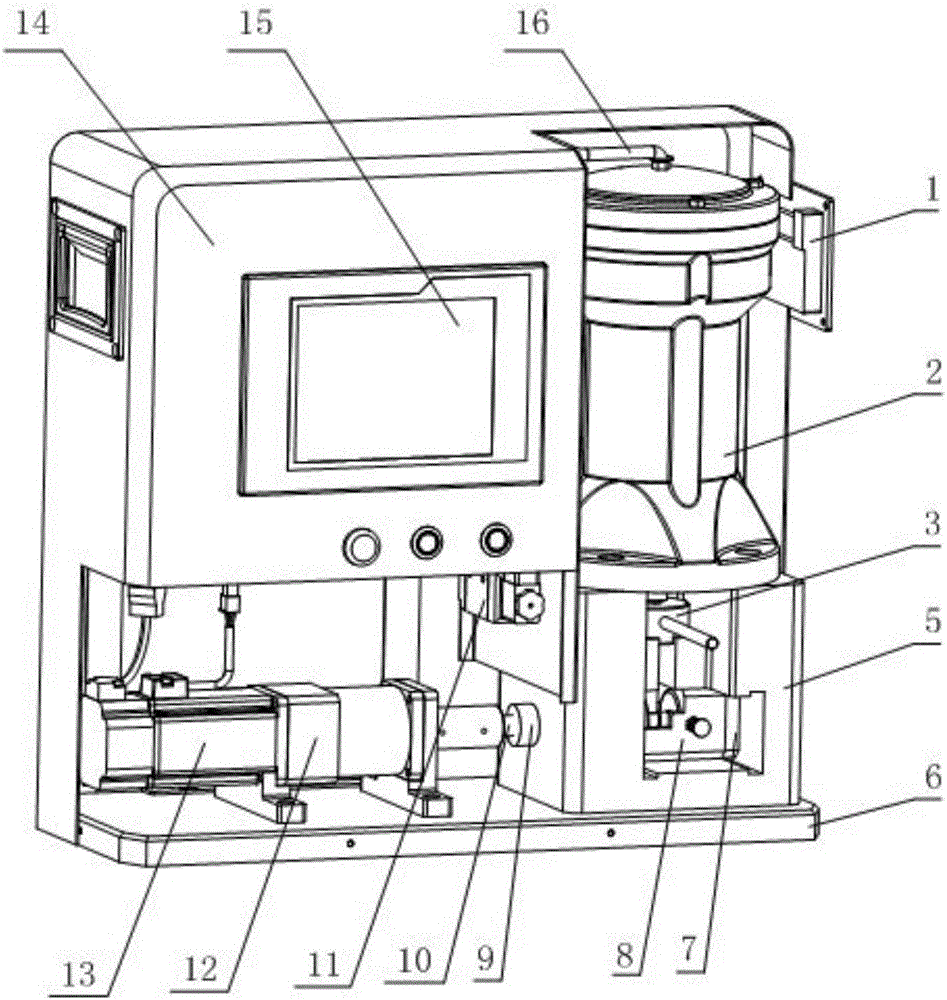

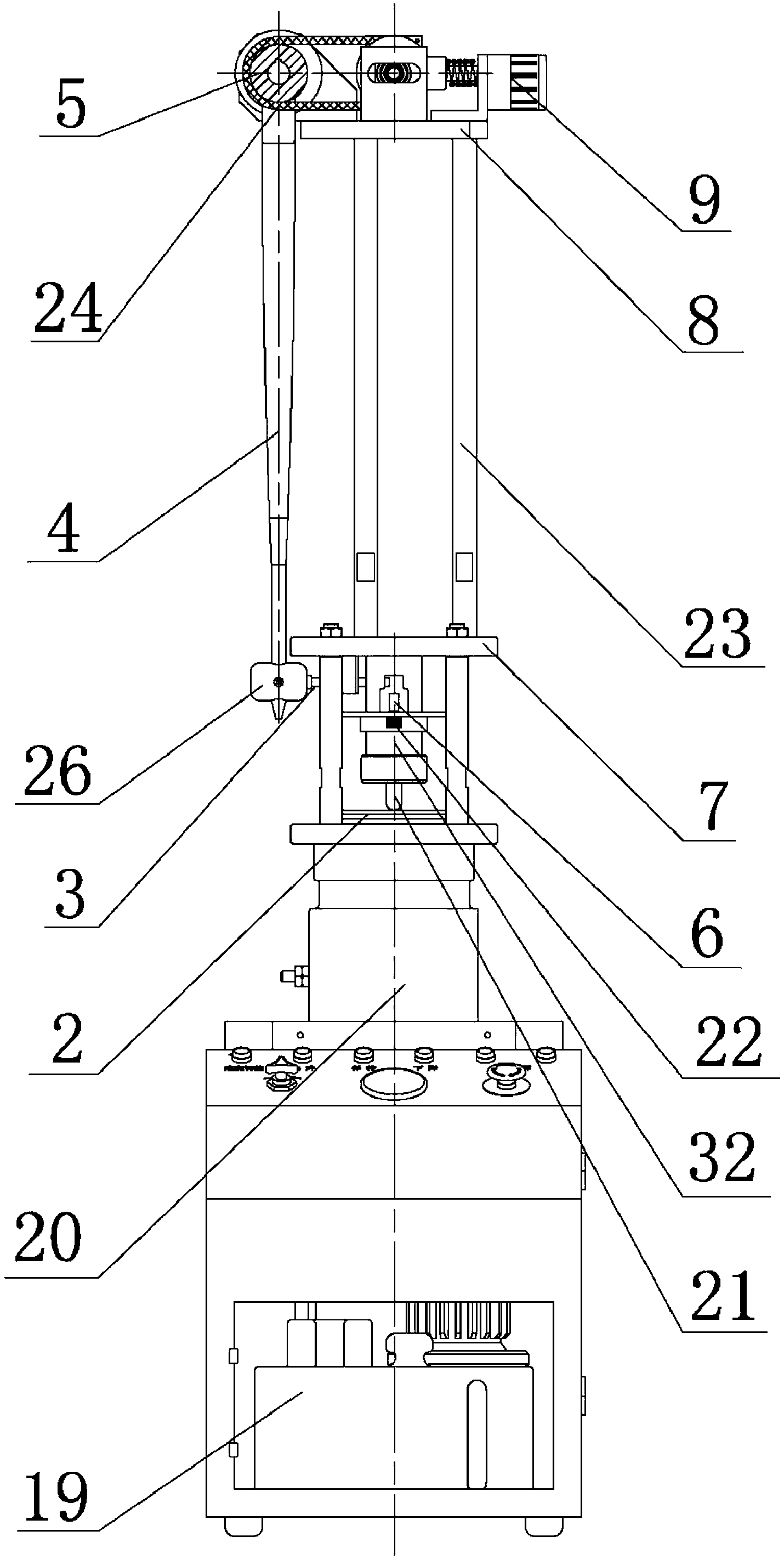

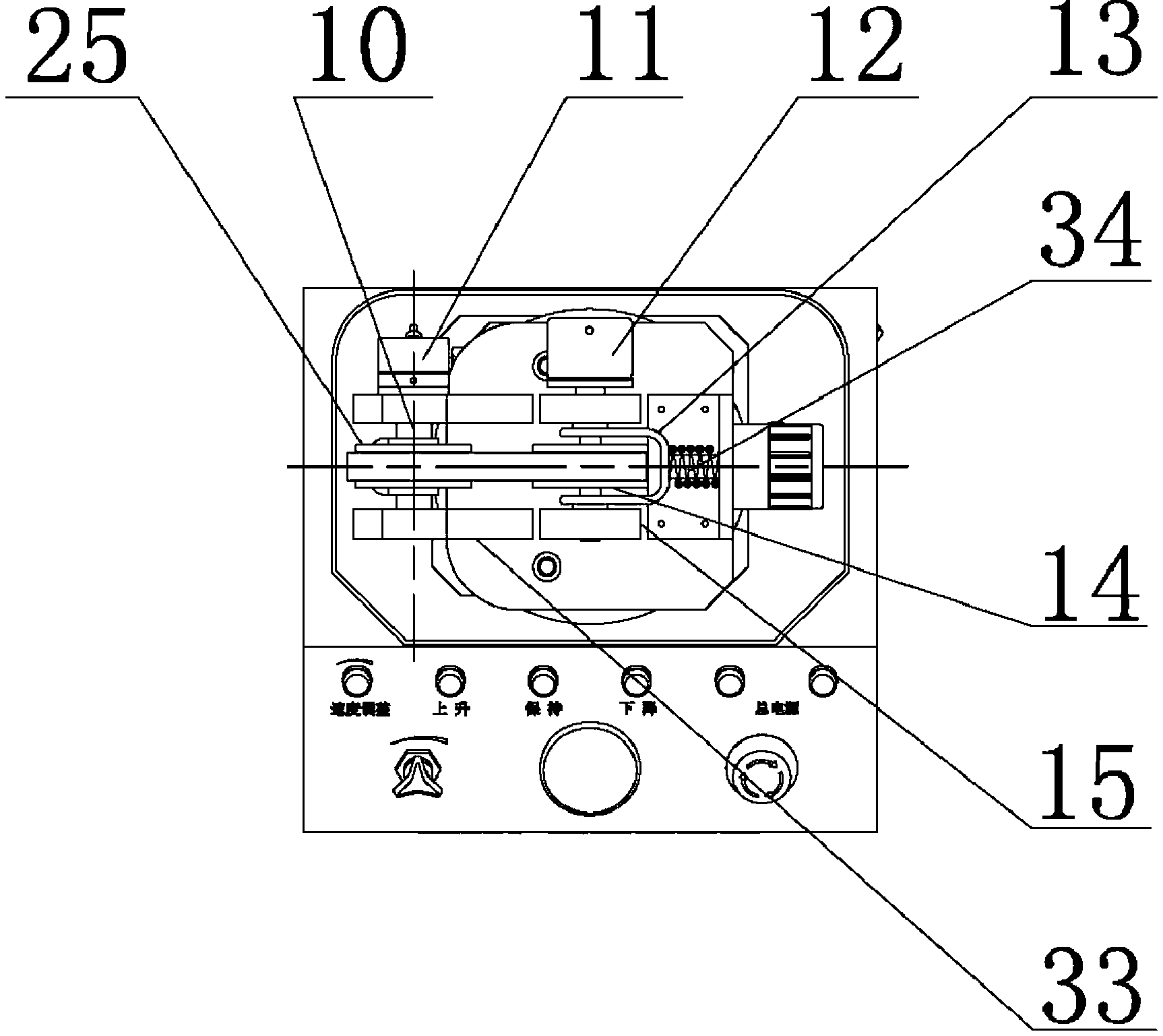

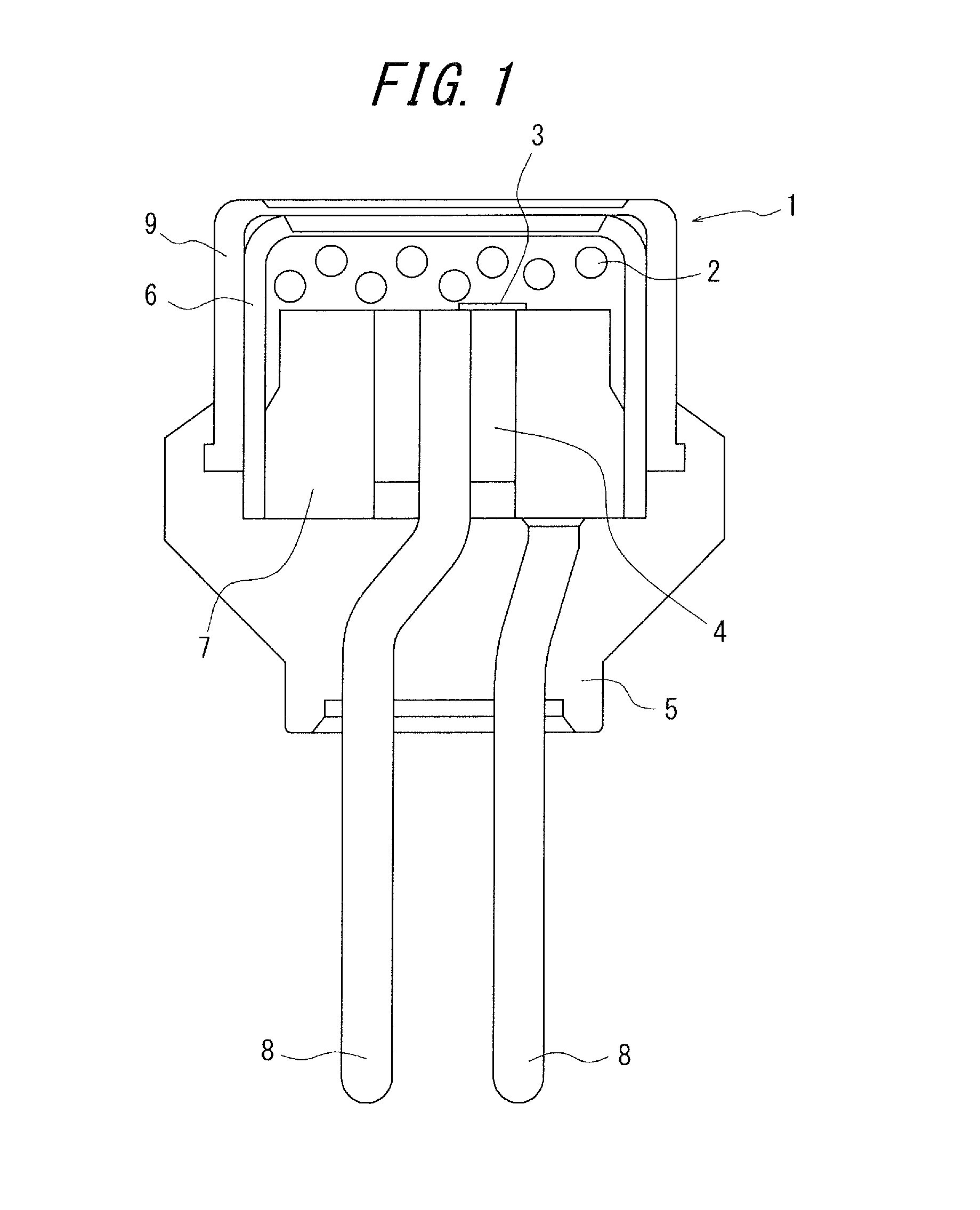

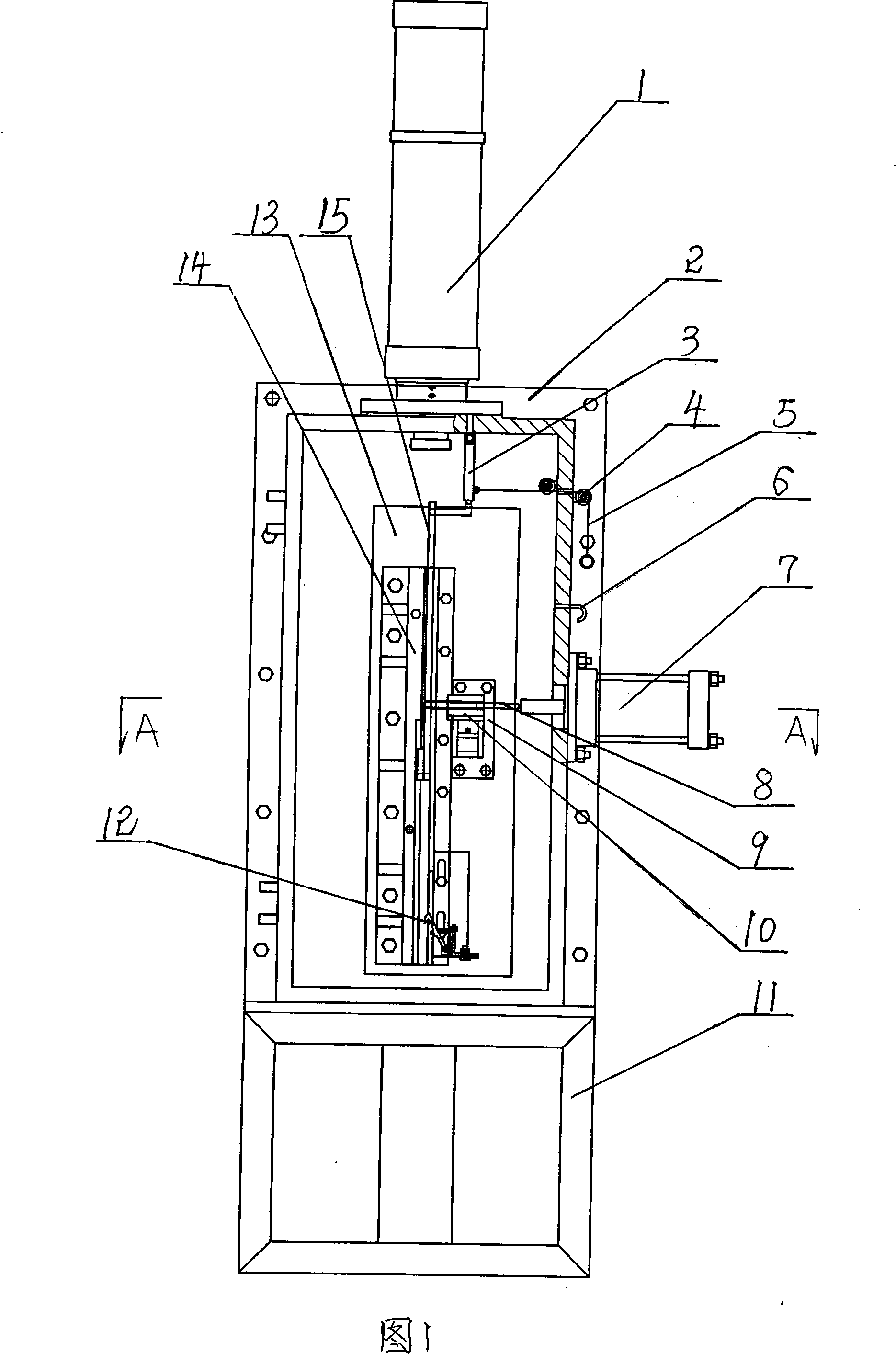

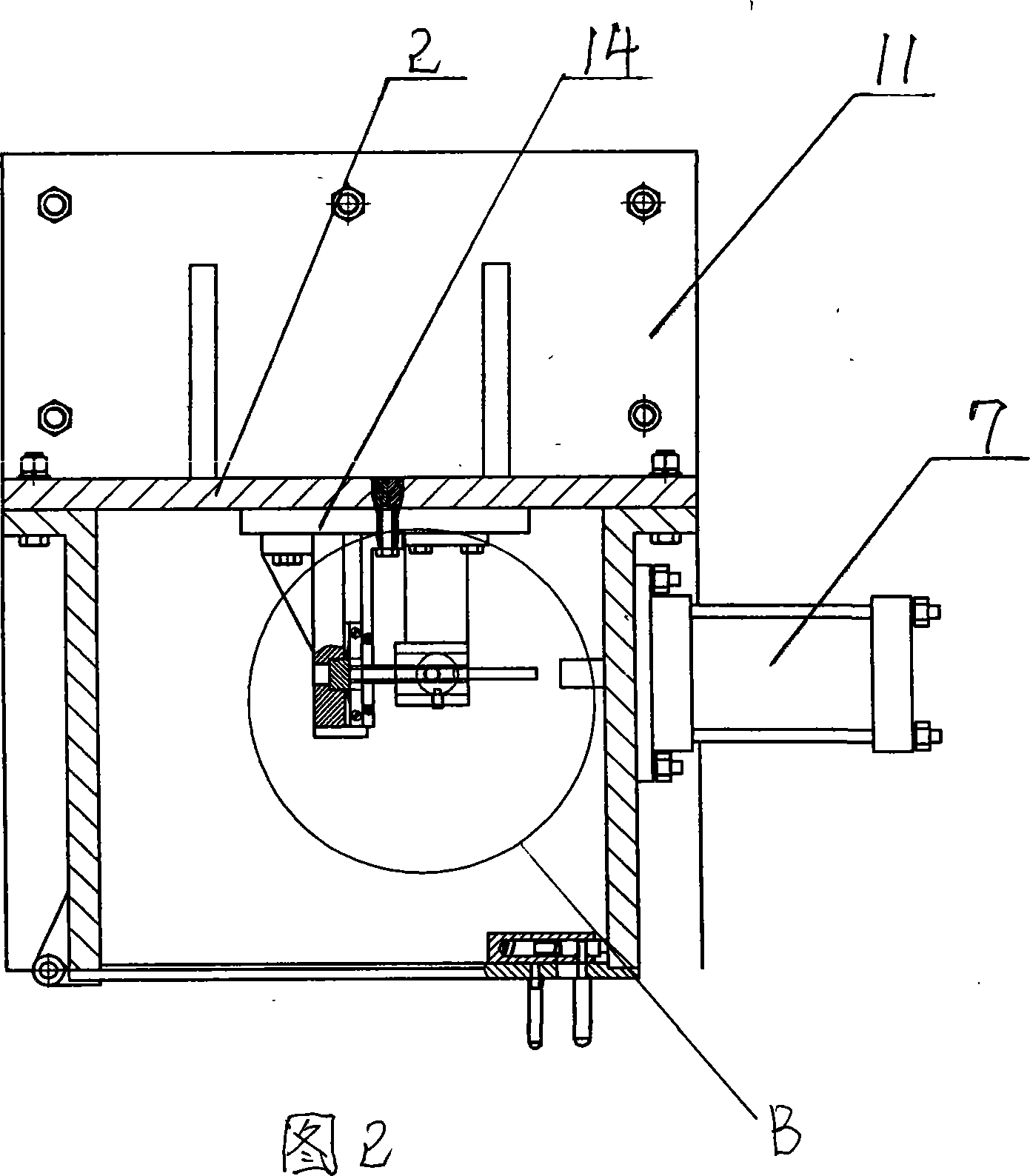

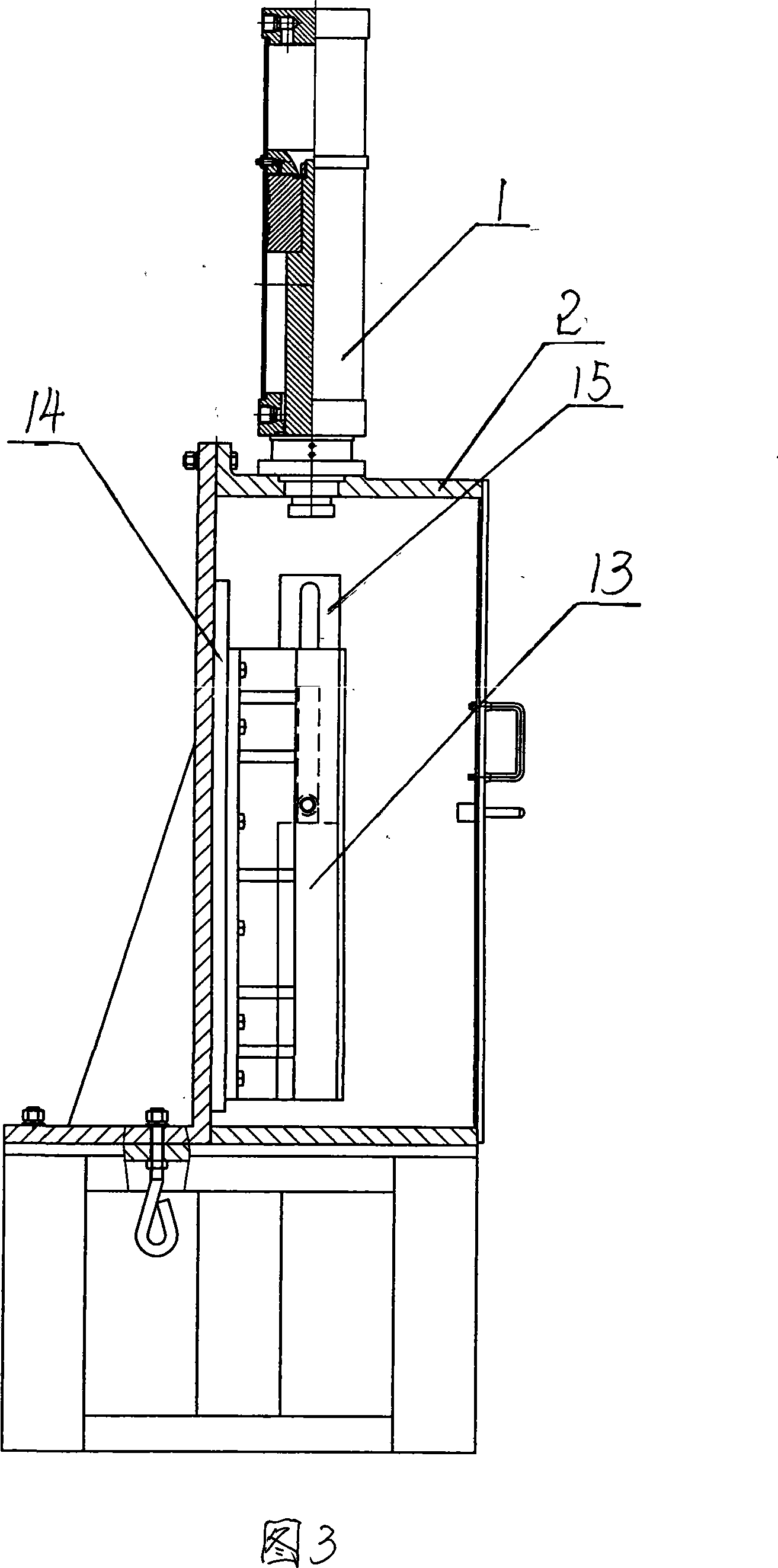

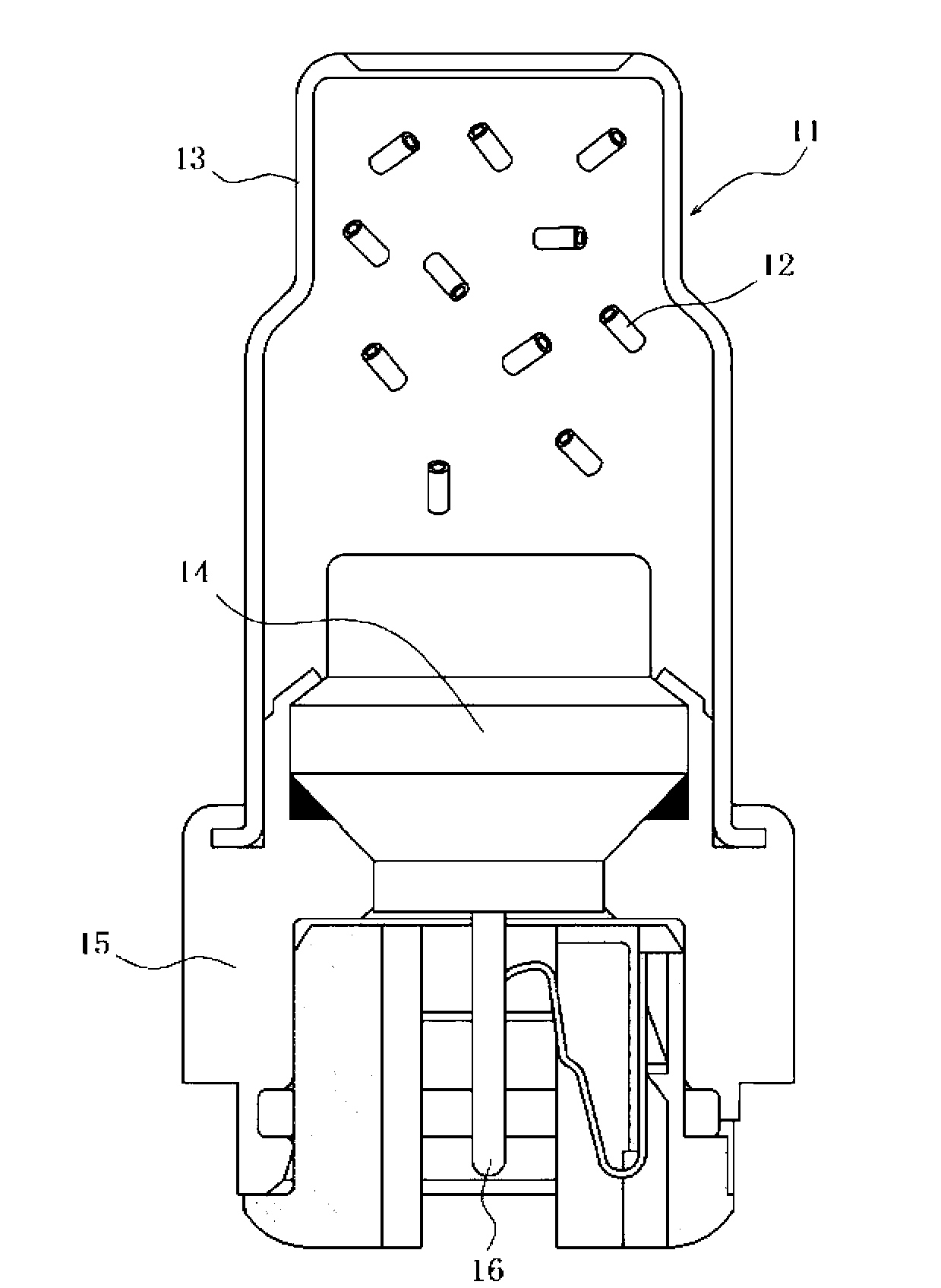

Explosive friction sensitivity instrument

InactiveCN101216478AEnsure safetyEasy to installFuel testingUsing mechanical meansFriction sensitivityEngineering

The invention relates to an explosive performance testing device, in particular to an explosive friction sensitivity tester, which solves the problems of the prior art such as low automation degree, low test accuracy, difficulty in ensuring test condition and complex operation. The explosive friction sensitivity tester comprises a box body, a belt clip support fixed on the inner wall on one side in the box body, a friction belt chip inserted on the belt clip support, an impact cylinder fixed on the upper wall of the box body above the friction belt clip, a sample support base with a rotation hole and fixed on one side of the belt chip support, a support base inserted in the rotation hole on the sample support base for accommodating explosive, an explosive support tube inserted in the hole of the support base, and a top bar penetrating through the explosive support tube, wherein one end of the top bar corresponds to the friction belt clip and the other end of the top bar is butted against with a pre-tightening cylinder fixed on the sidewall of the box body. The invention has the characteristics of preciseness, feasibility, applicability, convenience, safety, etc. The invention can test the safety and the reliability of explosives, and has wide application range.

Owner:BEIHANG UNIV +1

Safe and sulfur-free firework bursting powder and propelling powder and preparing method thereof

The invention discloses safe and sulfur-free firework bursting powder and propelling powder and a preparing method thereof, and relates to the technical field of fireworks. The firework bursting powder is prepared from, by weight, 15-35 parts of carbon powder, 5-60 parts of potassium perchlorate and 15-70 parts of potassium nitrate. The firework propelling powder is prepared from, by weight,15-35parts of carbon powder, 5-60 parts of potassium perchlorate, 15-70 parts of potassium nitrate, 5-10 parts of adhesive and a proper amount of solvent. The firework bursting powder and propelling powderdo not contain sulfur, metal, benzene or the like, have no toxicity, reduce the air pollution, generate less smoke, have zero percussion sensitivity and friction sensitivity, guarantee safety and environmental protection, have a low moisture absorption rate and stable performance, reduce the ignition point properly, have flammability, high safety performance and propelling performance, do not easily cause barrel blasting, and reduce the production cost; the preparing method of the sulfur-free firework bursting powder and propelling powder is simple and safe.

Owner:张宏善

Thermosetting low-vulnerability explosive and preparation method thereof

InactiveCN109206283AImprove energy performanceReduce vulnerabilityNon-explosive/non-thermic compositionsFriction sensitivityDetonator

The invention relates to a thermosetting low-vulnerability explosive and a preparation method thereof. The thermosetting low-vulnerability explosive comprises the following components: 52%-64% of an explosive; 25%-37% of metal fuel; 4%-9% of a binder; 2%-6% of a plasticizer; 0.5-3% of a curing agent; and 0.1%-1% of a desensitization agent. The thermosetting low-vulnerability explosive provided bythe invention has excellent process performance, good fluidity and levelling properties, a 5h viscosity of less than 500 Pa.s, a yield value of less than 200Pa, a density of greater than 1.8g / cm<3>, adetonation velocity of greater than 7600m / s, explosion heat of greater than 6800kJ / mol, detonation pressure of greater than 22GPa, friction sensitivity of less than 40%, and impact sensitivity of less than 20%; The response levels of fast cook-off test, slow cook-off test and bullet impact test are all combustion, and the results of detonator test and partition plate test are both detonation-free. And the energy performance and low vulnerability of the explosive provided by the invention are both superior to the American PBXN-109 formula.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Igniting powder composition for igniters

InactiveCN103052609AImprove securityImprove responsivenessBelt retractorsPedestrian/occupant safety arrangementFriction sensitivityPerchlorate

Provided is an igniting powder composition which satisfies the current ignition sensitivity required for the igniting powder to be used in igniters that are actuated by an electric signal and which exhibits reduced friction sensitivity. An igniting powder composition for igniters, characterized by being prepared by blending together (A) a metal hydride, (B) at least one kind of metal powder selected from the group consisting of tungsten powder, molybdenum powder, aluminum powder, titanium powder and magnesium powder, and (C) a perchloric acid salt.

Owner:NIPPON KAYAKU CO LTD

Sulfur-free propellant powder

InactiveCN105016933ALow moisture absorptionGood storage stabilityInorganic oxygen-halogen salt explosive compositionsFireworksPerformance index

The invention discloses sulfur-free propellant powder composed of the following components in parts by weight: 34-36 parts of potassium perchlorate, 24-26 parts of carbon powder, 7-9 parts of calcium stearate, 4-6 parts of phenolic resin, 14-16 parts of hydroxyethyl cellulose and 16-18 parts of polytetrafluoroethylene. The propellant powder contains no sulfur components so that environment pollution caused by sulfur dioxide and sulfide is eliminated when fireworks are displayed; no restricted articles are contained, so that the environment-friendly property is greatly improved; the emission performance is better than that of the traditional black powder under the same working condition; all safety performance indexes such as shock sensitivity and friction sensitivity are excellent, so that potential safety hazards are fundamentally reduced; and the propellant powder is low in moisture rate, favorable in storage stability and capable of overcoming the defect that the black powder easily absorbs moisture.

Owner:江西省东安新材料有限公司

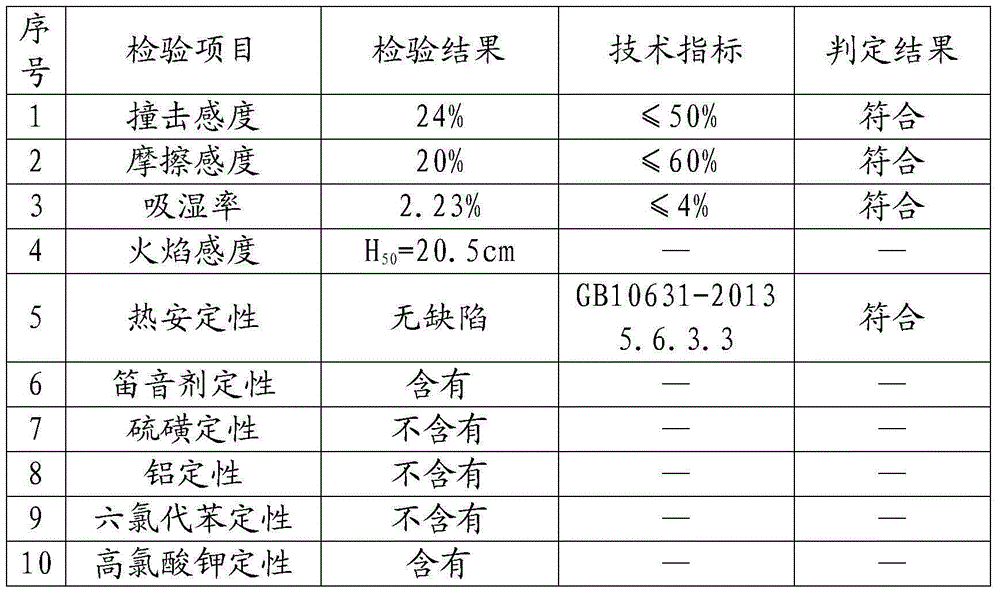

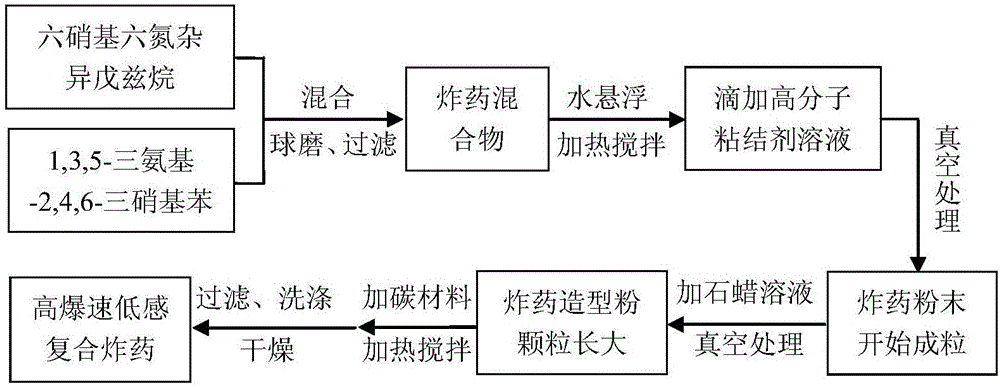

High-detonation-velocity low-sensitivity composite explosive and preparation method thereof

InactiveCN106220458ASolve the technical problem of high mechanical sensitivityLow impact sensitivityExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention discloses a high-detonation-velocity low-sensitivity composite explosive and a preparation method thereof. The preparation method comprises the following steps: weighing hexanitro-hexaaza-isopentaisowurtzitane and 1,3,5-triamino-2,4,6-trinitrobenzene, adding deionized water, a surfactant and zirconium oxide milling balls, carrying out mechanical ball milling by using a planetary ball mill, filtering, washing with deionized water, and drying to obtain an explosive mixture; adding deionized water into the explosive mixture, stirring, heating, dropwisely adding a high-polymer adhesive solution, and carrying out vacuum treatment; dropwisely adding a paraffin solution while keeping heating, stirring and vacuum treatment; and adding a carbon material, stirring, filtering the material, carrying out deionized washing, and drying to obtain the high-detonation-velocity low-sensitivity composite explosive. The high-detonation-velocity low-sensitivity composite explosive can effectively implement the explosive detonation velocity of up to 9000 m / s or above, and the impact sensitivity and friction sensitivity are respectively less than 10%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

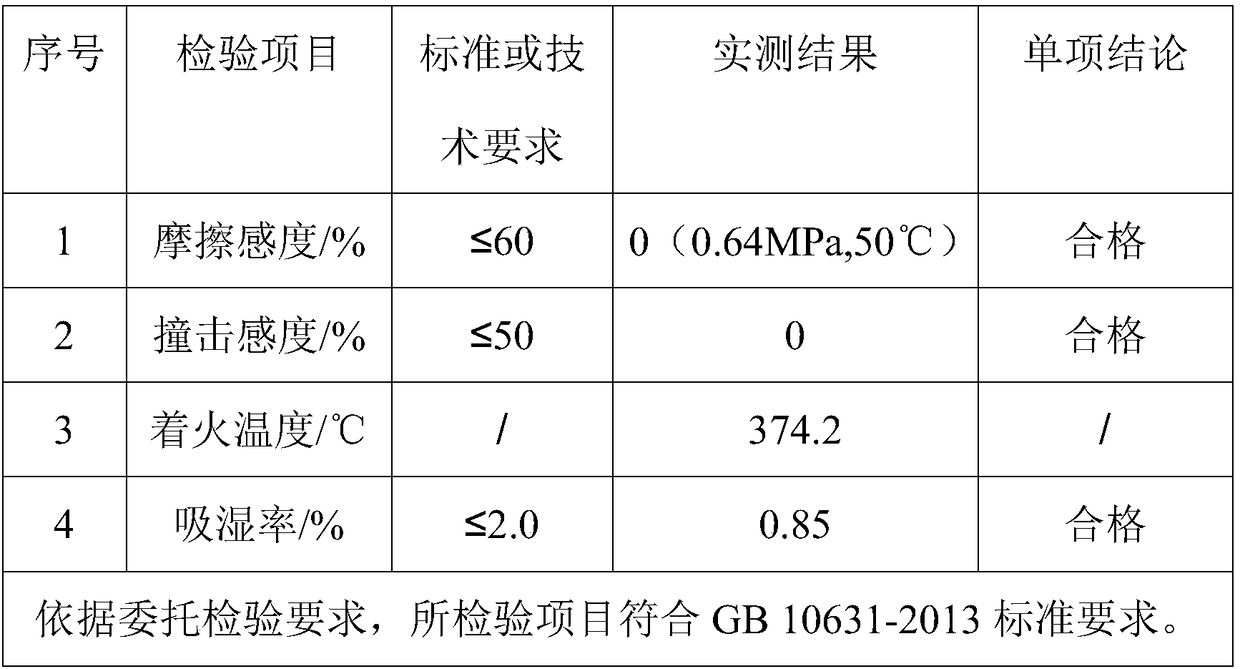

Sulfur-free shoot charge for fireworks and preparation method thereof

InactiveCN105481618AReduce dosageReduce security risksExplosivesPotassium nitrateFriction sensitivity

The invention provides a sulfur-free shoot charge for fireworks and a preparation method thereof. The sulfur-free shoot charge for fireworks comprises potassium perchlorate, potassium hydrogen terephthalate, potassium nitrate, charcoal and phenolic resin in a mass ratio of (50-70) to (20-40) to (4-6) to (3-5) to (0.5-1.5), wherein the grain sizes of the raw materials are 200-300 mesh. The invention also provides the preparation method of the sulfur-free shoot charge for fireworks. Experiments prove that through determination under certain conditions, the product of the sulfur-free shoot charge for fireworks has friction sensitivity of 0-18%, impact sensitivity of 0, ignition temperature of 423 DEG C, moisture absorption ratio of 0.87% and good 48-hour thermal stability at 75 DEG C.

Owner:ZHONGXIANG FENGSHAN FIREWORK CO LTD

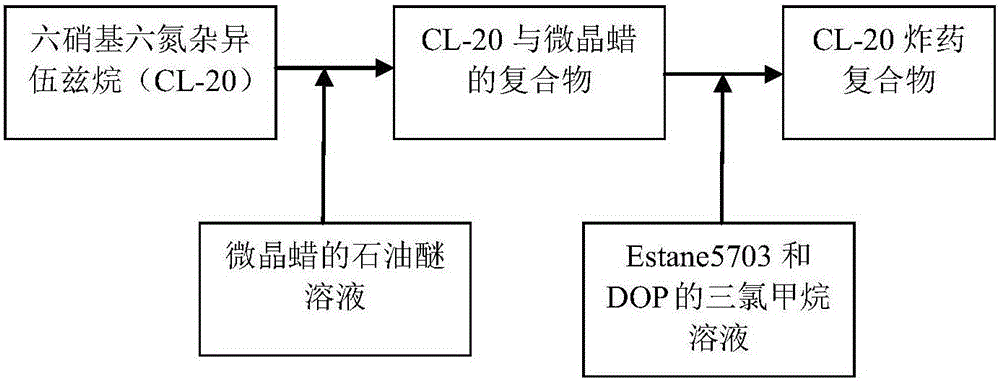

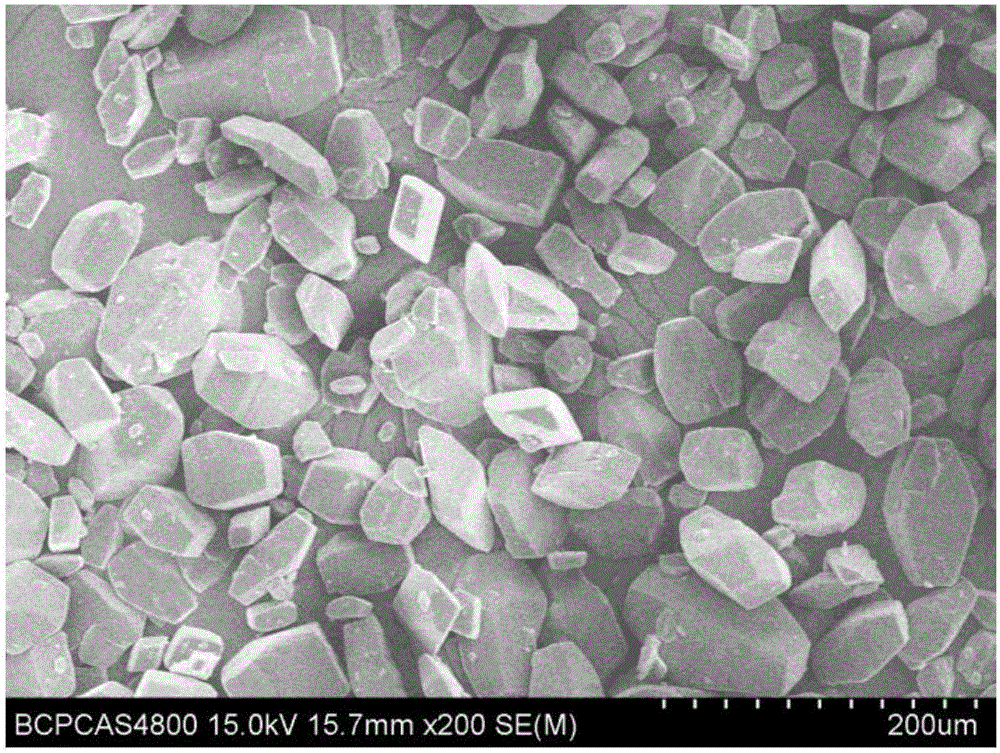

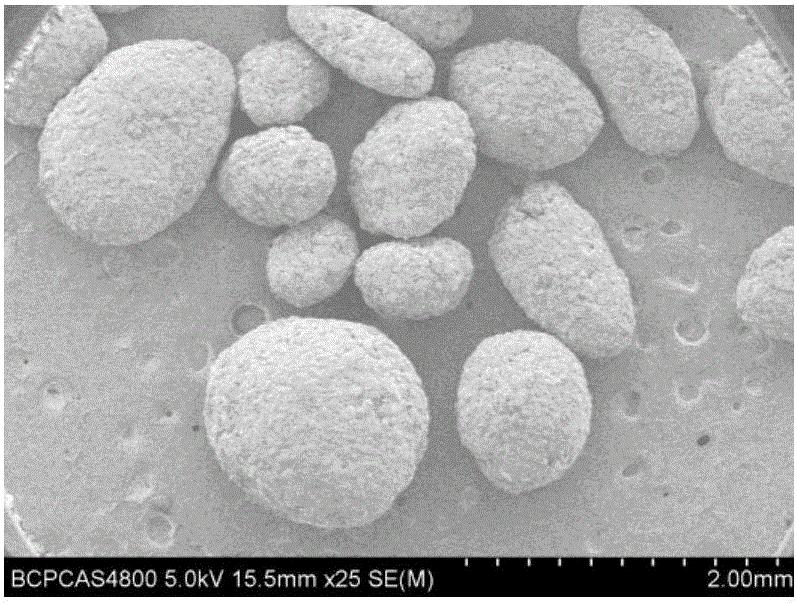

Method for coating CL-20 explosive with plasticized Estane5703

InactiveCN106083494AUniform particle sizeLow impact sensitivityNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusFriction sensitivityMicrocrystalline wax

The invention relates to a method for coating a CL-20 (hexanitrohexaazaisowurtzitane) explosive with plasticized Estane5703. The method comprises the following steps: coating the surface of CL-20 with a desensitizer microcrystalline wax to prepare a CL-20 and microcrystalline wax compound, and coating the surface of the CL-20 and microcrystalline wax compound with Estane5703 to prepare a CL-20 explosive compound. The method allows a uniform and compact film to be formed on the surface of the CL-20 explosive, so the mechanical sensitivity of the CL-20 explosive is substantially reduced. The CL-20 explosive compound prepared in the invention and the coating film thereof are controlled to be in a nanometer range, account for 2-4% of the total system, and have small influences on the energy of the CL-20 explosive. The bump sensitivity of the coated CL-20 explosive is reduced to 52-72% from 100%, and the friction sensitivity of the coated CL-20 explosive is reduced to 40-80% from 100%.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

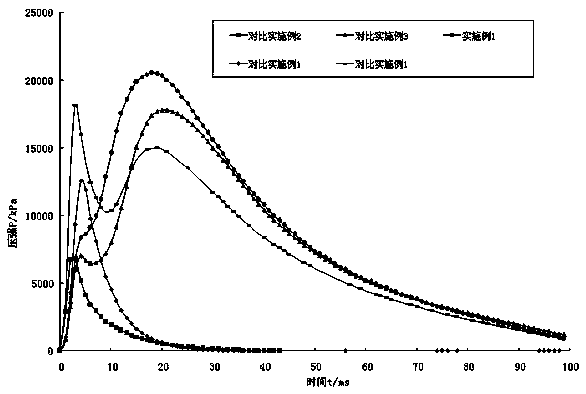

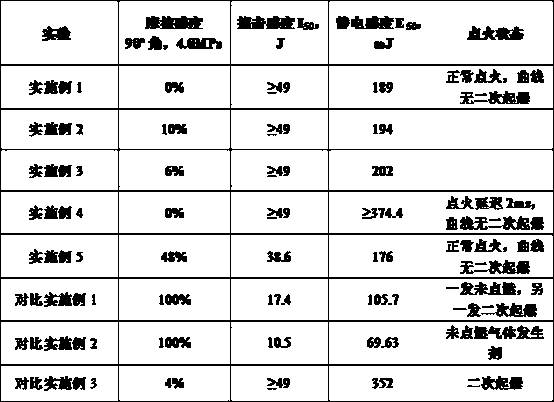

Safety airbag igniting powder composition and preparation method of safety airbag igniting powder composition

InactiveCN106699490AImprove securityLow mechanical sensitivityExplosive ingredient compoundingFriction sensitivityPotassium nitrate

The invention provides a safety airbag igniting powder composition, aiming at overcoming the disadvantage that a sealing foil or a powder cup needs to be designed when grain-shaped igniting powder is used, the problem that the safety performance of boron-potassium nitrate igniting powder is poor, and a low-temperature igniting problem. The safety airbag igniting powder composition is prepared from the following components according to the content: 10 percent to 20 percent of boron powder, 80 percent to 90 percent of potassium nitrate and 0 to 2 percent of a process auxiliary agent; the components are pressed and molded through a rotary tablet press so as to prepare cylindrical powder sheets. The safety airbag igniting powder composition is mainly appalied to an igniting device of a safety airbag gas generator and has the main characteristics that igniting powder has relatively good safety performance and mechanical sensitivity including friction sensitivity and impact sensitivity is relatively small; the safety airbag igniting powder composition is not exploded basically under the stimulation of friction and impact effects. Meanwhile, the igniting powder can still be normally ignited at a low temperature of -40 DEG C+ / -2 DEG C, and a phenomenon of double peaks of an indoor pressure curve of the gas generator, namely secondary explosion, under a low-temperature condition does not occur; the igniting powder has the advantages of rapid ignition and slow starting pressure.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Explosive with aromatic for environmental protection safety firecrackers

InactiveCN1559999AImprove securitySimple recipeAlkali metal salt explosive compositionsFriction sensitivityFirecracker

The invention relates to a potassium chlorate-free and sulfur-free fragrant environmental- protection safety powder of firecrackers and its components are compounded of potassium perchlorate, Al powder, perlite powder and sandalwood powder. It has simple formula, a few components, good chemical stability and safety, no potassium chlorate and no sulfur, eliminates the defects of strong impact and friction sensitivity, high danger, etc, and has the advantages of low mechanical sensitivity and high safety, excellent bang rate of setting off firecrackers and sound level value.

Owner:易显云

Sulfur-free environment-friendly gun propellant

The invention discloses a sulfur-free environment-friendly gun propellant which comprises the following components in parts by weight: 65 parts of potassium acid phthalate, 15 parts of hemp stem carbon powder, 10 parts of an epoxy resin, 2 parts of graphite powder and 5 parts of lime. The gun propellant manufactured according to the formula is applied to display shells, potted flowers, colored bead barrels, display shell rocket propulsion powder and the like. The sulfur-free environment-friendly gun propellant is excellent in safety performance indexes, the friction sensitivity and percussion sensitivity degree are zero, and the potential safety hazards are eliminated; according to the formula, the sulfur component is completely eliminated, so that pollution of sulfur dioxide and sulfides on the environment is eliminated during firework display; and moreover, the gun propellant does not contain forbidden materials; and the environmental protective performance is greatly improved.

Owner:LIUYANG CHENGFA TECH

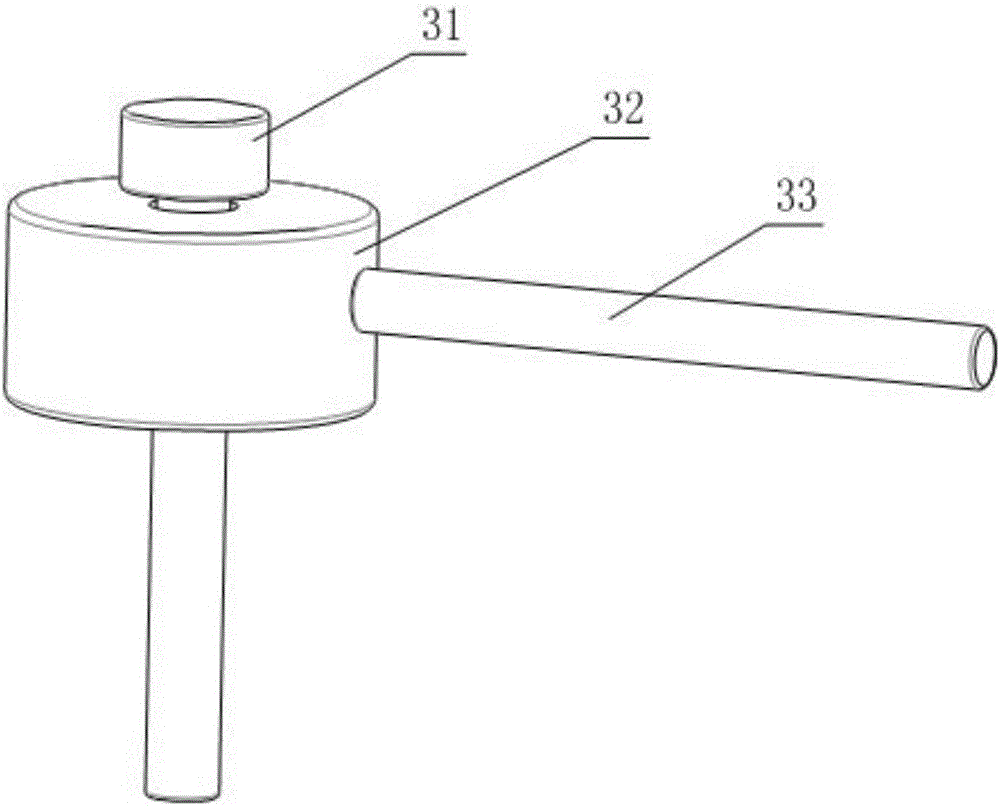

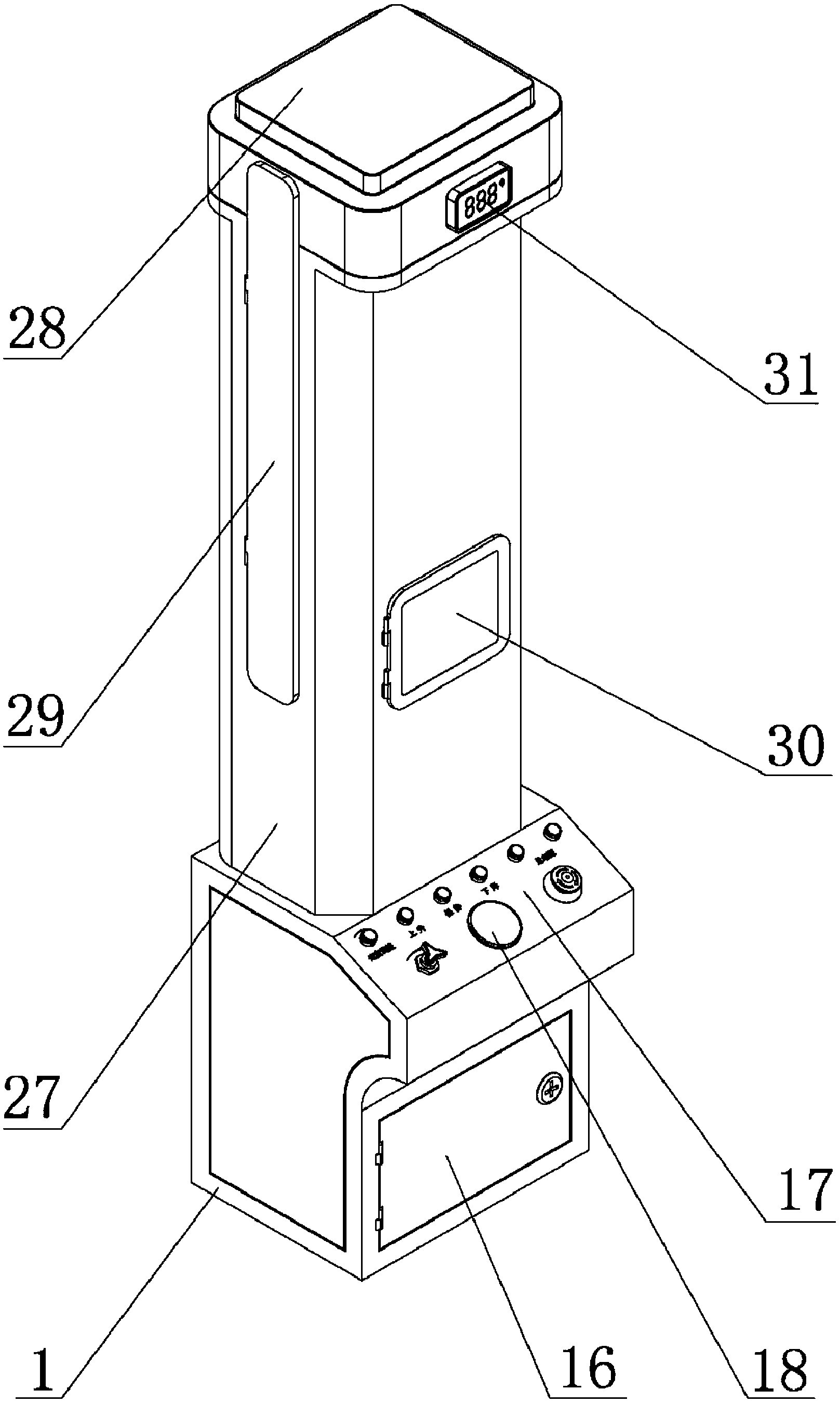

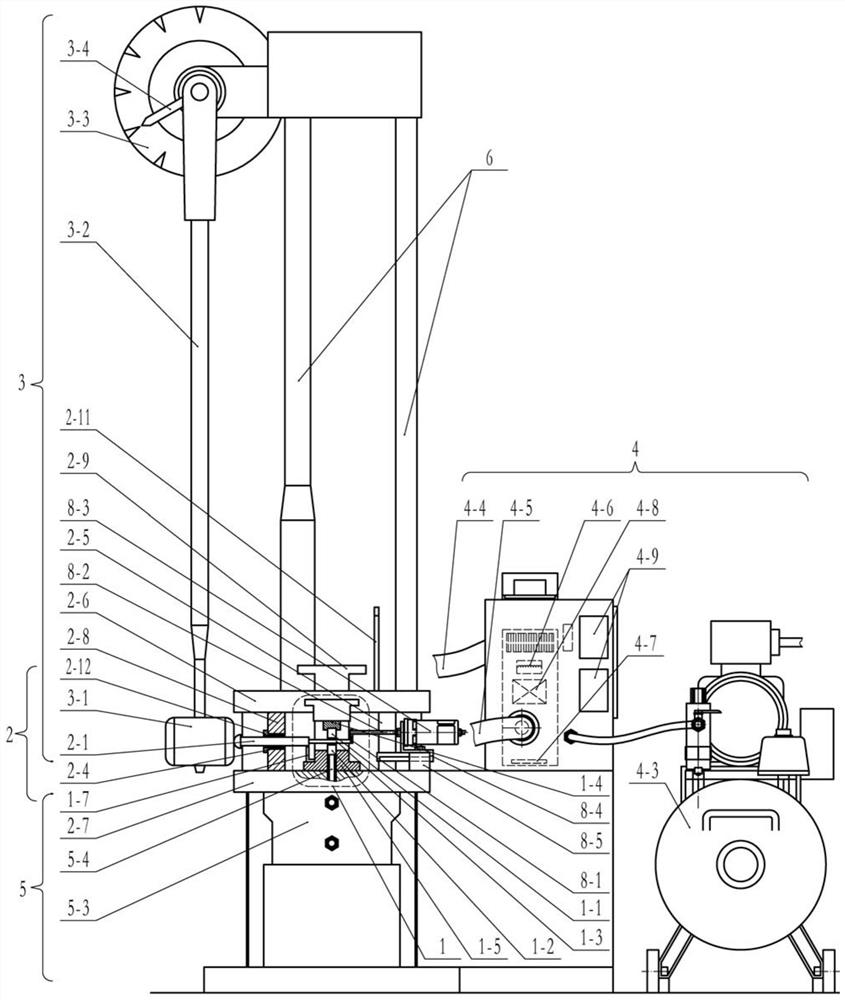

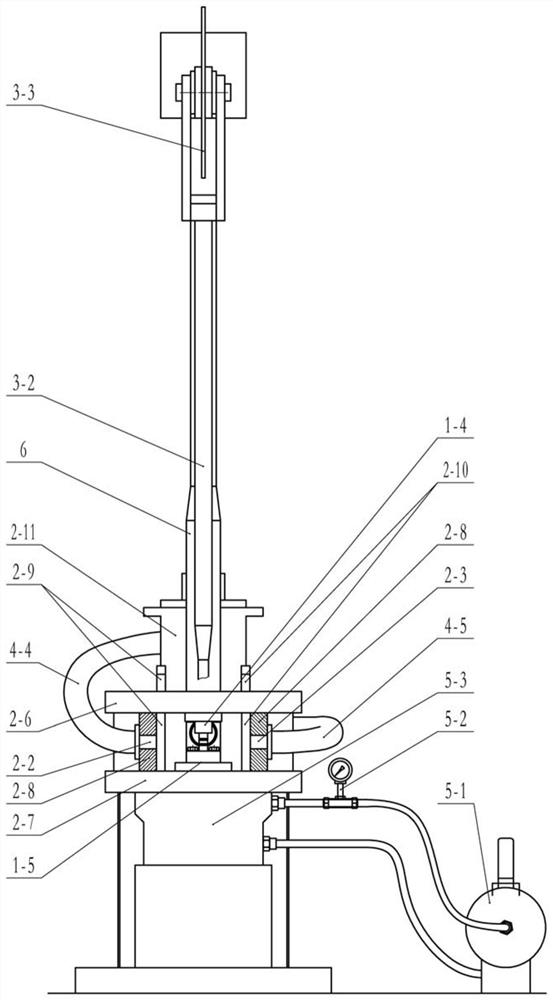

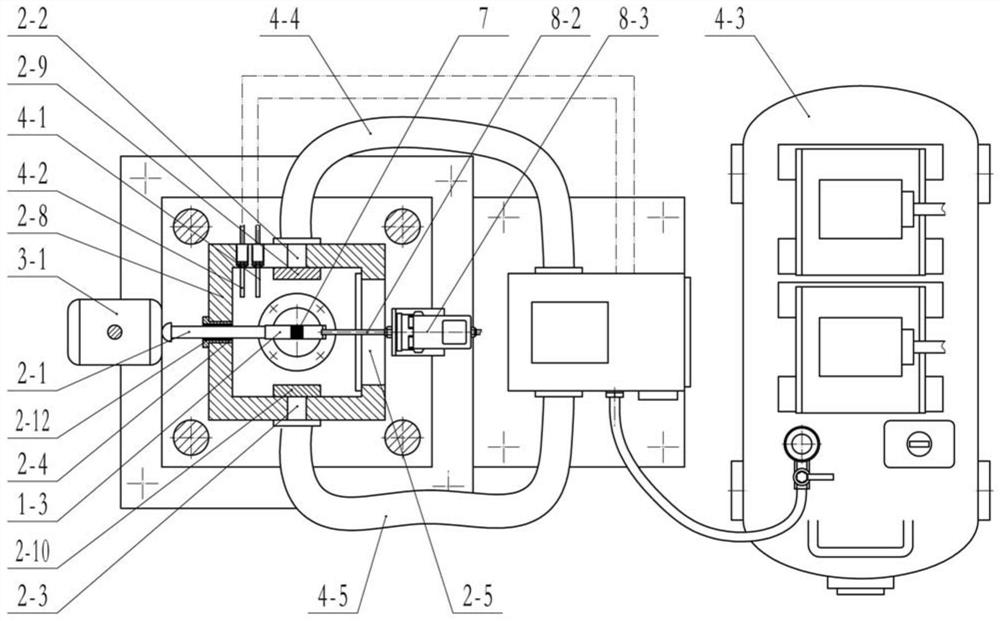

Device and method for testing friction sensitivity of explosives and powders

PendingCN111707607AEliminate distractionsAccurate locationUsing mechanical meansMaterial analysisFriction sensitivityExplosive Agents

The invention relates to the technical field of material performance testing, and provides a device and method for testing the friction sensitivity of explosives and powders. The testing device comprises a sample loading system, an explosion chamber, a pendulum bob mechanism, a temperature and humidity control system, a pressure loading system, and a rack. According to the invention, the influences of the temperature, humidity, speed and pressure are considered comprehensively, the influence of adverse factors of friction loss is reduced, the test control of temperature and humidity is increased, and the accuracy and controllability of speed are improved; and the influence of contact materials and surface roughness is also considered. More comprehensive and accurate friction sensitivity data can be obtained, and the influence of all parameters on friction safety in the actual explosive production and processing technology is reflected. The device and method are suitable for various explosive monomer semi-finished products, new components, new formulas, new types, medicaments, slurries and tablets. Friction sensitivity data obtained through the method can also be used for supporting and guiding mathematical model establishment, numerical calculation, analog simulation, new formulas, new equipment, new processes and other research and development work.

Owner:BEIJING UNIV OF CHEM TECH

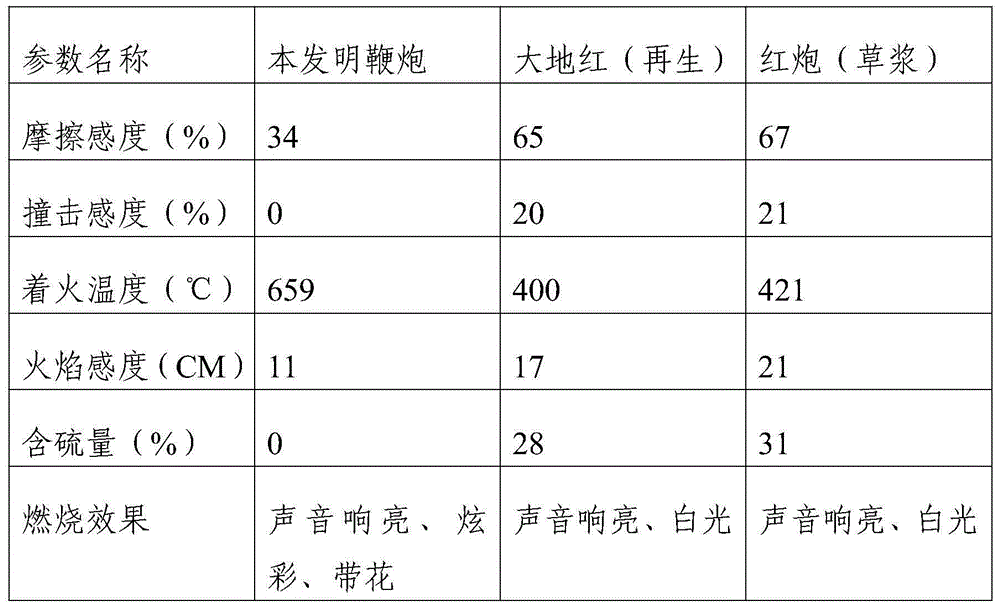

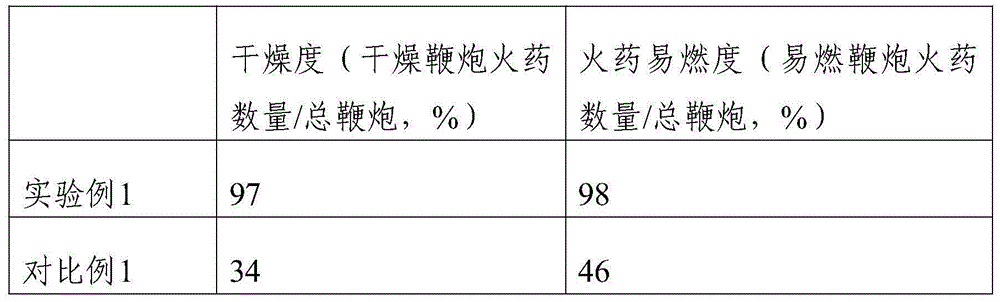

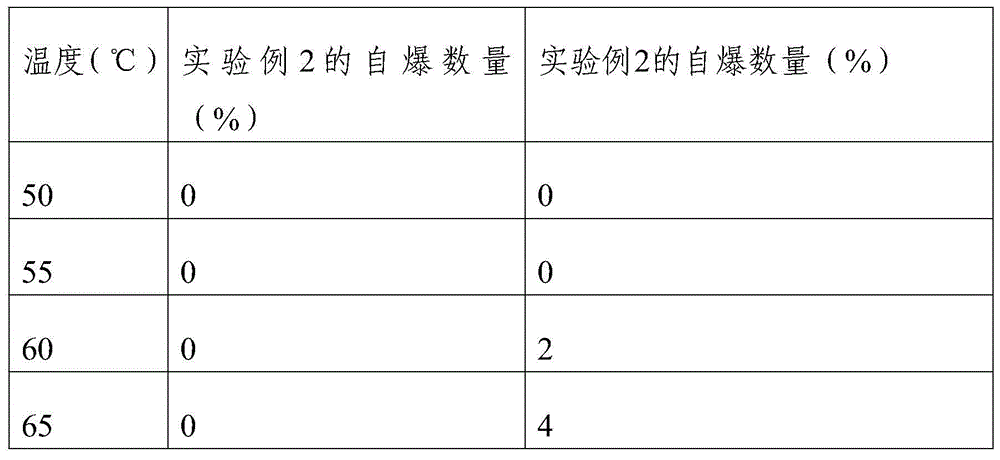

Safe environment-friendly colorful firecracker reagent and method for preparing colorful firecracker by using reagent

ActiveCN104829401AReduced friction sensitivityLow impact sensitivityExplosivesFireworksSpontaneous combustionFriction sensitivity

The invention provides a safe environment-friendly colorful firecracker reagent and a method for preparing a colorful firecracker by using the reagent. The colorful reagent comprises a component A and a component B. The manufacturing technique is implemented by coating the component B on the component A. The reagent is free of potassium chlorate or any other national forbidden component, and is free of sulfides. In the firecracker prepared by the method, the component A is coated with the component B, and the component B has the functions of heat insulation, water resistance, collision prevention and the like, thereby overcoming the defect that the component A can be easily moisturized, can be easily exploded by impact, can easily generate spontaneous combustion due to high temperature and the like. Thus, the firecracker has the characteristics of high reaction speed, clear sound, multiple colors, low impact sensitivity, low friction sensitivity, low flame sensitivity, high ignition temperature, high safety, no sulfur and the like.

Owner:雍和平

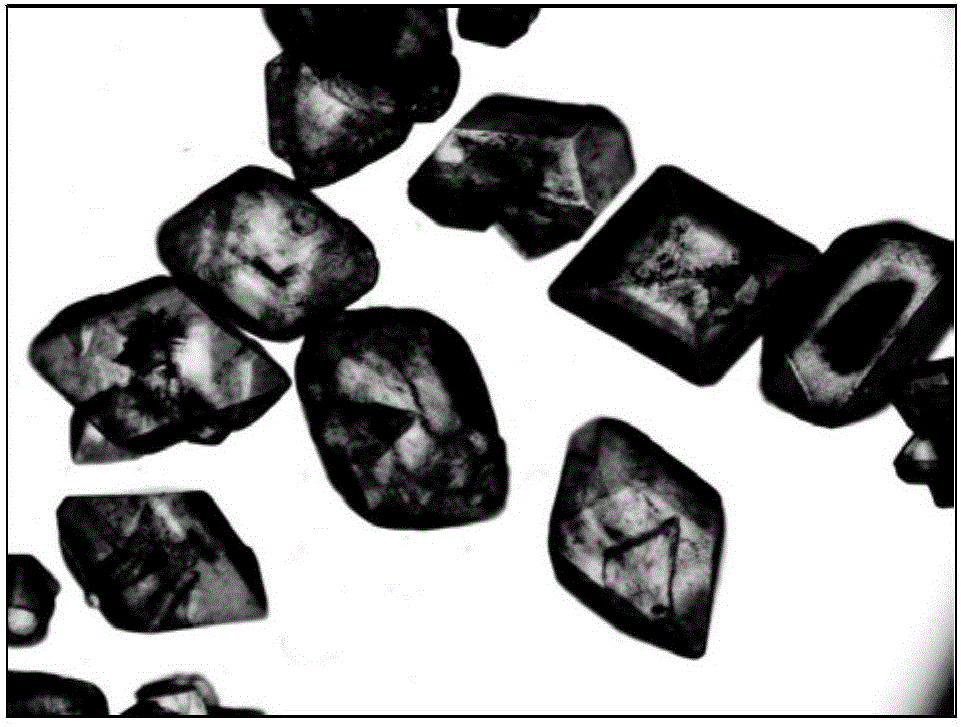

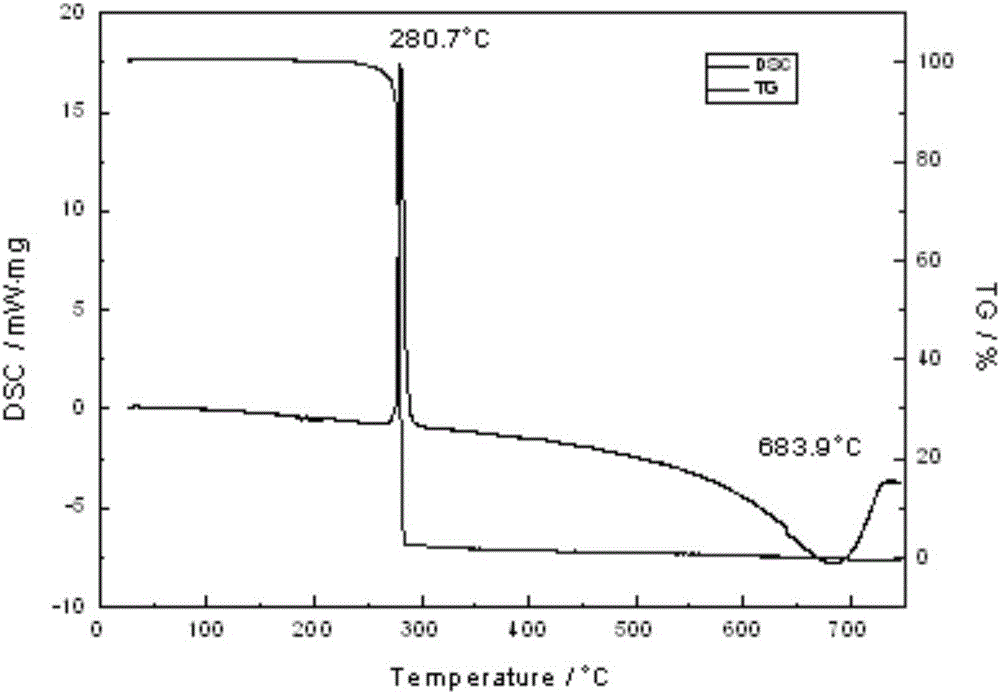

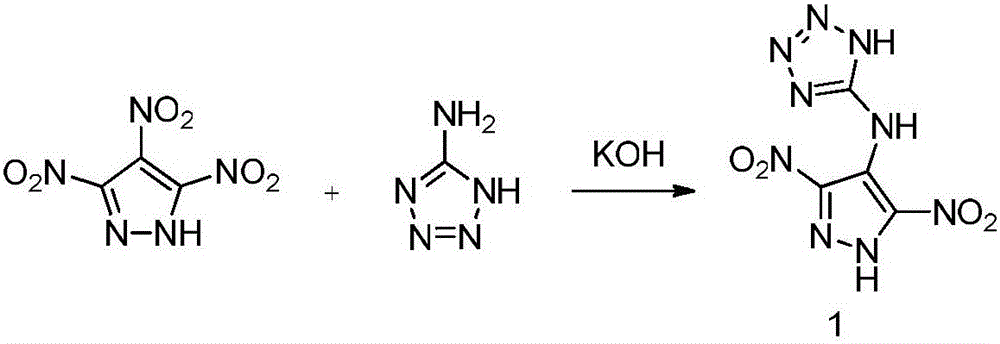

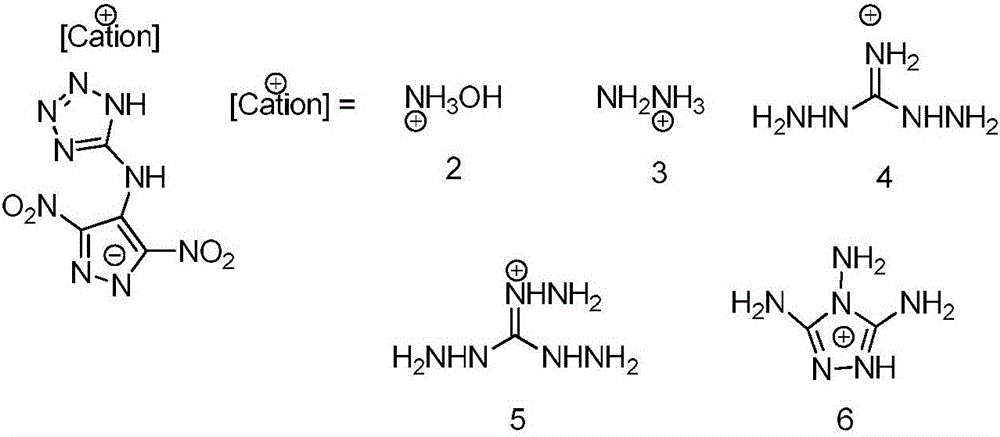

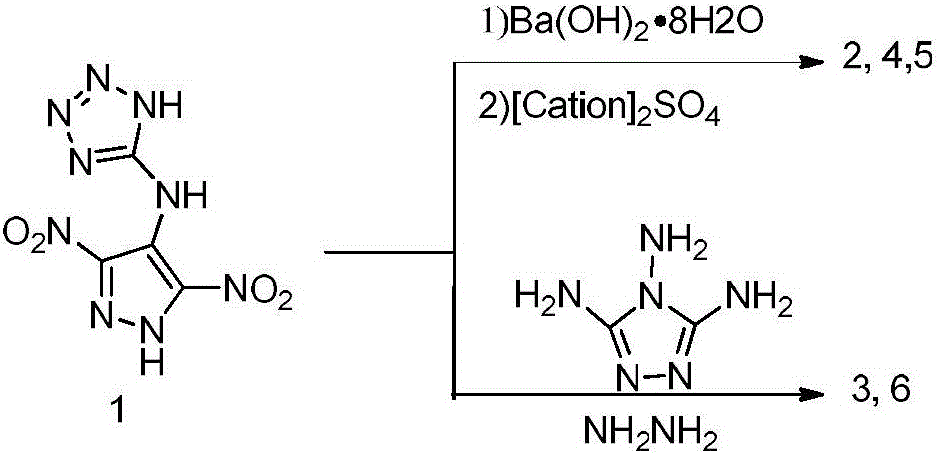

Preparation method and performance of high-energy insensitive N-(3,5-binitro-1H-pyrazol-4-yl)-1H-tetrazole-5-amine ionic salt structure

InactiveCN106432192AHigh densityHigh nitrogen contentOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityHigh energy

The invention provides a preparation method and performance measurement of N-(3,5-binitro-1H-pyrazol-4-yl)-1H-tetrazole-5-amine (1) and energetic ionic salt thereof, and belongs to the technical field of energetic materials. The synthesis method comprises the steps of adding 3,4,5-trinitropyrazol, 5-amino tetrazole and water into a thick-wall sealed pipe, adjusting the pH to 7 by KOH, performing heating reaction for 48 hours, treating to obtain solid 1,1, and enabling reaction between the solid 1,1 and corresponding cationic sulfate to obtain a target product. The preparation method is simple in synthesis, stable in performance and easy in amplification. In the product, the density is high and is 1.79 to 1.86 g*cm<-3>, the decomposition temperature is high and is 279 to 296 DEG C, the impact sensitivity is 35 to 40 J, the friction sensitivity is 84 to 360 N, the detonation velocity exceeds 9,000 m*s<-1>, the nitrogen content is high and is 51.09 to 60.86 percent, the comprehensive performance is excellent, and a potential application value is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Micro-smoke sulfur-free agent for firecracker

The invention relates to a micro-smoke sulfur-free agent for a firecracker. The micro-smoke sulfur-free agent for the firecracker is prepared from the following components in parts by weight: 30 parts of bamboo charcoal powder, 10-30 parts of potassium perchlorate, 10-20 parts of nanosiliver powder, 5-15 parts of nano rare earth oxides, 2-6 parts of charcoal powder, 2-5 parts of titanium sponge powder and 1-4 parts of agilawood powder. The firecracker using the agent provided by the invention is micro-smoke, sulfur-free and environment-friendly during combustion. The firecracker has fragrance of bamboo and agilawood during combustion, and the friction sensitivity, the impact sensitivity and the moisture absorption are superior to the state standards.

Owner:浏阳市吉祥环保材料开发有限公司

Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt

InactiveCN104447762AThe synthesis method is simpleMild conditionsOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityDetonation

The invention discloses energetic ionic salts of a 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and a preparation method of the energetic ionic salts, and belongs to the technical field of energetic materials. The synthesis method comprises the following steps: reacting a silver salt of the 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide with corresponding hydrochloride of energetic cation; filtering and participating; and evaporating filtrate and removing a solvent, so as to obtain a target product. The energetic ionic salts are simple in synthesis method, and easy to industrialize. The 6 energetic ionic salts disclosed by the invention are relatively high in density (rho is 1.77-1.97g / cm<3>); the impact sensitivity is greater than 40J; the friction sensitivity is greater than or equal to 324N; the energetic ionic salts belong to insensitive explosives; and all energetic ionic salts are excellent in calculating detonation performance, and are energetic materials with potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

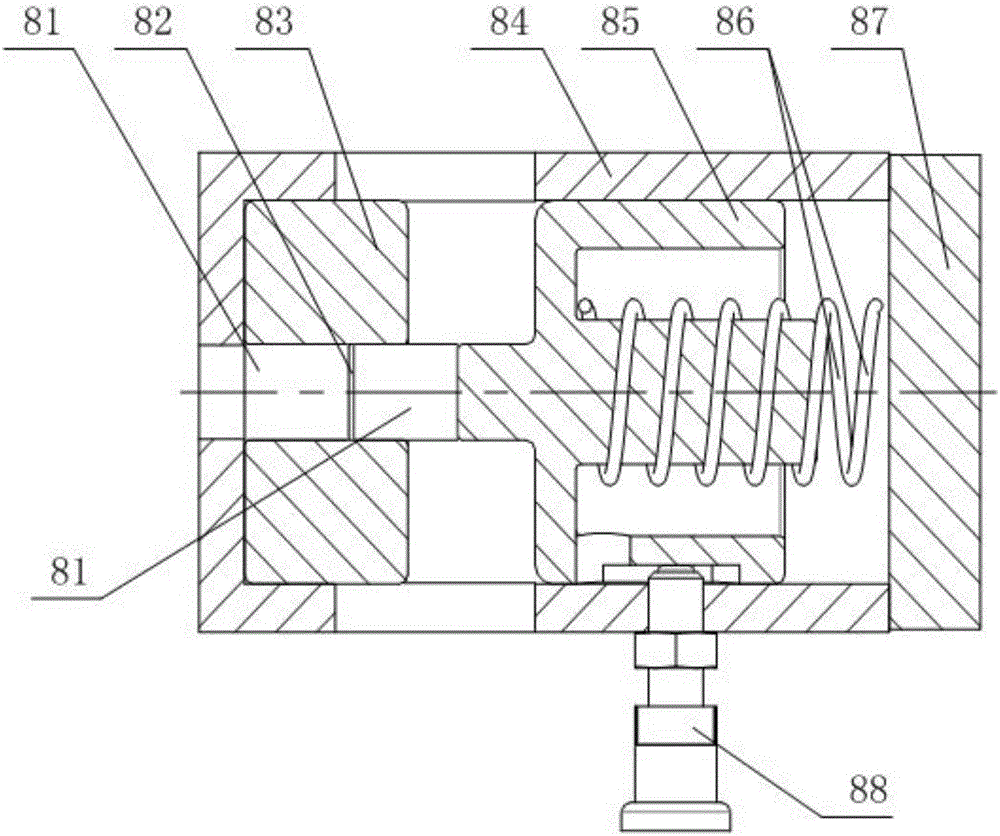

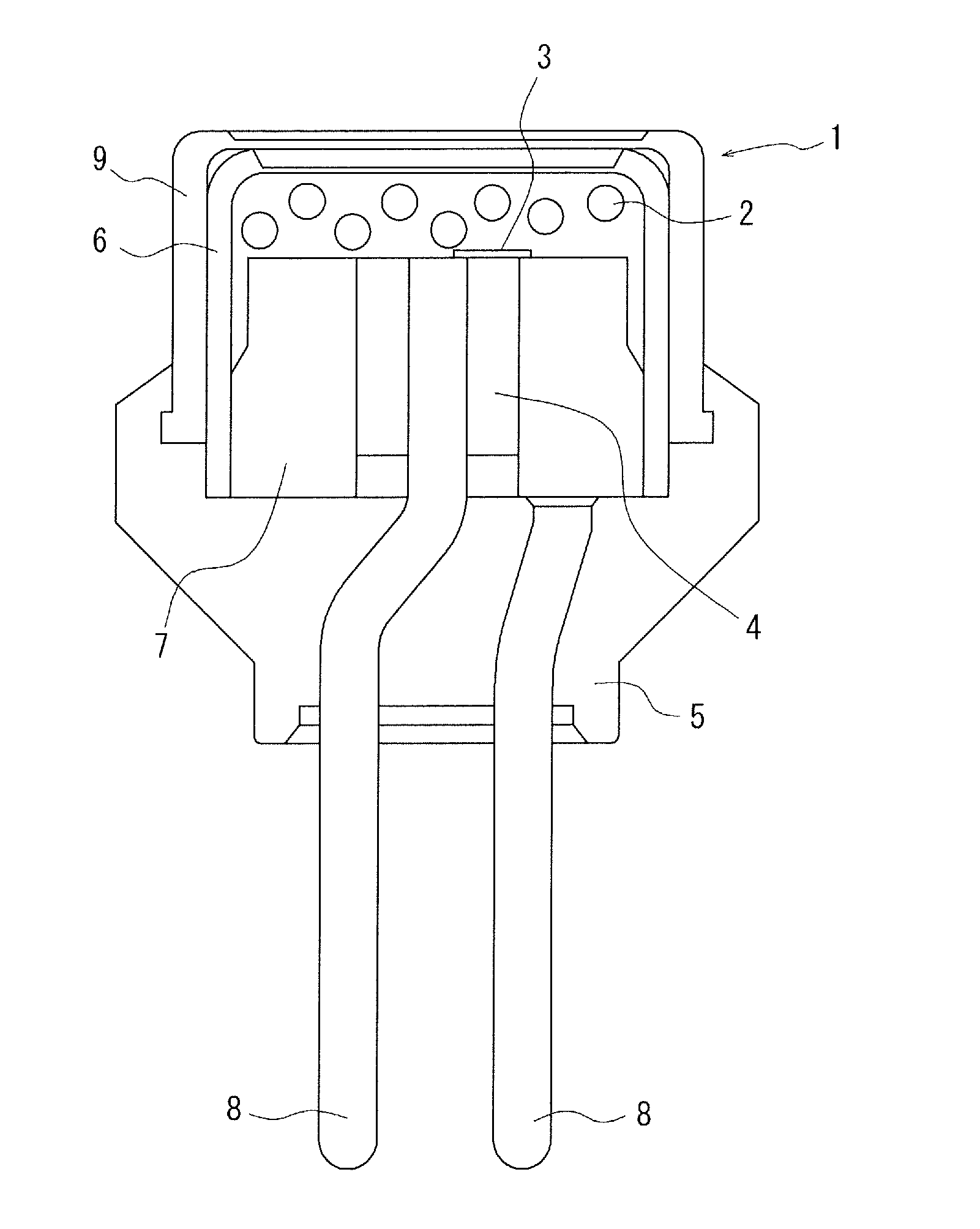

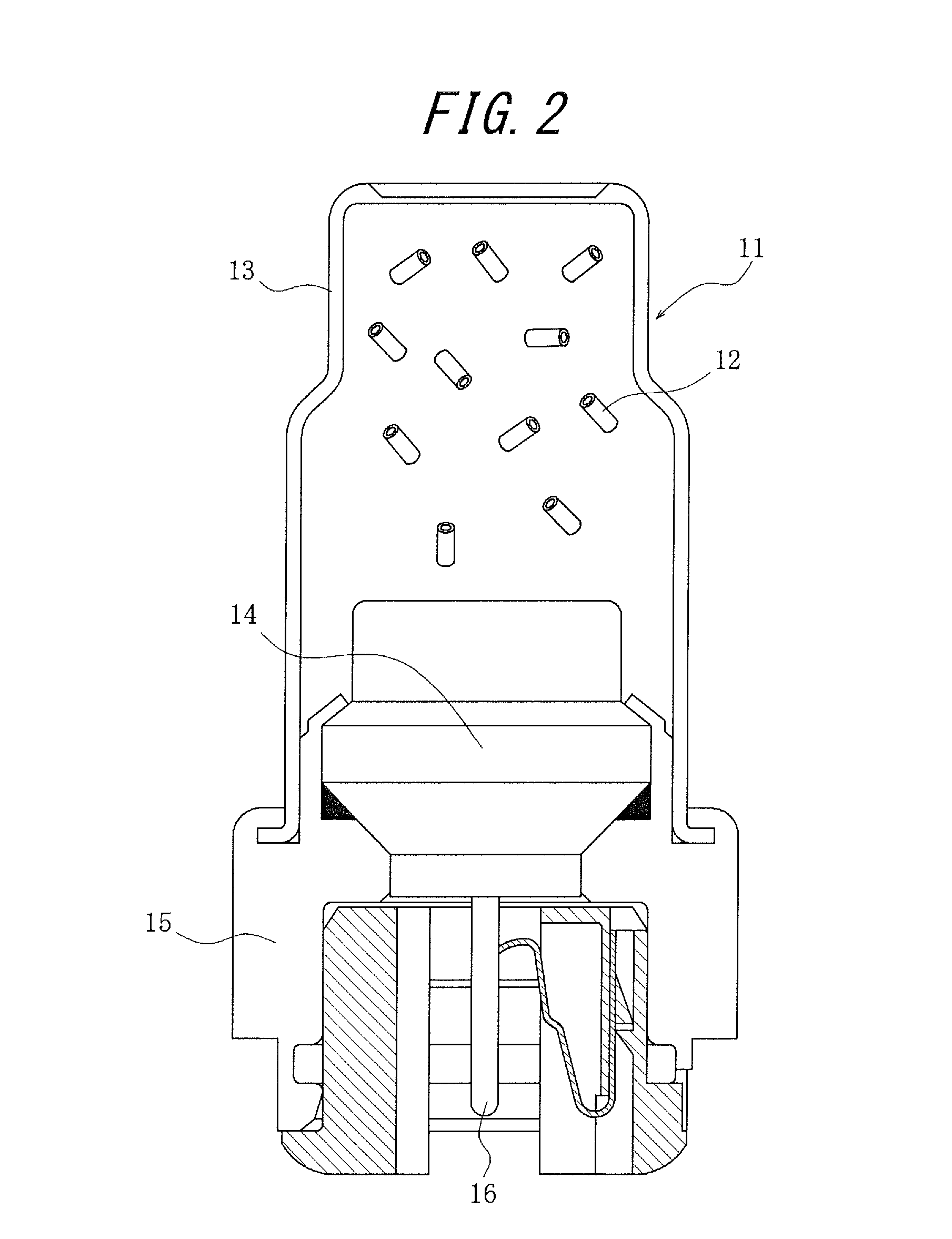

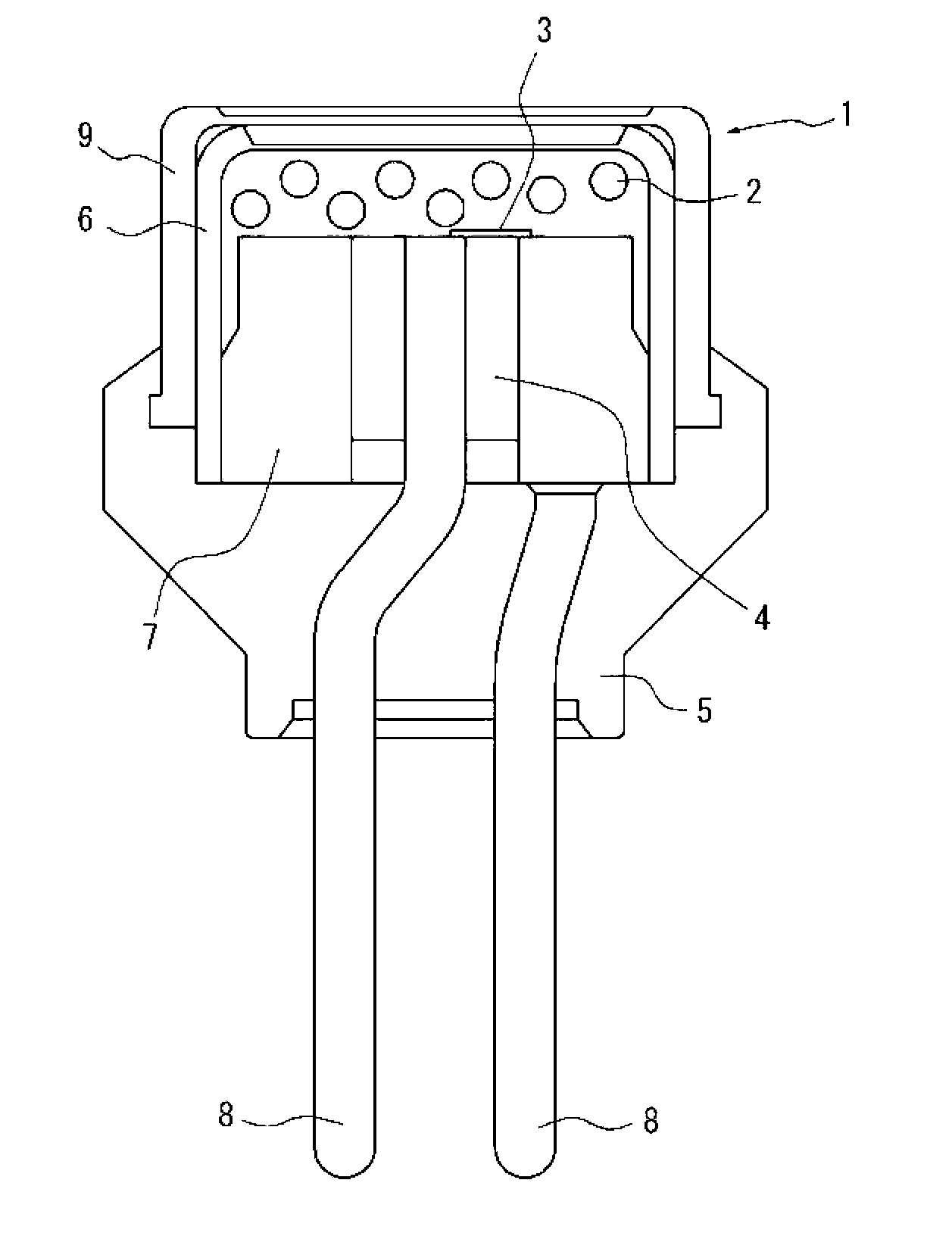

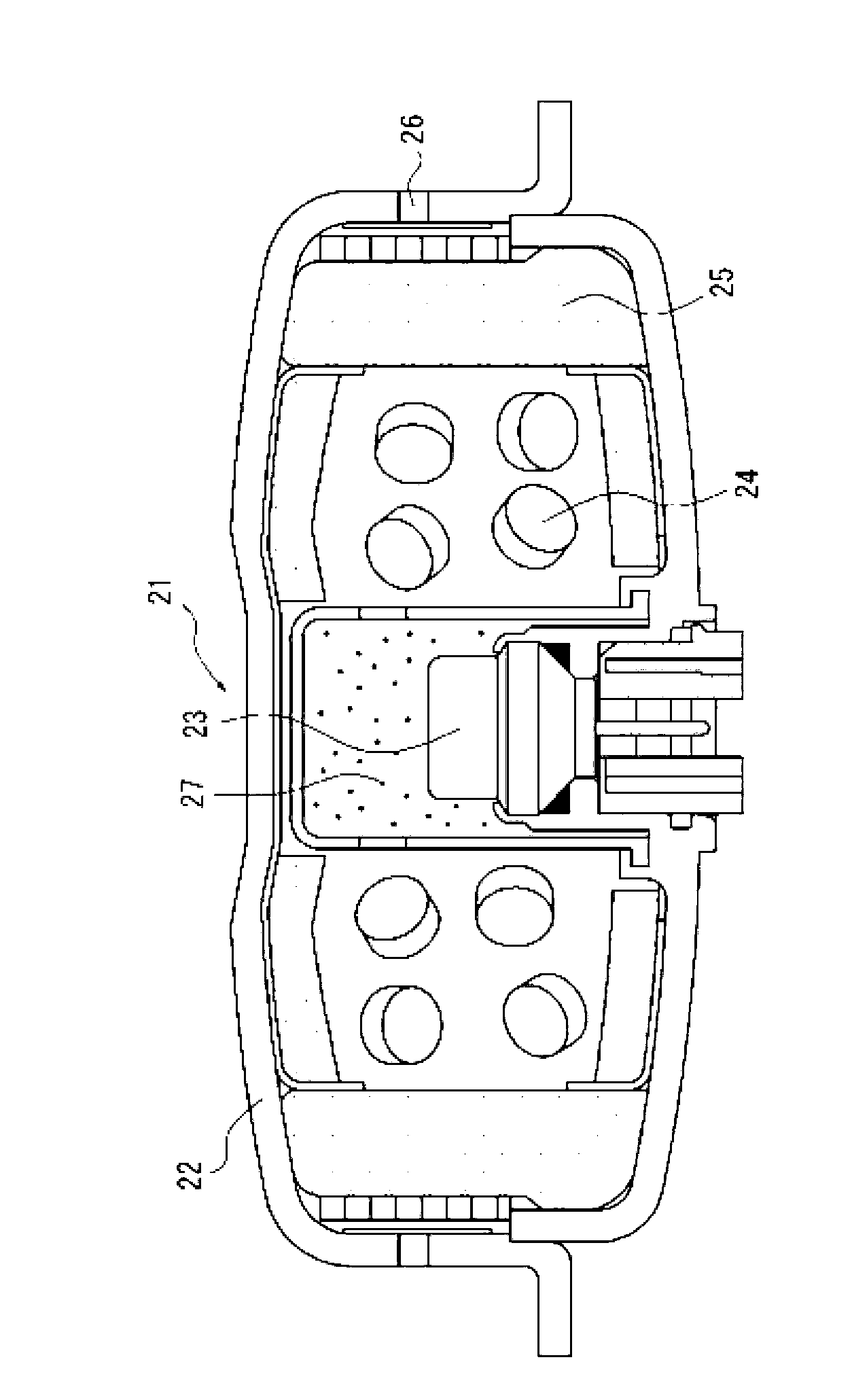

Testing device for measuring impact sensitivity and friction sensitivity of energetic material

PendingCN106442106AReduce weightSmall sizeInvestigating abrasion/wear resistanceFriction sensitivityTest sample

The invention discloses a testing device for measuring the impact sensitivity and friction sensitivity of an energetic material. The testing device comprises a case, a servo motor, an air pipe and a pneumatic knocking hammer, wherein an air outlet pipe orifice of the air pipe is communicated with an air inlet of the pneumatic knocking hammer in a sealed manner; a test sample impact testing cavity corresponding to the pneumatic knocking hammer is formed in the right side of the bottom of the case; an impact rod component is movably mounted in the test sample impact testing cavity, and an impact column component is arranged corresponding to the impact rod component; the servo motor, a lead screw and an ejector rod are sequentially connected; a test sample friction testing cavity is formed in the test sample impact testing cavity; a sliding column sleeve is movably mounted in the test sample friction testing cavity; a left sliding column and a right sliding column are arranged in the sliding column sleeve; an energetic material friction sensitivity test sample is arranged between the left and right sliding columns; the positions of the bottom of a piston hammer body of the pneumatic knocking hammer and the outer wall of the test sample friction testing cavity correspond to each other. The device has the characteristic of multifunction, and can be used for simultaneously testing the impact sensitivity and friction sensitivity of the energetic material.

Owner:HUNAN JUNCHENG TECH

Automatic friction sensitivity instrument

InactiveCN102707031AEasy to stake outAngle hover precisionFuel testingUsing mechanical meansTest performanceFriction sensitivity

The invention relates to an automatic friction sensitivity instrument. An oil supplier is arranged in a hydraulic tank and connected with a hydraulic cylinder which abuts against the bottom of a hydraulic jacking device; a bracket base is positioned above the hydraulic jacking device, a test sample friction device is arranged on the bracket base; an ejector rod and a sensor are arranged between the test sample friction device and the hydraulic jacking device; a transmission platform is positioned above the bracket base, an electric magnet is arranged on the transmission platform and attracts a pull rod; the pull rod is connected with a driving wheel and a drive motor and pulls the driving wheel and the drive motor to move on a motor guide holder; the drive motor drives the driving wheel and drives a driven wheel by a driving belt; the driven wheel is connected with a swing rod by a driven shaft; a heavy punch is arranged on the swing rod; a firing pin is positioned between the heavy punch and the test sample friction device so as to enable the heavy punch to strike the firing pin and the test sample friction device sequentially; and a photoelectric encoder is arranged on the driven shaft and rotates along with the driven shaft. The friction sensitivity instrument has the advantages of having high automation degree and accurate test performance, being time-saving and effort-saving, and the like.

Owner:HUNAN JUNCHENG TECH

Fireworks detonating agent without chlorate and perchlorate

InactiveCN1640856ALow moisture absorptionReduced friction sensitivityExplosivesDecompositionFireworks

The firework exploding and sounding agent without chlorate and perchlorate comprises composite oxidant, inflammable sulfur, easy-to-burn aluminum powder and density regulating agent, and features the composite oxidant comprising potassium nitrate 10-50 wt%, barium nitrate 50-90 wt% and potassium permanganate 0-25 wt%. The firework exploding and sounding agent has also added pH regulating agent boric acid and deactivating agent magnesia or stearic acid. The firework exploding and sounding agent has high heat stability, no decomposition under 75 deg.c and minus 25-35 deg.c for 48 hr, friction sensitivity lower than 60 %, knocking sensitivity lower than 50 %, no burning and explosion in falling test and sympathetic detonation test, high fire approaching performance and no special requirement in firing line, and may be used in type B and type C firework products.

Owner:刘青春

Sulfur-free propellant and preparation method thereof

ActiveCN106316725AReduce pollutionLow costInorganic oxygen-halogen salt explosive compositionsFriction sensitivitySulfur

The invention provides sulfur-free propellant. The sulfur-free propellant is prepared from 35wt%-52 wt% of potassium perchlorate, 5 wt%-15 wt% of a filling agent, 8 wt%-20 wt% of a bonding agent, 5 wt%-18 wt% of calcium stearate and 10 wt%-30 wt% of potassium acid phthalate by taking the total weight of the sulfur-free propellant as a standard. The sulfur-free propellant is low in friction sensitivity, impact sensitivity and moisture absorption capacity and high in thrust, and meanwhile pollution to the environment is reduced.

Owner:陈绍清

Ignition powder composition for igniter

InactiveUS20130305952A1Lowered friction sensitivityReduce frictionPedestrian/occupant safety arrangementBlastingFriction sensitivityPerchlorate

An ignition powder composition for igniter of which friction sensitivity can be lowered with the required firing current sensitivity being achieved is provided as ignition powder for an igniter that is activated by an electrical signal. The ignition powder composition for igniter contains metal hydride (A); metal powder (B) that is one or more selected from the group consisting of tungsten powder, molybdenum powder, aluminum powder, titanium powder, and magnesium powder; and perchlorate (C).

Owner:NIPPON KAYAKU CO LTD

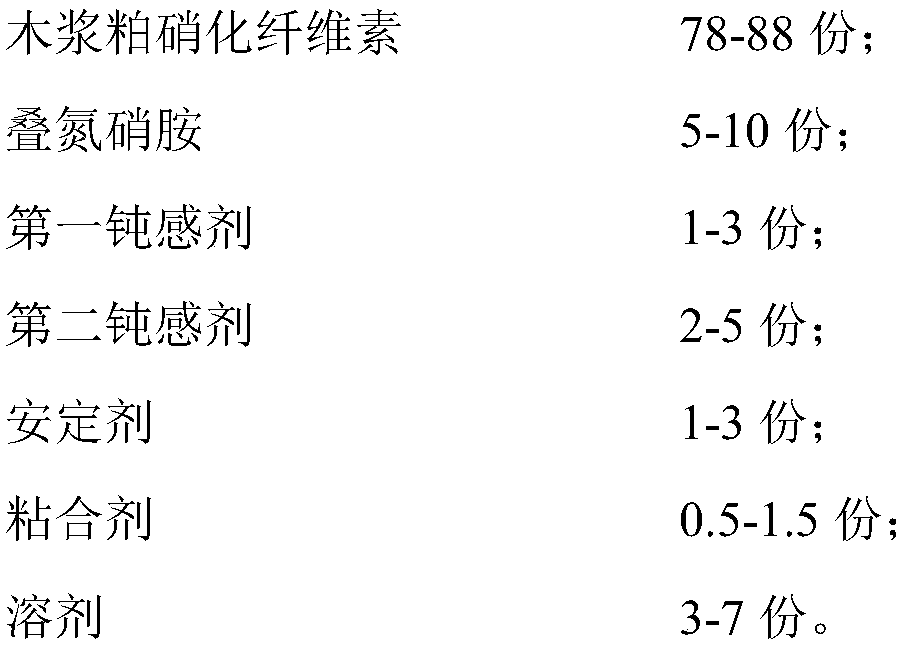

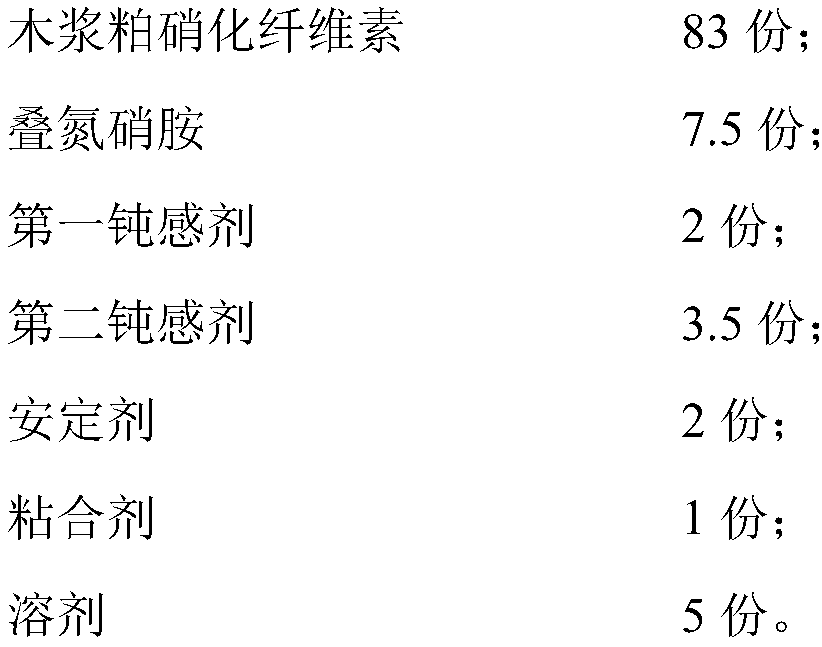

Safe and environment-friendly launched medicinal composition

InactiveCN108424338AFriction Sensitivity ZeroImpact Sensitivity ZeroNitrated explosive compositionsNitrocelluloseAdhesive

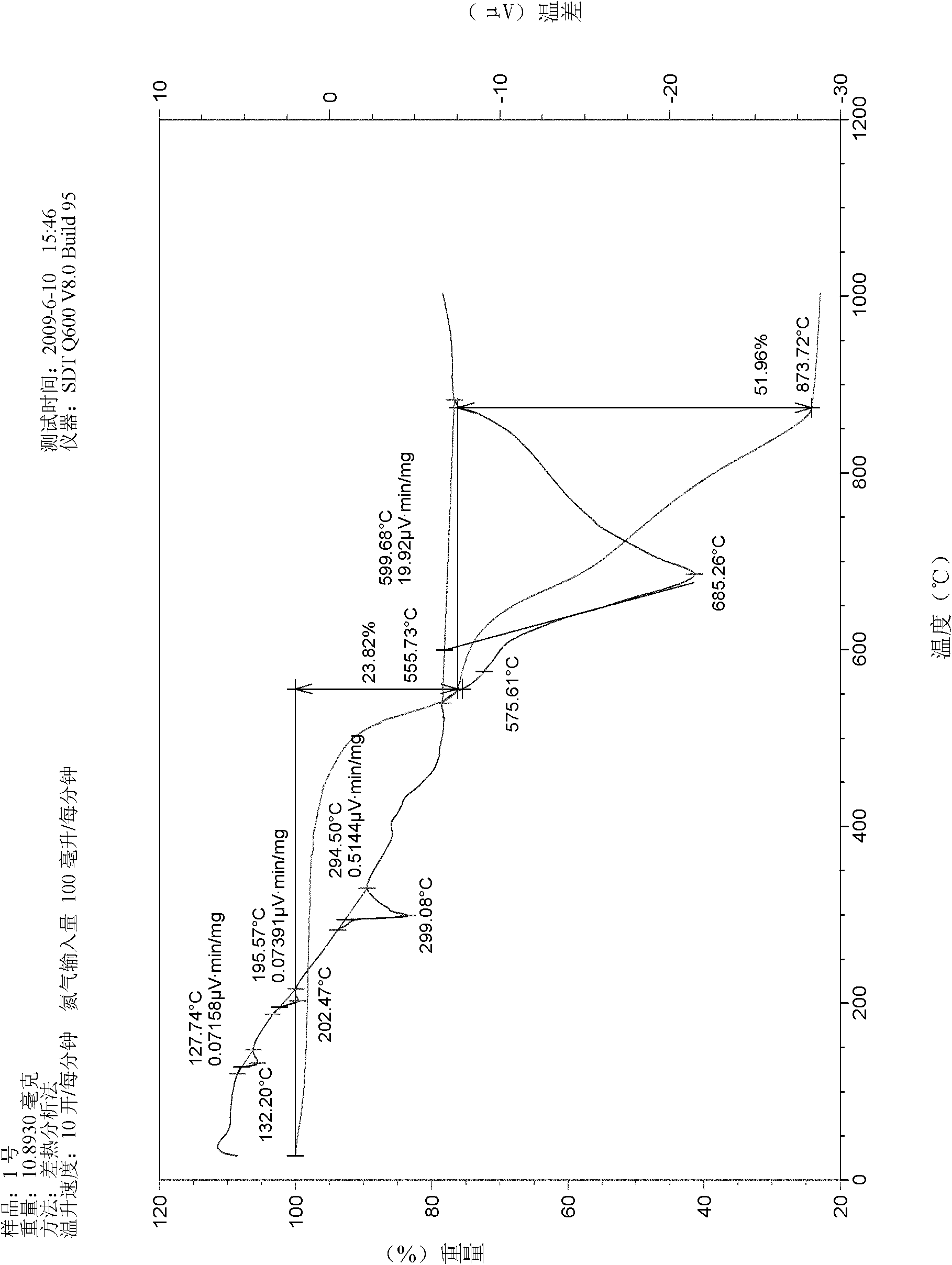

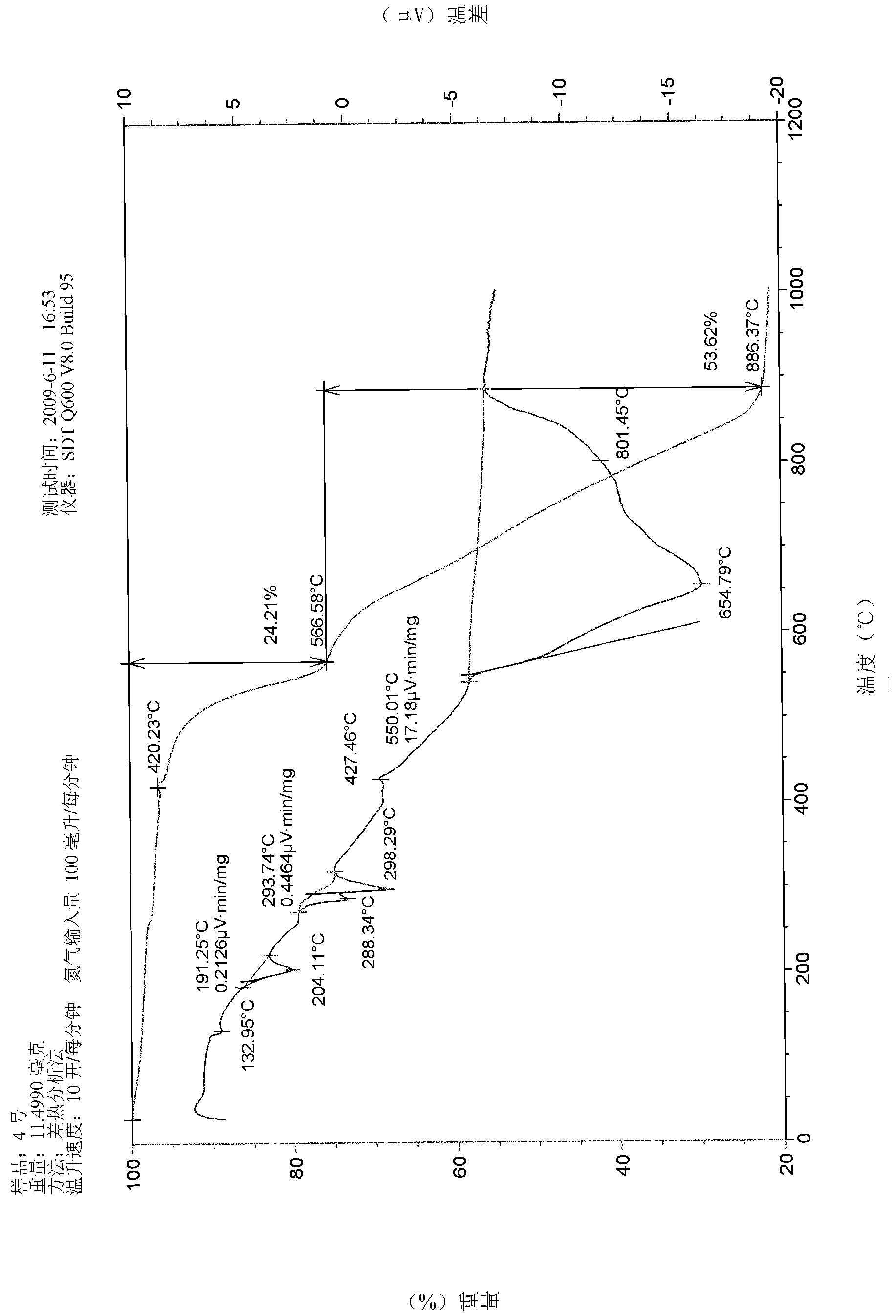

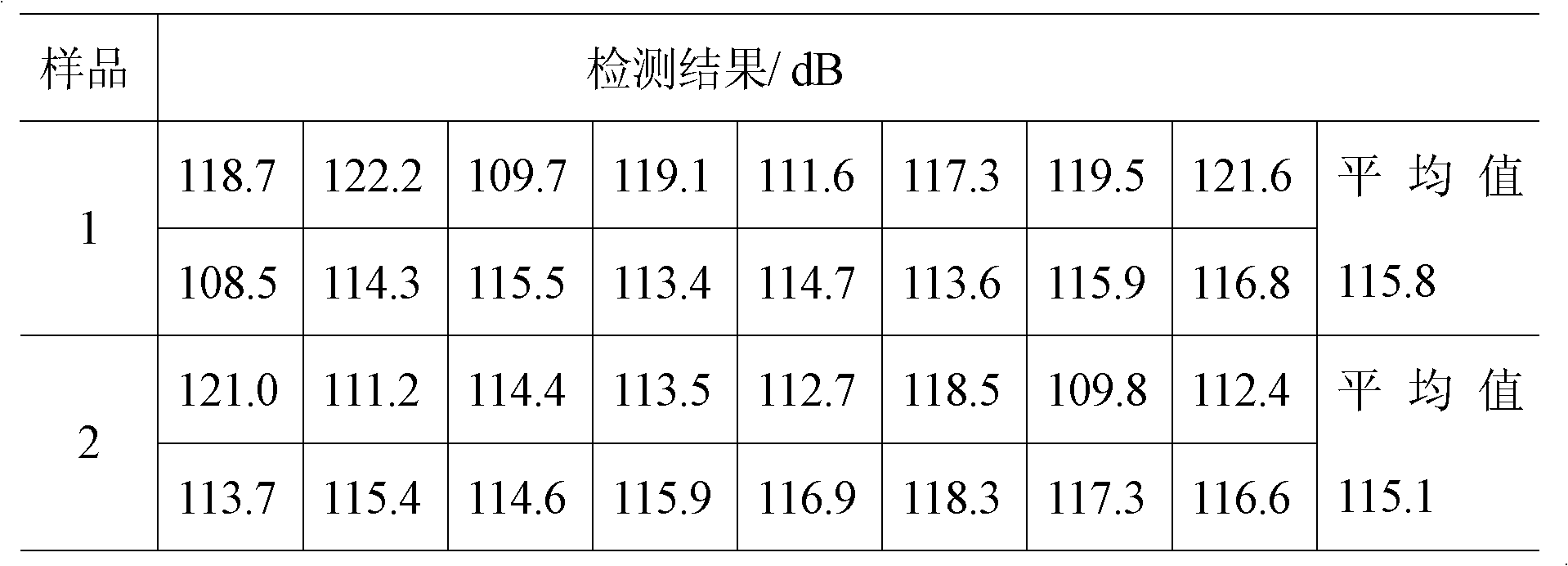

The invention discloses a safe and environment-friendly launched medicinal composition. The safe and environment-friendly launched medicinal composition comprises the following raw materials in partsby weight: 78-88 parts of wood pulp nitrocellulose, 5-10 parts of azidonitramine, 1-3 parts of a first desensitizing agent, 2-5 parts of a second desensitizing agent, 1-3 parts of a stabilizing agent,0.5-1.5 parts of an adhesive and 3-7 parts of a solvent. The launched medicinal composition provided by the invention has the friction sensitivity and impact sensitivity of 0, the moisture absorptionrate being lower than 1%, does not contain sulfur in components, has the thrust being 5-7 times that of the conventional black powder, is small in environment pollution and high in safety performance, has relatively good safety, stability, heat resistance, cold resistance and other properties, can meet using requirements, and has a relatively good market application prospect.

Owner:吴小戈

Composite oxidizing compound for firework

InactiveCN101475422ASafe and reliable performanceLow priceExplosivesFriction sensitivityBarium nitrate

The invention provides a composite oxidant for fireworks. The composite oxidant consists of the following raw materials in percentage by weight: 20 to 55 percent of potassium perchlorate, 40 to 65 percent of barium nitrate, 1 to 10 percent of monobase powder and 2 to 8 percent of ferric oxide. The composite oxidant for the fireworks has safe performance and low price; the moisture absorption rate is less than 1 percent; the friction sensitivity and the impact sensitivity are zero; and the fireworks produced by the oxidant have the explosion rate and the paper breaking rate of over 98 percent and have safety, stability and long storage time.

Owner:王平安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt](https://images-eureka.patsnap.com/patent_img/f8c8e8c6-ce5e-440a-9a0c-5d6e96a6222e/BDA0000627189290000021.PNG)

![Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt](https://images-eureka.patsnap.com/patent_img/f8c8e8c6-ce5e-440a-9a0c-5d6e96a6222e/BDA0000627189290000022.PNG)

![Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt Energetic ionic salts of 7-nitryl-4-ketone-4,8-dihydro-[1,2,4] triazole [5,1-d] [1,2,3,5] tetrazine-2-oxide and preparation method of energetic ionic salt](https://images-eureka.patsnap.com/patent_img/f8c8e8c6-ce5e-440a-9a0c-5d6e96a6222e/BDA0000627189290000041.PNG)