Method for making metallization treatment of fabric surface

A surface metal and fabric technology, which is applied in the field of metallization treatment of the fabric surface by plasma technology, can solve the problems of affecting the treatment effect and product quality stability, the plasma atmosphere cannot be controlled, and the vacuum degree of the system is not easy to increase. Combination of fastness, low processing temperature, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Substrate: Modified polyester filament and its fabric.

[0021] Plasma generator: capacitive coupling.

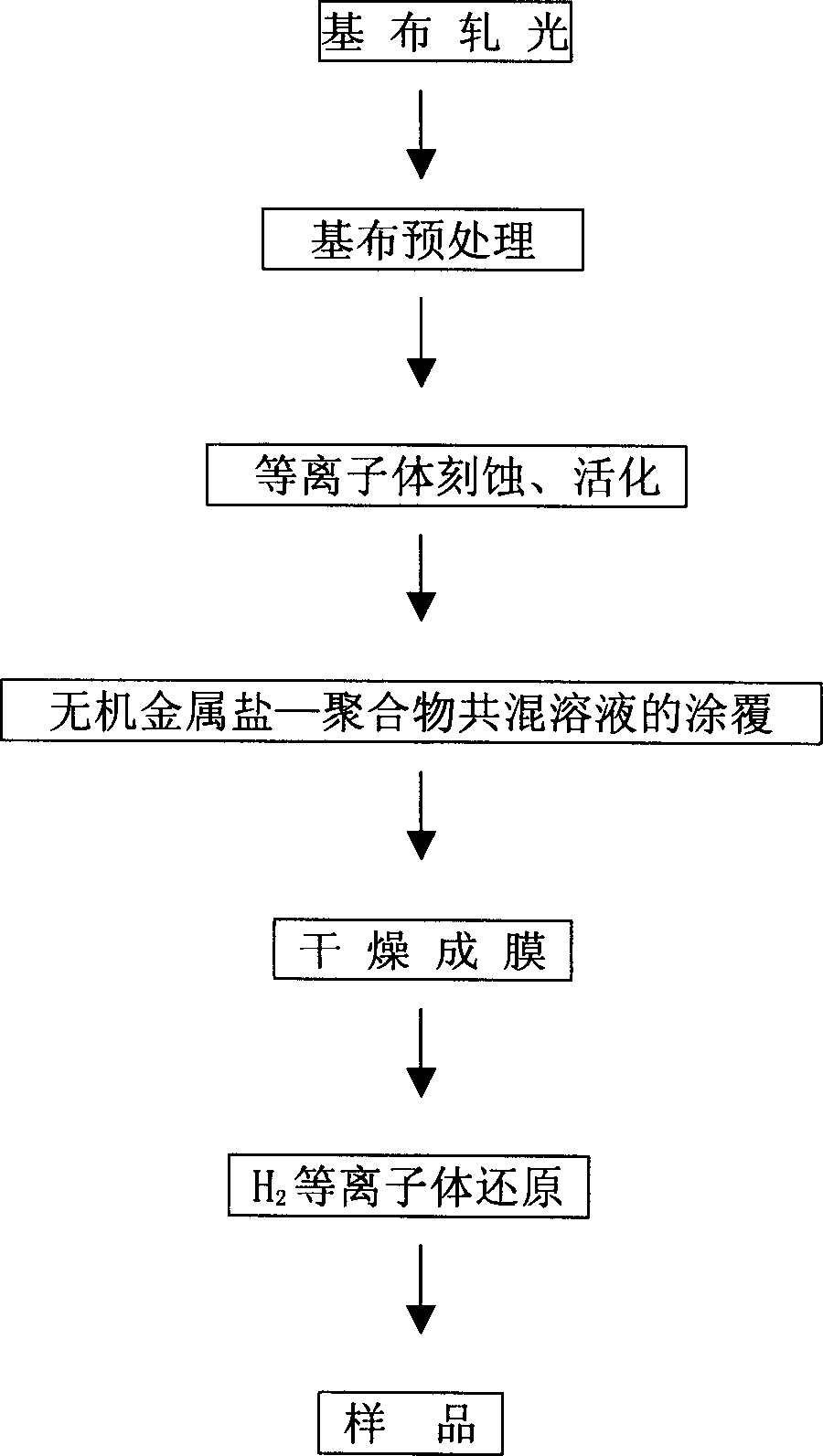

[0022] Process flow: calendering of base fabric - vacuum drying - low temperature plasma etching and activation - inorganic metal salt-polymer complex coating - drying into film - hydrogen Plasma reduction.

[0023] Process parameters:

[0024] 1) Calendering: temperature 160°C, pressure 400KN, fabric movement speed 15-20m / min;

[0025] 2) Vacuum drying: vacuum degree 50Pa, drying temperature 90°C, drying time 2 hours;

[0026] 3) Low-temperature plasma treatment: the vacuum degree of the background is 0.1Pa, the working gas is argon, the discharge power is 80W, and the treatment time is 30 seconds;

[0027] 4) Coating of inorganic metal salt-polymer complex:

[0028] Composition of coating solution: CuCl 2 (10%w) + polyvinyl alcohol 1788 (30%w) + water (60%w); dissolve polyvinyl alcohol in distilled water, add CuCl 2 After being fully stirred, it becomes a bl...

Embodiment 2

[0032] Substrate: Polypropylene fabric.

[0033] Plasma generator: inductive coupling.

[0034] Process flow: fabric calendering - vacuum drying - low temperature plasma etching and activation - coating of inorganic metal salt-polymer complex - drying film - hydrogen Plasma reduction.

[0035] Process parameters:

[0036] 1) Calendering: temperature 180°C, pressure 300KN, fabric movement speed 25m / min;

[0037] 2) Vacuum drying: vacuum degree 100Pa, drying temperature 80°C, drying time 2 hours;

[0038] 3) Low-temperature plasma treatment: the vacuum degree of the background is 0.1Pa, the working gas is a mixture of argon and nitrogen, the discharge power is 40W, and the treatment time is 1 minute;

[0039] 4) Coating of inorganic metal salt-polymer complex:

[0040] The composition of the coating solution is: AgNO 3 (20%w) + polyacrylonitrile (30%w) + chloroform (50%w); dissolve polyacrylonitrile in distilled water, add AgNO 3 After being fully stirred, it becomes a bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com