Patents

Literature

63results about How to "Reduced friction sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur-free nitrogen-free high-temperature-resistant environment-friendly firework propellant and preparation method thereof

The invention relates to a sulfur-free nitrogen-free high-temperature-resistant environment-friendly firework propellant and a preparation method thereof, and belongs to the technical field of fireworks and crackers. The sulfur-free micro-smoke high-temperature-resistant firework propellant is prepared from the following components in parts by weight: 55-75 parts of polytetrafluoroethylene with the particle size of 50-300 microns; 5-25 parts of aluminum powder with the particle size of 5-75 microns; 5-25 parts of zinc powder and 5-15 parts of copper powder with the particle size of 5-75 microns; 2-10 parts of calcium silicate with the particle size of 20-150 microns; 0.5-5 parts of a silane coupling agent; and 1-5 parts of an energetic binder. The preparation method adopts the processes of chemical modification, coating, powder mixing, granulation, drying and the like, and is simple in process, free of special process requirements, low in cost and convenient for batch production. The obtained product has the advantages of no sulfur, slight smoke, no environmental pollution, low impact or friction sensitivity, high temperature resistance, static resistance, high safety and the like, and can be widely applied to the production of propellant powder for fireworks and crackers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

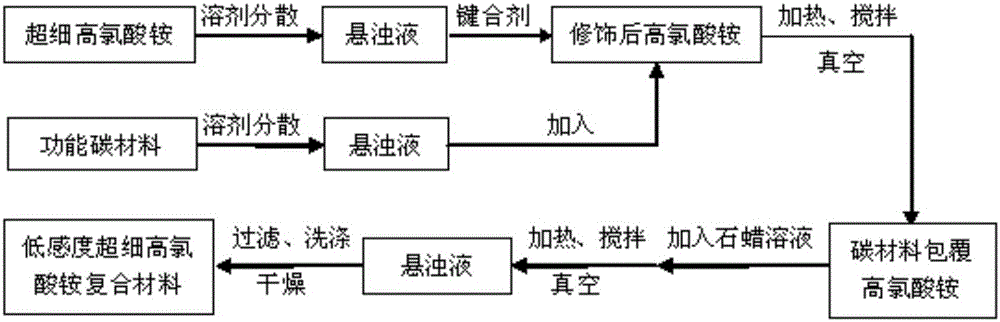

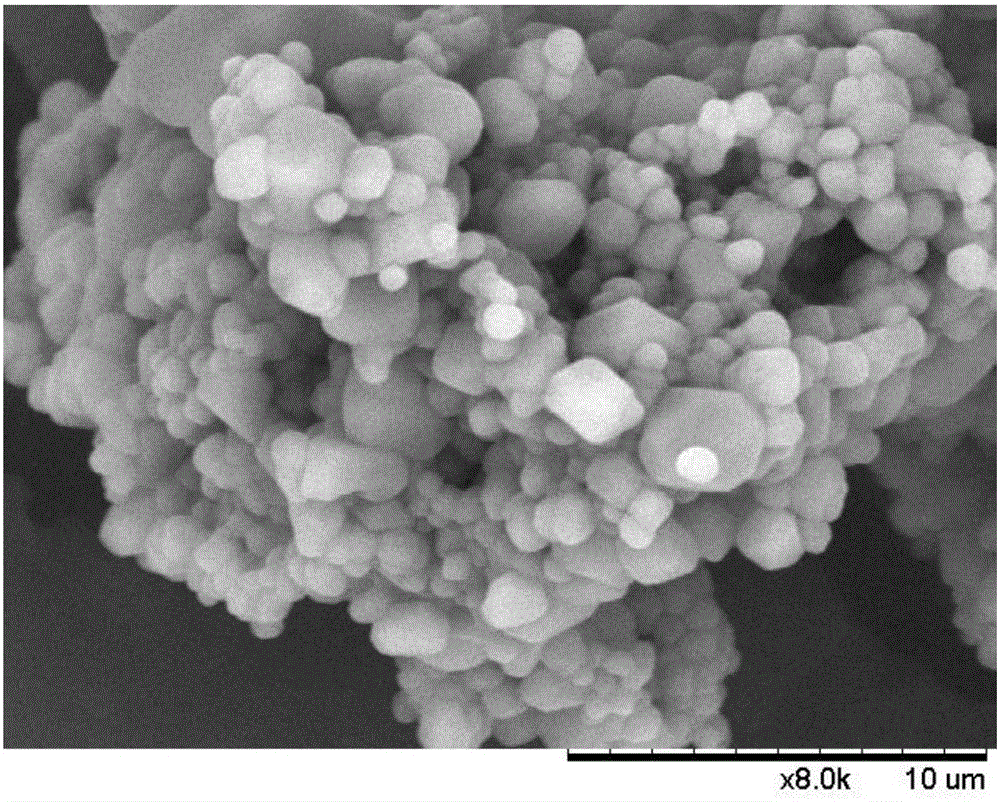

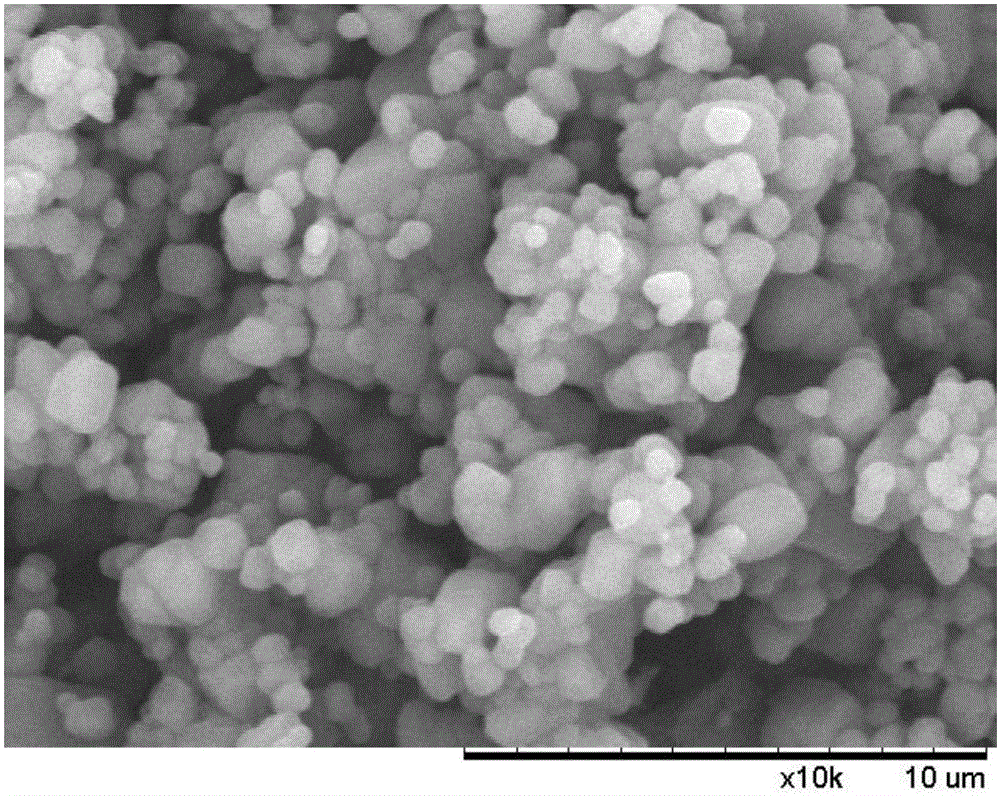

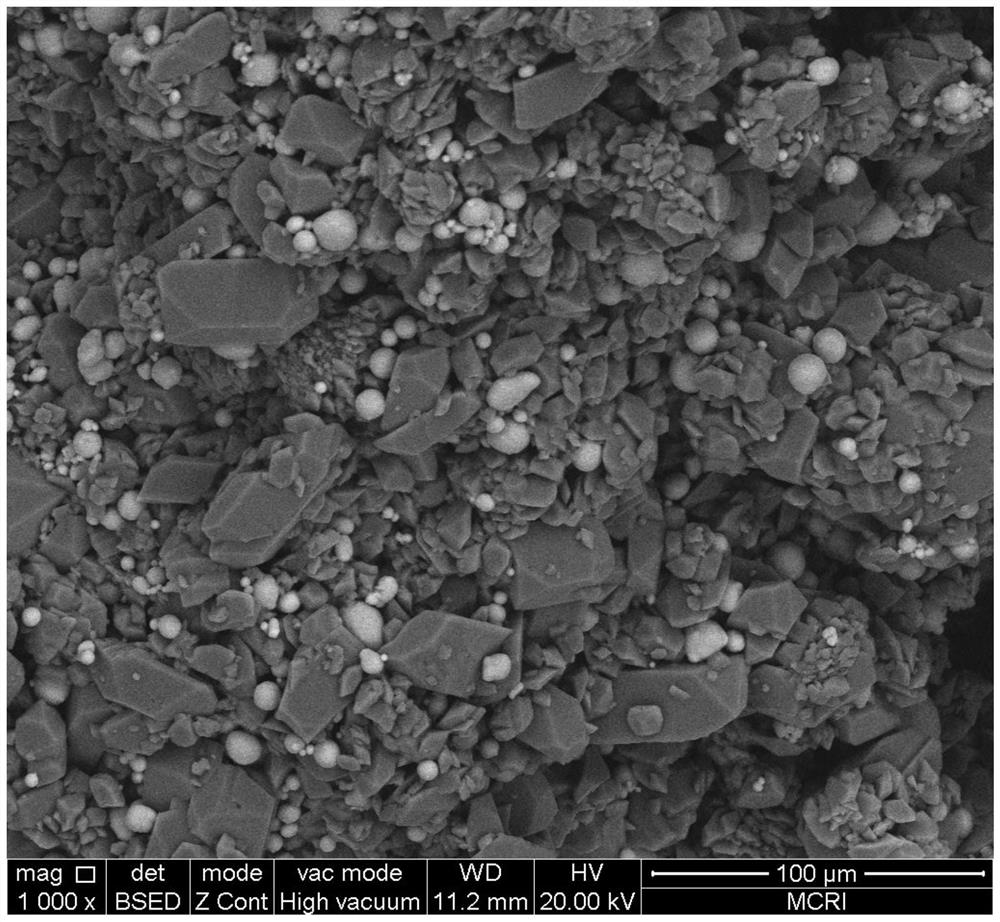

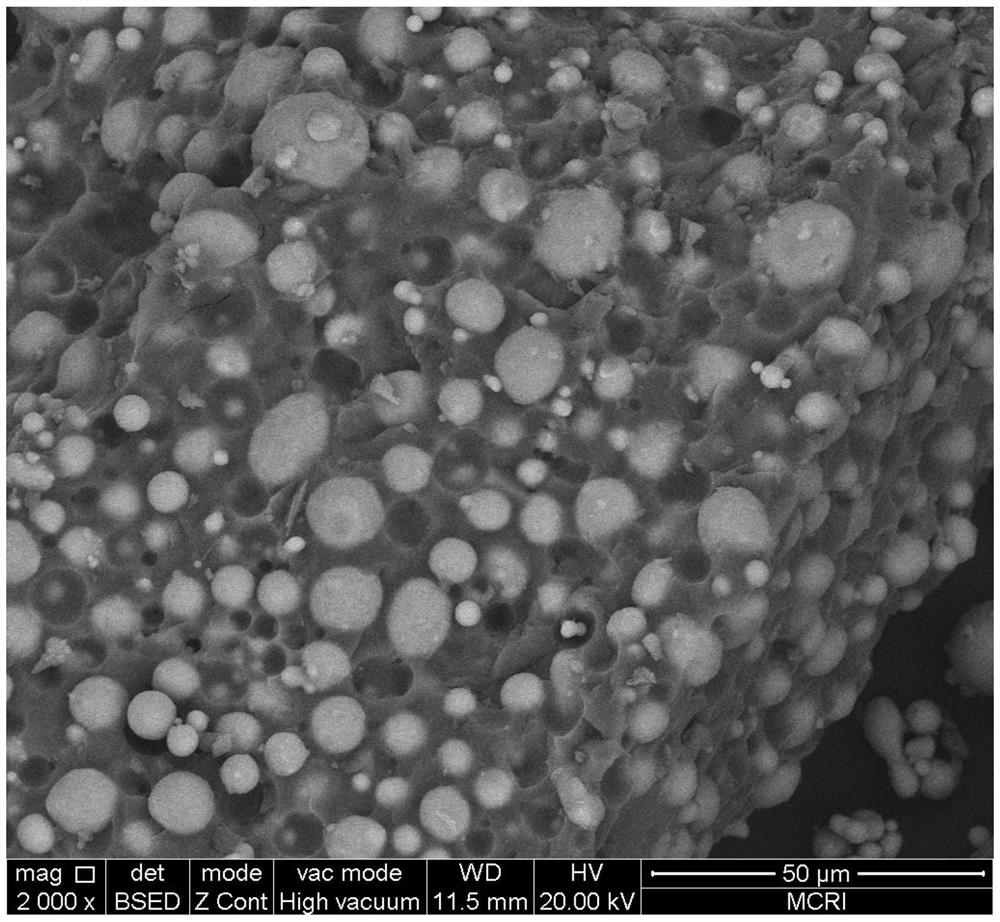

Low-sensitivity ultrafine ammonium perchlorate composite material and preparation method thereof

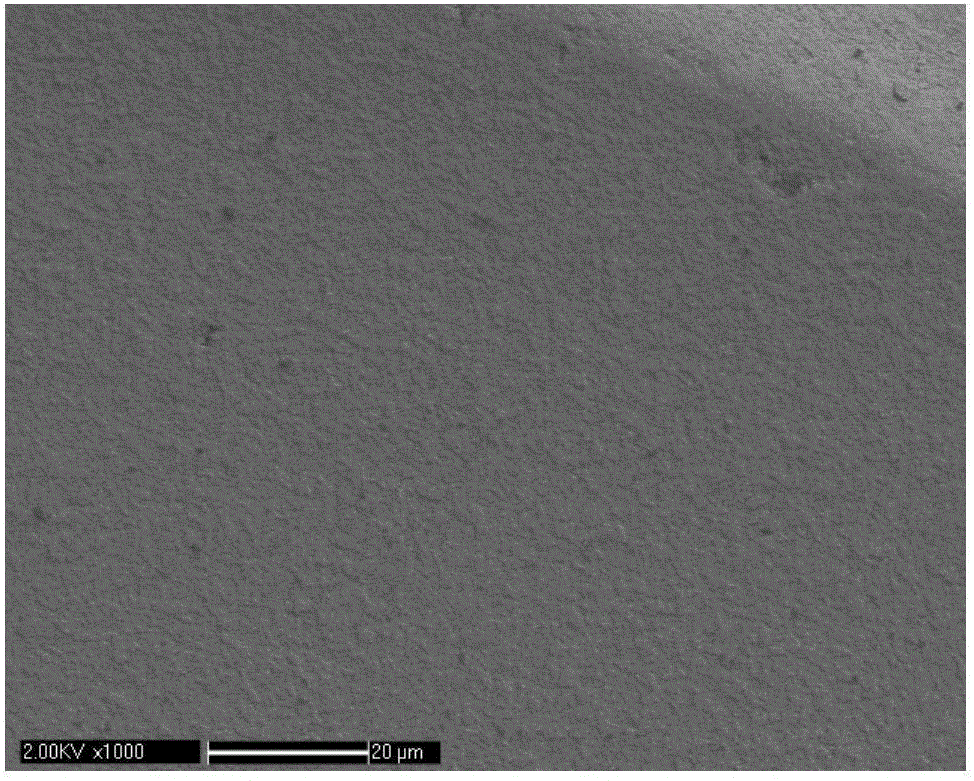

ActiveCN105152823ASimple processMild reaction conditionsAmmonium perchlorate explosive compositionsSmooth surfaceShock sensitivity

The invention discloses a low-sensitivity ultrafine ammonium perchlorate composite material and a preparation method thereof. The method comprises the following steps: dispersing ultrafine ammonium perchlorate in an organic solvent to form a suspension, modifying the suspension by a bonding agent under stirring, heating and vacuum conditions, coating by using a functional carbon material dispersed in an organic solvent under the stirring, heating and vacuum conditions, processing by using a paraffin / petroleum ether solution, filtering, washing, and drying to obtain the low-sensitivity ultrafine ammonium perchlorate composite material. The method is suitable for preparing low-sensitivity composite materials of various granularities and various morphologies of ultrafine ammonium perchlorate, and has the advantages of simple process flow, mild reaction conditions, good reappearance, high yield, and easy amplified preparation; and the obtained composite material has the advantages of good dispersion, smooth surface, uniform granularity distribution, and obviously reduced bumping sensitivity and friction sensitivity.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation method for reducing mechanical sensitivity of HMX

ActiveCN105801324ADoes not change crystal shapeDoes not change densityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityFiltration

The invention provides a preparation method for reducing mechanical sensitivity of HMX. The preparation method comprises the following steps of: preparing an alkali solution with a pH value being 8-11; dissolving catechol substances into the alkali solution to obtain a catechol alkali solution with concentration being 0.1g / L-20g / L, wherein the pH value of the completely dissolved solution is greater than 7; putting HMX into the catechol alkali solution and stirring for 0.1-24 hours to obtain a mixed dispersion liquid; carrying out suction filtration cleaning on the mixed dispersion liquid treated in the step III, and cleaning the mixed dispersion liquid by distilled water; drying the mixed dispersion liquid for 1-24 hours at a temperature of 50-80 DEG C to obtain an modified HMX material. The preparation method is simple in process, and physical characteristics such as crystal shape, density and the like of the HMX are not changed; and the modified HMX material has relatively low mechanical sensitivity, so that the friction sensitivity can be reduced by 30%, characteristic height is improved by more than one time, and therefore, the HMX has relatively high safety performance.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

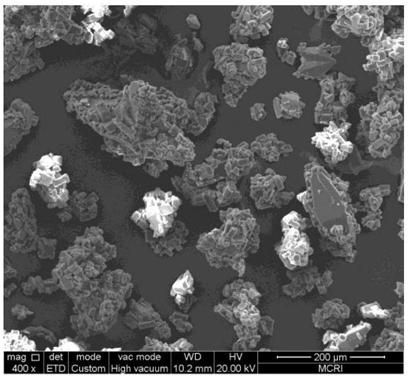

Method for coating CL-20 explosive with plasticized Estane5703

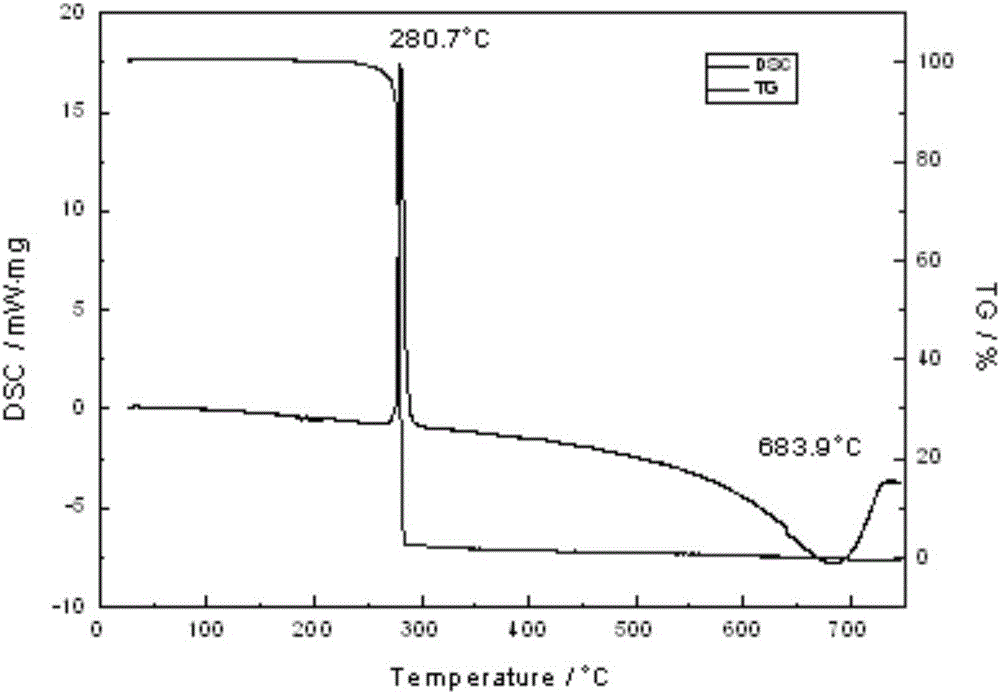

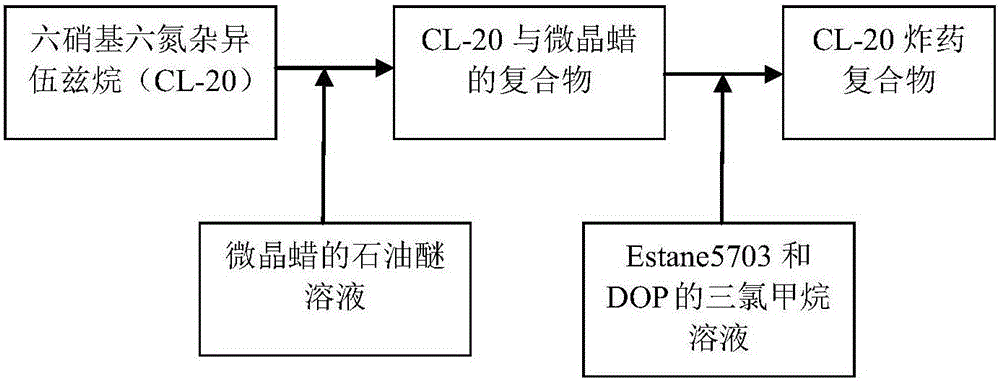

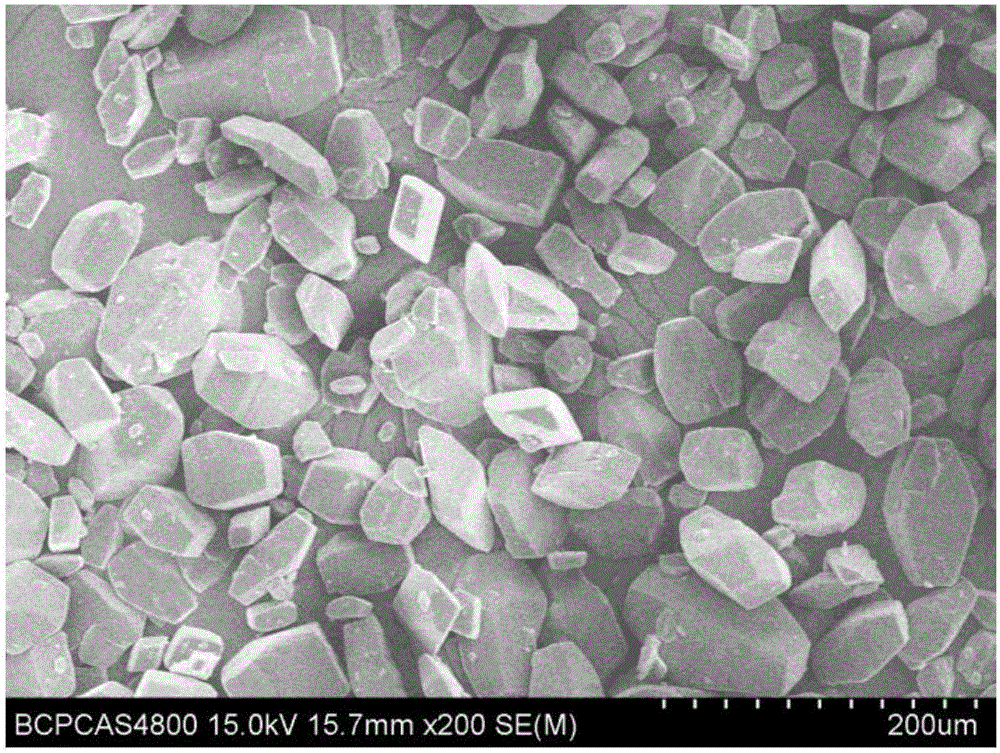

InactiveCN106083494AUniform particle sizeLow impact sensitivityNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusFriction sensitivityMicrocrystalline wax

The invention relates to a method for coating a CL-20 (hexanitrohexaazaisowurtzitane) explosive with plasticized Estane5703. The method comprises the following steps: coating the surface of CL-20 with a desensitizer microcrystalline wax to prepare a CL-20 and microcrystalline wax compound, and coating the surface of the CL-20 and microcrystalline wax compound with Estane5703 to prepare a CL-20 explosive compound. The method allows a uniform and compact film to be formed on the surface of the CL-20 explosive, so the mechanical sensitivity of the CL-20 explosive is substantially reduced. The CL-20 explosive compound prepared in the invention and the coating film thereof are controlled to be in a nanometer range, account for 2-4% of the total system, and have small influences on the energy of the CL-20 explosive. The bump sensitivity of the coated CL-20 explosive is reduced to 52-72% from 100%, and the friction sensitivity of the coated CL-20 explosive is reduced to 40-80% from 100%.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

Safe oxidant for firecrackers

A safe oxidant for firecrackers comprises the following components by weight percent: 20%-60% of puffed potassium nitrate, 0.5%-2% of organic encapsulant, 20%-65% of modified potassium perchlorate, 0.1%-2% of magnesium nitrate, 5%-15% of barium nitrate and 5%-15% of catalyst. The preparation method comprises the following steps: puffing potassium nitrate, coating the puffed potassium nitrate and magnesium nitrate with the organic encapsulant, adding the modified potassium perchlorate, barium nitrate and catalyst and obtaining the safe oxidant by mixing the mixture evenly. The oxidant has good safety and low cost, the various indexes of the oxidant meet the national standards, the stacking density is small, and the explosive load for each firecracker is small, thus greatly reducing the comprehensive cost for users and possessing large promotional value.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

Fireworks detonating agent without chlorate and perchlorate

InactiveCN1640856ALow moisture absorptionReduced friction sensitivityExplosivesDecompositionFireworks

The firework exploding and sounding agent without chlorate and perchlorate comprises composite oxidant, inflammable sulfur, easy-to-burn aluminum powder and density regulating agent, and features the composite oxidant comprising potassium nitrate 10-50 wt%, barium nitrate 50-90 wt% and potassium permanganate 0-25 wt%. The firework exploding and sounding agent has also added pH regulating agent boric acid and deactivating agent magnesia or stearic acid. The firework exploding and sounding agent has high heat stability, no decomposition under 75 deg.c and minus 25-35 deg.c for 48 hr, friction sensitivity lower than 60 %, knocking sensitivity lower than 50 %, no burning and explosion in falling test and sympathetic detonation test, high fire approaching performance and no special requirement in firing line, and may be used in type B and type C firework products.

Owner:刘青春

Environment-friendly type safety fireworks firecracker gun powder oxidant

InactiveCN101265146AHigh decomposition temperatureRaise the ignition temperatureExplosivesFirecrackerBarium nitrate

The invention discloses an environment-friendly safe gunpowder oxidizer of fireworks and firecrackers, and belongs to the chemical field. The environment-friendly safe gunpowder oxidizer is mixed and made by potassium hyperchlorate, strontium nitrate, barium nitrate and flame retardant material. The gunpowder oxidizer is characterized in simple prescription, good safety, no potassium chlorate, no sulfur, etc., and is widely used in the industries such as firecrackers, fireworks, etc., and is an ideal safe gunpowder oxidizer.

Owner:祁阳县梅溪镇第二鞭炮厂

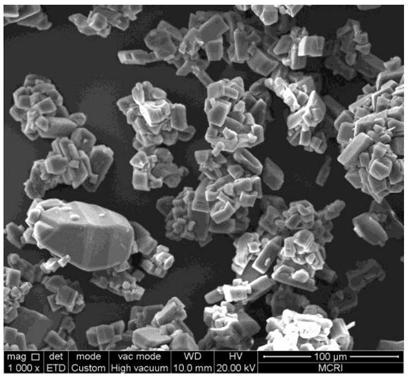

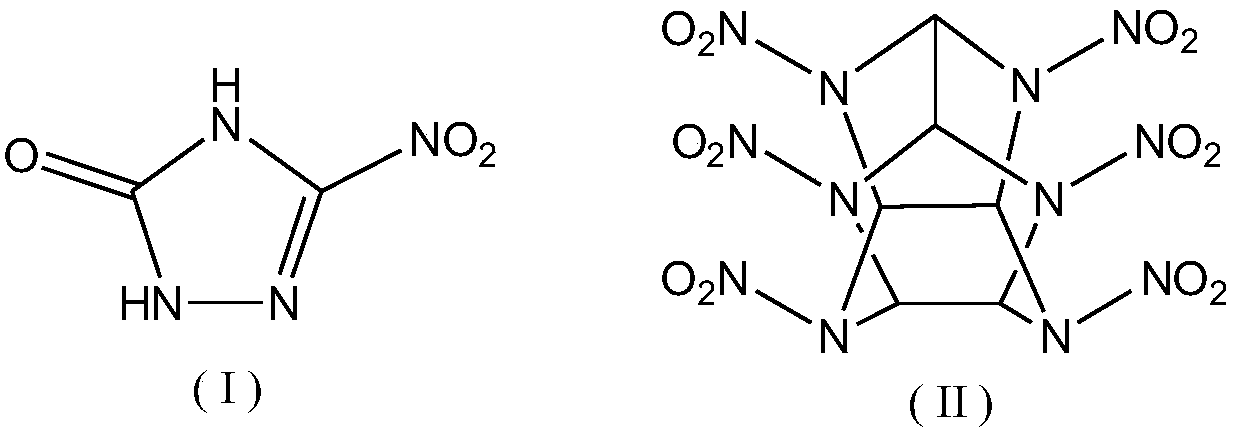

Low mechanical sensitiveness high-energy composite explosive and preparation method

InactiveCN109053341ALow mechanical sensitivityReduced friction sensitivityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsChemistryHigh energy

The invention discloses a low mechanical sensitiveness high-energy composite explosive which consists of NTO (Nitrogen Tetroxide) and CL-20, wherein the mass ratio of CL-20 to NTO is 1:(0.5-1.5). Thepreparation method comprises the following steps: putting an NTO explosive solid into water, stirring, and increasing the temperature till NTO is completely dissolved so as to obtain an NTO solution;putting the CL-20 explosive solid and a surfactant into water, controlling the temperature to be less than 20 DEG C, stirring so as to obtain a CL-20 water suspension, slowly putting the NTO solutioninto the water suspension of CL-20, filtering, washing, and drying, thereby obtaining the NTO / CL-20 composite explosive. The composite explosive disclosed by the invention has the advantages of beinghigh in density, high in explosion speed, low in mechanical sensitiveness, and the like, the mechanical sensitiveness of CL-20 is effectively degraded, and the security of CL-20 is improved.

Owner:XIAN MODERN CHEM RES INST

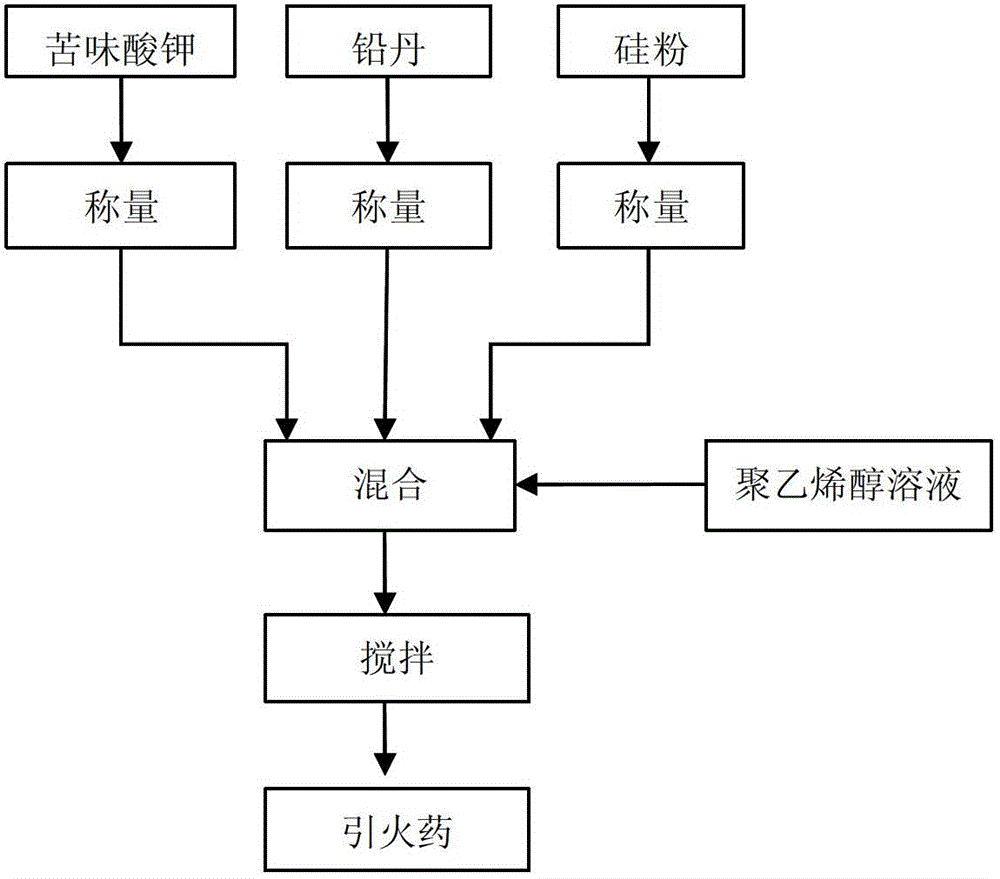

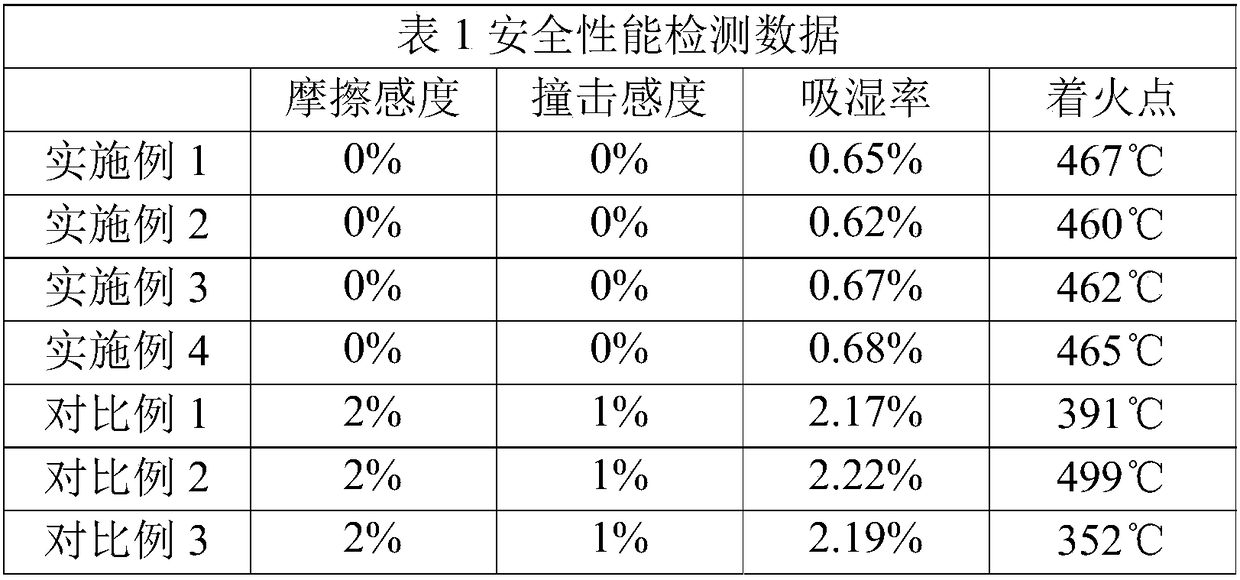

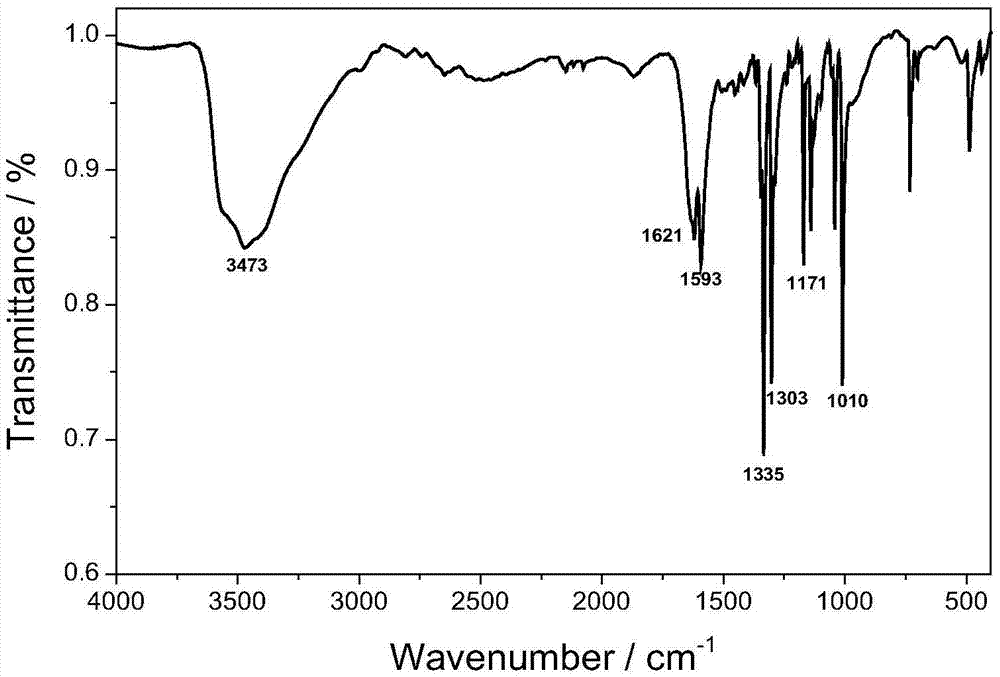

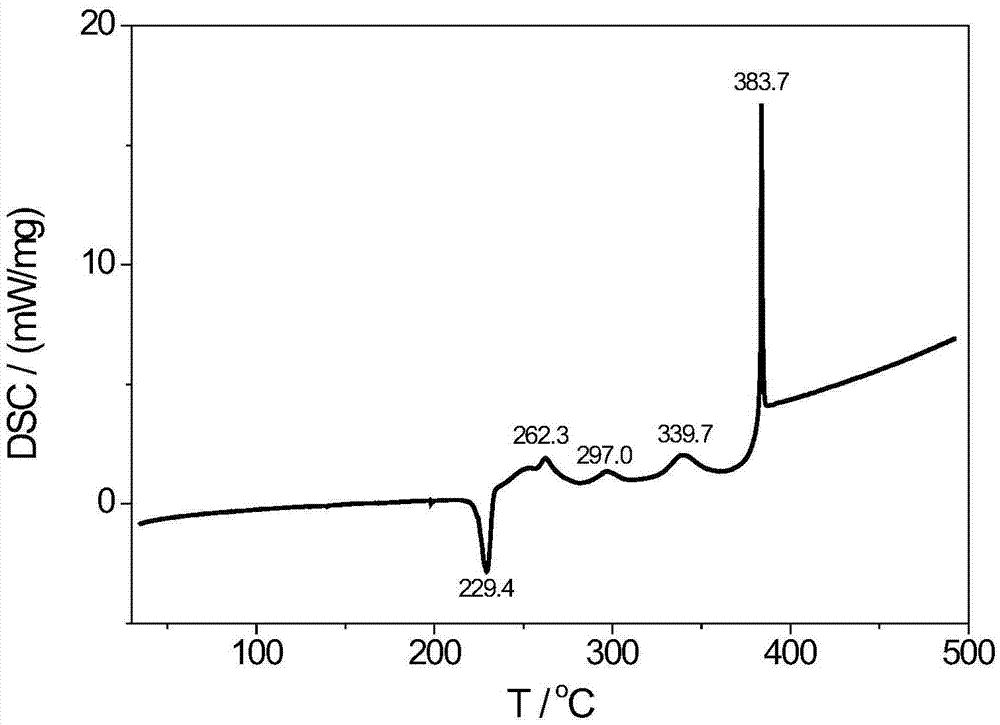

Manufacturing method of potassium picrate-red lead silicon series electric ignition charge

InactiveCN102875268AImprove ignition abilityGood flame sensitivityNitrated metallo-organic explosive compositionsIntrinsic safetyElectricity

The invention aims to provide a manufacturing method of a potassium picrate-red lead silicon series electric ignition charge. The manufacturing method comprises the steps of: weighing, mixing, smearing the ignition charge and the like, so that the ignition charge has better flame sensitivity and lower mechanical strength; and thus, the ignition capacity of the electric ignition charge is high, and the intrinsic safety and reliability during production and use can be effectively improved.

Owner:FUJIAN CIVILIAN BLASTING CHEM

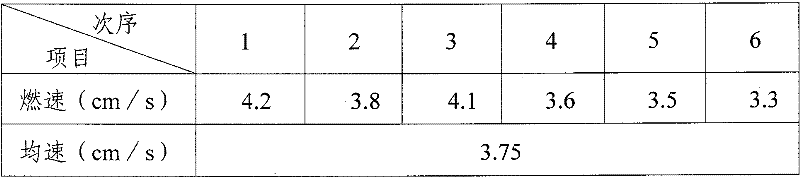

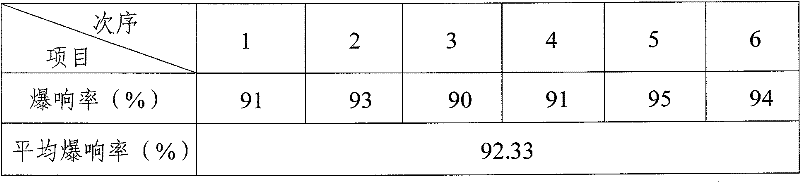

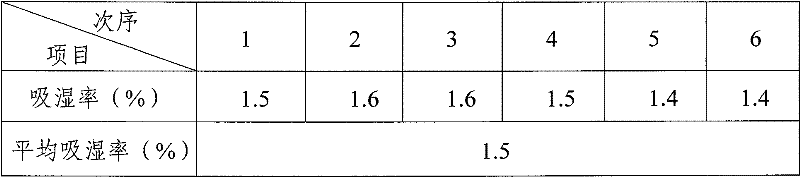

Propellant powder and preparation method

InactiveCN108947748AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusNitrated explosive compositionsMoisture absorptionShock sensitivity

The invention provides propellant powder and a preparation method. The propellant powder comprises 30-50 parts of potassium permanganate, 8-20 parts of a binding agent, 10-20 parts of potassium hydrogen phthalate and 20-40 parts of a combustible agent, wherein the combustible agent is a mixture of nitrocotton and charcoal powder. The propellant powder has low friction sensitivity and impact sensitivity, low moisture absorption rate and strong thrust and meanwhile reduces the environmental pollution.

Owner:胡惠娟

Novel colored and fragrant firecracker

The invention discloses a novel colored and fragrant firecracker which is prepared from the following components in parts by weight: 50-70 parts of potassium perchlorate, 1-3 parts of acetylene black, 5-9 parts of ammonium chloroplatinate, 8-15 parts of magnesium powder, 7-15 parts of aluminum powder, 5-10 parts of titanium white, 6-10 parts of iron powder, 5-15 parts of aged folium artemisiae argyi powder, 6-25 parts of Artemisia santonica powder, 8-16 parts of strontium carbonate, 2-6 parts of phenol formaldehyde resin, 2-6 parts of polyvinyl chloride, 4-12 parts of strontium nitrate, 9-30 parts of sulfur, 1-6 parts of shellac, 10-50 parts of barium nitrate, 10-50 parts of calcium nitrate, 2-5 parts of sodium nitrate, 0.5-1 part of rosin, 2-25 parts of antimony sulfide, 1-3 parts of vegetable oil and 15-35 parts of hard charcoal powder. The invention has the advantages of reasonable product formula, high safety performance and favorable explosion effect, and integrates fireworks and crackers; after the firecracker is ignited, the firecracker can generate dual effects of fireworks and crackers, has beautiful colors and fragrant smell, and can last for a long time.

Owner:李辉

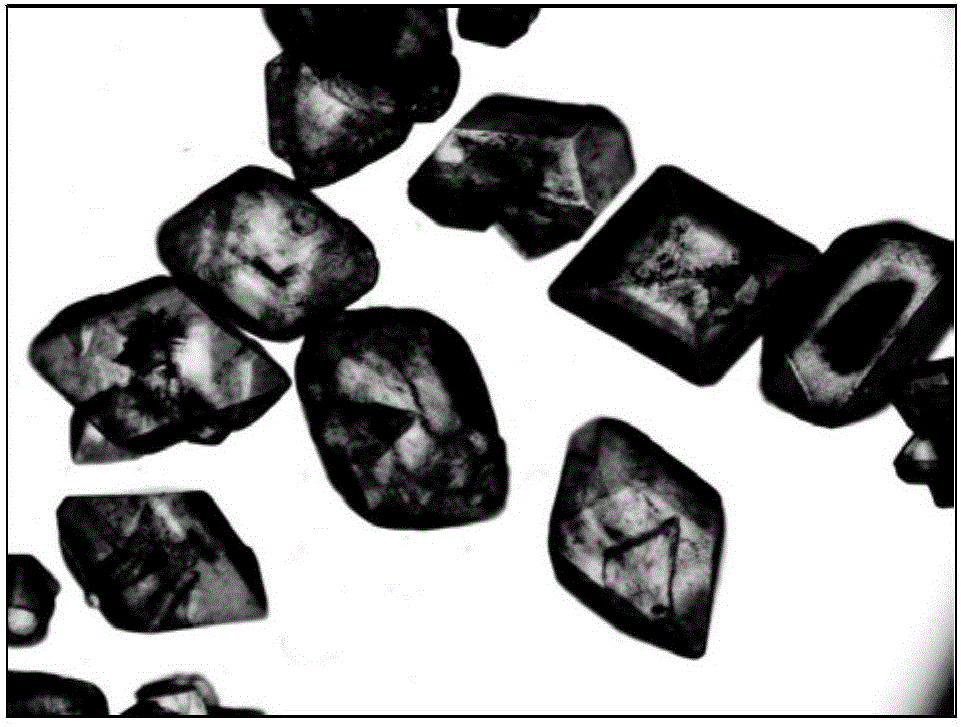

1,1'-dihydro-5,5'-bistetrazole-lead coordination polymer and preparation method thereof

InactiveCN105440070AReduced friction sensitivityEasy to prepareLead organic compoundsPressure gas generationHydrogenFiltration

The invention discloses a coordination polymer and a preparation method thereof. A unit cell of the coordination polymer contains a 1,1'-dihydro-5,5'-bistetrazole ligand, a lead (II) ion and three coordinated water molecules. The preparation method comprises the following steps: dissolving 1,1'-dihydro-5,5'-bistetrazole and lead salt in a solvent, filtering the solution, heating the solid to 60-160 DEG C, maintaining the temperature for 2-48 hours, reducing the temperature to 10-40 DEG C at a rate of 1-10 DEG C per hour, precipitating a colorless crystal and carrying out suction filtration and airing, thus obtaining the coordination polymer. The prepared coordination polymer has higher nitrogen content and can serve as a single-compound explosive or solid propellant burning rate modifier.

Owner:XIAN MODERN CHEM RES INST

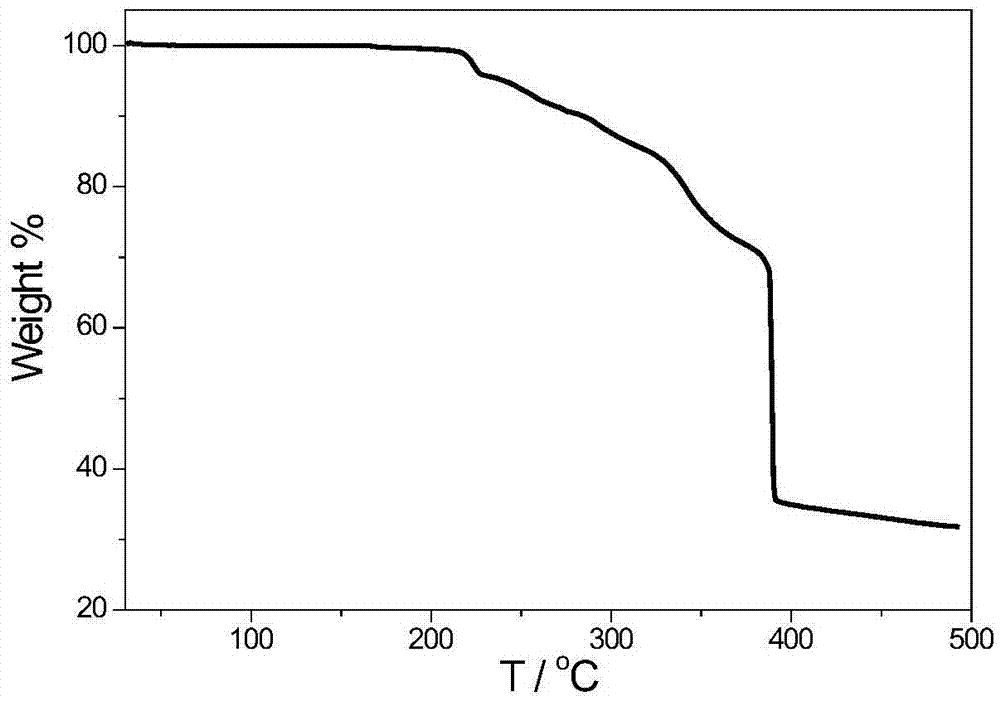

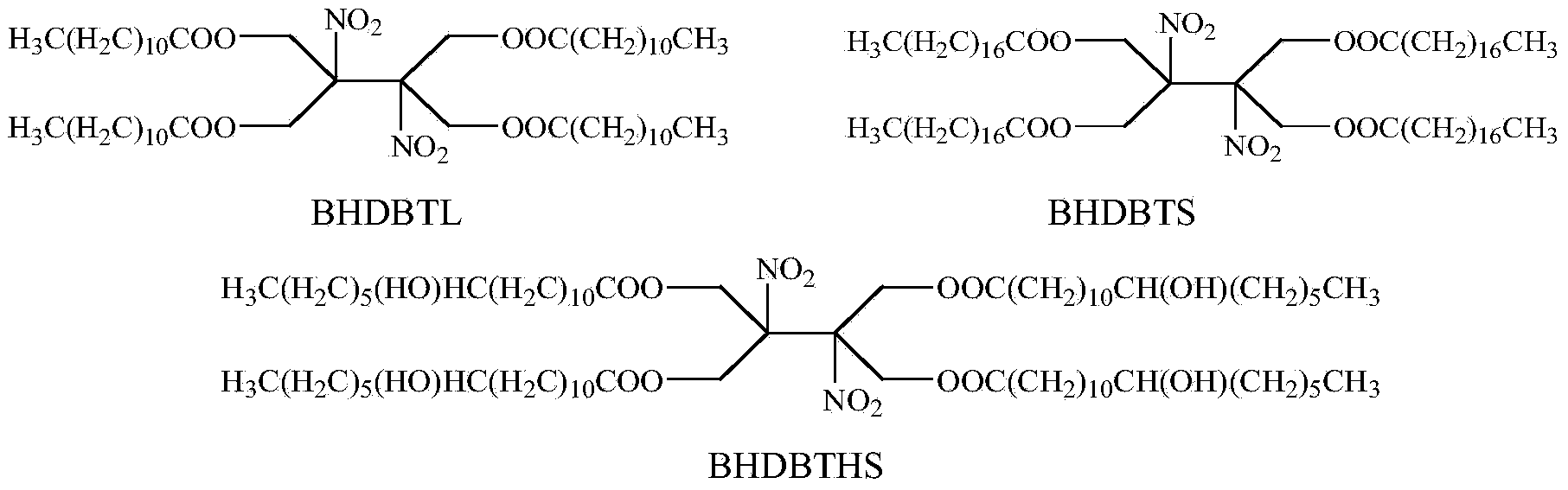

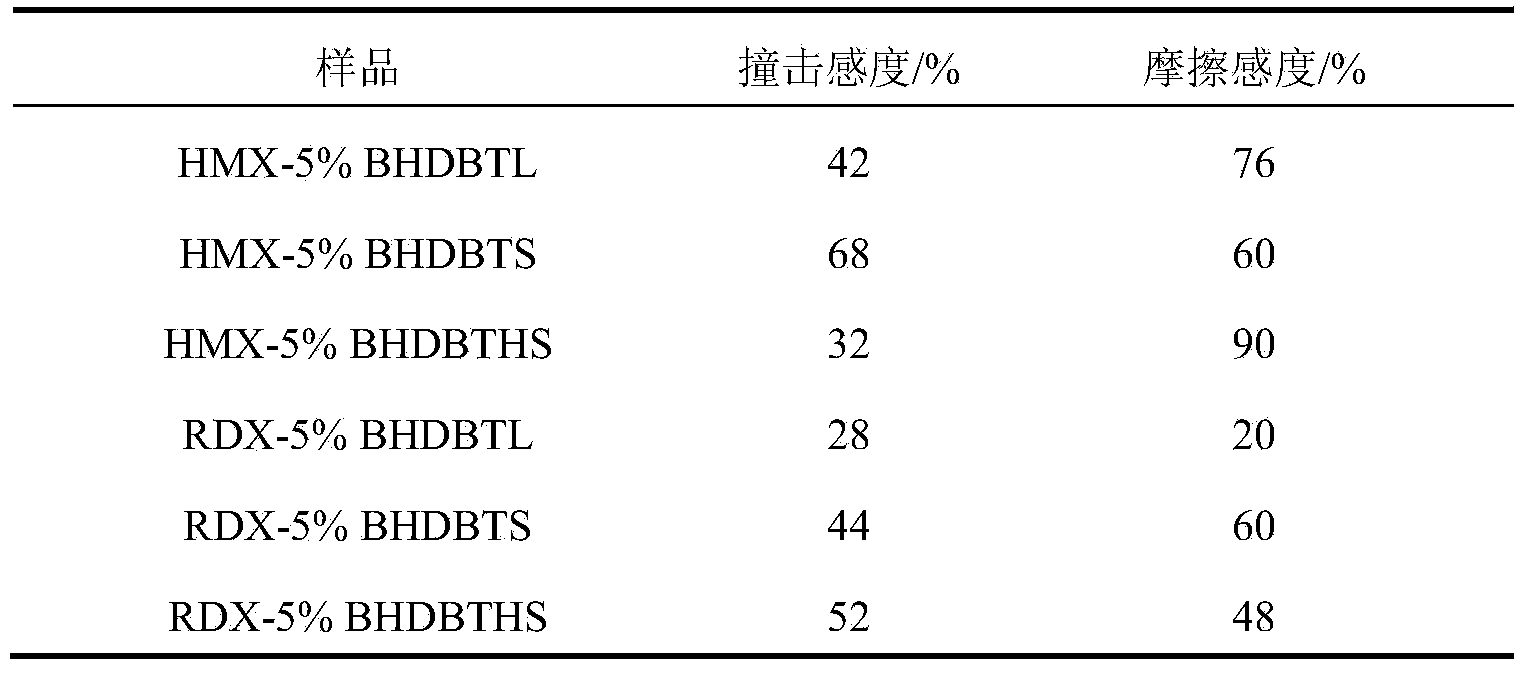

Method for coating RDX cyclotrimethylene trinitramine and HMX cyclotetramethylene tetranitramine and coating material thereof

ActiveCN103641670AImprove performanceLow impact sensitivityNon-explosive/non-thermic compositions1,4-ButanediolHydroxystearic Acid

The invention discloses a method for coating RDX cyclotrimethylene trinitramine and HMX cyclotetramethylene tetranitramine and a coating material thereof. The coating material is 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetralaurate, 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetrastearate or 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetra(12-hydroxystearic acid) ester. The method for coating RDX and HMX comprises the following steps: adding RDX or HMX and the wrapping material into acetone or DMSO (Dimethylsulfoxide); fully stirring; heating to 50 DEG C; dropwise adding the mixed liquor by a heat preserving dropper to quickly stirred water; and filtering and drying to constant weight. Compared with conventional inertial materials, the adopted coating material comprises two nitro groups in the molecular structure, and performances of RDX and HMX coated with the wrapping material are improved to a certain extent. The mechanical sensitivity test results show that the degree of percussion sensitivity and the frictional sensitivity of RDX coated with BHDBTL, BHDBTS and DHDBTHS are remarkably lower than those of a simple substance RDX. The degree of percussion sensitivity of HMX coated with BHDBTL, BHDBTS and DHDBTHS are remarkably lower than those of a simple substance HMX and the frictional sensitivity tends to get reduced.

Owner:NANJING UNIV OF SCI & TECH

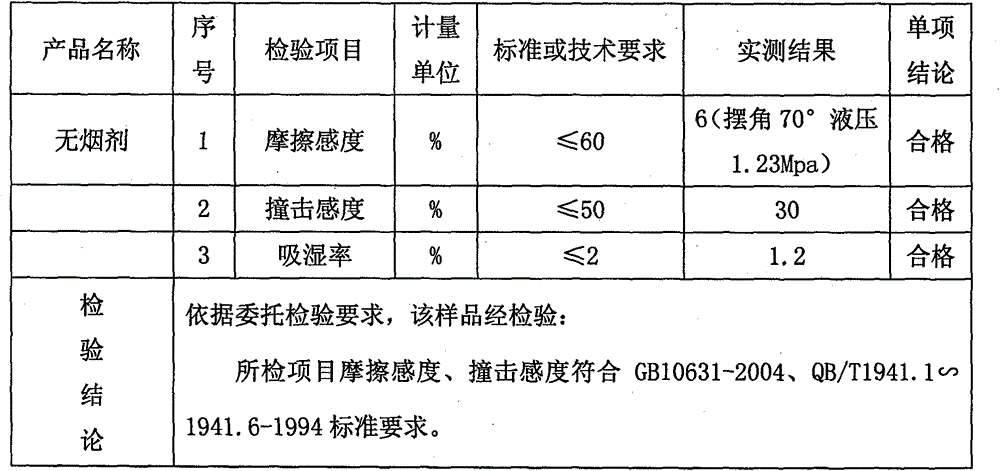

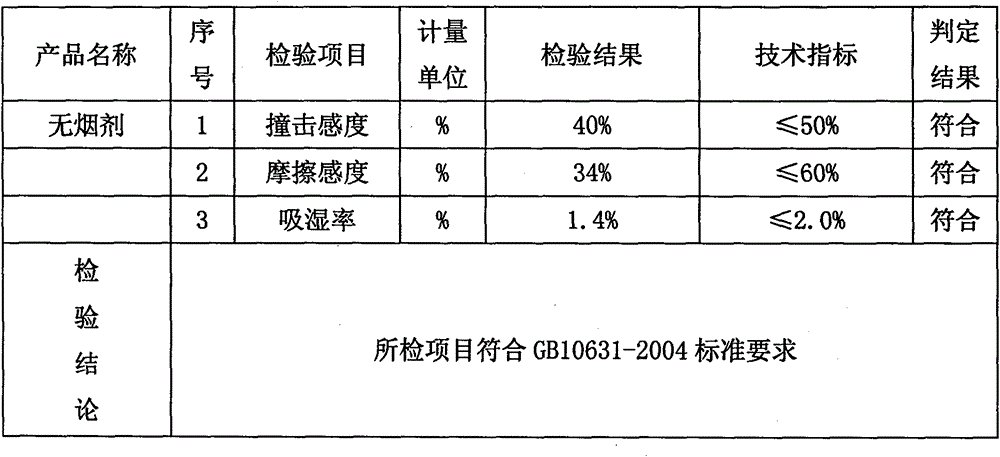

Smokeless emission chemical for fireworks

The invention relates to a smokeless emission chemical for fireworks. The smokeless emission chemical consists of the following components in parts by weight: 20-120 parts of nitrocellulose, 5-10 parts of graphite, 5-25 parts of carboxymethylcellulose, 3-40 parts of charcoaled hemp stalk powder, 3-40 parts of charcoaled fir powder, 2-30 parts of ammonium dichromate, 10-30 parts of barium nitrate and 5-40 parts of potassium perchlorate. The smokeless emission chemical produces smoke only after being burnt, which is 80% less than that of fireworks made from conventional materials; the smokeless emission chemical is free from sulfur dioxide, and the riction sensitivity, collision degree, heat absorption, wet absorption and compatibility are superior to those of the common military saltpeter.

Owner:杨培江

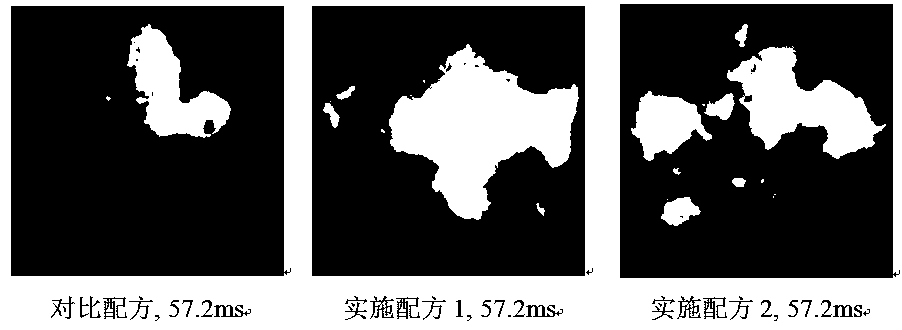

Composite oxidant used for fireworks and crackers and preparation method thereof

InactiveCN101597195ALow impact sensitivityReduced friction sensitivityExplosivesPolyvinyl butyralFireworks

The invention relates to a composite oxidant used for fireworks and crackers and a preparation method thereof, belonging to the field of fireworks and crackers. The composite oxidant used for fireworks and crackers comprises the following components in a certain mass ratio: potassium perchlorate, potassium nitrate, ammonium perchlorate, polyvinyl butyral and catalysts. The composite oxidant is obtained by the following steps: carrying out the evaporation crystallization on the components of the composite oxidant respectively; grinding and mixing the components and precipitating a layer of polyvinyl butyral outside the mixed components. The crackers are obtained by preparing the composite oxidant, sulfur, aluminum powder and perlite powder into a pyrotechnic composition. By testing, the mechanical sensitivity, hygroscopicity and cracker sound level of the pyrotechnic composition conform to the national standards.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

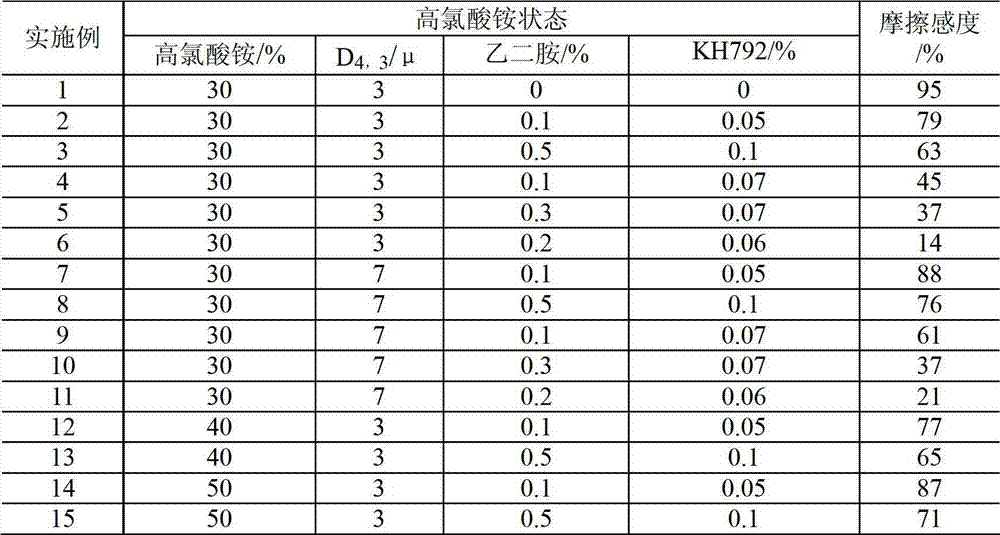

Ammonium perchlorate

InactiveCN103030485AReduce defectsReduced friction sensitivityPressure gas generationFriction sensitivityInorganic salts

The invention discloses ammonium perchlorate, belonging to the field of inorganic salt. The technical scheme is as follows: ammonium perchlorate is the key component, ammonium perchlorate is coated by ethylenediamine and KH792, the granularity D4,3 of ammonium perchlorate is 3-7 micrometers, ethylenediamine is 0.1%-0.5%, and KH792 is 0.05%-0.1%; and ethylenediamine is analytically pure. Fine-grained ammonium perchlorate is processed mainly by an airstream pulverization method, for the reason of the characteristics of the technique, more edges and defects exist on the surface of ammonium perchlorate, the ammonium perchlorate granules are easy to collide with each other and generate hot points, and the friction sensitivity of the compound solid propellant is increased. Ethylenediamine and KH792 are used as surface active agents for coating the surface of ammonium perchlorate, thus, the defects on the surface of ammonium perchlorate can be reduced, and the influence on the friction sensitivity of the compound solid propellant is lowered.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Polyurethane coated modified potassium chlorate and preparation method and applications thereof

InactiveCN103242113AExcellent flexibility and cushioningLow costAlkali metal salt explosive compositionsToluene diisocyanatePotassium chlorate

The invention discloses a kind of polyurethane coated modified potassium chlorate. The polyurethane coated modified potassium chlorate is of a core-shell structure, takes potassium chlorate as an inner core and takes polyurethane as a coating shell, and the mass ratio of the polyurethane to the potassium chlorate is 0.1-0.05:1. The invention also discloses a preparation method of the polyurethane coated modified potassium chlorate. The preparation method comprises the following steps: adding toluene diisocyanate and dehydrated polypropylene glycol into an organic solvent, adding potassium chlorate particles, heating, stirring, and carrying out condensed backflow; cooling a reaction system, adding a dehydrated dimethylolpropionic acid and a catalyst into the reaction system, stirring and carrying out condensed backflow; adding dehydrated butanediol into the reaction system, stirring and carrying out condensed backflow; and adding dehydrated triethylamine, and after the obtained object is fully stirred, carrying out solid-liquid separation, and drying obtained solid particles so as to obtain products. A polyurethane coated modified potassium chlorate product disclosed by the invention can be used as an oxidant for fireworks and crackers, and can reduce the mechanical sensitivity of potassium chlorate containing pyrotechnic compositions and increase the thermal security and stability thereof.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

HMX-based boraxal-containing explosive

InactiveCN108675910AReduce topographical defectsIncrease contentExplosivesPressure gas generationMass ratioMetallurgy

The invention relates to HMX-based boraxal-containing explosive. The explosive is prepared from the following various ingredients in percentage by patent: 60-68% of HMX, 15-25% of B-A1 composite powder and 14-18% of bonding agent, wherein the mass ratio of powder B to powder Al in the B-A1 composite powder is 1:1. The explosive can be used as the main charge of high-strength and high-security ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Novel potassium perchlorate paper firing line for firecrackers

InactiveCN101973828BImprove performanceIncrease burn rateInorganic oxygen-halogen salt explosive compositionsFusesFirecrackerPulp and paper industry

Owner:陕西省蒲城县新型花炮技术推广中心

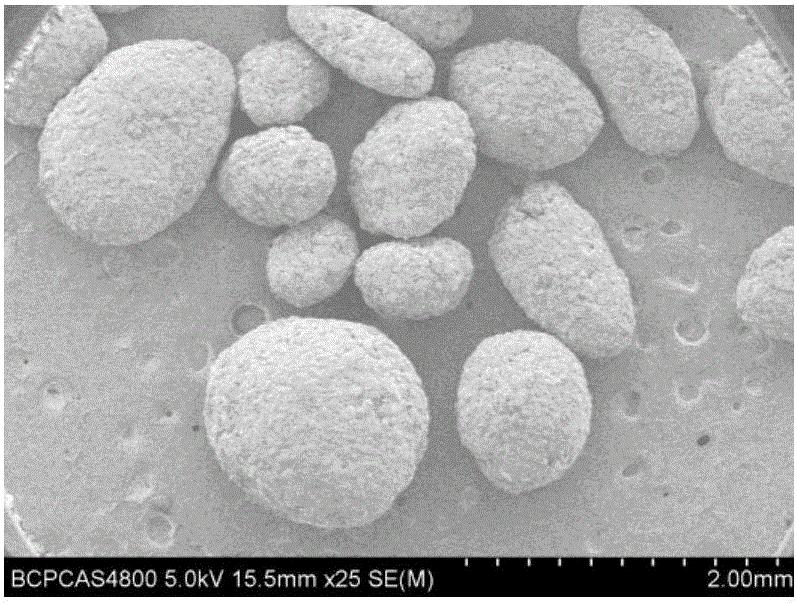

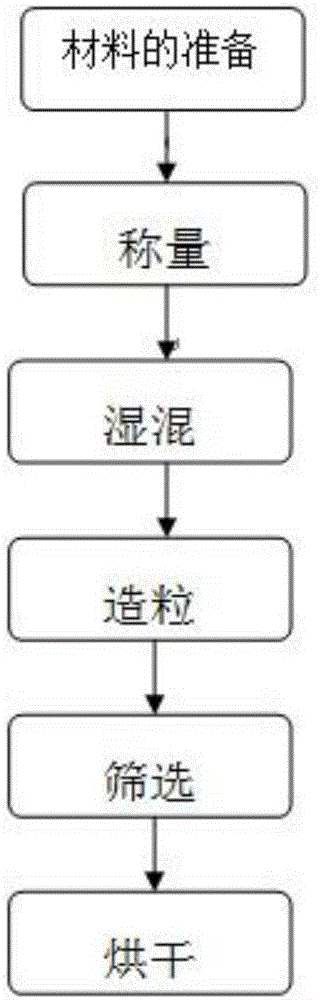

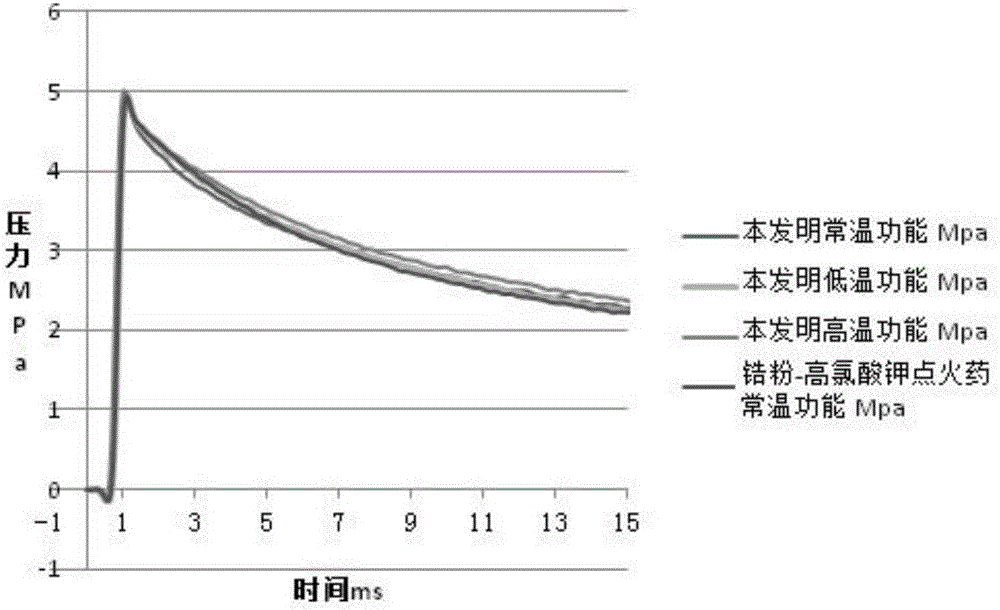

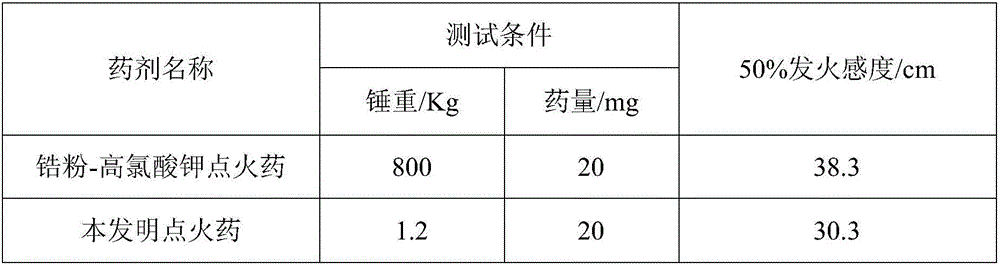

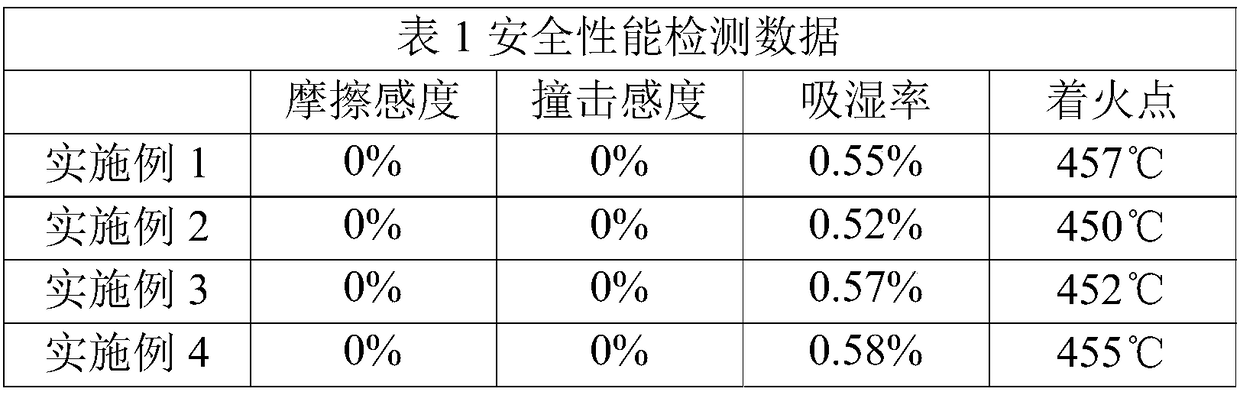

Igniter reagent of airbag device and preparation method of igniter reagent

InactiveCN106278774AGood ignition functionReduced friction sensitivityPyrophoric compositionsChemistryBatch production

The invention discloses an igniter reagent of an airbag device. The igniter reagent comprises the following raw material components in percentage by mass: 20-45% of a combustible agent, 50-78% of an oxidant, 0.5-5% of a combustion improver and the balance of an adhesive, wherein the total mass percentage of the components is 100%. A preparation method of the igniter reagent comprises the following steps: performing wet mixing on the raw materials, cutting a reagent into spheres, putting the spheres into a granulator for pelletizing, screening uniform reagent granules, and finally drying the regent, thereby obtaining the igniter reagent. The igniter reagent disclosed by the invention has a good ignition function, is relatively low in percussion sensitivity degree, friction sensitivity degree and static electric spark sensitivity degree, is not self-combusted when being heated, collided and the like, is relatively high in security in both the production process and the use process, and is simple in preparation method, low in raw material price, low in cost, applicable to large-scale on-batch production and relatively high in cost performance.

Owner:陕西庆华汽车安全系统有限公司

Rock powdery emulsion explosive and preparation method thereof

The invention relates to a rock powdery emulsion explosive and a preparation method thereof. The rock powdery emulsion explosive is produced by that: an emulsion is formed by mixing a water phase ingredient and an oil phase ingredient in a mixer, then the emulsion is vacuum dried to be powder, and porous granulated ammonium nitrate is added into the powder. The rock powdery emulsion explosive provided in the invention, which is a high-performance safe explosive, is simple in composition; high in explosive power; and low in toxic gas content, impact sensitivity and mechanical sensitivity. The preparation method is simple and safe, and no inert substance is added into the explosive.

Owner:SICHUAN YAHUA IND GRP

Preparation method of perdeuterated CL-20

InactiveCN111471052AHigh yieldHigh purityIsotope introduction to heterocyclic compoundsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAcetic acidPtru catalyst

The invention relates to a preparation method of perdeuterated CL-20, and belongs to a synthesis technology of a deuterated energetic material. According to the method, deuterated N,N'-di-tert-butyl ethane-1,2-diimine and deuterated benzylamine are used as raw materials, deuterated acetic acid is used as a catalyst to synthesize an intermediate product that is deuterated hexabenzyl hexaazaisowurtzitane. Compared with a traditional method, the yield of the deuterated hexabenzyl hexaazaisowurtzitane is obviously increased; by adopting the deuterated hexaacetyl hexaazaisowurtzitane as a nitrification precursor for nitrification, the product does not contain impurities such as pentanitromonoformyl hexaazaisowurtzitane, and the obtained deuterated CL-20 is high in purity. Compared with common CL-20, the prepared perdeuterated CL-20 has better detonation performance and improved safety and better facilitates practical application.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Propellant and preparation method

InactiveCN108840782AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusNon-explosive/non-thermic compositionsHydrogenAdhesive

The invention provides a propellant and a preparation method. The propellant is prepared from the following components: 30-50 parts of potassium permanganate, 8-20 parts of an adhesive, 10-20 parts ofpotassium hydrogen phthalate, 20-40 parts of a combustible agent and 5-10 parts of iron(II,III) oxide, wherein the combustible agent is a mixture of pearl powder and charcoal powder. The propellant has low friction sensitivity and impact sensitivity, low moisture absorption rate and strong thrust, and environmental pollution is reduced.

Owner:胡惠娟

Low-sulfur firecracker chemicals and preparation method thereof

InactiveCN106116997AReduce sulfur contentHigh sulfur contentExplosive ingredient compoundingFumed silicaSodium potassium tartrate

The invention discloses low-sulfur firecracker chemicals and a preparation method thereof. The low-sulfur firecracker chemicals includes an oxidizing agent and a combustible agent, the oxidizing agent is composed of potassium perchlorate and barium nitrate oxide components and fumed silica and tartaric acid and / or sodium potassium tartrate additive components; the combustible agent is composed of magnalium and sulphur. The low-sulfur firecracker chemicals is low in cost of raw materials, simple in preparation method, good in explosion loudness, fire connecting capability, combustion rate and storage stability and the like when the chemicals is used in firecrackers, low in environmental pollution, low in injury to human bodies and wide in application prospect.

Owner:杨吉明

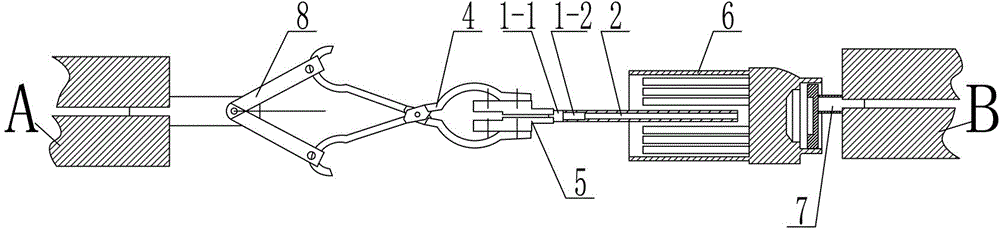

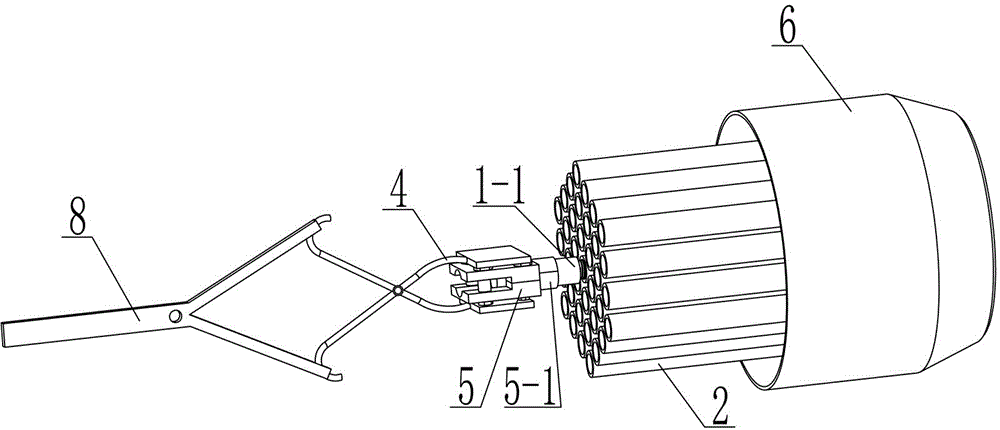

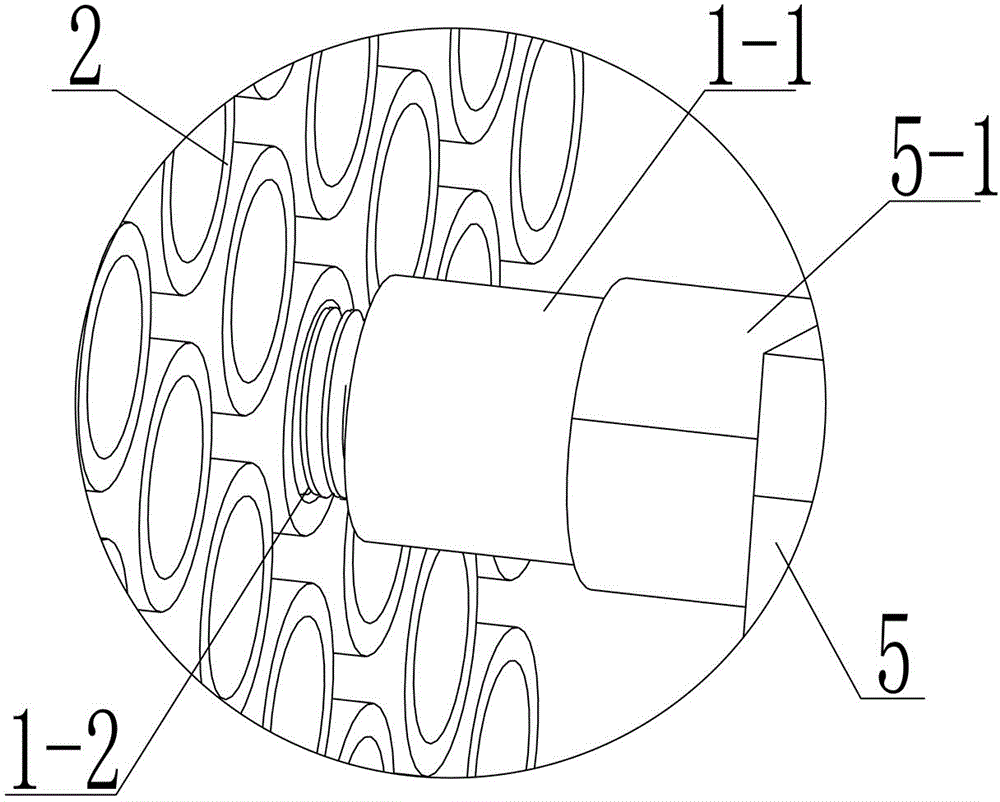

Clamp assembly for testing adhesive force between tubular propellant and chemical fixing adhesive tape

InactiveCN104155238AProtection from being crushedIncreased friction sensitivityUsing mechanical meansMaterial analysisSpontaneous combustionFriction sensitivity

The invention relates to a clamp assembly and in particular relates to a clamp for testing adhesive force between a tubular propellant and a chemical fixing adhesive tape. The clamp for testing the adhesive force between the tubular propellant and the chemical fixing adhesive tape comprises a copper bar, a connection clamp, a tension rack, a fixture clamp and a shell, wherein a medical tube is arranged in the shell. According to the clamp for testing the adhesive force between the tubular propellant and the chemical fixing adhesive tape, the adhesive tape is used as an auxiliary material for increasing friction force and reducing friction sensitivity; the chemical tube and the copper bar are tightly wrapped with the adhesive tape, so that the copper bar and the chemical tube are integrated into a whole; a semicircular tube is arranged on the connection clamp; an inner thread is designed on the semicircular tube, so that the semicircular tube can be clamped; the spontaneous combustion and the spontaneous explosion generated by the friction in the drawing process are avoided; the safety problem in the testing process is solved; the working efficiency is improved.

Owner:NO 63908 TROOPS PLA +1

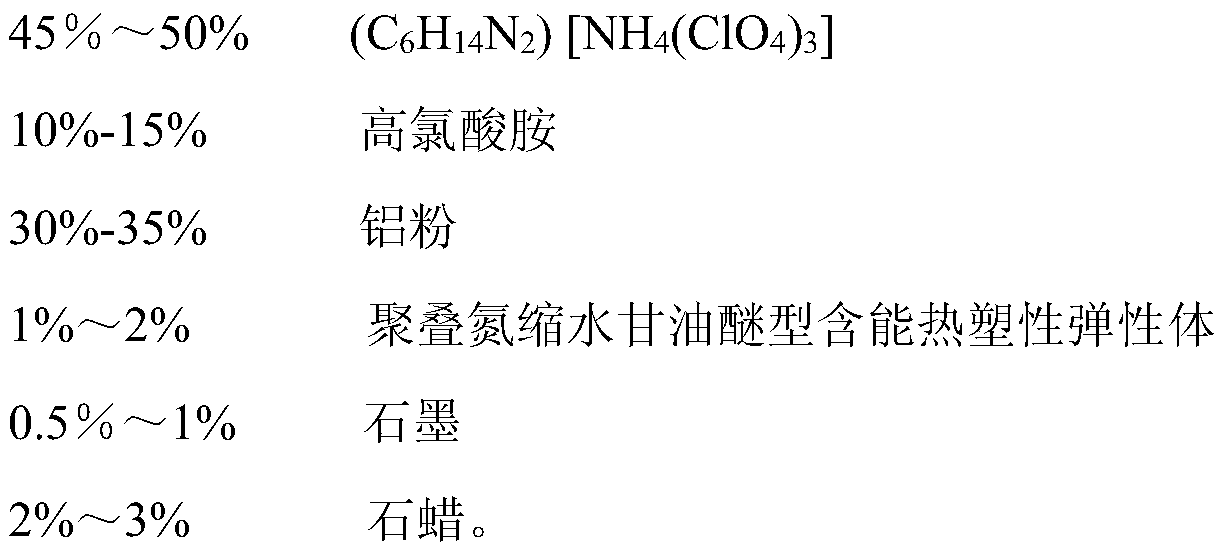

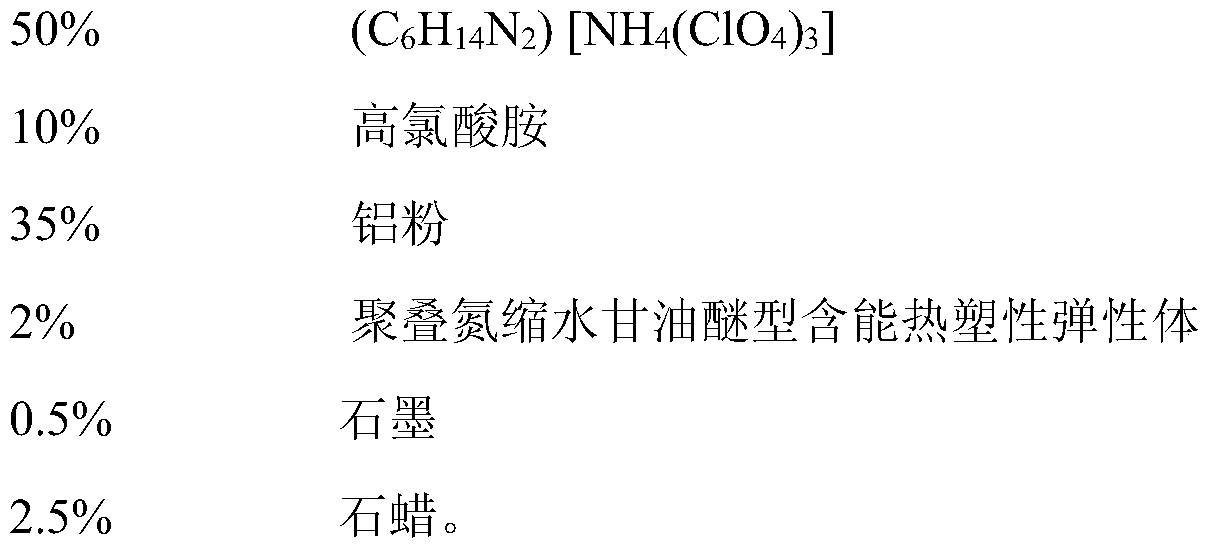

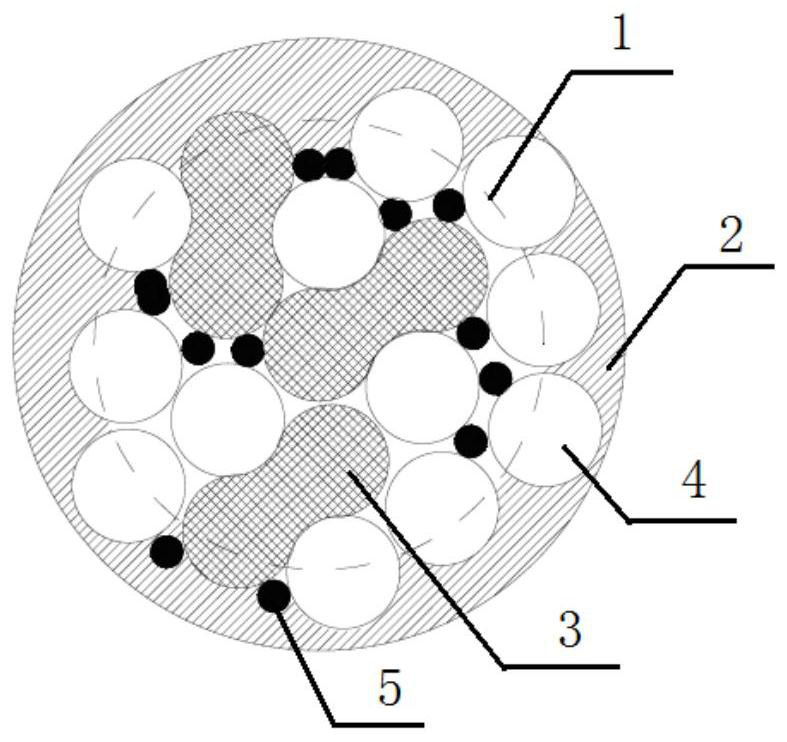

Aluminum-containing explosive composition

ActiveCN111004075ARelatively high molding densityReduced friction sensitivityExplosivesElastomerHigh energy

The invention discloses an aluminum-containing explosive composition, and aims to solve the problems of high mechanical sensitivity and low energy of a (C6H14N2)[NH4(ClO4)3] compound. The aluminum-containing explosive composition comprises (C6H14N2)[NH4(ClO4)3], ammonium perchlorate, glycidyl azide polymer energetic thermoplastic elastomer, aluminum powder, graphite and paraffin, and is relativelylow in mechanical sensitivity and high in explosion heat energy. The aluminum-containing explosive composition is mainly used for air blasting type weapon ammunition charging.

Owner:XIAN MODERN CHEM RES INST

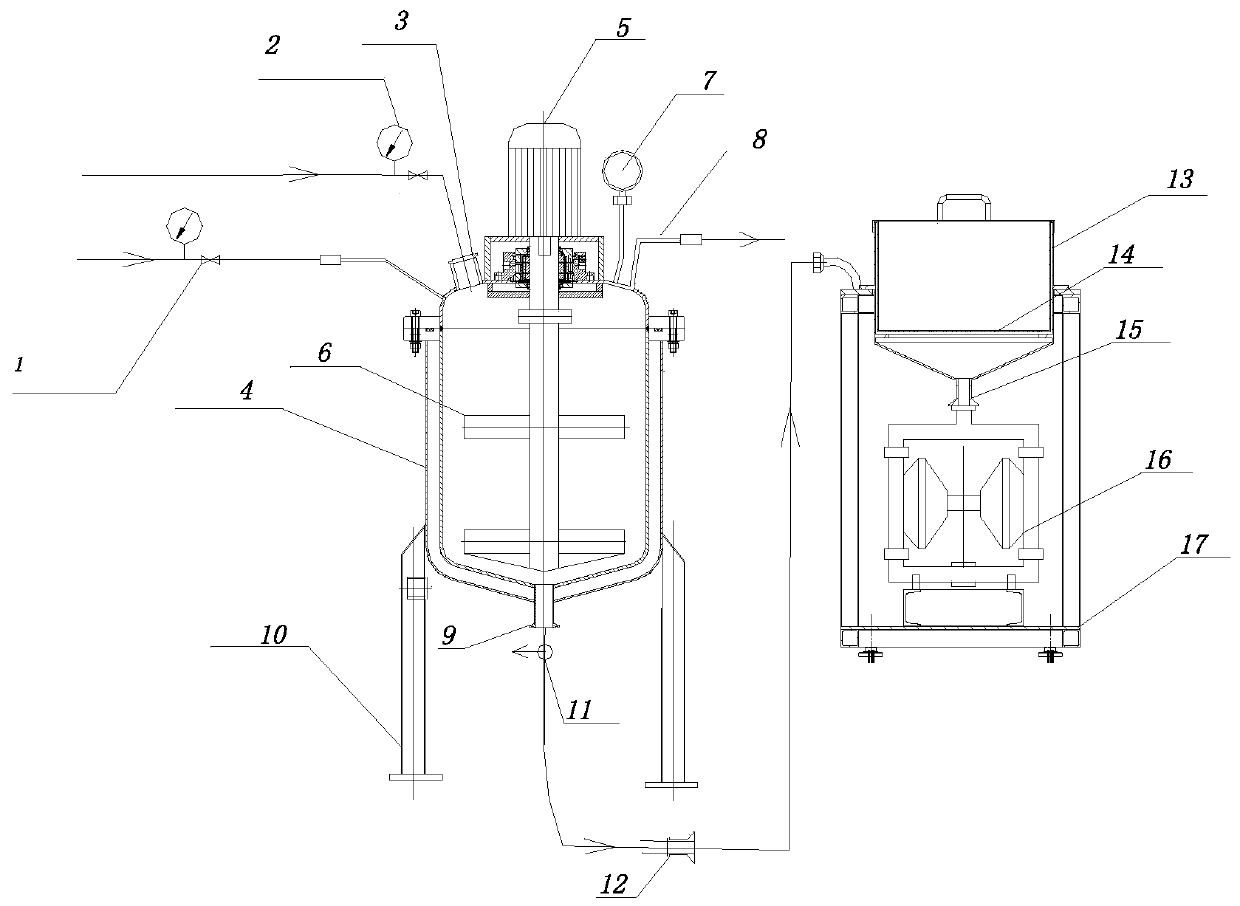

Passivation and filter equipment for aluminum fluoropolymer mechanically activated energetic material

InactiveCN110523361AImprove securityImprove processing efficiencyRotary stirring mixersTransportation and packagingDiaphragm pumpHigh energy

The invention provides passivation and filter equipment for an aluminum powder / polytetrafluoroethylene mechanically activated energetic material. The equipment includes a passivation tank, a passivation tank support, an explosion-proof electric motor, stirring paddles, a gas inlet valve, a gas discharge pipe, a pressure gauge, a feed opening, a feed valve, a material outlet, a filter hopper, a material conveying pipeline, a pneumatic three-way ball valve, a first pneumatic diaphragm pump, a second pneumatic diaphragm pump, a filtrate receiving device, a filter device support and a filter cloth. The equipment provided by the invention is suitable for passivation and filter treatment of the aluminum powder / polytetrafluoroethylene mechanically activated energetic material, and can effectivelyimprove the safety of the material outlet process of the aluminum powder / polytetrafluoroethylene mechanically activated energetic material and improve process efficiency; and compared with a materialprepared by an original process, the aluminum powder / polytetrafluoroethylene mechanically activated energetic material prepared by the equipment provided by the invention has the advantages of high energy and low sensitivity.

Owner:XIAN MODERN CHEM RES INST

Composite explosive structure and preparation process

ActiveCN112939711AStrong detonation output capabilityIncreased blast temperatureNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsTEX-explosiveAluminium powder

The invention provides a composite explosive structure and a forming process. The composite explosive structure comprises mixed crystal particles, and the mixed crystal particles are coated with a coating film; the mixed crystal particles comprise CL-20 explosives and aluminum powder, and the CL-20 explosives and the aluminum powder are locally bonded through a binder; and the coating film is composed of paraffin, talcum powder and sodium dodecyl benzene sulfonate. The mixed crystal particles are realized through mixed crystal dispersion and mixed crystal kneading processes; and the coating film is realized through solution preparation and paddle-free mixing processes. The composite explosive structure has high detonation output capacity, and compared with conventional mixing of blended explosives in the same proportion, the temperature of an explosion field is increased by 100 DEG C or above; the Gurney coefficient is increased by 5%; and the shock wave overpressure is improved by more than 10%. The composite explosive structure provided by the invention has high safety, and the impact sensitivity and the friction sensitivity are reduced by more than 10% compared with a same-proportion crystal embedding structure and a conventional mixed structure.

Owner:XIAN MODERN CHEM RES INST

Smokeless cellulose

ActiveCN102795949BImprove securityQuality improvementNitrocellulose explosive compositionsCelluloseFiber

The invention discloses a smokeless cellulose which is used for preparing fireworks. The smokeless cellulose is a solid-state micropowder or particle agent. The invention is characterized in that the smokeless cellulose is prepared by nitrating plant fiber and comprises the following components in parts by weight: 100 parts of plant fiber, 40-80 parts of 60-98% nitric acid, 10-50 parts of 60-98% sulfuric acid, 0.5-5 parts of diphenylamine, 0.5-5 parts of camphor, 1-10 parts of sodium carbonate and 50-100 parts of solvent, wherein the plant fiber is one or mixture of pulverized corn cob, corn stalk, bamboo, boon, peanut shell, reed and sugar cane waste residue in any weight ratio; the mixture of nitric acid and sulfuric acid is used as a nitrating agent; the mixture of diphenylamine and camphor is used as a stabilizer; and the solvent is alcohol, banana oil, aether or acetone. The invention has the advantages of high safety, high stability, no smoke, no smell, no toxicity, no dust, environmental protection and the like.

Owner:浏阳市华金烟花制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com