Patents

Literature

2977results about How to "Dimensionally stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oriented polymer implantable device and process for making same

InactiveUS20100191292A1Reduce cross sectionHigh strengthSuture equipmentsLigamentsFastenerBone screws

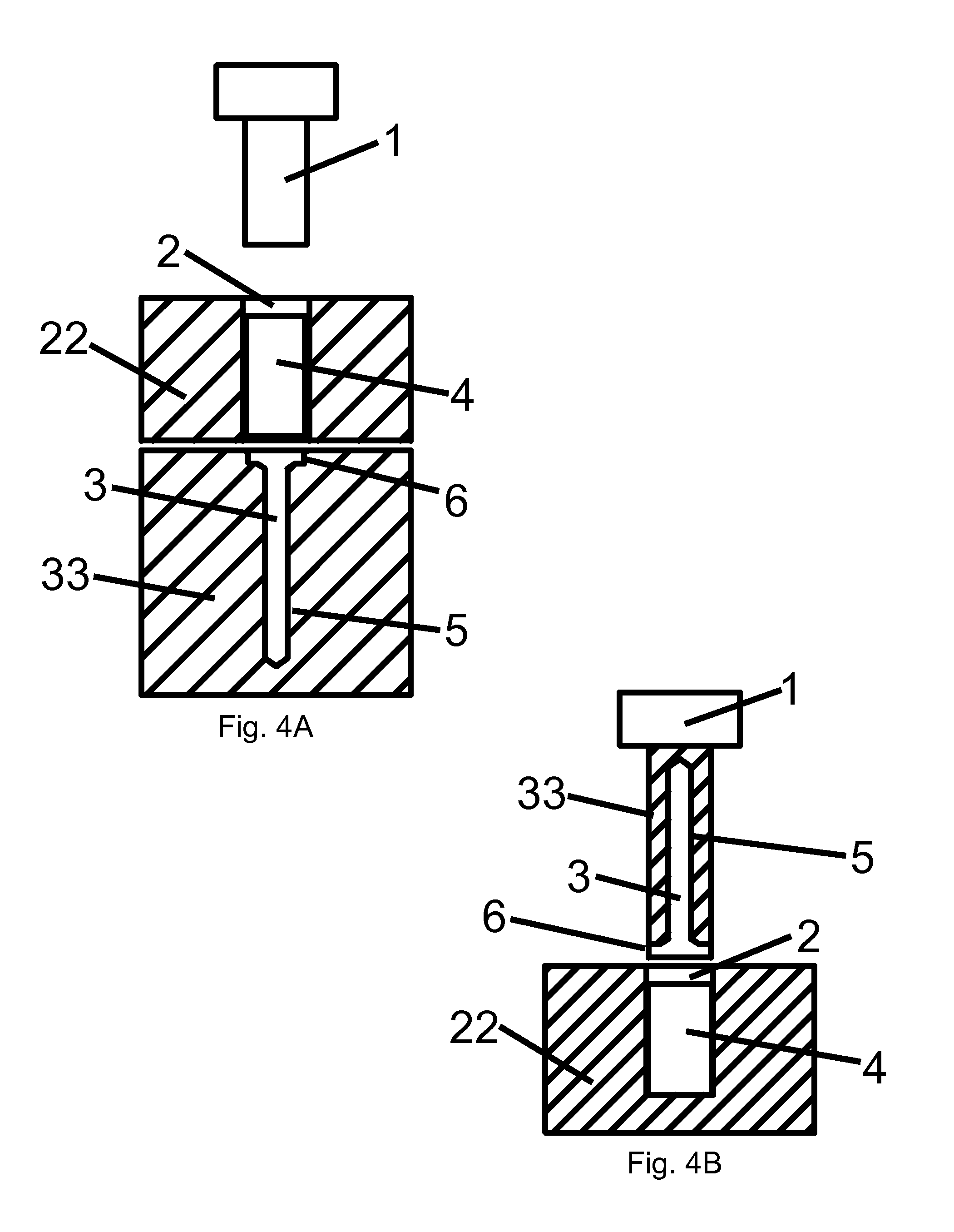

A device is formed by a discontinuous process into a bone screw, plate, or fastener, wherein the device has a degree of polymer alignment and strength, and upon reheating above glass transition temperature of the polymer, the device remains dimensionally stable, as it maintains its dimensions, strength, and degree of polymer orientation. In practice of the present invention, the polymer slug is pressed into the die cavity by the actuation of ram press, causing the slug to conform to the die cavity.

Owner:KENSEY NASH CORP

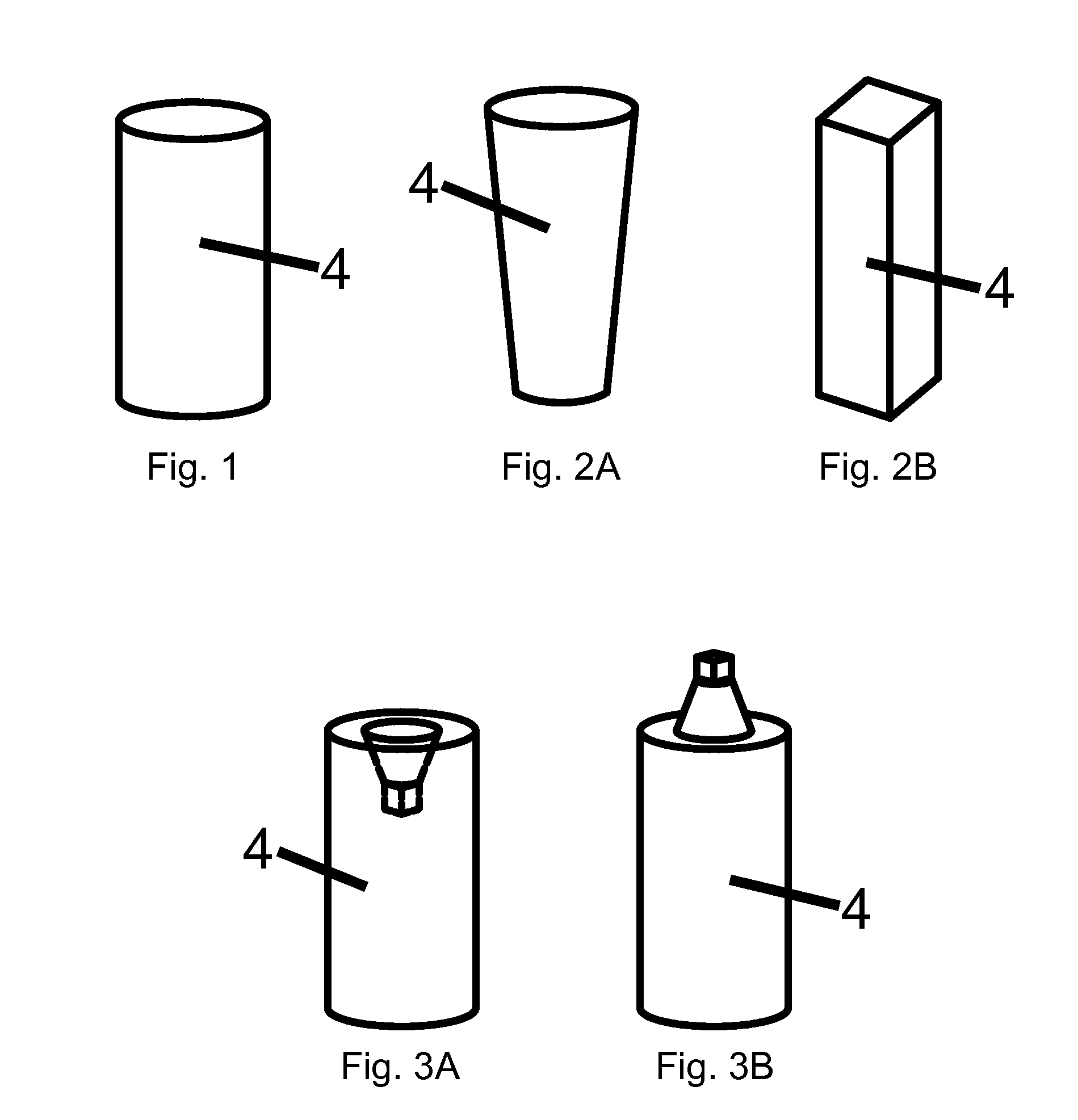

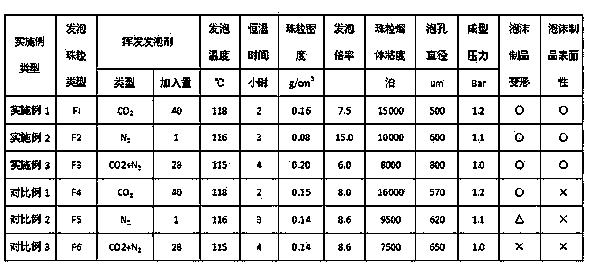

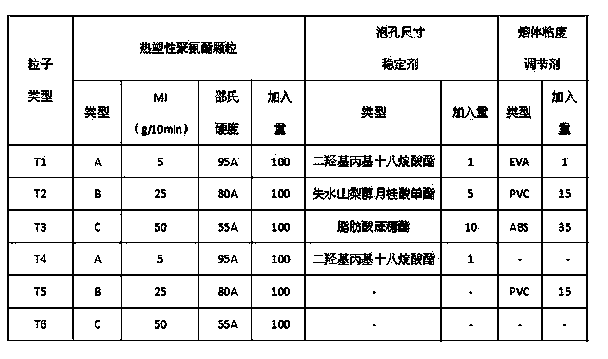

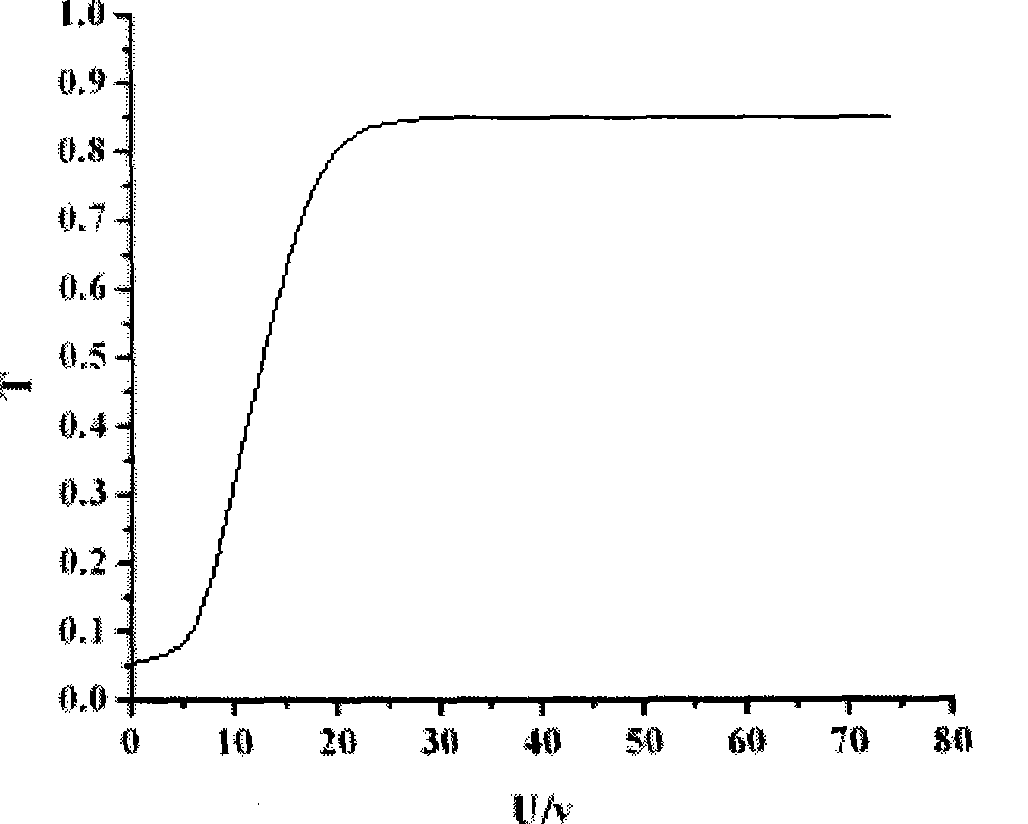

Foaming thermoplastic polyurethane bead and preparation method thereof

ActiveCN103642200AExtended melt processing temperature rangeImprove athletic abilityChemistryMelt viscosity

The invention discloses a foaming thermoplastic polyurethane bead. The foaming bead comprises 100 parts of thermoplastic polyurethane particles, 1-10 parts of cell size stabilizer, and 1-35 parts of melt viscosity modifier. The bead is prepared through the following steps: steeping the thermoplastic polyurethane particles containing a cell size stabilizer and a melt viscosity modifier in an aqueous suspension and foaming by volatilizing foaming agent. The melt viscosity of the foaming thermoplastic polyurethane bead is 8000-15000 poise below 180 DEG C, the size of the prepared foaming thermoplastic polyurethane bead is stable, the diameter of the cell is uniform, the surface is bright, the yield of the product is high, the foaming thermoplastic polyurethane bead has good sintering property even under lower vapor pressure, and the molding foam product deforms slightly and has low shrinking percentage compared with the size of the die, good dimensional stability and attractive appearance.

Owner:MIRACLL CHEM

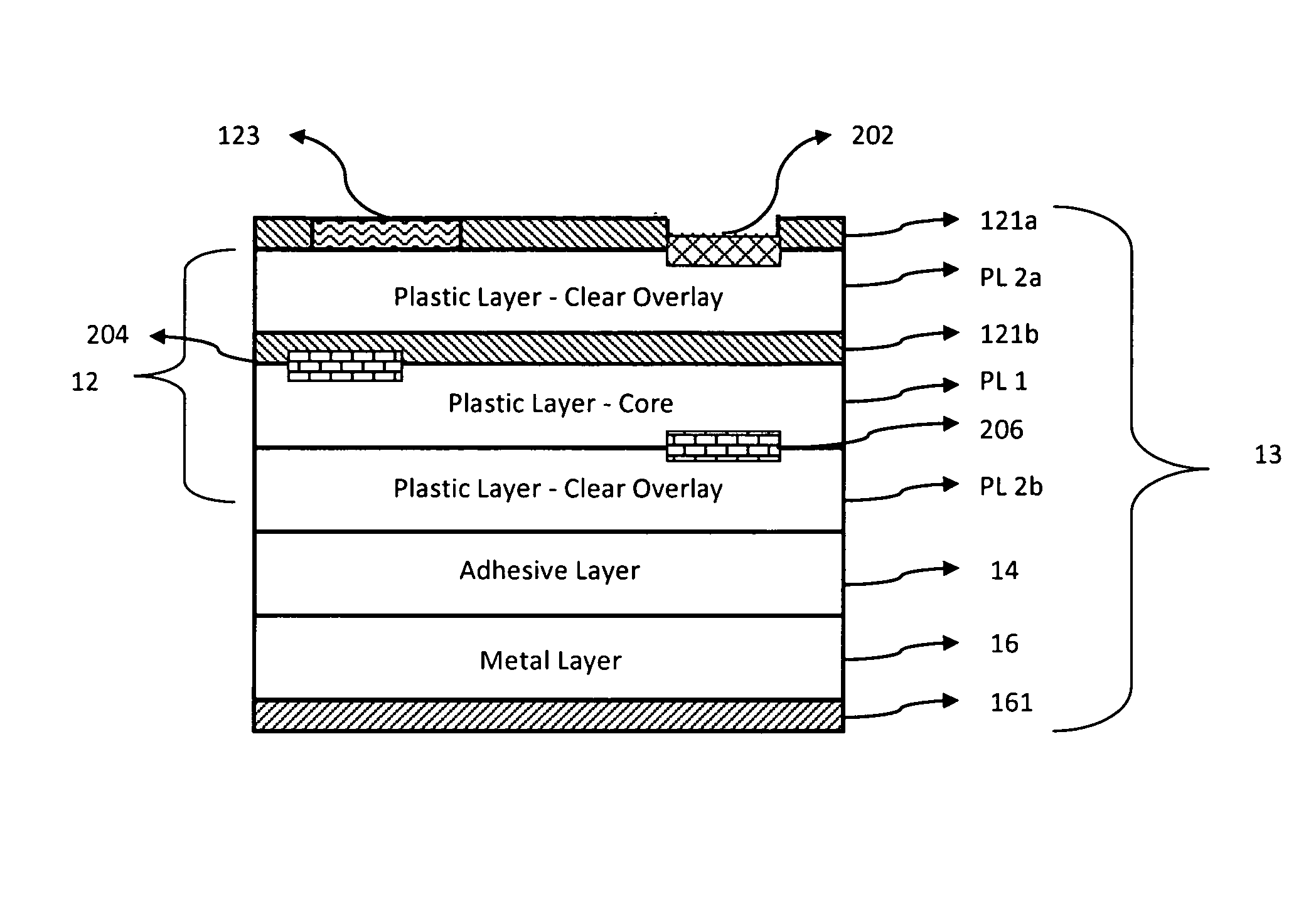

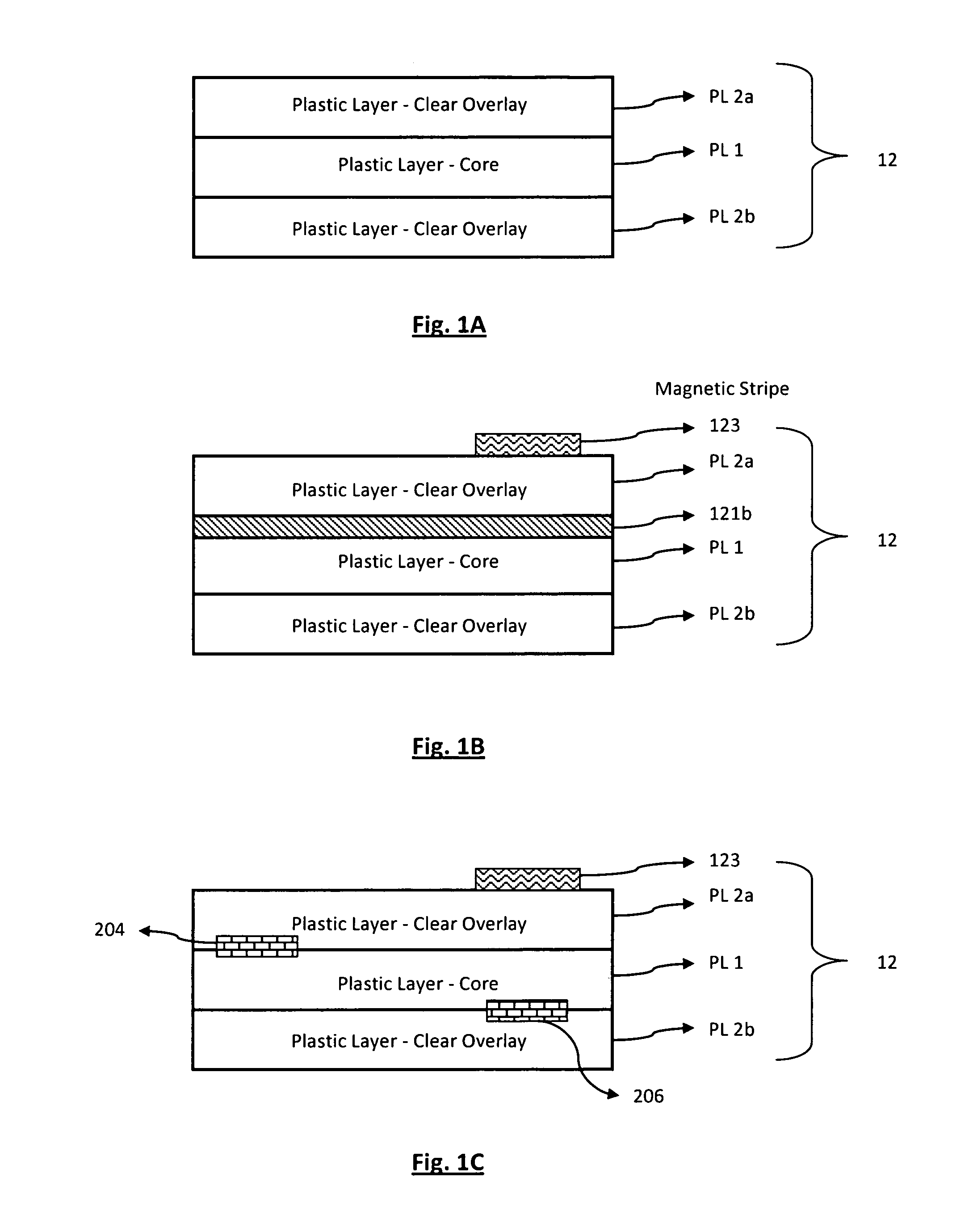

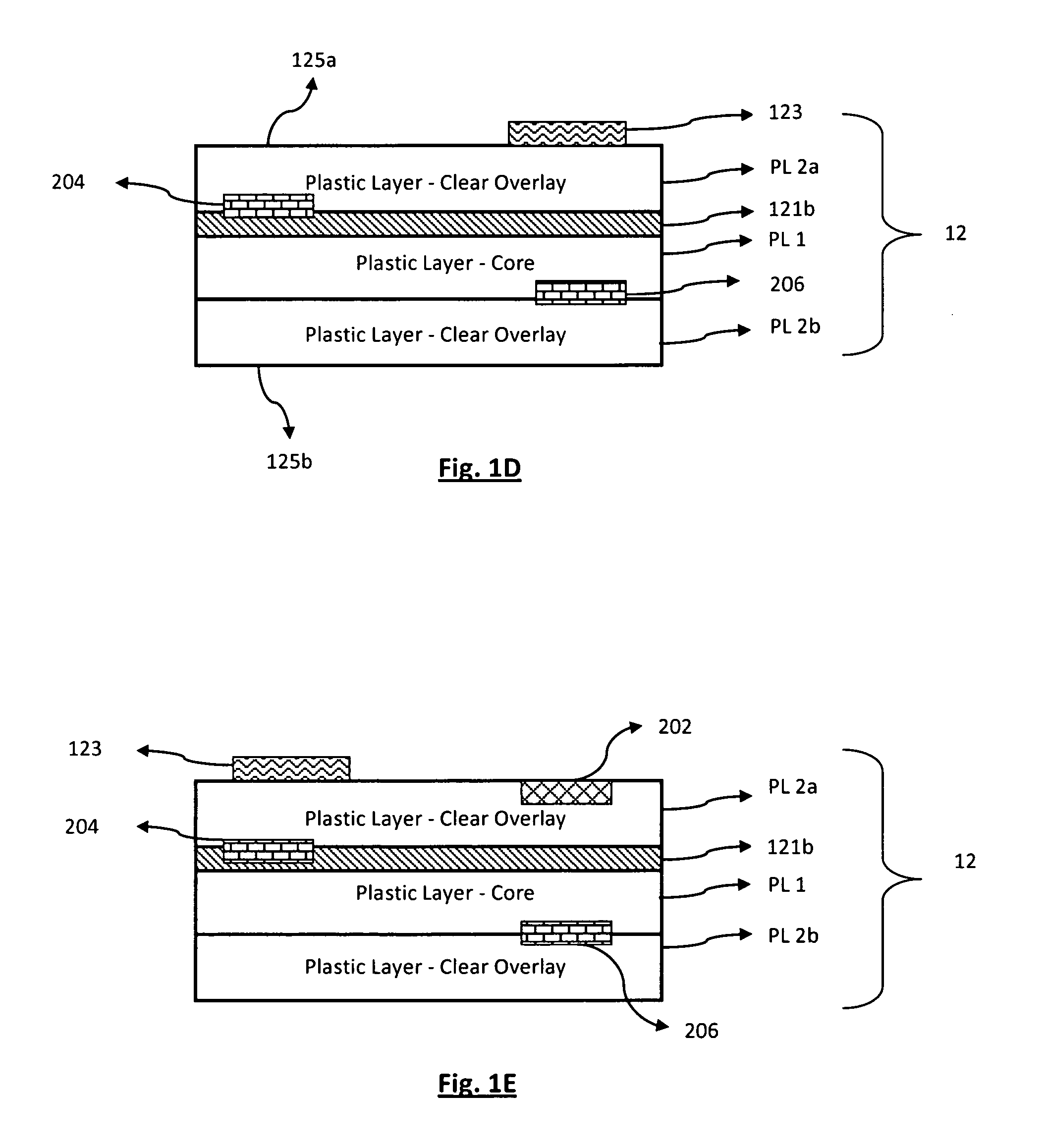

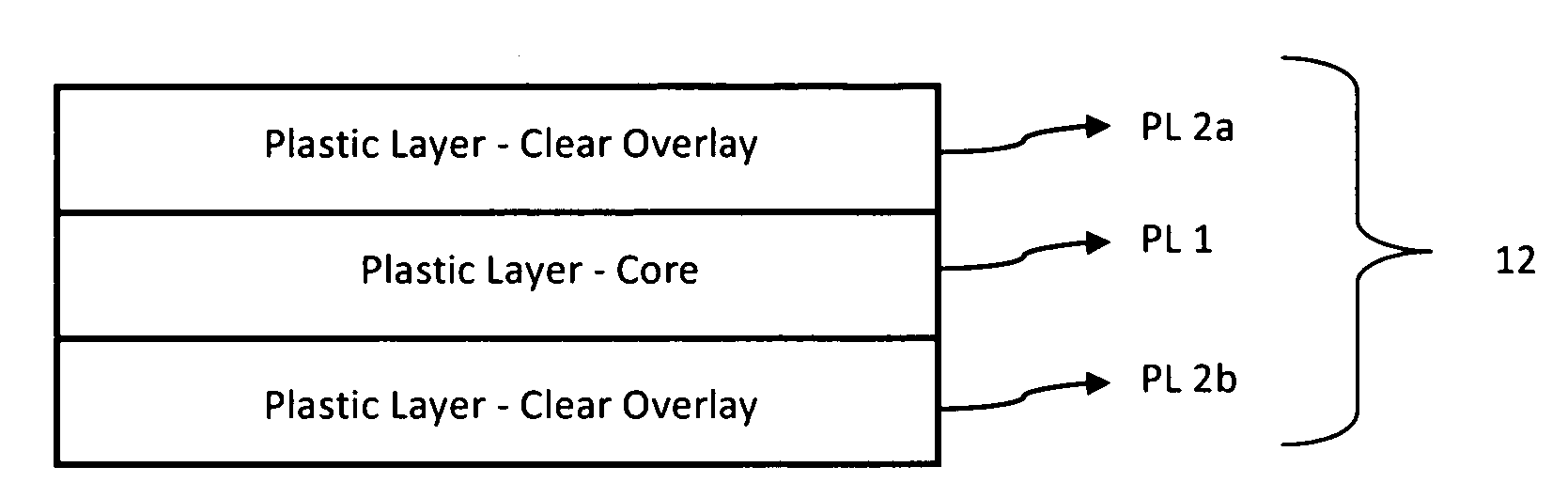

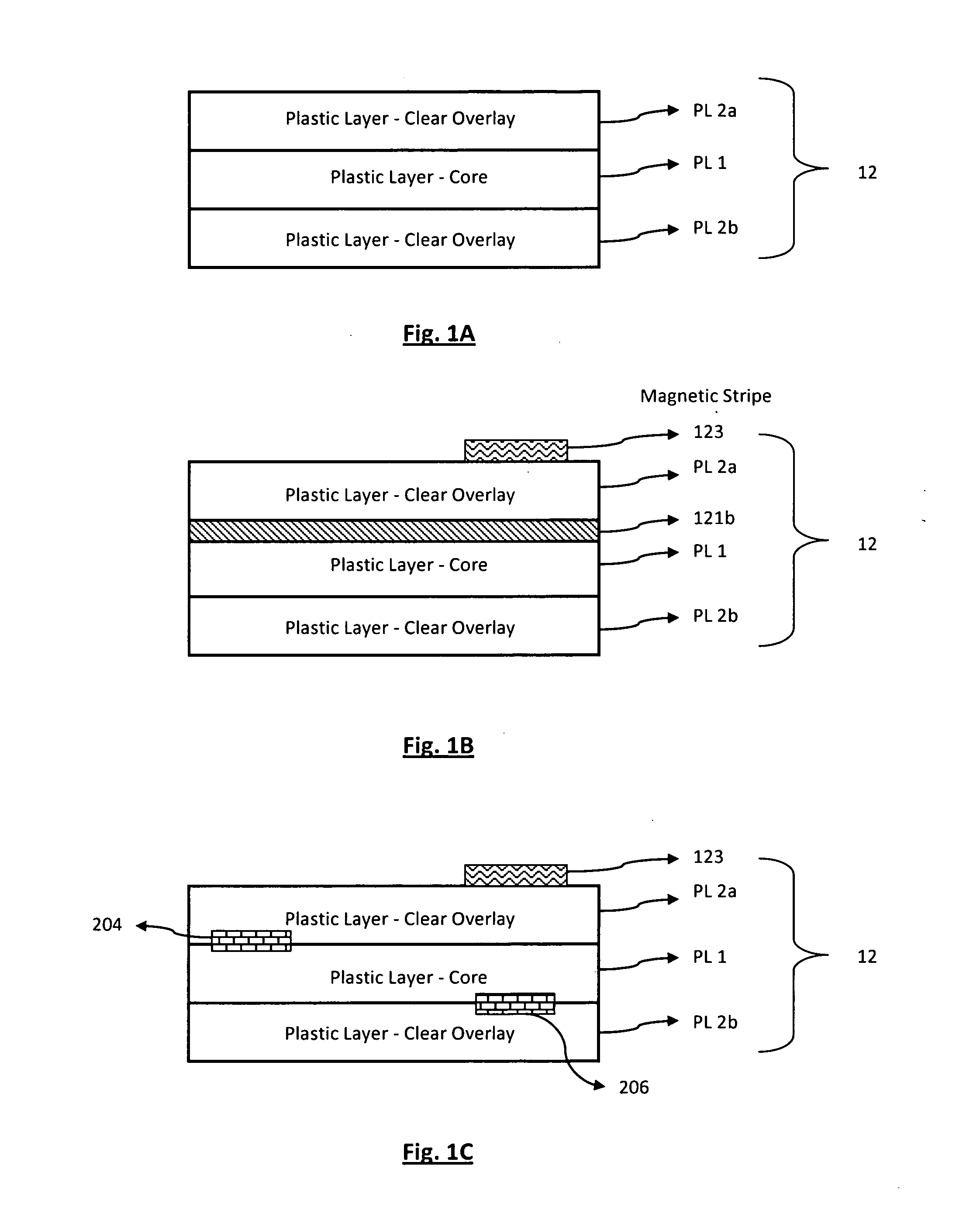

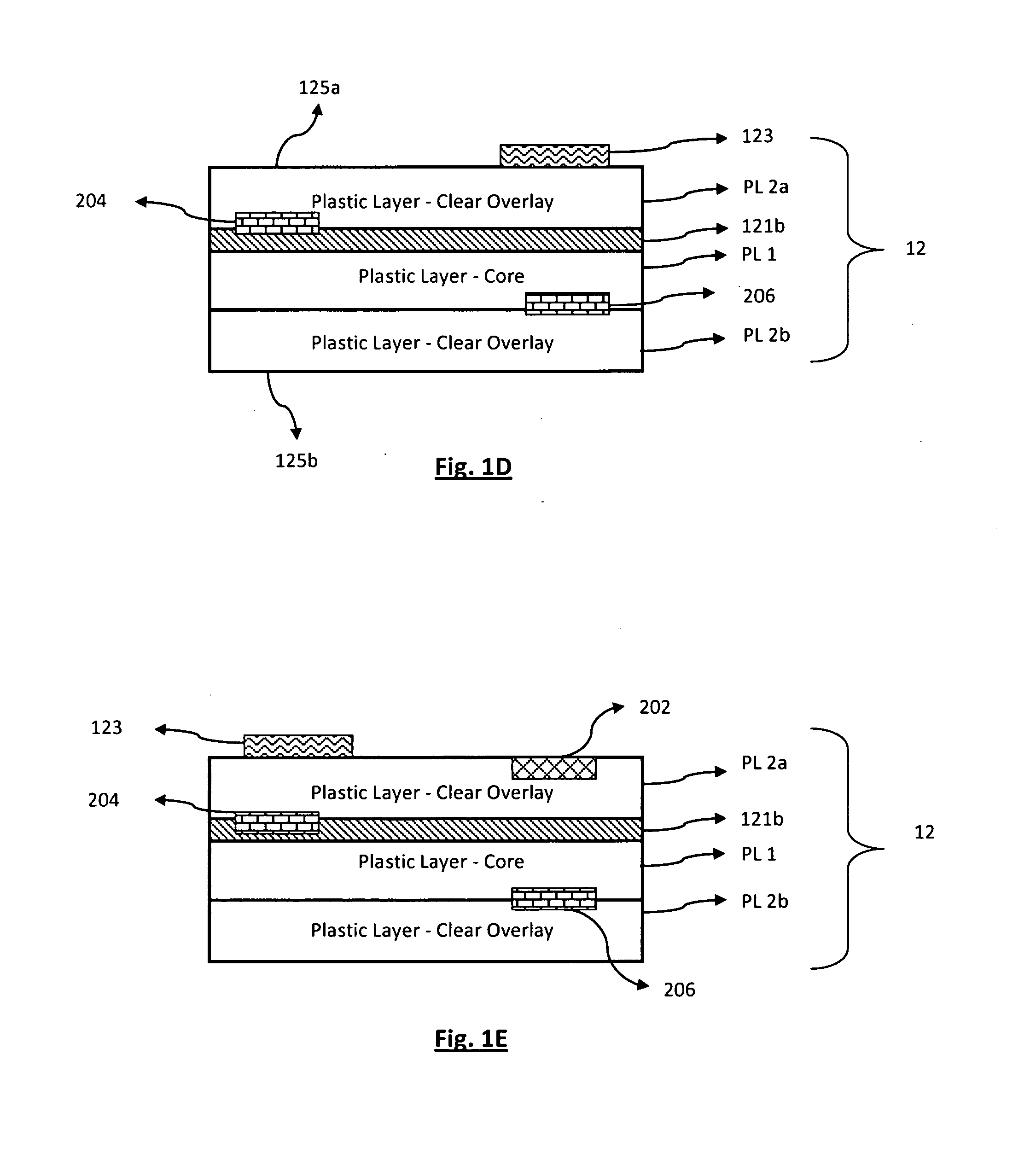

Combination card of metal and plastic

ActiveUS8672232B2Dimensionally stableReduce changesOrnamental structuresSpecial ornamental structuresAdhesiveEngineering

A card formed in accordance with the invention includes a first assembly comprised of multiple plastic layers attached via an adhesive to a metal layer. The multiple plastic layers forming the first assembly are laminated under a first selected temperature and pressure conditions to preshrink the multiple plastic layers, stress relieve the first assembly and render the first assembly dimensionally stable. The laminated first assembly is then attached to a metal layer via an adhesive layer to form a second assembly which is then laminated at a temperature below the first selected temperature to form a card which is not subjected to warpage and delamination.

Owner:COMPOSECURE LLC

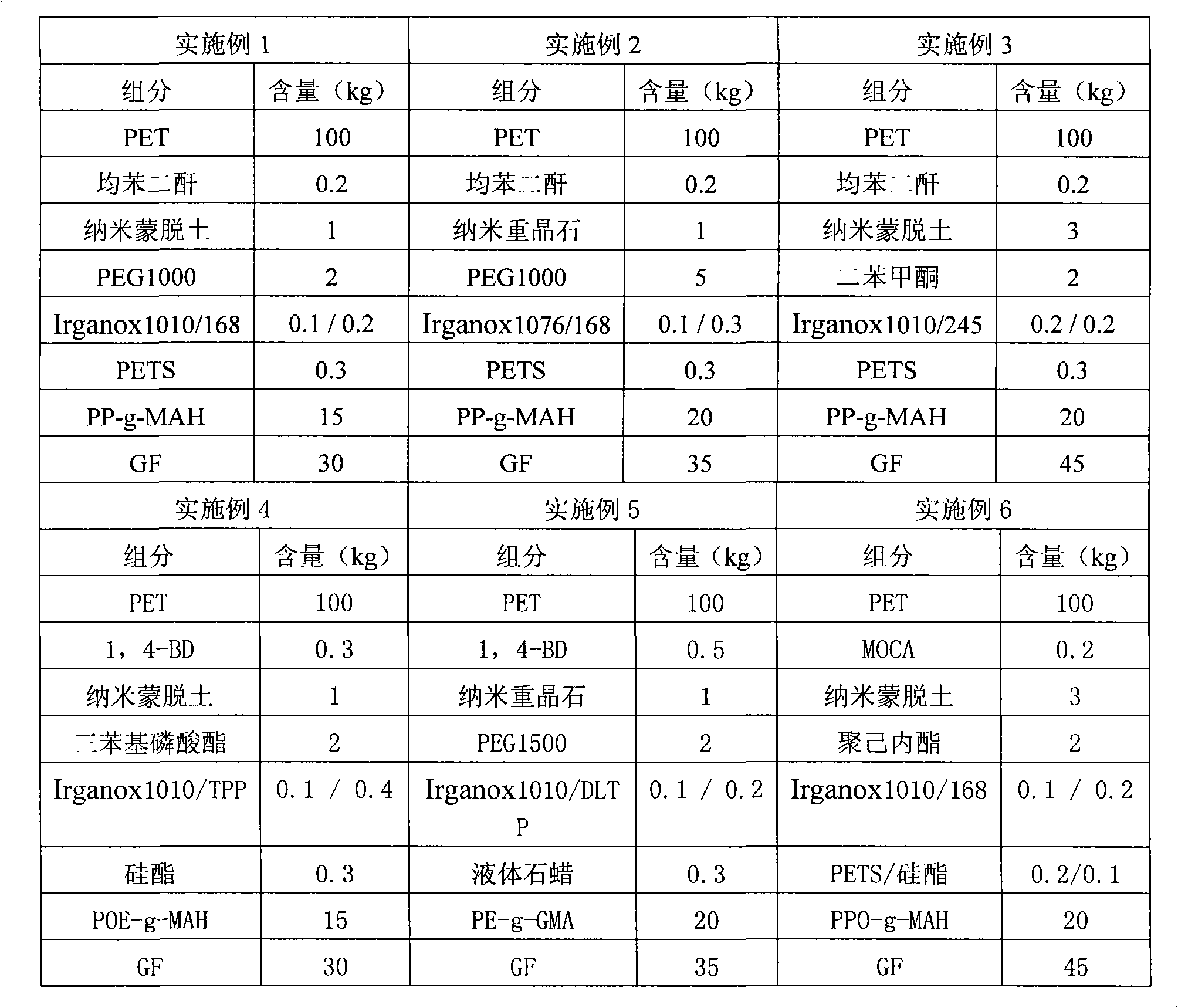

Glass fiber reinforced polyethylene glycol terephthalate composite material and preparation thereof

The invention relates to a PET glass fiber reinforced composite material, which has the following components based on weight proportion: 100 portions of PET, 10-45 portions of alkali-free glass fibers, 5.0-25 portions of toughener, 0.1-10 portions of crystallization promoter, 0.1-1.0 portion of chain extender, 0.5-5.0 portions of nucleating agent, 0.1-0.5 portion of antioxidant and 0.3-0.5 portion of lubricant. The preparation method is that the components are evenly mixed on a high-speed mixer and melted and blended by a twin-screw extruder to prepare the composite material. The composite material has the advantages of good mobility, high tensile strength and high impact strength, which aims to realize low-cost and high-quality PET engineering plastic scale production to effectively substitute for high-grade plastics and expensive imported special materials.

Owner:SHANGHAI UNIV +1

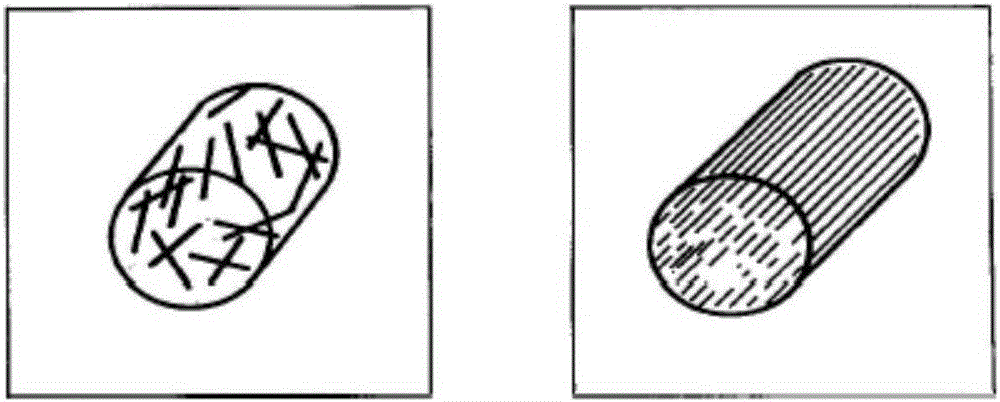

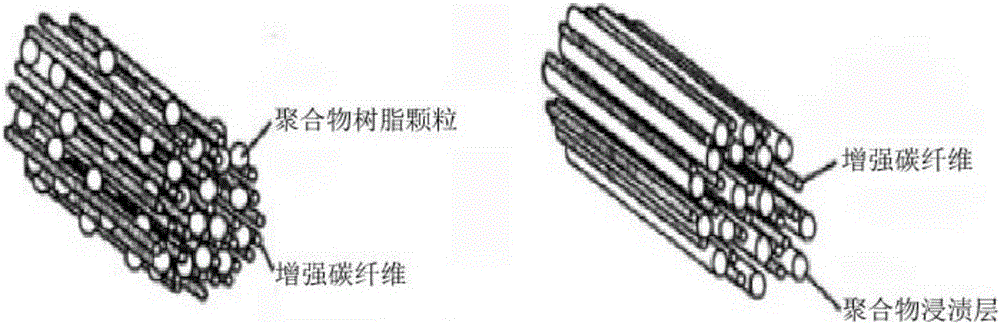

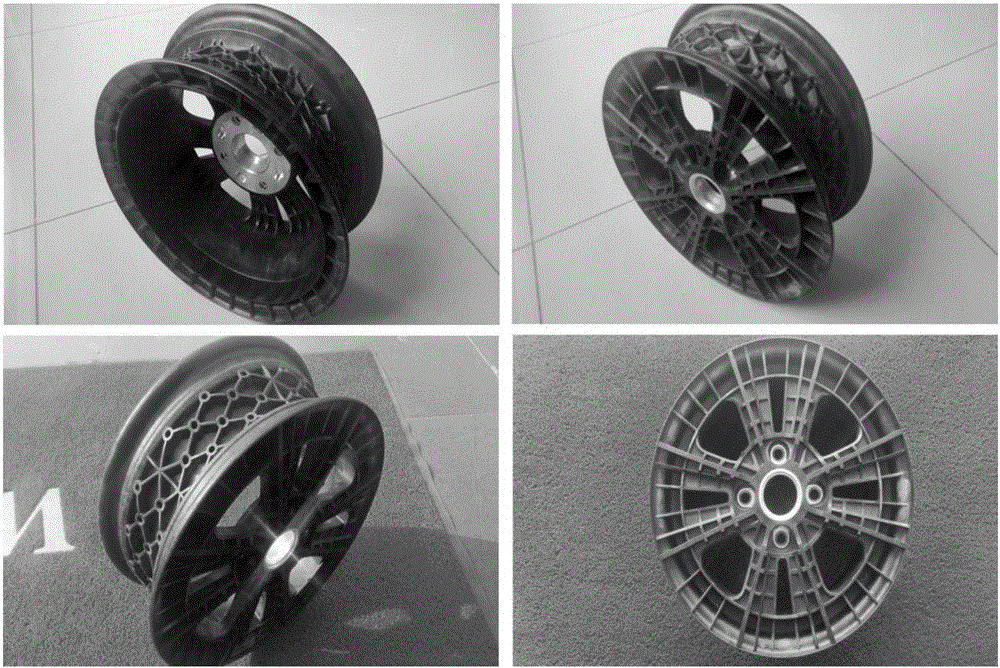

Continuous long carbon fiber reinforced thermoplastic nanocomposite and preparation method and application thereof

The invention discloses a continuous long carbon fiber reinforced thermoplastic nanocomposite and a preparation method and application thereof. The nanocomposite comprises, by weight, 40 to 70% of long carbon fiber (LCF), 25 to 40% of thermoplastic resin, 3 to 15% of a filler and 2 to 5% of an auxiliary agent; and an isostatic pressing fusion resin impregnation compound process is employed to prepare the multi-component blend composite with a multi-phase structural characteristic. In a processed and shaped part product, the reservation length of LCF is 0.5 to 15 mm and meets the requirement that normal distribution is no less than 80%. The nanocomposite provided by the invention has excellent performances and characteristics like small specific gravity, high strength, good toughness, good thermal and heat conductivity, wear resistance, corrosion resistance, fatigue resistance, simple production technology and low processing cost of the product.

Owner:河南中煌节能电器有限公司

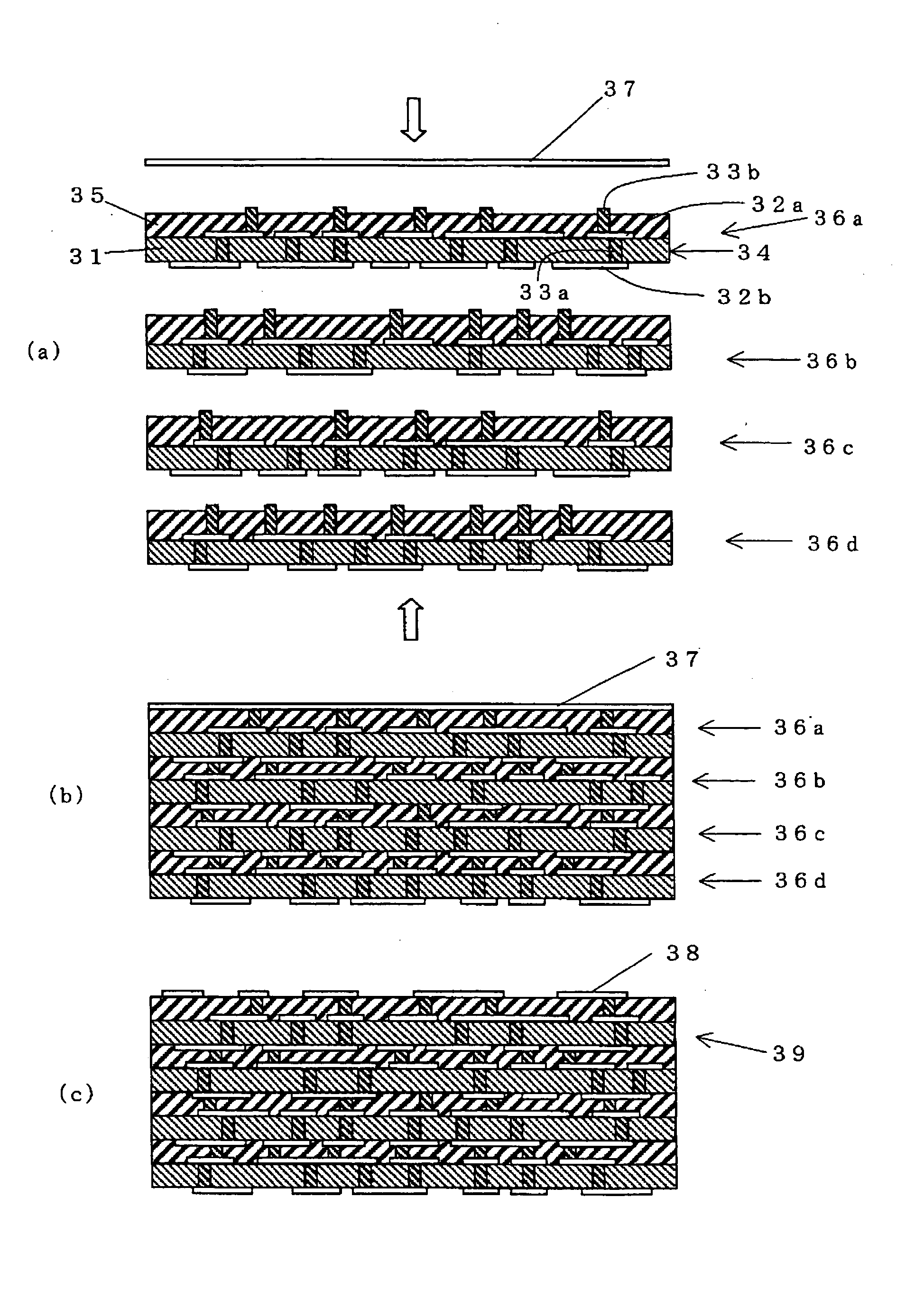

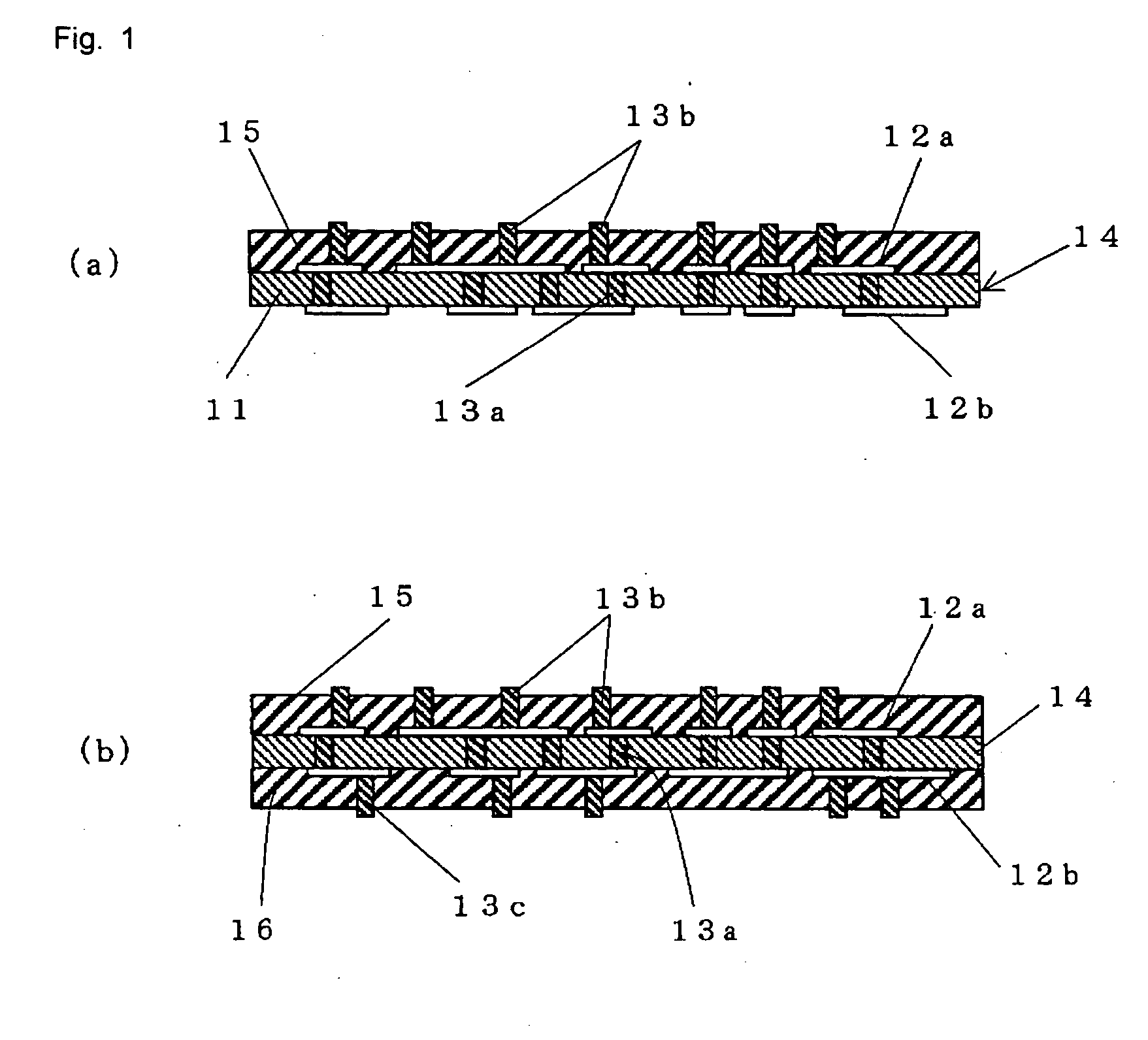

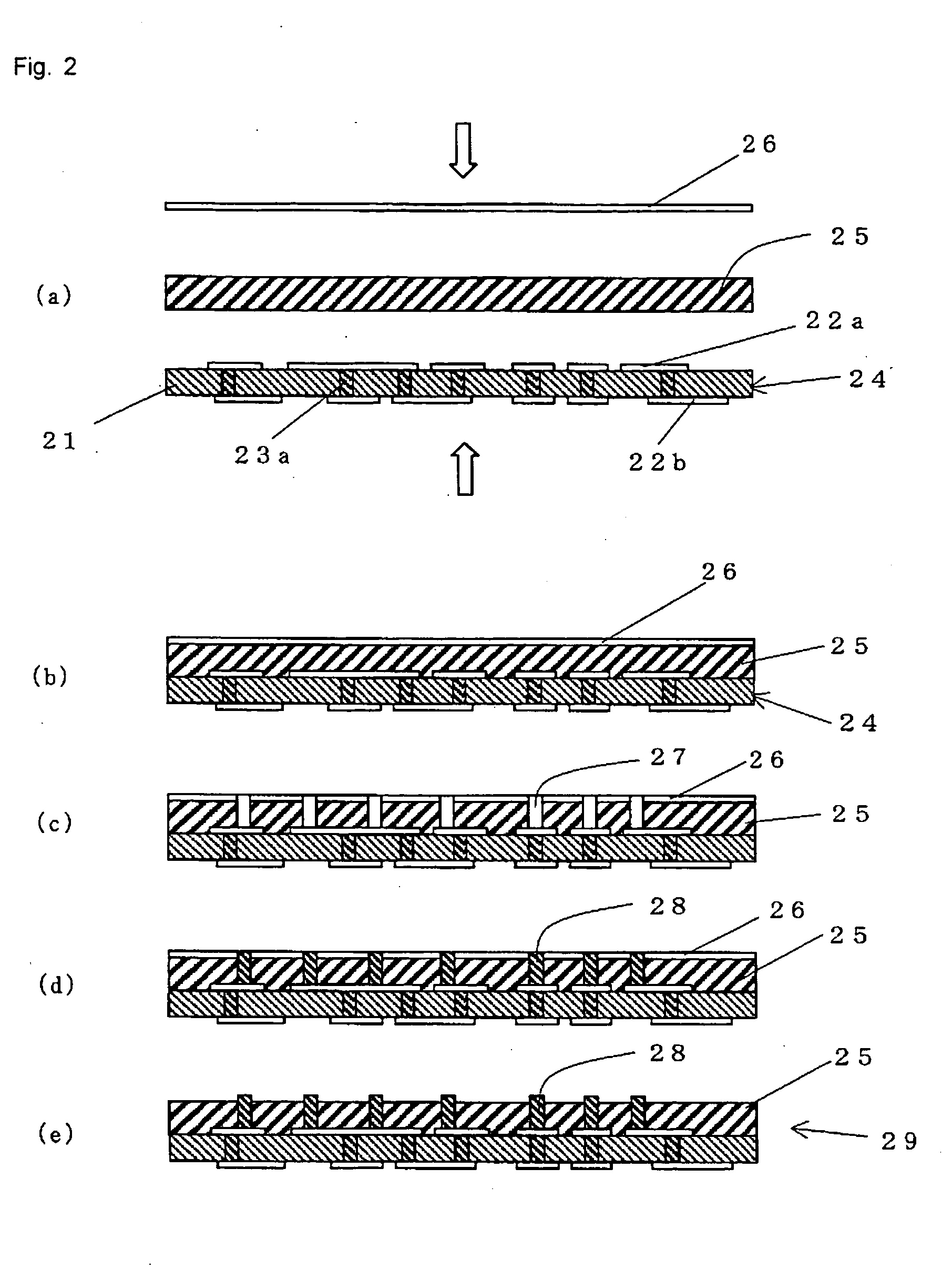

Wiring substrate for intermediate connection and multi-layered wiring board and their production

InactiveUS20050016764A1Handle with easeHigh alignment accuracyPrinted circuit assemblingPrinted circuit aspectsElectrical conductorEngineering

There is provided a wiring substrate for intermediate connection comprising: (1) a wiring board having a plurality of wiring layers which are connected through a via hole conductor(s) with each other; and (2) a prepreg sheet having a via hole conductor(s) at a predetermined position(s) which sheet is disposed on at least one side of the wiring board.

Owner:PANASONIC CORP

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

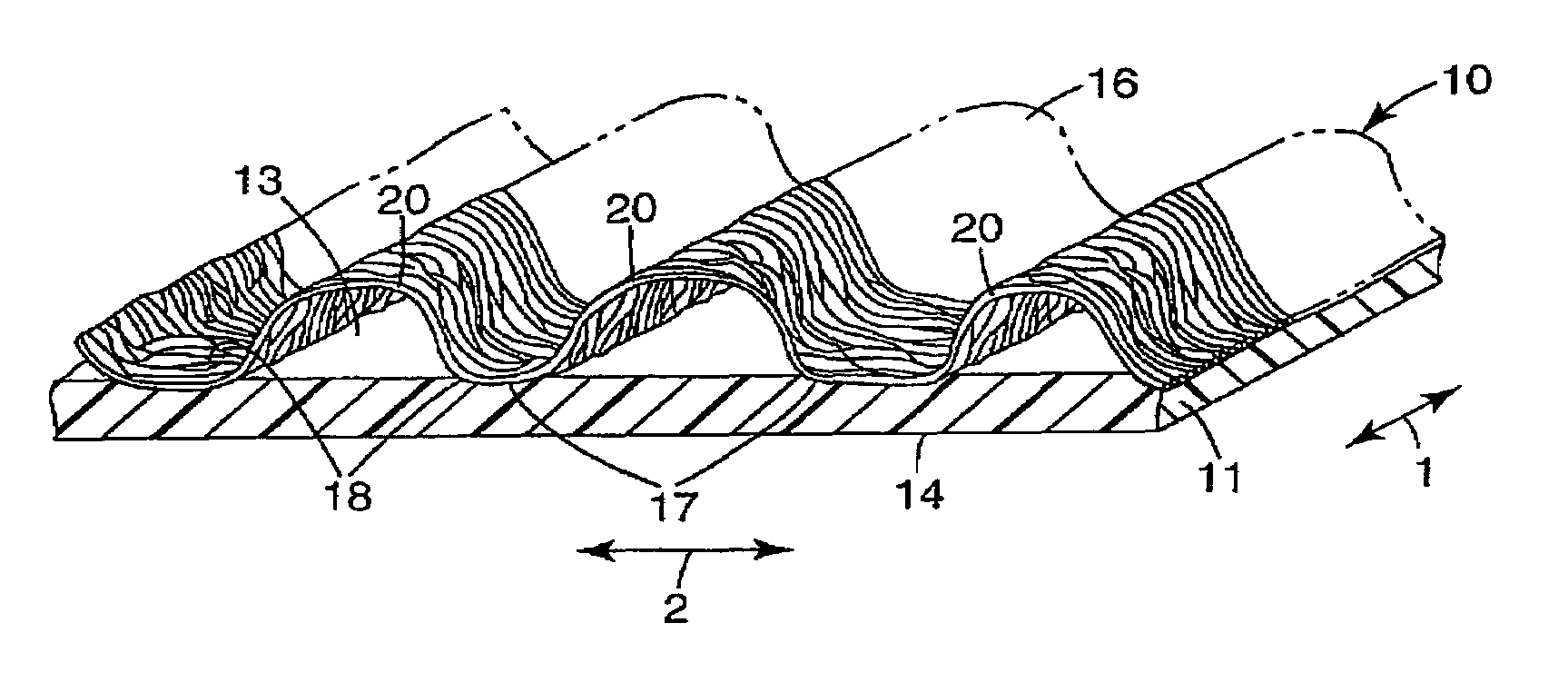

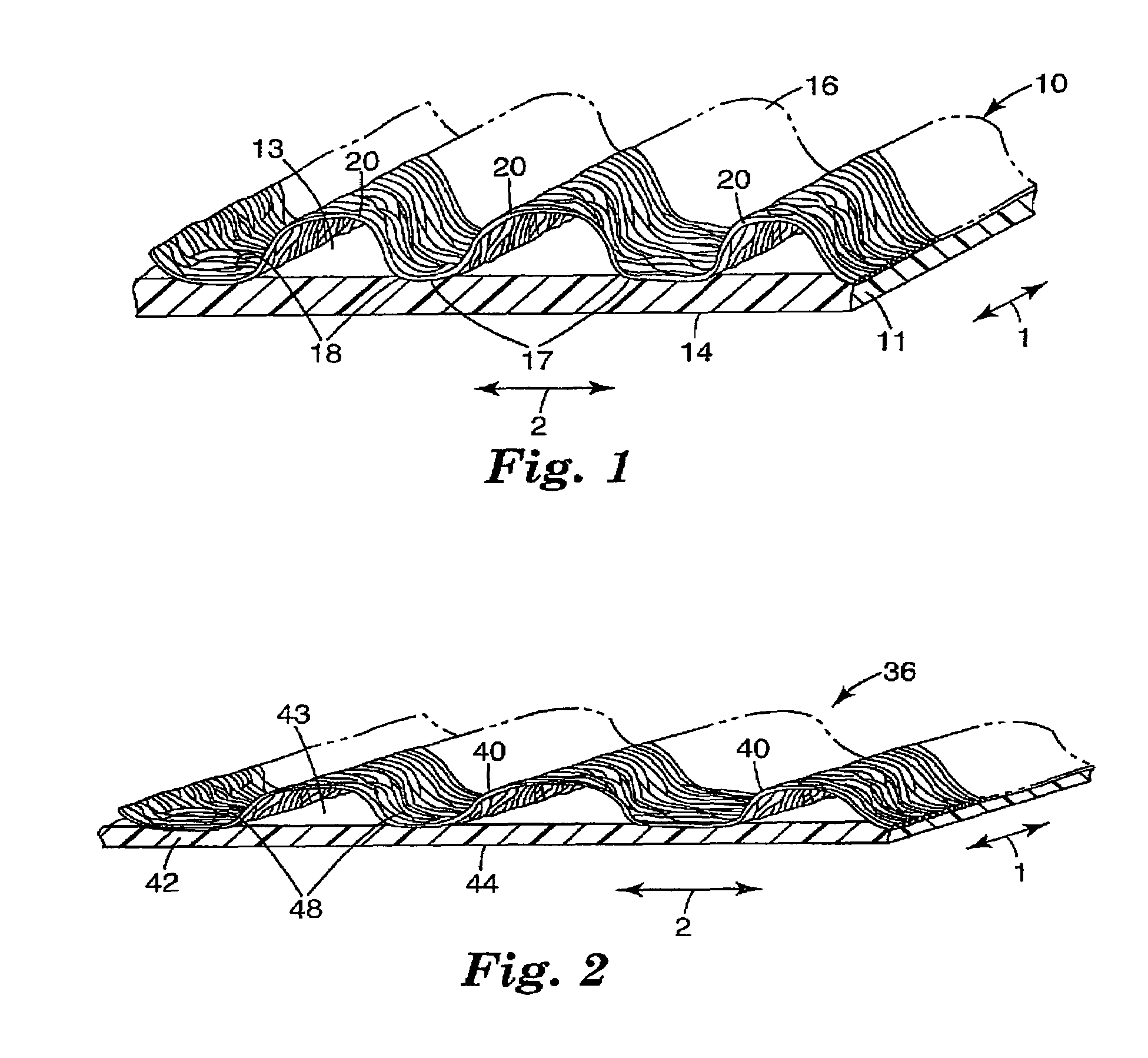

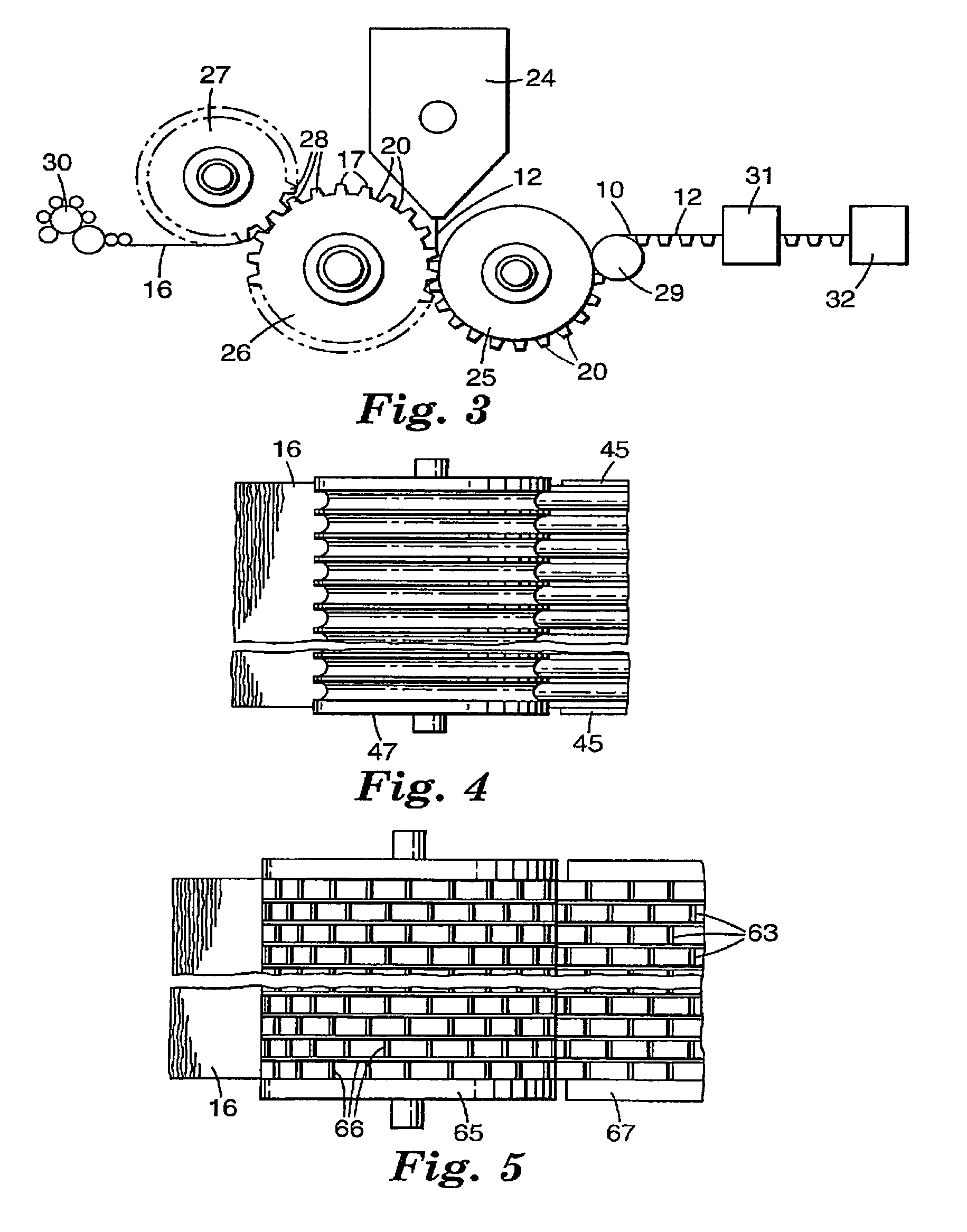

Loop fabric

ActiveUS7303805B2High strengthLow costMechanical working/deformationDecorative surface effectsEngineeringFastener

Owner:3M INNOVATIVE PROPERTIES CO

Fiber-reinforced resin-based composite material core and preparation method thereof

InactiveCN104672782AImprove promotion effectPromote the stability of the effectGlass fiberResin-Based Composite

The invention provides a fiber-reinforced resin-based composite material core. The composite material core is prepared from a fiber-reinforced composite material core in the inner part and an insulating layer on the outer layer, wherein the insulating layer is a glass fiber layer and has the thickness of 0.2-2mm. According to the fiber-reinforced resin-based composite material core, the internal structure is uniform, a layering phenomenon difficultly occurs, the strength is high, the toughness is high, and the cost is reduced.

Owner:STATE GRID CORP OF CHINA +3

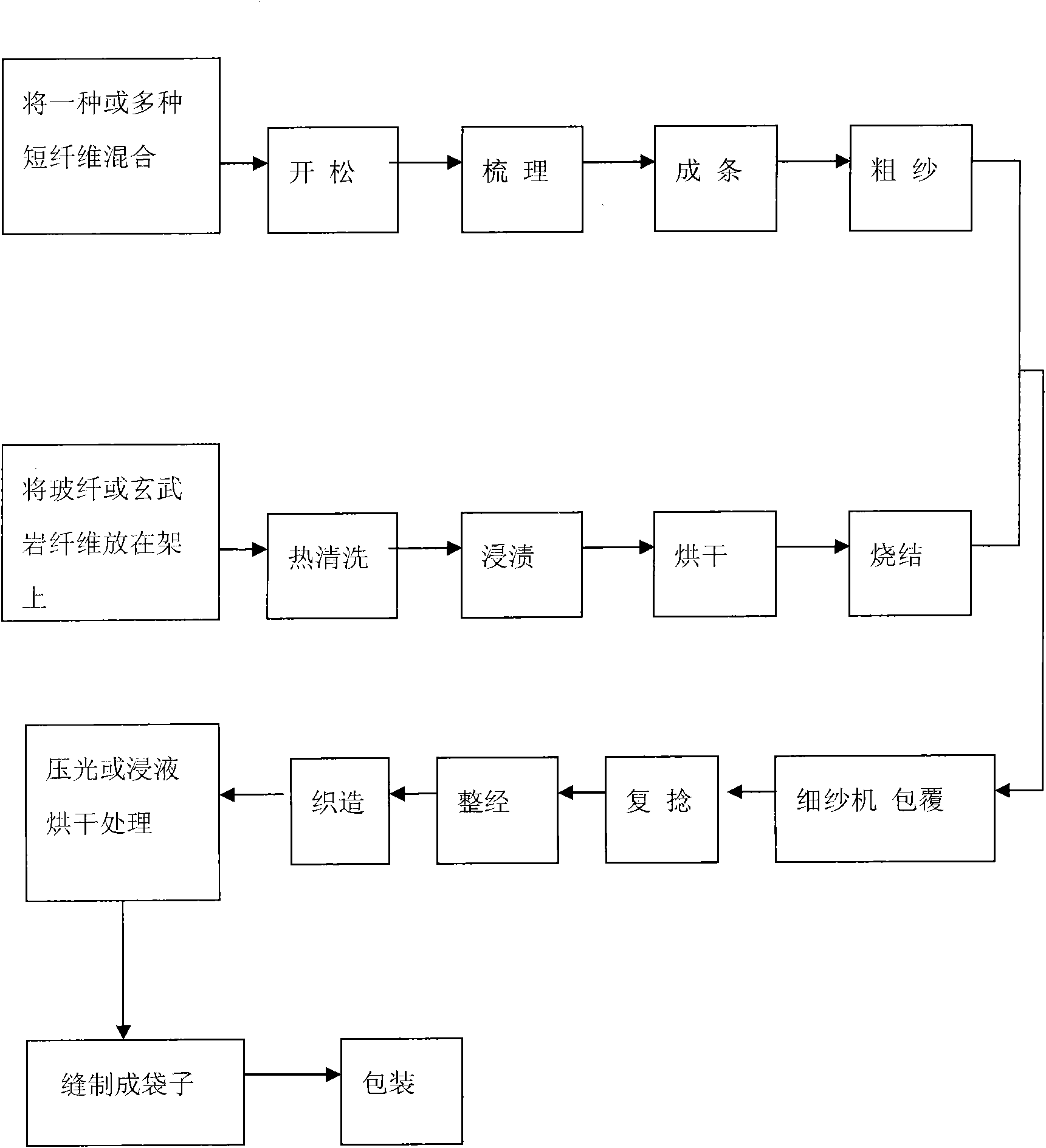

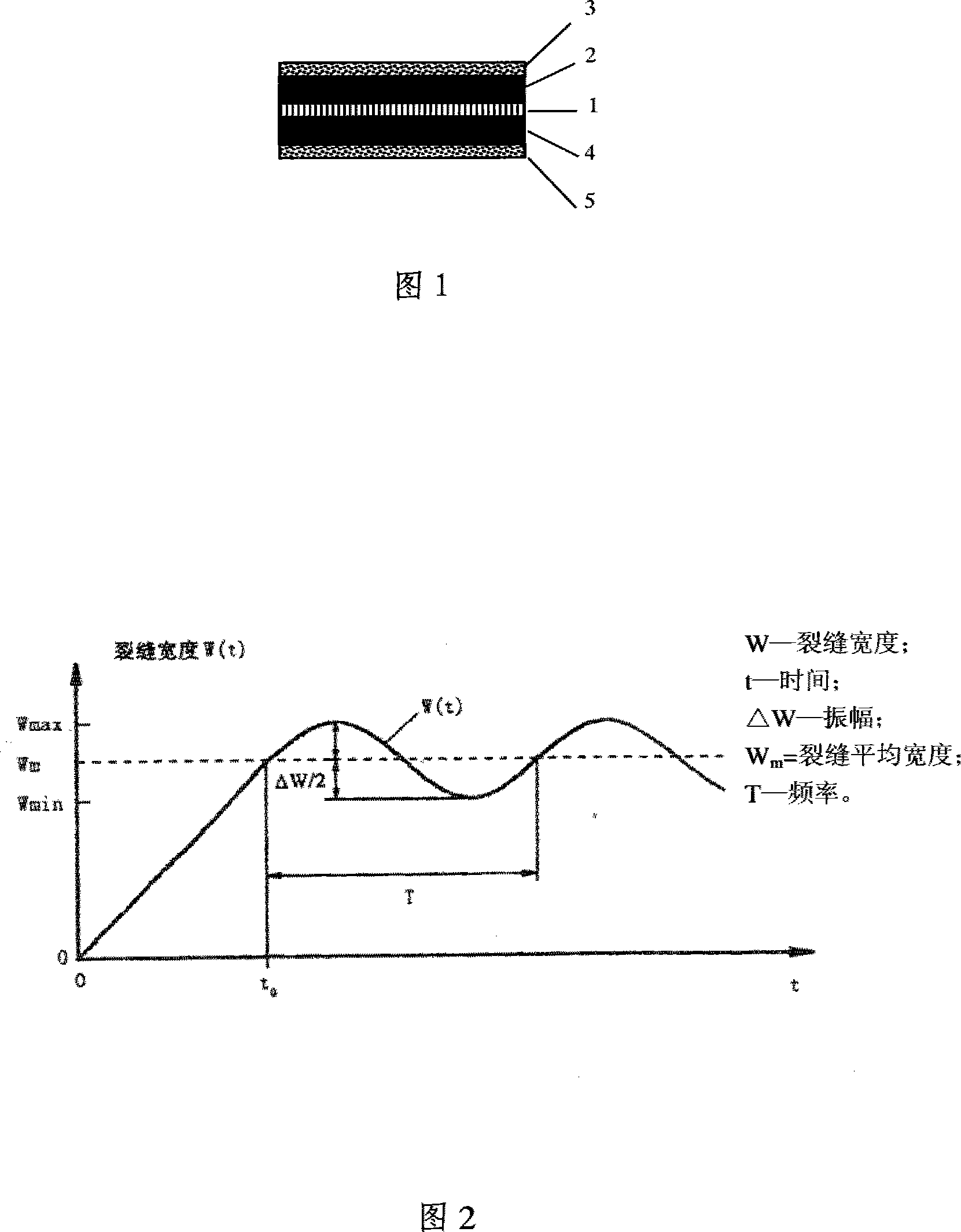

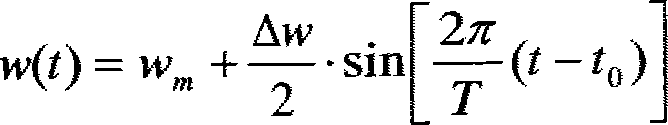

Composite covered yarn, and manufacturing method and use thereof

The invention relates to a composite covered yarn and a manufacturing method thereof and also relates to a high-temperature filter cloth. The composite covered yarn comprises an outer layer of coveredyarn made of short fiber and an inner layer of reinforcing rib made of long fiber, wherein the composite covered yarn is formed by using the covered yarn, made of one or a plurality of types of shortfibers, to cover the reinforcing rib or the metal wire reinforcing rib made of one or a plurality of types of long fibers by thermal cleaning, dipping, drying and sintering. The composite covered yarn manufactured by the method not only saves cost, but also combines the characteristics of high strength of the long fiber and good abrasion resistance and toughness of the short fiber and enhances service life, strength, high-temperature resistance and stability of the composite covered yarn. The composite covered yarn can be made into the filter cloth.

Owner:辽宁新洪源环保材料有限公司

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

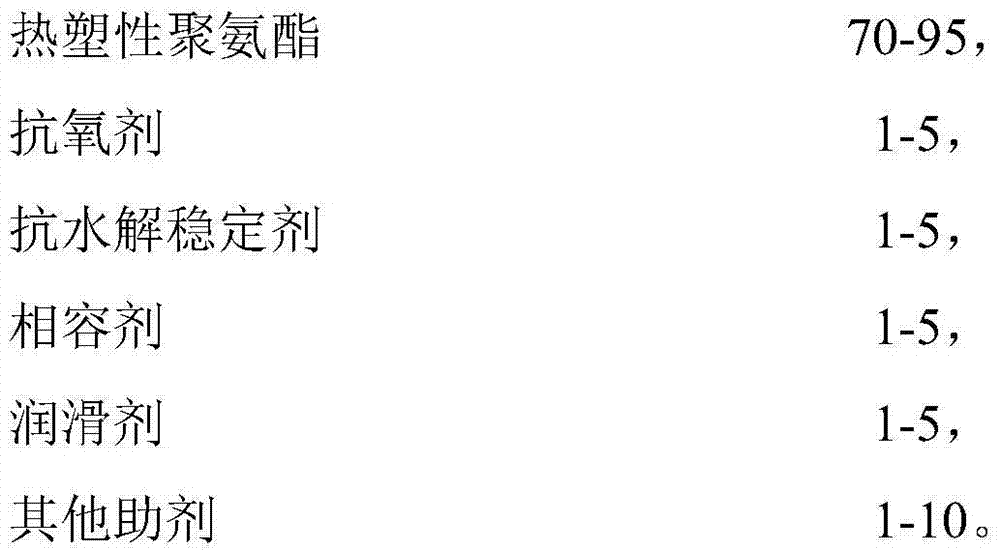

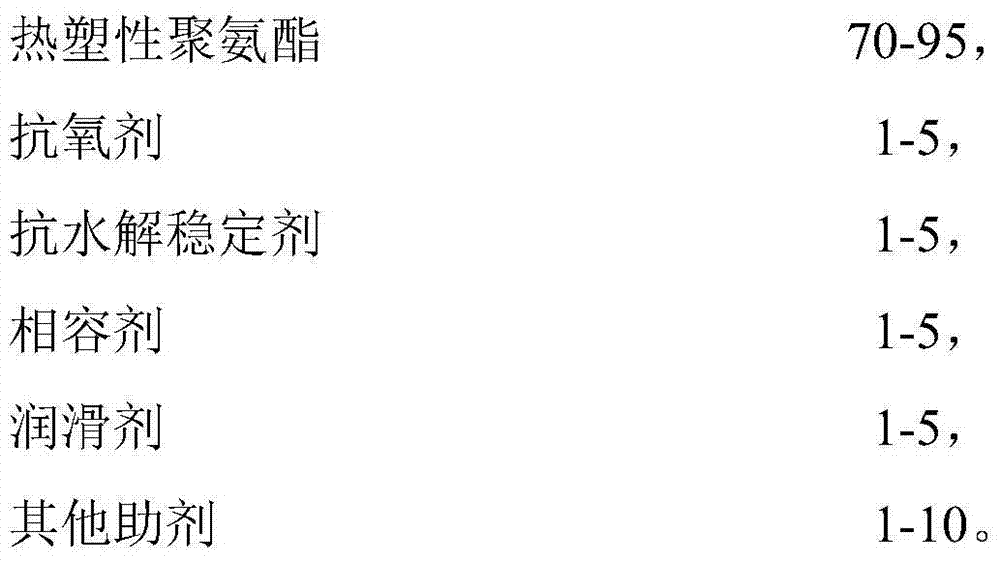

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

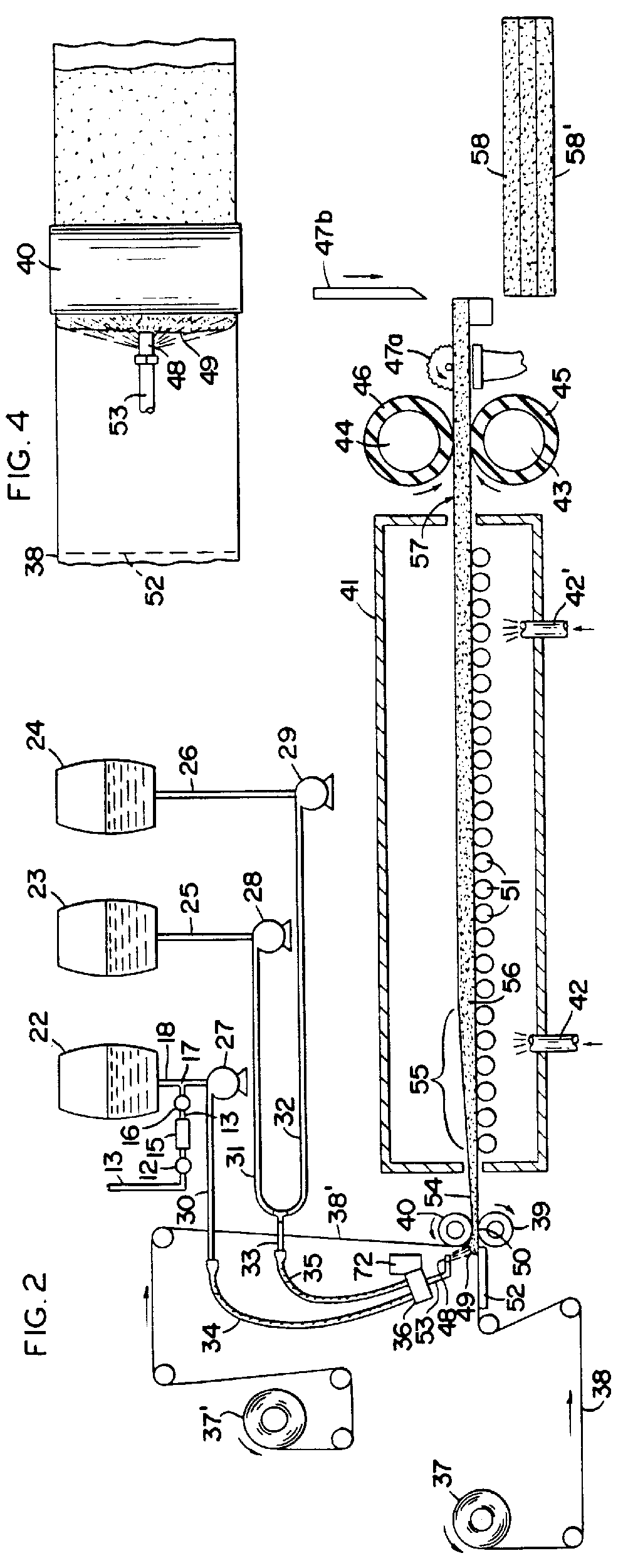

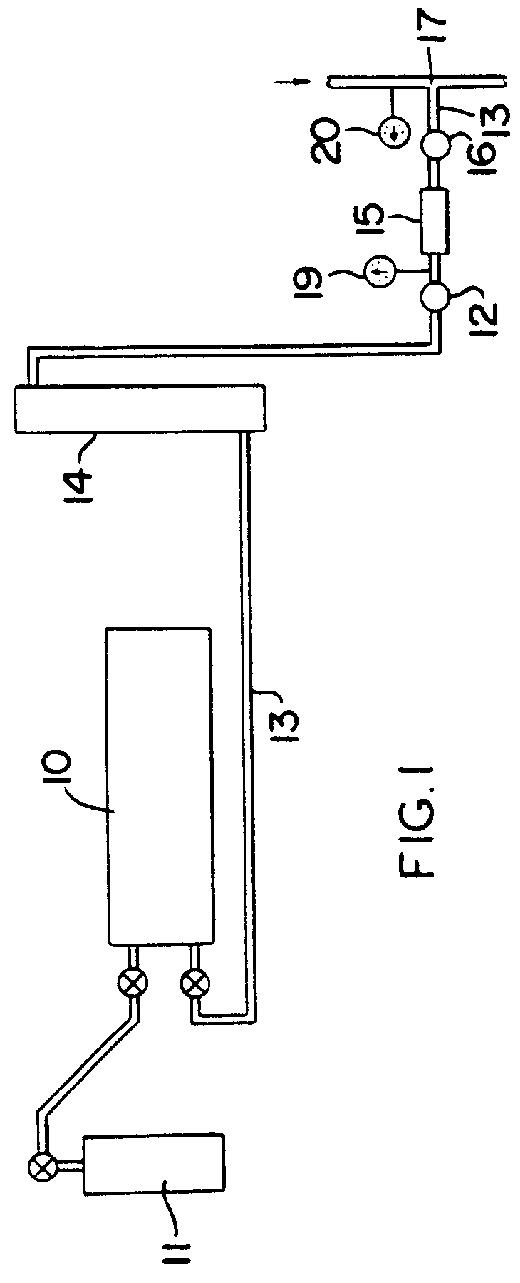

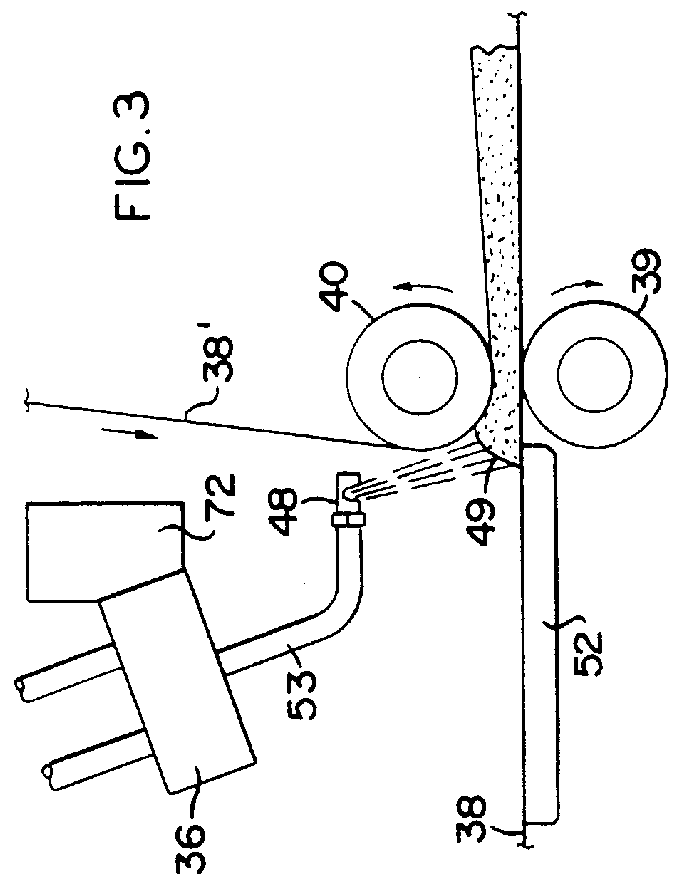

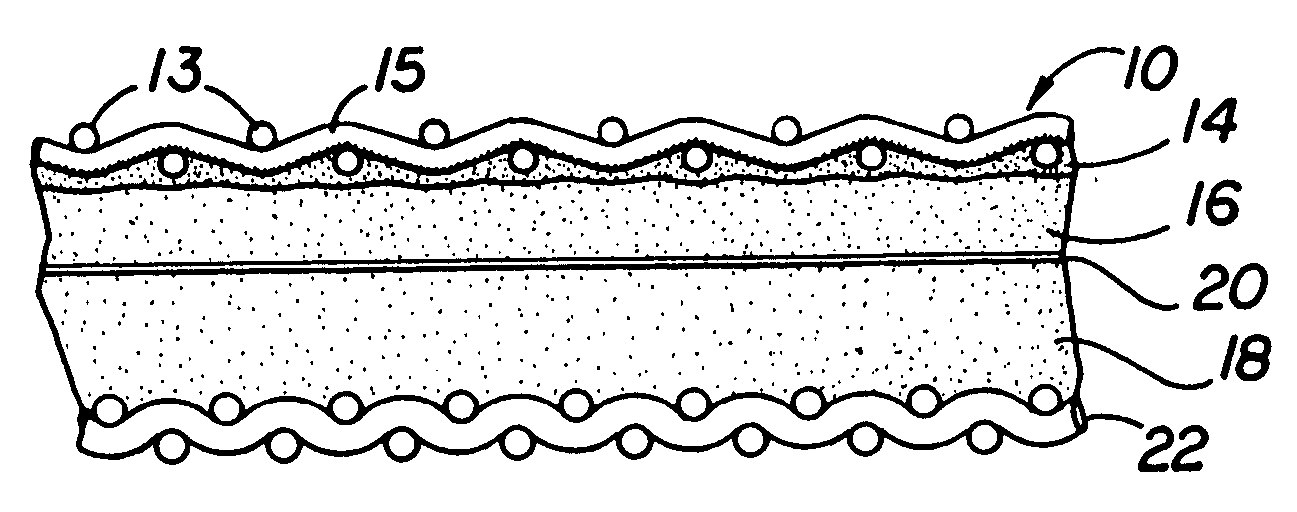

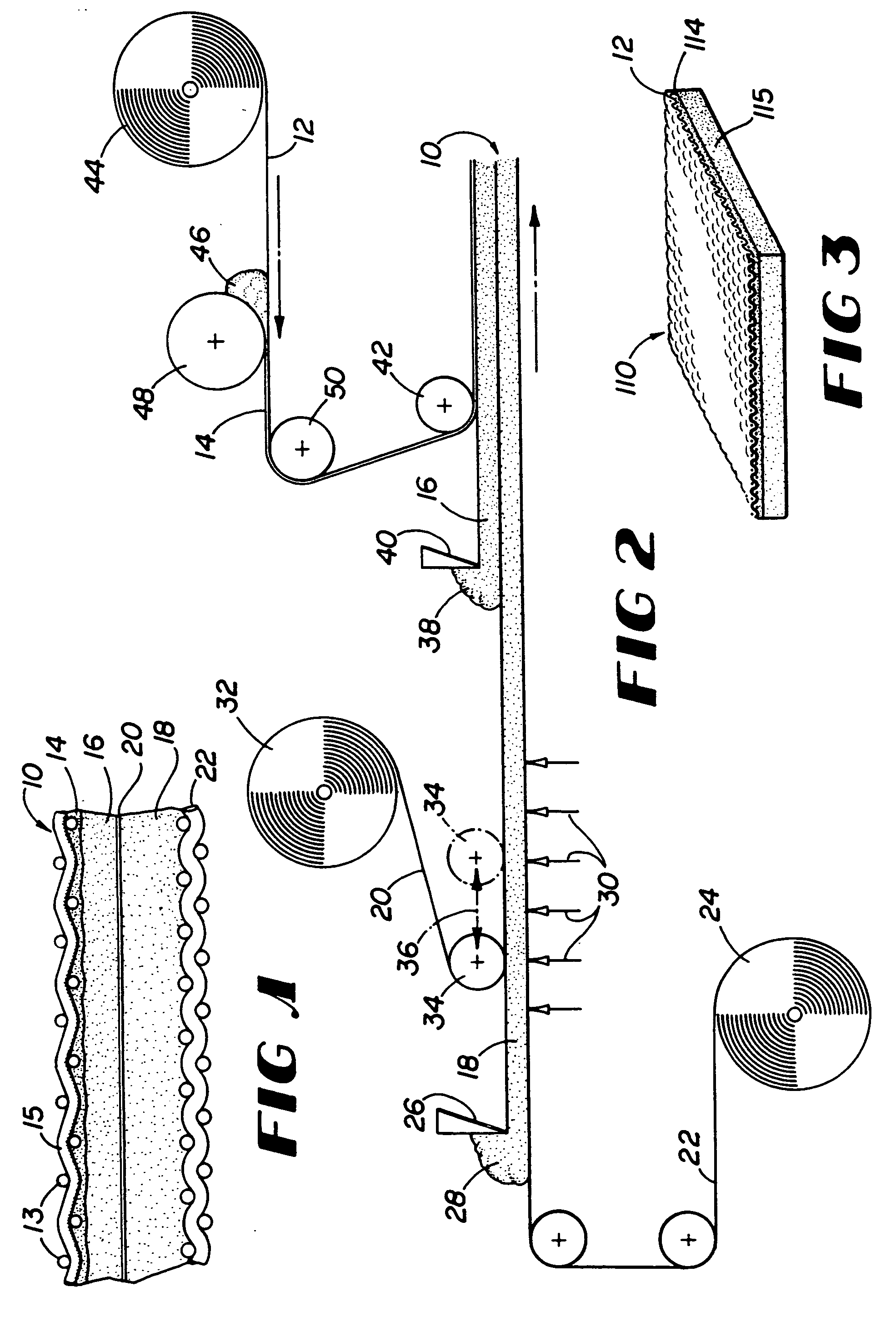

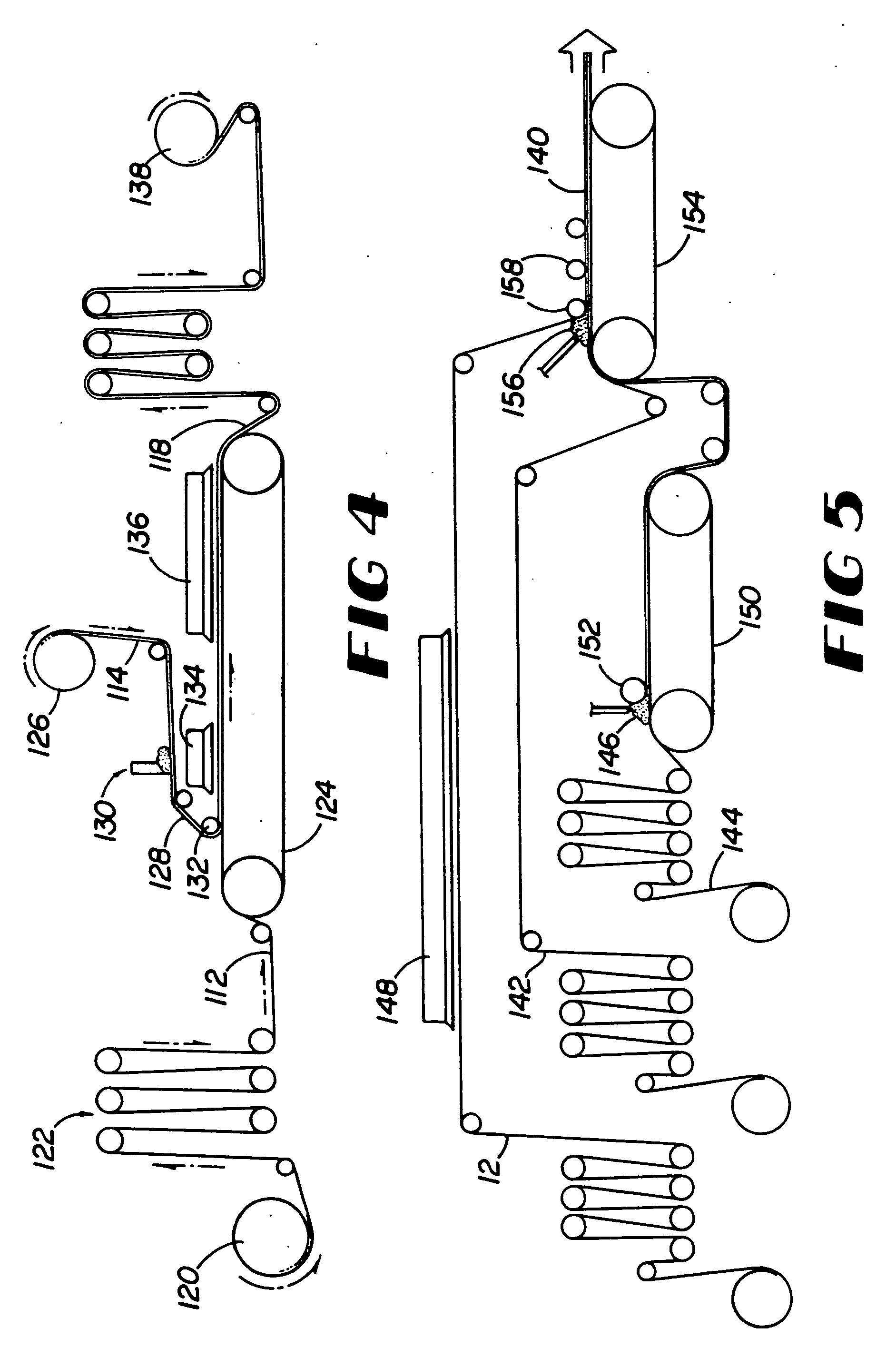

Faced foam insulation board and froth-foaming method for making same

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

Creep-resistant polypropylene composition and preparation method and application thereof

ActiveCN102344609AIncrease the interfacial bonding areaPerfect crystallinityElastomerPolymer science

The invention belongs to the field of material engineering and discloses a creep-resistant polypropylene composition and a preparation method and application thereof. The creep-resistant polypropylene composition is prepared from 40-80 percent by weight of polypropylene resin, 5-30 percent by weight of elastomer, 10-40 percent by weight of high-aspect-ratio (HAR) inorganic filler and 0.01-0.5 percent by weight of nucleating agent, wherein the nucleating agent is an alpha-crystal nucleating agent. In the invention, the polypropylene composition modified by the HAR inorganic filler and the alpha-crystal nucleating agent has high creep resistance; and an injection molding piece prepared from the polypropylene composition has stable size and small deformation under practical use conditions, and can fully meet the using requirements of relevant industries such as automobiles, home appliances and the like.

Owner:KINGFA SCI & TECH CO LTD +2

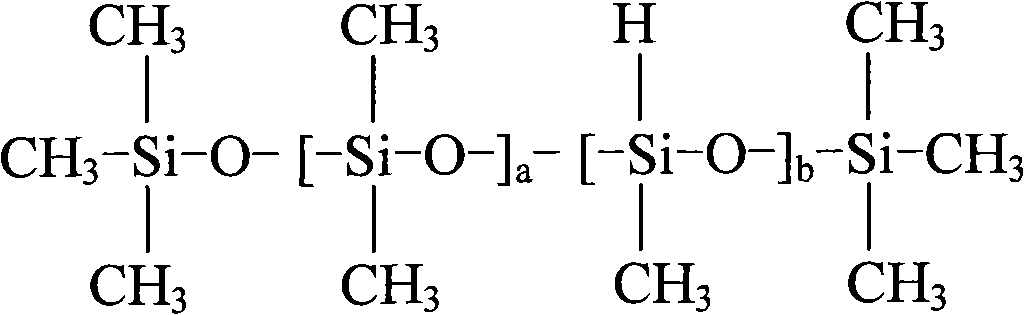

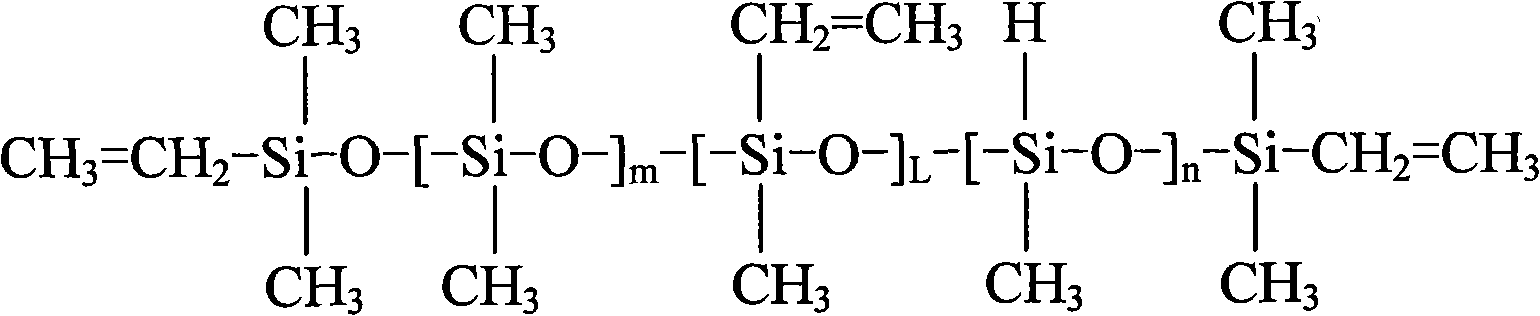

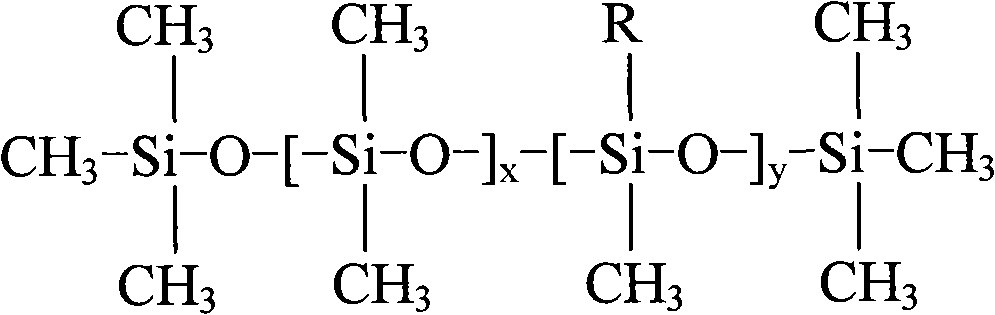

Silastic composition and preparation method thereof

The invention relates to a silastic composition and a manufacturing method thereof. The silastic composition comprises a component A and a component B, the component A is composed of mixing base adhesive and platinum coordination complex, whereas the component B is composed of the mixing base adhesive, hydrogen-containing silicone oil, a thickening agent and a depressor; the mixing mass ratio is: component A: component B is 0.5-99:1-99.5. The silastic composition of the invention is a solid-state mixing silastic containing platinum curing ingredient, so no curing ingredient is needed in the process of molding, besides, the vulcanization effect is good, the vulcanization moulding temperature is low, thus saving electricity, reducing exhaust emission and improving productivity; moreover, the silastic product is odorless and has fine physical and mechanical properties.

Owner:东莞市贝特利新材料有限公司

PC/ABS alloy modified engineering plastic dedicated for laptop casings and production method thereof

The invention discloses a PC / ABS alloy modified engineering plastic dedicated for laptop casings. The plastic comprises the following components in percentage by weight: 22% to 65% of polycarbonate, 1% to 10% of compatilizer, 22% to 65% of acrylonitrile-butadiene-styrene, 5% to 40% of mineral filling material, 0.3% to 1% of antioxidant, 3% to 20% of halogen-free fire retardant, 0.5% to 2% of dispersed lubricant, and 3% to 20% of flexibilizer. The invention also discloses a production method of the PC / ABS alloy modified engineering plastic dedicated for laptop casings. The PC / ABS alloy modified engineering plastic dedicated for laptop casings has the advantages of capability of being recycled and utilized, multi-choice of color and outer layer treatment, stable size, good heat radiation property, and high cost performance. The production method has the advantages of simple operation and suitability for mass production.

Owner:东莞市卡帝德塑化科技有限公司

Combination card of metal and plastic

ActiveUS20120325914A1Dimensionally stableReduce changesOrnamental structuresSpecial ornamental structuresAdhesiveEngineering

A card formed in accordance with the invention includes a first assembly comprised of multiple plastic layers attached via an adhesive to a metal layer. The multiple plastic layers forming the first assembly are laminated under a first selected temperature and pressure conditions to preshrink the multiple plastic layers, stress relieve the first assembly and render the first assembly dimensionally stable. The laminated first assembly is then attached to a metal layer via an adhesive layer to form a second assembly which is then laminated at a temperature below the first selected temperature to form a card which is not subjected to warpage and delamination.

Owner:COMPOSECURE LLC

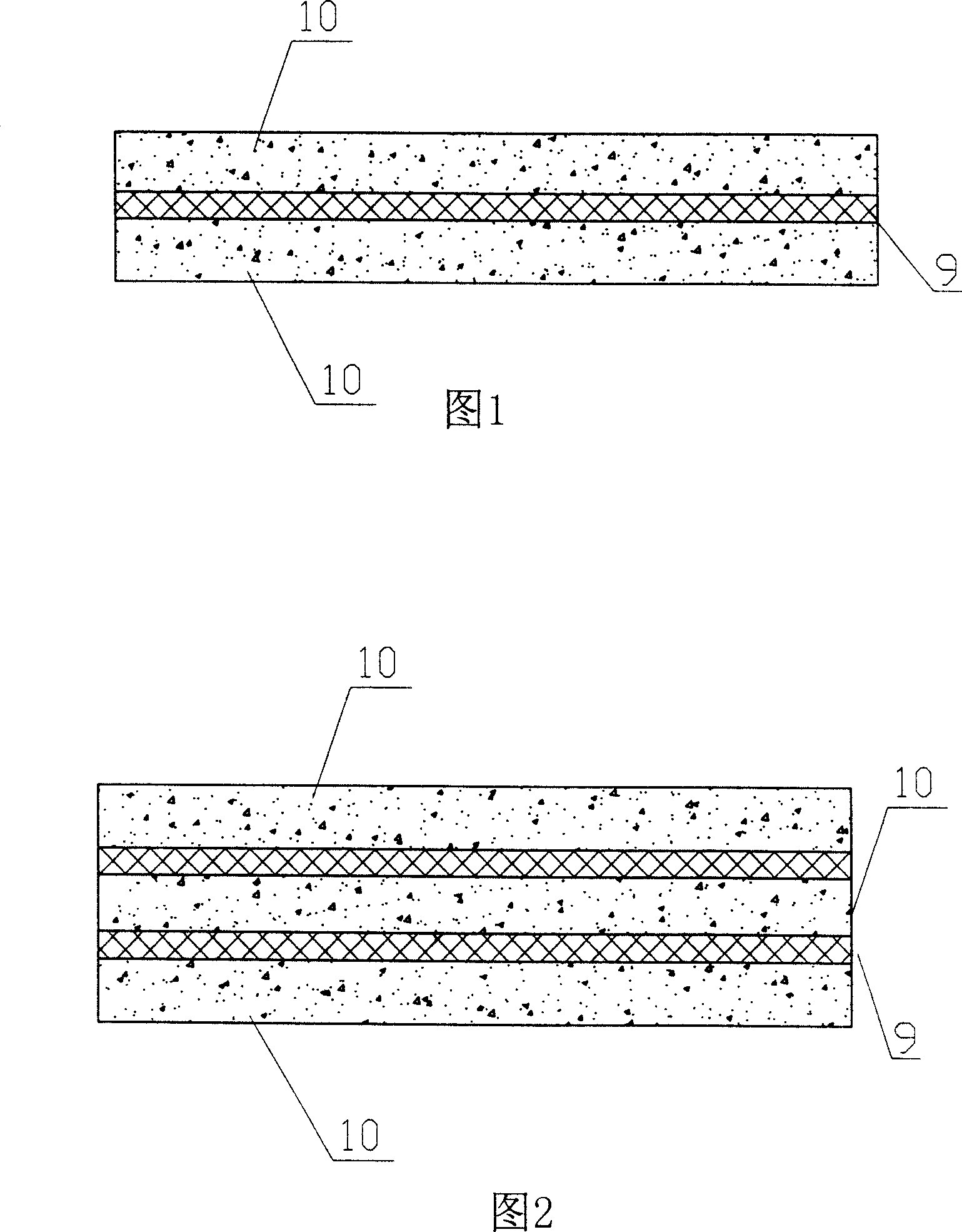

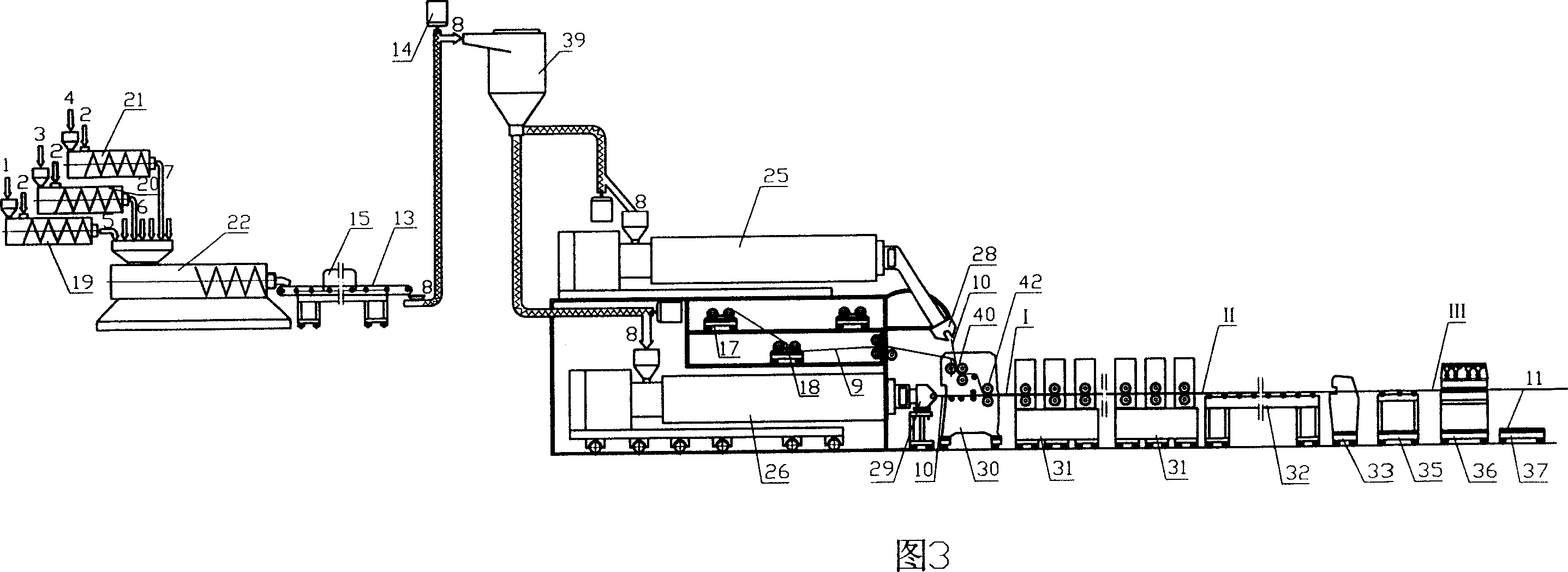

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

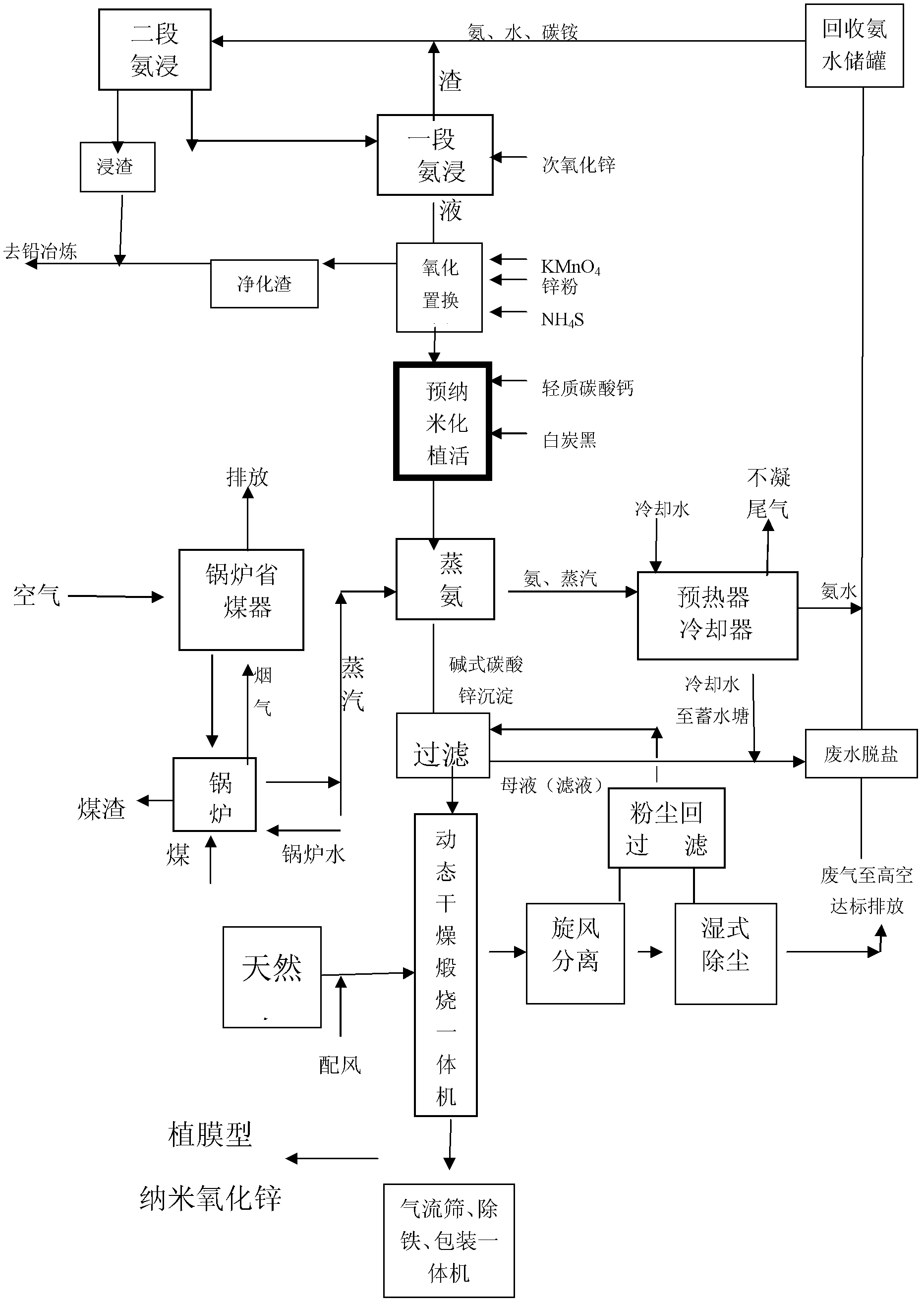

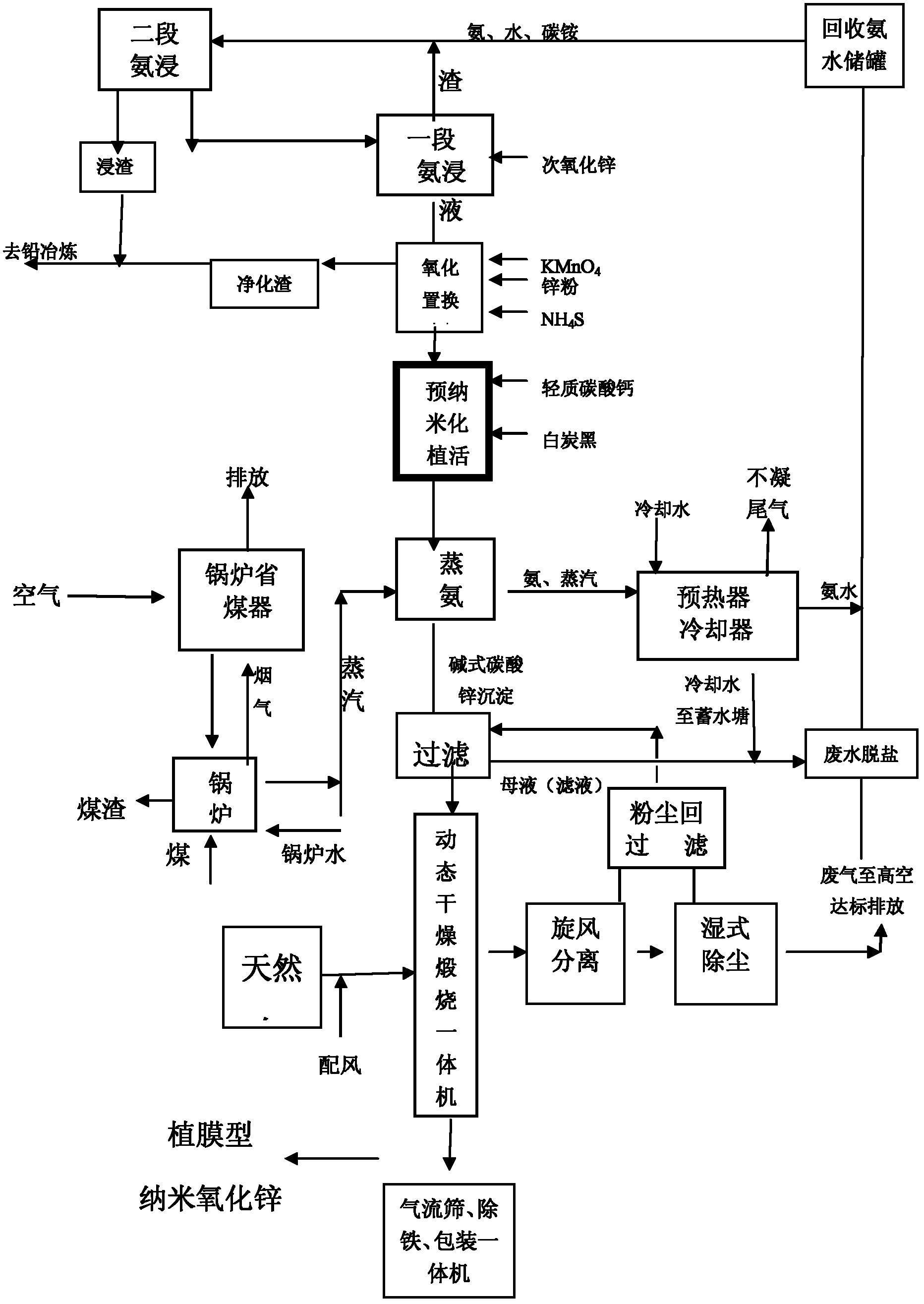

Film-coating production technology for nano zinc oxide

ActiveCN102515252AStable nano size and properties of nanomaterialsWell-developed grainsZinc oxides/hydroxidesNanotechnologyCarbonic acidTalc / Zinc Oxide

The invention provides a film-coating production technology for nano zinc oxide and belongs to the technical field of fine petrochemicals and chemicals. The technological process is that an alkali carbonic acid zinc film is coated uniformly on the surfaces of light calcium carbonate and inner pores thereof, subjected to decentralized processing, and then calcined and activated in a dynamic calcination furnace at the temperature of 400 to 500 DEG C, so as to prepare the nano zinc oxide. The nano zinc oxide prepared through the technology belongs to a low-zinc product (containing 24 to 30 percent zinc), has the advantages of stable nano size, stable nano material properties, completely developed crystal grains, small particle diameter, uniformity in distribution, low reunion degree, high activity and good dispersivity, and can be widely applied to rubber, tires, catalysis, magnetism, optics, electricity, chemistry, physics, biology and the like.

Owner:SHANOGUAN KAIHONG NANOMATERIAL

Hydrotalcite-rare earth-calcium zinc stablizer for PVC and its preparation method

InactiveCN101007878AImprove long-term thermal stabilityGood initial colorabilityChemical synthesisHydrotalcite

The invention discloses a PVC hydrotalcite- rare earth- calcium zinc stabilizing agent and the method for preparing the same, which in detail erlates to plastic composite stabilizing agent and the preaparing method, belonging to chemical field. The main component for stabilizing comprises column- supported hydrotalcite, unsaturated rare earth, and epoxy aliphatic acid calcium zinc, and it is prepared through chemical synthesis, reformed treatment and optimization compound. The product is characterized by outstanding thermal stabilizing effect, good first stage coloring property, sound plasticizing property, good transparenty, weatherability, improved quality, high effeciciency, no toxicity, no pollution, low cost. It can replace expensive organotin thermal stabilizing agent and is widely used in PVC product preparation, such as water- supply pipes, section bar, transparent granulate, film, medical apparatus, toy, fridge stamp and box sheet material.

Owner:扬州科宇化工有限公司

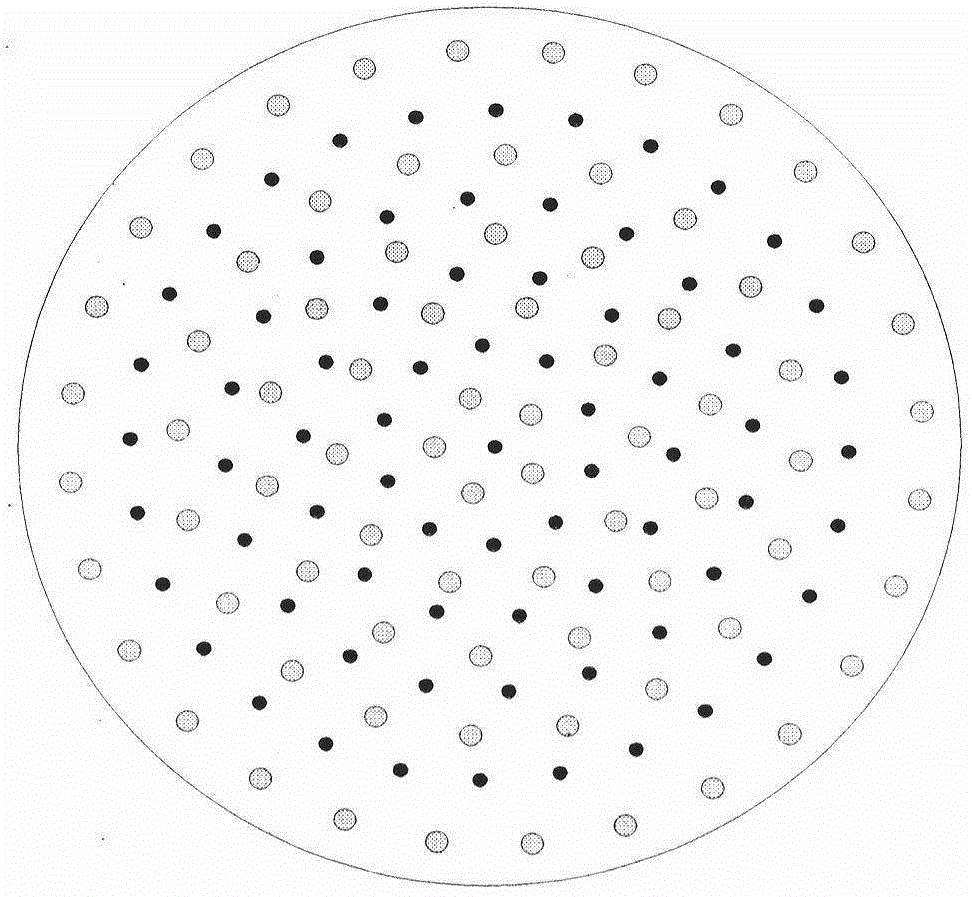

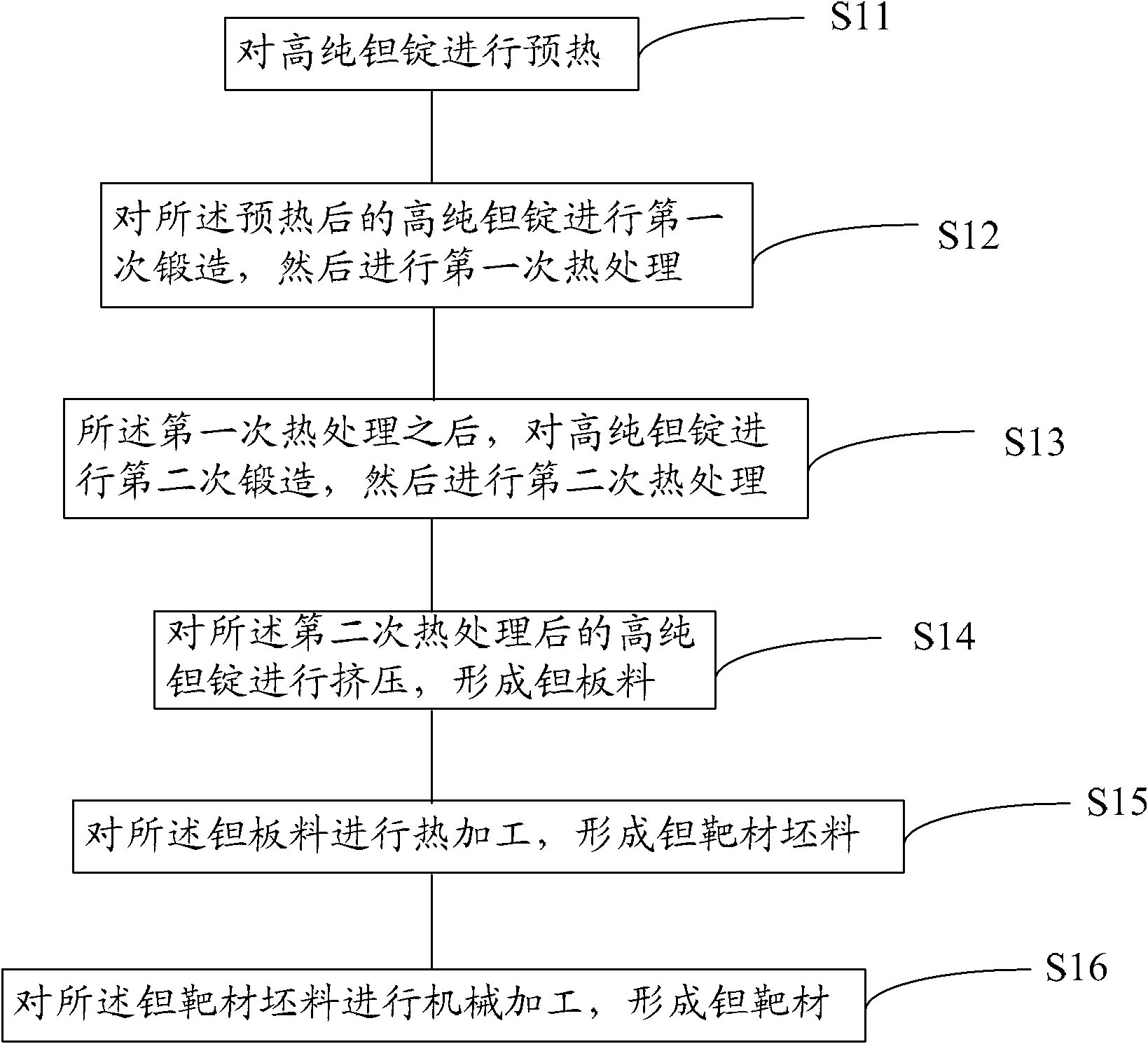

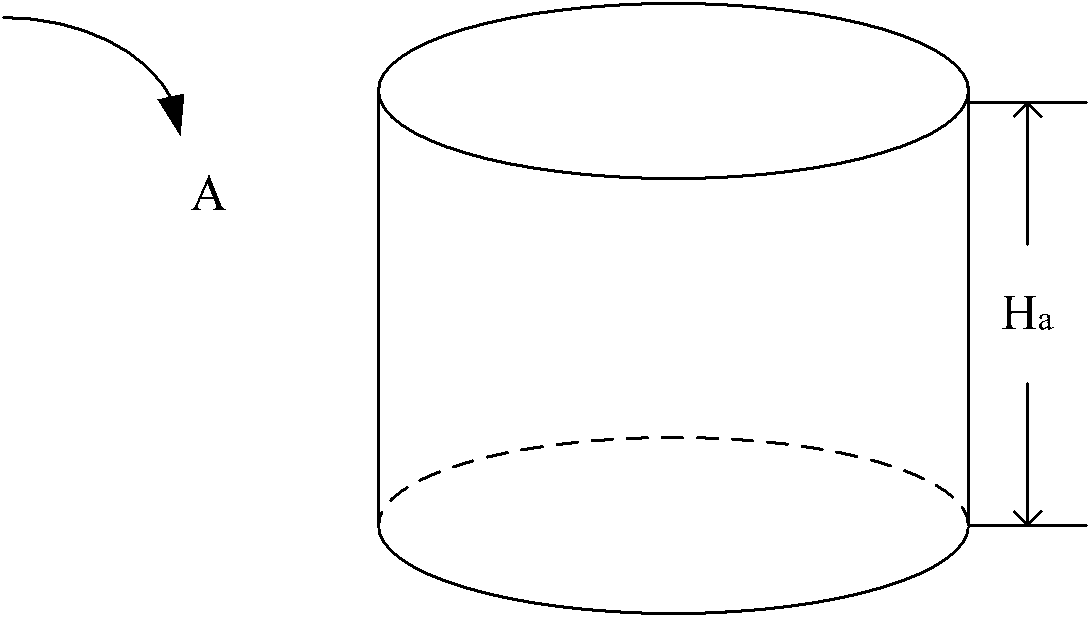

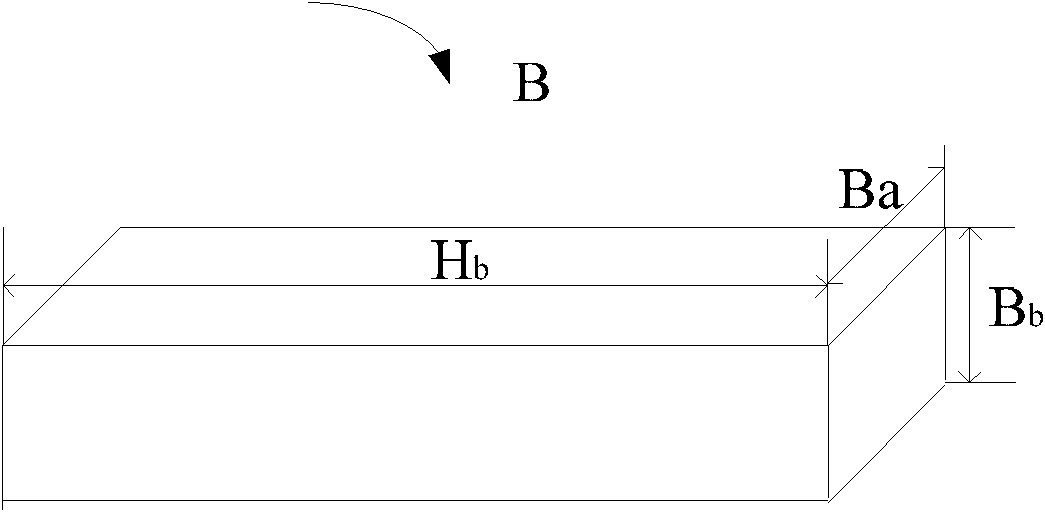

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Floor covering with woven face

InactiveUS20040198120A1Increase rate of changeReduce the chance of changeSynthetic resin layered productsFloor coveringsYarnPolyester

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

Method for fabricating soft knitting face fabric from cotton

InactiveCN101003936ADimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

Modified polylactic acid composite material suitable for 3D printing and preparation method of composite material

The invention relates to a modified polylactic acid composite material suitable for 3D printing and a preparation method of the composite material. The modified polylactic acid composite material suitable for 3D printing is prepared from the following raw materials in percentage by weight: 80-90% of polylactic acid, 6-10% of a flexibilizer, 1-2% of a nucleating agent, 1-3% of a dispersing agent, 1-2% of a chain extender and 1-3% of a compatilizer. The preparation method of the modified polylactic acid composite material suitable for 3D printing comprises the following steps: mixing the raw materials by virtue of a high-speed mixer, and extruding and drawing by using a single-screw extruder. Compared with the prior art, the composite material prepared by the method is good in flexibility; meanwhile, the impact strength, the heat resistance and the breakage elongation can be greatly improved; the printing is smooth when the composite material is used for 3D printing; the finished product has the advantages of smooth surface, beautiful and shapely appearance and stable size.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Flame-retardant synthetic paper

Owner:CHANGZHOU JINKA CARD BASE SHEET

Composition and film for producing polymer dispersion liquid crystal, and producing method thereof

InactiveCN101429436AGood compatibilityImprove thermal stabilityLiquid crystal compositionsMethacrylatePolymer science

The invention provides a composition for preparing polymer dispersed liquid crystal. The composition comprises polymerization monomer and light initiator; the polymerization monomer is at least one of acrylic ester, methacrylic acid ester, acrylic acid and methacrylic acid compounds or the mixture of at least one of the acrylic ester, the methacrylic acid ester, the acrylic acid and the methacrylic acid compounds and an unpolymerized composition containing hydrosulfide group, wherein the composition also comprises an acrylic acid triazine compound congaing crosslinking agent. The invention also provides a liquid crystal containing composition for preparing the polymer dispersed liquid crystal; moreover, the invention also provides polymer dispersed liquid crystal (PDLC) and a PDLC membrane prepared from the composition of the invention and a method for preparing the PDLC membrane. The PDLC membrane prepared from the composition of the invention has higher contrast, lower driving voltage and good thermal stability.

Owner:BYD CO LTD

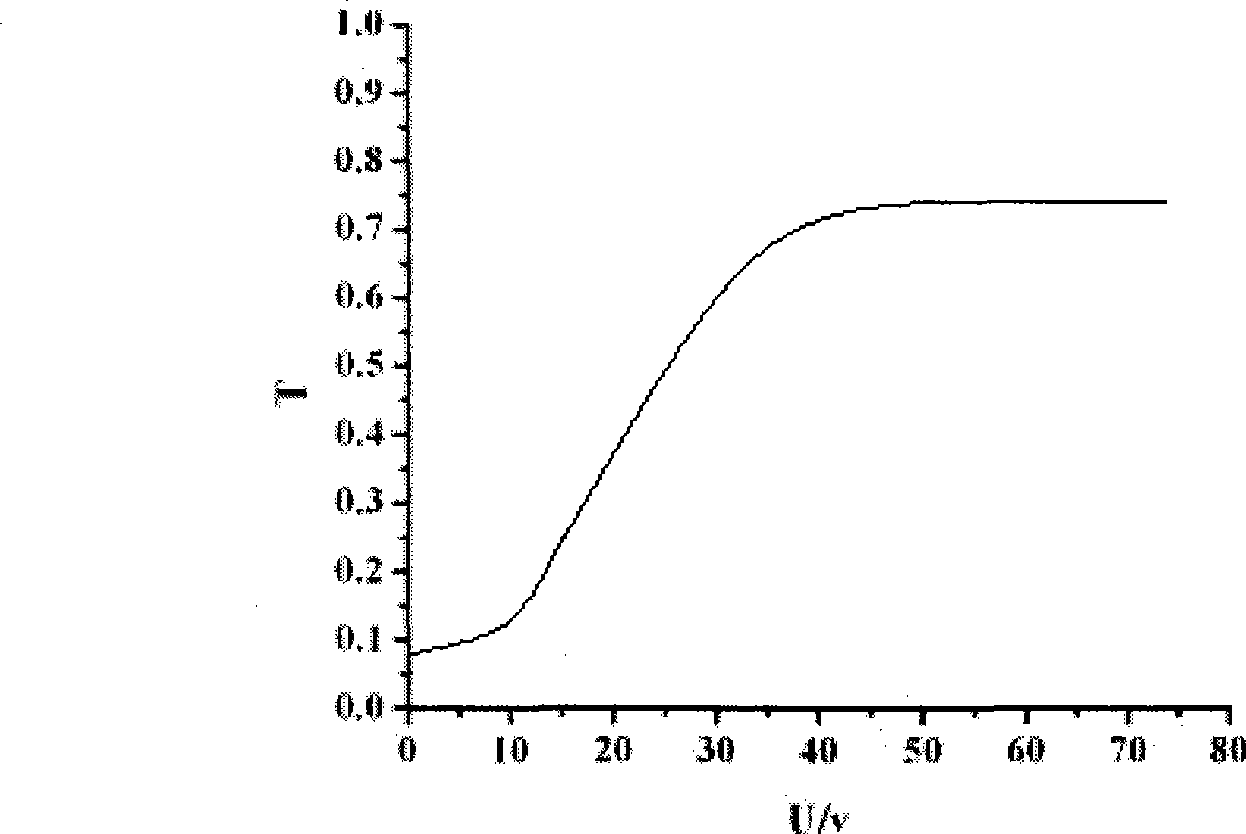

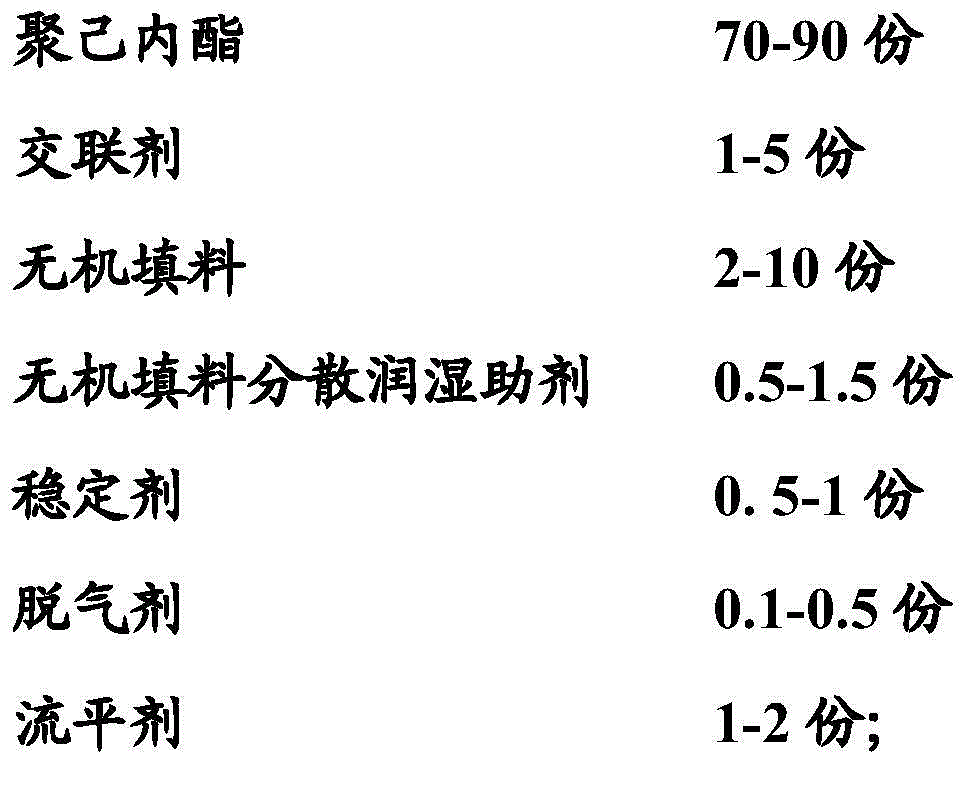

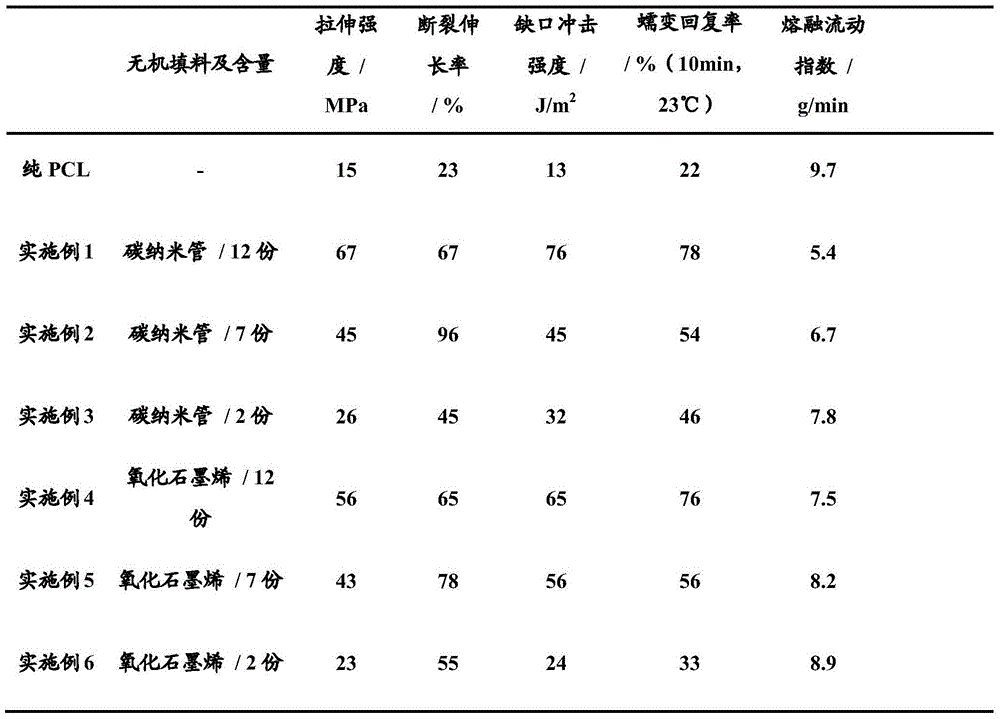

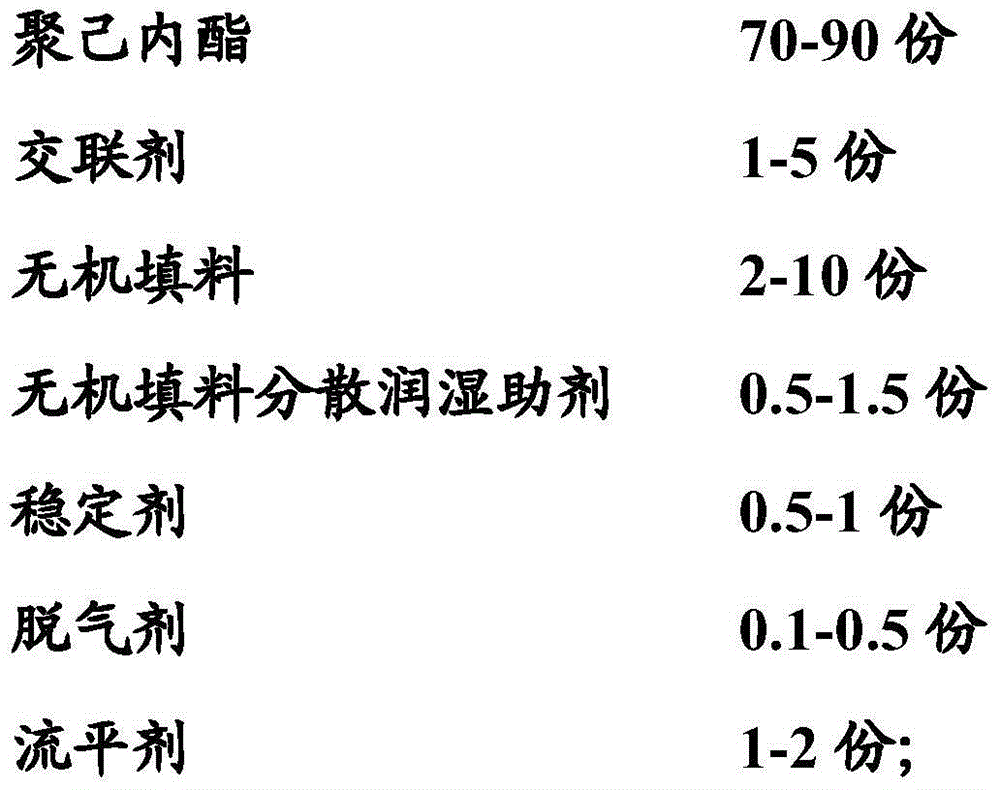

3D printing polycaprolactone material and preparation method thereof

The invention discloses a high-strength biodegradable polycaprolactone 3D printing material which comprises the following components in parts by weight: 70-90 parts of polycaprolactone, 1-5 parts of a crosslinking agent, 2-10 parts of an inorganic filler, 0.5-1.5 parts of an inorganic filler dispersing wetting auxiliary agent, 0.5-1 part of a stabilizer, 0.1-0.5 part of a degassing agent, and 1-2 parts of a leveling agent. With targeted selection of the inorganic components for modification treatment on polycaprolactone, the polycaprolactone modified material exerts excellent impact-resistance strength and creeping resistance. The material allows the degradable 3D printing material to exert better mechanical properties while broadening the 3D printing material type.

Owner:INST OF CHEM CHINESE ACAD OF SCI

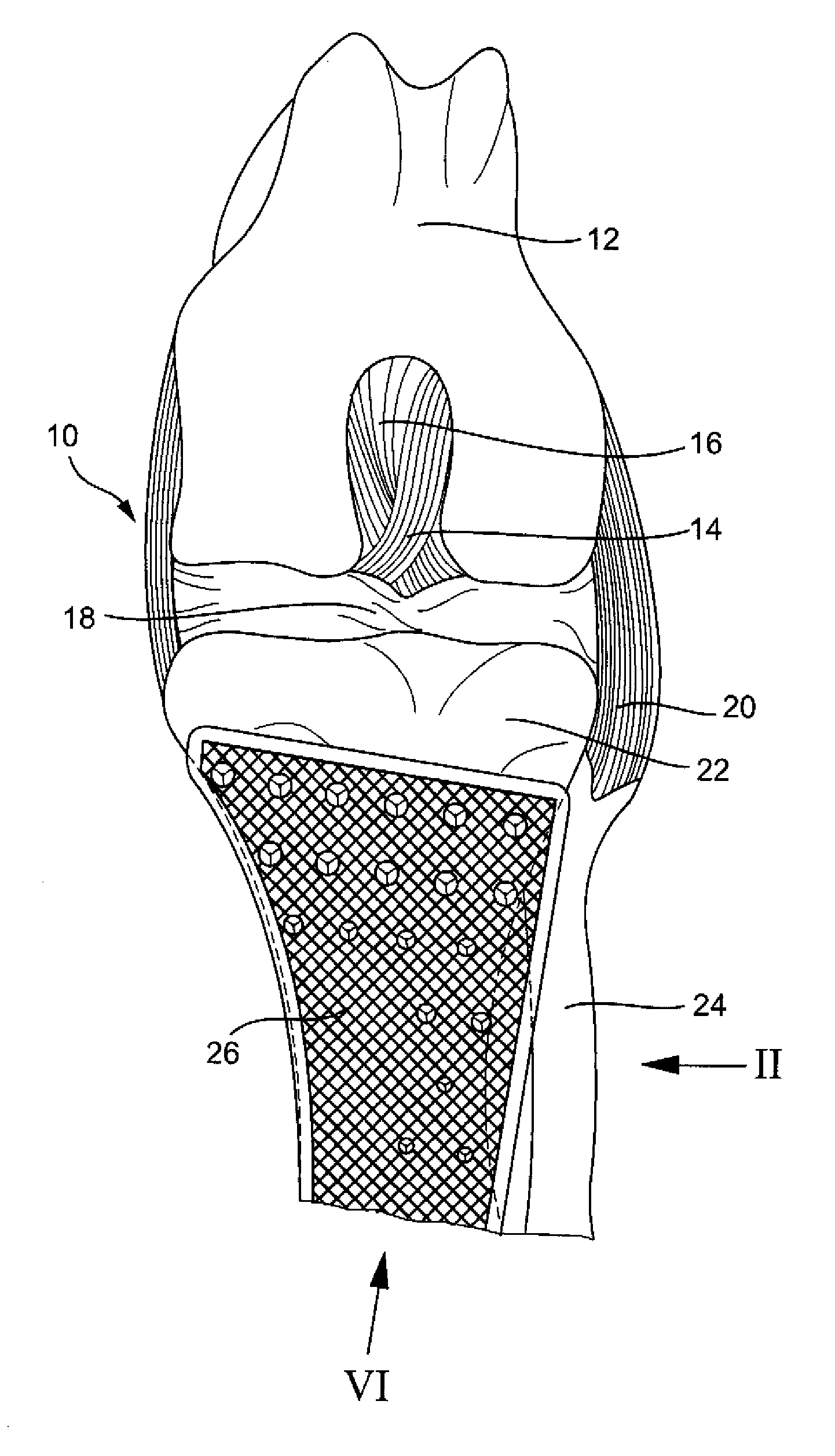

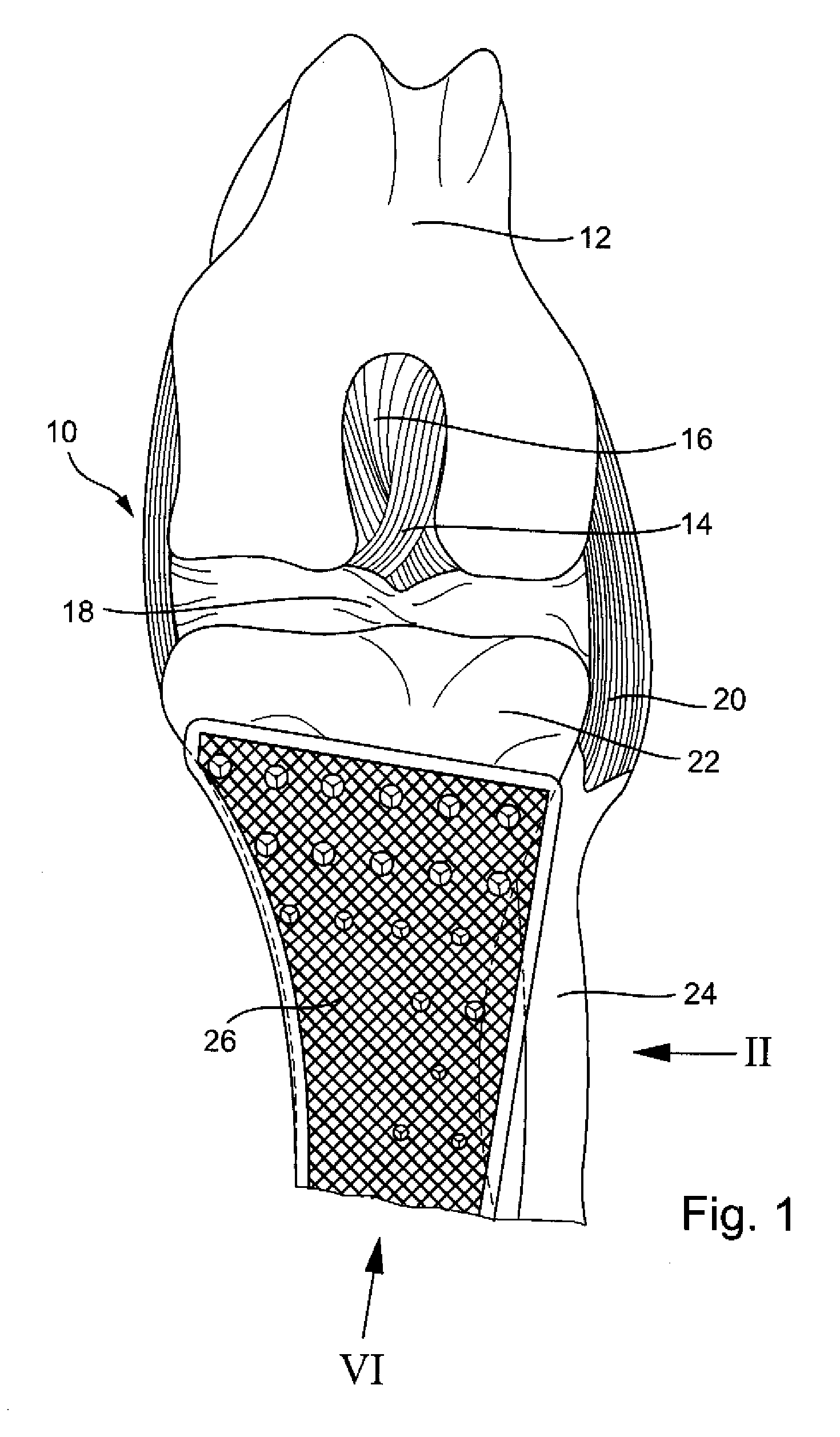

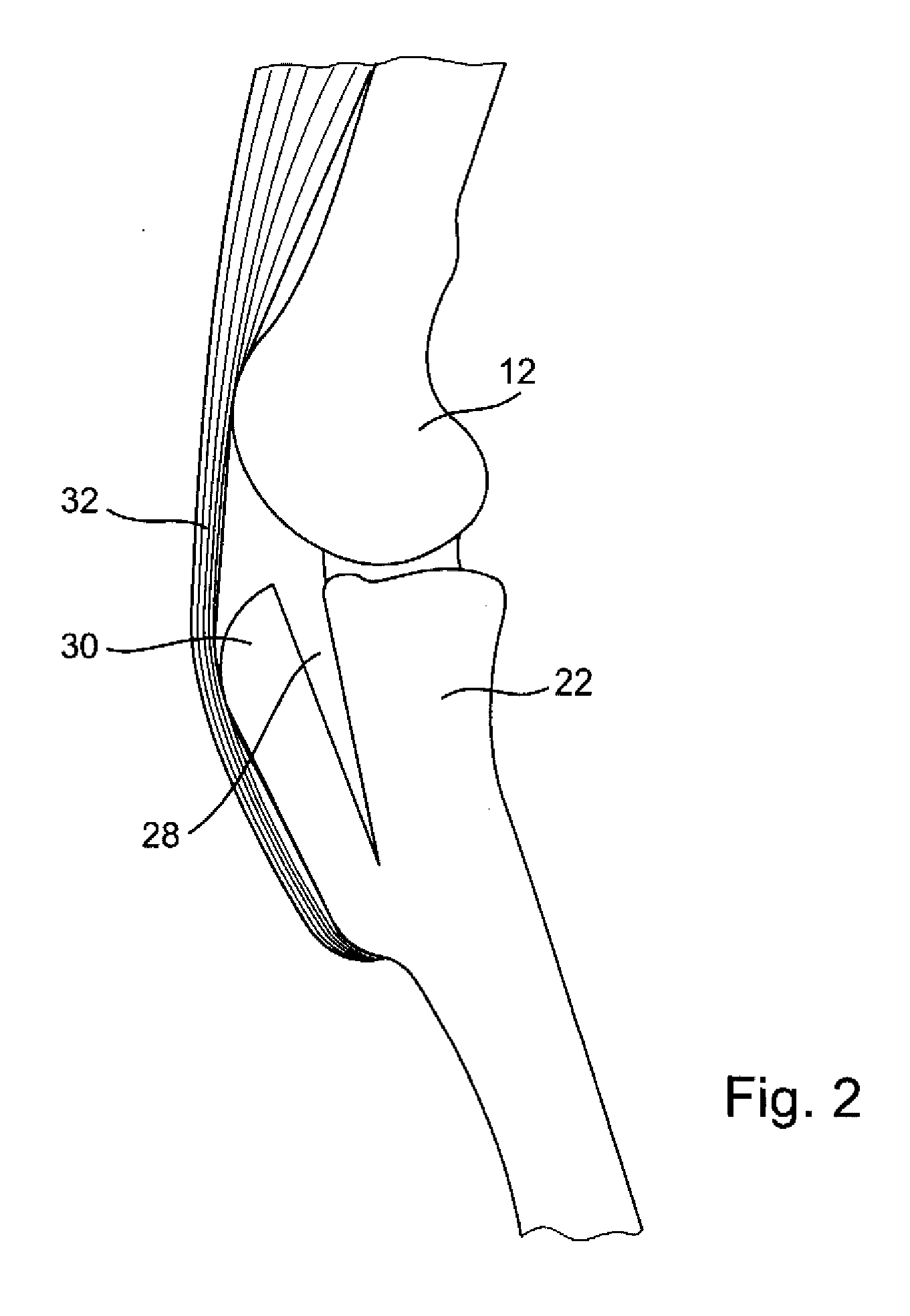

Tibia implant for tightening the patella tendons

ActiveUS20130030540A1Prevent movementRapid manufacturing methodJoint implantsSkullTibiaPlantaris tendon

A tibia implant for tightening the patella tendons, has a vertical cross section which in mounted position tapers downward, an essentially vertically arranged base plate which carries a sponge structure, wherein the sponge structure on both sides rests against a respective vertical cut surface of a vertical knee proximal incision of the tibia.

Owner:RITA LEIBINGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com