Patents

Literature

59results about How to "Well-developed grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano copper powder for electronic paste and preparation process

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

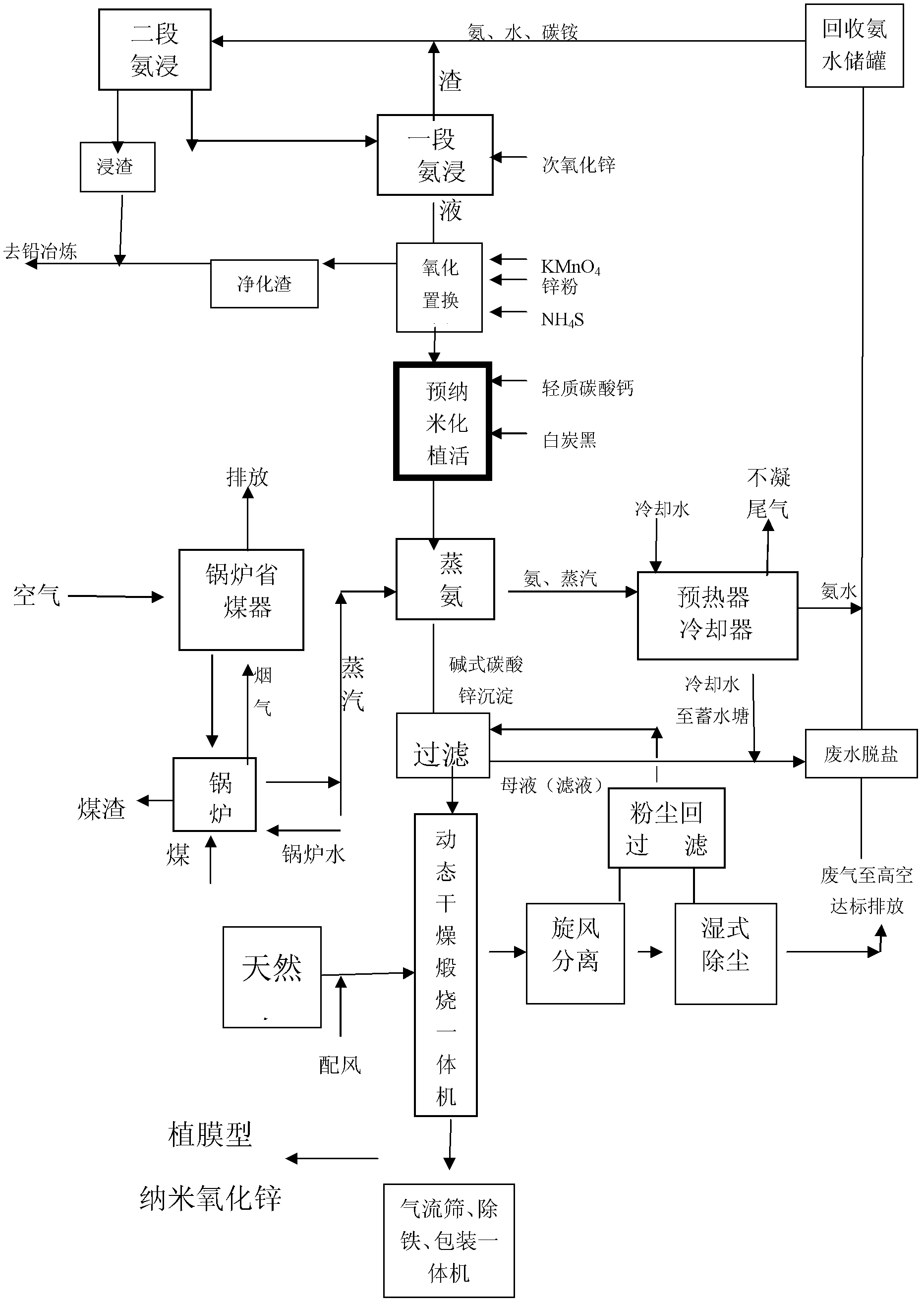

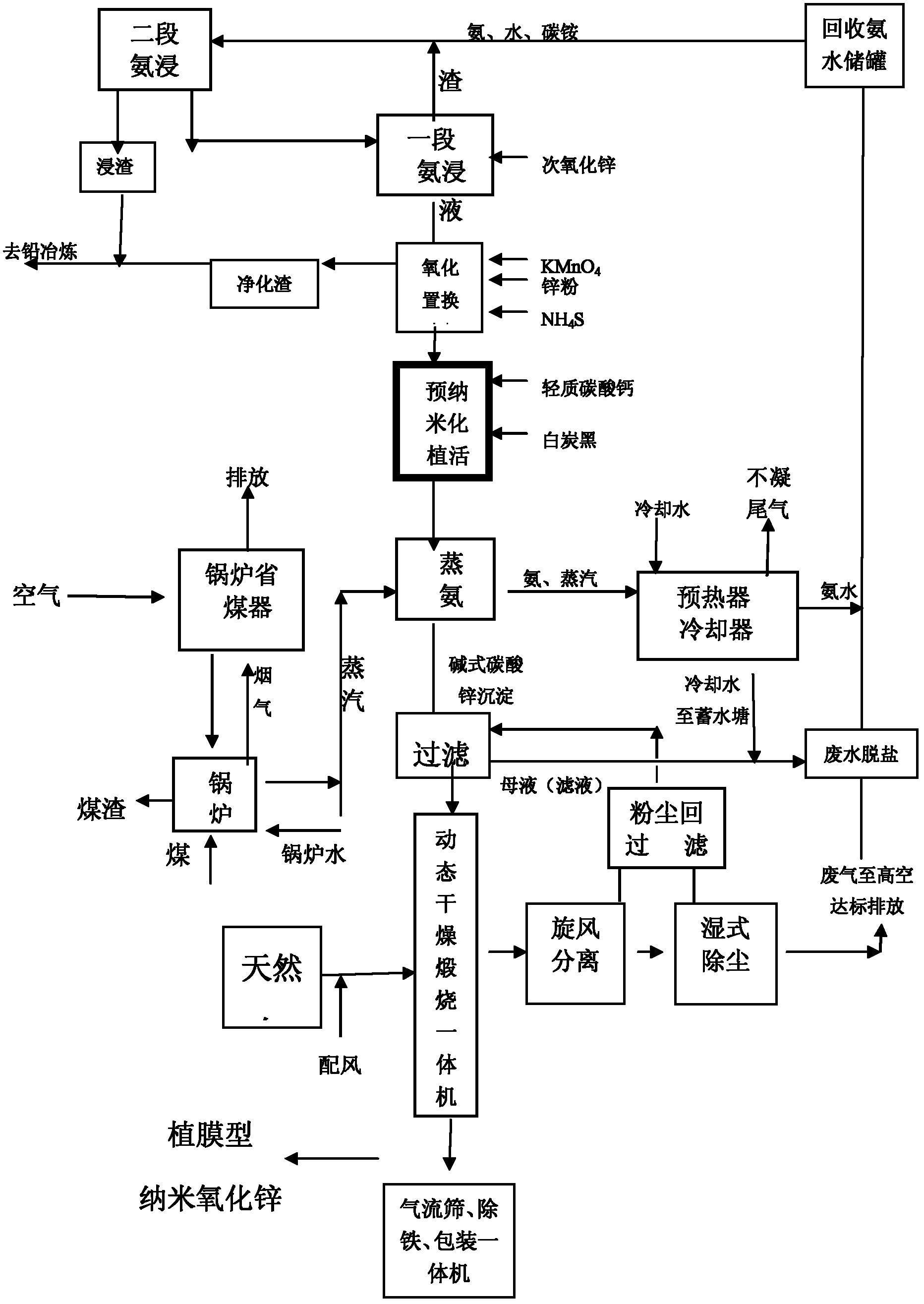

Film-coating production technology for nano zinc oxide

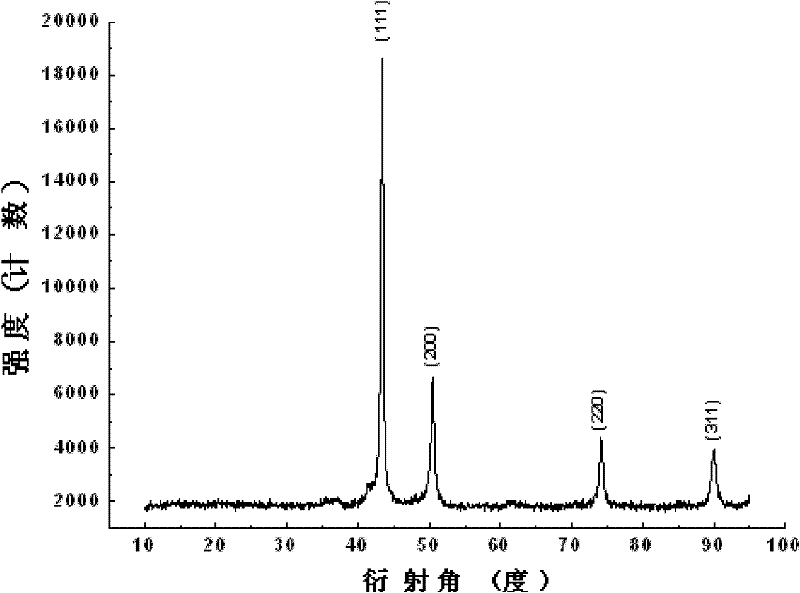

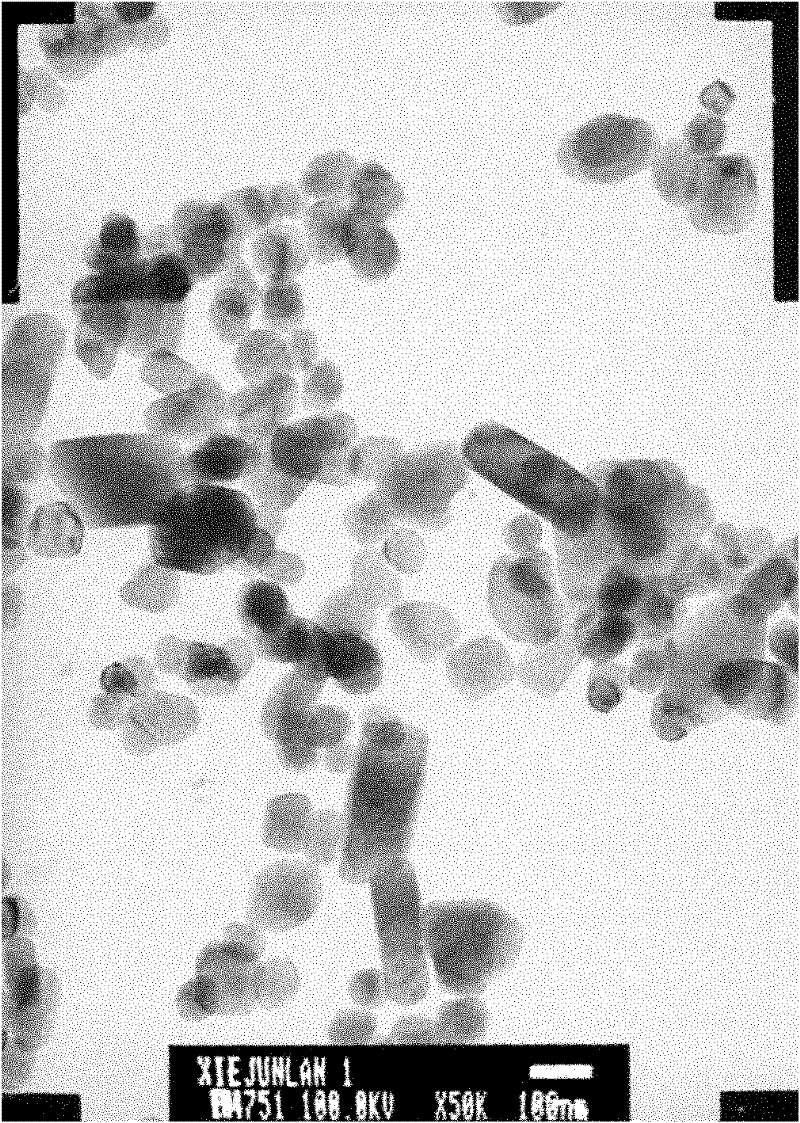

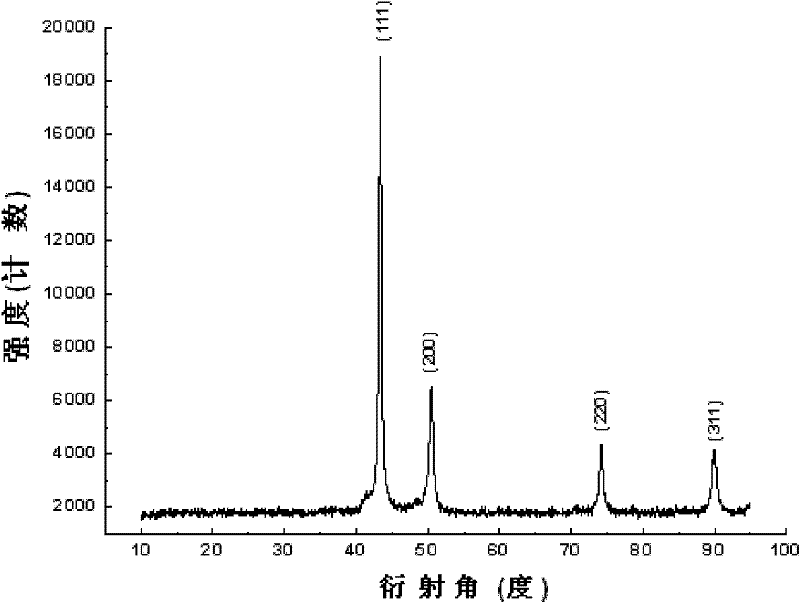

ActiveCN102515252AStable nano size and properties of nanomaterialsWell-developed grainsZinc oxides/hydroxidesNanotechnologyCarbonic acidTalc / Zinc Oxide

The invention provides a film-coating production technology for nano zinc oxide and belongs to the technical field of fine petrochemicals and chemicals. The technological process is that an alkali carbonic acid zinc film is coated uniformly on the surfaces of light calcium carbonate and inner pores thereof, subjected to decentralized processing, and then calcined and activated in a dynamic calcination furnace at the temperature of 400 to 500 DEG C, so as to prepare the nano zinc oxide. The nano zinc oxide prepared through the technology belongs to a low-zinc product (containing 24 to 30 percent zinc), has the advantages of stable nano size, stable nano material properties, completely developed crystal grains, small particle diameter, uniformity in distribution, low reunion degree, high activity and good dispersivity, and can be widely applied to rubber, tires, catalysis, magnetism, optics, electricity, chemistry, physics, biology and the like.

Owner:SHANOGUAN KAIHONG NANOMATERIAL

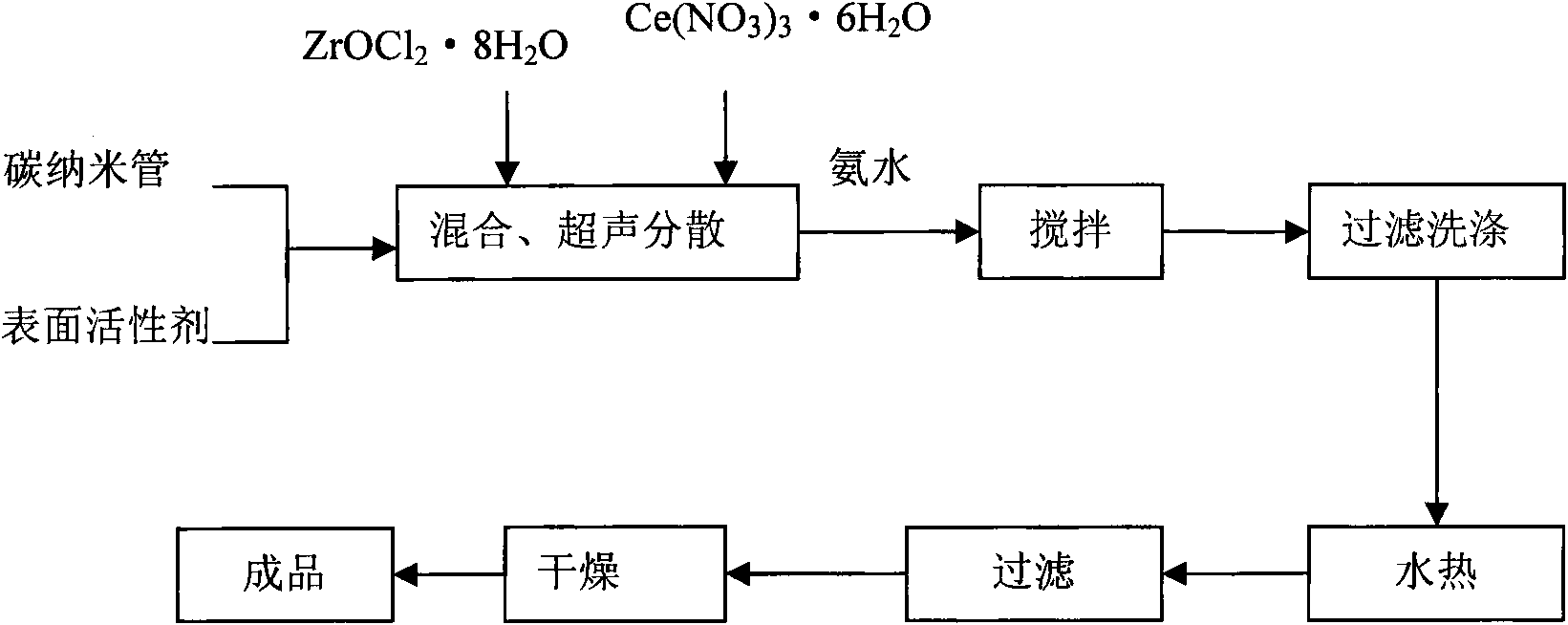

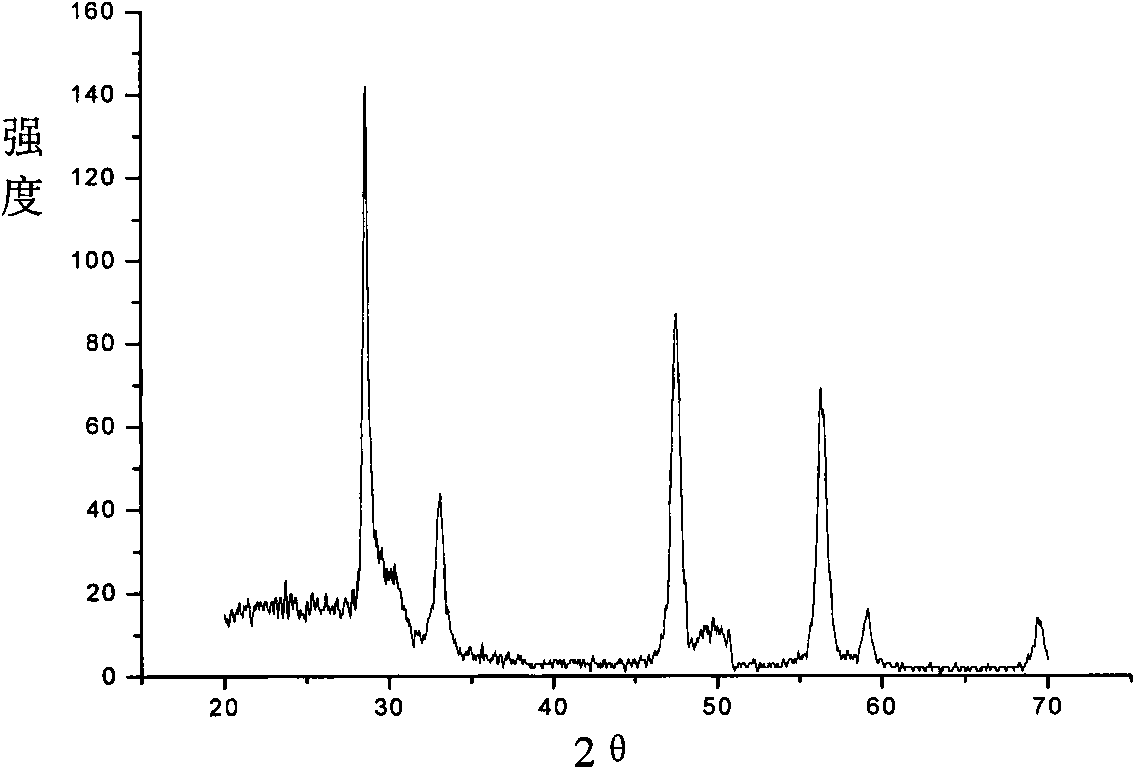

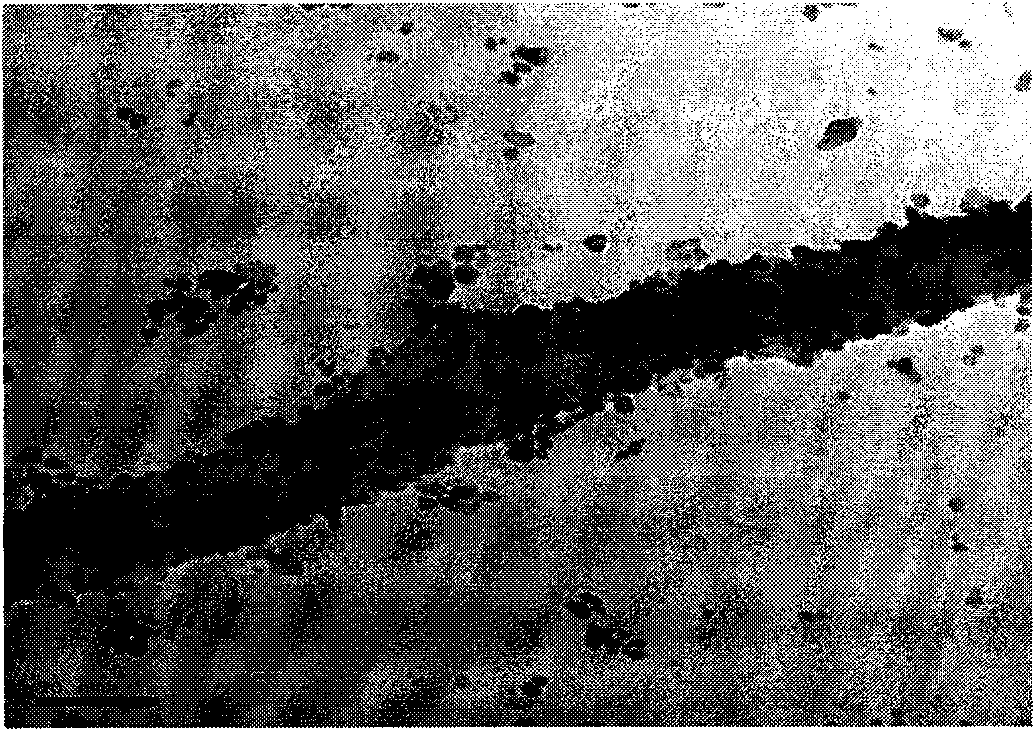

Method for preparing ZrO2-CeO2/CNTs composite nanotube by hydrothermal method

InactiveCN101767770AGood dispersionLarge specific surface areaNanostructure manufactureCatalyst activation/preparationCarbon nanotubeSurface-active agents

The invention discloses a method for preparing a ZrO2-CeO2 / CNTs composite nanotube by a hydrothermal method, which is a method for preparing a composite carbon nano tube based on nanoscale cerium oxide, nanoscale zirconia and a carbon nano tube. The preparation method comprises the steps of: sequentially adding the carbon nano tube, a surface active agent, zirconium oxychloride, cerous nitrate and deionized water which serve as raw materials according to stoichiometric ratio; performing ultrasonic dispersion to uniformly mix the raw materials; dripping ammonia water into the mixed raw materials until the pH value is 9.5; and performing hydro-thermal treatment to prepare a product, wherein the tube diameter of the prepared ZrO2-CeO2 / CNTs composite nanotube is between 50 and 80 nanometers, and a specific surface area reaches 70-150 m<2> / g; and the ZrO2-CeO2 / CNTs composite nanotube exists in the form of complete solid solution of a square / cubic system, the crystallinity reaches over 75 percent, and the ZrO2-CeO2 / CNTs composite nanotube is uniform in loading and has no agglomeration phenomenon. The method has the advantages of simple process, no need of high-temperature calcination, low energy consumption and the like.

Owner:GUANGDONG UNIV OF TECH

Method for treating arsenic-containing wastewater and solidifying arsenic

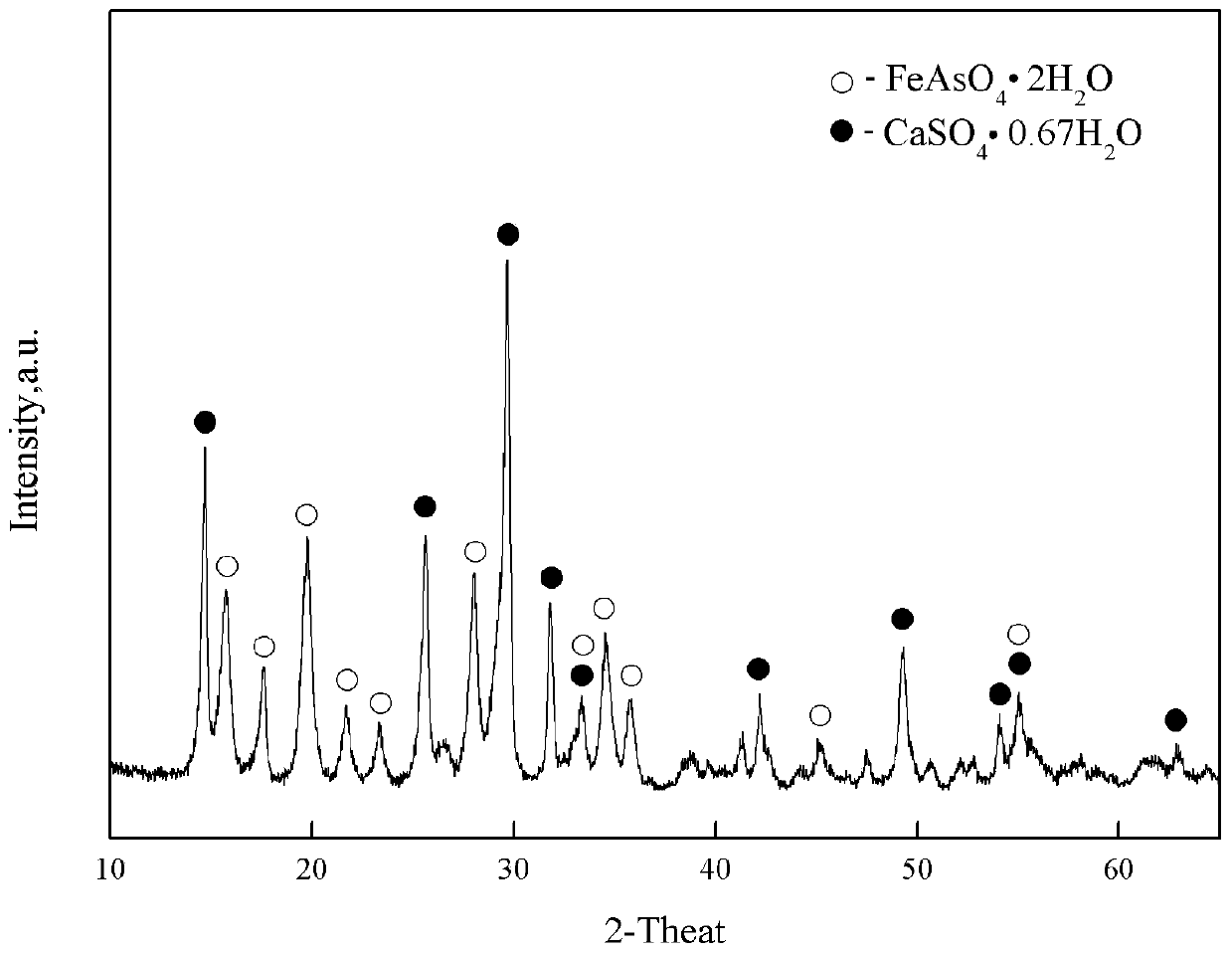

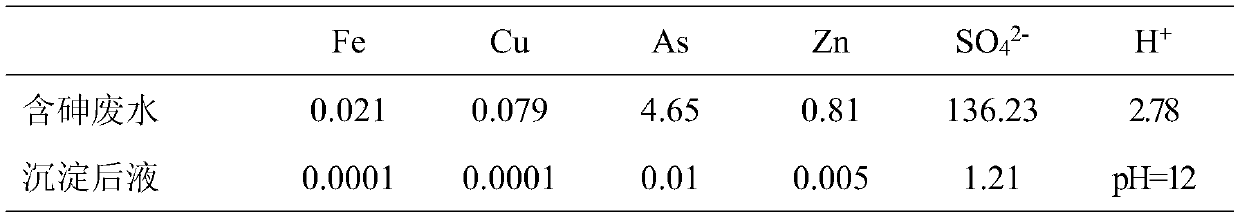

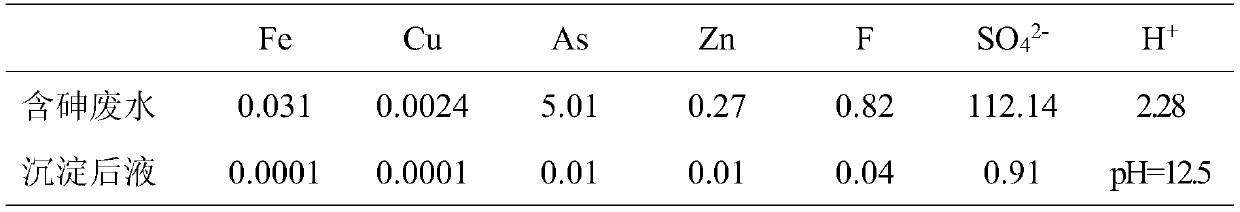

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

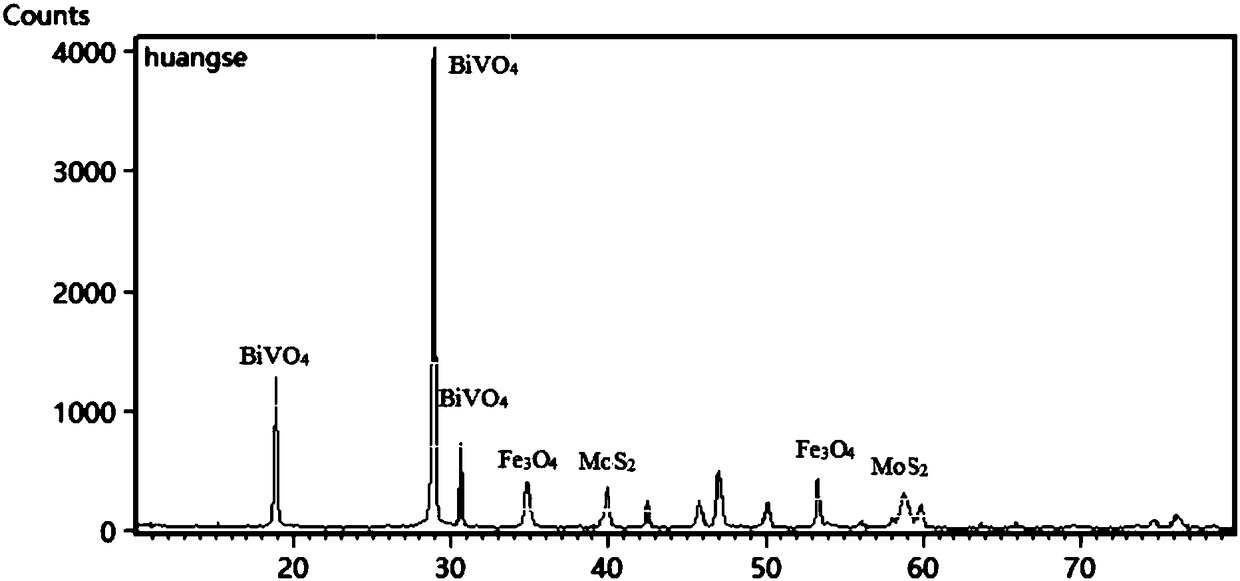

Fe3O4/MoS2/BiVO4 material preparing method, product and application of product

InactiveCN108355679AHigh reuse rateEasy to recycleWater/sewage treatment by irradiationWater treatment compoundsSodium acetateThiourea

The invention discloses a Fe3O4 / MoS2 / BiVO4 material preparing method, a product and an application of the product. The method comprises the steps: firstly, dissolving ferric chloride hexahydrate, sodium acetate and polyethylene glycol in ethylene glycol, carrying out a reaction at the temperature of 180-200 DEG C for 8-9 h, and thus obtaining ferric oxide; then, mixing sodium molybdate dehydrate,sodium molybdate tetrahydrate and thiourea evenly, adding ferroferric oxide, and carrying out a reaction for 22-24 h at the temperature of 180-200 DEG C, to obtain a Fe3O4 / MoS2 material; finally, dissolving bismuth nitrate pentahydrate and ammonium metavanadate in deionized water, adding the Fe3O4 / MoS2 material, mixing evenly, carrying out a reaction for 15-17 h at the temperature of 160-170 DEG C, and thus obtaining a Fe3O4 / MoS2 / BiVO4 composite material. When the composite material is used as a photocatalyst for treating tetracycline hydrochloride wastewater, the degradation rate can reach 90% or more, and the photocatalytic efficiency can be improved. At the same time, because of the presence of Fe3O4, the photocatalyst can be recovered more conveniently and simply for repeated experiments, the recovery cost of the photocatalyst is reduced, and the repeated utilization rate of the photocatalyst is improved.

Owner:CHANGAN UNIV

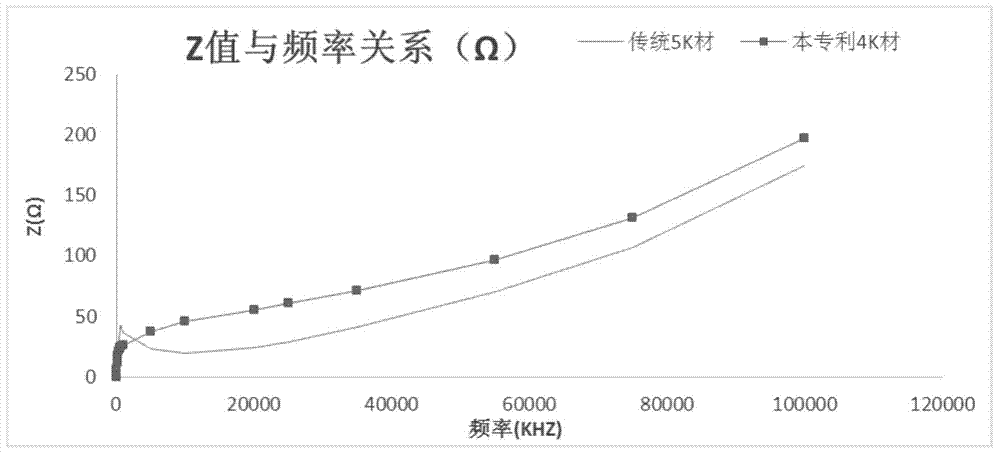

High-frequency high-impedance material of manganese-zinc ferrite and preparation method of high-frequency high-impedance material

The invention provides a high-frequency high-impedance material of manganese-zinc ferrite and a preparation method of the high-frequency high-impedance material. Under the premise that scientific ratio of iron to manganese to zinc in the manganese-zinc ferrite is ensured, a certain amount of micro-constituents are also added, and contain a plurality of metal ions: Cu<2+>, Ta<3+>, Ca<2+>, Co<2+>, Ti<4+>, Ni<2+>, Sn<4+>, Bi<3+>, V<5+>, Nb<5+>, Si<4+>, Mo<6+>, Mg<2+>, Al<3+>. The main constituents and a plurality of trace constituents work together; and the electromagnetic property of the material is changed by changing the grain boundary resistivity. Through detection, the impedance value of the high-frequency high-impedance material of the manganese-zinc ferrite rises along with increase of frequency (1KHz to 100MHz); the surface direct current is greater than or equal to 1Mohm; and the magnetic conductivity is between 3200 and 4800, and thus the high-frequency high-impedance material meets the application requirements of high-end original elements such as temperature-adjusting transformer elements of large air conditioners.

Owner:浙江恩大智能科技有限公司

Low-temp sintered aluminium nitride-base composition and its preparing process

A low-temp sintered AIN-base composition is prepared from AIN (50-80 wt%), lead borosilicate glass (15-50), and LiF (rest) through hot pressing and sinter, including heating and pressurizing by threestages, and holding temp at 950 or 1000 deg.C under 18-25 MPa for 2-8 hr. Its advantages include low sinter temp and density, high heat conductivity (11 W / m.k) and low cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

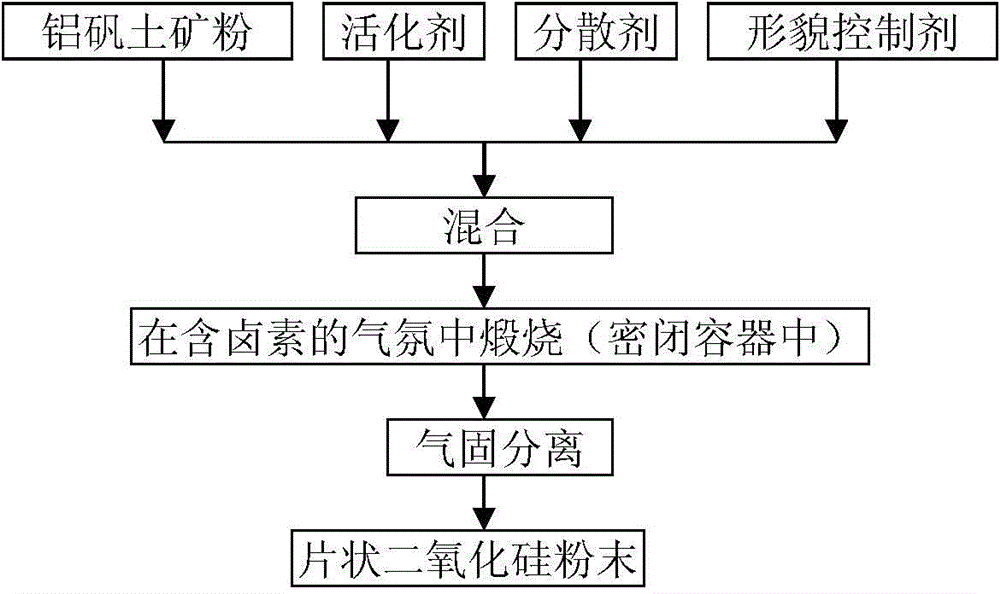

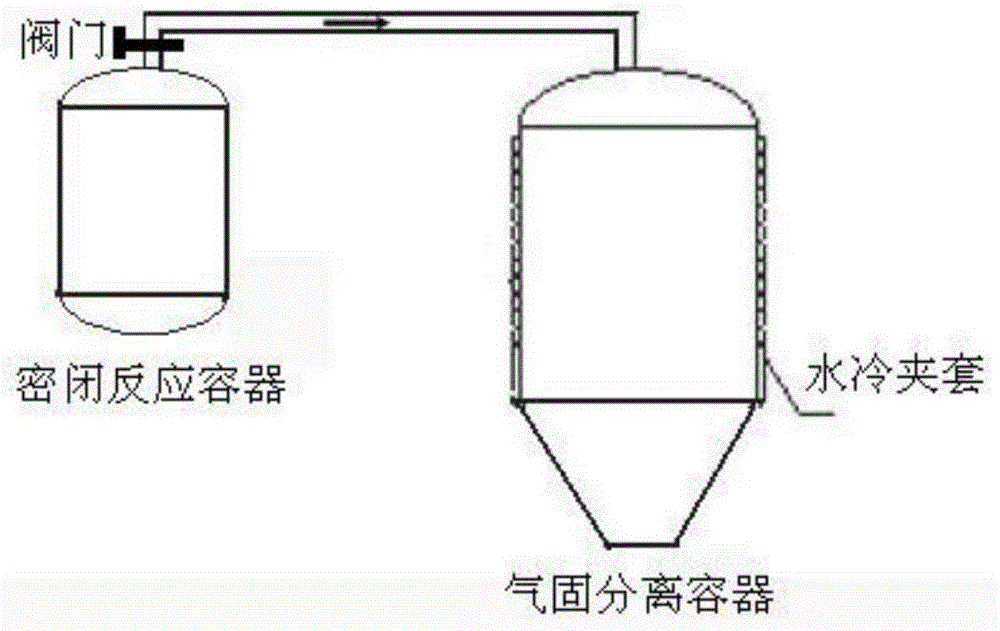

Method used for preparing flake-like silicon dioxide powder

The invention provides a method used for preparing flake-like silicon dioxide powder, and belongs to the technical field of powder particle size and morphology control. According to the method, bauxitic clay ore powder containing SiO2 is taken as a raw material; an activator, a dispersant, and a crystal grain morphology control agent are added into the raw material for uniform mixing; an obtained mixed powder is subjected to calcining in atmosphere containing halogen, and obtained silicon halide is subjected to hydrolysis so as to obtain silicon dioxide and halogen hydride; after calcining, the valve of a sealed reaction container is unsealed, so that high pressure gas in the sealed reaction container is delivered into a gas-solid separator with a larger volumn via expansion so as to realize gas-solid separation of silicon halide with gas phase and obtain the flake-like silicon dioxide powder, wherein the gas-solid separator is provided with a water cooling jacket. Thickness of the flake-like silicon dioxide powder is less than 0.2 <mu>m, and average diameter-to-thickness ratio is higher than 50. Reaction temperature of the method is relatively low; the method is simple; energy consumption is low; production cost is low; and the diameter-to-thickness ratio of the flake-like silicon dioxide powder can be adjusted.

Owner:贵州天合国润高新材料科技有限公司

Constant pressure hydro-thermal preparation method for barium zirconate titanate powder

Disclosed is a normal-pressure hydrothermal preparation method for barium zirconate titanate powder. Pure titanium tetrachloride is used as the source of titanium; zirconia oxygen dichlorohydrate is used as the source for zirconium; barium chloride is used as the barium source; sodium hydroxide is taken as the reaction agent; in conjunction with technology, the reaction conditions are timely and strictly controlled, thus the reaction speed is greatly accelerated and the sodium chloride and other remnants left after the reaction are easy to be washed to cause less pollution on environment. The reaction of the invention is carried through in normal-pressure and low-temperature environment, thus the various parameters in the reaction process can be easily adjusted and controlled. The barium zirconate titanate powder prepared through the invention has the advantages of integral grains, even granularity distribution, non-reunion, high activity and low cost, which can fully meet the requirements on the high-performance of barium zirconate titanate in the electronic industry.

Owner:仙桃市中星电子材料有限公司

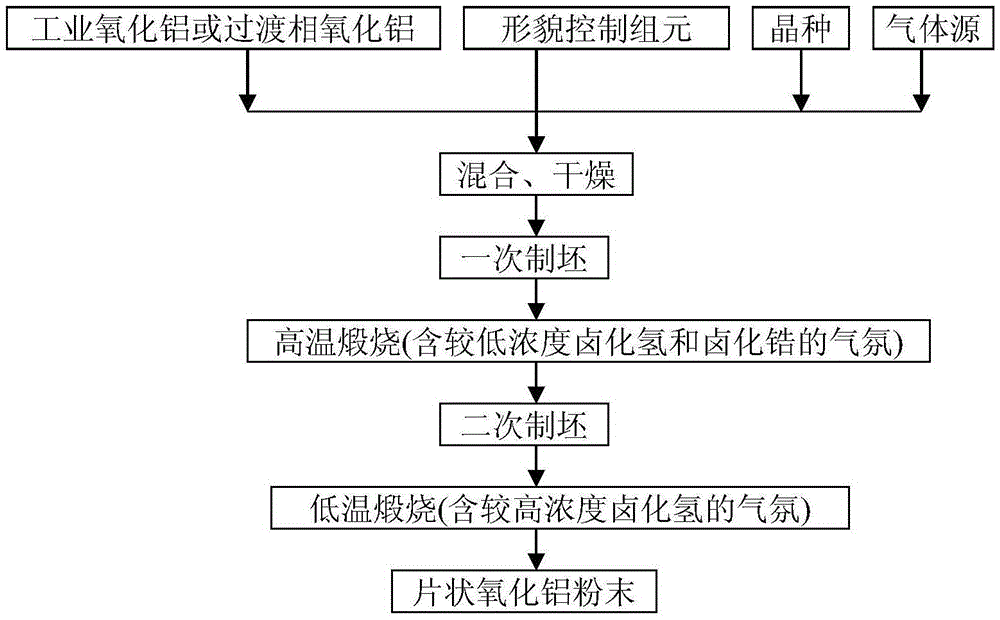

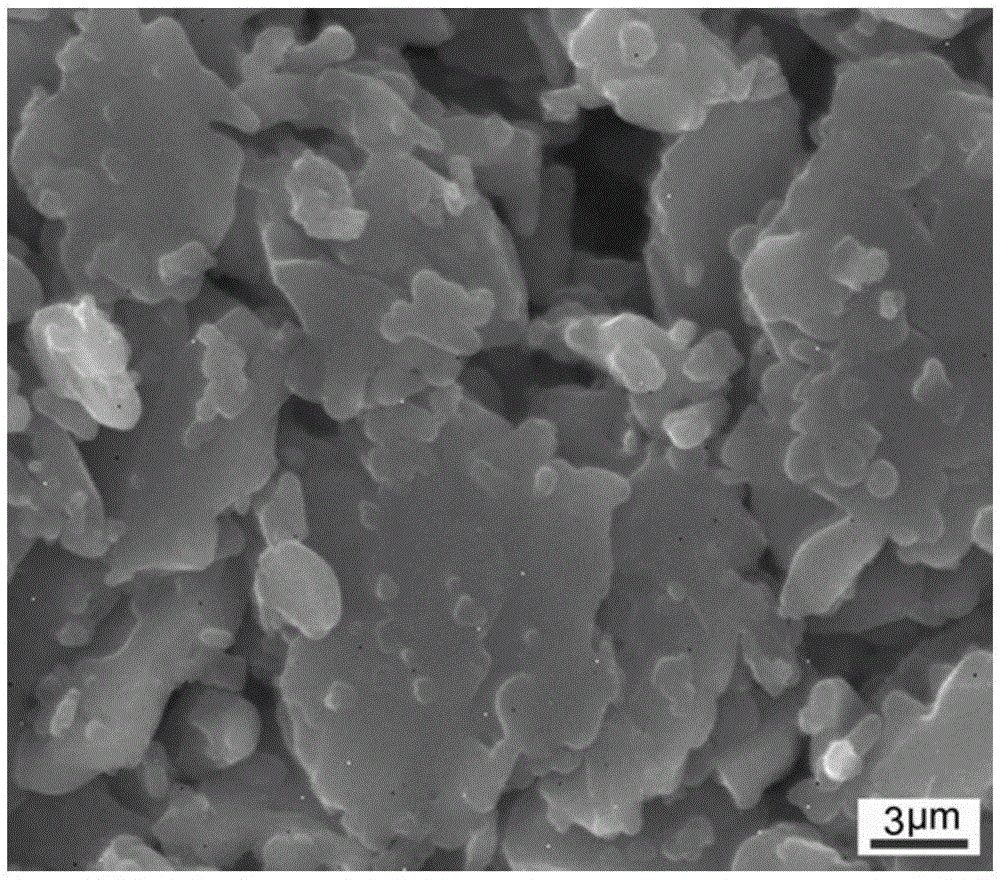

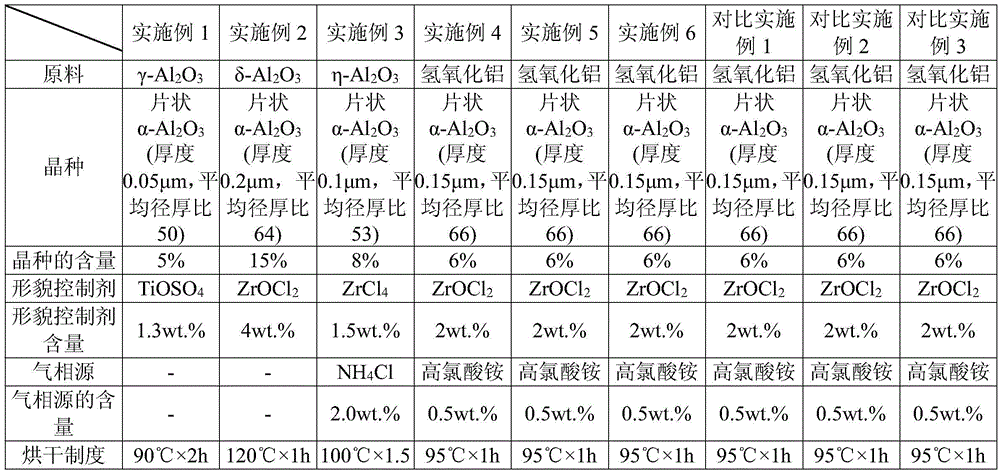

Method for preparing flaky alumina powder

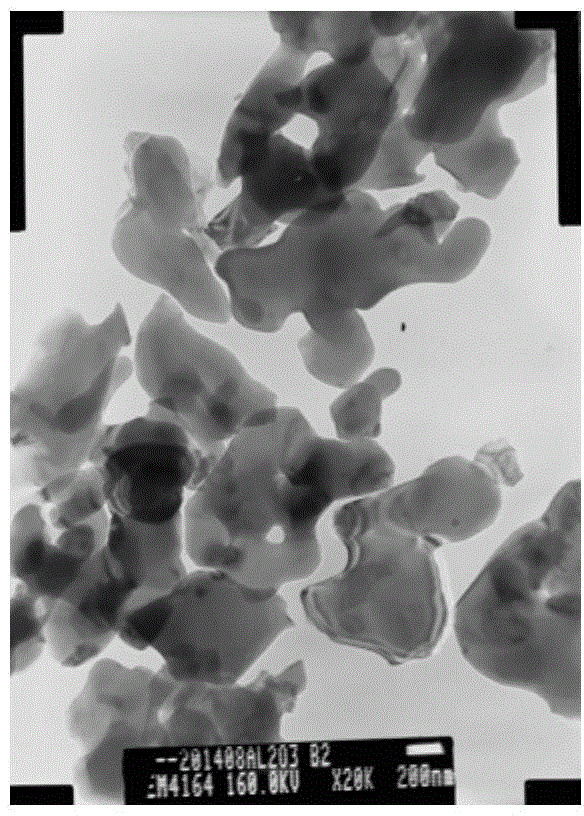

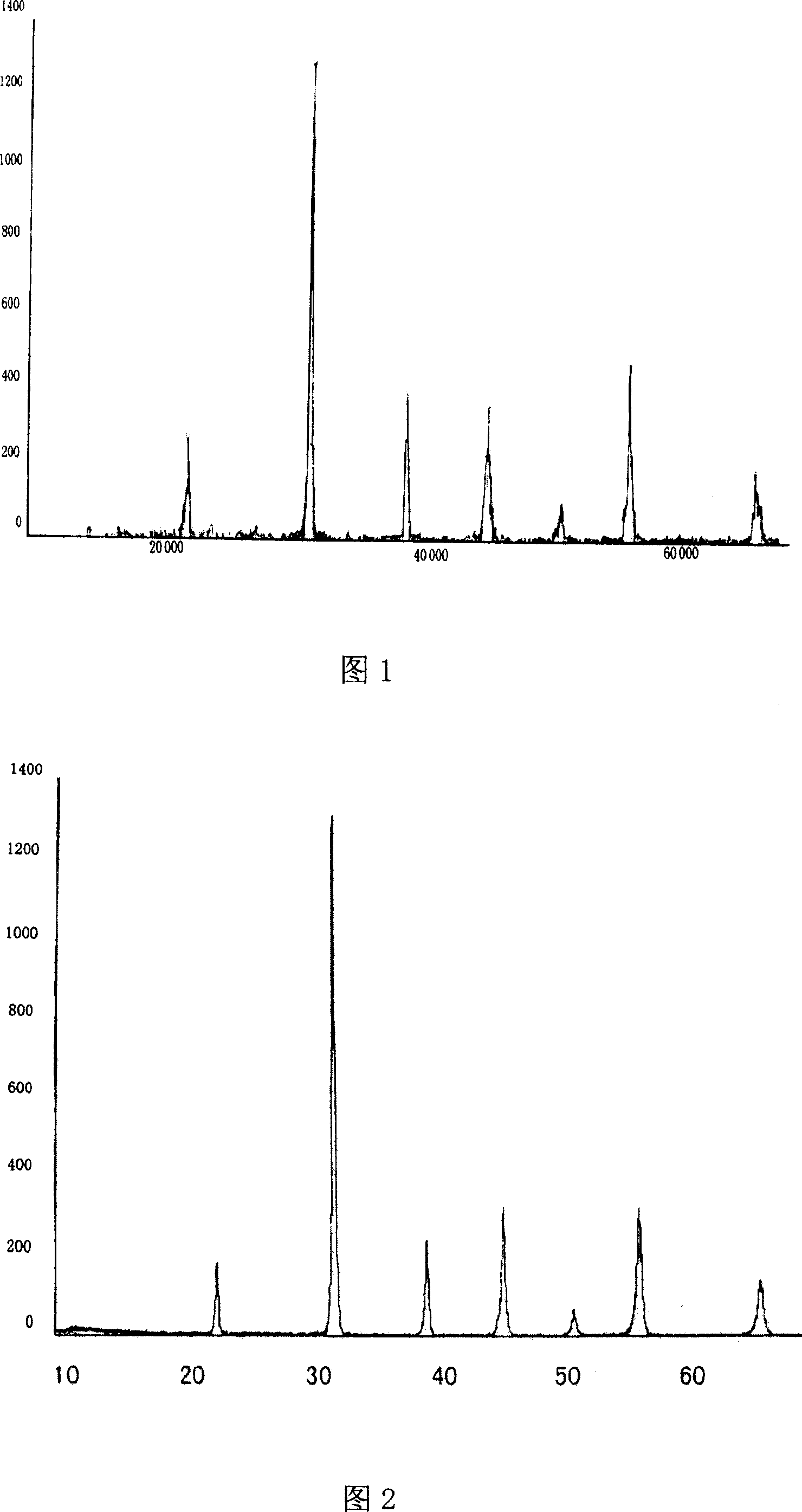

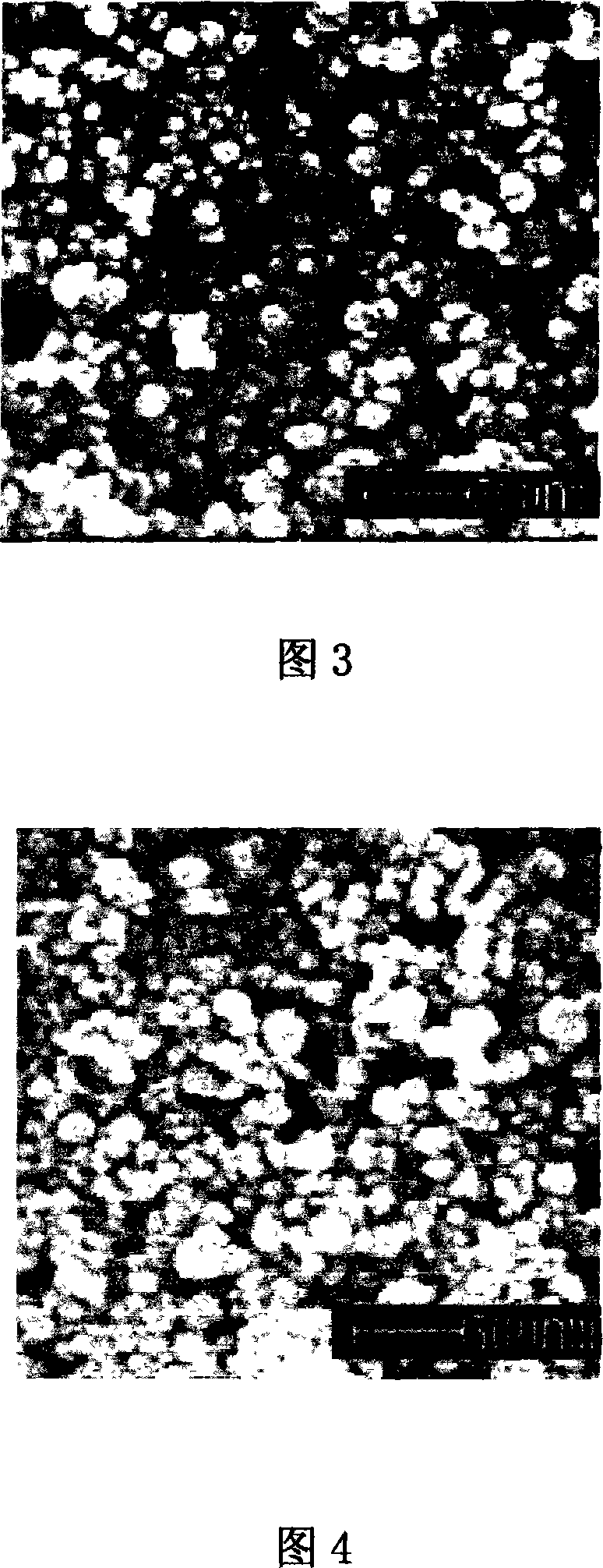

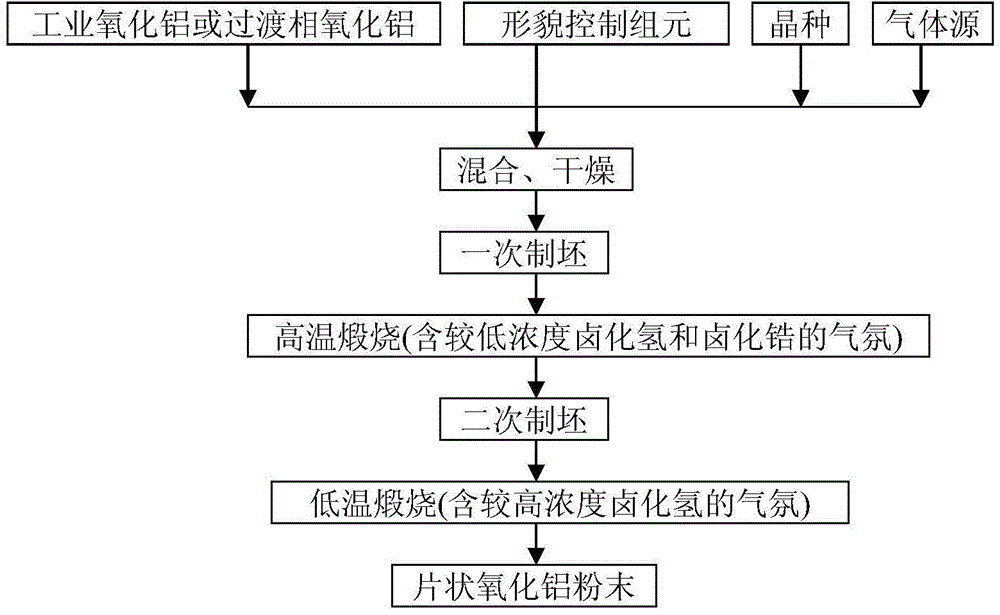

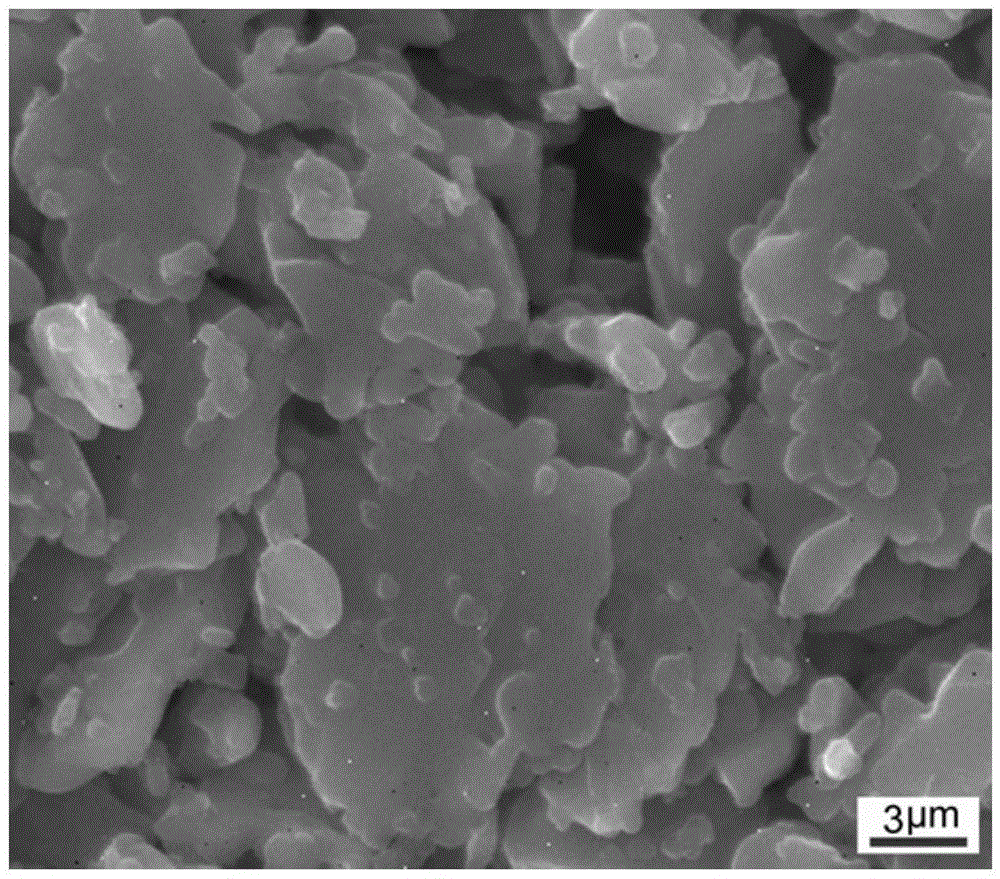

ActiveCN104556167AHigh activityIncrease the speed of diffusionAluminium oxides/hydroxidesRADIUSGrain shape

The invention provides a method for preparing flaky alumina powder, belonging to the technical field of powder particle size and shape control. The technical process comprises the following steps: by using industrial aluminum hydroxide or transitional-phase alumina powder as a raw material, adding a crystal seed and a crystal grain shape control agent into the raw material powder, uniformly mixing the raw material powder, and pressing into a billet; and carrying out high-temperature calcination on the billet in an atmosphere containing hydrogen halide and shape control component, crushing the calcination billet into powder, carrying out secondary forming, and carrying out low-temperature calcination in an atmosphere containing higher-concentration hydrogen halide, thereby obtaining the flaky alumina powder, of which the thickness is less than 0.2 mu m, the average radius-thickness ratio is greater than 50 and the alpha-Al2O3 content is 100%. The method has the advantages of simple preparation technique and low manufacturing cost.

Owner:贵州天合国润高新材料科技有限公司

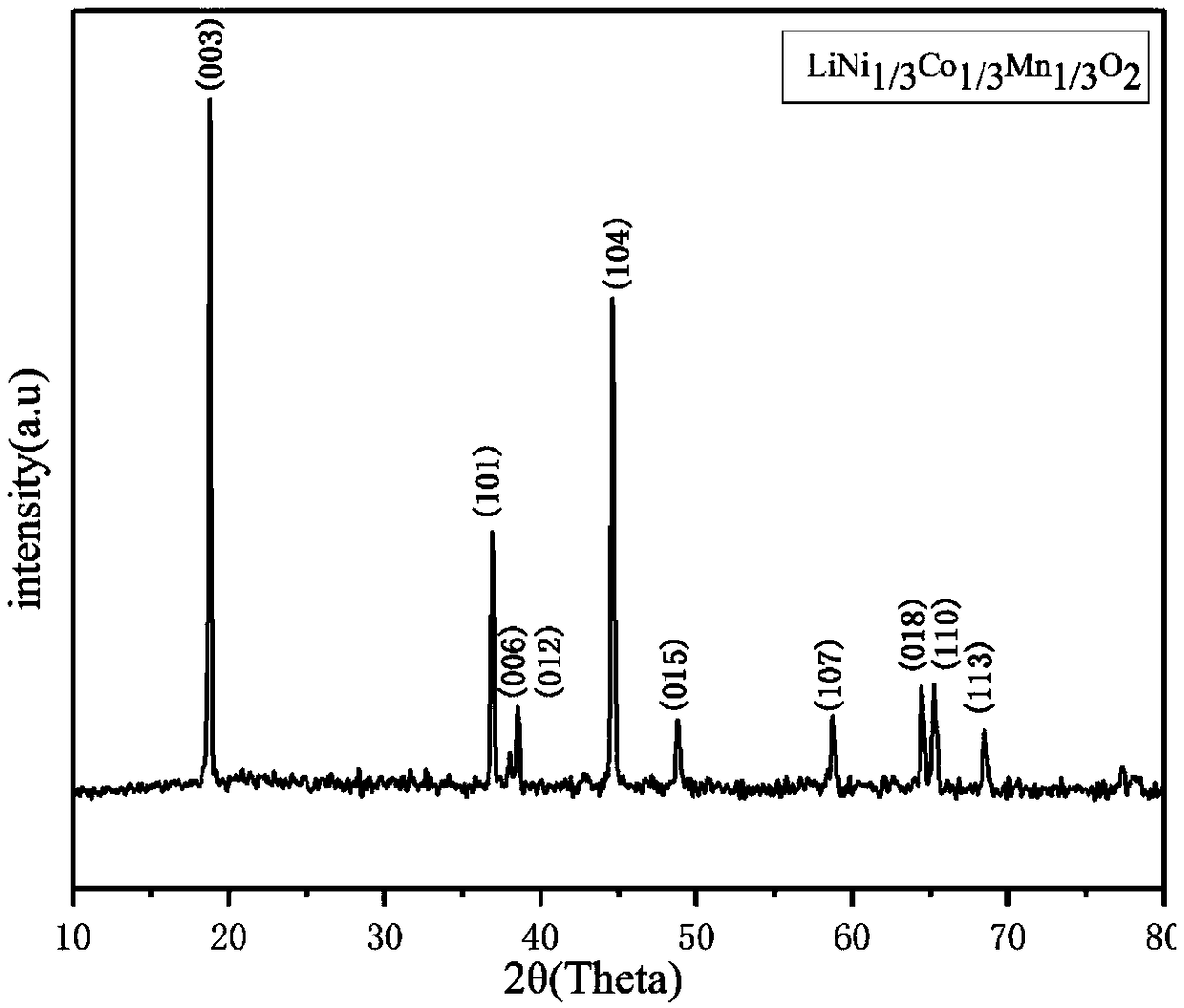

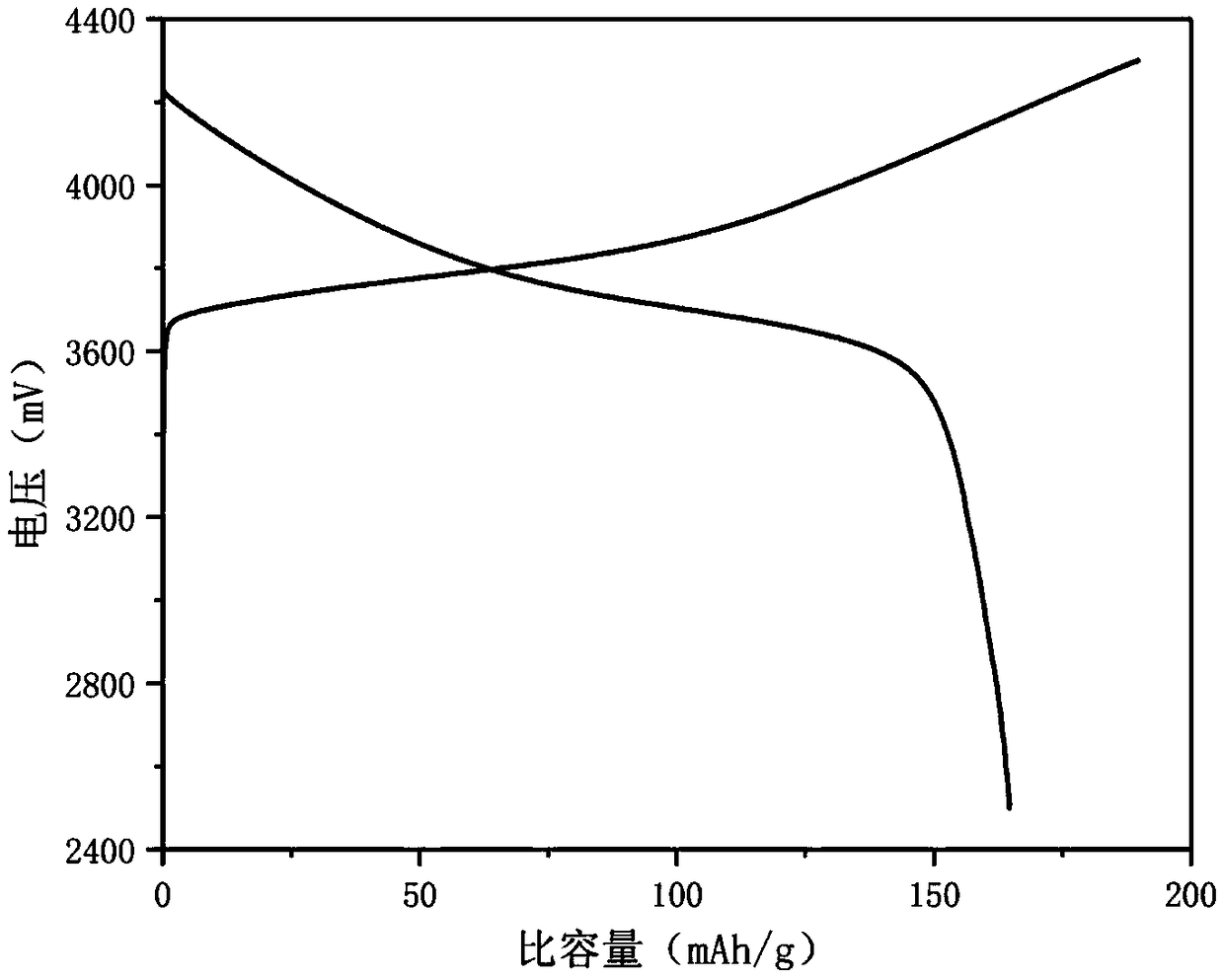

Preparation method of LiNixCoyMnl-x-yO2 cathode material for lithium ion battery

InactiveCN108899537AHigh specific capacityImproved magnification performanceSecondary cellsPositive electrodesFiberCarbon fibers

The invention discloses a preparation method of a LiNixCoyMnl-x-yO2 cathode material for a lithium ion battery. A NixCoyMnl-x-yCO3 precursor is prepared by adopting a solvent / hydrothermal method, wherein urea is utilized as a complexing agent, so as to avoid a phenomenon of segregation of transition metal ions, and ensure uniform precipitation of the transition metal ions, then by thoroughly mixing with a lithium source, LiNixCoyMnl-x-yO2 is prepared by utilizing a high-temperature solid phase method, and then the conductivity is improved by adding carbon fiber, thereby improving the rate performance of the LiNixCoyMnl-x-yO2 cathode material. The LiNixCoyMnl-x-yO2 cathode material obtained by the preparation method disclosed by the invention has relatively high specific capacity, good large rate performance and excellent cycle performance, and can be applied to various fields such as portable electronic devices, electric vehicles and energy storage equipment.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

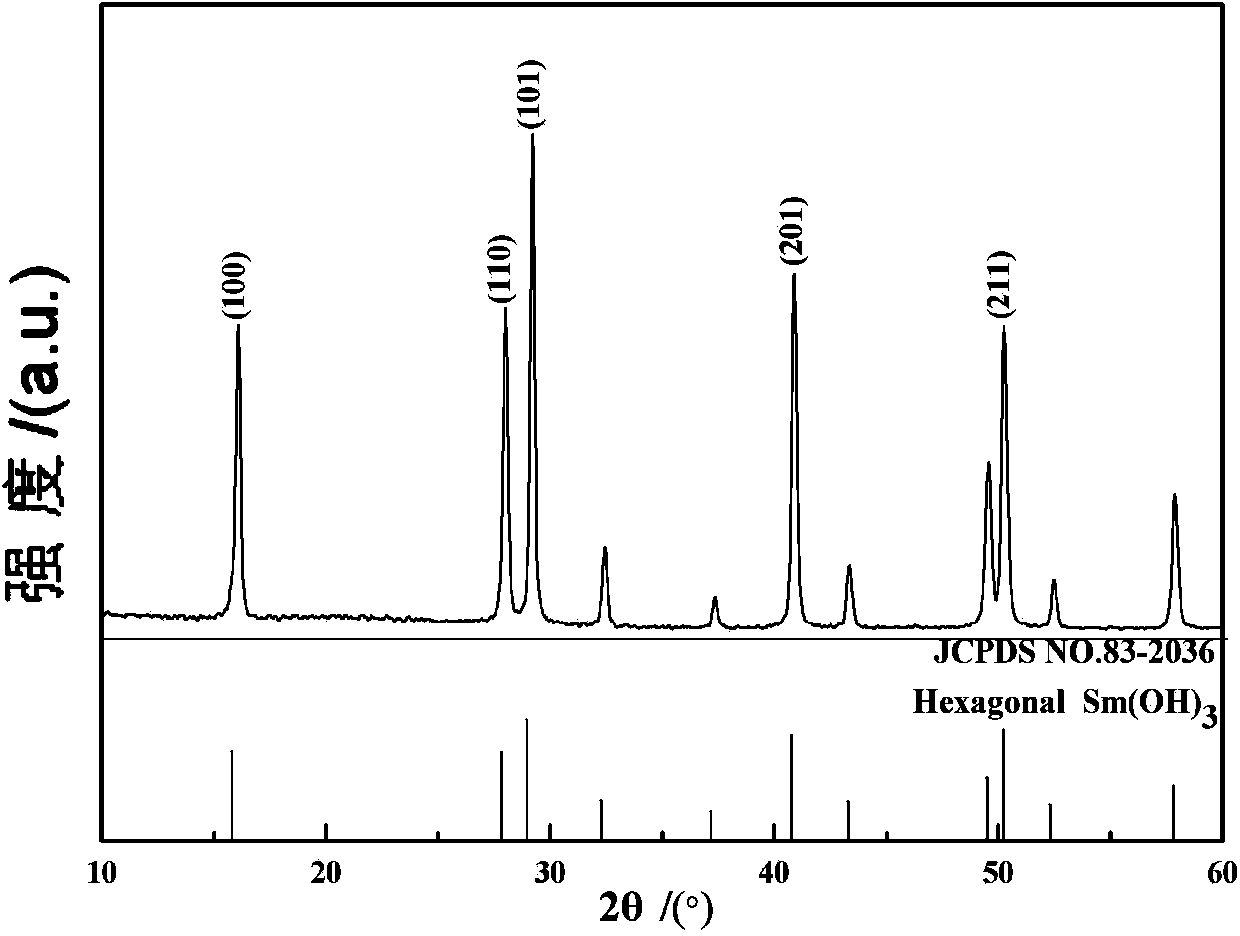

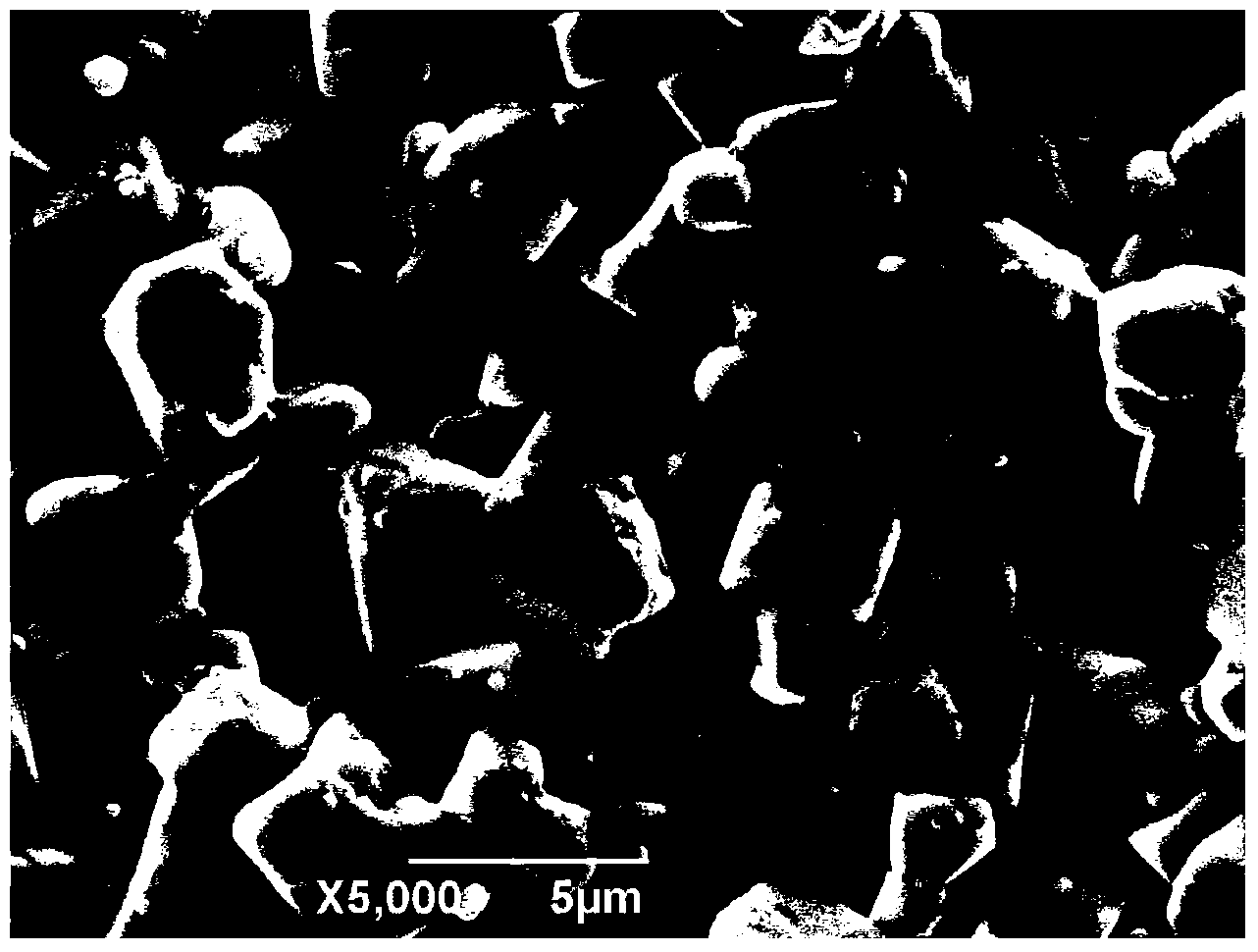

Preparation method of hexagonal-prism-shaped Sm(OH)3 nanocrystalline

ActiveCN103482672AHigh purityHigh crystallinityNanotechnologyRare earth metal compoundsDispersityDiethylenetriamine

A preparation method of hexagonal-prism-shaped Sm(OH)3 nanocrystalline comprises the steps that a solution A with the Sm<3+> concentration being 0.010-0.150mol / L is prepared by dissolving Sm(No3)3*6H2O in distilled water; a reaction precursor solution is formed by adjusting the pH value of the solution A to 7.0-11.0 through diethylenetriamine; the reaction precursor solution is poured into a hydrothermal synthesis reactor, the hydrothermal synthesis reactor is put in an electrothermal blowing dry box after being sealed, a reaction is conducted for 6-24 hours at the temperature of 50-120 DEG C, and after the reaction is finished, the hydrothermal synthesis reactor is naturally cooled to the room temperature; products are centrifugally washed for 4-6 times through distilled water and absolute ethyl alcohol, the products are collected and dried for 2-4 hours at the temperature of 60-80 DEG C in a vacuum mode, and the hexagonal-prism-shaped Sm(OH)3 nanocrystalline is obtained. According to the preparation method, instruments and equipment are simple, control is easy, operation is convenient, energy consumption is low, safety is good, and the hexagonal-prism-shaped Sm(OH)3 nanocrystalline prepared in the method is high in purity, strong in crystallinity, uniform in morphology, good in dispersity and controllable in grain growth.

Owner:盐城抱璞文化传媒有限公司

Method for preparing binderless BaTiO3 ceramic through microwave-assisted method

The invention discloses a method for preparing a binderless BaTiO3 ceramic through a microwave-assisted method. The method comprises the following steps: dissolving BaCl2.H2O and TiCl4 into deionized water, adding mineralizer NaOH, and uniformly stirring to obtain a coprecipitation precursor A; pouring the coprecipitation precursor A into the lining of a microwave hydrothermal reaction kettle, then placing the lining into the microwave hydrothermal reaction kettle for reaction, taking a reactant out after furnace temperature is naturally cooled to room temperature, washing, and drying to obtain nanometer BaTiO3 powder; briquetting the obtained BaTiO3 powder, and then screening and granulating obtained BaTiO3 powder blocks through a mesh screen to obtain powder with the granularity of 75-48 micrometers; and forming the obtained powder, sintering a formed billet to obtain the BaTiO3 ceramic after furnace cooling. The method disclosed by the invention omits the step of bonding agent addition in a preparation process, has the advantages of low preparation cost, easiness for operation, short reaction period, low sintering temperature, good ceramic density and excellent dielectric property of a product and achieves the dielectric constant up to 3000 and the dielectric loss less than 0.1 at the room temperature of a sample.

Owner:JIANGSU SHUSHI LIGHTING CO LTD

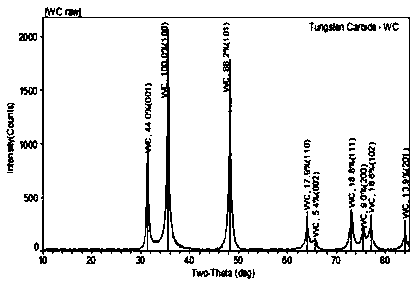

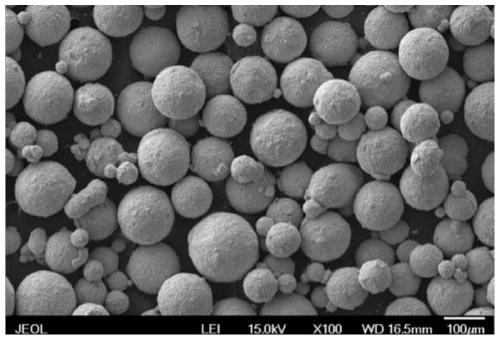

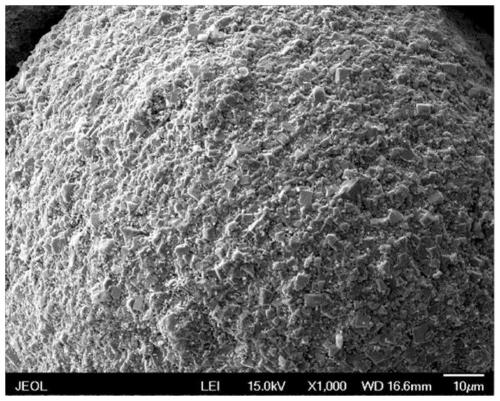

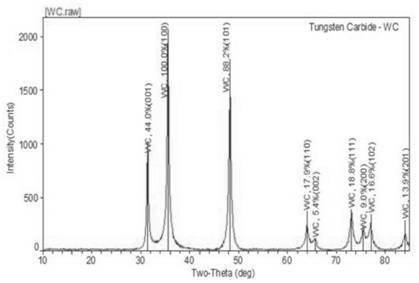

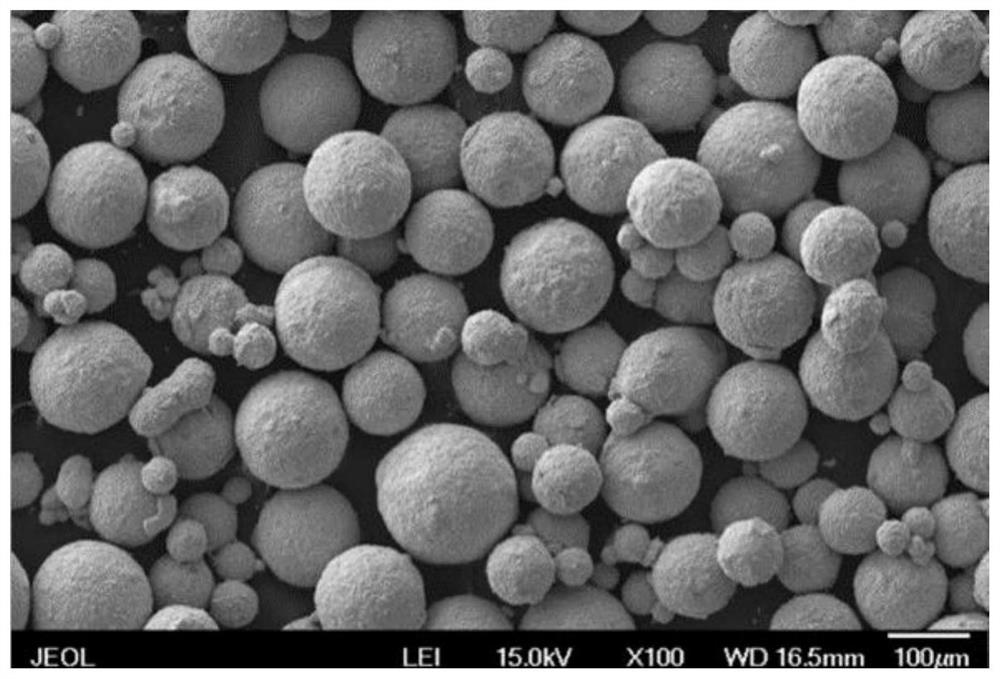

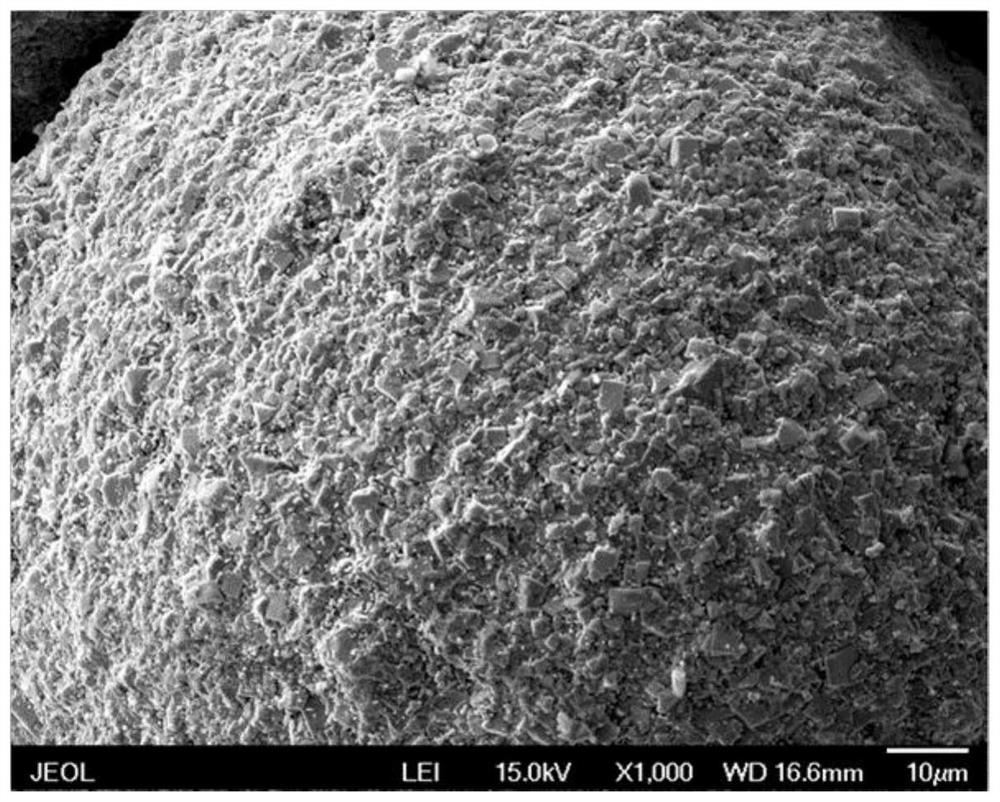

Powder material for 3D printing

ActiveCN110385430AHigh hardnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantAlloy

The invention provides a powder material for 3D printing. The powder comprises a wear-resistant phase and a binding phase, wherein a mixture of sintered WC-Co hard alloy spherical particles and tungsten carbide particles serves as the wear-resistant phase, and Co-based alloy serves as the bonding phase. The weight percentage of the wear-resisting phase is 20-60%, the weight percentage of the bonding phase is 40-80%, the weight percentage of the sintered WC-Co hard alloy spherical particles is 5-15%, and the weight percentage of the coarse-grained or monocrystalline tungsten carbide particles is 15-45%. The failure period can be effectively avoided or delayed, and the wear resistance and working efficiency of the material are improved.

Owner:SEED TECH CORP LTD

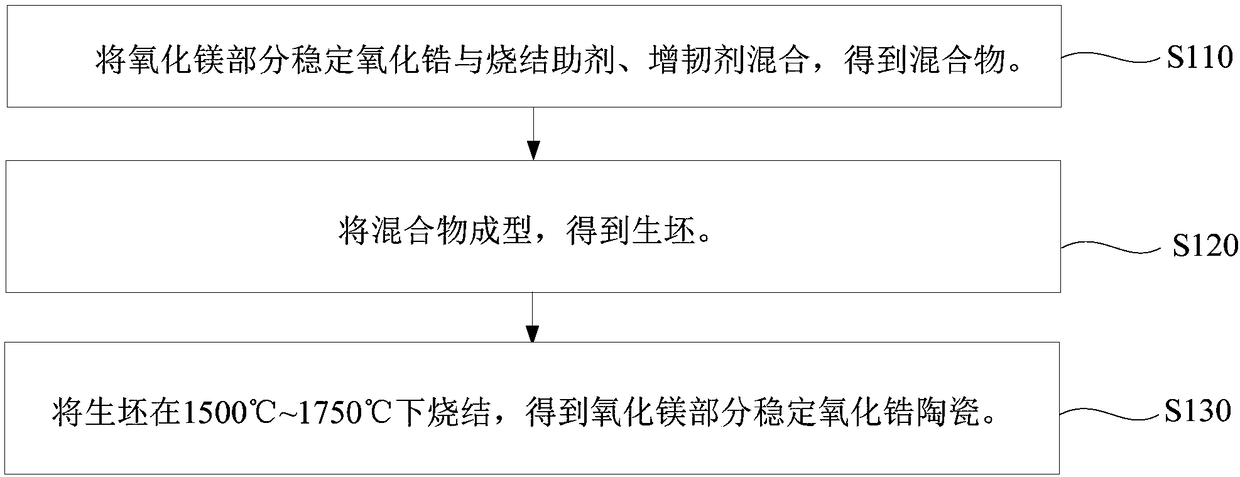

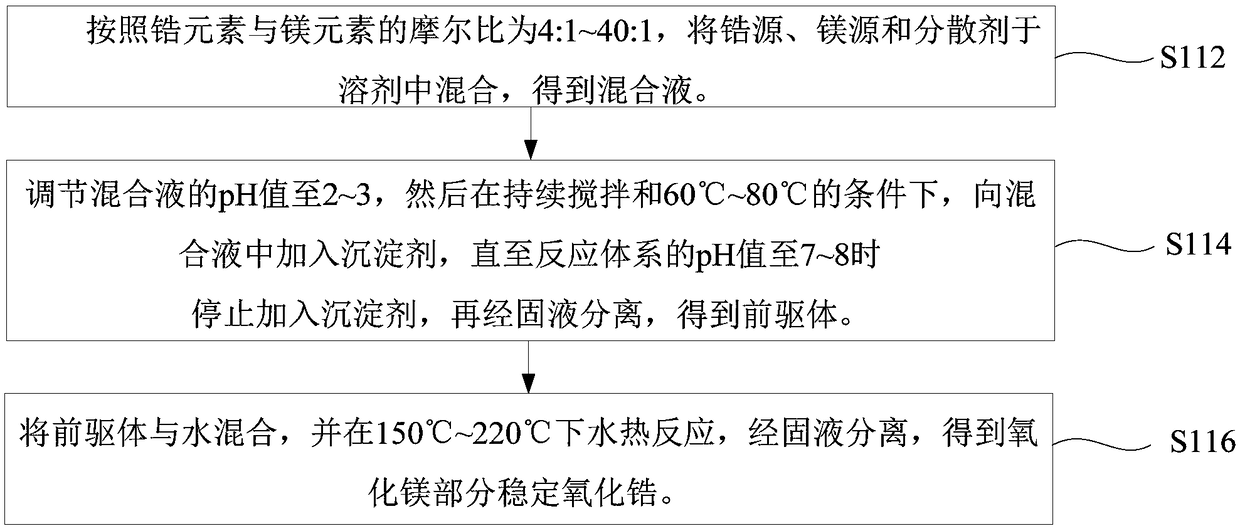

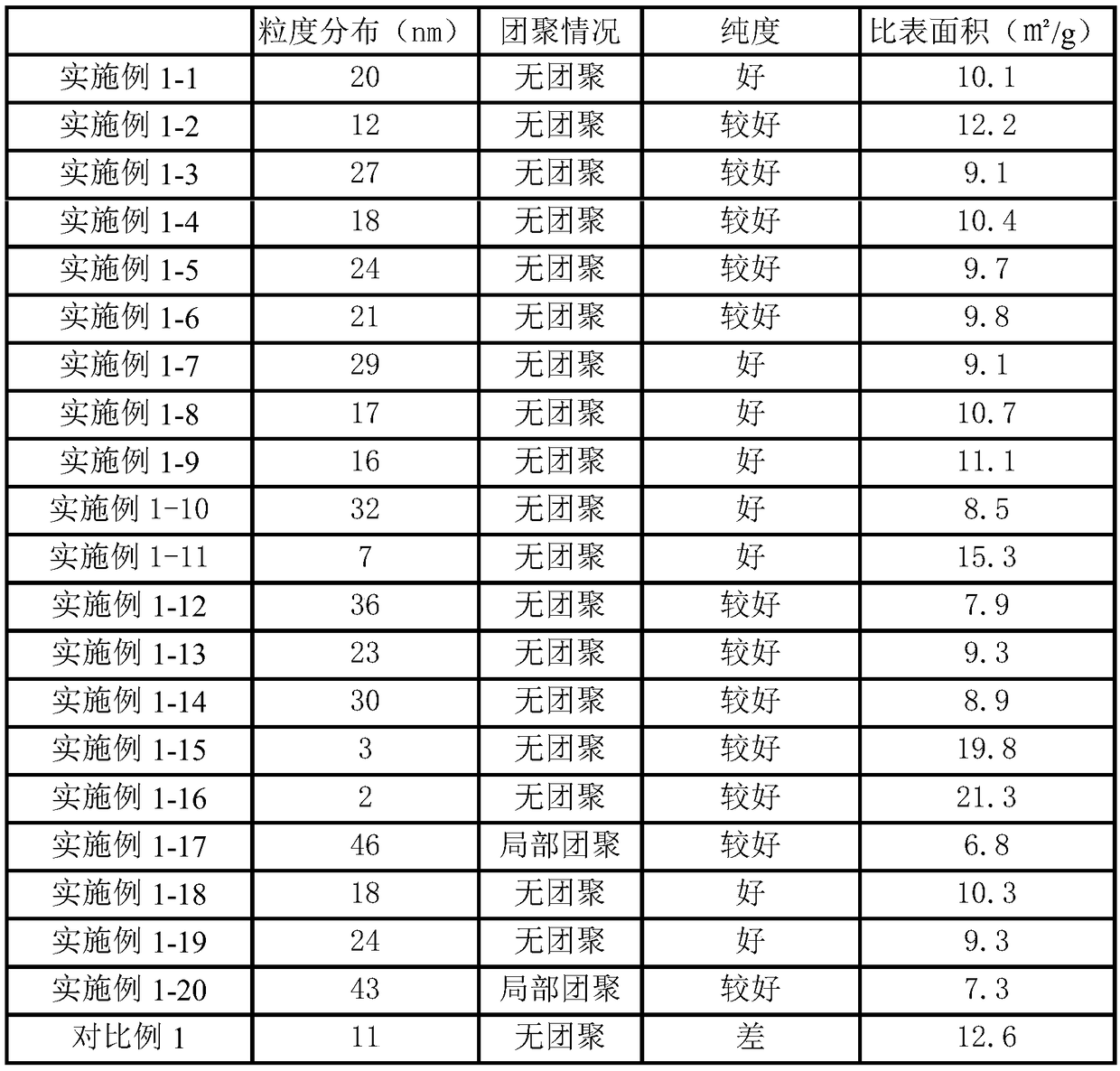

MgO partially stabilized ZrO, MgO partially stabilized ZrO ceramic, preparation methods of MgO partially stabilized ZrO and MgO partially stabilized ZrO ceramic and application of MgO partially stabilized ZrO ceramic

The invention relates to MgO partially stabilized ZrO, MgO partially stabilized ZrO ceramic, preparation methods of MgO partially stabilized ZrO and the MgO partially stabilized ZrO ceramic and an application of the MgO partially stabilized ZrO ceramic. The preparation method of MgO partially stabilized ZrO comprises following steps: a Zr source and an Mg source in a molar ratio of Zr to Mg being4:1-40:1 are mixed with a dispersing gent in a solvent, and a mixed solution is obtained; the pH value of the mixed solution is regulated to 2-3, under the condition of continuous stirring at 60-80 DEG C, epoxypropane is added to the mixed solution until the pH value of the reaction system reaches 7-8, and a precursor is obtained by solid-liquid separation; the precursor is mixed with water, the mixed solution is subjected to a hydrothermal reaction at 50-220 DEG C, and MgO partially stabilized ZrO is obtained by the solid-liquid separation. With the adoption of the method, MgO partially stabilized ZrO with higher sintering activity can be prepared, so that the MgO partially stabilized ZrO ceramic with higher bending strength and higher toughness is obtained.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Preparation of supported O3 catalyst and application thereof in COD removal of high-salt wastewater in coal chemical industry

ActiveCN109939695AUnique methodEasy to operateWater contaminantsCatalyst activation/preparationChemical industryCopper nitrate

The invention relates to a preparation method of a catalyst, in particular to a preparation method of a supported O3 catalyst. The preparation method of the catalyst adopts a hydrothermal method, andthe specific steps are as follows: firstly, a certain mass of gamma-Al2O3 is placed into a container, then potassium permanganate and copper nitrate trihydrate are added, 60-90L deionized water is added to dissolve fully, then the mixture is transferred to a reaction kettle for hydrothermal reaction, after the reaction, the mixture is washed by using deionized water until the water is colorless, the mixture is dried at 90-120 DEG C for 10-15h to obtain heterogeneous double metal oxide catalyst with gamma-Al2O3 supported with MnO2 and CuO, pseudo-boehmite and concentrated nitric acid are added,extruding is carried out, the mixture is dried at 90-120 DEG C for 10-15 h; the invention also provides the application of the catalyst in COD removal of high-salt wastewater in coal chemical industry: the method has the advantages of simple operation, low cost, reusable catalyst, good water treatment effect, large-scale application and no secondary pollution.

Owner:NINGXIA UNIVERSITY

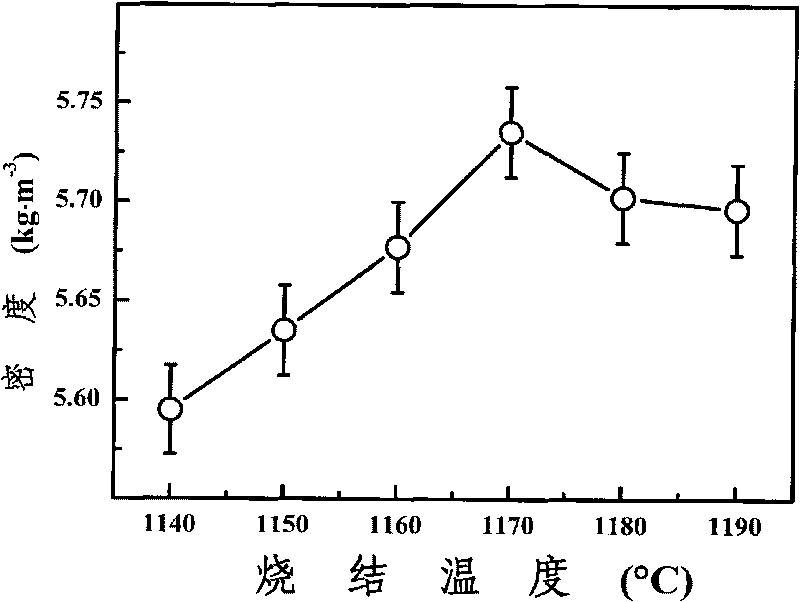

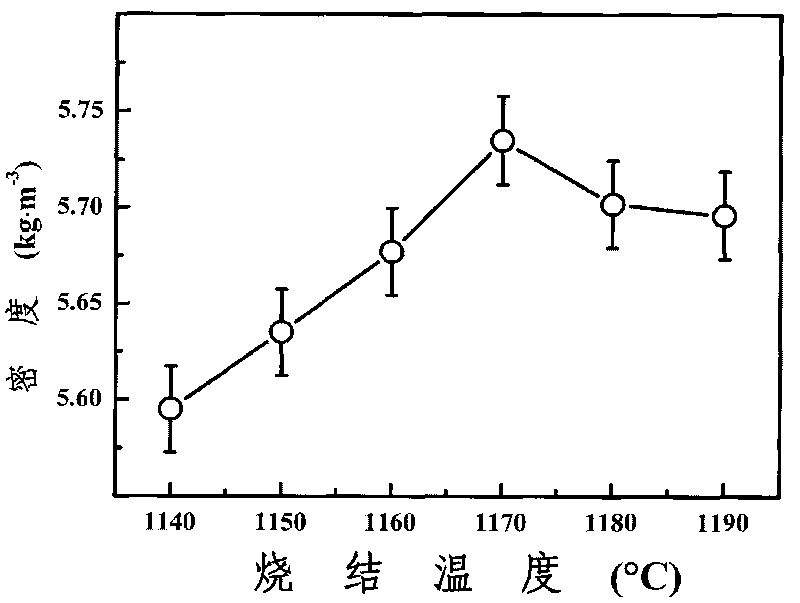

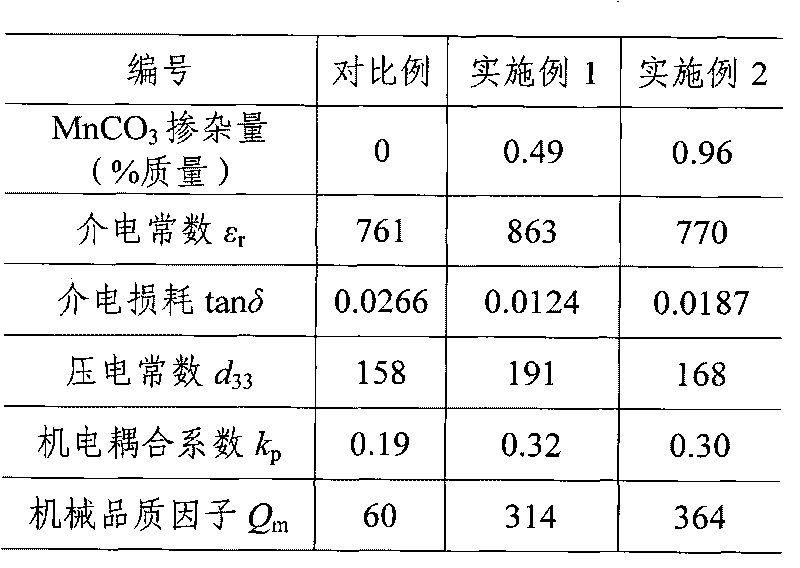

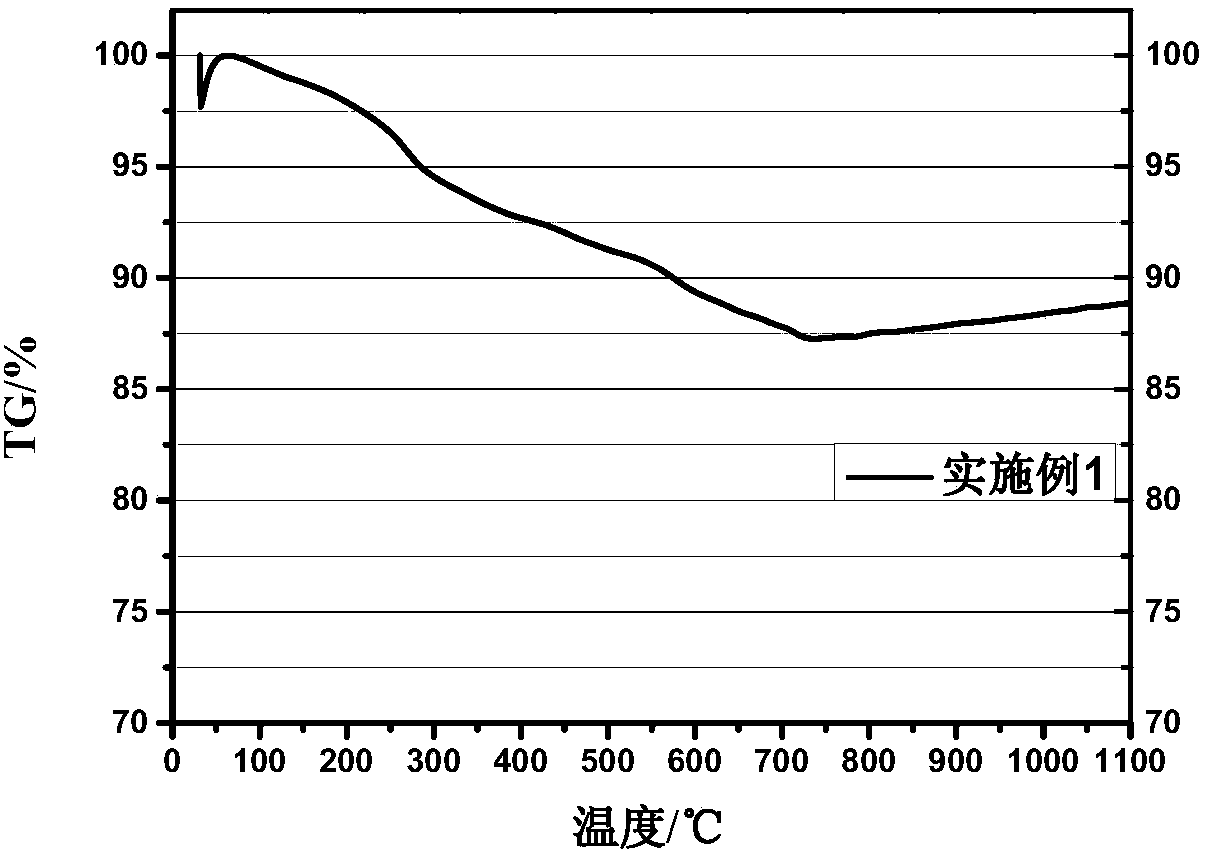

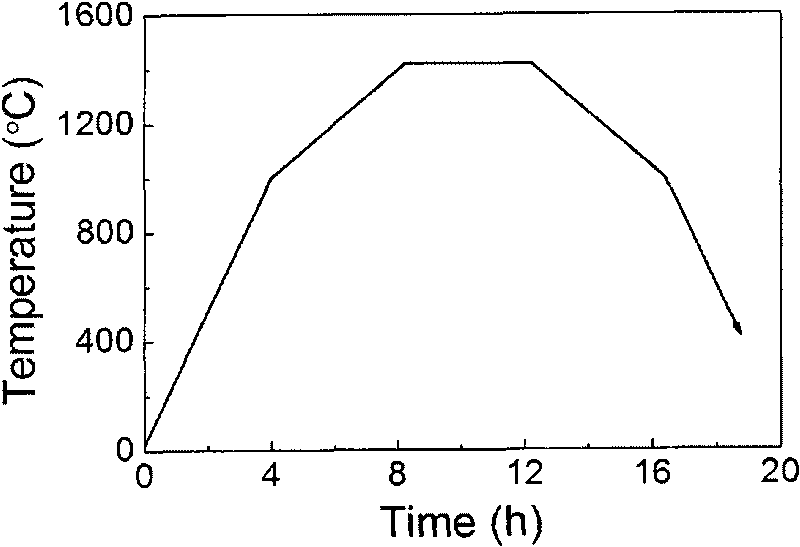

Lead-free piezoceramic material with manganese doping with bismuth titanate sodium group and preparation method thereof

The invention relates to a lead-free piezoceramic material with manganese doping with bismuth titanate sodium group and a preparation method thereof, belonging to the field of functional ceramics. The invention selects 80.15-84.61wt% of Bil / 2Nal / 2TiO3, 10.26-13.19wt% of Bil / 2K1 / 2TiO3, 2.17-5.44wt% of BaTiO3 as the substrate, and takes 0.32-1.28wt% of MnCO3 as the doping material, controls the pre-synthesizing temperature to a range of 800-950 DEG C and preserves the temperature for 1-4 hours; and keeps the sintering temperature to a range of 1130-1190 DEG C and preserves the temperature for 1-4 hours to obtain the novel lead-free piezoceramics. The piezoceramics obtained by utilizing the method provided in the invention have the advantages of high piezoelectric constant (191) and mechanical quality factor (314), good microcosmic structure, complete growth of crystal particles. The lead-free piezoceramics provided in the invention can be used for manufacturing piezoelectric devices such as piezoelectric sensor and actuator and the like.

Owner:XIANGTAN UNIV

Aluminum-chrome-magnesium refractory brick and preparing method thereof

The invention discloses an aluminum-chrome-magnesium refractory brick for glass industries and nonferrous industries and a preparing method of the aluminum-chrome-magnesium refractory brick. The aluminum-chrome-magnesium refractory brick is prepared from, by mass percentage, 10-30% of sub-white corundum with the particle size of 1-3 mm, 10-35% of aluminum magnesium spinel with the particle of 1-2mm, 5-15% of aluminum magnesium spinel with the particle size of 0.088-1 mm, 10-25% of an aluminum-chrome composite material with the particle size of 0.088-1 mm and 25-40% of an aluminum-chrome composite material with the particle size of 0.088 or below. Besides, a binding agent which accounts for 2-7% of the total mass of all the raw materials is added. By means of the prepared aluminum-chrome-magnesium refractory brick, the pollution of hexavalent chromium in residual bricks is reduced, and the problem of shortage of aluminum-chrome raw materials is solved. The aluminum-chrome-magnesium refractory brick has the advantages of being stable in production and preparation process, high in manufacturing yield, and excellent in erosion resistance and thermal shock stability, and can achieve agreat effect when applied to thermal storage chambers of glass kilns or rotary kilns for the nonferrous industries.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Low-hexavalent-chromium precipitated copper and chromium black pigment as well as preparation method and application thereof

ActiveCN108059187AWell-developed grainsImprove securityChromates/bichromatesDispersityInorganic salts

The invention belongs to the technical field of pigment synthesis and discloses a low-hexavalent-chromium precipitated copper and chromium black pigment as well as a preparation method and applicationthereof. The method comprises the following steps: (1) preparing a nitrate solution, preparing raw materials into the nitrate solution containing Cu<2+>, Cr<3+> and Fe<3+>; (2) preparing a combustionsolution, mixing the nitrate solution and auxiliary fuel to obtain the combustion solution; (3) carrying out low-temperature self-propagating combustion: after evaporating and concentrating the combustion solution, heating the solution in a heating device and initiating the self-propagating combustion; collecting a combustion product; (4) mixing and carrying out ball milling: carrying out the ball mixing on the combustion product and inorganic salt and mixing to obtain a mixture; (5) carrying out high-temperature calcining: putting the mixture into the heating device and carrying out the high-temperature calcining; (6) carrying out post-treatment: carrying out water washing on a product obtained by the high-temperature calcining and drying to obtain the copper and chromium black pigment.The copper and chromium black pigment prepared by the preparation method has the advantages of high purity, complete crystalline grains, good dispersity and low hexavalent chromium content; the pigment has a small average grain diameter which can reach 0.5mu m.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Nano barium titanate microcrystal and preparation method thereof, and barium titanate powder and preparation method thereof

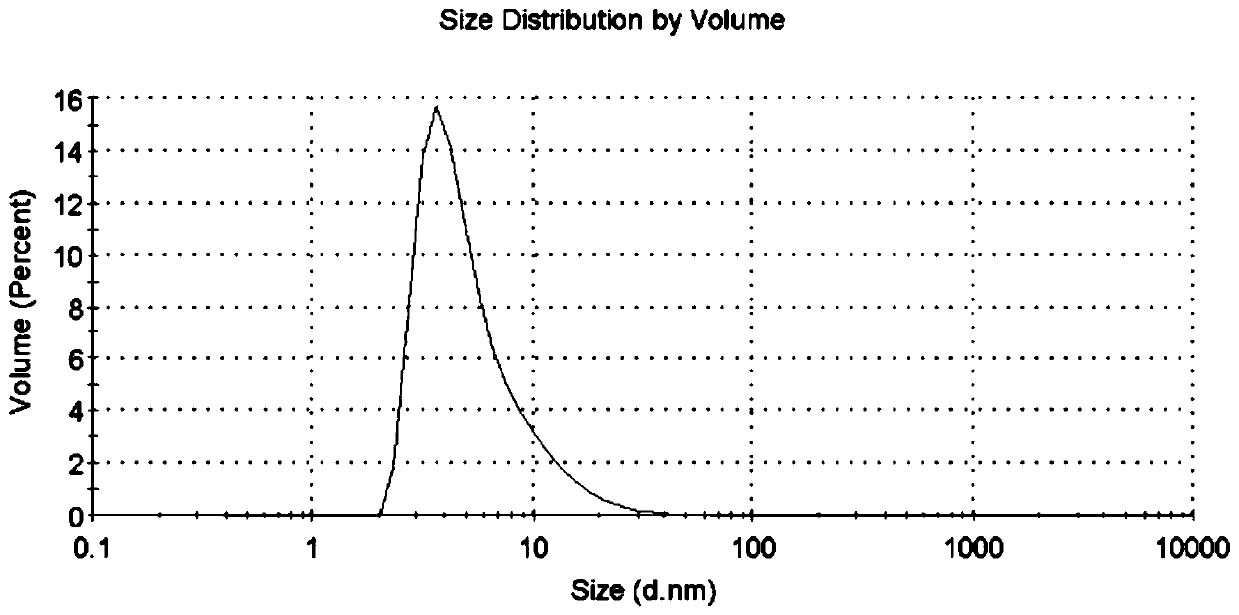

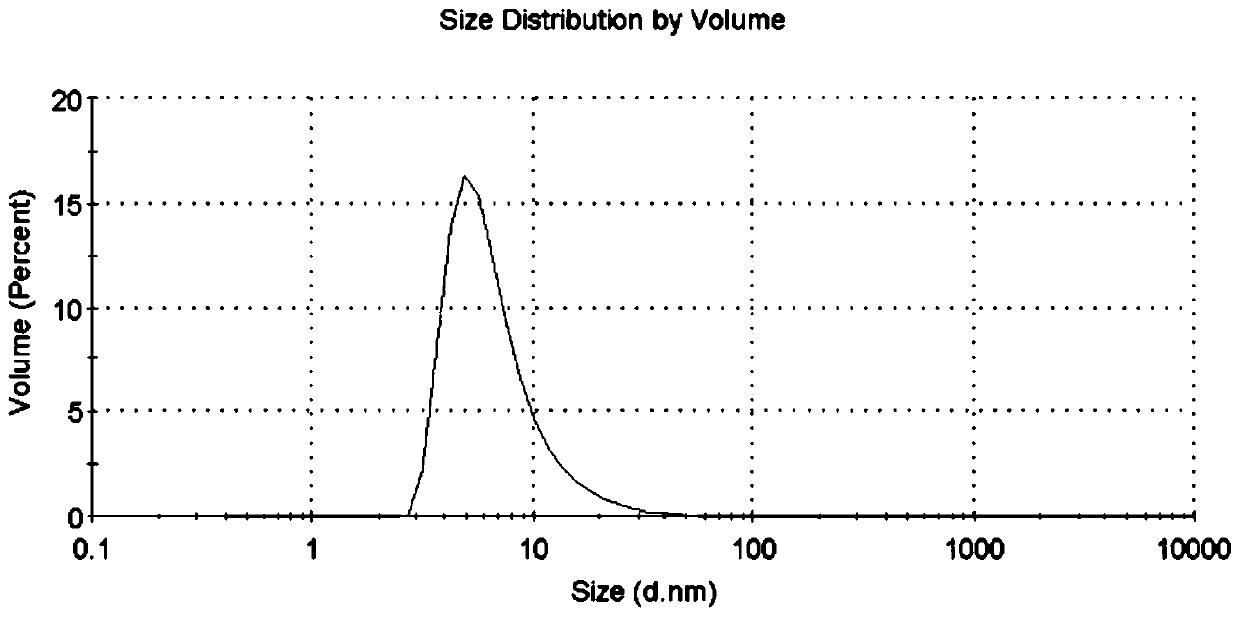

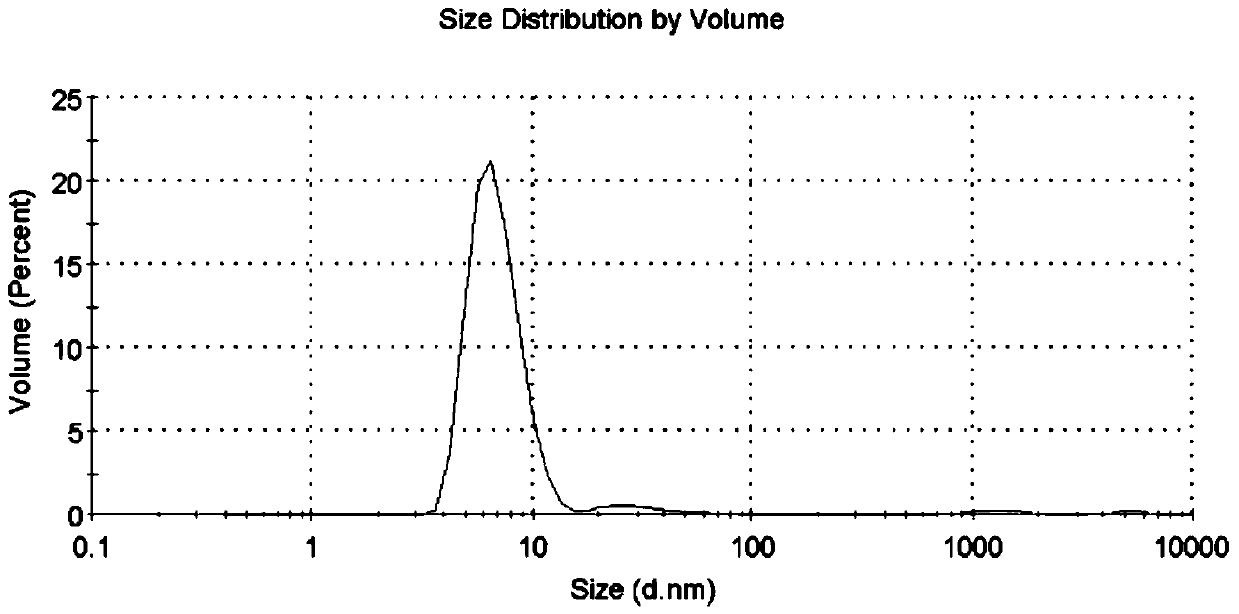

ActiveCN110092657ASmall and uniform particle sizeHigh purityAlkaline earth titanatesBarium titanateHydrothermal synthesis

The invention provides nano barium titanate microcrystals and a preparation method thereof, and barium titanate powder and a preparation method thereof, and relates to the technical field of nano materials. The preparation method of the nano barium titanate microcrystals comprises the following steps of: a nano titanium dioxide aqueous dispersion with the mass concentration of not less than 20% and a barium hydroxide aqueous solution are rapidly mixed to allow the temperature of the obtained mixed system to be at least 2 DEG C lower than the temperature of the barium hydroxide aqueous solutiondue to the rapid mixing of the two; under an inert atmosphere, the mixed system is subjected to normal pressure hydrothermal synthesis reaction at 90-110 DEG C, and reaction products are collected, washed and dried to obtain the nano barium titanate microcrystals. According to the preparation method of the nano barium titanate microcrystals, the nano barium titanate microcrystals with small particle diameter, uniform particle diameter distribution and high purity can be obtained, and the high-quality barium titanate powder can be obtained by calcining the nano barium titanate microcrystals serving as a raw material.

Owner:쑤저우바오순메이테크놀러지컴퍼니리미티드

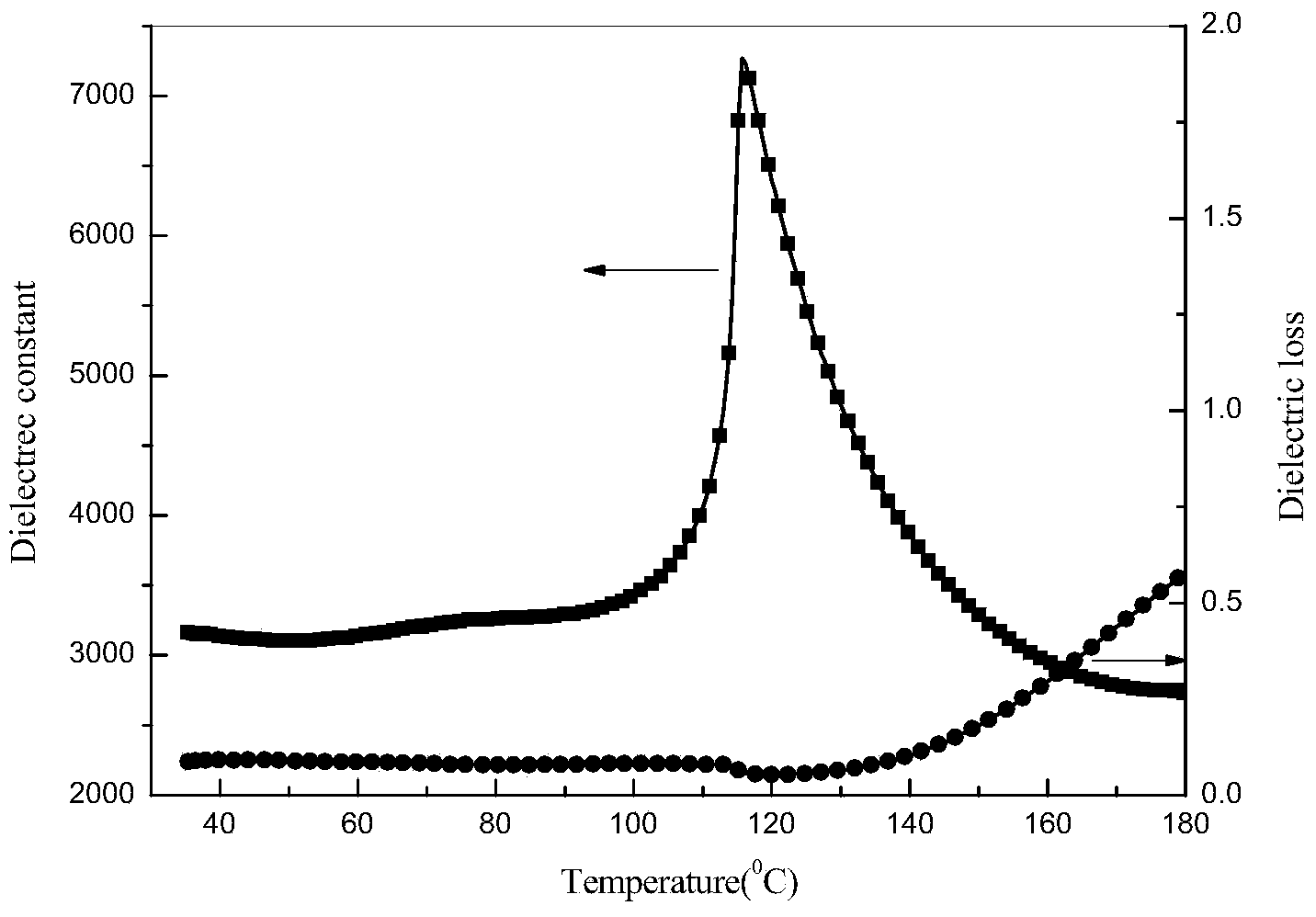

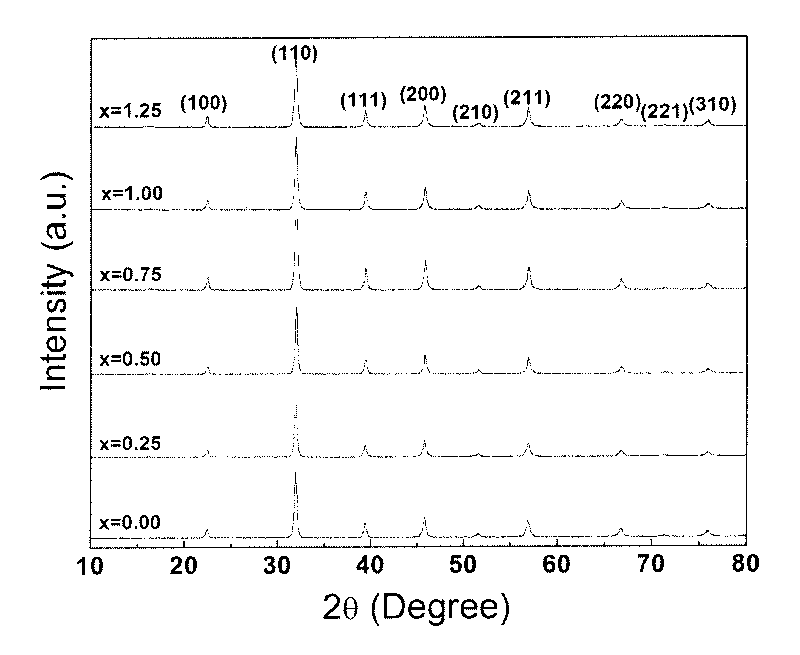

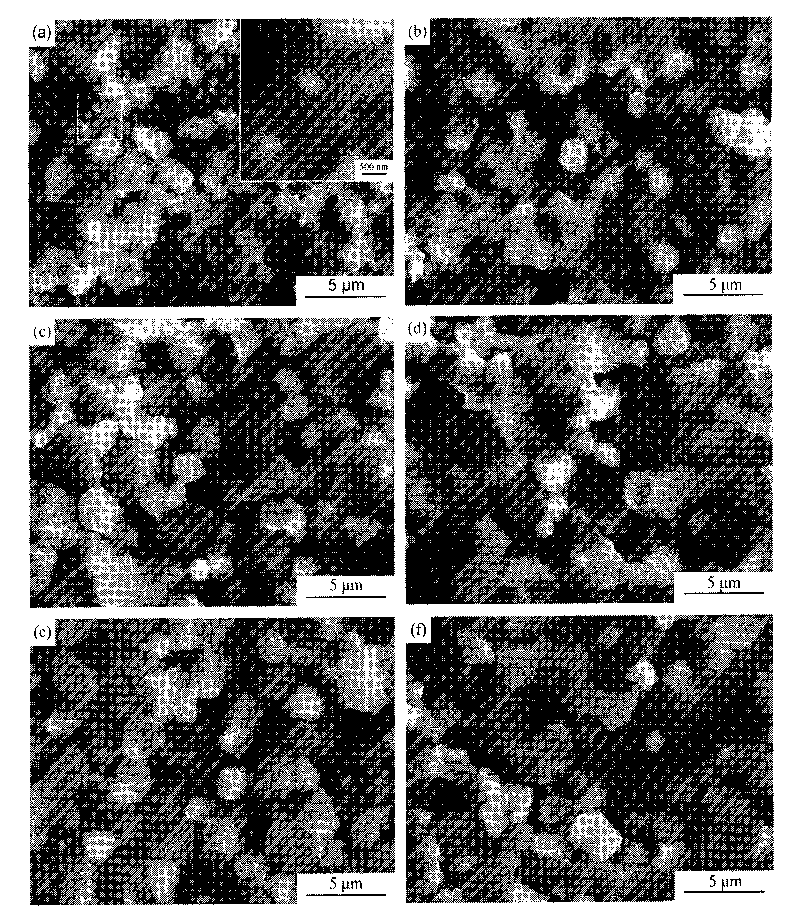

Transition element doped barium-strontium titanate based composite ceramic and preparation method thereof

ActiveCN101734907AImprove sintering performanceLow dielectric lossMicrowaveBarium strontium titanate

The invention relates to a transition element doped barium-strontium titanate based composite ceramic, which comprises 40 weight percent of xM-Ba0.6Sr0.4TiO3 and 60 weight percent of MgO, wherein M is a transition metal, and x is the molar ratio of the transition metal M to Ba0.6Sr0.4TiO3 and ranges from 0.25 to 1.25 percent. Because of the doping of the transition element, the pressure control adjustable rate of the M-Ba0.6Sr0.4TiO3 / MgO composite ceramic is improved, the microwave dielectric loss is greatly reduced, and meanwhile the breakdown field strengths of ceramic blocks are more than 28 kV / mm and can meet the using requirements of microwave dielectric materials.

Owner:GRIMAT ENG INST CO LTD

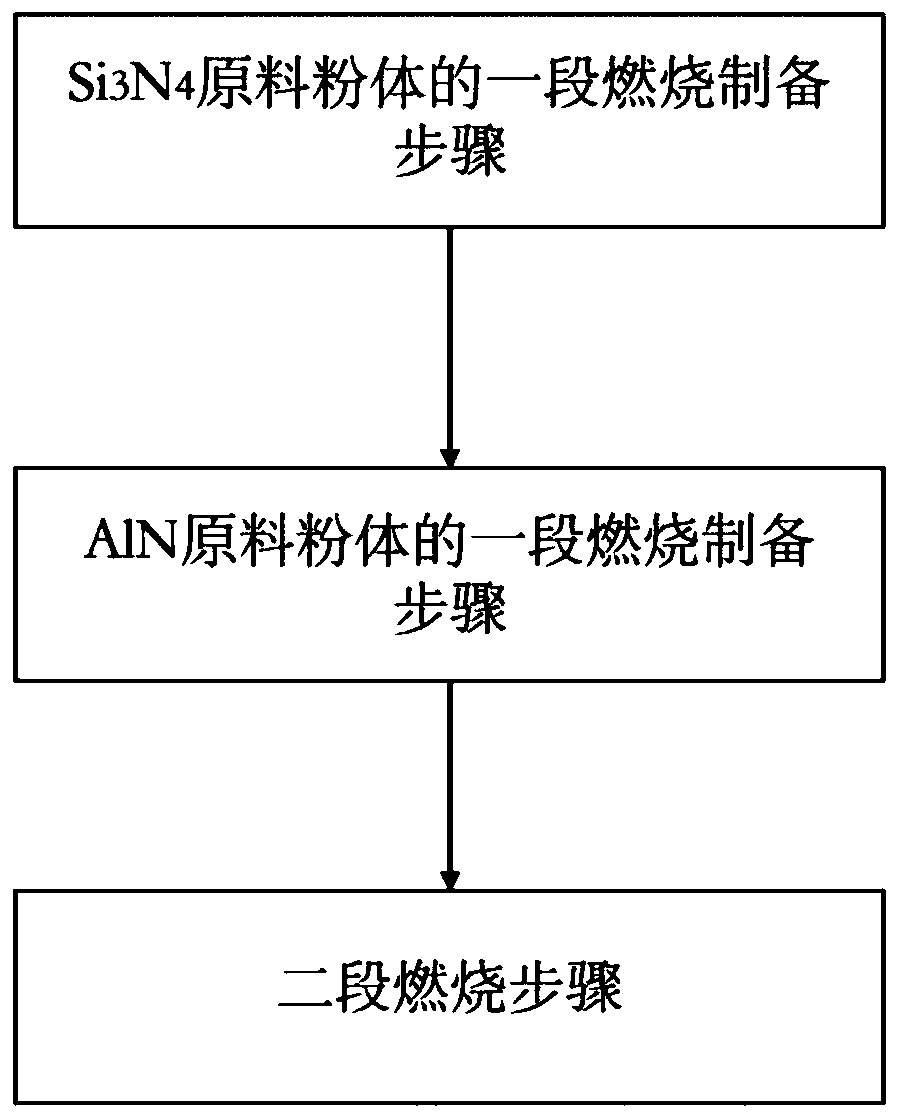

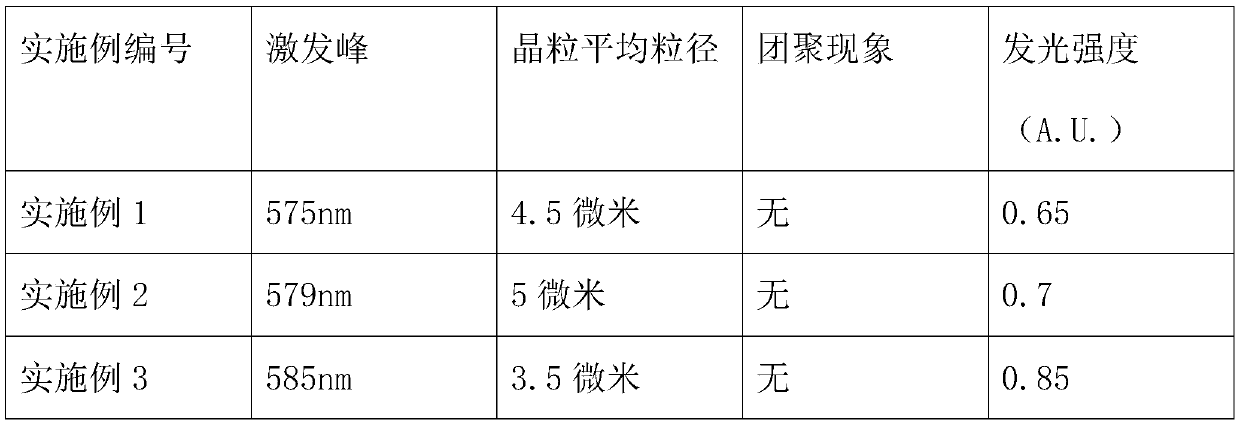

Phosphor powder material for LED lighting and preparation method thereof

ActiveCN108485657BReduce usageIncrease composition contentLuminescent compositionsNitrogen oxidesPhysical chemistry

The invention relates to a fluorescent powder material for light-emitting diode (LED) lighting and a preparation method thereof. A two-stage burning synthesis new technology is adopted for nitride andnitric oxide fluorescent powder for LED, so that two types of high-quality raw material powder, i.e., Si3N4 and AlN are prepared, and the nitride and nitric oxide fluorescent powder is further prepared. According to the fluorescent powder material for LED lighting and the preparation method provided by the invention, the influence rule of formula and process parameters on ingredients, structuresand performance of the prepared raw material powder and the fluorescent powder is systematically researched, and on the basis, through the process optimization, the Si3N4 and AlN raw material powder with low oxygen content and high activity, and the nitride and nitric oxide fluorescent powder with a complete crystal form and excellent light-emitting performance are prepared.

Owner:SHANDONG YICHANG LIGHTING TECH

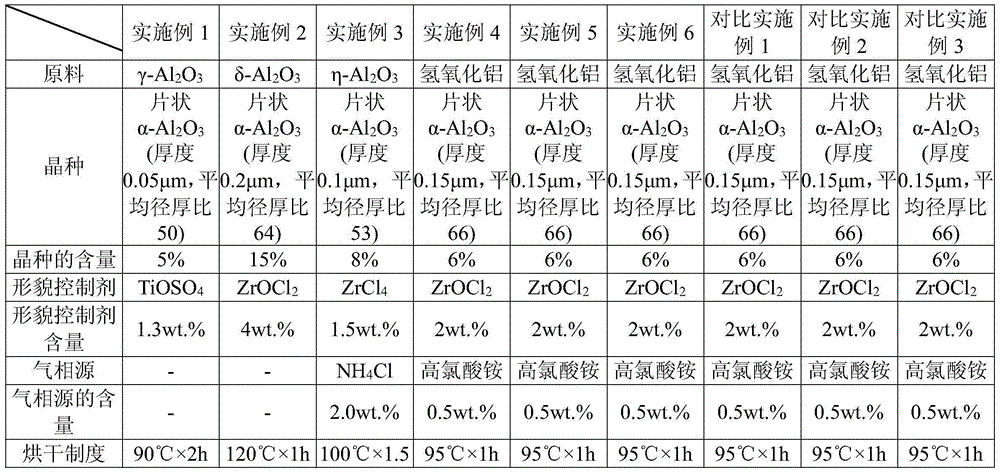

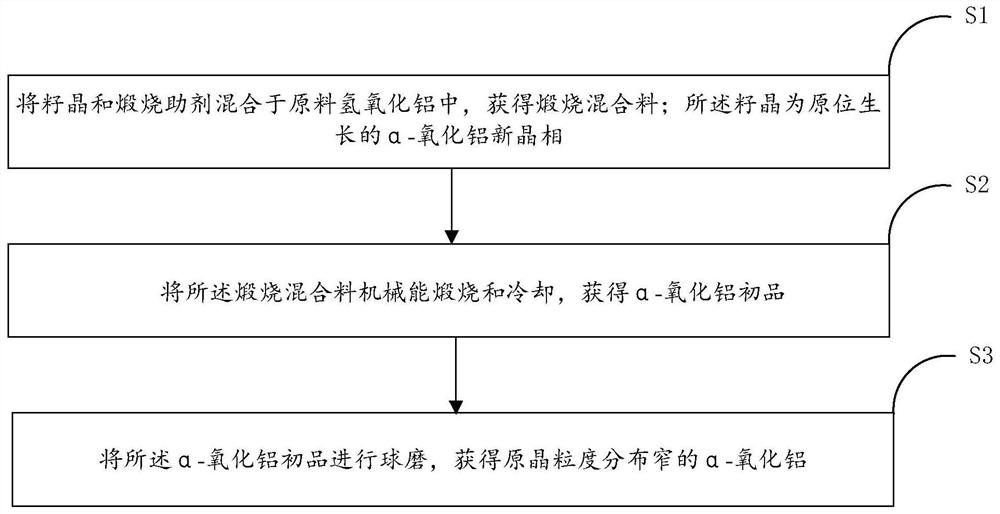

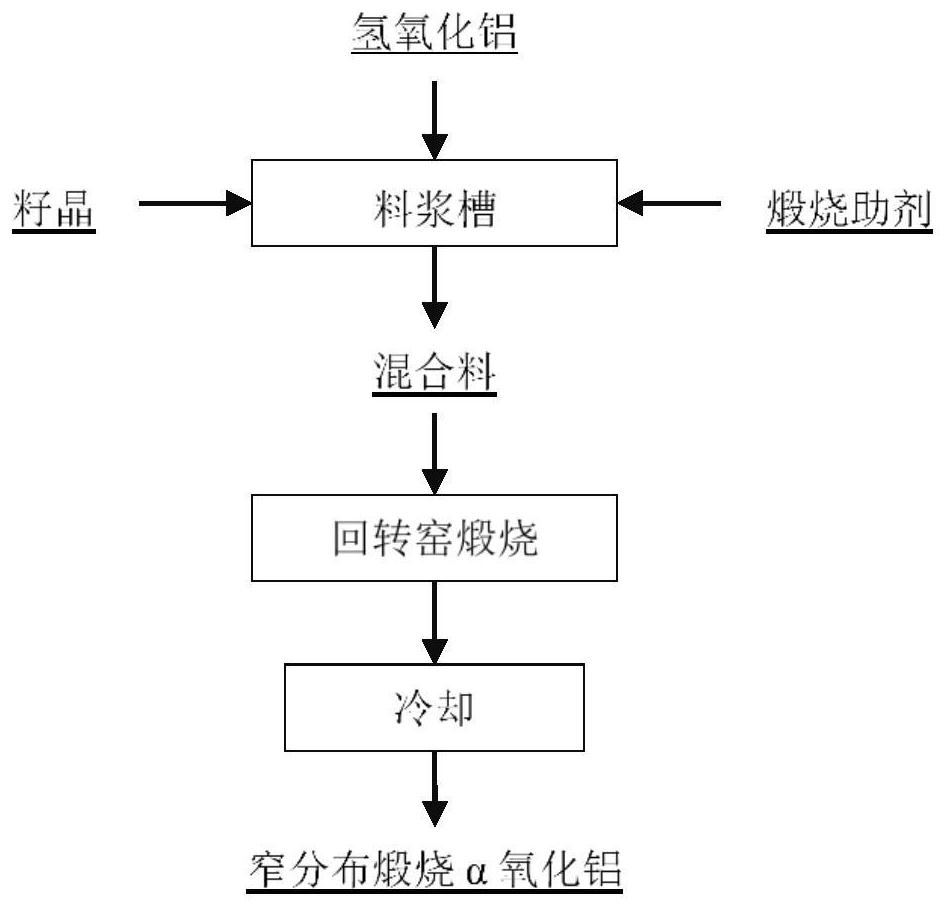

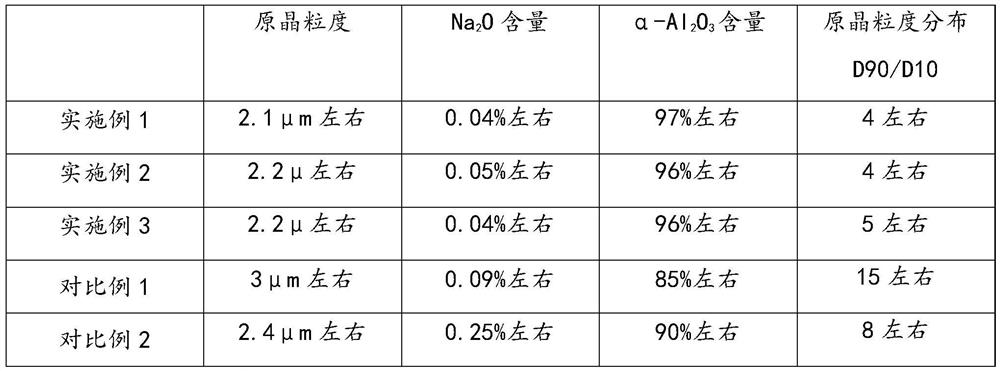

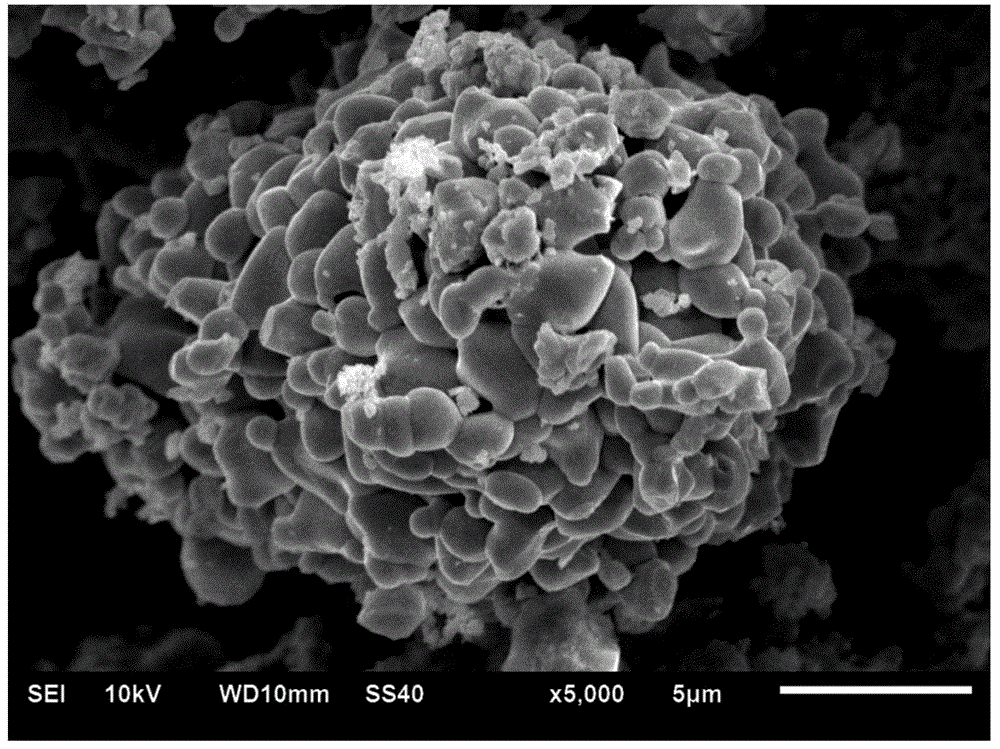

Preparation method of alpha-aluminum oxide with narrow original grain size distribution

ActiveCN113233488ARaw grain size distribution is narrowNarrow grain size distributionBulk chemical productionAluminium oxides/hydroxidesAluminium hydroxideMetallic materials

The invention particularly relates to a preparation method of alpha-alumina with narrow original grain size distribution, and belongs to the technical field of inorganic non-metallic materials. The preparation process comprises the following steps: taking aluminum hydroxide (Na2O content is 0.35-0.5%) as a raw material, adding a proper amount of seed crystals and a calcining aid, performing uniform mixing, performing calcining in a rotary kiln at 1,300-1,500 DEG C for 20-60 minutes, performing cooling, and performing ball-milling to a certain grain size, obtaining the original grain size narrow-distribution calcined alpha-alumina (D90 / D10 < = 4), and finally packaging the calcined alpha-alumina into a finished product to be sold. The alpha-aluminum oxide is prepared through seed crystal induction, the phase change temperature of the alpha-aluminum oxide is reduced, powder agglomeration is reduced, the original grain size narrow distribution (D90 / D10 < = 4) of the calcined alpha-aluminum oxide is controlled, and the re-sintering activity and the specific surface area of the alpha-aluminum oxide powder material and the mechanical performance, the compression resistance and the like of downstream products are remarkably improved.

Owner:中铝山东有限公司

A method for preparing nano-copper ferrite composite oxygen carrier by microwave hydrothermal method

InactiveCN103466715BSmall particlesWell-developed grainsMaterial nanotechnologyIron compoundsCopper nitrateReaction temperature

The invention discloses a method for preparing a nano-copper ferrite composite oxygen carrier by a microwave hydrothermal method, belonging to the technical field of chemical chain combustion. The method disclosed by the invention comprises the following steps: dissolving copper nitrate and ferric nitrate in deionized water, then performing ultrasonic treatment, dropwise adding excess ammonia water / urea solution, regulating the PH, performing centrifugal separation, washing a precipitate to be neutral, then placing the precipitate into a reaction kettle, adding a dispersing agent, adding the deionized water till 2 / 3-3 / 4 of the volume of the reaction kettle, placing the reaction kettle in a microwave oven with a water-cooled reflux device for heating, heating at the temperature of 150-220 DEG C for 10-20 hours, then cooling to room temperature and drying to get nano-copper ferrite. The copper ferrite prepared by adopting a hydrothermal synthesis method not only has uniform particle size, complete grain development and no agglomeration, but also is short in reaction time and low in reaction temperature. The copper ferrite prepared by applying the method disclosed by the invention has great application prospects in chemical chain combustion.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method for preparing flaky alumina powder

ActiveCN104556167BCrystal Morphology RulesImprove uniformityAluminium oxides/hydroxidesHigh concentrationHydrogen halide

Owner:贵州天合国润高新材料科技有限公司

Rock asphalt based demercuration adsorbent and preparation method thereof

PendingCN114307962AFully developedEvenly distributedWorking-up pitch/asphalt/bitumen by selective extractionOther chemical processesSorbentEnvironmental geology

The invention discloses a rock asphalt-based demercuration adsorbent and a preparation method thereof, and the preparation method comprises the following steps: carrying out hydrothermal reaction treatment on rock asphalt, and drying to obtain hydrothermal rock asphalt; washing and drying the hydrothermal rock asphalt with an organic solvent to obtain asphaltene, and processing the asphaltene into asphaltene particles; alkali is added into asphaltene particles for carbonization and activation, and a mixture containing the rock asphalt-based mercury removal adsorbent is obtained; mixing the mixture with water to form a mixed solution, and adding acid into the mixed solution to enable the mixed solution to be acidic so as to obtain an acidic mixed solution; and carrying out suction filtration on the acidic mixed solution by using water until the filtrate is neutral, filtering out residues, and drying to obtain the rock asphalt-based demercuration adsorbent. According to the invention, the adsorbent is developed to increase the adsorbability of Hg < 0 >, so that the mercury in the flue gas of the coal-fired power plant is efficiently removed, and up-to-standard emission of the mercury in the flue gas is ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD

A 3D printed powder material

ActiveCN110385430BImprove cutting performanceImprove bending strengthAdditive manufacturing apparatusTransportation and packagingSingle crystalCemented carbide

Owner:SEED TECH CORP LTD

Electric smelting magenisum aluminum spinel brick for coal water slurry gasifying furnace and preparation method thereof

The invention particularly relates to an electric smelting magenisum aluminum spinel brick for a coal water slurry gasifying furnace and a preparation method of the electric smelting magenisum aluminum spinel brick. The technical scheme is as follows: the preparation method comprises the following steps of: taking 58-74 wt% of industrial aluminum oxide powder and 26-42 wt% of light roasting magenisum oxide powder as raw materials; additionally adding carbon powder which is 0.5-3.0 wt% of the raw materials; uniformly agitating; putting the mixture into an electric arc furnace and electrically smelting by utilizing a 100-220 V voltage until all the raw materials are fused; continually smelting for 30-60 minutes and casting a smelted high-temperature synthetic material into a casting mould; then, placing the material into a tunnel kiln to be annealed by a belt mould under the condition of 1350-1550 DEG C, wherein the annealing period is 72-120 hours; discharging the material out of the kiln under the condition of 30-80 DEG C and de-molding; and finally, carrying out mechanical machining on a de-molded product to obtain the electric smelting magenisum aluminum spinel brick. The electric smelting magenisum aluminum spinel brick prepared by the invention has the characteristics of low apparent porosity, strong anti-stripping capability and good anti-coal-slag penetrating performance, and can better adapt to a working environment of a hot surface of a liner of the coal water slurry gasifying furnace.

Owner:WUHAN UNIV OF SCI & TECH

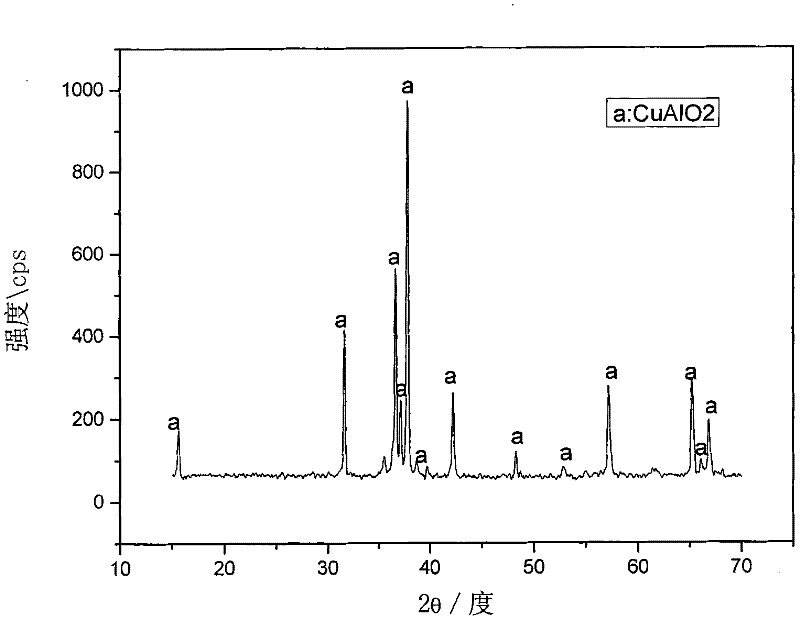

A kind of microwave hydrothermal method prepares the method for cualo2 thin film

A method for preparing CuAlO2 thin film by microwave hydrothermal method. First, copper acetate monohydrate is added to ethylene glycol to obtain solution A; then aluminum nitrate nonahydrate is added to solution A and the pH value is adjusted to 2.0-4.0 to form a uniform precursor material solution B; pour the B solution into the hydrothermal reactor, and immerse the silicon substrate in the B solution; seal the hydrothermal reactor, and put it into the MDS-8 type temperature-pressure dual-controlled microwave hydrothermal reactor; Select temperature control mode or pressure control mode for reaction and then naturally cool to room temperature; open the hydrothermal reactor, take out the silicon base, then wash several times with deionized water, absolute ethanol or isopropanol, and dry to obtain CuAlO2 film . The invention adopts microwave hydrothermal method to prepare CuAlO2 thin film. Not only the preparation cost is low, the operation is simple, and the reaction period is short, but also the product has high purity, complete grain development, uniform particle size distribution, controllable shape and no calcination treatment. The CuAlO2 thin film prepared according to the preparation method of the present invention is uniform and dense, and has strong bonding force.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of synthetic method of lithium manganate cathode material

Owner:株洲市海达新特材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com