Patents

Literature

983results about "Labels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Void-containing polyester shrink film

InactiveUS20050119359A1Improve performanceHigh opacitySynthetic resin layered productsLabelsPolyesterVolumetric Mass Density

Disclosed are polyester shrink films comprising a voiding agent dispersed within a continuous polyester phase. The voiding agent comprises at least one first polymer and at least one second polymer, in which the polymer components have selected physical properties such as glass transition temperature, melting point, tensile modulus, surface tension, and melt viscosity. The resulting shrink films have high opacity, a low coefficient of friction, lower density, low shrink force, and good printability. The films are useful for sleeve label and other shrink film applications, and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations. Also disclosed is a process for separating a void-containing polyester from a mixture of polymers.

Owner:SHELBY MARCUS DAVID +2

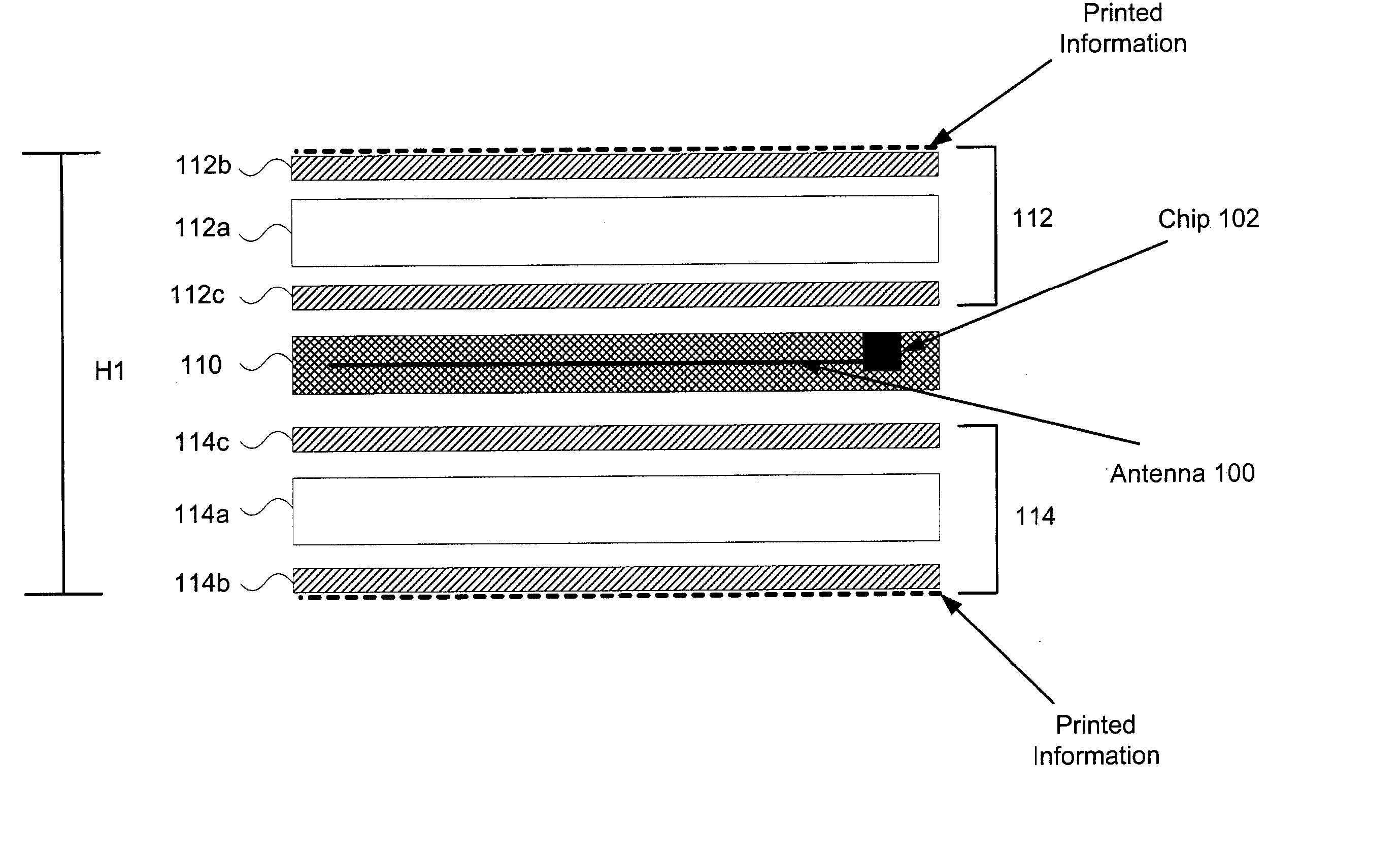

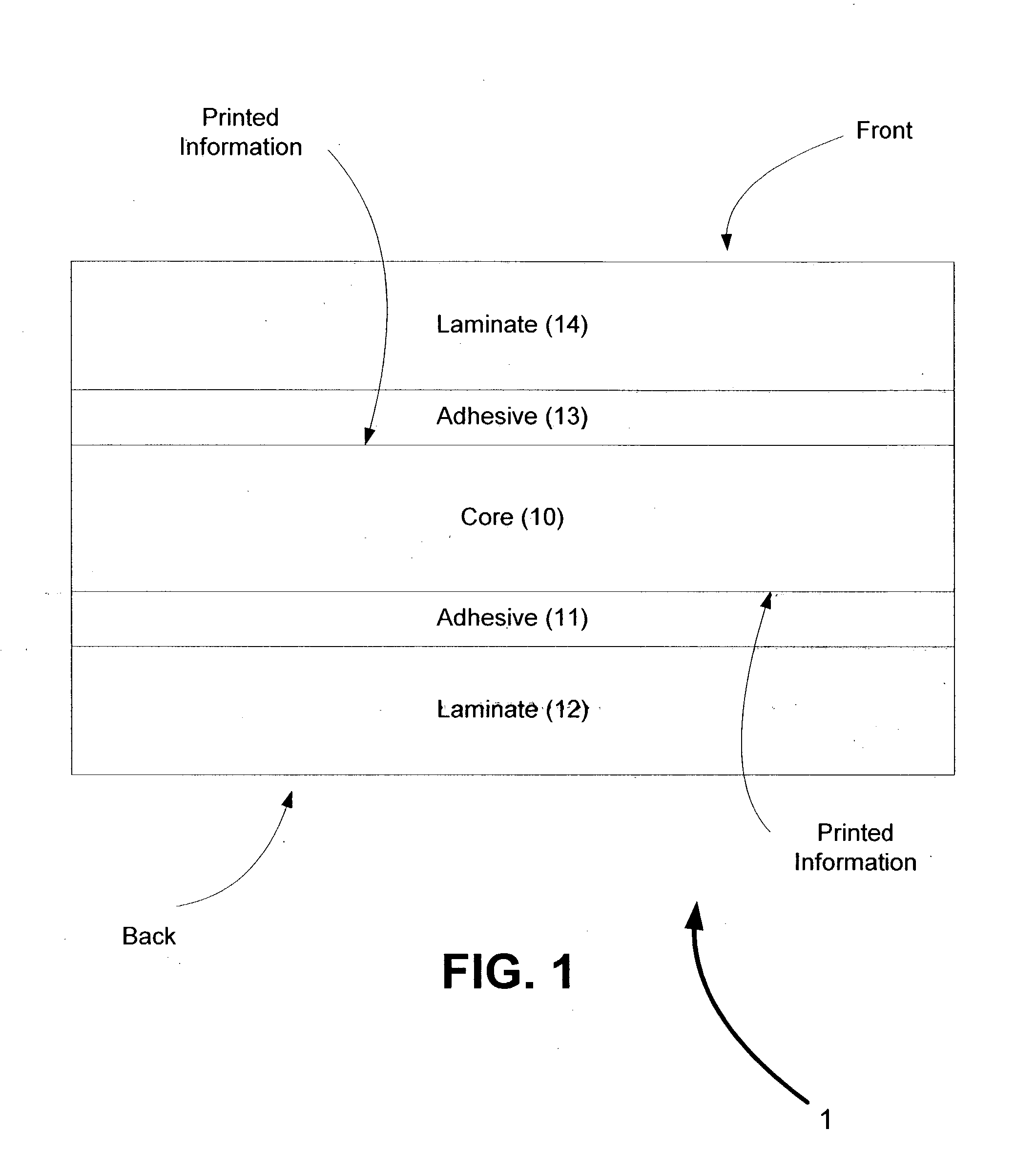

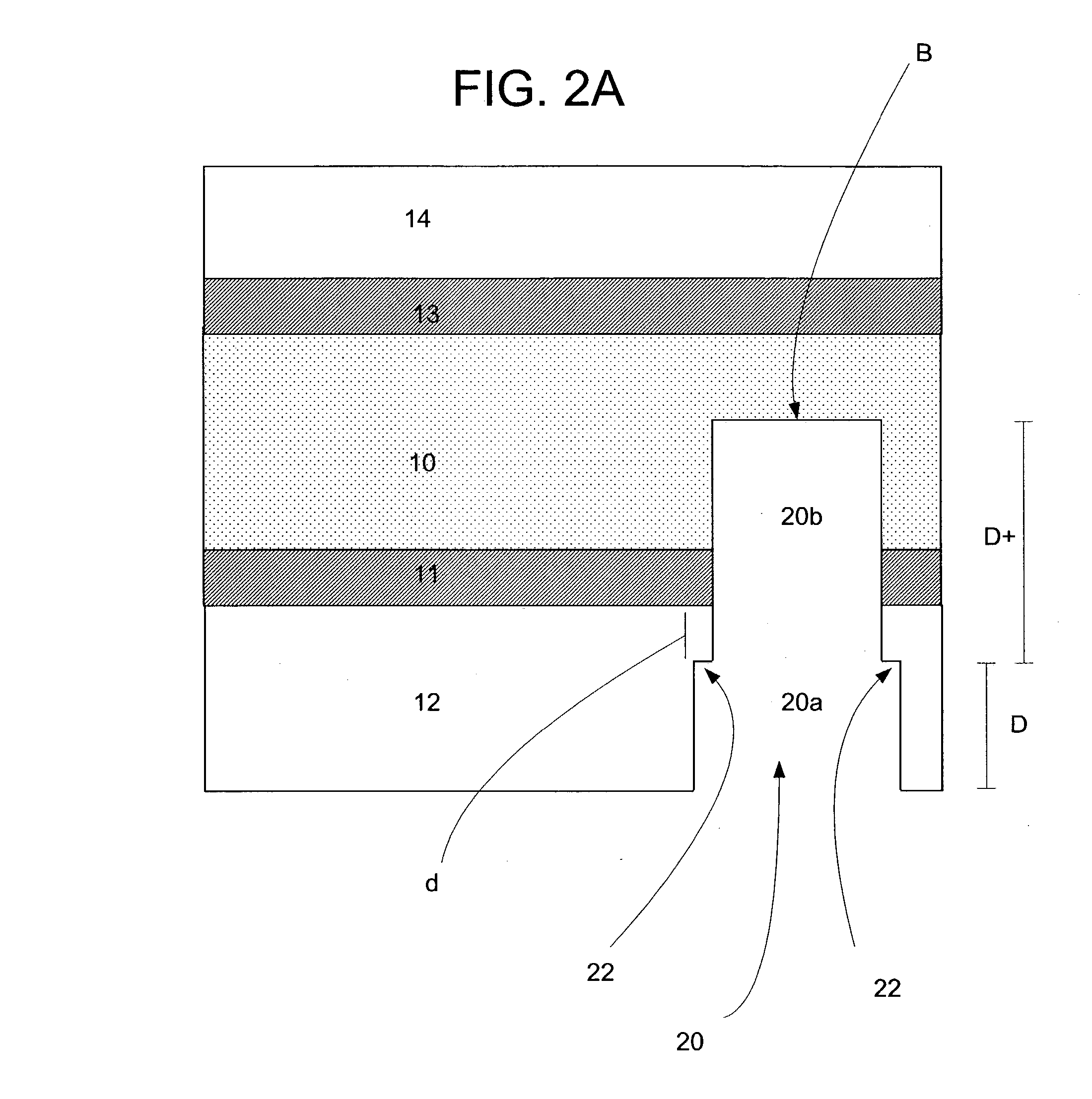

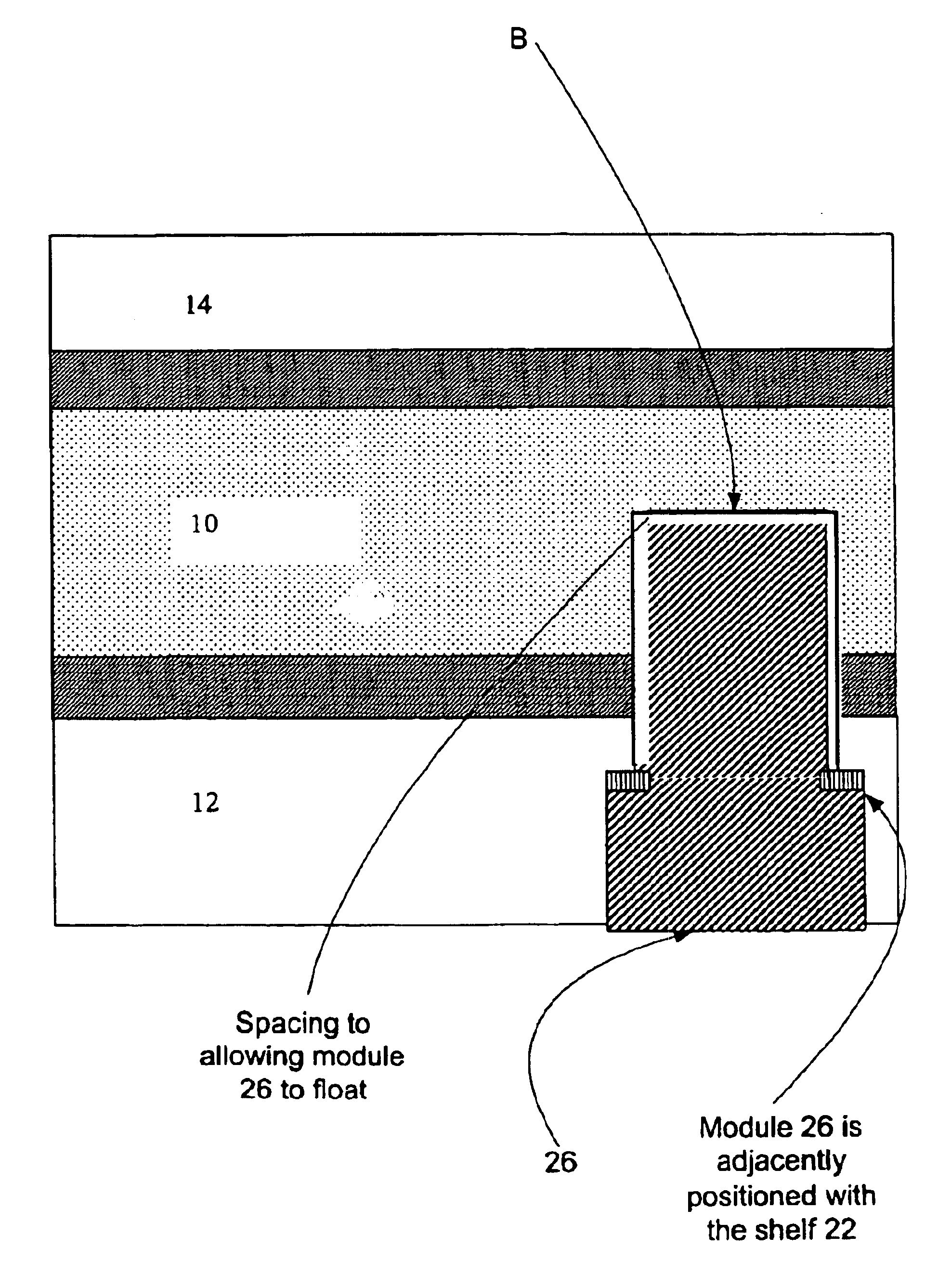

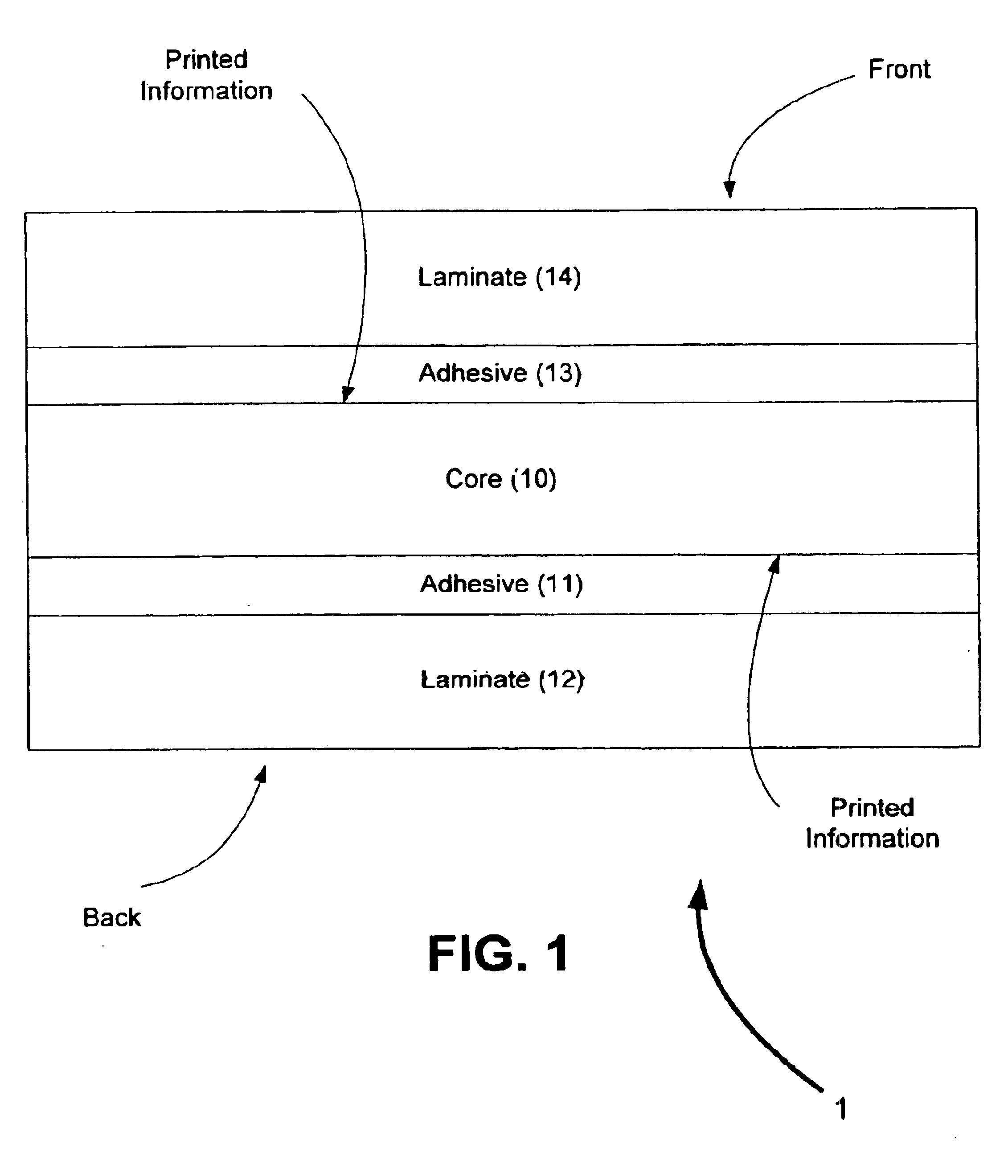

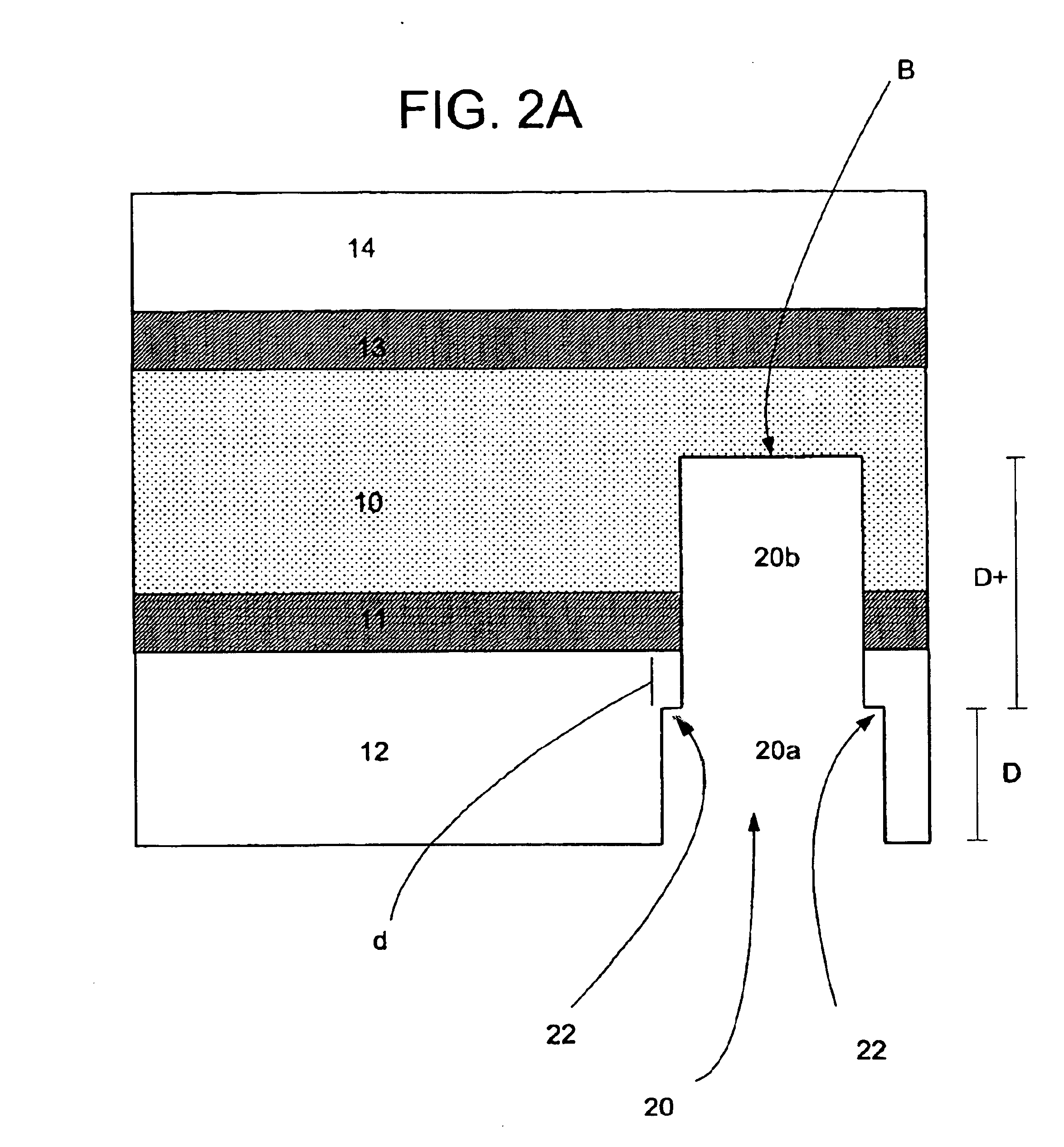

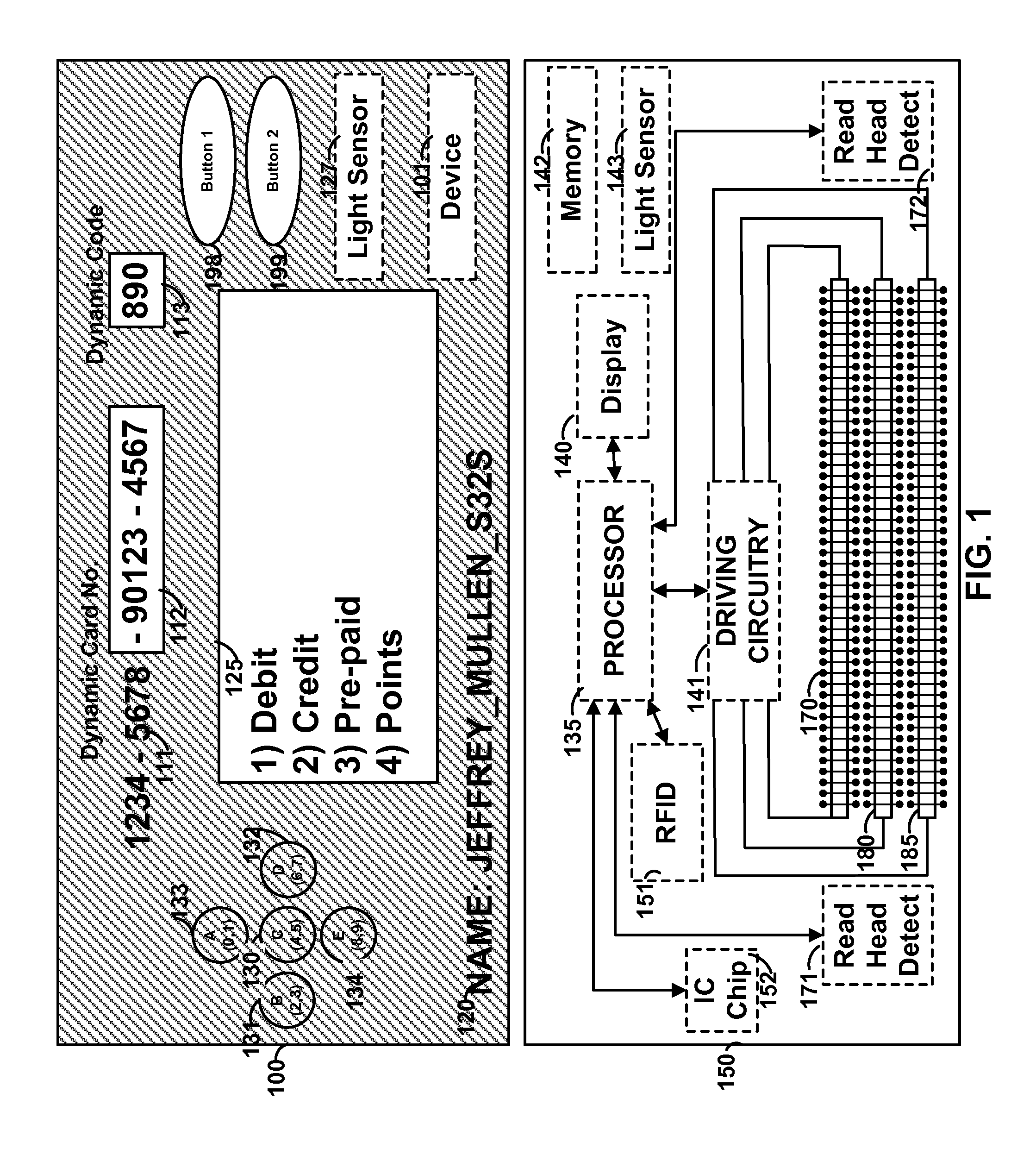

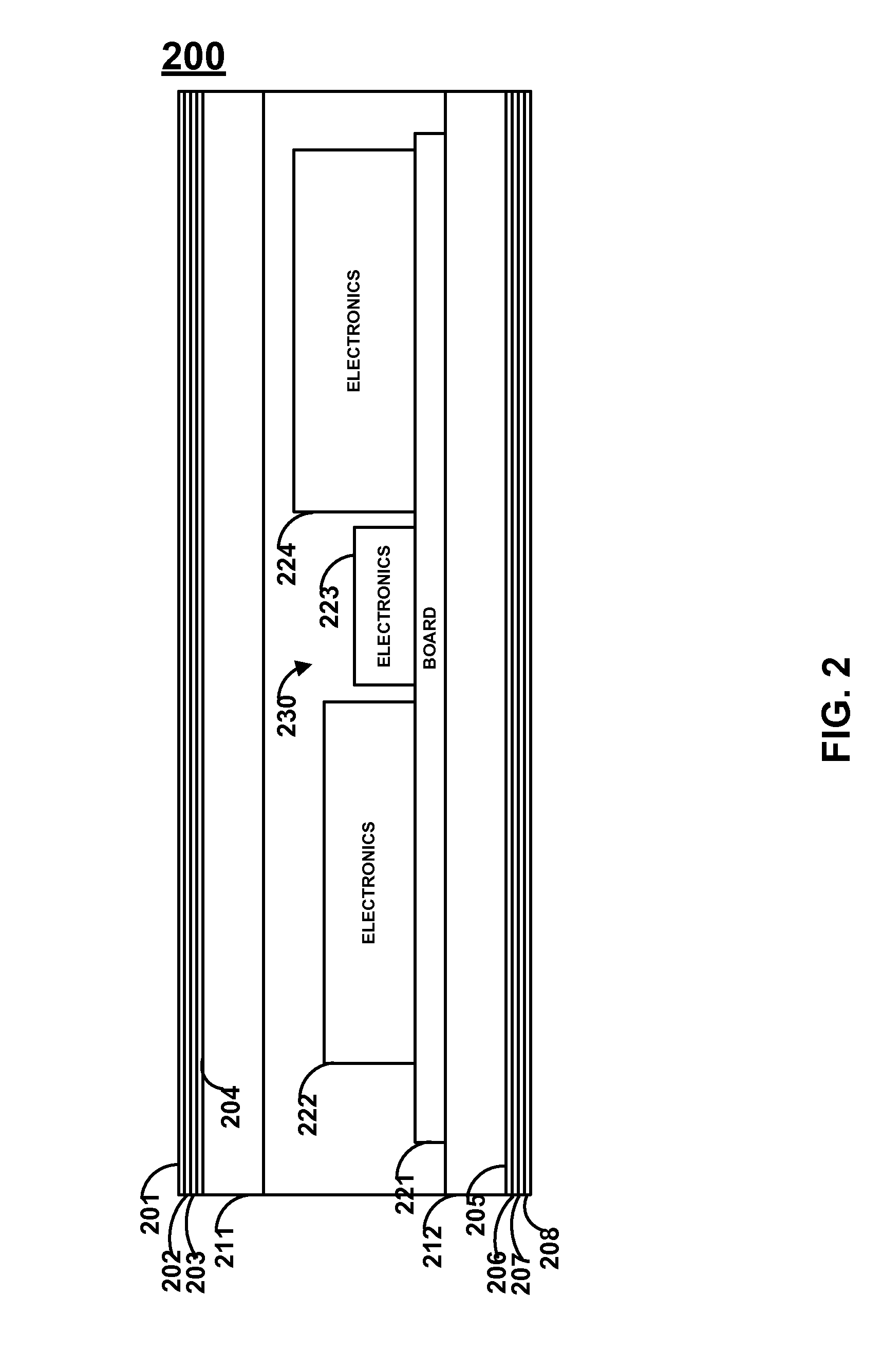

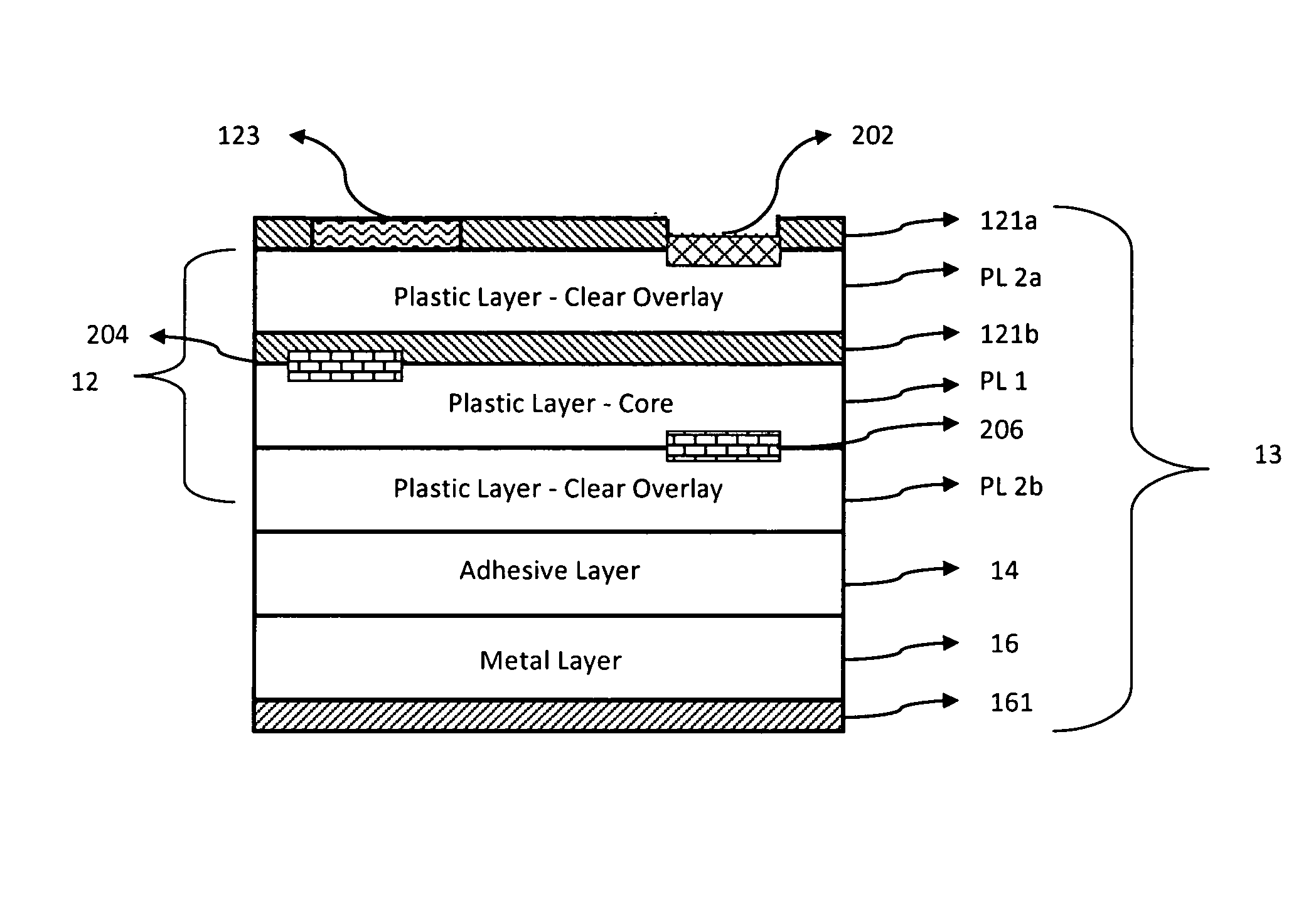

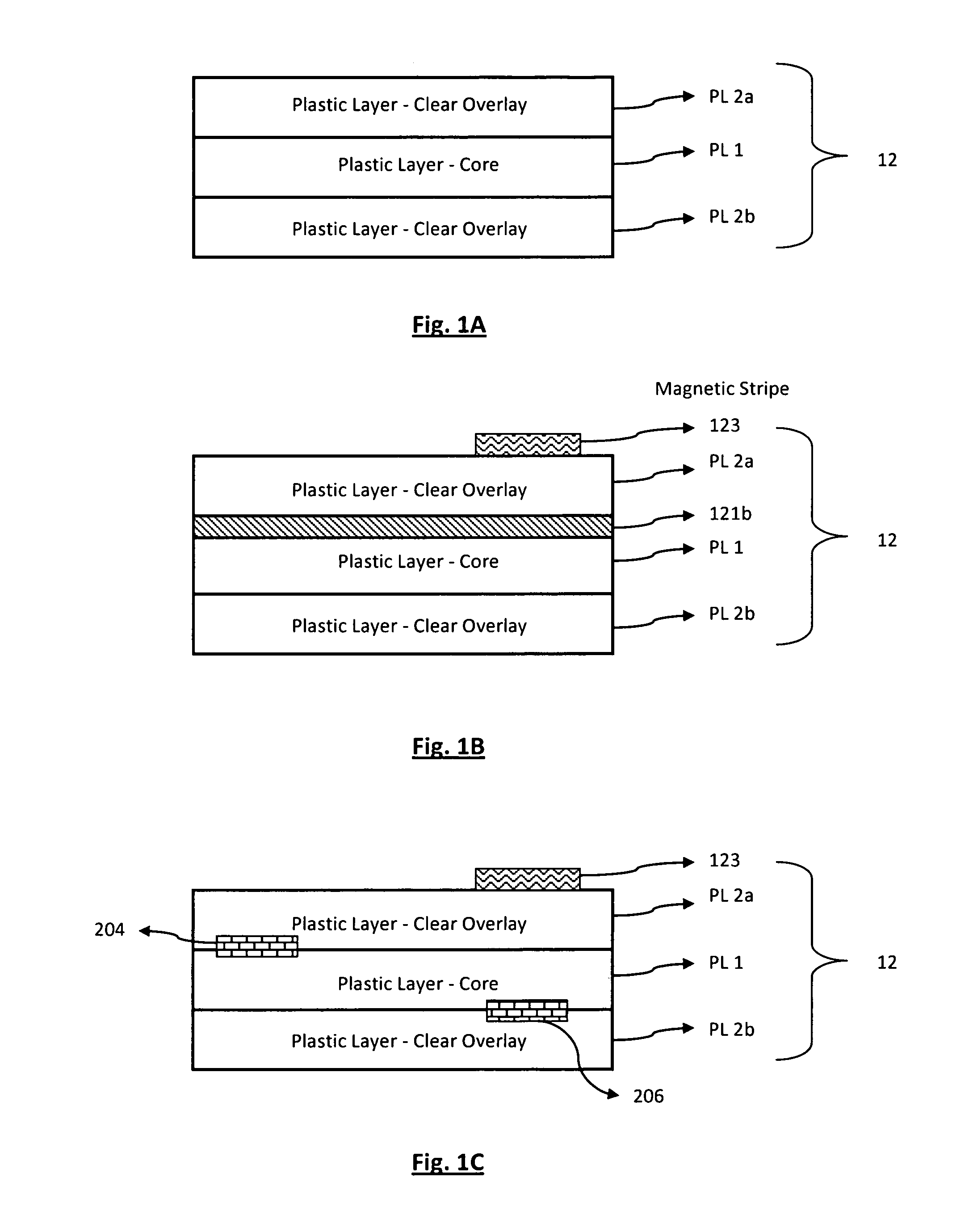

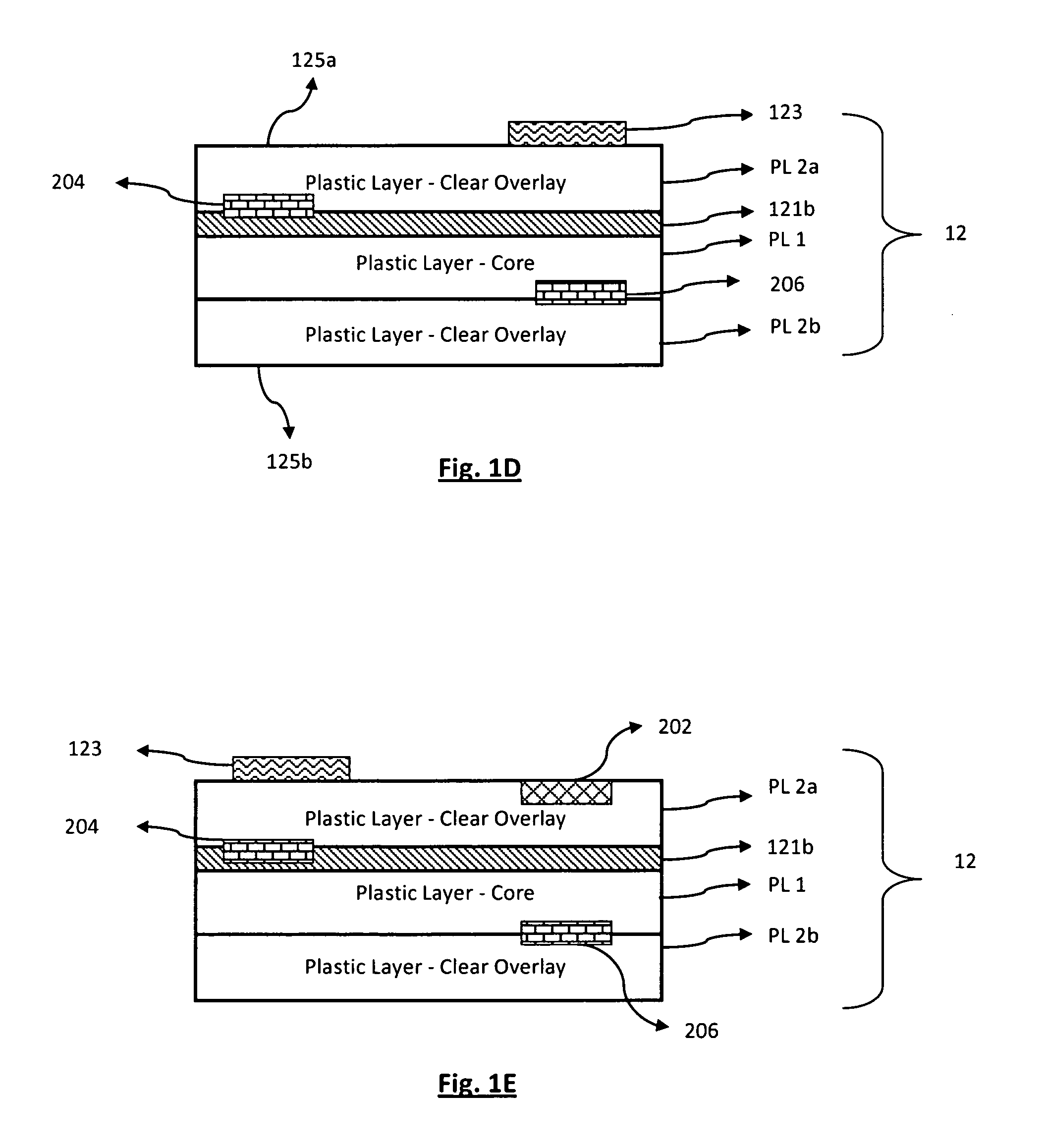

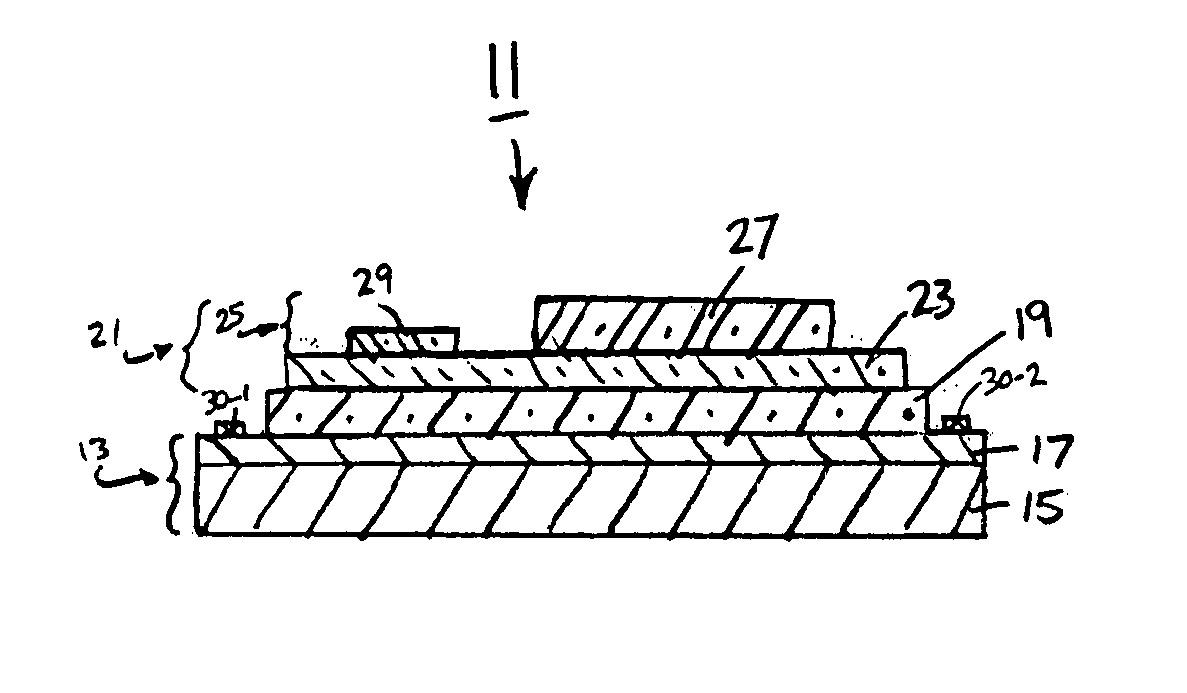

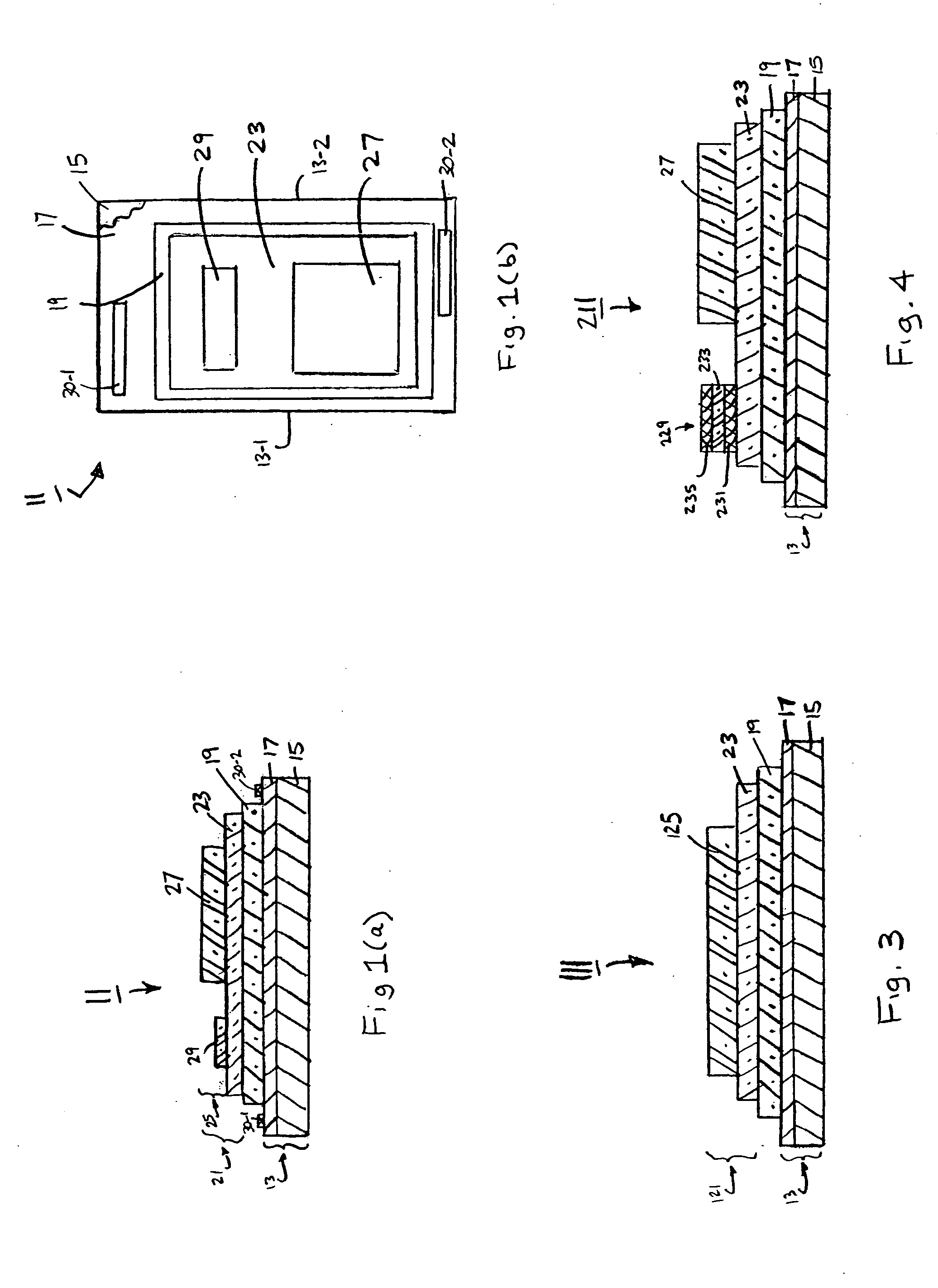

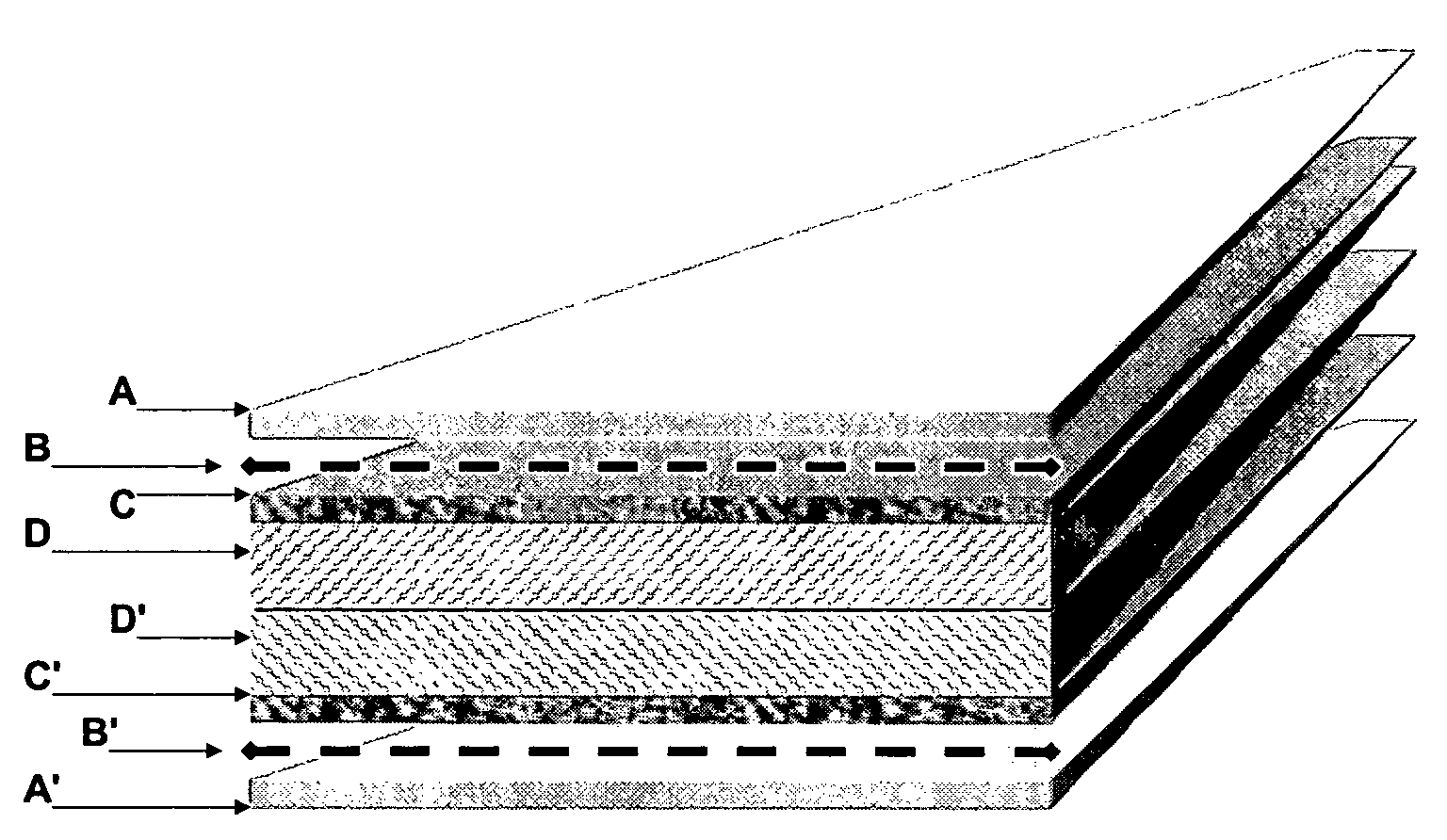

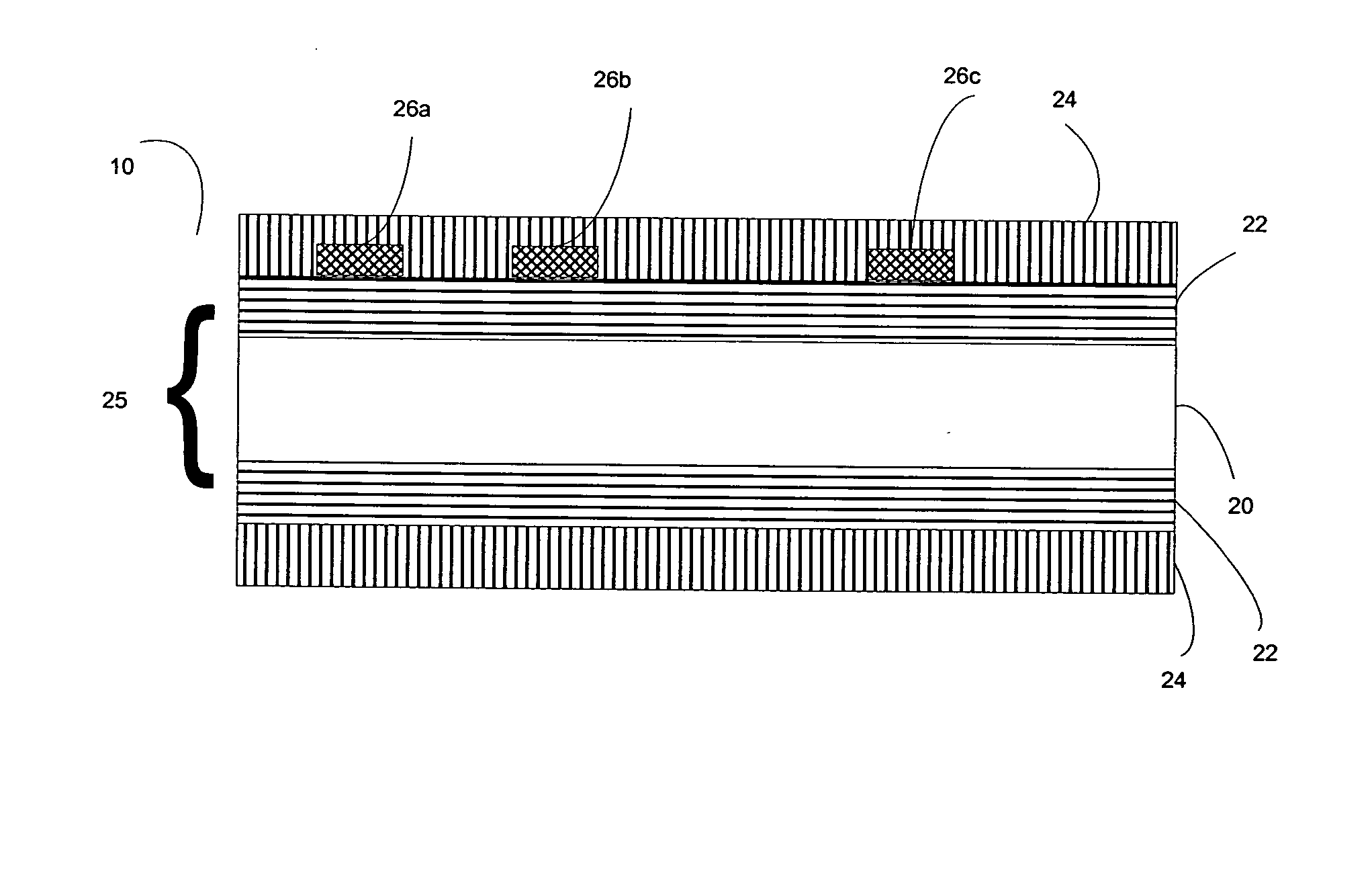

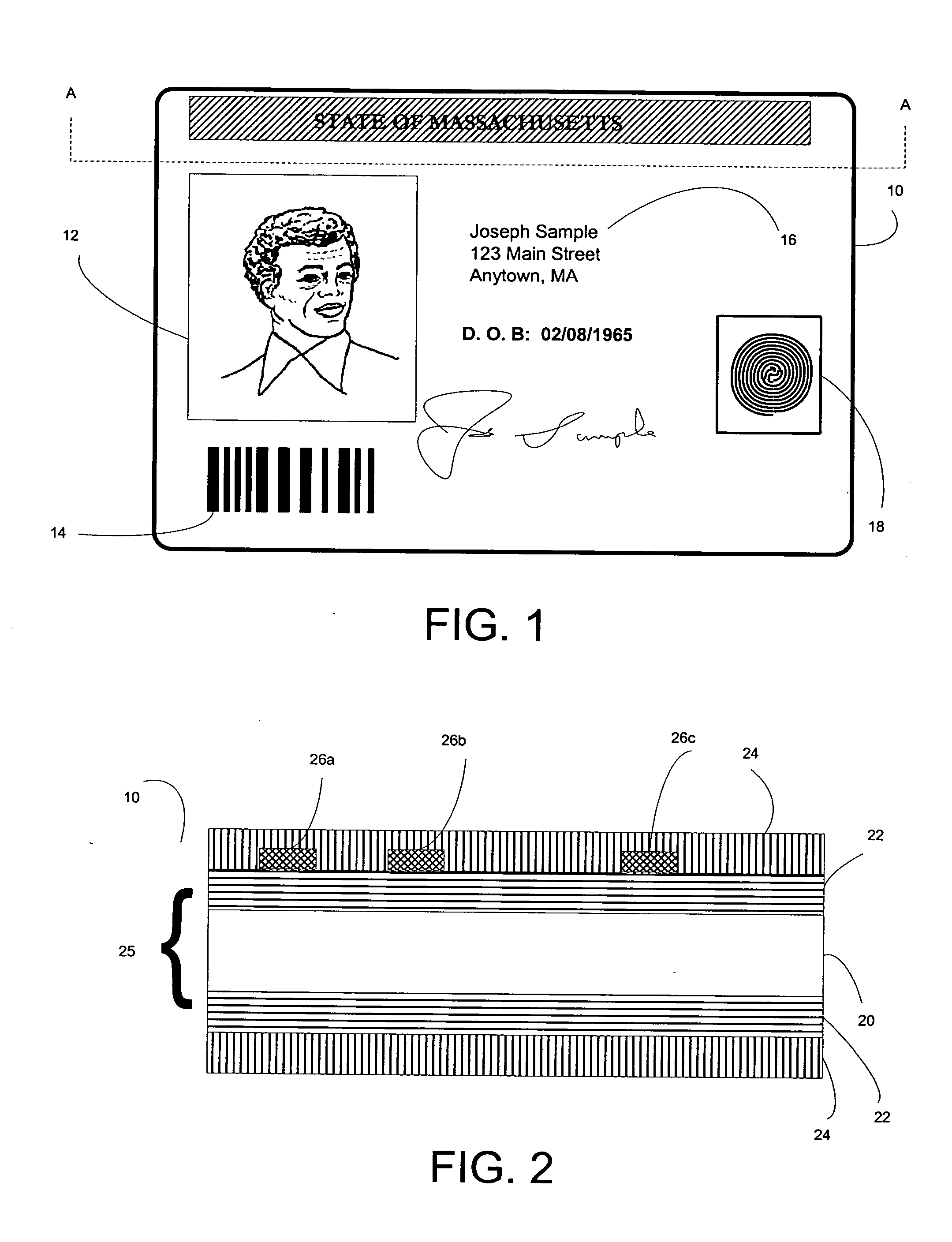

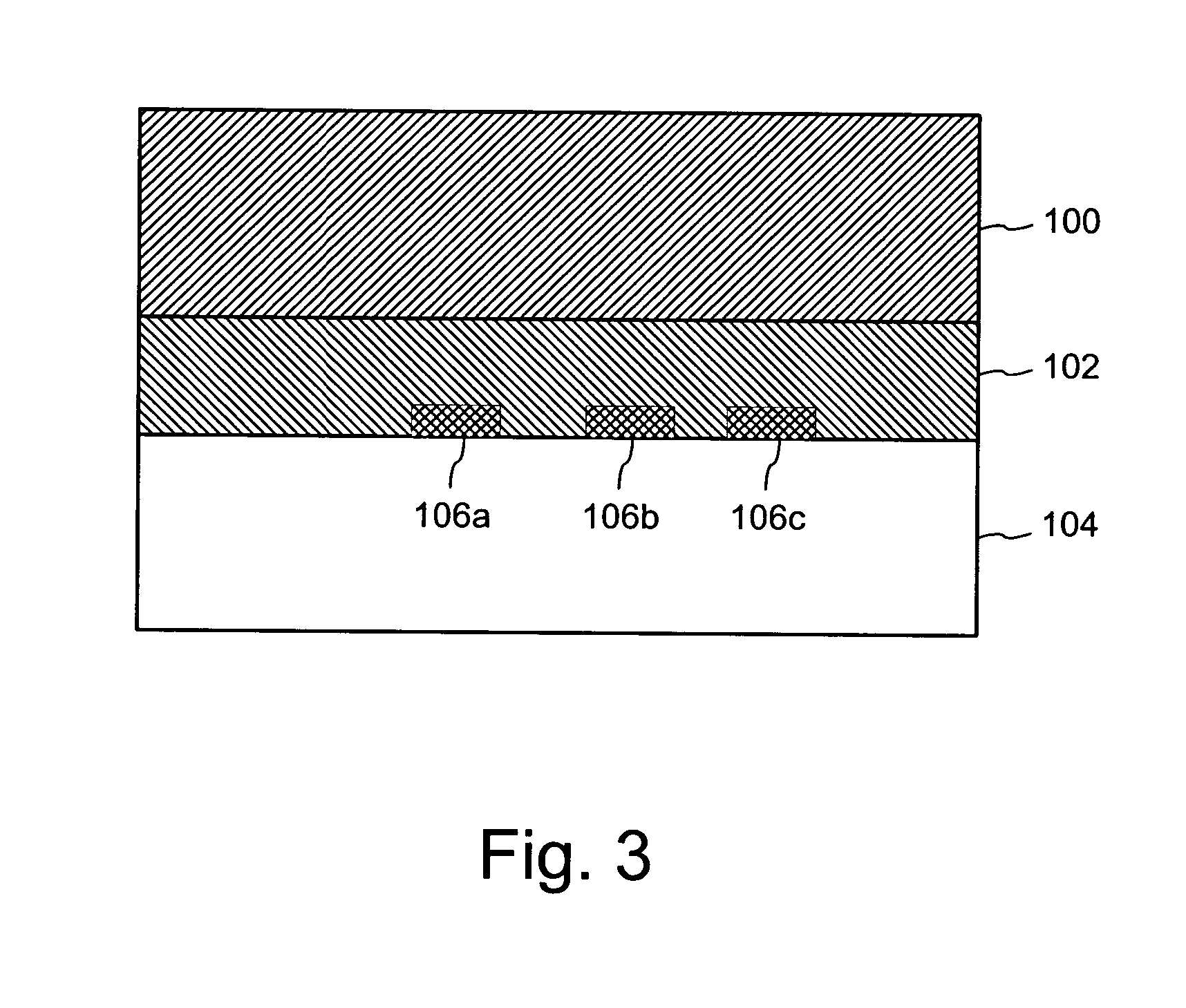

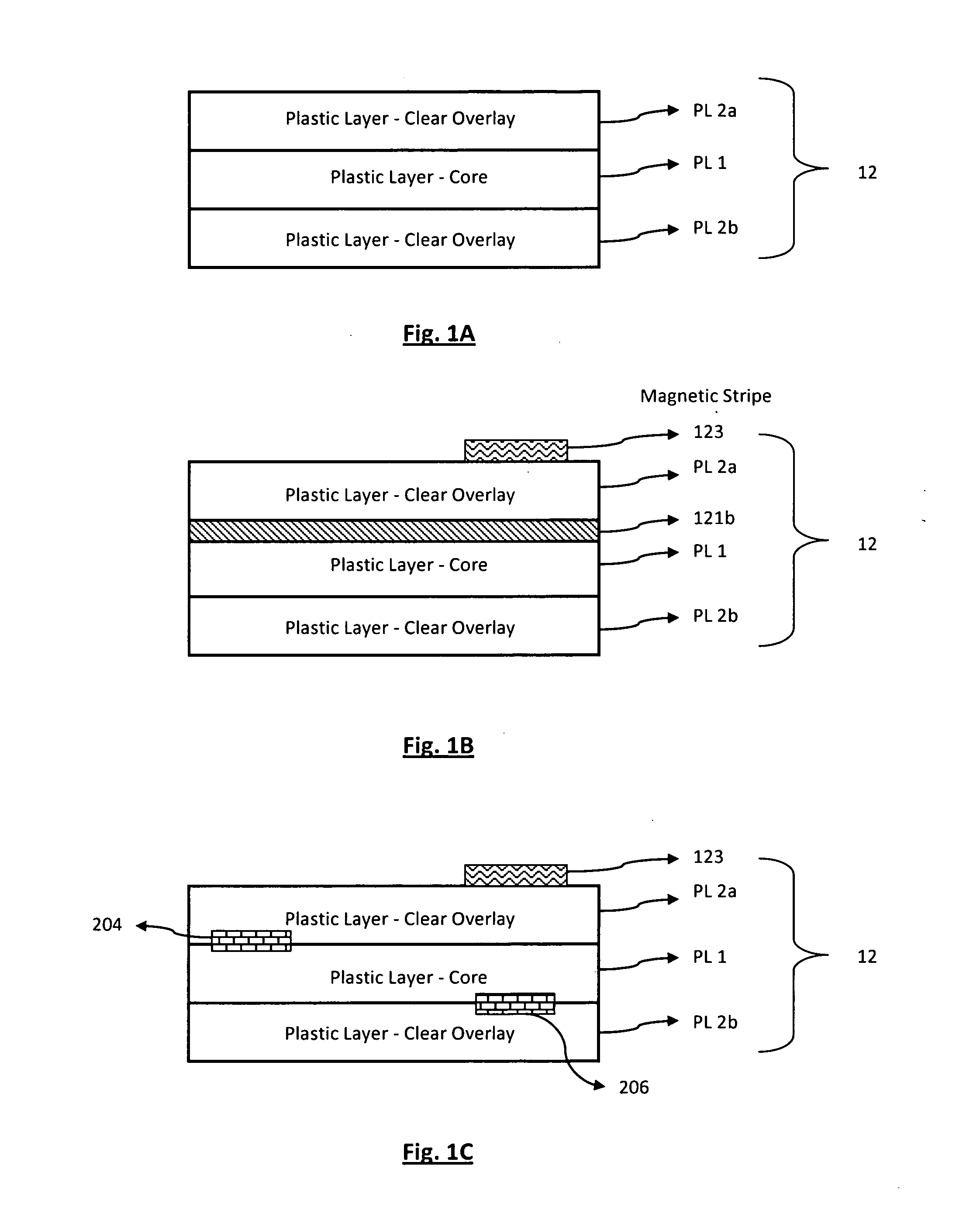

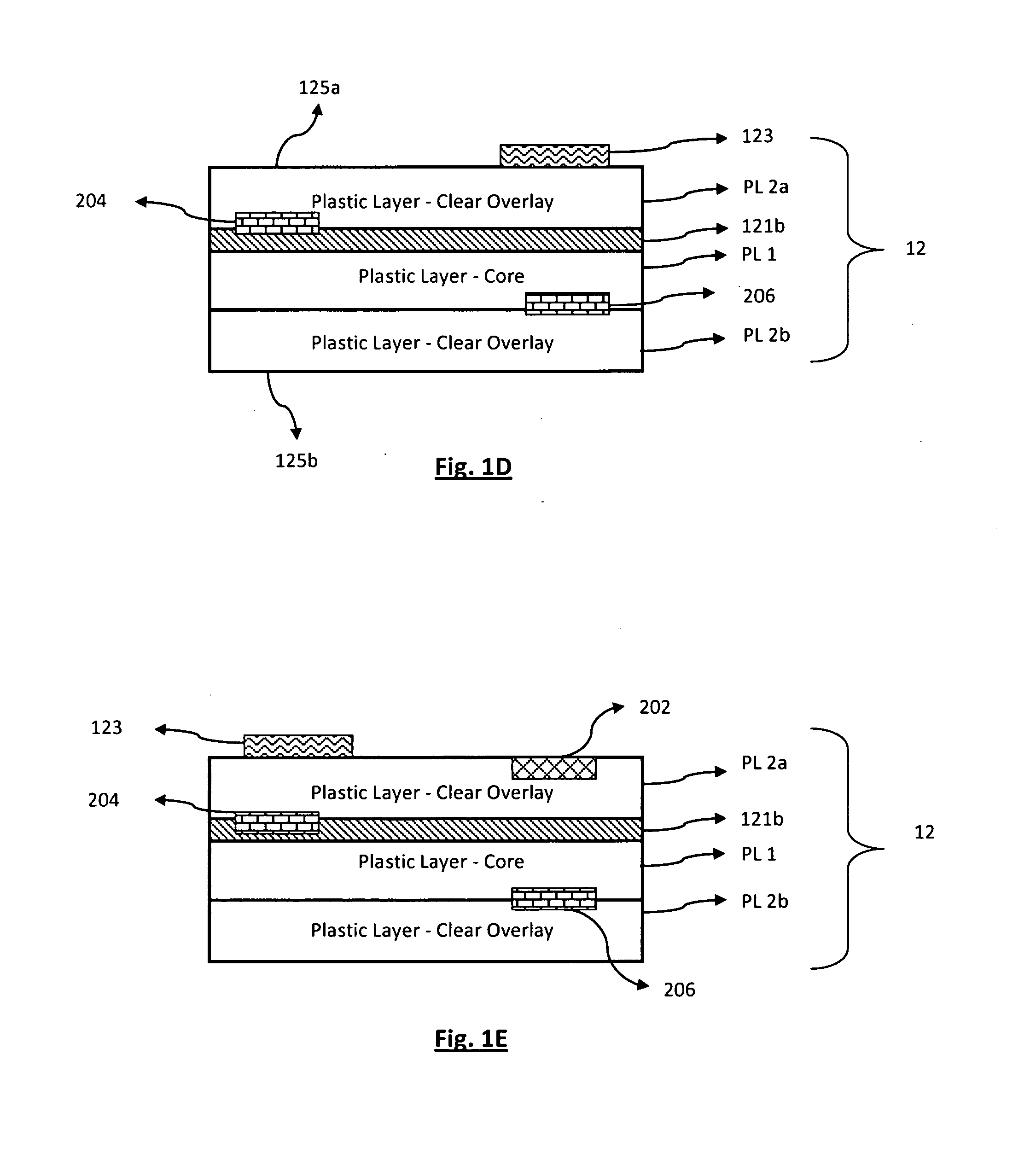

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS20030178495A1Improve security levelReduce chanceLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

Contact smart cards having a document core, contactless smart cards including multi-layered structure, pet-based identification document, and methods of making same

InactiveUS6843422B2Reduce crackingQuality improvementLayered productsMilling cuttersComputer moduleCompanion animal

The present invention relates to identification documents and smart cards. In one implementation, we provide a smart identification document including a document core. The document core is printed and laminated. The laminated core is milled to create a cavity. An integrated circuitry module is provided in the cavity. In one implementation, the cavity includes an upper cavity and a lower cavity. A laminate layer houses the upper cavity while the lower cavity extends into the document core. The upper cavity's aperture exceeds the aperture of the lower cavity resulting in a ledge in the laminate layer. A portion of the module may rest on the ledge, while another portion of the module may extend into the lower cavity. In another implementation, we provide a contactless smart card including a multi-layered structure. The structure includes a carrier layer including the smart card electronics. The carrier can be permeable (like a mesh or scrim) so that additional layers may be laminated into or through the carrier layer. A multi-layer structure provides a enhanced durability and helps protect the smart card electronics. In still another implementation, we provide a PET-based identification document. The PET-based document includes favorable durability and earth-friendly characteristics.

Owner:L 1 SECURE CREDENTIALING

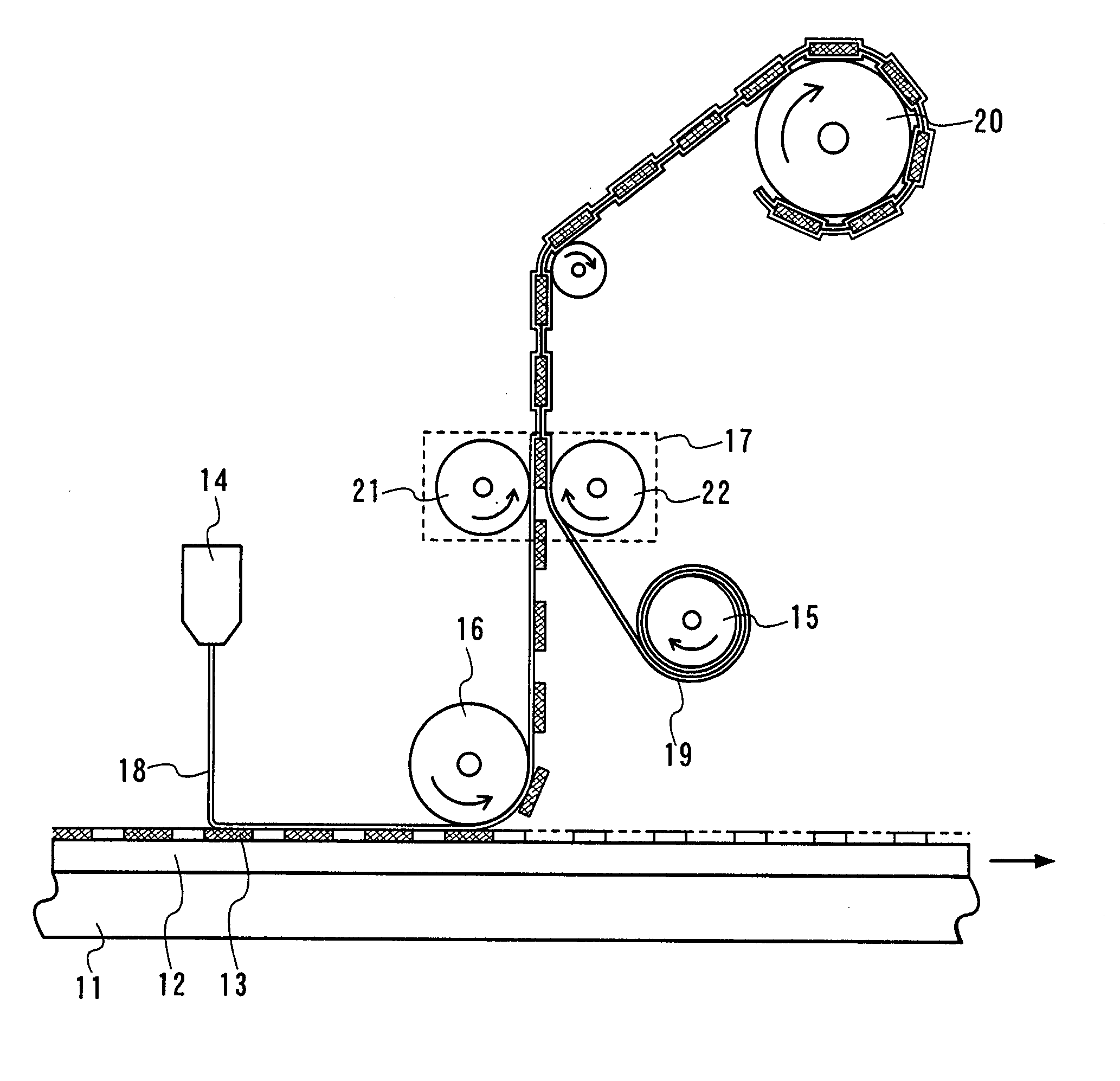

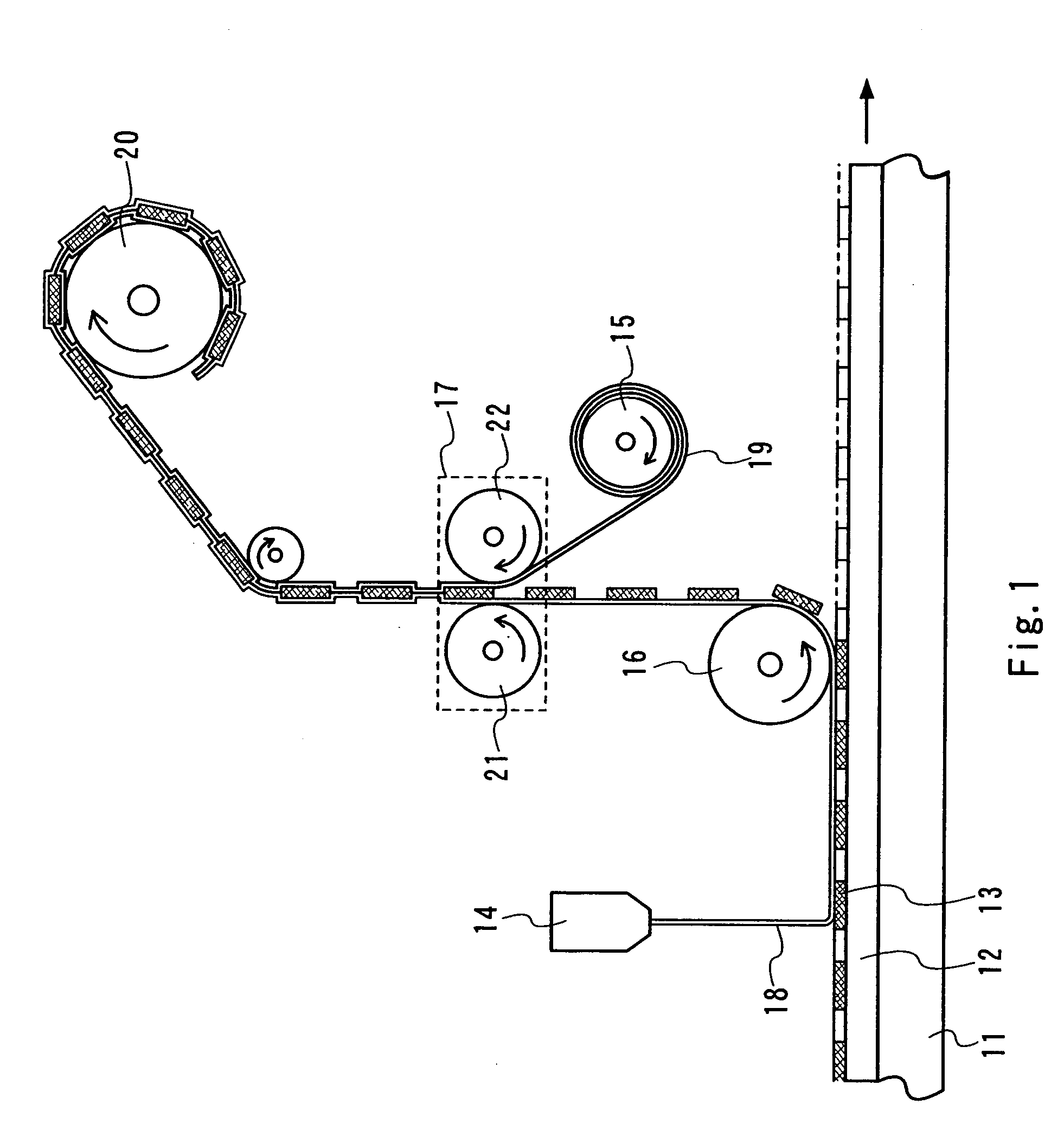

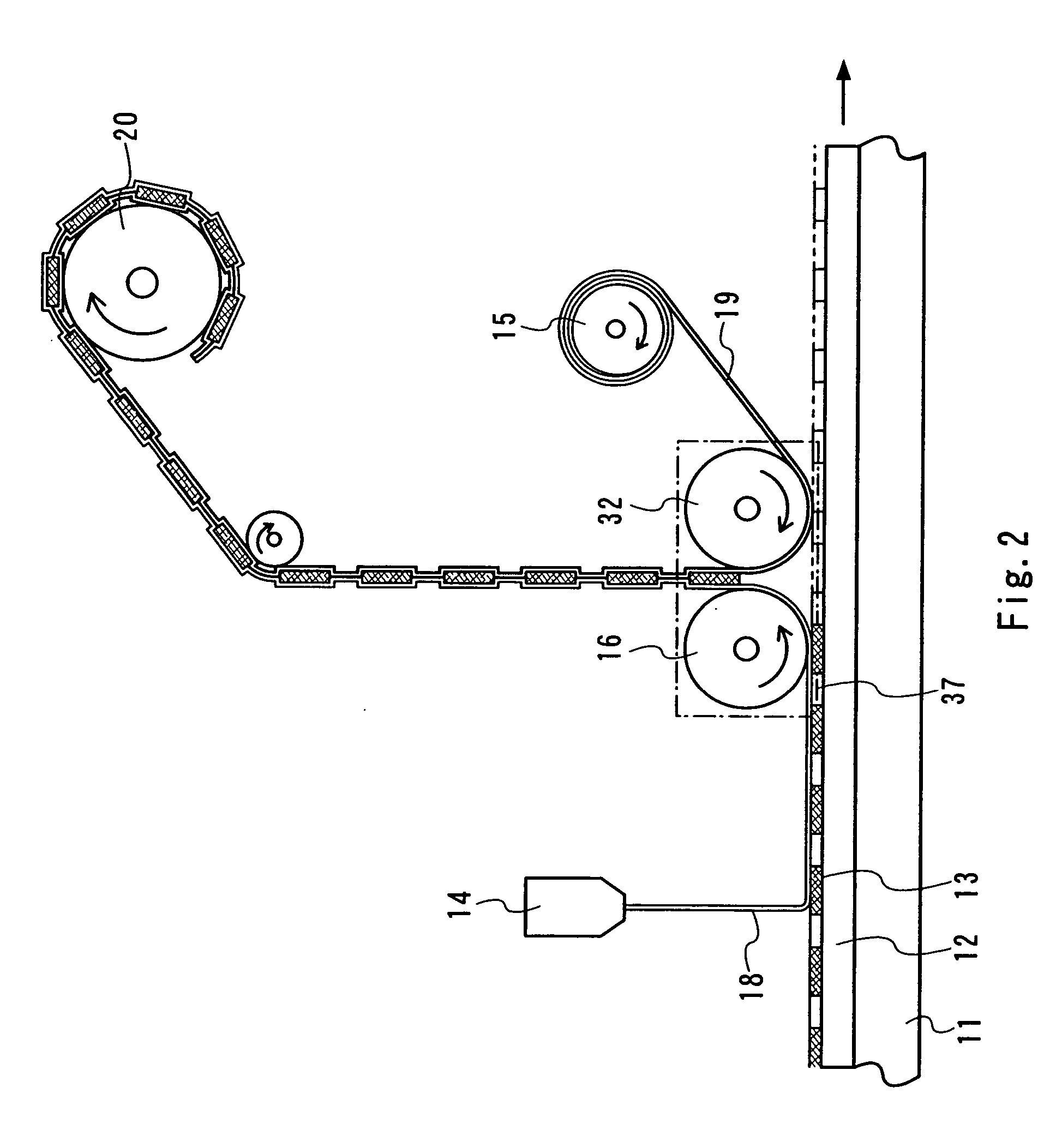

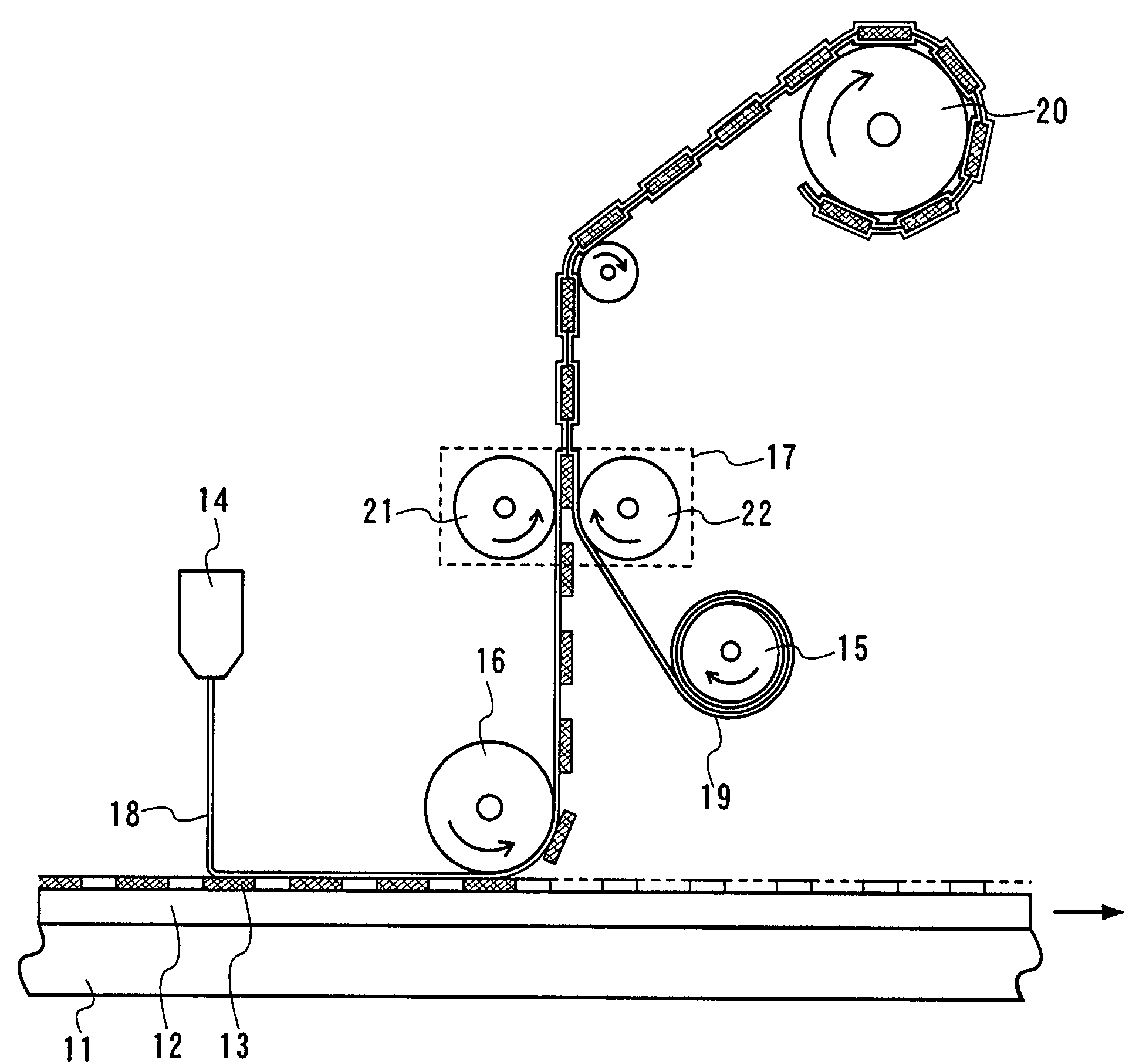

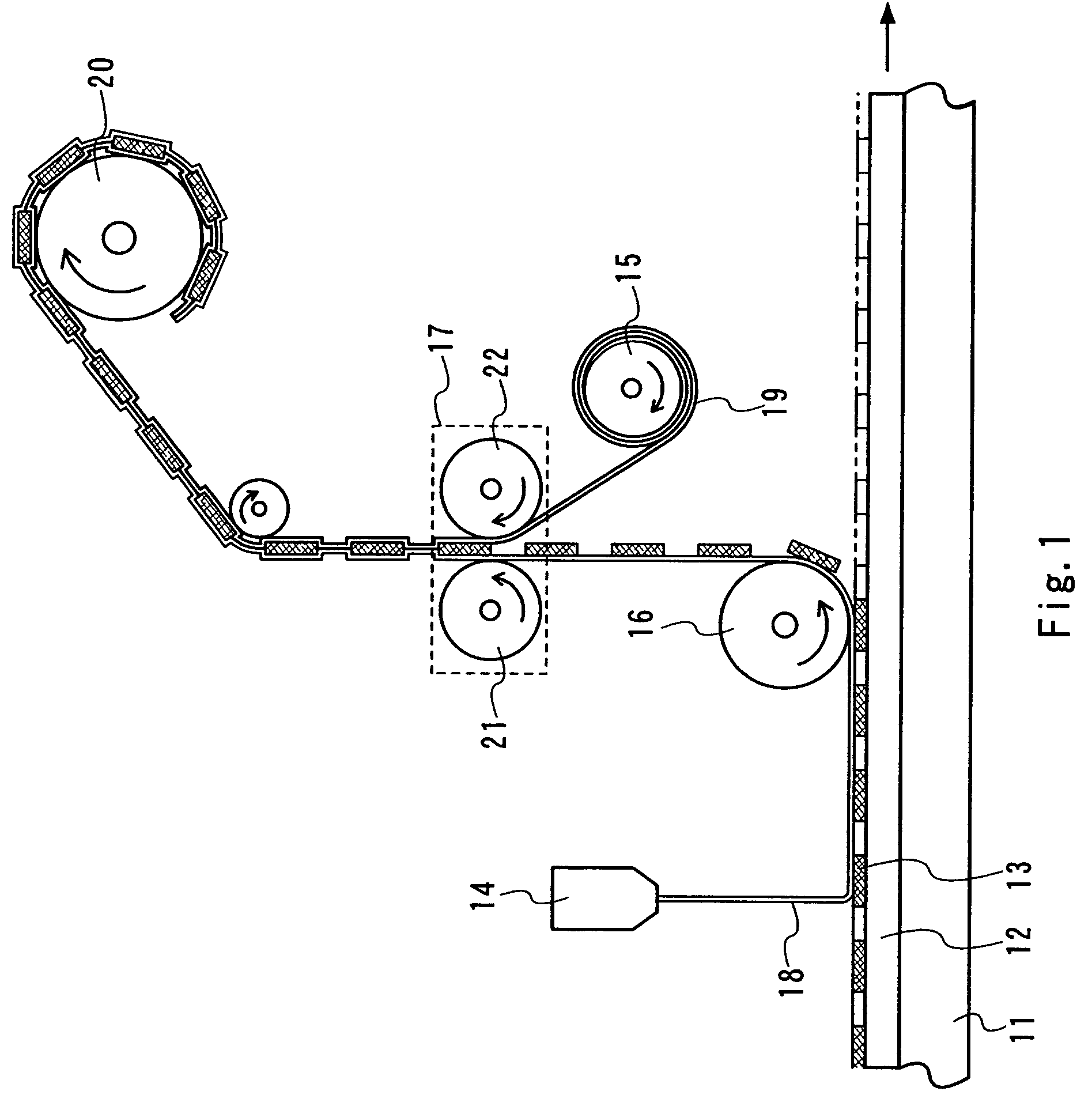

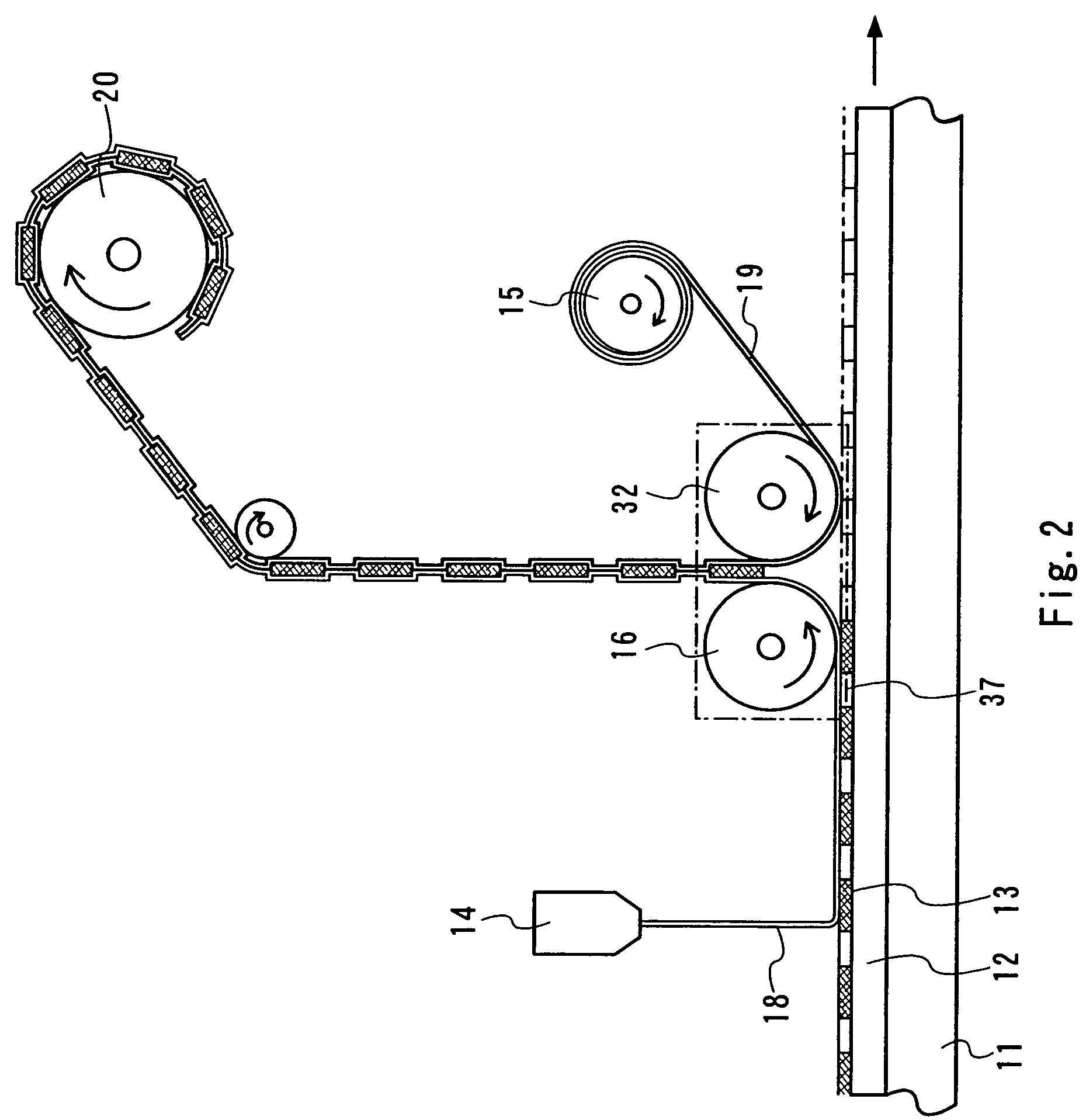

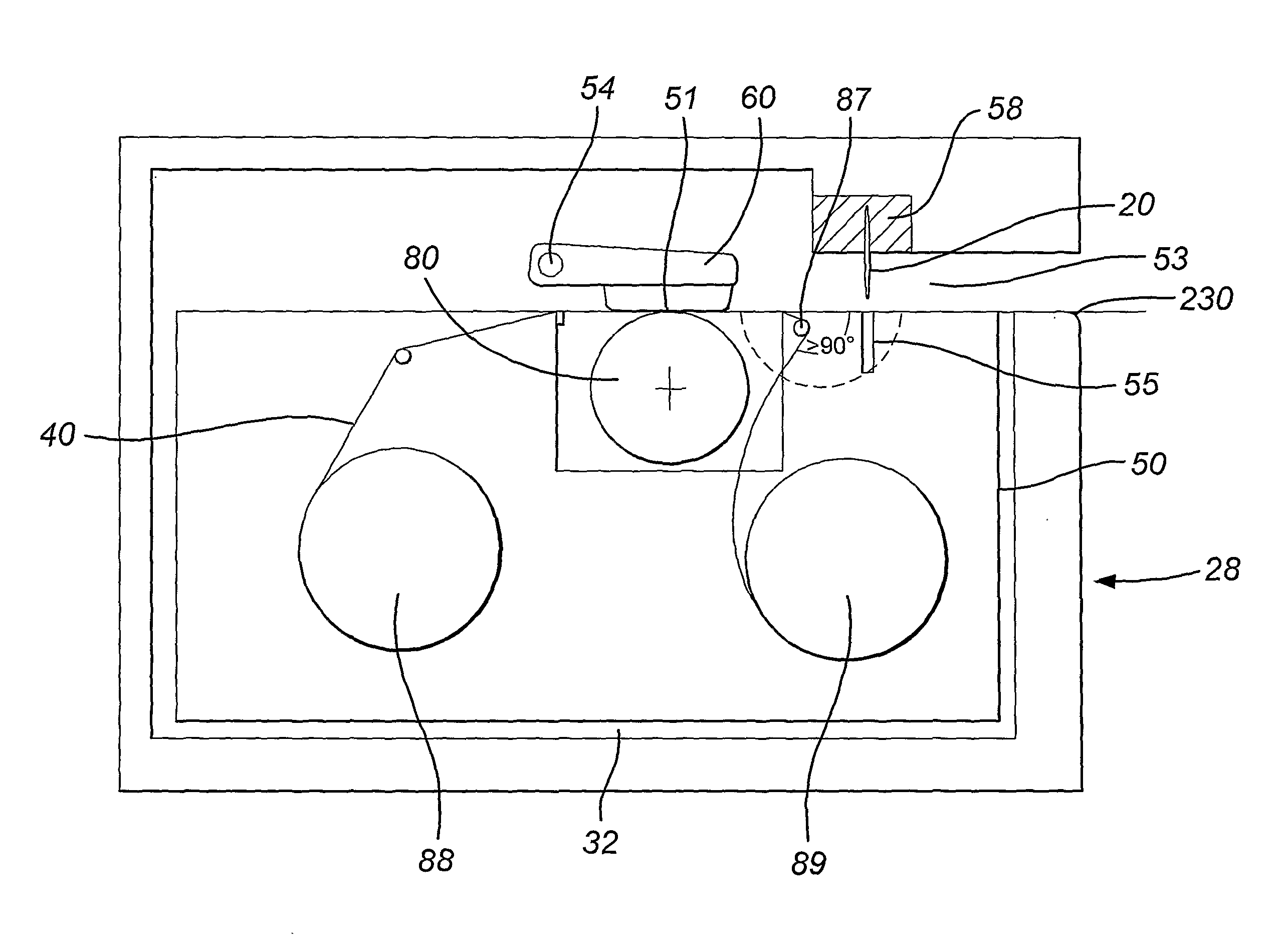

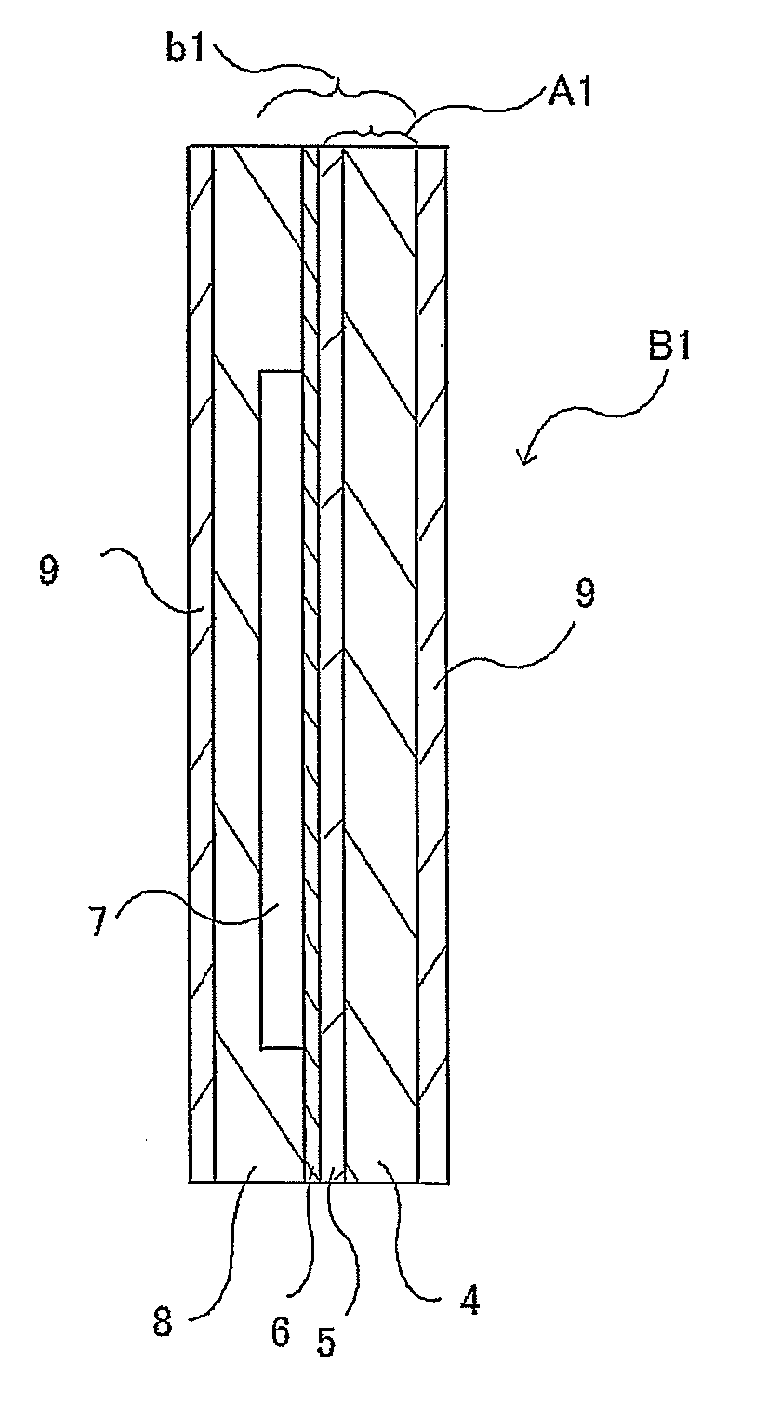

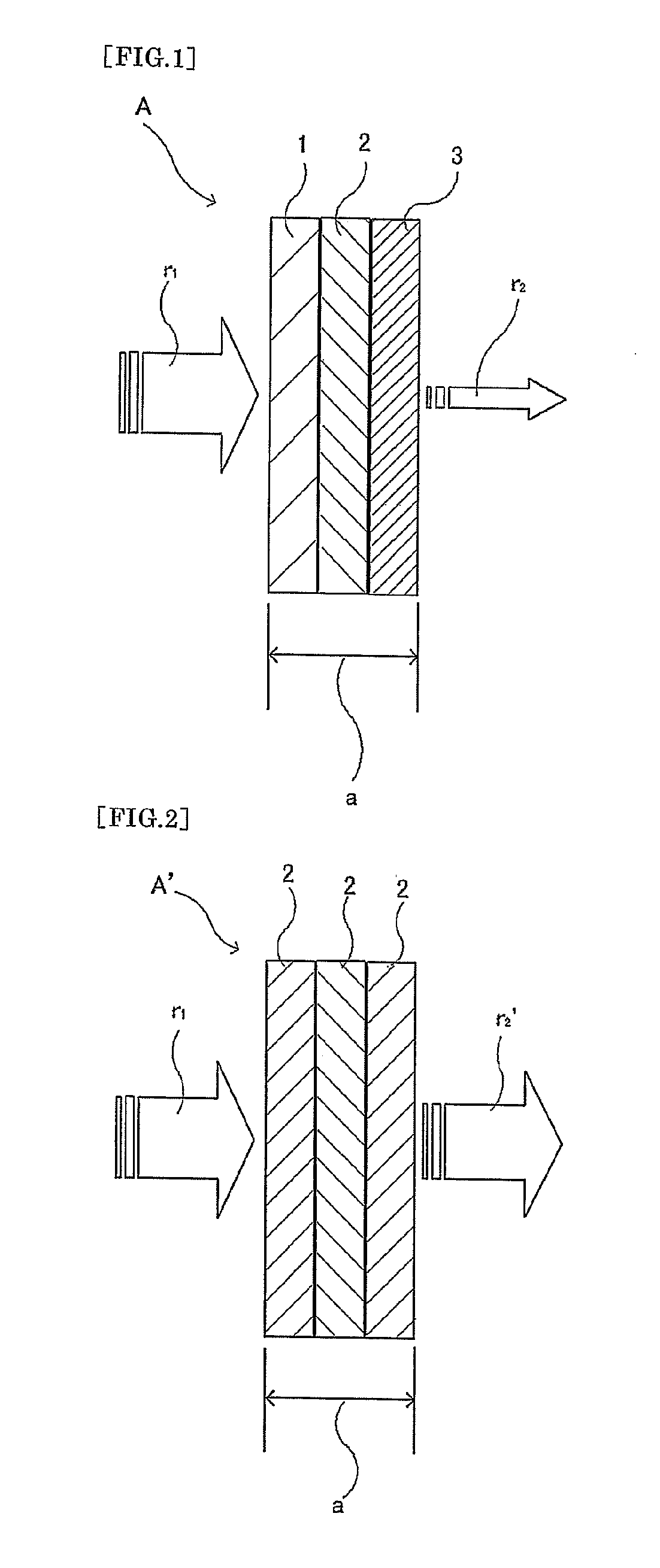

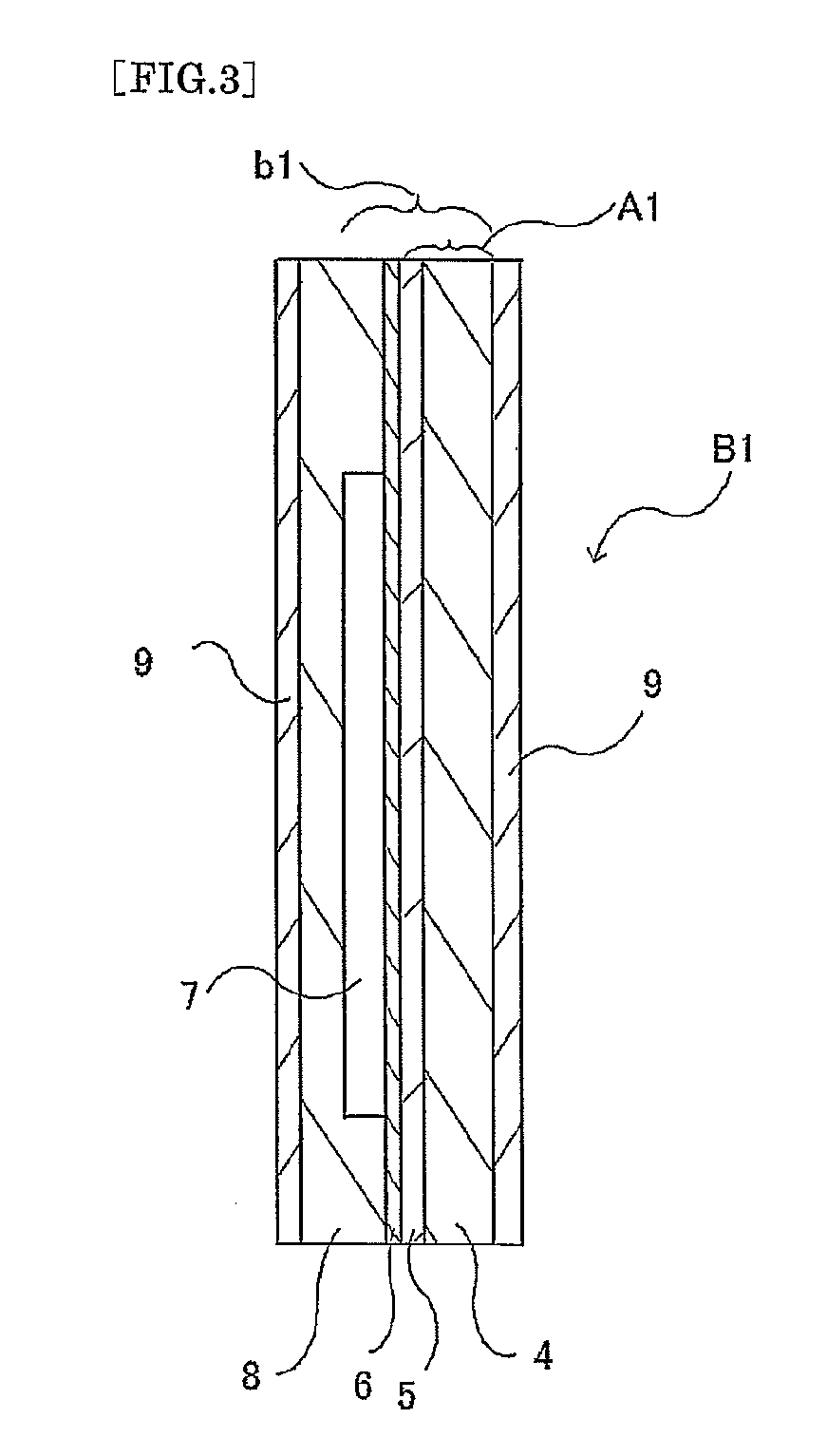

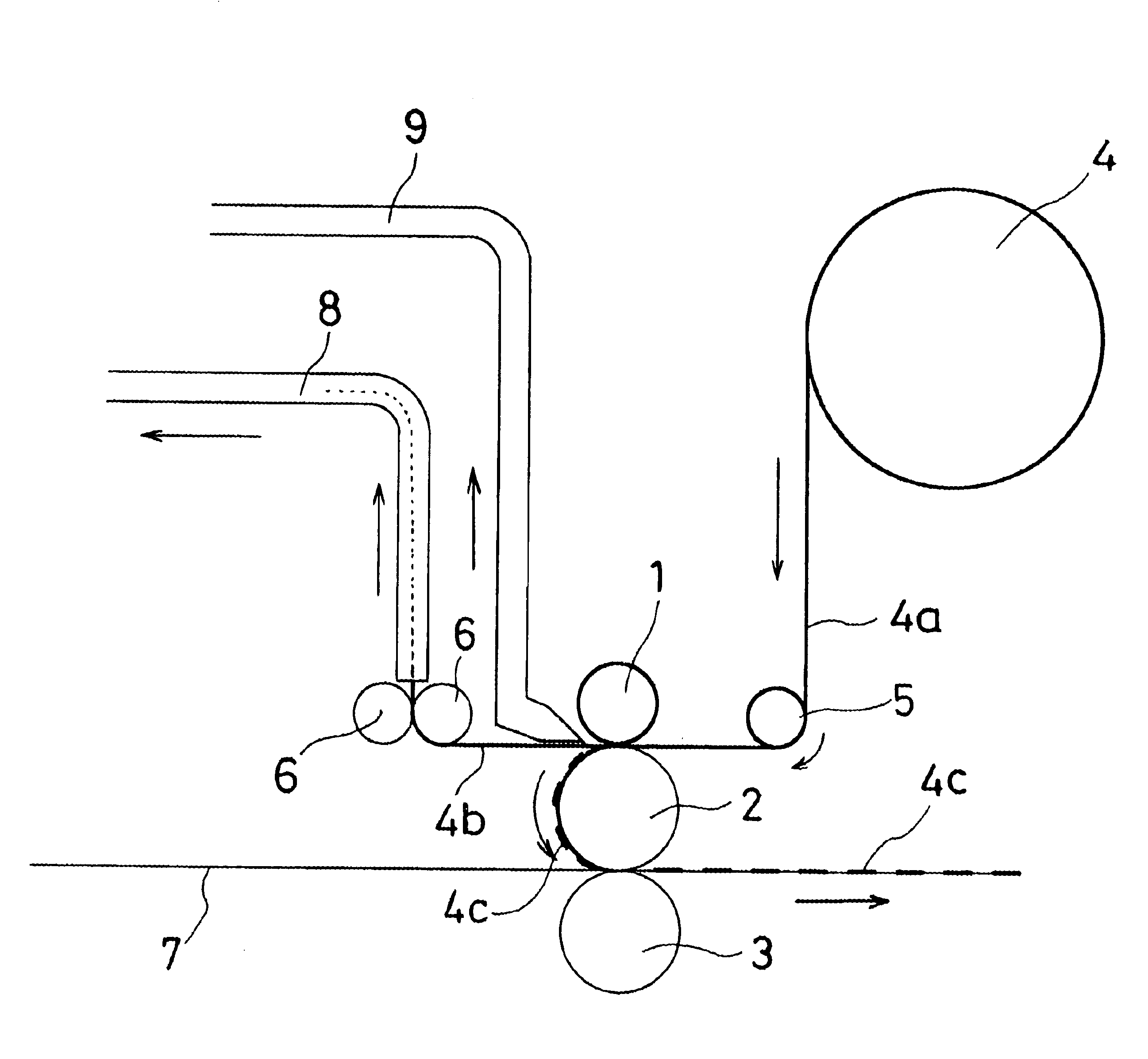

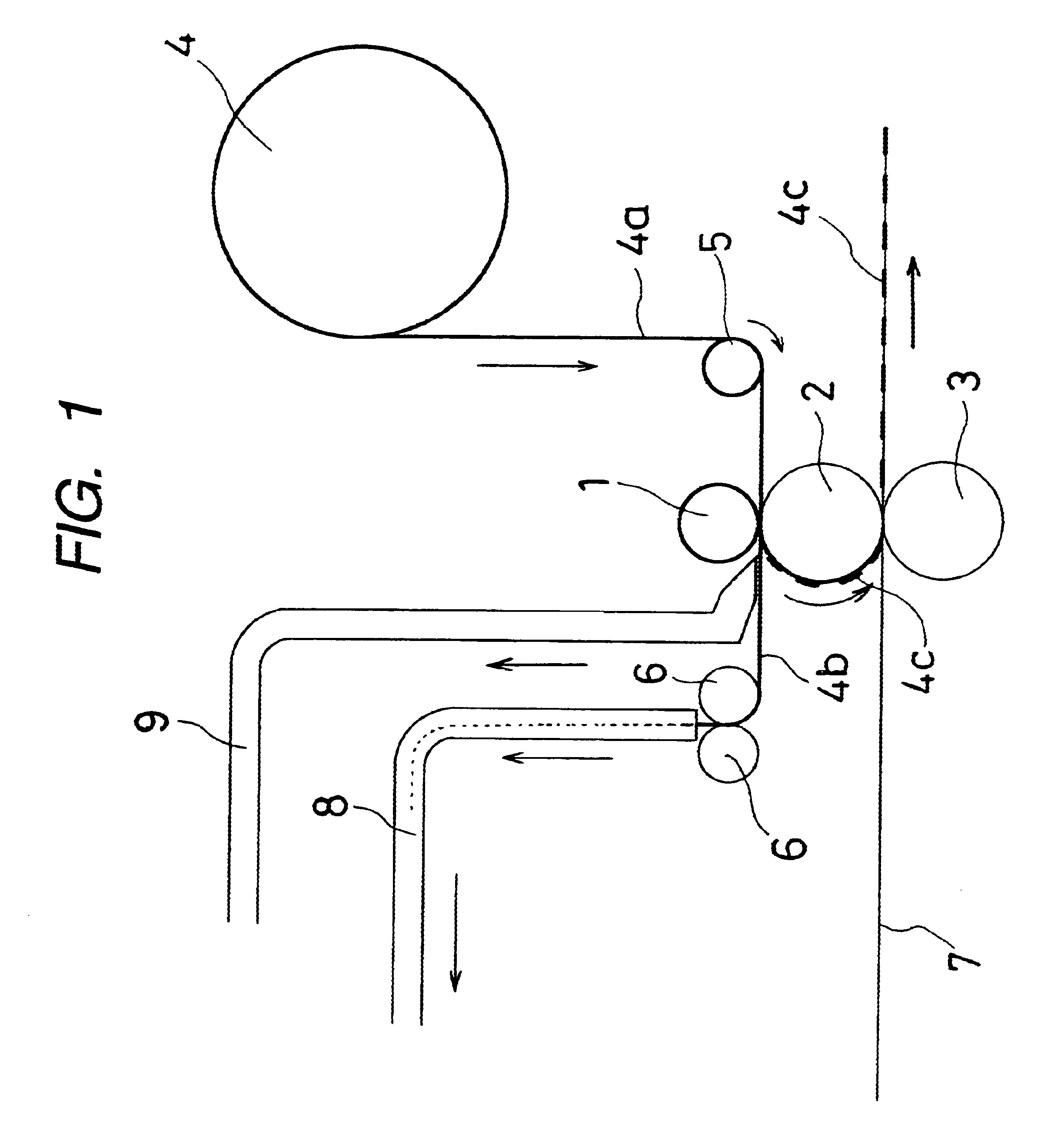

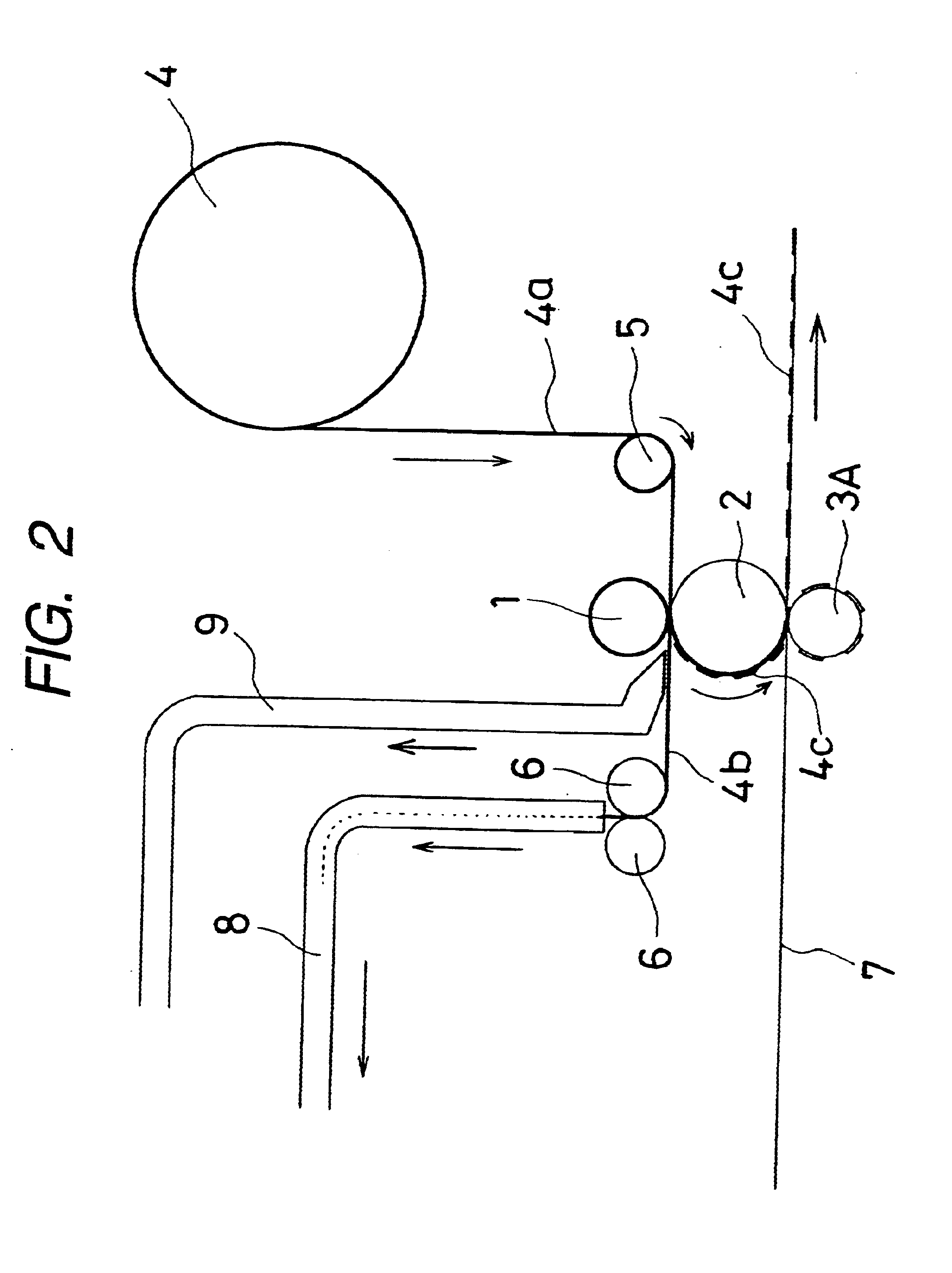

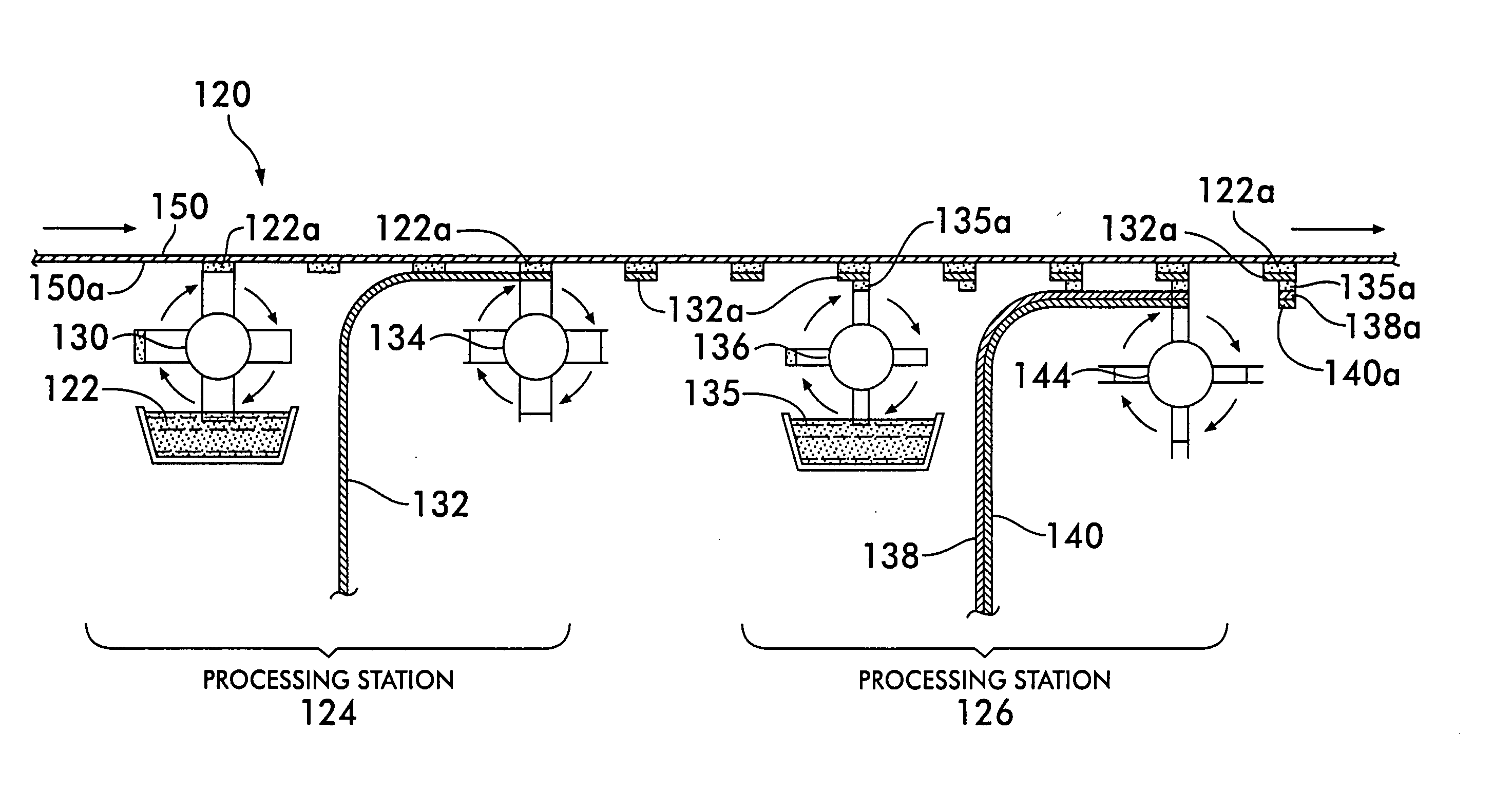

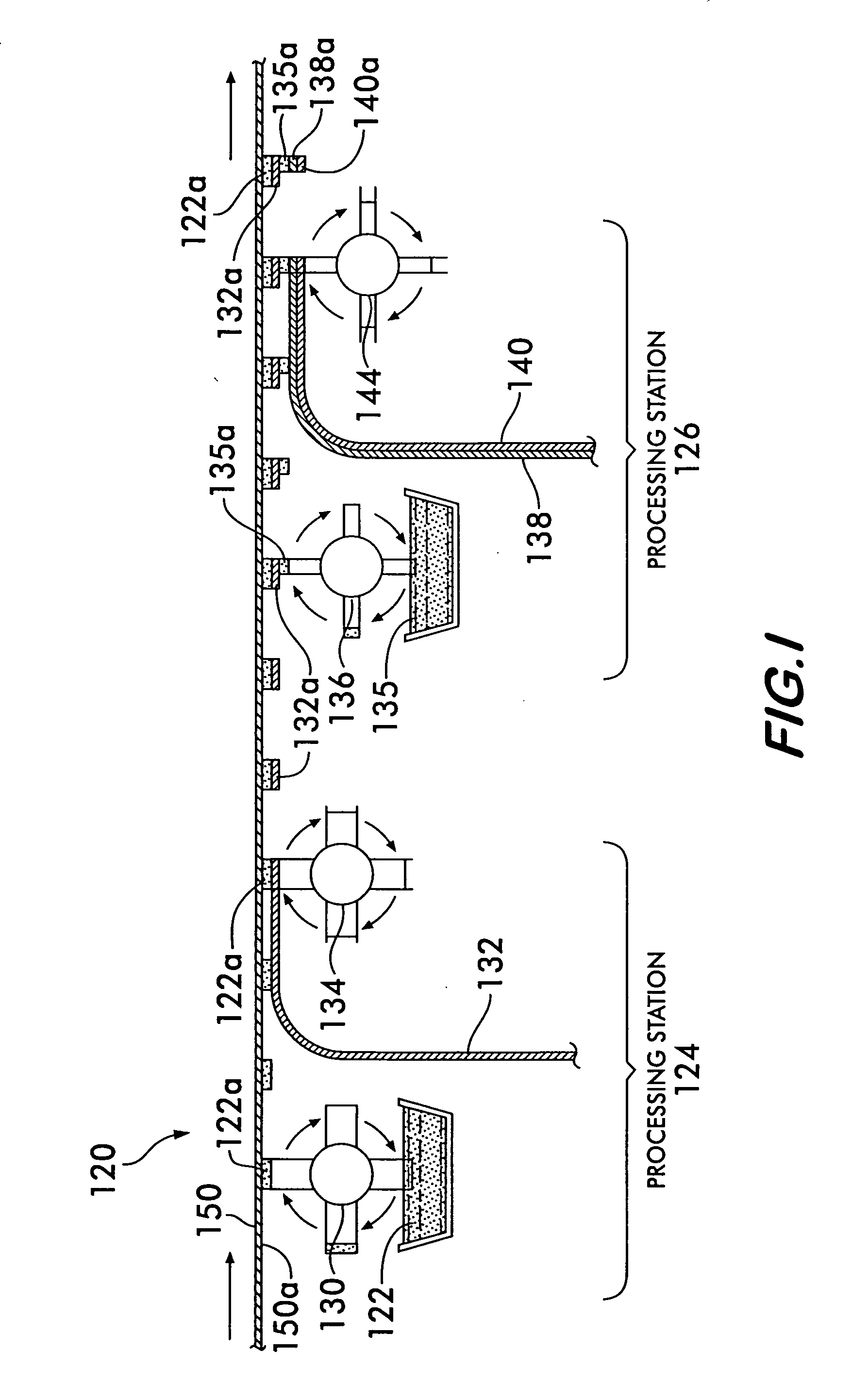

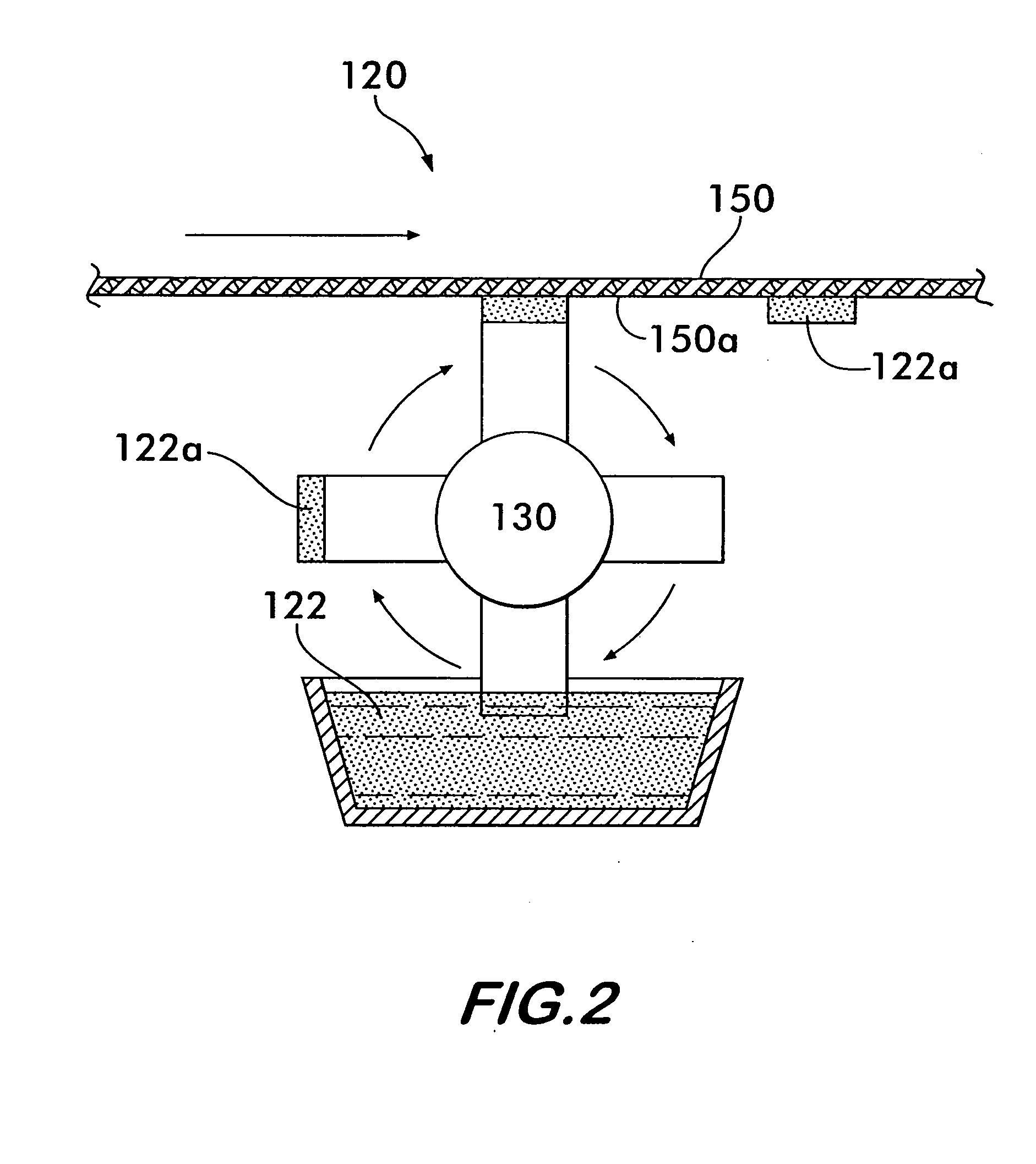

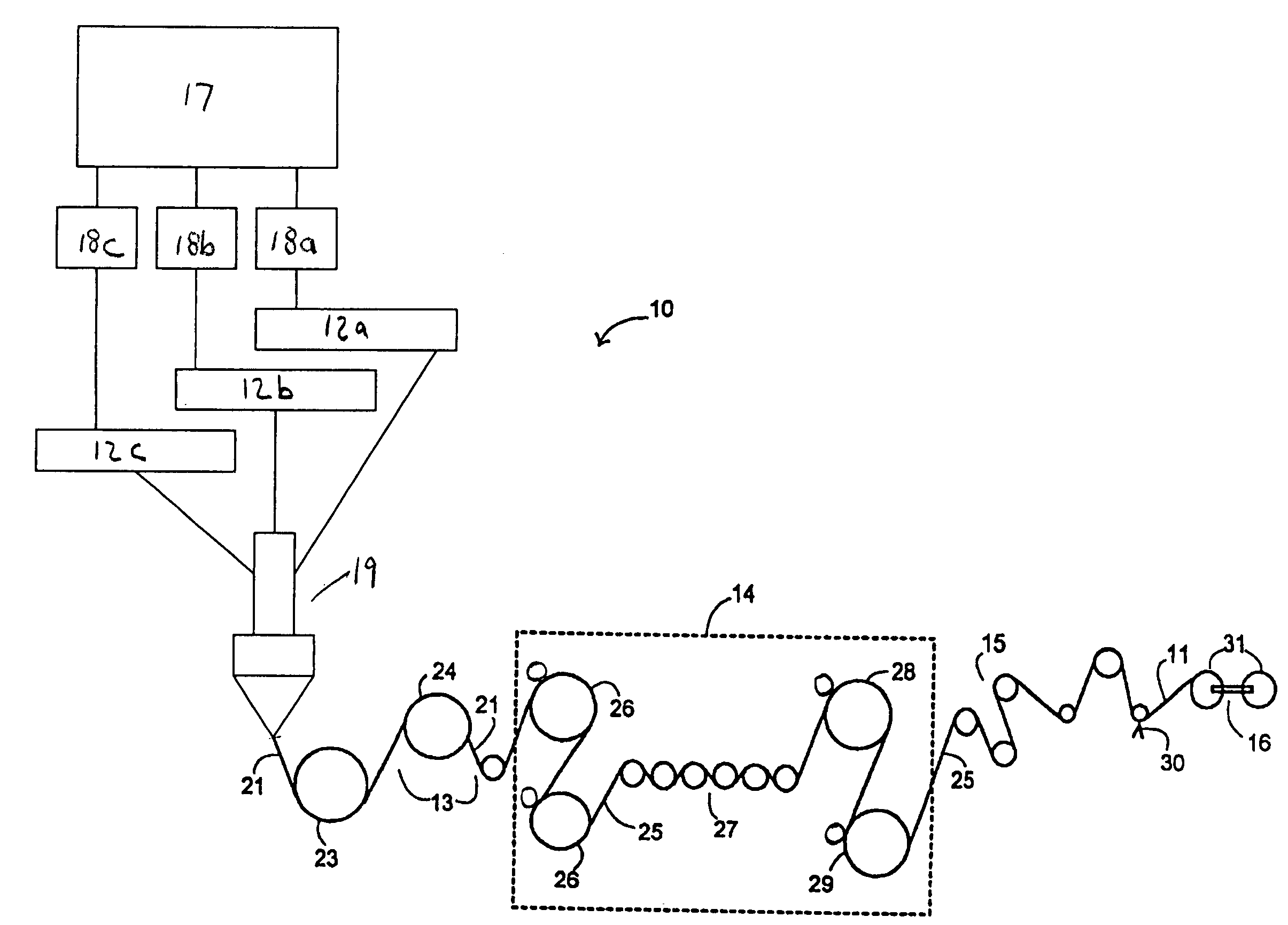

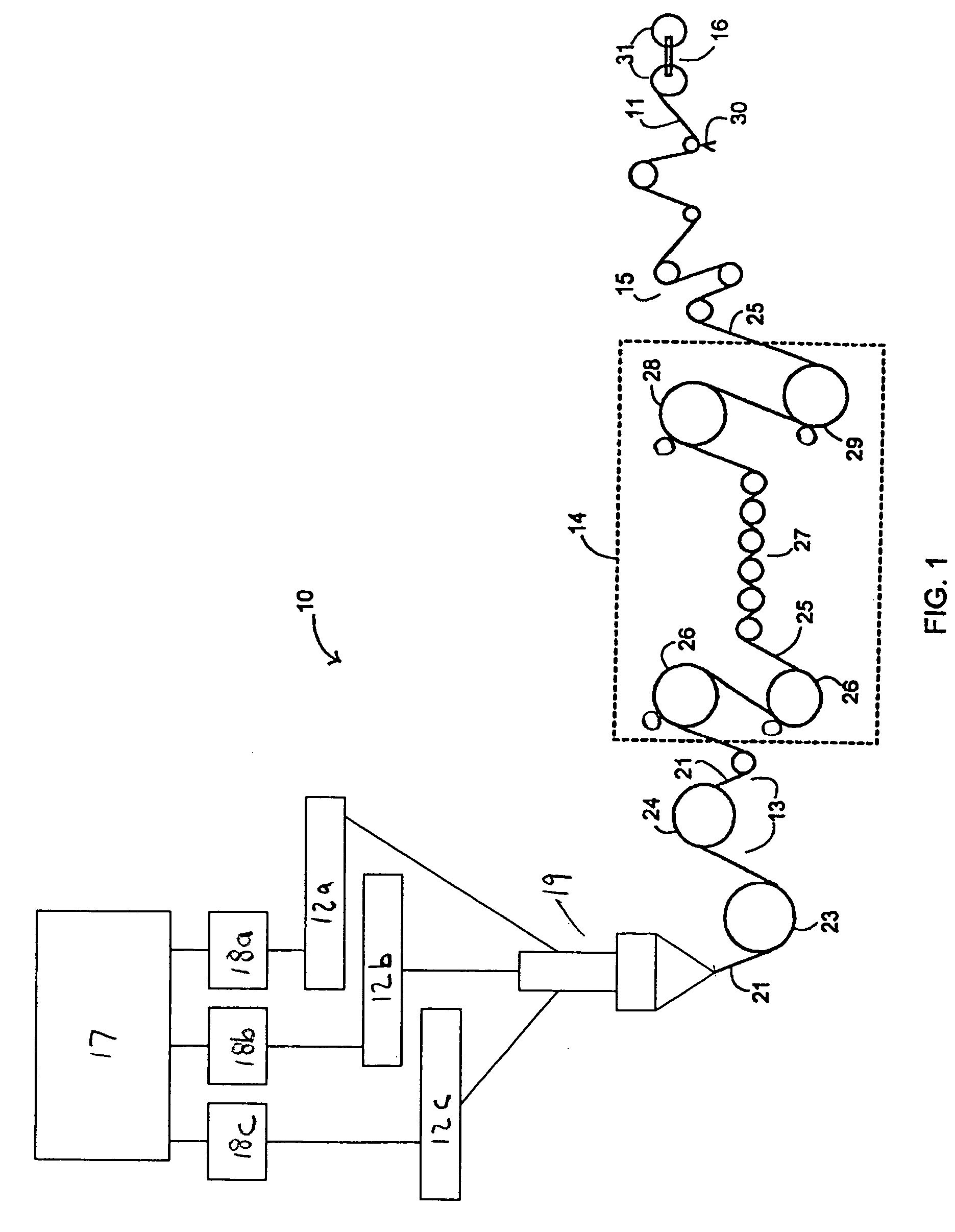

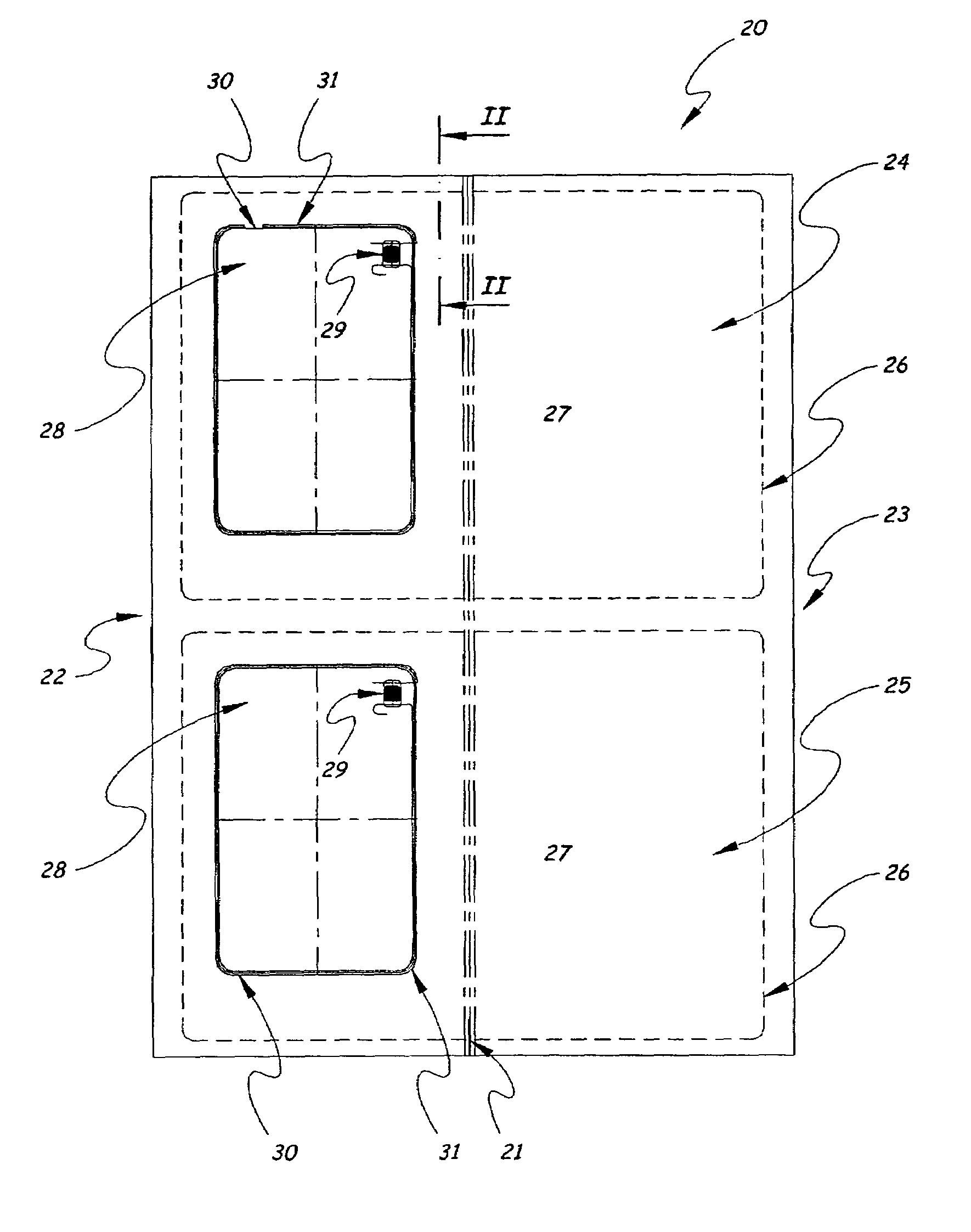

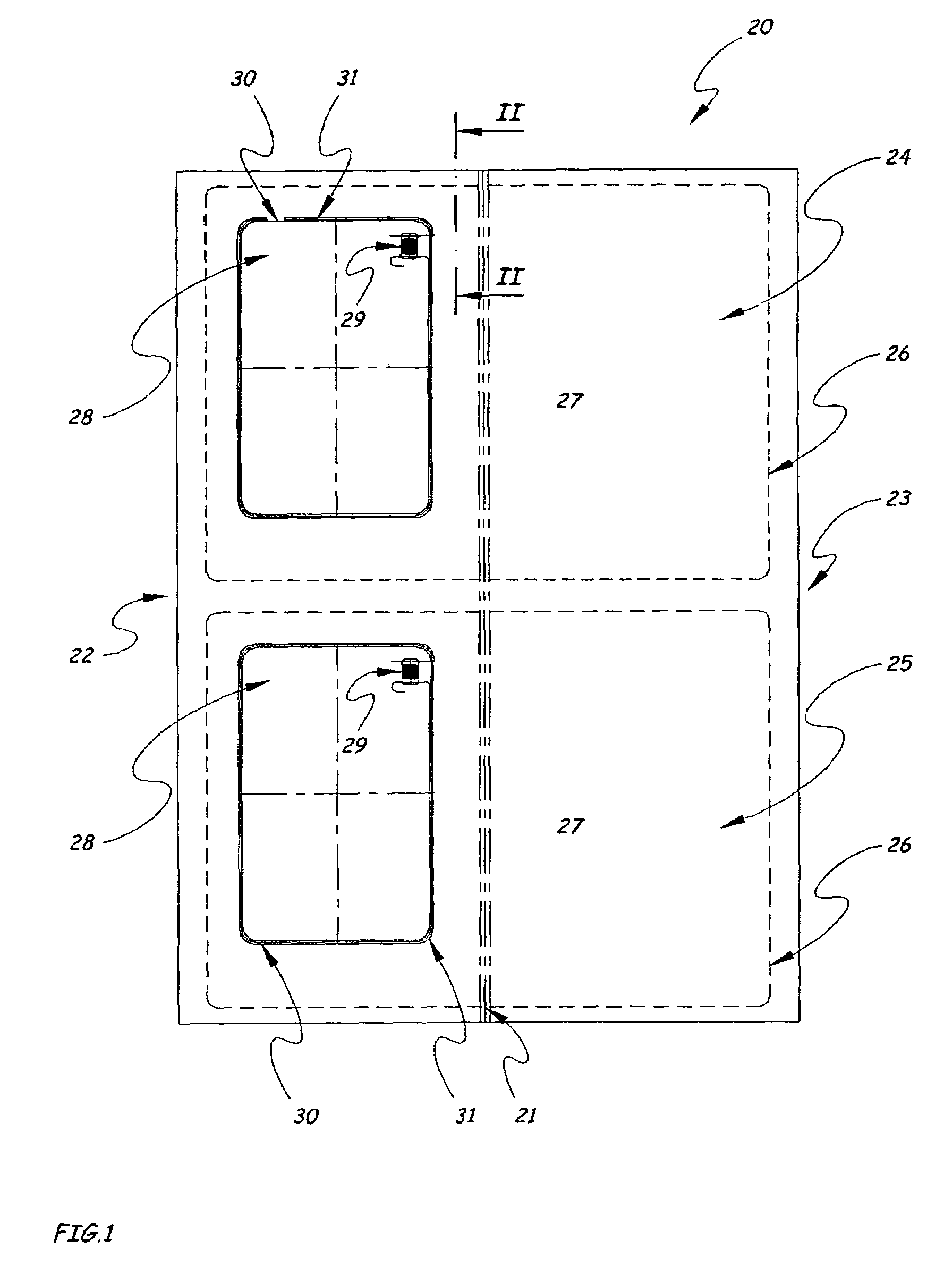

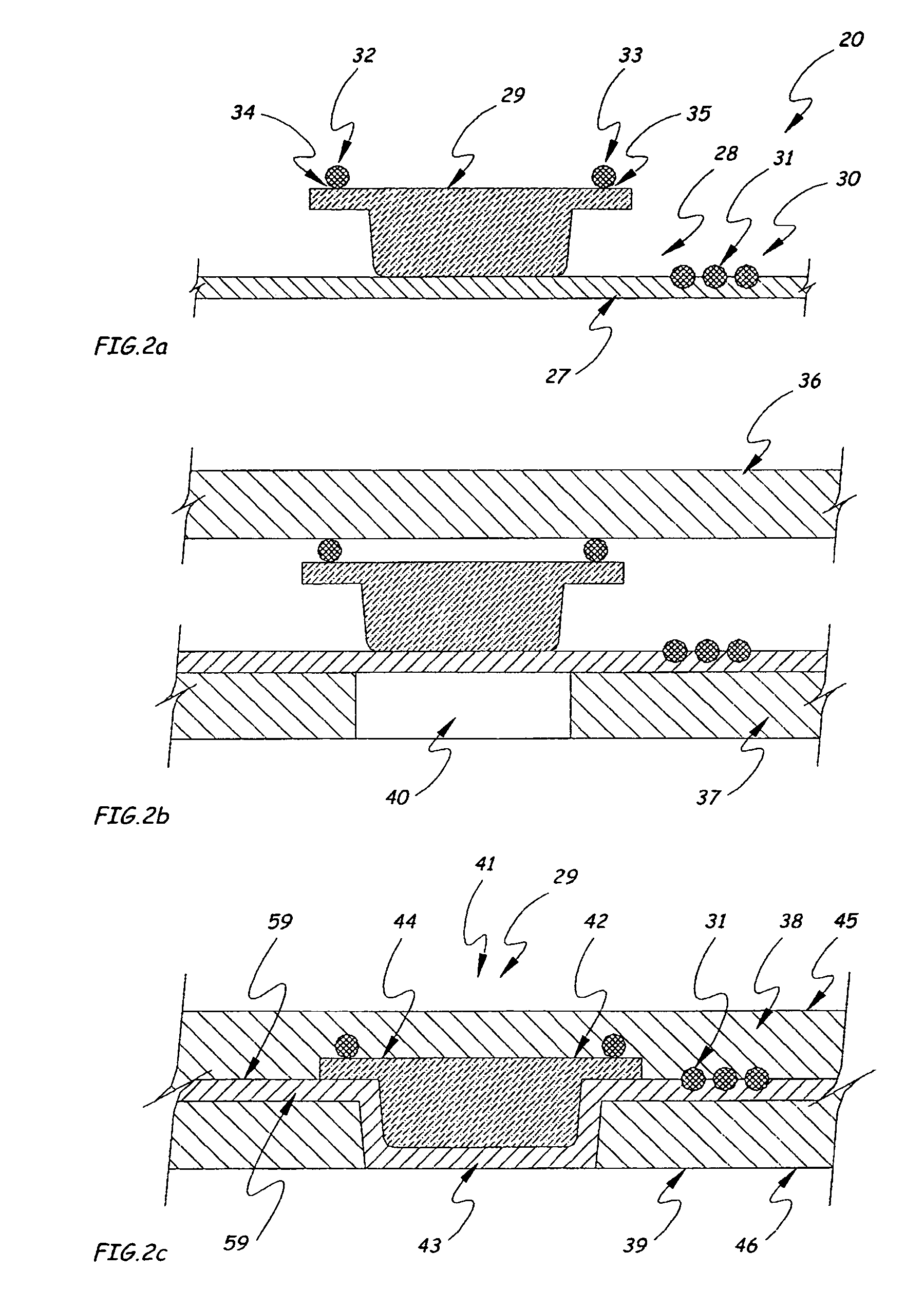

Laminating system, IC sheet, roll of IC sheet, and method for manufacturing IC chip

InactiveUS20060011288A1Avoid easy sealingIncrease productivitySolid-state devicesLaminationEngineeringIntegrated circuit

The invention provides a laminating system in which one of second and third substrates for sealing a thin film integrated circuit is supplied to a first substrate having the plurality of thin film integrated circuit while being extruded in a heated and melted state, and further rollers are used for supplying the other substrate, receiving IC chips, separating, and sealing. Processes of separating the thin film integrated circuits provided over the first substrate, sealing the separated thin film integrated circuits, and receiving the sealed thin film integrated circuits can be continuously carried out by rotating the rollers. Thus, the production efficiency can be extremely improved.

Owner:SEMICON ENERGY LAB CO LTD

Laminating system, IC sheet, roll of IC sheet, and method for manufacturing IC chip

InactiveUS7591863B2Avoid easy sealingIncrease productivitySolid-state devicesLaminationEngineeringIntegrated circuit

The invention provides a laminating system in which one of second and third substrates for sealing a thin film integrated circuit is supplied to a first substrate having the plurality of thin film integrated circuit while being extruded in a heated and melted state, and further rollers are used for supplying the other substrate, receiving IC chips, separating, and sealing. Processes of separating the thin film integrated circuits provided over the first substrate, sealing the separated thin film integrated circuits, and receiving the sealed thin film integrated circuits can be continuously carried out by rotating the rollers. Thus, the production efficiency can be extremely improved.

Owner:SEMICON ENERGY LAB CO LTD

Phosphor based authentication system

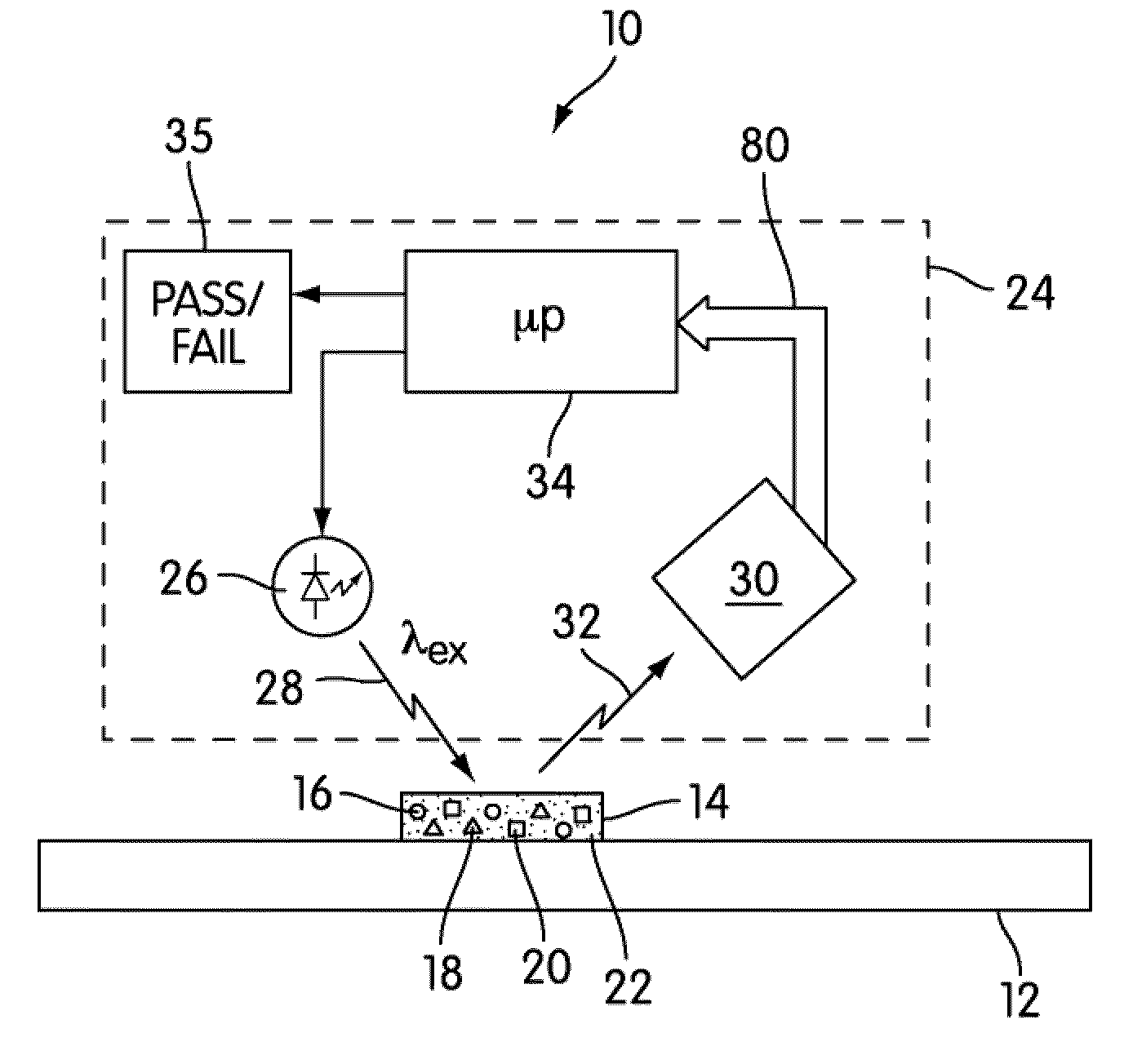

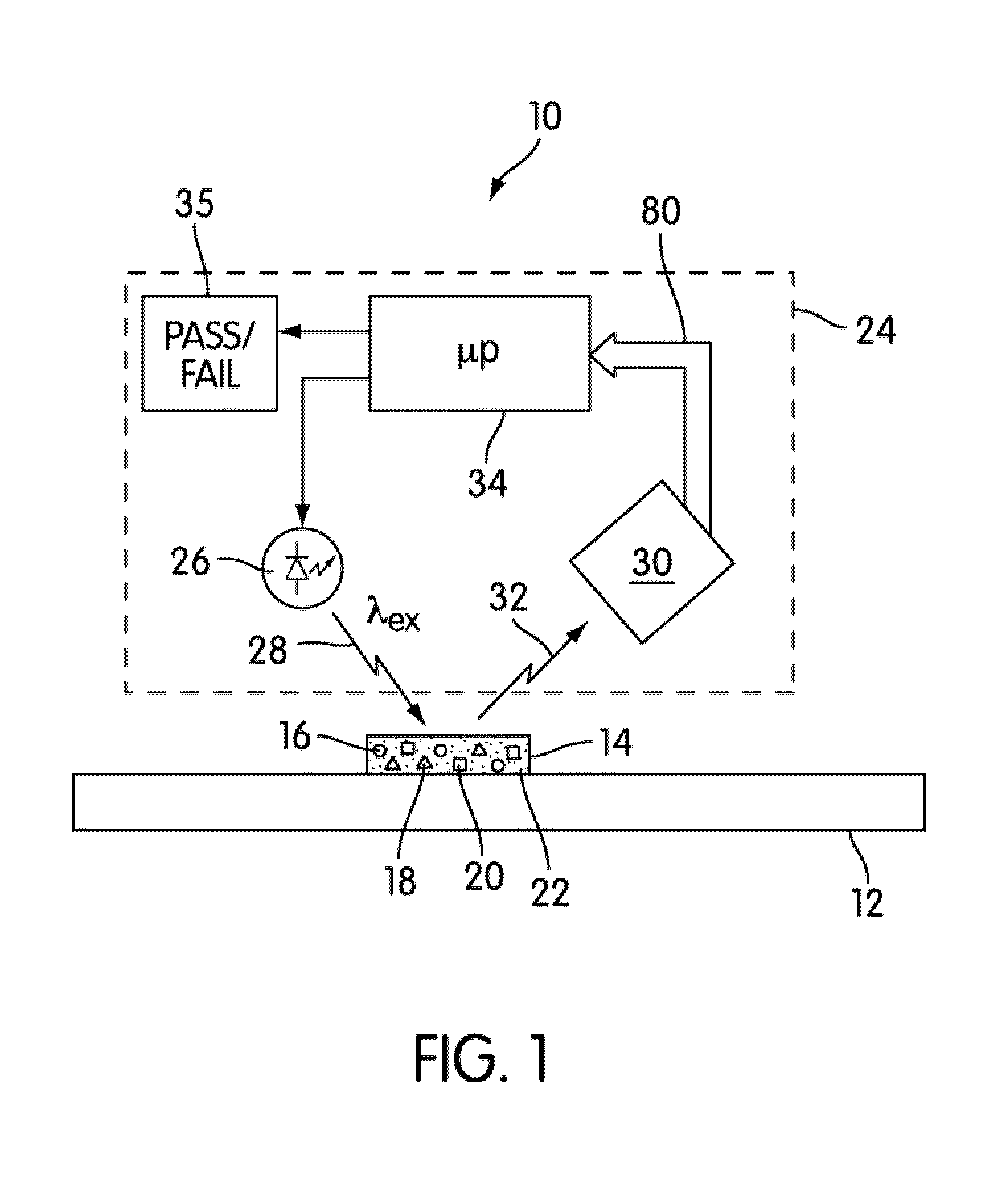

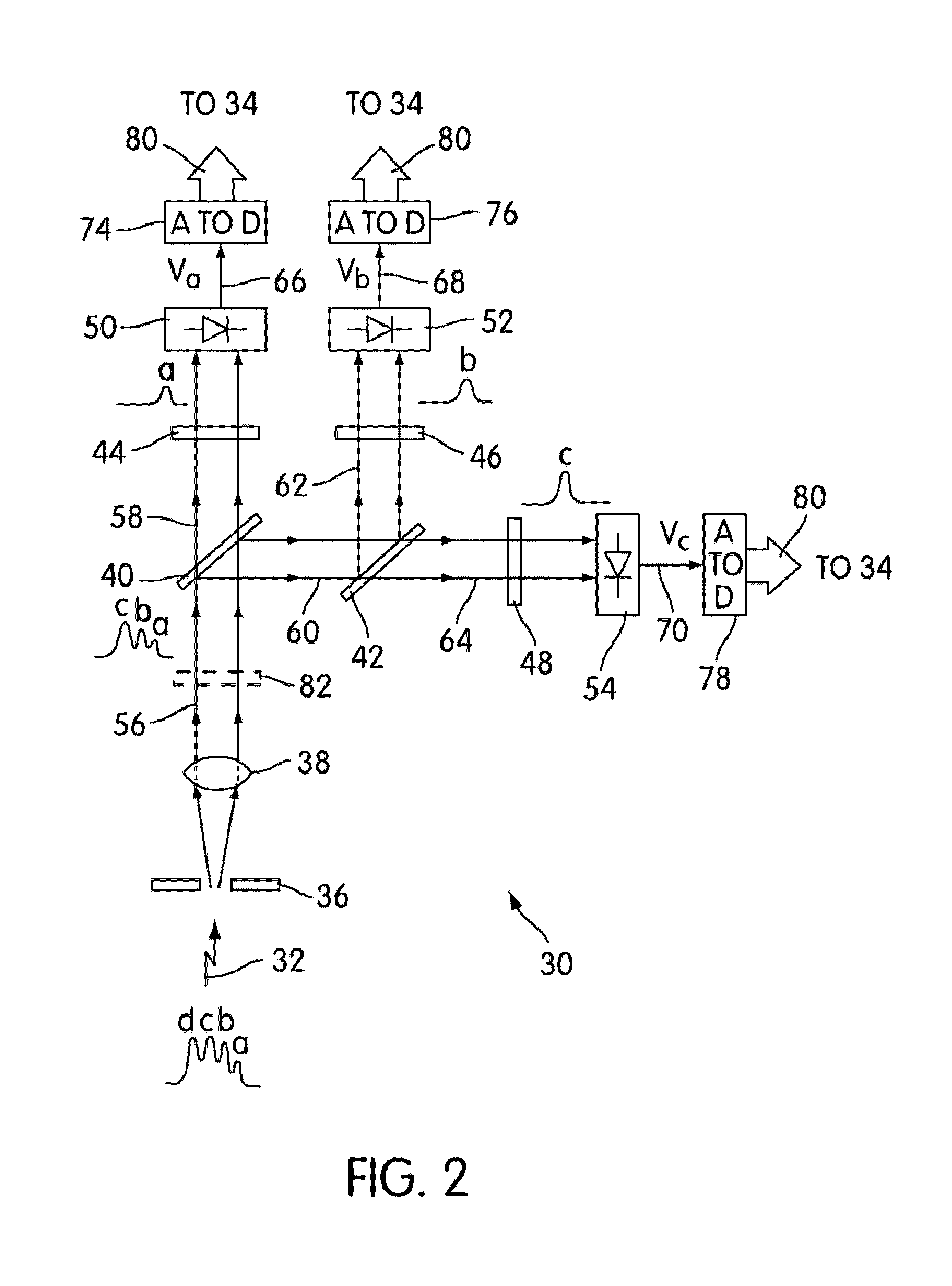

InactiveUS20100102250A1Eliminate risk of damageMinimize risk of damageOptical radiation measurementDecorative surface effectsPhotoluminescencePhosphor

A phosphor (photo-luminescent) material based authentication system in which a blend (mixture) of at least two, preferably three or more, phosphor materials are used as a photo-luminescent security marking which is applied to or incorporated within an article / document to be authenticated. Preferably, the phosphor materials are each excitable by “eye safe” excitation radiation comprising visible light of wavelength 380 nm to 780 nm. Moreover, when excited the security marking preferably also emits visible light thereby minimizing any risk of damage to an operator's eye in the event of accidental exposure to the excitation radiation and / or light generated by the photo-luminescent marking. The authenticity of the article / document can be authenticated by verification of the composition of the phosphor by exciting the marking and comparing one or more selected parameters of light emitted by the security marking with corresponding parameters of the characteristic emission spectrum of the authentic phosphor blend.

Owner:INTEMATIX

Systems and methods for advanced card printing

ActiveUS8322623B1Decreasing structural integrityIncrease whimsical and festive natureLayered product treatmentLaminationUltravioletWavelength

Layers of colored polymers are applied to a surface of a card and are hardened and adhered to a card via light such as ultraviolet or light having a wavelength in the blue spectrum. The layers may be applied to form three dimensional indicia on the surface of the card. For example, letters, numbers, logos, and other indicia (e.g., pictures) may be printed three dimensionally onto the surface of the card. Troughs may be formed via such layering such that indicia is provided as indentations into the added layers. Extensions may be formed via such layering such that indicia is provided as extensions from the added layers. Indicia may be provided via extensions and / or indentations. As such, embossed and / or engraved indicia may be provided on the surface of a card without impacting the structural integrity of the card.

Owner:DYNAMICS

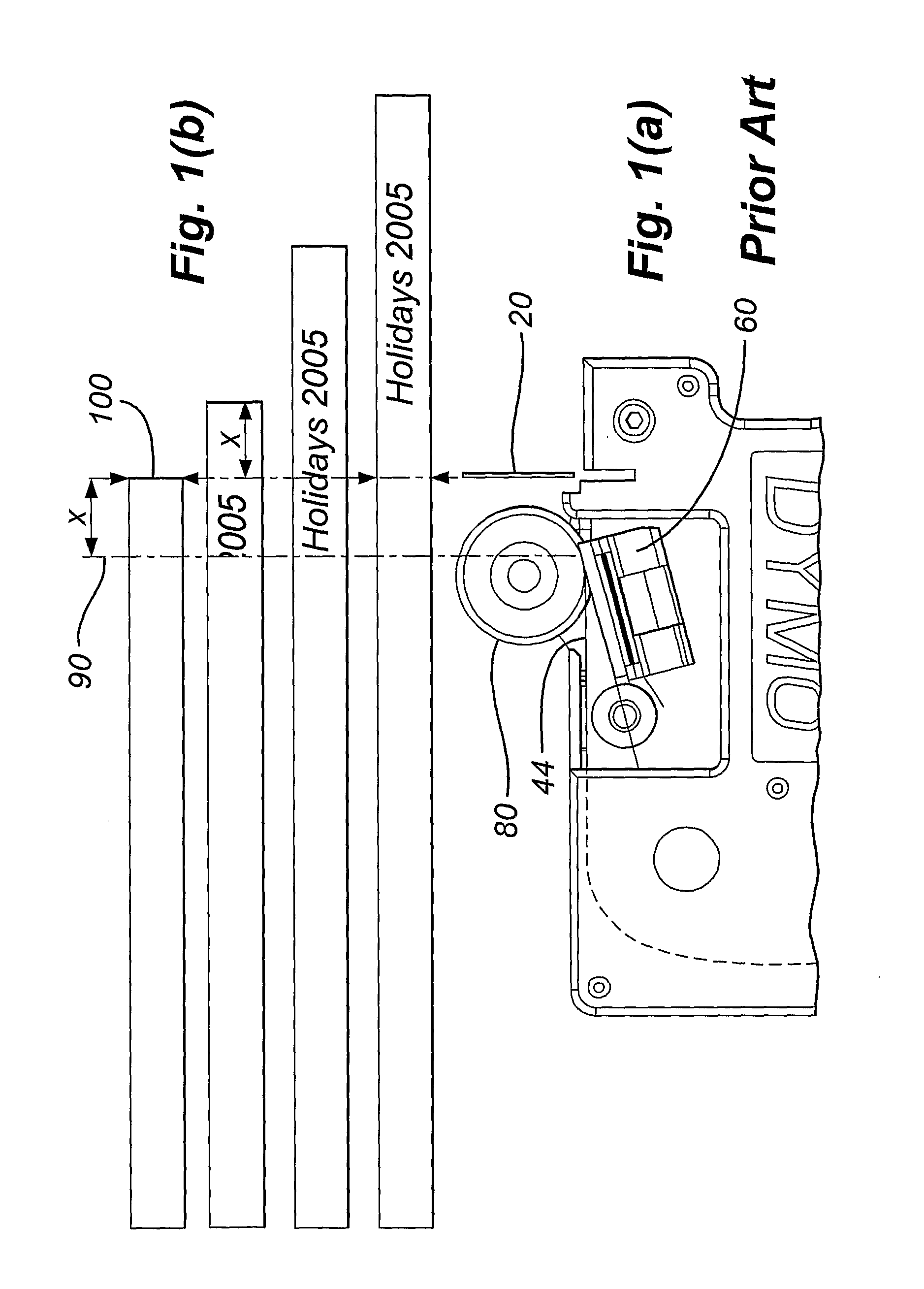

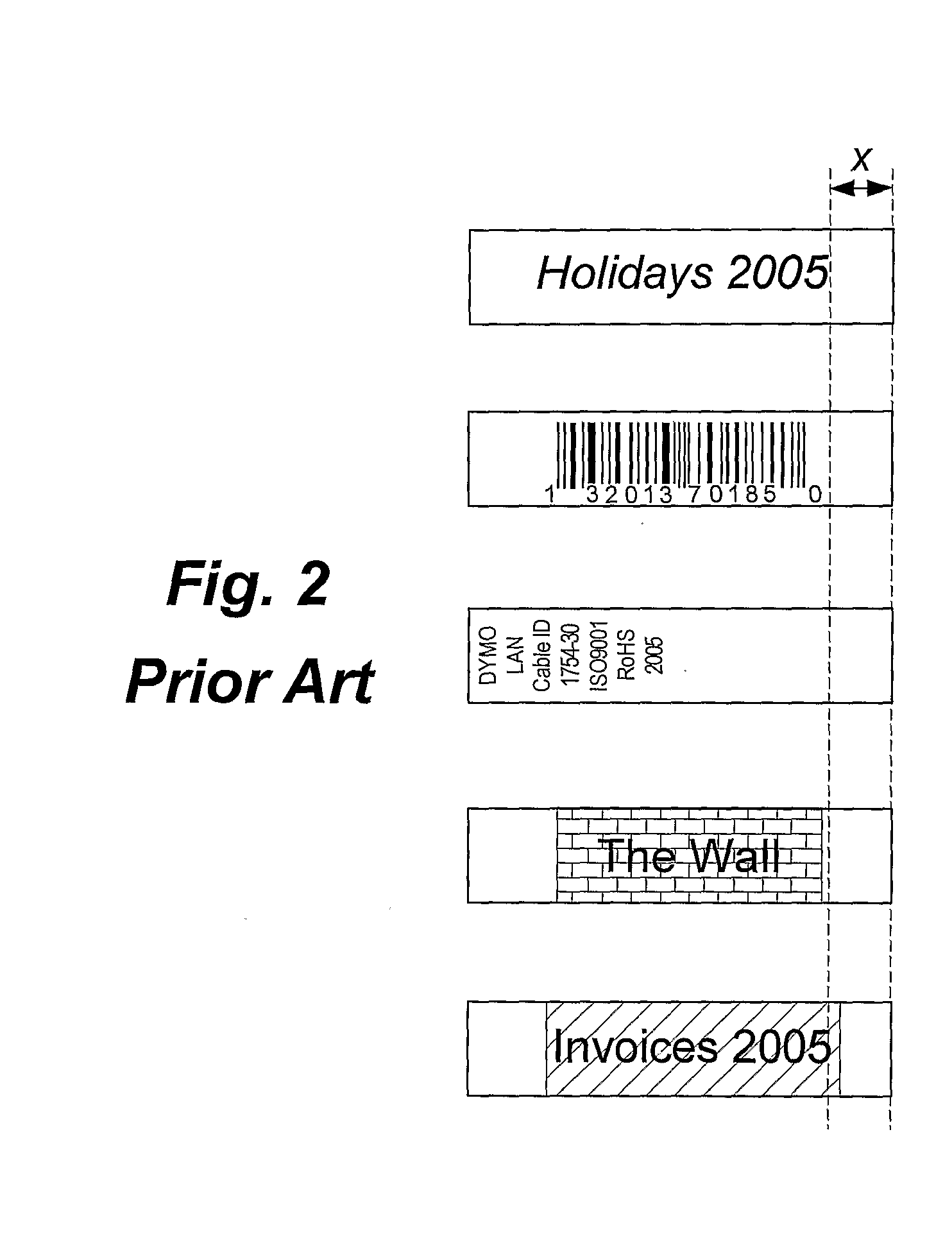

Tape Printing Apparatus and Tape Cassette

InactiveUS20100232862A1Lamination ancillary operationsSynthetic resin layered productsEngineeringElectrical and Electronics engineering

Owner:DYMO (BVBA)

Combination card of metal and plastic

ActiveUS8672232B2Dimensionally stableReduce changesOrnamental structuresSpecial ornamental structuresAdhesiveEngineering

A card formed in accordance with the invention includes a first assembly comprised of multiple plastic layers attached via an adhesive to a metal layer. The multiple plastic layers forming the first assembly are laminated under a first selected temperature and pressure conditions to preshrink the multiple plastic layers, stress relieve the first assembly and render the first assembly dimensionally stable. The laminated first assembly is then attached to a metal layer via an adhesive layer to form a second assembly which is then laminated at a temperature below the first selected temperature to form a card which is not subjected to warpage and delamination.

Owner:COMPOSECURE LLC

Electromagnetic shield sheet and RFID plate

InactiveUS20100096181A1Higher electromagnetic shielding effectImprove efficiencyMagnetic/electric field screeningSynthetic resin layered productsPliabilityElectromagnetic shielding

Provided is an electromagnetic shield sheet having an excellent electromagnetic shielding effect which can be sufficiently exhibited even when the sheet has a reduced thickness and a reduced weight. Furthermore, the electromagnetic shield sheet has an excellent molding efficiency and flexibility and can be used in a desired shape such as various shapes of a power supply box, an inner wall, or an electronic device for electromagnetic shielding. An RFID plate using the electromagnetic shield sheet is also provided. The electromagnetic shield sheet A has a polymer composition layer obtained by mixing a conductive material with a polymer material. The sheet A is formed by layering at least two of polymer composition layers 1, 2, 3 having different dielectric constants. The RFID plate is formed by layering the electromagnetic shield sheet A, an IC, and an antenna circuit.

Owner:ASAHI RUBBER +1

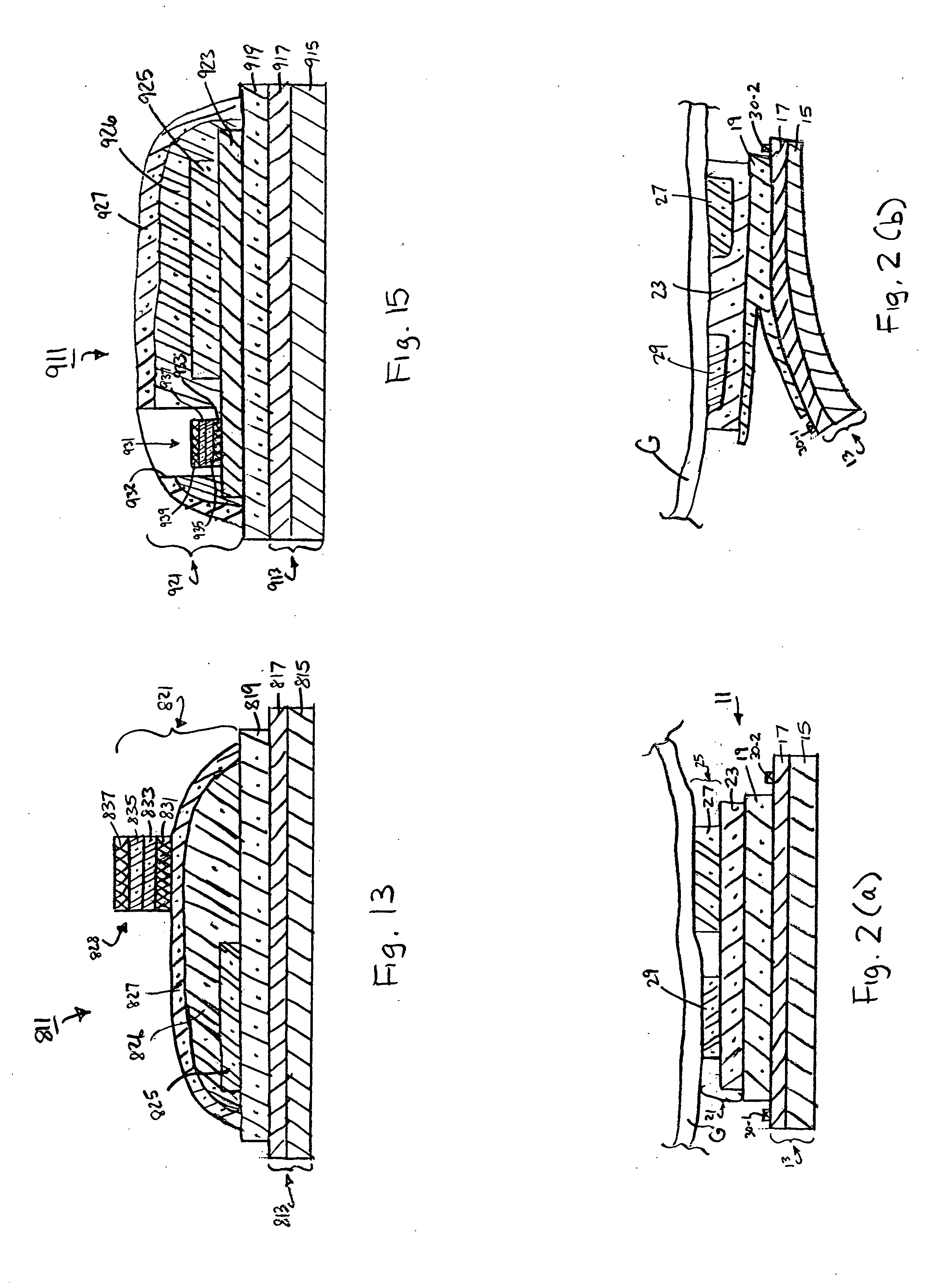

Heat-transfer label well-suited for labeling fabrics and methods of making and using the same

A method for labeling fabrics, such as fabric garments, and a heat-transfer label well-suited for use in said method. In one embodiment, the heat-transfer label comprises (i) a support portion, the support portion comprising a carrier and a release layer; (ii) a wax layer, the wax layer overcoating the release layer; and (iii) a transfer portion, the transfer portion comprising an adhesive layer printed onto the wax layer and an ink design layer printed onto the adhesive layer. Preferably, at least a portion of the ink design layer is printed using a variable printing technique, such as thermal transfer printing.

Owner:AVERY DENNISON CORP

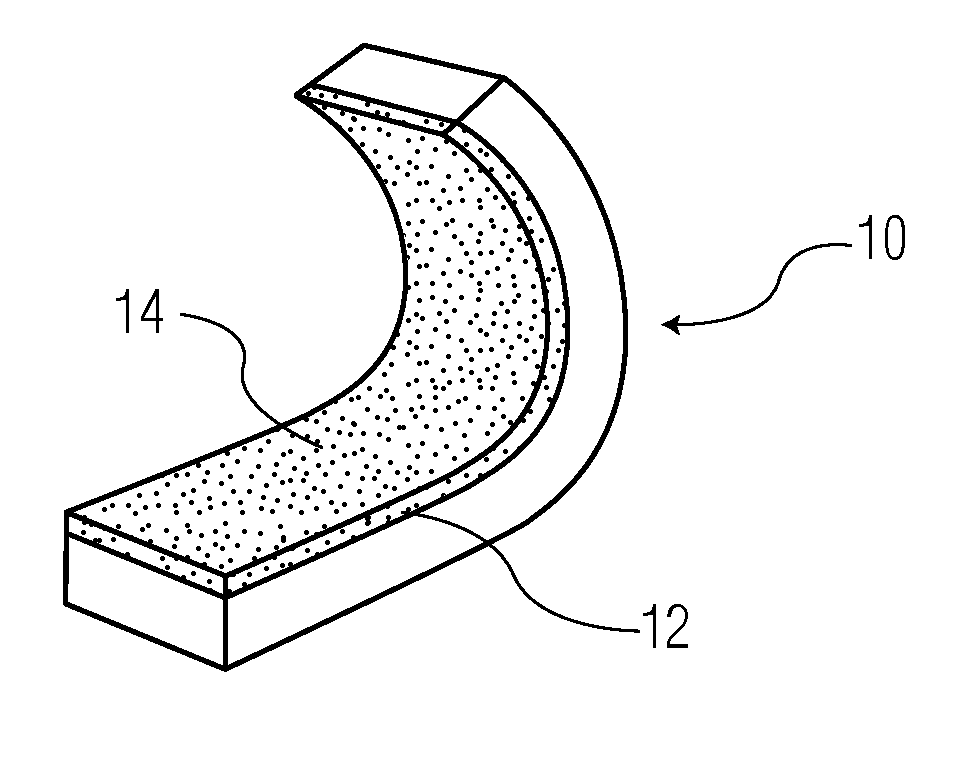

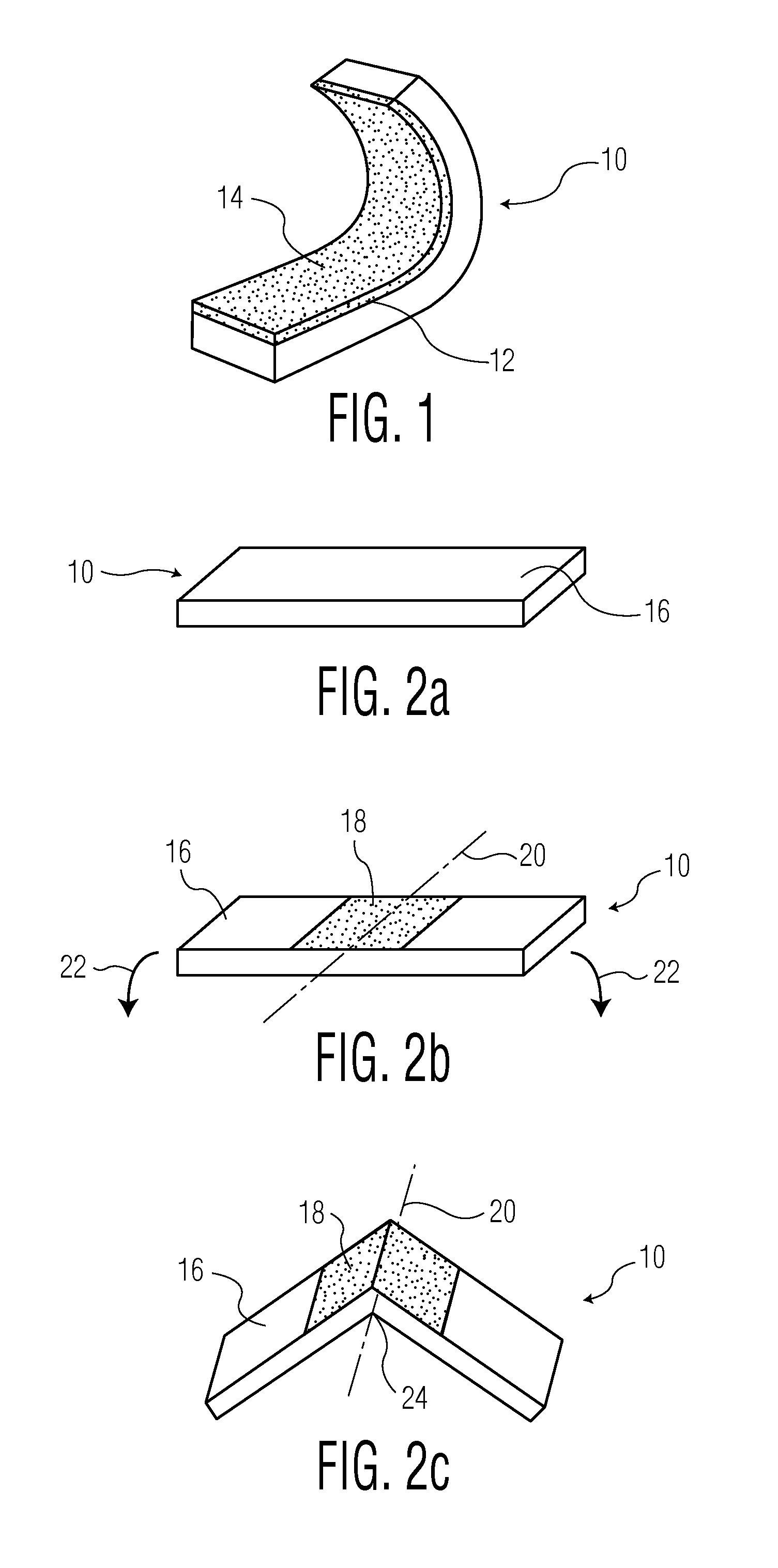

Bent Coated Articles

InactiveUS20110135884A1Material nanotechnologyLamination ancillary operationsCoated surfacePolymer science

Articles comprising a surface coated with a composition containing graphene sheets and at least one polymer binder where the articles have been bent at the coated surface after the coating was applied. Methods of making coated articles that are bent after coating.

Owner:VORBECK MATERIALS CORP

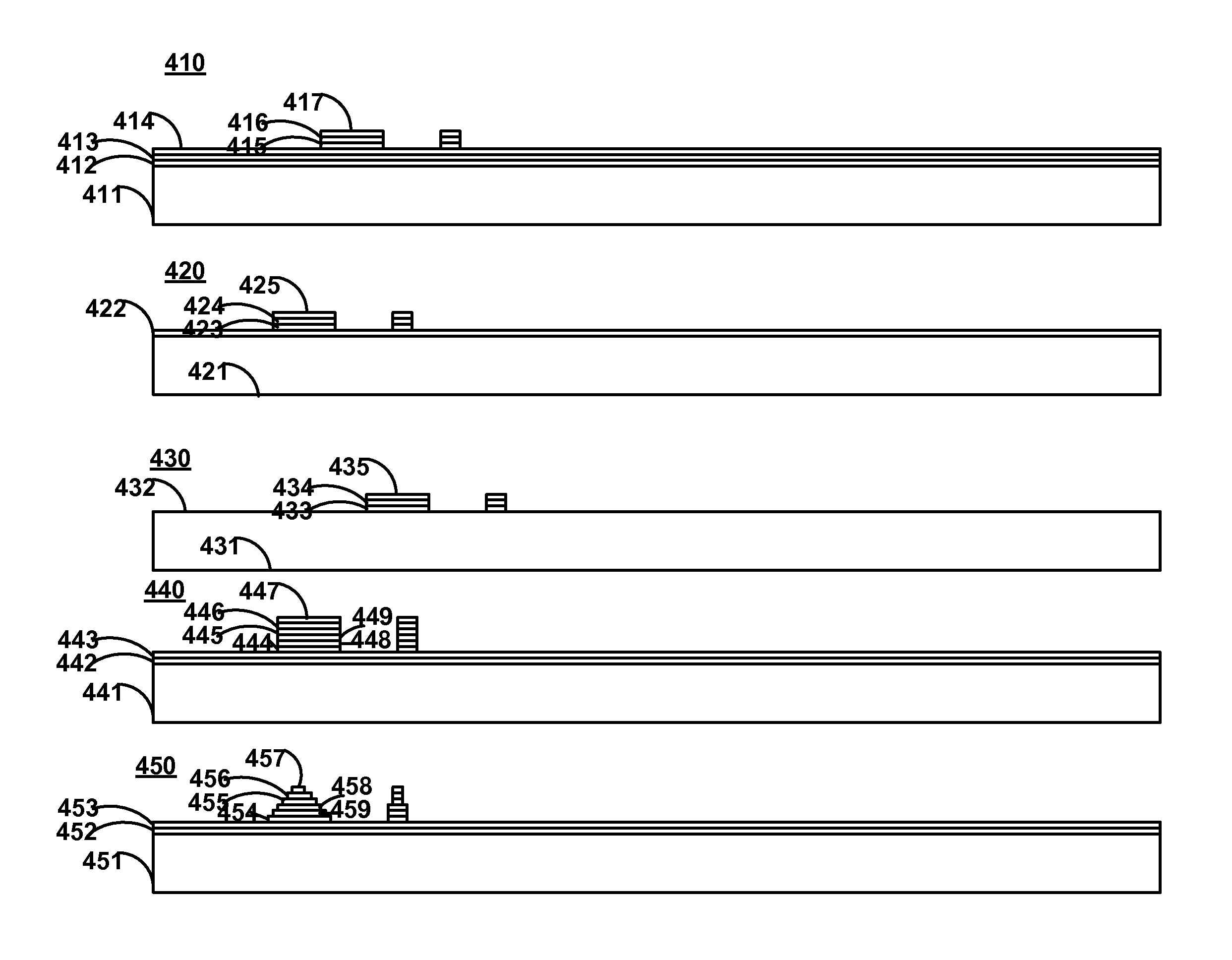

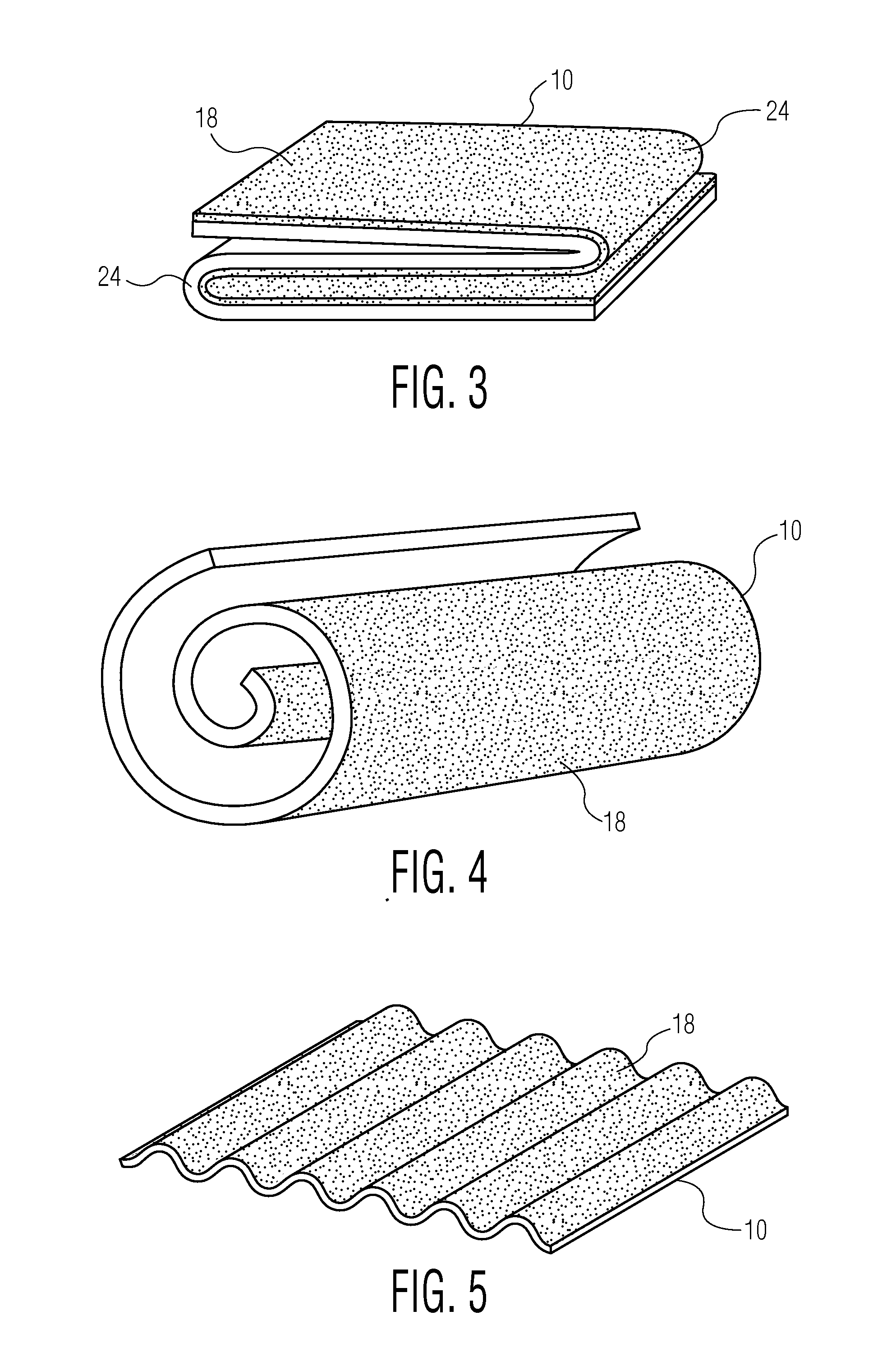

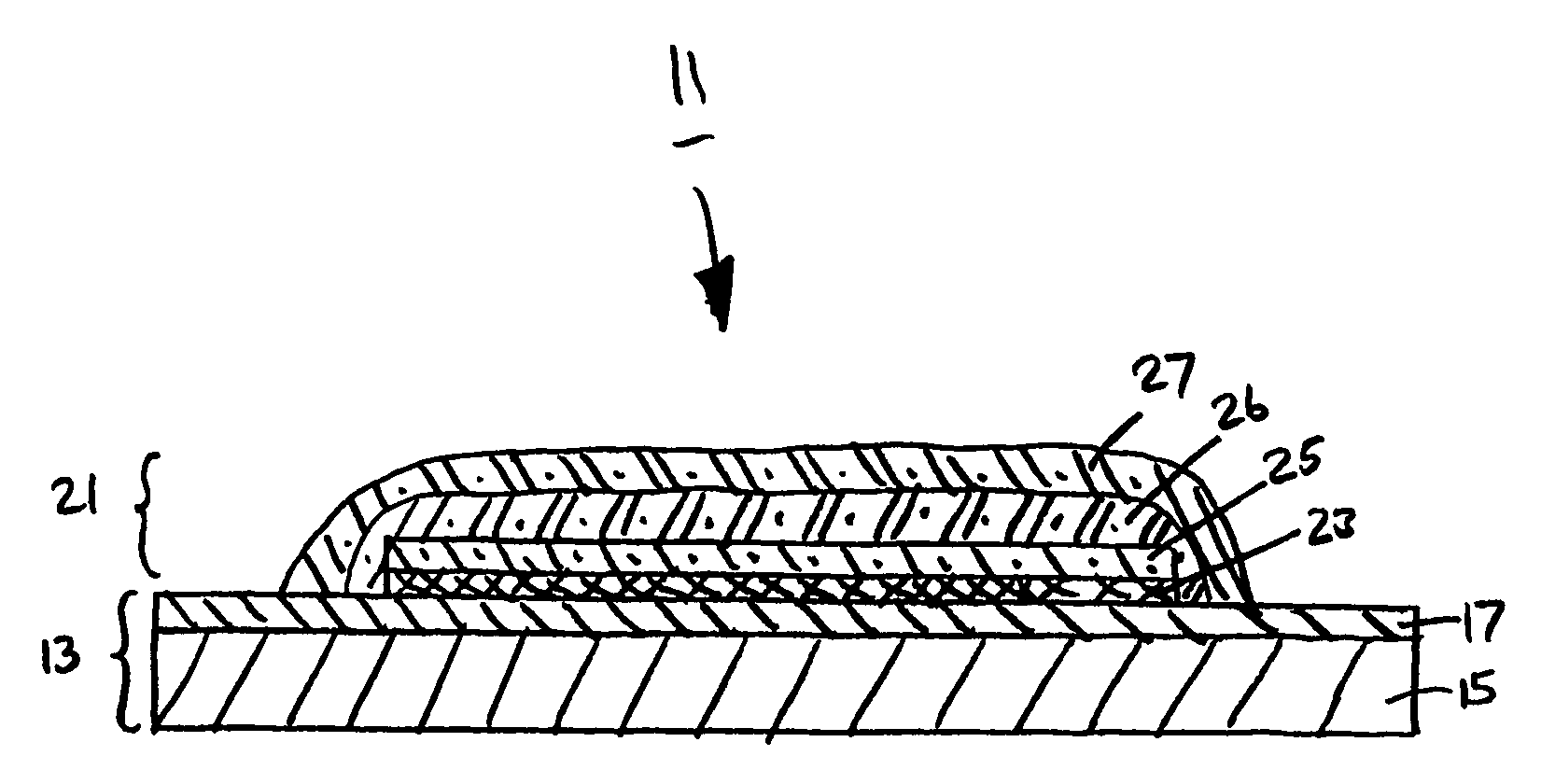

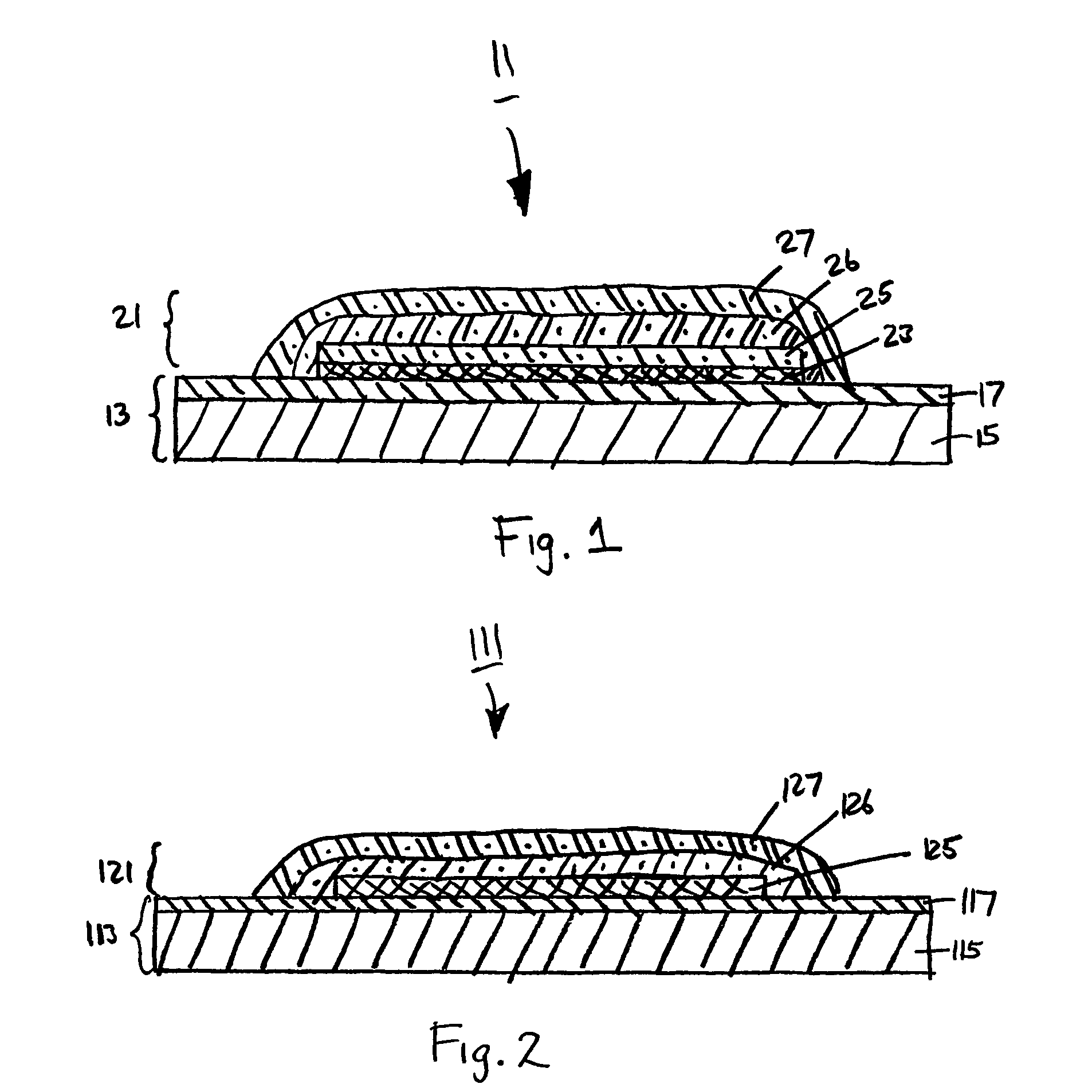

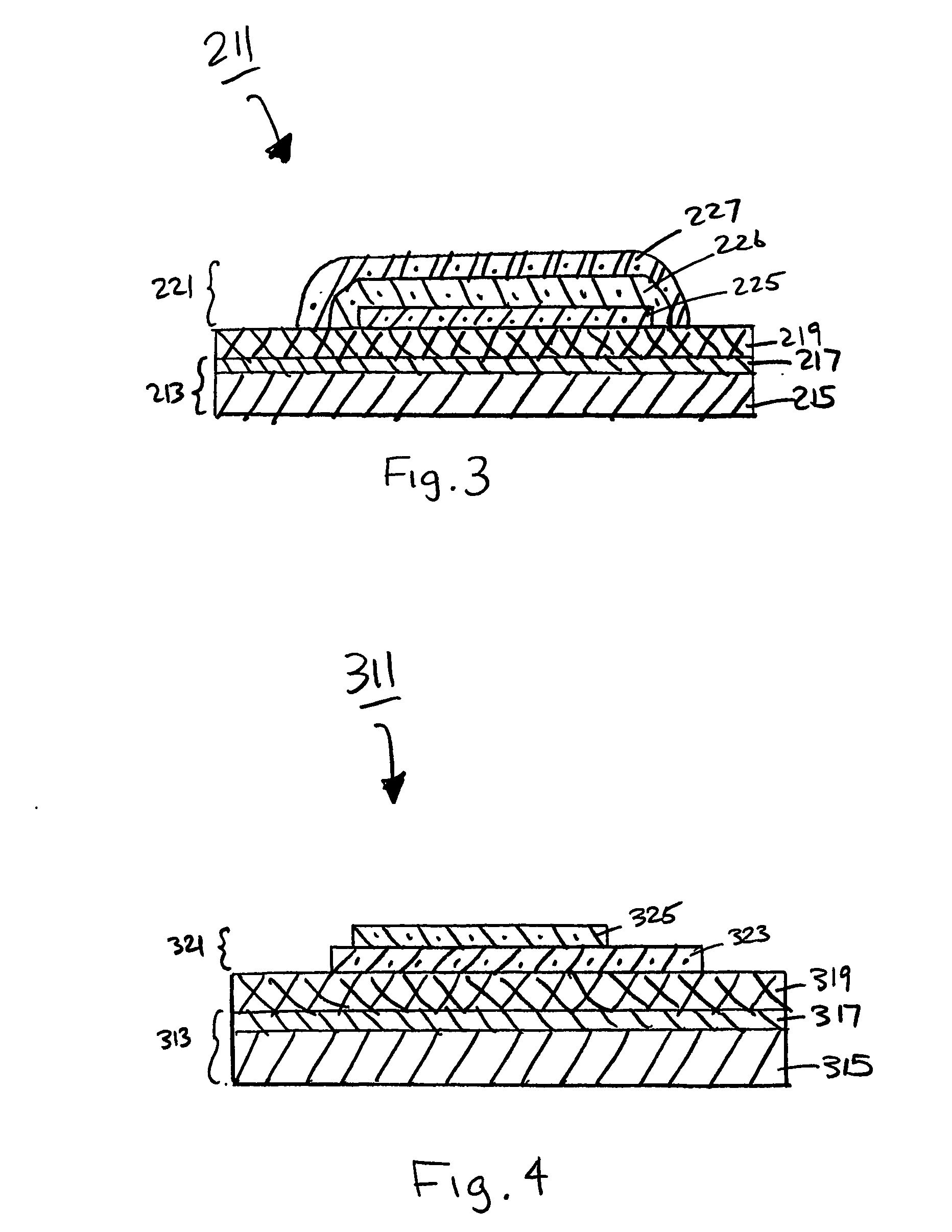

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

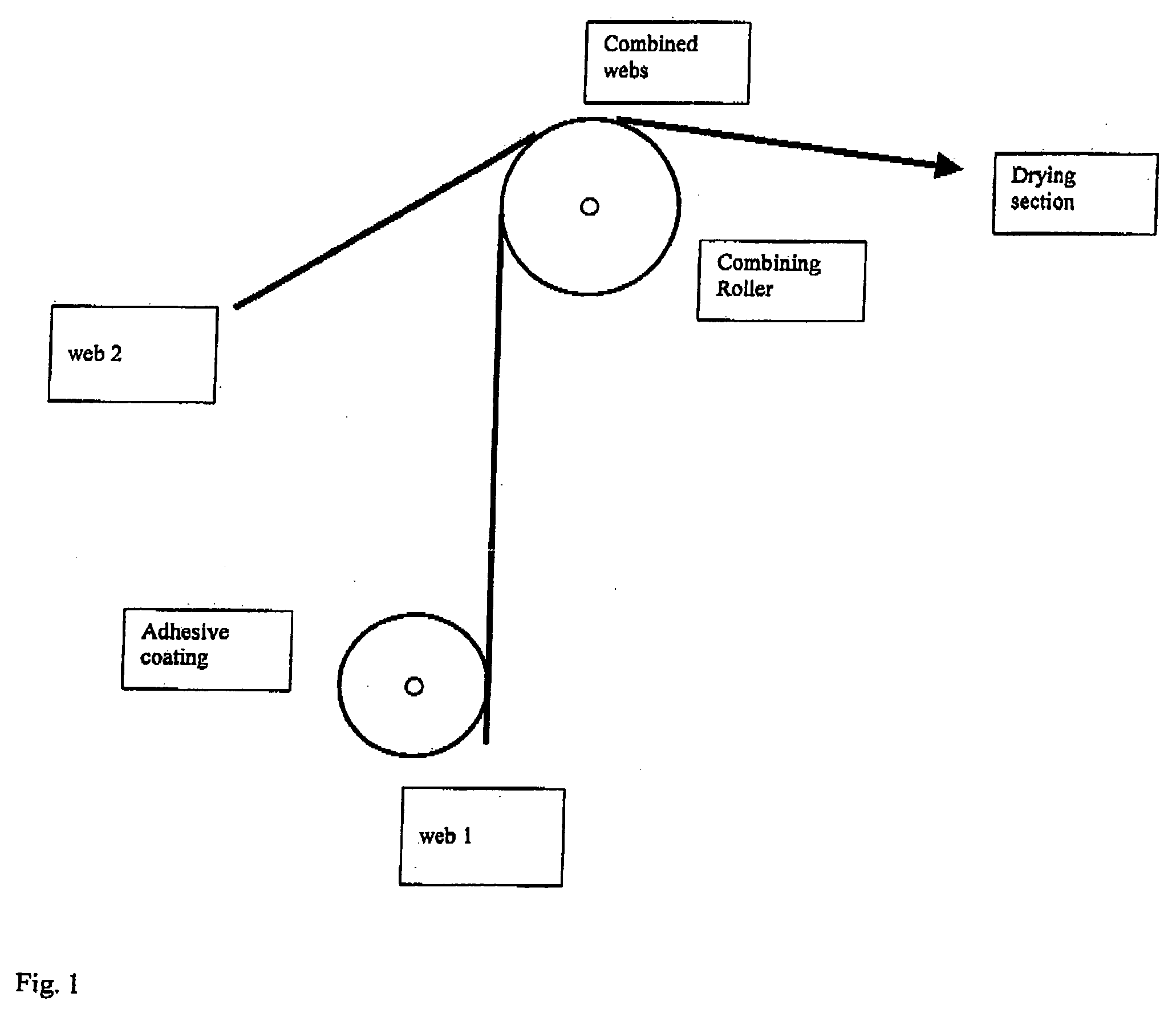

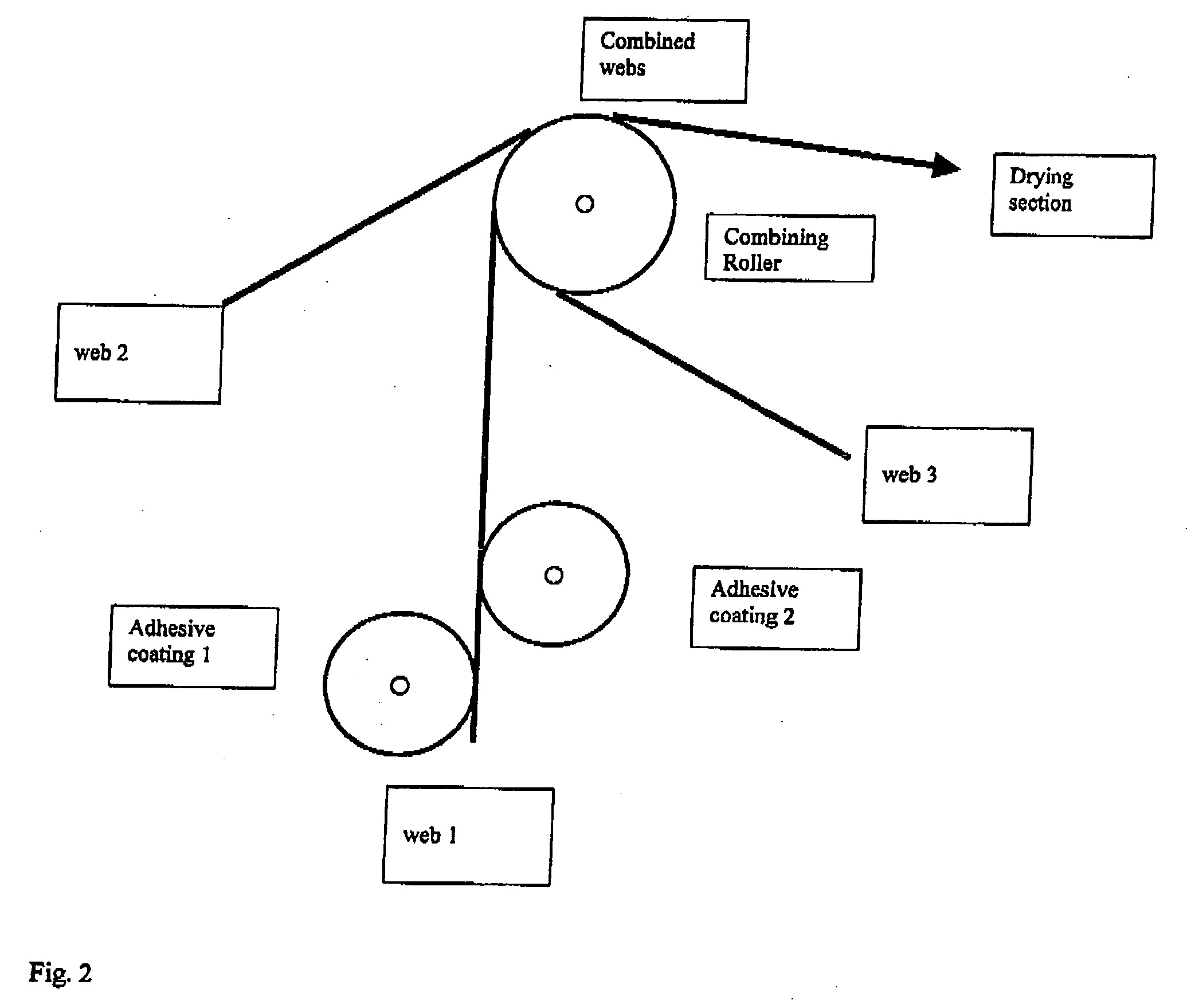

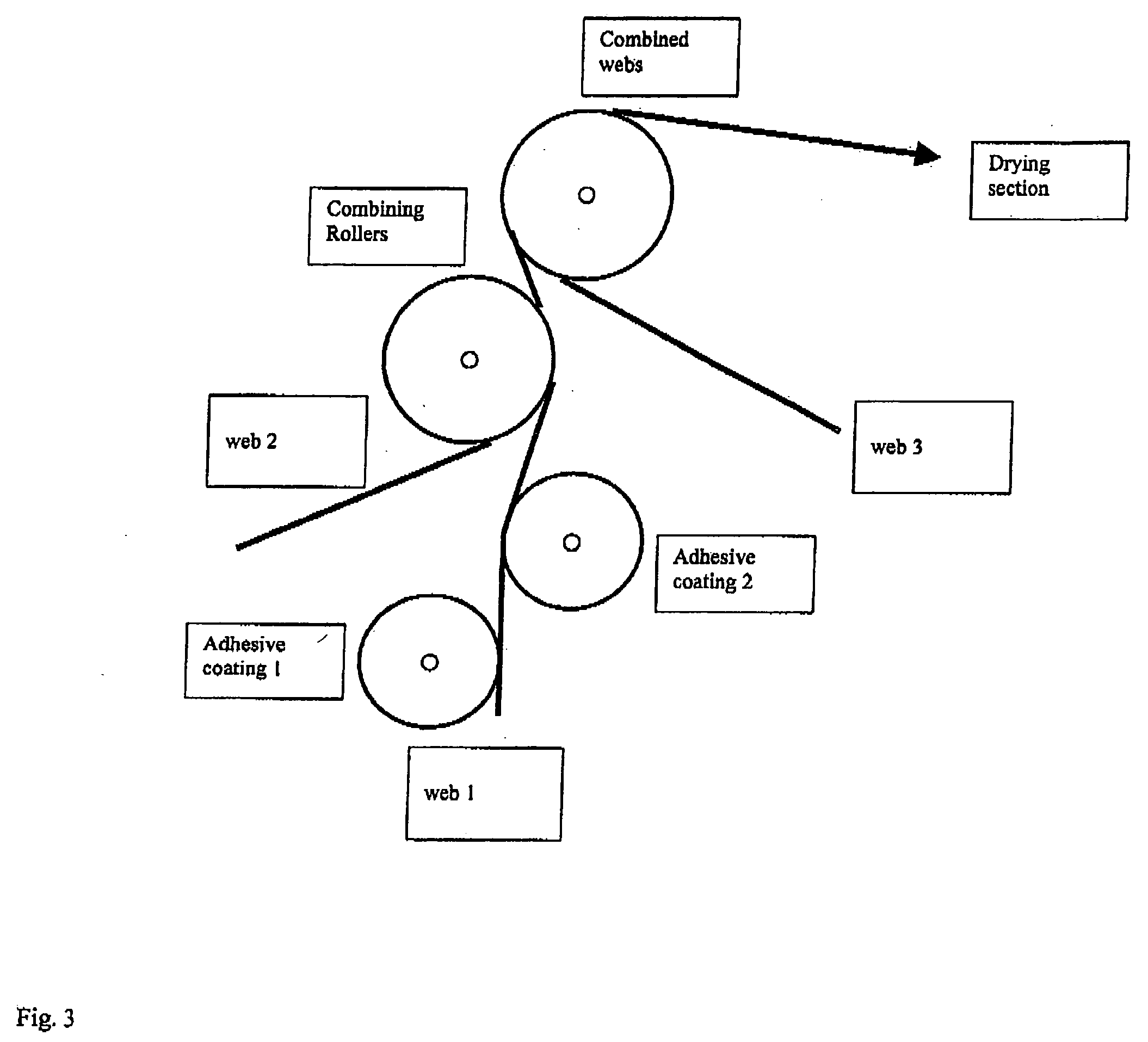

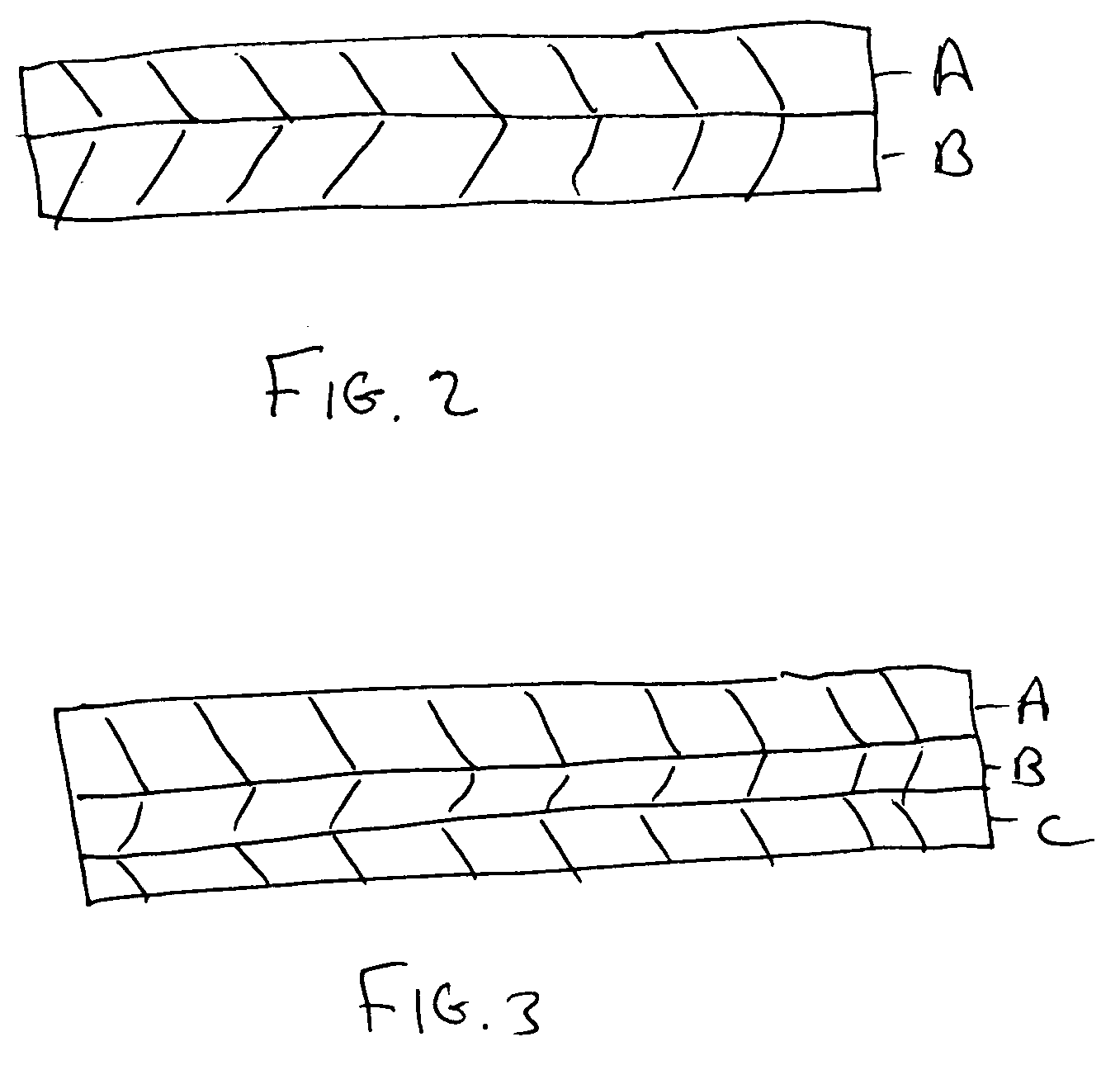

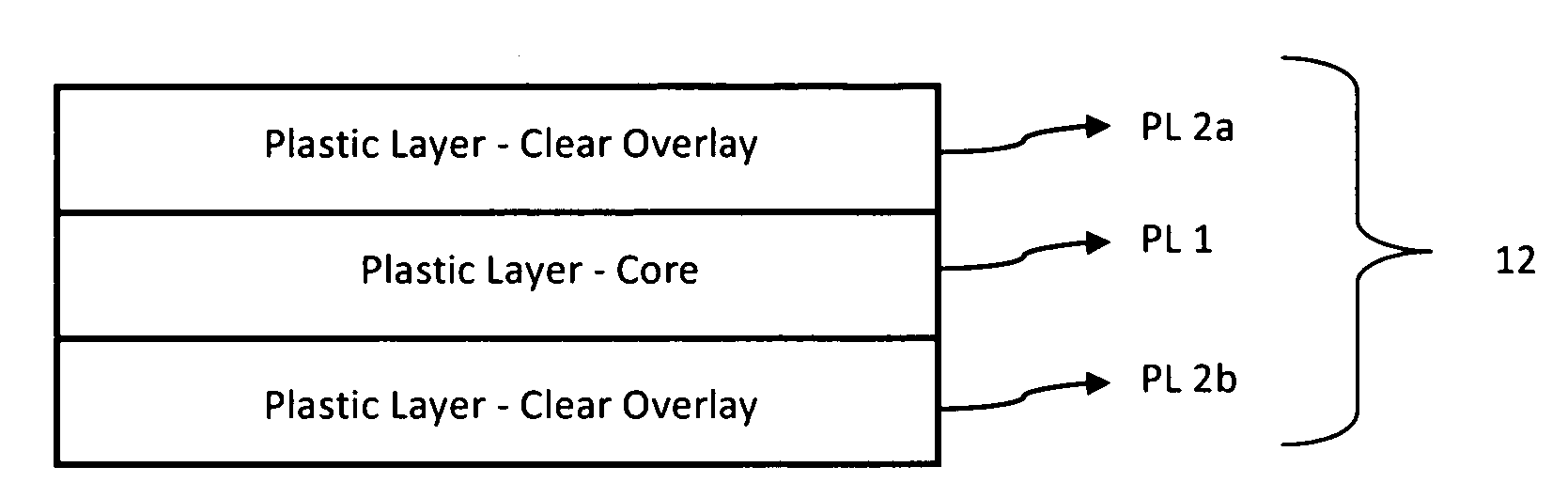

Laminating process and laminates resulting therefrom

InactiveUS20060194004A1Effective combinationIncrease speedAdhesive processesLamination ancillary operationsAdhesiveEngineering

A roll-to-roll lamination process for flexible webs including coating of at least one side of a first flexible web with a film forming adhesive and contacting the adhesive side(s) of the first flexible web to at least one of a second flexible web and a third flexible web on a transport roller while the combined webs are touching the transport roller from one side on a length of more than 5 mm without being further pressurized. Also, a 2 or more ply laminate of flexible webs comprising a first flexible web and a second flexible web, which are permanently attached by a film forming adhesive in a roll-to-roll lamination process, characterised in that the outer surface of the second flexible web has a heat sensitive recording layer and the first flexible web comprises fleece.

Owner:SIHL

Shrink sleeve label

A shrink film comprises a skin layer and a base layer. The skin layer may comprise polystyrene or modified polyester. The base layer may comprise alpha-olefin / cyclic-olefin copolymer or alpha-olefin / vinyl aromatic copolymer. The film has a free shrink at 100° C. of at least about 10%. The film is useful for shrink sleeve applications.

Owner:CRYOVAC INC

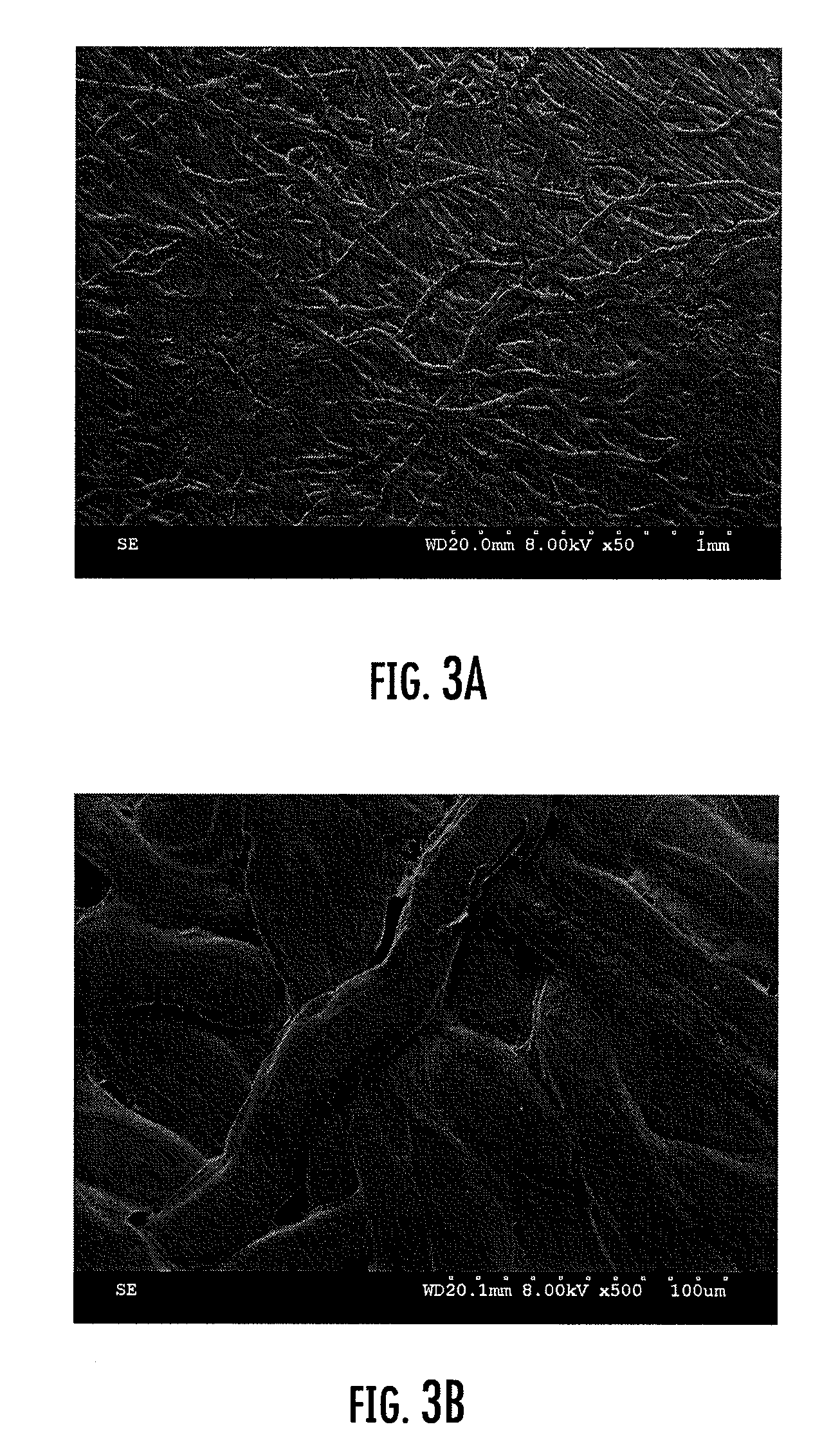

Bicomponent sheet material having liquid barrier properties

ActiveUS20070054579A1Improve breathabilityMaintain good propertiesGarment special featuresSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention provides a sheet material comprising bicomponent filaments having first and second polymer components that are arranged in substantially distinct zones within the filaments, with the first polymer component formed of a relatively lower melting polymer and the second component formed of a relatively higher melting polymer. The filaments of the nonwoven fabric layer are densely arranged and compacted against one another to form smooth, substantially nonporous opposite outer surfaces, and the nonwoven fabric layer are calendered such that the lower melting sheath polymer is fused to the contacting surface portions of adjacent filaments to impart strength and coherency to the nonwoven fabric layer. The sheet material has excellent breathability and liquid barrier properties and may be useful in house wrap, medical garments, and envelope applications.

Owner:FIBERWEB LLC

Matte biaxially oriented polylactic acid film

ActiveUS20100009208A1Minimize thermal shrinkage effectReduce internal stressBio-packagingSynthetic resin layered productsPolyolefinPolymer chemistry

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and a minority amount of polyolefin with a compatibilizing resin which is biaxially oriented such that a matte or opaque appearance is obtained. The laminate film may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Process for producing resonant tag

InactiveUS6618939B2Easy to manufactureStable resonant characteristicWave amplification devicesElectrical connection printed elementsMetal foilAdhesive

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet. The present invention has such advantages as no damage to the base sheet since the stamping-out operation for the metal foil and the thermal adhesion operation thereof to the base sheet are carried out in separate positions, and no requirement of carrier sheet because the resultant metal foil portion obtained by the stamping-out operation is sucked and held onto the surface of the transfer roll.

Owner:NOVATRON ELECTRONICS HANGZHOU

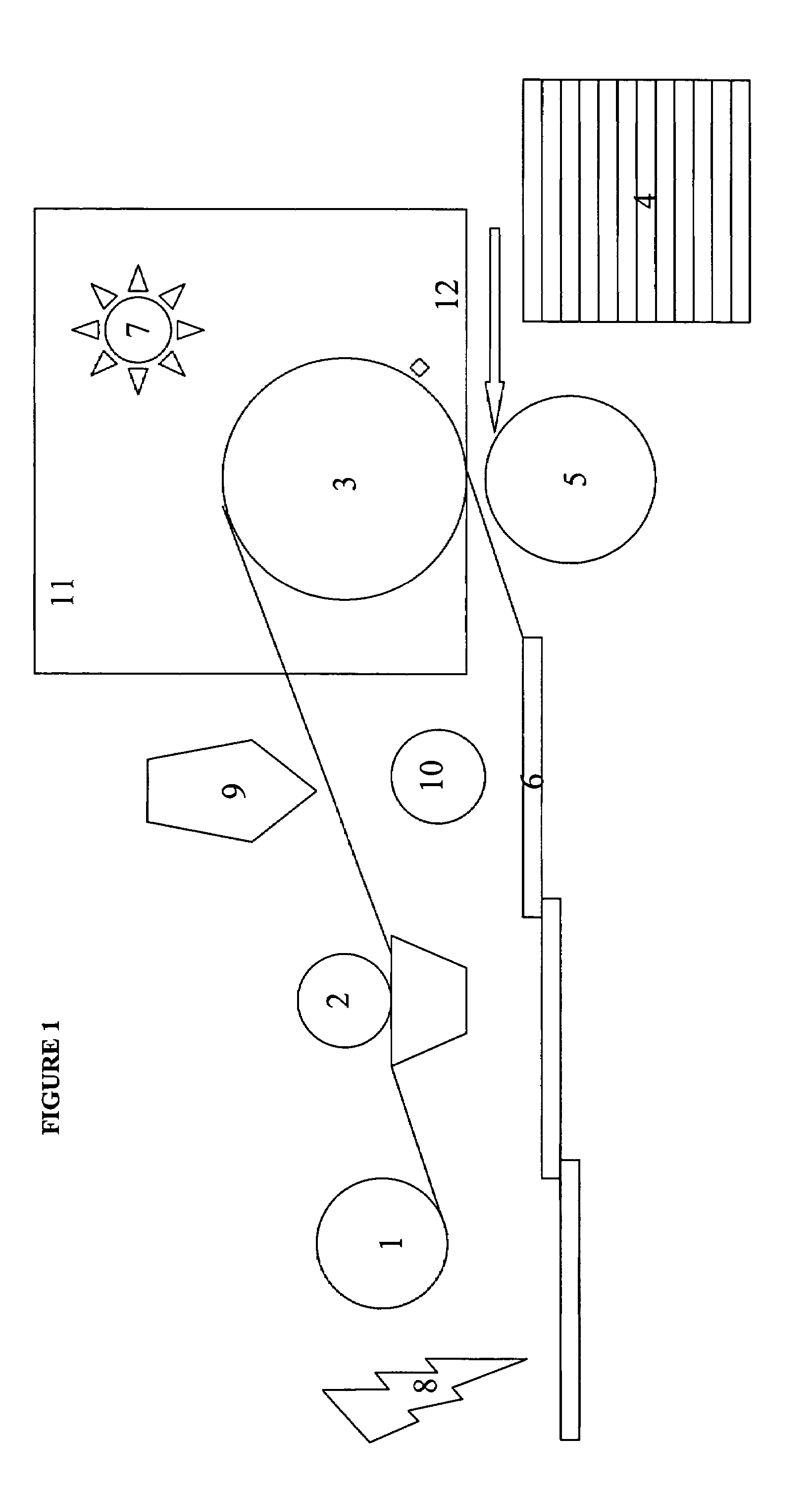

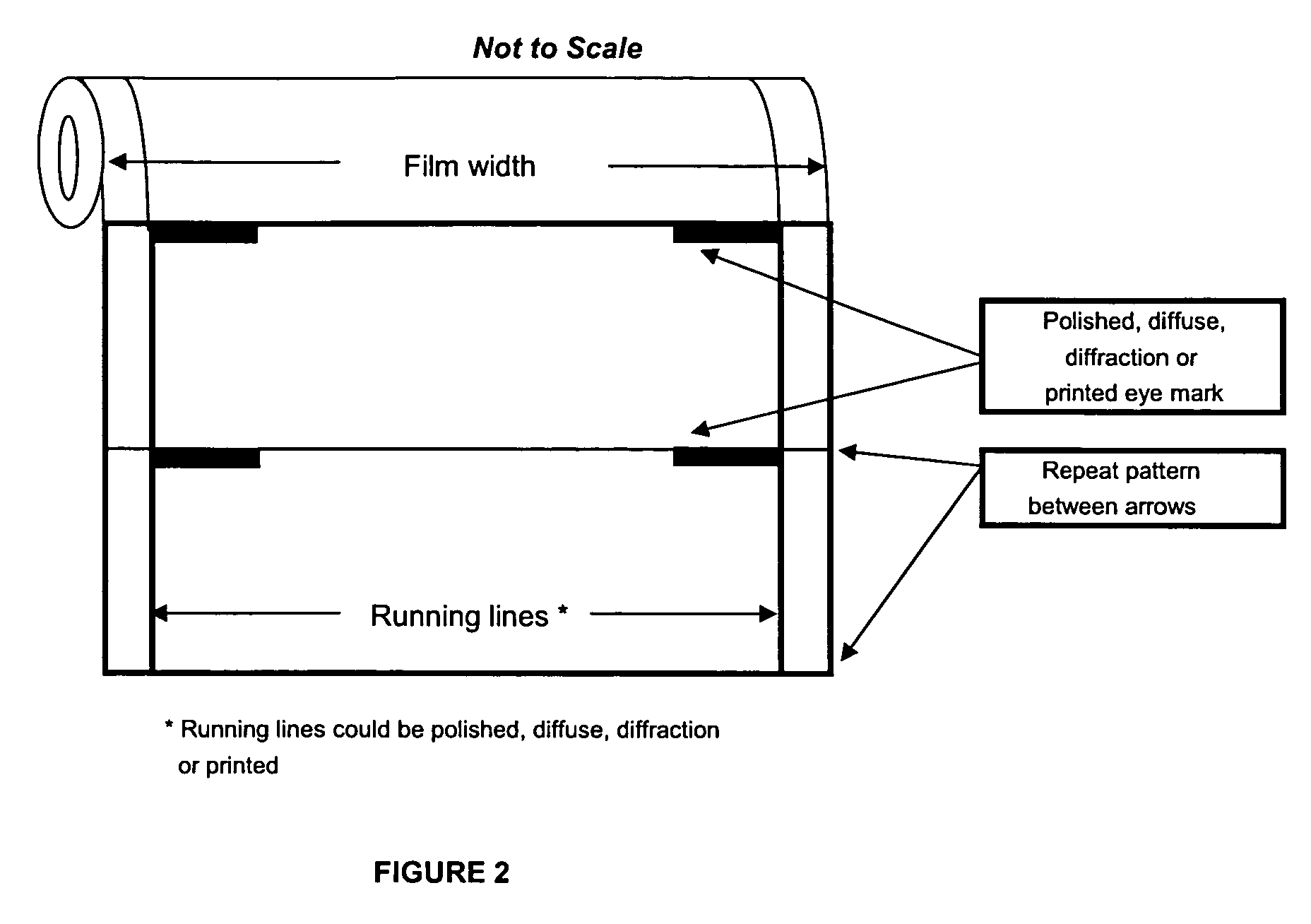

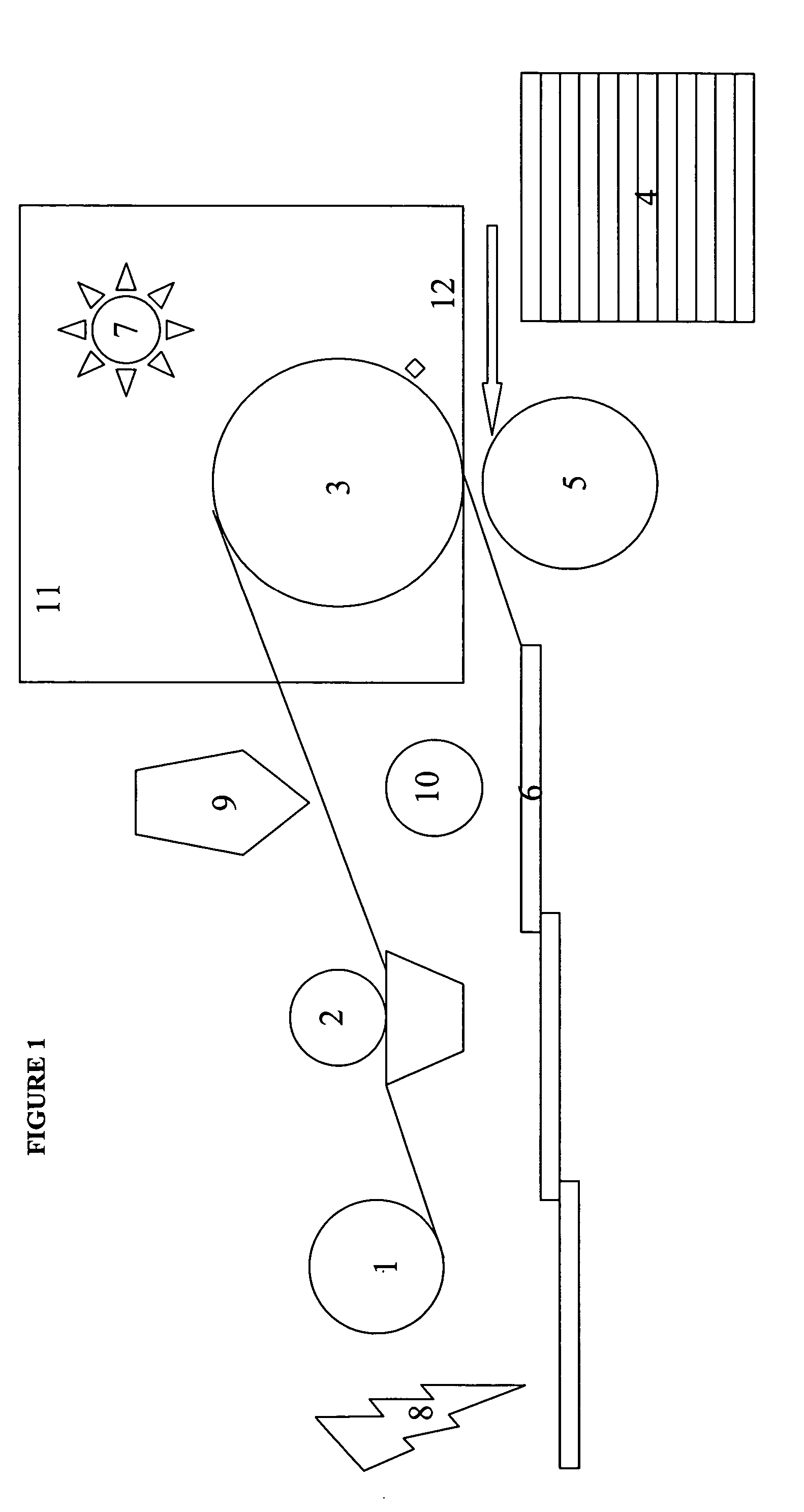

Process of making laminated sheet and product made by the process

A process of making an improved sheet / card laminate for packaging, signage, displays, transaction cards, ID cards and the like. The process comprises registering flat sheets to a film and then laminating the film or transferring coating(s) from the film to the individual, generally flat sheets via an adhesive. The film or coating(s) may include layered security, functional and / or decorative features.

Owner:ILLINOIS TOOL WORKS INC

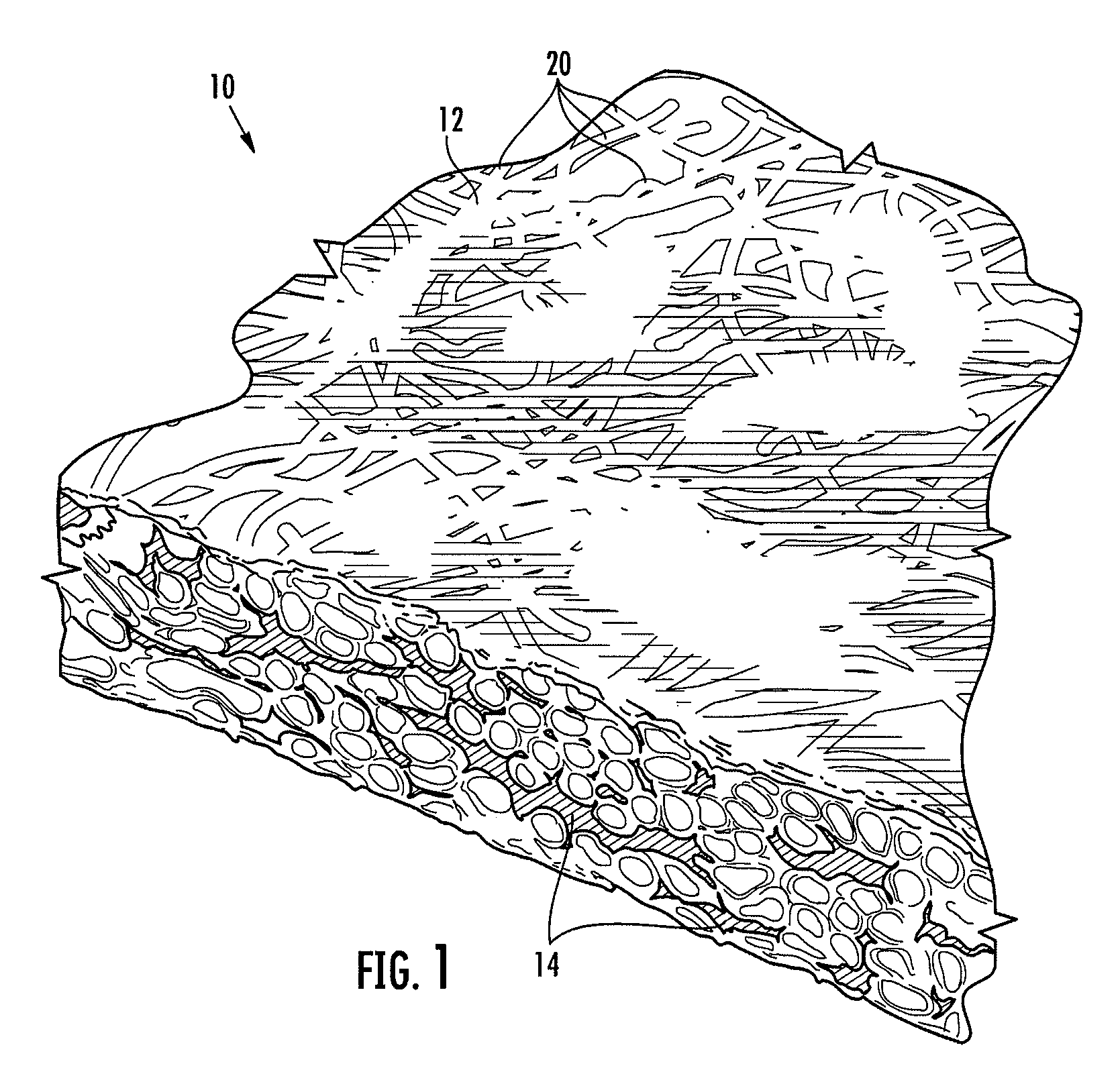

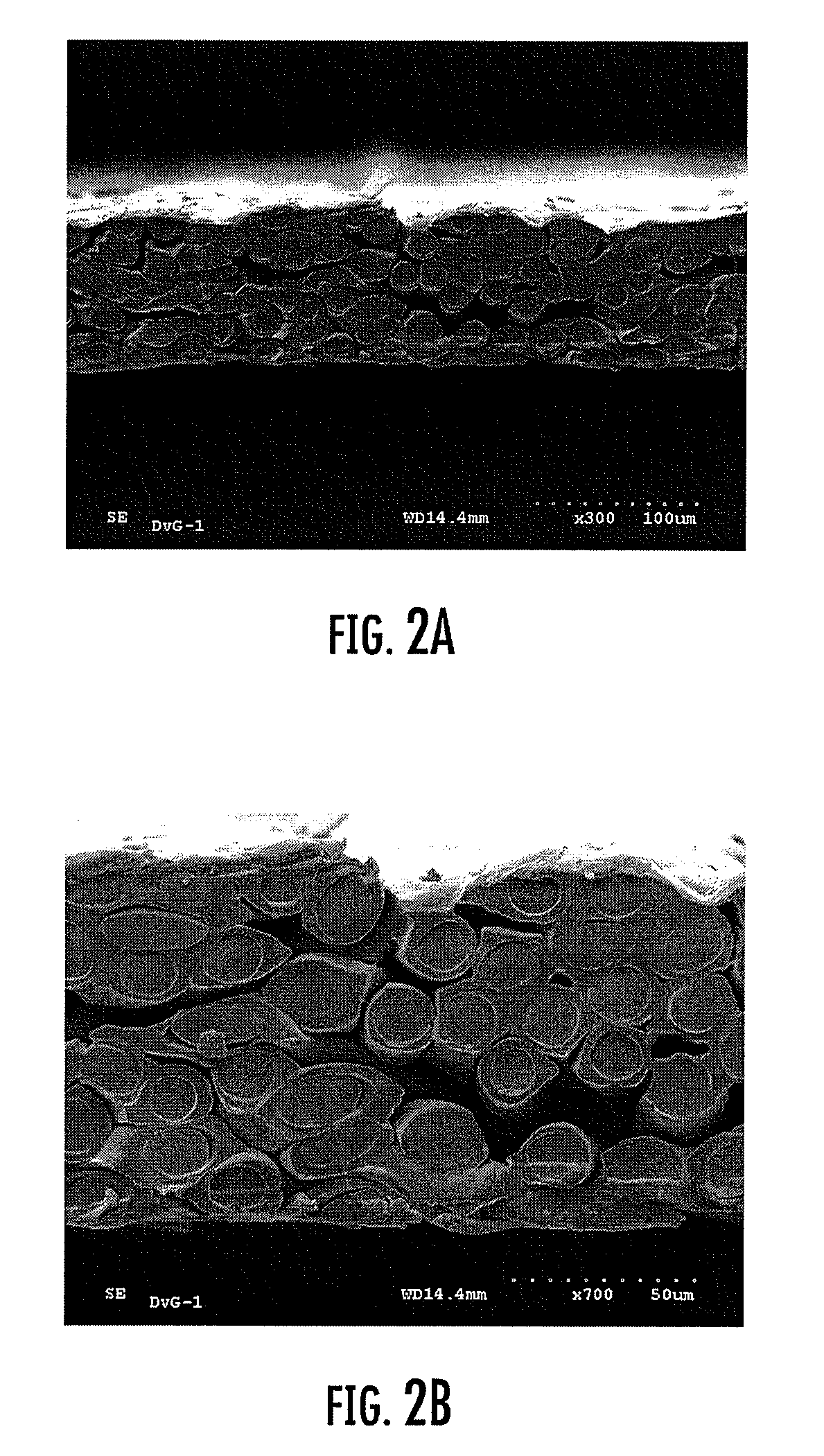

Compositions for the preparation of void-containing articles

ActiveUS7273894B2Efficiently formedEfficient voidingSynthetic resin layered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

Security tag system for fabricating a tag including an integrated surface processing system

A method of fabricating a tag includes the steps of applying a first patterned adhesive to the surface of the substrate and applying a first electrically conductive foil to the first patterned adhesive. A portion of the first electrically conductive foil not adhered to the first patterned adhesive is removed and a second patterned adhesive is applied to a portion of a surface area of the tag. A preformed second electrically conductive foil is applied to the second patterned adhesive to adhere the second electrically conductive foil to the surface of the substrate and portions of the first and second electrically conductive foils are electrically coupled to each other to form a tag circuit. A second patterned adhesive can be disposed between the first and second electrically conductive foils.

Owner:CHECKPOINT SYST INC

Document laminate formed from different polyester materials

InactiveUS20050084693A1Reduce adverse effectsImproved safety and durabilityRecord carriersDecorative surface effectsPolyesterAdhesive

A polyester laminate for an identification document is formed from different polyester materials. One of the polyester materials, such as PCTA, provides a durability property. Another of the polyester materials, such as PETG, provides a layer having a surface with a bonding property for bonding directly to a core without adhesive. The polyester material with the bonding property is selected to enable direct bonding to a printed core layer of TESLIN or polyester through a roll to roll or platen press process.

Owner:L 1 SECURE CREDENTIALING

Biaxially oriented polylactic acid film with improved moisture barrier

InactiveUS20100330382A1Improved barrier resistanceImprove moisture resistanceSynthetic resin layered productsLabelsSealantMetallizing

Owner:TORAY PLASTICS AMERICA

Process of making laminated sheet and product made by the process

A process of making an improved sheet / card laminate for packaging, signage, displays, transaction cards, ID cards and the like. The process comprises registering flat sheets to a film and then laminating the film or transferring coating(s) from the film to the individual, generally flat sheets via an adhesive. The film or coating(s) may include layered security, functional and / or decorative features.

Owner:ILLINOIS TOOL WORKS INC

Biaxially oriented polylactic acid film with high barrier

ActiveUS20100040904A1Good metal adhesionImproves the gas barrier of the metallized PLA filmSynthetic resin layered productsVacuum evaporation coatingMoisture barrierFood packaging

A multilayer film including a first layer including a polylactic acid polymer, a second layer of a metal primer, deposited upon one surface of the first polylactic acid polymer layer, and a third metal layer deposited on the second metal primer layer. This metal-primed and metallized polylactic acid film exhibits improved moisture barrier properties versus a non-metal-primed and metallized polylactic acid film and can be used as part of a lamination structure for food packaging applications.

Owner:TORAY PLASTICS AMERICA

Multilayer separable film or sheet

InactiveUS20060088695A1Low production costSaveDomestic sealsProtective equipmentElectrical and Electronics engineeringSheet material

A multilayer film having two or more separable adjacent layers. The multilayer film includes adjacent layers formed of compositions of dissimilar primary materials. Optionally, at least one of the layers contains a slip additive to change the release tension between adjacent layers. The multilayer film may include an adhesive layer between layers, with the adhesive layer more adhesion compatible with one of the layers than the other. The multilayer film may be a relatively inexpensive means to produce labels, films, sheets, containers, etc., requiring protection or isolation of one surface without the additional processes of gluing together individual dissimilar layers. Applications include, but are not limited to, the multilayer film being used as a seal to secure containers, including envelopes, and being imprinted and used as a multilayer labeling system. In one preferred embodiment, at least one layer of the multilayer film undergoes a visibly observable change when the at least one layer is released from at least one other layer; the visibly observable change is useful for many purposes, including, but not limited to, serving as a security mechanism within a container seal which, when the seal is broken, provides evidence that the container was opened.

Owner:COBURN THEODORE

Combination card of metal and plastic

ActiveUS20120325914A1Dimensionally stableReduce changesOrnamental structuresSpecial ornamental structuresAdhesiveEngineering

A card formed in accordance with the invention includes a first assembly comprised of multiple plastic layers attached via an adhesive to a metal layer. The multiple plastic layers forming the first assembly are laminated under a first selected temperature and pressure conditions to preshrink the multiple plastic layers, stress relieve the first assembly and render the first assembly dimensionally stable. The laminated first assembly is then attached to a metal layer via an adhesive layer to form a second assembly which is then laminated at a temperature below the first selected temperature to form a card which is not subjected to warpage and delamination.

Owner:COMPOSECURE LLC

Binding substrate for a document for personal identification and method for its production

ActiveUS7059535B2Easy to replaceFunction increaseOther printing matterRecord carriersThermoplasticEngineering

A transponder inlay for a document for personal identification is provided which has at least one ID page with a layered construction. The layered construction has a transponder substrate for positioning a transponder unit, and includes a chip unit and an antenna, and two inlay cover layers, which receives the transponder substrate between them. The transponder substrate is formed from a thermoplastic, and the inlay cover layers are made of a foamed plastic.

Owner:LINXENS HLDG SAS

Heat-Shrinkable Laminate Film, Molded Product and Heat Shrinkable Label Employing the Film, and Container

ActiveUS20080026170A1Low temperature shrinkabilityLittle natural shrinkageStampsWrappers shrinkageSurface layerWarm water

To provide a heat-shrinkable laminate film excellent in film elasticity (rigidity at room temperature), shrink finishing quality, transparency when incorporated as recycled and natural shrinkage and having delamination of the film suppressed, so that it is suitable for application in shrink wrapping, shrink bundling wrapping, shrink label, etc., and a plastic container provided with a heat shrinkable label made of such a film.A laminated film comprising a surface layer (S layer) composed mainly of a polyester resin, an intermediate layer (M layer) composed mainly of a styrene resin and an adhesive layer (AD layer) composed mainly of an adhesive resin, wherein its heat shrinkage is at least 30% in at least one direction when it is dipped in warm water of 80° C. for 10 seconds, or its tensile modulus of elasticity in a direction perpendicular to the main shrink direction is at least 1,200 MPa.

Owner:MITSUBISHI CHEM CORP

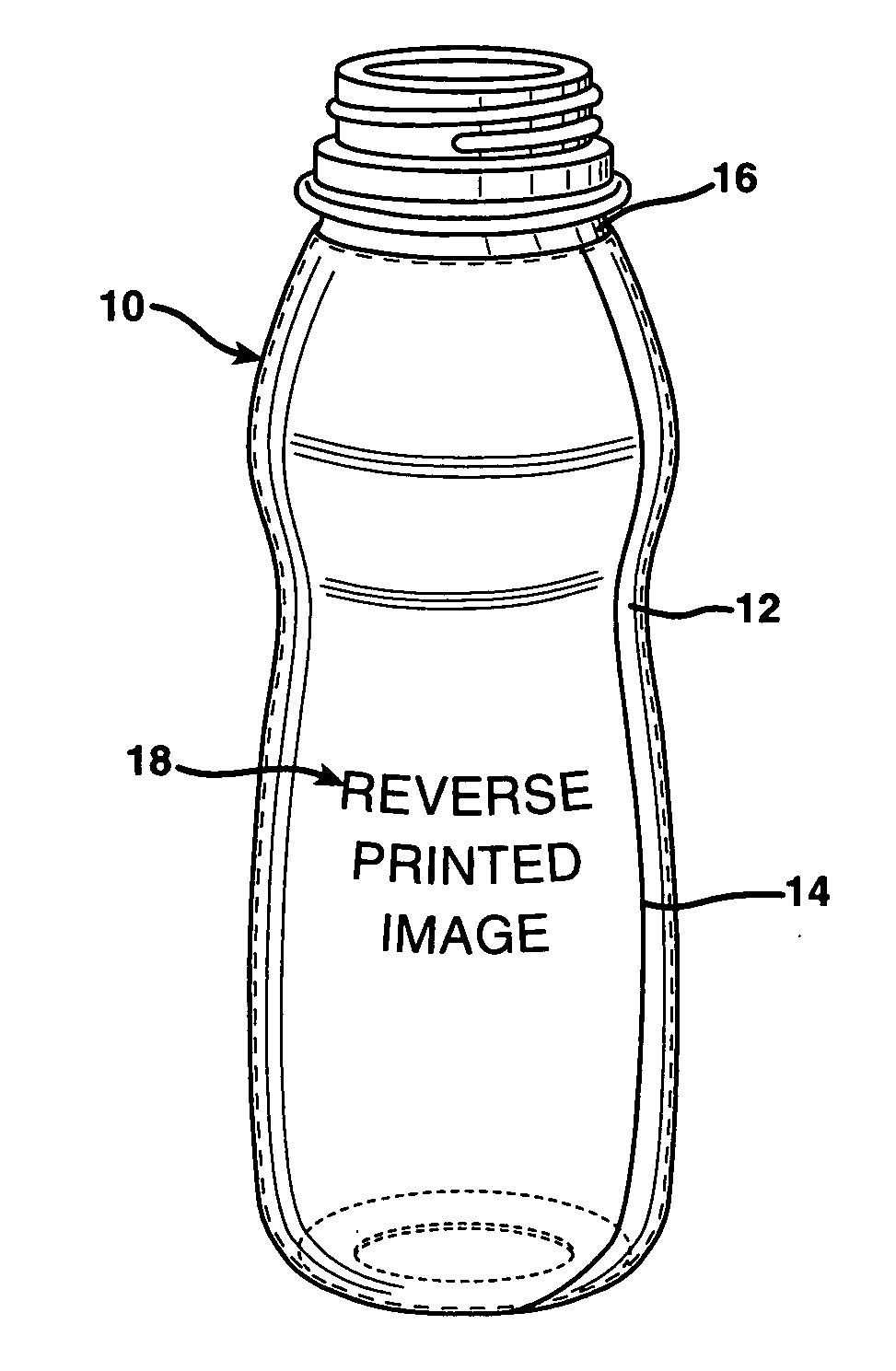

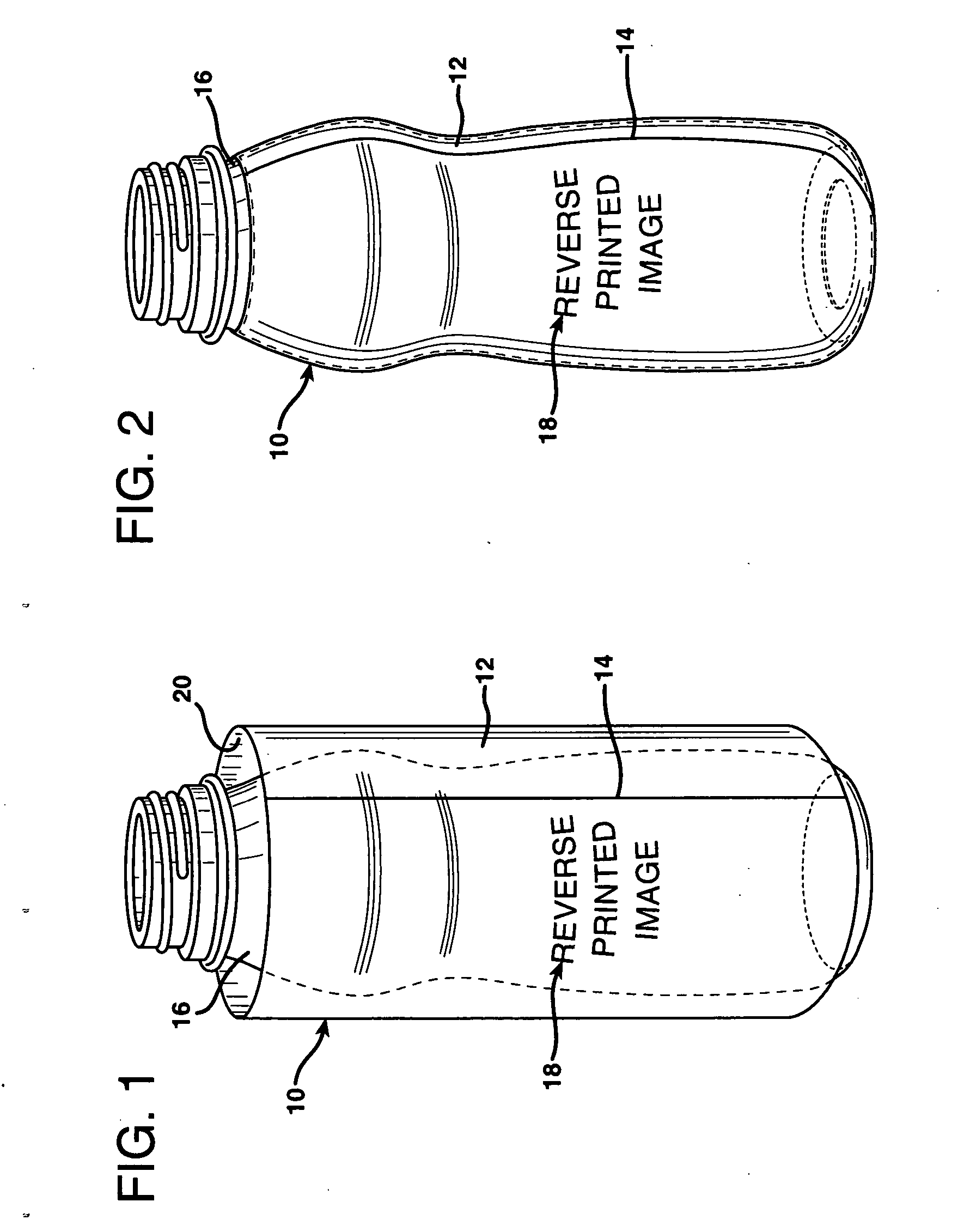

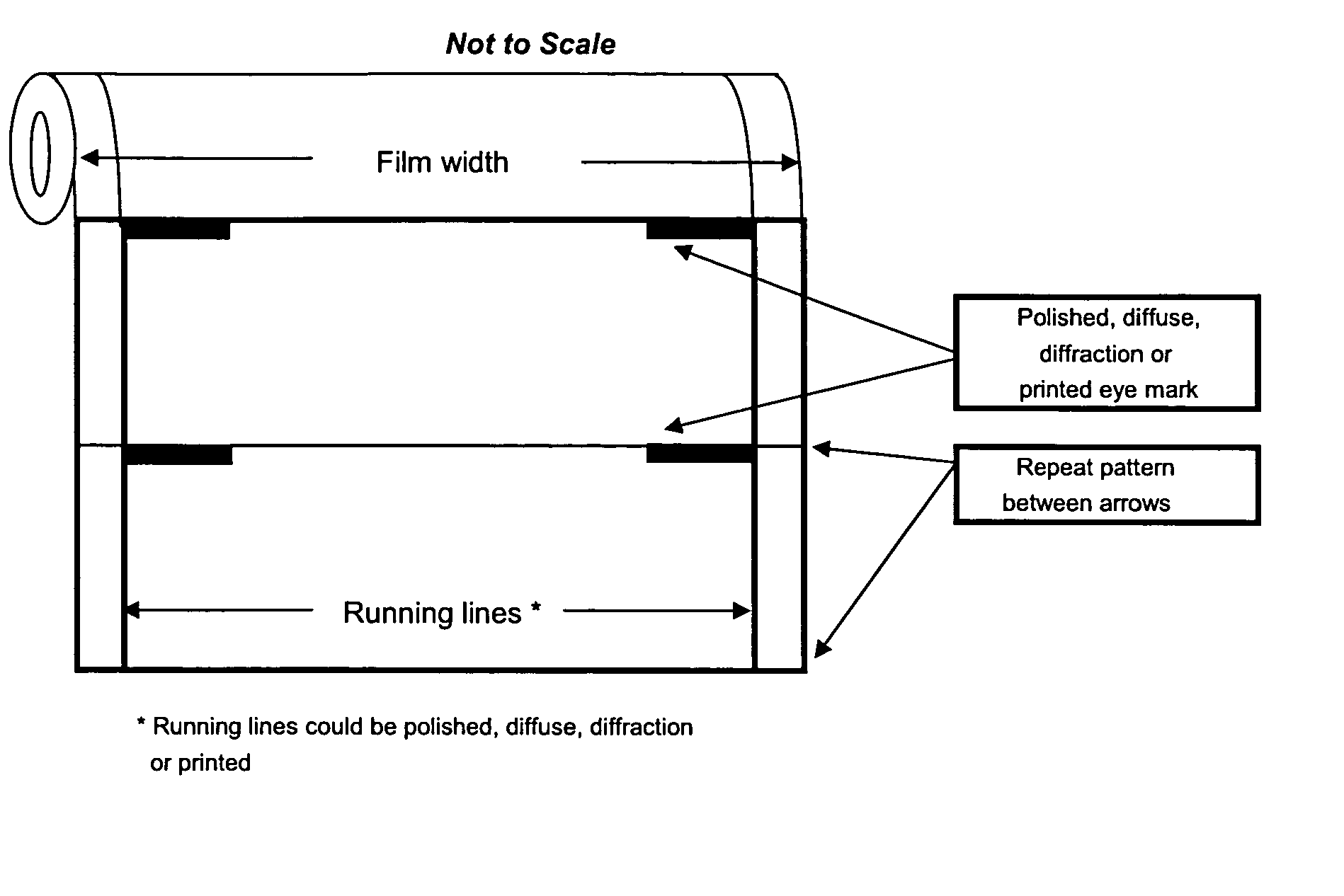

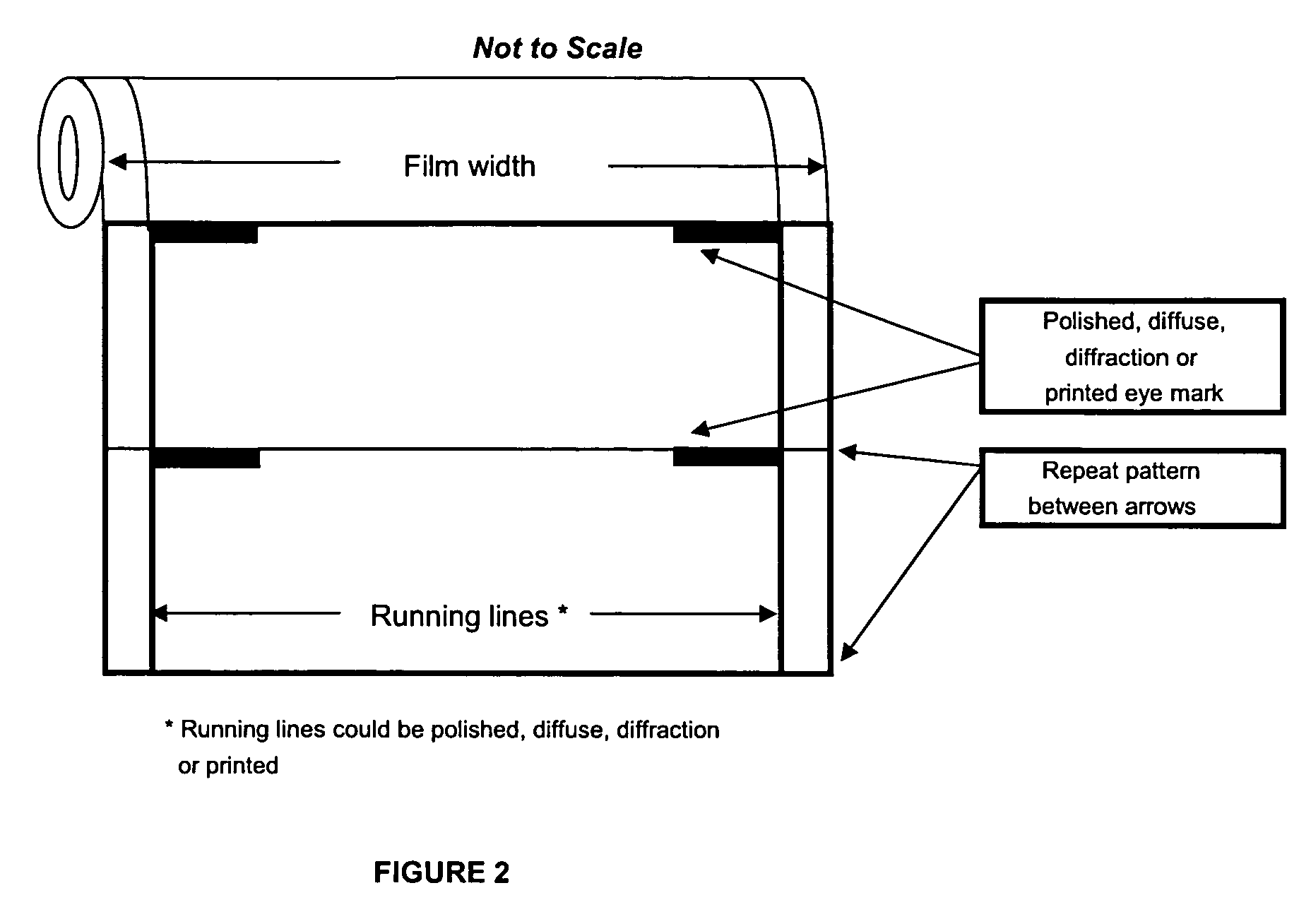

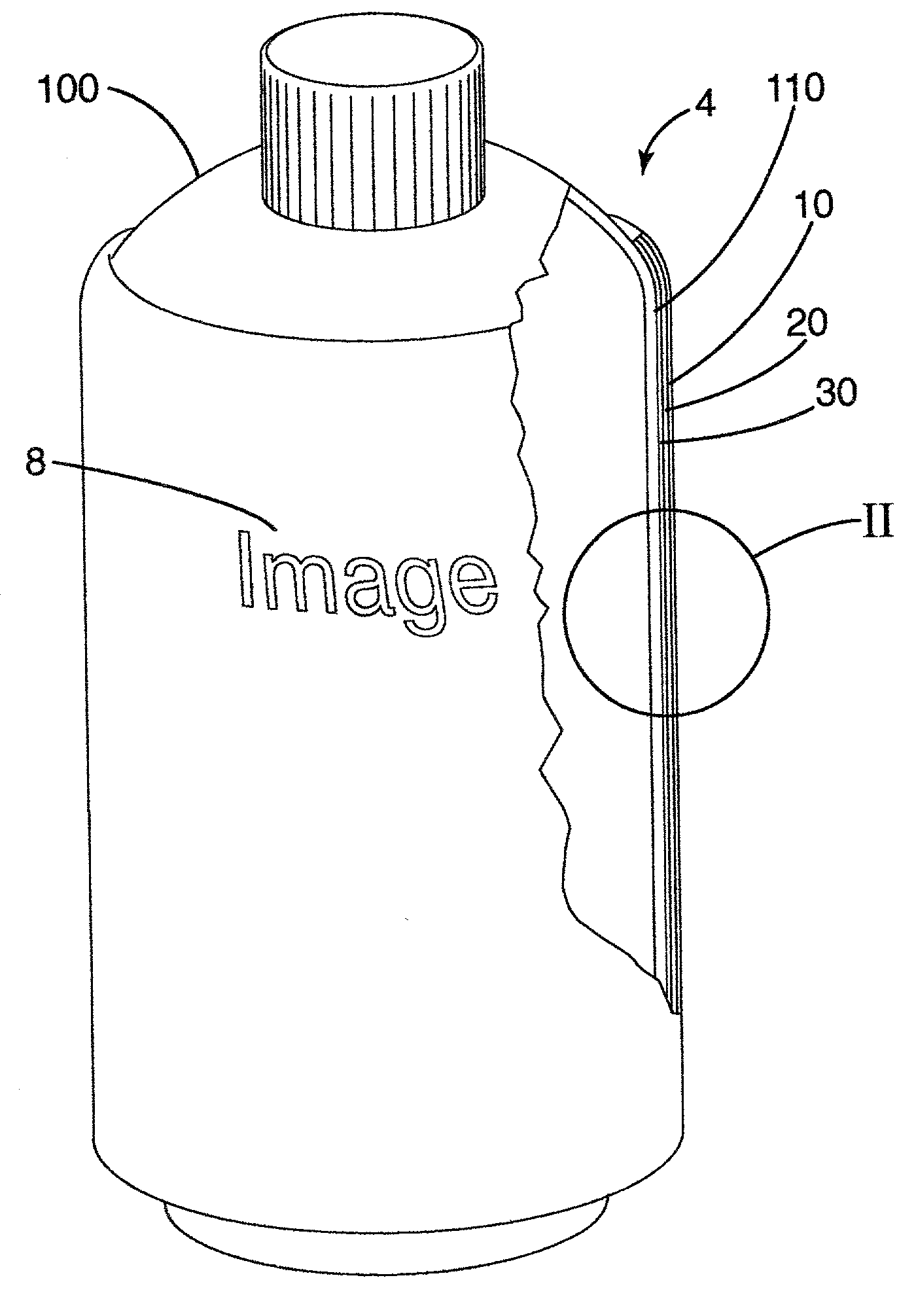

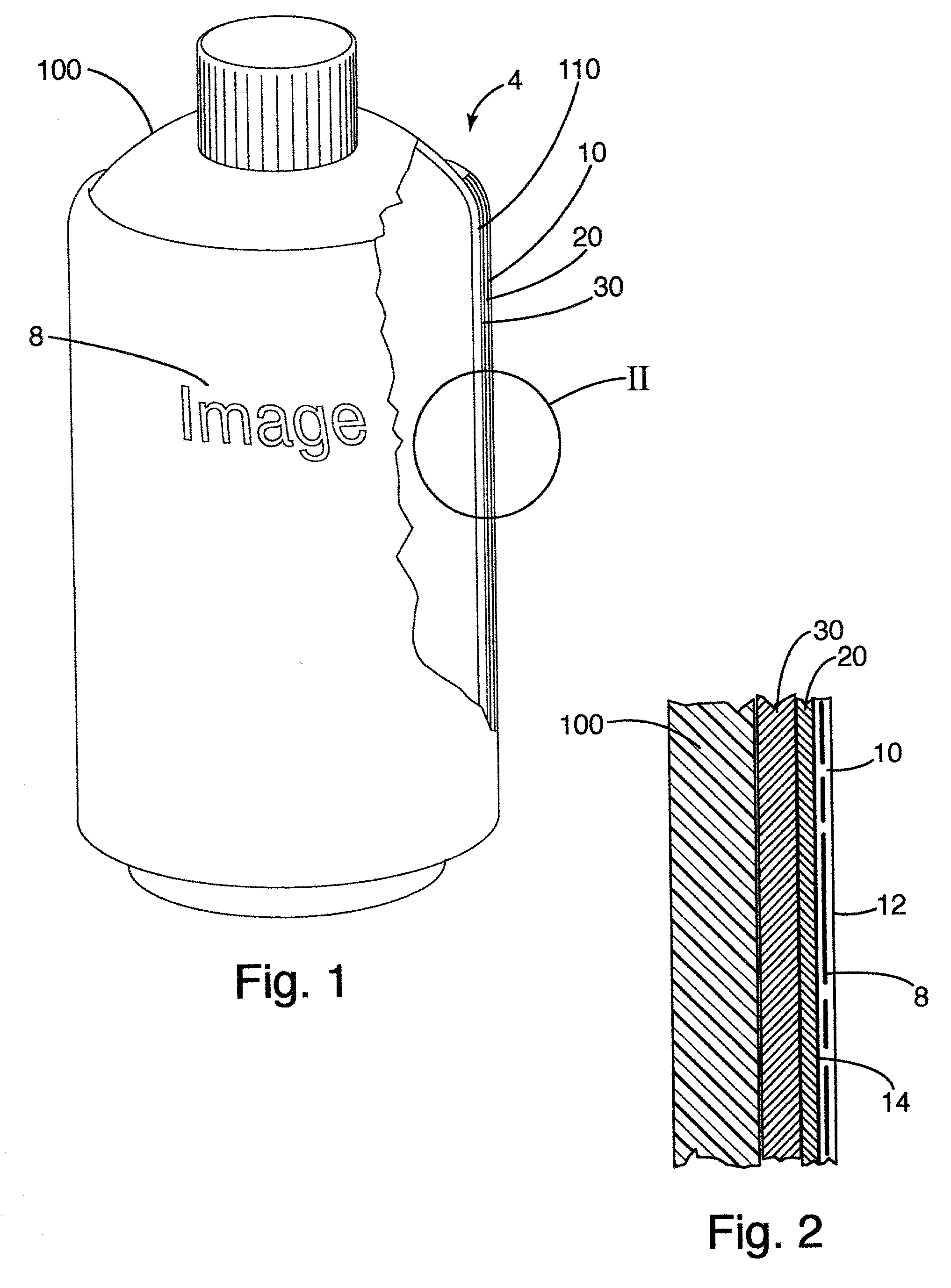

Metalized shrink label and related method of manufacture

InactiveUS20030021918A1Enhance image and graphic and overall appearanceEnhance image and graphicEnvelopes/bags making machineryLiquid surface applicatorsMetallic materialsThin membrane

A metalized shrink film for contoured containers and other articles and a process for manufacturing the same. A preferred metalized shrink film includes a heat-shrinkable film layer, a varnish disposed over the film on at least one side, and a metalized layer disposed over the varnish. The metalized layer is preferably viewable through the heat-shrinkable film layer. Preferably, the varnish is a clear and ultraviolet curable, and the heat-shrinkable film includes images or graphics. A preferred method of manufacturing the metalized shrink film includes: providing a heat-shrinkable film material; applying varnish over the film; and applying a metal material over the varnish and any regions of the film not covered by the varnish. Preferably, the heat shrink film is incorporated into a heat-shrinkable label or sleeve used on contoured containers, such as bottles. When the label or sleeve is shrunk over contours of the container, the metalized regions viewable through the film and the images or graphics on the film do not discolor or become cloudy near the contours.

Owner:UV COLOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com