Patents

Literature

60results about How to "Both hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet curing anti-drag paint in steel pipes

ActiveCN102079937AGood adhesionGood mechanical properties and chemical resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPrepolymerSteel quality

The invention relates to an ultraviolet curing anti-drag paint in steel pipes. Epoxy acrylate and polyester acrylate are combinedly used as prepolymers, and phosphate-modified acrylate resin is used as an adhesion promotor, thereby greatly increasing the adhesion; a mixture of two or three of tripropylene glycol diacrylate, isobornyl acrylate and ethoxylated trimethylolpropane triacrylate is selected as an active monomer, and multiple functional group monomers are selectively added for compounding, thereby simultaneously satisfying curing speed, hardness, adhesion, flexibility and other requirements; multiple initiator compounding systems are adopted so as to simultaneously implement curing on the surface layer and deep layer; the paint provided by the invention has favorable mechanical properties and chemical resistance on a steel substrate; after coating, the surface is very smooth, has favorable anti-drag effect, can effectively enhance the salt fog resistance and corrosion resistance of the coating and the transmission efficiency of the pipeline, and can be widely used in anti-drag corrosion prevention in transmission pipelines in the fields of oil transmission, gas transmission, water supply and drainage, and the like.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

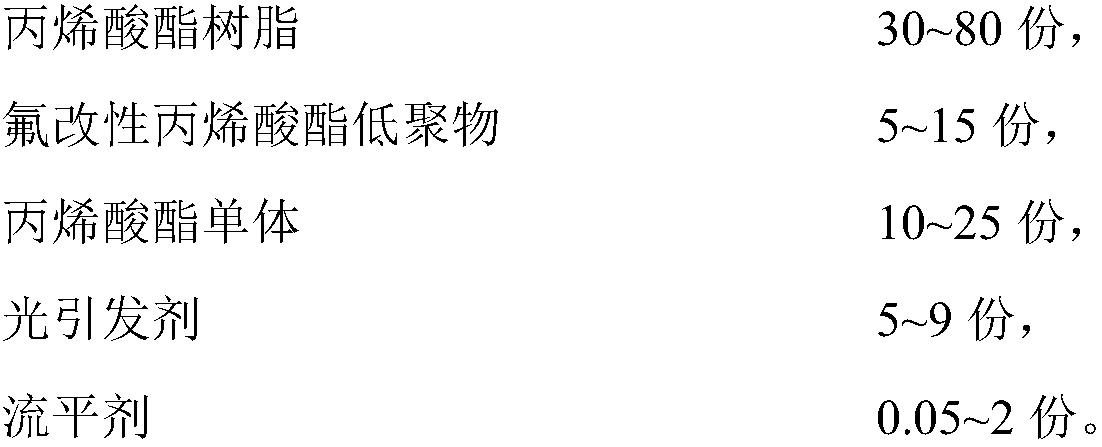

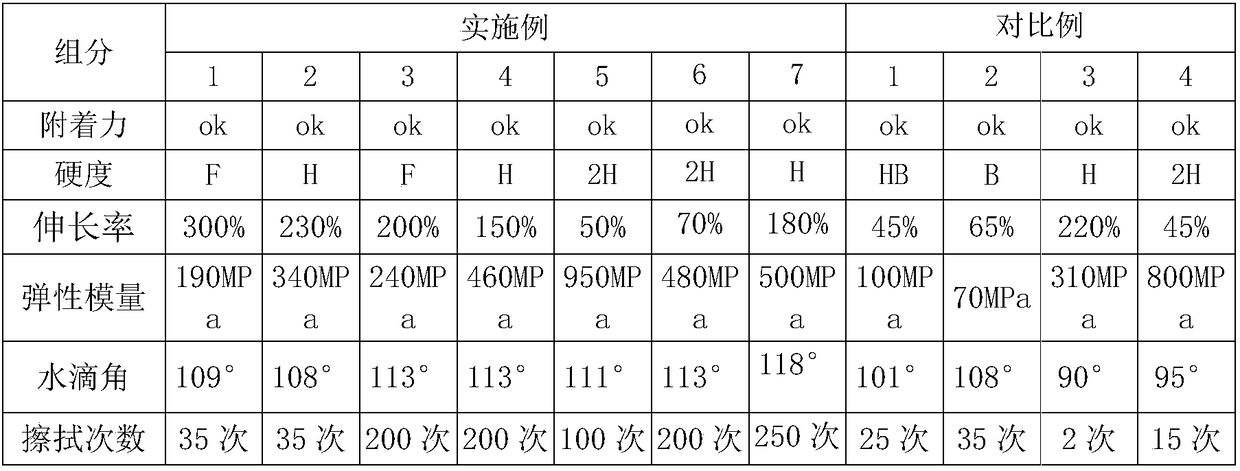

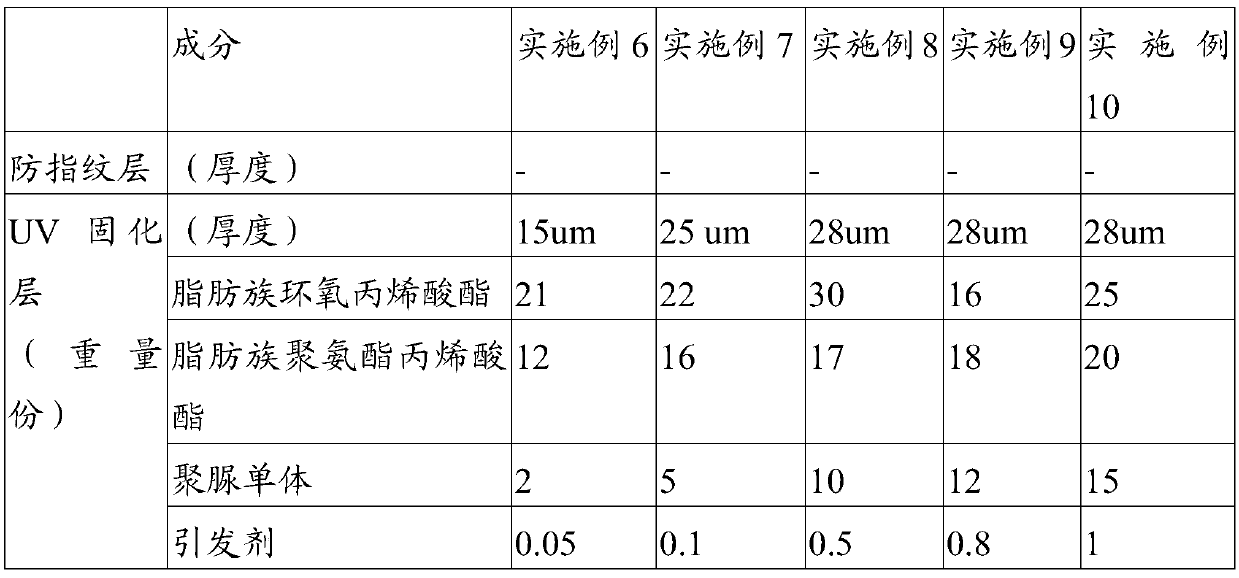

Flexible and stain-resistant ultraviolet curable coating composition and preparation method thereof

InactiveCN108264838AHas hardnessWith highlightsAntifouling/underwater paintsPaints with biocidesOligomerHardness

The invention provides a flexible and stain-resistant ultraviolet curable coating composition. The composition comprises, by weight, 30-80 parts of acrylate resin, 5-15 parts of a fluorine-modified acrylate oligomer, 10-25 parts of an acrylate monomer, 5-9 parts of a photoinitiator and 0.05-2 parts of a leveling agent. Compared with coatings in the prior art, the coating composition in the invention has a higher flexibility, and has the advantages of certain hardness, wear resistance, stain resistance, suitableness for bendable and crimped substrates, excellent comprehensive performances and wide applicability .

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

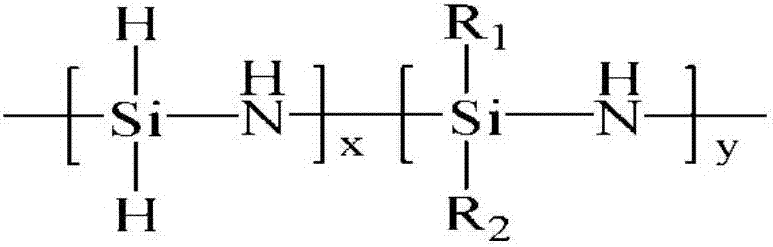

Self-cleaning superhard polysilazane hydrophobic coating and preparation and use method thereof

The invention discloses a self-cleaning superhard polysilazane hydrophobic coating and a preparation and use method thereof, and belongs to the technical field of super-hydrophobic coatings. The self-cleaning superhard polysilazane hydrophobic coating is prepared from the following components in parts by weight: 5 to 25 parts of organic-inorganic hybridized polysilazane, 15 to 30 parts of hydrophobic acrylate resin, 5 to 15 parts of nanometer silicon dixoide and 40 to 250 parts of organic solvent. The self-cleaning superhard polysilazane hydrophobic coating has the advantages that the excellent superhard, super-hydrophobic, scratch-resistant, abrasion-resistant and high-adhesion properties of a coating are realized; the defects of easiness in cracks, voids and the like in the inorganic polysilazane coating along with the increase of coating thickness are overcome; the problem of low hardness of the organic polysilazane is solved; the coating has the advantages that the hardness is high, the adhesion force is high, the easiness in falling and cracking of the coating is avoided, and the abrasion-resistant and scratch-resistant properties of the coating are ensured; the preparation technology is simple, the implementing is easy, and the preparation technology is suitable for widely popularized and applied.

Owner:BEIJING NEATRITION TECH CO LTD

Aging-resistant silver-plastic composite pipe

An anti-aging silver-plastic composite tube takes polyethylene, polypropylene or polyvinyl chloride as the matrix material and is composed of an outer tube and an inner tube. The composition and content of the outer tube are as follows (by weight parts): low-density polyethylene (LDPE0 and / or high-density polyethylene (HDPE), polypropylene (PP) or polyvinyl chloride (PVC) 100, silver powder 0.1-10, silver ash 0.1-5, antioxidant 1010 0.5-3, wax 0.5-3 and stearic acid HST 0.5-3. The inner tube is an LDPE, PP, PVC or metal tube. The composite tube in silver-white color has the advantages of good appearance, anti-ageing effect, resistance against deformation, brittle rupture and discoloration, long service life, recyclable materials, reduced material cost, and increased product quality.

Owner:姜晓兵

Inorganic modified high-temperature-resistant high-emissivity graphene coating and preparation method thereof

InactiveCN109880408AAdhesive performance is stableHigh bonding strengthAlkali metal silicate coatingsIonGraphene coating

The invention provides an inorganic modified high-temperature-resistant high-emissivity graphene coating. The inorganic modified high-temperature-resistant high-emissivity graphene coating is preparedfrom the following raw materials in parts by weight: 35-55 parts of an inorganic high-temperature adhesive; 3-10 parts by weight of an organic silicon resin emulsion; 1-10 parts by weight of a graphene dispersion liquid; 20-30 parts by weight of a functional filler; 1-4 parts by weight of an auxiliary agent; and 10-20 parts by weight of deionized water. According to the invention, the organic silicon resin emulsion and the inorganic high-temperature adhesive are subjected to hybridization reaction, thus normal-temperature curing of the inorganic adhesive can be accelerated, and the defects oflarge volume shrinkage in the curing process of the inorganic adhesive and easy generation of cracks and micro pores due to the rigidity of a formed film are effectively solved; the high radiation and high heat conductivity coefficient of graphene are utilized, and multiple functional fillers are supplemented, thus the emissivity of the prepared inorganic modified high-temperature-resistant high-emissivity graphene coating is 0.98 or above, and meanwhile the temperature resistance can reach 1200 DEG C. The invention also provides a preparation method of the inorganic modified high-temperature-resistant high-emissivity graphene coating.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD +1

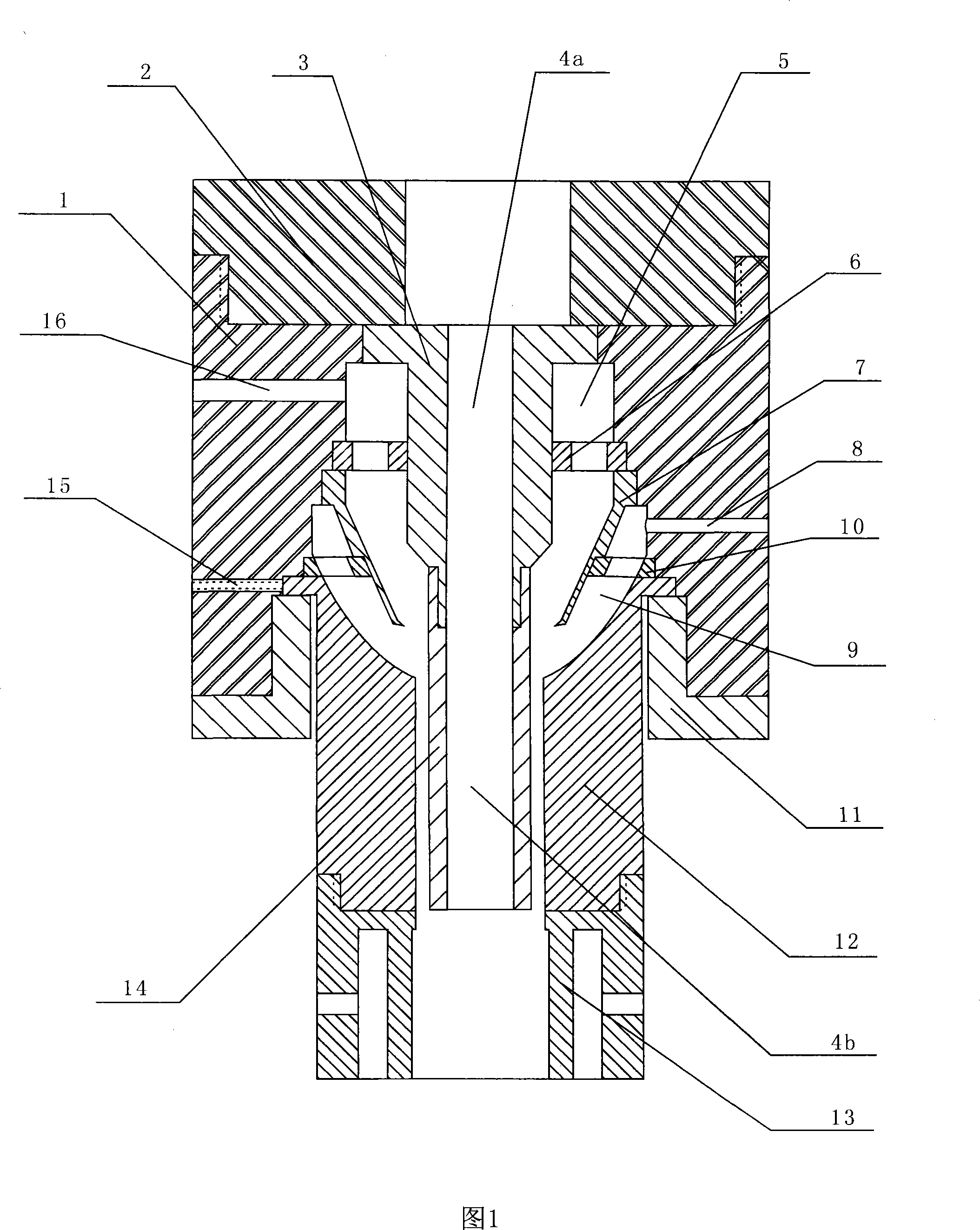

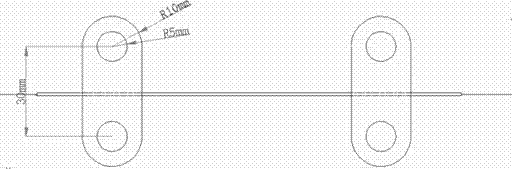

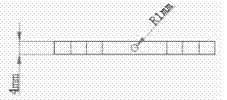

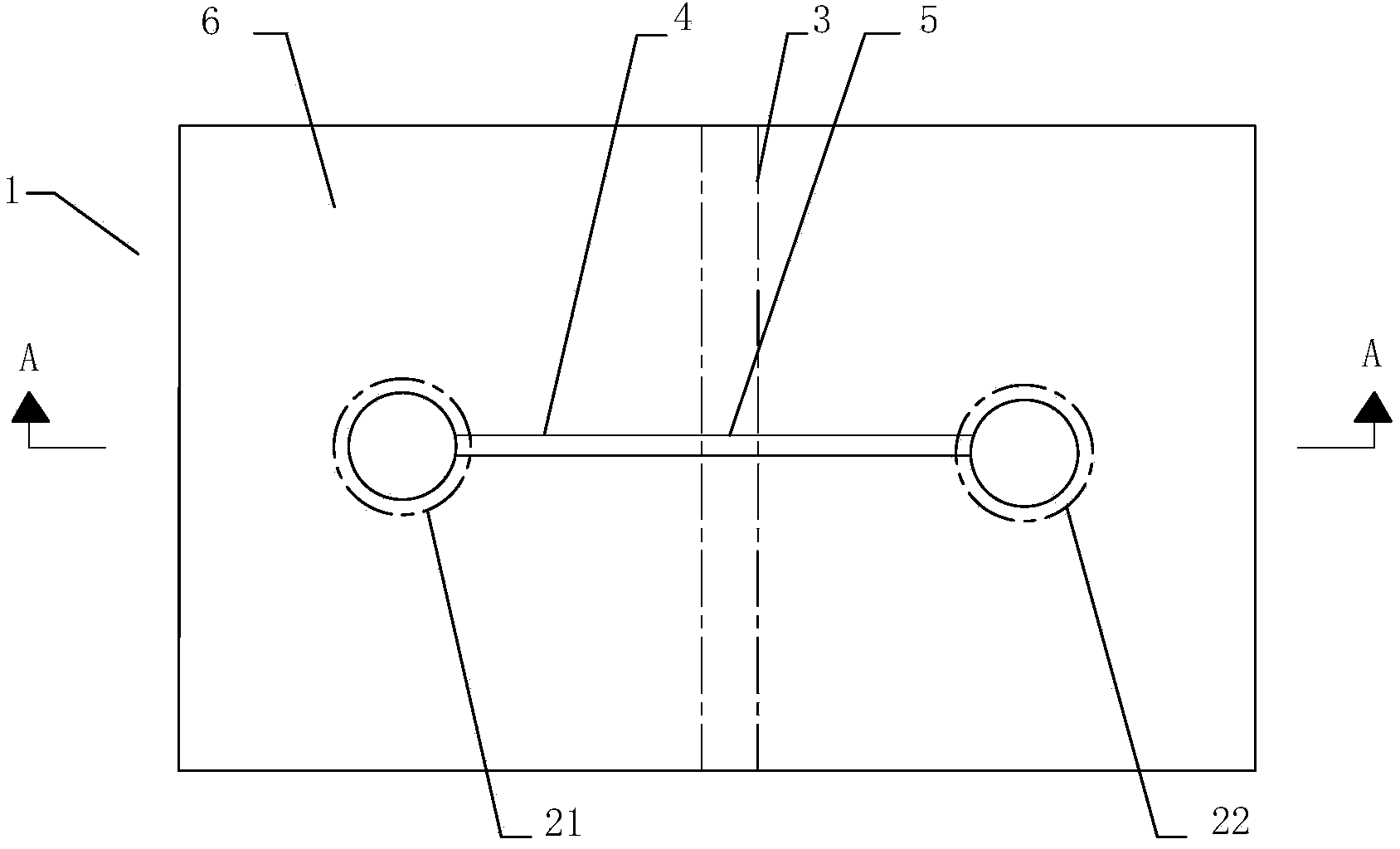

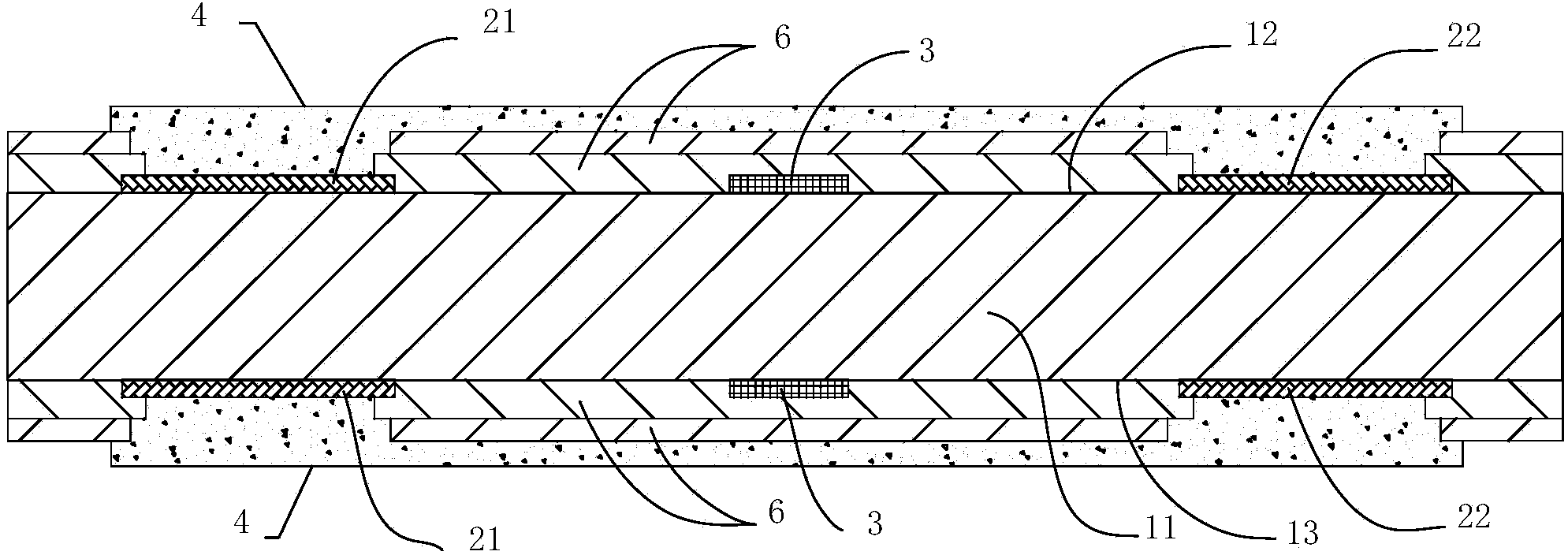

Metal packaged fiber Bragg grating sensor and manufacturing method thereof

InactiveCN102297706AImprove protectionHigh sensitivityMeasurement apparatus housingsConverting sensor output opticallyMetal fiberGrating

The invention discloses a metal-encapsulated fiber Bragg grating sensor and a manufacturing method thereof. By encapsulating the fiber Bragg grating in a steel pipe through a specific manufacturing method, the sensor of the invention improves the strain sensitivity compared with the prior art, and Easy to install.

Owner:黄堃

Solvent-free urethane composition

ActiveCN1894299AReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

A solvent-free composition is prepared, which is a composition comprising a polyol component (A) and a polyisocyanate component (B), wherein the polyol component (A) is composed of a low-molecular-weight polyol (A1) with a molecular weight of 350 or less. The viscosity of the aforementioned low-molecular polyol (A1) may be 500 mPa·s or less at 25°C. The aforementioned low-molecular polyol (A1) may be, for example, C2-6 alkylene glycol or the like. In addition, the polyol component (A) may be composed of a low-molecular polyol (A1) and a polymer polyol (A2) as a diluent. The aforementioned polyisocyanate component (B) may be a modified product or a derivative of polyisocyanate (for example, a multimer of diisocyanate, etc.). The aforementioned solvent-free composition may further contain an epoxy group-containing compound (aliphatic diol glycidyl ether, aliphatic polyhydric alcohol glycidyl ether having a hydroxyl group, etc.) (C) that may have a hydroxyl group. Such a solvent-free composition has a small load on the environment, has excellent coating film properties, and has high application efficiency.

Owner:日本硅石株式会社

Printed circuit board and manufacturing method thereof

InactiveCN103763854AIncrease the number of layers of conductive linesReduce thicknessPrinted circuit detailsConductive pattern formationMiniaturizationConductive materials

The invention discloses a printed circuit board and a manufacturing method of the printed circuit board. The printed circuit board comprises a substrate and is characterized in that at least one surface of the substrate is provided with two or more layers of conductive circuits which are overlaid vertically and arranged in a cross mode, an insulation material layer is arranged between every two vertically adjacent layers of conductive circuits, and the conductive circuits are isolated through the insulation material layers. According to the printed circuit board, conductive ink is adopted as conductive material for manufacturing the conductive circuits, and the multiple layers of conductive circuits arranged on the substrate in an overlaid mode are isolated through the insulation material layers, so that the layer number of the conductive circuits of the printed circuit board is increased, a laminated insulation hard board is not needed, the thickness of the printed circuit board is greatly reduced, and the printed circuit board is more adaptive to miniaturization electronic devices.

Owner:SHANGHAI MEADVILLE ELECTRONICS

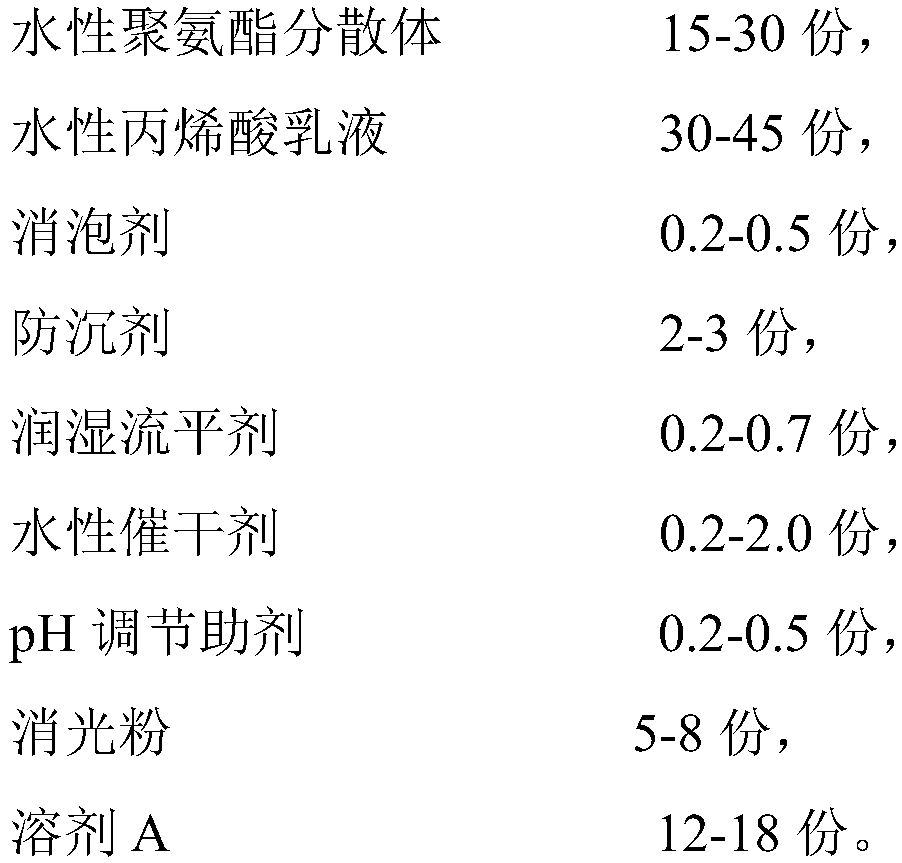

Ultra-gasoline resistant aqueous varnish and preparation method thereof

ActiveCN109749611AHigh hardnessImprove scratch resistancePolyurea/polyurethane coatingsSolventBiological activation

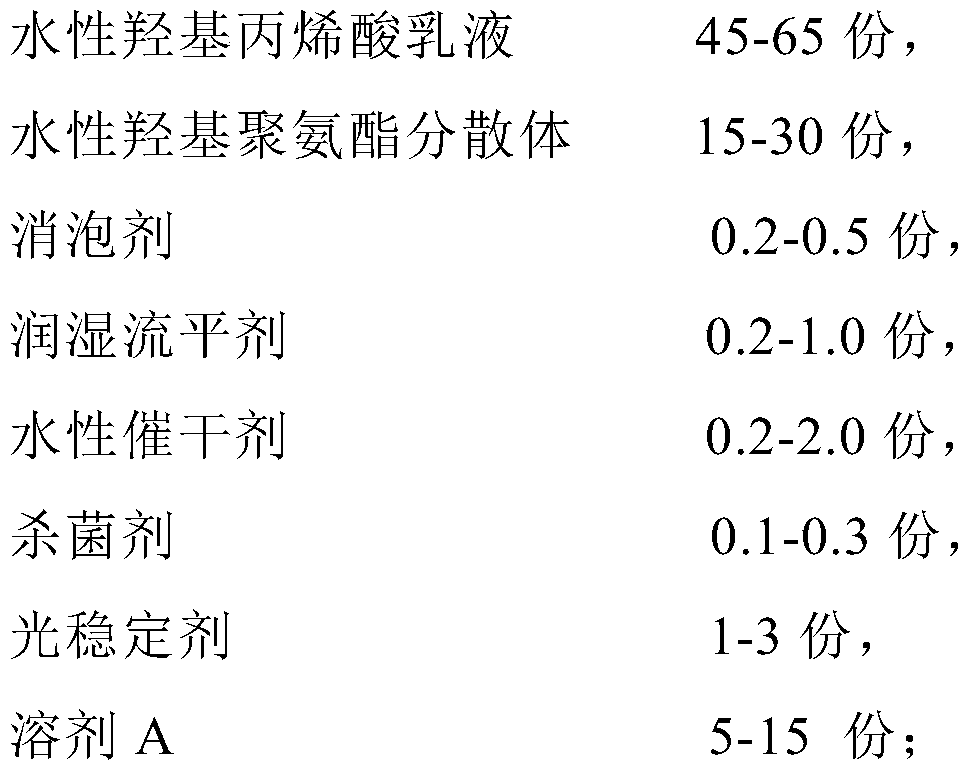

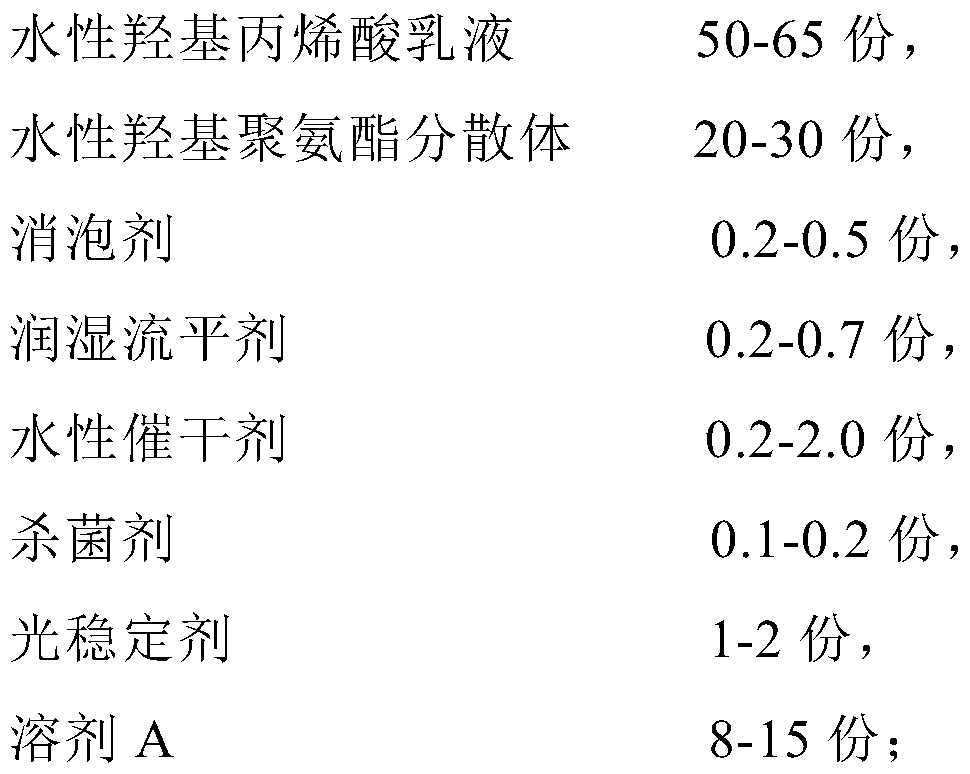

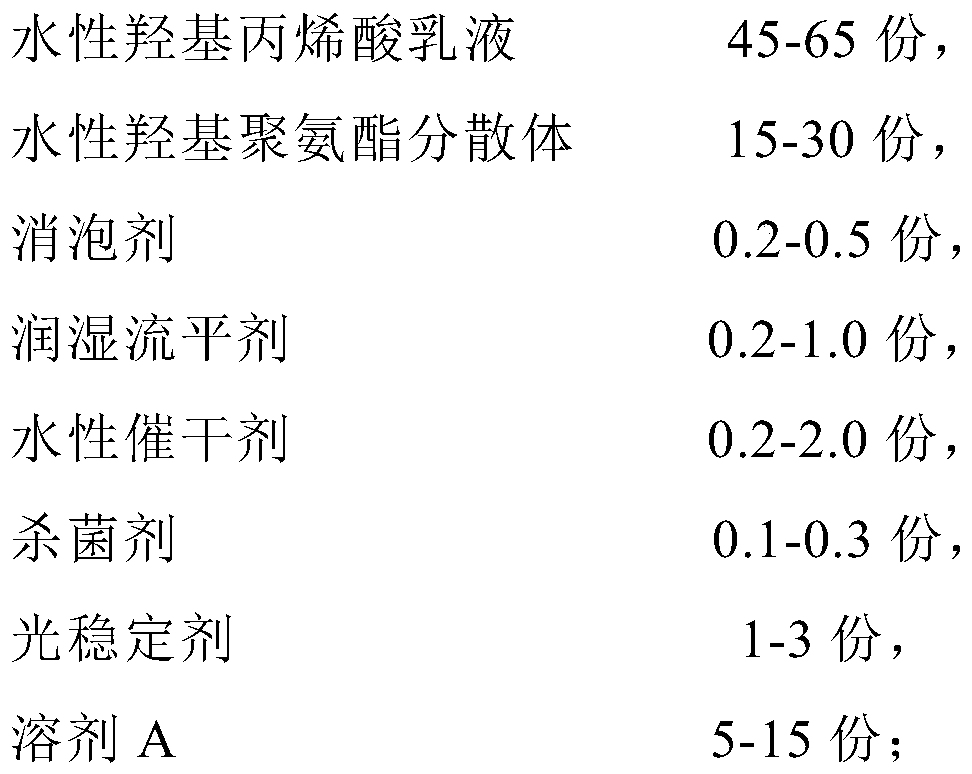

The invention relates to ultra-gasoline resistant aqueous varnish and a preparation method thereof. The aqueous varnish comprises a component A resin paint and a component B curing agent in a weight ratio of 3: 1, wherein the component A resin paint comprises 45-65 parts of aqueous hydroxyl acrylic emulsions, 15-30 parts of aqueous hydroxyl polyurethane dispersions, 0.2-0.5 part of a defoaming agent, 0.2-1.0 part of a wetting leveling agent, 0.2-0.6 part of an aqueous drier, 0.1-0.3 part of a bactericide, 1-3 parts of light stabilizers and 5-15 parts of solvents A; and the component B curing agent comprises 55-75 parts of curing agents and 10-30 parts of solvents B. Compared with the prior art, the preparation method is simple, raw materials are widely selected, and the prepared aqueous varnish has excellent chemical resistance, especially gasoline resistance, effectively improves surface drying speed and activation period, has good interlayer adhesion, and has the advantages of fast hardness establishment, high fullness and the like.

Owner:DONGLAI COATING TECH SHANGHAI

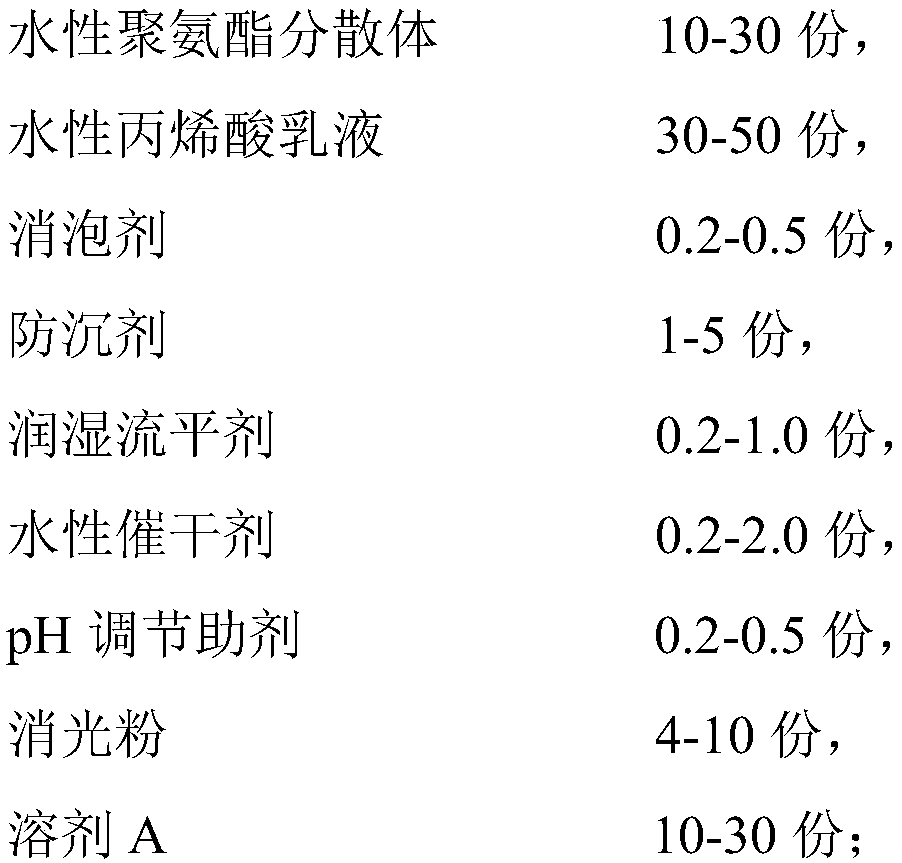

Water-based elastic paint with high drying speed and long activating period and preparation method thereof

InactiveCN107629656AGood touchGuaranteed hardnessPolyurea/polyurethane coatingsWater basedFoaming agent

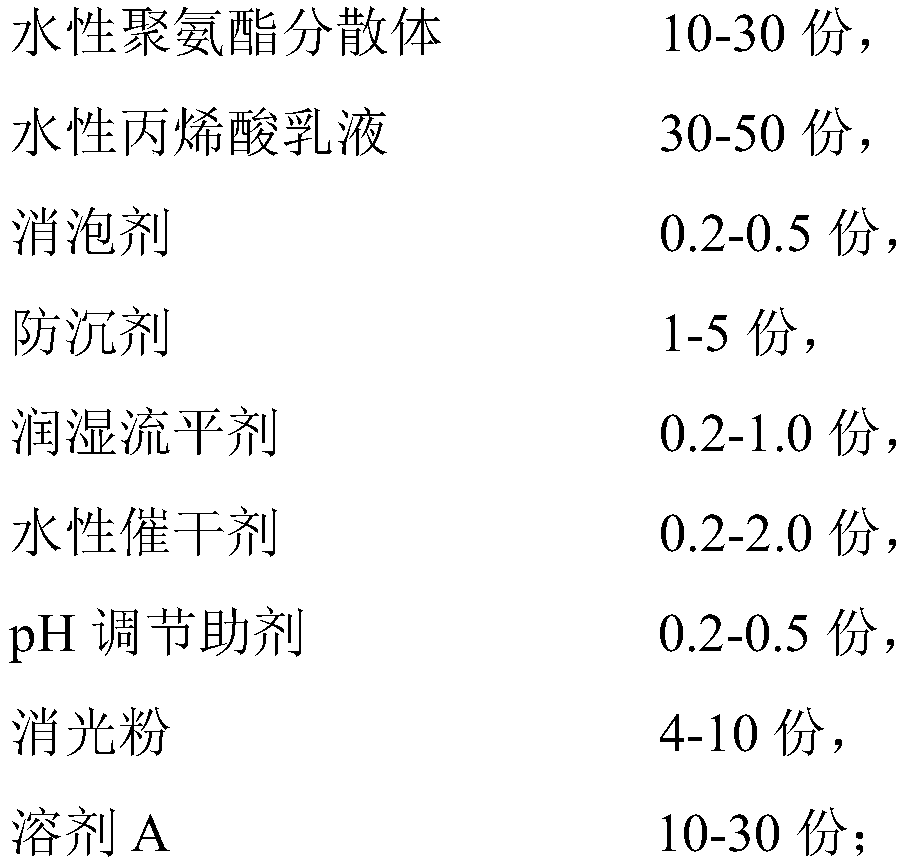

The invention relates to a water-based elastic paint with high drying speed and long activating period and a preparation method thereof. The elastic paint is prepared from a component A resin paint and a component B curing agent at mass ratio of 2:1, wherein the component A resin paint comprises 10-30 parts of waterborne polyurethane dispersoid, 30-50 parts of waterborne acrylic emulsion, 1-5 parts of anti-settling agent, 0.2-0.5 part of de-foaming agent, 0.2-1.0 part of wetting flatting agent, 0.2-0.6 part of water-based drier, 0.2-0.5 part of pH regulator additive, 5-10 parts of extinction powder and 10-30 parts of a solvent A and the component B curing agent comprises 55-70 parts of a curing agent and 15-35 parts of a solvent B. Compared with the prior art, the paint has the advantagesthat the preparation method is simple, the raw material source is wide and the prepared elastic varnish surface has excellent touch feel, high drying speed, long activating period, high transparency,high interlayer adhesion, high hardness and excellent anti-scratching property.

Owner:DONGLAI COATING TECH SHANGHAI

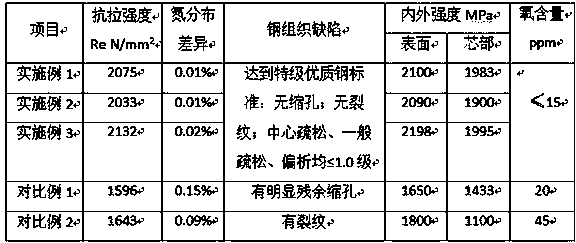

Preparation method of high-strength high-nitrogen rare earth stainless bearing steel

InactiveCN111334702AHigh nitrogen contentHigh strengthProcess efficiency improvementRare-earth elementMolten steel

The invention discloses a preparation method of high-strength high-nitrogen rare earth stainless bearing steel. The preparation method comprises the processes of primary smelting, refining, vacuum degassing, casting, pressurized electroslag remelting and heat treatment. Nitride is added in the pressurized electroslag remelting process, meanwhile, the nitrogen pressure is controlled, the nitrogen content in steel is increased to 0.3%-0.5%, the nitrogen increasing process is stable, and nitrogen distribution is uniform; rare earth elements are added before nitrogen dissolving to purify molten steel, so that the stability and uniformity of the nitrogen dissolving process are further improved, and the strength of the bearing steel is effectively improved; 80-90% of rare earth elements are usedfor purifying molten steel, the rest of rare earth elements are dissolved in the molten steel for microalloying, and the toughness of the bearing steel is remarkably improved through the two parts ofrare earth elements which are matched in a labor-division mode; and in addition, the mode of combining diffusion deoxidation, vacuum deoxidation and rare earth deep deoxidation is adopted, the deoxidation effect is guaranteed, meanwhile, use of aluminum is reduced, harm of the aluminum is reduced, and the anti-fatigue performance of the steel is improved.

Owner:DEQING TIANMA BEARING CO LTD

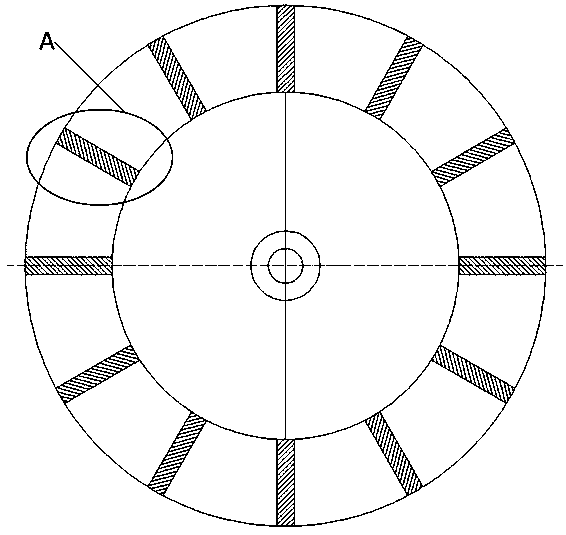

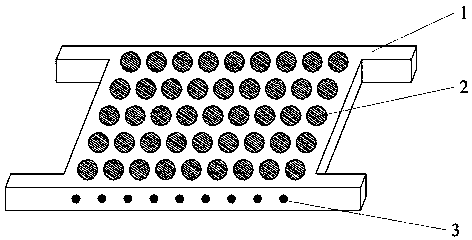

Wearing-resistant composite material fan coal mill hitting plate

The invention discloses a wearing-resistant composite material fan coal mill hitting plate which comprises a metal substrate, a composite material insert block, dowels and a rubber ring, wherein through holes and dowel holes I are uniformly formed in the metal substrate; one end of the composite material insert block protrudes out; the other end of the composite material insert block is a steppedshaft; one end of the stepped shaft is sleeved by the rubber ring; a dowel holes II are formed in the composite material insert block; dowel holes III are formed in the rubber ring; the composite material insert block is embedded into the metal substrate; the dowels penetrate through the dowel holes I in the metal substrate, the dowel holes III in the rubber ring and the dowel holes II in the composite material insert block; the cross section of the protruding end of the composite material insert block takes the shape of a circle or a polygon. By adopting the hitting plate, the wearing resistance of the hitting plate can be remarkably improved, the service life of the hitting plate can be greatly prolonged, and in addition, a ceramic / metal-based composite material can be replaced in time after being damaged or peeled off, so that the production and repairing cost can be lowered, and the production efficiency can be improved.

Owner:KUNMING UNIV OF SCI & TECH

Three-proofing coating for flexible printed circuit board

The invention relates to the technical field of printed circuit board protection and in particular relates to a three-proofing coating for a flexible printed circuit board. According to the three-proofing coating, the advantages of organic silicon resin and acrylic resin are integrated in formula, a low-toxicity efficient solvent is adopted for promoting dissolution and dispersion of the resin in water, a good curing effect is achieved, and ocimene has an effect of assisting in film formation and endows the coating with pleasant aroma; mixed resin is ultrasonically processed in the solvent at first technologically, so that the mixed resin easily reacts with other materials and is easily compatible with the materials, and the subsequent curing speed is increased; the prepared coating is a waterborne coating, is environmental friendly and has good waterproof moisture-resistant effects, and a cured paint film is good in hardness and toughness, can completely fit the flexible circuit board and is not easily cracked in vibration and bending processes of the flexible circuit board, so that three-proofing effects are further enhanced and the occurrence probability of circuit board faults caused by environmental factors is reduced.

Owner:乐凯特科技铜陵有限公司

Ultraviolet curing white base paint and construction process on medium density fiber by using same

ActiveCN102070982AGood flexibilityReduce shrinkage stressPretreated surfacesPolyurea/polyurethane coatingsPolyesterFiber

The invention discloses ultraviolet curing white base paint and a construction process on the medium density fiber by using same. The ultraviolet curing white base paint comprises the following components in parts by weight: 20-35 parts of urethane acrylate, 20-30 parts of modified polyester acrylate, 15-20 parts of monomer, 10-20 parts of filler, 3-5 parts of photoinitiator, 0.5-1 part of anti-settling agent and 0.2-0.3 parts of defoaming agent. The construction process of the invention comprises the following steps: firstly spraying quick-drying water-based white base paint on a bottom plate, polishing, coating the ultraviolet curing white base paint on the bottom plate once, performing ultreviolet curing, polishing, and then coating polyurethane (PU) colored paint. Compared with the traditional process, the adhesive force of the base paint used in the construction process of the invention is not lower than that of the base paint used in the traditional process, or even higher; and the operation is simple, the construction time is short, the efficiency can be greatly increased, the energy can be saved and the emissions of the volatile organic compound (VOC) can be greatly reduced.

Owner:HUIZHOU CHANGRUNFA PAINT

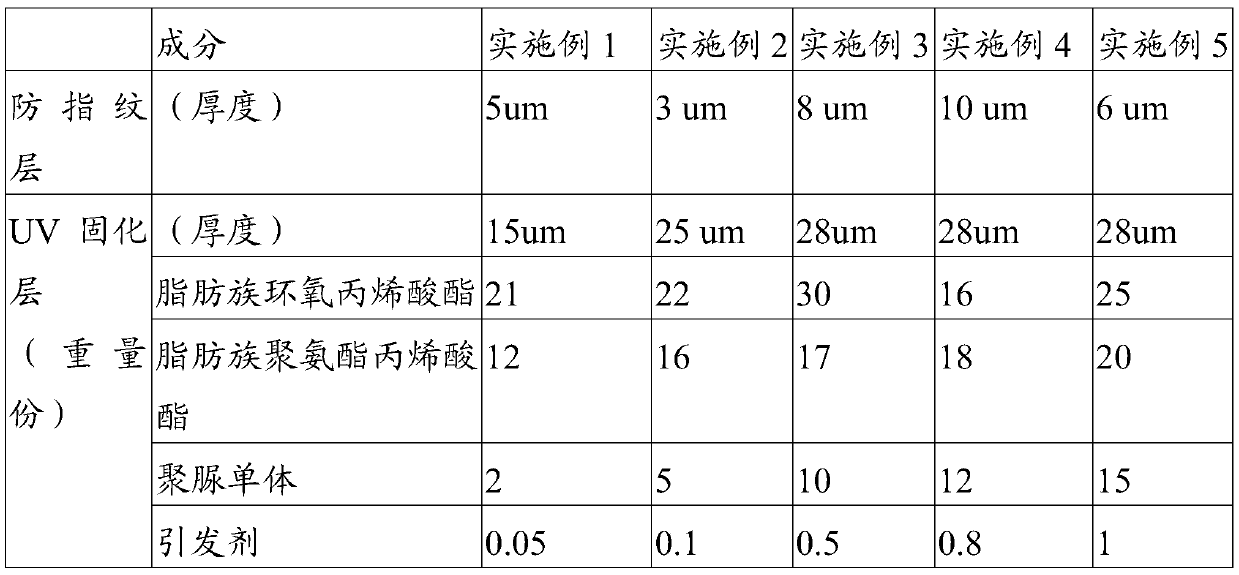

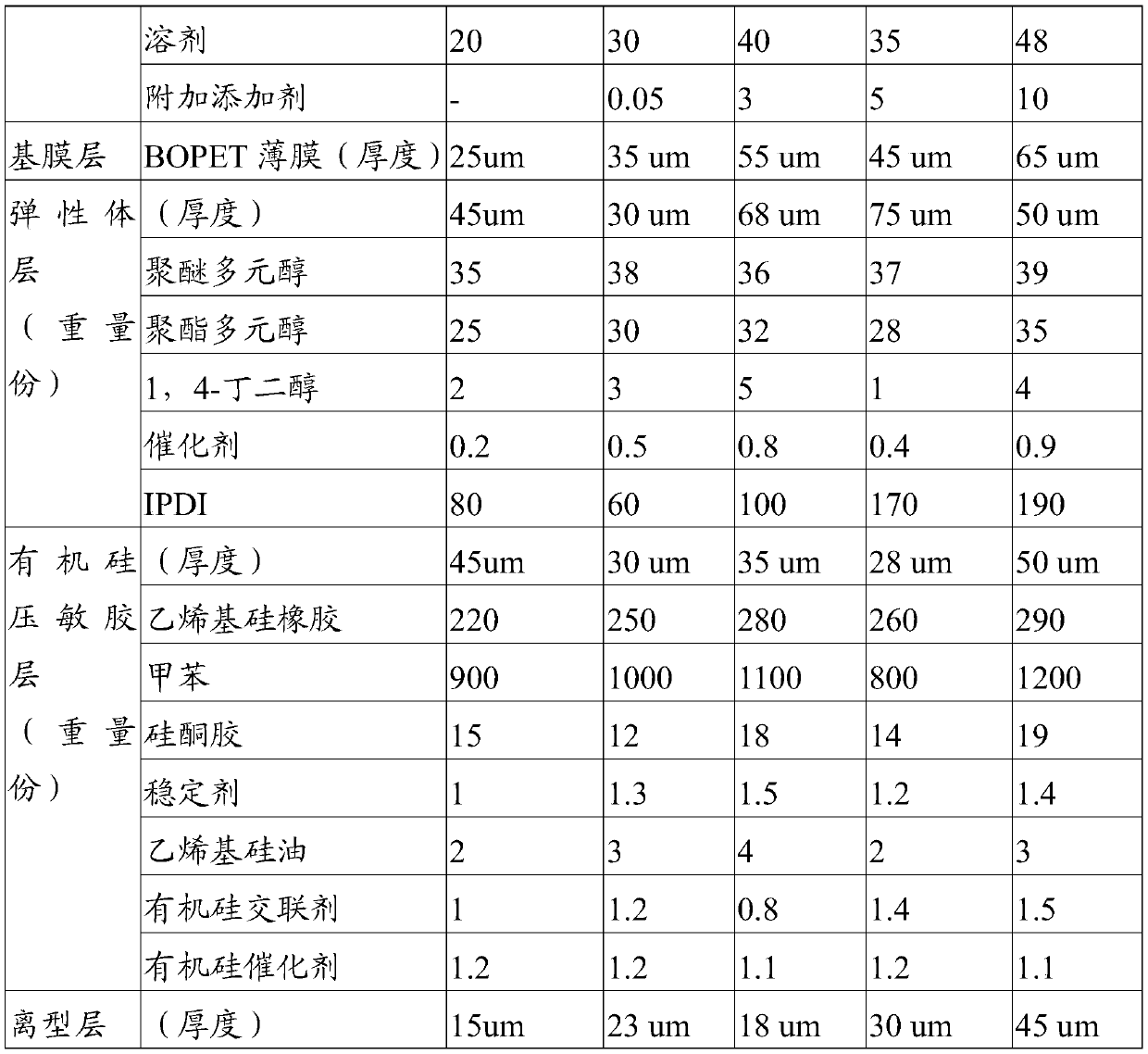

Protective film applied to curved display screen

ActiveCN111534244AImprove impact resistanceImprove fitNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerUV curing

The invention discloses a protective film applied to a curved display screen, and relates to the technical field of protective films. The protective film sequentially comprises a UV curing layer, a base film layer, an elastomer layer, an organic silicon pressure-sensitive layer and a release layer from top to bottom. The thickness of the protective film applied to the curved display screen is 150-400 [mu] m. According to the protective film applied to the curved display screen, the protective film sequentially comprises the UV curing layer, the base film layer, the elastomer layer, the organicsilicon pressure-sensitive adhesive layer and the release layer from top to bottom, and the impact resistance and the bendability of the protective film can be improved by arranging the elastomer layer and the protective film is easier to attach; the organic silicon pressure-sensitive adhesive layer is cooperatively used so that the adhesion of the protective film is improved, the problem that the edge of the curved screen is warped is effectively solved, the protective film has hardness and flexibility, and the protective film has the characteristics of good adhesion with the curved screen and no warping.

Owner:江西蓝海芯科技集团有限公司

Transparent water soluble resin

The invention provides a transparent water soluble resin. The preparation method of the transparent water soluble resin comprises: mixing polyethylene glycol and polyvinylpyrrolidone according to a weight ratio of 1:0.25-0.35, keeping temperature at 25 to 30 DEG C, stirring till the polyvinylpyrrolidone dissolves completely to obtain solution, mixing the solution and transparent urea formaldehyderesin solution according to a volume ratio of 1:3-4 to obtain glue solution, adding glacial acetic acid serving as a coagulator in an amount which is 5 to 15 percent based on the volume of the glue solution, fully stirring, pumping air for 2 to 5 minutes by using a vacuum pump till a large amount of air bubbles are not generated, standing till on air bubbles are generated on surface, and obtaining the transparent water soluble resin. The molecular weight of the polyethylene glycol is 600. The polyethylene glycol has the advantages of high success rate of the coating of biological specimens, easy cracking prevention, transparency and certain hardness, and can be used for post treatment in polishing, shaping and the like and preserve the original shape of biological specimen for a longer time.

Owner:CHONGQING NORMAL UNIVERSITY

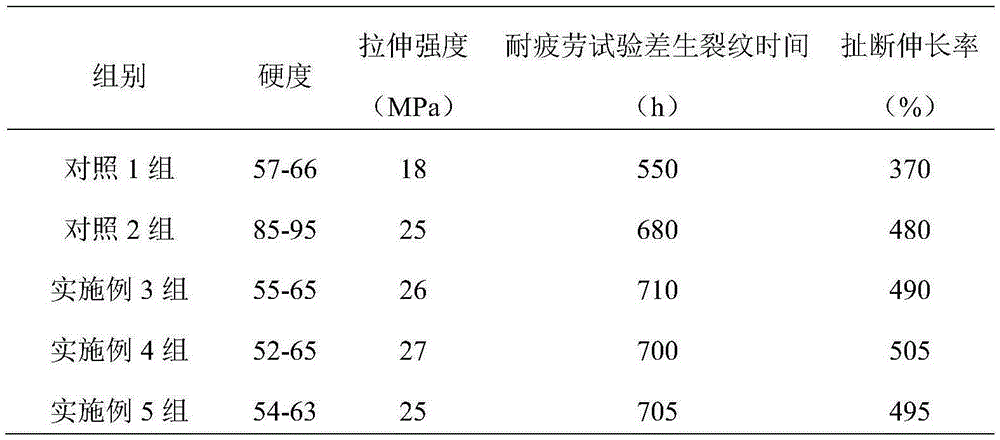

Rubber material for automobile transmission belt and preparation method therefor

The invention discloses a rubber material for an automobile transmission belt and a preparation method therefor. The rubber material is mainly prepared from the following ingredients in parts by weight: 60 parts of acrylic resin, 40-60 parts of styrene-butadiene rubber, 50-70 parts of natural rubber, 1-9 parts of coupling agent, 2-6 parts of curing agent, 1-7 parts of zinc oxide, 2-8 parts of isopropyl benzene hydroperoxide, 0.1-0.5 part of anti-aging agent, 0.3-0.7 part of accelerant and 30-40 parts of isopropyl alcohol. Compared with the prior art, the rubber material for the automobile transmission belt and the preparation method therefor disclosed by the invention have the advantages that the process is simple, the cost is low, the rubber material has the heat resistance and wear resistance of transmission belts in the prior art, and most importantly, wear resistance and tensile resistance can be simultaneously taken into account, so that the overall performance is excellent.

Owner:SUZHOU GOODTIME TECH DEV

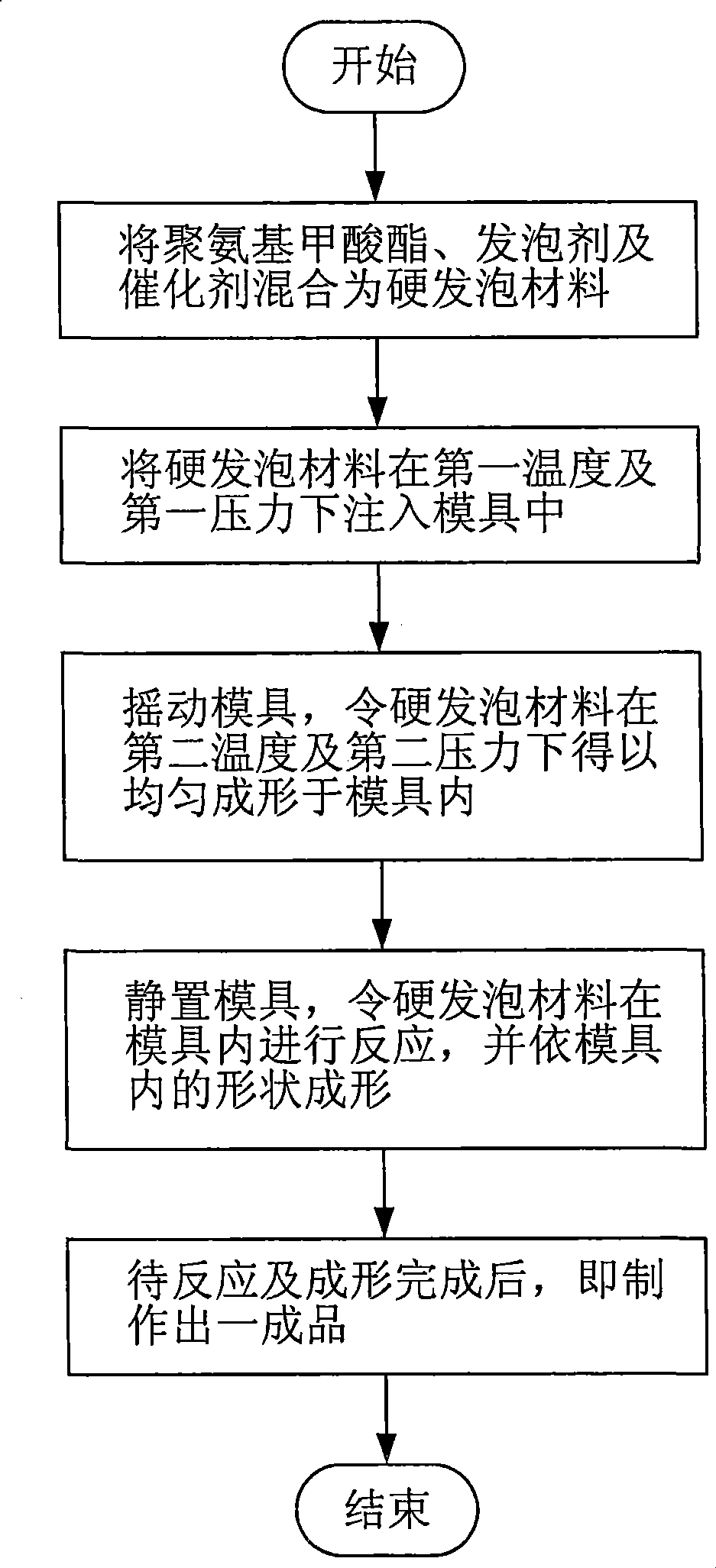

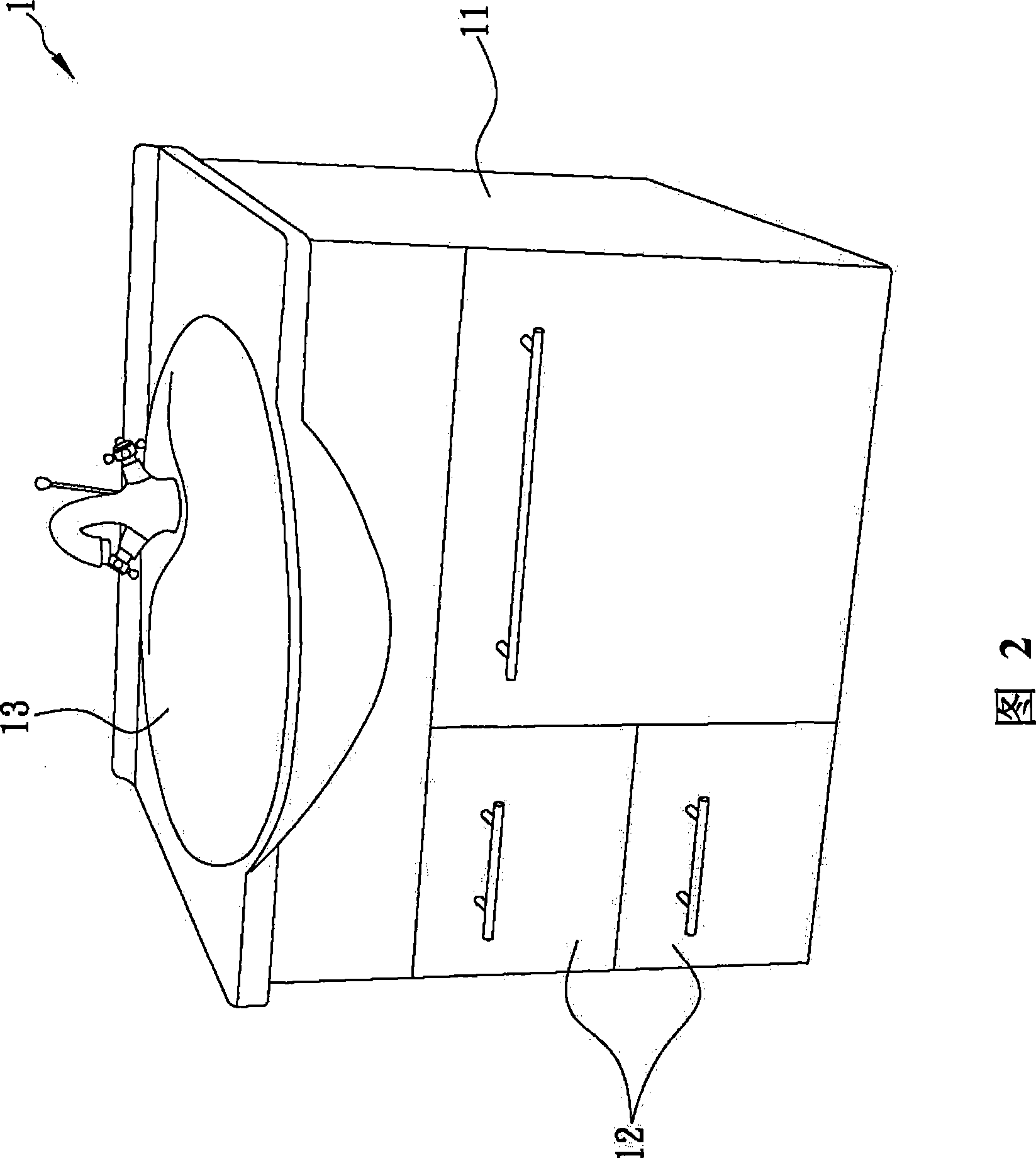

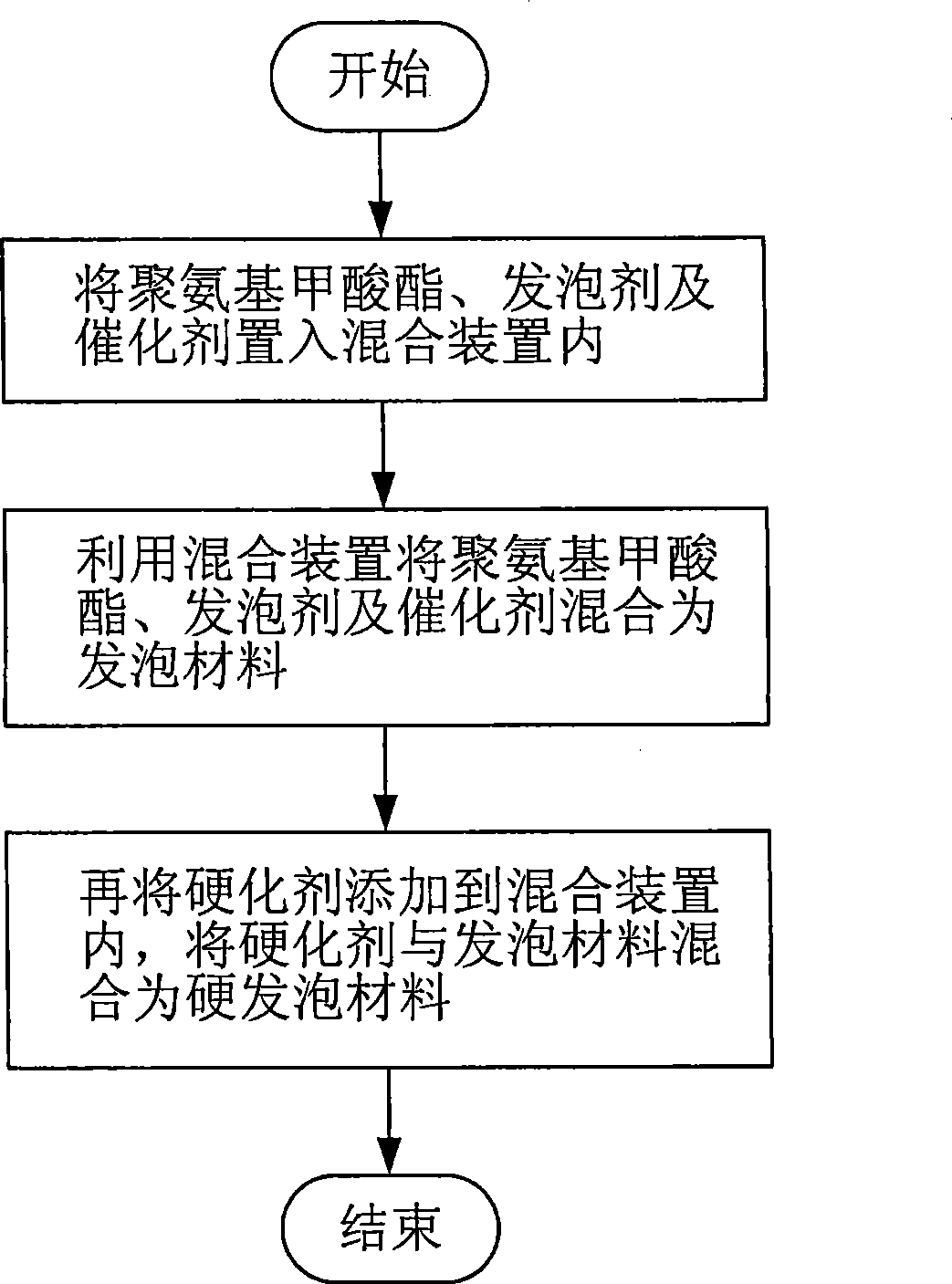

Method of preparing thermoplastic hard foam

The invention relates to a method for manufacturing a thermoplastic hard foaming body. The method comprises the following steps: mixing polyurethane, a foaming agent and a catalyst by a mixing device to produce a hard foaming material; injecting the hard foaming material in a mould; shaking the mould to make the hard foaming material evenly shaped in the mould; keeping the mould on standing to cause the hard foaming material to react in the mould and be shaped according to the shape in the mould; and producing a finished product without a joint close after reacting and shaping. The manufacture method not only has the characteristics of simple formulation and easy coloration and the like, but also can easily control fire resistance, humidity resistance, hardness and corrosion resistance of the manufactured finished product without joint seam.

Owner:许育乾

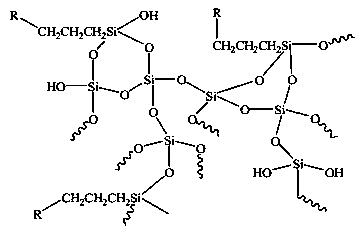

Hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin and preparation method therefor

ActiveCN108659192AFlexibleBoth hardnessPolyurea/polyurethane coatingsHyperbranched polyesterTransmittance

The invention discloses a hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin composition and a preparation method therefor. The hyperbranched structured anti-dazzle polyurethaneacrylate UV cured resin composition disclosed by the invention contains the following ingredients in percentage by weight: 10-80% of polyurethane acrylate with hyperbranched polyester as a core and 20-90% of polyurethane acrylate with hyperbranched polyether as a core. The hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin composition disclosed by the invention can achievean excellent anti-dazzle effect without additionally adding auxiliaries or carrying out surface treatment, has good light transmittance and has both hardness and flexibility.

Owner:无锡博加电子新材料有限公司 +1

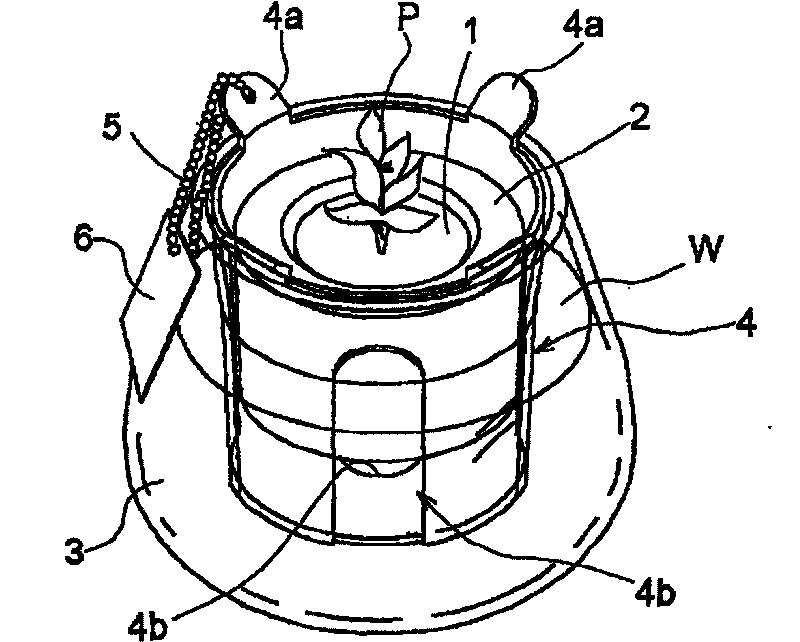

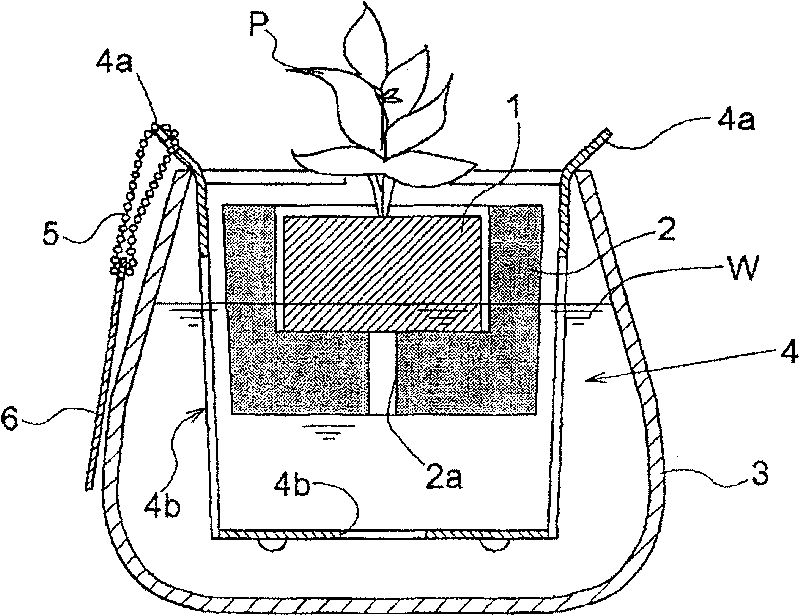

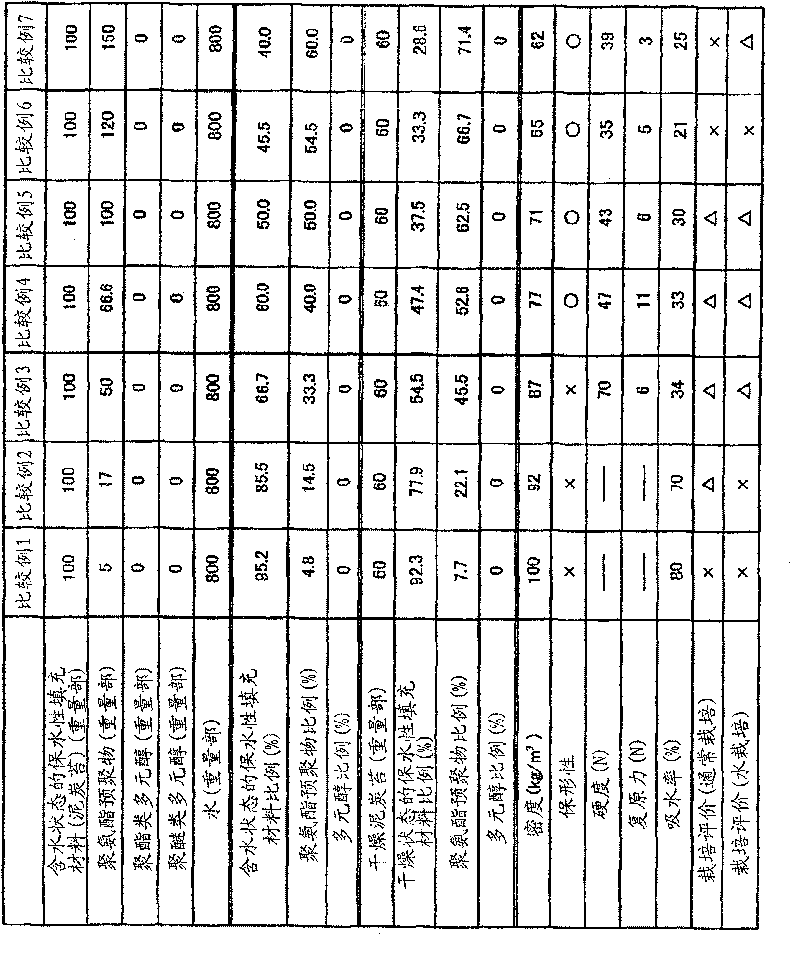

Plant cultivating base body and method of manufacturing the same

ActiveCN1838872BBoth water retentionBoth flexibilitySelf-acting watering devicesGrowth substratesPolyolFilling materials

Provided is a plant cultivating substrate which satisfies e.g. the water absorptivity required for plant cultivation, shape retentivity and flexibility and a method of manufacture thereof. In the plant cultivating substrate and the method of its manufacture, at least water-retentive filling material, water, urethane prepolymer and polyol are reacted with each other.

Owner:TOYOTA SUNTORY MIDORIE (SHANGHAI) CO LTD +1

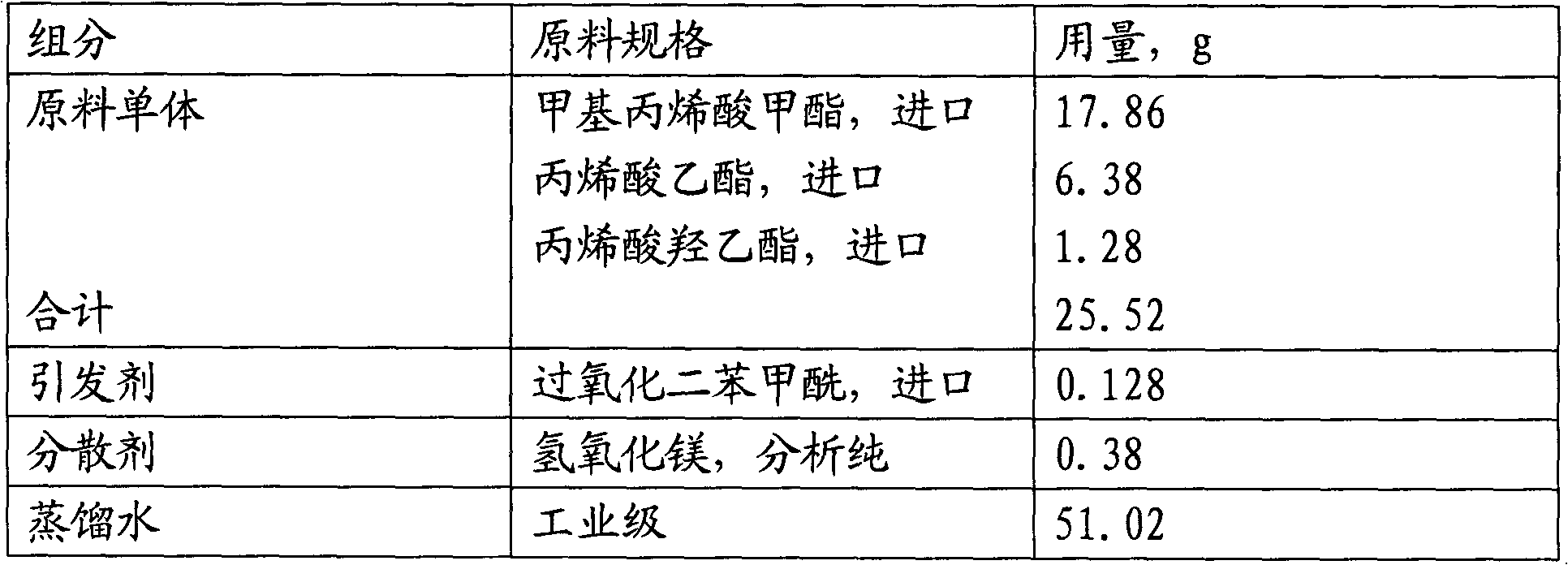

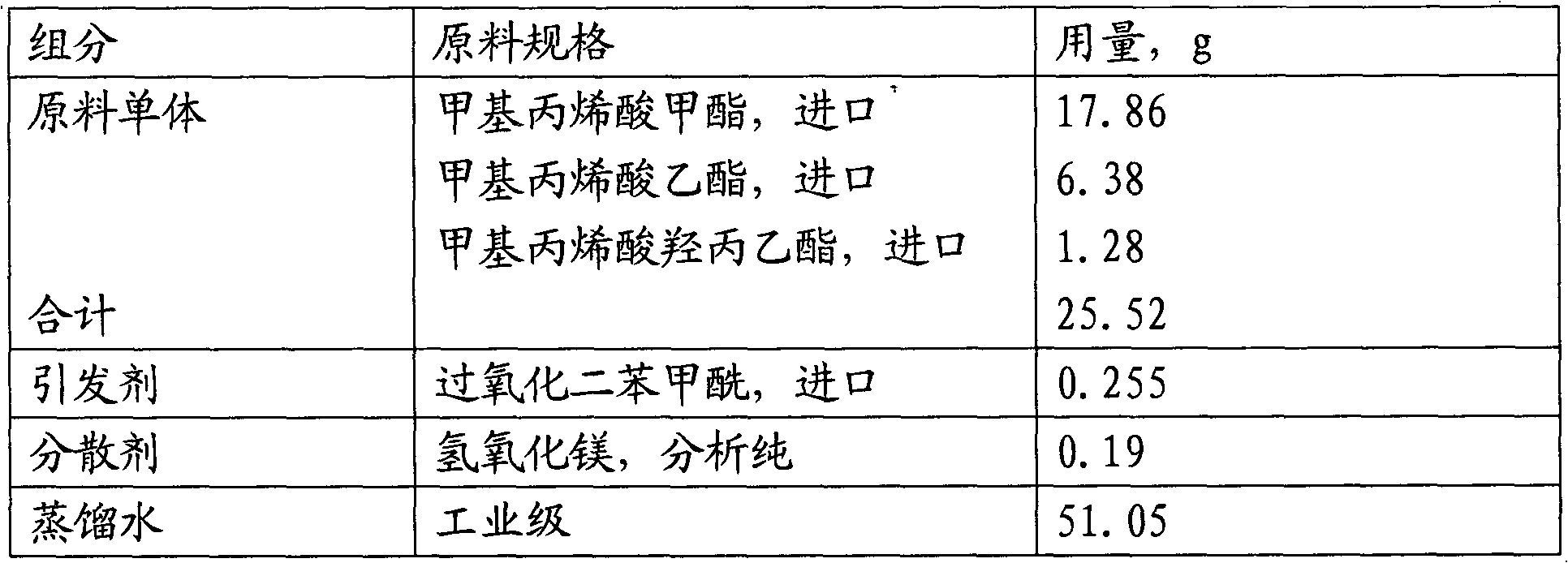

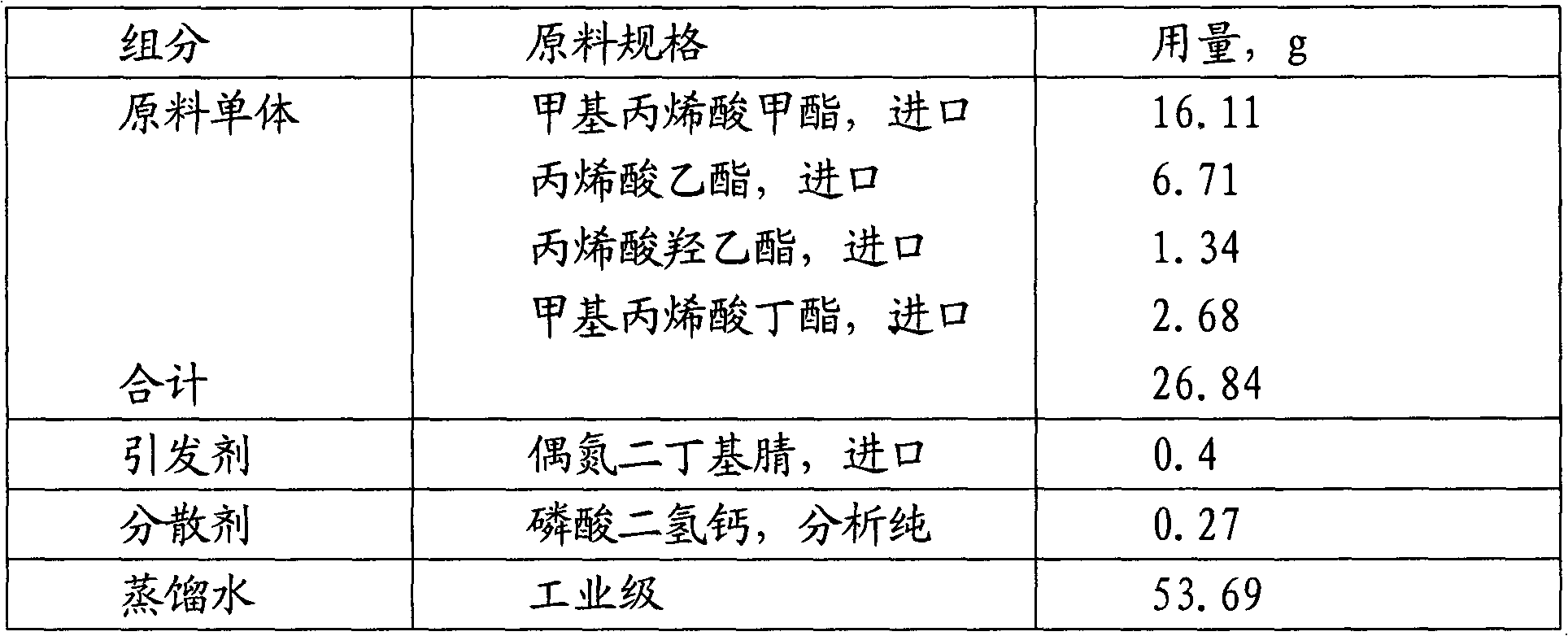

High molecular weight acrylic resin for polyvinylidene fluoride coiled material finish paint

ActiveCN102443098AHigh molecular weightOvercome the disadvantage that the molecular weight is not easy to increaseCoatings(Hydroxyethyl)methacrylateAcrylic resin

The invention relates to a high molecular weight acrylic resin for a polyvinylidene fluoride coiled material finish paint. The acrylic resin is combined with polyvinylidene fluoride resin as a coiled material finish paint base-material, is a bead-shape transparent particle and has a number-average molecular weight Mn higher than 90 thousand and molecular weight distribution Mw / Mn less than 2.0. The resin of the invention is prepared by a suspension polymerization method from material monomers of 50-80 wt% of methyl methacrylate and / or methyl acrylate, 10-40 wt% of ethyl acrylate and / or methyl methacrylate and 0-40 wt% of one or more selected from acrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, methacrylic acid, hydroxyethyl methacrylate, hydroxypropyl methacrylate, butyl acrylate and butyl methacrylate. The high molecular weight acrylic resin of the invention can be combined with a PVDF resin, and a prepared finish paint film has comprehensive properties the same as an imported one and better performances on MEK-resistant wiping frequency and artificial ageing resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

UV transfer glue formula and manufacturing process

InactiveCN109943270AFast curingEasy to diluteNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesShrinkage ratePliability

The invention discloses an UV transfer glue formula and a manufacturing process. The UV transfer glue formula is prepared from the following components in parts by weight: 30-38 parts of prepolymer, 56-65 parts of an acrylate monomer, 1-4 parts of a photoinitiator and 0.2-1 part of an auxiliary agent, wherein the acrylate monomer is a complex of single functional acrylate and double functional acrylate; the single functional acrylate is isobornyl acrylate and the double functional acrylate is 1,6-hexadiol diacrylate; the weight ratio of the single functional acrylate to the double functional acrylate is (3-4): (1-1.5). The manufacturing process comprises the following steps: first, preparing a complex of isobornyl acrylate and 1,6-hexadiol diacrylate; then preparing a prepolymer; and thenmixing the prepolymer, the acrylate monomer, the photoinitiator and the auxiliary agent to obtain the UV transfer glue. The UV transfer glue has the advantages of being high in curing speed, increasedin film forming crosslinking density, good diluting property, excellent glue flatting property, relatively small in volatility, relatively slight in smell, low in shrinkage rate and extremely good inadhesive force and has hardness, flexibility and scratch resistance.

Owner:广东信毅新材料有限公司

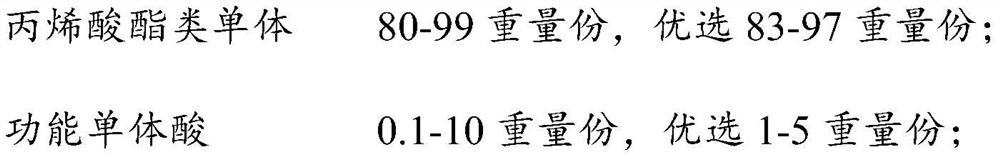

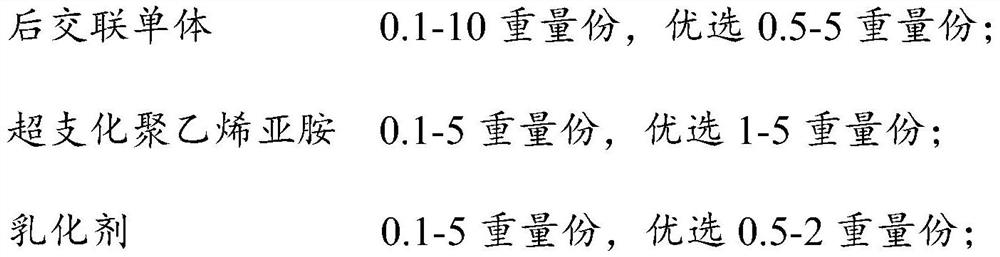

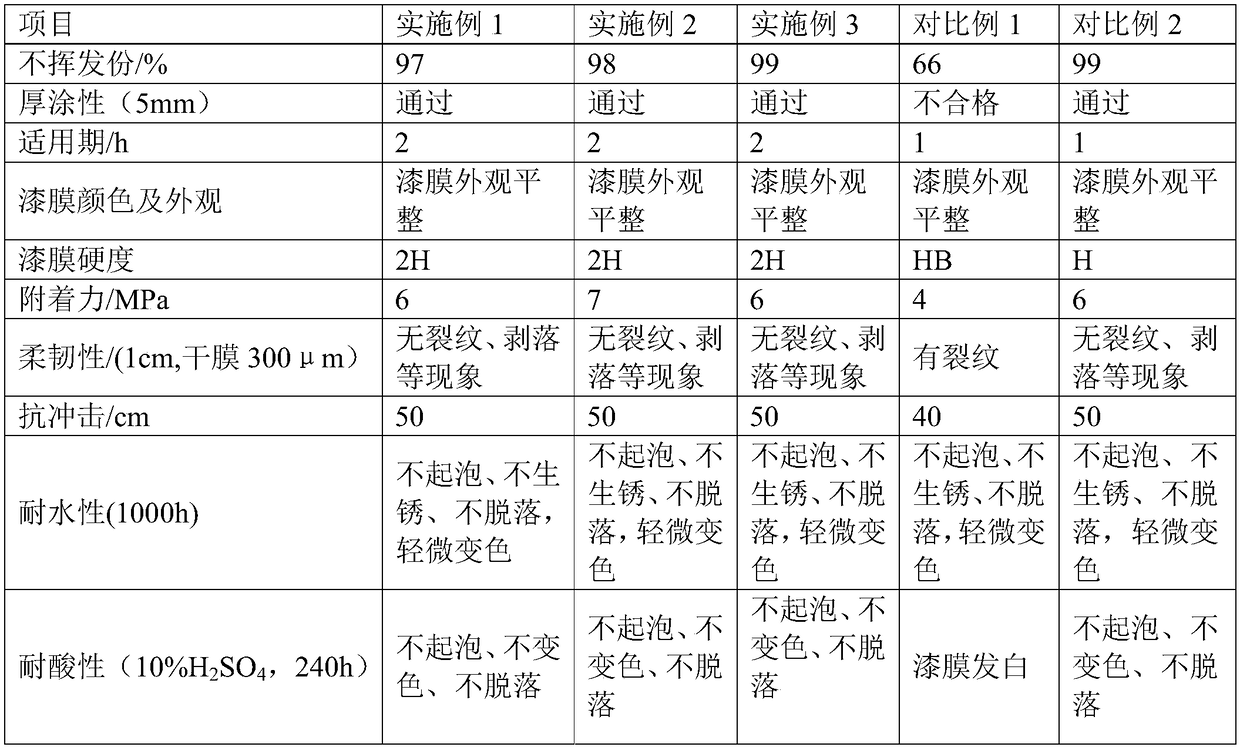

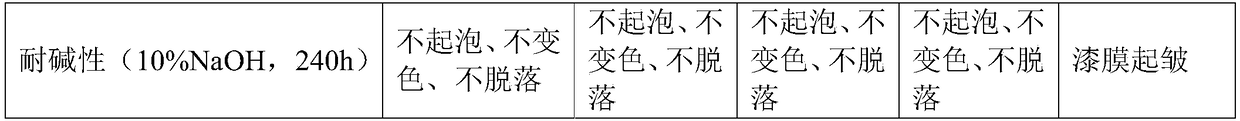

Hyperbranched polyethyleneimine doped and modified acrylic emulsion and preparation method thereof

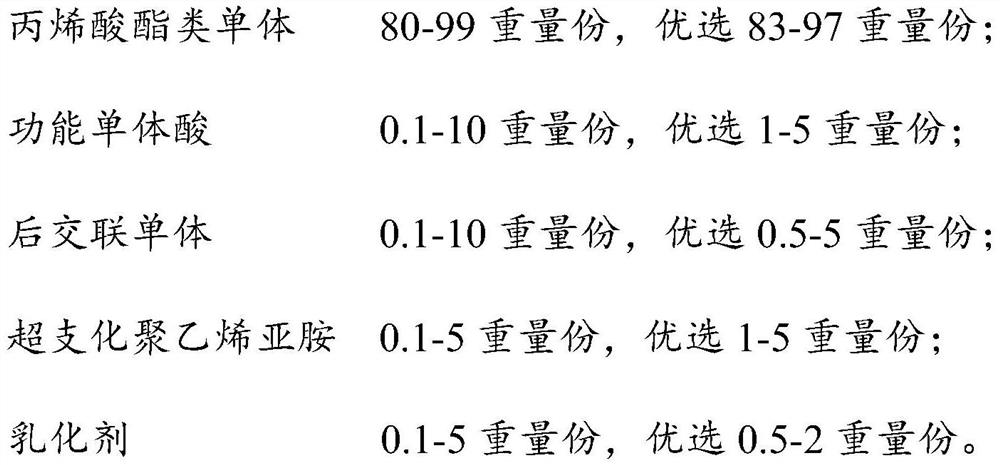

The invention provides a hyperbranched polyethyleneimine doped and modified acrylic emulsion and a preparation method thereof. The emulsion provided by the invention is particularly suitable for preparing a waterborne wood paint coating, and good paint film performance can be obtained. Hyperbranched polyethyleneimine is added into an acrylic emulsion which is neutralized to be weakly alkaline, anduniform mixing is carried out to obtain the hyperbranched polyethyleneimine doped and modified acrylic emulsion, wherein the acrylic emulsion is prepared by a polymerization reaction of components including an acrylate monomer, a functional monomer acid, a post-crosslinking monomers and an emulsifier; and the post-crosslinking monomer at least comprises at least one of diacetone acrylamide and ethylene glycol dimethacrylate.

Owner:WANHUA CHEM GRP CO LTD +2

Heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and preparation method thereof

InactiveCN109401600AHigh tensile strengthHigh compressive strengthAnti-corrosive paintsPolyurea/polyurethane coatingsSodium metasilicatePolyol

The invention discloses a heavy-load resistance and corrosion-resistance waterborne polyurethane floor coating and a preparation method thereof. The waterborne polyurethane floor coating comprises acomponent A, a component B and a component C, wherein the component A comprises polyol, an emulsifier, a defoaming agent, a flatting agent and water; the component B comprises polyisocyanate; and thecomponent C comprises white cement, toner, sodium metasilicate, a water reducing agent and quartz sand. The preparation method comprises the following steps that firstly, the component A and the component C are separately prepared, and then the three components A, B and C are mixed during use. The coating has low viscosity, high solid content, no solvent volatilization, rapid drying and long recoating time, can realize thick-film formation, and has high adaptability to coating environment, so that the requirements of various factories on rapid and environment-friendly coating are met.

Owner:JIANGSU HUAXIA PAINT MAKING

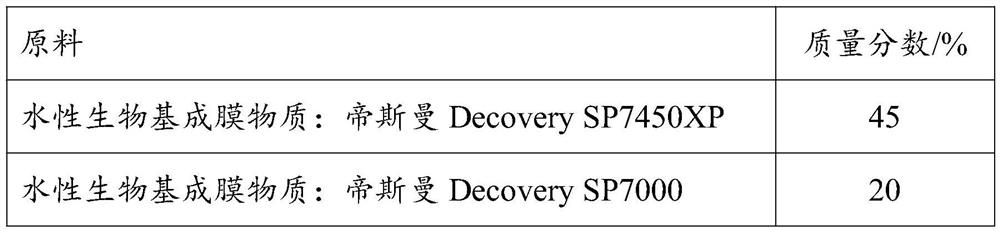

Bio-based water-borne wood coating and preparation method thereof

PendingCN112143310AHealth effectsComplies with chemical resistancePolyurea/polyurethane coatingsDefoaming AgentsMaterials science

The invention provides a bio-based water-borne wood coating and a preparation method thereof. The bio-based water-borne wood coating is prepared from the following components in percentage by mass: 55-85% of a water-borne bio-based film-forming substance, 0.2%-1% of a defoaming agent; 0.2%-1% of a substrate wetting agent; 0.5%-3% of a wetting dispersant; 0-25% of a pigment; 0-3% of an extinction auxiliary agent; 0.2%-1% of a hand feeling auxiliary agent; 0.1%-0.5% of an anti-sagging auxiliary agent; 0.2%-1.0% of a thickening agent; 3%-6% of a bio-based coalescing agent; 1%-5% of a scratch-resistant auxiliary agent; 0.2%-1% of a leveling agent; 2%-10% of deionized water. The bio-based content is larger than 20%, the requirements of GB18581-2020 are met, and the properties such as the hardness, the adhesive force, the adhesion resistance, the scratch resistance and the chemical resistance of the product can meet the requirements of GB23999-2009.

Owner:珠海展辰新材料股份有限公司 +1

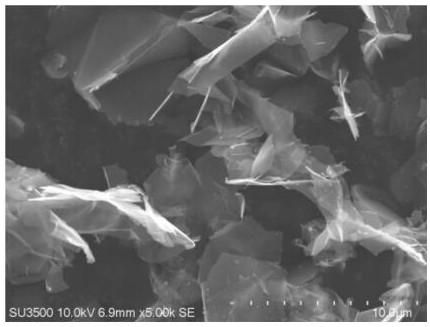

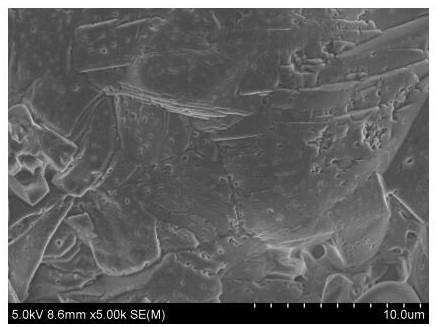

A kind of preparation method of natural mineral fiber/plant fiber degradable agricultural mulch film

ActiveCN113308936BRich sourcesReduce manufacturing costInorganic fibres/flakesNatural cellulose pulp/paperSoil sciencePlant fibre

The invention discloses a method for preparing a natural mineral fiber / plant fiber degradable agricultural mulching film. The natural mineral fiber is surface-modified and then mixed with natural plant fibers to prepare a degradable agricultural composite mulching film by a wet papermaking process, which is used for preparing the agricultural mulching film. The raw materials are environmentally harmless and biodegradable natural mineral fibers and plant fibers. The obtained agricultural film has both the hardness and rigidity of mineral fibers and the flexibility and toughness of plant fibers. Its mechanical properties are better than those of pure plants without mineral fibers. The fiber mulch film is increased by 15% to 50%; the invention not only solves the limited source of degradable agricultural mulch film raw materials and the production limitation of high cost, but also saves the amount of plant fiber and reduces the felling of forest trees.

Owner:LIUPANSHUI NORMAL UNIV

High-finish-degree antibacterial stainless steel pump valve casting and manufacturing method thereof

The invention discloses a high-finish-degree antibacterial stainless steel pump valve casting. According to the stainless steel pump valve casting, the use amount of elements such as Cu, Zr and Ag is properly increased on the basis that low-carbon steel has good toughness and plasticity, good casting mold forming performance is given to a stainless steel casting material, the hardness and toughness are achieved, corrosion resistance is extremely excellent, the certain antibacterial property is achieved, the situation that the surface of the material breeds bacteria and consequently use is affected can be prevented, crystal nucleuses can be refined effectively through the added rare earth element, the surface quality of the casting is improved, shrinkage cavities are reduced, and a high-finish-degree material is obtained; and the deoxygenation and impurity removal effects are achieved through a composite refining agent of nanometer Ca-RE intermediate phase alloy powder loaded by honeycomb ceramic powder and graphene, the slagging speed is high, efficiency is high, the degree of purity of molten steel can be increased effectively, the performance of stainless steel heat-treated multiple times is stable, and the energy-saving and efficient production effects of products are achieved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

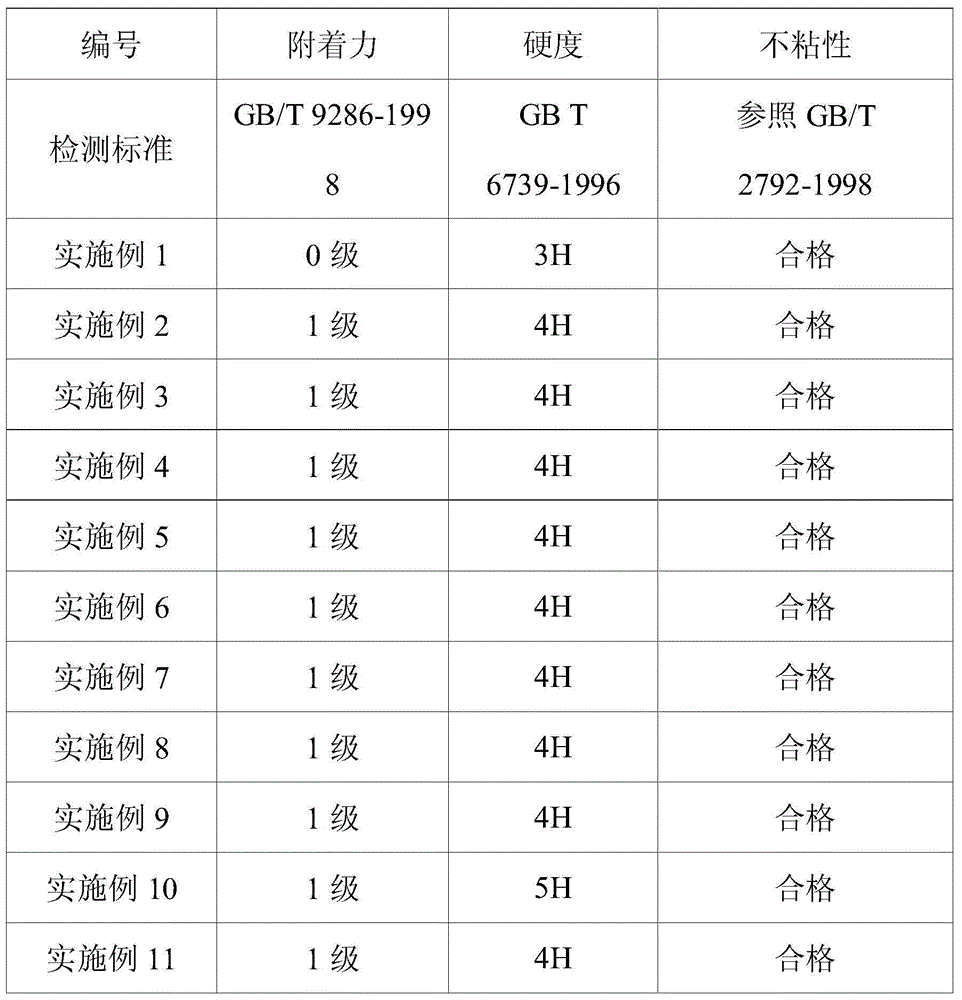

Anticorrosion demoulding powder combination and preparation method thereof

The invention discloses an anticorrosion demoulding powder combination and a preparation method of the anticorrosion demoulding powder combination. The combination is composed of FEVE fluororesin, fluorine-contained micro powder, silicon dioxide, titanium dioxide, a flatting agent, a defoaming agent and a curing agent. The preparation method comprises the steps that all components are weighed proportionally and stirred and premixed, then, melt extrusion is carried out through a screw extruder, and finally, through smashing and grinding, the anticorrosion demoulding powder combination is prepared. The anticorrosion demoulding powder combination is mainly applied to anticorrosion demoulding treatment of a surface of a rubber and plastic product moulding die, and the adhesive force between a combination coating and a base material of the die is high; the coating is good in anti-corrosion property and excellent in non-viscosity property, wear resistance and hardness are both considered, and the continuous demoulding performance is good; and the powder combination is low in VOC content and friendly to the environment.

Owner:JUHUA GROUP TECH CENT

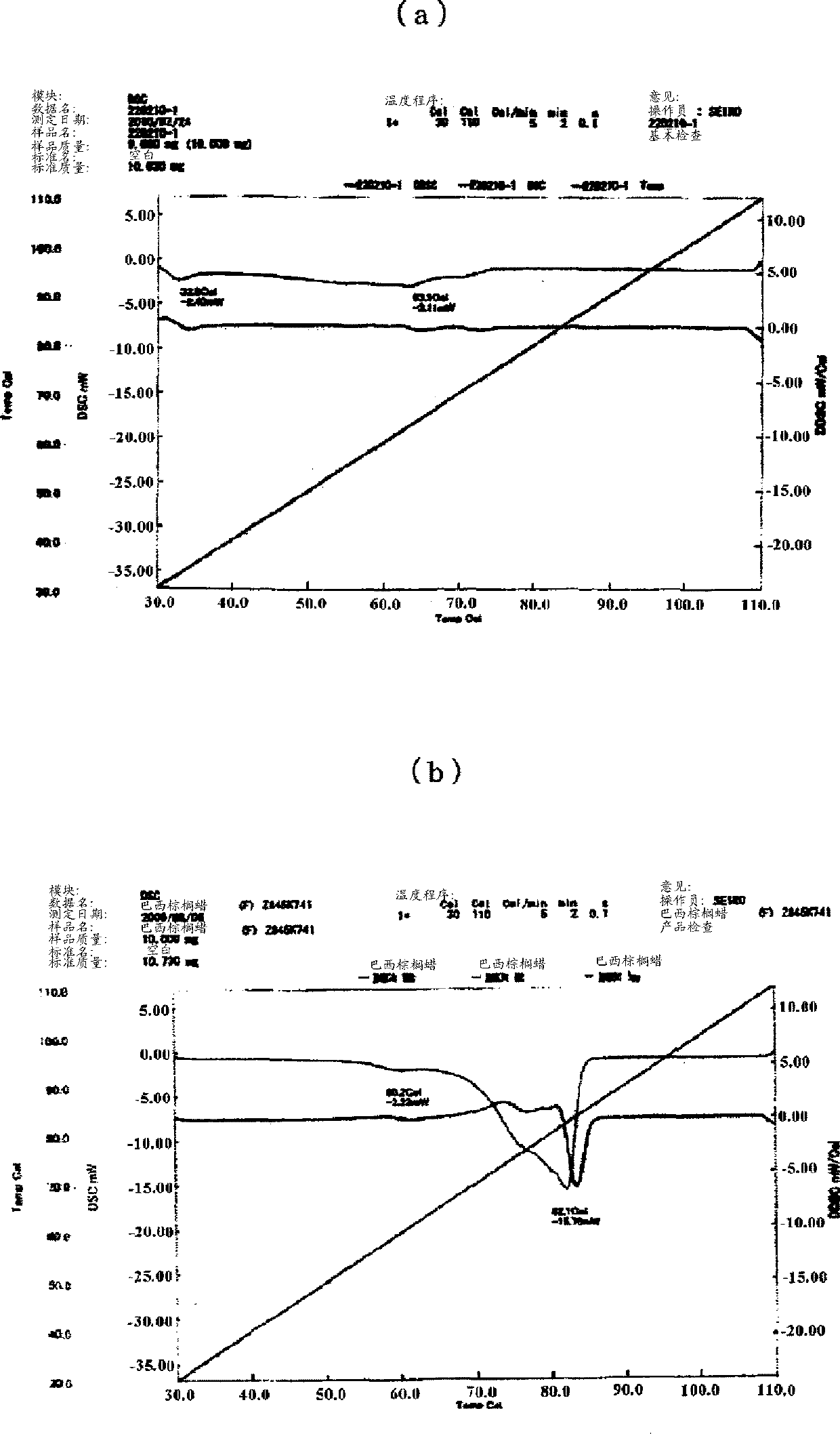

Resin composition and cosmetic containing said resin composition

ActiveCN104185657AConvenience filmExcellent adhesionCosmetic preparationsHair cosmeticsFractionationCarnuba wax

The present invention addresses the problem of providing a resin composition which can form a cosmetic film that exhibits excellent makeup durability and glossiness and non-tackiness and that combines a certain level of hardness and flexibility and therefore does not give a feeling of heaviness. This resin composition is characterized by: being obtained from carnauba wax through fractionation; and having a softening point of 55 to 80 DEG C and an iodine number of 20 to 55.

Owner:KOBAYASHI KOSE CO LTD

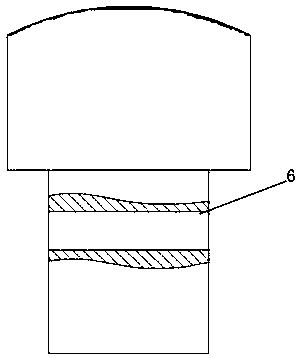

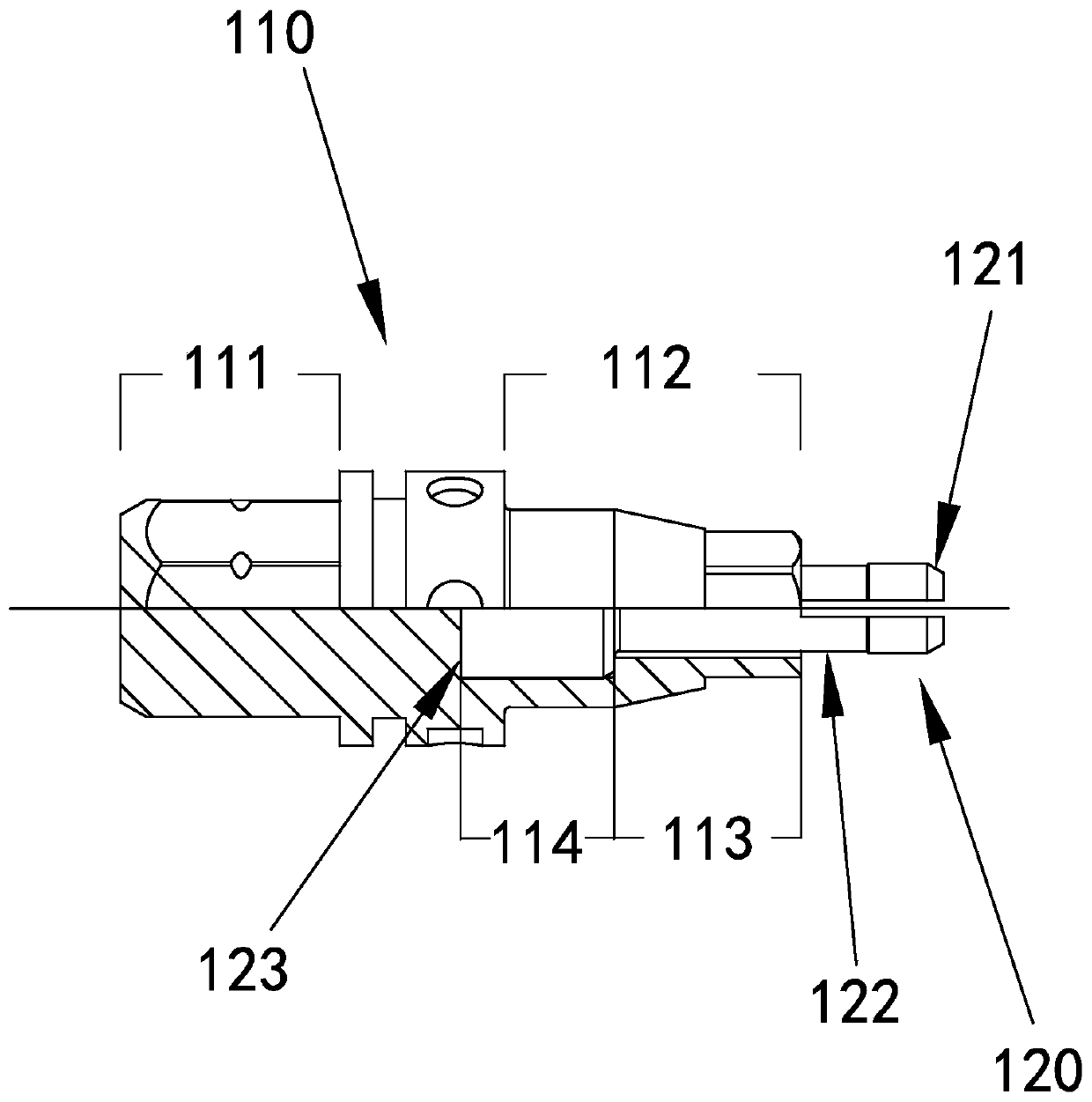

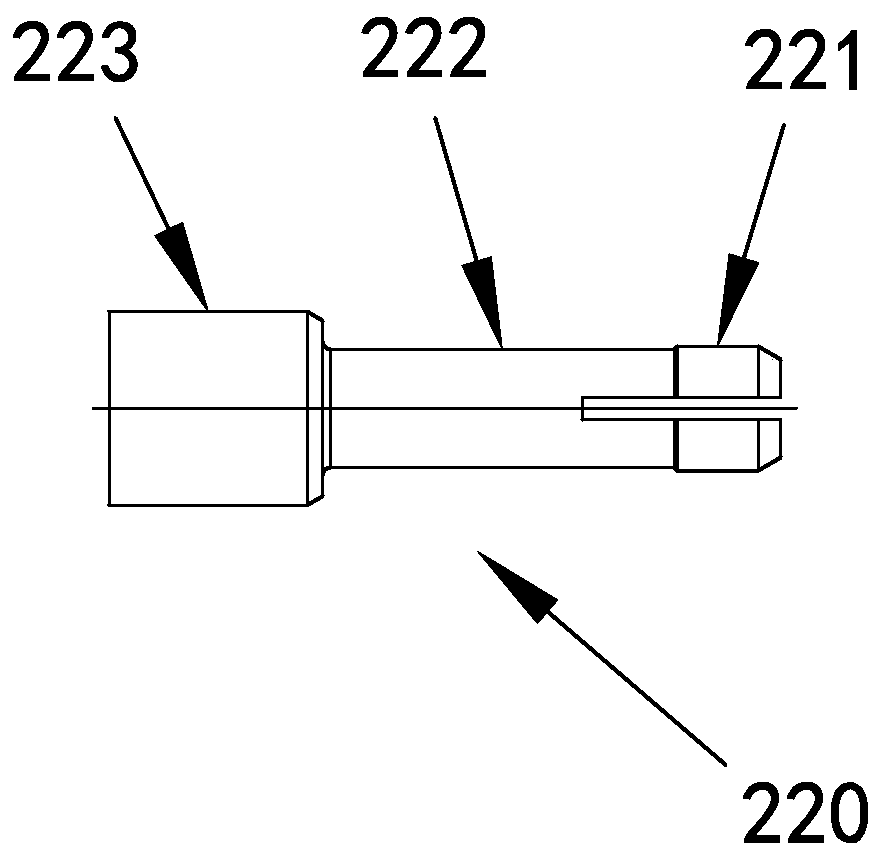

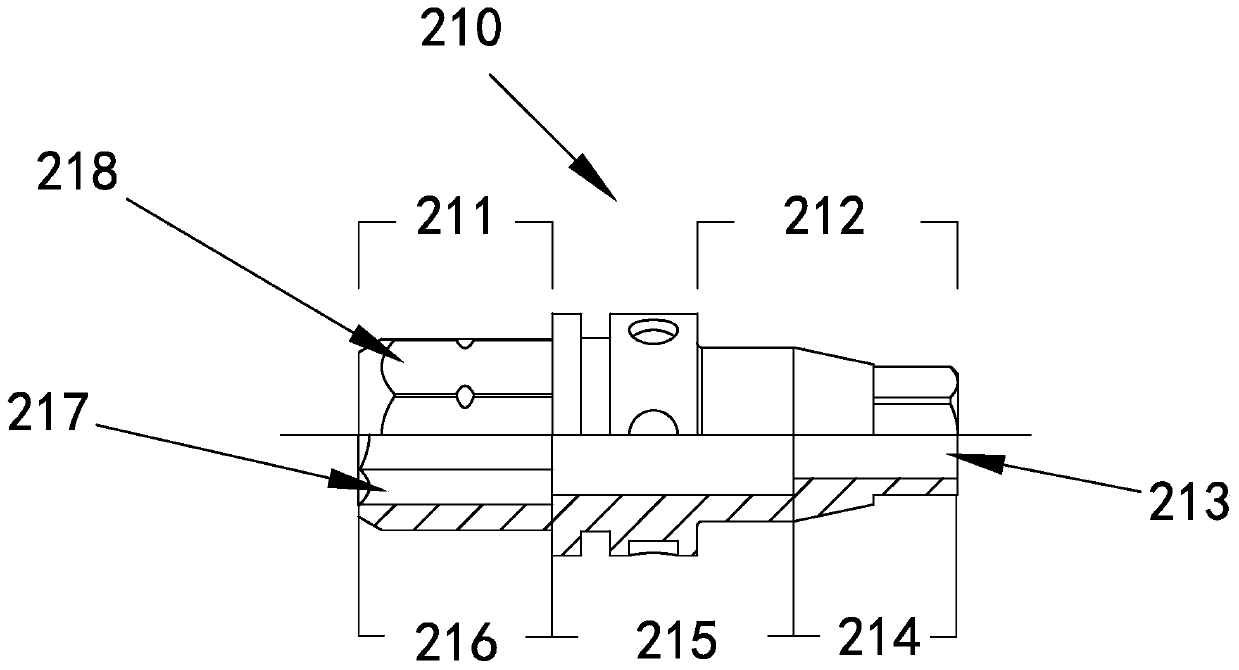

Dental implant carrying device and implantation tool assembly

The invention discloses a dental implant carrying device. The dental implant carrying device comprises a carrying body and a connecting body, wherein the carrying body is a columnar component; an implantation tool combination section is arranged at one end of the surface of the carrying body; a dental implant combination section is arranged at the other end of the surface of the carrying body; theimplantation tool combination section is matched with an external implantation tool interface; the dental implant combination section is matched with an external abutment interface of a dental implant; the connecting body is a columnar component, is coaxial with the carrying body and comprises a connecting rod and a joint; one end of the connecting rod is connected with the dental implant combination section, and the other end of the connecting rod is connected with the joint; the diameter of the connecting rod is smaller than that of the joint; and the carrying body is a medical metal component, and the connecting body is a non-toxic high polymer material component. The connecting body is made of a material with good elasticity, and the carrying body is made of a material with relativelyhigh hardness, so that the assembled dental implant carrying device has both elasticity and hardness, and the overall material cost and processing cost are far lower than those of the existing carrying device.

Owner:广东中科安齿生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com