Patents

Literature

954 results about "Chemical waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical waste is a waste that is made from harmful chemicals (mostly produced by large factories). Chemical waste may fall under regulations such as COSHH in the United Kingdom, or the Clean Water Act and Resource Conservation and Recovery Act in the United States. In the U.S., the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA), as well as state and local regulations also regulate chemical use and disposal. Chemical waste may or may not be classed as hazardous waste. A chemical hazardous waste is a solid, liquid, or gaseous material that displays either a “Hazardous Characteristic” or is specifically “listed” by name as a hazardous waste. There are four characteristics chemical wastes may have to be considered as hazardous. These are Ignitability, Corrosivity, Reactivity, and Toxicity. This type of hazardous waste must be categorized as to its identity, constituents, and hazards so that it may be safely handled and managed. Chemical waste is a broad term and encompasses many types of materials. Consult the Material Safety Data Sheet (MSDS), Product Data Sheet or Label for a list of constituents. These sources should state whether this chemical waste is a waste that needs special disposal.

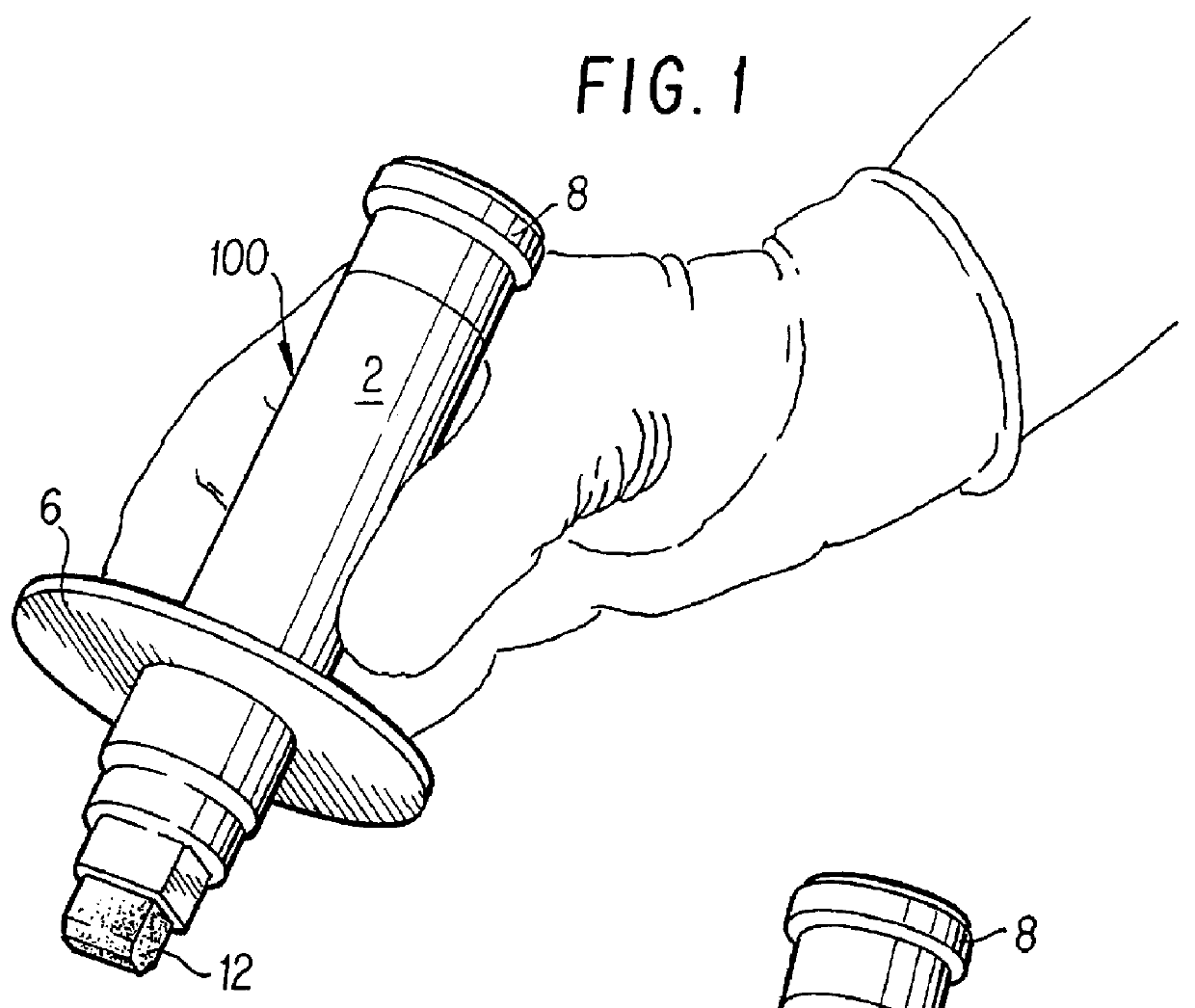

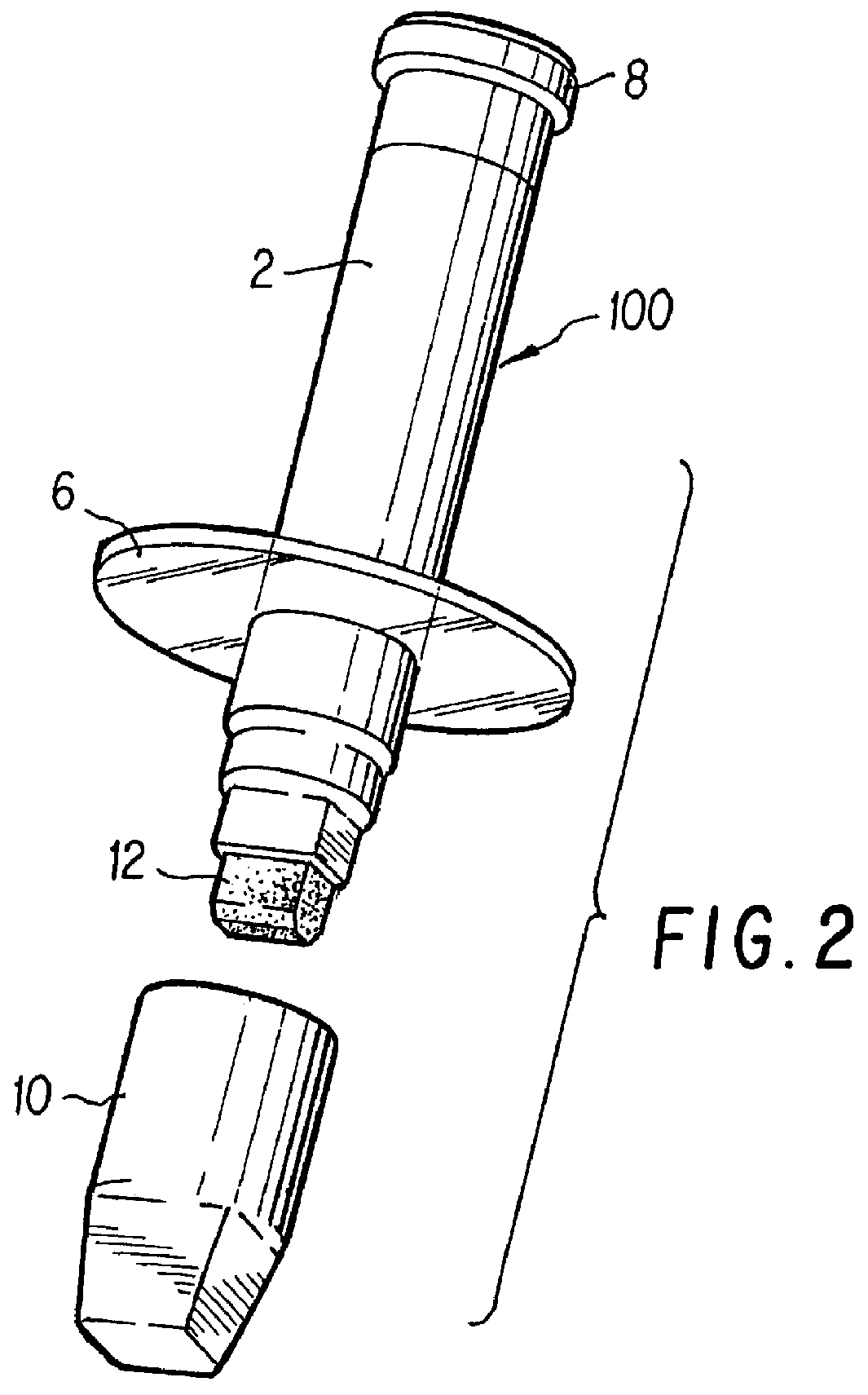

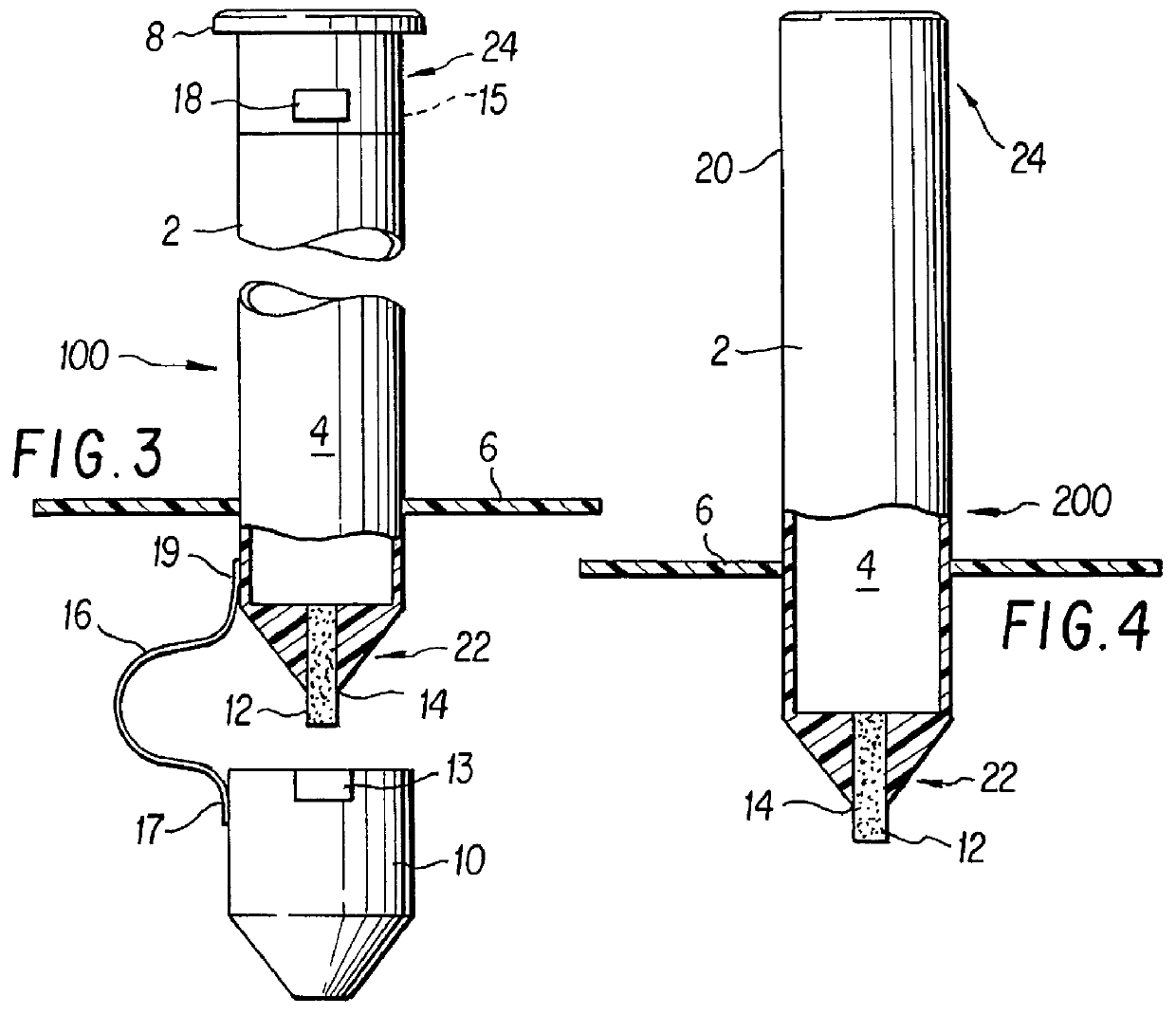

Applicator for flowable materials

InactiveUS6010263ARisk preventionReduce in quantityLiquid surface applicatorsWriting connectorsMetal coatingHand held

The present invention relates to an applicator for flowable materials to facilitate the repair of damaged metal coatings by allowing the user to quickly, safely, and accurately apply a metal coating solution to a specific portion of a metal surface, alleviating the need to re-immerse the entire metal item in a coating bath. This is particularly advantageous where the metal item is a portion of an automobile chassis or an aircraft which cannot be easily removed. Further, the applicator is a hand-held device which features a safety collar which protects the user from potentially harmful treatment solutions and, because the applicator enables the user to deliver metal coatings accurately and efficiently, chemical waste is essentially eliminated.

Owner:HENKEL KGAA

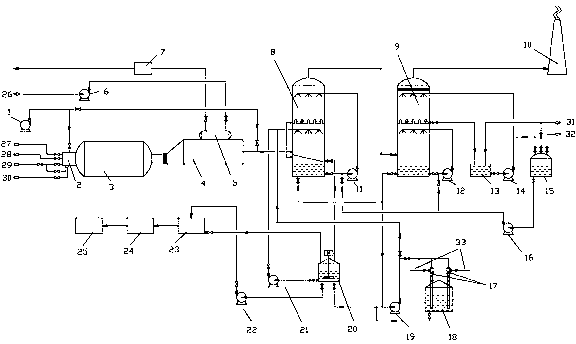

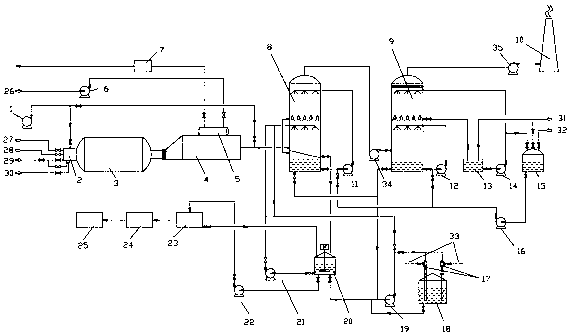

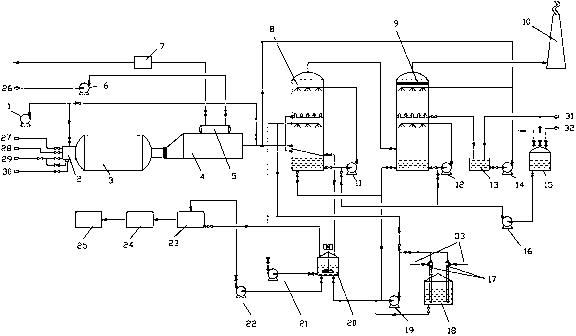

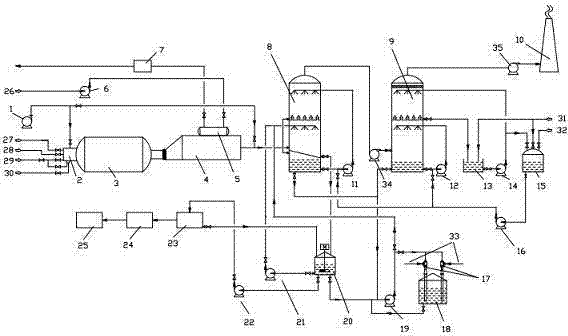

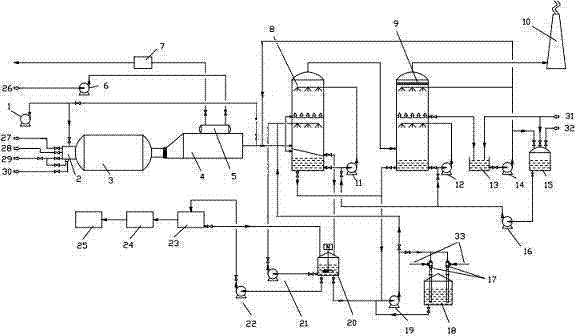

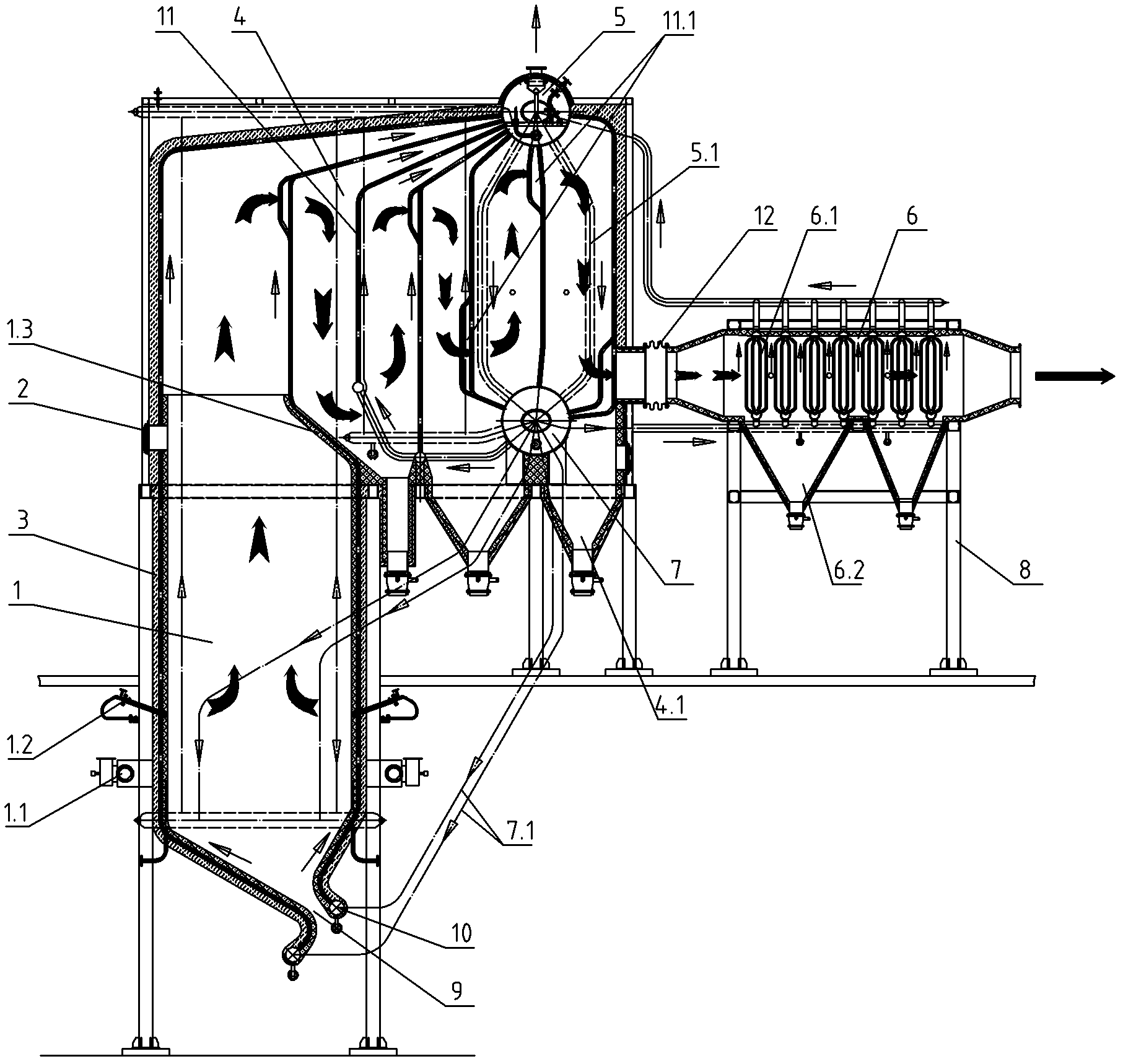

Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

InactiveCN103301732AReach the purpose of recyclingDispersed particle separationEnergy inputHigh heatSulfur dioxide

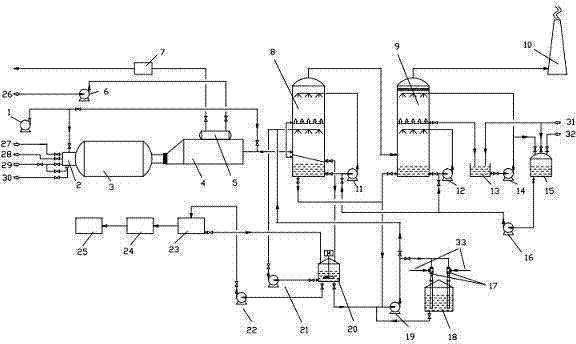

The invention belongs to the technical field of chemical waste gas treatment, and mainly relates to a device and a process for recycling and treating hydrogen sulfide-containing chemical acid waste gas. The process for recycling and treating hydrogen sulfide-containing chemical acid waste gas comprises the following steps of: igniting and completely burning the hydrogen sulfide-containing chemical acid waste gas into sulfur dioxide-rich high-temperature flue gas, recycling much heat and adjusting the temperature of the flue gas by cold air, and enabling the flue gas to enter an adsorption tower; completely absorbing the sulfur dioxide in the flue gas by utilizing an alkaline solution, removing less alkaline solution and sulfite contained in the flue gas absorbed by the alkaline solution, and exhausting the demisted pure flue gas to the atmosphere. The sulfite, which is generated by absorbing sulfur dioxide by the alkaline solution, is oxidized, concentrated, crystallized and dried to obtain side product sulfate.

Owner:义马煤业集团煤生化高科技工程有限公司 +1

Method for producing alcohol and feed by utilizing seaweed chemical waste material

InactiveCN101024847AEconomic Industrial TechnologyEnvironmental Industrial TechnologyAnimal feeding stuffMicroorganism based processesLiquid wasteChemical industry

The invention discloses a method for producing alcohol and feed by alga chemical waste, i.e. using the cellulose-containing waste residues as raw materials formed in the course of producing sodium alginate, mannitol, I or trehalose glue products in the alga chemical industry, making enzymatic hydrolysis by cellulase and anaerobic fermentation by brewing yeast or double fermentation by cellulase producing bacteria and brewing yeast, then making solid-liquid separation and obtaining alcohol and feed. And the invention provides economic, environmental protection and effective industrial technique for waste residues and waste liquid in the alga chemical industry, able to turn waste into wealth and provide important technical support for full and high value utilization of alga resources and development of alga circulating economy.

Owner:SHANDONG UNIV

Chemical industrial gypsum building materials and method for manufacturing same

InactiveCN101139198AImprove protectionSimple production processSolid waste managementSlurryQuenching

The present invention relates to a chemical gesso building material, which consists of the following components according to weight ratio: 30-60 percent of waste gesso, 15-25 percent of powder coal; 20-30 percent of scoria and 5-20 percent of cement material. The chemical waste stone includes titanium gesso and phosphor gesso. The scoria includes titanium scoria, steel residue, water quenching residue and silicon powder stone. The chemical gesso also includes an assistant agent with the weight ratio of 0-5 percent. The preparation method for the chemical gesso building material includes the following steps: the raw materials are to be prepared according to the corresponding weight ratio for each component; the components are mixed and grinded to prepare the material slurry, and then is to be pressed into a mould; the mould is kept for more than 7 days. The present invention uses the chemical waste residue as the main materials and adopts simple process and equipments; without any calcining, the chemical gesso building products with much better physical force performance can be manufactured. The present invention is with much greater economical benefit and social benefit.

Owner:深圳清研创业投资有限公司

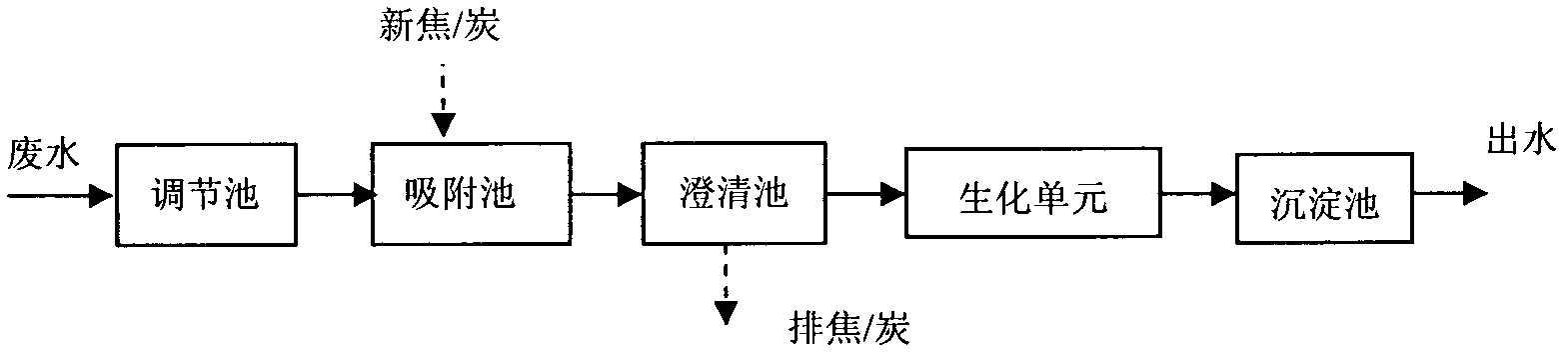

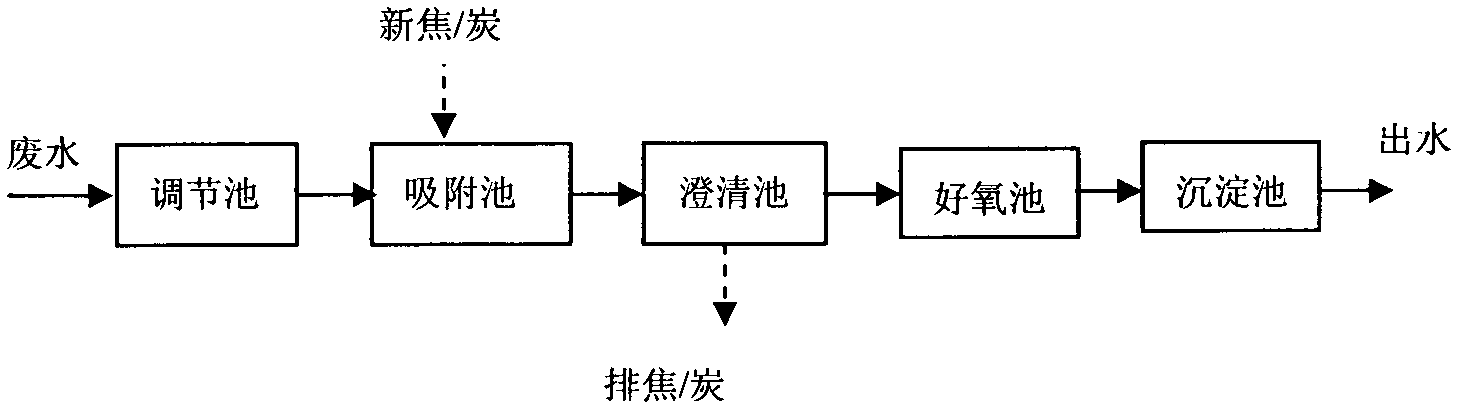

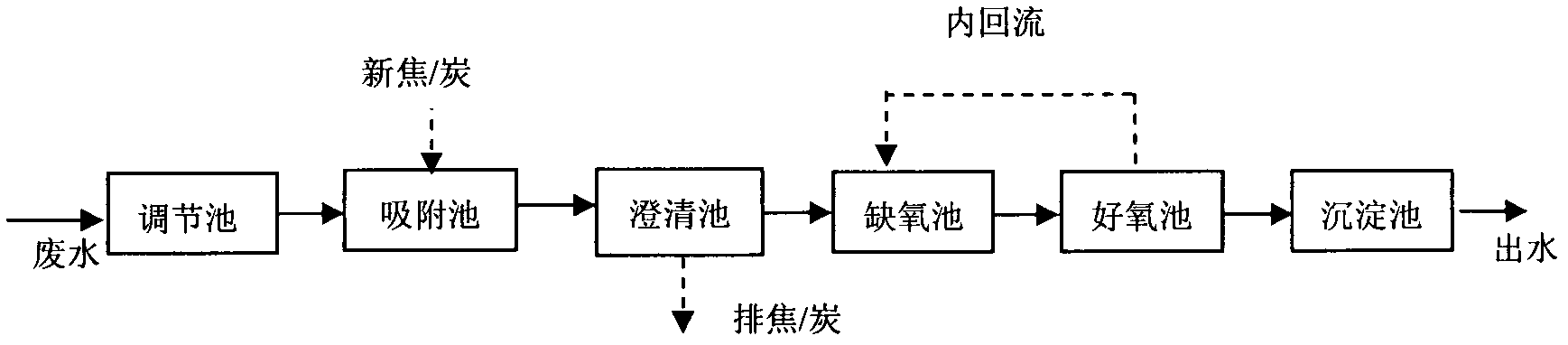

Process for treating coal chemical waste water

ActiveCN102001789AImprove biodegradabilityEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbonActivated sludge

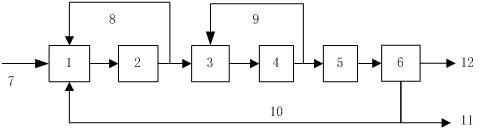

The invention relates to a process for treating coal chemical waste water, wherein a method combining active material adsorption and biochemical treatment is adopted. The method comprises the following steps of: firstly, introducing coal chemical waste water in a waste water regulating reservoir; secondly, introducing the waste water subjected to adsorption treatment by an adsorption tank into a clarification reservoir for sedimentation; then introducing the waste water subjected to the treatment of the clarification reservoir into a biochemical unit for biochemical treatment; and finally, introducing the waste water subjected to the biochemical treatment into a sedimentation reservoir for sedimentation treatment. In the technical scheme, macromolecular organic pollutants are removed through adsorption, therefore, the requirement of the subsequent biochemical treatment is met, and the problems of insufficient utilization of pores of activated carbon and incomplete exertion of the adsorbability of the activated carbon due to the influence of sludge when the activated carbon is added into an activated sludge aeration tank in the prior art are solved; and the process for treating coal chemical waste water has high efficiency and can sufficiently utilize the pores of the activated carbon and ensure the full exertion of the adsorbability of the activated carbon.

Owner:北京国能普华环保工程技术有限公司 +1

Advanced treating method of biochemical tail water based on magnetic resin

InactiveCN101905931AReduce churnSimple processWater contaminantsMultistage water/sewage treatmentWater basedLoss rate

The invention relates to an advanced treating method of biochemical tail water based on magnetic resin, which belongs to the technical field of treatment of chemical waste water. The advanced treating method comprises the steps of: adding magnetic resin in a reactor; introducing biochemical tail water to flow through the reactor, and pumping a mixed liquid of resin and clean water to the reactor from a fresh resin pot; precipitating the treated mixed water in a magnetic or natural mode; returning a part of the precipitated resin to the reactor, and delivering the other part to a regeneration tank; adding a regeneration agent in the regeneration tank to regenerate the resin, and purifying for recycling or disposing the used regeneration agent; delivering the regenerated resin to a fresh resin storage tank for standby use, and recycling the resin in the reactor as required. By utilizing the advantages that the magnetic resin is easily to be separated and regenerated by magnetism and the like, and by combining the traditional processes of coagulation, air flotation and the like, the invention realizes advanced treatment to biochemical tail water rapidly, conveniently, economically and efficiently. The quality of the output water is stable and meets the requirements for advanced treatment or recycling, and the loss rate of the resin is 1 / 1,000,000 lower than that of the water being treated.

Owner:NANJING UNIV

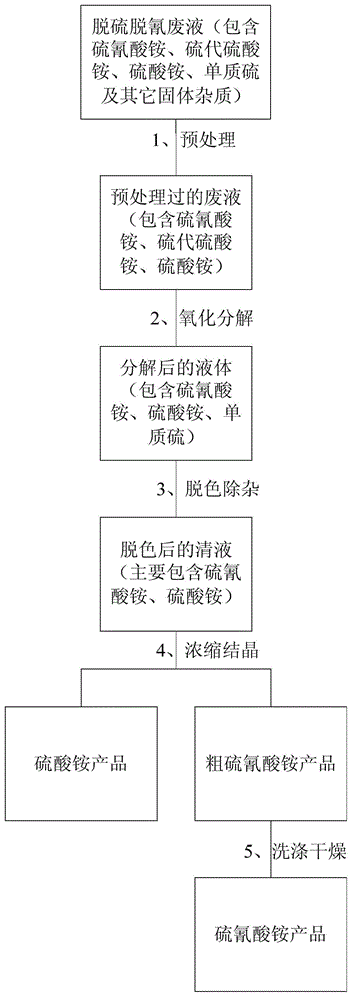

Method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization/decyanation waste liquor

InactiveCN102976361AEfficient decompositionHigh purityThiocyanic acidAmmonium sulfatesPollutionAmmonium sulfate

The invention provides a method for recycling ammonium salt from chemical waste liquor generated in the desulfurization / decyanation process of coke oven gas, and particularly, the invention provides a method for extracting high-purity ammonium thiocyanate and ammonium sulphate from coking desulfurization / decyanation waste liquor. The purities of ammonium thiocyanate and ammonium sulphate produced by using the method disclosed by the invention are greatly improved in comparison with those of products produced by contrasted embodiments. According to the method disclosed by the invention, high-purity products can be prepared under the condition of only carrying out one-time step-by-step concentration, so that the wastewater discharge amount is reduced and the environment pollution of coking plants is alleviated; and high-purity and high-added-value chemical raw materials are recycled, thereby increasing the economic benefits of enterprises.

Owner:BEIJING RISUN TECH CO LTD

Multi-pore high-strength sintering permeable floor brick

InactiveCN105330318ASolve intractableHigh porosityCeramic materials productionCeramicwarePolyvinyl alcoholSlag

The invention discloses a multi-pore high-strength sintering permeable floor brick. The multi-pore high-strength sintering permeable floor brick is prepared from, by weight, 40-43 parts of sewage plant sludge, 6-7 parts of rice hulls, 4-5 parts of potassium feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 29-31 parts of basalt rubble, 5-6 parts of sawdust, 9-11 parts of mesoporous silica, 0.8-1 part of a silane coupling agent kh560, 3-4 parts of polyvinyl alcohol fibers, 7-9 parts of blast furnace slag and 2-3 parts of chemical waste gypsum powder. According to the multi-pore high-strength sintering permeable floor brick, the mesoporous silica, the sawdust and the polyvinyl alcohol fibers are added in preparation of the brick, and a composite through hole structure can be formed through sintering molding after technological modification; in addition, multiple pores distributed densely are obtained by reasonably regulating the particle size of mixed aggregates; meanwhile, the product is high in compressive strength, firm, durable and high in permeable coefficient.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

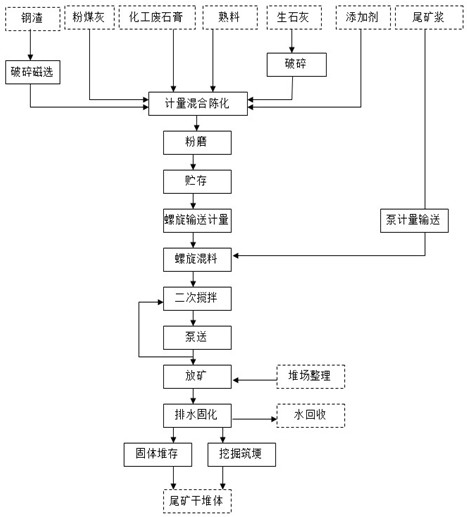

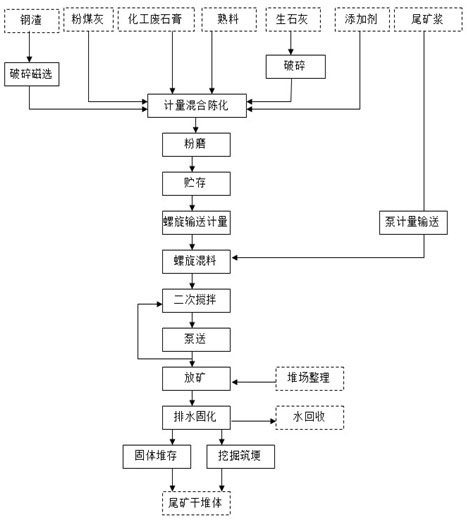

Curing and dry-piling method of iron tailings

The invention relates to a curing and dry-piling method of iron tailings, belonging to the technical field of mine safety. The curing and dry-piling method comprises the following steps of: adding a curing agent and a chemical additive produced by adopting steel slag, chemical waste gypsum, clinker, coal ash and quick lime in tailing pulp, and synchronously realizing precipitation, water drainage and curing and pile-up by secondary mixing and stirring. Compared with the prior art, the curing and dry-piling method has the advantages of simple technical process, low cost, small occupied area and high safety, and is a new method for safe pile-up of the iron tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

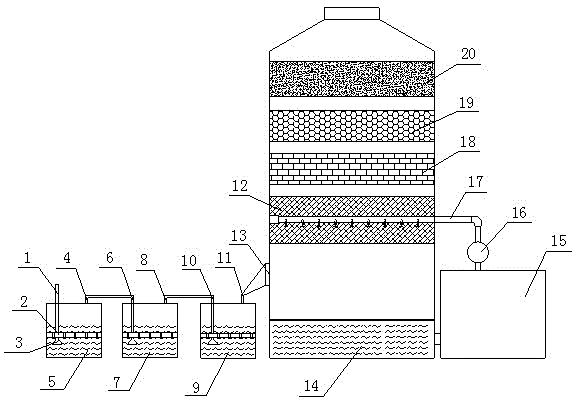

Chemical waste gas treatment equipment

InactiveCN103599686ASmall segmentationThe reaction is fully absorbedUsing liquid separation agentChemical treatmentActivated carbon

The invention relates to chemical waste gas treatment equipment which comprises a first water tank, a second water tank and a chemical treatment tank, wherein a first outlet of the first water tank is connected with a chemical treatment inlet of the chemical treatment tank; a chemical treatment outlet of the chemical treatment tank is connected with a second inlet of the second water tank; a second outlet of the second water tank is communicated with a gas inlet of a waste gas treatment tower; a spraying layer, a dehydration layer and an activated carbon layer are sequentially arranged inside the waste gas treatment tower; a first inlet, the chemical treatment inlet and a second inlet of the first water tank are all extended to the positions under the liquid level; partitioning plates are arranged inside the first water tank, the second water tank and the chemical treatment tank; the partitioning plates are positioned under the liquid level; small holes are formed in the partitioning plates; the first inlet, the chemical treatment inlet and the second inlet are all inserted to the positions below the partitioning plates. By adopting the partitioning plates with the small holes, large bubbles can be cut into small bubbles, so that a gas can be sufficiently reacted and absorbed inside a liquid, and moreover the bubbles can be distributed in a large area without stirring, so that the equipment is beneficial to absorption of harmful gases by the liquid.

Owner:KUNSHAN YICHENG CHEM VESSEL

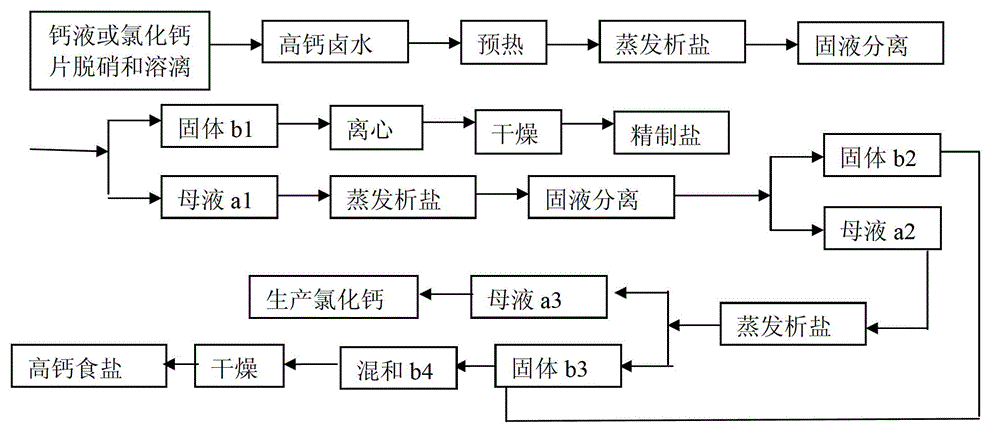

High-calcium edible salt produced by calcium-containing mirabilite-type mineral halide and producing method thereof

The invention discloses a high-calcium edible salt and a preparation method of the high-calcium edible salt, wherein the high-calcium edible salt is prepared by the following steps of: replacing all or partial fresh water by an ammonia-soda waste liquid or a water solution containing calcium chloride, and injecting into a mirabilite-type mine to obtain high-calcium brine; evaporating and condensing the high-calcium brine; implementing solid-liquid separation on the material liquid; evaporating and condensing the mother liquid twice; mixing solids obtained from various times of solid-liquid separation on the material liquid; after mixing, centrifuging and separating the mixture until the solid contains 2-4% of water; and drying to obtain the high-calcium edible salt which is rich in calcium ions. The high-calcium edible salt disclosed by the invention is accordant with standard of GB28050-2011 General Principles for Nutrition Label of Prepackaged Foods, Food Safety National Standard, and the preparation method disclosed by the invention reserves the natural calcium element in the 1000m deep well salt; and meanwhile, the chemical wastes are turned into raw materials for other industries, thus having a significance of protecting the environment.

Owner:江苏苏盐井神股份有限公司 +1

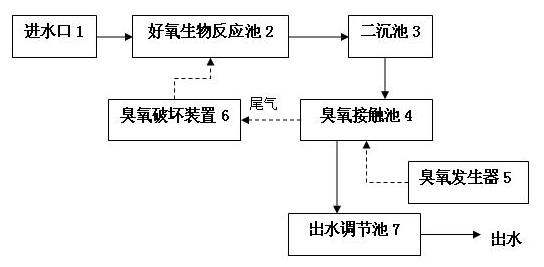

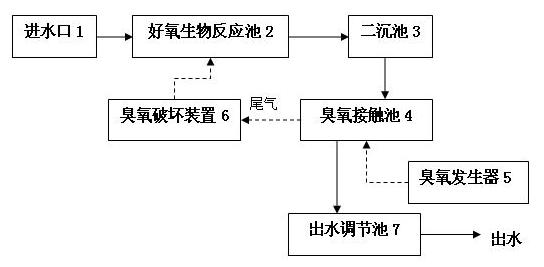

Treatment method of high-chroma chemical waste water

InactiveCN102139995AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment by oxidationActivated sludgeIndustrial waste water

The invention relates to a treatment method of high-chroma chemical waste water, relating to the technical field of industrial waste water treatment. The treatment method comprises the following steps of: (1) inputting the pretreated high-chroma chemical waste water into an aerobic biochemical treatment system for treatment; (2) treating in a solid-liquid separation system; (3) carrying out ozone oxidation treatment in an ozone treatment system comprising an ozone contact pond, an ozone generator, a porous aeration disc and an ozone destruction device; (4) introducing the treated industrial waste water into an outflow water regulation pond for treatment, then discharging, wherein the chroma of the outflow water is 19 degrees (Pt-Co), the content of COD (Chemical Oxygen Demand) is 69 mg / L, and the content of residual ozone contained in a tail gas is 1.7 g / h. The invention has the advantages of more effectively treating the high-chroma chemical waste water by increasing ozone decoloration treatment on the basis of a common activated sludge method and being capable of recycling the tail gas subjected to the ozone decoloration treatment for an aeration pond of the aerobic biochemical treatment system, effectively reducing the treatment cost and enhancing the treatment efficiency of the high-chroma chemical waste water.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Method for removing organic oxygenated chemicals in water

InactiveCN103496776AAvoid wastingAvoid latent heat of vaporizationWater contaminantsWater/sewage treatmentGasolineWastewater

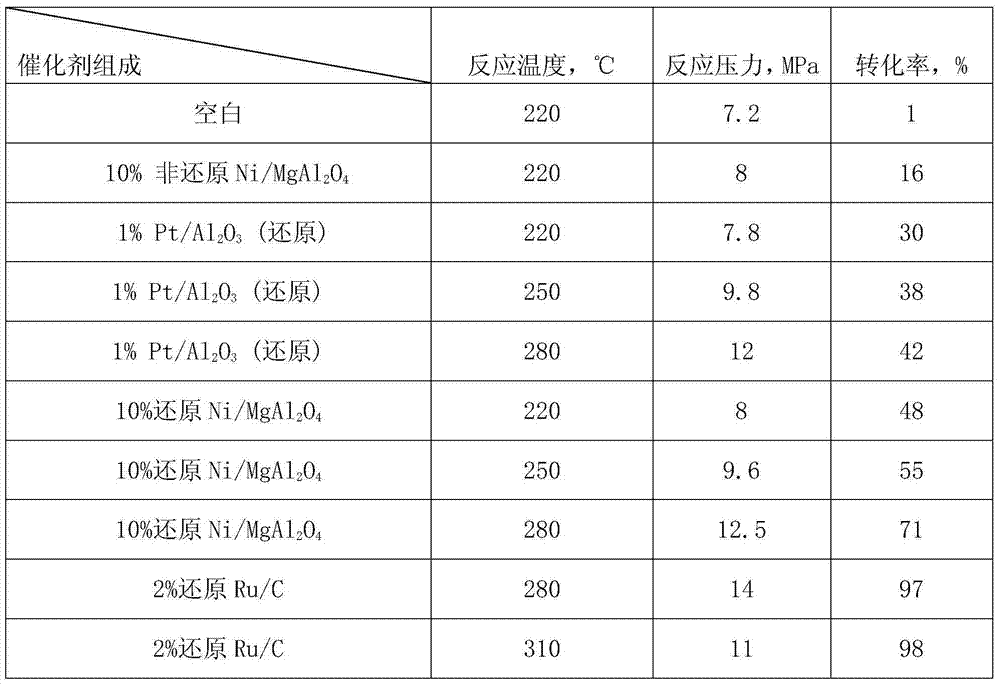

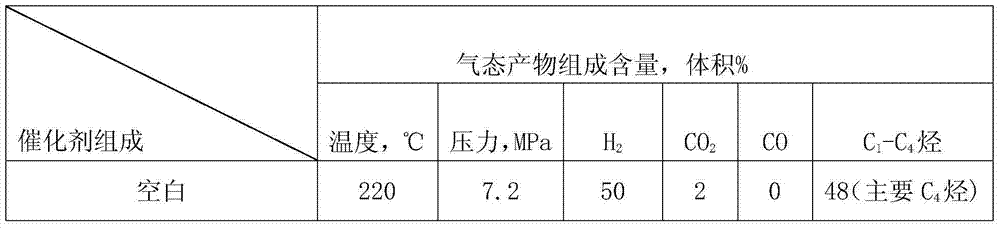

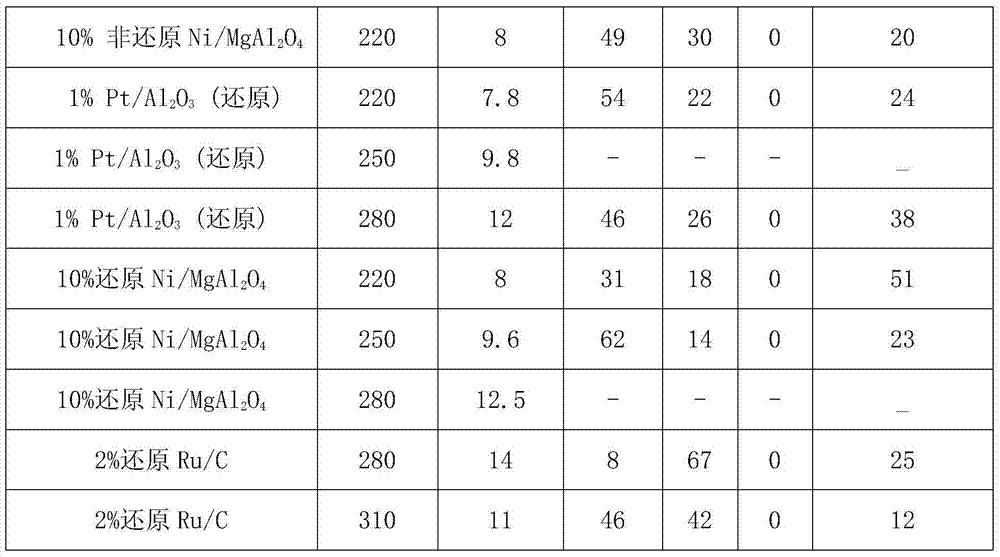

The invention discloses a method for removing organic oxygenated chemicals in water. The method includes the following step that under the action of a catalyst, the organic oxygenated chemicals in the water are enabled to be subjected to aqueous-phase reforming reaction at the temperature of 100-350 DEG C and under atmospheric pressure of 1-250, so that the organic oxygenated chemicals in the water is changed into gaseous products to be removed from water. The method can be used for treating organic oxygenated chemical waste water produced by Fischer Tropsch, processes for preparing light olefin, arene and gasoline from the organic oxygenated chemicals, and other production processes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

InactiveCN103301732BReach the purpose of recyclingDispersed particle separationEnergy inputCold airFlue gas

The invention belongs to the technical field of chemical waste gas treatment, and mainly relates to a device and a process for recycling and treating hydrogen sulfide-containing chemical acid waste gas. The process for recycling and treating hydrogen sulfide-containing chemical acid waste gas comprises the following steps of: igniting and completely burning the hydrogen sulfide-containing chemical acid waste gas into sulfur dioxide-rich high-temperature flue gas, recycling much heat and adjusting the temperature of the flue gas by cold air, and enabling the flue gas to enter an adsorption tower; completely absorbing the sulfur dioxide in the flue gas by utilizing an alkaline solution, removing less alkaline solution and sulfite contained in the flue gas absorbed by the alkaline solution, and exhausting the demisted pure flue gas to the atmosphere. The sulfite, which is generated by absorbing sulfur dioxide by the alkaline solution, is oxidized, concentrated, crystallized and dried to obtain side product sulfate.

Owner:义马煤业集团煤生化高科技工程有限公司 +1

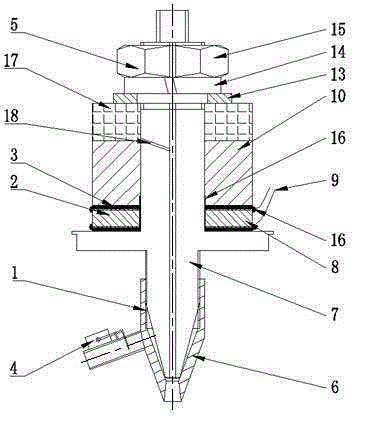

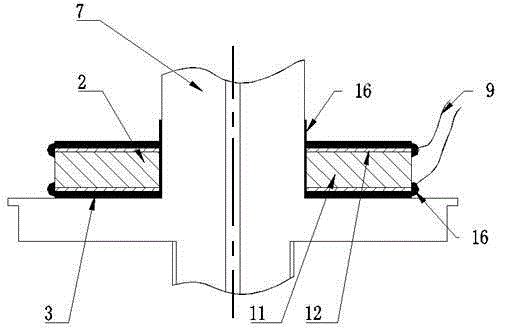

Ultrasonic-pneumatic electrostatic nozzle

InactiveCN104549813AIncrease the degree of atomizationImprove adsorption capacityLiquid spraying apparatusSpray discharge apparatusElectricityHigh pressure

An ultrasonic-pneumatic electrostatic nozzle comprises a spray rod with a tiny liquid flow channel processed in the axis, an ultrasonic generator, a nozzle air tap, a high-voltage electrostatic generator. The nozzle air tap surrounds the end of the spray rod to form the nozzle, a support device is arranged in the middle of the spray rod, the ultrasonic generator and the high-voltage electrostatic generator are pressed and fixed on one side face, away from the nozzle, of the support device through a fastening device, the ultrasonic generator is provided with a piezoelectric wafer, a backseat and a lead, the lead is connected to the piezoelectric wafer, short pulse of voltage acts on two poles of the piezoelectric wafer through the lead, the piezoelectric wafer elastically deforms so as to generate elastic oscillation, the high-voltage electrostatic generator is provided with an electrode to be connected with the liquid flow channel in the axis of the spray rod, and the high-voltage electrostatic generator applies high voltage static on liquid passing through the liquid flow channel of the spray rod. The nozzle is simple in structure, convenient to operate, safe and reliable, adjustable in spray flux and distance and the like, and is of great significance to spray effect improvement and reduction of chemical waste.

Owner:YANGZHOU UNIV

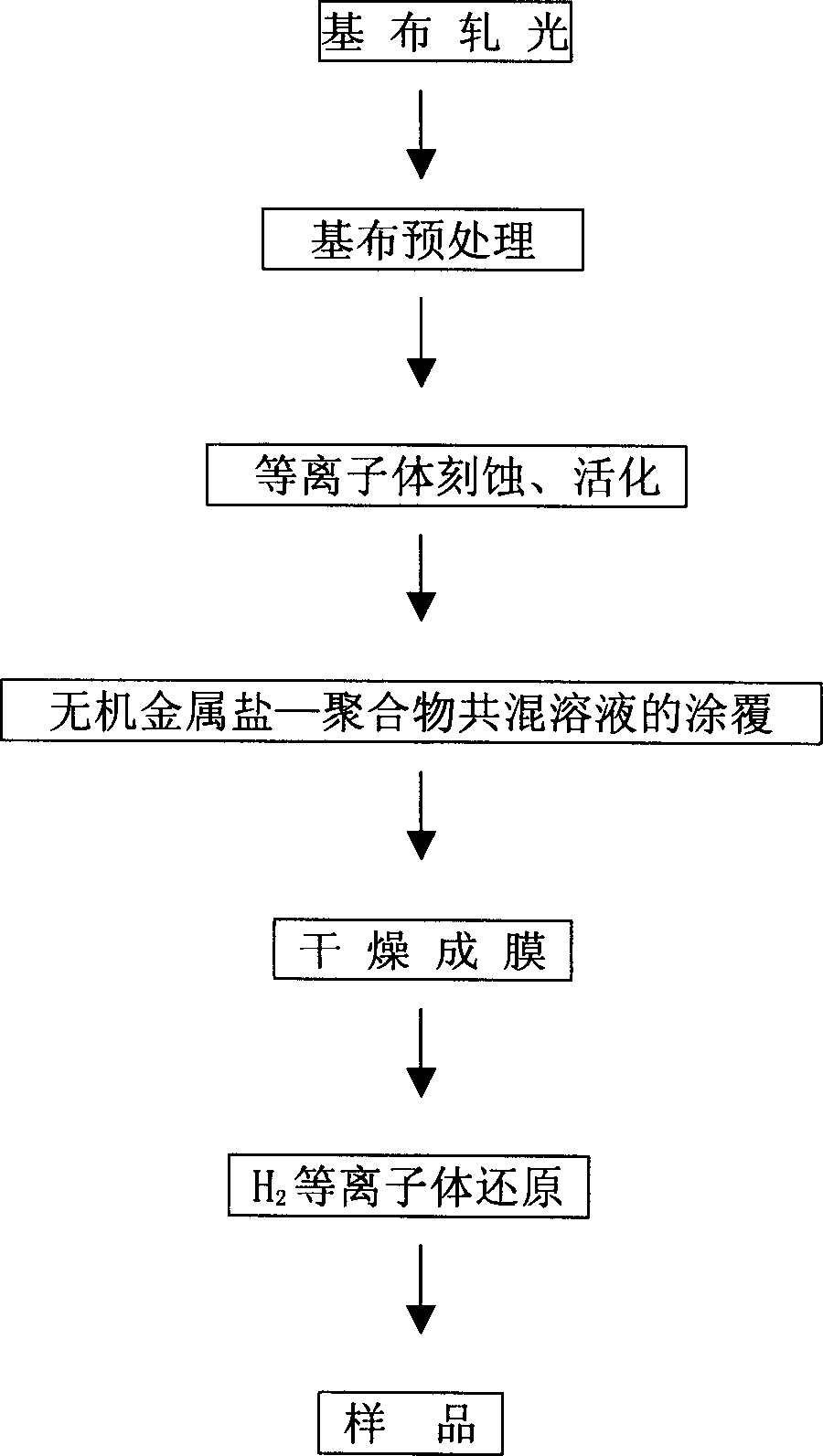

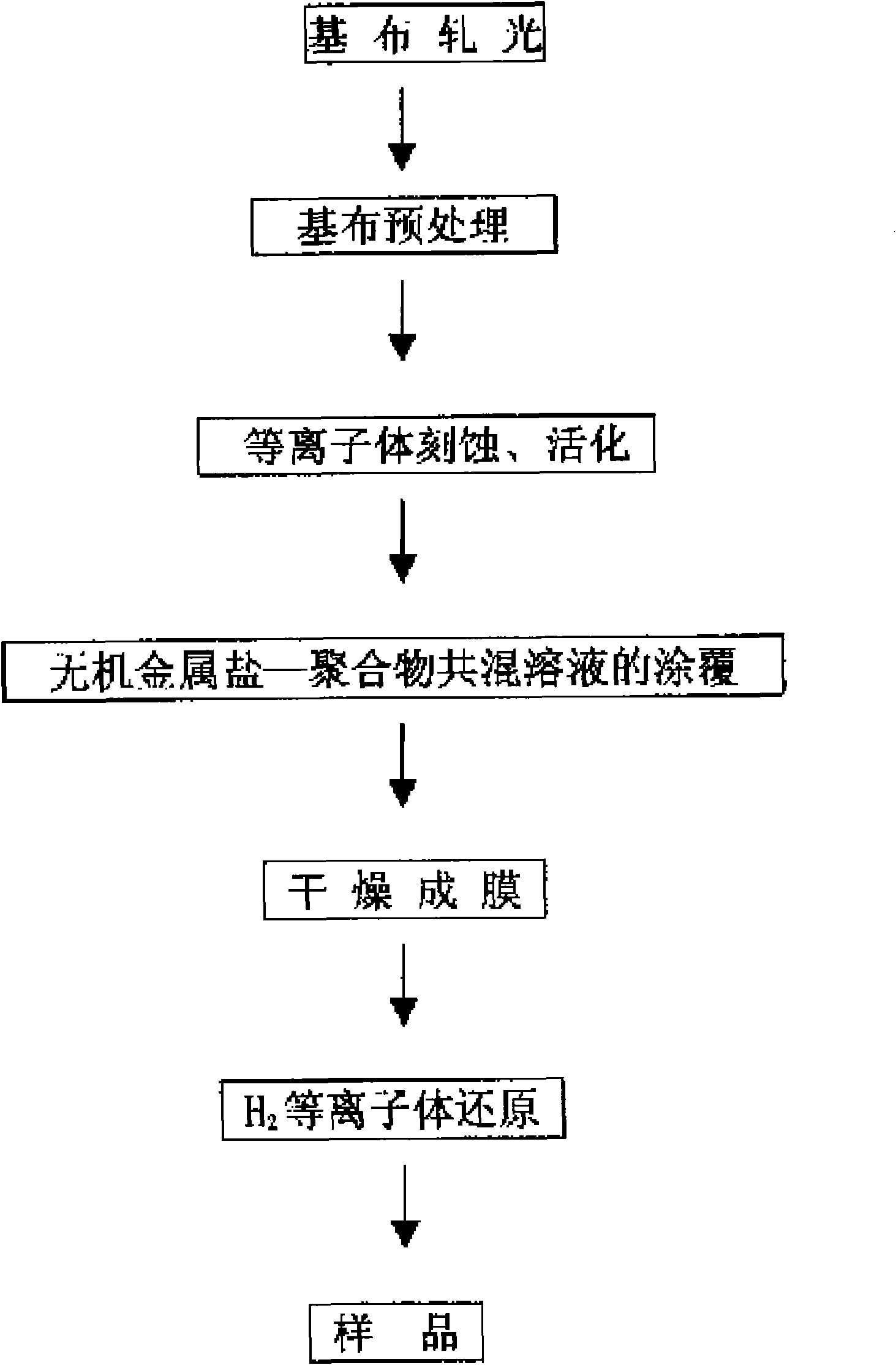

Method for making metallization treatment of fabric surface

InactiveCN1400354AImprove bindingImprove bonding fastnessPhysical treatmentChemical LinkageSurface cleaning

The present invention utilizes low-temp. plasma body to treat and implement surface cleaning, etching and activaling processes of the fabric, and adopts inorganic metal salt-polymer complex coating layer, and uses hydrogen gas plasma body to make reduction so as to obtain the chemically-bonded surface metallized fabric between coating layer and base body. Said invented method is simple in process, effective, can prevent treatment of chemical waste liquor, its product can be used in microwave and electromagnetic shielding effect, reflective, heat-insulating, decorative and fire-resisting materials.

Owner:SUZHOU UNIV

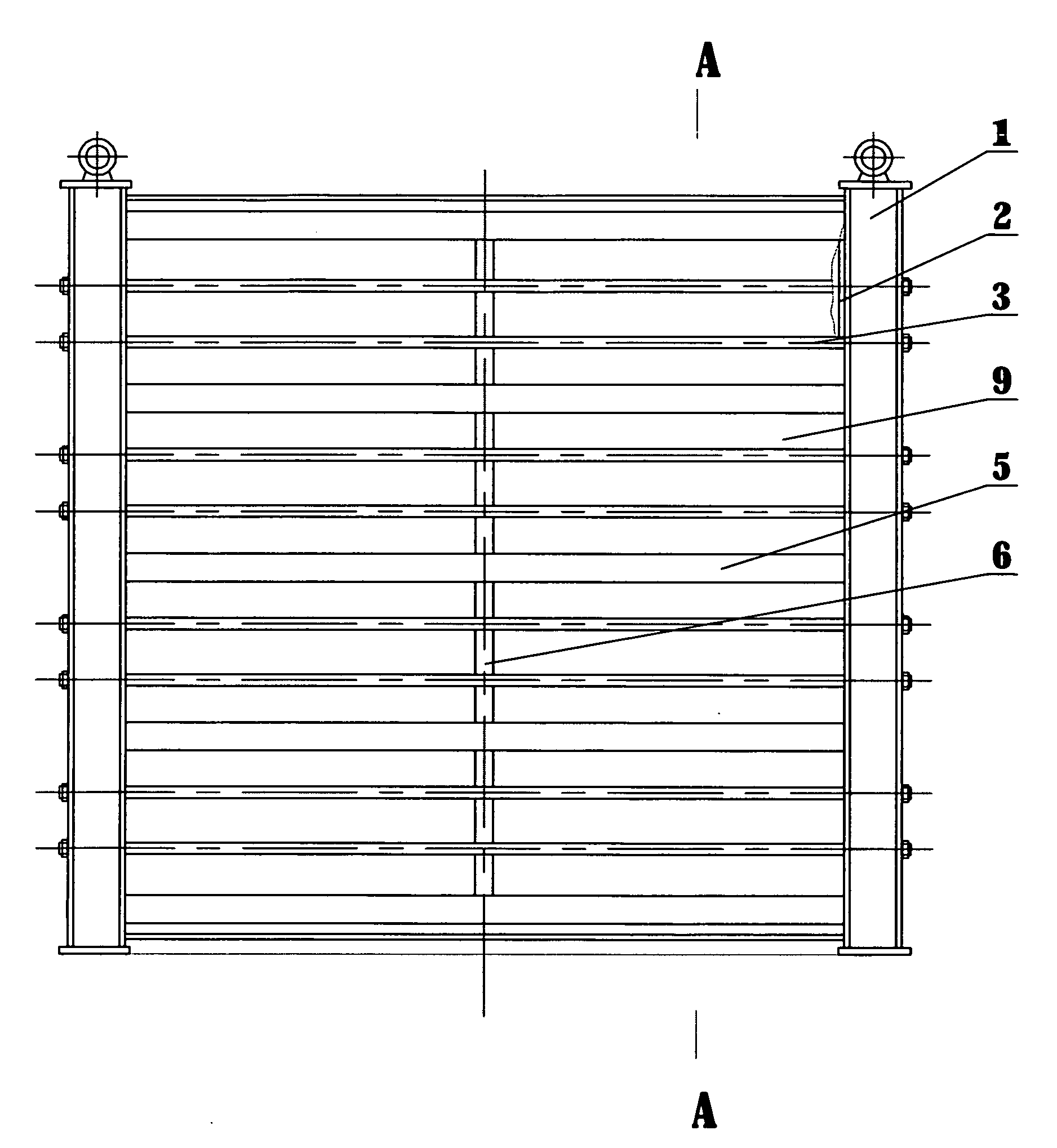

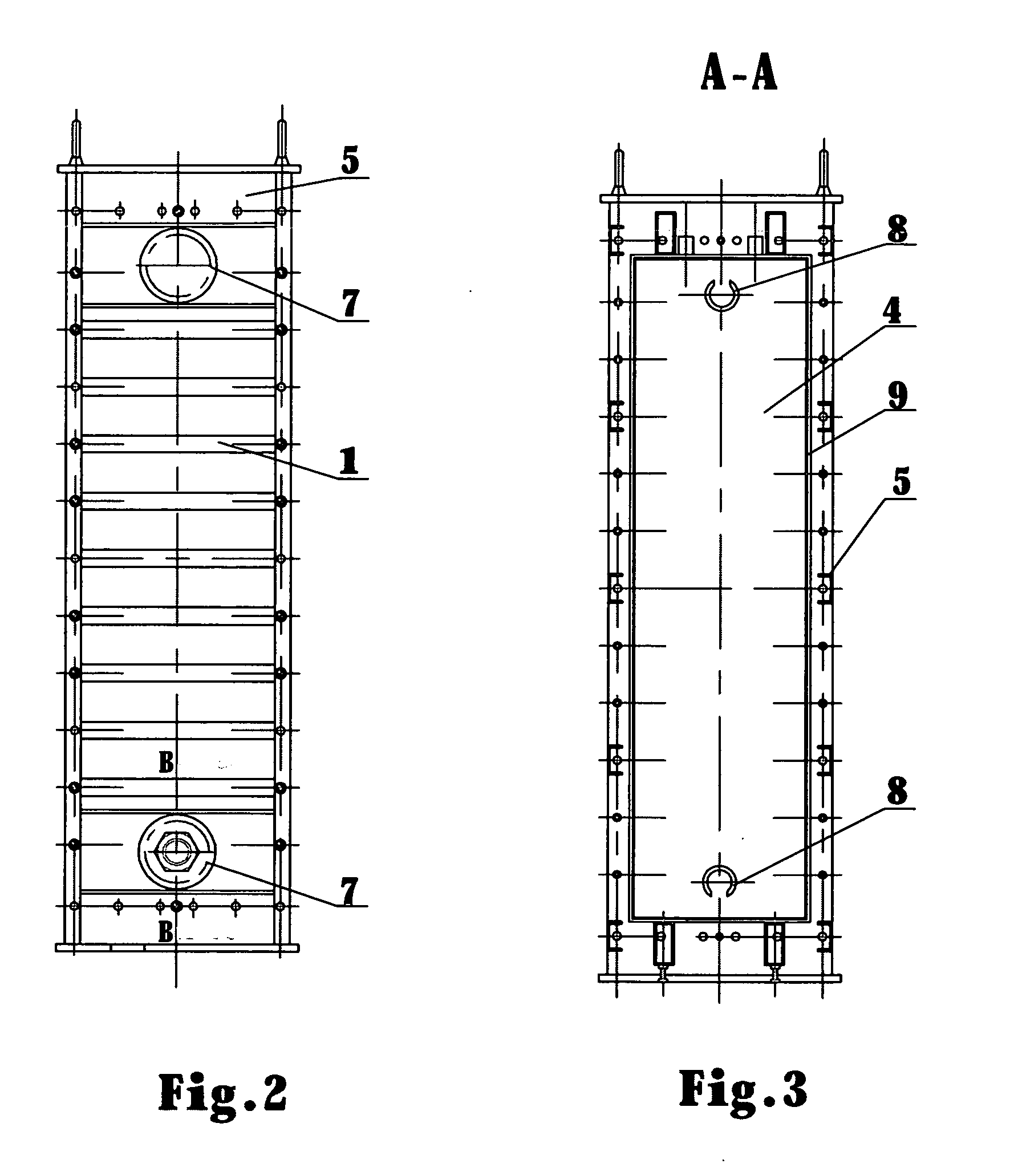

Incineration boiler for saline waste liquid

ActiveCN102588980AReduce processing costsWaste liquid incineration system is simpleIncinerator apparatusSteam boilersLiquid wasteCombustion chamber

The invention discloses an incineration boiler for saline waste liquid, which mainly structurally comprises a combustor, a waste liquid spray gun, a heat-insulation hearth combustion chamber, a radiation cooling chamber, an upper boiler barrel (a steam drum), a lower boiler barrel, a convection tube bundle, an ash hopper, a boiler wall and a steel frame. As a heat-insulation hearth and a space of the hearth of the incineration boiler are large, the saline waste liquid is preheated, dissolved and combusted quickly and thoroughly after being sprayed into the boiler, noxious substances in the waste liquid can be effectively removed by means of incineration, melted sodium salt alkali liquor is gathered on the lower portion of the hearth along four walls of the hearth and then is drained out of the boiler via an alkali liquor outlet to be recycled, and high-temperature flue gas generated by the incineration boiler sequentially enters the multi-stage radiation cooling chamber and the convection tube bundle so that heat energy is recycled. The incineration boiler is simple in manufacturing process, convenient in maintenance and safe and stable in running, chemical waste gas can be simultaneously incinerated, and the incineration boiler is applicable to popularization and application in terms of treatment of saline waste liquid and waste gas in the industries of chemical engineering and paper making.

Owner:大连科林能源工程技术开发有限公司

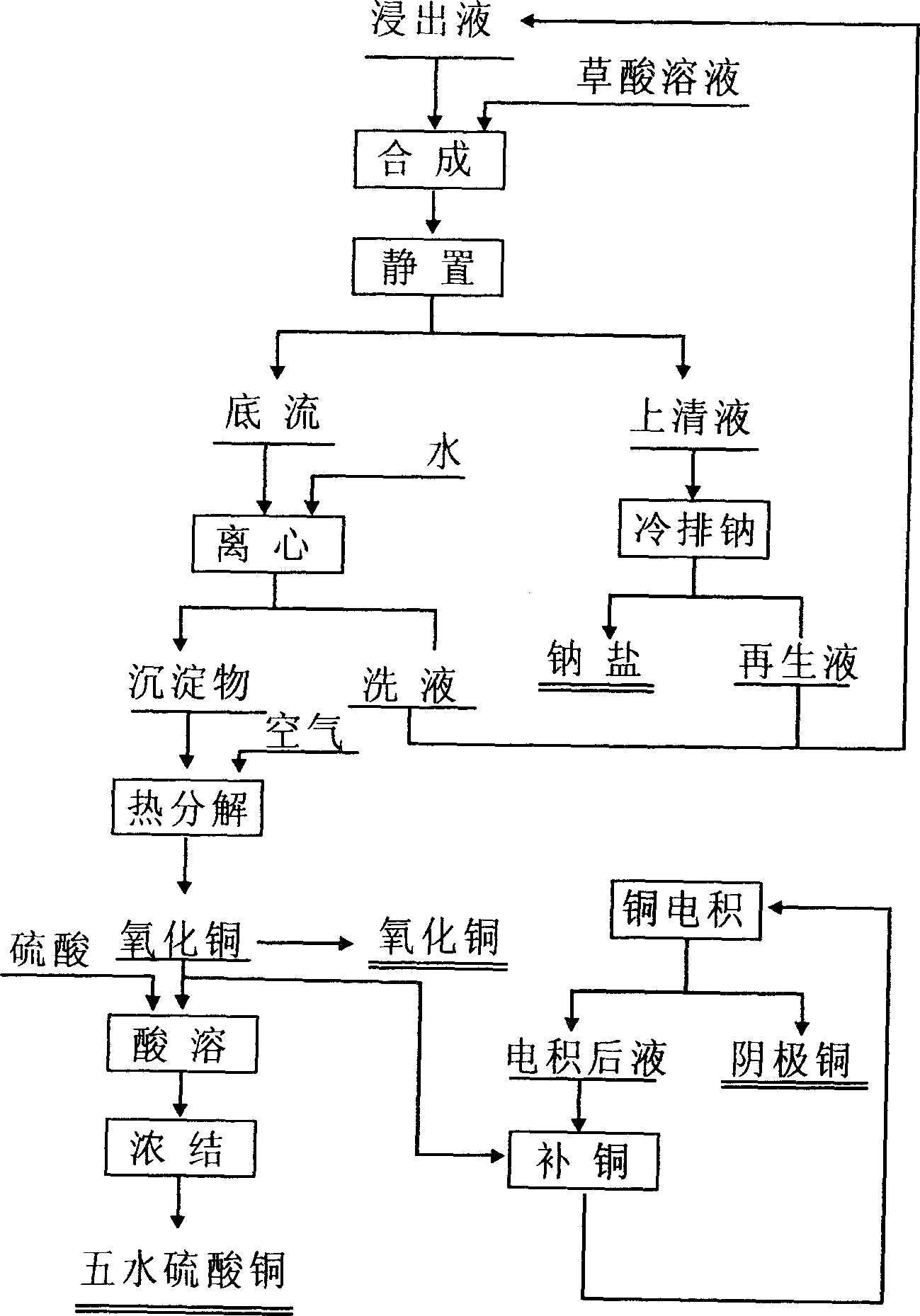

Method for extracting copper from organic silicon chemical waste residue leaching liquid of chloride and mixed salts containing copper

InactiveCN1844422AGuaranteed separation effectLow costPhotography auxillary processesCopper oxides/halidesChemical industryDecomposition

The invention selects oxalic acid solution to act as the precipitating agents of organosilicon chemical industry waste slag leachate of copper chlorate or mixture salt system, after filtering, washing and drying of the process residue of copper oxalic acid, heat decomposition in oxidizing atmosphere and at the temperature of 500~900 centigrade, the production of copper oxide is obtained by product yield cool-down. The yield acid of oxalic acid precipitation process is retuned organosilicon chemical industry waste slag leachate system to act as infusion. After the heat decomposition copper oxide dissolves in sulphuric acid, the solution can be used in electrodepositing cathode copper or regenerating copper sulphate, also can be used to produce cathode copper by copper electrodepositing solution dissolution regeneration electrodeposition, also sell as commercial copper oxide.

Owner:范有志

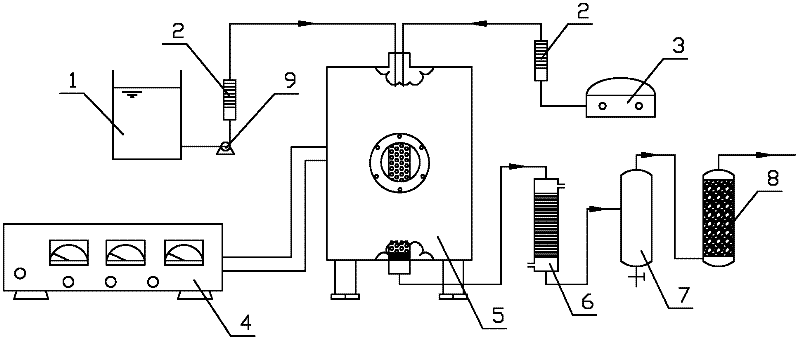

Method and equipment for processing chemicals waste water by catalytic oxidation of activated carbon induced by microwaves

InactiveCN102381741AHigh removal rateNo secondary pollutionWater/sewage treatment by irradiationWater/sewage treatment by oxidationWater dischargeCatalytic oxidation

The invention discloses a method for processing chemicals waste water by catalytic oxidation of activated carbon induced by microwaves, comprising the following steps: firstly, the waste water and air enters an activated carbon reaction bed, and the reaction of inducing the catalytic oxidation of the activated carbon by the microwaves is conducted in the activated carbon reaction bed; and secondly, water discharged from the activated carbon reaction bed is subjected to gas-liquid separation after being condensed, separated liquid is emitted when reaching the standard, and separated gas is emitted by reaching the standard by being processed by adsorption. The invention also discloses equipment adopting the method. The method for inducing the catalytic oxidation of the activated carbon by the microwaves has a plurality of advantages as follows: the degradation rate is high, the processing time is short, the degradation is conducted under normal pressure, the requirements on equipment material is low, the investment cost on a system one time is small, and the like. Simultaneously, as microwave technology is adopted for processing sewage, a sewage processing project can be miniaturized and decentralized, and drain contamination pipe networks can be reduced, so that the water environment of humanity can realize virtuous circle, and higher economic benefits can be realized.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

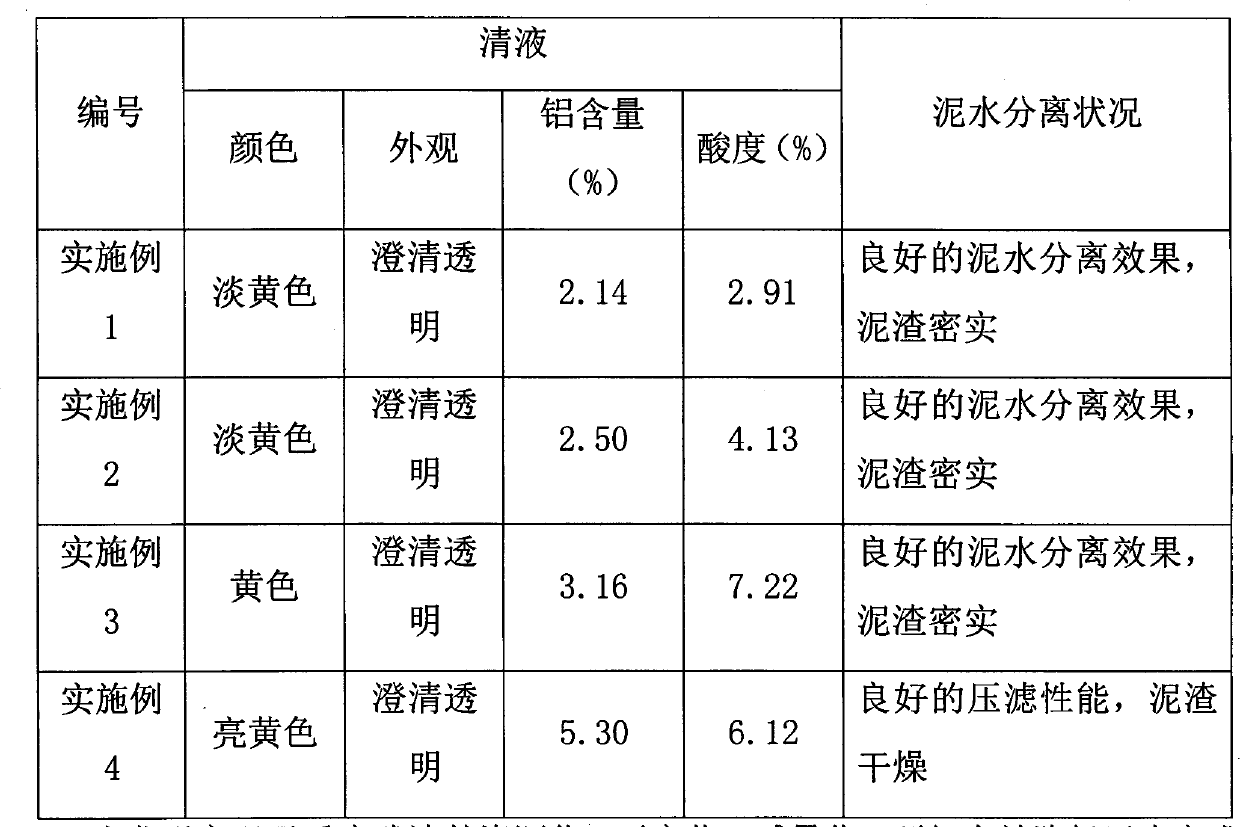

Utilization method for polymeric aluminium reaction residues

ActiveCN101905898ASuccessfully achieved reductionAchieve reductionSolid waste disposalAluminium chloridesAluminium chlorohydrateSolid reaction

The invention relates to a technology for treating chemical wastes, in particular to a treatment and utilization method for polymeric aluminium reaction residues. The method comprises the following specific steps: (1) putting 4%-20% (by weight parts of HCl) of inorganic mixed acid and reaction residues in the weight ratio of 1:6-1:2 into reaction equipment, evenly mixing, and reacting while stirring at the temperature of 50-110 DEG C for 0.5-2h; and (2) throwing reaction liquid into a sedimentation tank for sedimentation for 0.5-2h or directly utilizing a filter-press to carry out solid-liquid separation, wherein the obtained clear liquid is aluminiferous acid liquor capable of being reused in the polymeric aluminium production process. The invention comprehensively utilizes the solid reaction residues, turns waste materials into things of value, reduces the yield of the solid residues in the polymeric aluminium production process, saves the handling expenses for the residues, reduces the usage amount of calcium aluminate powder and bauxite in the polymeric aluminium production process, saves production cost and improves product quality.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

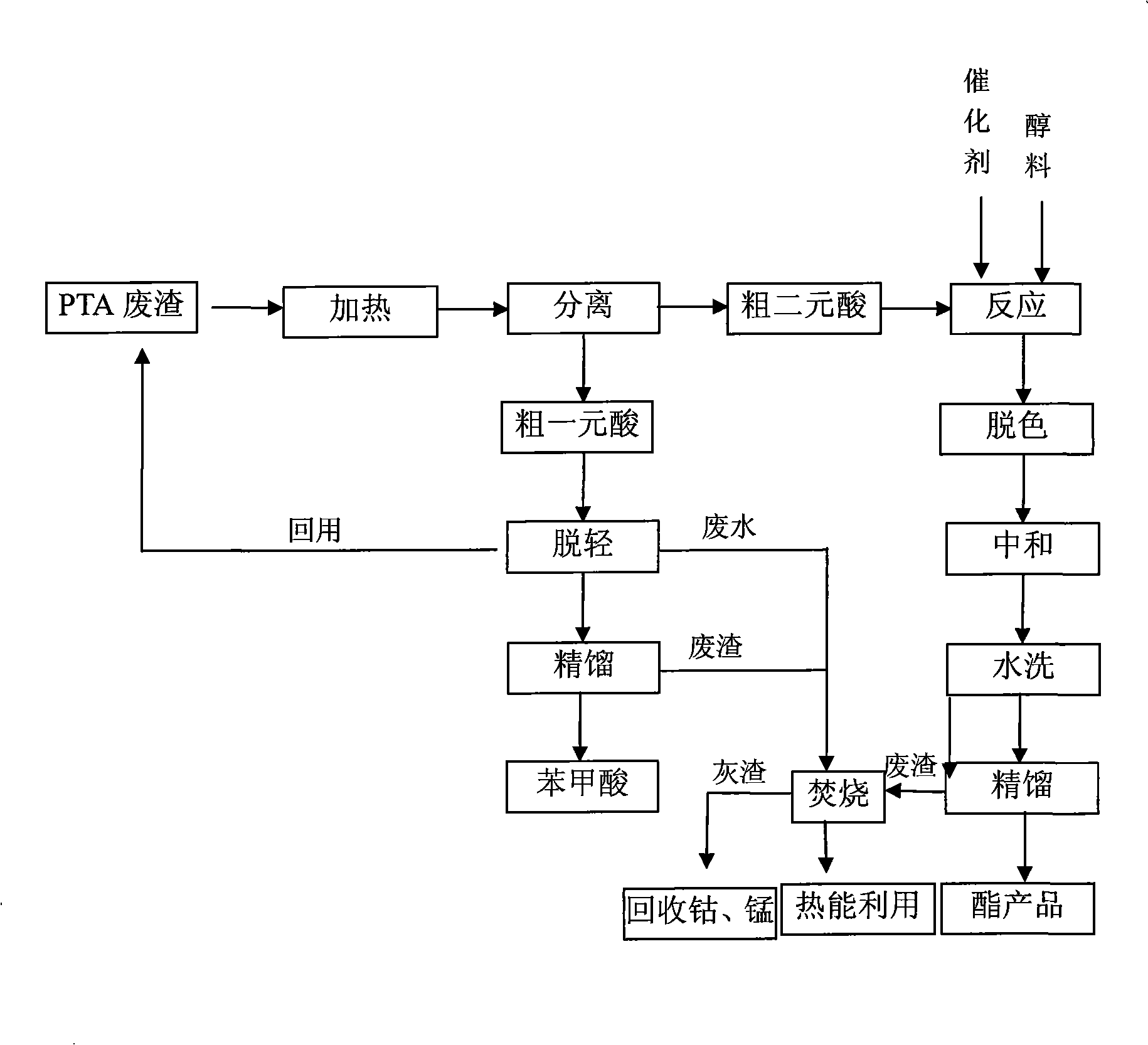

Resource treatment method for fine terephthalic acid waste residue

ActiveCN101513641ARealize resourcesHarmlessOrganic compound preparationSolid waste disposalBenzoic acidManganese

Owner:TAIXING FUCHANG SOLID WASTE TREATMENT CO LTD

Fabric surface metallization processing method

InactiveCN102758352AImprove bindingImprove bonding fastnessPhysical treatmentPlasma technologySurface cleaning

The invention belongs to the technical field of textile material functional finishing, and especially relates to a method for carrying out metallization processing upon fabric surface with a plasma technology. According to the invention, with low-temperature plasma processing, fabric surface cleaning, etching and activating are realized. An inorganic metal salt-polymer complex is used for coating; and hydrogen plasma is used for reducing, such that a surface metallized fabric is obtained, wherein a coating and a substrate are bonded with chemical bonds. The method is simple and effective. With the method provided by the invention, a defect of poor bonding force between a metal layer and substrate cloth in prior arts is overcome, and chemical waste liquid treatment is avoided. The product can be used in microwave and electromagnetic shielding materials, reflective and insulation materials, and decorative and fire preventing materials.

Owner:SUZHOU OPS PLASMA TECH

Liquid treatment module

InactiveUS20100059382A1Easy to handleReduce operating currentSludge treatmentFatty/oily/floating substances removal devicesFruit juiceCompound (substance)

The present invention relates to a liquid treatment module, which comprises power distribution panels, electrode plates and a framework with side plates. The two power distribution panels are fixed on the two side plates. The power distribution panels have electrode plates located on inner side of the panels. There are two or more double-sided electrode plates placed in stacks between the two distribution panels which are connected to the DC power supply through the electric wires. There are separators placed between the adjacent electrode plates to provide the flow channels. Each flow channel is connected with the inlet and outlet holes on the side plates. The exposed surface of the power distribution panels, double-sided electrode plates and the separators are bonded and sealed by the insulating package. This invention has characteristics of simple structure, large liquid handling capacity, high efficiency, and can be used to process liquids of various kinds including water, wine, fruit juices, beverages, dairy products and chemical wastes from various sources for impurities removal.

Owner:EST WATER & TECH

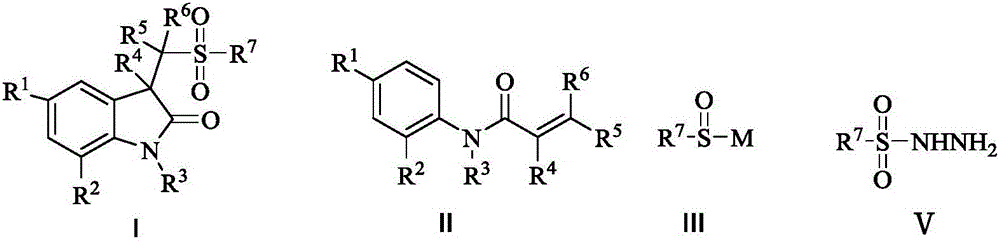

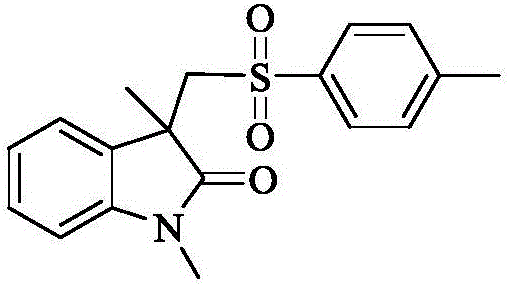

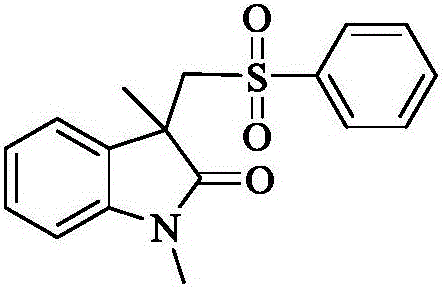

Electrochemical catalysis synthesis method of 3-sulfonyl substituted oxo indoles compound

ActiveCN106048648AReduce usageIncrease productionElectrolysis componentsElectrolytic organic productionElectrolysisSulfohydrazide

The invention discloses an electrochemical catalysis synthesis method of a 3-sulfonyl substituted oxo indoles compound, and belongs to synthesis of compounds. The method uses a sulfoacid reagent represented by a formula (III) or sulfonyl hydrazine represented by a formula (V) or N-substituted acrylamide represented by a formula (II) as a raw material in a single-cell electrolytic tank; and in presence of an electrocatalyst, the raw material is electrolyzed in electrolyte at a certain temperature to obtain the 3-sulfonyl substituted oxo indoles compound represented by a formula (I). The method firstly adopts an operation-simple electrochemical catalysis indirect electrolysis method to synthesize the 3-sulfonyl substituted oxo indoles compound, uses the single-cell electrolytic tank and constant-current electrolysis, uses a cheap and easy-obtained graphite piece as a working electrode, largely reduces the cost, in particular, reduces heavy metal or chemical-metered oxidant, prevents generation of chemical wastes, is simpler in operation, and is more suitable for industrial production.

Owner:BEIJING UNIV OF TECH

Technology for processing comprehensive waste water from acrylonitrile and acrylic fibers production

ActiveCN102190408AReduce refluxIncrease concentrationMultistage water/sewage treatmentNature of treatment waterAcrylonitrileOxygen

The invention relates to a technology for processing comprehensive chemical waste water from acrylonitrile and acrylic fibers production and is directed to the field of environment engineering technology. According to the invention, an aeration reaction, a biology hydrolysis acidification, a denitrification nitrogen removal and an aerobic biological treatment are adopted. The waste water is classified into C, N and S grade. The toxicity problem for microbes caused by the waste water is solved; the biological treatment capability and waste water processing effect are improved. The technology is characterized by simple and reasonable process flow. The operation cost is reduced. The technology is suited for industrial application and biology processing of high sulfur high nitrogen organic waste water of the same kind.

Owner:博瑞德环境集团股份有限公司

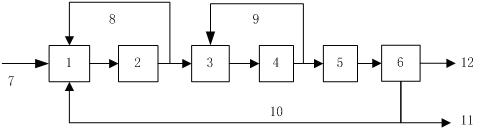

Full-solid-waste burn-free foamed concrete based on tail gas carbonization and preparation method and application thereof

ActiveCN110204258AProduction energy saving and environmental protectionHigh mechanical strengthSolid waste managementCeramicwareFoam concreteWarm water

The invention belongs to the technical field of full-solid-waste burn-free foamed concrete, and particularly relates to full-solid-waste burn-free foamed concrete based on tail gas carbonization and apreparation method and application thereof. The foamed concrete is prepared from, by weight, 35-62% of red mud, 25-50% of carbide slag, 2-12% of fly ash, 2-18% of industrial gypsum, 4-15% of an alkali activator, 0.5-2% of a foaming agent, 0.5-1% of a water reducing agent and the balance warm water. By adopting chemical waste as the alkali activator, in combination with the red mud, the carbide slag, the fly ash and the industrial gypsum, the foamed concrete with a thermal insulation function is prepared, comprehensive utilization of multiple solid waste is achieved, the problems of low resource utilization of solid waste and utilization of industrial tail gas are solved, more economical and environment-friendly effects are achieved, and the preparation process is easier and more convenient.

Owner:SHANDONG UNIV

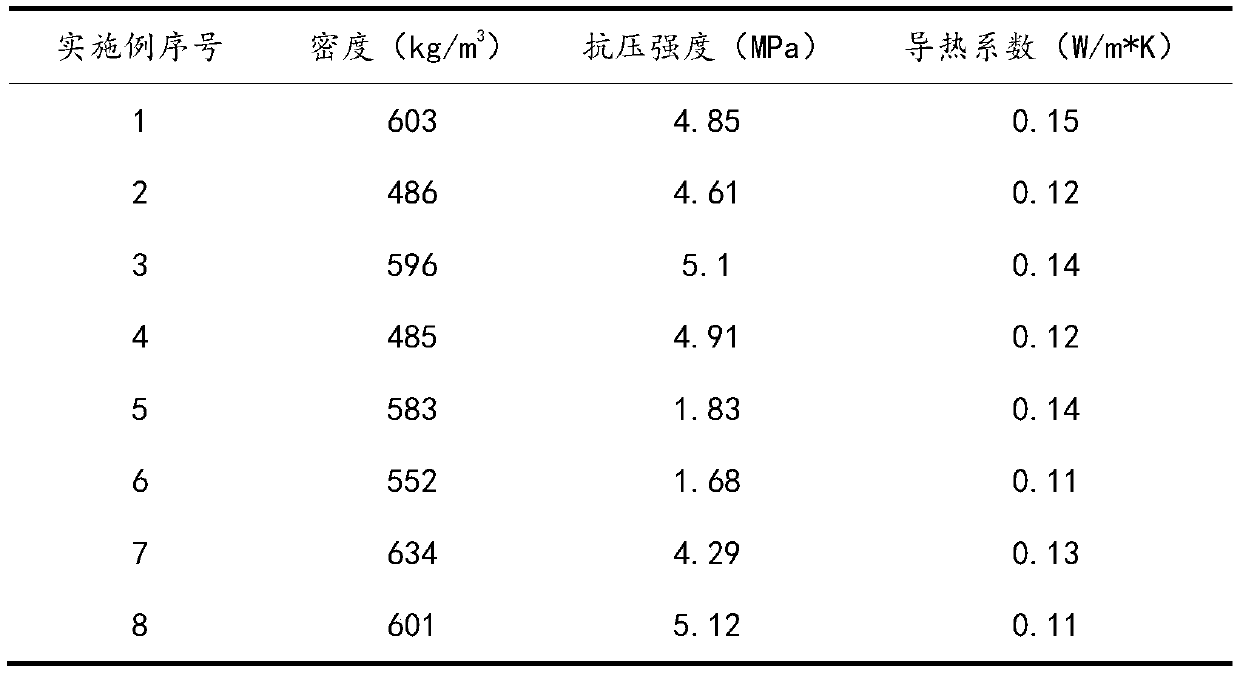

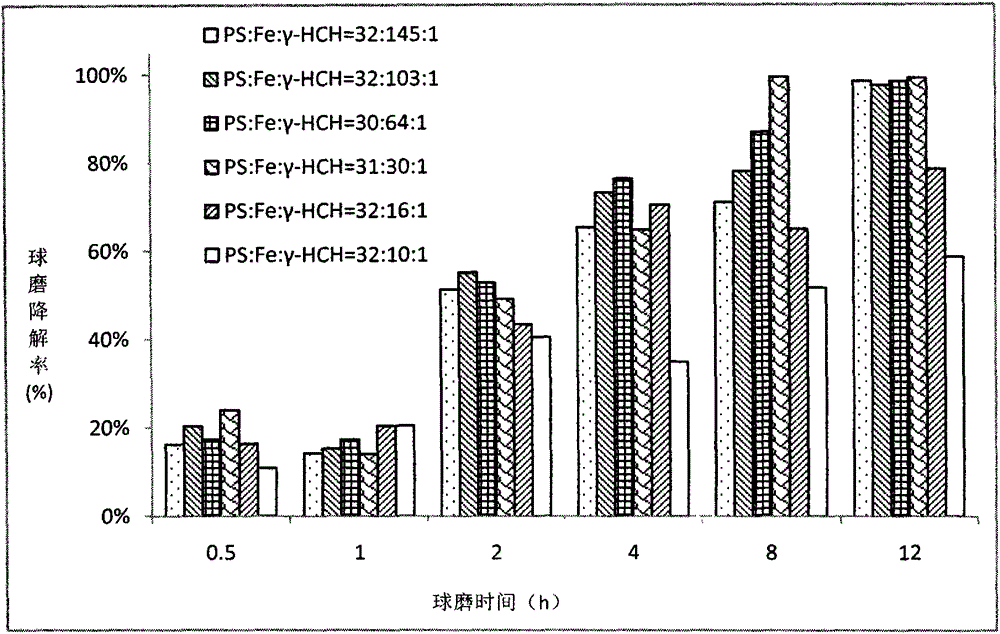

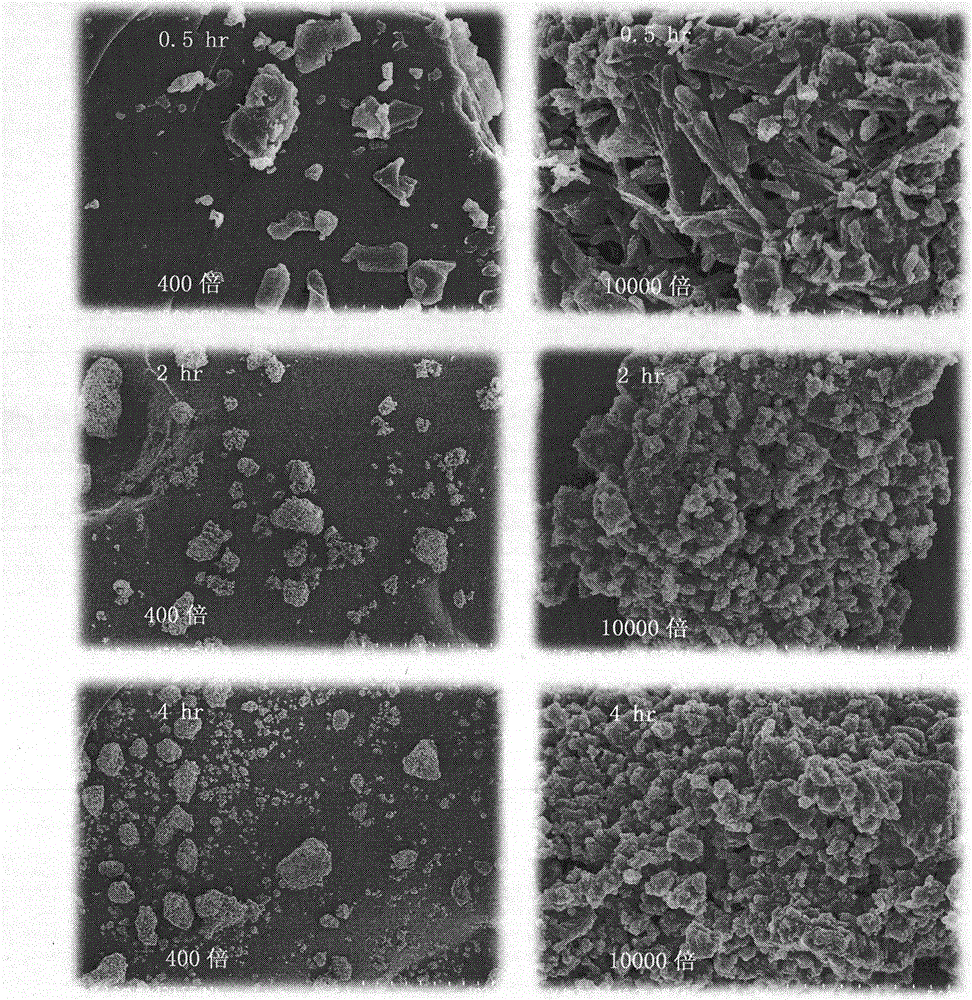

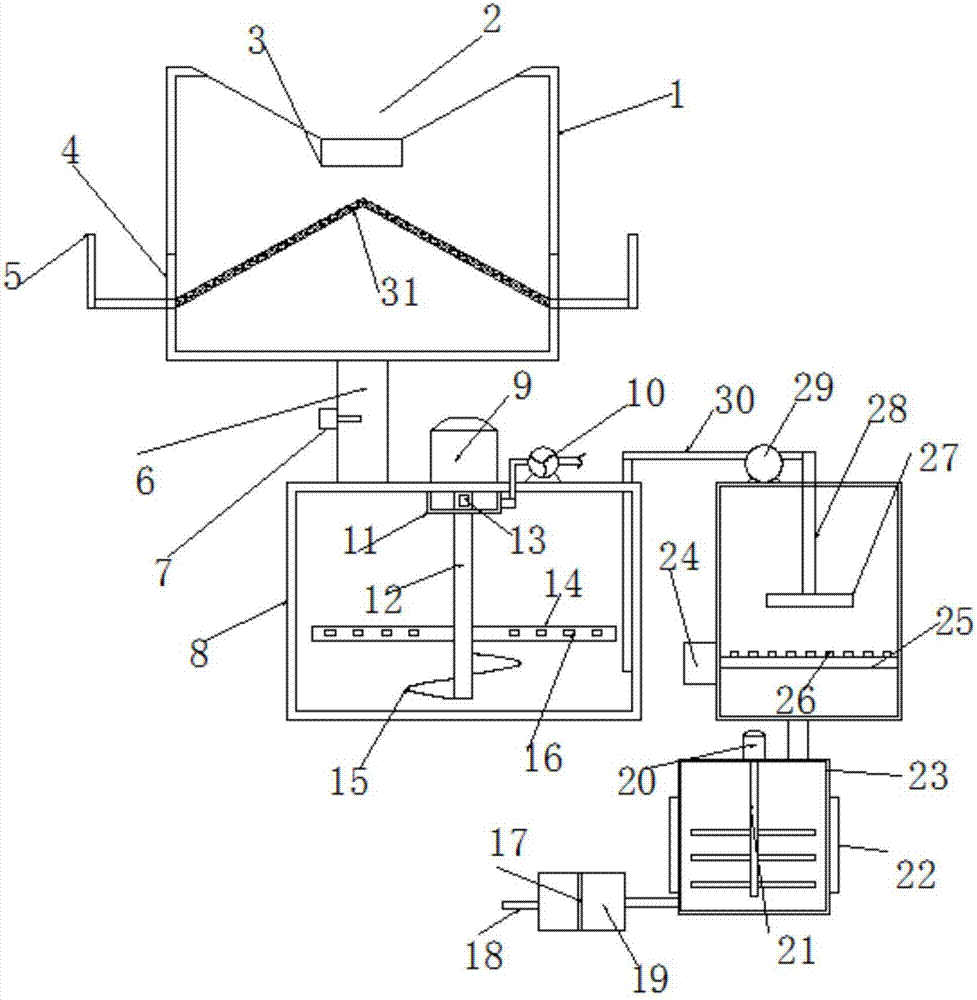

Persulfate enhanced ball-milling treatment method of chemical waste

InactiveCN104784863ARapid responseShort reaction timeContaminated soil reclamationPersulfateChemical compound

The invention discloses a persulfate enhanced ball-milling treatment method of chemical waste. Persulfate assisted by a co-grinding agent is used, and a local high-temperature high-pressure environment is instantly generated under an action of mechanical force generated from high-speed revolution of a ball mill to induce generation of sulfate free radicals with strong oxidizing property, so that an organic compound can be quickly decomposed through oxidation. According to the invention, the method can be used for treating chemicals such as various waste pesticides, household medicaments, and fire retardants; the treating time is short; the efficiency is high; and fast treatment of chemical waste can be realized.

Owner:BEIJING NORMAL UNIVERSITY

Coal chemical industry wastewater treatment device

InactiveCN107244775AQuick mixAids in filteringTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisWastewaterEngineering

The invention discloses a coal chemical wastewater treatment device, which comprises a pretreatment box, a feed hopper is arranged at the upper port of the pretreatment box, a feeding pipe is arranged at the lower end of the feeding hopper, and the inside of the pretreatment box below the feeding pipe is There is a conical filter screen, the lower end of the conical filter screen is in contact with the inner wall of the pretreatment box, and there are several discharge ports on the pretreatment box where the lower end of the conical filter screen is located, and the pretreatment box outside the discharge port is fixed with a collection Enclosure, a detection tube is fixed in the middle of the lower end of the pretreatment box, and a pH detector and a flow meter are arranged on the outside of the detection tube. The structure of the invention is simple and reasonable, and the material can be guided during pretreatment, thereby facilitating the removal of impurities. At the same time, the rotary spraying treatment is used during neutralization, so that the two raw materials can be mixed quickly, which helps to increase the neutralization speed, thereby keeping the sewage neutral, which is helpful for the later membrane filtration treatment, and is practical powerful.

Owner:ZHENGZHOU JIACHEN CHEM TECH CO LTD

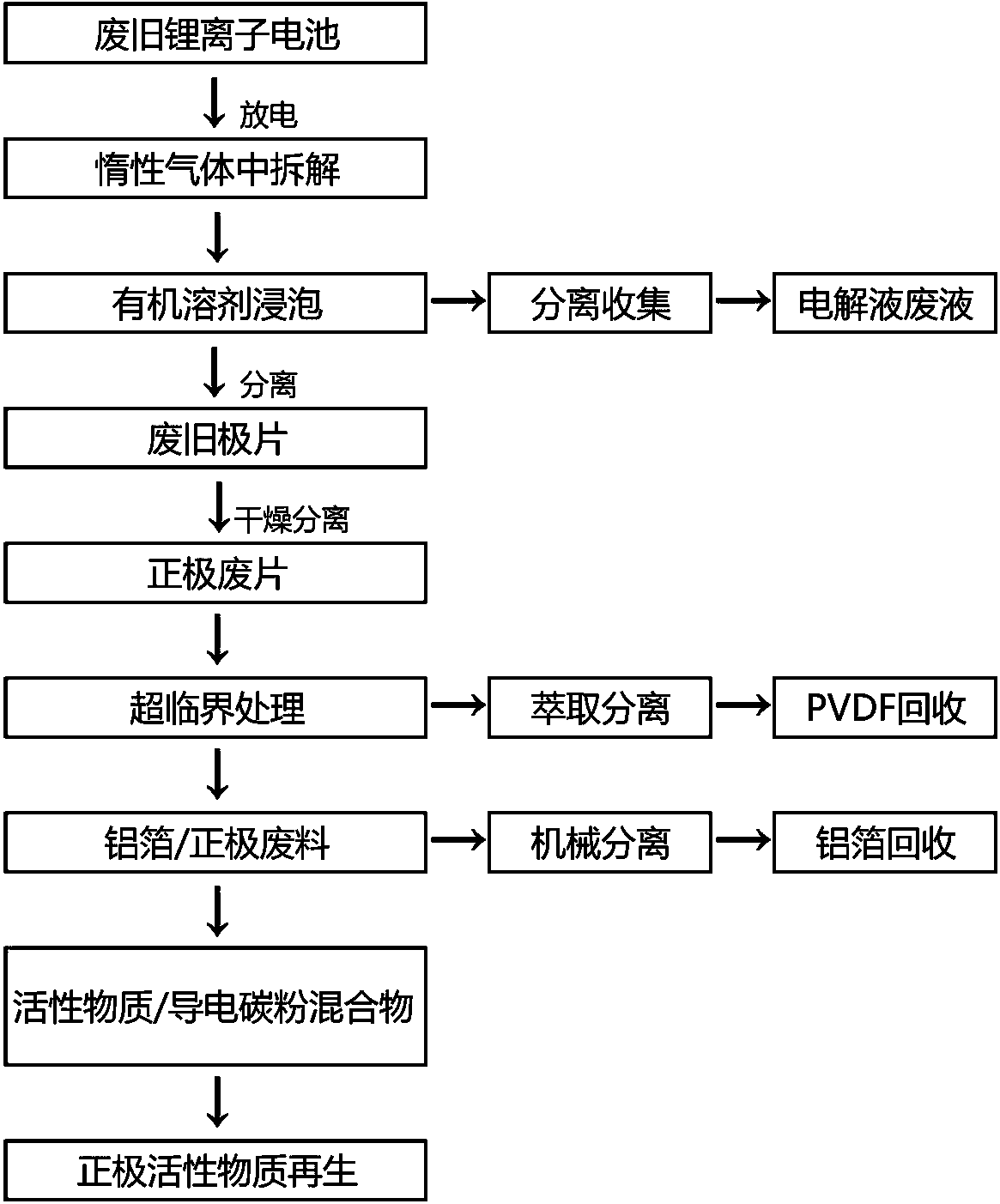

Lithium ion battery waste cathode piece recycling method

InactiveCN108736086ACost-effective recycling methodGreen recycling methodWaste accumulators reclaimingBattery recyclingToxic materialSodium-ion battery

The invention discloses a method for recycling polyvinylidene fluoride (PVDF), aluminum and cathode wastes (a mixture of active substances and conductive carbon powder) in waste battery cathode piecesof lithium ion batteries by virtue of a supercritical fluid extraction process. The method comprises the following steps: firstly disassembling cathodes of the lithium ion batteries, soaking in an organic solvent, taking out, carrying out drying treatment, and obtaining cathode pieces which do not contain electrolyte; then carrying out supercritical extraction treatment on the treated cathode pieces, namely dissolving a binder PVDF in the cathode pieces into a supercritical fluid, and extracting and separating the binder PVDF; mechanically separating remaining aluminum foils and the cathode wastes which lose cohesiveness and are mutually stripped; and directly taking the separated cathode wastes as a raw material for producing a lithium ion battery cathode material. The method disclosed by the invention does not use an acid-base fluid to treat electrodes or carry out high-temperature incineration, so that chemical waste liquor or toxic waste gas is not produced; and by virtue of the supercritical extraction treatment way, the recycled aluminum foils, PVDF and cathode wastes can be directly taken as the raw material to be recycled, so that the method has the advantages of economy,high efficiency and environmental friendliness.

Owner:苏州威星能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com