Patents

Literature

741 results about "Potassium chlorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

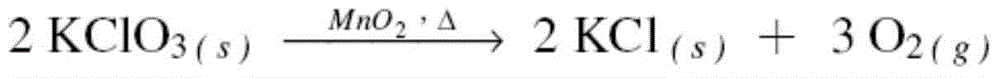

Potassium chlorate is a compound containing potassium, chlorine and oxygen, with the molecular formula KClO₃. In its pure form, it is a white crystalline substance.

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

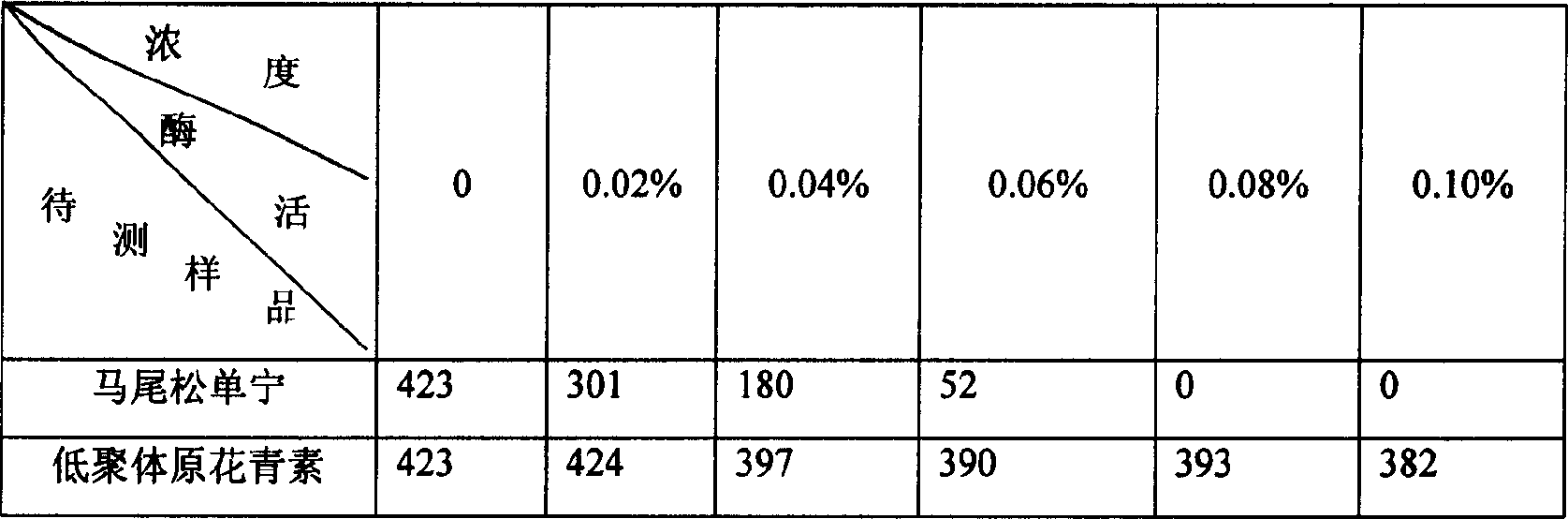

Procyanidins oligomer and its preparing method and use

InactiveCN1654463AStrong Antioxidant FunctionStrong antibacterial functionOrganic chemistryAnimal feeding stuffAntioxidantFeed additive

The present invention relates to one kind of protocyanidin oligomer and its production process and application in food, health article, feed additive and animal medicine. The protocyanidin oligomer is dimer, trimer and tetramer, and is produced with condensated tannin as material and through oxidizing degradation with hydrogen peroxide or potassium chlorate as oxidant to obtain yellow or brown semi-transparent liquid and subsequent separation and purification. The protocyanidin oligomer of the present invention has powerful antioxidant function and antibiotic function, and my be used in food owing to no astringent taste and no negative effect on the activity of amylase in digestive tract, as feed additive to reduce coccidiosis infection of fowls and low cholesterol content in egg.

Owner:浙江德清利欣生物科技有限公司

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Preparation method for coal combustion improver

The invention relates to a preparation method for a coal combustion improver. After common coal is added with coal additives for combustion, the effect of energy saving and emission reduction is obvious and effective. The preparation method comprises the following steps that: 1. high-stability sodium chlorate and potassium chloride react with each other to produce potassium chlorate when water is added and the sodium chlorate and the potassium chloride are dissolved; 2. leavening agent sodium acetate is introduced to conduct base exchange with humate in coal, low ignition point humate is produced and the ignition performance of the coal is reduced; and 3. ferric oxide required by the formula is compound insoluble in water. Thereby, ferric chloride and calcium oxide are used to react with each other to produce ferric oxide when water is added and the ferric chloride and the calcium oxide are dissolved. Other products in the market do not at all have the preparation and application characteristics of the three compounds.

Owner:GUANGHUA SCI & TECH SHANGHAI +1

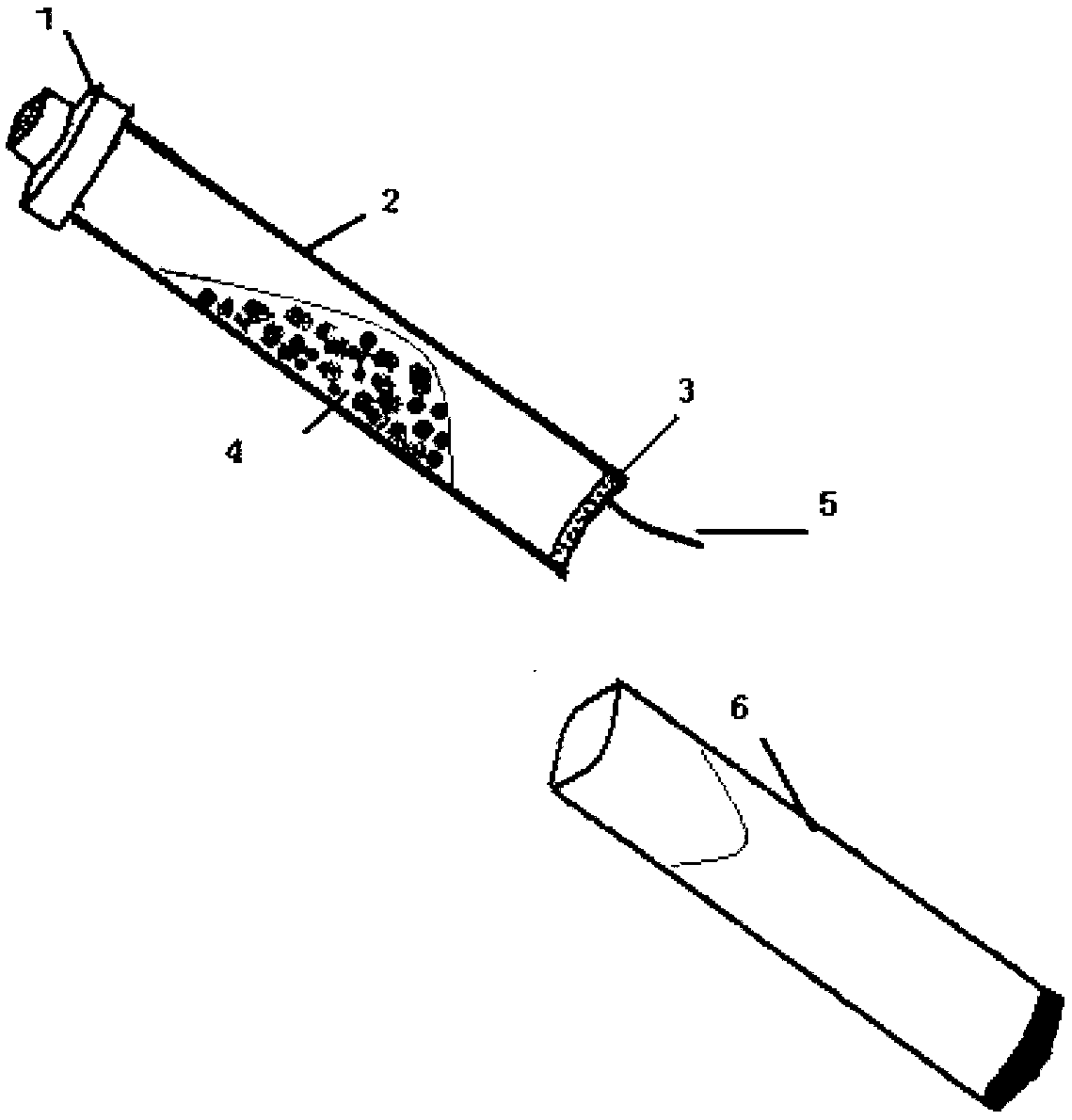

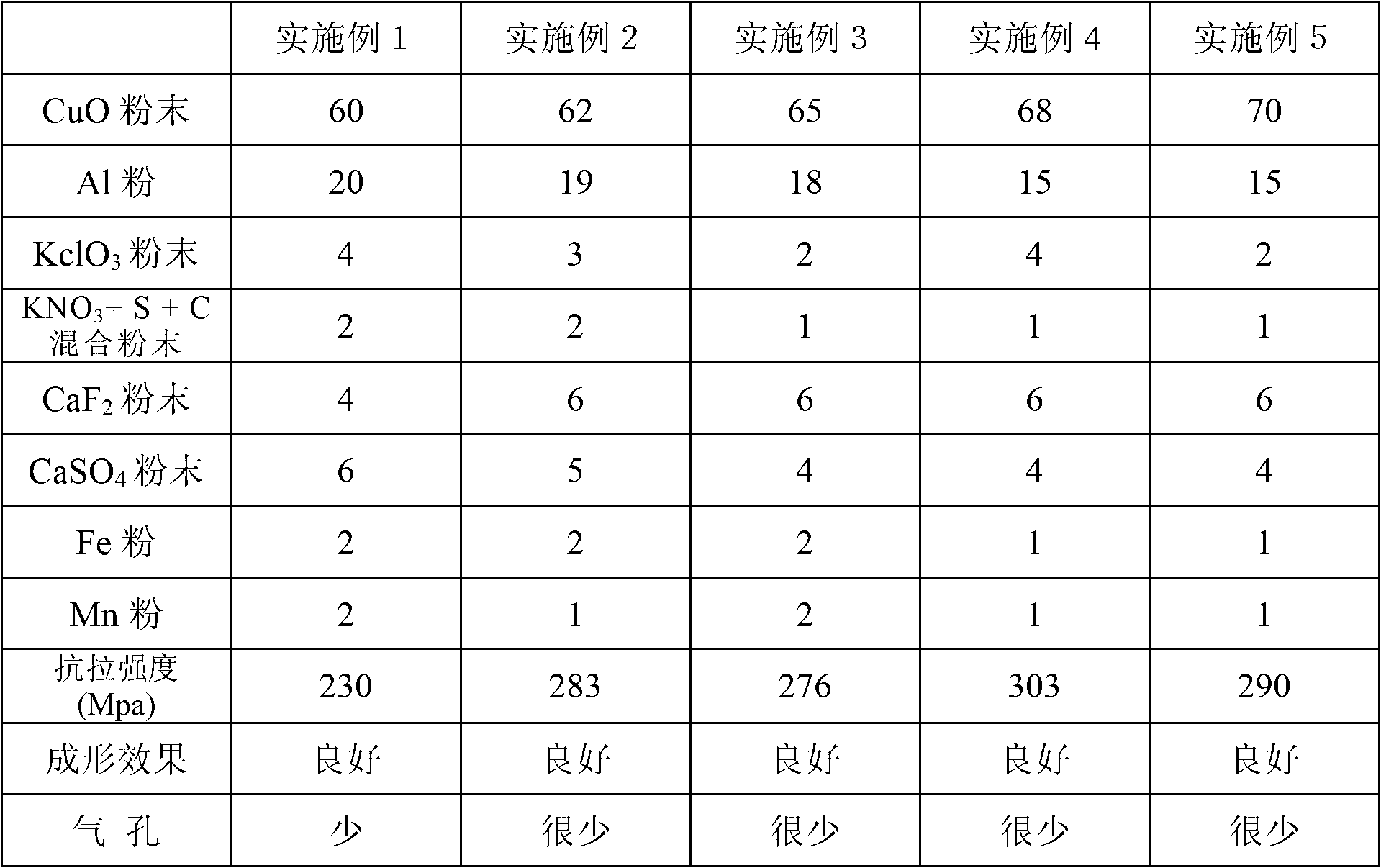

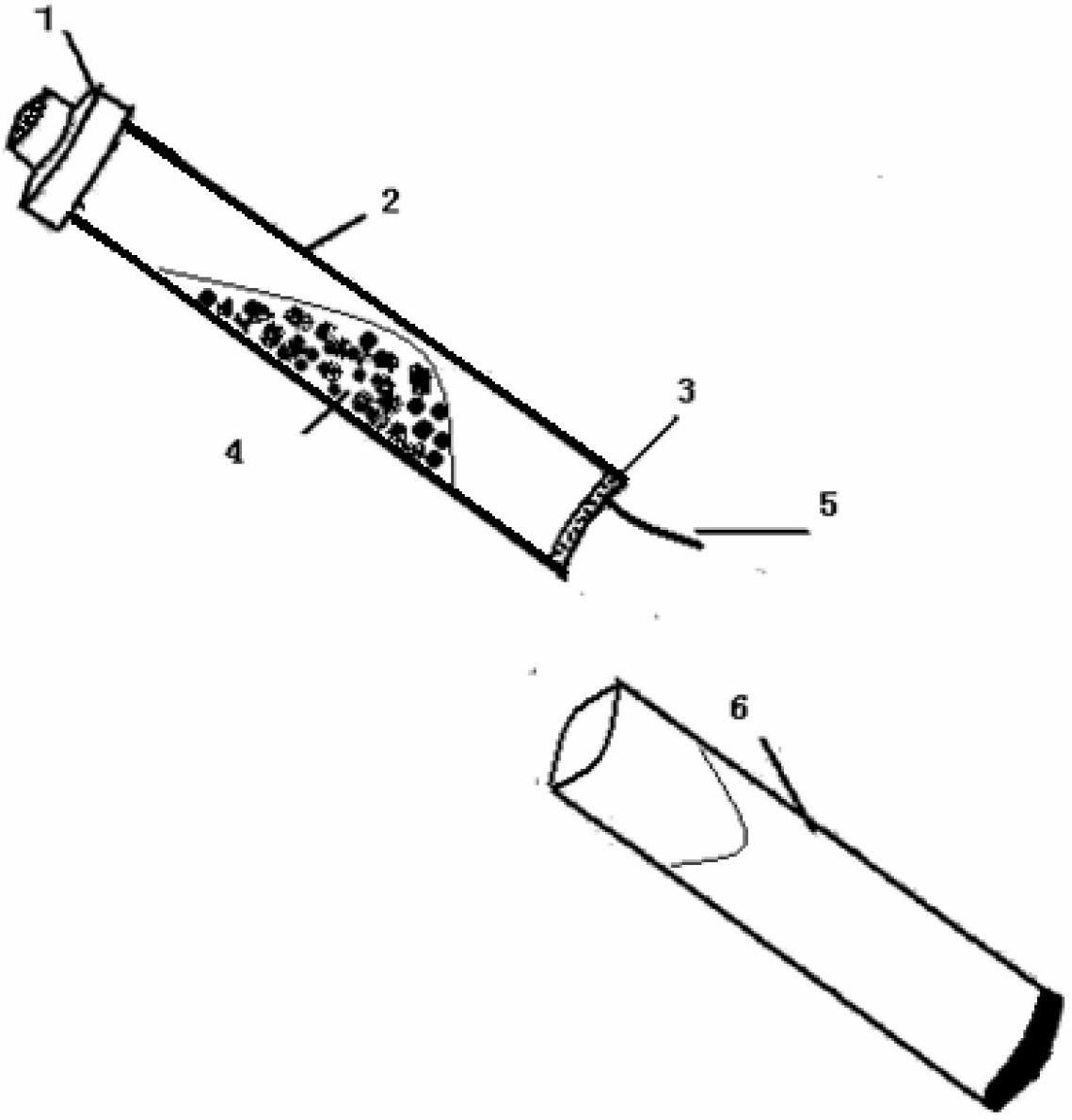

Simple electroless welding pen and preparation method of electroless welding pen

InactiveCN102699521AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a simple electroless welding pen, which comprises a cartridge, welding flux and a lead. The welding flux is thermite; the simple electroless welding pen comprises the raw material constituents by weight percent: 60-70% of CuO (cupric oxide) powder, 15-20% of Al (aluminum) powder, 2-4% of KClO3 (potassium chlorate), 1-2% of KNO3 (potassium nitrate)+S (sulfur)+C (carbon) mixed powder, 4-6% of CaF2 (calcium fluoride) powder, 4-6% of CaSO4 (calcium sulfate) powder, 1-2% of Fe (Ferrum) powder and 1-2% of Mn (manganese) powder; and the mixed powder is KNO3, S and C freely mixed. According to the method disclosed by the invention, the problems of inexhaustive slag separation and more welding line defects in the welding lines in the prior art are solved without any welding device and power supply. The preparation method has the advantages of simple preparation process and simple, fast and safe welding operation, and is particularly suitable for field emergency operation.

Owner:TIANJIN UNIV

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1150952CStrong fire extinguishing functionRealize total flooding fire extinguishingFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, a lot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Room-temperature efficient ozone decomposition catalyst and preparation method thereof

ActiveCN102513106AGuaranteed conditions that generate the desired valenceRich in channelsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporDecomposition

The invention discloses a room-temperature efficient ozone decomposition catalyst and a preparation method thereof. The catalyst is prepared by the following steps of: preparing manganese nitrate, cerous nitrate and silver nitrate into a solution according to a mol ratio of 1: (0.3-0.5): (0.01-0.1); taking potassium carbonate and / or potassium bicarbonate as a precipitant, taking potassium chlorate as an oxidant, and precipitating to prepare active components; and then, adding N,N-diethyl ethylamine and crystallizing in a reaction kettle at a temperature in a range of 180-220 DEG C; after the crystallization, carrying out filter pressing to obtain sediments with the water content of 70-80 wt%; and then, adding a binding agent and a pore-forming agent and uniformly agitating; conveying the mixture into a banded extruder to be extruded and molded into cylindrical grains; drying the cylindrical grains at a temperature in a range of 80-100 DEG C and adding the dried cylindrical grains intoa muffle furnace to be roasted at a temperature in a range of 450-550 DEG C. The ozone decomposition catalyst provided by the invention has the advantages of capabilities of completely purifying thousands of ppm of ozone at the room temperature and resisting the violent fluctuation of the ozone concentration, good water vapor resistance and long service life.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

High efficiency blooming-promoting foliage-spraying microbial fertilizer

InactiveCN1370408ALow costFacilitate differentiation workBiocideAnimal repellantsAnimal sciencePhosphate

The high efficiency blooming-promoting foliage spraying microbial fertilizer includes a mixture of amino acid of seven cytokinins, red sugar, potassium chlorate, mineral salt of nucleotide, ethylene,abscisic acid and potassium dihydrogen phosphate as main agent and a synergist comprising farm washing powder for foliage penetration, absorption and adhesion. It can promote blossom bud differentiation of fruit trees, especially longan, litchi, Shatian shaddock, and other substropical fruit trees. It has the features of low cost, high safety, high efficiency and no pollution.

Owner:谢明阳

Method for recycling metal oxides from waste SCR (selective catalytic reduction) catalyst

InactiveCN104611564ASolve the problem of landfill occupying a large amount of land resourcesProcess efficiency improvementLand resourcesWater resources

A method for recycling metal oxides from a waste SCR (selective catalytic reduction) catalyst is characterized in that: crushing, soaking and purifying by adsorption the waste SCR catalyst, adding NaOH solution according to the proportion, heating to 80 DEG C, then adding potassium chlorate to oxidize tetravalent vanadium in the raw material to pentavalent vanadium, regulating aqueous phase pH in the solution to 1.7-1.8 by NH4Cl, boiling for 1-2H, precipitating vanadium, refining to obtain pure ammonium metavanadate, adding HCl into filtrate in which vanadium is separated, regulating the pH to 4.5-5.0, adding CaCl2 solution, precipitating CaMoO4, filtering, and processing filter cake with HCl into H2MoO4 and H2WO4. The method solves the problems that a large number of land resources are occupied by landfill of the waste SCR catalyst, and soil and water resource are contaminated by toxic metals contained in the waste SCR catalyst, and the purpose of changing waste material into things of value and turning harmful things into beneficial things can be achieved.

Owner:沈阳远大环境工程有限公司

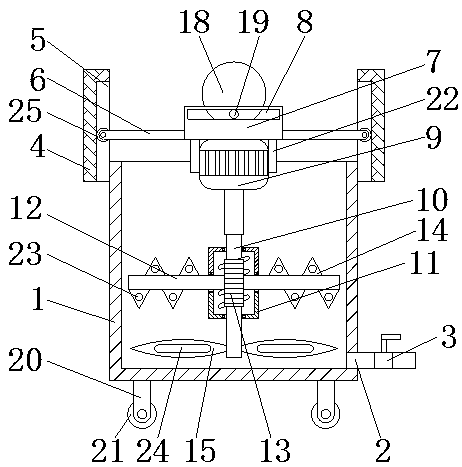

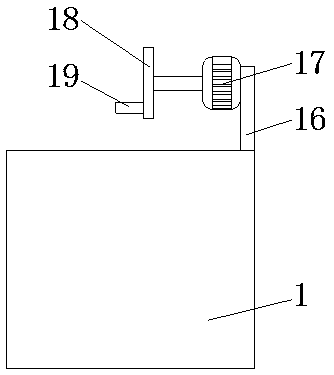

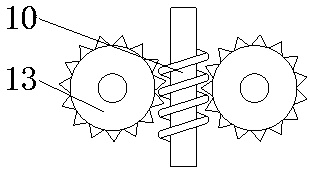

Stirring equipment for production of potassium chlorate

PendingCN107670535AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingReciprocating motionEngineering

The invention discloses stirring equipment for production of potassium chlorate. The stirring equipment for production of potassium chlorate comprises a box, wherein the bottom of the right side of the box communicates with a discharging tube; a valve is arranged on the surface of the discharging tube; tops of two sides of the box are fixedly connected with supporting plates separately; chutes areformed in opposite sides of the supporting plates; a cavity of each chute is slidably connected with a sliding rod; the end, which is away from the cavity of the corresponding chute, of each slidingrod extends to the outside of the corresponding chute and is fixedly connected with a movable plate; an elongated hole is formed in the top of the front surface of each movable plate; and the bottom of each movable plate is fixedly connected with a first motor. By cooperation of the movable plates, the elongated holes, a second motor, a rotating plate and a guiding rod, the movable plates can vertically move in a reciprocating manner, and drive worms, cross rods, stirring teeth and stirring blades to move vertically, materials in the cavity of the box can be fully stirred, the material stirring efficiency is improved, and the material reaction speed is increased.

Owner:LEIYANG JINYUE SCI & TECH DEV

Production method of antique wood

The invention relates to a production method of antique wood. The method includes: (1) wood selection: selecting wood with a moisture content of 6-25%; (2) color change treatment: putting pre-treated wood into a sealable container divided into an upper space and a lower space that are communicated by a hole, placing wood on the upper part, then introducing ammonia water of certain concentration into the lower space of the container, observing the color change of the inner wood, pumping out the ammonia water from the container when the color change meets the requirement, collecting and storing the ammonia water, and taking out the wood; (3) antique treatment: coating the wood surface with a mixed solution of nitric acid and potassium chlorate by a bristle brush, then using a damp cloth to wipe the surface, coating the wood surface with a 0.5% potassium permanganate solution, then applying a sodium sulfite saturated solution, and wiping the surface with a clean damp cloth; and (4) aging treatment: aging the withdrawn antique wood. The antique wood made by the invention has uniform color, good antique effect, and deep treatment depth.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process

InactiveCN104971594AEfficient removalReduce equipment costsDispersed particle separationAir quality improvementPotassium manganateSlurry

The invention discloses a gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process. According to the process, ozone is used as a gas-phase oxidant to oxidize one part of nitric oxide in flue gas into high-valence-state nitric oxide capable of being absorbed by slurry; any one or a mixture solution of more of hydrogen peroxide, sodium hypochlorite, sodium chlorite, sodium chlorate, sodium persulfate, potassium chlorate, potassium hypermanganate and potassium dichromate is sprayed to be used as a liquid-phase oxidant to oxidize the residual high-valence-state nitric oxide in the flue gas into the high-valence-state nitric oxide; and the flue gas enters an absorption tower and a magnesium hydroxide solution is sprayed to absorb the high-valence-state nitric oxide. Compared with the prior art, the process firstly adopts two times of oxidization of a gas phase and a liquid phase and a magnesium oxide wet process is used for absorbing so that a target of efficiently removing the nitric oxide is realized; and by virtue of the technical scheme, the use amount of the ozone is reduced, the equipment cost and operation cost are reduced and the denitration efficiency is improved and can reach more than or equal to 93%.

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

Boiler coal combustion-improving denitrifying agent composition and preparation method thereof

The invention relates to an additive product suitable for coal-fired boilers in the petroleum, chemical and power industries and provides a boiler coal combustion-improving denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-8 parts of sodium carbonate, 3-7 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 6-15 parts of urea, 4-10 parts of ammonium carbonate, 4-10 parts of ammonium chloride, 3-9 parts of ferric oxide, 7-22 parts of potassium permanganate, 7-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 4-8 parts of chromium sesquioxide, 2-6 parts of manganese oxide, 4-8 parts of zinc oxide, 4-8 parts of copper chloride, 2-6 parts of copper oxide, 2-6 parts of copper carbonate, 3-7 parts of zinc sulfate, 2-5 parts of zinc nitrate, 0.5-1.5 parts of barium molybdate, 1-2 parts of titanium oxide, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of copper sulfate, 0.2-0.5 part of cerium oxide, 1-3 parts of penetrating agent JFC and 0.1-0.2 part of lignosulphonate. The composition is efficient in combustion improving, has high coal saving rate and prolongs the service lives of the boilers.

Owner:GANSU HEIMA PETROCHEM ENG

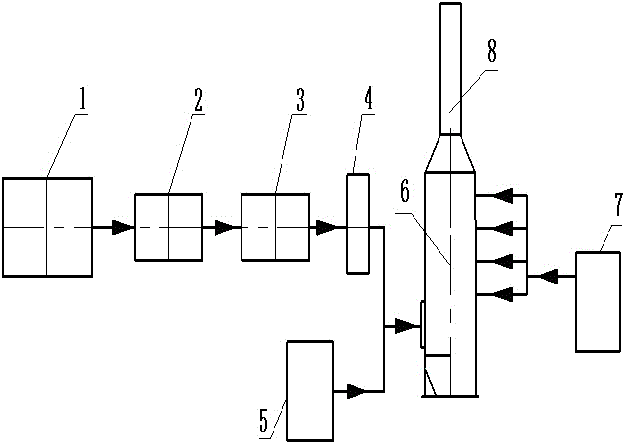

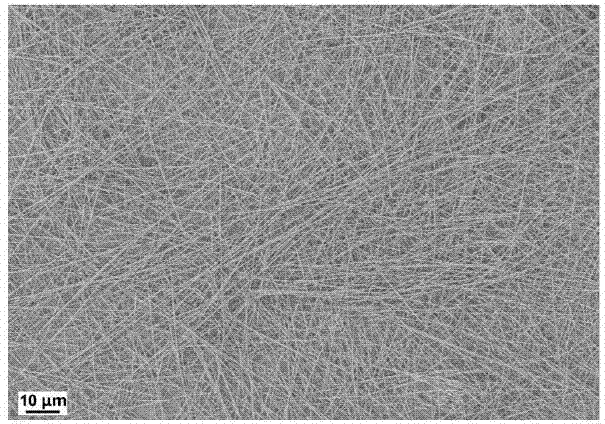

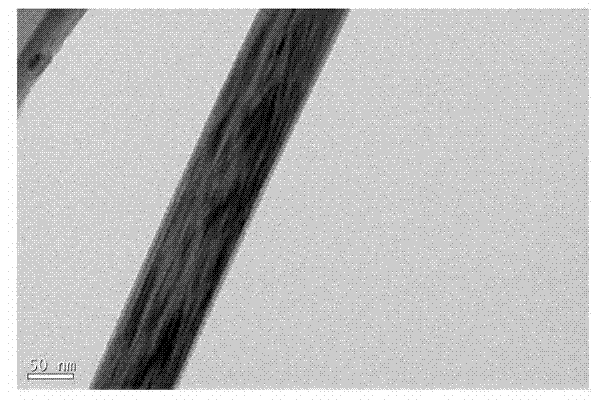

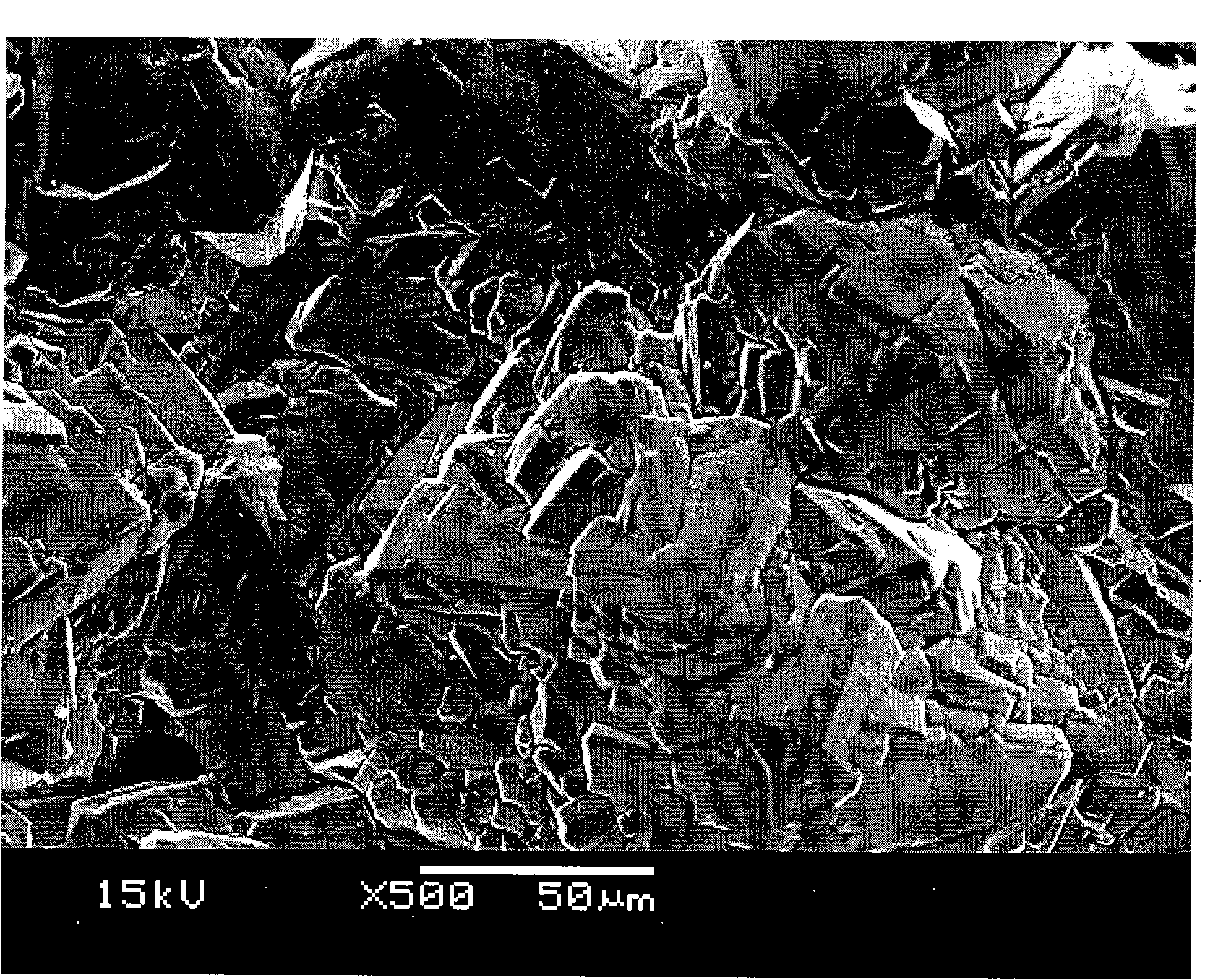

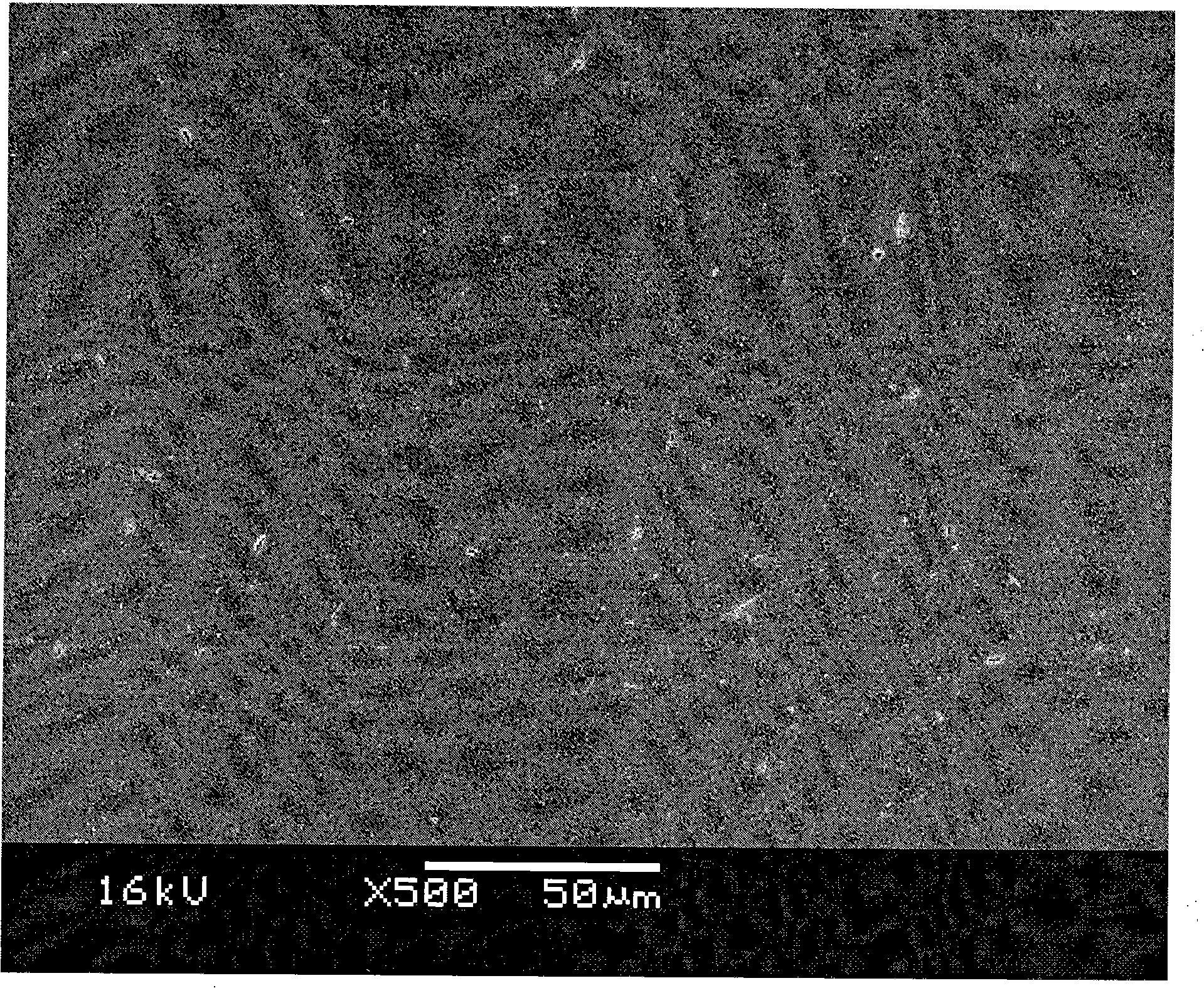

Preparation method of extra-long manganese dioxide nanowires

ActiveCN103193273AGood modification effectEvenly distributedNanotechnologyManganese oxides/hydroxidesNanowireEthylic acid

The invention discloses a preparation method of extra-long manganese dioxide nanowires. The method comprises using manganese sulfate as a reducing agent, potassium chlorate as an oxidizing agent, and potassium acetate and acetic acid as an additive, performing a hydrothermal reaction for 6-24 hours under 140-200 DEG C in a polytetrafluoroethylene-lined autoclave, naturally cooling, washing and filtering products, and drying to obtain the extra-long manganese dioxide nanowires with a diameter of 50-150 nanometers and a length of more than 100 [mu]m. The method can synthesize the extra-long manganese dioxide nanowires for one step, is relatively low in synthesis temperature and production cost, accords with conditions of large-scale industrial application, and has a wide application prospect.

Owner:GUANGDONG UNIV OF TECH

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

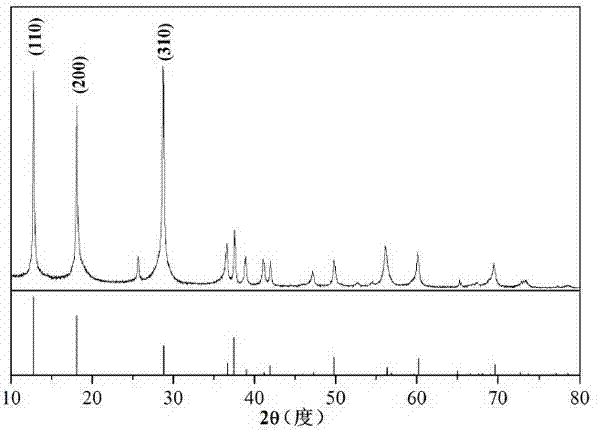

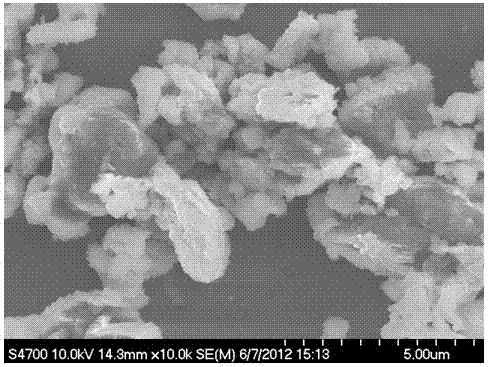

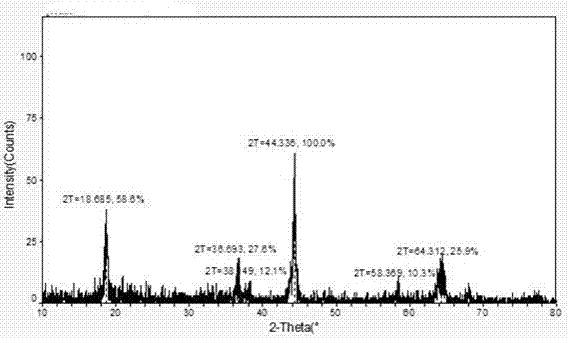

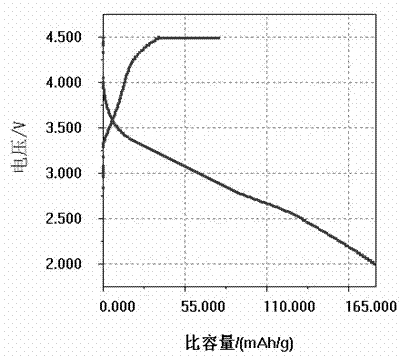

Li-rich Fe-Mn based cathode material for lithium ion battery and preparation method of Li-rich Fe-Mn based cathode material

InactiveCN103682322ALow costIncrease working voltageCell electrodesSecondary cellsLithium hydroxideManganese

The invention relates to a Li-rich Fe-Mn based cathode material for a lithium ion battery and a preparation method of the Li-rich Fe-Mn based cathode material, and belongs to the technical field of lithium ion batteries. The chemical formula of a lithium manganese iron oxygen cathode material solid solution is Li1.2Mn0.4Fe0.4O2, the lithium manganese iron oxygen cathode material solid solution adopts a layered alpha-NaFeO2 structure and a rock salt structure, the space group of the layered alpha-NaFeO2 structure is R3m, and the space group of the rock salt structure is Fm3m. The Li-rich Fe-Mn based cathode material is prepared through three steps of coprecipitation, hydrothermal reaction and solid phase sintering: firstly, the hydroxide of ferro-manganese is prepared through a coprecipitation method, and the reaction pH value and temperature are controlled, the hydroxide precursor of ferro-manganese is mixed with lithium hydroxide, a mineralizer and potassium chlorate for hydrothermal reaction for 8-48 hours at a temperature of 220 DEG C, and then mixed with a certain amount of lithium hydroxide, and sintering is performed for 16-20 hours at a temperature of 500-750 DEG C, so that ferro-manganese-based solid solution cathode material with high capacity is prepared. The technological process is simple, the operation is convenient, and particle size of crystals can be controlled well.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting nickel and molybdenum from nickel-molybdenum ore

InactiveCN102140576AHigh recovery rateWon't happenProcess efficiency improvementSodium chlorateMolybdenum compounds

The invention discloses a method for extracting nickel and molybdenum from nickel-molybdenum ore, comprising the following steps of: (a) in the presence of an oxidizing agent, leaching the finely-ground nickel-molybdenum ore from an acid solution and filtering to obtain a leachate, wherein the oxidizing agent is sodium chlorate or potassium chlorate; (b) adding a first alkaline compound in the leachate, adjusting the pH value of the leachate to be 1.5-3.5 and filtering to respectively obtain a precipitation and a supernate; (c) adding a second alkaline compound in the supernate, adjusting thepH value of the supernate to be 5-7 and filtering to obtain a nickel-containing compound; and (d) leaching the precipitation in an alkali liquor, filtering to obtain a molybdenum-containing leachate,and extracting and re-extracting the molybdenum-containing leachate to obtain a molybdenum-containing compound. By using the method, the sodium chlorate or potassium chlorate is used as the oxidizingagent, the higher leaching rate of the nickel and molybdenum and the higher recovery rate of the nickel and molybdenum can be obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Method for preparing series titanium-iron alloy by smelting titanium raw material

A method to produce a series of ferrotitanium by smelting the titanium material in Panxi area. The technology steps are as following: the titanium material in Panxi area, calcareous metallurgy accessories and calcium-sodium treatment reagent will be delivered into the revolving burner, they will be warm-up fast, and then will be delivered into blendor by connecting barn to be uniformly mixed. And then aluminium, iron system material, auxiliary reducers and potassium chlorate will be orderly added in from the batch bin, when the material and the auxiliary material in the blendor have been uniformly mixed, they will drop into the smelting furnace, which has been warmed up, by the connecting barn, the igniter will be added in, and the inhibiting agent will be added when the reaction get over for about 2-3 minutes, they will be cooled for 20-40h, and at last the residue and the ferrotitanium will be separated. The ferrotitanium product will enter warehouse after being checked and paclaged. The material source of this patent is assured, and the production technology is on the safe side, the product quality of the ferrotitanium made by it is stable, and it fulfills the different needs of all kinds of steel industry, so it the myth that the Panxi vanadium-titinium magnetite can not produce high ferrotitanium because the impurity of it is high, and it fills up the blank in our country.

Owner:攀枝花市银江金勇工贸有限责任公司

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Combustion assisting agent with aeration combustion-supporting and coal saving function

The invention offer strong oxygen combustion supporting synergy coal saving combustion adjuvant. Its main technique feature is proportioning the following each preparation by weight part ratio according to coal quality: strong oxidant: potassium permanganate, potassium chlorate, potassium nitrate, hydrogen peroxide, hexamethylene tetramine, potassium perchlorate; strong catalyst: manganese dioxide, magnesia; scale remover: calcium oxide dolomite fines, calcium carbonate; fume clearing agent: sodium carbonate, active magnesia, light magnesium oxide; desulfurizer: alumina, magnesium silicate, barium nitrate; leavening agent: industry using sodium chloride; diatomite: pumice, boric sludge; ferric oxide is very fit for low grade coal. The advantages of the invention are that it can make low grade coal burn fully, increase thermal efficiency, save energy, no pollution; and it can save fund for corporation; it can save 100-250 thousand yuan per ten thousand ton coal; and the coal saving rate can reach 15-25%.

Owner:迟万斌

Energy-saving environment protection fire coal additive agent and method of manufacturing the same

The invention discloses an energy-saving environmental protection fire coal additive, which comprises 20 to 36 portions of potassium nitrate, 40 to 60 portions of manganese dioxide, 40 to 60 portions of potassium chlorate, 20 to 38 portions of sodium nitrate, 30 to 50 portions of EDTA, 15 to 30 portions of hexamethylene tetramine, 25 to 35 portions of ammonium nitrate, 10 to 30 portions of sodium carbonate and 40 to 60 portions of peroxy calcium carbonate. The fire coal additive also comprises 25 to 45 portions potassium permanganate. The preparation method of the fire coal additive is that formula material is prepared according to the above energy-saving environmental protection fire coal additive; the chosen formula materials are grinded into powder by a grinder; the power-like materials are added with 1000-portion water and are homogenously stirred and placed for 24-hour. The fire coal additive is capable of promoting the combustion of the coal, and has dramatic sulfur-fixing and dust removal and energy-saving functions, lowers the carbon content of the slag, reduces the harmful gas and smoke dischange volume, saves the coal-fired consumption and improves the furnace thermal efficiency.

Owner:何丹

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Non-sulphur firecracker components and preparation thereof

The invention discloses a sulfur-free firecracker medicament and a method for the production thereof, and the medicament constituents are 50 to 70 parts of potassium perchlorate, 20 to 45 parts of aluminum powder, 5 to 20 parts of pearl powder, 10 to 30 parts of modified wood flour, and 0 to 5 parts of a mixture of ferroferric oxide and manganese dioxide or one material thereof. The preparation of the sulfur-free firecracker medicament is mainly characterized in that the wood flour undergoes the imbibitions treatment and the surface treatment by adopting a potassium nitrate and a micro-crystalline wax respectively. The sulfur-free environment-friendly firecracker produced by the sulfur-free firecracker medicament system of the invention has advantages of sonorous sound when setting off the firecracker, high rate of sonority, non discharge of noxious gas of sulfur dioxide, easy obtaining of constituents and materials, rather low cost, not containing prohibited articles such as potassium chlorate and being fully fit to replace the current sulfur-bearing firecracker.

Owner:湖南省浏阳金生花炮有限公司

Method for preparing metal polysilicate flocculant

InactiveCN102101711AImprove stabilityGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationSilicic acid

The invention relates to a method for preparing a metal polysilicate flocculant. At present, the metal polysilicate flocculant is higher in production cost. The method comprises the following steps of: adding green vitriol and waste acid which are produced during production of titanium white into a reaction vessel together with industrial potassium chlorate and stirring to obtain viscous polymeric ferric sulfate; adding water to dilute sodium silicate into sodium silicate aqueous solution, wherein the weight content of SiO2 in the sodium silicate aqueous solution is 2 to 3 percent; adding the waste acid which is produced during the production of the titanium white into the sodium silicate aqueous solution, adjusting pH value of the sodium silicate aqueous solution to be between 3.5 and 4.5, and stirring at normal temperature to obtain polysilicate solution; and adding the polymeric ferric sulfate into the polysilicate solution, uniformly stirring, standing and activating for 10 to 24 hours to obtain the metal polysilicate flocculant. A byproduct produced by the production of the titanium white is low in cost; and the prepared flocculant has the characteristics of high stability, wide application range and good flocculation effect.

Owner:HANGZHOU RONGSHENG ENVIRONMENTAL PROTECTION TECH

Blasting fuse of high-safety firecracker and preparation method thereof

InactiveCN101270015AStable chemical propertiesLow mechanical sensitivityInorganic oxygen-halogen salt explosive compositionsFuse detonationYarnDecomposition

The present invention relates to a preparation method of a safe firing cable of firecrackers. In the method, yarn is used as a carrier to infuse the following medicines, which are used raw materials, according to the following steps. The medicines comprise potassium perchlorate, potassium terephthalic acid, ammonium dichromate, polyethylene alcohol, moisture resistant agent, charcoal and sulfur. The method has the following steps: the potassium perchlorate, the potassium terephthalic acid, the ammonium dichromate, the charcoal, the sulfur and the polyethylene alcohol are arranged in a container according to the weight ratio; water with a certain proportion is added into the container; the mixture is stirred so that the medicines can be dissolved in the water; then the moisture resistant agent is added; and the mixture is mixed well; the yarn is infused in the container, taken out and then sent to a drying device to be dried; thus the safe firing cable can be prepared. In the method, the yarn is used as the carrier to infuse the medicines of the firing cable; the production is simple; the amount of the medicines is reduced; the method is safe; and the cost is reduced. The application of the potassium perchlorate has the advantages of low oxygen content, low decomposition temperature, excellent stability and low sensitivity. Thus the application of the potassium perchlorate is superior to the application of potassium chlorate. The firing cable solves the problems of storage, transportation and insecurity in use.

Owner:醴陵神马花炮有限公司

Method for extracting high-purity manganese dioxide from manganese slag

The invention discloses a method for extracting high-purity manganese dioxide from manganese slag, which comprises the following steps of: at normal temperature, adding dilute sulfuric acid in an amount 1.1-1.5 times the theoretical amount into the manganese slag and leaching metal impurity ions in the manganese slag; filtering to obtain an acid solution with the pH of 1.0-2.0, adding a sodium chlorate or potassium chlorate solution in an amount 1.1-1.5 times the theoretical amount into the acid solution, carrying out hydro-thermal reaction for 1-3 hours at the temperature of 120-150 DEG C, filtering manganese dioxide precipitates generated by the reaction, carrying out acid washing with 0.05-0.15mol / L-1 of dilute sulfuric acid, drying at the temperature of 60-120 DEG C after water washing, and calcining for 1-2 hours at the temperature of 350-450 DEG C to obtain the manganese dioxide with the product purity of larger than 98 percent. In the invention, the extraction ratio of the manganese in the manganese slag can reach more than 93 percent, the purity of the obtained manganese dioxide can reach more than 98 percent, the economic value of products is high, and the method has short process flow and simple operation.

Owner:BOHAI UNIV

Carburization prevention coating for ultralow carbon stainless steel casting

The invention discloses a carburization prevention coating for an ultralow carbon stainless steel casting. The carburization prevention coating is prepared by mixing 50 to 60 weight percent of white corundum powder, 5 to 10 percent of oxidant, 3 to 8 percent of sintering aid, 1 to 3 percent of organic binder, 2 to 5 percent of bentonite suspending agent, 0.2 to 0.4 percent of aid, and 28.8 to 38.2 percent of solvent; the granularity of the white corundum powder is less than or equal to 3 mu m, the granularity of the oxidant is less than or equal to 5 mu m, and the granularity of talcpowder isless than or equal to 5 mu m; the oxidant is one or more of potassium nitrate, potassium permanganate, potassium dichromate, and potassium chlorate; the sintering aid is one or more of talcpowder, feldspar powder, mica powder, and clay; and the organic binder is rosin or resin; and the solvent is ethanol or isopropanol, the concentration of ethanol is more than or equal to 95 percent, and the concentration of the isopropanol is more than or equal to 98 percent. The coating is poured into some ultralow carbon stainless steel castings of water turbine blades, and the thickness of a surface carburization layer of the ultralow carbon stainless steel casting on which the carburization prevention coating prepared according to the formula is poured is less than or equal to 3mm, and is obviously superior to that of the common coating.

Owner:SHENYANG RES INST OF FOUNDRY

Method for reinforcing in-situ combustion exploitation oil reservoir

ActiveCN104594863ARapid decomposition reactionAvoid going outConstructionsFluid removalCombustionOxygen

The invention provides a method for reinforcing an in-situ combustion exploitation oil reservoir. The method comprises the steps that an injection-production pattern is deployed; a heating device is tripped in an injection segment of an injection well shaft, and started for heating; manganese dioxide is injected into the injection well shaft, the injection speed of the manganese dioxide is 0.01-50 tons per day, and the injection amount of the manganese dioxide is one ton to 50 tons; potassium chlorate is injected into the injection well shaft, the injection speed of the potassium chlorate is 0.01-50 tons per day, and the injection amount of the potassium chlorate is four tons to 50 tons; air is injected into the injection well shaft, and the injection speed of the air is 10,000-15,000 Nm3 per day; an oil layer is combusted and kept combusted; continuous oil extraction is carried out through a production oil; in the production process, the temperature of the oil layer and the temperature of fluid produced by the production well are monitored, and when it is monitored that the maximum temperature of the combustion area of the oil layer is lowered by more than 50 DEG C, the temperature of the fluid produced by the production well is lowered by more than 30 DEG C, and manganese dioxide, potassium chlorate and oxygen are injected to an injection end again.

Owner:PETROCHINA CO LTD

Preparation method of nanoscale stannic oxide hollow sphere

InactiveCN102583266ANo pollution in the processRaw materials are cheap and easy to getNanotechnologyElemental selenium/telluriumGas detectorPotassium hypochlorite

The invention belongs to the field of nano materials and relates to a preparation method of a nanoscale stannic oxide hollow sphere. The method is characterized in that stannous salts and oxidants serve as reaction materials and a hydro-thermal method is used for preparation under the acidic condition at the PH value between 1.0 and 4.0; the stannous salts consist of at least one of stannous sulfate, stannous chloride and stannous oxalate; the oxidants consist of at least one of hydrogen peroxide, chloric acid, hypochlorous acid, potassium chlorate, sodium chlorate, potassium hypochlorite and sodium hypochlorite; and PH value of solutions is adjusted by one of sulphuric acid, hydrochloric acid, oxalic acid and sodium hydroxide. The preparation method does not use any sacrificial templates and organic solvents and is environmentally friendly, simple in process, mild in reaction condition, low in energy consumption, easy to control, high in product purity, and suitable for large-scale industrial production. The nanoscale stannic oxide hollow sphere can be applicable to gas sensors, lithium ion batteries, catalysts and photoelectronic devices.

Owner:SHANDONG UNIV

Rapid synthesis method of drinking water treatment agent (i.e. potassium ferrate)

InactiveCN101597087AGreat tasteEfficient killingIron compoundsSodium/potassium compoundsFerric hydroxideSynthesis methods

The invention discloses a rapid synthesis method of a drinking water treatment agent (i.e. potassium ferrate). The method directly utilizes the industrial pure ferric hydroxide Fe(OH)3, the self-prepared potassium hypochlorite (KClO) saturated solution and the deionized water as raw materials for preparing potassium ferrate. The process comprises the following steps: preparing the potassium ferrate by the potassium hypochlorite (KClO) saturated solution and the industrial pure ferric hydroxide Fe(OH)3, adding the CuCl22H2O stabilizer for solid liquid separation, adding the KOH for recrystallization and purification, and washing and removing impurity by the normal pentane and the inorganic ethanol; and performing vacuum drying and sealing. The method has the advantages of simple process, good quality of the products and low production cost.

Owner:张亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com