Preparation method of modified gelatin

A gelatin modification technology, which is applied in the field of preparation of modified gelatin, can solve the problem of limited number of side chain amino groups or carboxyl groups, and achieve the effects of increasing swelling performance, good application prospects, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

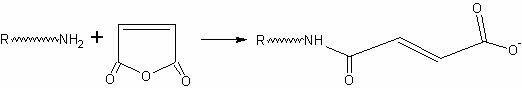

Method used

Image

Examples

Embodiment 1

[0032] Tetrahydrofuran solvent 1L, gelatin particles (300g), gelatin grinding to make the particle size finer to 80 mesh, so as to meet the conditions of solid-liquid phase reaction. Dissolve 3% (30g) succinic anhydride in tetrahydrofuran solvent, suspend and swell the ground gelatin particles in the mixed liquid phase, add 0.01% (0.1g) nicotinamide as catalyst, 0.01% (0.1g) poly Ethylene glycol is used as a cocatalyst, and the reaction temperature is controlled at 50°C. The reaction is carried out in a colloid mill, and the reaction is ground for 4 hours to obtain modified gelatin. After the reaction, most of the tetrahydrofuran solvent was removed by filtration. For a small amount of residual solvent, due to the low boiling point of tetrahydrofuran, the residual solvent was completely removed by vacuuming. The degree of modification of the gelatin is measured by a formaldehyde titration method, and the modified gelatin with a modification degree greater than 90% and no solve...

Embodiment 2

[0034]Tetrahydrofuran solvent 1L, gelatin particles (300g), gelatin grinding to make the particle size finer to 80 mesh, so as to meet the conditions of solid-liquid phase reaction. Maleic anhydride 3% (30g) was dissolved in tetrahydrofuran solvent, the ground gelatin particles were suspended and swelled in the mixed liquid phase, 0.01% (0.1g) nicotinamide was added as a catalyst, 0.01% (0.1g) poly Ethylene glycol is used as a cocatalyst, and the reaction temperature is controlled at 50°C. The reaction is carried out in a colloid mill, and the reaction is ground for 4 hours to obtain modified gelatin. After the reaction, most of the tetrahydrofuran solvent was removed by filtration. For a small amount of residual solvent, due to the low boiling point of tetrahydrofuran, the residual solvent was completely removed by vacuuming. The degree of modification of the gelatin is measured by a formaldehyde titration method, and the modified gelatin with a modification degree greater th...

Embodiment 3

[0036] Tetrahydrofuran solvent 1L, gelatin particles (300g), gelatin grinding to make the particle size finer to 80 mesh, so as to meet the conditions of solid-liquid phase reaction. Acetic anhydride 4% (40ml) was dissolved in tetrahydrofuran solvent, the ground gelatin particles were suspended and swelled in the mixed liquid phase, 0.01% (0.1g) nicotinic acid was added as catalyst, 0.01% (0.1g) polyethylene Diol is used as a cocatalyst, the reaction temperature is controlled at 60°C, the reaction is carried out in a colloid mill, and the reaction is ground for 5 hours to obtain modified gelatin. After the reaction, most of the tetrahydrofuran solvent was removed by filtration. For a small amount of residual solvent, due to the low boiling point of tetrahydrofuran, the residual solvent was completely removed by vacuuming. The degree of modification of the gelatin is measured by a formaldehyde titration method, and the modified gelatin with a modification degree greater than 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com