Patents

Literature

52 results about "Shock sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shock sensitivity is a comparative measure of the sensitivity to sudden compression (by impact or blast) of an explosive chemical compound. Determination of the shock sensitivity of a material intended for practical use is one important aspect of safety testing of explosives. A variety of tests and indices are in use, of which one of the more common is the Rotter Impact Test with results expressed as FoI (Figure of Insensitivity.) At least four other impact tests are in common use, while various "gap tests" are used to measure sensitivity to blast shock. Julius-Peters KG is a notable German company which manufactures testing apparatus for these tests.

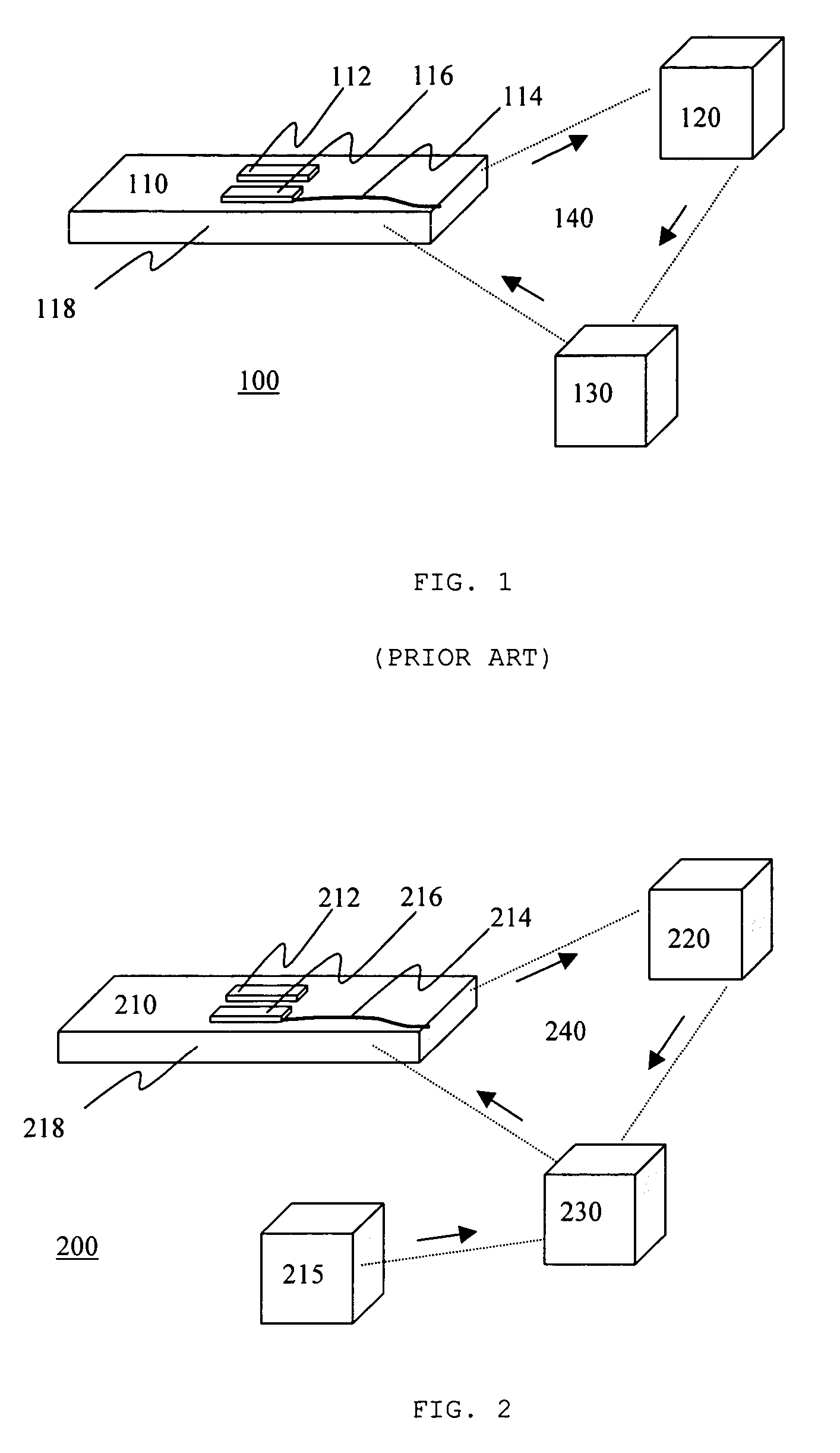

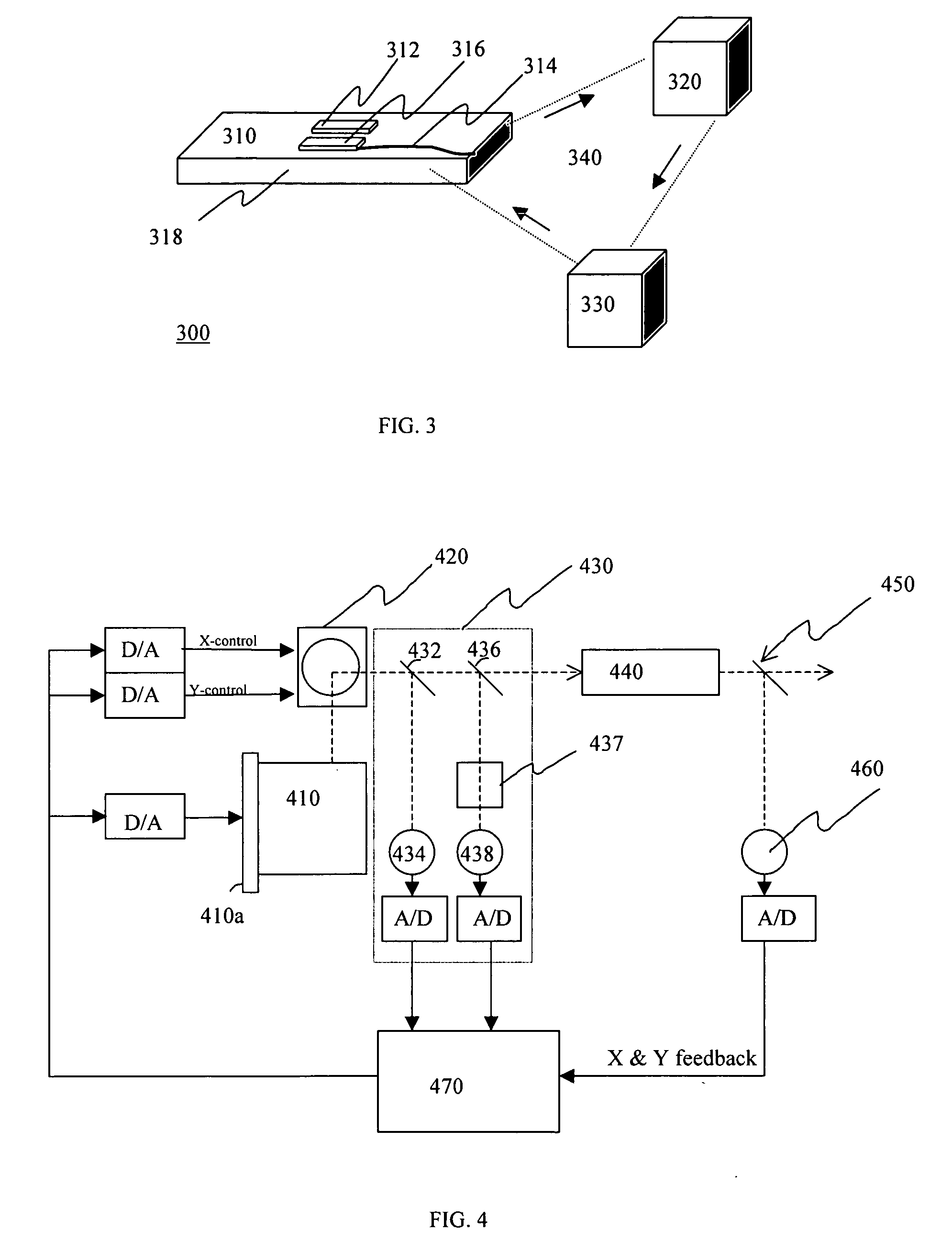

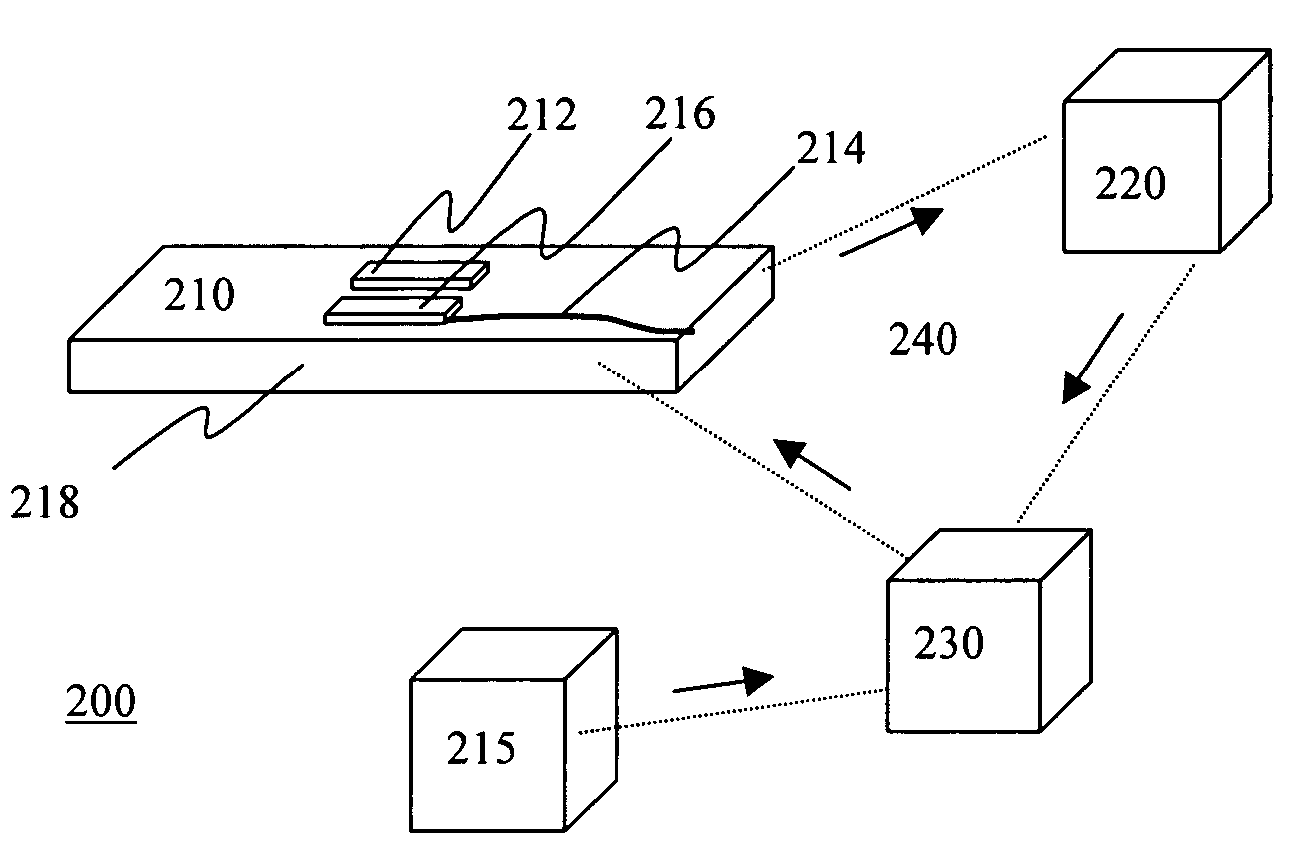

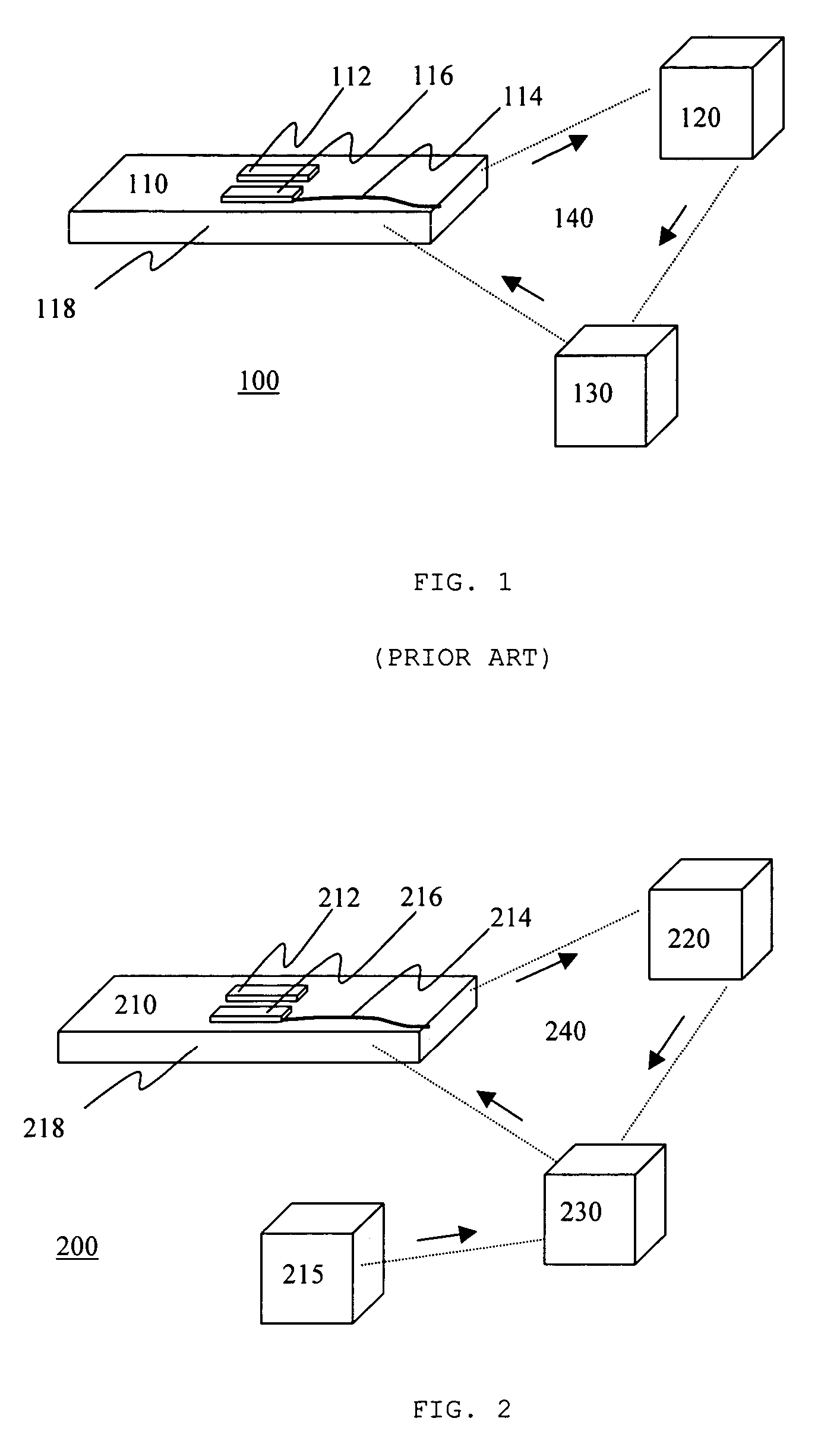

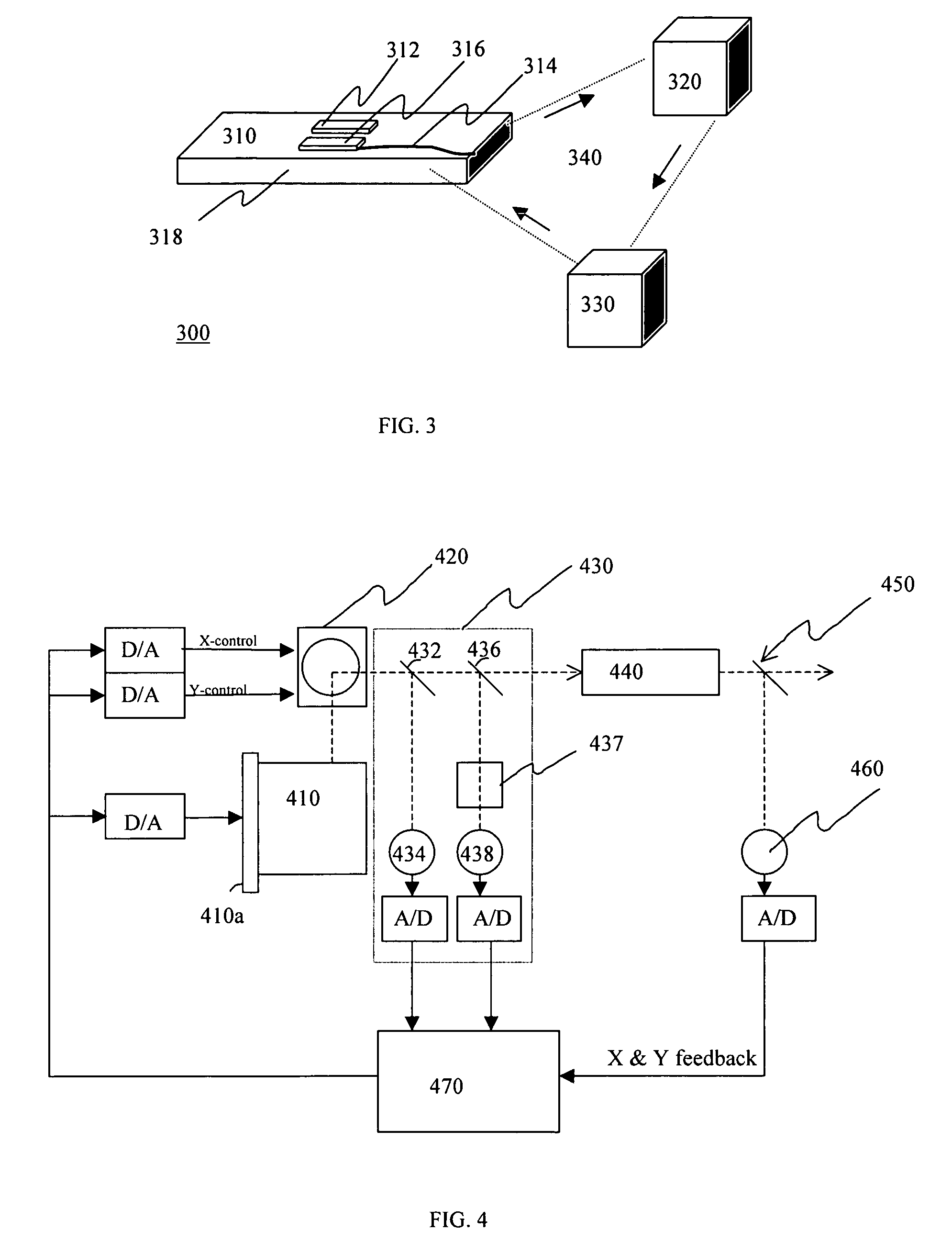

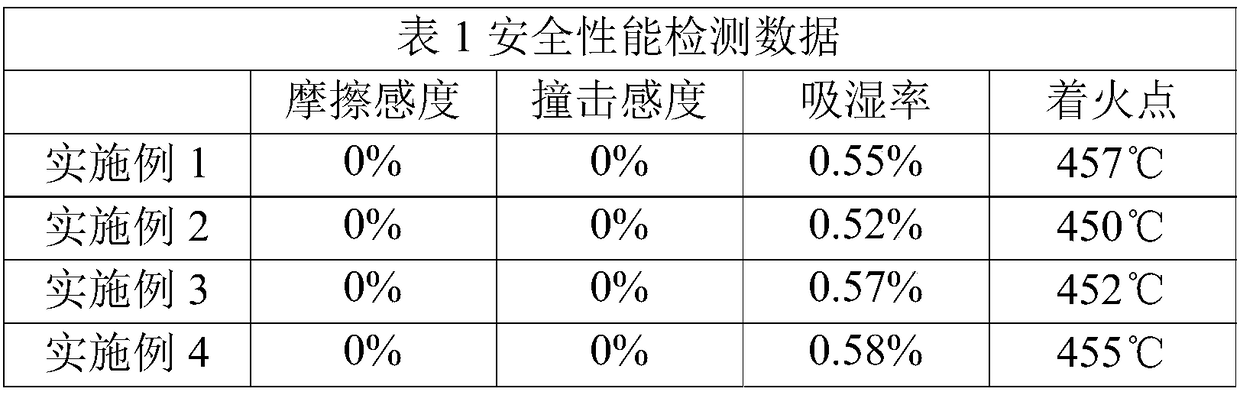

Method and system for reducing operational shock sensitivity of MEMS devices

ActiveUS20060010985A1Decreased shock sensitivityReduces operational shock sensitivityAcceleration measurement using interia forcesForce measurementControl signalClosed loop

A method and system for reducing operational shock sensitivity of a MEMS device includes a closed-loop control circuit for controlling the MEMS device and a shock detector for detecting a shock experienced by the MEMS device. The closed-loop control circuit includes a movable MEMS structure, a detector for sensing a position of the MEMS structure and for providing a first feedback signal related to the sensed position, and a processor for receiving the first feedback signal and for providing a control signal used to control the MEMS device. The shock detector, which according to a preferred embodiment is the MEMS structure itself, is used for detecting the shock experienced by the MEMS device and for generating a second feedback signal, which is used to alter the control signal such that a response of the closed-loop control circuit to the shock is minimized.

Owner:LUMENTUM OPERATIONS LLC

High energy insensitive press-fitting high polymer bonded explosive

ActiveCN107879867AHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

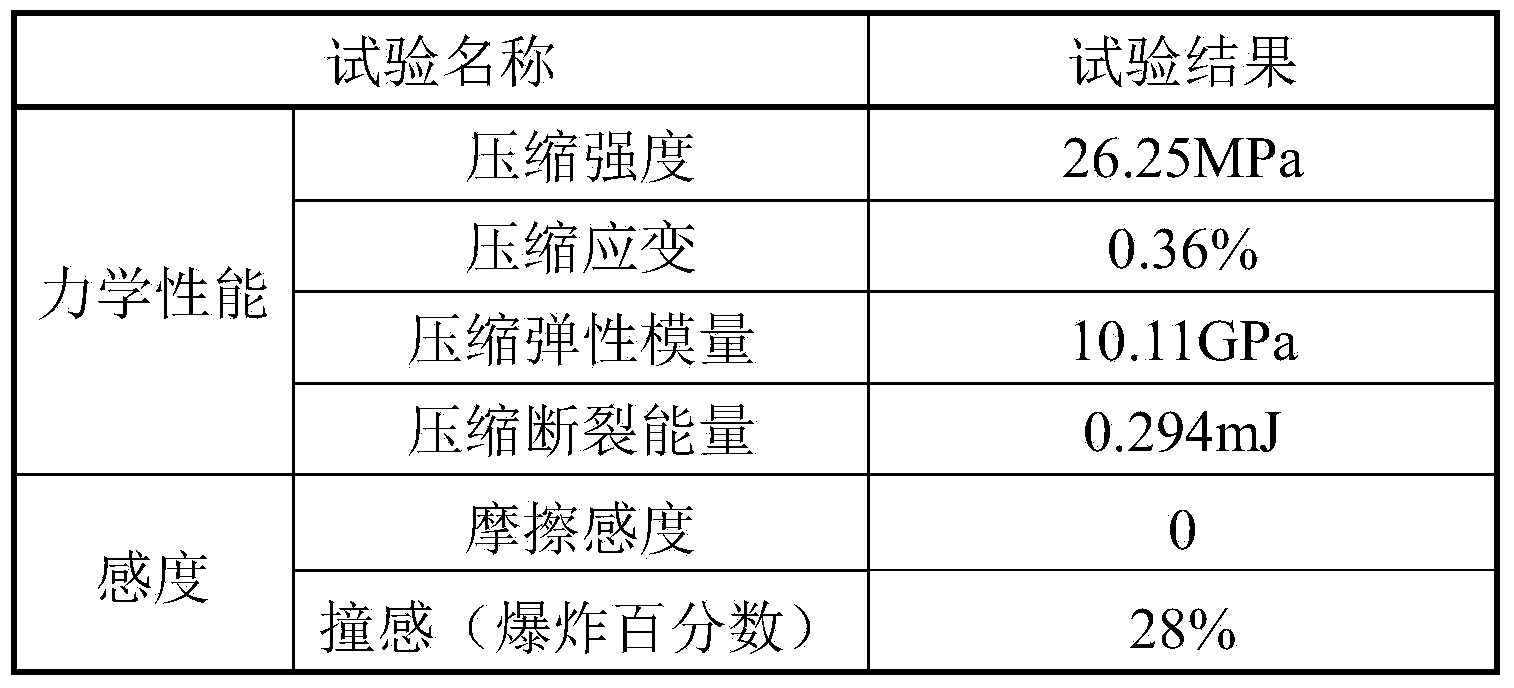

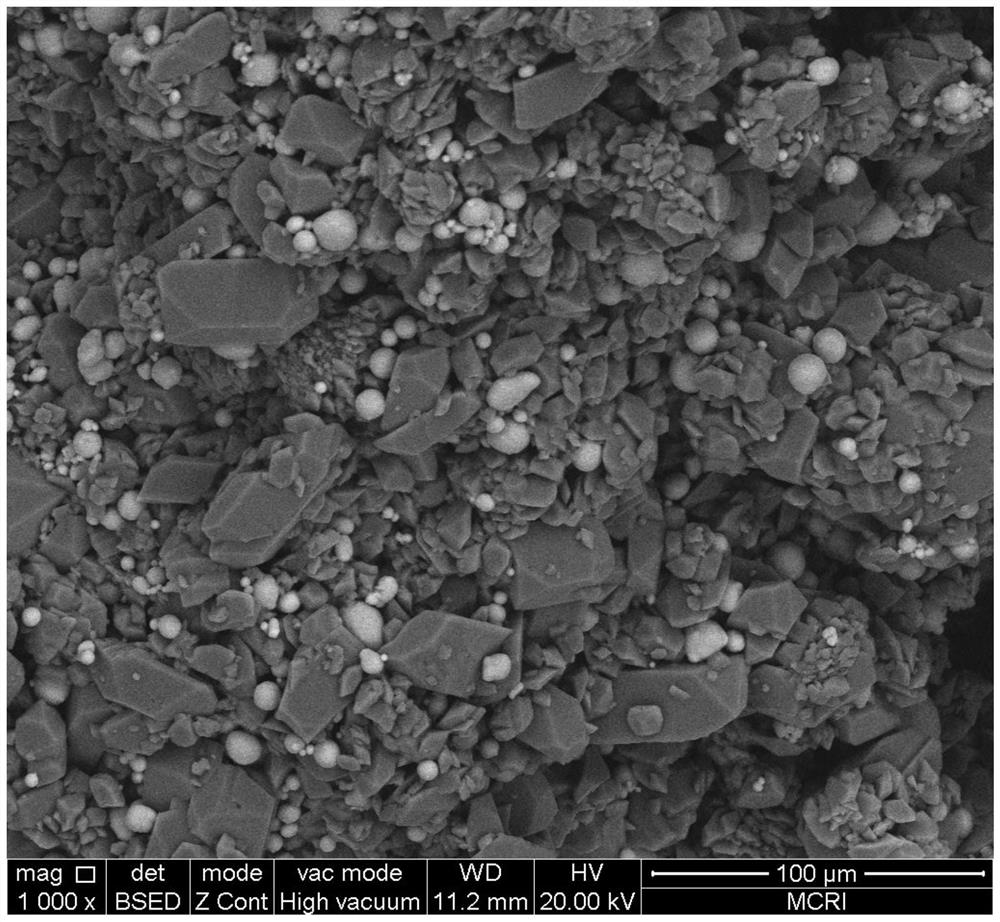

Metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and preparation method thereof

ActiveCN103588595AHigh strengthImprove toughnessNitroglycerine explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMetal fiberFriction sensitivity

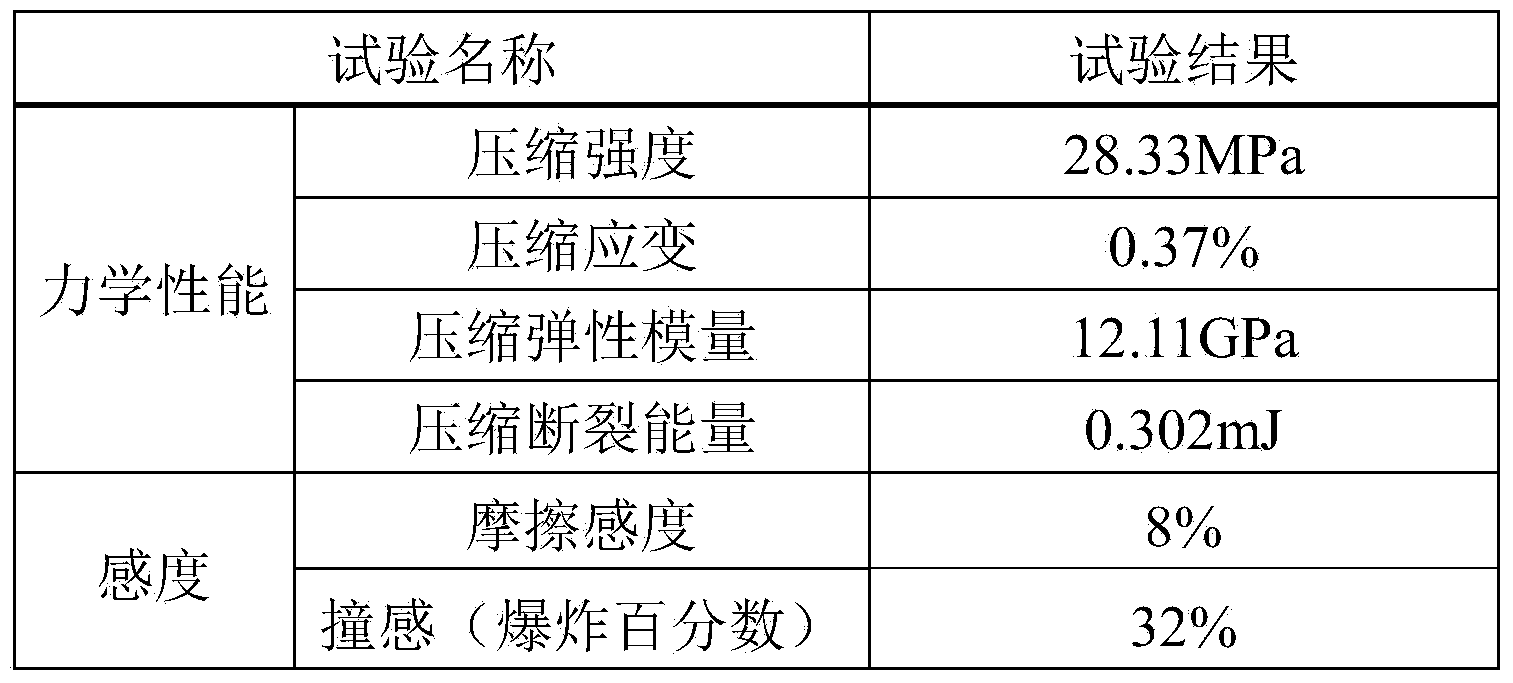

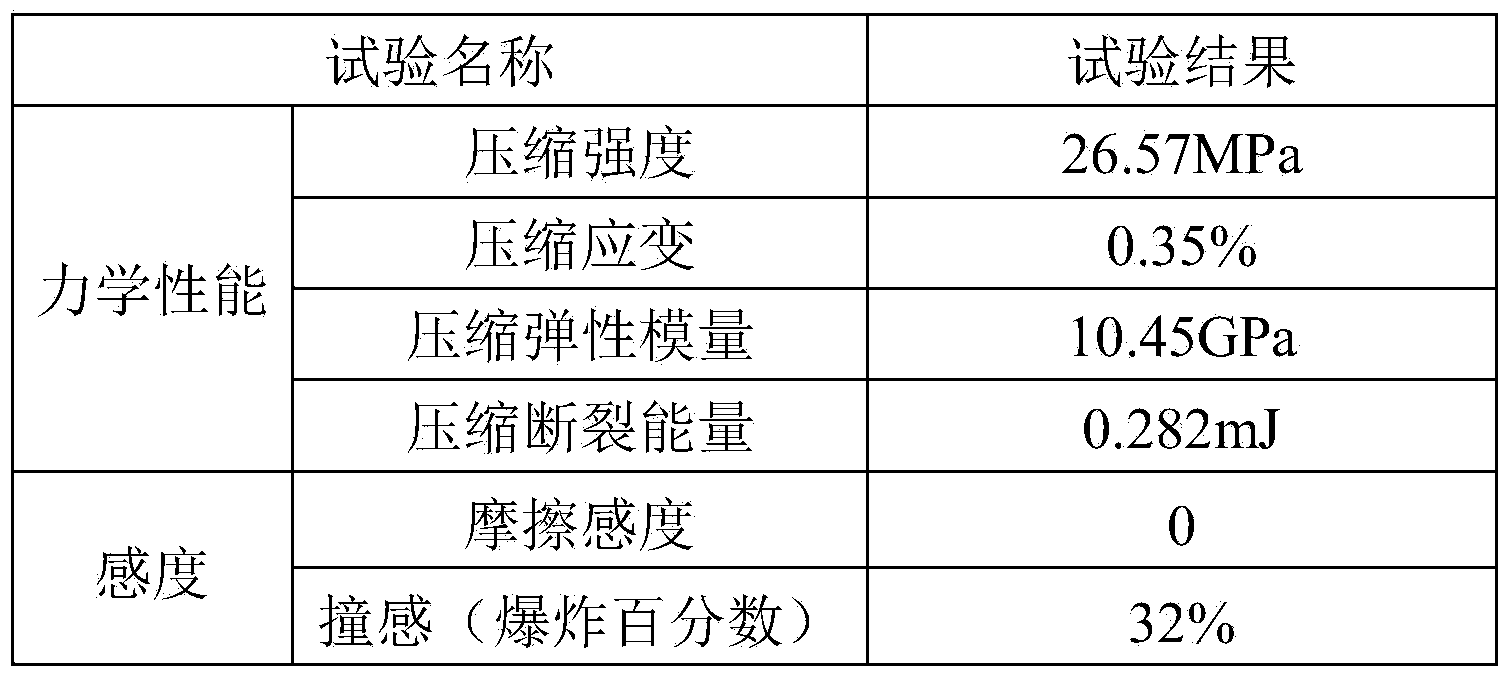

The invention discloses metal fiber toughened and enhanced TNT (trinitrotoluene)-based melt-cast explosive and a preparation method thereof. The melt-cast explosive comprises components in parts by weight as follows: 30-40 parts of TNT, 60-70 parts of hexogen or octogen, 0-3 parts of metal fiber and 0-2 parts of paraffin. The preparation method comprises the steps as follows: a surfactant solution is used for treating the metal fiber; materials are compounded; the materials are placed in an explosive melting machine for mixing; and casting is performed under atmospheric pressure. The TNT-based melt-cast explosive has the mechanical properties as follows: the compressive strength is larger than or equal to 24 MPa, the compressive strain is larger than or equal to 0.33%, the compressive modulus of elasticity is larger than or equal to 9 GPa, lower mechanical sensitivity is provided, the friction sensitivity is 0%-10%, and the impact sensitivity is 20%-40%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

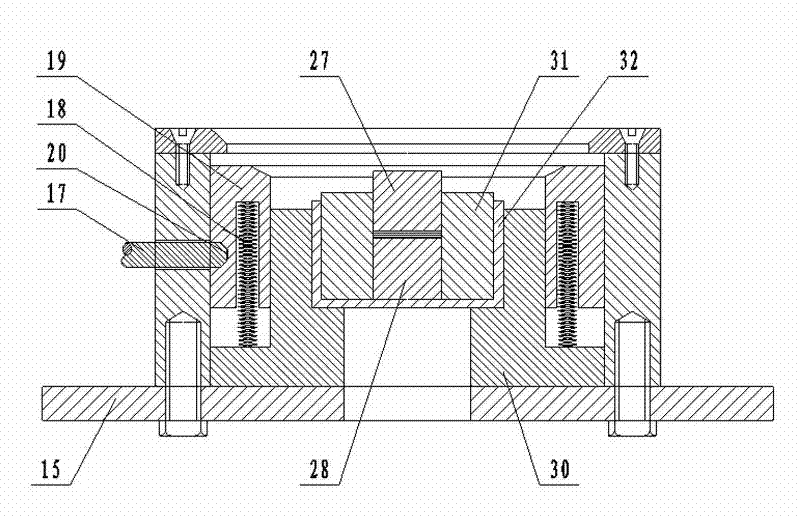

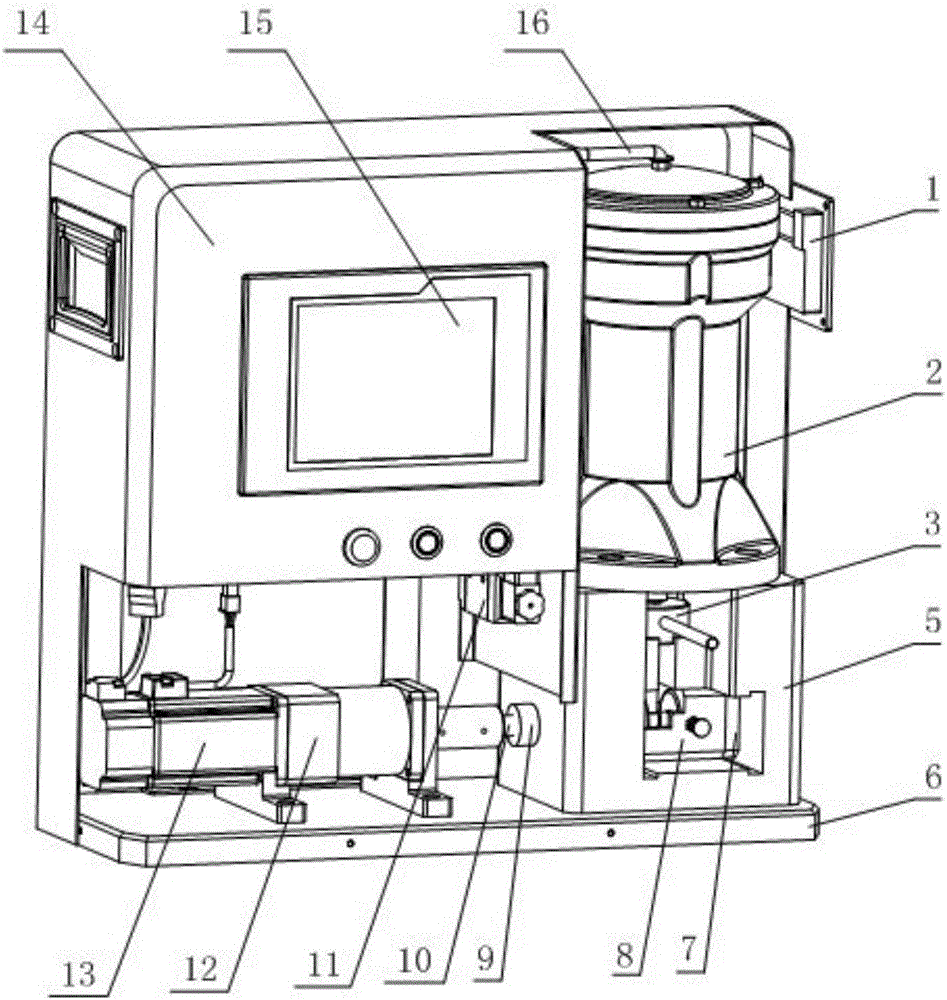

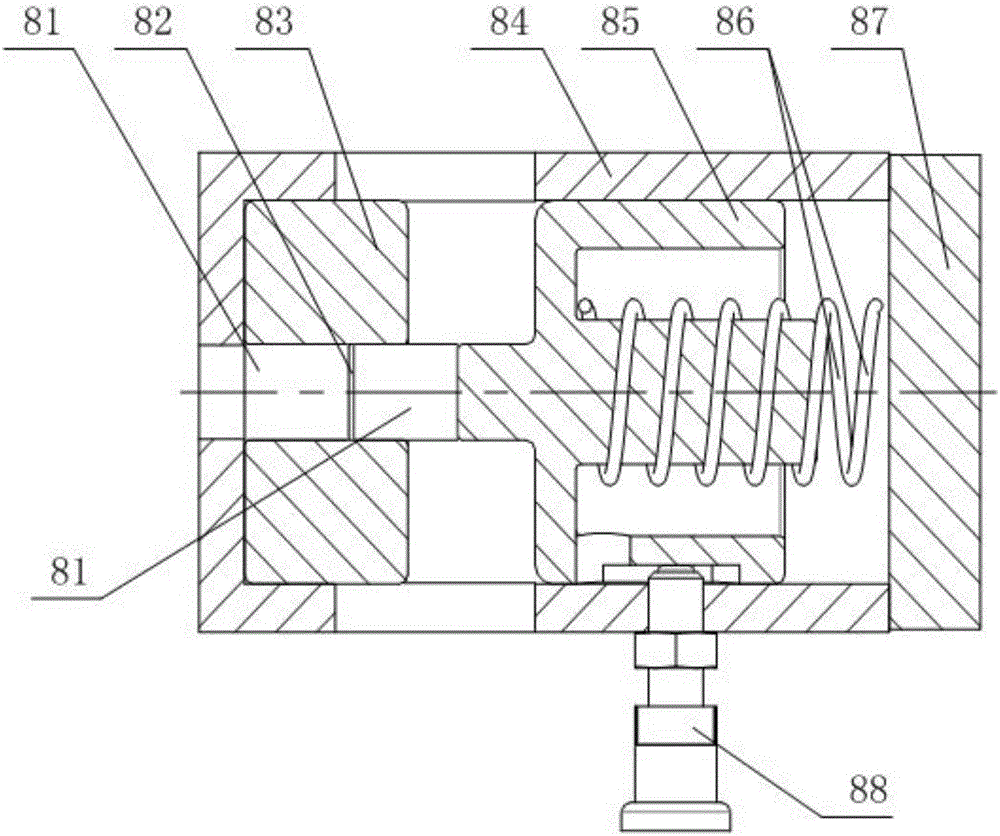

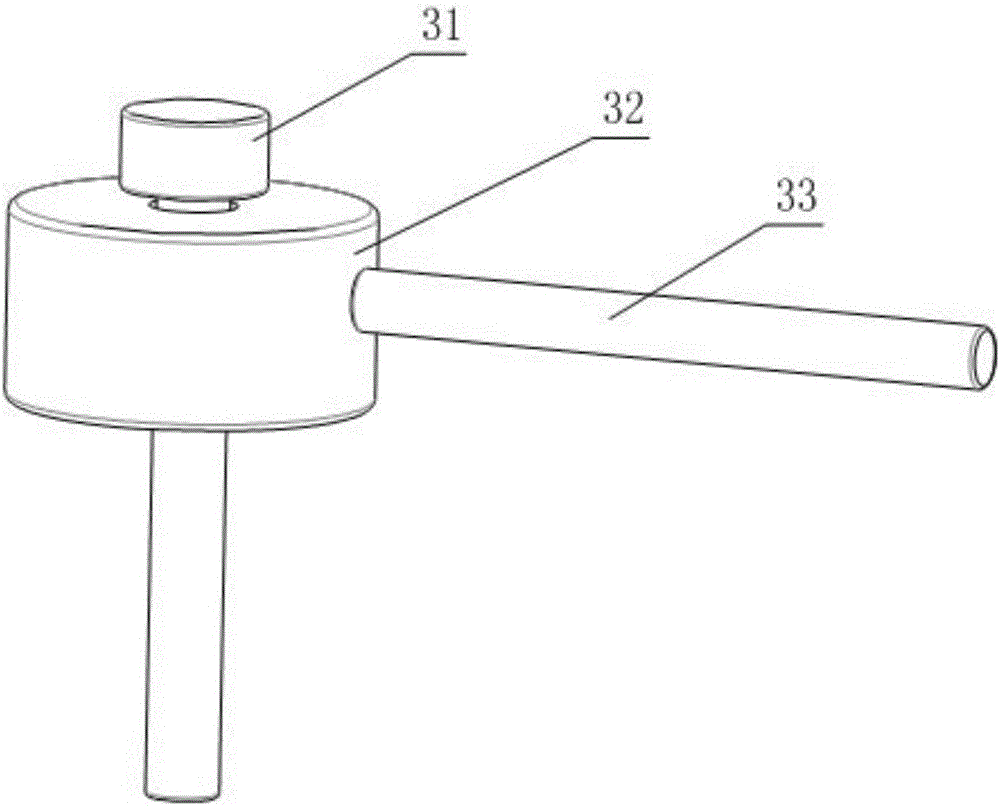

Explosive collision sensitivity instrument

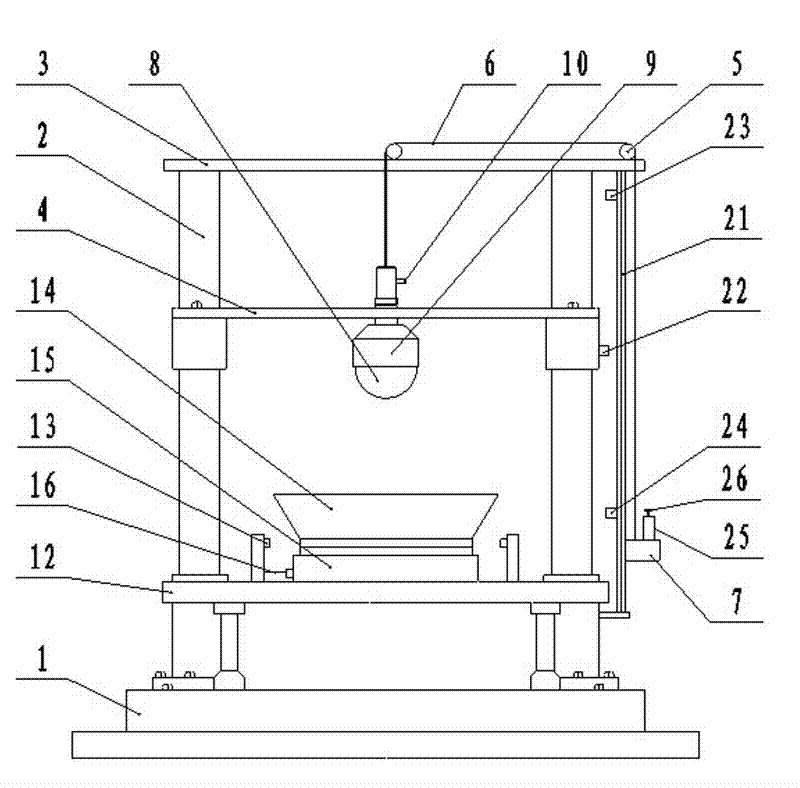

InactiveCN102230877ASolving Consistency IssuesSolve the accuracy problemUsing mechanical meansMaterial analysisShock sensitivityEngineering

The invention relates to an explosive performance detection device, in particular to an explosive collision sensitivity instrument, which is mainly used for solving the problems of poor testing consistence, low testing accuracy and difficulty in ensuring the testing conditions existing in the conventional collision sensitivity testing device. The explosive collision sensitivity instrument comprises a drop hammer elevating and positioning mechanism, a drop hammer fixing and releasing mechanism, a collision device mechanism, an optically-controlled anti-secondary-collision mechanism and an integral control mechanism, wherein the drop hammer elevating and positioning mechanism comprises a base, an elevating guide rail which is vertically fixed on the upper surface of the base, an upper fixed plate which is horizontally fixed at the top end of the elevating guide rail and an elevating plate of which the end part is connected with the elevating guide rail in a sliding manner; and the drop hammer fixing and releasing mechanism comprises a drop hammer, a drop hammer sucking cover and a vacuum pump connecting pipe. The explosive collision sensitivity instrument has the characteristics of Custer and 12-type tool testing structures, can be used for detecting the sensitivity properties such as collision explosion probability, characteristic drop height and the like of an explosive, and can be used for detecting the safety performance of the explosive.

Owner:ZHONGBEI UNIV

Fine-particle high-energy low-sensitivity explosive compound and preparation method thereof

ActiveCN104193564ALow mechanical sensitivitySuitable for mass productionNitroparaffin explosive compositionsFriction sensitivityOrganic solvent

The invention relates to a fine-particle high-energy low-sensitivity explosive compound and a preparation method thereof. The method comprises the following steps: mixing an explosive with a macromolecular bonder according to a weight part ratio of 100 to (2-5), and stirring at 40-60 DEG C for dissolving in an organic solvent to obtain an explosive compound solution with 5%-30% by weight of explosives; putting the explosive compound solution into an ejection tank, pumping air into the ejection tank to increase the pressure in the ejection tank to be 0.3-0.7MPa, ejecting the explosive compound solution into an explosive antisolvent with the temperature of -10 DEG C to 10 DEG C, performing centrifugal separation on a solid product, washing, and drying to obtain the explosive compound. According to the explosive compound, explosive particles are micron-sized, the CL-20 surface is densely wrapped with the macromolecular bonder in the form of an interwoven mesh shape, the impact sensitivity of the wrapped CL-20 is reduced to be 24%-40% from 100%, and the friction sensitivity is reduced to be 66%-92% from 100%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Impact and thermal force composite testing device of explosive

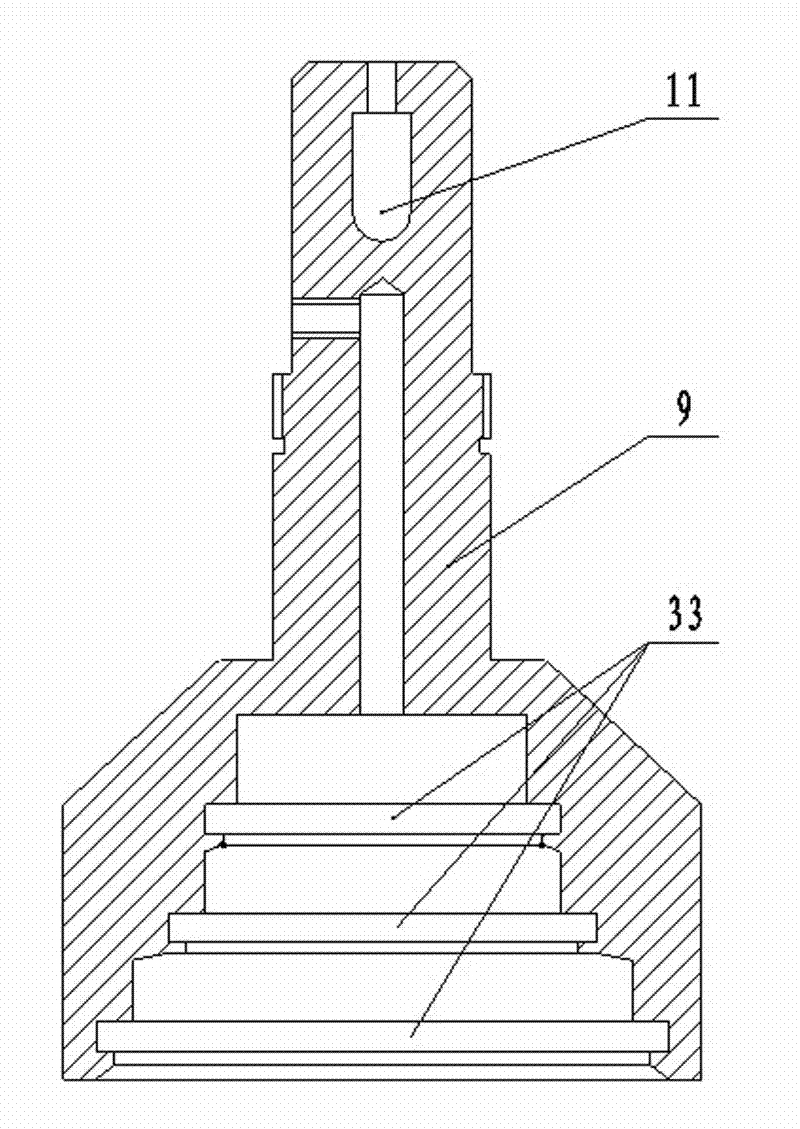

InactiveCN103323491AGet impact sensitivityTest crash safetyMaterial exposibilityUsing mechanical meansThermal forceShock sensitivity

The invention discloses an impact and thermal force composite testing device of an explosive. The device comprises a base, a strike anvil, a strike rod, a drop hammer and a heating device, wherein the bottom of the strike anvil is embedded in the base, and the strike anvil is used for placing an explosive piece, the strike rod is arranged above the strike anvil, the drop hammer is arranged above the strike rod, and the heating device can be used for heating the base. According to the device disclosed by the invention, the heating device used for heating the base is arranged, and can transfer heat to the explosive piece, the temperature of the explosive piece can be set, and impact tests at different heights can be carried out by utilizing the drop hammer to impact, so that impact sensitivities of the explosive piece under different temperatures are achieved, and evaluation means are provided for the safety of the explosive under a high-temperature condition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

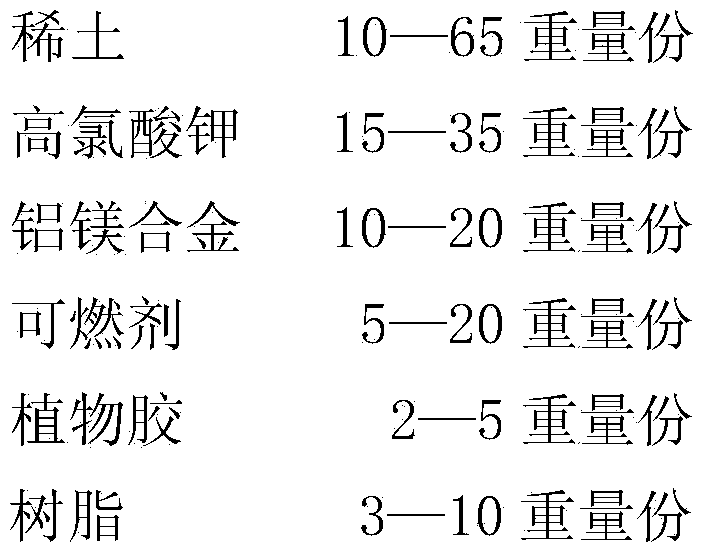

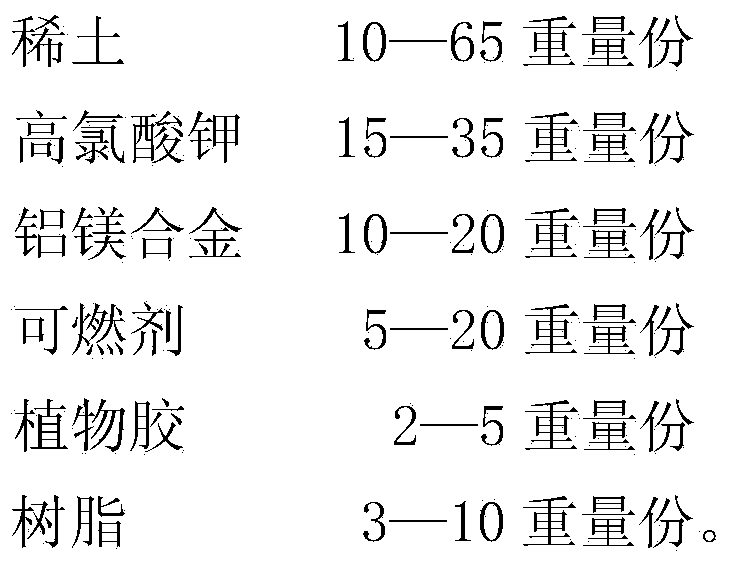

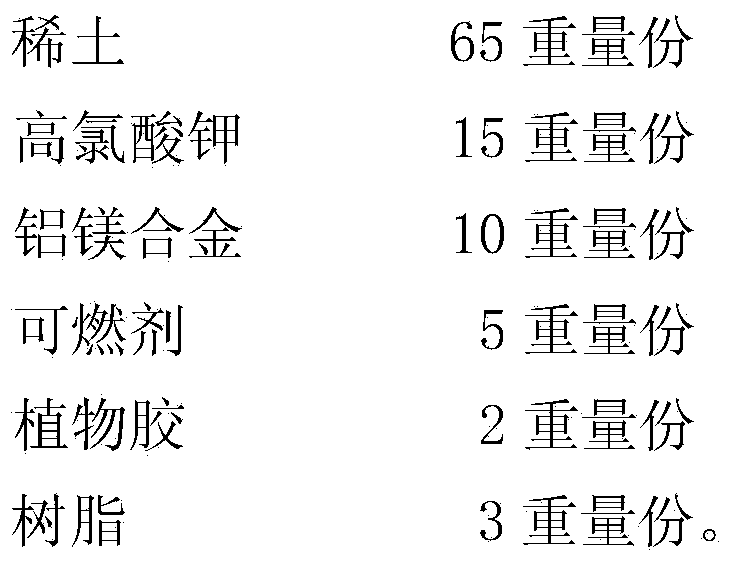

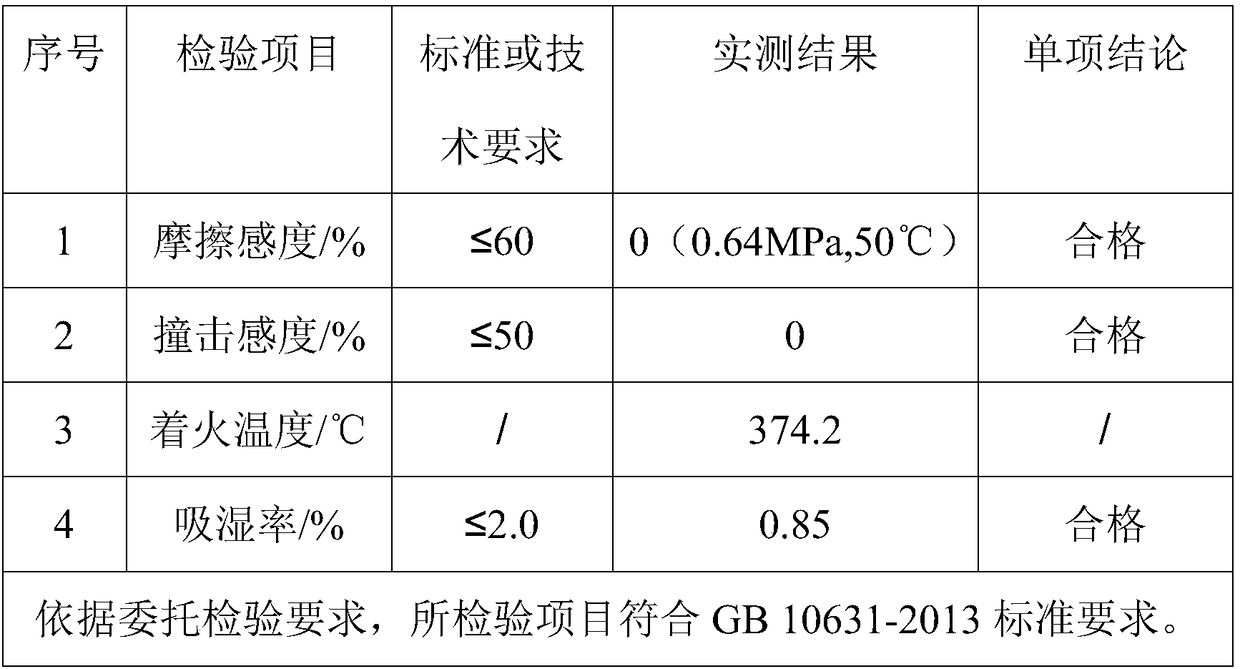

Environment-friendly firework propellant

The invention discloses an environment-friendly firework propellant which is characterized by being composed of the following components in parts by weight: 10-65 parts of rare earth, 15-35 parts of potassium perchlorate, 10-20 parts of aluminum magnesium alloy, 5-20 parts of combustible agent, 2-5 parts of plant gum and 3-10 parts of resin, wherein the combustible agent is selected from any one or combined by any two from hemp xyloid stem carbon powder and Chinese fir carbon powder at any proportion, and the plant gum is a rice flour adhesive. The environment-friendly firework propellant is free of chlorate, small in horizontal launching force, low in moisture absorption property, low in impact and friction sensitivity, small in dosage of charges for preparing fireworks, slight in smoke, long in shelf life and displaying time, free of residues after displaying, good in physical and chemical stability, simple in processing technology and suitable for various firework propellants.

Owner:喻自达

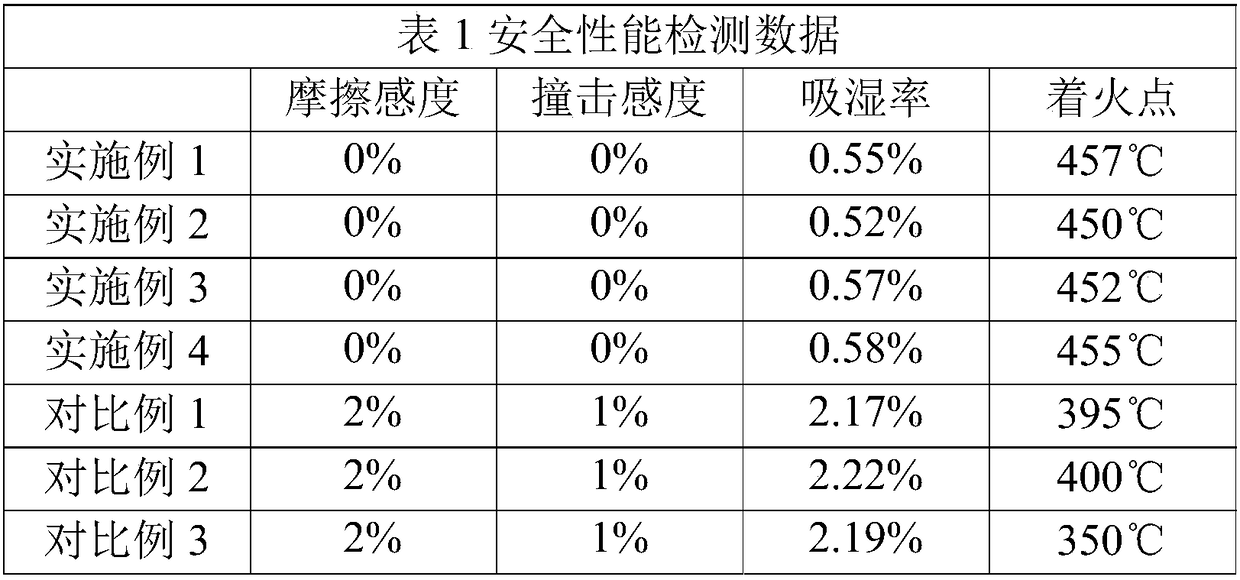

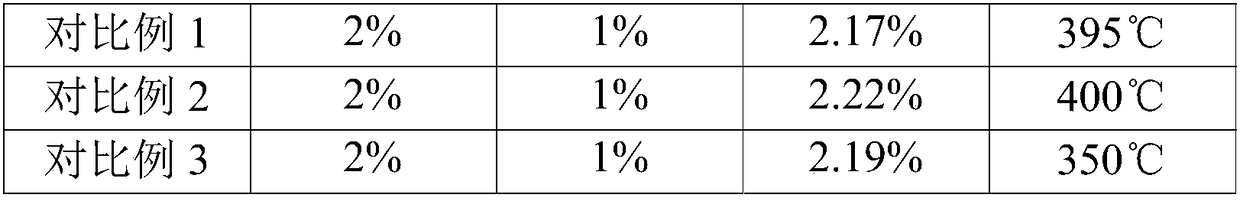

Safe and sulfur-free firework bursting powder and propelling powder and preparing method thereof

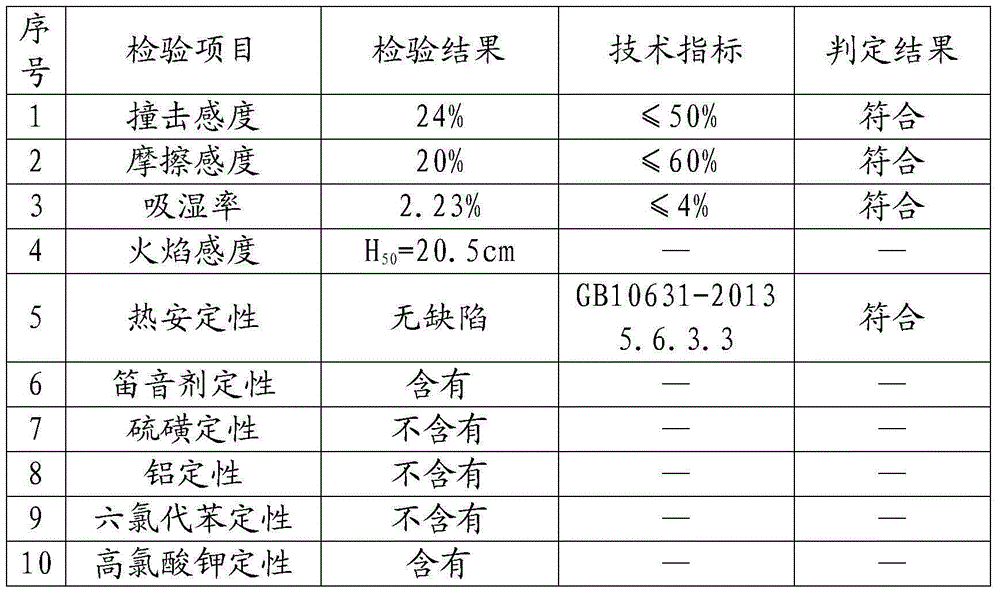

The invention discloses safe and sulfur-free firework bursting powder and propelling powder and a preparing method thereof, and relates to the technical field of fireworks. The firework bursting powder is prepared from, by weight, 15-35 parts of carbon powder, 5-60 parts of potassium perchlorate and 15-70 parts of potassium nitrate. The firework propelling powder is prepared from, by weight,15-35parts of carbon powder, 5-60 parts of potassium perchlorate, 15-70 parts of potassium nitrate, 5-10 parts of adhesive and a proper amount of solvent. The firework bursting powder and propelling powderdo not contain sulfur, metal, benzene or the like, have no toxicity, reduce the air pollution, generate less smoke, have zero percussion sensitivity and friction sensitivity, guarantee safety and environmental protection, have a low moisture absorption rate and stable performance, reduce the ignition point properly, have flammability, high safety performance and propelling performance, do not easily cause barrel blasting, and reduce the production cost; the preparing method of the sulfur-free firework bursting powder and propelling powder is simple and safe.

Owner:张宏善

Sulfur-free propellant powder

InactiveCN105016933ALow moisture absorptionGood storage stabilityInorganic oxygen-halogen salt explosive compositionsFireworksPerformance index

The invention discloses sulfur-free propellant powder composed of the following components in parts by weight: 34-36 parts of potassium perchlorate, 24-26 parts of carbon powder, 7-9 parts of calcium stearate, 4-6 parts of phenolic resin, 14-16 parts of hydroxyethyl cellulose and 16-18 parts of polytetrafluoroethylene. The propellant powder contains no sulfur components so that environment pollution caused by sulfur dioxide and sulfide is eliminated when fireworks are displayed; no restricted articles are contained, so that the environment-friendly property is greatly improved; the emission performance is better than that of the traditional black powder under the same working condition; all safety performance indexes such as shock sensitivity and friction sensitivity are excellent, so that potential safety hazards are fundamentally reduced; and the propellant powder is low in moisture rate, favorable in storage stability and capable of overcoming the defect that the black powder easily absorbs moisture.

Owner:江西省东安新材料有限公司

Sulfur-free environment-friendly gun propellant

The invention discloses a sulfur-free environment-friendly gun propellant which comprises the following components in parts by weight: 65 parts of potassium acid phthalate, 15 parts of hemp stem carbon powder, 10 parts of an epoxy resin, 2 parts of graphite powder and 5 parts of lime. The gun propellant manufactured according to the formula is applied to display shells, potted flowers, colored bead barrels, display shell rocket propulsion powder and the like. The sulfur-free environment-friendly gun propellant is excellent in safety performance indexes, the friction sensitivity and percussion sensitivity degree are zero, and the potential safety hazards are eliminated; according to the formula, the sulfur component is completely eliminated, so that pollution of sulfur dioxide and sulfides on the environment is eliminated during firework display; and moreover, the gun propellant does not contain forbidden materials; and the environmental protective performance is greatly improved.

Owner:LIUYANG CHENGFA TECH

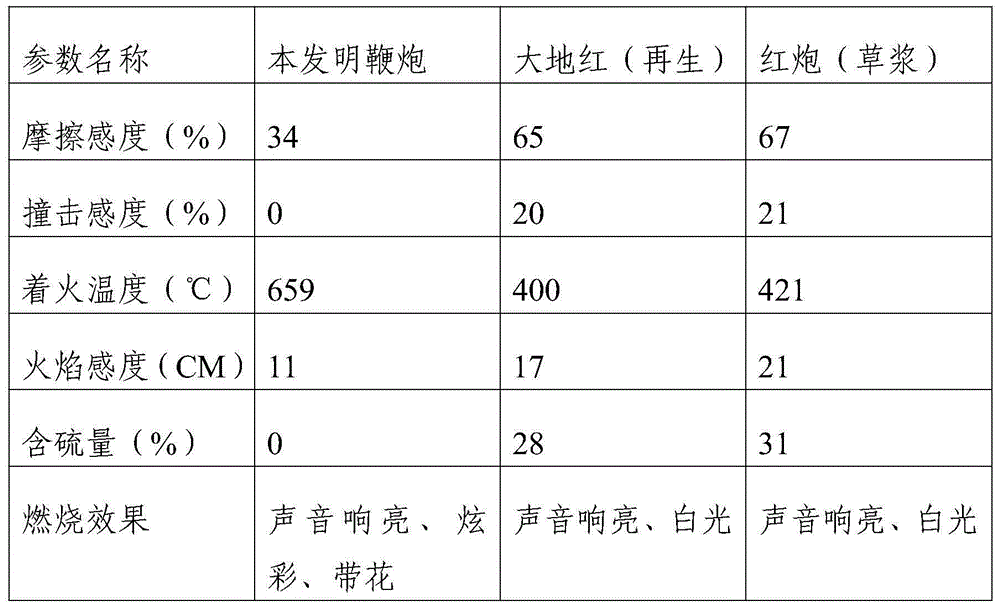

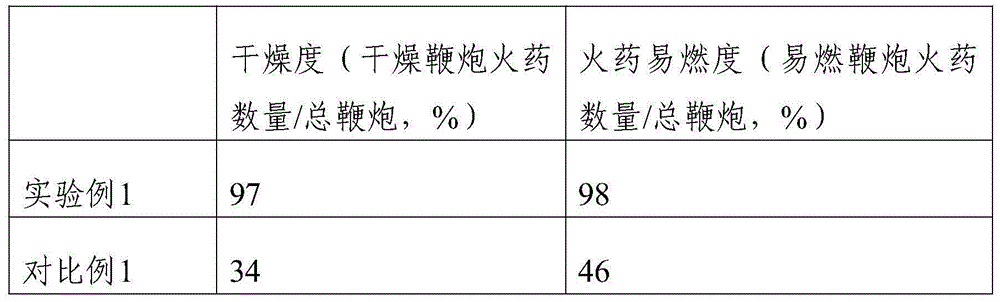

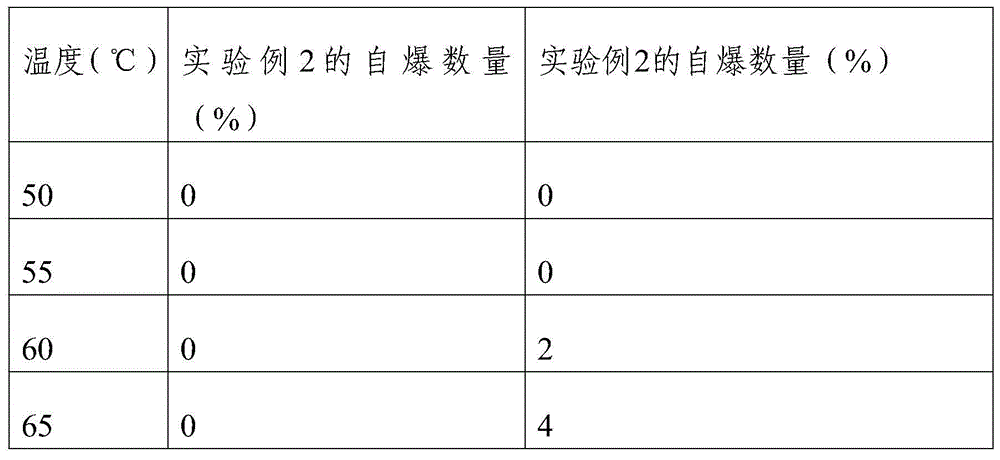

Safe environment-friendly colorful firecracker reagent and method for preparing colorful firecracker by using reagent

ActiveCN104829401AReduced friction sensitivityLow impact sensitivityExplosivesFireworksSpontaneous combustionFriction sensitivity

The invention provides a safe environment-friendly colorful firecracker reagent and a method for preparing a colorful firecracker by using the reagent. The colorful reagent comprises a component A and a component B. The manufacturing technique is implemented by coating the component B on the component A. The reagent is free of potassium chlorate or any other national forbidden component, and is free of sulfides. In the firecracker prepared by the method, the component A is coated with the component B, and the component B has the functions of heat insulation, water resistance, collision prevention and the like, thereby overcoming the defect that the component A can be easily moisturized, can be easily exploded by impact, can easily generate spontaneous combustion due to high temperature and the like. Thus, the firecracker has the characteristics of high reaction speed, clear sound, multiple colors, low impact sensitivity, low friction sensitivity, low flame sensitivity, high ignition temperature, high safety, no sulfur and the like.

Owner:雍和平

Testing device for measuring impact sensitivity and friction sensitivity of energetic material

PendingCN106442106AReduce weightSmall sizeInvestigating abrasion/wear resistanceFriction sensitivityTest sample

The invention discloses a testing device for measuring the impact sensitivity and friction sensitivity of an energetic material. The testing device comprises a case, a servo motor, an air pipe and a pneumatic knocking hammer, wherein an air outlet pipe orifice of the air pipe is communicated with an air inlet of the pneumatic knocking hammer in a sealed manner; a test sample impact testing cavity corresponding to the pneumatic knocking hammer is formed in the right side of the bottom of the case; an impact rod component is movably mounted in the test sample impact testing cavity, and an impact column component is arranged corresponding to the impact rod component; the servo motor, a lead screw and an ejector rod are sequentially connected; a test sample friction testing cavity is formed in the test sample impact testing cavity; a sliding column sleeve is movably mounted in the test sample friction testing cavity; a left sliding column and a right sliding column are arranged in the sliding column sleeve; an energetic material friction sensitivity test sample is arranged between the left and right sliding columns; the positions of the bottom of a piston hammer body of the pneumatic knocking hammer and the outer wall of the test sample friction testing cavity correspond to each other. The device has the characteristic of multifunction, and can be used for simultaneously testing the impact sensitivity and friction sensitivity of the energetic material.

Owner:HUNAN JUNCHENG TECH

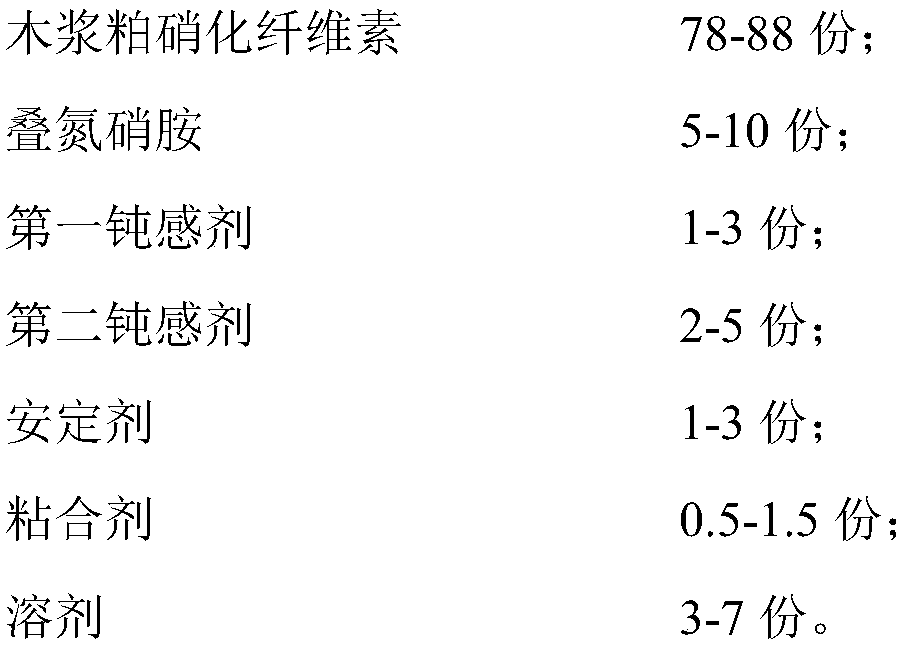

Safe and environment-friendly launched medicinal composition

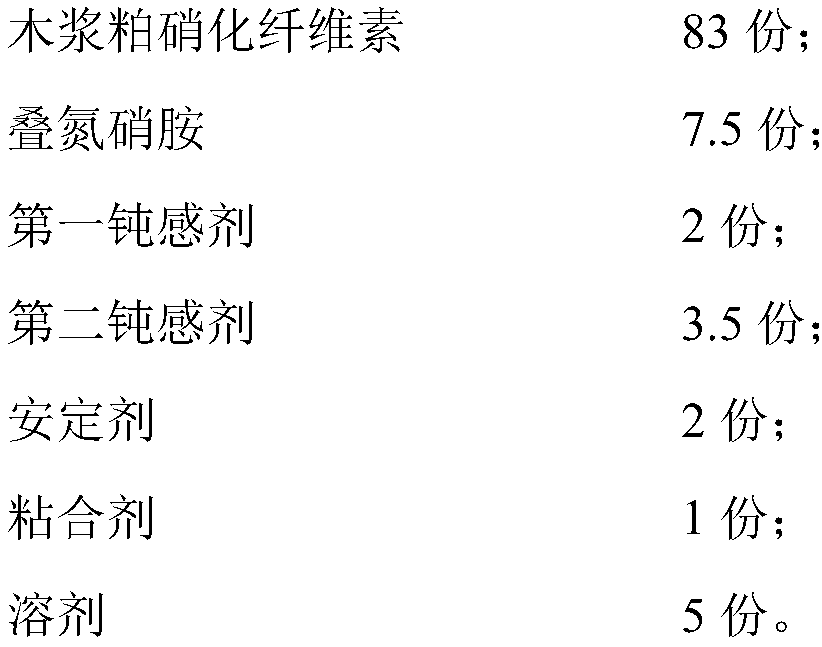

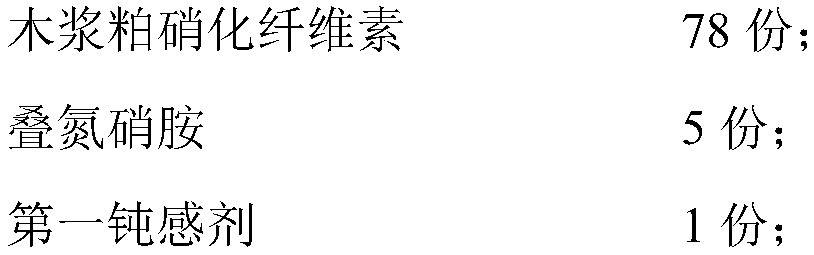

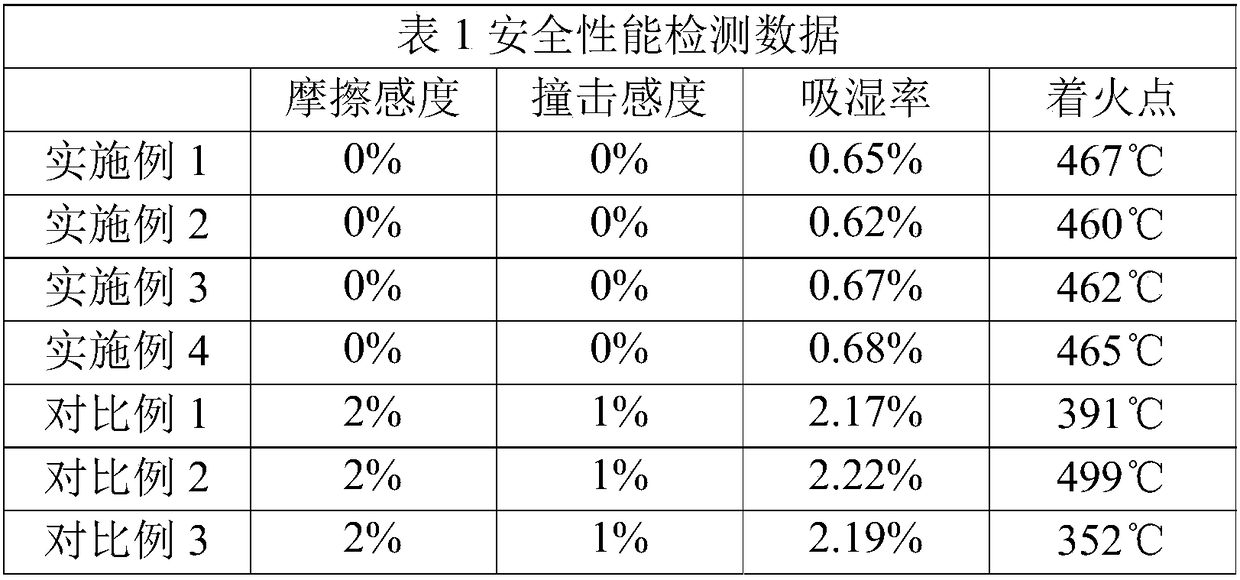

InactiveCN108424338AFriction Sensitivity ZeroImpact Sensitivity ZeroNitrated explosive compositionsNitrocelluloseAdhesive

The invention discloses a safe and environment-friendly launched medicinal composition. The safe and environment-friendly launched medicinal composition comprises the following raw materials in partsby weight: 78-88 parts of wood pulp nitrocellulose, 5-10 parts of azidonitramine, 1-3 parts of a first desensitizing agent, 2-5 parts of a second desensitizing agent, 1-3 parts of a stabilizing agent,0.5-1.5 parts of an adhesive and 3-7 parts of a solvent. The launched medicinal composition provided by the invention has the friction sensitivity and impact sensitivity of 0, the moisture absorptionrate being lower than 1%, does not contain sulfur in components, has the thrust being 5-7 times that of the conventional black powder, is small in environment pollution and high in safety performance, has relatively good safety, stability, heat resistance, cold resistance and other properties, can meet using requirements, and has a relatively good market application prospect.

Owner:吴小戈

Composite oxidizing compound for firework

InactiveCN101475422ASafe and reliable performanceLow priceExplosivesFriction sensitivityBarium nitrate

The invention provides a composite oxidant for fireworks. The composite oxidant consists of the following raw materials in percentage by weight: 20 to 55 percent of potassium perchlorate, 40 to 65 percent of barium nitrate, 1 to 10 percent of monobase powder and 2 to 8 percent of ferric oxide. The composite oxidant for the fireworks has safe performance and low price; the moisture absorption rate is less than 1 percent; the friction sensitivity and the impact sensitivity are zero; and the fireworks produced by the oxidant have the explosion rate and the paper breaking rate of over 98 percent and have safety, stability and long storage time.

Owner:王平安

Propellant powder and preparation method

InactiveCN108947748AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusNitrated explosive compositionsMoisture absorptionShock sensitivity

The invention provides propellant powder and a preparation method. The propellant powder comprises 30-50 parts of potassium permanganate, 8-20 parts of a binding agent, 10-20 parts of potassium hydrogen phthalate and 20-40 parts of a combustible agent, wherein the combustible agent is a mixture of nitrocotton and charcoal powder. The propellant powder has low friction sensitivity and impact sensitivity, low moisture absorption rate and strong thrust and meanwhile reduces the environmental pollution.

Owner:胡惠娟

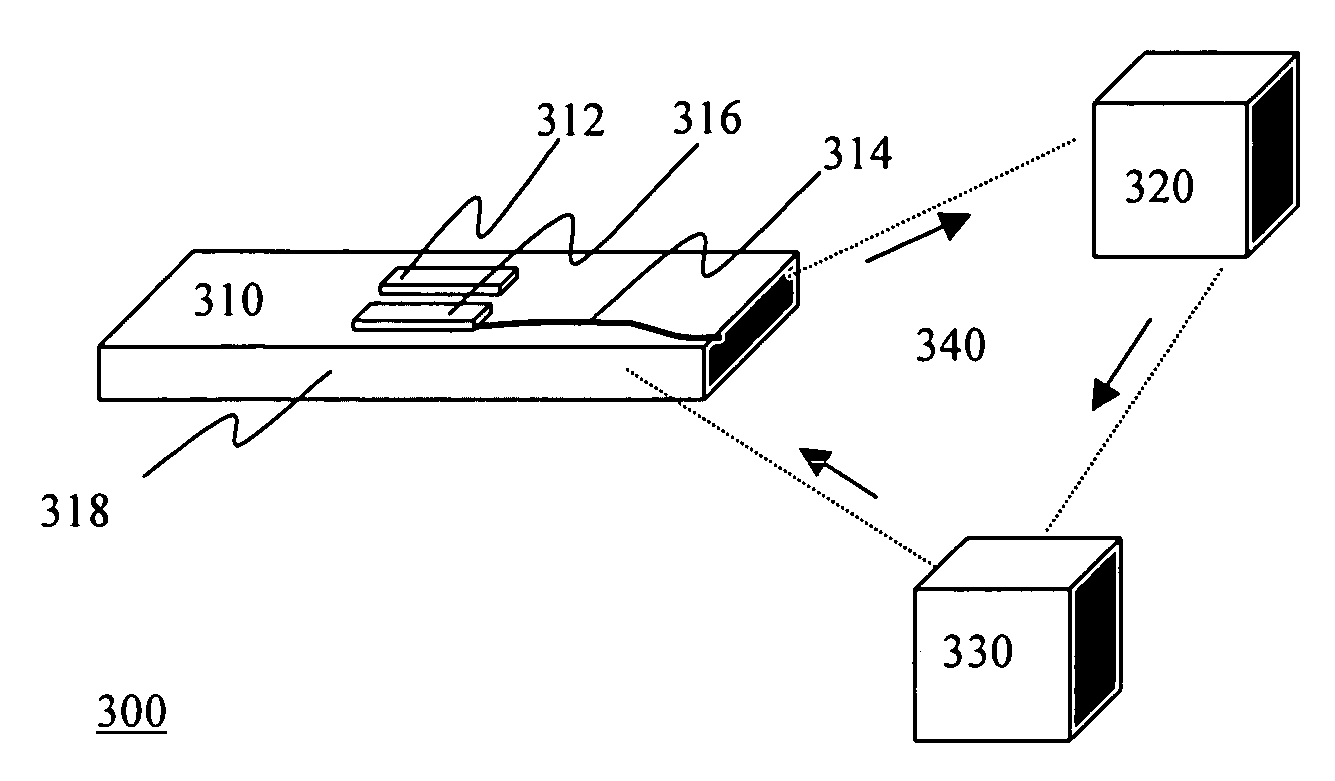

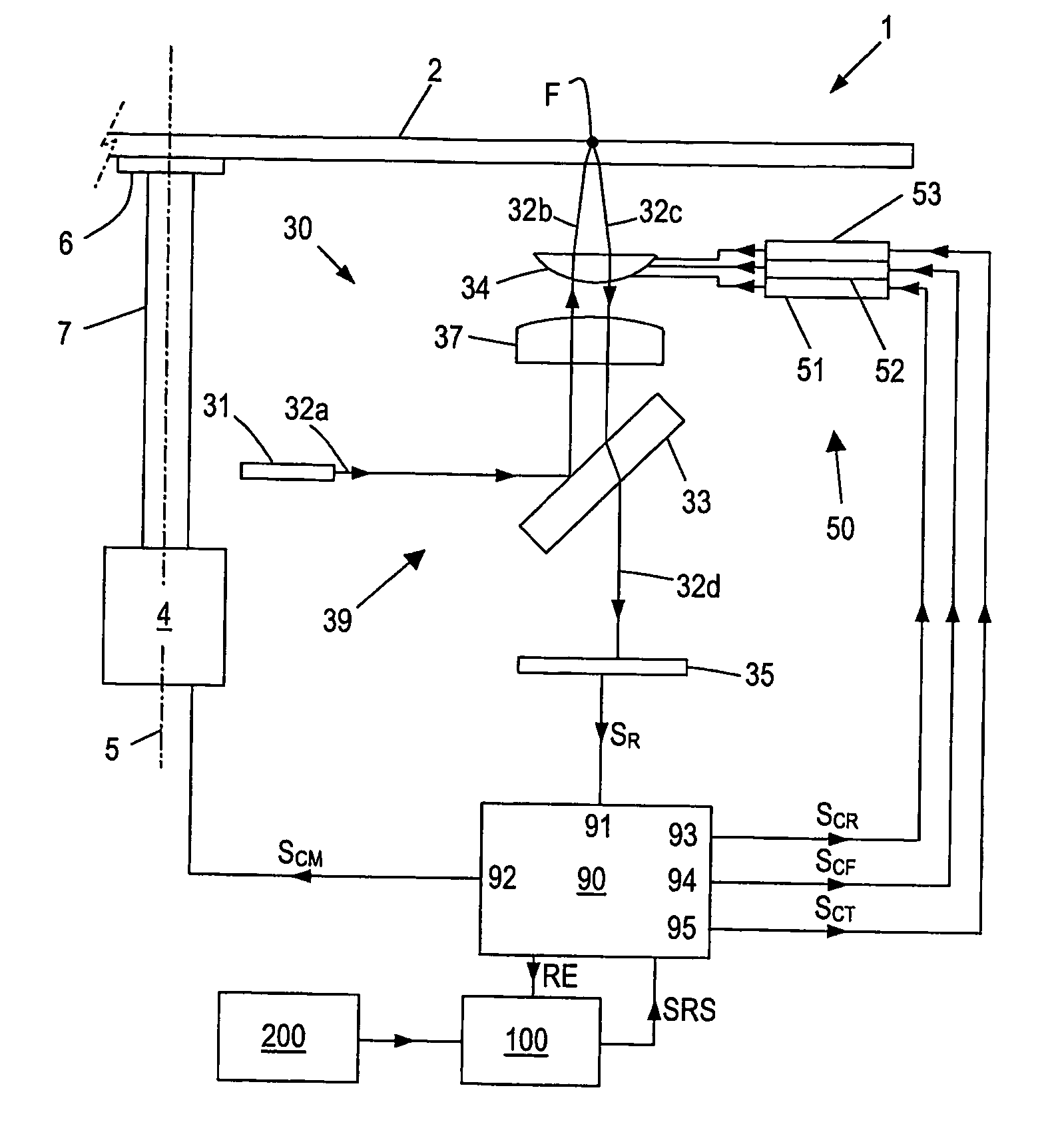

Method and system for reducing operational shock sensitivity of MEMS devices

InactiveCN1721318AReduced running shock sensitivityReduced responseAcceleration measurement using interia forcesMechanical oscillations controlControl signalClosed loop

A method and system for reducing operational shock sensitivity of a MEMS device includes a closed-loop control circuit for controlling the MEMS device and a shock detector for detecting a shock experienced by the MEMS device. The closed-loop control circuit includes a movable MEMS structure, a detector for sensing a position of the MEMS structure and for providing a first feedback signal related to the sensed position, and a processor for receiving the first feedback signal and for providing a control signal used to control the MEMS device. The shock detector, which according to a preferred embodiment is the MEMS structure itself, is used for detecting the shock experienced by the MEMS device and for generating a second feedback signal, which is used to alter the control signal such that a response of the closed-loop control circuit to the shock is minimized.

Owner:JDS UNIPHASE CORP

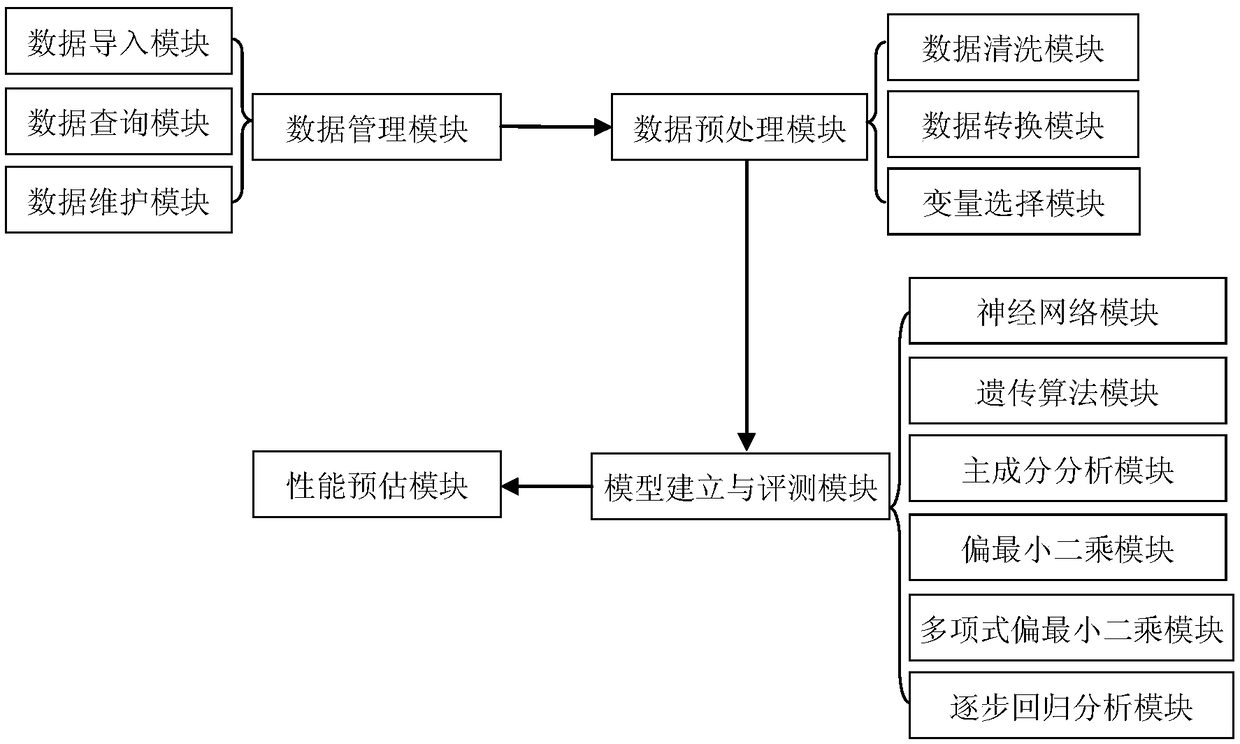

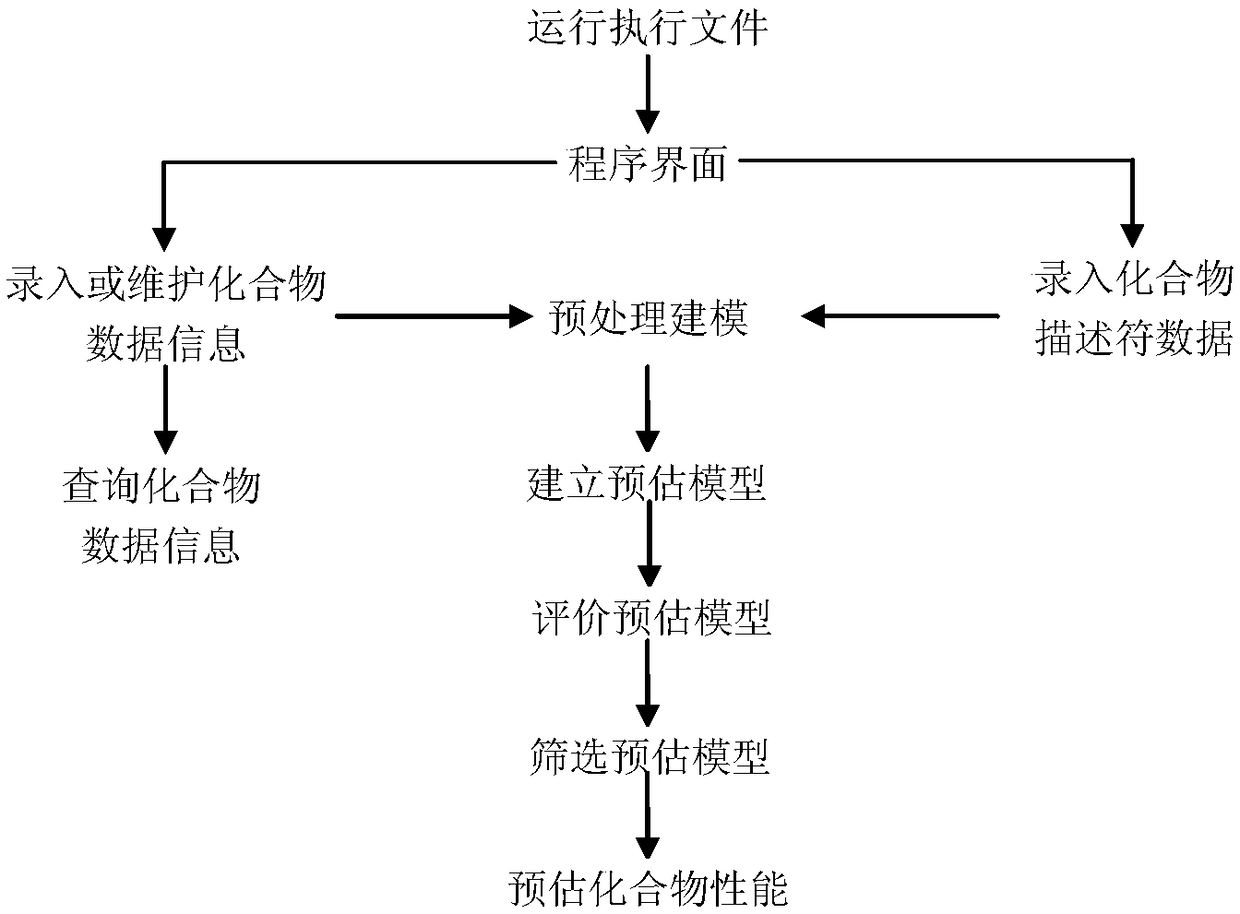

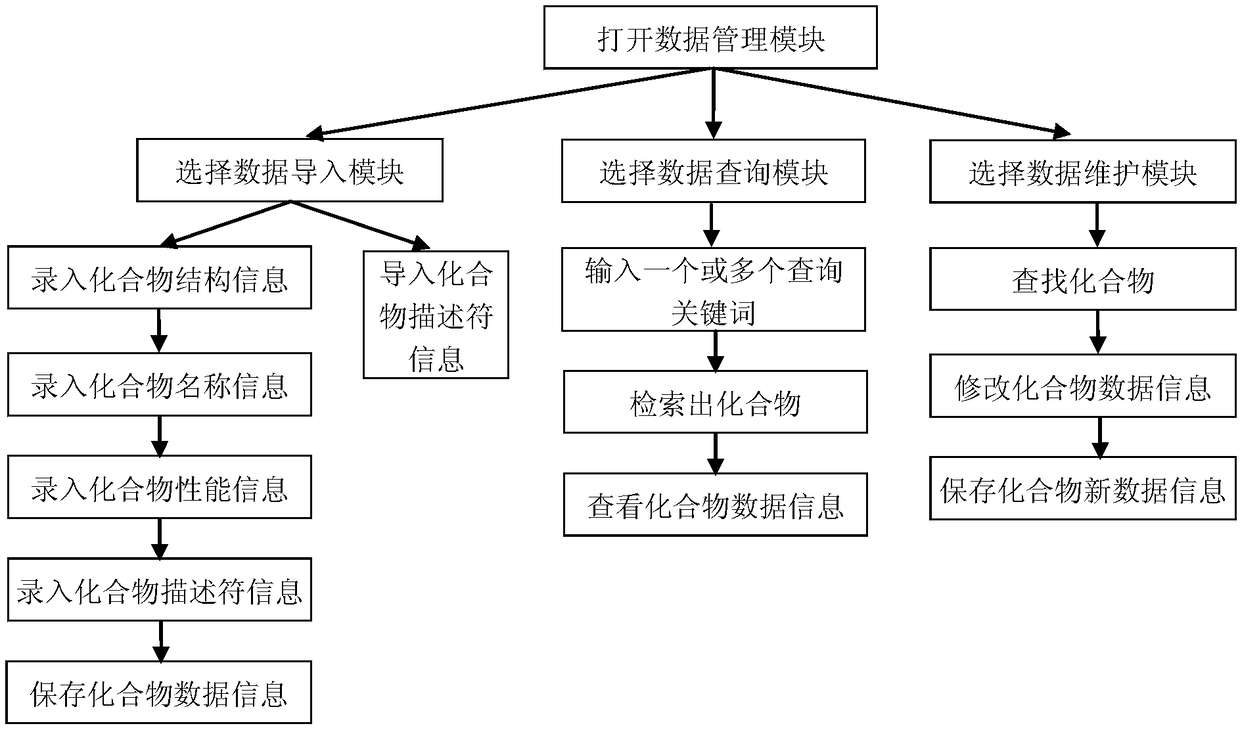

Performance estimating system of energy-containing compound

ActiveCN109411029AAvoid blind synthesisIncrease flexibilityChemical property predictionCheminformatics data warehousingChemical compoundData management

The invention discloses a performance estimating system of an energy-containing compound. The performance estimating system comprises (1) a data management module, (2) a data preprocessing module, (3)a model establishing and evaluating module and (4) a performance estimating module. The system is used for querying and estimating the performance of density, formation enthalpy, detonation speed, detonation heat, detonation pressure and impact sensitivity of the energy-containing compound, and has the advantages of convenient use, fast and accurate performance estimation and the like.

Owner:XIAN MODERN CHEM RES INST

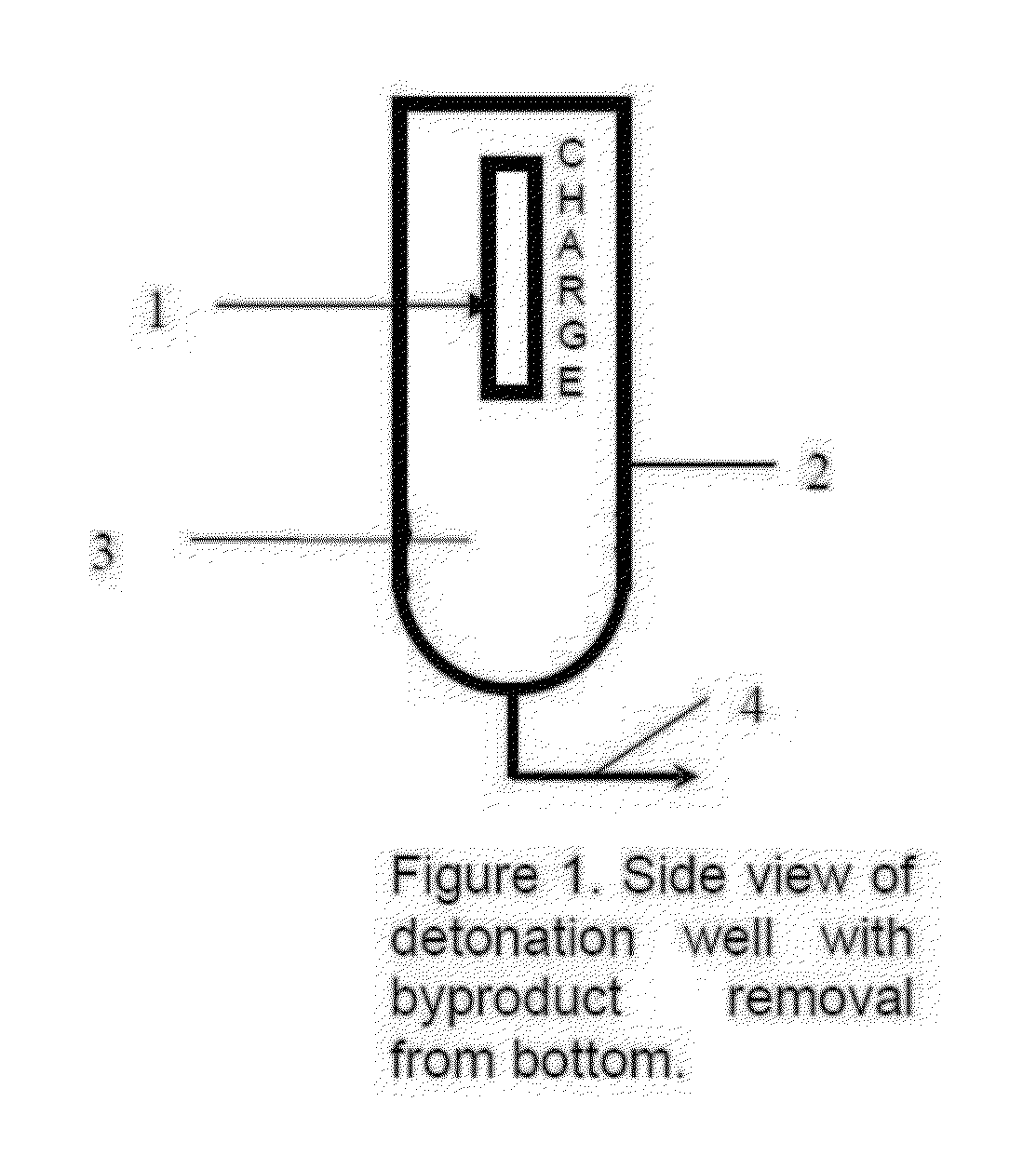

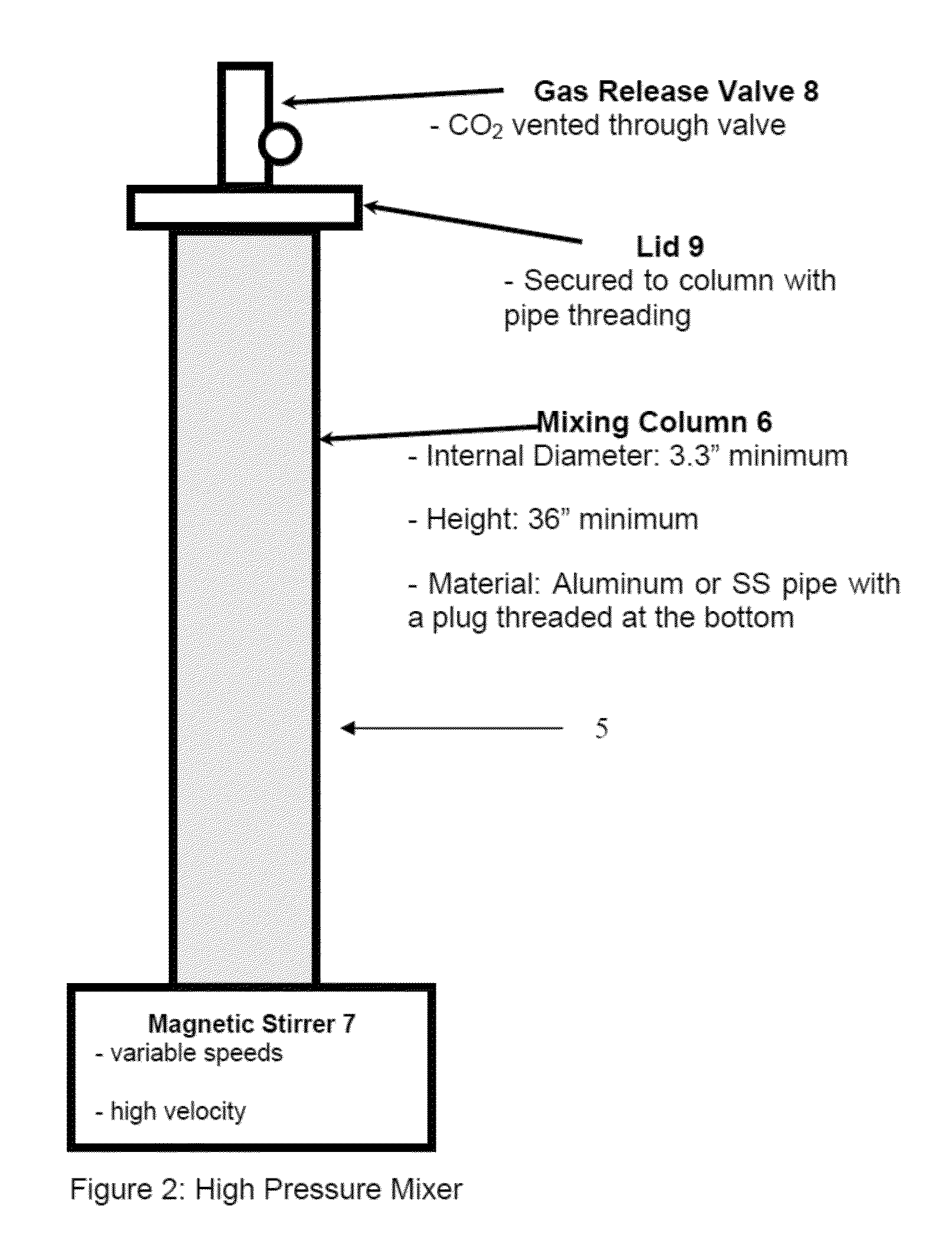

Explosive Formulations of Mixture of Carbon Dioxide and a Reducing Agent and Methods of Using Same

ActiveUS20160046538A1Low cost of ingredientsIncrease variabilityUltra-high pressure processesAluminium oxide/hydroxide preparationEmulsion explosiveANFO

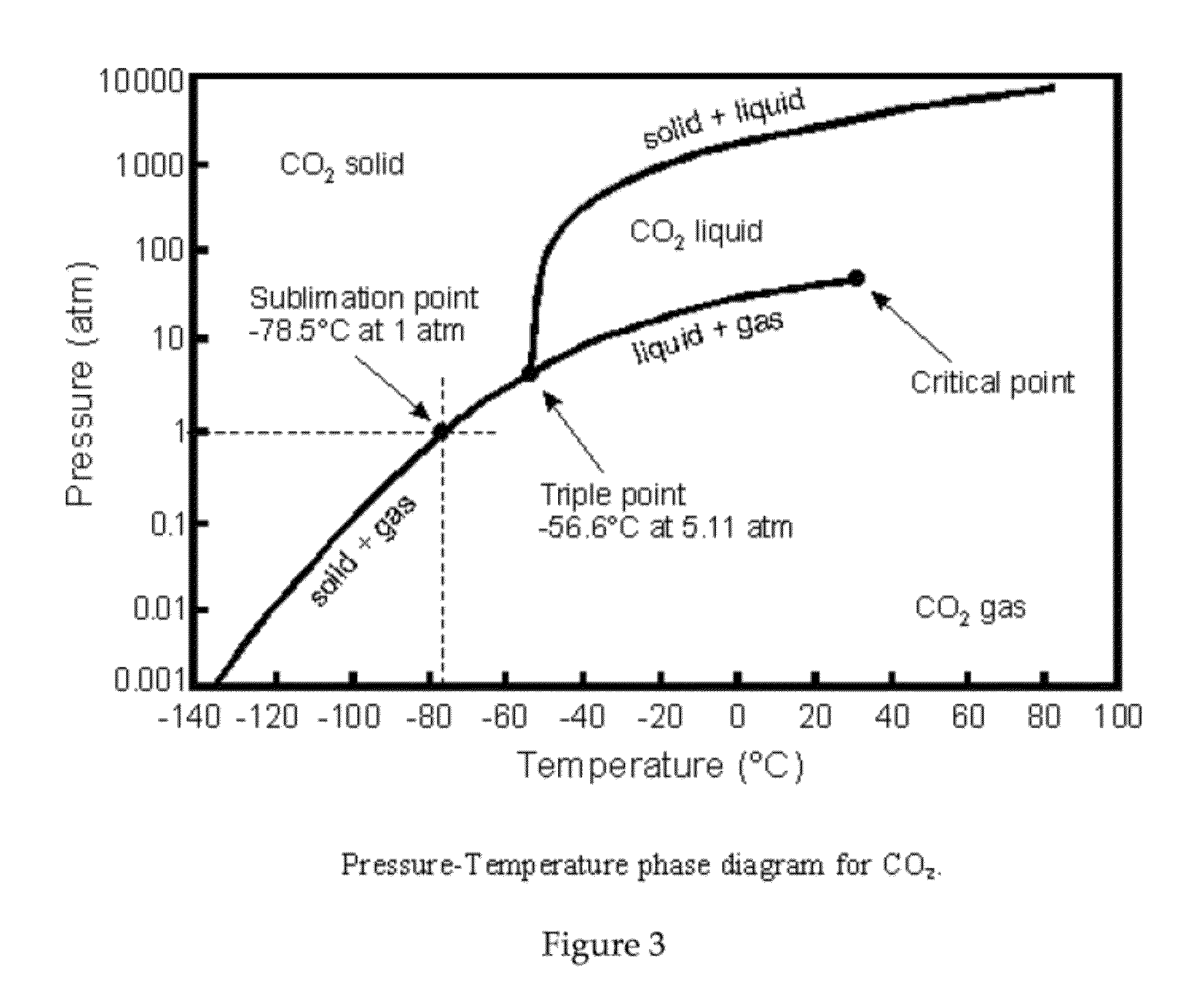

The disclosure relates to embodiments of an explosive formulation comprising a detonable mixture of an oxidizing agent such as carbon dioxide, and a material that decomposes the oxidizing agent exothermically (a reducing agent), and additives that increase the mixture's shock sensitivity. The formulations may be used in a method to produce diamonds or nano oxides or in other applications that use traditional explosives such as, but not limited to: ammonium nitrate and fuel oil combinations (ANFO), watergel explosives, emulsion explosives and RDX.

Owner:SWANSON DAREN NORMAND

Trinitride and synthesis method thereof, and application thereof as heat-resisting initiating explosive

InactiveCN103864035APowerful detonationMetal azide explosive compositionsHydrazoic-acids/azides/halogen-azidesDetonatorDecomposition

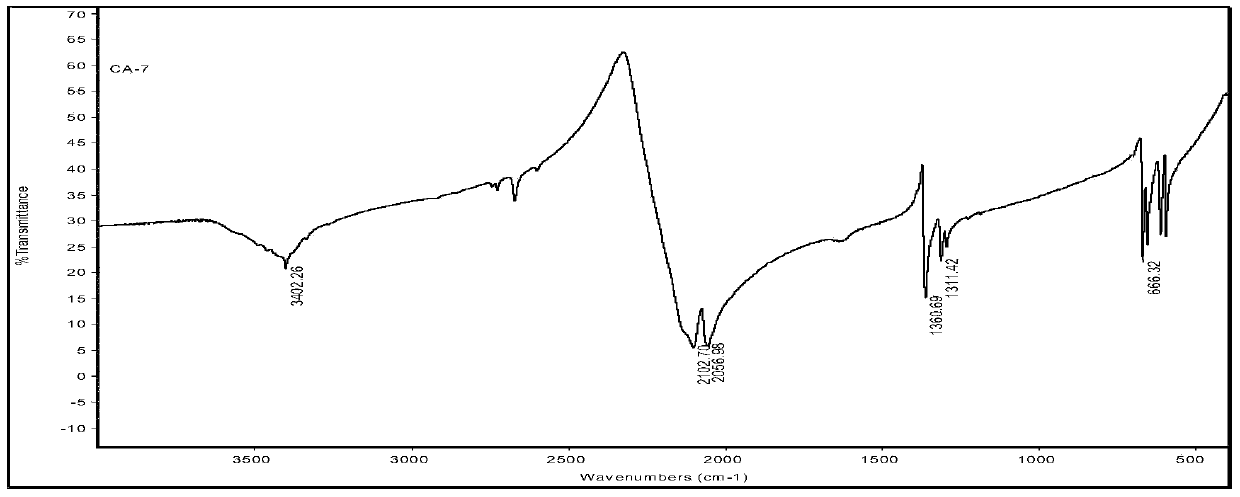

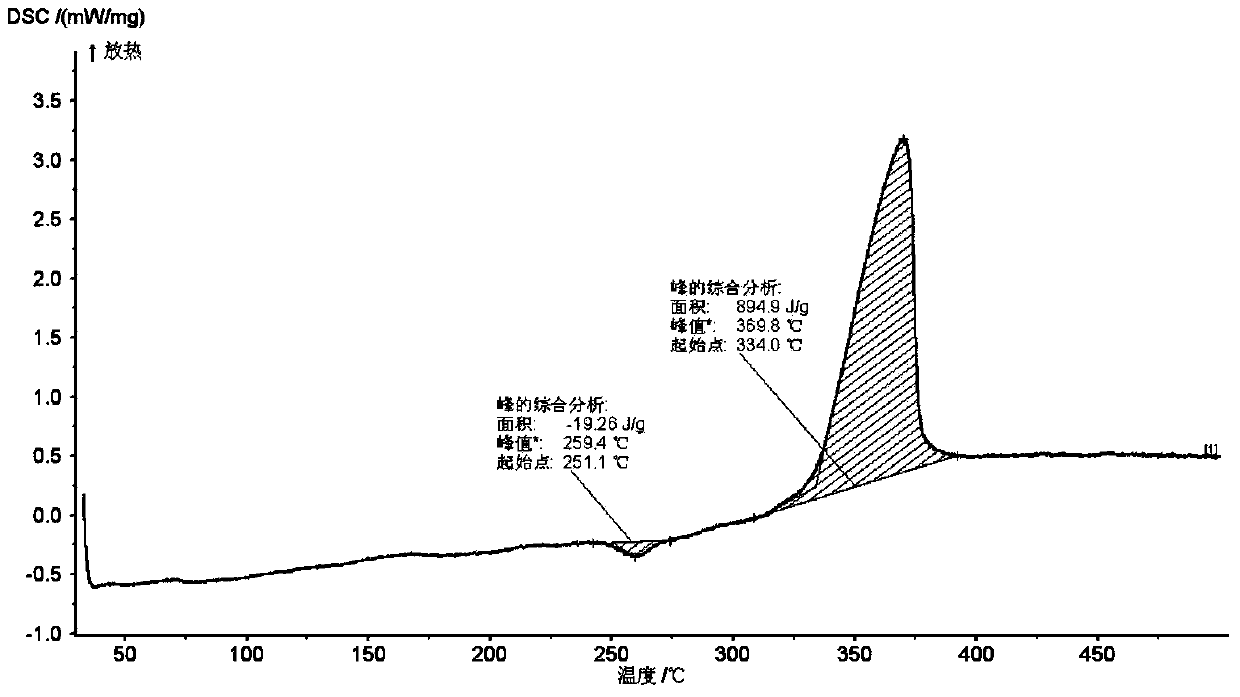

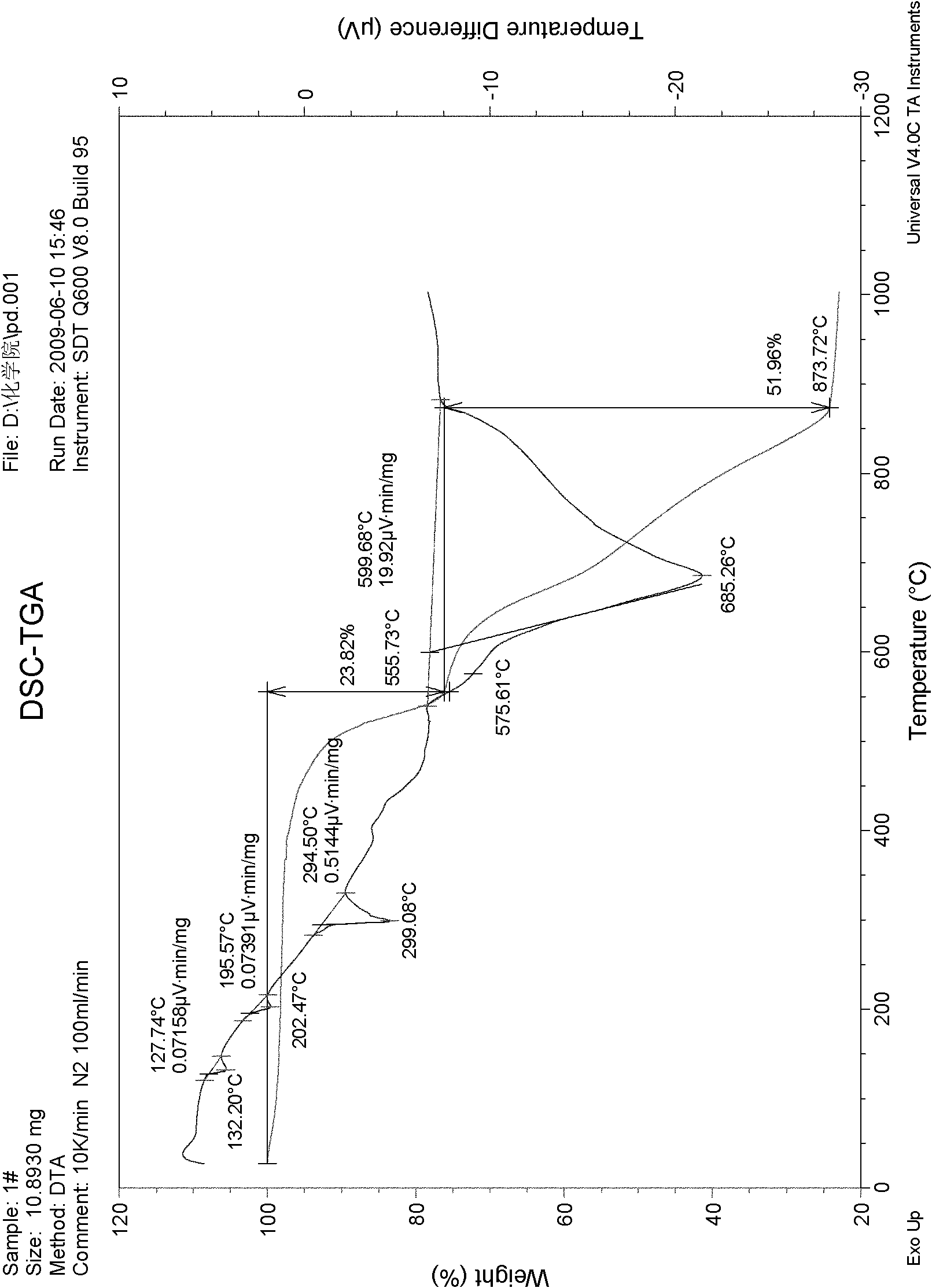

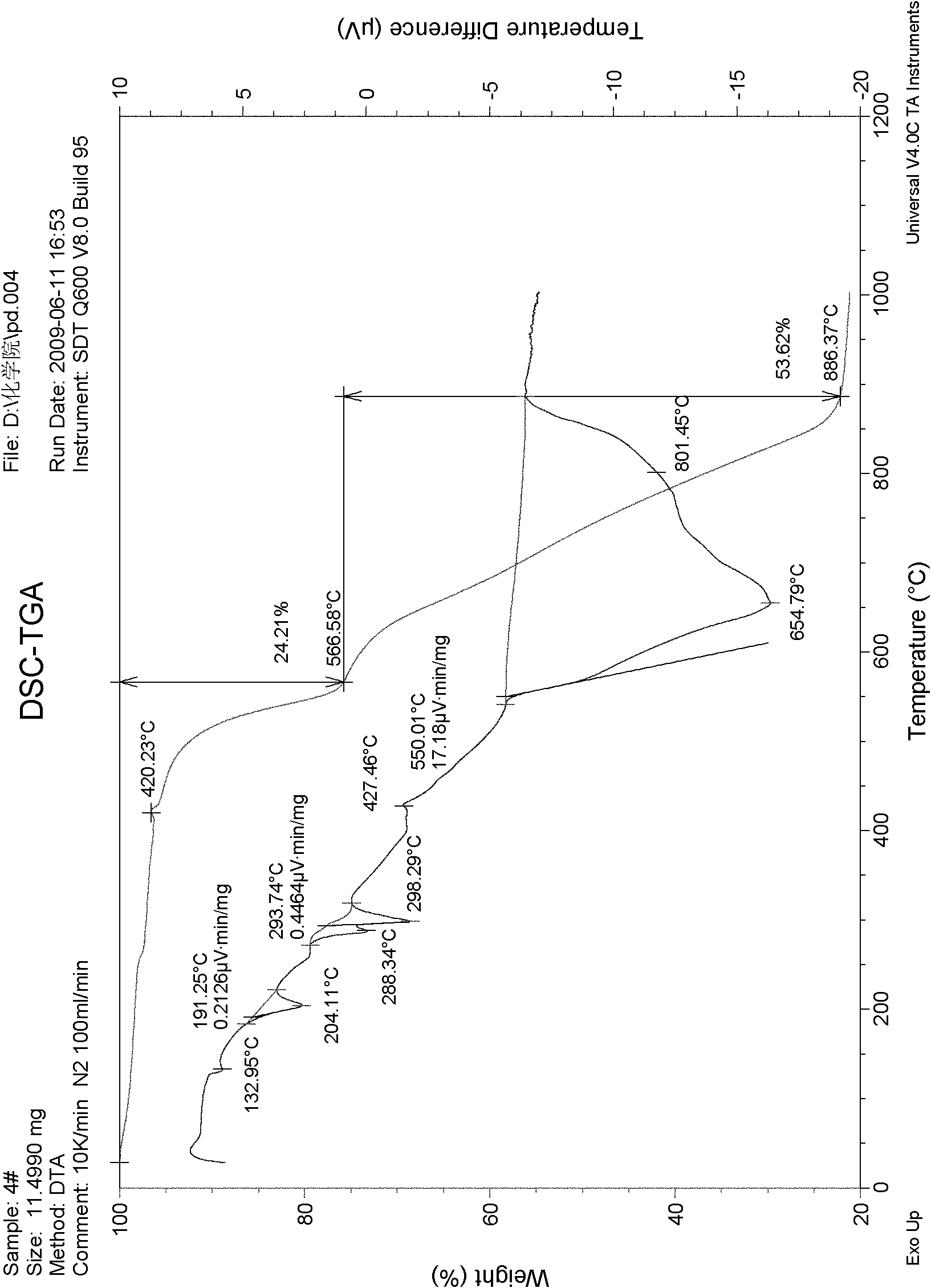

The invention proposes a trinitride and a synthesis method thereof, and application thereof as a heat-resisting initiating explosive. The chemical name of the trinitride is azide cadmium, the molecular formula is Cd(N3)2, the trinitride reacts through a cadmium nitrate solution and a sodium azide solution under the conditions of required reaction temperature, material ratio, charging sequence, reaction time and pH value of a reaction solution, so as to obtain the azide cadmium. The performance of the azide cadmium is subjected to comprehensive assessment by a test. The impact sensitivity of carbonic anhydrase (CA) is equivalent to that of lead azide while the friction sensitivity and the static-electric sensitivity are more insensitive than those of the lead azide; the decomposition peak temperature of the CA is higher than that of the lead azide, and achieves 334-370 DEG C; the explosion temperature can be up to 417-426 DEG C; the initiating power of the CA is much stronger than that of the lead azide. Thus, the CA can be applied to heat-resisting detonators and various miniature detonators instead of the lead azide.

Owner:中国兵器工业第二一三研究所

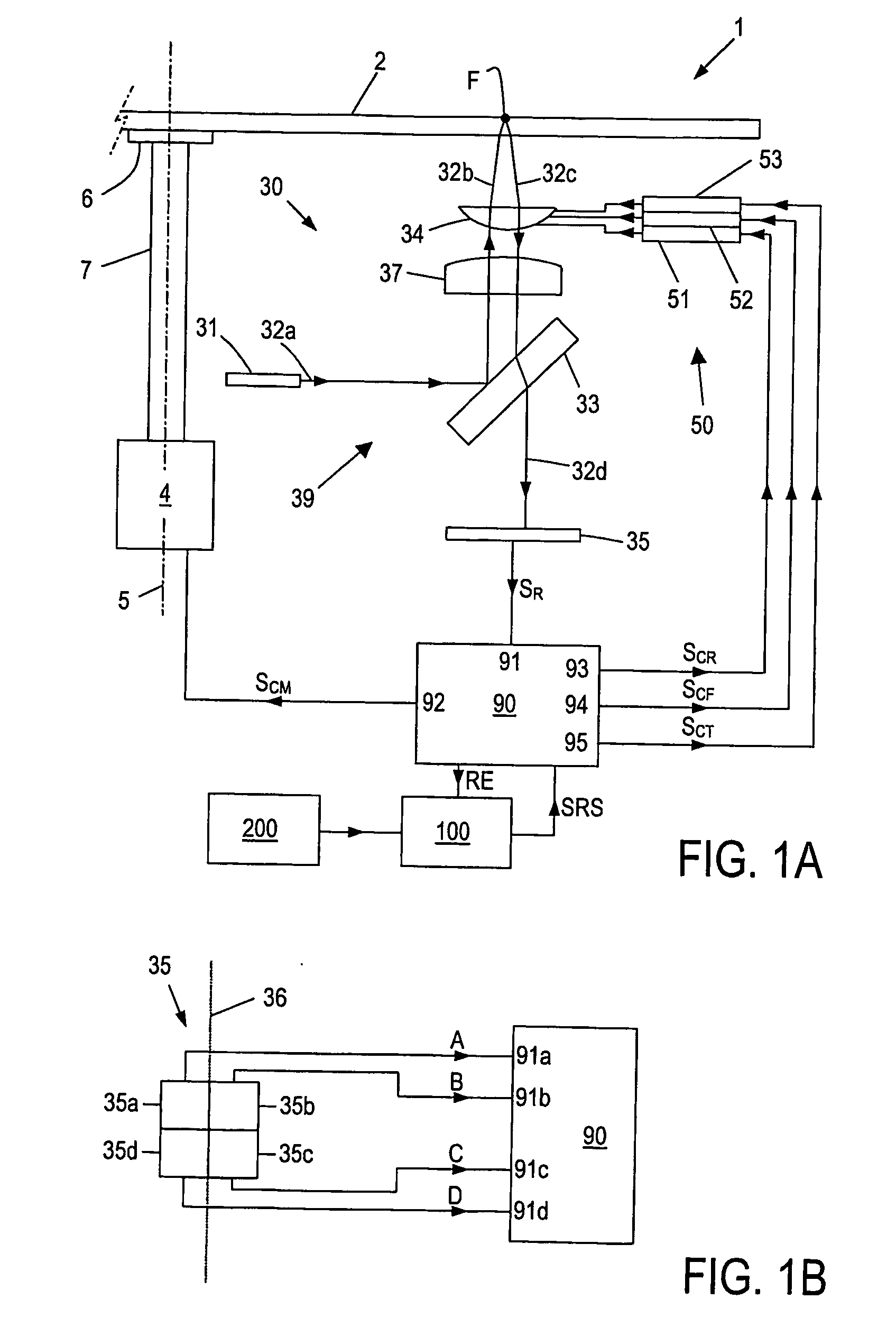

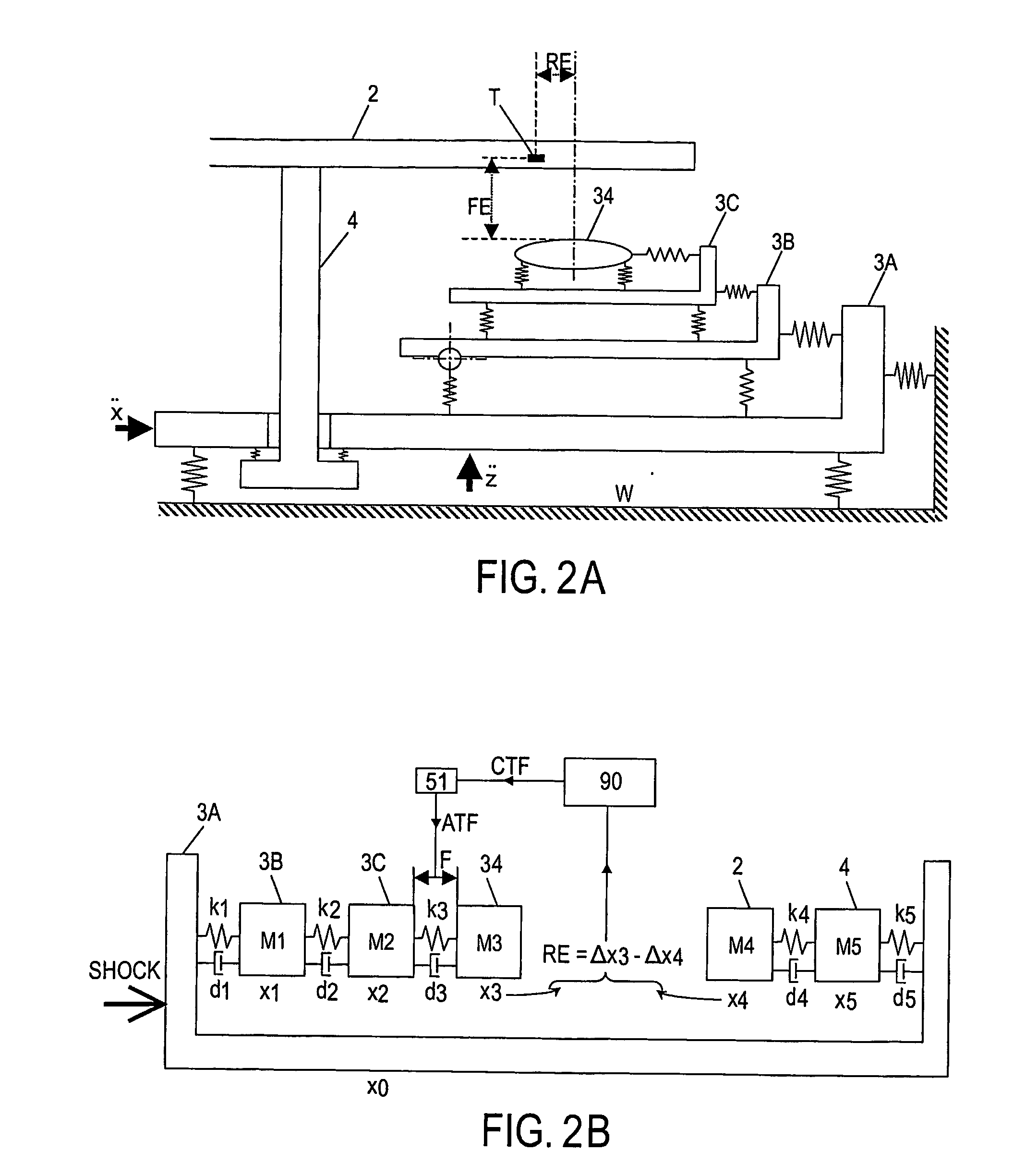

Disc drive apparatus

InactiveUS20060291355A1Track finding/aligningAcceleration measurement using interia forcesControl signalEngineering

A method is described for detecting a mechanical shock in a disc drive apparatus (1) of a type comprising: scanning means (30) for scanning record tracks of a disc (2) and for generating a read signal (SR); actuator means (50) for controlling the positioning of at least one read / write element (34) of said scanning means; a control circuit (90) for receiving said read signal (SR), deriving at least one error signal (RE) from said read signal, and generating at least one actuator control signal (SCR) on the basis of said error signal. The method comprises the steps of: -determining a shock sensitivity function (SSHOCK) which describes the relationship between shocks (OExT) and said error signal; determining or at least approximating an inverse shock sensitivity function (S-lSHOCK) as the inverse of said shock sensitivity function (SSHOCK);—and applying said inverse shock sensitivity function (Sl-SHOCK)on said error signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Propellant and preparation method thereof

InactiveCN108929184AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusShock sensitivityMoisture absorption

The invention provides a propellant and a preparation method thereof. The propellant is prepared from the following components: 30-50 parts of potassium permanganate, 8-20 parts of binder, 10-20 partsof potassium hydrogen phthalate and 20-40 parts of combustible agent, wherein the combustible agent is a mixture of magnesium powder and charcoal dust. The propellant is low in friction and impact sensitivity, small in moisture absorption rate, high in thrust and also capable of reducing environmental pollution.

Owner:胡惠娟

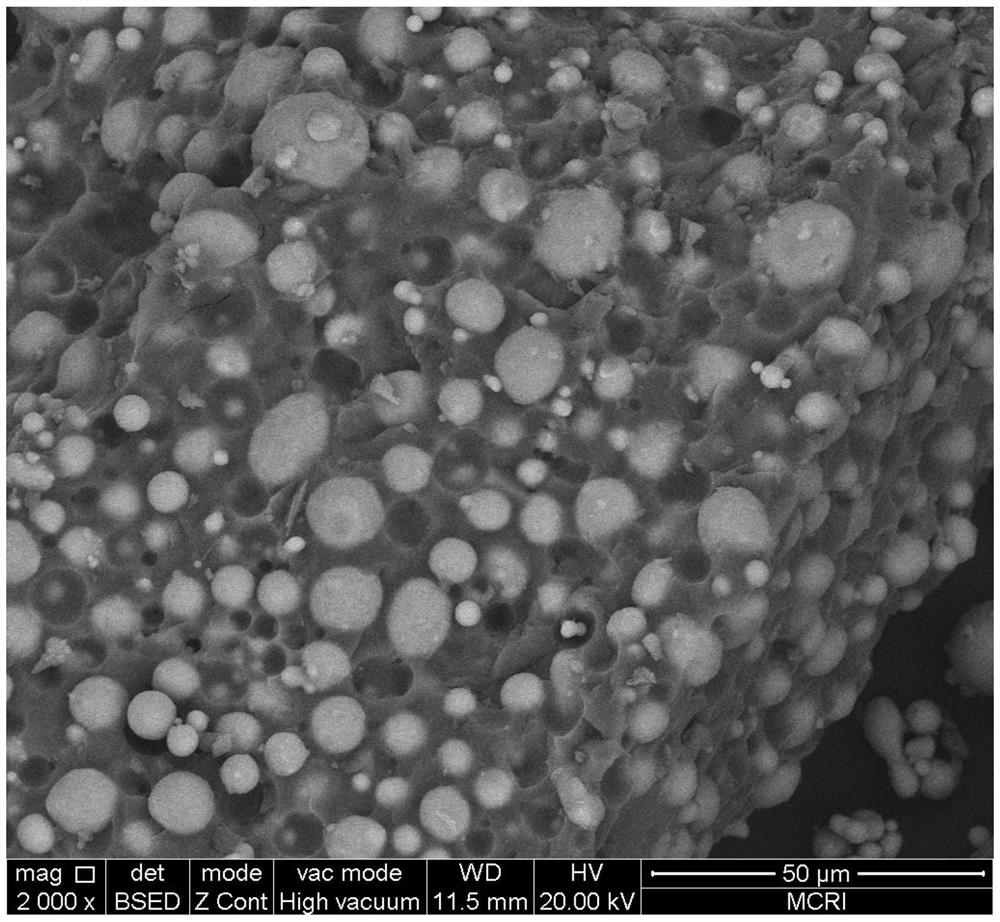

Rock powdery emulsion explosive and preparation method thereof

The invention relates to a rock powdery emulsion explosive and a preparation method thereof. The rock powdery emulsion explosive is produced by that: an emulsion is formed by mixing a water phase ingredient and an oil phase ingredient in a mixer, then the emulsion is vacuum dried to be powder, and porous granulated ammonium nitrate is added into the powder. The rock powdery emulsion explosive provided in the invention, which is a high-performance safe explosive, is simple in composition; high in explosive power; and low in toxic gas content, impact sensitivity and mechanical sensitivity. The preparation method is simple and safe, and no inert substance is added into the explosive.

Owner:SICHUAN YAHUA IND GRP

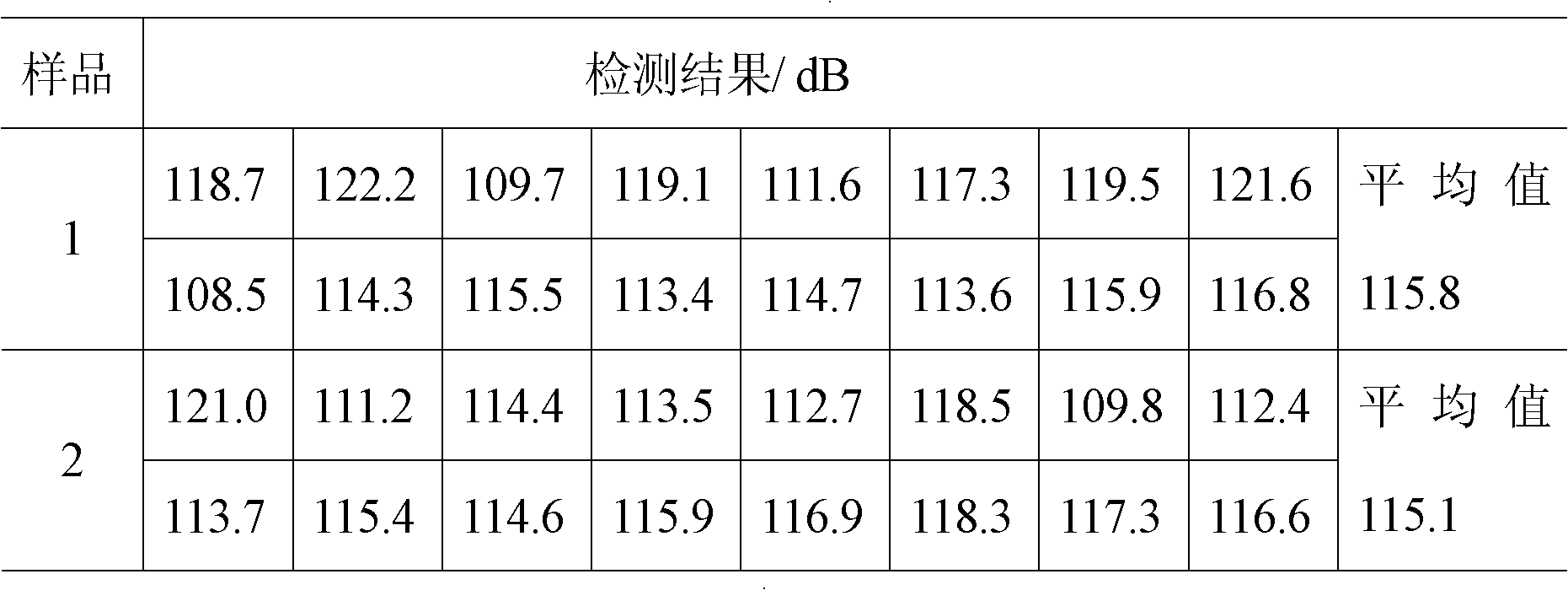

Oxidizer for firework explosive agent and preparation thereof

The invention discloses an oxidizer for firework explosive agent and preparation thereof. The oxidizer consists of the following mass components: 20 to 50 percent of potassium perchlorate, 0 to 30 percent of potassium nitrate, 30 to 50 percent of barium nitrate mixture and 1 to 5 percent of complexing agent, wherein the complexing agent is tartaric acid or potassium sodium tartrate. The fireworks manufactured by using the oxidizer is characterized in that: the burn rate is over 98 percent; the sound level ranges from 100dB to 140dB; the pressure of gas product rises from 0.69MP to 2.07MP within 1.74ms and the pH value of pyrotechnic composition is between 5 and 9; the water content is less than or equal to 1.5 percent; the regain is less than or equal to 2.0 percent; the thermal stability ensures a decomposing phenomenon does not occur at 75+ / -2DEG C within 48 hours; the friction sensitivity is less than or equal to 40 percent; and the sensitivity to impact is less than or equal to 0 percent. The oxidizer meets the requirements of national standards of Firework Safety and Quality. The manufacturing process of the oxidizer is simple, the cost is low and the application prospect is good.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

Method and system for reducing operational shock sensitivity of MEMS devices

ActiveUS7096741B2Reduces operational shock sensitivityReducing and/or limiting the response of a control system theretoAcceleration measurement using interia forcesForce measurementControl signalClosed loop

A method and system for reducing operational shock sensitivity of a MEMS device includes a closed-loop control circuit for controlling the MEMS device and a shock detector for detecting a shock experienced by the MEMS device. The closed-loop control circuit includes a movable MEMS structure, a detector for sensing a position of the MEMS structure and for providing a first feedback signal related to the sensed position, and a processor for receiving the first feedback signal and for providing a control signal used to control the MEMS device. The shock detector, which according to a preferred embodiment is the MEMS structure itself, is used for detecting the shock experienced by the MEMS device and for generating a second feedback signal, which is used to alter the control signal such that a response of the closed-loop control circuit to the shock is minimized.

Owner:LUMENTUM OPERATIONS LLC

Rubber type high-temperature metal particle generator

ActiveCN109232144AImprove reliabilityImprove securityExplosivesPressure gas generationFriction sensitivityCompression molding

A rubber type high-temperature metal particle generator is prepared from components in weight ratio as follows: 1%-6% of an adhesive, 45%-60% of an oxidizing agent, 30%-40% of fuel, 1%-4% of a desensitizing agent, 0%-2% of a plasticizer, 4%-10% of a burning temperature regulator and 0.5%-2% of a property modifier. The generator needs no curing crosslinking and has short production cycle and low cost. Compression molding property of the generator is good, room-temperature one-way compression is performed, and density of a generator grain is 98.5% (phi 40 mm) of the theoretical density when specific pressure is lower than 240 MPa. Metal particles generated by the generator are at the temperature of about 1800-2200 K and have density higher than 2.0 g / cm<3>, friction sensitivity lower than 20% and shock sensitivity of 0.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Propellant and preparation method

InactiveCN108840782AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusNon-explosive/non-thermic compositionsHydrogenAdhesive

The invention provides a propellant and a preparation method. The propellant is prepared from the following components: 30-50 parts of potassium permanganate, 8-20 parts of an adhesive, 10-20 parts ofpotassium hydrogen phthalate, 20-40 parts of a combustible agent and 5-10 parts of iron(II,III) oxide, wherein the combustible agent is a mixture of pearl powder and charcoal powder. The propellant has low friction sensitivity and impact sensitivity, low moisture absorption rate and strong thrust, and environmental pollution is reduced.

Owner:胡惠娟

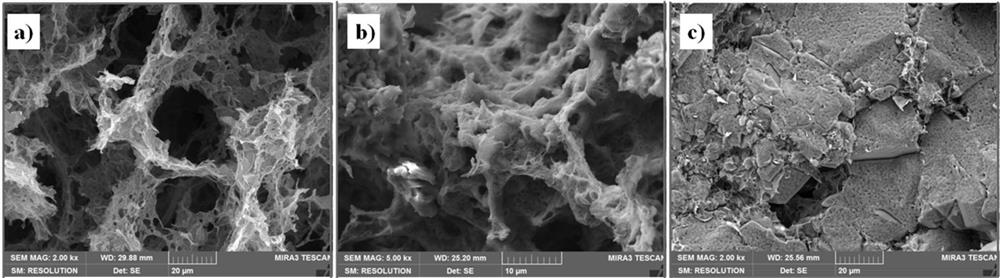

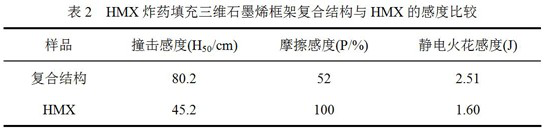

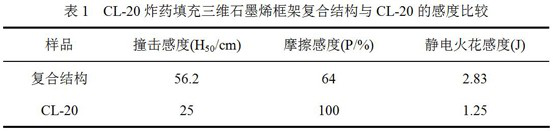

Preparation method of high-energy explosive filled three-dimensional graphene frame composite structure

ActiveCN111908989ARecrystallization achievedReduce sensitivityGrapheneExplosive working-up apparatusFriction sensitivityTEX-explosive

The invention discloses a preparation method of a high-energy explosive filled three-dimensional graphene frame composite structure. A three-dimensional graphene frame structure prepared by reductionand self-assembly of a two-dimensional graphene oxide nano material is used as a template, and a high-energy explosive solution is introduced into the three-dimensional graphene frame structure. Thenthe explosive solution is recrystallized in the frame structure of the template by utilizing an external acting force, and the formed explosive crystal grows in a limited space of the frame structurein an oriented manner. Finally, an explosive filling frame composite structure is contructed, and an explosive solution is added for multiple times to crystallize, thereby obtaining the high-energy explosive filling three-dimensional graphene frame composite structure. According to the method, the dispersity of graphene in the composite explosive system can be improved, the mass and heat transfercharacteristics of the composite system are improved, the impact sensitivity, the friction sensitivity and the electrostatic spark sensitivity of the explosive are effectively reduced, and the safetyperformance is improved.

Owner:ZHONGBEI UNIV

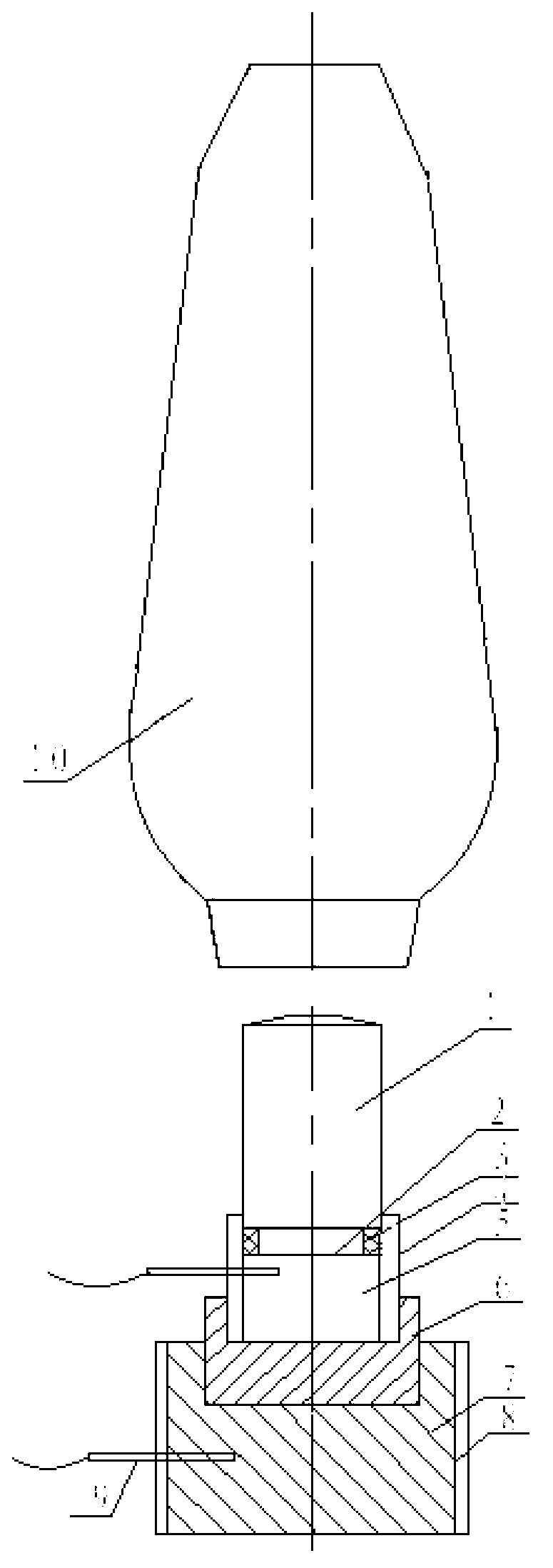

Explosive recrystallization preparation method and device for explosive crystallization

InactiveCN106699488AImprove quality consistencySolve efficiency problemsExplosive working-up apparatusShock sensitivityEngineering

The invention discloses an explosive recrystallization preparation method and a device for explosive crystallization. An explosive stock solution is poured into a grille crystallizing pan, and then the grille crystallizing pan is placed in a precise constant-temperature heating water tank, heated to 59-61 DEG C and kept at the constant temperature; a top-end air suction system is started, and the air suction speed is stabilized at 0.73-0.77 m / s, so that all explosives are crystallized. The device for explosive crystallization comprises the precise constant-temperature heating water tank, the grille crystallizing pan and the top-end air suction system, wherein the grille crystallizing pan is placed in constant-temperature water in the precise constant-temperature heating water tank, so that the periphery and the bottom of the grille crystallizing pan can be heated by the constant-temperature water, the top-end air suction system is arranged right above the grille crystallizing pan, and a grille of the grille crystallizing pan is arranged on the inner bottom surface of the grille crystallizing pan. The method and the device have a function of precisely controlling the temperature and the volatilization speed of the recrystallized stock solution, the initiation sensitivity of prepared explosives is obviously improved, the shock sensitivity is greatly reduced, and the production efficiency is substantially improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

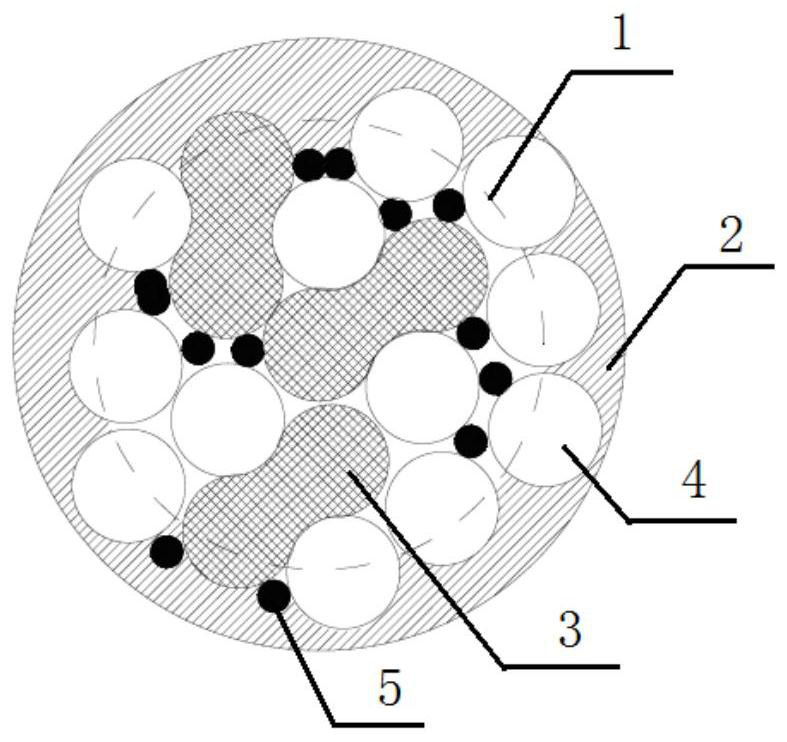

Composite explosive structure and preparation process

ActiveCN112939711AStrong detonation output capabilityIncreased blast temperatureNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsTEX-explosiveAluminium powder

The invention provides a composite explosive structure and a forming process. The composite explosive structure comprises mixed crystal particles, and the mixed crystal particles are coated with a coating film; the mixed crystal particles comprise CL-20 explosives and aluminum powder, and the CL-20 explosives and the aluminum powder are locally bonded through a binder; and the coating film is composed of paraffin, talcum powder and sodium dodecyl benzene sulfonate. The mixed crystal particles are realized through mixed crystal dispersion and mixed crystal kneading processes; and the coating film is realized through solution preparation and paddle-free mixing processes. The composite explosive structure has high detonation output capacity, and compared with conventional mixing of blended explosives in the same proportion, the temperature of an explosion field is increased by 100 DEG C or above; the Gurney coefficient is increased by 5%; and the shock wave overpressure is improved by more than 10%. The composite explosive structure provided by the invention has high safety, and the impact sensitivity and the friction sensitivity are reduced by more than 10% compared with a same-proportion crystal embedding structure and a conventional mixed structure.

Owner:XIAN MODERN CHEM RES INST

A kind of smoky and sulfur-free firecracker agent

The invention relates to a micro-smoke sulfur-free agent for a firecracker. The micro-smoke sulfur-free agent for the firecracker is prepared from the following components in parts by weight: 30 parts of bamboo charcoal powder, 10-30 parts of potassium perchlorate, 10-20 parts of nanosiliver powder, 5-15 parts of nano rare earth oxides, 2-6 parts of charcoal powder, 2-5 parts of titanium sponge powder and 1-4 parts of agilawood powder. The firecracker using the agent provided by the invention is micro-smoke, sulfur-free and environment-friendly during combustion. The firecracker has fragrance of bamboo and agilawood during combustion, and the friction sensitivity, the impact sensitivity and the moisture absorption are superior to the state standards.

Owner:浏阳市吉祥环保材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com