Patents

Literature

150results about How to "Safe reaction conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

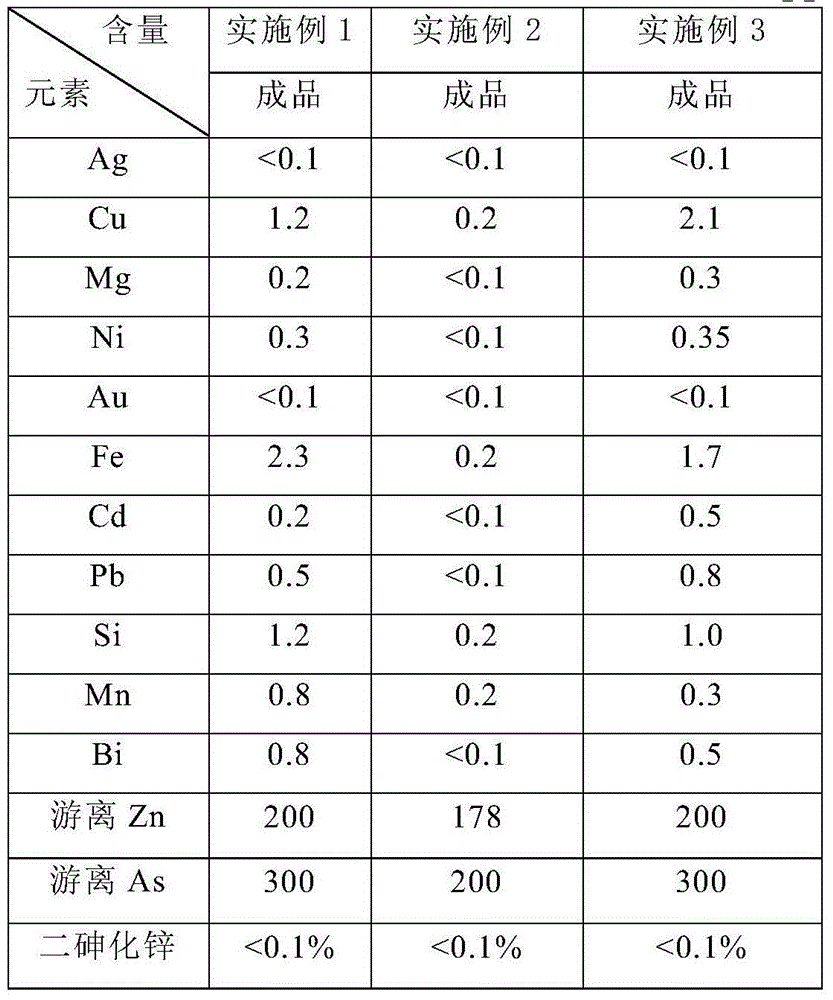

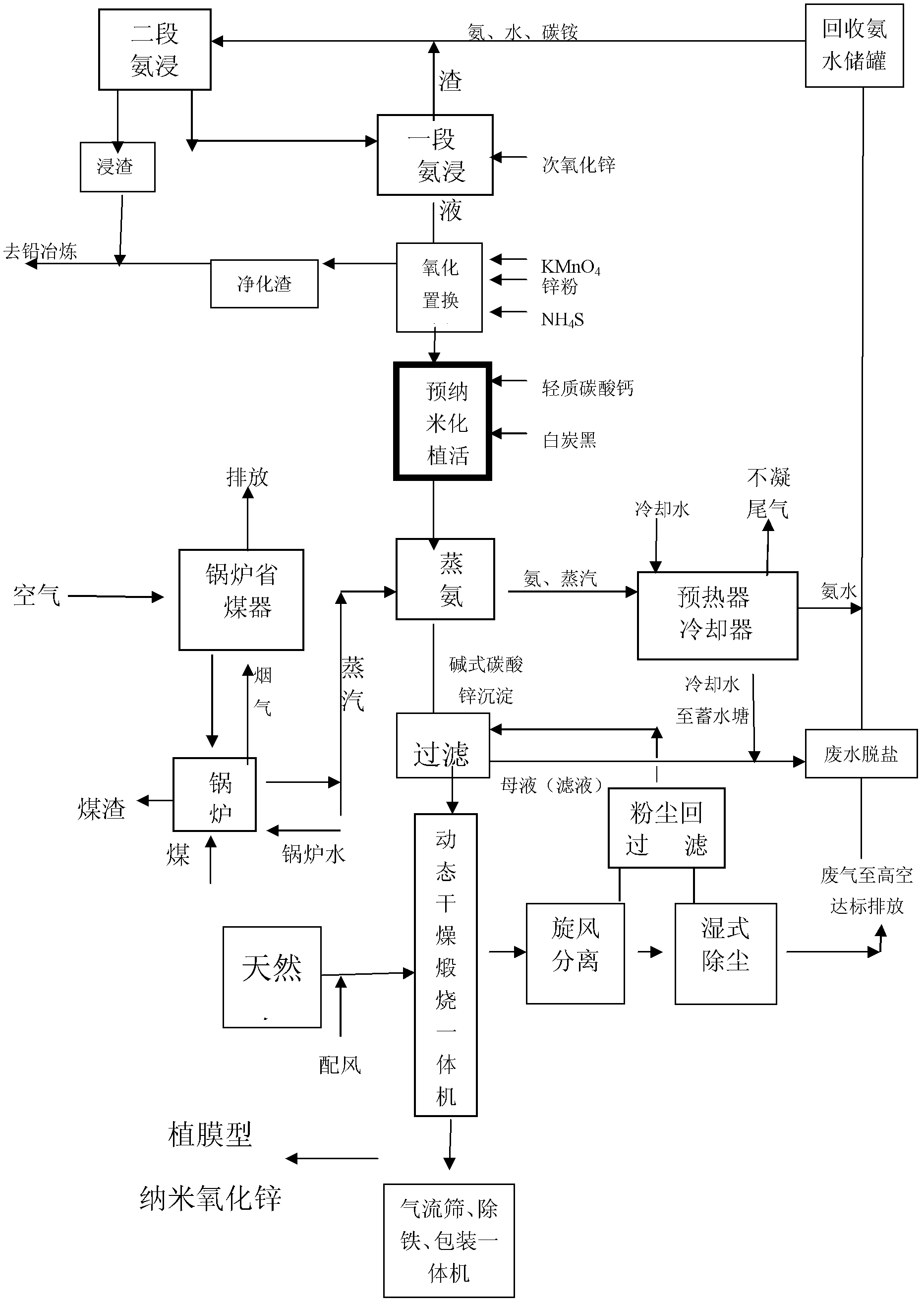

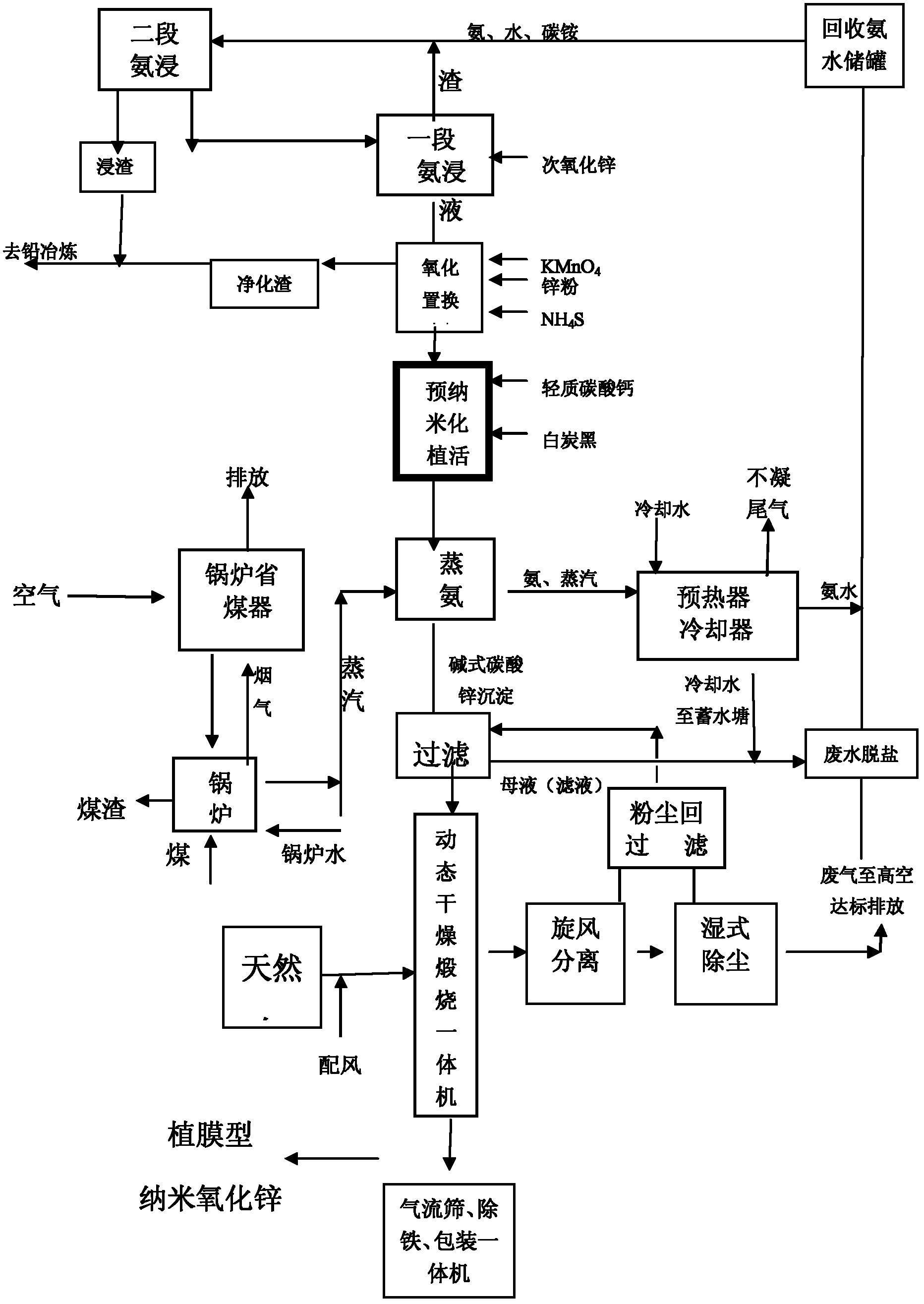

Film-coating production technology for nano zinc oxide

ActiveCN102515252AStable nano size and properties of nanomaterialsWell-developed grainsZinc oxides/hydroxidesNanotechnologyCarbonic acidTalc / Zinc Oxide

The invention provides a film-coating production technology for nano zinc oxide and belongs to the technical field of fine petrochemicals and chemicals. The technological process is that an alkali carbonic acid zinc film is coated uniformly on the surfaces of light calcium carbonate and inner pores thereof, subjected to decentralized processing, and then calcined and activated in a dynamic calcination furnace at the temperature of 400 to 500 DEG C, so as to prepare the nano zinc oxide. The nano zinc oxide prepared through the technology belongs to a low-zinc product (containing 24 to 30 percent zinc), has the advantages of stable nano size, stable nano material properties, completely developed crystal grains, small particle diameter, uniformity in distribution, low reunion degree, high activity and good dispersivity, and can be widely applied to rubber, tires, catalysis, magnetism, optics, electricity, chemistry, physics, biology and the like.

Owner:SHANOGUAN KAIHONG NANOMATERIAL

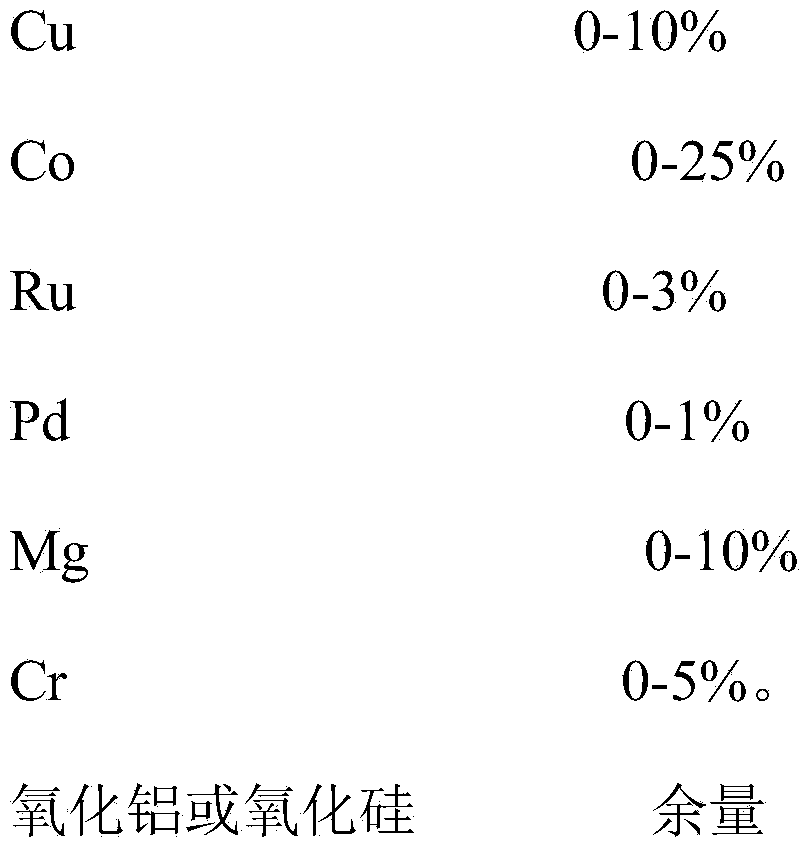

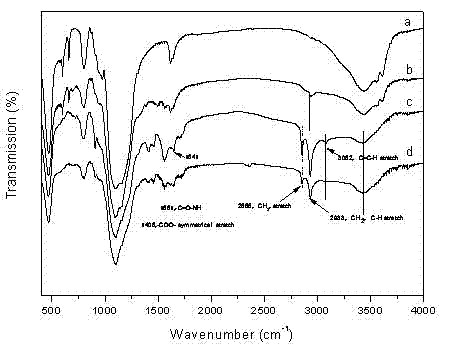

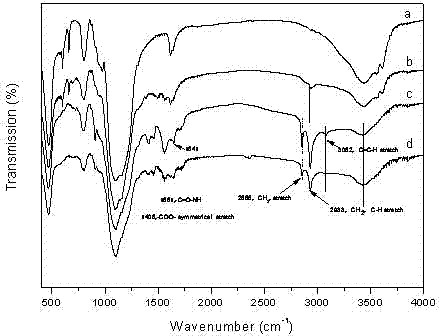

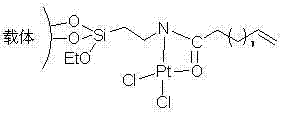

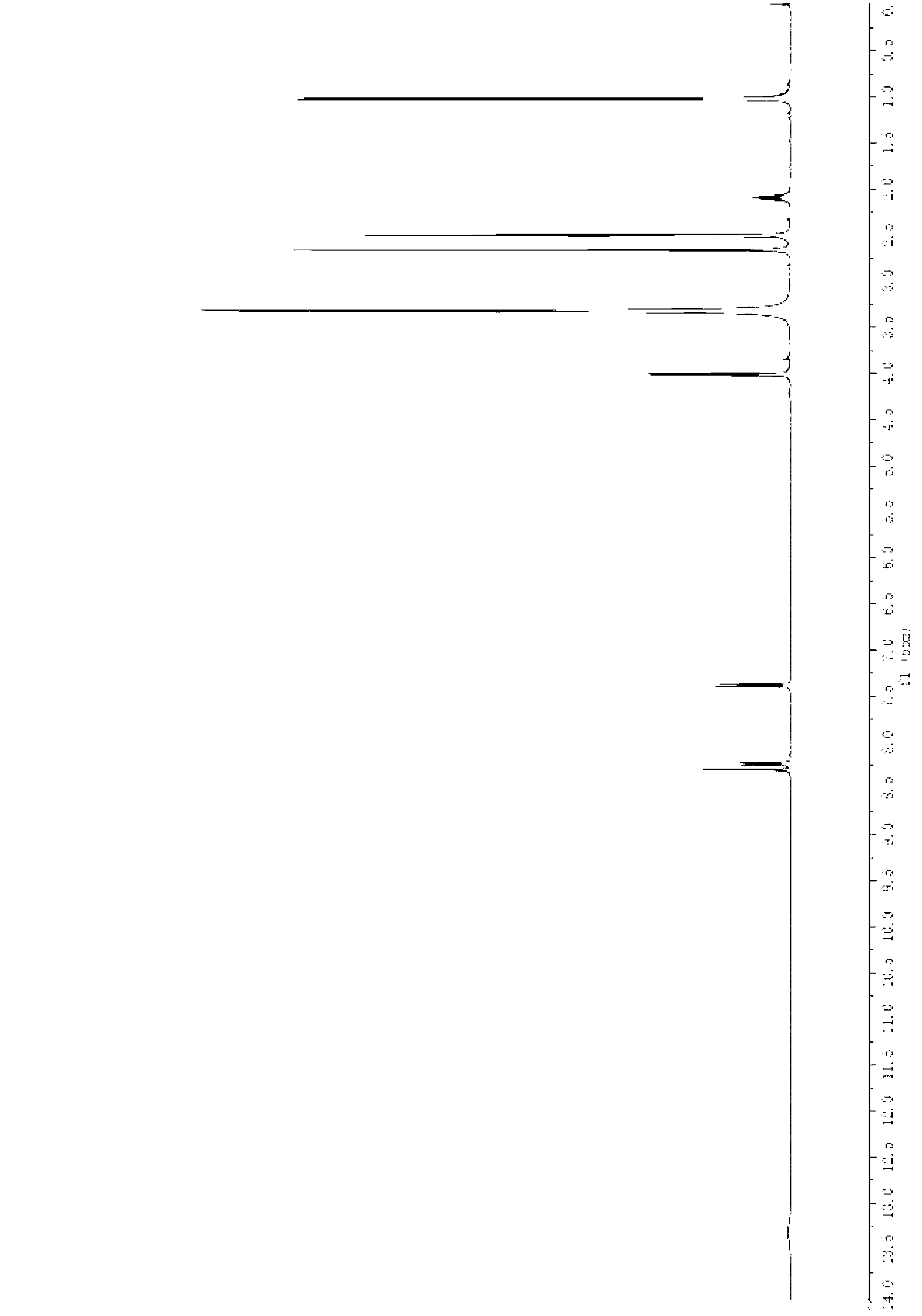

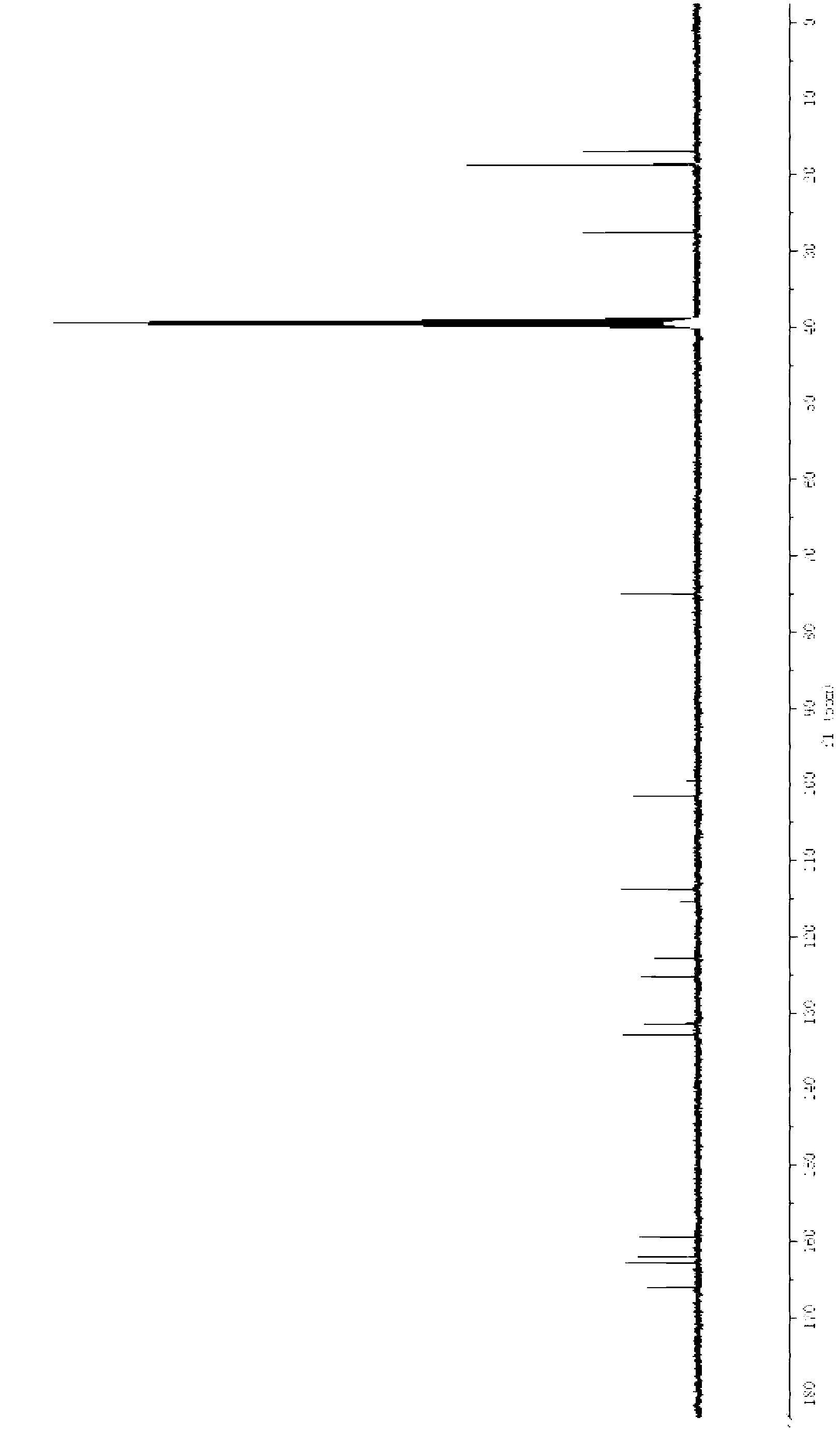

Supported hydrosilylation catalyst and preparation method thereof

InactiveCN102188996AEfficient CatalysisImprove catalytic performanceSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrosilylationStructural formula

The invention relates to a supported hydrosilylation catalyst and a preparation method thereof, and aims to provide a heterogeneous catalyst suitable for hydrosilylation and a preparation method thereof. When the catalyst is used, the reaction conditions are mild; and the catalyst is safe and effective and conveniently separated from the product, and can be recycled. The catalyst provided by the invention has the structural formula shown in the specification. The preparation method provided by the invention comprises the following steps: 1) modifying the carrier surface with a coupling agent;2) modifying the carrier surface with a functional group compound; and 3) preparing the catalyst through coordination complexing with a platinum compound.

Owner:HANGZHOU NORMAL UNIVERSITY

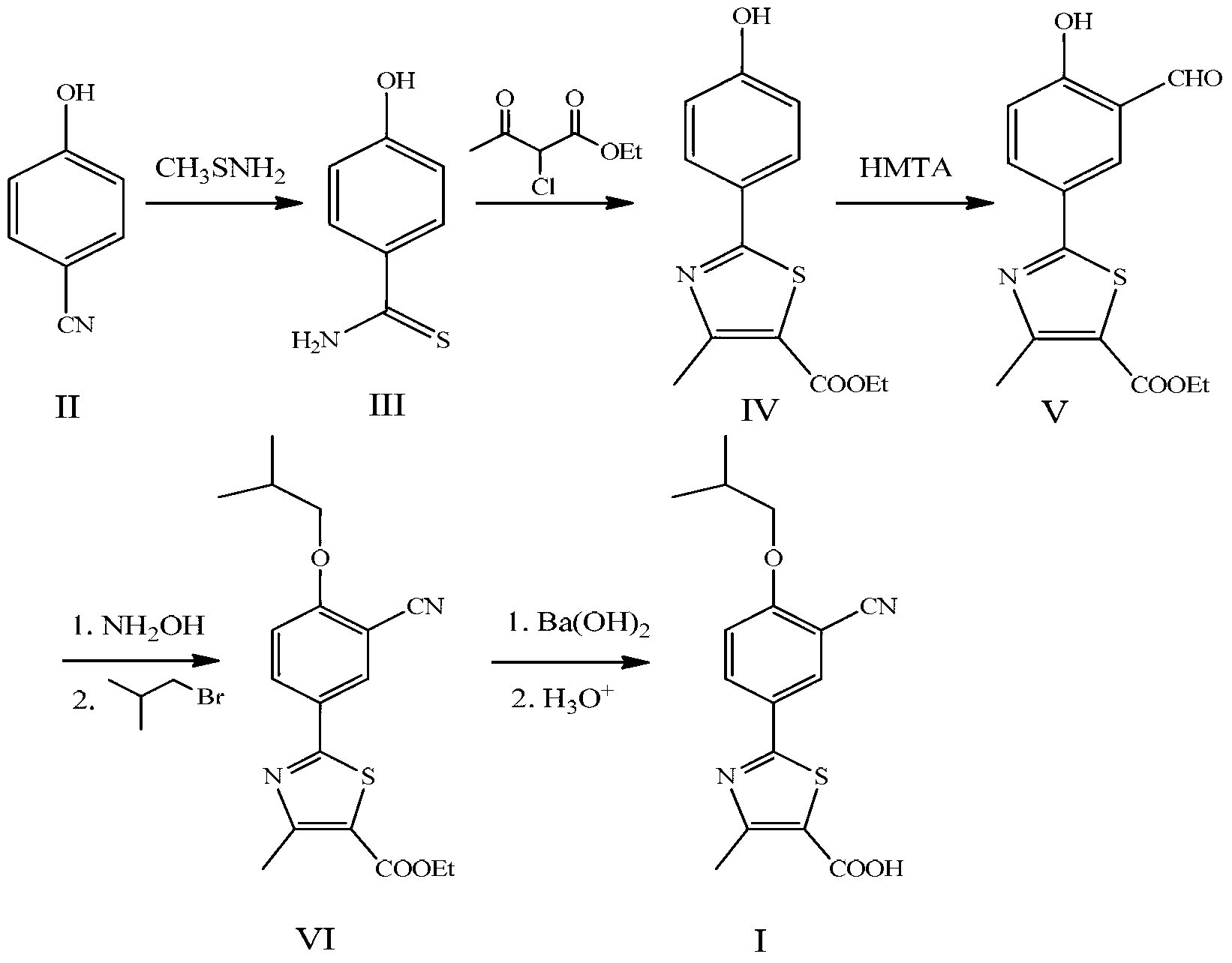

Preparation method for febuxostat

InactiveCN103304512ALow costReduce operation processOrganic chemistryHydroxylamine HydrochlorideToxic material

The invention discloses a preparation method for febuxostat. The preparation method for febuxostat comprises the following steps of: by using 4-hydroxybenzonitrile and thioacetamide as raw materials, and reacting in hydrochloric acid solution to prepare 4-hydroxythiobenzamide; carrying out a reaction on 4-hydroxythiobenzamide and 2-chloroacetoacetic acid ethyl ester to prepare 2-(4-hydroxylphenyl)-4-methylthiazol-5-carboxylic acid ethyl ester; carrying out a reaction on the obtained compound and hexamine in the mixed acid system of methanesulfonic acid and trifluoroacetic acid to prepare 2-(3-formyl-4-hydroxylphenyl)-4-methylthiazole-5-carboxylic acid ethyl ester; synthesising 2-(3-nitrile-4-isobutoxylphenyl) -4-methylthiazole-5-carboxylic acid ethyl ester from the compound, hydroxylamine hydrochloride, potassium carbonate, iso-butyl bromide and the like in a polar protonic solvent via a one-pot method; and finally hydrolyzing in an alkaline condition to obtain the target product, namely, febuxostat. The total yield of the preparation method for febuxostat disclosed by the invention is increased to 66%, the separation steps are reduced, any extremely toxic substance is not involved, and the environmental pollution is less.

Owner:SOUTH CHINA UNIV OF TECH

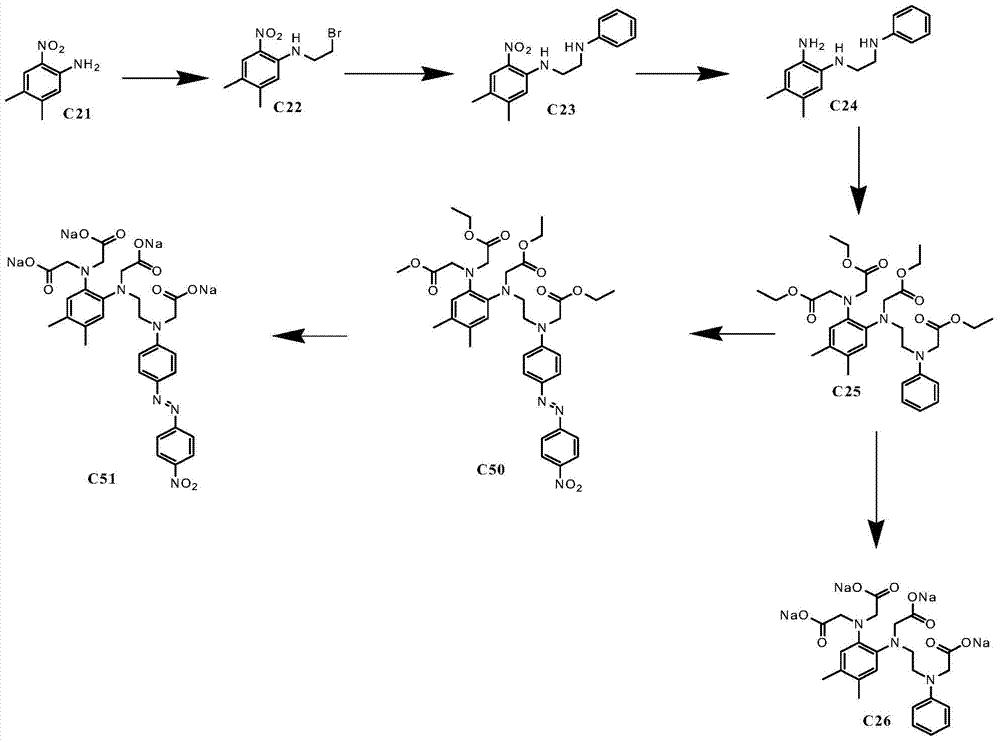

Compound for determining content of metal ions in water environment, and its application

ActiveCN104292204AMild reaction conditionsSafe reaction conditionsOrganic chemistryMaterial analysis by observing effect on chemical indicatorFluorescenceDiethylenetriamine

The invention discloses an organic compound for detecting the content of metal ions. The compound adopts diethylenetriamine as a complexation main body, allows one ethylidene and amino groups to be aromatized and converted into 1,2-diaminobenzene and aniline in order to form anilinoethyl phenylenediamine, three amino groups are connected with different complexing groups, and a series of organic compounds formed in the invention can be used as metal ion complexes. The complexes and metal ion complexes, especially cadmium and mercury ion complexes, form a complex capable of causing the color or fluorescence change of an indicator in order to detect the content of metal ions. The compound can be applied in environmental detection, and can also be applied in the detection of the field of biomedicines.

Owner:FORLIGHTS DETECTION TECH LLC SUZHOU

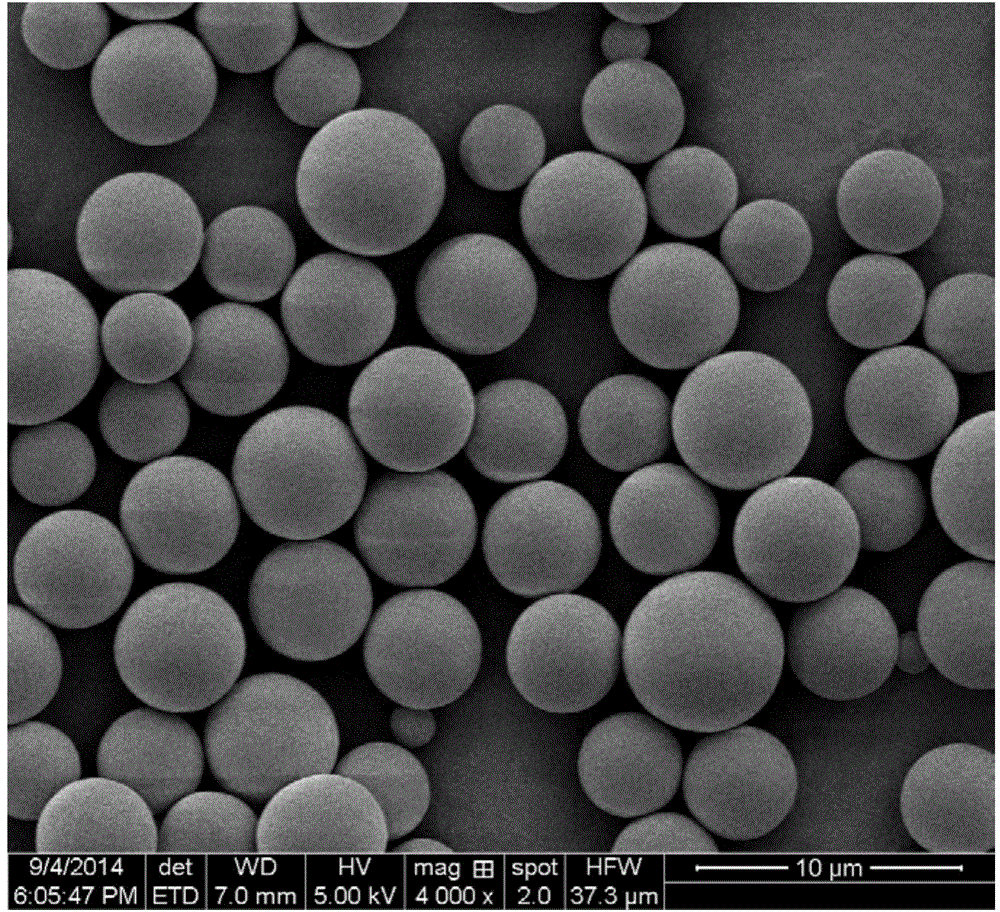

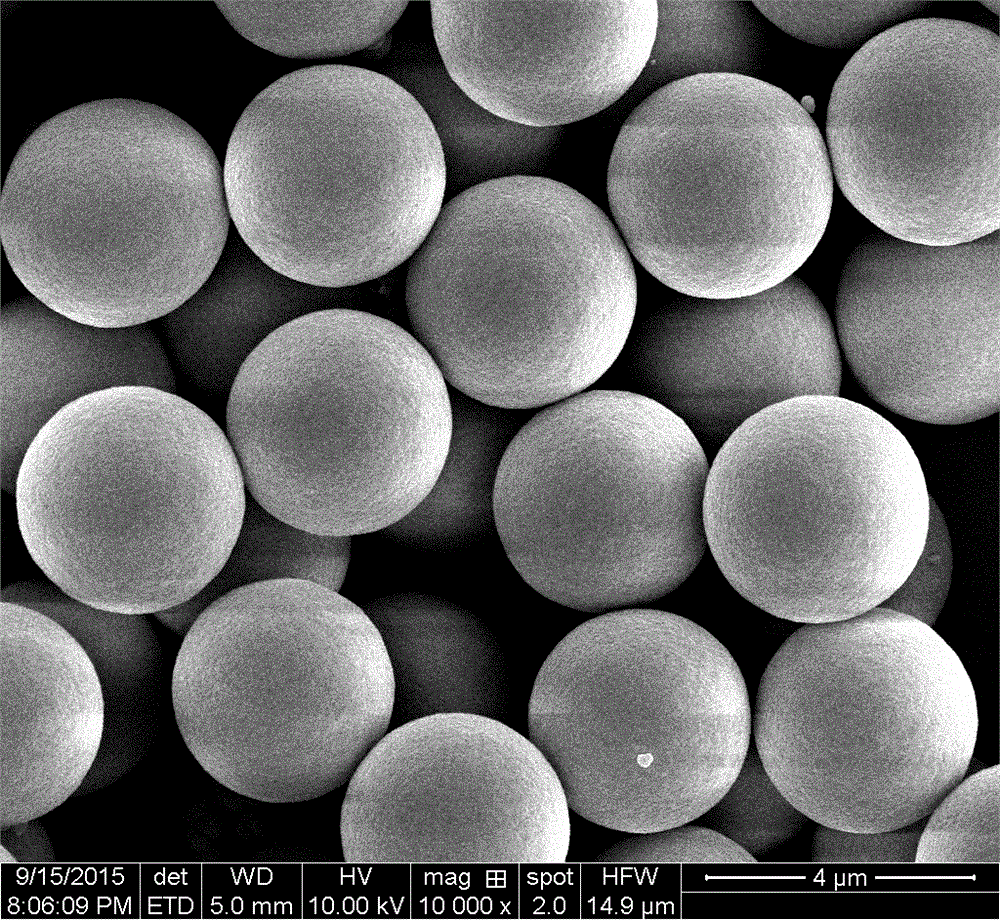

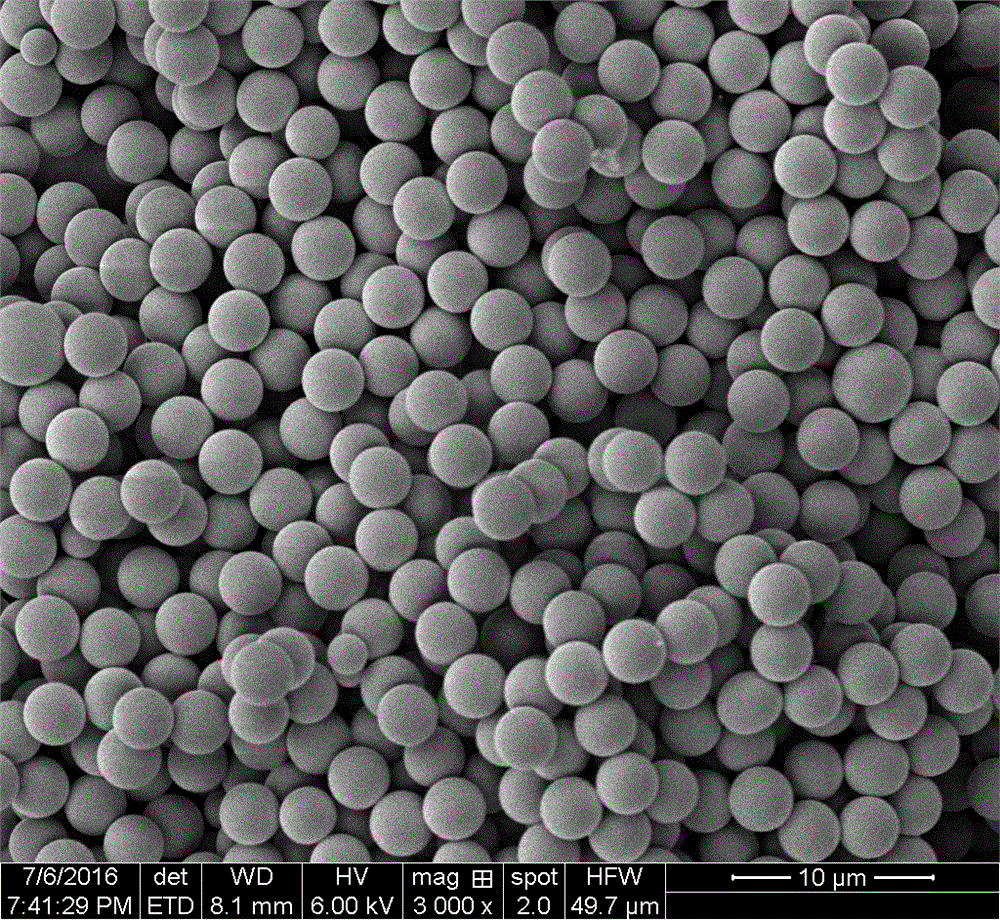

Highly cross-linked monodisperse epoxy-group-containing polymeric microsphere and preparation method thereof

InactiveCN104788609AGood dispersionGood spherical shapeMicroballoon preparationMicrocapsule preparationEpoxyCross-link

The invention relates to a highly cross-linked monodisperse epoxy-group-containing polymer microsphere and a preparation method thereof. The microsphere contains an epoxy group, methacrylic acid glycidyl ester is used as a monomer, divinyl benzene (DVB) is used as a cross-linking agent, and the microsphere is obtained through polymerization; the particle size of the microsphere is 2 to 10 [mu]m, and the polydispersity index is 1.04 to 1.07. The preparation method comprises the following steps: (1), methacrylic acid glycidyl ester, the DVB and an initiating agent are together added into a solvent for uniform mixing, after nitrogen is introduced, sealing is performed, the reaction temperature is controlled to be 82 to 90 DEG C, and the reaction time lasts for 3 to 5 hours; (2), a reaction product obtained in the step (1) is washed and dried, so that the polymer microsphere is obtained. The polymer microsphere prepared by the invention contains the epoxy group, the epoxy group is an active group, derivative reaction is facilitated, and the problems of high hydrophobicity, high probability of non-specific adsorption can be solved.

Owner:UNIV OF JINAN

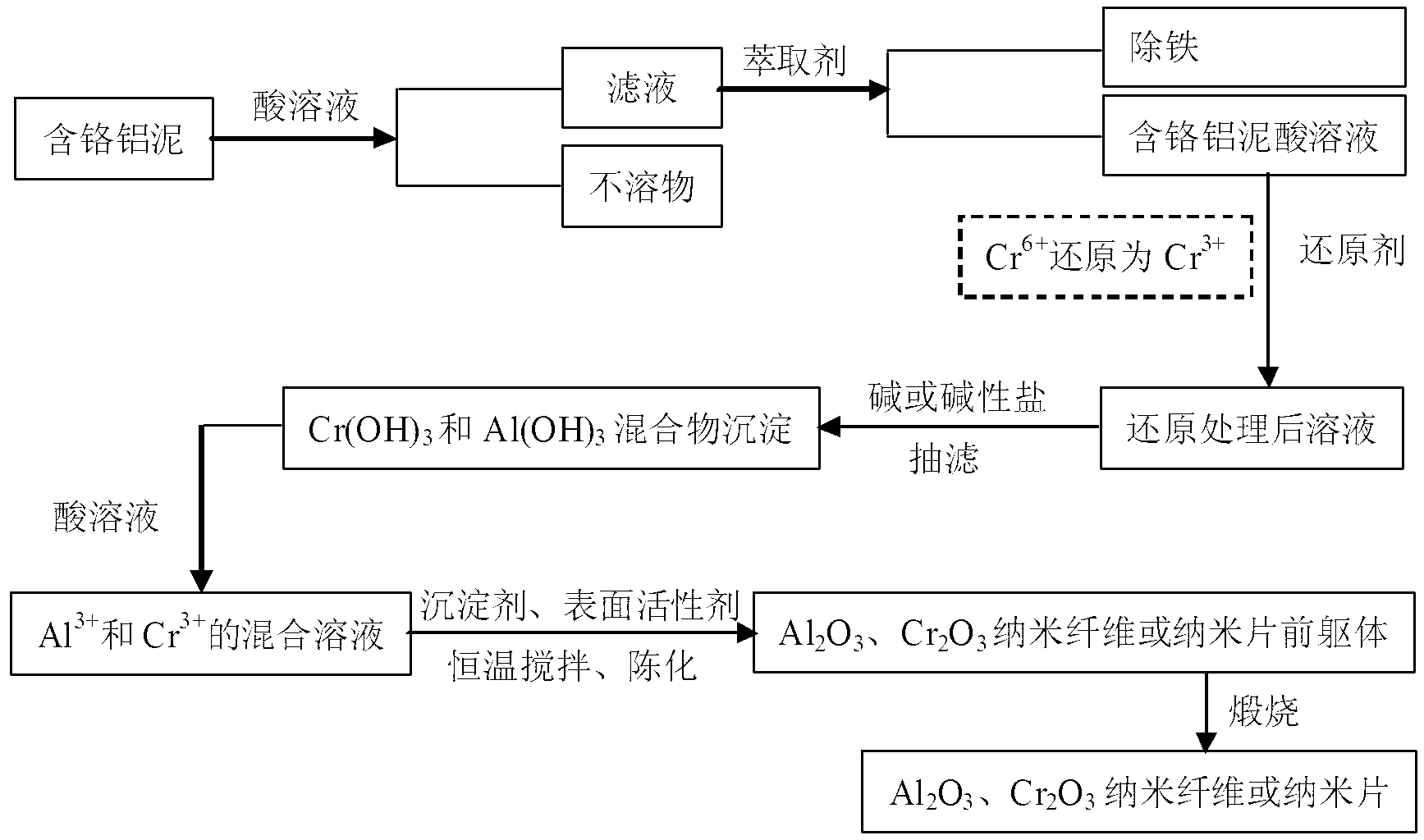

Al2O3, Cr2O3 composite nanofiber or nanosheet prepared from chromium-bearing aluminium sludge and preparation method thereof

InactiveCN103225131AQuick responseMild reaction conditionsMaterial nanotechnologyInorganic material artificial filamentsComposite nanofibersSludge

The invention mainly relates to an Al2O3, Cr2O3 composite nanofiber or nanosheet prepared from chromium-bearing aluminium sludge and a preparation method thereof. The method is performed according to the following steps: dissolving aluminium sludge with acid, removing iron, reducing, preparing a mixture of Al(OH)3 and Cr(OH)3, preparing an Al2O3, Cr2O3 composite nanofiber or nanosheet precursor, and finally preparing the Al2O3, Cr2O3 composite nanofiber or nanosheet. The preparation method provided by the invention has advantages of rapid reaction speed, mild and safe condition, controllable morphology and size of the product and low cost, and is suitable for popularization and application.

Owner:BOHAI UNIV

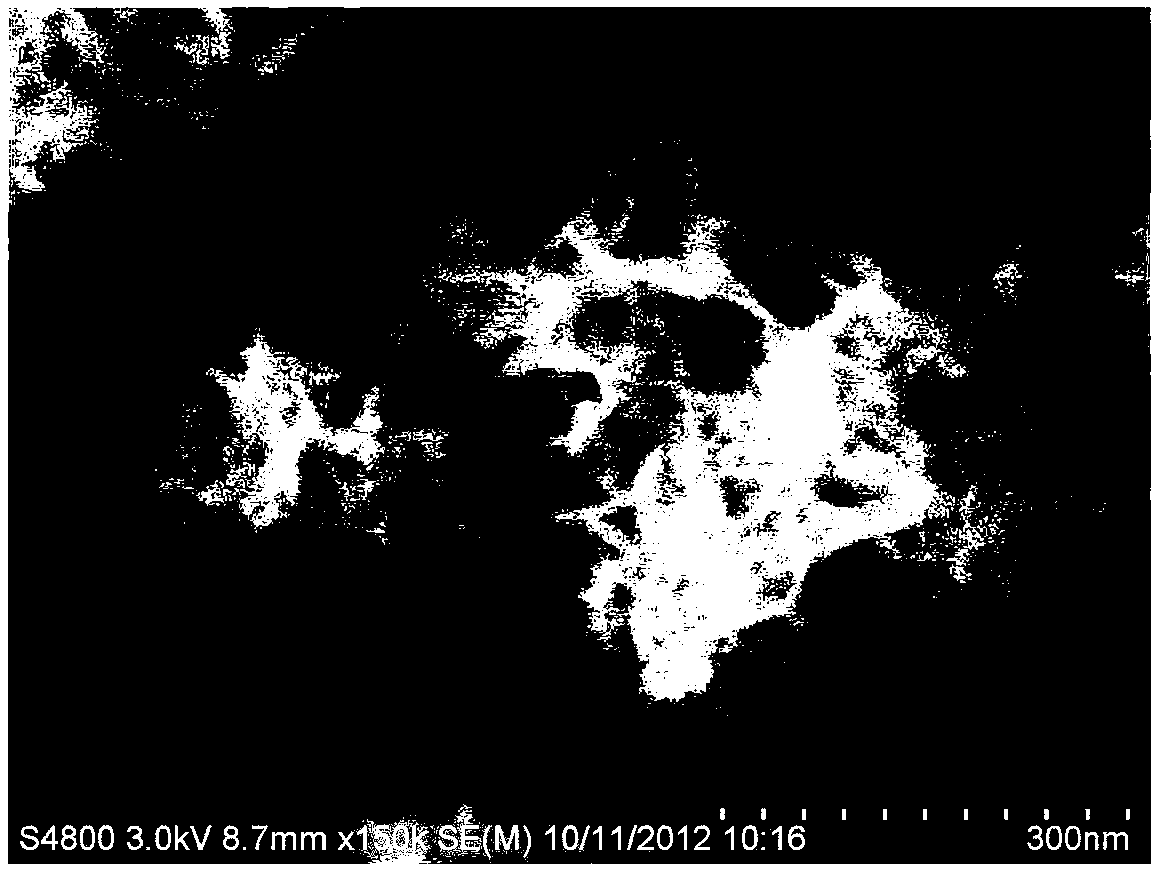

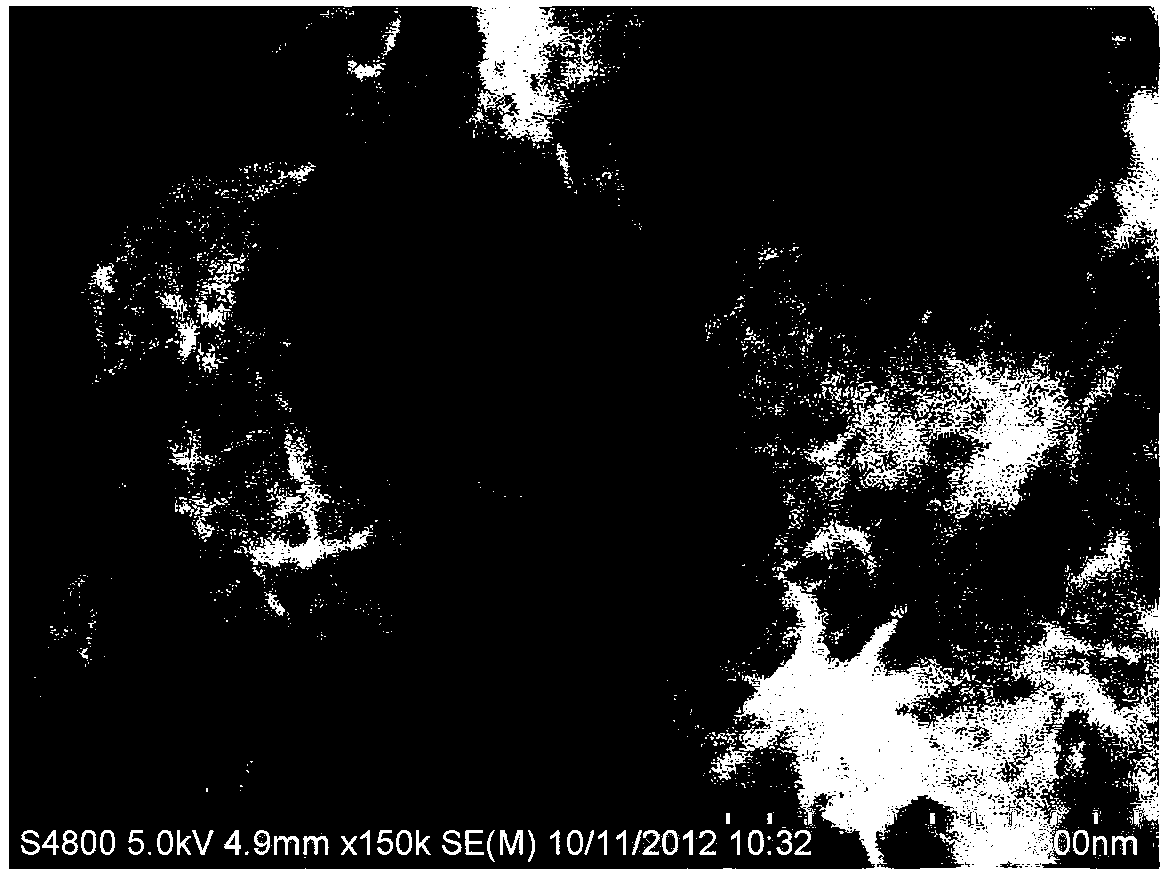

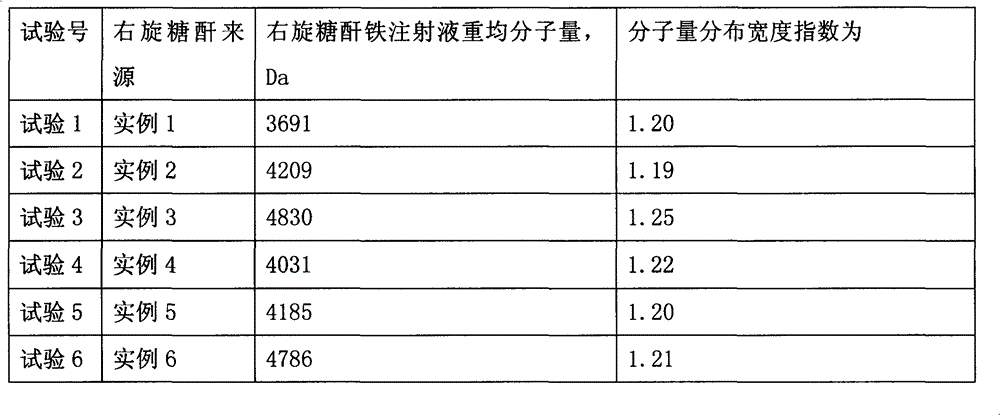

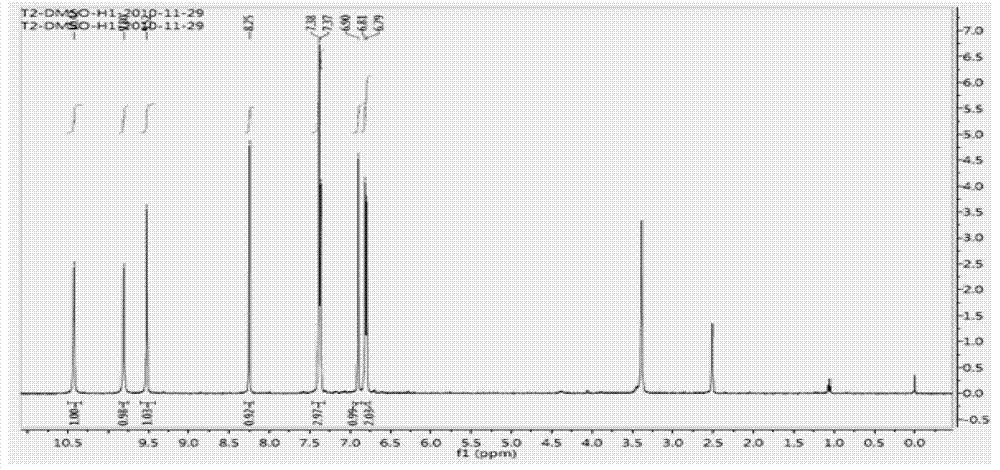

Preparation method for dextran with weight average molecular weight of 3000-6000Da

ActiveCN102942638AMild reaction conditionsEasy to controlMetabolism disorderBlood disorderEnzymeWeight distribution

The present invention utilizes dextran enzyme to direct degrade dextran with a weight average molecular weight of 7000-80000Da including micro-molecular dextran (i.e., dextran 10), small molecular dextran (i.e., dextran 20), low molecular dextran (i.e., dextran 40), middle molecular dextran (i.e. dextran70) to special micro-molecular dextran with a weight average molecular weight of 3000-6000Da. The special micro-molecular dextran can be used as a raw material for preparation of special micro-molecular iron dextran. The preparation method is mild and safe in reaction conditions, less in three wastes, easy to control the weight average molecular weight of the final product dextran, narrow in molecular weight distribution, simple in process, rare in dextran loss, and low in production costs. The product after degradation does not need to be processed, and can be directly used for oxidation and complexation to produce high-quality special micro-molecular iron dextran.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +3

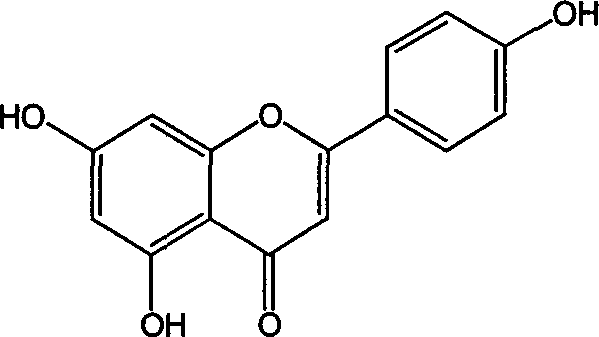

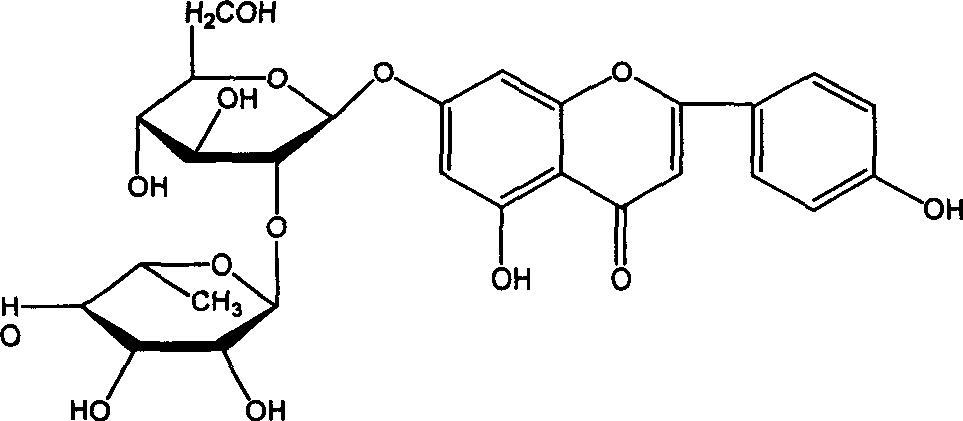

Preparation process of polyhydroxy isoflavone

ActiveCN103087027AHarm reductionAchieve room temperature reactionOrganic chemistryCyanideBenzyl cyanide

The invention relates to a preparation method of polyhydroxy isoflavone. The polyhydroxy isoflavone comprises 4',6,7-trihydroxy isoflavone and 3',4',6,7-tetrahydroxy isoflavone. According to the invention, the large-scale preparation of 4',6,7-trihydroxy isoflavone and 3',4',6,7-tetrahydroxy isoflavone can be realized by treating cheap and easily-acquired chemical raw materials including 3,4-dimethoxy phenol, 3,4-dimethoxy benzyl cyanide and hydroxybenzyl cyanide as starting materials through optimal research on Hoesch reaction, carburization n-cyclohexylmaleimide reaction and demethylation protection. The preparation method of polyhydroxy isoflavone disclosed by the invention is economic, efficient, environment-friendly, safe and easy to industrialize. The 4',6,7-trihydroxy isoflavone and the 3',4',6,7-tetrahydroxy isoflavone can be applied to the research and the development of new medicines in the aspects of medicines, food hygiene and the like.

Owner:中国人民解放军第三军医大学军事预防医学院

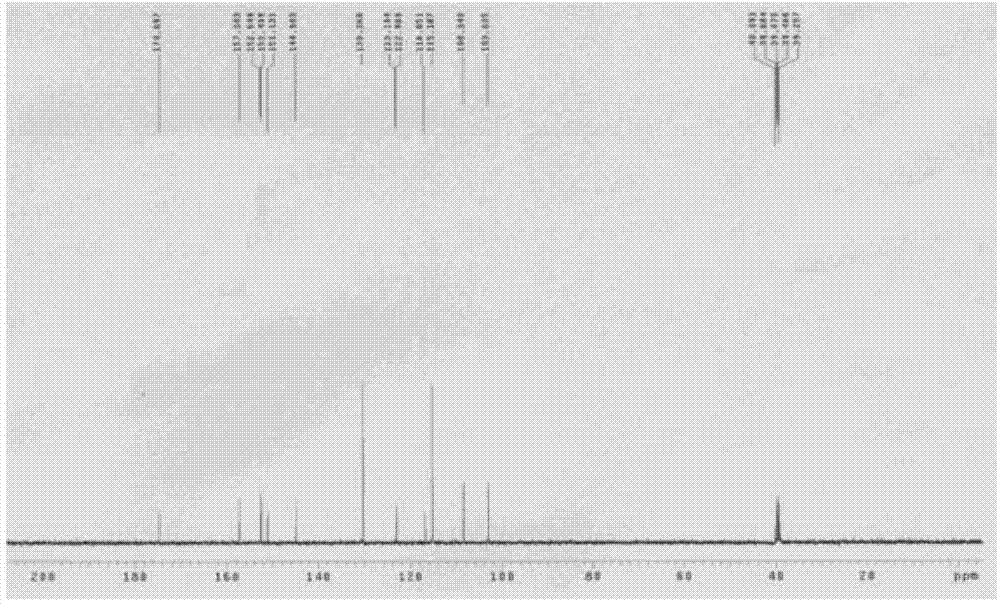

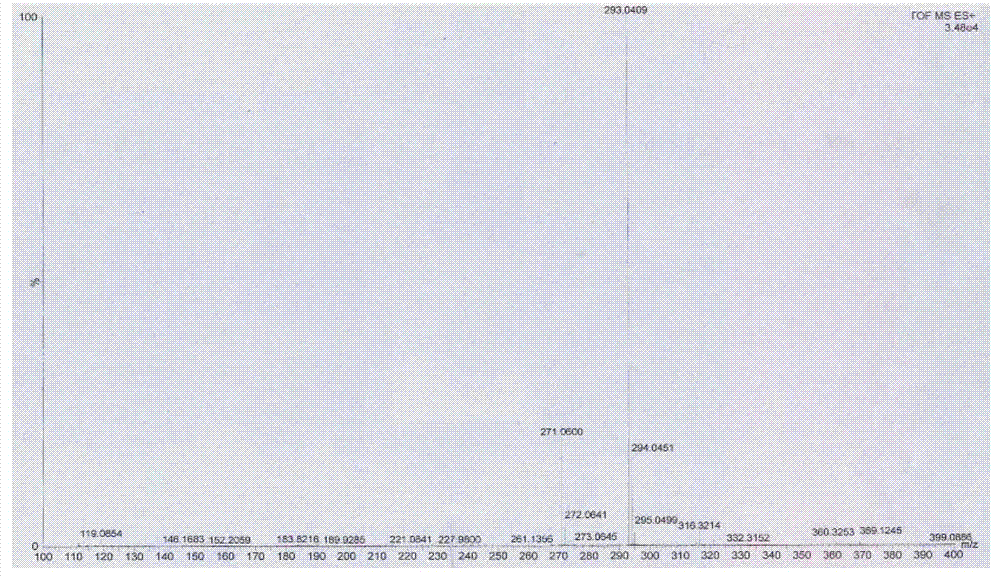

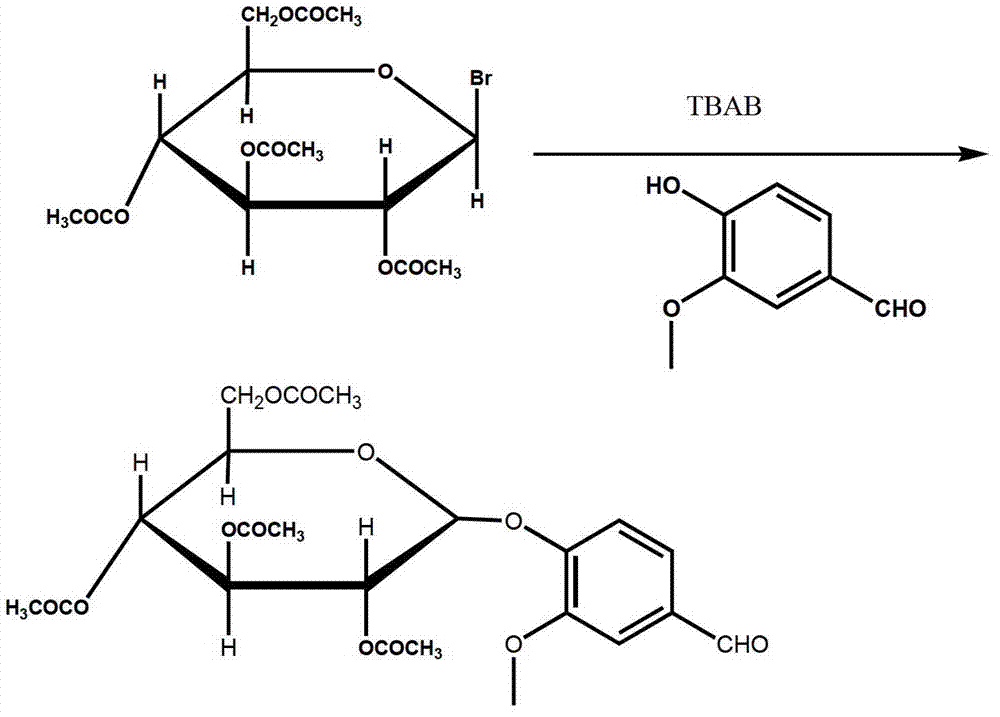

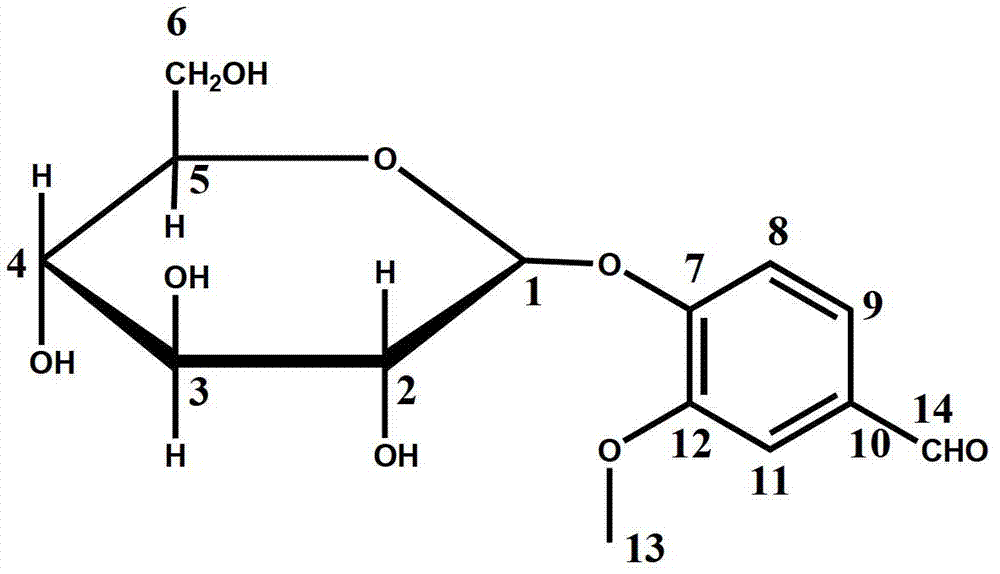

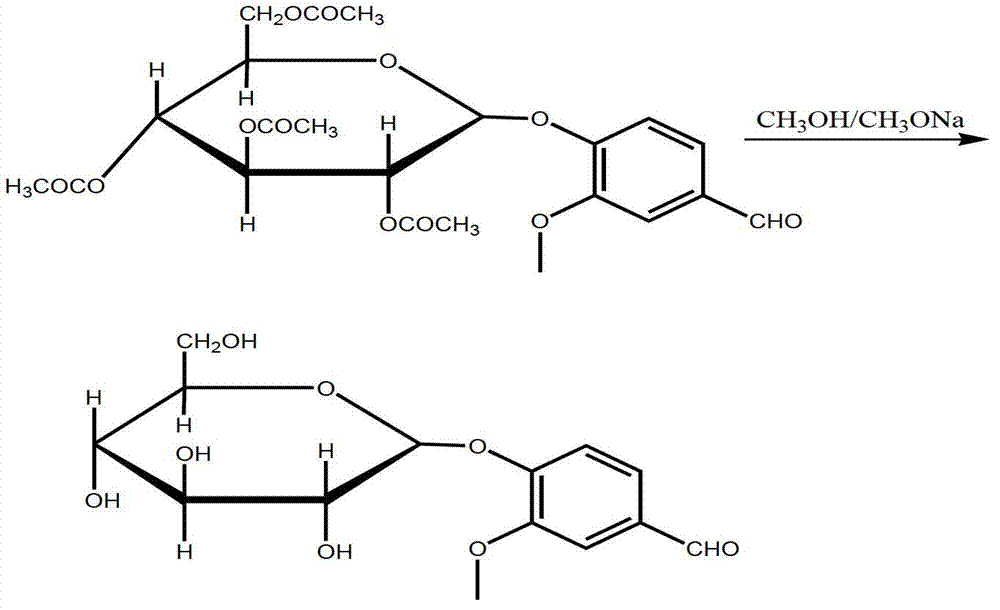

Preparation method of vanillin glucoside and application of vanillin glucoside in tobacco flavoring

ActiveCN103159806AMild reaction conditionsSimple stepsSugar derivativesTobacco treatmentChemistryMethanol

The invention provides a preparation method of vanillin glucoside. The preparation method of the vanillin glucoside comprises firstly, using tetra-acetyl-bromo-glucose to react with vanillin to combine into tetra-acetyl-glucose vanillin, and using the tetra-acetyl-glucose vanillin to react with sodium methylate to obtain the vanillin glucoside. The vanillin glucoside has the advantages of being mild in reaction condition, safe, simple in procedure, easy to industrially produce, and the like. When the vanillin glucoside is applied in tobacco, the vanillin glucoside is capable of obviously improving richness of cigarette aromas, and reducing irritation of side flow smoke, and meanwhile is incapable of increasing cost of cigarette production, and therefore the vanillin glucoside has wide application prospects in tobacco industry.

Owner:HUBEI CHINA TOBACCO IND

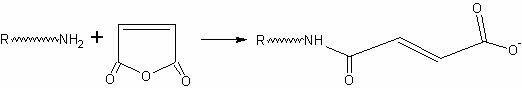

Preparation method of modified gelatin

The invention relates to a preparation method of a modified gelatin, which comprises the following steps of: (a) grinding large-particle gelatin to ensure that the gelatin is thinned to have a particle size of over 80 meshes; and (b) dissolving an acylation agent into tetrahydrofuran for mixing, putting the gelatin particles, which are thinned by grinding, into a blended liquid phase through suspension swelling, and performing acylation reaction by taking nicotinic acid, nicotinamide or acidylated histidine as a reaction catalyst and polyglycol as a cocatalyst to obtain the modified gelatin. Compared with the former unmodified gelatin, part of amino groups of the modified gelatin are closed, and the modified gelatin is grafted with acrylate of which one end still has free carboxyl groups, so multi-aspect properties of the gelatin are changed and improved, and after modification, the water solubility and swelling property of the gelatin are obviously increased, and the stability is also increased to a certain extent. Besides, a solvent, a modifier and a catalyst in the process of the reaction are nontoxic, so the serviceable range of the modified gelatin is enlarged, the reaction condition is mild and safe, and the modified gelatin is suitable for industrial production and has a good application prospect.

Owner:ZHEJIANG UNIV OF TECH

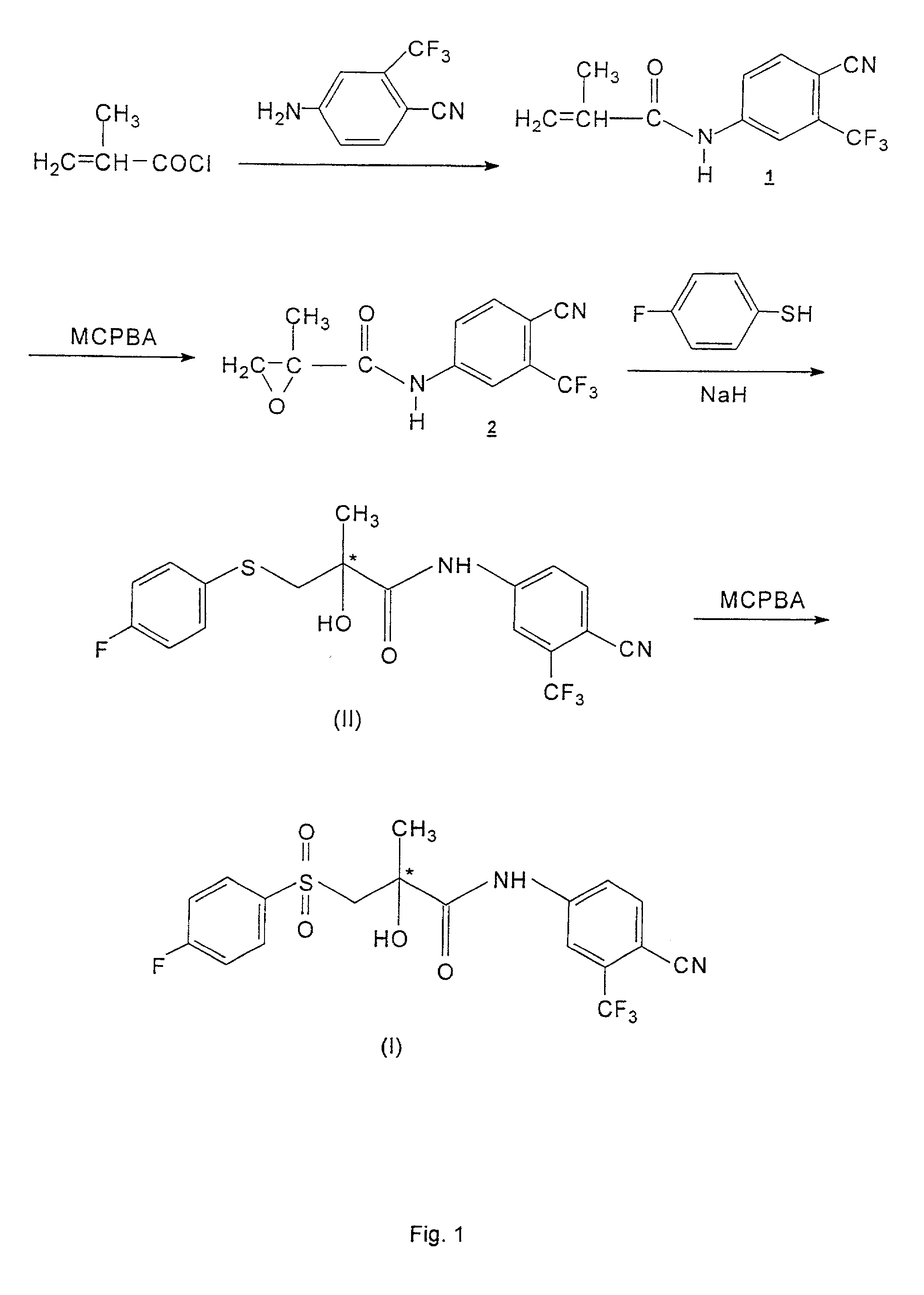

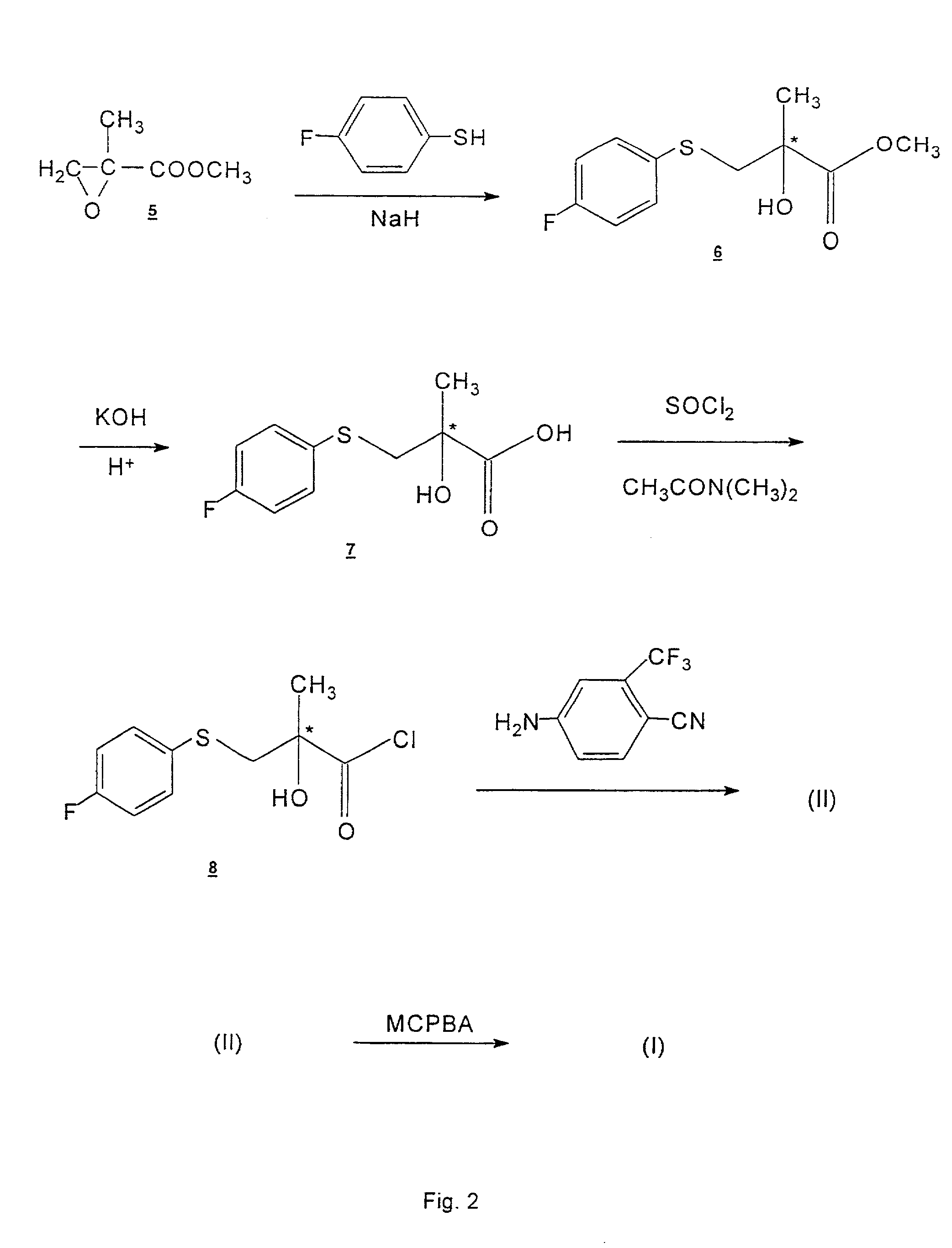

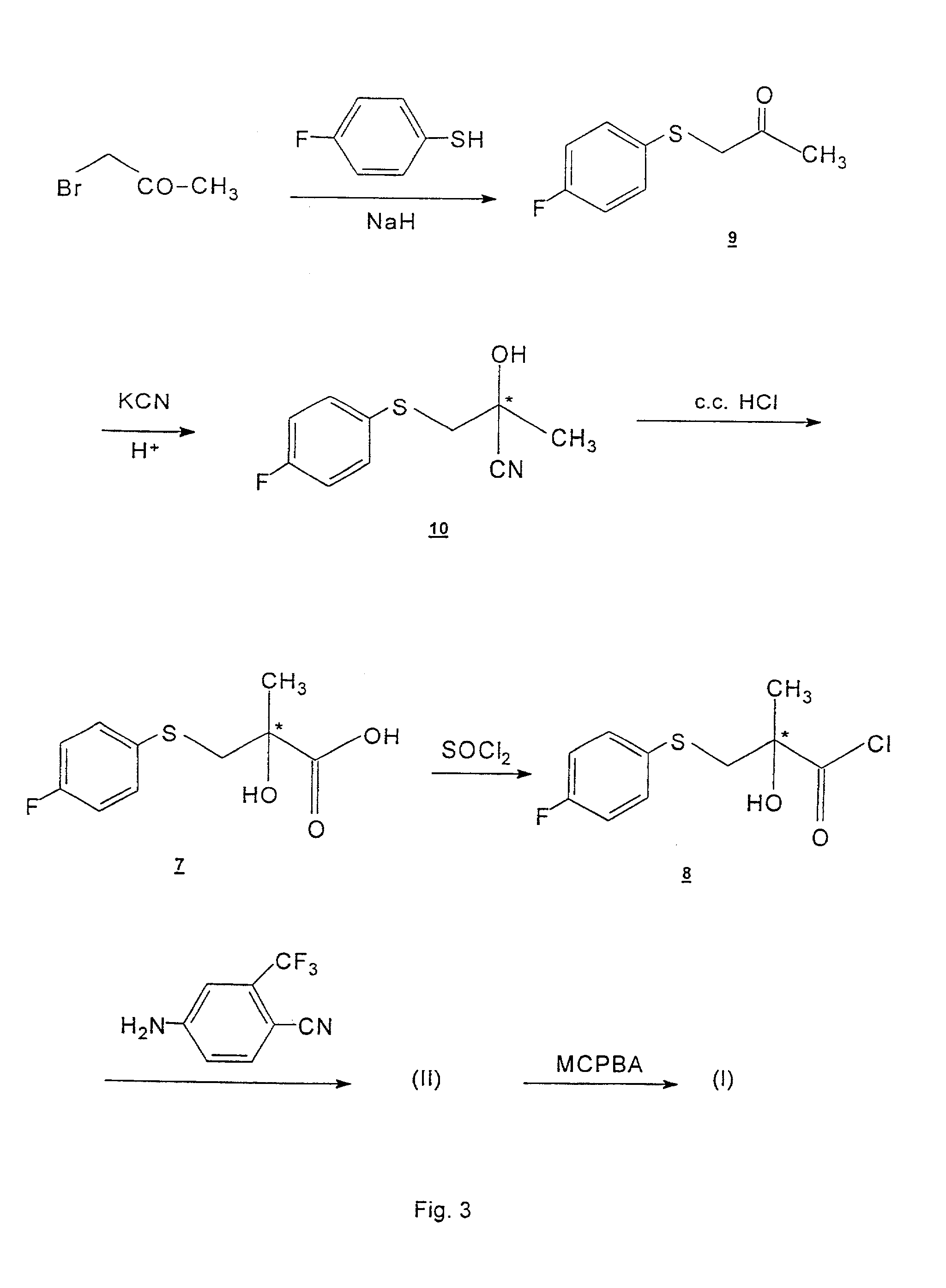

Process for the synthesis of N-(4-cyano-3-trifluoromethylphenyl)-3-(4-fluorophenylsulfonyl)-2-hydroxy-2-methylpropionamide

InactiveUS7199257B1Increase speedReadily availableCarboxylic acid nitrile preparationOrganic compound preparationAcyl groupPhenyl group

A new process is disclosed for the synthesis of racemic or optically pure N-[4-cyano-3-trifluoro-methyl-phenyl]-3[4-fluorophenyl-sulfonyl]-2-hydroxy-2-methylpropionamide. The process includes the formation of several novel intermediates in the synthesis.

Owner:RICHTER GEDEON VEGYESZETI GYAR RT

Method for producing naphthalene water reducing agent

The invention discloses a method for producing naphthalene water reducing agent, which comprises the following steps: (1) sulphonating: adding naphthalene, concentrated sulfuric acid and anhydrous sodium sulfate while stirring into a reactor, and making the materials react at 160-165 DEG C for 2-3 hours, wherein the molar ratio of the naphthalene to the concentrated sulfuric acid is 1:1.3 to 1.5, and the addition amount of the anhydrous sodium sulfate is 5-9% by the weight percent of the concentrated sulfuric acid; (2) hydrolyzing: adding water to the reaction solution to control the acidity at 27-29%, and stirring for 30 minutes; (3) condensing: adding formaldehyde to the reaction solution, and making the formaldehyde react with the reaction solution at 100-110 DEG C for 3-4 hours, wherein the molar ratio of the formaldehyde to naphthalene sulfonate is 0.7 to 1.5:1; (4) neutralizing: adding alkali to the reaction solution to neutralize the reaction solution, and controlling the pH value at 7-9; and (5) filtering: filtering to remove unnecessary sulfate to obtain the naphthalene water reducing agent. The method for producing the naphthalene water reducing agent by adopting one pot has the advantages of cheap and readily available raw materials, safe and mile reaction condition, simple process, safe operation, high reaction yield and low cost and can be used for industrial production on a large scale.

Owner:上海新浦特种助剂有限公司

Green synthesis method of D-calcium pantothenate

InactiveCN108129346AEasy to operateMild reaction conditionsOrganic compound preparationCarboxylic acid amide separation/purificationFilter cakeCalcium

The invention discloses a green synthesis method of D-calcium pantothenate. The green synthesis method of D-calcium pantothenate provided by the invention comprises the steps that beta-alanine is added into methyl alcohol; then, a calcium source is added; temperature rise and stirring are performed for reaction; filtering is performed; filter liquid is collected; filter liquid is subjected to temperature cooling; then, D-pantolactone is added; stirring reaction is performed; seed crystals are added; stirring reaction is continuously performed; after the reaction is finished, water is added; crystallization is continuously performed at -15 DEG C to -20 DEG C; then, filtering and washing are performed; filtering cake and filtering liquid are respectively collected; the filtering cake is dried; the filtering liquid is subjected to acid hydrolysis; DL-pantolactone is recovered. The green synthesis method has the advantages that the D-calcium pantothenate is prepared from calcium pantothenate; the process route operation is simple; the reaction conditions are mild; safety is realized; the environment is protected; the raw materials are cheap and can be easily obtained; the industrial adaptability is high; the wastes are few; the used raw materials can be recovered and utilized; the goal of clean production is reached.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

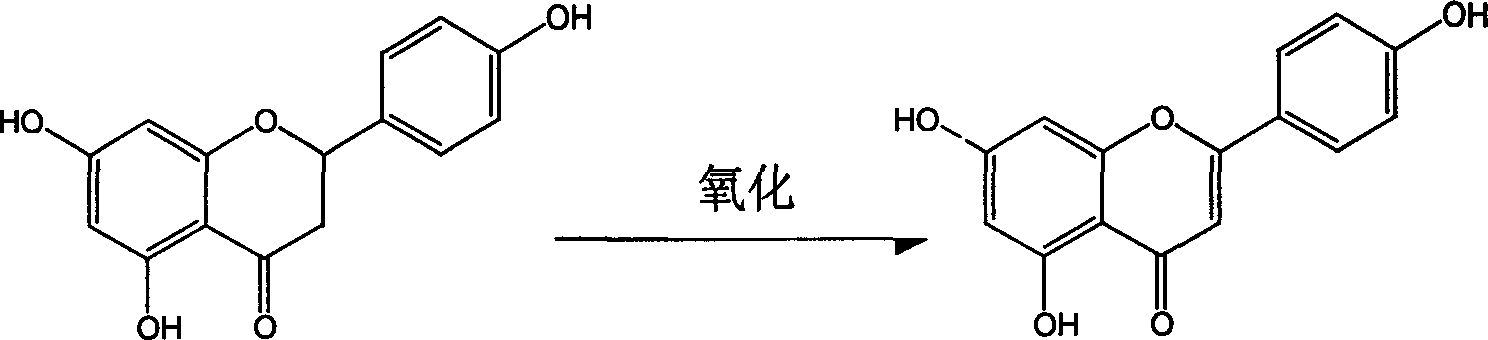

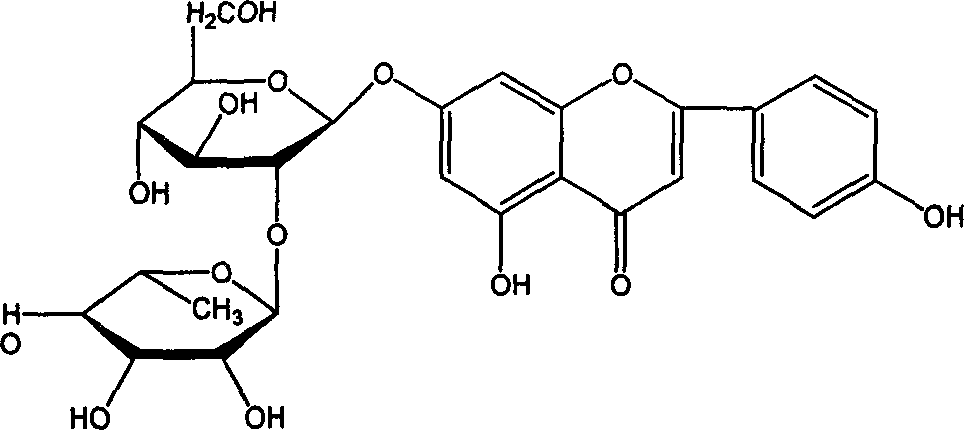

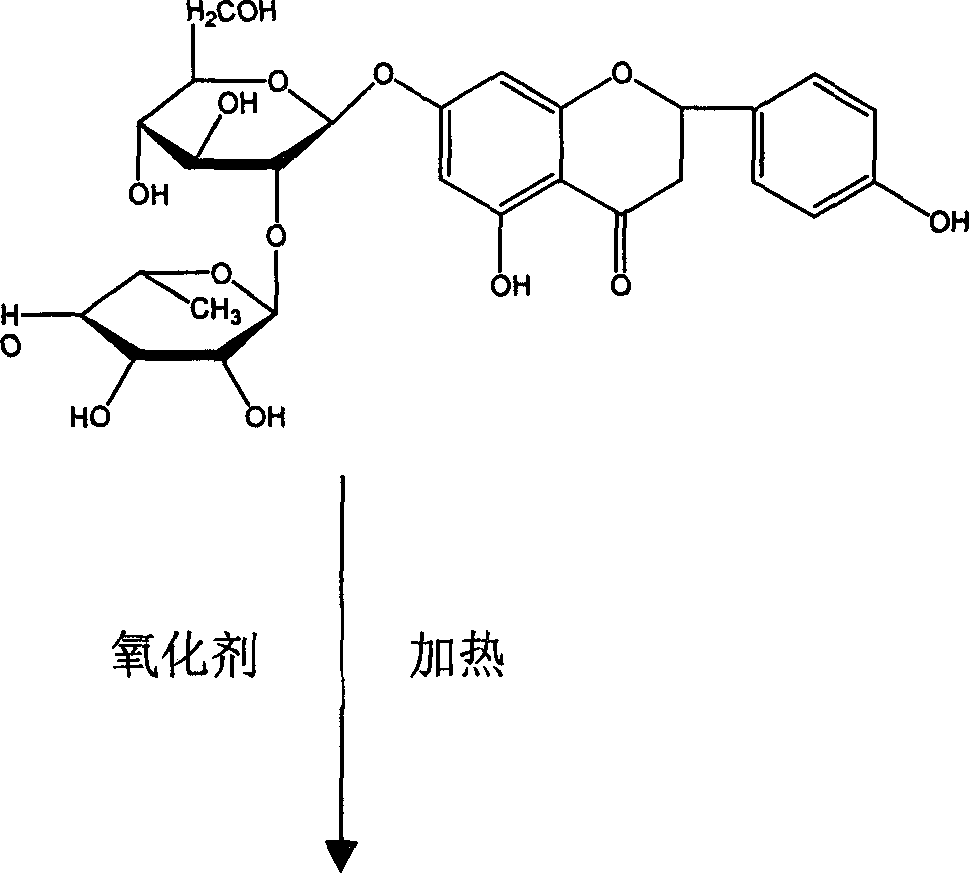

Process for semi-synthesizing of apiolin

The invention discloses a semi compounding method for apium celery element that uses natural extract as basic raw material. It uses pomelo peel element as raw material, 1, 4-dioxy cyclohexane as reaction solvent, taking oxidative dehydrogenation reaction with iodine to form raw apium celery element. Taking multi-steps recrystallizing, the refined apium celery element would be gained. The invention is easy to operate, stable reacting condition, easy to control. The yield would be 60-70% and the purity could be over 97%. And it is low cost, no harmful to the environment.

Owner:ZHEJIANG TIANCAO BIOTECHNOLOGY CO LTD

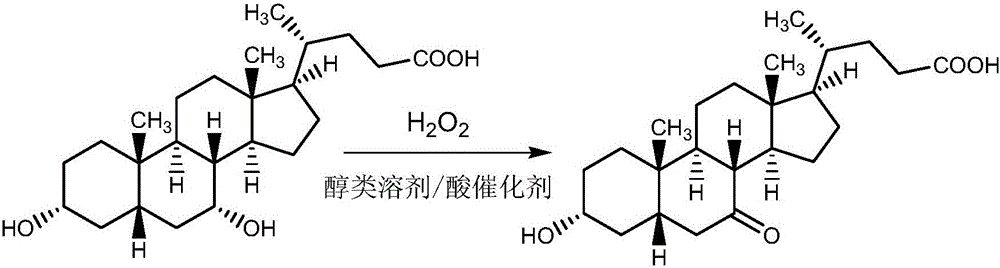

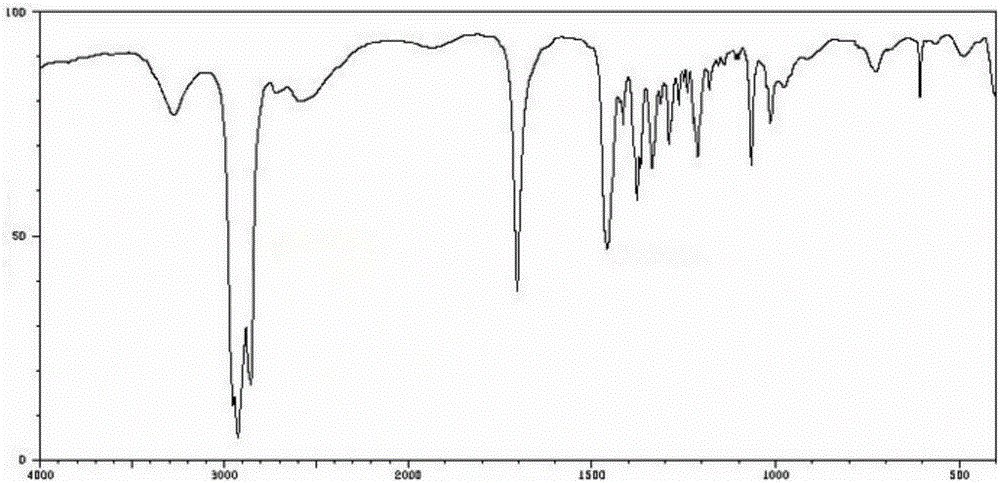

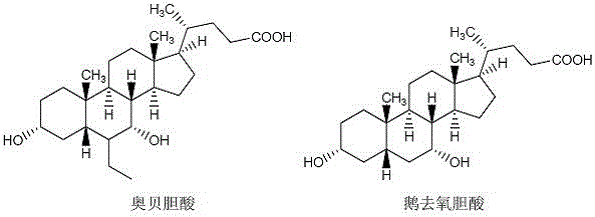

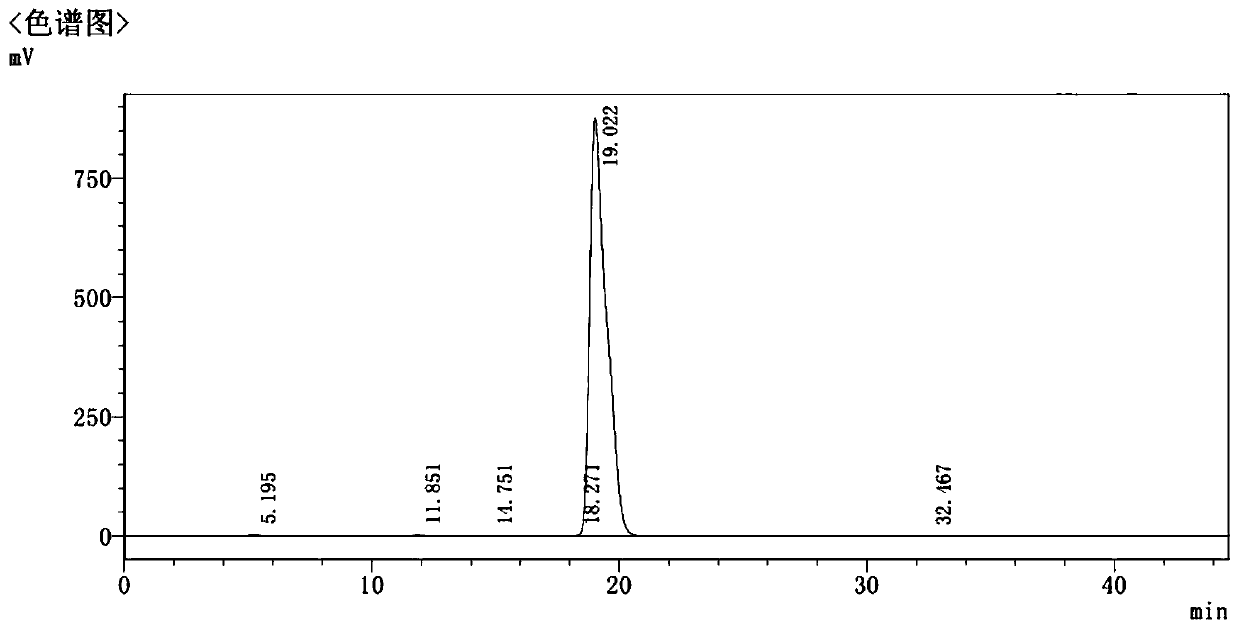

Preparation method of 3Alpha-hydrol-7-oxo-5Beta-cholanic acid

InactiveCN105669815AMild reaction conditionsSafe reaction conditionsSteroidsChenodeoxycholic acidOxygen

The invention discloses a preparation method of 3α-hydroxy-7-oxo-5β-cholanic acid. Specifically, the preparation method of the present invention uses hydrogen peroxide as an oxidizing agent to oxidize chenodeoxycholic acid with the participation of an acid catalyst to obtain 3α-hydroxy-7-oxo-5β-cholanic acid, wherein chenodeoxycholic acid The mass ratio between acid and hydrogen peroxide is 1:0.05~0.15. The preparation method of the invention has the characteristics of mild and safe reaction conditions, simple and controllable operation, low cost, high yield, low pollution, etc., and has broad development and application prospects.

Owner:SUZHOU JINGYE MEDICINE & CHEM

Method for preparing 3-hydroxy butyrate

InactiveCN109796326AReduce subsequent purification treatmentEasy to operateCarboxylic acid salt preparationChemical synthesisFiltration

The invention discloses a method for preparing 3-hydroxy butyrate, and relates, and relates to the technical field of chemical synthesis and comprises the following steps of: adding an aluminum-nickelalloy catalyst into ethyl acetoacetate, carrying out acyl hydrogenation reaction at the temperature of 40-100 DEG C under a normal pressure, and carrying out suction filtration after the reaction isfinished to obtain 3- hydroxyl butyrate ethyl; dissolving the 3-hydroxybutyrate ethyl in water, adding inorganic base for reaction, decolorizing with activated carbon after reaction, filtering, concentrating the filtrate, crystallizing, and drying to obtain the 3-hydroxy butyrate. The method has the advantages of short reaction steps, cheap and easily obtained raw materials, mild reaction conditions, no need of pressurization, simple and safe operation and low requirement on production equipment; the adopted aluminum-nickel alloy catalyst is simply and easily obtained, can be recycled and reused, the production cost can be better controlled, the prepared product has high purity, the yield is high and the cost advantage is obvious, and the method is suitable for industrial production.

Owner:宣城菁科生物科技有限公司 +1

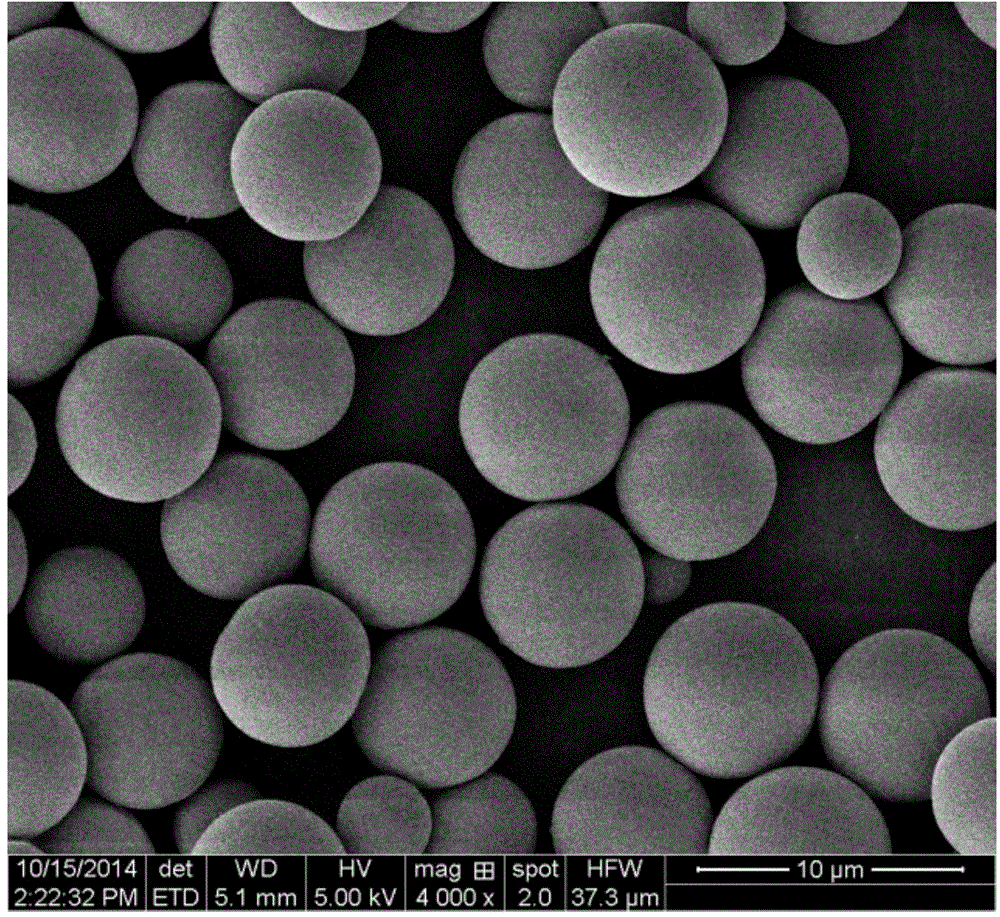

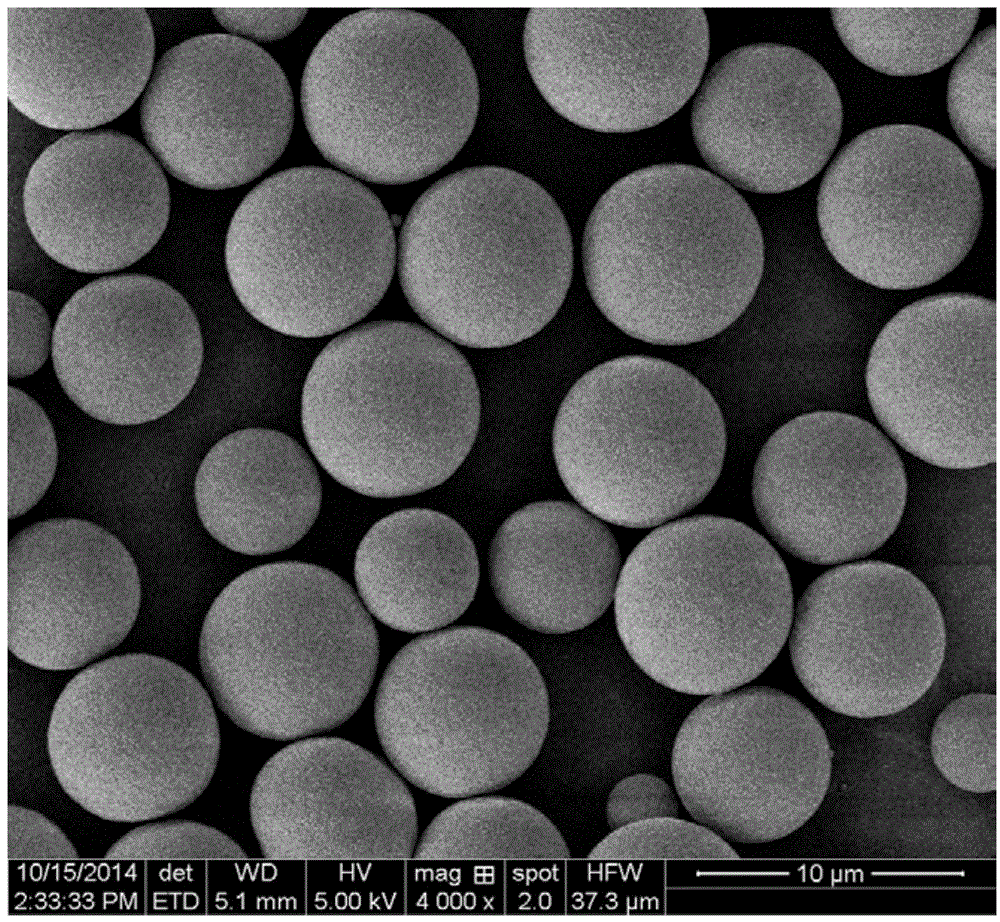

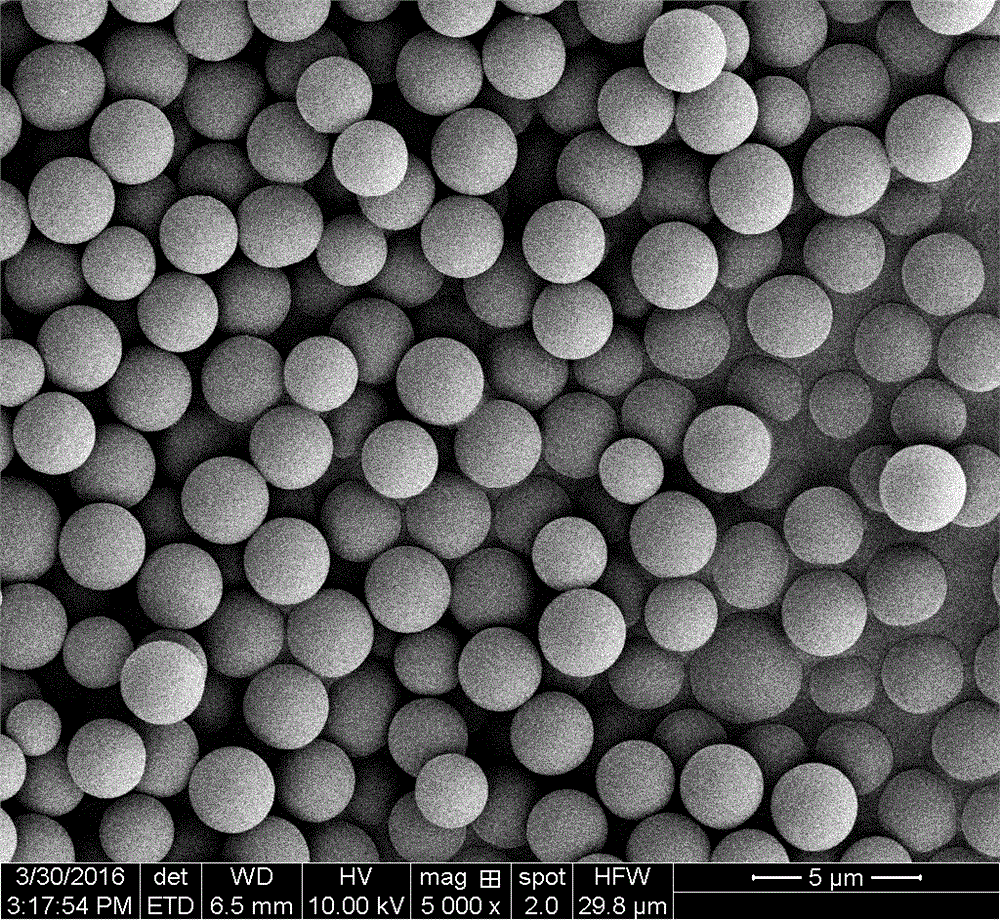

Super-hydrophobic monodisperse polymer microspheres and preparation method thereof

The invention relates to super-hydrophobic monodisperse polymer microspheres and a preparation method thereof. The method comprises the following steps: by adopting precipitation polymerization, adding lauryl metbacrylate, divinyl benzene and an initiator to a solvent, mixing evenly, putting the mixture into a stainless steel reaction kettle and sealing; controlling a reaction temperature to be 82-200 DEG C and the reaction time to be 1-12h; and carrying out washing and centrifugal precipitation on the obtained product by using a solvent, and drying to obtain the super-hydrophobic monodisperse polymer microspheres. The microspheres are simple in preparation process and short in elapsed time; the monomer input amount reaches 20%; the yield of the microspheres is higher than 90%; the raw materials are fluoride-free monomers; the microspheres are friendly to environment and low in price; and industrial production is easy to implement.

Owner:UNIV OF JINAN

Process for synthesizing lacquer leafide

ActiveCN1793157ALow costMild reaction conditionsSugar derivativesSugar derivatives preparationSolventChemistry

The invention relates to a compounding method for leaf sumac glycoside that uses natural extract as raw material. It uses naringin as raw material, 1, 4-dioxygen cyclohexane as reaction solvent, taking oxidative dehydrogenation reaction with iodine to gain raw leaf sumac glycoside. After multi-steps of recrystlizing, the refined leaf sumac glycoside would be gained. The invention is easy to operate, and is easy to separate and purifying. The yield could be 50-65%, and purity could be over 98%. It is low cost, and no pollution to environment.

Owner:浙江天草生物科技股份有限公司

Preparation method of formamide

ActiveCN103539689ALow costEliminate pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAir blowerDecarburization

The invention relates to a preparation method of formamide, belonging to the field of chemical material synthesis. The preparation method comprises the following steps of: ventilating carbon monoxide obtained by treating a tail gas into a reactor; reacting with liquid ammonia under a condition with pressure of 1 MPa-8 MPa under action of an alkaline catalyst, and distilling after the reaction is finished to obtain formamide. The tail gas treatment comprises the following steps of: pressurizing the yellow phosphorus tail gas to 45 KPa-55 KPa through an air blower, removing acid gas in the tail gas by alkali liquor after water-washing, and obtaining carbon monoxide after desulfurization, compression as well as purification treatment; compressing the calcium carbide tail gas to 2.0 MPa-2.1 MPa after removing dust and cooling, thus obtaining carbon monoxide through deoxidation, decarburization and desulfuration. According to the preparation method of the formamide disclosed by the invention, CO in the tail gas is sufficiently utilized, and one-step method production is adopted, so that CO and liquid ammonia can react under low pressure; reaction condition is mild and safe, so that not only is material cost as well as requirements on equipment lowered, but also product yield and product quality are improved.

Owner:LINHAI LIANSHENG CHEM

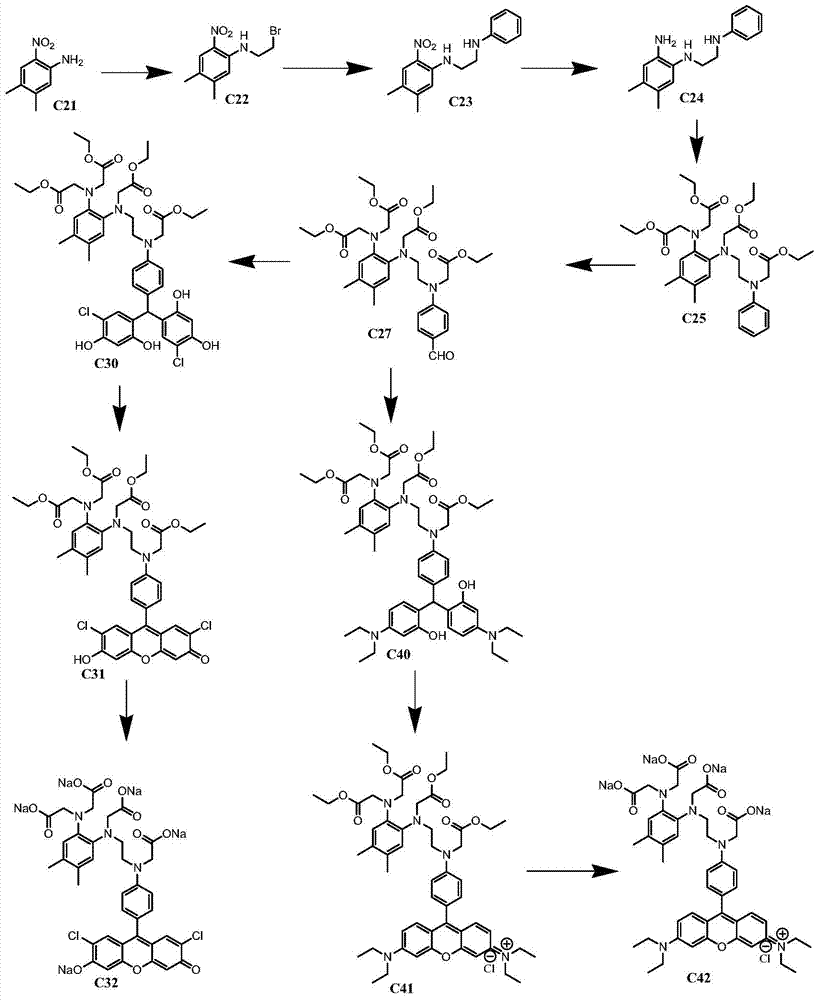

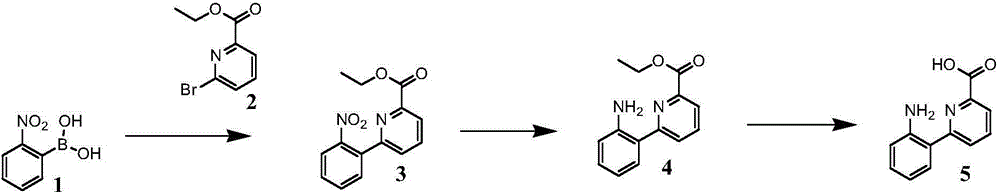

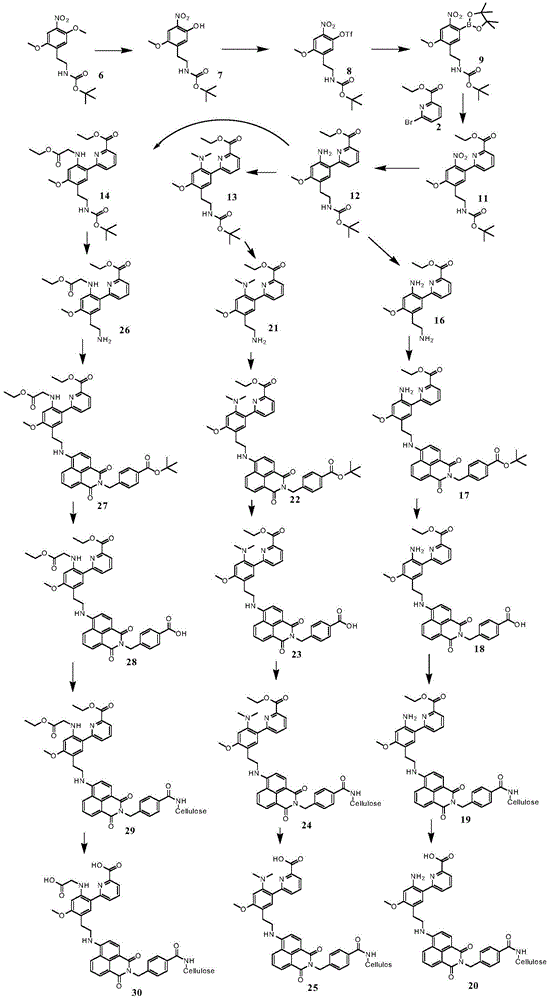

Organic compounds used for detecting metal ion contents in solutions and applications thereof

ActiveCN104829593AHigh selectivityImprove efficiencyOrganic chemistryMaterial analysis by observing effect on chemical indicatorIon contentFormic acid

The invention relates to organic compounds used for detecting metal ion contents in solutions. The organic compounds can be used for biomedicine, environment monitoring, and the like. By introduction of color developing groups or fluorophores into ortho positions or the para position of 2-substituted phenyl of 2-(2'-substituted phenyl)-pyridine-6-carboxylic acid, and by utilization of the intramolecular charge transfer (ICT) principle or the photoinduced electron transfer (PET) principle, color developing or fluorescence intensity changes with changes of ion contents in solutions, so that contents of the metal ions in the solutions can be calculated according to ultraviolet absorption values or the fluorescence intensity. The organic compounds can be fixed onto surfaces of polymers and prepared into reversible metal ion sensors that can be used for a plurality of times, thus achieving real-time monitoring of contents of trace metal ions, making the whole analysis process automatic and largely increasing the efficiency.

Owner:FORLIGHTS DETECTION TECH LLC SUZHOU

Amphipathic tadpole-shaped block copolymer and preparation method thereof

InactiveCN106750334AEasy to purifyEasy to implementPharmaceutical non-active ingredientsEmulsion deliveryPolyesterBiocompatibility Testing

The invention discloses an amphipathic tadpole-shaped block copolymer and a preparation method thereof, and belongs to the technical field of the preparation of high molecular materials. Aliphatic polyester with alpha,omega-double terminal thiol and poly(N-vinyl caprolactam) with terminal alkynyl are first prepared, and then, through a thiol-yne click reaction between the aliphatic polyester and the poly(N-vinyl caprolactam), an amphipathic single tadpole-shaped block copolymer I is made; four-arm star-shaped polyester with terminal thiol and the poly(N-vinyl caprolactam) with the terminal alkynyl are prepared, and then, through a thiol-yne click reaction between the four-arm star-shaped polyester and the poly(N-vinyl caprolactam), an amphipathic double tadpole-shaped block copolymer II is made. A copper-catalysis-free thiol-yne reaction is applied to the preparation of a tadpole-shaped block copolymer; the pollution problem of a product, which is caused by the use of a copper catalyst, is solved; an obtained product is pure and is easily purified; a reaction condition is easily realized and is safe; the reaction efficiency is high; the amphipathy, the temperature responsiveness, biodegradability and the biocompatibility are integrated on the product; the amphipathic tadpole-shaped block copolymer has a wide application prospect in the field of biological medicines.

Owner:YUNNAN NORMAL UNIV

Preparation method for simvastatin by adopting enzymatic synthesis

ActiveCN103725726AFew reaction stepsReduce the number and content of impuritiesFermentationChemistryAcylation

The invention discloses a preparation method for simvastatin by adopting enzymatic synthesis. The method comprises the following steps: carrying out basic hydrolysis on lovastatin so as to obtain a alkaline hydrolysis product; carrying out enzyme hydrolysis on the prepared alkaline hydrolysis product under the existence of immobilized hydrolase so as to obtain enzymic hydrolysate and 2,2-dimethyl acyl-S-methyl propionate, wherein the immobilized hydrolase is a composite which is formed by immobilizing lovastatin hydrolase on porous resin; carrying out acylation reaction on the prepared enzymic hydrolysate and 2,2-dimethyl acyl-S-methyl propionate under the existence of immobilized acylase so as to obtain acylate, wherein the immobilized acylase is a composite which is formed by immobilizing lovastatin acylation enzyme on the porous resin; and carrying out cyclization on the prepared acylate so as to obtain the simvastatin. By adopting the the method disclosed by the invention, the total molar yield of the simvastatin achieves 80%, the content of total impurities in the simvastatin is smaller than or equal to 0.5%; the content of a single impurity in the simvastatin is smaller than or equal to 0.2%; the content of the lovastatin in the simvastatin is smaller than or equal to 0.2%. The technology is significantly better than an existing production technology of the simvastatin.

Owner:福安药业集团烟台只楚药业有限公司

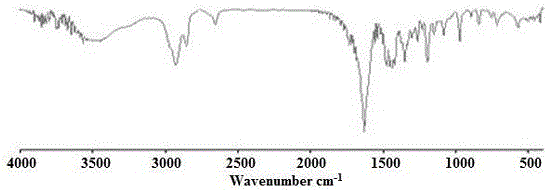

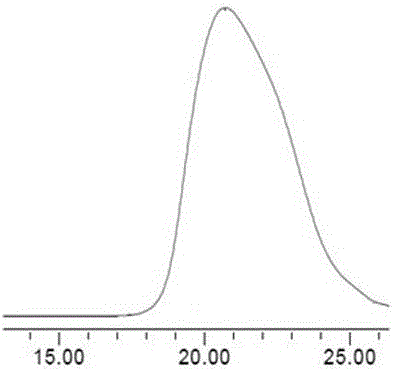

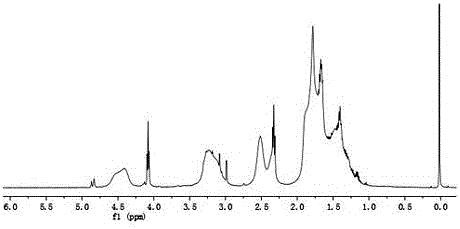

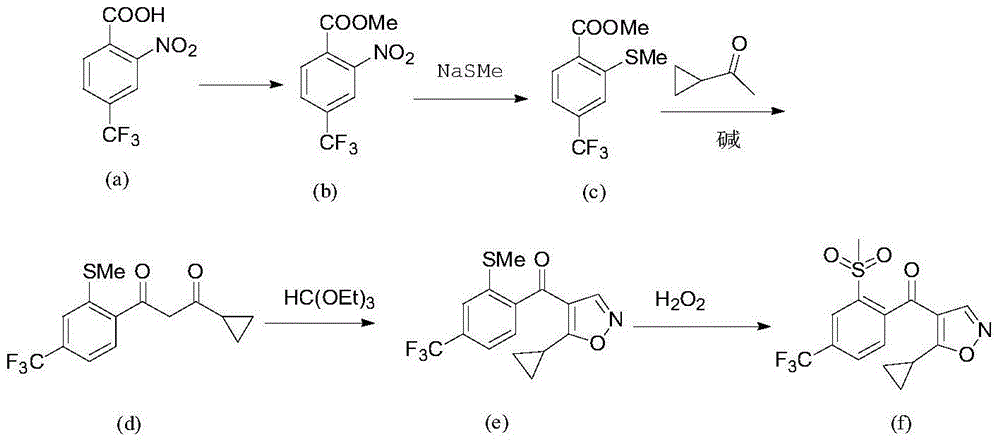

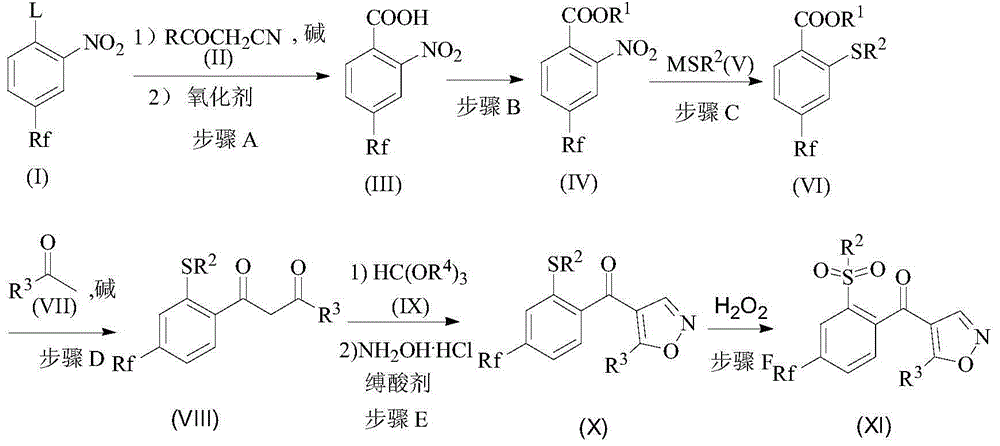

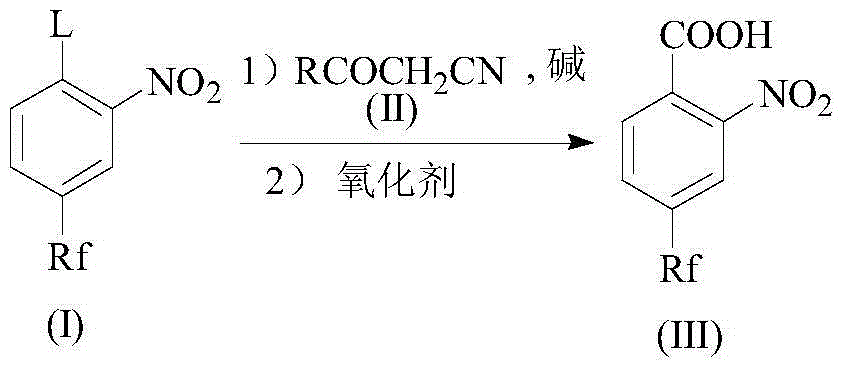

Preparation method of isoxazole compound and isoxazole compound intermediate

ActiveCN105712944AMild reaction conditionsSafe reaction conditionsOrganic compound preparationSulfide preparationHydroxylamine HydrochlorideMethyl Ketone

The present invention discloses a preparation method of an isoxazole compound and an isoxazole compound intermediate. According to the method, an intermediate acid (III) is prepared by substitution reaction of a compound (I) as a raw material and a compound (II) in the presence of a base and then oxidation reaction; an intermediate (IV) is prepared by methyl esterification of the intermediate acid (III); an intermediate (VI) is prepared by thionation of the intermediate (IV); an intermediate (VIII) is prepared by condensation of the intermediate (VI) and cyclopropyl methyl ketone under basic conditions; an intermediate (X) is prepared by ene-etherification reaction of the intermediate (VIII) and ortho-formate and then cyclization with hydroxylamine hydrochloride; and the isoxazole compound (XI) is prepared by oxidation of methylthio groups of the intermediate (X) by hydrogen peroxide. Raw materials are readily available, yield is high, purity is high, three-waste is low, cost is low, and the preparation method has good industrial value.

Owner:ZHEJIANG ZHUJI UNITED CHEM

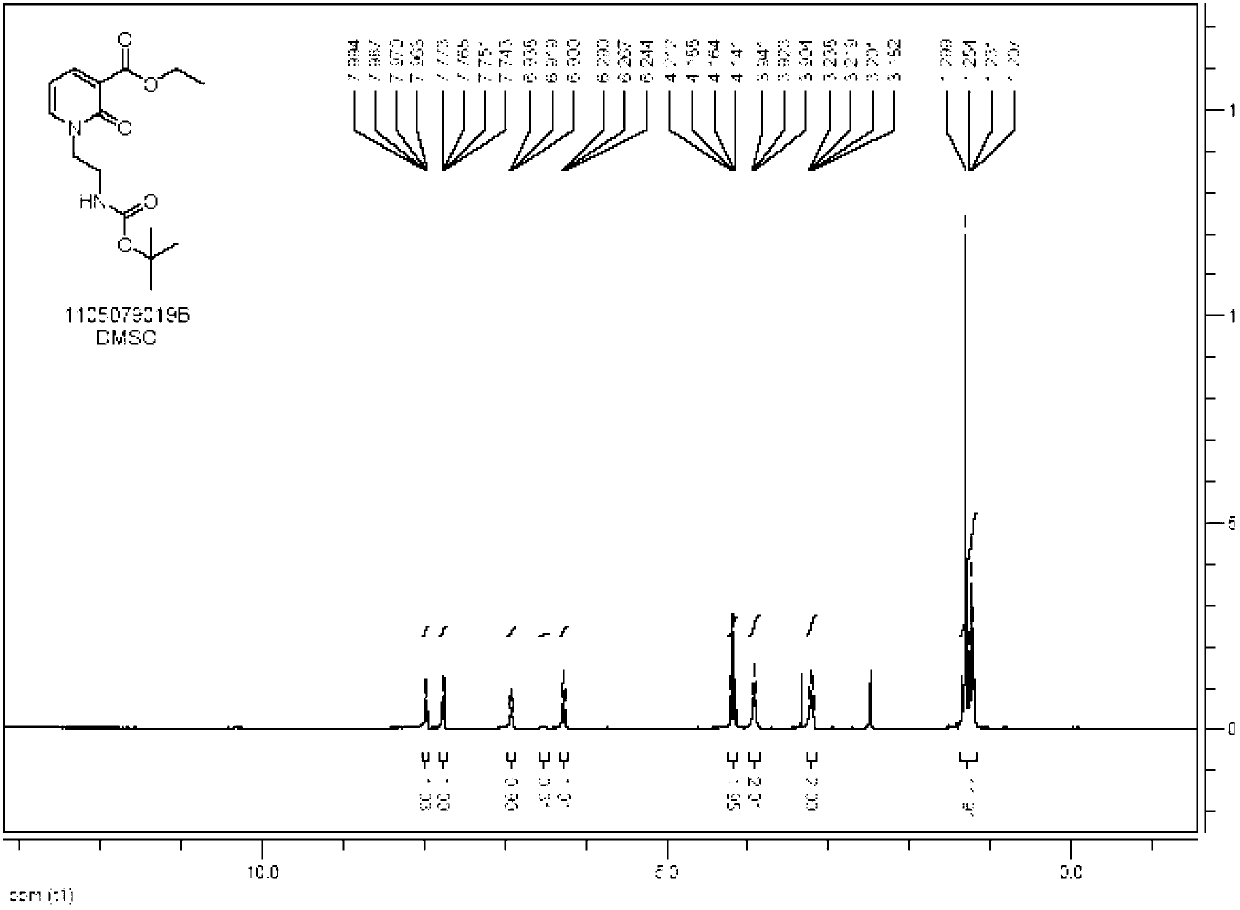

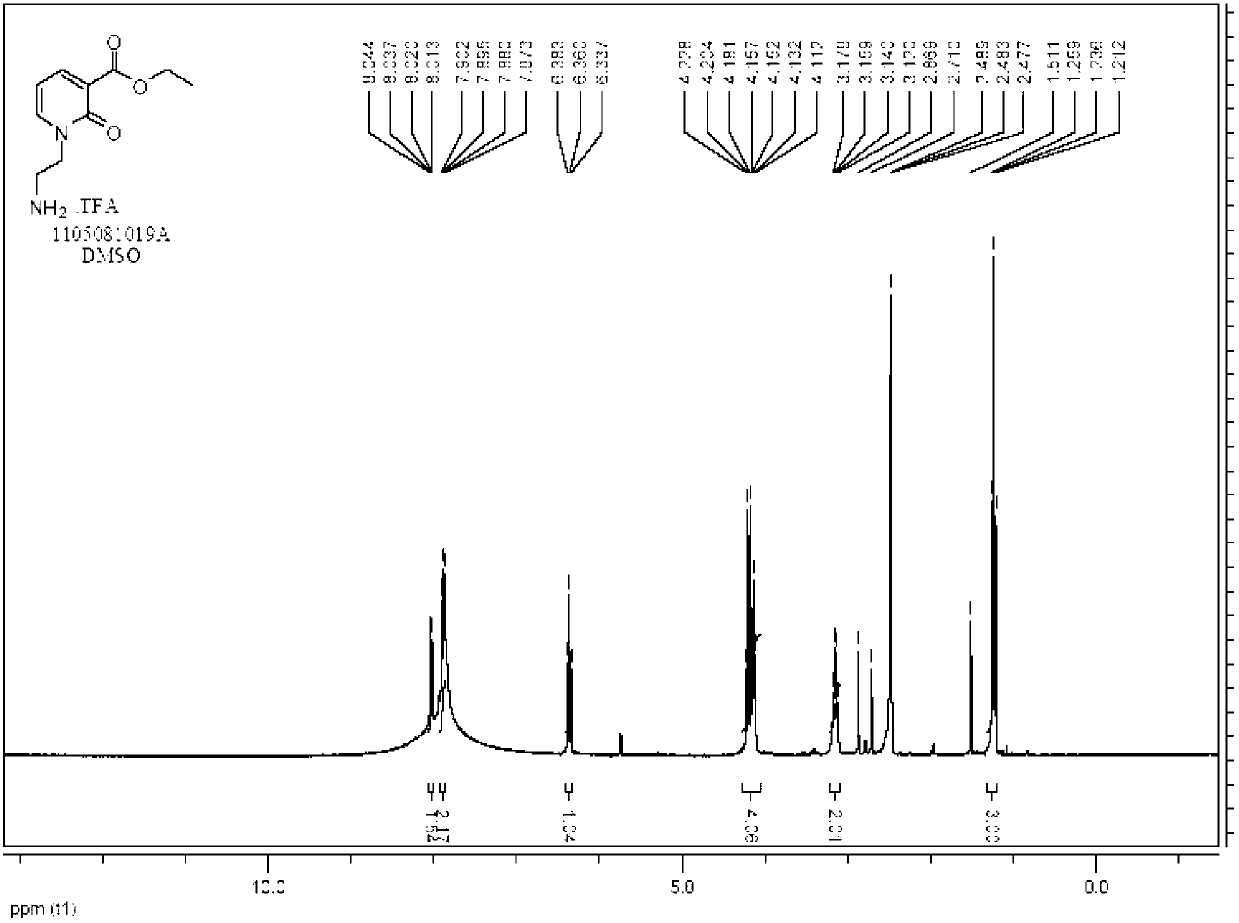

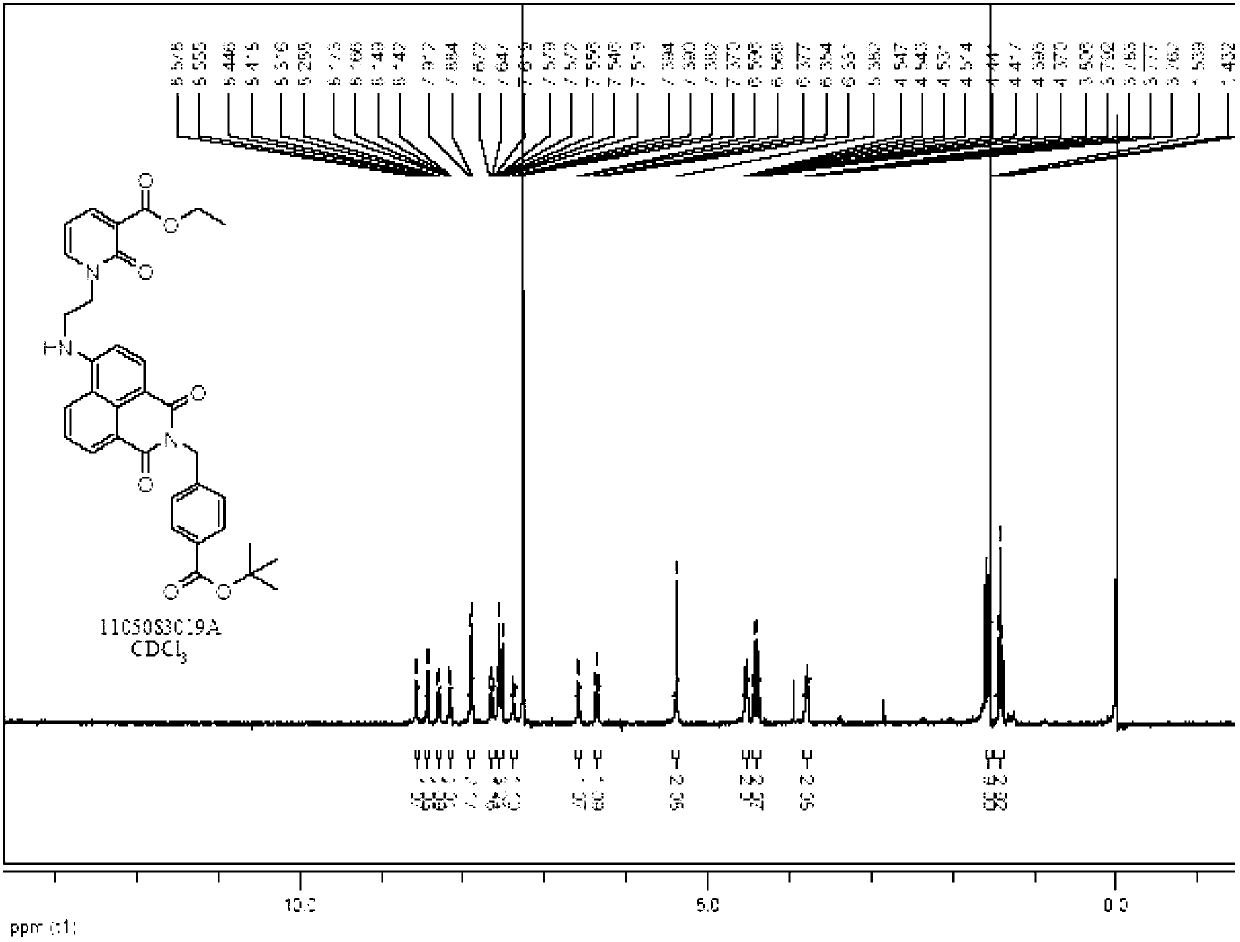

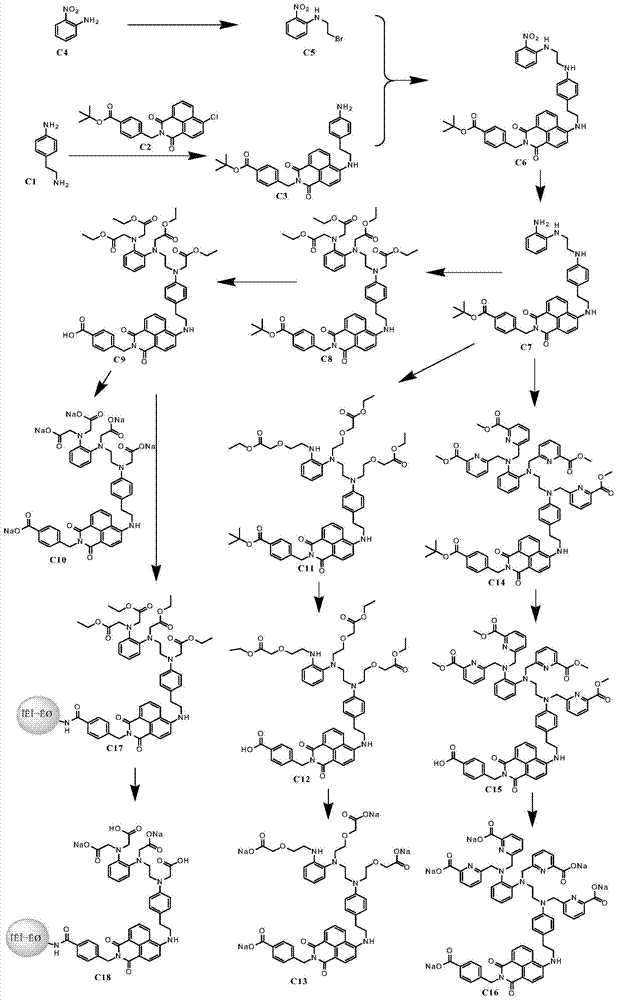

Preparation method of octahydrocyclopentane[C]pyrrole

The invention provides a preparation method of octahydrocyclopentane[C]pyrrole. The preparation method is characterized in that under the promotion action of Lewis acid, by one step, a cyclopentylimide compound (II) is reduced into the octahydrocyclopentane[C]pyrrole (I) by a boron reducing agent.

Owner:ZUNYI MEDICAL UNIVERSITY

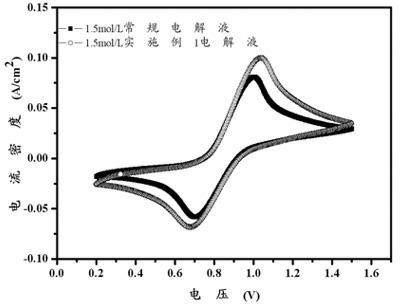

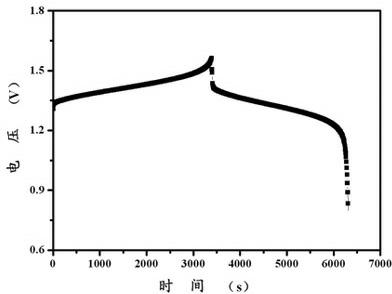

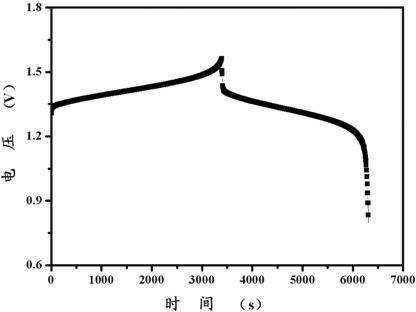

Preparation method of ion vanadium redox battery electrolyte

The invention discloses a preparation method of ion vanadium redox battery electrolyte. The method comprises the following steps: 1. mixing vanadium pentoxide powder and sulfuric acid solution, heating and stirring until the temperature is 50-250DEG C to obtain turbid liquid of the mixed the vanadium pentoxide powder and the sulfuric acid water solution; 2. preparing organic reductant water solution, wherein the organic reductant comprises any one of C1-4 water soluble alcohols and water soluble aldehydes; 3. adding the sulfuric acid water solution into the turbid liquid, sealing the outlet of a reaction container, heating, stirring, and controlling temperature to be between 50 and 250DEG C; after reaction ends, opening the outlet of the container, and continuously heating for 5-180 minutes; and after solution is cooled to room temperature, carrying out constant volume to obtain the vanadium redox battery electrolyte. The method has the advantages of low raw material cost, wide resource, simple and easily-operated technology, moderate and safe reaction condition and short reaction period and is suitable for large-batch production, and the vanadium redox battery electrolyte with low cost and high performance is prepared, and the vanadium redox battery electrolyte shows favorable electrochemistry performance in the charging and discharging experiment.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Preparation method of 2,2-difluoroethylamine

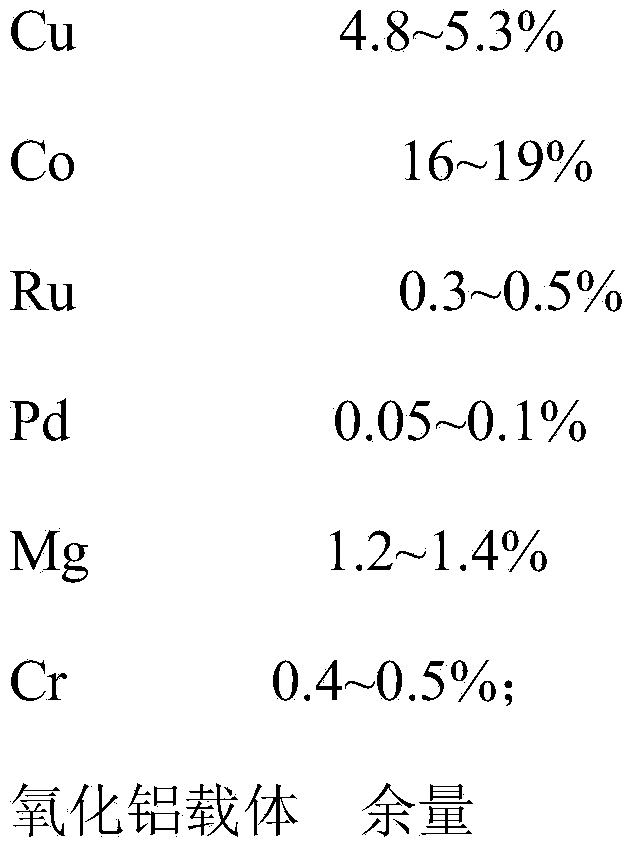

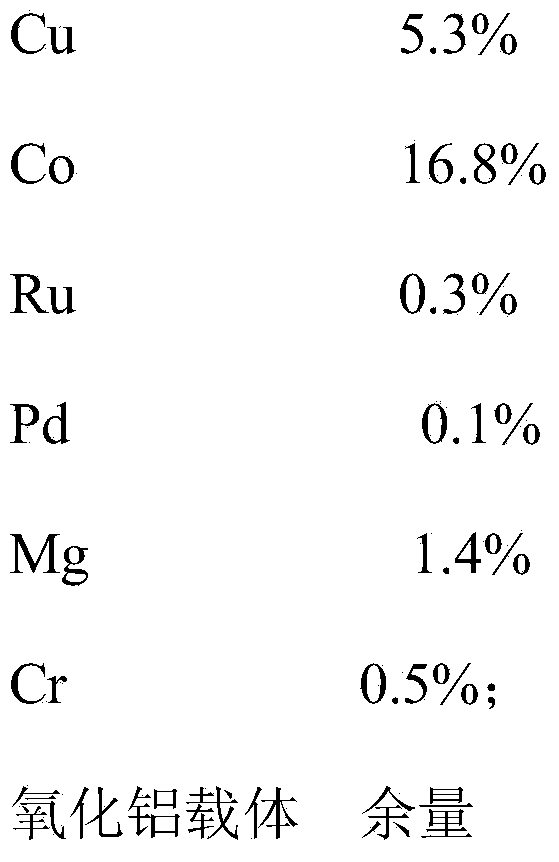

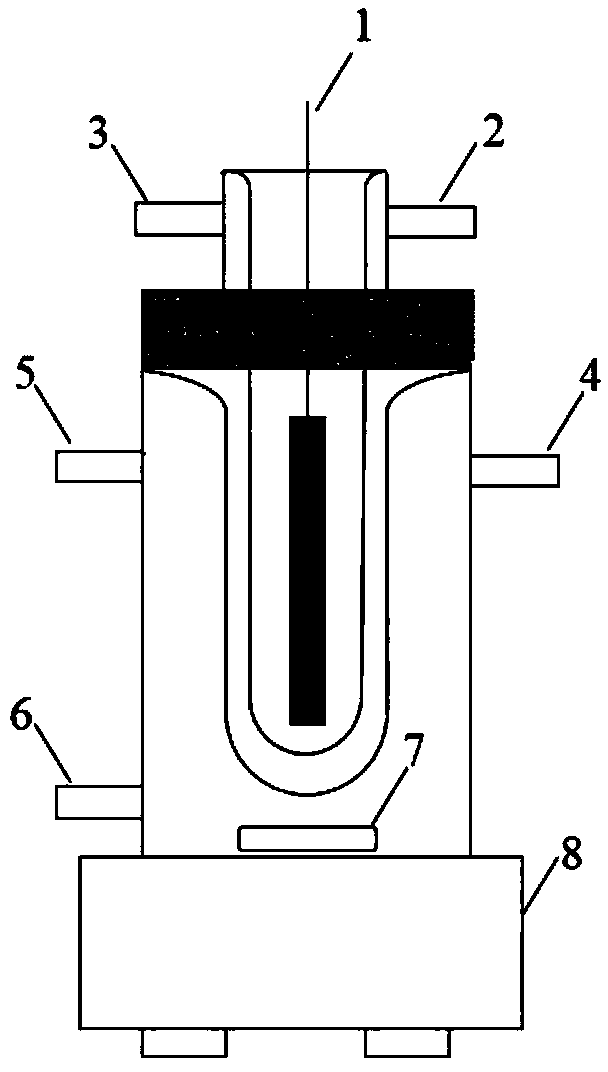

ActiveCN104030928AMild reaction conditionsSafe reaction conditionsOrganic compound preparationAmino compound preparationHydrogen atmosphereFixed bed

The invention discloses a preparation method of a 2,2-difluoroethylamine. The preparation method comprises the step of reacting 2,2-difluoroethanol with ammonia in hydrogen atmosphere in the presence of a catalyst, thereby obtaining the 2,2-difluoroethylamine. The method has the advantages that the reaction is carried out in a tubular fixed bed reactor at a lower pressure, the reaction conditions are mild and safe, the conversion rate and the yield of the reaction both are relatively high, few by-products are generated, continuous production can be realized easily, and the catalyst can be used for a long time and also can be regenerated.

Owner:HUBEI HAIZHIJIE CHEM

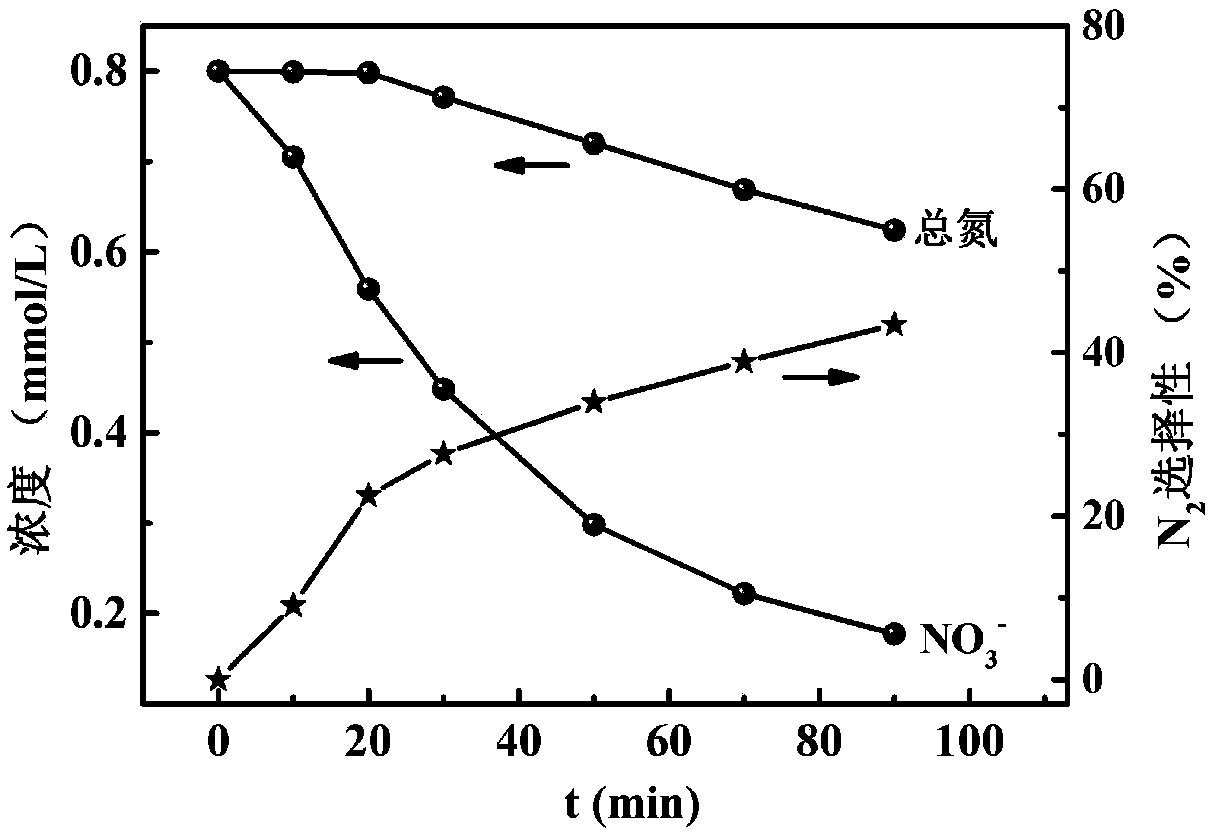

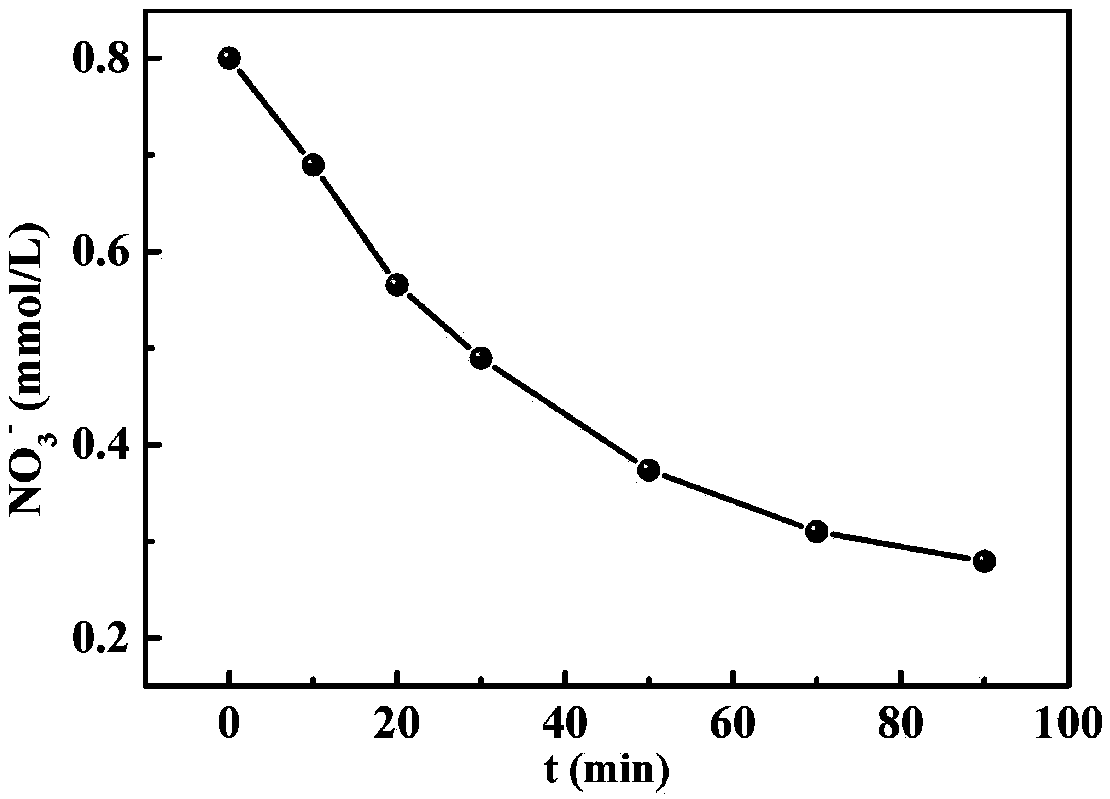

Nitride catalyst for efficient photocatalytic reduction of nitrate in water and water treatment method thereof

ActiveCN109622019AReduce concentrationGood removal effectPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsQuantum dot

The invention belongs to the field of nitrate reduction in water, and particularly relates to a nitride catalyst for efficient photocatalytic reduction of nitrate in water and a water treatment methodthereof. The method comprises the following steps of preparing the nitride catalyst for the photocatalytic reduction of the nitrate in the water by adopting different methods; putting the prepared catalyst into nitrate-containing industrial wastewater to be treated, and conducting photocatalytic reduction of the nitrate in the water under ultraviolet light irradiation. The catalyst for the photocatalytic reduction of the nitrate in the water is a nitride type, and includes transition type nitride, covalent type nitride, nitride of different morphologies, defect nitride, nitride loaded with ametal and a metal quantum dot, a composite of nitride and a metal oxide and nitride loaded on different carriers. The method has the advantages of simple equipment, easy control, mild reaction conditions and the like; the prepared nitride catalyst can efficiently and stably remove the nitrate in sewage, and have good stability.

Owner:HARBIN ENG UNIV

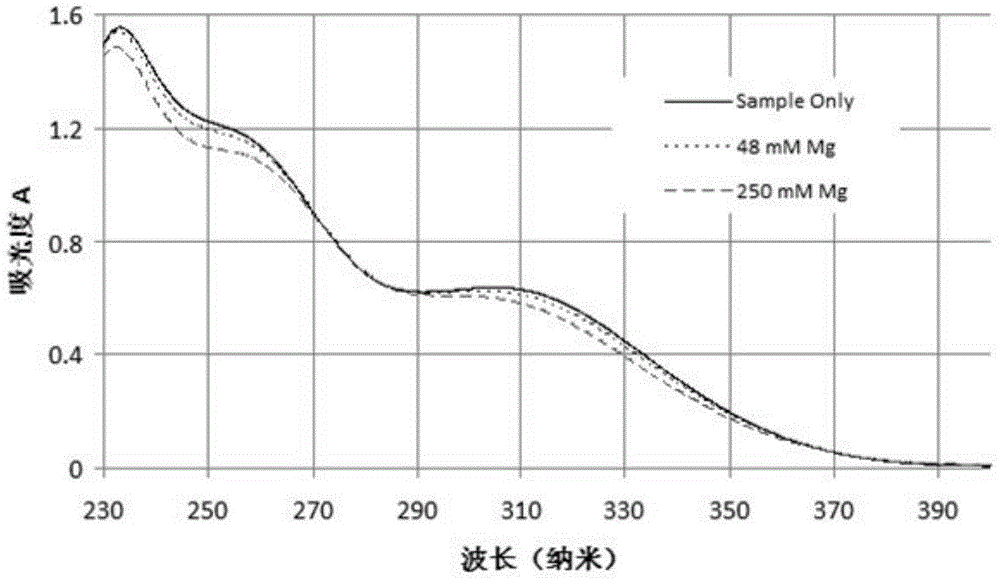

Compounds for detecting content of micro magnesium ions and application thereof

InactiveCN102702170AHigh fluorescence efficiencyNarrow detection rangeOrganic chemistryFluorescence/phosphorescenceIon contentFormic acid

The invention relates to compounds for detecting the content of micro magnesium ions as well as a preparation method and an application. The compounds for detecting the content of the micro magnesium ions adopt the following structural general formula, wherein R1, R2 and R3 are arbitrary groups; and Y is functional groups with fluorescence developing. The compounds for detecting the content of the micro magnesium ions leads chromophore in 2-hydroxypyridine-3-formic acid, so that the fluorescence efficiency of molecules is improved, fluorescence response is more obvious when the detection range is narrowed down, and the detection sensitivity is improved at the same time. When the content of the magnesium ions changes, the fluorescence intensity of the magnesium ions is changed along with the content, so that the content of the magnesium ions in solution can be calculated according to the fluorescence intensity of the magnesium ions, the process analysis of the content of the micro magnesium ions can be achieved, and the efficiency, the sensitivity and the repeatability can be improved greatly; and in addition, the compounds can be used for detecting the content of the magnesium ions in new technical researches in various fields, the application range of the compounds can be enlarged greatly, and the compounds are convenient for people to use.

Owner:TIANJIN HEOWNS BIOCHEM TECH

Method for preparing fluorine-containing nonionic surfactant

ActiveCN106832256AMild reaction conditionsProcess is easy to controlTransportation and packagingMixingIodideNonionic surfactant

The invention relates to the technical field of fluorine-containing nonionic surfactants and in particular relates to a method for preparing a fluorine-containing nonionic surfactant. The preparation method comprises the following steps: reacting perfluoroalkyl iodides with polyoxyethylene ethers containing vinyl or allyl, removing light components from the obtained products, thereby obtaining the nonionic surfactant. The preparation method disclosed by the invention is readily available in raw materials, mild and safe in reaction conditions, easily controllable in process and high in yield, and the yield reaches 93% or higher.

Owner:济南齐氟新材料技术有限公司

Preparation method for zinc arsenide

ActiveCN104944468AQuick responseControl of arsenic vapor pressureArsenic compoundsRoom temperatureIngot

The invention provides a preparation method for zinc arsenide. The preparation method comprises the following steps: weighing high-purity arsenic particles and high-purity zinc ingots with corresponding weights according to the molar proportion of arsenic and zinc in zinc arsenide, uniformly paving the weighed high-purity arsenic particles in a crucible boat, then covering the high-purity zinc ingots on the high-purity arsenic particles, and then horizontally placing the crucible boat in a plain-end quartz tube; vacuumizing the plain-end quartz tube filled with the high-purity arsenic particles and the high-purity zinc ingots by a vacuum unit, and then carrying out high-temperature sealing for the plain-end quartz tube by virtue of oxyhydrogen flame; placing the sealed plain-end quartz tube in a horizontal synthesis furnace, heating and insulating for a period of time, and then stopping heating and naturally cooling the horizontal synthesis furnace; after the horizontal synthesis furnace is cooled to a normal temperature, taking out the horizontal synthesis furnace and knocking open the plain-end quartz tube to obtain a high-purity zinc arsenide crystal. The preparation method provided by the invention increases the reaction speed of the synthesis process, can well control the arsenic vapour pressure during the synthesis process, and enables the reaction to be complete and adequate.

Owner:FIRST RARE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of octahydrocyclopentane[C]pyrrole Preparation method of octahydrocyclopentane[C]pyrrole](https://images-eureka.patsnap.com/patent_img/80ca25cc-67e8-4f57-88d6-7b23d5da6e30/BDA0000425297380000011.PNG)

![Preparation method of octahydrocyclopentane[C]pyrrole Preparation method of octahydrocyclopentane[C]pyrrole](https://images-eureka.patsnap.com/patent_img/80ca25cc-67e8-4f57-88d6-7b23d5da6e30/BDA0000425297380000012.PNG)

![Preparation method of octahydrocyclopentane[C]pyrrole Preparation method of octahydrocyclopentane[C]pyrrole](https://images-eureka.patsnap.com/patent_img/80ca25cc-67e8-4f57-88d6-7b23d5da6e30/BDA0000425297380000013.PNG)