Patents

Literature

278 results about "Metallizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallizing is the general name for the technique of coating metal on the surface of objects. Metallic coatings may be decorative, protective or functional. Techniques for metallization started as early as mirror making. In 1835, Justus von Liebig discovered the process of coating a glass surface with metallic silver, making the glass mirror one of the earliest items being metallized. Plating other non-metallic objects grew rapidly with introduction of ABS plastic. Because a non-metallic object tends to be a poor electrical conductor, the object's surface must be made conductive before plating can be performed. The plastic part is first etched chemically by a suitable process, such as dipping in a hot chromic acid-sulfuric acid mixture. The etched surface is sensitized and activated by first dipping in tin(II) chloride solution, then palladium chloride solution. The processed surface is then coated with electroless copper or nickel before further plating. This process gives useful (about 1 to 6 kgf/cm or 10 to 60 N/cm or 5 to 35 lbf/in) adhesion force, but is much weaker than actual metal-to-metal adhesion strength.

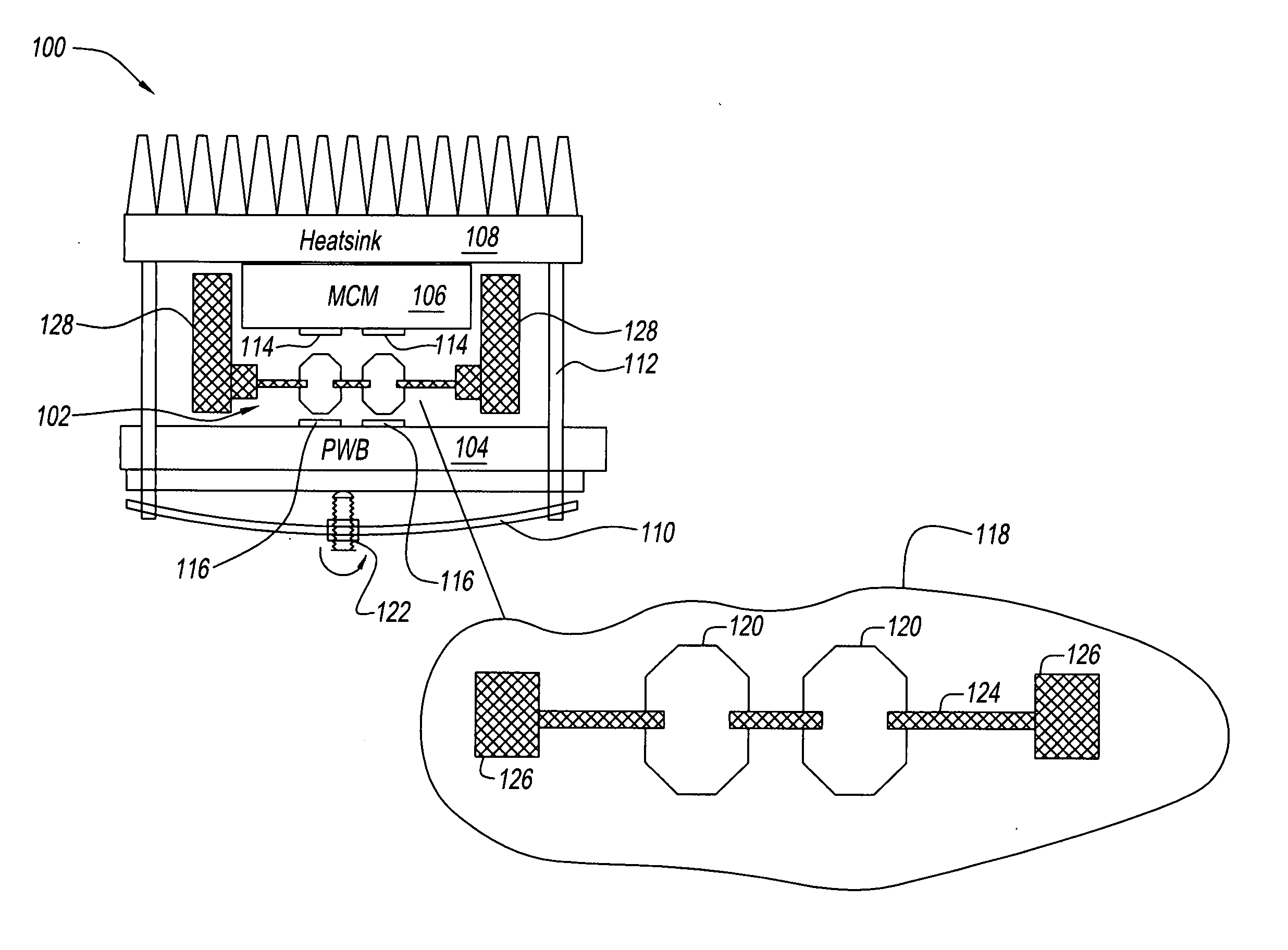

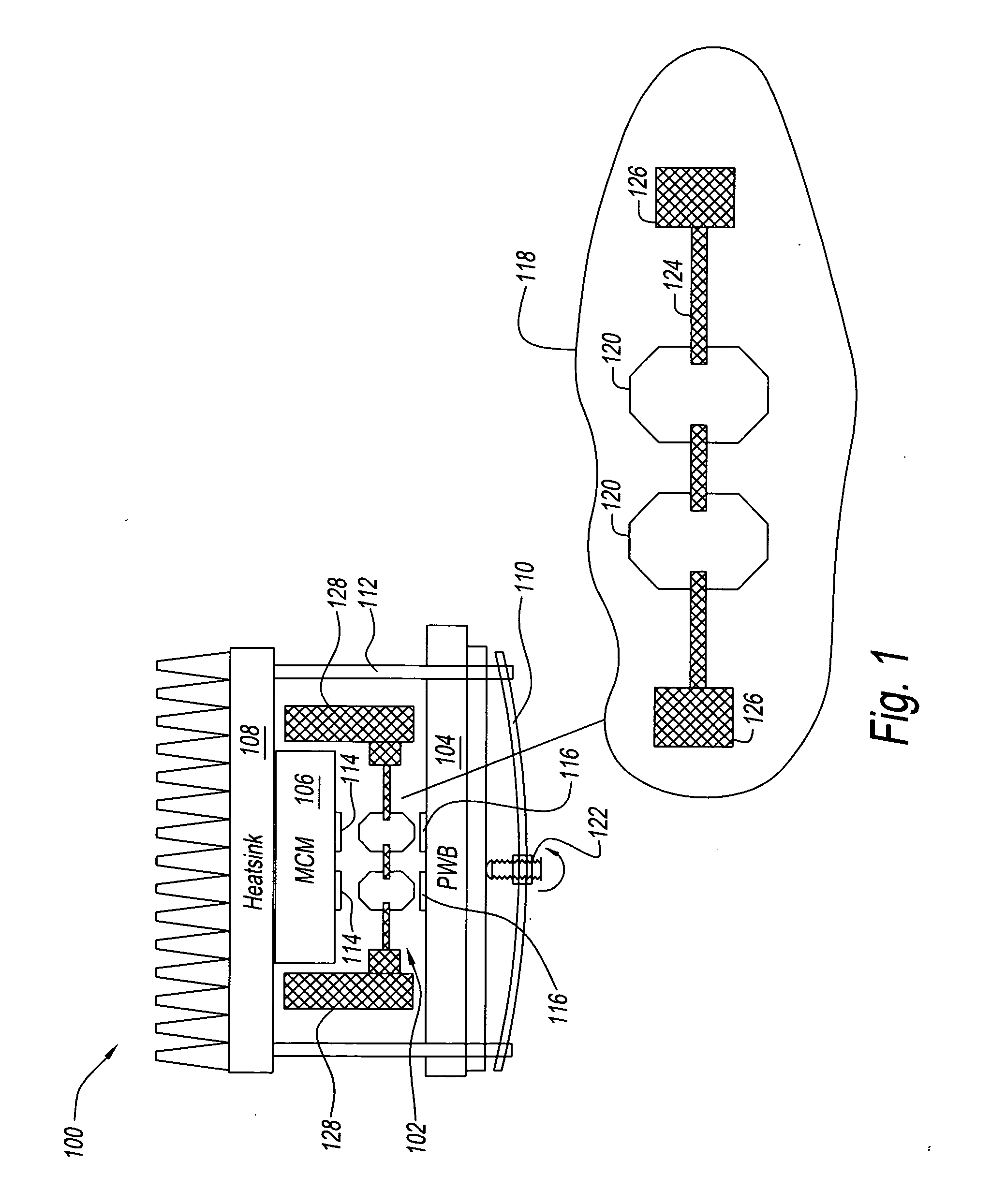

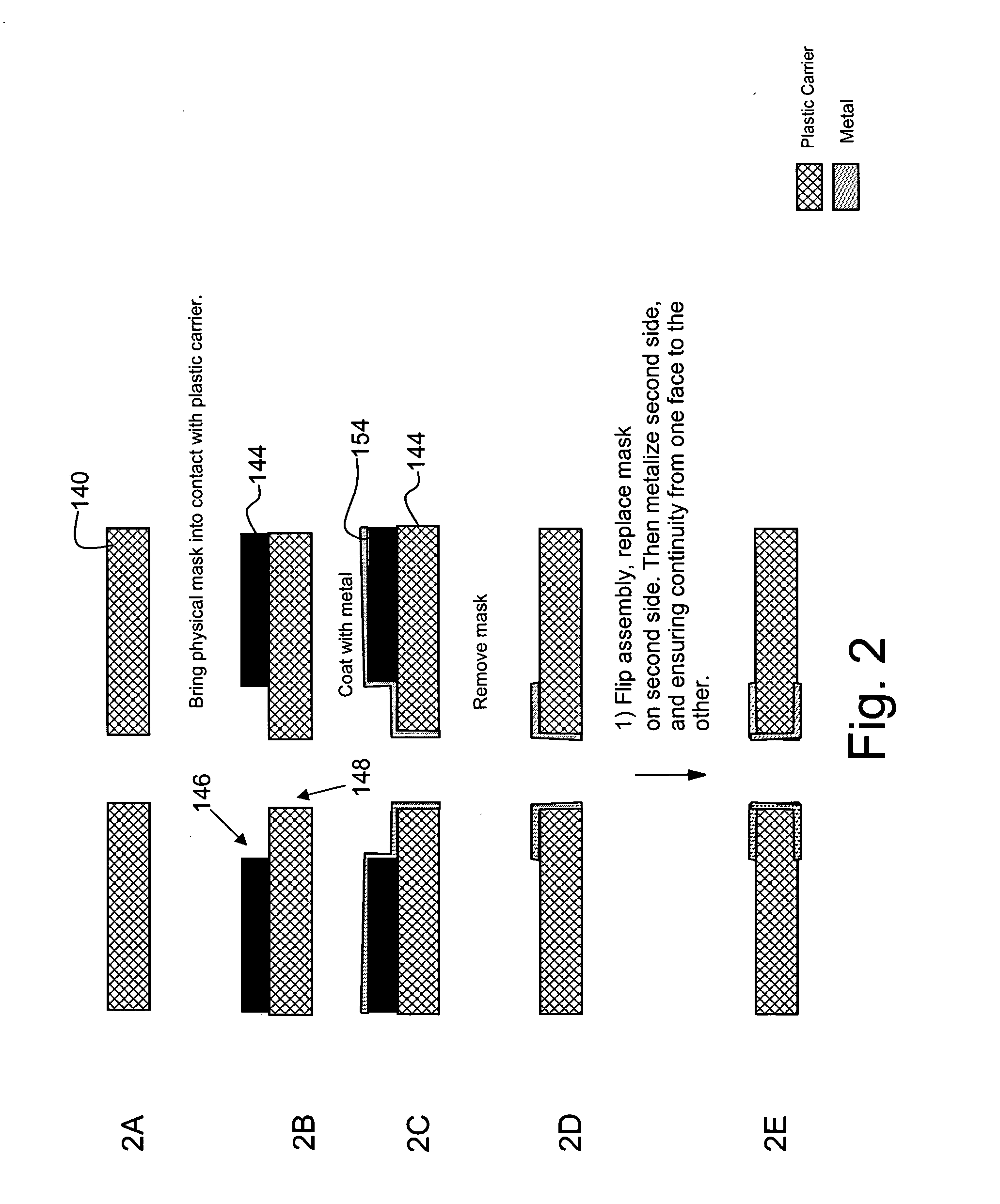

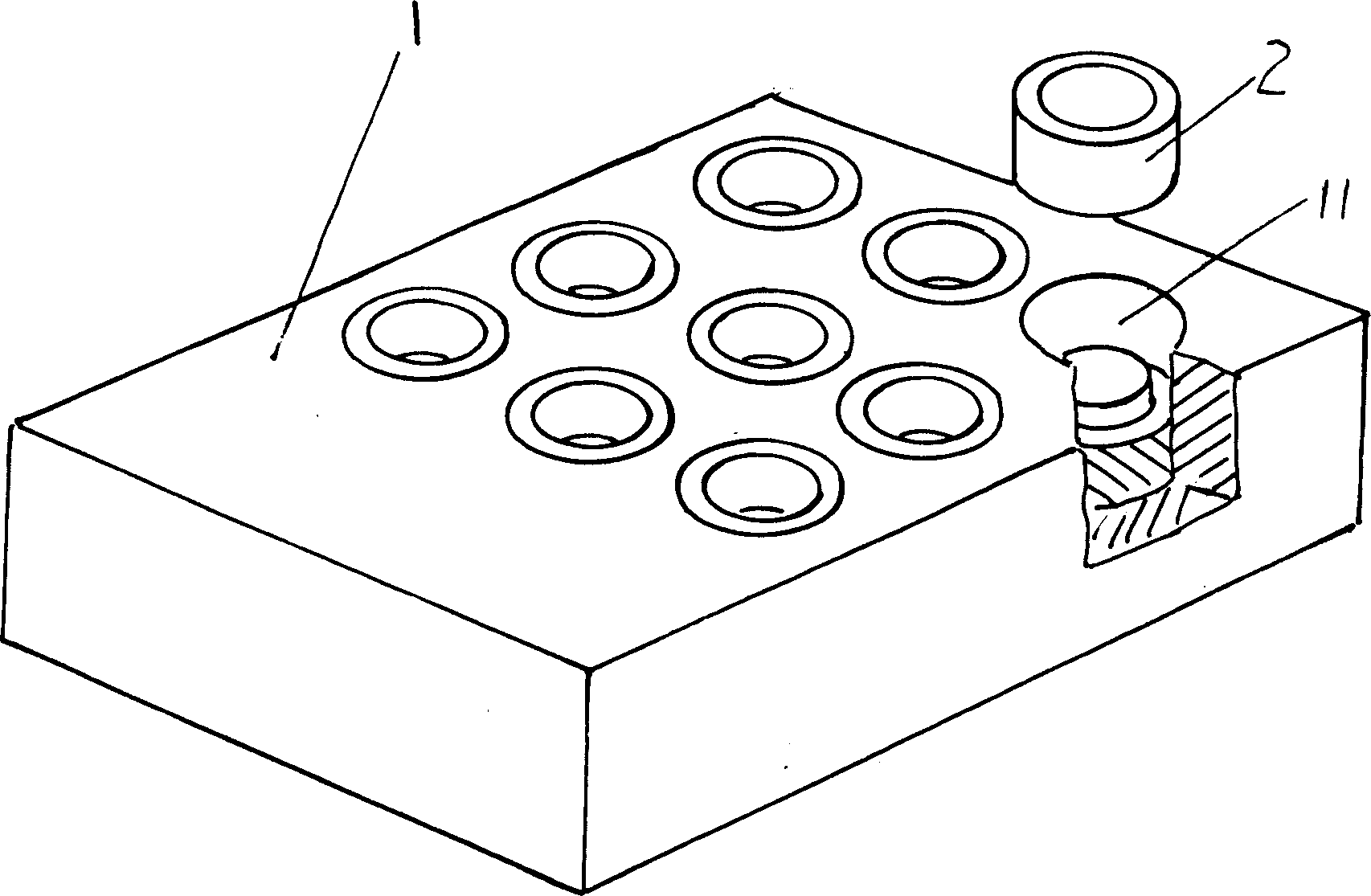

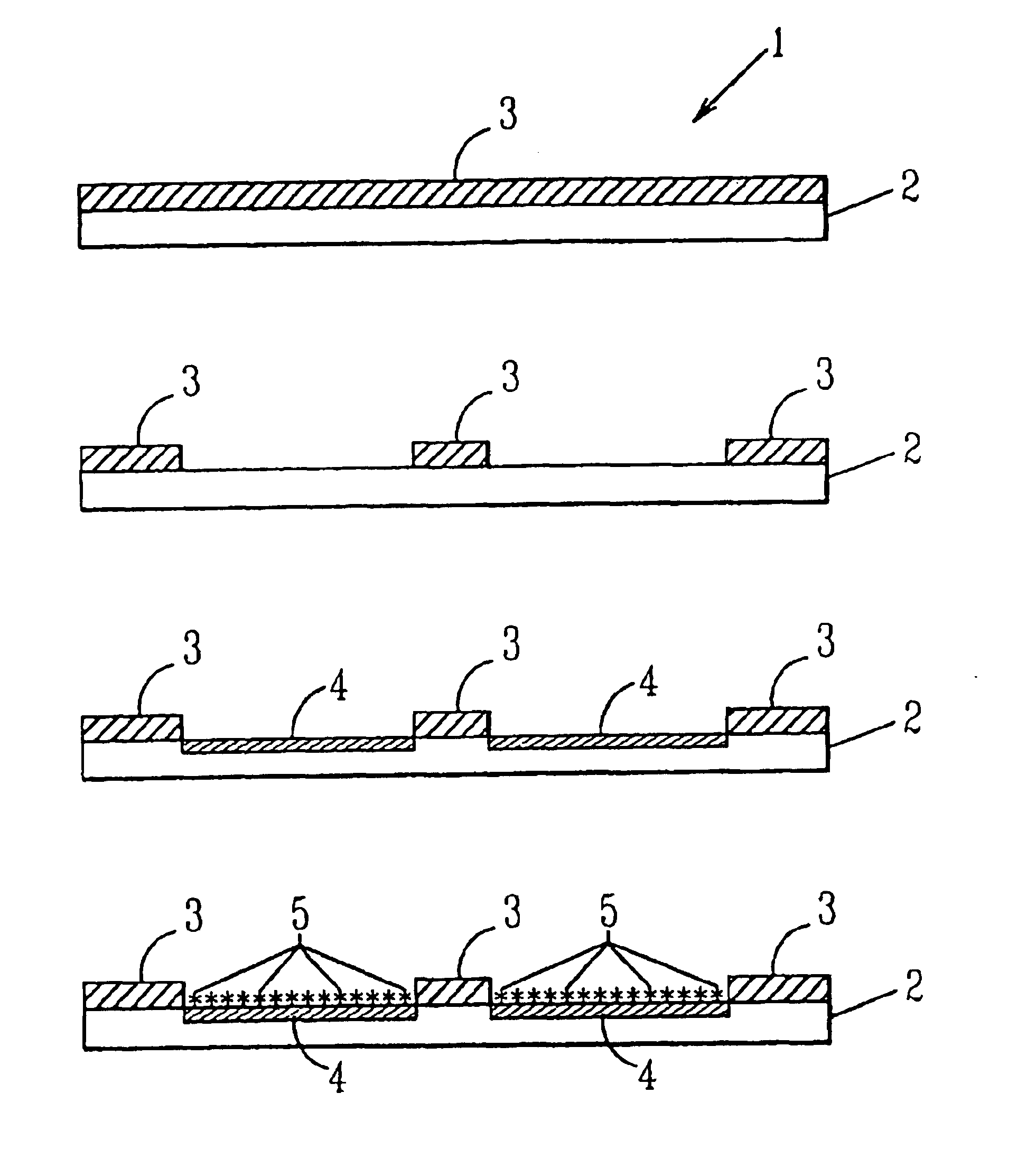

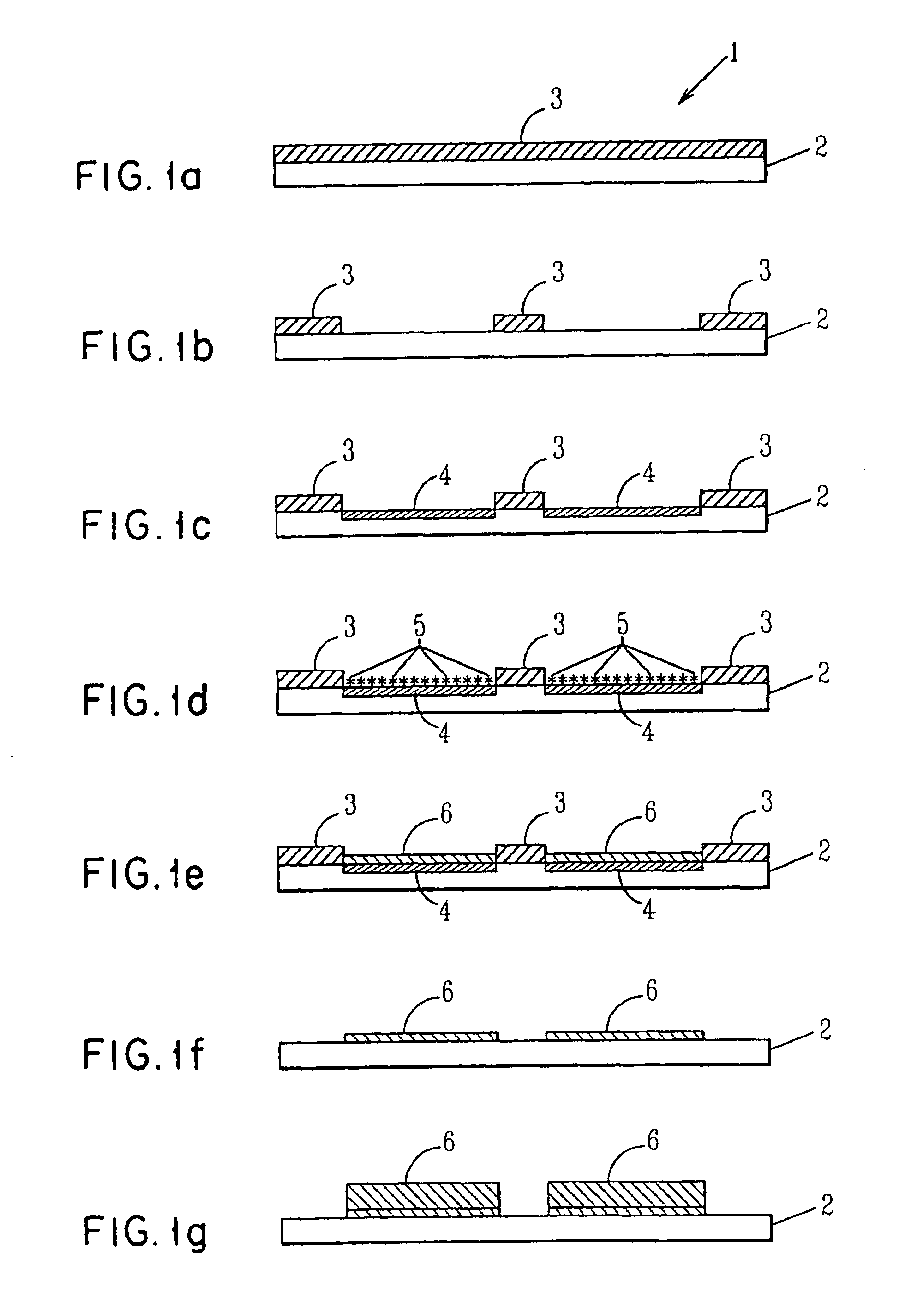

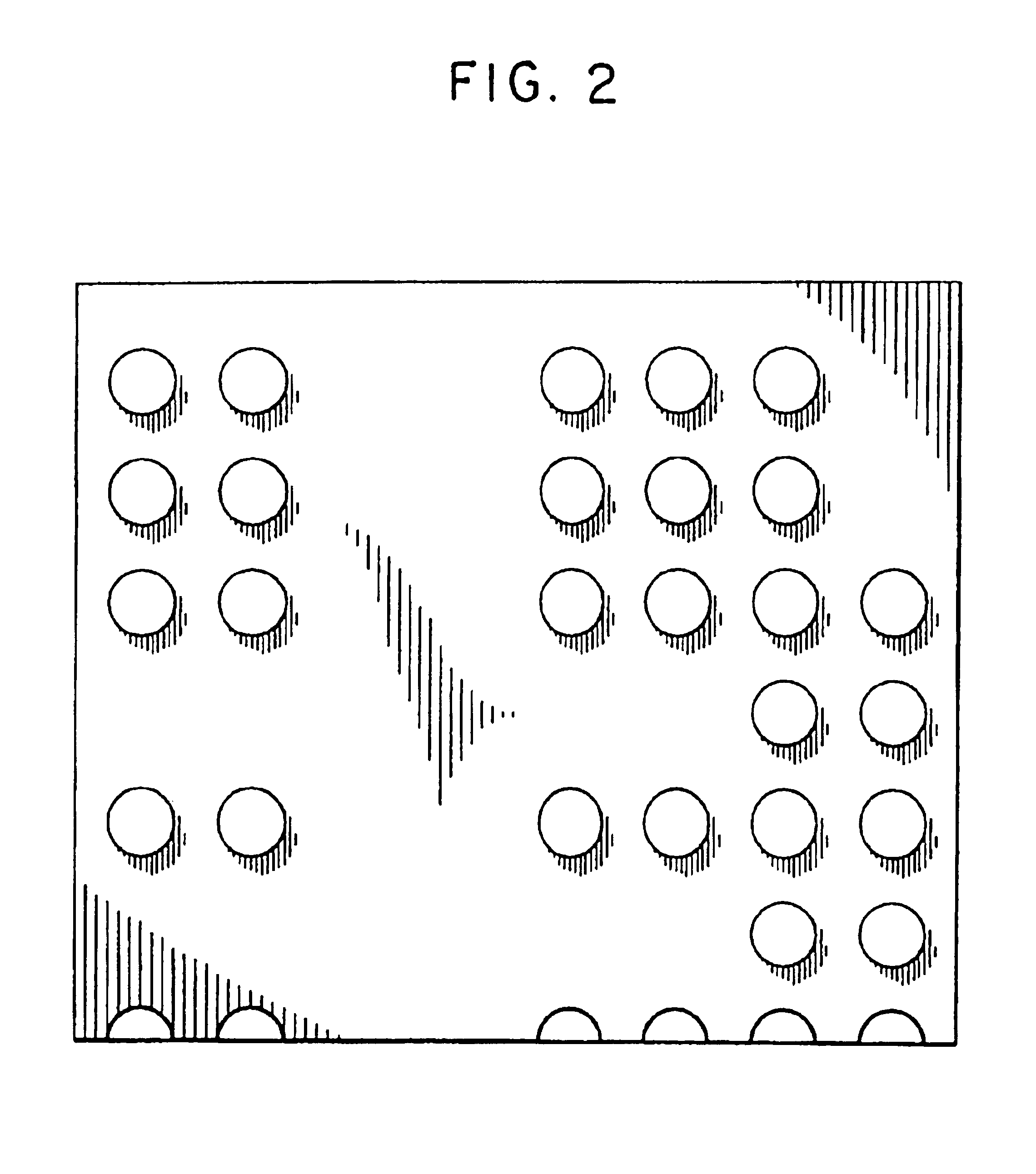

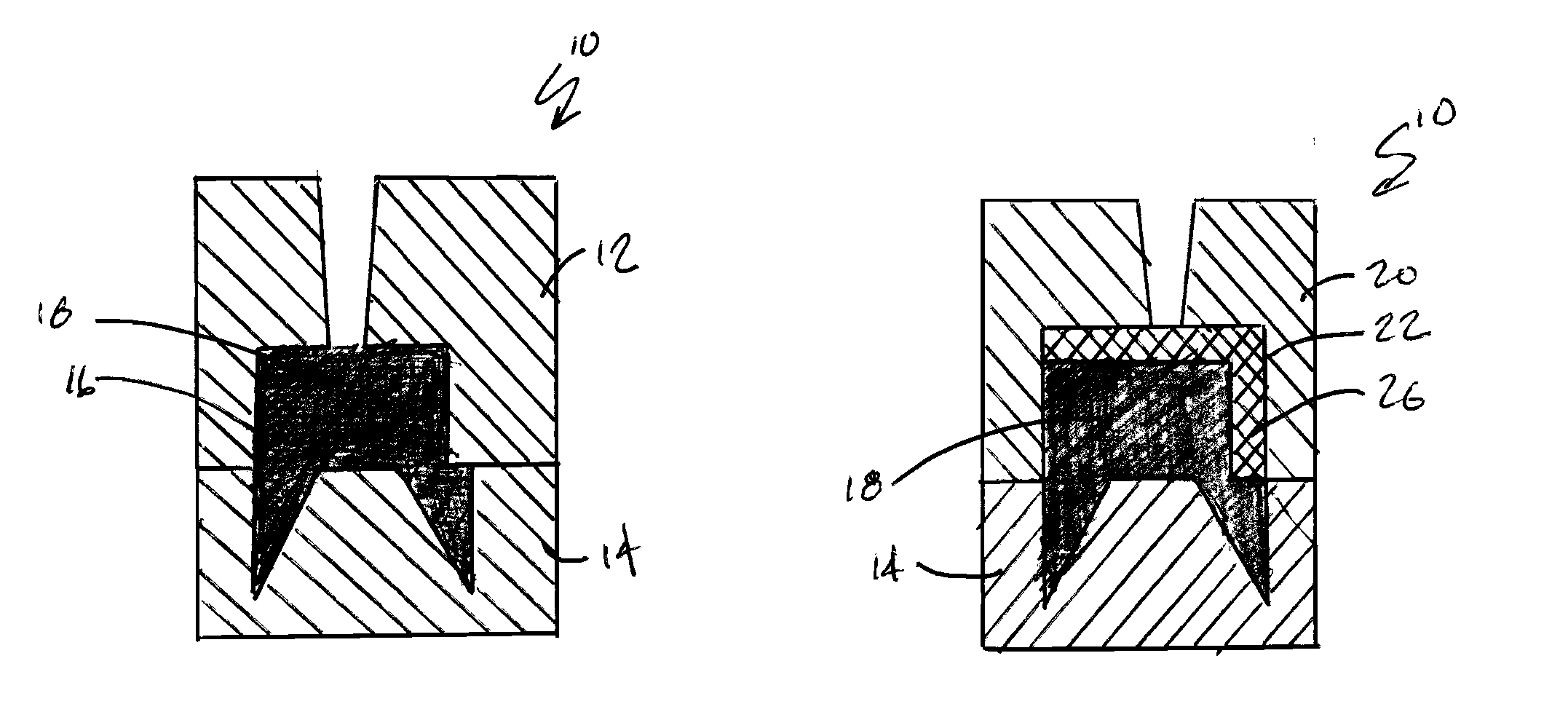

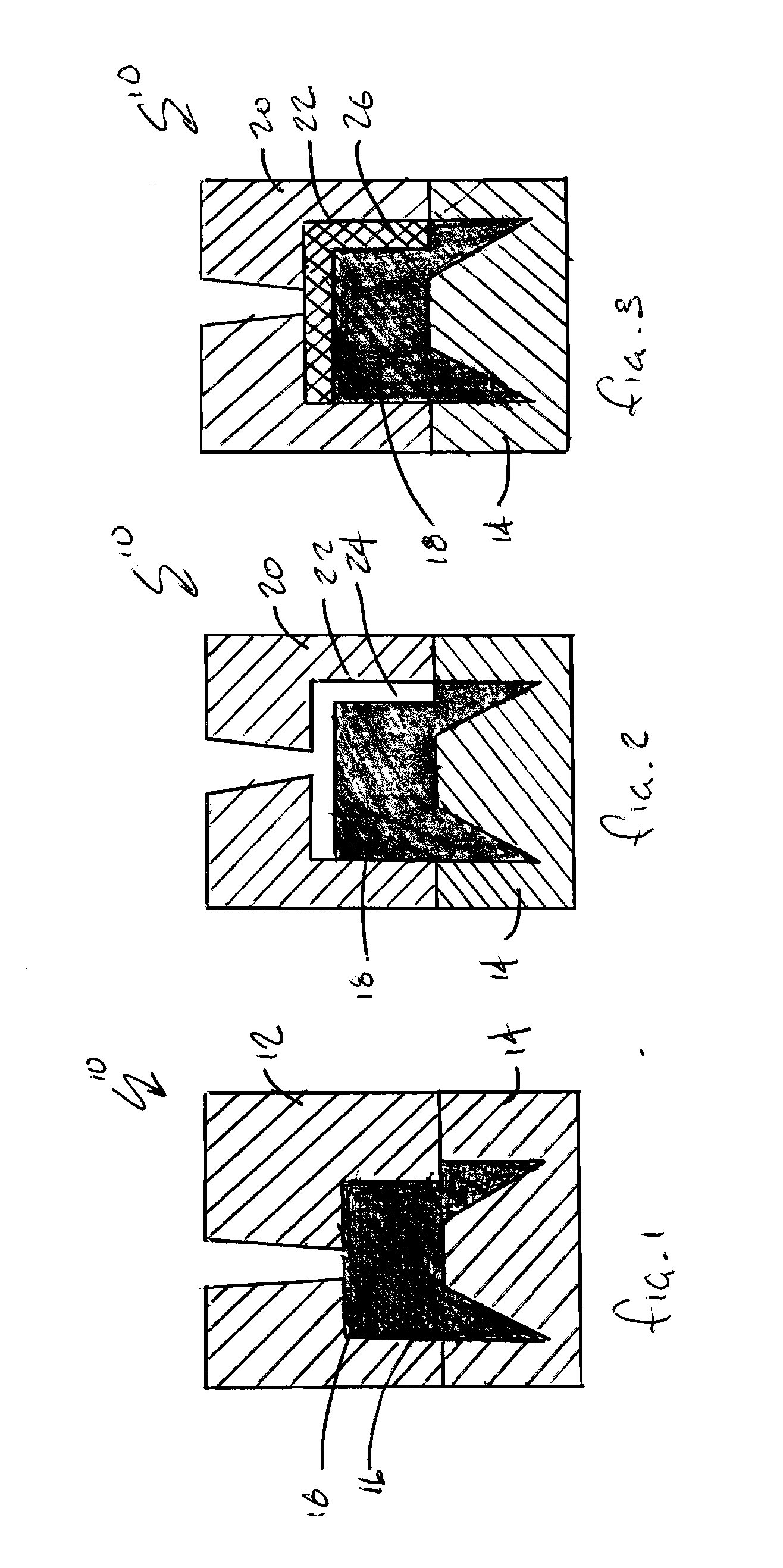

Interposer with electrical contact button and method

ActiveUS20050106902A1Printed circuit assemblingSemiconductor/solid-state device detailsInterposerEngineering

An interposer having one or more hollow electrical contact buttons disposed in a carrier. The interposer is formed by disposing sacrificial posts in vias of the carrier. The electrical contact buttons are formed on the sacrificial posts by a metallizing process in desired pattern using a mask. The sacrificial posts are made of a material that thermally decomposes upon application of heat without altering the carrier or the electrical contact buttons.

Owner:GLOBALFOUNDRIES US INC

Biaxially oriented polylactic acid film with improved moisture barrier

InactiveUS20100330382A1Improved barrier resistanceImprove moisture resistanceSynthetic resin layered productsLabelsSealantMetallizing

Owner:TORAY PLASTICS AMERICA

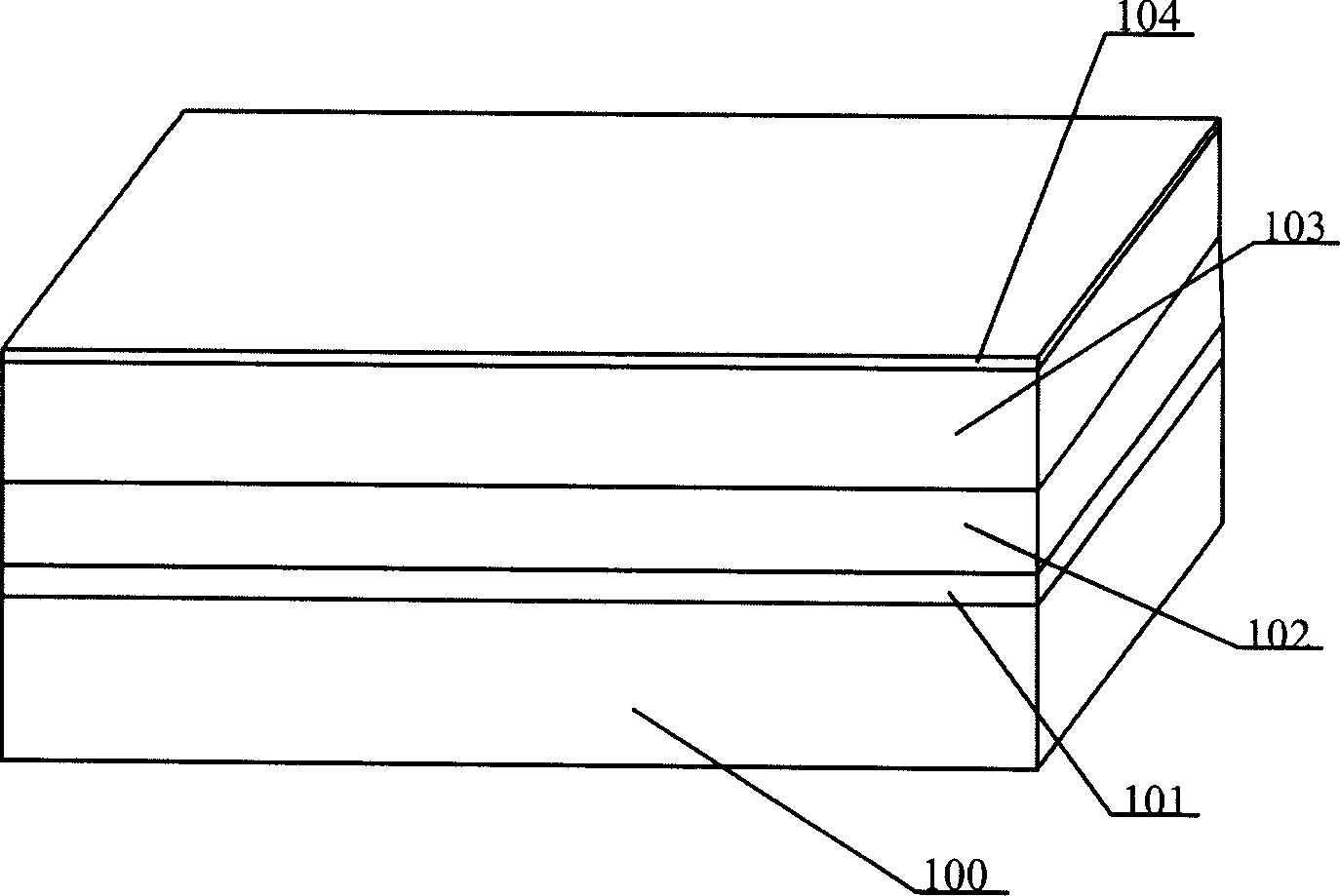

Biaxially oriented polylactic acid film with high barrier

ActiveUS20090148713A1Improve barrier propertiesRemain biodegradableSynthetic resin layered productsDomestic articlesPolymer sciencePolyolefin

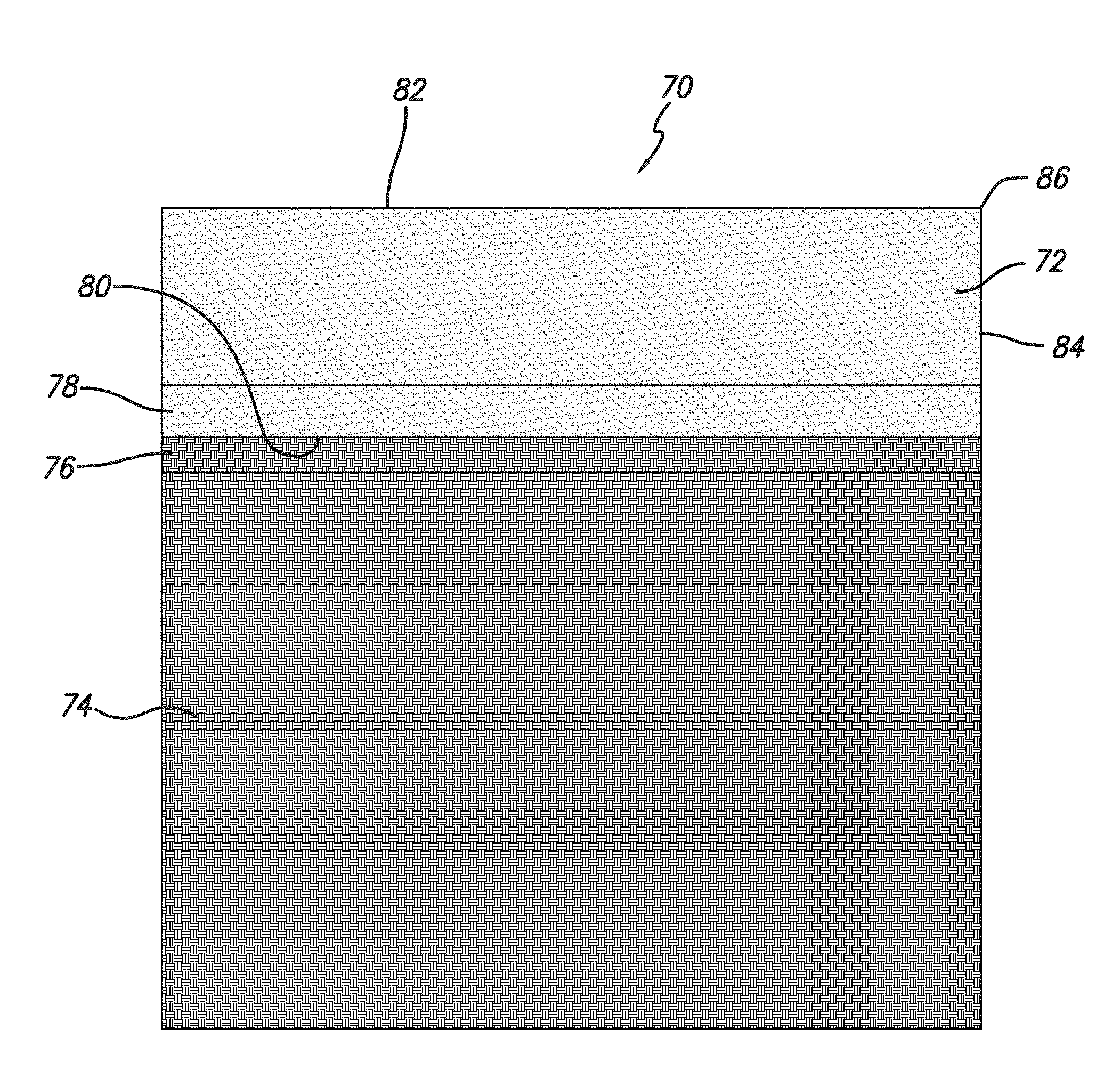

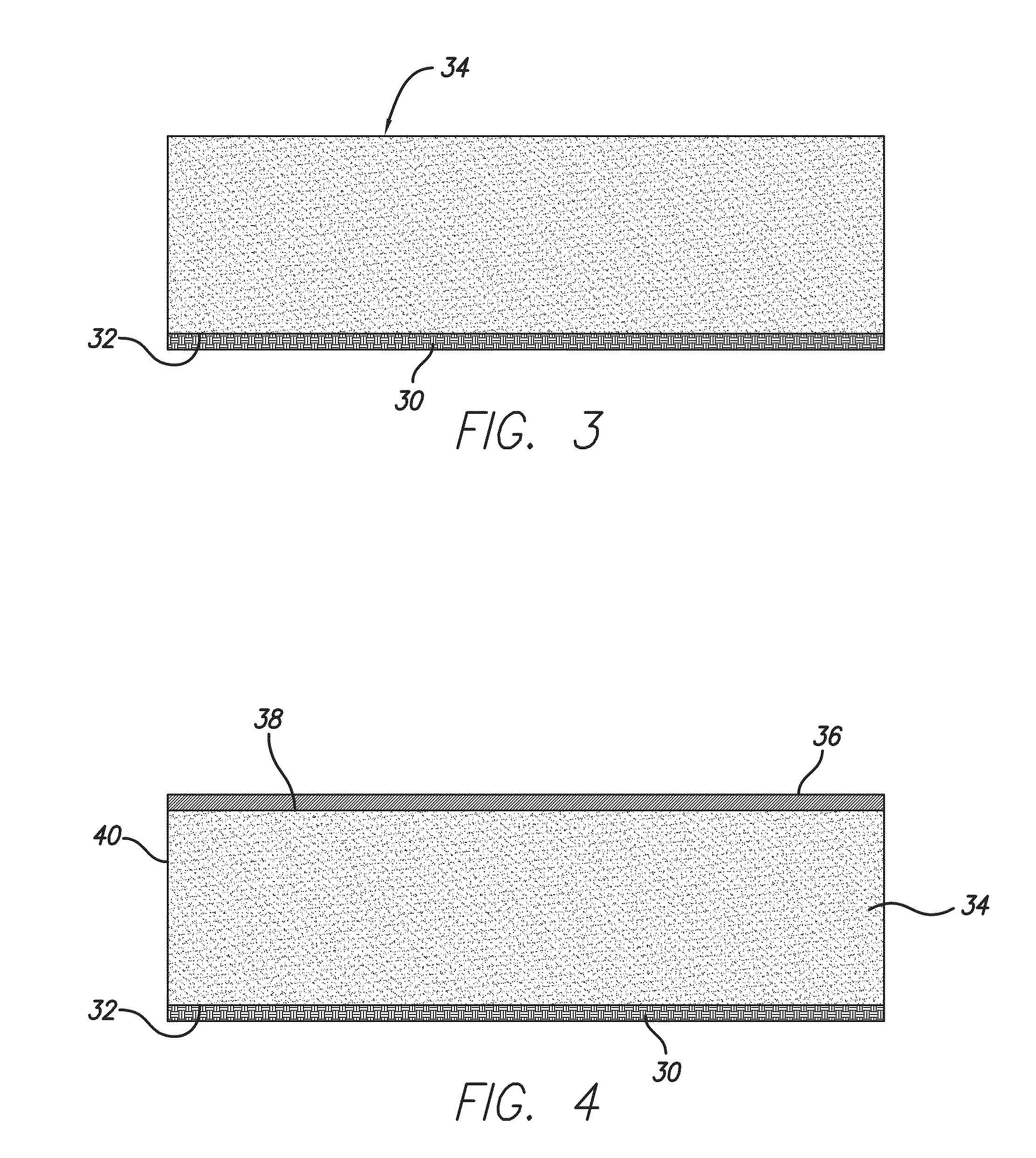

A metallized laminate film exhibiting improved moisture barrier property as well as maintaining a high bio-polymer content and degradability property is disclosed. The laminate film includes a first core layer of polylactic acid polymer and a second skin layer comprising a polyolefin metal receiving layer. The metal receiving layer or the core layer, or both, may be blended with an amount of polar-modified tie-resin to improve bonding. Alternatively, a discrete tie-resin layer may be interposed between the polyolefin metal receiving layer and the crystalline polylactic acid polymer core layer. The polyolefin metal receiving layer may be discharge-treated on the side opposite the core layer and metallized.

Owner:TORAY PLASTICS AMERICA

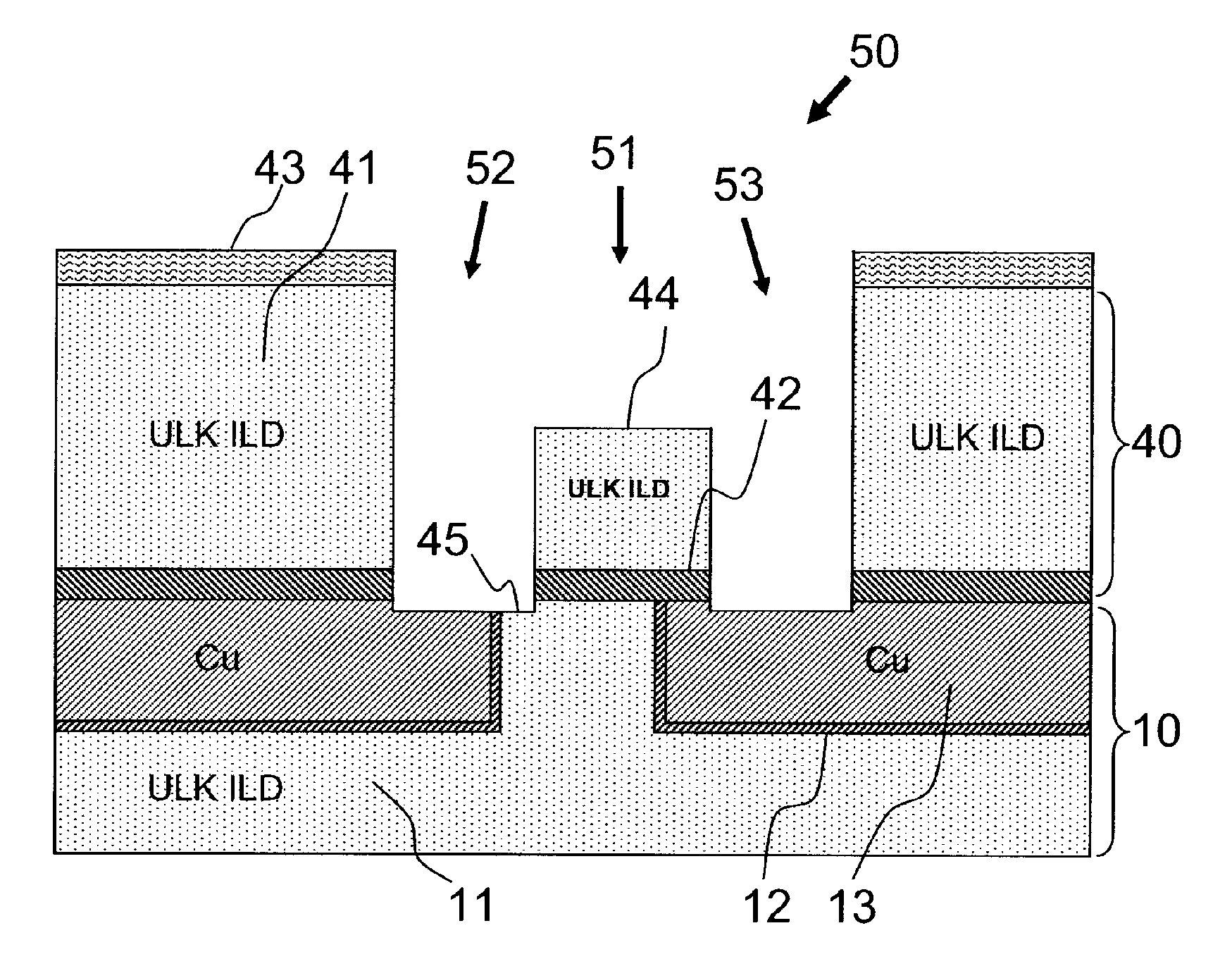

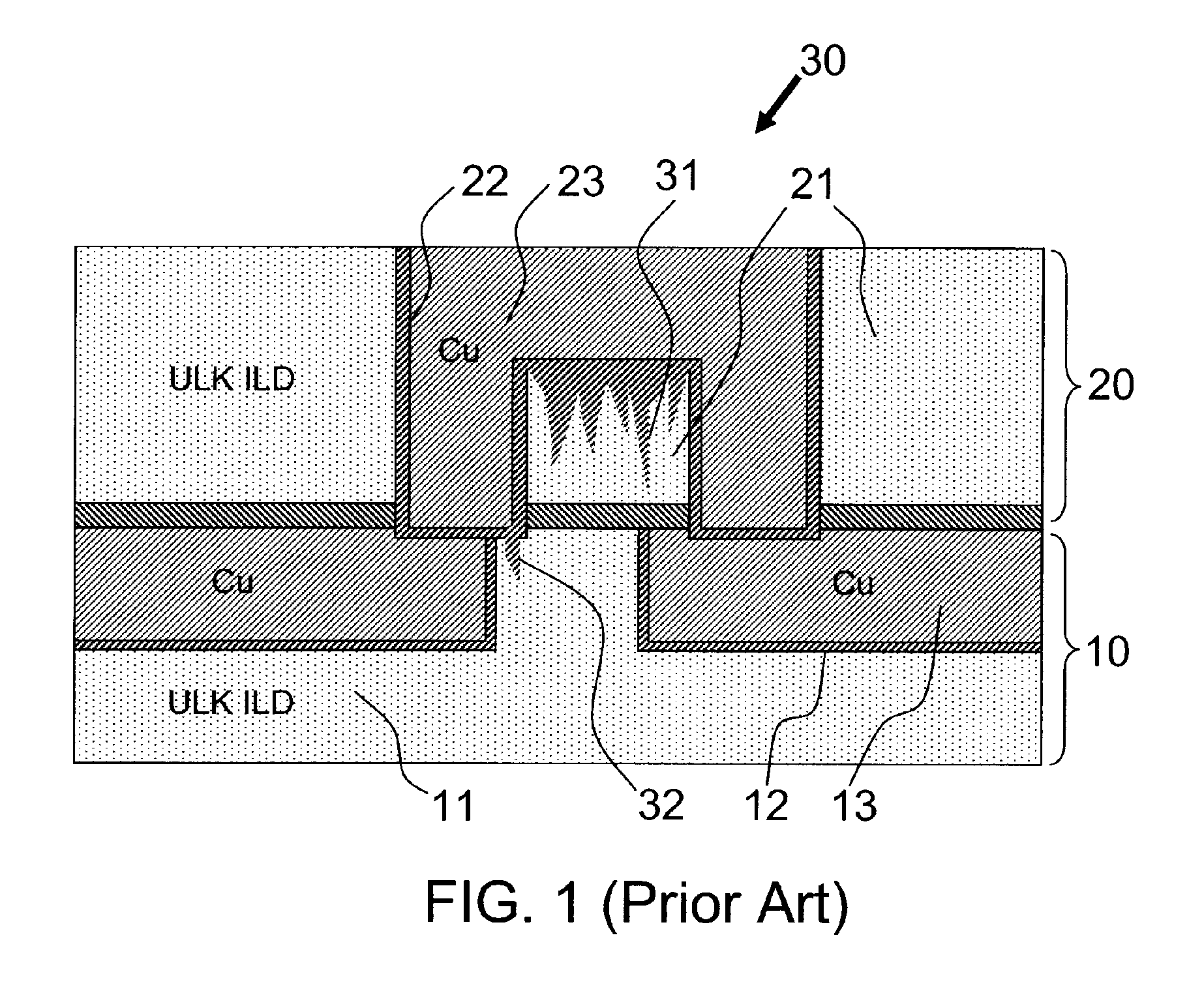

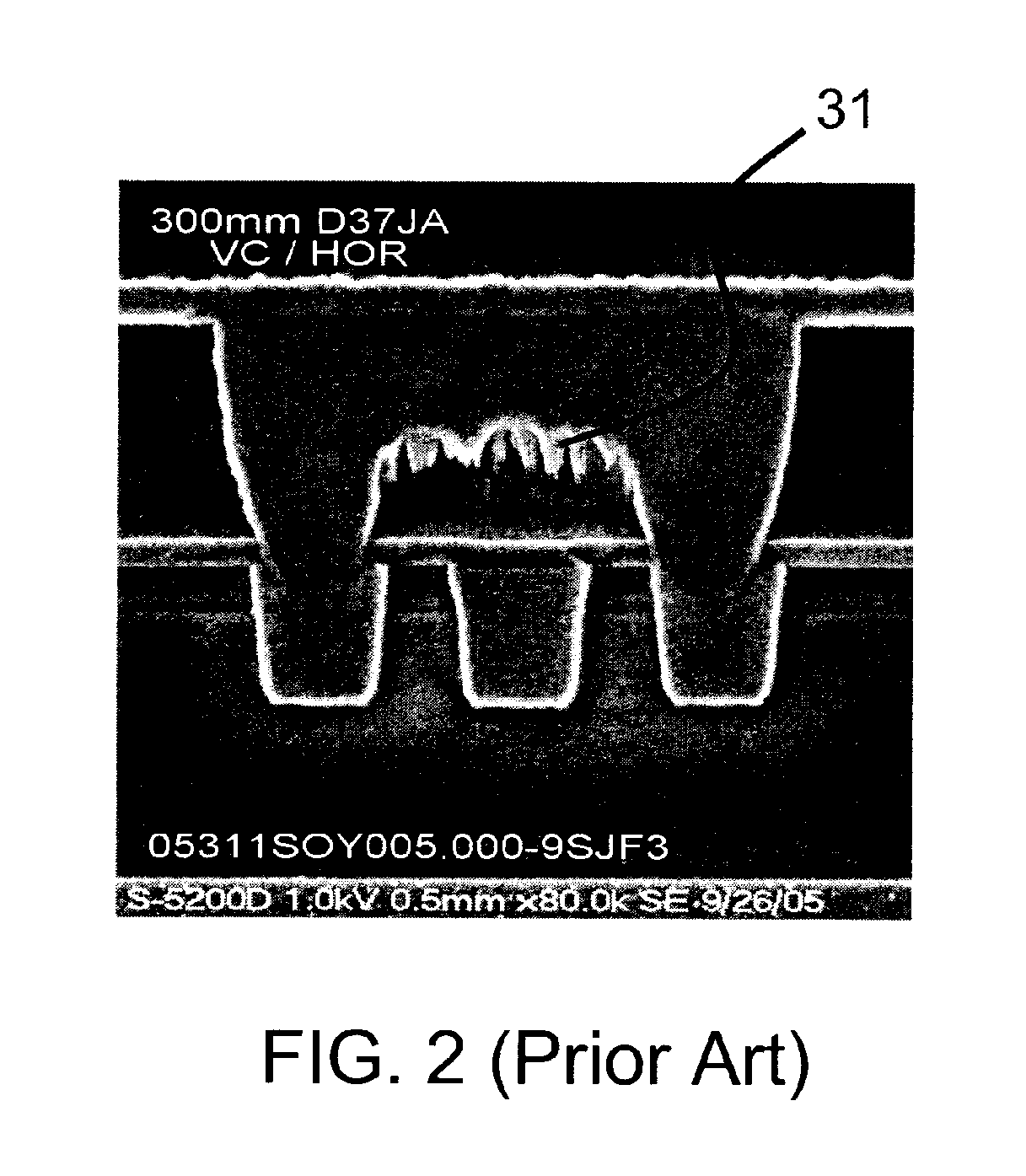

Surface treatment of inter-layer dielectric

InactiveUS20070222081A1Semiconductor/solid-state device detailsSolid-state devicesDielectricInter layer

When an interconnect structure is built on porous ultra low k (ULK) material, the bottom of the trench and / or via is usually damaged by a following metallization process which may be suitable for dense higher dielectric materials. Embodiment of the present invention may provide a method of forming an interconnect structure on an inter-layer dielectric (ILD) material. The method includes steps of treating an exposed area of said ILD material to create a densified area, and metallizing said densified area.

Owner:GLOBALFOUNDRIES INC

Biaxially oriented polylactic acid film with high barrier

ActiveUS7951438B2Improve barrier propertiesImprove metallized moisture and oxygen barrierSynthetic resin layered productsLaminationPolymer sciencePolyolefin

A metallized laminate film exhibiting improved moisture barrier property as well as maintaining a high bio-polymer content and degradability property is disclosed. The laminate film includes a first core layer of polylactic acid polymer and a second skin layer comprising a polyolefin metal receiving layer. The metal receiving layer or the core layer, or both, may be blended with an amount of polar-modified tie-resin to improve bonding. Alternatively, a discrete tie-resin layer may be interposed between the polyolefin metal receiving layer and the crystalline polylactic acid polymer core layer. The polyolefin metal receiving layer may be discharge-treated on the side opposite the core layer and metallized.

Owner:TORAY PLASTICS (AMERICA) INC

Diamond Bonded Construction with Improved Braze Joint

ActiveUS20100300767A1Improve thermal stabilityImproved degree of attachmentDrill bitsConstructionsMetallic materialsMetallizing

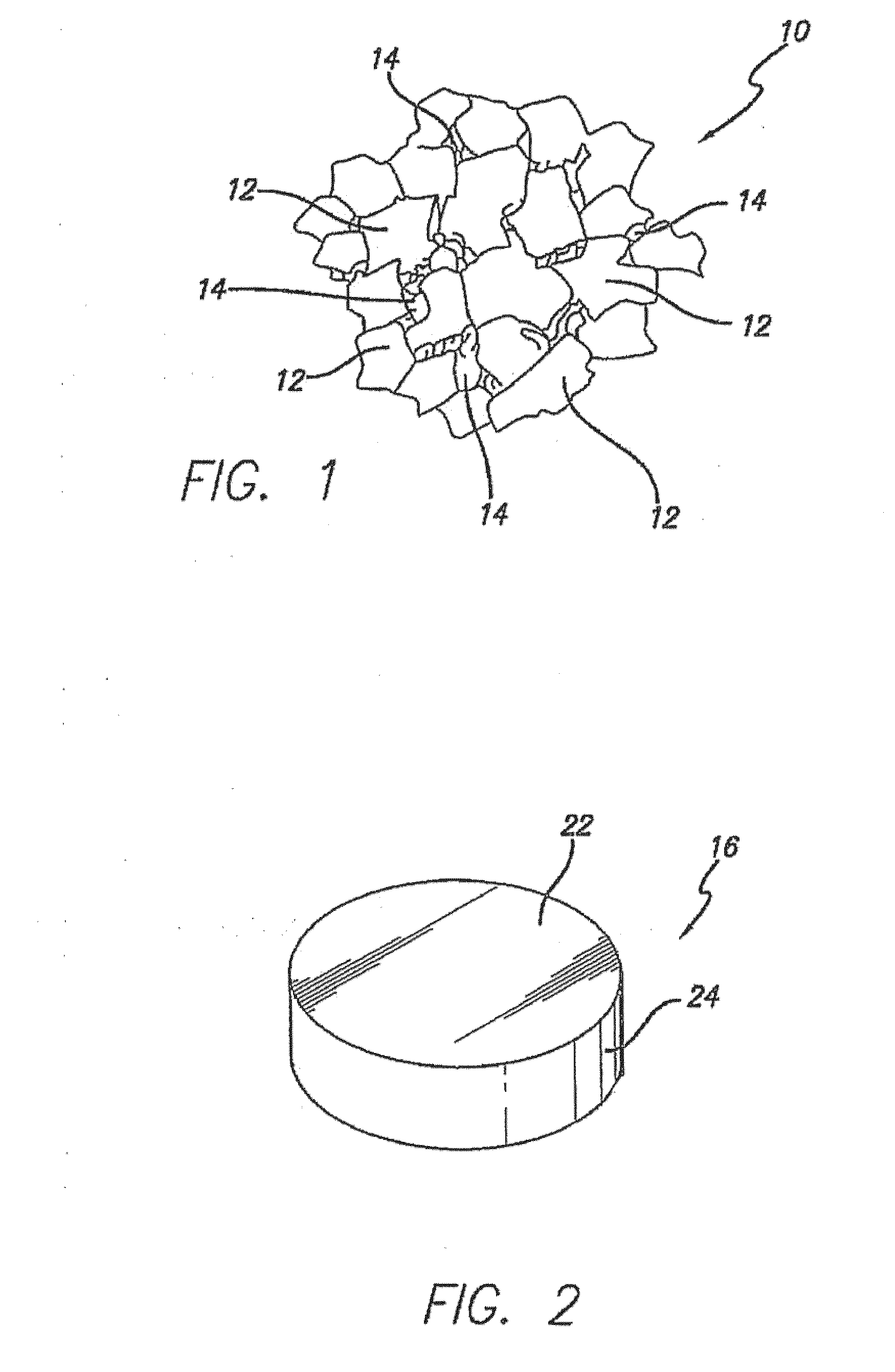

Diamond bonded constructions comprise a body comprising a plurality of bonded together diamond grains with interstitial regions disposed between the grains that are substantially free of the catalyst material used to initially sinter the body. A metallic substrate is attached to the body, and a braze joint is interposed between the body and the substrate. The body is metallized to include a metallic material disposed along a substrate attachment surface in contact with the braze joint, wherein the metallic material is different from the braze joint material. The metallic material may exist within a region of the body extending fully or partially into the body, and / or may exist as a layer extending away from the substrate attachment surface. The body includes a working surface characterized by empty interstitial regions or by interstitial regions filled with an infiltrant material, wherein the infiltrant material is different from the metallizing material.

Owner:SMITH INT INC

In situ polymerization preparing method for carbon nano tube and polytene composite material

InactiveCN1640923AExcellent ElectricalImprove mechanical propertiesIn situ polymerizationCarbon nanotube

The present invention relates to the preparation process of one kind of composite carbon nanotube / polyethylene material. Single or multiple wall carbon nanotube is treated with oxidant to obtain functional carbon nanotube with hydroxyl, carbonyl and carboxyl groups on the surface; and further reacted with alkyl metallizing compound in inert atmosphere to connect metal organic matter component capable of catalyzing ethylene polymerization to obtain carbon nanotube supporting olefin polymerization catalyst. In the presence of alkyl metallizing compound as catalyst assistant, the prepared carbon nanotube supporting olefin polymerization catalyst catalyzes ethylene polymerization to obtain the composite carbon nanotube / polyethylene material. The composite material has two components homogeneously dispersed, electric and mechanical performance higher than other polyethylene material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Melt-solidified substance, copper alloy for melt-solidification and method of manufacturing the same

ActiveUS20100297464A1Strength and resistanceEasy to getPlungersArc welding apparatusMetallizingImpurity

A melt-solidified substance includes melt-solidified portions formed by welding, build-up spray welding, metallizing or fusing. The melt-solidified portions have the alloy composition containing Zr: 0.0005 to 0.05 mass %, P: 0.01 to 0.34 mass %, Cu: the remainder and satisfying the relationship between the contents of P and Zr, [P] / [Zr]=0.3 to 20, and the mean grain size in the macrostructure after melt-solidification is 300 μm or less. If Fe and / or Ni are contained in the melt-solidified portion as inevitable impurities, the content of Fe or Ni is restricted to be 0.3 mass % or less when either Fe or Ni is contained, and the total content of Fe and Ni is restricted to be 0.4 mass % or less when both Fe and Ni are contained.

Owner:MITSUBISHI SHINDOH CO LTD

Ceramic metallizing process

The ceramic metallizing process belongs to the field of ceramic metallizing technology. The ceramic metallizing process includes the following steps: compounding metallizing paste via ball milling; cleaning fixture via decontaminating, deoiling and stoving; holding ceramic base in the fixture and setting on printer table; locating printing web plate and regulating angle of printer scraper; printing metallizing paste onto one end of the ceramic base; and stoving and baking to seep to obtain metallized ceramic device. The present invention has the advantages of 60 % raised ceramic sealing strength, baking and seeping temperature lowered to 1400-1450 deg.c, easy control of the metallizing paste thickness and raised painting efficiency.

Owner:CHANGSHU CITY YINYANG CERAMIC CO LTD

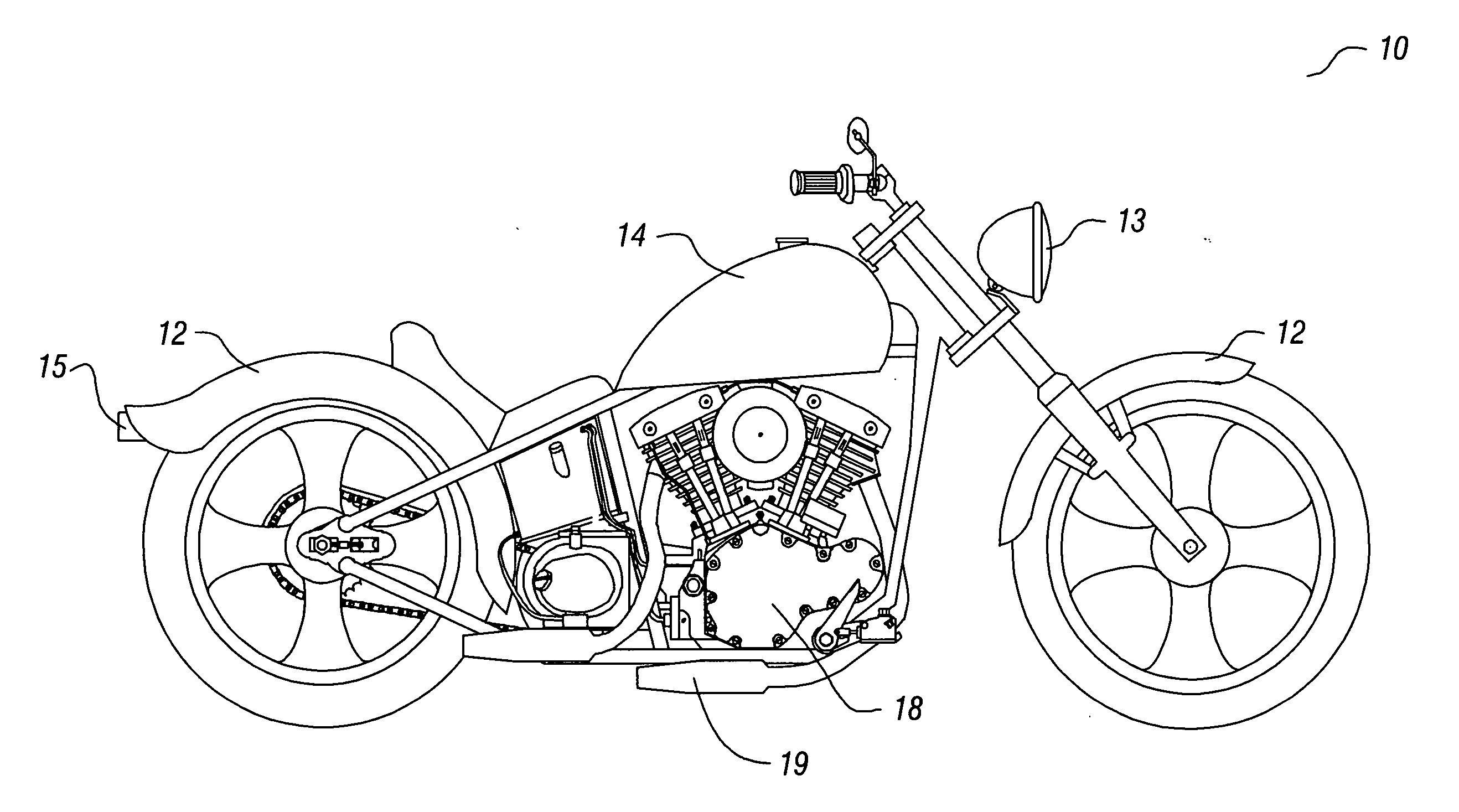

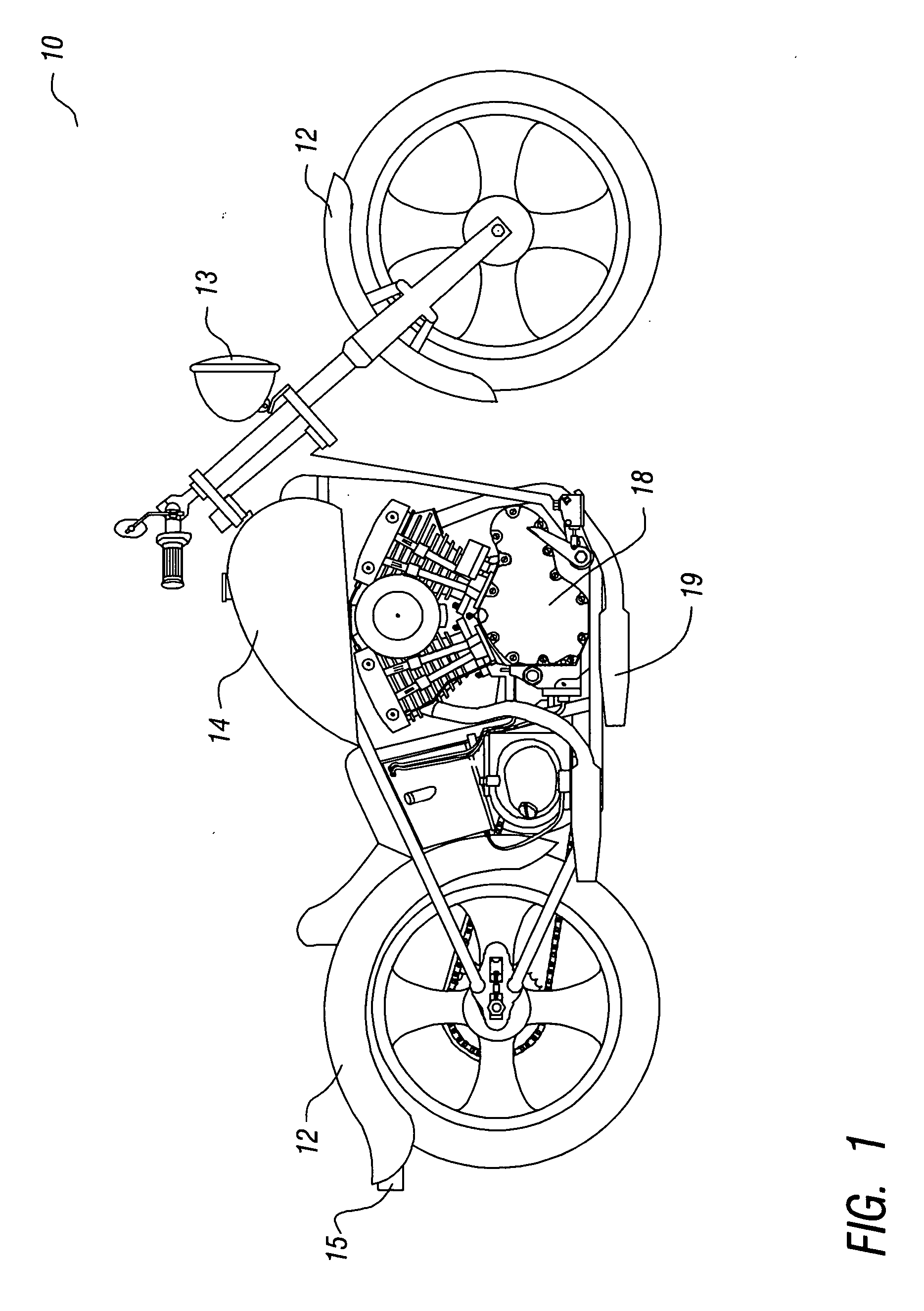

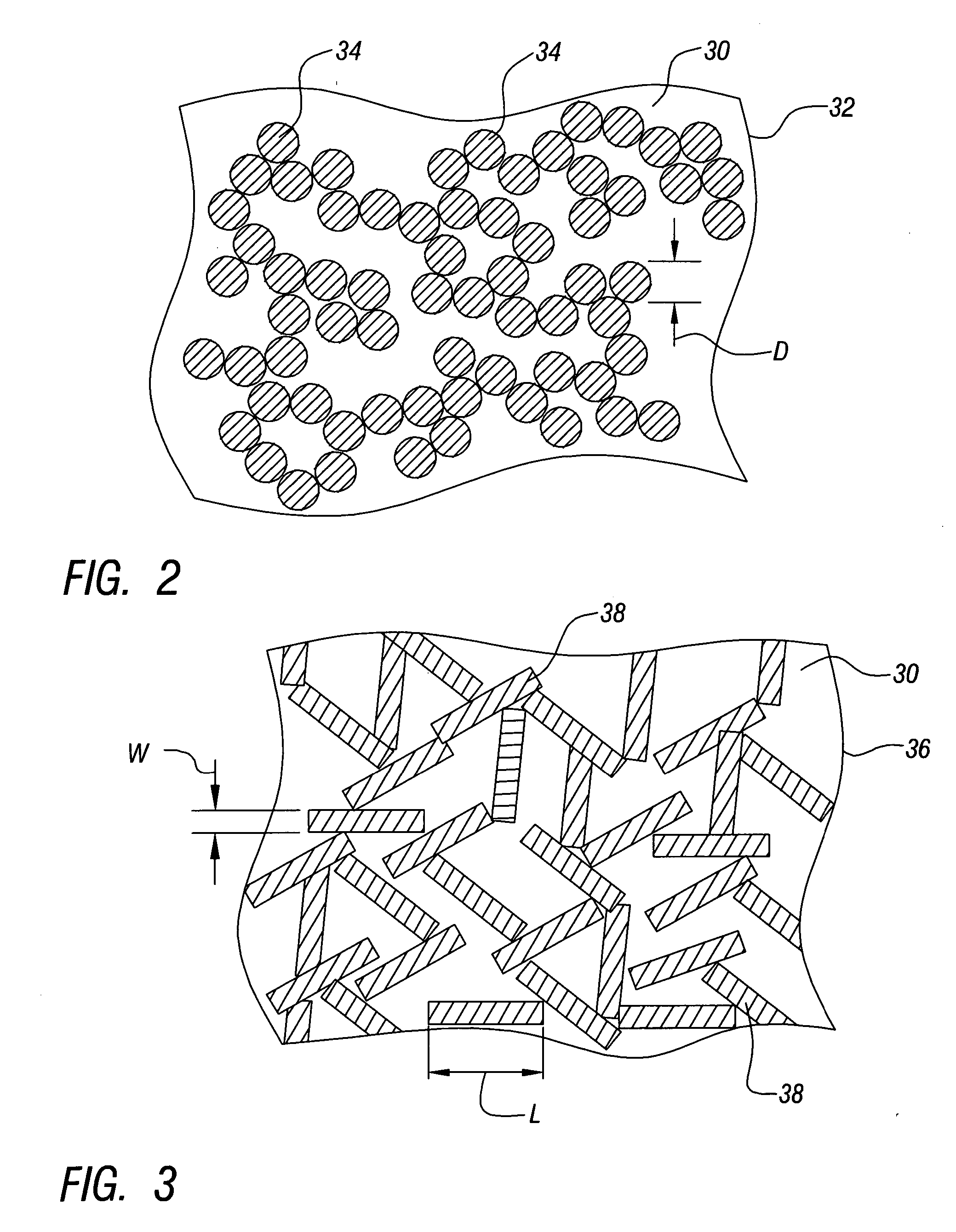

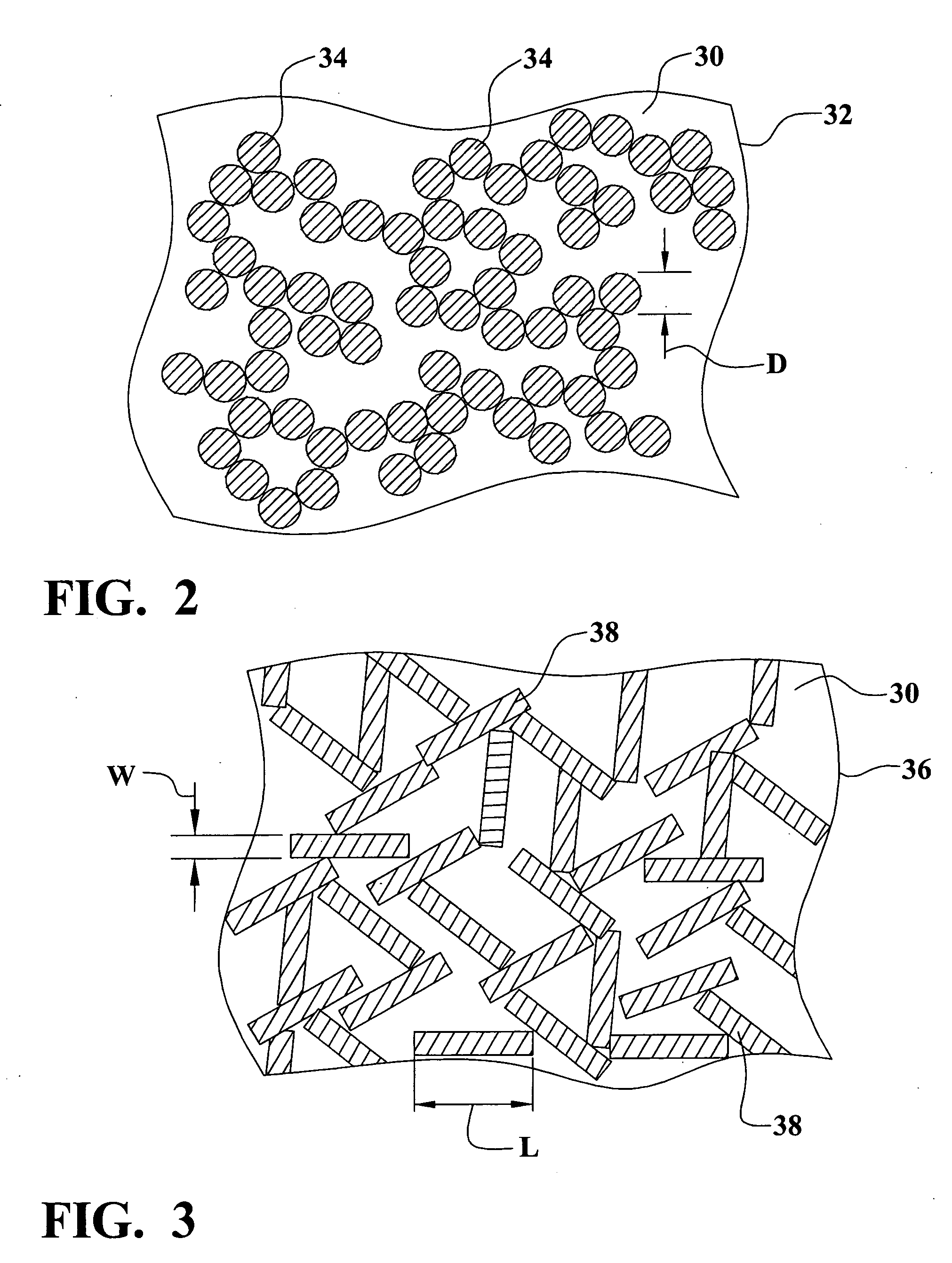

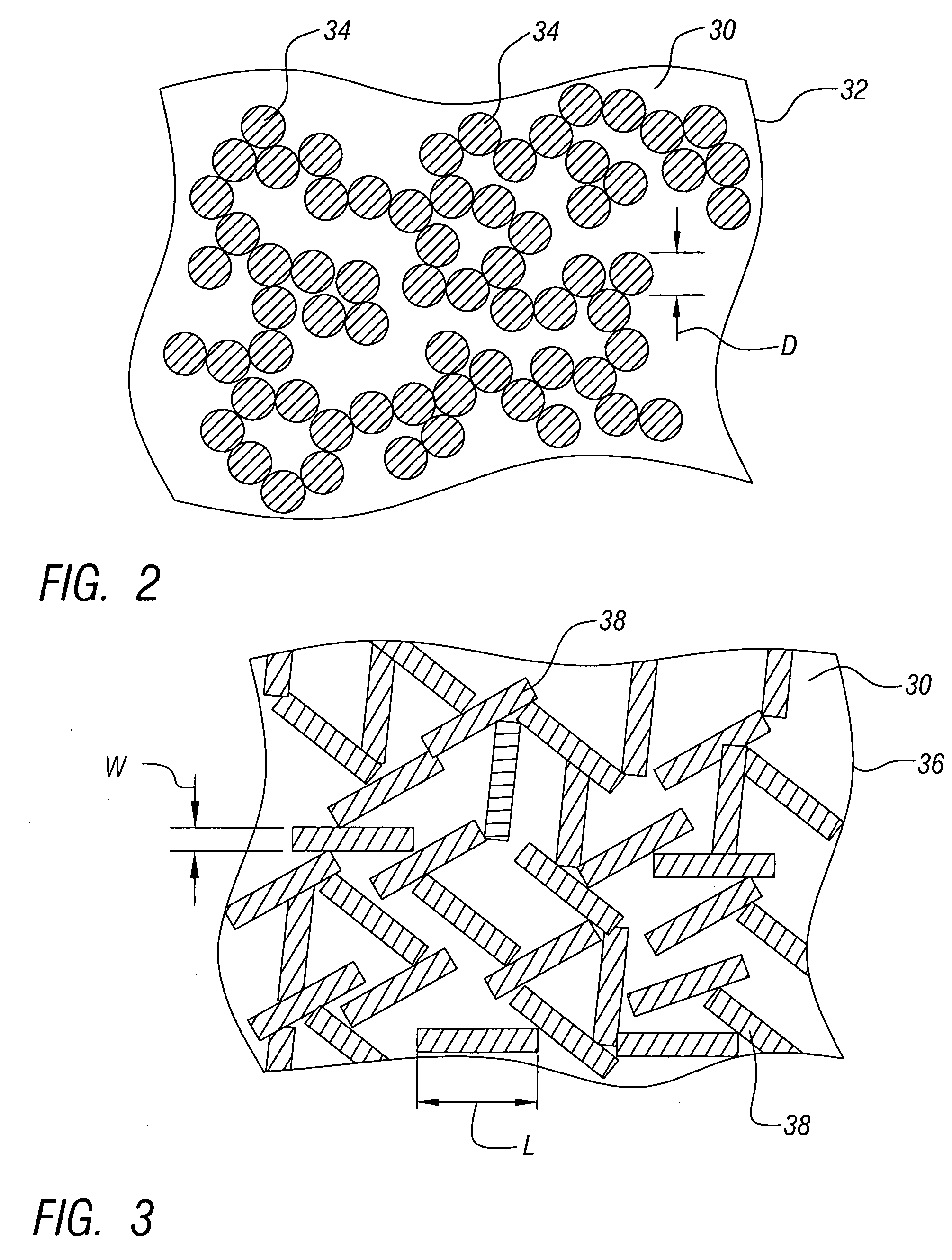

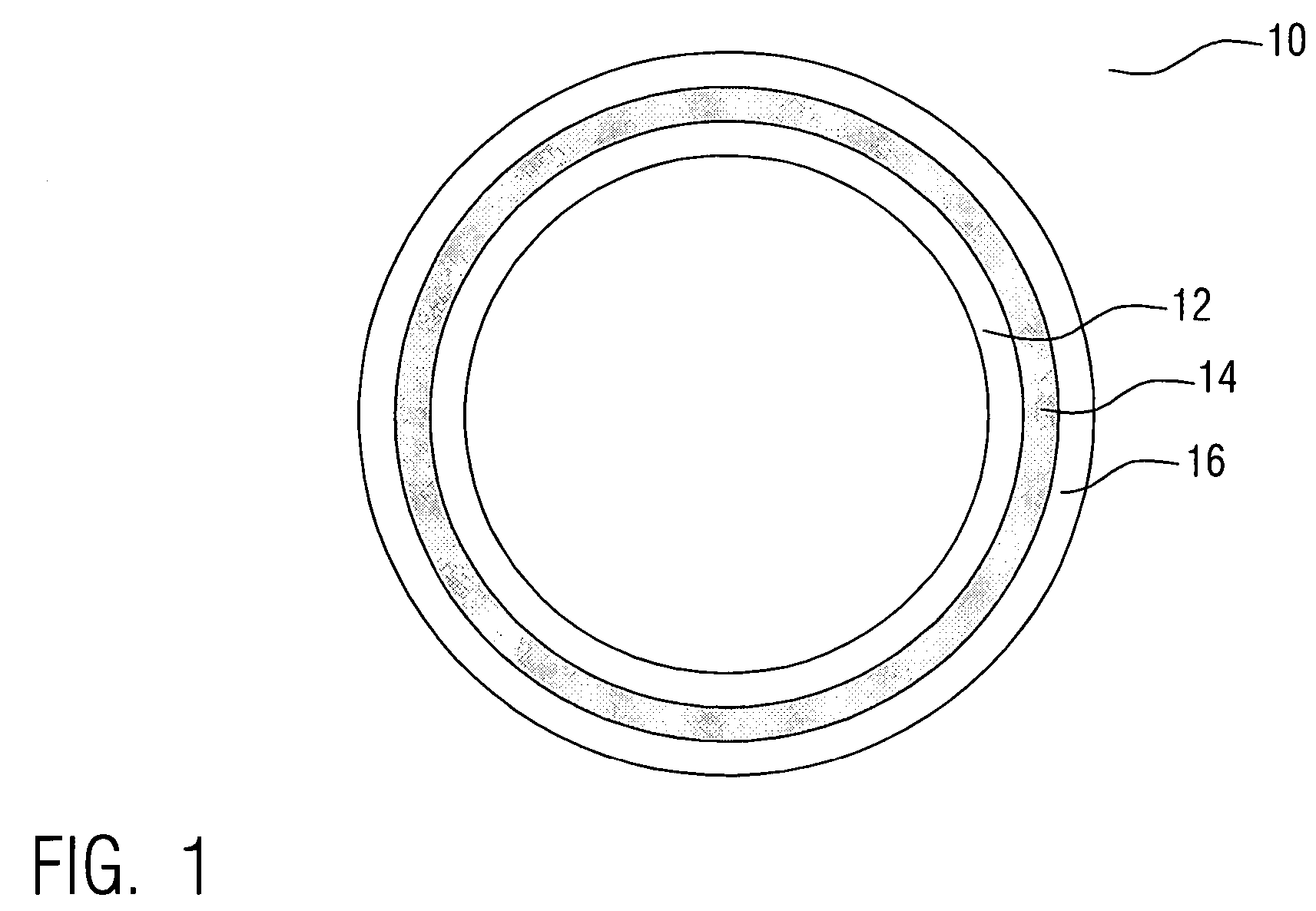

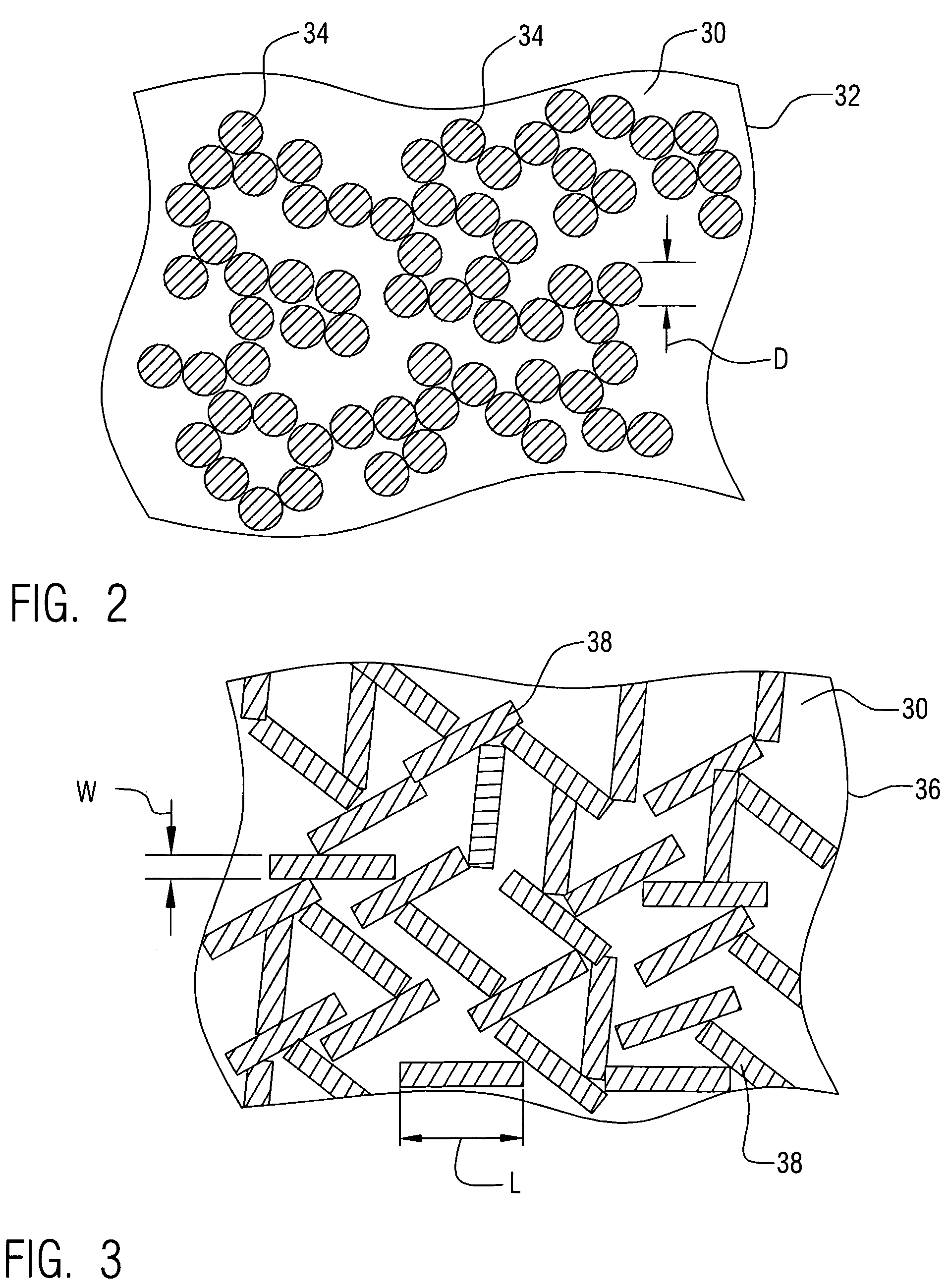

Low cost components for use in motorcycle, marine, and racing applications manufactured from conductive loaded resin-based materials

Motorcycle, marine, and racing components are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

Means of seeding and metallizing polyimide

InactiveUS7033648B1Improve adhesionRadiation applicationsDecorative surface effectsEngineeringMetallizing

Owner:IBM CORP

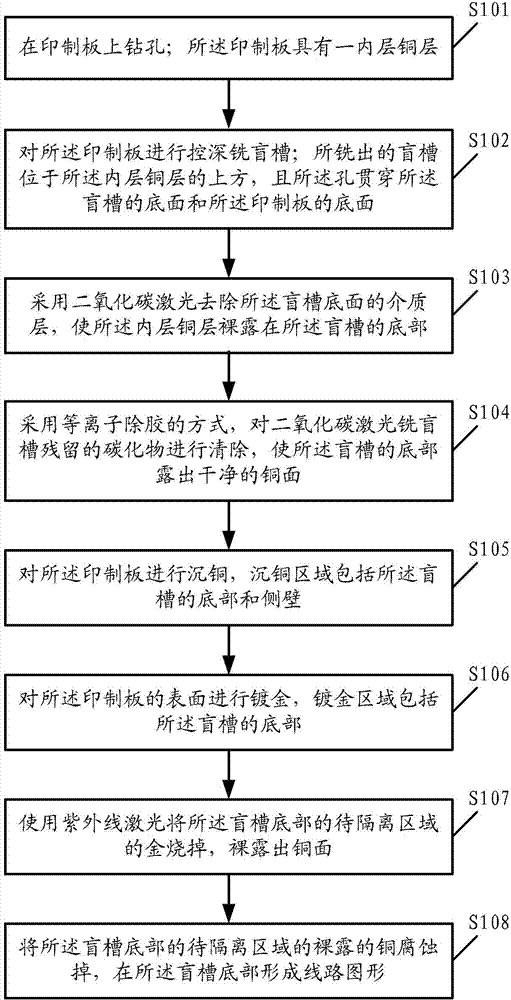

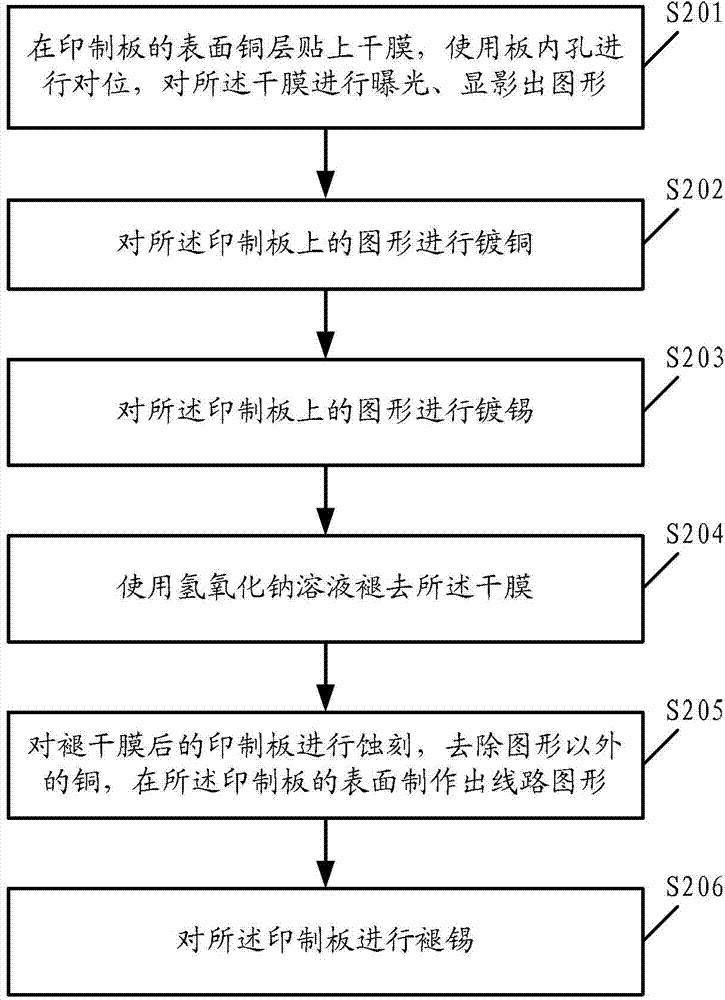

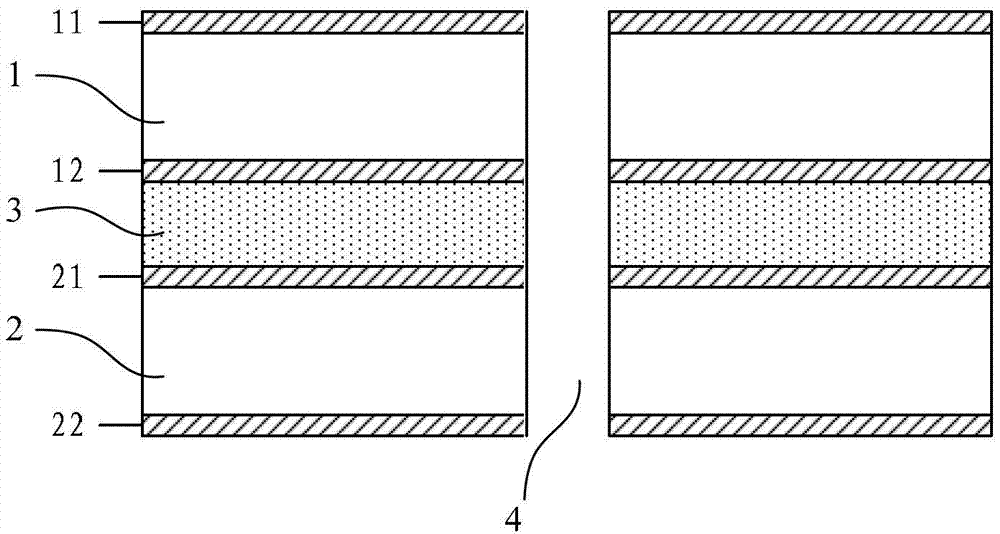

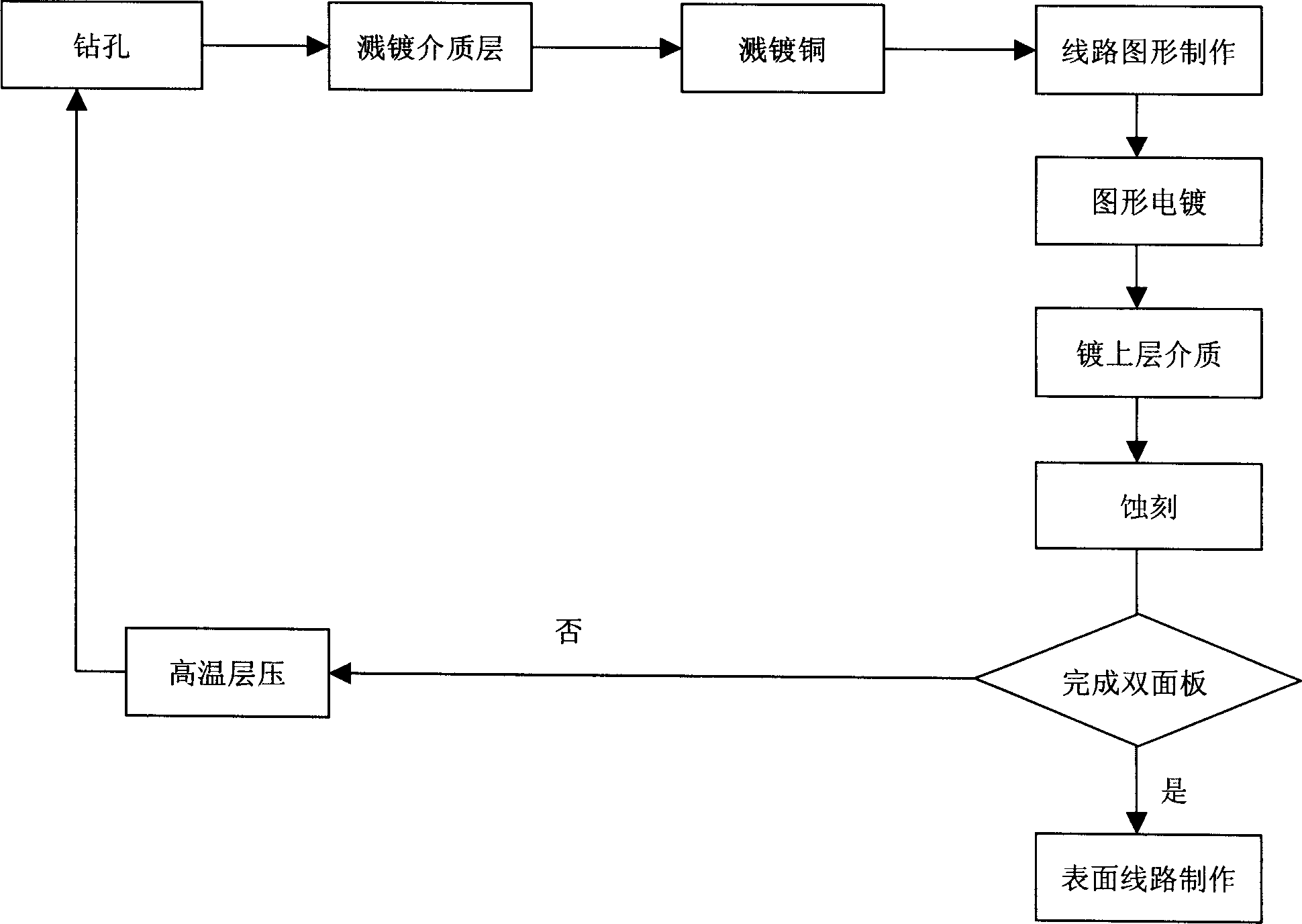

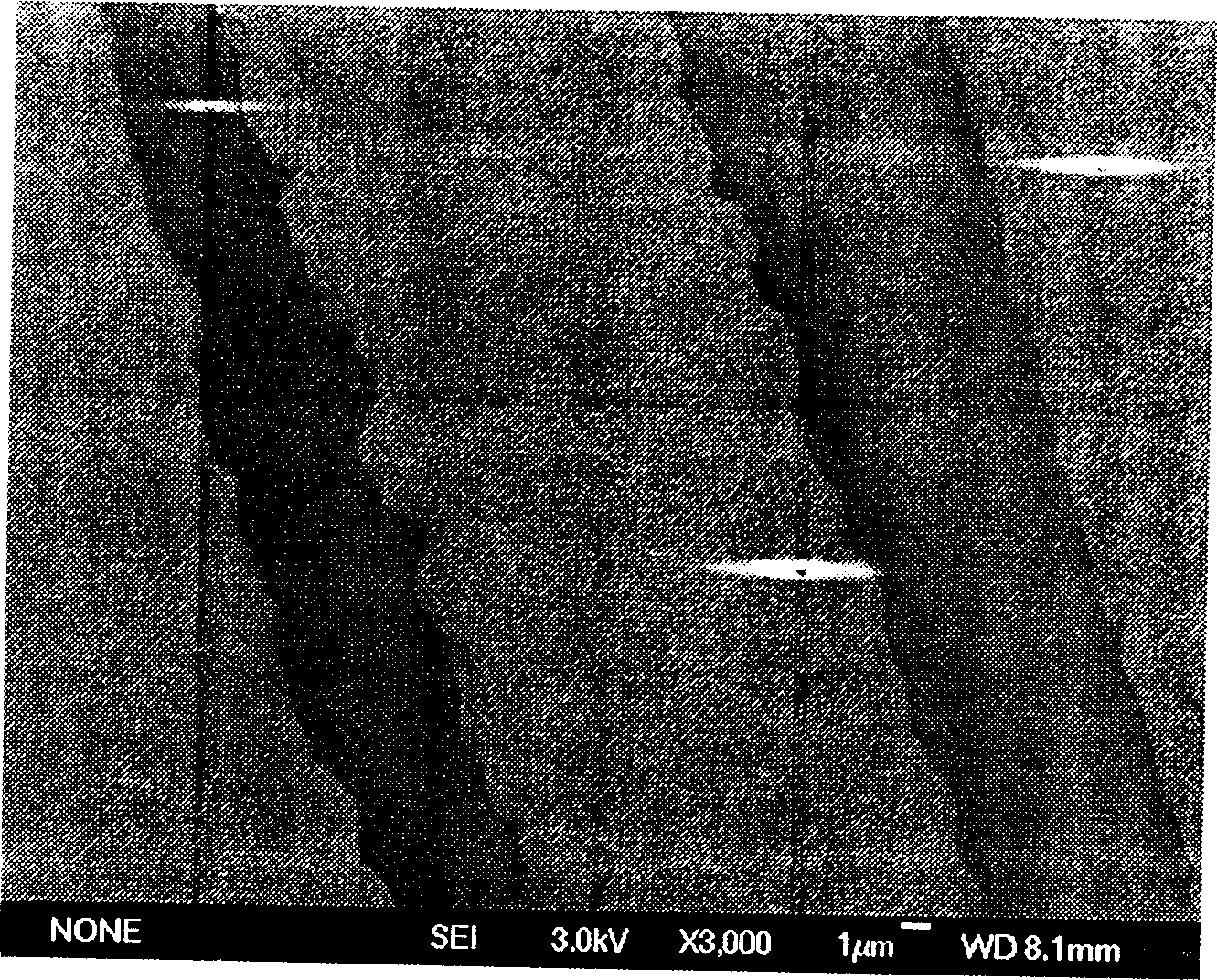

Method for processing patterns in blind slot of printed circuit board

ActiveCN103079350AMeet design and assembly performance requirementsImprove pass rateConductive material chemical/electrolytical removalCopper platingProcess patterns

The invention discloses a method for processing patterns in a blind slot of a printed circuit board. The method comprises the following steps of drilling a hole in the printed circuit board; forming an inner copper layer on the printed circuit board; milling the blind slot with controlled depth on the printed circuit board; exposing the inner copper layer at the bottom of the blind slot; carrying out electroless copper plating on the printed circuit board, wherein the electroless copper plating areas comprise the bottom and the side walls of the blind slot; plating gold on the surface of the printed circuit board, wherein the gold plating area comprises the bottom of the blind slot; using an ultraviolet ray to burn the gold on the area to be isolated at the bottom of the blind slot, and exposing the copper surface; and corroding the exposed copper on the area to be isolated at the bottom of the blind slot, so as to form a circuit pattern at the bottom of the blind slot. The method disclosed by the embodiment of the invention has the advantages that the metallizing of the side wall of the blind slot is realized, the metallic through hole and the circuit pattern are manufactured at the bottom of the blind slot, and the qualified rate of the pattern is improved.

Owner:GCI SCI & TECH

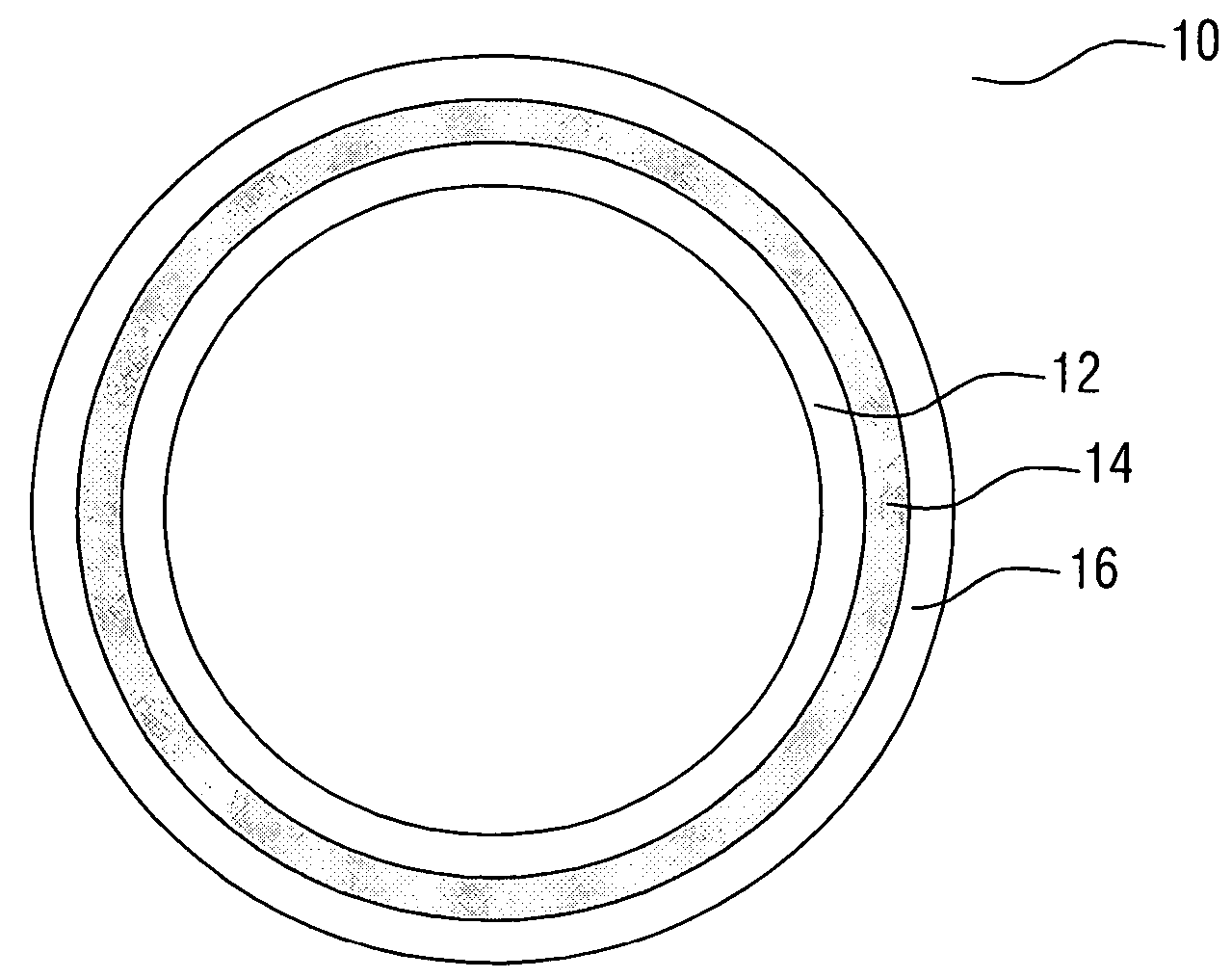

Low cost vehicle fuel system components manufactured from conductive loaded resin-based materials

InactiveUS20060113696A1Reduce weightEasy to chargeFilament/thread formingEngine controllersMetal fibersMetallizing

Vehicle fuel system components are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

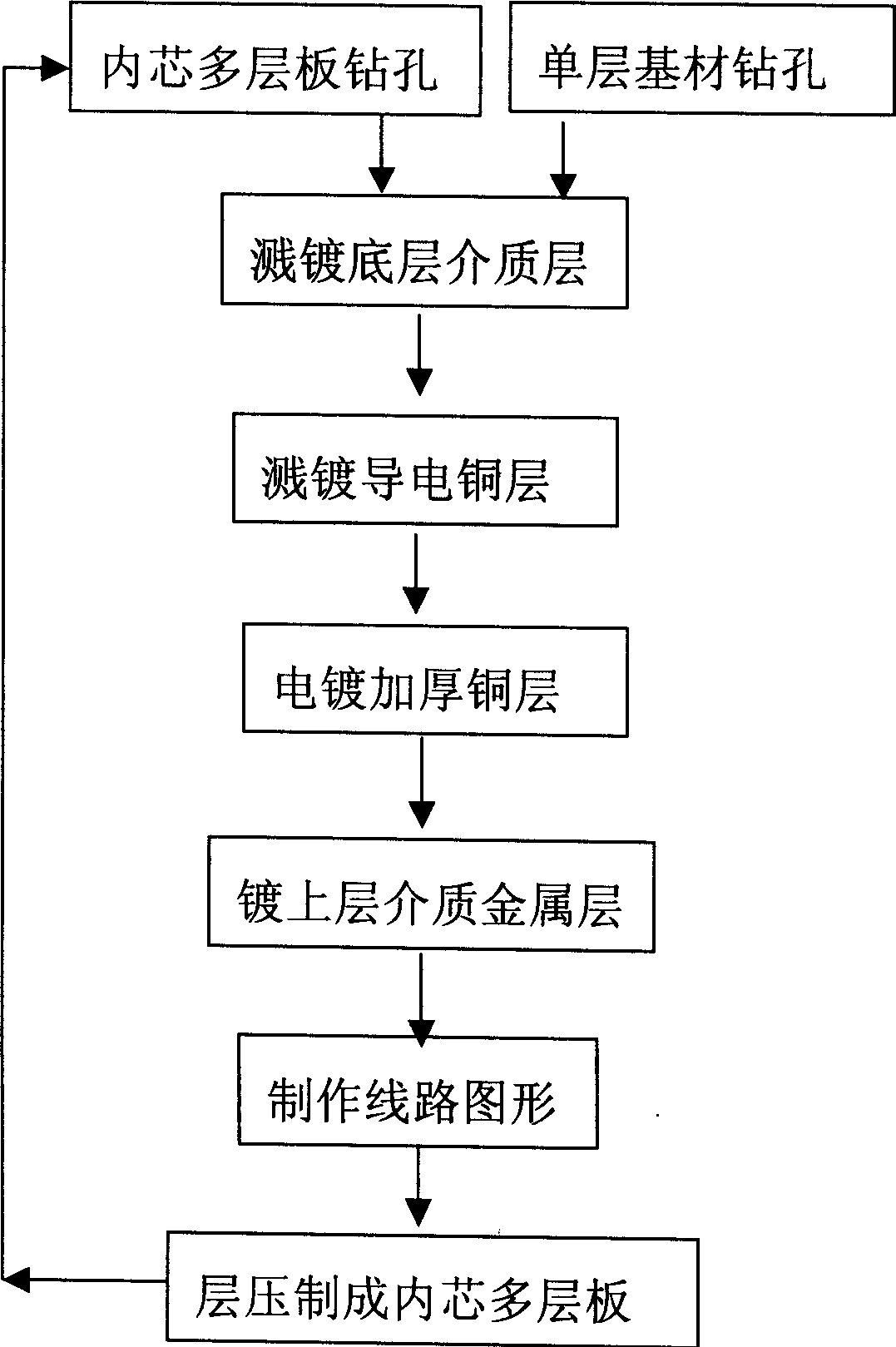

Magnetically controlled sputtering process of making printed circuit board

InactiveCN1527656AFlexible thickness controlAvoid inhomogeneityMultilayer circuit manufacturePrinted element electric connection formationCopper platingOptoelectronics

The present invention provides one kind of magnetically controlled sputtering process of making printed circuit board. The process includes the following steps: drilling holes on the single layer base material; magnetically controlled sputtering the bottom dielectric and metal layer on the drilled single layer base material; magnetically controlled sputtering conducting copper layer on the single layer base material; drilling holes on multilayer board; magnetically controlled sputtering bottom dielectric and metal layer on the drilled multilayer board; magnetically controlled sputtering conducting copper layer on the drilled multilayer board; and repeating the foregoing steps until reaching the required layer number of the printed circuit board. The present invention combines unique hole forming method and sputtering method and has raised copper-plating and hole-metallizing efficiency, raised reliability and high fine circuit making capacity.

Owner:曹波 +2

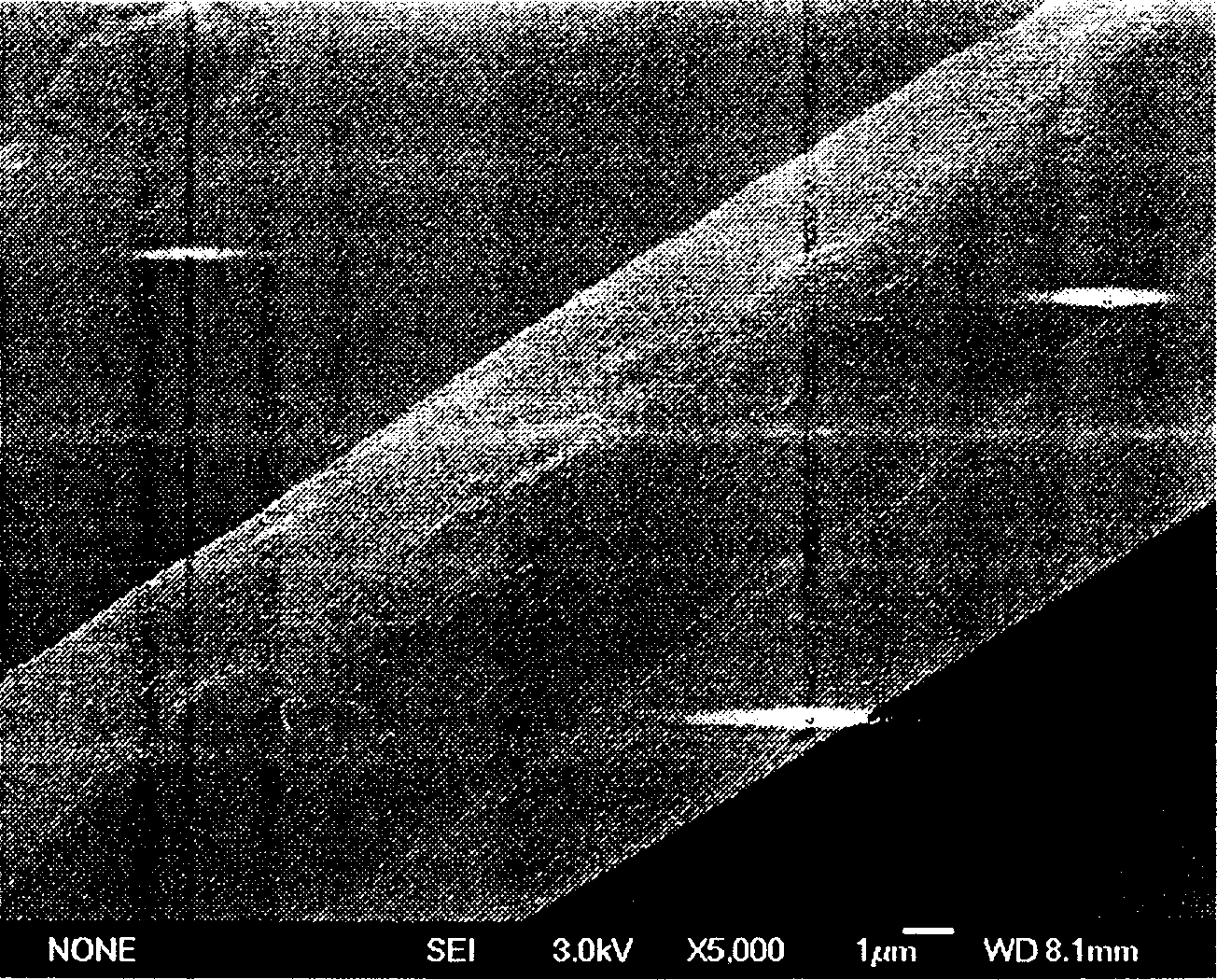

Technology for plating nano-metal on fiber

InactiveCN101660125AImprove conductivityGood flexibilityVacuum evaporation coatingSputtering coatingWater basedCopper plating

The invention relates to a technology for plating nano-metal on fiber, which is characterized in that natural fiber or chemical fiber is selected for producing a substrate, and cleaning, washing by water and drying pretreatment are carried out on the substrate; sputtering film coating is implemented on the surface of the substrate after the pretreatment; and a water-based polyurethane protective layer is coated on the surface of the substrate after plating a metal film, and the substrate after the treatment of coating with a protective layer is washed by water and dried, thereby obtaining a finished product. Silver-plated fabric has very high conductive performance and flexible performance, and the shielding effect can be more than 40DB which is much higher than copper and nickel-plated conductive fabric in the current market; and zinc-plated fiber simultaneously has good anti-bacterial and anti-ultraviolet functions.

Owner:邵楠 +1

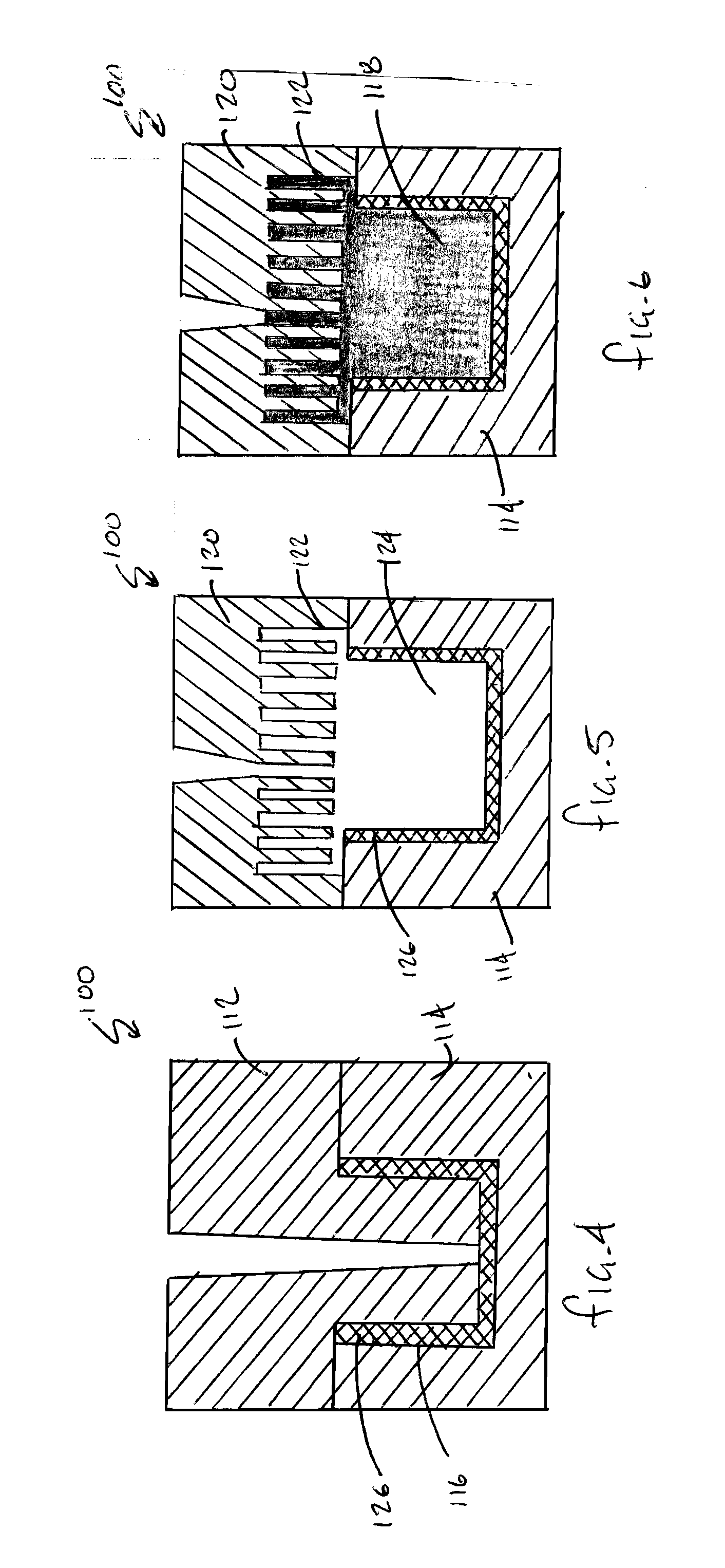

Method of two shot mold metallizing of polymer components

InactiveUS20060231231A1Highly durable and resistant to wearEasy to operateGearingCylindersThin layerNet shape

A component is provided that is net shape molded using a polymer to form the core structure and which includes an integrally formed metallized coating or layer on at least one of the exterior surfaces thereof. The process of forming the component includes two-shot molding process wherein a thin layer of metal or the base polymer component is molded, the mold is adjusted and then the remainder of the part is molded. Alternately, an insert molding process may be employed such that after the polymer base part is formed, it may be placed into a mold cavity that is slightly larger than the entire part, thereby allowing substantially the entire exterior surface of the part to be over molded with a molten metal.

Owner:COOL OPTIONS

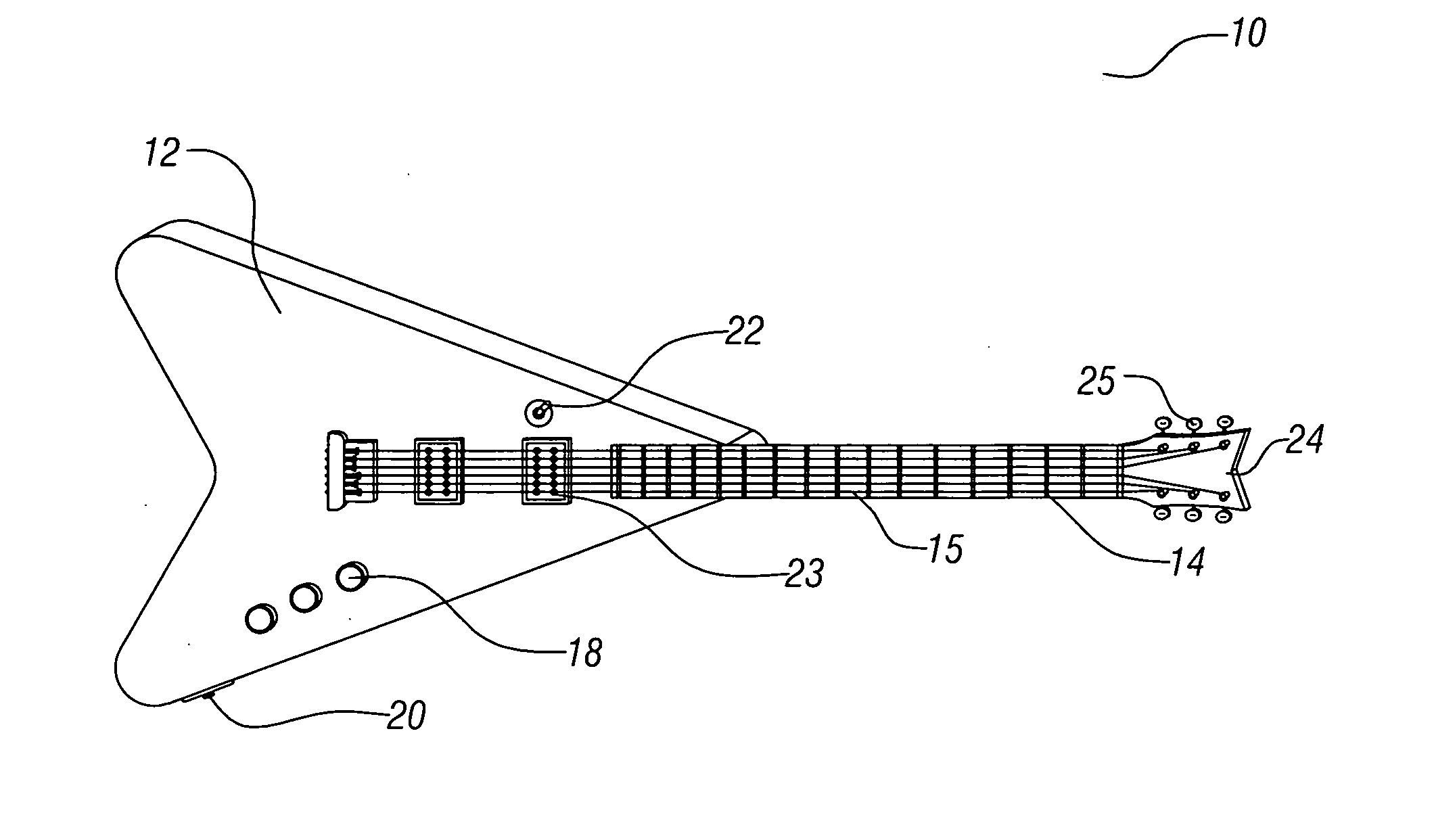

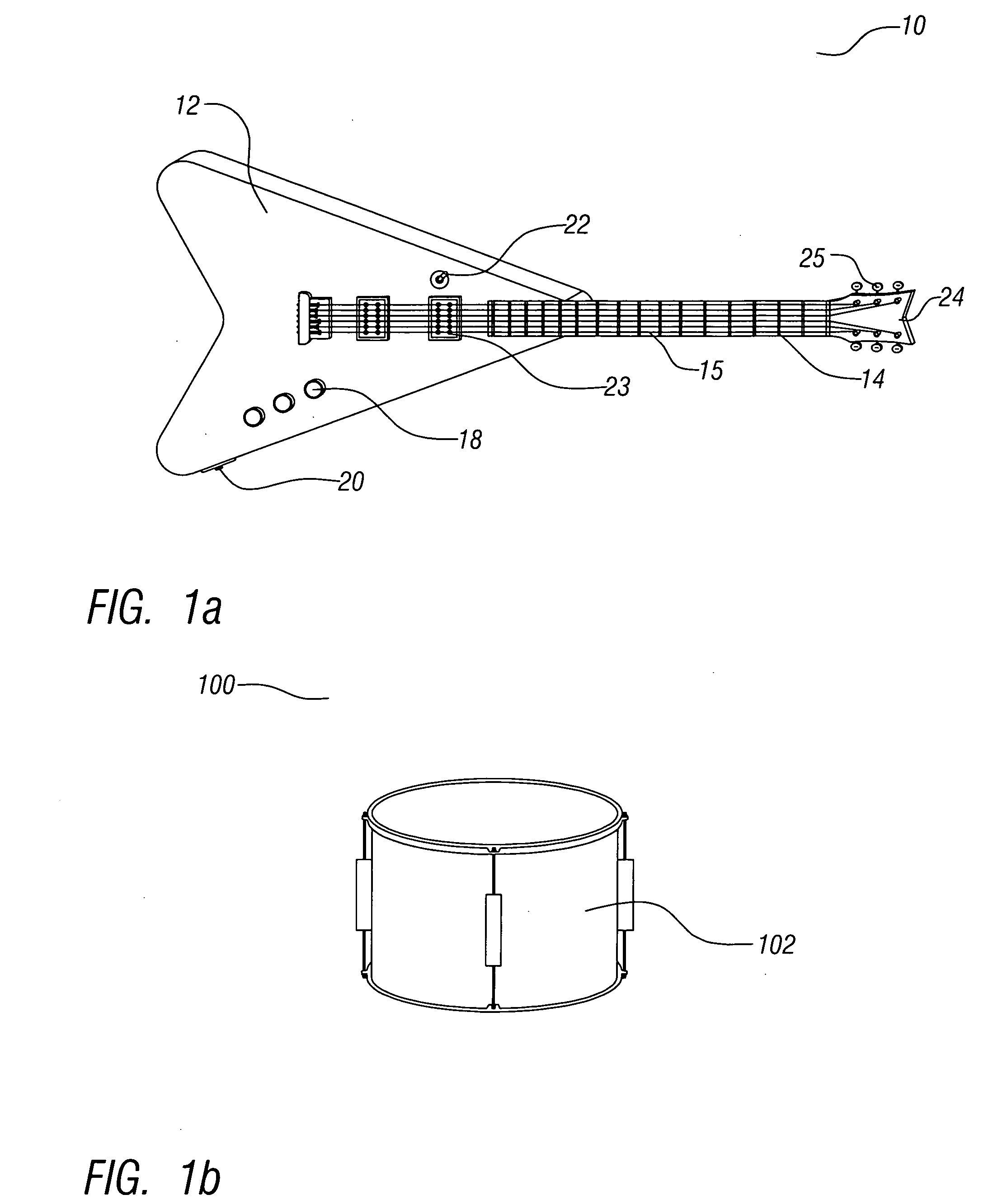

Musical instruments and components manufactured from conductively doped resin-based materials

Musical instruments are formed of a conductively doped resin-based material. The conductively doped resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductively doped resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:AISENBREY THOMAS

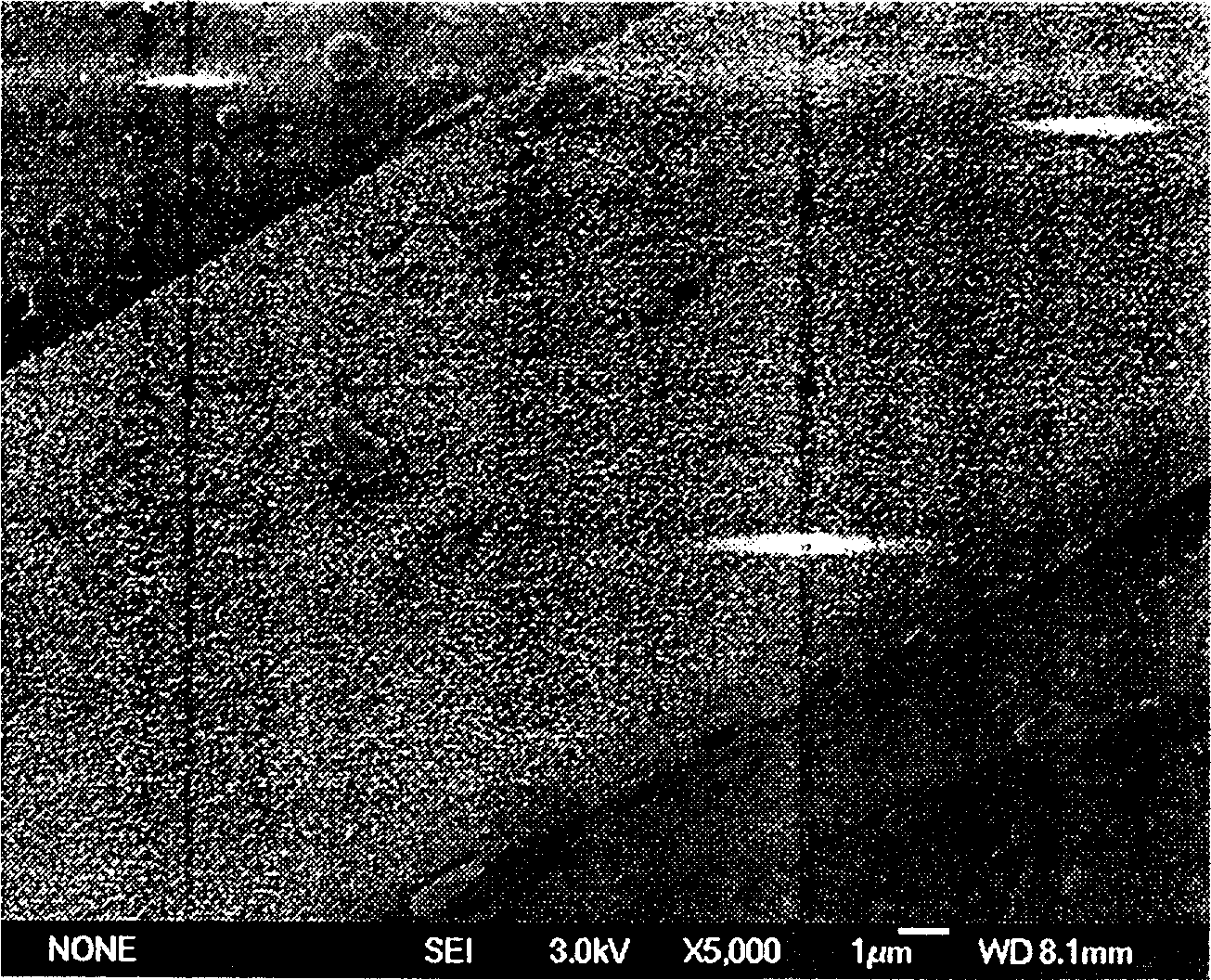

Production process of conductive fabric via plasma treatment

InactiveCN1436889AImprove adhesion fastnessIncrease contact areaPhysical treatmentFiberElectromagnetic shielding

The present invention relates to the preparation of conductive fabric and is especially plasma treatment process of conductive fabric with coated conducting metal layer on the surface and thus electrothermal, antistatic, electromagnetic shielding and other functions. The process includes the steps of: defatting and decontaminating substrate materail, electrochemical activating, metallizing and surface treatment as well as characterized low temperature plasma treatment step before the electrochemical activating step to etch the surface of fabric fiber at the conditions of 20-400 W power and 1-100 Pa air pressure and for 40 min. The said etching effect on the surface of fabric raise the fastness of metal layer on the fabric.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Powder for ceramic metallizing paste and its prepn

The powder for ceramic metallizing paste and its preparation process belongs to the field of ceramic metallizing material applying technology. The ceramic metallizing powder consists of molybdenum powder in 60-80 weight portions and glass phase component in 20-40 weight portions. The powder for ceramic metallizing paste has reasonable composition, proper metal titanium content, capacity of strengthening activity of the metallizing layer and ceramic, raised sealing strength of metallized ceramic, metallizing sintering temperature lowered to 1400-1450 deg.c and expanded compact sintering temperature range.

Owner:CHANGSHU CITY YINYANG CERAMIC CO LTD

Method for carrying out full dry method composite film plating on metal surface

InactiveCN102758176AHard and smooth surfaceReduce consumptionVacuum evaporation coatingSputtering coatingComposite filmCyanide

The invention discloses a method for carrying out full dry method composite film plating on a metal surface, and relates to a treatment method of the metal surface. The invention provides a method for carrying out full dry method composite film plating on metal surface capable of obtaining a highly bright metal appearance through only a layer of PVD (Physical Vapor Deposition) plated metal film and finish without spraying a primer. The method comprises the following steps: mechanically polishing and cleaning a metal blank; plating a metal film on the cleaned metal blank; organically spraying the obtained sample and solidifying at high temperature to obtain a product. After test, the obtained metalized metal product has the advantages of antisepsis, corrosion resistance, weather resistance, temperature resistance and colorful property, the surface is hard and smooth, and is comparable to the quality of the conventional hydroelectric plating metal product, roughening, activating and washing processes in the conventional hydroelectric plating are removed, no any harmful electroplating liquid medicine is added, in particular, toxic hexavalent chromium and cyanide are not used, meanwhile, the process has less metal consumption and few waste gas, and is completely free of wastewater discharge and low in cost, and the method is suitable for bathroom, electronics, electrical appliance and automobile industries.

Owner:NINGBO RUNNER INDAL CORP

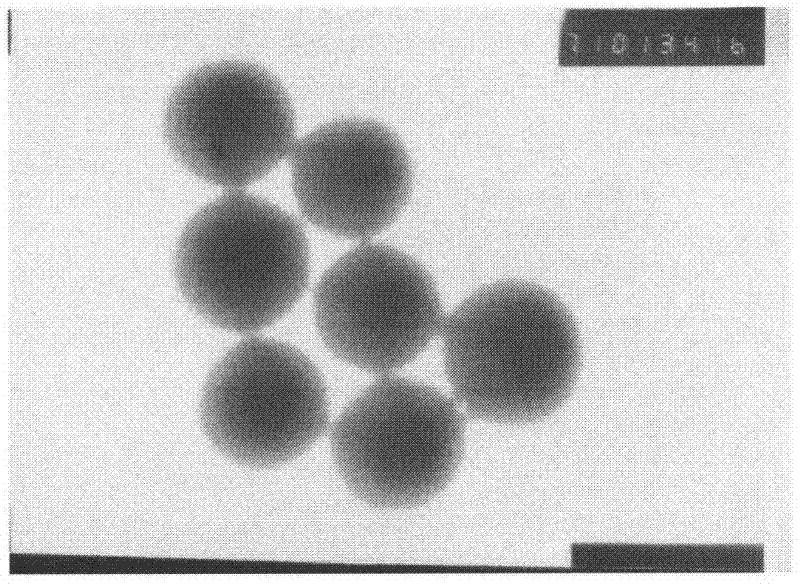

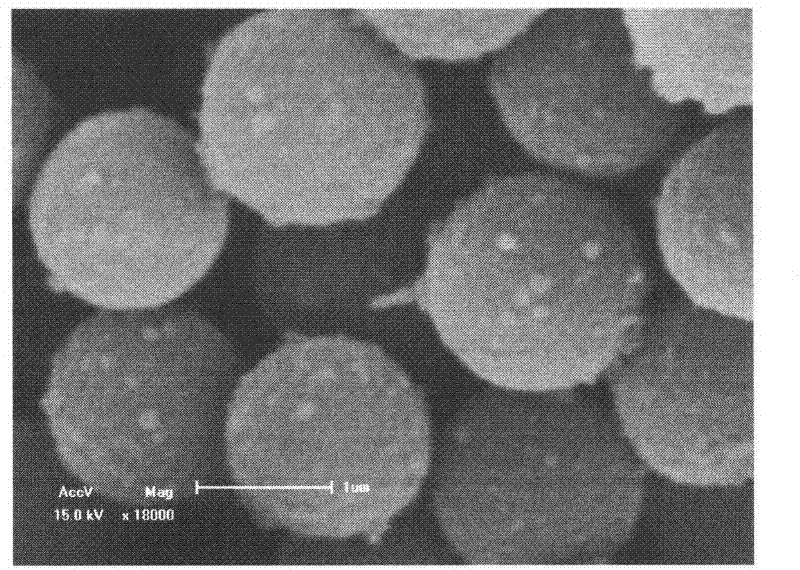

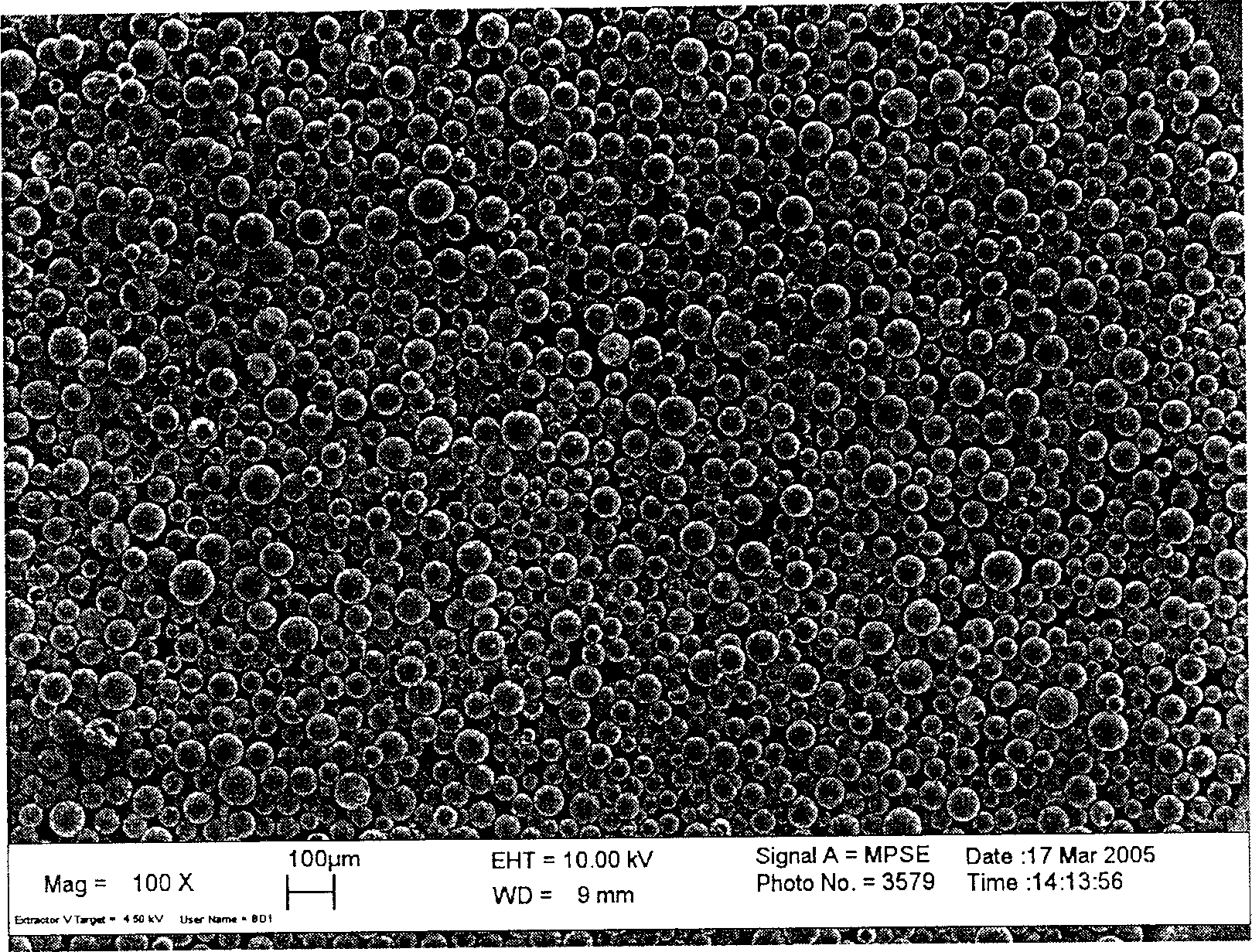

Method for preparing monodisperse silver-coated microspheres for anisotropic conductive adhesive

InactiveCN102206818ASimple preparation processThe preparation process is simple and reliableNon-macromolecular adhesive additivesLiquid/solution decomposition chemical coatingMicrosphereAnisotropic conductive adhesive

The invention relates to a method for preparing monodisperse silver-coated microspheres, and belongs to the fields of silver-coated microspheres, electronic connecting materials and the like. The method comprises the following steps of: preparing monodisperse melamine formaldehyde resin (MF) microspheres by using a dispersion polymerization method; roughing, sensitizing, activating and chemically plating a nickel metal and a silver metal by taking the microspheres as mother spheres so as to obtain the monodisperse silver-coated MF microspheres. The MF mother spheres have the advantages of simple and reliable preparation process, high efficiency, controllable grain size, good monodispersibility and the like. Because the MF microspheres contain active groups such as amino acid, hydroxyl and the like, the coat is complete and high in binding force, the grain size of the silver-coated microspheres can be controlled in a range of 1.0-3.9mu m, the dispersion coefficient epsilon is 0.045-0.067, the monodispersibility is high, the decomposition temperature is about 300DEG C, and the thermal stability is high; moreover, the preparation method is simple and high-efficiency, has the advantages of industrial production, and has good application prospect in the fields of electronic connecting materials such as anisotropic conductive adhesives and the like.

Owner:NANJING INST OF TECH

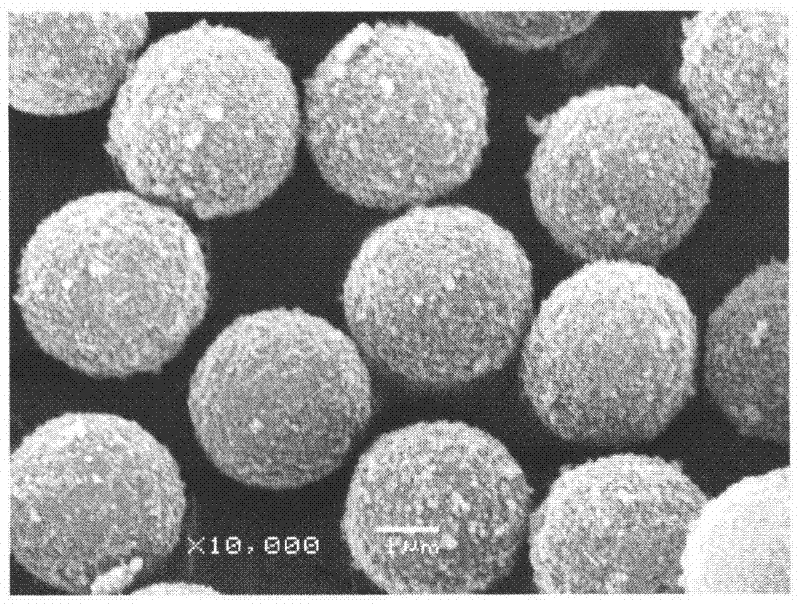

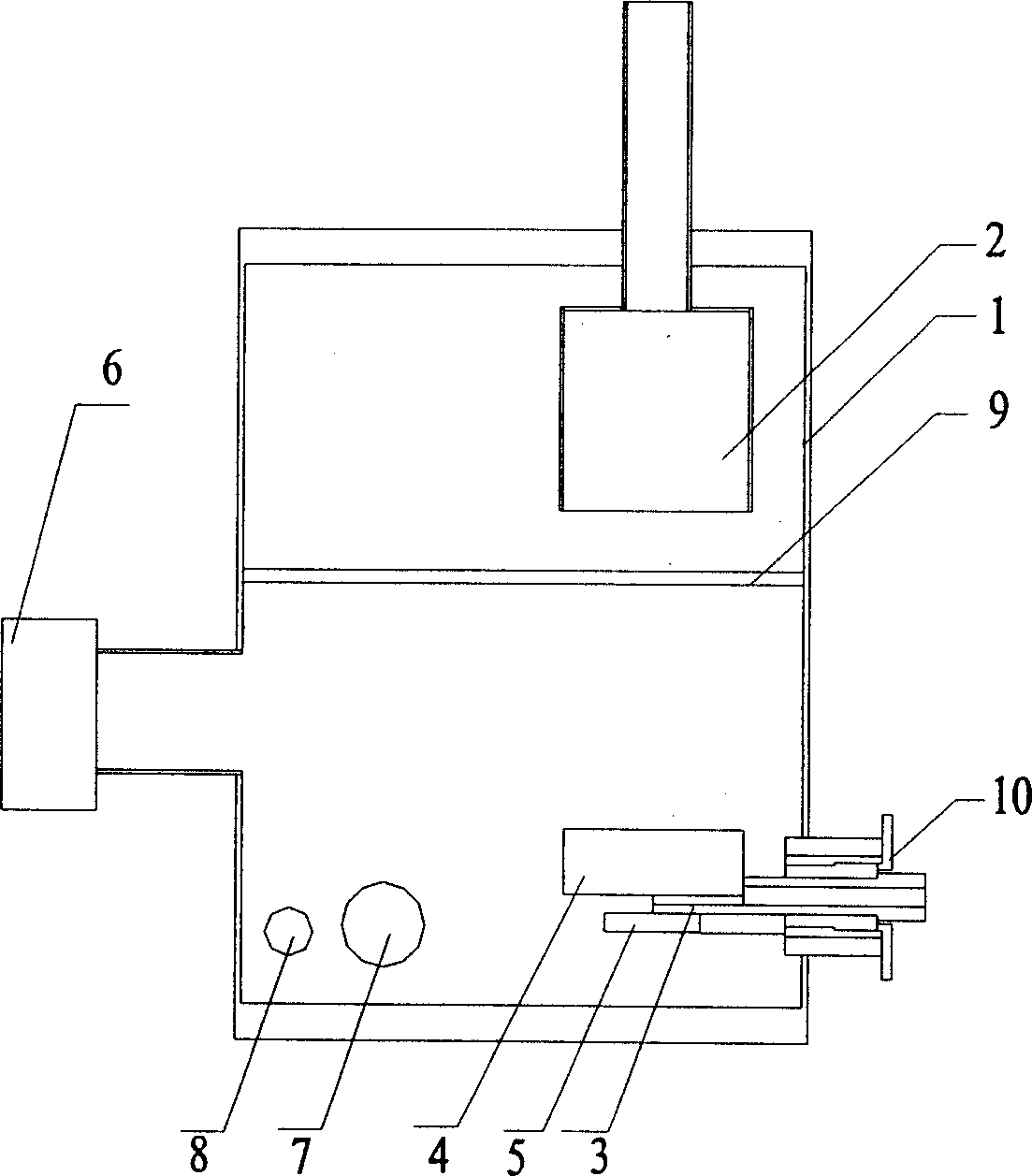

Technology of vacuum metal film plating on microparticle surface and its equipment

InactiveCN1718845AImprove uniformityImprove compactnessVacuum evaporation coatingSputtering coatingSputteringIt equipment

A technology and equipment for the vacuum plating of metallic film on the surface of microparticles features that the specimen holder is connected with the plating equipment having ultrasonic or mechanical vibration generator. Said technology includes such steps as providing microparticles and sputtering metal target, fixing target and microparticle utensil, turning on mechanical pump for vacuumizing, turning on molecular pump for further vacuumizing, turning on ultrasonic or mechanical vibrator, regulating power, frequency and time, and sputtering.

Owner:BEIHANG UNIV +2

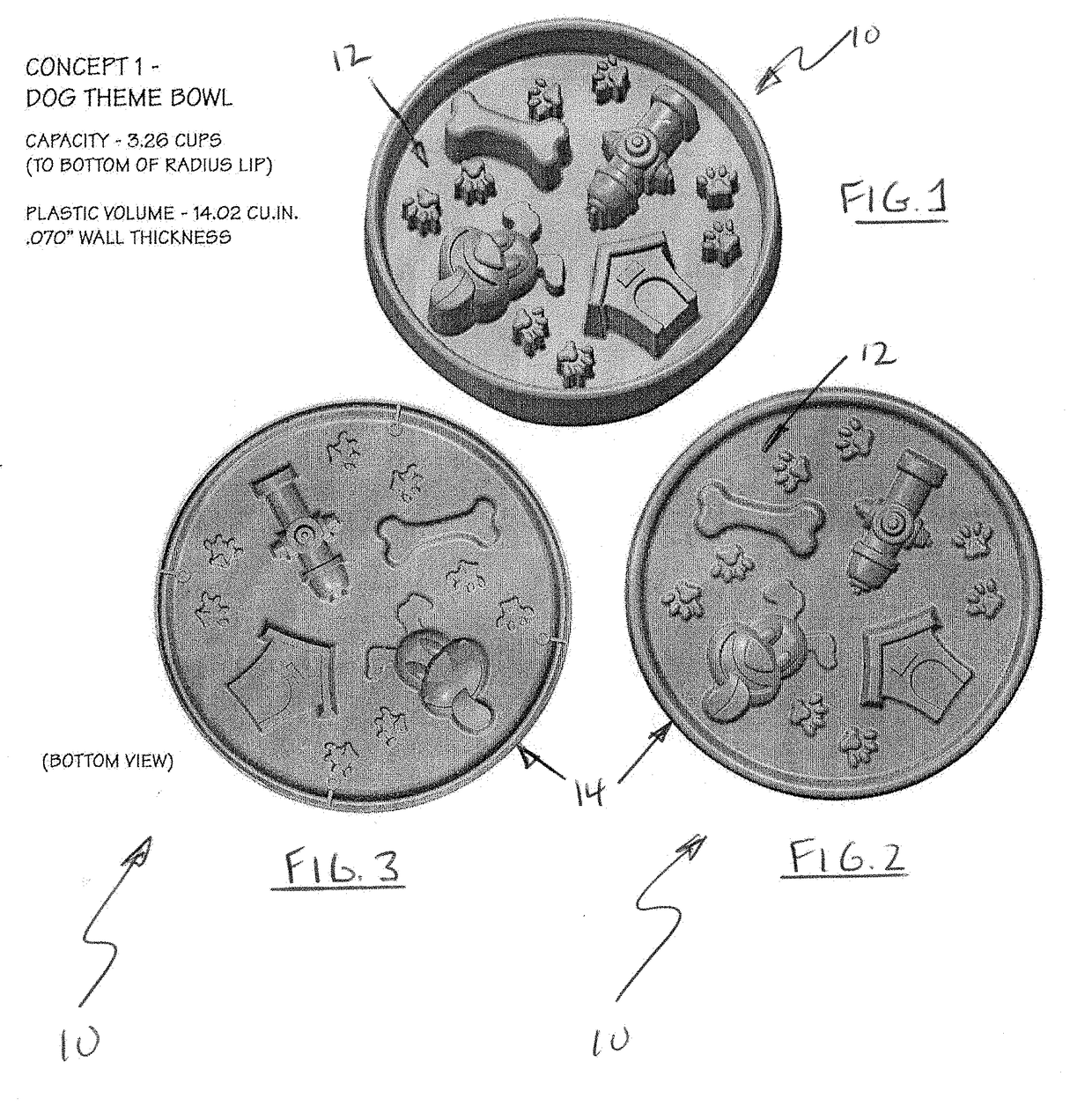

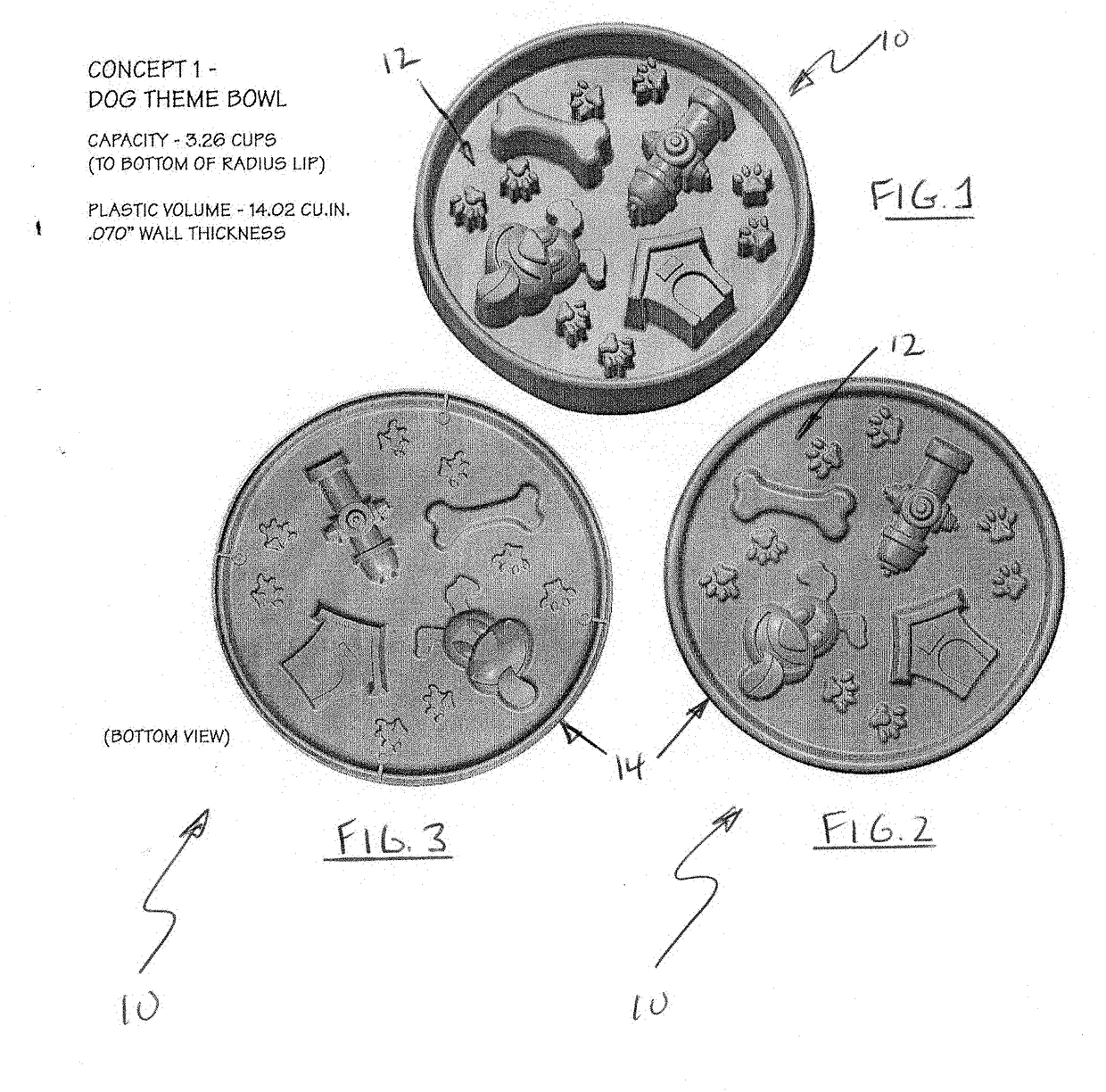

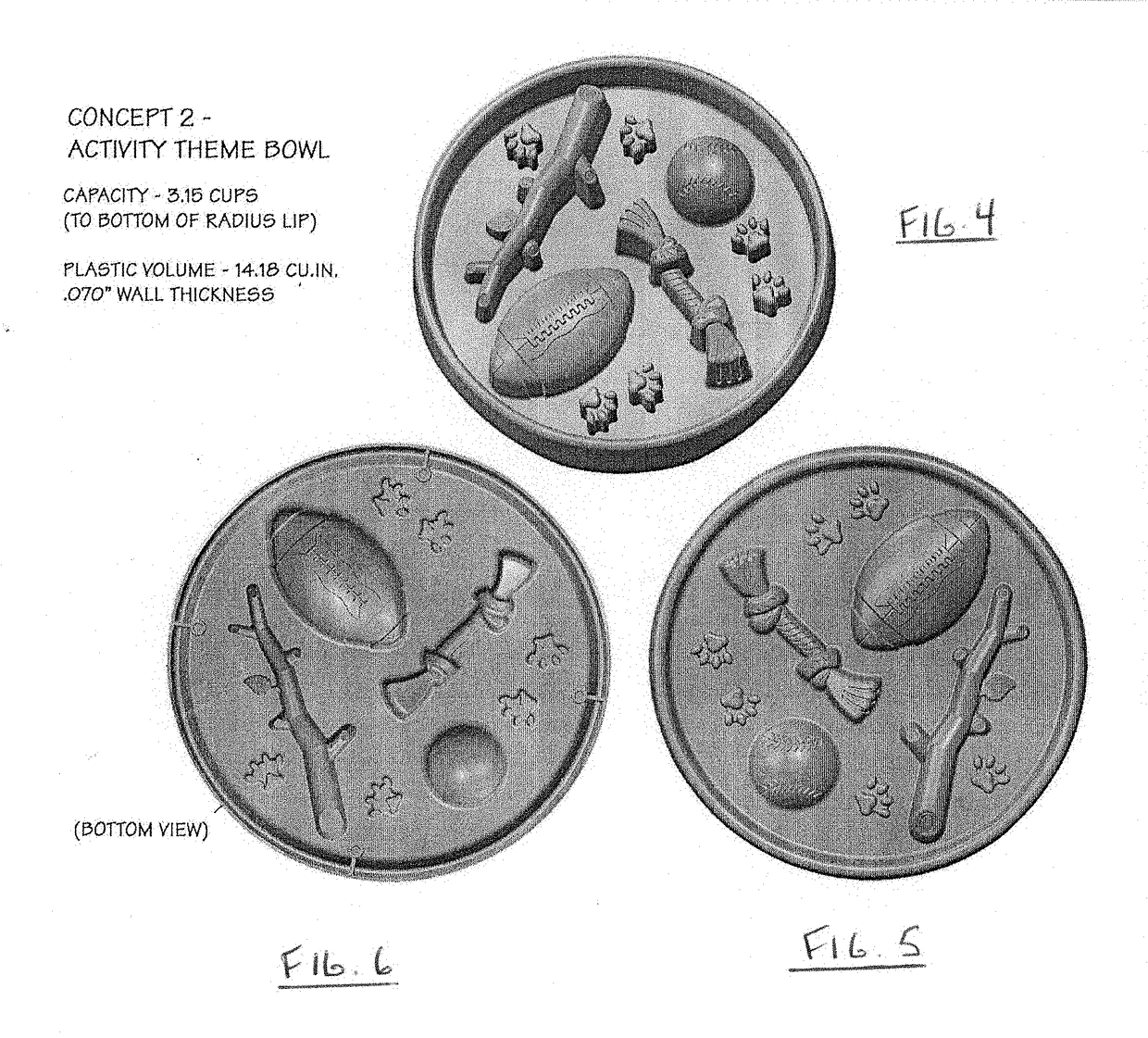

Metallized Plastic Pet Product

InactiveUS20180133991A1Not be readily and shapedMetallic coatingAnimal watering devicesAnimal feeding devicesBlow moldingSurface finish

A variety of pet related products are provided formed initially of plastic and finalized with a metallized surface finish. The pet product is molded using injection molding, rotational molding, vacuum forming, blow molding, compression molding, thermoforming or other plastic forming techniques that can provide a structure having a shape that cannot be readily or economically shaped by metal stamping or other conventional metalworking method. The semi finished plastic part is then subjected to a metallizing process in an individualized non-contiguous manner, where a thin metallic layer is deposited on at least one of the product surfaces. The resultant pet product item simulates the appearance metal, and may provide the durability, cleanability and the general antimicrobial nature resulting metal surfaces.

Owner:OUR PETS

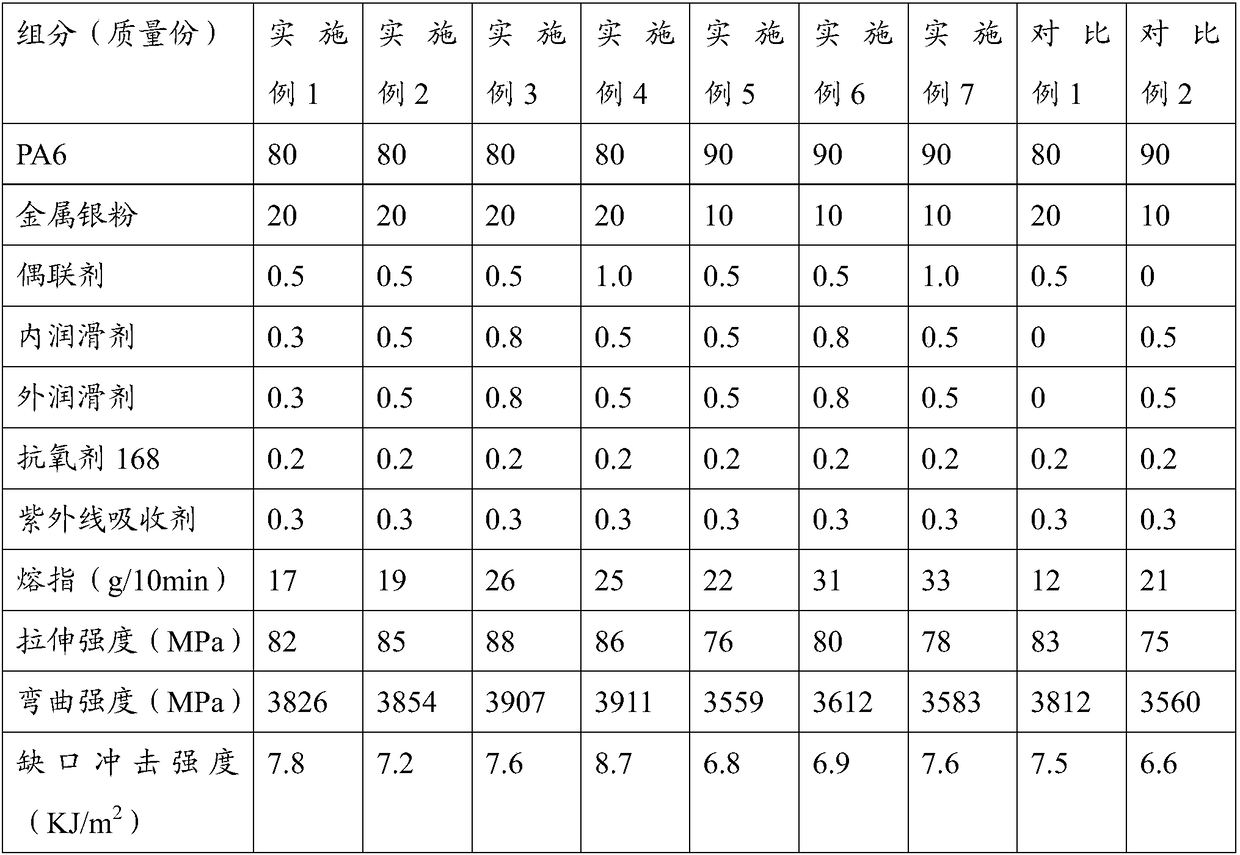

High flow non-spraying metallic silver polyamide composition and preparation method thereof

The application discloses a high flow non-spraying metallic silver polyamide composition and a preparation method thereof. The high flow non-spraying metallic silver polyamide composition is preparedfrom the following raw materials: PA6 resin, a metallic silver powder, a coupling agent, an internal lubricant, an external lubricant, an antioxidant, an ultraviolet light absorber, amino-silicone oil, a flame retardant, calcium stearate, MBS, SMA, silicon dioxide, a magnesium salt whisker, hollow glass-beads, EBS, glass fiber, a compatilizer and ABS; the composition has good flowability; injection molding parts are easy to be welded at welding lines; meanwhile, by adding the coupling agent, the welding strength is better, and the appearance of the weld lines is ensured; the composition has high flow characteristic and solves the problem of obvious welding lines of a product. The composition nylon resin has better compatibility with metal powder particles and ensures the welding strength of the welding lines of the product; the composition has non-spraying properties and replaces an electroplating or vacuum plating metal mode, so that the cost is significantly reduced and environment friendliness is achieved.

Owner:南京跃贝新材料科技有限公司

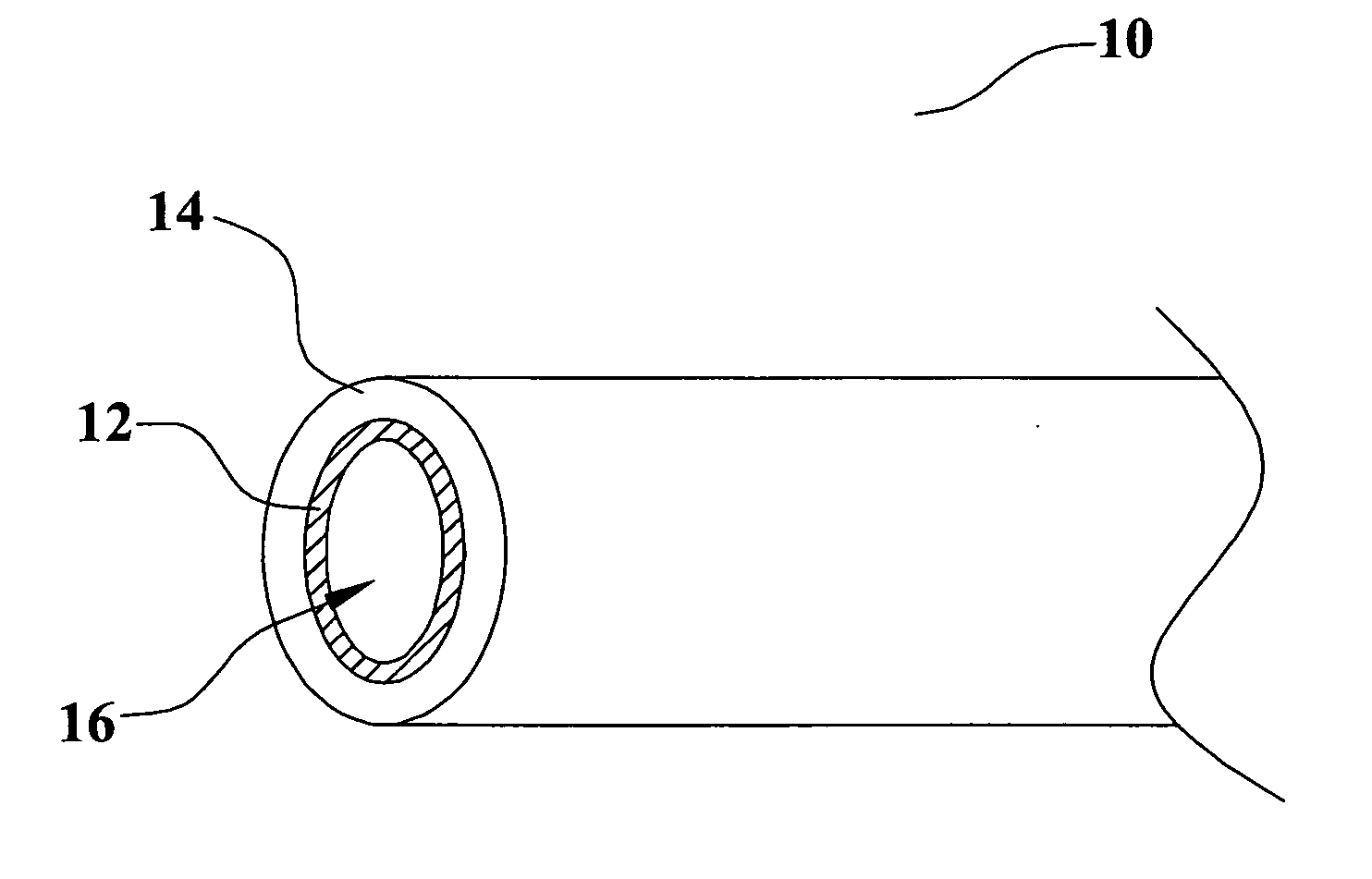

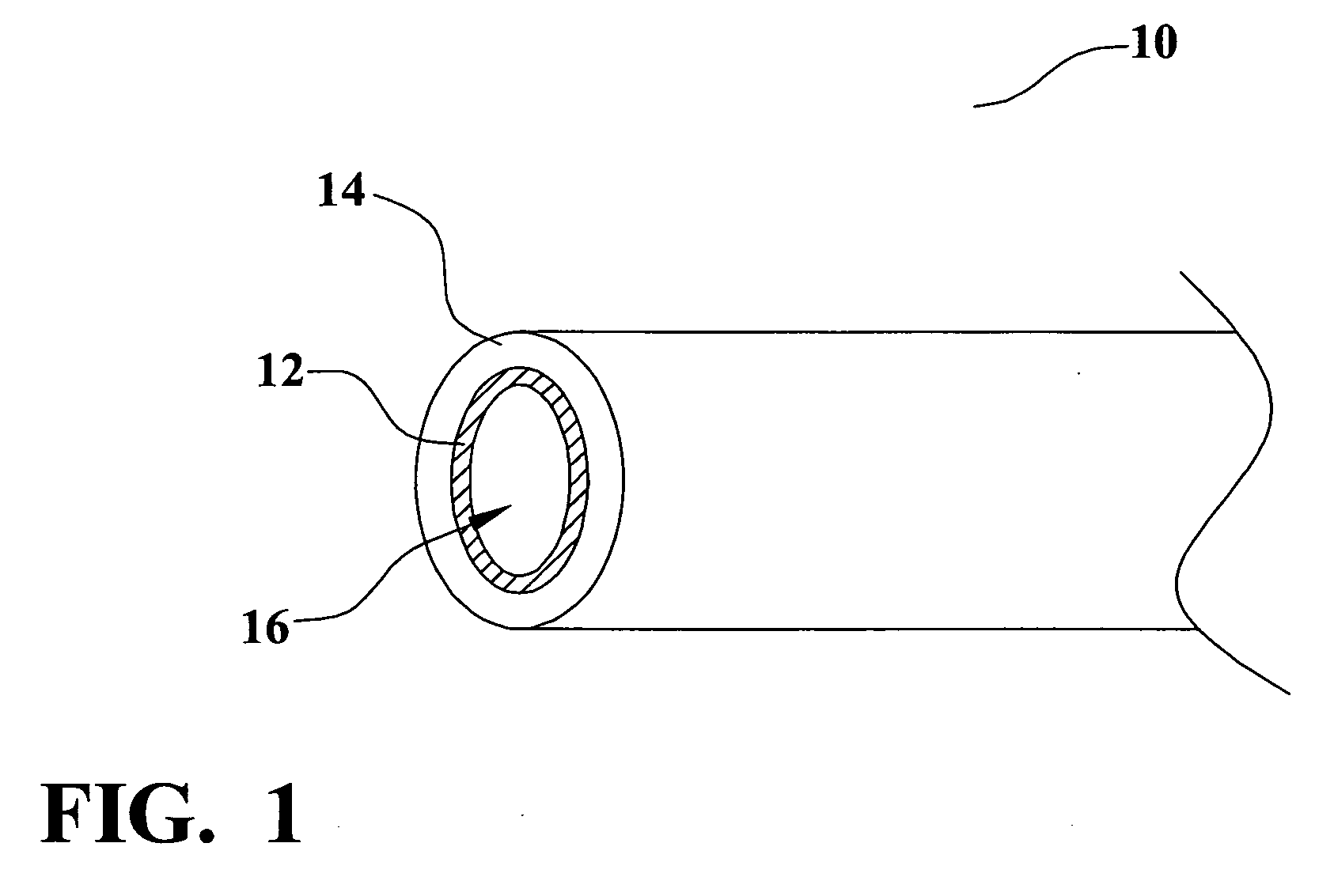

Low cost detectible pipe and electric fencing manufactured from conductive loaded resin-based materials

InactiveUS7268562B2Guaranteed to workNon-insulated conductorsPipe laying and repairElectricityMetal fibers

Detectable pipe and electric fence are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are metals or conductive non-metals or metal plated non-metals. The micron conductive fibers may be metal fiber or metal plated fiber. Further, the metal plated fiber may be formed by plating metal onto a metal fiber or by plating metal onto a non-metal fiber. Any platable fiber may be used as the core for a non-metal fiber. Superconductor metals may also be used as micron conductive fibers and / or as metal plating onto fibers in the present invention.

Owner:INTEGRAL TECHNOLOGY INC

Chrome coated surfaces and deposition methods therefor

InactiveUS20070207310A1Method is time-consume and expensiveQuality improvementVacuum evaporation coatingPretreated surfacesPlatinumMetal coating

A plasma vapor deposition method for producing highly reflective and adherent metal or metal alloy decorative coatings on articles such as automotive fixtures is described. The improved coatings are particularly applicable to chrome based coatings on automobile fixtures and accessories, including wheels, hubcaps, bumpers and door handles. The method also provides plated metal coatings such as gold, platinum and silver for jewelry and industrial tools.

Owner:METASCAPE

Metallized animal house curtain

An animal house curtain comprising a metallized composite sheet can be made from a sheet layer having two outer surfaces, the sheet layer comprising at least one of a nonwoven fabric, woven fabric, nonwoven fabric-film laminate, woven fabric-film laminate, film and composites thereof, and at least one coating on at least one outer surface of the sheet layer, said coating comprising a metal coating layer having a thickness between about 15 nanometers and about 200 nanometers adjacent the outer surface of the sheet layer and wherein the emissivity of the composite sheet is less than about 0.50. Optionally, an organic coating layer of a composition containing a material selected from the group consisting of compounds, polymers, oligomers and combinations thereof, having a thickness between about 0.2 micrometer and about 2.5 micrometers can be deposited on the metal layer.

Owner:EI DU PONT DE NEMOURS & CO

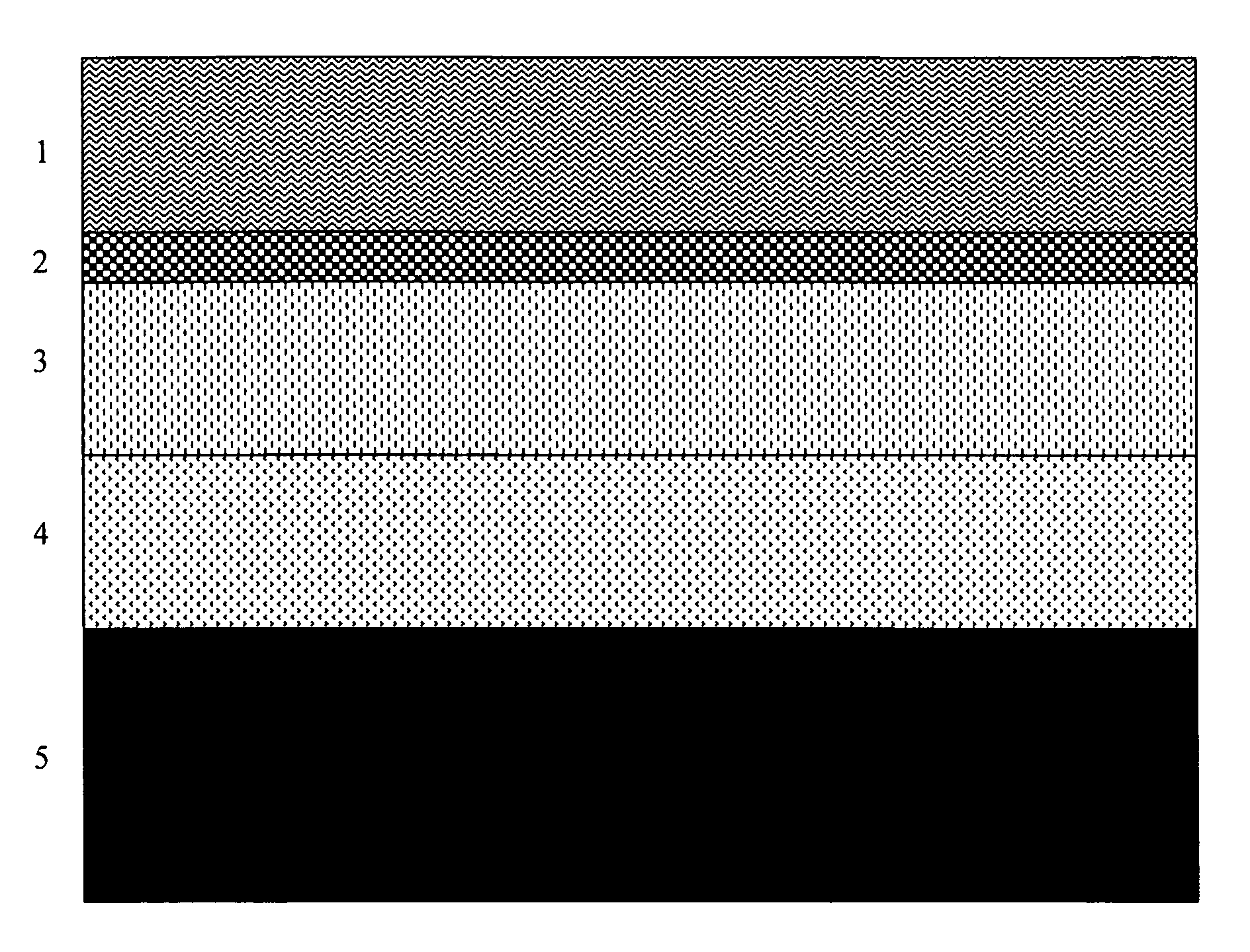

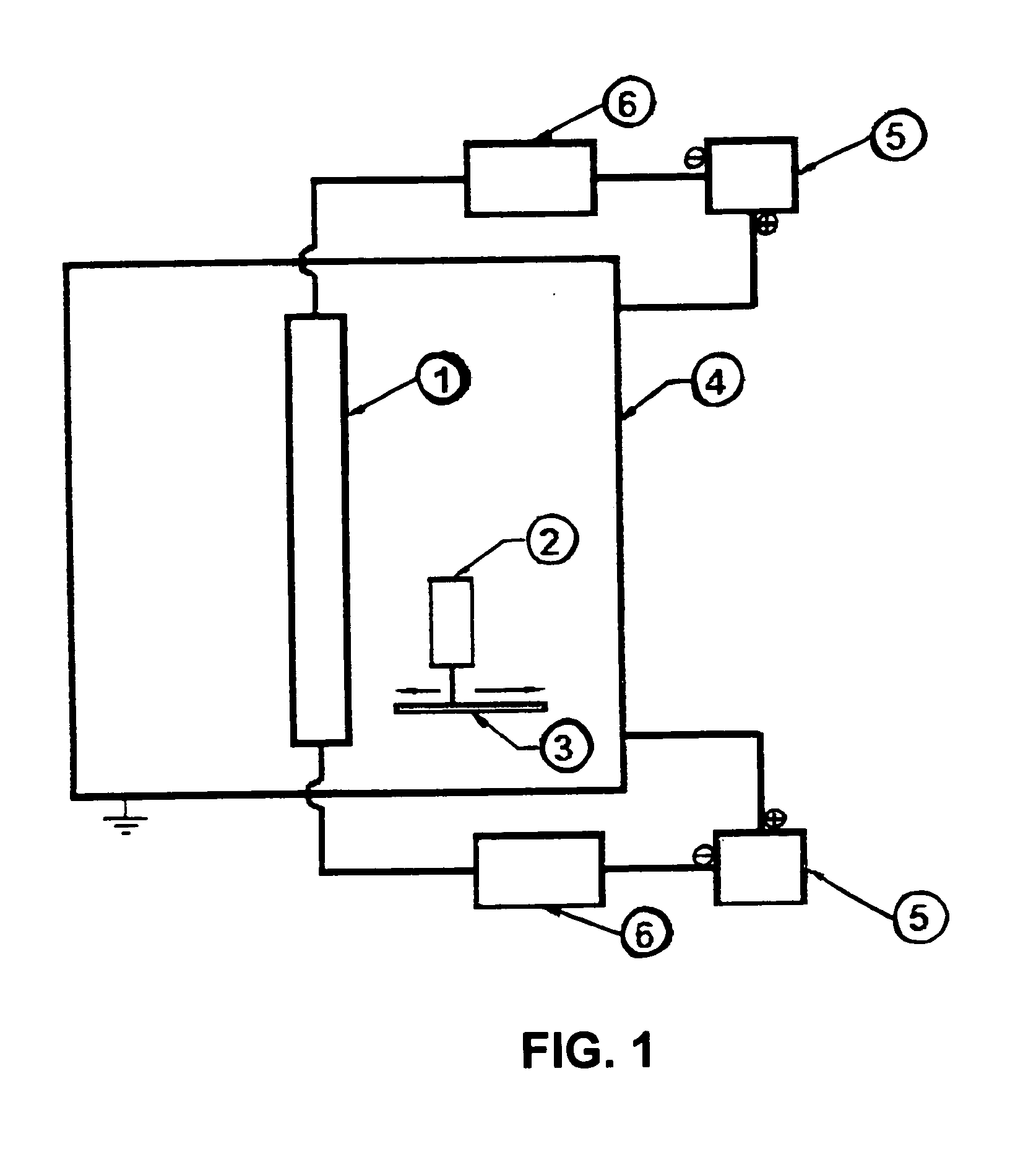

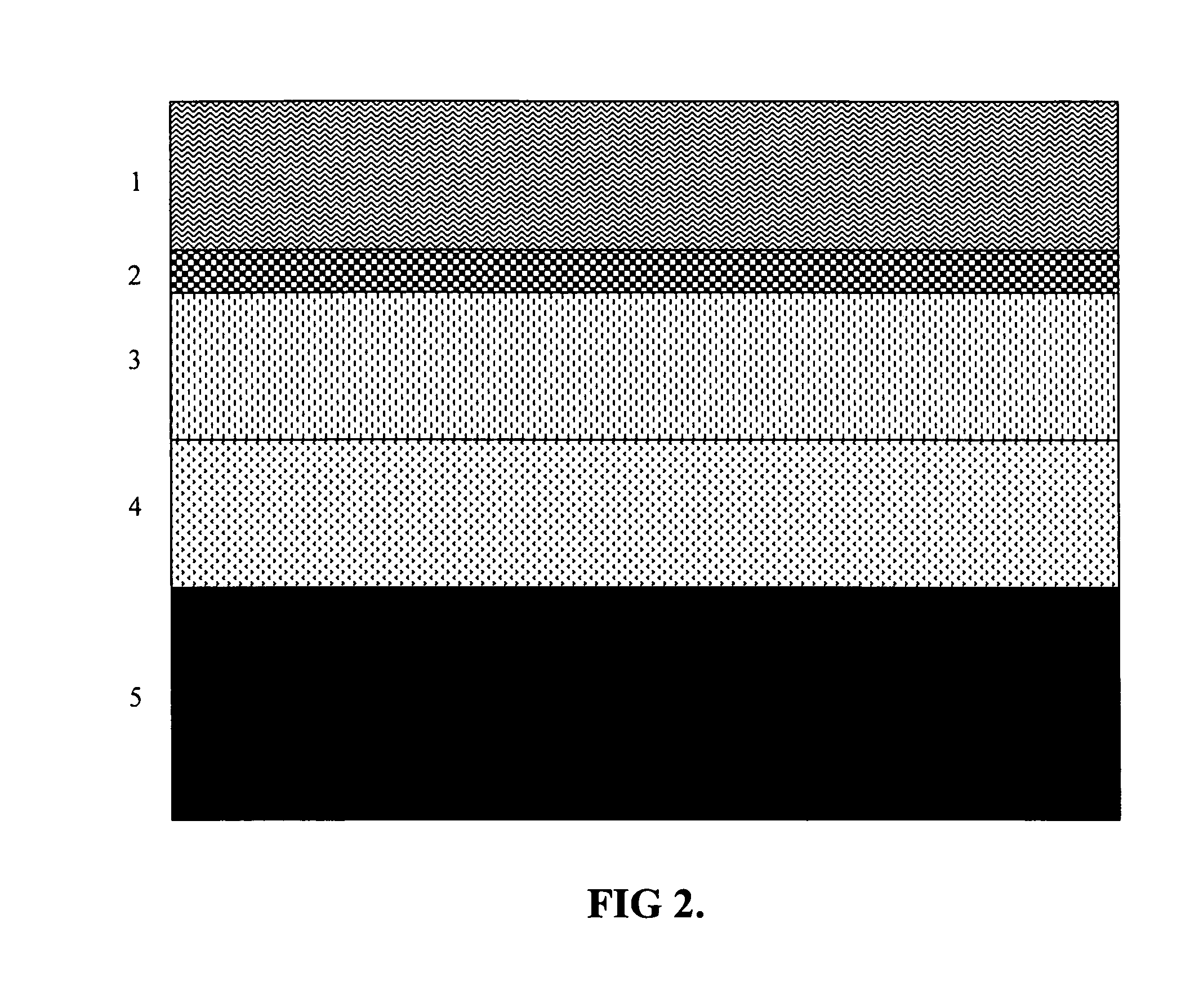

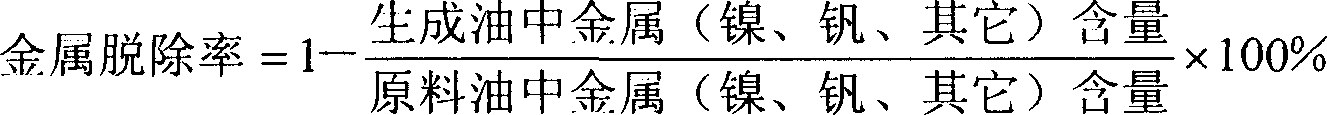

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN1782033AImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateHydrogen

The slag oil hydrogen de-metallizing catalyst contains a kind of macroporous alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The alumina carrier has medium pore size of 25-35 nm, pore volume of 1.2-2.0 ml / g, and specific surface area 200-350 sq m / g, and is prepared through mixing ammonium aluminum carbonate and one kind of nitrogen containing compounds except acid, forming and roasting. Compared with available slag oil hydrogen de-metallizing catalysts, the catalyst of the present invention has high hydrogen de-metallizing performance and simple preparation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

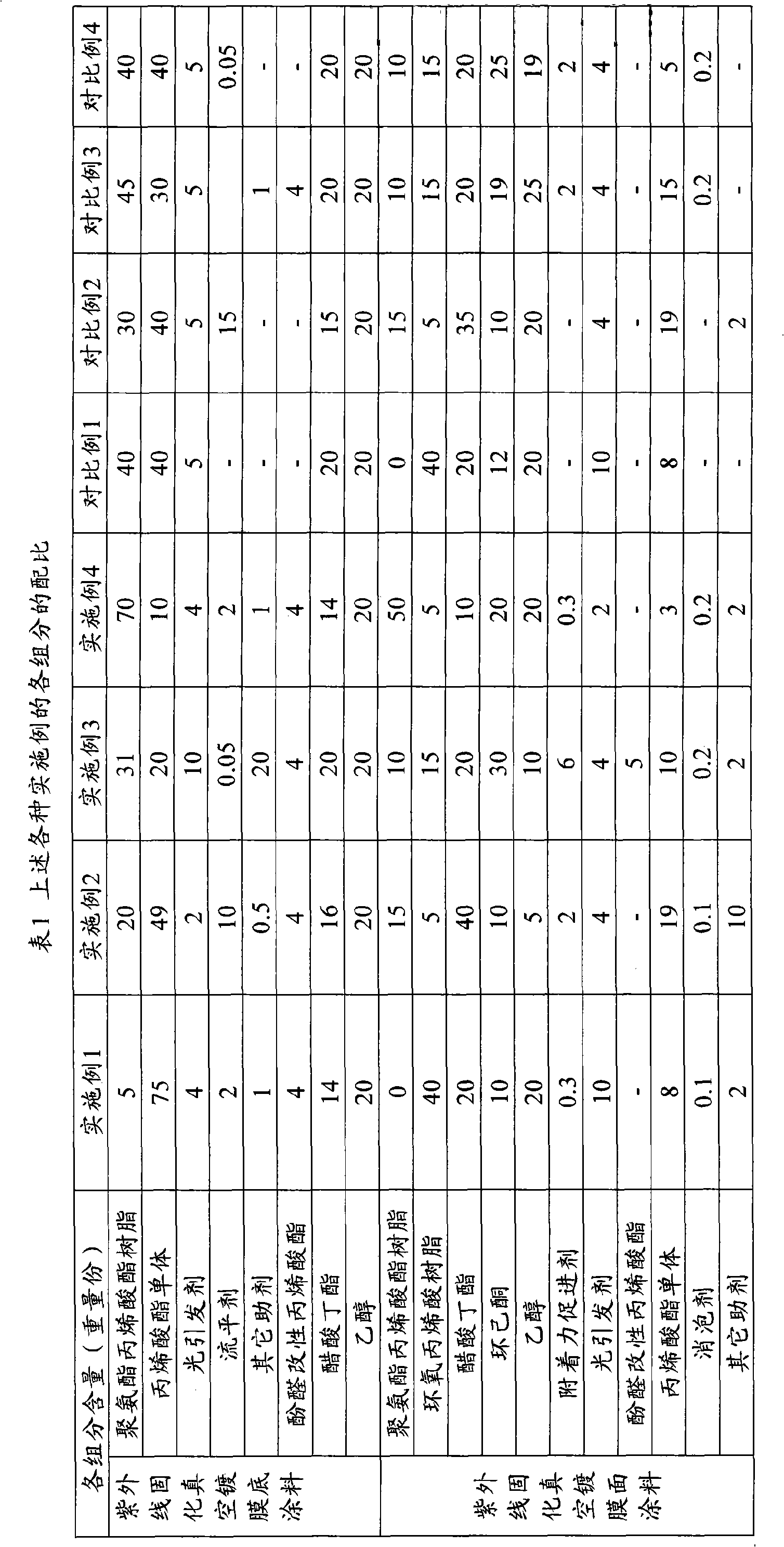

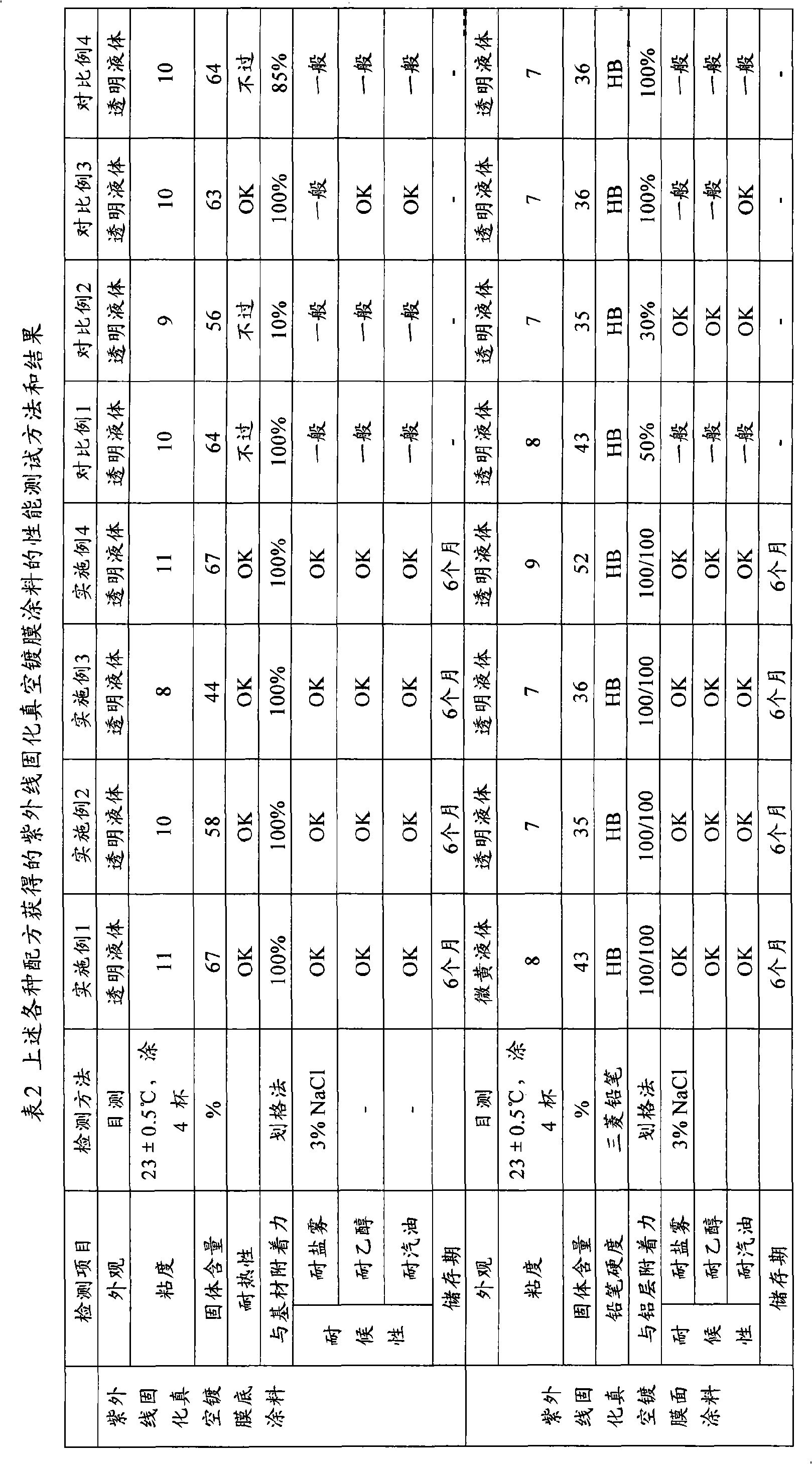

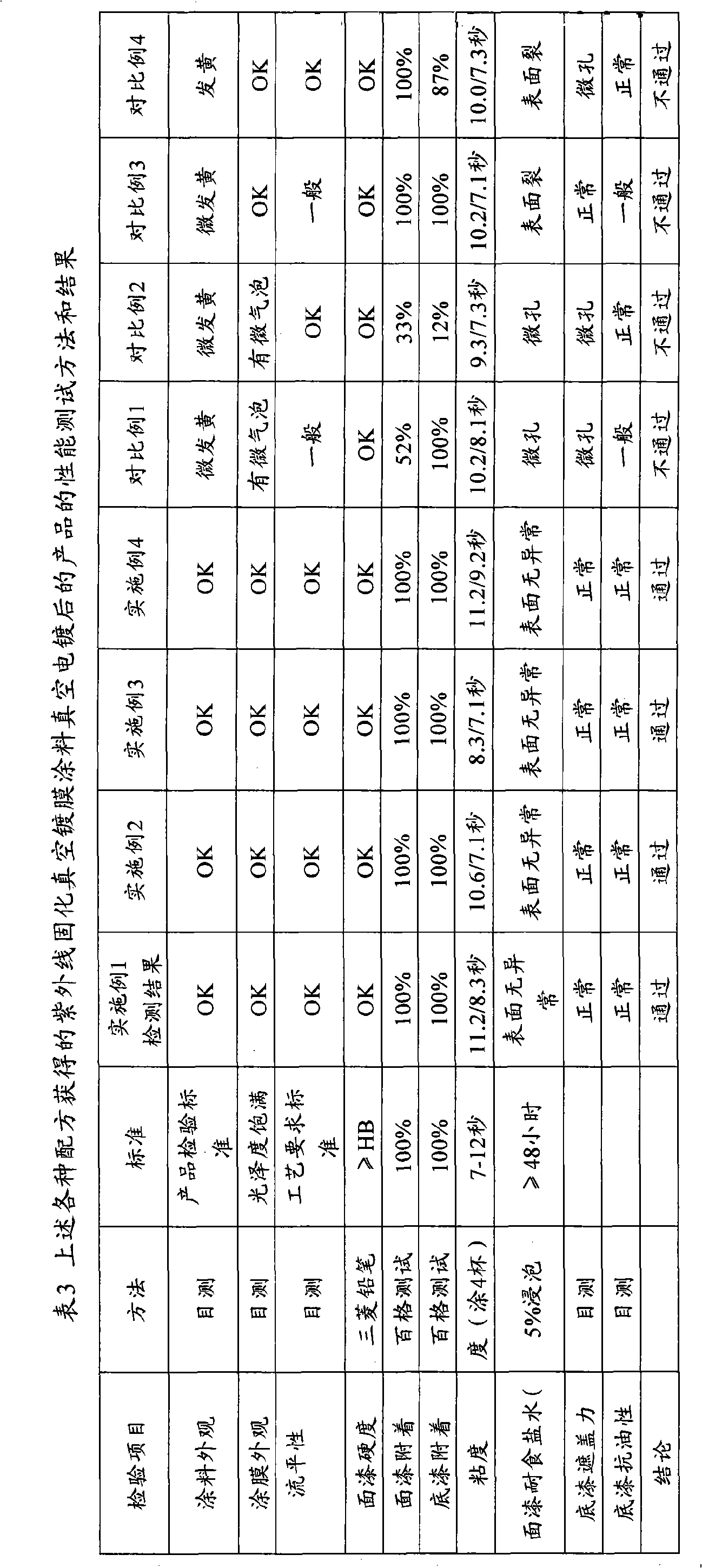

Ultraviolet curing vacuum metallizing coating

InactiveCN101280154AOptimize diluent monomerImprove adhesionVacuum evaporation coatingSputtering coatingCyclohexanoneAcrylic resin

The invention provides ultraviolet curing vacuum plating coating which includes ultraviolet curing vacuum plating primer and ultraviolet curing vacuum plating surface coating; the ultraviolet curing vacuum plating primer part by weight comprises 5-70 portions of urethane acrylate resin, 10-80 portions of acrylate monomer, 2-10 portions of light initiator, 0.05-10 portions of leveling agent, 0.5-20 portions of other auxiliary agents; the ultraviolet curing vacuum plating surface coating part by weight comprises 0.5-50 portions of urethane acrylate resin, 5-40 portions of epoxy acrylic resin, 20-40 portions of butyl acetate, 10-30 portions of cyclohexanone, 5-20 portions of ethanol, 0.3-6 portions of adhesion promoter and 0.5-15 portions of light initiator. The ultraviolet curing vacuum plating coating in the invention has the advantages of high heat resistance, good adhesive force and good weatherability.

Owner:SHANGHAI HIUV NEW MATERIALS

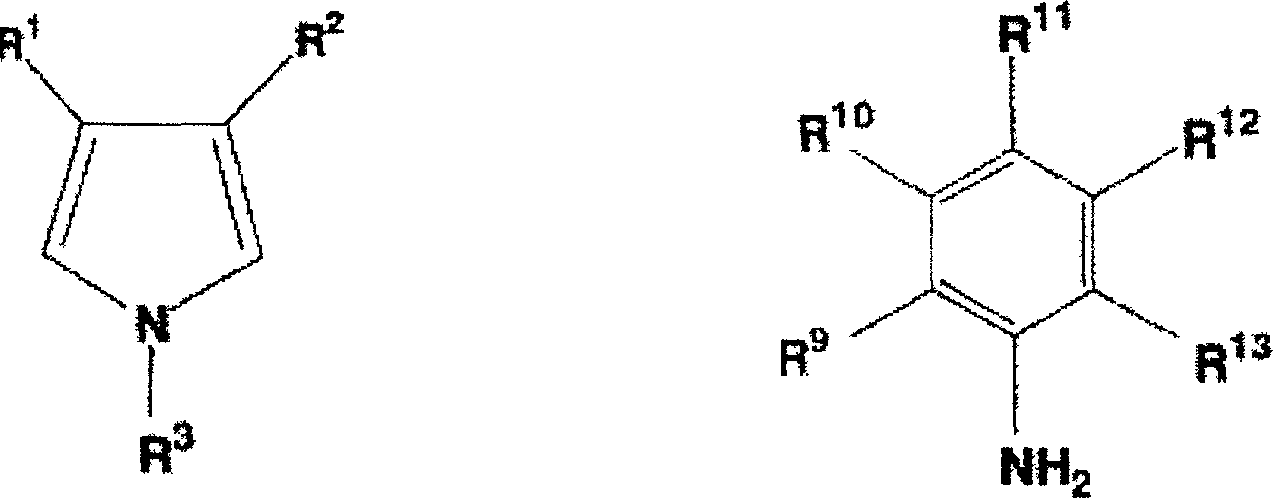

Pretreatment and pretreatment solution for direct porous metallizing printing IC board

ActiveCN101029409AParticle size controllableImprove stabilityPrinted element electric connection formationCopper platingConductive polymer

An electroplating pre-treatment liquid and its production are disclosed. The process is carried out by oxidation polymerizing pyrrole with aniline under existence of adulterant, oxidant and surface activator to obtain conductive polymer, separating conductive polymer and re-dispersing in water to obtain the final product. It's simple and cheap, has better stability, and saves noble metals and no environmental pollution.

Owner:溧阳常大技术转移中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com